Patents

Literature

110 results about "Triple junction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A triple junction is the point where the boundaries of three tectonic plates meet. At the triple junction each of the three boundaries will be one of 3 types - a ridge (R), trench (T) or transform fault (F) - and triple junctions can be described according to the types of plate margin that meet at them (e.g. Transform-Transform-Trench, Ridge-Ridge-Ridge, or abbreviated F-F-T, R-R-R). Of the many possible types of triple junction only a few are stable through time ('stable' in this context means that the geometrical configuration of the triple junction will not change through geologic time). The meeting of 4 or more plates is also theoretically possible but junctions will only exist instantaneously.

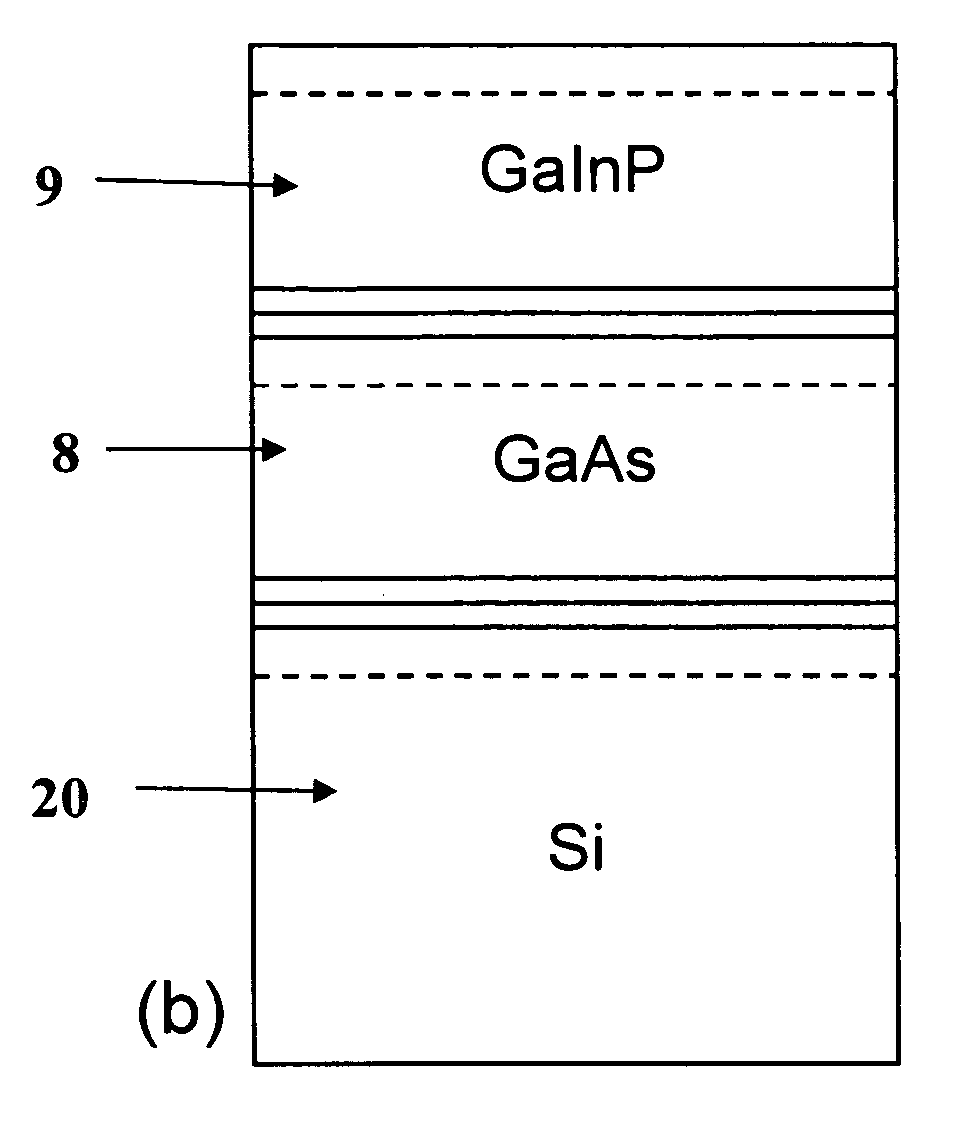

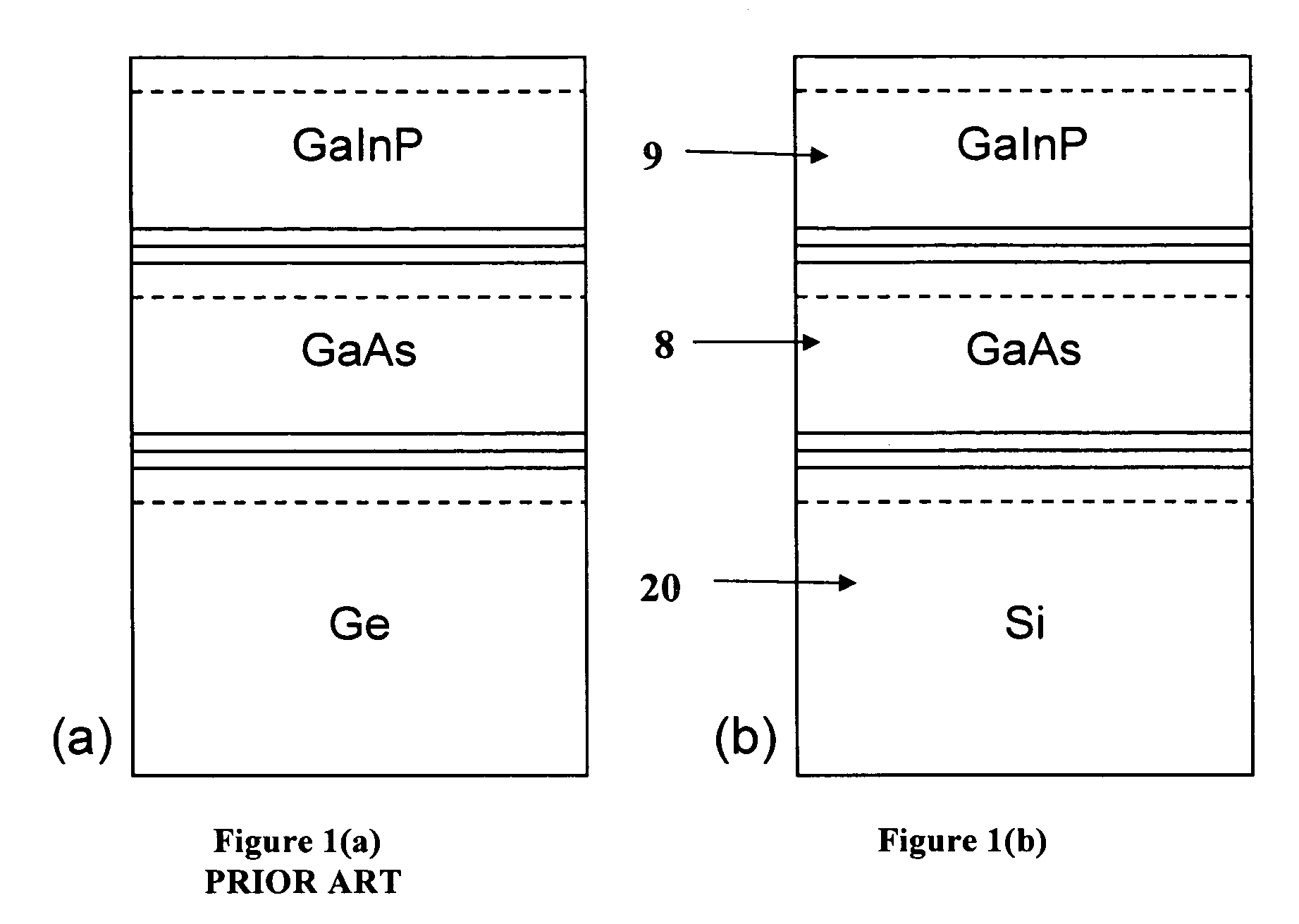

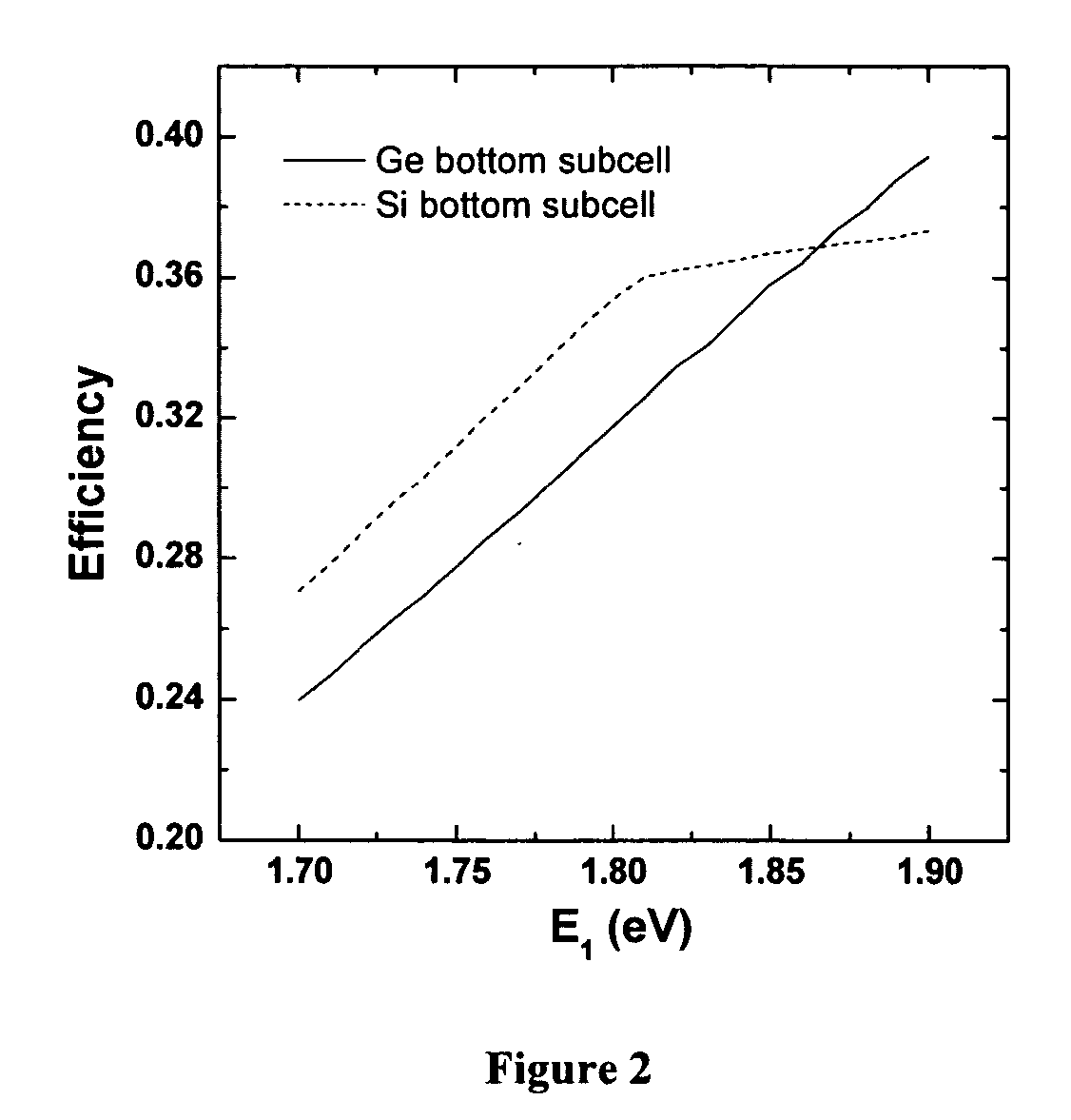

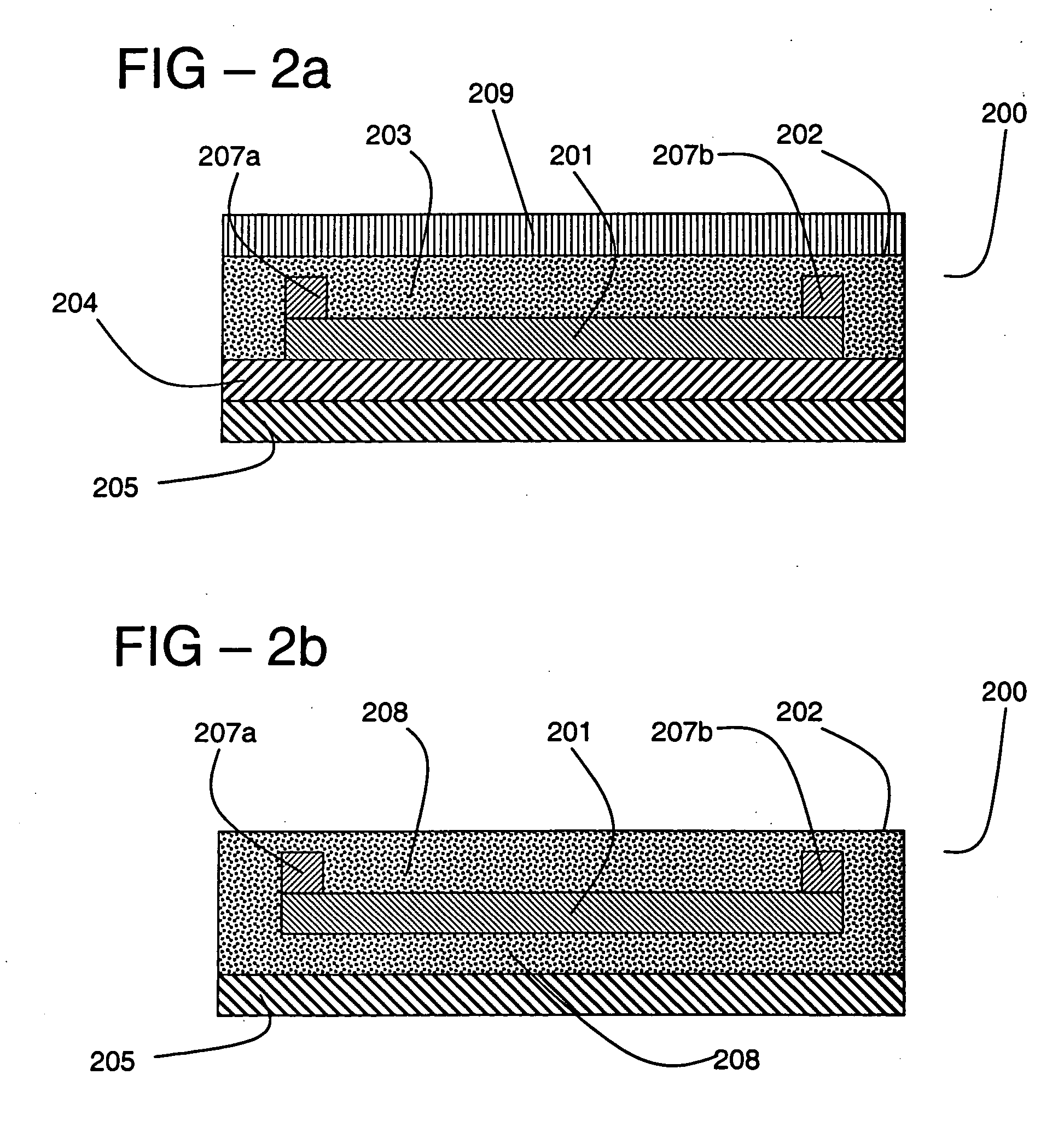

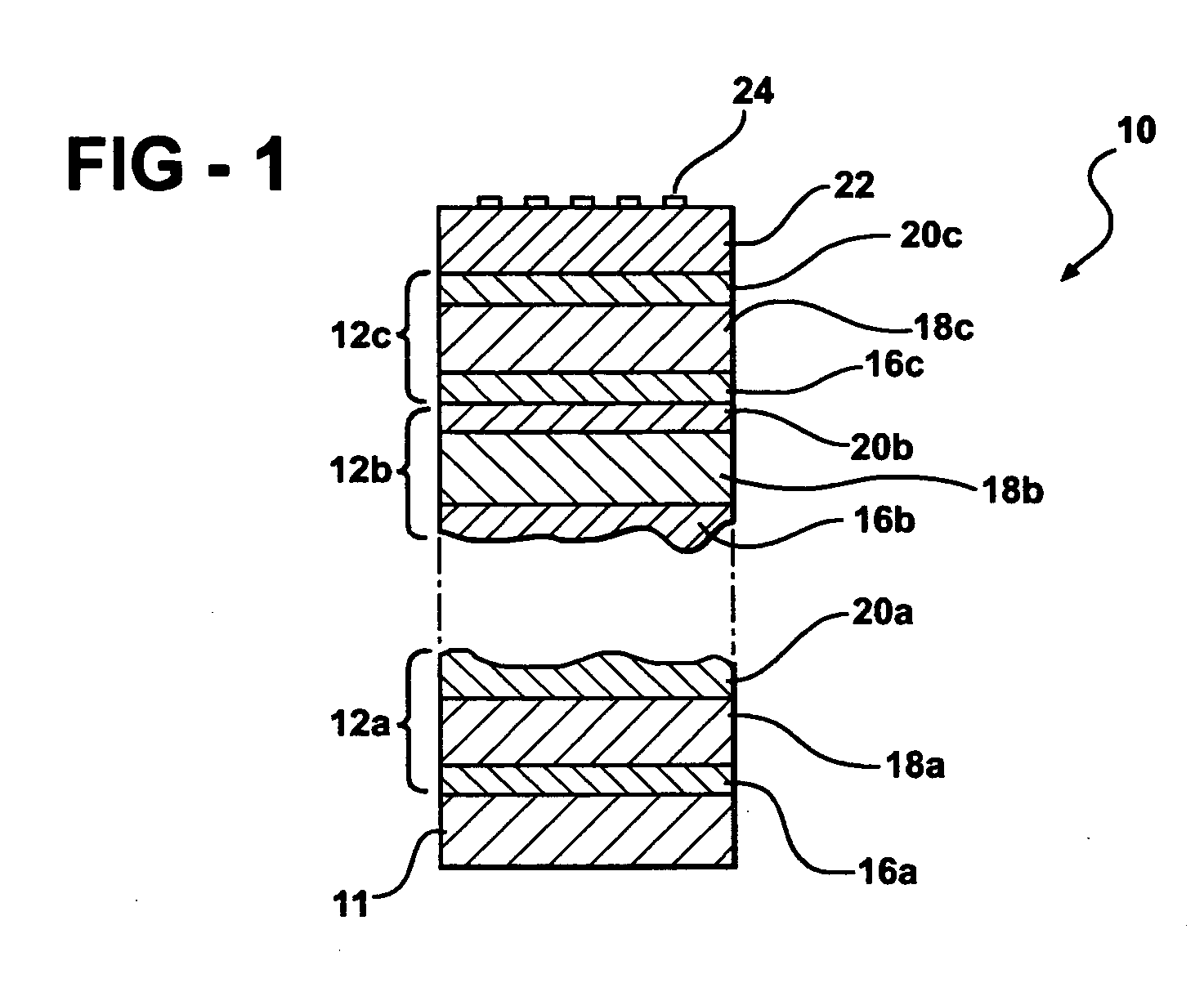

GaInP / GaAs / Si triple junction solar cell enabled by wafer bonding and layer transfer

InactiveUS20060021565A1Polycrystalline material growthFinal product manufactureBond interfaceWafer bonding

A multi-junction solar cell includes a silicon solar subcell, a GaInP solar subcell, and a GaAs solar subcell located between the silicon solar subcell and the GaInP solar subcell. The GaAs solar subcell is bonded to the silicon solar subcell such that a bonded interface exists between these subcells.

Owner:AONEX TECH

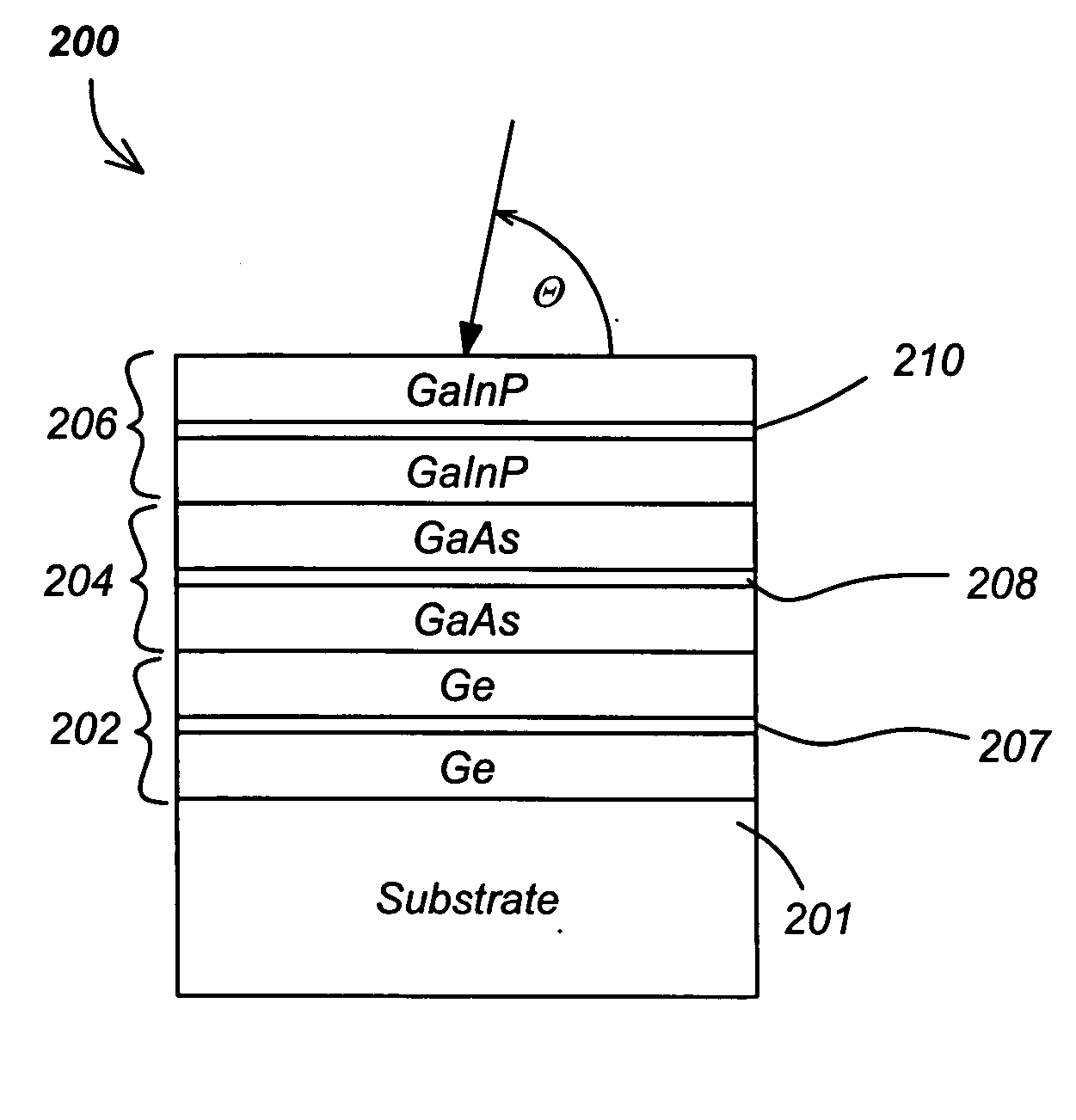

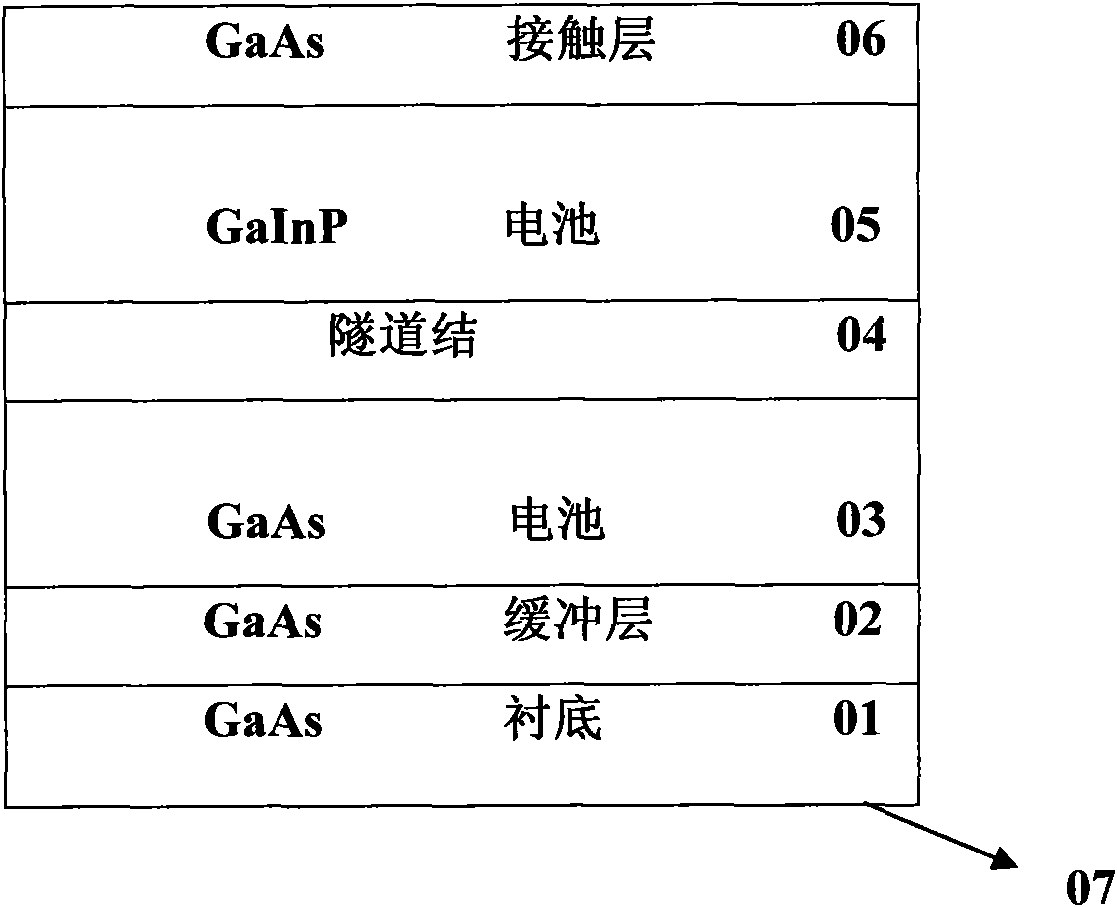

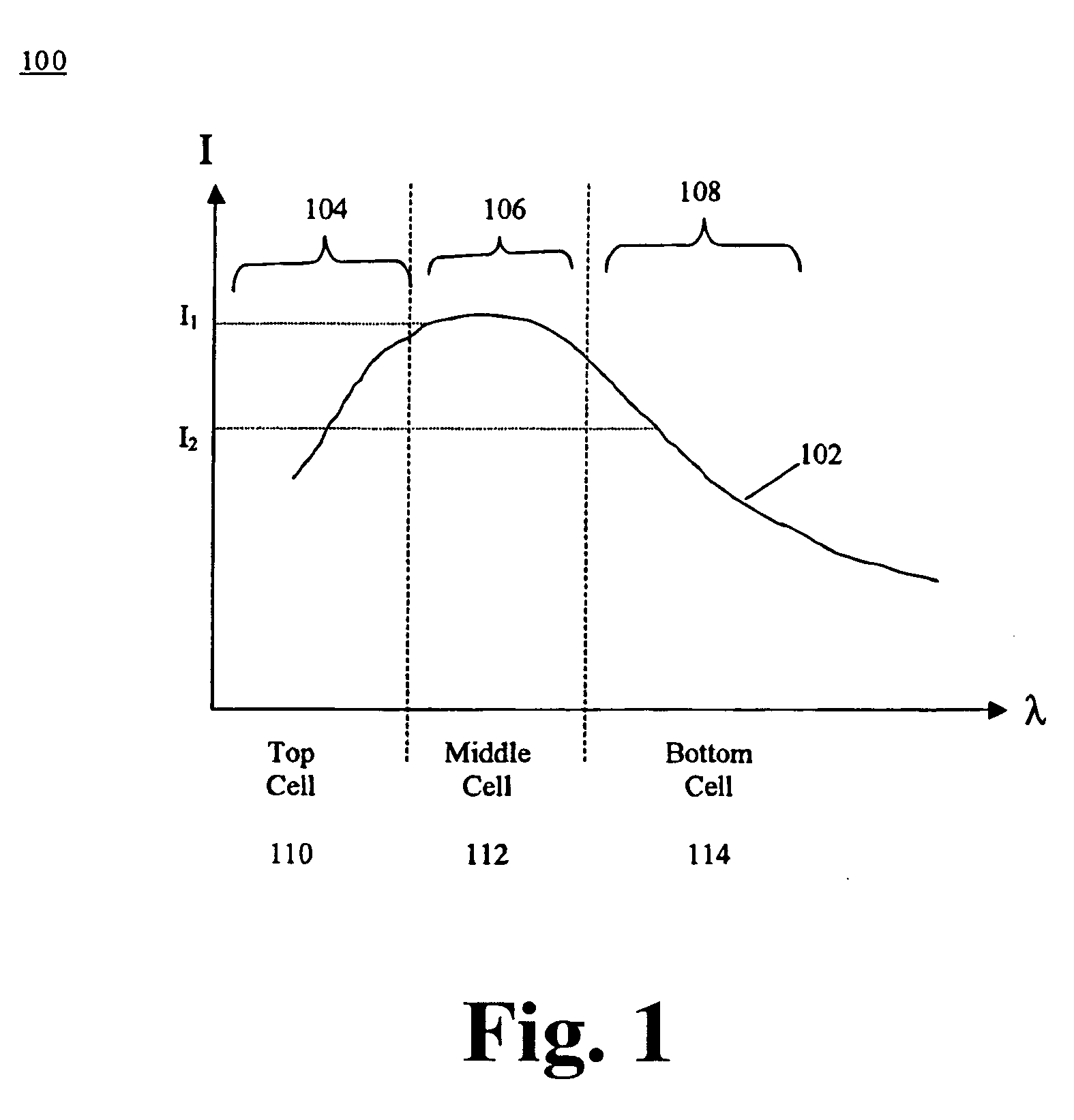

Method and apparatus of multiplejunction solar cell structure with high band gap heterojunction middle cell

InactiveUS7071407B2Final product manufactureSemiconductor/solid-state device manufacturingHeterojunctionTriple junction

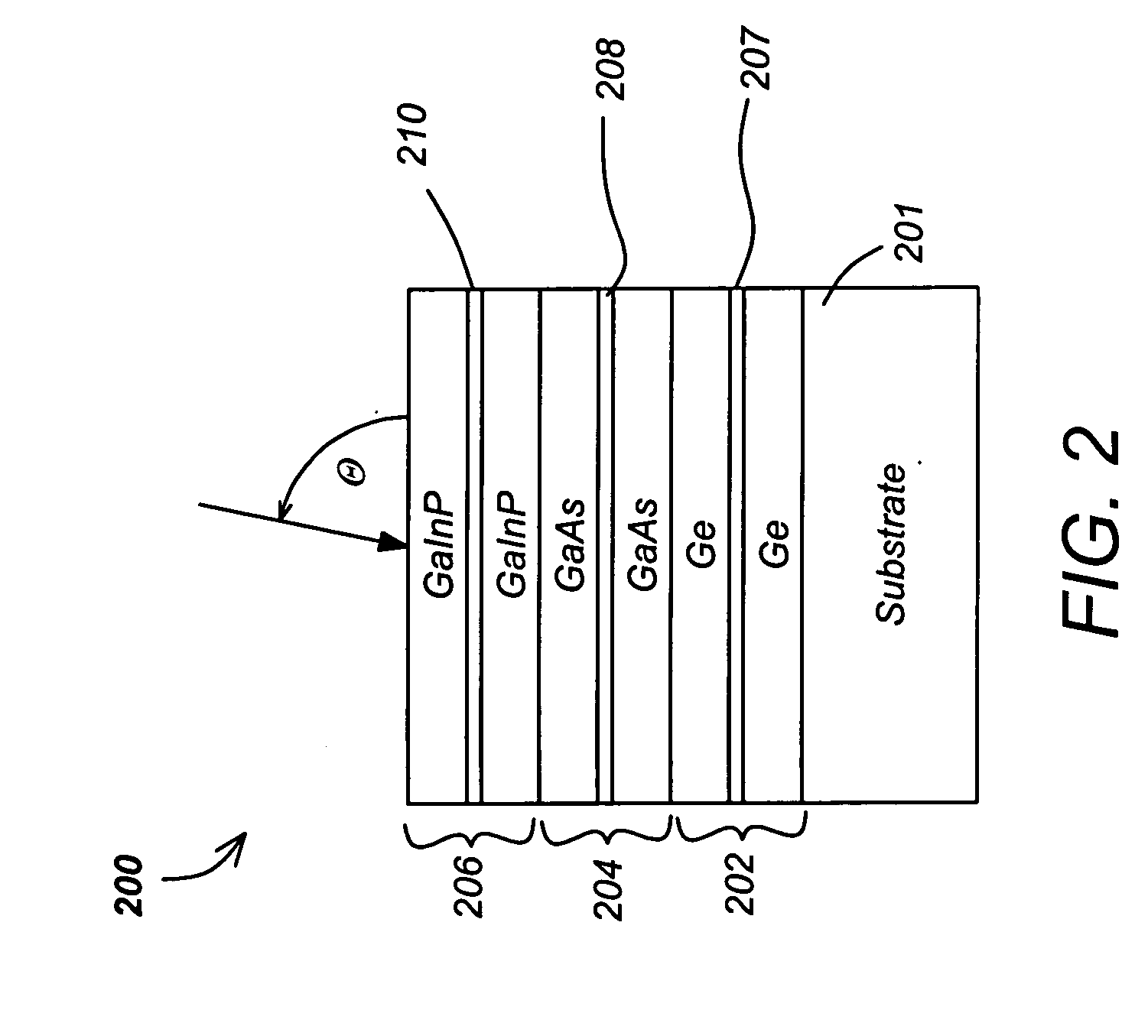

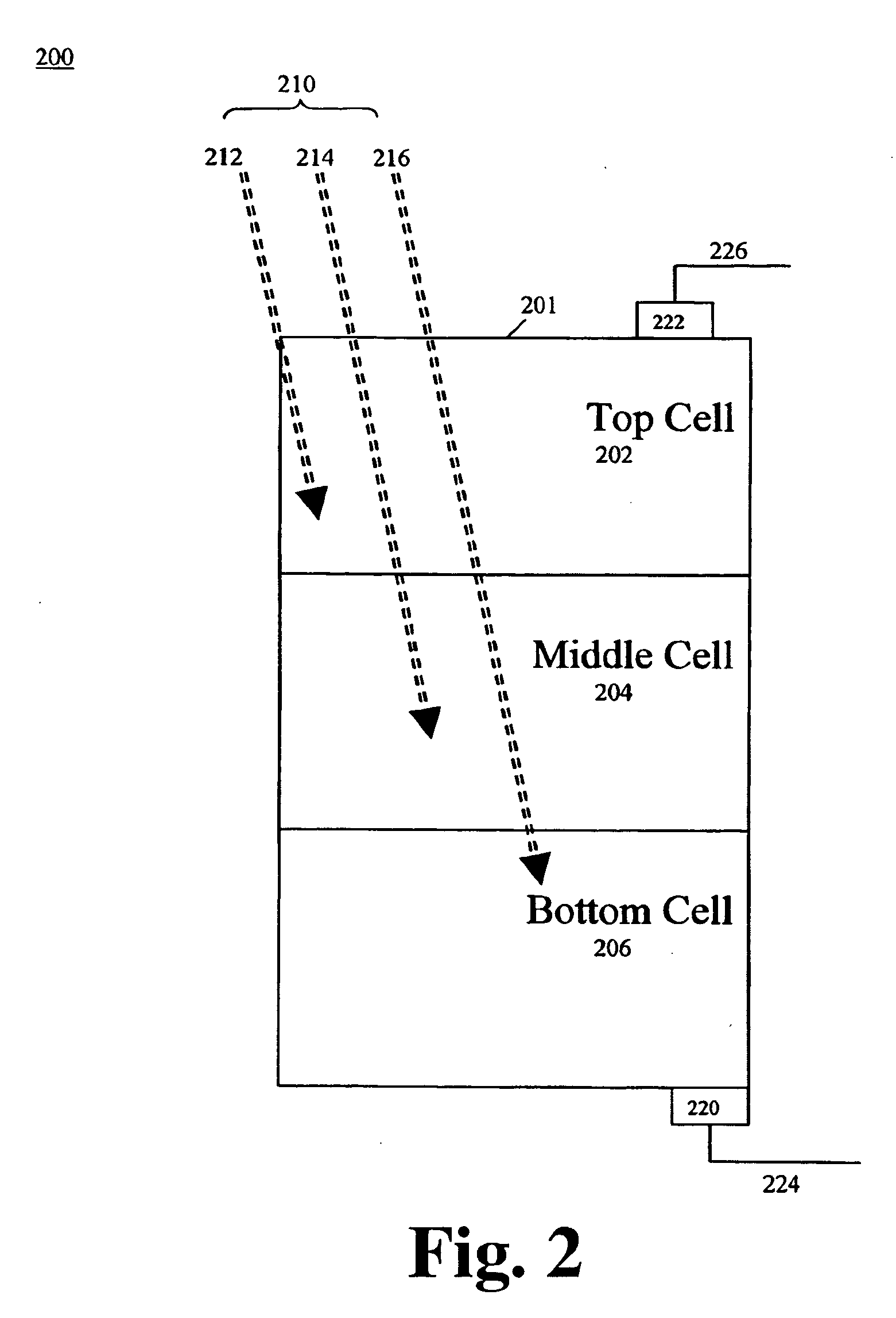

A method and a multijunction solar device having a high band gap heterojunction middle solar cell are disclosed. In one embodiment, a triple-junction solar device includes bottom, middle, and top cells. The bottom cell has a germanium (Ge) substrate and a buffer layer, wherein the buffer layer is disposed over the Ge substrate. The middle cell contains a heterojunction structure, which further includes an emitter layer and a base layer that are disposed over the bottom cell. The top cell contains an emitter layer and a base layer disposed over the middle cell.

