Patents

Literature

852results about "Thermionic cathode manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

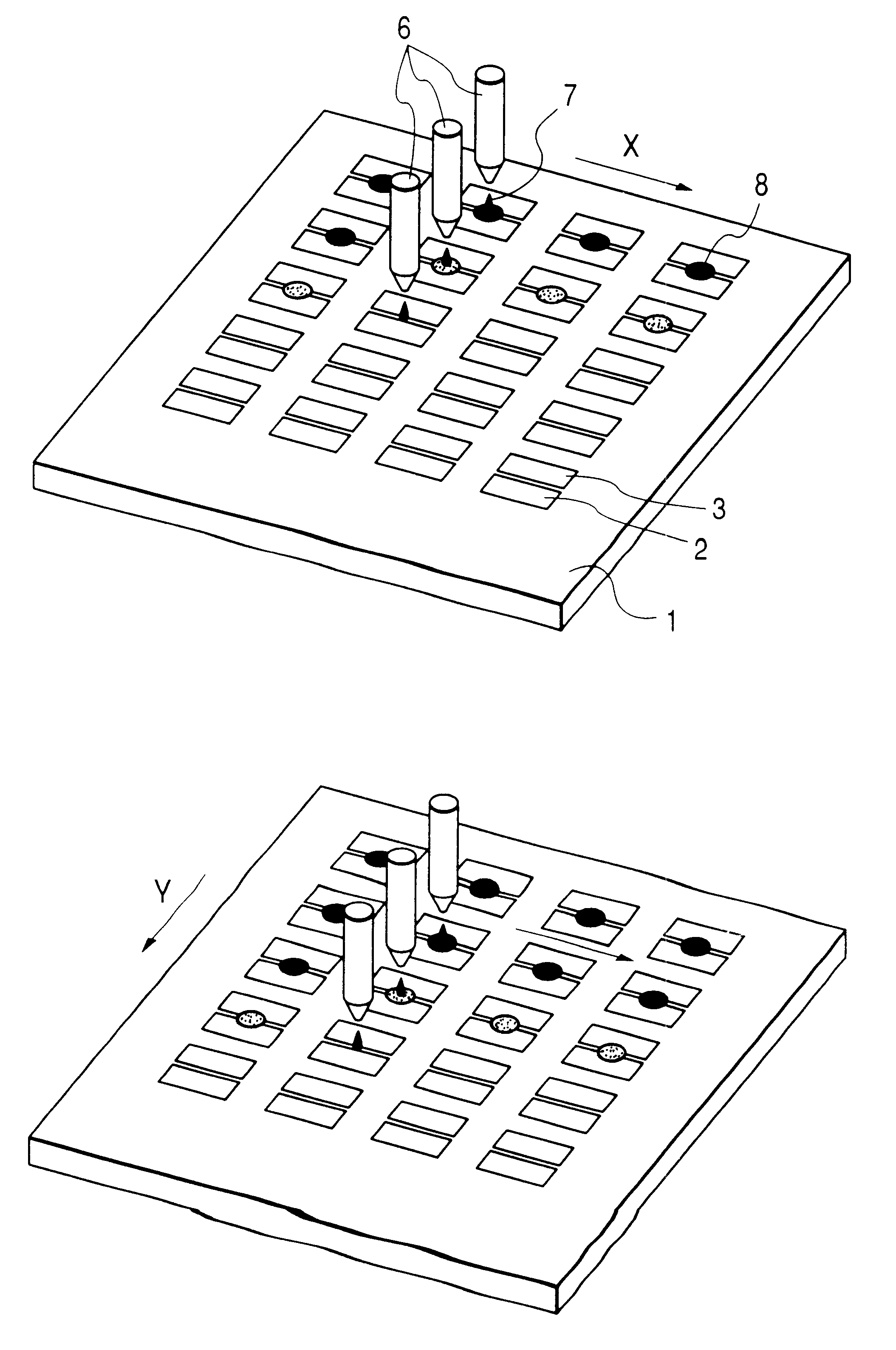

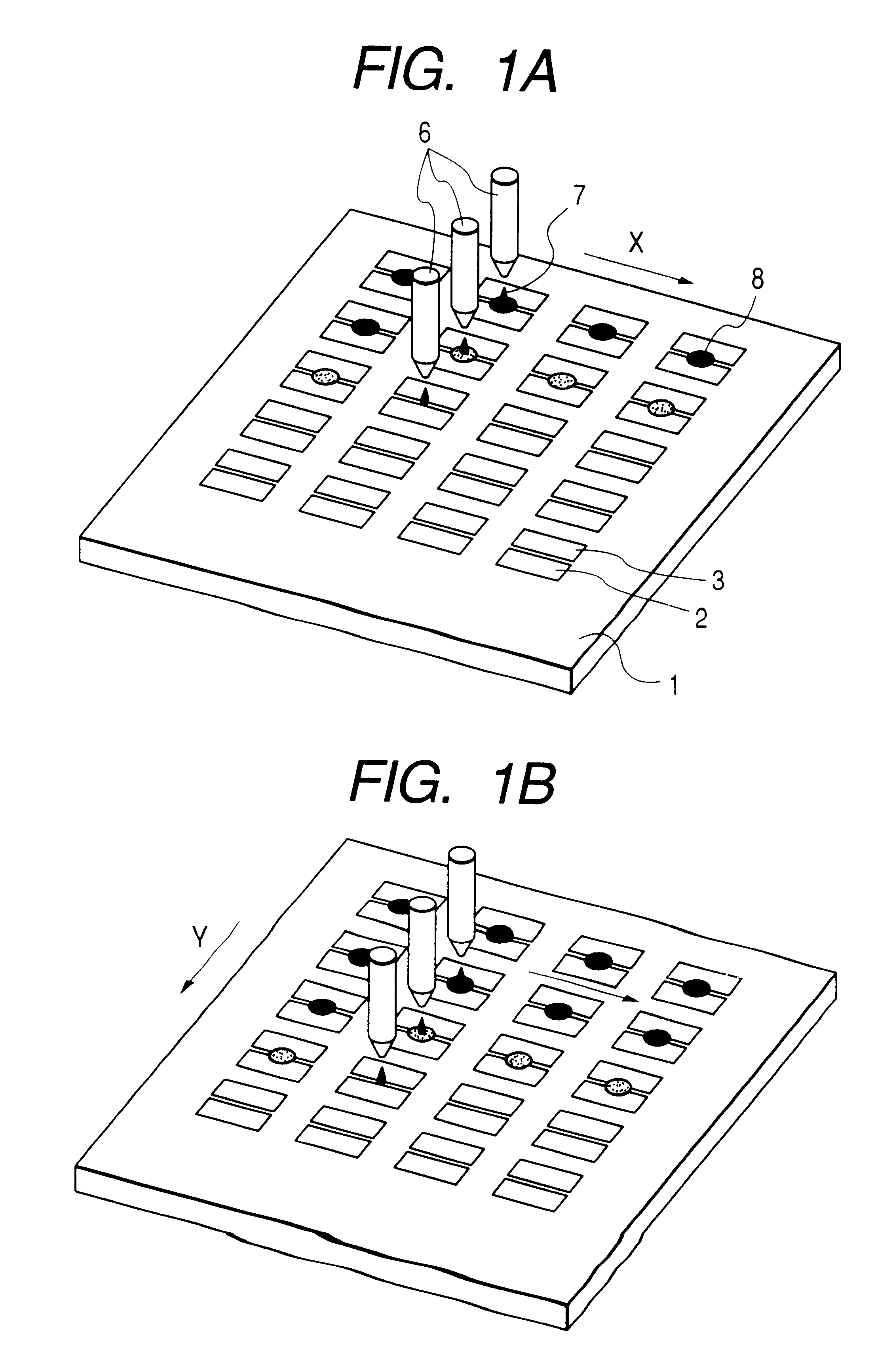

Method and apparatus for filling liquid crystal display (LCD) panels

InactiveUS6055035AElectroluminescent light sourcesVessels or leading-in conductors manufactureLiquid-crystal displayEngineering

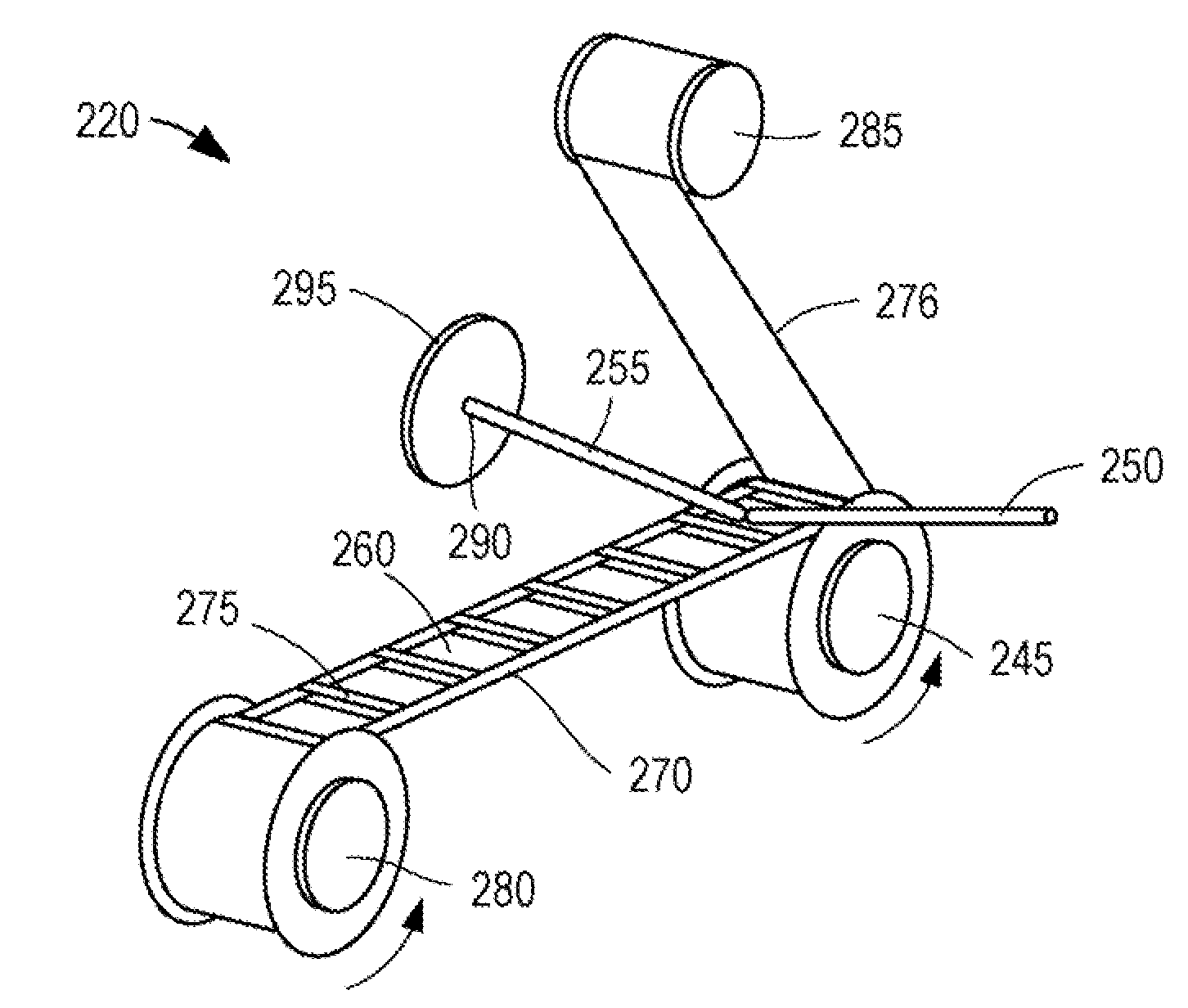

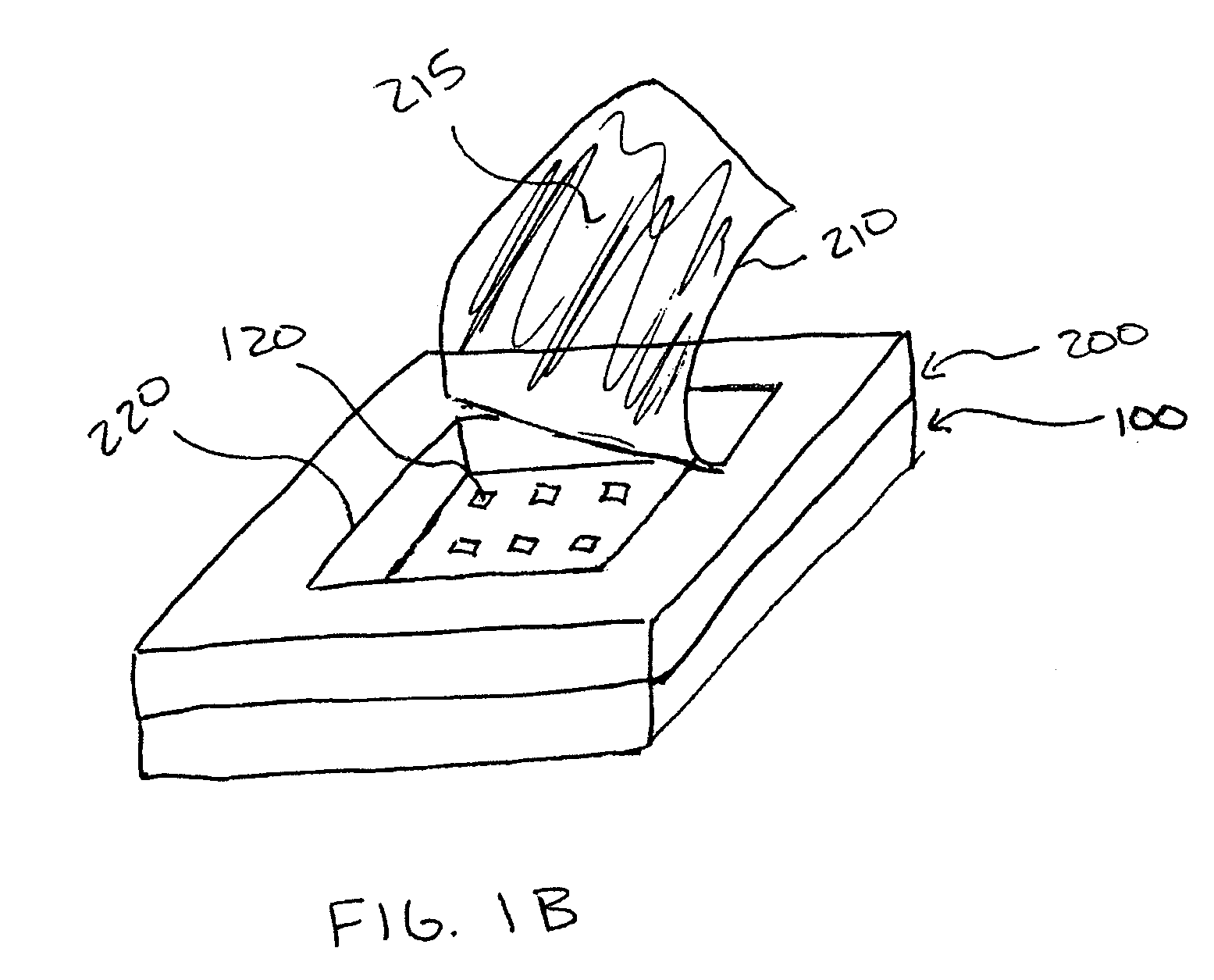

A system, apparatus, and method for filling a display panel having first and second plates, with liquid crystal material, includes a nozzle for depositing a layer of liquid crystal material over a surface of a first plate of the panel, a scanning arm, coupled to the nozzle, for uniformly forming the layer of liquid crystal material over the surface of the first plate of the panel, and an attachment mechanism for placing the second plate over the first plate having the liquid crystal material thereover, thereby to form the display panel.

Owner:AU OPTRONICS CORP

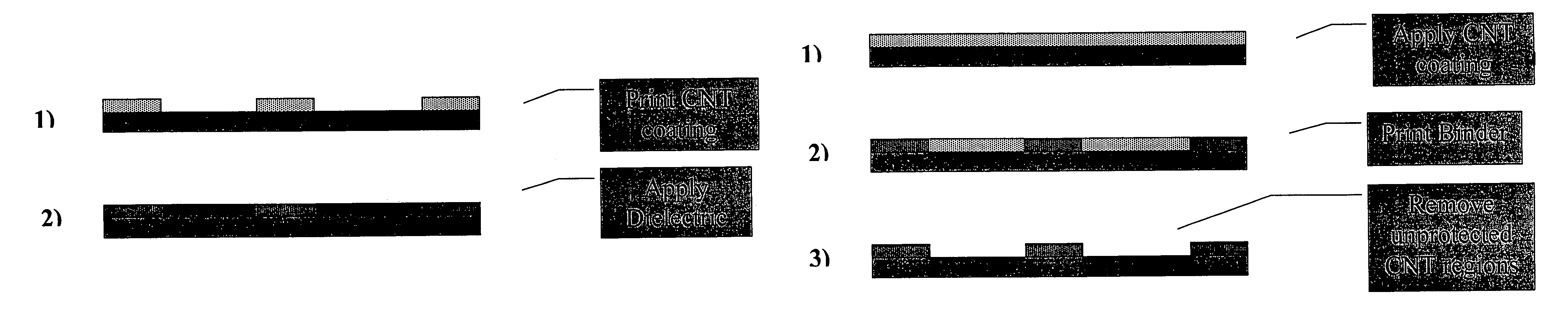

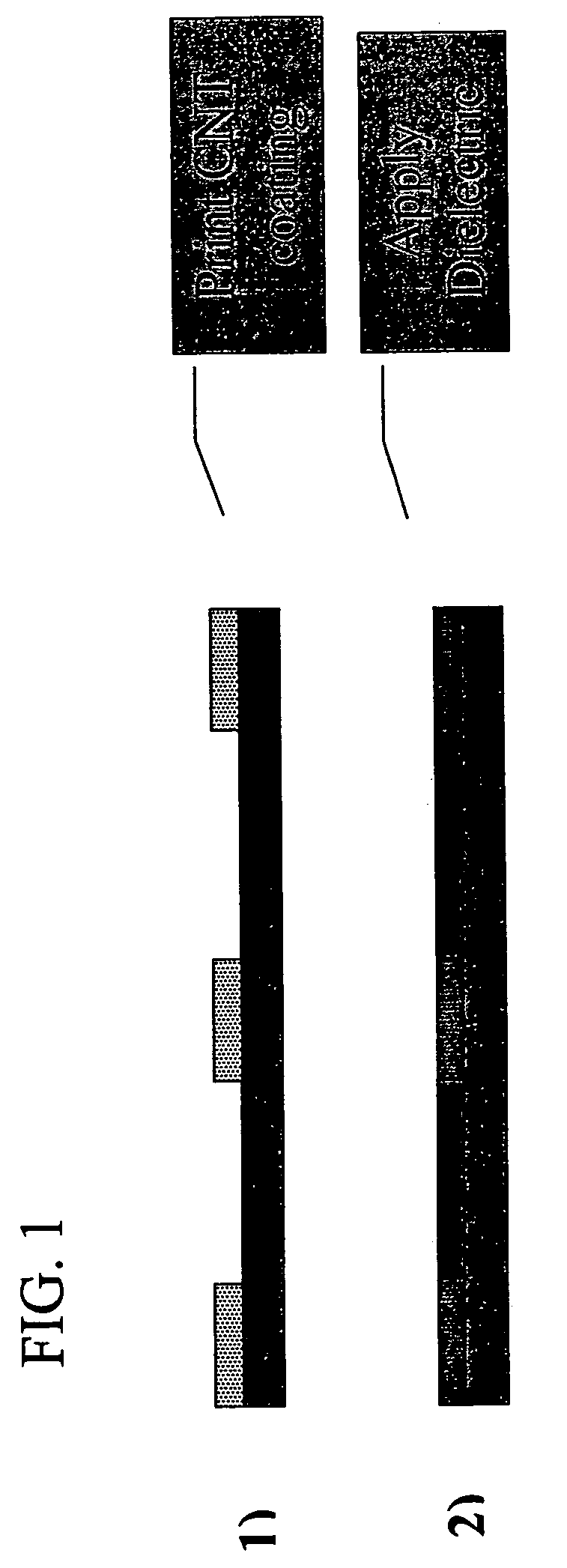

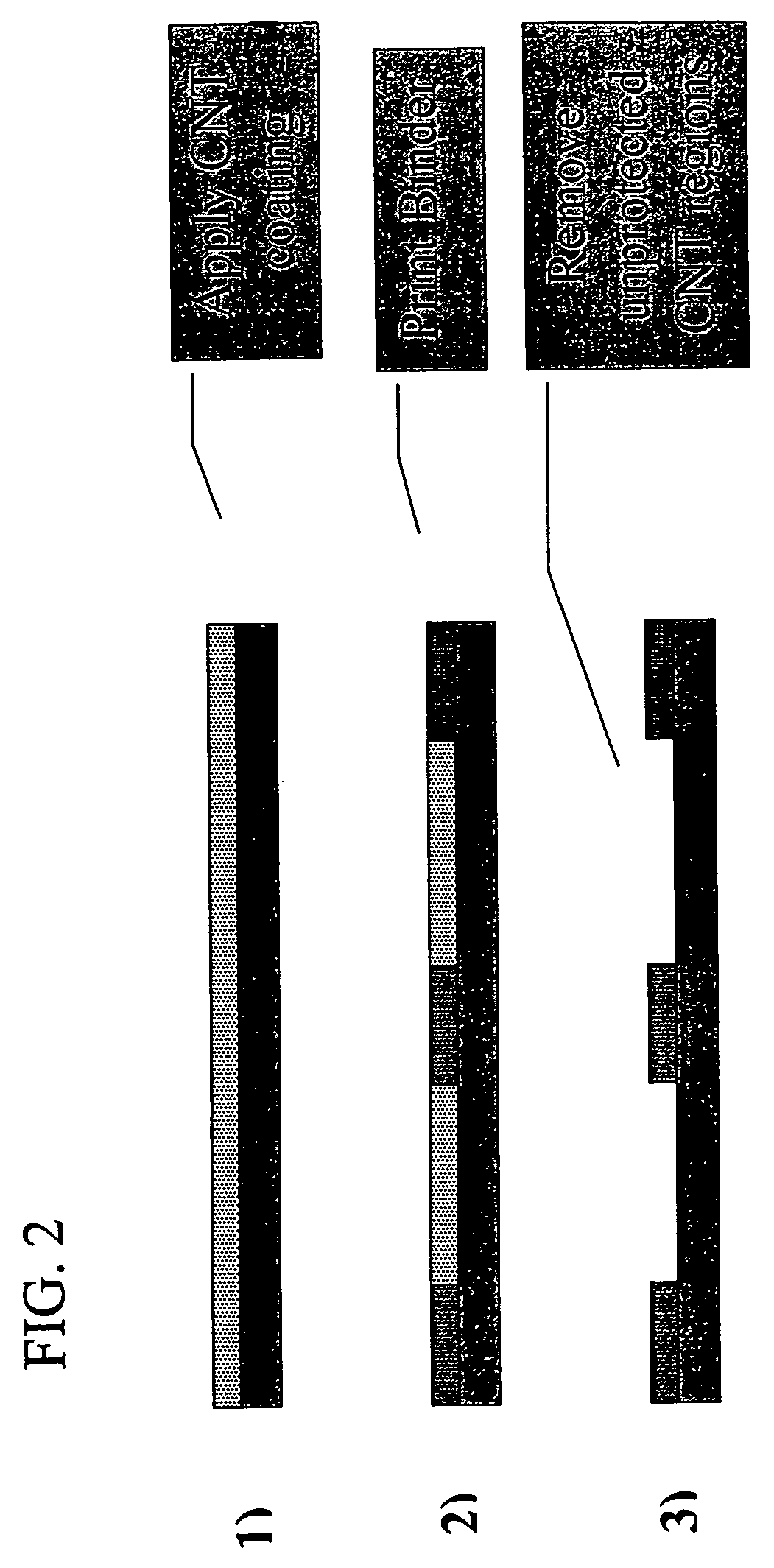

Method for patterning carbon nanotube coating and carbon nanotube wiring

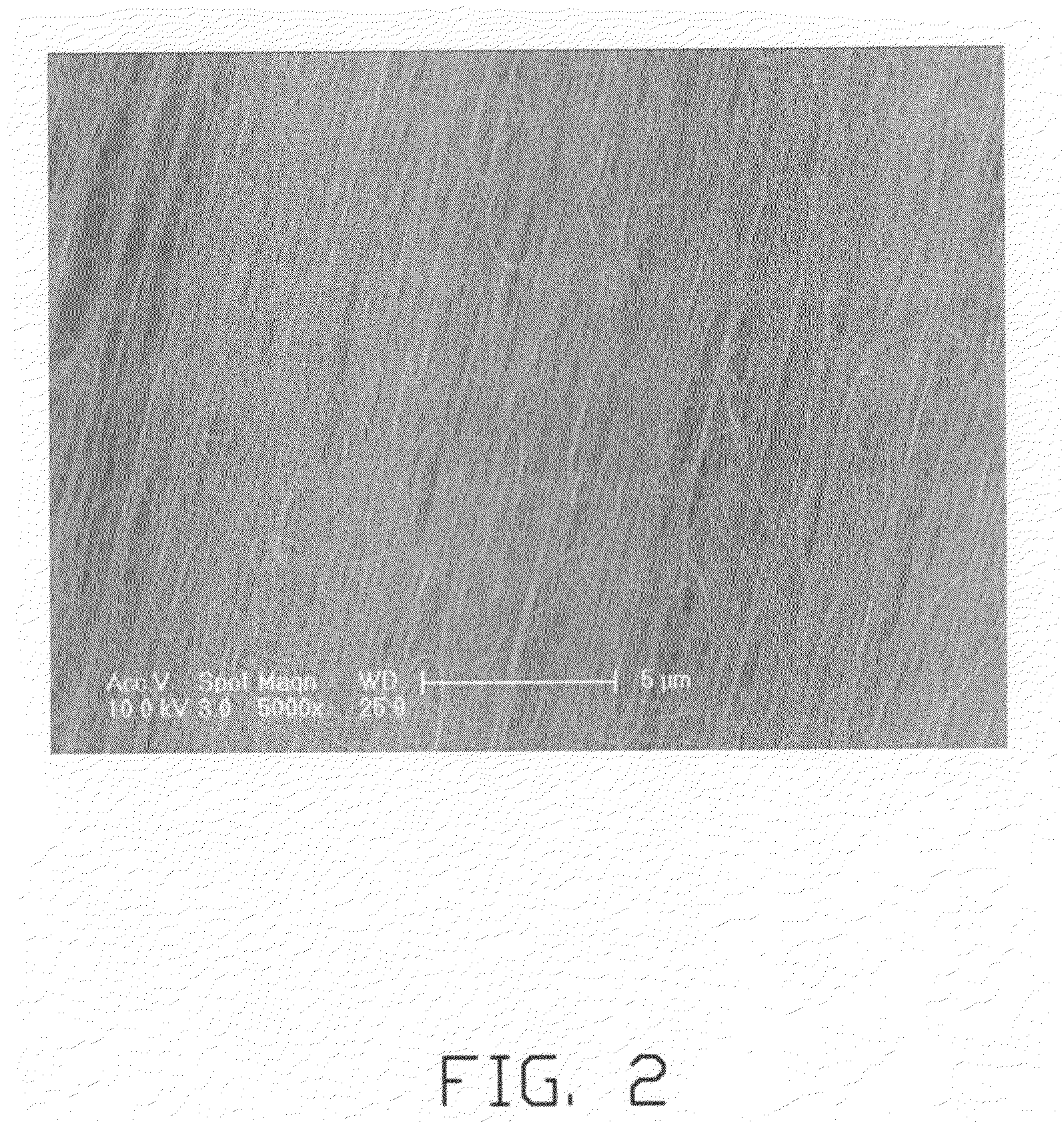

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:EIKOS

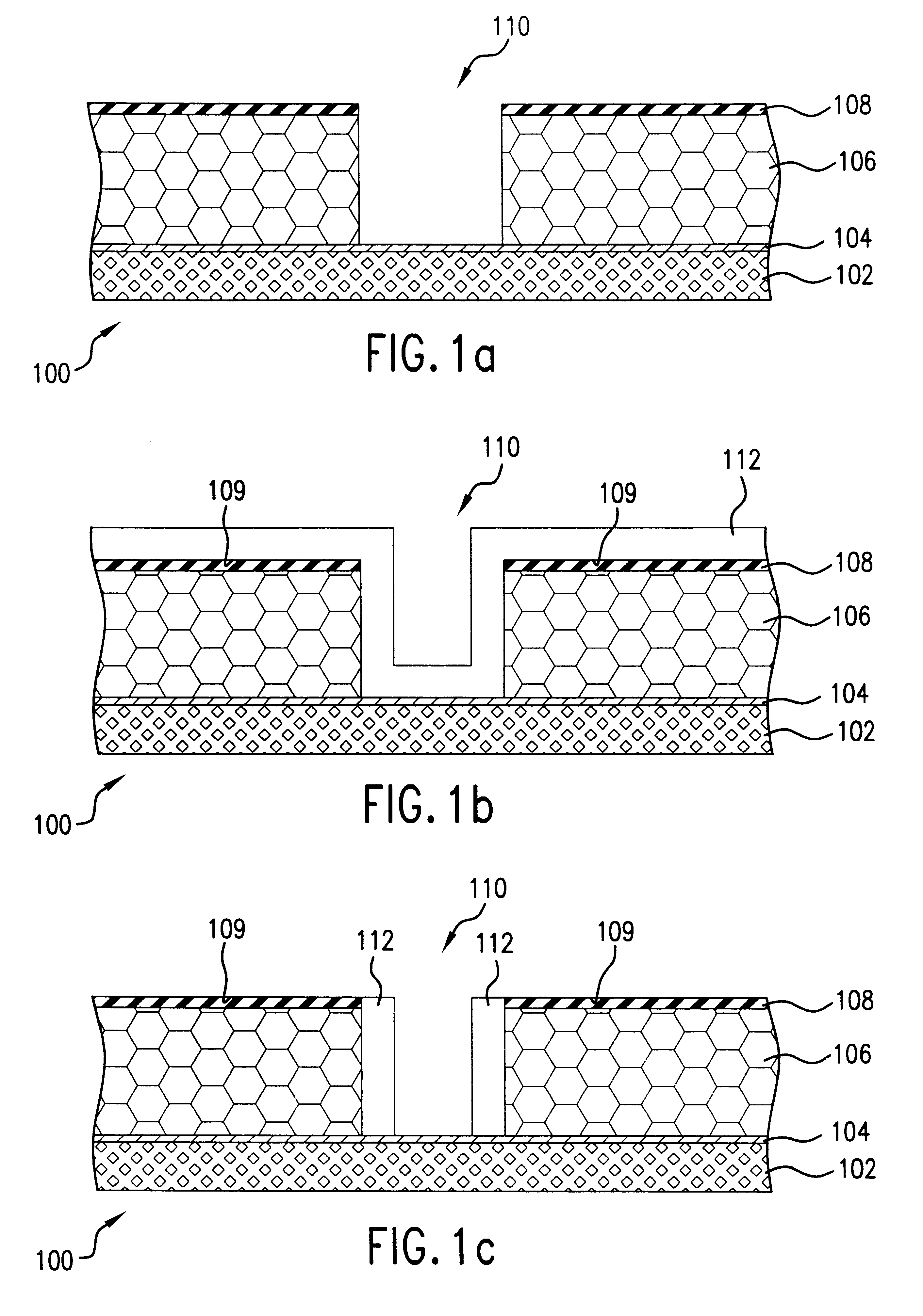

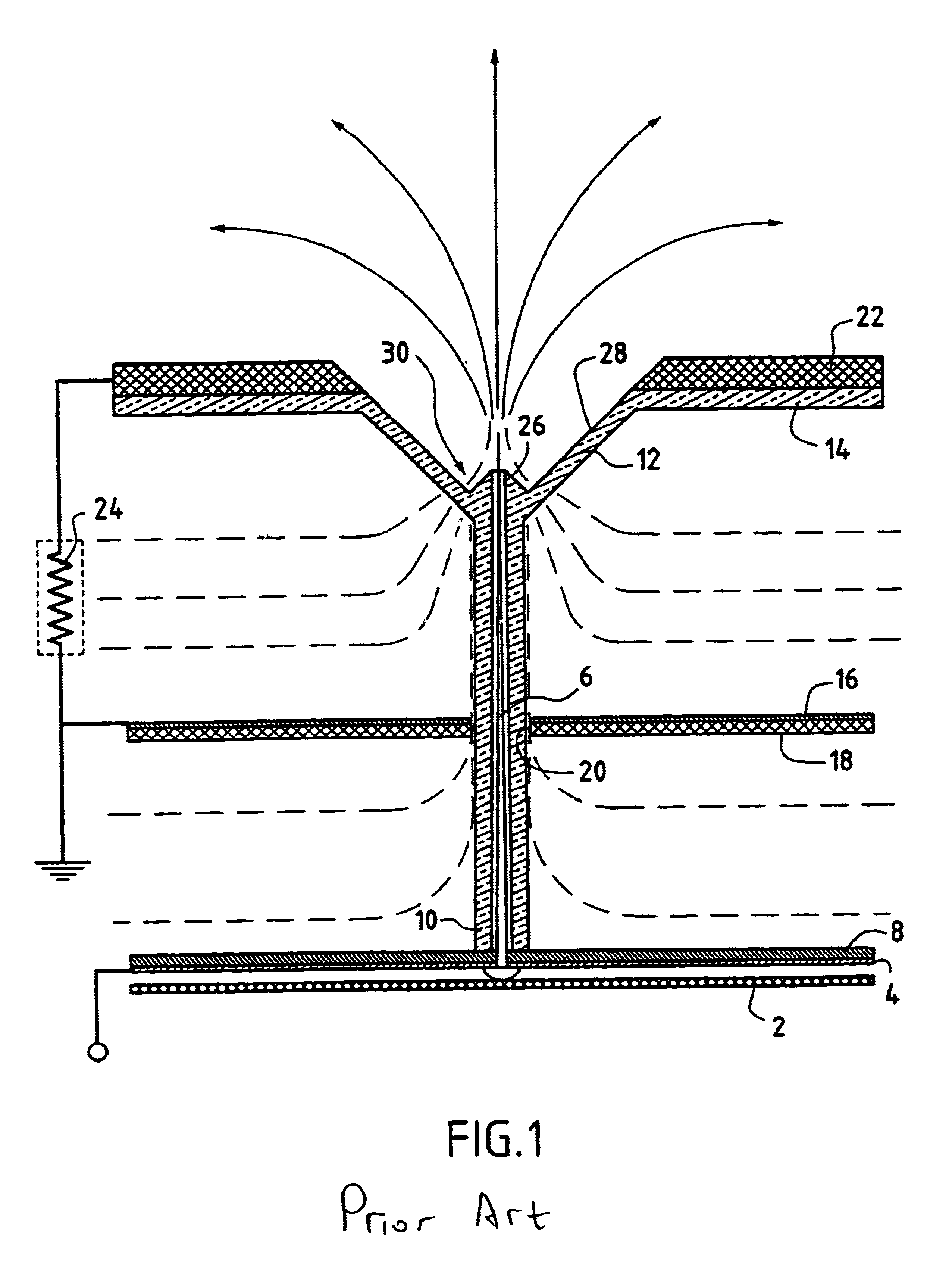

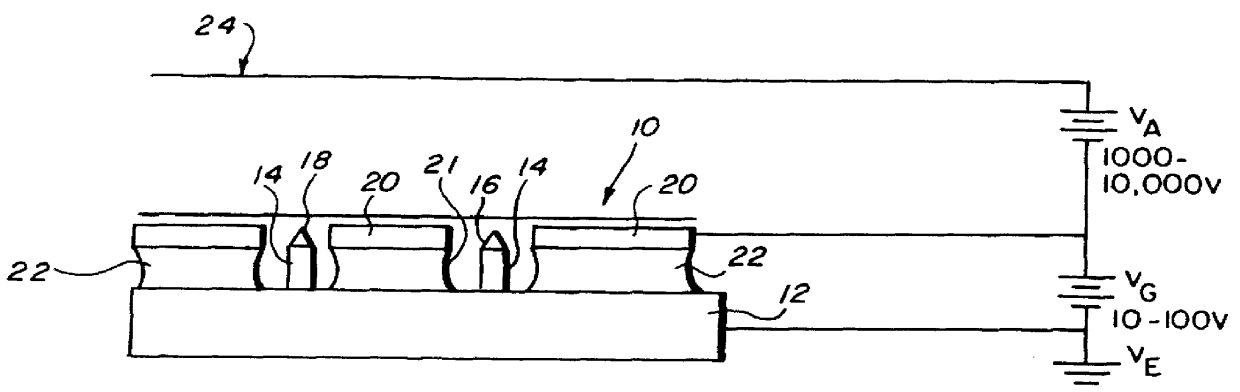

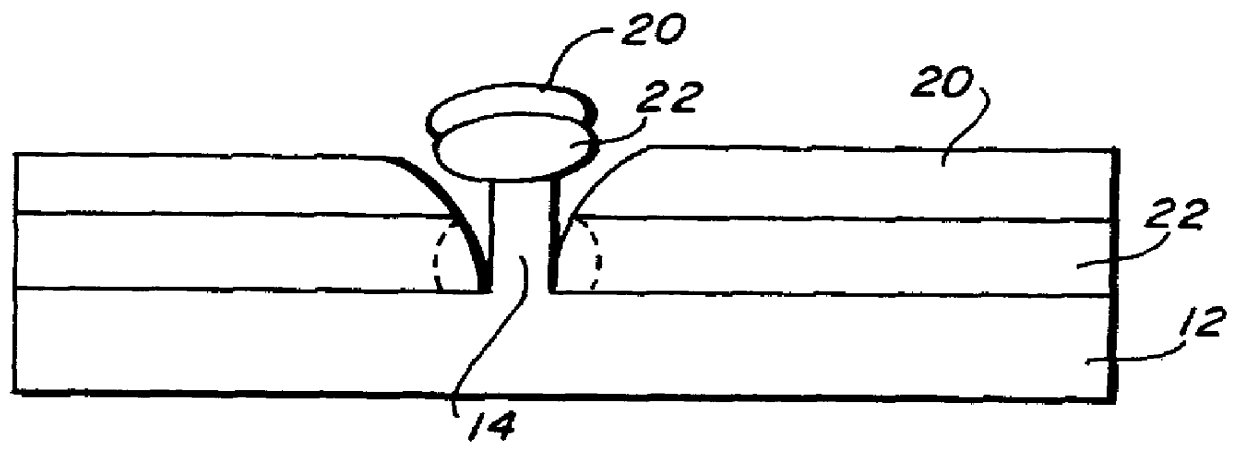

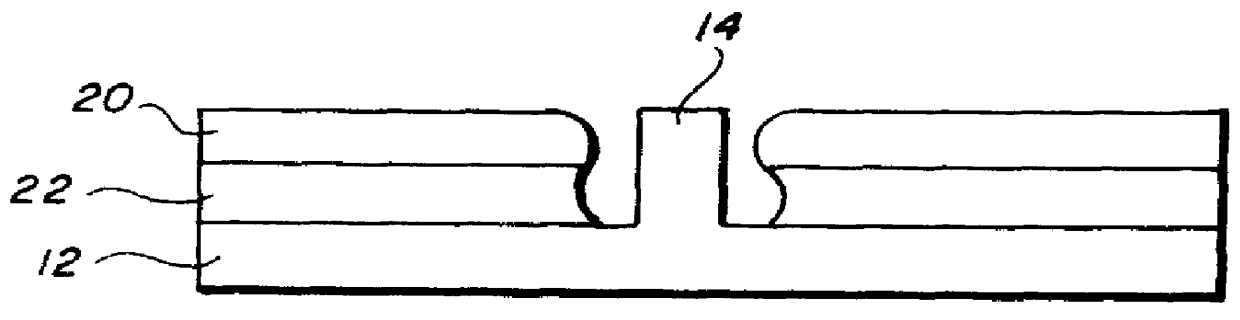

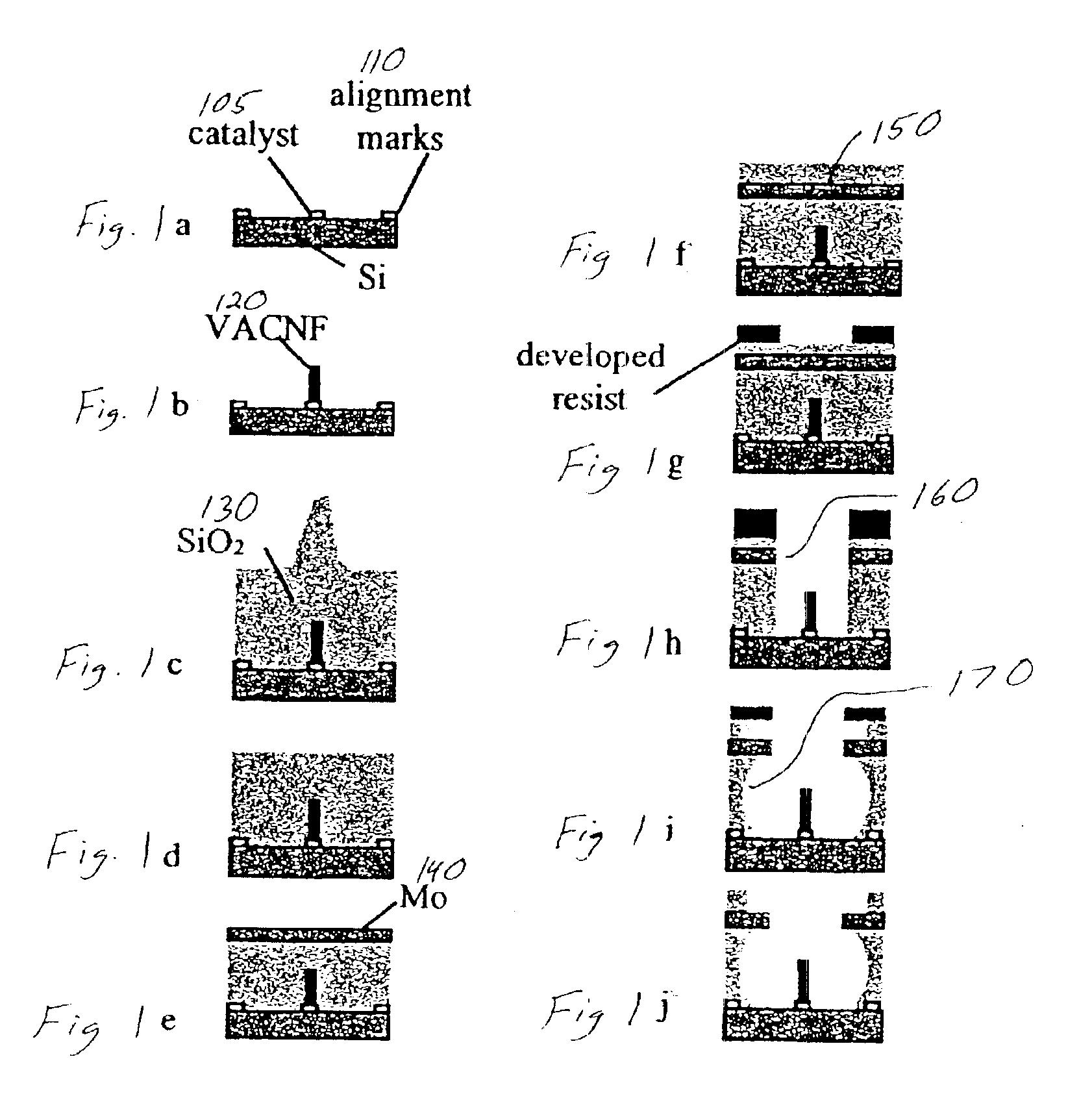

Methods for manufacture of self-aligned integrally gated nanofilament field emitter cell and array

InactiveUS6440763B1Clean and inert surfaceImprove stabilityElectric discharge tubesNanoinformaticsEngineeringNanometre

The present invention discloses a new field emitter cell and array consisting of groups of nanofilaments forming emitter cathodes. Control gates are microprocessed to be integrally formed with groups of nanofilament emitter cathodes on a substrate. Groups of nanofilaments are grown directly on the substrate material. As a result, the control gates and groups of nanofilaments are self-aligned with one another.

