Hydrophobic coated paper substrate for polymer emulsion topcoats and method for making same

A hydrophobic, paper-based technology used in coatings, pigmented coatings, papermaking, etc., that can solve problems such as loss of structural integrity, wet cups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

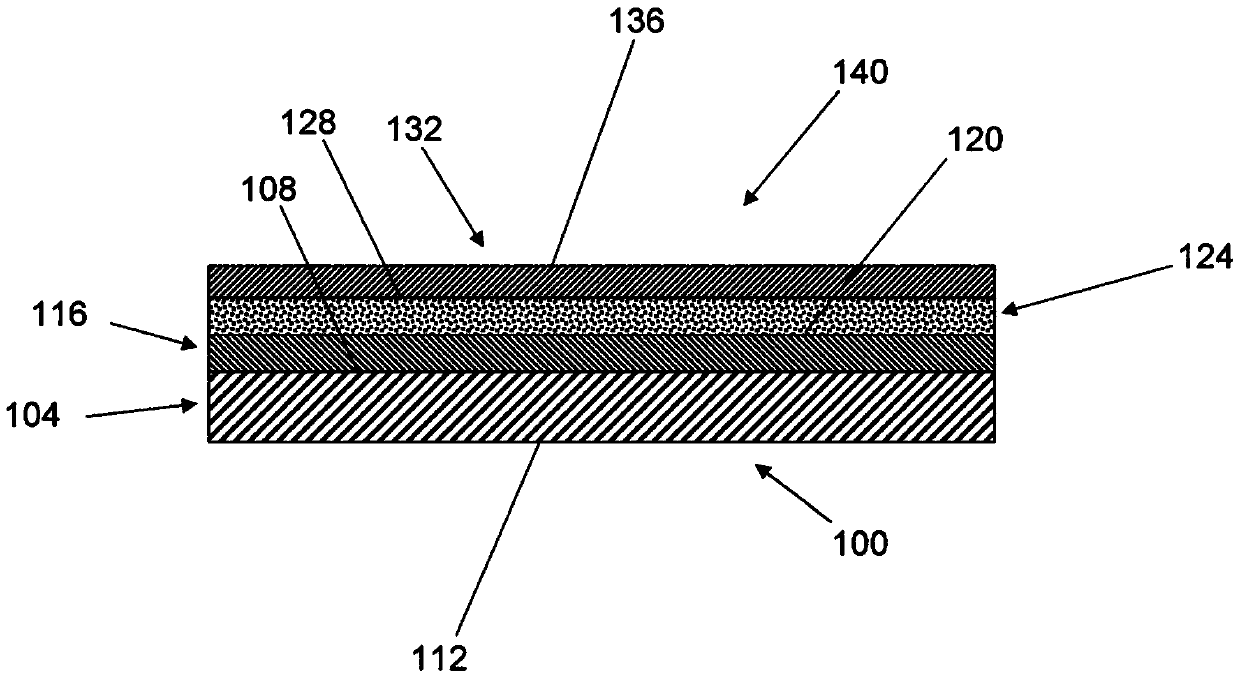

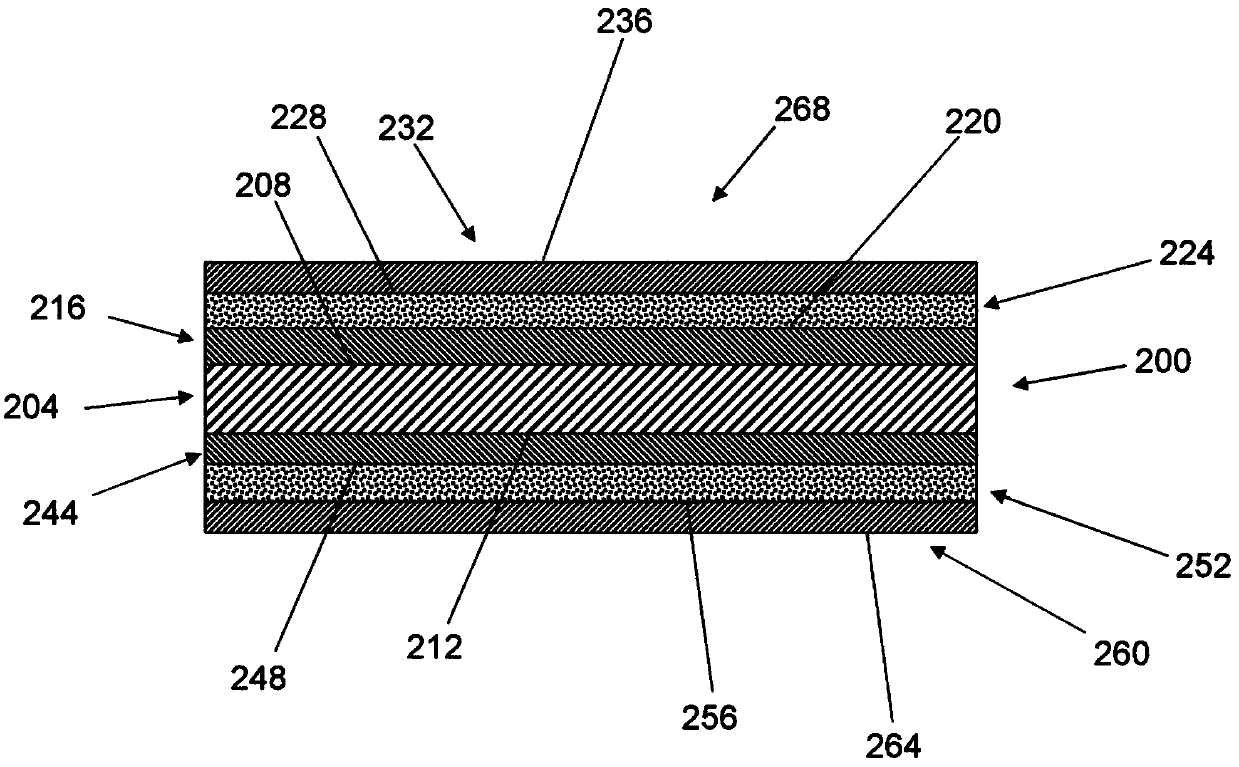

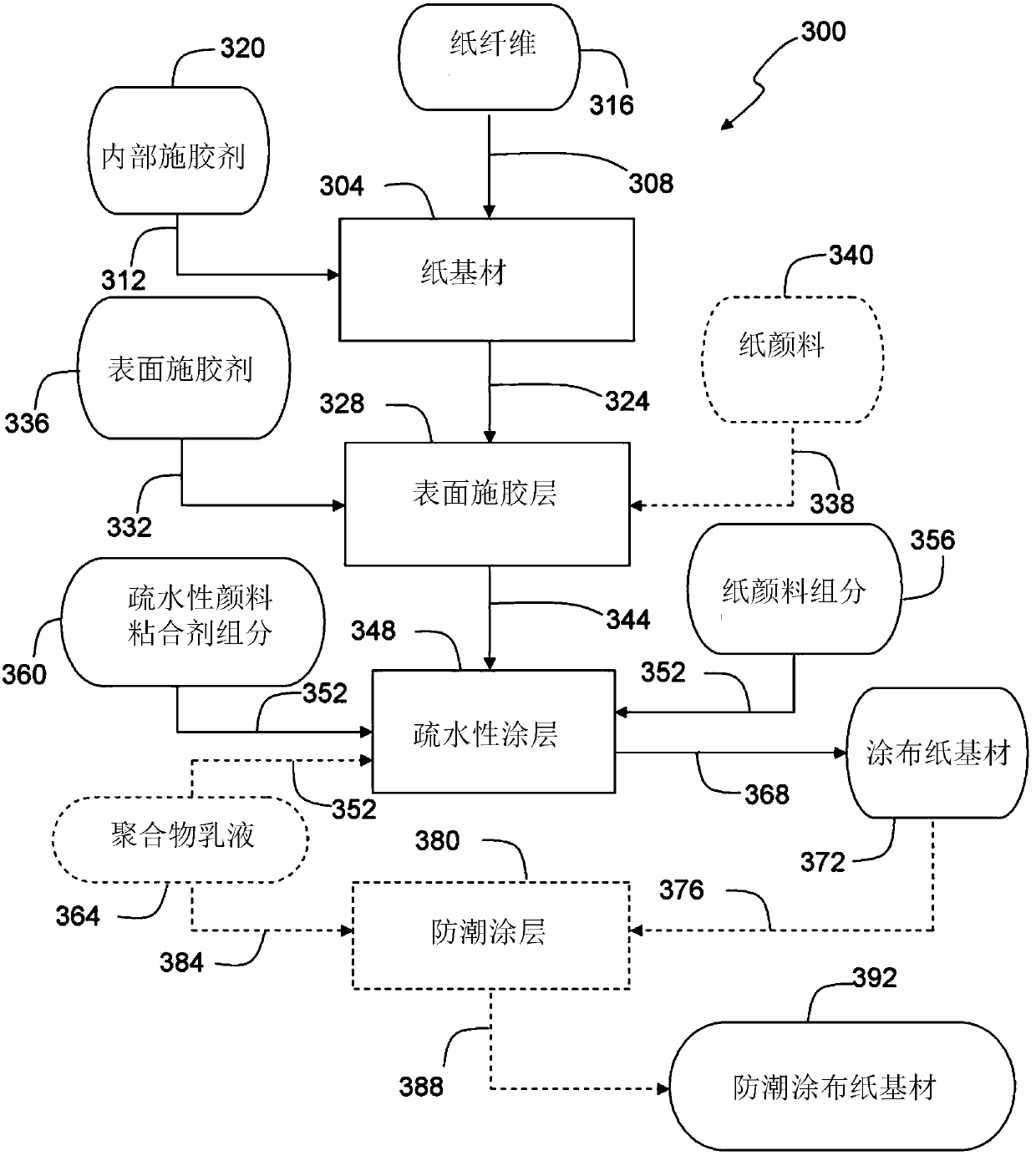

[0109] Coated paper substrates (eg, 12 or 24 point thickness and 257 or 165 basis weight paperboard) were formed as follows: The control (C) sample was a commercially available 24 point coated paperboard with 12-16 lb / 3msf coat weight of conventional pigmented coatings designed for paper substrates used in lithographic and flexographic printing. Samples S-1 and S-2 used a commercially available 14 point uncoated cup with a size press layer containing starch size. The uncoated cups were coated with a hydrophobic coating formulation (shown in Table 1 below) using a wire wound rod and then dried in a forced air oven at a temperature of 110°C for 2 minutes. The resulting hydrophobic pigment coating (HPC) layer had a coating weight of 10 lb / 3 msf. Moisture barrier coatings were then also applied to these HPC layers using wire wound rods from a commercially available polyethylene terephthalate (PET) emulsion coating (Sustainable Fiber Solutions, SFS Coating 230HS). Samples S-3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com