Patents

Literature

2141 results about "Electron gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electron gun (also called electron emitter) is an electrical component in some vacuum tubes that produces a narrow, collimated electron beam that has a precise kinetic energy. The largest use is in cathode ray tubes (CRTs), used in nearly all television sets, computer displays and oscilloscopes that are not flat-panel displays. They are also used in field emission displays (FEDs), which are essentially flat-panel displays made out of rows of extremely small cathode ray tubes. They are also used in microwave linear beam vacuum tubes such as klystrons, inductive output tubes, travelling wave tubes, and gyrotrons, as well as in scientific instruments such as electron microscopes and particle accelerators. Electron guns may be classified by the type of electric field generation (DC or RF), by emission mechanism (thermionic, photocathode, cold emission, plasmas source), by focusing (pure electrostatic or with magnetic fields), or by the number of electrodes.

Integrated high-frequency generator system utilizing the magnetic field of the target application

ActiveUS8786284B2Easily and simply adapted for DNP operationSmall and compactMeasurements using double resonanceTubes with helical electron streamInternal modeMicrowave

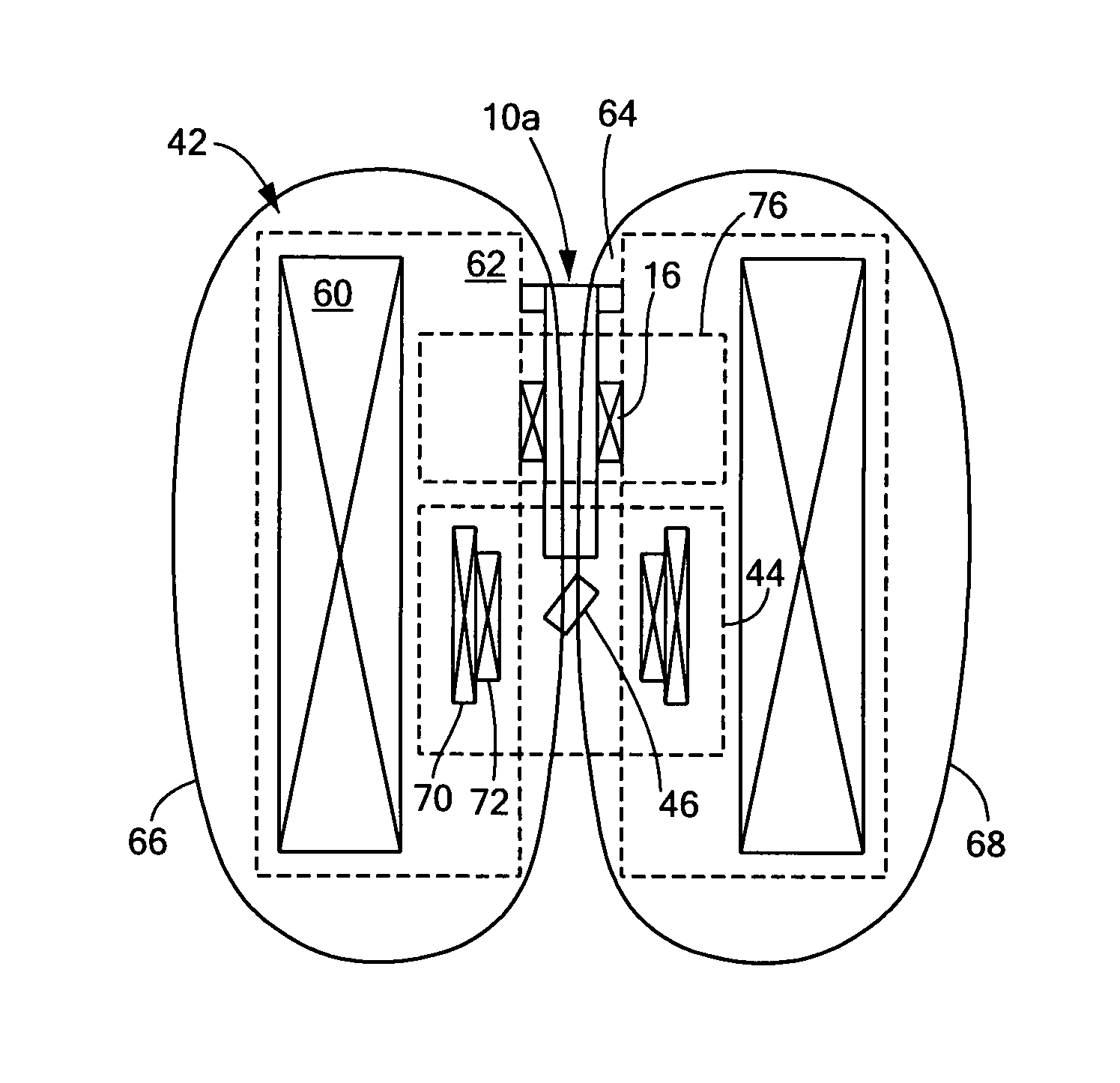

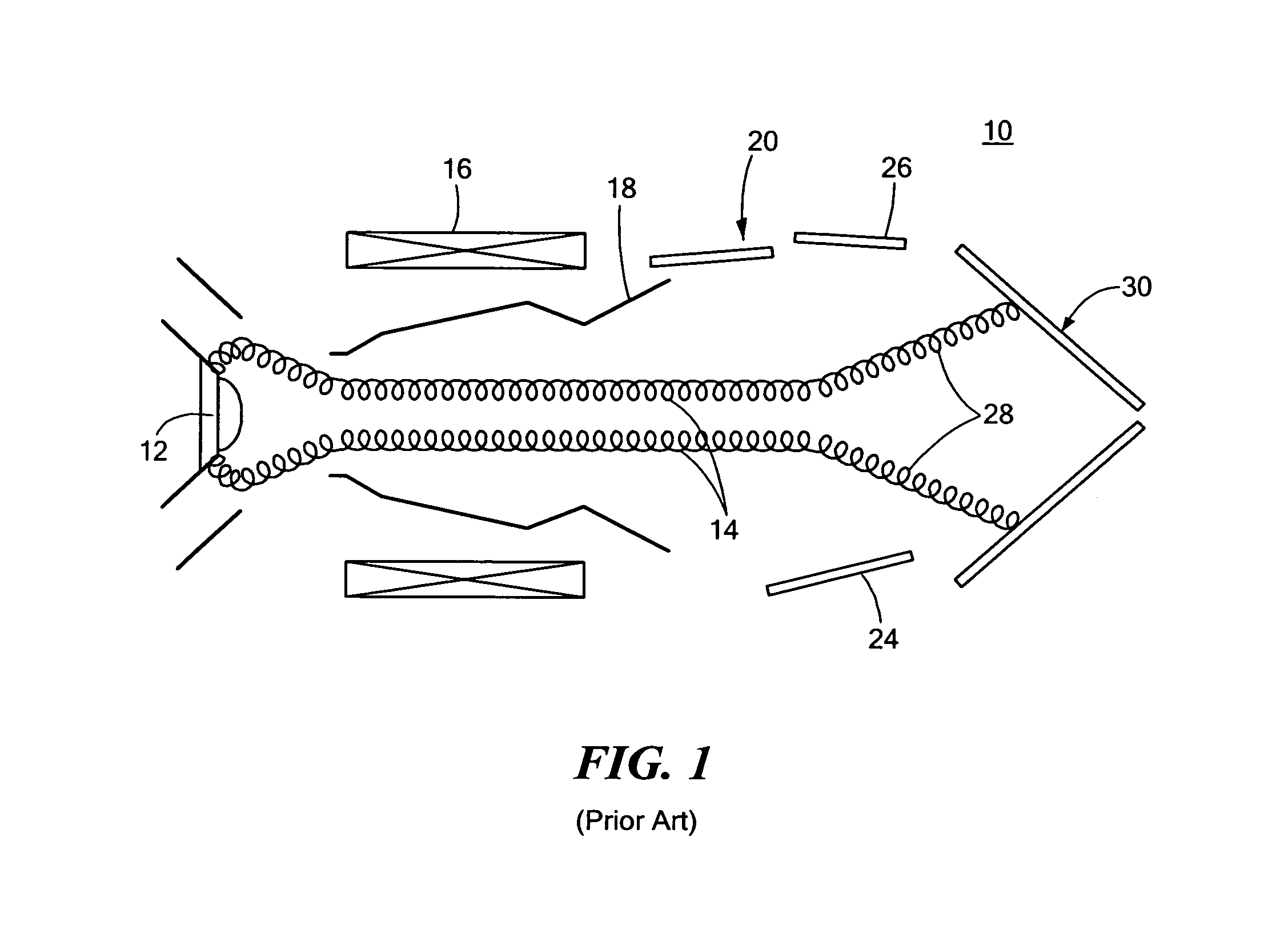

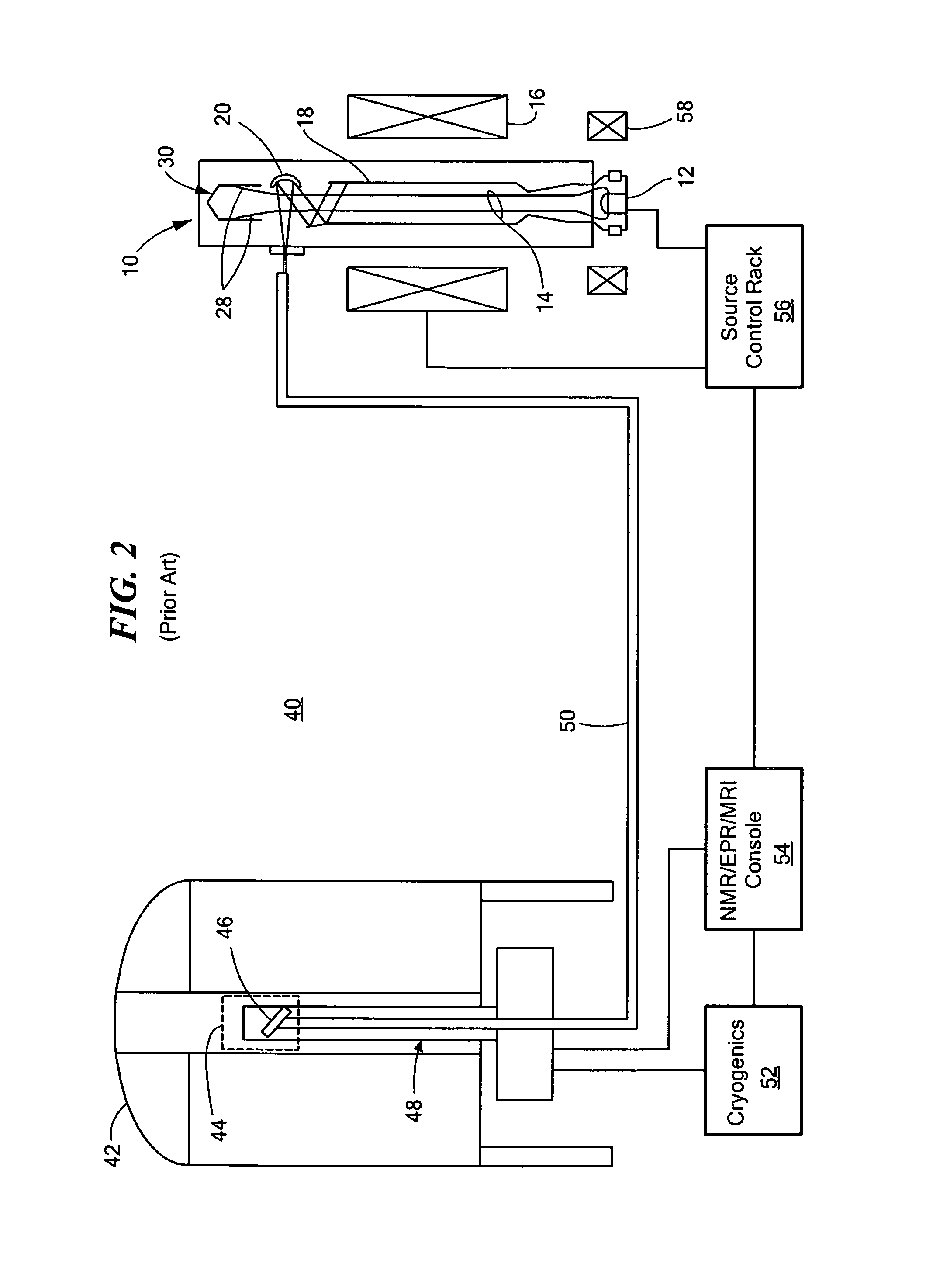

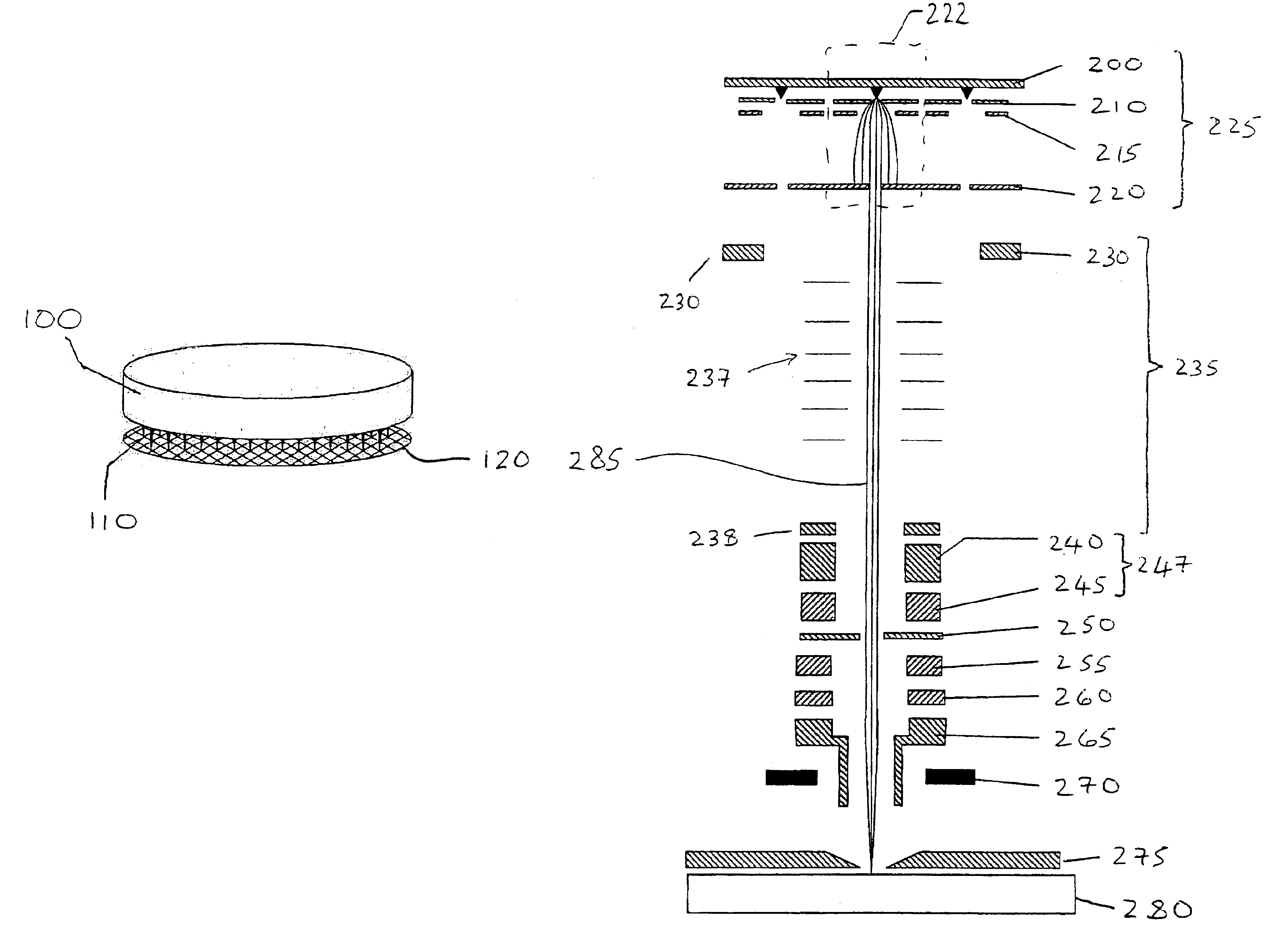

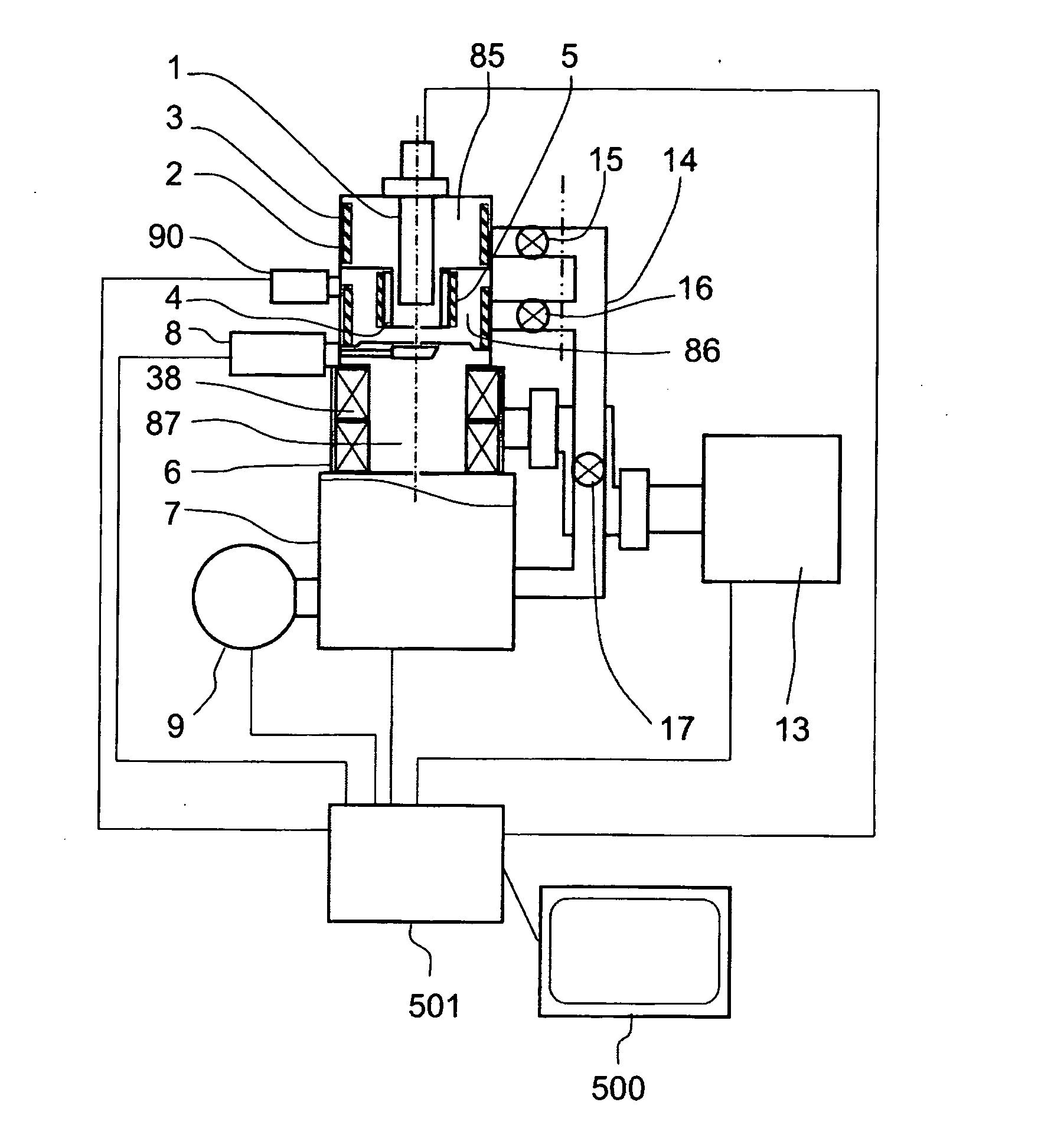

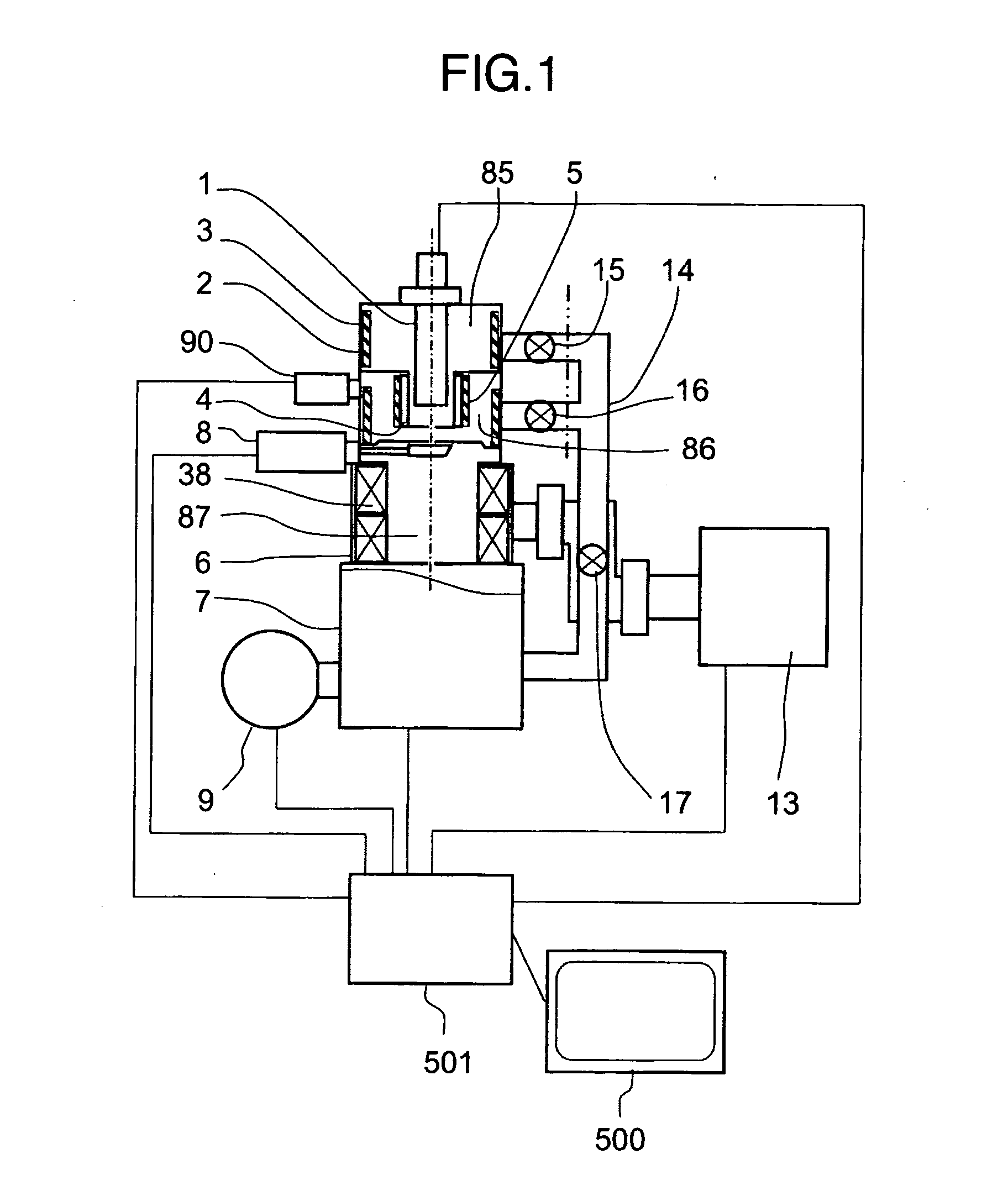

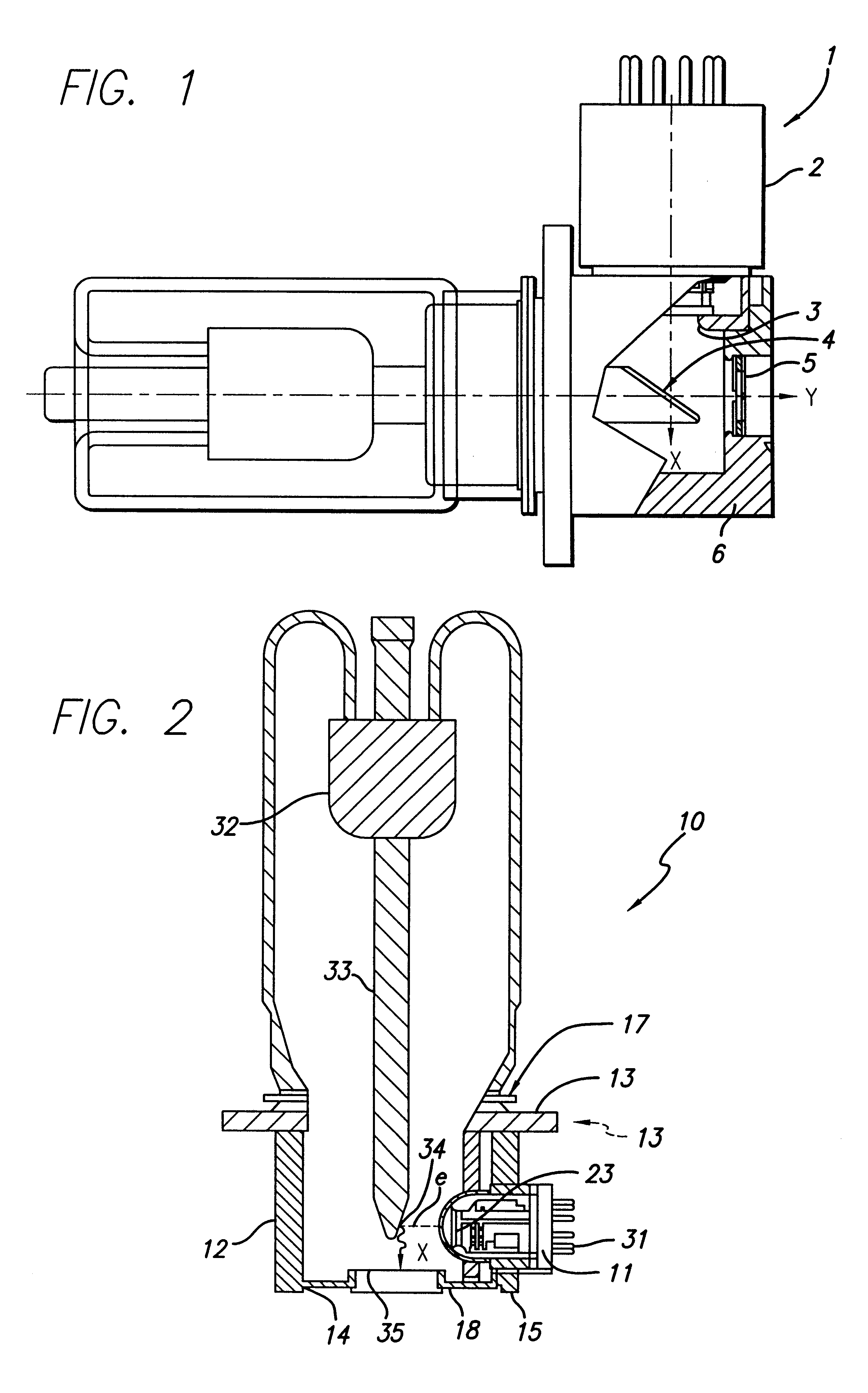

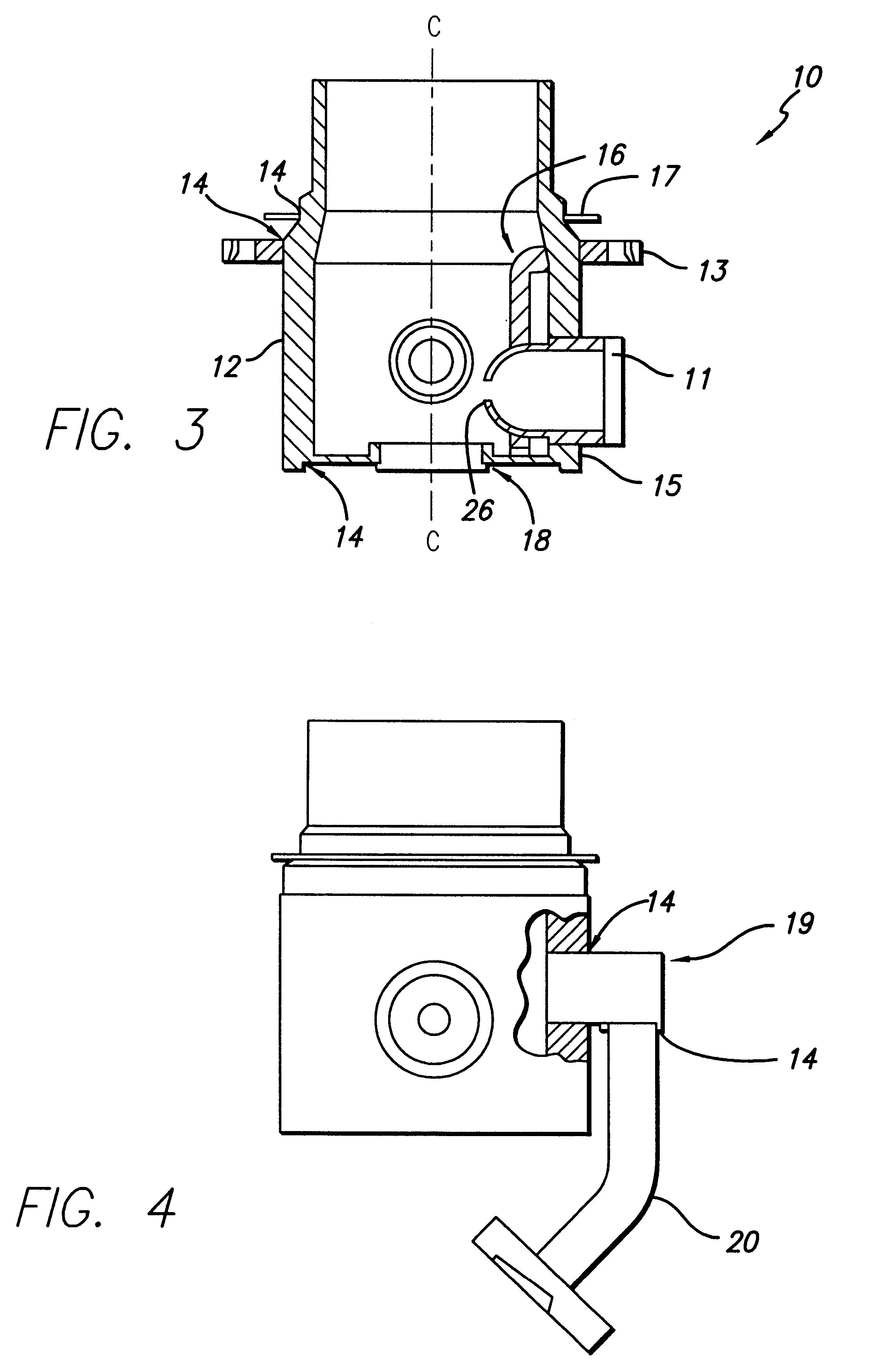

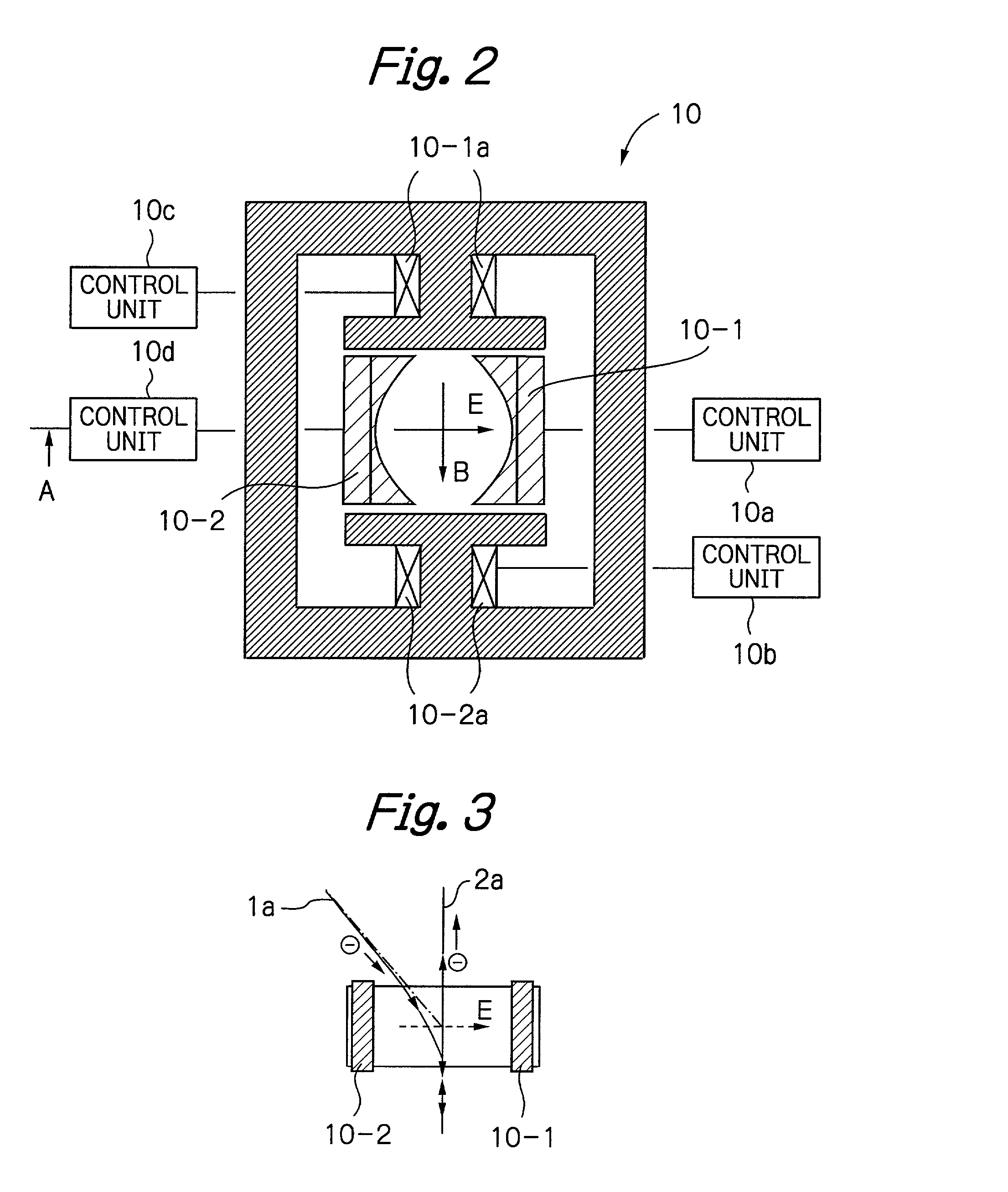

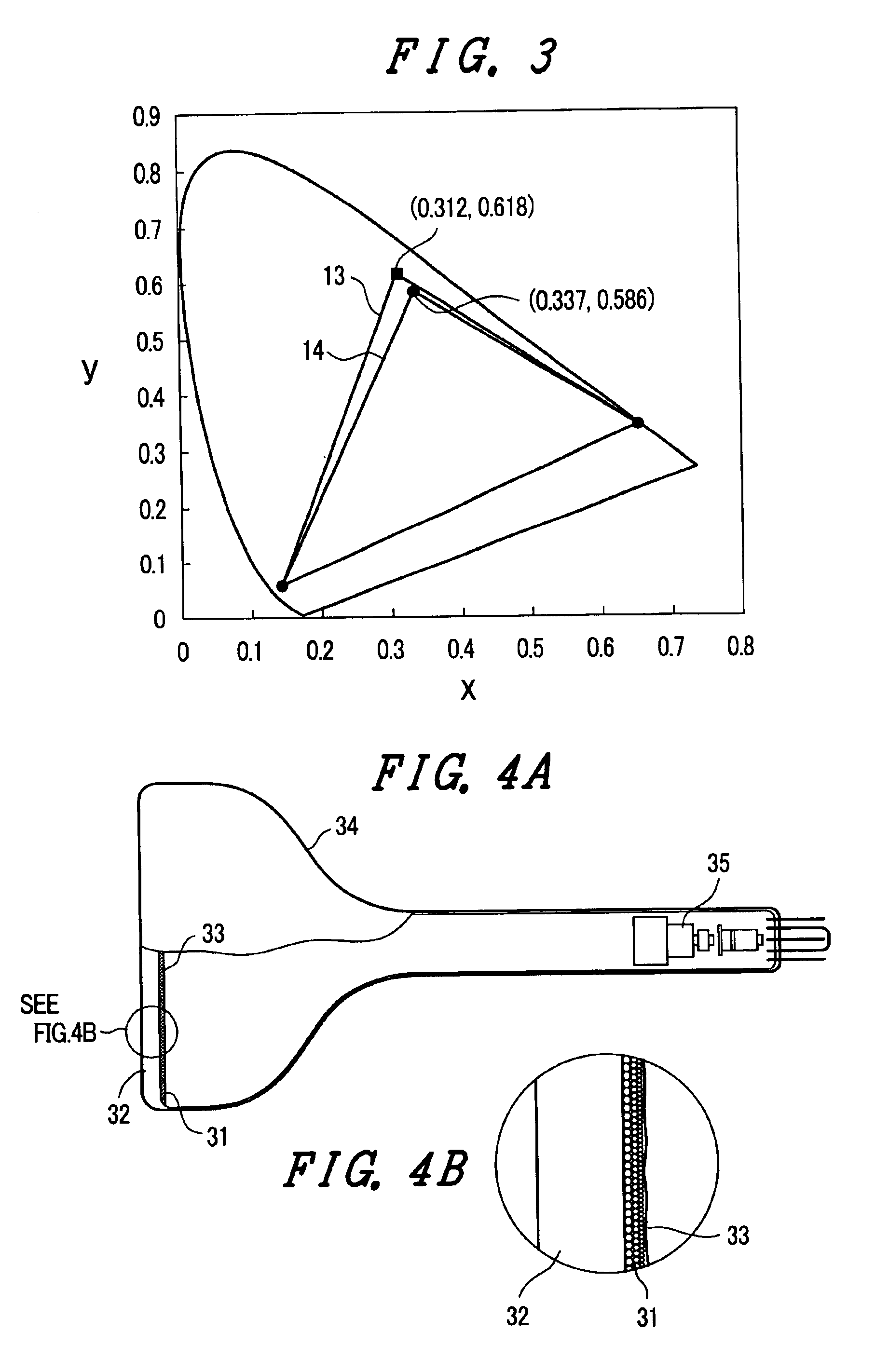

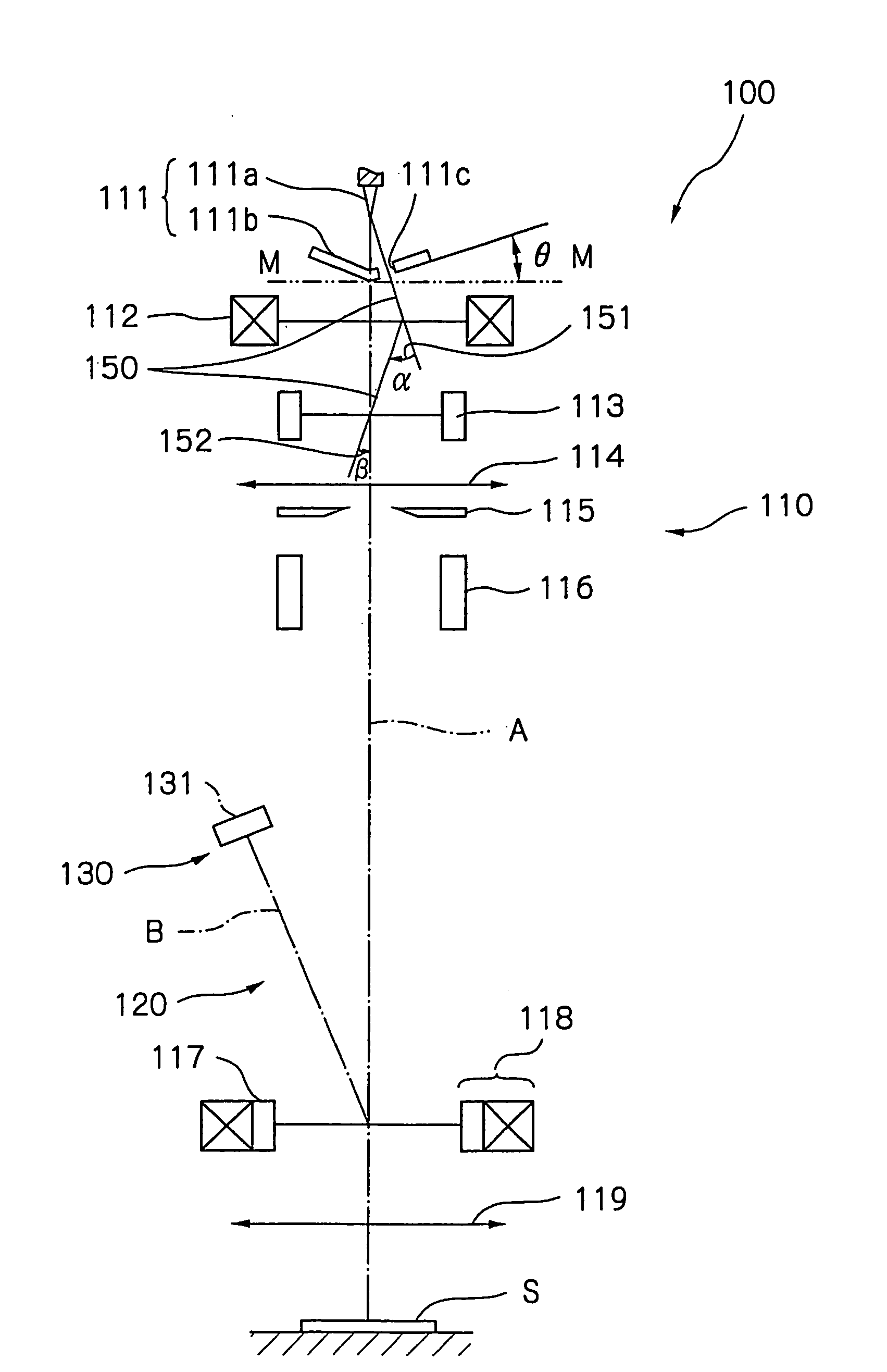

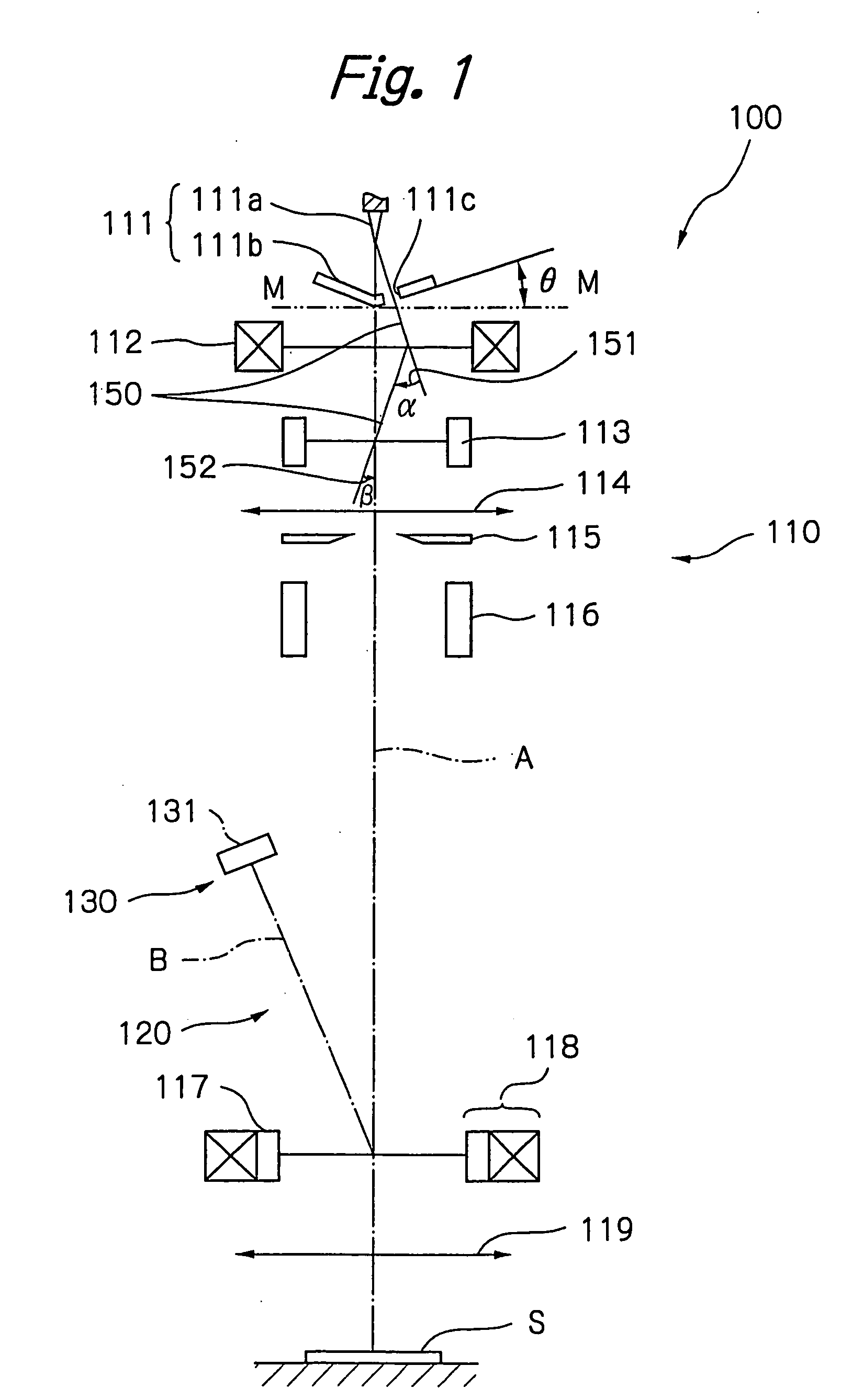

An integrated high-frequency generator system utilizing the magnetic field of the target application including a magnetic resonance magnet having an application zone and a high-frequency (microwave / terahertz) generator zone in the magnetic field of the magnetic resonance magnet; and a high-frequency (microwave / terahertz) generator disposed in the high-frequency (microwave / terahertz) generator zone and utilizing the magnet field of the magnetic resonance magnet to generate the high-frequency (microwave / terahertz) radiation. The magnetic resonance magnet may have an auxiliary magnetic field source for modifying the magnetic field profile in the high-frequency (microwave / terahertz) generator zone. The high-frequency (microwave / terahertz) generator may include an electron gun for generating an electron beam adapted to be focused by a magnetic field source having a spatially rising region, a homogenous region and a decaying region, an interaction structure for generating high-frequency (microwave / terahertz) radiation, an internal mode converter in the homogenous region for extracting the high-frequency (microwave / terahertz) radiation through a window, and a reduced collector disposed substantially in the homogenous region before the electron beam spreads in the decaying region.

