Patents

Literature

82results about How to "Even and stable heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

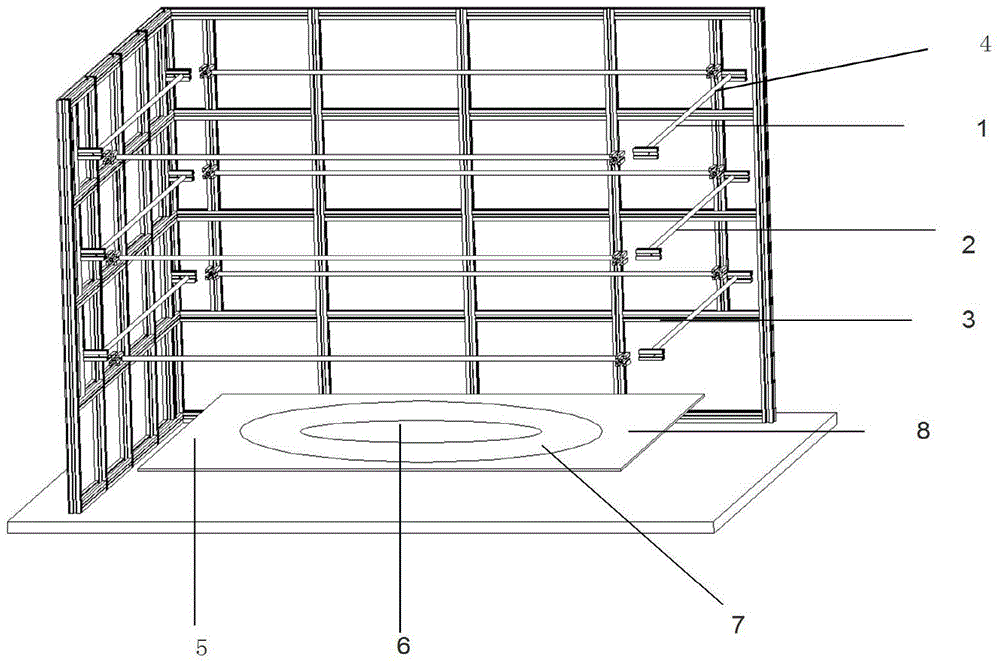

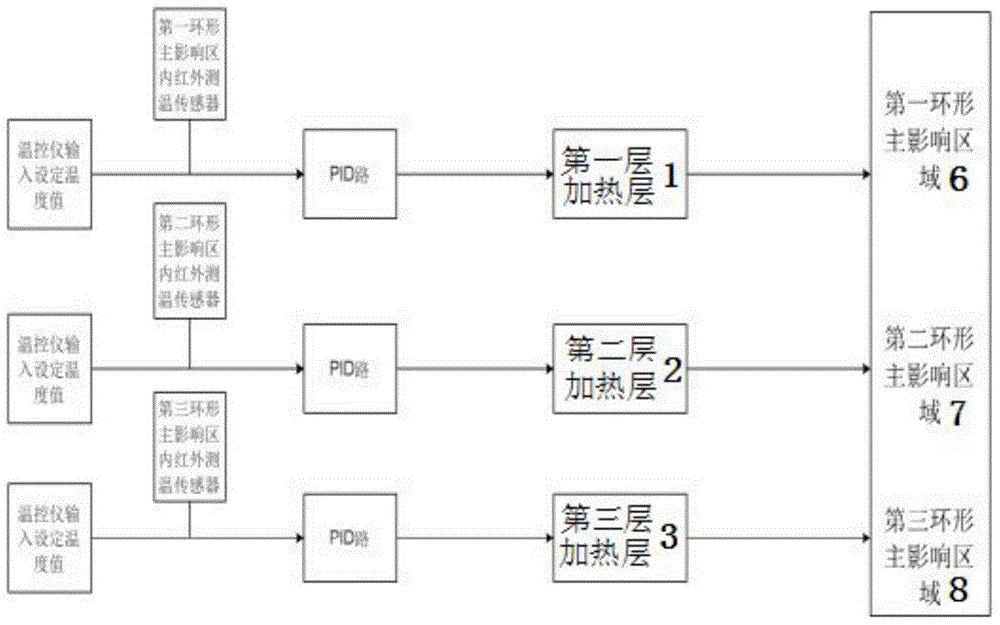

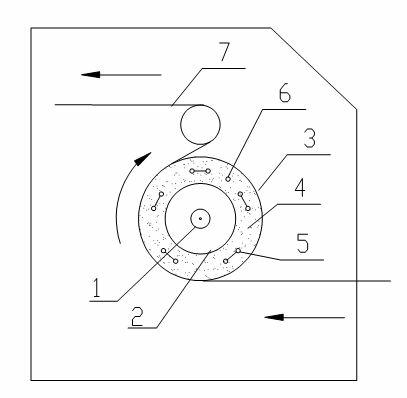

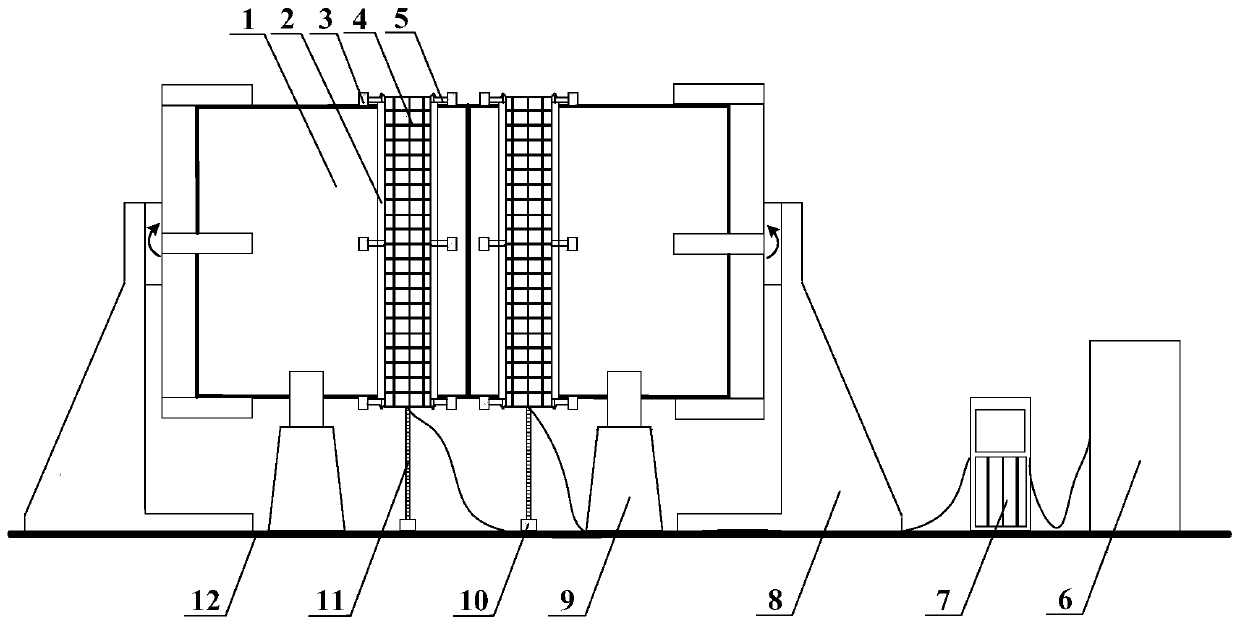

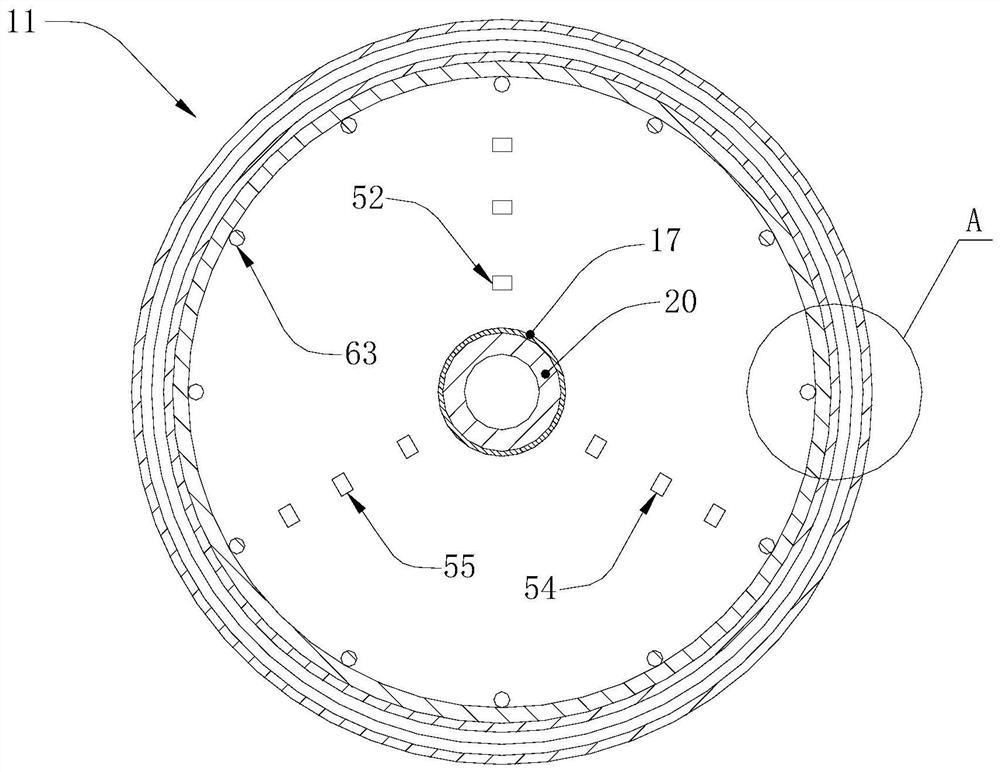

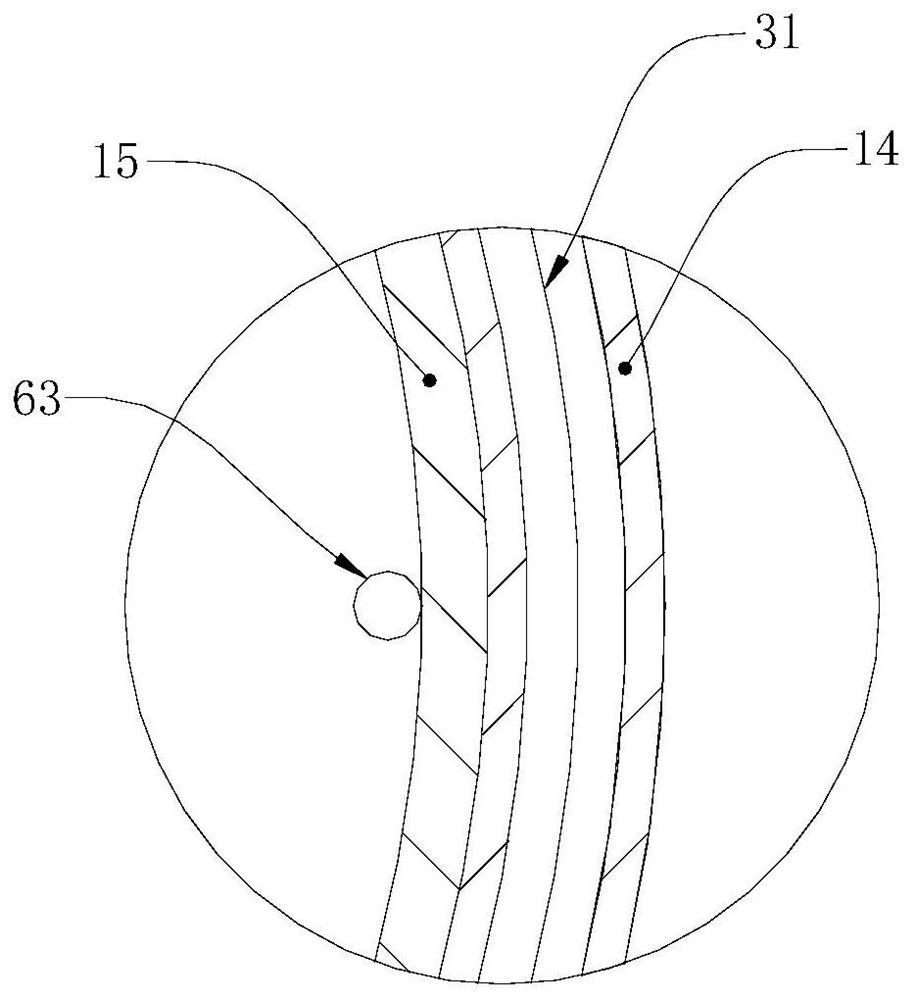

Method for preheating large-size selective laser sintering sub region

ActiveCN105034394AOvercome App ShortcomingsEasy to operateAdditive manufacturing apparatusSelective laser sinteringMetallurgy

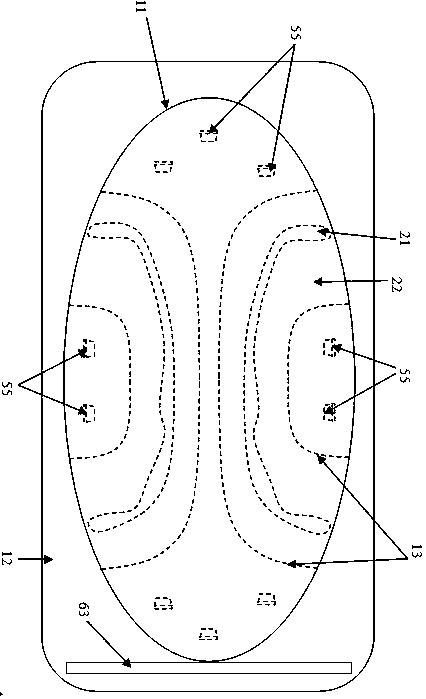

The invention provides a method for preheating a large-size selective laser sintering sub region. The method includes the steps that firstly, a large-size powder bed body is preheated, and two to three different heating layers are divided above the powder bed body at different height intervals; the heights of all the heating layers are adjusted, and a heating array composed of heating modulator tubes is distributed on each heating layer; secondly, the powder bed body is divided into a corresponding number of annular heating main influence regions automatically according to the number of the heating layers, and the annular main influence regions are overlapped to form a total heating region of the powder bed body; and thirdly, the heating array of each heating layer is controlled by a corresponding independent PID closed-loop, and the uniformity of the temperature field of the whole powder bed body is controlled and improved by controlling the uniformity of a temperature field of the heating main influence regions, corresponding to all the heating layers, of the powder bed body. By means of the method for preheating the large-size selective laser sintering sub region, the uniformity of the preheating temperature field of the powder bed body of a workbench top is improved, and therefore the quality of parts manufactured through an SLS process and working efficiency are improved.

Owner:XI AN JIAOTONG UNIV

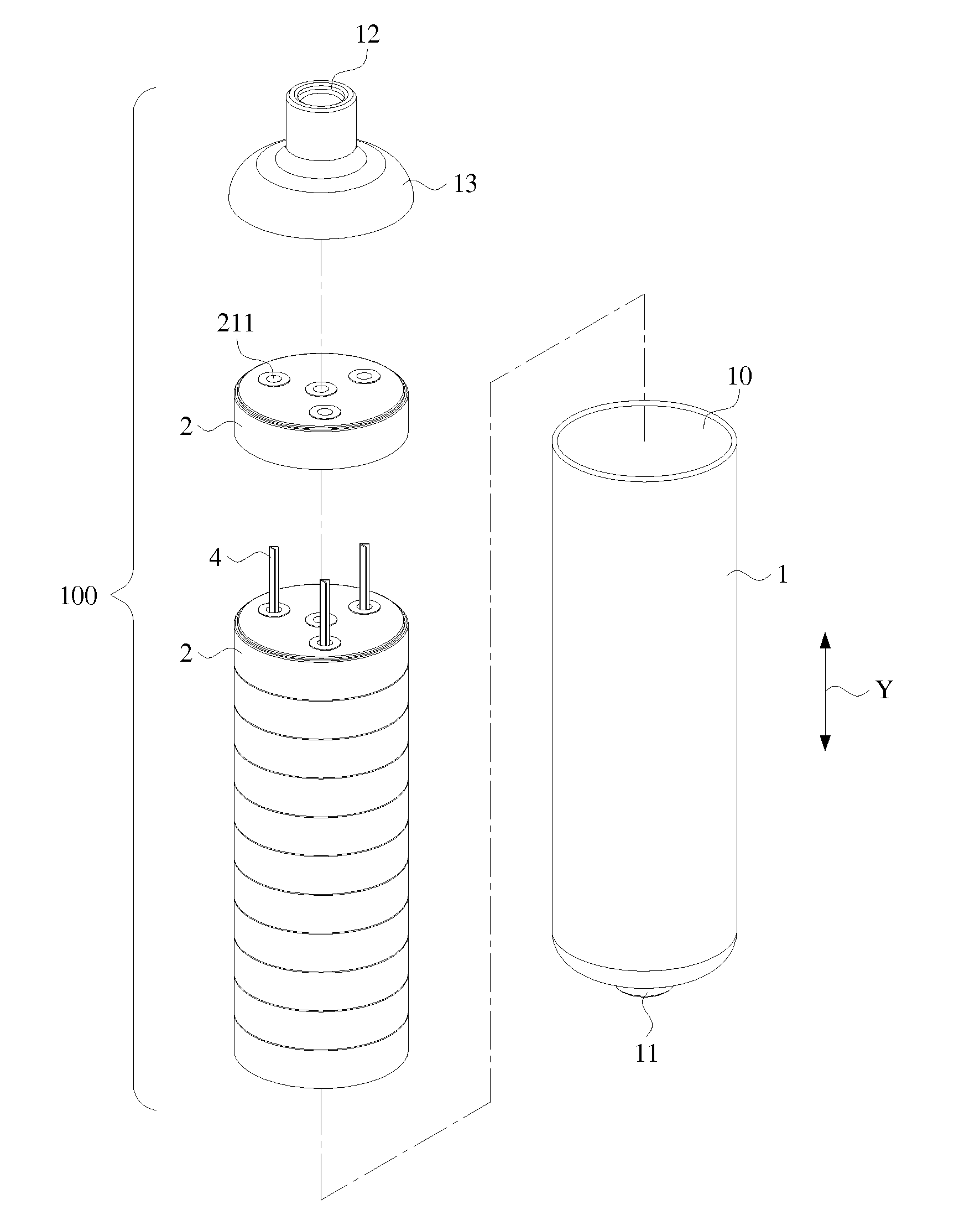

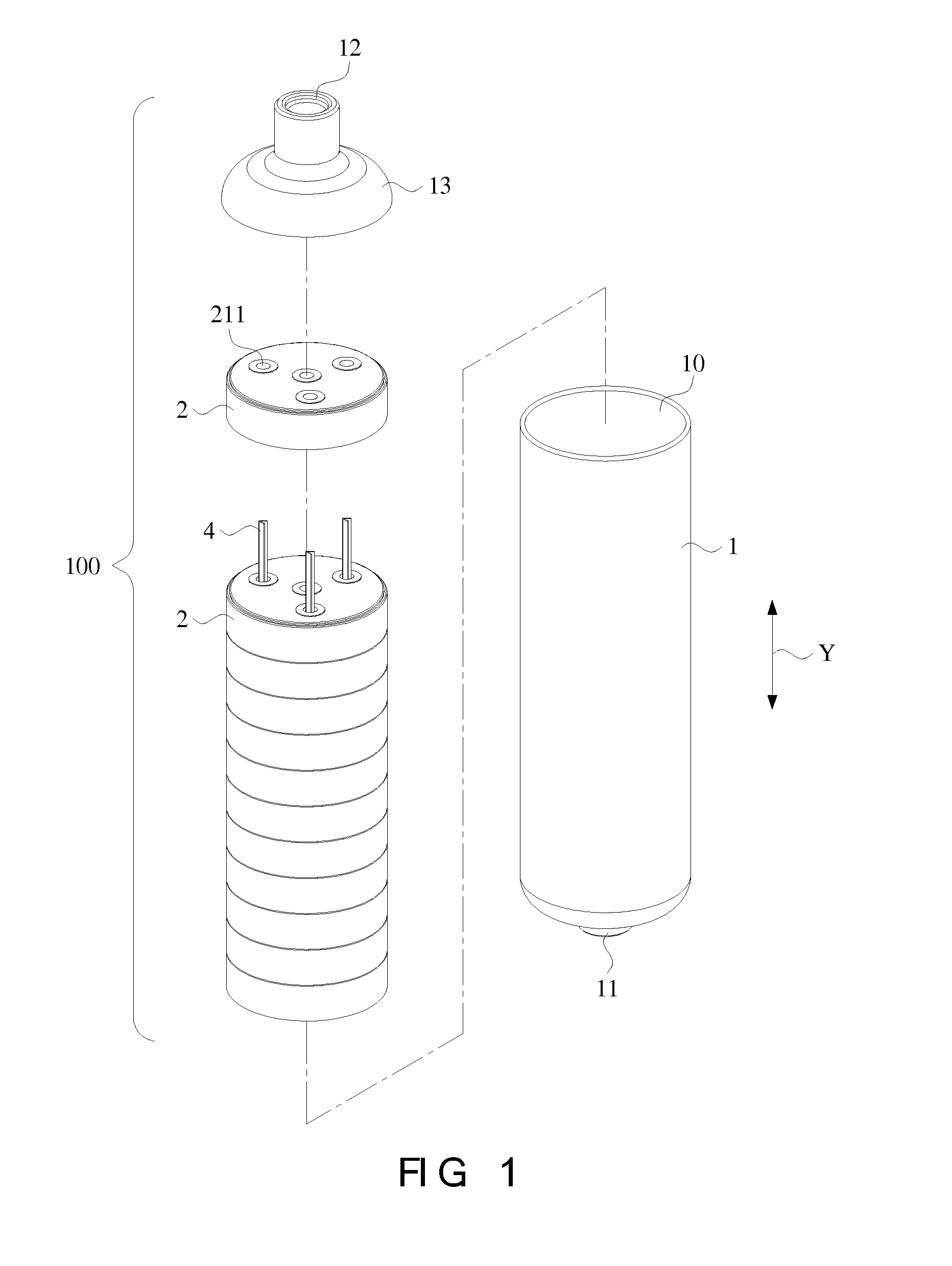

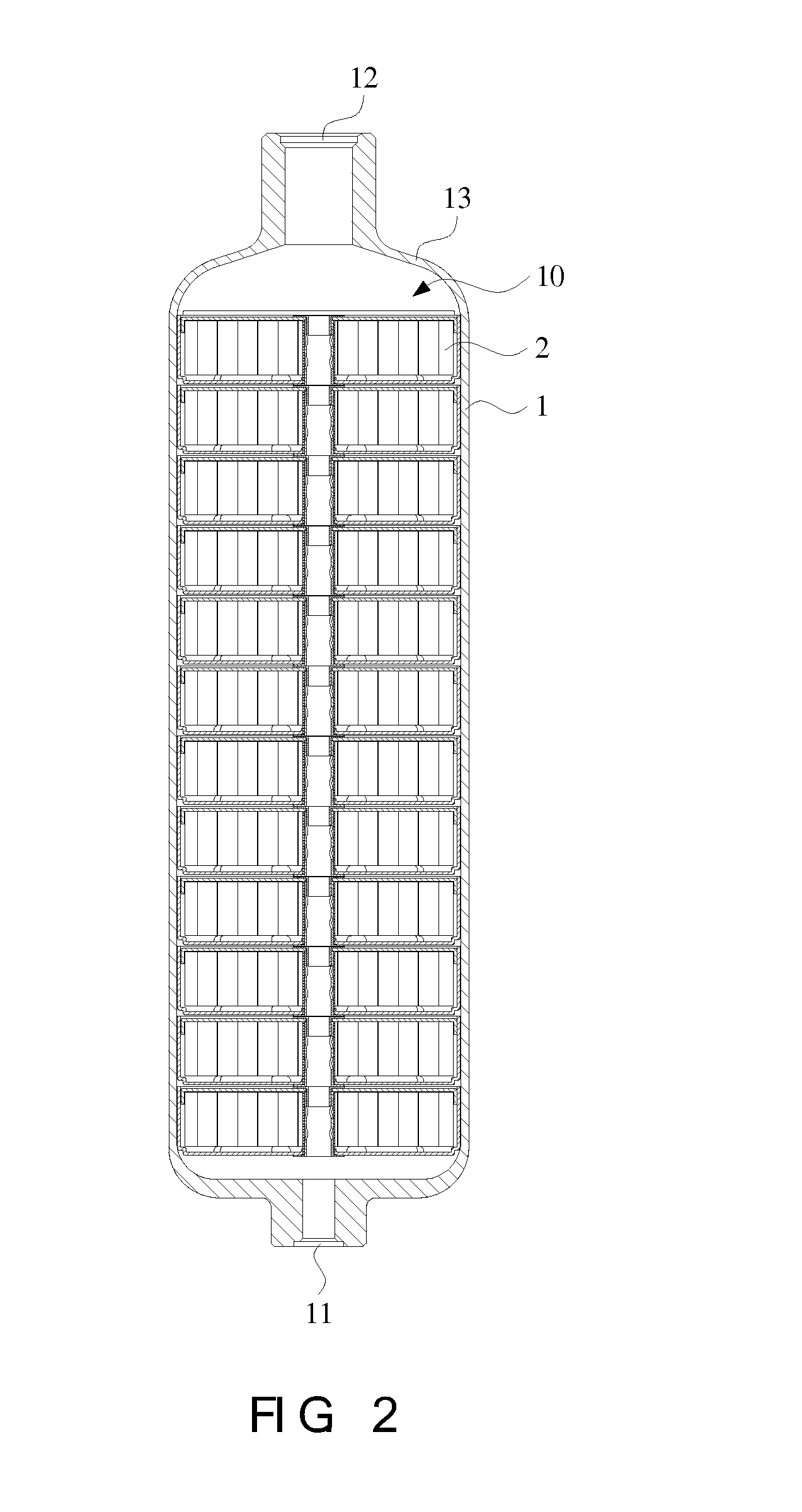

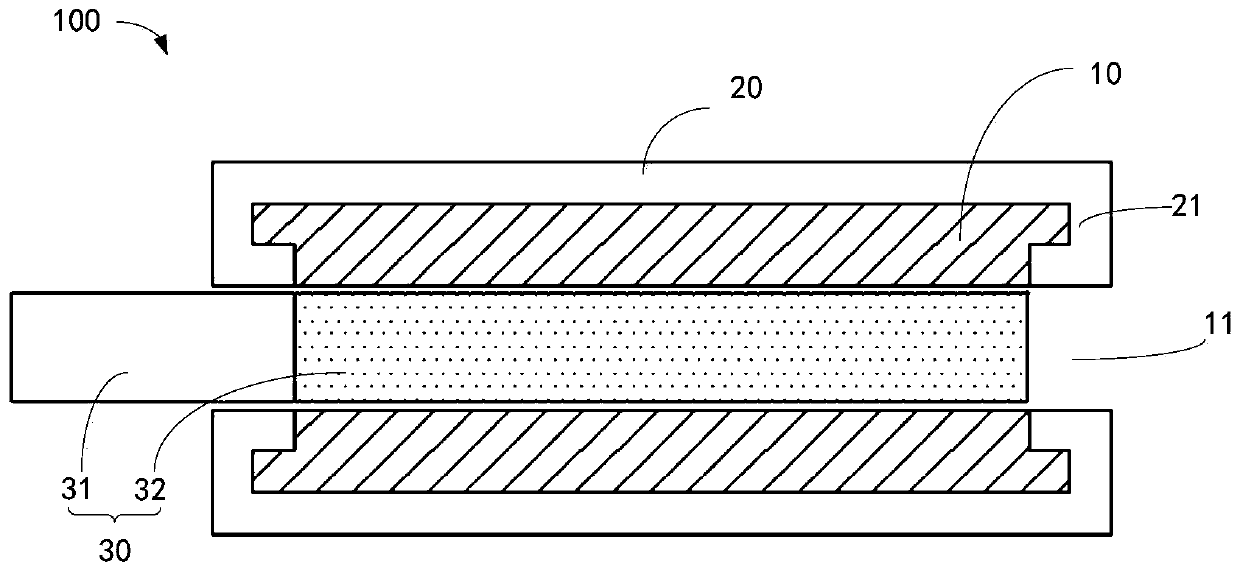

Gas storage cartridge

InactiveUS20120160711A1Easy to assemblePrecise positioningOther accessoriesContainer/bottle contructionEngineeringGas release

