Patents

Literature

448results about "Discharge tube electron guns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

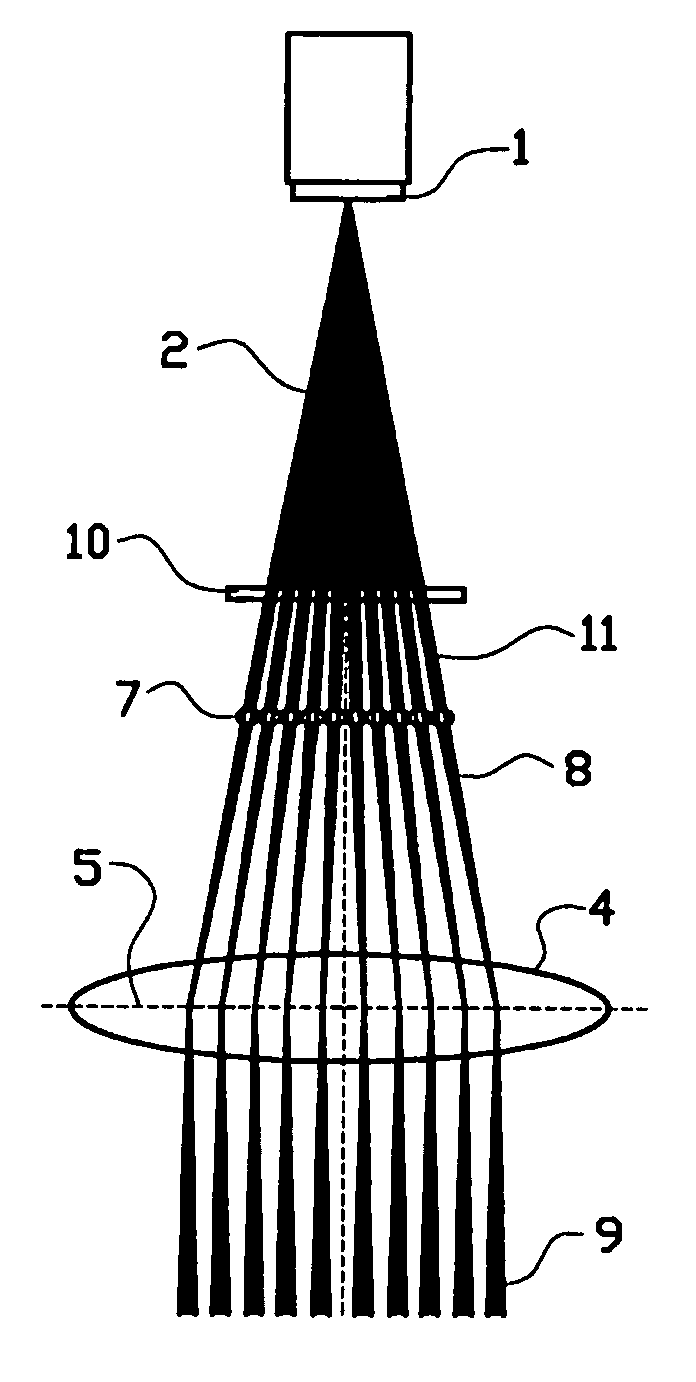

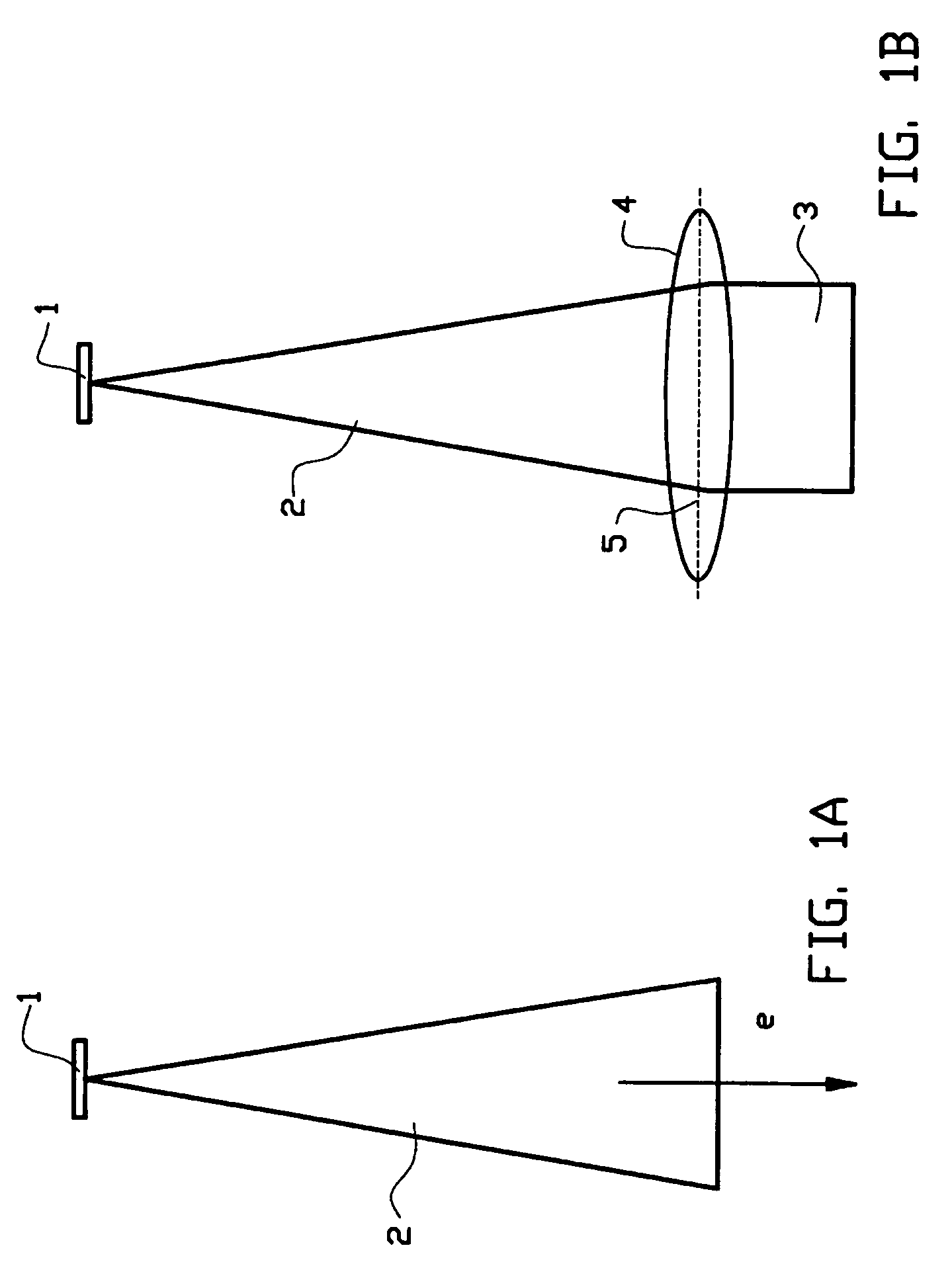

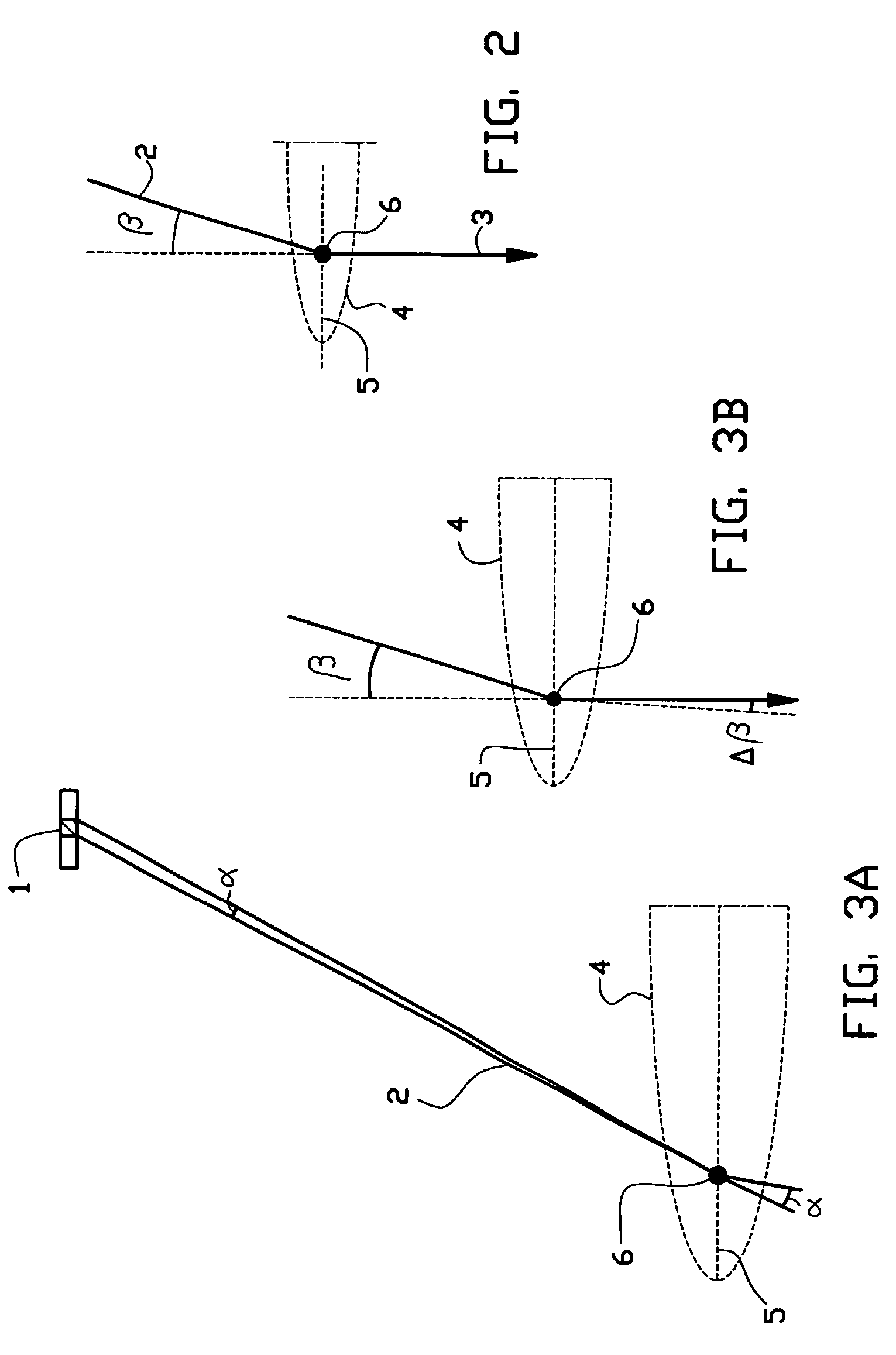

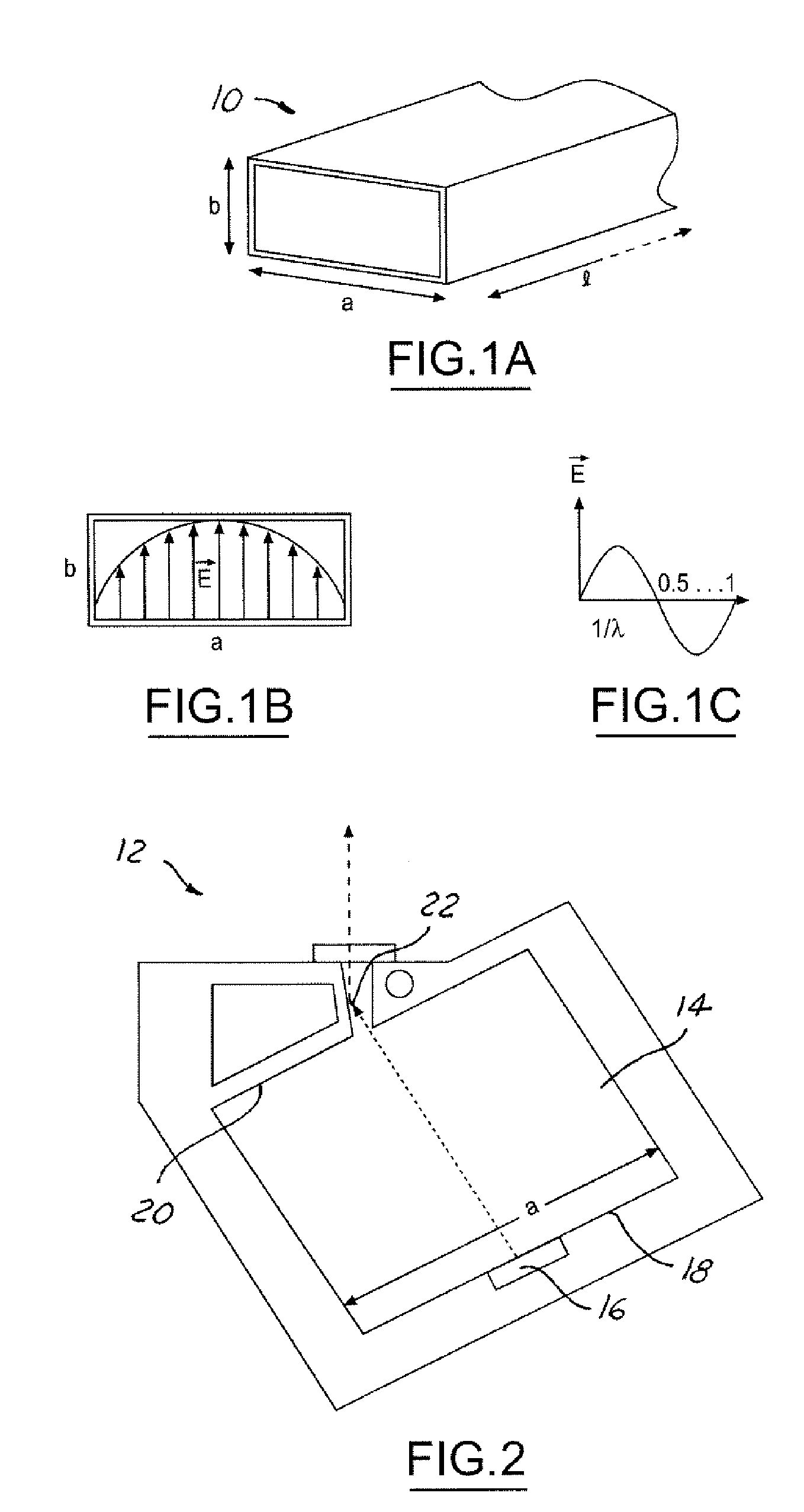

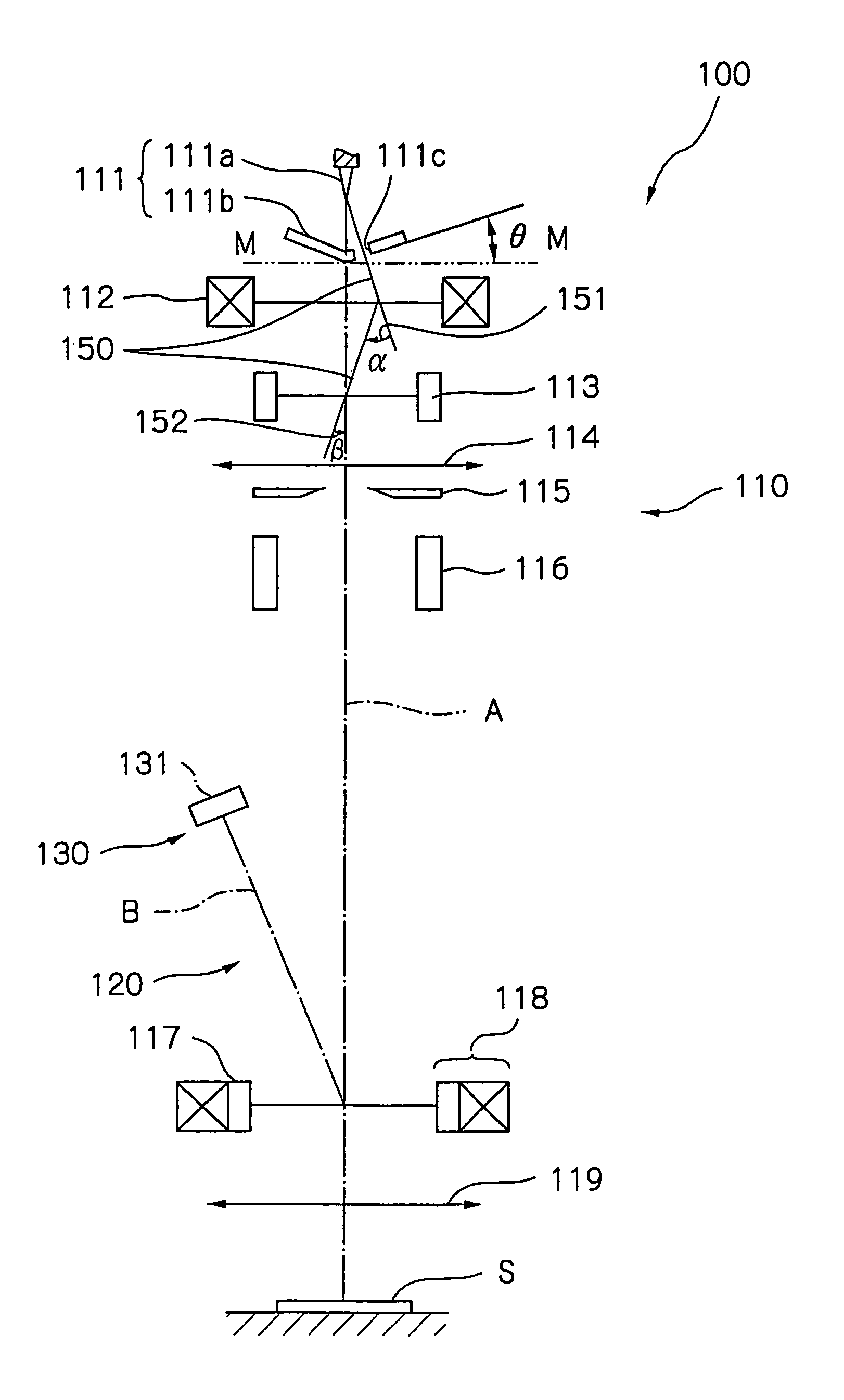

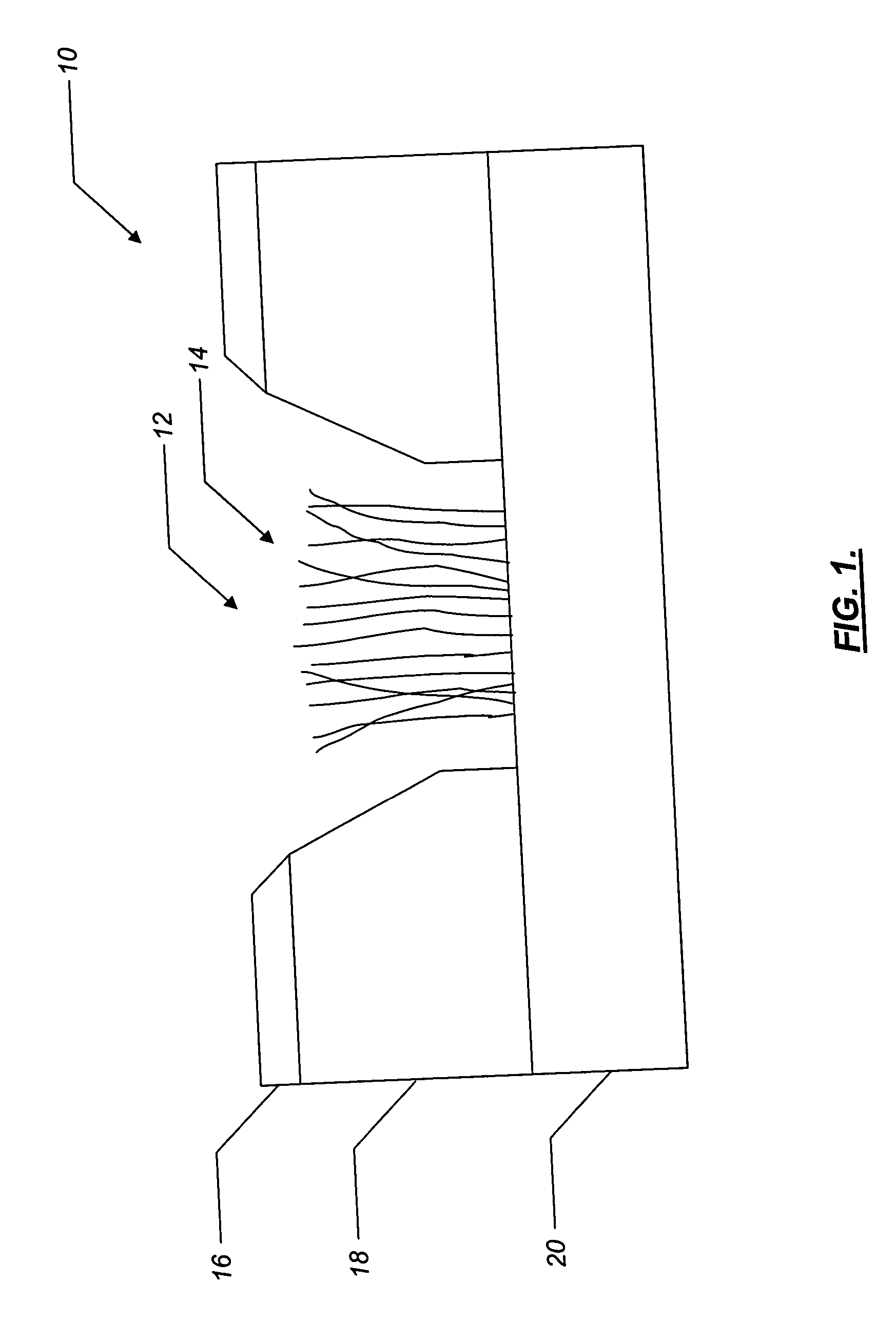

Apparatus for generating a plurality of beamlets

ActiveUS7129502B2Reduce blurThermometer detailsStability-of-path spectrometersMolecular physicsCharged particle beam

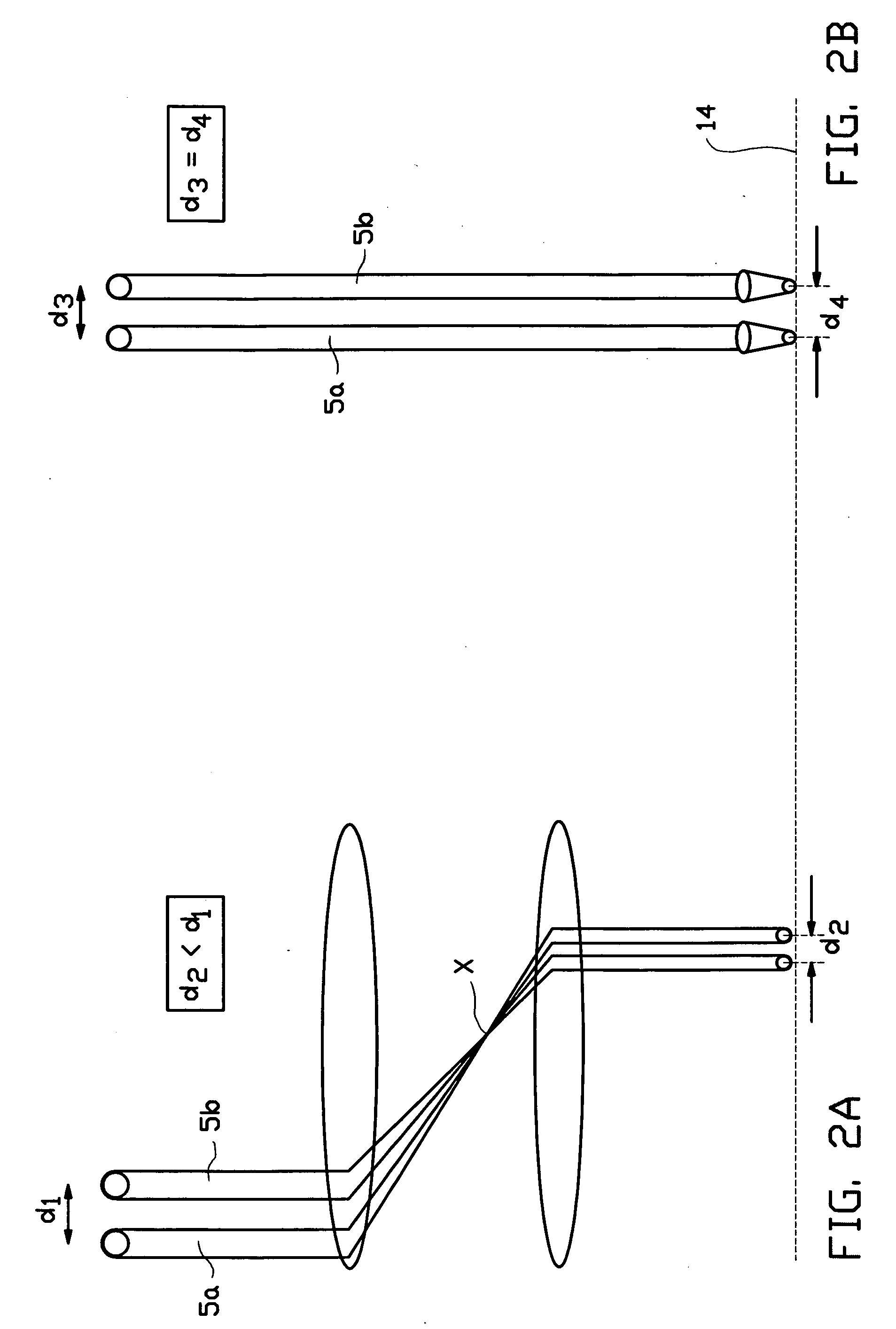

The invention relates to an apparatus for generating a plurality of charged particle beamlets, comprising a charged particle source for generating a diverging charged particle beam, a converging means for refracting said diverging charged particle beam and a lens array comprising a plurality of lenses, wherein said lens array is located between said charged particle source and said converging means.In this way, it is possible to reduce aberrations of the converging means.

Owner:ASML NETHERLANDS BV

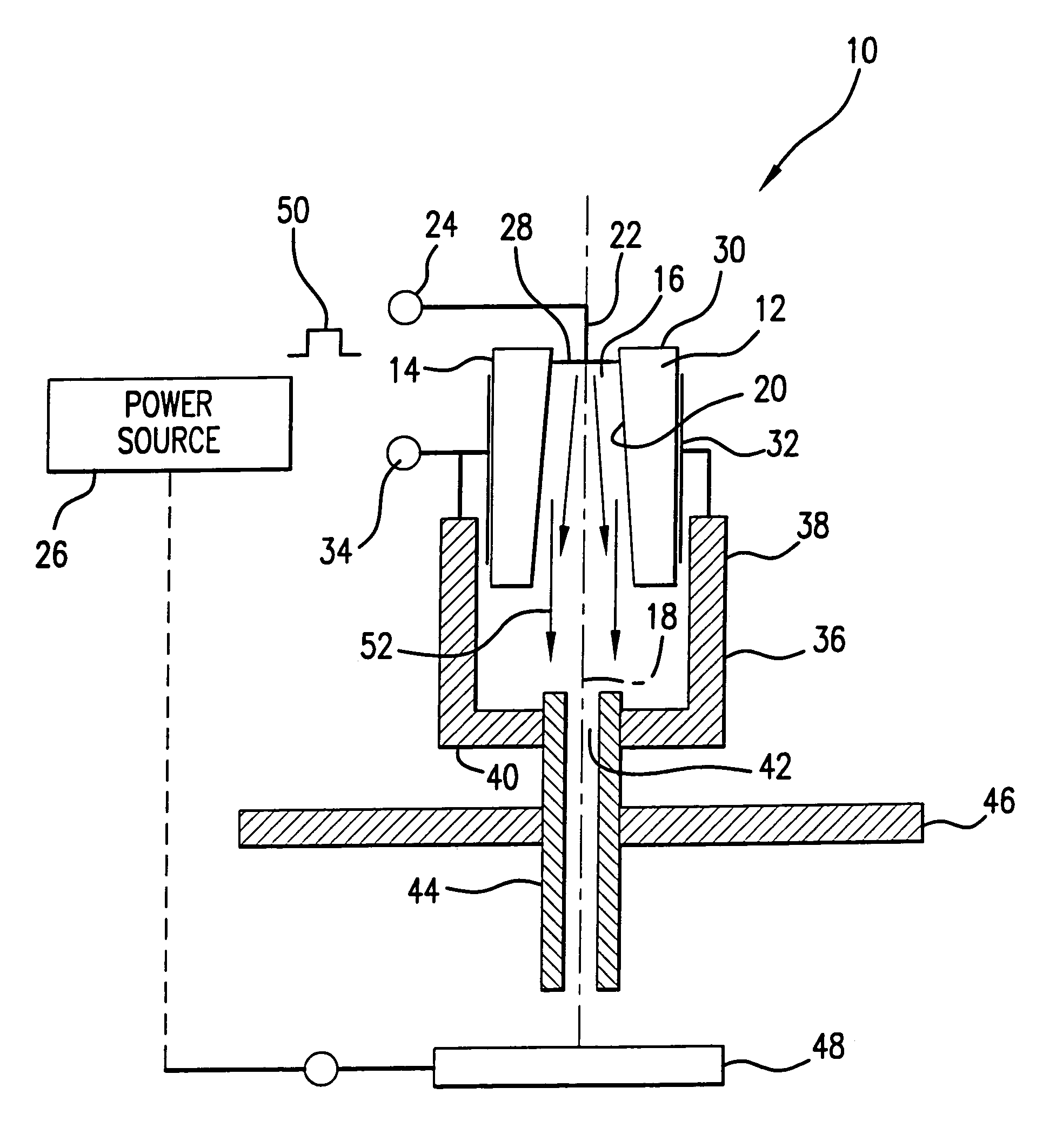

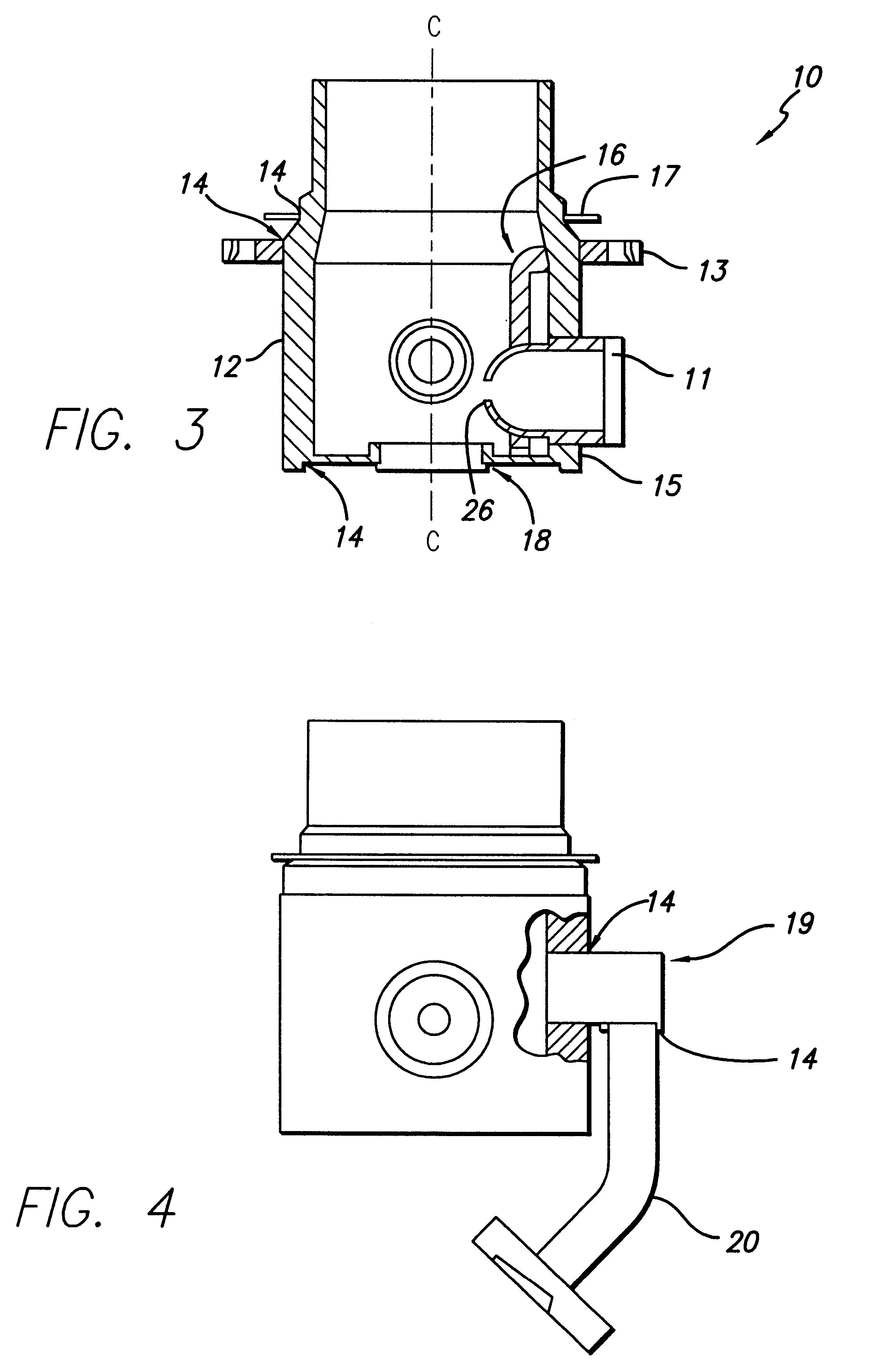

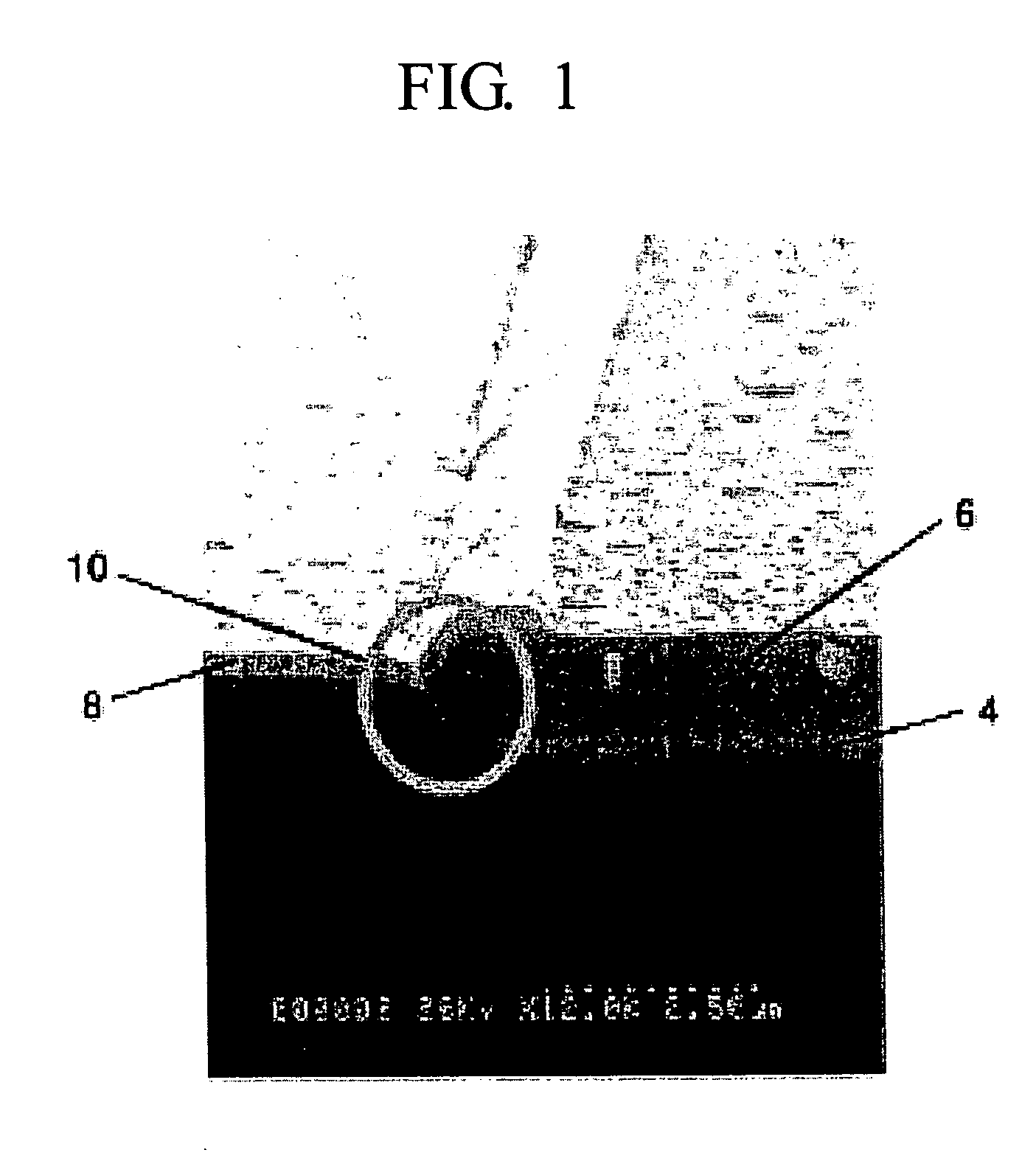

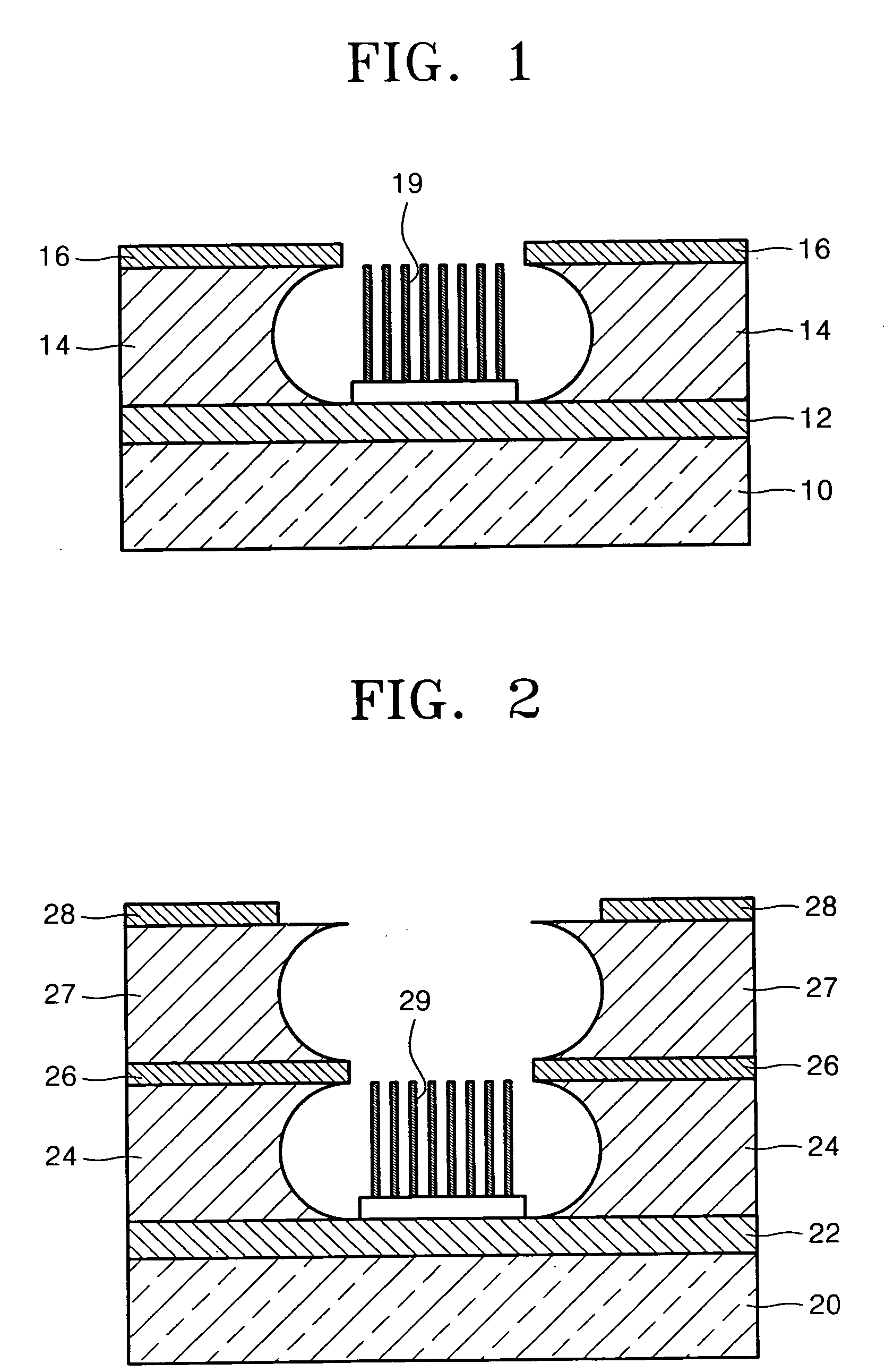

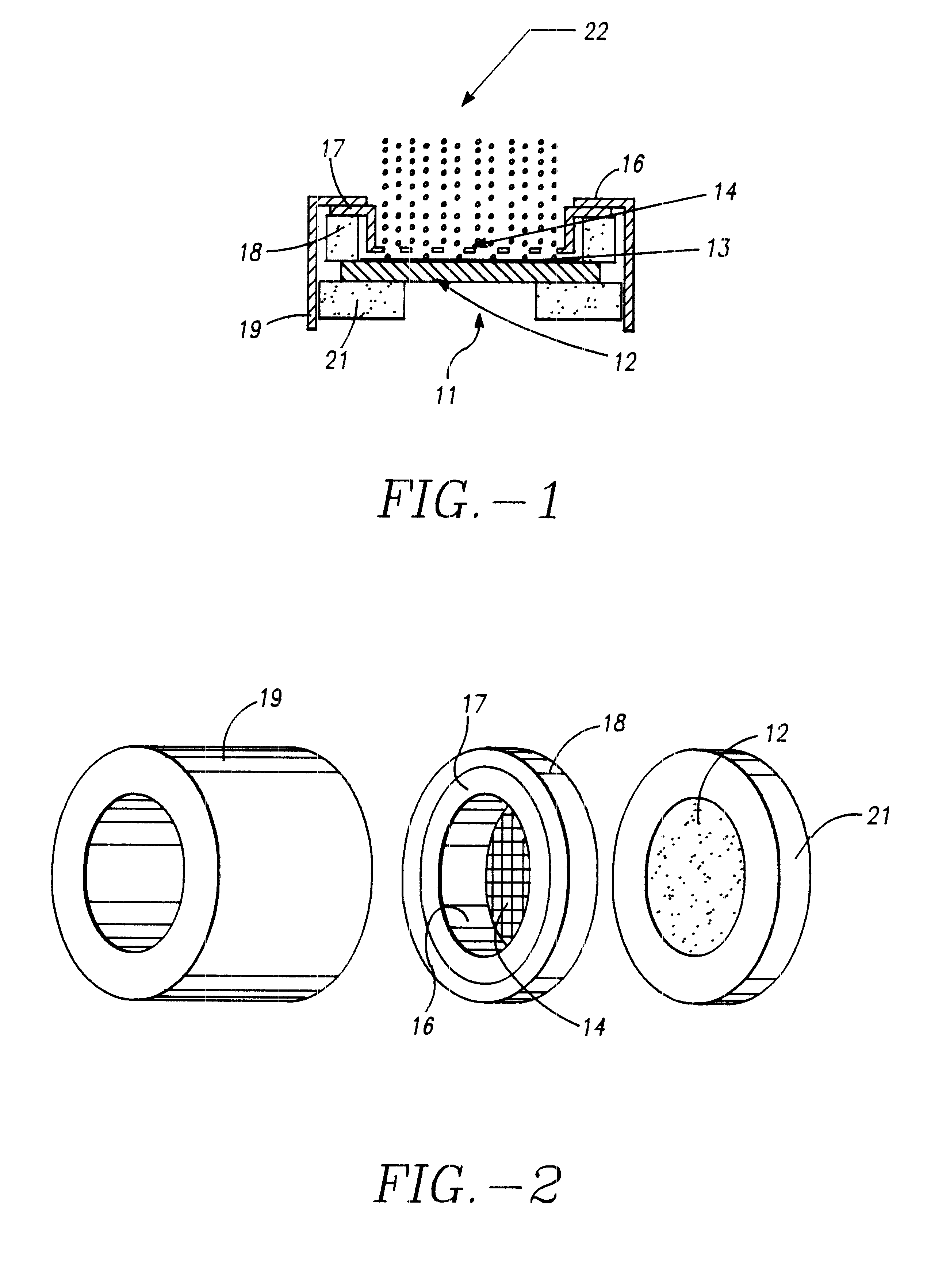

Cylindrical electron beam generating/triggering device and method for generation of electrons

ActiveUS7122949B2Intensity controllableLong lastingDischarge tube electron gunsSolid cathode detailsDielectricElectron source

A surface discharge device performing functions of a trigger and electron beam generator includes a cylinder shaped member formed from a dielectric material with dielectric constant ε>100, in which a central opening is formed having a conical or cylindrical shape. An internal electrode is electrically coupled to the internal surface of the cylinder shaped member. An external electrode covers the external surface of the cylinder shaped member. A triggering pulse is applied between the external and internal electrodes to generate emission of electrons in the central opening and formation of the conducting plasma to ignite the device and serve as a source of electrons for generating an electron beam. The conducting plasma charges a capacitor formed by the cylinder shaped dielectric member and the external electrode. The cylinder shaped member is positioned in a hollow cathode having a central bore hole in the bottom. An anode is positioned remotely from the cathode and an electric field exists dynamically in space between the cathode and anode for at least a portion of the duration of the triggering pulse.

