Cup mat body paper and production method thereof

A production method and coaster technology, applied in the field of papermaking, can solve the problems of not being able to meet the high bulkiness requirements of the coaster, not being able to use packaging, and not being able to save resources, etc., and achieve the effects of high water absorption, hygiene protection, and moisture protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

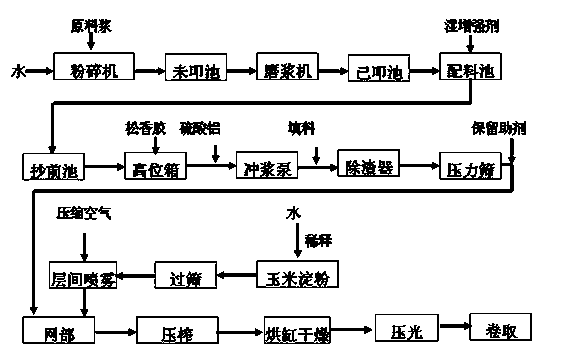

Method used

Image

Examples

Embodiment 1

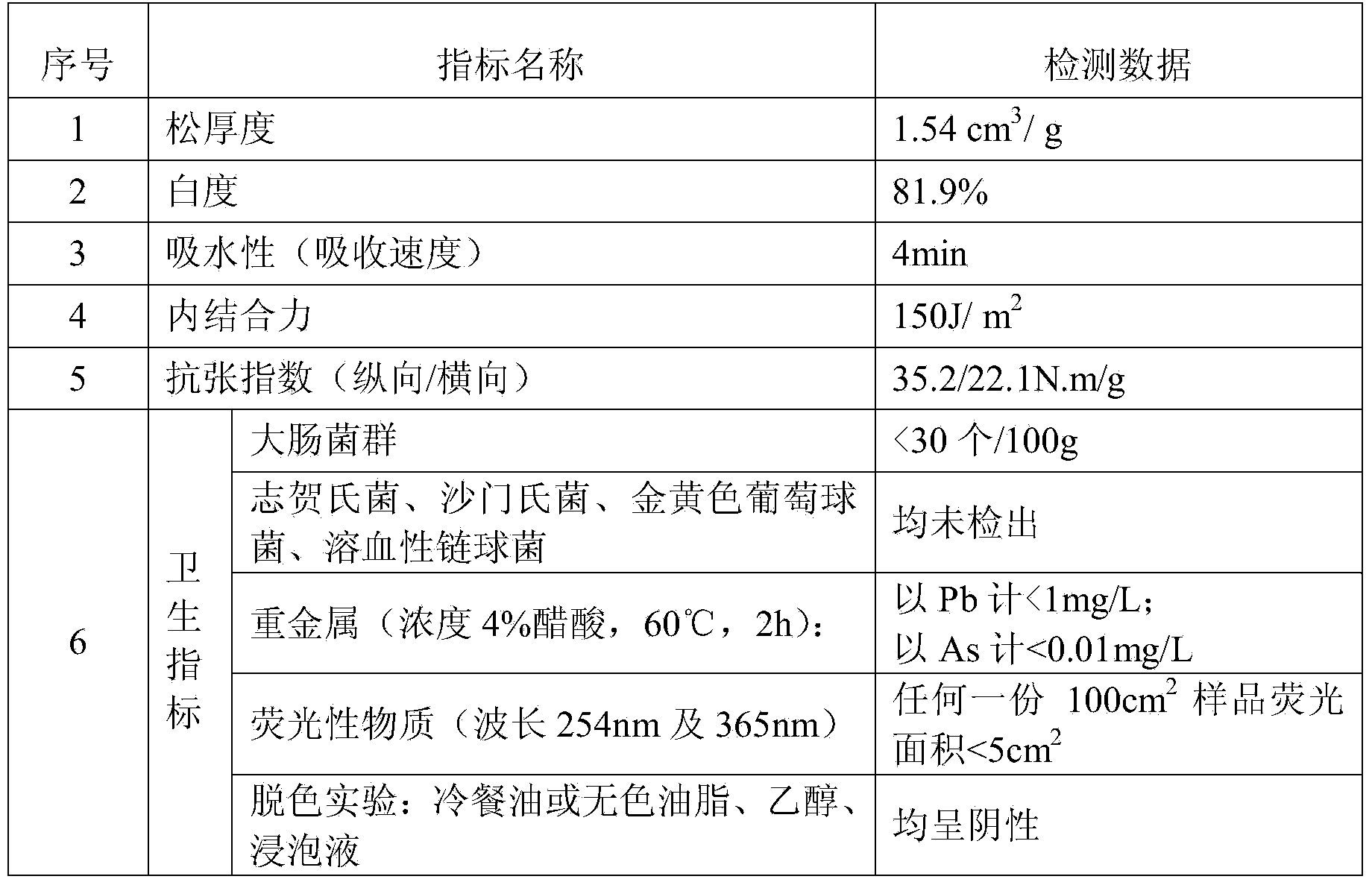

[0016] Example 1, 350g / m 2 Production steps of type A coaster

[0017] 1) Pulverization, the pulp made by refining the three basic raw materials of softwood pulp, hardwood pulp and mechanical pulp, the pulp freeness CSF control of pulp raw materials: softwood pulp 430mL, hardwood pulp 500mL, mechanical pulp 430mL ;

[0018] 2) Batching and sizing, according to the raw material formulations of the surface layer, bottom layer, and core layer, batching in their respective batching tanks, the raw materials of the surface layer and the bottom layer are composed of coniferous wood pulp and hardwood pulp; the raw materials of the core layer are composed of coniferous wood pulp and mechanical pulp; the batching and sizing process also sequentially add wet strengthening agent, rosin size, aluminum sulfate, filler and retention aid;

[0019] 3) Papermaking, the three-layer slurry after batching is divided into three layers and enters the wire part for papermaking, and the starch bondi...