Owner:BRIDGE 12 TECH

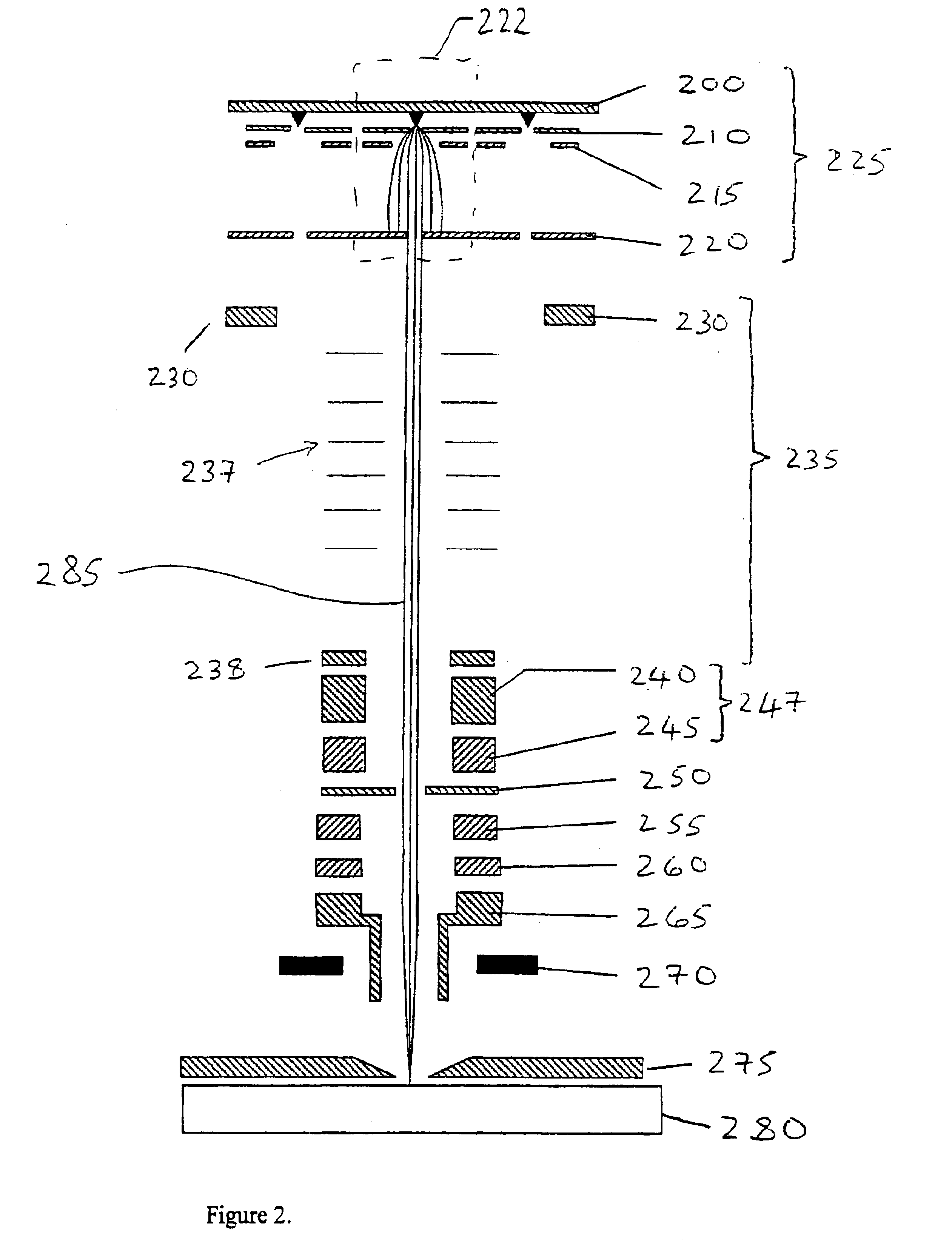

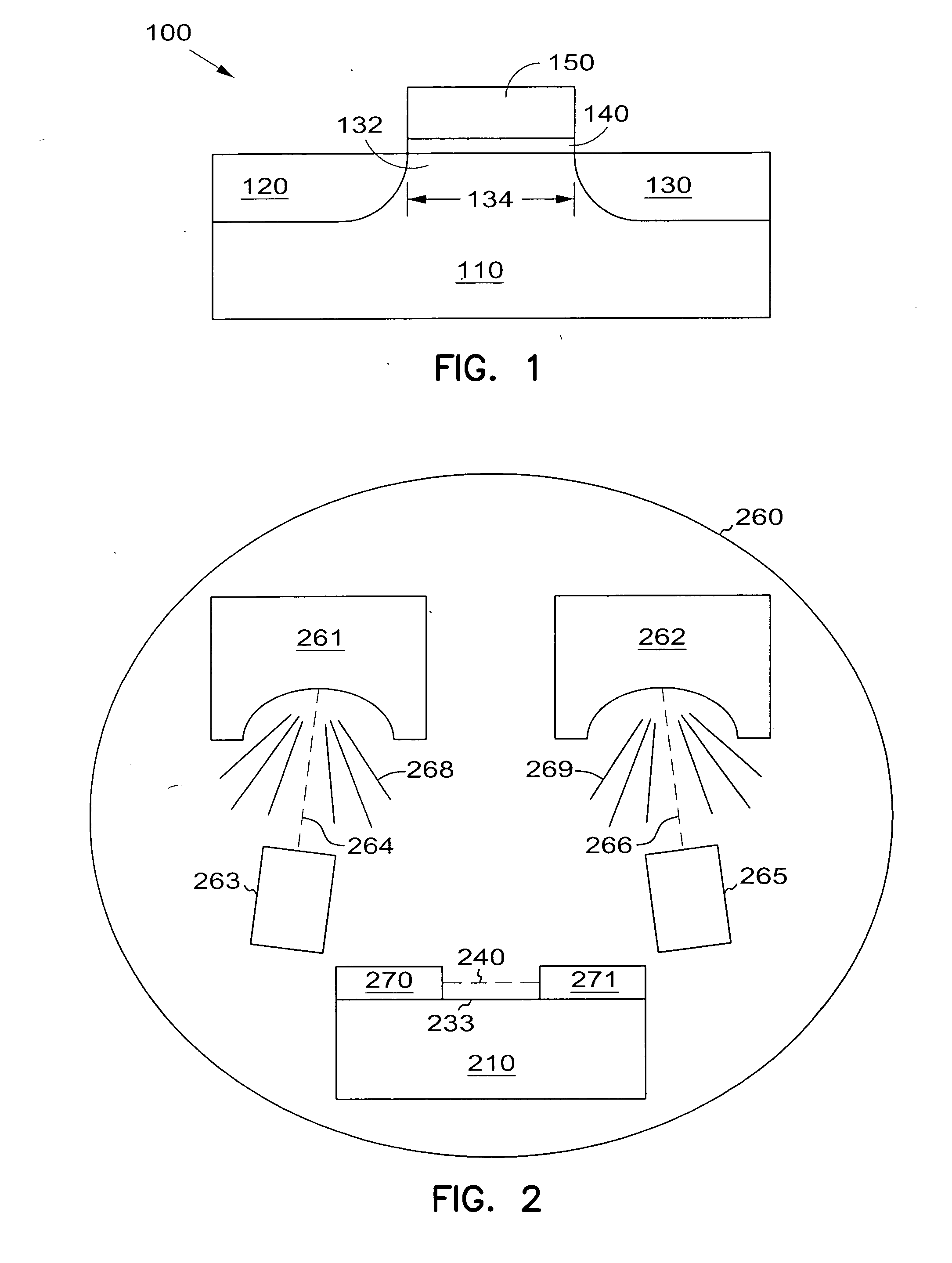

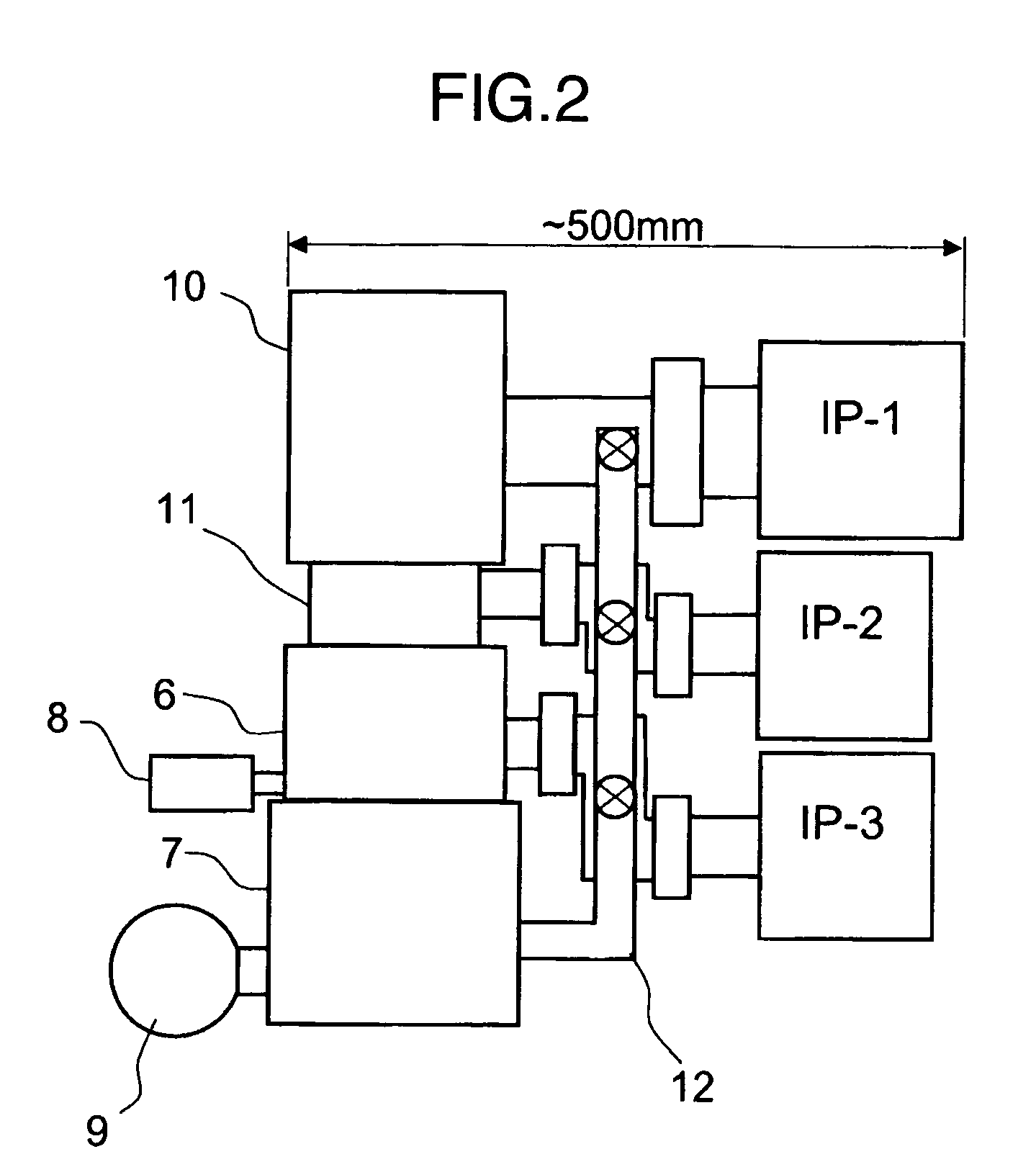

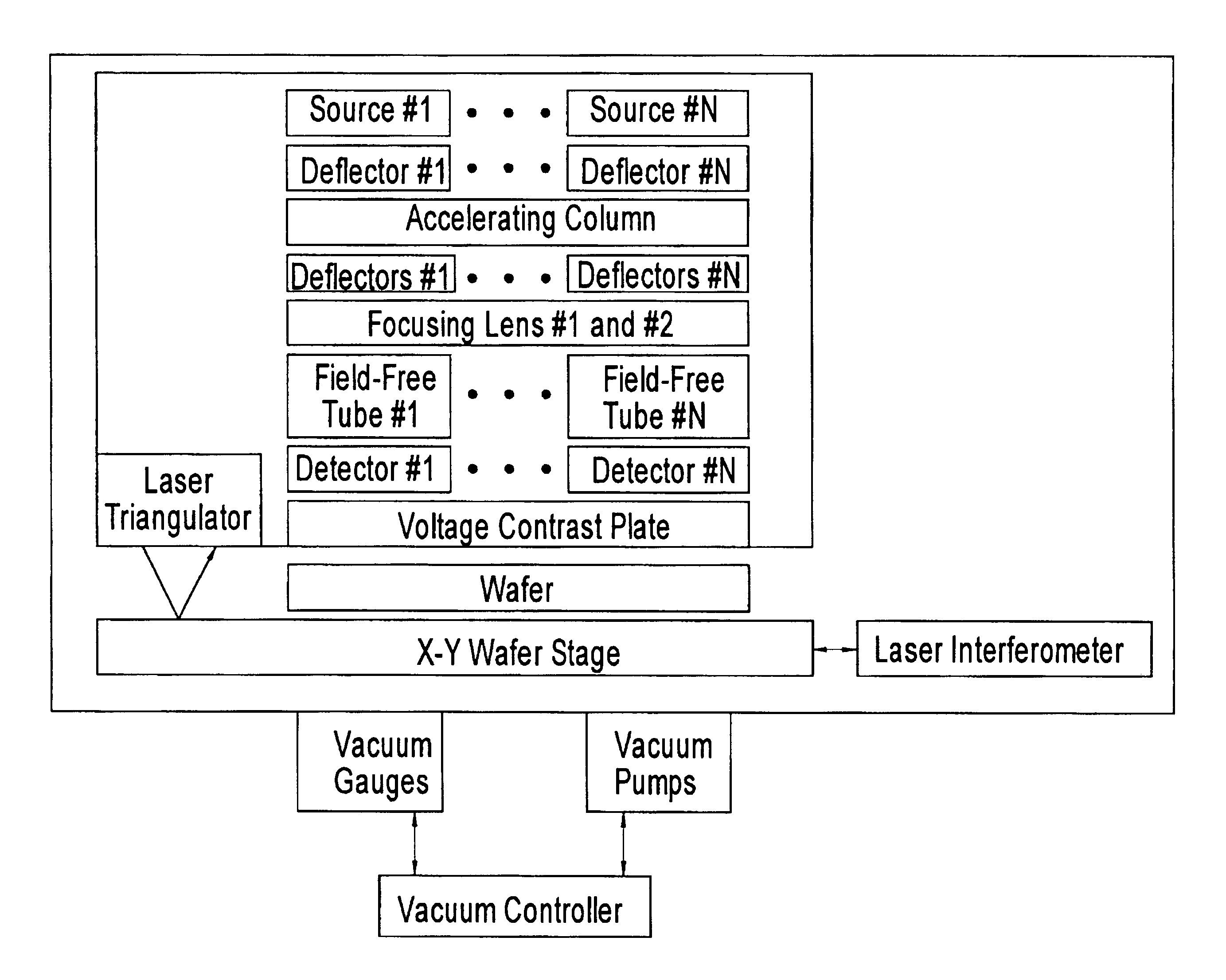

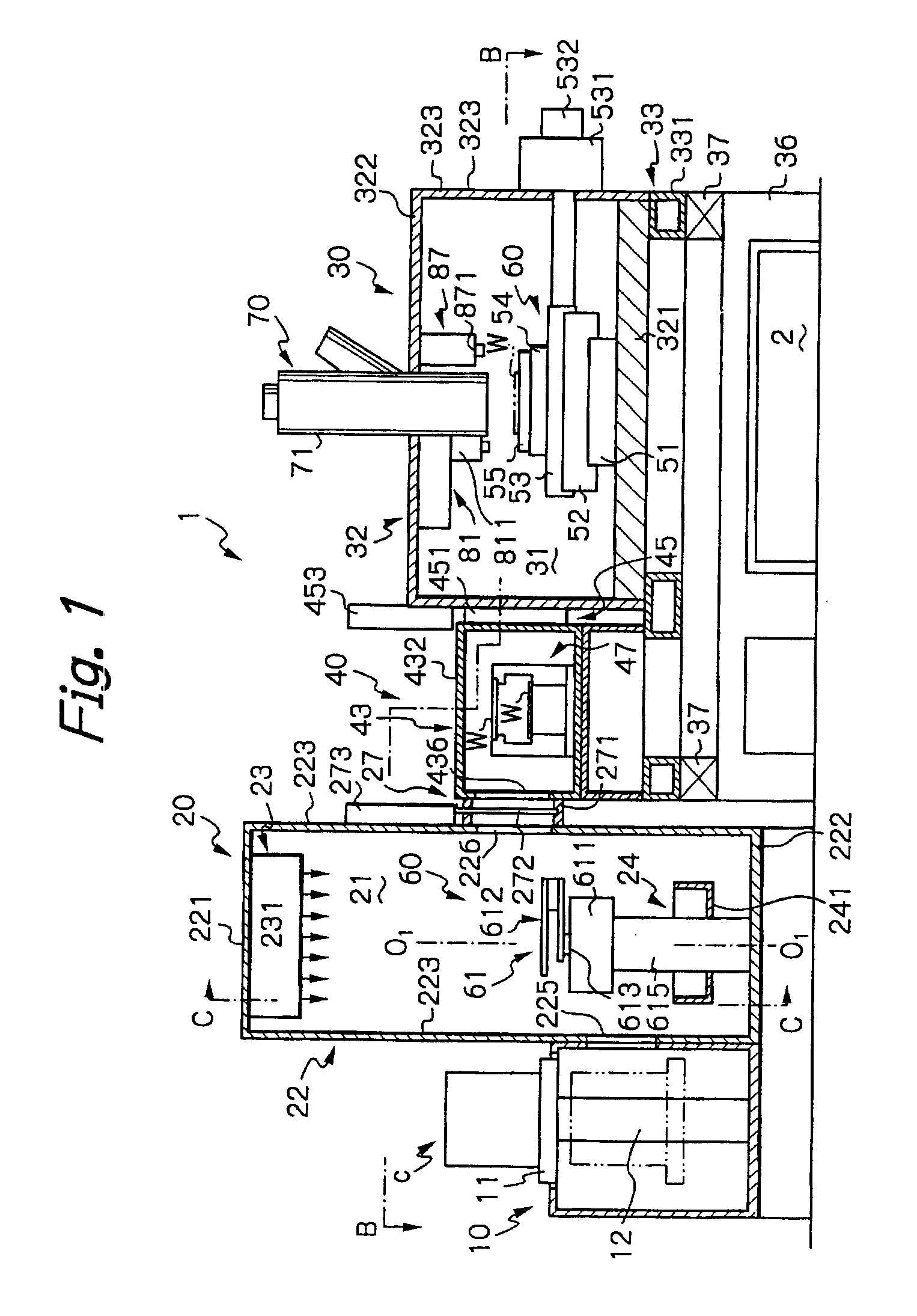

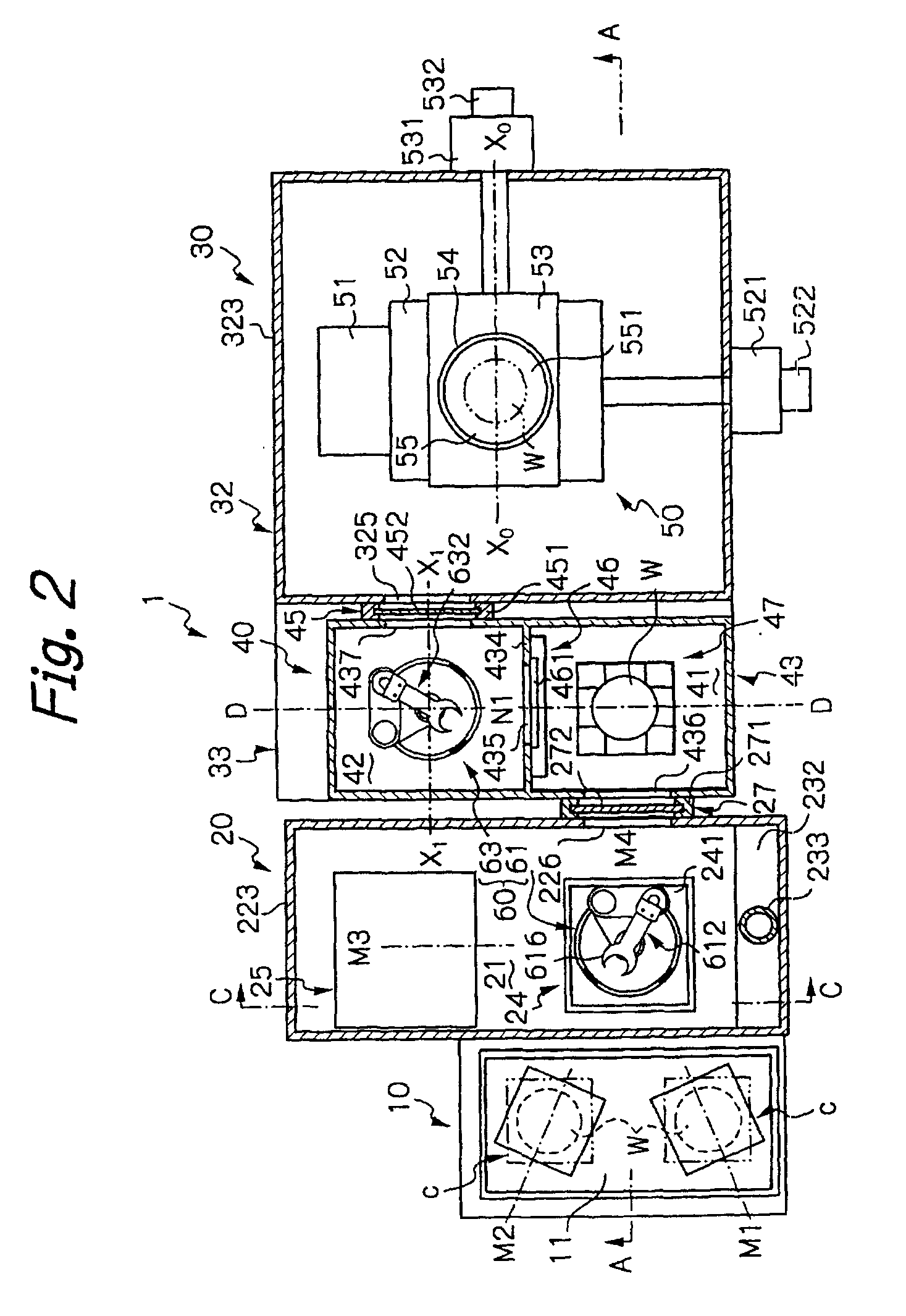

Multi-beam multi-column electron beam inspection system

InactiveUS6844550B1Material analysis using wave/particle radiationRadiation/particle handlingSystems designData stream

