Patents

Literature

164results about "Photodevelopable thick film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

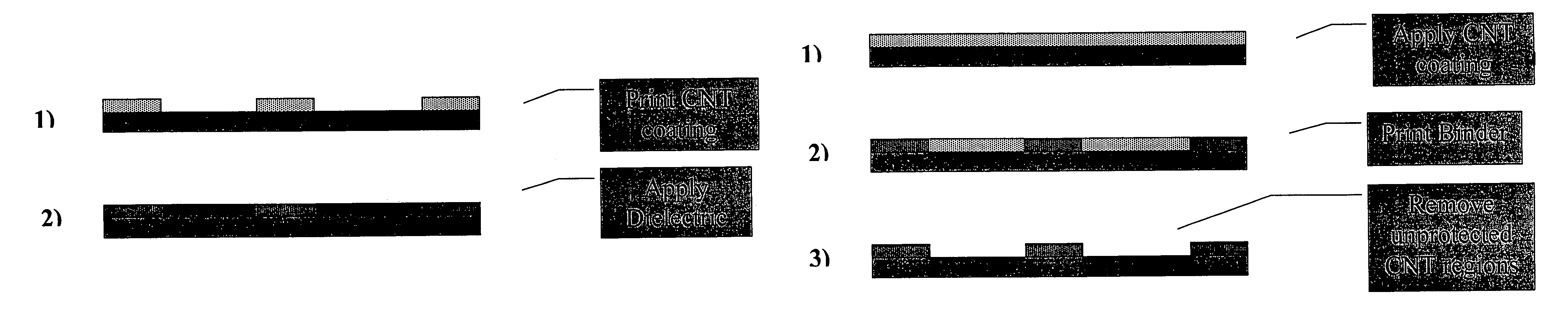

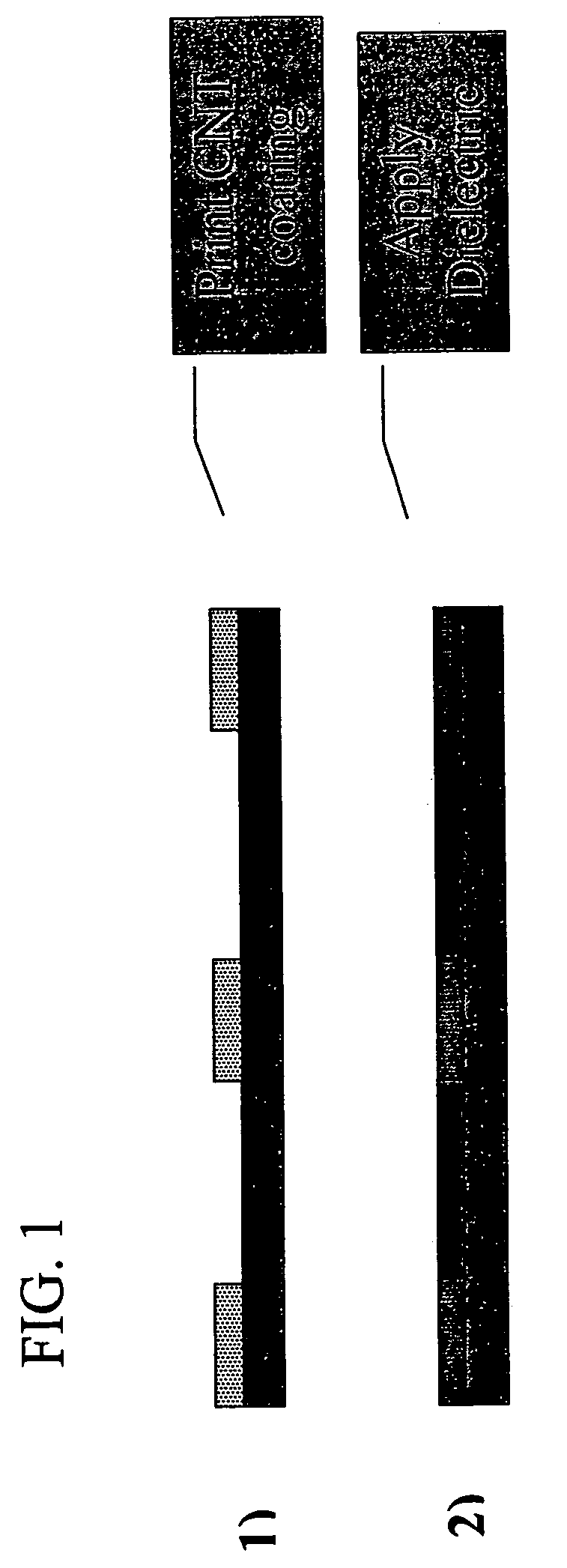

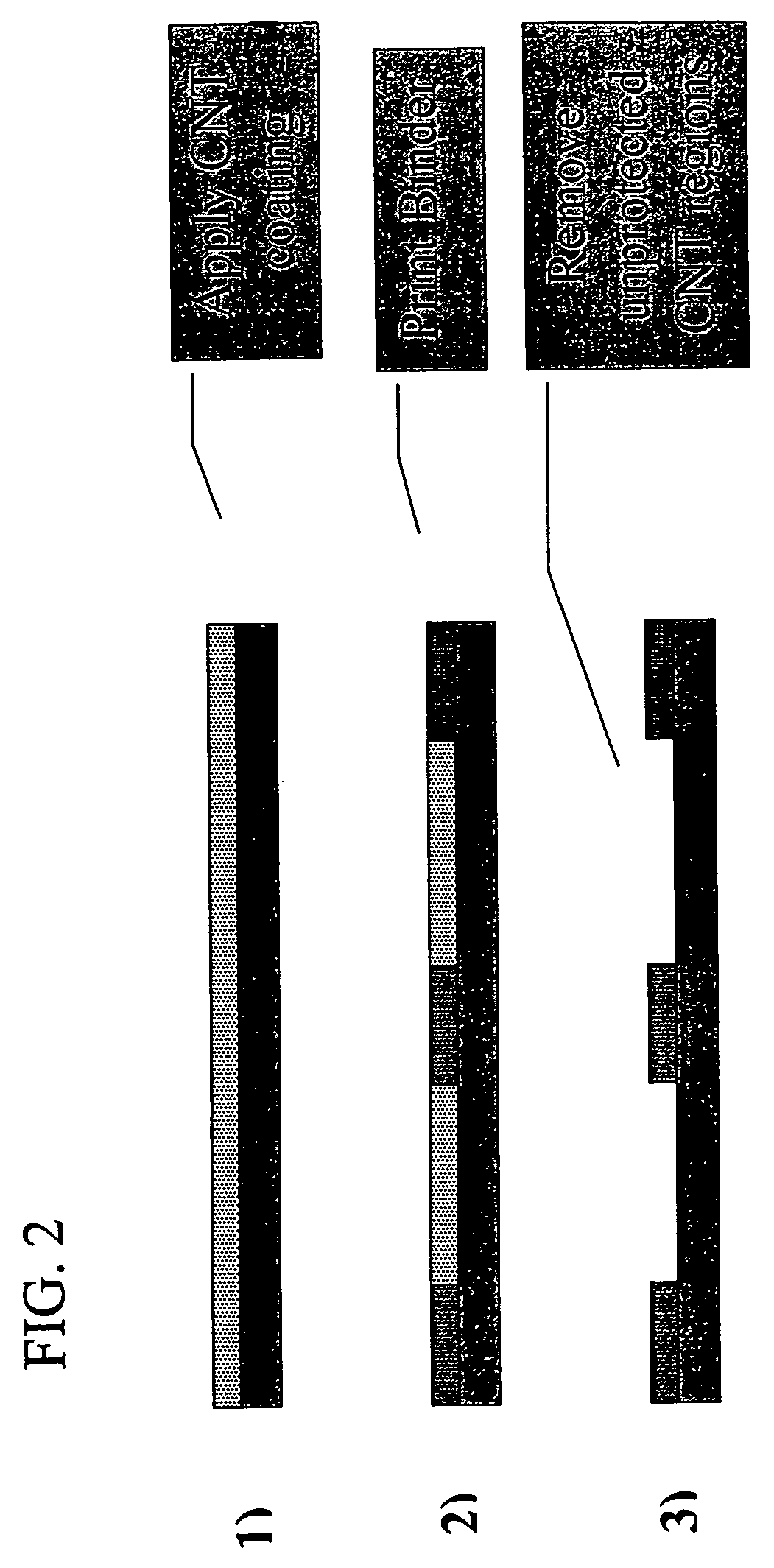

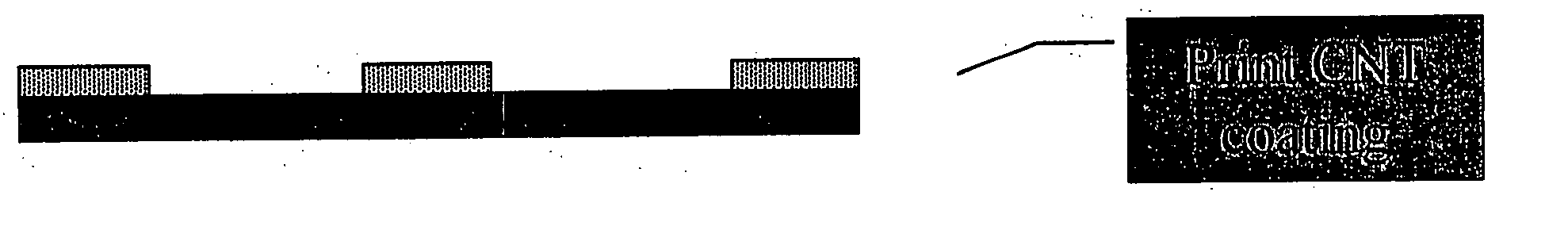

