In-situ oxygen compensated-scanning electron vapor deposition (IOC-SEVD) device and method thereof

A vapor deposition and scanning technology, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of large fluctuation range of condition parameters, difficult control of coating quality, and difficult temperature control. Long life, low preparation and maintenance costs, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

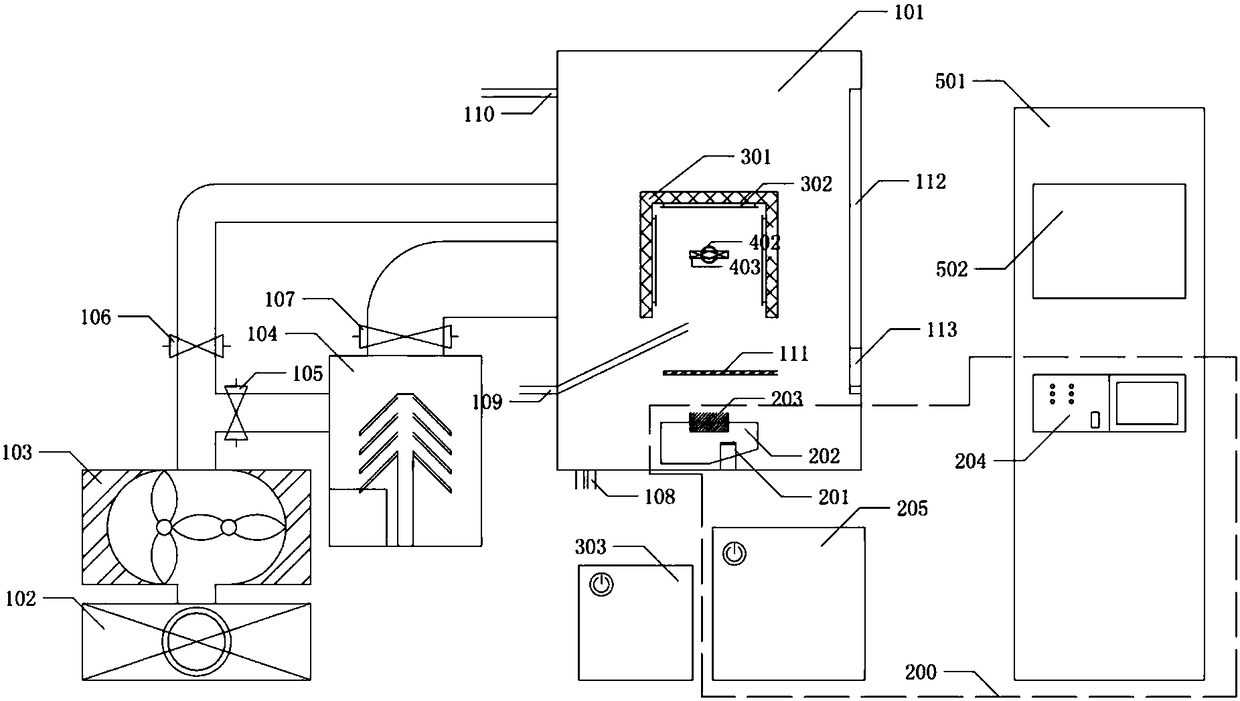

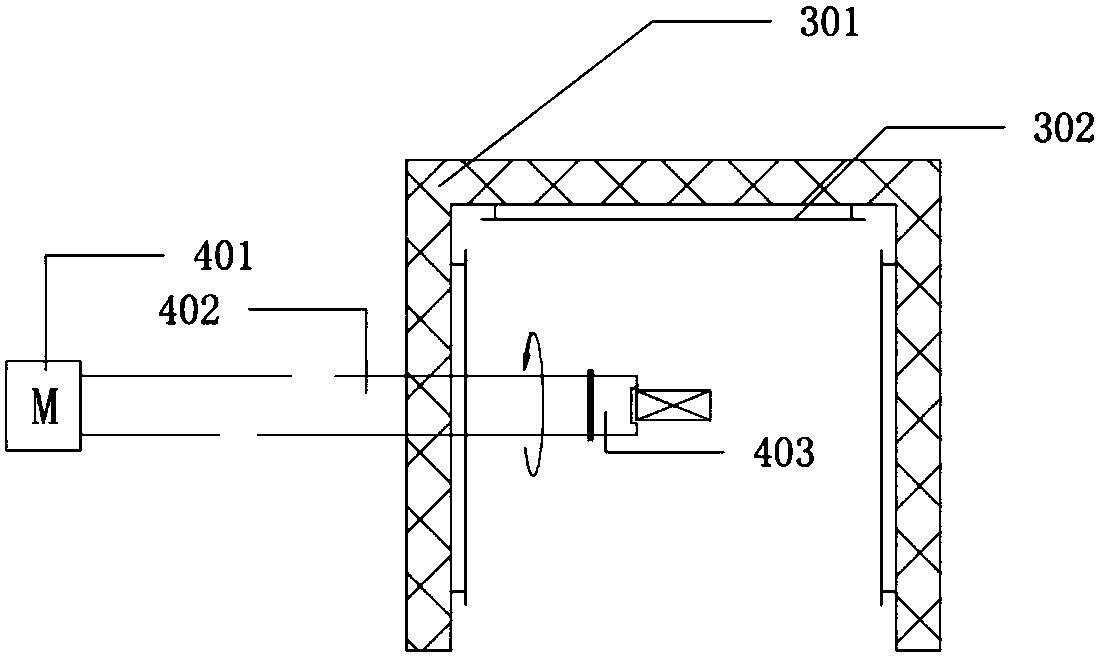

