Patents

Literature

440results about How to "Improve sizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AKD emulsion and method for producing the same

The invention relates to an AKD emulsion and a preparation method thereof, which belongs to the Paper Chemicals field. Nonionic monomer, positive ion monomer and natural high molecular compound are used to a generate glycerol polymerization reaction for preparing positive ion polymer which is used as emulsifying agent under the effect of compound evocating agent, and then the AKD emulsion is prepared by using the method of mechanical stirring and emulsification. The AKD emulsion is used for glue blending in the slurry and on the surface of paper making, thereby improving glue blending effect and reducing glue blending cost.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

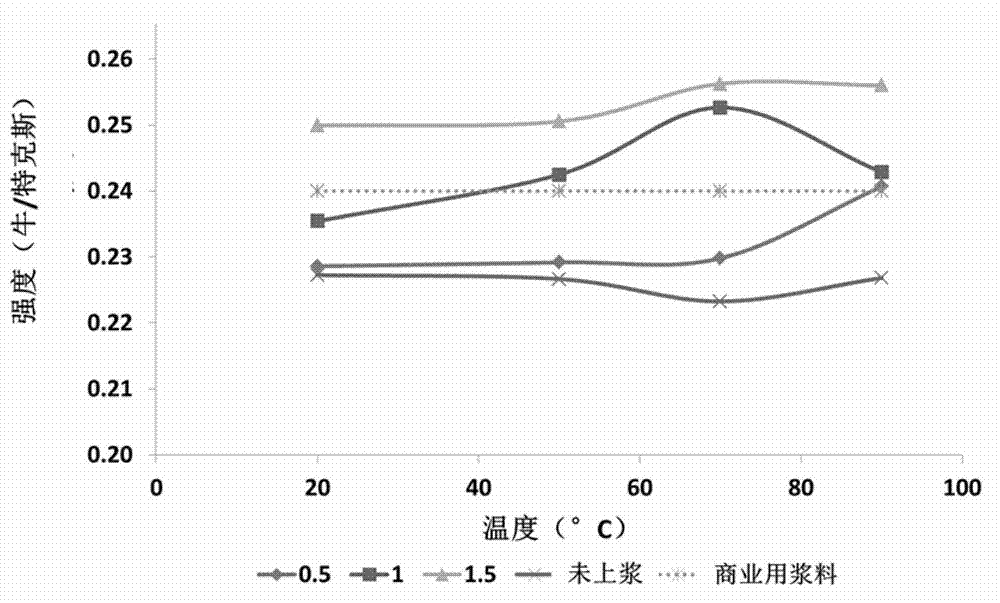

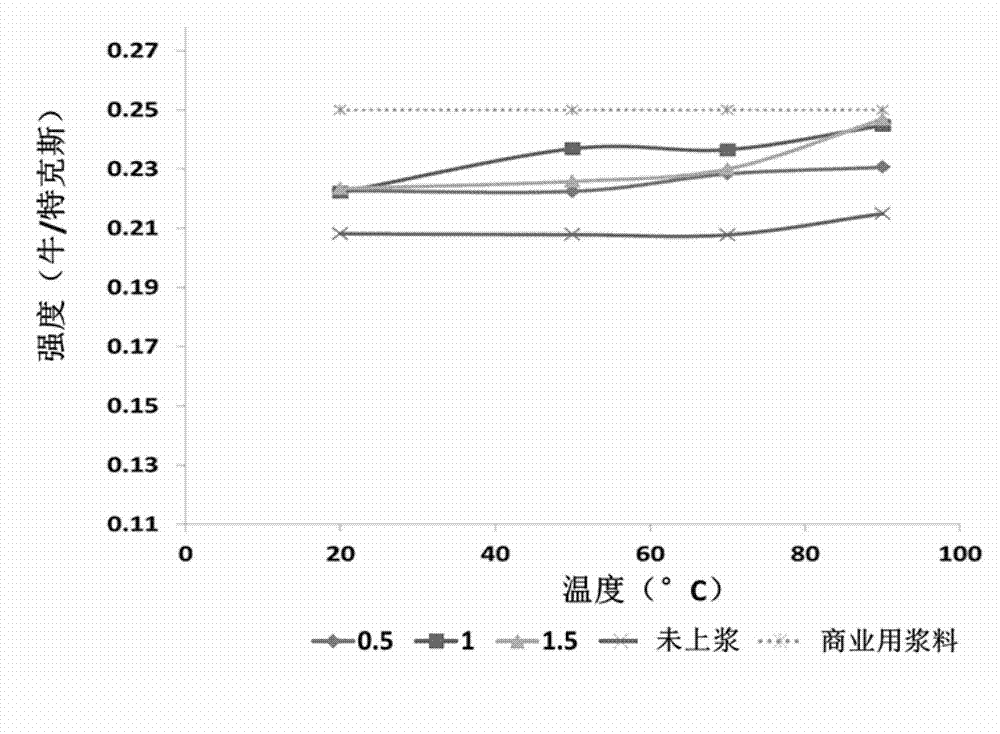

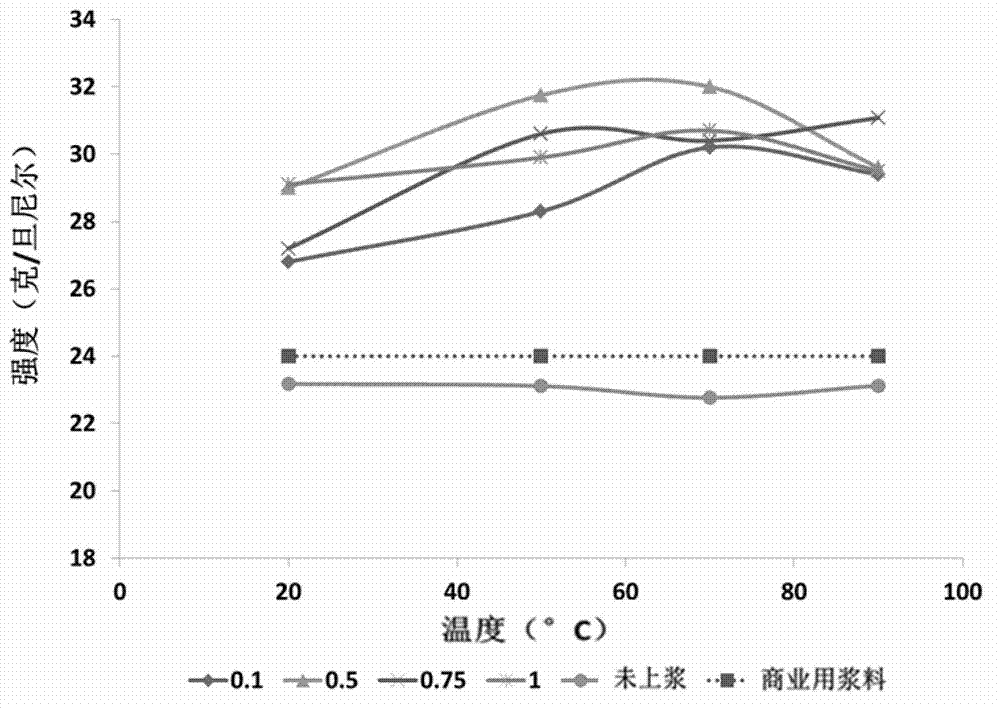

Preparation method of proteins and protein-based sizes for warp sizing

InactiveCN103087332AGood film formingGood mechanical propertiesFibre treatmentProtein proteinChemistry

The invention relates to a preparation method of proteins and protein-based sizes for warp sizing. The method comprises the following steps: (1) taking, putting the protein raw materials, such as plant proteins, animal proteins or animal-protein-based-materials, which are taken as size raw materials, into a sodium hydroxide solution or an alcohol solution, heating the obtained mixture for 30-60 minutes under the constant temperature condition of 20-90 DEG C, adjusting the pH value of the obtained mixture to be 7-8, removing undissolved precipitates through centrifugation or suction filtration, and eventually producing proteins or protein-based sizes; and (2) soaking thick yarns, spun yarns, fabrics or other textile materials into the sizes for 5-10 minutes at 20-90 DEG C, and after fabrics are soaked in the sizes, carrying out constant-speed rolling in the thickness direction of the fabrics. The proteins and the protein-based sizes prepared by using the method disclosed by the invention have good biodegradable properties, and can be directly applied to the sizing of cotton yarns, polyesters, polyester cotton blended yarns and other blended yarns, and the size preparation is low in cost and does not pollute the environment.

Owner:DONGHUA UNIV

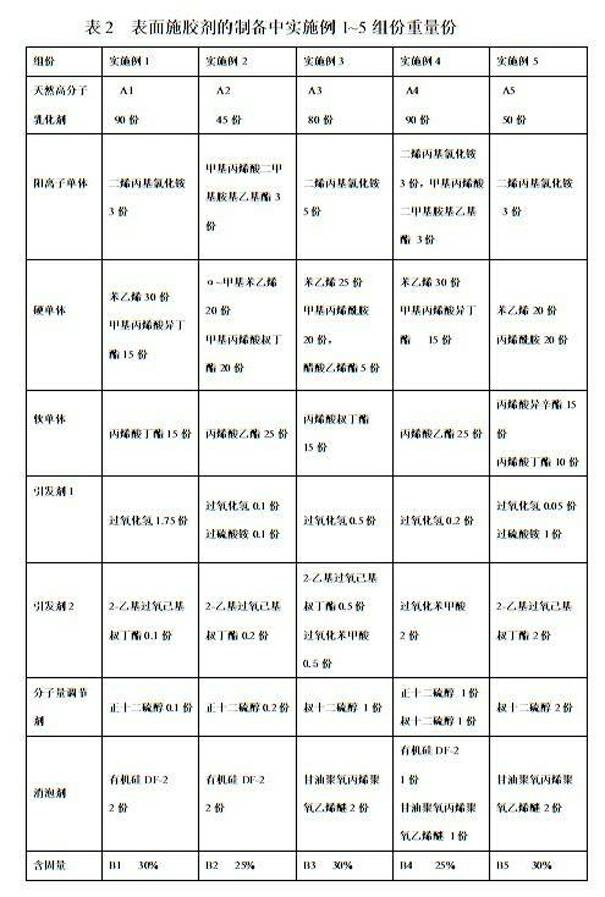

Novel cationic surface sizing agent and preparation method thereof

ActiveCN102140768AStrong interference abilityImprove stabilityWater-repelling agents additionPaper coatingEnvironmental resistanceInterference resistance

The invention provides a novel cationic surface sizing agent and a preparation method thereof, relating to a paper surface treating agent. The traditional sizing agent adopts an emulsifying agent which can result in poor storage stability of products and poor stability of a prepared coating liquid, especially poor interference resistance to foreign ions and the to-be-improved foaminess of the coating liquid. The invention provides a novel cationic surface sizing agent and a preparation method thereof. The novel cationic surface sizing agent comprises 15-50 of natural polymer, 30-70 of water, 0.01-0.1 of natural polymeric modifier, 5-50 of hard monomer, 8-45 of soft monomer, 0.5-10 of cationic monomer, 0.03-5 of evocating agent 1, 0.03-5 of evocating agent 2, 0.03-5 of molecular weight modifier and 0.1-10 of defoamer. The solid content is controlled to be 25-30% by adding water. The invention overcomes the disadvantages in the prior art for producing the surface sizing agent, and the sizing agent provided by the invention is an environment-friendly product which has the advantages of low cost, good stability, high interference resistance to foreign ions, low foaminess and high sizing performance.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