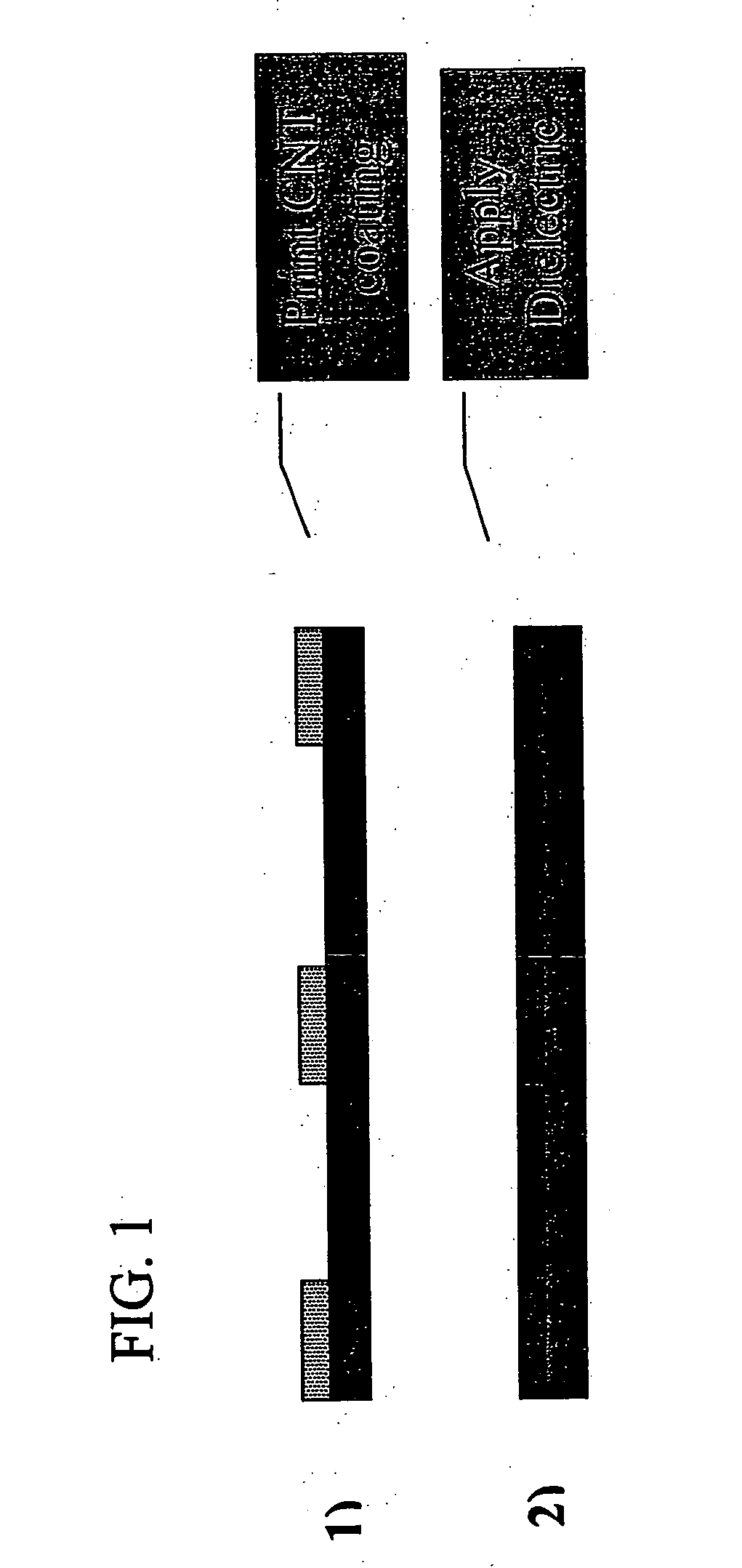

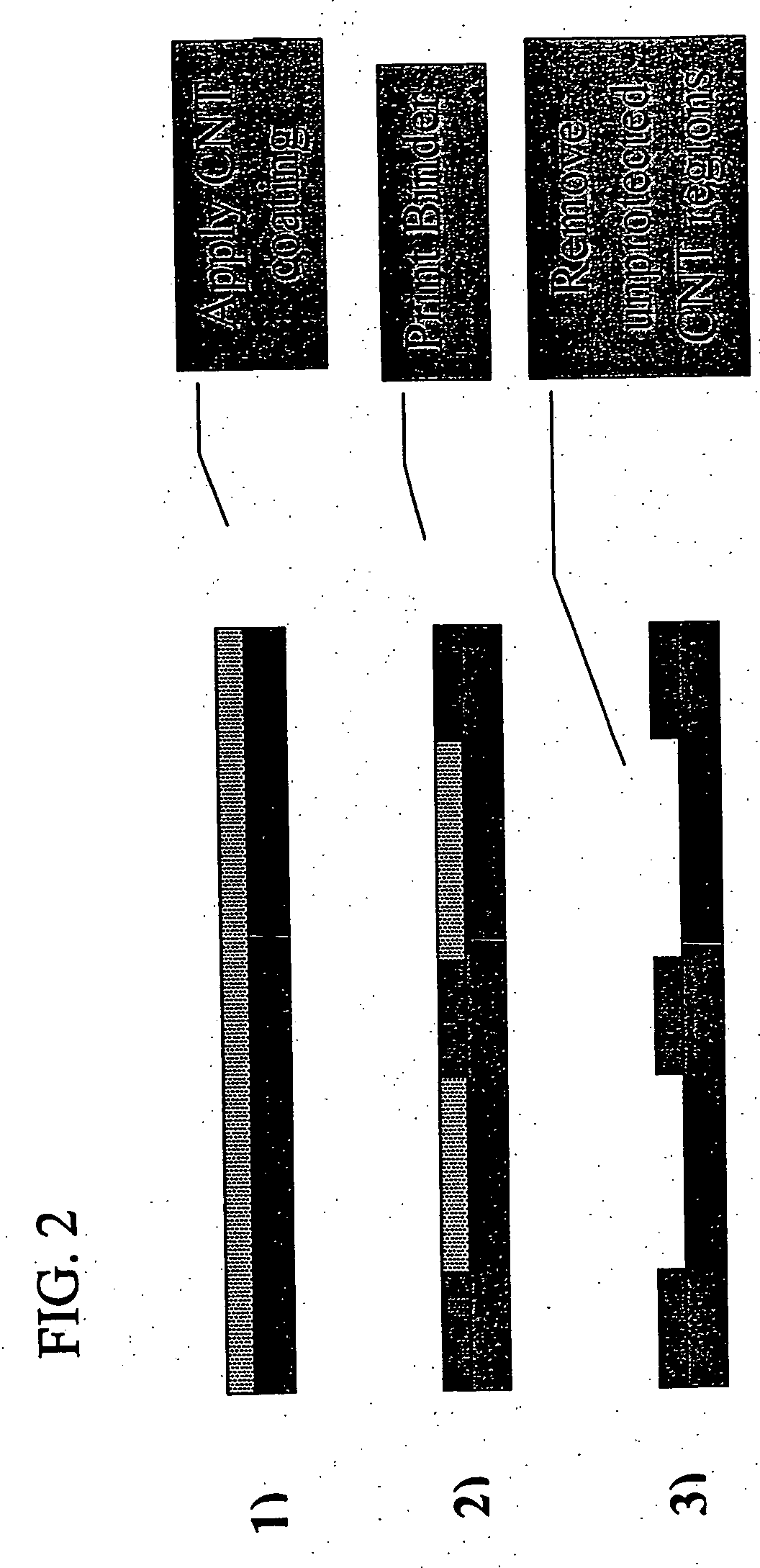

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:EIKOS

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:ARTHUR DAVID J +1

Nanopastes as patterning compositions for electronic parts

InactiveUS6921626B2Good dispersionLow viscosityRadiation applicationsSemiconductor/solid-state device manufacturingInorganic nanoparticlesElectrically conductive

The present invention provides methods of making an electronic part in which a nanopaste composed of inorganic nanoparticles and a carrier is applied onto a surface of a substrate. The composition is then processed to form an electrically conductive pattern area that adheres to the surface of the substrate. Optionally, the conductivity of the pattern area may be improved by heating.