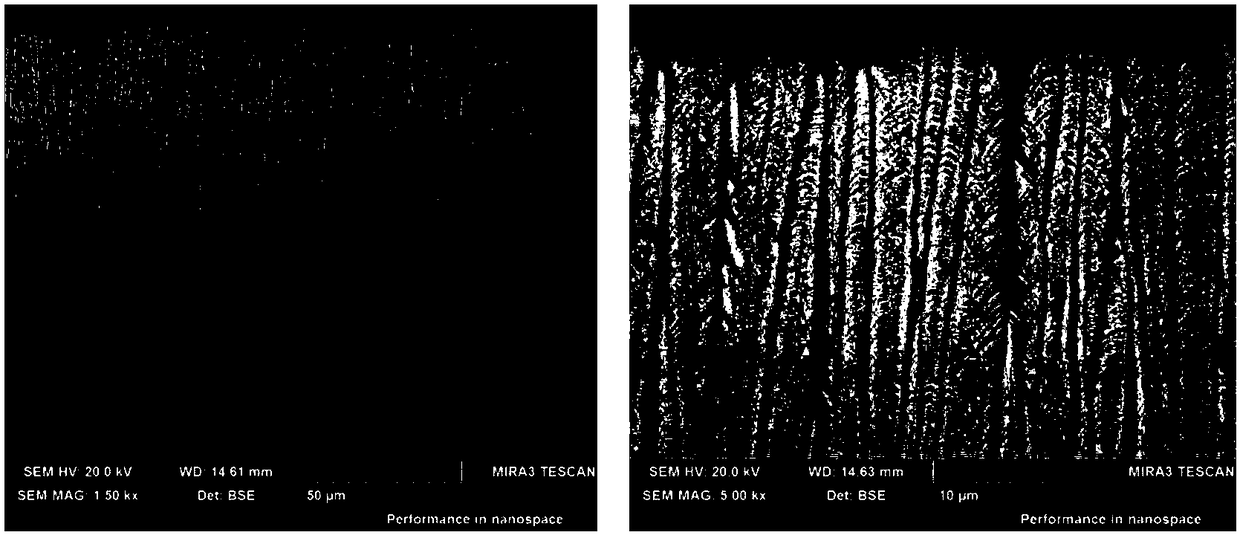

[0035] The present invention aims at the defects existing in the existing physical vapor deposition device when preparing metal oxides, especially columnar structure thermal barrier coatings, and proposes an in-situ oxygen supplement type scanning electron beam vapor deposition (IOC-SEVD) device. In the invention, the resistance radiation heating is used to replace the direct electron gun in the traditional electron beam ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com