Owner:NEOCERA

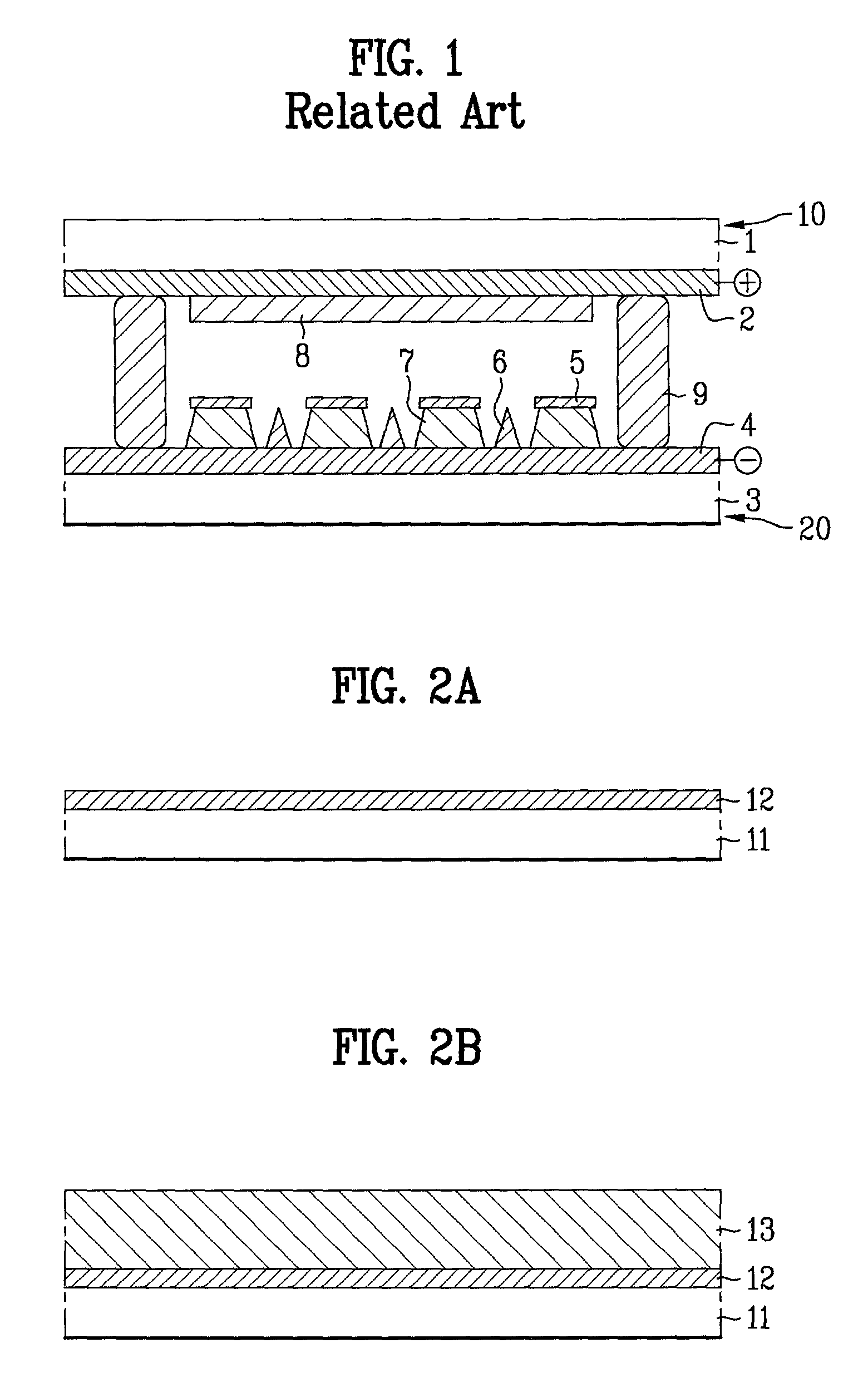

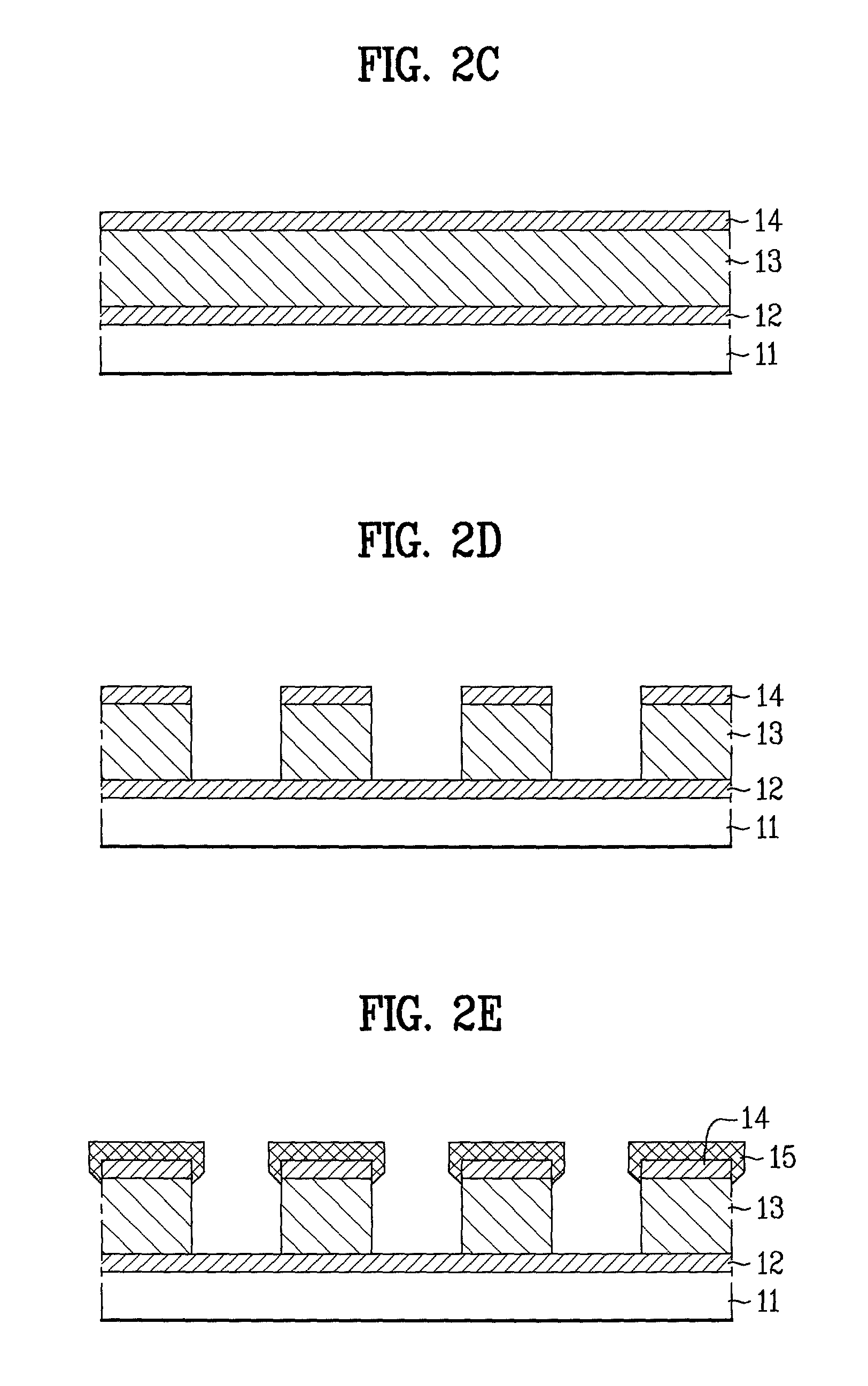

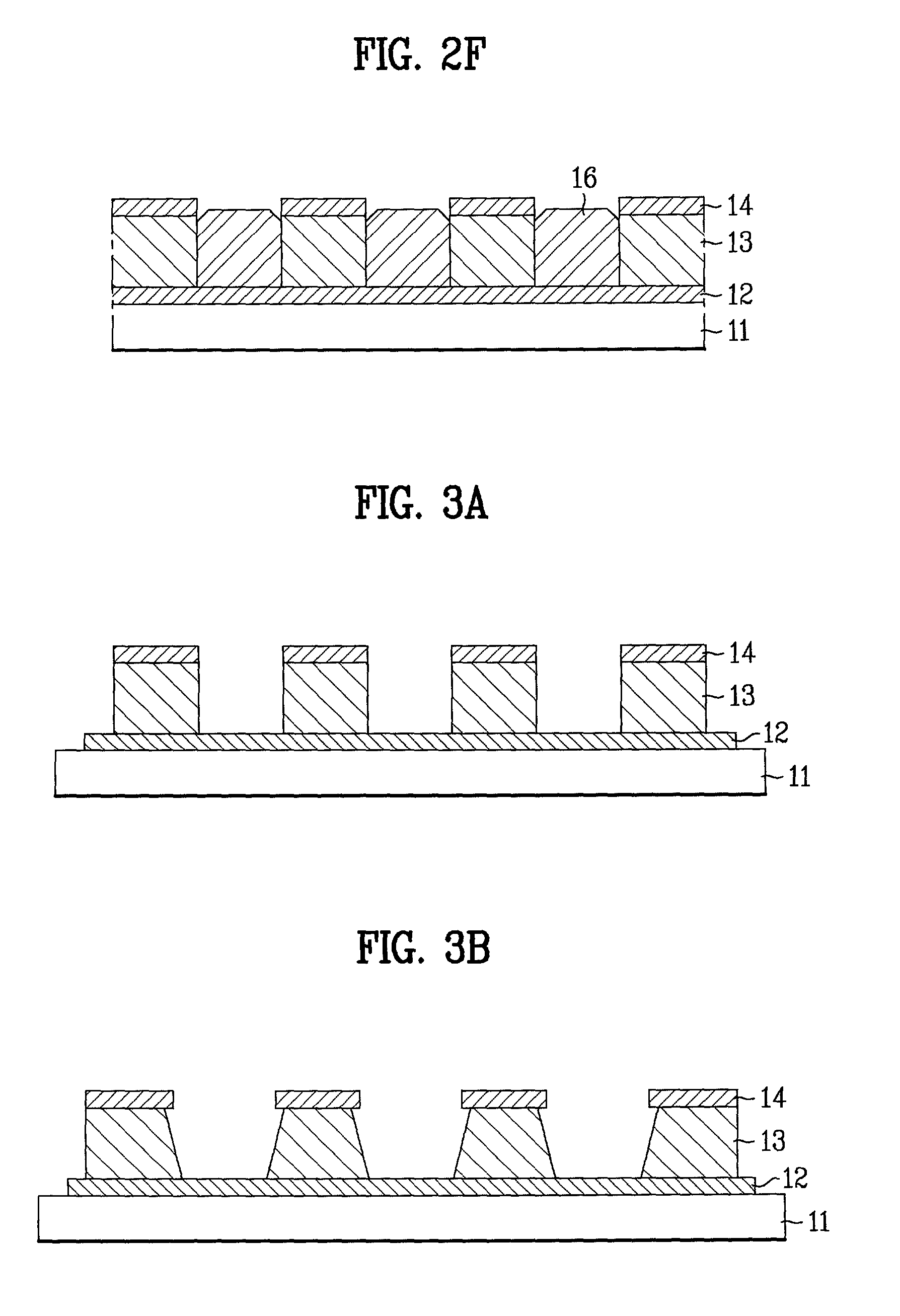

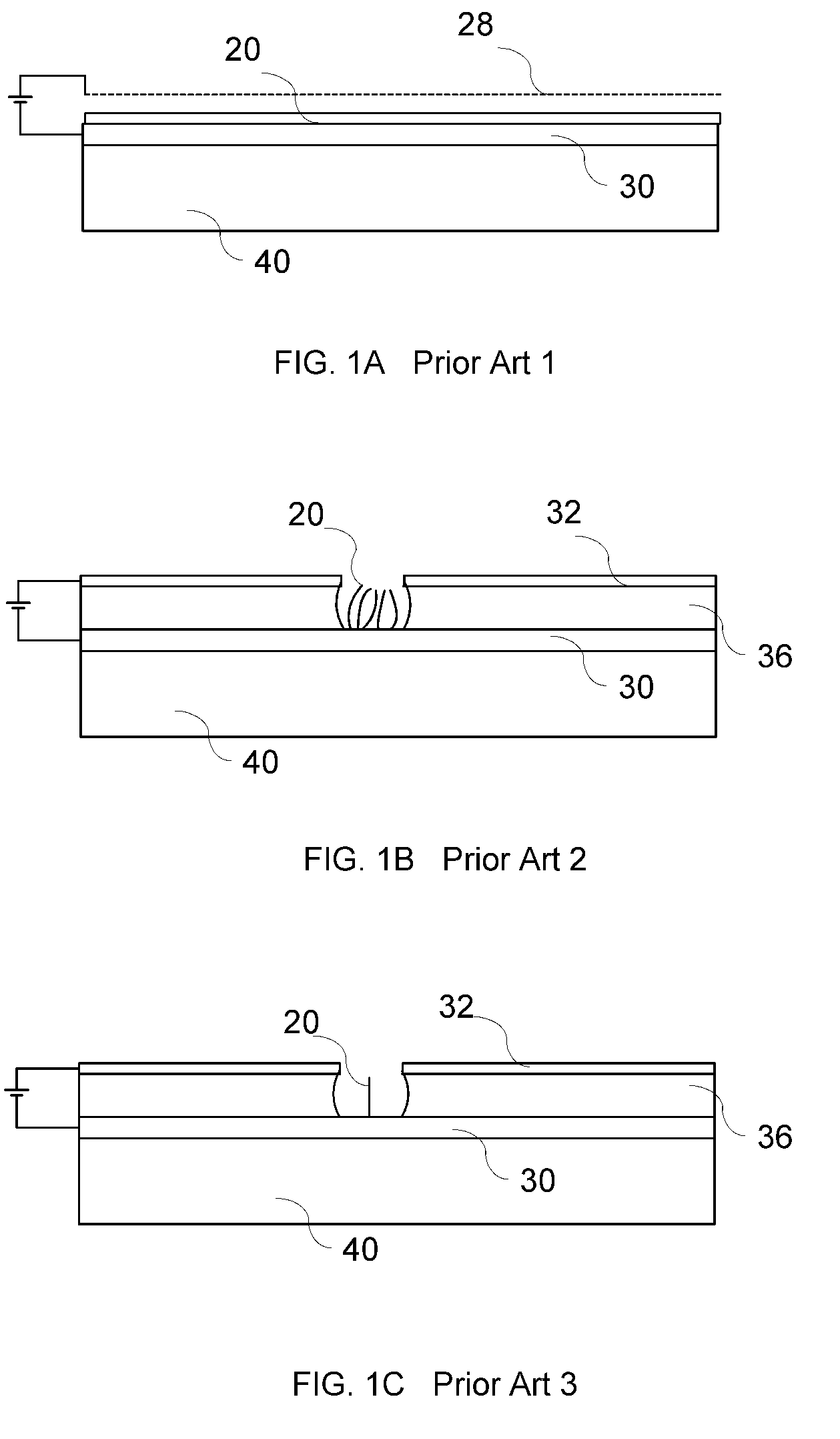

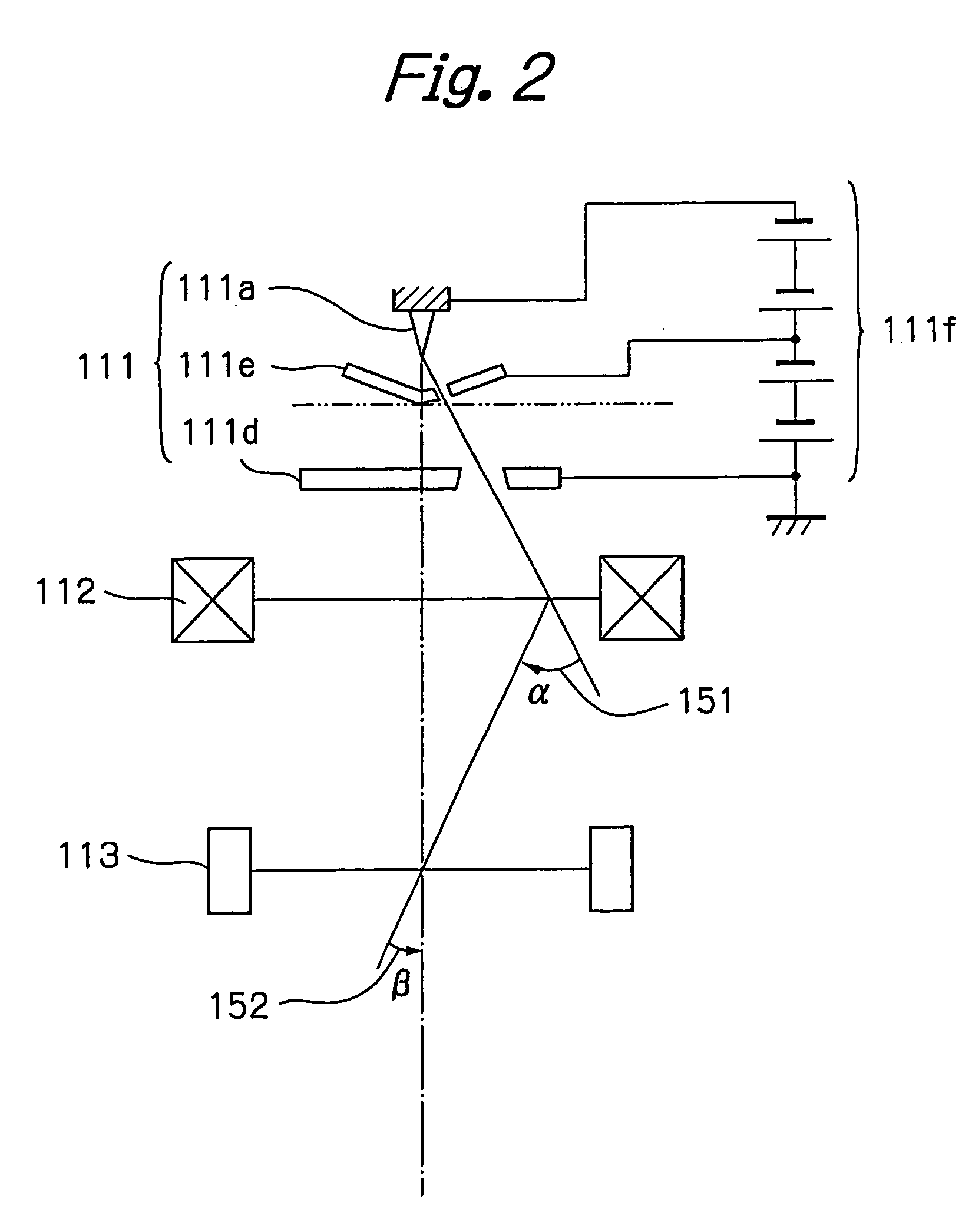

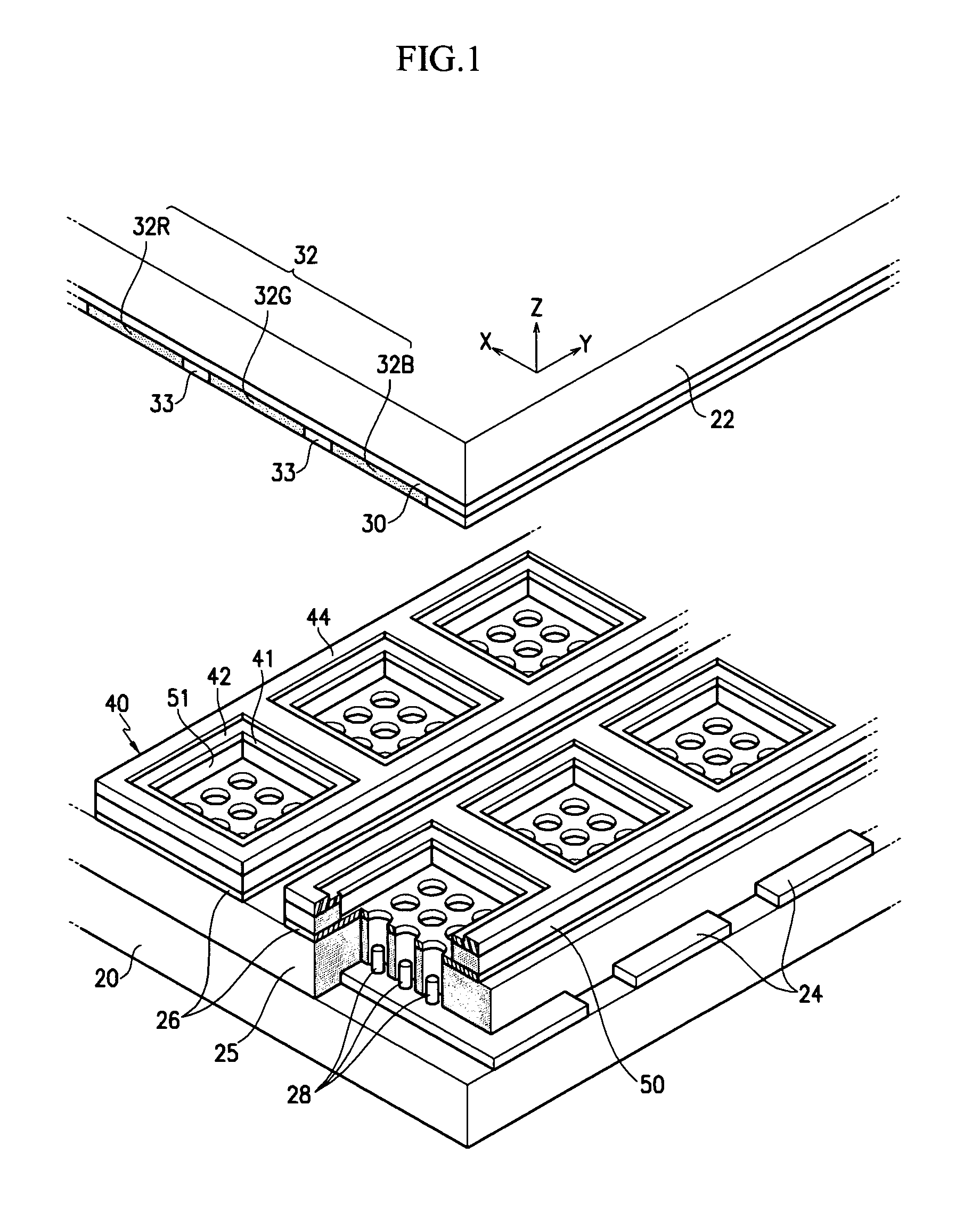

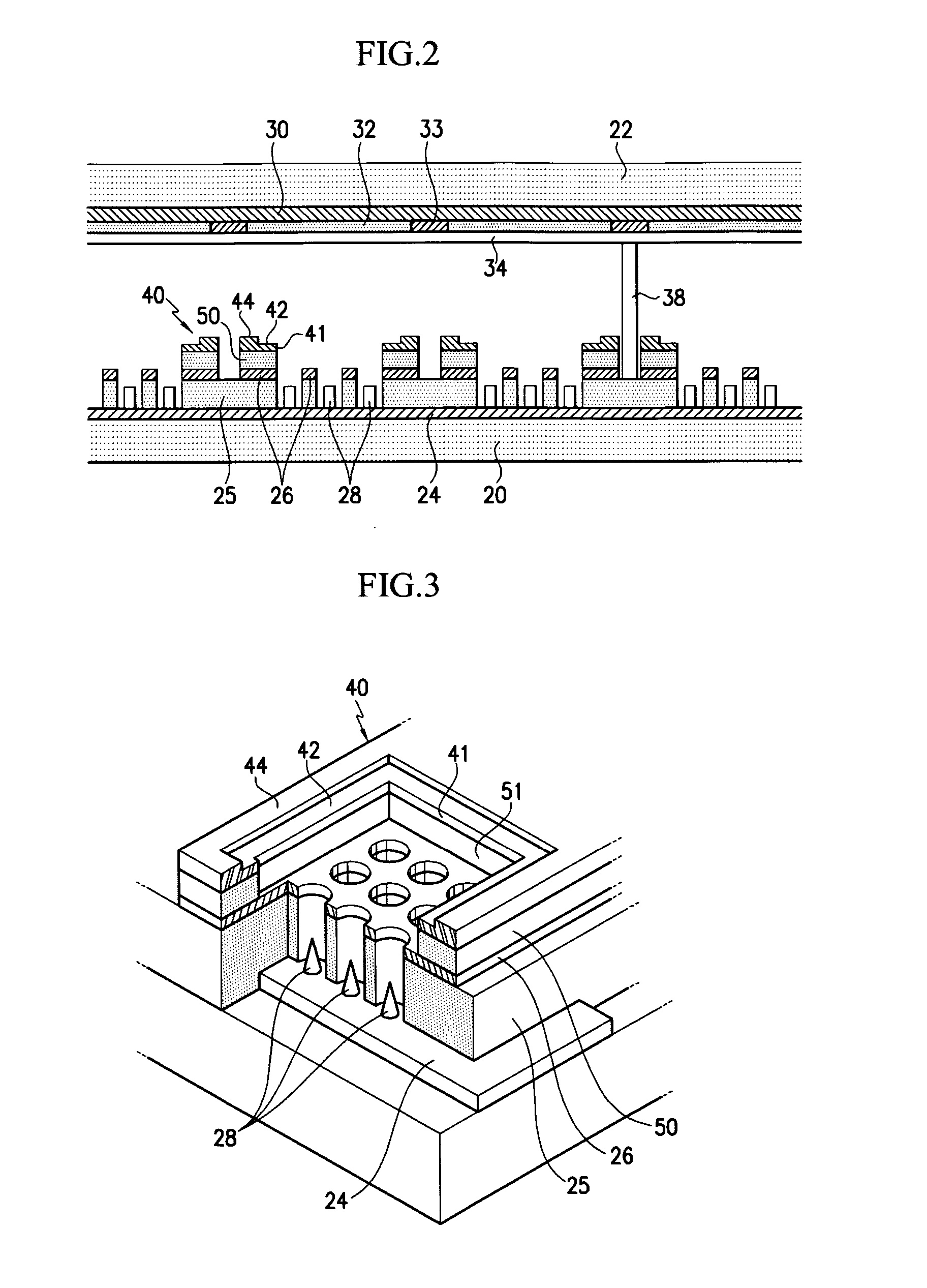

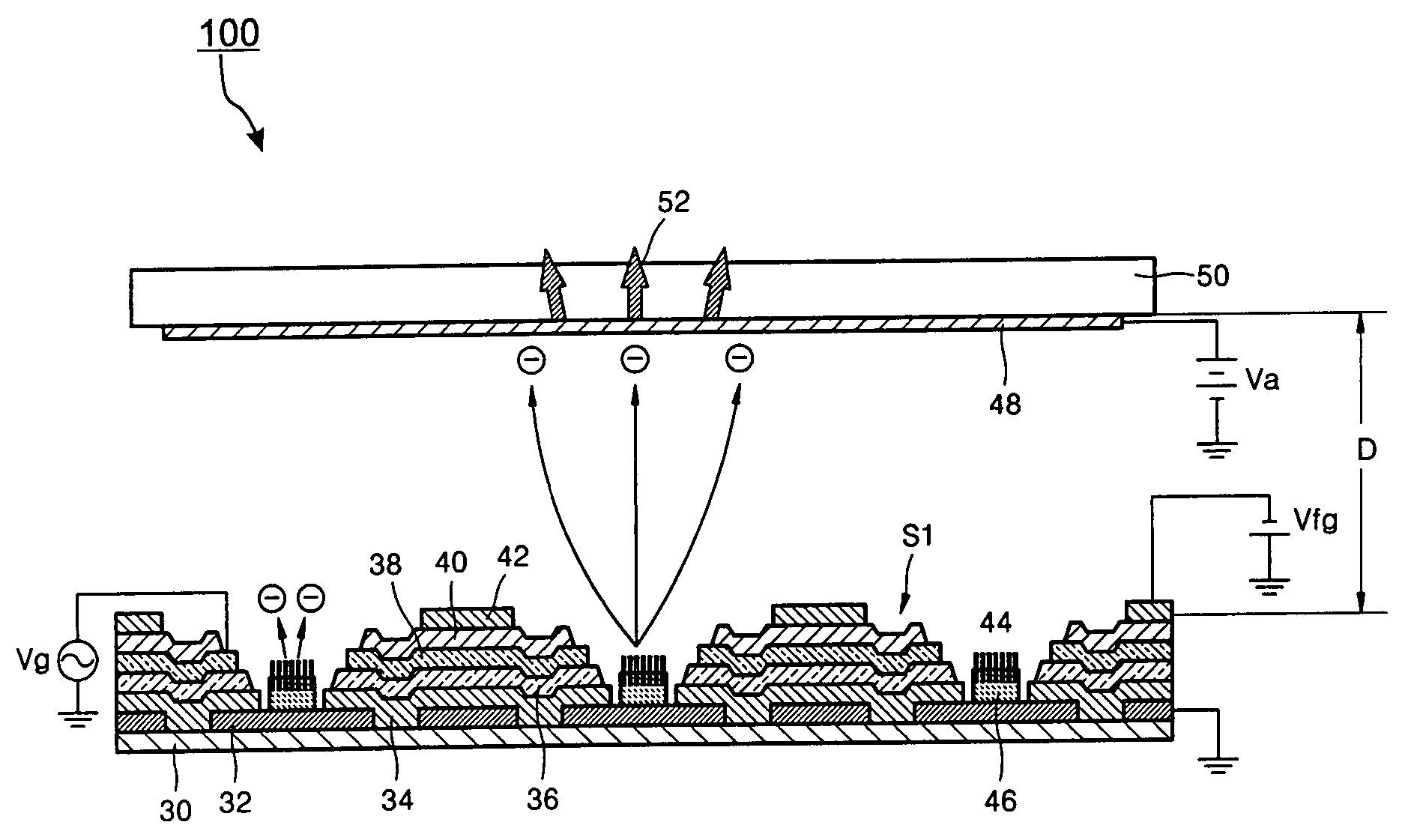

Field emission display and method for fabricating the same

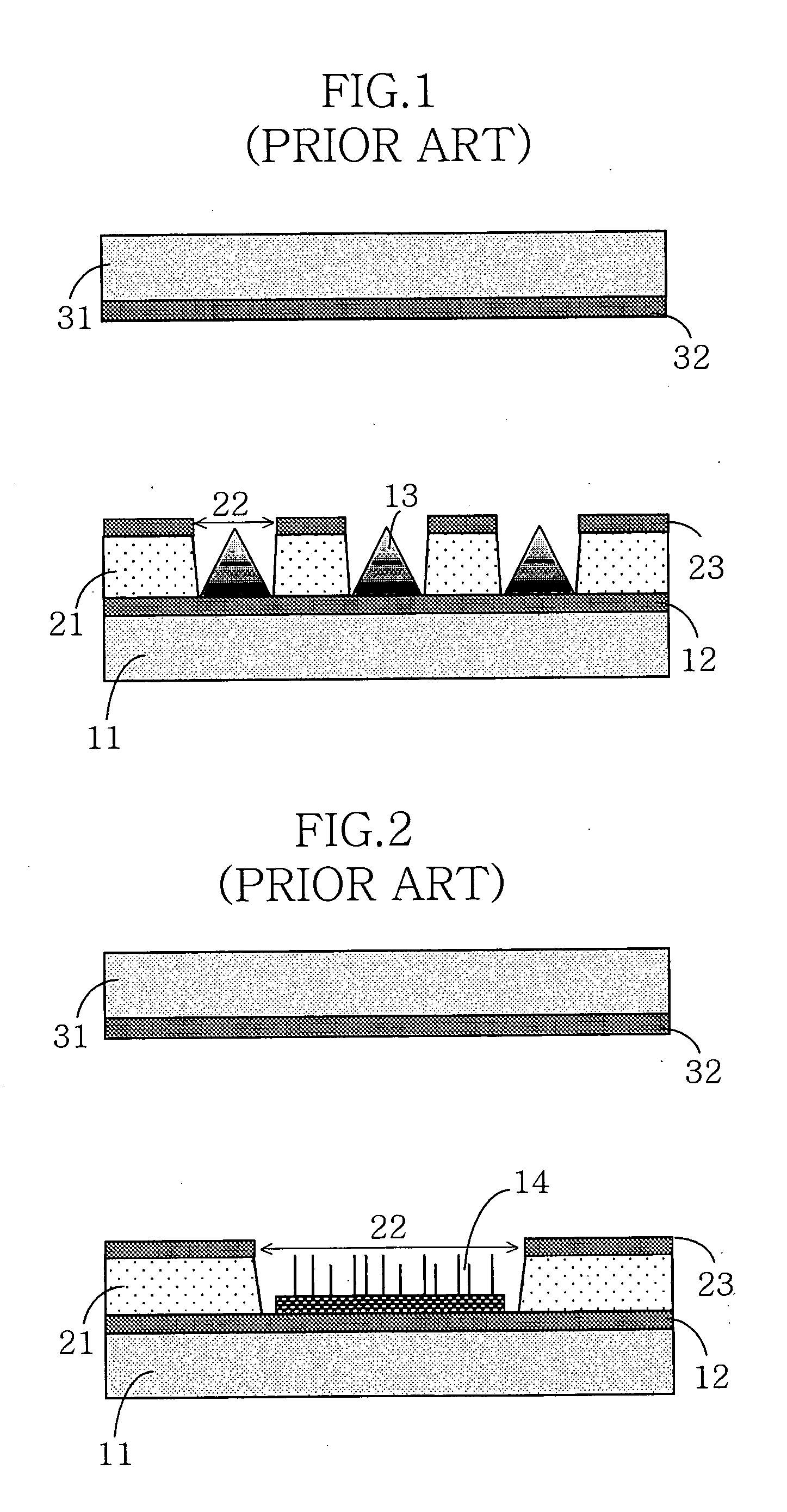

InactiveUS20010004979A1Stable driving voltageUniform characteristicsMaterial nanotechnologyDecorative surface effectsLow voltageCarbon nanotube

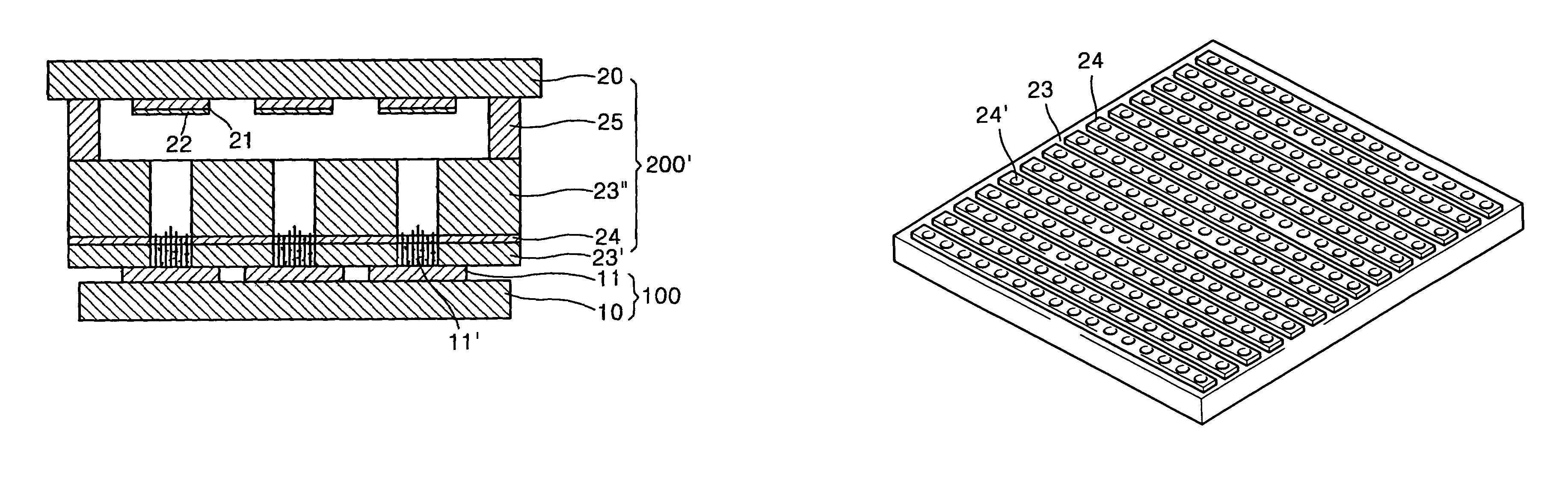

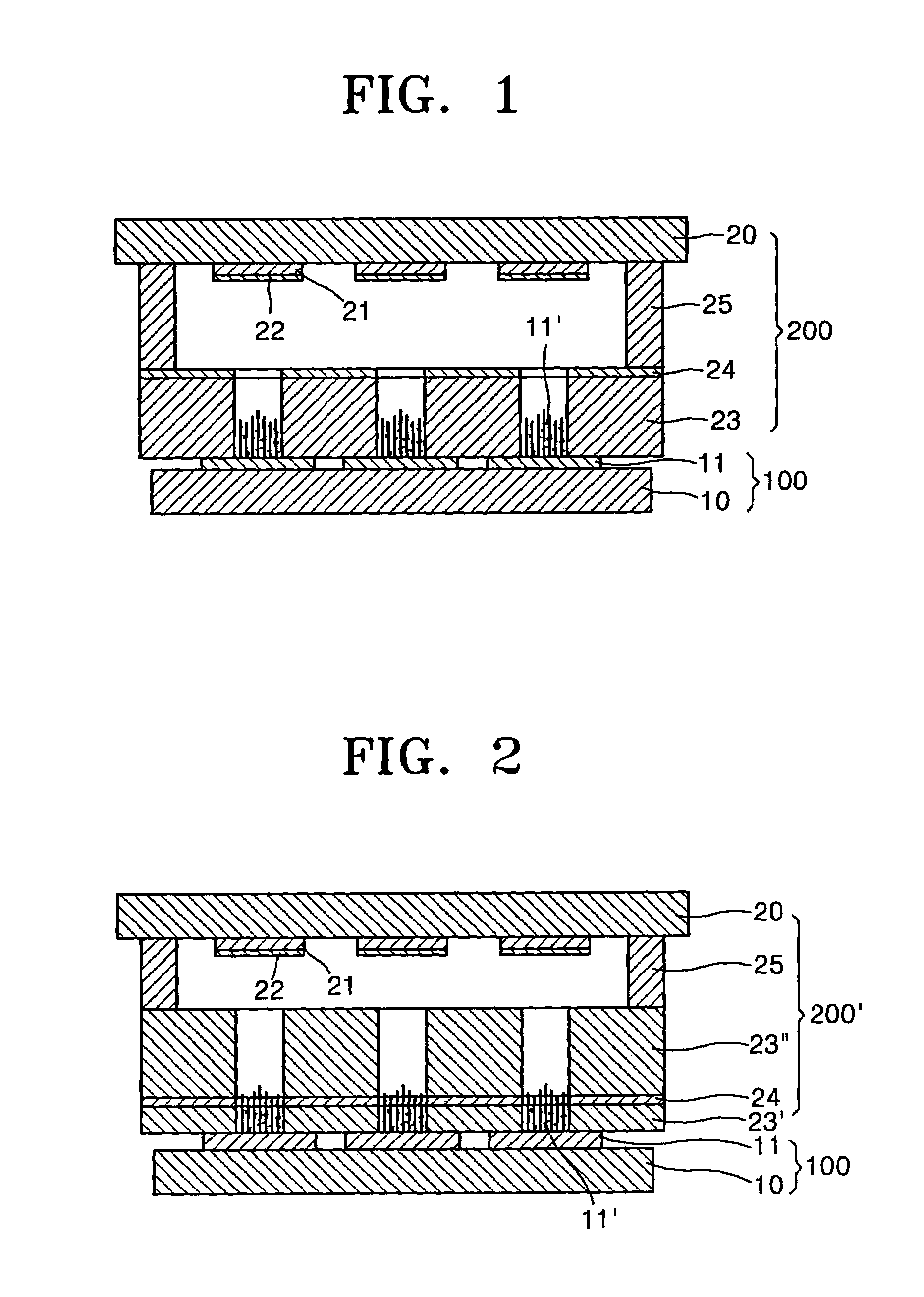

Field emission display and method for fabricating the same, the field emission display including a cathode array having a cathode electrode formed on a substrate, insulating layers and carbon nanotube films for use as emitter electrodes formed alternately on the cathode electrode, and a gate electrode formed on the insulating layer, thereby permitting fabrication of a large sized cathode plate at a low cost because the film is formed by screen printing and exposure, which can reduce the cumbersome steps in fabrication of the related art Spindt emitter tip, and both a low voltage and a high voltage FEDs because the carbon nanotube film used as the emitter has a low work function, with an easy and stable electron emission capability.

