Patents

Literature

285results about "Rosin addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

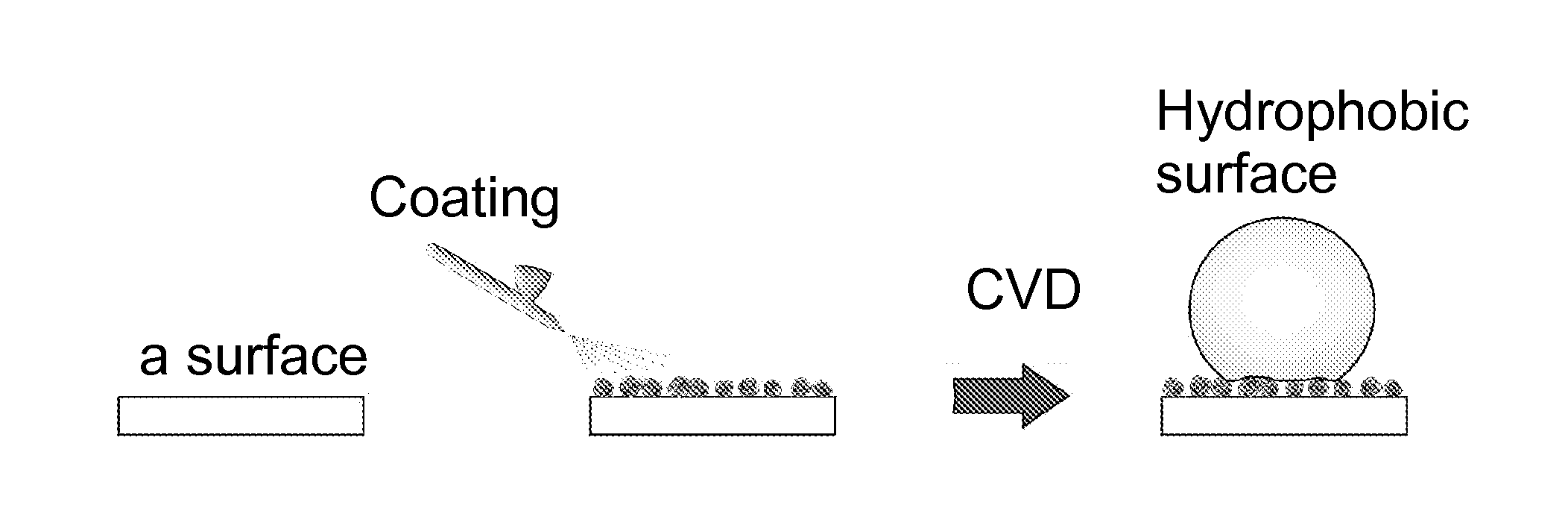

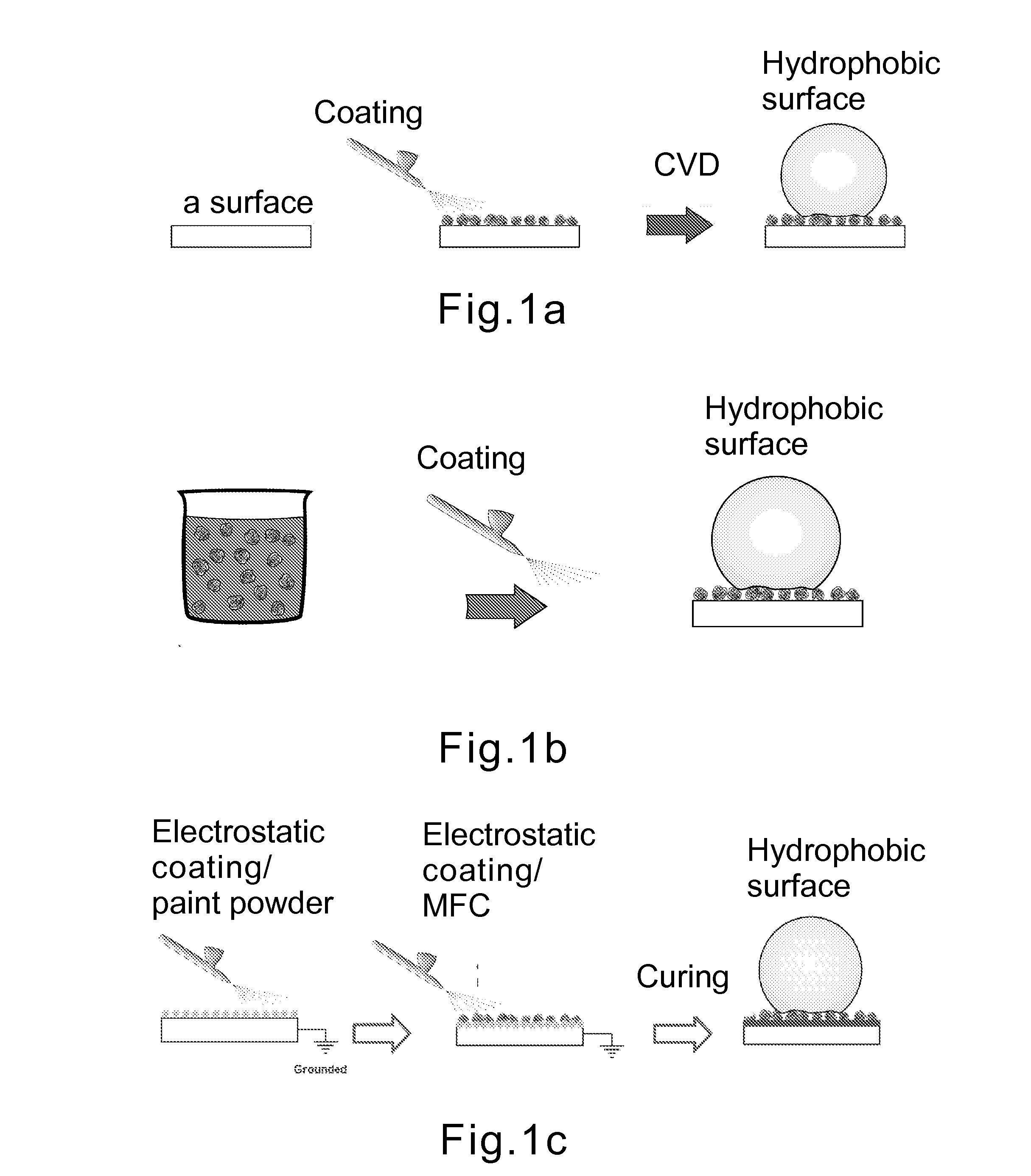

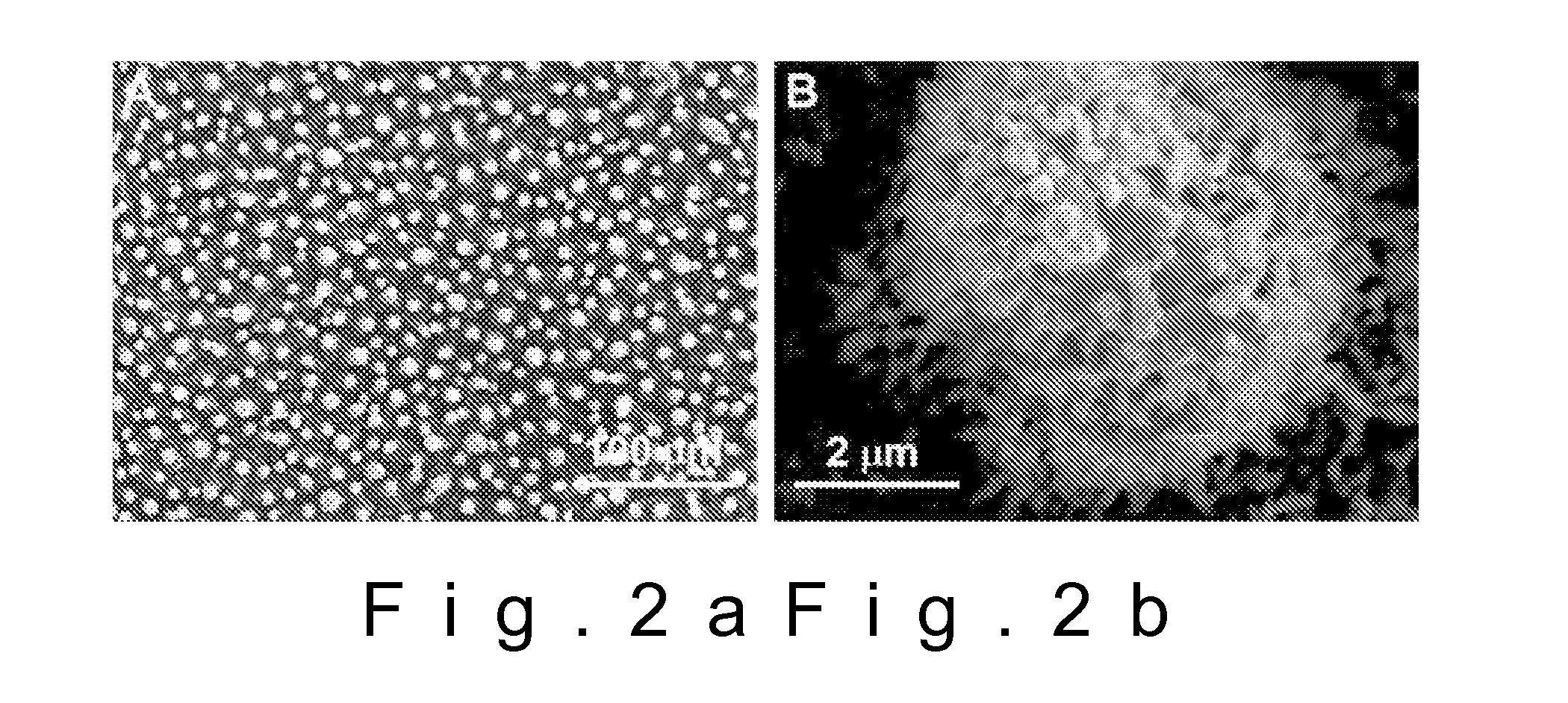

Hydrophobic coating and a method for producing hydrophobic surface

InactiveUS20140130710A1Similar in sizeIncrease contact angleElectric shock equipmentsWater-repelling agents additionPolymer chemistryHydrophobic surfaces

A method for producing a superhydrophobic surface, which includes cellulosic material. The cellulosic material includes nanocellulose particles and the method includes adding the nanocellulose particles to a surface and hydrophobizing the nanocellulose particles with a modifier before, during and / or after the addition of the particles. The invention further relates to a hydrophobic coating.

Owner:UPM-KYMMENE OYJ

Crepe facilitating composition

InactiveUS20070000630A1Improve stress distributionGood flexibilityMechanical working/deformationSpecial paperFiberWater insoluble

The invention relates to a crepe facilitating aqueous composition comprising at least one water-insoluble, non-surface active thermoplastic material having a softening or melting point within the range of from 40° C. to 100° C., and at least one water-soluble polymer, preferably a cationic water-soluble polymer. As the composition is comprised in a wet fibre web during creping thereof, a more uniform creping is obtained while the integrity of the web is preserved and dust formation is reduced, and a tissue product having improved properties is provided.

Owner:BIM KEMI

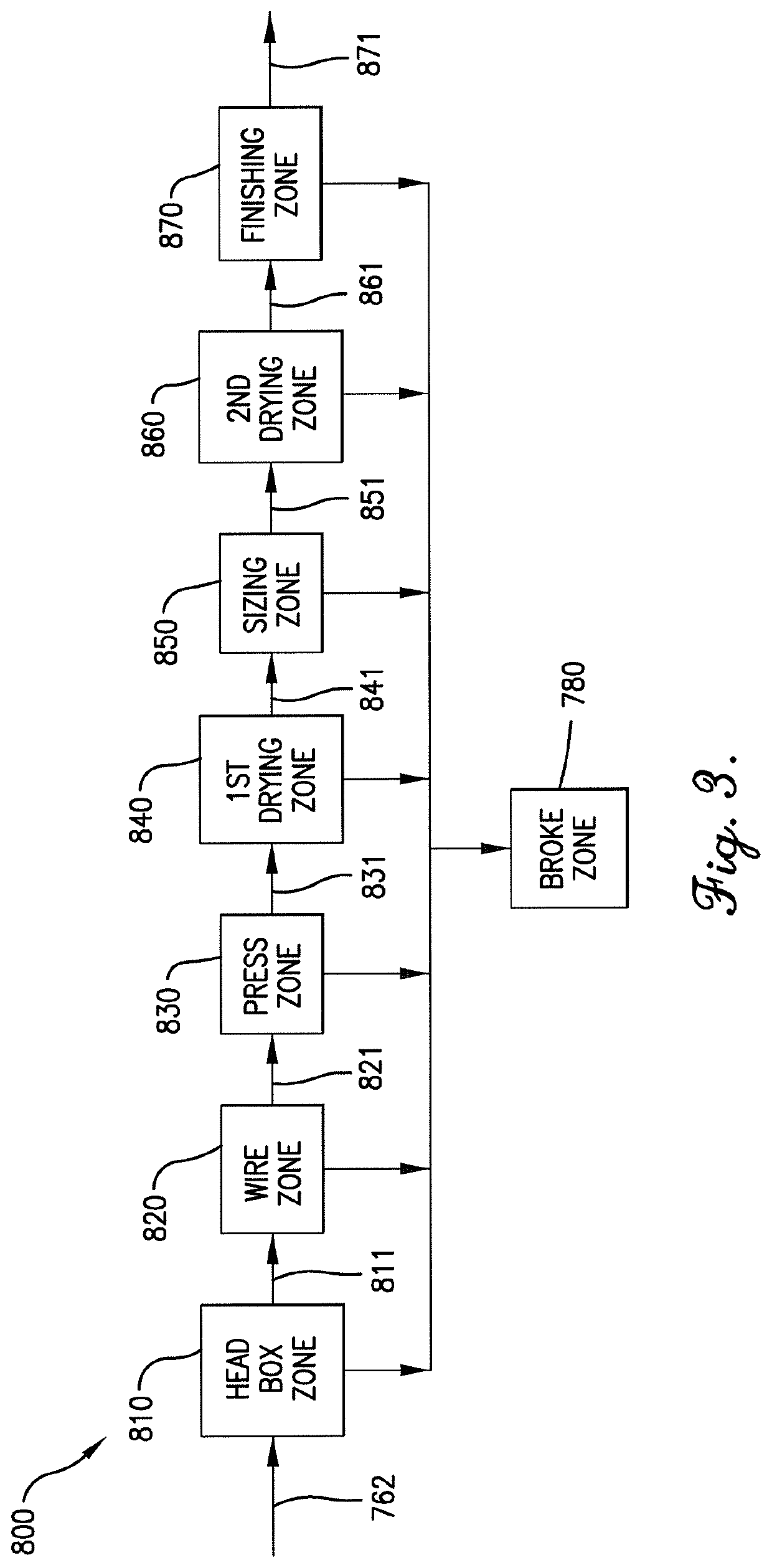

Composition of matter in a post-refiner blend zone

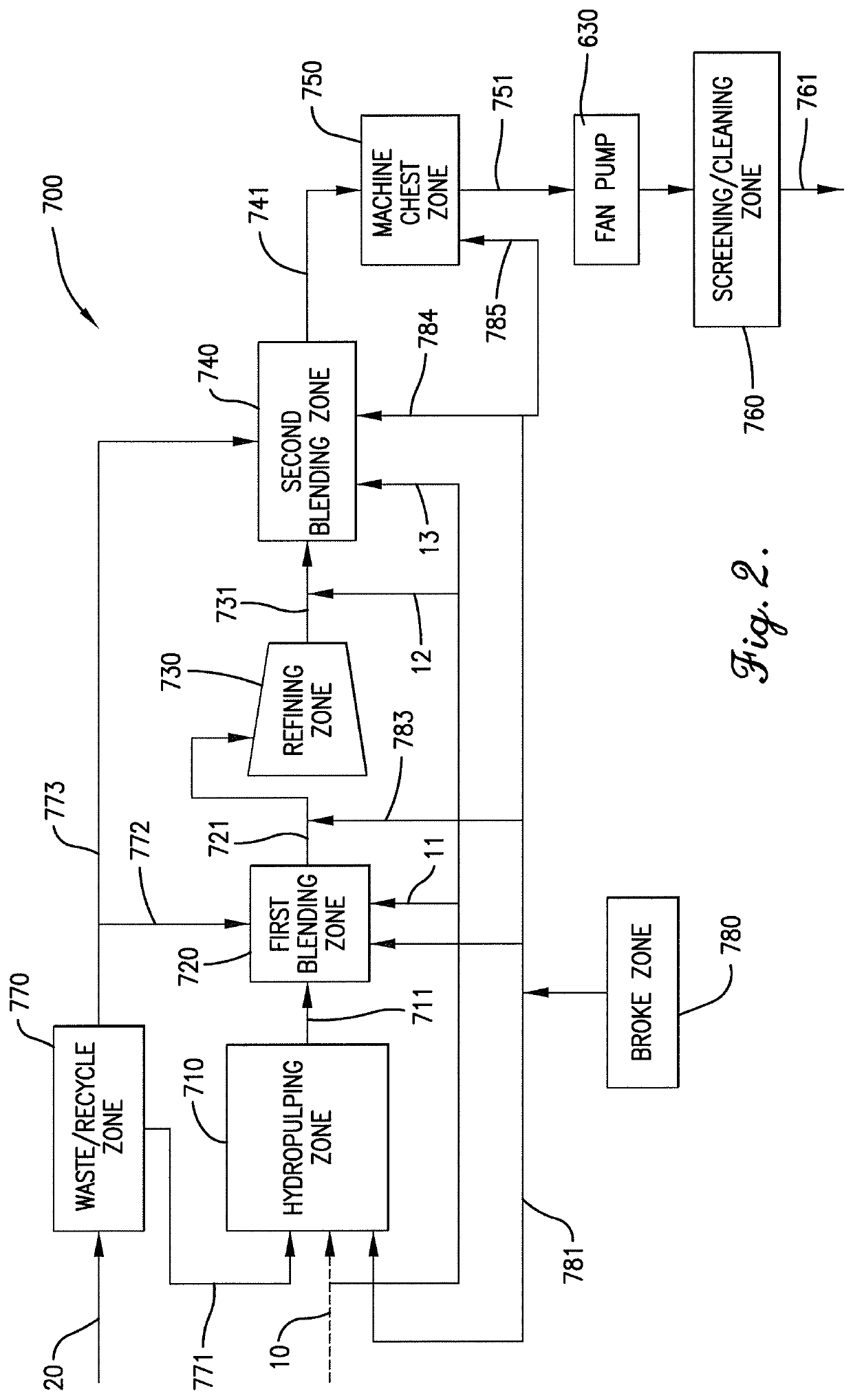

ActiveUS20200063358A1Reduce consistencyLow variabilityWater-repelling agents additionReinforcing agents additionPolymer scienceCellulose fiber

After cellulose fibers and cellulose ester fibers are co-refined, they are fed to a blend tank continuously feeds a wet laid process. The composition in the blend tank includes co-refined cellulose fibers and cellulose ester fibers and one or more additives, and the cellulose ester fibers have a denier per filament (DPF) of less than 3, a cut length of less than 6 mm, crimped, or non-round with a DPF of less than 3.