Owner:KODAK POLYCHROME GRAPHICS

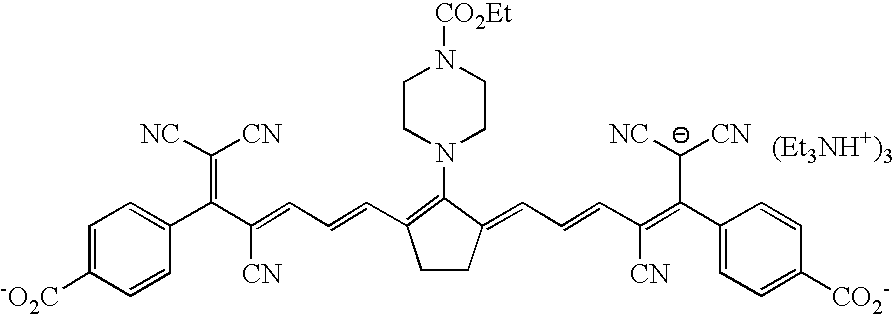

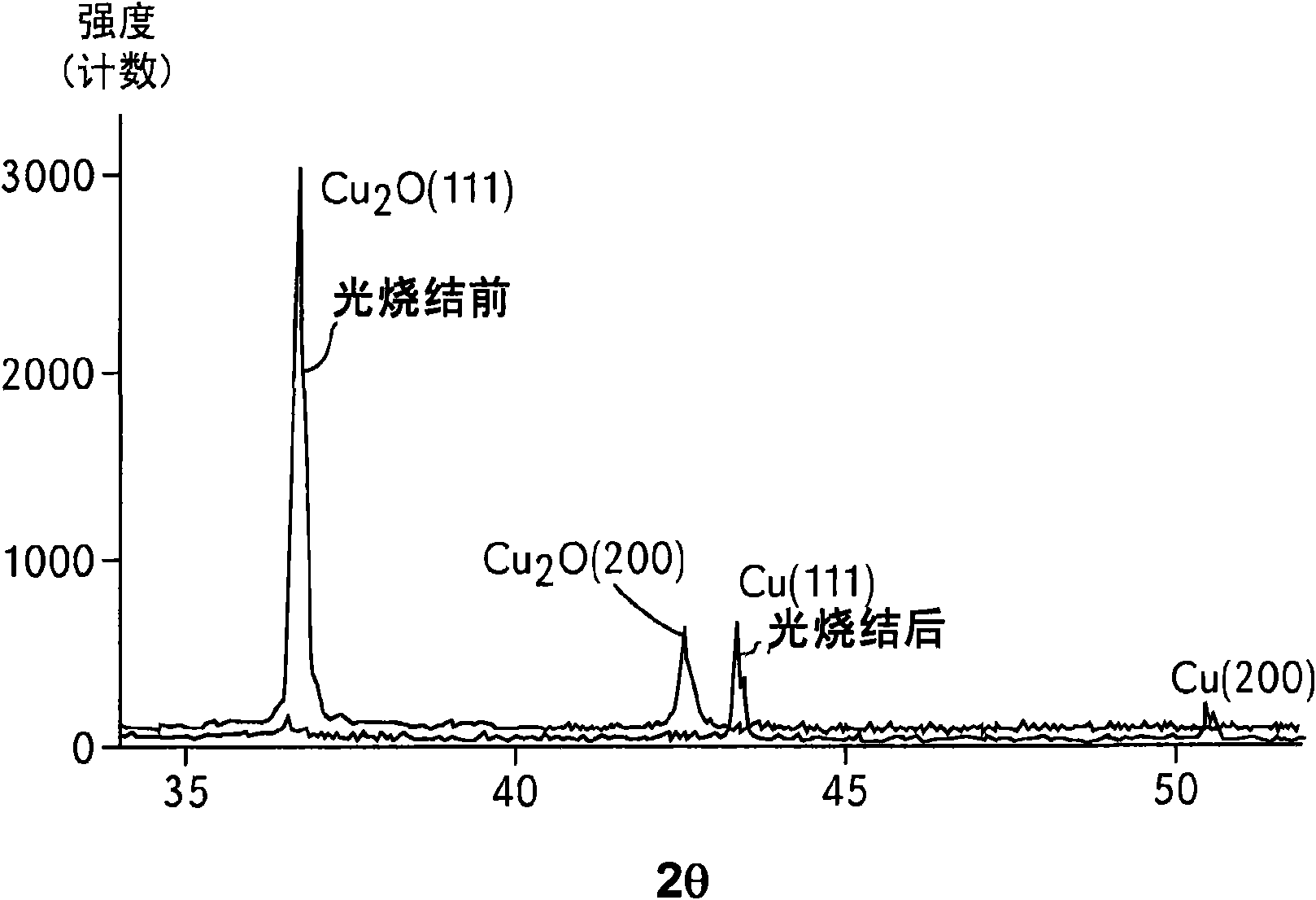

Metallic ink

ActiveCN101801674AMaterial nanotechnologyTransportation and packagingOptoelectronicsCopper nanoparticle

Forming a conductive film comprising depositing a non-conductive film on a surface of a substrate, wherein the film contains a plurality of copper nanoparticles and exposing at least a portion of the film to light to make the exposed portion conductive. Exposing of the film to light photosinters or fuses the copper nanoparticles.