Owner:SOLAERO TECH CORP

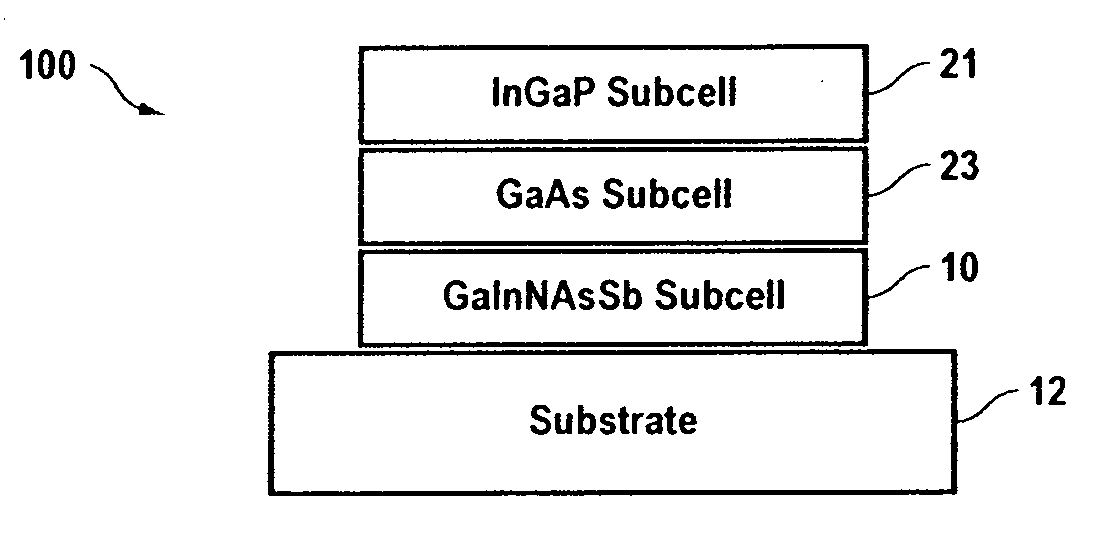

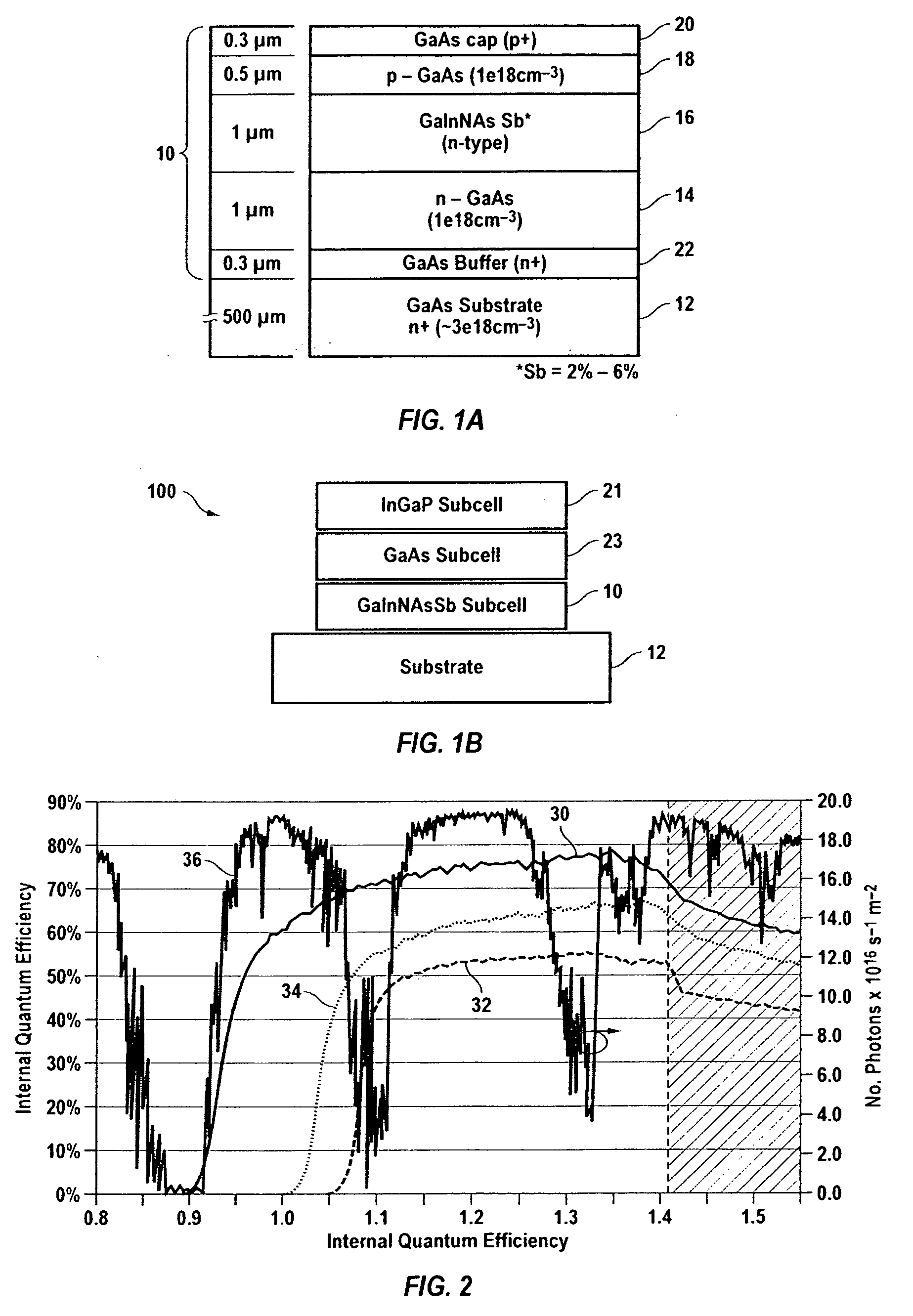

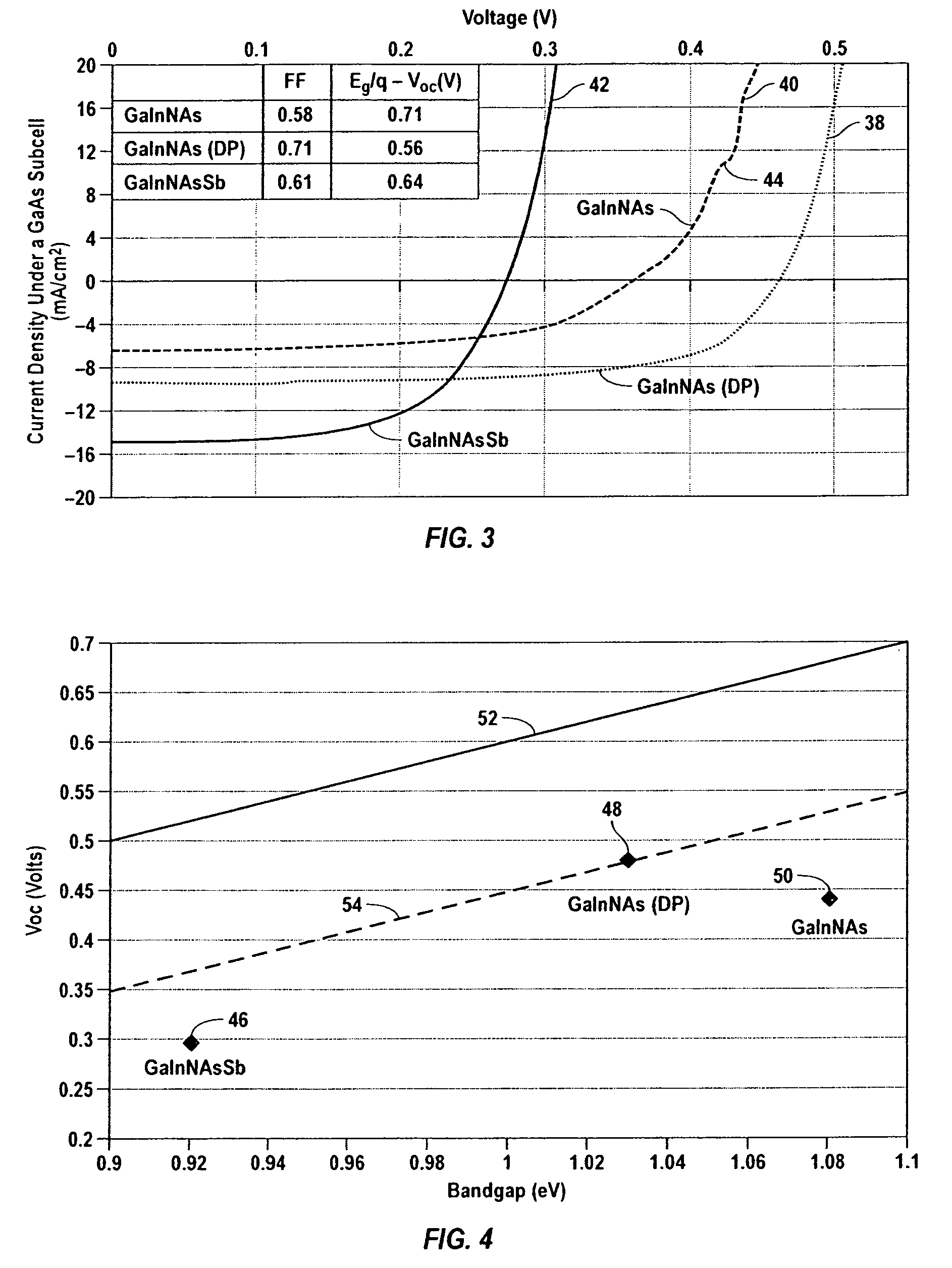

GaInNAsSb solar cells grown by molecular beam epitaxy

InactiveUS20090014061A1Improve featuresPromote efficient solar energy conversionFinal product manufacturePhotovoltaic energy generationIndiumSemiconductor alloys

A high efficiency triple-junction solar cell and method of manufacture therefor is provided wherein junctions are formed between different types of III-V semiconductor alloy materials, one alloy of which contains a combination of an effective amount of antimony (Sb) with gallium (Ga), indium (In), nitrogen (N, the nitride component) and arsenic (As) to form the dilute nitride semiconductor layer GaInNAsSb which has particularly favorable characteristics in a solar cell. In particular, the bandgap and lattice matching promote efficient solar energy conversion.

Owner:CACTUS MATERIALS INC +1

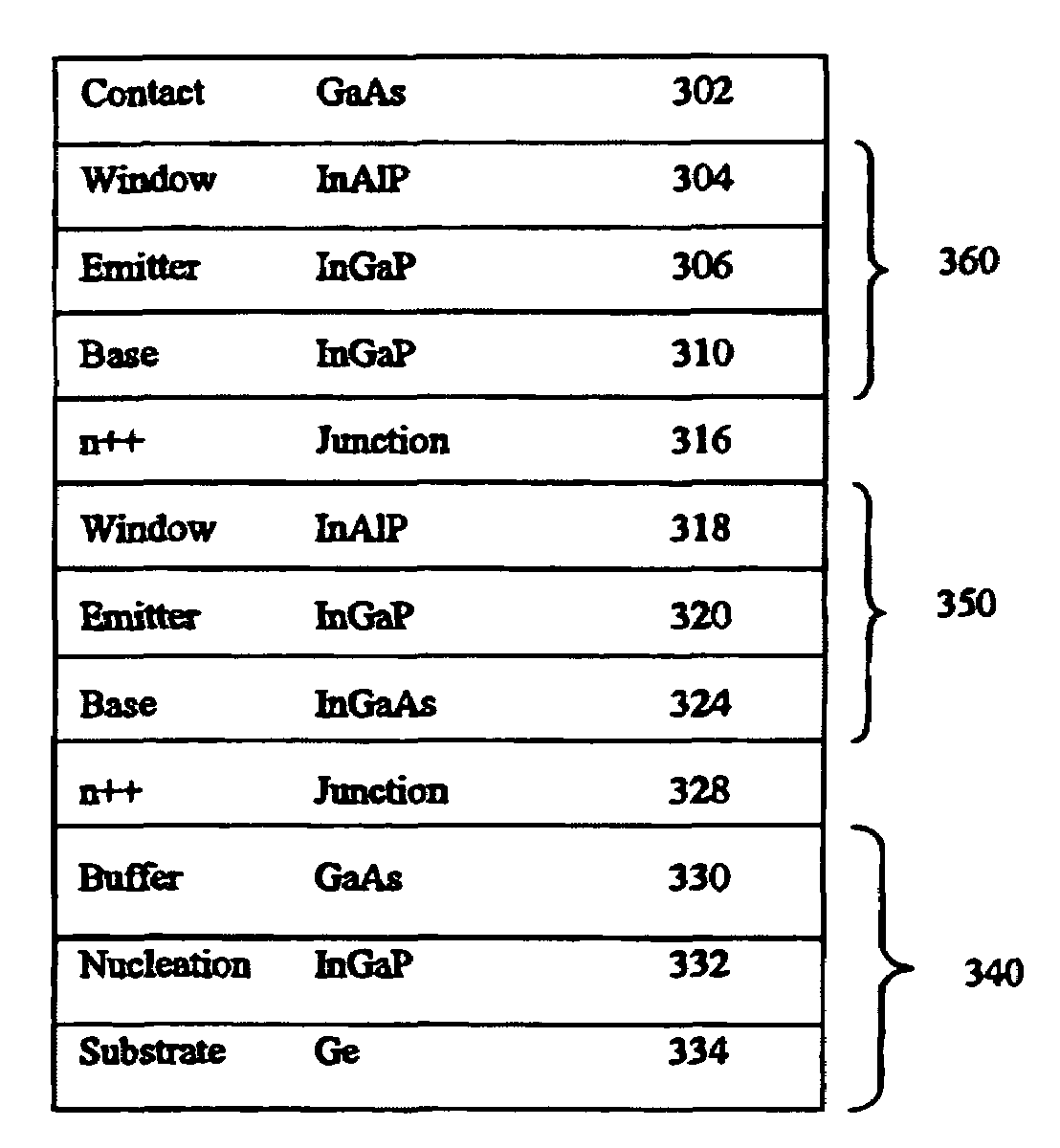

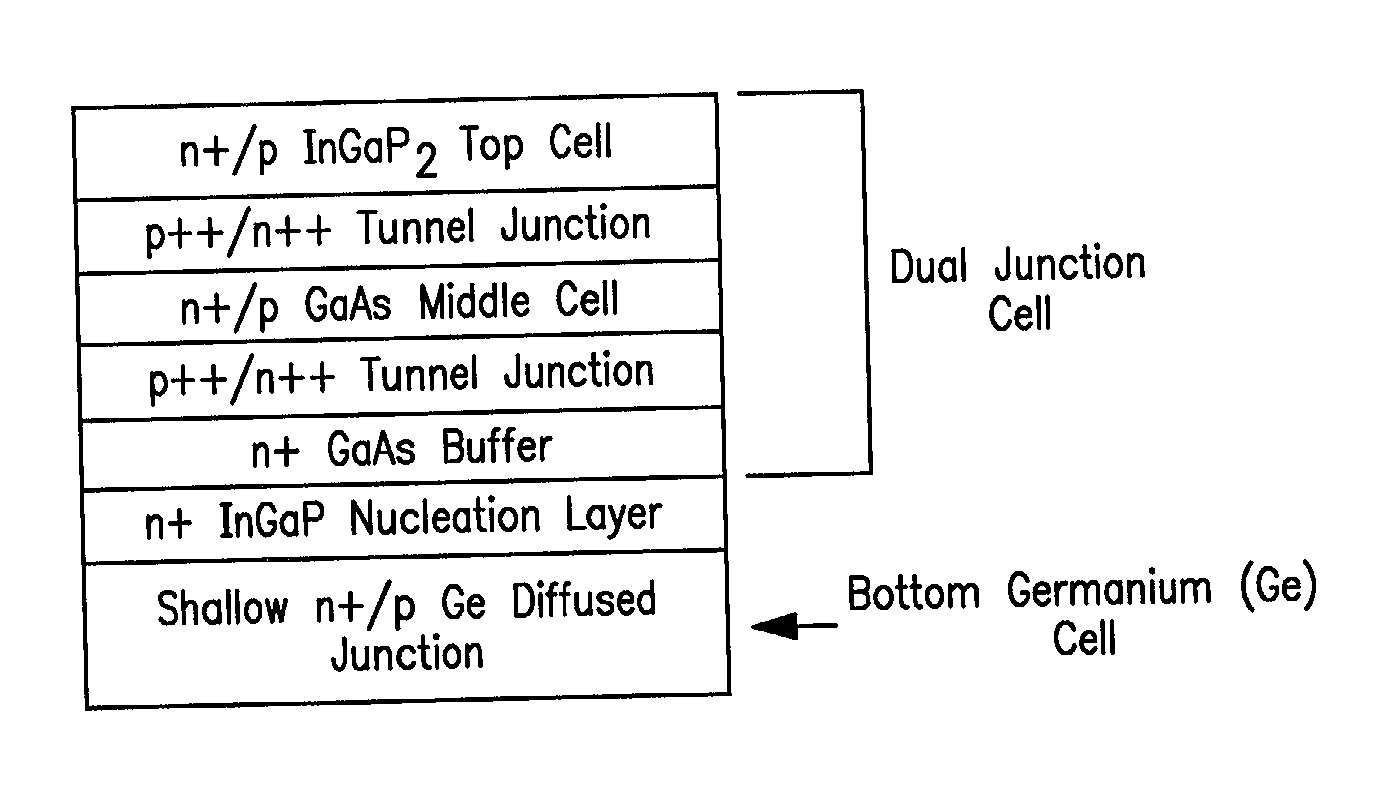

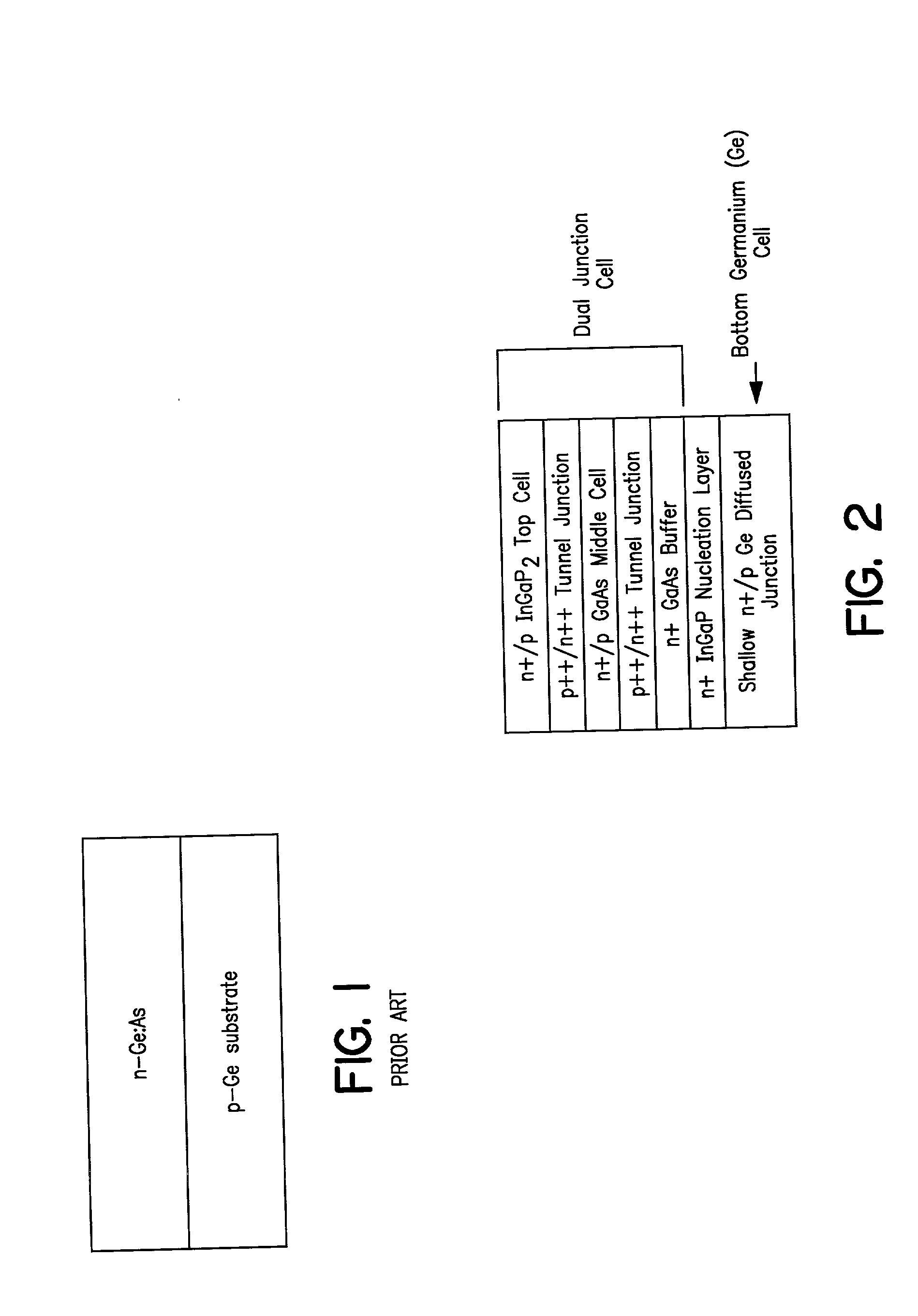

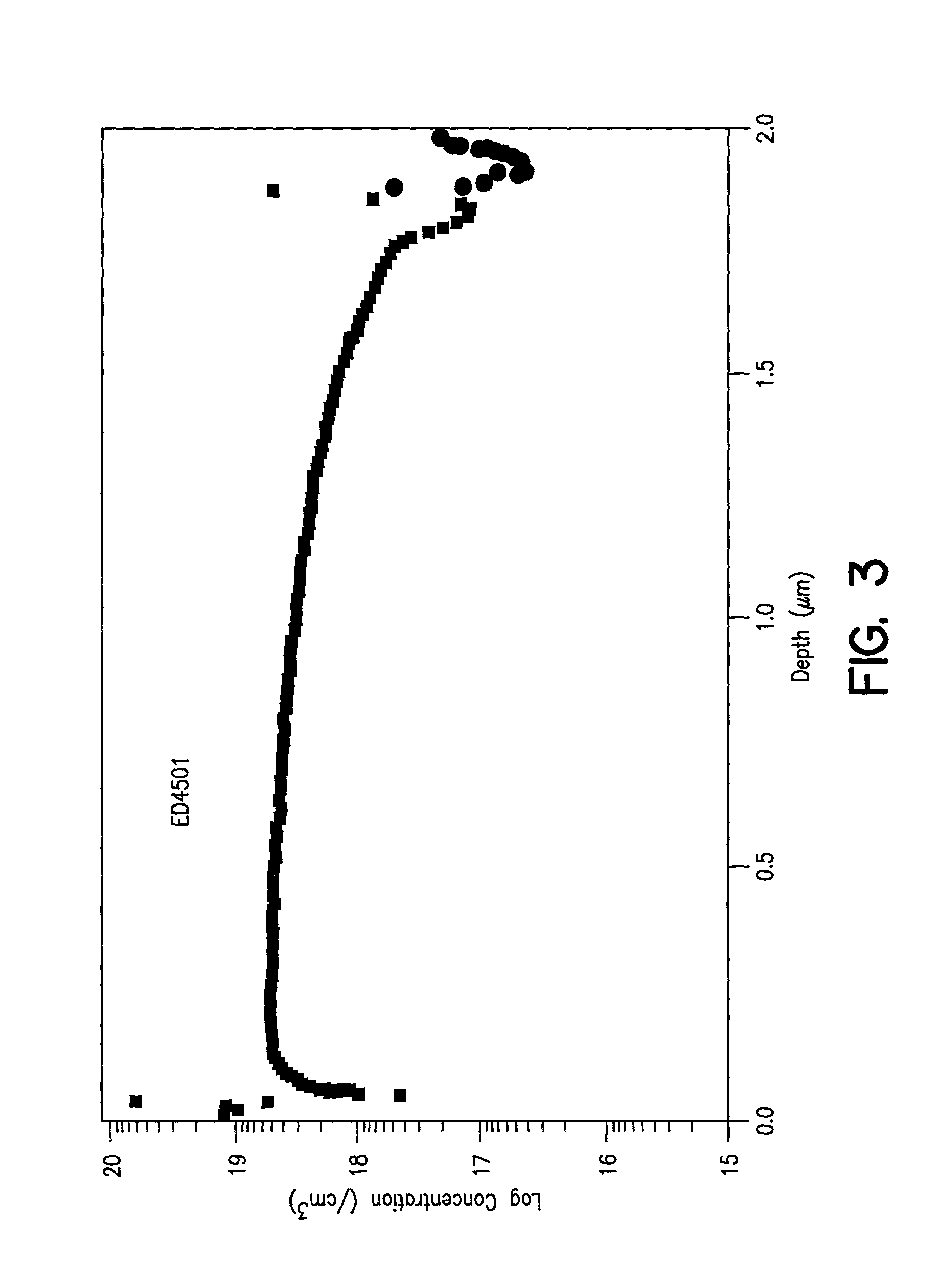

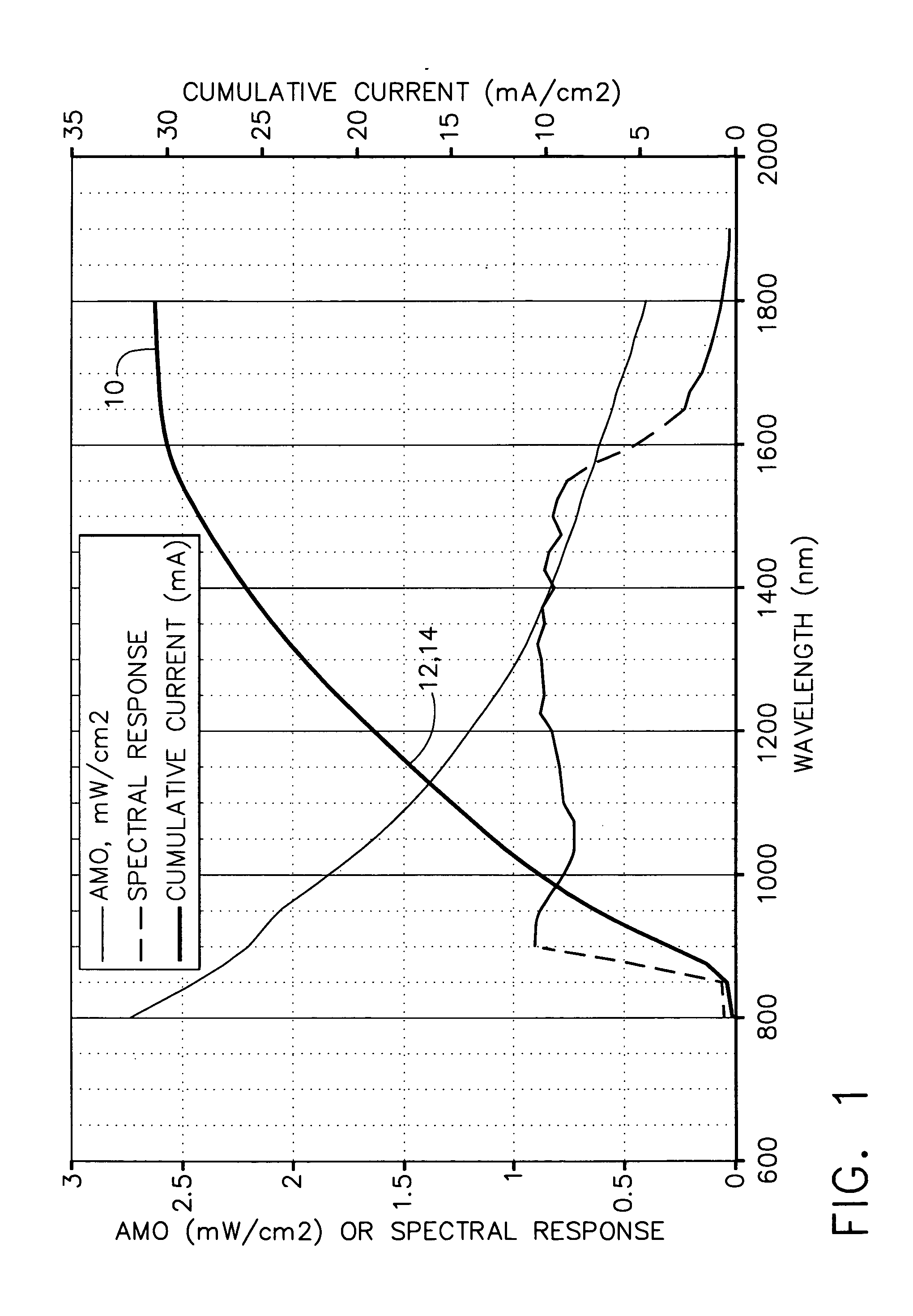

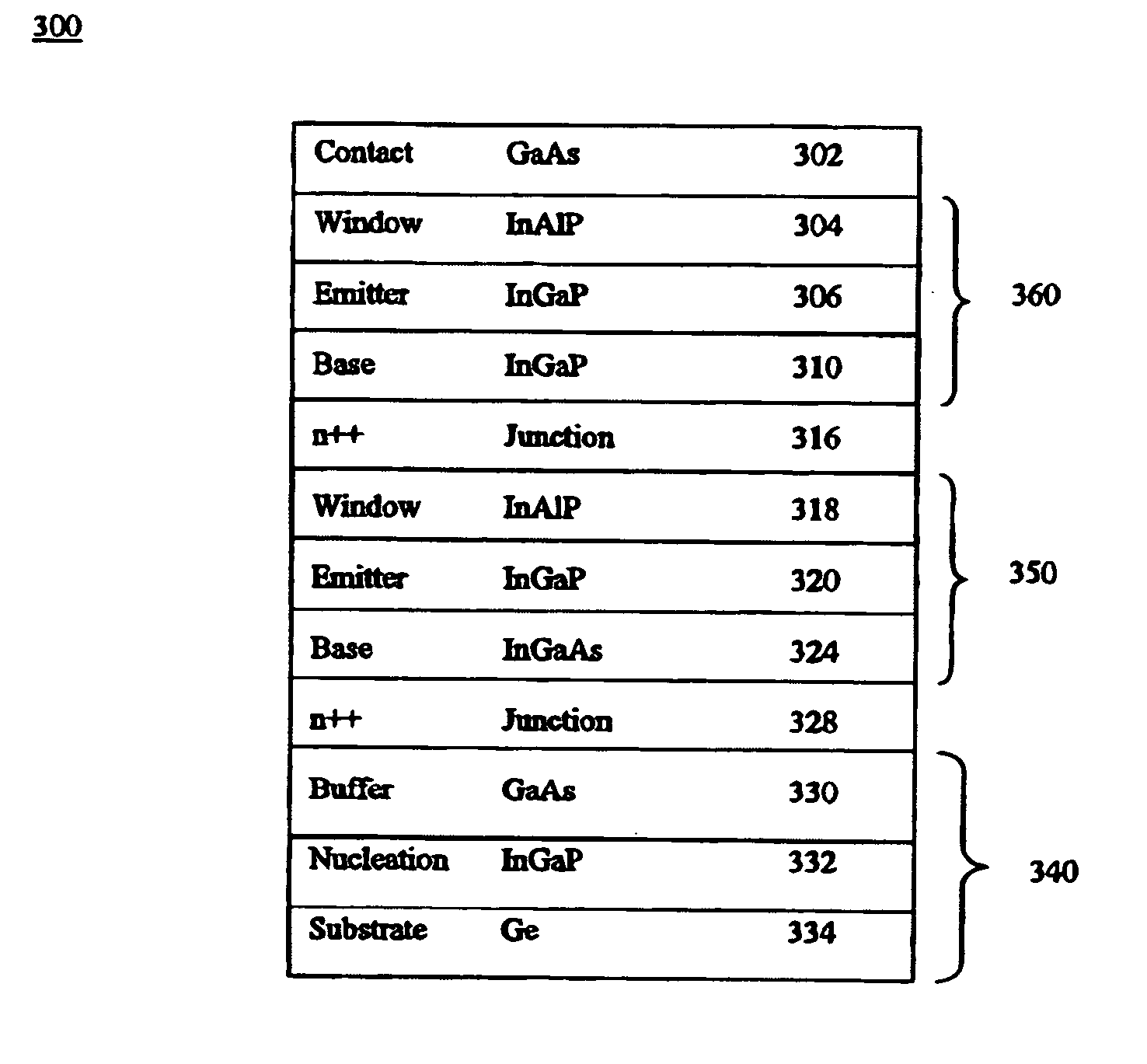

Apparatus and method for optimizing the efficiency of germanium junctions in multi-junction solar cells

InactiveUS20020040727A1PV power plantsSemiconductor/solid-state device manufacturingDopantDiffusion barrier

Apparatus and Method for Optimizing the Efficiency of Germanium Junctions in Multi-Junction Solar Cells. In a preferred embodiment, an indium gallium phosphide (InGaP) nucleation layer is disposed between the germanium (Ge) substrate and the overlying dual-junction epilayers for controlling the diffusion depth of the n-doping in the germanium junction. Specifically, by acting as a diffusion barrier to arsenic (As) contained in the overlying epilayers and as a source of n-type dopant for forming the germanium junction, the nucleation layer enables the growth time and temperature in the epilayer device process to be minimized without compromising the integrity of the dual-junction epilayer structure. This in turn allows the arsenic diffusion into the germanium substrate to be optimally controlled by varying the thickness of the nucleation layer. An active germanium junction formed in accordance with the present invention has a typical diffused junction depth that is ⅕ to ½ of that achievable in prior art devices. Furthermore, triple-junction solar cells incorporating a shallow n-p germanium junction of the present invention can attain 1 sun AM0 efficiencies in excess of 26%.