A gas storage cartridge includes a sealed cartridge unit for storing a gas storage material. The gas storage cartridge is defined by a first slab, a peripheral wall, and a second slab. At least one gas-guiding channel is accommodated within a receptacle of the gas storage cartridge. The first slab has a first gas inlet / outlet port and the second slab has a second gas inlet / outlet port aligned with the gas-guiding channel. Consequently, a gas is guided into the receptacle through the gas-guiding channel to be adsorbed by the gas storage material within the receptacle of the gas storage cartridge. Alternatively, the gas released from the gas storage material can be guided to the first gas inlet / outlet port and the second gas inlet / outlet port through the gas-guiding channel.

Owner:ASIA PACIFIC FUEL CELL TECH

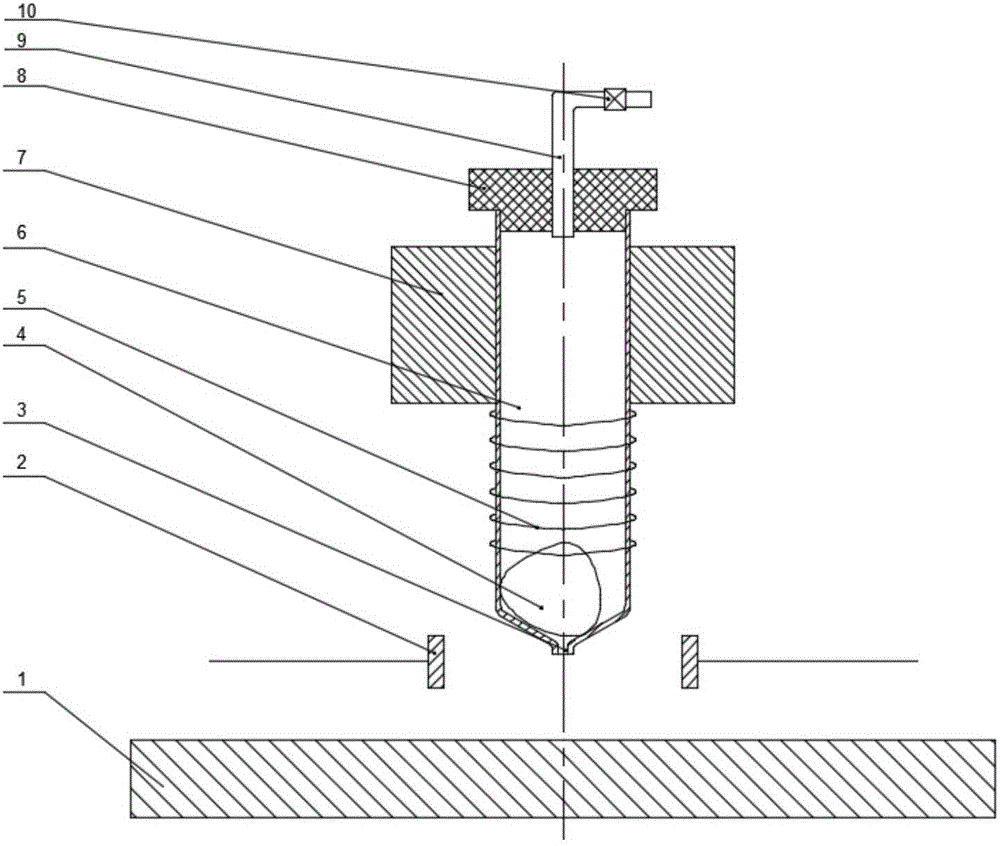

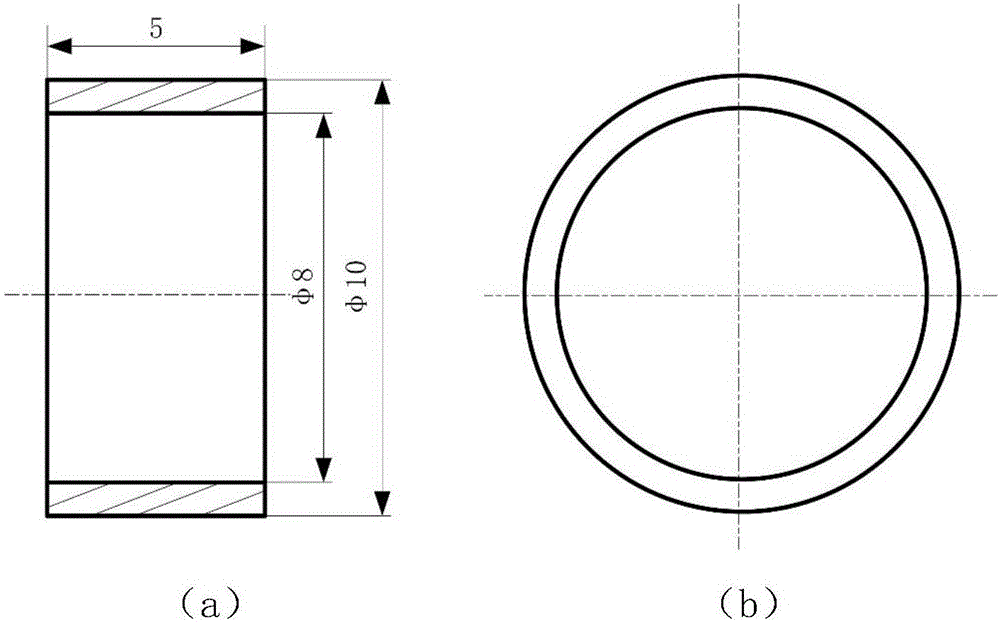

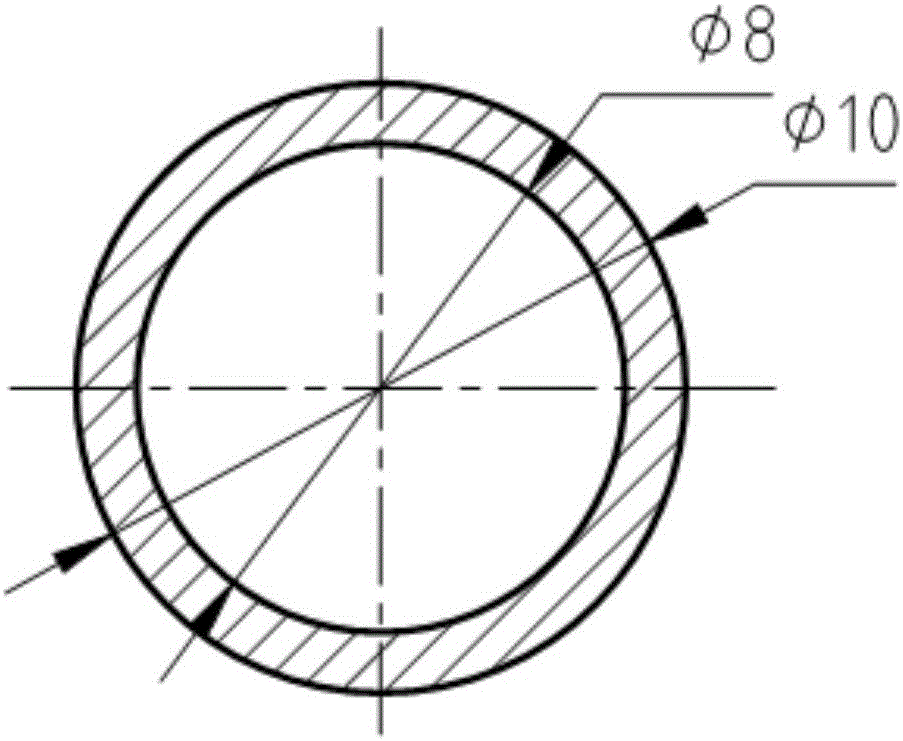

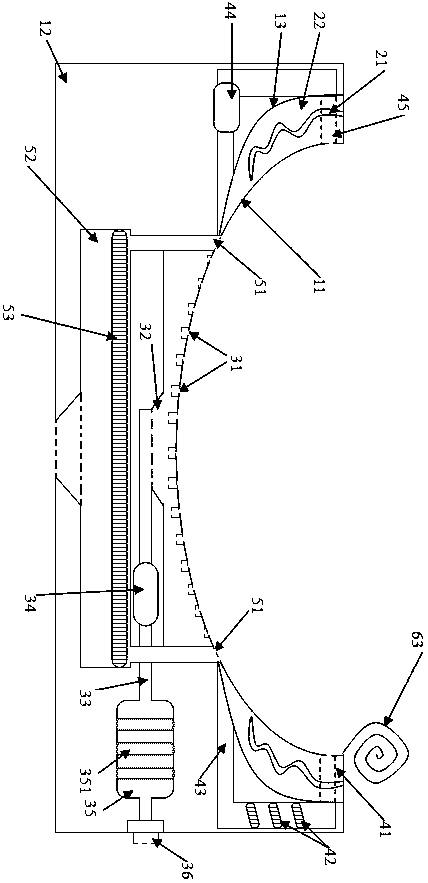

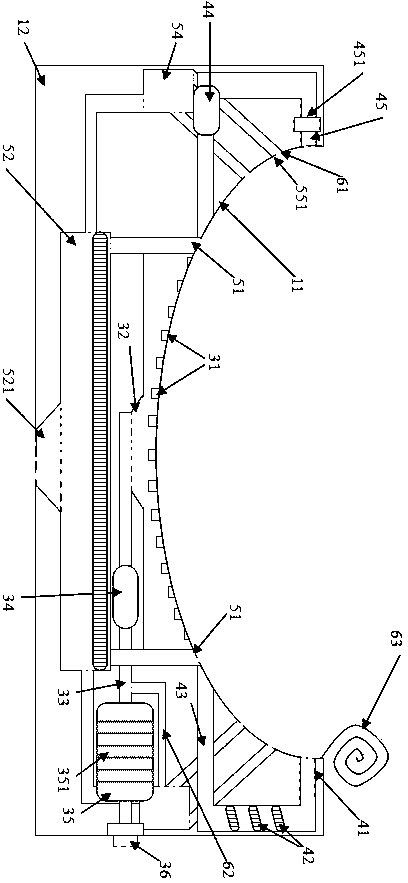

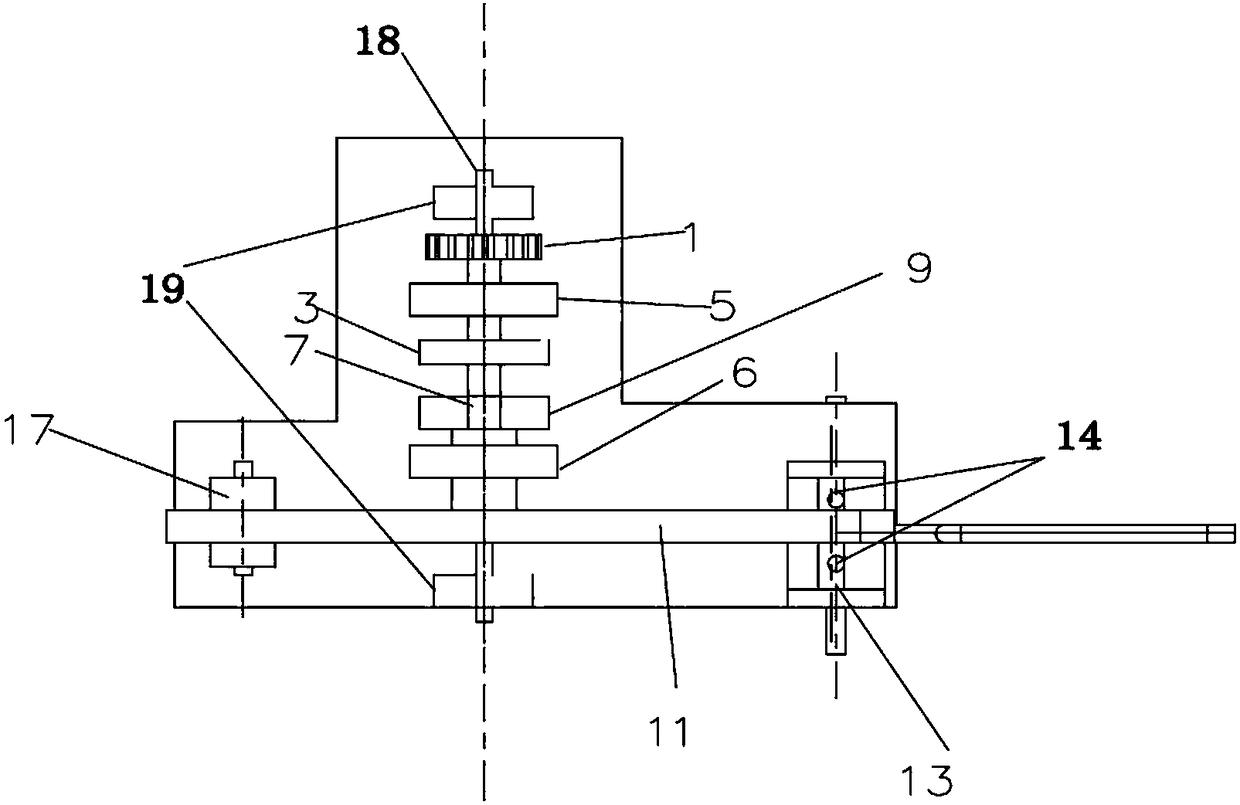

Device and method for rapidly forming metal part through induction heating

InactiveCN105903970AHeating evenlyEven and stable heatingAdditive manufacturing apparatusCrucibleMachining

The invention discloses a device and method for rapidly forming a metal part through induction heating. The device comprises a base plate, a front heating unit and an induction smelting unit. The base plate is located below the induction smelting unit and used as a platform for metal part forming. The front heating unit is located between the base plate and the induction smelting unit and used for forming a uniform temperature field. The induction smelting unit comprises a support and a smelting crucible arranged on the support. An induction coil is arranged on the smelting crucible. The outlet end of the smelting crucible is provided with a smelting crucible nozzle opposite to the base plate. The inlet end of the smelting crucible is connected with an air inlet through a rubber plug and used for providing inert gas for the smelting crucible. The method is used for achieving induction heating and rapid forming of the metal part through the device. The device and method have the advantages of being high in machining flexibility, small in subsequent machining amount and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

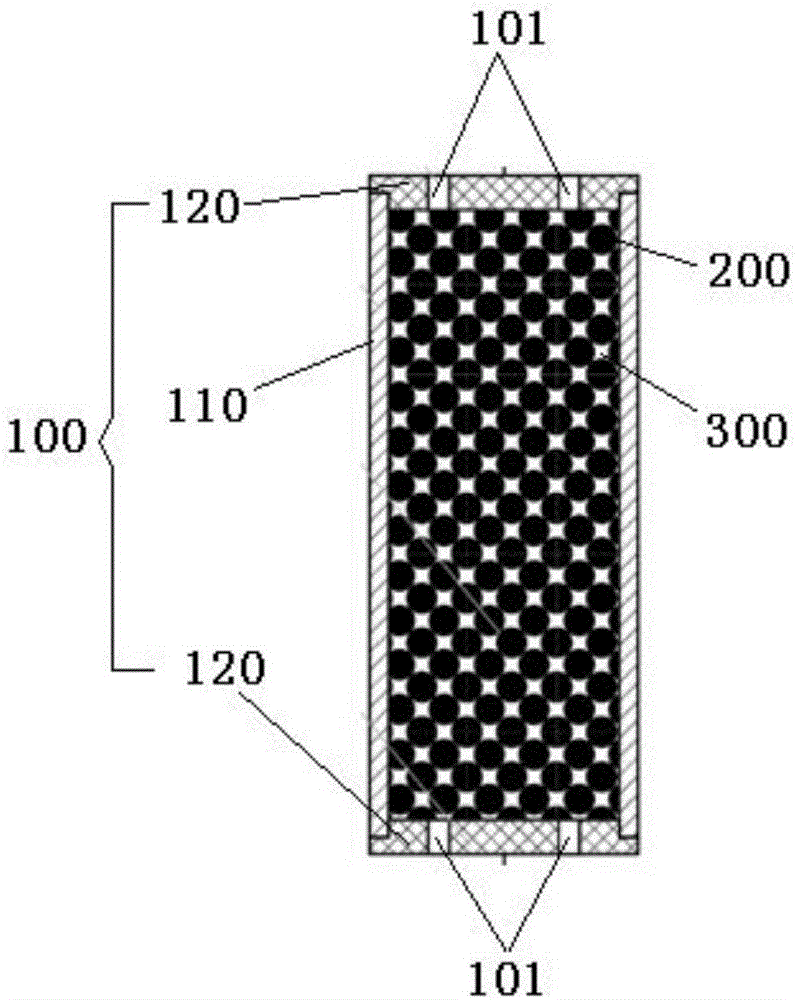

Device and method for generating aerosol

The invention provides a device and a method for generating aerosol. The device comprises a shell, a plurality of conductive particles and aerosol matrixes. The shell is of a hollow structure, and air holes are formed in the shell; the shell comprises a shell body and at least two conductors, and the conductors are arranged on the shell body at intervals; the shell is filled with the conductive particles, the adjacent conductive particles are in contact with one another, and each conductor is in contact with at least one conductive particle; the shell is filled with the aerosol matrixes, and the aerosol matrixes are in contact with the multiple conductive particles. The device and the method have the advantages that the multiple conductive particles are used as heating elements and are distributed inside the shell, the aerosol matrixes are in contact with the surfaces of the conductive particles, can be uniformly and stably heated by heat generated by the electrified conductive particles and can be heated and atomized to obtain the aerosol, the aerosol can be released via the air holes, and accordingly the aerosol matrixes can be effectively prevented from being carbonized in heating procedures.

Owner:SHANGHAI TOBACCO GRP CO LTD

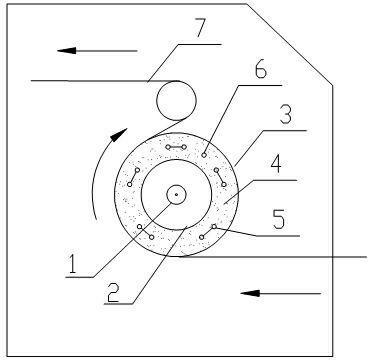

Vacuum coating machine

InactiveCN103469163AImprove efficiencySimple structureVacuum evaporation coatingSputtering coatingIon beamEngineering

The invention discloses a vacuum coating machine. The vacuum coating machine comprises a vacuum chamber (1), wherein an electronic gun (2) and an auxiliary ion source (3) are arranged at the lower part of a cavity of the vacuum chamber (1), a substrate frame over against the electronic gun (2) and the auxiliary ion source (3) are arranged above the electronic gun (2) and the auxiliary ion source (3), a substrate heater (5) is arranged at the outer side of the substrate frame (4); a light-operated system (6) and a crystal-operated system (7) are arranged at a connecting part of the top of the substrate frame (4) and the cavity top of the vacuum chamber (1), the electronic gun (2), the auxiliary ion source (3), the light-operated system (6) and the crystal-operated system (7) are connected with a monitoring device through signal lines. The substrate heater is used for stably and uniformly heating the substrate before coating film so as to improve the compactness and the uniformity of the film; an ion beam is used for bombarding the growing film to form a film structure with uniform compactness, the stability and quality of the coated film are improved so that the aim of improving the optical and mechanical performances of the coated film is achieved.