Owner:SEC OF THE NAVY AS REPRESENTED BY THE UNITED STATES OF AMERICA THE

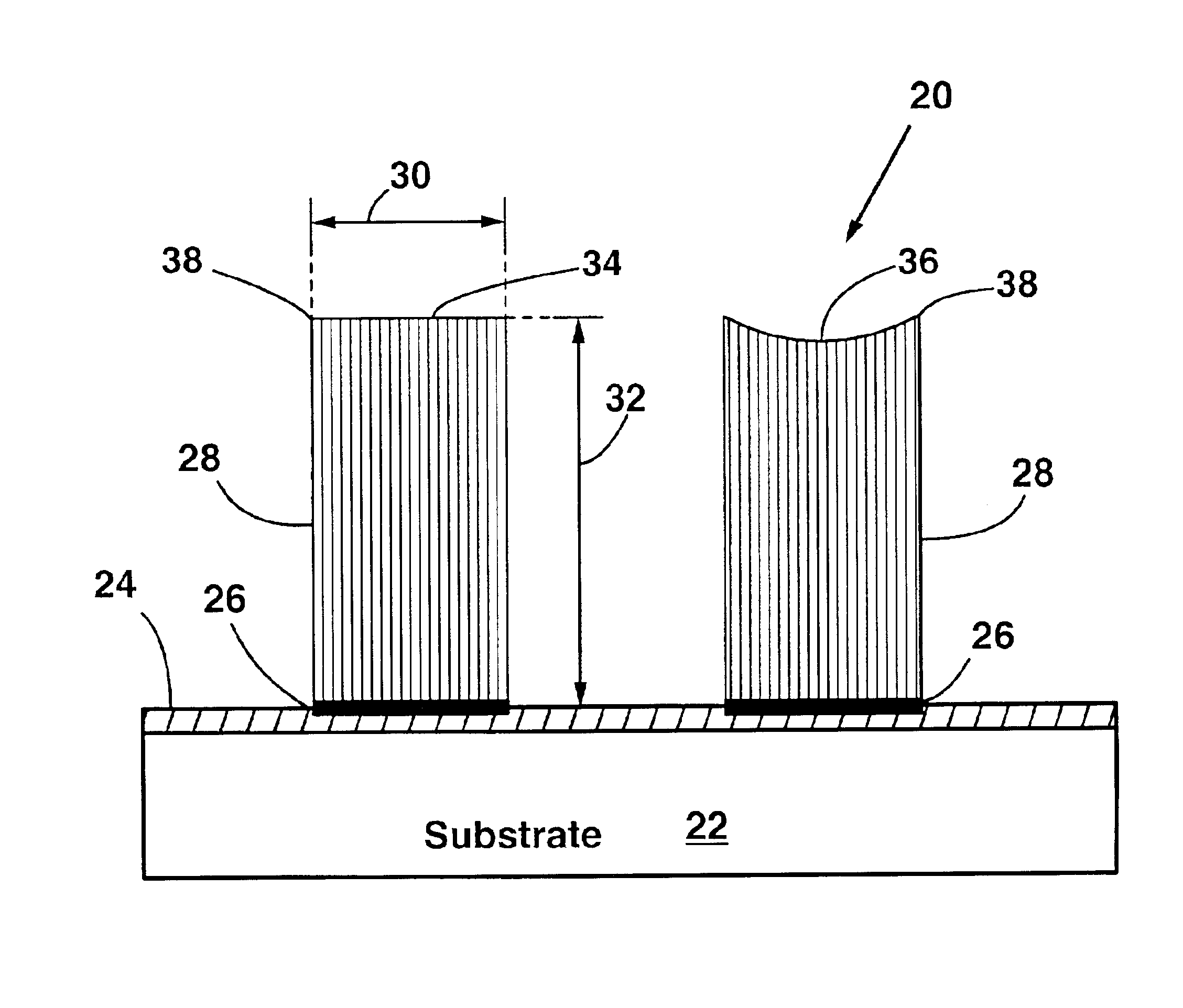

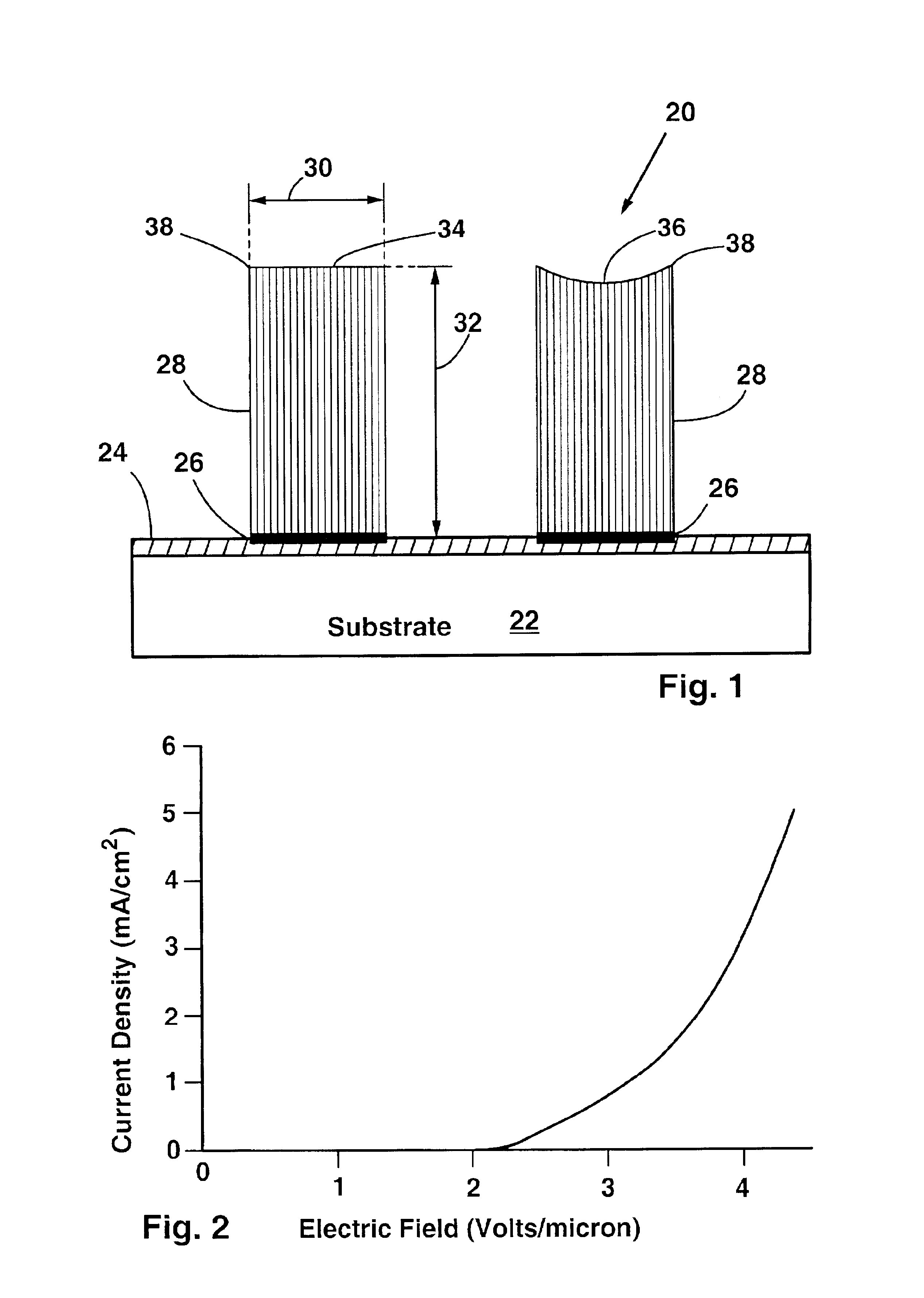

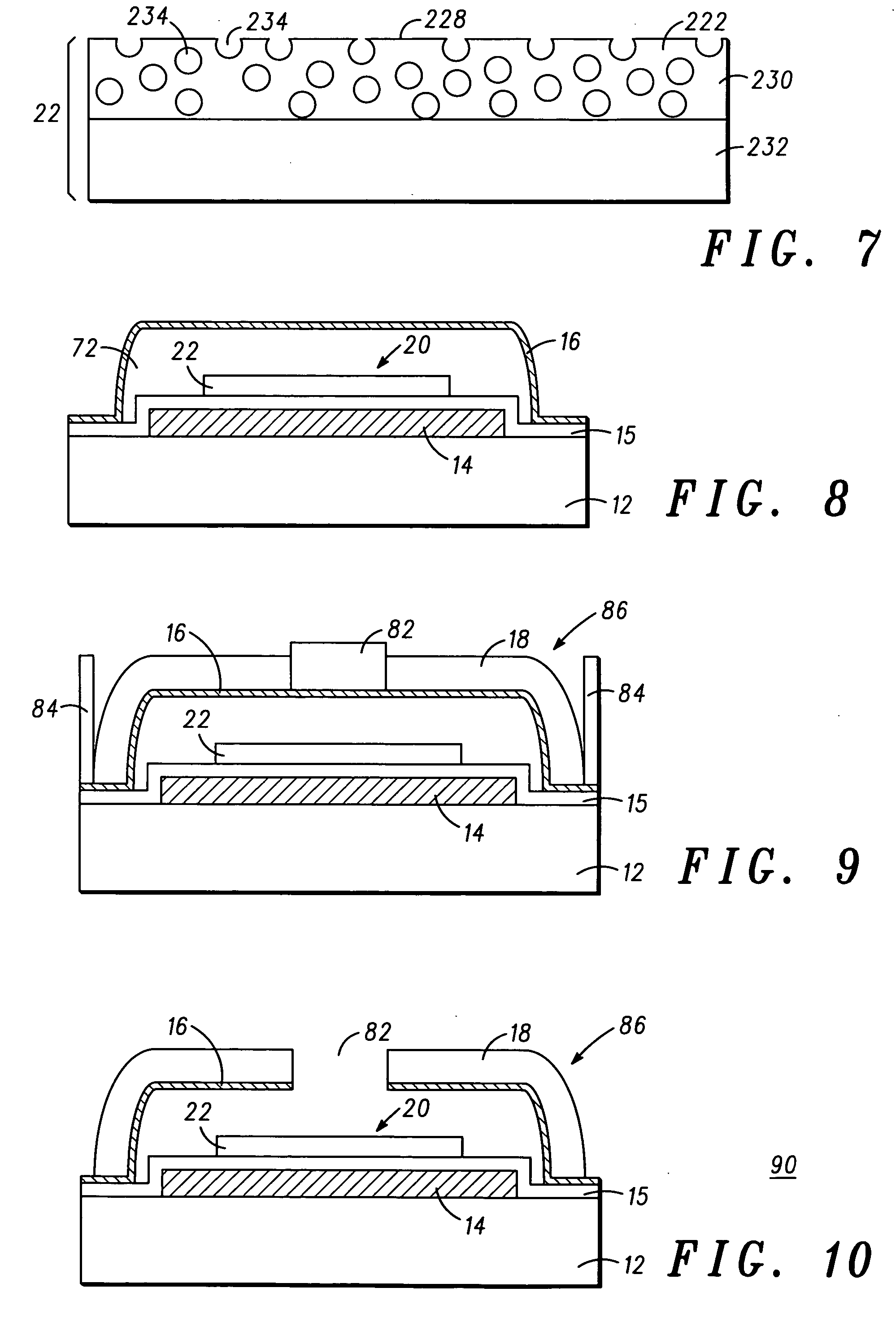

Self-oriented bundles of carbon nanotubes and method of making same

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

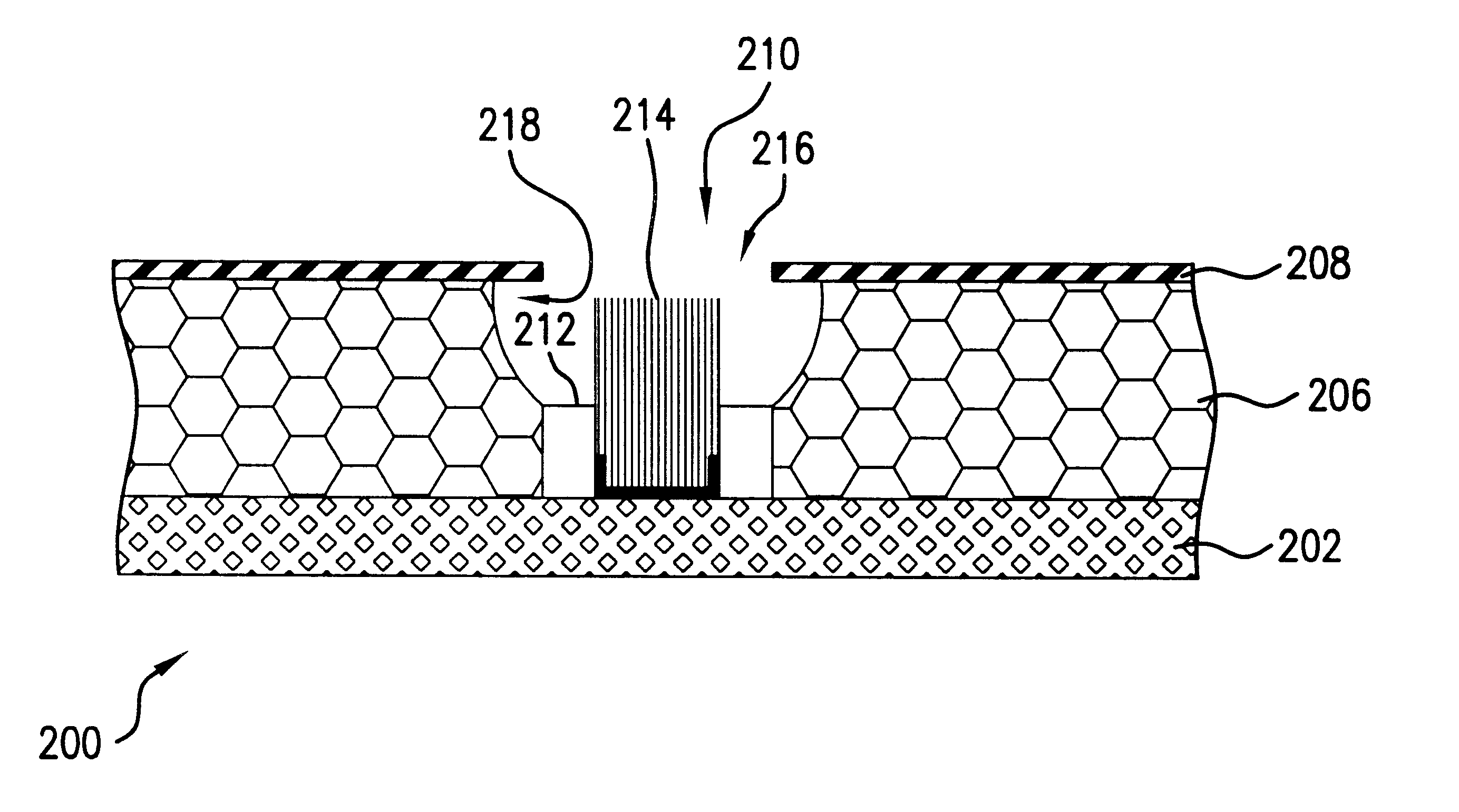

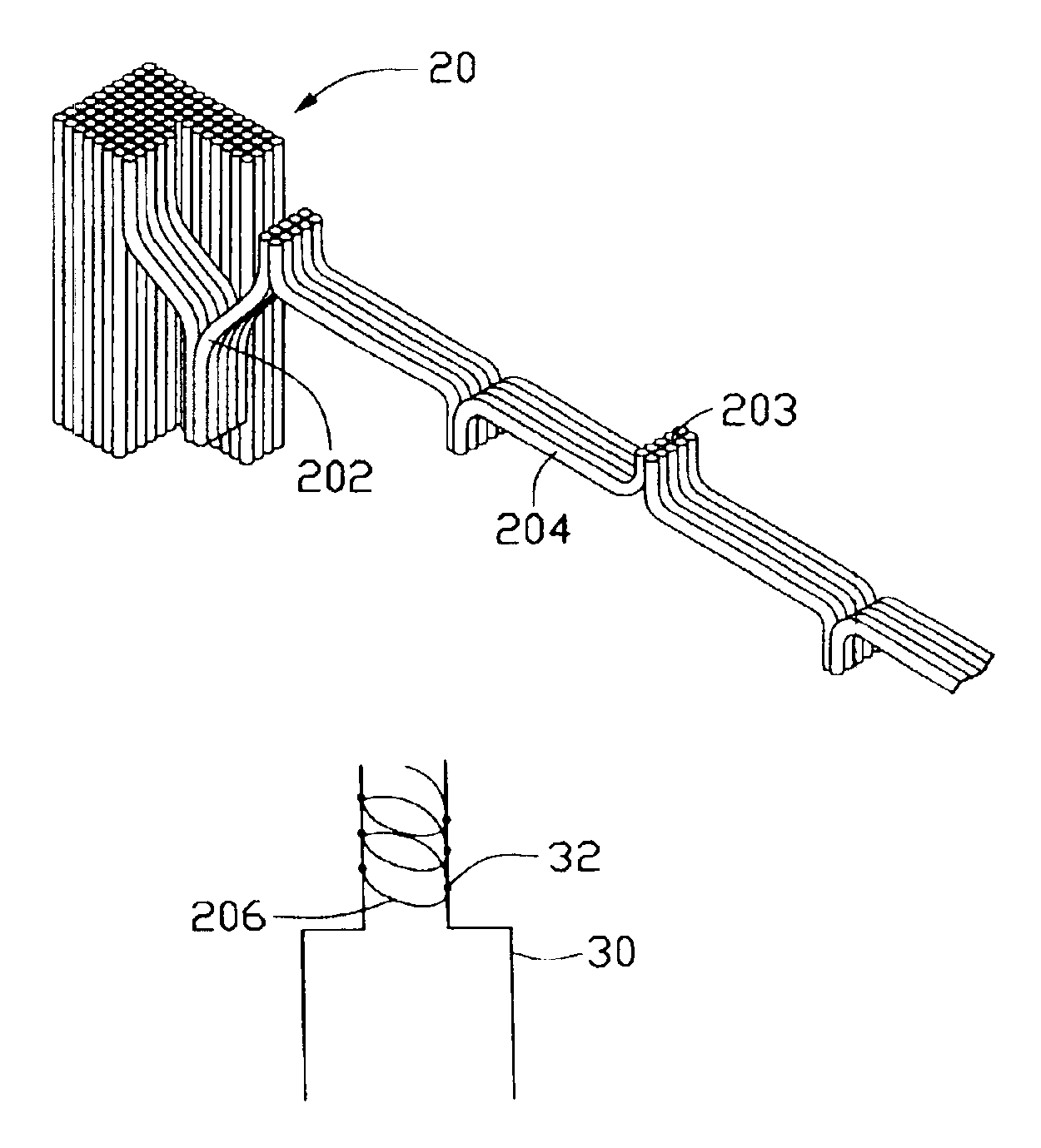

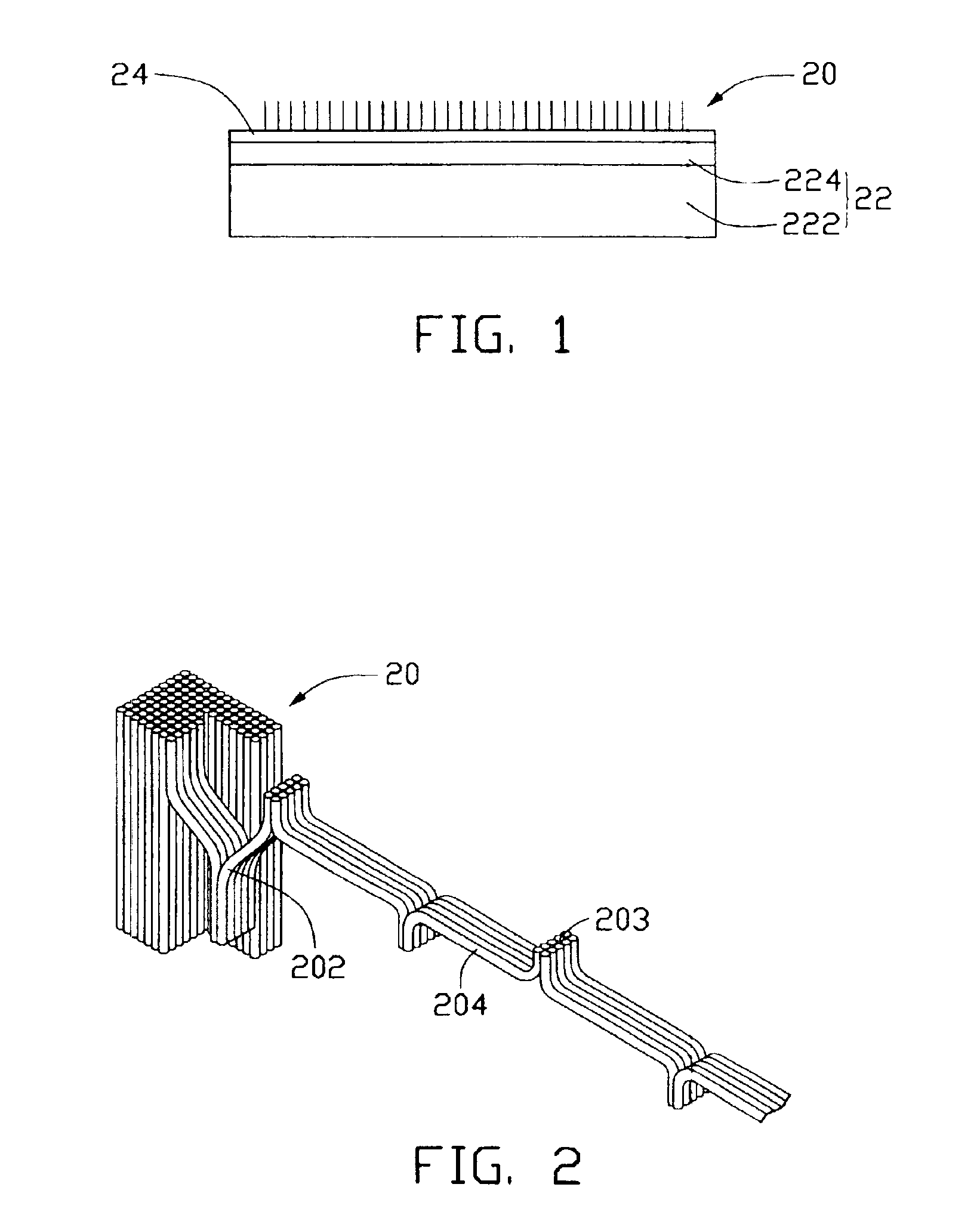

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

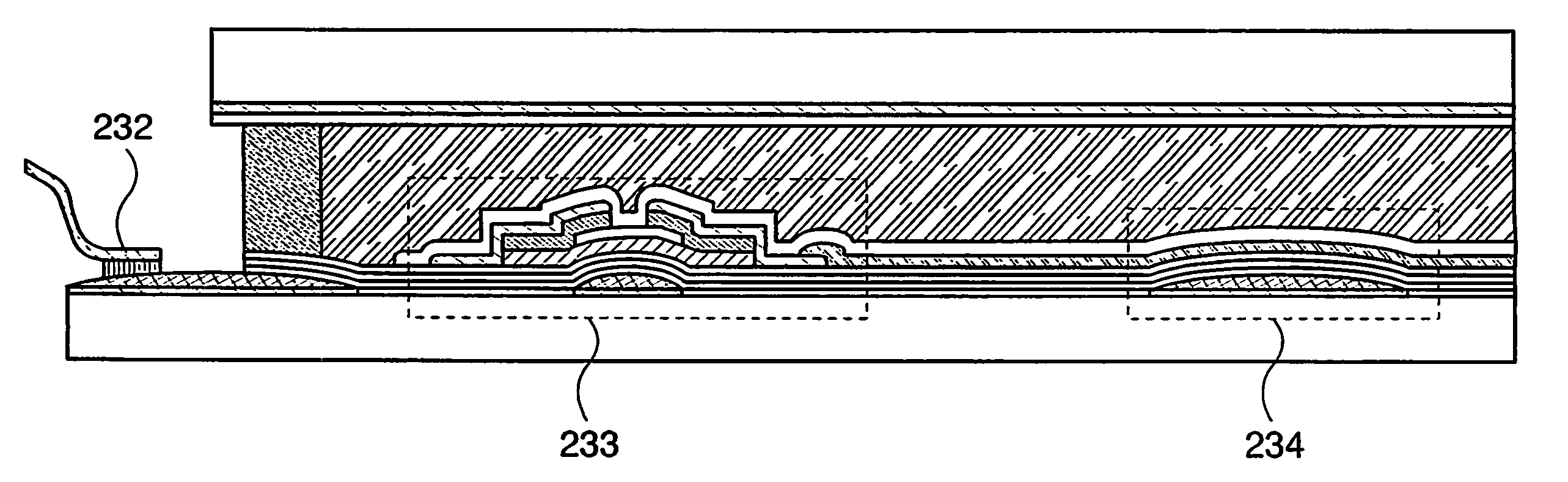

Liquid crystal display device and method for manufacturing the same, and liquid crystal television receiver

InactiveUS20070051952A1Improve material efficiencySimplify manufacturing stepsProjectorsSolid-state devicesTelevision receiversEngineering

At least one or more of a conductive layer which forms a wiring or an electrode and a pattern necessary for manufacturing a display panel such as a mask for forming a predetermined pattern is formed by a method capable of selectively forming a pattern to manufacture a liquid crystal display device. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition in accordance with a particular object is used as a method capable of selectively forming a pattern in forming a conductive layer, an insulating layer, or the like.