Owner:SOLAERO TECH CORP

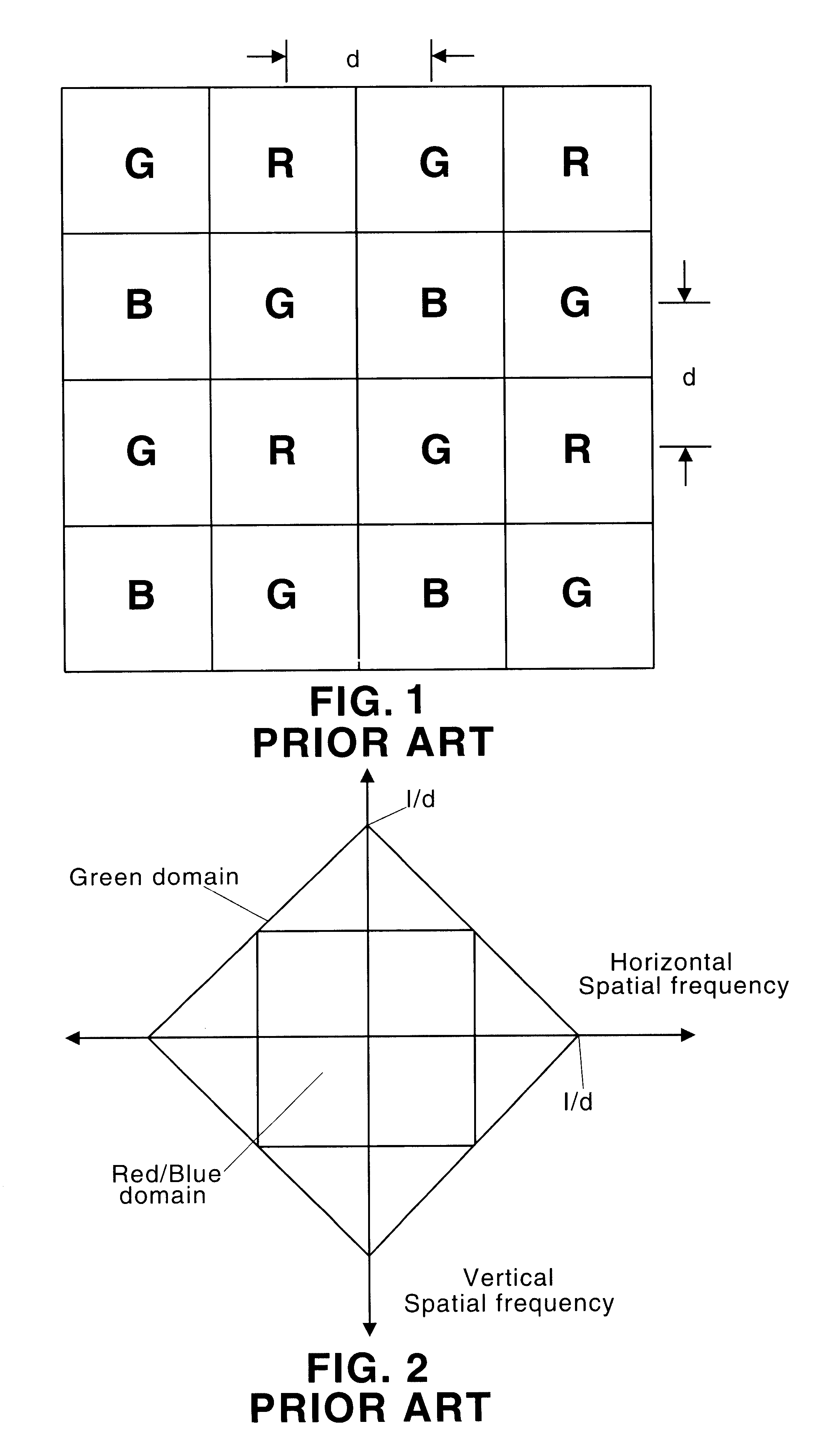

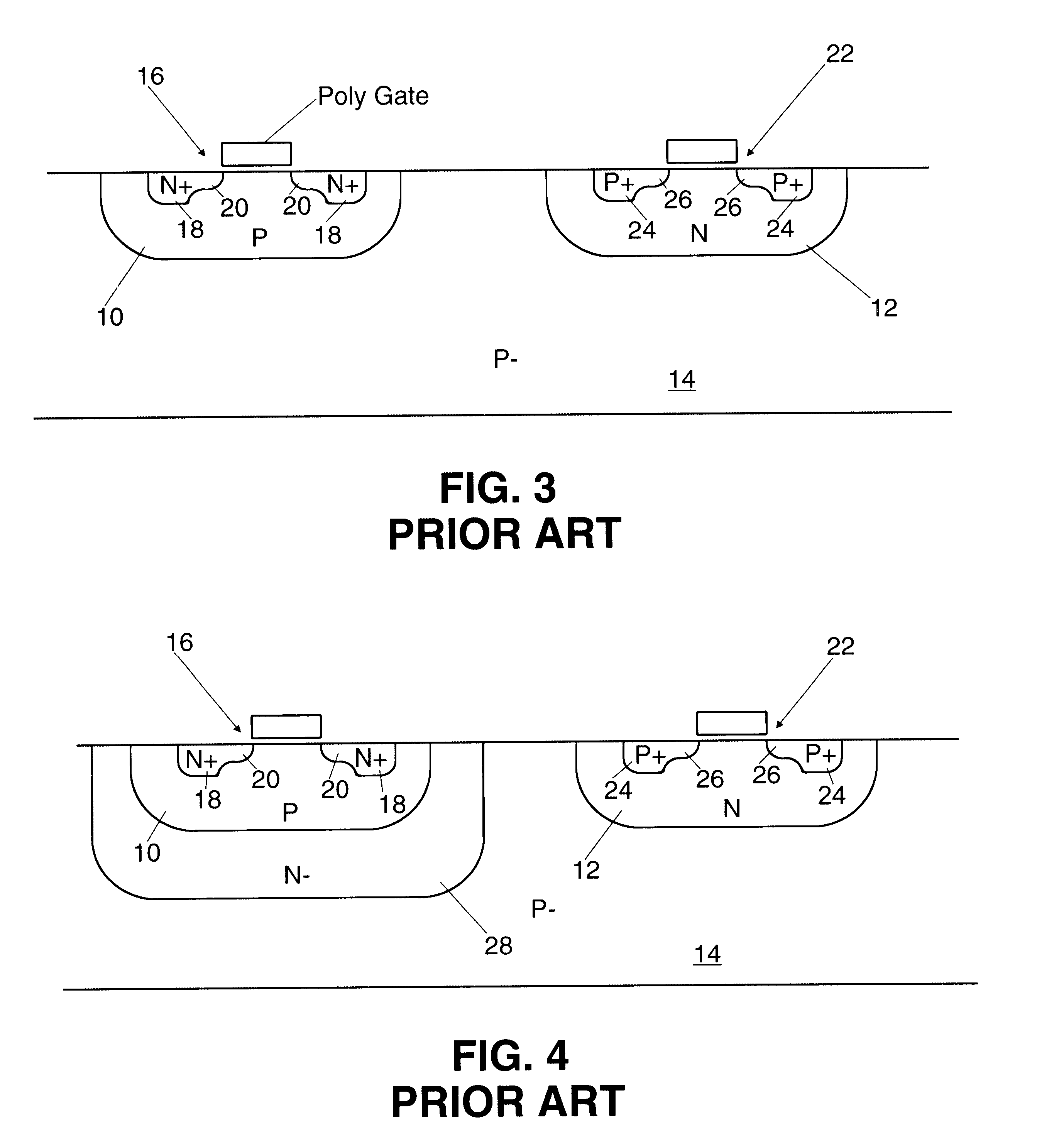

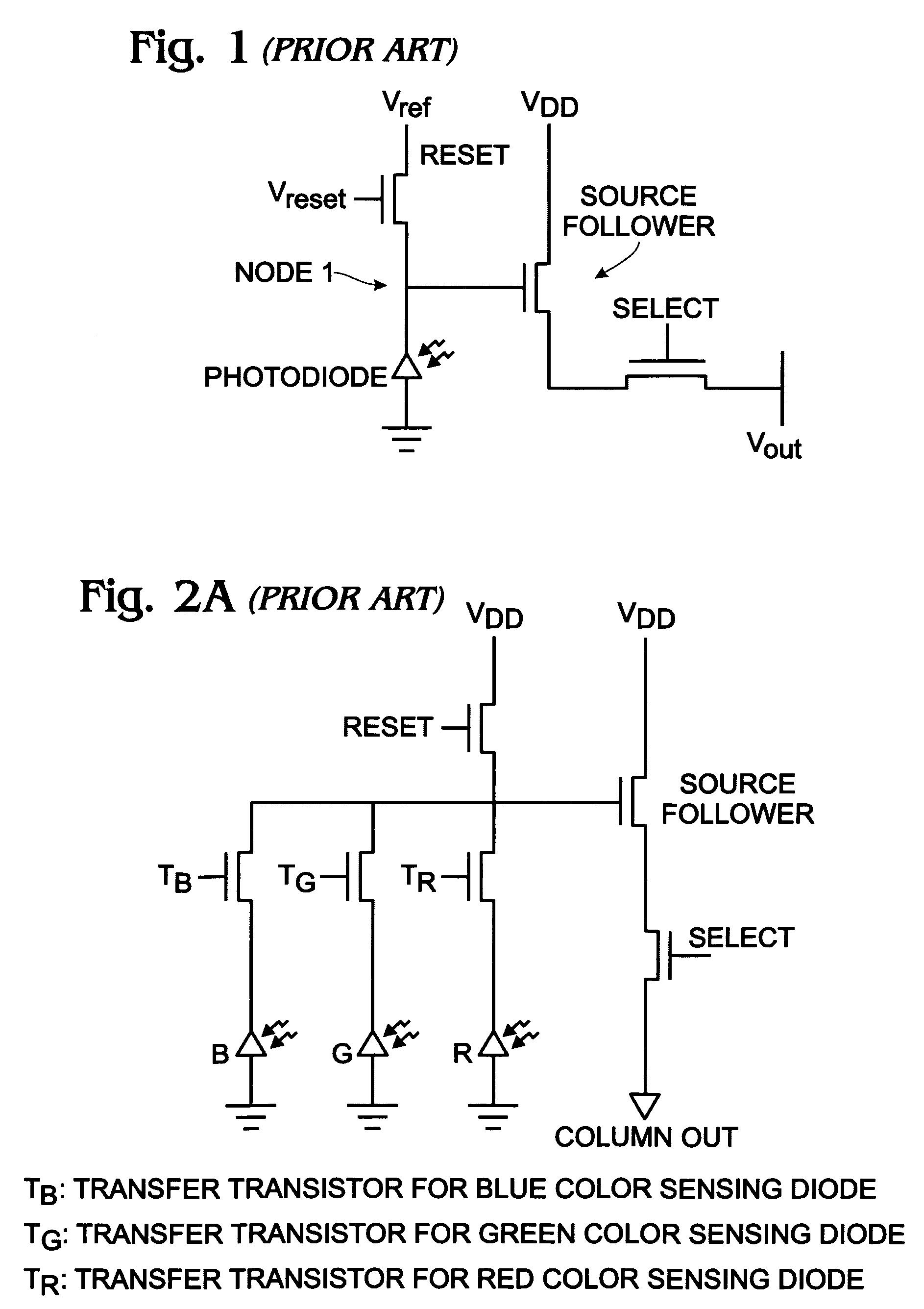

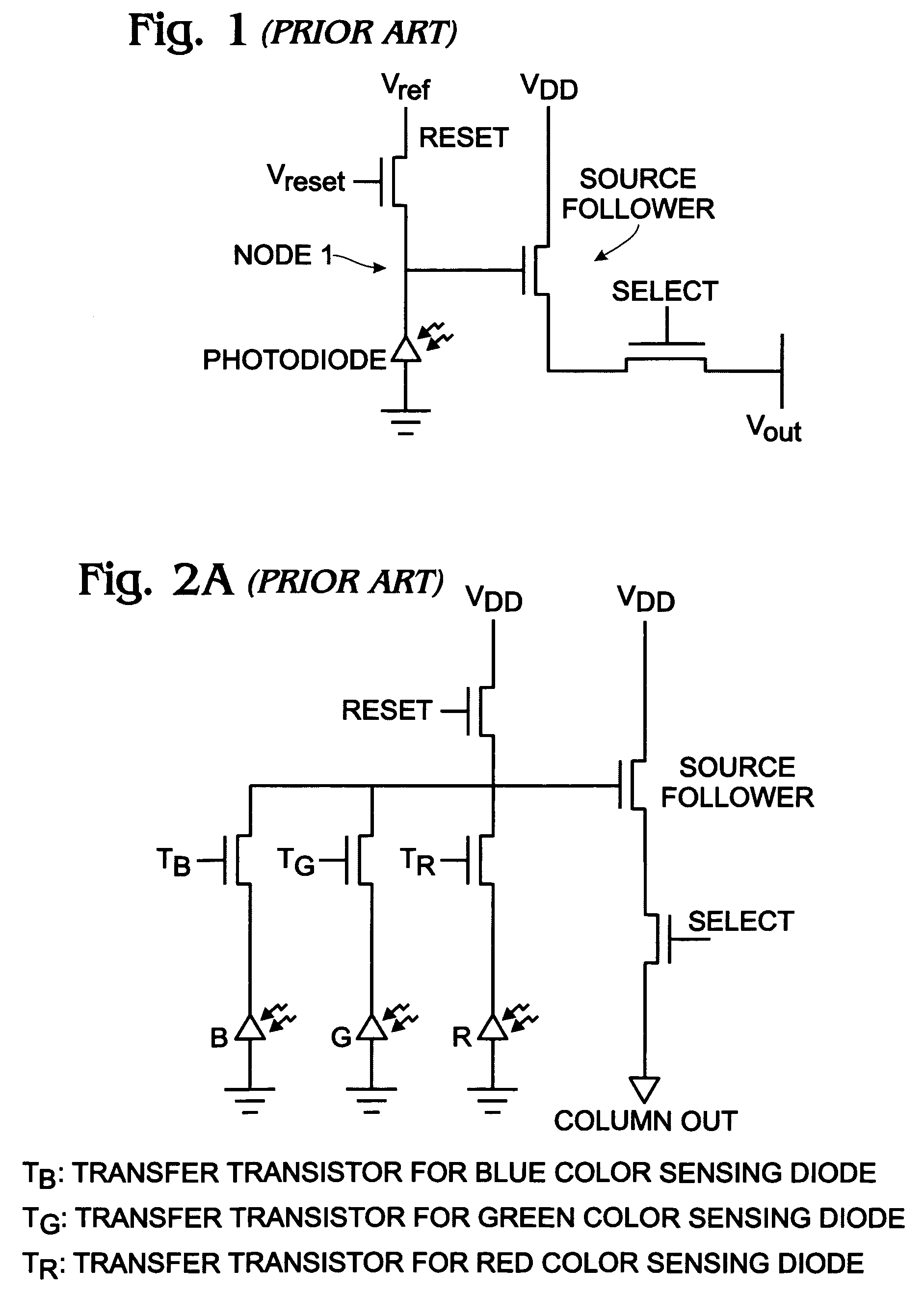

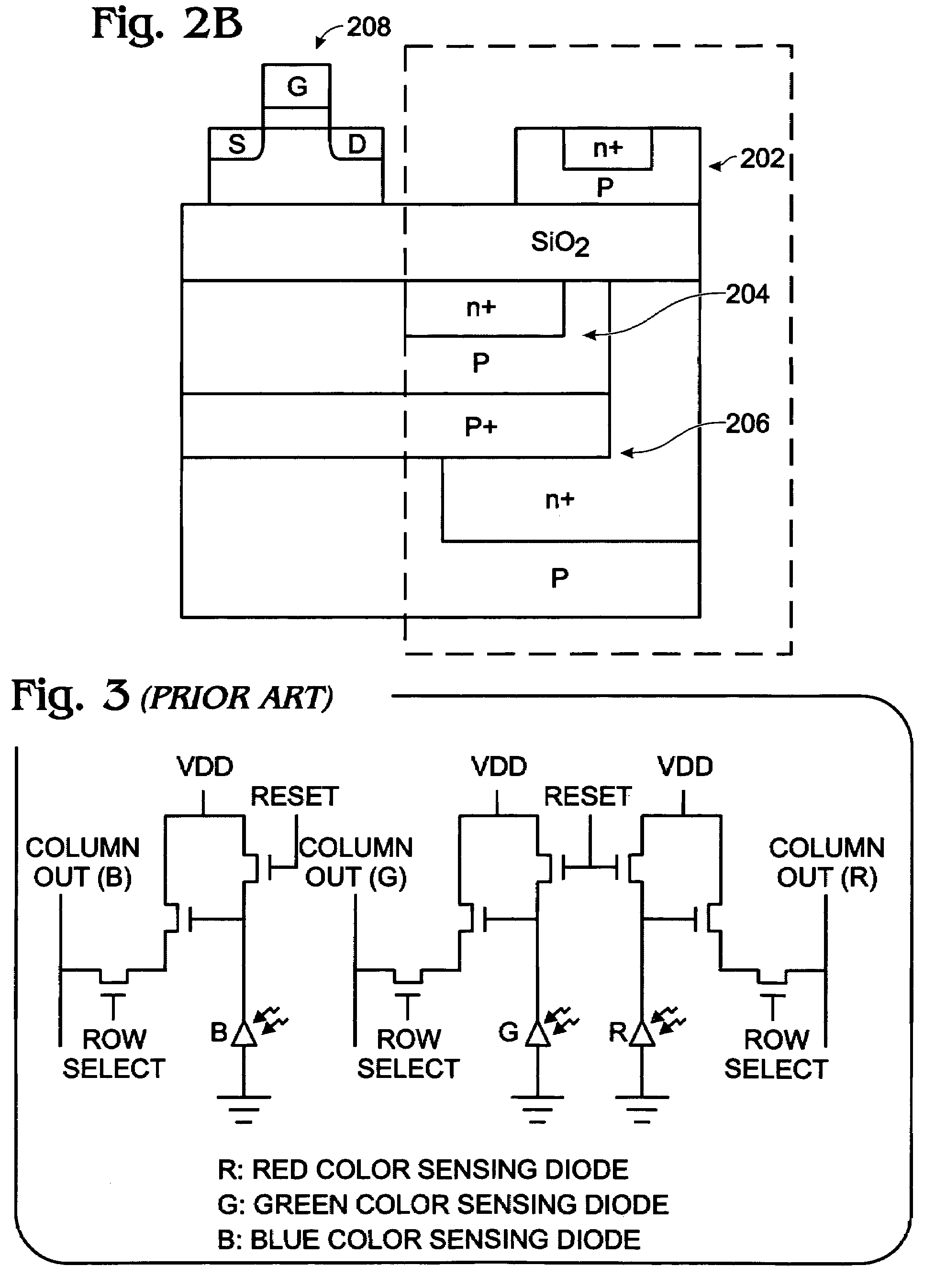

Method for storing and retrieving digital image data from an imaging array

InactiveUS6731397B1Television system detailsDigitally marking record carriersCMOS sensorDigital data

A method for storing digital information from an image sensor comprises the steps of providing an image sensor producing three-color output data at each of a plurality of pixel locations; providing a digital storage device coupled to the image sensor; sensing three-color digital output data from the image sensor; and storing said three-color output data as digital data in the digital storage device without performing any interpolation on the three-color output data. The data may be compressed prior to storage and expanded after retrieval from storage. In a preferred embodiment, the image sensor comprises a triple-junction active pixel sensor array.

Owner:FOVEON

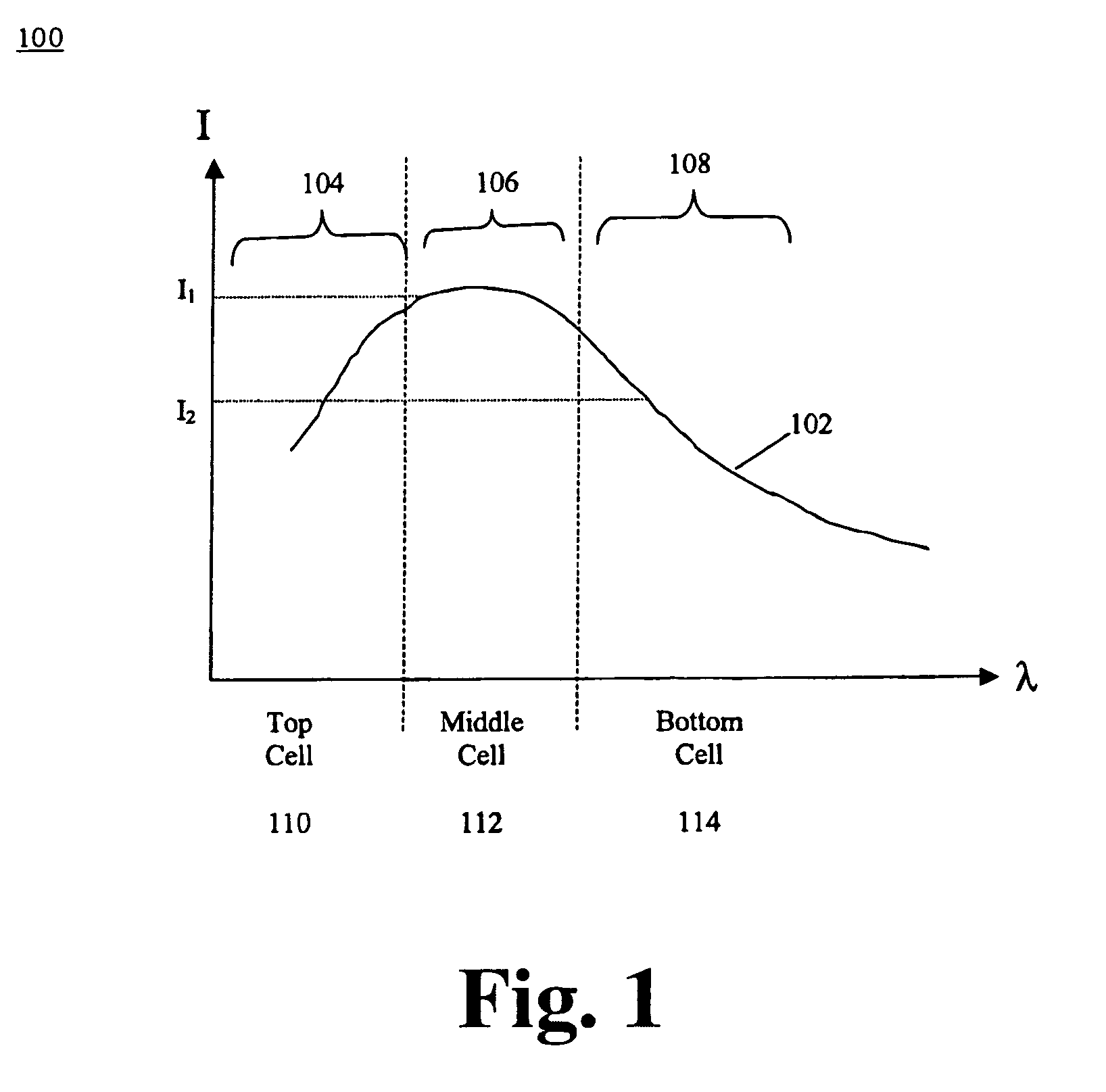

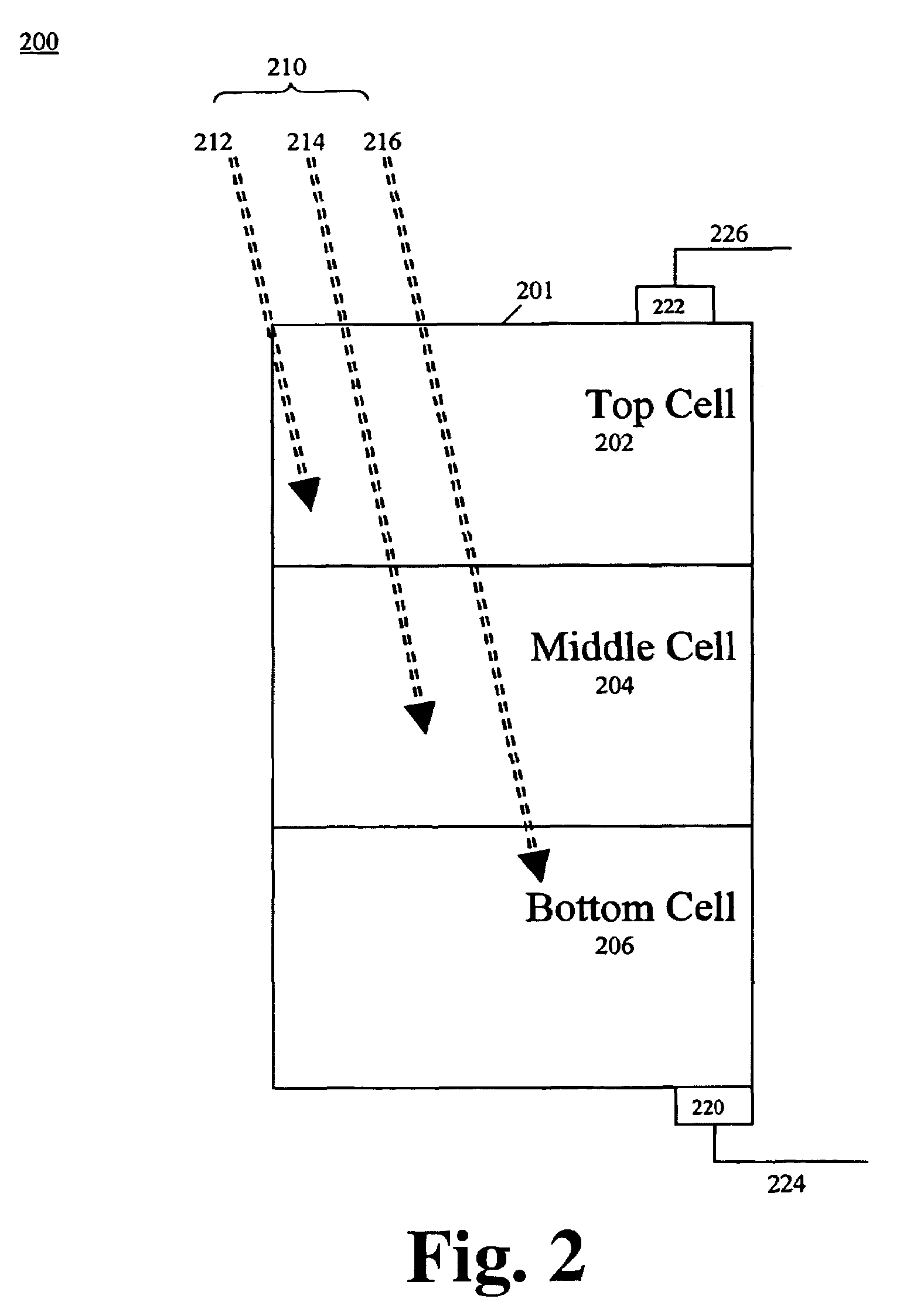

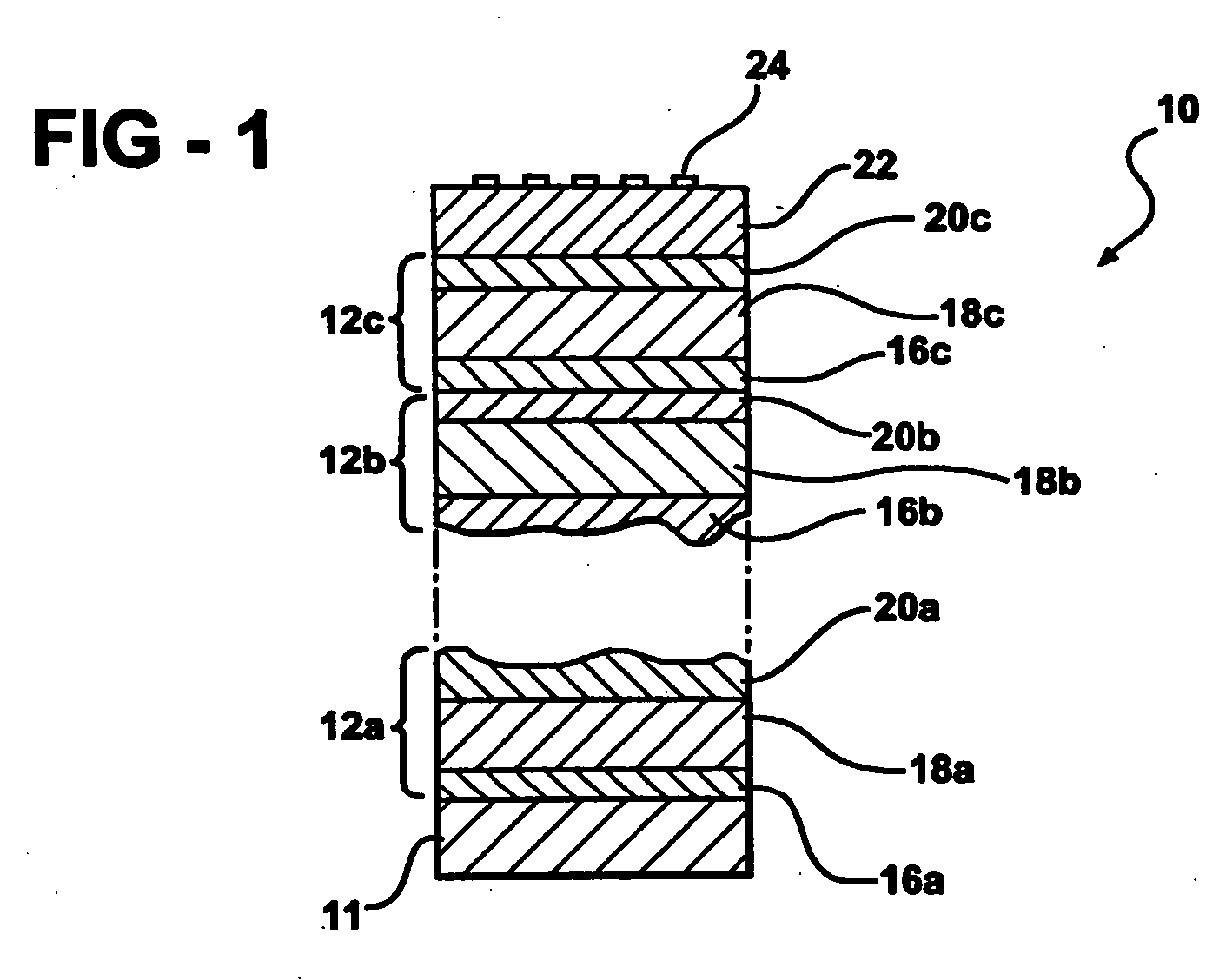

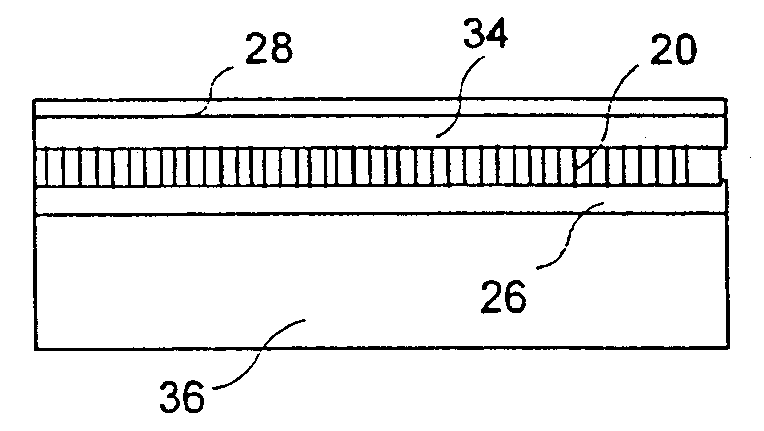

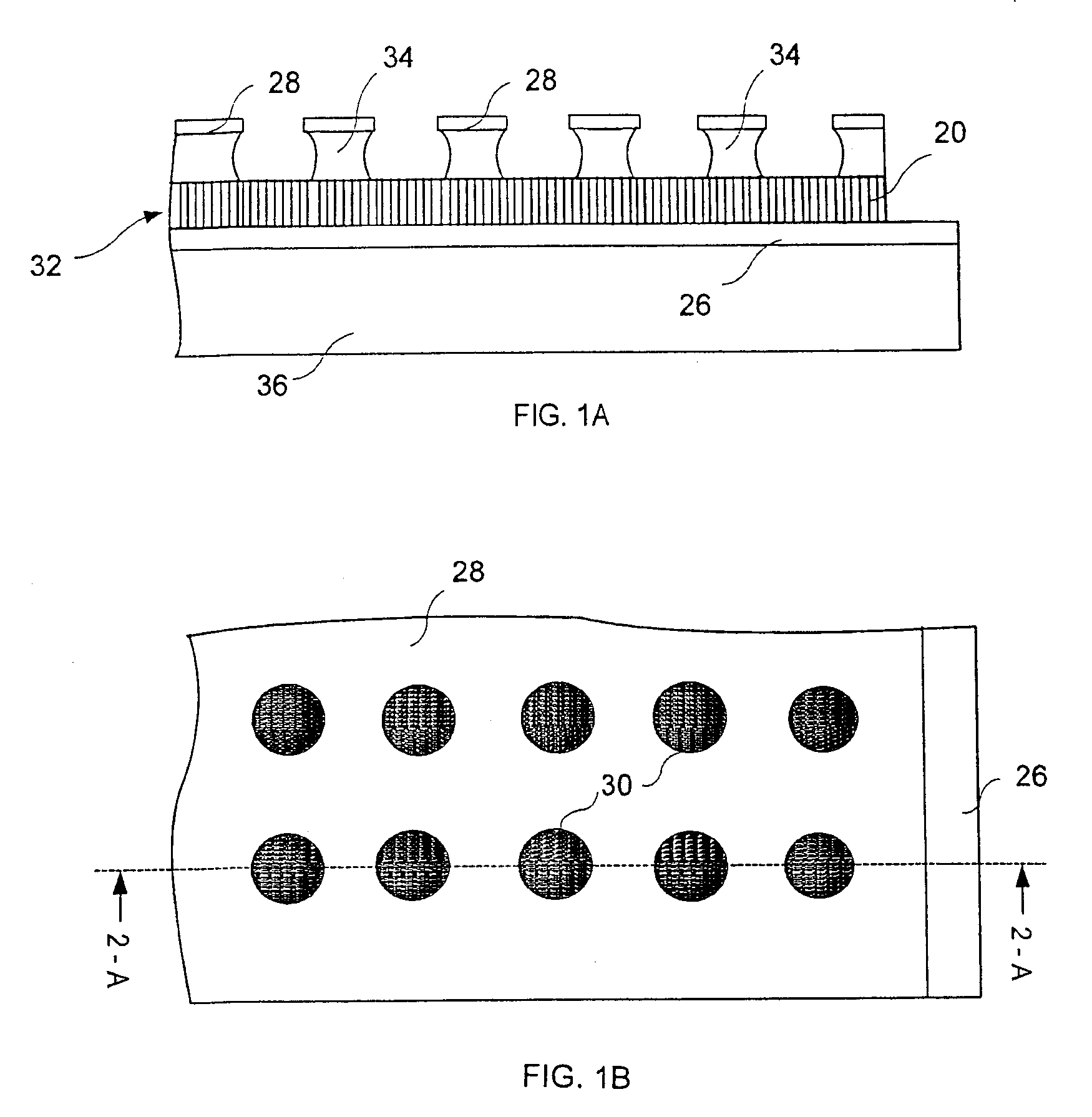

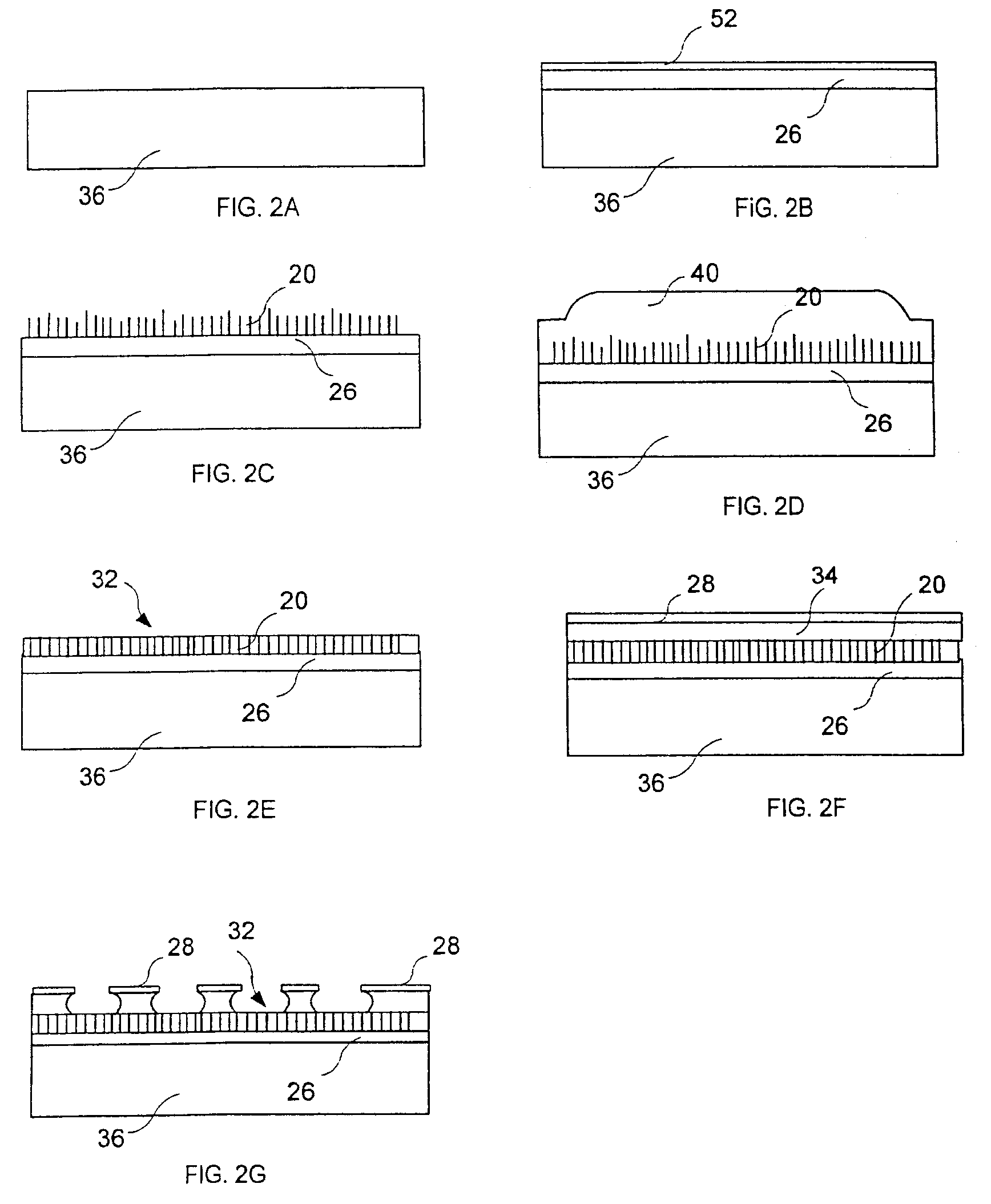

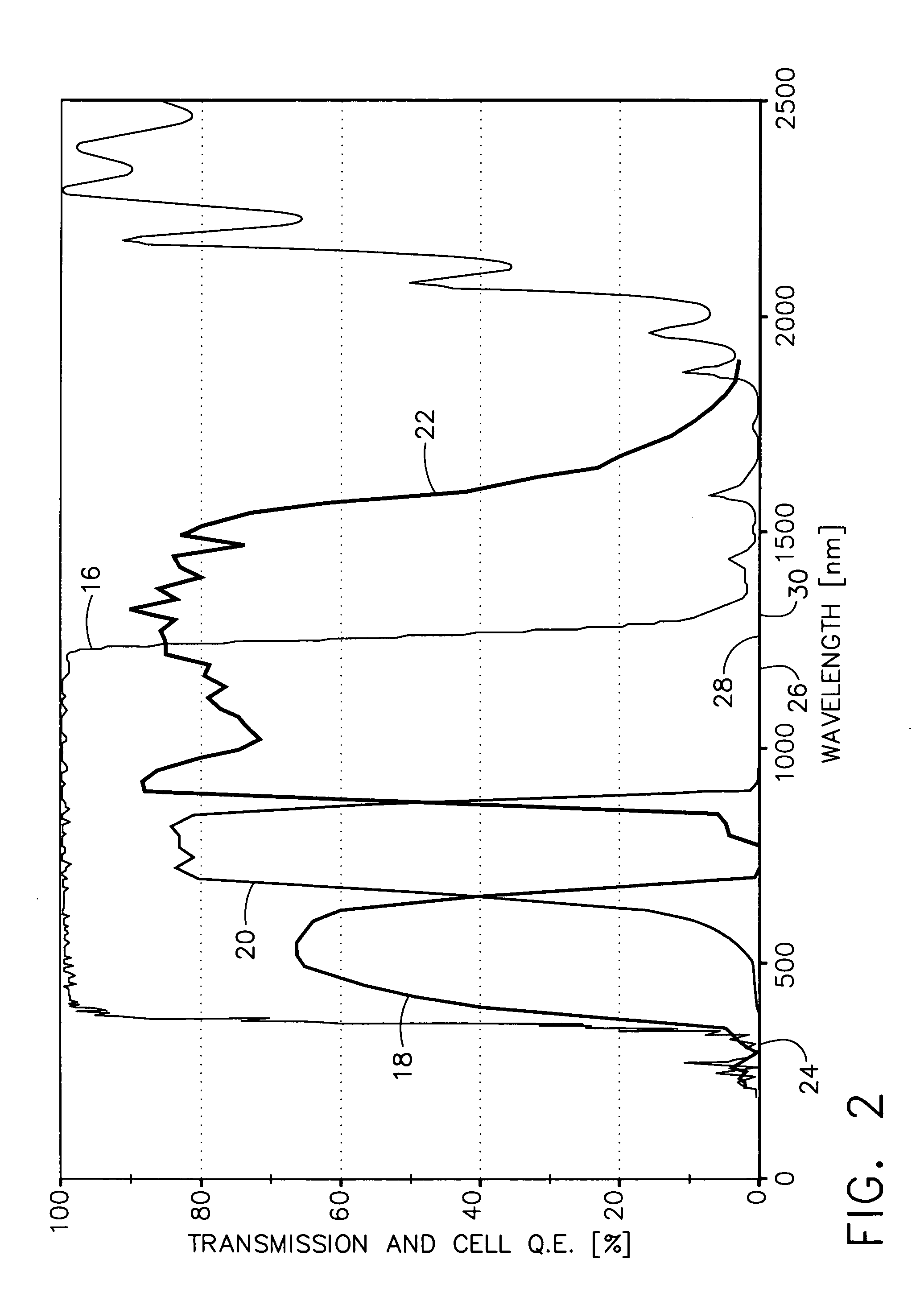

Notch filter for triple junction solar cells

ActiveUS20070137694A1High and low indexFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

A solar cell and method for producing same is disclosed. The solar cell includes a multijunction solar cell structure and a notch filter designed to reflect solar energy that does not contribute to the current output of the multijunction solar cell. By reflecting unused solar energy, the notch filter allows the solar cell to run cooler (and thus more efficiently) yet it still allows all junctions to fully realize their electrical current production capability.