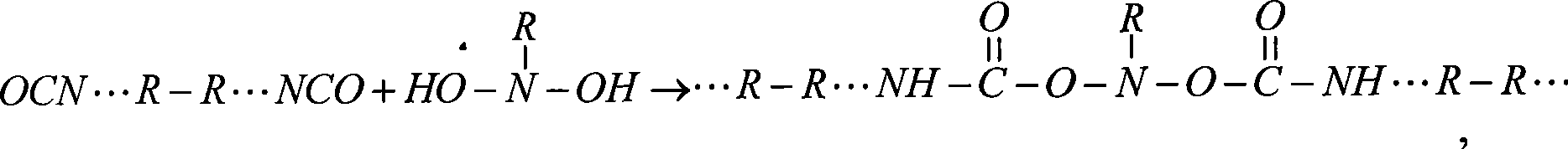

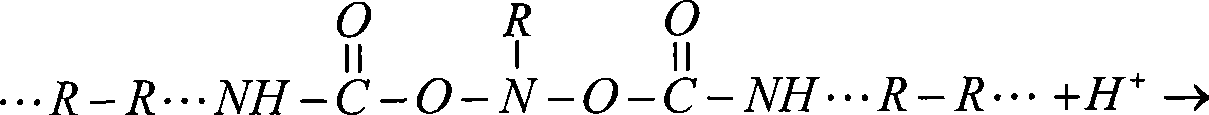

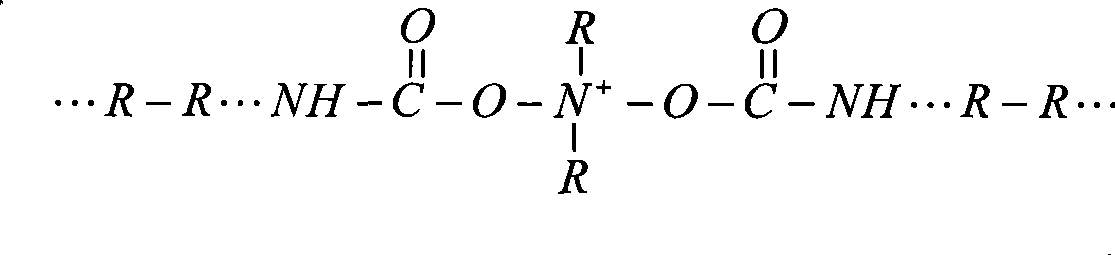

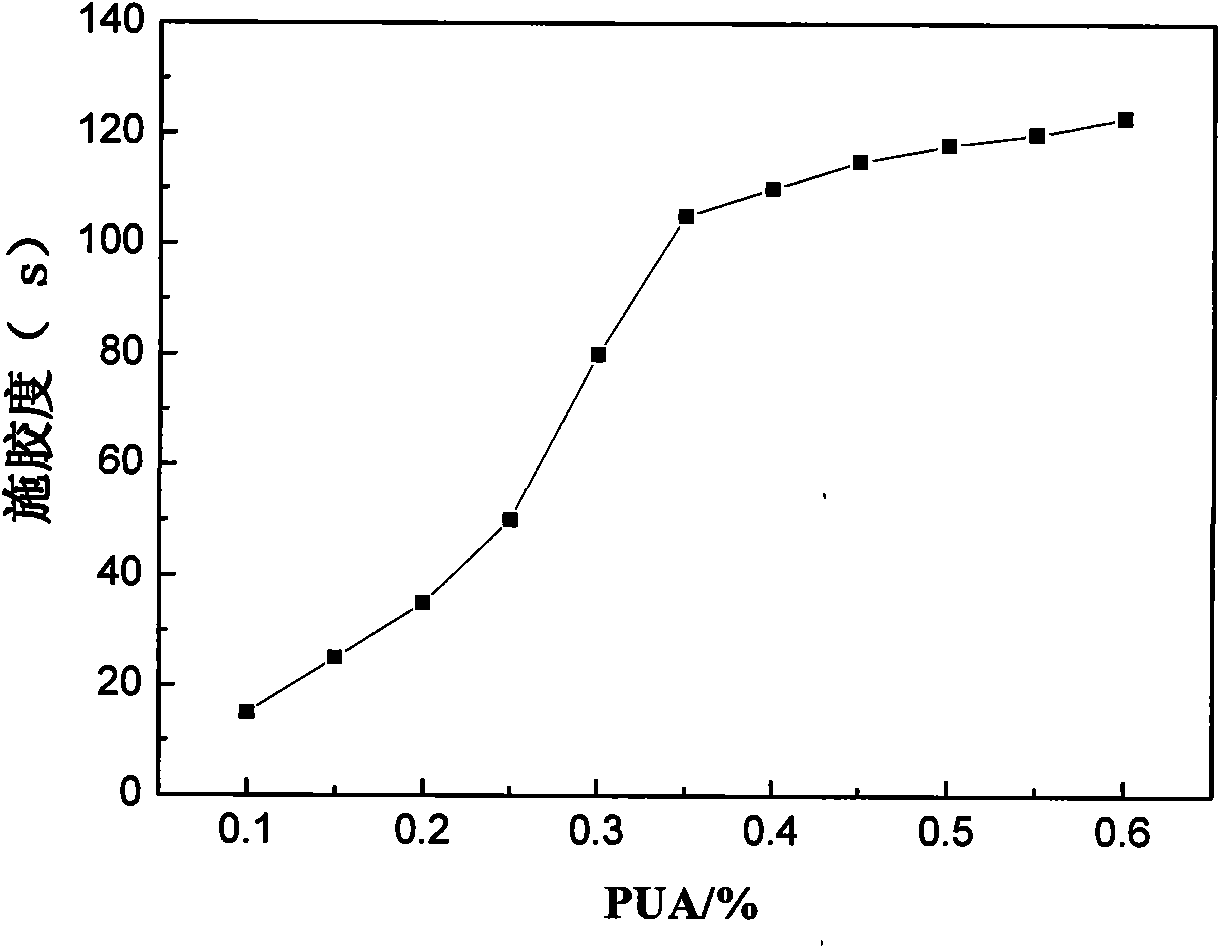

Preparation and use of cation aqueous polyurethane emulsion

InactiveCN101440152ASave energyEasy to processWater-repelling agents additionPulp material addition processesPolyesterPolyethylene glycol

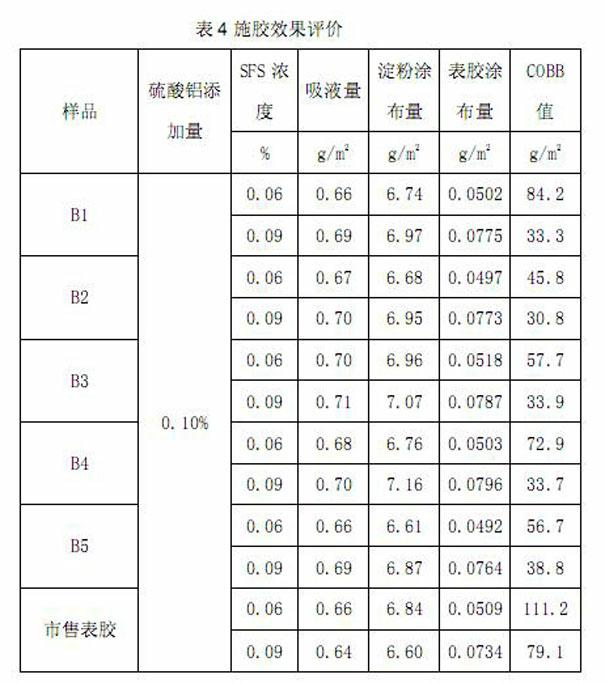

The invention relates to a method for preparing cationic waterborne polyurethane surface sizing agent capable of being used as paper and paperboard surface sizing agent. Toluene di-isocyanate (TDI), polyester dibastic alcohol, polyethylene glycol, 1,4-butanediol and N-methyldiethanolamine as a hydrophilic chain extender are selected to synthesize a cationic waterborne polyurethane emulsion by an internal emulsification method. The prepared polyurethane emulsion can be well used in cooperation with aluminum sulfate, poly aluminum and other aluminum salts. When the prepared polyurethane emulsion is used in cooperation with starch, aluminum salts and the like for the surface sizing of paper and paperboards, good sizing effects can be obtained, and the correlation of the paper and the paperboards can be greatly improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