Owner:LG ELECTRONICS INC

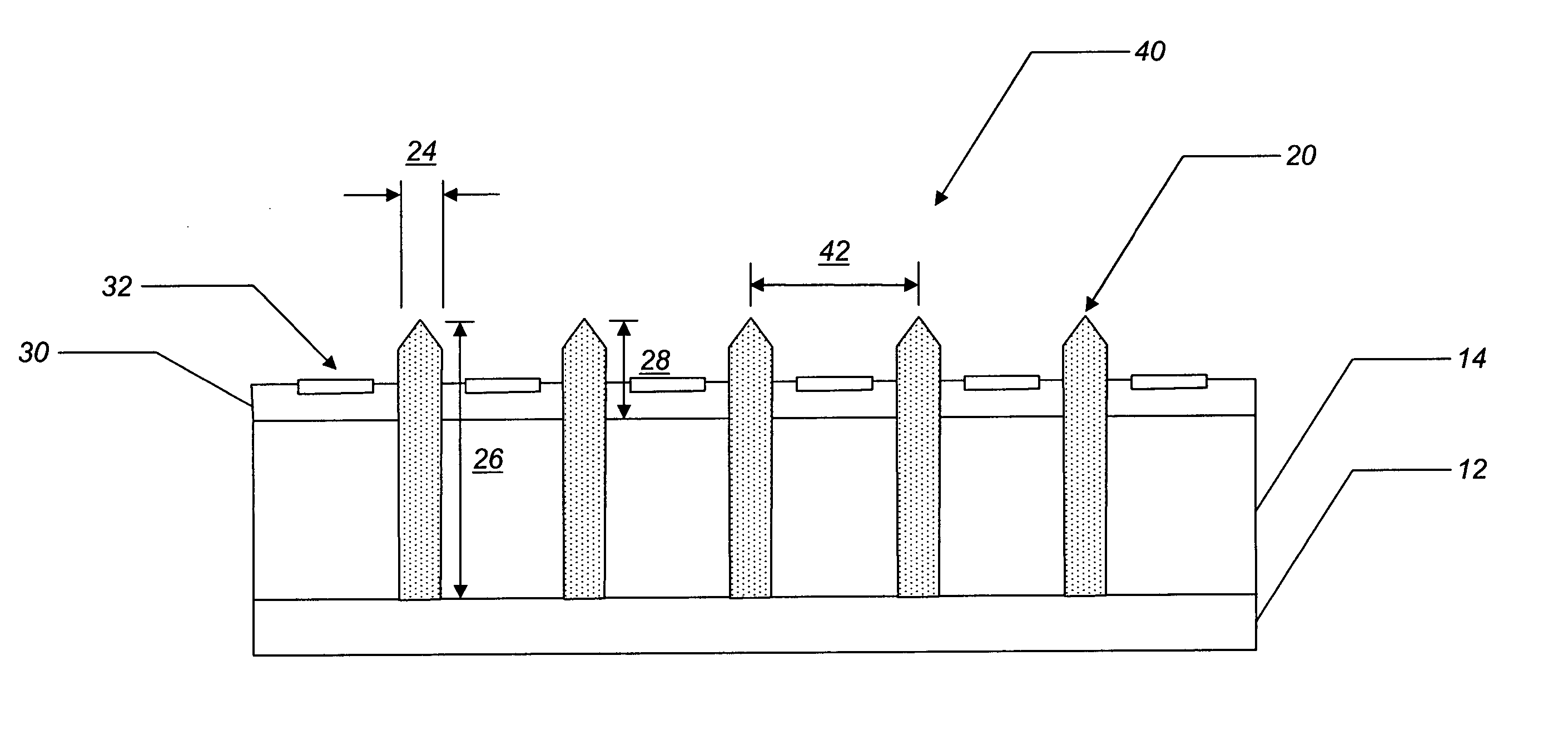

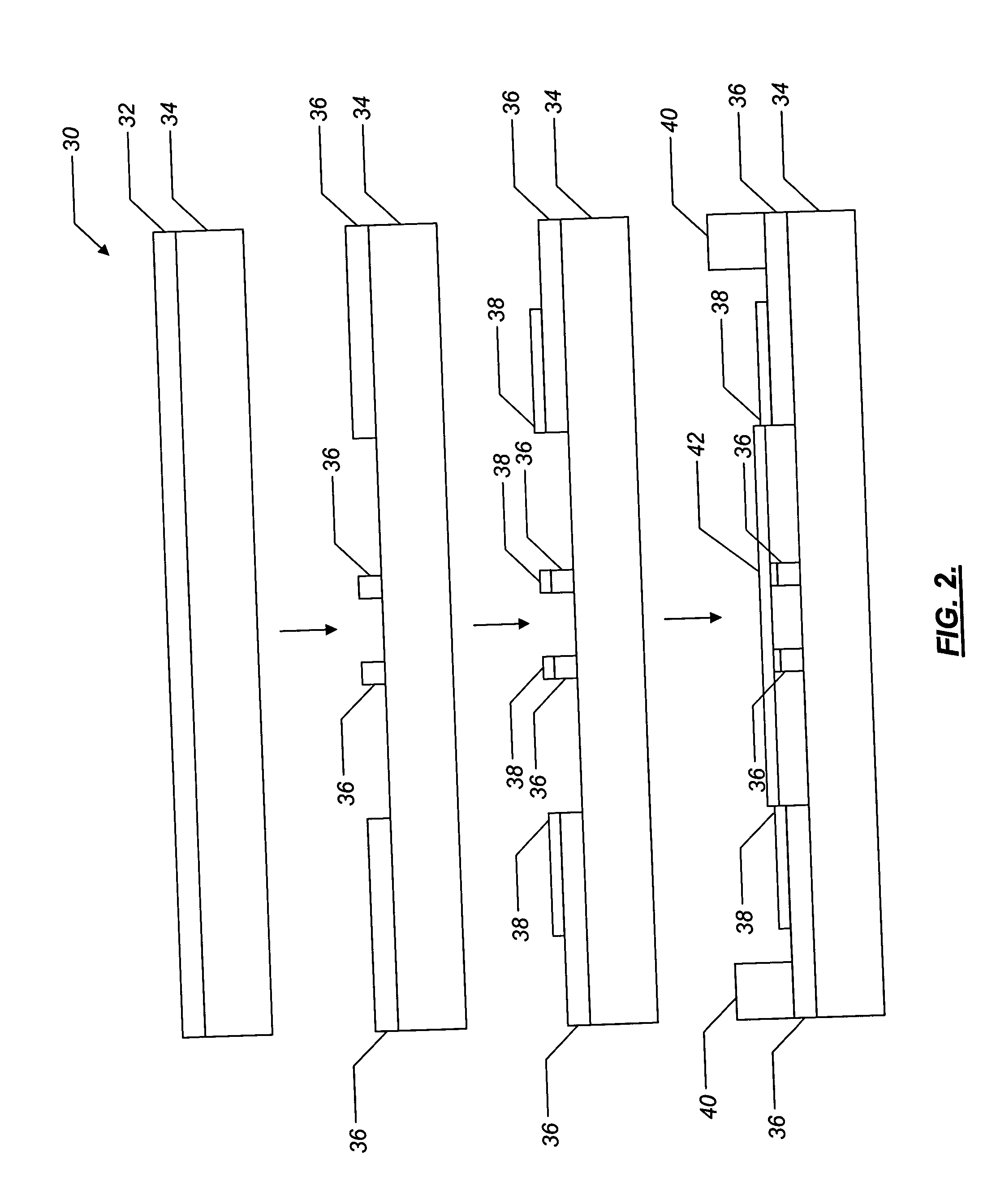

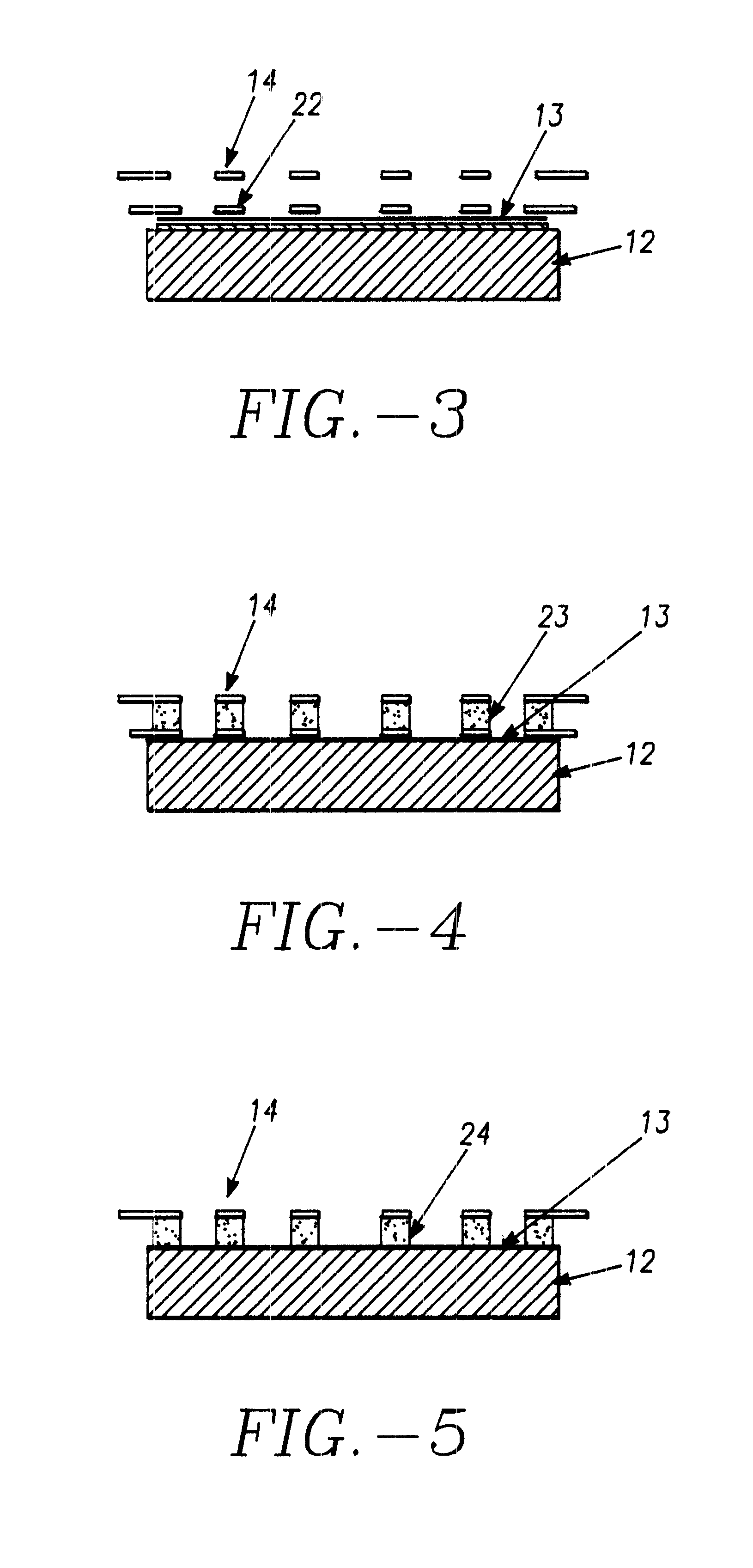

Methods for manufacture of self-aligned integrally gated nanofilament field emitter cell and array

InactiveUS6440763B1Clean and inert surfaceImprove stabilityElectric discharge tubesNanoinformaticsEngineeringNanometre

The present invention discloses a new field emitter cell and array consisting of groups of nanofilaments forming emitter cathodes. Control gates are microprocessed to be integrally formed with groups of nanofilament emitter cathodes on a substrate. Groups of nanofilaments are grown directly on the substrate material. As a result, the control gates and groups of nanofilaments are self-aligned with one another.

Owner:SEC OF THE NAVY AS REPRESENTED BY THE UNITED STATES OF AMERICA THE

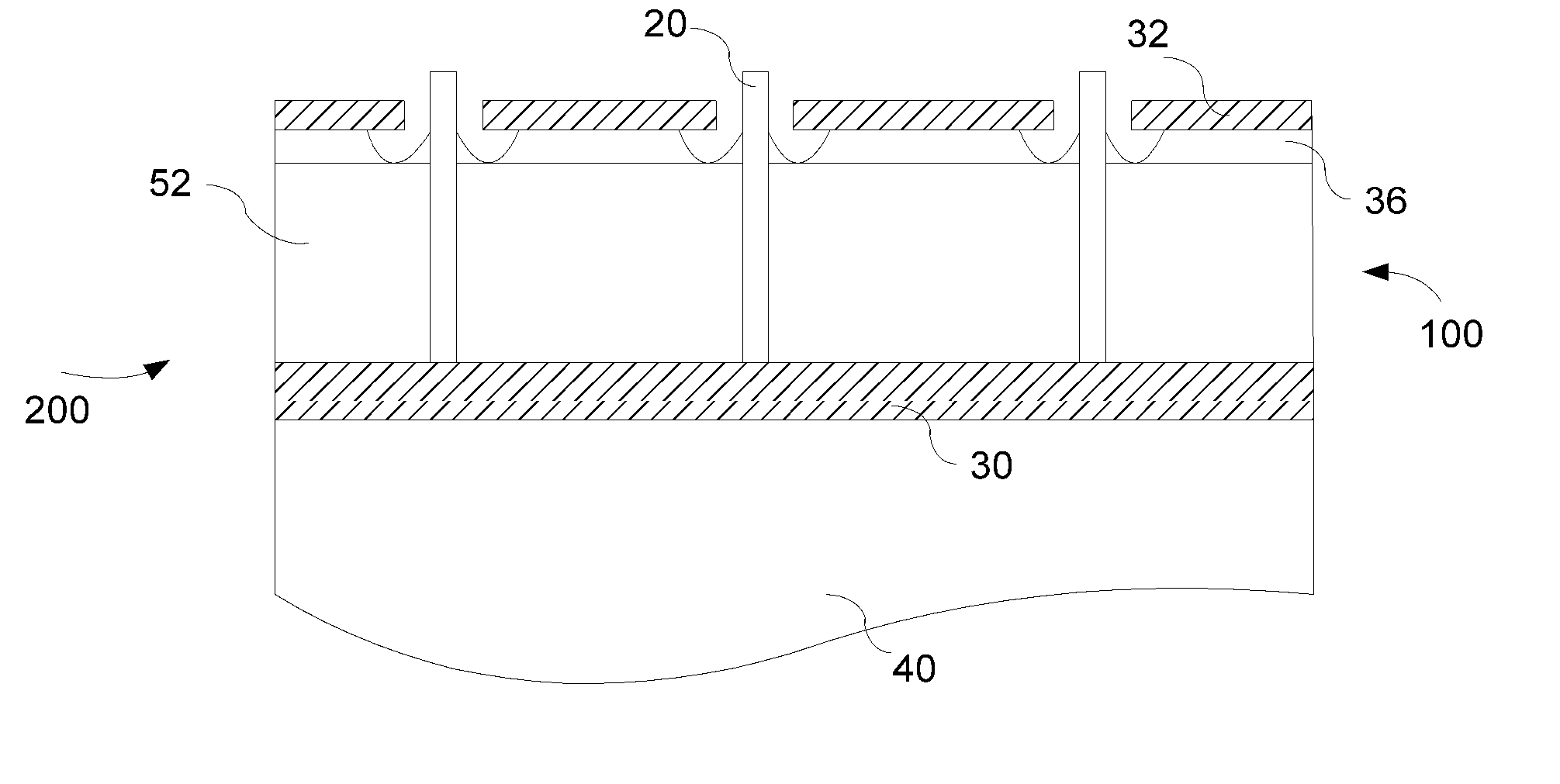

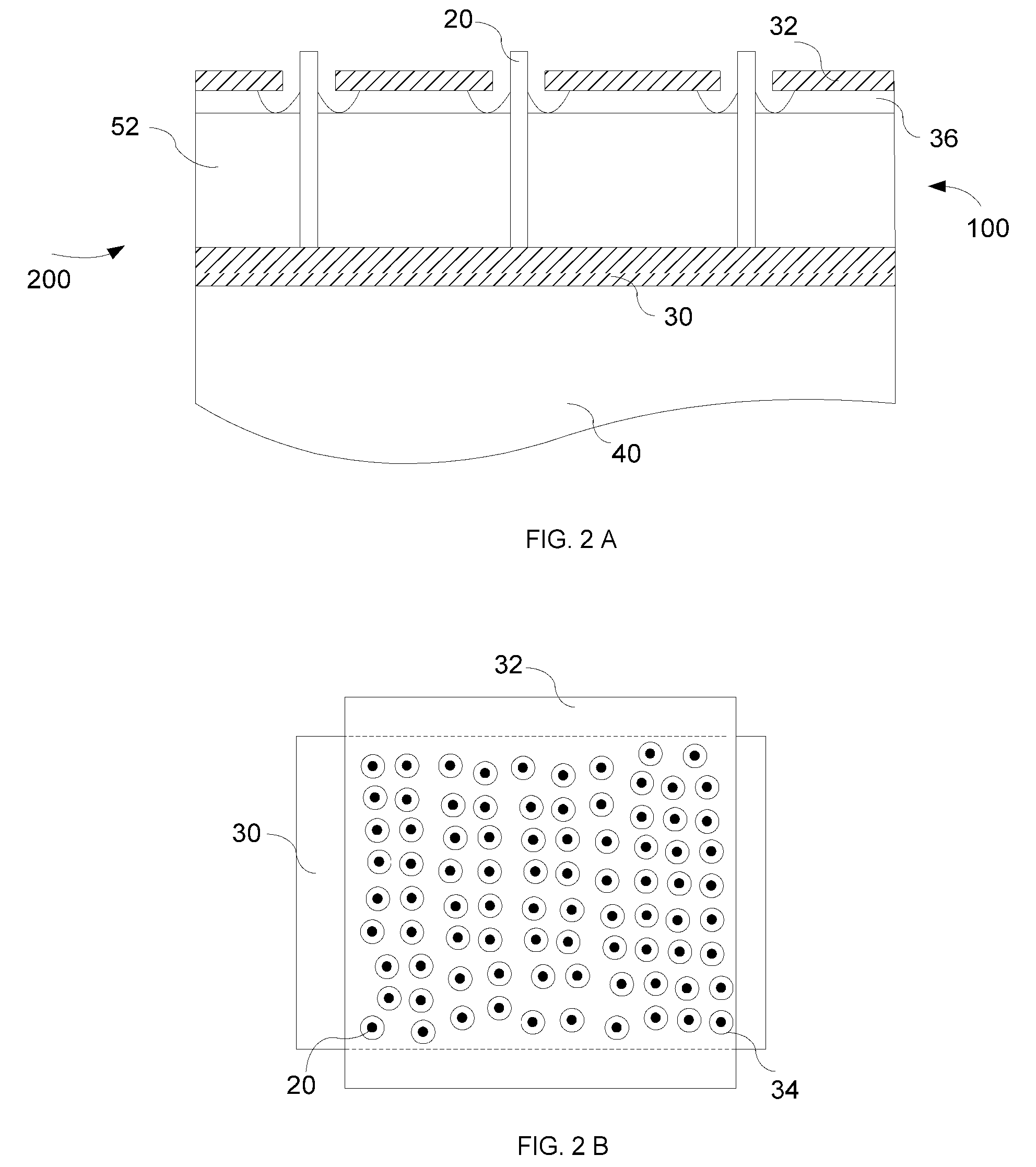

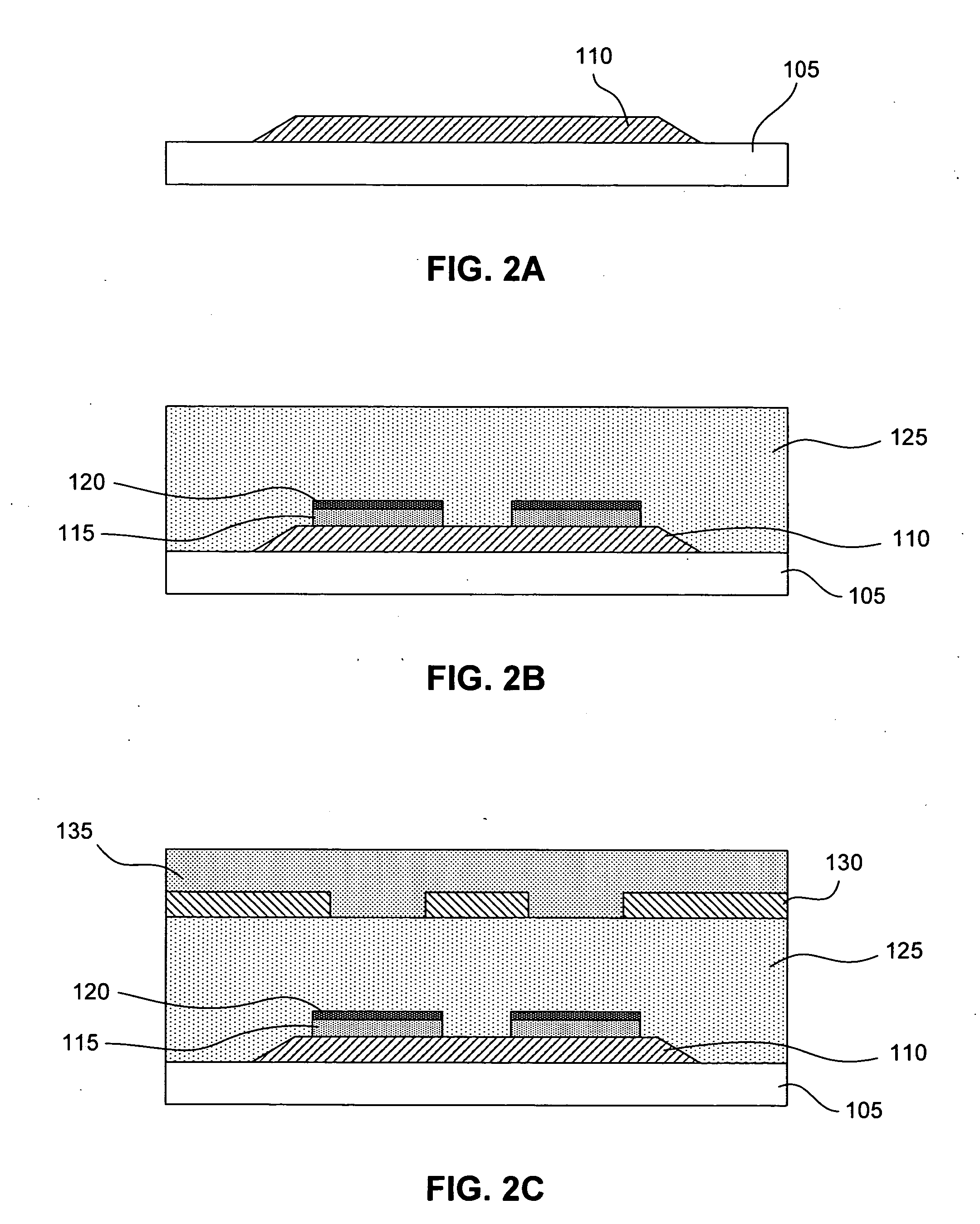

Low voltage electron source with self aligned gate apertures, fabrication method thereof, and luminous display using the electron source

InactiveUS20050127351A1Narrow diameterHigh densityNanoinformaticsThermionic cathodesHigh current densityHigh energy

An electron source include a first cathode electrode disposed over a substrate and terminated to provide electrons; an emitter layer disposed over the cathode electrode and formed from one or plurality vertically aligned and mono-dispersed nano-structures that are truncated to the same length, embedded in a solid matrix and protruding above the surface for emitting electrons; an insulator disposed over the emitter layer and having one or plurality of apertures, each is self-aligned with and exposes one nano-structure in the emitter layer; and a second gate electrode disposed over the insulator, having one or plurality of apertures self-aligned with the apertures in the insulator and terminated to extract electrons from the exposed nano-structures through the apertures. The gate aperture is substantially less than one micrometer and the gated nano-structures can have a density on the order of 108 / cm2. Such an electron source can be modulated with an extra low voltage, emits electrons with high current density and high uniformity, and operates with high energy-efficiency and long lifetime.

Owner:TOLT ZHIDAN LI

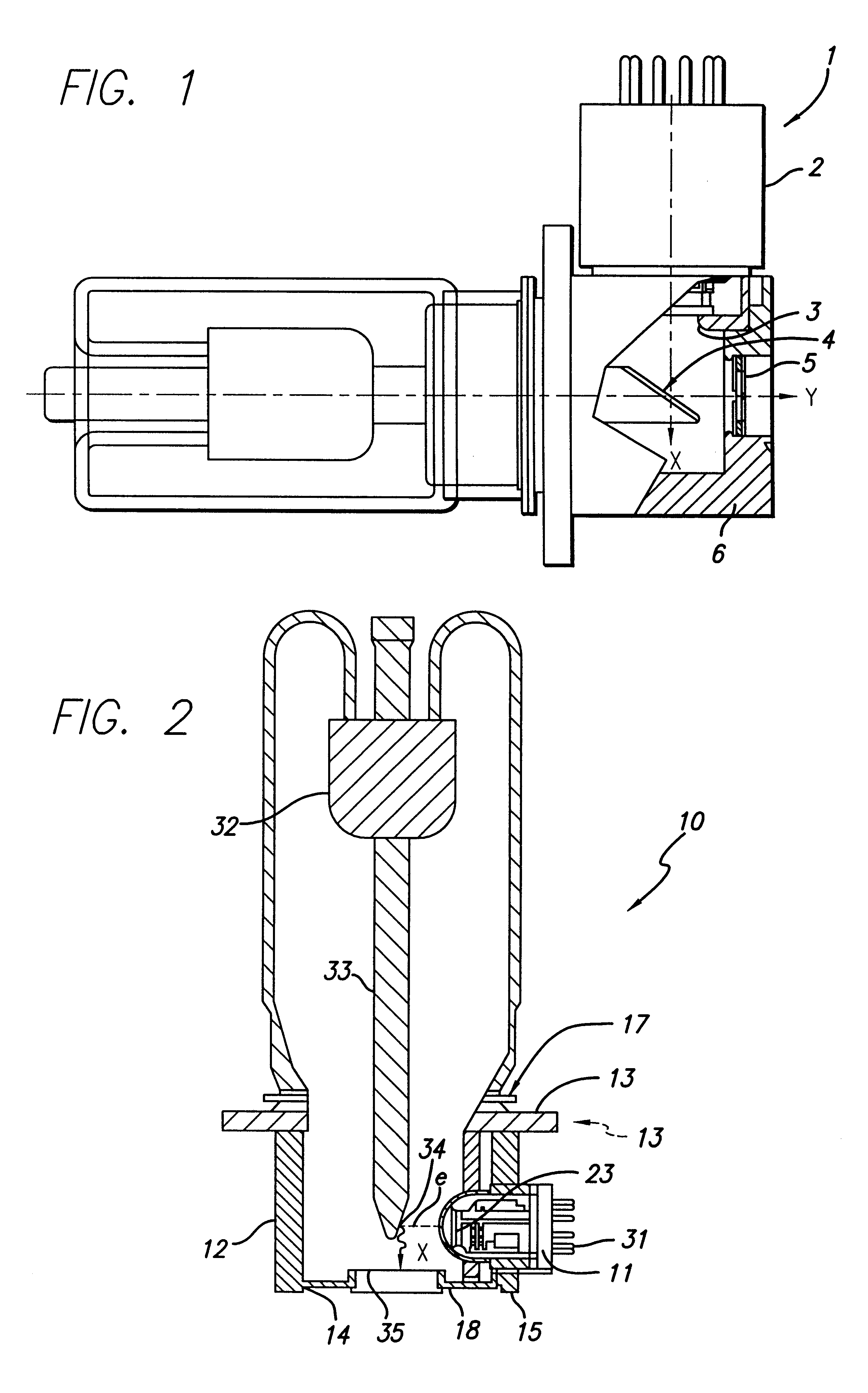

X-ray tube

InactiveUS6229876B1Enhances electron beam focusing capabilityLow possible surface fieldX-ray tube electrodesCathode ray concentrating/focusing/directingX-raySpherical shaped

An x-ray tube comprising an electron gun assembly having an electron gun container housing an electron generator for generating electrons in a first direction along a first axis. The beam of electrons impinges upon an anode which emits x-rays in response to the beam of electrons. The gun container is characterized by having a discharge end comprising a solid spherical shape.

Owner:KEVEX X RAY

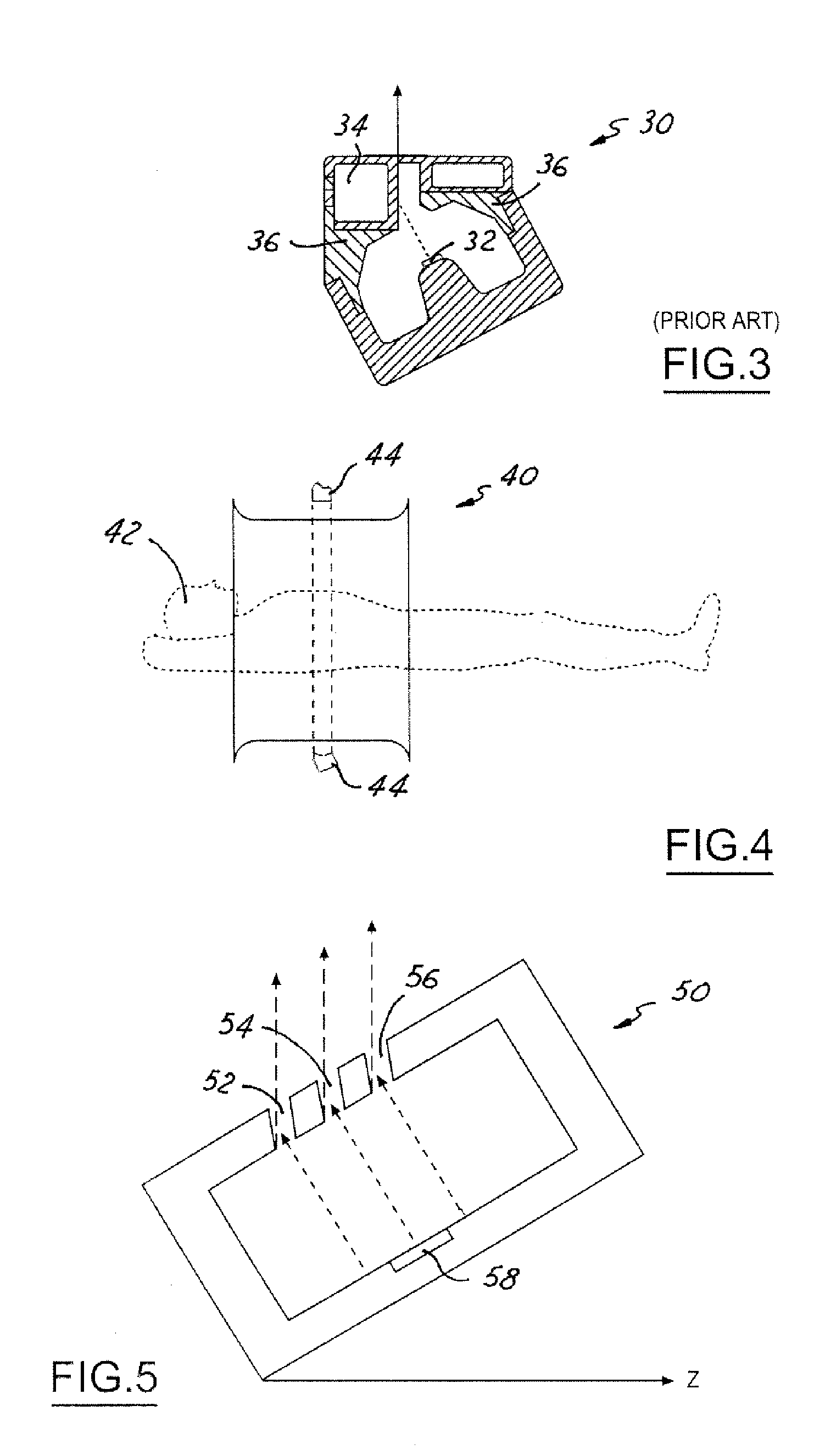

RF accelerator for imaging applications

ActiveUS7206379B2Drawback can be obviatedLower component costsX-ray tube electrodesDischarge tube electron gunsComputed tomographyX-ray

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

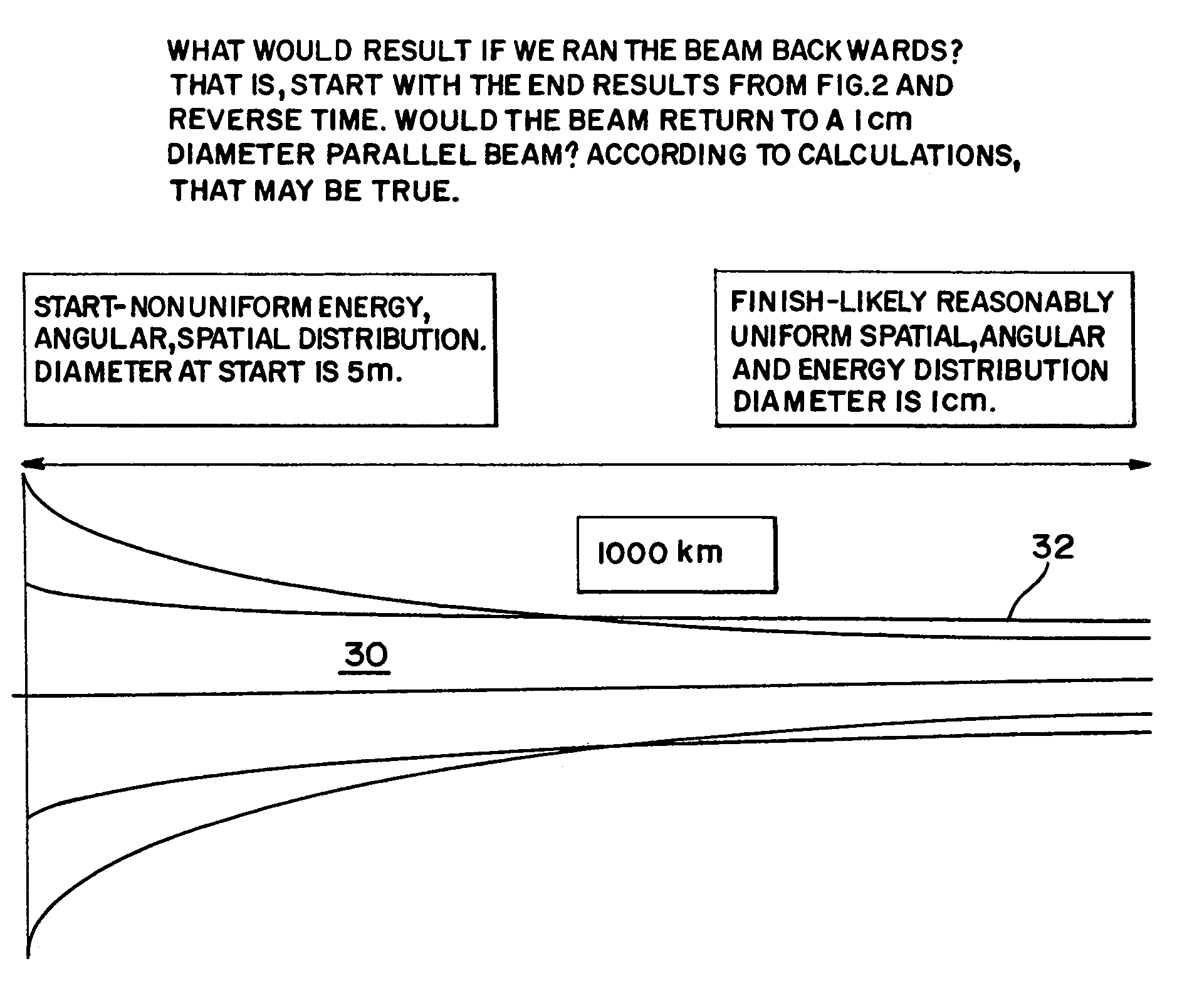

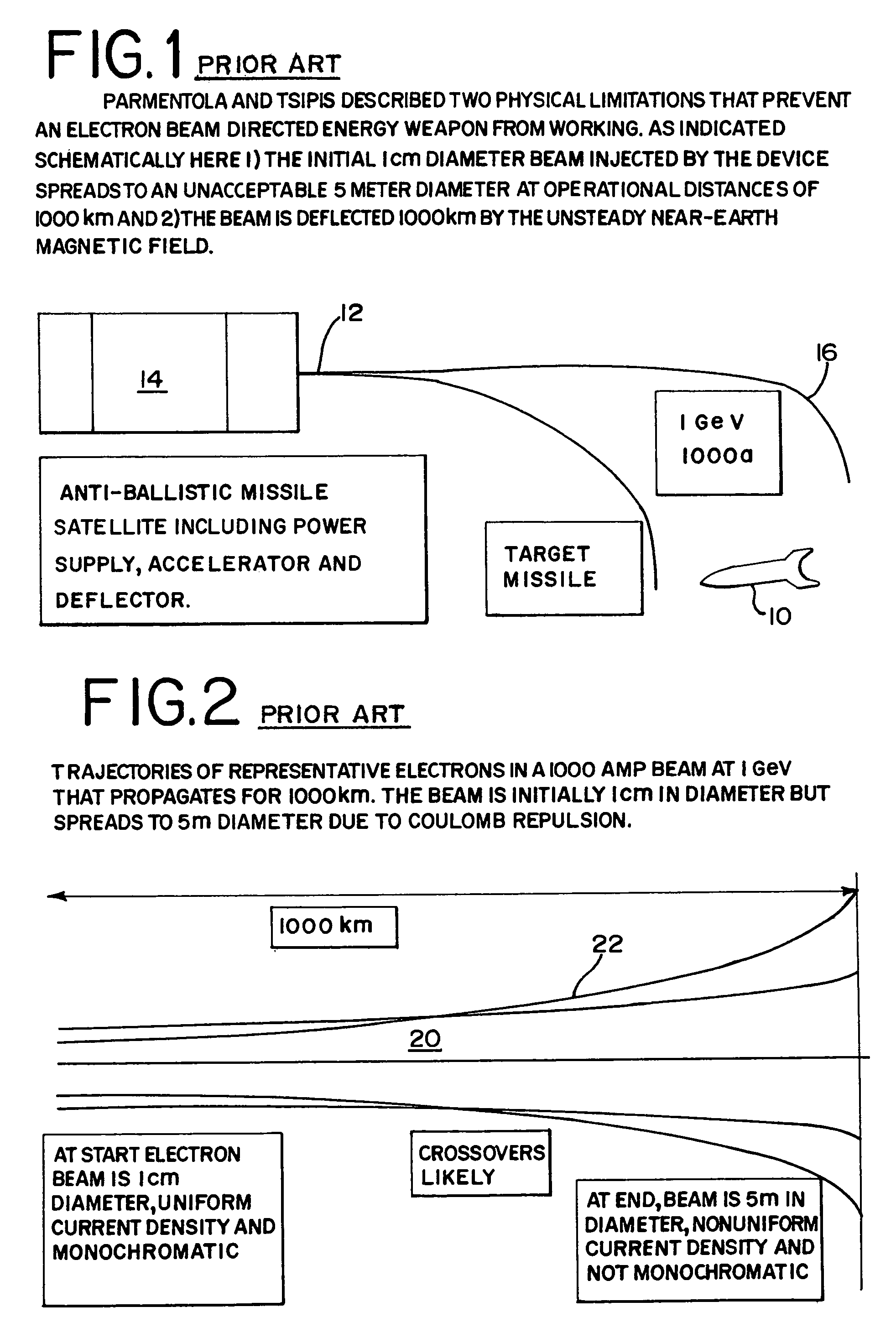

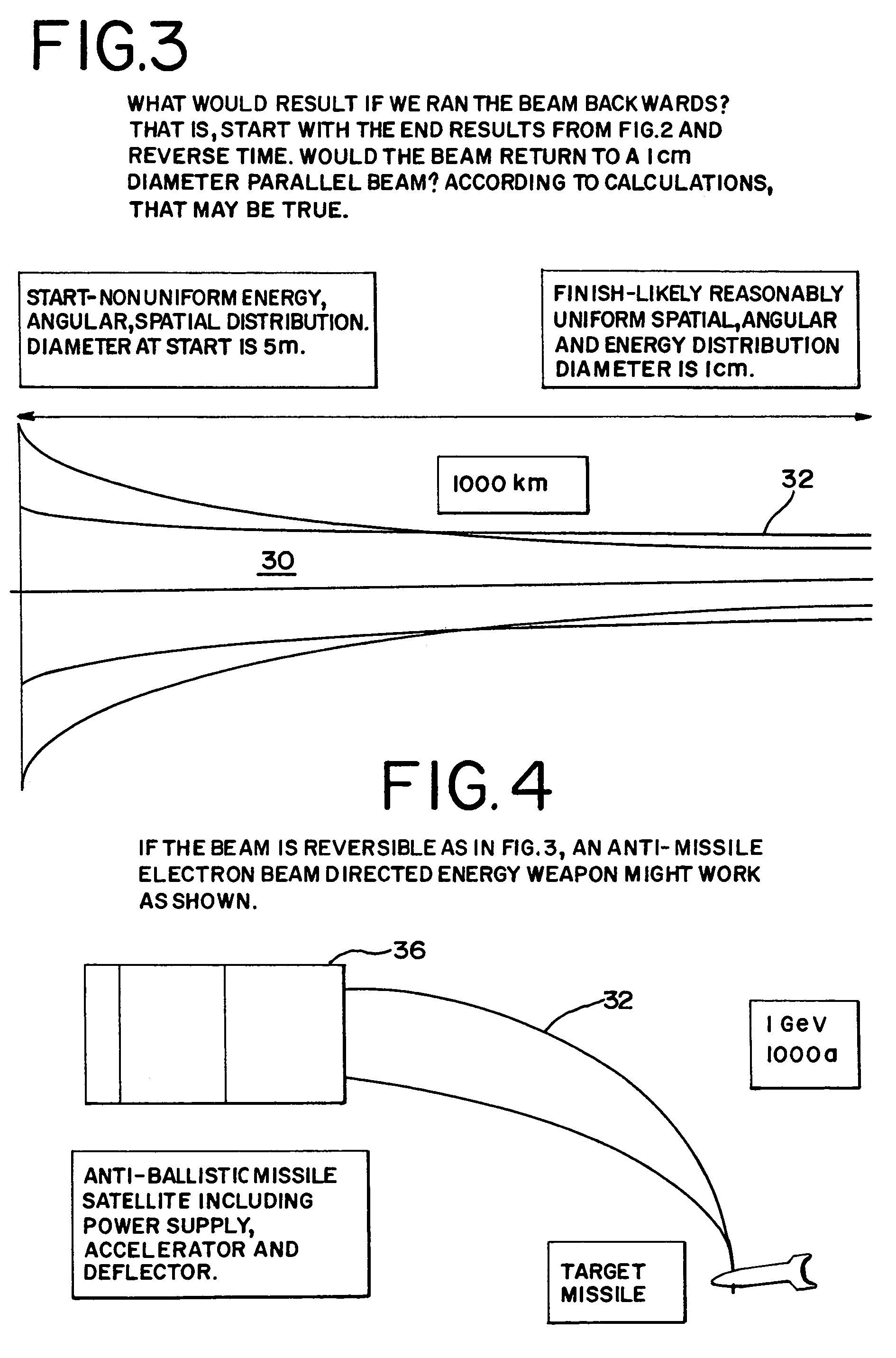

Electron beam directed energy device and methods of using same

InactiveUS7282727B2Avoid excessive distanceLess detectableDefence devicesThermometer detailsX-rayEnergy device

A method and apparatus is disclosed for an electron beam directed energy device. The device consists of an electron gun with one or more electron beams. The device includes one or more accelerating plates with holes aligned for beam passage. The plates may be flat or preferably shaped to direct each electron beam to exit the electron gun at a predetermined orientation. In one preferred application, the device is located in outer space with individual beams that are directed to focus at a distant target to be used to impact and destroy missiles. The aimings of the separate beams are designed to overcome Coulomb repulsion. A method is also presented for directing the beams to a target considering the variable terrestrial magnetic field. In another preferred application, the electron beam is directed into the ground to produce a subsurface x-ray source to locate and / or destroy buried or otherwise hidden objects including explosive devices.