Owner:THE BOEING CO

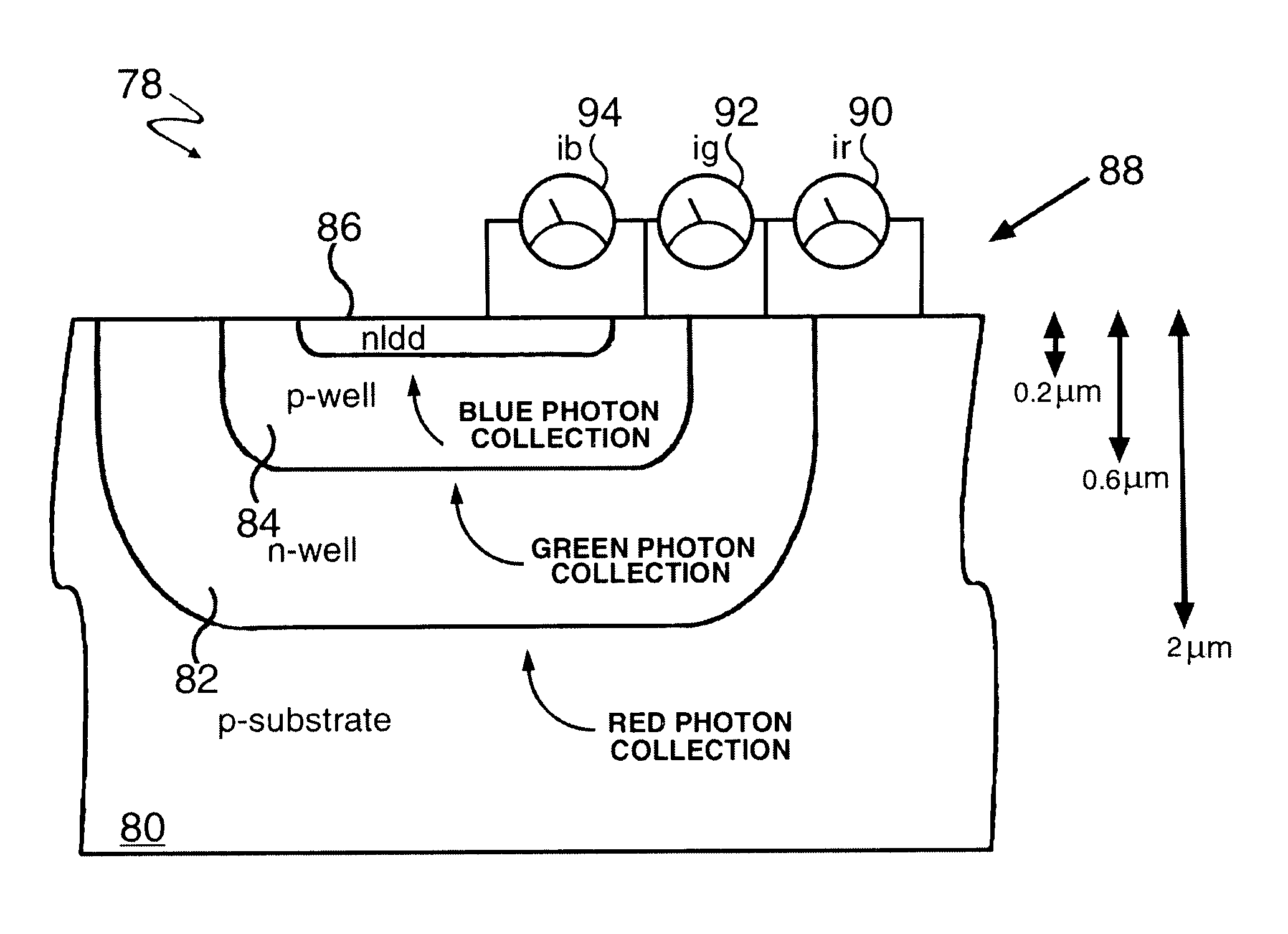

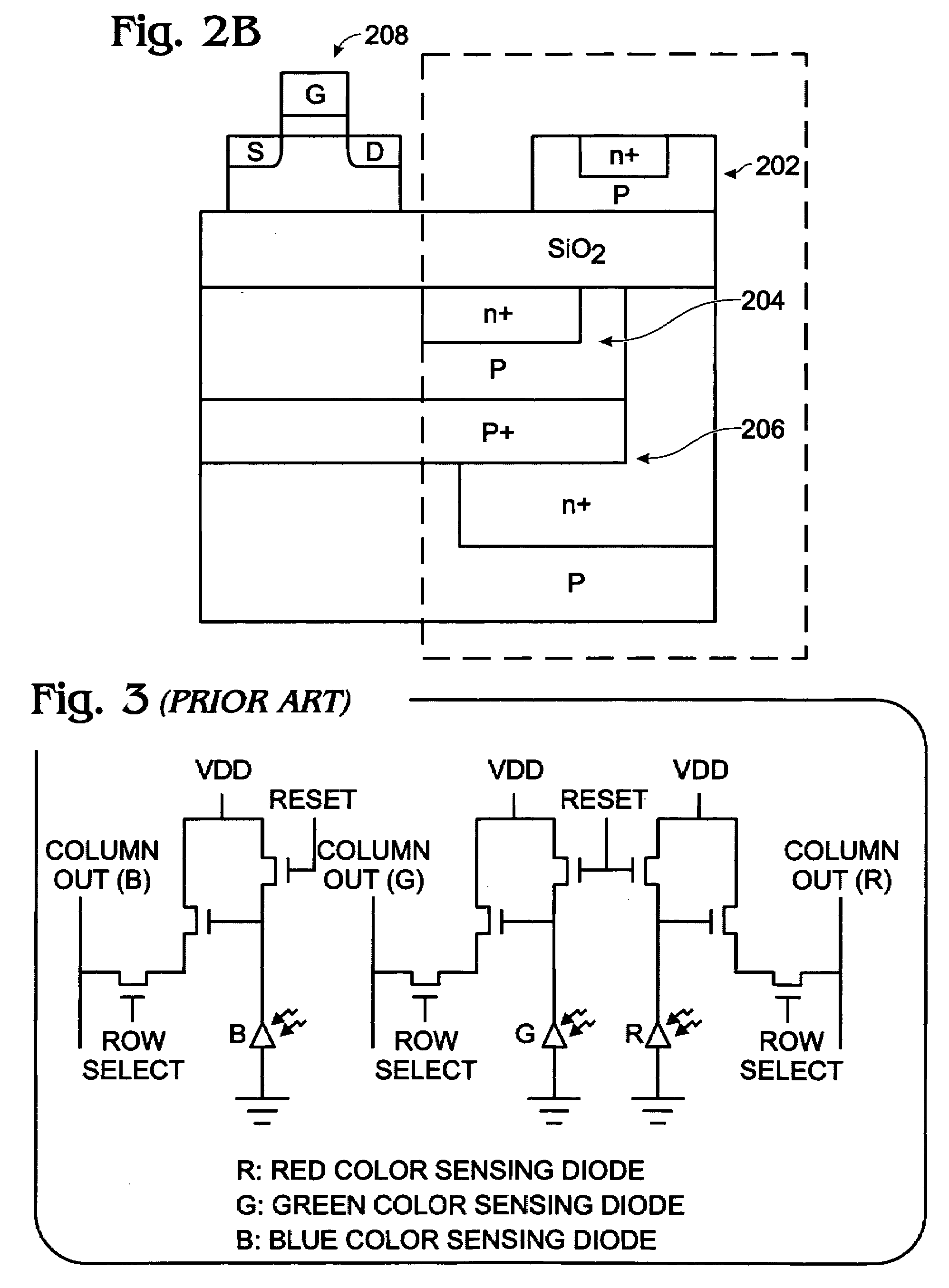

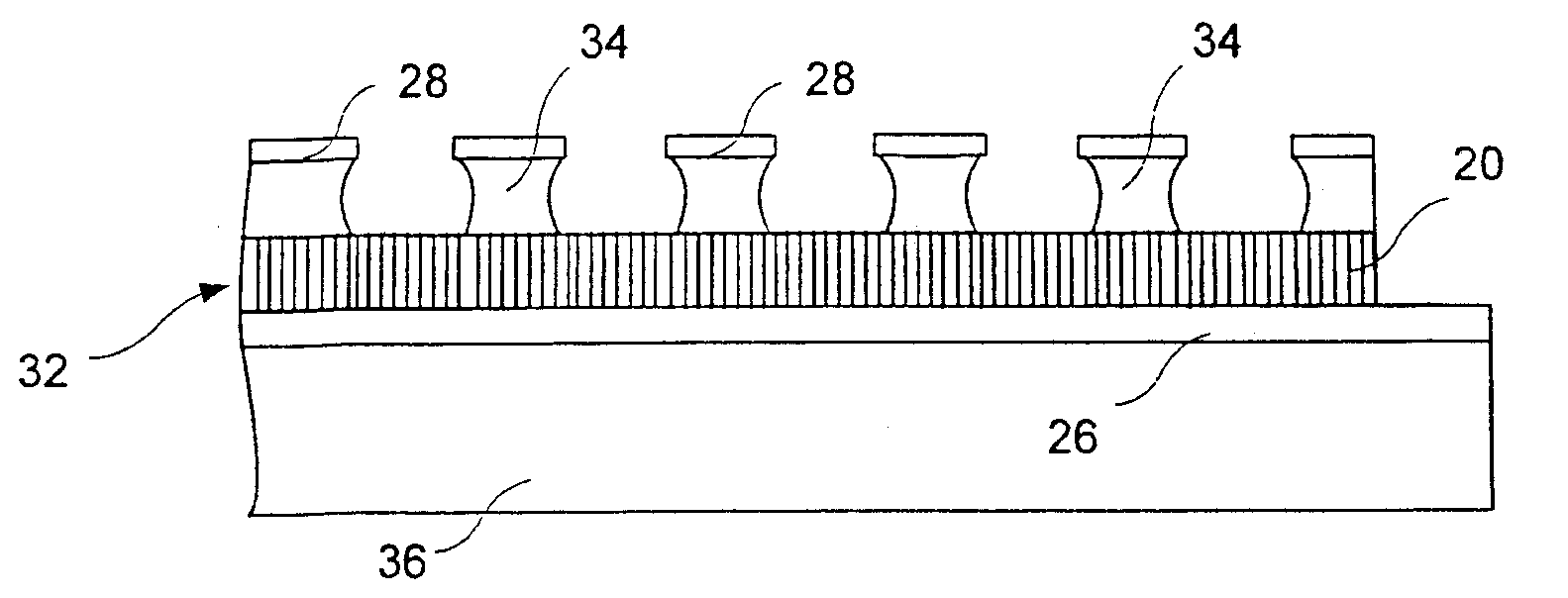

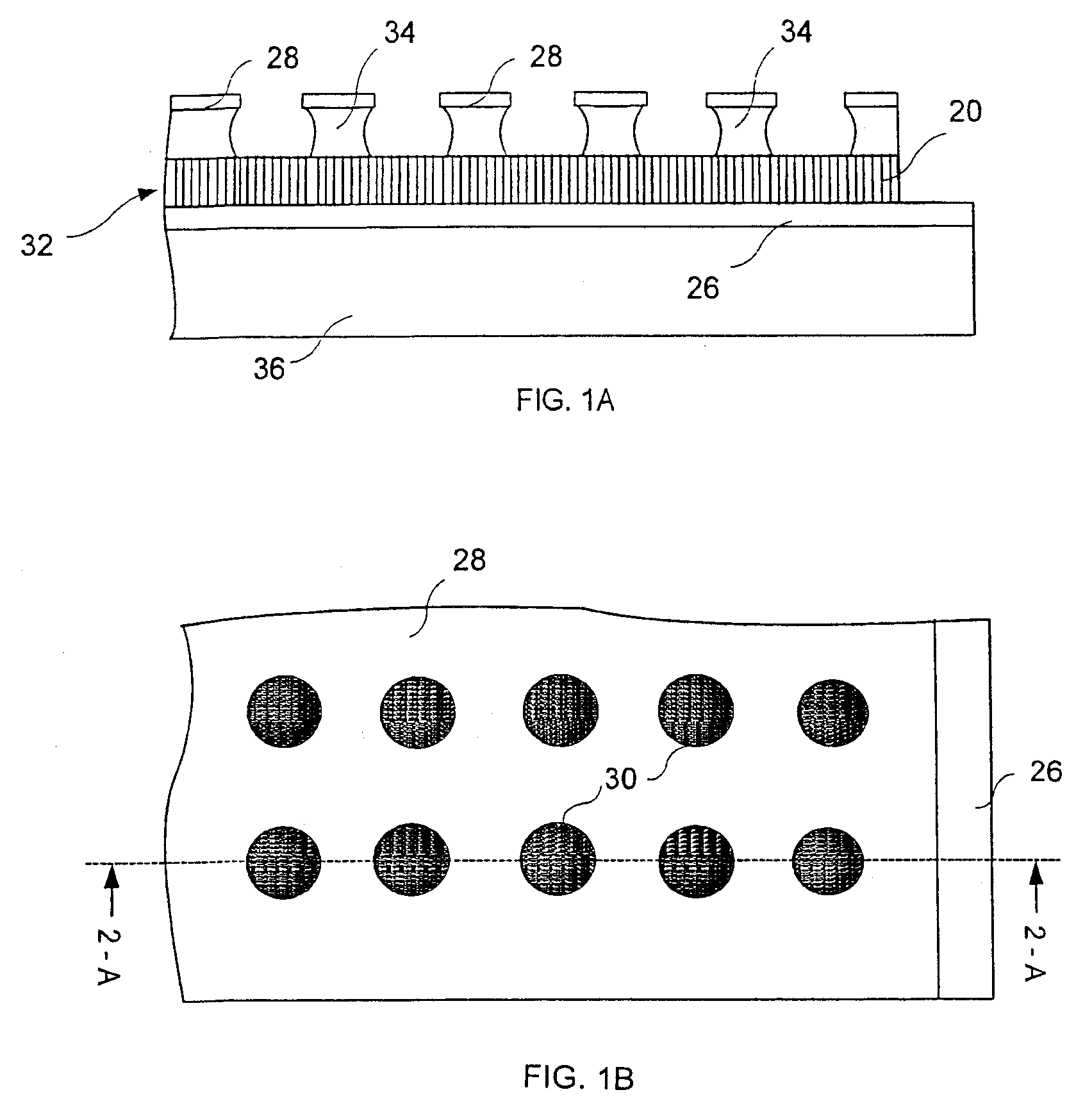

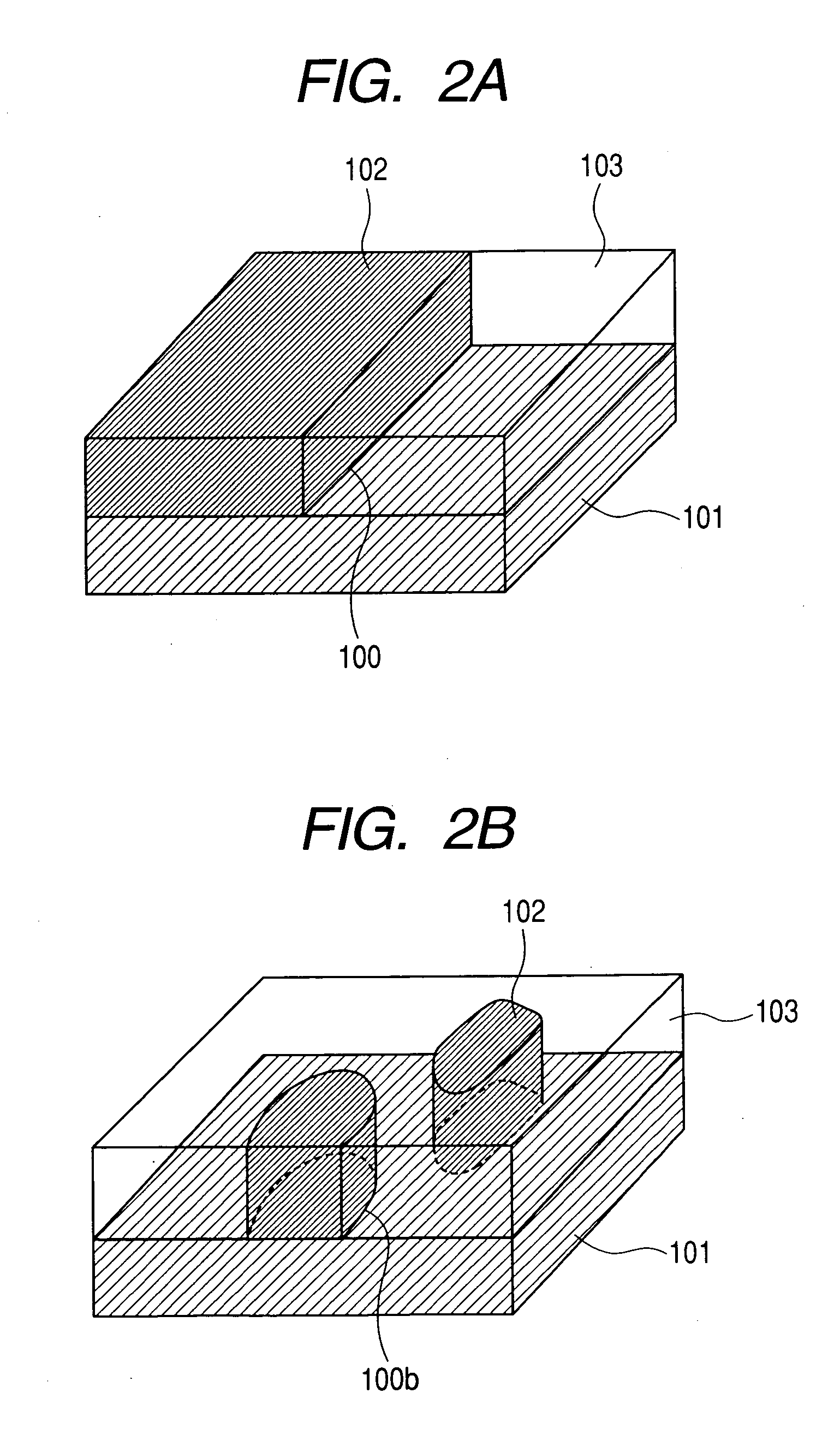

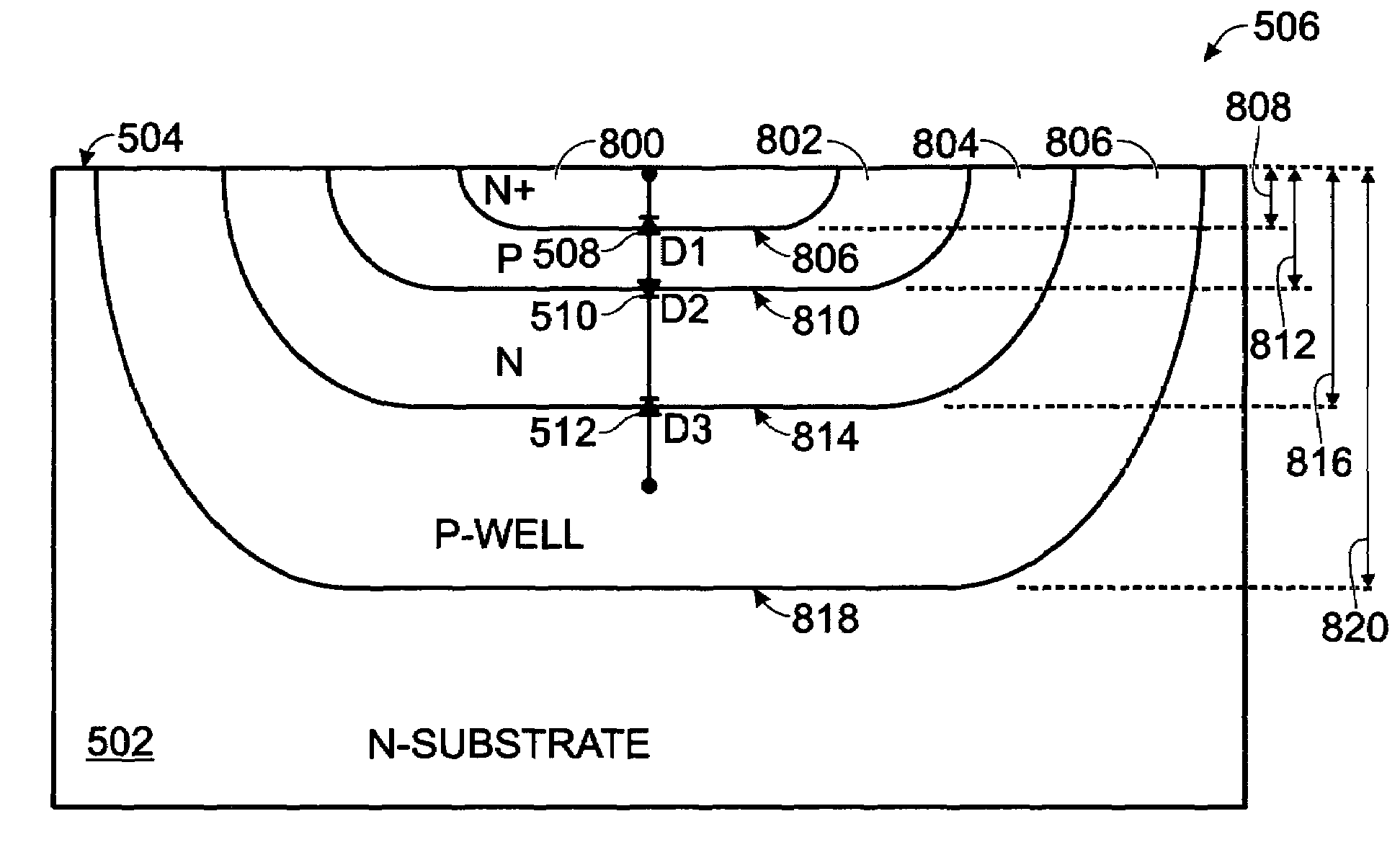

Triple-junction filterless CMOS imager cell

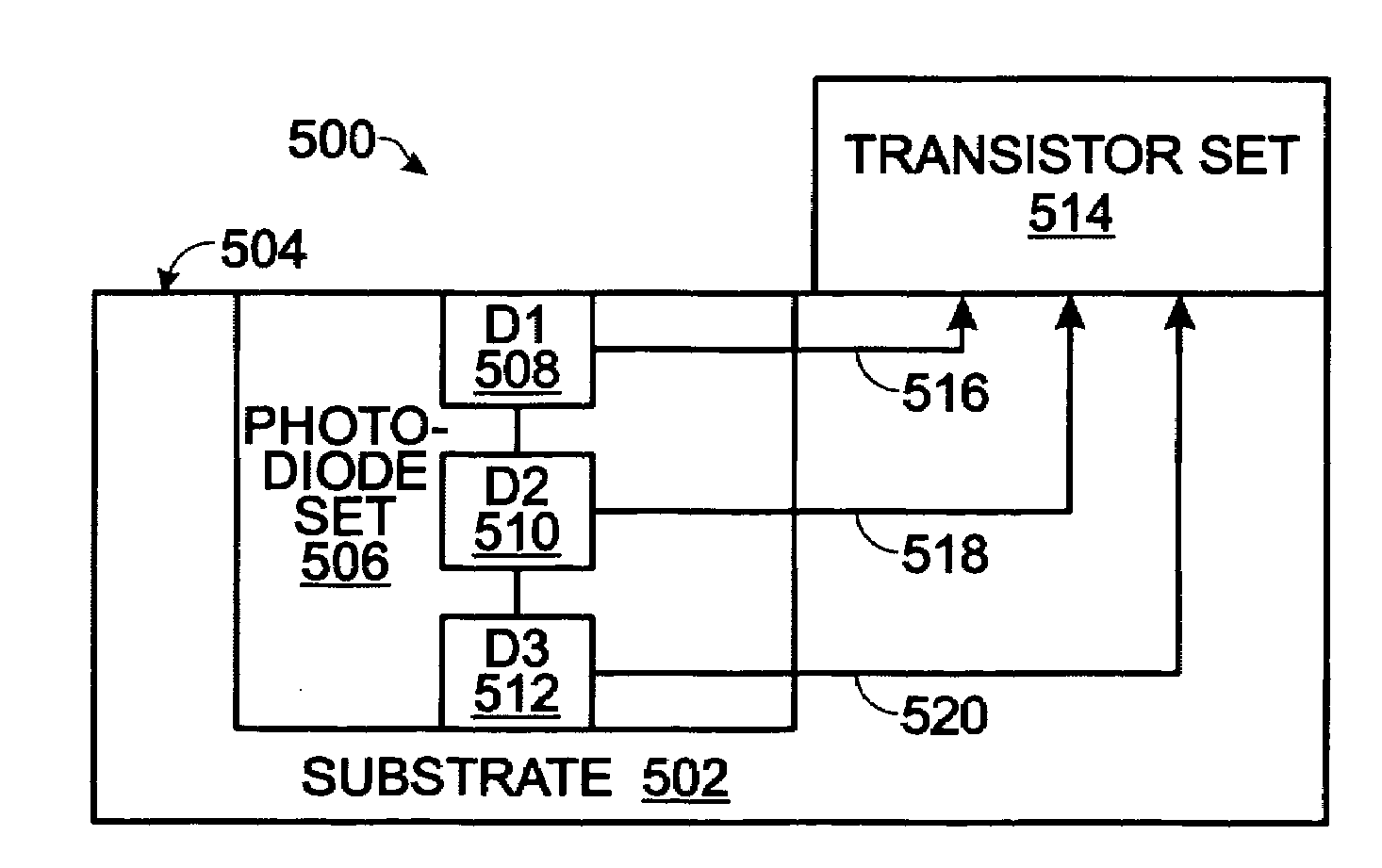

InactiveUS20070218580A1Reduce areaSolid-state devicesSemiconductor/solid-state device manufacturingCMOSTriple junction

A triple-junction complimentary metal-oxide-semiconductor (CMOS) filterless color imager cell is provided. The imager cell is made from a bulk silicon (Si) substrate. A photodiode set including a first, second, and third photodiode are formed as a triple-junction structure in the Si substrate. A transistor set is connected to the photodiode set, and detects an independent output signal for each photodiode. Typically, the transistor set is formed in the top surface of the substrate. For example, the Si substrate may be a p-doped Si substrate, and the photodiode triple-junction structure includes the first photodiode forming a pn junction from an n+-doped region at the Si substrate top surface, to an underlying p-doped region. The second photodiode forms a pn junction from the p-doped region to an underlying n-well, and the third photodiode forms a pn junction from the n-well to the underlying p-doped Si substrate.

Owner:SHARP KK

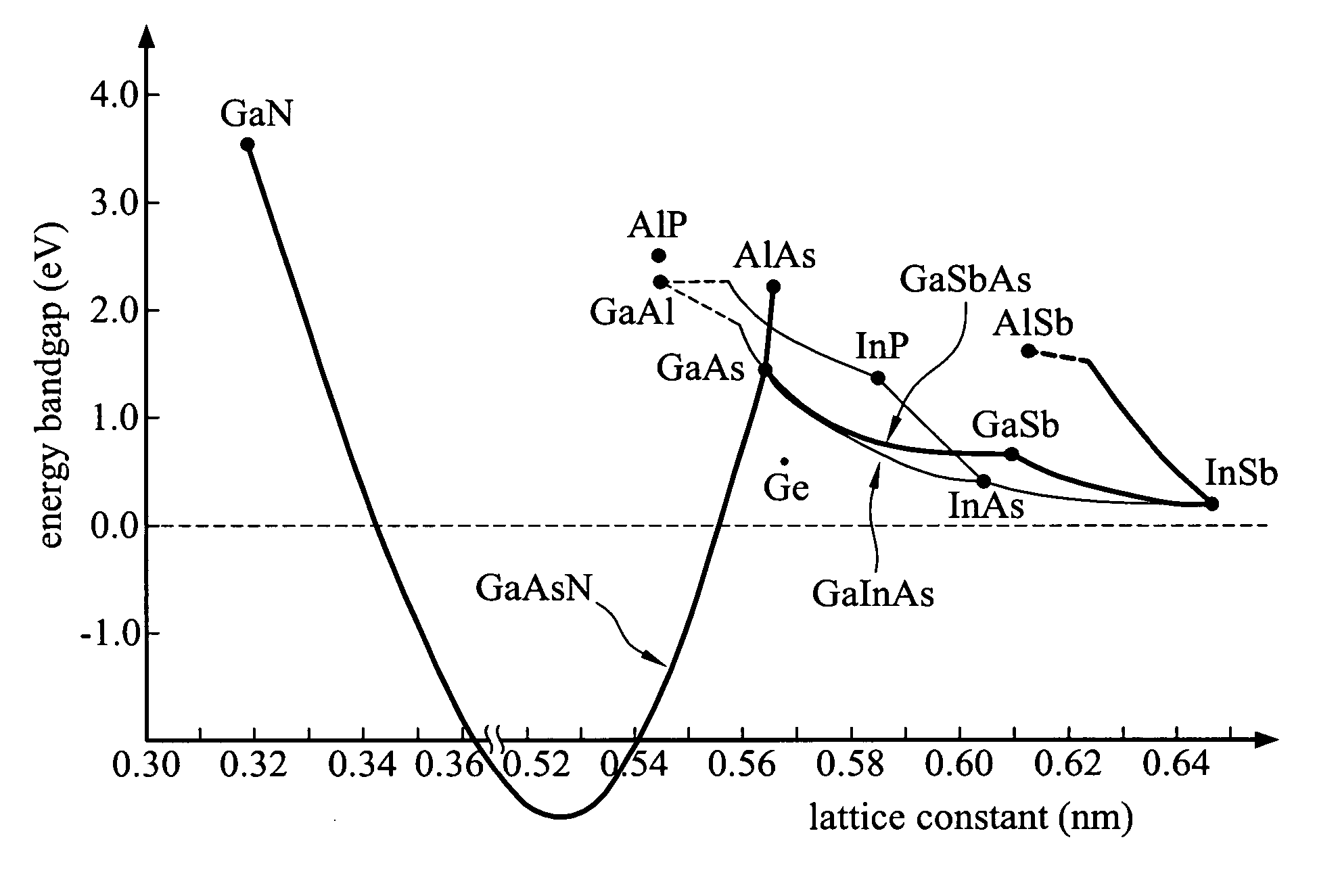

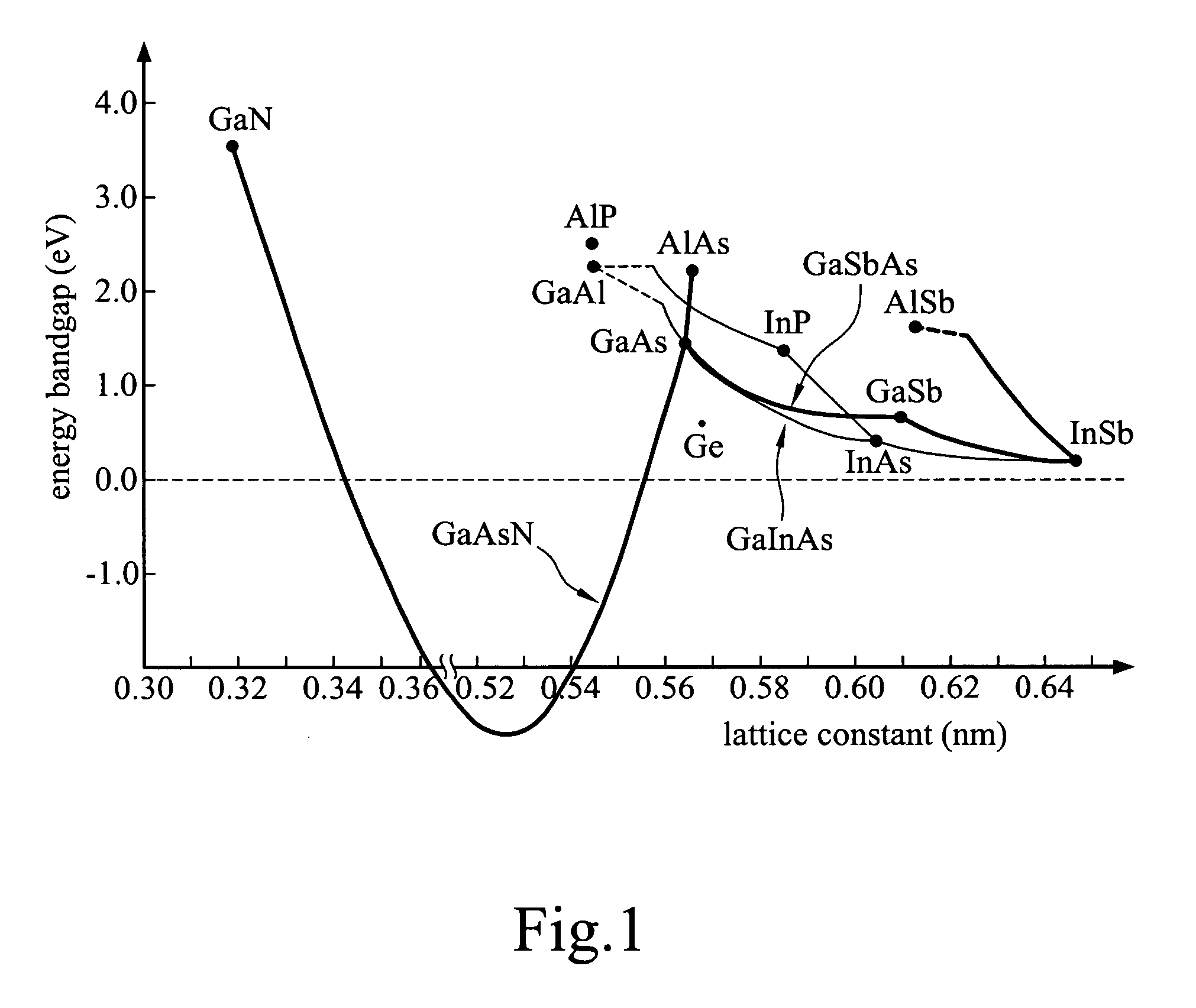

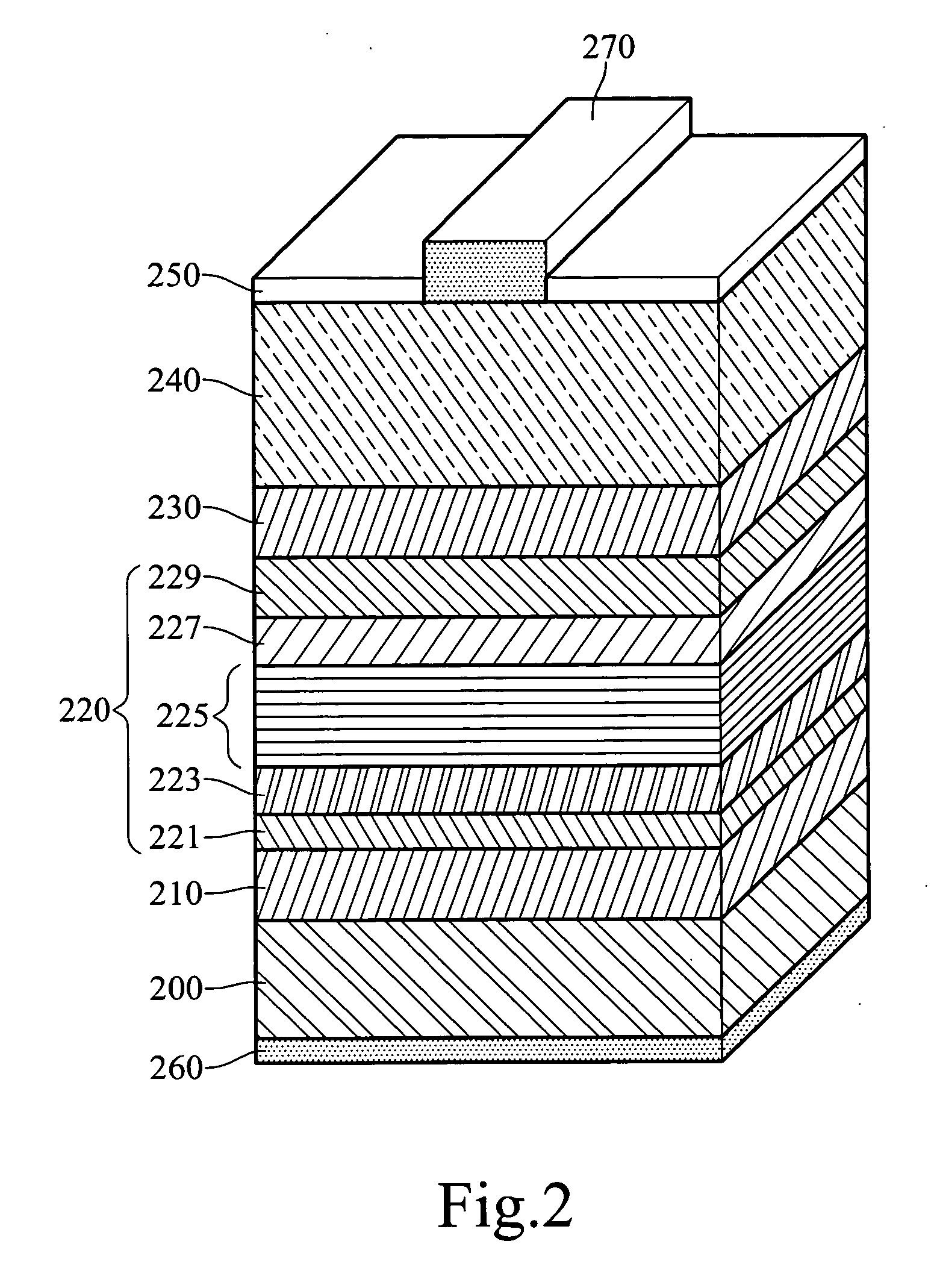

Solar cell with superlattice structure and fabricating method thereof

InactiveUS20070151595A1High carrier mobilityPreferable advantageSemiconductor/solid-state device manufacturingNanoopticsEngineeringCritical thickness

A solar cell with a superlattice structure and a fabricating method thereof are provided, which includes fabricating a superlattice structure of GaAsN / GaInAs, GaAsN / GaSbAs, or GaAsN / GaInSbAs between a base and an emitter of a middle cell of a triple junction solar cell by a strain-compensation technology. The provided solar cell not only decreases crystalline defects and increases the critical thickness of the crystal, but also makes the energy bandgap of GaAsN and GaInAs reach around the energy of 1.0 eV (electron volt). Hence, the absorption region can be raised to around the energy of 1.0 eV to enhance the efficiency of the solar cell.