Owner:SEMICON ENERGY LAB CO LTD

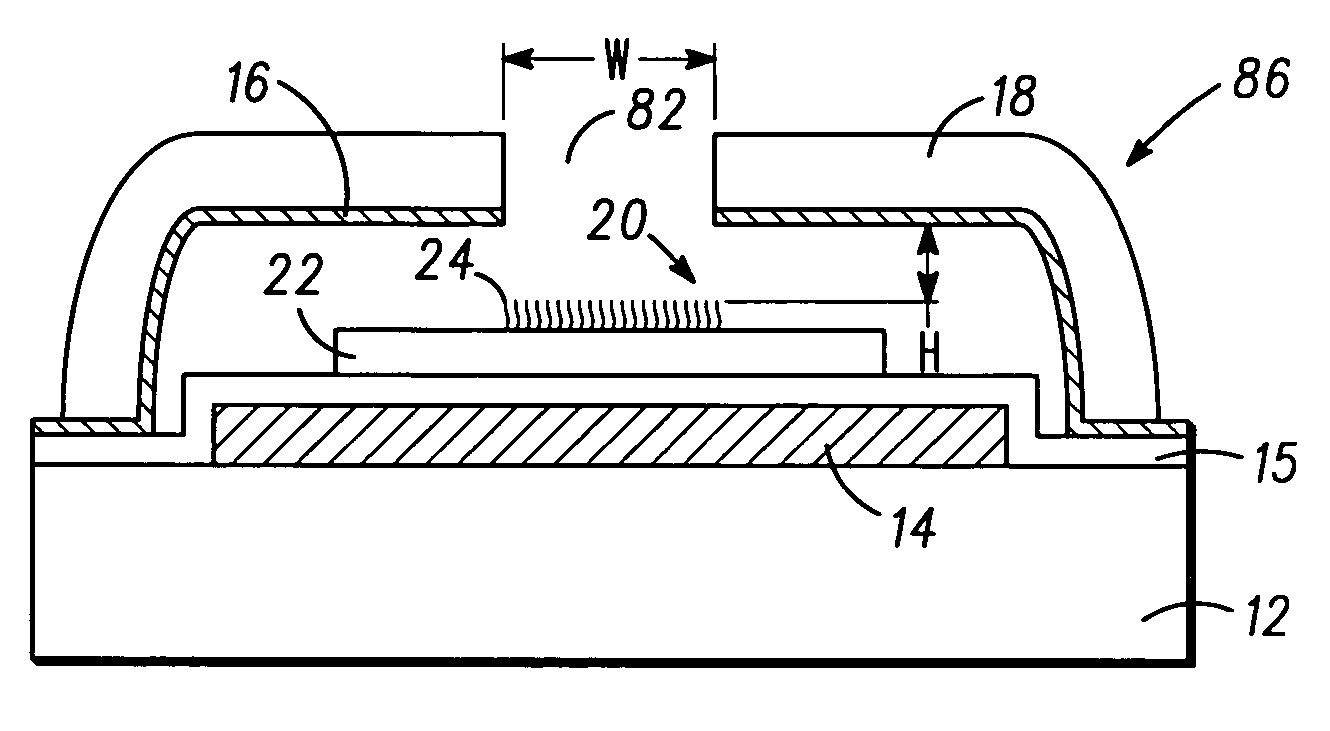

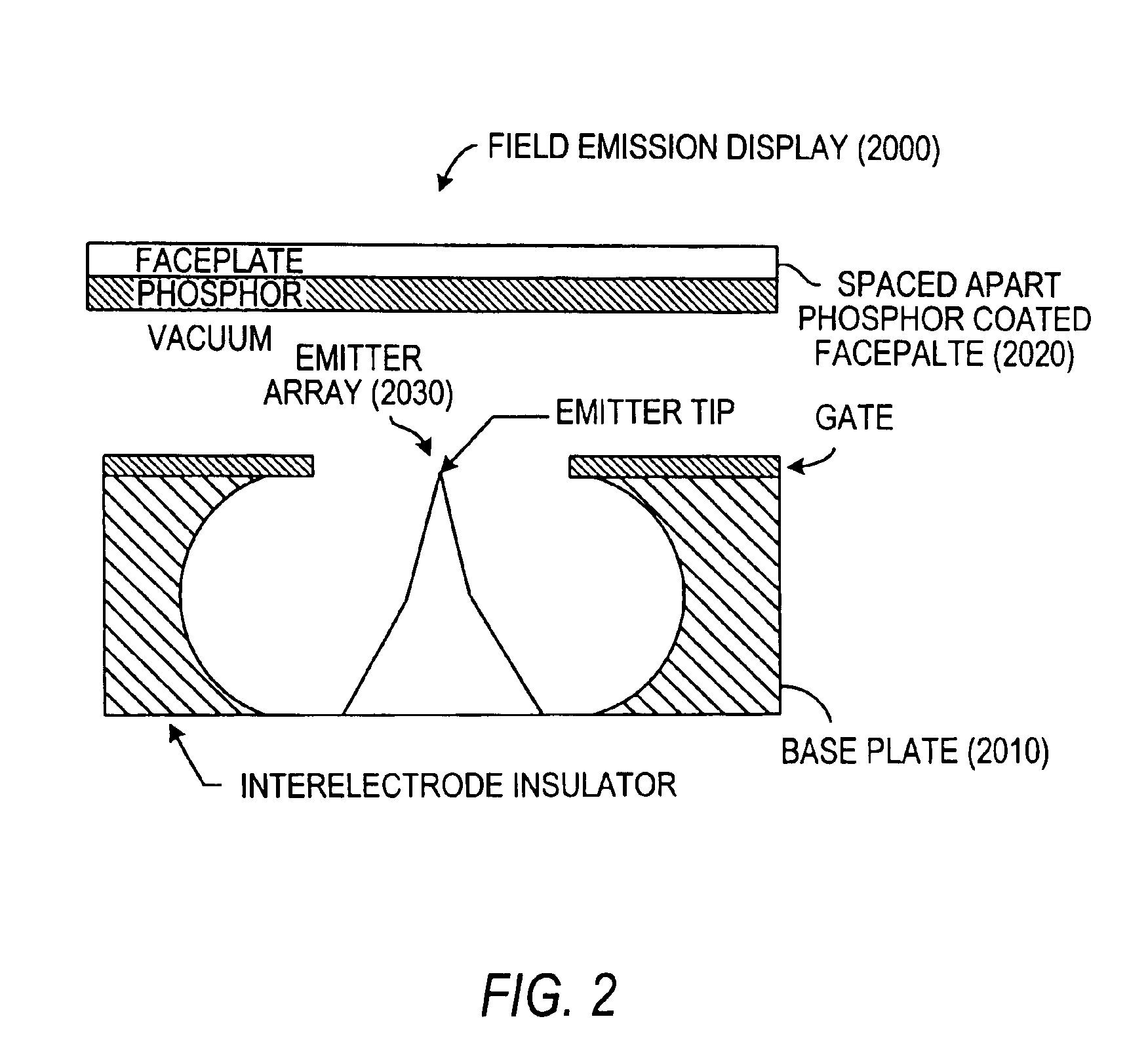

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

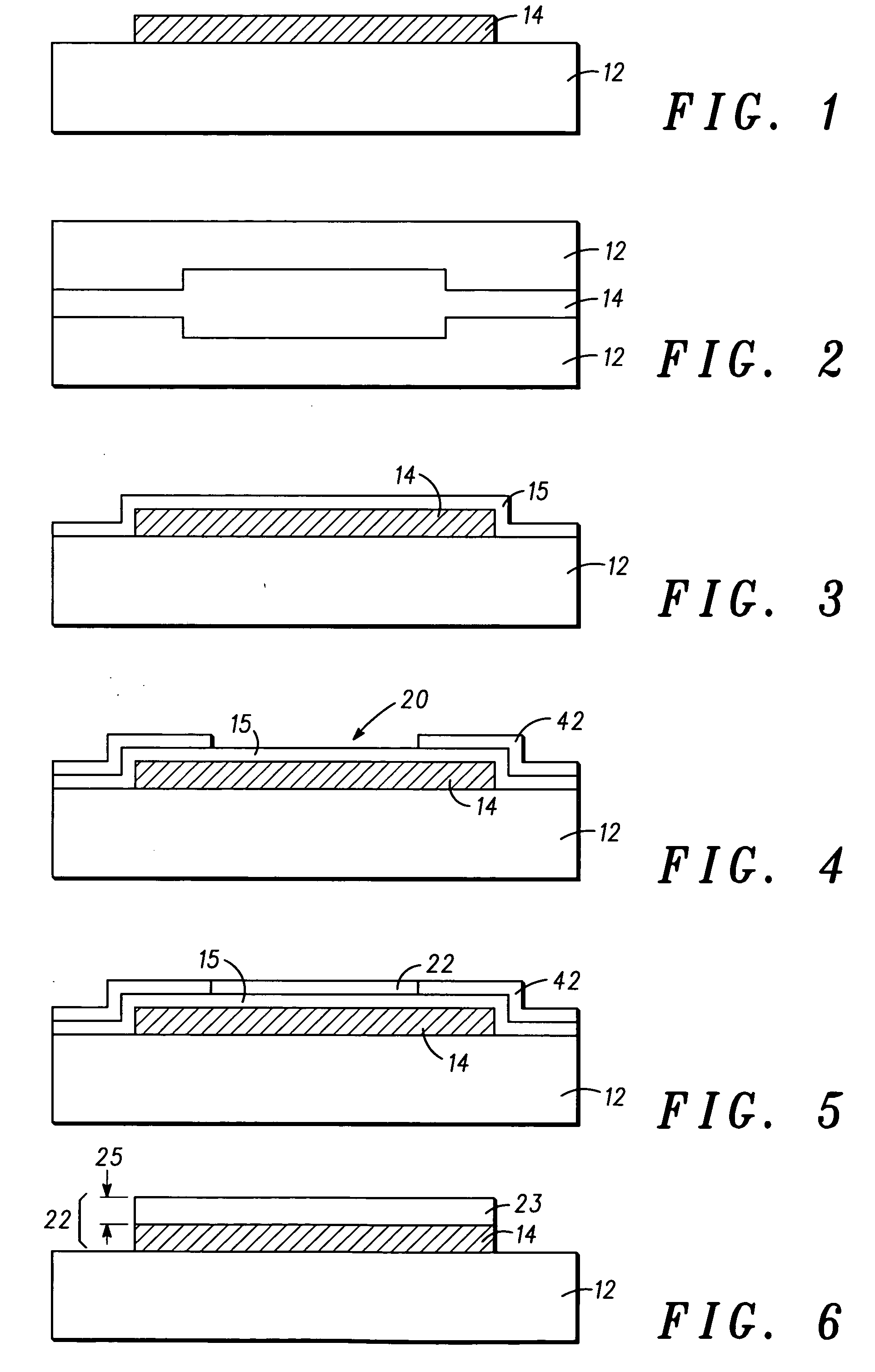

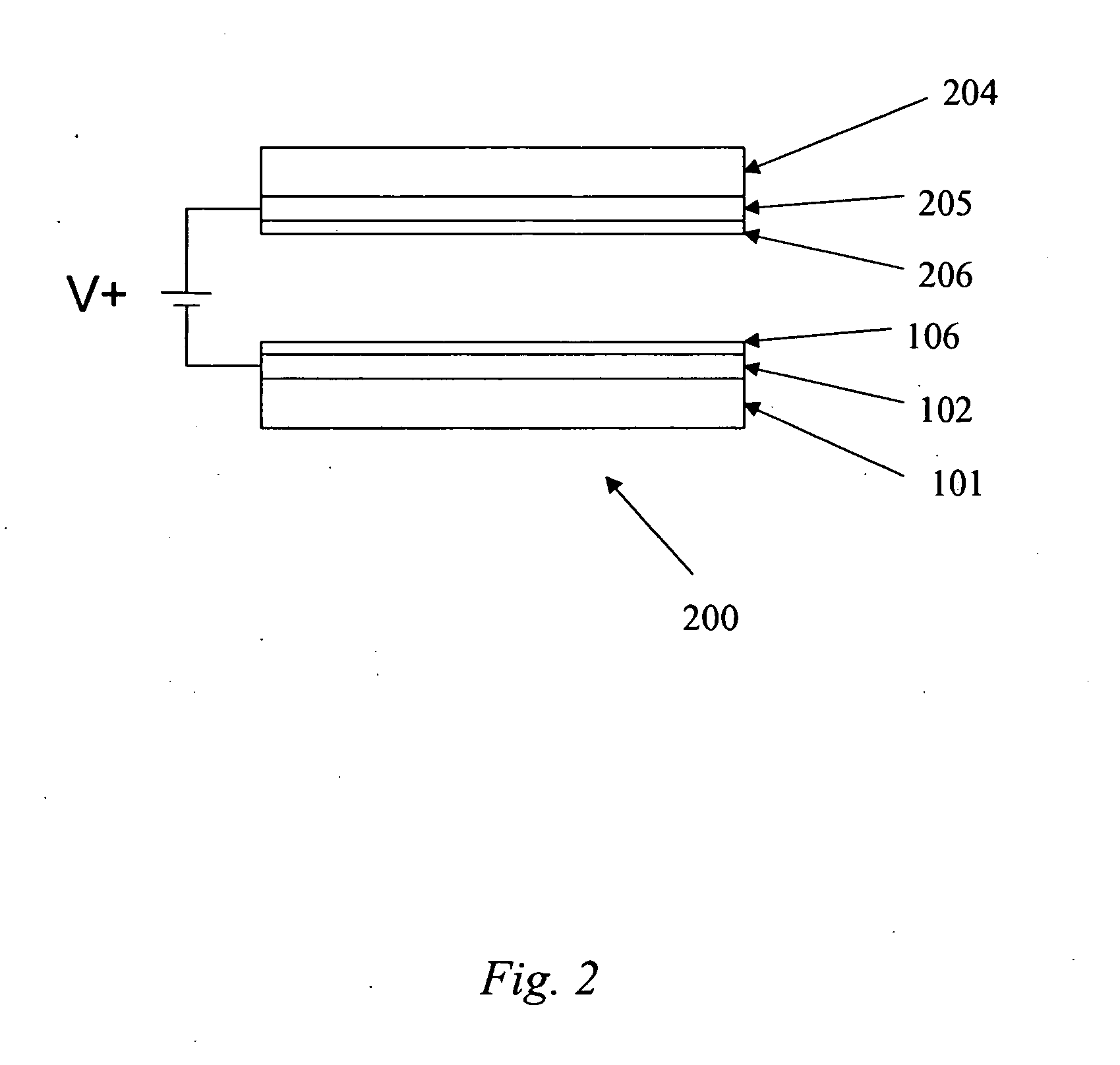

Method of making encapsulated display devices

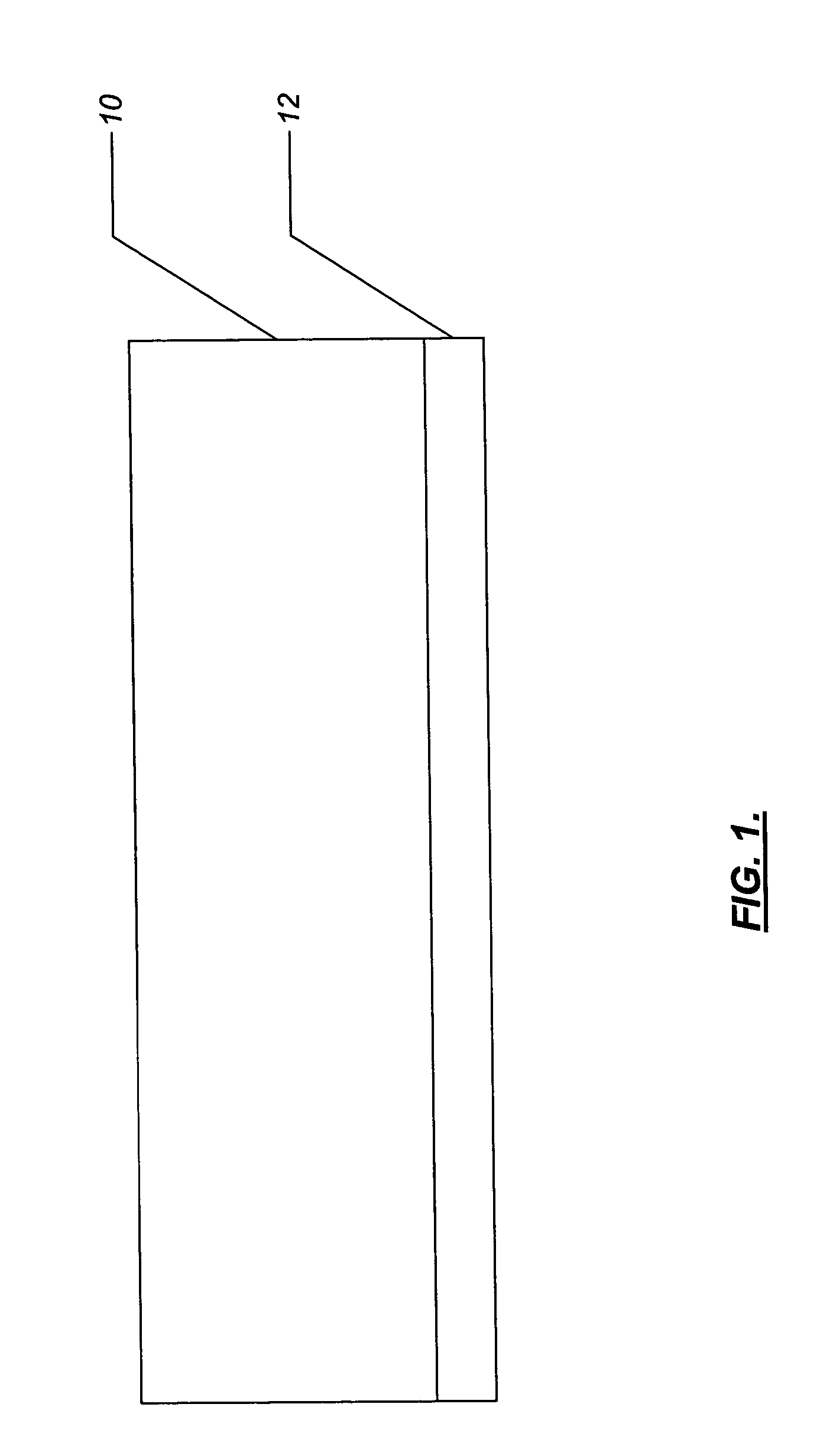

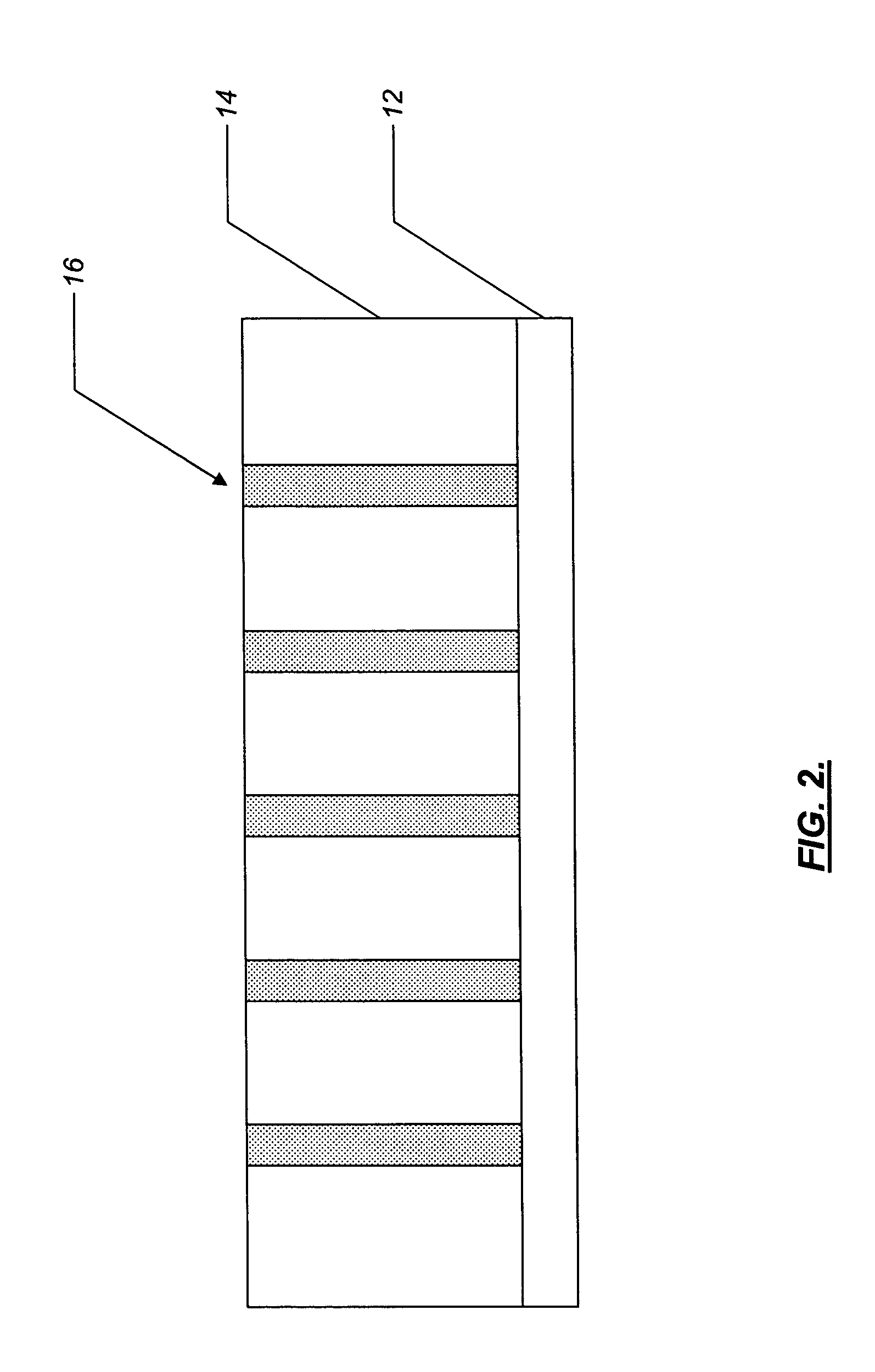

InactiveUS6923702B2Static indicating devicesSemiconductor/solid-state device detailsDisplay deviceComputer science

An encapsulated display device. The device includes a substrate, an environmentally sensitive display device adjacent to the substrate, and at least one first barrier stack adjacent to the environmentally sensitive display device. The barrier stack encapsulates the environmentally sensitive display device. It includes at least one first barrier layer and at least one first polymer layer. The encapsulated display device optionally includes at least one second barrier stack located between the substrate and the environmentally sensitive display device. The second barrier stack includes at least one second barrier layer and at least one second polymer layer. A method for making an encapsulated display device is also disclosed.

Owner:SAMSUNG DISPLAY CO LTD

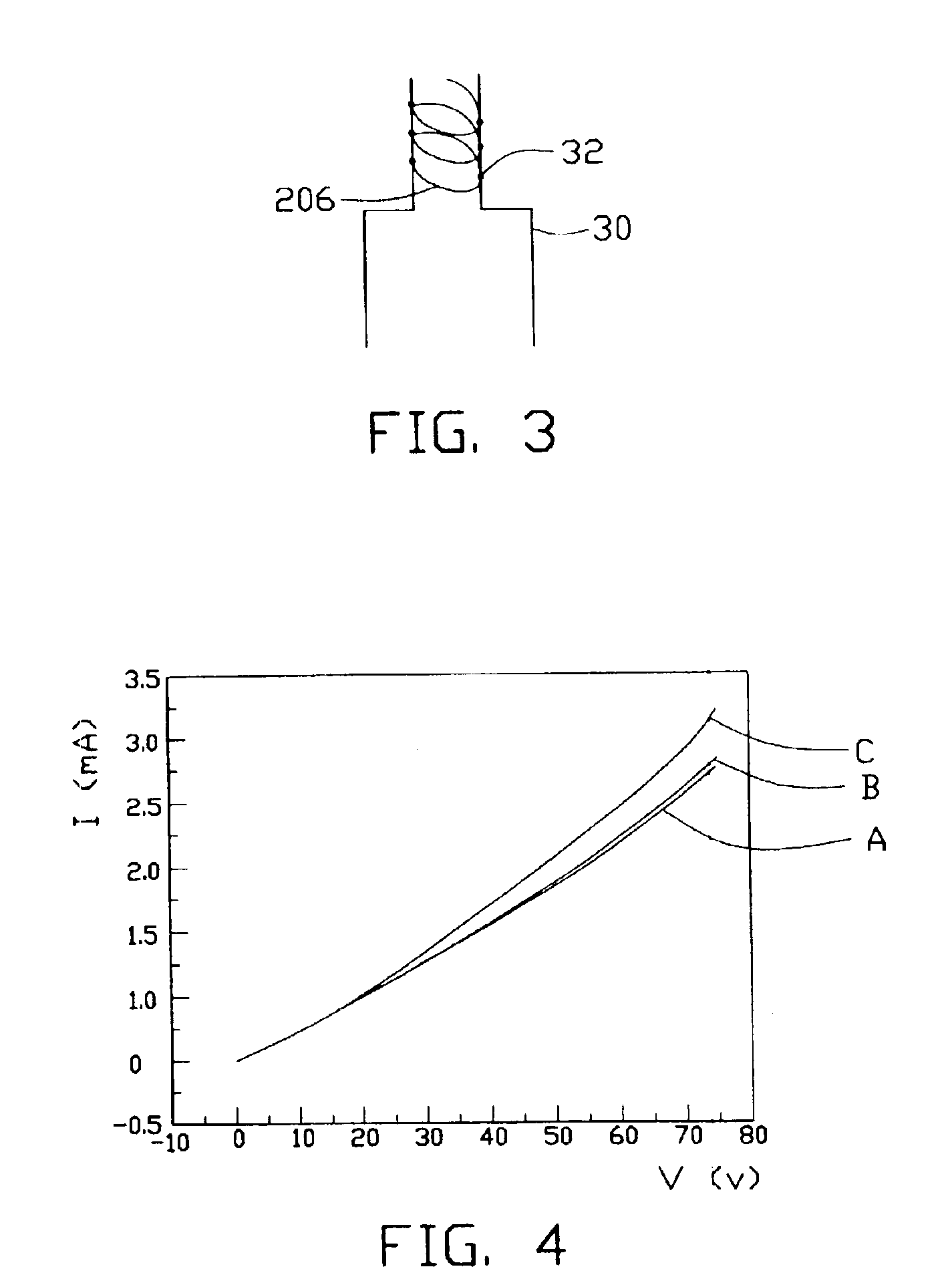

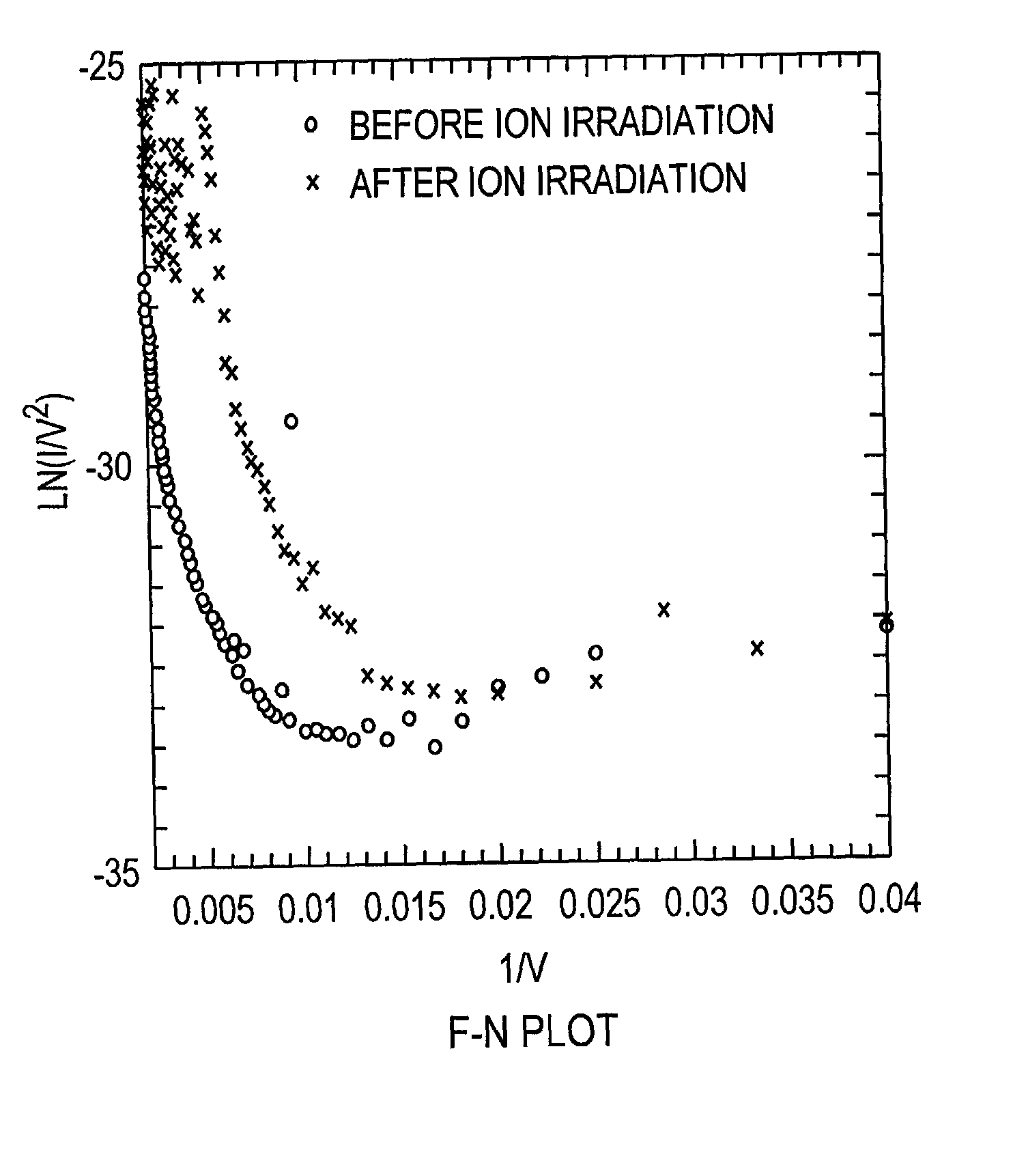

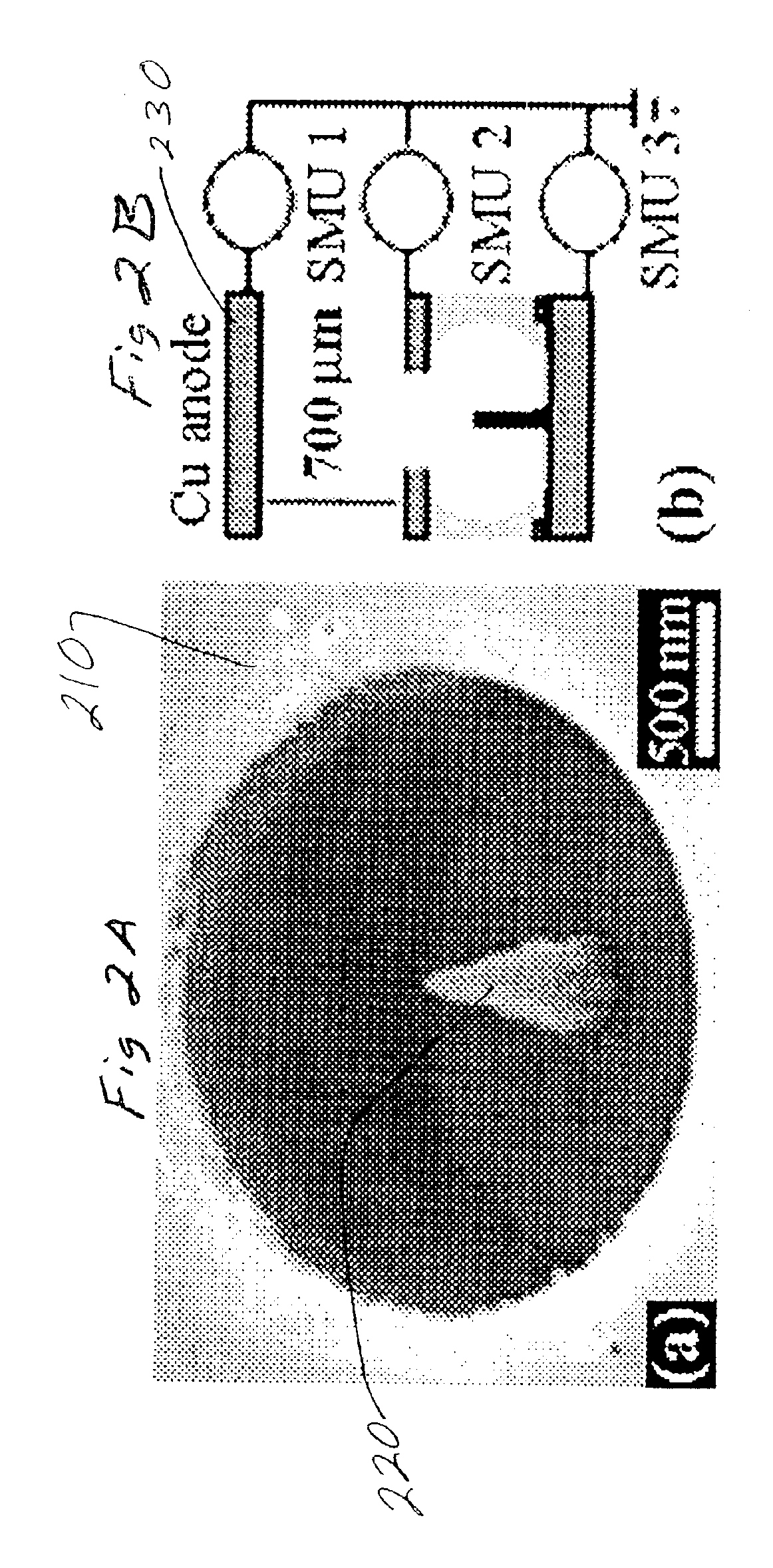

Field emission devices using ion bombarded carbon nanotubes

InactiveUS6911767B2Reduce voltageAccelerate emissionsCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

Thermionic electron emission device and method for making the same

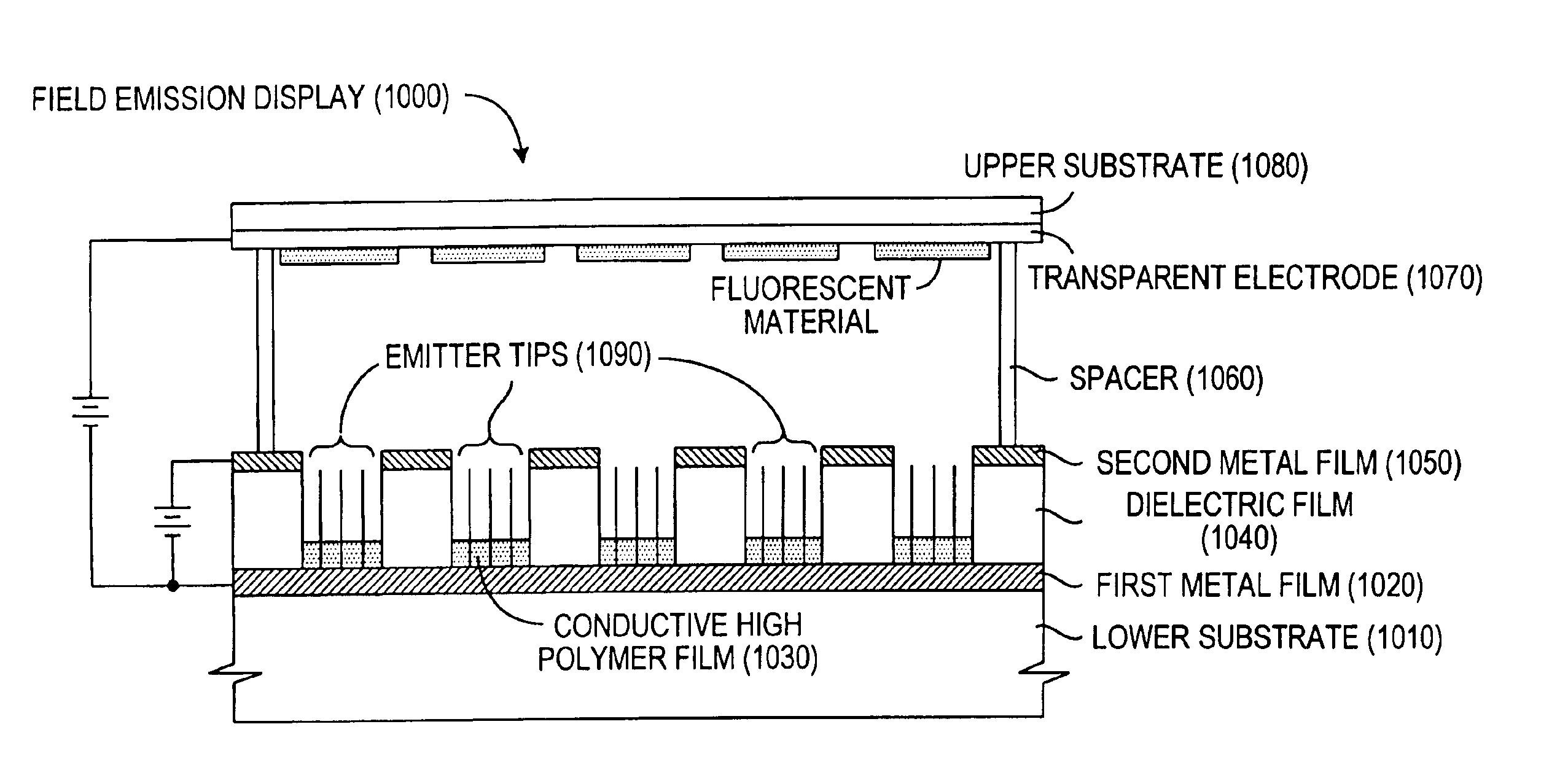

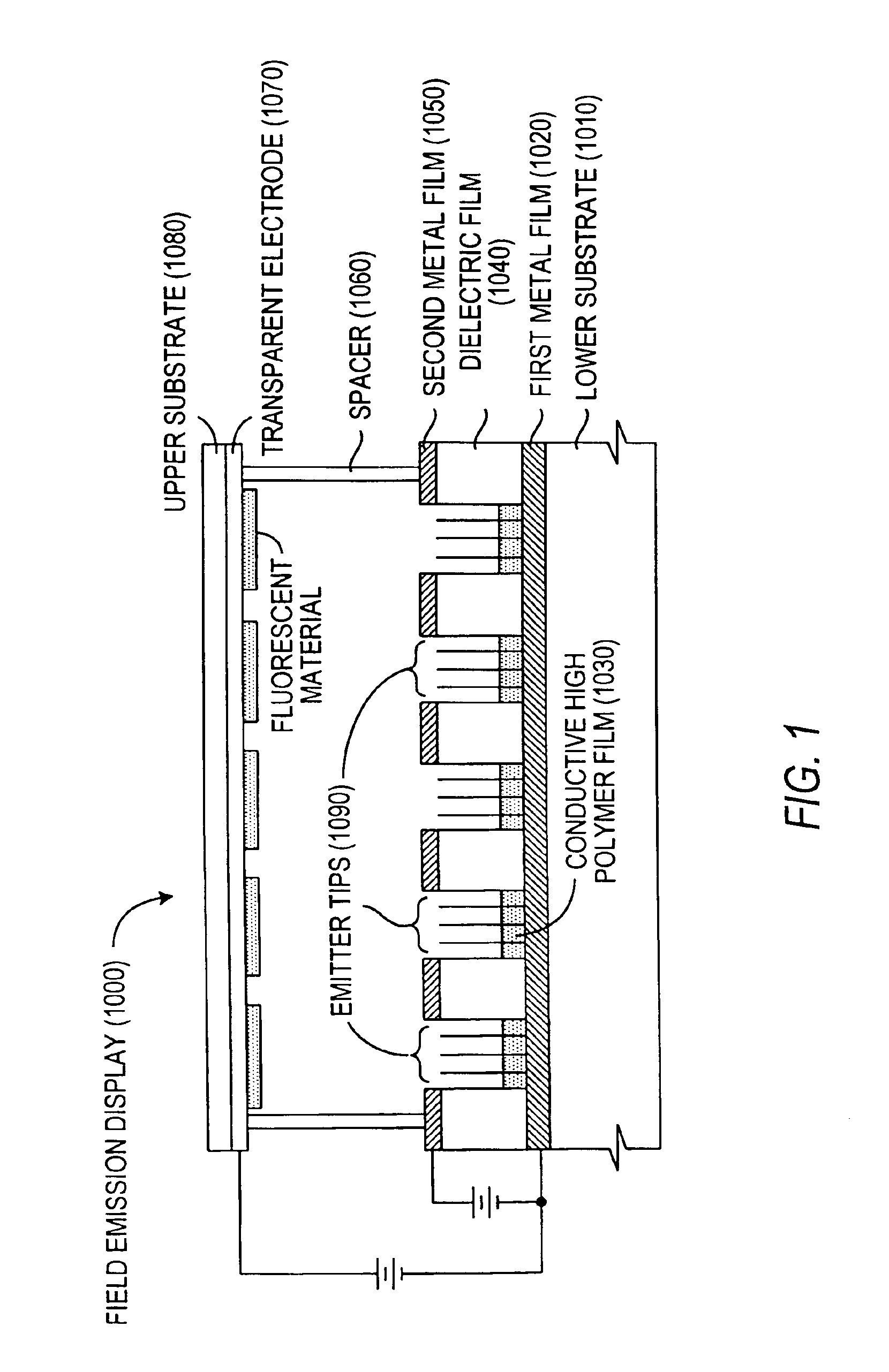

ActiveUS20090167137A1Excellent thermal electron emitting propertyIncrease brightnessTube/lamp screens manufactureControl electrodesCarbon nanotubeElectron

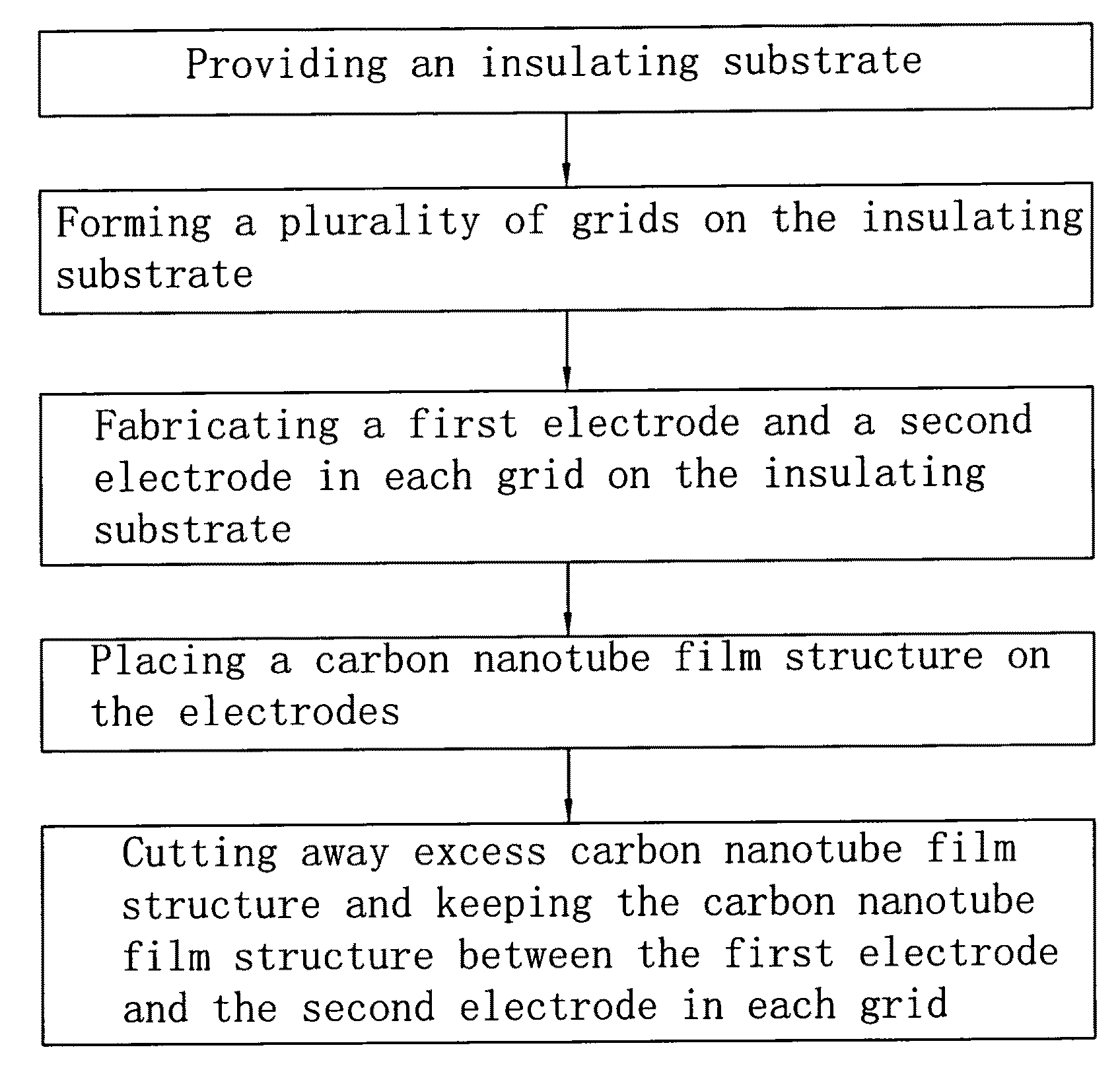

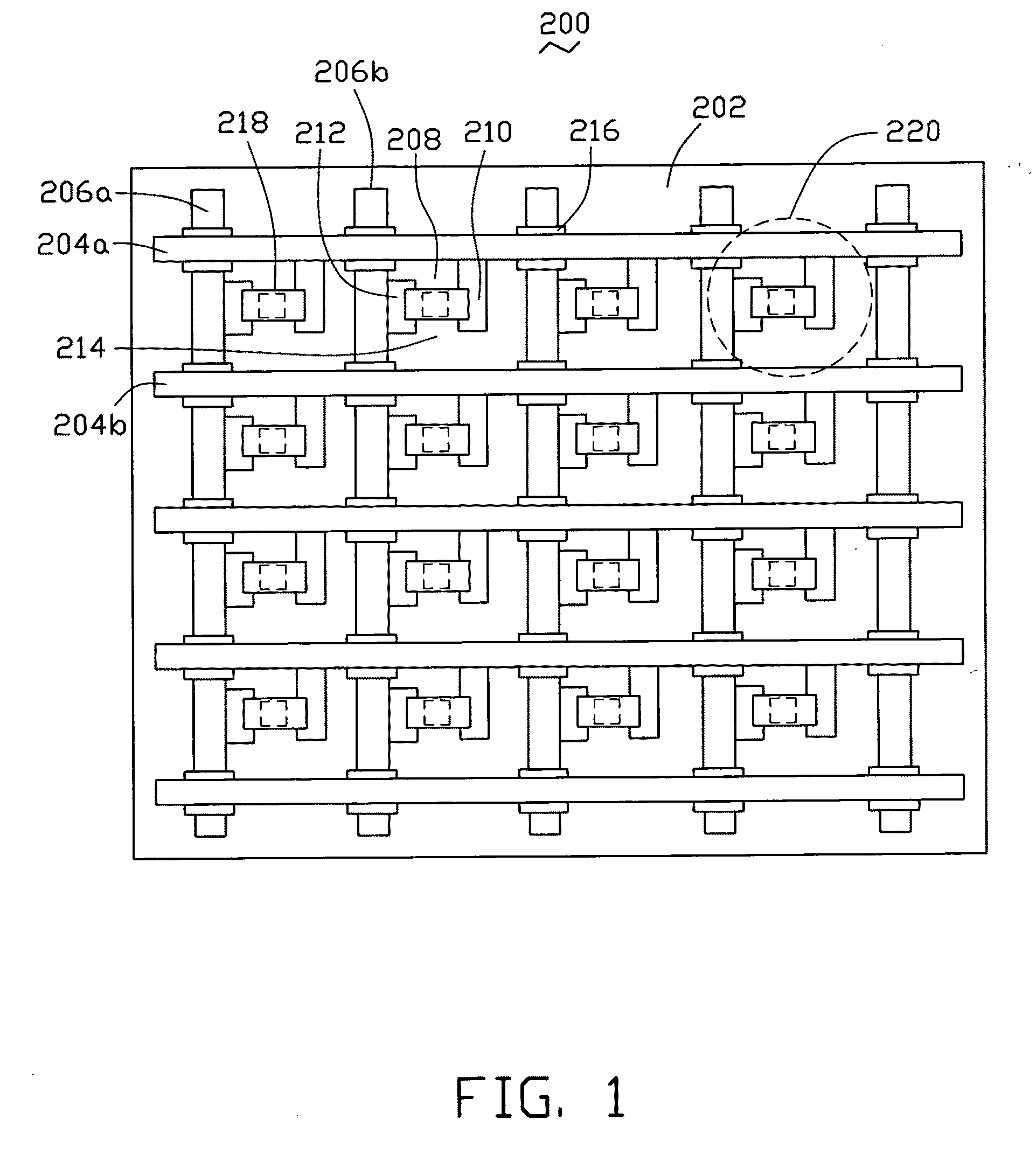

A thermionic electron emission device includes an insulating substrate, and one or more grids located thereon. The one or more grids include(s) a first, second, third and fourth electrode down-leads located on the periphery thereof, and a thermionic electron emission unit therein. The first and second electrode down-leads are parallel to each other. The third and fourth electrode down-leads are parallel to each other. The first and second electrode down-leads are insulated from the third and fourth electrode down-leads. The thermionic electron emission unit includes a first electrode, a second electrode, and a thermionic electron emitter. The first electrode and the second electrode are separately located and electrically connected to the first electrode down-lead and the third electrode down-lead respectively. Wherein the thermionic electron emitter includes a carbon nanotube film structure.