Owner:EASTMAN CHEM CO

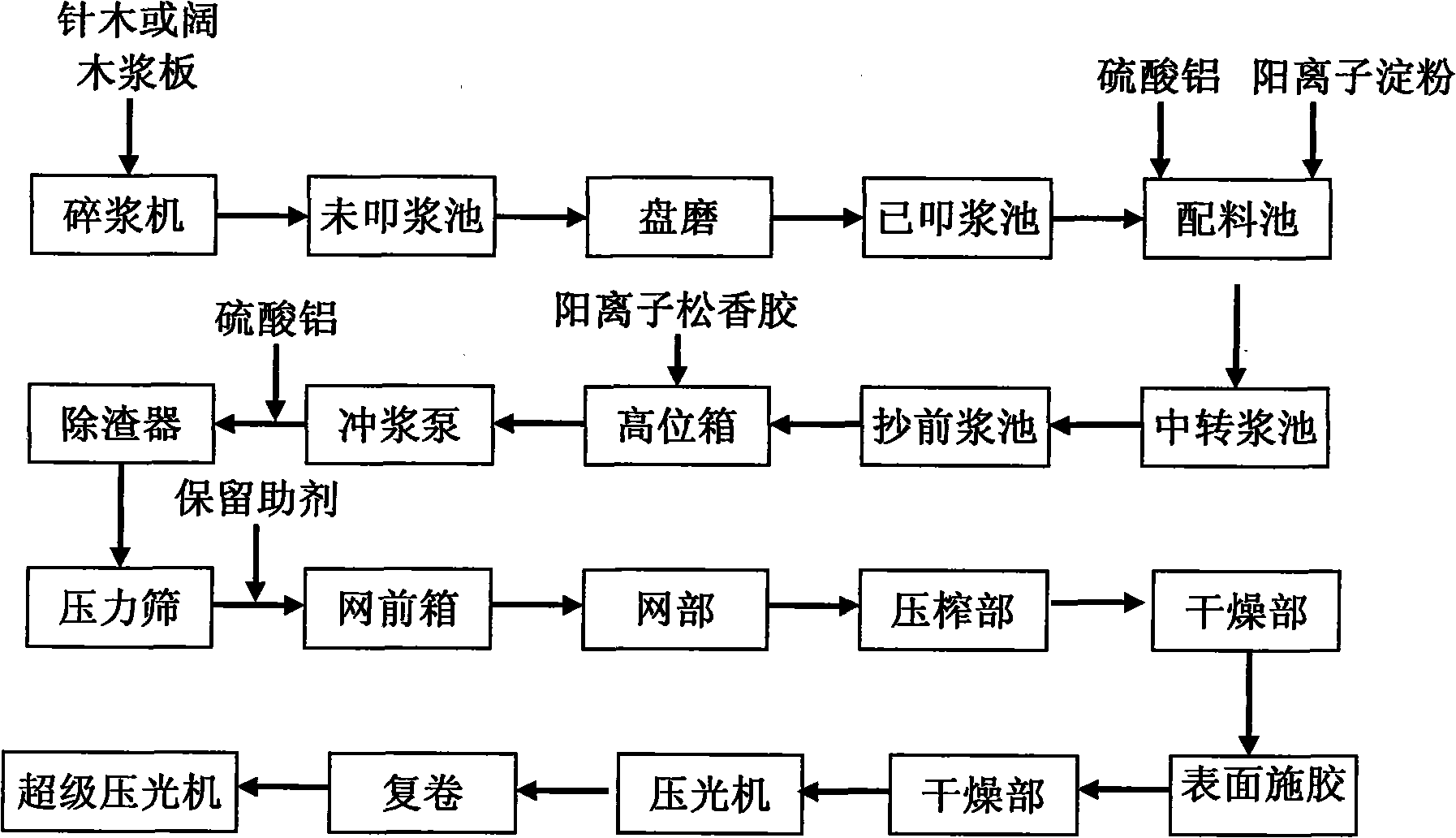

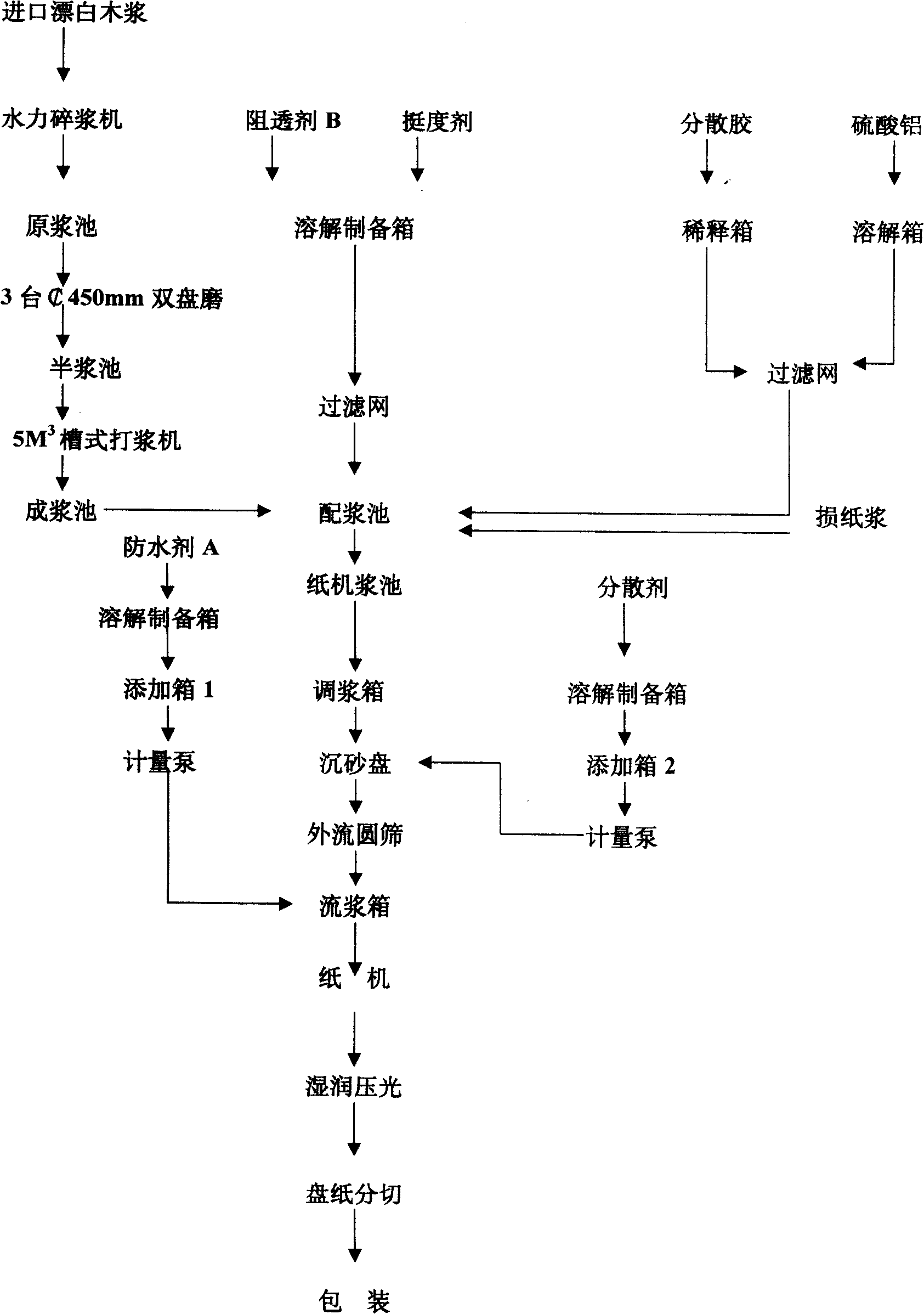

Method for producing metallic high temperature transfer base paper

ActiveCN101255662AImprove high temperature resistanceHigh strengthNatural cellulose pulp/paperWax additionFiberExtremely good

The invention discloses the production method of a metal high temperature transfer printing base paper, including to use 50-70% blanching needle wood-pulp and 30-50% blanching broad-leaf wood-pulp to be the raw material, which is pulped by a pulper, then is added by beating with chemical auxiliary materials: 1-4% a wet strength agent, 1-3% a high temperature resistance agent, 1- 4% starch, 2-4% aluminum sulfate, 1.0-2.5% a rosin milk, 0.1-1.5% a remover, and 0.03 -0.1% a retention agent to make into a slurry; after making, the slurry is rewound to be the base paper when passing through a rewinder. The transfer printing base paper produced by the method has the advantages of extremely good high temperature resistance, being able to satisfy the request of the metal high temperature transfer printing, fine superficial smoothness, and full patterns, bright color and good transfer printing effect after printed. The intensity of the paper is very high, which can satisfy the need of the transfer printing, and the paper is crispness, is not coking and has good stripping paper effect after transfer printed on metal; the waste paper can be recycled to be used as secondary fiber, which saves resources and protects environment.

Owner:HUANGSHAN XINLONG SPECIALITY PAPER

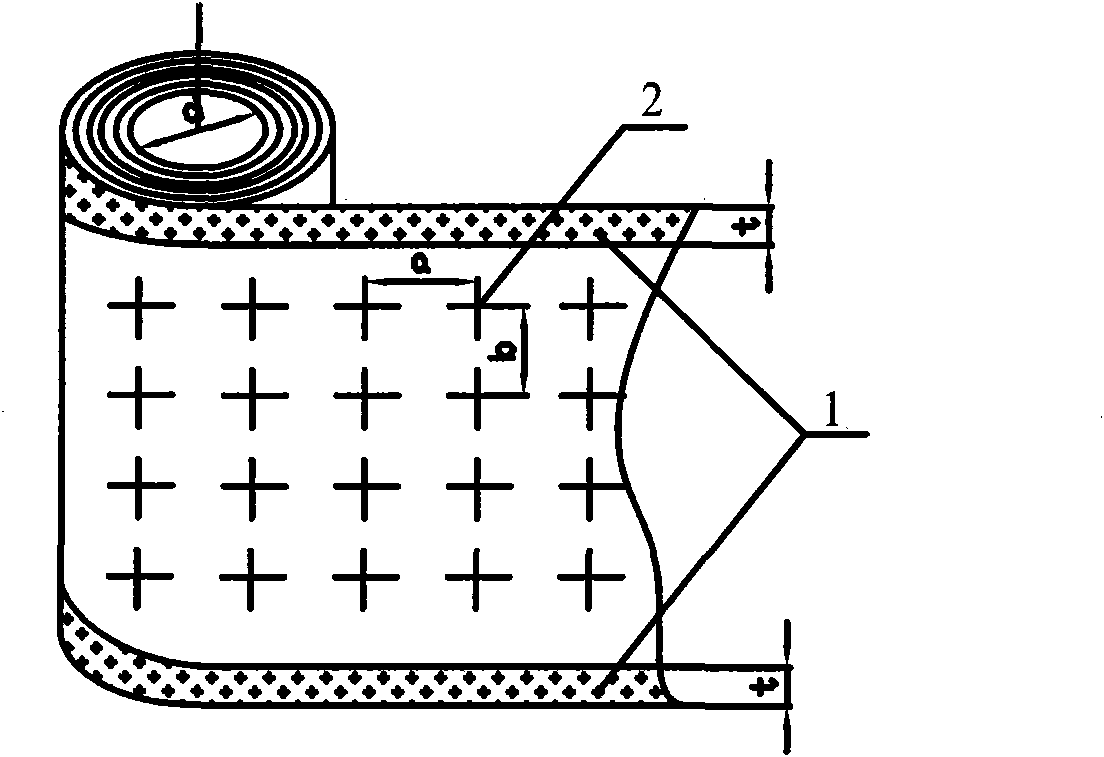

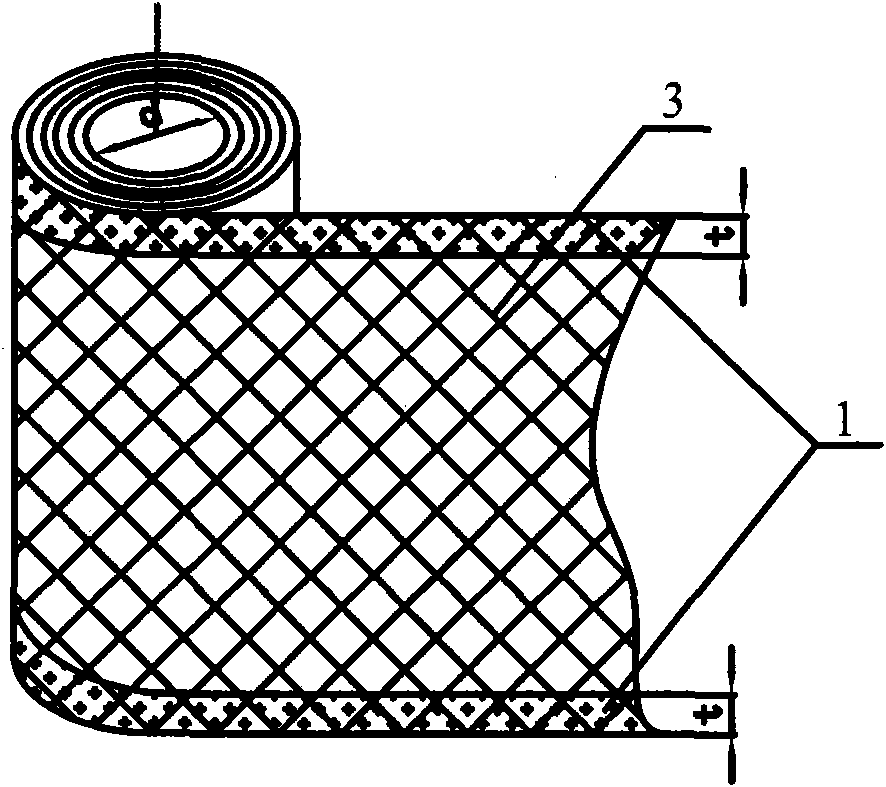

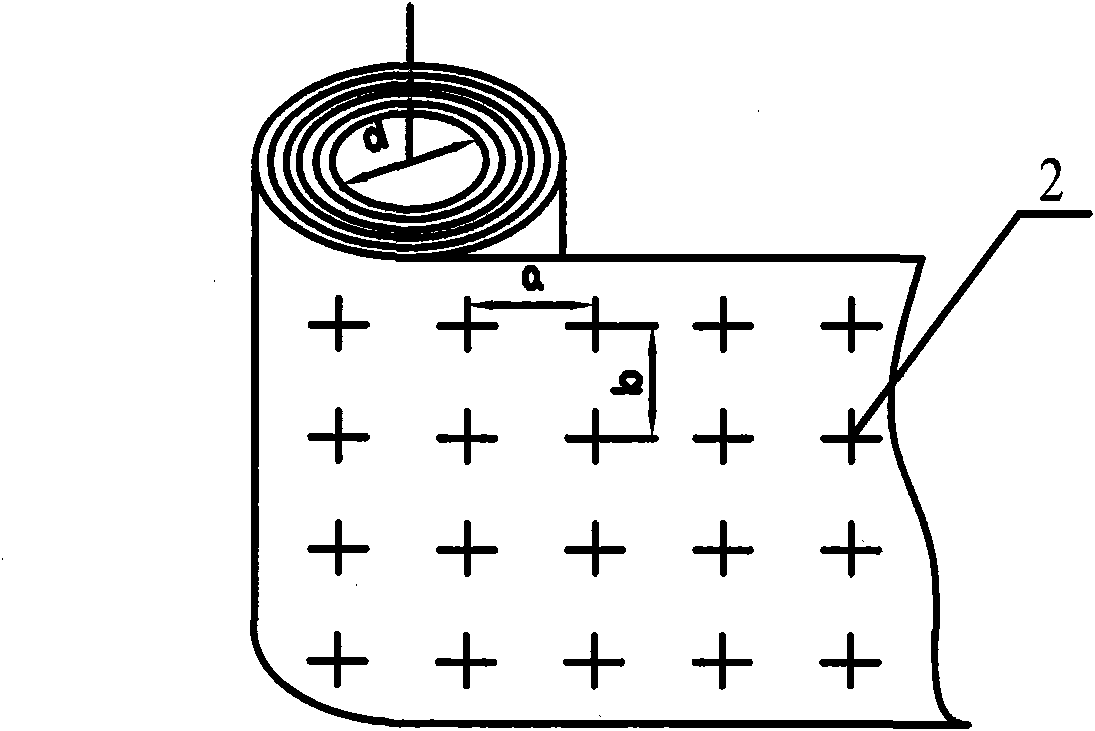

Biogas residue fiber mulch film and manufacturing method thereof

ActiveCN101659760ANo pollutionNo chemical pollutionNatural cellulose pulp/paperReinforcing agents additionGround temperatureManufacturing technology