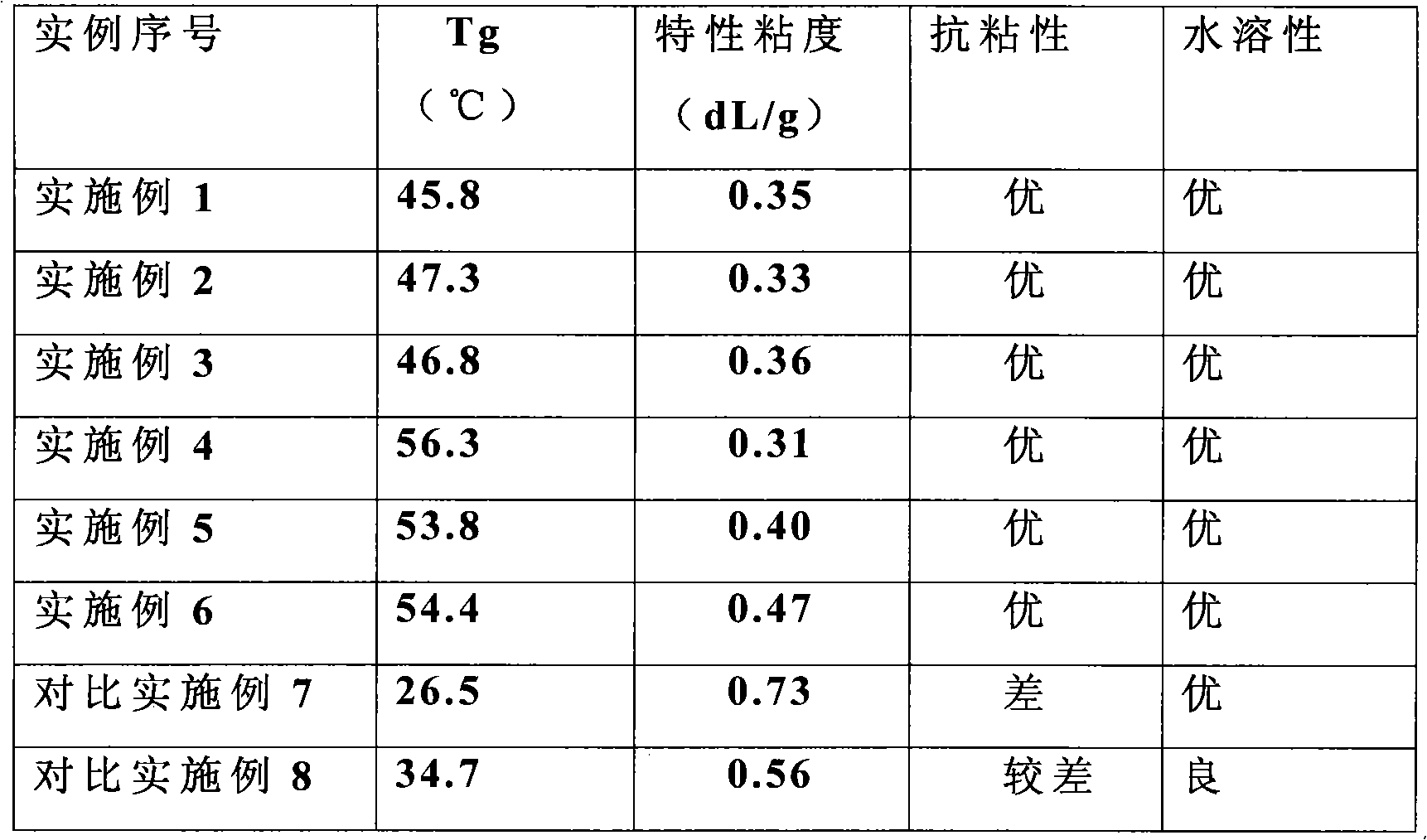

Method for preparing water-soluble sulfo-copolyester

The invention discloses a method for preparing water-soluble sulfo-copolyester used in textile slurry. The method comprises the following steps of: performing esterification reaction or transesterification on dibasic acid / ester at least containing isophthalic acid, sulfo-dibasic acid or ester and terephthalic acid and dibasic alcohol at least containing ethanediol to obtain polycondensation prepolymer; and performing polycondensation under reduced pressure to obtain a product, wherein the molar ratio of the dibasic acid to the dibasic alcohol is 1:1.3-1:1.8; the materials are put at one time; and the polycondensation prepolymer is obtained in one step. The method has the advantages of not using expensive polyethylene glycol materials, adopting a lower molar ratio of the dibasic acid to the dibasic alcohol, putting the materials at one time, reducing cost, along with simple process. The product has high water solubility and higher glass-transition temperature, is suitable for storage, and has good effect in slurry.