Owner:TSINGHUA UNIV +1

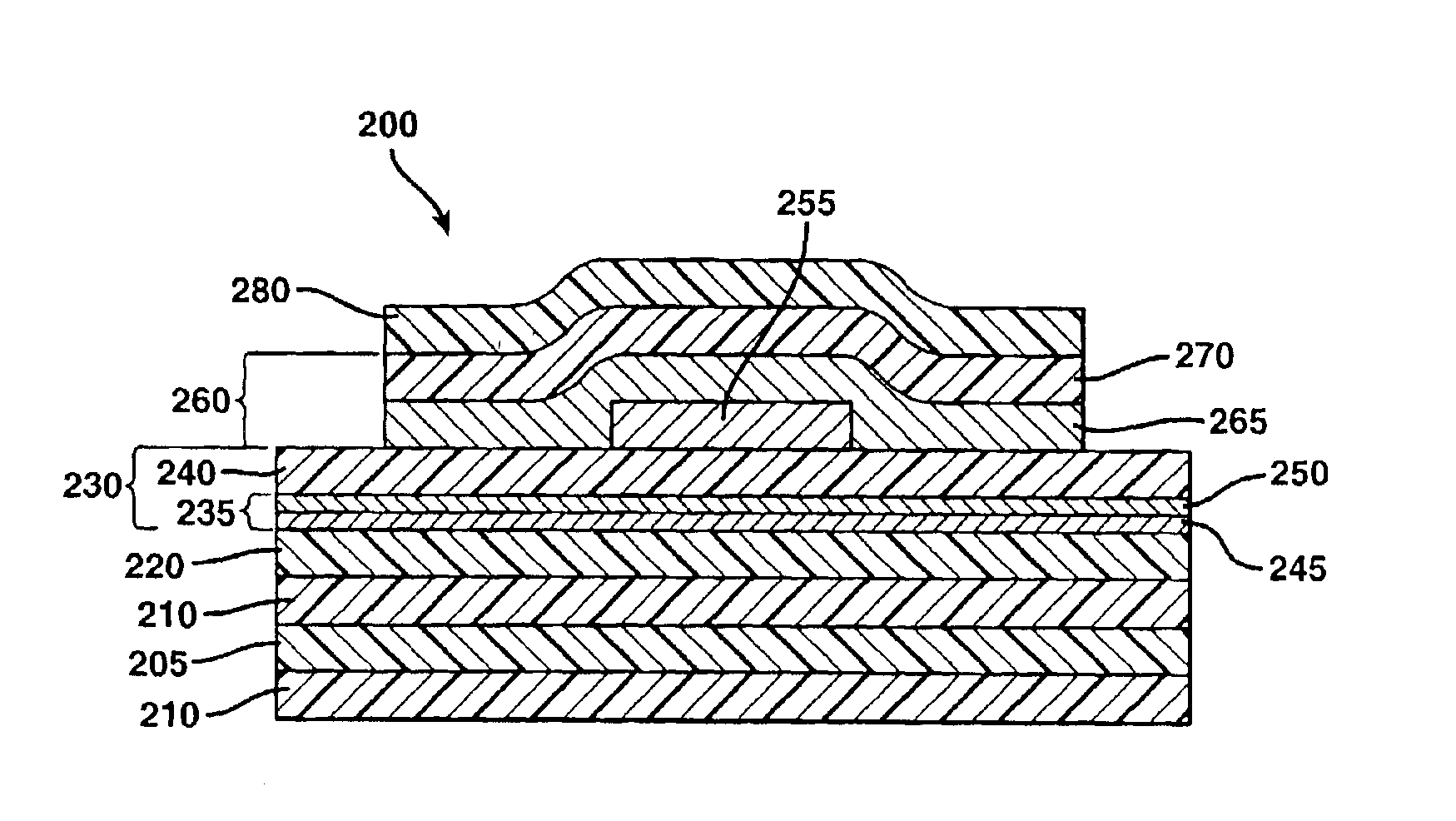

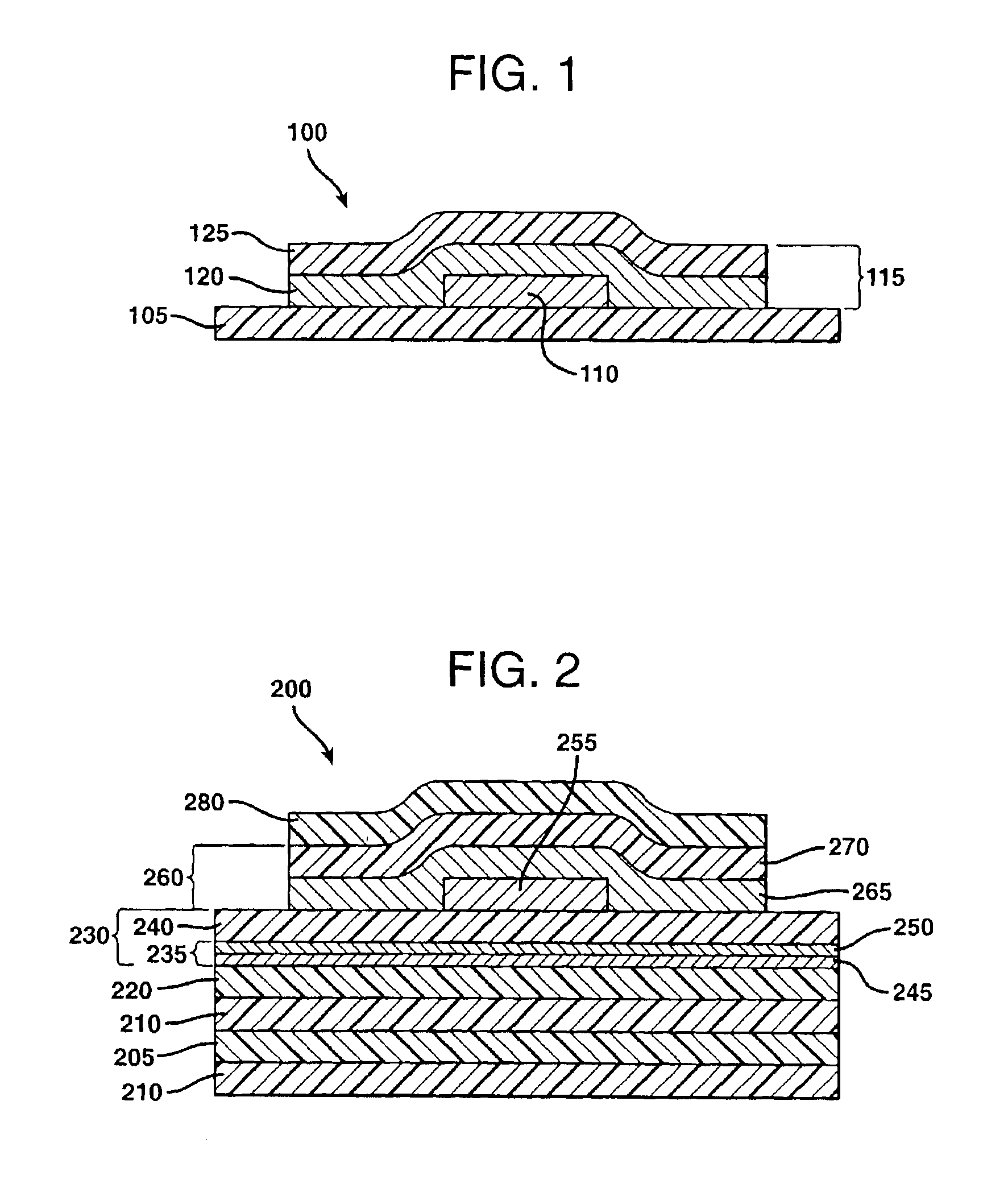

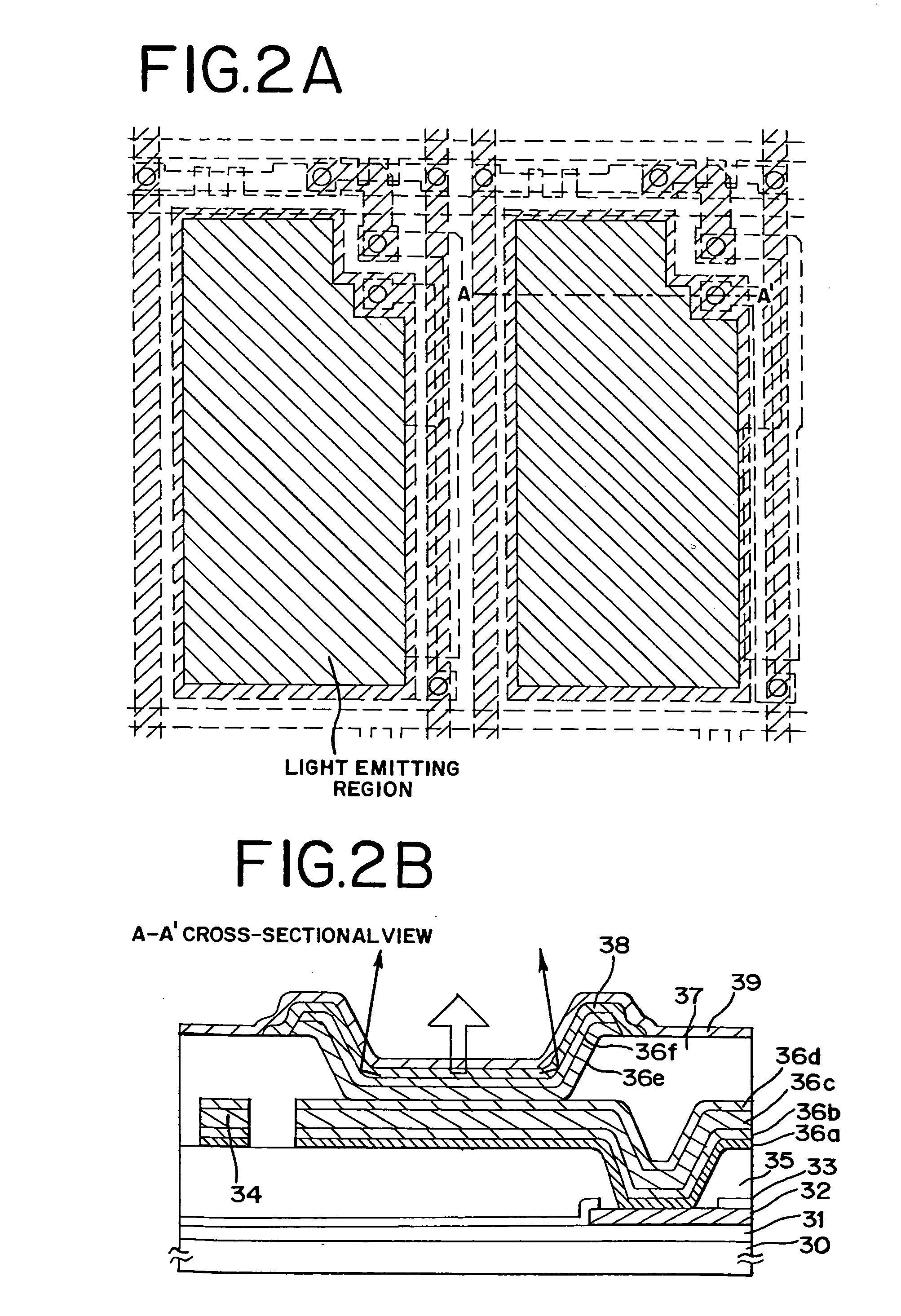

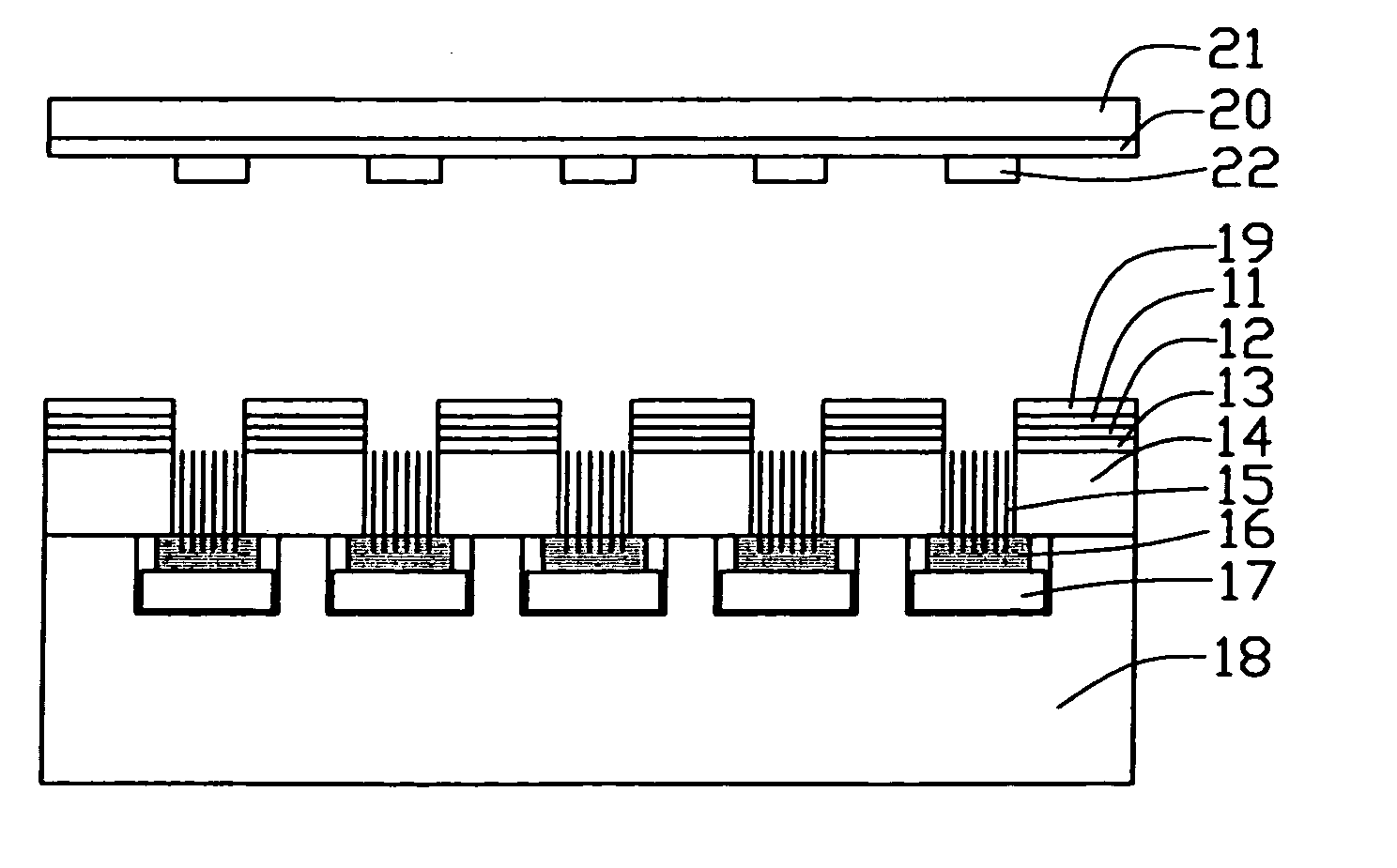

Light emitting device and manufacturing method of the same

InactiveUS20080252207A1High film resistanceLow membrane resistanceDischarge tube luminescnet screensElectroluminescent light sourcesLight emitting deviceElectrode

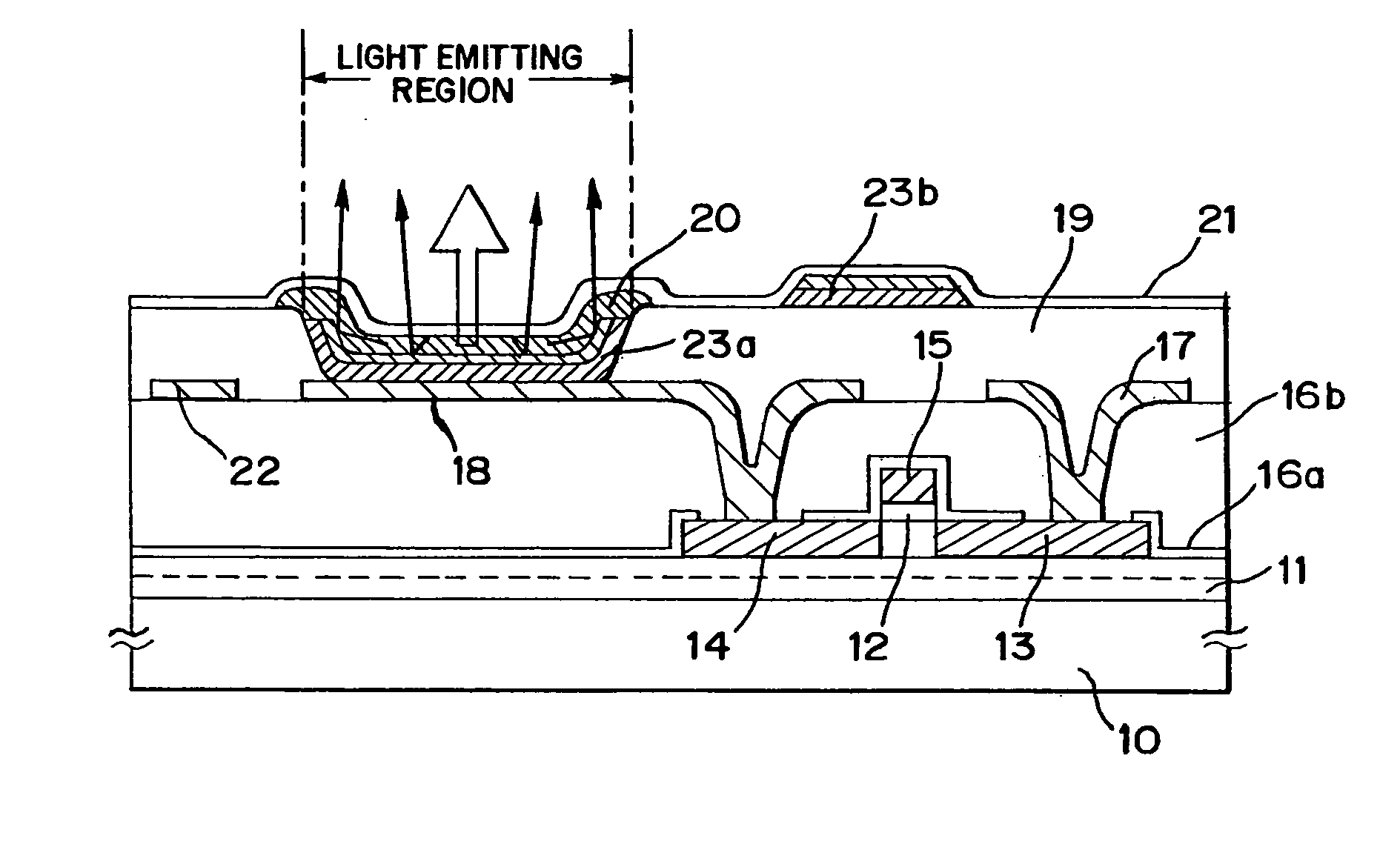

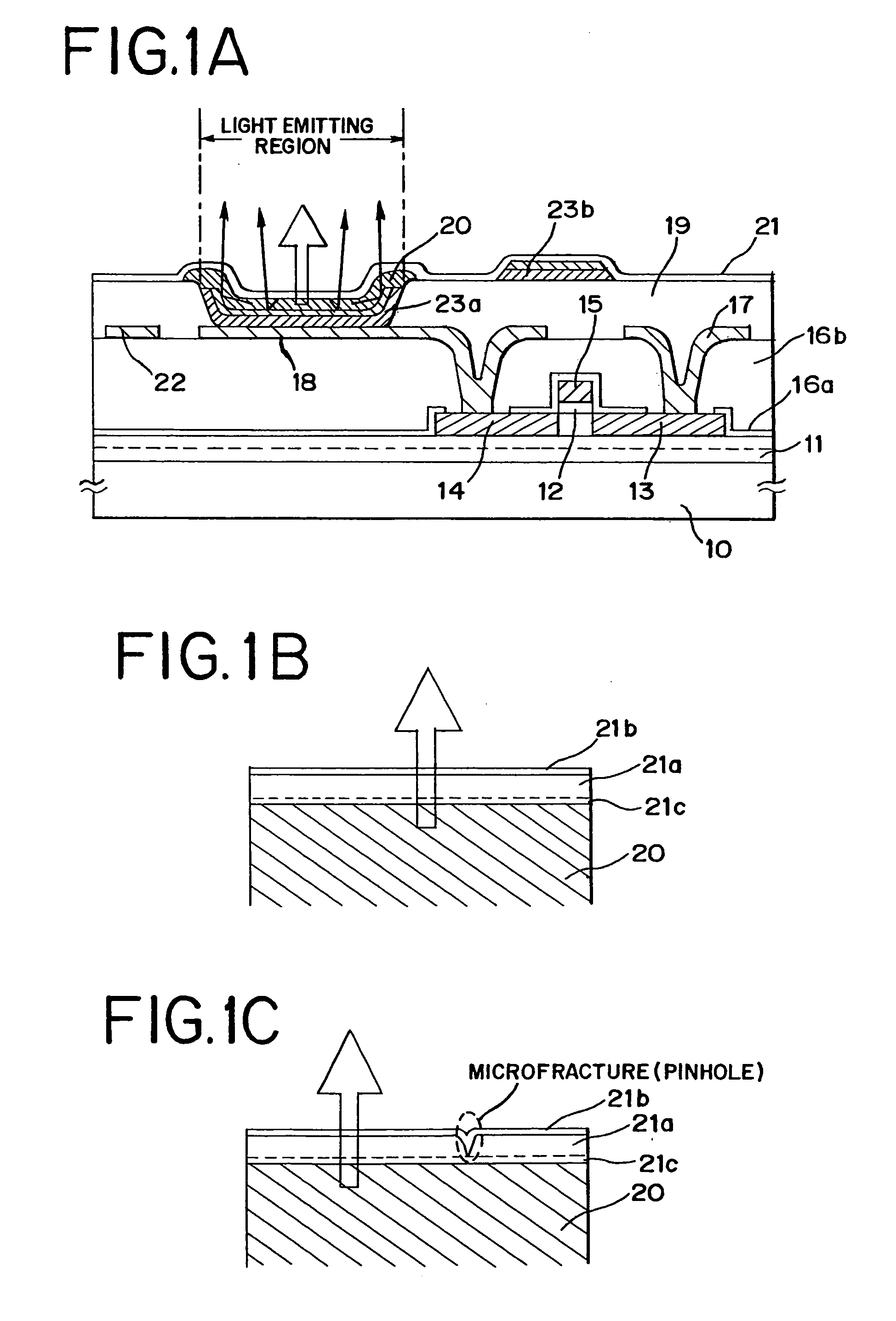

Not all of light generated in the light emitting layer comprising the organic material are taken out in the desirable direction. For example, light emitted in the lateral direction (the direction parallel to the substrate face) is not taken out and therefore is a loss. An object of the present invention is to provide a light emitting device structured so as to increase the amount of light which is taken out in a certain direction after emitted from a light emitting element, as well as a method of manufacturing this light emitting device.In the present invention, an upper end portion of an insulating material 19 that covers an end portion of a first electrode 18 is formed to have a curved surface having a radius of curvature, a second electrode 23a is formed to have a slant face as going from its center portion toward its end portion along the curved surface. Light emitted from a light emitting layer comprising an organic material 20 that is formed on the second electrode 23a is reflected at the slant face of the second electrode 23a to increase the total amount of light taken out in the direction indicated by the arrow in FIG. 1A.

Owner:SEMICON ENERGY LAB CO LTD

Electron-emitting element and electron source, field emission image display device, and fluorescent lamp utilizing the same and methods of fabricating the same

Disclosed are an electron-emitting element having a large operating current at a low operating voltage and excellent operation stability, and an electron source, an image display device and the like utilizing such an electron-emitting element, and further a method of fabricating such an element with few process steps at low cost. A cold cathode member is configured utilizing hybrid particle of a first particle serving to emit electrons into the space and a second particle being in the vicinity of the first particle and serving to control the position of the first particle. In this configuration, it is preferable that the first particle have a higher electron emission efficiency than the second particle and that the second particle be conductive.

Owner:PANASONIC CORP

Method of fabricating nano-structured surface and configuration of surface enhanced light scattering probe

InactiveUS7384792B1Increase surface adsorption capacityAvoid pollutionRadiation pyrometryRaman scatteringNanostructureLight scattering

A method to fabricate an optical scattering probe and the method includes the steps of a) depositing an conductive layer on a substrate followed by depositing a noble metal layer on top of the conductive layer and then an aluminum layer on top the noble metal layer; b) anodizing the aluminum layer to form a porous aluminum oxide layer having a plurality of pores; and c) etching the plurality of pores through the aluminum oxide layer and the noble metal layer for forming a nano-hole array. In a preferred embodiment, the step of etching the plurality of pores through the aluminum oxide layer and the noble metal layer further comprising a step of widening the pores followed by removing the aluminum oxide layer for forming a plurality of noble metal column on top of the conductive layer.