Owner:无锡启晖光电科技有限公司

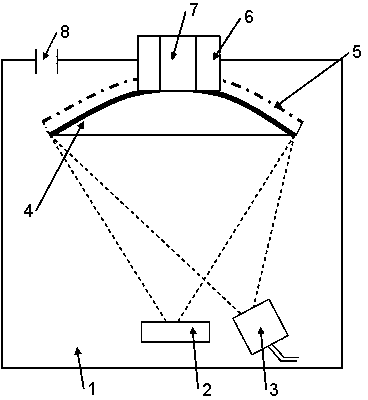

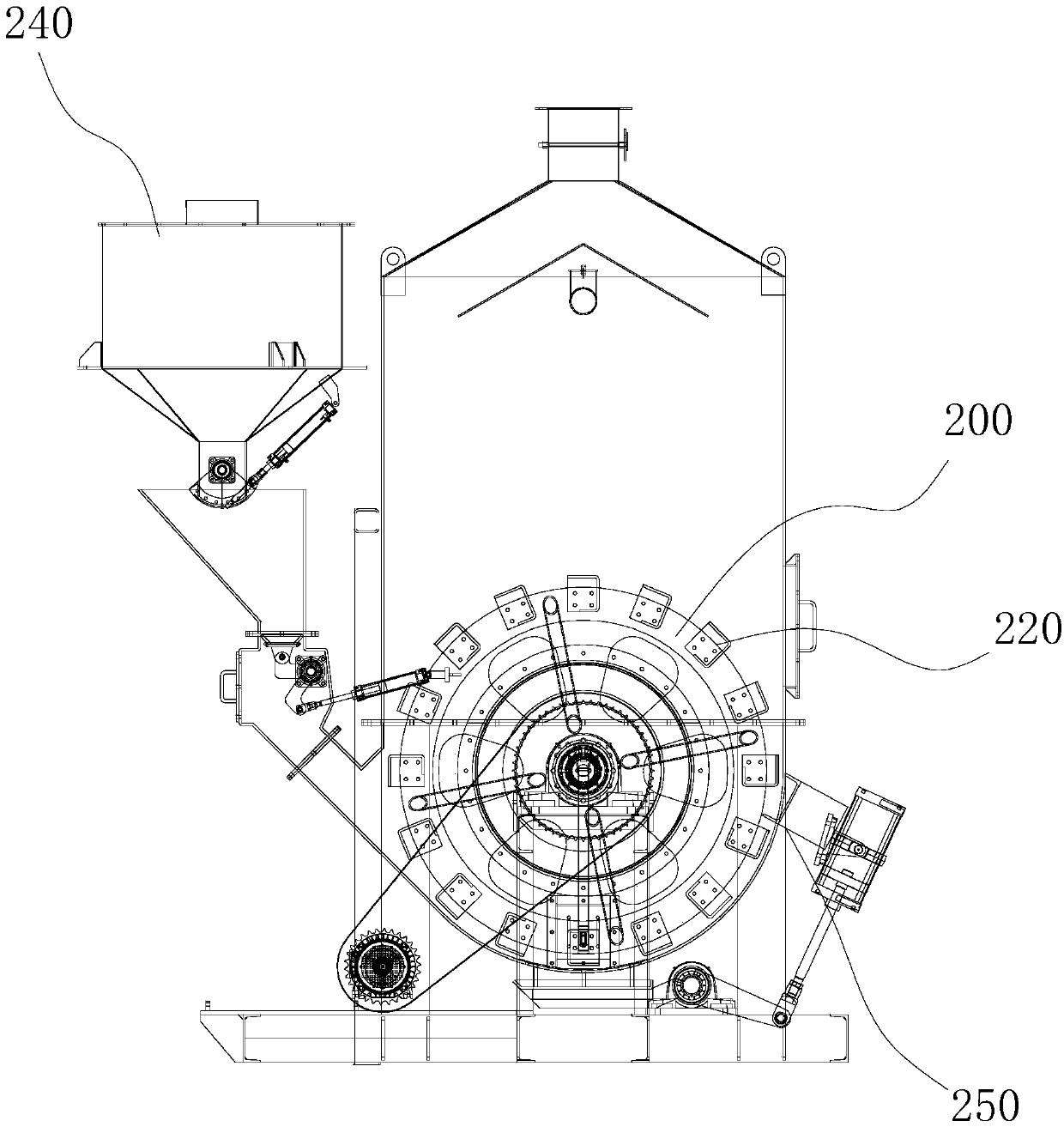

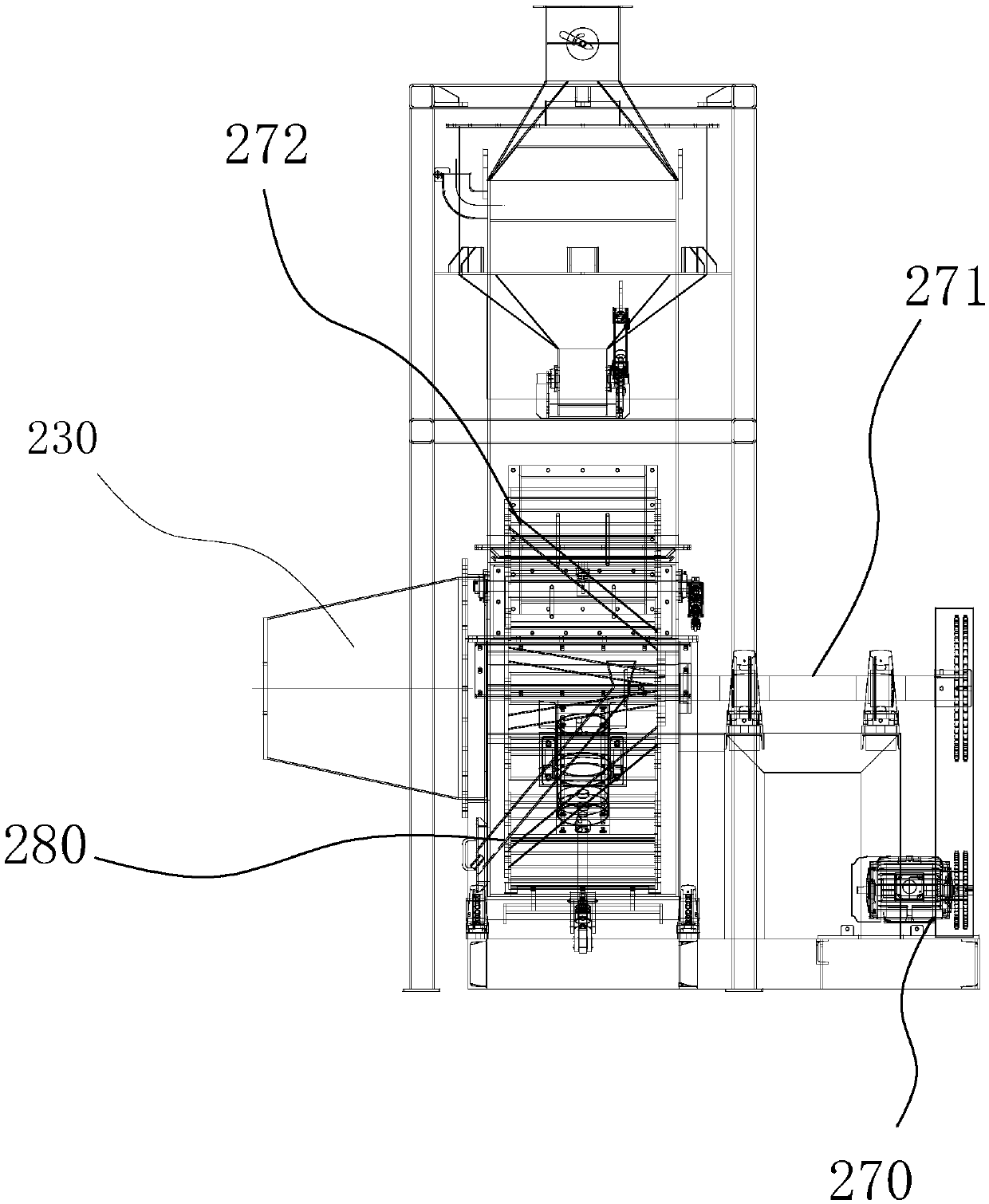

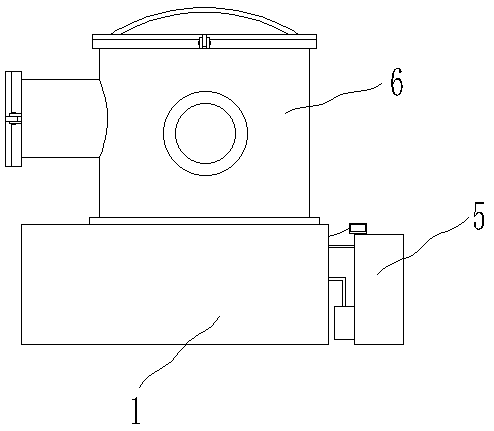

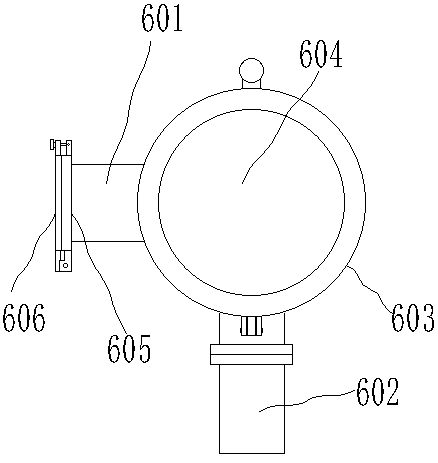

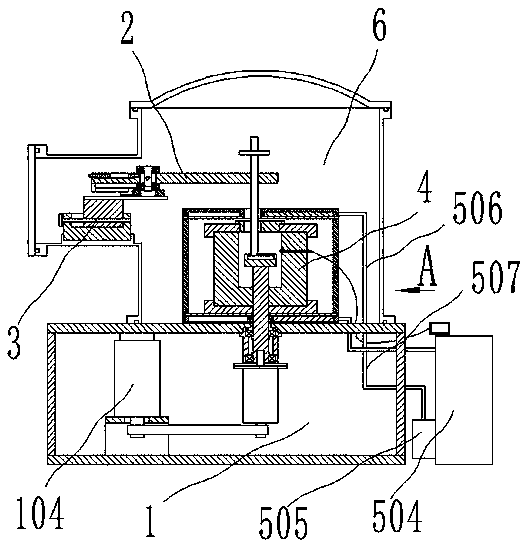

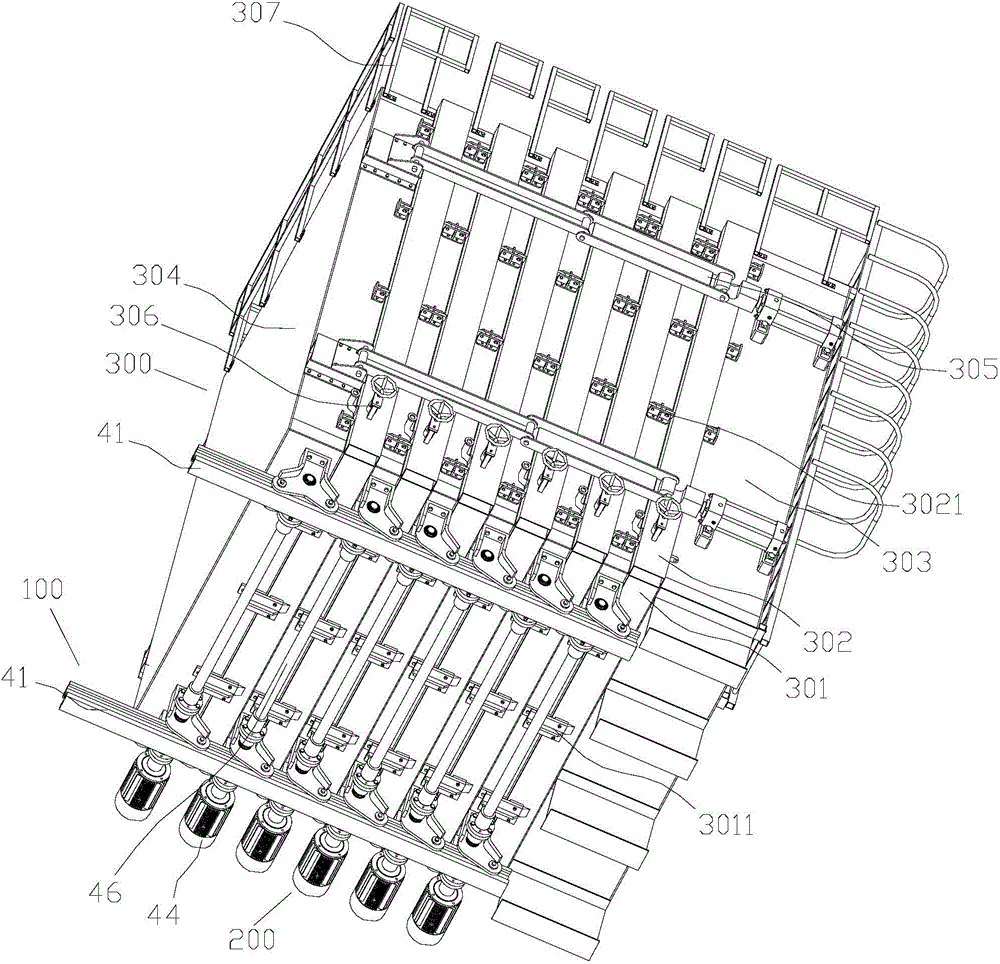

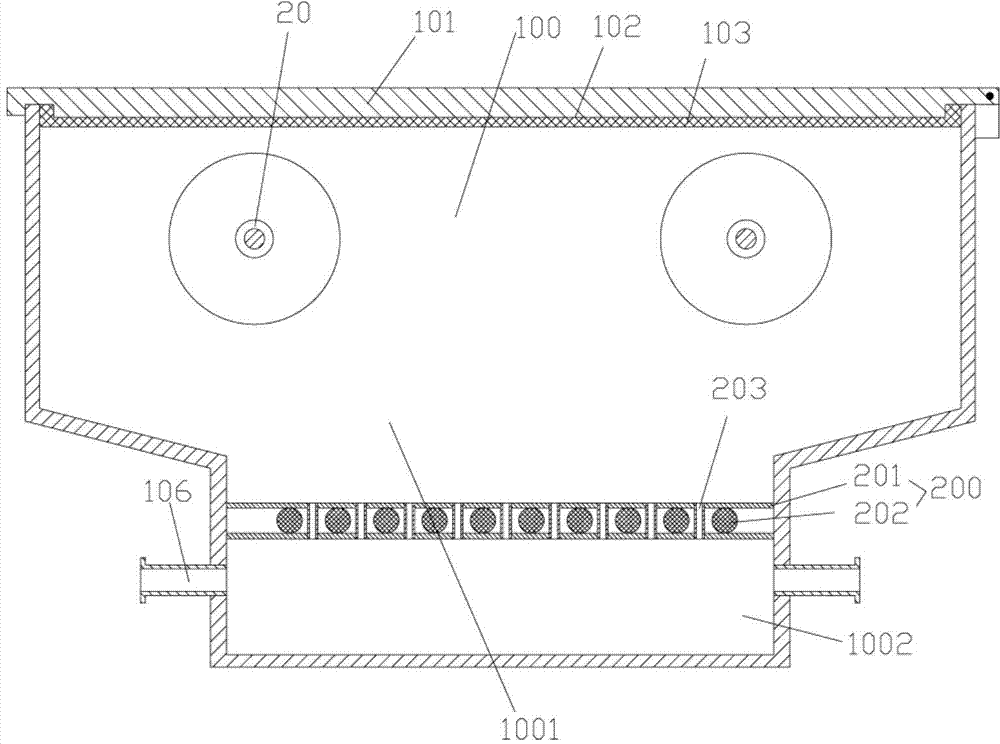

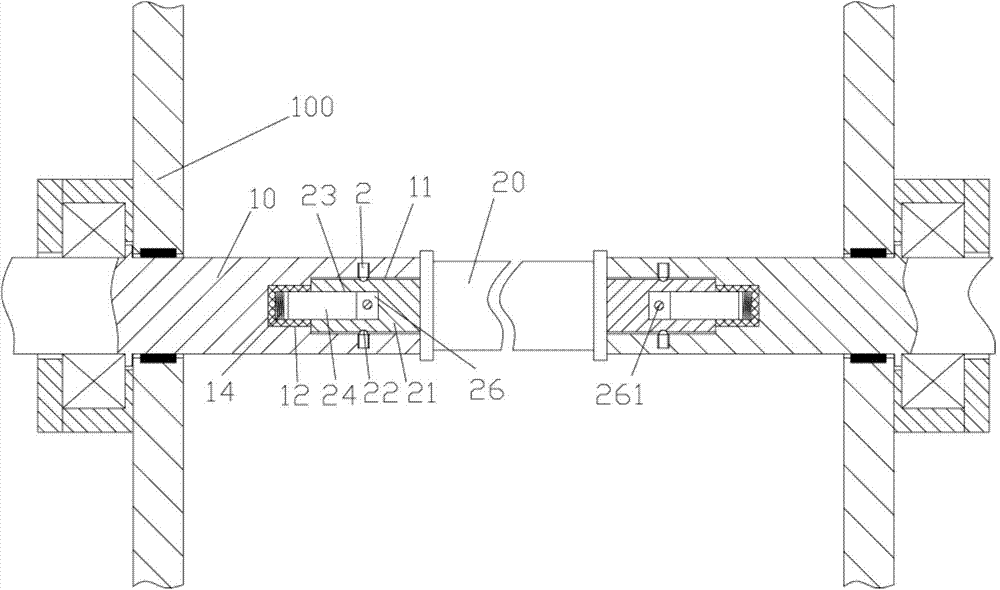

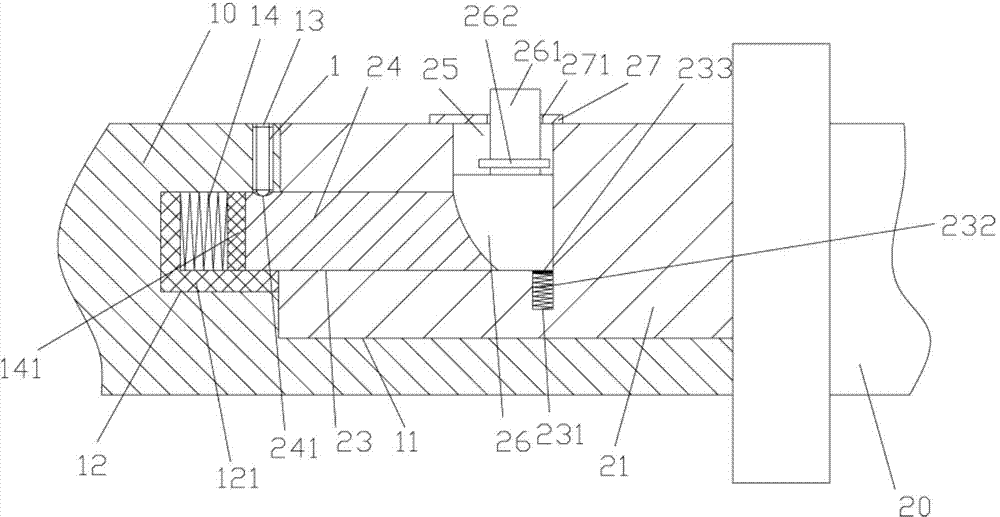

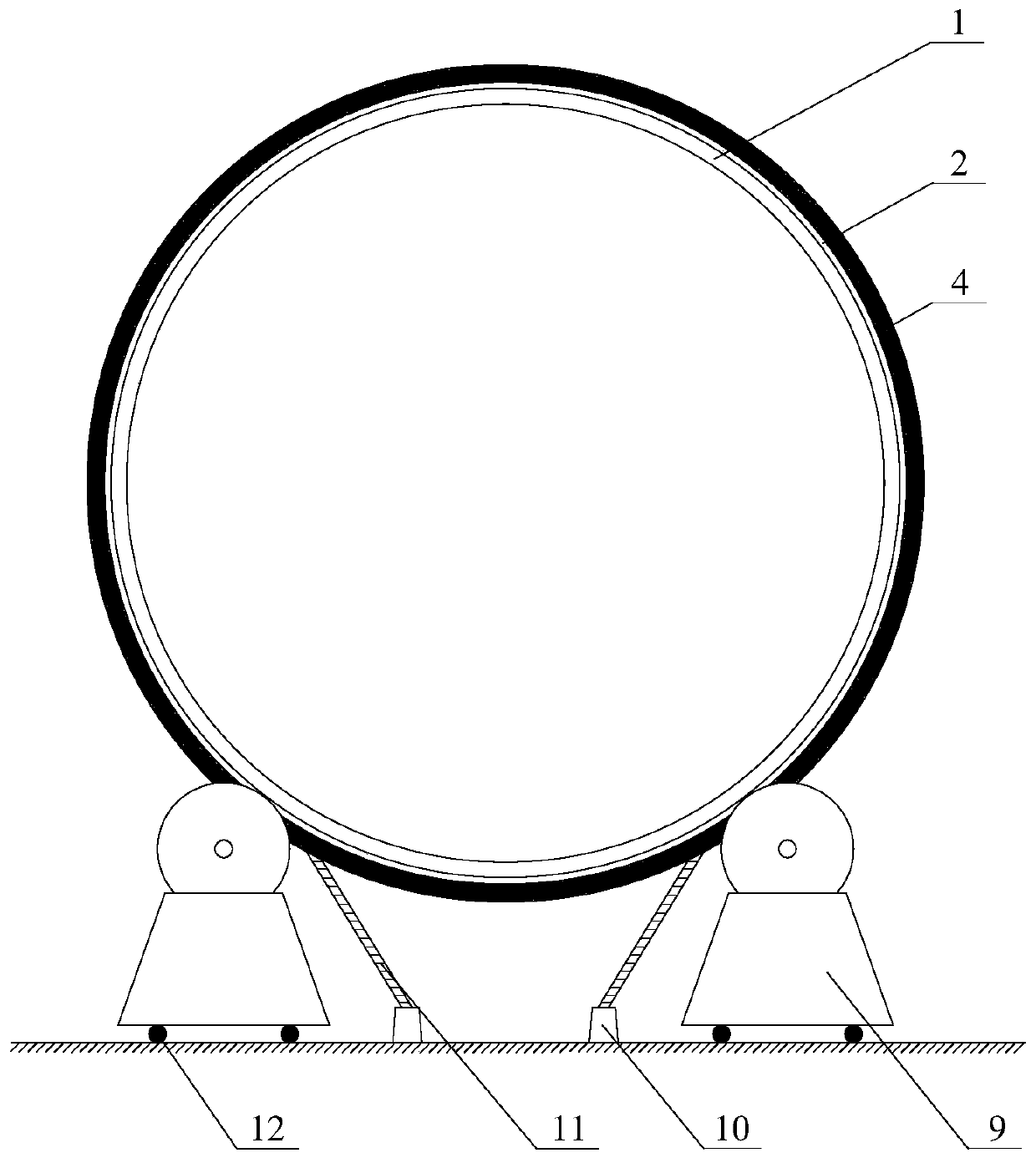

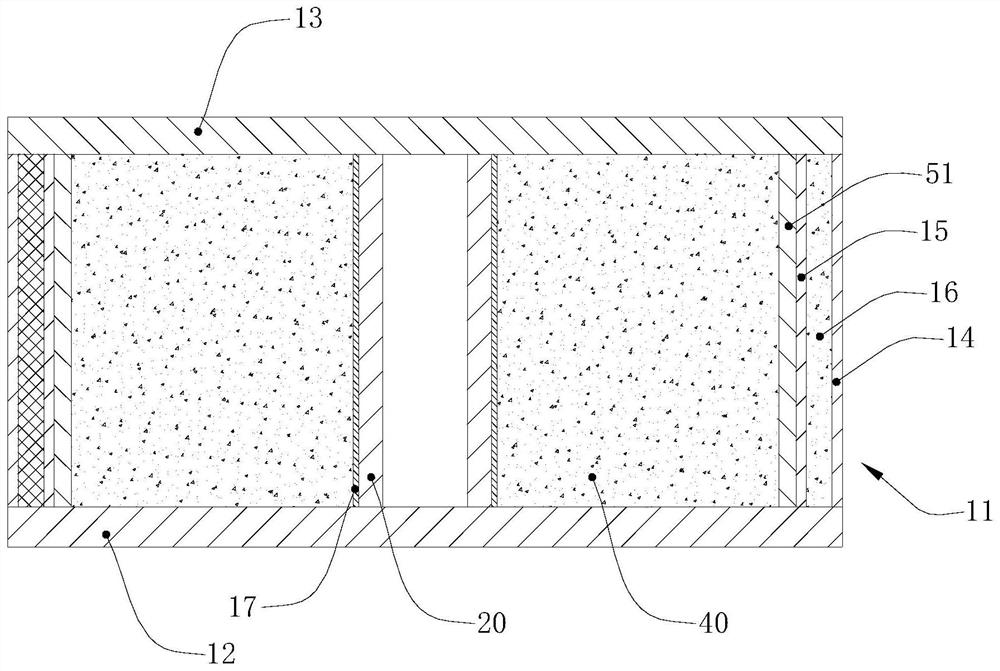

Precoated sand production line

PendingCN109590432AEven and stable heatingGood coating effectMould handling/dressing devicesProduction lineEngineering

The invention belongs to the technical field of precoated sand production and particularly relates to a precoated sand production line. The precoated sand production line comprises a raw sand materialbin, a heating machine, a mixer, a sieve shaker and a finished product material bin. A pair of stirring wheels are arranged inside the heating machine. The edge of each stirring wheel is uniformly provided with multiple sand stirring hoppers. The stirring wheels rotate to drive the sand stirring hoppers to move in the circumferential direction. The side face of the heating machine is provided with a burning machine, wherein the burning machine outputs heat to the rotating centers of the stirring wheels. The mixer is arranged below the heating machine and internally provided with a rotating disc. The rotating disc is provided with a pair of rolling wheels. The sieve shaker is internally provided with a crushing net. According to the precoated sand production line, materials are conveyed from a high position to a low position through gravity flow; a feeding hopper lifter and a discharging hopper lifter are adopted to assist in conveying, from the low position to the high position, of the materials; equipment is reasonable in arrangement, and energy is effectively saved; the heating machine conducts heating stably and uniformly; an eccentric double-grinding wheel of the mixer is goodin film coating effect; sand obtained after mixing is subjected to crushing, screening and cooling; a precoated sand product is excellent in quality; and the work efficiency is high.