Owner:苏州瀚海化学有限公司

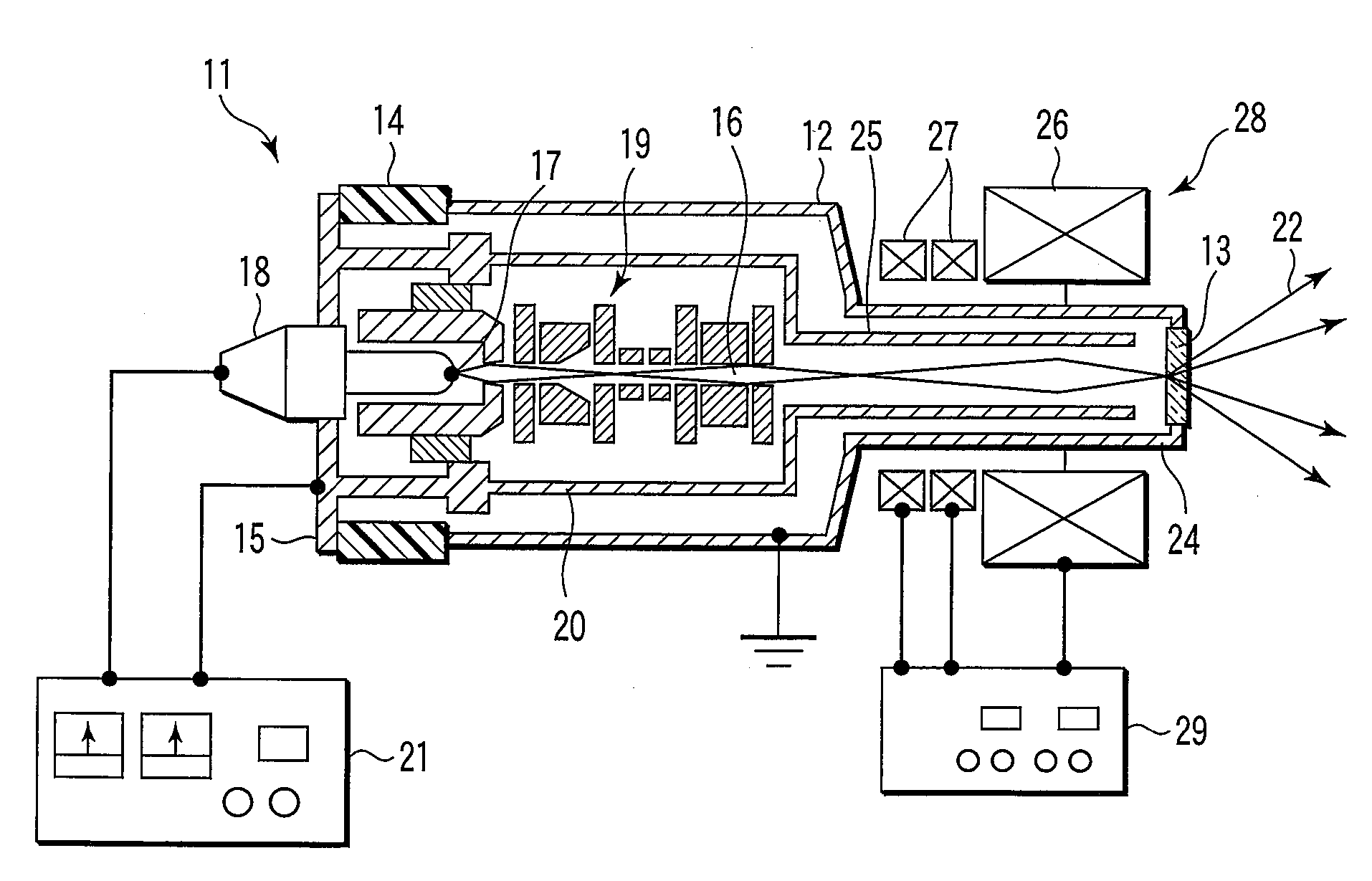

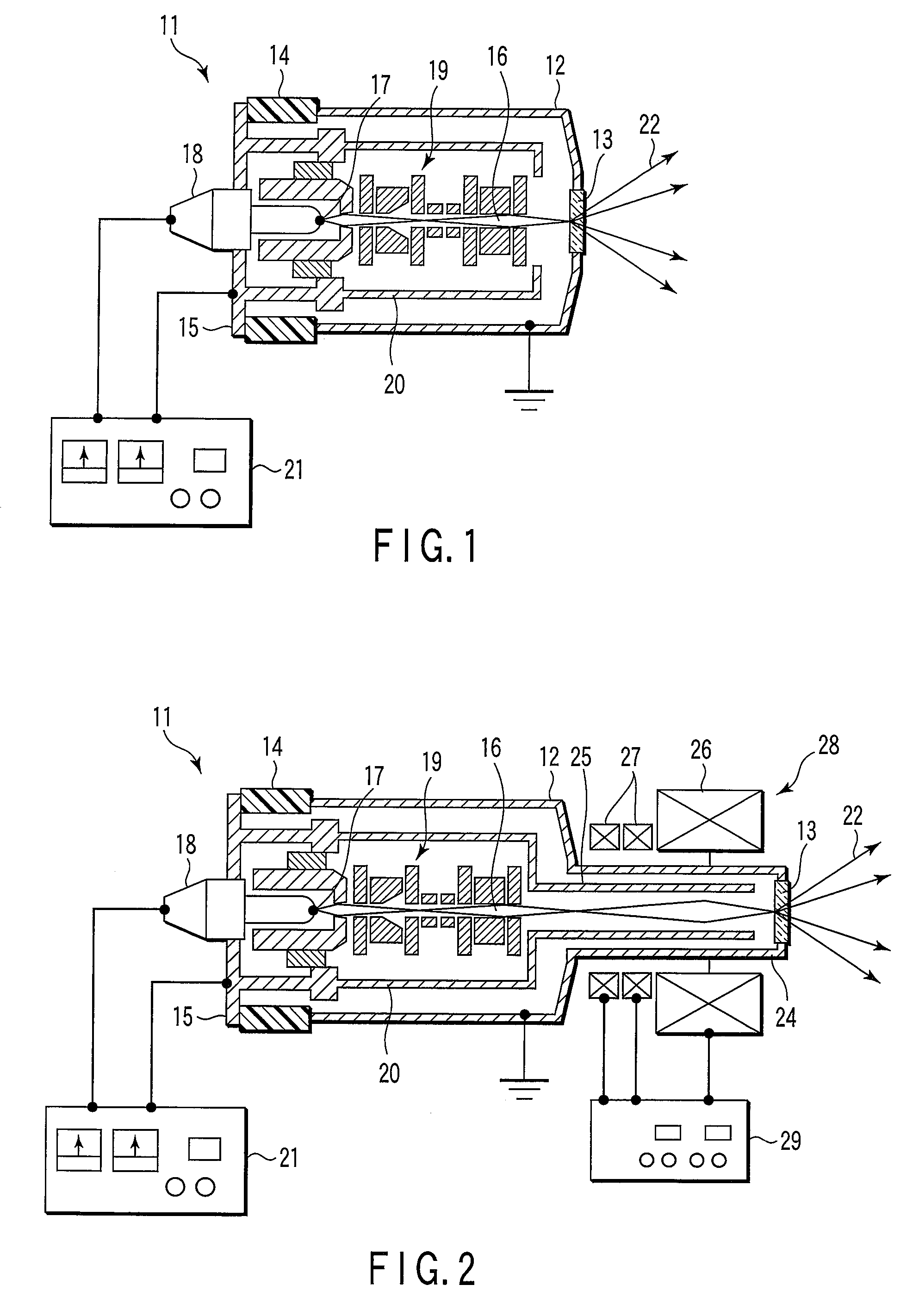

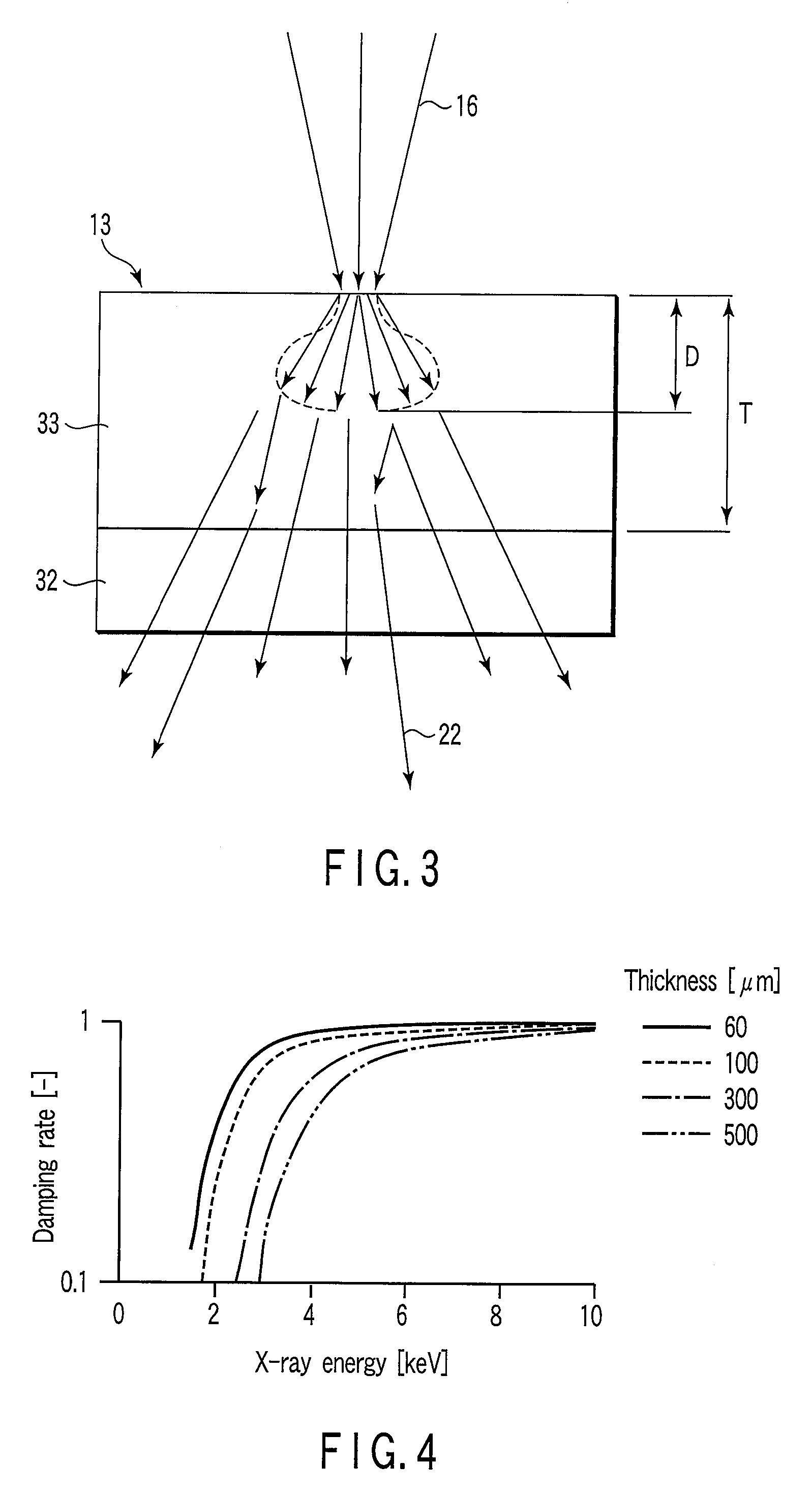

X-ray source

InactiveUS7649980B2Weaken energyImprove sizing effectX-ray tube electrodesCathode ray concentrating/focusing/directingX-rayElectron

Owner:THE UNIV OF TOKYO +1

Textile size and preparation method thereof

The invention discloses a high-performance and environment-friendly textile size and a preparation method thereof. By using the reactivity of activated polyethylene glycol, textile size is modified by animal glue and the modified animal glue is compounded with high-performance starch and a sizing assistant to develop the novel high-performance size capable of replacing dirty size polyethylene glycol size in the yarn sizing and weaving of cotton, viscose and blended yarn thereof. The size comprises the following components in percentage by weight: 5-10 percent of polyethylene glycol modified animal glue, 70-90 percent of modified starch and 5-25 percent of high-efficiency assistant. In addition, the size has excellent sizing fluid and sizing film performance and sizing performance.

Owner:YIXING JUNDA SLURRY TECH

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

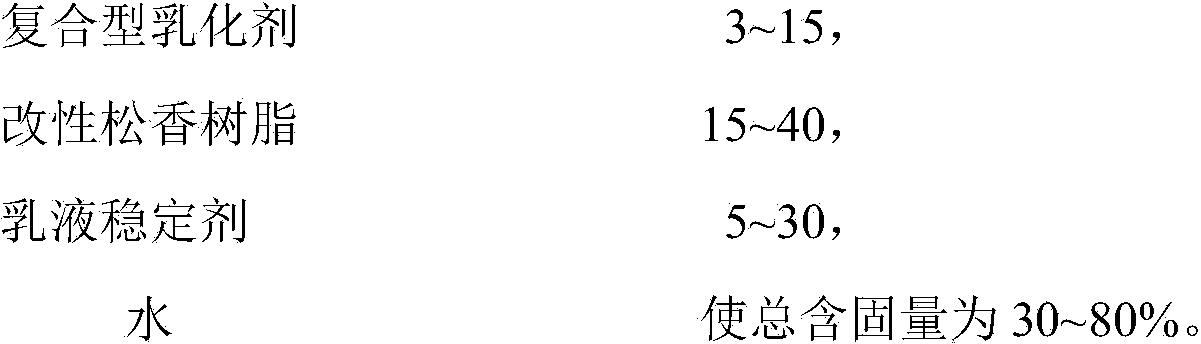

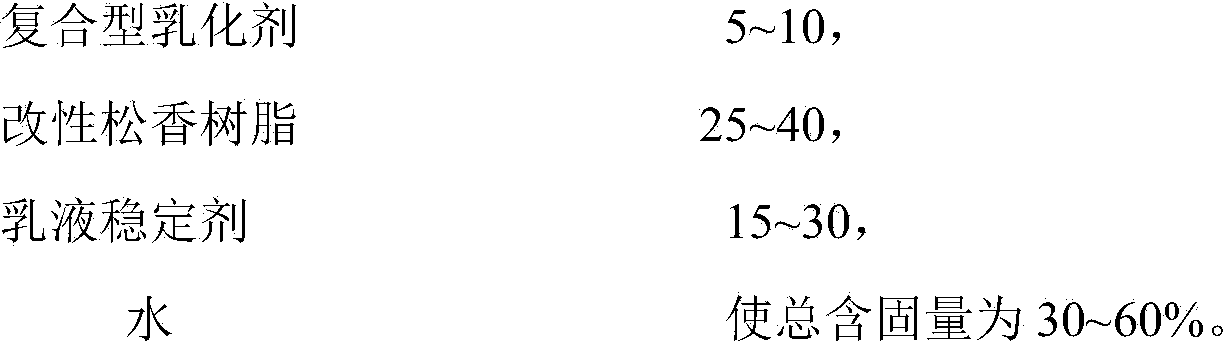

Novel cationic rosin sizing agent and application thereof

ActiveCN103628356AImprove mechanical stabilityGood chemical stabilityWater-repelling agents additionTotal solid contentEmulsion

The invention relates to the field of papermaking, aims at solving the problems that in the preparation process of the existing cation dispersing rosin latex, a solvent does not have a complete environment-friendly effect and is troublesome in recovery; after the solvent is removed, instability is possibly brought to an emulsifying agent and dispersed rosin, so that a rosin sizing agent is poor in mechanical stability, and the rosin sizing efficiency is not ell improved. The invention provides a novel cationic rosin sizing agent and application of the novel cationic rosin sizing agent in papermaking additive. The novel cationic rosin sizing agent comprises the following components by weight percent: 3-15% of a composite type emulsifying agent, 15-40% of modified rosin resin and 5-30% of an emulsion stabilizer; water is added into the components, so that the total solid content is 30-80%. When the sizing agent is used, emulsion particles are stable in performance, the sizing effect is remarkable, and the environment-friendly production is achieved.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

Preparation method of pickering emulsion type asa papermaking sizing agent

InactiveCN102268839AEmulsification process is simpleImprove stabilityWater-repelling agents additionMagnesium saltMicroparticle

The invention provides a method for preparing Pickering emulsion type alkenyl succinic anhydrides (ASA) papermaking sizing agent. The method comprises the following steps of: intercalating quaternary ammonium salt into nano cation-based modified montmorillonite to prepare nano solid fine grain emulsifier; dispersing the nano solid fine grain emulsifier and magnesium salt into deionized water to form a water phase, mixing the water phase and oil phase ASA, and emulsifying the mixture through high speed shearing to obtain the Pickering emulsion type ASA papermaking sizing agent, wherein the volume ratio of the oil phase to the water phase is (1:1)-(1:6). The Pickering emulsion type ASA papermaking sizing agent is coupled with the emulsion and stabilization characteristics of organic surfaceactive substances and inorganic solid fine grains; compared with the emulsion which is emulsified and stabilized by independently using the surface active substances, the Pickering emulsion type ASA papermaking sizing agent is more stable and higher in sizing efficiency; furthermore, the preparation process is simple, and the ASA can be emulsified into stable emulsion without adding any surfactant and high-molecule polyelectrolyte; and the using amount of the emulsifier is small and the emulsifying cost is low.

Owner:SOUTH CHINA UNIV OF TECH

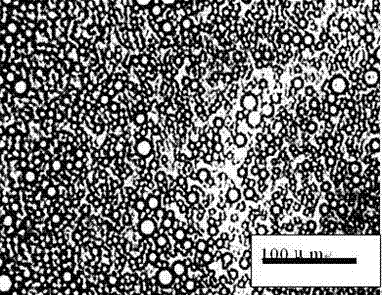

Method for preparing core-shell soap-free surface sizing agent

InactiveCN101205696AUniform particle size distributionImprove sizing effectWater-repelling agents additionPolymer scienceRoom temperature

The invention discloses a preparation method of nucleocapsid soap free surface sizing agent and comprises the following procedures that: (1) firstly, water, macromolecule polymers and monomers are mixed according to the mass ratio of 8.5:1.5 to 6.5:3.5, then proper molecular weight regulator are added and uniformly stirred; the monomers comprise a function monomer, an acrylate kind soft monomer, a hard monomer and an ion monomer; (2) in a stirring state, a part of mixture which accounts for 10 percent to 60 percent of the total mixture mass of the acrylate kind soft monomer, the hard monomer and the ion monomer is added and heated to 73 to 75 DEG C; evocating agent solution which accounts for 20 percent to 50 percent of the total evocating agent mass is then added; after 20 to 60 minutes, the mixture is heated to 76 to 82 DEG C; (3) then the residual mixture of the acrylate kind soft monomer, the hard monomer and the ion monomer and the residual evocating agent solution are respectively added; (4) the mixture is heated to 80 to 82 DEG C for heat preservation, has reaction for 2h to 3h, cooled to the room temperature and filtered, thereby achieving the nucleocapsid soap free surface sizing agent.