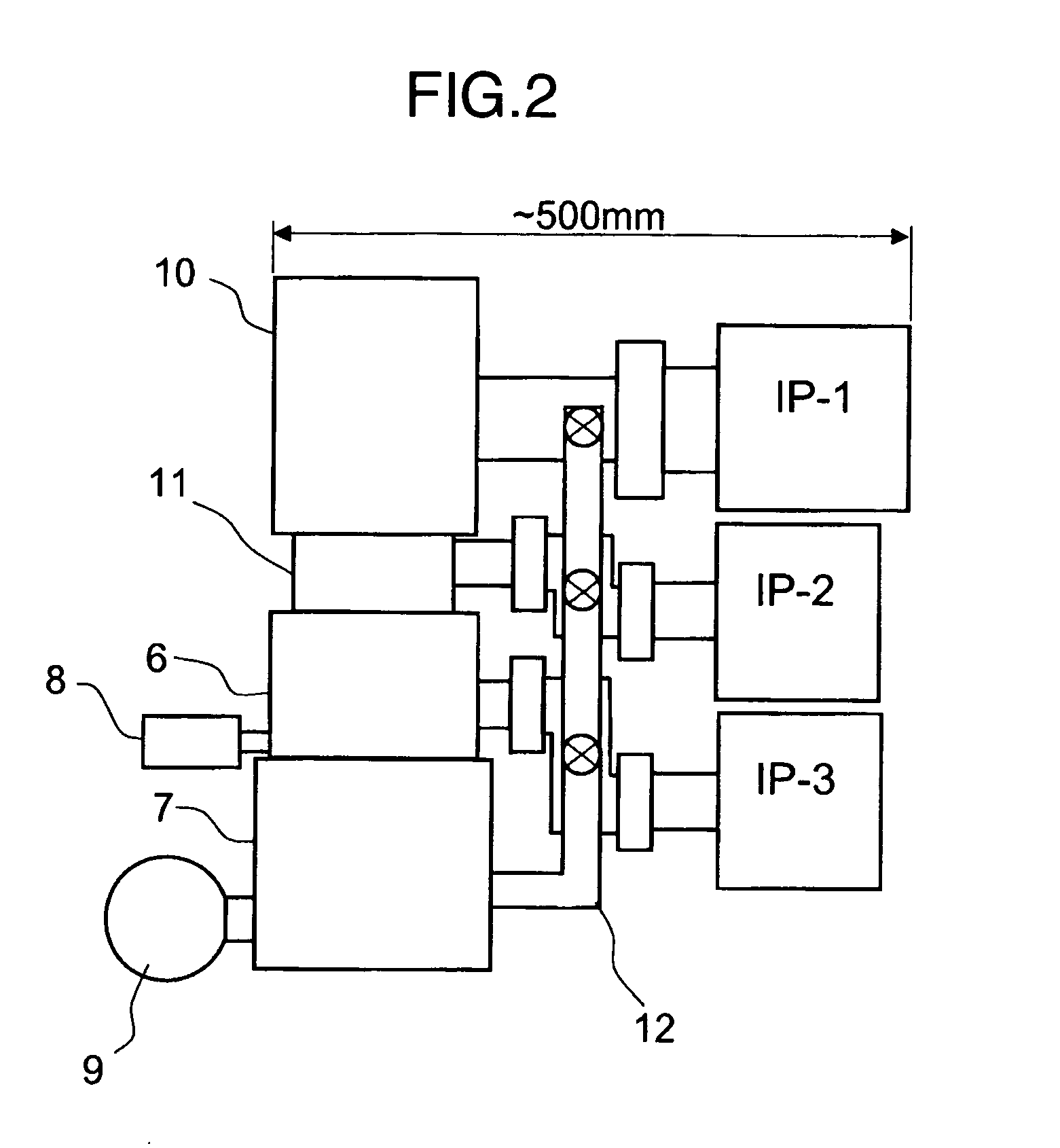

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

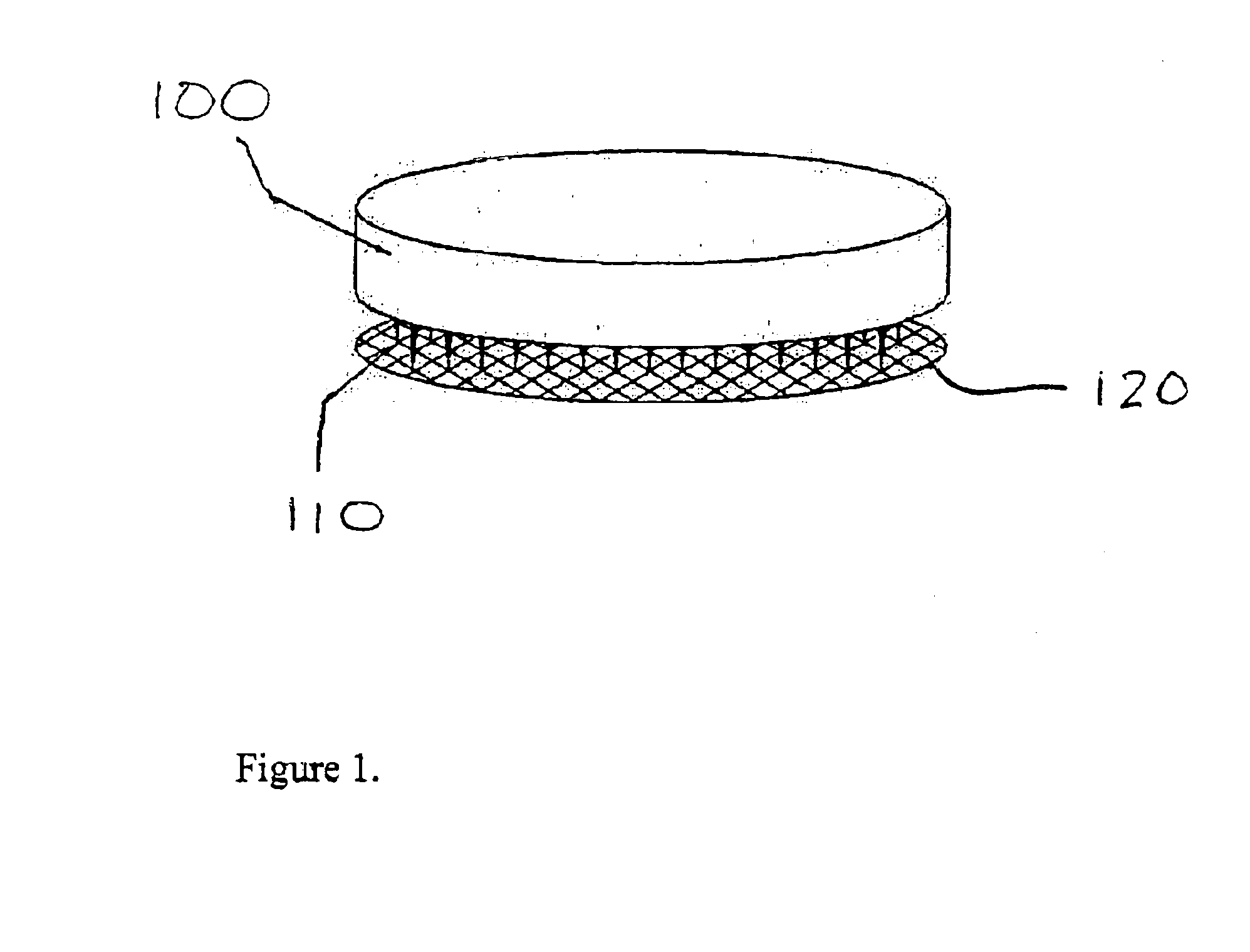

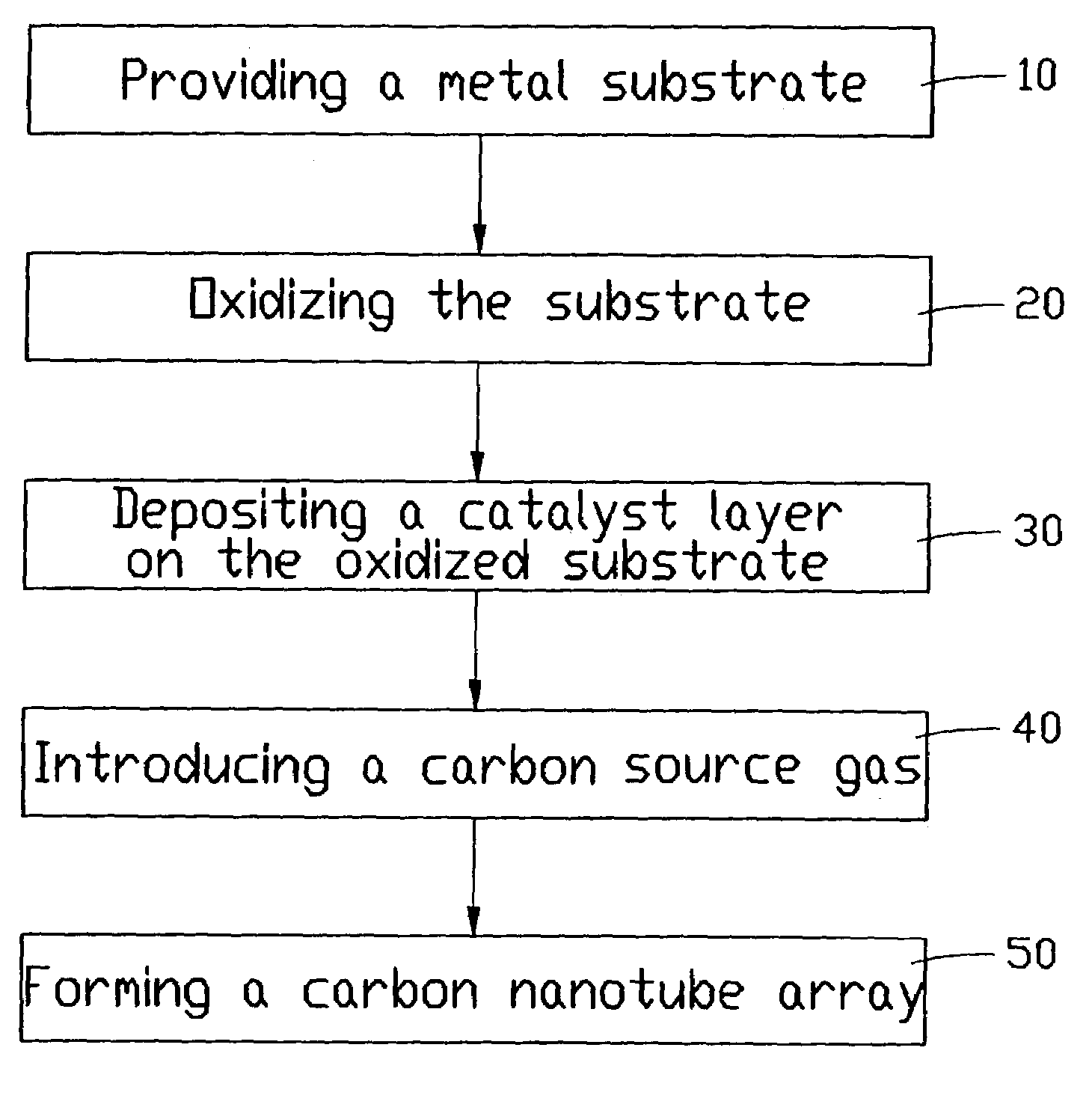

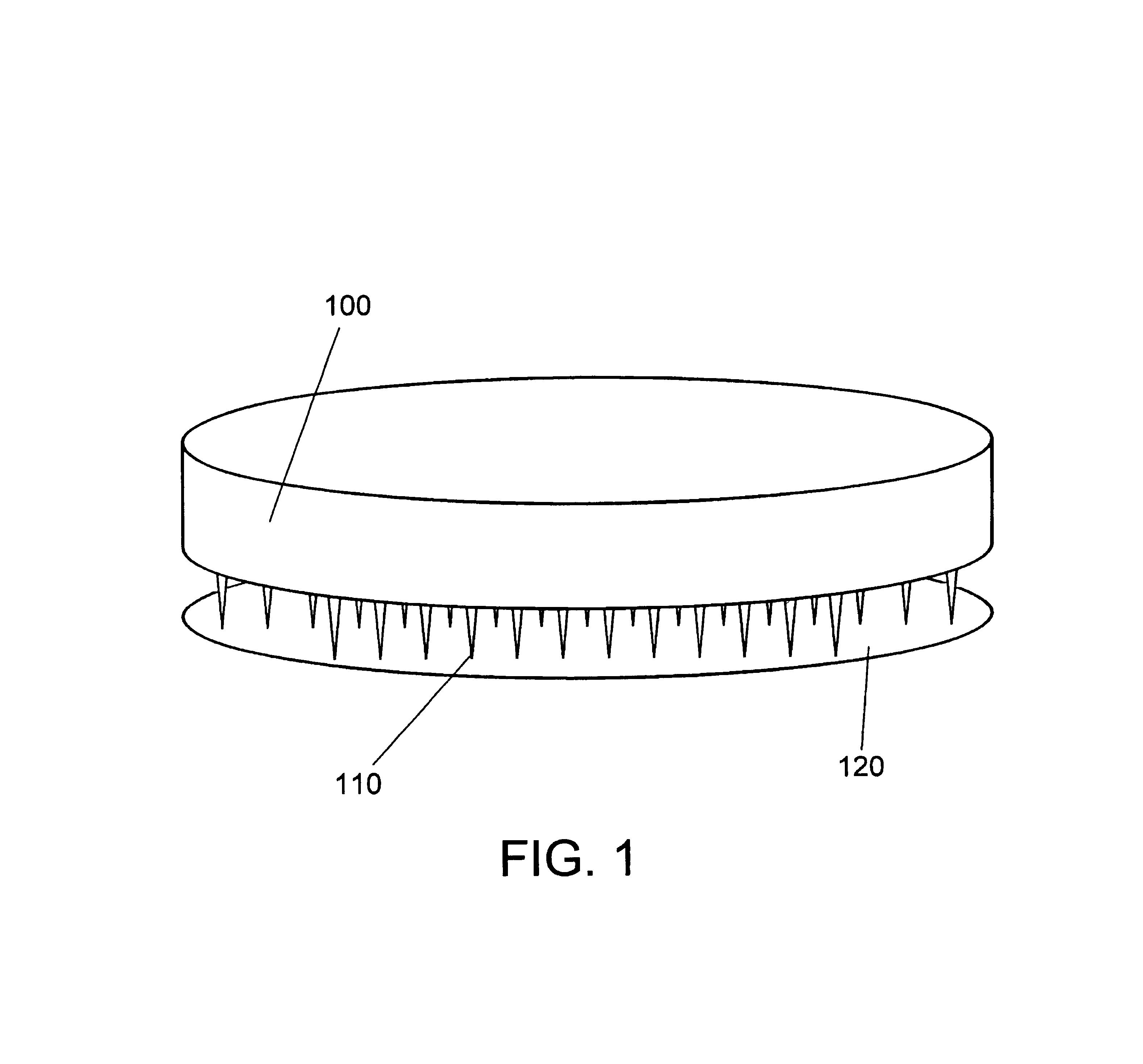

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

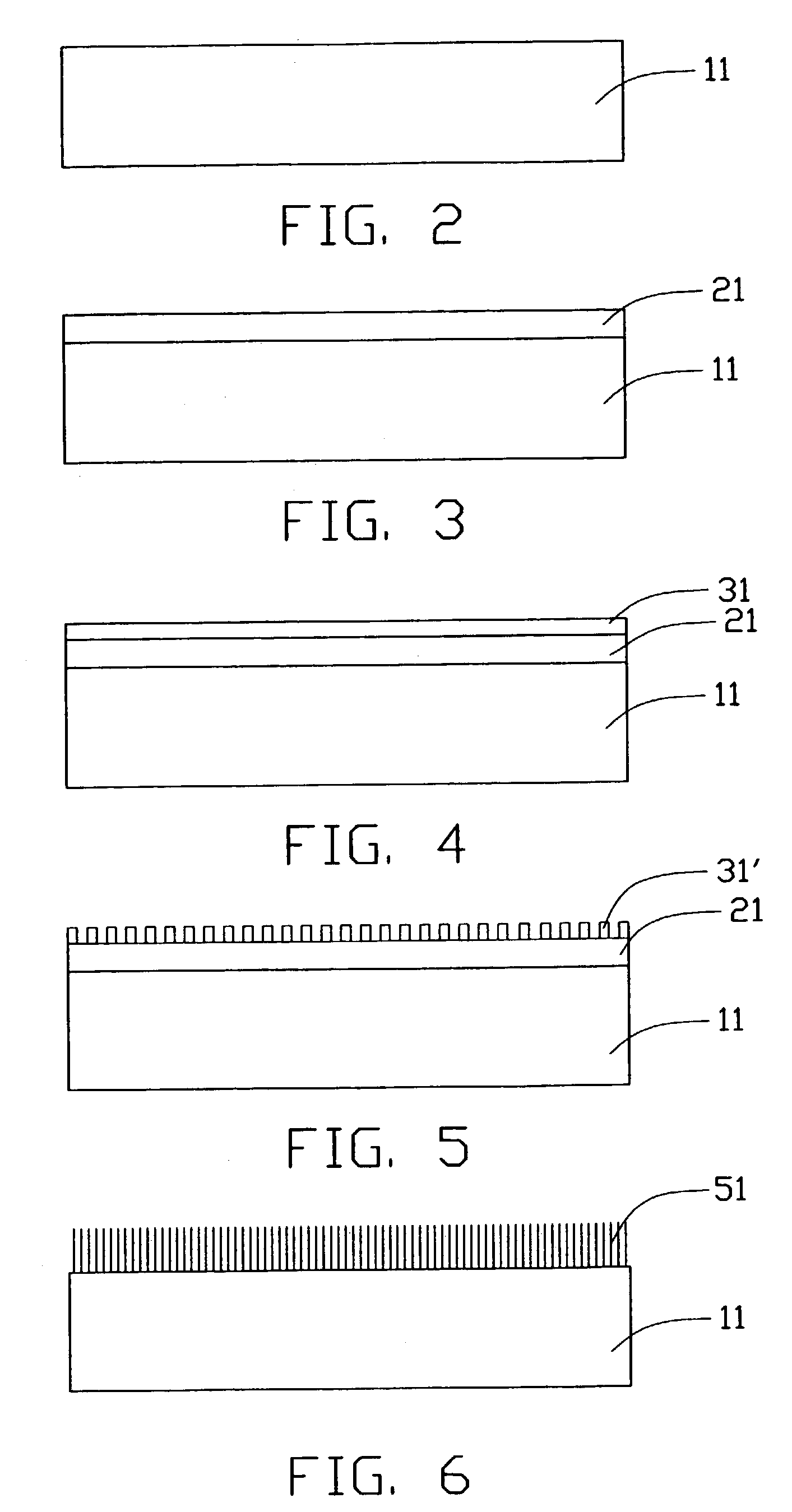

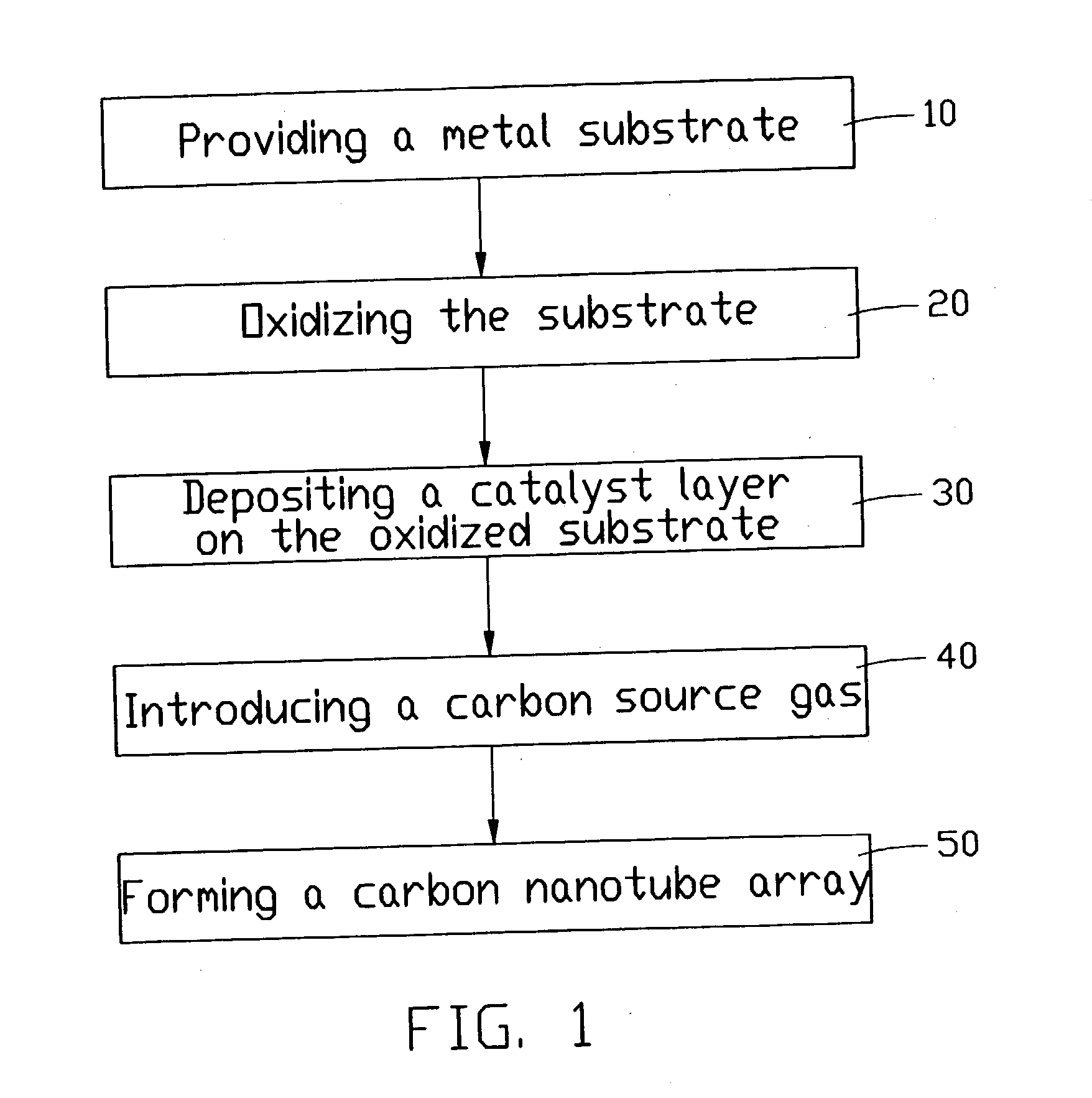

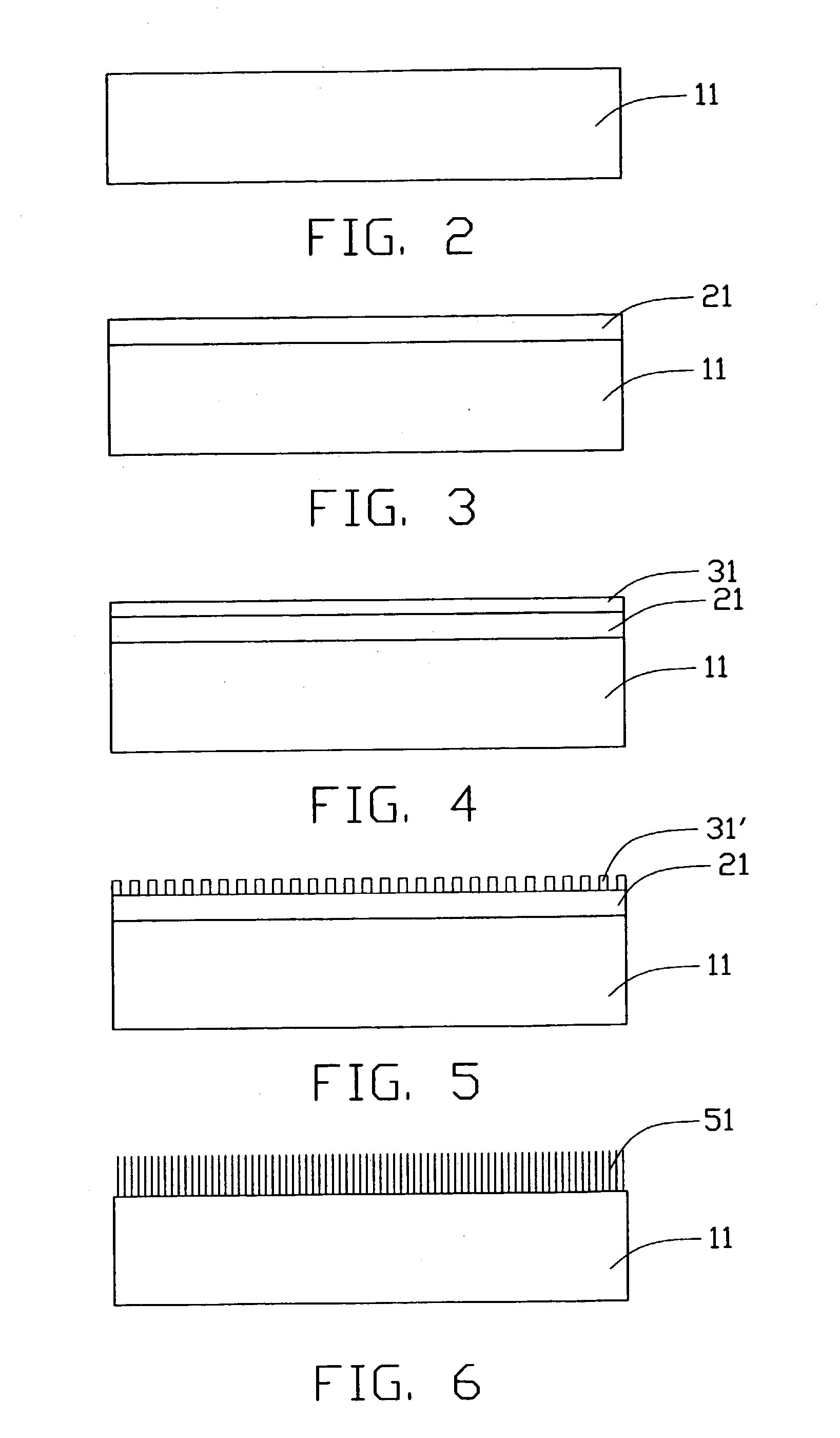

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS9079248B2High resolutionHigh pressure levelAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedImage resolution

Owner:ARCAM AB

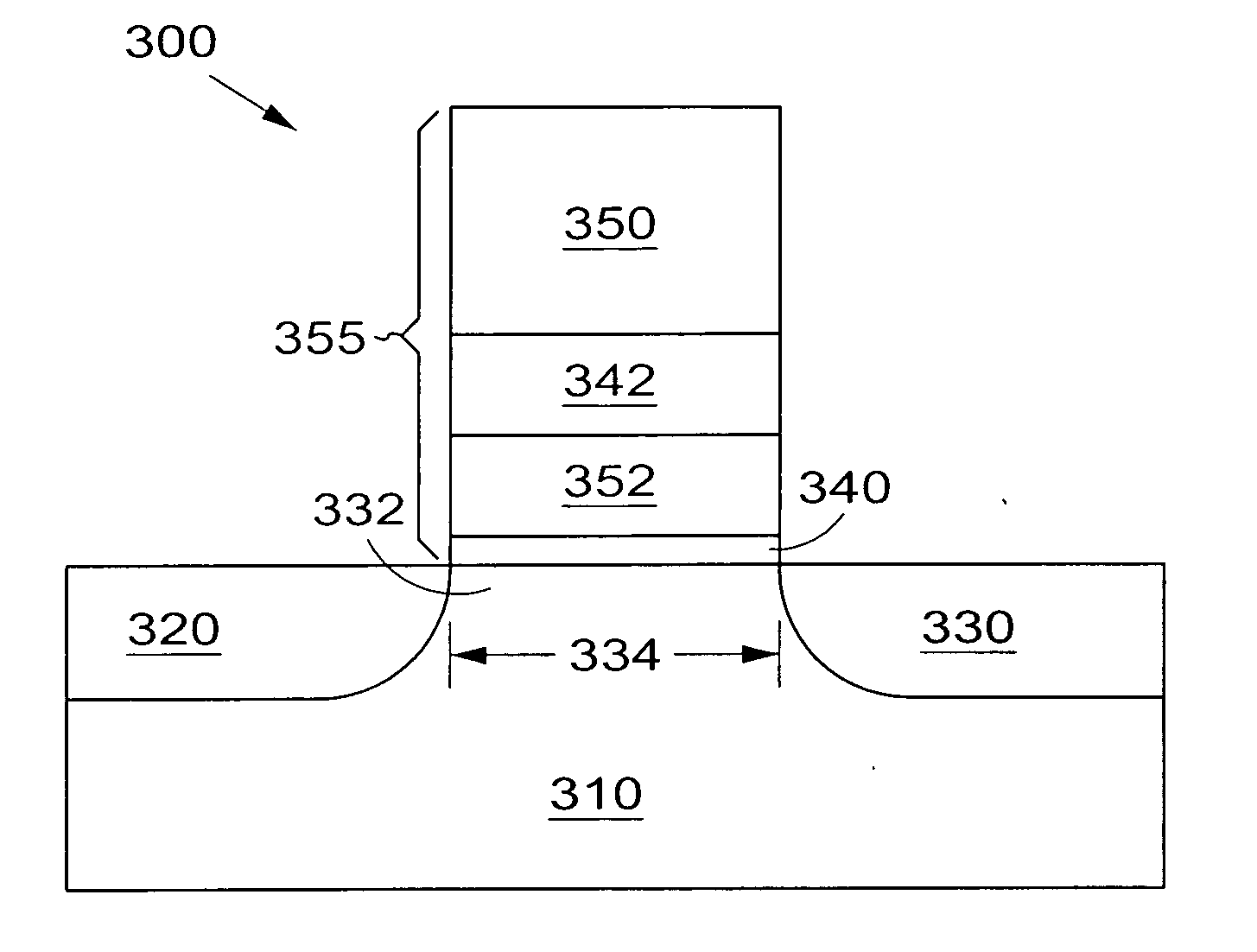

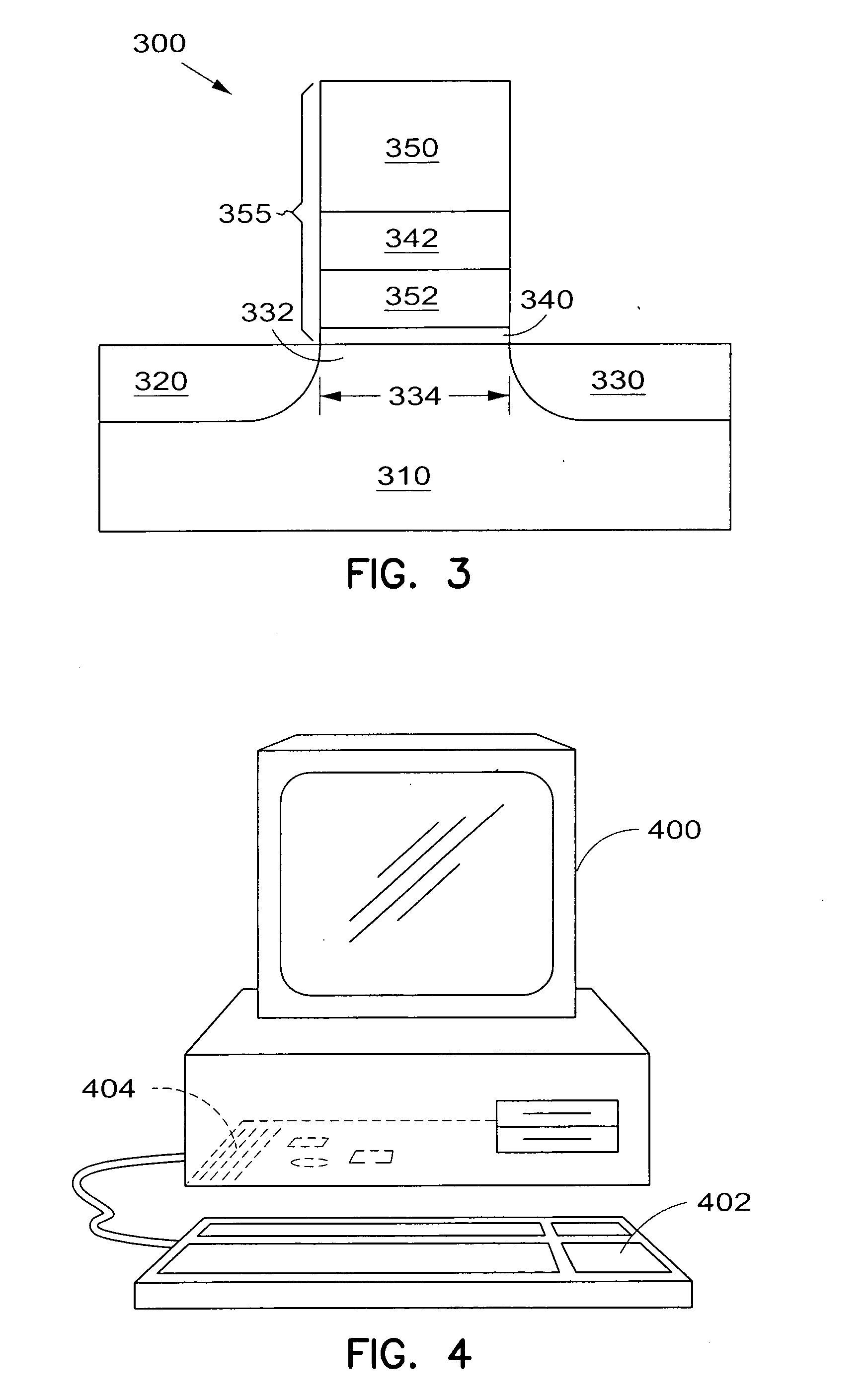

Evaporated LaAlO3 films for gate dielectrics

InactiveUS20050145957A1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricEquivalent oxide thickness

A gate dielectric containing LaAlO3 and method of fabricating a gate dielectric contained LaAlO3 produce a reliable gate dielectric having a thinner equivalent oxide thickness than attainable using SiO2. The LaAlO3 gate dielectrics formed are thermodynamically stable such that these gate dielectrics will have minimal reactions with a silicon substrate or other structures during processing. A LaAlO3 gate dielectric is formed by evaporating Al2O3 at a given rate, evaporating La2O3 at another rate, and controlling the two rates to provide an amorphous film containing LaAlO3 on a transistor body region. The evaporation deposition of the LaAlO3 film is performed using two electron guns to evaporate dry pellets of Al2O3 and La2O3. The two rates for evaporating the materials are selectively chosen to provide a dielectric film composition having a predetermined dielectric constant ranging from the dielectric constant of an Al2O3 film to the dielectric constant of a La2O3 film. In addition to forming a LaAlO3 gate dielectric for a transistor, memory devices, and information handling devices such as computers include elements having a LaAlO3 gate electric with a thin equivalent oxide thickness.

Owner:MICRON TECH INC

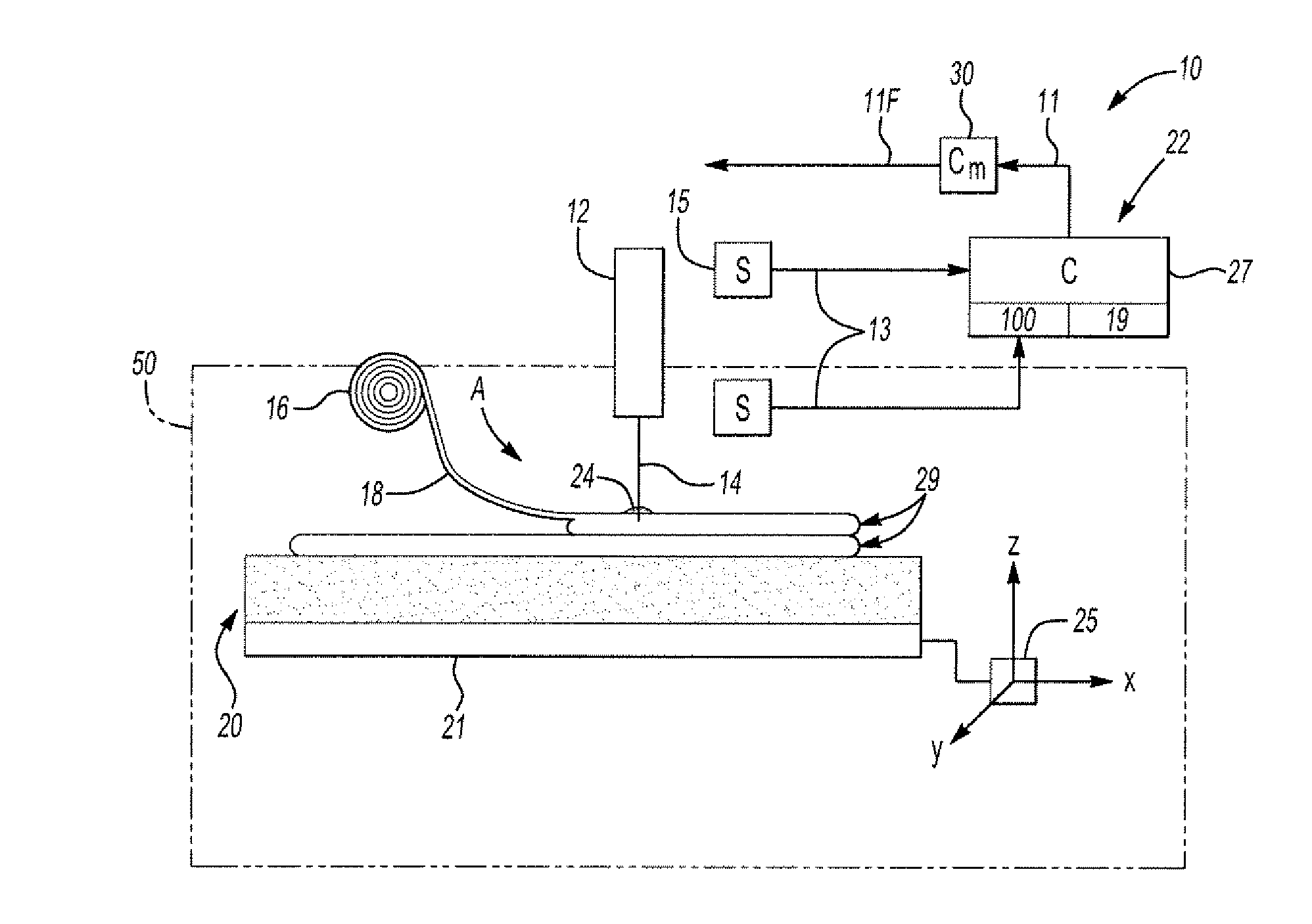

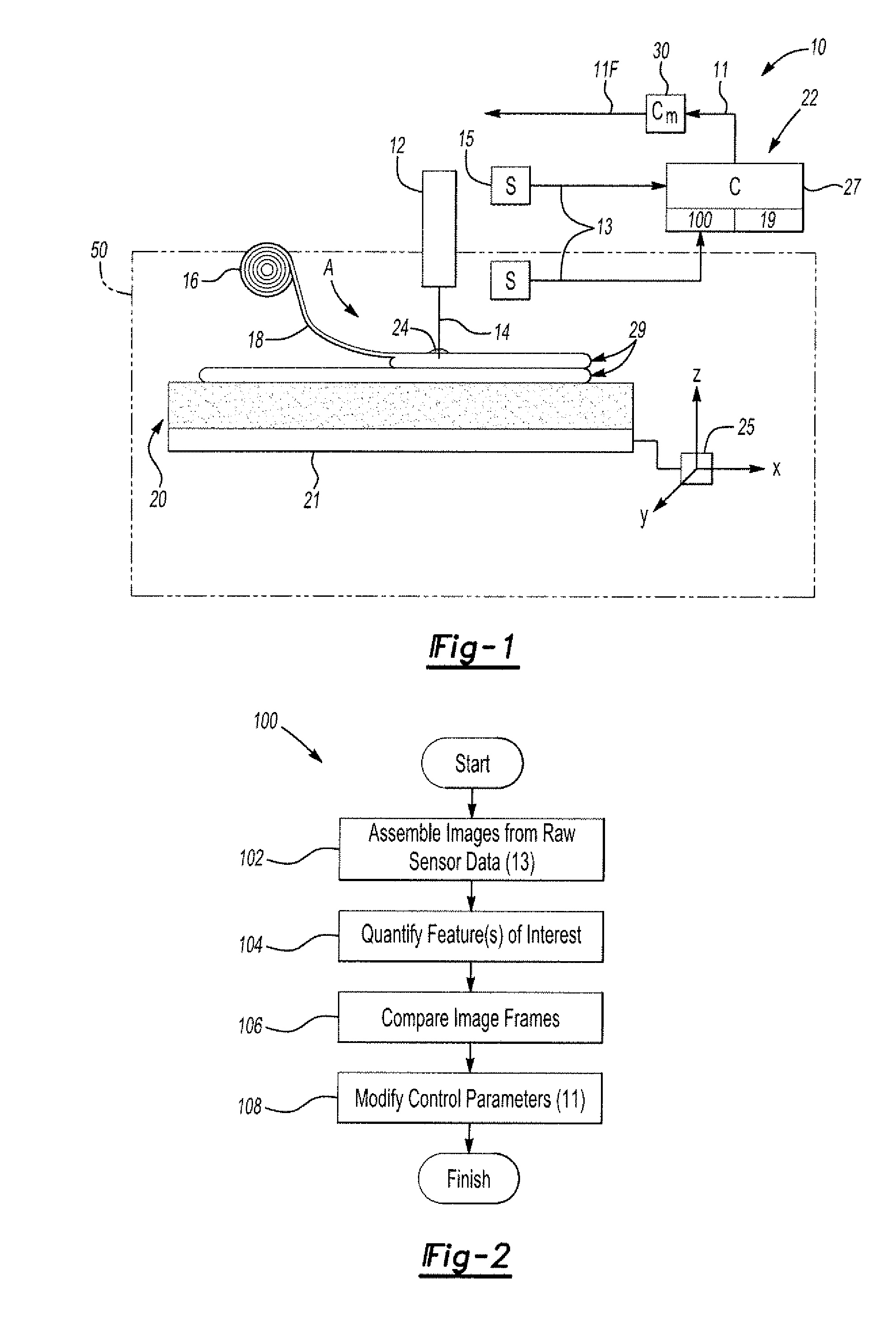

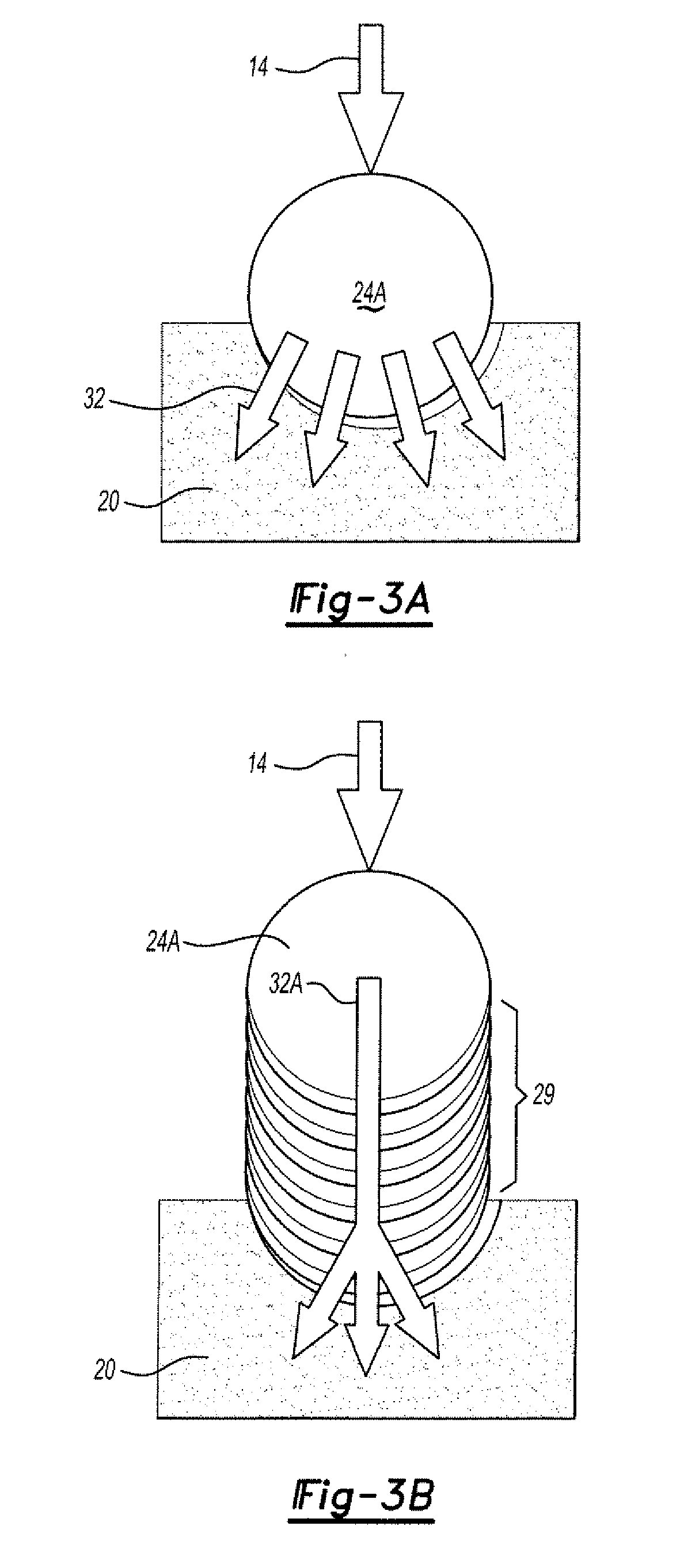

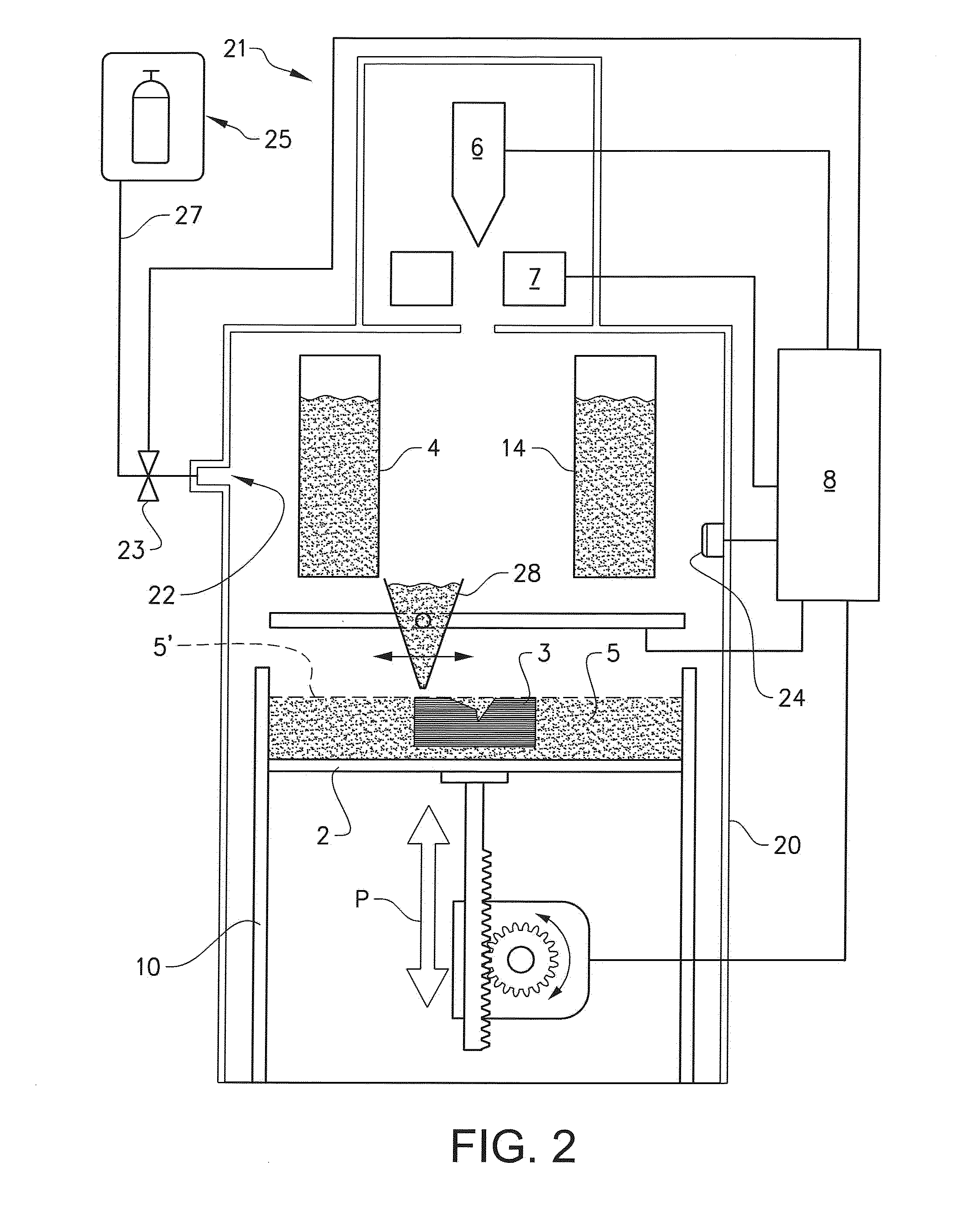

Closed-Loop Process Control for Electron Beam Freeform Fabrication and Deposition Processes

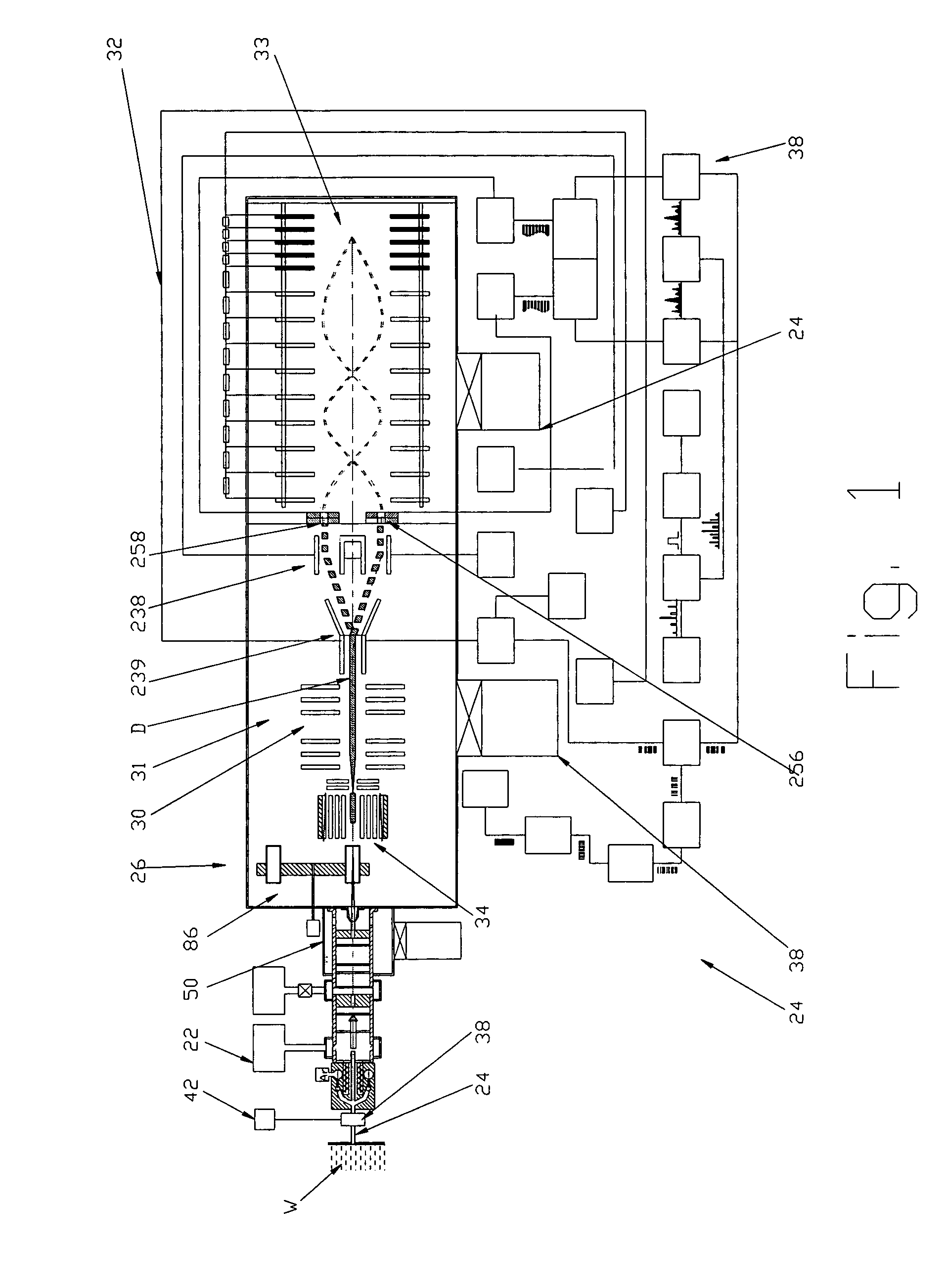

InactiveUS20100260410A1Electric discharge tubesCharacter and pattern recognitionClosed loopEngineering