Owner:RETSKY MICHAEL W

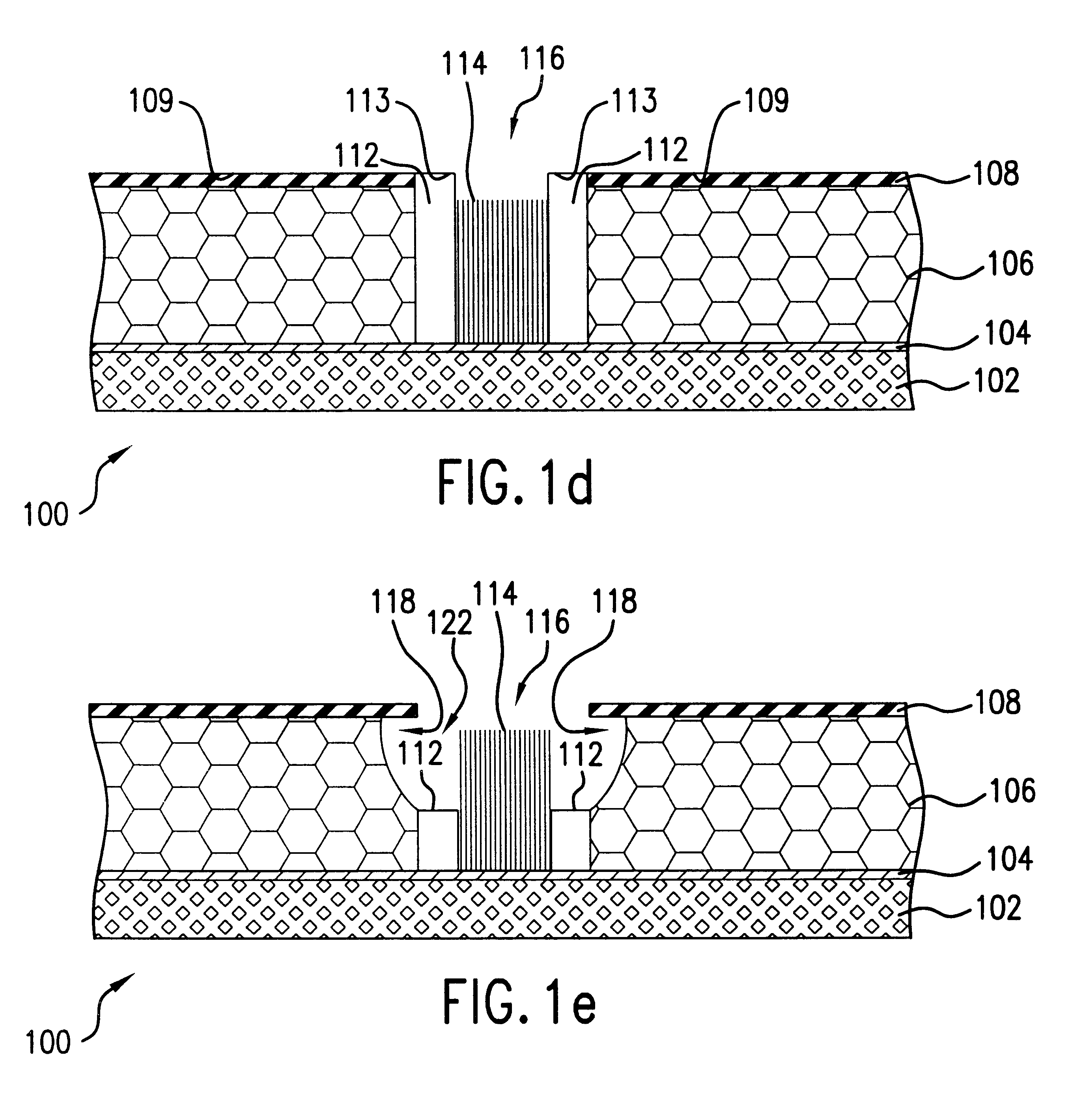

Self-aligned gated rod field emission device and associated method of fabrication

ActiveUS20050067935A1Discharge tube luminescnet screensLamp detailsCylindrical channelField emission device

A self-aligned gated field emission device and an associated method of fabrication are described. The device includes a substrate and a porous layer disposed adjacent to the surface of the substrate, wherein the porous layer defines a plurality of substantially cylindrical channels, each of the plurality of substantially cylindrical channels aligned substantially parallel to one another and substantially perpendicular to the surface of the substrate. The device also includes a plurality of substantially rod-shaped structures disposed within at least a portion of the plurality of substantially cylindrical channels defined by the porous layer and adjacent to the surface of the substrate, wherein a portion of each of the plurality of substantially rod-shaped structures protrudes above the surface of the porous layer. The device further includes a gate dielectric layer disposed on the surface of the porous layer, wherein the gate dielectric layer is disposed between the plurality of substantially rod-shaped structures. The device still further includes a conductive layer selectively disposed on the surface of the gate dielectric layer, wherein the conductive layer is selectively disposed between the plurality of substantially rod-shaped structures.

Owner:GENERAL ELECTRIC CO

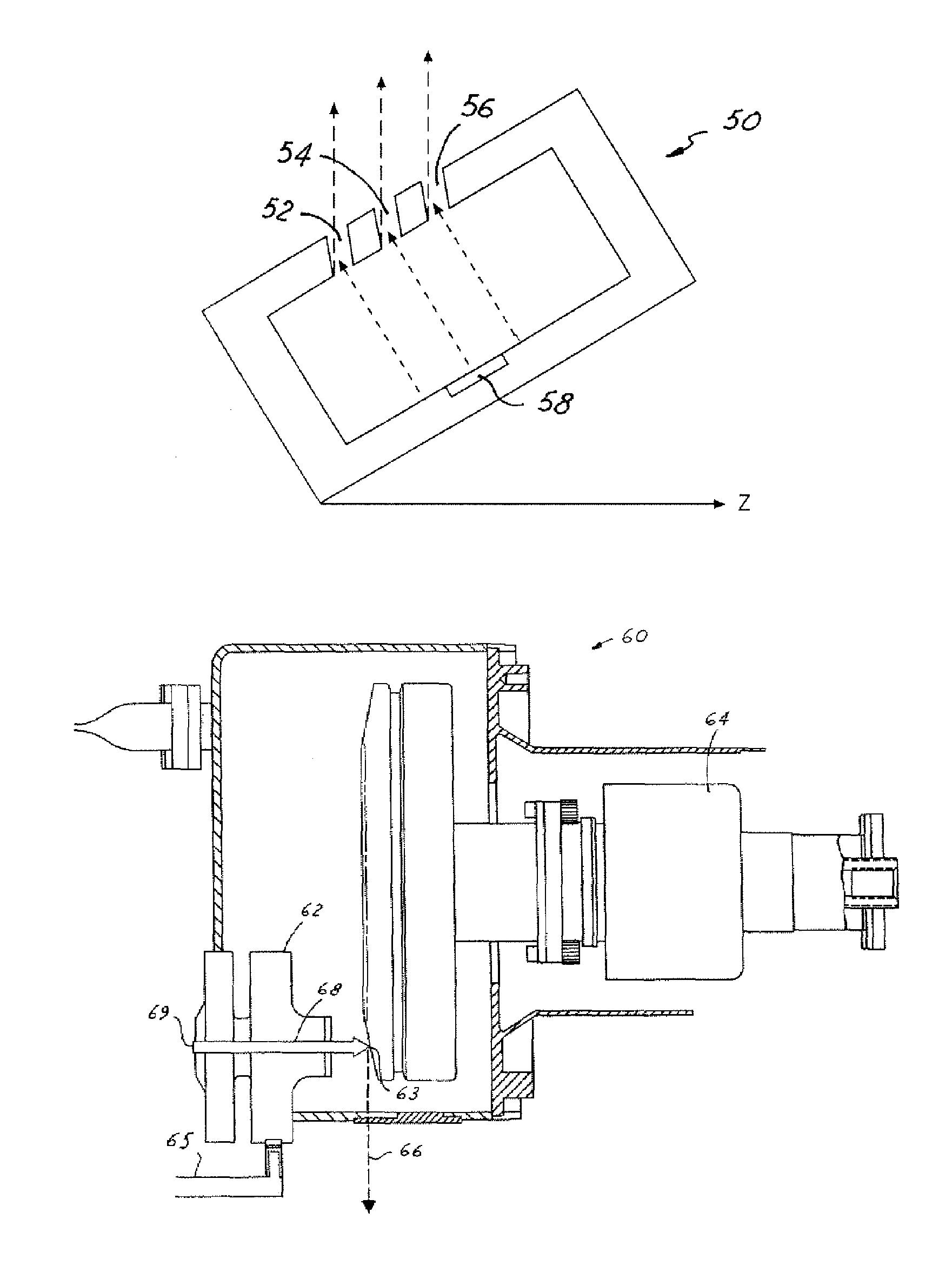

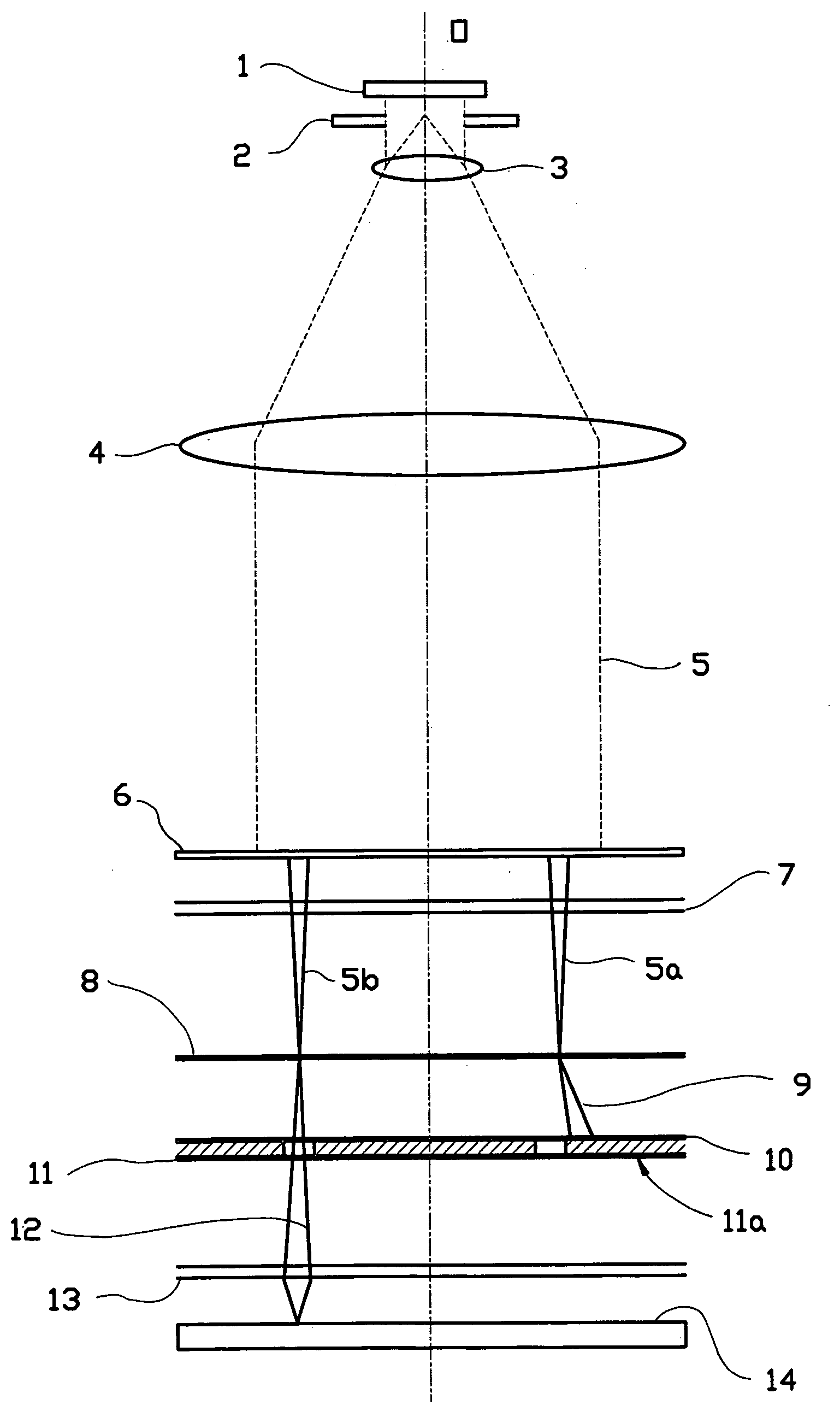

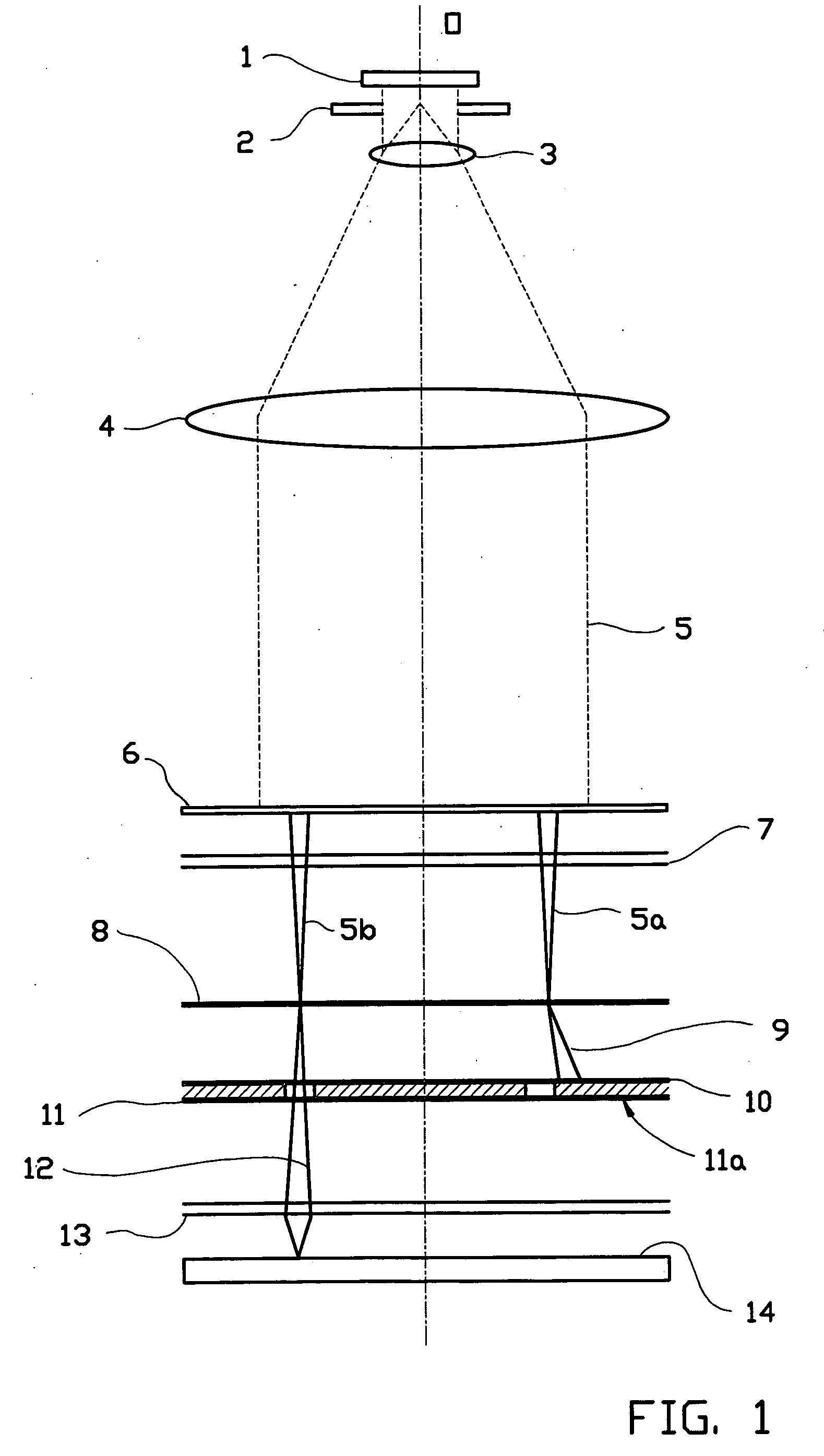

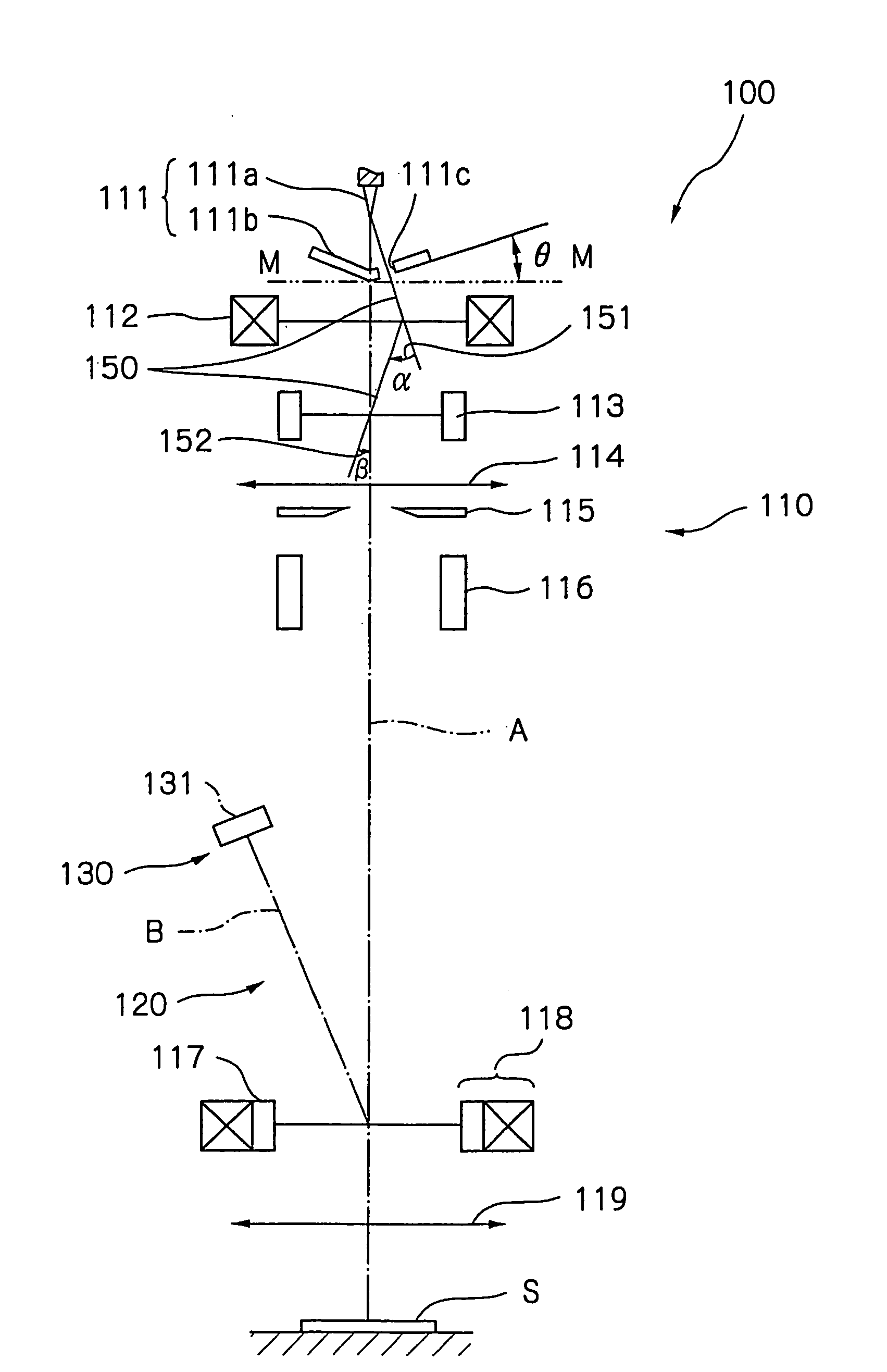

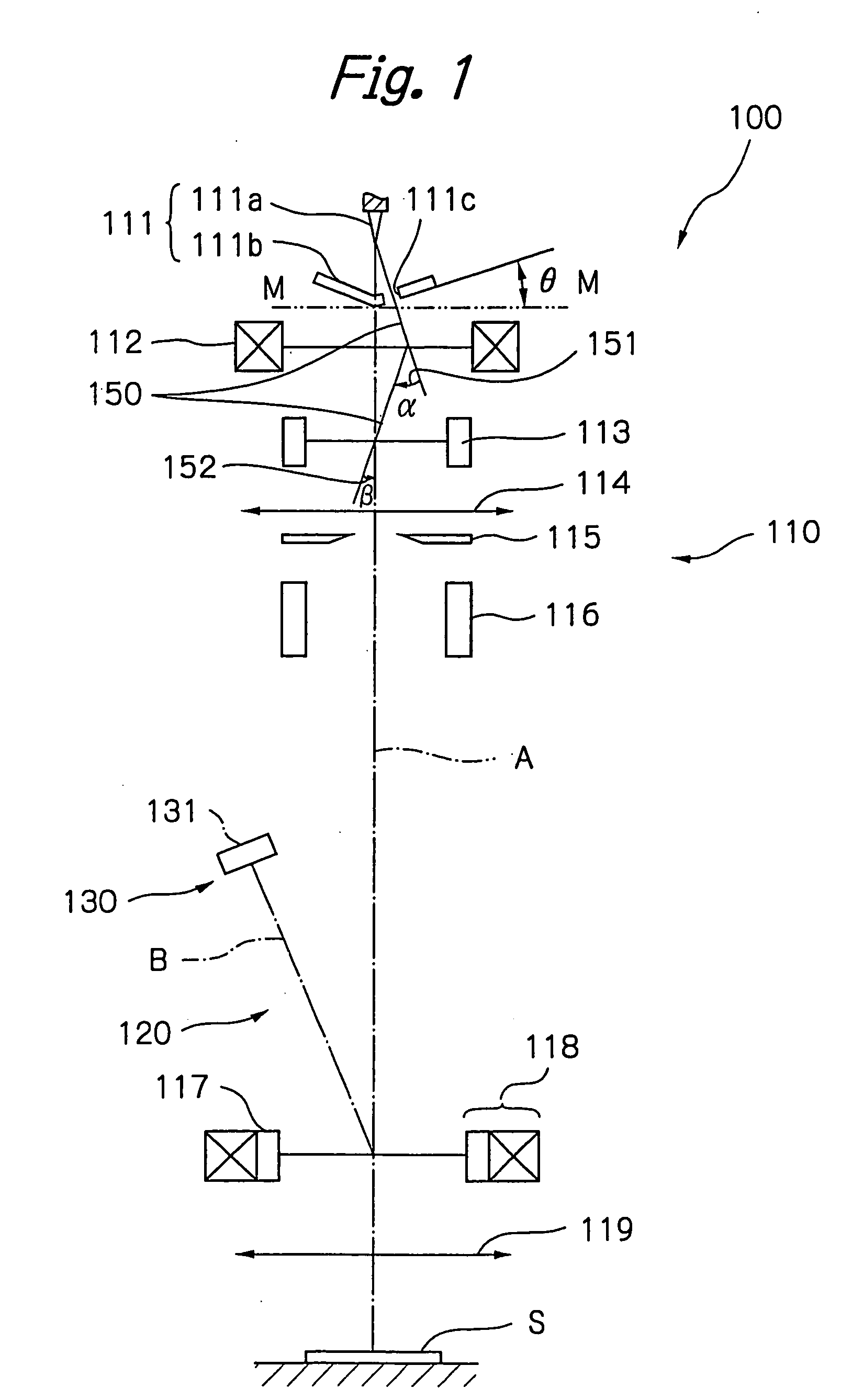

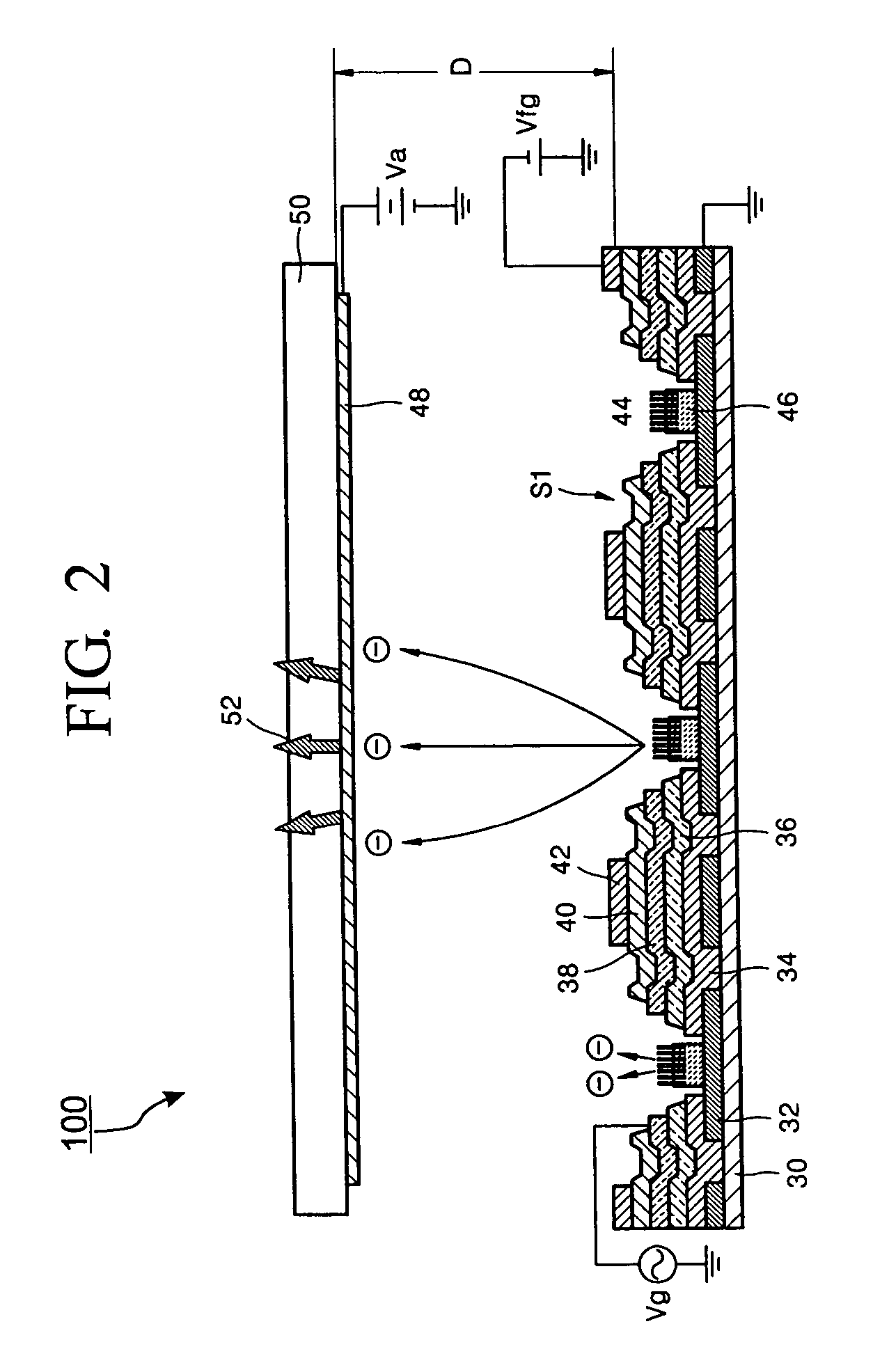

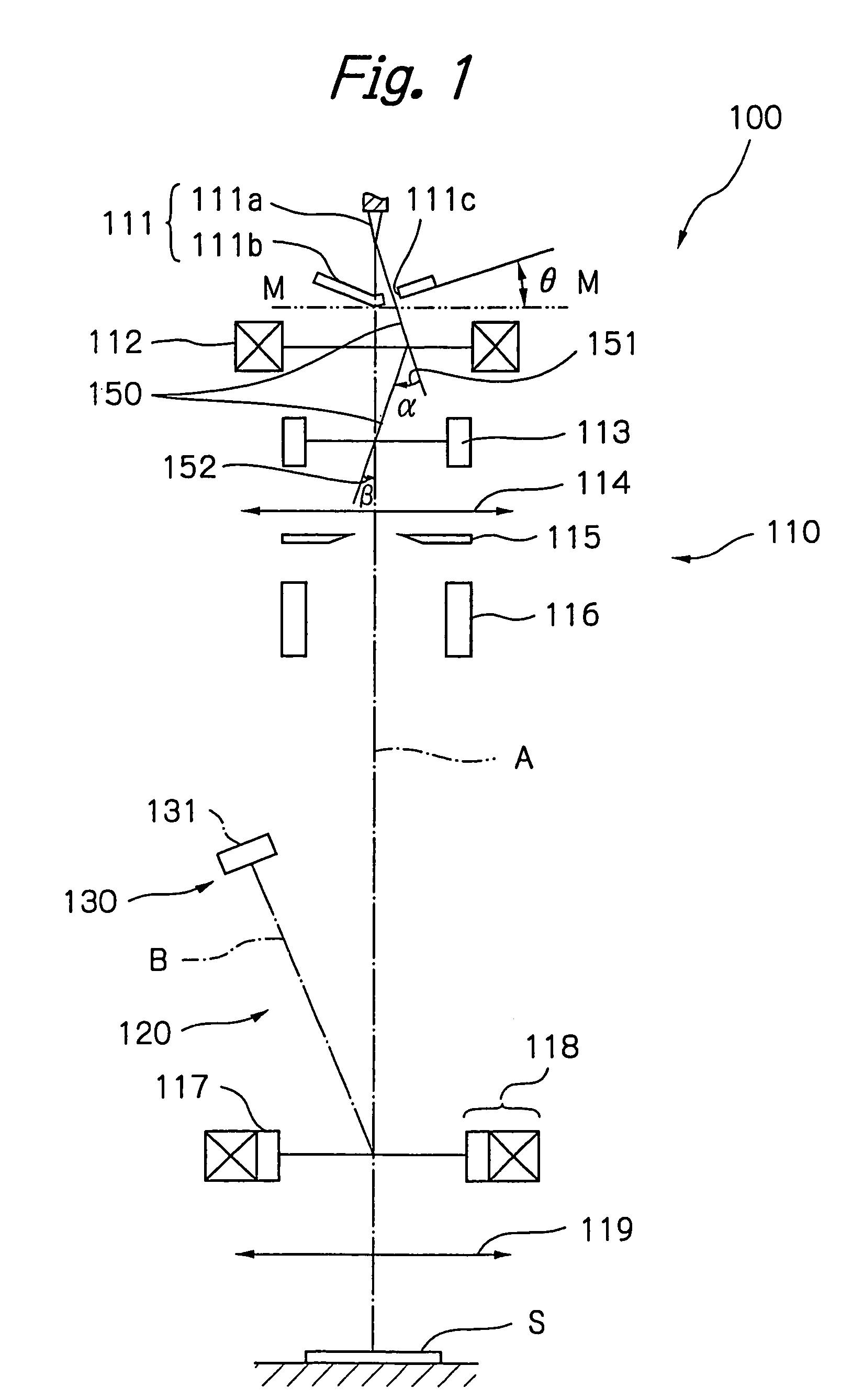

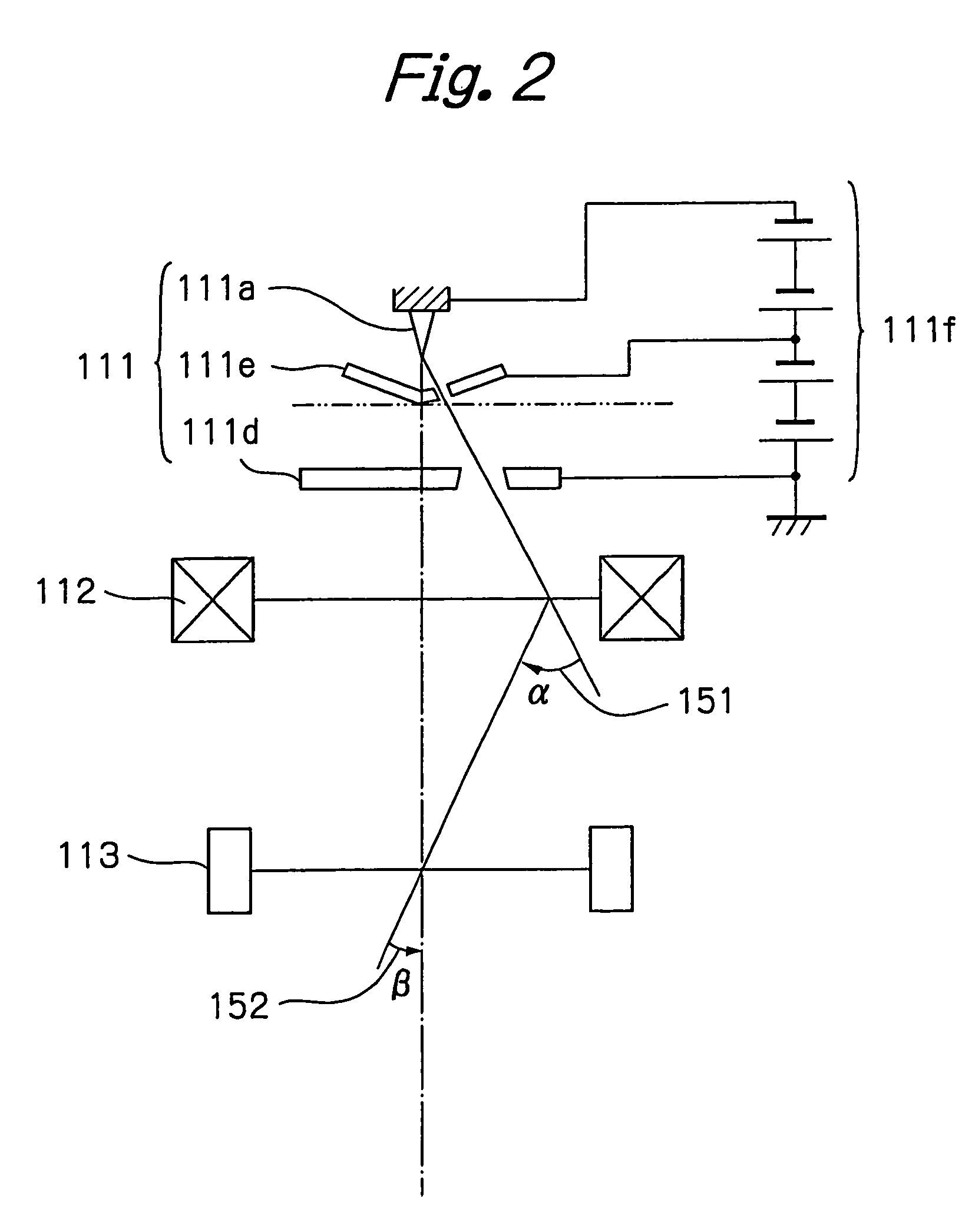

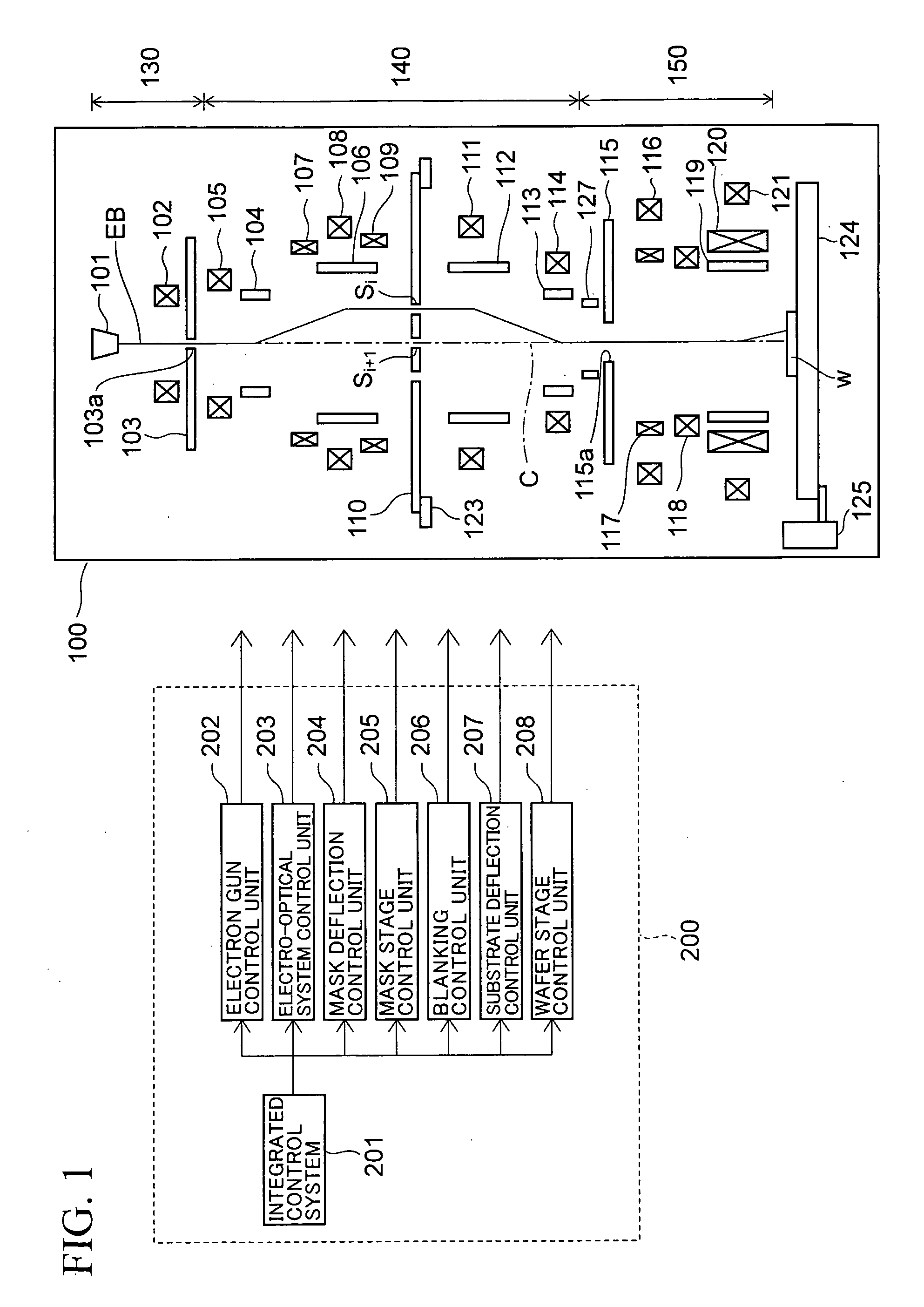

Electron beam exposure system

InactiveUS20050211921A1Improve performanceHigh resolutionThermometer detailsNanoinformaticsTarget surfaceControl signal

The invention relates to an electron beam exposure apparatus for transferring a pattern onto the surface of a target, comprising: a beamlet generator for generating a plurality of electron beamlets; a modulation array for receiving said plurality of electron beamlets, comprising a plurality of modulators for modulating the intensity of an electron beamlet; a controller, connected to the modulation array for individually controlling the modulators, an adjustor, operationally connected to each modulator, for individually adjusting the control signal of each modulator; a focusing electron optical system comprising an array of electrostatic lenses wherein each lens focuses a corresponding individual beamlet, which is transmitted by said modulation array, to a cross section smaller than 300 nm, and a target holder for holding a target with its exposure surface onto which the pattern is to be transferred in the first focal plane of the focusing electron optical system.