The invention relates to a biogas residue fiber mulch film and a manufacturing method thereof, which belong to the technologies of protective cultivation biomass materials of paddy and upland crops. The fiber mulch film consists of biogas residue fibers, plant fibers and an environment-friendly functional auxiliary agent, wherein the biogas residue fibers account for 50-90%, the plant fibers account for 10-50%, and the sum of the two types of the fibers is 100% by weight of dry matters; and the environment-friendly functional auxiliary agent mainly comprises rosin, bauxite and a wet strengthening agent and accounts for 6%-7.4% of 100% of the total weight of the two types of the fiber dry matters. The manufacturing technology adopts the biological and mechanical way for preparing the fibersand pulp and adds the environment-friendly functional auxiliary agent for manufacturing paper and forming the film. The biogas residue fiber mulch film has excellent performance for inhibiting the breeding of weeds and can simultaneously adjust the ground temperature, preserve the soil moisture, increase the humidity, improve the ecological environment of the crops, can be completely biodegradedduring the growth period of the crops, improve the content of organic matters in the soil, have no residue or pollution and realize good economy.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for preparing high-strength corrugated paper

InactiveCN105369669AImprove moisture resistanceImprove physical strengthReinforcing agents additionSynthetic cellulose/non-cellulose material pulp/paperFiberFiltration

The invention relates to the technical field of papermaking and specifically relates to a method for preparing high-strength corrugated paper. The method comprises the steps that (1) plant ingredients and waste paper are selected, pulped in water, then put into a pulper for smashing in order to dissociate the ingredients into fibers, and treated by filtration and screening to remove the crude fibers and impurities, primary pulp is made through pulp beating, and a beating degree of the primary pulp is between 35 DEG SR and 45 DEG SR; (2) 80-120 parts by weight of the primary pulp made at the step (1) is extracted, 5-15 parts by weight of polyvinyl alcohol fibers and 1-5 parts by weight of silicon dioxideare added into the primary pulp, and the mixture is thoroughly mixed; (3) a cation rosin sizing and a wet strength agent are added into the mixture obtained at the step (2), and the mixture is thoroughly stirred and dehydrated to obtain papermaking pulp with a moisture content of 10%-20%; and (4) the paper is manufactured through papermaking of a papermaking machine, the paper is treated by surface sizing, oppression, drying and rolling, and finally the corrugated paper is obtained. The corrugated paper prepared by the method provided by the invention has the advantages of high strength and applicability to more fields.

Owner:FUJIAN LONGCHUANG IND DESIGN

Methods and compositions for papermaking

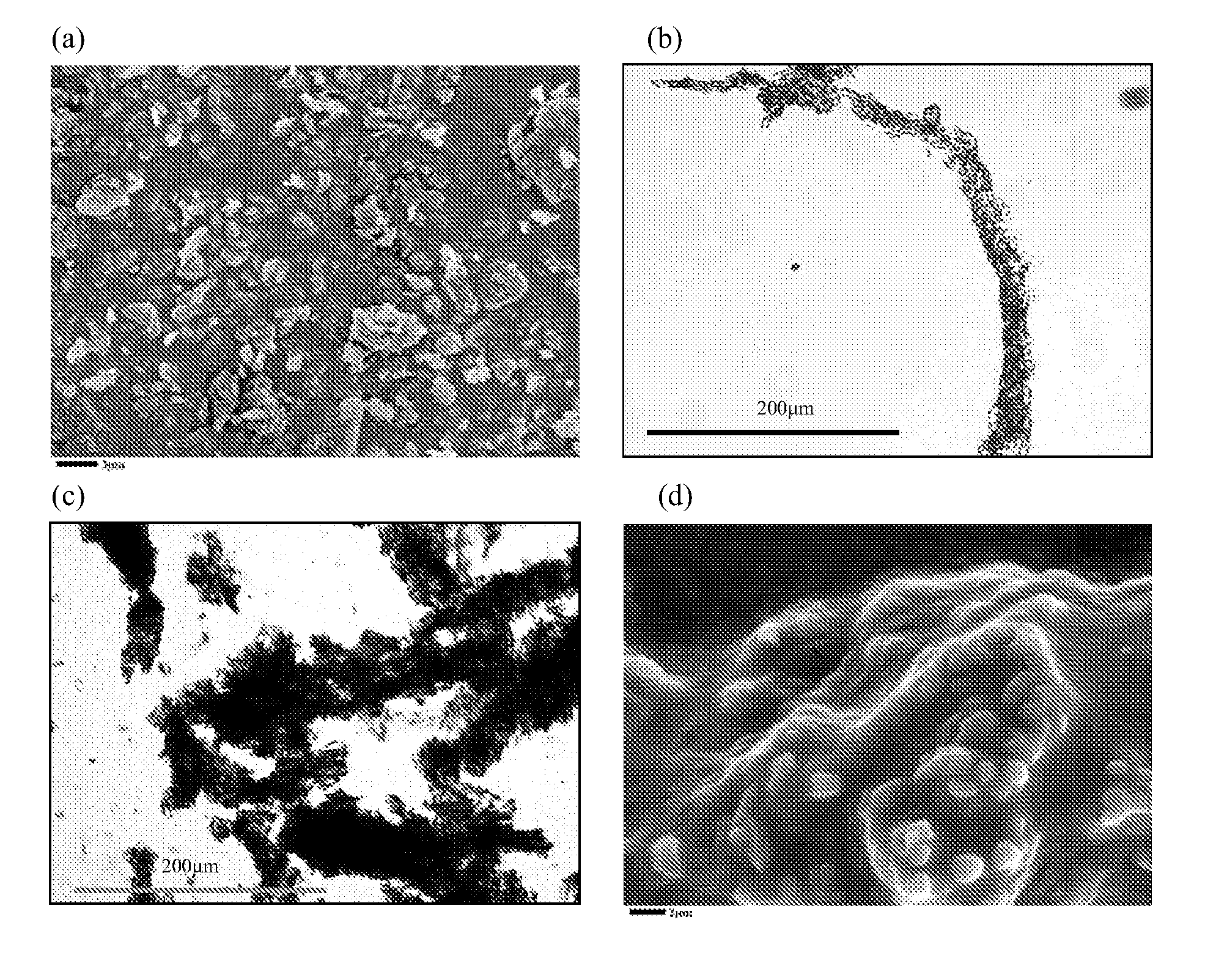

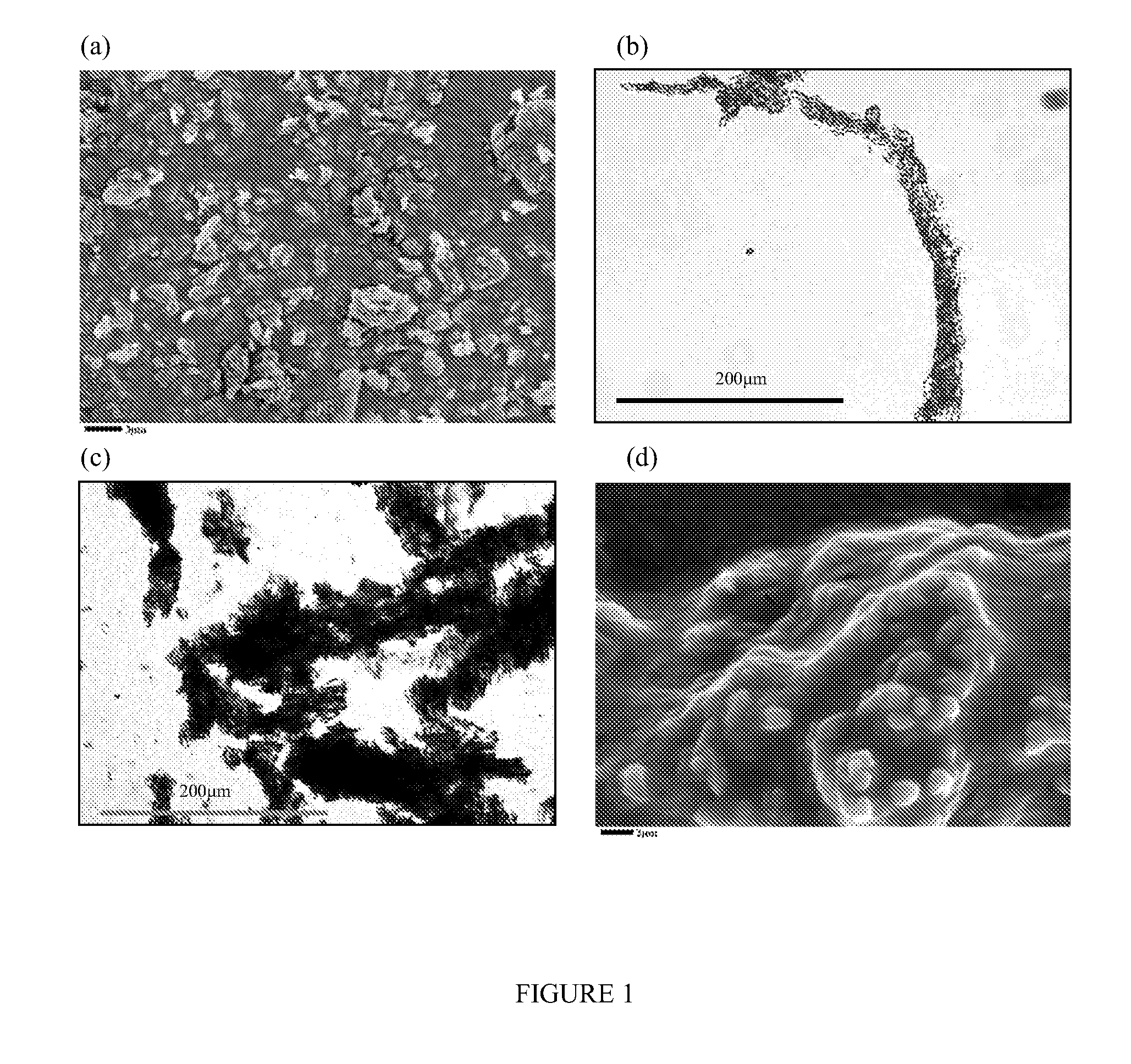

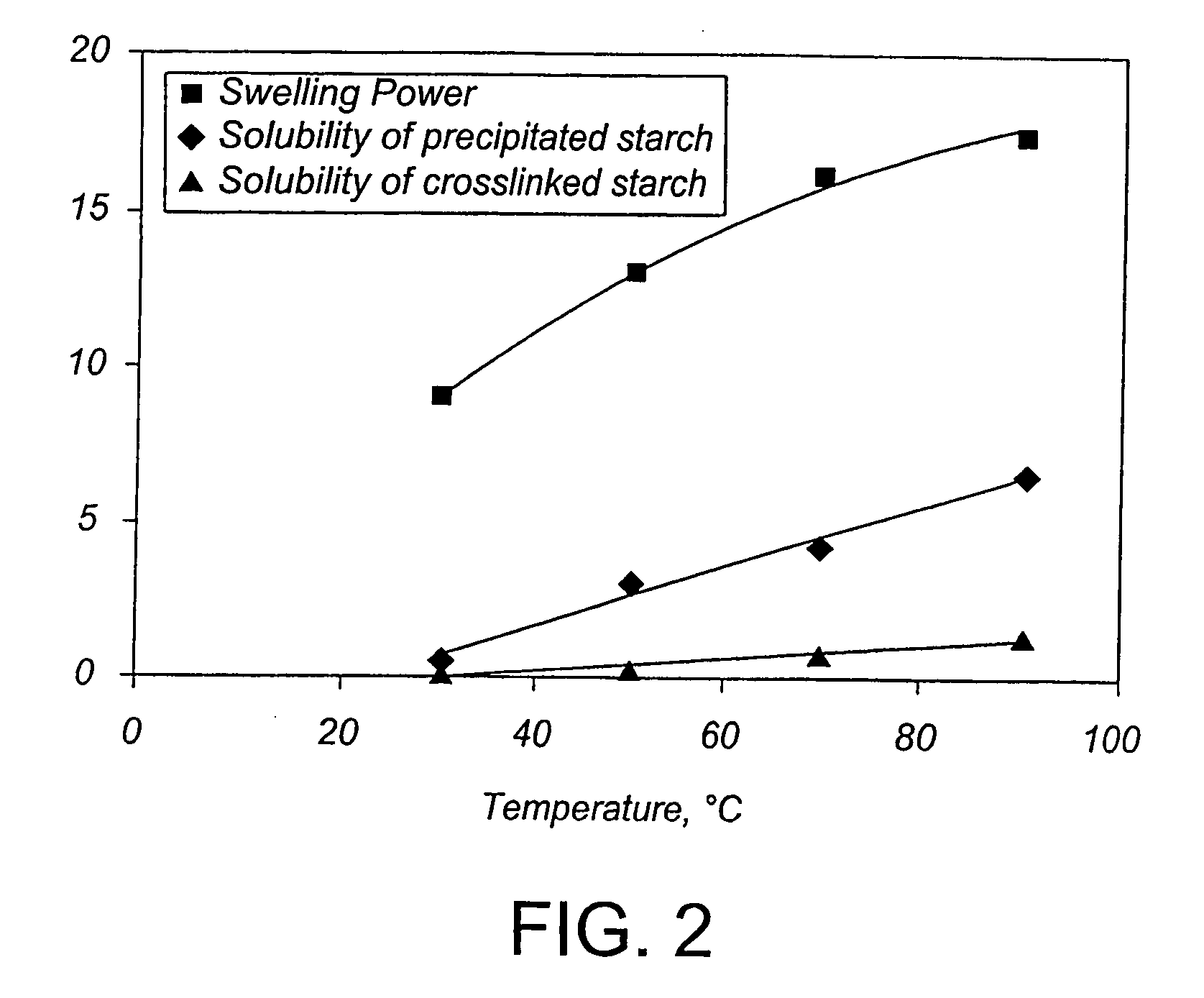

The present invention relates to methods for making modified fillers for use in a papermaking process, methods for making a paper using the modified fillers, and modified fillers and paper produced therewith. In one aspect, the present invention provides a method for making a modified filler for use in a papermaking process, which comprises applying a starch composition comprising starch to a reaction composition comprising at least one of fatty acid, rosin acid, and ammonium sulfate to form a reaction mixture; and applying a filler composition comprising a filler to the reaction mixture, whereby forming a modified filler. In another aspect, the present invention provides a method of using a modified filler in a papermaking process, which comprises applying a modified filler to a composition comprising fiber to form a mixture; and processing the mixture, whereby producing a paper.

Owner:GEORGIA TECH RES CORP

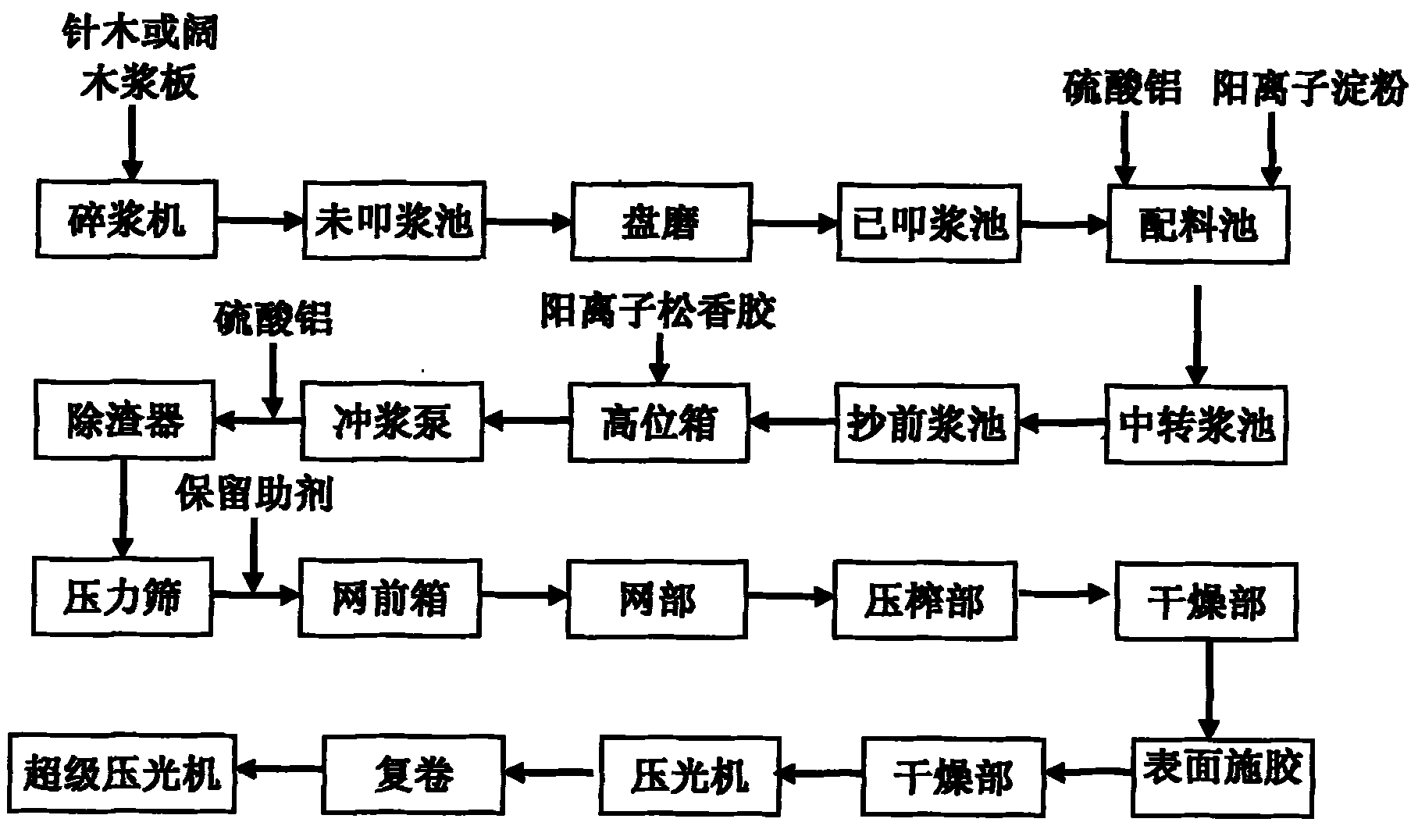

Method for producing computer-to-plate lining paper

ActiveCN101787662ASolve acidityStrong acidNatural cellulose pulp/paperWater-repelling agents additionAluminium sulfateComputer to plate

The invention provides a method for producing computer-to-plate (CTP) lining paper, which is characterized in that: the lining paper is produced by using a common multi-cylinder long mesh paper machine, and the production process comprises the following steps: pulp beating, pulp proportioning, paper manufacturing with pulps, surface sizing, press polish and rewinding to produce base paper, then carrying out subsequent press polish treatment on the base paper to produce finished paper; the CTP lining paper is produced from paper pulps which are made of hardwood pulps and softwood pulps, chemical additive cationic starch, cationic dispersed rosin size and auxiliary sizing agent aluminum sulfate serving as raw materials. In the method, the cationic dispersed rosin size is used and the auxiliary sizing agent aluminum sulfate is added for two times on a proportioning pool and at an outlet of a fan pump, so that the problem of producing the CTP lining paper by using cationic dispersed rosin acid sizing technology is successfully solved. The pH value of the water extract of the produced base paper is kept within a range of 5.2 to 5.8, so that the key indicator of the paper, namely, the pH value of the water extract of the paper, meets the quality requirement on the CTP lining paper.