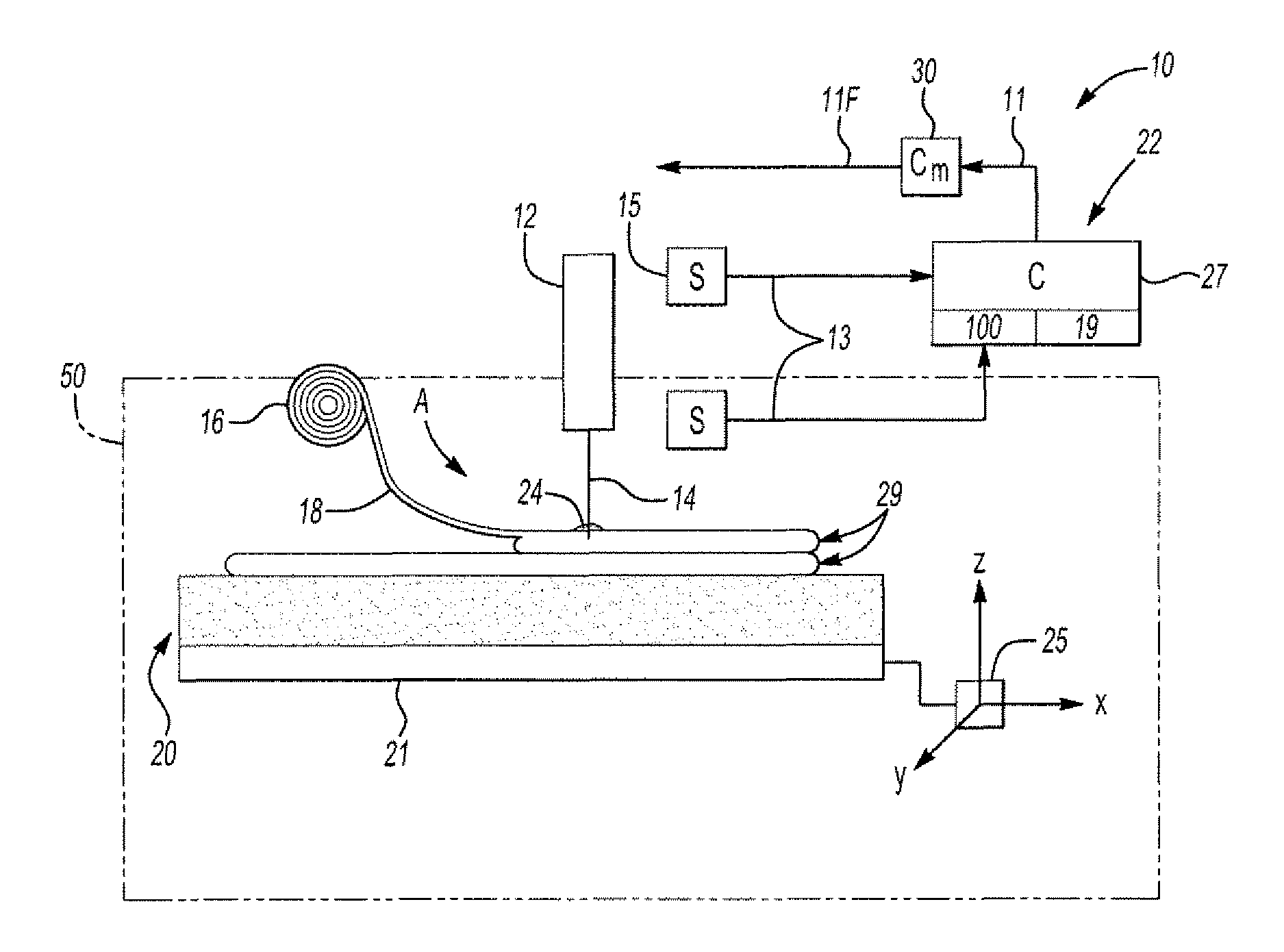

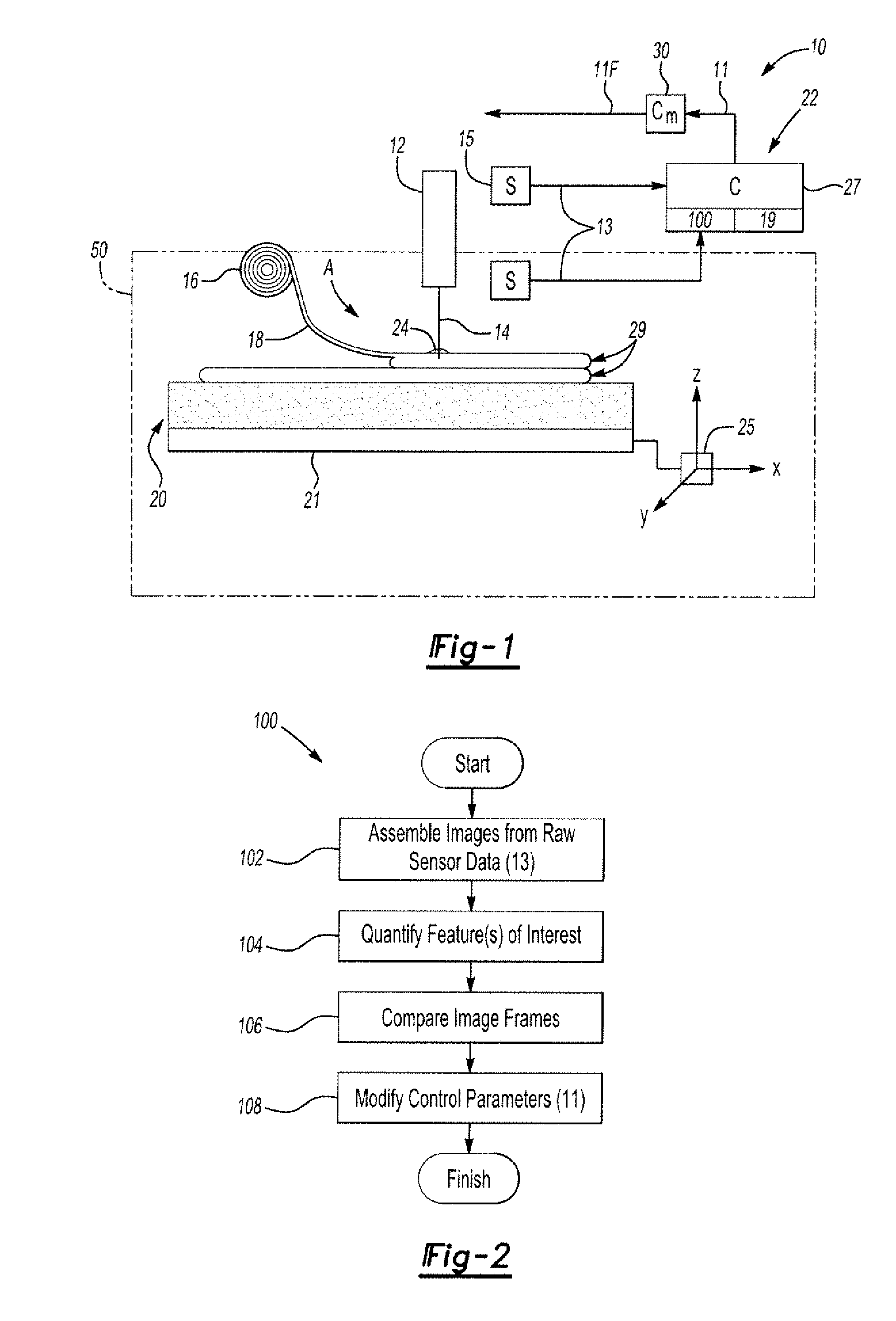

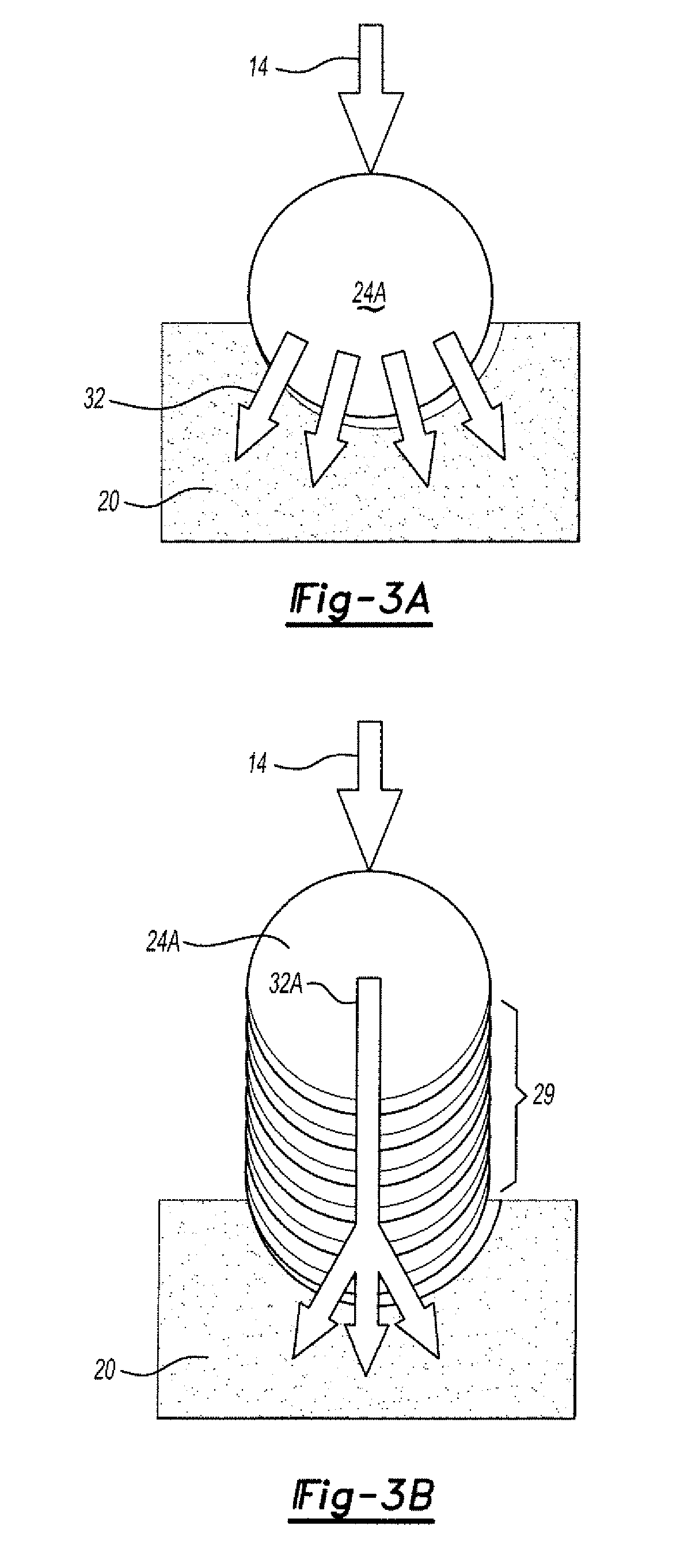

A closed-loop control method for an electron beam freeform fabrication (EBF3) process includes detecting a feature of interest during the process using a sensor(s), continuously evaluating the feature of interest to determine, in real time, a change occurring therein, and automatically modifying control parameters to control the EBF3 process. An apparatus provides closed-loop control method of the process, and includes an electron gun for generating an electron beam, a wire feeder for feeding a wire toward a substrate, wherein the wire is melted and progressively deposited in layers onto the substrate, a sensor(s), and a host machine. The sensor(s) measure the feature of interest during the process, and the host machine continuously evaluates the feature of interest to determine, in real time, a change occurring therein. The host machine automatically modifies control parameters to the EBF3 apparatus to control the EBF3 process in a closed-loop manner.

Owner:NASA

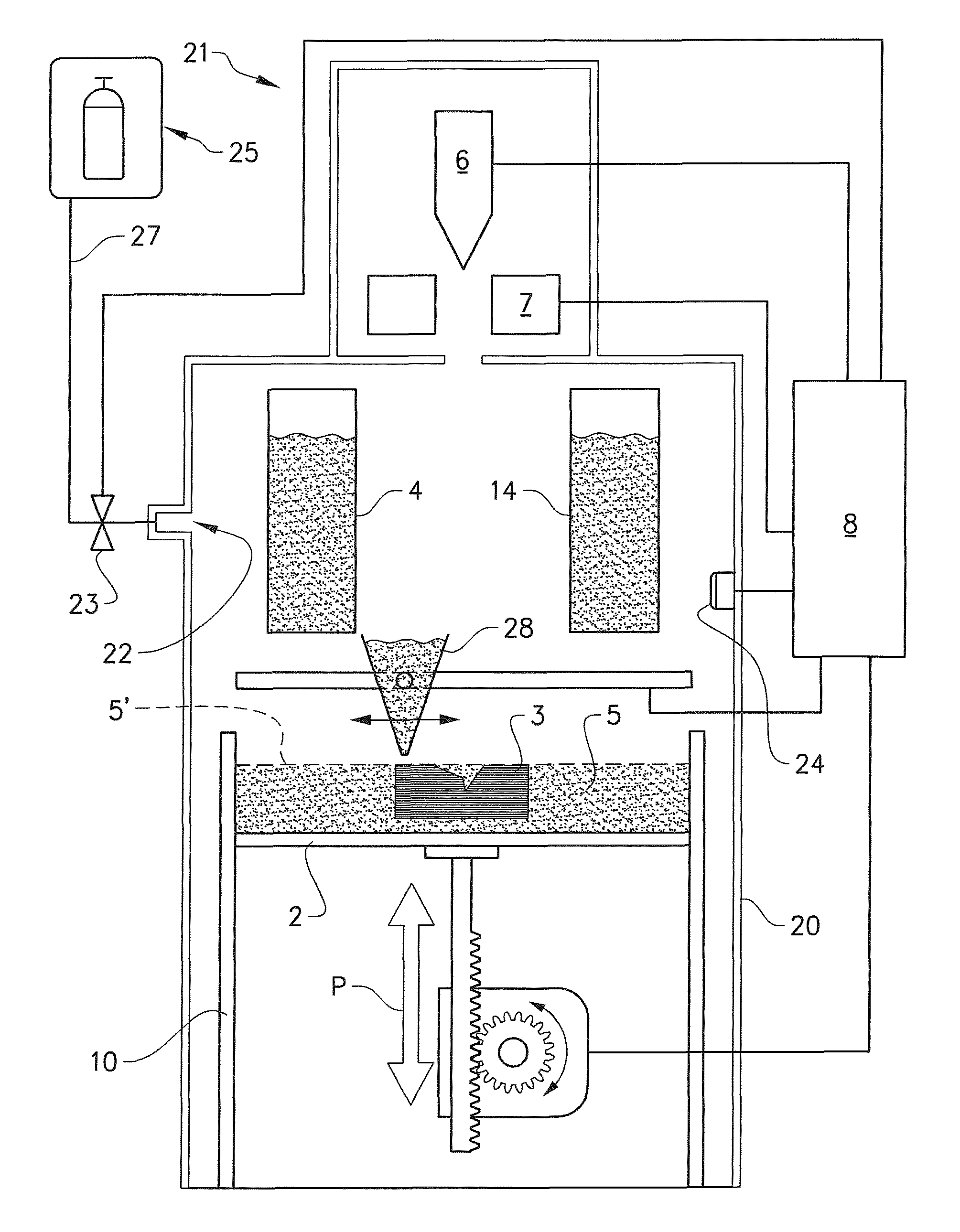

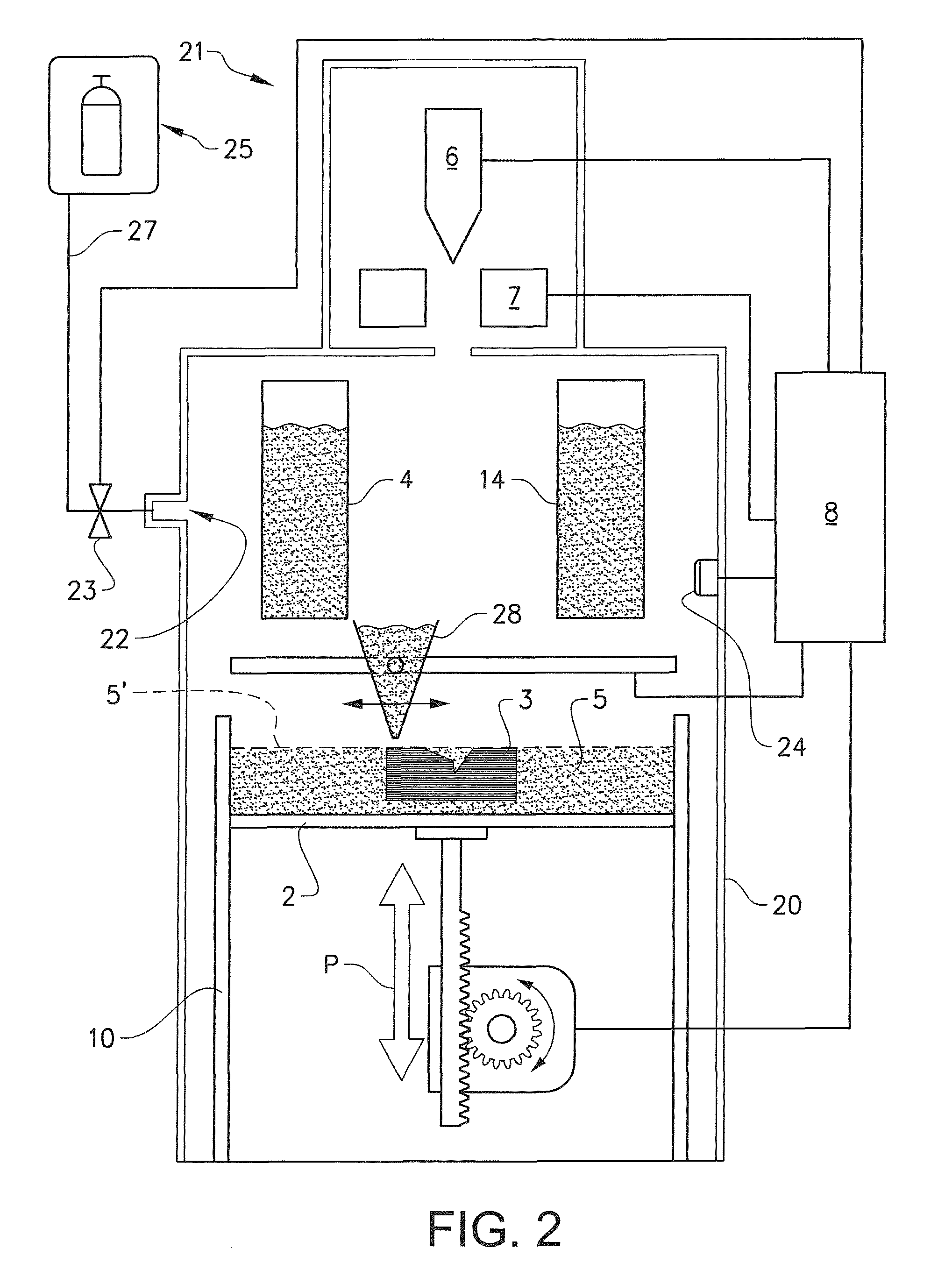

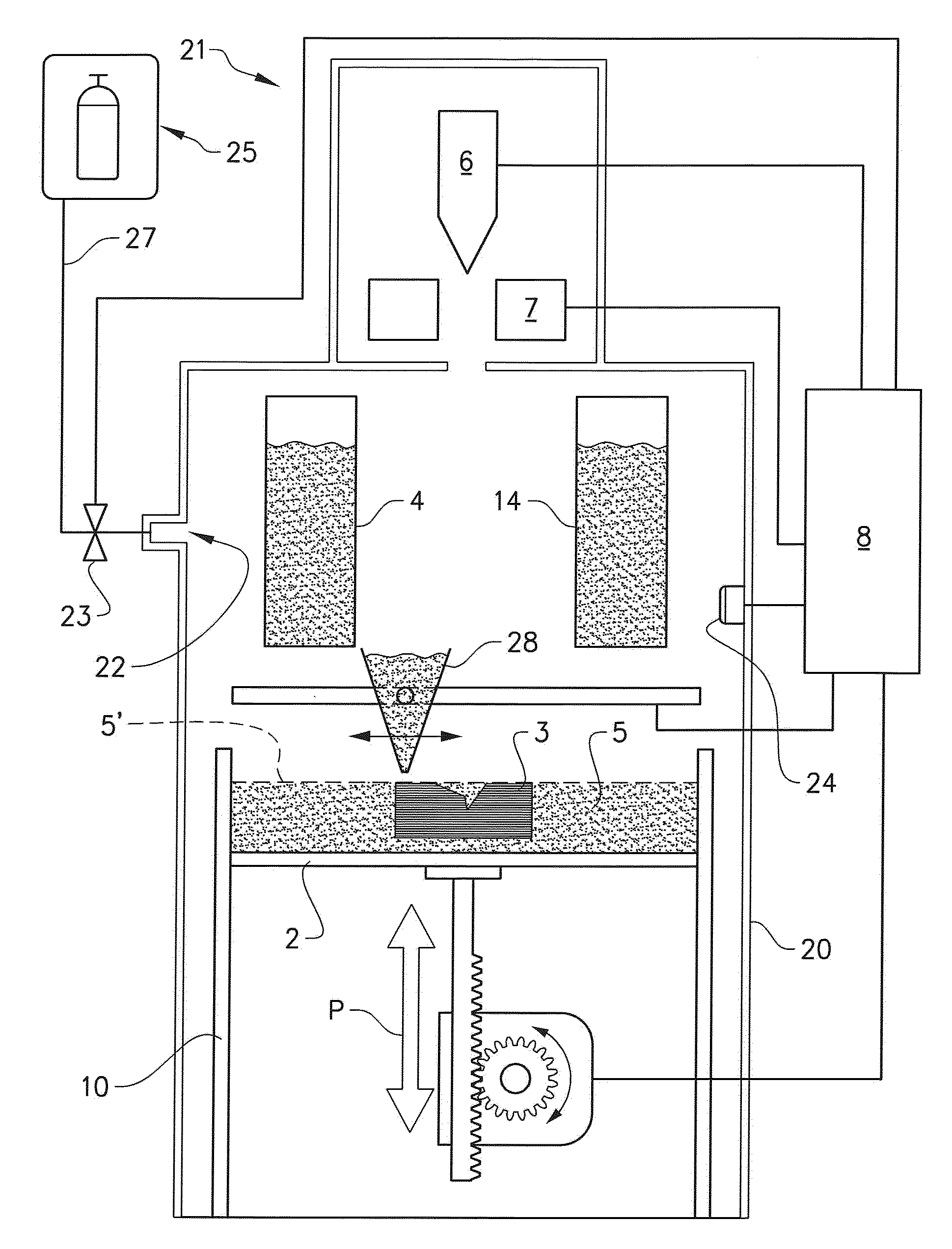

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

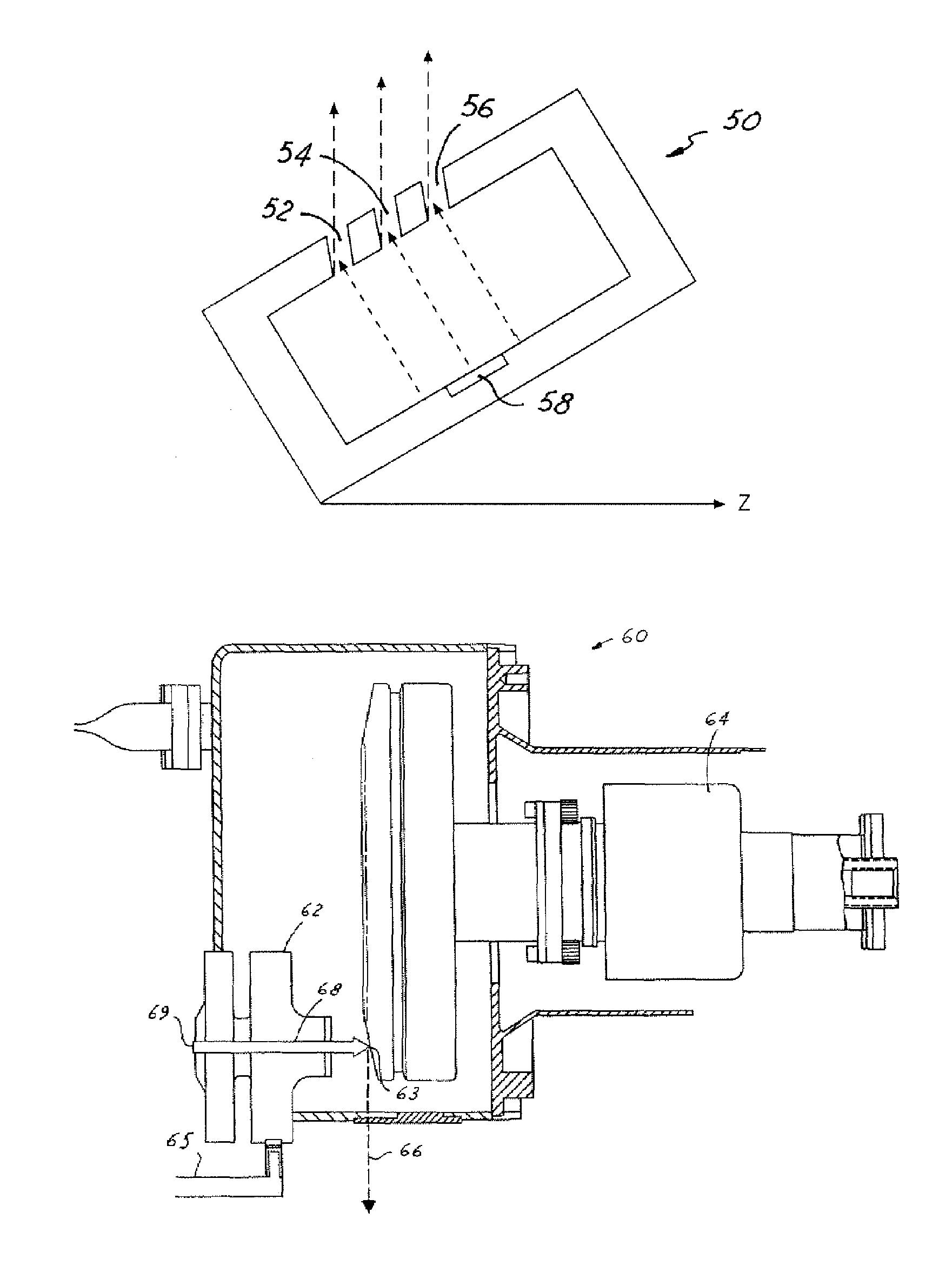

ActiveUS20140370323A1High pressure levelHigh beam qualityAdditive manufacturing apparatusIncreasing energy efficiencyImage resolutionVacuum chamber

A method for increasing the resolution when forming a three-dimensional article through successive fusion of parts of a powder bed, said method comprising providing a vacuum chamber, providing an electron gun, providing a first powder layer on a work table inside said vacuum chamber, directing an electron beam from said electron gun over said work table causing the powder layer to fuse in selected locations to form a first cross section of said three-dimensional article, providing a second powder layer on said work table, directing the electron beam over said work table causing said second powder layer to fuse in selected locations to form a second cross section of said three-dimensional article, reducing the pressure in the vacuum chamber from a first pressure level to a second pressure level between the providing of said first powder layer and said second powder layer.

Owner:ARCAM AB

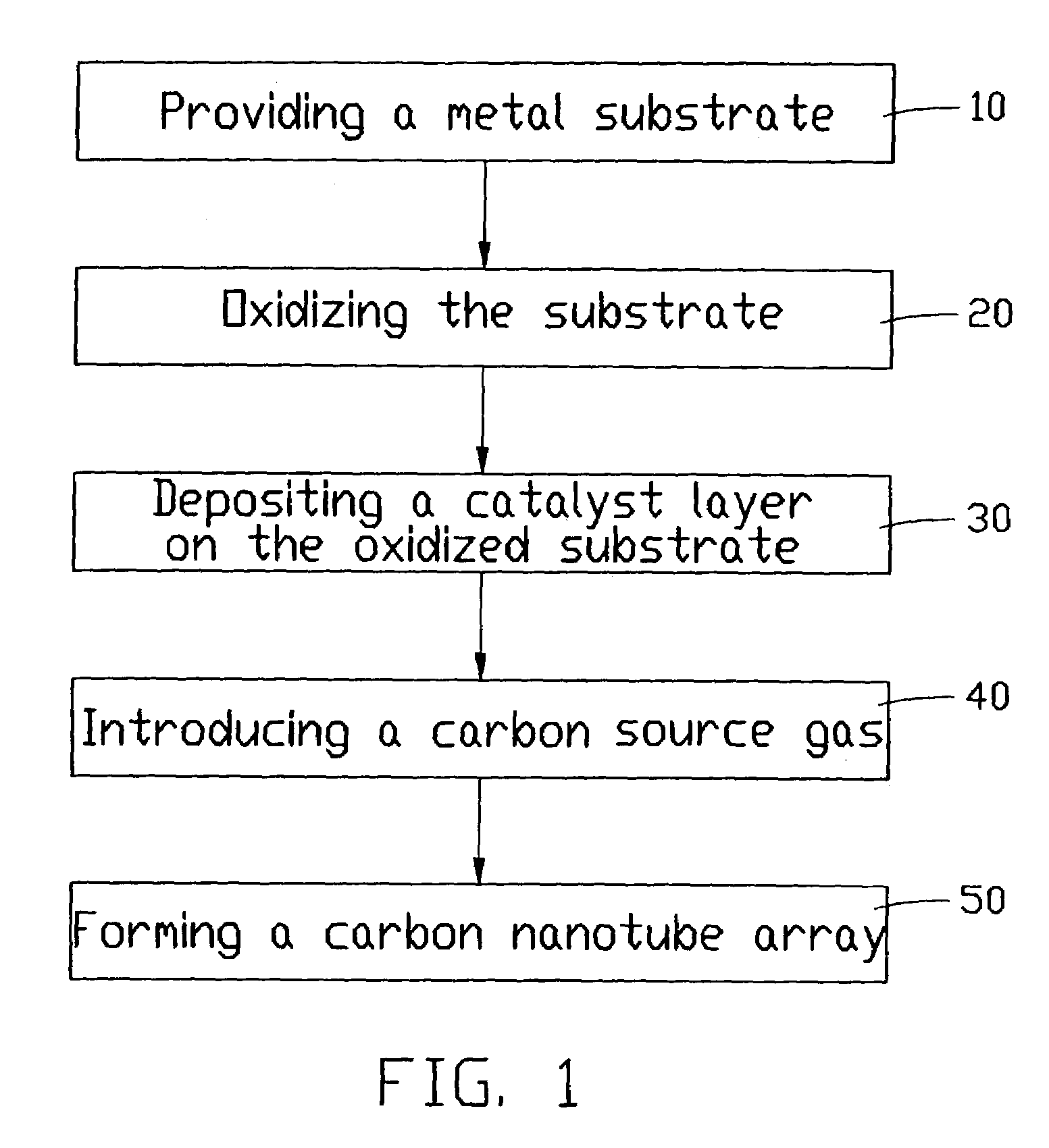

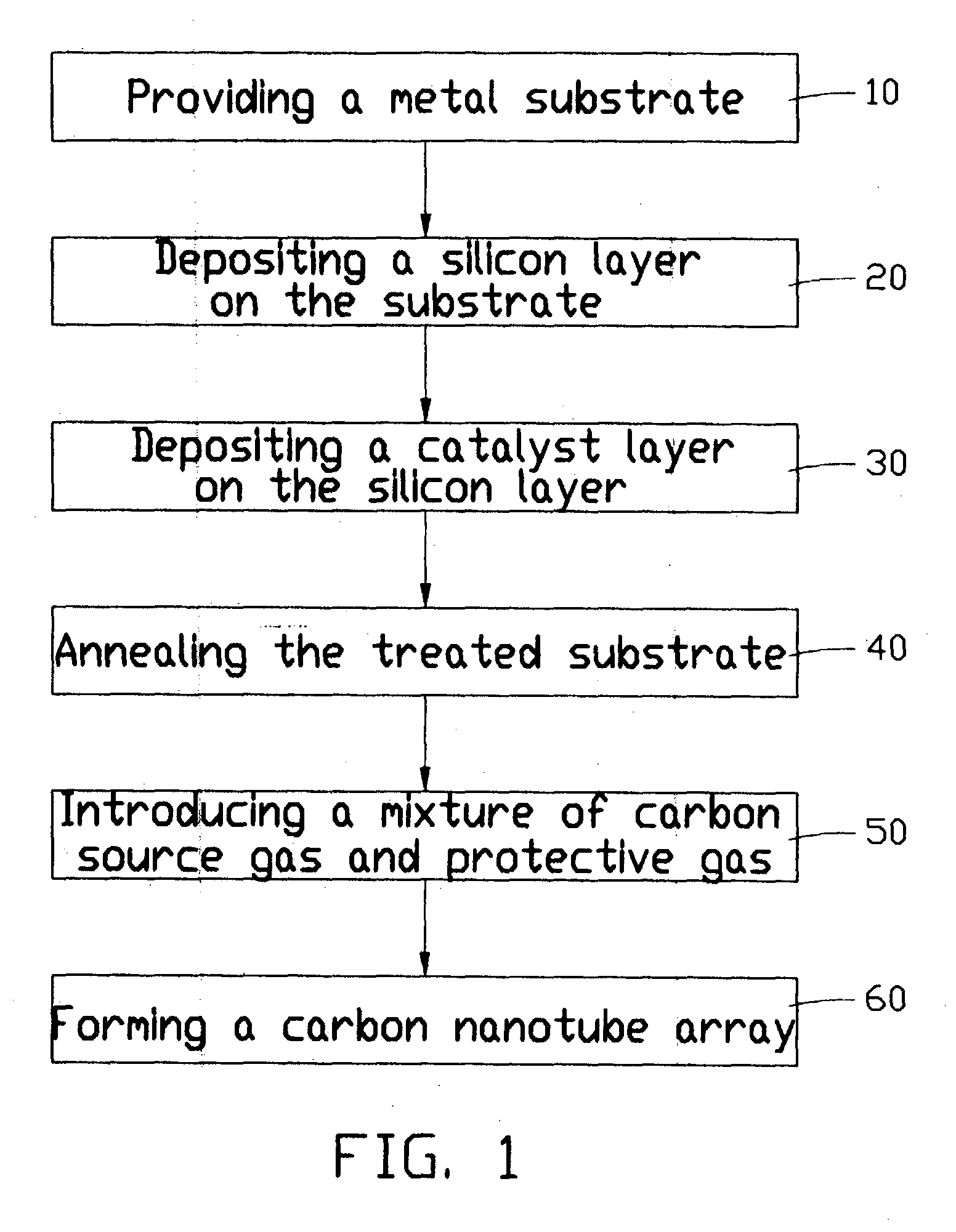

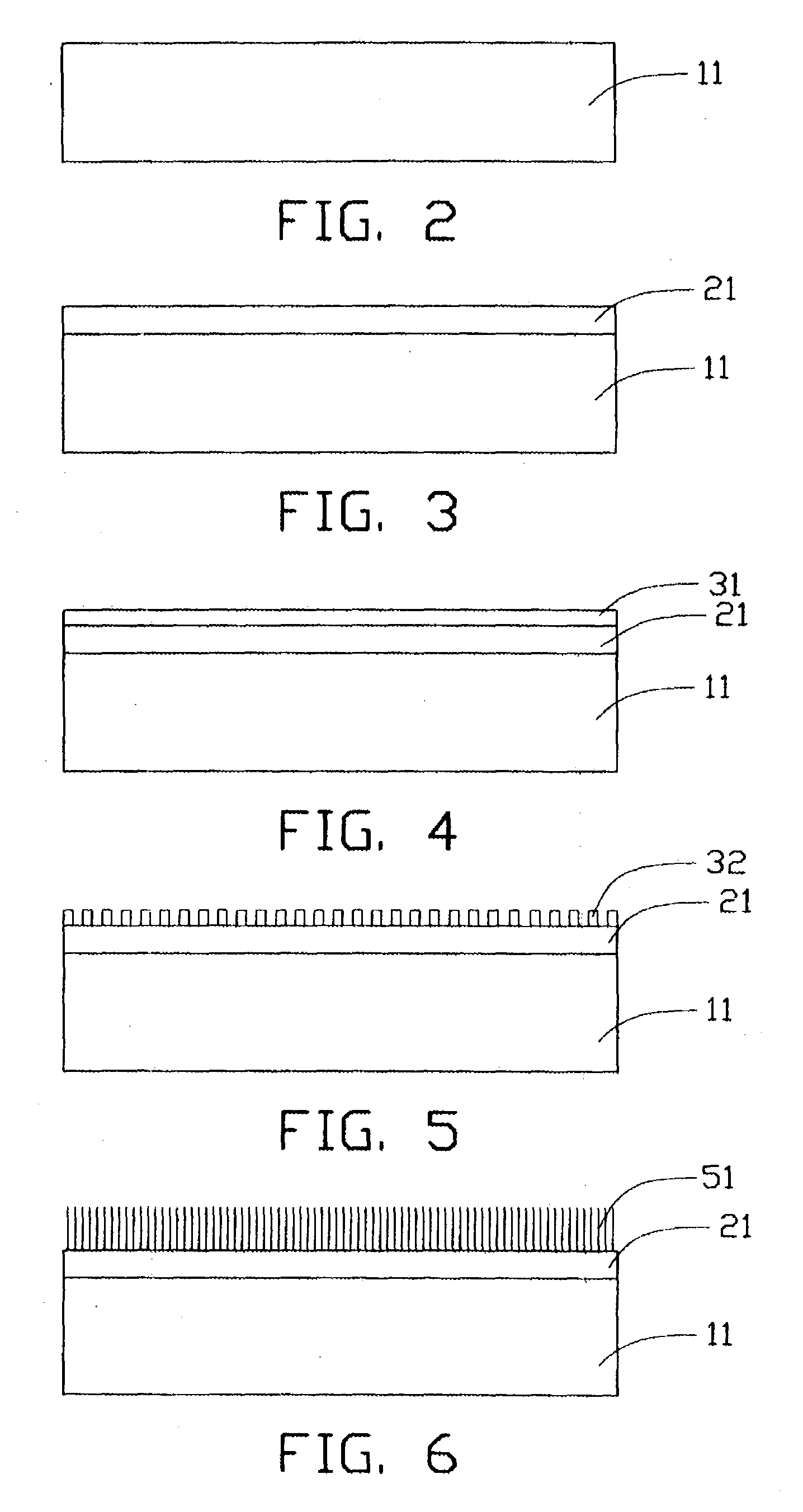

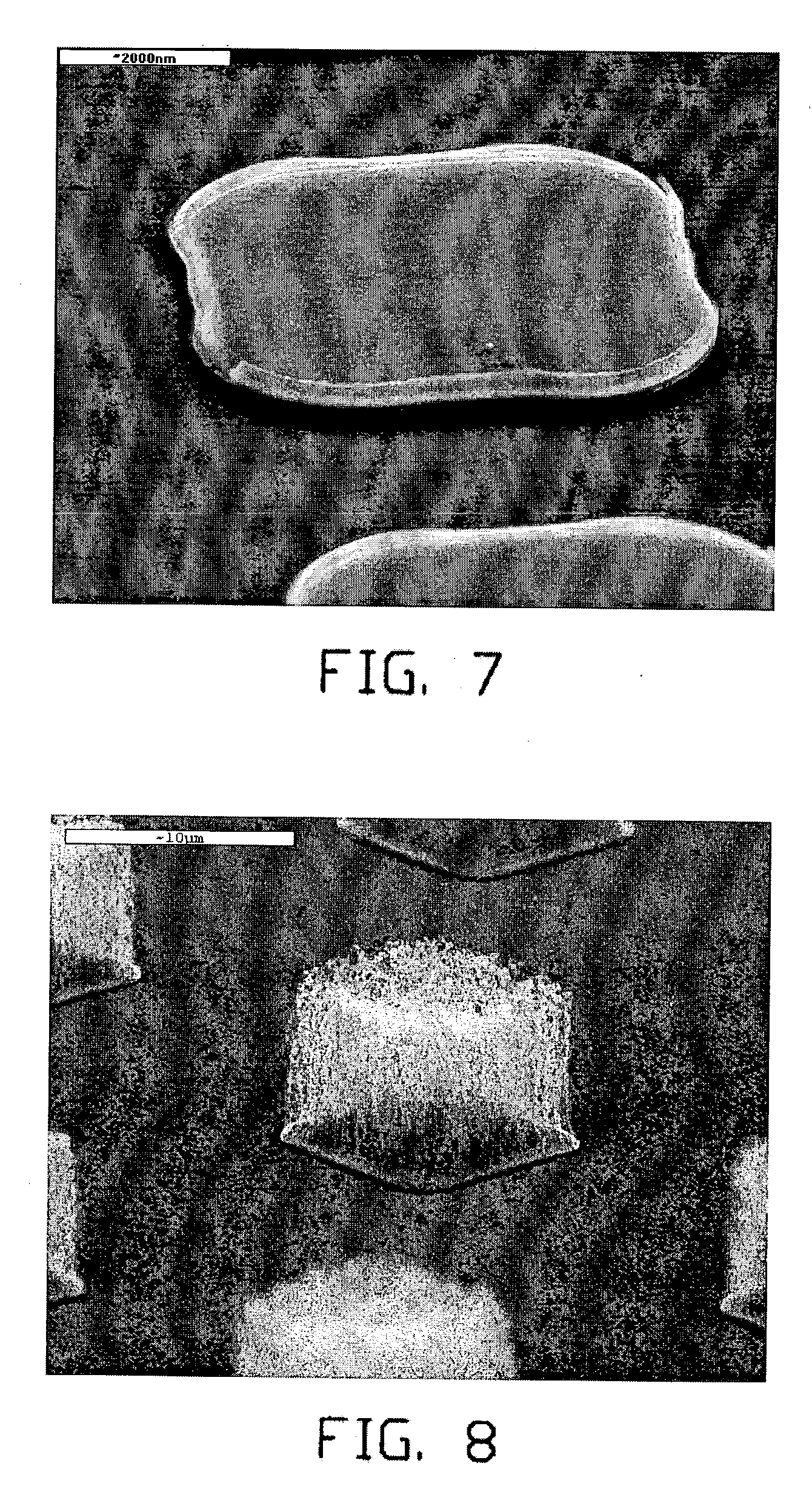

Carbon nanotube array and method for forming same

ActiveUS20040101468A1Damage formationInhibition formationMaterial nanotechnologyLayered productsField emission deviceMetallic materials

A method for forming a carbon nanotube array on a metal substrate includes the following steps: providing a metal substrate (11); depositing a silicon layer (21) on a surface of the metal substrate; depositing a catalyst layer (31) on the silicon layer; annealing the treated substrate; heating the treated substrate up to a predetermined temperature in flowing protective gas; introducing a carbon source gas for 5-30 minutes; and thus forming a carbon nanotube array (51) extending from the treated substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

Closed-loop process control for electron beam freeform fabrication and deposition processes

A closed-loop control method for an electron beam freeform fabrication (EBF3) process includes detecting a feature of interest during the process using a sensor(s), continuously evaluating the feature of interest to determine, in real time, a change occurring therein, and automatically modifying control parameters to control the EBF3 process. An apparatus provides closed-loop control method of the process, and includes an electron gun for generating an electron beam, a wire feeder for feeding a wire toward a substrate, wherein the wire is melted and progressively deposited in layers onto the substrate, a sensor(s), and a host machine. The sensor(s) measure the feature of interest during the process, and the host machine continuously evaluates the feature of interest to determine, in real time, a change occurring therein. The host machine automatically modifies control parameters to the EBF3 apparatus to control the EBF3 process in a closed-loop manner.

Owner:NASA

Charged particle beam apparatus

InactiveUS20060231773A1Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsGetterFree space

A small-sized charged particle beam apparatus capable of maintaining high vacuum even during emission of an electron beam is provided. A nonevaporative getter pump is placed upstream of differential pumping of an electron optical system of the charged particle beam apparatus, and a minimum number of ion pumps are placed downstream, so that both the pumps are used in combination. Further, by mounting a detachable coil on an electron gun part, the inside of a column can be maintained under high vacuum with a degree of vacuum in the order of 10−8 Pa.