Owner:OPTOTRACE TECH

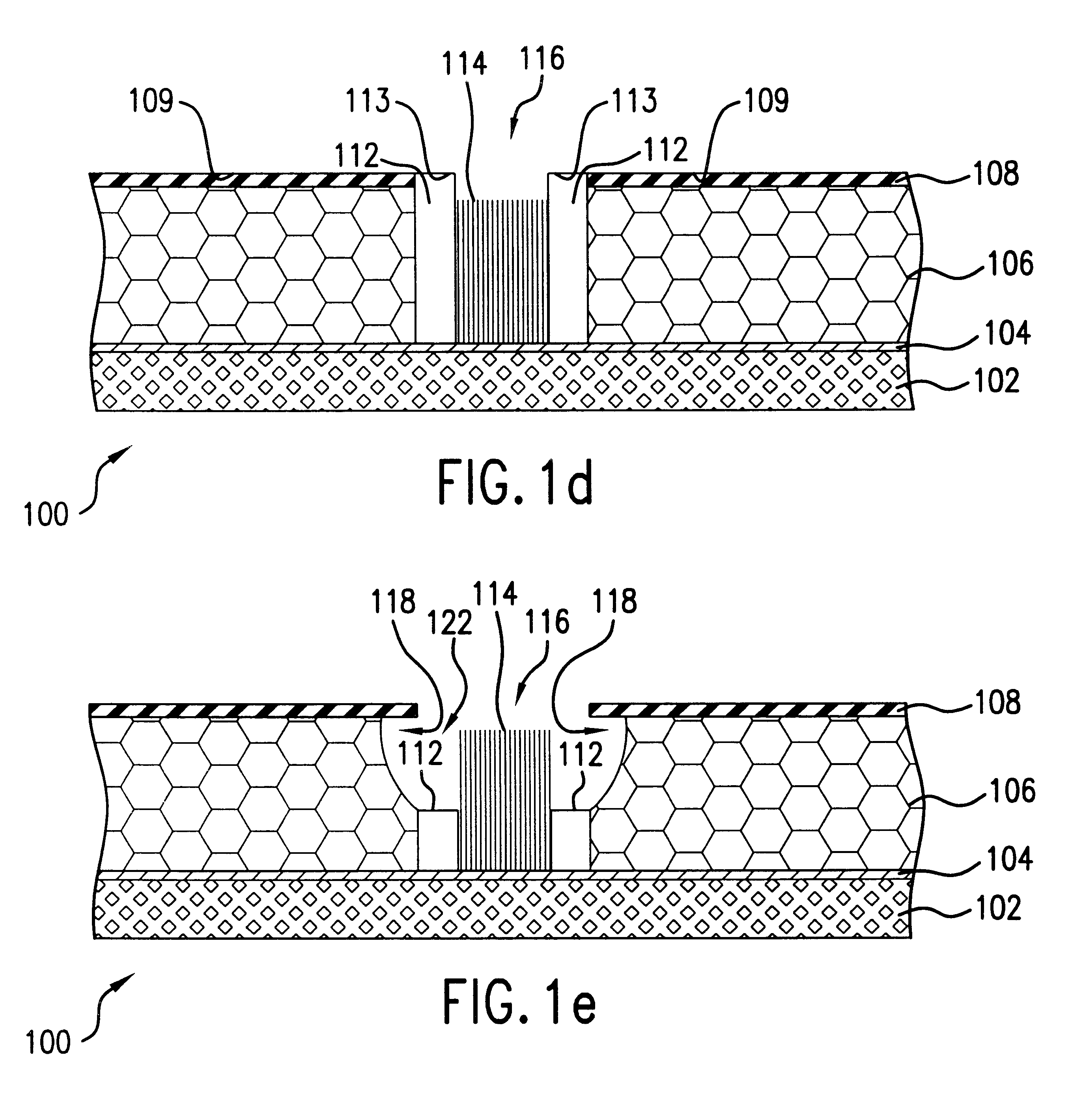

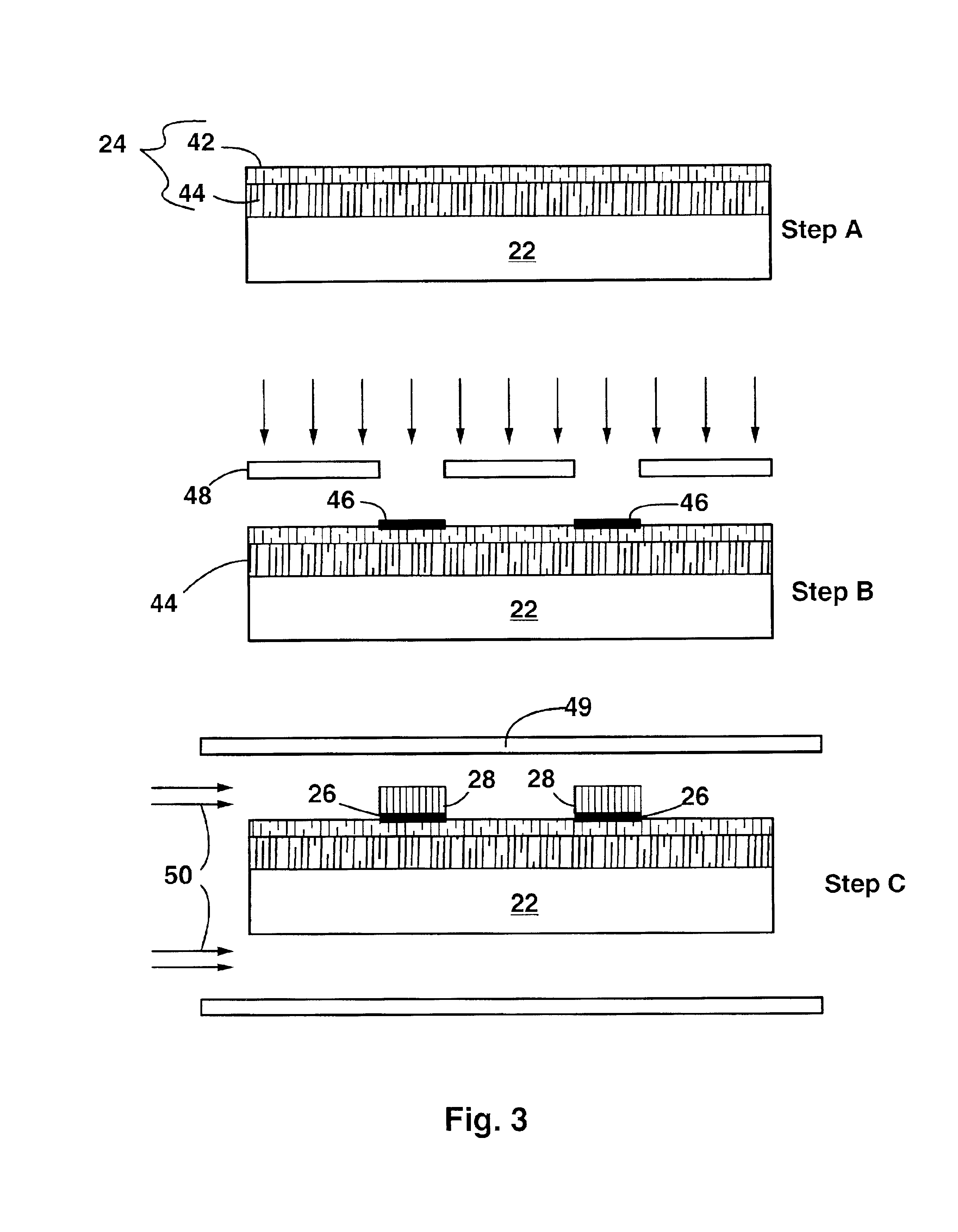

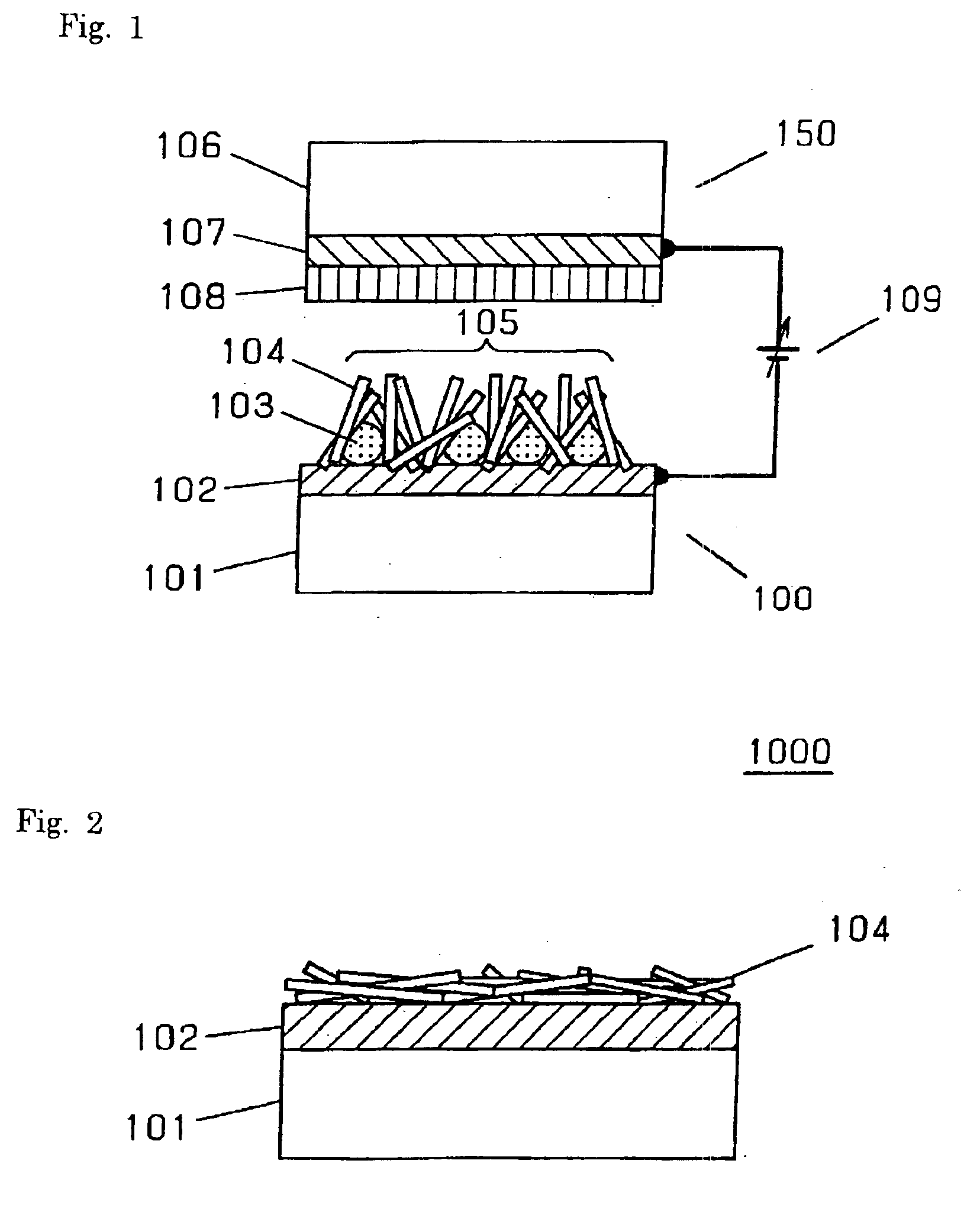

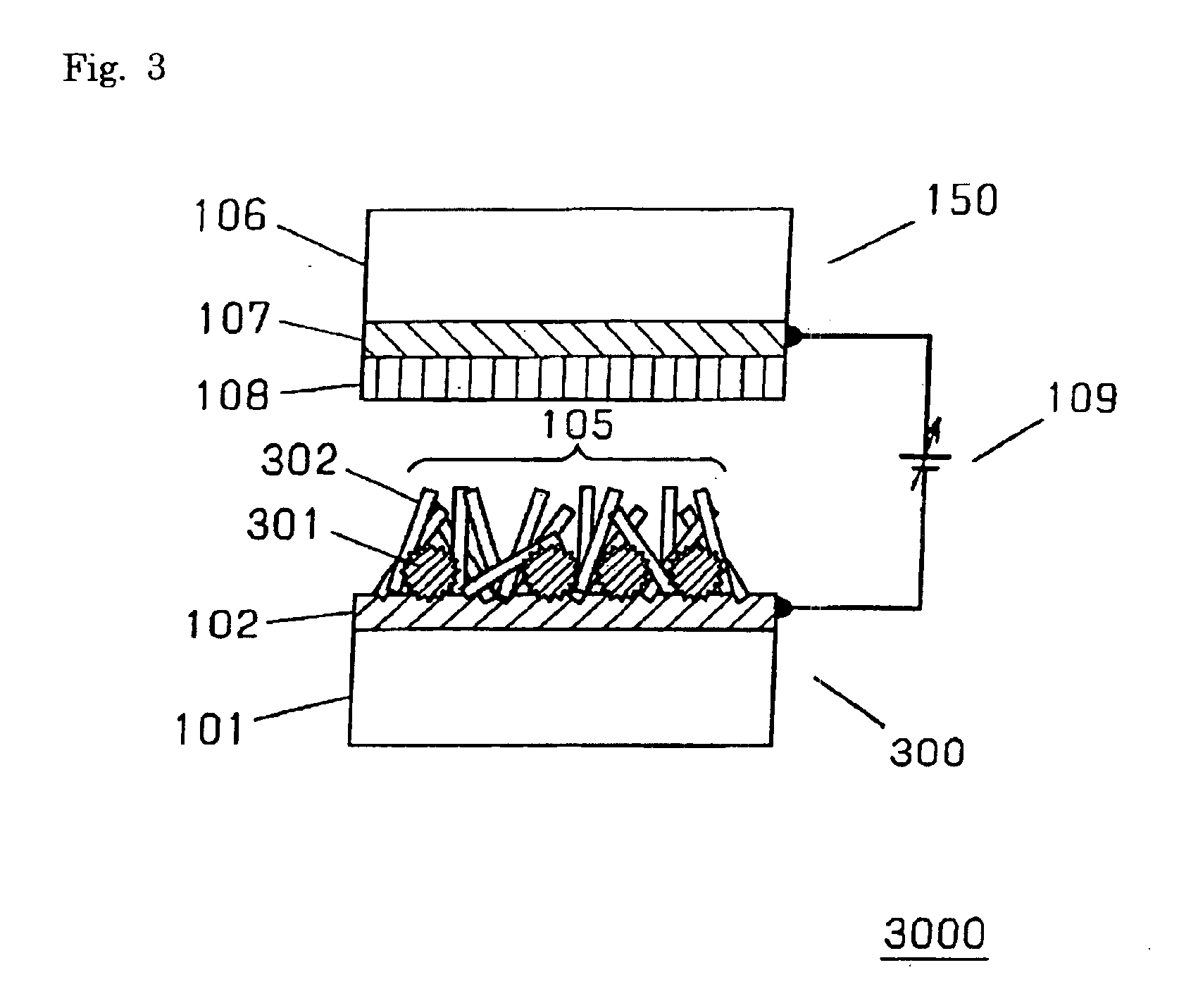

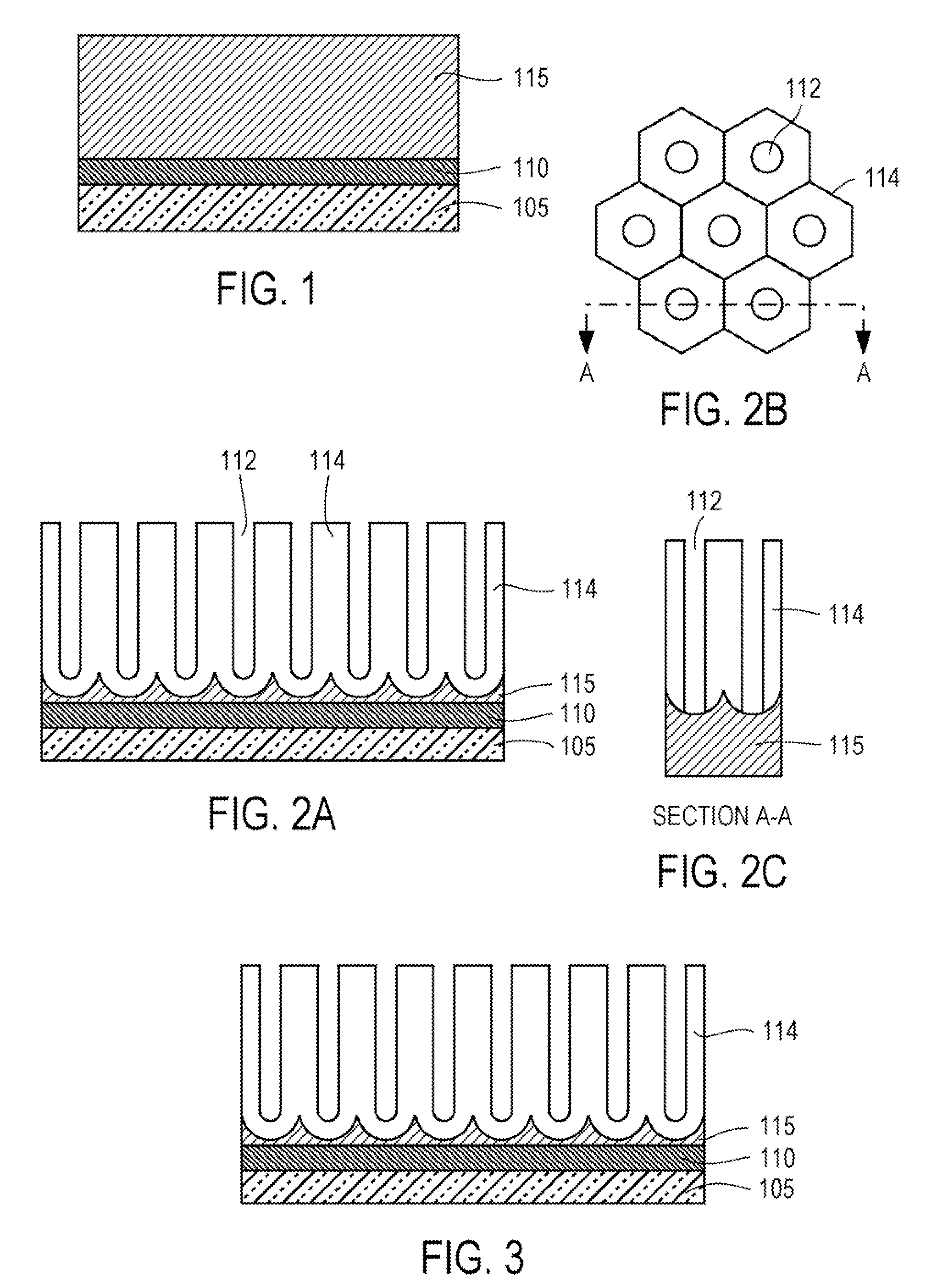

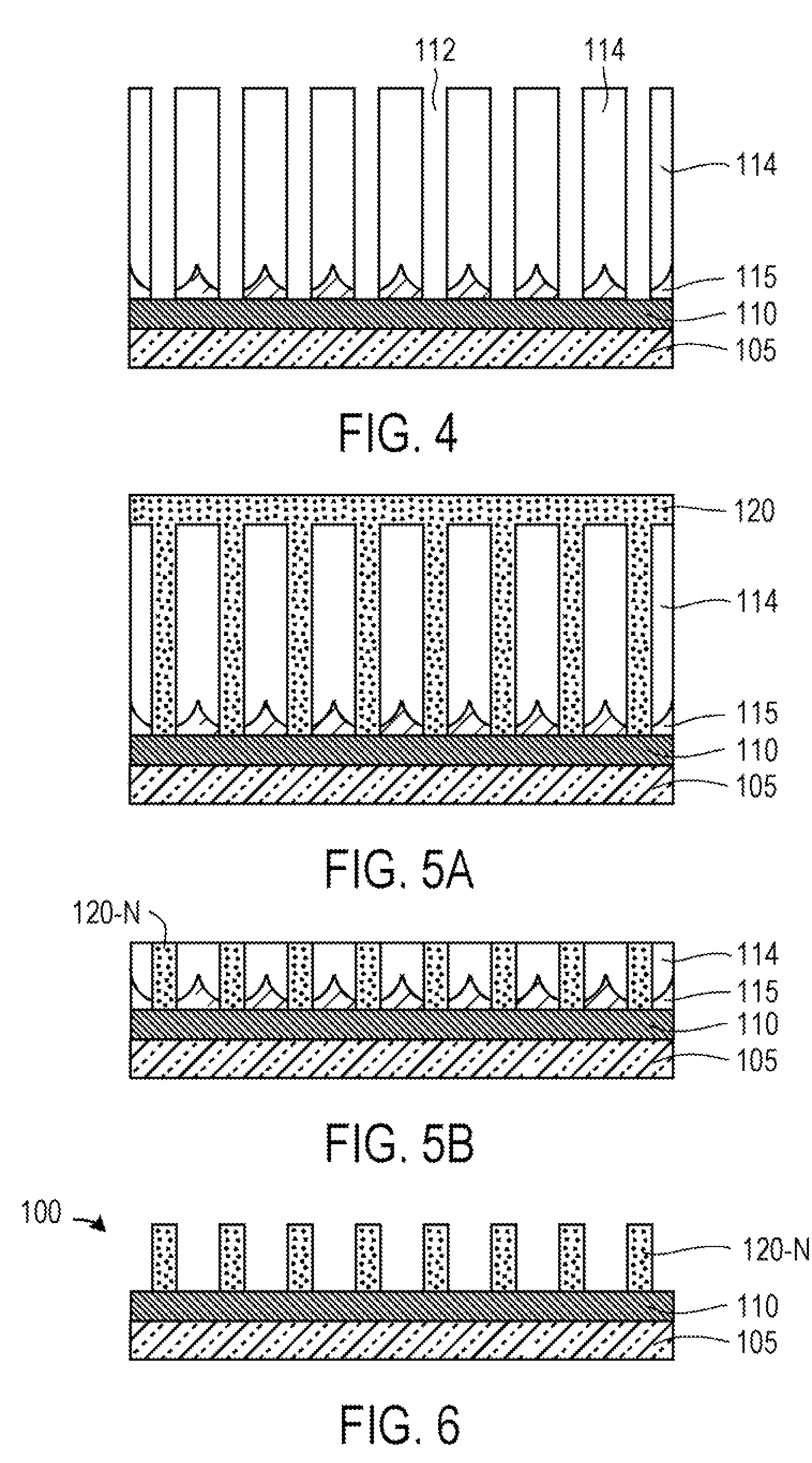

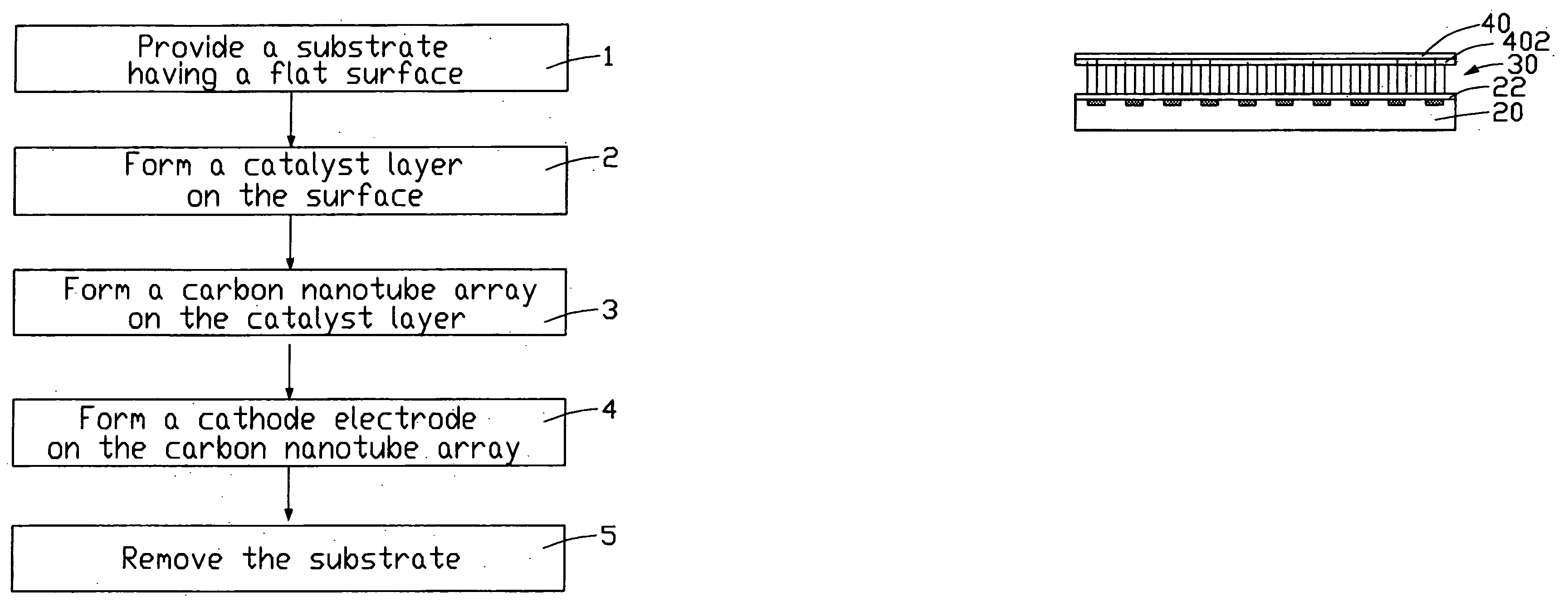

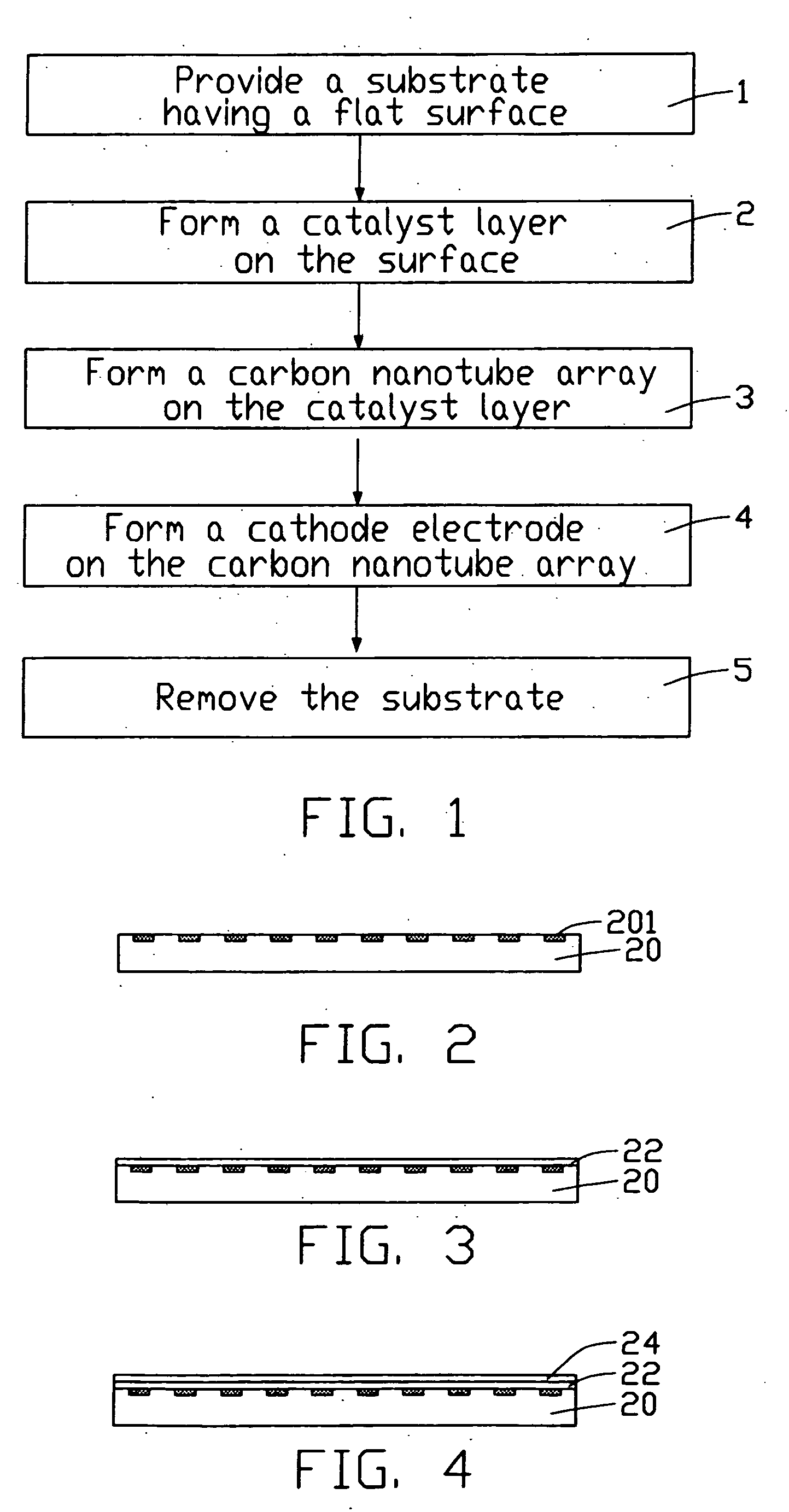

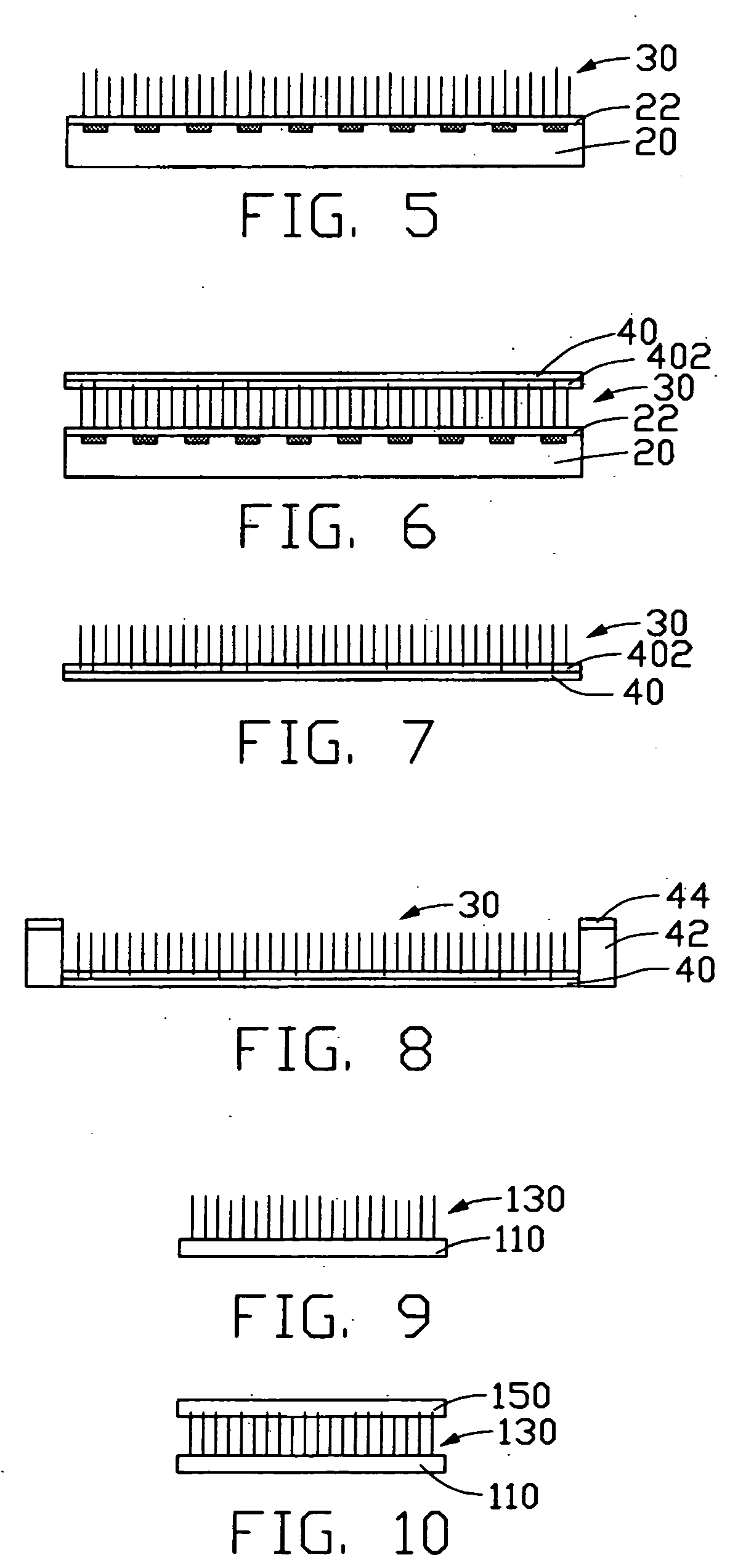

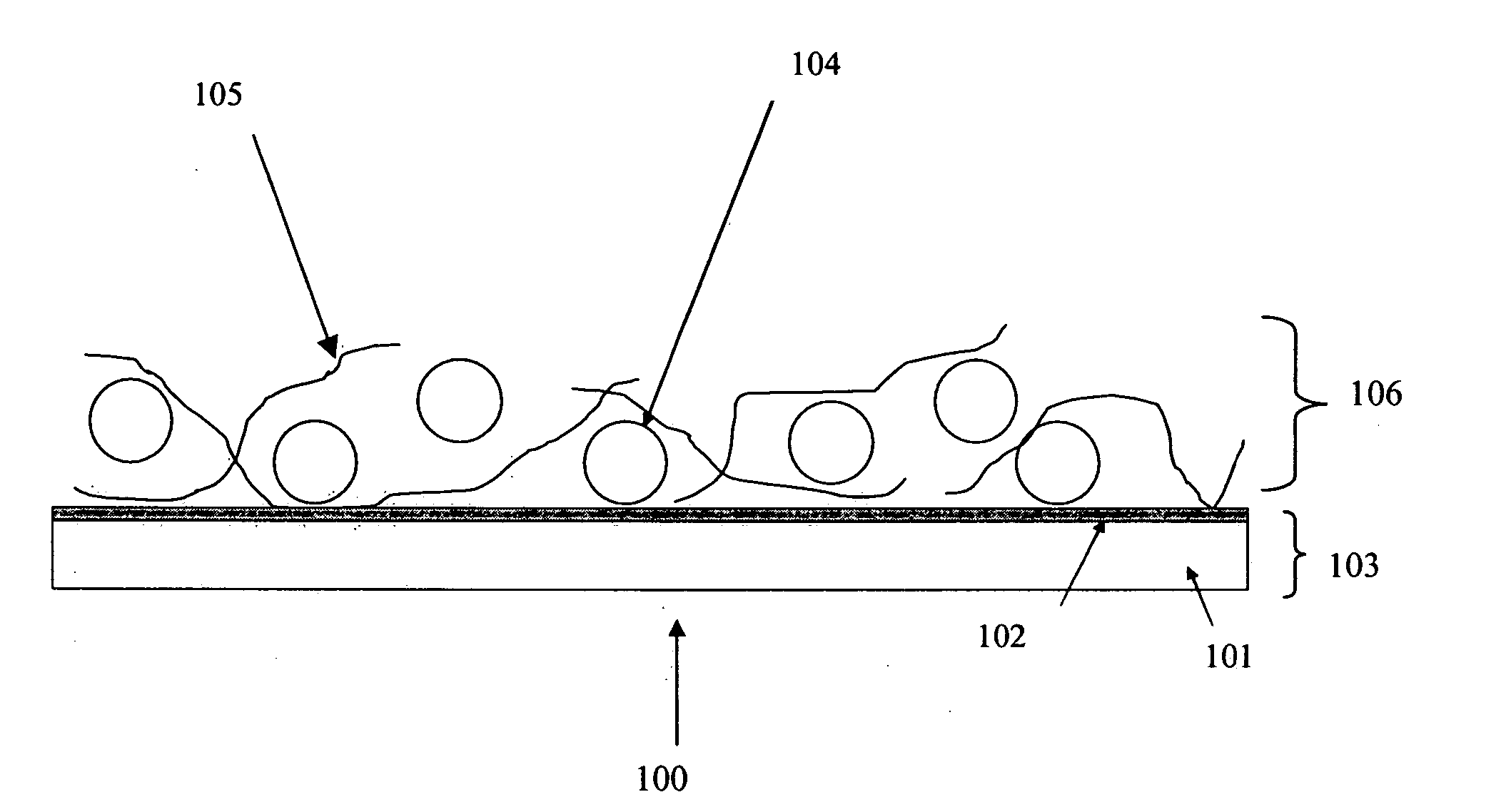

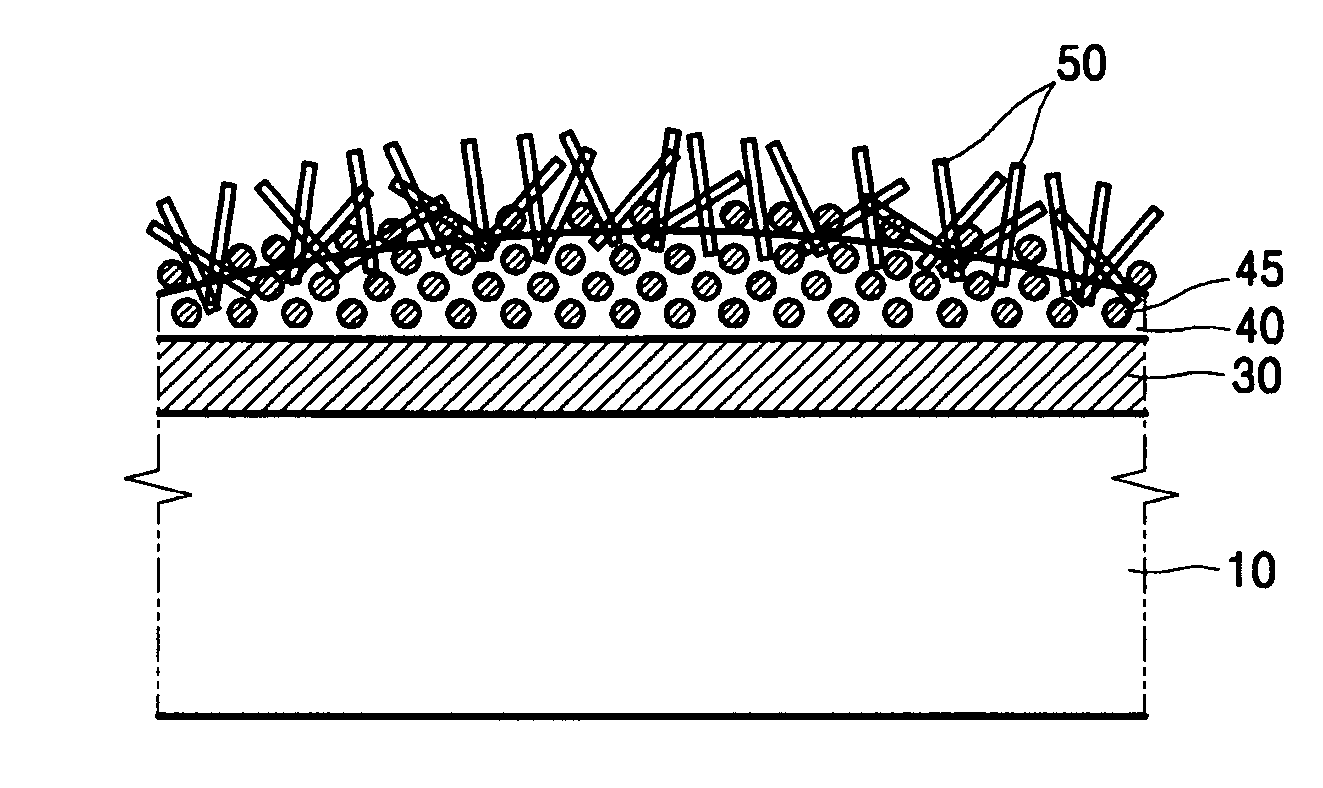

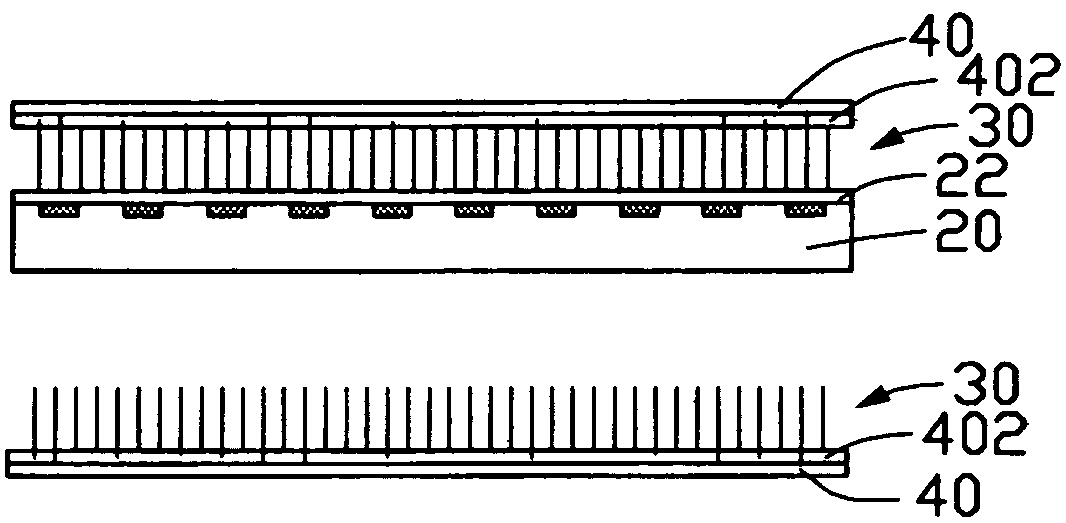

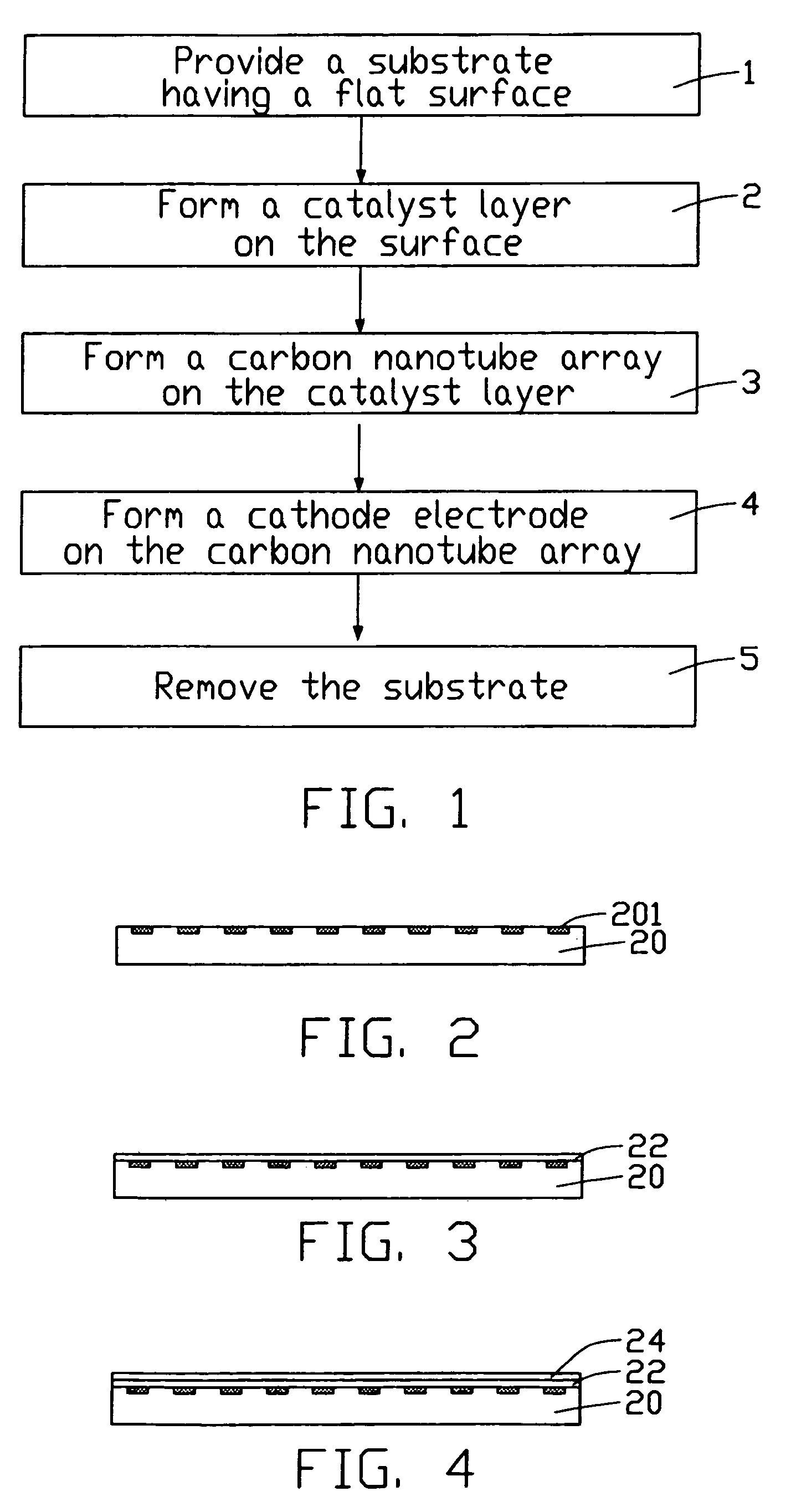

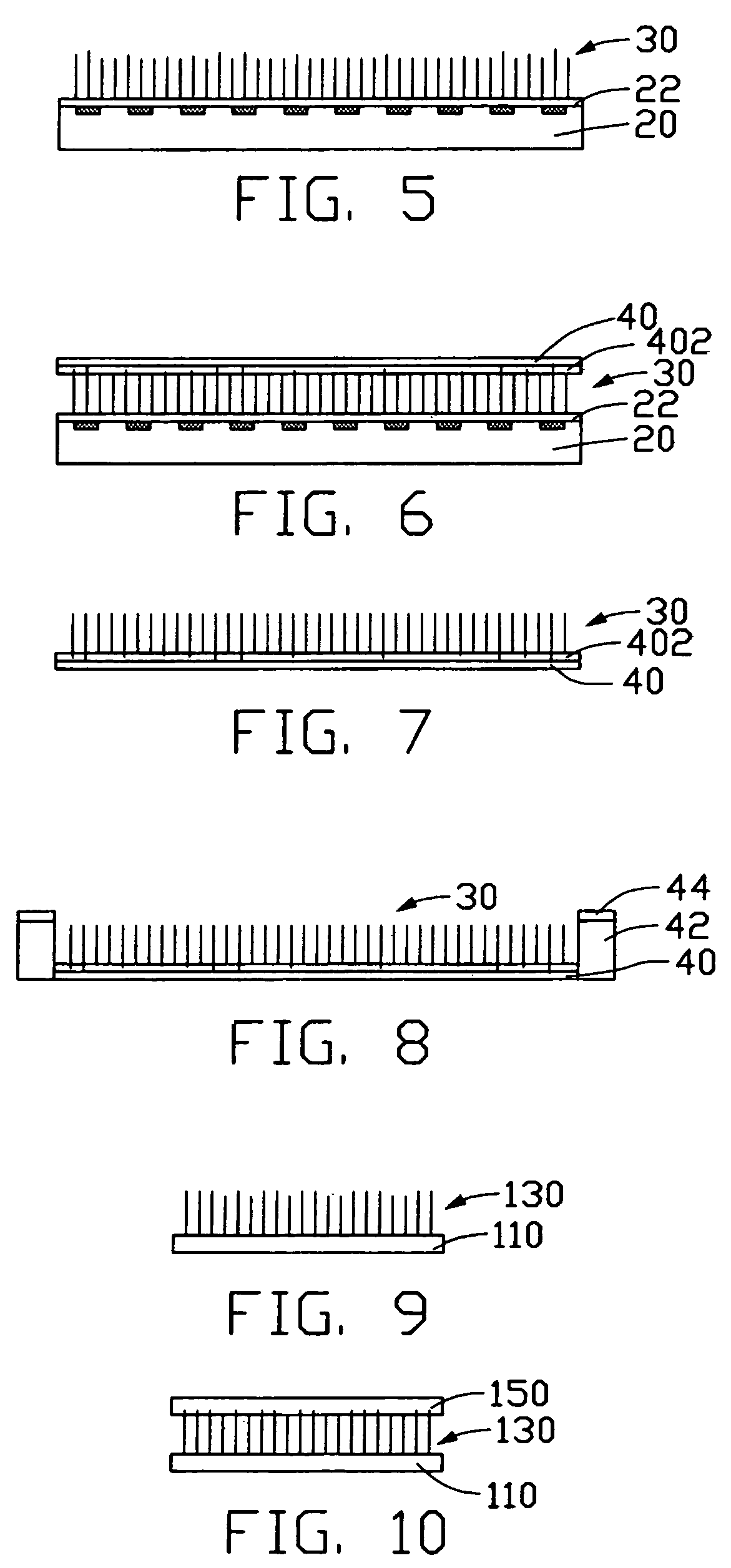

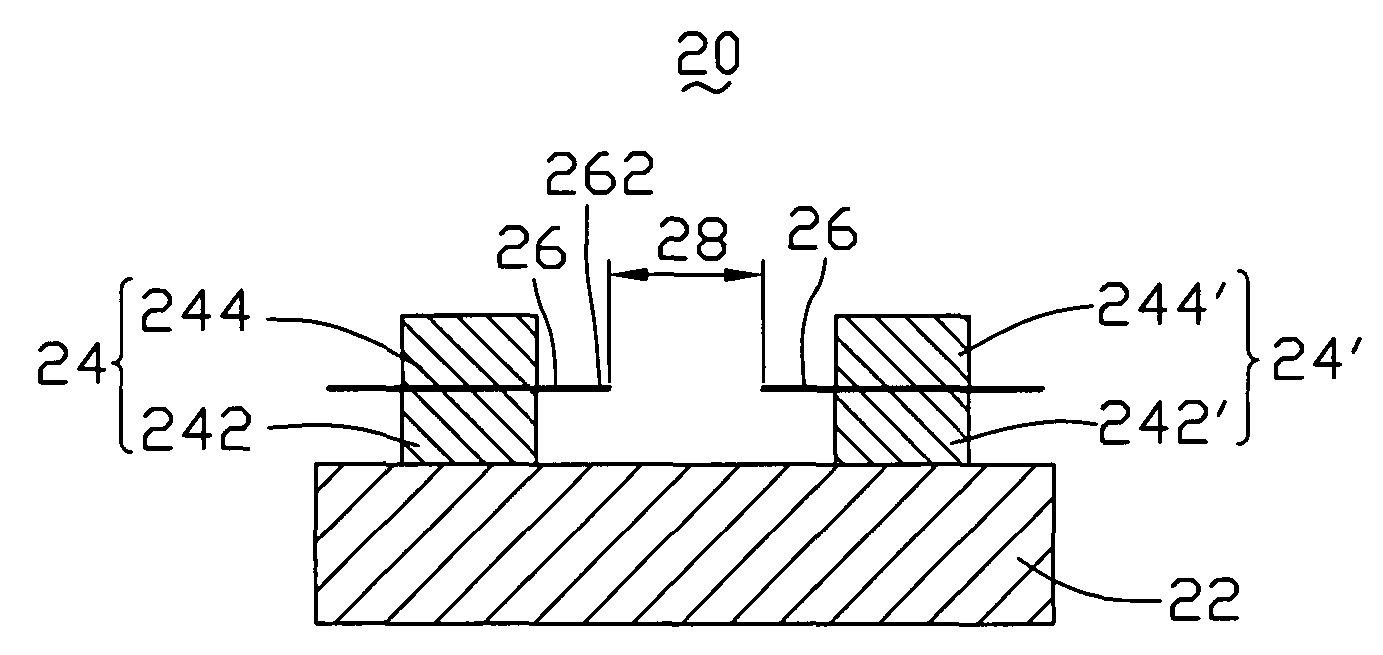

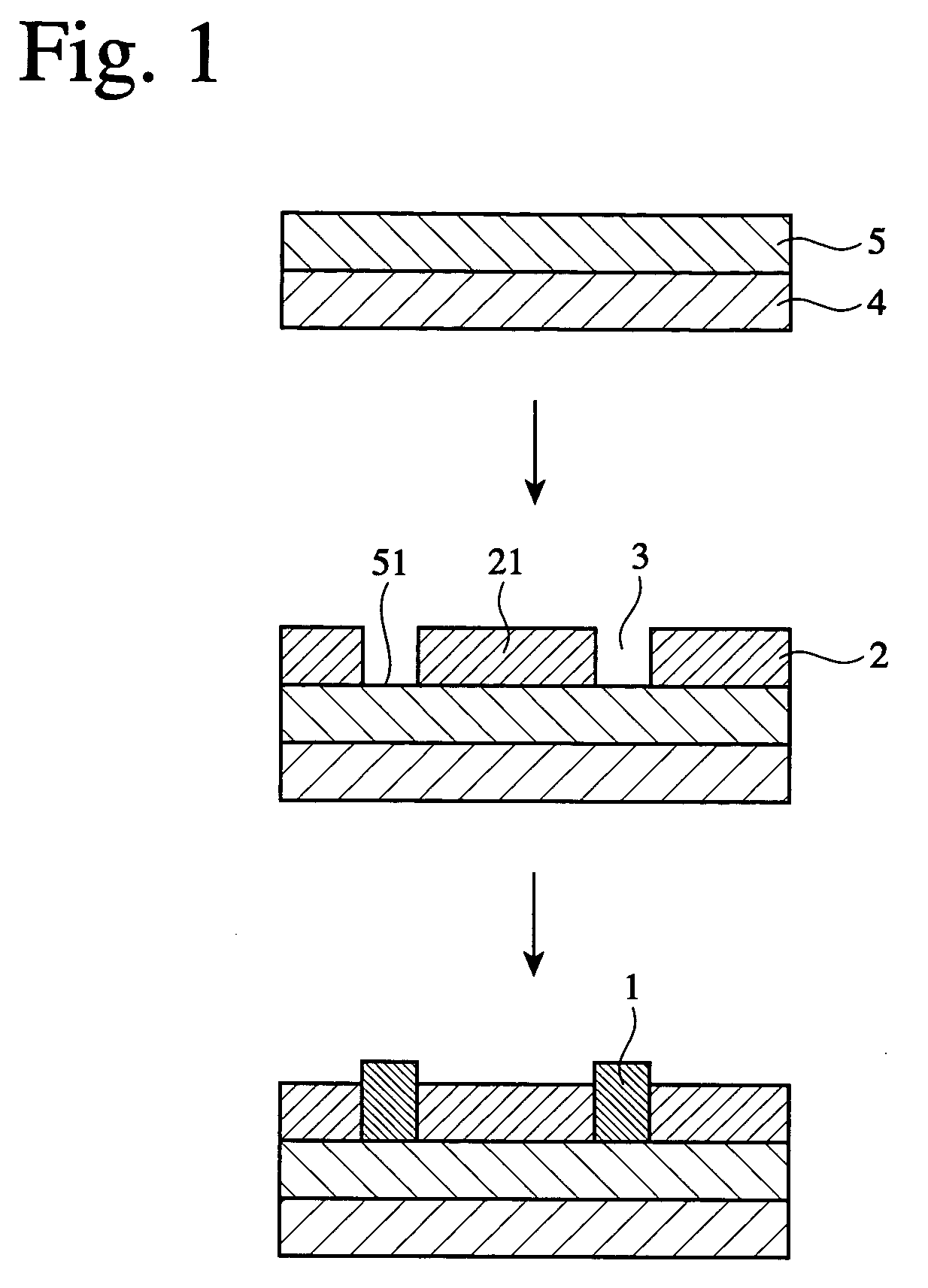

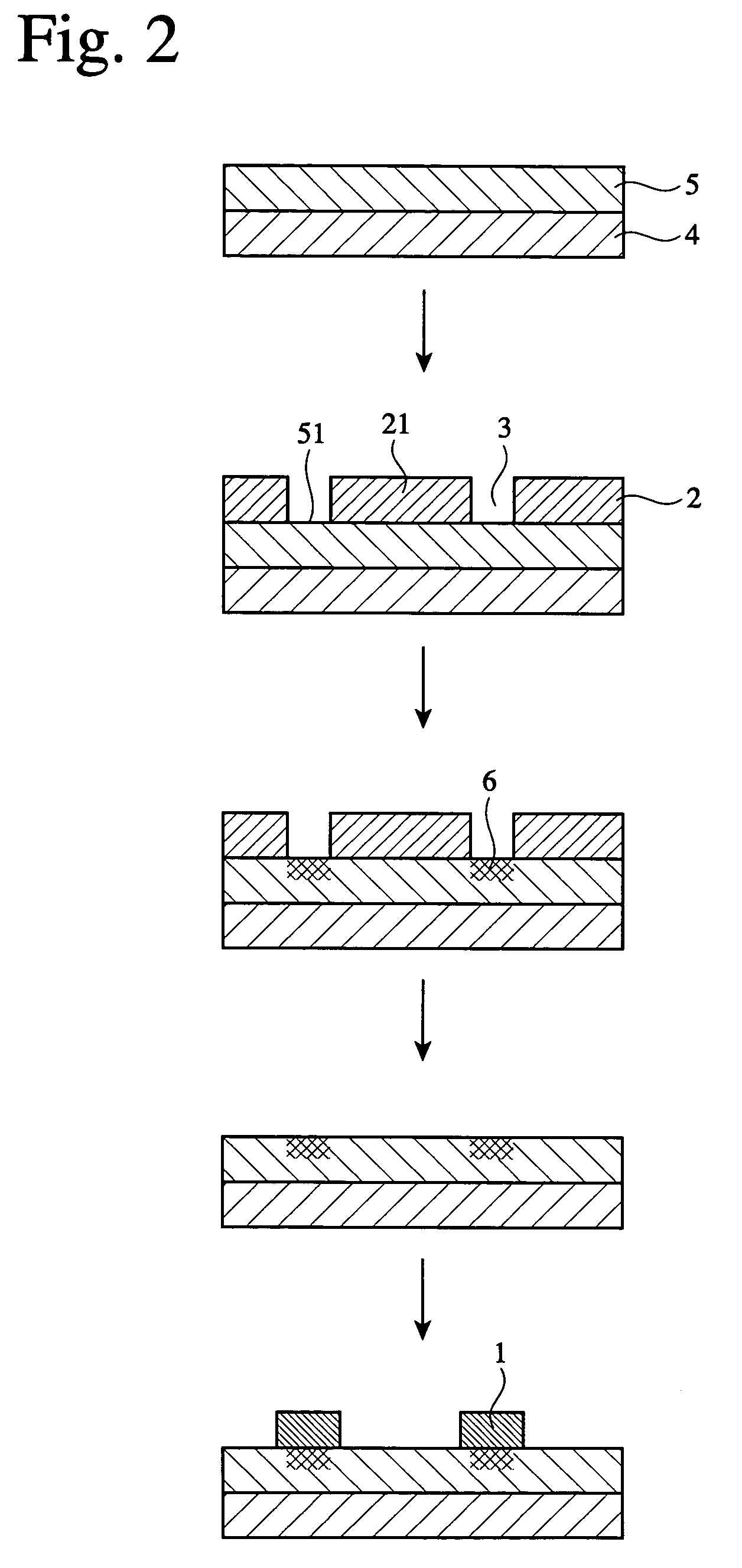

Method for making carbon nanotube-based field emission device

ActiveUS20040209385A1Surface cleaningEnhanced electron emission capabilityMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

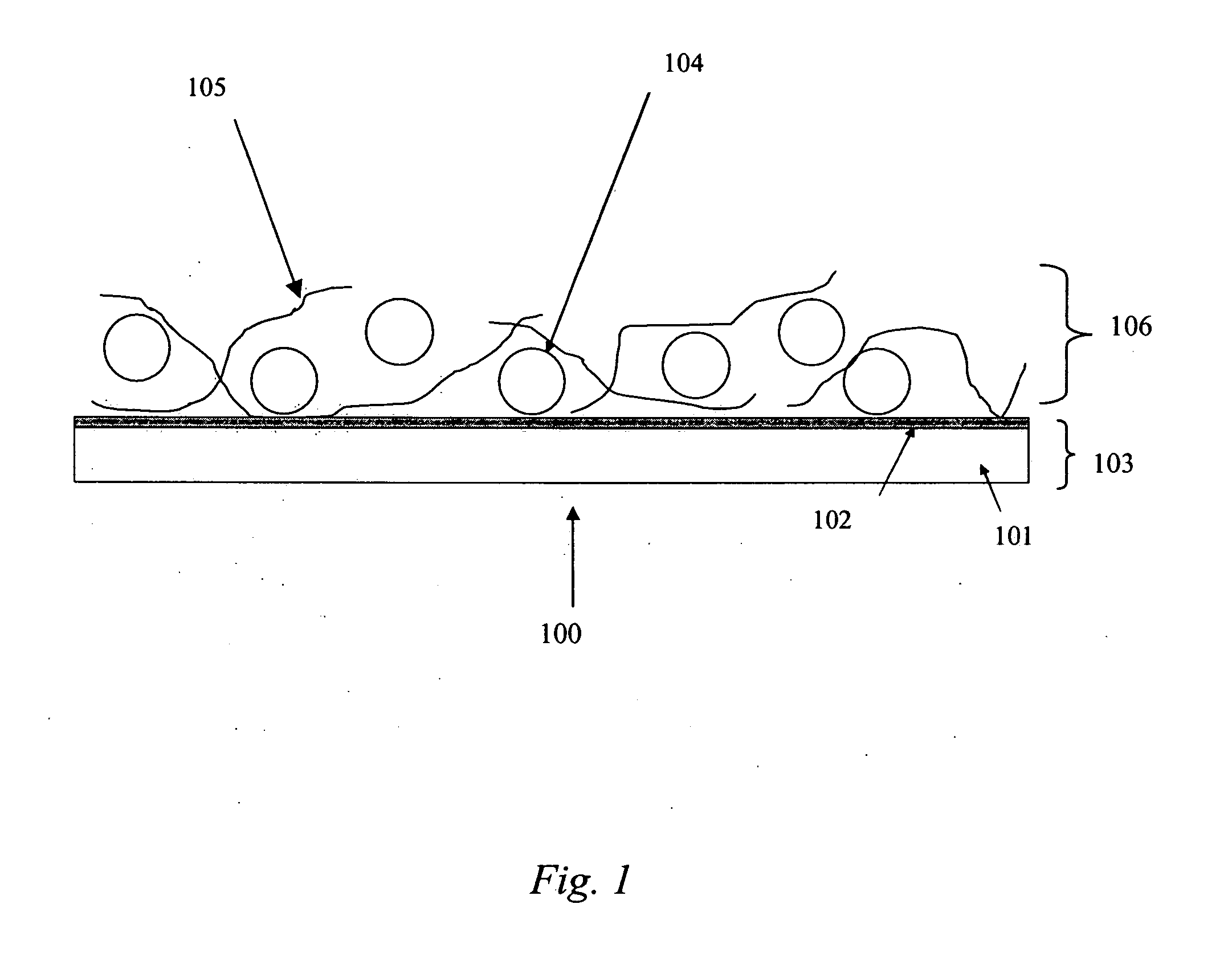

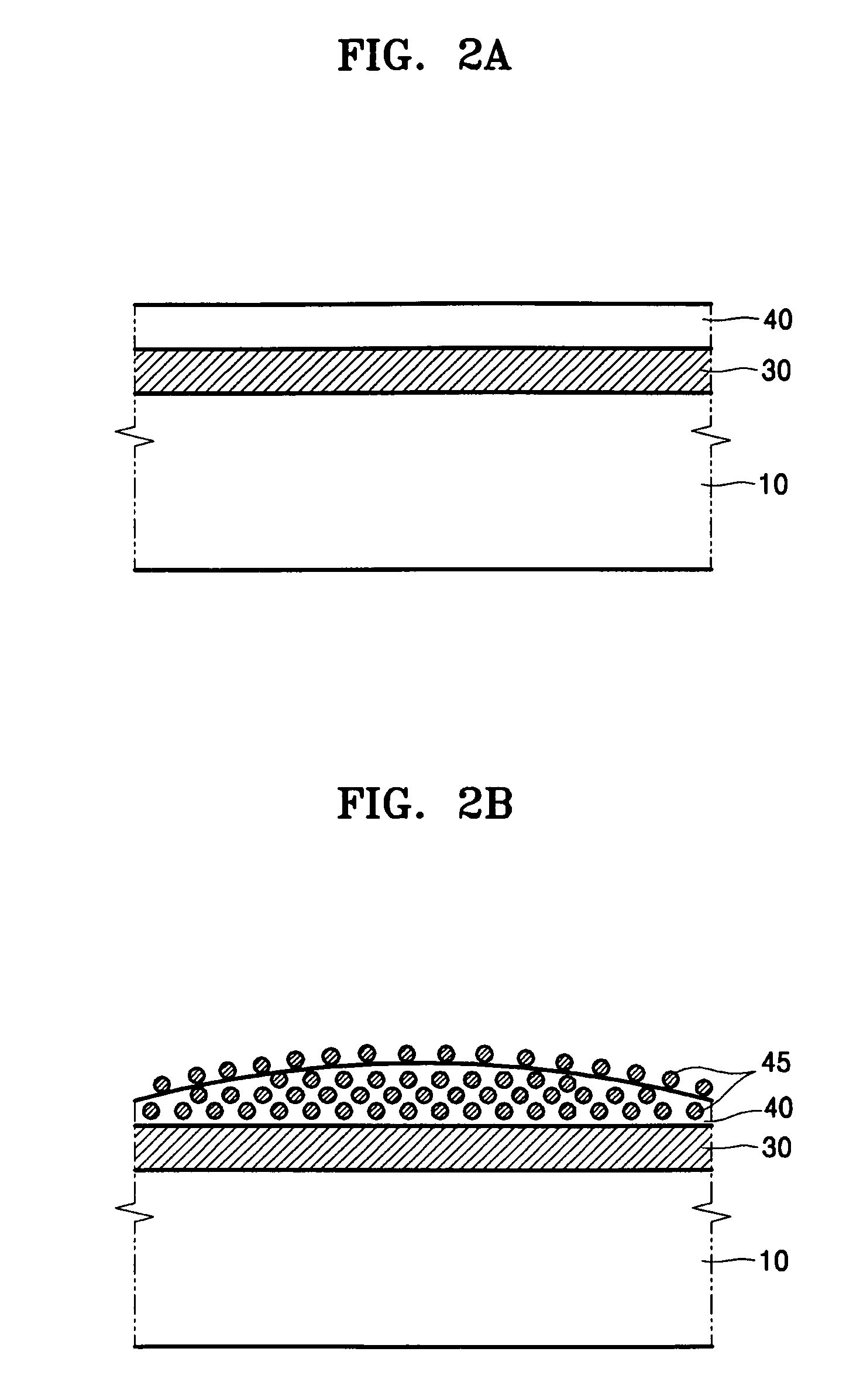

Enhanced field emission from carbon nanotubes mixed with particles

ActiveUS20050001528A1Optimizing electron field emission performanceEmission reductionDischarge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

The present invention is directed toward cathodes and cathode materials comprising carbon nanotubes (CNTs) and particles. The present invention is also directed toward field emission devices comprising a cathode of the present invention, as well as methods for making these cathodes. In some embodiments, the cathode of the present invention is used in a field emission display. The invention also comprises a method of depositing a layer of CNTs and particles onto a substrate to form a cathode of the present invention, as well as a method of controlling the density of CNTs used in this mixed layer in an effort to optimize the field emission properties of the resulting layer for field emission display applications.

Owner:SAMSUNG ELECTRONICS CO LTD

Field emission devices using ion bombarded carbon nanotubes

InactiveUS20030044519A1Easy to disassembleReduce voltageCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

Method of growing carbon nanotubes and method of manufacturing field emission device using the same

InactiveUS7479052B2Superior field emission characteristicLow costMaterial nanotechnologyCarbon compoundsField emission deviceVolumetric Mass Density

Methods of growing carbon nanotubes and manufacturing a field emission device using the carbon nanotubes are provided. The method of growing carbon nanotubes includes the steps of preparing a substrate, forming a catalyst metal layer on the substrate to promote the growing of the carbon nanotubes, forming an amorphous carbon layer on the catalyst metal layer where the amorphous carbon layer partially covers the catalyst metal layer, and growing the carbon nanotubes from a surface of the catalyst metal layer. The carbon nanotubes are grown in a portion of the surface of the catalyst metal layer that is not covered by the amorphous carbon layer. In the method of growing carbon nanotubes, the carbon nanotubes are grow at a low temperature. A density of carbon nanotubes can be controlled to improve field emission characteristics of an emitter of a field emission device.