Owner:SOUTH CHINA UNIV OF TECH

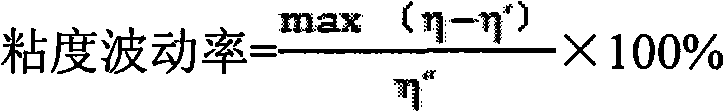

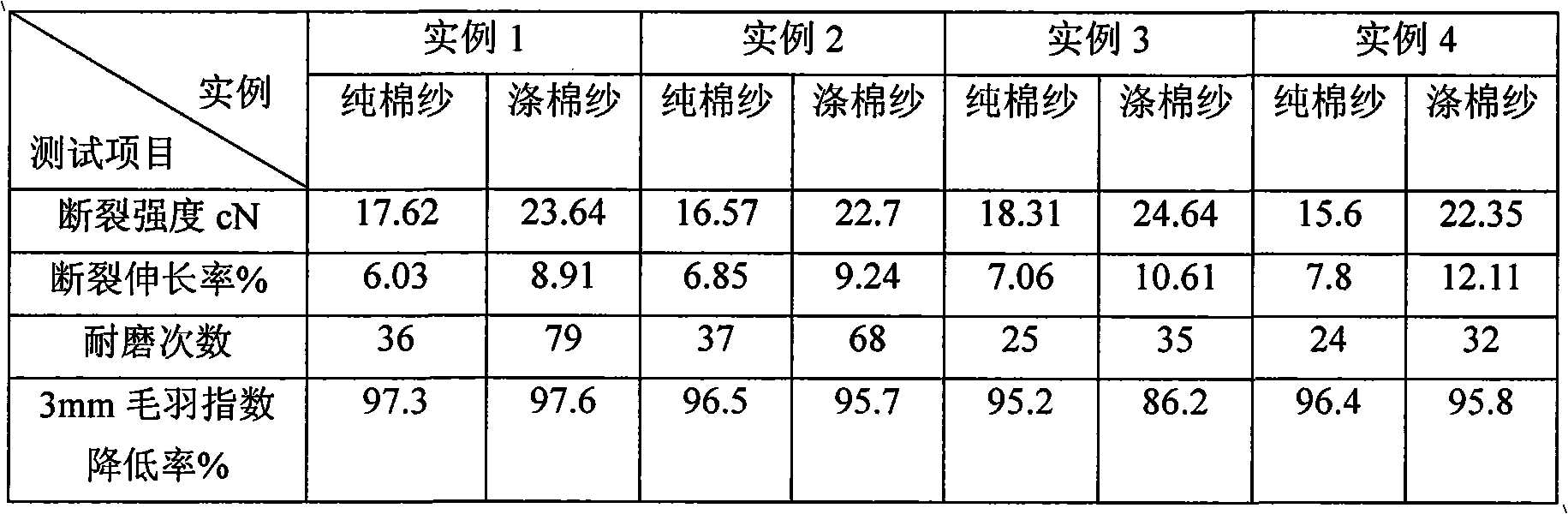

Organic montmorillonite/acrylic acid size and preparation method thereof

The invention relates to organic montmorillonite / acrylic acid size and a preparation method thereof. The size comprises the following raw materials by weight: 2 to 5 portions of organic montmorillonite, 10 to 13 portions of acrylic acid, 35 to 37 portions of ethyl acrylate, 12 to 15 portions of butyl acrylate, 5 to 8 portions of methyl methacrylate, 180 to 220 portions of deionized water, 0.5 to 0.8 portion of initiator, and 2.5 to 3.5 portions of composite emulsifying agent. The preparation method for the size comprises the following steps: preparation of the organic montmorillonite, pretreatment of the raw materials, synthesis of the organic montmorillonite / acrylic acid size, and insulating and cooling processes. The size has the advantages of good sizing performance, convenience for size mixing and small viscosity fluctuation rate, and can reduce or fully replace PVA; and the preparation method has the advantages of simple process, low cost and environmental friendliness, is applicable to industrialized production, and is applicable to sizing for high-grade high-density cotton yarns and high-grade high-density trueran yarn.

Owner:DONGHUA UNIV

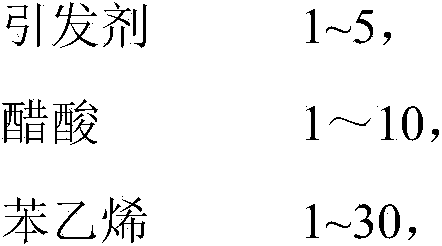

Preparation method of surface sizing agent of cationic polyurethane/cationic styrene-acrylic composite emulsion

ActiveCN101654893AImprove sizing effectReduce sizing costsWater-repelling agents additionPaper/cardboardWater bathsPolyethylene glycol

The invention relates to a preparation method of a surface sizing agent of cationic polyurethane / cationic styrene-acrylic composite emulsion, belonging to the field of paper making chemicals. The preparation method comprises the following steps: adding isophorone diisocyanate, 1,4-butanediol and dehydrated polyethylene glycol oxide into a four-hole boiling flask, and increasing the temperature; stirring and dropwise adding the butanone solution of a cationic chain extender to obtain a prepolymer; decreasing the temperature; adding acid for neutralization; adding acetone for dilution; stirringthe mixture; and then, adding a proper amount of acetone to reduce the viscosity of the prepolymer; adding deionized water into the prepolymer for emulsification; adjusting the pH value to 5-7, and removing the acetone and the butanone to obtain cationic aqueous polyurethane emulsion; and adding the prepared cationic polyurethane, emulsifier and deionized water into the four-hole boiling flask; heating the mixture in the water bath with nitrogen gas protection; stirring the mixture, and increasing the temperature; and adding the water solution of phenyl ethylene, acrylic ester, cationic monomer, acrylamide and water-soluble azo initiators for reaction for 2-4h, cooling the mixture, and then, discharging to obtain a finished product. The invention can improve the sizing effect and reduce the sizing cost.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Composite water based carbon fiber sizing agent and preparation method and use method thereof

ActiveCN107022901ASolve the problem of sizing carbon fibers that cannot be used for high temperature resistant thermoplastic resin matrix compositesGood sizing effectCarbon fibresEpoxyWater based

The invention relates to a composite water-based carbon fiber sizing agent and a preparation method and a use method thereof, and belongs to the field of carbon fiber manufacturing. Waterborne polyamide imide / epoxy resin is adopted for compounding; the obtained water-based carbon fiber sizing agent is applied to both conventional thermosetting resin and a thermoplastic matrix, and is specially suitable for high temperature-resistant engineering plastics such as polyether-ether-ketone (PEEK), polyimide (PI) and polyphenylene sulfide (PPS).