Owner:ASML NETHERLANDS BV

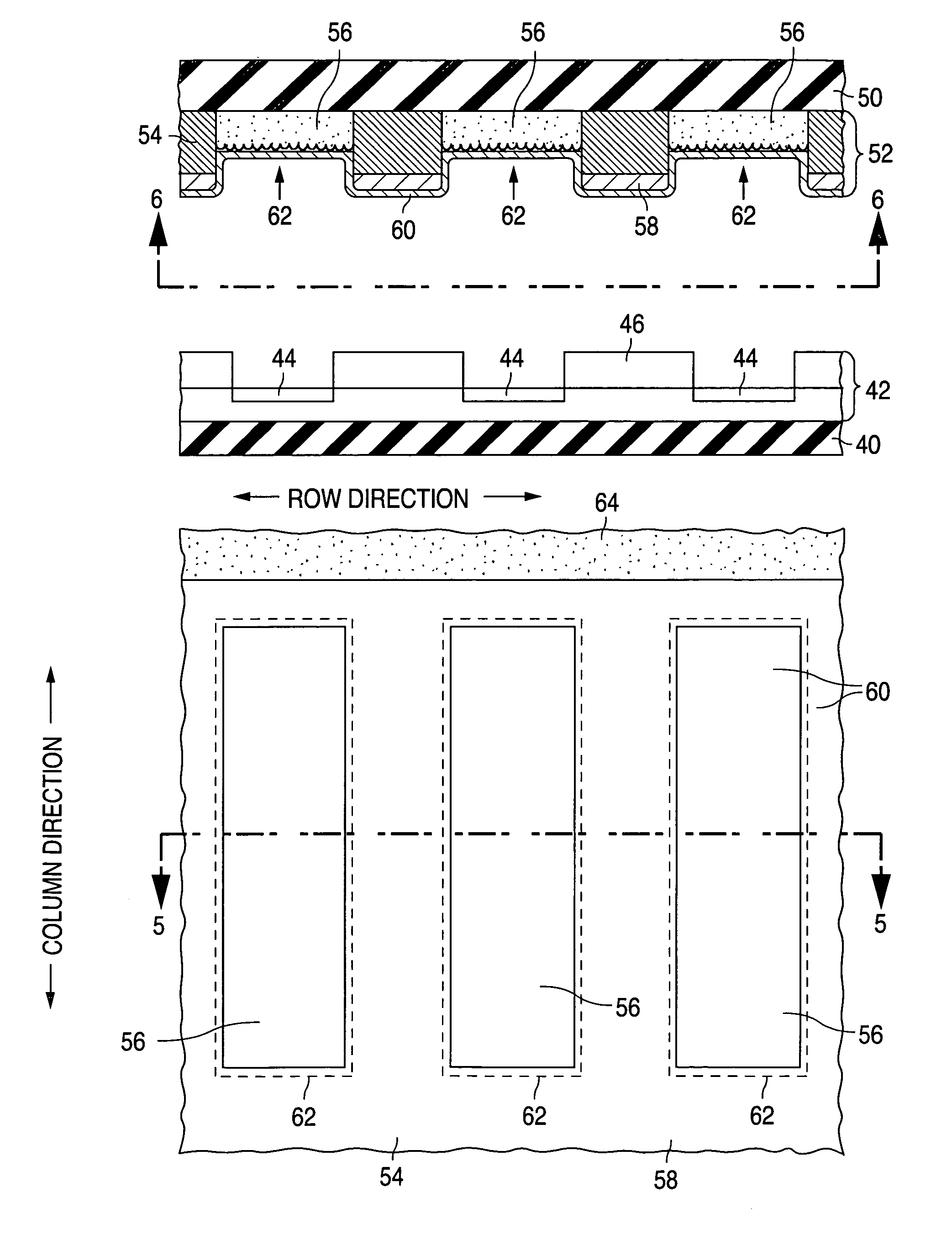

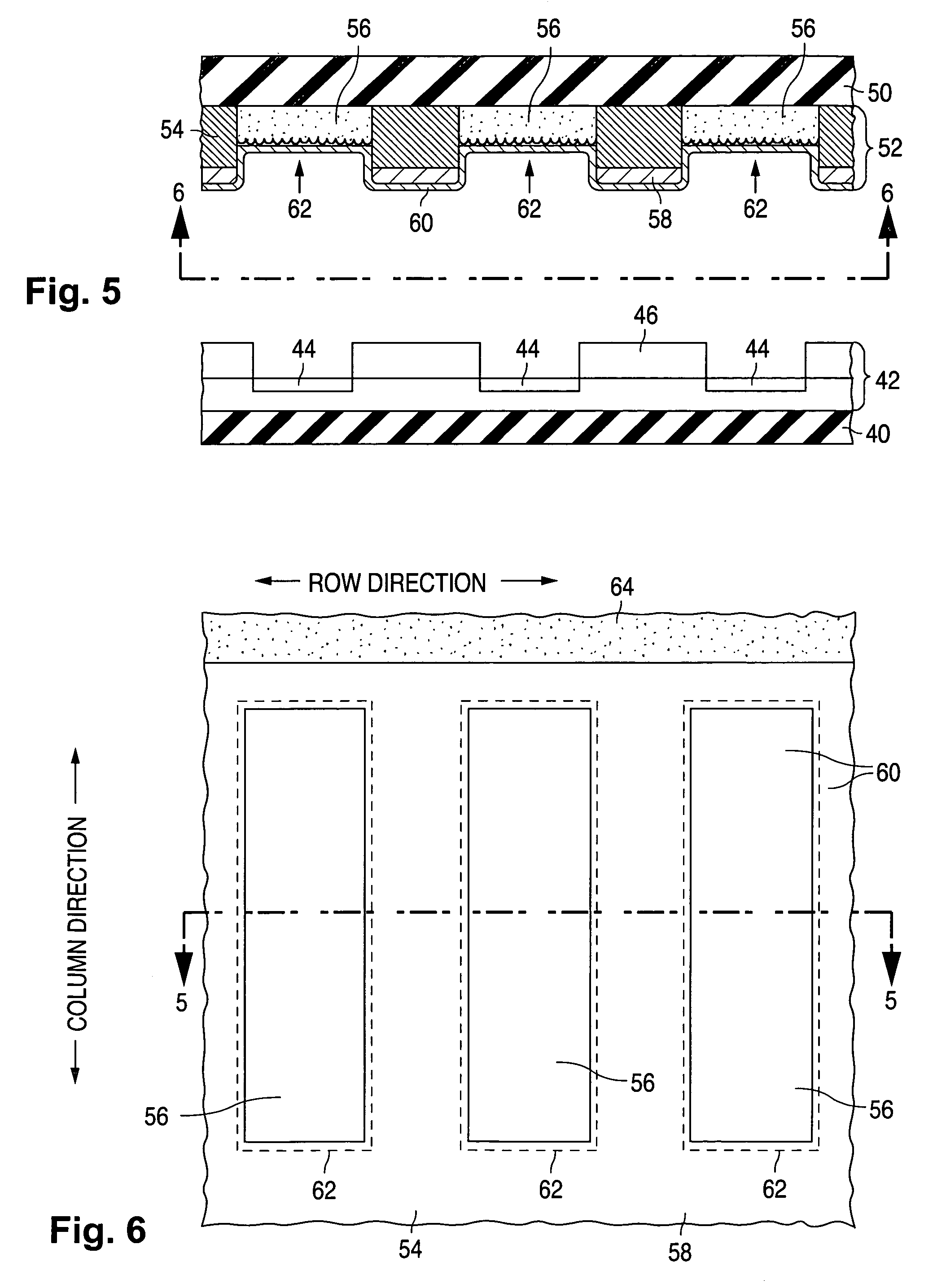

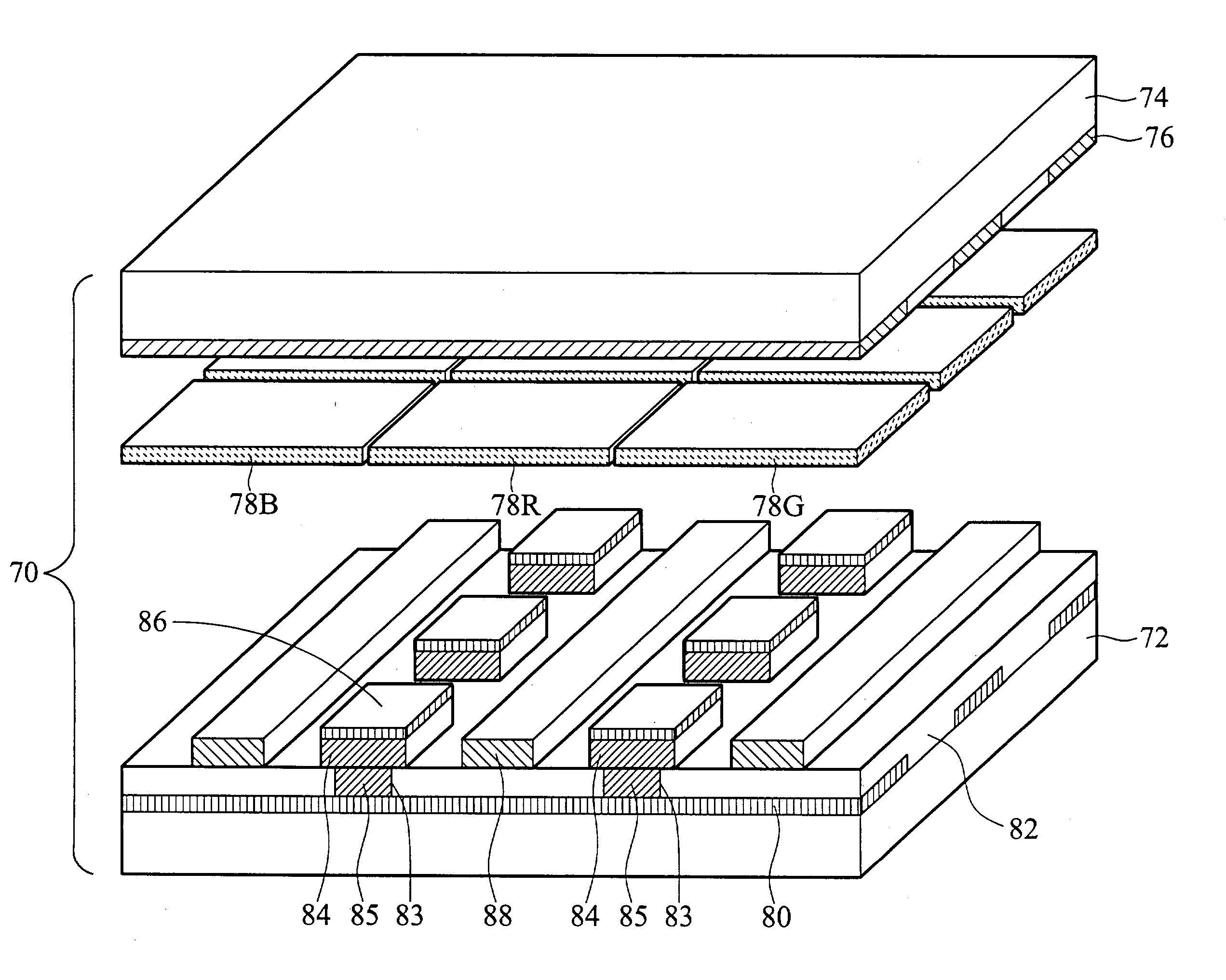

Field emission array with carbon nanotubes and method for fabricating the field emission array

InactiveUS6976897B2Simple film formationTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersPhosphorCarbon nanotube

A field emission array adopting carbon nanotubes as an electron emitter source, wherein the array includes a rear substrate assembly including cathodes formed as stripes over a rear substrate and carbon nanotubes; a front substrate assembly including anodes formed as stripes over a front substrate with phosphors being deposited on the anodes, a plurality of openings separated by a distance corresponding to the distance between the anodes in a nonconductive plate, and gates formed as stripes perpendicular to the stripes of anodes on the nonconductive plate with a plurality of emitter openings corresponding to the plurality of openings. The nonconductive plate is supported and separated from the front substrate using spacers. The rear substrate assembly is combined with the front substrate assembly such that the carbon nanotubes on the cathodes project through the emitter openings.

Owner:SAMSUNG SDI CO LTD

Electron beam apparatus and a device manufacturing method by using said electron beam apparatus

InactiveUS20040119023A1Reduce the overall diameterSmall diameterStability-of-path spectrometersMaterial analysis using wave/particle radiationOptical axisCrystal orientation

An electron beam apparatus, in which an electron beam emitted from an electron gun having a cathode and an anode is focused and irradiated onto a sample, and secondary electrons emanated from the sample are directed into a detector, the apparatus further comprising means for optimizing irradiation of the electron beam emitted from the electron gun onto the sample, the optimizing means may be two-stage deflectors disposed in proximity to the electron gun which deflects and directs the electron beam emitted in a specific direction so as to be in alignment with the optical axis direction of the electron beam apparatus, the electron beam emitted in the specific direction being at a certain angle with respect to the optical axis due to the fact that, among the crystal orientations of said cathode, a specific crystal orientation allowing a higher level of electron beam emission out of alignment with the optical axis direction.

Owner:EBARA CORP

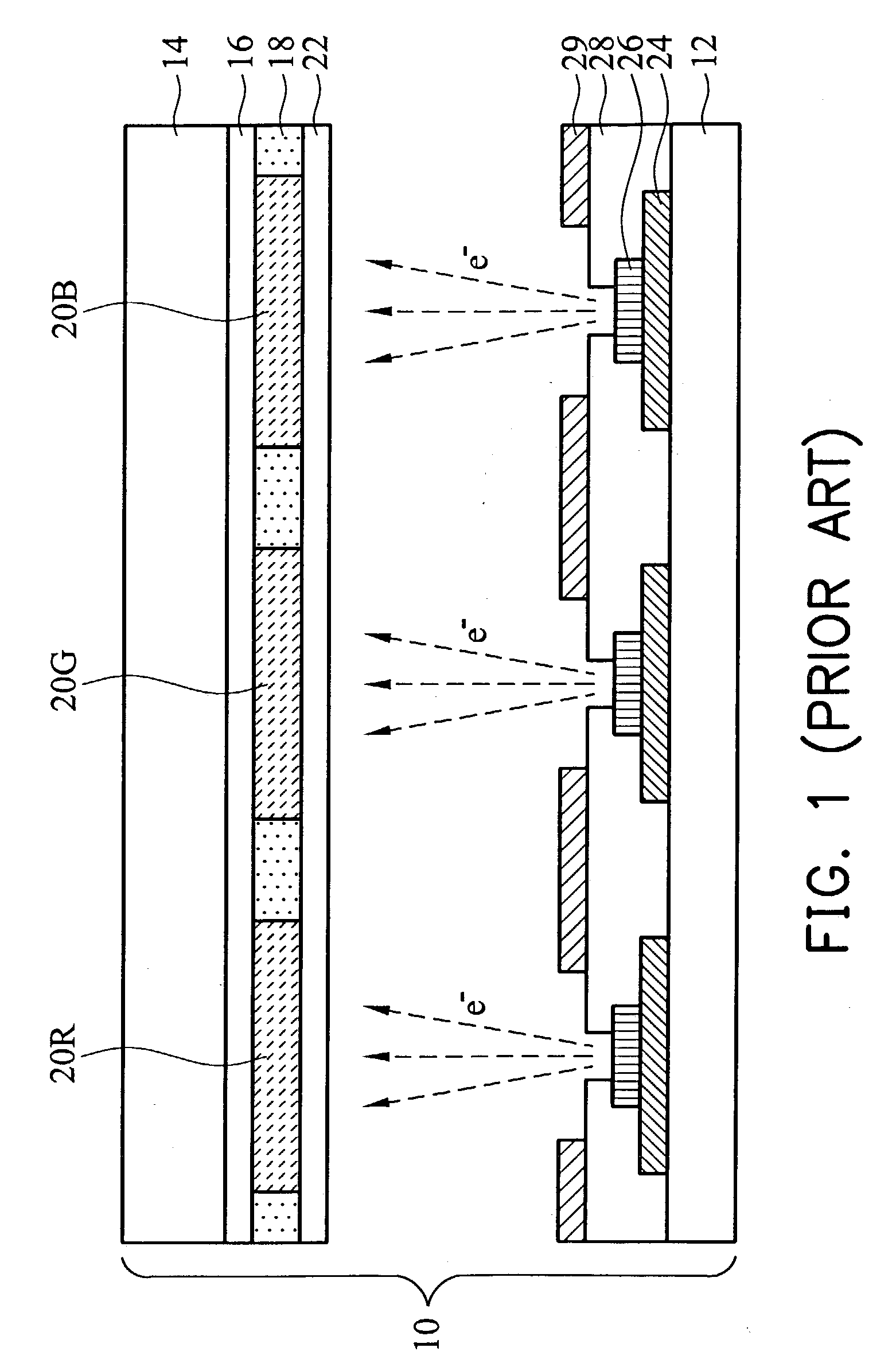

Electron emission device

InactiveUS20050184647A1Simple structureSufficient beam focusing capacityDischarge tube luminescnet screensElectrode and associated part arrangementsLight beamThin layer

An electron emission device is provided comprising first and second substrates facing each other and separated from each other by a predetermined distance. An electron emission unit is disposed on the first substrate, and an image display unit is disposed on the second substrate. A focusing electrode comprising a plurality of beam-guide holes is disposed between the first and second substrates. The portion of the focusing electrode located near a beam-guide hole comprises a thin layer. The remainder of the focusing electrode comprises a thick layer having a thickness larger than the thickness of the thin layer.

Owner:SAMSUNG SDI CO LTD

Field emission display having carbon nanotube emitter and method of manufacturing the same

InactiveUS20050035701A1Good step coverageReduce leakage currentNanoinformaticsElectrode and associated part arrangementsSilanesCarbon nanotube

Provided is a field emission display (FED) with a carbon nanotube emitter and a method of manufacturing the same. A gate stack that surrounds the CNT emitter has a mask layer that covers an emitter electrode adjacent to the CNT emitter, and a gate insulating film, a gate electrode, a focus gate insulating film (SiOx, X<2), and a focus gate electrode formed on the mask layer. The focus gate insulating film has a thickness 2 μm or more, and preferably 3˜15 μm and is preferably made using PECVD. A flow rate of silane and nitric acid for forming the focus gate insulating film and / or the gate insulating film are maintained at 50˜700 sccm and 700˜4,500 sccm, respectively. By doing so and by making the oxide thick, the oxide is less apt to crack and thus less apt to generate a leakage current.

Owner:SAMSUNG SDI CO LTD

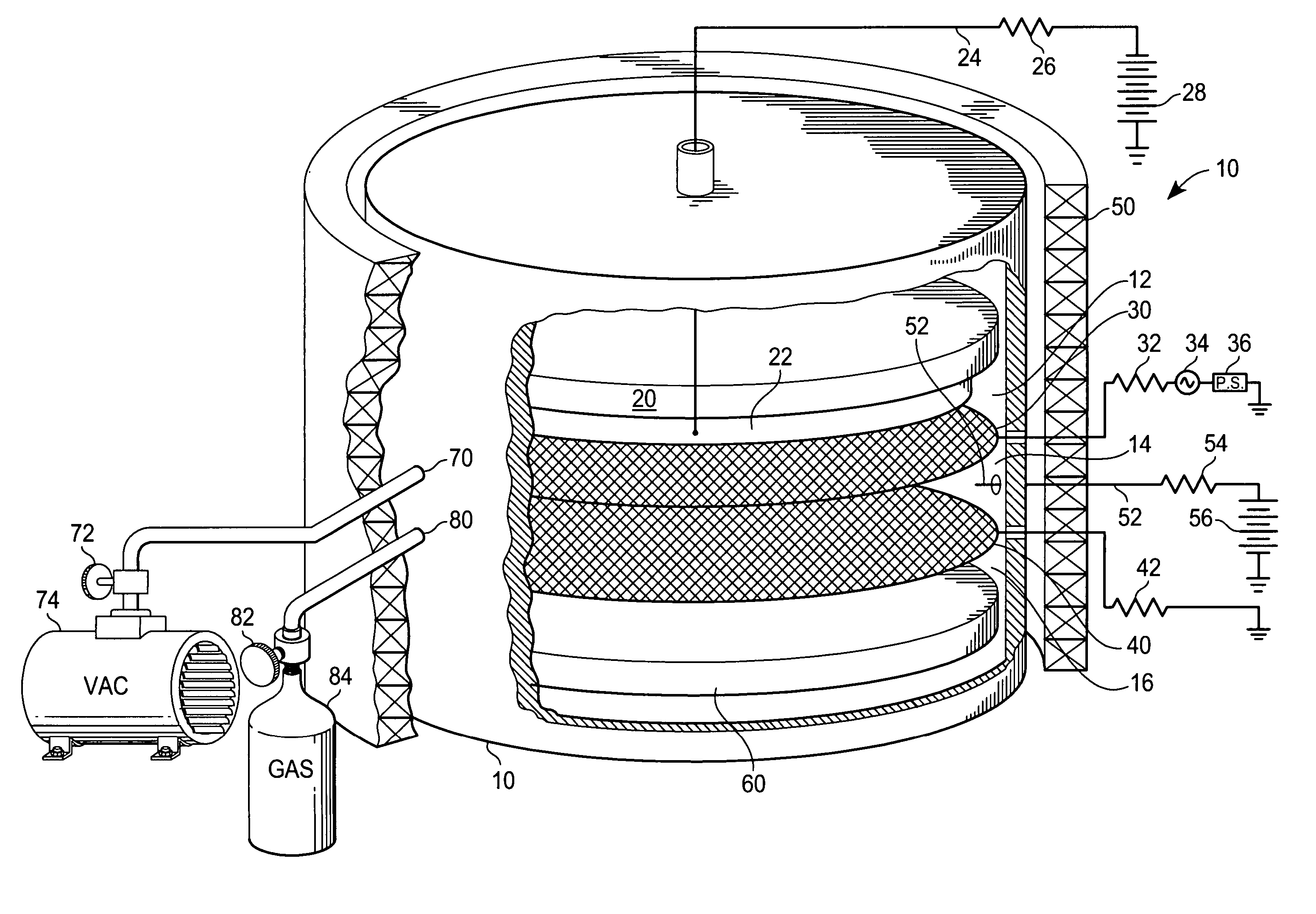

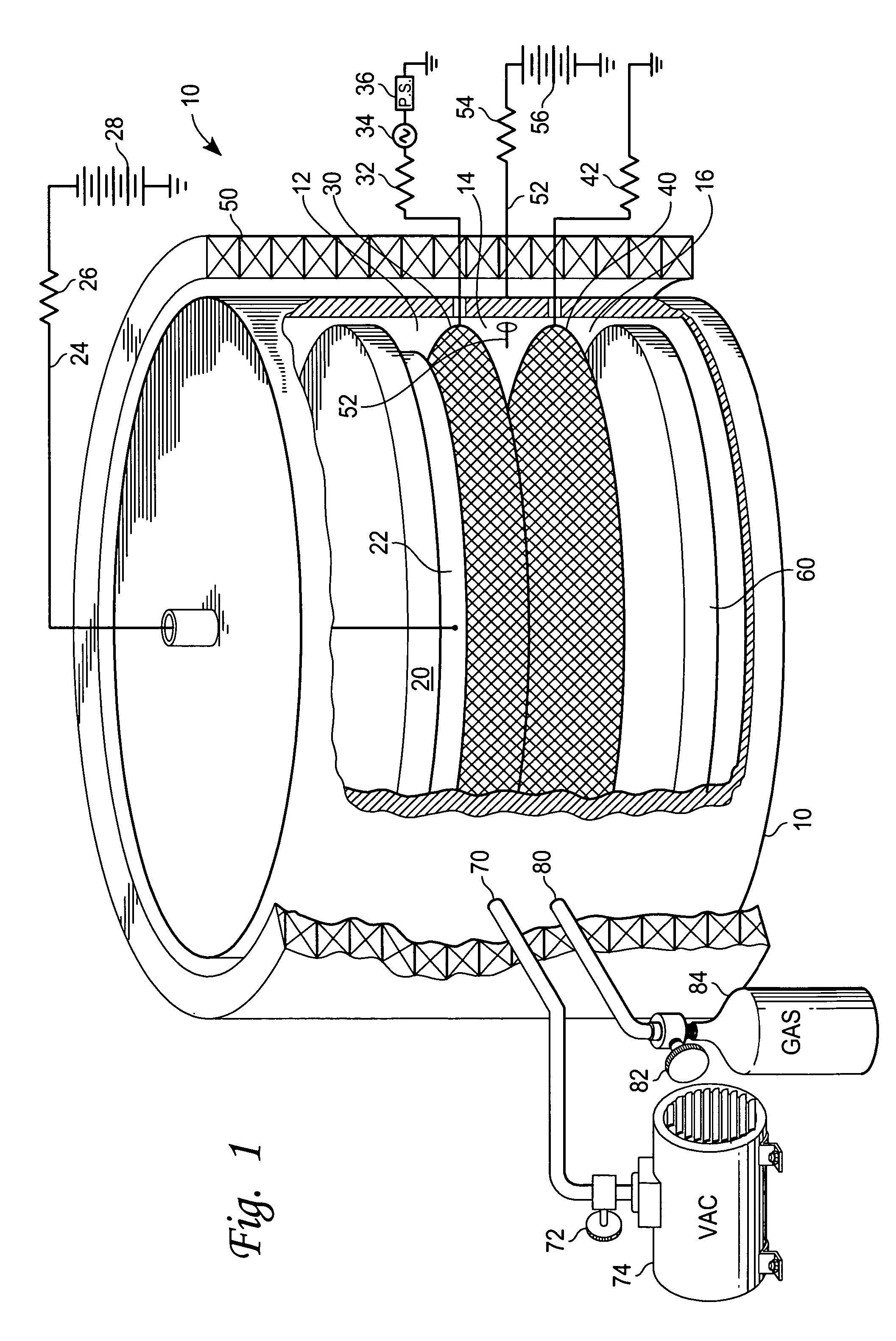

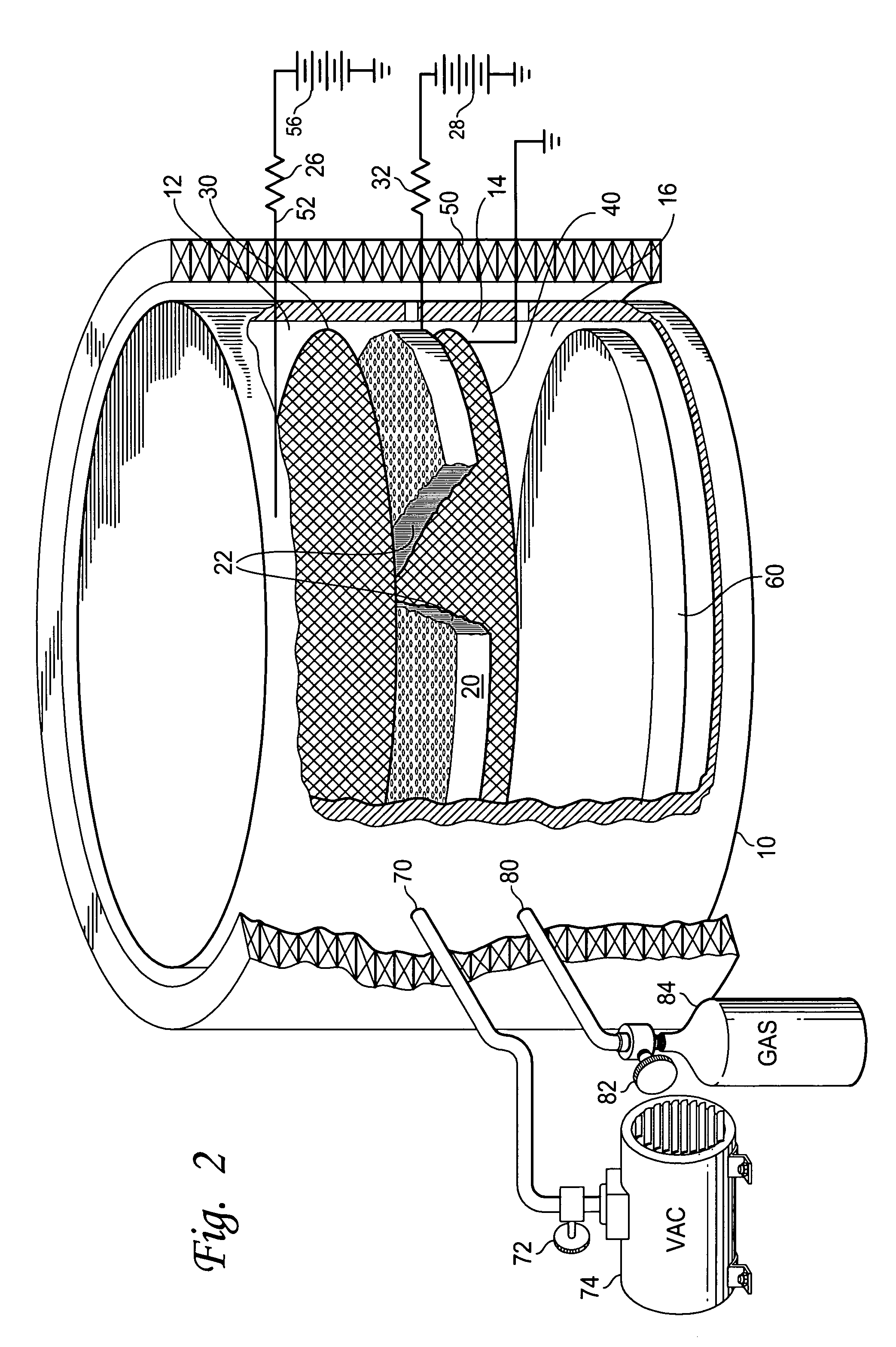

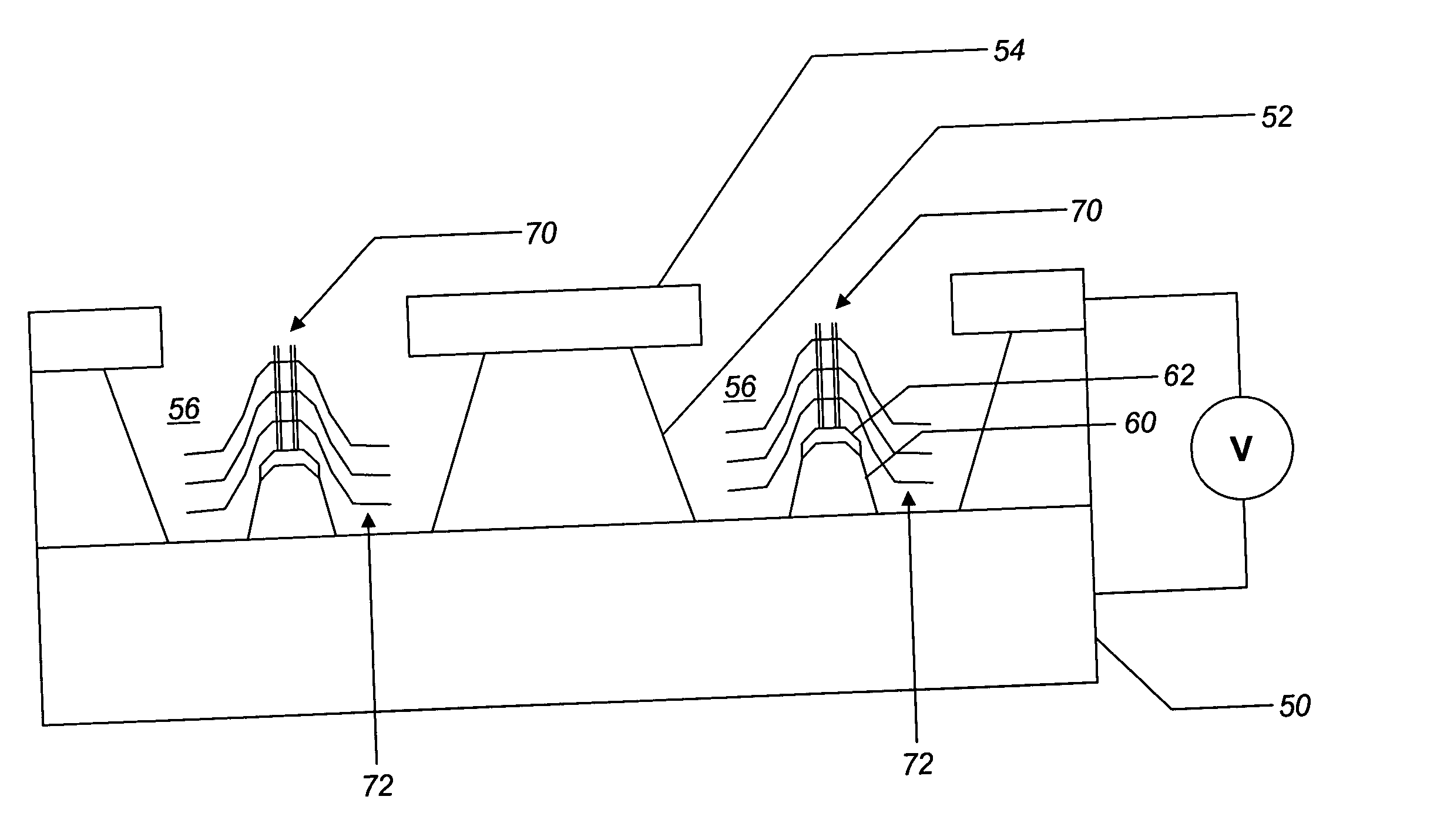

Ion plasma beam generating device

ActiveUS6975073B2Reducing electron emissionWide range of fieldsElectric discharge tubesElectric arc lampsDopantWire grid

An electron beam device wherein a low temperature gaseous plasma is generated in a chamber divided by two parallel wire grids. A semiconductor wafer serves as a cathode drawing ions from the plasma to impinge on the wafer, generating secondary electrons that are accelerated toward an anode on the opposite side of the grids where a target resides. In order to have a beam with uniform cross-sectional flux characteristics, the semiconductor wafer is doped with a graded dopant concentration that promotes a uniform beam.

Owner:ADASTRA TECH

Field emission device, display adopting the same and method of manufacturing the same

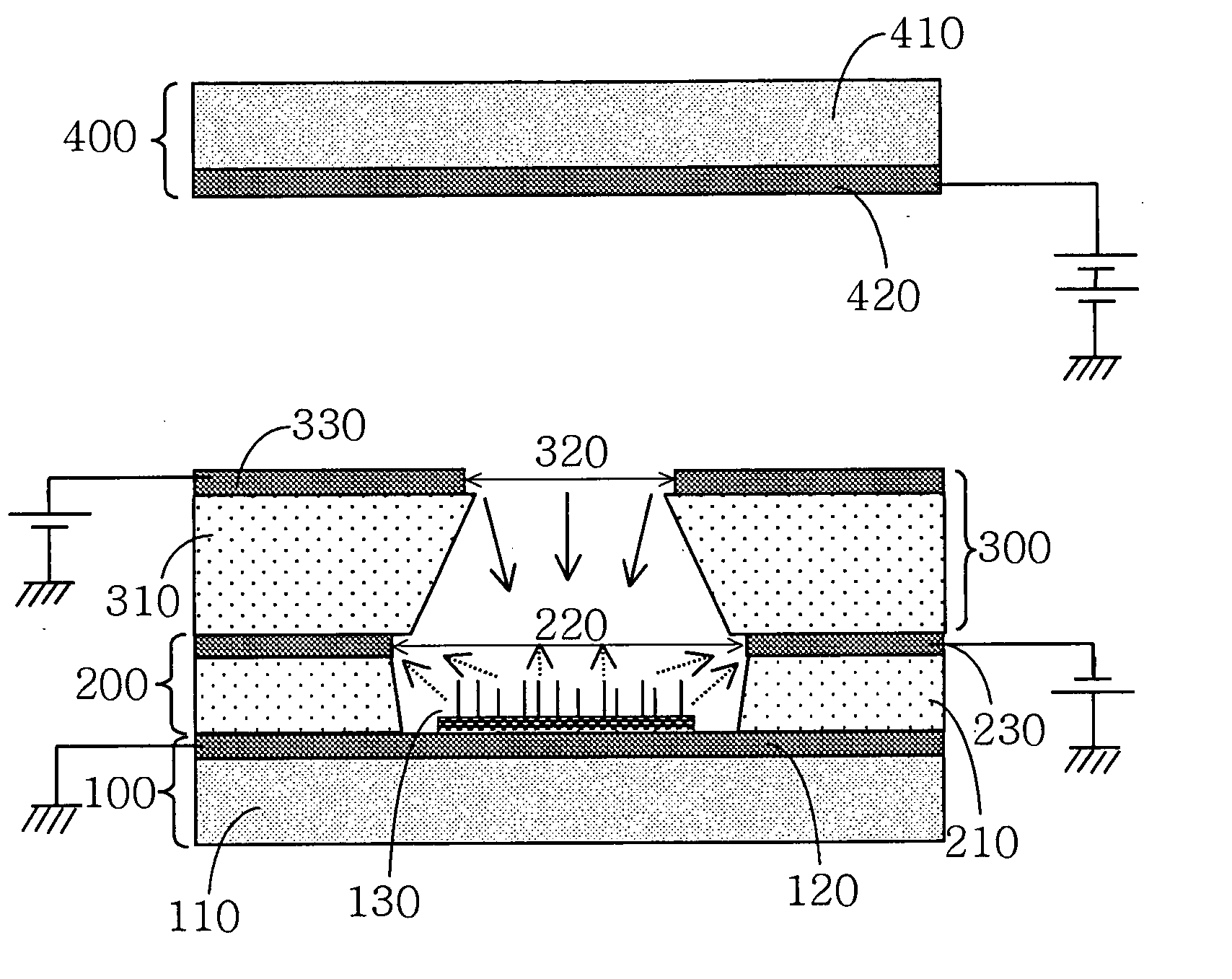

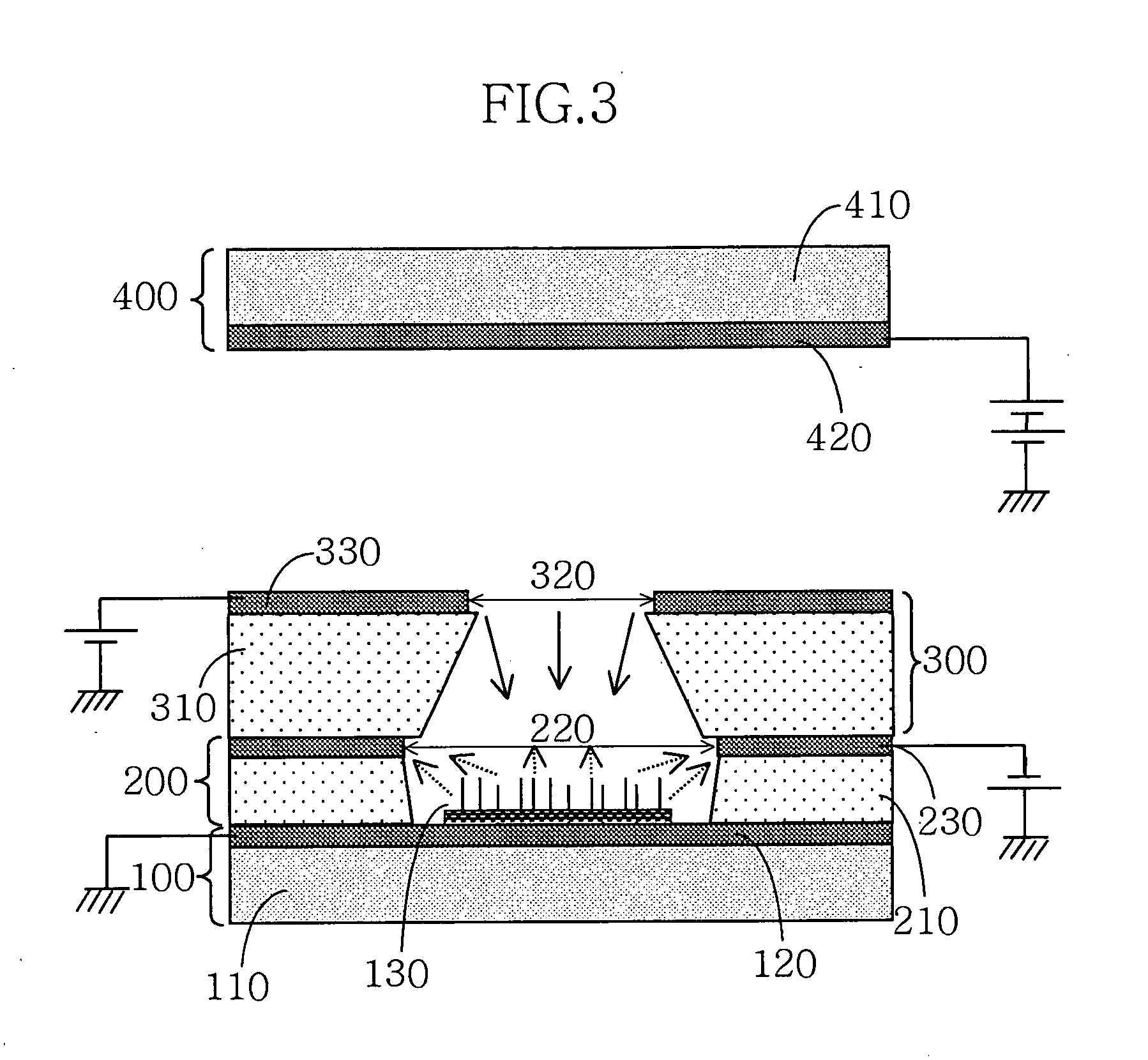

InactiveUS20050133779A1Improves electron beam focusingStatic indicating devicesNanoinformaticsField emission deviceDisplay device

A field emission device comprises a glass substrate, an emitter electrode formed on the glass substrate, a carbon nanotube (CNT) emitter formed on the emitter electrode, and a gate stack formed around the CNT emitter for extracting electron beams from the CNT emitter and focusing the extracted electron beams onto a given position. The gate stack includes a mask layer covering the emitter electrode and provided around the CNT emitter, a gate insulating layer formed on the mask layer to a predetermined height, a mirror electrode formed on an inclined plane of the gate insulating layer, a gate electrode formed on the gate insulating layer and spaced apart from the mirror electrode, and a focus gate insulating layer and a focus gate electrode sequentially formed on the gate electrode. The field emission device is manufactured and employed in a display device in accordance with the present invention.