Owner:天阳机械设备有限公司

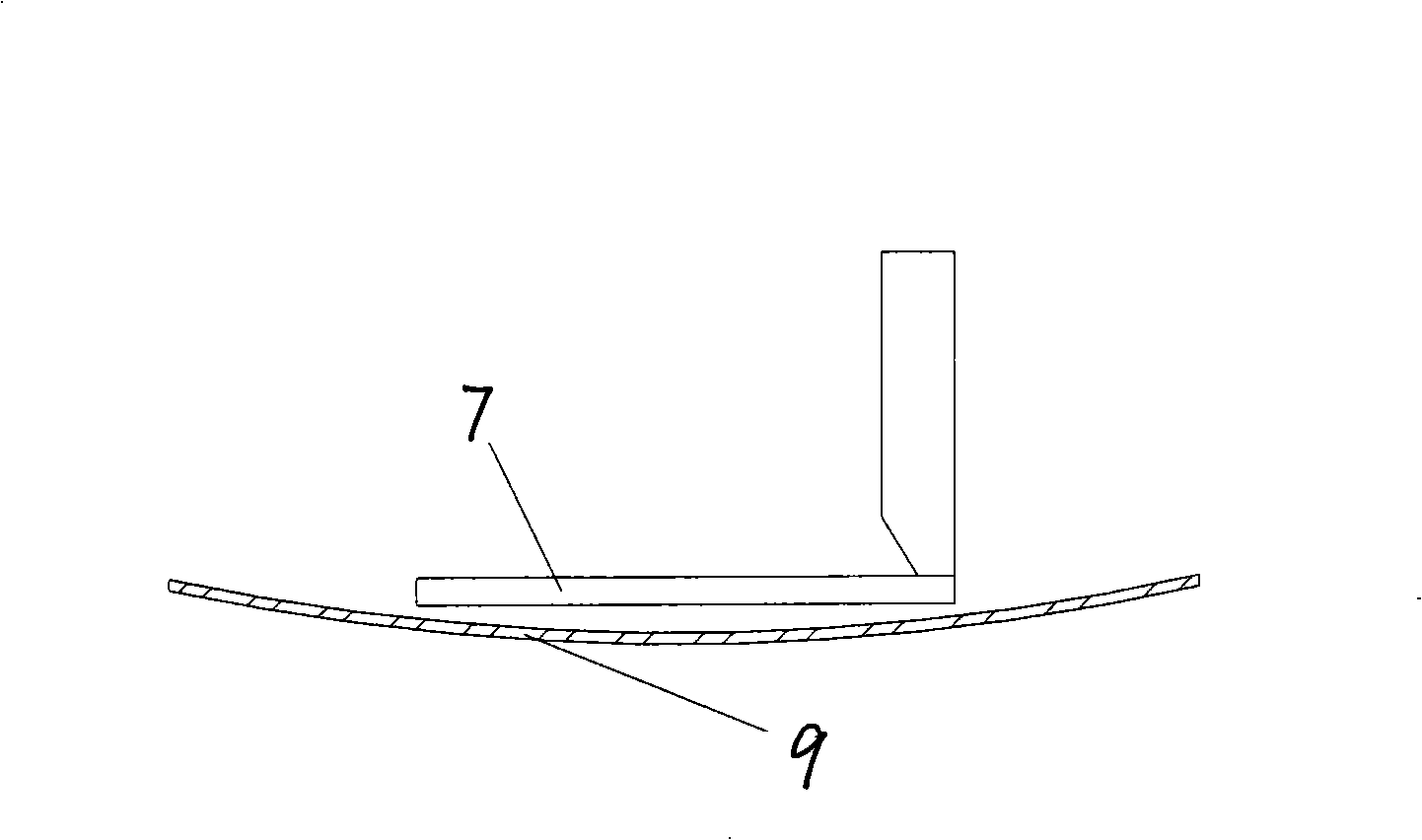

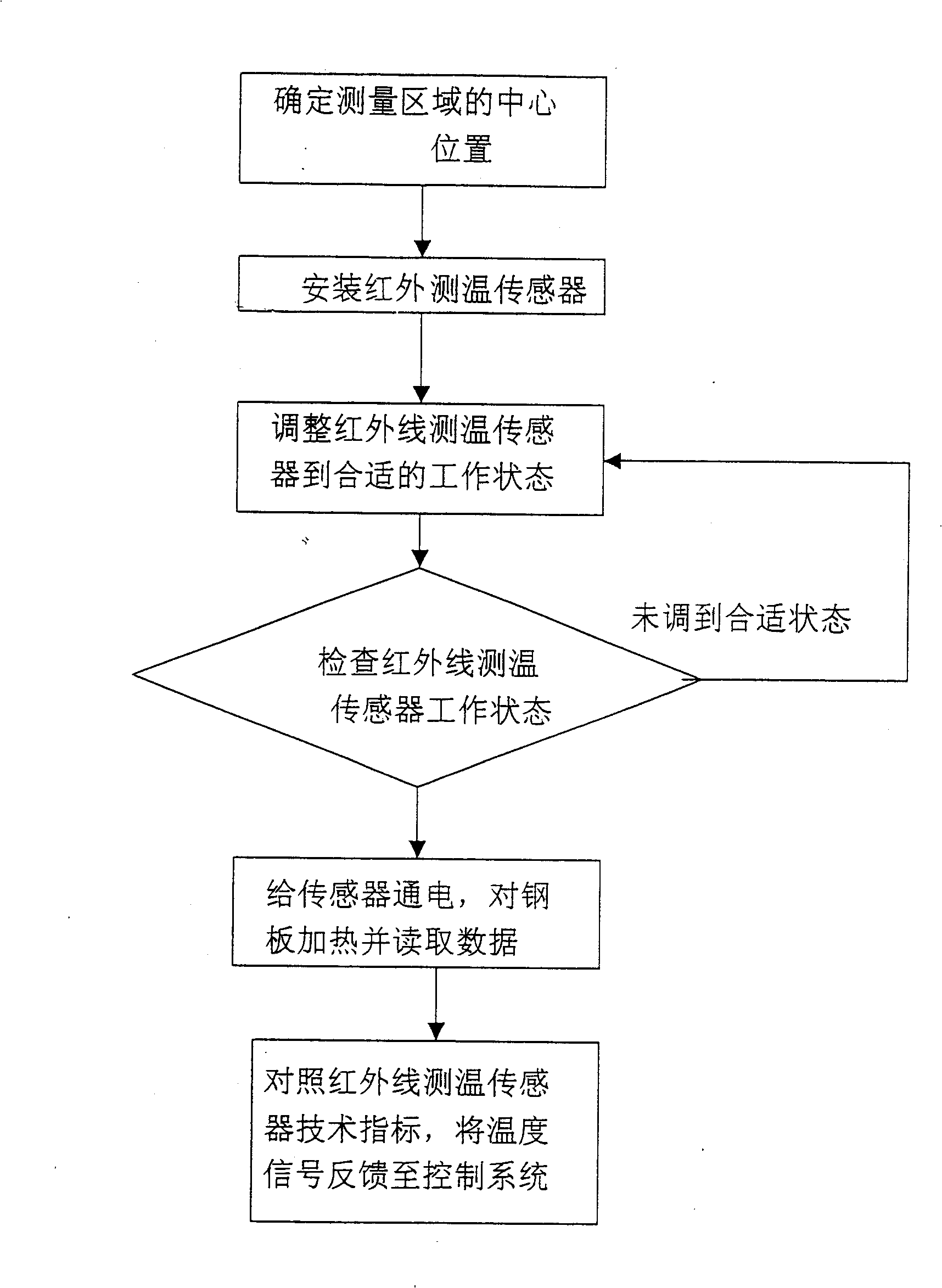

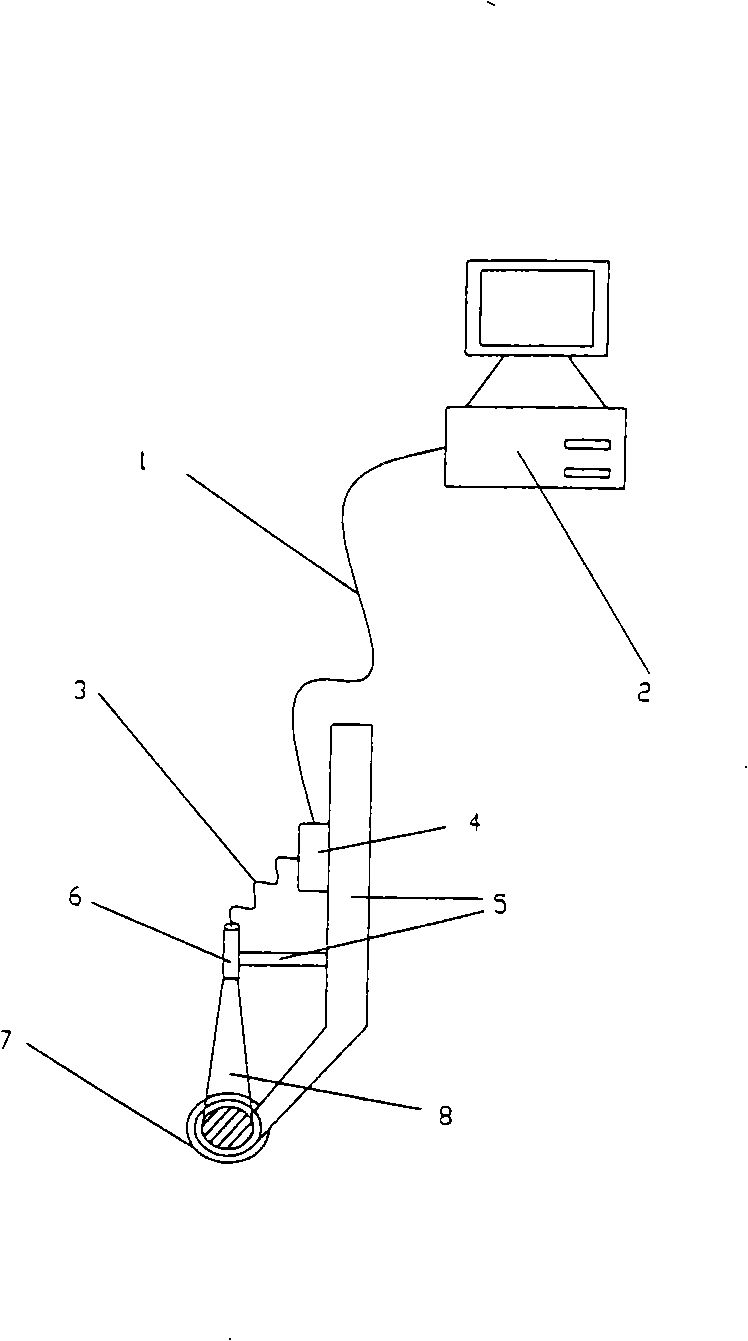

High frequency induction heated temperature measuring equipment and its temperature measuring method thereof

InactiveCN101319935AEven and stable heatingAccurate measurementPyrometry using electric radation detectorsFeedback controlElectric signal

The invention discloses a temperature measuring method for high frequency induction heating which is characterized by including the following steps of: A, confirming the central position of a measuring area according to the position of an annular loop; B, fixing an infrared temperature measuring sensor just above the central position of the measuring area and a measuring head is over against the central position; C, adjusting the infrared temperature measuring sensor into a working state; D, electrifying the sensor and reading an electric signal outputted by the sensor when heating; E, converting the electric signal into a temperature signal. The temperature measuring device and the temperature measuring method of the invention are adopted to carry out instant temperature measuring on high frequency induction heating, convert the obtained electric signal into the temperature signal by the calculation and processing of a computer, display the temperature signal and form a feedback control on the output power of the high frequency induction, thus being beneficial for the high frequency induction heating to be carried out uniformly and stably. The temperature measuring method has a simple structure, is conveniently operated and can accurately measure the temperature in real time.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

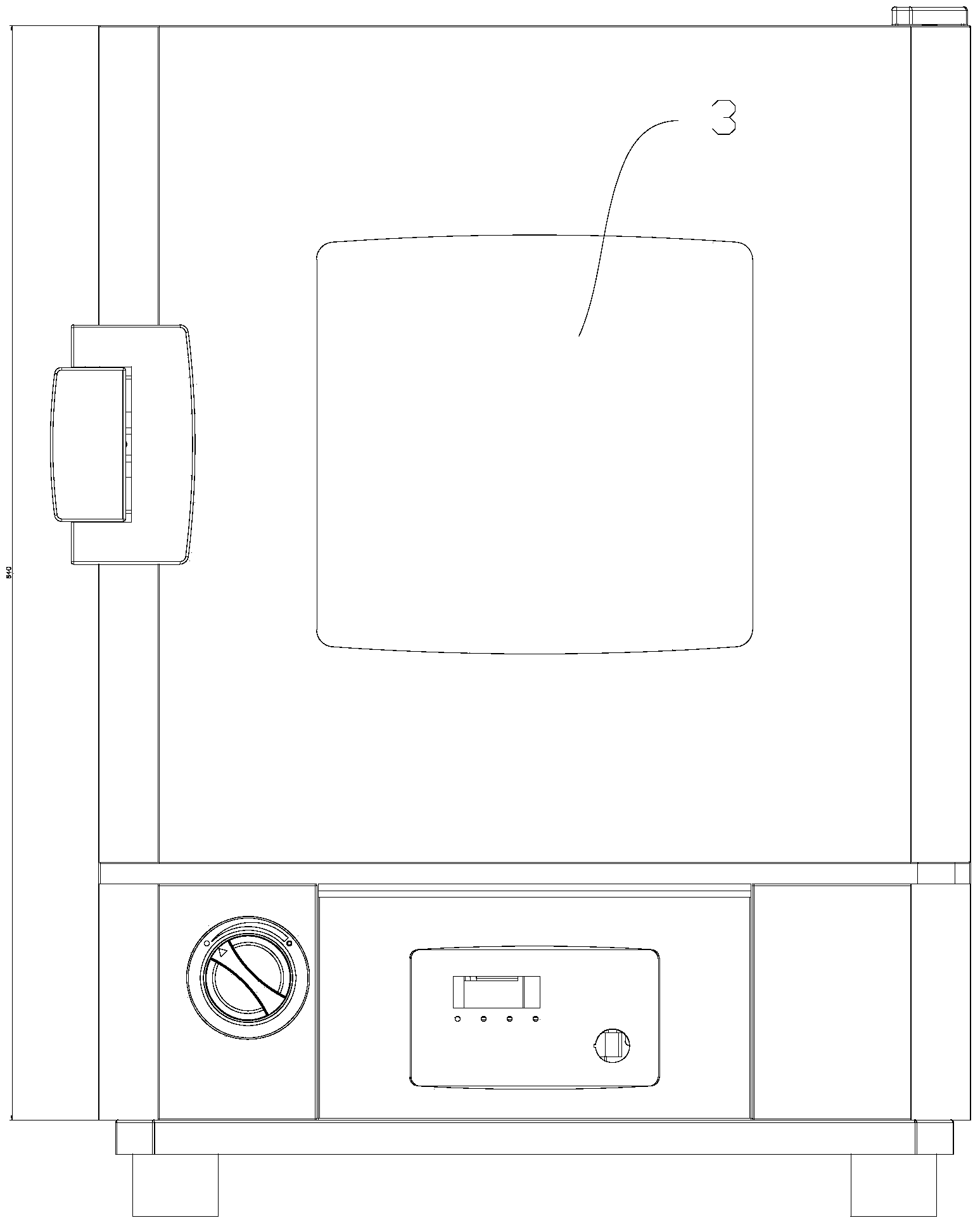

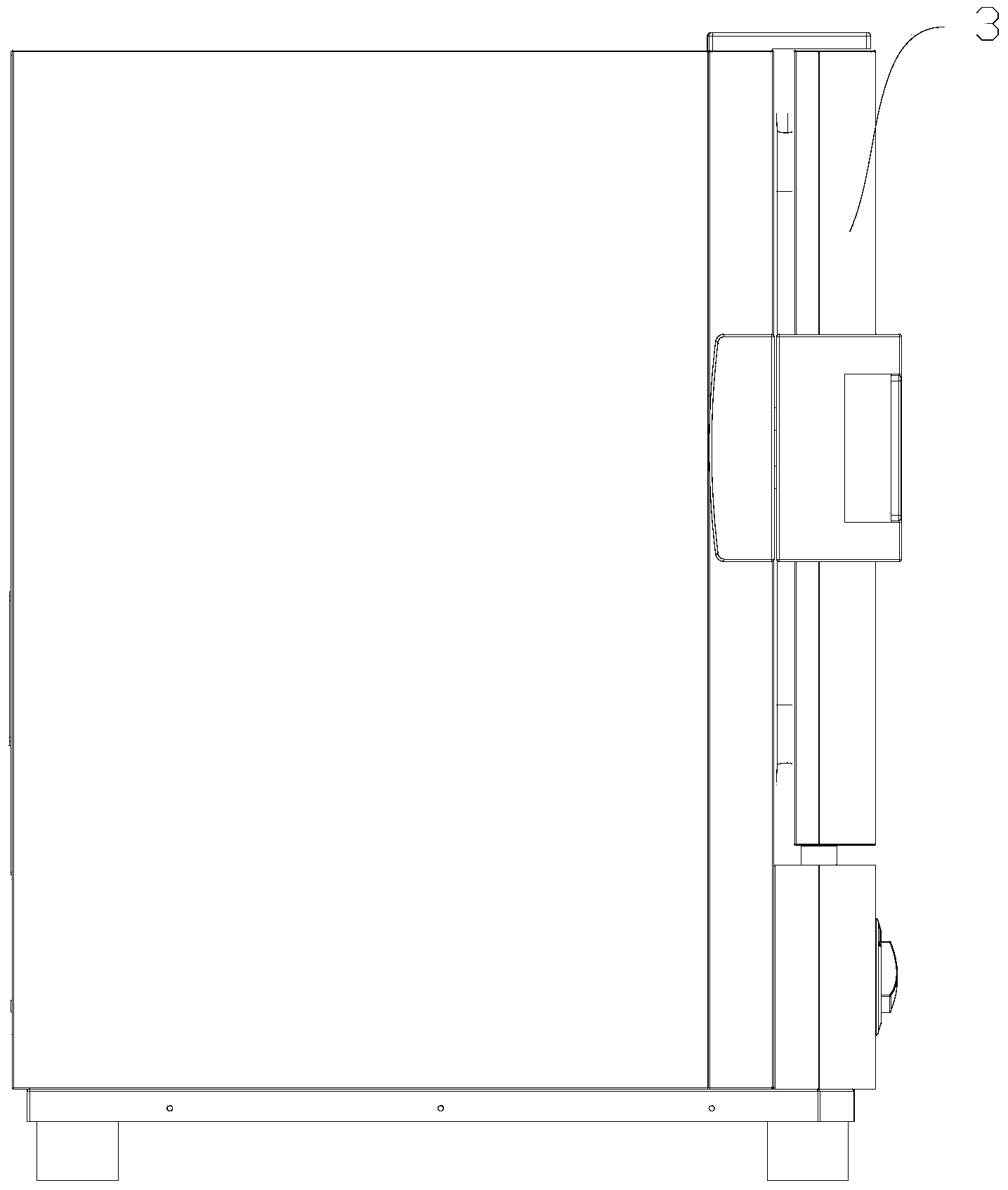

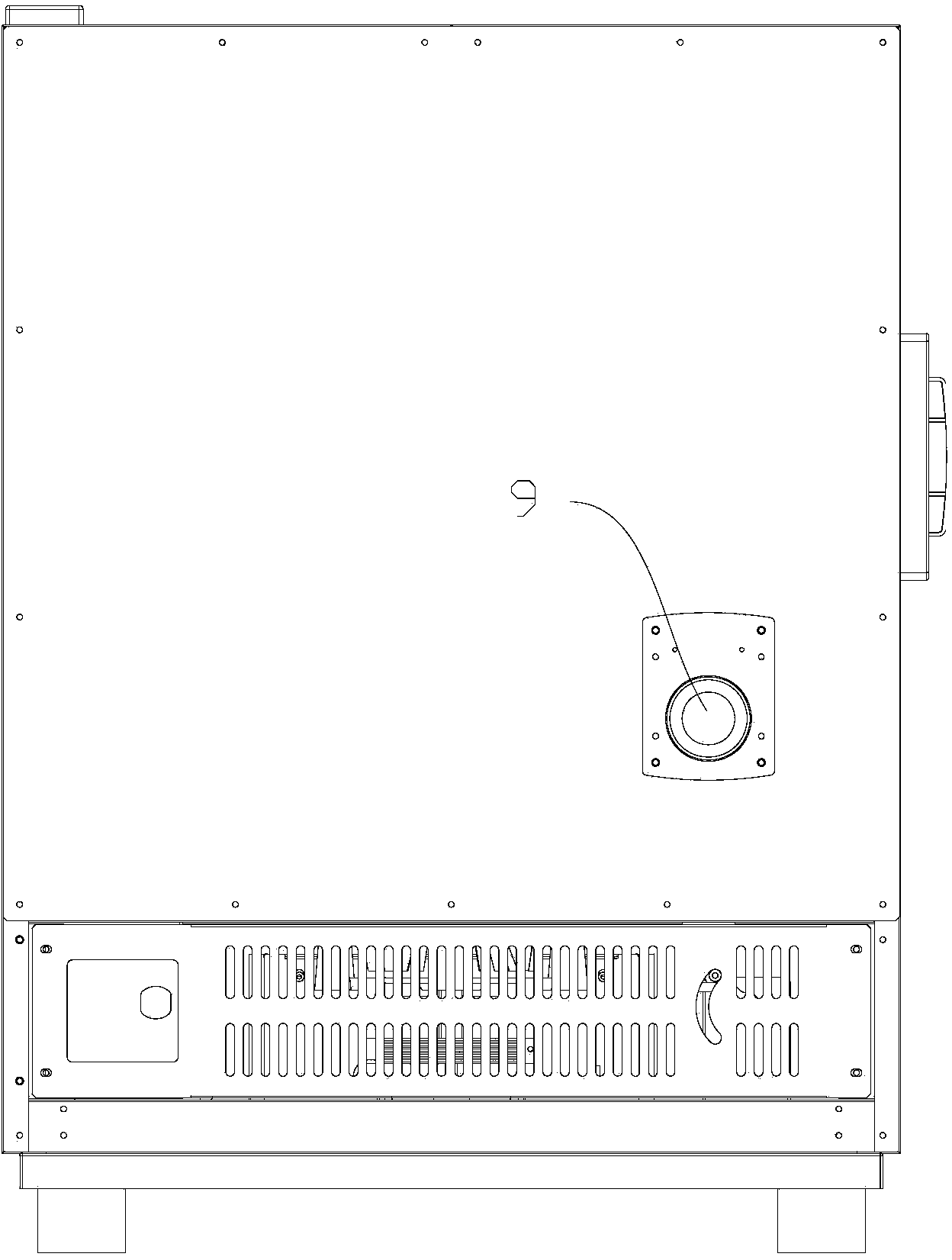

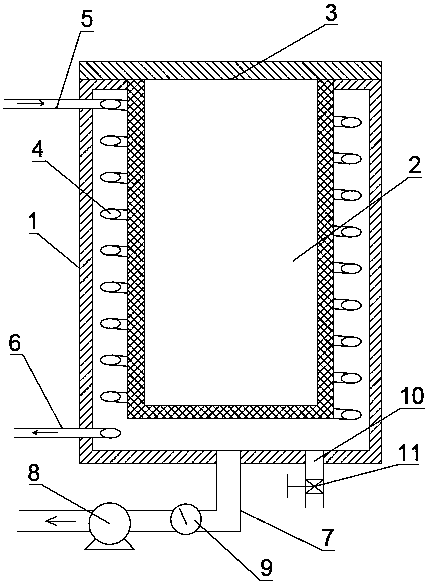

Drying constant-temperature test box

InactiveCN103908981AGood technical effectHeating evenlyHeating or cooling apparatusEnclosures/chambersTemperature controlAir velocity

The invention relates to a laboratorial culture tank and discloses a drying constant-temperature test box. The drying constant-temperature test box comprises an insulating layer, a constant-temperature air circulating device and a front door, wherein the insulating layer and the front door form a closed constant-temperature inner cavity; the constant-temperature air circulating device comprises a motor, a wind wheel and a circulating air duct; the motor drives the wind wheel to rotate, the circulating air duct comprises an air exhausting duct and an air inlet duct, one end of the air exhausting duct is connected with an air outlet of the wind wheel, the other end of the air exhausting duct is communicated with the constant-temperature inner cavity, the air exhausting duct comprises an air duct cover plate arranged above the wind wheel, one or more exhausting holes are formed in the air duct cover plate, an air velocity sensor is arranged between the air duct cover plate and a draught fan, a heating device is arranged on the inner side, close to the air inlet duct, of a first exhausting hole, and a temperature sensor is arranged between the first exhausting hole and the heating device. The drying constant-temperature test box has the advantages that stable hot air circulation can be realized in the constant-temperature inner cavity, and the test box can be uniformly heated, is good in temperature control effect and high in precision and has a high application value.