Owner:HITACHI HIGH-TECH CORP

Carbon nanotube array and method for forming same

ActiveUS20040184981A1Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceMetallic materials

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

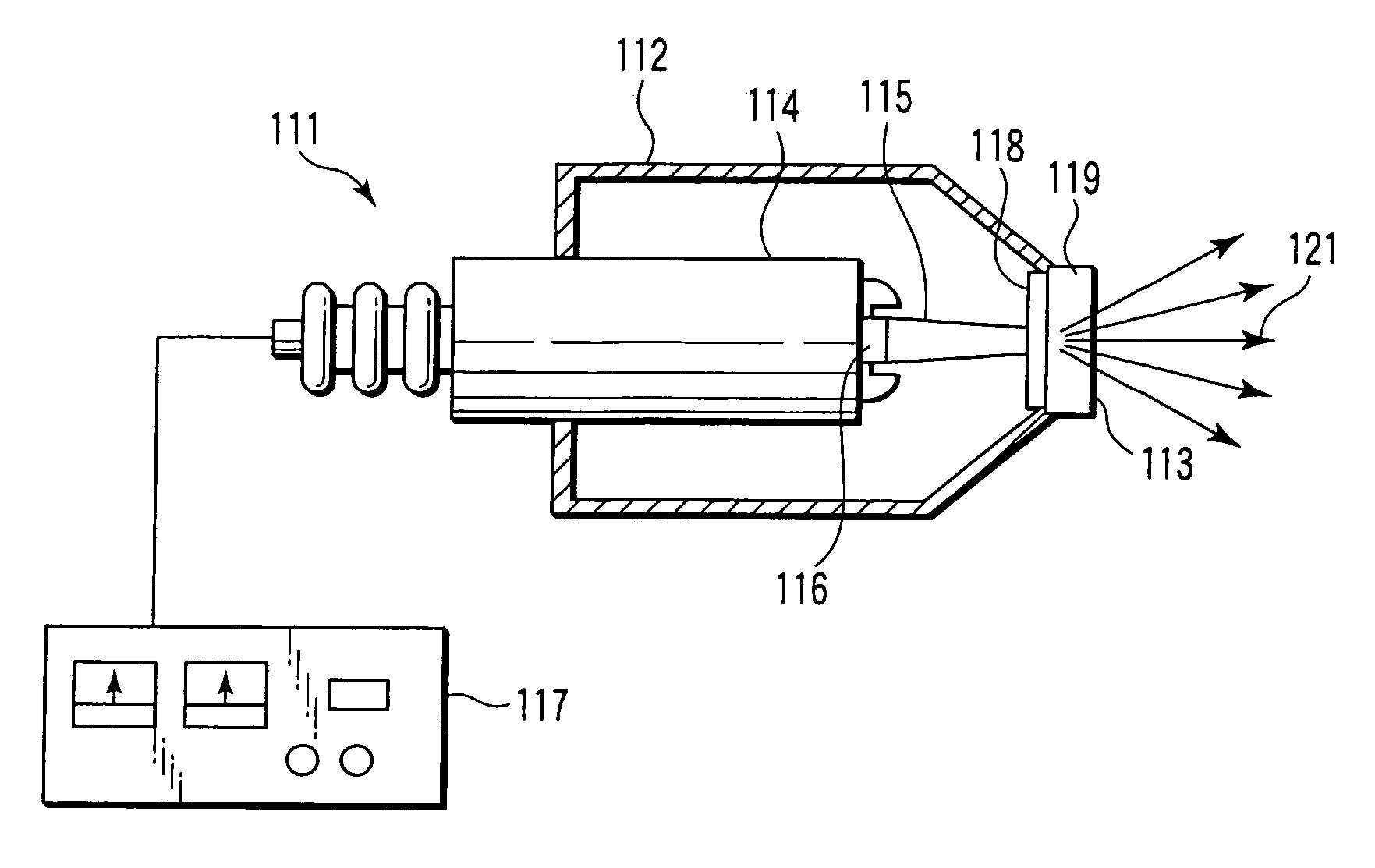

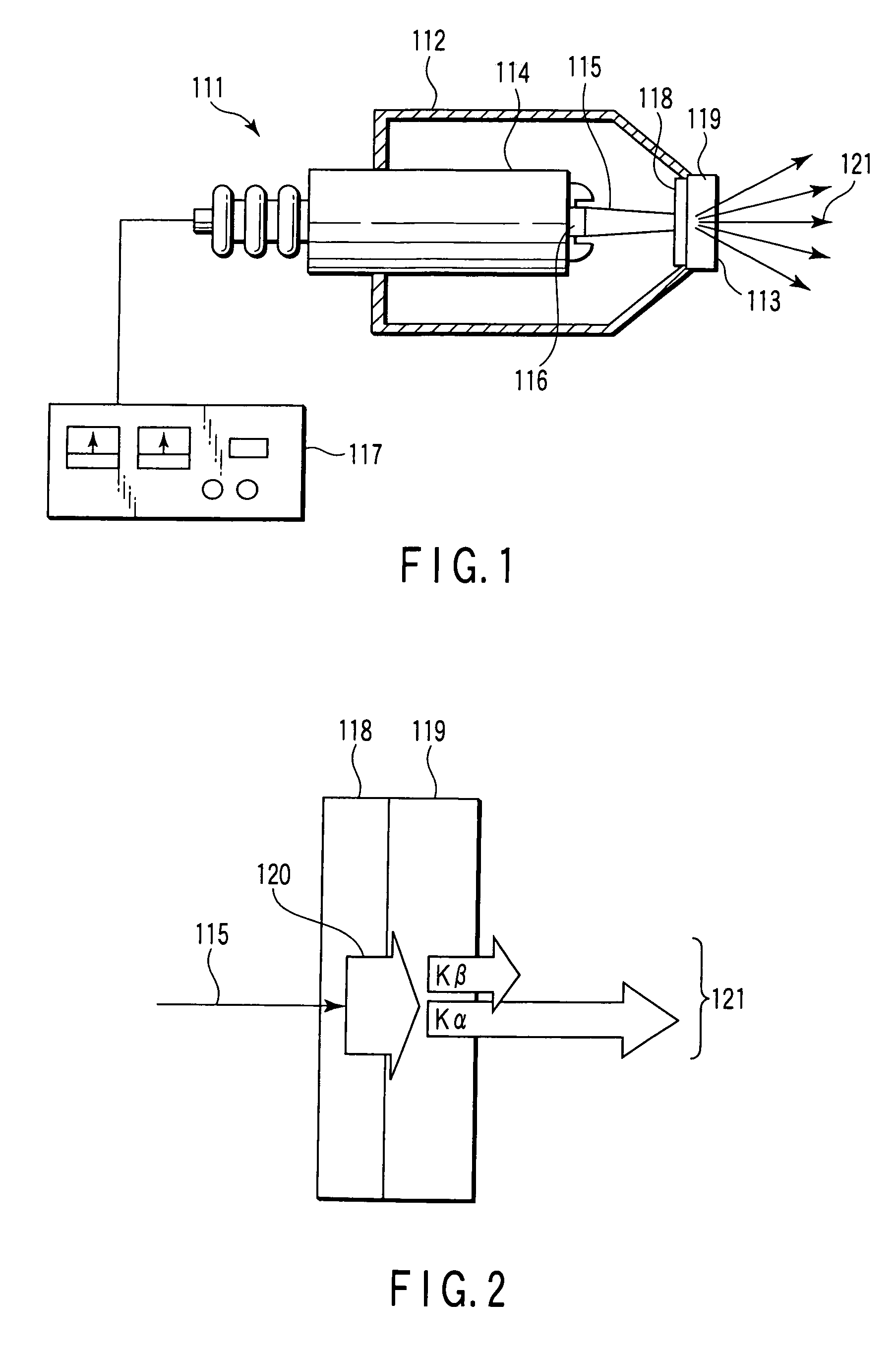

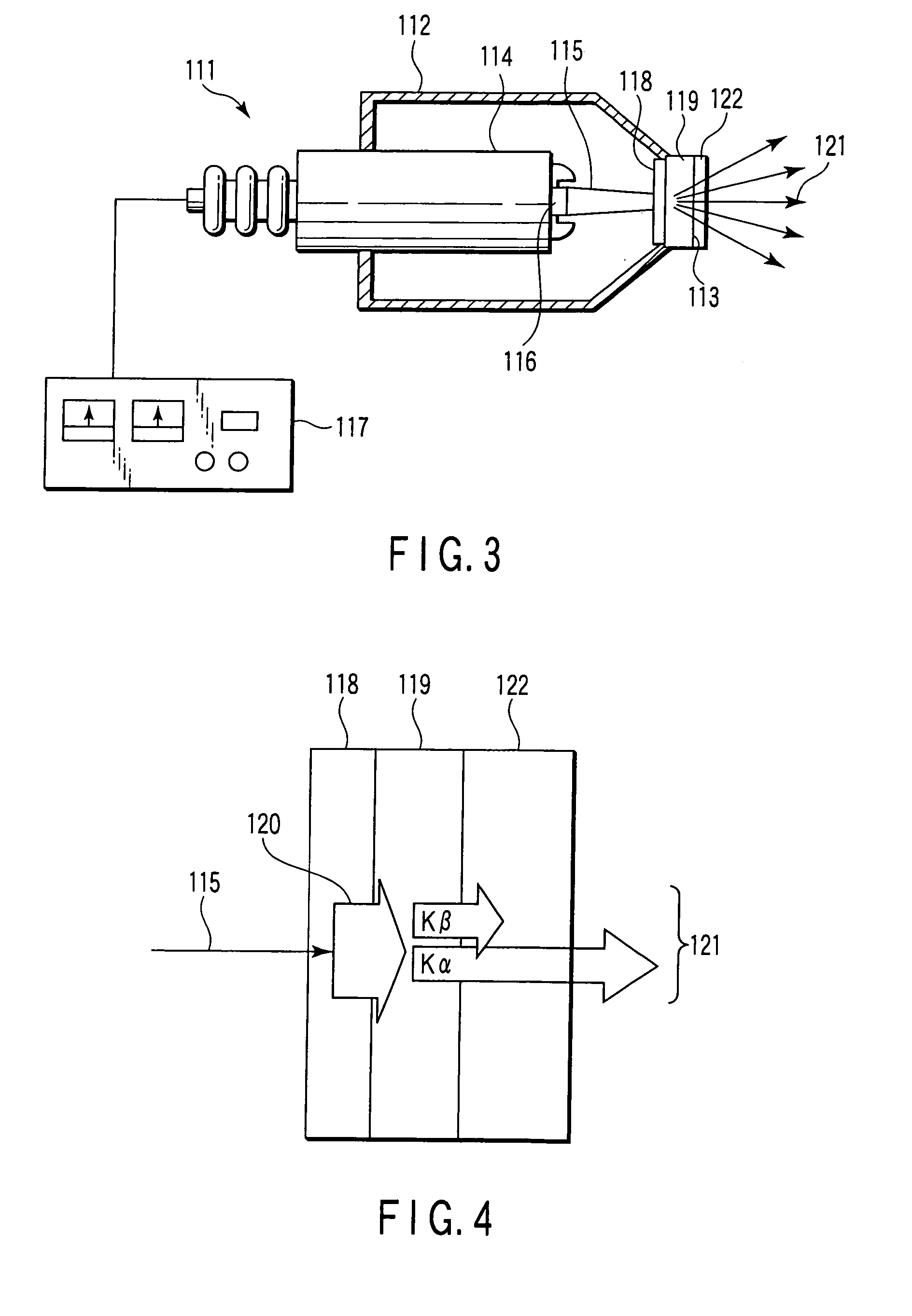

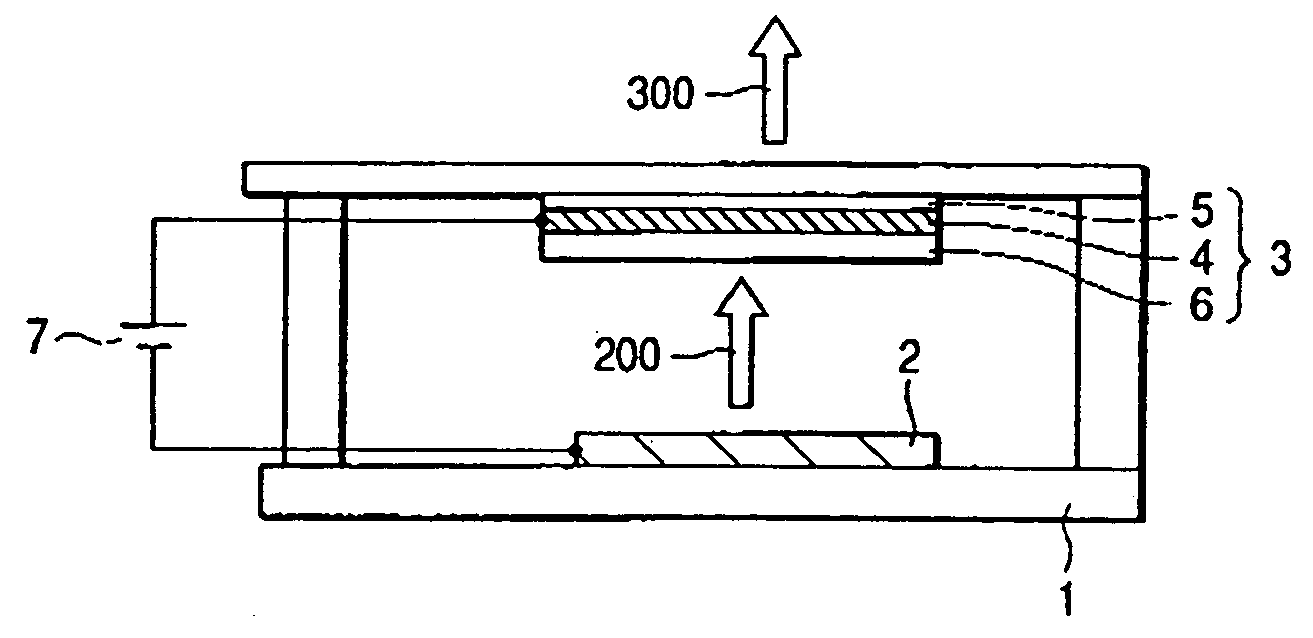

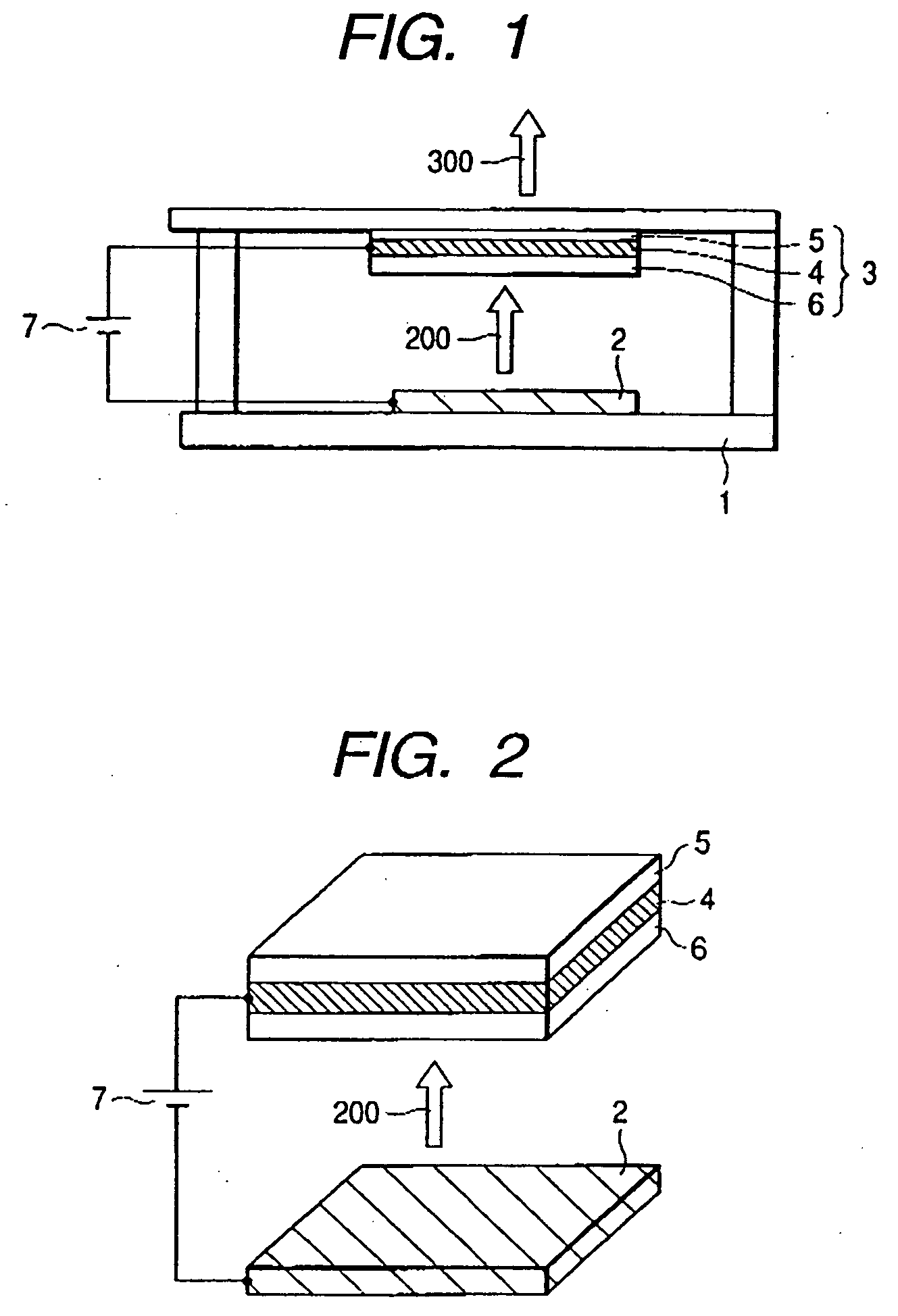

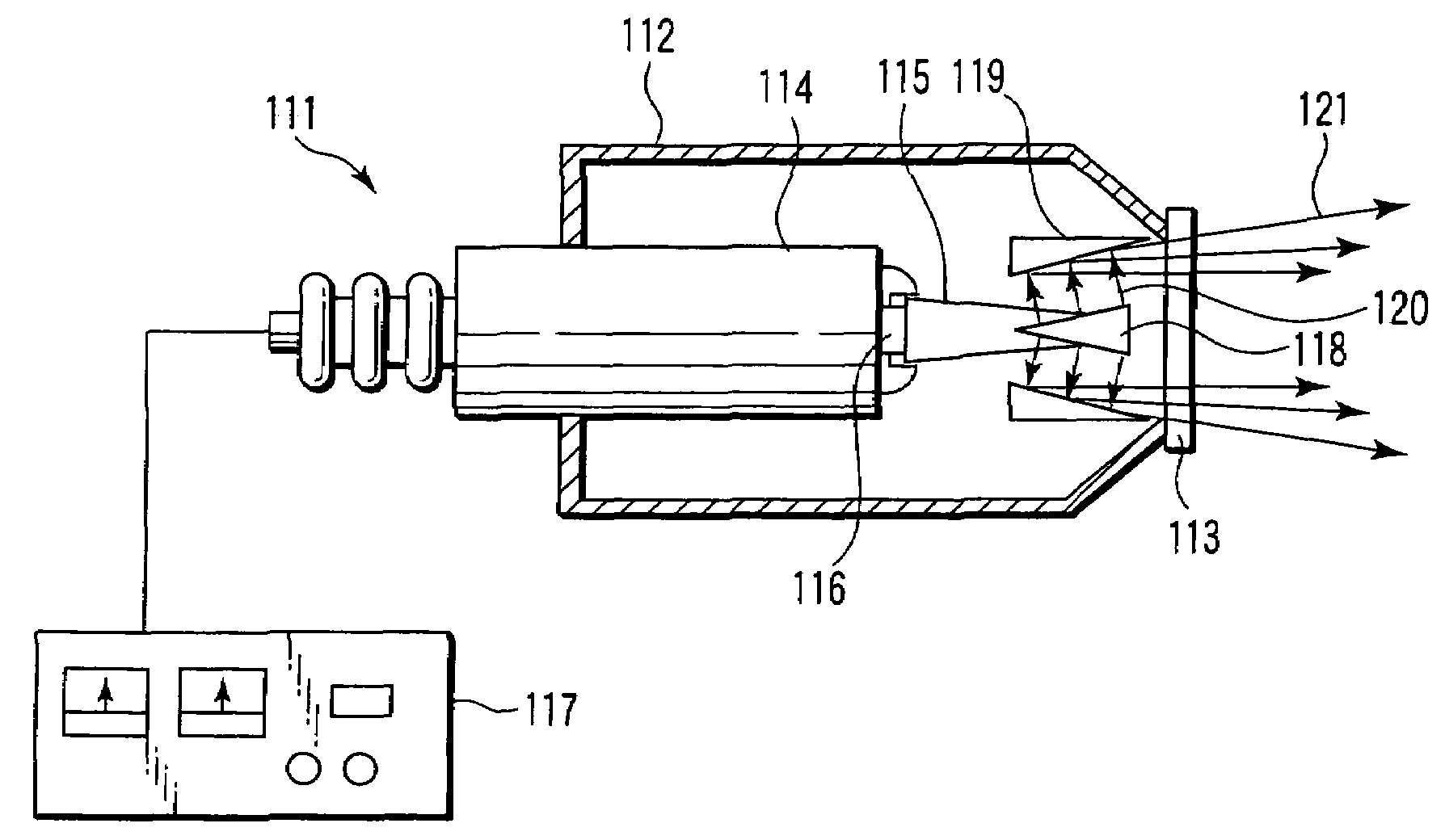

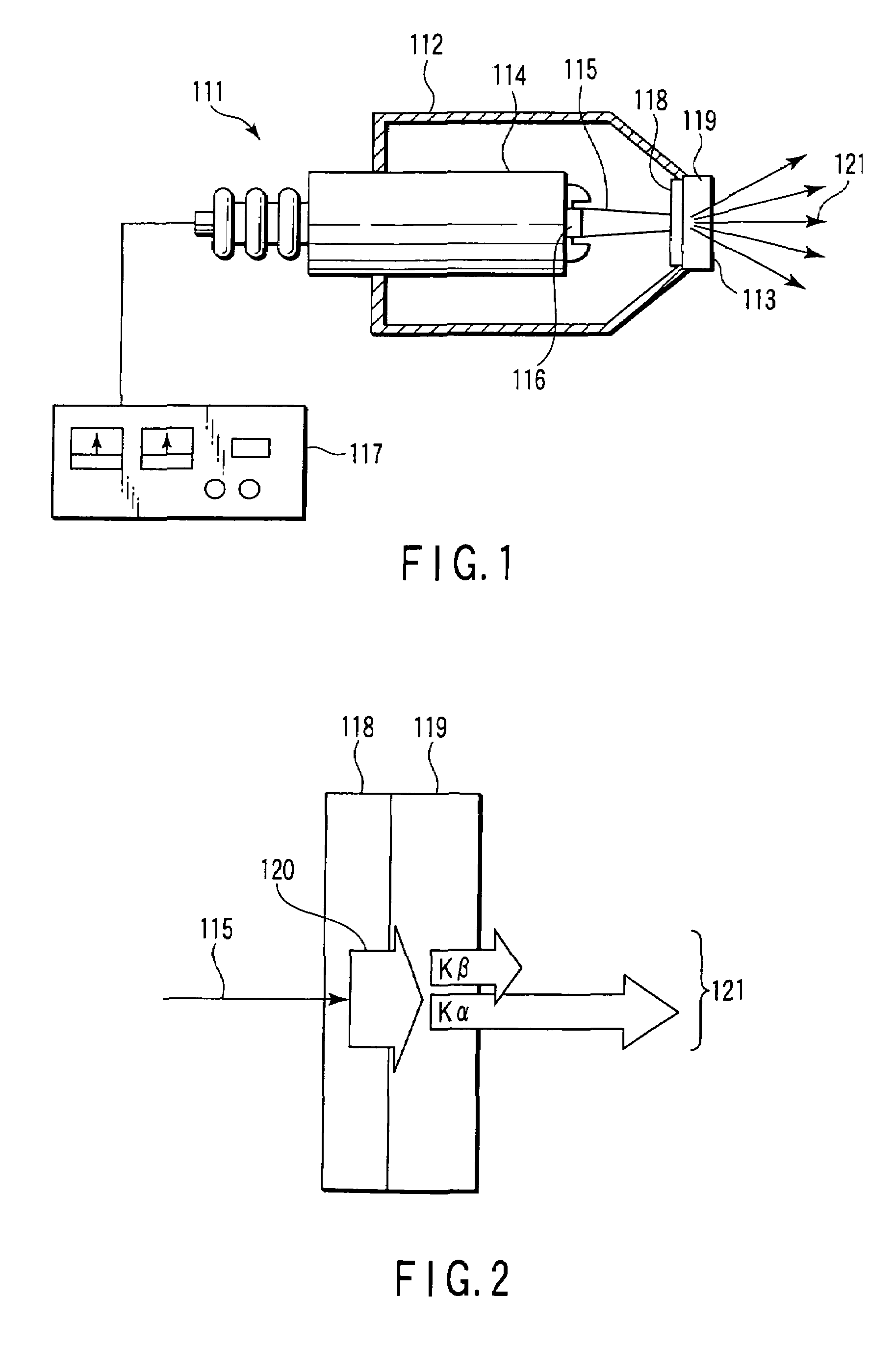

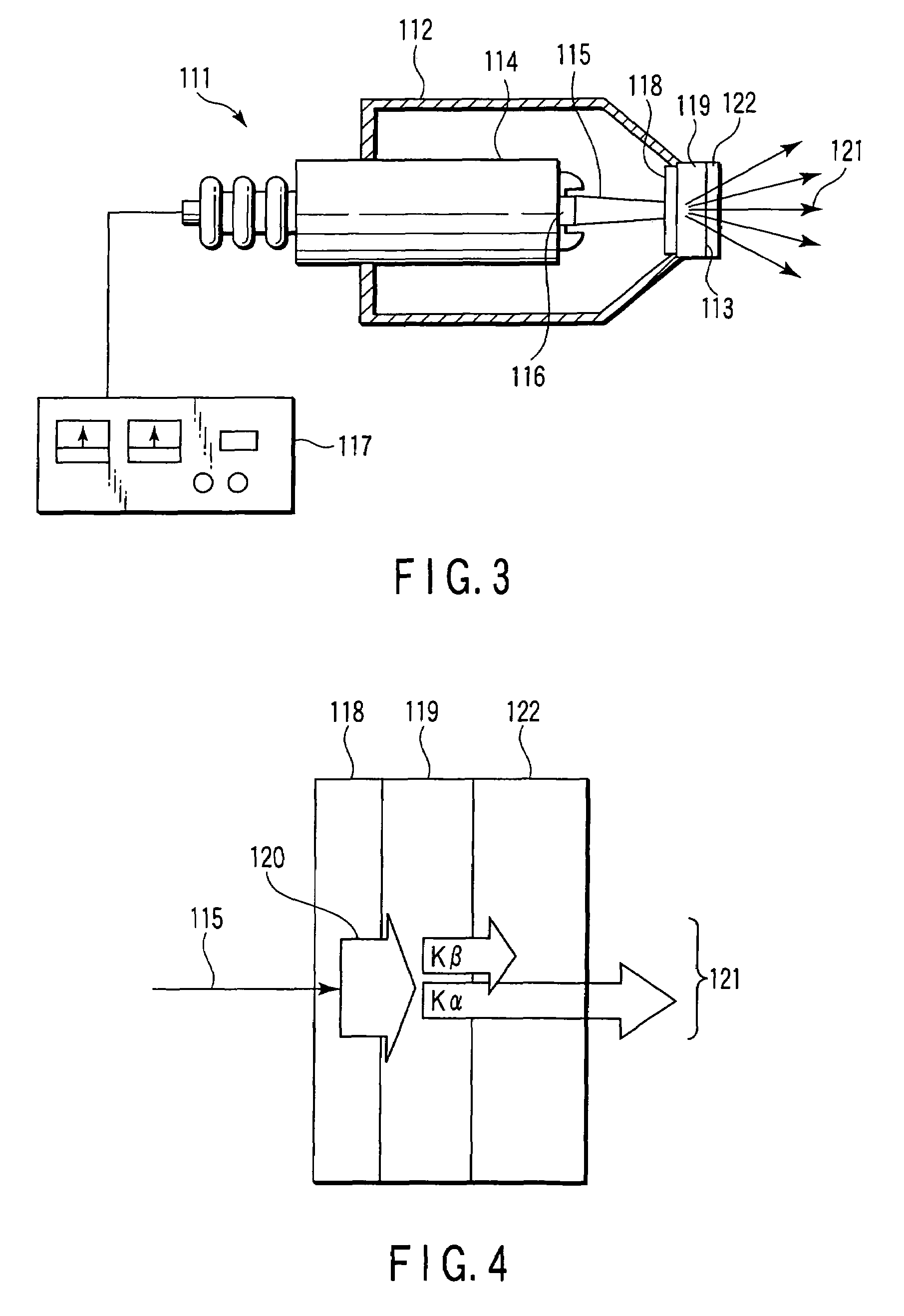

X-ray source and fluorescent X-ray analyzing apparatus

InactiveUS20080084966A1Eliminates unwanted noise componentGenerate efficientlyX-ray tube laminated targetsMaterial analysis using wave/particle radiationFluorescenceX-ray

The present invention relates to an X-ray source for emitting a characteristic X-ray and a fluorescent X-ray analyzing apparatus using the X-ray source. A secondary target is arranged in superposition on a primary target. An electron beam generated by an electron gun enters the primary target, which passes and emits a continuous X-ray. The secondary target transmits and emits a characteristic X-ray excited by the continuous X-ray emitted from the primary target. The primary target and the secondary target are superposed one on the other, so that the continuous X-ray emitted from the primary target efficiently excites the secondary target thereby to efficiently generate the characteristic X-ray.

Owner:TOSHIBA ELECTRON TUBE & DEVICES

X-ray tube

InactiveUS6229876B1Enhances electron beam focusing capabilityLow possible surface fieldX-ray tube electrodesCathode ray concentrating/focusing/directingX-raySpherical shaped

An x-ray tube comprising an electron gun assembly having an electron gun container housing an electron generator for generating electrons in a first direction along a first axis. The beam of electrons impinges upon an anode which emits x-rays in response to the beam of electrons. The gun container is characterized by having a discharge end comprising a solid spherical shape.

Owner:KEVEX X RAY

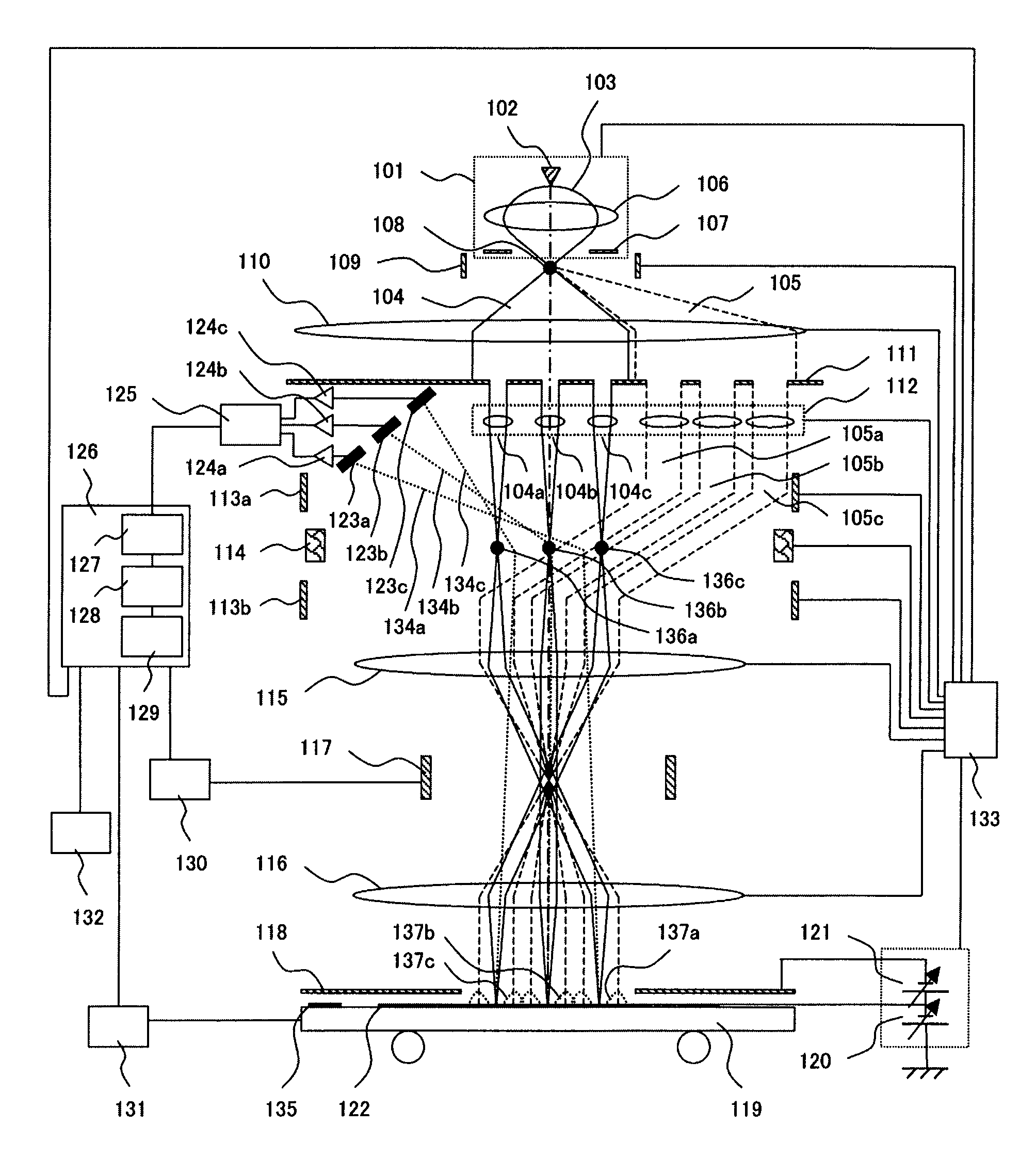

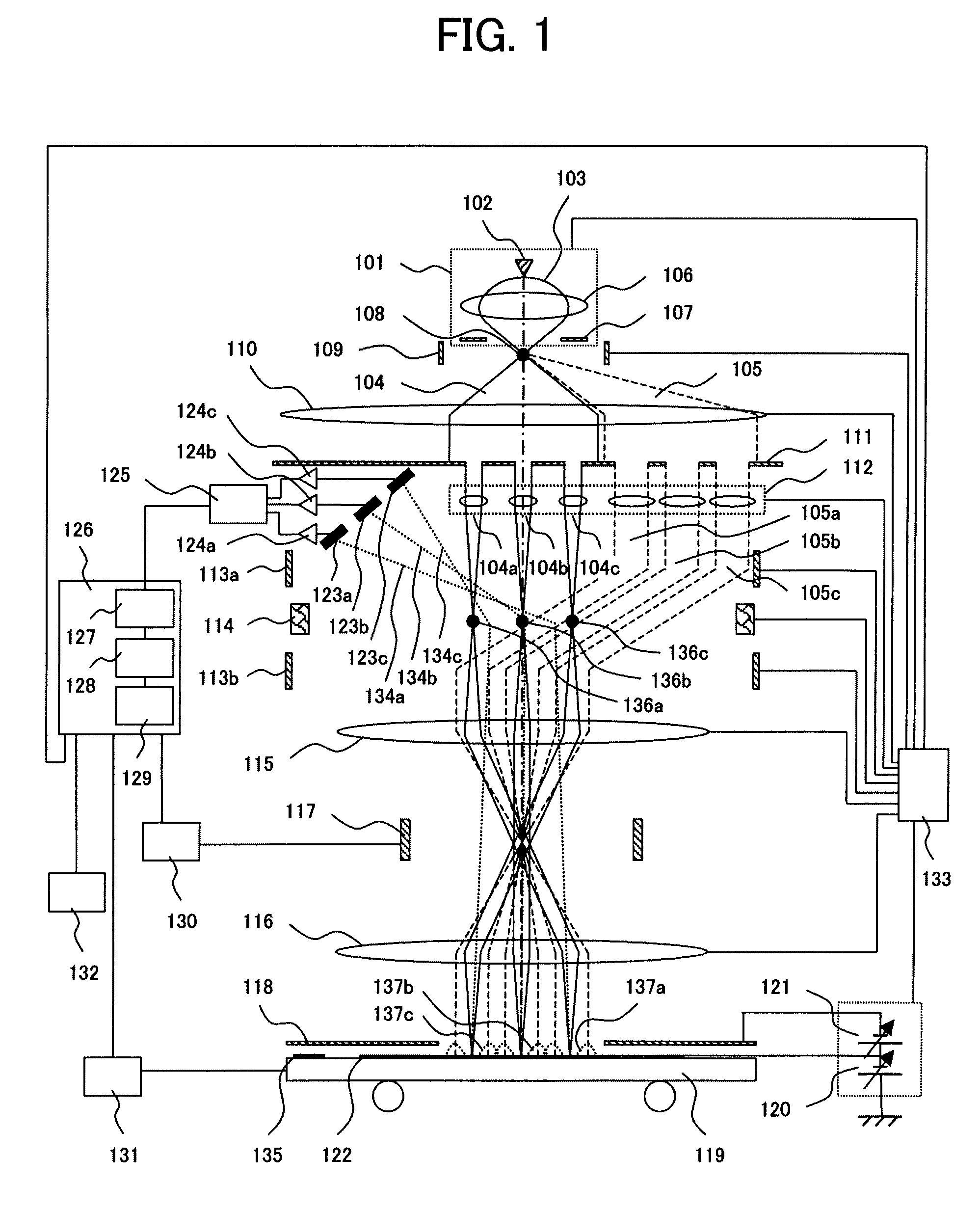

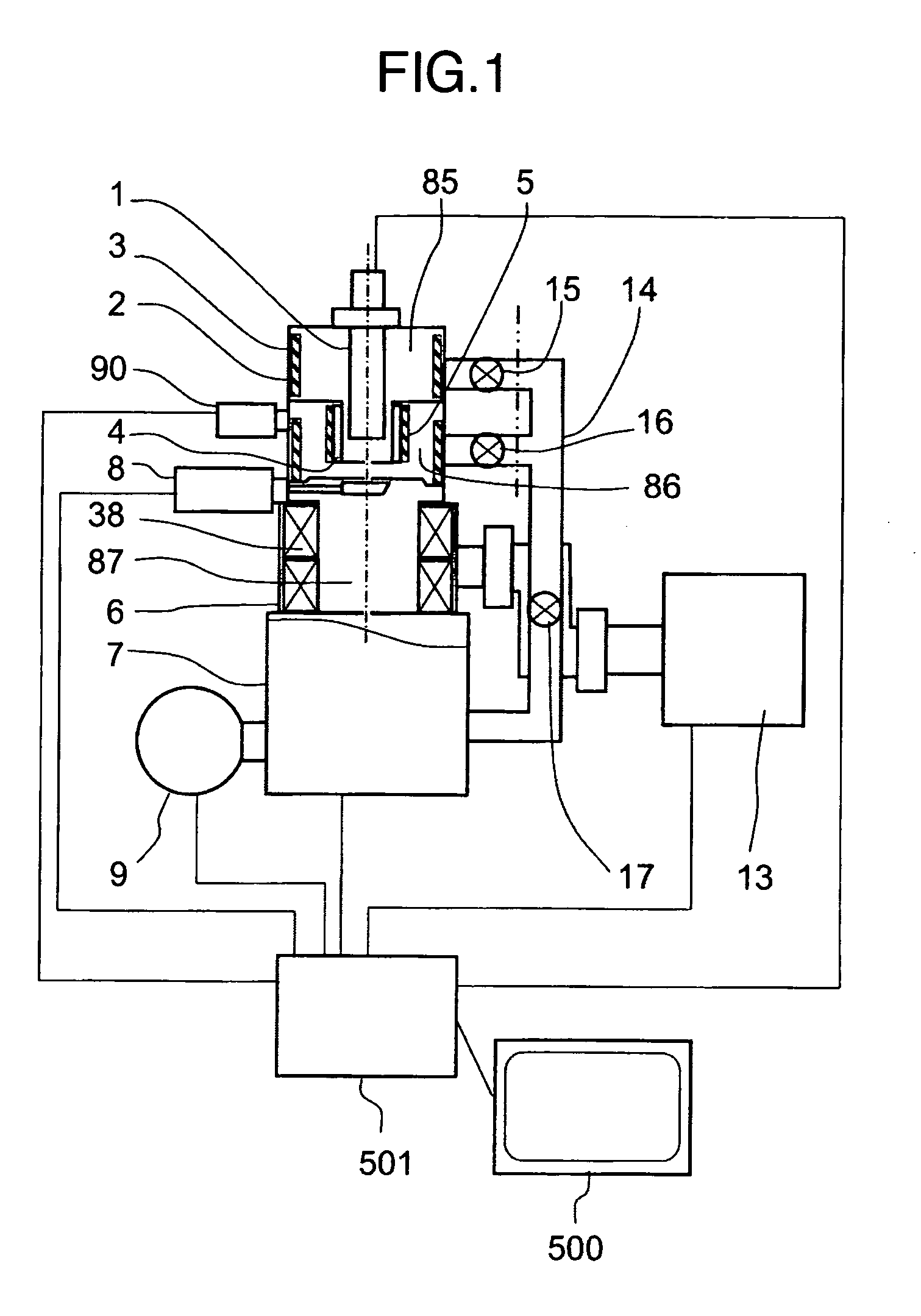

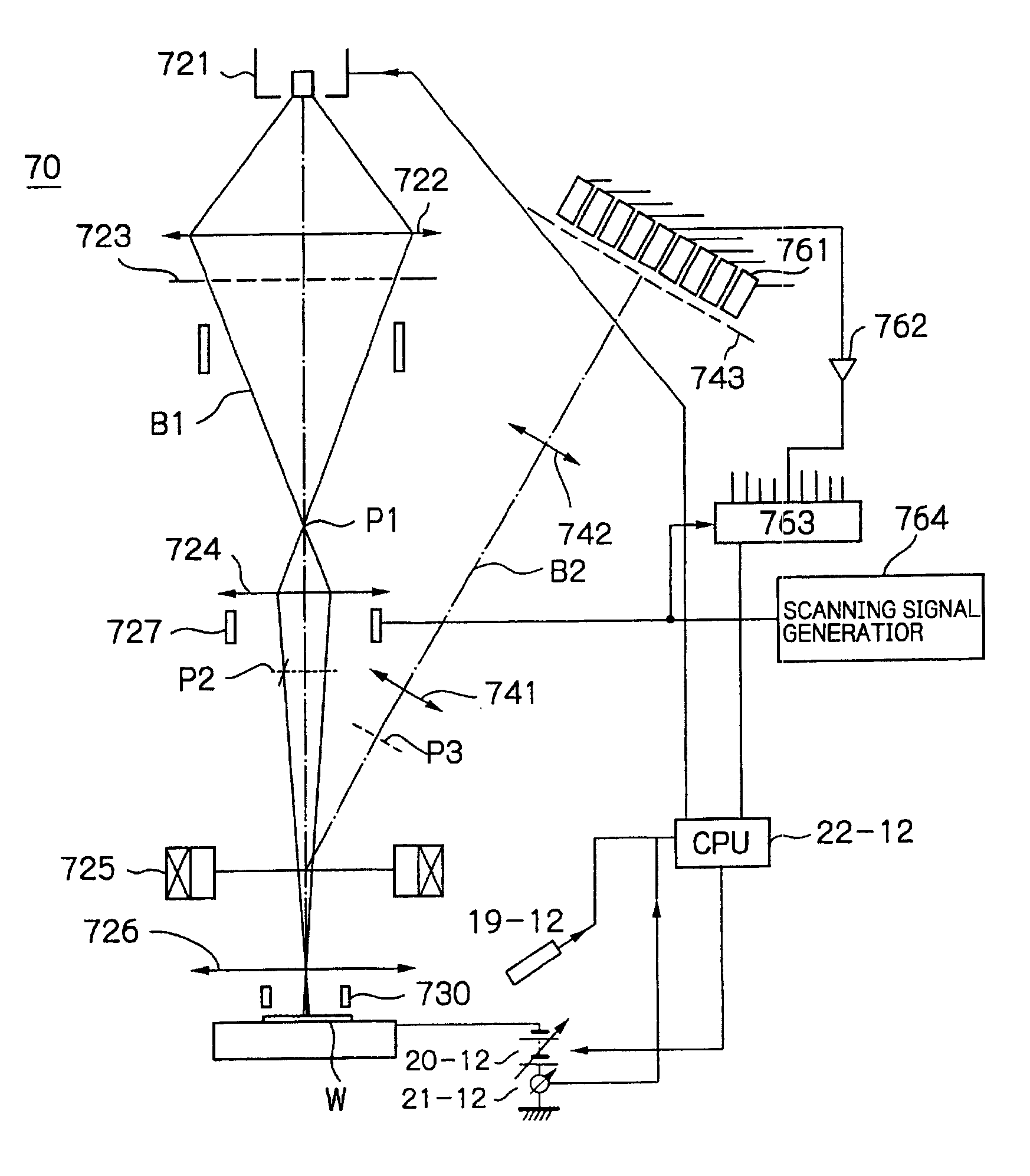

Electron beam inspection system and inspection method and method of manufacturing devices using the system

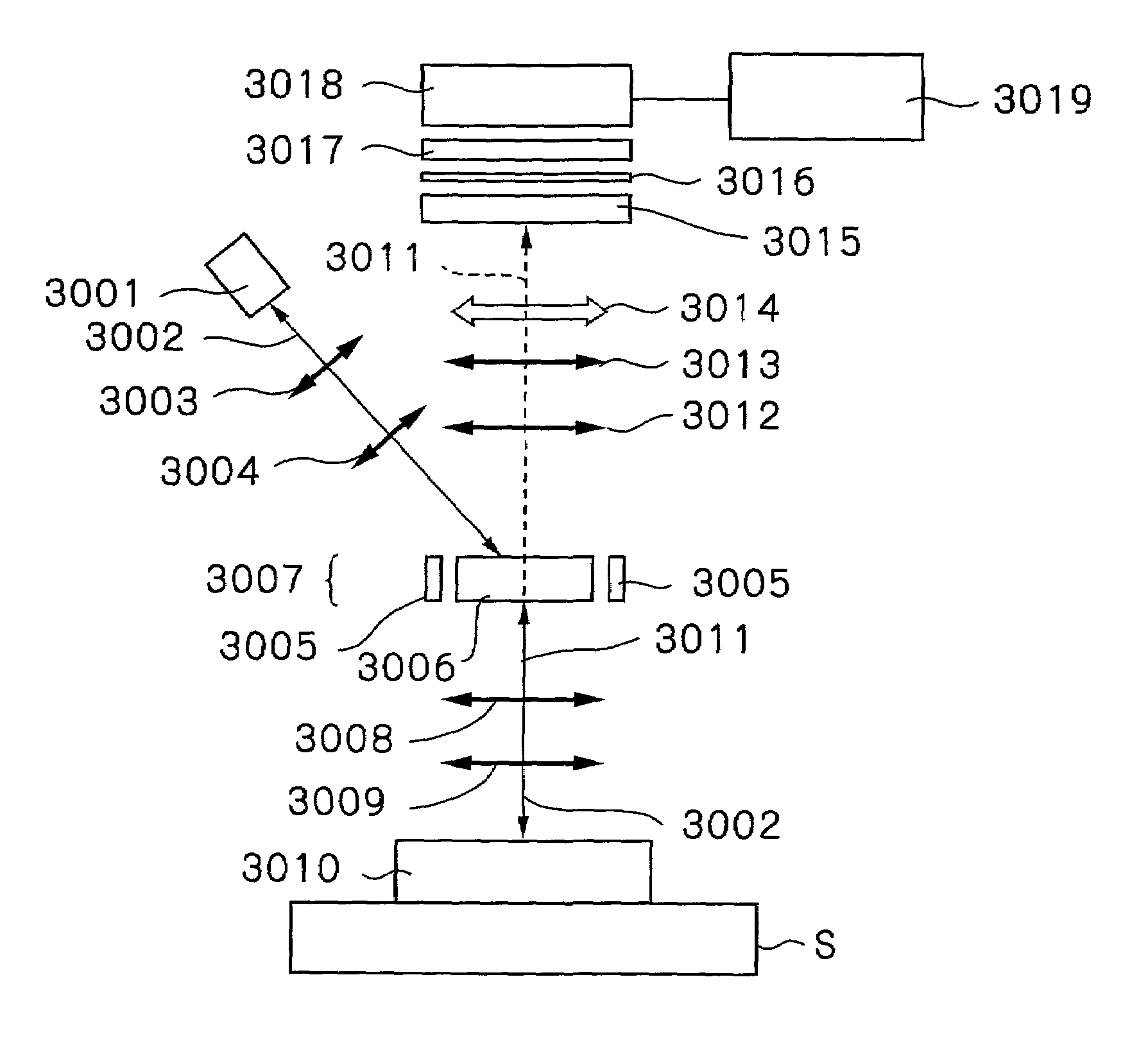

InactiveUS6992290B2Inspection speed is fastImprove inspection speedMaterial analysis using wave/particle radiationElectric discharge tubesLine sensorSecondary electrons

An electron beam inspection system of the image projection type includes a primary electron optical system for shaping an electron beam emitted from an electron gun into a rectangular configuration and applying the shaped electron beam to a sample surface to be inspected. A secondary electron optical system converges secondary electrons emitted from the sample. A detector converts the converged secondary electrons into an optical image through a fluorescent screen and focuses the image to a line sensor. A controller controls the charge transfer time of the line sensor at which the picked-up line image is transferred between each pair of adjacent pixel rows provided in the line sensor in association with the moving speed of a stage for moving the sample.