Owner:IND TECH RES INST +1

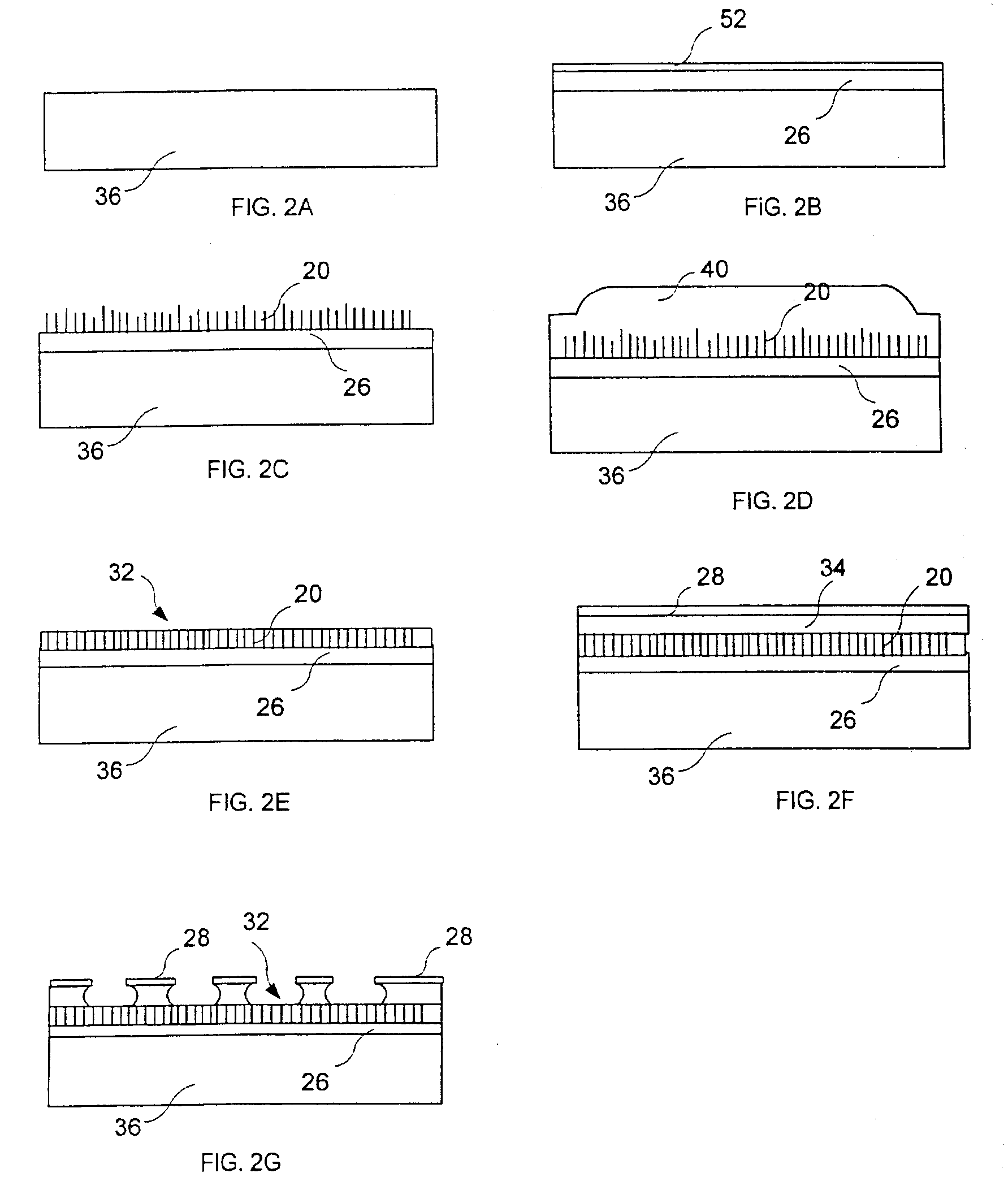

Electron emitting composite based on regulated nano-structures and a cold electron source using the composite

InactiveUS20070003472A1Low modulation voltageHigh aspect ratioElectric discharge tubesNanoinformaticsElectron sourceNanostructure

A field emission electron source includes a substrate, a first conductive electrode terminated to provide electrons, an emitting composite layer for emitting electrons, and a second electrode insulated from the emitter layer and terminated to extract electrons through vacuum space. The emitting composite layer lies between and parallel to the said first and the second electrodes, and comprises nano-structures embedded in a solid matrix. One end of the nano-structures is truncated and exposed at the surface of the emitter layer so that both the length and the apex of the nano-structure are regulated and the exposed nano-tips are kept substantially the same distance from the gate electrode. The embedding material is chosen to form triple junctions with the exposed tip to further enhance the field.

Owner:TOLT ZHIDAN L

Fire resistant laminate and photovoltaic module incorporating the fire resistant laminate

InactiveUS20060201545A1Reduce manufacturing costSufficient transparencyPhotovoltaic supportsPV power plantsAmorphous siliconEngineering

The present invention discloses a fire resistant laminate and incorporating the laminate into an encapsulant for a photovoltaic module that may be used in a photovoltaic building material. More particularly, the present invention relates to fire resistant encapsulant that may be used in a triple junction amorphous silicon photovoltaic module that is fire resistant on a wide variety of buildings roofs, including residential housing, and that is flexible and lightweight. A fire resistant additive, such as solid glass spheres, may be added to encapsulant material to produce a fire resistant, cut resistant, lightweight photovoltaic device.

Owner:ENERGY CONVERSION DEVICES INC

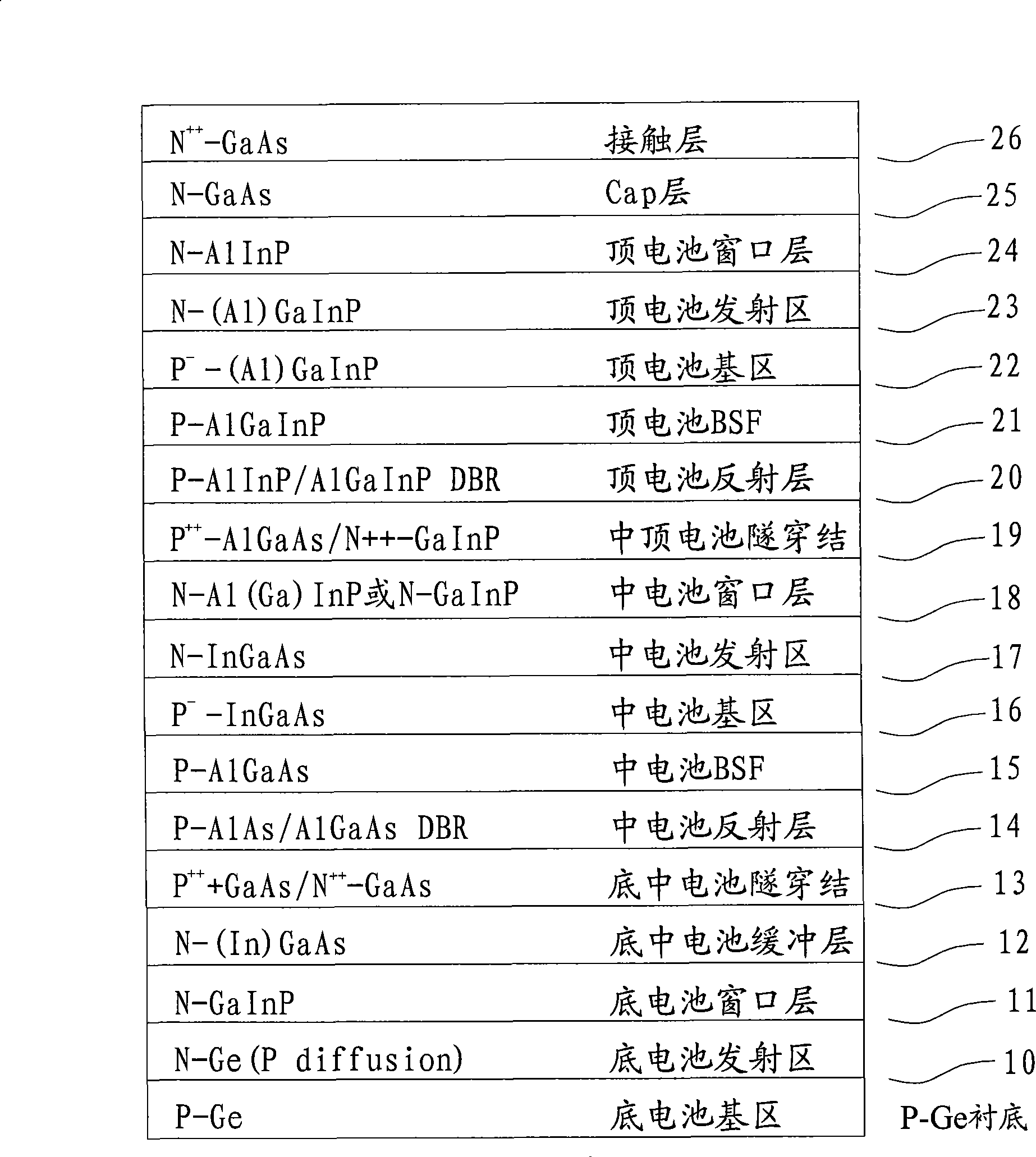

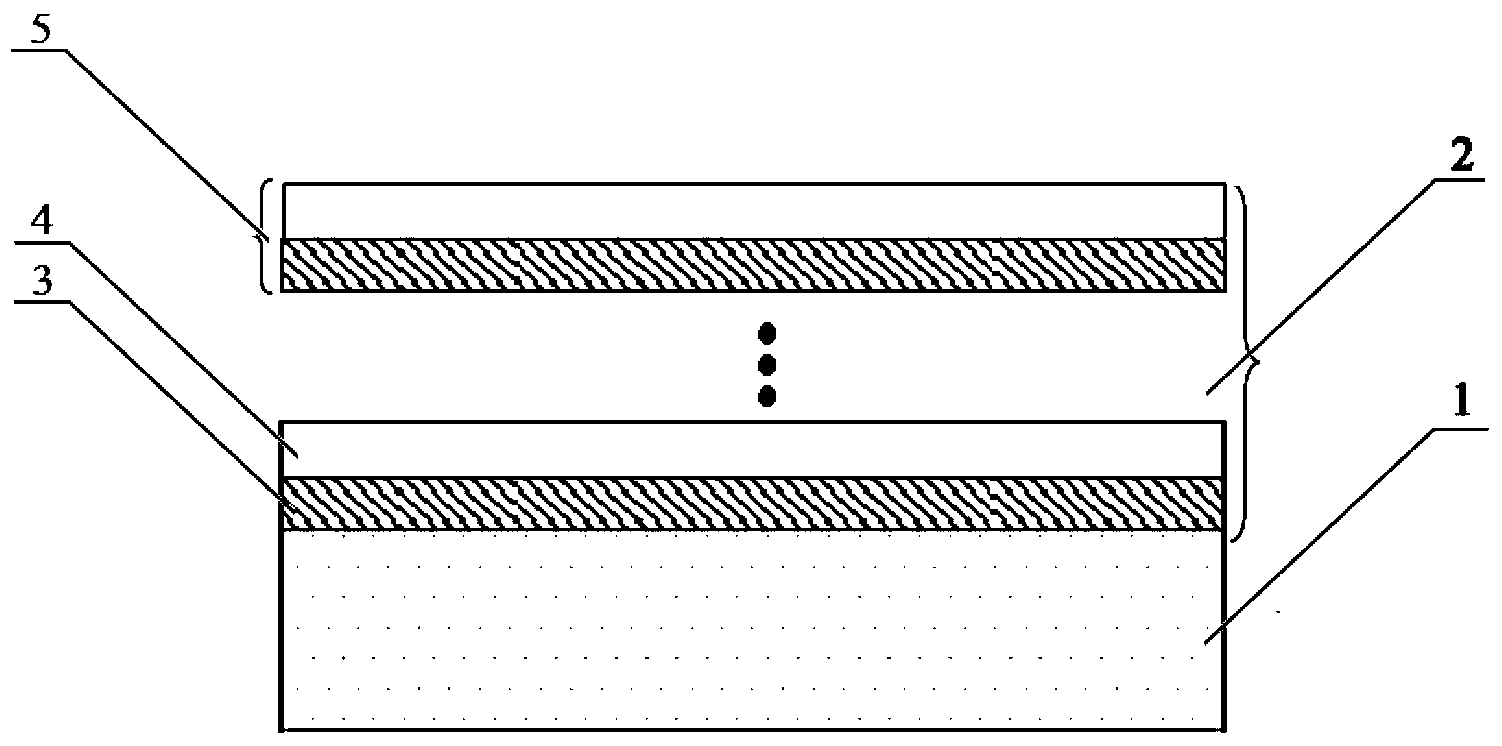

Three connection solar cell having reflection layer and manufacturing method therefor

ActiveCN101388419AImprove absorption efficiencyReduce thicknessFinal product manufacturePhotovoltaic energy generationSemiconductor materialsIntermediate cell

The invention discloses a triple-junction solar cell with a reflecting layer and a production method thereof, wherein a semiconductor material layer of the triple-junction solar cell which comprises two sets of Bragg reflecting layers (DBR) is grown on a P-Ge substrata, and the two sets of Bragg reflecting layers (DBR) are respectively a set of AlInP / AlGaInP top cell reflecting layer which is used to reflect shortwave photons and a set of AlAs / AlGaAs intermediate cell reflecting layer which is used to reflect intermediate-wave photons. The structure can reduce the thickness of the cell, reduces the free path of non-equilibrium carriers, and increases the efficiency of photo-electronic conversion.

Owner:XIAMEN CHANGELIGHT CO LTD

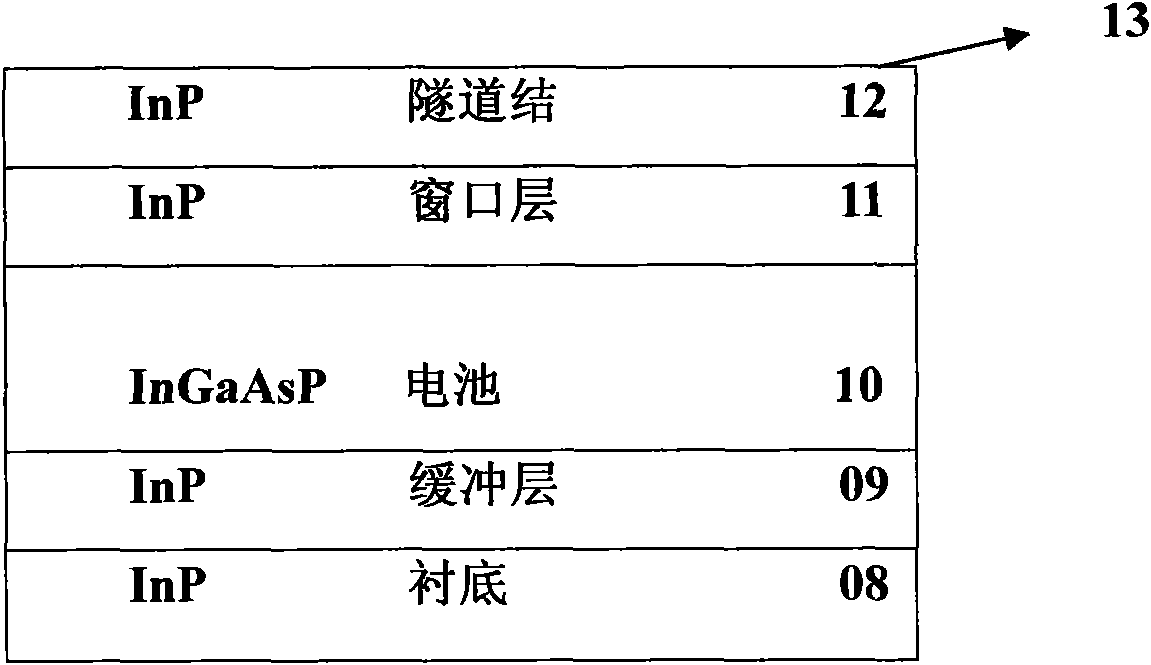

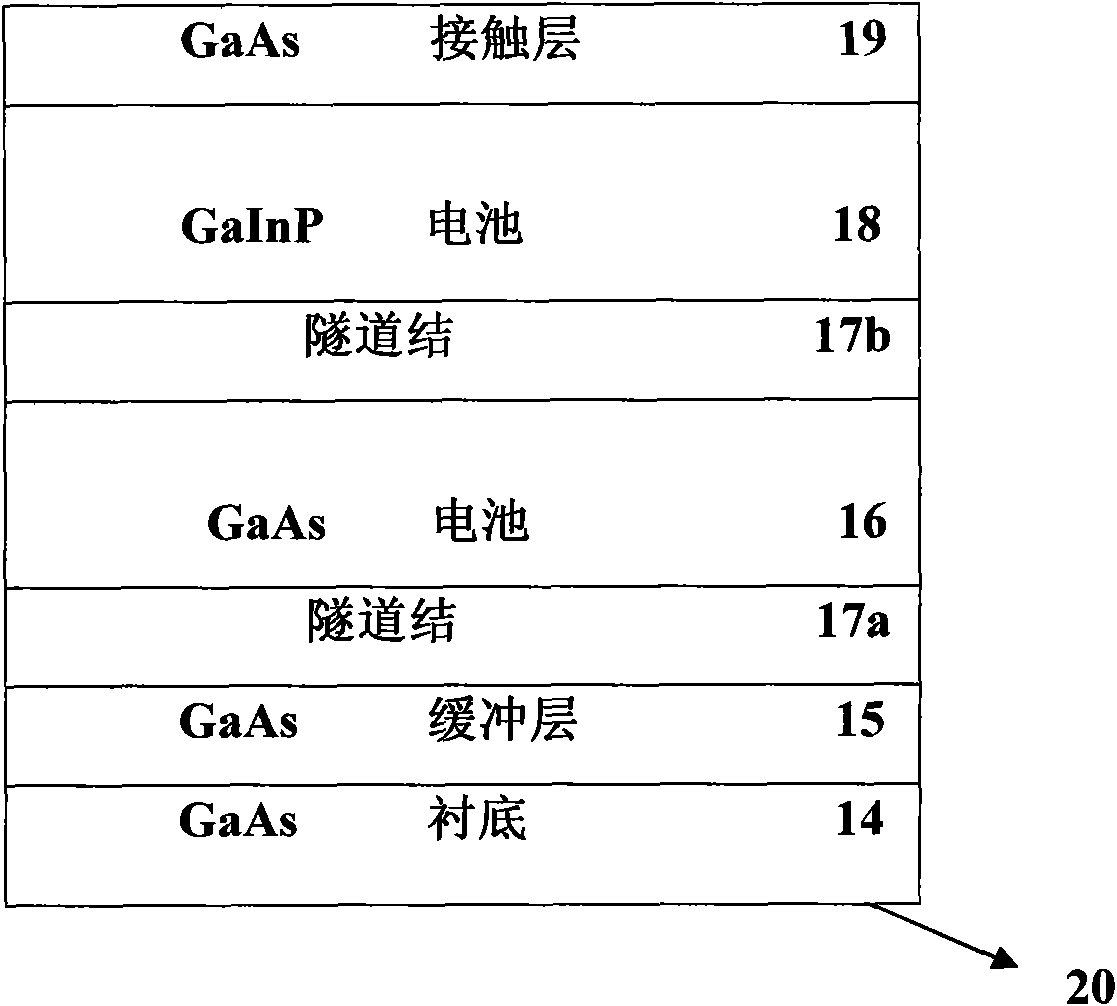

Wafer-bonding-based triple-junction solar cell and preparation method thereof

InactiveCN102184980AImprove efficiencyReduce lossesFinal product manufacturePhotovoltaic energy generationThinningWafer bonding

The invention relates to a wafer-bonding-based triple-junction solar cell and a preparation method thereof. The solar cell comprises a GaInP / GaAs double-junction cell and an InGaAsP single-junction cell of which the lattices are matched with each other, wherein the two cells are connected in series in a way of wafer bonding. The preparation method comprises the following steps of: sequentially growing and forming the GaInP / GaAs double-junction cell and the InGaAsP single-junction cell by a metal organic chemical vapor deposition (MOCVD) method and the like; thinning, polishing and cleaning the bonding face of the GaInP / GaAs double-junction cell, and bonding the GaInP / GaAs double-junction cell with the InGaAsP cell; and making an upper electrode and a lower electrode respectively form the target product. A band gap combination of 1.90eV, 1.42eV and 1.00eV can be formed; the growing difficulty of materials is reduced; solar spectrum is fully used; current mismatch between subcells and heat loss in a photoelectric conversion process are reduced; the internal quantum efficiency of a 1.00eV cell is improved at the same time; and then the cell efficiency is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