Owner:ZHENJIANG DADONG PULP & PAPER

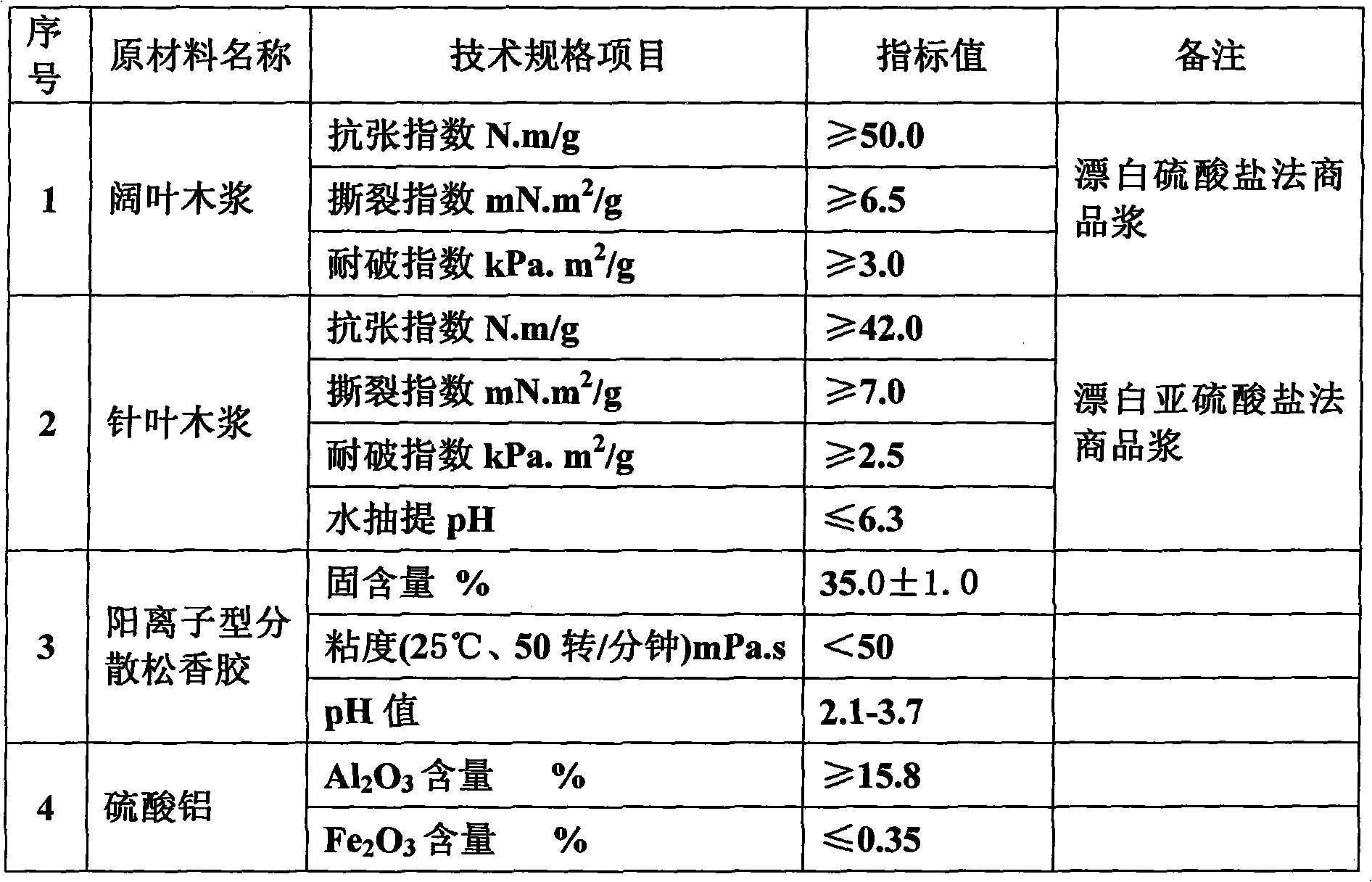

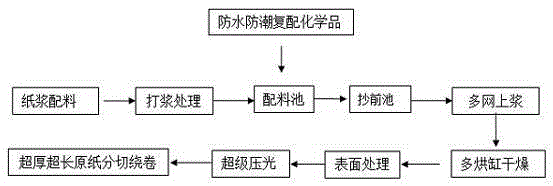

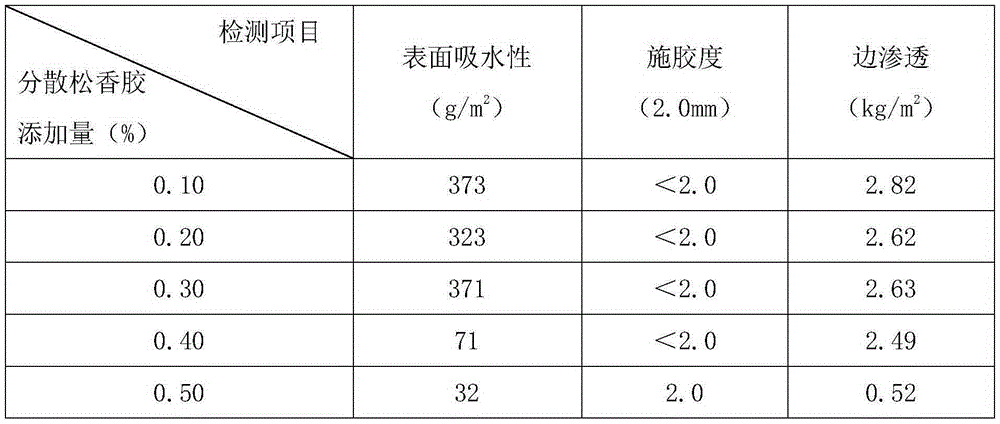

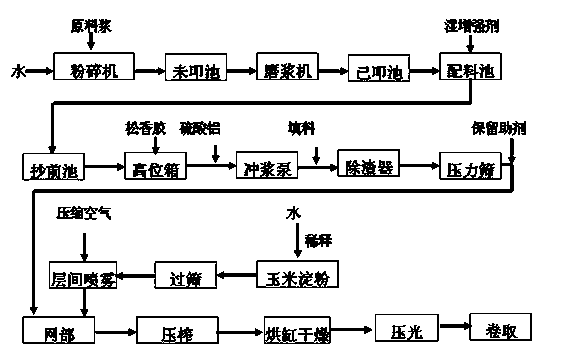

Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

InactiveCN105350375AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsFiberFibrillation

The present invention discloses a waterproof and damp-proof raw paper dedicated for electronic paper tapes, and a preparation method thereof. The method is characterized in that untwining and fibrillation are carried out on pulp fibers, fibrillation and cutting are further carried out so as to enable a pulp beating degree to reach 45 degree SR to 48 degree SR and a fiber wet weight to be reduced to 5.5 g to 8.0 g; and a water-resistant damp-proof composition is added in each layer, 1.0%-2.5% of the water-resistant damp-proof composition is added in relative to 100 parts of the pulp fibers, the water-resistant damp-proof composition including 0.15+-0.015 % of a wet strength agent PAE, 0.50+-0.05 % of gum rosin or an alkyl ketene dimer (AKD), 0.10+-0.01 % of silicon and fluorine type polymers, and 0.15+-0.015 % of ammonium zirconium carbonate. According to the above method, defibrination treatment is utilized, and a water-resistant damp-proof functional chemical is added in the pulp and coated on the surface of paper, surface water absorption and an edge permeation index of the raw paper are lowered than like products on the market, and water-resistance and damp-proofness of the raw paper are the best.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Vacuum type thermal transfer printing body paper and method for preparing same

ActiveCN102677522AImprove performanceLow costNatural cellulose pulp/paperSpecial paperTextile printerProcess engineering

The invention relates to vacuum type thermal transfer printing body paper and a method for preparing the same. The vacuum type thermal transfer printing body paper is used for printing processing carrier materials of aluminum section bars. The method includes preparing raw materials including 20-5-wt% of softwood pulp, 48-70wt% of hardwood pulp and 0.1-20wt% of talc; performing repulping for the prepared raw materials for 3 to 10 minutes; performing defibrination for the pulp mixture, then feeding the pulp mixture into a machine chest in a beating manner, and then feeding the pulp mixture into a proportioning pond in a beating manner while adding auxiliaries into the proportioning pool to realize proportioning; feeding the proportioned pulp into a pulp regulating pond to be regulated in a beating manner, and sequentially enabling the pulp to enter a papermaking forebay, a paper machine high-level box, a paper machine mesh and a paper machine squeezing portion to obtain a primary printing body paper product; adding auxiliaries into the paper machine high-level box; setting the vacuum degree of the paper machine mesh to range from 0.05MPa to 2.0MPa and the vacuum degree of the paper machine squeezing portion to range from 2.0MPa to 4.0MPa; and drying to obtain a finished product. The vacuum type thermal transfer printing body paper is degradable and is low in cost, fine in body paper performance and convenient to use.

Owner:ANJI DACHENG PAPER

Glueing method for papermaking process

InactiveCN1851123AImprove compatibilityGood neutral sizing effectWater-repelling agents additionPaper/cardboardAluminum sulphatePaperboard

The invention relates to a glue-applying method during papermaking, applying glue to the paper pulp in the front-web pulp supply system of the papermaking wet part, completing glue application by a four-element glue applying system with rosin- containing neutral glue 3-30 kg, aluminum sulphate 1-40 kg, low-molecular weight polymer A with high charge density 0.1-10 kg and high-molecular weight polymer B 0.1-10 kg. And the method is strongly compatible with basic fillings in the practical production, and has good neutral glue applying effect, and can be widely applied to producing neutral paper and paperboards.