Owner:EBARA CORP

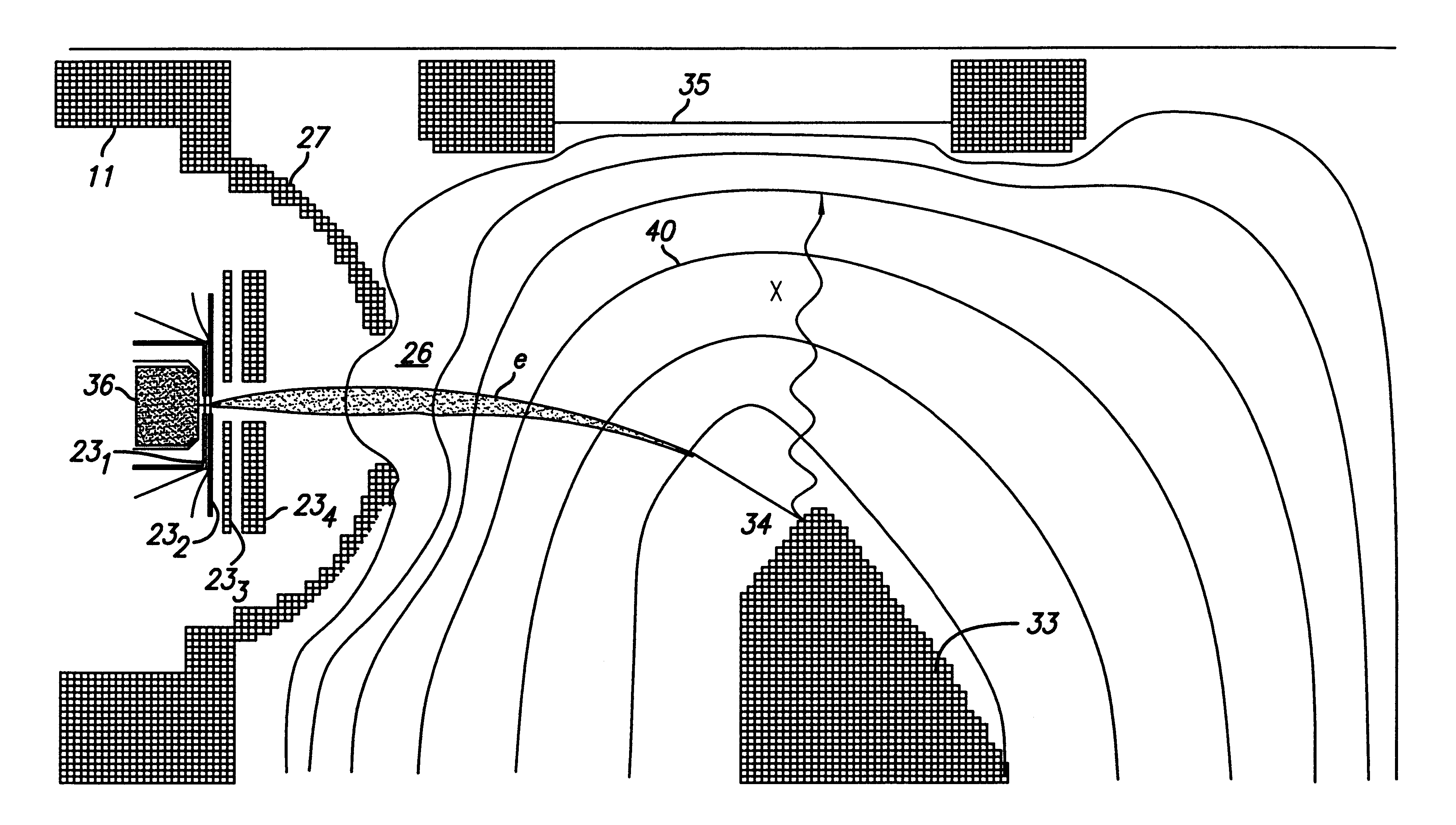

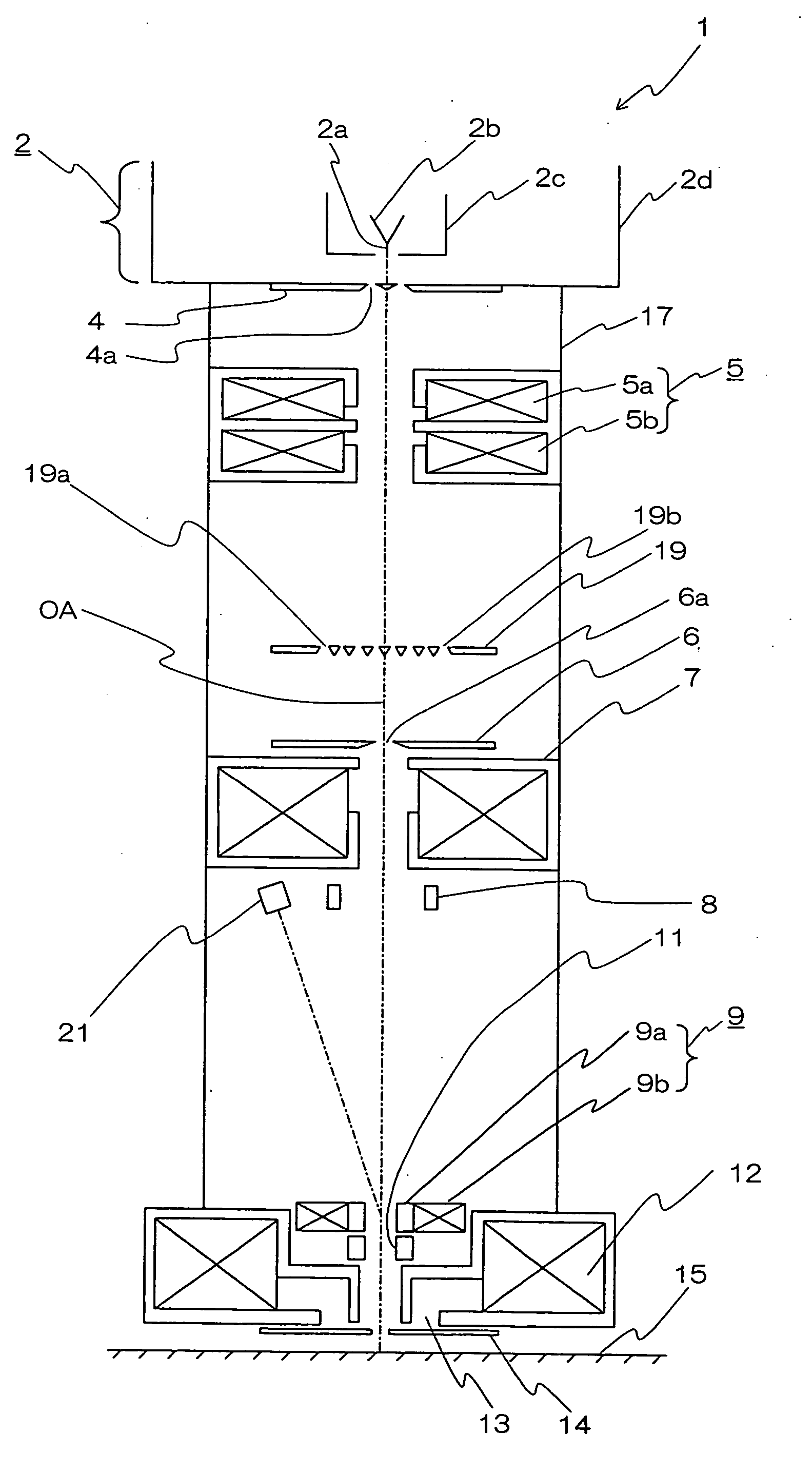

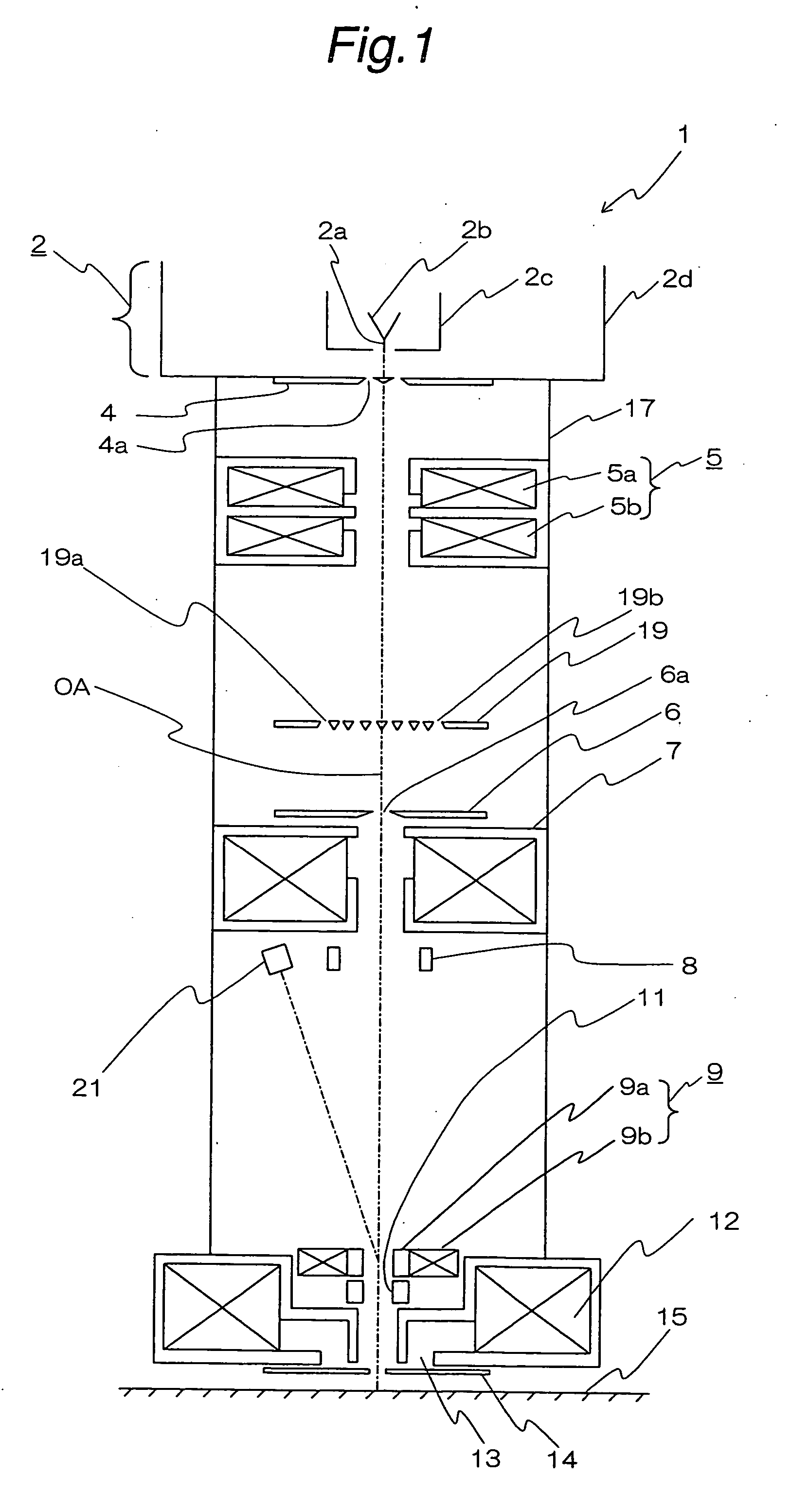

Projection electron beam apparatus and defect inspection system using the apparatus

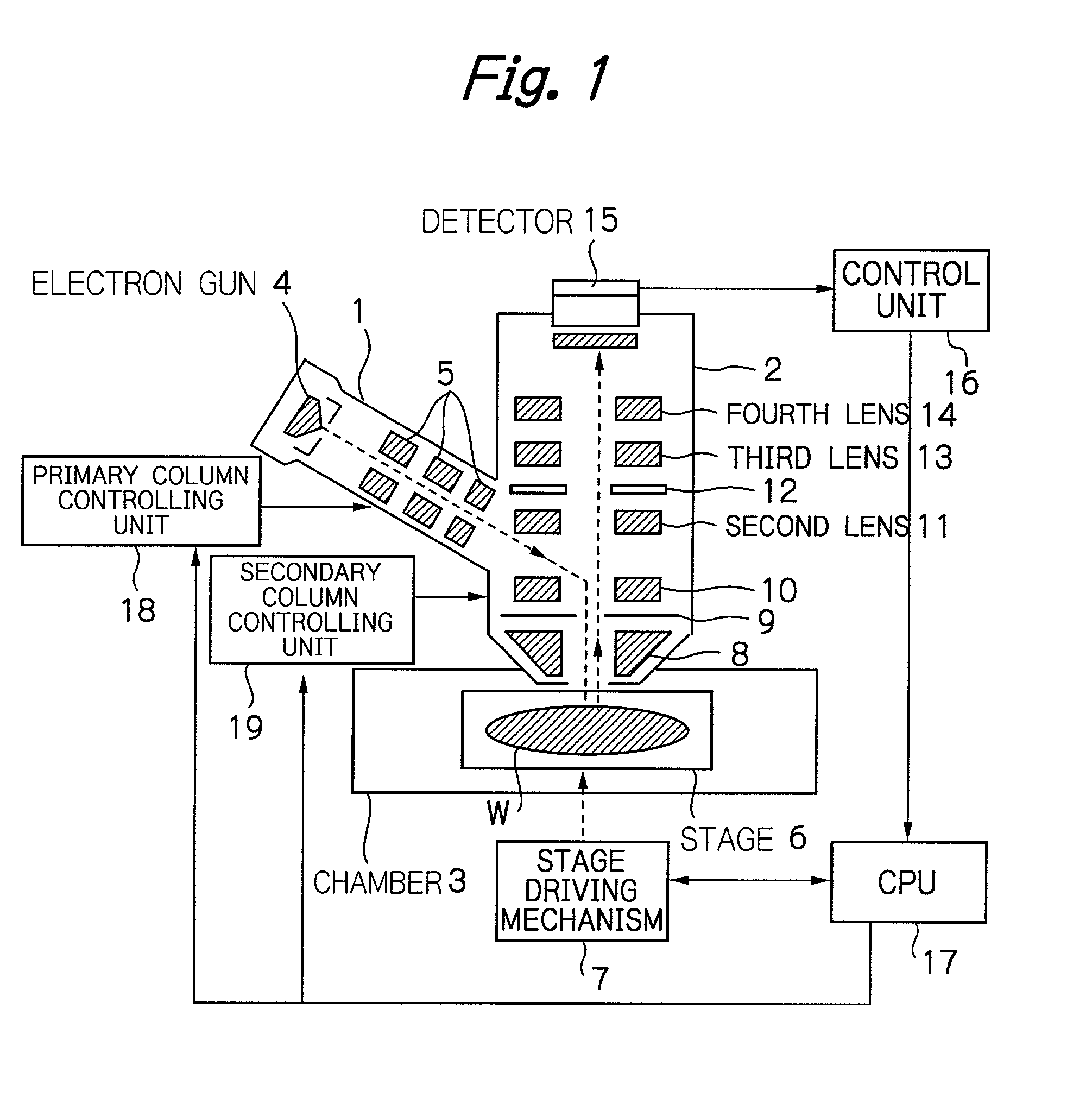

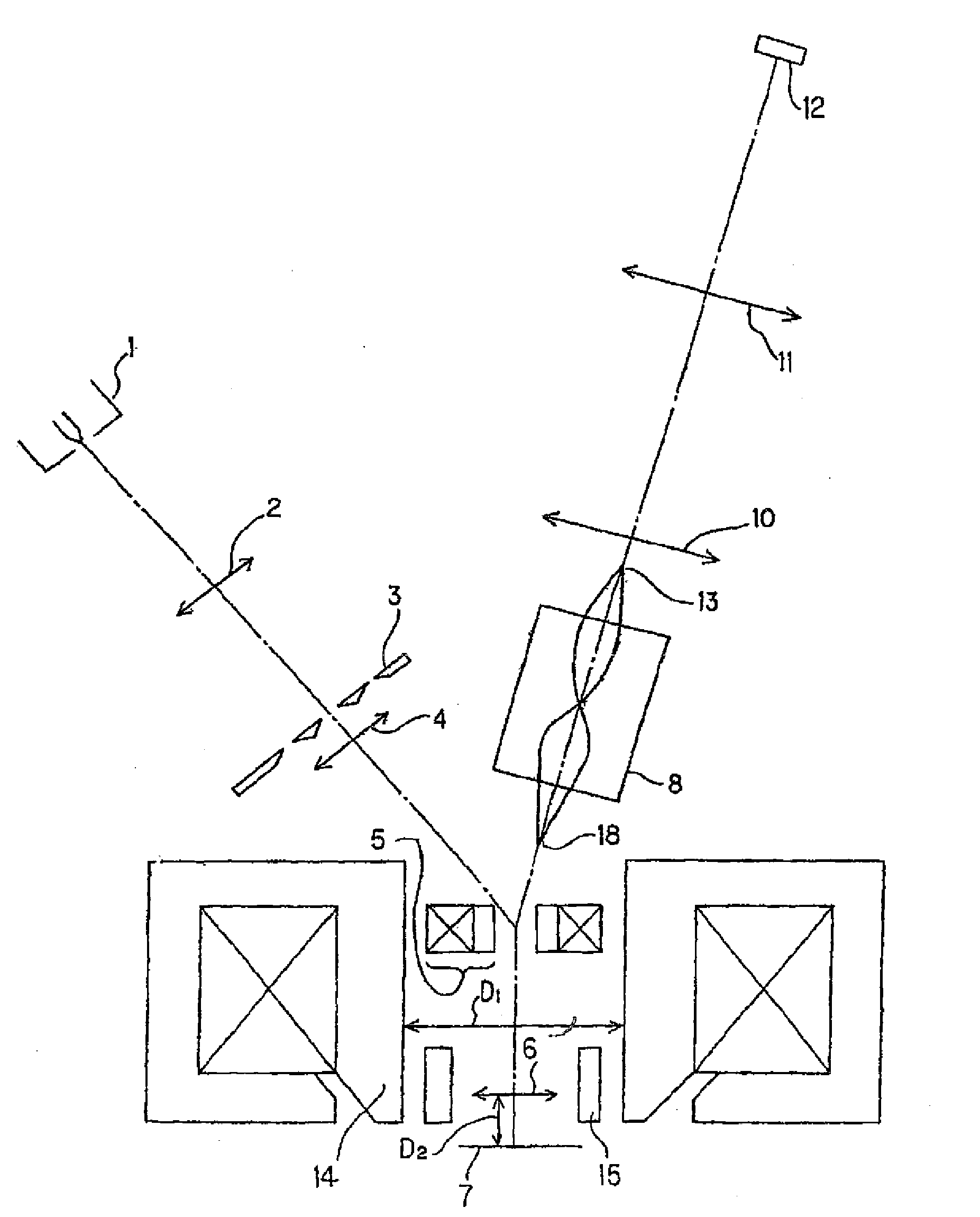

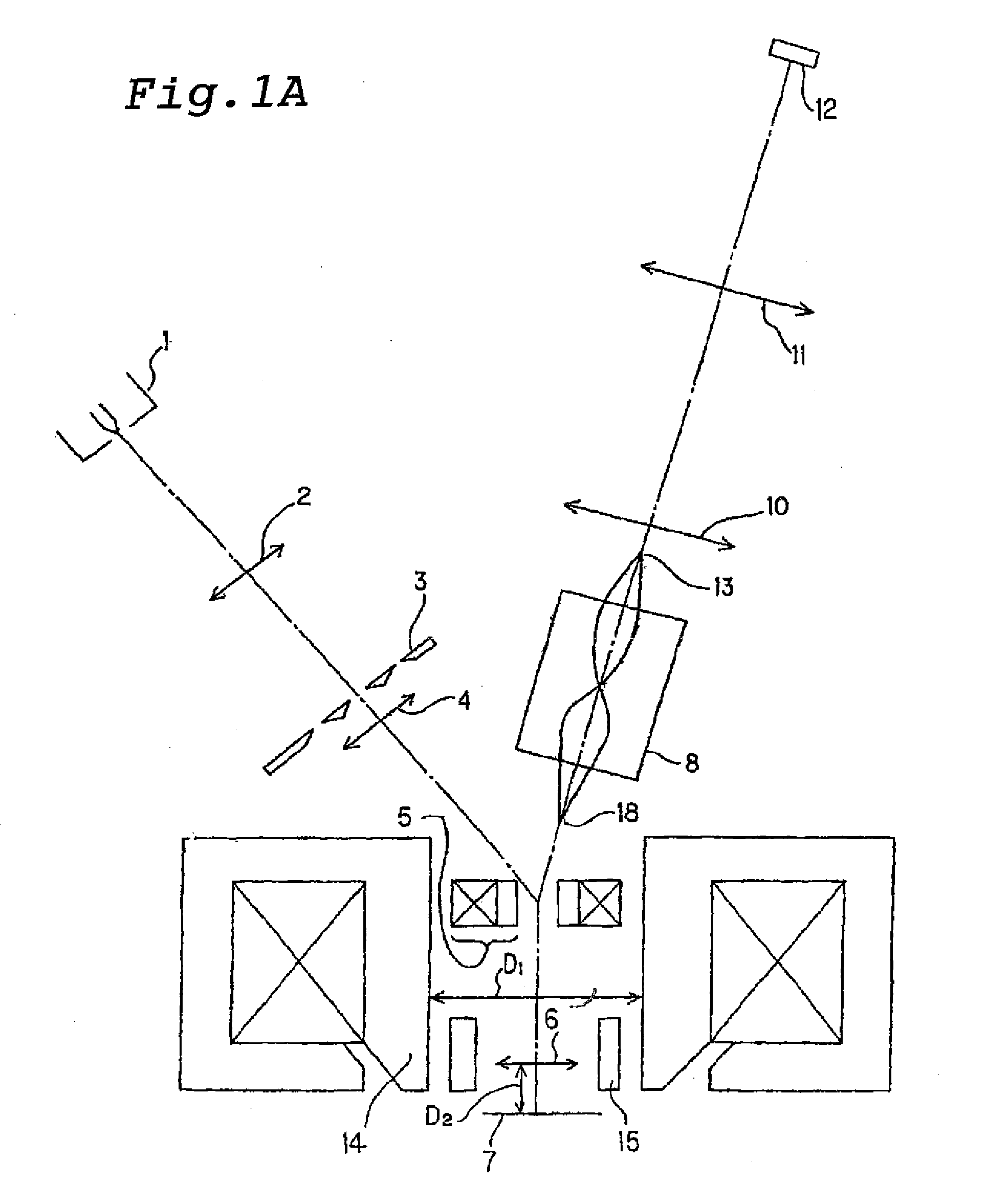

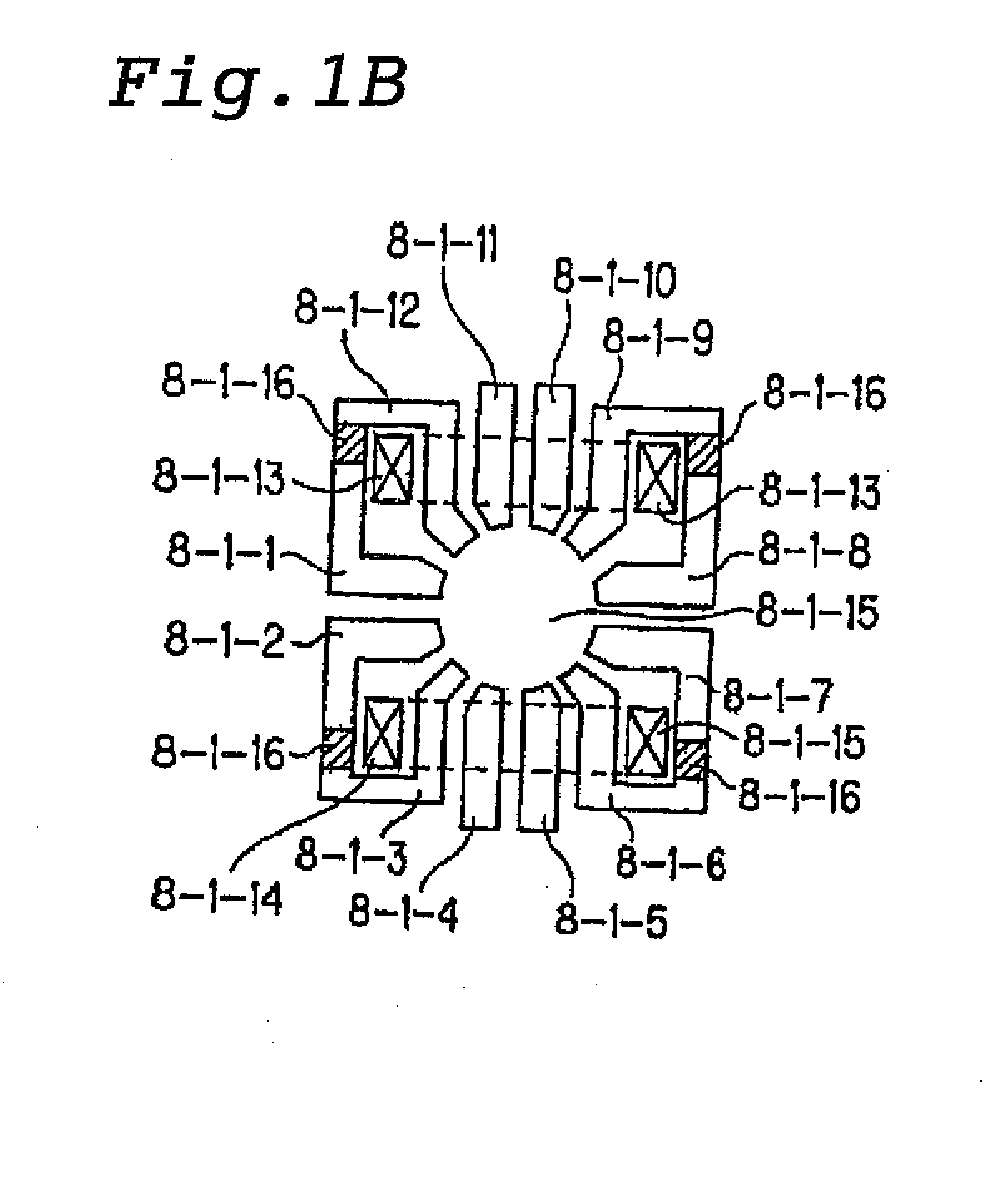

InactiveUS20090212213A1Increase currentImprove throughputMaterial analysis using wave/particle radiationElectric discharge tubesWien filterTransmittance

A sample is evaluated at a high throughput by reducing axial chromatic aberration and increasing the transmittance of secondary electrons. Electron beams emitted from an electron gun 1 are irradiated onto a sample 7 through a primary electro-optical system, and electrons consequently emitted from the sample are detected by a detector 12 through a secondary electro-optical system. A Wien filter 8 comprising a multi-pole lens for correcting axial chromatic aberration is disposed between a magnification lens 10 in the secondary electro-optical system and a beam separator 5 for separating a primary electron beam and a secondary electron beam, for correcting axial chromatic aberration caused by an objective lens 14 which comprises an electromagnetic lens having a magnetic gap defined on a sample side.

Owner:KK TOSHIBA

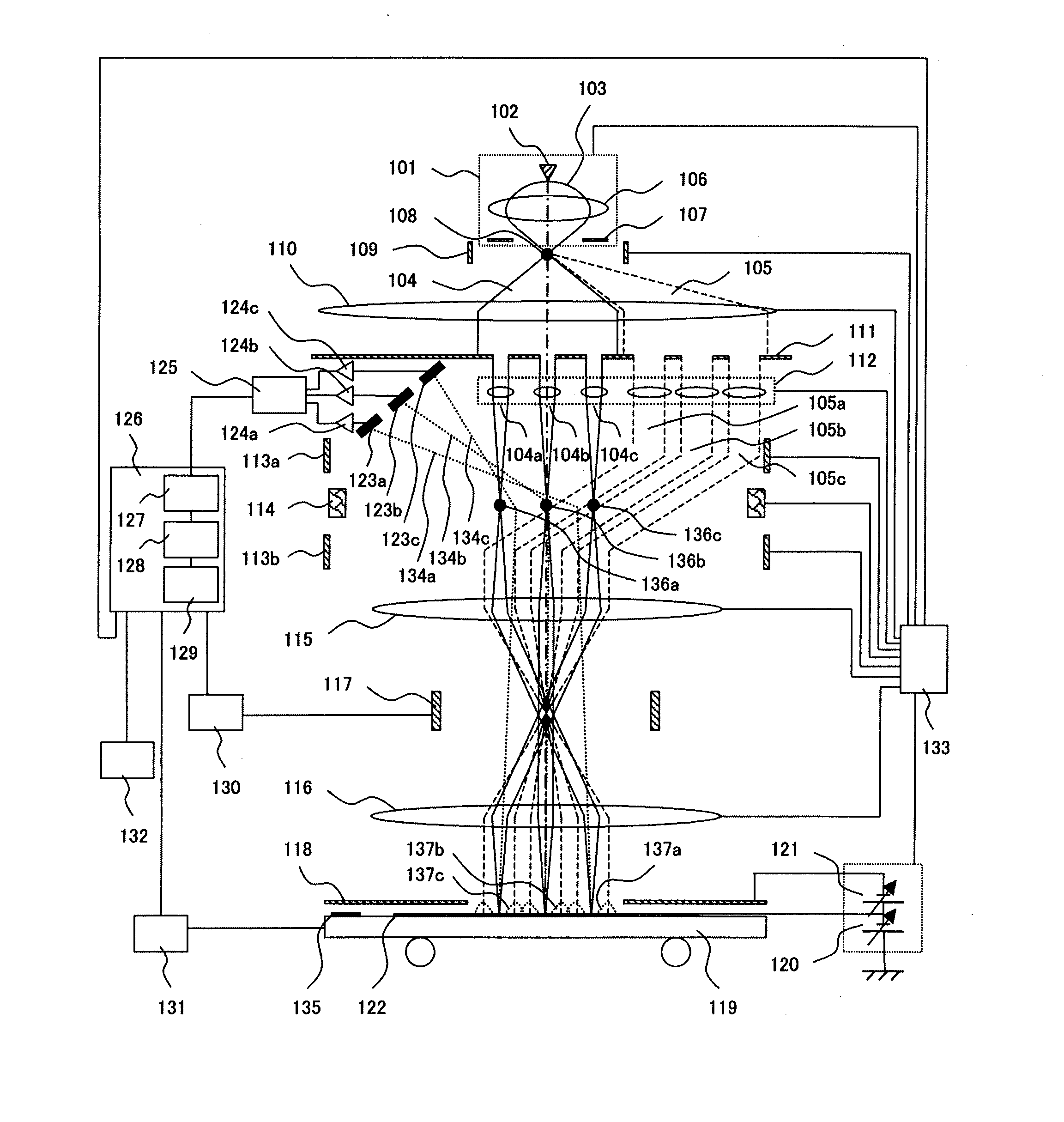

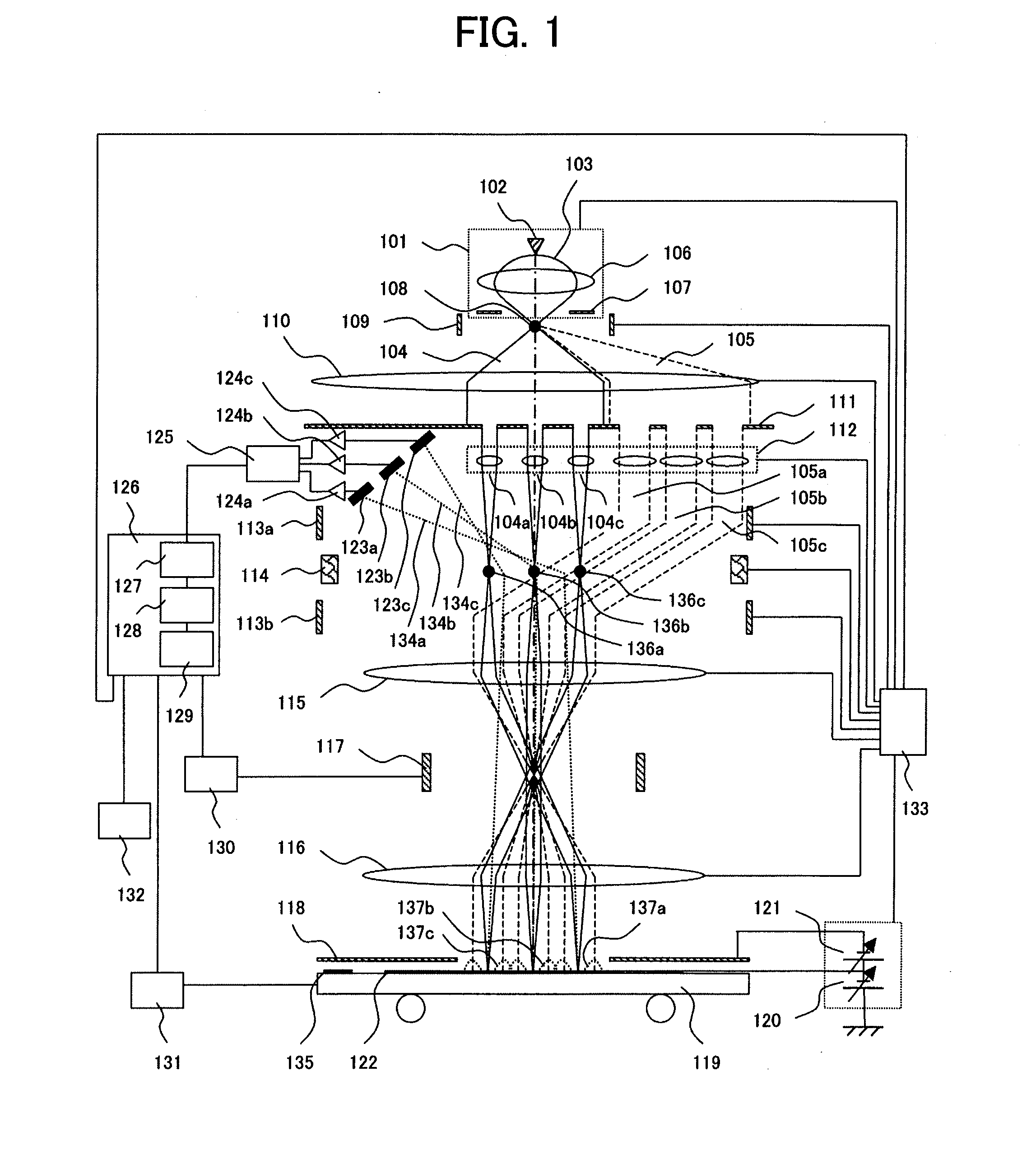

Charged particle beam applied apparatus

ActiveUS8350214B2Easy to implementMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementBeam scanningSource image

Provided is a multi-beam type charged particle beam applied apparatus in an implementable configuration, capable of achieving both high detection accuracy of secondary charged particles and high speed of processing characteristically different specimens. An aperture array (111) includes plural aperture patterns. A deflector (109) for selecting an aperture pattern through which a primary beam passes is disposed at the position of a charged particle source image created between an electron gun (102), i.e., a charged particle source, and the aperture array (111). At the time of charge-control beam illumination and at the time of signal-detection beam illumination, an aperture pattern of the aperture array (111) is selected, and conditions of a lens array (112), surface electric-field control electrode (118) and the like are switched in synchronization with each beam scanning. Thus, the charges are controlled and the signals are detected at different timings under suitable conditions, respectively.