Owner:SAMSUNG SDI CO LTD

Electron beam apparatus and a device manufacturing method by using said electron beam apparatus

InactiveUS7005641B2Improve throughputIncrease exposureMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementOptical axisCrystal orientation

Owner:EBARA CORP

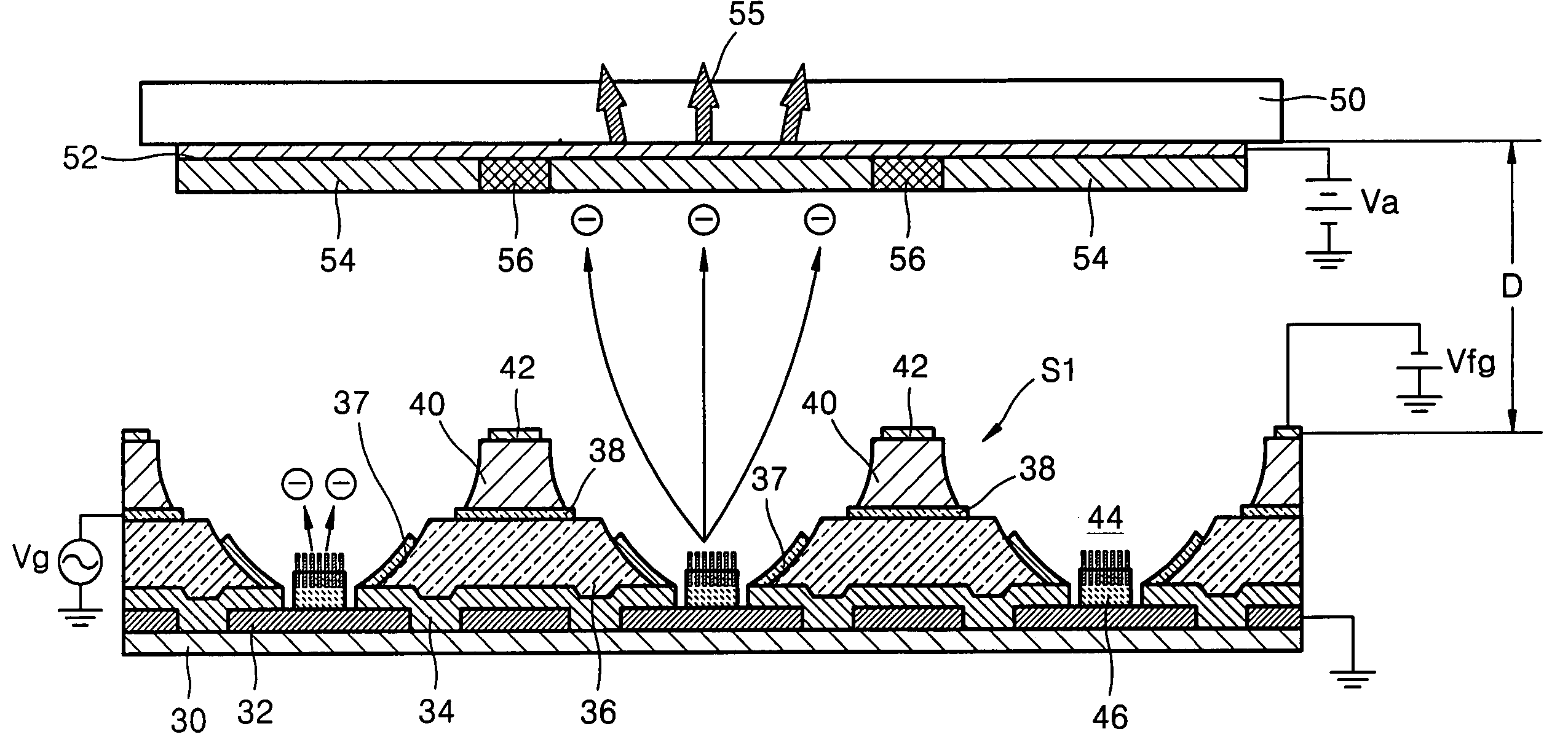

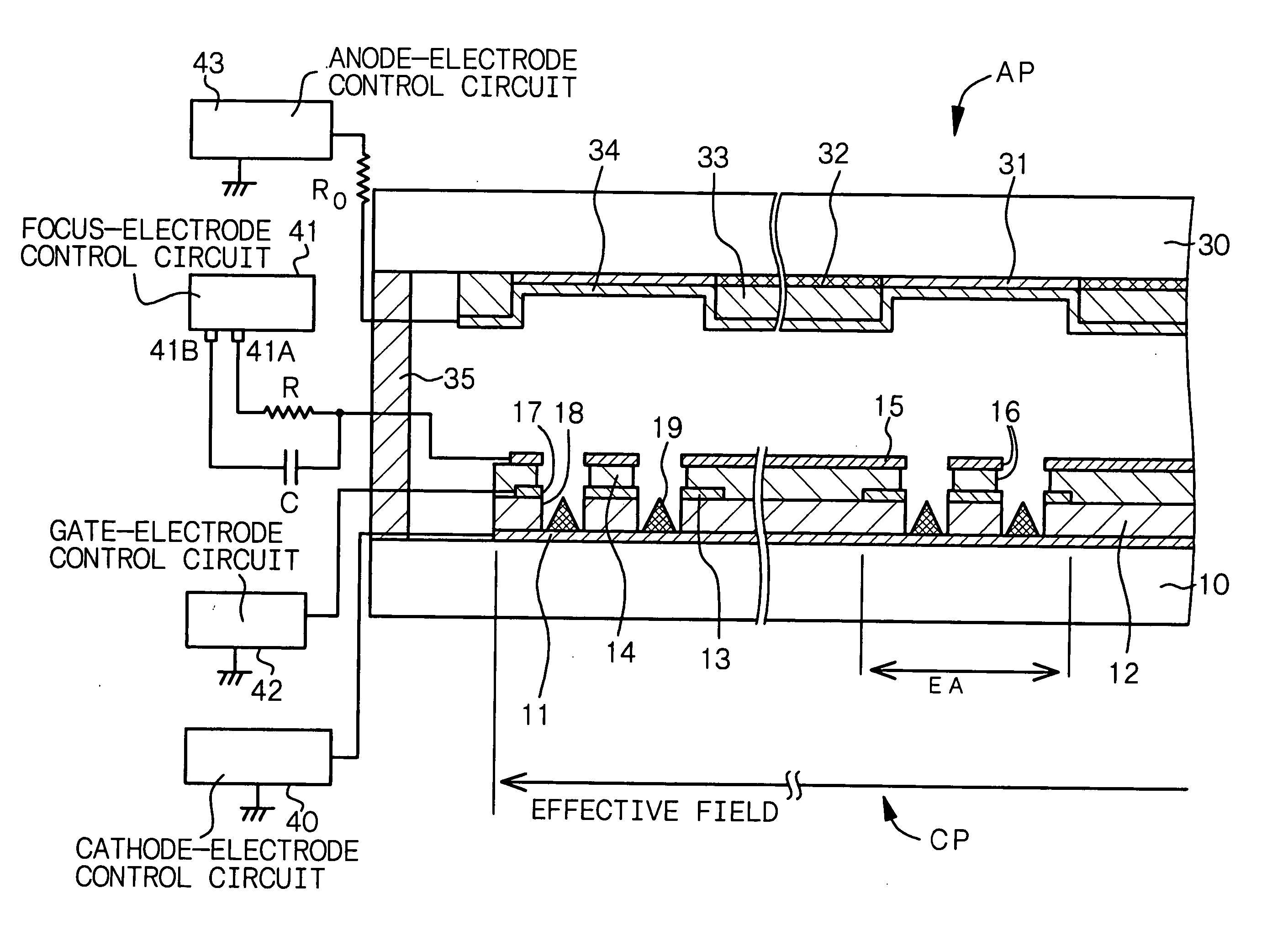

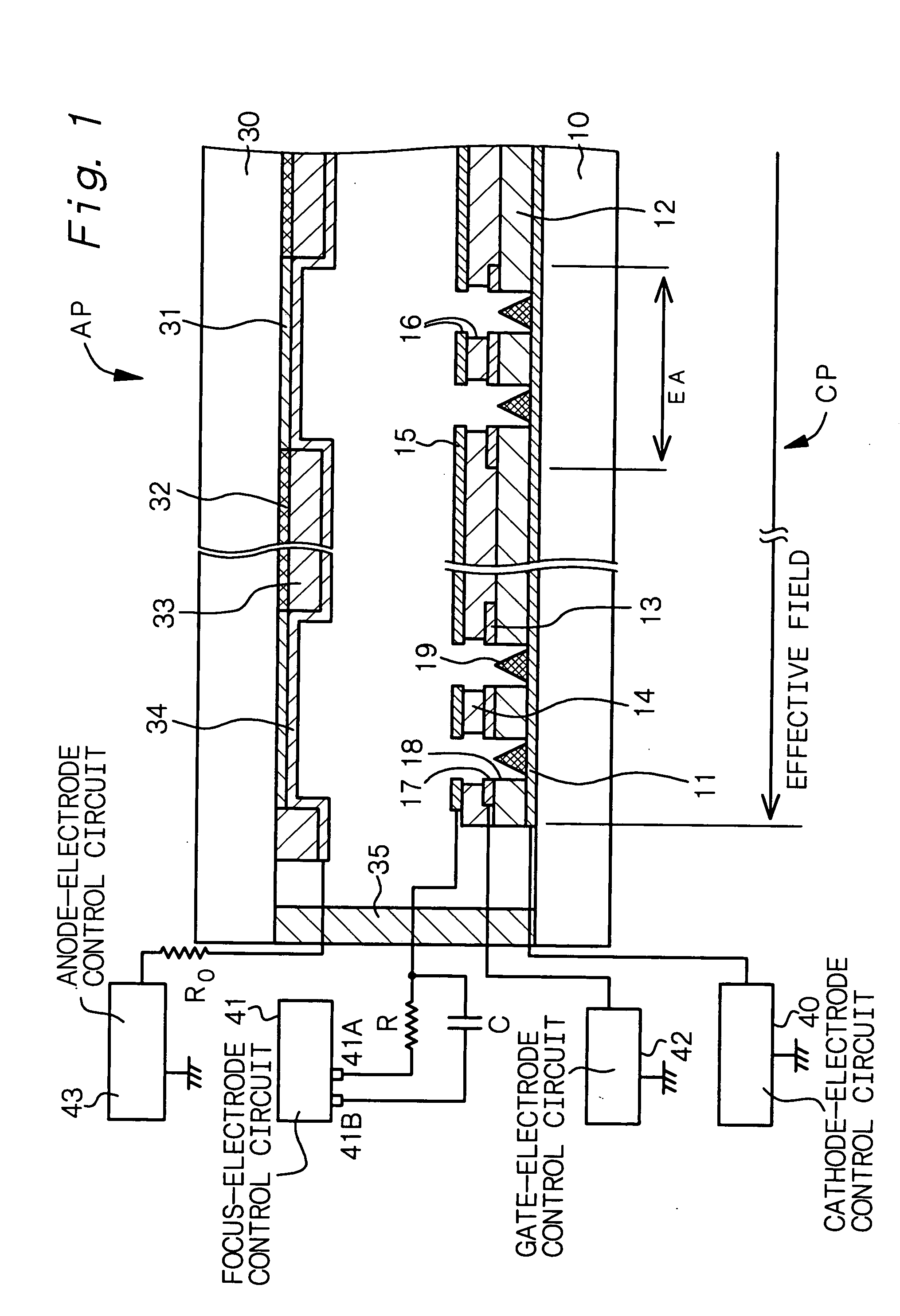

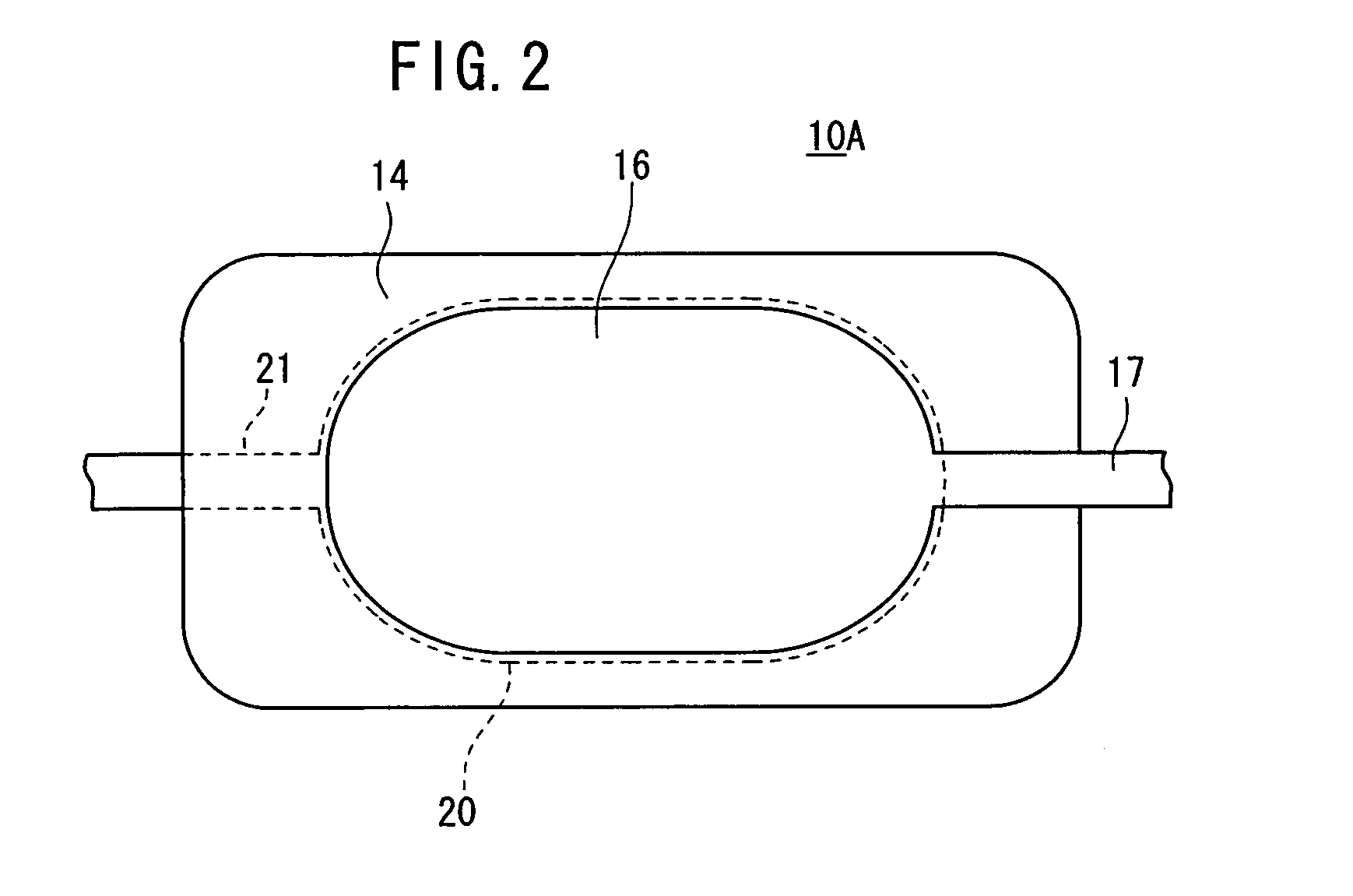

Cold cathode electric field electron emission display device

InactiveUS20050082964A1Increase display contrastAvoid collisionDischarge tube luminescnet screensStatic indicating devicesCapacitancePhosphor

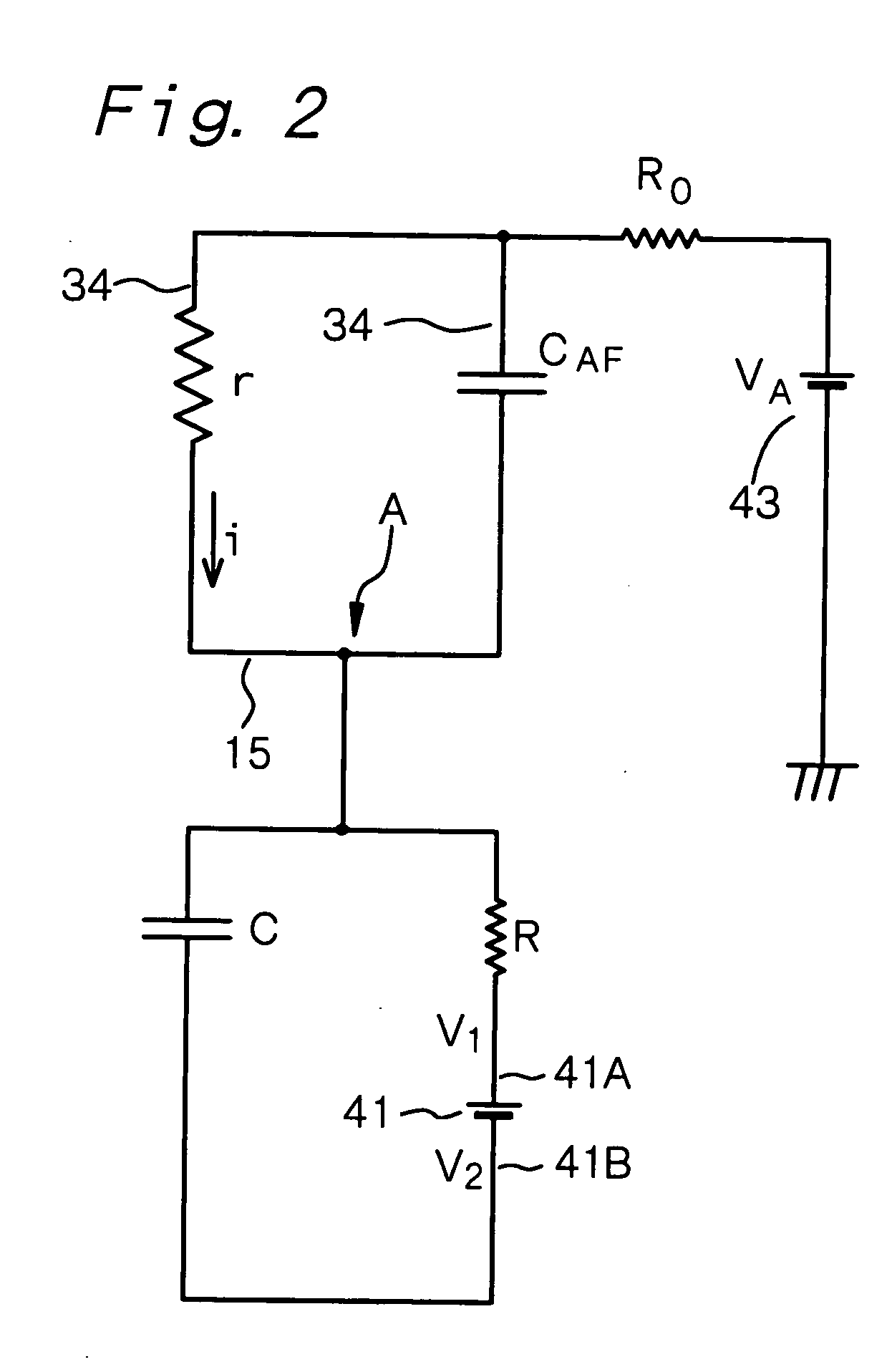

A cold cathode field emission display comprising at least (A) a display panel having a cathode panel CP provided with a plurality of electron-emitting regions EA and an anode panel AP provided with a phosphor layer 31 and an anode electrode 34, said cathode panel and said anode panel being bonded to each other in their circumferential regions, (B) a focus-electrode control circuit 41, (C) a resistance element R, and (D) a capacitor C, in which the focus electrode 15 formed in the electron-emitting region EA is connected to a first voltage-output portion 41A of the focus-electrode control circuit 41 through the resistance element R, and the focus electrode 15 is further connected to a second voltage-output portion 41B of the focus-electrode control circuit 41 through the capacitor C.

Owner:SONY CORP

Field emission device

ActiveUS20050057168A1Reduce leakage currentEasy to controlControl electrodesDischarge tube luminescnet screensField emission deviceGate leakage current

A field emission device including a cathode having an electric field emitter for emitting electrons, a field emission inducing gate for inducing electron emission, and an anode for receiving the emitted electrons. A field emission suppressing gate is interposed between the cathode and the field emission inducing gate for suppressing electron emission, so that problems such as gate leakage current, electron emission due to anode voltage, and electron beam spreading of the conventional field emission device are significantly overcome.

Owner:ELECTRONICS & TELECOMM RES INST

Electron emission element

InactiveUS20050212398A1Increase freedomEasy to makeDischarge tube luminescnet screensCathode ray tubes/electron beam tubesElectric forceElectron source

By making a cathode substrate function as a cathode and applying a voltage to the cathode and an anode, an electron emission element emits an electron from an electron source provided on the cathode substrate, and irradiates the electron onto an electron irradiation surface formed on the anode surface. The electron source is thread-type and provided on the cathode substrate. A deflecting voltage generates the electric field around the electron source. The electron source including a charge receives a power from the generated electric field to curve. Therefore, an irradiation position of the electron moves on the electron irradiation surface. Since it becomes unnecessary to move the electron irradiation surface and the electron source, a configuration of the electron emission element or an apparatus including the electron emission element is not complicated, and can be miniaturized and simple. Further, since the electron source curves, a tip of the electron source and the electron irradiation surface can be close, and a size of a beam spot at the irradiation position can be maintained constant. Therefore, since a mechanism for correcting the size of the beam spot is unnecessary, the configuration of the electron emission element or the apparatus including the electron emission element can be much simpler.

Owner:PIONEER CORP

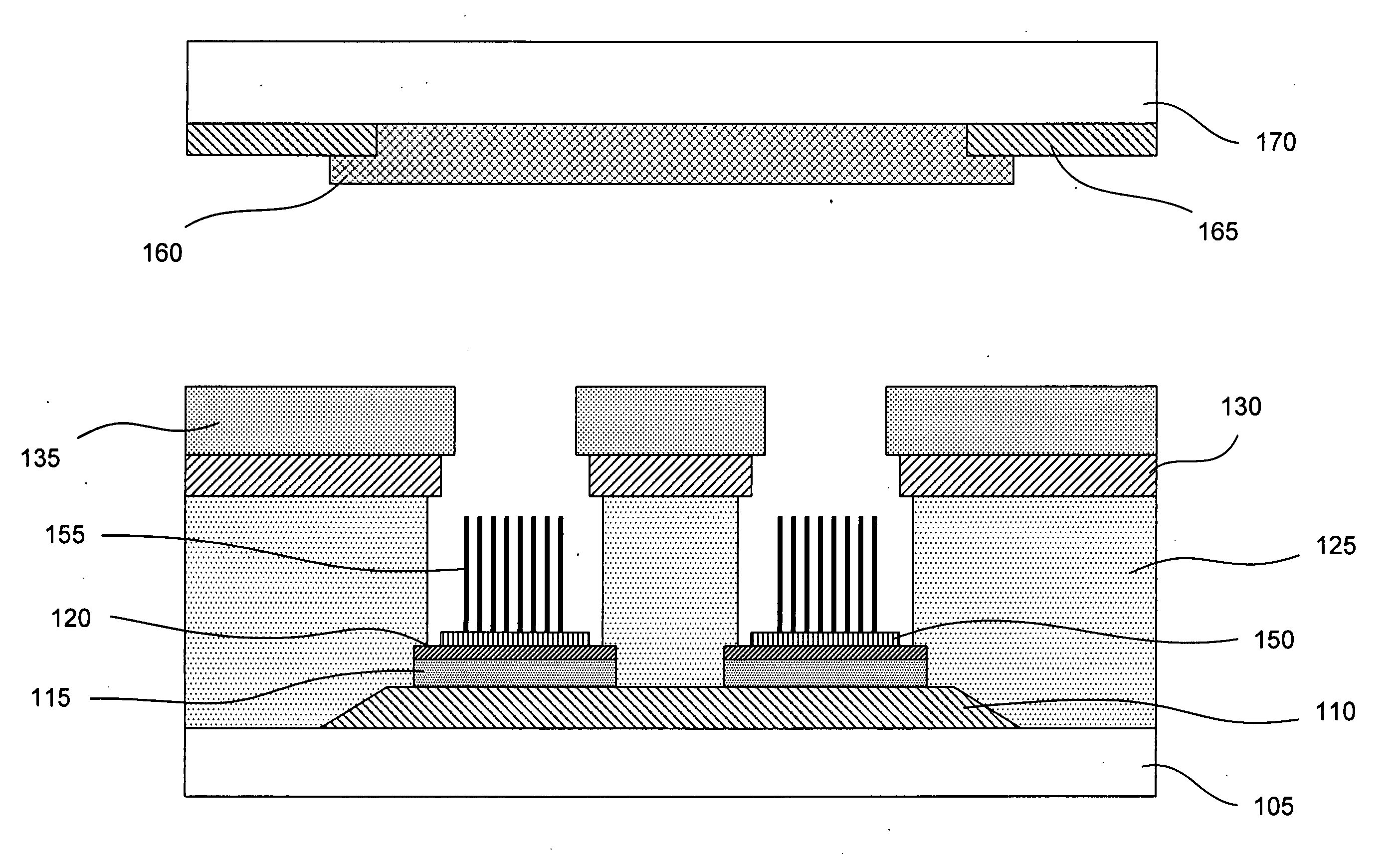

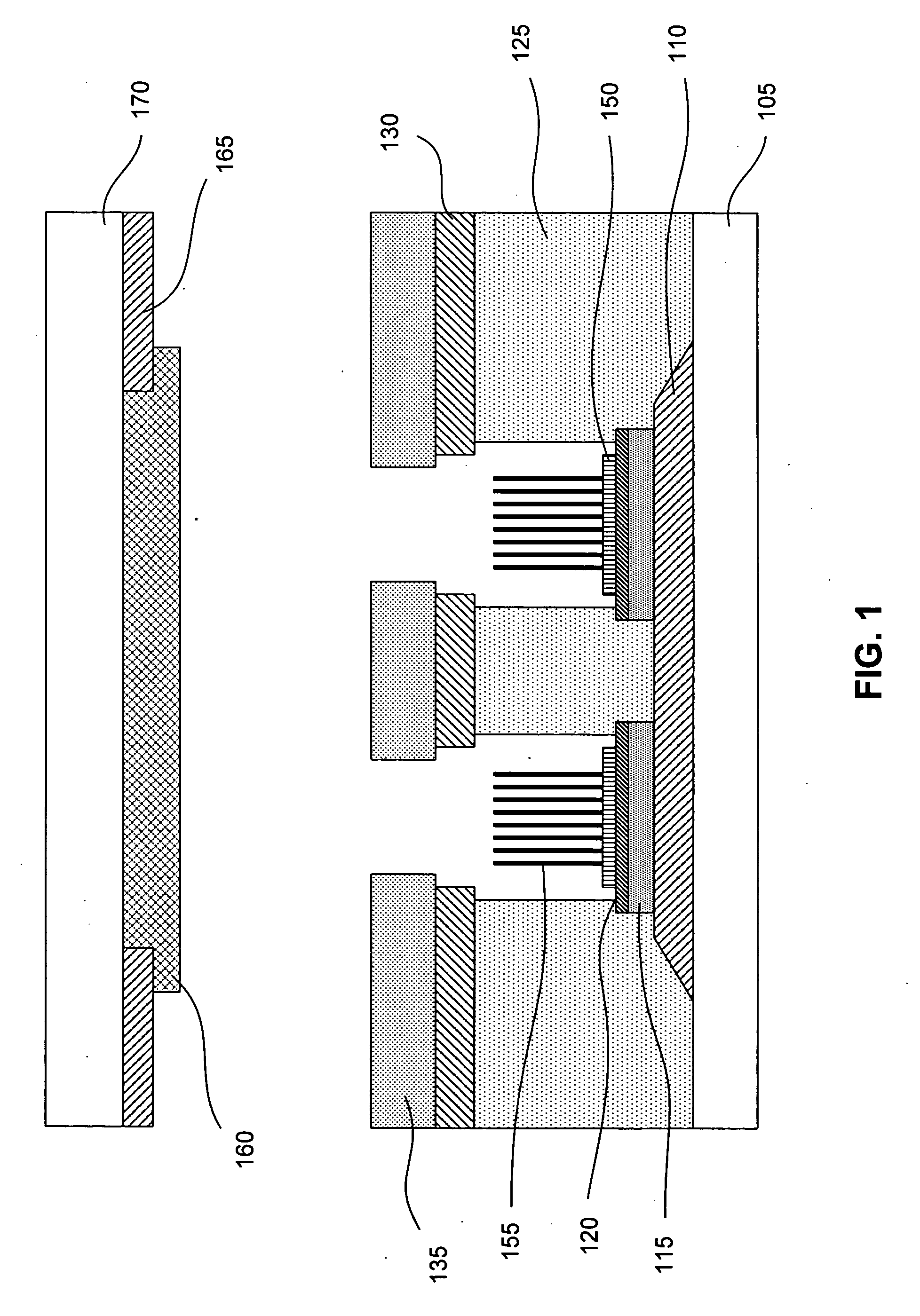

Light-emitting and electron-emitting devices having getter regions

InactiveUS7315115B1Improve performanceEasy to manufactureTube/lamp screens manufactureGetteringLight emitting deviceElectron

A light-emitting device contains getter material (58) typically distributed in a relatively uniform manner across the device's active light-emitting portion. An electron-emitting device similarly contains getter material (112, 110 / 112, 128, 132, and 142) typically distributed relatively uniformly across the active electron-emitting portion of the device.

Owner:CANON KK +1

Emitter structure with a protected gate electrode for an electron-emitting device

InactiveUS20050236963A1Minimize exposureAvoid arcingDischarge tube luminescnet screensCathode ray tubes/electron beam tubesField emission deviceOptoelectronics

A cathode structure of a field emission device includes a gate electrode that is protected by a passivation layer. In one method for manufacturing such a field emission device, an emitter hole is formed through an insulating layer such that the passivation layer overhangs the gate layer, which overhangs an insulating layer. When used in a display system, the gate layer is exposed to an emitter electrode but shielded from an anode.

Owner:ARROW CAPITAL +1

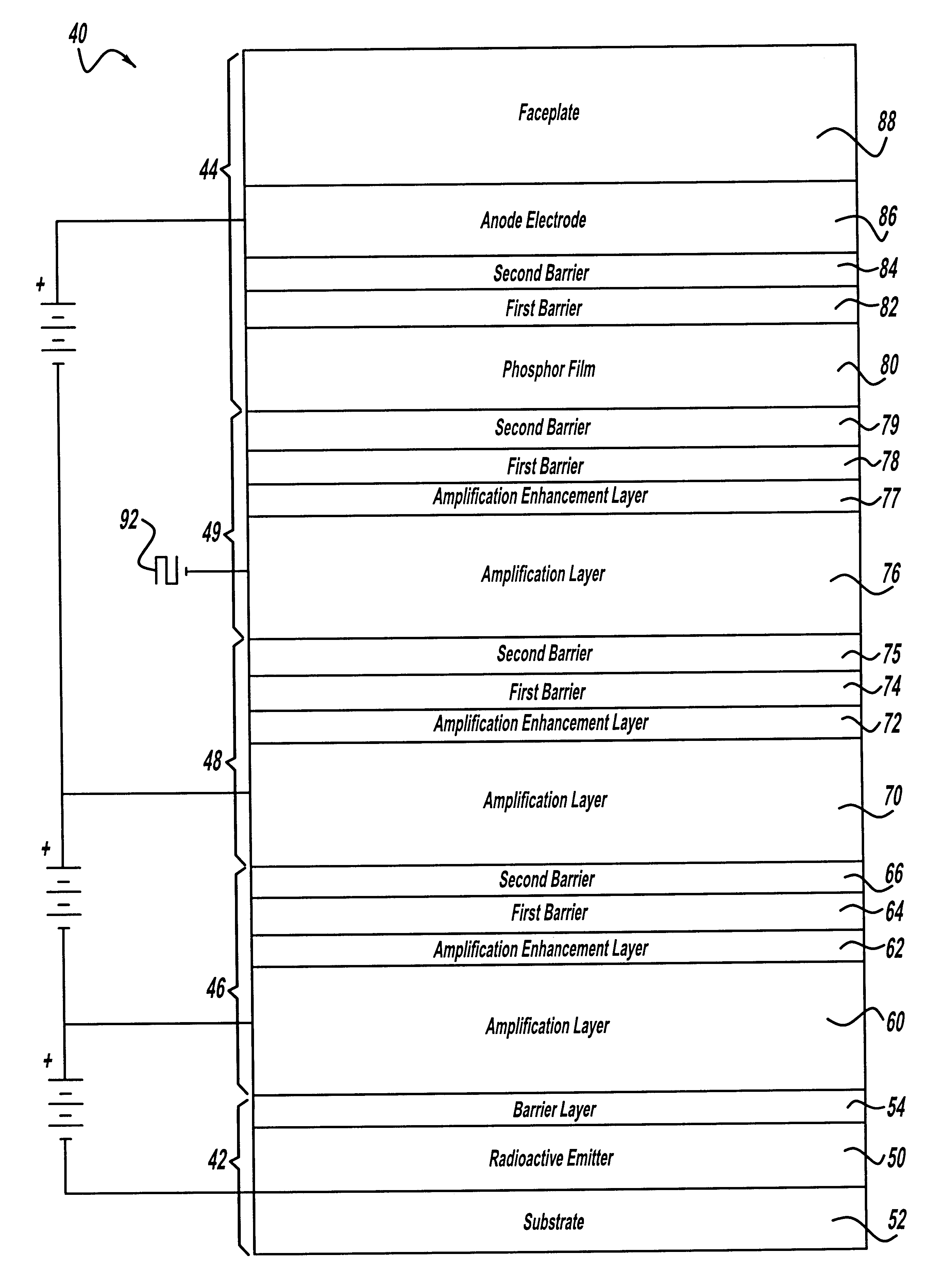

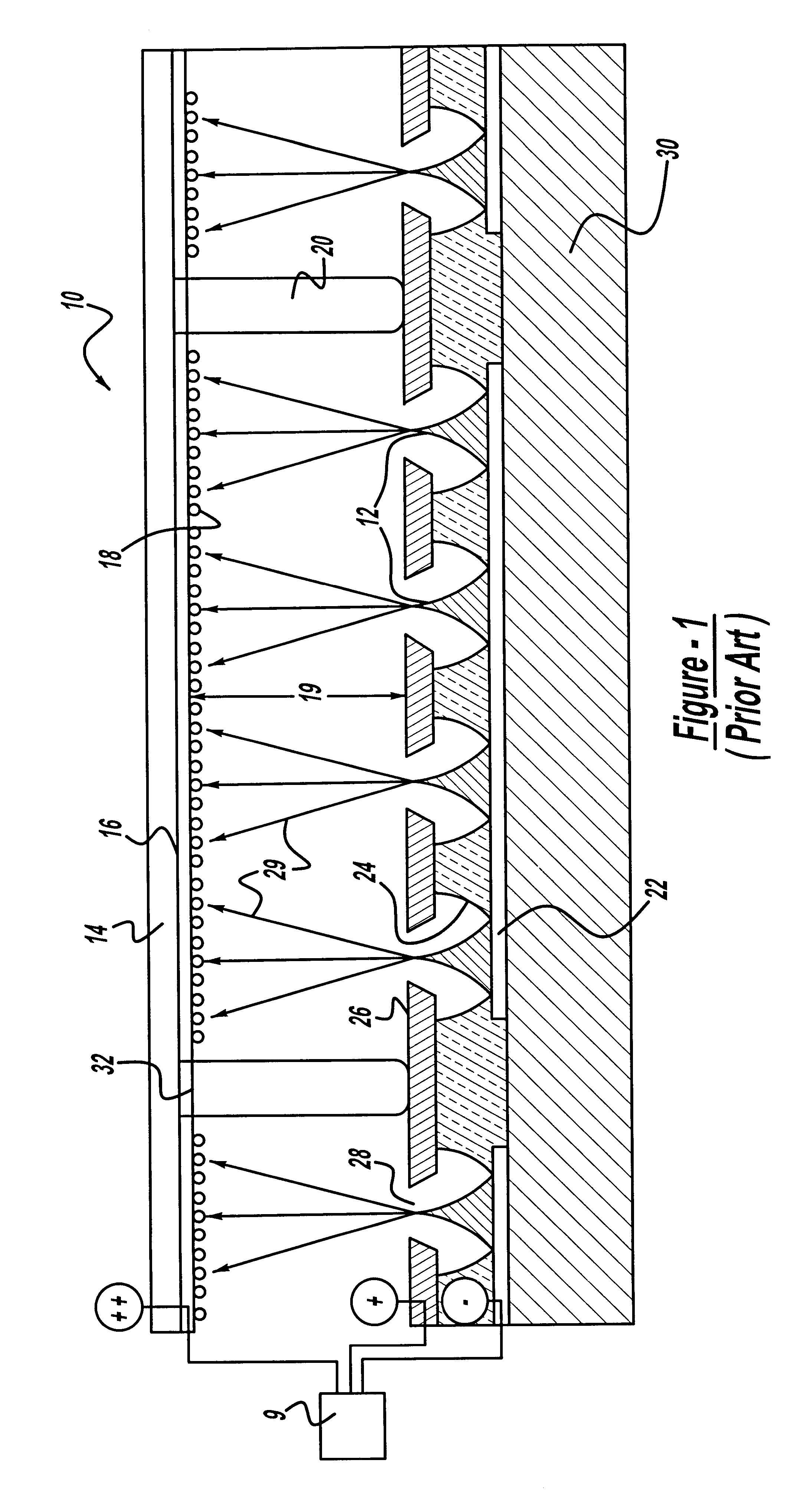

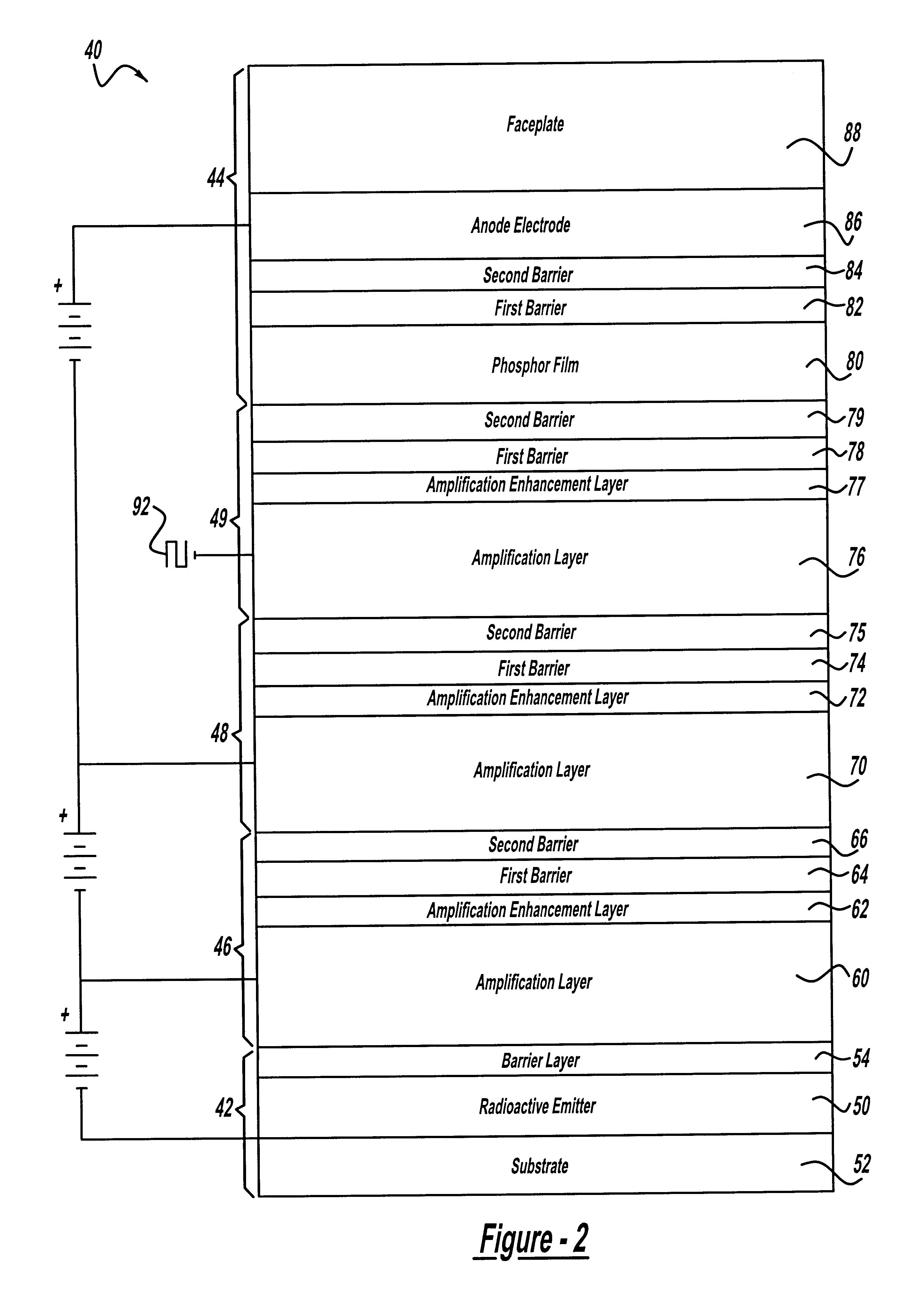

Radioactive cathode emitter for use in field emission display devices

InactiveUS6215243B1Low costImprove efficiencyDischarge tube luminescnet screensElectrode and associated part arrangementsField emission displayElectron

Cathodoluminescent field emission display devices features a radioactive cathode emitter which is used to produce primary electron emissions to drive the FED device. Radioactive emitters eliminate the need for complex emitter structures, such as conventional Spindt cathodes. In addition, the use of a radioactive emitter allows for an "all-firm" FED, and thus represents an improvement over existing devices by reducing emitter to phosphor spacing, as well as eliminating the use of internal vacuums.