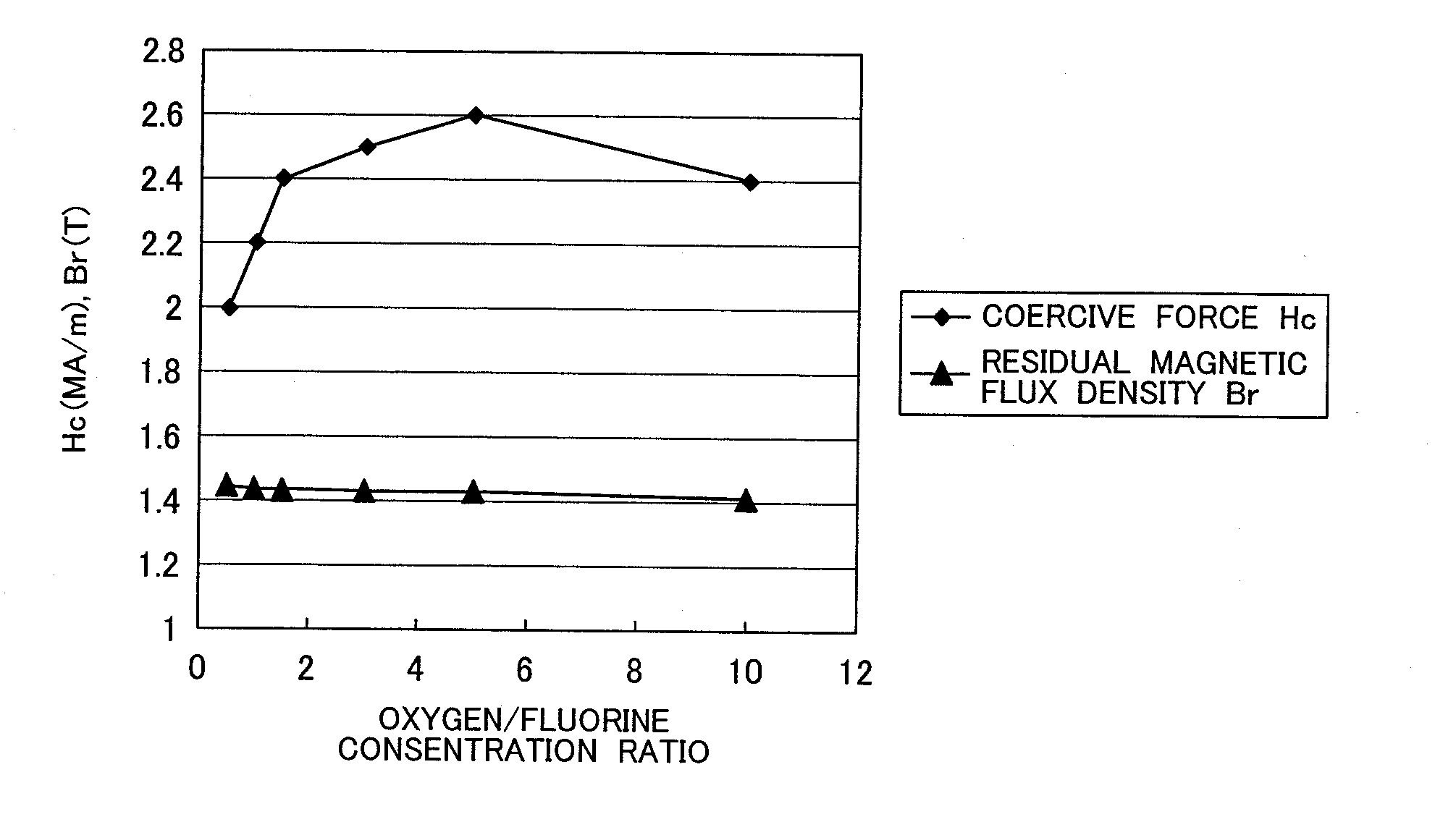

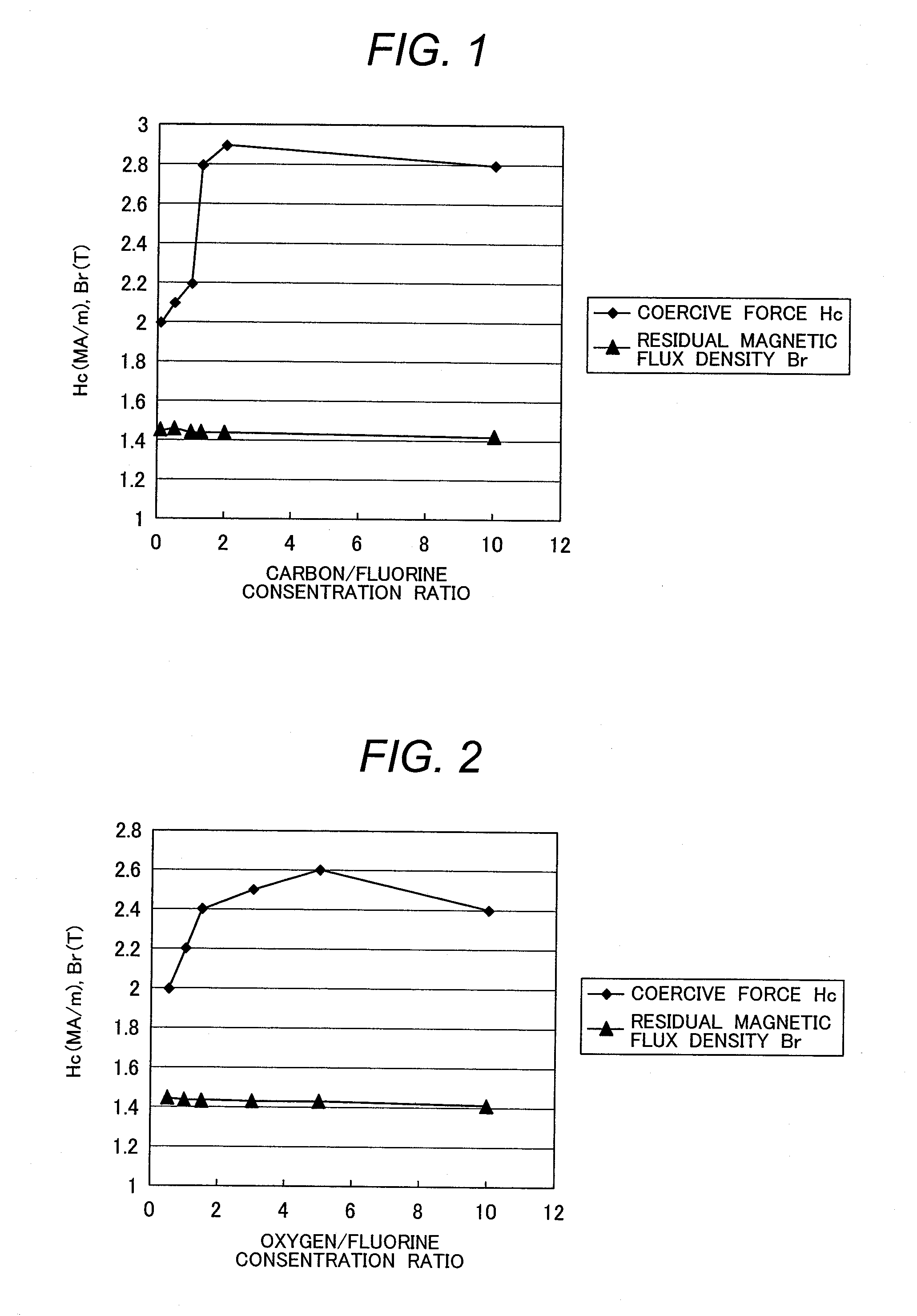

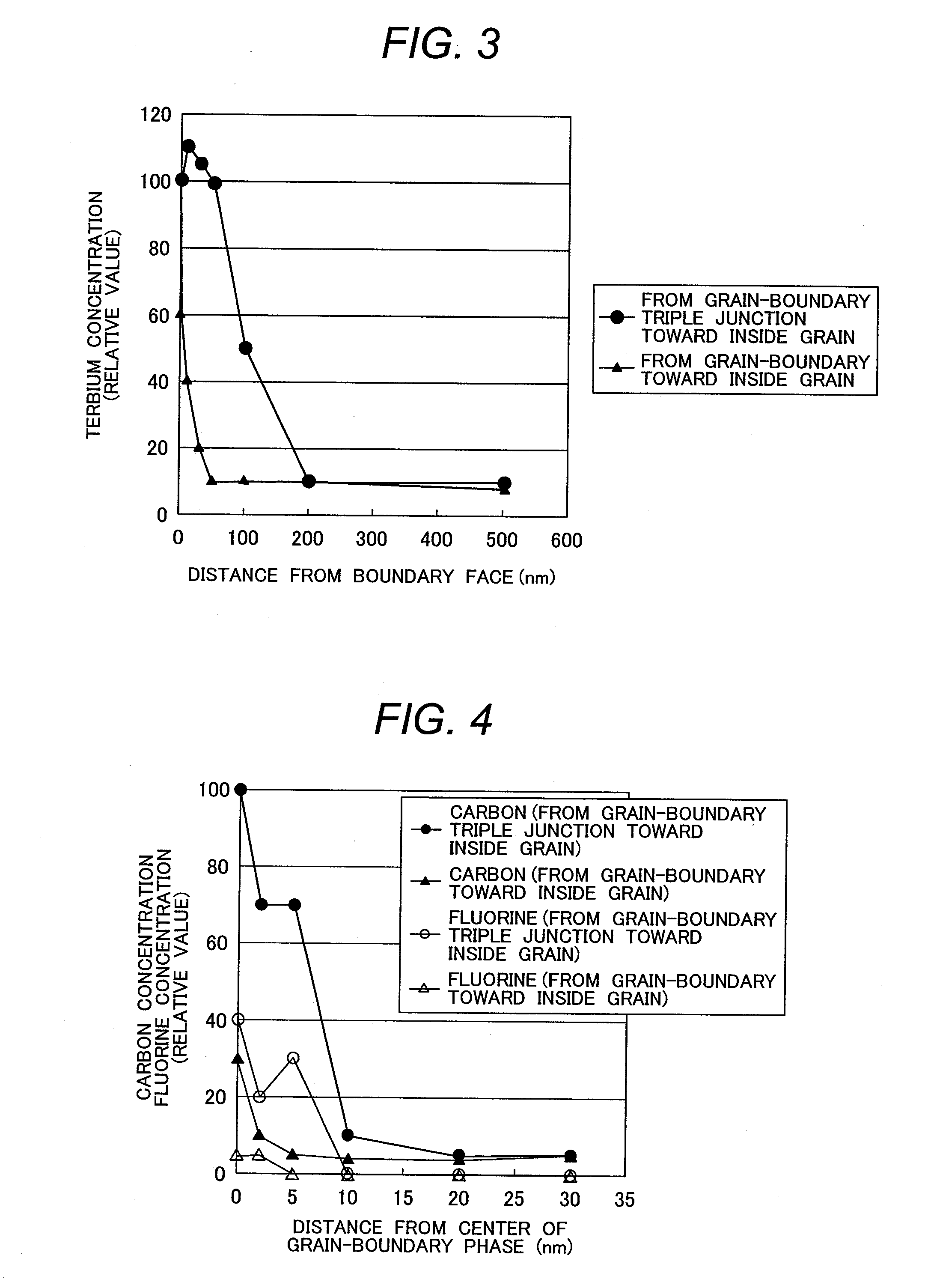

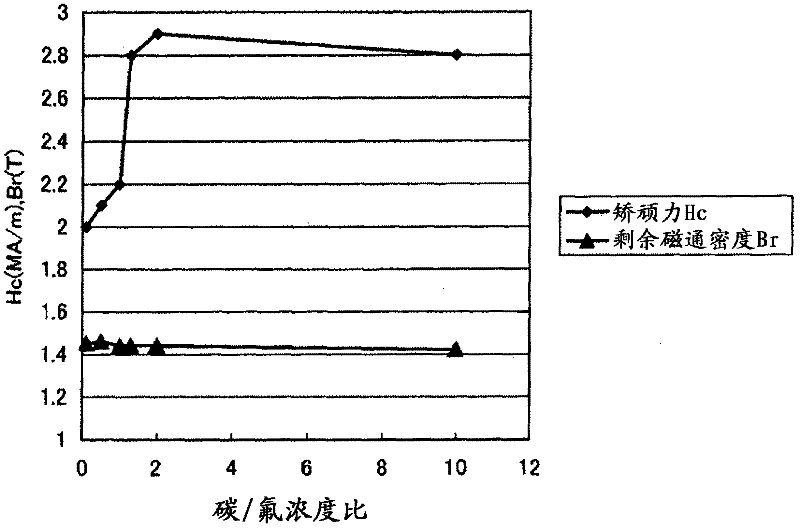

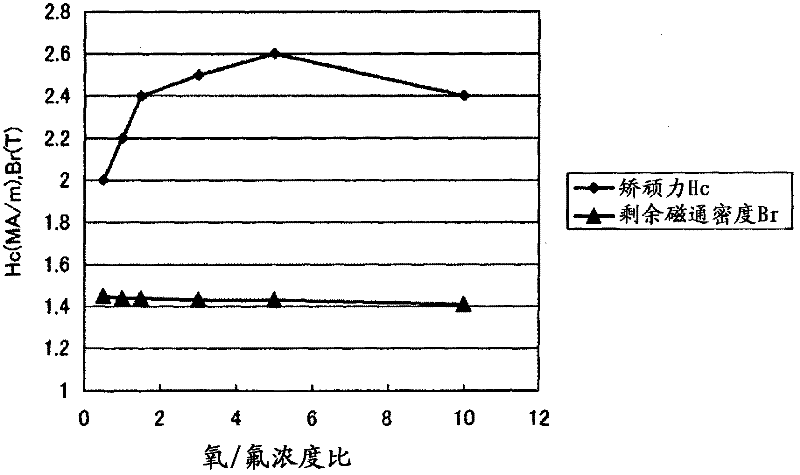

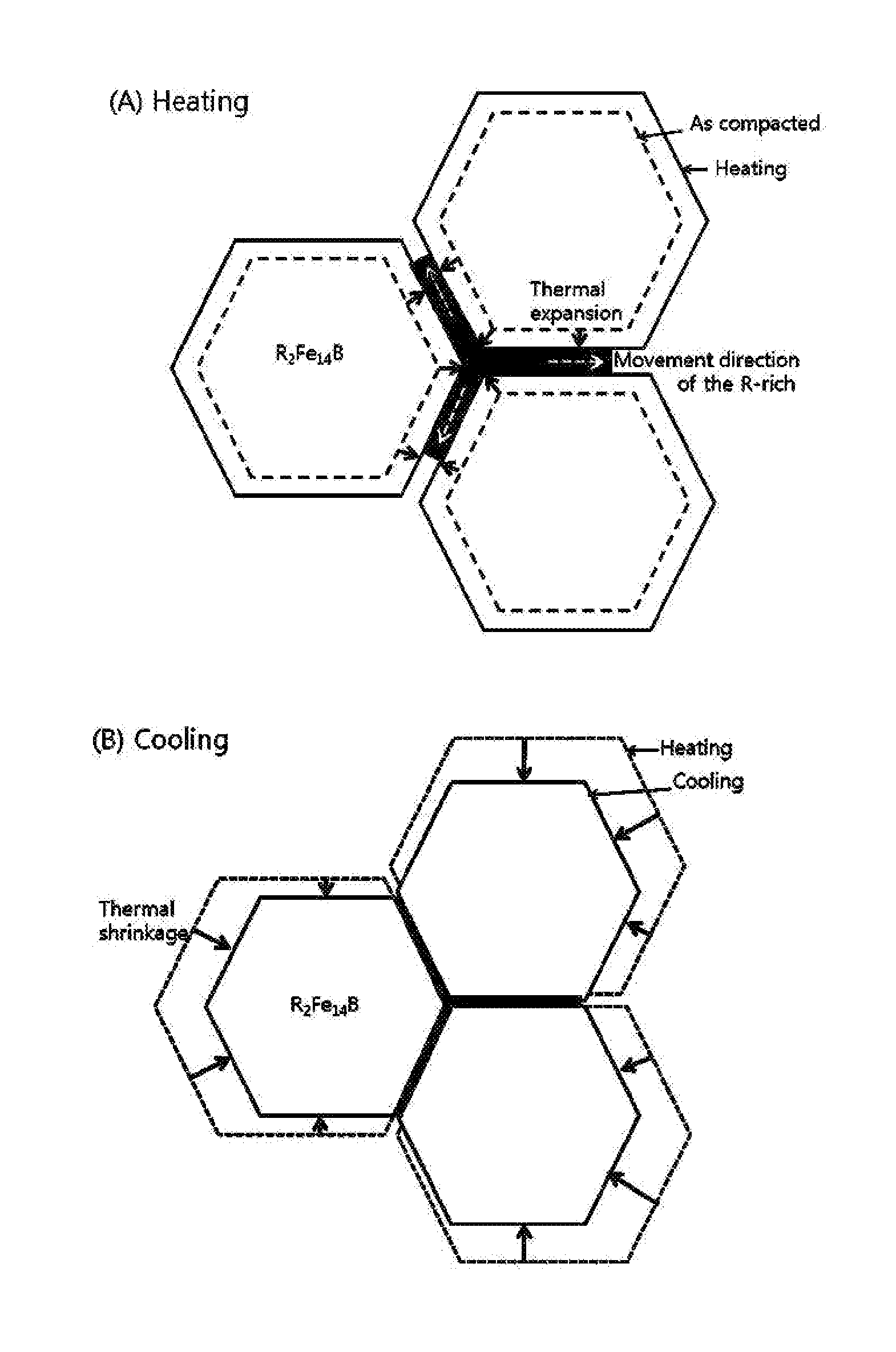

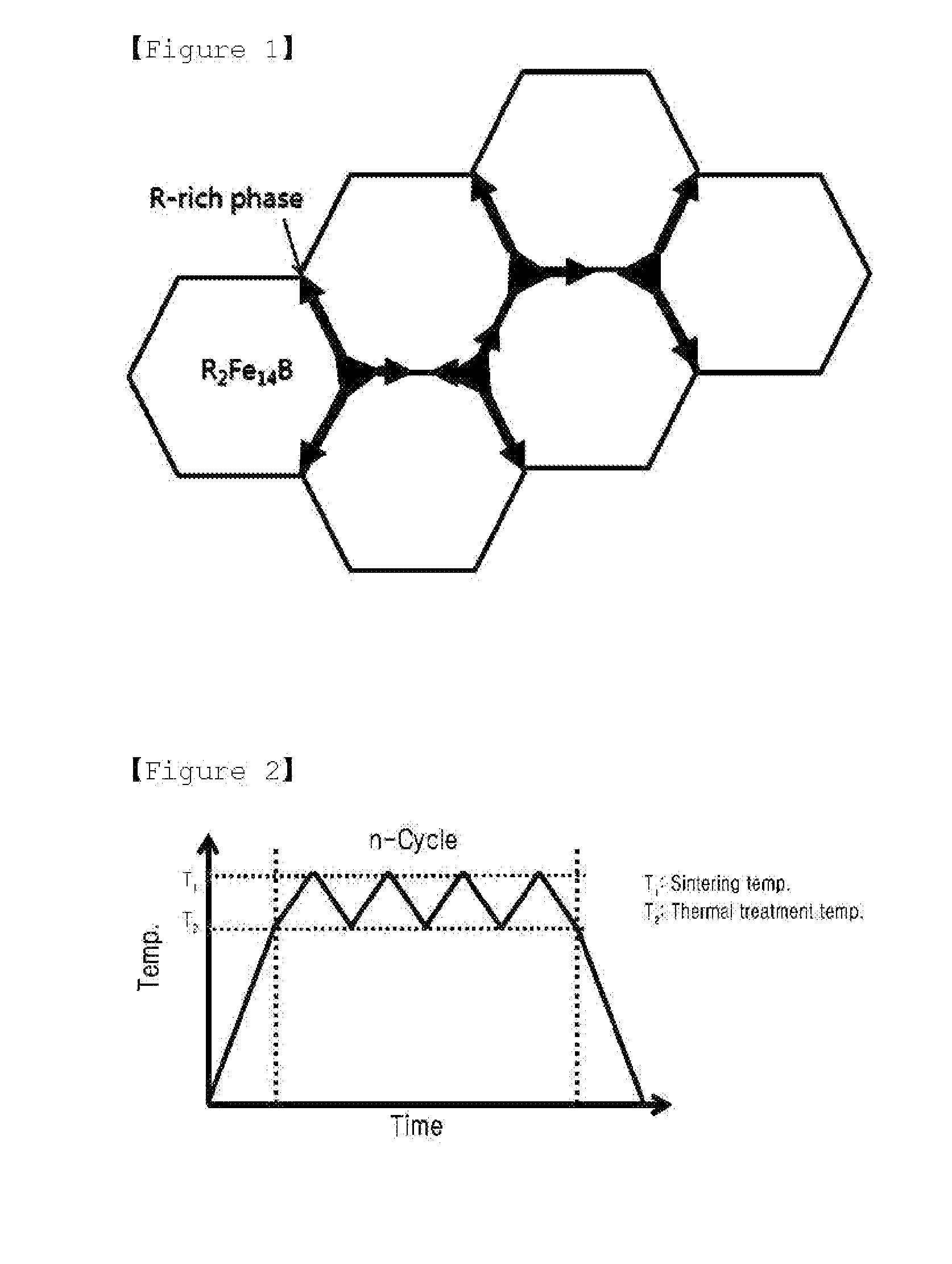

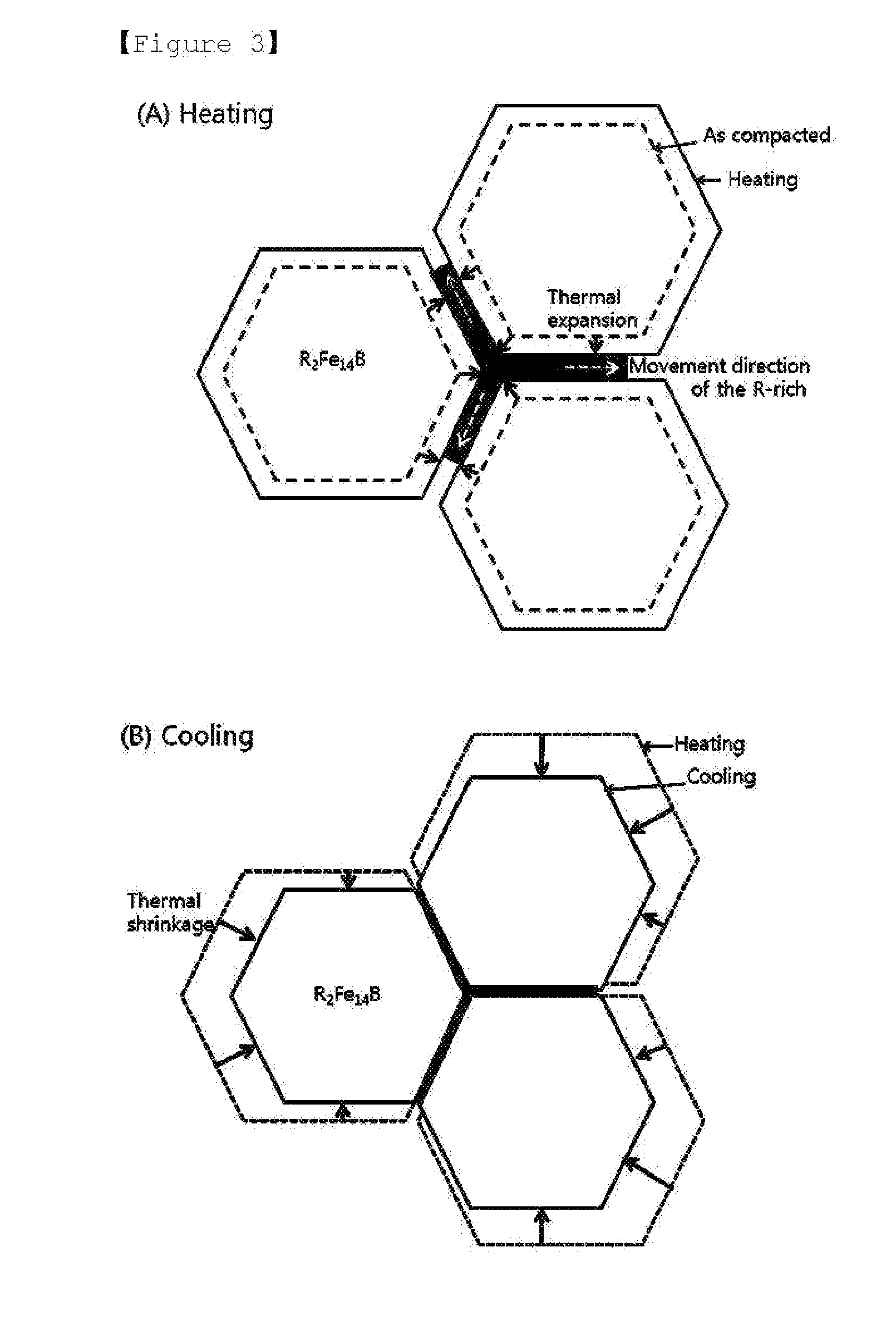

Sintered magnet and rotating electric machine using same

InactiveUS20120025651A1Low heat treatment temperatureIncreasing the thicknessSynchronous machine detailsInorganic material magnetismRare-earth elementPrill

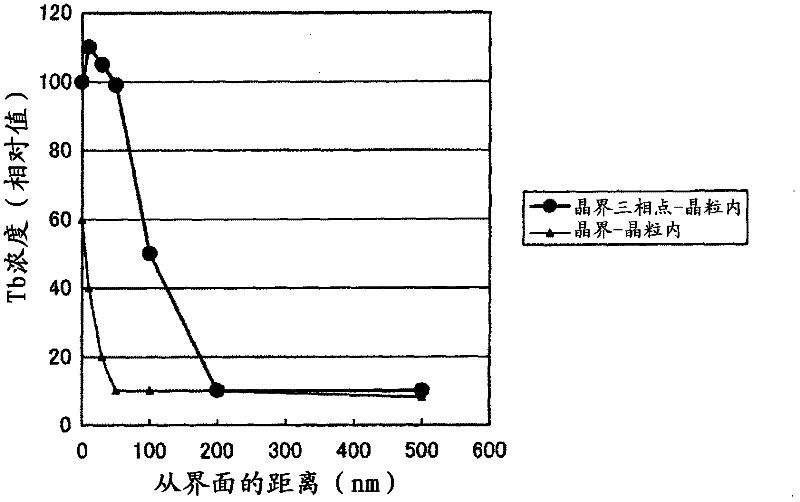

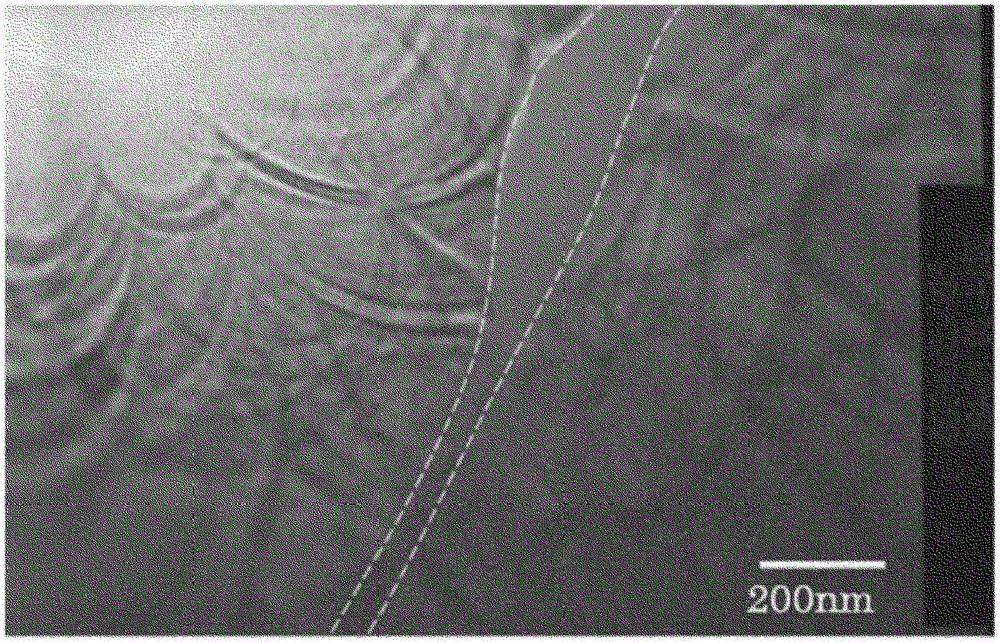

A sintered magnet according to the present invention is a sintered magnet configured from a magnetic powder grain having Nd2Fe14B as a main component, in which: fluorine, a heavy rare earth element, oxygen, and carbon are segregated in part of grain-boundary regions of said sintered magnetic powder grain; concentration of the carbon is higher than concentration of the fluorine at a grain-boundary triple junction of the grain-boundary region; and concentration of the heavy rare earth element decreases from said grain-boundary triple junction toward an inside of said magnetic powder grain.

Owner:HITACHI LTD

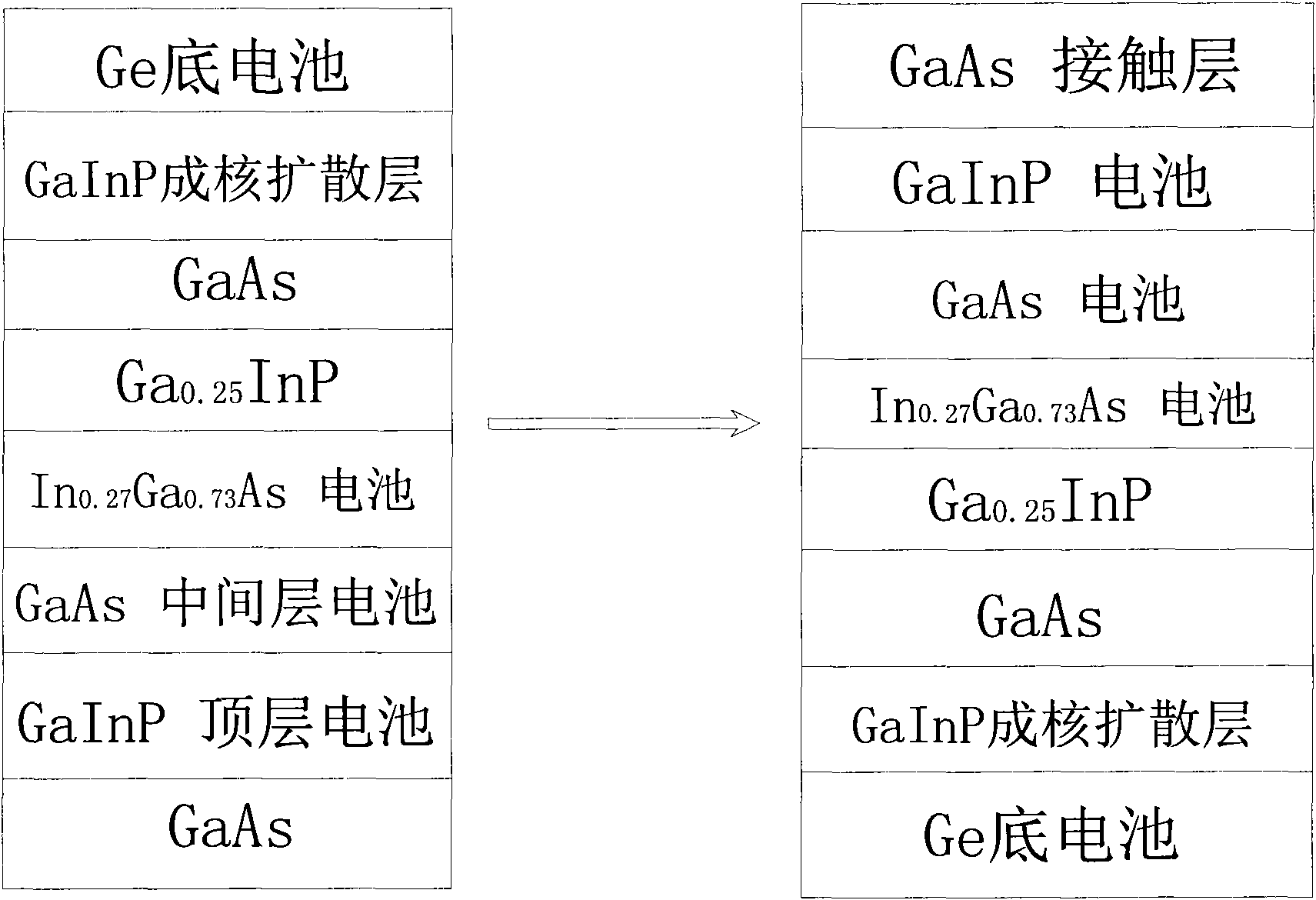

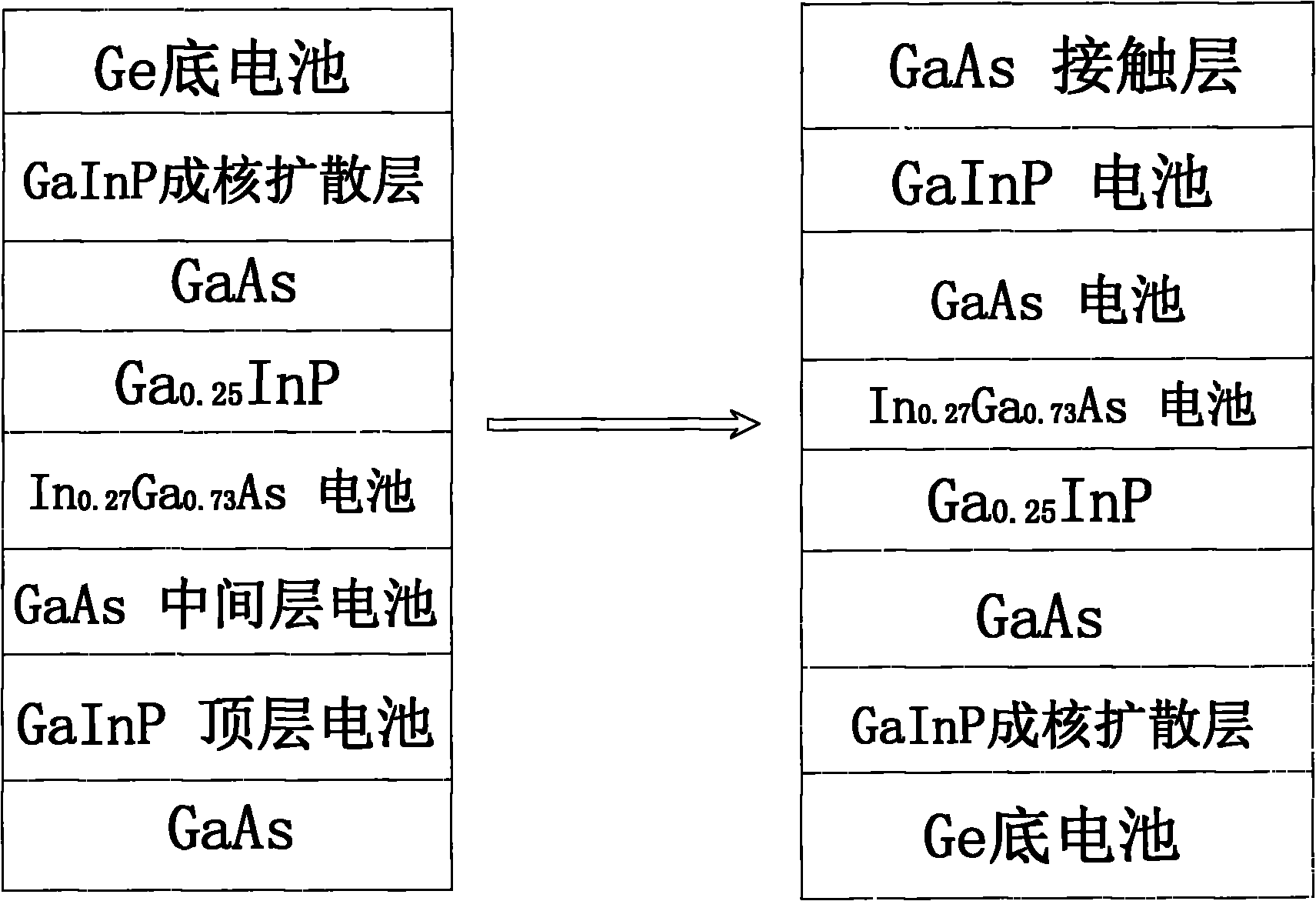

Method for manufacturing quadri-junction GaInP/GaAs/InGaAs/Ge solar cells

InactiveCN101859813AReduce lossAchieve absorptionPhotovoltaic energy generationSemiconductor devicesLattice mismatchEngineering

The invention discloses a method for manufacturing quadri-junction GaInP / GaAs / InGaAs / Ge solar cells. In the method, by adopting a wafer bonding method, triple-junction GaInP / GaAs / InGaA solar cells based on inverted structural growth are integrated with a Ge solar cell uniwafer; and a Ge cell is fully utilized to serve as the basic cell of the four cells and a supporting substrate, thus achieving quadri-junction solar cells with the band-gap energy of 1.9 / 1.4 / 1.0 / 0.67eV, realizing absorption and energy conversion of a solar full-spectrum to a larger extent and obtaining the conversion efficiency above 45%. The method lowers high cost caused by a plurality of different substrates adopted in a mechanical cascade solar cell system as well as complicated optical system and optical loss in an optical integrated battery; and meanwhile the method effectively solves the problem of lattice mismatch of a growth uniwafer quadri-junction cascade semiconductor solar cell material, achieves high voltage and low current output, and lowers resistance consumption in the high-power concentrator cell.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