Owner:SAMSUNG SDI CO LTD

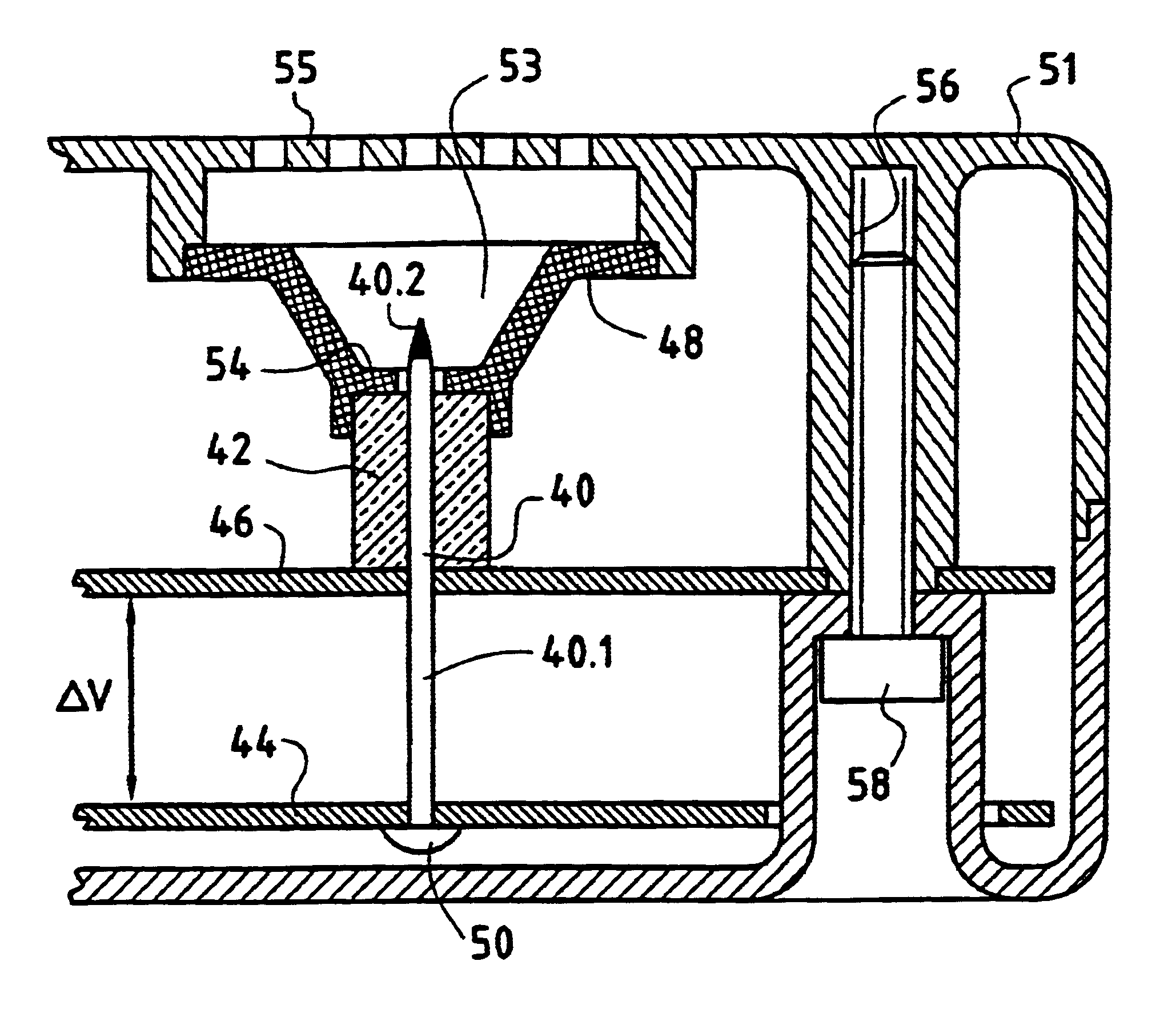

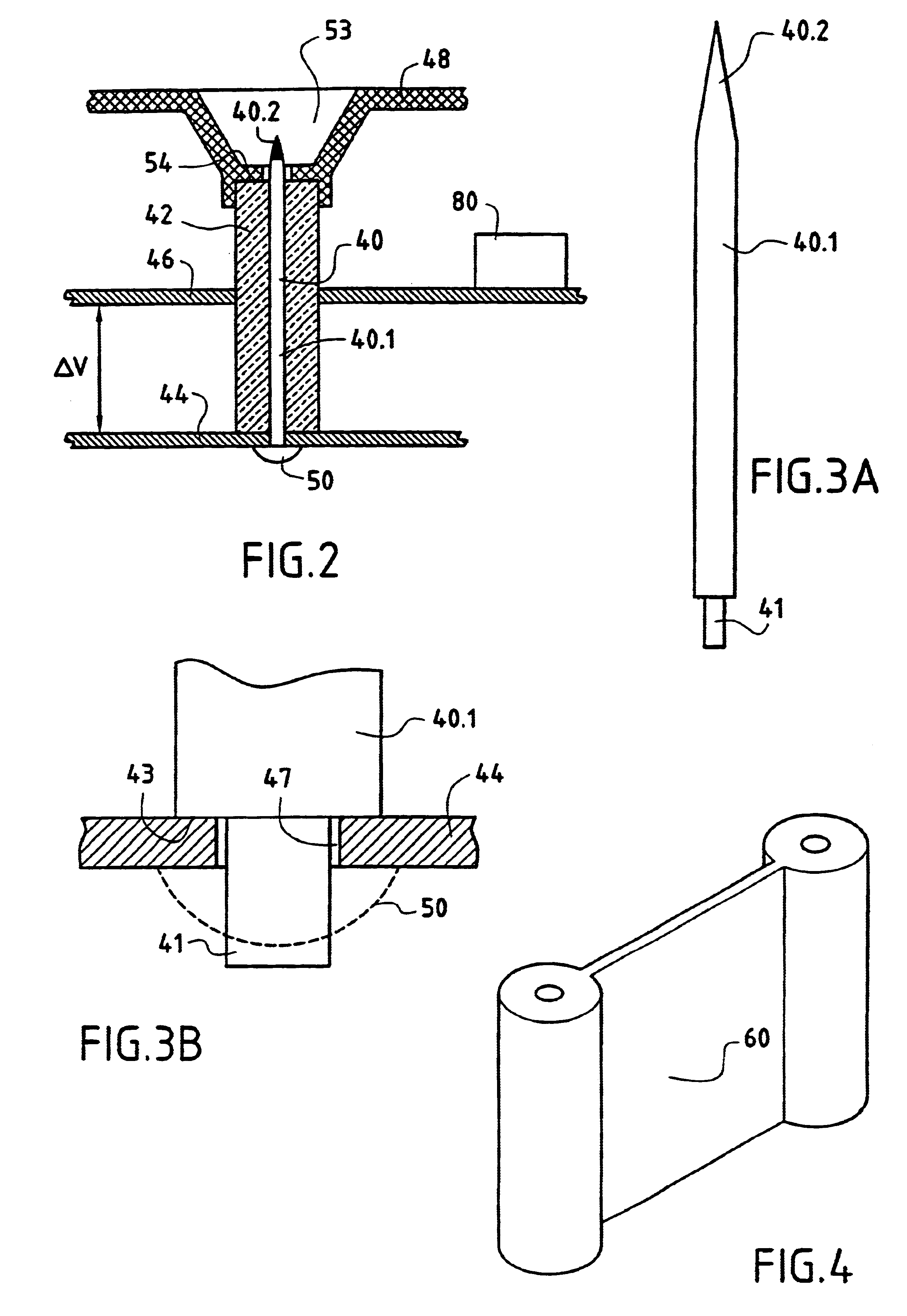

Ion generating device

InactiveUS6735830B1Material analysis by optical meansVessels or leading-in conductors manufacturePolyesterGlass fiber

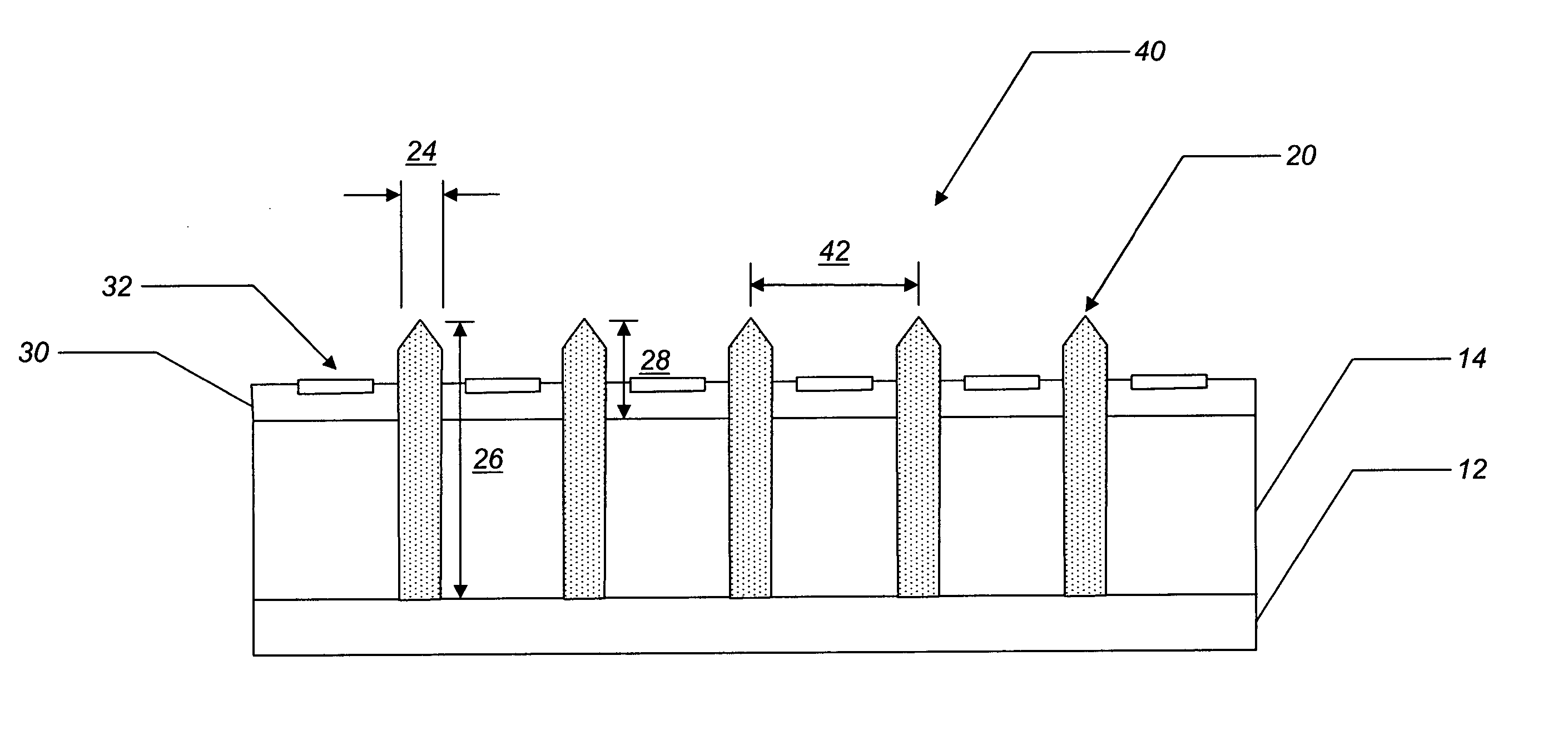

The invention relates to apparatus for generating ions in a gaseous medium, the apparatus comprising one or more needles (40) each presenting a shank (40.1) and an emitter end (40.2), a sheath (42) of composite material comprising glass fiber reinforced unsaturated polyester surrounding the shank (40.1) of each needle, and means (44, 46, 80) for applying a voltage between two portions of the shank of each needle.

Owner:GENIE & ENVIRONNEMENT

Method for depositing carbon nanotubes on a substrate of a field emission device using direct-contact transfer deposition

ActiveUS7357691B2Launch evenlyImprove flatnessMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

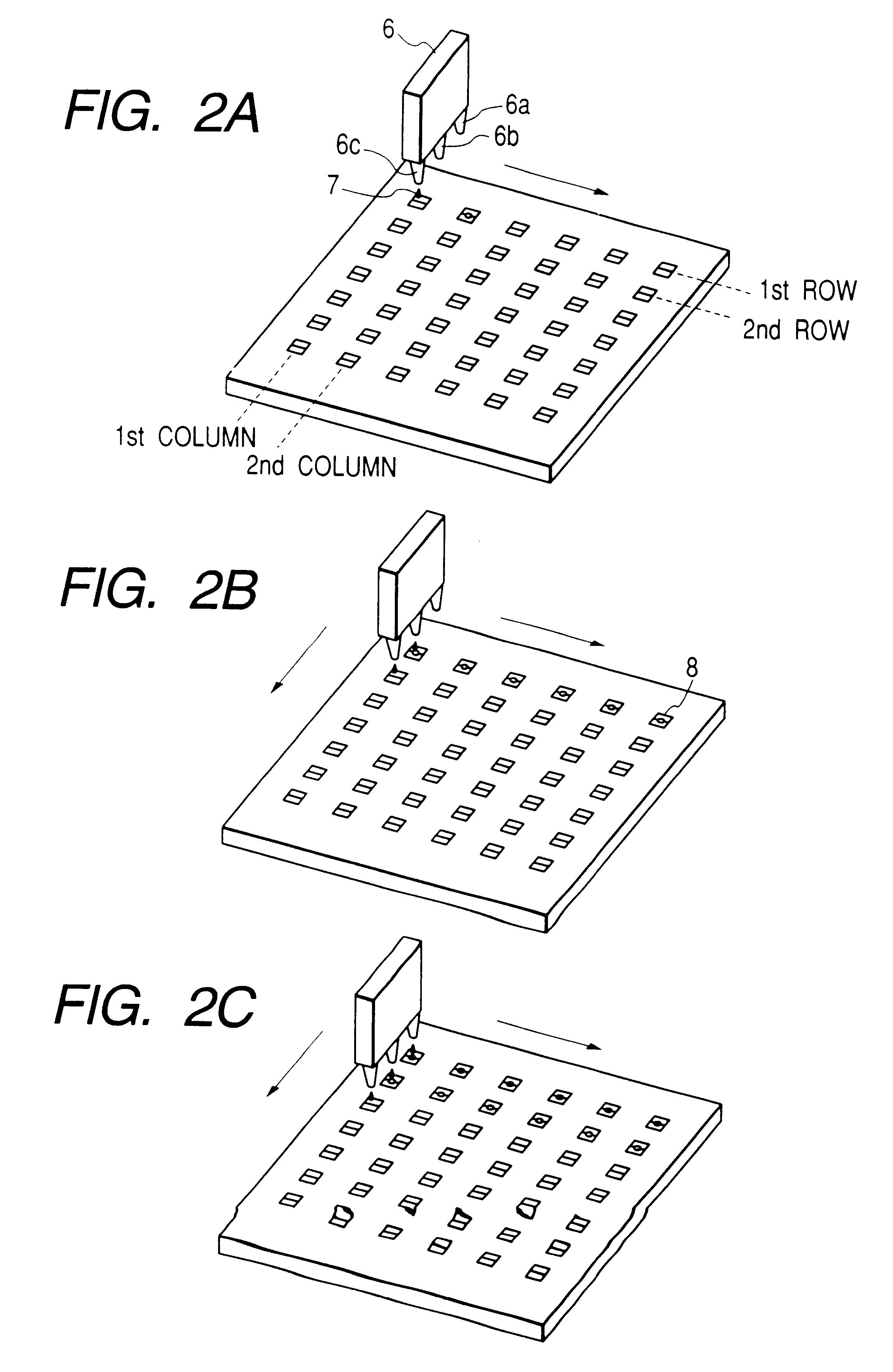

Method and apparatus for producing electron source using dispenser to produce electron emitting portions

InactiveUS6220912B1Vessels or leading-in conductors manufacturePhoto-emissive cathodes manufactureElectron sourceEngineering

In order to suppress variation in delivery amounts in dispensing a material for forming electron emitting portions, a substantially homogeneous material is dispensed from a plurality of output portions to each of plural objective portions. This averages amounts of the material dispensed to the respective objective portions even if there is variation in delivery amounts of material from the respective output portions.

Owner:CANON KK

Self-aligned gated rod field emission device and associated method of fabrication

ActiveUS20050067935A1Discharge tube luminescnet screensLamp detailsCylindrical channelField emission device

A self-aligned gated field emission device and an associated method of fabrication are described. The device includes a substrate and a porous layer disposed adjacent to the surface of the substrate, wherein the porous layer defines a plurality of substantially cylindrical channels, each of the plurality of substantially cylindrical channels aligned substantially parallel to one another and substantially perpendicular to the surface of the substrate. The device also includes a plurality of substantially rod-shaped structures disposed within at least a portion of the plurality of substantially cylindrical channels defined by the porous layer and adjacent to the surface of the substrate, wherein a portion of each of the plurality of substantially rod-shaped structures protrudes above the surface of the porous layer. The device further includes a gate dielectric layer disposed on the surface of the porous layer, wherein the gate dielectric layer is disposed between the plurality of substantially rod-shaped structures. The device still further includes a conductive layer selectively disposed on the surface of the gate dielectric layer, wherein the conductive layer is selectively disposed between the plurality of substantially rod-shaped structures.