Owner:HITACHI HIGH-TECH CORP

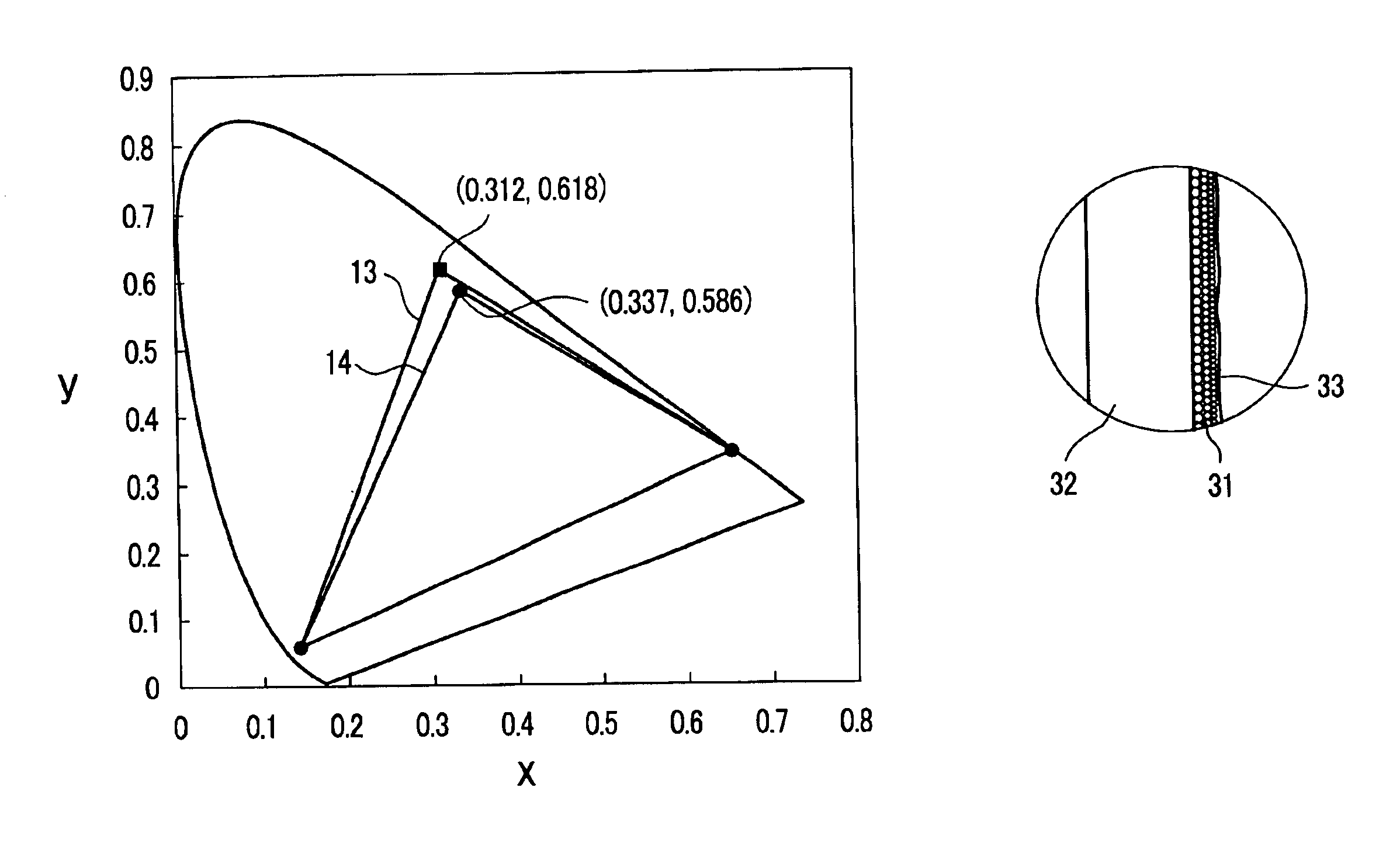

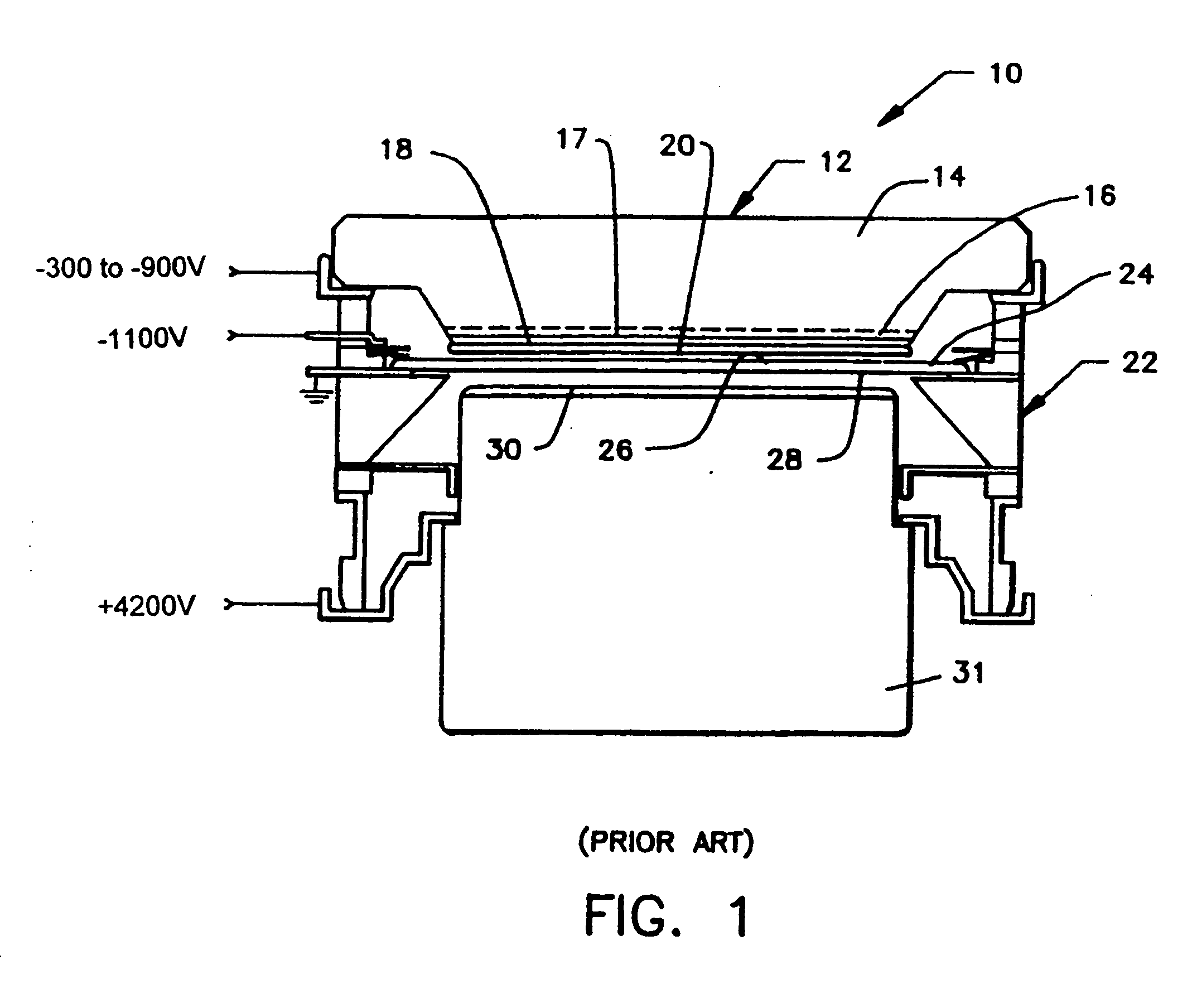

Display device

ActiveUS6940221B2Reduce harmImprove extinctionDischarge tube luminescnet screensLamp detailsRare-earth elementFluorescence

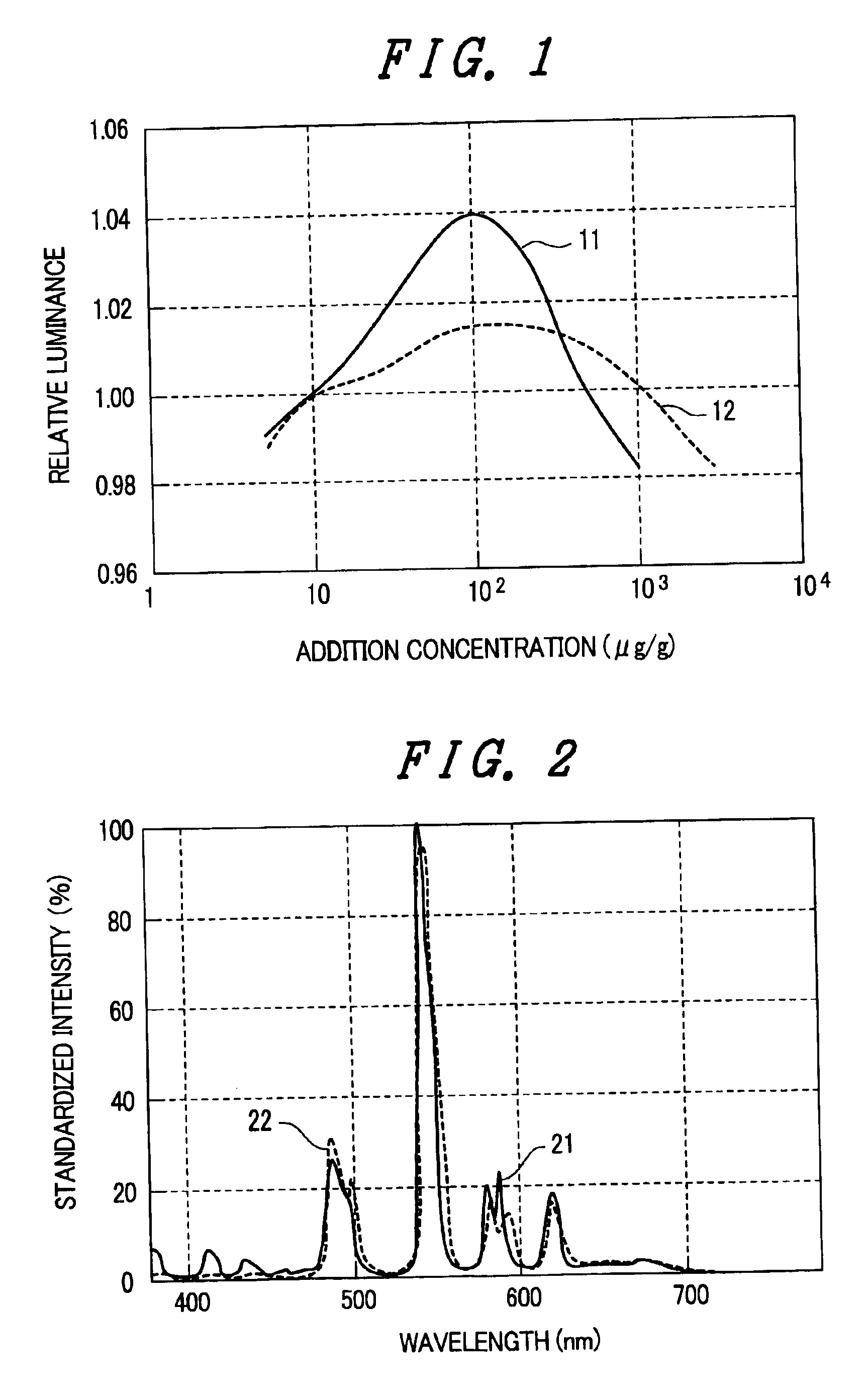

The present invention can further enhance the light emission characteristics of phosphor excited by the irradiation of electron beams of high density. In a cathode ray tube including a phosphor film, a faceplate panel which constitutes a screen, an aluminum vapor-deposited film, a funnel and an electron gun, phosphor which constitutes the phosphor film applied to the faceplate panel is constituted of a terbium activated phosphor which is produced by substituting a portion of yttrium (Y) in base material crystals which contain zinc (Zn), yttrium (Y), silicon (Si) and oxygen (O) as main constitutional elements with terbium ion (Tb3+) and a trace amount of rare earth element ion is added to the terbium activated phosphor.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

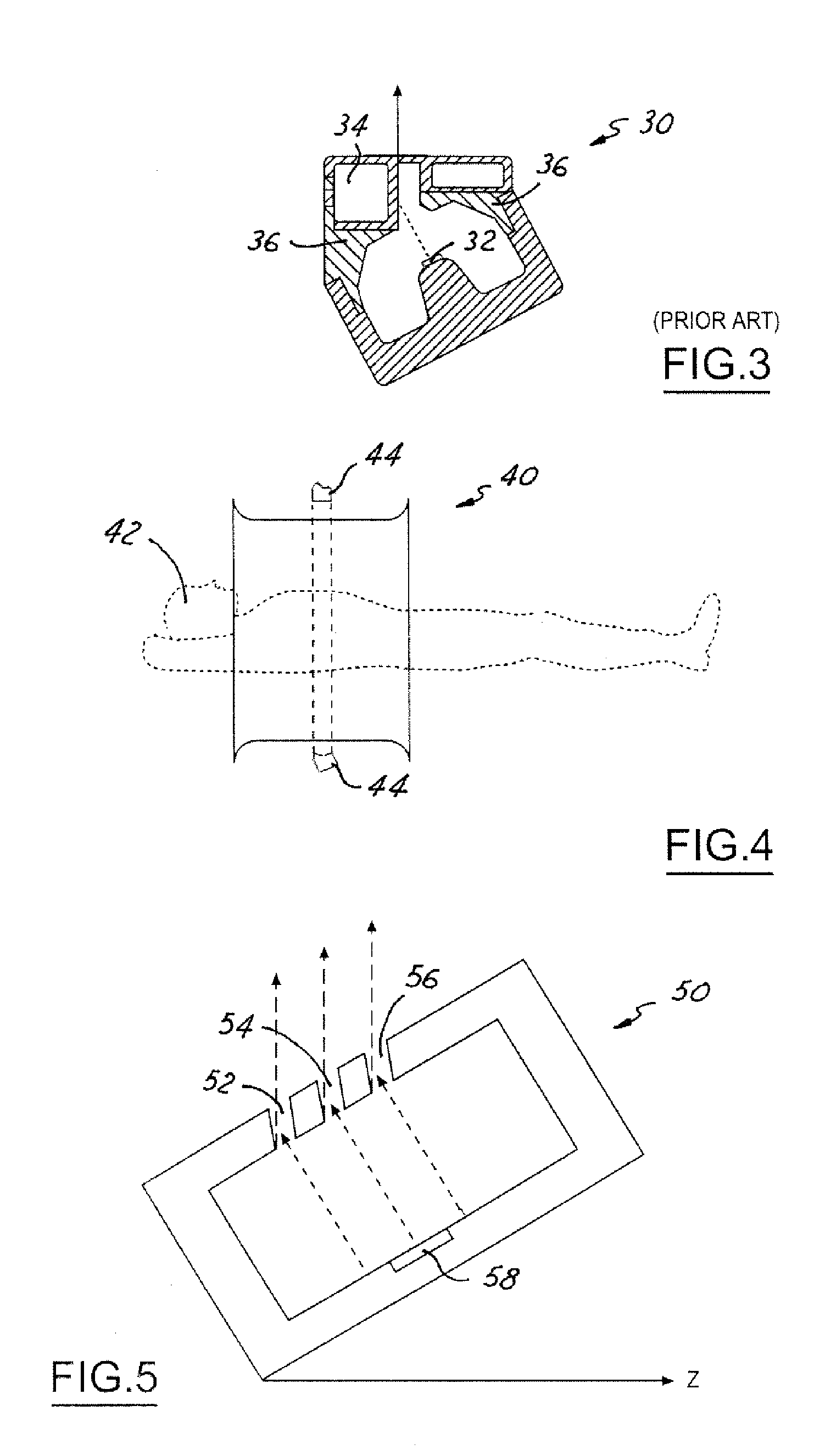

RF accelerator for imaging applications

ActiveUS7206379B2Drawback can be obviatedLower component costsX-ray tube electrodesDischarge tube electron gunsComputed tomographyX-ray

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Electron-beam excitation laser

InactiveUS20040218651A1Laser active region structureExcitation process/apparatusDielectricElectron source

An electron-beam excitation laser has a laser structure with a light emitter and reflectors on one hand and an electron source on the other hand, wherein at least part of the light emitter or reflectors has a multidimensional photonic crystal structure. An electron-beam excitation laser includes an electron source emitting electrons and a laser structure consisting of a light emitter and reflectors, accelerates electrons from the electron source, and irradiates the electrons to the laser structure to emit a laser beam from the laser structure, wherein the reflectors and / or the light emitter in the laser structure are formed with multidimensional photonic crystals in which dielectrics with different dielectric constants are arrayed in a plurality of directions at periodic intervals, and one of the dielectrics with different dielectric constants may be formed with a light-emitting material.

Owner:CANON KK

Charged particle beam apparatus

InactiveUS7582885B2Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsRemoving coilGetter

Owner:HITACHI HIGH-TECH CORP

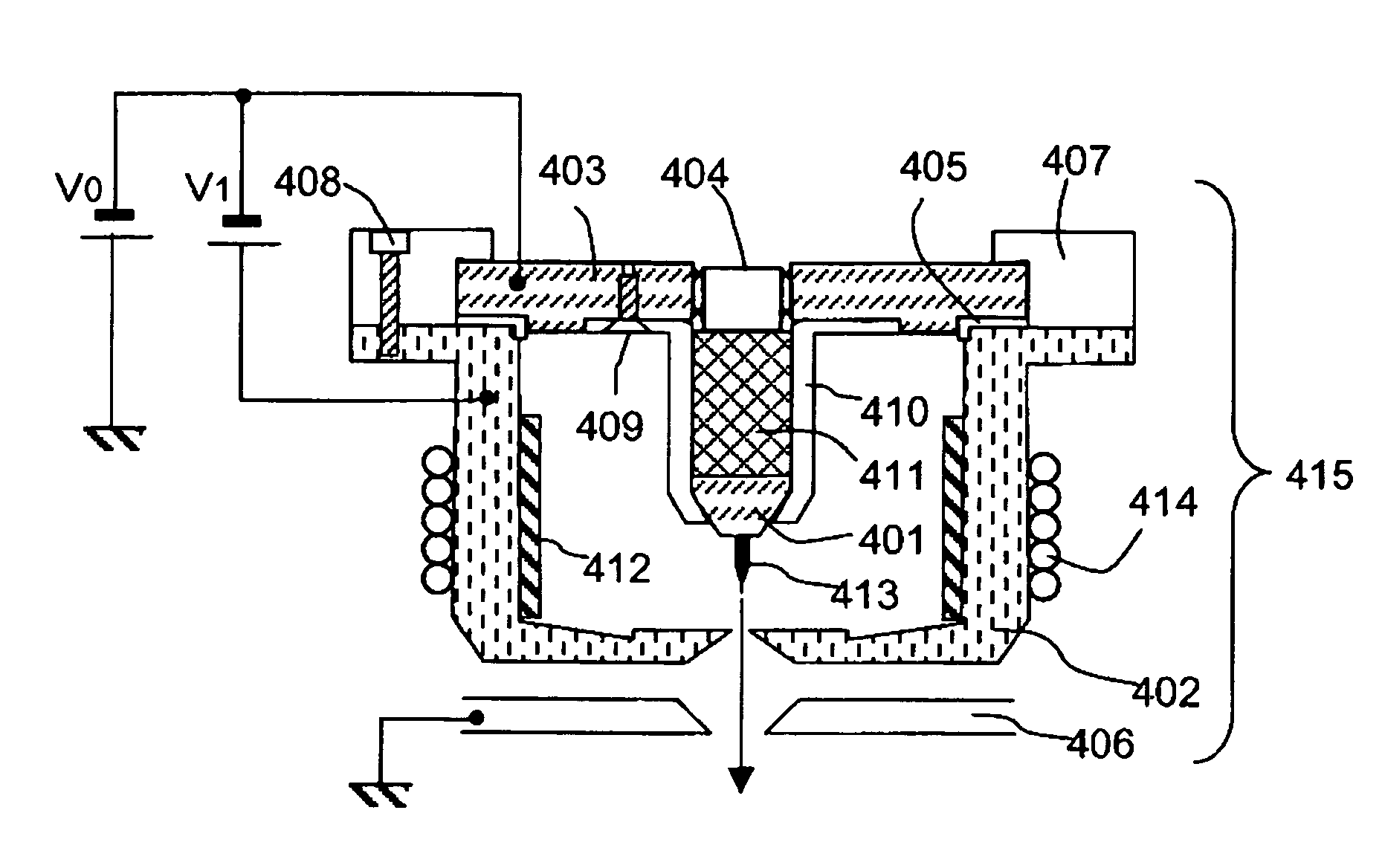

Ionization device for aerosol mass spectrometer and method of ionization

ActiveUS20050178975A1Efficient methodTime-of-flight spectrometersMaterial analysis by optical meansEnergy controlVoltage source

The ionization device of the present invention is intended for use in conjunction with an aerosol TOF MS operating in a continuous mode and is capable of ionizing particulated substances in a wide range of particle masses. In the illustrated embodiment, the ionization unit consists of three coaxial cylindrical bodies having a three aligned longitudinal slits for directing electron beams from externally located electron gun onto the axially arranged flow of droplets. The cylindrical bodies are connected to voltage sources so that the external cylindrical body functions as an anode that extracts electrons from the current-heated filament. The central cylindrical body, in combination with the aforementioned anode, serves as an electron-energy control member for precisely controlling and selecting the energy of electrons that reach the flow of particles, while the inner cylindrical body functions as a decelerating member that can be used for adjusting energy of electrons which reached the flow of particles. The heated filament of each electron gun, which is used as a source of electrons, is inclined with respect to the aforementioned longitudinal axis whereby modulation applied to the elongated outer electrode of the electron gun provides different ionization conditions for specific particles of predetermined masses for analysis of which the aerosol TOF MS is tuned.

Owner:NANOMAT

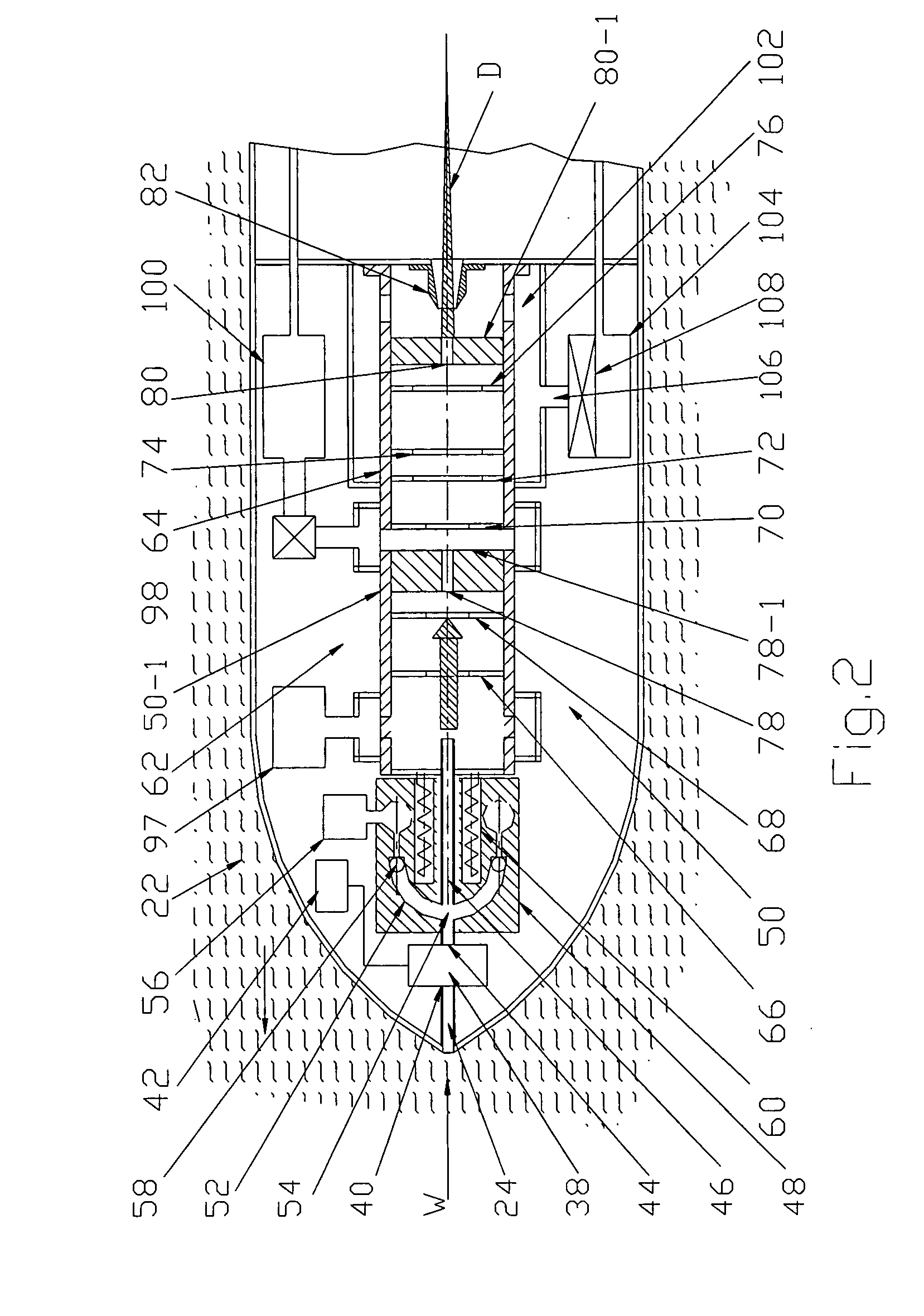

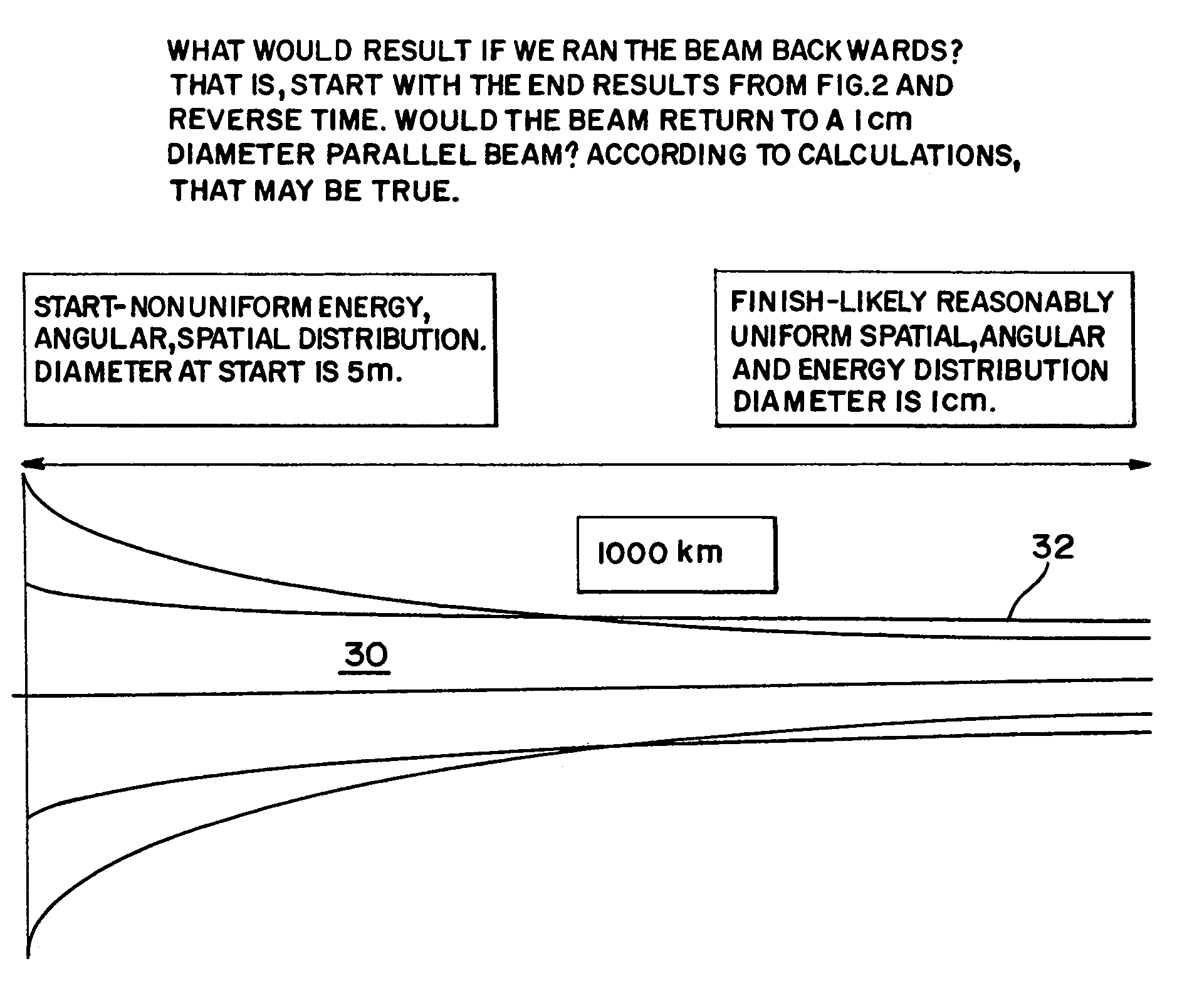

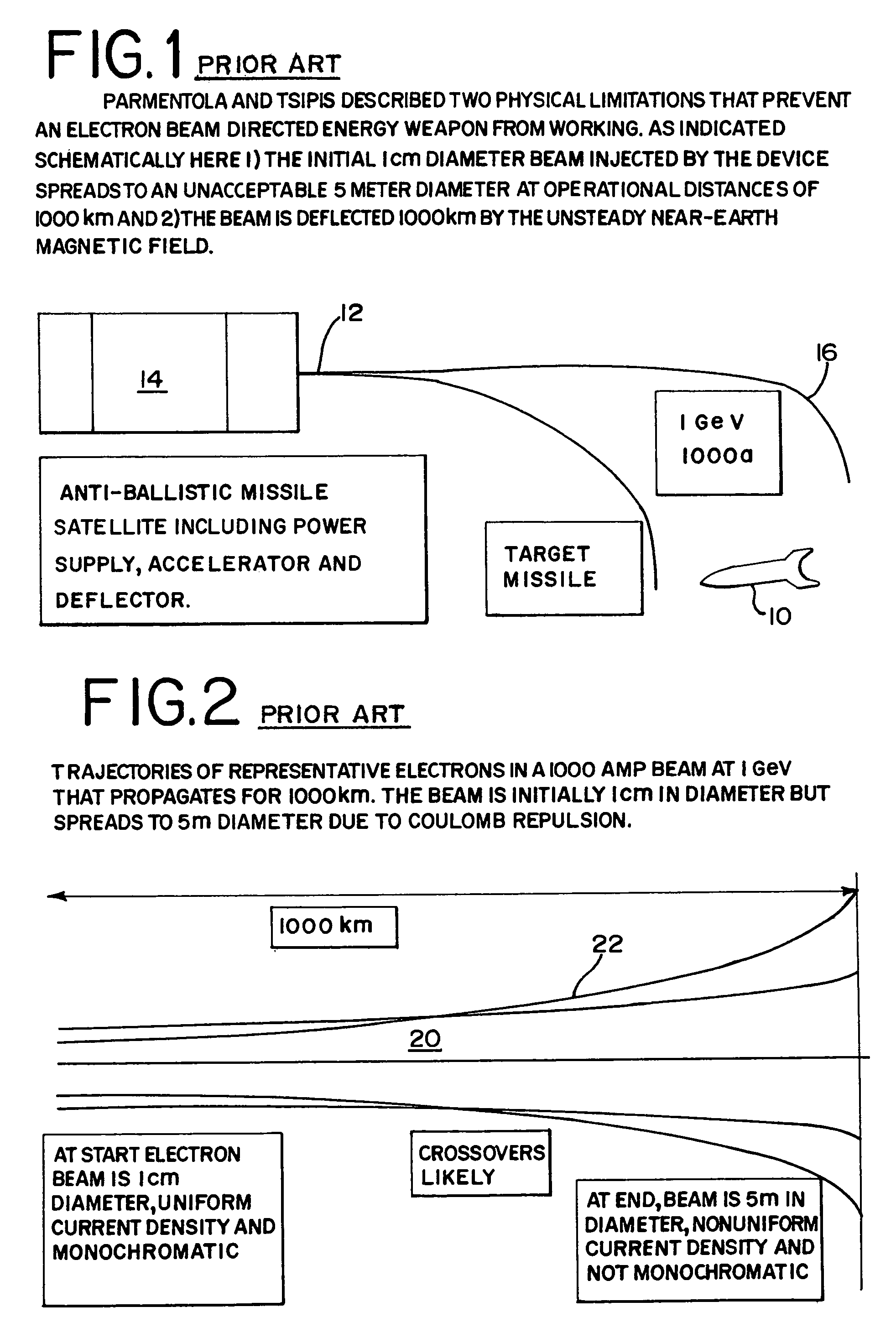

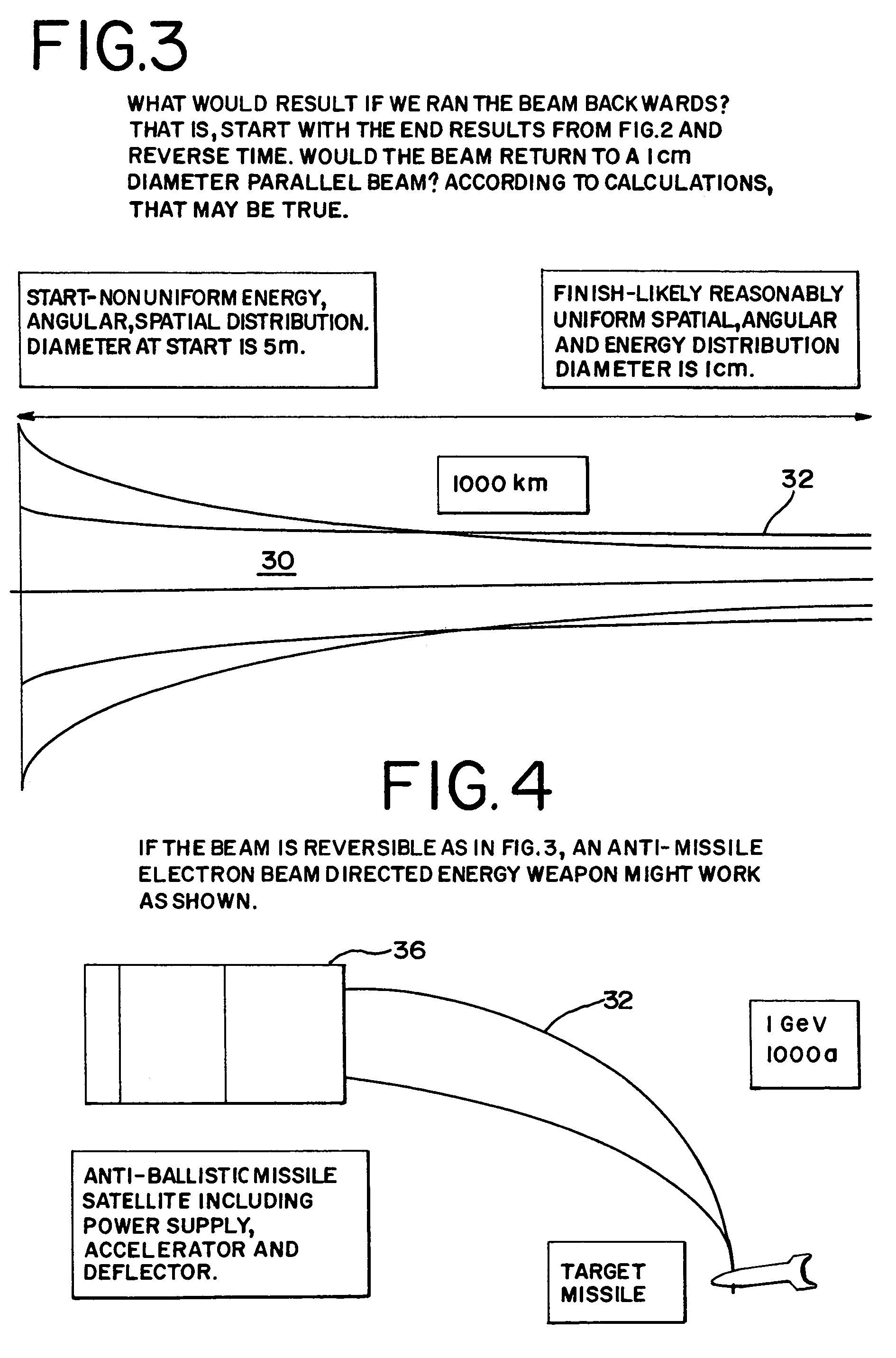

Electron beam directed energy device and methods of using same

InactiveUS7282727B2Avoid excessive distanceLess detectableDefence devicesThermometer detailsX-rayEnergy device

A method and apparatus is disclosed for an electron beam directed energy device. The device consists of an electron gun with one or more electron beams. The device includes one or more accelerating plates with holes aligned for beam passage. The plates may be flat or preferably shaped to direct each electron beam to exit the electron gun at a predetermined orientation. In one preferred application, the device is located in outer space with individual beams that are directed to focus at a distant target to be used to impact and destroy missiles. The aimings of the separate beams are designed to overcome Coulomb repulsion. A method is also presented for directing the beams to a target considering the variable terrestrial magnetic field. In another preferred application, the electron beam is directed into the ground to produce a subsurface x-ray source to locate and / or destroy buried or otherwise hidden objects including explosive devices.

Owner:RETSKY MICHAEL W

X-ray source and fluorescent X-ray analyzing apparatus

InactiveUS7809113B2Eliminates unwanted noise componentGenerate efficientlyX-ray tube laminated targetsMaterial analysis using wave/particle radiationSoft x rayX-ray

Owner:TOSHIBA ELECTRON TUBE & DEVICES

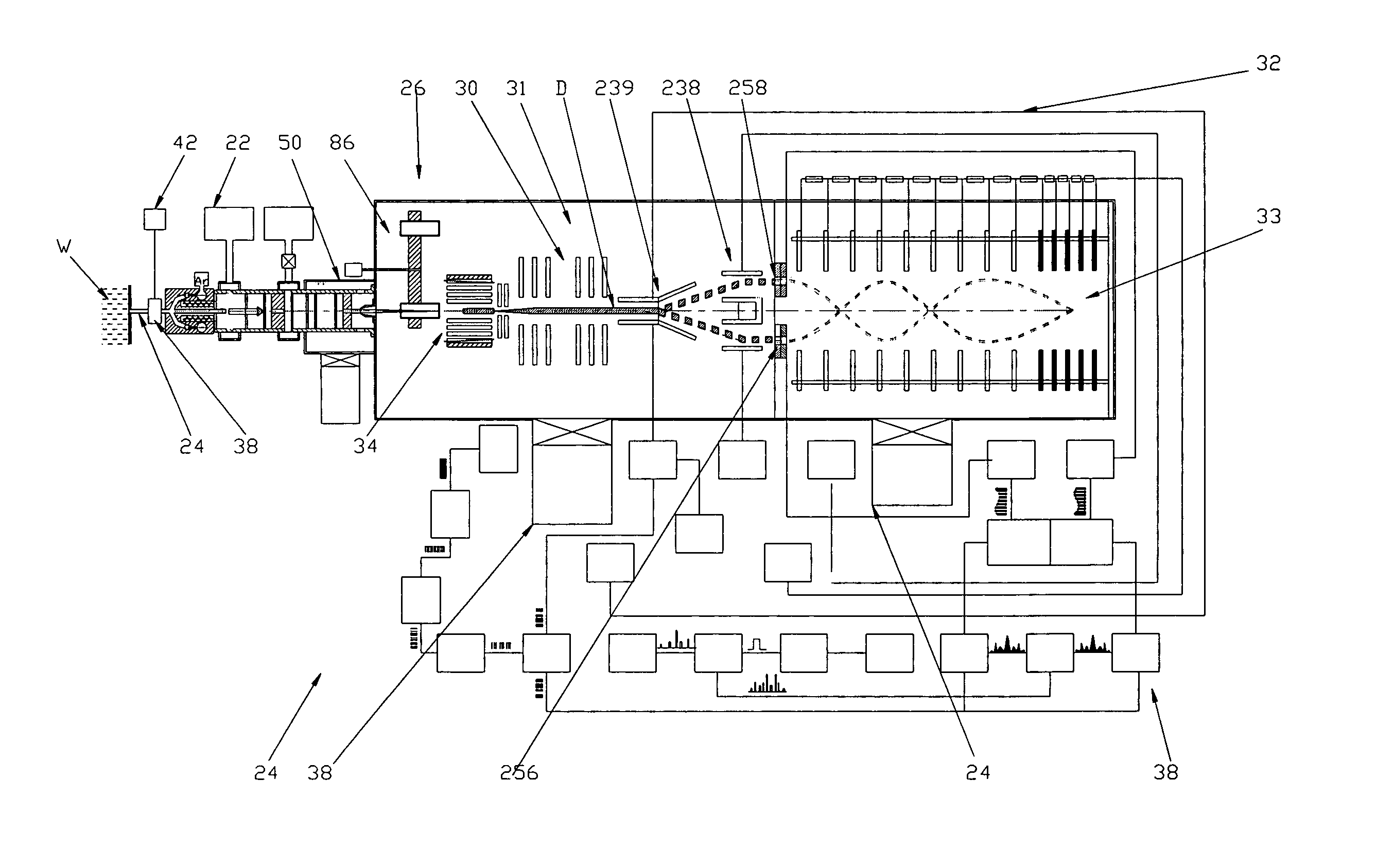

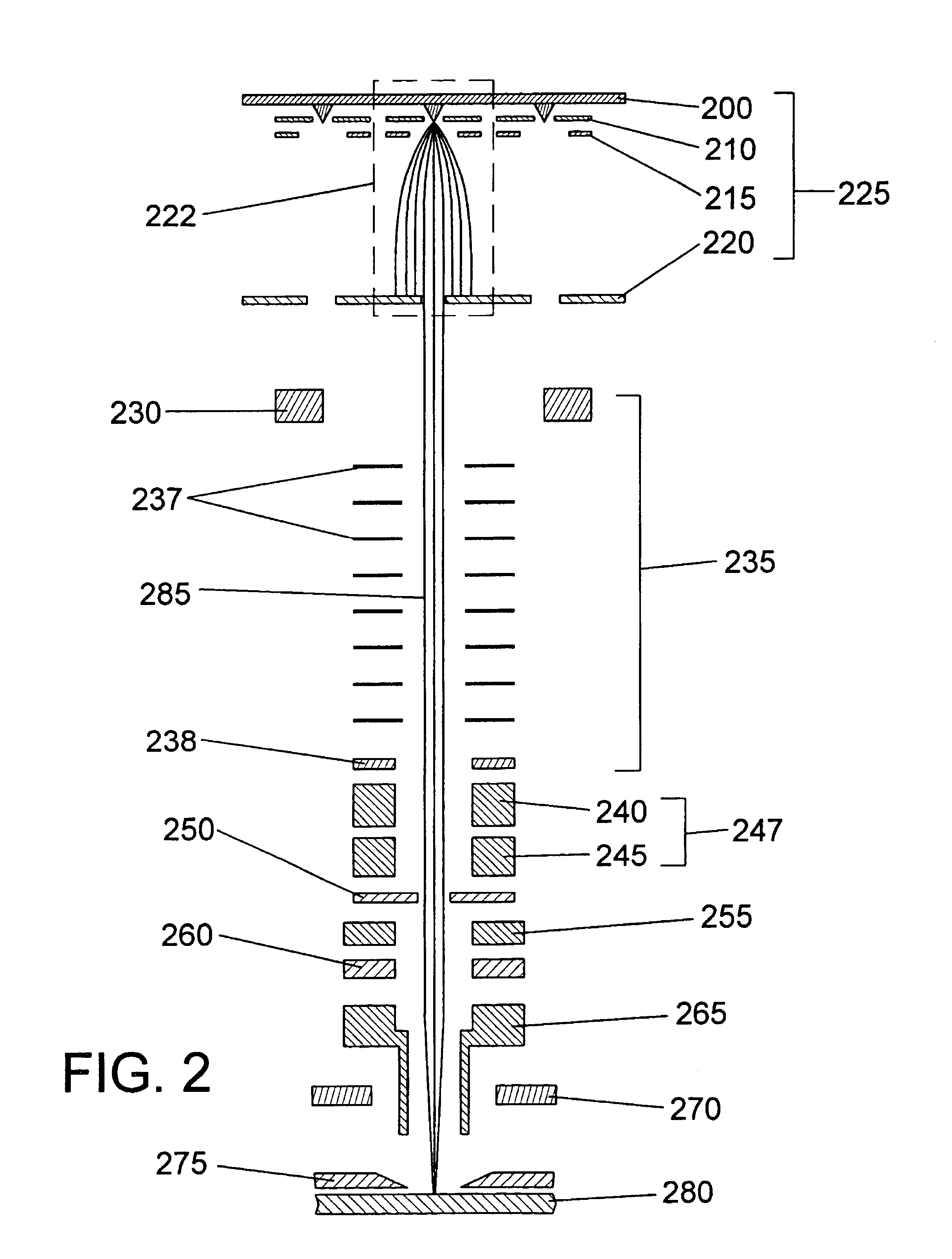

Electron beam apparatus and a device manufacturing method by using said electron beam apparatus

InactiveUS20040119023A1Reduce the overall diameterSmall diameterStability-of-path spectrometersMaterial analysis using wave/particle radiationOptical axisCrystal orientation

An electron beam apparatus, in which an electron beam emitted from an electron gun having a cathode and an anode is focused and irradiated onto a sample, and secondary electrons emanated from the sample are directed into a detector, the apparatus further comprising means for optimizing irradiation of the electron beam emitted from the electron gun onto the sample, the optimizing means may be two-stage deflectors disposed in proximity to the electron gun which deflects and directs the electron beam emitted in a specific direction so as to be in alignment with the optical axis direction of the electron beam apparatus, the electron beam emitted in the specific direction being at a certain angle with respect to the optical axis due to the fact that, among the crystal orientations of said cathode, a specific crystal orientation allowing a higher level of electron beam emission out of alignment with the optical axis direction.