Owner:BEIJING UNIV OF CHEM TECH

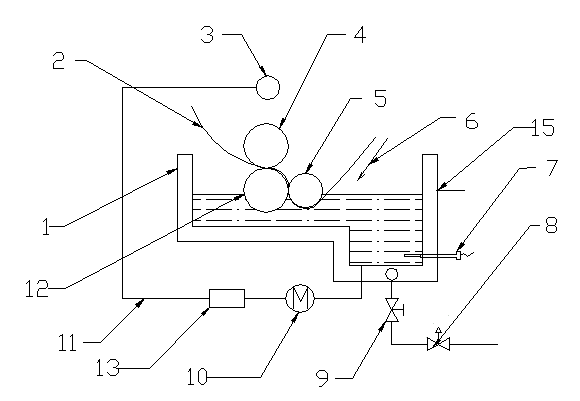

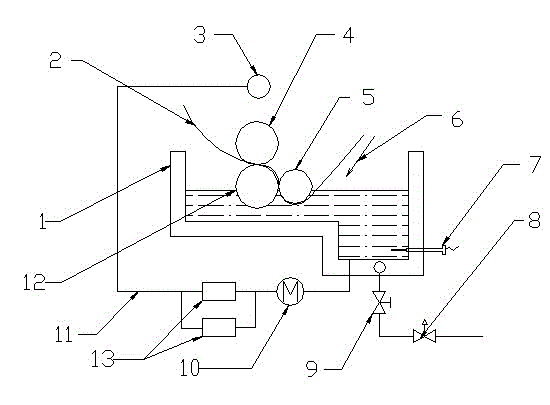

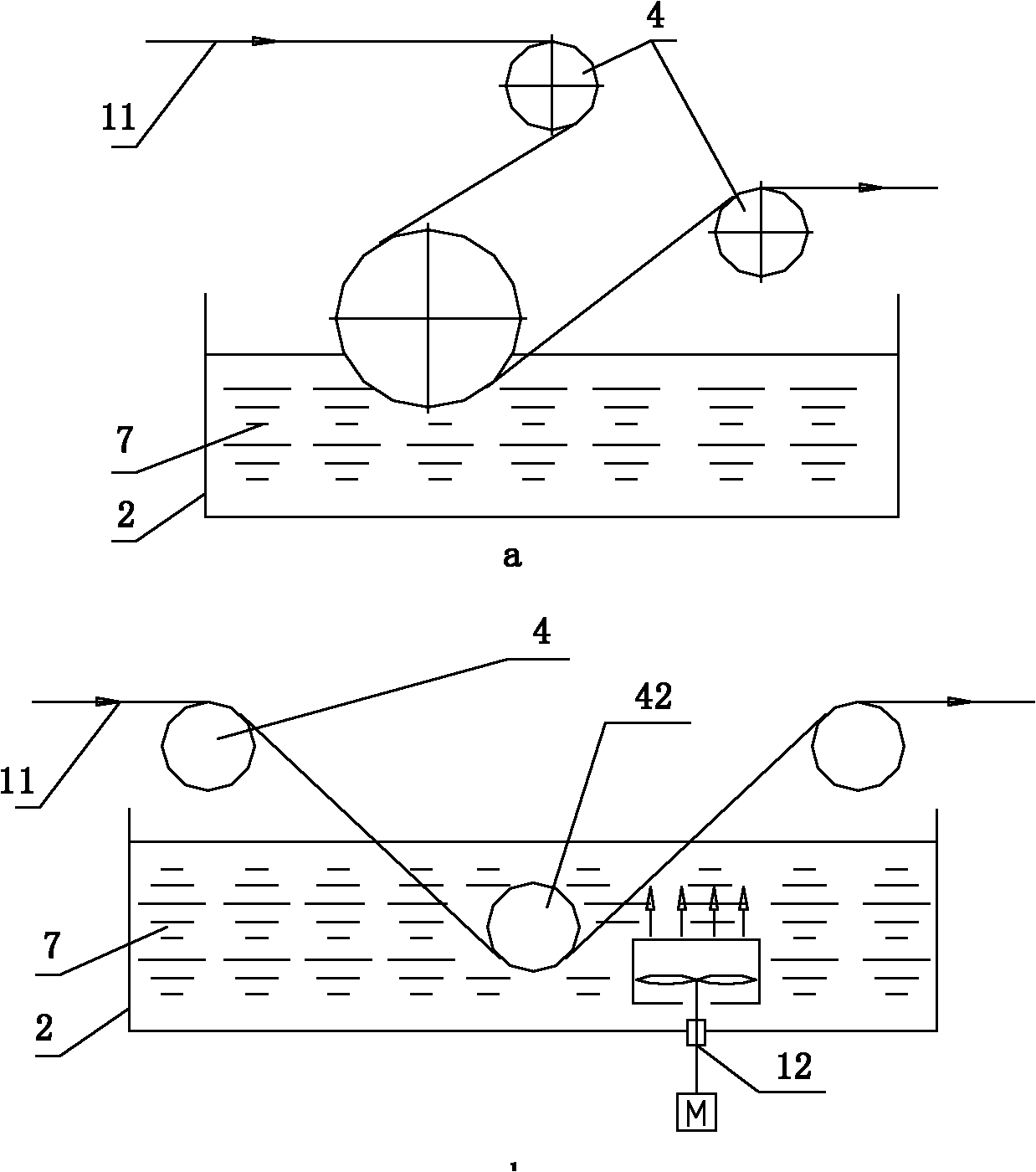

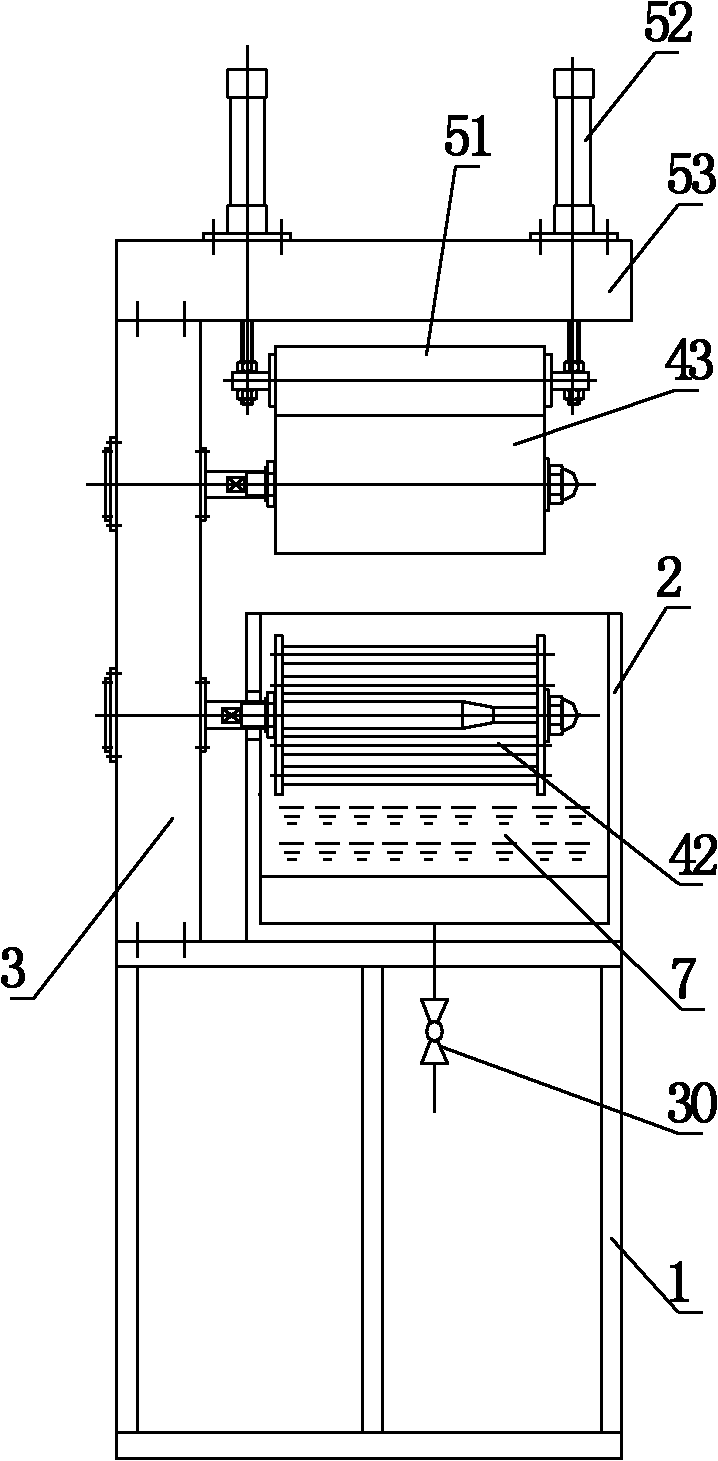

Secondary sizing device of glass fiber

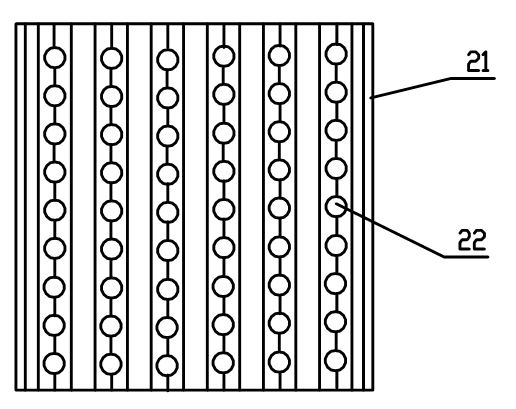

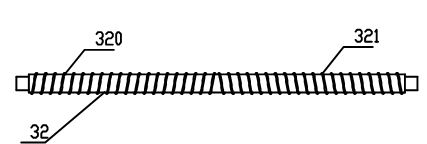

ActiveCN104153136AGuaranteed pureAdjustable temperatureTextile treatment machine arrangementsTextile treatment by pouringGlass fiberYarn

The invention provides a secondary sizing device of glass fiber. The secondary sizing device of the glass fiber comprises a pulp pool, a sizing system, a pulp pool heating system and a filtering device, wherein the sizing system comprises a sizing roller set and a pulp pouring device, and the sizing roller set is arranged in the pulp pool, is used for sizing warp yarns of the glass fiber, and comprises at least three sequentially-arranged sizing rollers; the pulp pouring device comprises a pulp pouring pipe and a pulp pouring head; the pulp pool heating system comprises a heat preservation layer and a temperature adjusting device, the heat preservation layer is arranged on the outer side of the pulp pool in an enclosing mode, and the temperature adjusting device comprises a temperature sensor, a controller and a temperature adjusting actuating mechanism; the filtering device is used for filtering pulp in the pulp pouring device and is fixedly arranged on the pulp pouring pipe. According to the secondary sizing device of the glass fiber, the pulp pool heating device is arranged, the temperature of the pulp in the pulp pool can be adjusted, the situation that the quality of glass fiber cloth is affected by pulp oxidation film forming is avoided, and the production cost is reduced.

Owner:TAIJIA GLASS FIBER

Prepn process of high purity alkenyl succinic anhydride

InactiveCN1609092ARaise the ratioImprove sizing effectOrganic compound preparationCarboxylic compound preparationSuccinic anhydrideMaleic anhydride

The present invention is preparation process of high purity C18 alkenyl succinic anhydride. C18 olefin of purity over 90 % and maleic anhydride in the molar ratio of 1.0-1.2 as material are made to react at 180-250 deg.c temperature and 1.0-2.0 kg / sq cm pressure for 15-17 hr; and the reaction product is rectified to obtain high purity alkenyl succinic anhydride. The present invention has simple technological process, simple material composition, simple product structure and high product purity, and the product may be used in gluing paper with excellent effect.

Owner:魏素芬

Emulsion nano composite acrylic acid copolymerization slurry and preparation method thereof

The present invention relates to fabric sizing material, and is especially one kind of environment friendly nanometer composite fabric sizing agent of acrylate copolymer emulsion and its preparation process. The fabric sizing agent comprises acrylate copolymer size and inorganic material, and has solid content of 10-50 wt%. The preparation process includes the following steps: adding clay into water and regulating pH value to form homogeneous clay dispersing liquid; compounding oil soluble monomer solution; compounding water soluble monomer solution with alkali regulated pH value; mixing clay dispersing liquid, oil soluble monomer solution, water soluble monomer solution, emulsifier and initiator via stirring; heating for copolymerization; regulating pH value and filtering to obtain product. The fabric sizing agent has simple preparation process and high performance.

Owner:QINGDAO UNIV

Preparation method of epoxy resin-modified cation waterborne polyurethane emulsion

InactiveCN102432798AIncrease the degree of sizingHigh folding resistanceWater-repelling agents additionEpoxyEmulsion

The invention provides a preparation method of an epoxy resin-modified cation waterborne polyurethane emulsion. The preparation method comprises the following steps of: firstly, pre-polymerizing: carrying out a pre-polymerizing reaction on oligomer polyalcohol, isocyanate and organic tin catalyst according to the mass fraction at the temperature of 60-80DEG C for 1-3 hours; secondly, extending a chain: adding a micromolecule hydroxyl monomer, a hydrophilic extended chain agent and epoxy resin in a reactor and carrying out a chain extension reaction at the temperature of 60-80DEG C for 0.5-2 hours; thirdly, neutralizing: adding a neutralizing agent in the reactor and finishing a salt forming reaction; and fourthly, emulsifying: adding deionized water at constant speed to obtain a modified cation waterborne polyurethane emulsion. The preparation method provided by the invention has the advantages of simpleness in operation of process, energy saving, environment friendliness and the like. According to the preparation method of the epoxy resin-modified cation waterborne polyurethane emulsion which is provided by the invention, by adding the epoxy resin and introducing a cross-linking structure, the size resistance, the fold-resisting times and the ring crash index of sized paper are improved.