Owner:GENERAL ELECTRIC CO

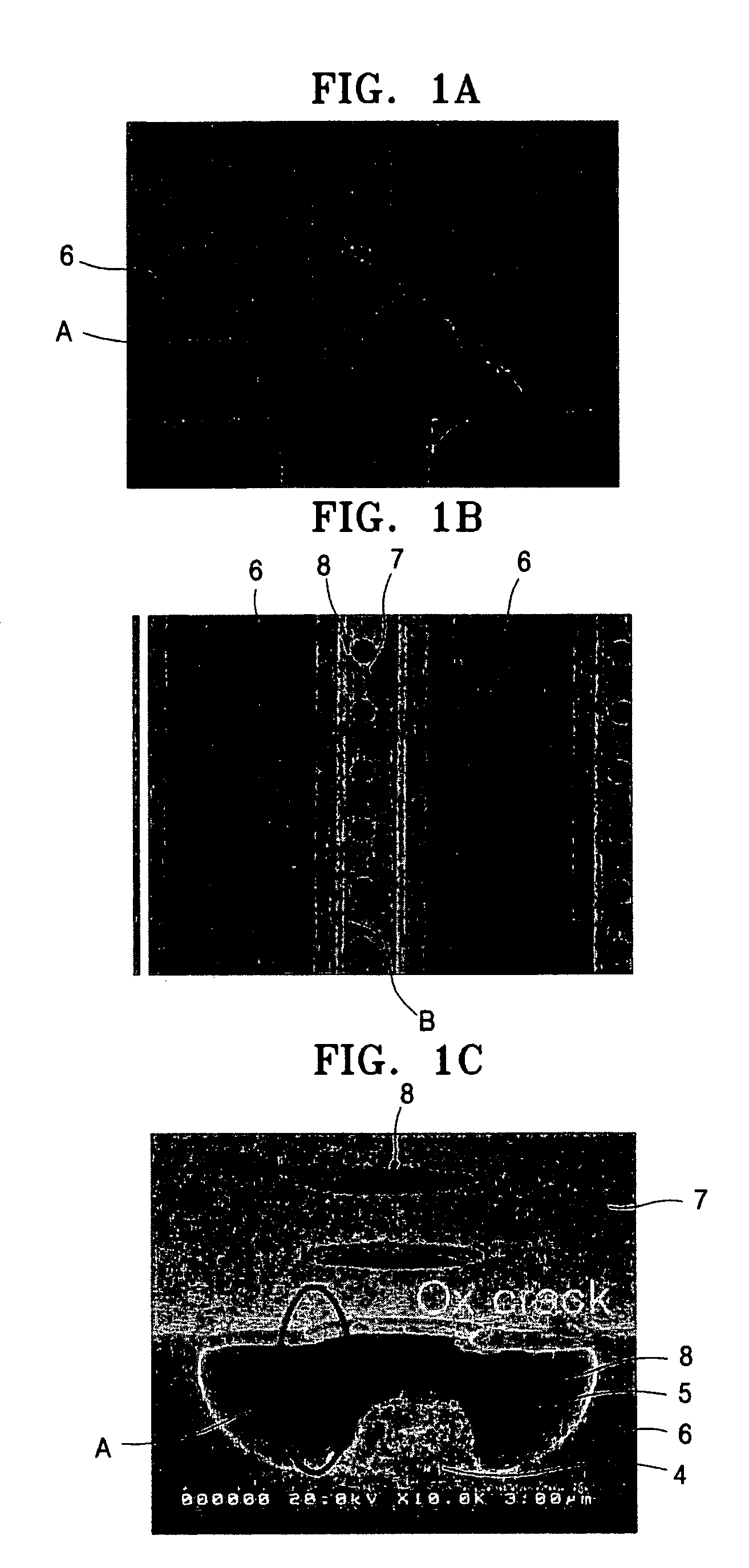

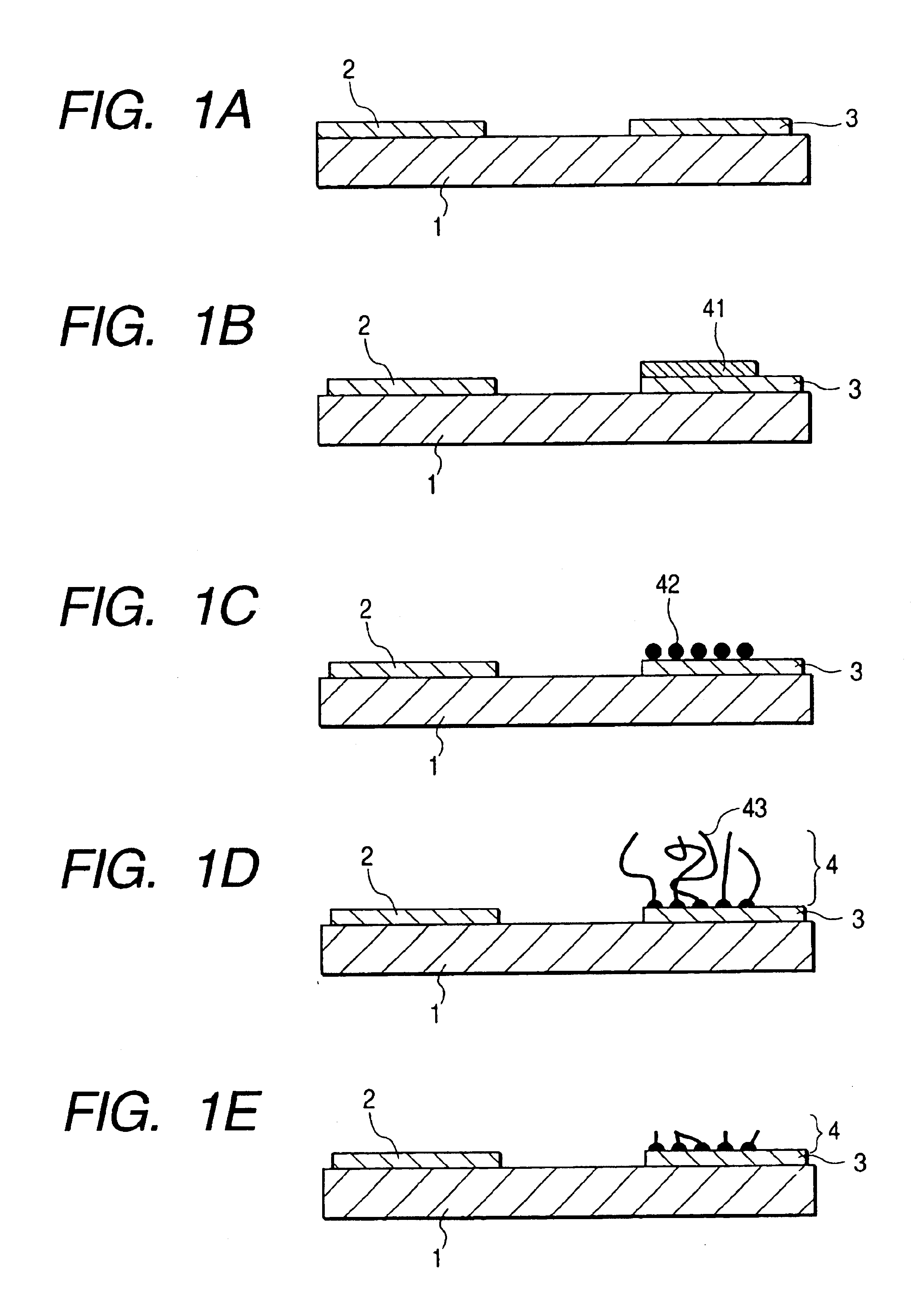

Method for fabricating electron emitter

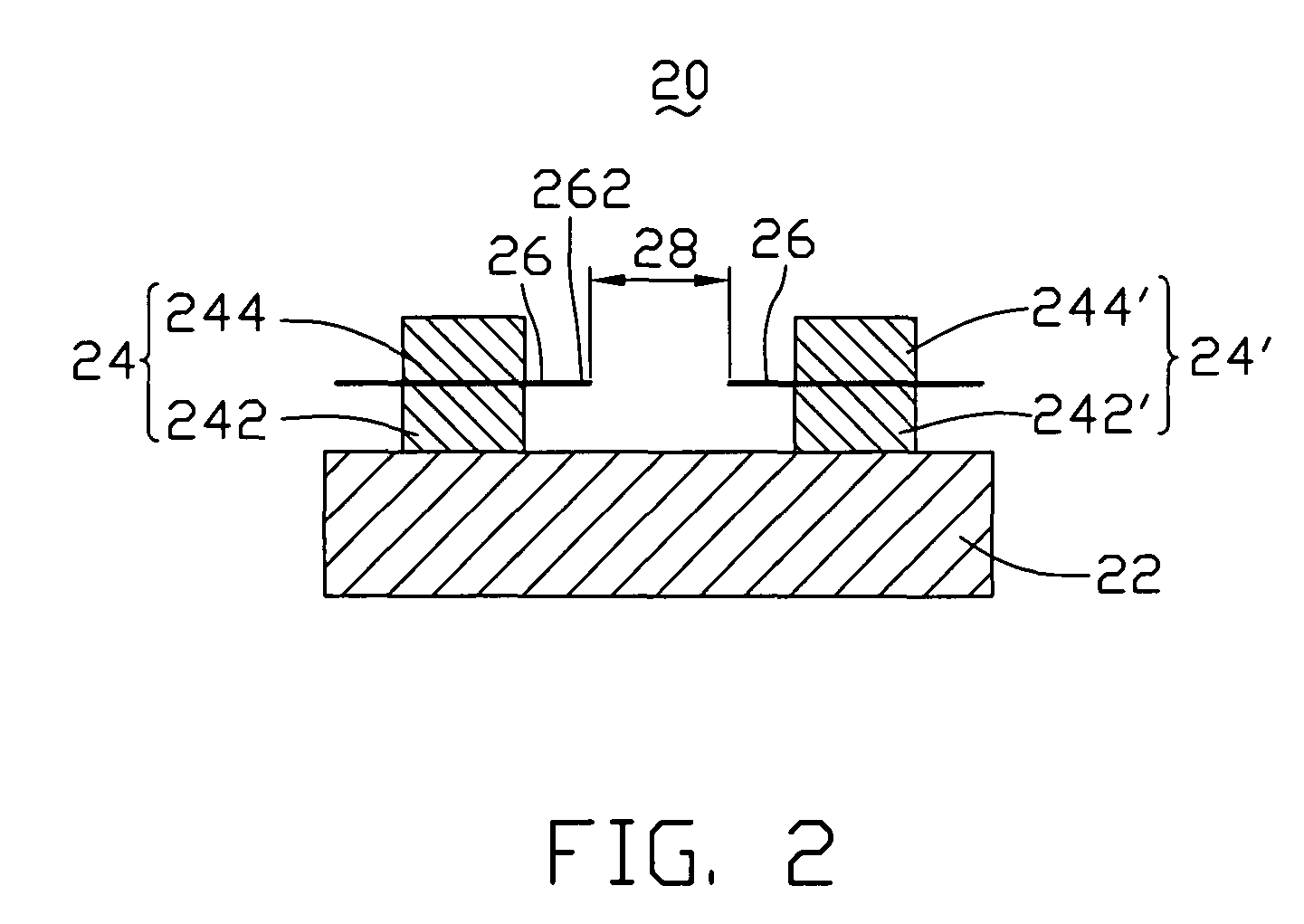

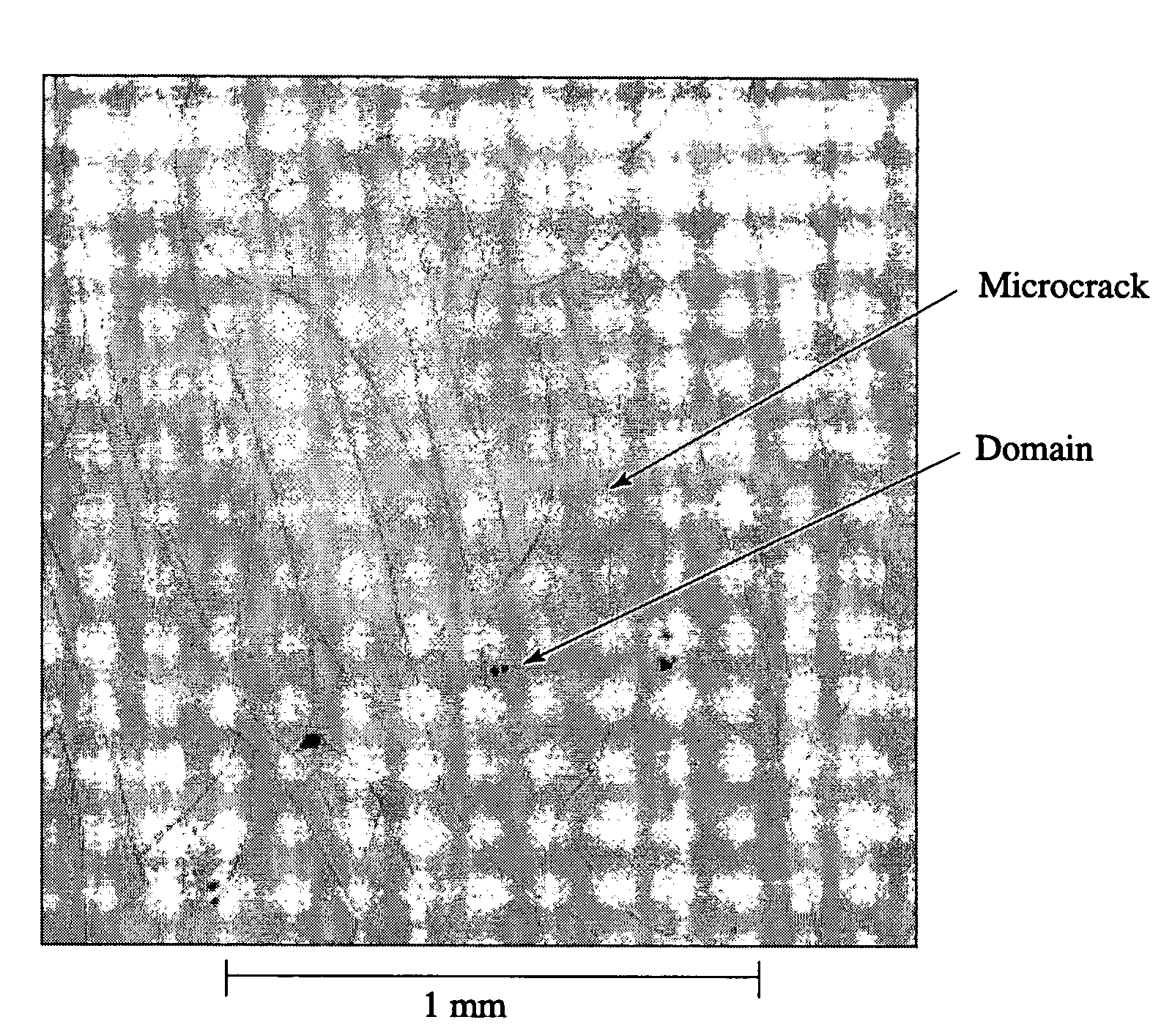

ActiveUS7780496B2Low efficiencyDischarge tube luminescnet screensCathode ray tubes/electron beam tubesCarbon nanotubeFissure

A method for fabricating a surface-conduction electron emitter includes the steps of: (a) providing a substrate; (b) disposing two lower layers on the surface of the substrate, the two lower layers are parallel and apart from each other; (c) disposing a plurality of carbon nanotube elements on the lower layers; (d) disposing two upper layers on the two lower layers, and thereby, sandwiching the carbon nanotube elements therebetween; and (e) forming a micro-fissure between the carbon nanotube elements.

Owner:TSINGHUA UNIV +1

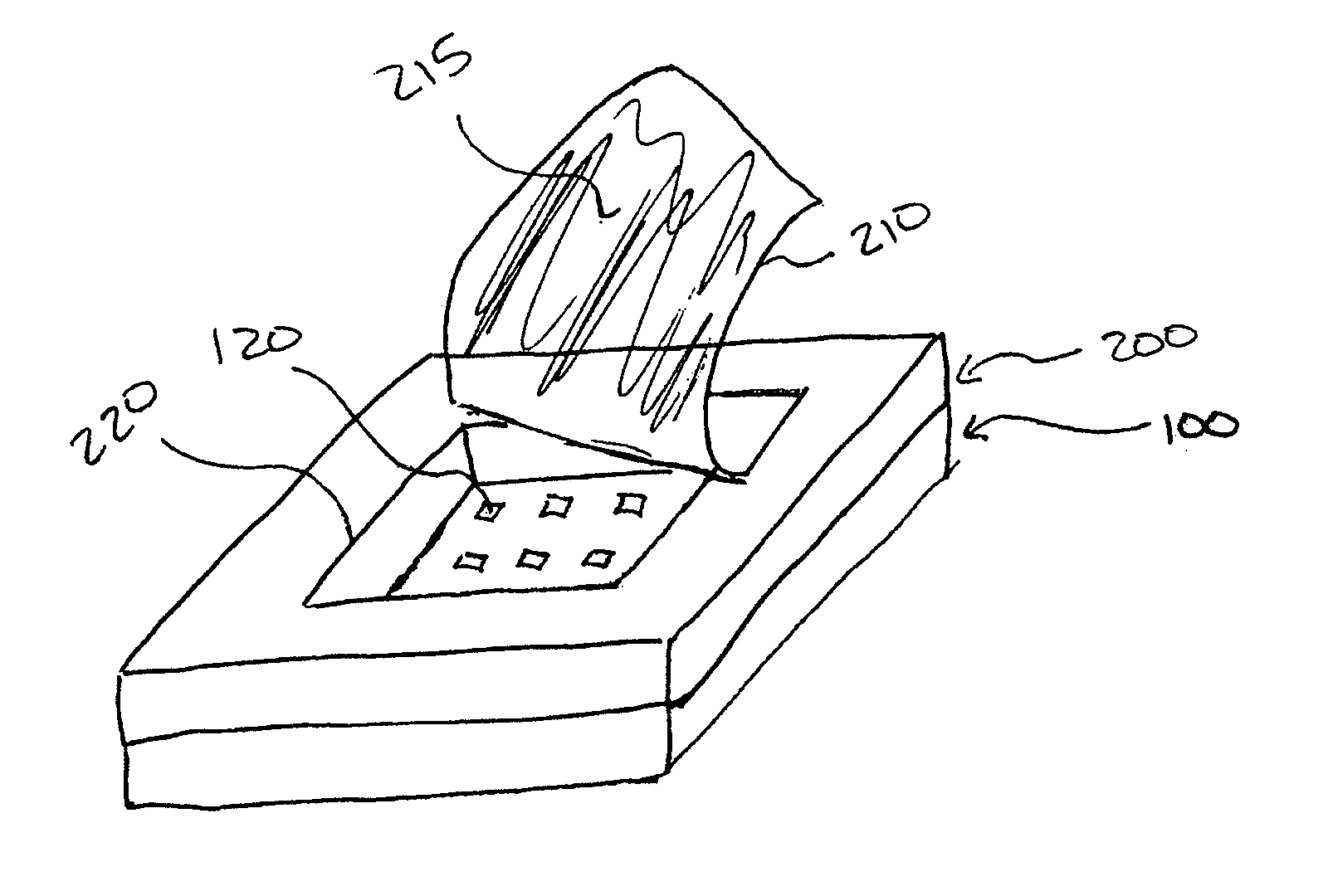

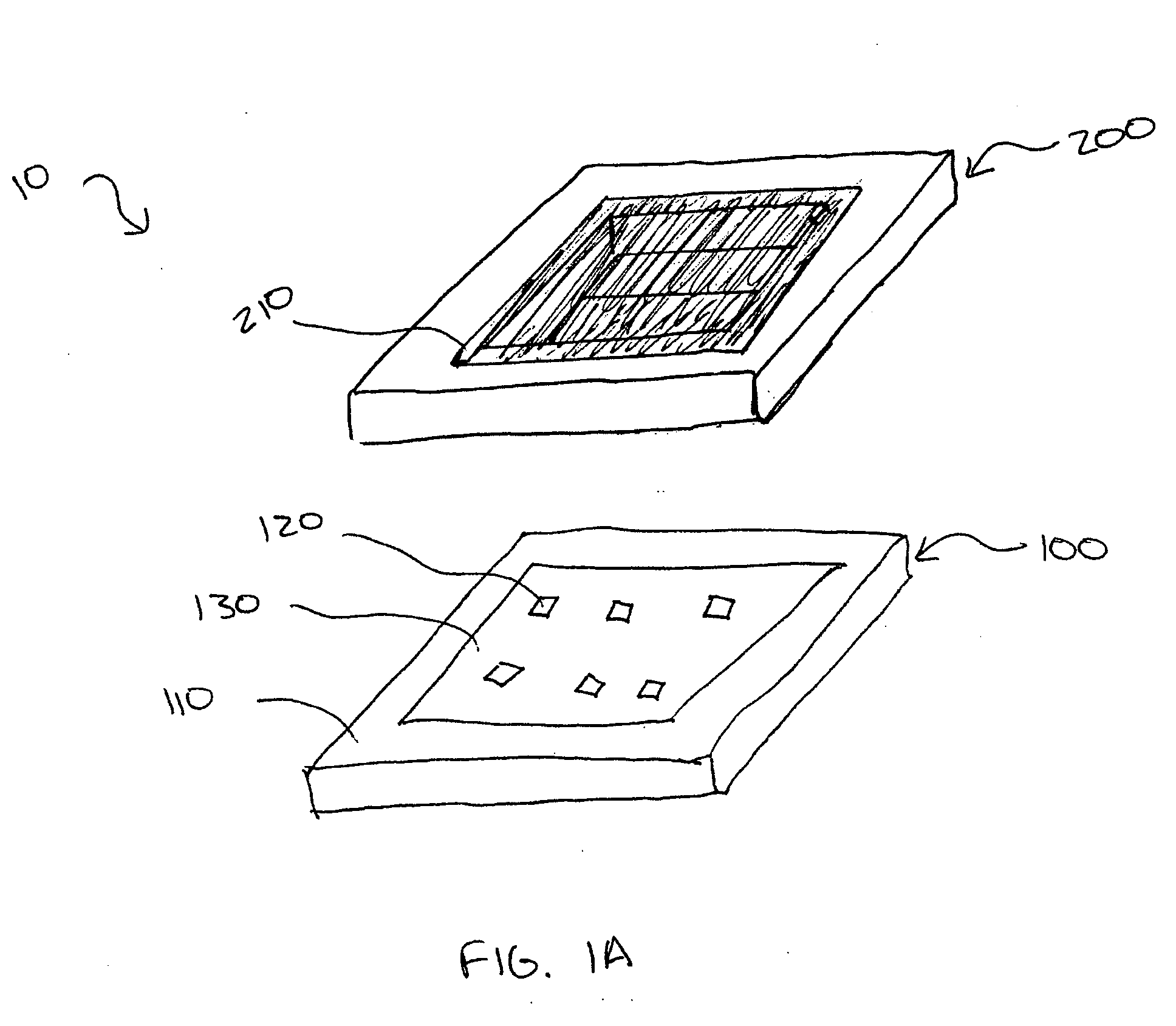

Nano-enhanced raman spectroscopy substrate packaging structure

Packaged NERS-active structures are disclosed that include a NERS substrate having a NERS-active structure thereon, and a packaging substrate over the NERS substrate having an opening therethrough, the opening in alignment with the NERS-active structure. A membrane may cover the opening in the packaging substrate. In order to perform nanoenhanced Raman spectroscopy, the membrane may be removed, and an analyte placed on the NERS substrate adjacent the NERS-active structure. The membrane may be replaced with another membrane after the analyte has been placed on the substrate. The membrane may maintain the pristine state of the substrate before it is deployed, and the replacement membrane may preserve the substrate and analyte for archival purposes. Also disclosed are methods for performing NERS with packaged NERS-active structures.

Owner:HEWLETT PACKARD DEV CO LP

Atomically sharp field emission cathodes

InactiveUS6113451AClarity is not affectedImprove uniformityElectric discharge tubesVessels or leading-in conductors manufactureSingle crystalElectron

An electron emitting device characterized by a monocrystalline substrate, a plurality of monocrystalline nanomesas or pillars disposed on the substrate in a spaced relationship and extending generally normally therefrom, monocrystalline self-assembled tips disposed on top of the nanomesas, and essentially atomically sharp apexes on the tips for field emitting electrons. A method for making the emitters is characterized by forming a gate electrode and gate electrode apertures before forming the tips on the nanomesas.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

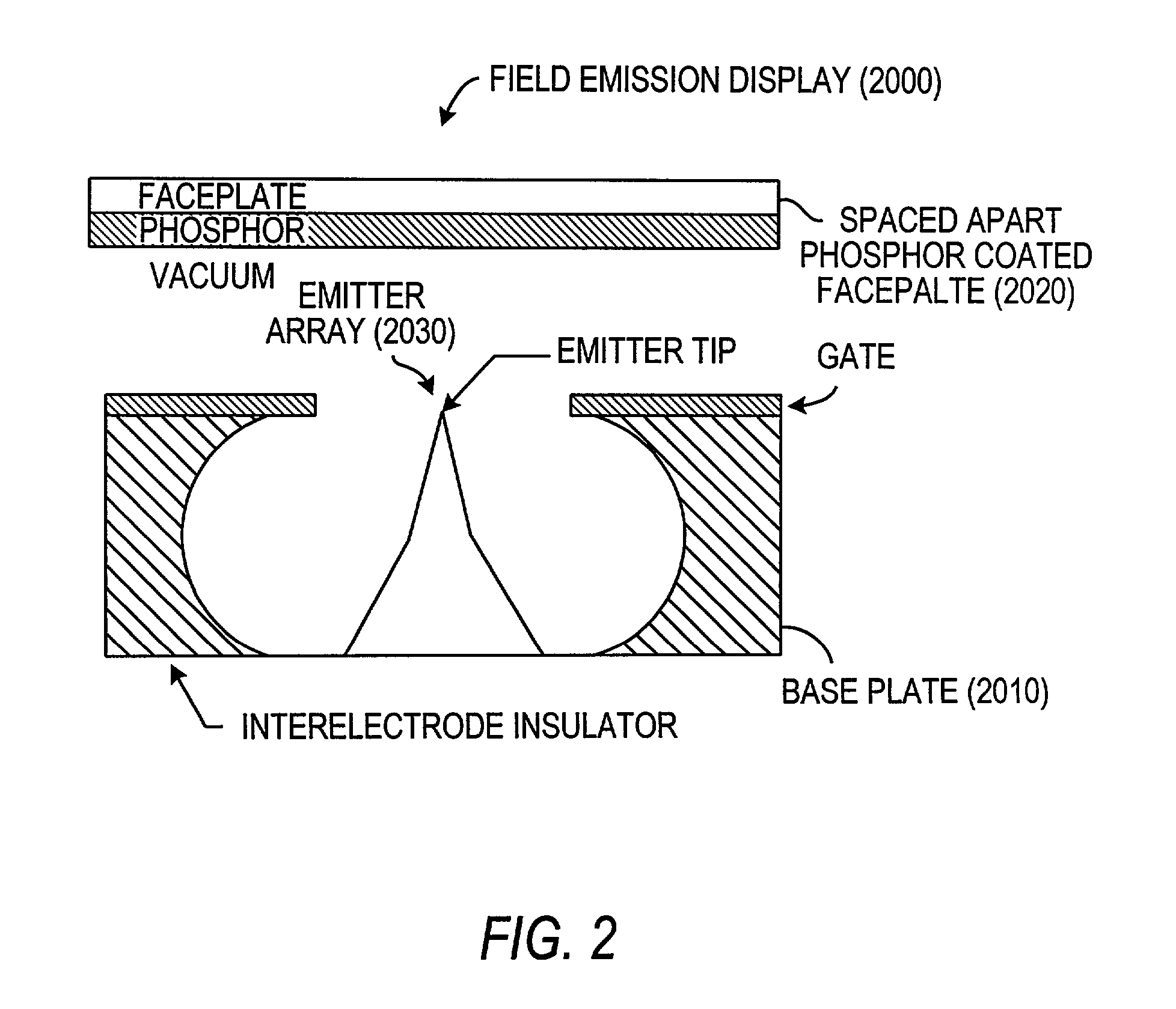

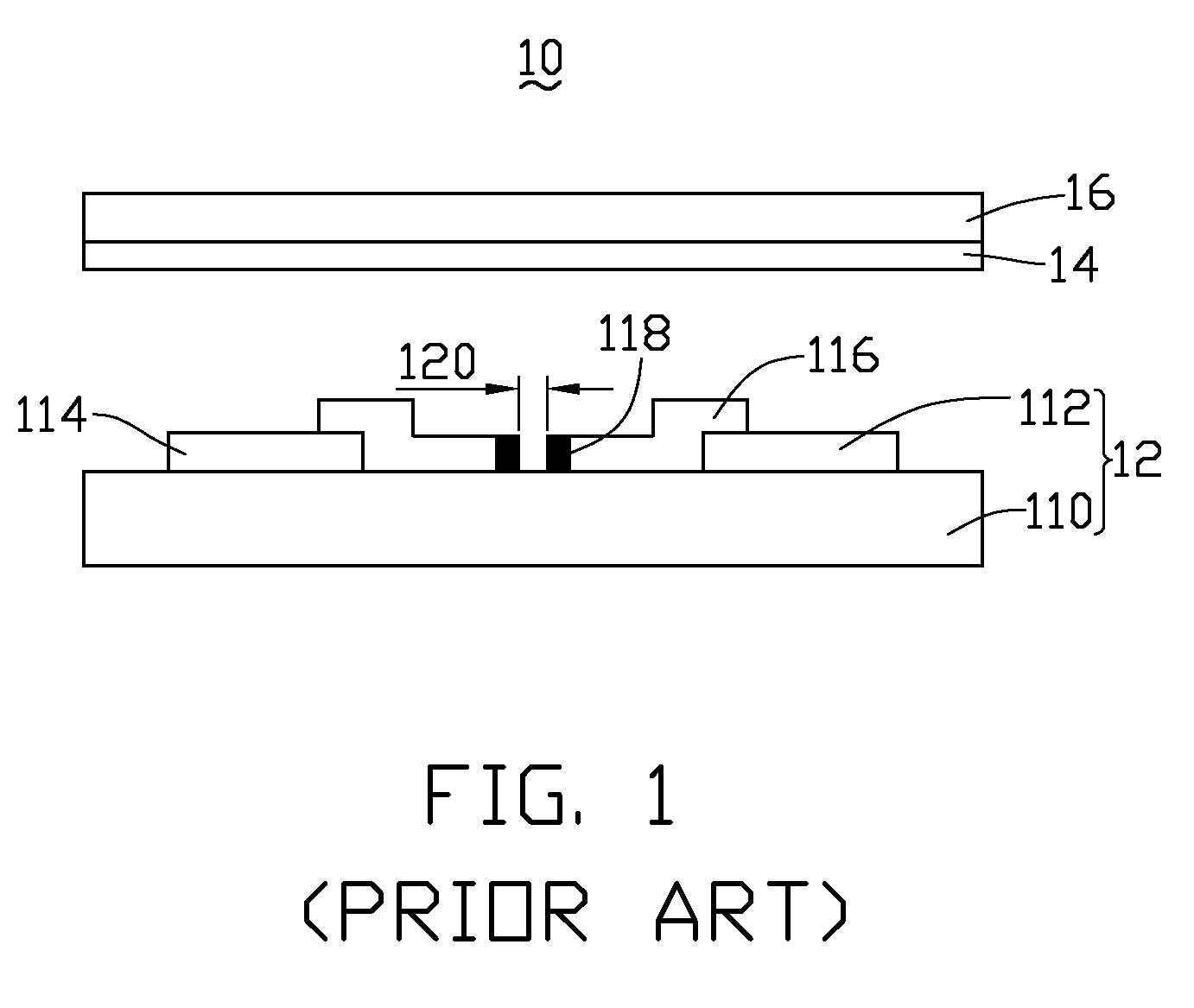

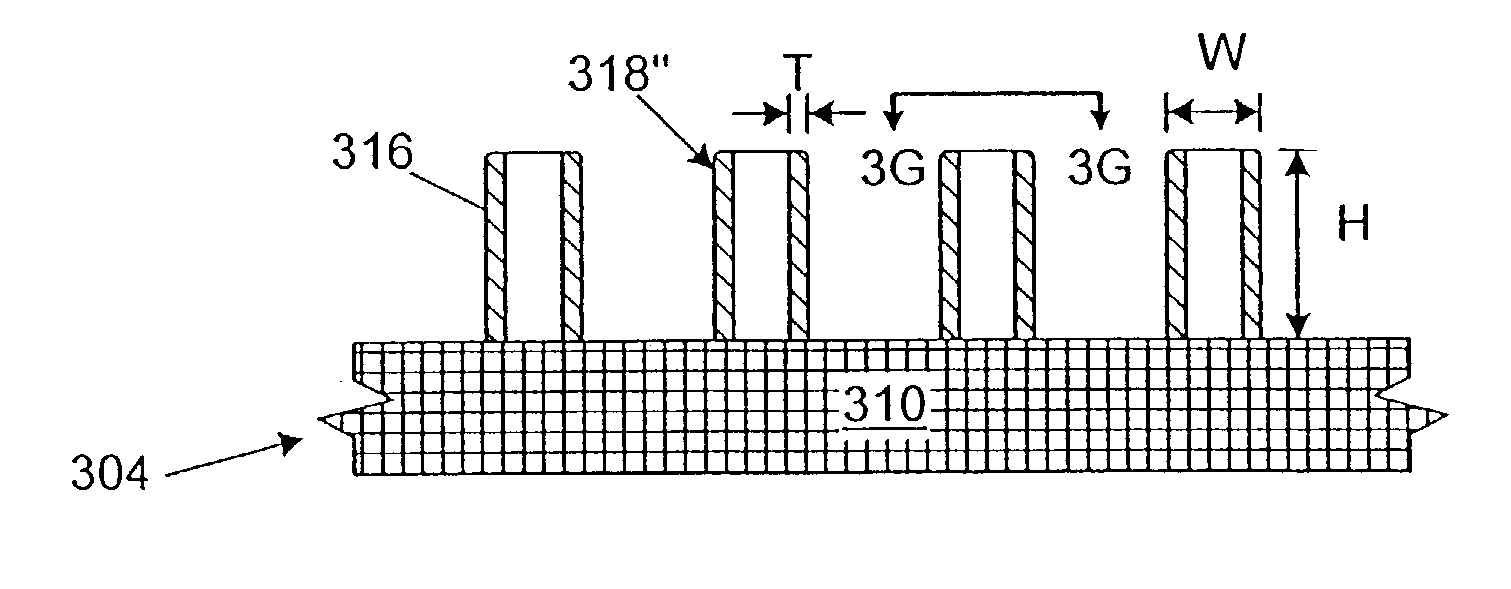

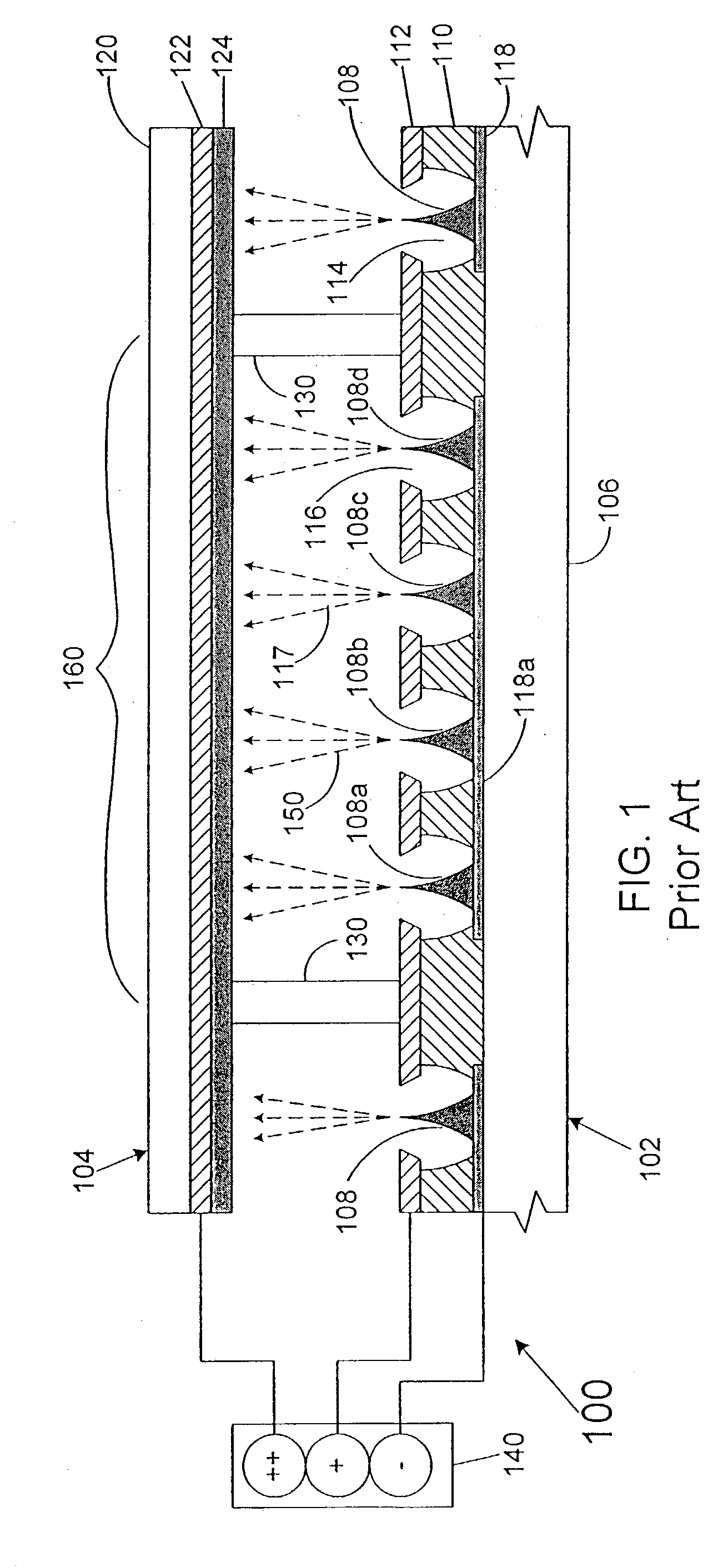

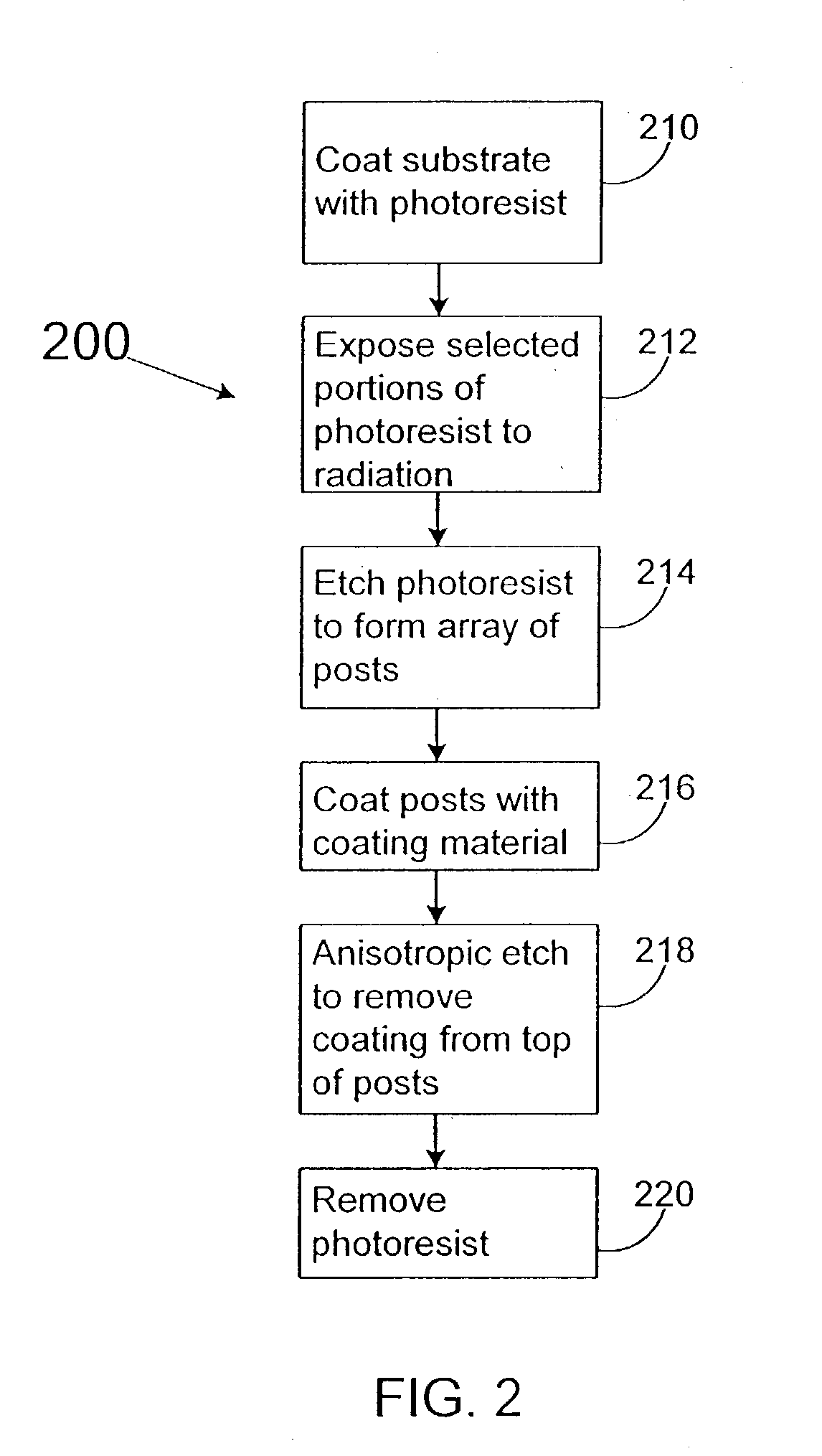

Spacers for field emission displays

InactiveUS20030085650A1Precise positioningQuality improvementCathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsField emission displayDisplay device

The disclosed method for forming a field emission display includes forming a cathode and an anode, forming a plurality of photoresist posts over the cathode, and coating the posts with a coating material. The coating material forms sidewalls around the posts. The photoresist posts may then be removed from within the sidewalls. The anode may then be fitted onto the sidewalls so that the sidewalls function as spacers in the field emission display.