Owner:XUTEMP TEMPTECH

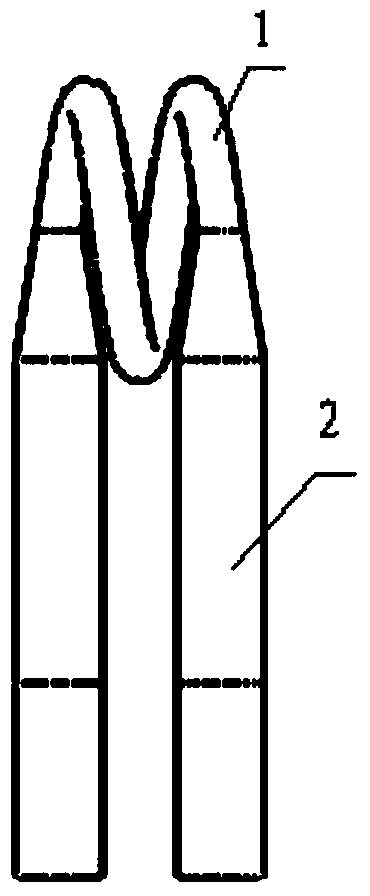

Electric heating device and system

InactiveCN103592723AEven and stable heatingAvoid unevennessCoupling light guidesElectric heatingElectricity

The invention discloses an electric heating device and system. The device comprises a heating body, two electrodes and a ceramic shell, wherein the two electrodes are connected to the two ends of the heating body, a cavity is formed inside the ceramic shell, the heating body is placed in the cavity, a notch which penetrates through the thickness direction of the ceramic shell and is communicated with the cavity is formed in the top of the ceramic shell, and the heating body is of a spiral structure. Due to the position of the spiral structure, the spiral axis of the spiral structure is approximately perpendicular to the extending direction of the notch from top to bottom, and a pair of twisted optical fibers extending in the thickness direction of the ceramic shell can enter the position between two spiral rings of the spiral structure downwards from the notch. Due to the facts that the electric-heating mode is adopted in the electric heating device, the heating body is of the spiral structure and is clamped by the ceramic shell, and the optical fibers are heated between the two spiral rings of the spiral structure, heating is even and stable, and the defect that flame heating is not stable or even enough is overcome. Meanwhile, temperature heat stress and structural heat stress are distributed reasonably, and positions with stress concentration do not exist.

Owner:CENT SOUTH UNIV

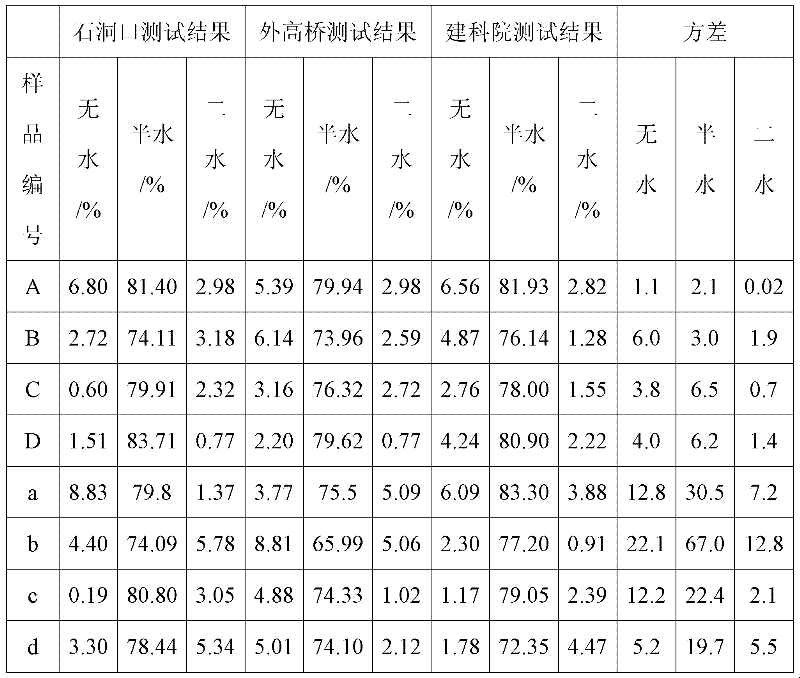

Method for quickly analyzing phase component of building gypsum

InactiveCN102175555ASimplify the test operation processQuick combinationWeighing by removing componentHydration reactionRepeatability

The invention belongs to the technique of building material analysis and relates to a method for quickly analyzing a phase component of building gypsum. The defects in the prior art are as follows: the demand on analytical instrument is high, the demand on the test condition is high, the analysis time is long and the operation steps are complex. The method comprises the following three steps: for quickly finishing the phase component analysis for the building gypsum, by utilizing the principle that the building gypsum loses the adhered water at 50 plus / minus 5 DEG C, loses all the crystal water above 180 DEG C and can have hydration reaction with water, the anhydrous gypsum in the building gypsum can combine with water in a 95% ethanol solution so as to form the hemi-hydrated gypsum, and the dihydrate gypsum cannot be generated by combining the hemi-hydrated gypsum with the water, wherein the three steps are as follows: measuring the contents of the adhered water and the anhydrous gypsum, measuring the content and purity of the hemi-hydrated gypsum, and measuring the content of the dihydrate gypsum. The method provided by the invention has the advantages that the analysis device is simple, only one halogen moisture tester is required, the test time is short, and the analysis result has stability and repeatability.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Vacuum high-temperature friction-wear tester

PendingCN111380766AImprove accuracyEasy to operateInvestigating abrasion/wear resistanceEngineeringMachine

The invention relates to material surface performance test equipment, and particularly relates to a vacuum high-temperature friction-wear tester. The tester is characterized in that a vacuum cover isarranged above a machine base, a force measuring assembly, an adjusting support, a heating furnace assembly and a cooling circulation system are arranged in the vacuum cover, the cooling circulation system is connected above the machine base, the heating furnace assembly is arranged in the cooling circulation system, a supporting connecting pipe is arranged at the left end of the vacuum cover, theadjusting support is connected in the supporting connecting pipe, the left end of the force measuring assembly is connected to the adjusting support, the right end of the force measuring assembly isconnected with a loading rod, the loading rod penetrates through the force measuring assembly, the heating furnace assembly comprises a furnace body, a heating cavity is formed in the furnace body, the loading rod is inserted into the heating cavity, a friction disc is arranged in the heating cavity, a detection piece is clamped between the loading rod and the friction disc, the lower end of the friction disc is connected with a rotating shaft, the rotating shaft penetrates through the heating furnace assembly and the cooling circulation system, the lower end of the rotating shaft is rotationally connected into the machine base, and the side wall of the vacuum cover is further connected with a molecular pump unit.

Owner:兰州华汇仪器科技有限公司

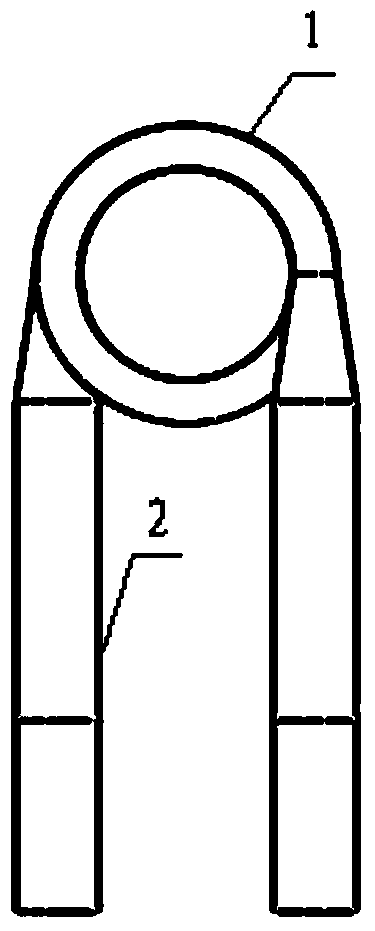

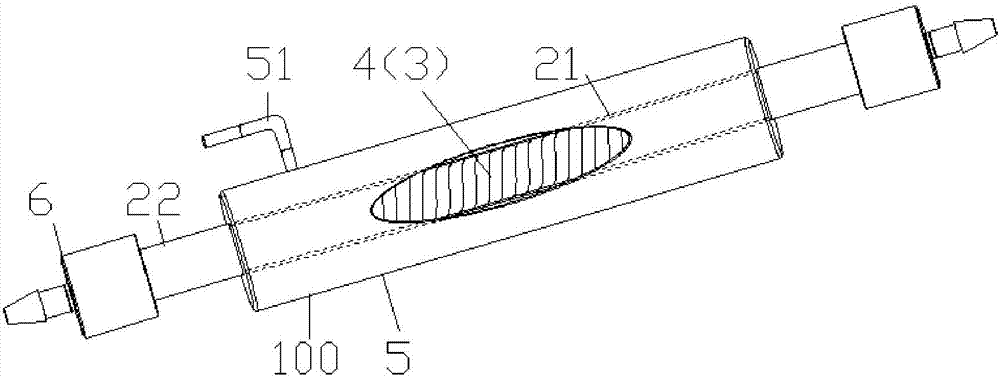

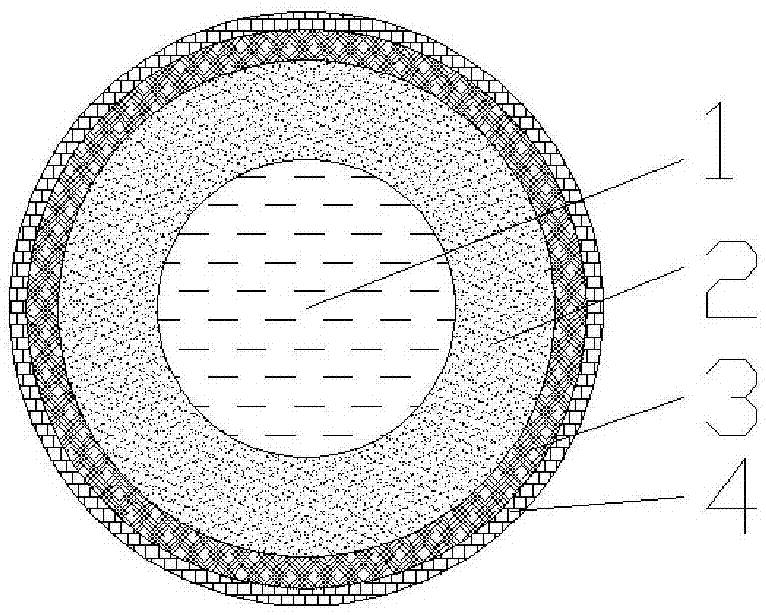

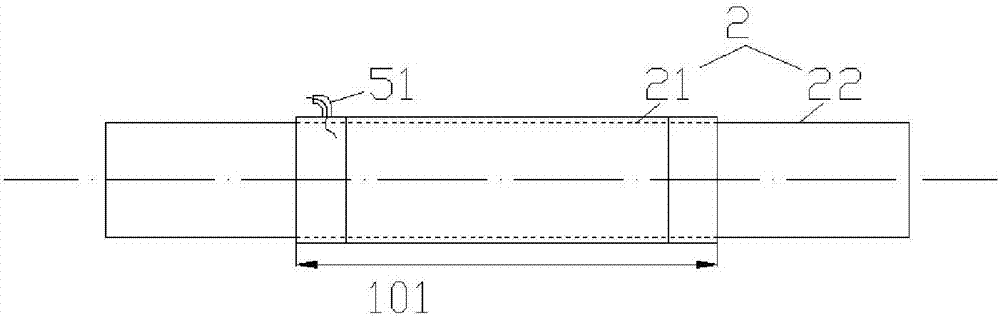

Roller type heat-conducting oil heating system of digital sizing machine

InactiveCN102383280AEven and stable heatingEasy temperature controlHeating/cooling textile fabricsEngineeringThermistor

The invention discloses a roller type heat-conducting oil heating system of a digital sizing machine, comprising a rolling shaft (1). The roller type heat-conducting oil heating system is characterized in that the rolling shaft (1) is externally provided with an inner barrel (2) and an outer barrel (3) in sequence; heat-conducting oil (4) is sealed between the inner barrel (2) and the outer barrel (3); and heat-conducting strips (5) are arranged in the heat-conducting oil (4). A temperature sensor (6) is arranged in the heat-conducting oil (4). In the roller type heat-conducting oil heating system disclosed by the invention, the heating is uniform and stable, the temperature is easy to control and the good use effect is achieved; the defect that the original system adopts a thermistor for heating is overcome, and fabric is directly heated and set after expanding, so that the heat efficiency is higher, similarly the working is more energy-saving, and the production cost of enterprises is further reduced.

Owner:无锡市德赛数码科技有限公司

Heating device for heating smoke cartridge and HNB (heat not burning) electronic cigarette

The embodiment of the invention relates to the technical field of electronic cigarettes, and discloses a heating device for heating a smoke cartridge. The device comprises an infrared ceramic assembly, a heating assembly and a power supply module, and is characterized in that the infrared ceramic assembly is in a hollow cylinder shape and is provided with an open cavity for accommodating the smokecartridge; the power supply module is connected with the heating assembly and used for supplying power to the heating assembly; and the heating assembly is arranged on the infrared ceramic assembly and used for heating the infrared ceramic assembly so as to excite the infrared ceramic assembly to radiate infrared rays and conduct infrared heating on the smoke cartridge. Compared with the traditional infrared coating heating, the heating device adopts the infrared ceramic assembly to radiate infrared rays to directly radiate and heat the smoke cartridge contained in the ceramic assembly, so that on one hand, infrared ray radiation is uniform and stable, and the smoke cartridge can be uniformly and stably heated, and on the other hand, shielding of other media is avoided, the infrared ray utilization rate is high, and the heating efficiency is also high.

Owner:深圳市辰昱科技有限公司

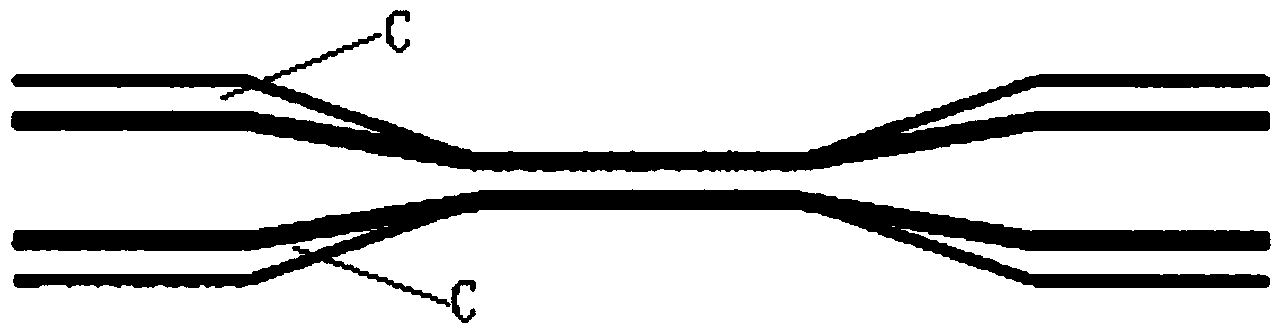

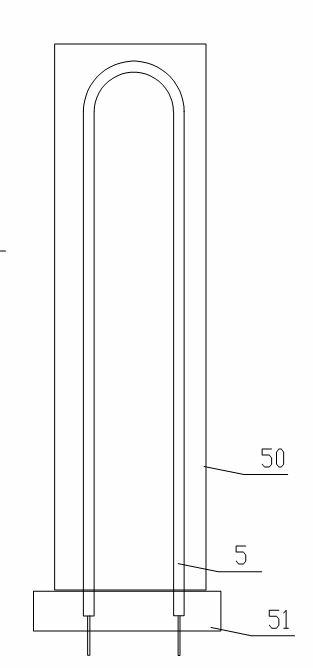

Hot press molding mechanism for electrode lugs of lithium-ion power batteries

InactiveCN105014950AHeating fastEven and stable heatingCell component detailsElectrical conductorAdhesive

The invention relates to a hot press molding mechanism for electrode lugs of lithium-ion power batteries. The hot press molding mechanism comprises a middle hot press mechanism and a metal conductor heating mechanism, wherein the middle hot press mechanism is used for compositing electrode lug adhesives and a metal conductor together through hot press. The middle hot pressing mechanism is provided with an upper hot press end socket and a lower hot press end socket which are synchronously and oppositely driven by cylinders. A left metal strap heating mechanism and a right metal strap heating mechanism are arranged on the two sides of the hot pressing mechanism respectively. Each metal strap heating mechanism is provided with an upper heating pipe and a lower heating pipe which are arranged on a support to form a 45-degree angle. The perpendicular distance between the surfaces of modulator tubes and the surface of a metal strap is 20 mm. The power of the four heating pipes is regulated to be the same. Every two heating pipes in the same set are on a perpendicular straight line and fixedly arranged on the two sides of the metal conductor to form a shape like a Chinese character 'ba'. The horizontal distance between the heating pipes and the end sockets is 15 mm. By means of the hot pressing forming mechanism, the hot sealing molding time of the power large electrode lugs can be effectively shortened, the excellent hot sealing adhesion effect is provided, the size stability and the appearance of rubber blocks molded through hot press are improved, the hot press molding mechanism is suitable for continuous production, and the production efficiency is improved.

Owner:WUXI BAISHIJIE METAL PROD TECH

Anti-corrosion insulating safe liquid heating tube

PendingCN107484274ASimple structureEasy to operateOhmic-resistance heating detailsHeating element shapesControl systemCorrosion resistant

The invention discloses an anti-corrosion insulating safe liquid heating tube, and the heating tube sequentially comprises a ceramic tube, a heating film, an insulating layer and a housing from the inside to the outside. The interior of the ceramic tube is provided with heated liquid. The ceramic tube is provided with a main body part located at the center, and end parts located at two sides. The heating film wraps the external surface of the main body part of the ceramic tube, and the insulating layer wraps the external surface of the heating film. The housing is disposed at the inner sides of the end parts of the ceramic tube. The outer side of one end part of the housing is also connected with a lead outgoing tube, and is also connected with a connector. The heating film is welded with a lead, and the lead is led out of the lead outgoing tube and is connected with a power system and an external control system. The liquid heating tube is also provided with a temperature sensor. The tube is uniform and stable in heating, is stable and reliable in layer distribution, is long in service life, prevents the overheating of the surface of the heating tube from causing the repeated operation of a thermal protector and damaging a product, and can effectively avoid the defects that a common liquid heating tube is not resistant to corrosion and dry burning causes the damages.