Owner:SHAANXI UNIV OF SCI & TECH

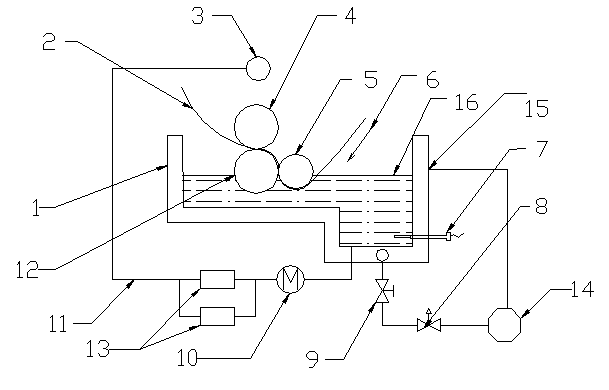

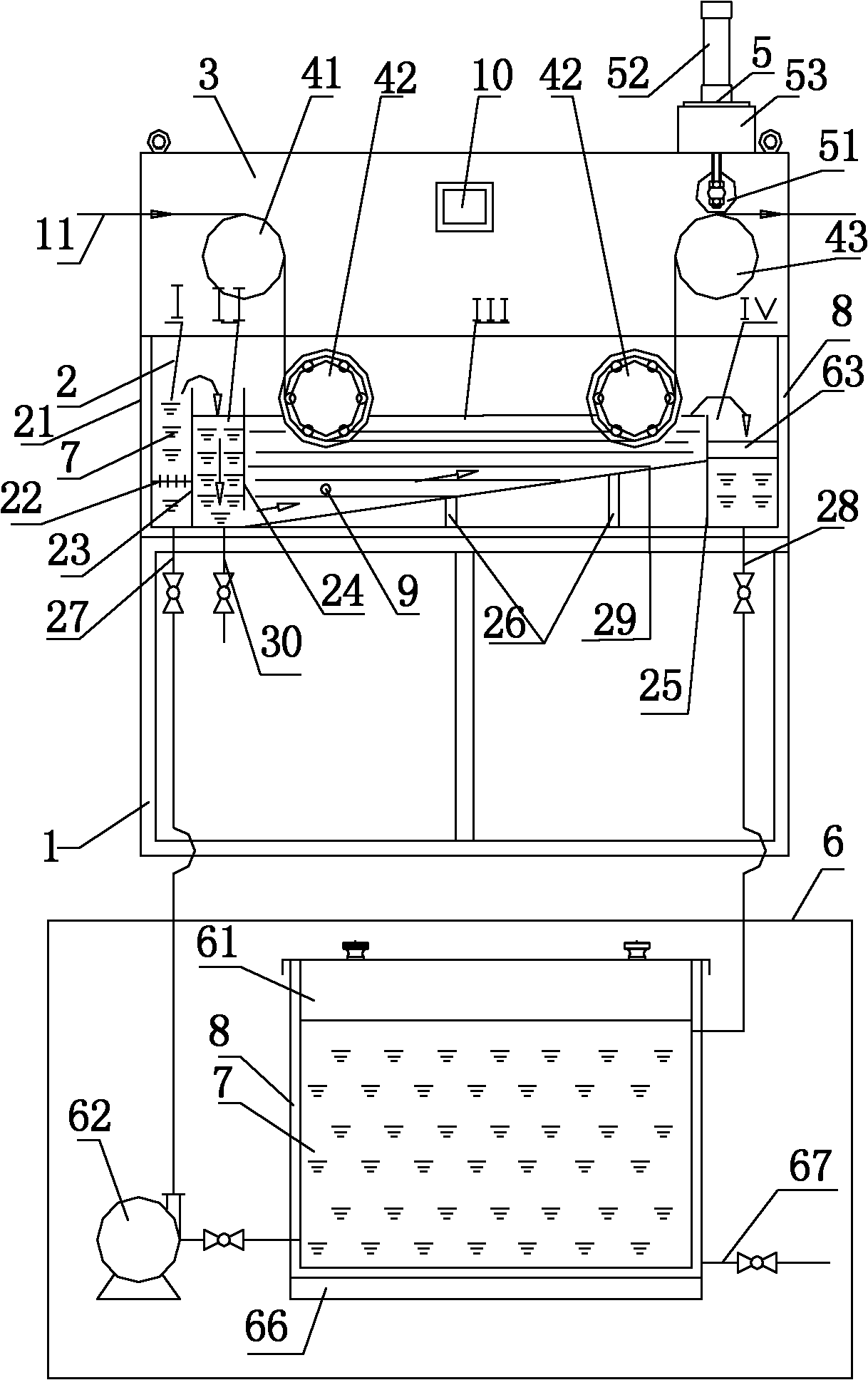

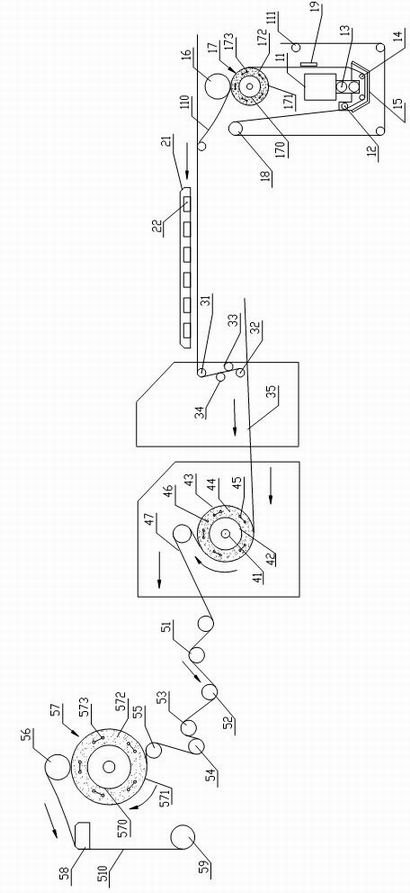

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

Biodegradable solid particle emulsifier and papermaking sizing agent

ActiveCN105056830AImprove stabilityImprove sizing effectWater-repelling agents additionTransportation and packagingPolymer scienceGlycolic acid

The invention relates to a biodegradable solid particle emulsifier and a papermaking sizing agent and belongs to the technical field of papermaking sizing agents and related industrial emulsifiers. The biodegradable solid particle emulsifier short for CPs is prepared from cellulose nanocrystals and polylactic-co-glycolic acid. An ASA emulsion prepared from CPs is a Pickering emulsion, has the liquid drop particle size being about 3.4 mu m, has higher stability and cannot gather particles, precipitate or separate out water after being placed for 24 hours; the emulsion can still keep good performance of the papermaking sizing agent after being placed for 3 hours; the preparation process is simple, few emulsifiers are used, the emulsification cost is low, and the emulsifier has biodegradability and has little pollution to the environment.

Owner:山东熙来淀粉有限公司

Fabric stiffening adhesive paste, preparation method thereof and forming cloth

ActiveCN104830255AGood water solubilityHigh viscosityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesHazardous substanceDouble bond

The invention discloses fabric stiffening adhesive paste, a preparation method thereof and forming cloth. The fabric stiffening adhesive paste comprises the following raw materials: vinyl acetate, organosilicone monomers containing unsaturated double bonds, butyl acrylate, polyvinyl alcohol, a silane coupling agent, a sodium salt chelating agent, a defoaming agent, deionized water, an initiator and a preservative. The finished fabric stiffening adhesive paste does not contain hazardous substances such as formaldehyde, heavy metal and the like, is free of toxicity and off-odor, is safe and reliable, has very strong adhesive force to multiple chemical fabrics, and is applicable to cotton cloth, chemical fabrics, linen, wool fabrics, silk and blended fabrics; the glossiness, hardness and hand feeling are improved without changing colored light of cloth, and the processed cloth does not easily absorb moisture and ease back and has storability.

Owner:佛山永恒达新型建材有限公司

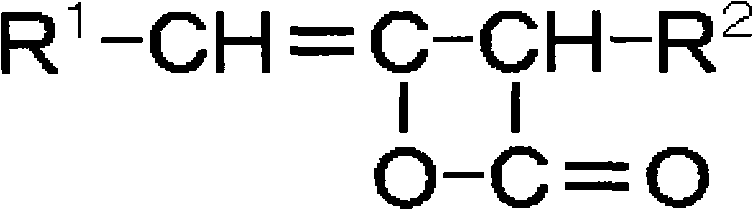

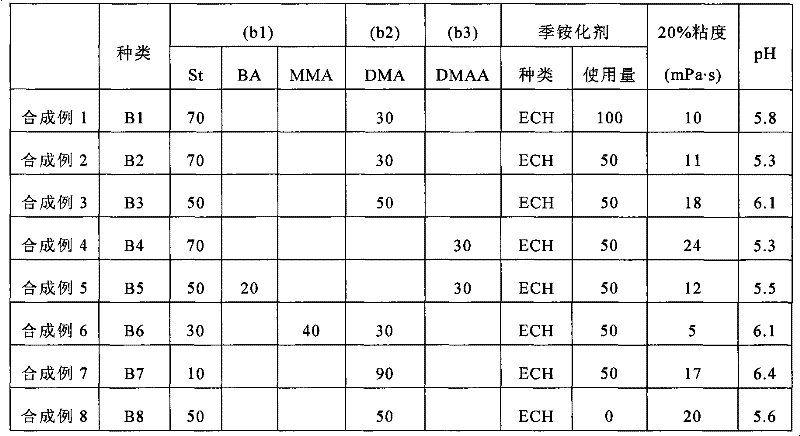

Surface-sizing agent

InactiveCN1402805AImprove mechanical stabilityGood storage stabilityWater-repelling agents additionPaper/cardboardHydrophilic monomerShellac

A surface-sizing agent for papermaking which itself is excellent in mechanical stability and storage stability, and which is highly suitable for the sizing of acidic to neutral papers. When applied to papers for information, especially ink-jet printing papers, the sizing agent imparts excellent suitability for ink-jet printing. When the sizing agent is used to prepare a coating fluid, the coating fluid is significantly reduced in foaming. The sizing agent has excellent compatibility with other chemicals to be used in combination therewith. The surface-sizing agent is characterized by being obtained by polymerizing a nonionic hydrophilic monomer (b) with a hydrophobic monomer (d) in the presence of an alkali salt of shellac (a) and then mixing a polymeric dispersant (e) therewith.

Owner:SEIKO PMC CORP

High-performance nanometer-modified acrylic size and its production method

The present invention belongs to the field of new polymer material, and discloses one kind of nanometer modified high performance acrylic acid size and its preparation process. The acrylic acid size is prepared with nanometer level titania powder, acrylic acid, acrylamide acrylonitrile and butyl acrylate as main synthesized material, oleic acid as modifier and ammonium sulfate as initiator. Owing to the nanometer material with reinforcing effect, wear resistance and high permeability, and the acrylic acid monomer with functional group similar to that in fabric fiber structure, the size has excellent permeating and coating performance and high adhesion, forms complete, antiwear, tough and elastic size film, and may be used in sizing fabric of cotton, Dacron, etc. including fabric warp with high density and high weaving difficulty.

Owner:DONGHUA UNIV

Environment-friendly type textile sizing agent

Owner:SUZHOU RUNHONG TRADING

Method for preparing cation high molecular base petroleum resin neutral sizing agent

InactiveCN101649579AImprove stabilityImprove sizing effectWater-repelling agents additionPaper/cardboardFiberHigh pressure

The invention discloses a method for preparing a cation high molecular base petroleum resin neutral sizing agent. The method comprises the following steps: under the function of an organic solvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, a cation monomer and the like, as a copolymerization monomer and preparing cation saponin-free benzene emulsion by saponin-free emulsion polymerization; taking the cation saponin-free benzene emulsion as a cation high molecular emulsifying agent, emulsifying and dispersing petroleum resin modified by maleic anhydride and preparing cation high molecular base petroleum resin neutral sizing agent emulsion with favorable stability and sizing performance by homogenizing at high pressure. The product has favorable stability and sizing performance; the cation high molecular base petroleum resin neutral sizing agent prepared by the invention has stronger cation performance, particles have positive charges and are beneficial to retenting and combining with paper fibre, and the cation high molecular emulsifying agent also has a certain sizing synergistic action, thereby enhancing the stabilityand the sizing performance of the emulsion greatly.

Owner:SHAANXI UNIV OF SCI & TECH

Surface glue coating agent and preparation method thereof

ActiveCN108004841AHigh surface sizing propertiesImprove sizing effectWater-repelling agents additionPaper coatingCross-linkUnsaturated monomer

The invention discloses a surface glue coating agent and a preparation method thereof. The surface glue coating agent is prepared from the following ingredients through copolymerization: cross-linkedetherified cationic modified starch, first unsaturated monomers, second unsaturated monomers, cationic monomers and function monomers, wherein the cross-linked etherified cationic modified starch is prepared from the following raw materials in parts by mass: 80 to 90 parts of starch, 4 to 12 parts of cationic etherifying agents and 1.5 to 7 parts of cross-linking agents. The preparation method ofthe surface glue coating agent comprises the steps of preparing the cross-linked etherified cation modified starch and preparing the surface glue coating agent. The prepared surface glue coating agenthas high surface glue coating performance; a good glue coating effect is still realized under the condition of low glue coating quantity or relative severe environment glue coating environment; the advantages of fast curing, high cost performance, safety and environment-friendly effect and the like are also realized.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Neutral rosin sizing agent and its prepn

The rosin sizing agent consists of main components including modified rosin, tall oil, stearic acid, pine gum and paraffin; and supplementary material including polyethenoxy ether sulfo succinate, abietate, polymer dispersant and disinfectant. It is prepared through low pressure process with relatively high controllability and production quality stability. The sizing agent has high compatibility with calcium carbonate stuffing, high sizing effect, low production cost and less mildew produced in storage. The sizing agent is suitable for use in producing high-grade paper and paper card.