Embodiment 2

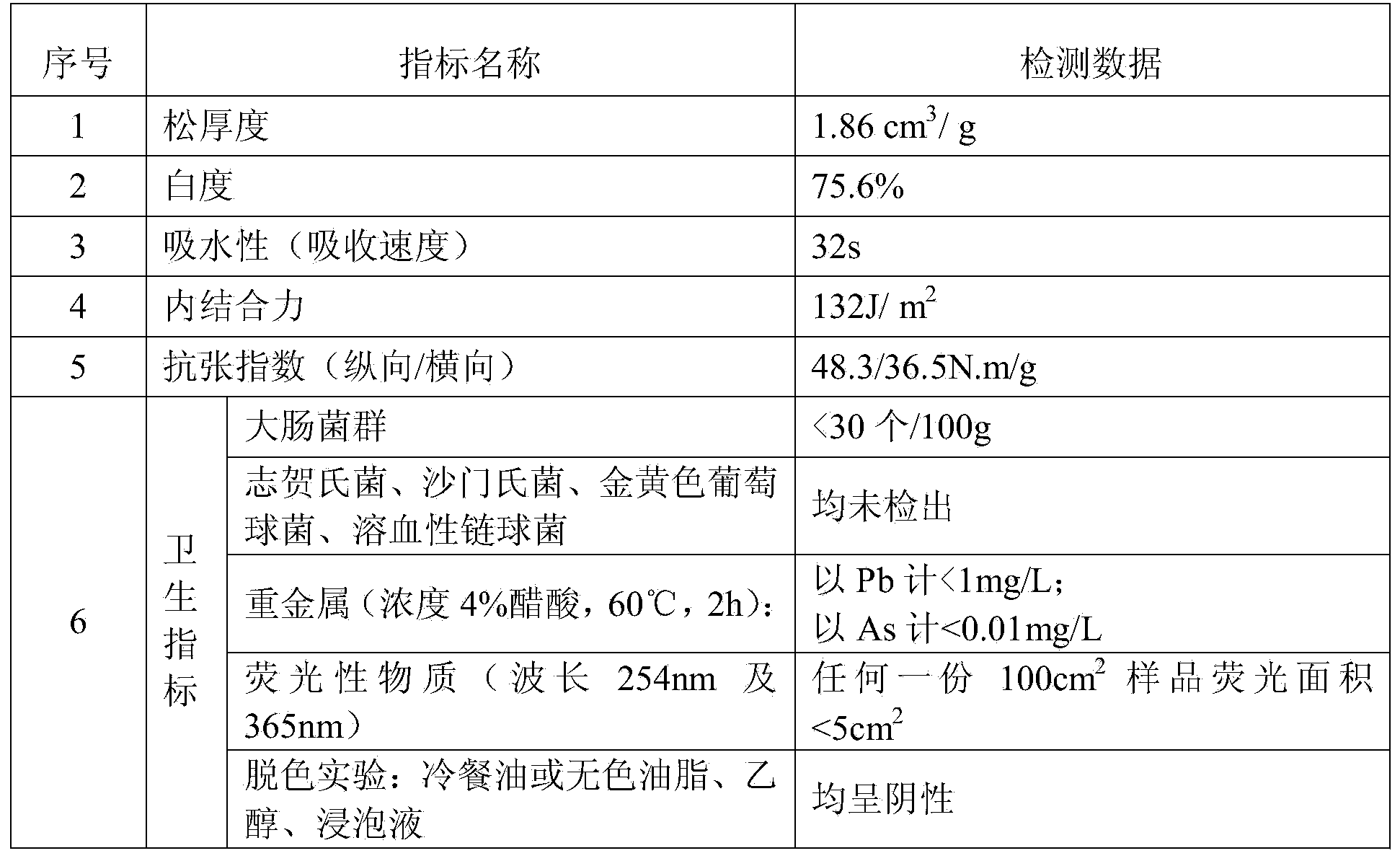

[0035] Example 2, 380g / m 2 B type coaster base paper production steps:

[0036] 1) Crushing, the basic raw materials of coniferous wood pulp and mechanical pulp are refined into pulp, and the pulping freeness CSF control of pulp raw materials: 440mL of coniferous wood pulp and 430mL of mechanical pulp;

[0037] 2) batching and sizing, according to the raw material formula of surface layer, bottom layer and core layer, batching in respective batching tanks respectively, the raw material composition of surface layer and bottom layer is coniferous wood pulp and mechanical pulp; the raw material composition and weight ratio of core layer are Softwood pulp and mechanical pulp; the batching and sizing process also sequentially adds wet strengthening agent, rosin size, aluminum sulfate, filler and retention aid;

[0038] 3) Papermaking, the three-layer slurry after batching is divided into three layers and enters the wire part for papermaking, and the starch bonding layer is formed ...

Embodiment 3

[0054] Example 3, 380g / m 2 Type A coaster base paper and production method thereof

[0055] 1) Pulverization, the pulp made by refining the three basic raw materials of softwood pulp, hardwood pulp and mechanical pulp, the pulp freeness CSF control of pulp raw materials: softwood pulp 430mL, hardwood pulp 500mL, mechanical pulp 430mL ;

[0056] 2) Batching and sizing, according to the raw material formulations of the surface layer, bottom layer, and core layer, batching in their respective batching tanks, the raw materials of the surface layer and the bottom layer are composed of coniferous wood pulp and hardwood pulp; the raw materials of the core layer are composed of coniferous wood pulp and mechanical pulp; the batching and sizing process also sequentially add wet strengthening agent, rosin size, aluminum sulfate, filler and retention aid;

[0057] 3) Papermaking, the three-layer slurry after batching is divided into three layers and enters the wire part for papermaking,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com