Owner:上海埃格环保科技有限公司

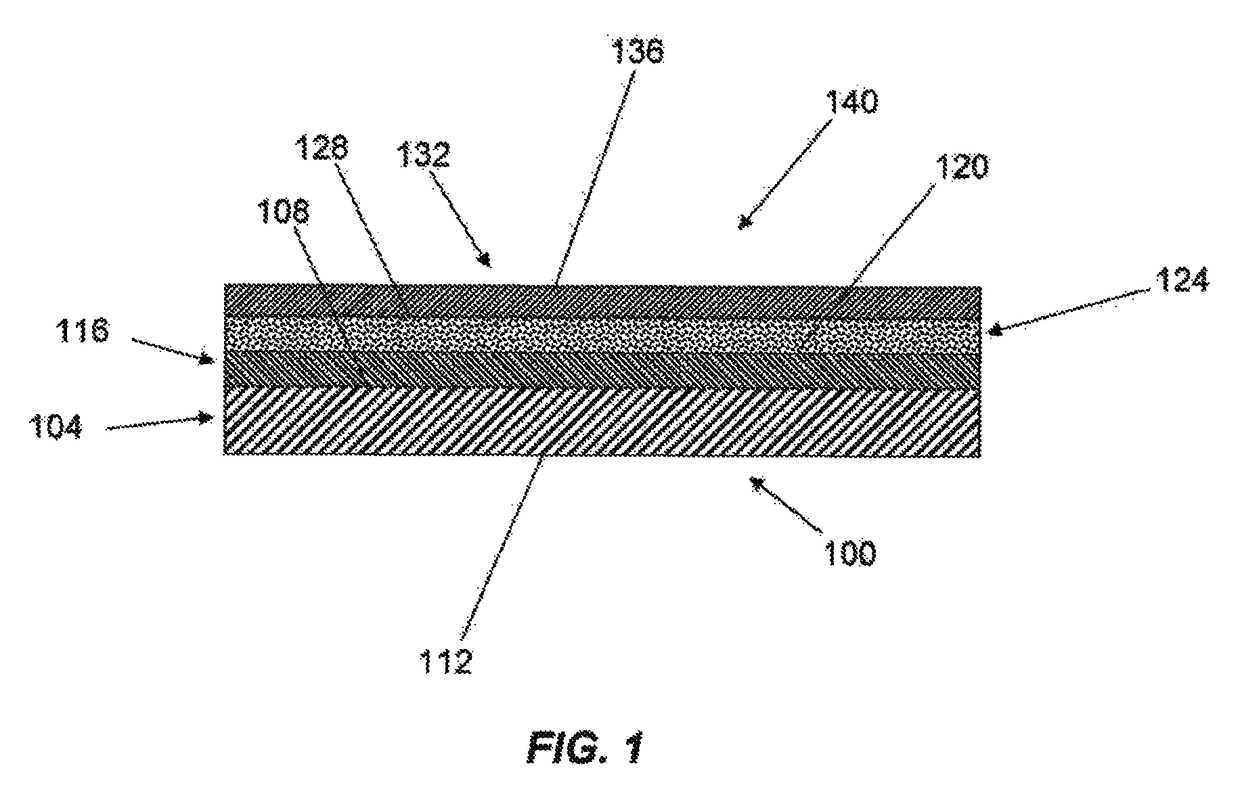

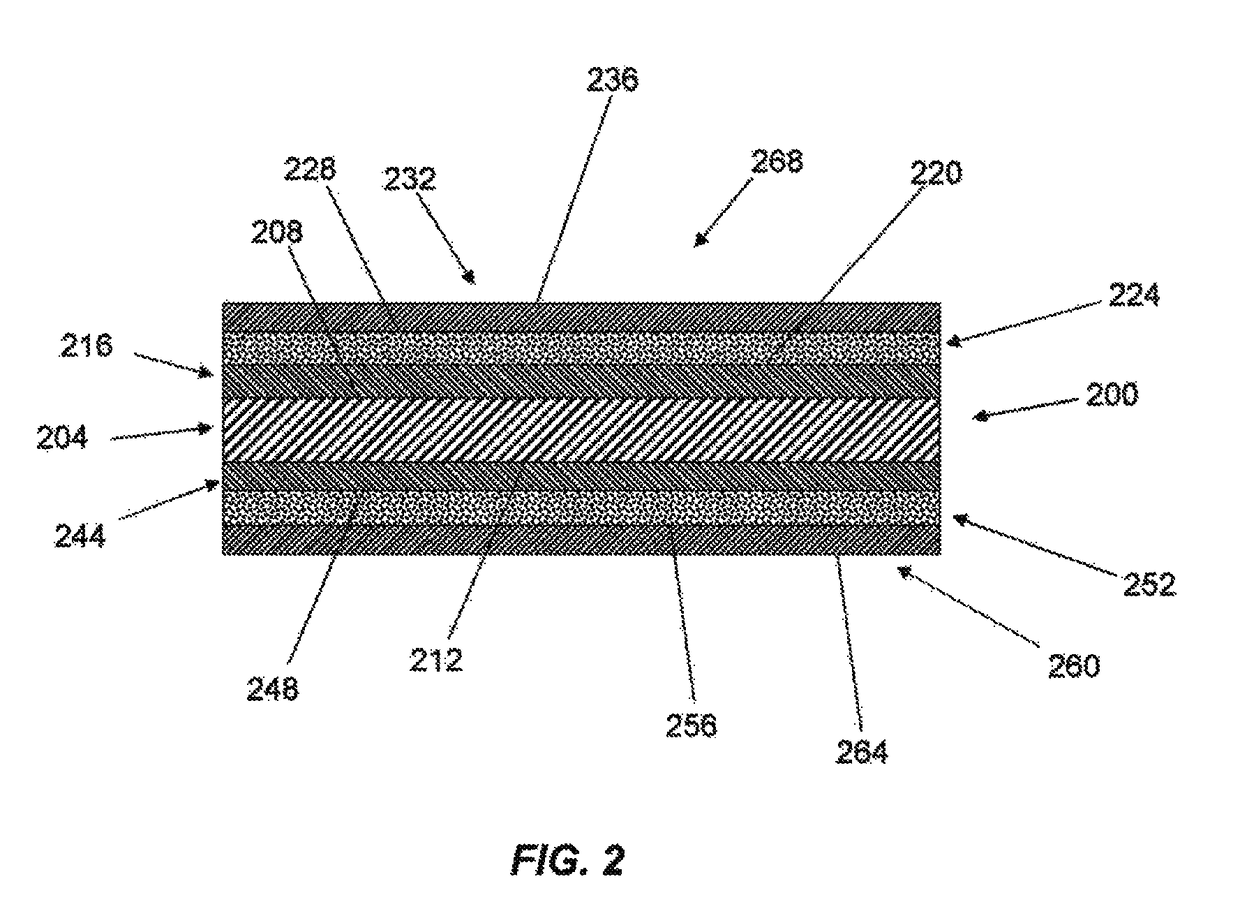

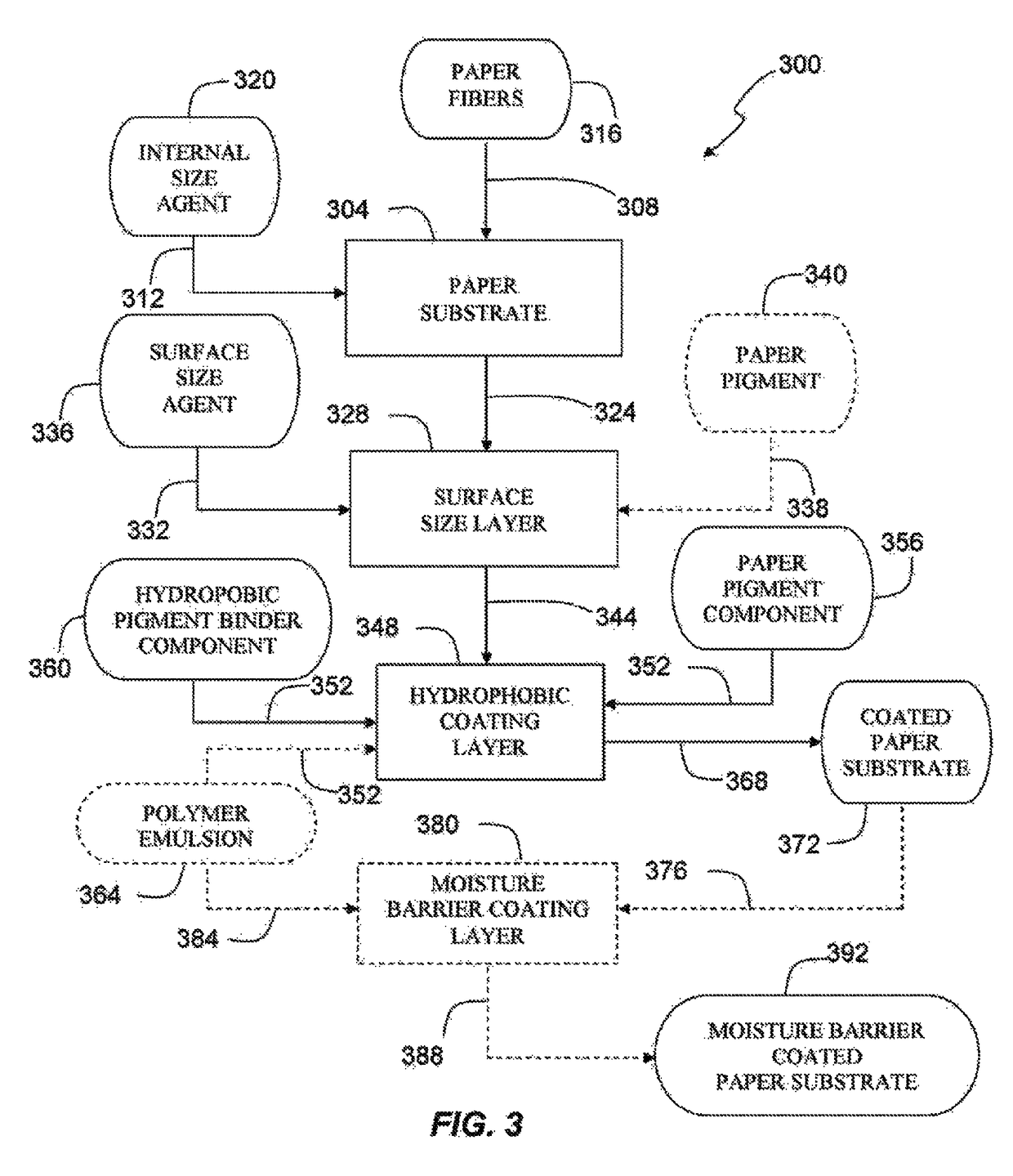

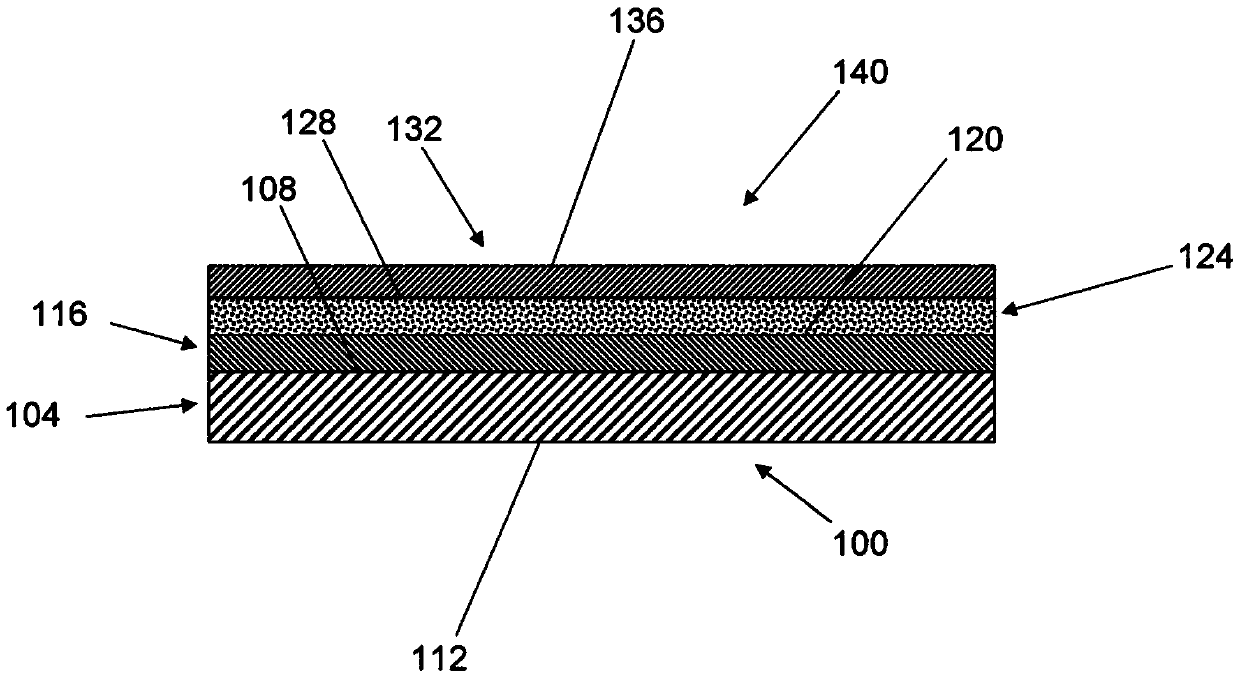

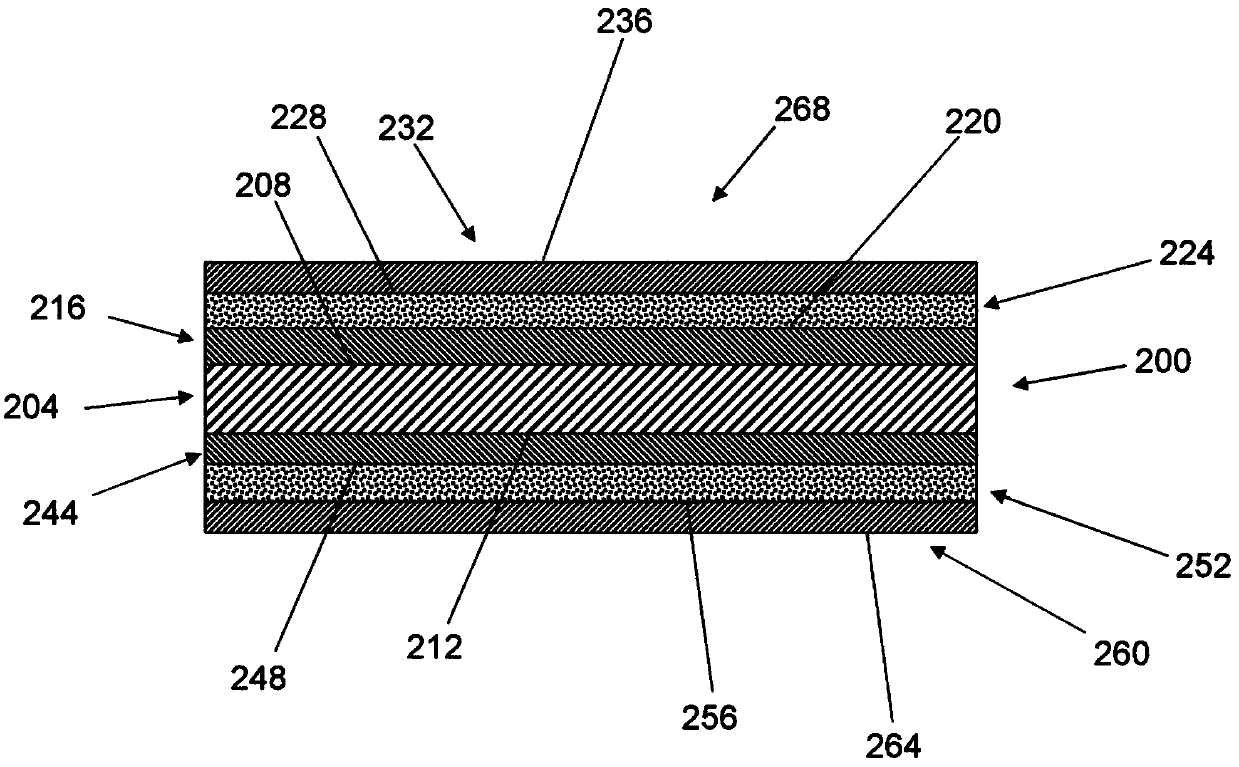

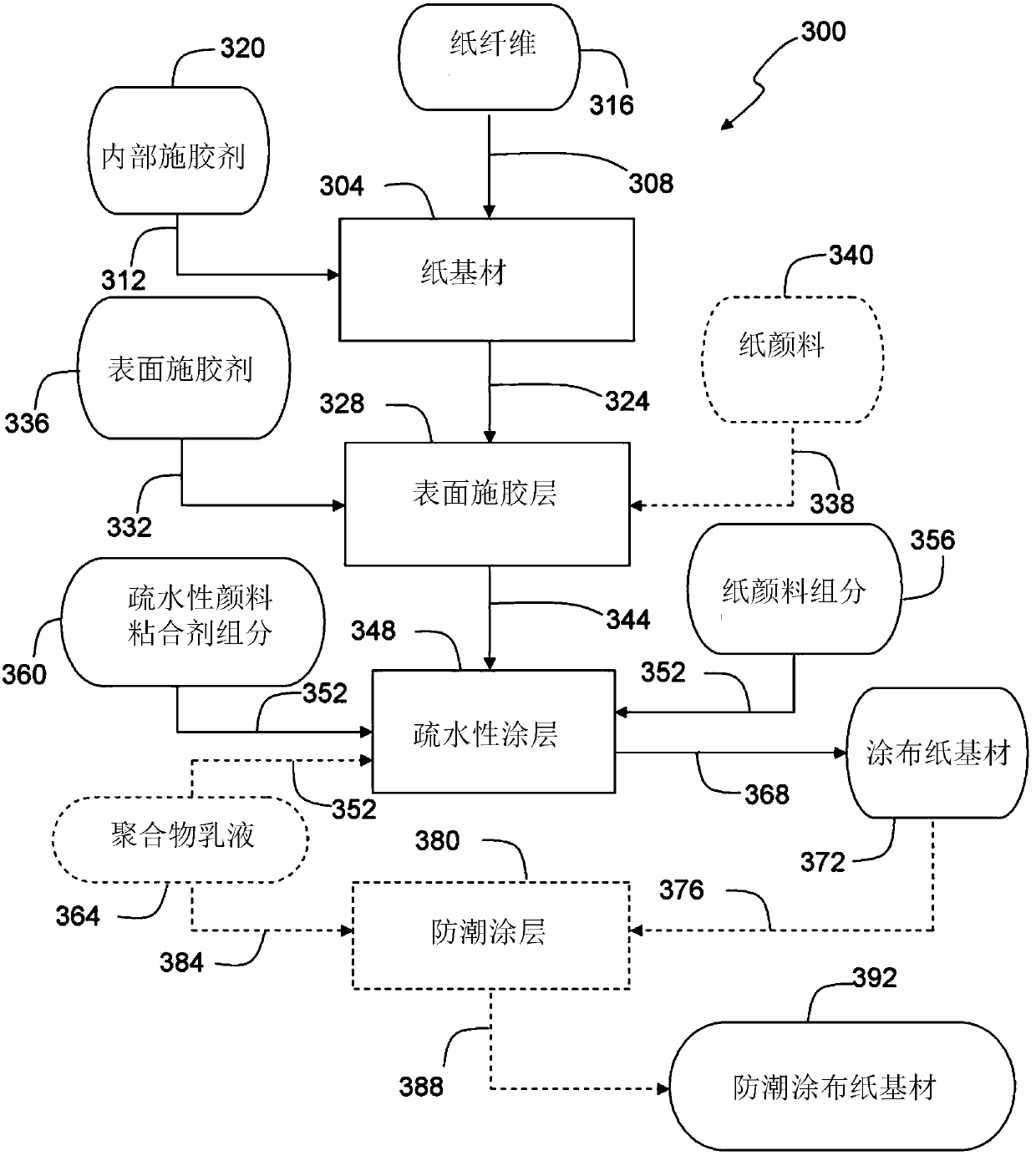

Hydrophobic coated paper substrate for polymer emulsion topcoats and method for making same

A hydrophobic coated paper substrate formed from a paper substrate of paper fibers and internal sizing agent, a surface size layer of one or more surface sizing starches, optionally one or more non-starch hydrophobic surface sizing agents, and optionally one or more paper pigments, on at least one surface of the paper substrate, and at least one hydrophobic pigmented coating layer of a paper pigment component and a hydrophobic pigment binder component on at least one surface size layer. Also a method for preparing such coated paper substrates.

Owner:GRAPHIC PACKAGING INT

Graphene nanometer far-infrared anion composite fiber conductive heating film and preparation method thereof

InactiveCN106900089AAdjustable surface resistivityEfficient releasePaper/cardboardRosin additionSurface resistivityFar infrared

The invention relates to the field of improving an electric heating element, in particular to a graphene nanometer far-infrared anion composite fiber conductive heating film and a preparation method thereof. The conductive heating film is prepared by the plant fiber pulp, graphene powder glue, nanometer bamboo charcoal fiber powder or nanometer far-infrared anion powder through the grinding, mixing, stirring, stir-frying, drying, pressing and winding processes. During preparation, through the steps of grinding, mixing and stirring, the plant fiber is processed by a disc mill into a broom shape so as to be more easily combined with the graphene powder glue, the graphene powder glue is added to mix and stir, and then a fiber dispersant and the nanometer bamboo fiber powder or nanometer far-infrared anion powder are added to stir evenly. According to the invention, the conductive heating film has the characteristic of adjustable surface resistivity, can be used for an antistatic circuit, can effectively release the charge, and also has the functions of far-infrared emission and anion release to play roles both in purifying and disinfecting and in human health.

Owner:王敏

Hydrophobic coated paper substrate for polymer emulsion topcoats and method for making same

InactiveCN107709665AInhibit surface adhesionCoatings with pigmentsWater-repelling agents additionFiberPulp and paper industry

A hydrophobic coated paper substrate formed from a paper substrate of paper fibers and internal sizing agent, a surface size layer of one or more surface sizing starches, optionally one or more non-starch hydrophobic surface sizing agents, and optionally one or more paper pigments, on at least one surface of the paper substrate, and at least one hydrophobic pigmented coating layer of a paper pigment component and a hydrophobic pigment binder component on at least one surface size layer. Also a method for preparing such coated paper substrates.

