Three connection solar cell having reflection layer and manufacturing method therefor

A technology for solar cells and reflective layers, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as slow progress, increased free path of non-equilibrium carriers, and lattice constant mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

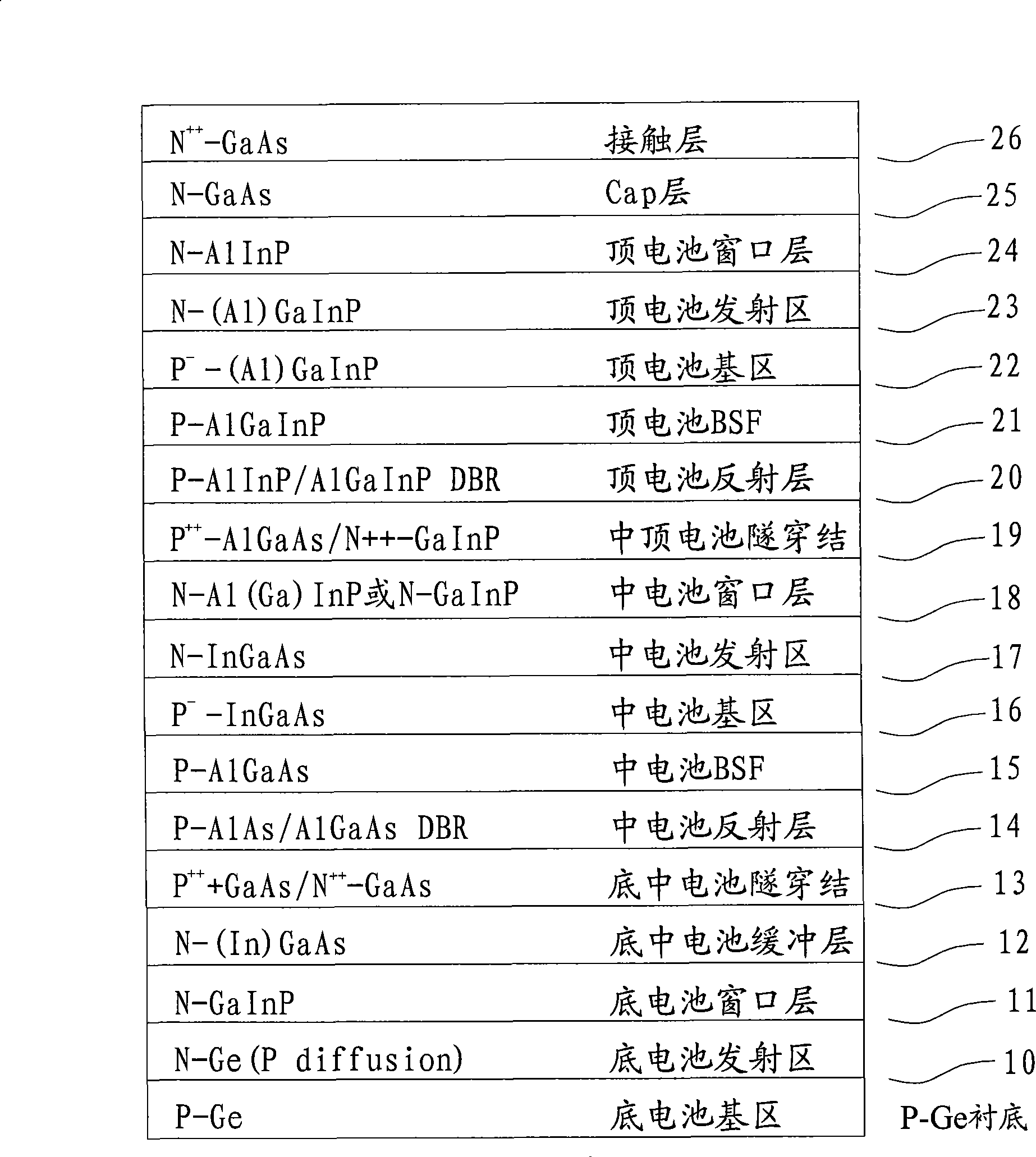

[0023] Such as figure 1 Shown is a triple-junction solar cell with a reflective layer disclosed in the present invention. The semiconductor material layer of the triple-junction solar cell (bottom cell, middle cell and top cell) comprising two sets of Bragg reflectors (DBR) is grown on a P-Ge substrate. The two sets of Bragg reflectors (DBR) are a set of aluminum indium phosphide AlInP / aluminum gallium indium phosphide AlGaInP top cell reflector 20 for reflecting short-wave photons and a set of aluminum arsenide AlAs / aluminum gallium arsenide AlGaAs for reflecting medium-wave photons Battery reflective layer 14.

[0024] The specific structure and manufacture are as follows, each growth is using metal-organic vapor deposition MOCVD technology.

[0025] P diffusion is performed on the P-Ge substrate at 500-700° C. to form a P-Ge bottom cell base region / N-Ge bottom cell emitter region 10 .

[0026] Due to the use of P diffusion, N-GaInP is used as the bottom cell window layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com