Owner:BIHE ELECTRIC TAICANG CO LTD

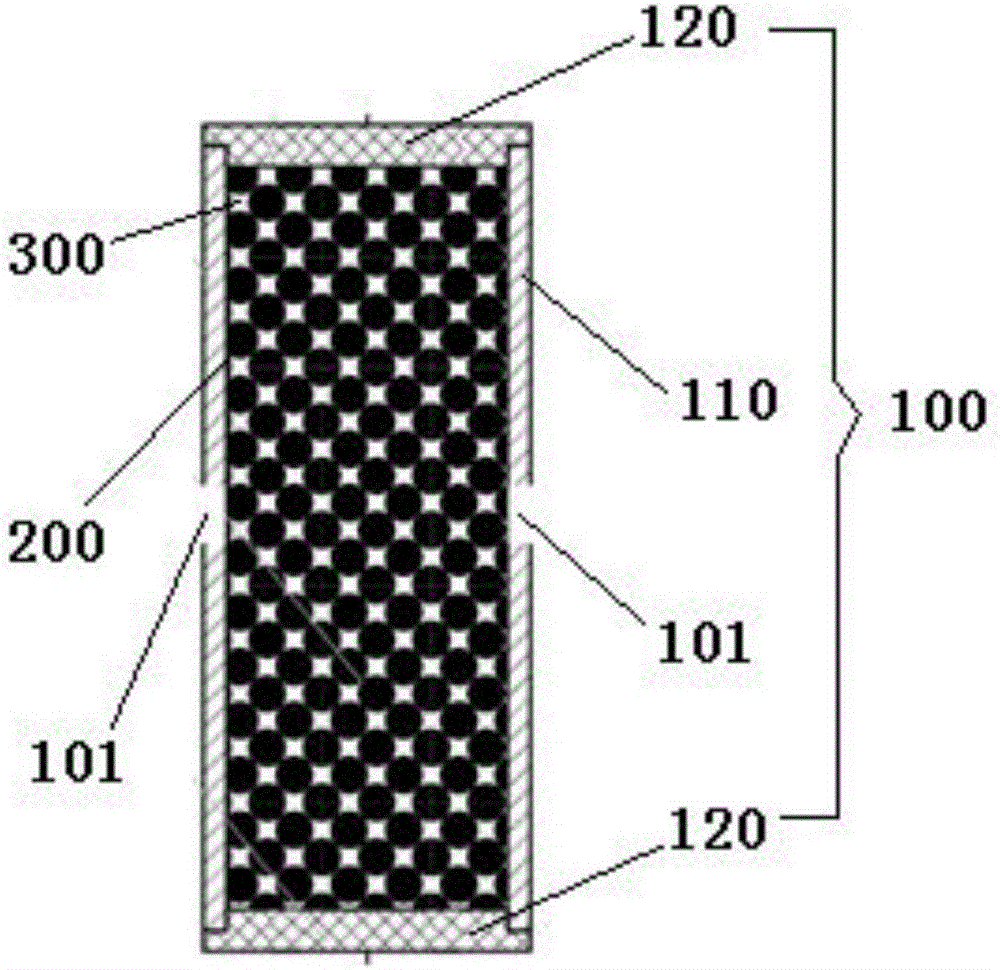

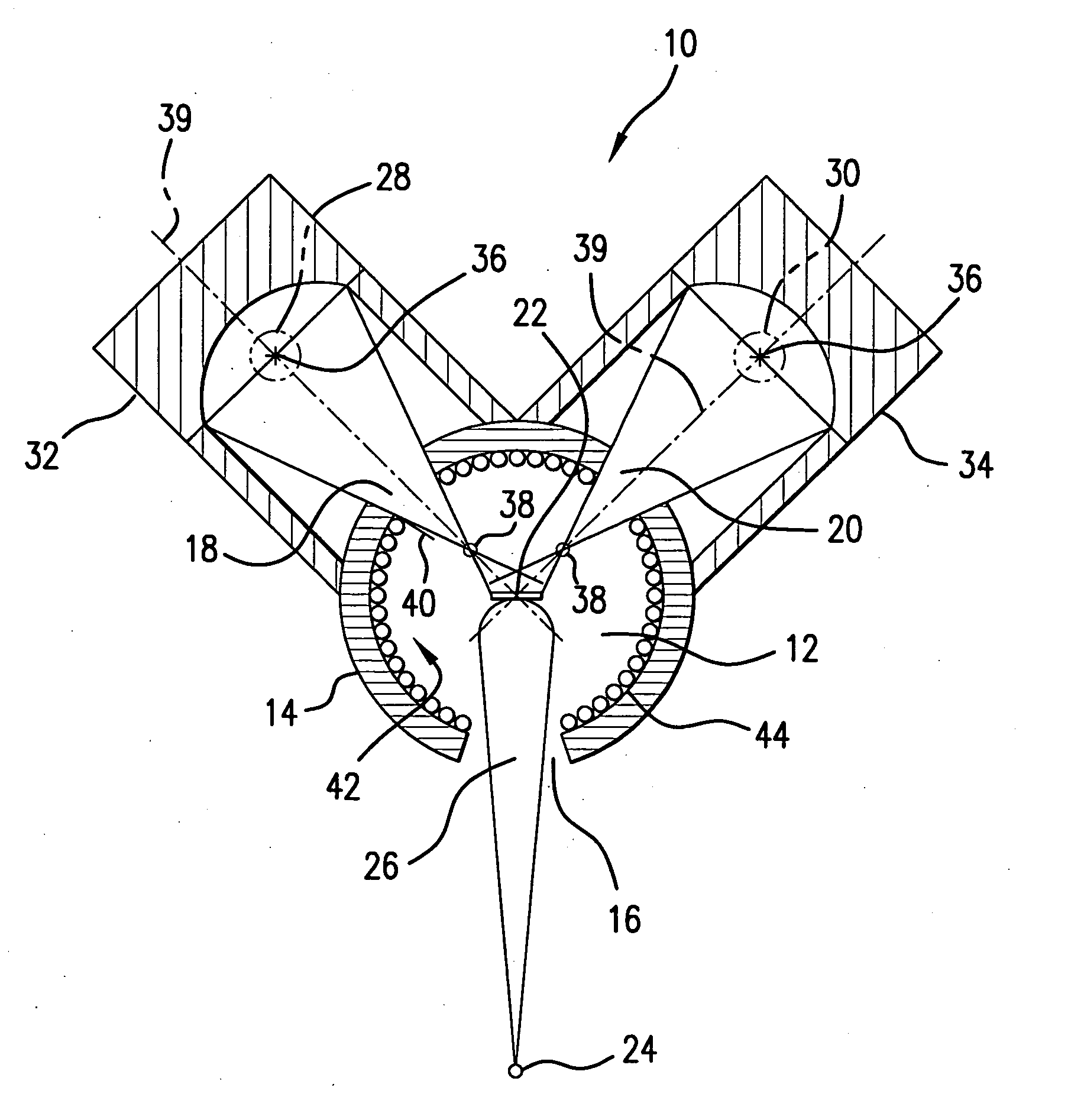

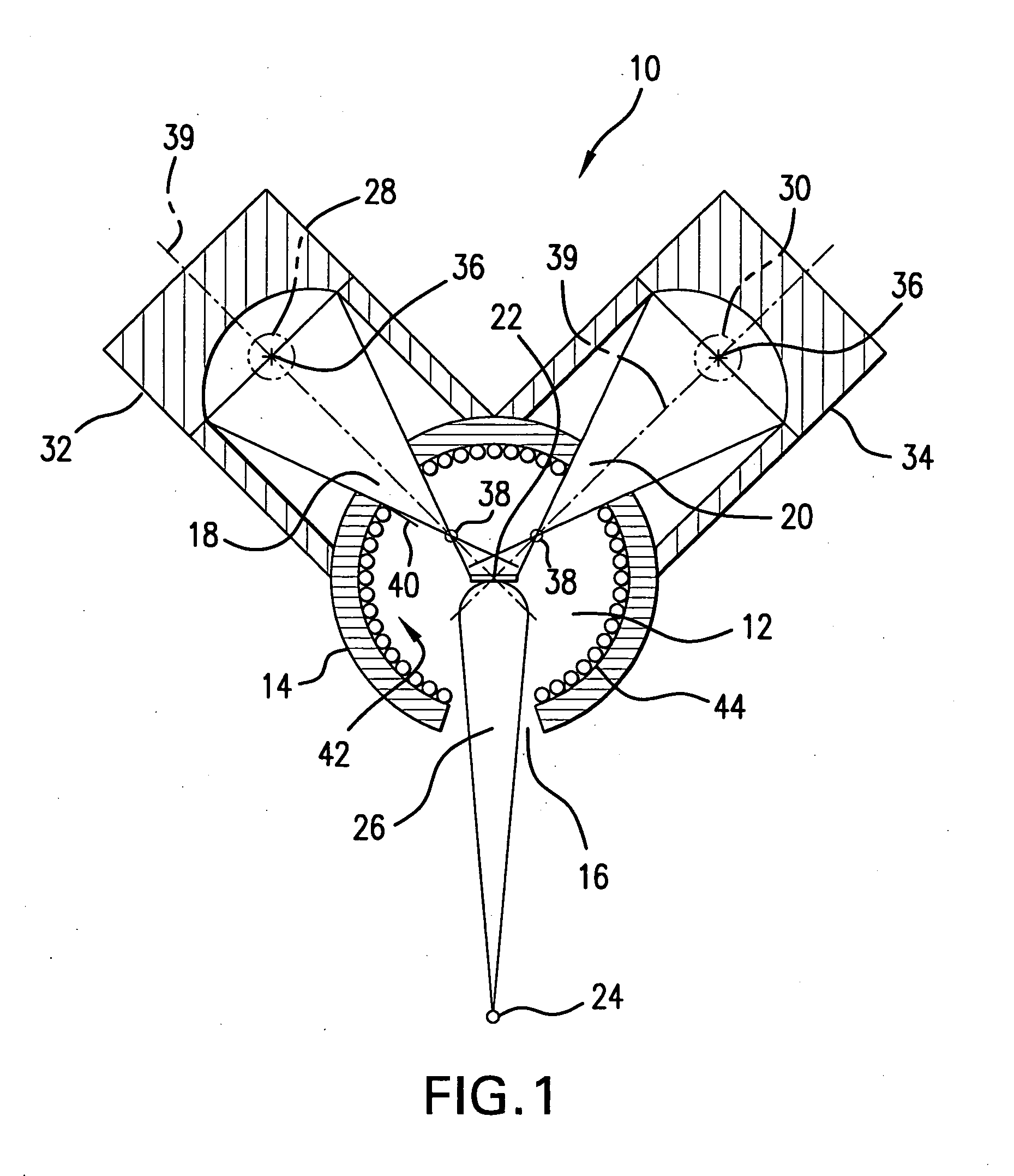

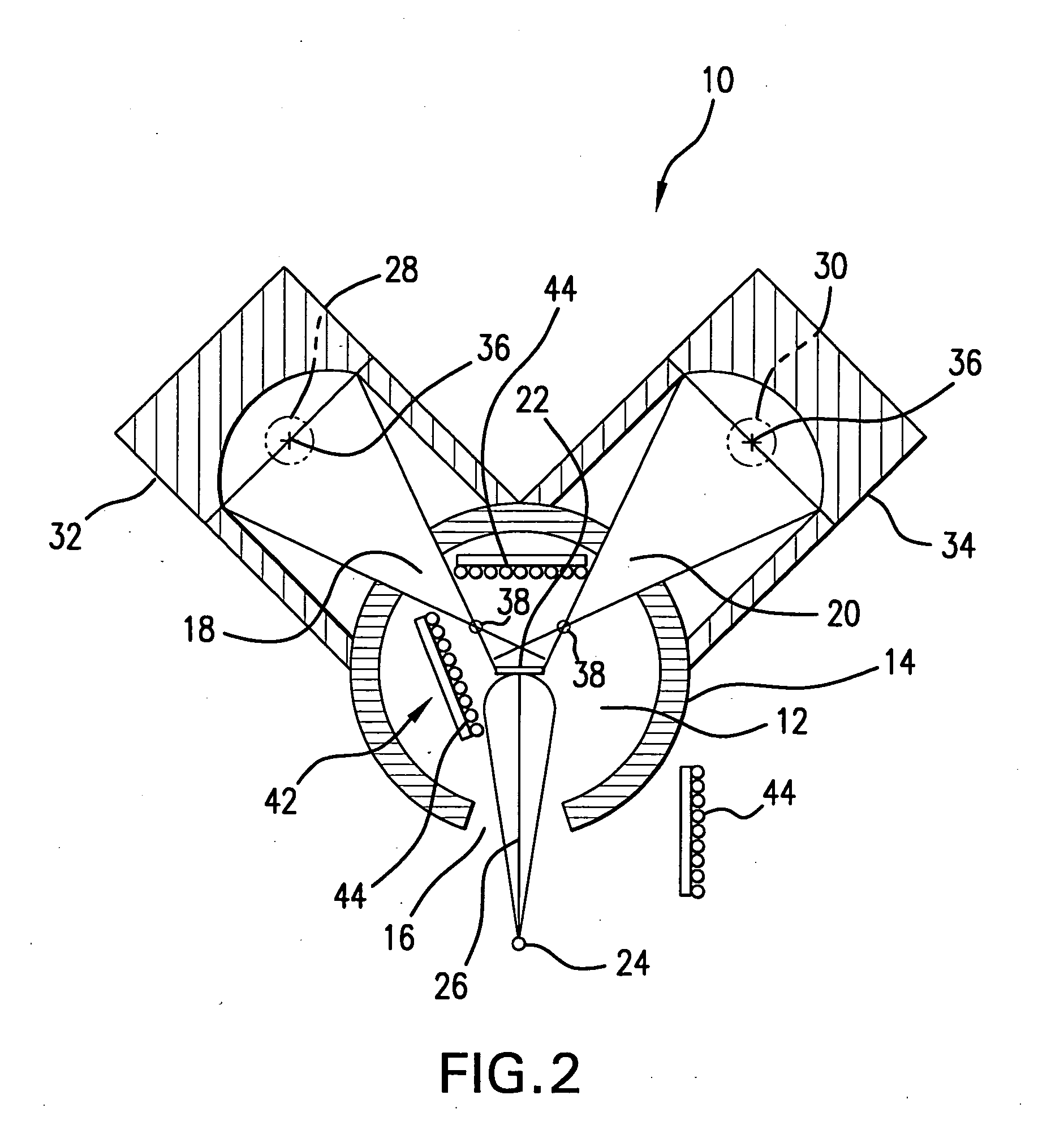

Non-contact heater and method for non-contact heating of a substrate for material deposition

ActiveUS20050253160A1Even and stable heatingAvoid depositionBaking ovenSemiconductor/solid-state device manufacturingOptoelectronicsEffective temperature

A heater for the non-contact heating of an object, such as a substrate for material deposition, includes a housing defining a deposition cavity and a source of radiation outside the deposition cavity. A reflector is optically coupled to the source of radiation to collect the radiation and to focus it on the radiation path. The reflector may have different shapes. If, for example, the reflector is an ellipsoidal reflector, the source of radiation then is mounted in a first focus, the substrate is located in the other focus, and the radiation path is positioned on the main focal axis of the ellipsoidal reflector. The radiation from the source of radiation is delivered to the substrate inside the deposition cavity through a radiation path(s) formed in the housing wall to heat the substrate to the temperature Ts, so that T1<Ts<T2, where T1 is the temperature of the housing wall, while T2 is the effective temperature of the source of radiation.

Owner:NEOCERA

A household intelligent bathtub bathing device

The invention relates to a household intelligent bathtub bath device, which comprises a bathtub shell system, an insulation system, an air bath system, a defoaming system, a circulating water system and a drying system. By setting the insulation system, the user can keep the water temperature in the bathtub body not to cool with the outside temperature when bathing, thereby increasing the comfortof the bathing. As that air bath system is arranged, bubbles emit from the bottom during the bubble bath process, the air bath system can not only massage the user with bubbles, but also form foam onthe surface of the water body. By setting a defoaming system, the foam formed on the surface of the water body can be discharged from the side first after the bath is finished, and then the water bodyis released from the bottom through the circulating water system, and the bathtub body is filled with water again to realize the cleaning of the user. At last, the bath is complete by drying the userafter the bath through the drying system.

Owner:林美云

In-situ oxygen compensated-scanning electron vapor deposition (IOC-SEVD) device and method thereof

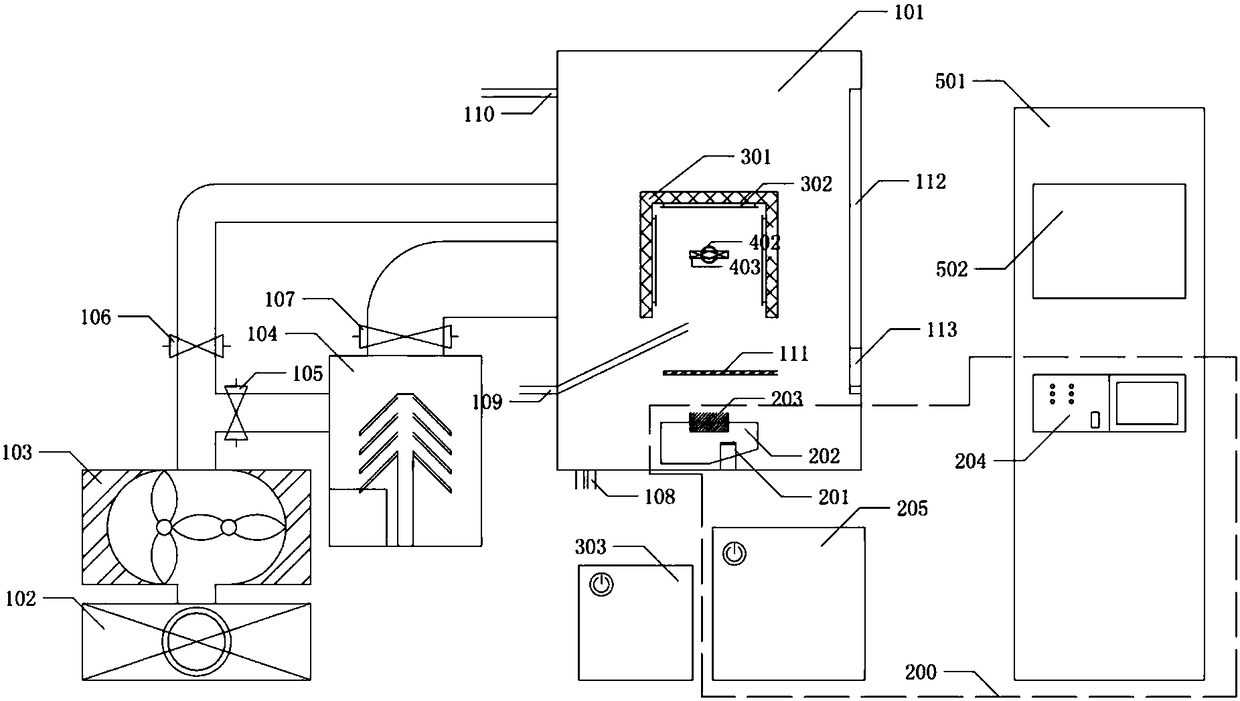

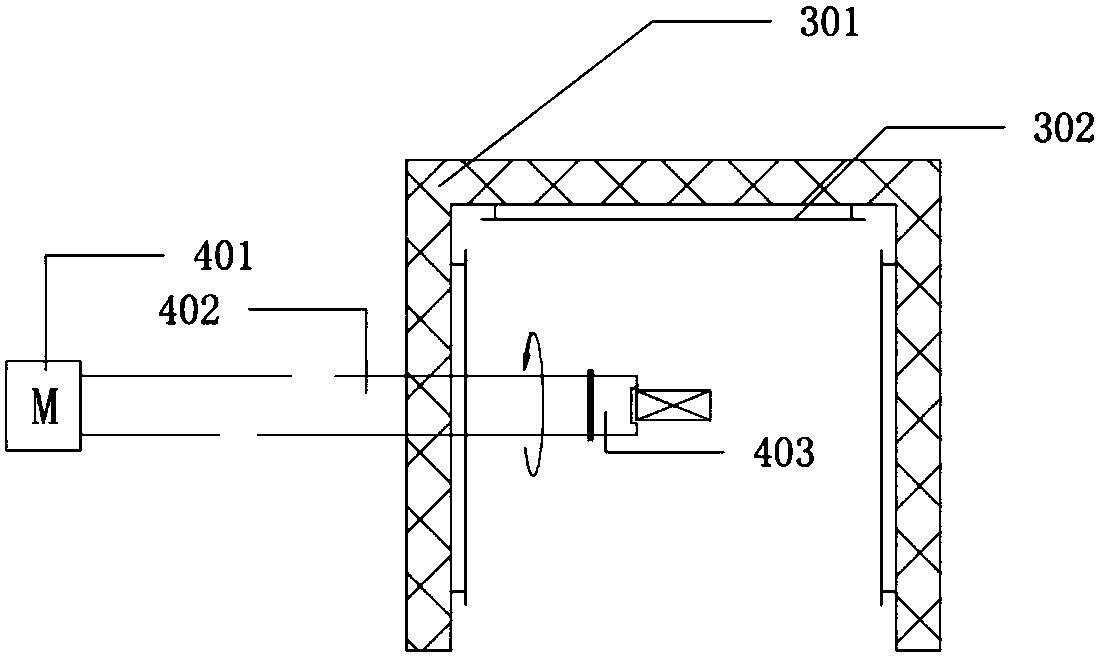

ActiveCN108286036AQuality improvementReduce manufacturing costVacuum evaporation coatingSputtering coatingMicrostructureThermal barrier coating

The invention discloses an in-situ oxygen compensated-scanning electron vapor deposition (IOC-SEVD) device and a method thereof. The device comprises a vacuum system, an e-type electronic gun, a heater, a workpiece rotation holder and a control and display module, wherein the vacuum system comprises a vacuum pump and a vacuum cavity; the e-type electronic gun comprises an electronic gun emitting seat, an electronic gun deflection scanning magnetic field and a rotary water-cooling crucible; the heater comprises heater strips and a heating power supply connected through a circuit; the workpiecerotation holder comprises a rotation motor, a transmission shaft and a holder; and the control and display module comprises a device integrated state displayer and an electronic gun control panel. Themethod is that thermal barrier coating is prepared by utilizing the device. Through the device and the method, the thermal barrier coating with uniform columnar microstructures and high whole performance is prepared, so that the preparation requirements that the thermal barrier coating has high performance, high stability and high industrial productivity are met.

Owner:XIANGTAN UNIV

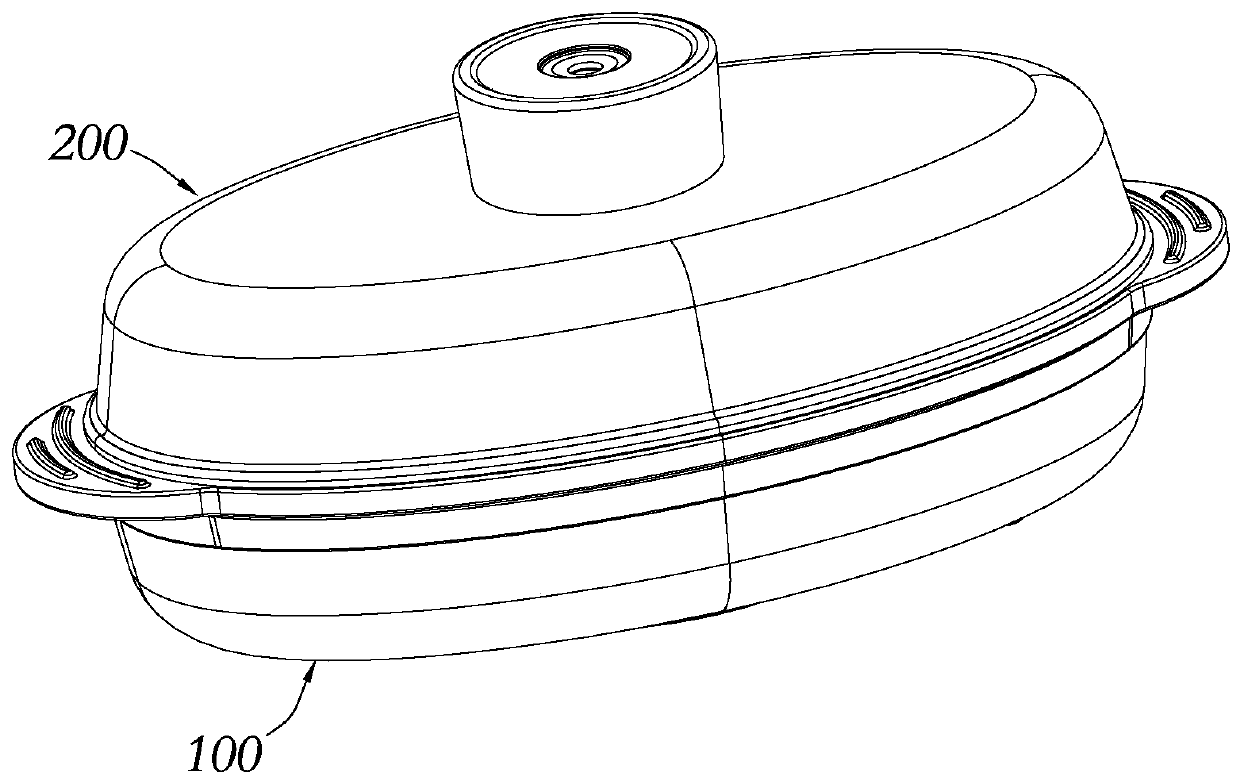

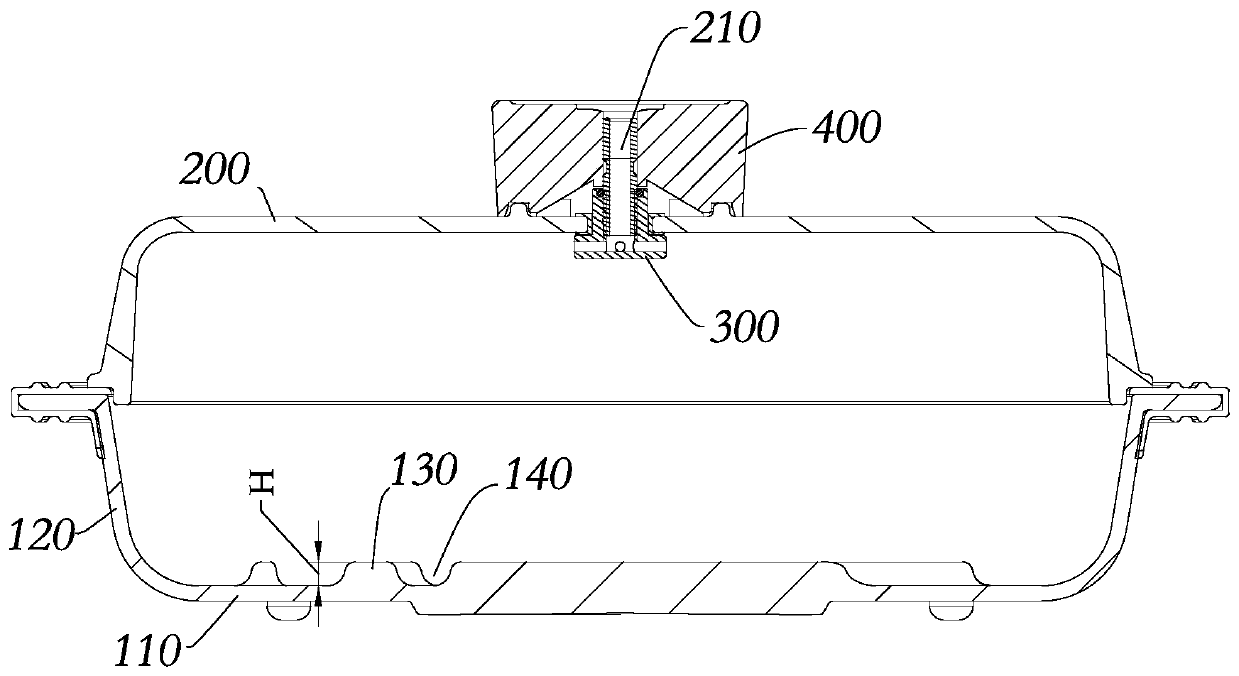

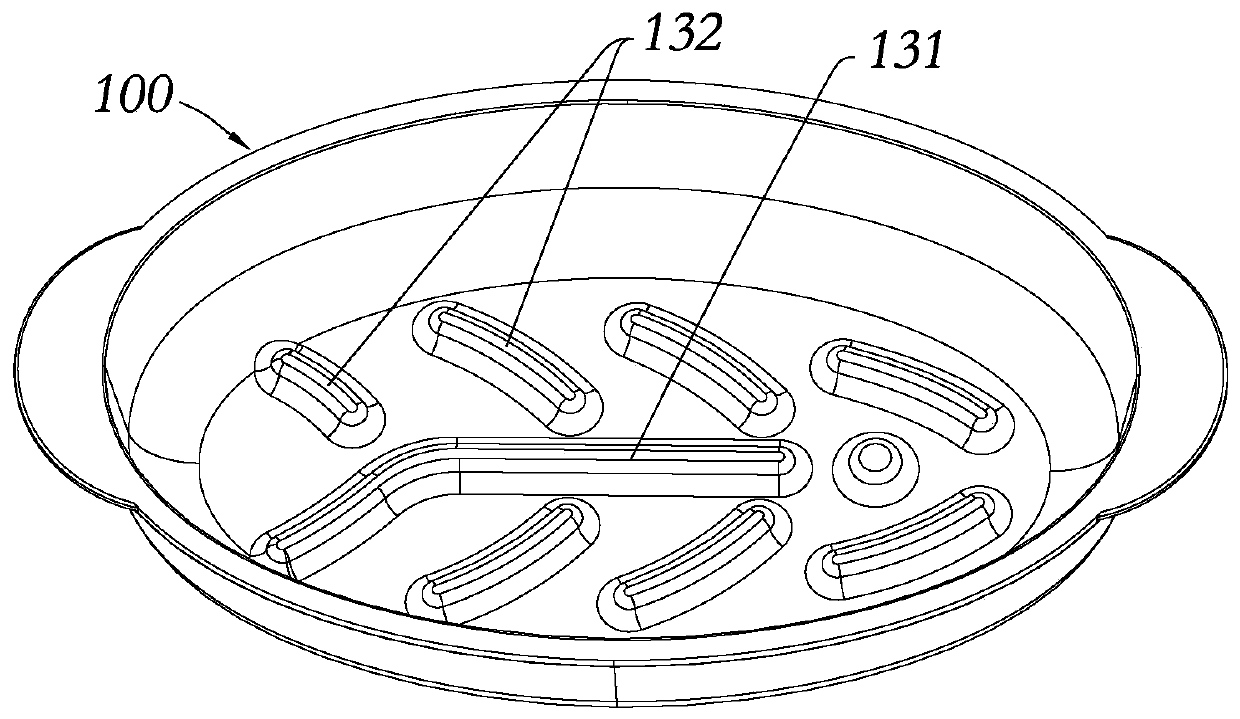

Fish steaming container and steam heating type cooking instrument

The invention discloses a fish steaming container and a steam heating type cooking instrument, and belongs to the field of kitchen household appliances. The problem that in the prior art, a common fish dish is adopted for steaming fish, and heating is not uniform is solved. The fish steaming container comprises a dish body and a dish cover. The dish body and the dish cover are matched to form a steam cavity. The dish cover is provided with a steam input channel through which steam can be introduced into the steam cavity. A protrusion for bearing a fish body is arranged on the dish face of thedish body. A gap for steam inflowing is formed between the fish body and the dish face through the protrusion. Due to the fact that the gap for steam inflowing is formed between the fish body and thedish face through the protrusion, in the cooking process, steam inside the steam cavity can permeate the lower portion of the fish body through the gap, the steam flowability is greatly improved, thesteam can wrap the fish body all-dimensionally, and the fish body is heated to be more uniform.