Owner:上海埃格环保科技有限公司

Digital sizing machine

ActiveCN101985797ARealize automatic computer controlEven and stable heatingHeating/cooling textile fabricsStretchingProcess engineeringHeating system

The invention discloses a digital sizing machine, which is characterized by mainly comprising a digital sizing machine sizing system, a digital sizing machine curing system, a digital sizing machine expander, a digital sizing machine drum-type conduction oil heating system, and a digital sizing machine receiving system which are arranged in turn. In the digital sizing machine sizing system, five processes of sizing, curing, heating, expanding and receiving are integrated, automatic computer control is completely realized, and the defects that a plurality pieces of equipment are simultaneouslyused in the prior art are overcome. The digital sizing machine adopts electric automation; and the big body phenomenon (concave middle part) is easy to occur in the traditional processes of sizing and expanding, the sizing is non-uniform, and the quality of fabric is easily influenced in the process of expanding. The digital sizing machine is driven by a drum and a conduction band reasonably so as to integrally finish sizing and expanding automation, the labor is saved, and the efficiency is improved.

Owner:无锡市德赛数码科技有限公司

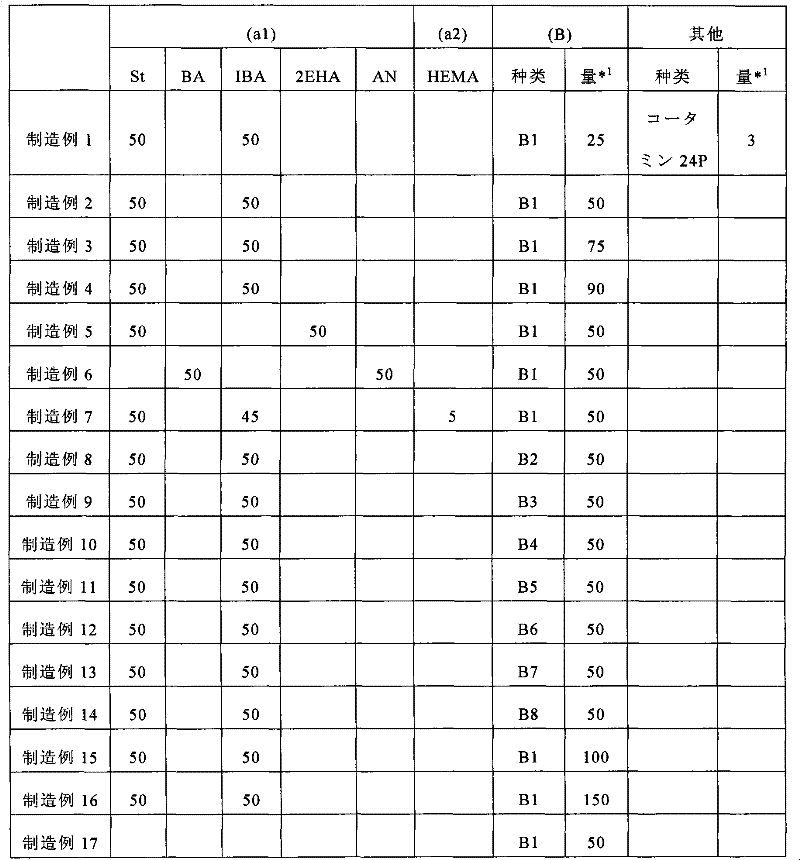

Surface sizing agent for papermaking, surface sizing coating liquid and paper

ActiveCN102261015AReduce generationSuppresses the decrease in the coefficient of frictionWater-repelling agents additionPaper coatingEmulsionPapermaking

PROBLEM TO BE SOLVED: To provide a papermaking surface sizing agent and a surface sizing coating liquid with which good sizing effect can be obtained, the decrease of frictional coefficient is suppressed and the agglomerate generated during coating on paper can be reduced, and to further provide a paper with excellent sizing effect.SOLUTION: A papermaking surface sizing agent of aqueous emulsion type is used which includes polymer (C) obtained by polymerization of vinyl monomer (A) including hydrophobic monomer (a1) in the presence of cationic water soluble polymer (B), a water soluble aluminium compound (D) and alkyl ketene dimer and / or alkenyl ketene dimer (E).

Owner:ARAKAWA CHEM IND LTD

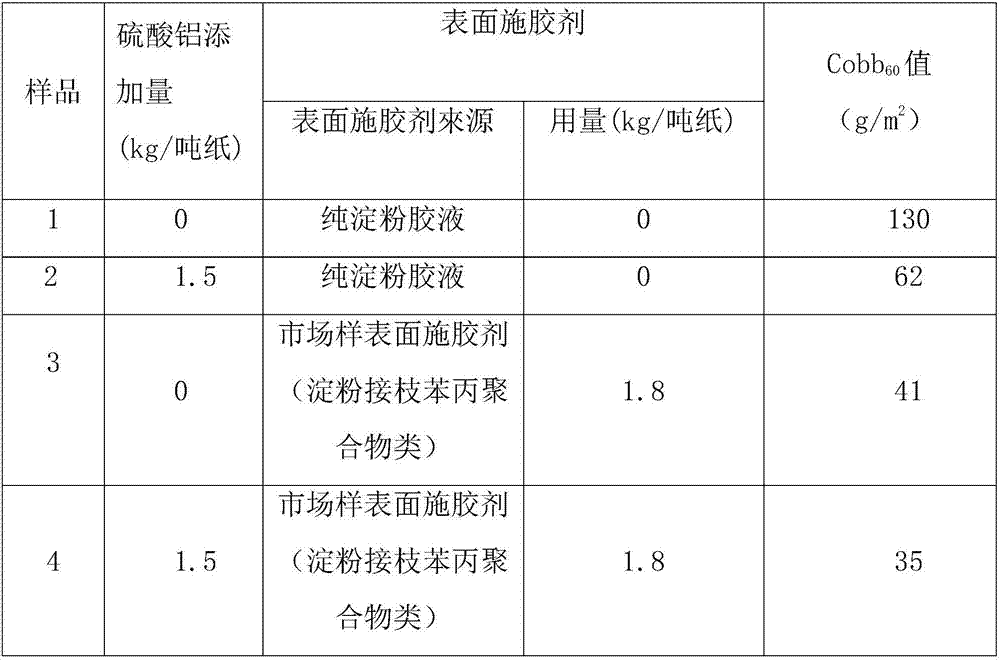

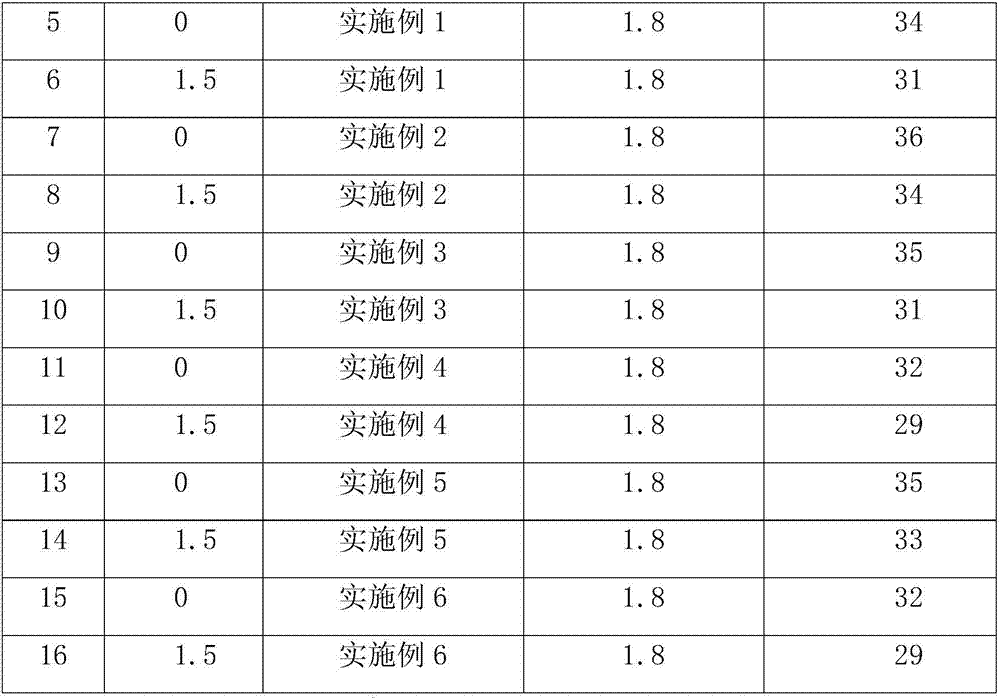

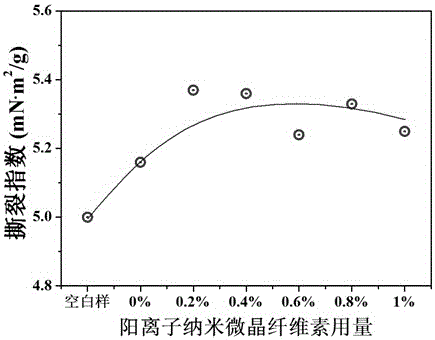

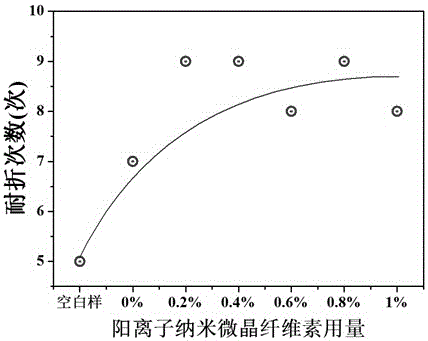

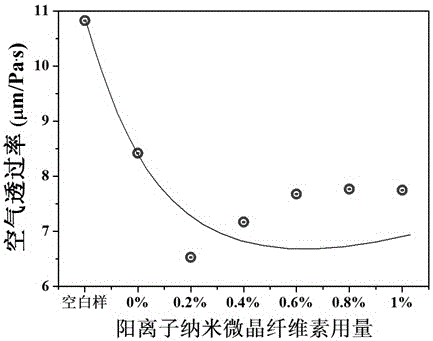

Preparation method for cation nanocrystalline cellulose enhanced papermaking surface sizing agent

ActiveCN105780589AThe process is simple and easy to controlEasy to operateWater-repelling agents additionChemistryEmulsion

The invention relates to a preparation method for a cation nanocrystalline cellulose enhanced papermaking surface sizing agent.According to the preparation method, firstly, edible corn starch is gelatinized and compounded with cation styrene-acrylic emulsion; secondly, cation nanocrystalline cellulose is used for enhancing the composite emulsion; lastly, a Mayer coating machine is used for conducting surface sizing on fine dried noodle cardboard paper.According to the prepared surface sizing agent, the edible corn starch and the nanocrystalline cellulose are used as main raw materials, application of synthetic latex cation styrene-acrylic emulsion is omitted, and this conforms to the strategy of sustainable development.The cation nanocrystalline cellulose enhanced papermaking surface sizing agent is simple in preparation process and good in flowing property, a good barrier property is given to the paper, and meanwhile the mechanical property and surface property of the paper can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com