Owner:ST CLAIR INTPROP CONSULTANTS

Electron gun, electron beam exposure apparatus, and exposure method

InactiveUS20080211376A1Avoid damageEasy to useNanoinformaticsElectrode and associated part arrangementsElectron sourceOptical axis

An electron gun having an electron source emitting electrons includes: an acceleration electrode which accelerates the electrons; an extraction electrode which has a spherical concave surface having the center on an optical axis and facing the electron emission surface, and which extracts an electron from the electron emission surface; and a suppressor electrode which suppresses electron emission from a side surface of the electron source. In the electron gun, an electric field is applied to the electron emission surface while the electron source is kept at a low temperature in such an extent that sublimation of a material of the electron source would not be caused, to cause the electron source to emit a thermal field emission electron.

Owner:ADVANTEST CORP

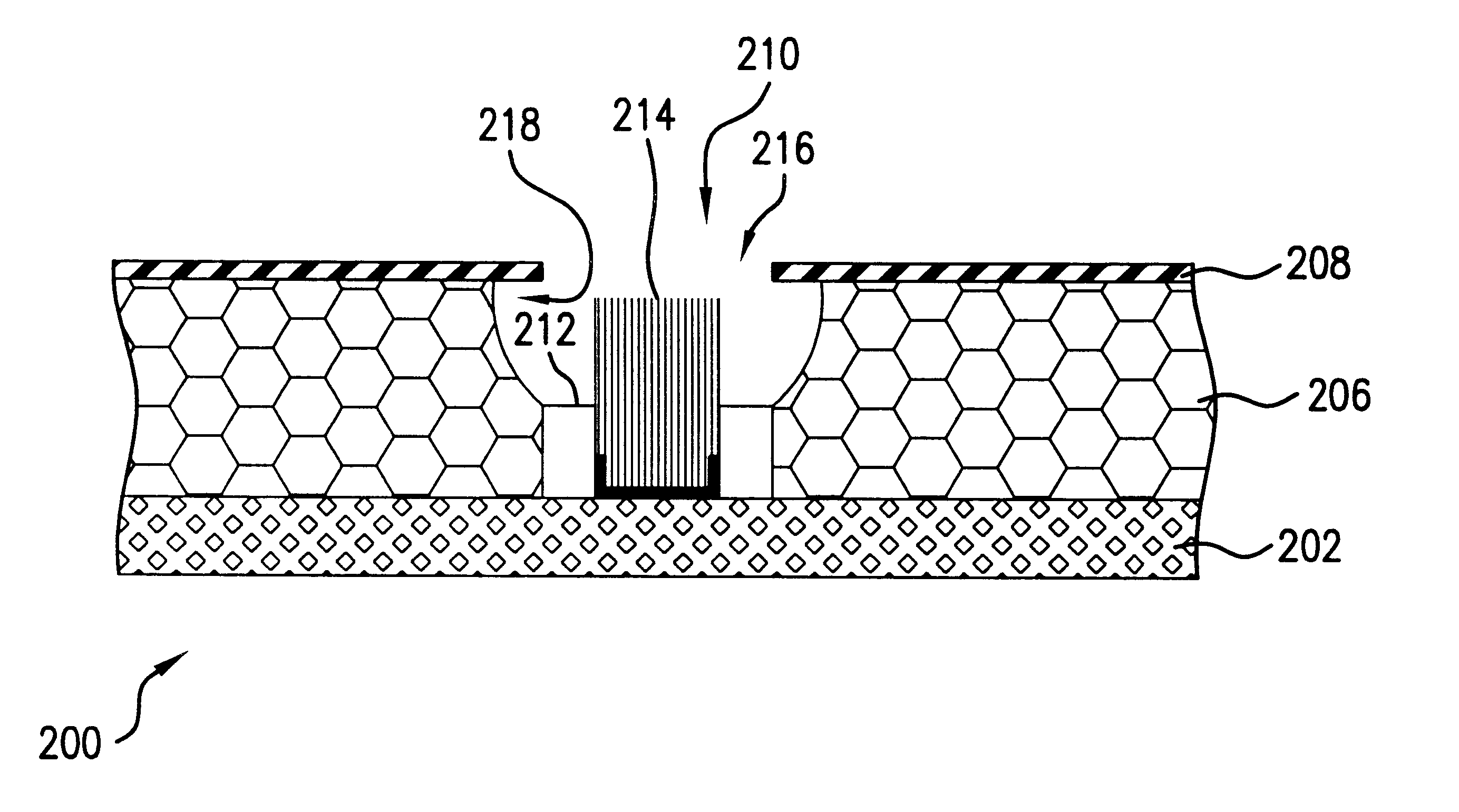

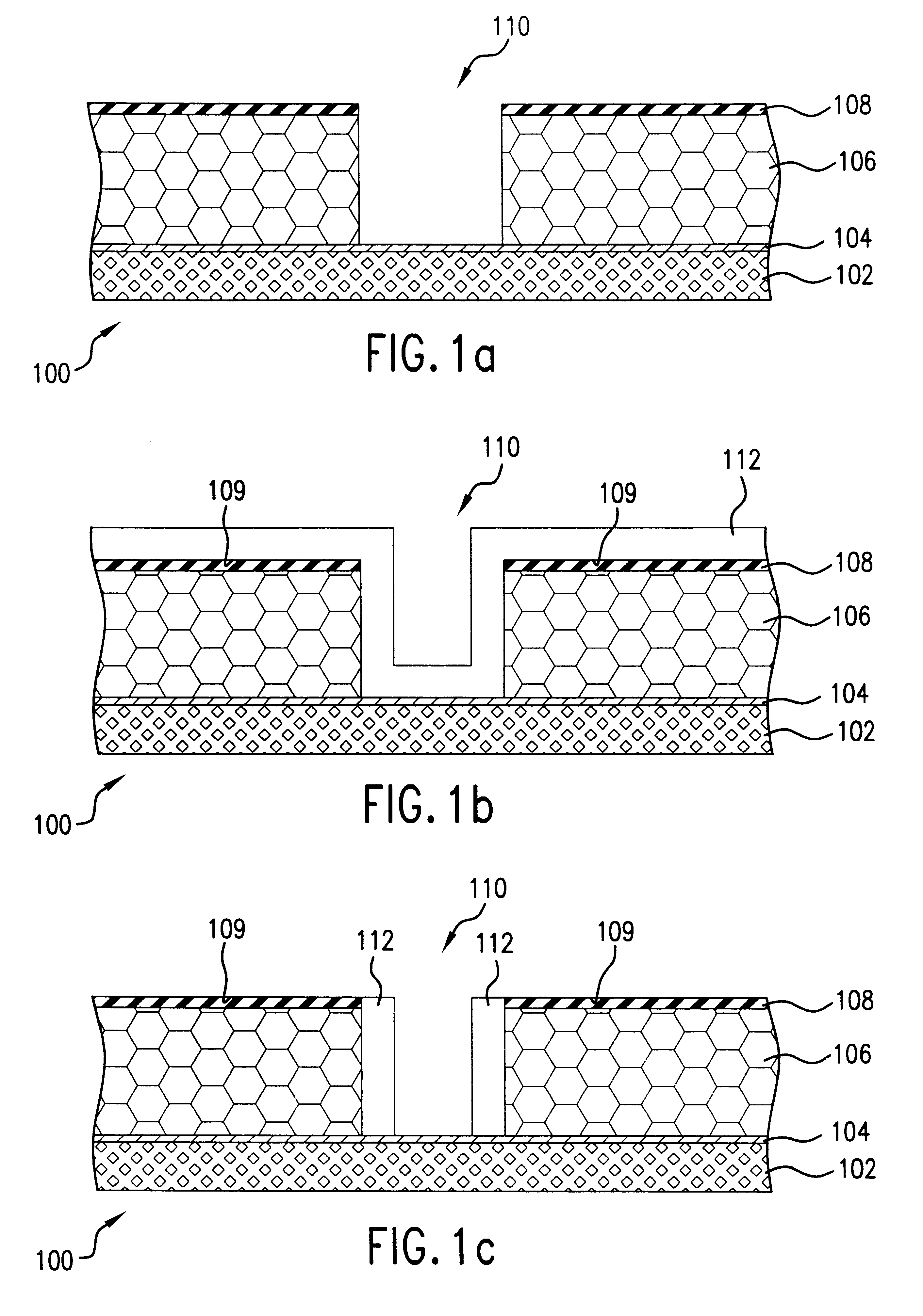

Self-aligned gated carbon nanotube field emitter structures and associated methods of fabrication

InactiveUS20050067936A1Simple and cost-effective and efficientDischarge tube luminescnet screensElectric discharge tubesElectrical conductorField line

A method for fabricating a self-aligned gated carbon nanotube field emitter structure includes providing a substrate, depositing a dielectric material on the surface of the substrate and depositing a conductor layer on the surface of the dielectric material. The method also includes selectively etching the conductor layer to form an opening and selectively etching the dielectric material to form a micro-cavity. The method further includes depositing a base layer structure in the micro-cavity adjacent to the surface of the substrate, wherein the base layer structure has a substantially conical shape, and depositing a catalyst on a portion of the surface of the base layer structure, wherein the catalyst is suitable for growing at least one carbon nanotube. The method still further includes applying an electrical potential to the substrate and the conductor layer, wherein the electrical potential generates a plurality of electrical field lines that are deflected around the surface of the base layer structure, and wherein the plurality of electrical field lines have a strength that is greatest in a direction substantially perpendicular to the surface of the substrate. Finally, the method includes growing at least one carbon nanotube from the catalyst in the presence of the plurality of electrical field lines, wherein the at least one carbon nanotube is grown in a direction substantially perpendicular to the surface of the substrate.

Owner:GENERAL ELECTRIC CO

Electron emitter and method of producing the same

InactiveUS7307383B2Improve electron emission efficiencyIncrease the number ofWeighing apparatus using elastically-deformable membersDischarge tube luminescnet screensTriple junctionElectron

An electron emitter includes an emitter section having a plate shape, a cathode electrode formed on a front surface of the emitter section, and an anode electrode formed on a back surface of the emitter section. A gap is formed between an outer peripheral portion of the cathode electrode and the front surface of the emitter section. The front surface of the emitter section contacts a lower surface of the outer peripheral portion to form a base end as a triple junction. The gap expands from the base end toward a tip end of the outer peripheral portion.

Owner:NGK INSULATORS LTD

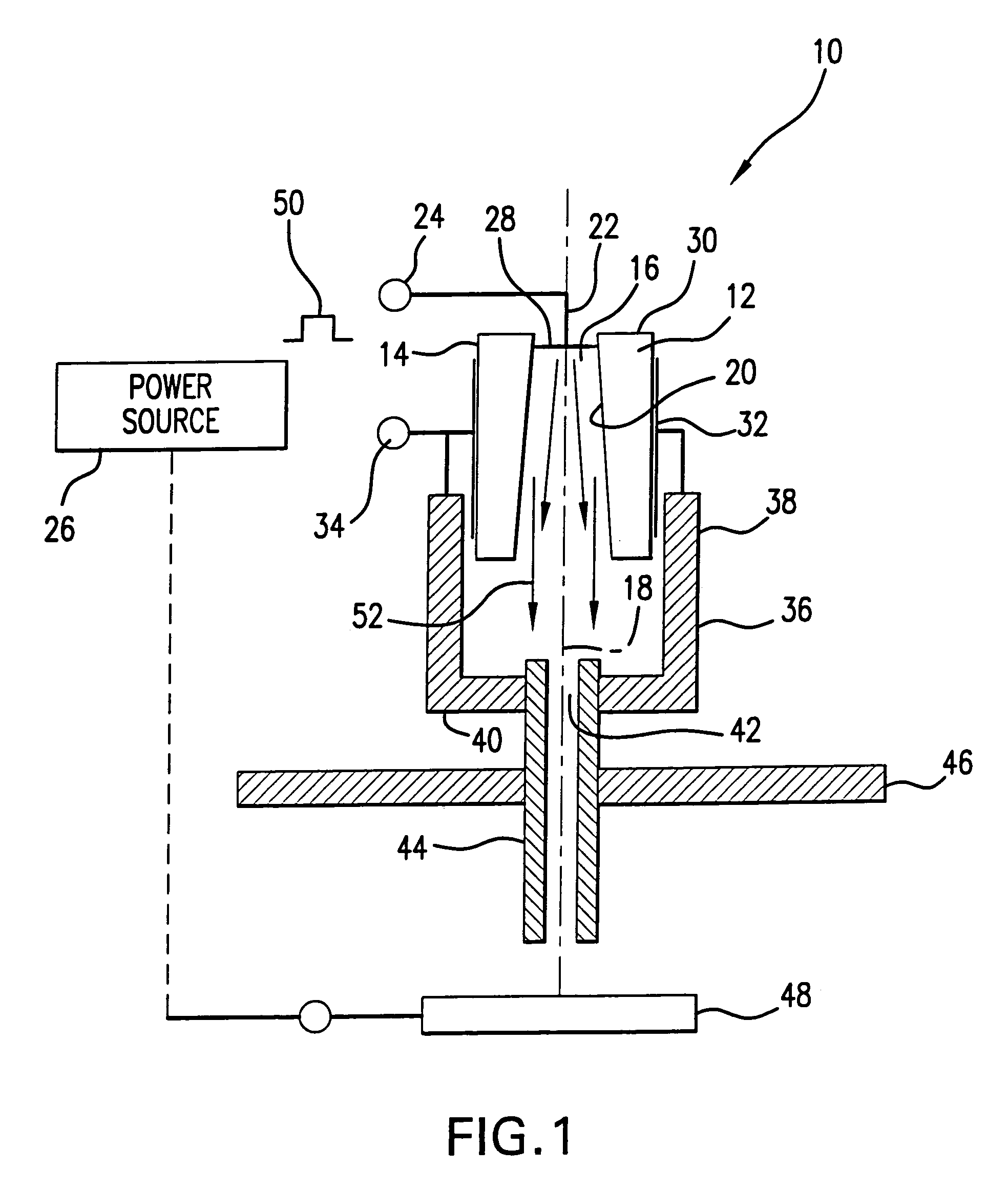

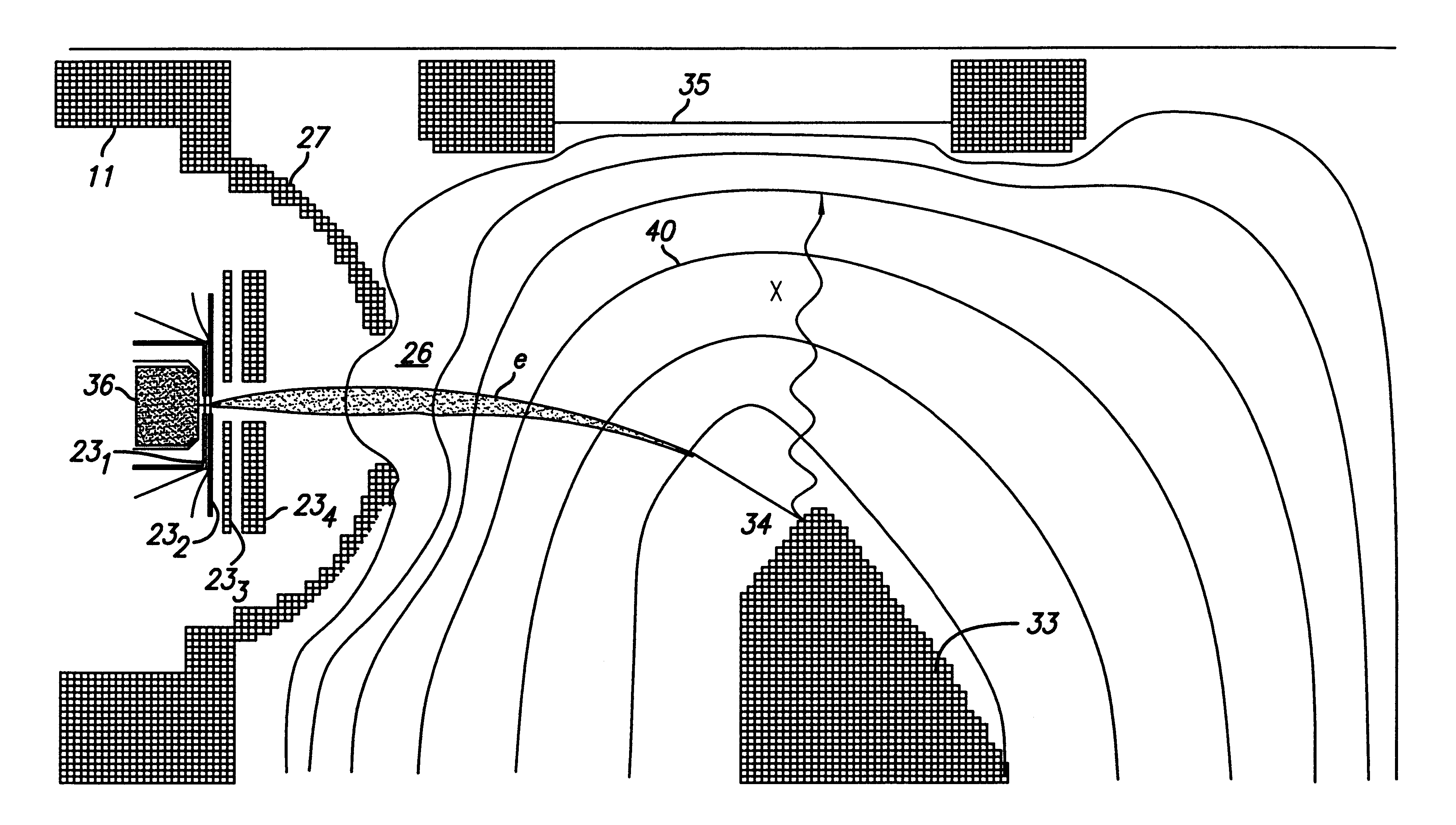

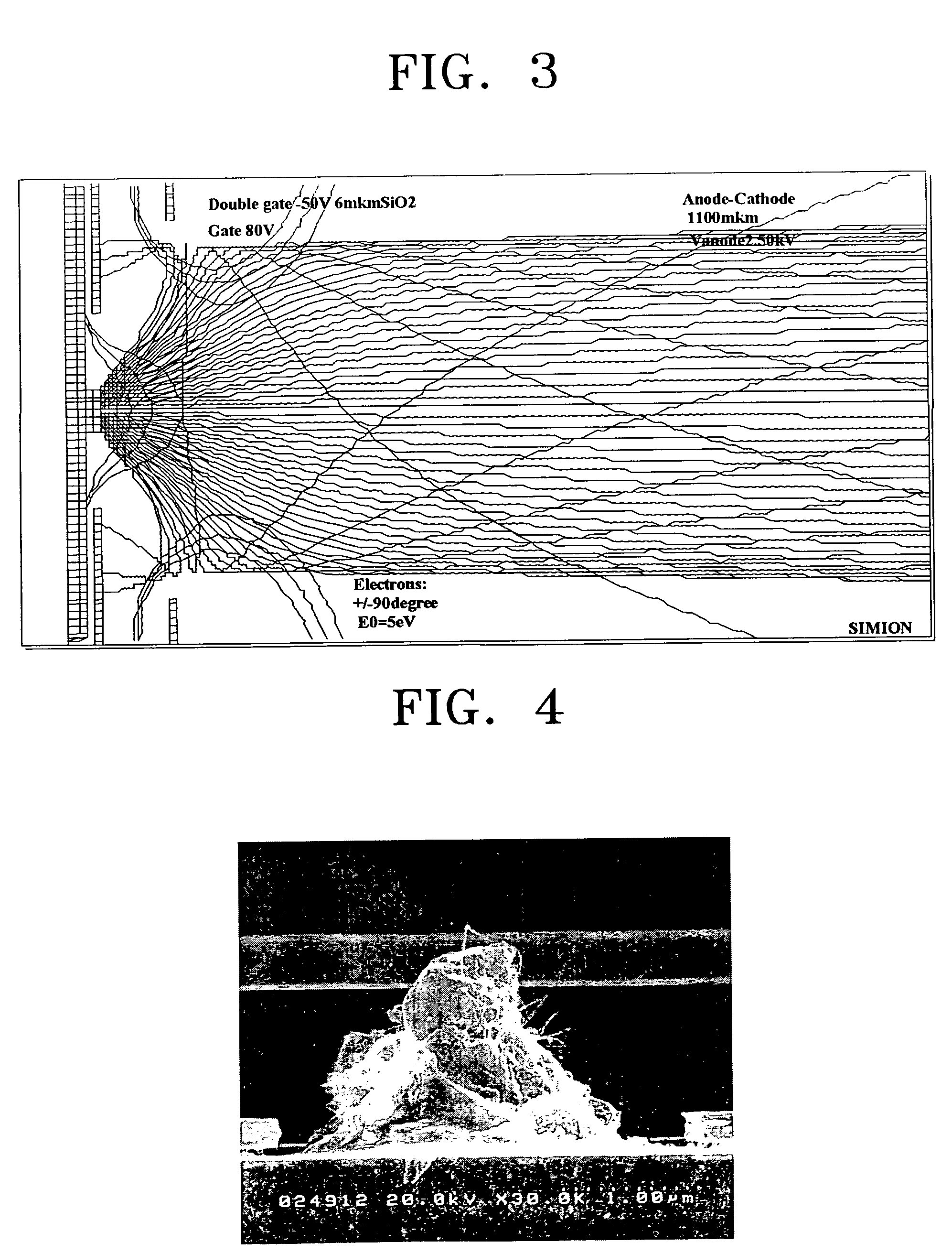

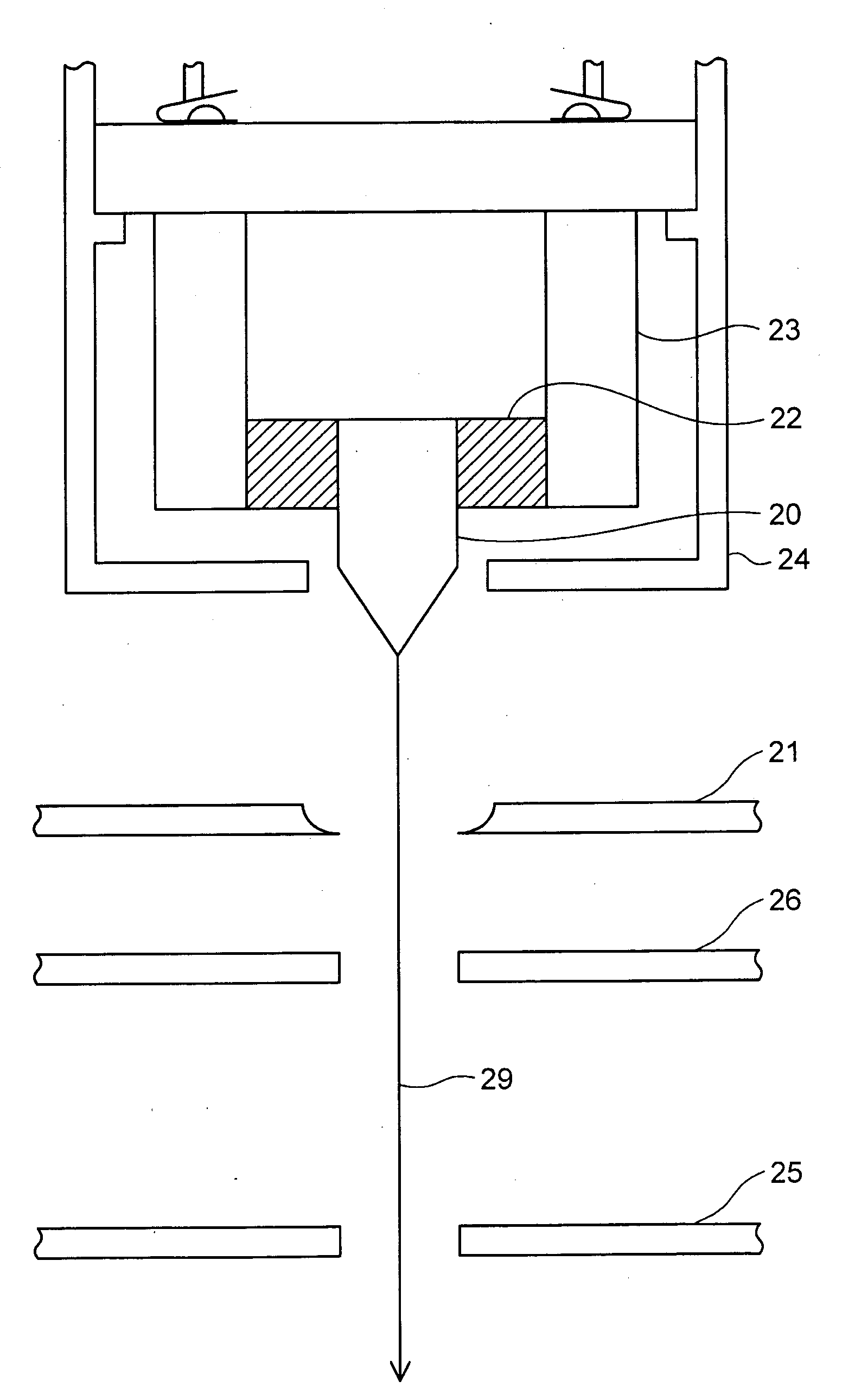

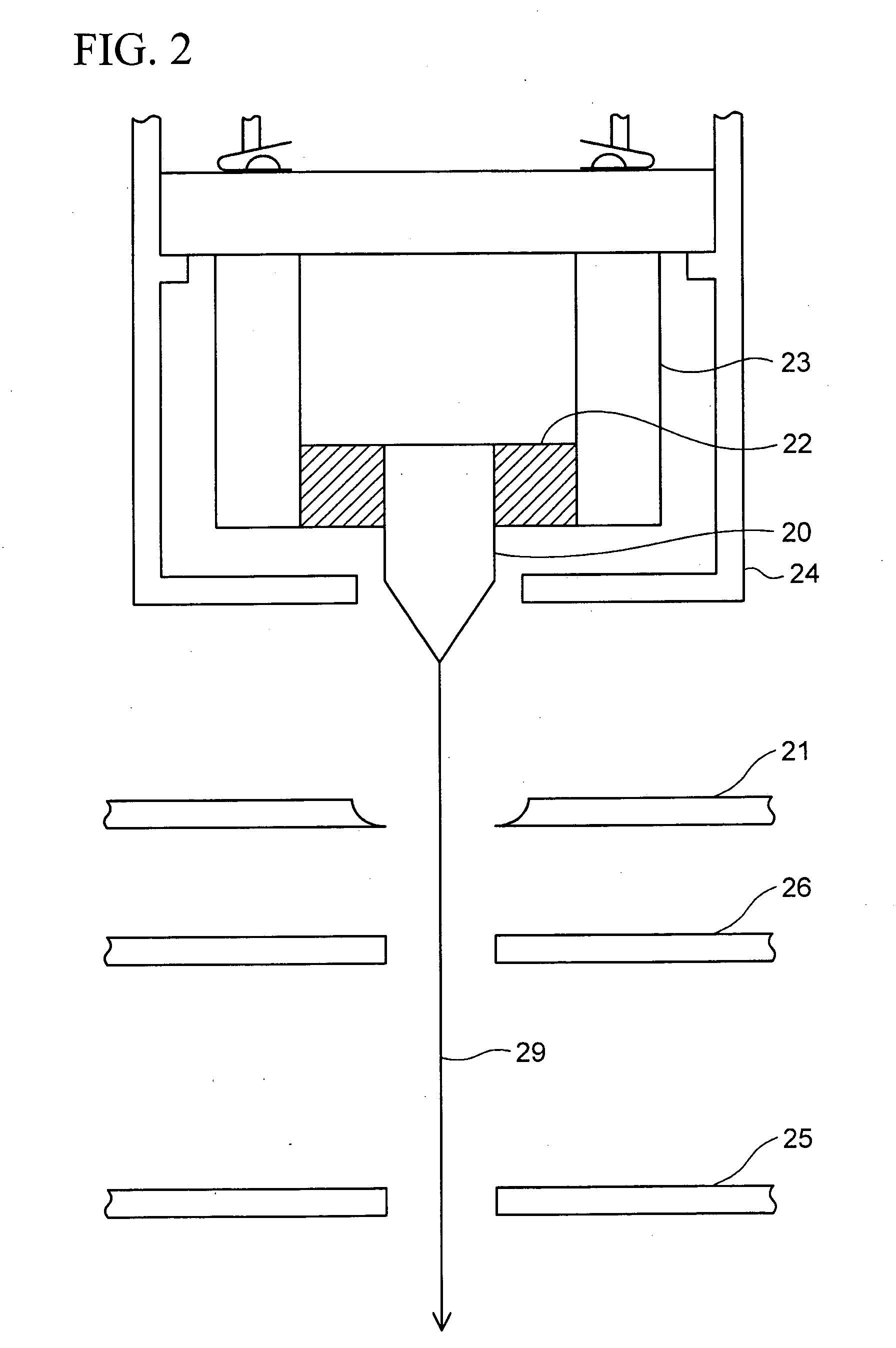

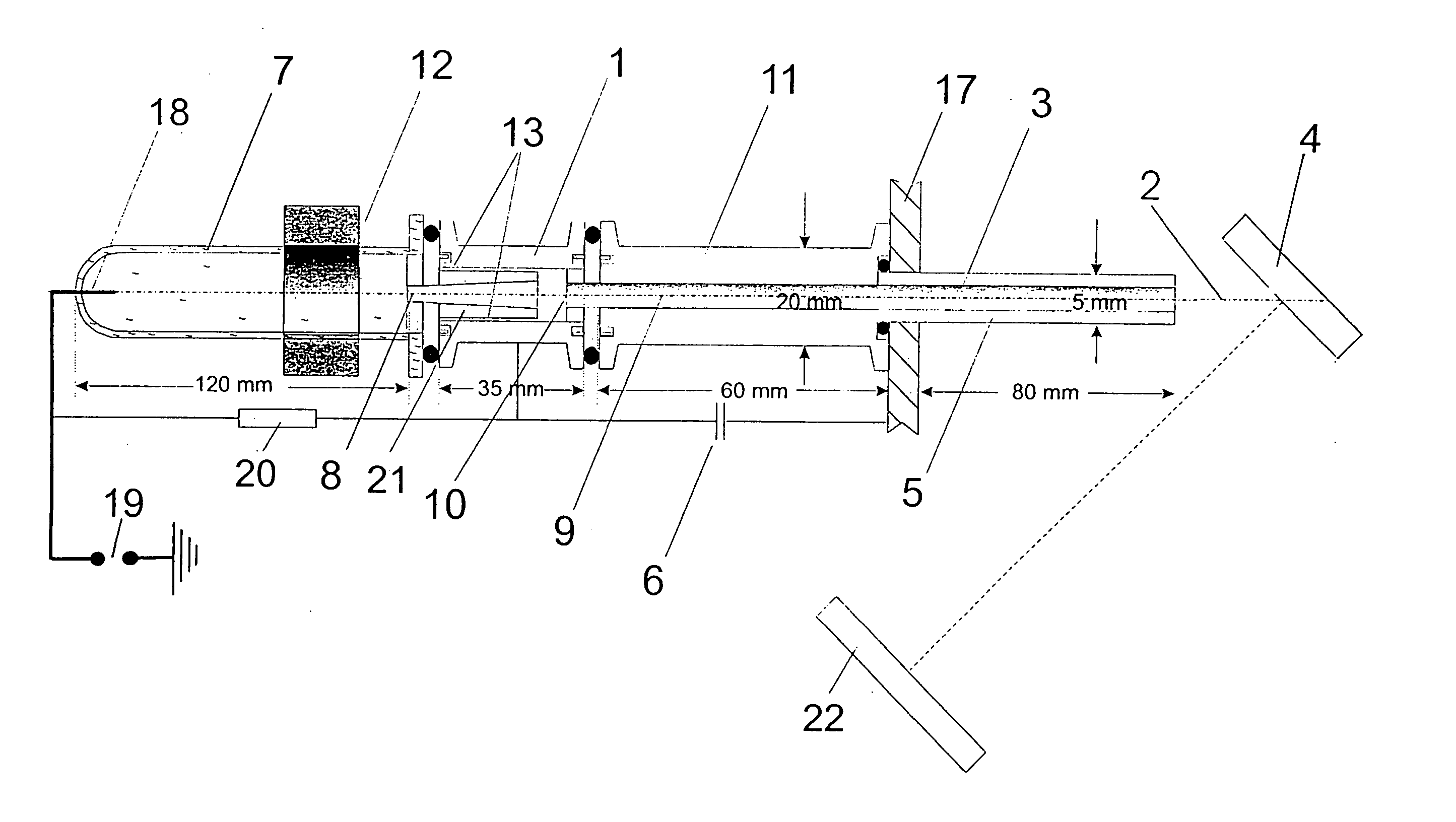

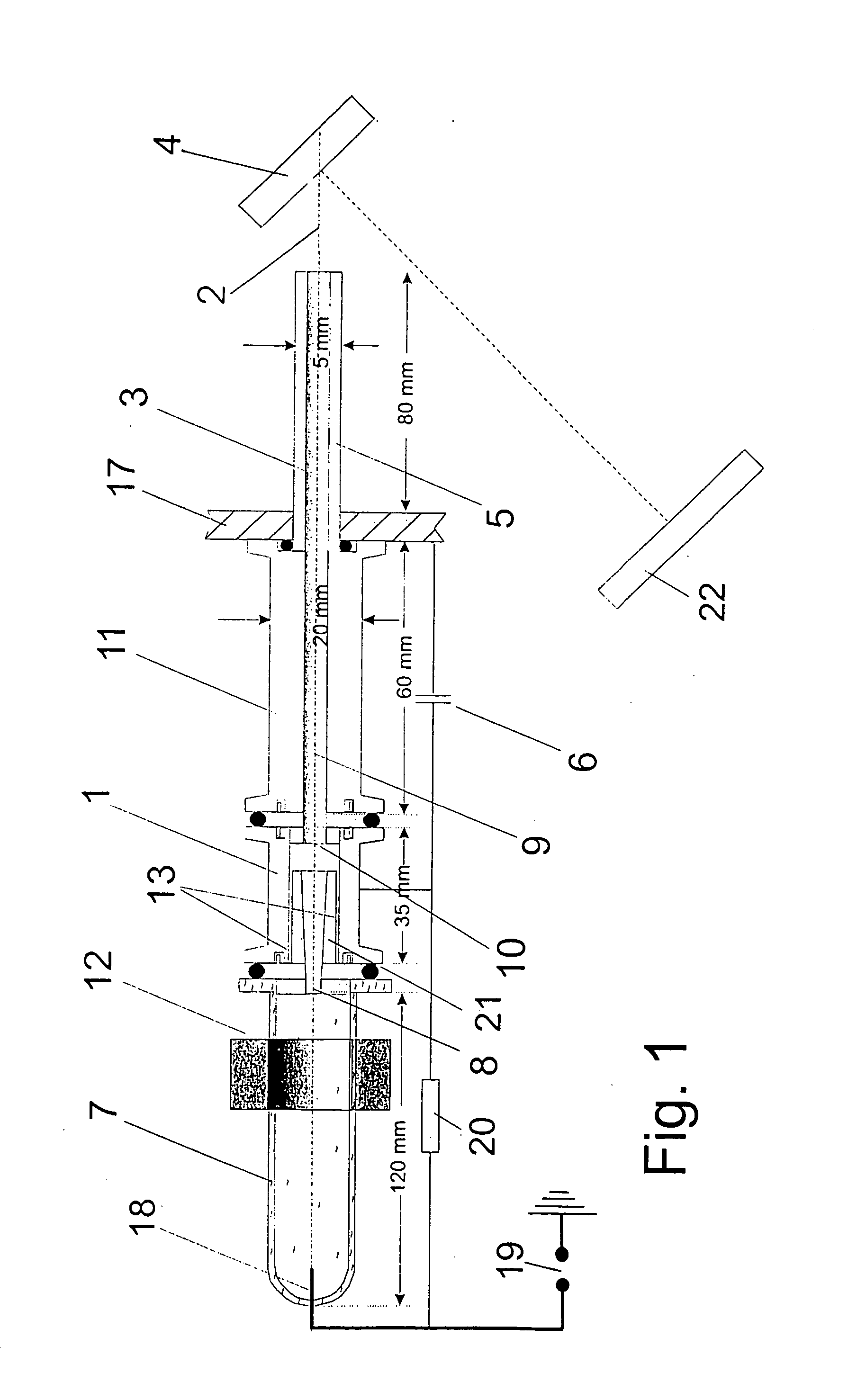

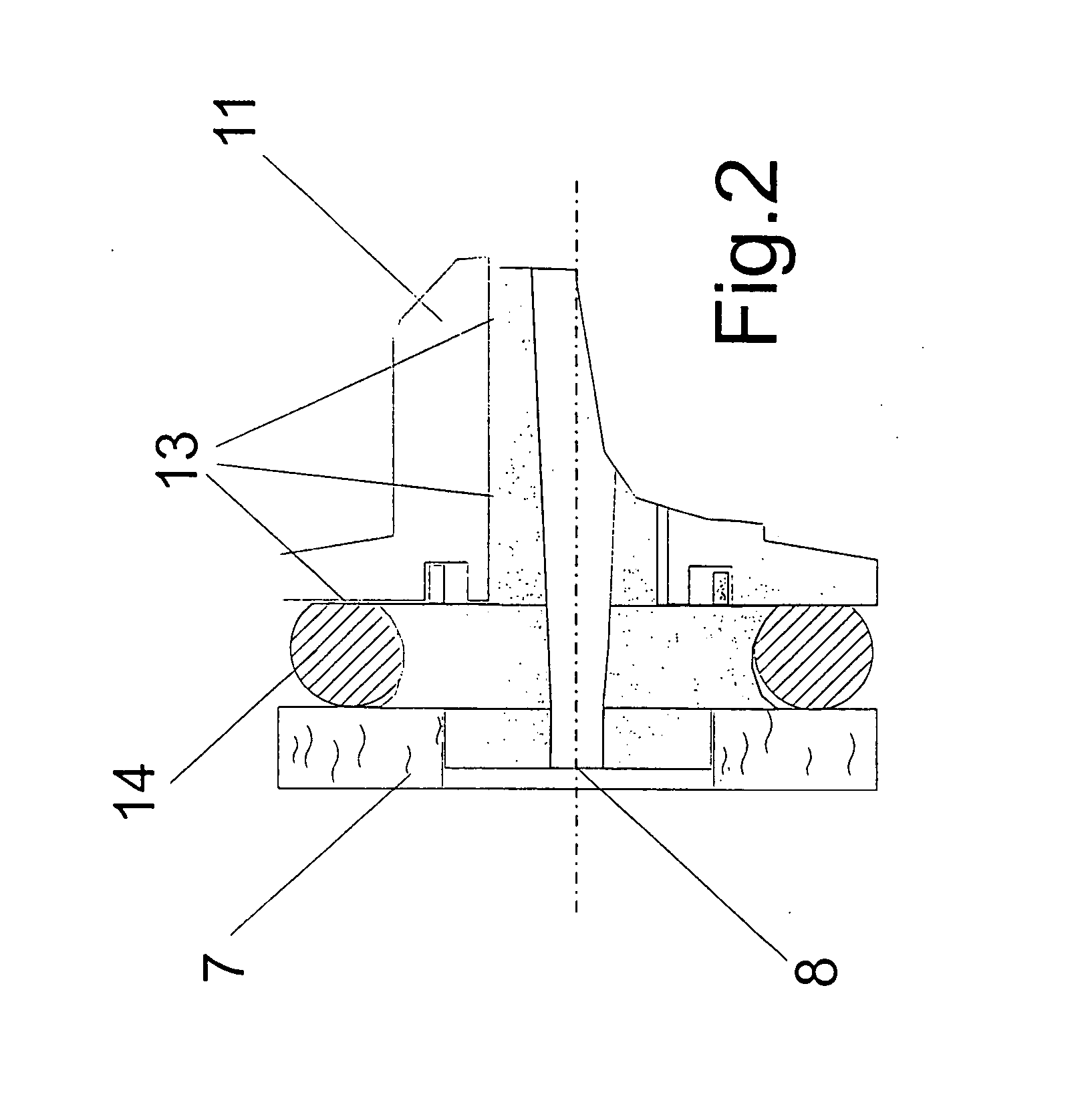

Channel spark source for generating a stable focussed electron beam

ActiveUS20050012441A1Not to damageProlong lifeVacuum evaporation coatingSputtering coatingCharge carrierPressure difference

In a channel spark source triggered by gas discharge for generating a stable focused electron beam, a gas supply for a hollow cathode thereof is provided which generates in the hollow cathode a pressure differential so that the multiplication of charge carriers in a trigger plasma of a trigger plasma source connected to the hollow cathode provides for a reliable gas discharge and the formation of a stable electron beam which exits the arrangement and which does not damage the internal passages of the arrangement.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