Owner:MICRON TECH INC

Network conductor and its production method and use

ActiveUS7172822B2Maintain good propertiesLow resistivityConductive layers on insulating-supportsSolid-state devicesNetwork structureConductive materials

Owner:FUJIFILM CORP +1

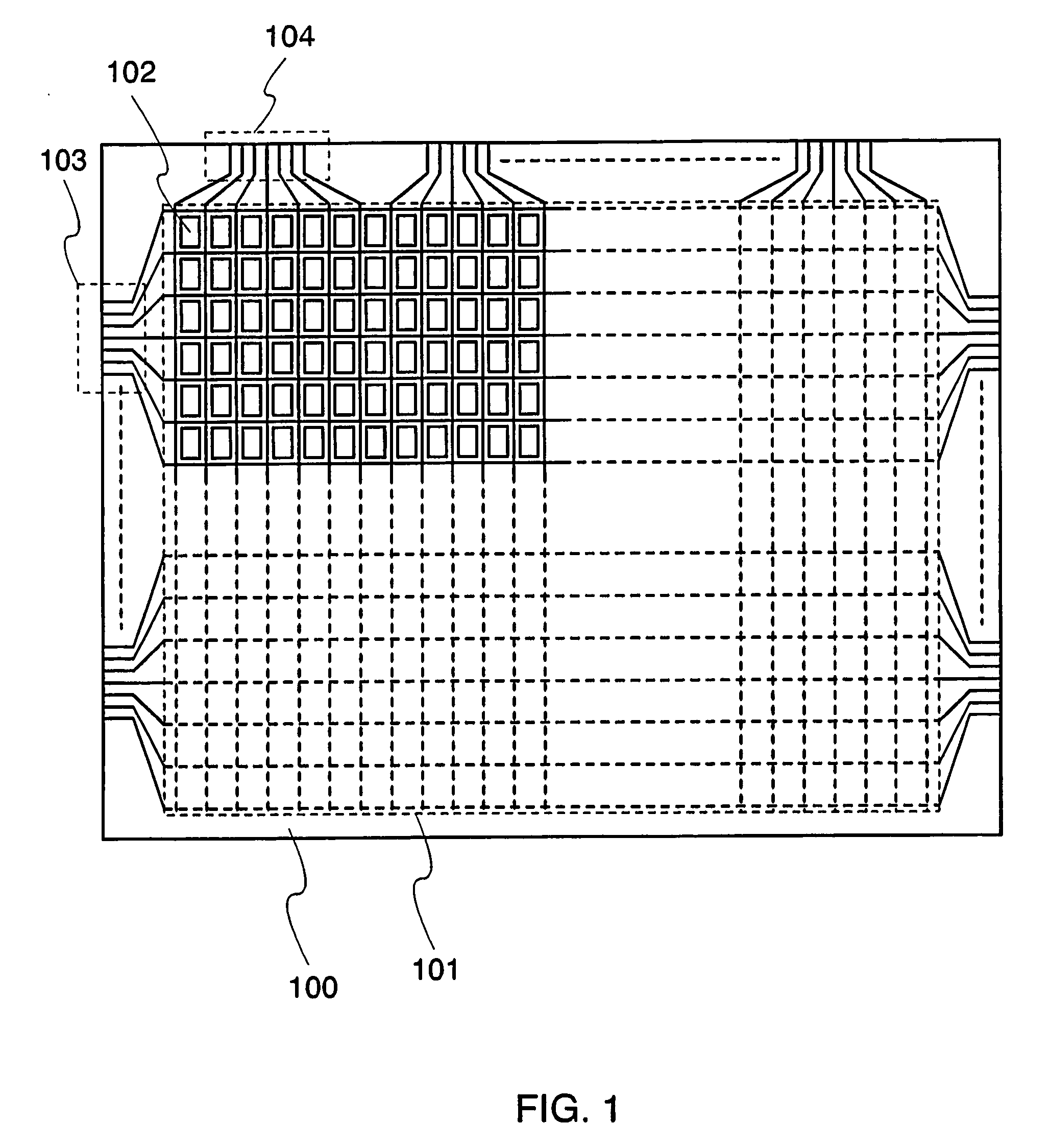

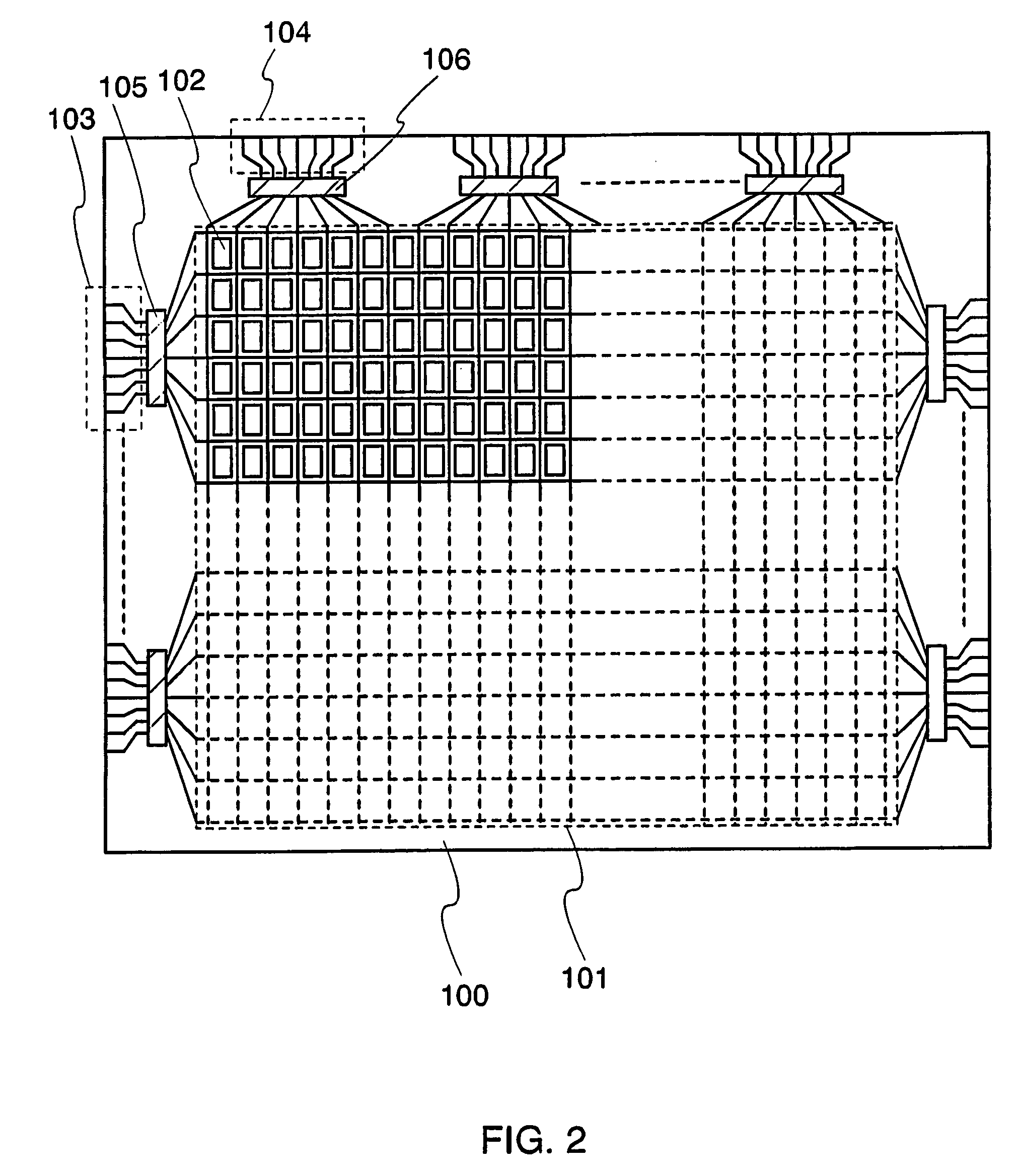

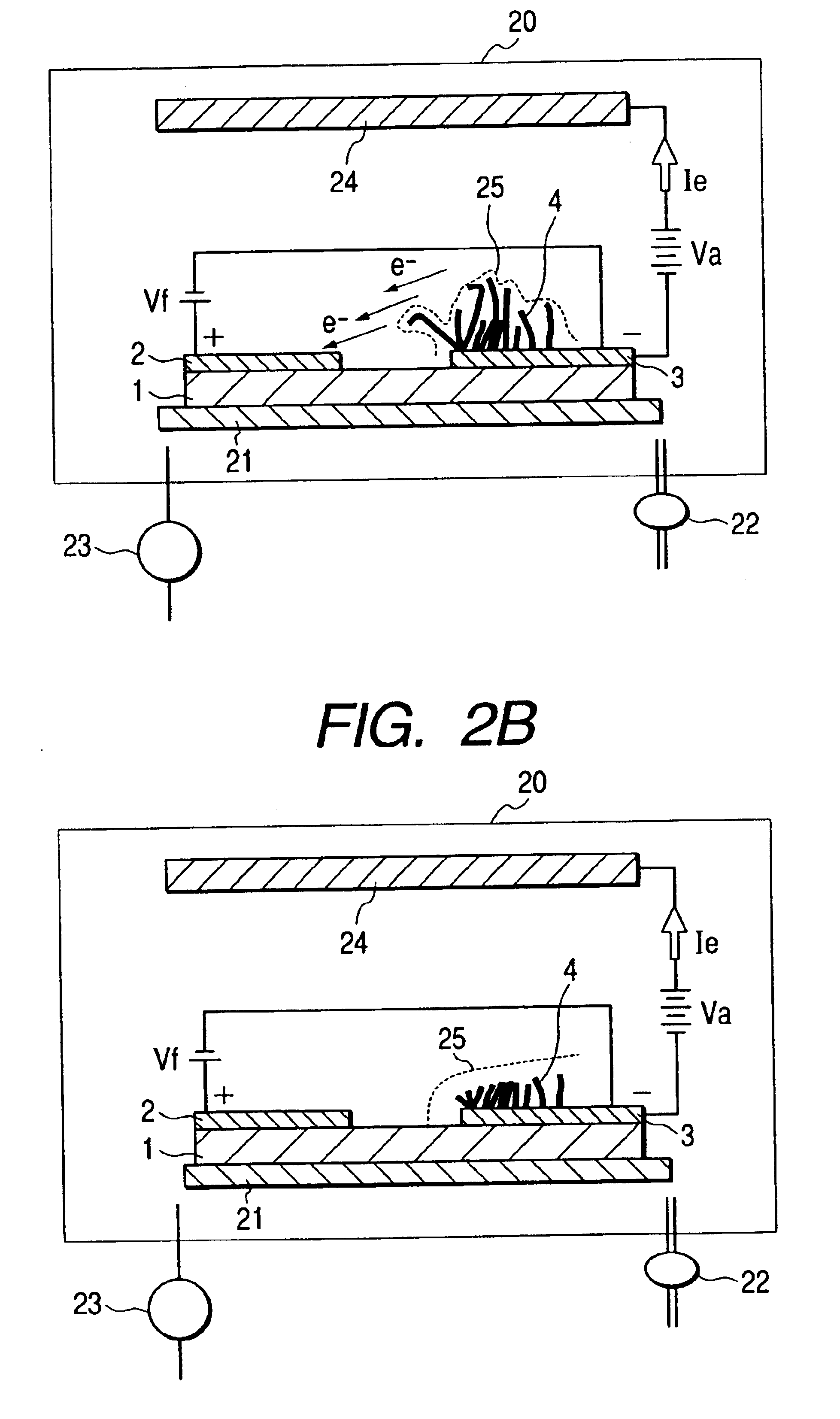

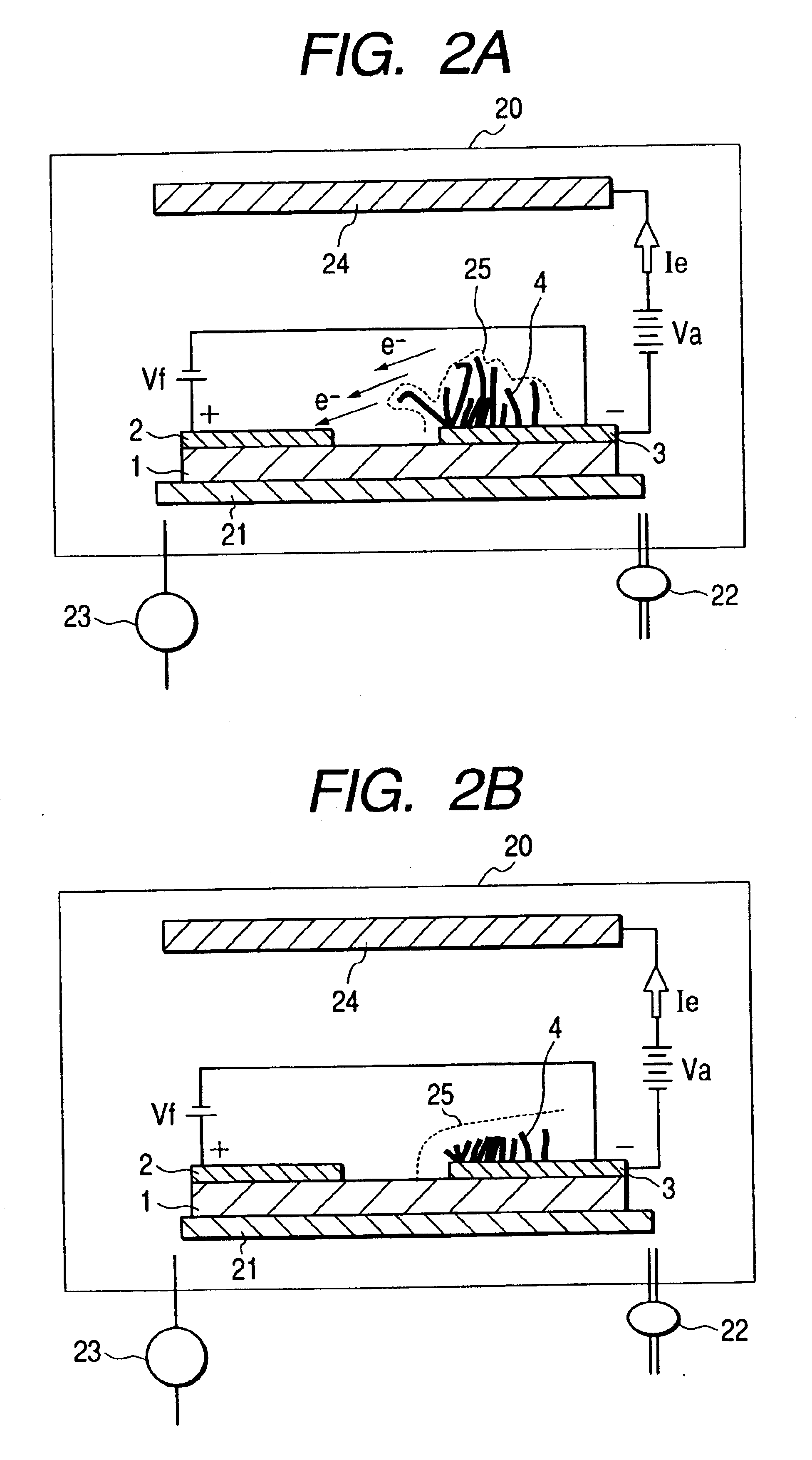

Electron-emitting device, electron source, image-forming apparatus, and method for producing electron-emitting device and image forming apparatus

InactiveUS6848962B2Reduce the differenceUniform and stableSparking plugsCathode ray tubes/electron beam tubesFiberElectron source

A method for producing a durable electron-emitting device having a uniform electron emission characteristic, an electron source, and an image-forming apparatus having a uniform display characteristic for a long period are provided. The method for producing an electron-emitting device according to the present invention includes the steps of: disposing a cathode electrode on a surface of a substrate; providing an electrode opposite the cathode electrode; disposing plural pieces of fiber containing carbon as a main component on the cathode electrode; and applying potential higher than potential applied to the cathode electrode under depressurized condition to an electrode opposite the cathode electrode.

Owner:CANON KK

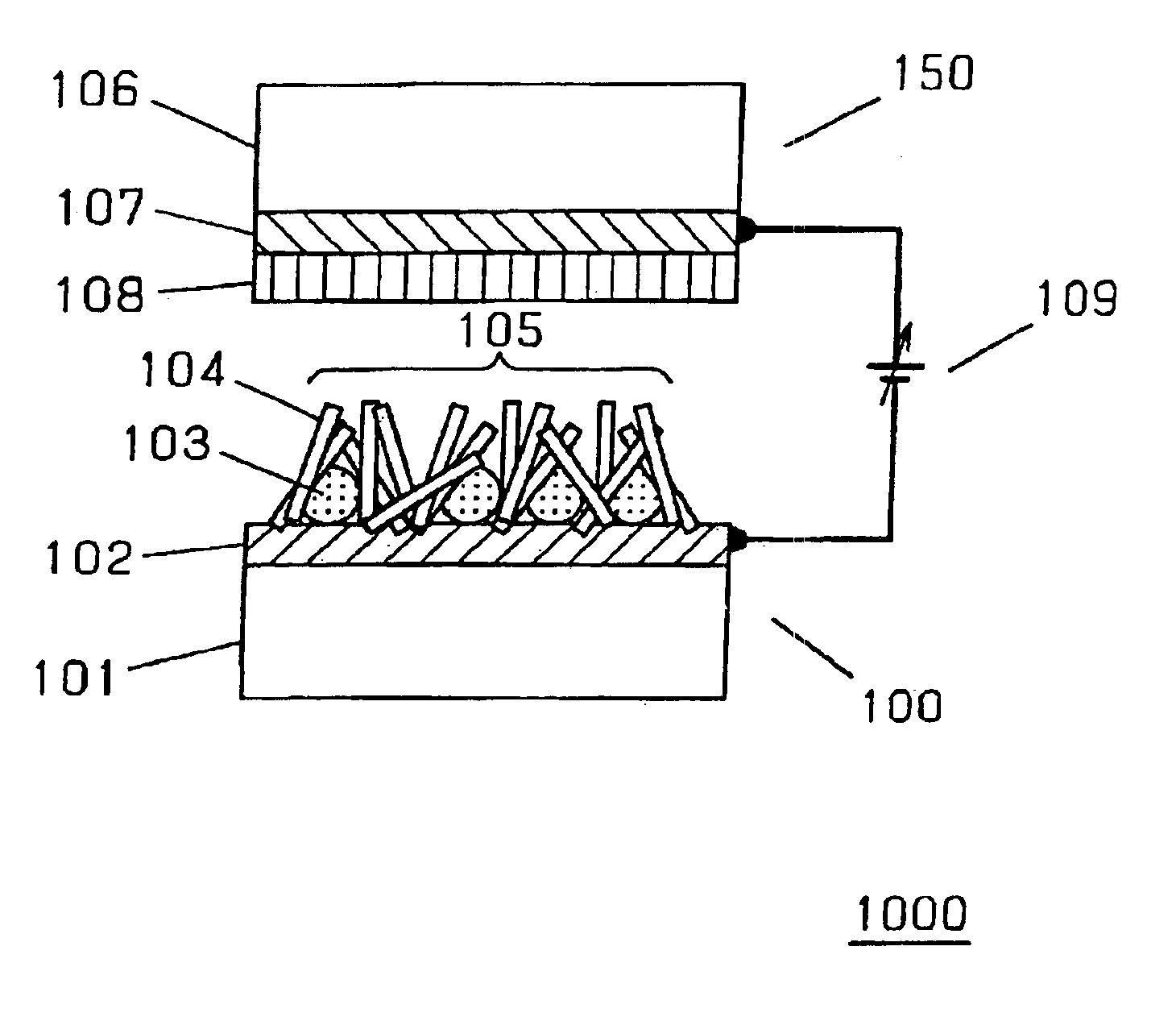

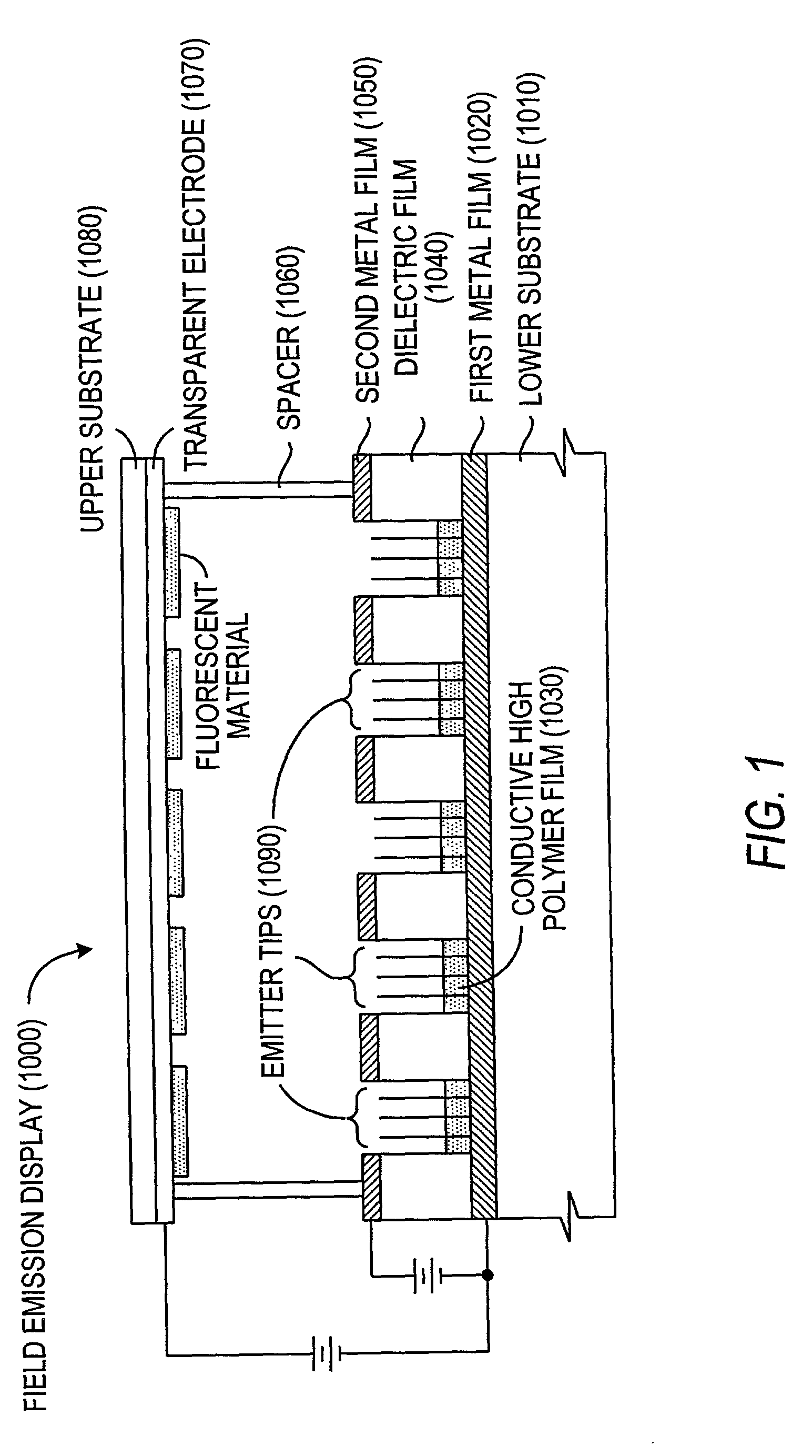

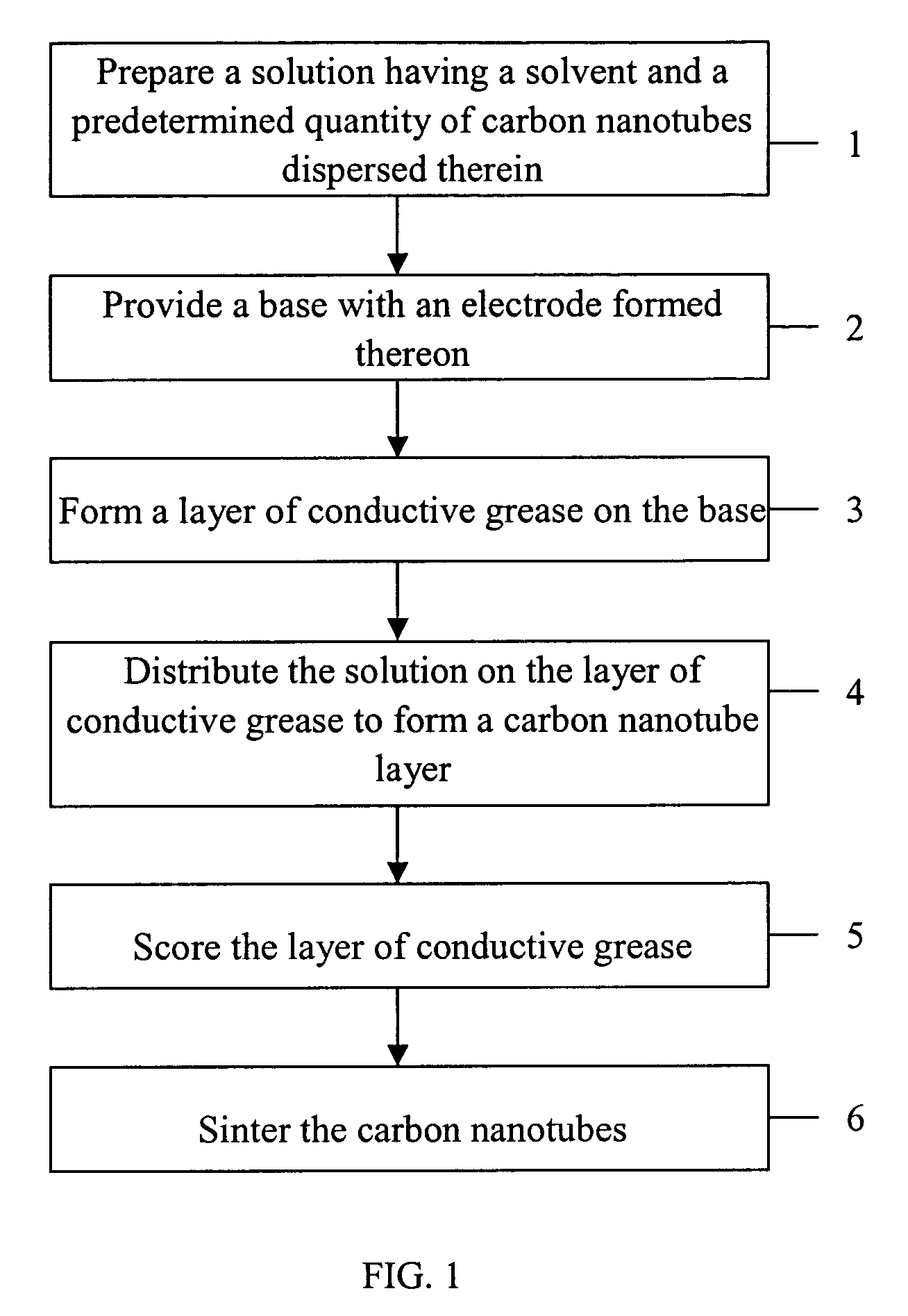

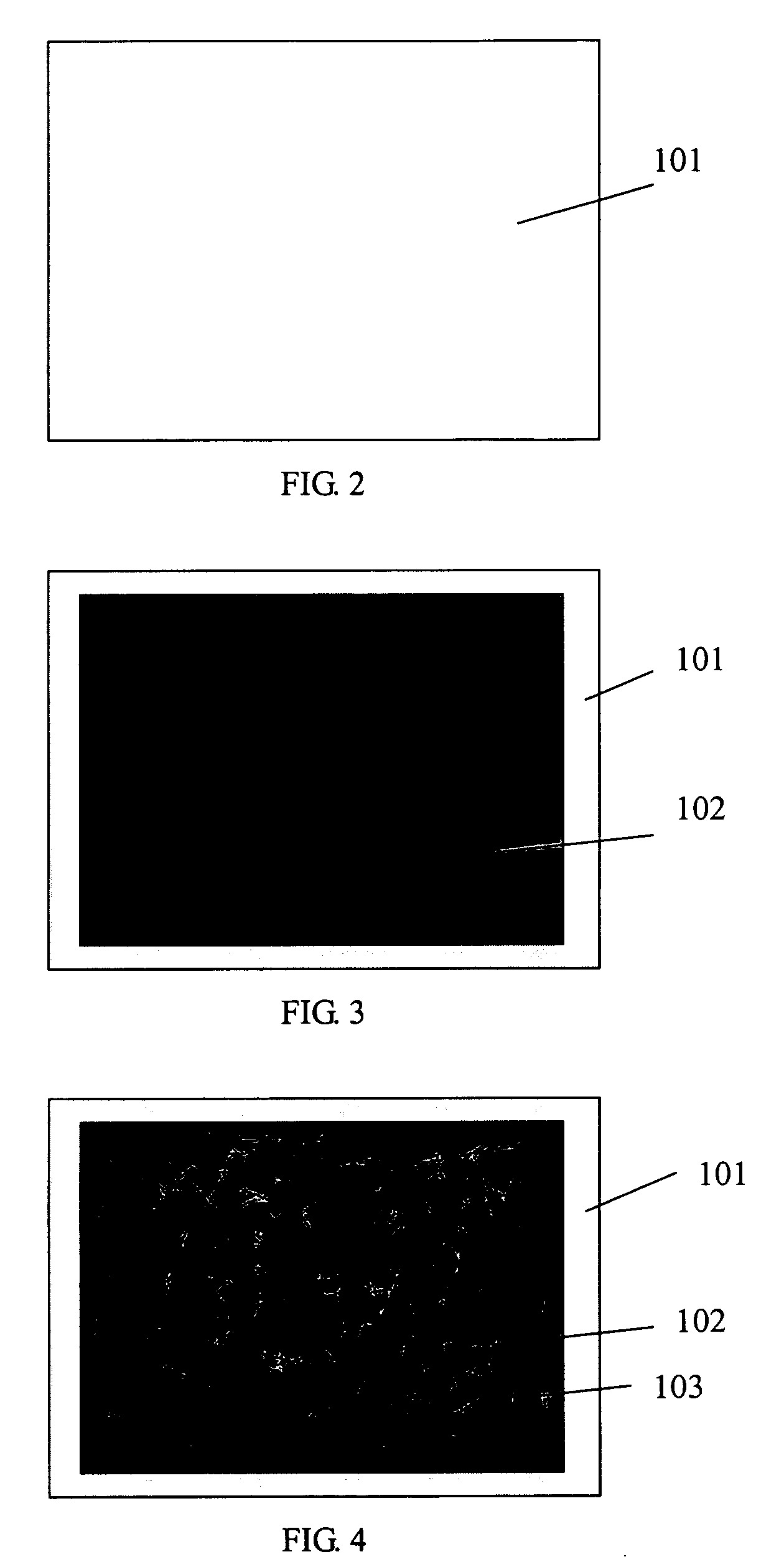

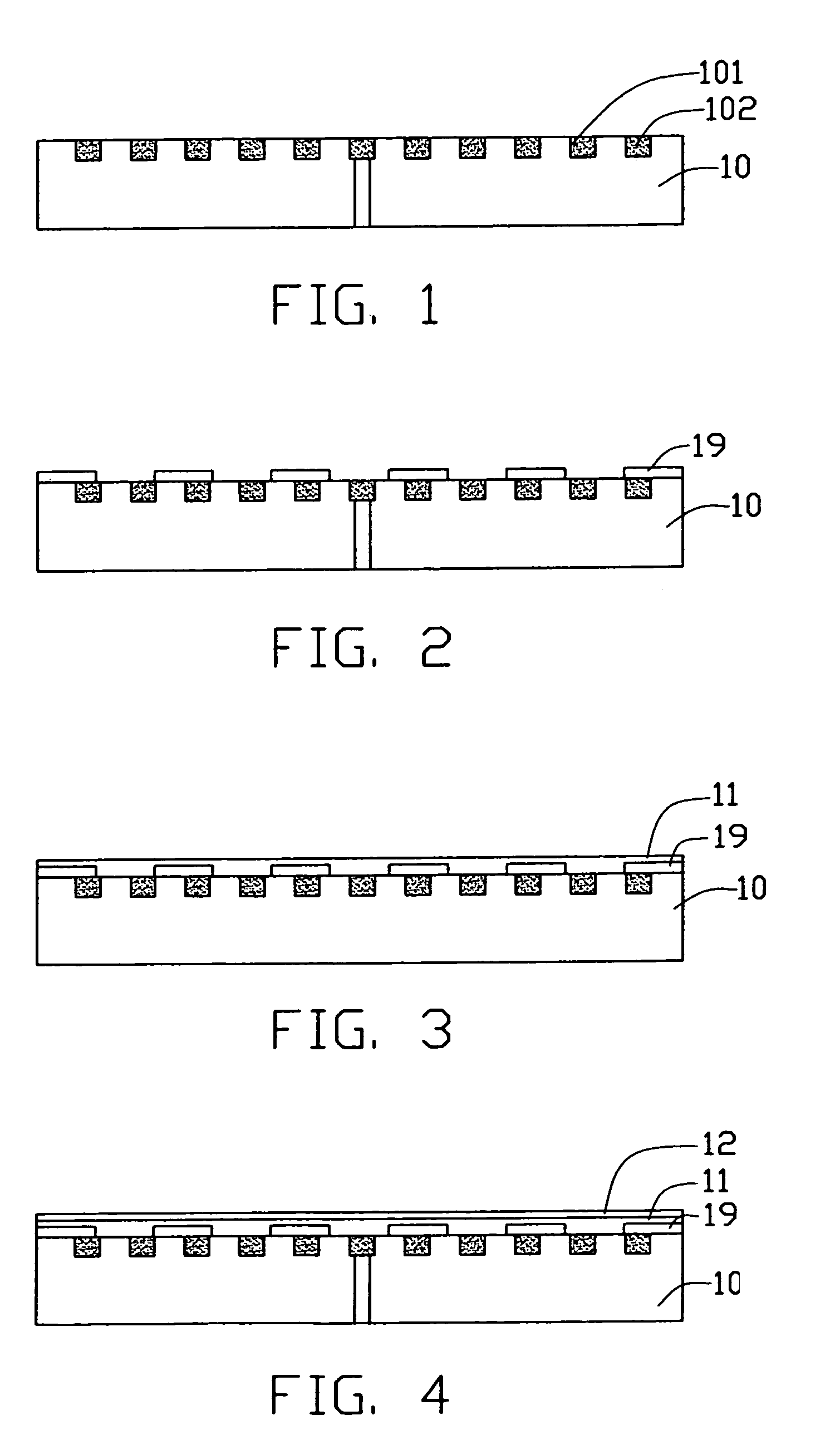

Method for making a carbon nanotube-based field emission cathode device

ActiveUS20050236951A1Improve Field Emission EfficiencyAccelerate emissionsElectric discharge tubesNanoinformaticsCarbon nanotubeSolvent

A preferred method for making a carbon nanotube-based field emission cathode device in accordance with the invention includes the following steps: preparing a solution having a solvent and a predetermined quantity of carbon nanotubes dispersed therein; providing a base with an electrode (101) formed thereon; forming a layer of conductive grease (102) on the base; distributing the solution on the layer of conductive grease to form a carbon nanotube layer (103) on the conductive grease; and scoring the layer of conductive grease, for separating first ends of at least some of the carbon nanotubes from the conductive grease for attaining effective carbon nanotube field emission cathode.

Owner:HON HAI PRECISION IND CO LTD +1

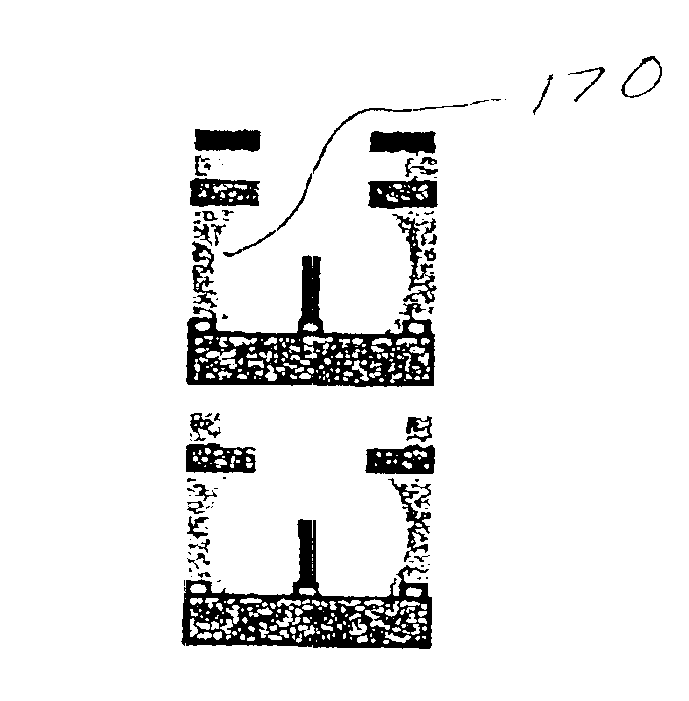

Gated fabrication of nanostructure field emission cathode material within a device

InactiveUS6858455B2Electric discharge tubesDecorative surface effectsField emission deviceDielectric

Gated field emission devices and systems and methods for their fabrication are described. A method includes growing a substantially vertically aligned carbon nanostructure, the substantially vertically aligned carbon nanostructure coupled to a substrate; covering at least a portion of the substantially vertically aligned carbon nanostructure with a dielectric; forming a gate, the gate coupled to the dielectric; and releasing the substantially vertically aligned carbon nanostructure by forming an aperture in the gate and removing a portion of the dielectric.

Owner:UT BATTELLE LLC

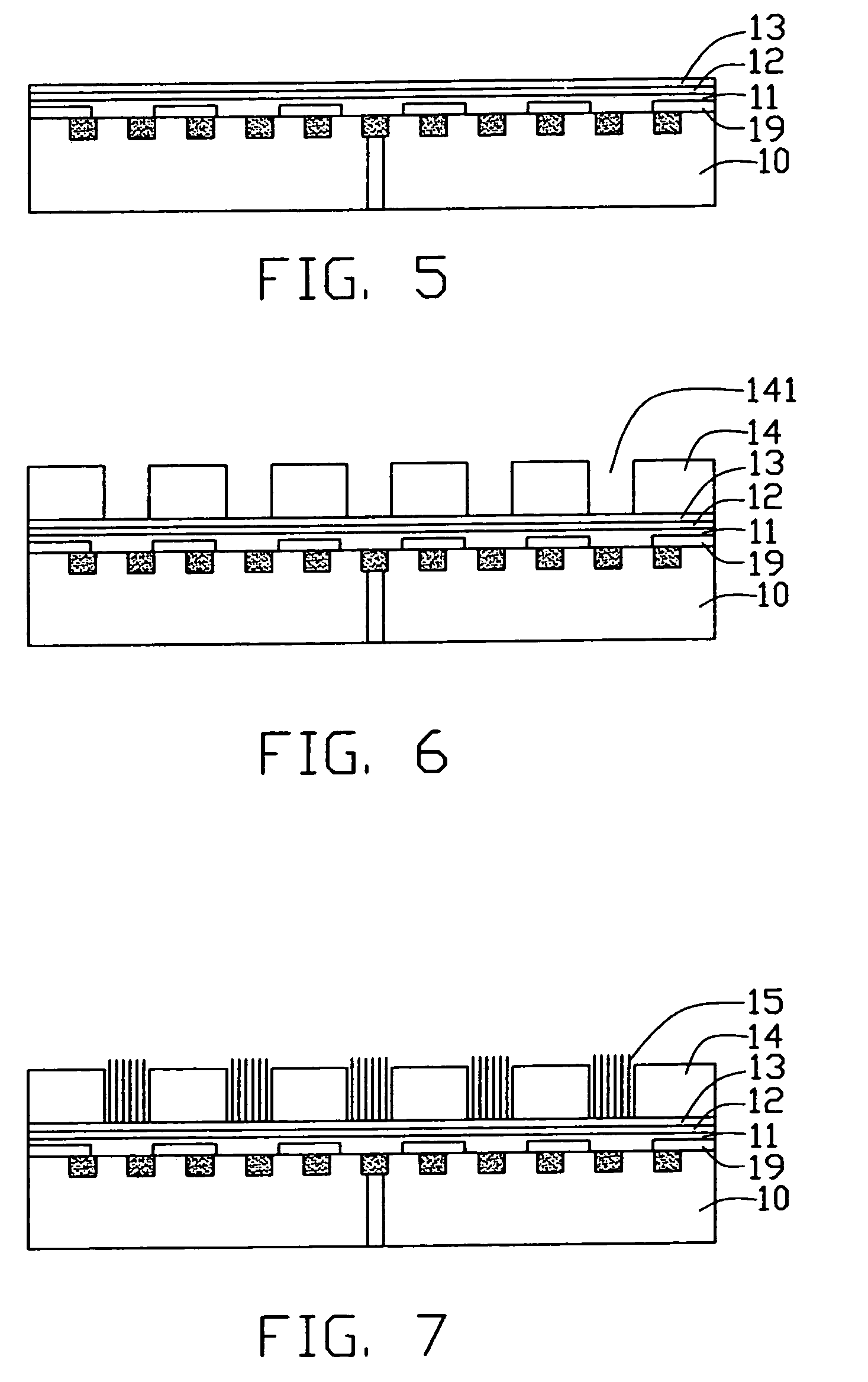

Method for making a carbon nanotube-based field emission display

A method for making a field emission display includes: (1) providing a detachable substrate having a plane surface; (2) forming gate electrodes in a predetermined pattern on the plane surface of the detachable substrate; (3) forming an intermediate layer on the gate electrodes; (4) forming a catalyst layer on the intermediate layer; (5) forming a spacer in a manner corresponding to a predetermined pattern on the layer of catalyst material; (6) forming carbon nanotube arrays extending from the layer of catalyst material; (7) forming cathode electrodes on first ends of the carbon nanotube arrays; and (8) removing the detachable substrate, and removing portions of the intermediate layer corresponding to positions of the carbon nanotube arrays so as to expose opposite second ends of the carbon nanotube arrays that face toward the gate electrodes.

Owner:HON HAI PRECISION IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com