Owner:JOYOUNG CO LTD

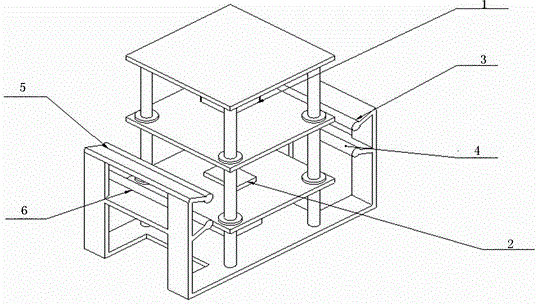

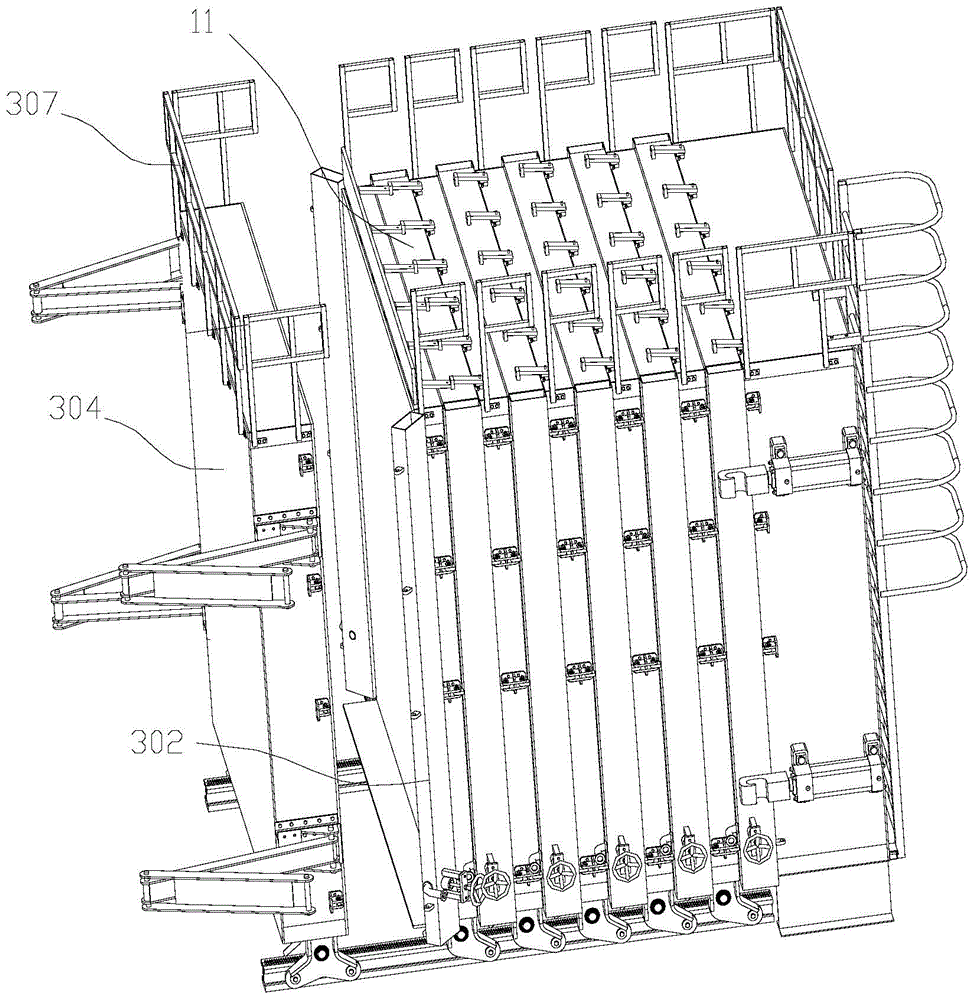

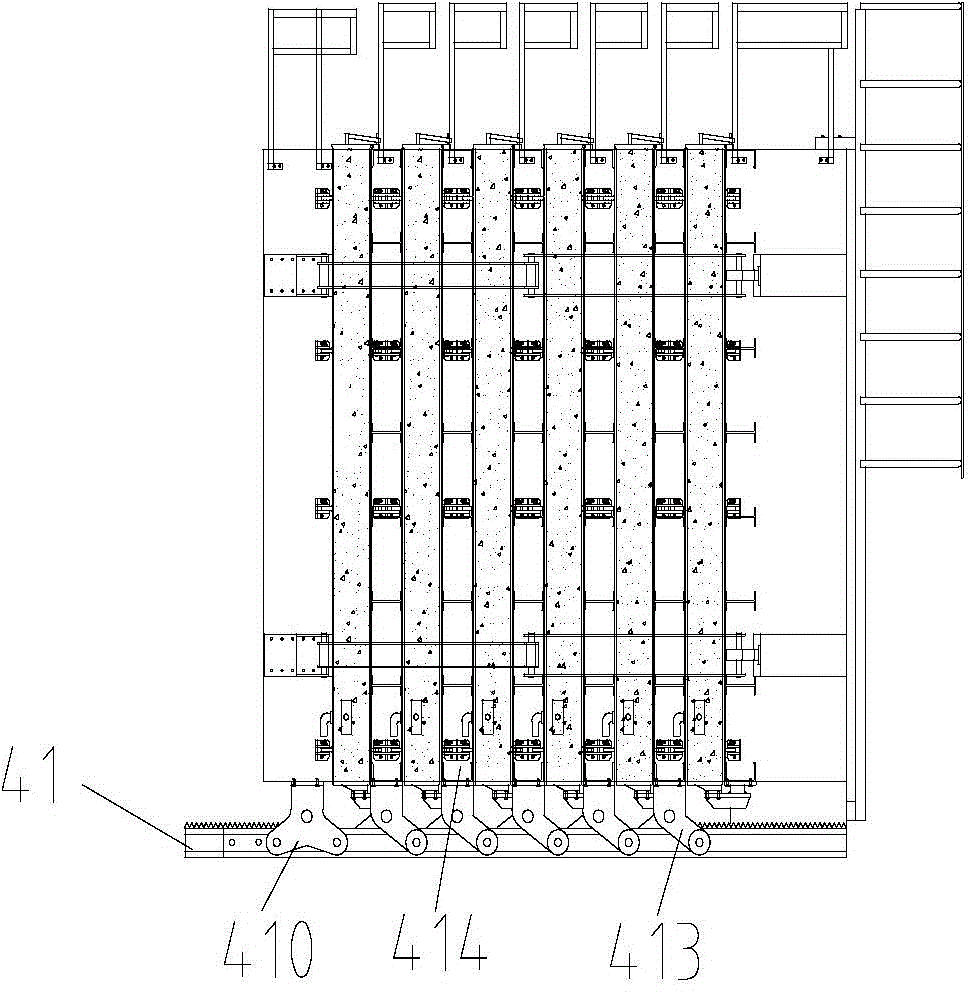

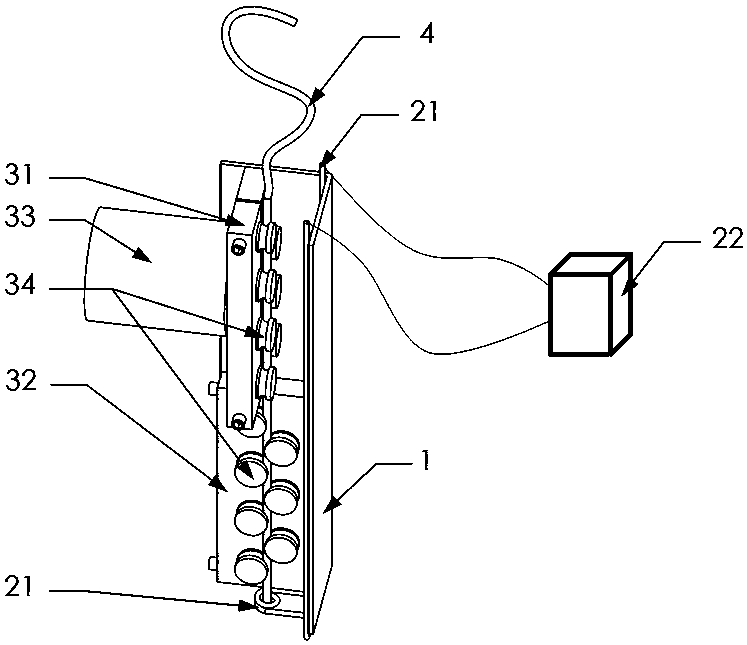

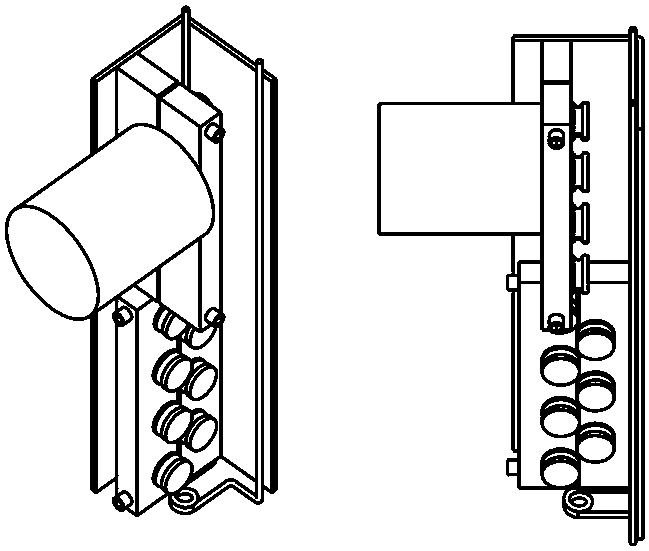

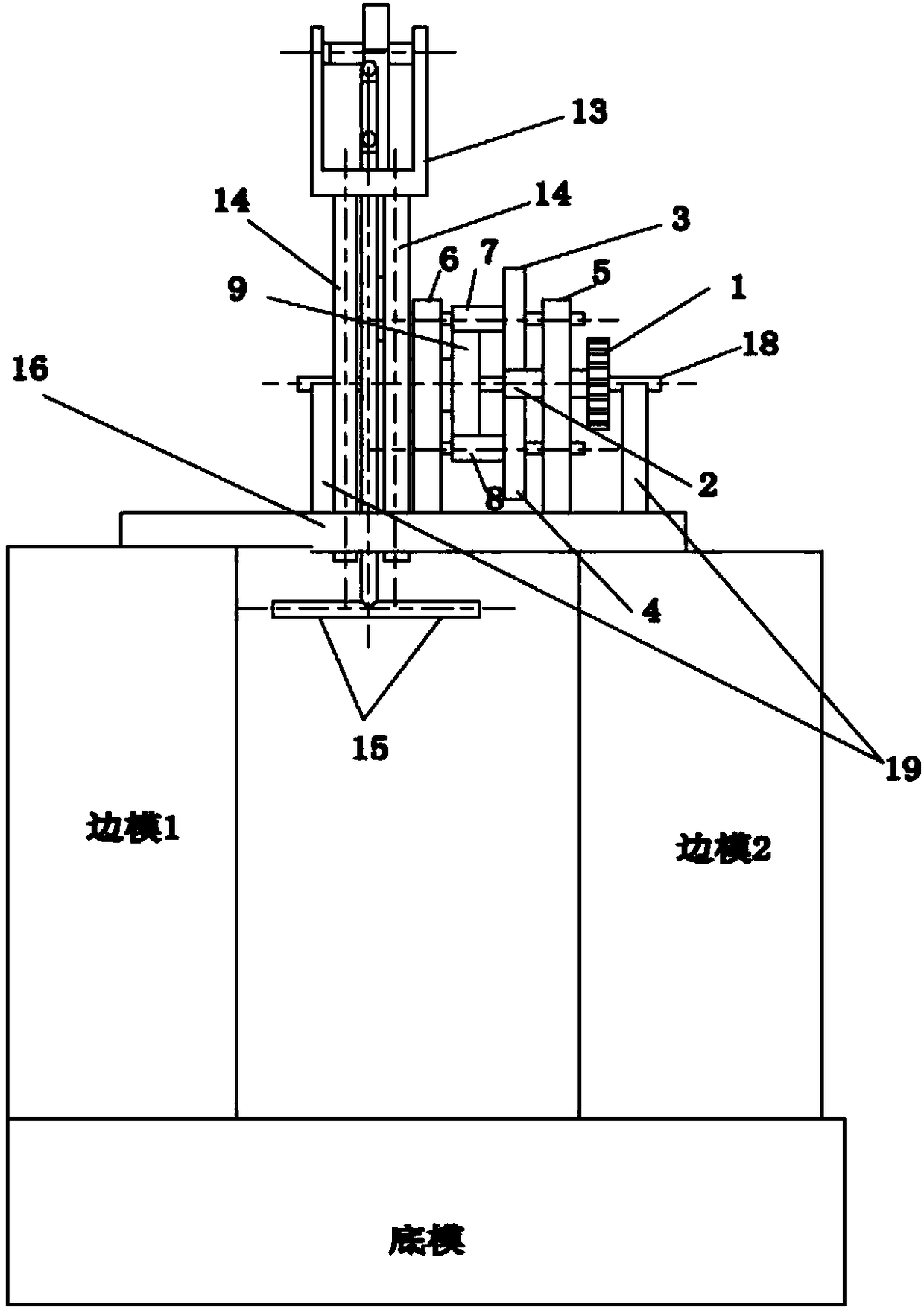

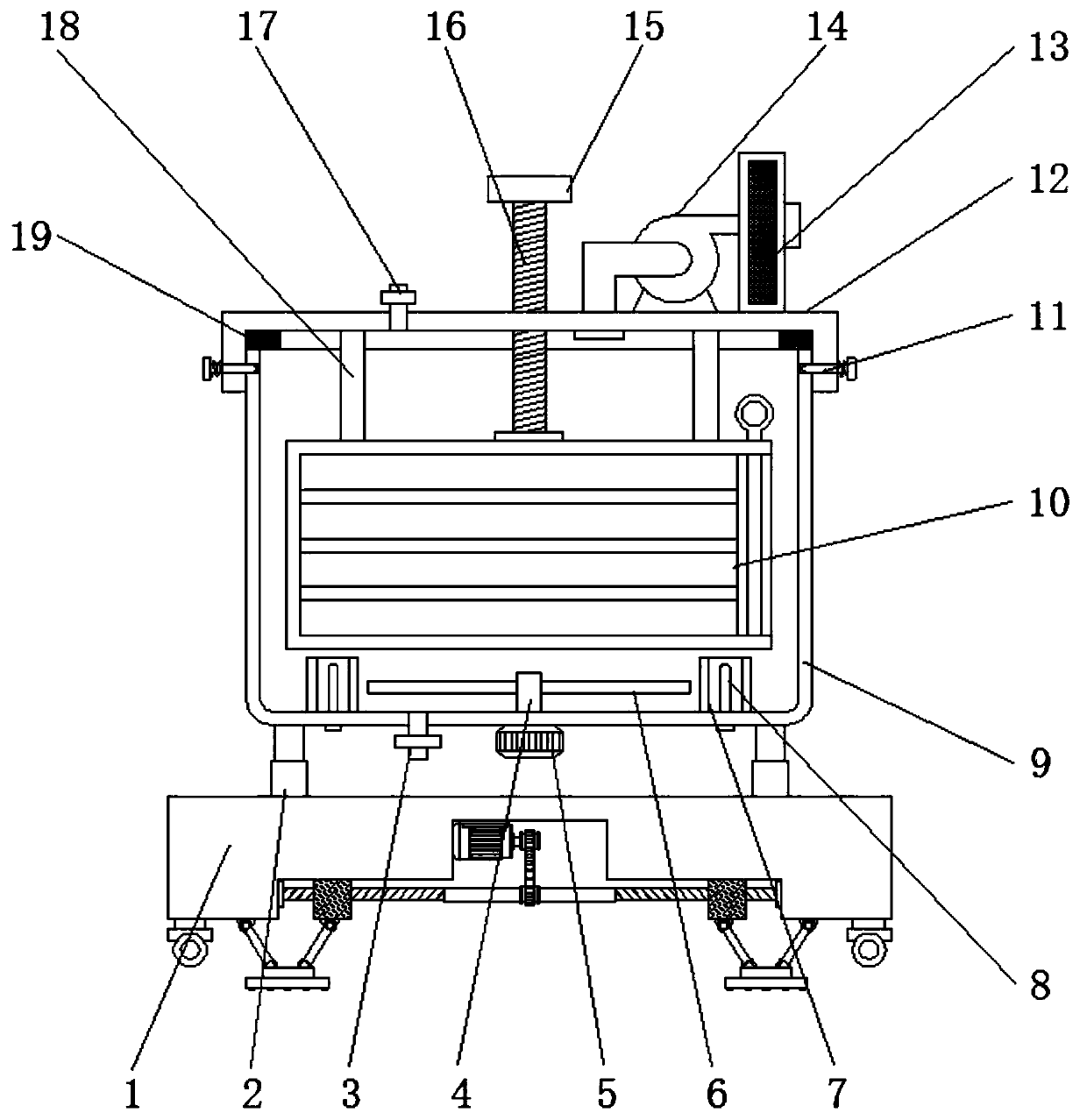

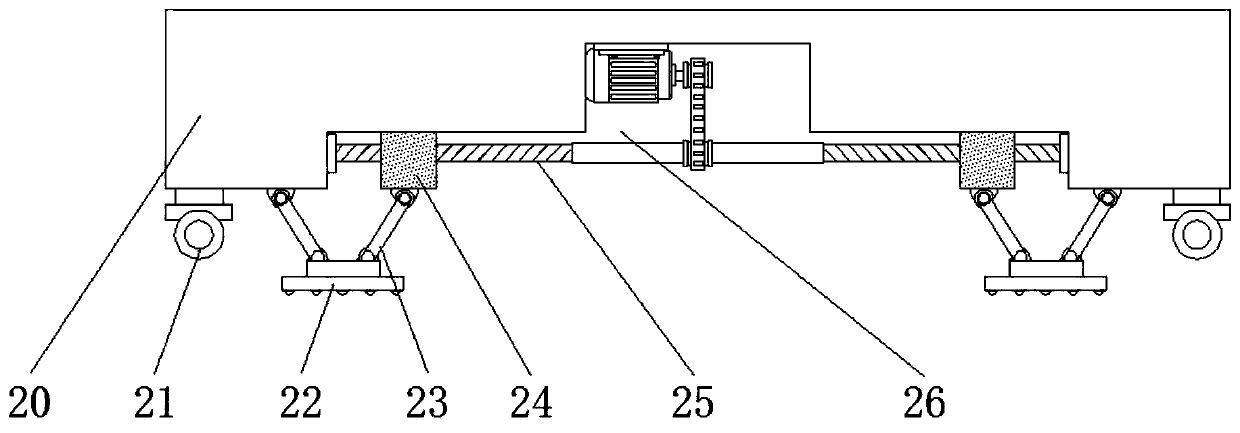

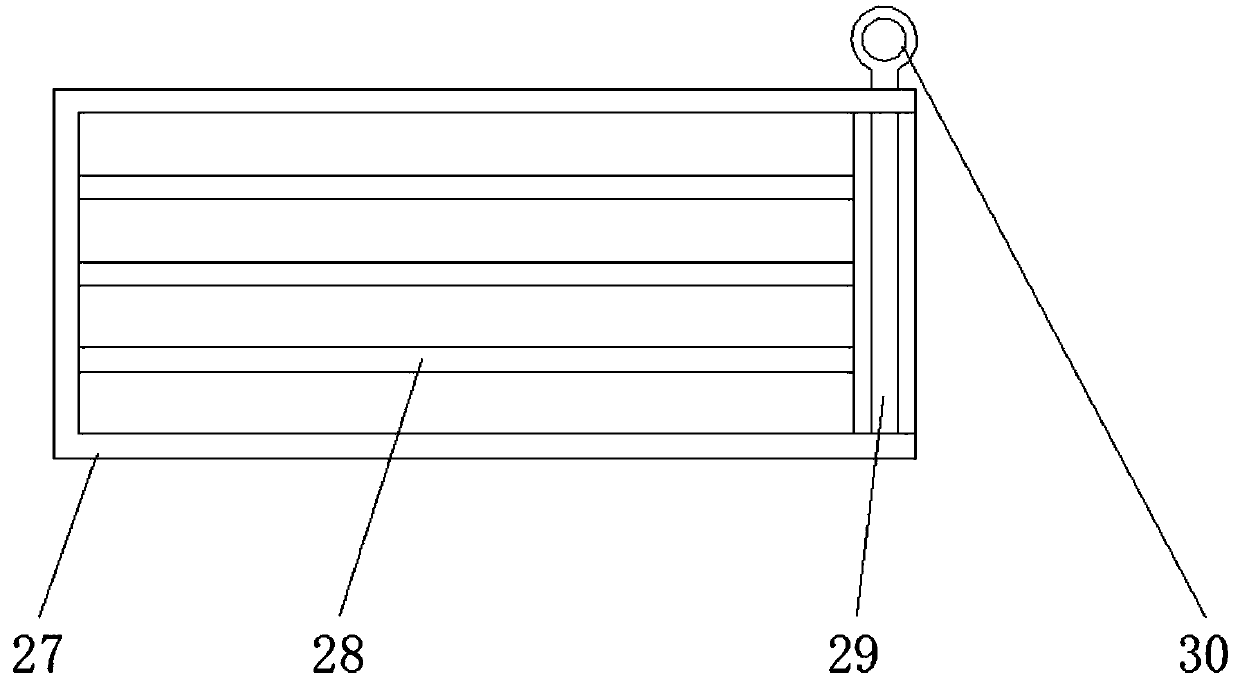

Group erecting formwork for prefabricated parts

InactiveCN104960077AEasy temperature controlNot suitable for burning outMouldsCeramic shaping mandrelsEngineeringProduction quality

The invention provides a group erecting formwork for prefabricated parts. The group erecting formwork comprises a track system, a drive system and a formwork system, wherein the track system comprises two or more tracks, the drive system comprises a drive power source and a drive connecting device, the drive power source is connected with the track system through the drive connecting device, the formwork system is arranged on the track system and comprises a bottom formwork body, an erecting formwork body and a side formwork body, and the bottom formwork body, the erecting formwork body and the side formwork body are spliced to form a forming cavity for at least one prefabricated part. At least one of the bottom formwork body, the erecting formwork body and the side formwork body is of a two-layer structure, a cavity is formed in the middle of each two-layer structure, a liquid or gas dielectric heating source is arranged in each cavity, and in this way, the formwork system can be driven to move on the tracks horizontally to carry out formwork splicing and disassembling, which is beneficial for improving the production efficiency; by means of the dielectric heating sources, it can be ensured that the group erecting formwork can be used normally in a low-temperature environment, and the production quality of the prefabricated parts is improved.

Owner:CHINA MINSHENG ZHUYOU

Electromagnetic induction heating 3D printing extrusion head and method

InactiveCN109421258AHigh strengthHigh precisionManufacturing heating elements3D object support structuresDirect heating3d printer

The invention relates to an electromagnetic induction heating 3D printing extrusion head and method. The electromagnetic induction heating 3D printing extrusion head comprises a bracket, an electromagnetic induction heating coil and a set of wire feeding mechanism with straightening function. The electromagnetic induction heating 3D printing extrusion head and method can be compatible with both metal and non-metal wires. The electromagnetic induction heating head and the wire feeding mechanism are mounted on the bracket, and the wire feeding mechanism feeds wires into the electromagnetic induction heating coil of a heating head. The electromagnetic induction heating coil is coupled with an electrical pulse generator, and pulsed current in the electromagnetic induction heating coil generates an alternating magnetic field and current in the metal wires or metal linings. The metal wires can be heated directly to melt. For the non-metal wires, the metal linings needs to be added to the coil, and the non-metal wires are heated to melt through the metal linings. The bracket is coupled with a motion mechanism of a 3D printer to achieve three-dimensional positioning relative to a model, and molten materials is smeared at the designated position to realize 3D printing. According to the electromagnetic induction heating 3D printing extrusion head and method, compatible 3D printing of themetal and non-metal wires is realized.

