Electron emitting composite based on regulated nano-structures and a cold electron source using the composite

a composite and electron source technology, applied in the field of controlled electron emission of cold electron sources, can solve the problems of low yield, high cost and low yield associated with the fabrication process, and the hope of deriving an electron source of high emission site density from a vertically aligned cnt array has largely unfulfilled, and achieves low modulation voltage, high emission site and current density, and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

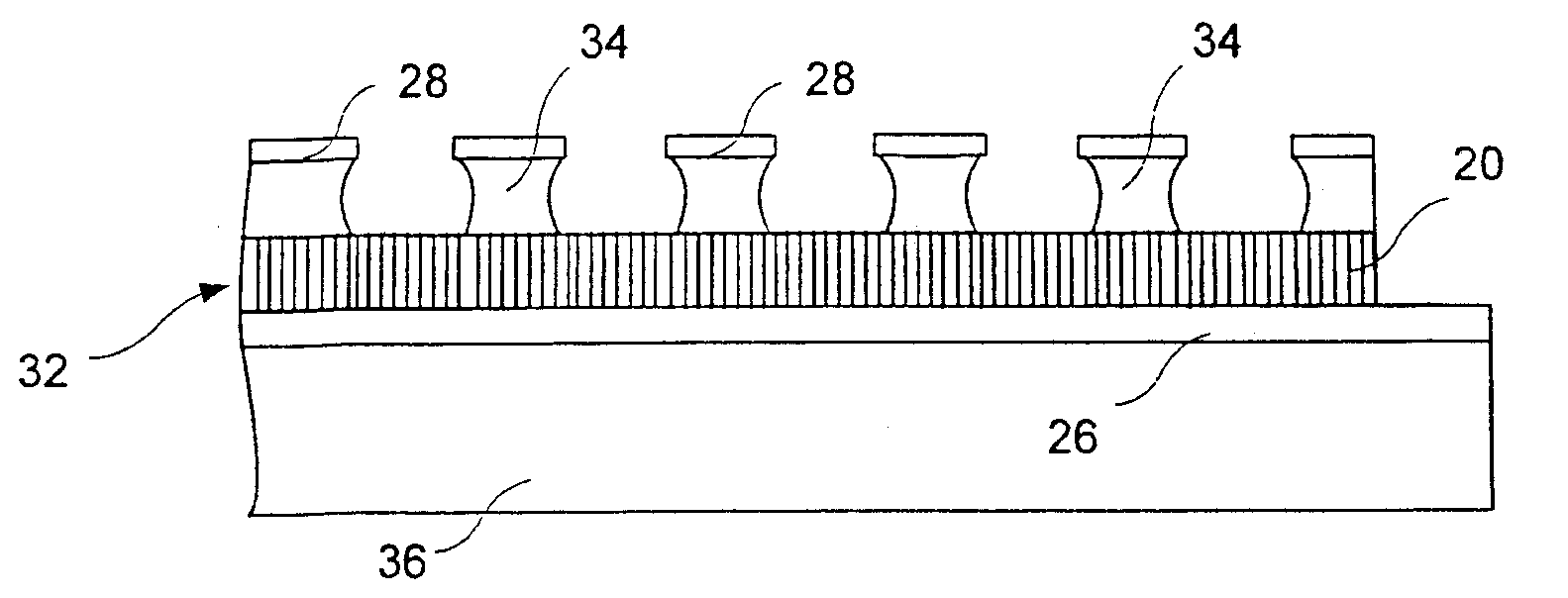

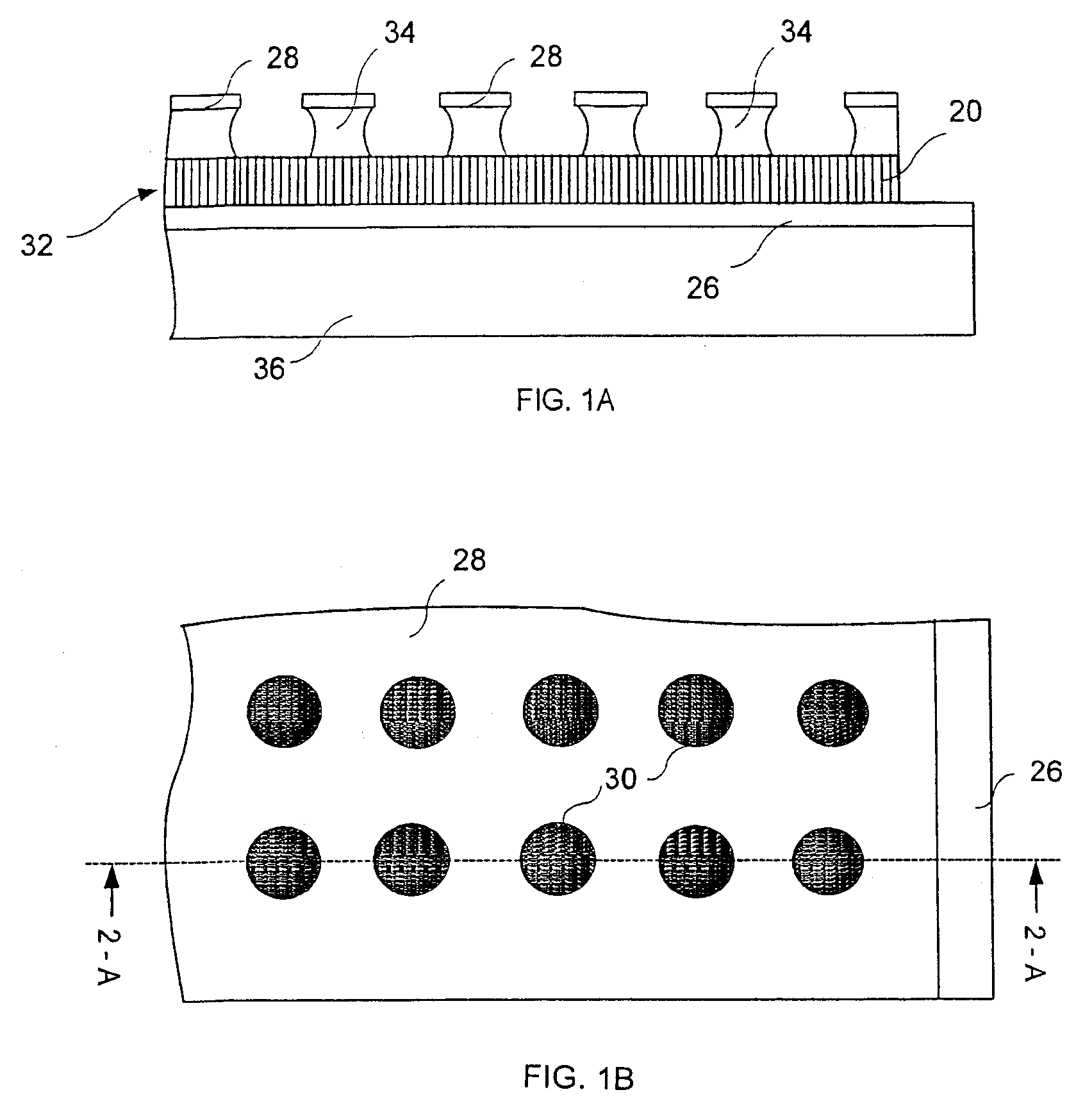

[0086]FIG. 1 illustrates an electron source by current invention using vertically aligned CNT 20. It includes a substrate 36, a cathode 26 deposited on the substrate, an emitter layer 32, a gate electrode 28 insulated from the emitter layer by a gate insulator 34. Apertures 30 are opened in the gate electrode and gate insulator to extract electrons from the exposed CNT tips in the emitter layer 32.