Owner:EBARA CORP

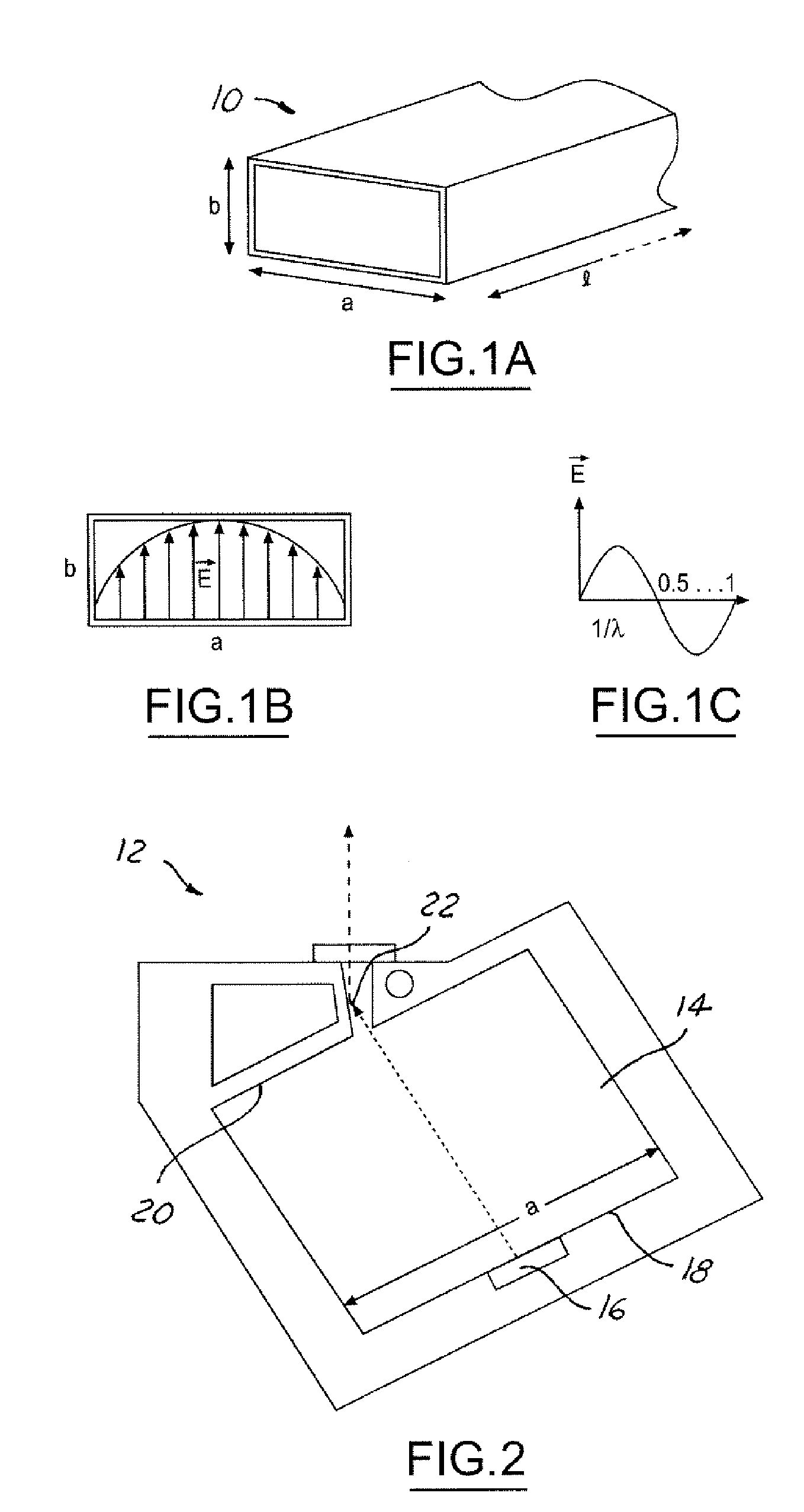

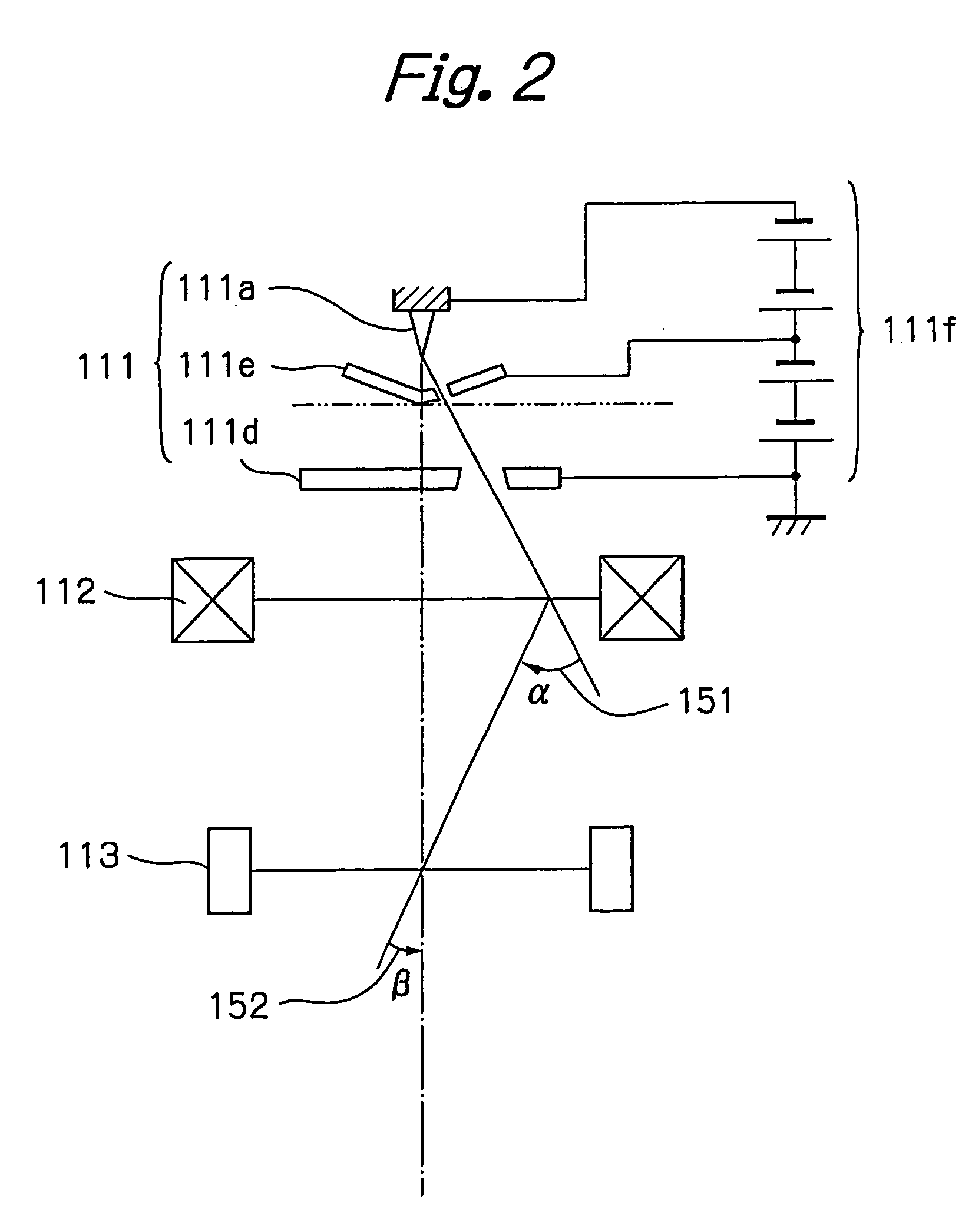

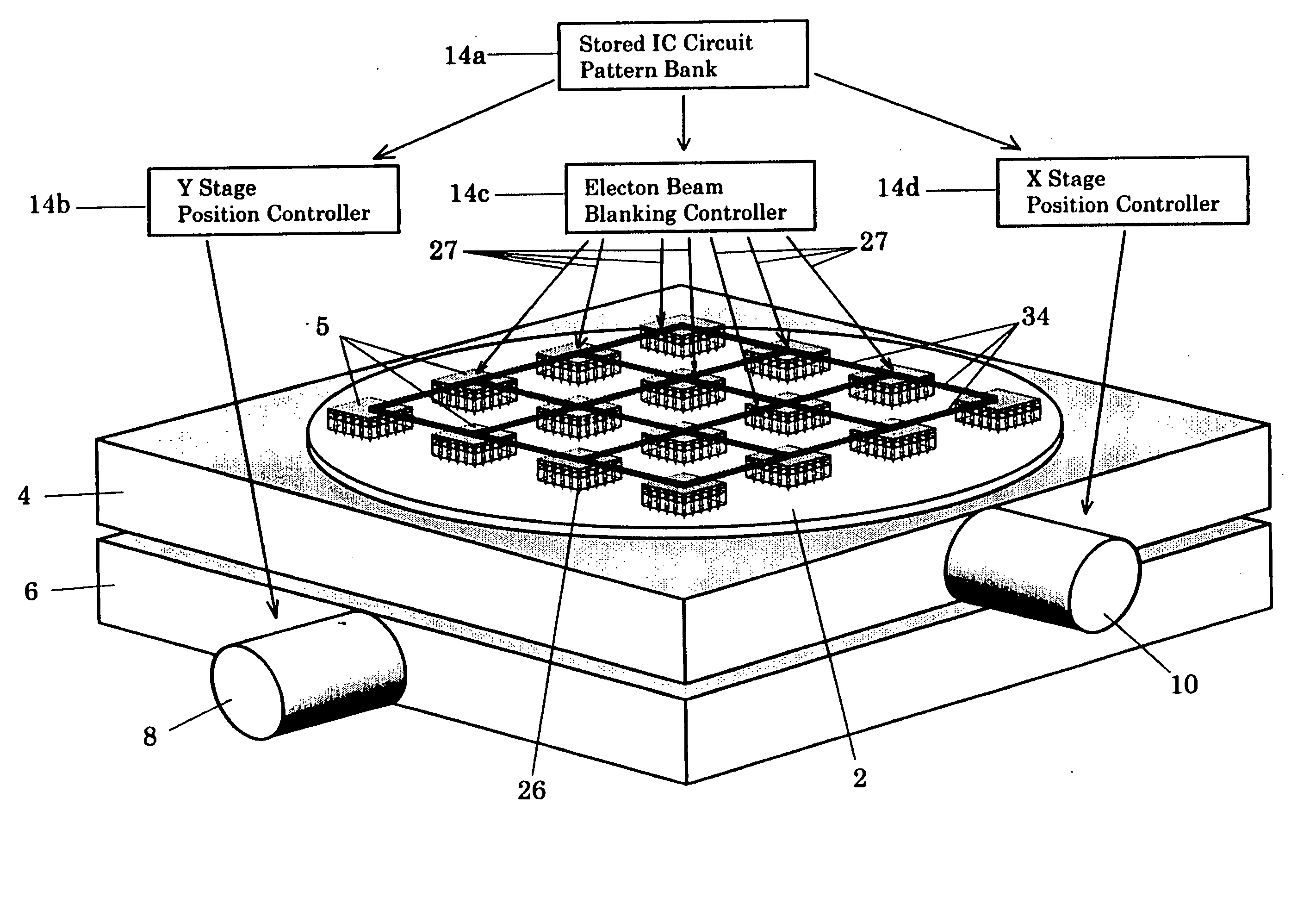

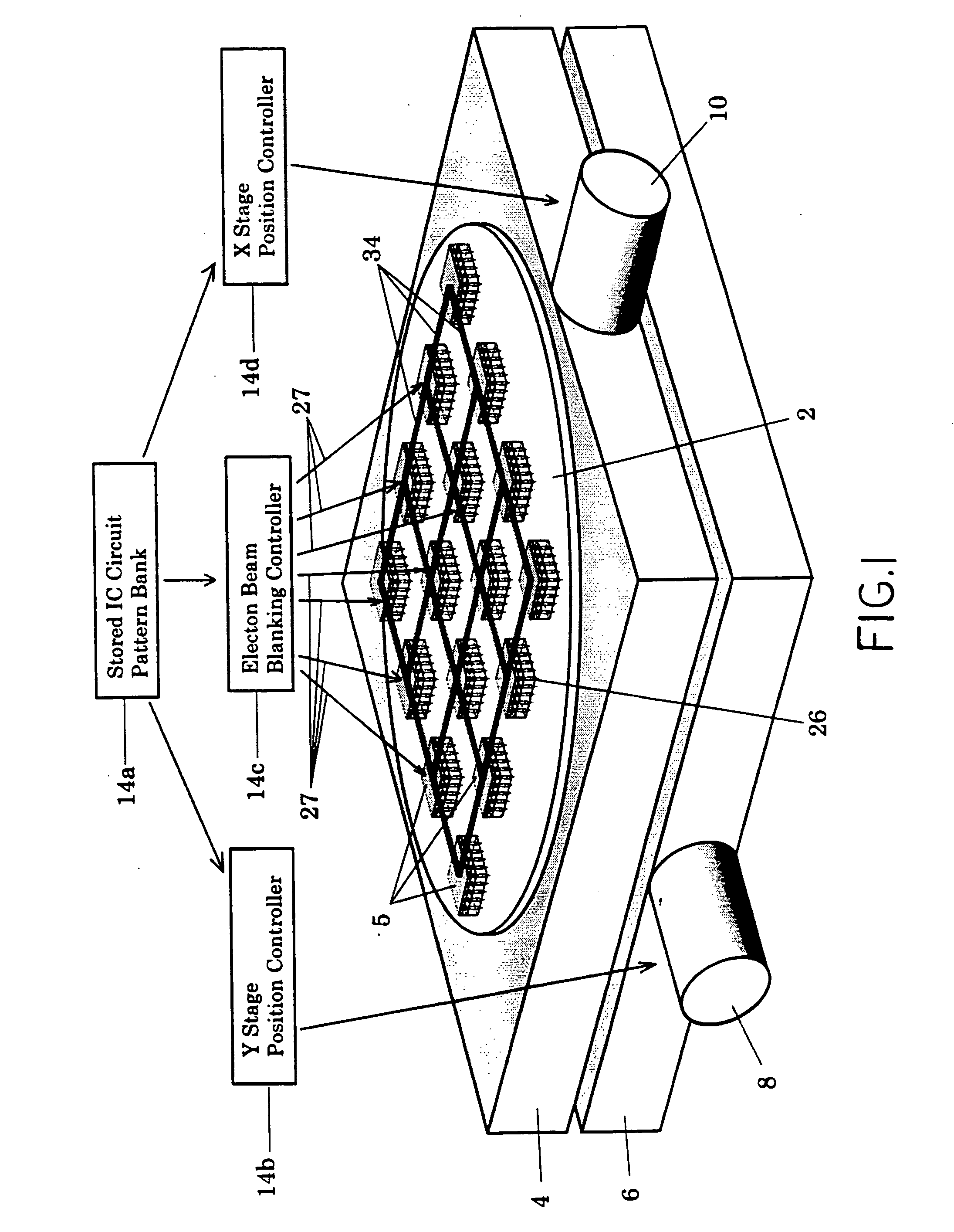

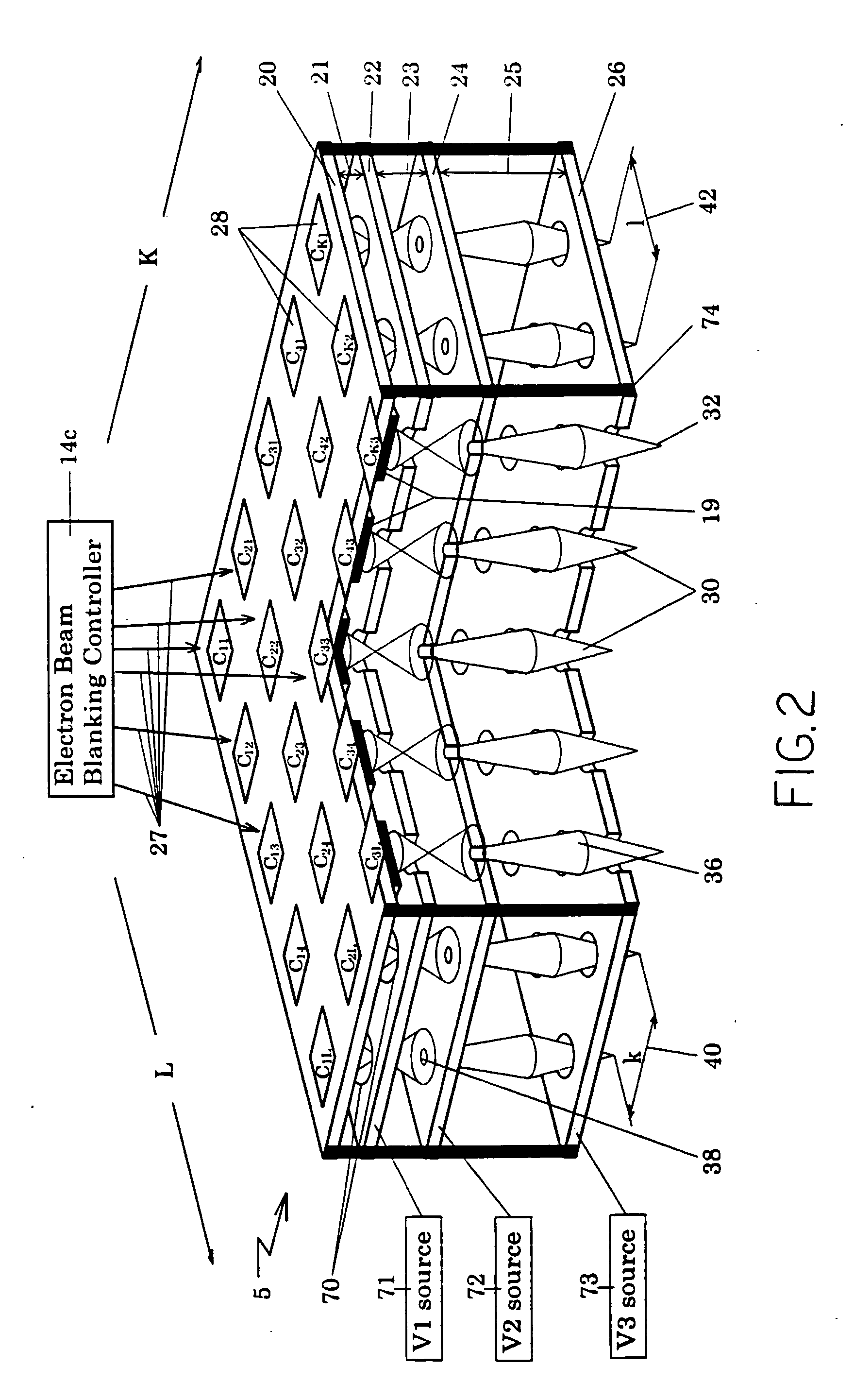

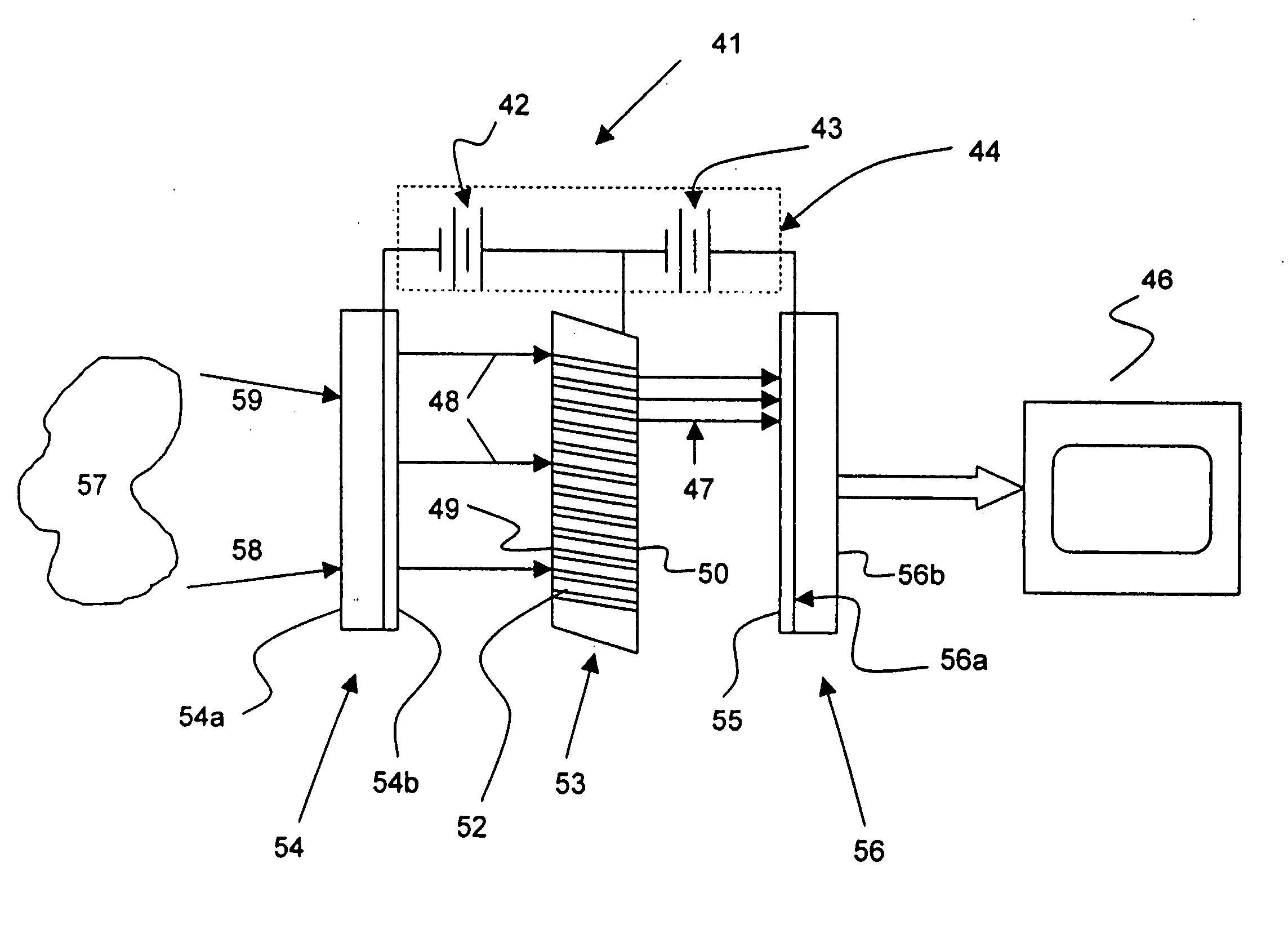

Parallel multi-electron beam lithography for IC fabrication with precise X-Y translation

InactiveUS20050253093A1Low costReduce decreaseMaterial analysis using wave/particle radiationElectric discharge tubesLithographic artistLight beam

A maskless, direct write electron lithography apparatus for accurately and simultaneously writing plural sub-micron patterns on a silicon substrate employs plural parallel electron beams with precise X-Y mechanical translation of the substrate to provide low cost, high throughput integrated circuit (IC) fabrication. Plural compact micro electron gun assemblies arranged in a I×J rectangular grid each simultaneously expose one IC pattern on the substrate, with each electron gun assembly including a K×L array of individually controlled electron guns emitting K×L electron beams. The regular, small spacing between electron beams in each array, i.e., approximately 1 mm or less, requires a correspondingly small X-Y translation of the substrate to write the entire wafer. Each electron gun array includes plural AC blanked cathodes and DC biased plates having plural aligned beam passing apertures. A computer controlled pattern generator synchronized with wafer X-Y translation controls the duration and timing of the cathode blanking signals.

Owner:GORSKI RICHARD M +2

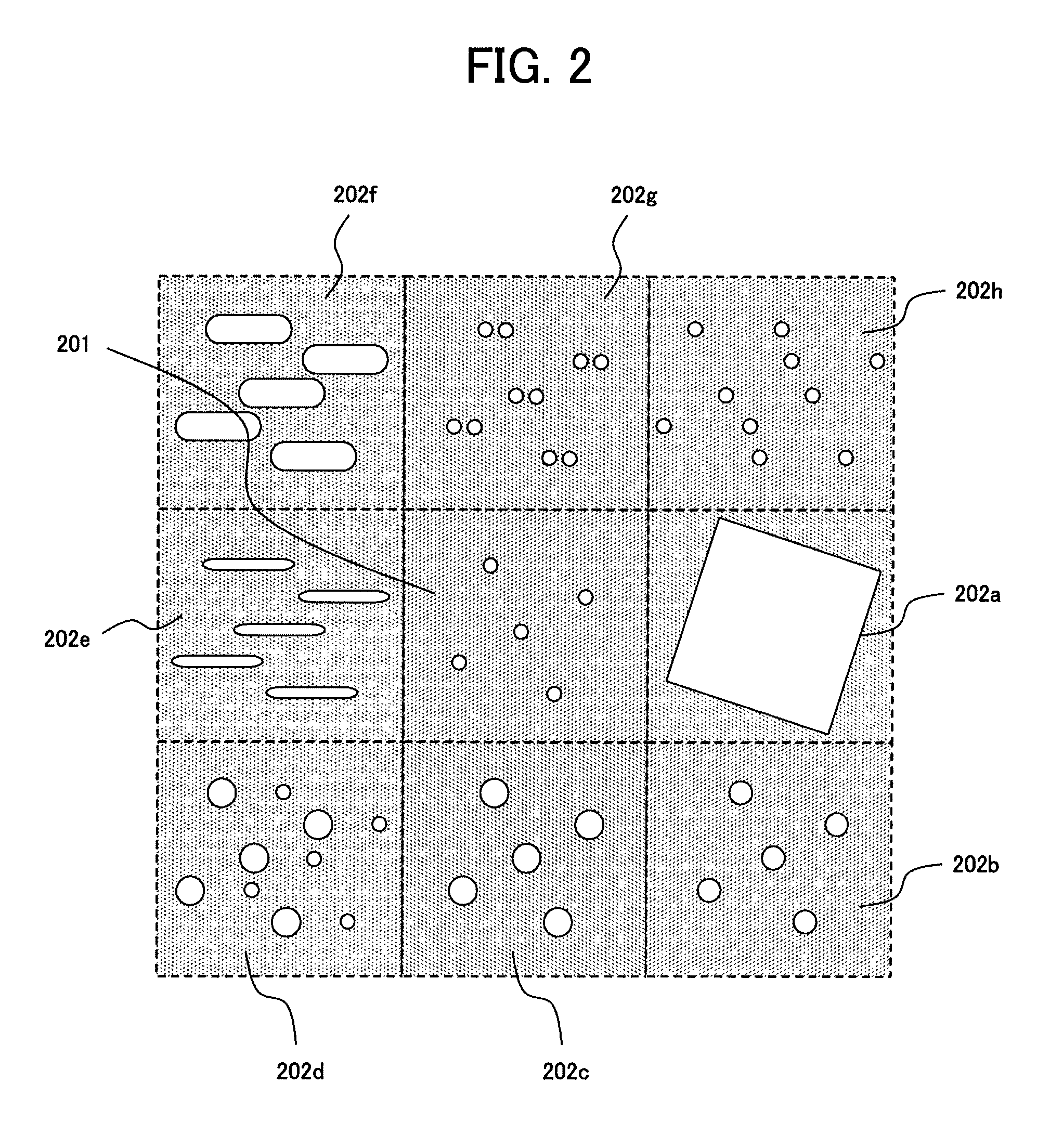

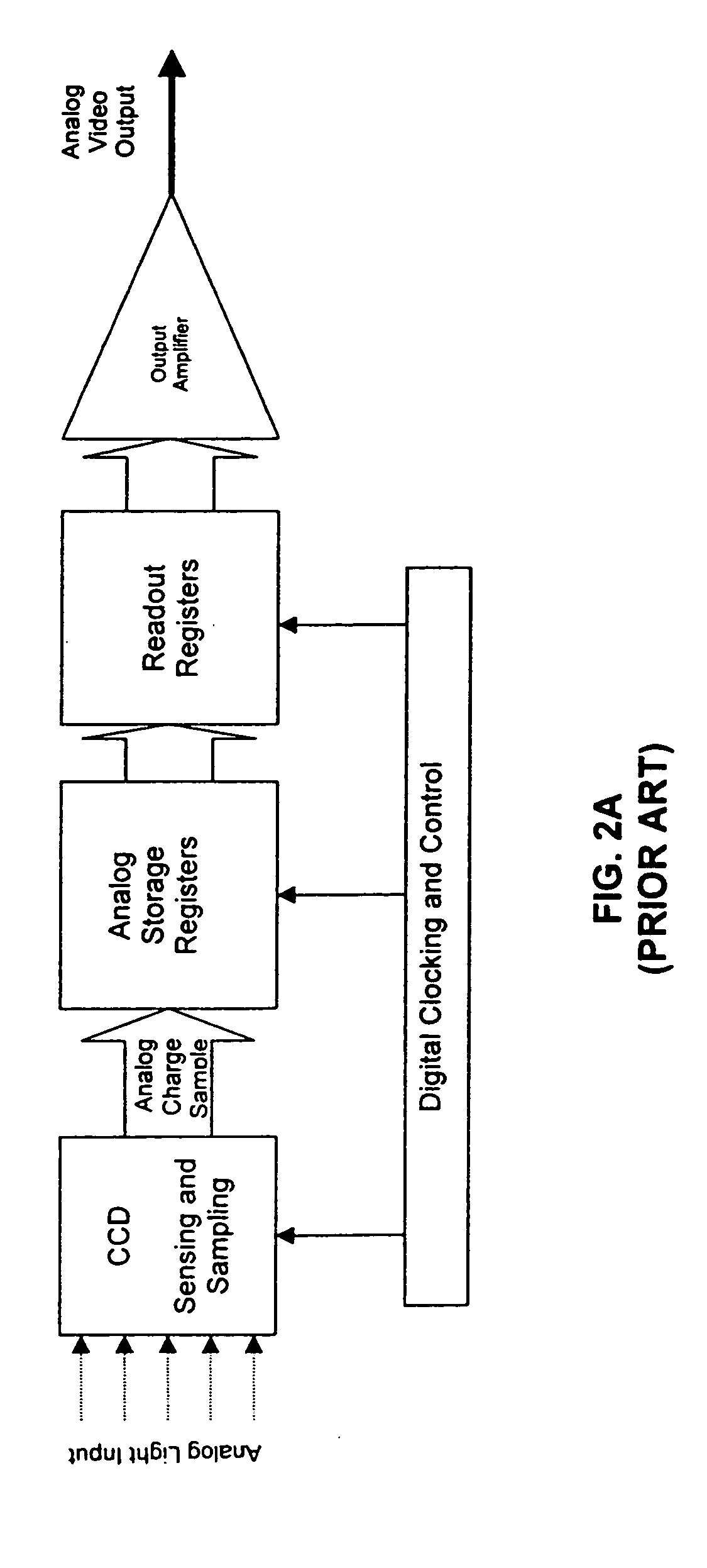

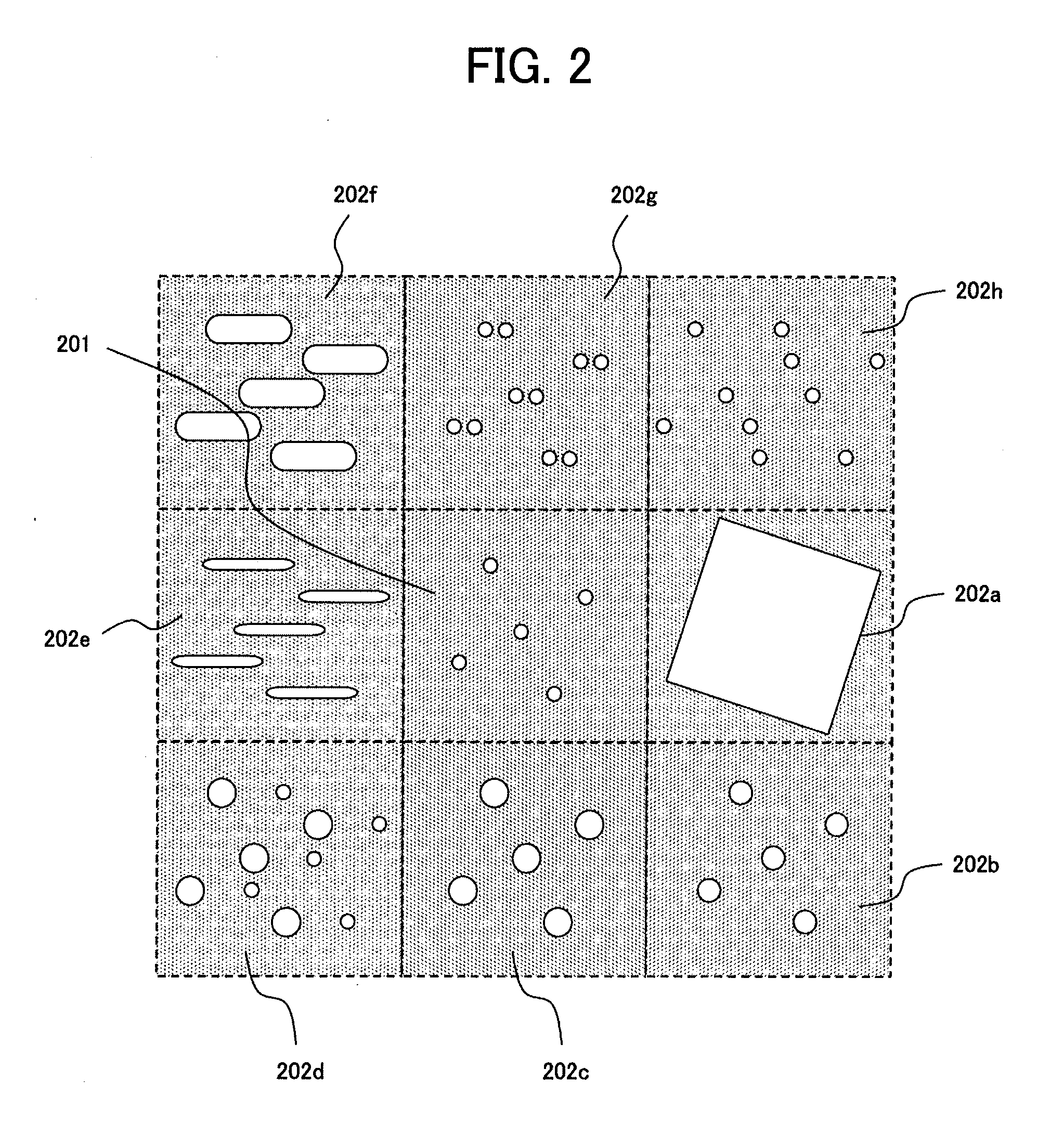

Intensified hybrid solid-state sensor

InactiveUS20050167575A1Television system detailsMaterial analysis by optical meansChannel patternImage signal

An intensified solid-state imaging sensor includes a photo cathode for converting light from an image into electrons, an electron multiplying device for receiving electrons from the photo cathode, and a solid-state image sensor including a plurality of pixels for receiving the electrons from the electron multiplying device through a plurality of channels of the electron multiplying device. The solid-state image sensor generates an intensified image signal from the electrons received from the electron multiplying device. The plurality of channels are arranged in a plurality of channel patterns, and the plurality of pixels are arranged in a plurality of pixel patterns. Each of the plurality of channel patterns is mapped to a respective one of the plurality of pixel patterns such that electron signals from each of the plurality of channel patterns is substantially received by the single respective one of the plurality of pixel patterns.

Owner:ELBIT SYSTEMS OF AMERICA LLC

Multi-beam multi-column electron beam inspection system

ActiveUS6977375B2Material analysis using wave/particle radiationRadiation/particle handlingData streamSecondary electrons

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

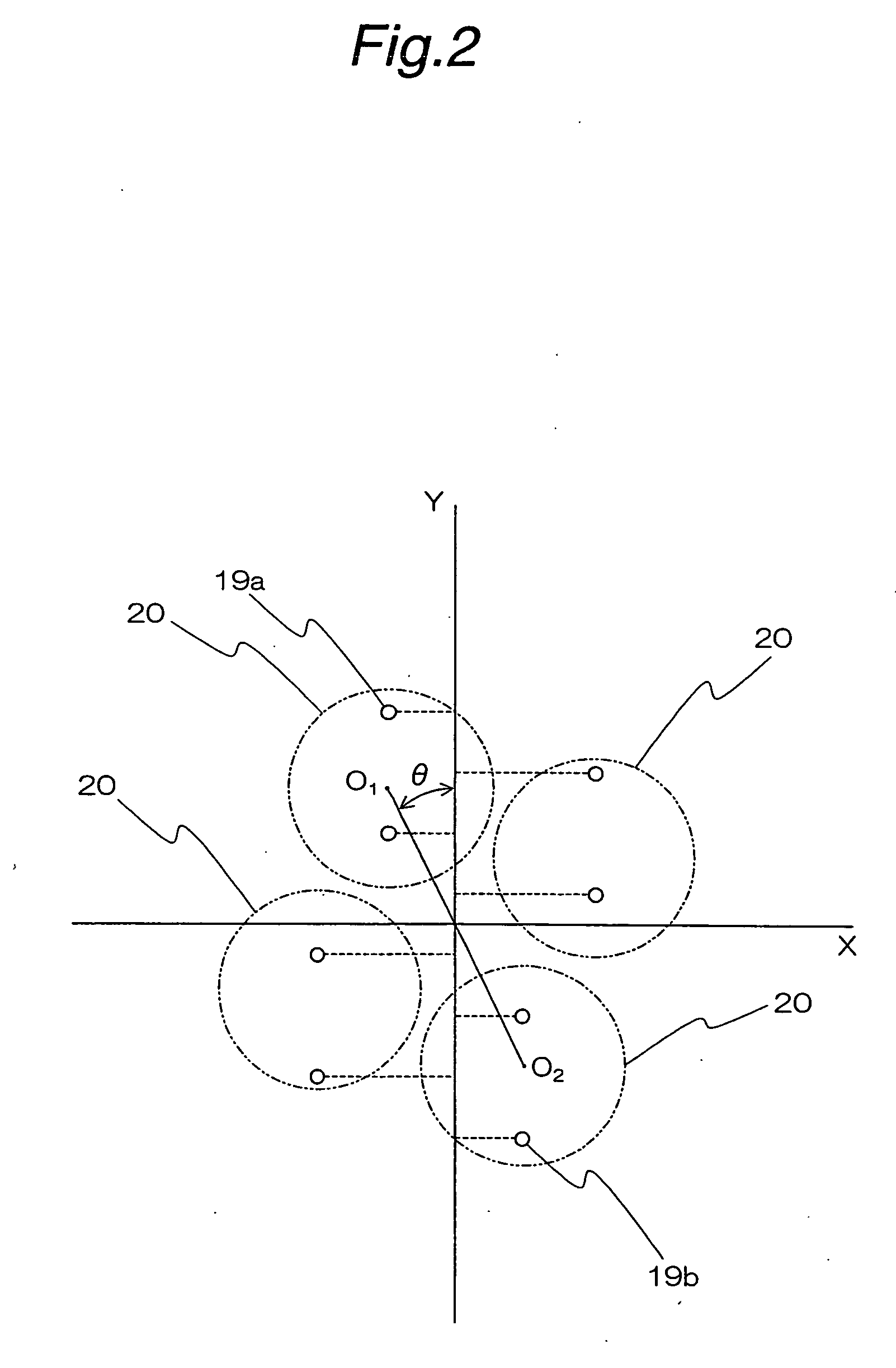

Electron beam apparatus and method of manufacturing semiconductor device using the apparatus

ActiveUS7095022B2Improve throughputReduce throughputMaterial analysis using wave/particle radiationElectric discharge tubesOptical axisSecondary electrons

The present invention provides an electron beam apparatus for irradiating a sample with primary electron beams to detect secondary electron beams generated from a surface of the sample by the irradiation for evaluating the sample surface. In the electron beam apparatus, an electron gun has a cathode for emitting primary electron beams. The cathode includes a plurality of emitters for emitting primary electron beams, arranged apart from one another on a circle centered at an optical axis of a primary electro-optical system. The plurality of emitters are arranged such that when the plurality of emitters are projected onto a straight line parallel with a direction in which the primary electron beams are scanned, resulting points on the straight line are spaced at equal intervals.

Owner:EBARA CORP

System and method for evaluation using electron beam and manufacture of devices

InactiveUS20060060790A1Extended service lifeEliminate the effects ofMaterial analysis using wave/particle radiationElectric discharge tubesMagnifying glassElectron gun

An electron beam apparatus having a longer life time of cathode, and allowing a plurality of electron beams to be arranged adequately around an optical axis and five or more electron beams to be formed from a single electron gun. The electron beams emitted from a cathode made of ZrO / W (tungsten zirconium oxide) or a cathode made of carbide of transition metal to the off-optical axis directions may be converged on a sample to scan it. The apparatus includes a plate for reducing a vacuum conductance defined between the electron gun chamber side and the sample side, and apertures are formed through the plate at locations offset from the optical axis allowing for the passage of the electron beams. In order to evaluate a pattern on the sample, the electron beam emitted from the electron gun is incident to the sample surface via an objective lens. The objective lens is composed of a flat electrode having an aperture centered on the optical axis and placed in parallel with the sample surface and an electromagnetic lens including a gap formed in a side facing to the sample. Further, in order to inspect a mask, spacing among a plurality of electron beams after having passed through the mask are extended by a magnifying lens and thus widely spaced electron beams are then converted into optical signal in a scintillator.

Owner:EBARA CORP

Charged particle beam applied apparatus

ActiveUS20110272576A1Easy to implementMaterial analysis using wave/particle radiationElectric discharge tubesBeam scanningSource image

Provided is a multi-beam type charged particle beam applied apparatus in an implementable configuration, capable of achieving both high detection accuracy of secondary charged particles and high speed of processing characteristically different specimens. An aperture array (111) includes plural aperture patterns. A deflector (109) for selecting an aperture pattern through which a primary beam passes is disposed at the position of a charged particle source image created between an electron gun (102), i.e., a charged particle source, and the aperture array (111). At the time of charge-control beam illumination and at the time of signal-detection beam illumination, an aperture pattern of the aperture array (111) is selected, and conditions of a lens array (112), surface electric-field control electrode (118) and the like are switched in synchronization with each beam scanning. Thus, the charges are controlled and the signals are detected at different timings under suitable conditions, respectively.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com