Owner:GRAPHIC PACKAGING INT

High stability cation dispersion rosin size and manufacture method thereof

ActiveCN101255668AImprove stabilityHigh solid contentWater-repelling agents additionRosin additionAlcoholRoom temperature

The invention relates to a high stable cationic dispersive rosin size and the preparation method, the content of a free rosin in the rosin size is more than 35%, the shelf life of the rosin size is longer than 1 year, after diluted by water, milkiness dispersive rosin sizes with different concentrations is obtained. The preparation method is that: firstly, under the conditions of room temperature and atmospheric pressure, the alcohol solution of 30-50% rosin or modified rosin is mixed with a cationic complex emulsifier which is made of a nonionic surfactant, a cationic surfactant and a cationization maleic rosin according to the weight ratio of 2:1-1.5:1-1.2, then the alcohol solvent is distilled because of vacuum. The rosin can be used in a papermaking technology in the process of papermaking.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +1

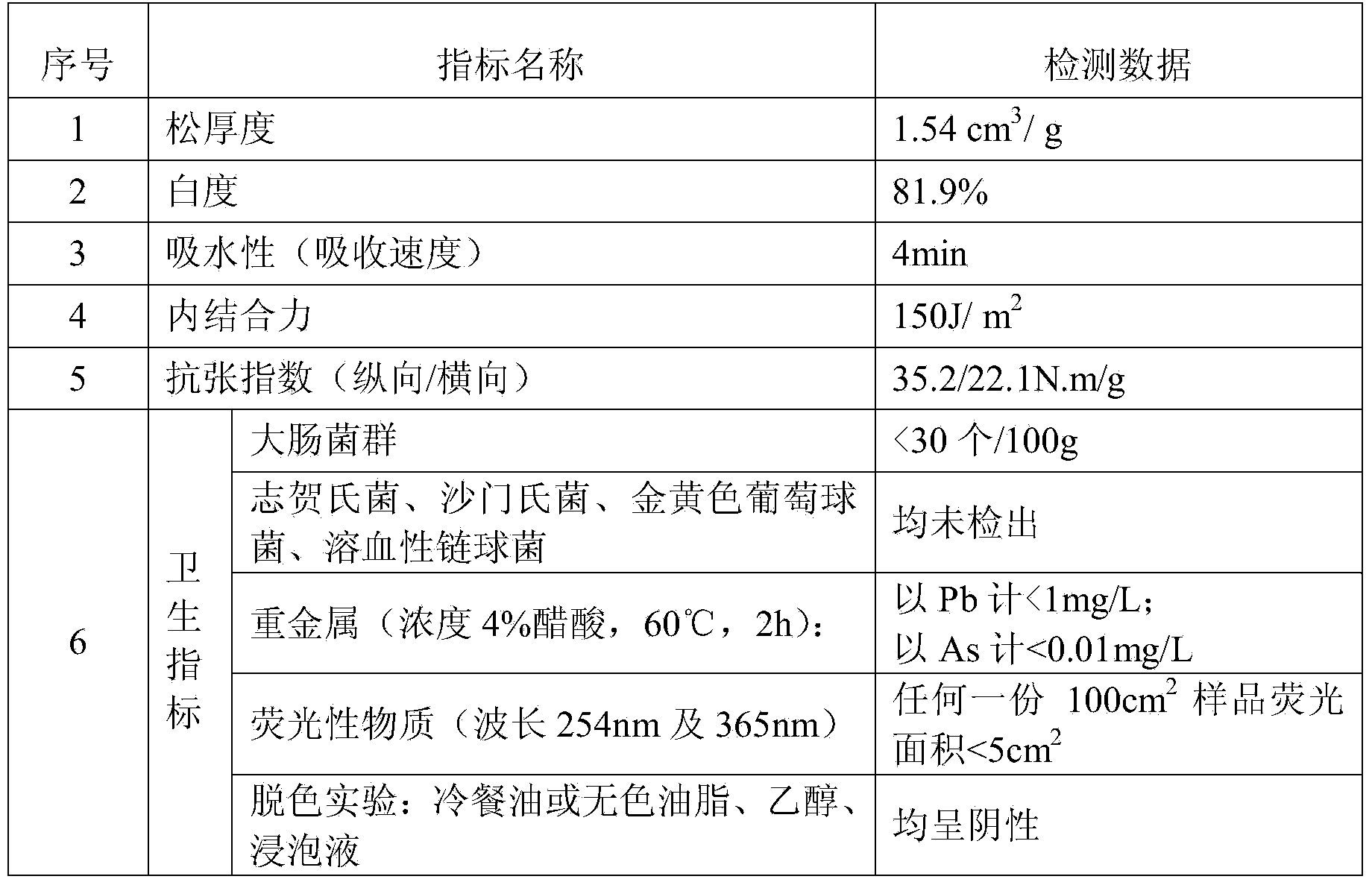

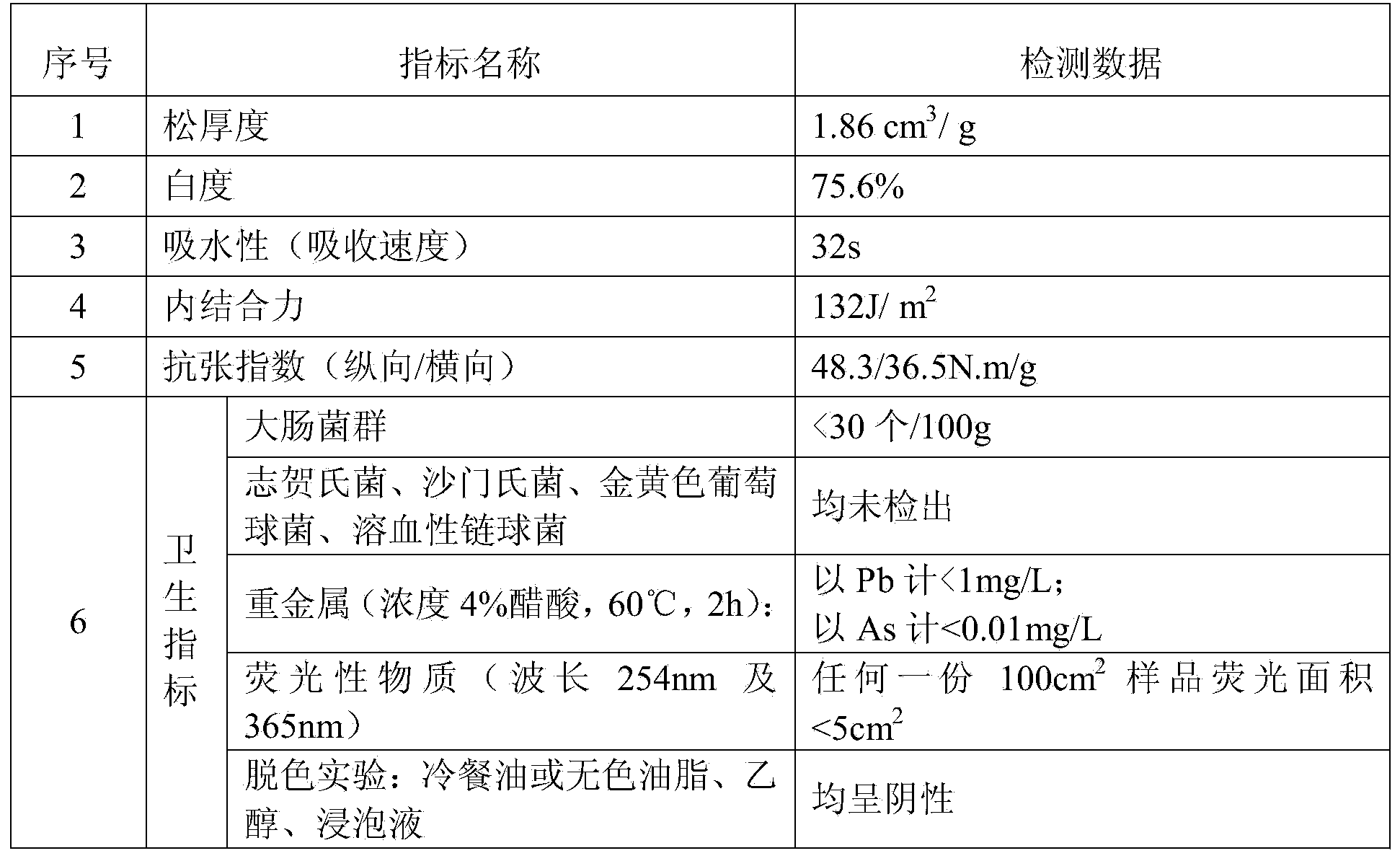

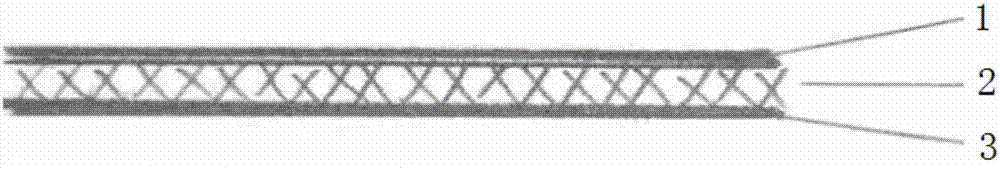

Cup mat body paper and production method thereof

ActiveCN104018388AIncrease bulkImprove water absorptionSpecial paperPaper/cardboardSulfateFood packaging

The invention belongs to the paper making technology and relates to cup mat body paper and a production method thereof. The cup mat body paper is formed by a face layer, a core layer and a bottom layer. Two of needle-point leaf wood pulp, hardwood pulp and mechanical pulp are used as raw material pulp of all the layers. A starch layer is formed between every two layers in a spraying mode so as to improve the bonding strength between every two layers. The needle-point leaf wood pulp is bleached sulfate process needle-point leaf wood pulp, the hardwood pulp is bleached sulfate process hardwood pulp, and the mechanical pulp is chemically bleached hot-ground mechanical pulp. A common triple-lap long-net multi-cylinder paper machine can be used for producing the cup mat body paper which is high in water-absorbing property and large in bulk, meets the requirement of the hygienic standard of the body paper for food packaging and is used for placing food and being packaged in bottle covers.