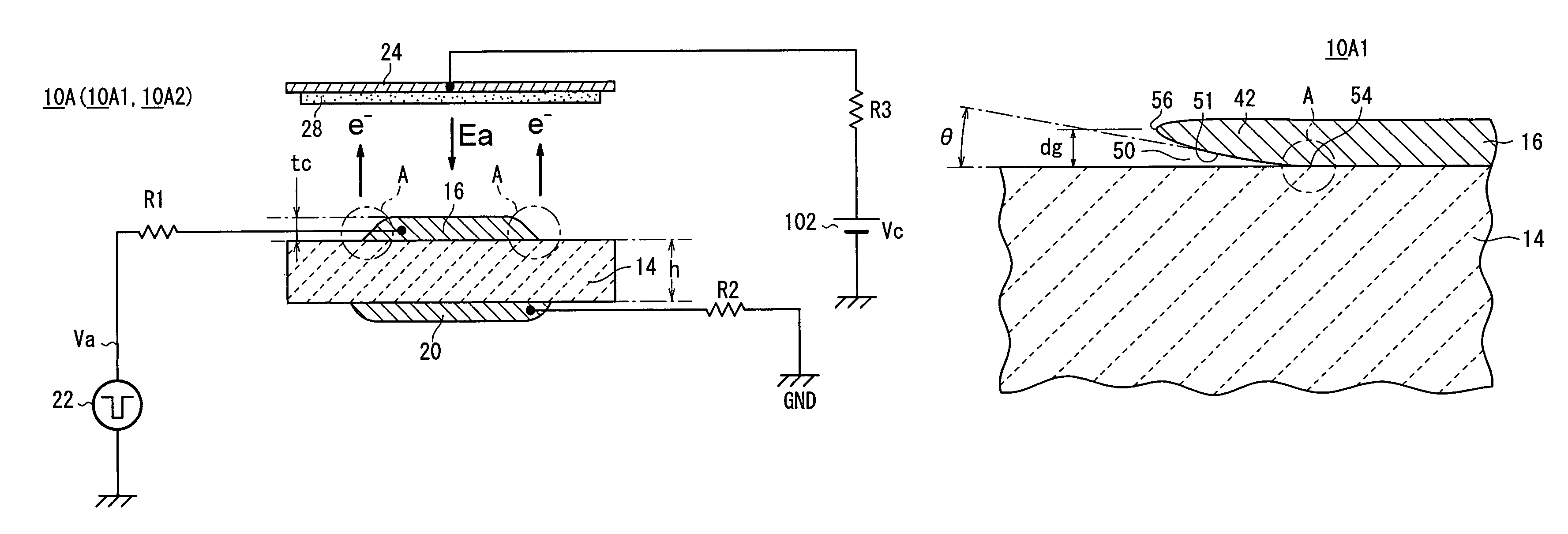

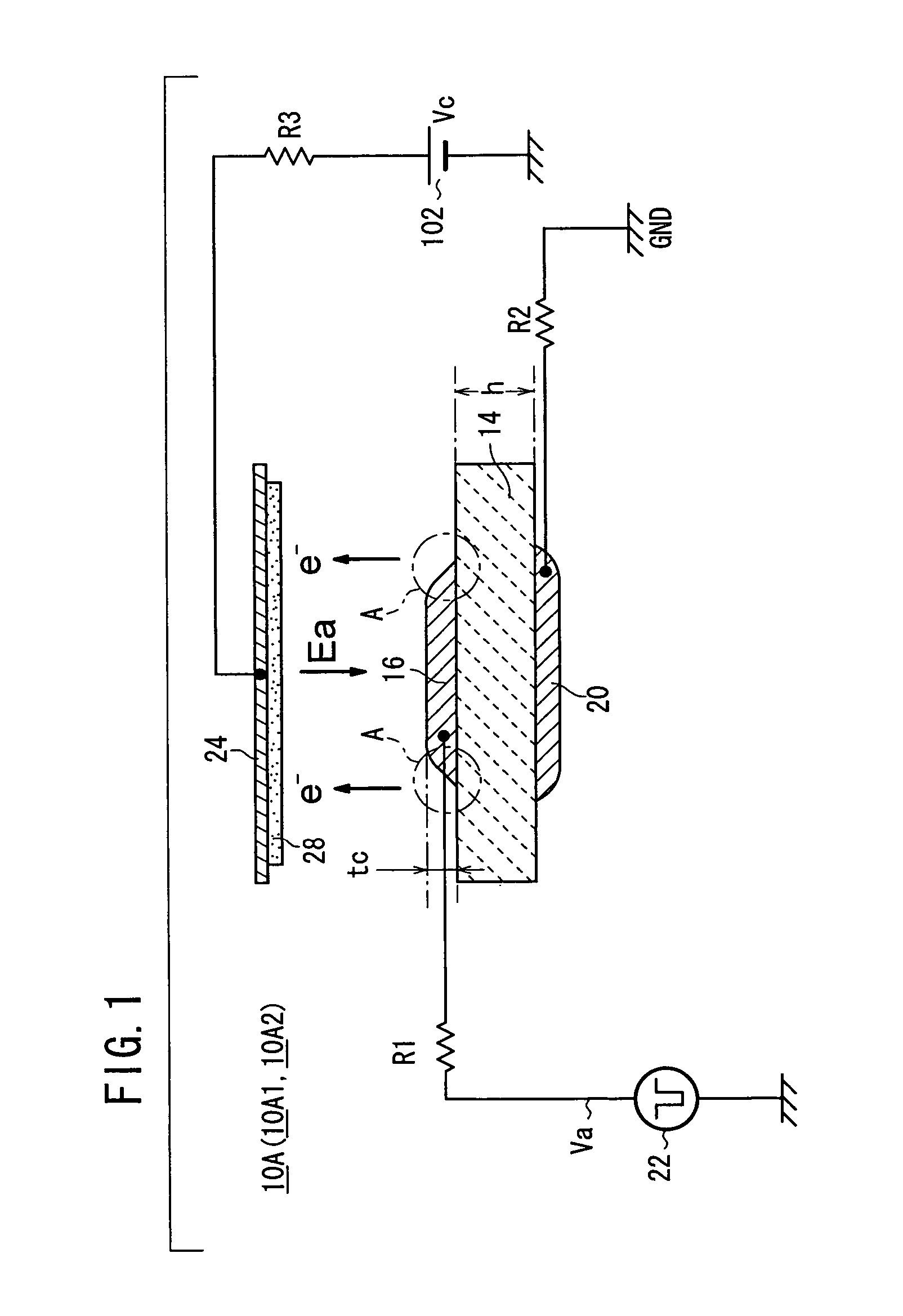

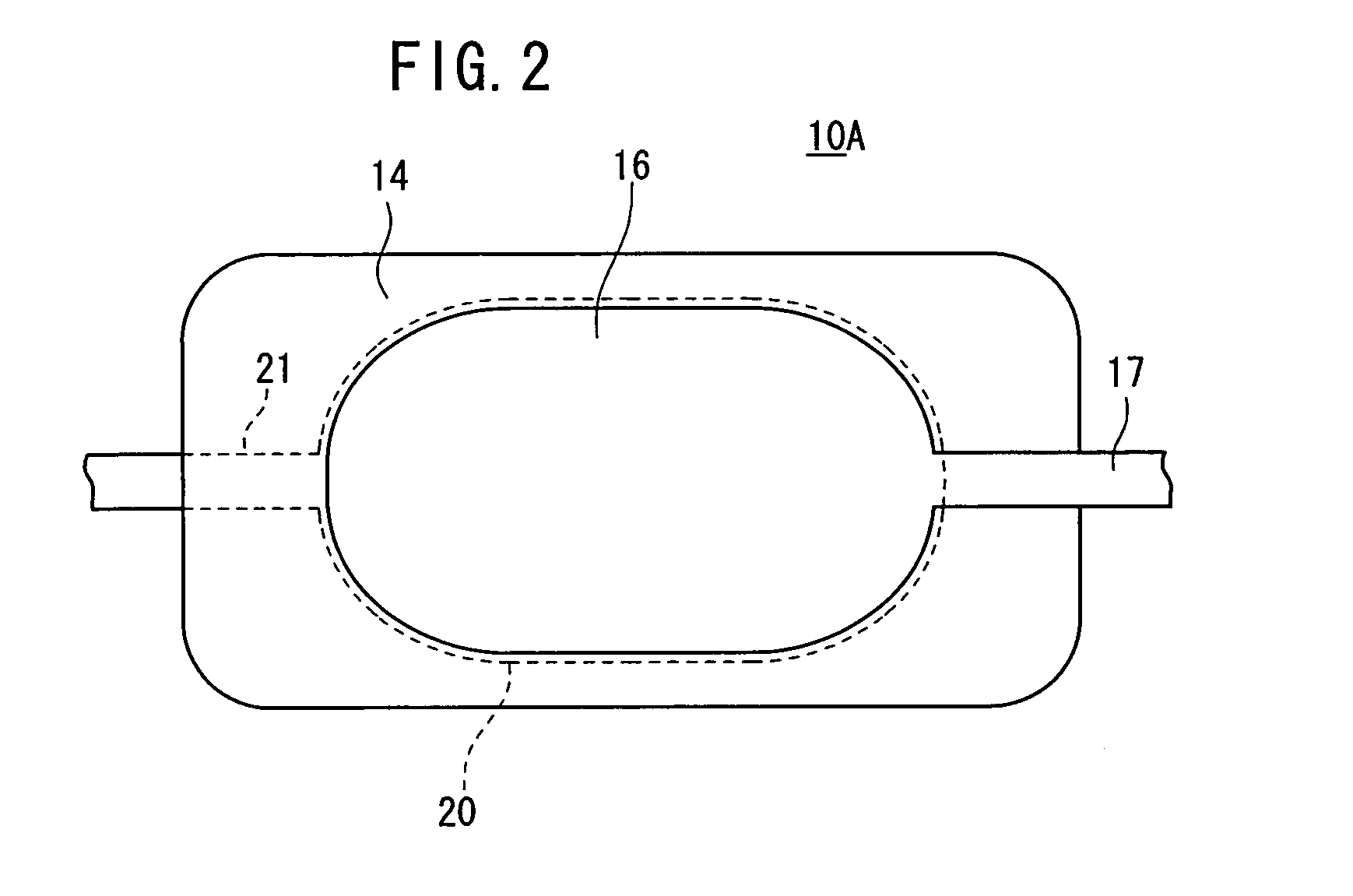

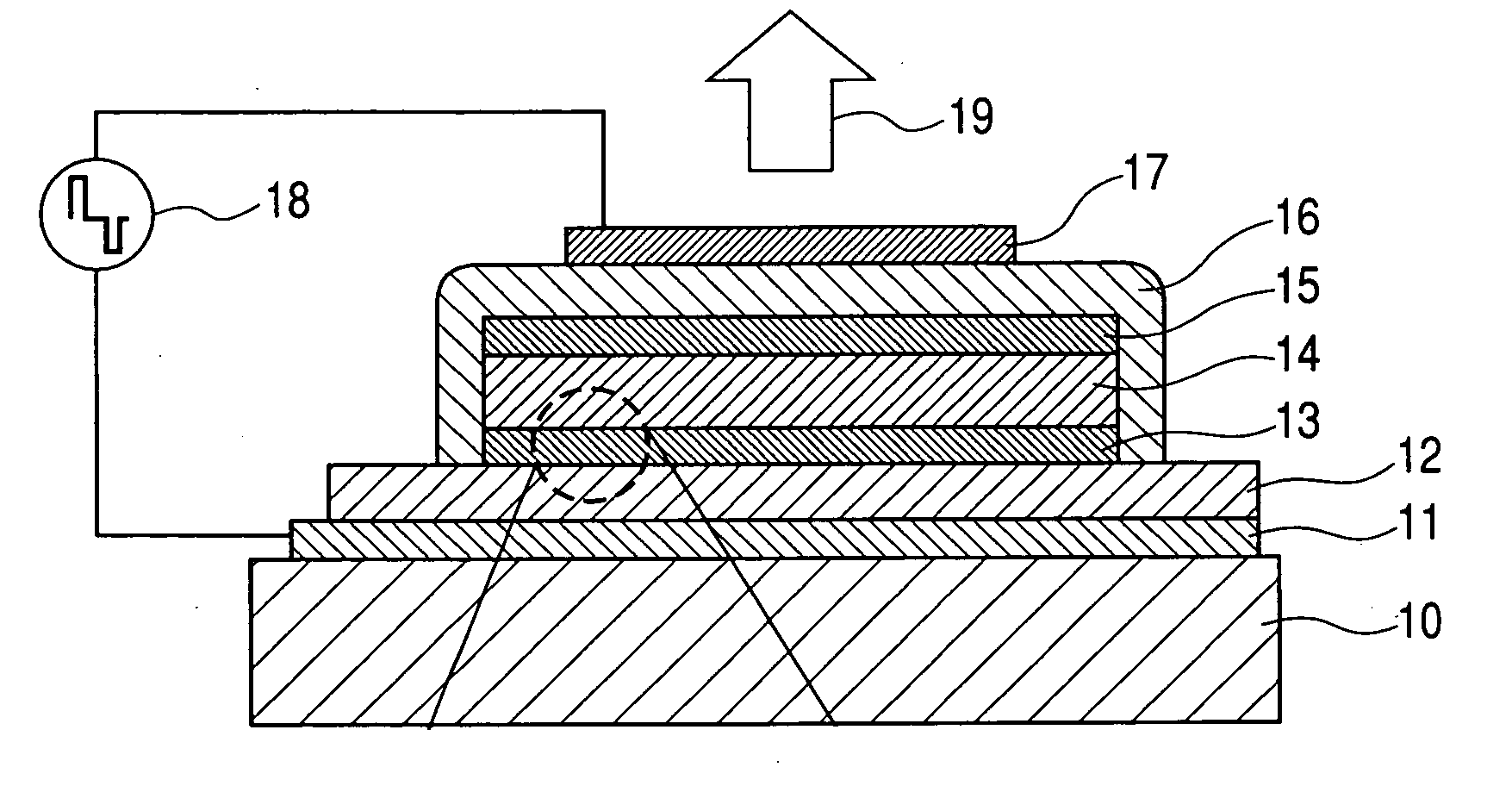

Electron emitter and method of producing the same

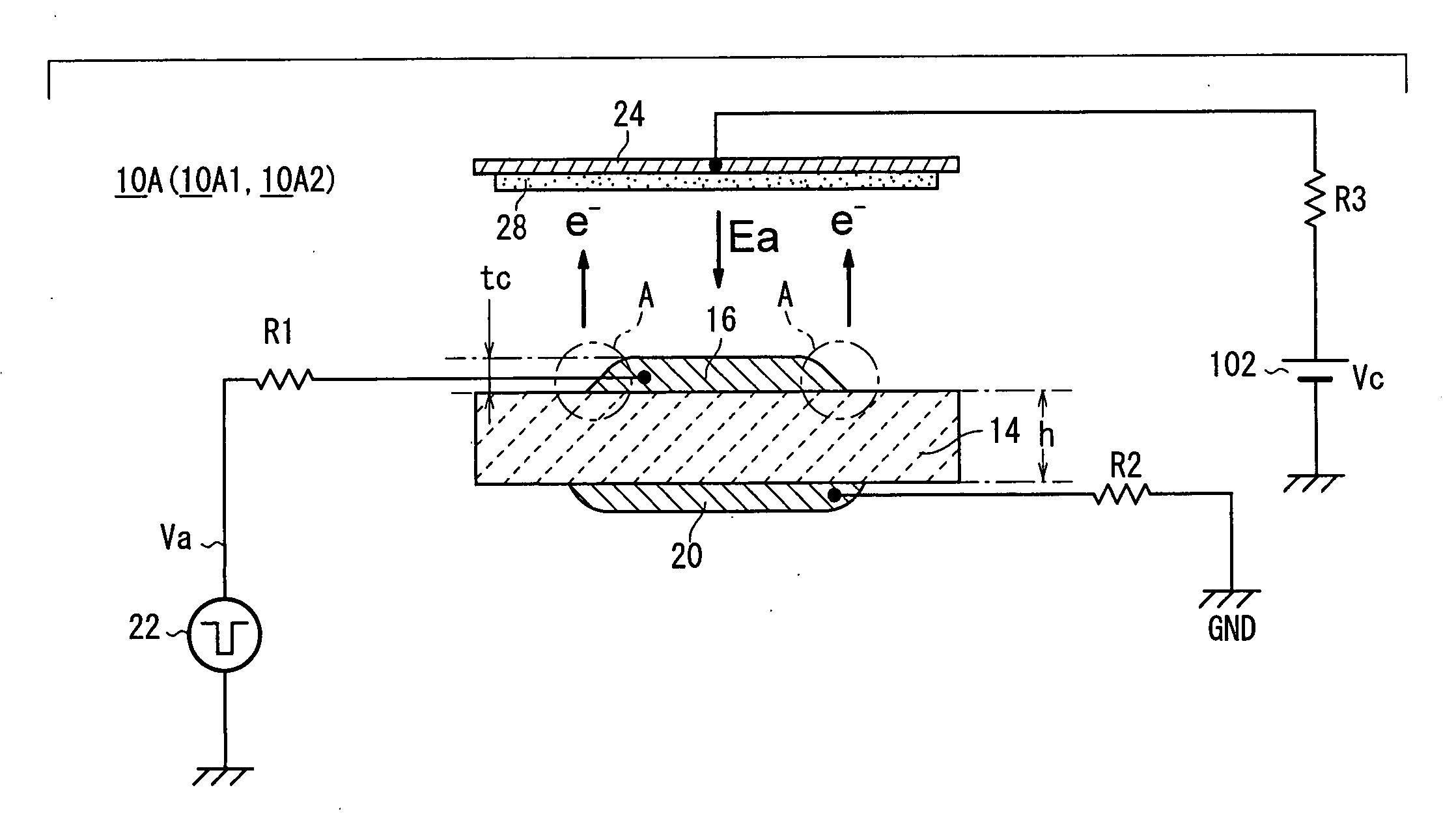

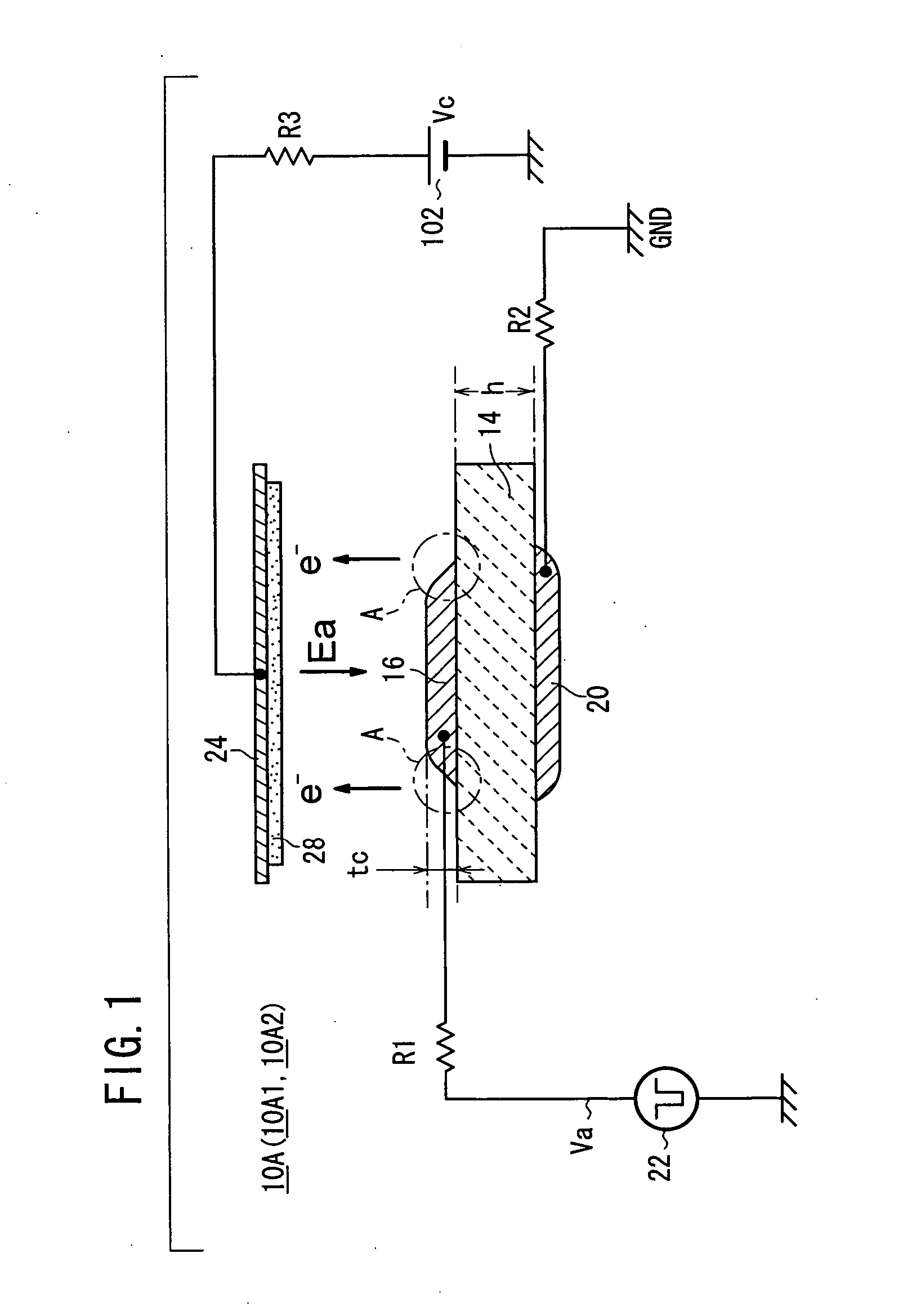

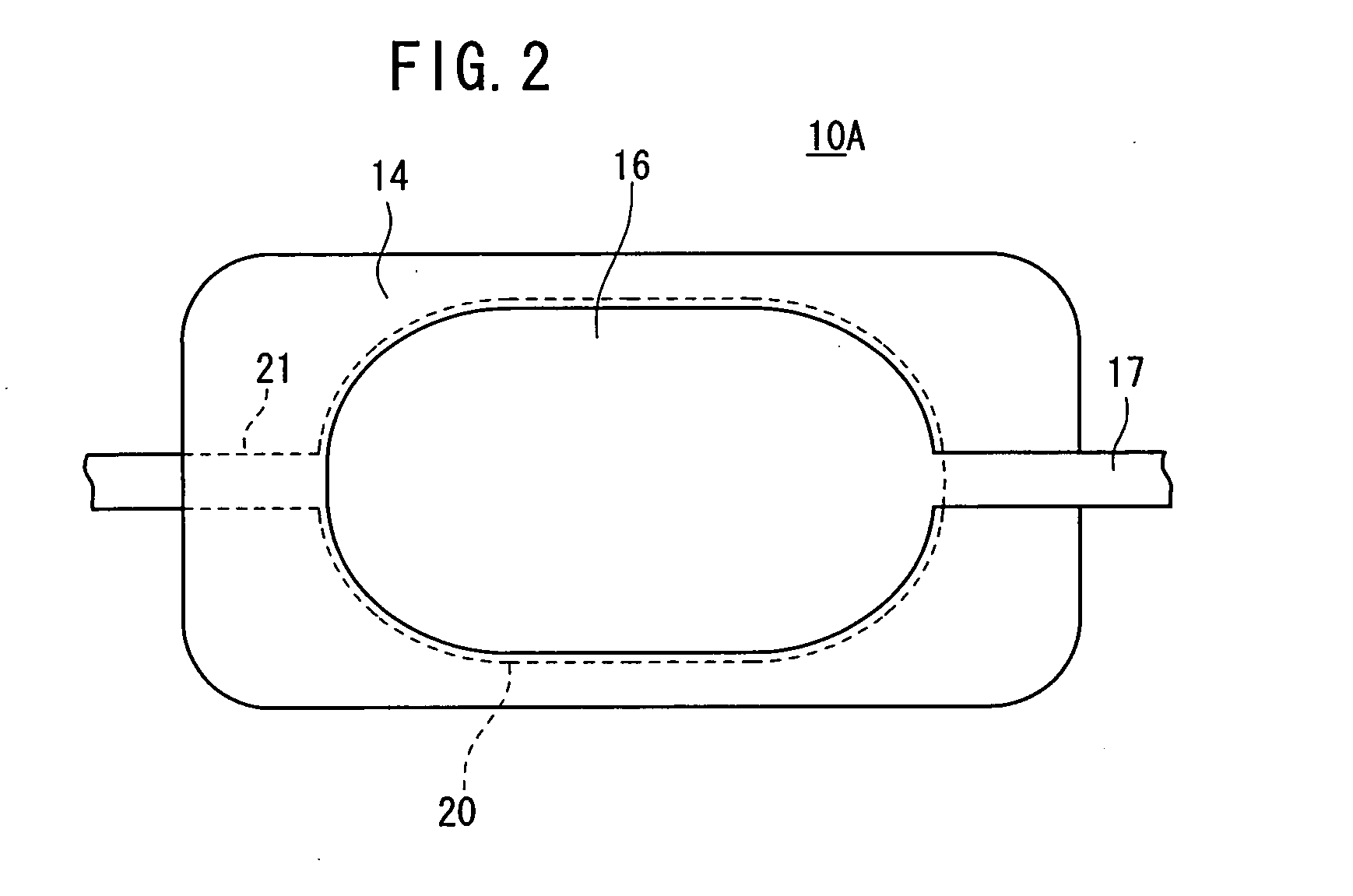

InactiveUS7307383B2Improve electron emission efficiencyIncrease the number ofWeighing apparatus using elastically-deformable membersDischarge tube luminescnet screensTriple junctionElectron

An electron emitter includes an emitter section having a plate shape, a cathode electrode formed on a front surface of the emitter section, and an anode electrode formed on a back surface of the emitter section. A gap is formed between an outer peripheral portion of the cathode electrode and the front surface of the emitter section. The front surface of the emitter section contacts a lower surface of the outer peripheral portion to form a base end as a triple junction. The gap expands from the base end toward a tip end of the outer peripheral portion.

Owner:NGK INSULATORS LTD

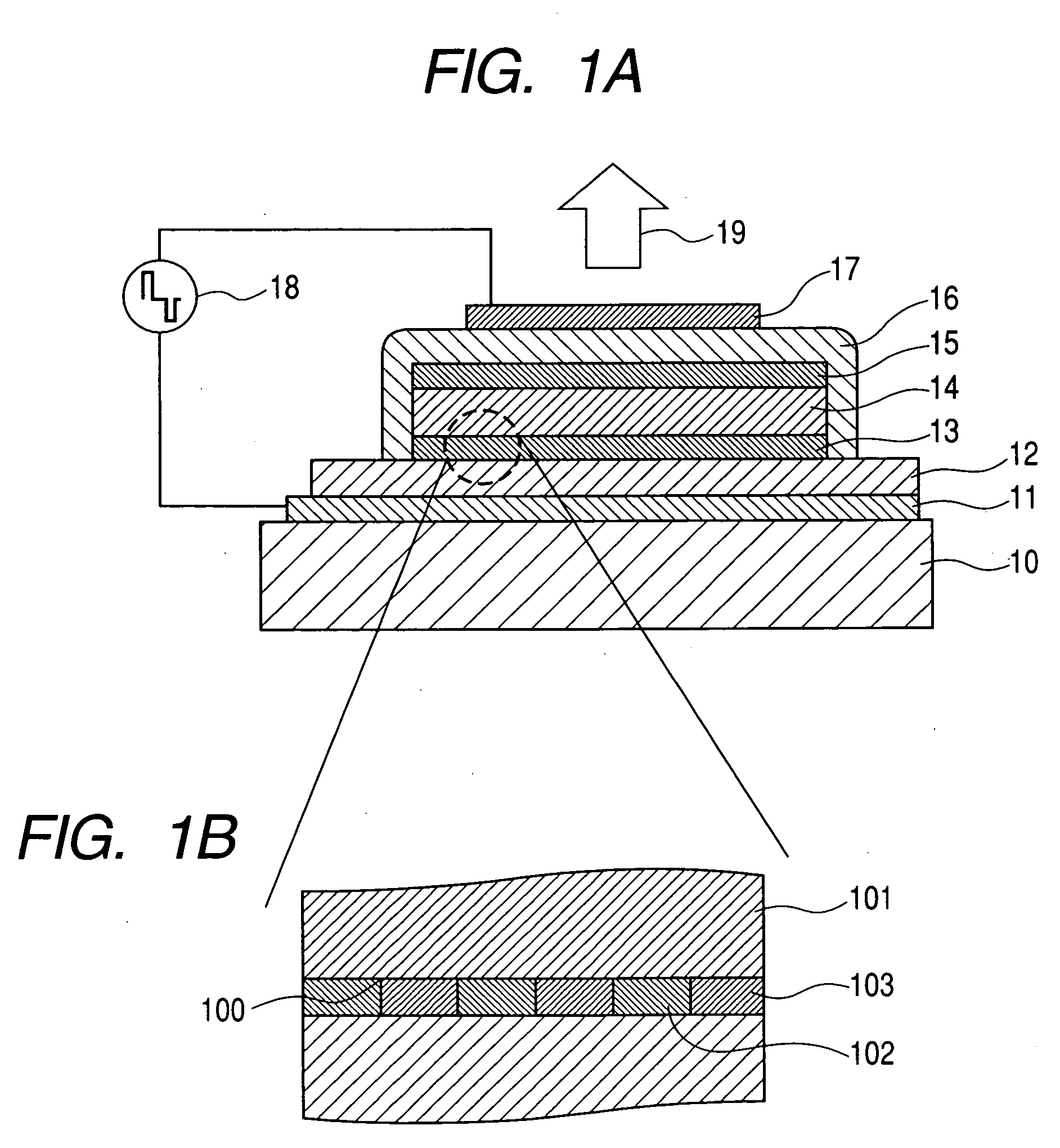

Light-emitting device and production method thereof

InactiveUS20060043410A1Light efficiencyProduct lightDischarge tube luminescnet screensElectroluminescent light sourcesTriple junctionLight emission

A light-emitting device is provided that is excellent in light emission efficiency and stability. The light-emitting device has a first part of a first dielectric constant, a second part of a second dielectric constant and a third part of a third dielectric constant, and has a triple junction where they are in contact with one another. Moreover, a first and a second electrode are provided for applying a voltage for controlling an electric field at the triple junction and in the vicinity thereof. Further, at least one of the first, the second and the third parts is a constituted by light-emitting material, and the triple junction forms a closed line.

Owner:CANON KK

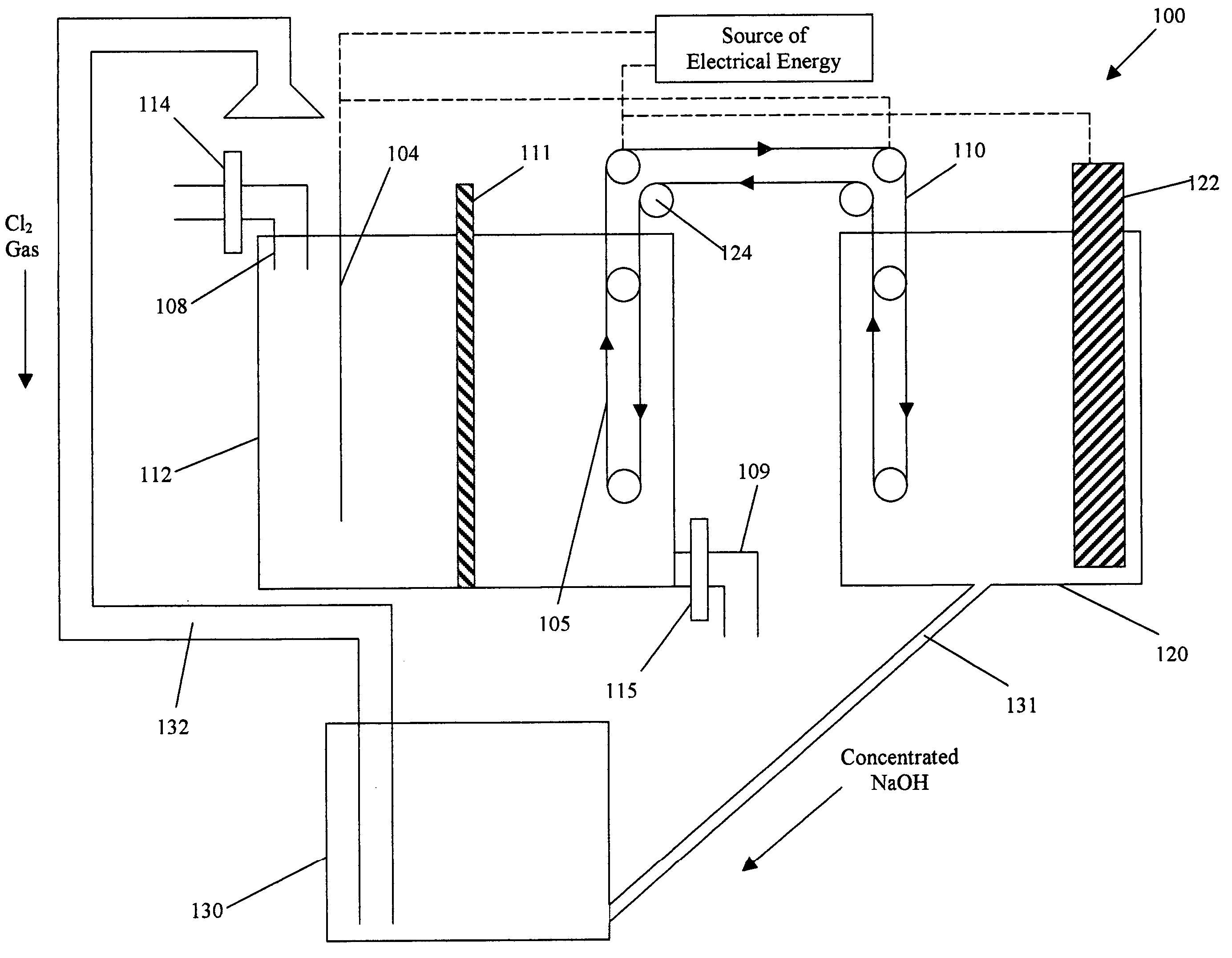

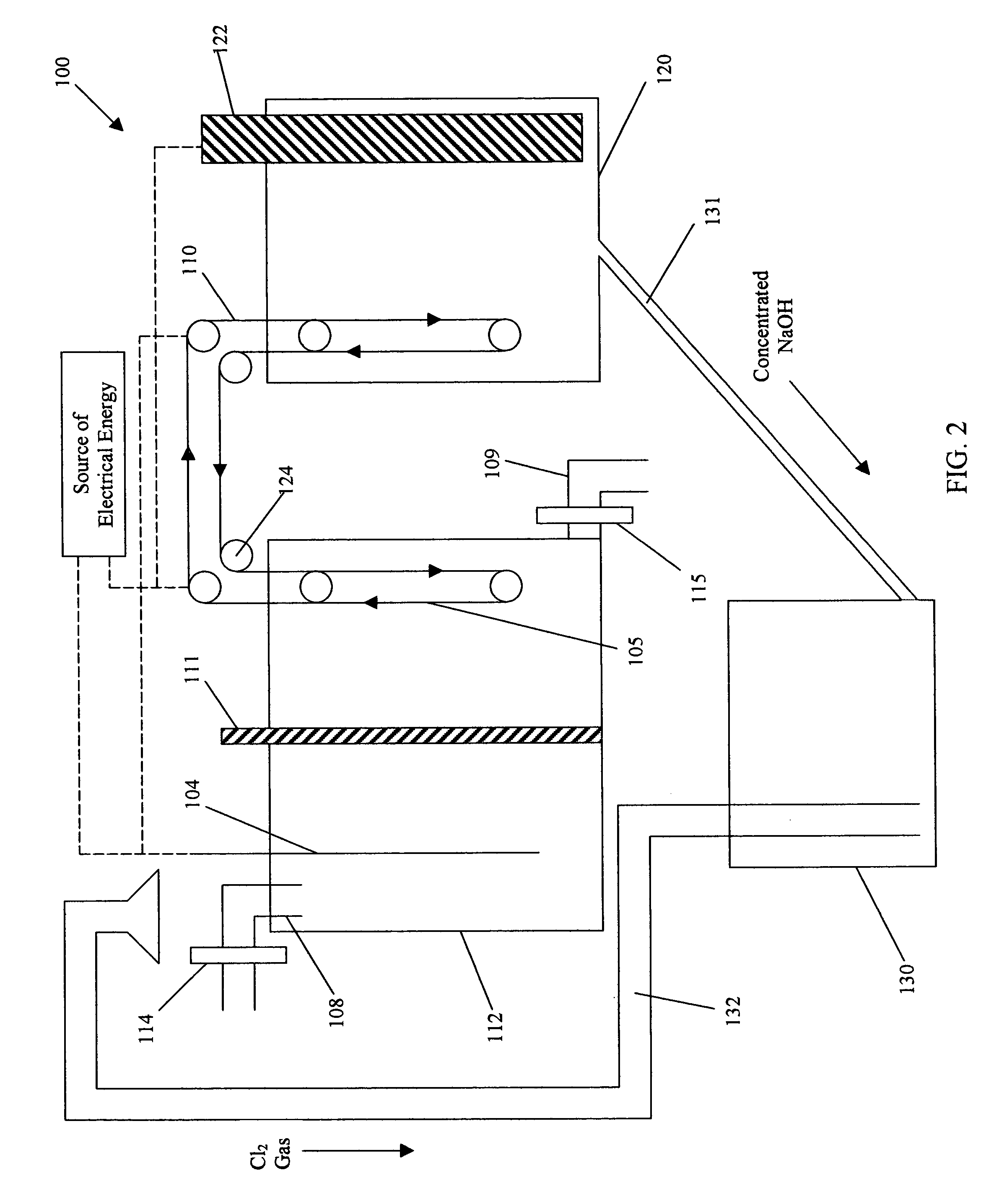

Process and apparatus for removing chloride and sodium ions from an aqueous sodium chloride solution

InactiveUS20050092618A1Reduce salt (NaCl) contentFuel and primary cellsCellsSodium amalgamTriple junction

The present invention discloses a process and apparatus for removing sodium and chloride ions from an aqueous sodium chloride solution, such as seawater or brine. The process includes electrolyzing aqueous sodium chloride to remove chloride and sodium ions in the form of chlorine gas and sodium metal. Preferably, a photovoltaic device, such as a triple junction amorphous silicon solar cell, provides the electrical energy for the electrolysis. The process utilizes electrode material that facilitates the production of chlorine gas and inhibits the evolution of hydrogen from the aqueous sodium chloride solution. The sodium is deposited onto a metal surface having a high hydrogen overpotential to produce sodium amalgam. The processed solution from the electrolysis has a reduced sodium chloride content and may be further processed to produce fresh water for human consumption or agricultural purposes. The sodium amalgam is removed from the aqueous sodium chloride solution and transported to and coupled against an air depolarizing fuel cell in water to produce electrical power with the sodium air fuel cell, power that may be used to operate the apparatus or other machinery. The product of the reaction between the sodium amalgam and the fuel cell is sodium hydroxide that may be reacted with the chlorine gas to produce sodium hypochlorite.

Owner:ENERGY CONVERSION DEVICES INC

Electron emitting composite based on regulated nano-structures and a cold electron source using the composite

InactiveUS20060284537A1Low modulation voltageHigh aspect ratioControl electrodesDischarge tube luminescnet screensElectron sourceTriple junction

A field emission electron source includes a substrate, a first conductive electrode terminated to provide electrons, an emitting composite layer for emitting electrons, and a second electrode insulated from the emitter layer and terminated to extract electrons through vacuum space. The emitting composite layer lies between and parallel to the said first and the second electrodes, and comprises nano-structures embedded in a solid matrix. One end of the nano-structures is truncated and exposed at the surface of the emitter layer so that both the length and the apex of the nano-structure are regulated and the exposed nano-tips are kept substantially the same distance from the gate electrode. The embedding material is chosen to form triple junctions with the exposed tip to further enhance the field.

Owner:TOLT ZHIDAN L

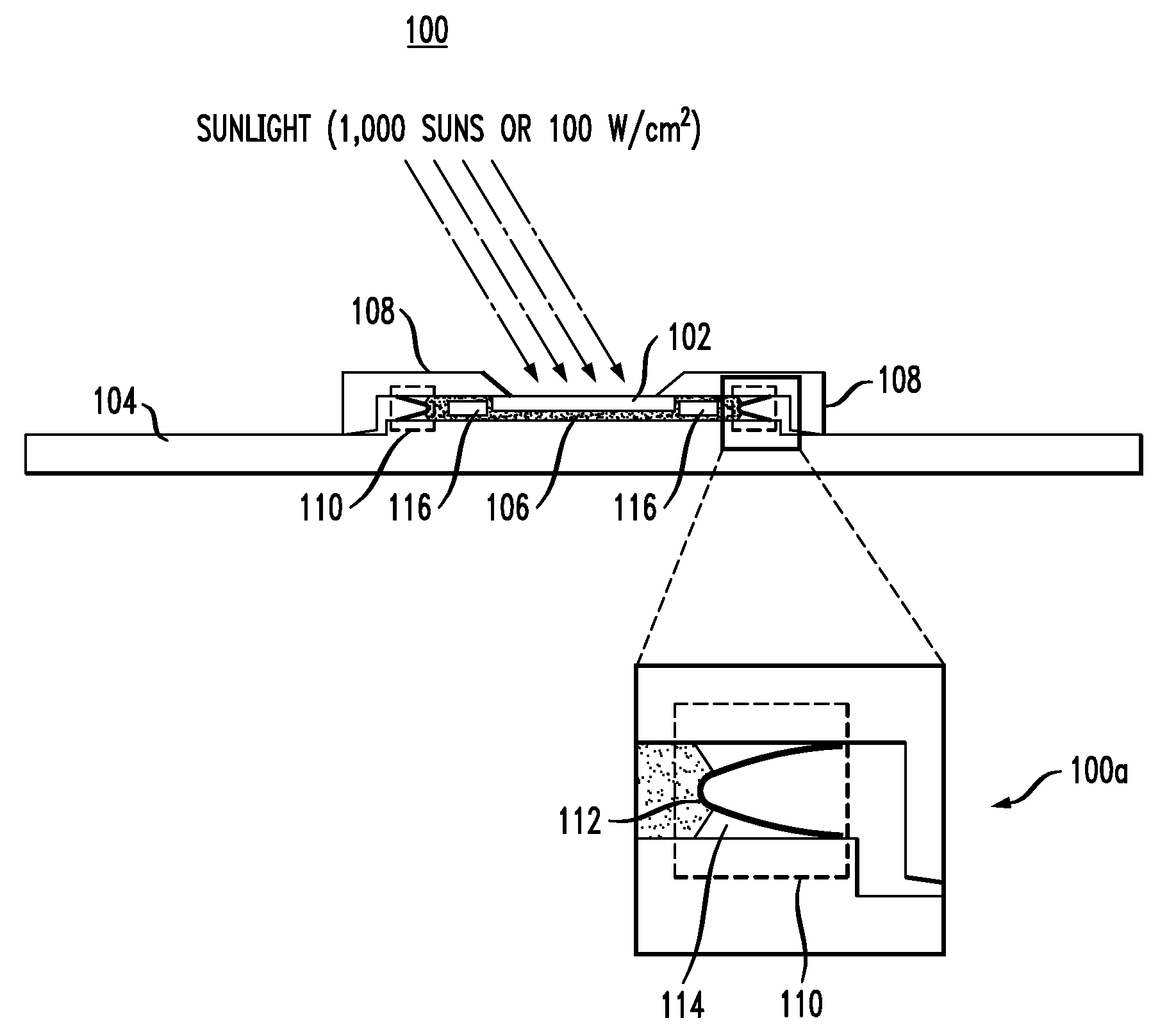

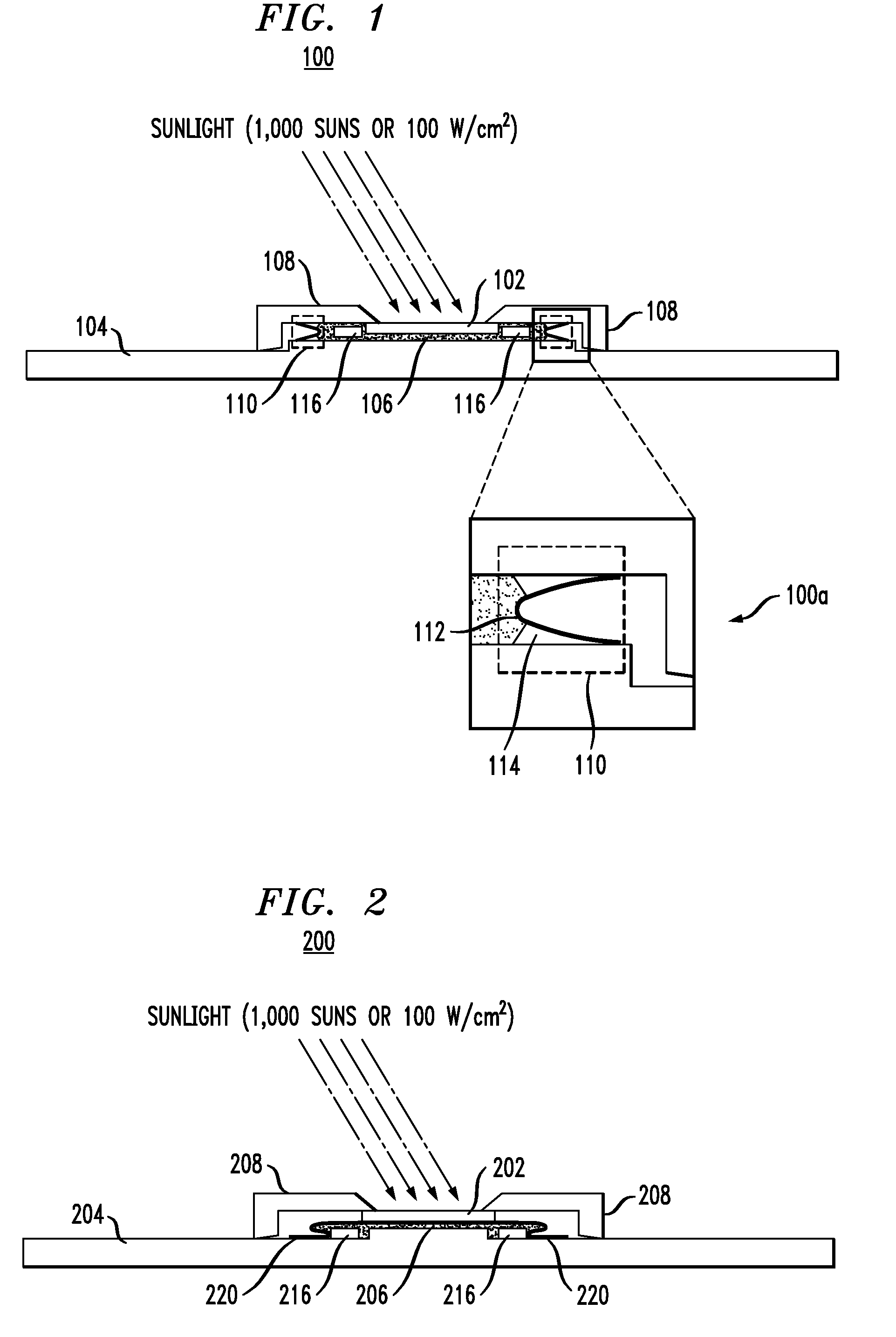

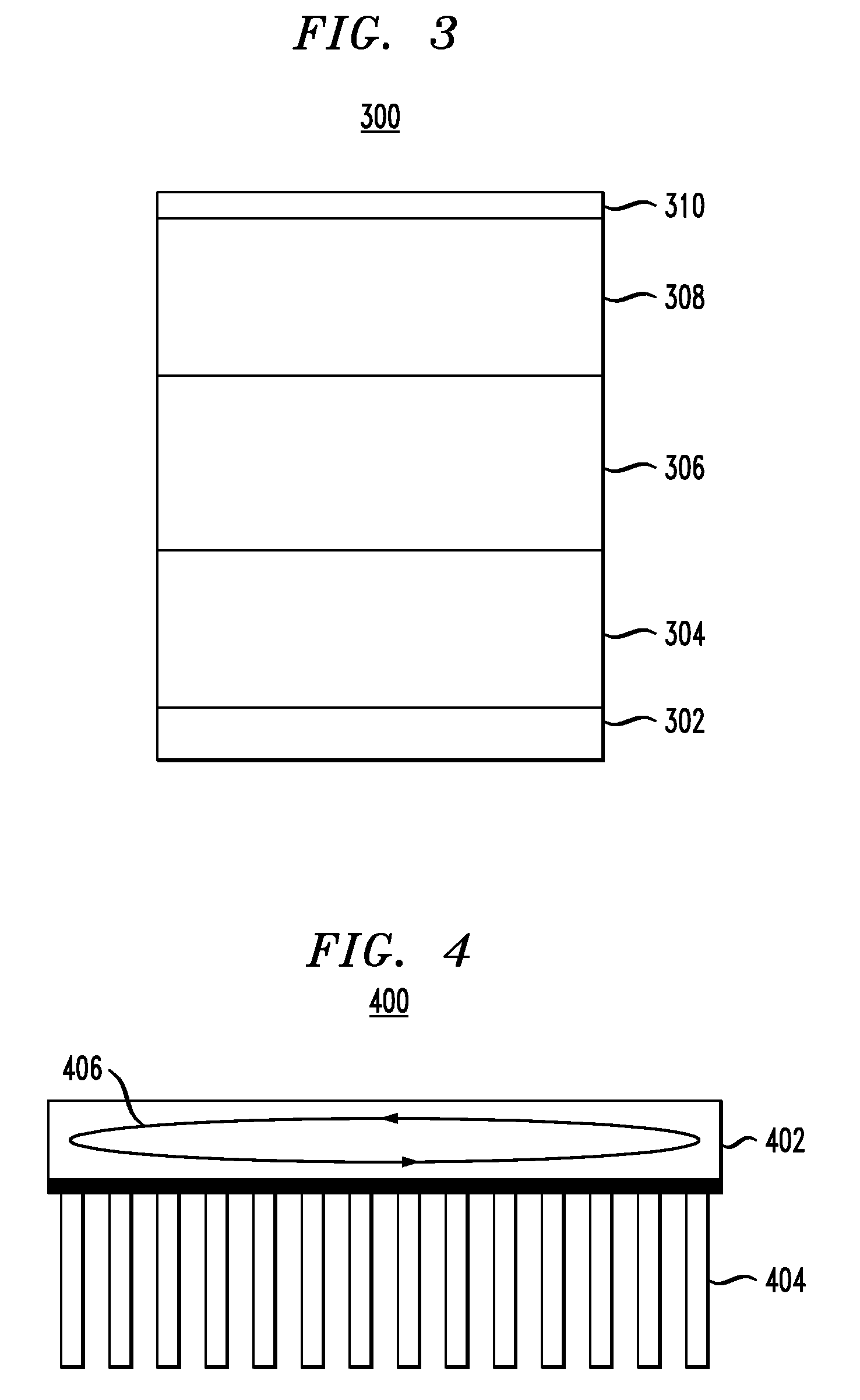

Techniques for Cooling Solar Concentrator Devices

InactiveUS20090084435A1Photovoltaic energy generationSemiconductor devicesManufacturing technologyEngineering

Solar concentrator devices and techniques for the fabrication thereof are provided. In one aspect, a solar concentrator device is provided. The solar concentrator device comprises at least one solar converter cell; a heat sink; and a liquid metal between the solar converter cell and the heat sink, configured to thermally couple the solar converter cell and the heat sink during operation of the device. The solar converter cell can comprise a triple-junction semiconductor solar converter cell fabricated on a germanium (Ge) substrate. The heat sink can comprise a vapor chamber heat sink. The liquid metal can comprise a gallium (Ga) alloy and have a thermal resistance of less than or equal to about five square millimeter degree Celsius per Watt (mm2° C. / W).

Owner:IBM CORP

Sintered magnet and rotating electric machine using same

InactiveCN102308342AImprove heat resistanceReduce usageInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementElectric machine

Owner:HITACHI LTD

Electron emitter and method of producing the same

InactiveUS20050073261A1Improve electron emission efficiencyImprove distributionDischarge tube luminescnet screensStatic indicating devicesTriple junctionElectron

An electron emitter includes an emitter section having a plate shape, a cathode electrode formed on a front surface of the emitter section, and an anode electrode formed on a back surface of the emitter section. A gap is formed between an outer peripheral portion of the cathode electrode and the front surface of the emitter section. The front surface of the emitter section contacts a lower surface of the outer peripheral portion to form a base end as a triple junction. The gap expands from the base end toward a tip end of the outer peripheral portion.