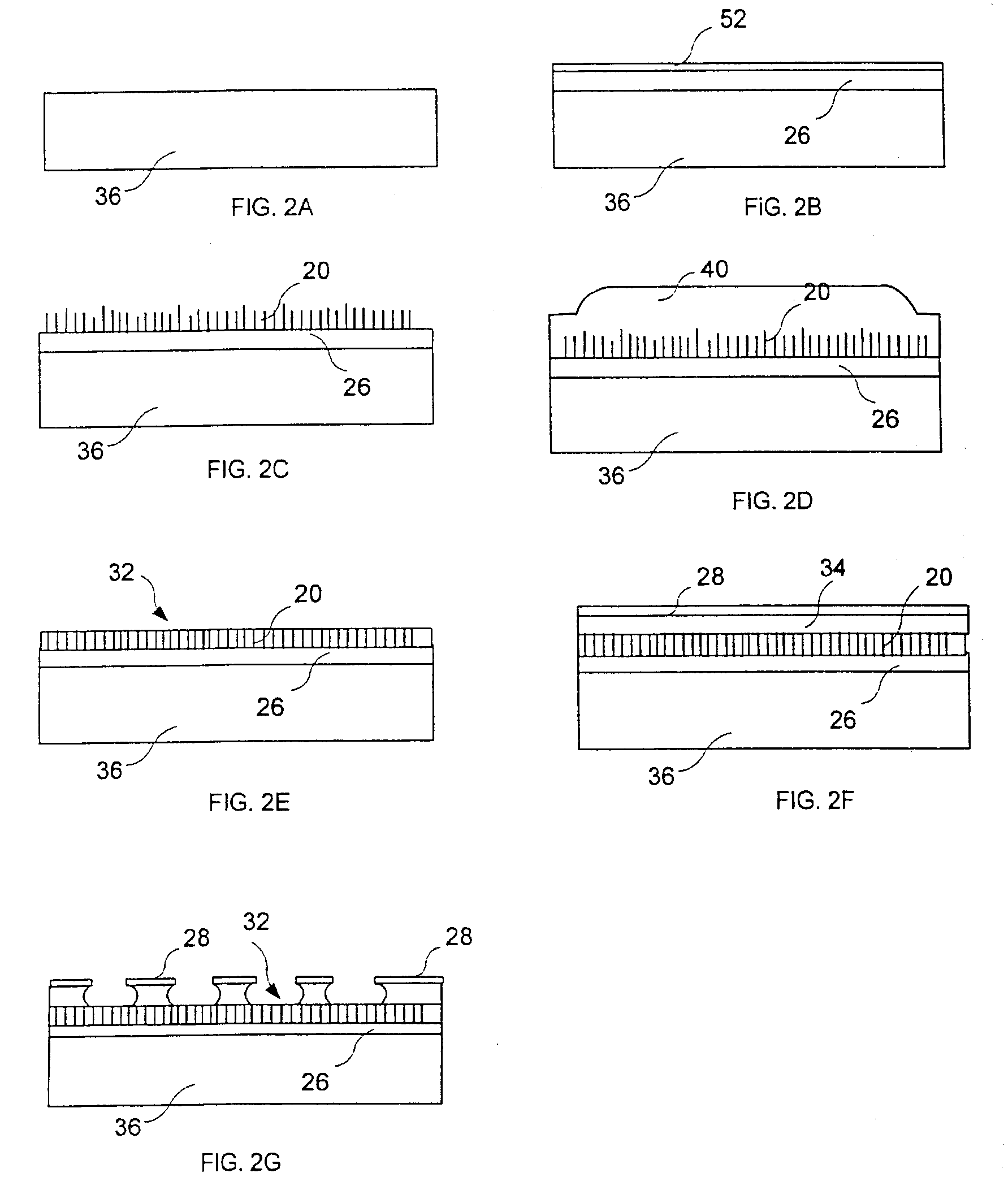

[0087]FIG. 2 depicts one of possible fabrication process flows for the source shown in FIG. 1. The process starts with a substrate 36 shown in FIG. 2A. Examples are Si or glass. A first conductive cathode layer 26 and a thin catalyst layer 52 are then deposited, as is shown in FIG. 2B. Examples of the first conductive layer and catalyst are Cr and Ni respectively. The conductive layer should be chosen so that it does not prohibit CNT growth with the presence of catalyst. The catalyst layer is made of many Ni dots of nanometer size. An array of vertically aligned CNT 20 is then grown, as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com