Owner:ZHENJIANG DADONG PULP & PAPER

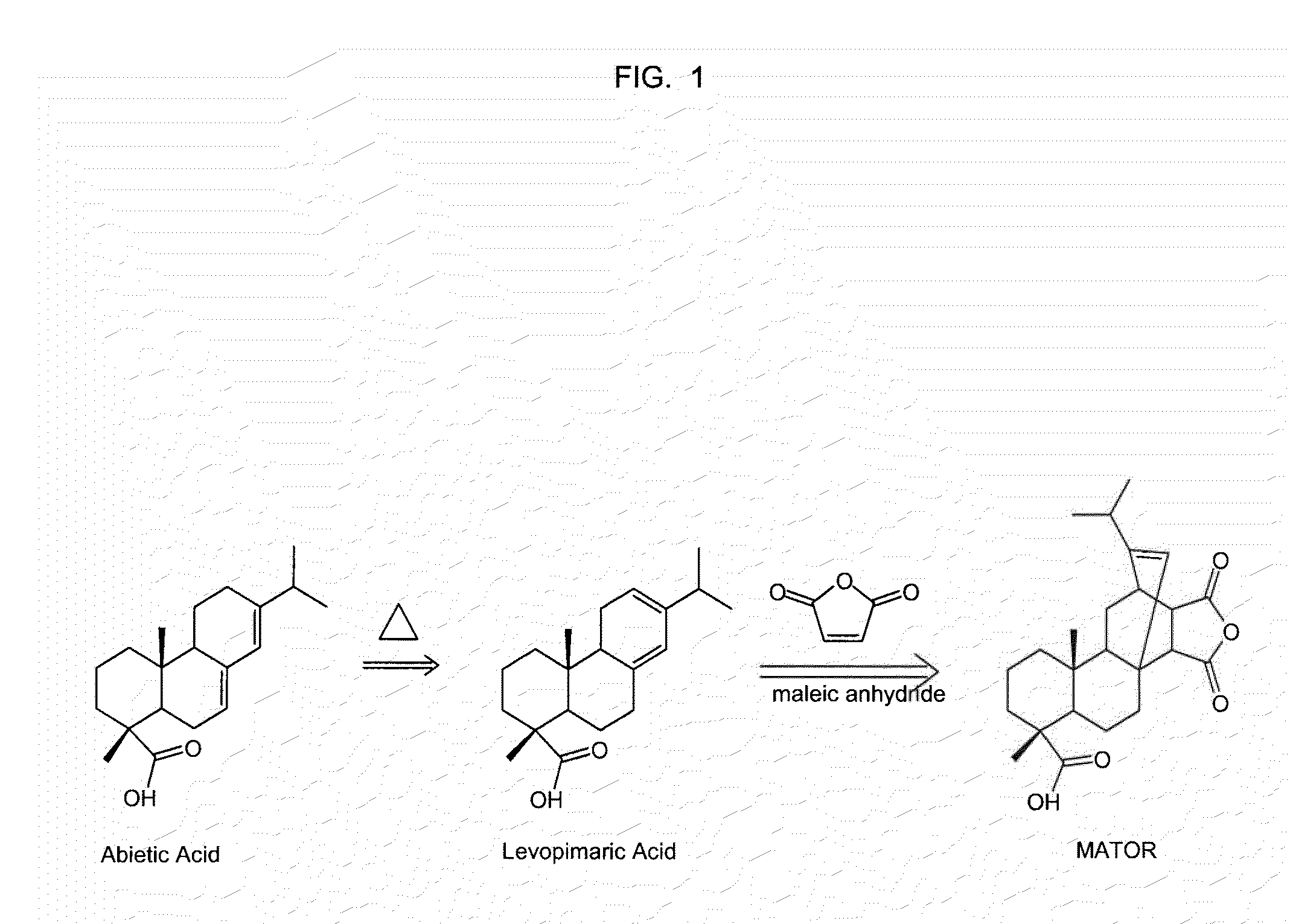

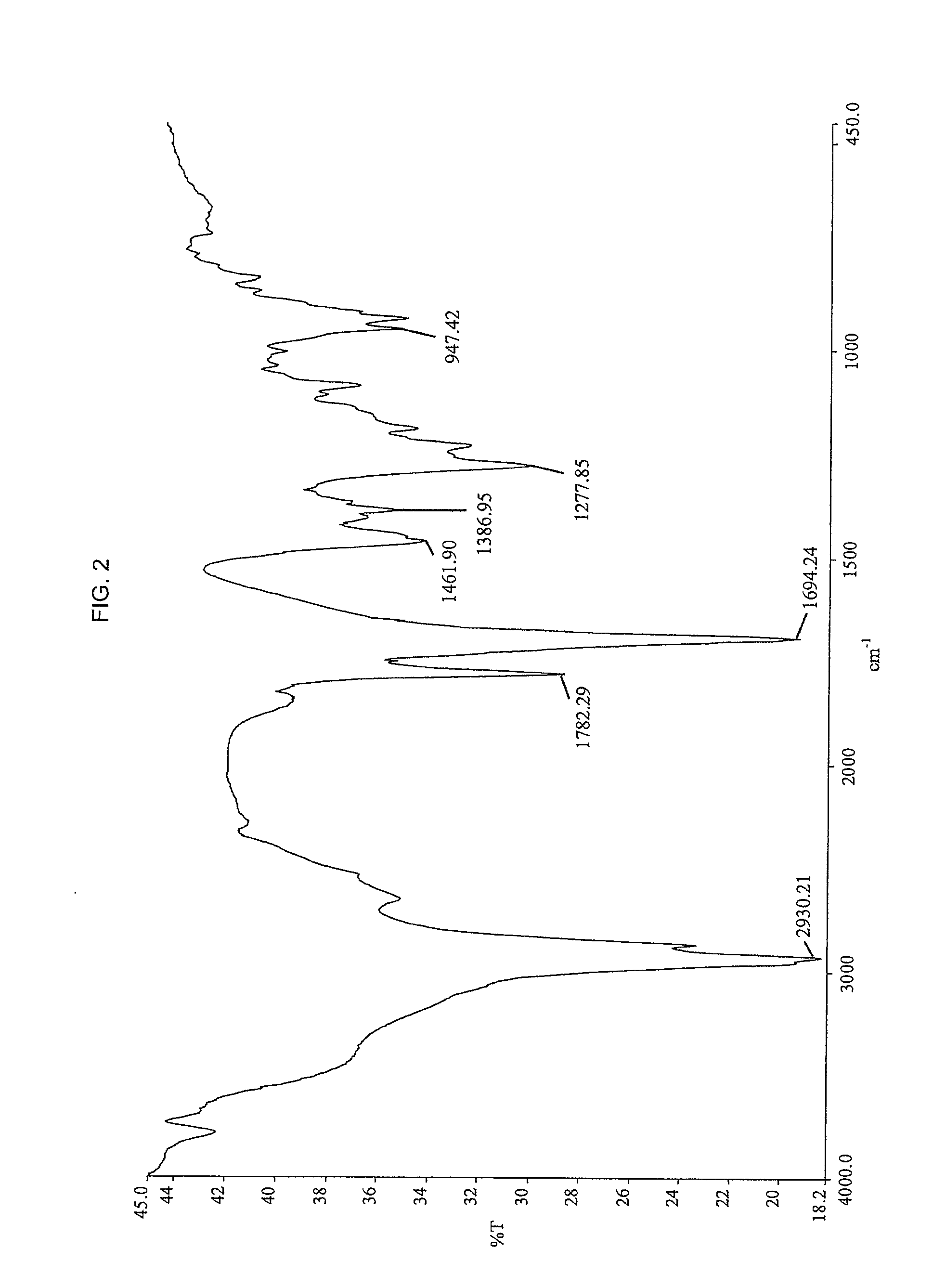

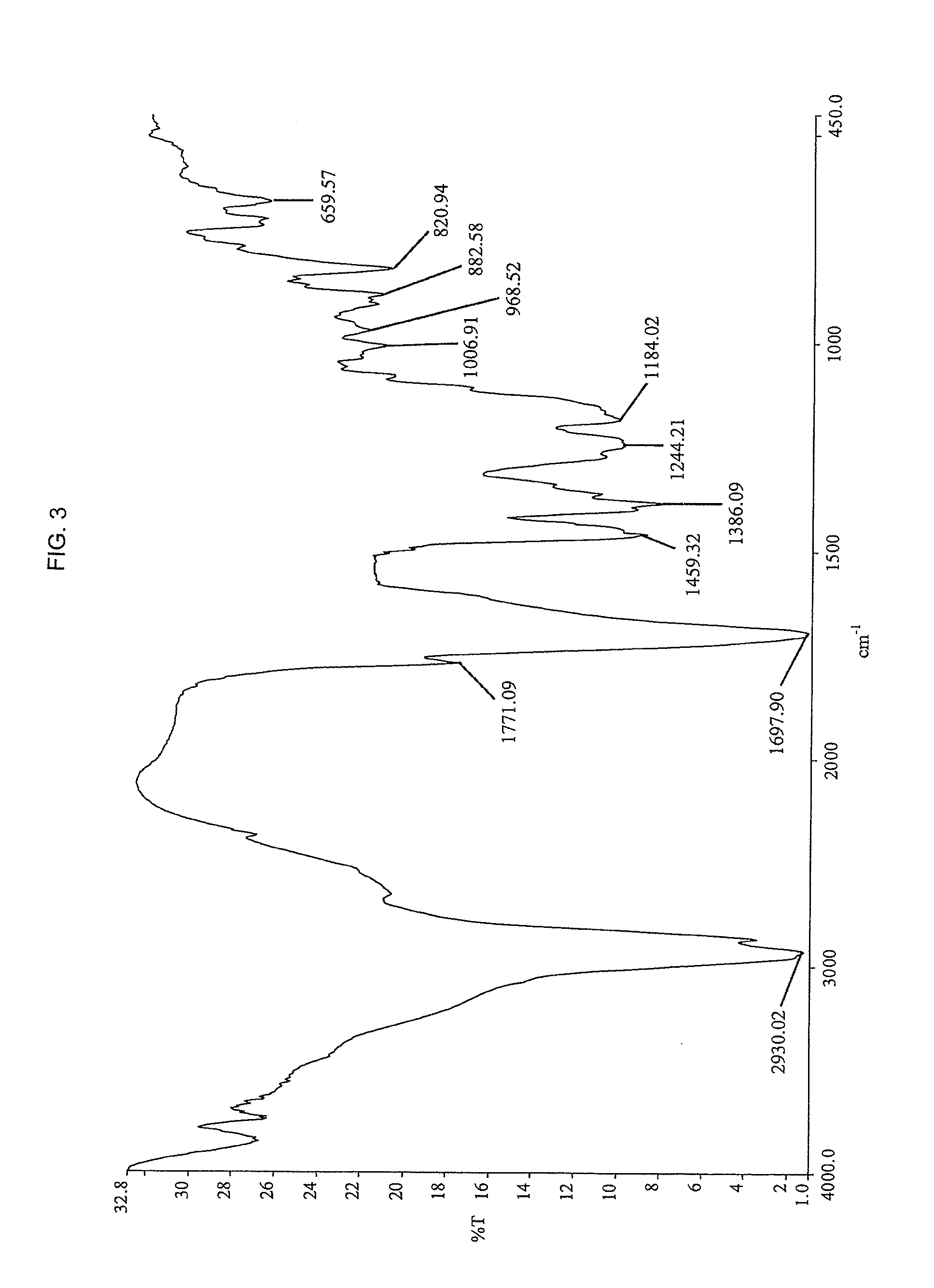

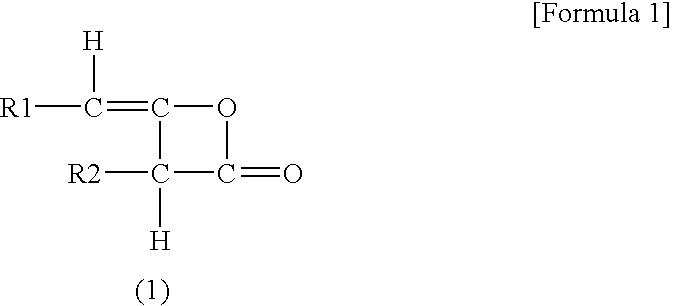

Imidized and amidized rosin compositions for paper sizes and other applications

Rosin is modified by maleation and then by imidization resulting in attaching a cationic polymer or cationic material upon the rosin. Alternatively, rosin can be fumarated and then cationic material attached by amide links. The products may be used for an efficient paper size and other applications of rosin products.

Owner:PLASMINE TECH

Method for preparing cation colophony/AKD neutral sizing agent

InactiveCN101649580AImprove stabilityImprove sizing effectWater-repelling agents additionPaper/cardboardFiberHigh pressure

The invention relates to a method for preparing a cation colophony / AKD neutral sizing agent. The method comprises the following steps: under the function of an organic solvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, acrylamide and a derivative thereof, a cation monomer and the like, as a copolymerization monomer and preparing cation saponin-free benzene emulsion by saponin-free emulsion polymerization; taking the cation saponin-free benzene emulsion as a cation high molecular surfactant, emulsifying and dispersing colophony andlong-chain alkyl ketene multimer (AKD) and preparing cation colophony / AKD emulsion with favorable stability and sizing performance by homogenizing at high pressure. The invention does not use a smallmolecular emulsifying agent and cation starch in the preparation process of a product and overcomes the defects of easy bubbling, poor stability, poor sizing effect and the like of the traditional AKD emulsion. The cation colophony / AKD emulsion prepared by the invention has stronger cation performance, particles have positive charges and are beneficial to remaining and combining with paper fibre,and the cation high molecular surfactant also has a certain sizing synergistic action, thereby enhancing the stability and the sizing performance of the emulsion greatly.

Owner:SHAANXI UNIV OF SCI & TECH

Neutral rosin sizing agent and its prepn

The rosin sizing agent consists of main components including modified rosin, tall oil, stearic acid, pine gum and paraffin; and supplementary material including polyethenoxy ether sulfo succinate, abietate, polymer dispersant and disinfectant. It is prepared through low pressure process with relatively high controllability and production quality stability. The sizing agent has high compatibility with calcium carbonate stuffing, high sizing effect, low production cost and less mildew produced in storage. The sizing agent is suitable for use in producing high-grade paper and paper card.

Owner:上海埃格环保科技有限公司

Method for making manual watercolour paper

ActiveCN105970716AGood paint effectStrong aging resistanceAgeing prevention agents additionWater-repelling agents additionPapermakingGelatin

The invention belongs to the technical field of papermaking, and discloses a method for making manual watercolour paper. The method comprises the following steps that 1, pulping is carried out; 2, gluing in pulp is carried out; 3, the pulp is poured into a container, water is added, and the mixture is fully mixed to be uniform; 4, paper fishing is carried out; 5, wet paper squeezing is carried out; 6, vacuum water absorption is carried out; 7, double rollers are used for embossing; 8, drying is carried out through a drying cylinder; 9, surface gluing is carried out, wherein the surface of dried finished paper is coated with gelatin or polypropylene glue or polypropylene glue, and natural drying is carried out. The manual watercolour paper good in drawing performance, high in ageing resistance and capable of meeting the individual needs of painters is obtained.

Owner:龙游鹏辰新材料科技有限公司

Graphene composite material far-infrared anion heating core electric heating floor and manufacturing process thereof

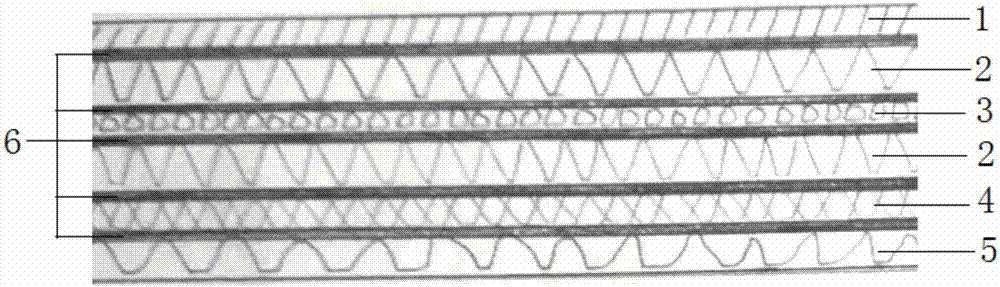

PendingCN107083833AImprove conductivityHigh electrothermal conversion rateNatural cellulose pulp/paperCovering/liningsFiberCarbon fibers

The invention belongs to the field of heating of electric heating floors and particularly relates to a graphene composite material far-infrared anion heating core electric heating floor and a manufacturing process thereof. The top of a heat preservation layer is connected with a back balance layer through an adhesive layer; the top of the back balance layer is connected with a solid wood composite plate or a high-density plate through an adhesive layer; the top of the solid wood composite plate or the high-density plate is connected with a graphene nanometer far-infrared anion composite fiber conductive heating film through an adhesive layer; the top of the graphene nanometer far-infrared anion composite fiber conductive heating film is connected with another solid wood composite plate or the high-density plate through an adhesive layer; and the top of the solid wood composite plate or the high-density plate is connected with a venner through an adhesive layer. According to the graphene composite material far-infrared anion heating core electric heating floor and the manufacturing process thereof, in order to save more energy and meet the requirement that the function of electric heating floors needs to be extended, the current advanced graphene raw material is adopted as a heater because the graphene material is recognized as having the optimal electric conductivity and heat conductivity, is superior to electric heating materials such as carbon fibers and carbon nano tubes, and has the higher electricity-heat transformation rate and far infrared radiation property.

Owner:北京绿能嘉业新能源有限公司

Finely cut paper product for use in mixing with resin, ecologically sound resin composition comprising the same, and ecologically sound molded resin article using the composition

InactiveUS20090236063A1Increase brightnessAvoid problemsSpecial paperPaper after-treatmentNatural fiberSynthetic resin

An object of the invention is to provide a finely cut paper product exhibiting a good workability in the production of a paper-resin composition comprising a mixture of a resin and a natural fiber, and improve the fluidity of an ecologically sound paper-resin composition using the finely cut paper product, so as to improve the moldability thereof when the composition is subjected to a working such as injection molding. An other object thereof is to restrain the generation of yellowing or the generation of an odor.The finely cut paper product for use in mixing with resin according to the invention is obtained by pulverizing neutral or alkaline pigment-free coated paper which comprises 70 to 100% by mass of hardwood bleached chemical pulp, 0 to 20% by mass of softwood bleached chemical pulp and 0 to 20% by mass of an inorganic filler, and has an ISO brightness of 70% or more. The ecologically sound paper-resin composition comprising it comprises 50% or more by mass of the above-mentioned finely cut paper product for use in mixing with resin, wherein the balance is made mainly of a synthetic resin, or wherein the main component is made of the above-mentioned finely cut paper product for use in mixing with resin and a biodegradable resin.

Owner:HOKUETSU PAPER MILLS

Method for making corrugated paper

InactiveCN104452411AImprove moisture resistanceHigh strengthWater-repelling agents additionReinforcing agents additionFiberPolyvinyl alcohol

The invention provides a method for making corrugated paper. The method includes the following steps that first, wax-bearing waste paper is selected to be used as a raw material for making the corrugated paper; second, the wax-bearing waste paper is pulped, pulp is subjected to screening, purifying and pulping treatment, the ash content of the pulp is made to be smaller than 8%, and the beating degree of fibers is 35-40 degrees SR; third, cation rosin size, aluminum sulfate and wet strength agents are added into the pulp to be evenly mixed; fourth, forming, dehydrating, squeezing and drying are conducted to obtain semi-finished corrugated paper; fifth, the semi-finished paper is subjected to surface sizing treatment, wherein the glue solution contains polyvinyl alcohol; sixth, drying is carried out, so that the finished corrugated paper is obtained. The corrugated paper produced through the manufacturing method is good in moisture resistance and high in strength and has a good application prospect.

Owner:NINE DRAGONS PAPER TAICANG LTD

Method for manufacturing outer bag paper of fruit raising bags by using adherography

InactiveCN102660890ASimple production processFastReinforcing agents additionWax additionPaper productionPrinting ink

A method for manufacturing outer bag paper of fruit raising bags by using adherography comprises repulping, slurry matching, net portion shaping, dehydrating by squeezing, stoving, rolling and separately cutting body paper products obtained by rewinding. Offset printing comprises mixing black printing ink and printing on a machine. The outer bag paper of the fruit raising bags produced by the method can be separated into body paper and an ink layer, shading performance is achieved by printing the black ink layer on the body paper, and the method has the advantages of being simple in body paper production process, capable of producing by using a long net paper machine, rapid in speed, low in cost, less in pollution and the like, and simultaneously solves the problem that carbon black in a lamination method and used in the liquid for dying causes pollution, use ratio is low, a circular net paper machine is slow in speed and the like. The black printing ink is used for printing, anti-liquid-permeation performance of the paper can be improved, simultaneously the paper has good opaqueness, is not prone to fade, keeps high compliance and air permeability.

Owner:SHAANXI UNIV OF SCI & TECH

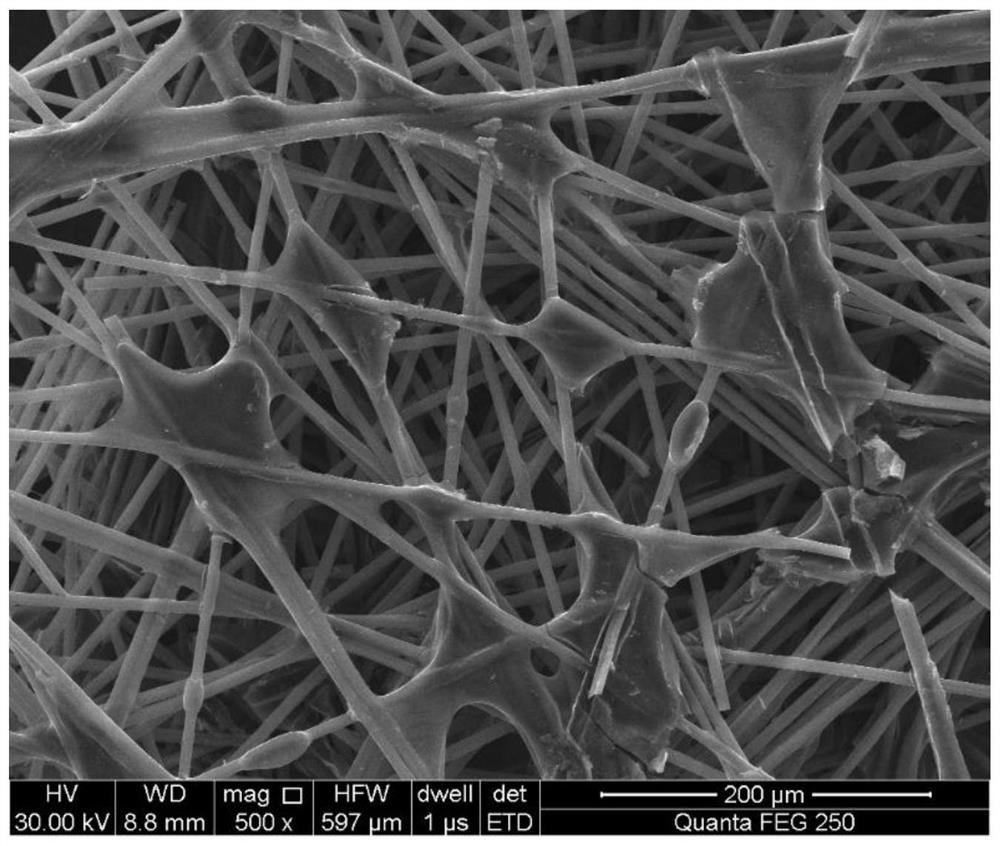

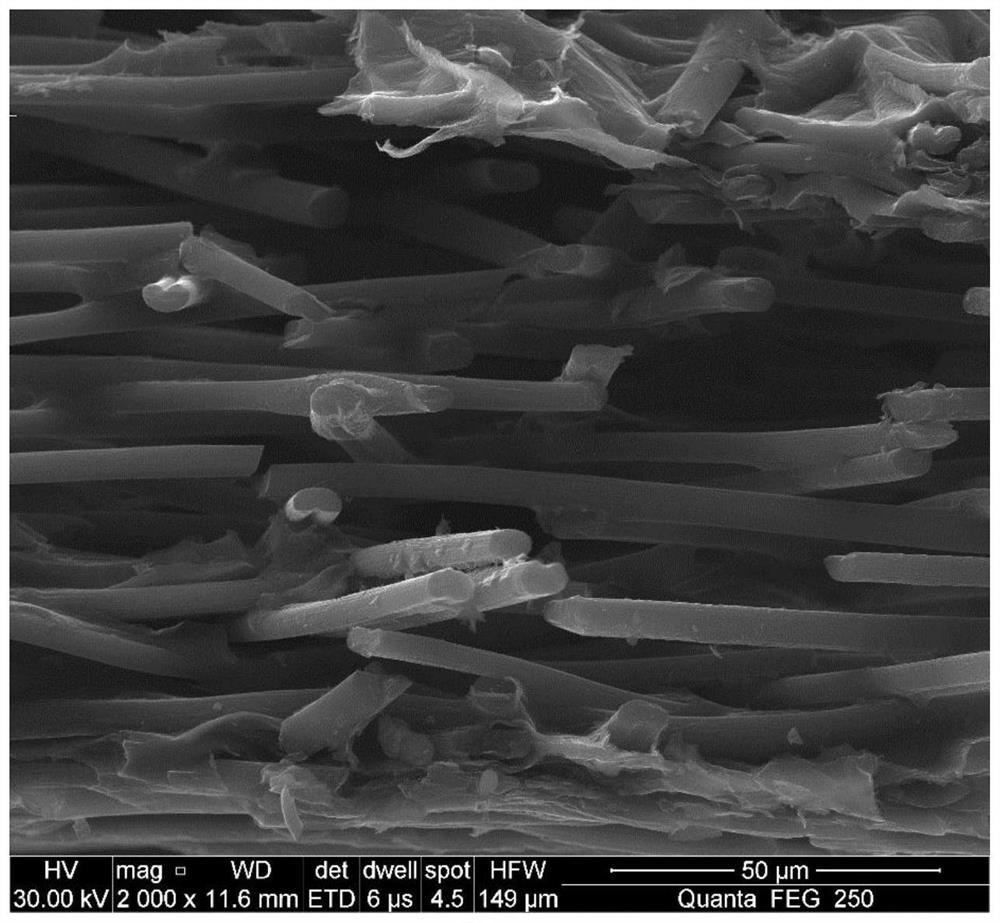

Preparation method of gradient pore structure carbon paper

ActiveCN113322713AEnhanced mass transferImprove heat transfer performanceCell electrodesSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The invention discloses a preparation method of carbon paper with a gradient pore structure, which comprises the following steps: separately degumming and oxidizing carbon fibers with different length-diameter ratios, and respectively dispersing the treated carbon fibers in a dispersant solution to form carbon fiber slurry with different length-diameter ratios; sequentially carrying out gradient layering and inclined net forming on the carbon fiber slurry according to the length-diameter ratio of carbon fibers from high to low to obtain a carbon felt precursor with a three-dimensional net structure; dipping the carbon felt precursor in a resin solution, taking out the dipped precursor, and conducting drying to obtain a carbon felt; and firstly hot-pressing the carbon felt into carbon paper body paper, and then conducting carbonization and graphitization treatment to obtain the gradient pore structure carbon paper. According to the invention, gradient layering is carried out in sequence from high to low according to the length-diameter ratio of the slurry carbon fiber, so that the prepared carbon paper has a gradient pore structure, communicating pores are formed in the carbon paper, the pore diameter changes in a gradient manner along the normal direction on the plane of the carbon paper, a pressure gradient is formed in a diffusion channel, the gas conveying efficiency can be improved, and the mass transfer and heat transfer performances of the carbon paper are effectively improved.