Owner:叶定容

Novel jig dying machine shell with heating device

ActiveCN104711801AQuick installationQuick disassemblyLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringMechanical engineering

The invention discloses a novel jig drying machine shell with a heating device. The novel jig drying machine shell comprises a shell, wherein the outer wall of the shell is hinged with a shell cover; the middle of the shell cover is provided with a cover body bulged part extending downwards; the cover body bulged part sleeves a rubber seal sleeve internally in an insertion mode, and is fixed on the rubber seal sleeve; the outer side wall of the rubber seal sleeve elastically presses the inner side wall of the top of the shell; two sides of the bottom of the shell are connected with two connecting water pipes in a communicated mode; the left and right side walls of the shell are hinged with pushing air cylinders; pushing rods of the pushing air cylinders are hinged to the bottom edges of at left and right sides of the shell cover; the heating device is fixed on the inner wall of the bottom of the shell; two side walls of the shell are hinged with rotation shafts; one end surfaces, extend into the shell, of the rotation shafts are provided with insertion grooves; bottom ends of the insertion grooves are provided with extension holes. The pushing air cylinders are adopted for opening the shell cover automatically so as to reduce the labor of workers; meanwhile, an electric heat wire type heating coil pipe is used for heating, is only affected by a power supply, and can be used for simply, conveniently and rapidly to mount and dismount of a fabric reel shaft.

Owner:汪建建

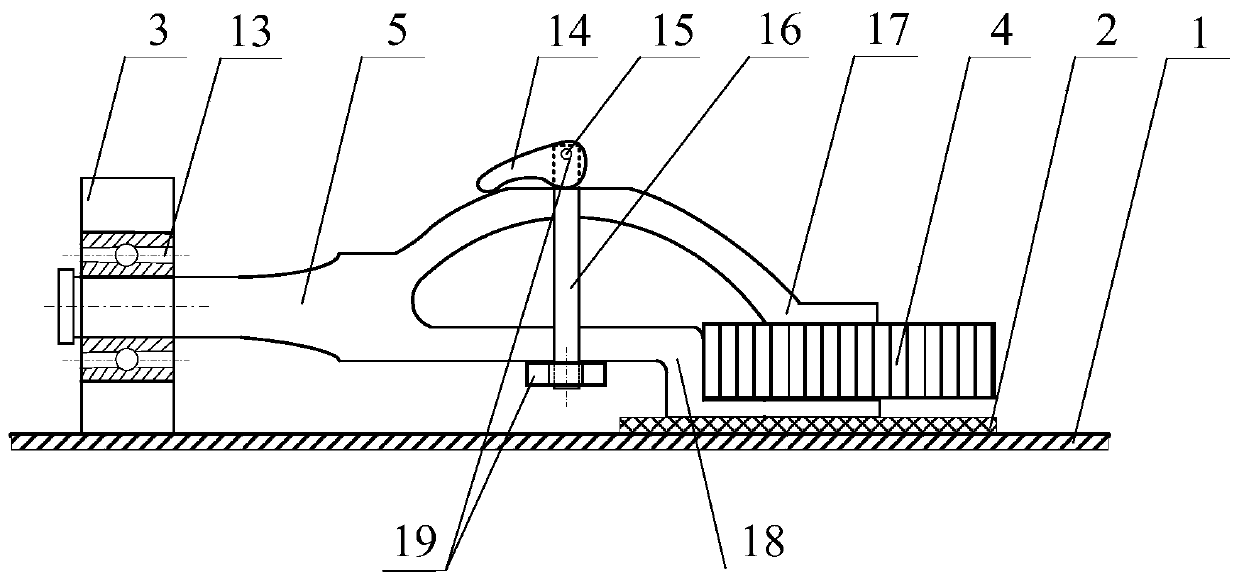

Pre-welding preheating and post-welding heat treatment device for tank body

ActiveCN111421265AEven and stable heatingImprove practicalityElectric heatingWelding/cutting auxillary devicesThermodynamicsEngineering

The invention provides a pre-welding preheating and post-welding heat treatment device for a tank body. The device comprises rollers, electric heating bands, calipers, a temperature controller, two positioners and hinges. The two electric heating bands are disposed around the tank body and distributed on both sides of a weld joint, and the calipers are arranged on both sides of the electrical heating bands. One ends of the calipers operatively clamp the sides of the electric heating bands, the other ends of the calipers are rotatably connected to the rollers, and the hinges are connected to the electric heating bands. The ends, away from the electric heating bands, of the hinges are fixed. The heating temperature of the electric heating bands is controlled through the temperature controller, pre-welding preheating, during-welding heat preservation and post-welding heat treatment of the tank body are achieved, and the tank body does not need to be transferred in the whole heat treatmentprocess. The electric heating bands are connected with the rollers through the calipers and tensioned through the hinges, so that the electric heating bands cannot rotate along with the tank body, heating is uniform and stable, equipment connected with the electric heating bands cannot be twisted, and the practicability is high.

Owner:WUHAN UNIV OF TECH

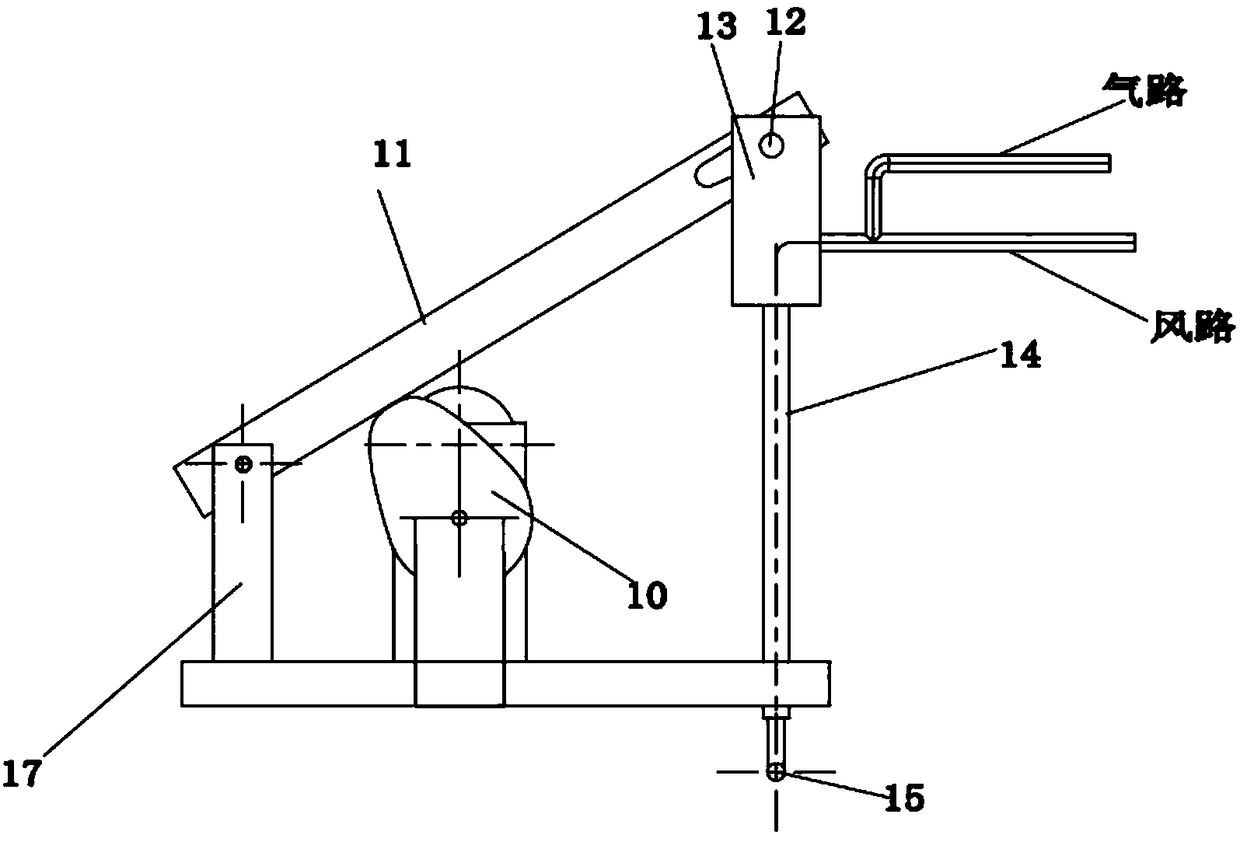

Spray nozzle flame heating device for casting die

InactiveCN108202129AAvoid damageEven and stable heatingFoundry mouldsFoundry coresImpellerSpray nozzle

The invention relates to a spray nozzle flame heating device for a casting die, and belongs to the technical field of metallurgical casting. One end of a base of the device is hinged with one end of aswing rod through a stand; a vertical moving pair is formed by the other end of the base and a guiding column of which the lower end is fixed with a flame spray nozzle; a moving pair is formed by theupper end of the guiding column and a sliding groove formed in the other end of the swing rod through a pin shaft; cam supports fixed to the base are arranged between the stand and the guiding column; a rotatable cam forming a cam pair together with the middle part of the swing rod is supported on the cam supports; an air-driven impeller is also supported on the cam supports; and the impeller isin transmission connection with the cam through speed reduction transmission. After the device disclosed by the invention is adopted, because the flame spray nozzle can do a reliable motion accordingto an ideal lifting rule, heating is stable and uniform, an operation is safe and convenient, later-period casting quality is effectively ensured, and die damage caused by local over-heat is completely avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

High-ground-temperature surrounding rock tunnel structure simulation test device

InactiveCN111983193AHigh precisionImprove scienceEarth material testingData acquisitionClassical mechanics

The invention discloses a high-ground-temperature surrounding rock tunnel structure simulation test device, and belongs to the technical field of tunnel engineering. The high-ground-temperature surrounding rock tunnel structure simulation test device comprises a stratum simulation system, a tunnel structure simulation system, a high-ground-temperature simulation system and a data acquisition system. Wherein a surrounding rock simulation layer is arranged between the stratum simulation system and the tunnel structure simulation system, the high-ground-temperature simulation system provides heatfor the stratum simulation system, the heat is transmitted to the tunnel structure simulation system through the surrounding rock simulation layer, and a data acquisition system is used for acquiringheat data in the surrounding rock simulation layer and the tunnel structure simulation system. The device can simulate a high-ground-temperature stratum and a high-ground-temperature tunnel, so thatsurrounding rock thermodynamic characteristics and heat transfer tests can be carried out on the high-ground-temperature tunnel, meanwhile, a surrounding rock simulation layer is uniformly and stablyheated in a sand bath heating mode, it is guaranteed that a surrounding rock temperature field strictly meets the axial symmetry condition, and the accuracy and scientificity of the tests are improved.

Owner:SOUTHWEST JIAOTONG UNIV

Wood soaking treatment method

ActiveCN109571676AEasy to moveReduce mobile costsWood treatment detailsWood heatingEngineeringElectric motor

The invention discloses a wood soaking treatment method. The wood soaking treatment method includes steps of shifting equipment by travel wheels 21, driving lead screws 25 to rotate by a motor after the equipment is shifted to reach specified locations, driving sliders 24 to slide along the horizontal directions by the lead screws, and allowing the sliders 24 to pass connecting rods 23 to drive support plates 22 so as to put up a base body 20 and separate the travel wheels 21 from a bottom surface. The wood soaking treatment method has the advantages that the soaking equipment can be conveniently shifted by the travel wheels, and accordingly the shifting cost for the soaking equipment can be reduced; the travel wheels can be put up by the support plates after the soaking equipment is shifted to reach the specified locations, and accordingly the stability of the soaking equipment can be improved when the soaking equipment is placed; wood can be layered by a soaking frame, waterproof agents can be stirred by heating pipes, and automatic communication channel selection of temperature measurement nodes in a soaking tank and the soaking frame can be effectively matched.

Owner:湖北千川门窗有限公司

Silkworm cocoon evacuation direct steaming device and silkworm cocoon evacuation direct steaming method using silkworm cocoon evacuation direct steaming device

The invention relates to the technical field of silkworm cocoon processing, in particular to a silkworm cocoon evacuation direct steaming device. The device comprises an outer barrel body and an innerbarrel body, a sealing end cover is arranged at an opening structure, the inner barrel body is arranged inside the outer barrel body, a plurality of vent holes are formed in the barrel wall of the inner barrel body in an uniform array, a steam pipe is arranged in the gap between the inner barrel body and the outer barrel body, and an evacuation tube is arranged at the bottom of the outer barrel body. The silkworm cocoon evacuation direct steaming method using the above device places silkworm cocoons into a net bag, then places the silkworm cocoons inside the inner barrel body, uses an evacuation pump to evacuate the inside of the outer barrel body, and conducts heating by the steam pipe, the taken silkworm cocoons are allowed to stand, and a follow-up silkworm production process is entered. The silkworm cocoon evacuation direct steaming device and the silkworm cocoon evacuation direct steaming method using the device can effectively improve the purity and yield of a silk yarn producedthrough the silkworm cocoons by a reasonable device structure design and a process design, and simultaneously make the level of the silk yarn reach 5A.

Owner:浙江华锋丝业股份有限公司

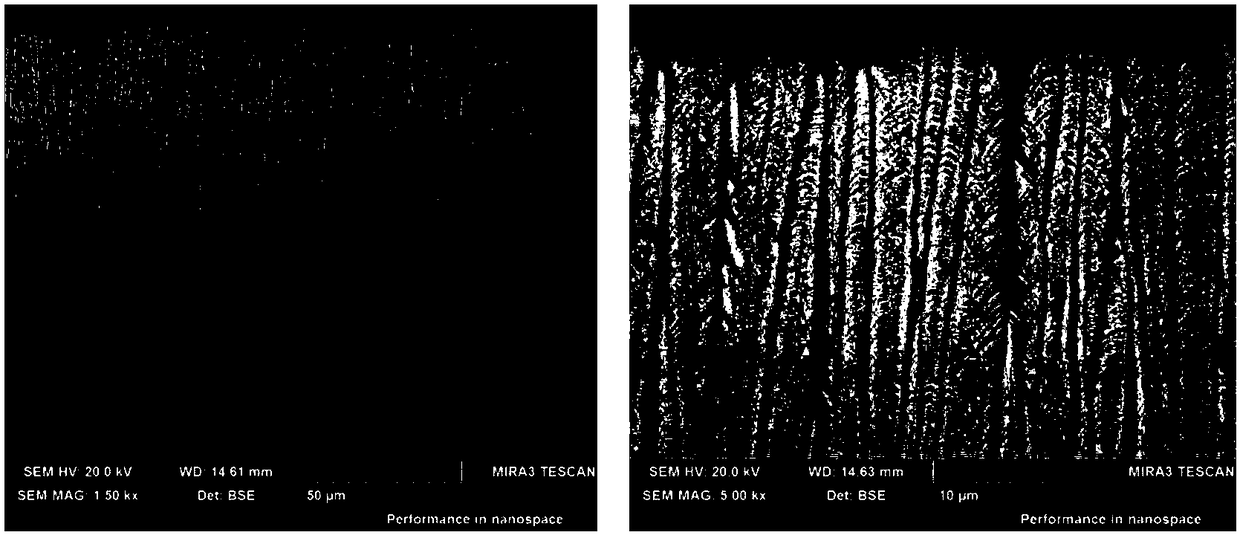

Aluminum alloy surfacehydrophobic treatment technology

ActiveCN109865949AImprove hydrophobicityImprove corrosion resistanceLaser beam welding apparatusNanosecond laserMicro nano

The invention discloses an aluminum alloy surface hydrophobic treatment technology. The aluminum alloy surface hydrophobic treatment technology comprises the following steps that (1) soaking in an ethanol solution is conducted; (2) soaking in an sodium hydroxide solution is conducted; (3) heating and temperature conserving are conducted; (4) a pre-modified aluminum plate is obtained; and (5) nanosecond laser level processing is conducted on the obtained pre-modified aluminum plate. According to the aluminum alloy surface hydrophobic treatment technology, by the cooperative function processed by all steps, a hydrophobic micro-nano structure with a clear level can be established on the processed aluminum alloy surface, the contacting angle of the processed aluminum alloy surface is greatly increased, the hydrophobic performance of the aluminum alloy surface can be greatly improved, and the corrosion resistant performance of the processed aluminum alloy surface can be improved to a certain extend.

Owner:重庆新西亚铝业(集团)股份有限公司

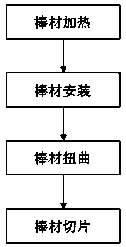

Processing method for improving toughness of bar material

InactiveCN109454137AStubborn coefficient is uniform and stableIncrease the stubbornness coefficientShaping toolsMetal-working feeding devicesElectromagnetic inductionHeating furnace

The invention relates to a processing method for improving the toughness of a bar material. According to the processing method, the bar material is heated to a preset temperature through an electromagnetic induction heating furnace, the temperature of the heated bar material is stabilized to be in a preset temperature floating range through an infrared temperature control device, so that heating of the bar material is uniform and stable, moreover, the bar material can be kept in the preset temperature floating range before twisting, the stability and the uniformity of the bar material during twisting are guaranteed, and then the strength coefficient of the formed bar material is uniform and stable; and the strength coefficient of the bar material can be improved by 20-30% by twisting the bar material by a preset angle, one end, mounted close to the rotating end of a twisting device, of the twisted and formed bar material and one end, mounted close to the fixed end of the twisting device, of the twisted and formed bar material are removed, and then the bar material is evenly cut into a plurality of sections so that the different use requirements for supporting strength and installation space in a vehicle can be met, moreover, processing is convenient, and the acquisition is easy.

Owner:江苏天宝利自动化科技有限公司

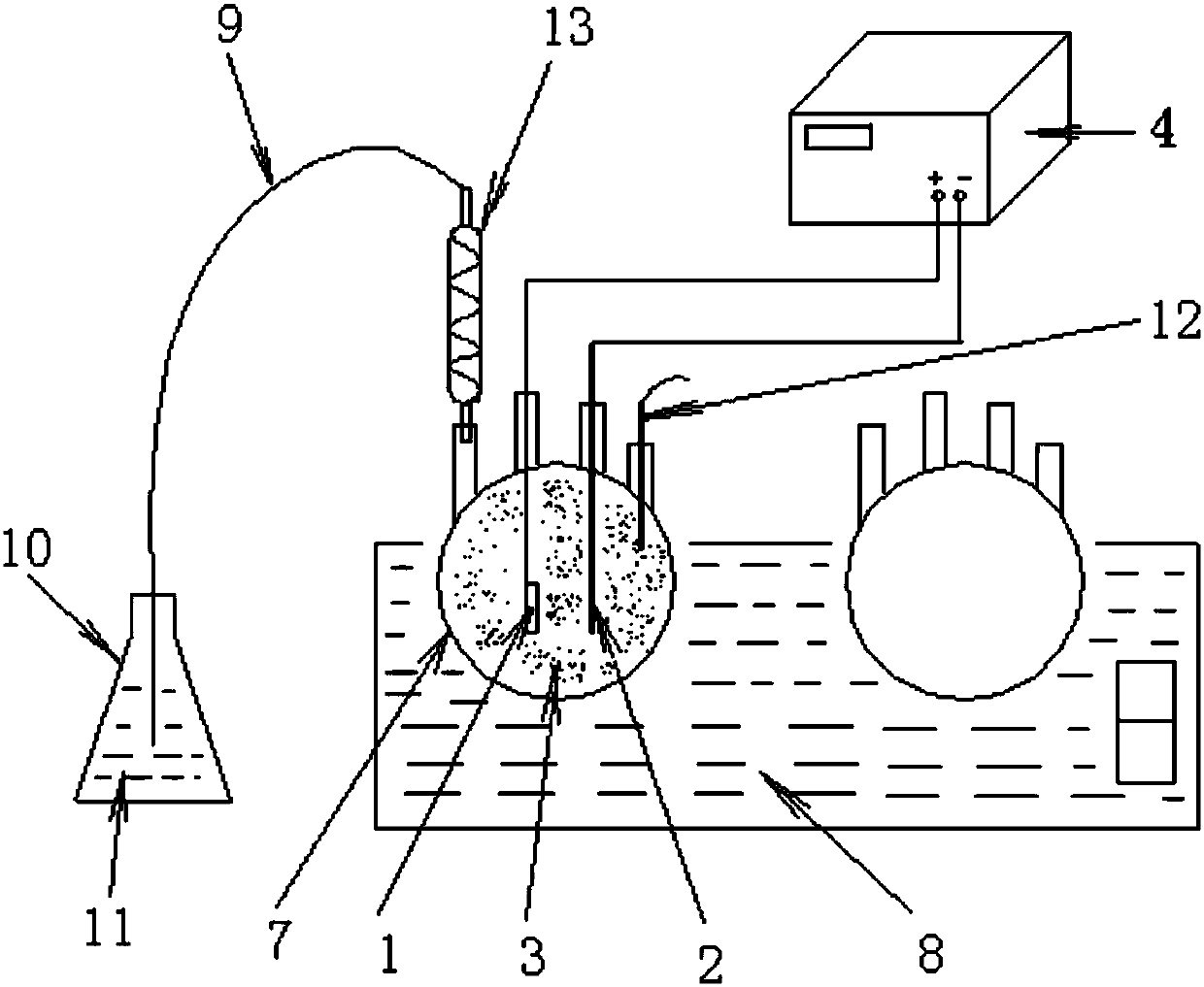

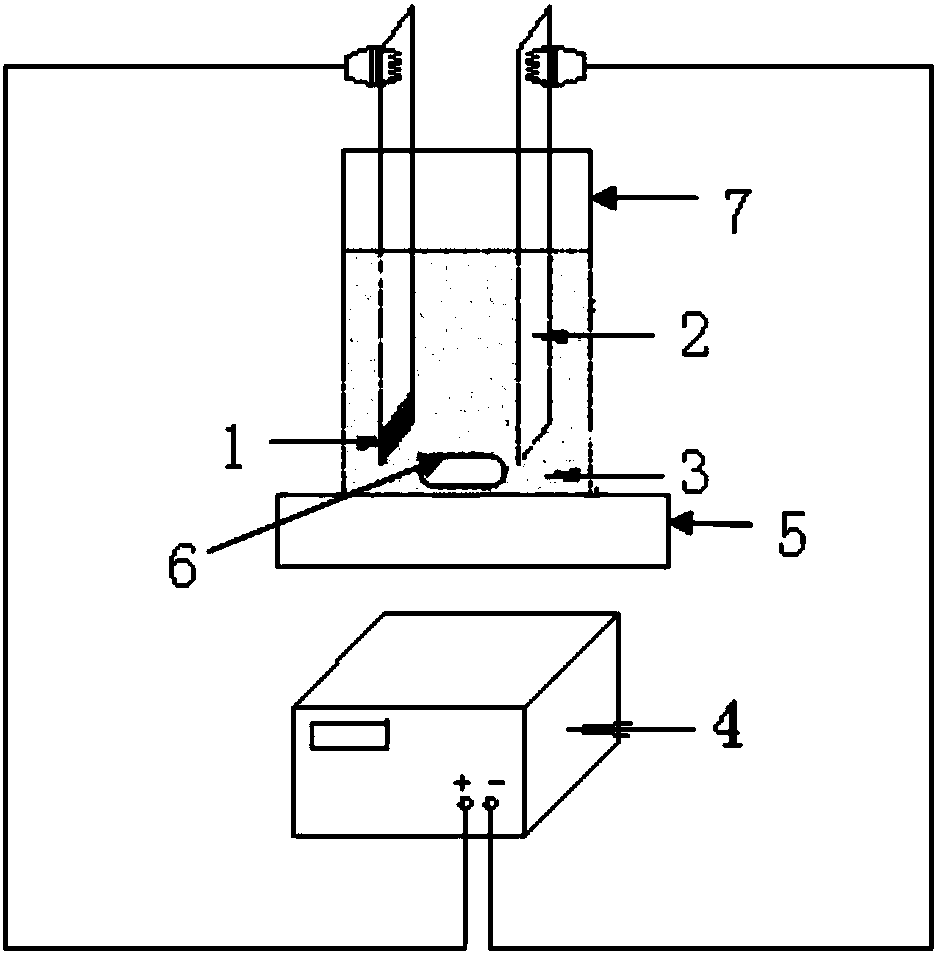

Testing method and device for accelerated life of oxygen evolution titanium anode

PendingCN107843794AOvercoming the disadvantages of temperature inconsistencyEven and stable heatingEnvironmental/reliability testsMaterial electrochemical variablesElectrolytic agentWarm water

The invention relates to the field of the electrolytic technology, and especially discloses a testing method and device for the accelerated life of an oxygen evolution titanium anode. The device comprises a power supply, a flask, a warm water bath and a titanium plate, and the interior of the flask is provided with electrolyte. The body of the flask is disposed in the warm water bath. The oxygen evolution titanium anode and the titanium plate are respectively inserted into the electrolyte in the flask. The positive electrode of the power supply is connected with the oxygen evolution titanium anode, and the negative electrode of the power supply is connected with the titanium plate. The device improves the testing stability and precision of the accelerated life of the oxygen evolution titanium anode, does not cause harmful gas during testing, and is good in environmental protection performance.

Owner:JIANGYIN ANCAN ELECTROCHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com