Owner:NGK INSULATORS LTD

Triple-junction filterless CMOS color imager cell

InactiveUS7470946B2Reduce areaSolid-state devicesSemiconductor/solid-state device manufacturingCMOSPhotodiode

Owner:SHARP KK

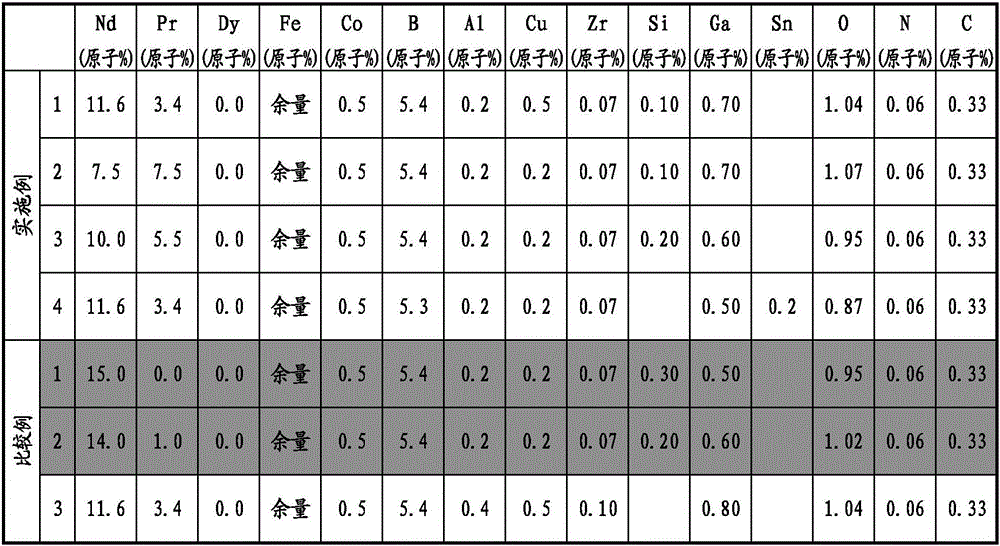

R-(Fe, Co)-B sintered magnet and making method

ActiveCN106710766AInductances/transformers/magnets manufactureMagnetic materialsBorideSintered magnets

The invention relates to a R-(Fe, Co)-B sintered magnet and a making method. An R-(Fe,Co)-B base sintered magnet consisting essentially of 12-17 at% of R containing Nd and Pr, 0.1-3 at% of M1 (typically Si), 0.05-0.5 at% of M2 (typically Ti), B, and the balance of Fe, and containing R2(Fe,Co)14B as a main phase has a coercivity of at least 10 kOe. The magnet contains a M2 boride phase at a grain boundary triple junction, and has a core / shell structure that the main phase is covered with a grain boundary phase. The grain boundary phase is composed of an amorphous and / or nanocrystalline R'-(Fe,Co)-M1' phase consisting essentially of 25-35 at% of R' containing Pr, 2-8 at% of M1' (typically Si), up to 8 at% of Co, and the balance of Fe. A coverage of the main phase with the R'-(Fe,Co)-M1' phase is at least 50%, and the bi-granular grain boundary phase has a width of at least 50 nm.

Owner:SHIN ETSU CHEM CO LTD

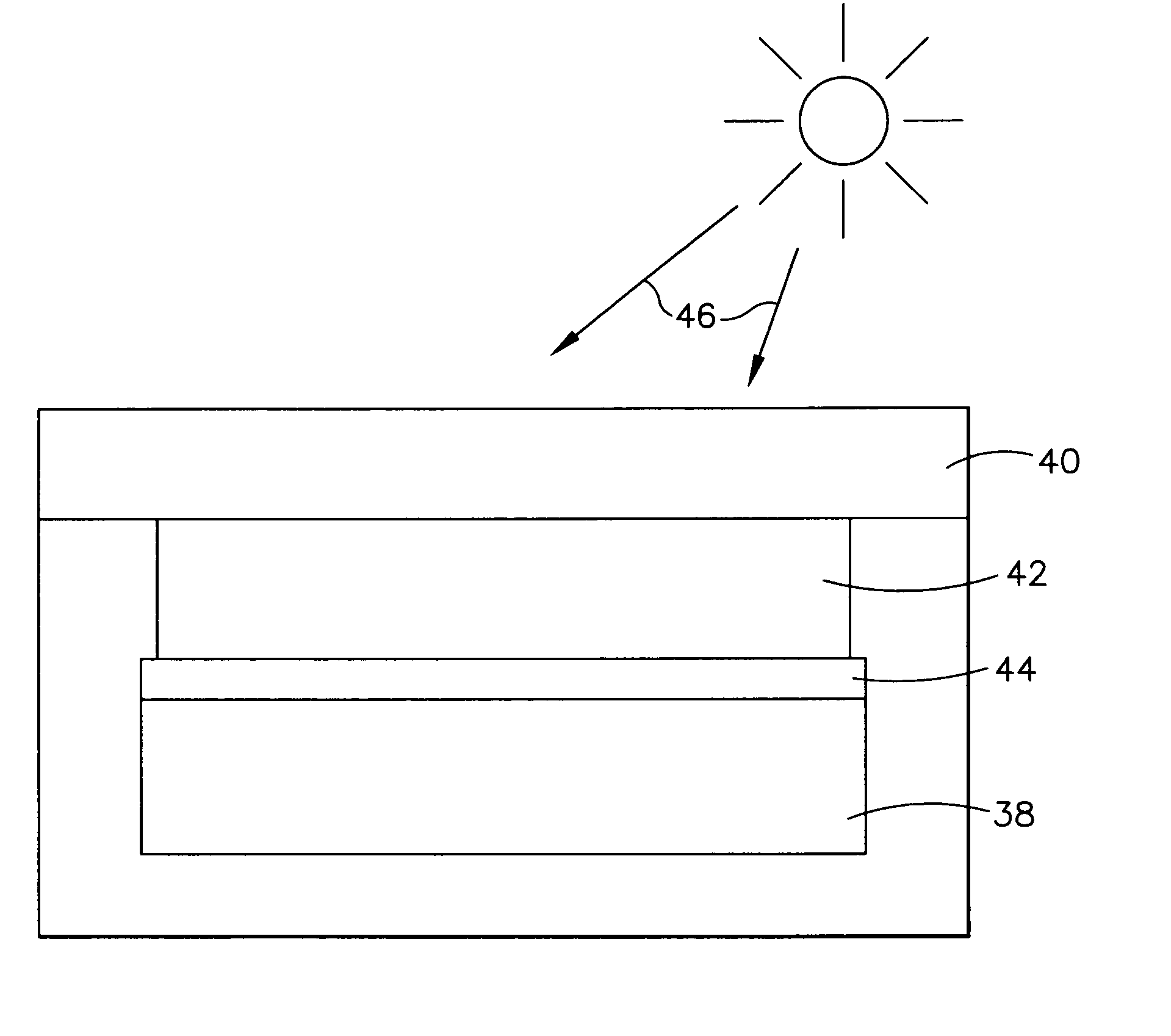

Solar power collection with near infrared wideband reflector coating

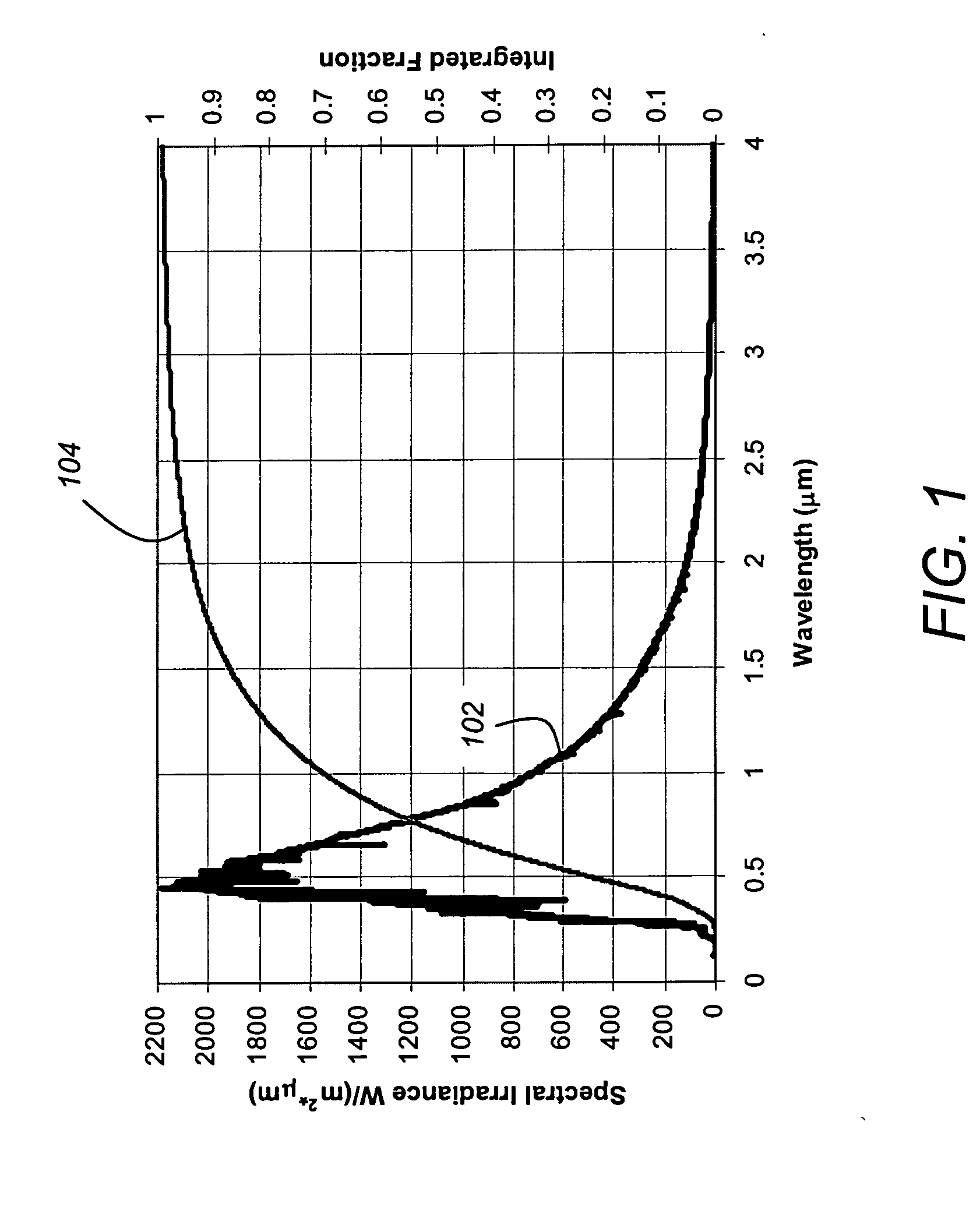

InactiveUS20050103374A1Lower operating temperatureImprove conversion efficiencyPV power plantsPhotovoltaic energy generationSolar angleLow earth orbit

A near infrared (NIR) wideband reflector coating designed to start reflecting solar energy wavelengths from at least 1.2 microns in a typical geosynchronous earth orbit or medium earth orbit satellite and from at least 1.3 microns in a typical low earth orbit satellite. Also, the (NIR) wideband reflector coating reflects solar energy wavelengths below 0.35 microns in all three applications. This invention works on triple junction (TJ) solar cells. The performance of at least 1.2-microns is on solar panels with near-normal incident solar angle, typical of Geosynchronous Earth Orbit (GEO) and Medium Earth Orbit (MEO) satellites. The performance of at least 1.3-microns is on solar panels with wide range of incident solar angles, a design requirement for Low Earth Orbit (LEO) satellites.

Owner:THE BOEING CO

R-fe-b sintered magnet with enhanced mechanical properties and method for producing the same

InactiveUS20130284969A1Improve coercive forceImprove mechanical propertiesInorganic material magnetismCeramic shaping apparatusSintered magnetsTriple junction

Disclosed are an R—Fe—B sintered magnet and a method for producing the same. More specifically, provided is an R—Fe—B (R=Nd, Dy, Pr, Tb, Ho, La, Ce, Sm, Gd, Er, Tm, Yb, Lu or Th) sintered magnet having a structure in which R2Fe14B crystal grains as major phases are surrounded with R-rich phases, wherein a dihedral angle between two adjacent R2Fe14B crystal grains and the R-rich phase contacting the R2Fe14B crystal grains is 70° or less in a triple junction formed by the R2Fe14B crystal grains. The sintered magnet maintains a high coercive force and exhibits improved mechanical properties and is thus applicable to motors or permanent magnets used at high temperatures.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

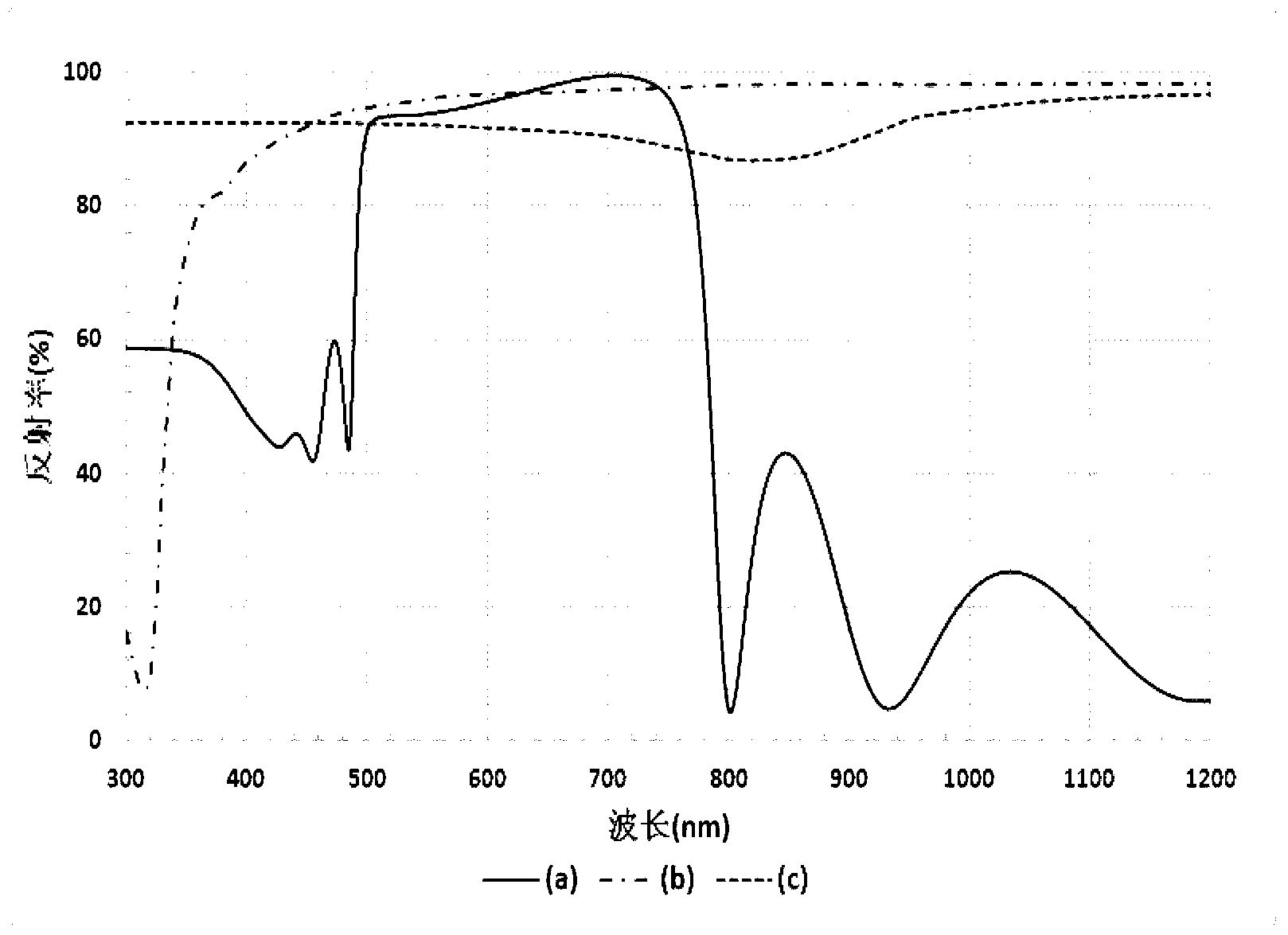

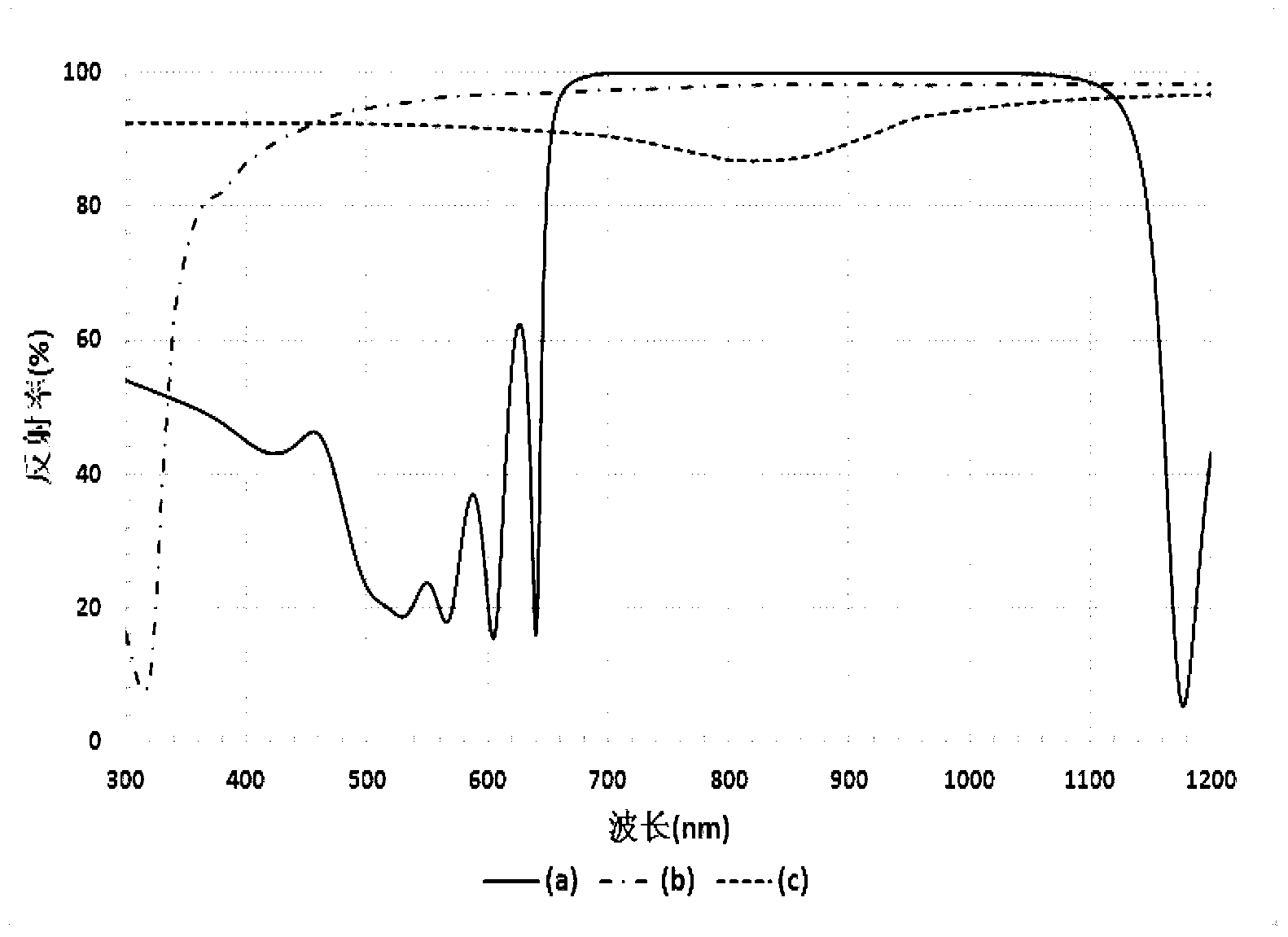

Photonic crystal back reflector provided with adjustable forbidden band and applied to silicon-based thin-film solar cell

InactiveCN103296145AImprove reflectivityIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationBack reflectorRefractive index

The invention discloses a photonic crystal back reflector provided with an adjustable forbidden band and applied to a silicon-based thin-film solar cell. The photonic crystal back reflector is composed of low-refraction-index media and high-refraction-index media which are overlapped in a periodic mode. Through adjustment of the thickness of a period, an average reflectivity of 96% can be obtained in a wave band of 500-750mm, an average reflectivity of 99% can be obtained in a wave band of 650-1100nm, and an average reflectivity of 99% can be obtained in a wave band of 700-1200nm. The photonic crystal back reflector is suitable for serving as a back reflector of a unijunction amorphous silicon thin film solar cell, a back reflector of a double-junction amorphous silicon / microcrystalline silicon laminated solar cell and a back reflector of a triple-junction amorphous silicon / amorphous silicon germanium / amorphous silicon laminated solar cell. The photonic crystal back reflector provided with the adjustable forbidden band and applied to the silicon-based thin-film solar cell has the advantages that due to the fact that a photonic crystal is used as the back reflector of the silicon-based thin-film solar cell, the problems that an Ag back reflector is high in cost and other metal back reflectors are low in reflectivity are solved, high efficiency and decrease of the cost of raw materials are guaranteed, improvement of the open-circuit voltage of the cell is facilitated, the stability of the cell is improved, the photonic crystal back reflector is compatible with the cell technology, reduction of equipment investment and the plant area is facilitated, and productivity is improved.

Owner:NANKAI UNIV

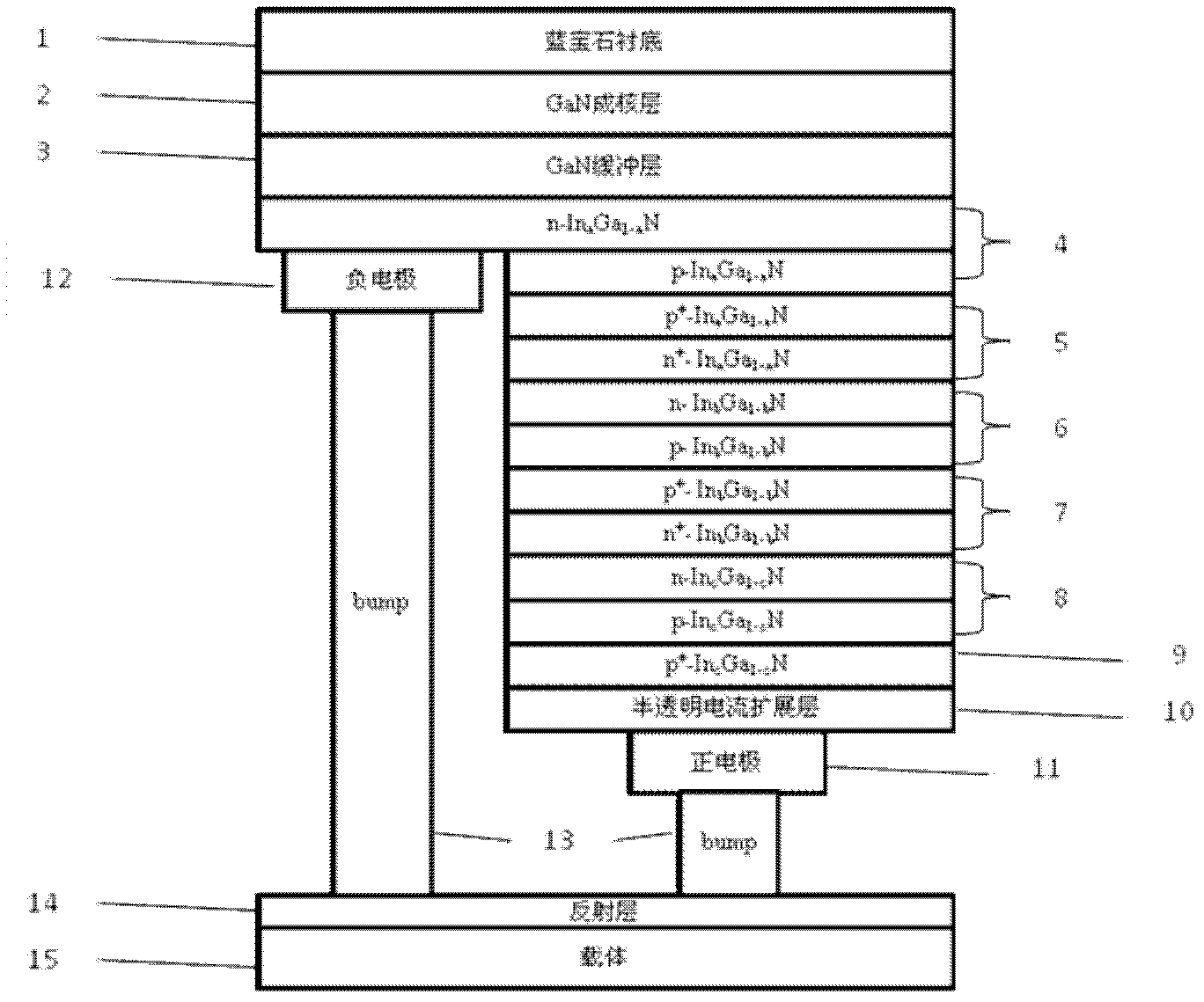

Inverted triple-junction InGaN solar cell

InactiveCN102324443AFully absorbedAchieve contactPhotovoltaic energy generationSemiconductor devicesQuantum efficiencyPower flow

The invention relates to an inverted triple-junction InGaN solar cell. The inverted triple-junction InGaN solar cell comprises a substrate, an anode below the semi-transparent current expansion layer and a cathode below a first InGaN cell, wherein a GaN nucleating layer, a GaN buffering layer and a semi-transparent current expansion layer between a triple-junction InGaN cell and a tunnel junction are arranged below substrate in sequence; a cap layer is placed between the semi-transparent current expansion layer and a third InGaN cell; and the anode and the cathode are bonded on a carrier evaporated with a reflective layer through a metal convex point. According to the invention, solar spectrum is sufficiently absorbed by adopting the inverted triple-junction solar cell and a high-dosage layer after the InGaN material growing process as the cap layer, the metal convex point and the carrier; the external quantum efficiency exceeds 70%; the photoelectric conversion efficiency is increased, the service life of the cell is prolonged, the working stability of the cell is enhanced; and the cell can be directly used as a complete cell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Method and apparatus of multiplejunction solar cell structure with high band gap heterojunction middle cell

ActiveUS20050199281A1Increase the bandgapFinal product manufacturePV power plantsHeterojunctionSolar cell

A method and a multijunction solar device having a high band gap heterojunction middle solar cell are disclosed. In one embodiment, a triple-junction solar device includes bottom, middle, and top cells. The bottom cell has a germanium (Ge) substrate and a buffer layer, wherein the buffer layer is disposed over the Ge substrate. The middle cell contains a heterojunction structure, which further includes an emitter layer and a base layer that are disposed over the bottom cell. The top cell contains an emitter layer and a base layer disposed over the middle cell.

Owner:SOLAERO TECH CORP

Method for manufacturing double-faced epitaxial growth GaAs triple-junction solar cell

ActiveCN103000758AImprove photoelectric conversion efficiencyImprove performanceRenewable energy productsSemiconductor devicesLattice mismatchManufacturing cell

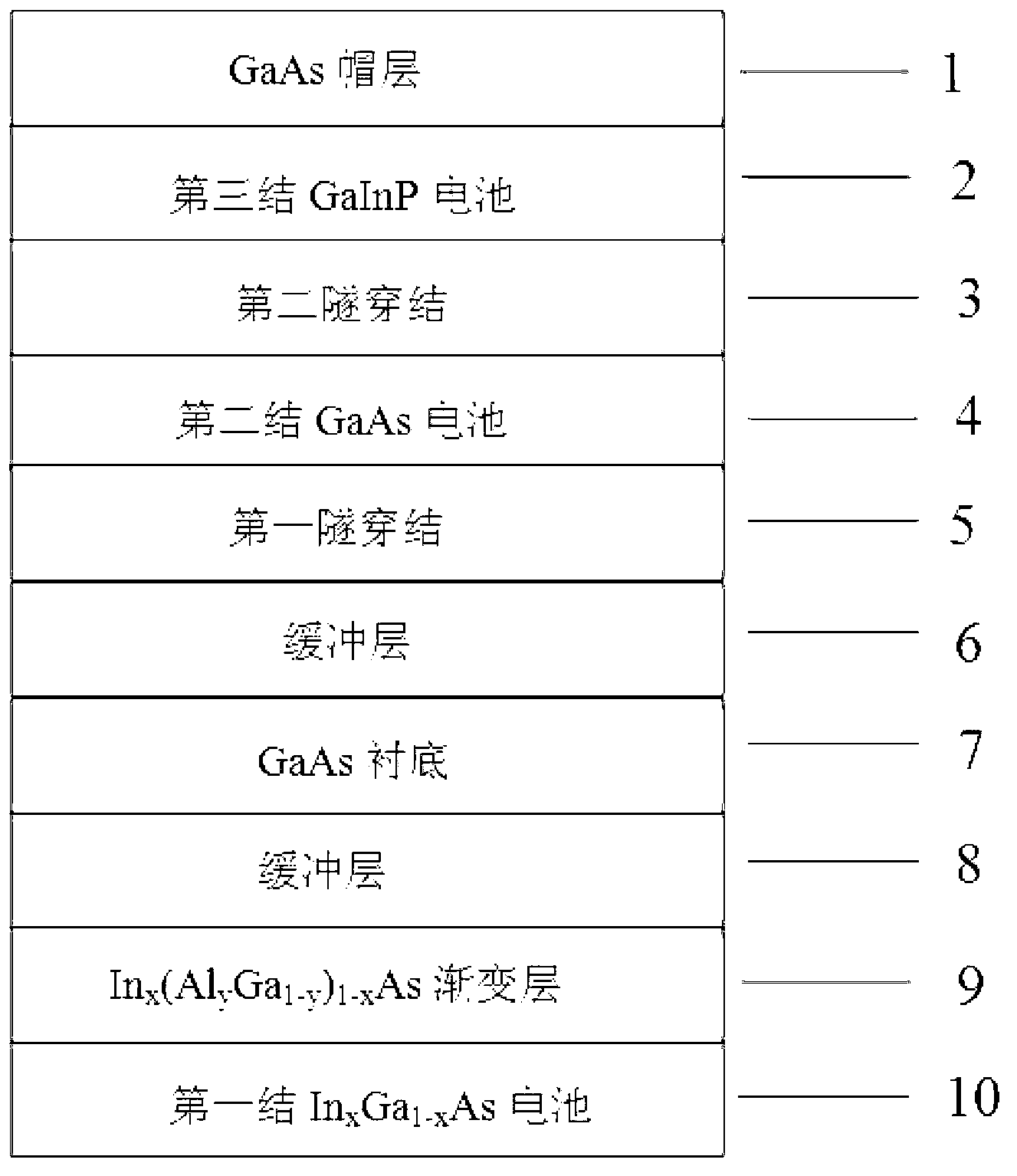

The invention relates to a method for manufacturing a double-faced epitaxial growth GaAs triple-junction solar cell. The method includes sequentially forming a GaAs buffer layer, an In<x>(Al<y>Ga<1-y>)<1-x>As gradient layer and a first-junction In<x>Ga<1-x>As cell on one face of a GaAs substrate in an epitaxial growth manner; and sequentially forming a GaAs buffer layer, a first tunnel junction, a second-junction GaAs cell, a second tunnel junction, a third-junction GaInP cell and a GaAs cap layer on the other face of the GaAs substrate in an epitaxial growth manner. The GaAs substrate is turned over to be subjected to double-faced epitaxial growth, so that influence of dislocation due to isolation lattice mismatch to the first-junction cell and the second-junction cell which are grown on the back face of the substrate is avoided, the photovoltaic conversion efficiency of the cell is improved, the stable performance of the cell is guaranteed, a process for manufacturing cell is simplified, the manufacturing cost of the cell is lowered, the cell production efficiency is improved, and mass production is easy to implement.

Owner:TIANJIN LANTIAN SOLAR TECH +2

High-concentration photovoltaic power generation heating supply system

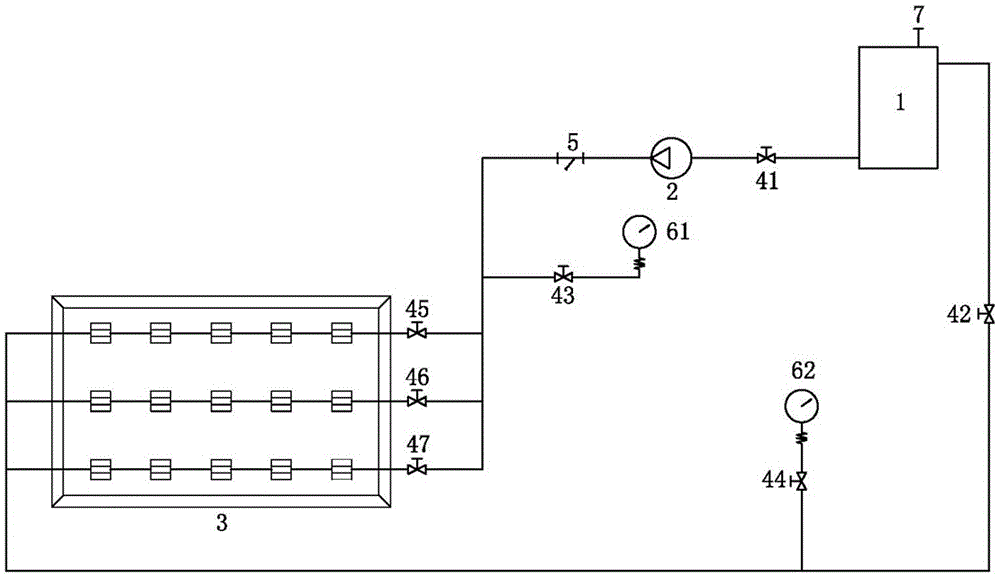

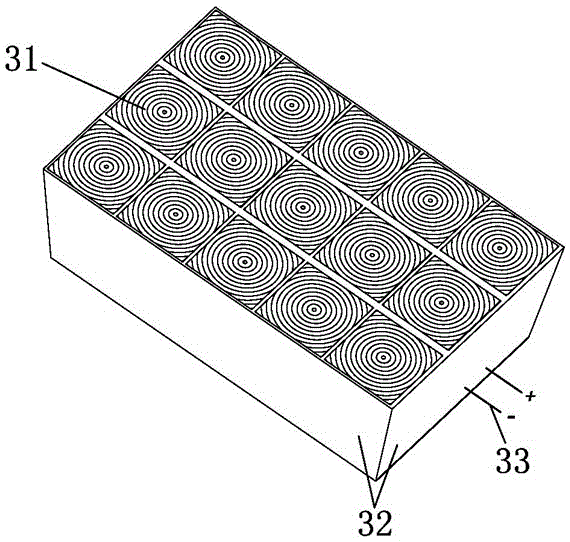

InactiveCN105162412ARealize comprehensive utilizationImprove utilization efficiencySolar heat devicesPhotovoltaicsHigh concentrationEngineering

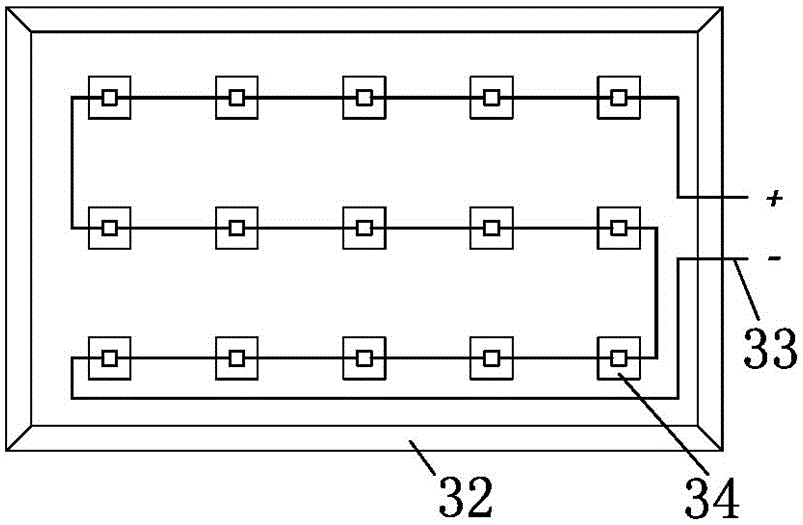

The invention relates to a high-concentration photovoltaic power generation heating supply system. The heating supply system comprises a water tank, a water pump and a high-concentration photovoltaic photo-thermal mechanism; the high-concentration photovoltaic photo-thermal mechanism comprises at least one group of photovoltaic photo-thermal components; each group of the photovoltaic photo-thermal components comprise at least two serially-connected or shunt-wound photovoltaic photo-thermal mechanisms; each photovoltaic photo-thermal mechanism comprises a Fresnel lens and a photovoltaic receiving mechanism; the photovoltaic receiving mechanism comprises a secondary optical prism, a solar photovoltaic battery and water-cooling heat-exchanging members which are connected in sequence; a power generation mechanism is formed by the Fresnel lens, the secondary optical prism and the solar photovoltaic battery; a circulating water pipeline of the high-concentration photovoltaic photo-thermal mechanism is formed by the water-cooling heat-exchanging members in a series-wound or shunt-wound manner; and a circulating water heating supply loop is formed by the water tank, the water pump and the circulating water pipeline in a serial-wound manner. When a gallium arsenide triple junction battery is used as the photovoltaic battery of the system, the system can realize photoelectric conversion efficiency greater than 20% and photo-thermal conversion efficiency of 55% at the seam time, and the highest solar energy utilization rate of the system can reach greater than 75%.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com