Owner:CENT SOUTH UNIV

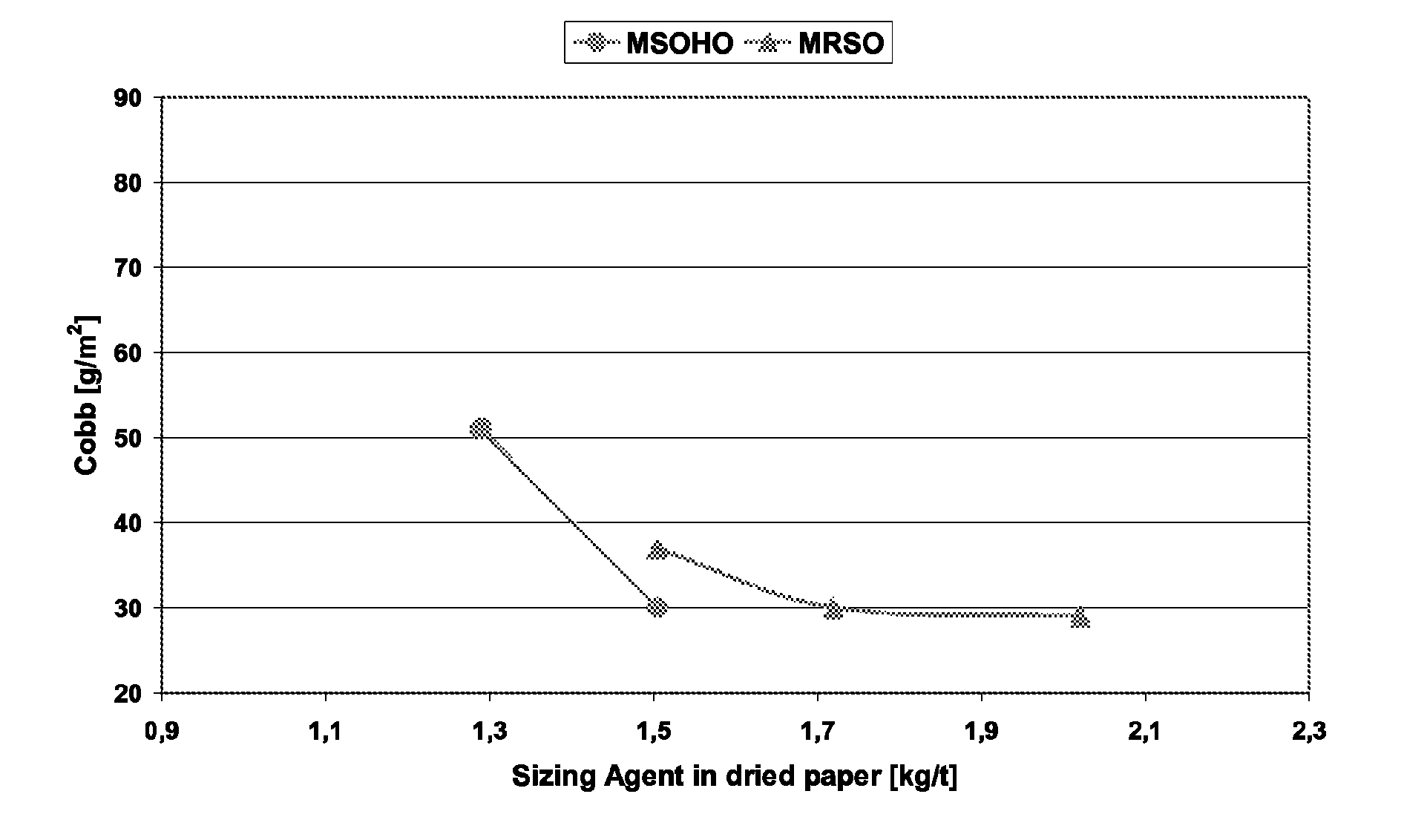

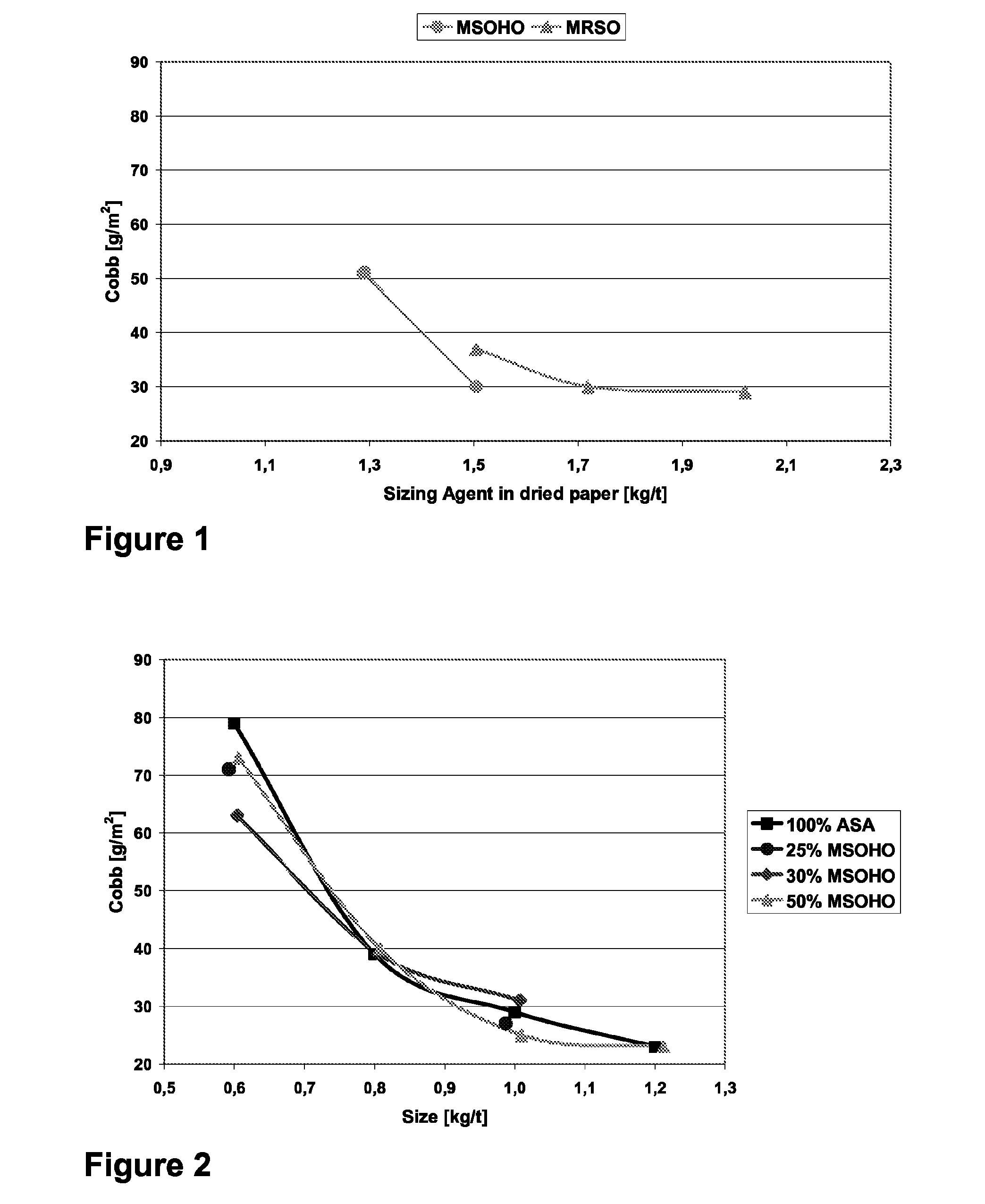

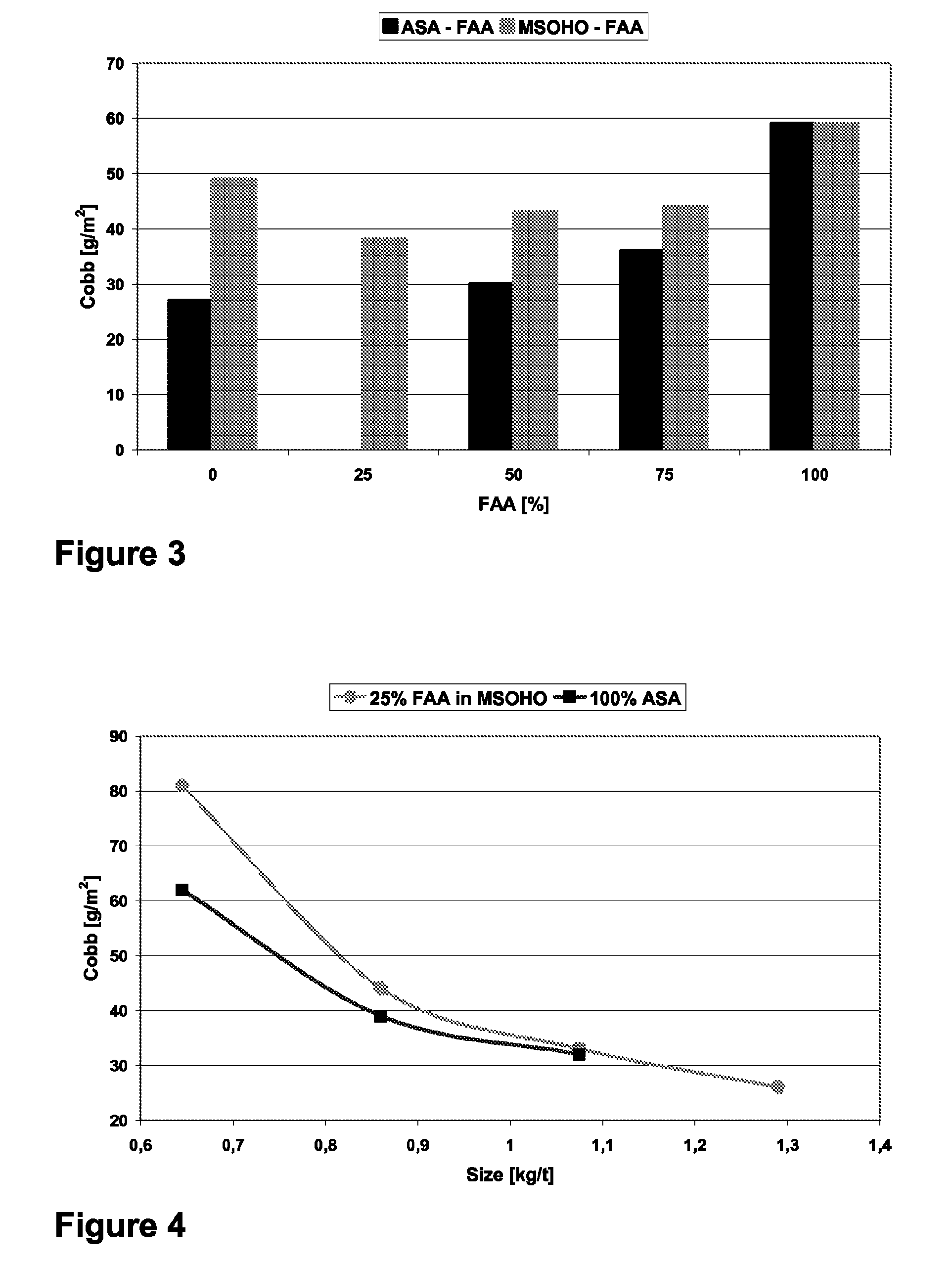

Product for the sizing of paper

The present invention relates to a paper sizing agent and emulsion comprising a maleated vegetable oil size wherein at least 50% by weight of the total fatty acids of the triglycerides are monounsaturated. The invention also relates to a process for the preparation of such maleated vegetable oil size.

Owner:KEMIRA OY

Plastic-emulated printing paper and its manufacturing technique

InactiveCN101265683AFine paperStrong ink absorptionSpecial paperWater-repelling agents additionFiberEcological environment

An analogical printing paper belongs to the technology field of papermaking, and is made through the following steps: adding 1.0-1.5 weight parts of barrier used for improving the smoothness and the permeability resistance of the paper, 2.0-2.5 weight parts of water resisting agent used for improving the water resistance of the paper and a proper amount of auxiliary agent to 100 weight parts of the paper pulp; papermaking; wetting and calendaring. By adopting the material of bleached plant fiber, the inventive method includes pulping, sizing, adding the chemical auxiliary agent and papermaking on the multi-cylinder line mesh paper machine to obtain the base paper, then wetting and supercalendering. The printing paper has the advantages that the paper has the appearance the feature of a polypropylene film-brightness and transparence, which, as packaging material instead of Bopp, is capable of fully degrading and protecting the ecological environment; in addition to the refined paper quality and high oil absorbency, the analogical printing paper has fine printing quality and high water resistance, in case of raining and drenching, the paper is capable of water resisting, keeping the paper surface smooth and being free from deformation, breakage and decoloring. The paper is applicable to the packaging material and plays a role in the moisture-proof preservation of the food and is capable of extending 30% of the preservation period.

Owner:BAOJI JIANZHONG WUYI PAPER

Graphene nano far infrared negative ion composite fiber conductive heating plate and production process

InactiveCN107197549AImprove conductivityHigh electrothermal conversion rateNon-macromolecular organic additionPaper/cardboardFiberCarbon fibers

The invention belongs to the field of a heating plate made from an electric heating material, and particularly relates to a graphene nano far infrared negative ion composite fiber conductive heating plate and a production process. The conductive heating plate comprises an impregnated glass fiber fabric layer, a heating core and an impregnated glass fiber fabric layer; the impregnated glass fiber fabric layer and the impregnated glass fiber fabric layer are respectively arranged at the top and the bottom of the heating core; and the heating core is a graphene nano far infrared negative ion composite fiber conductive heating film. In order to save energy better and play the requirement of the conductive heating plate for expanding functions, according to the invention, graphene advanced nowadays is used as a raw material; and as a heating body, the graphene material is a recognized material with the best electrical conductivity and thermal conductivity, is superior to electric heating materials such as carbon fibers, carbon nanotubes and the like, and is higher in electric-thermal conversion rate and stronger in far infrared radiation.

Owner:北京绿能嘉业新能源有限公司

Preparation method of molded pulp plastic packaging material

ActiveCN107083724AImprove retentionImprove smoothnessPolycrystalline material growthFrom normal temperature solutionsMolded pulpPolyvinyl alcohol

The invention discloses a preparation method of a molded pulp plastic packaging material, and belongs to the technical field of packaging materials. The molded pulp plastic packaging material is prepared through the following steps: soaking a waste single-face corrugated board in deionized water, crushing, pulping, washing to remove impurities, adding into the deionized water to prepare a pulp suspension solution, taking a land plaster as a raw material, doping with aluminum chloride to obtain a compound gypsum crystal whisker, gelatinizing a corn starch, compounding the corn starch with span-80 and tween-60 to prepare a compound emulsifier, modifying rosin through the compound emulsifier, cationic polyacrylamide and polyvinyl alcohol, finally mixing the pulp suspension solution, the compound emulsifier and a modified rosin size, filtering water, forming, demolding, reshaping through hot pressing. According to a prepared molded pulp, a size film is generated on the surface of a paper film through the compound gypsum crystal whisker and the modified rosin size, so that the moisture content of a wet green is reduced, the structure strength of the wet green is improved, the tearing phenomenon easily occurring in the demolding process is avoided, and the rate of finished products is increased.

Owner:YIXING XINTIANDI PACKING PROD

Waterproof vibration plate for speaker

InactiveUS20070137820A1Improve waterproof performanceEnvironmental pollution causedNatural cellulose pulp/paperSpecial paperWaxEmulsion

There is provided a speaker that uses a waterproof vibration plate that is obtained by forming a water repellent layer containing wax on a surface of paper pulp by the use of a wax-based emulsion in a suspension of the paper pulp, then forming a binder layer containing rosin or alkyl ketene dimmer on a surface of the water repellent layer by the use of a rosin sizing agent or an alkyl ketene dimmer sizing agent in the suspension, then forming an oil repellent layer containing a fluorinated resin on a surface of the binder layer by the use of a fluorine-based resin emulsion in the suspension, then forming the paper pulp into paper, and then heating and drying the same.

Owner:OG KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com