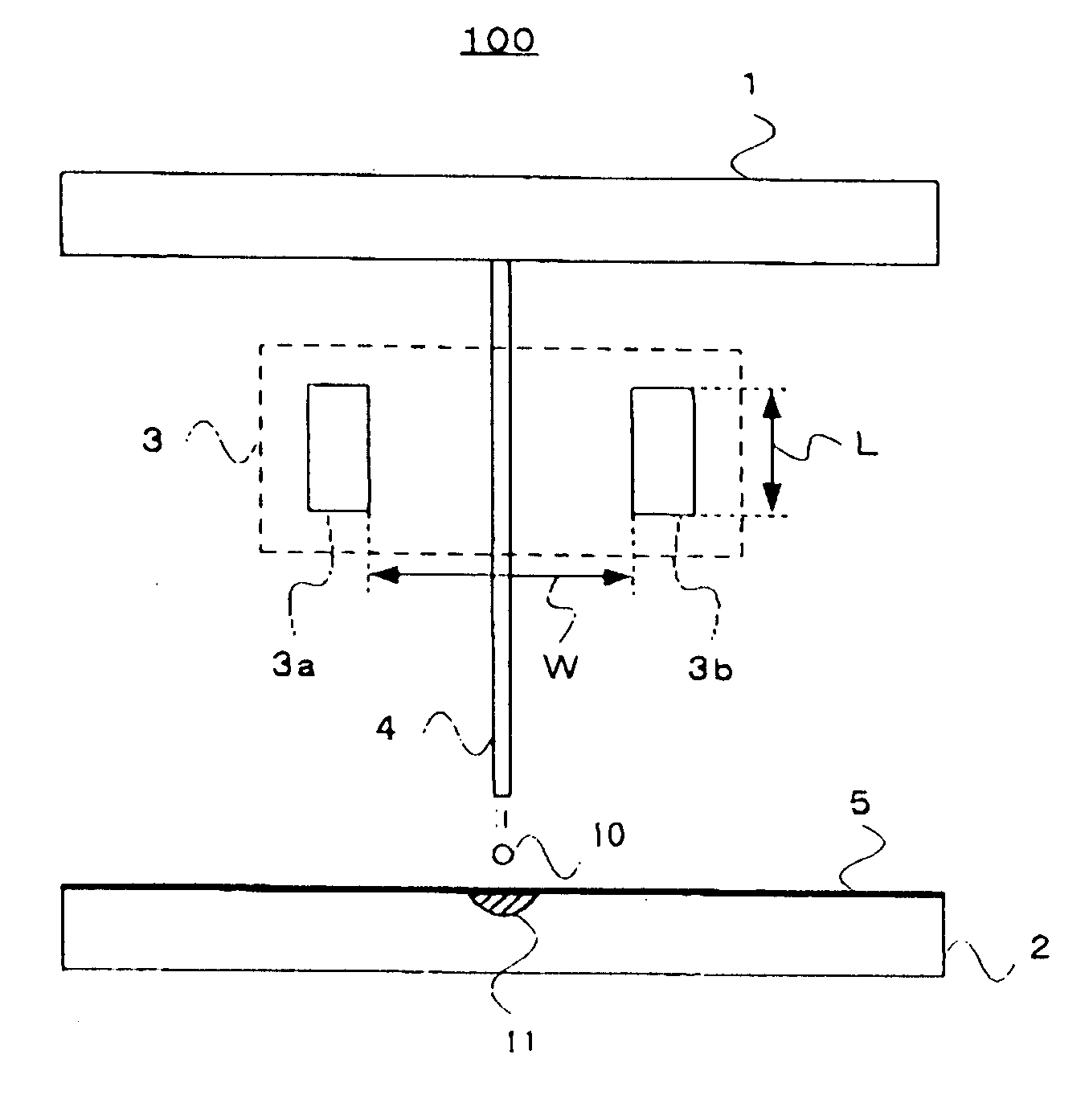

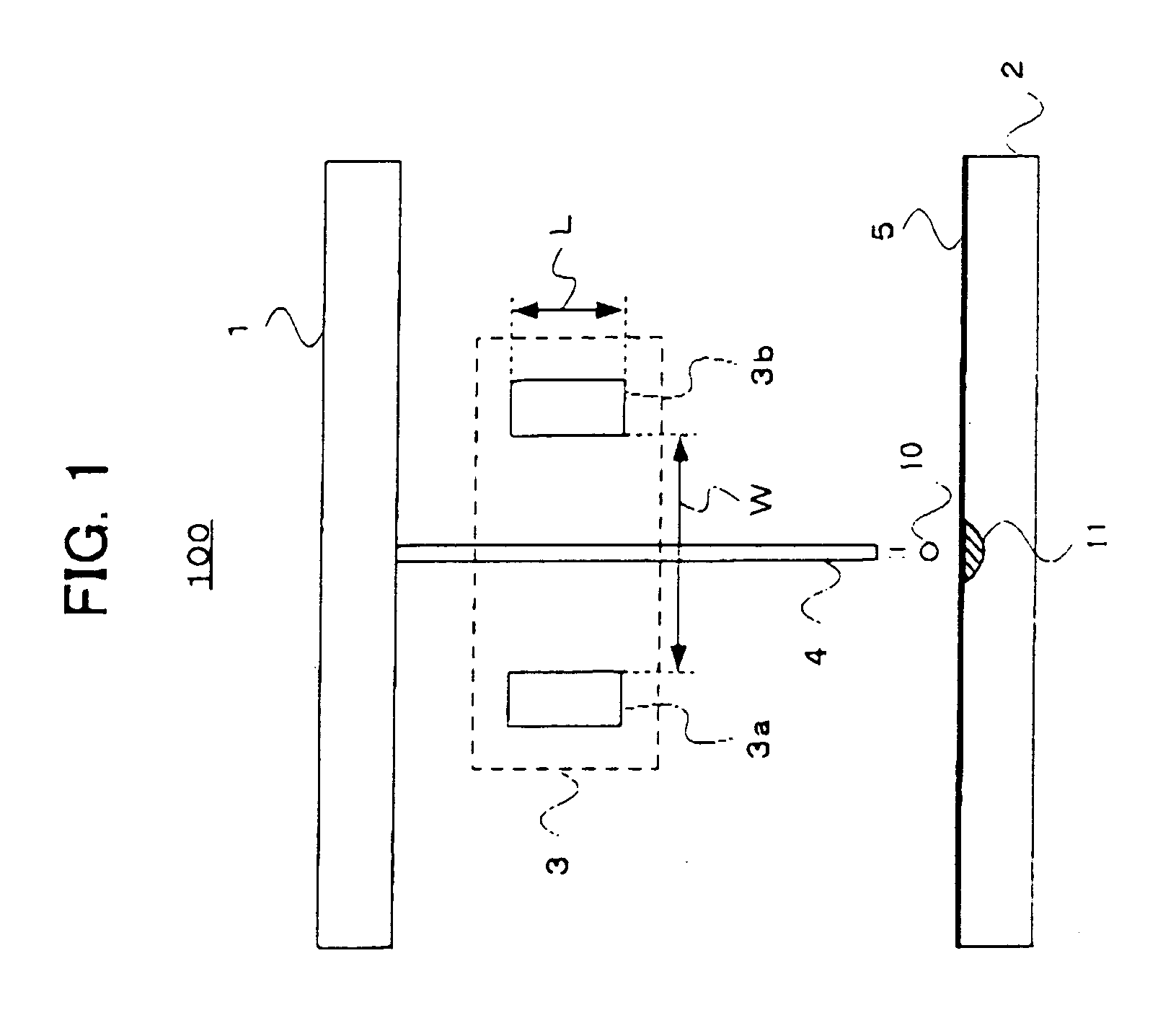

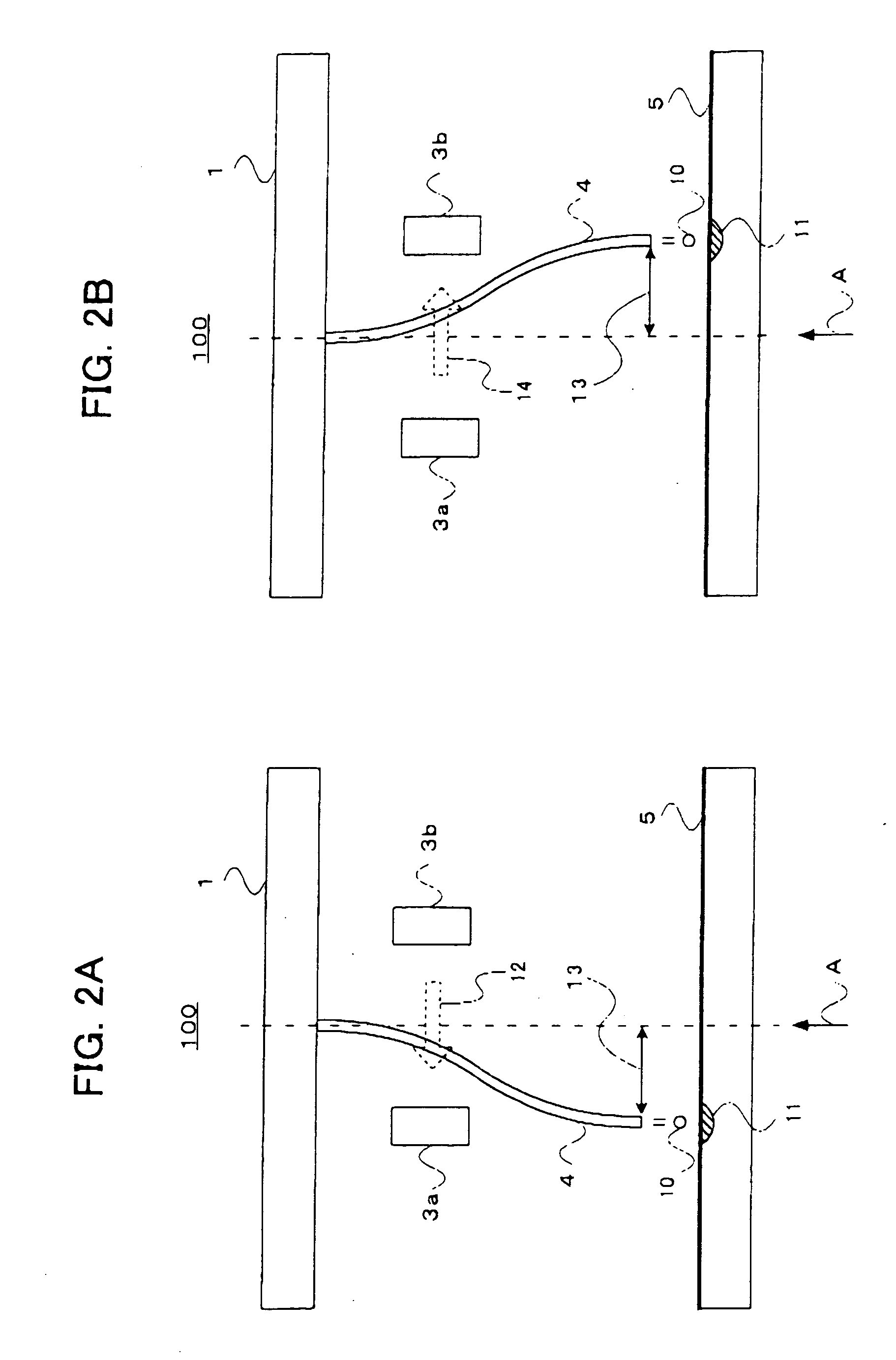

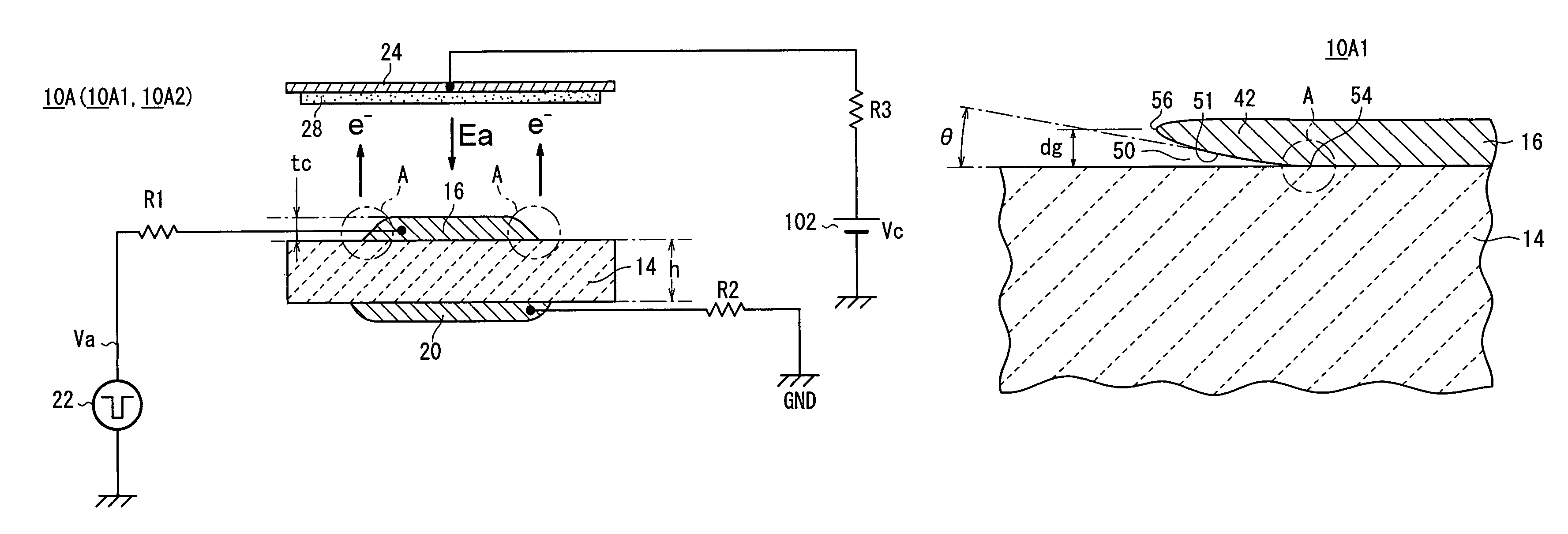

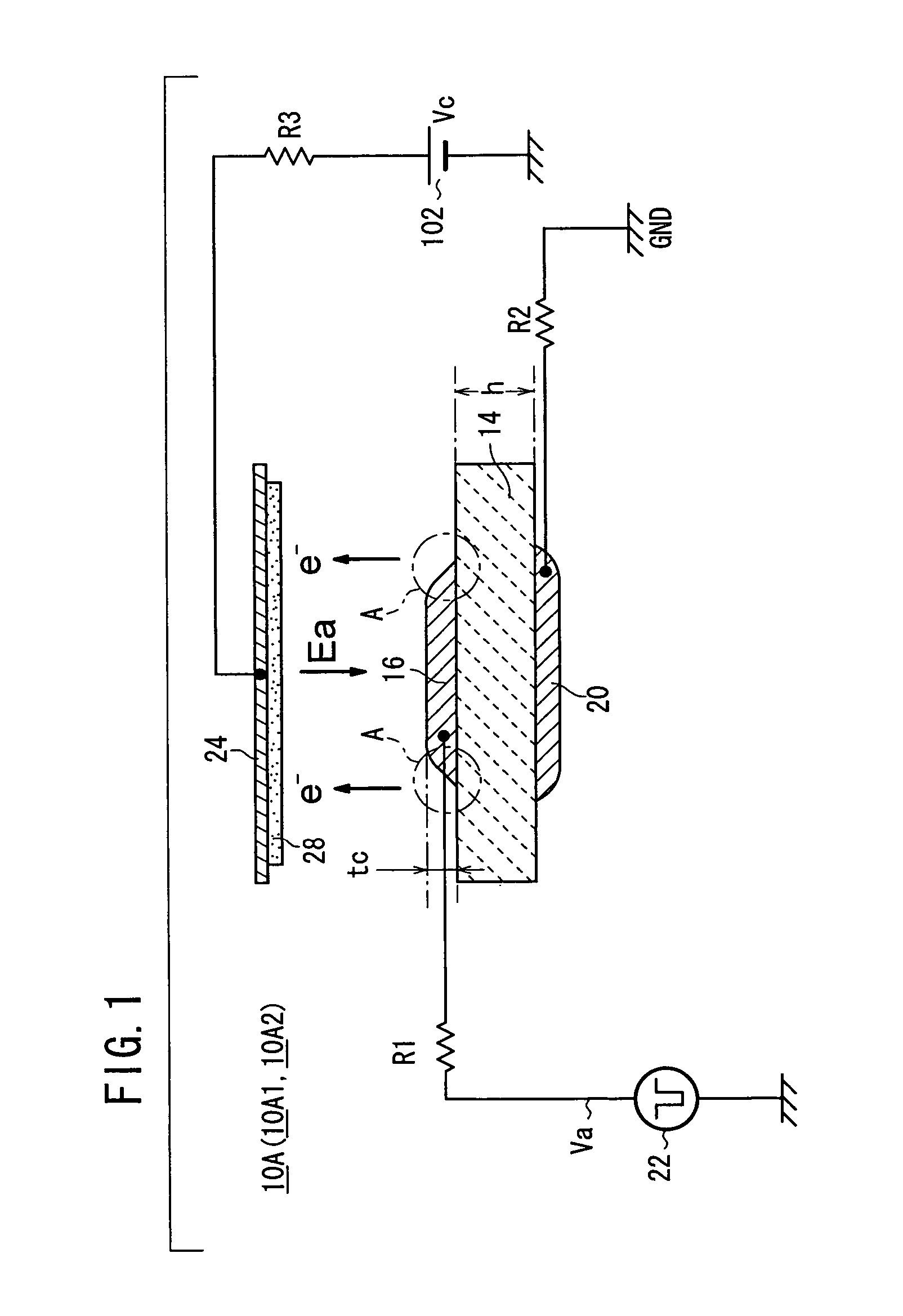

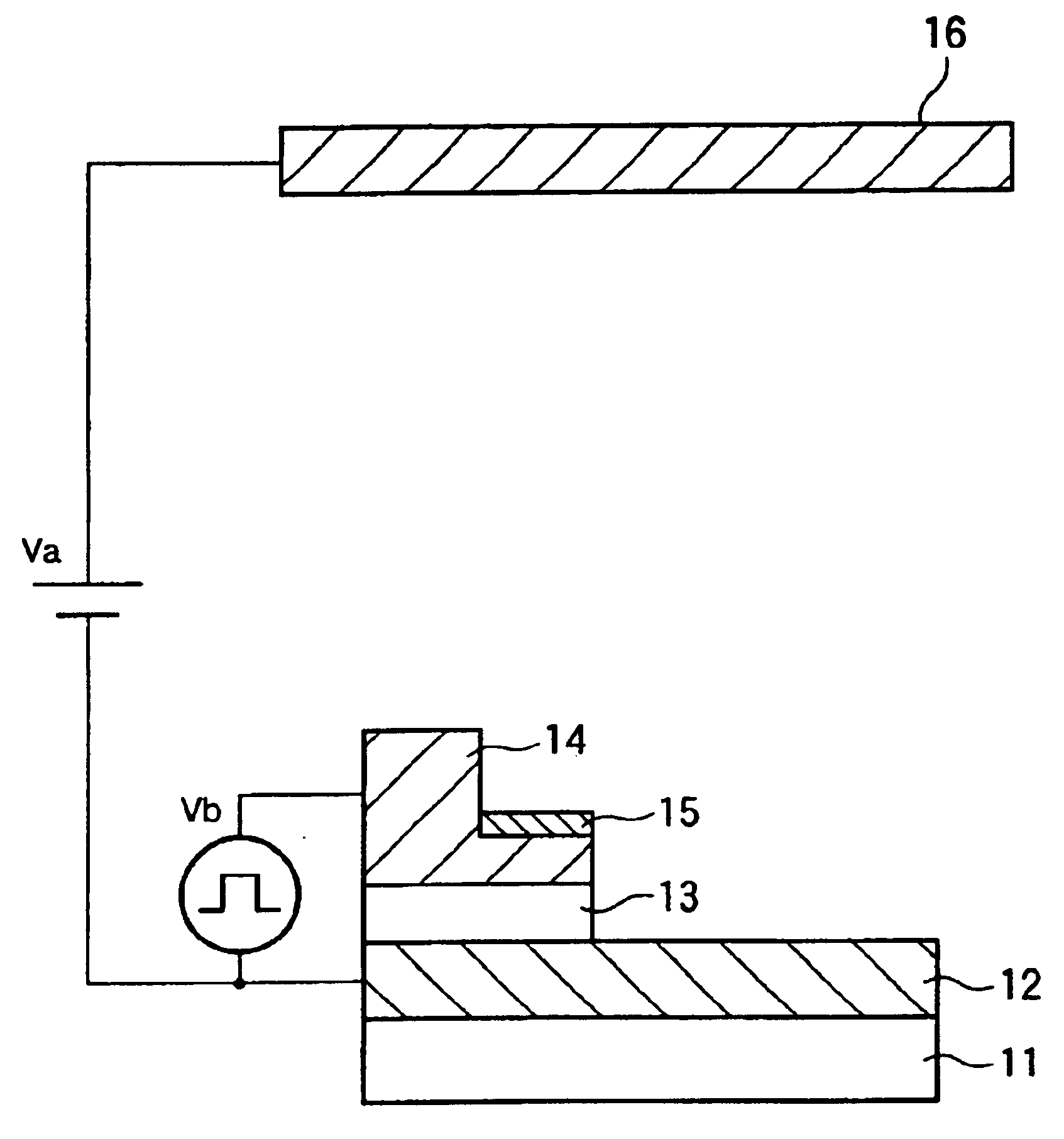

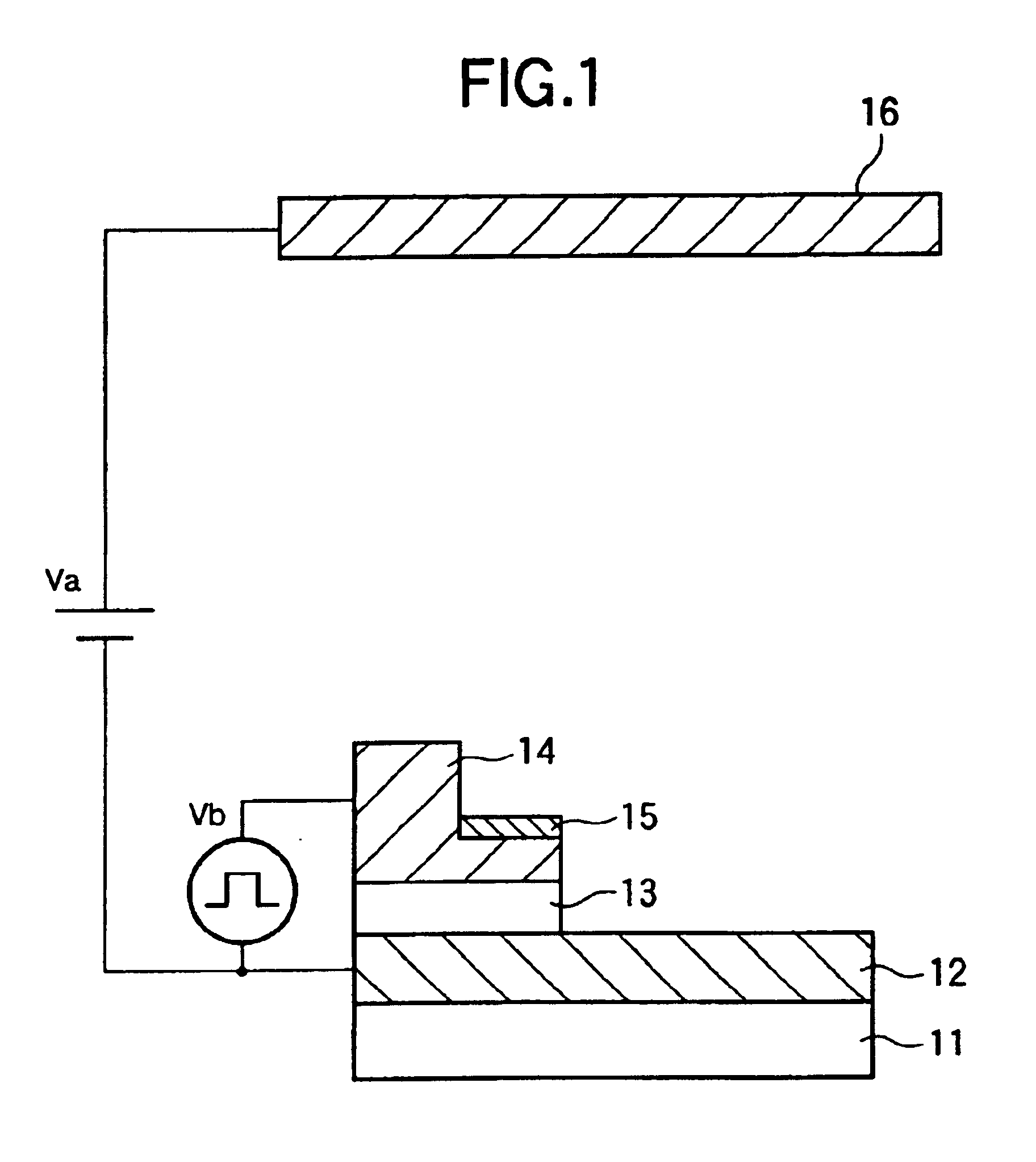

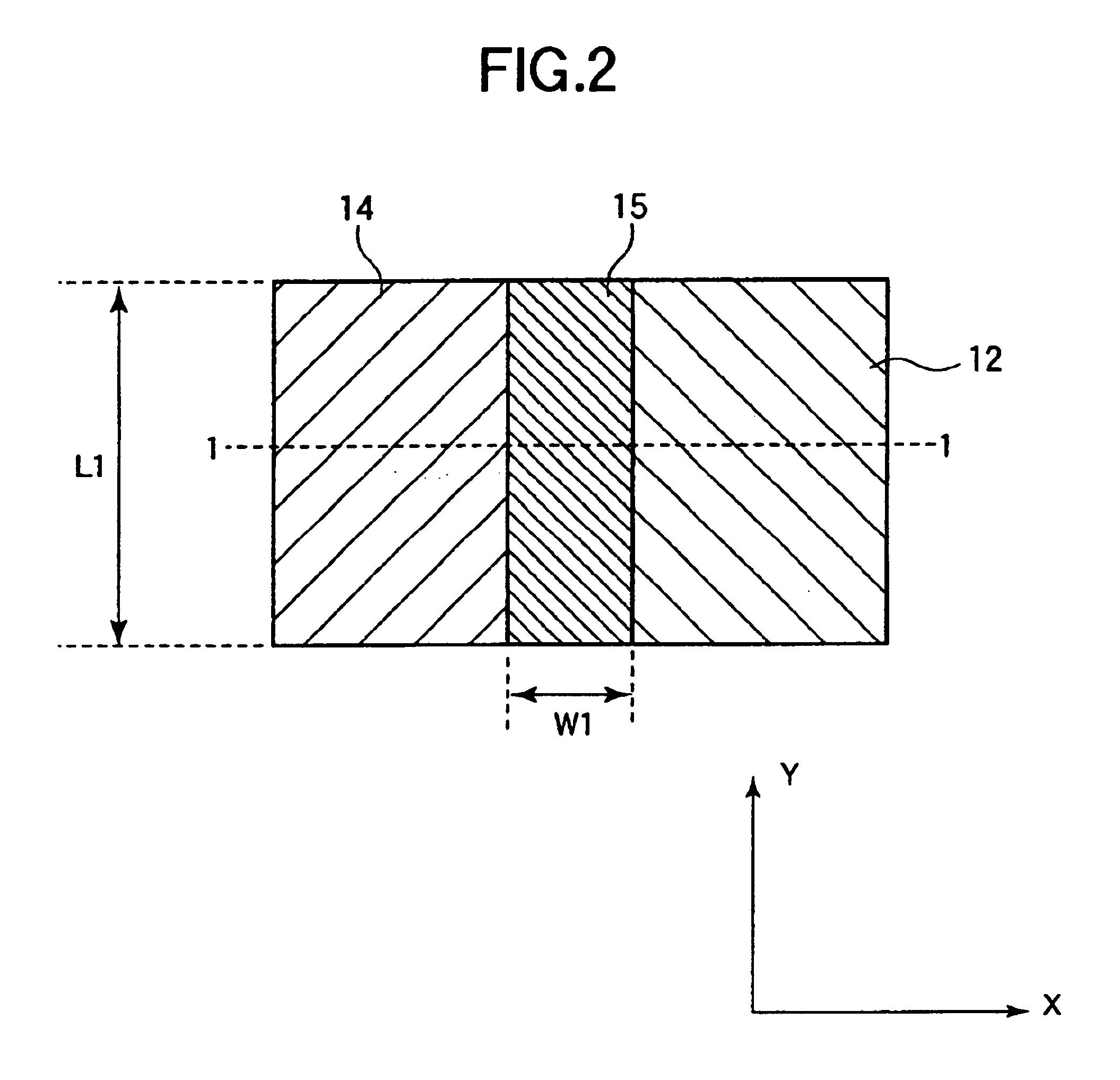

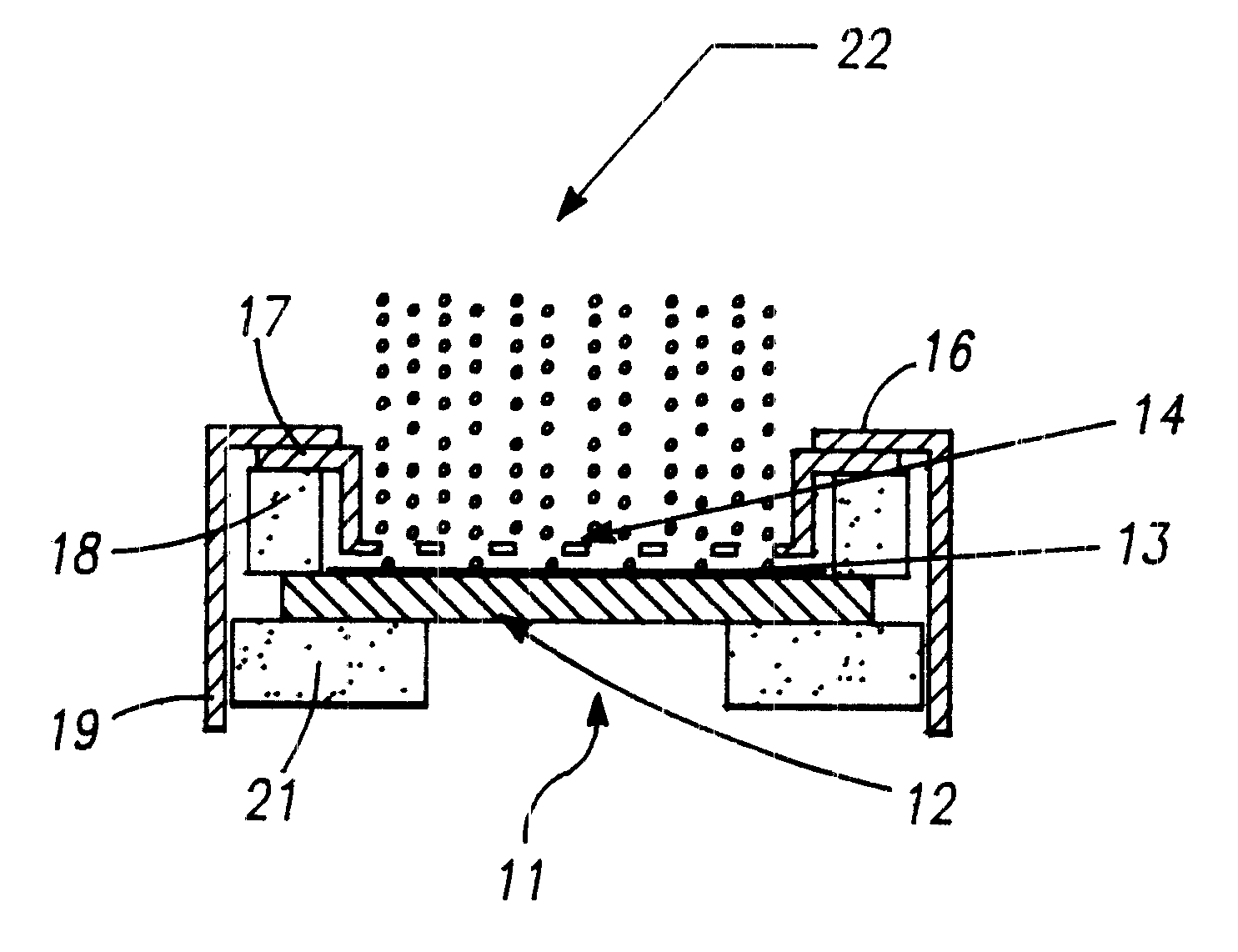

Method of driving image-forming apparatus and apparatus thereof

InactiveUS6975288B2Reduce the amount of solutionIncrease the diameterTelevision system detailsImage/pattern display tubesElectron sourceImage formation

Disclosed is an electron-emitting device, an electron source, and an image-forming apparatus that have uniform electron-emitting characteristics, emit electron beams whose diameters are small, have simple constructions, and are easy to be manufactured. The electron-emitting device comprising: a first electrode arranged on a surface of a substrate; an insulating layer arranged on the first electrode; a second electrode arranged on the insulating layer; and an electron-emitting film arranged on the second electrode, where the second electrode has two side surfaces that oppose each other in a direction parallel to the surface of the substrate, and the electron-emitting film is arranged so as to be shifted toward one of the two side surfaces.

Owner:CANON KK

Electron source

InactiveUS6534923B2Inexpensive and simple and efficientControl electrodesNanoinformaticsElectron sourceNanostructured carbon

An electron source including a nanostructured carbon electron-emitting film and an electron extraction grid spaced closely adjacent the surface of said film.

Owner:MICROWAVE POWER TECH

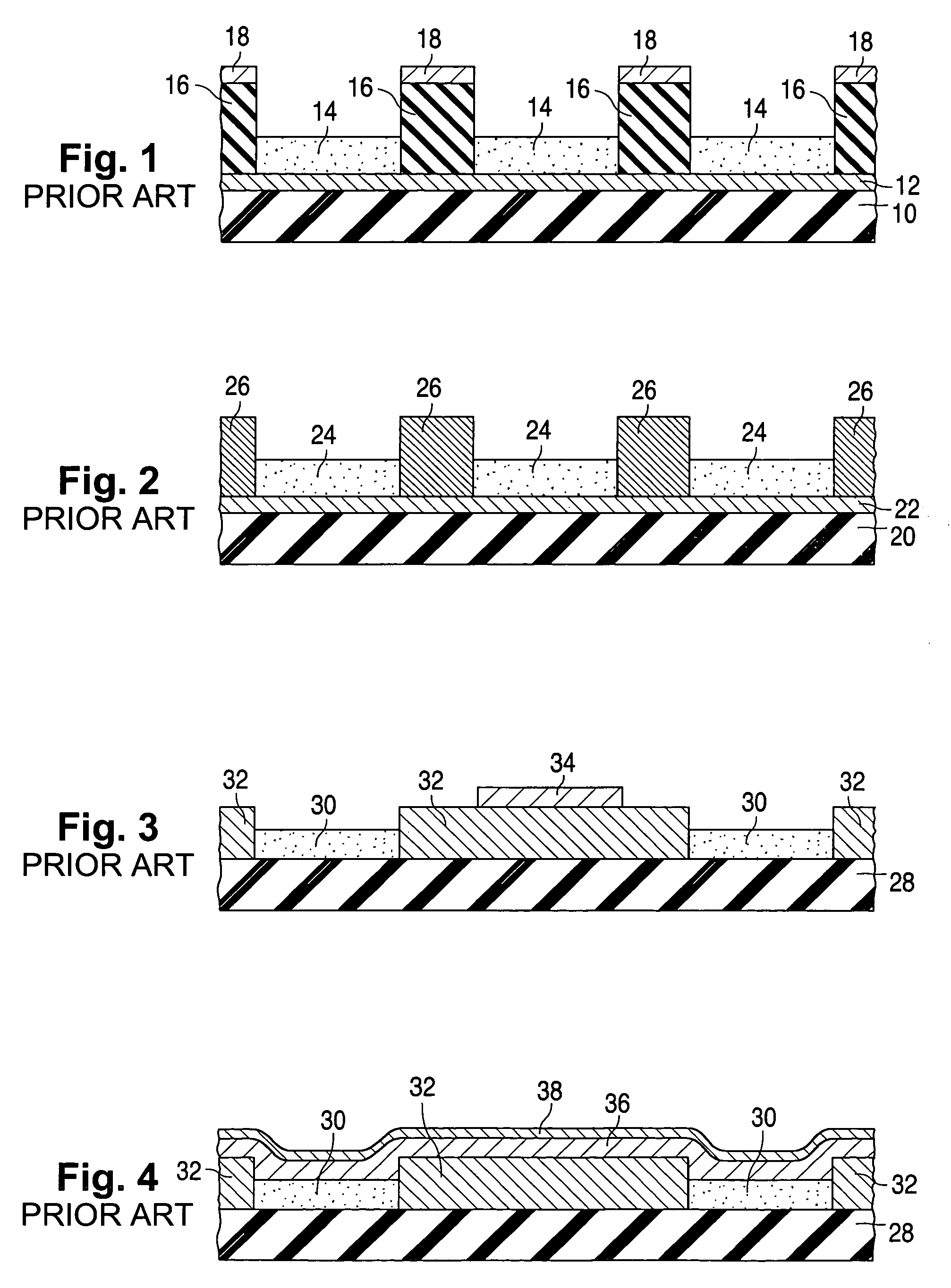

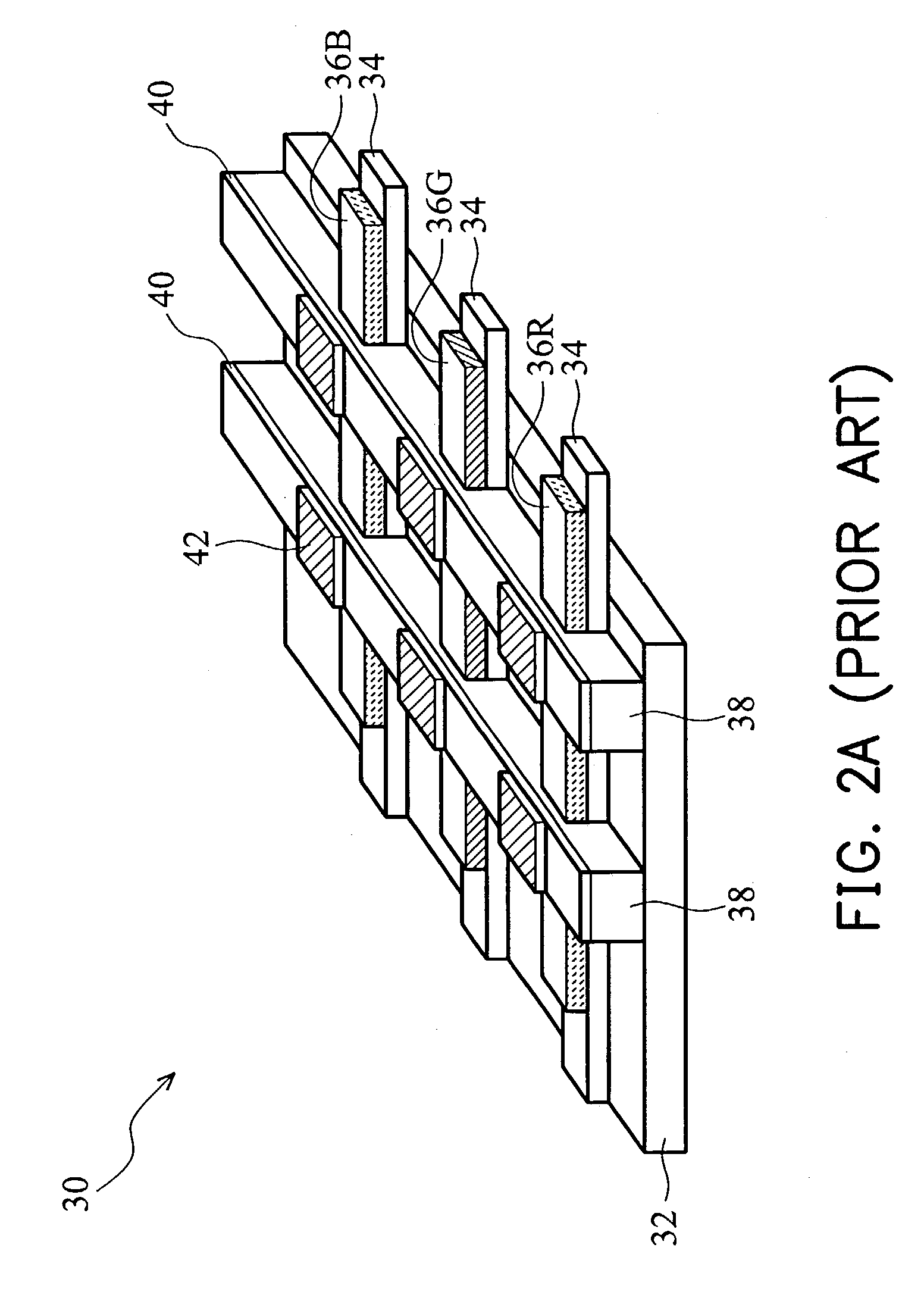

Triode structure of field emission display and fabrication method thereof

InactiveUS20040104668A1Discharge tube luminescnet screensLamp detailsField emission displayCathode ray

A triode structure of a field emission display and fabrication method thereof. A plurality of cathode layers arranged in a matrix is formed overlying a dielectric layer. A plurality of emitting layers arranged in a matrix is formed overlying the cathode layers, respectively. A plurality of lengthwise-extending gate lines is formed on the dielectric layer, in which each of the gate layers is disposed between two adjacent columns of the cathode layers.

Owner:IND TECH RES INST

Popular searches

Beam/ray focussing/reflecting arrangements Beam/ray deflecting arrangements Material analysis by optical means Beam deviation/focusing by electric/magnetic means Radiation therapy Chemical conversion by chemical reaction Chemical vapor deposition coating Gas discharge lamp details Carbon preparation/purification Fibre chemical features

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com