Owner:ISHIHARA CHEM

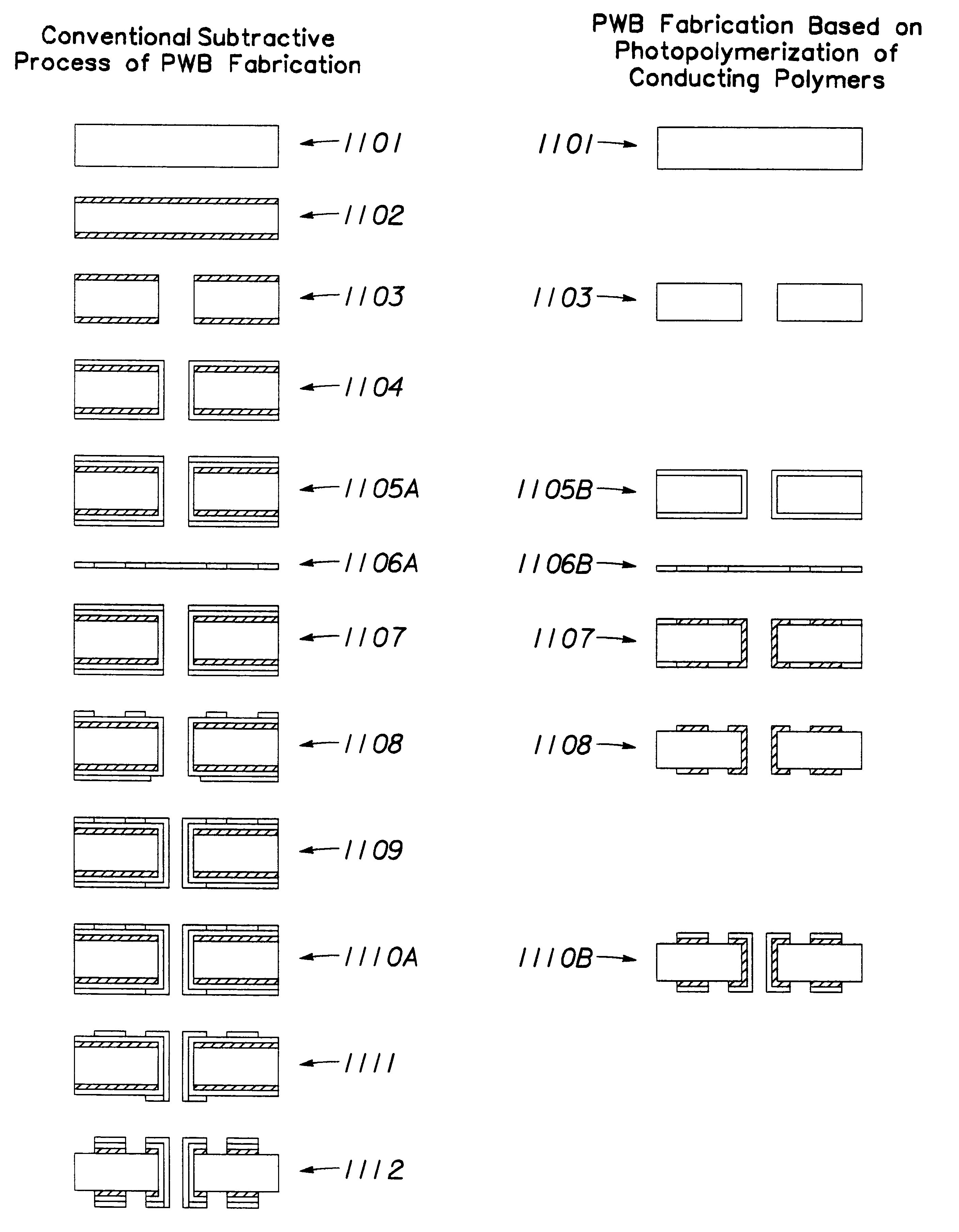

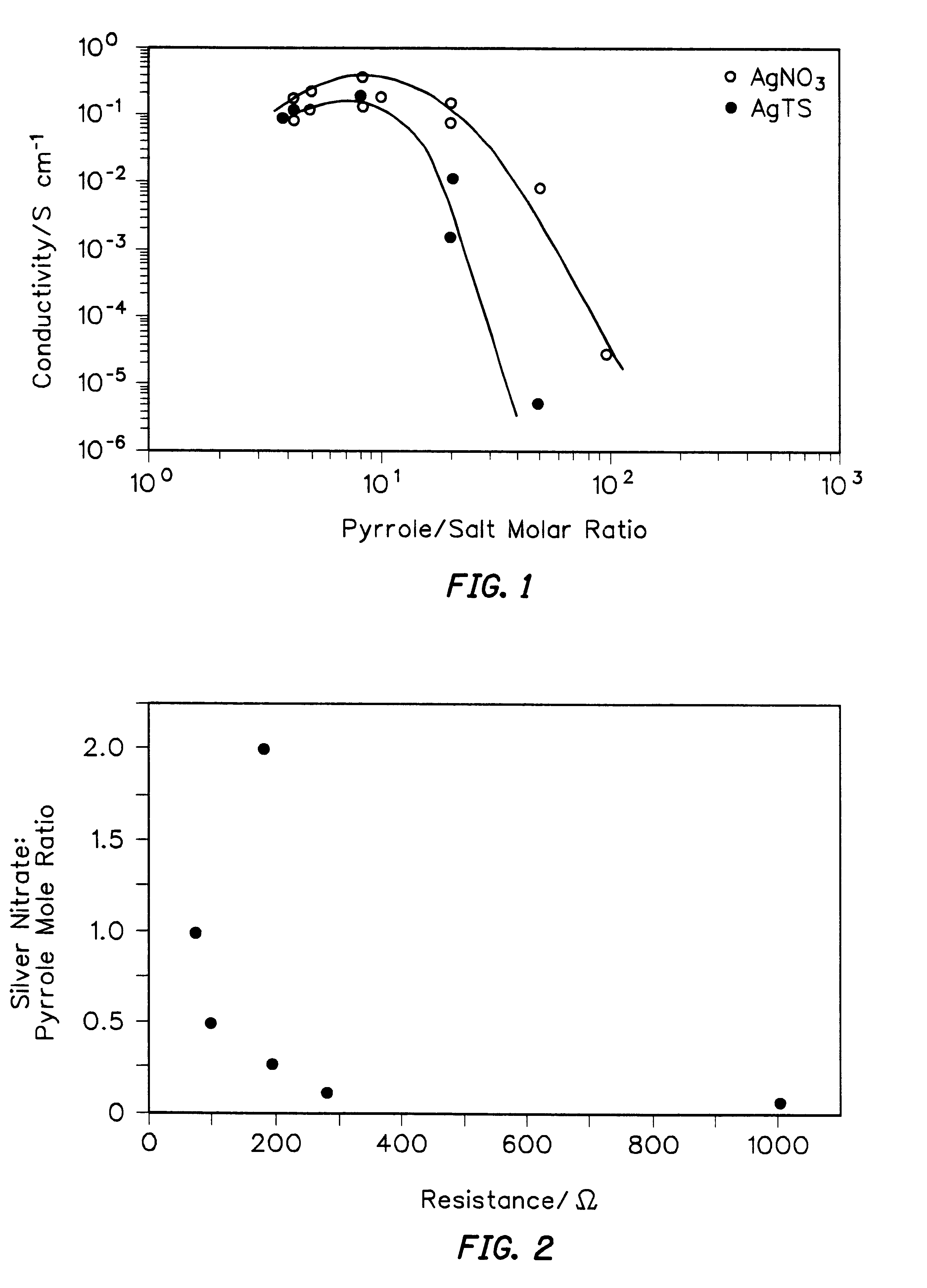

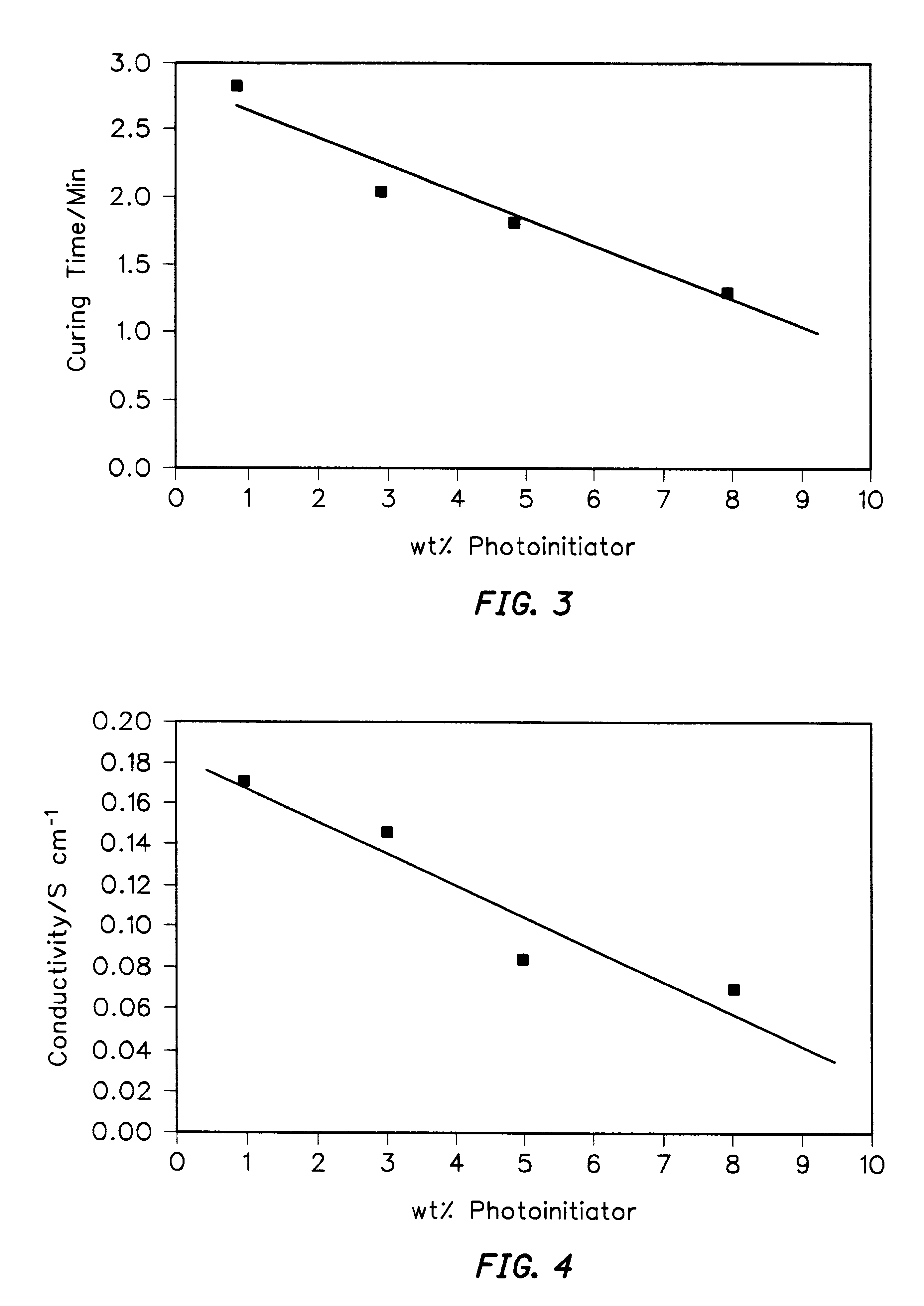

Method of forming electronically conducting polymers on conducting and nonconducting substrates

InactiveUS6210537B1Magnetic/electric field screeningPhotomechanical apparatusConductive polymerLaser light

The present invention provides electronically conducting polymer films formed from photosensitive formulations of pyrrole and an electron acceptor that have been selectively exposed to UV light, laser light, or electron beams. The formulations may include photoinitiators, flexibilizers, solvents and the like. These solutions can be used in applications including printed circuit boards and through-hole plating and enable direct metallization processes on non-conducting substrates. After forming the conductive polymer patterns, a printed wiring board can be formed by sensitizing the polymer with palladium and electrolytically depositing copper.

Owner:LYNNTECH

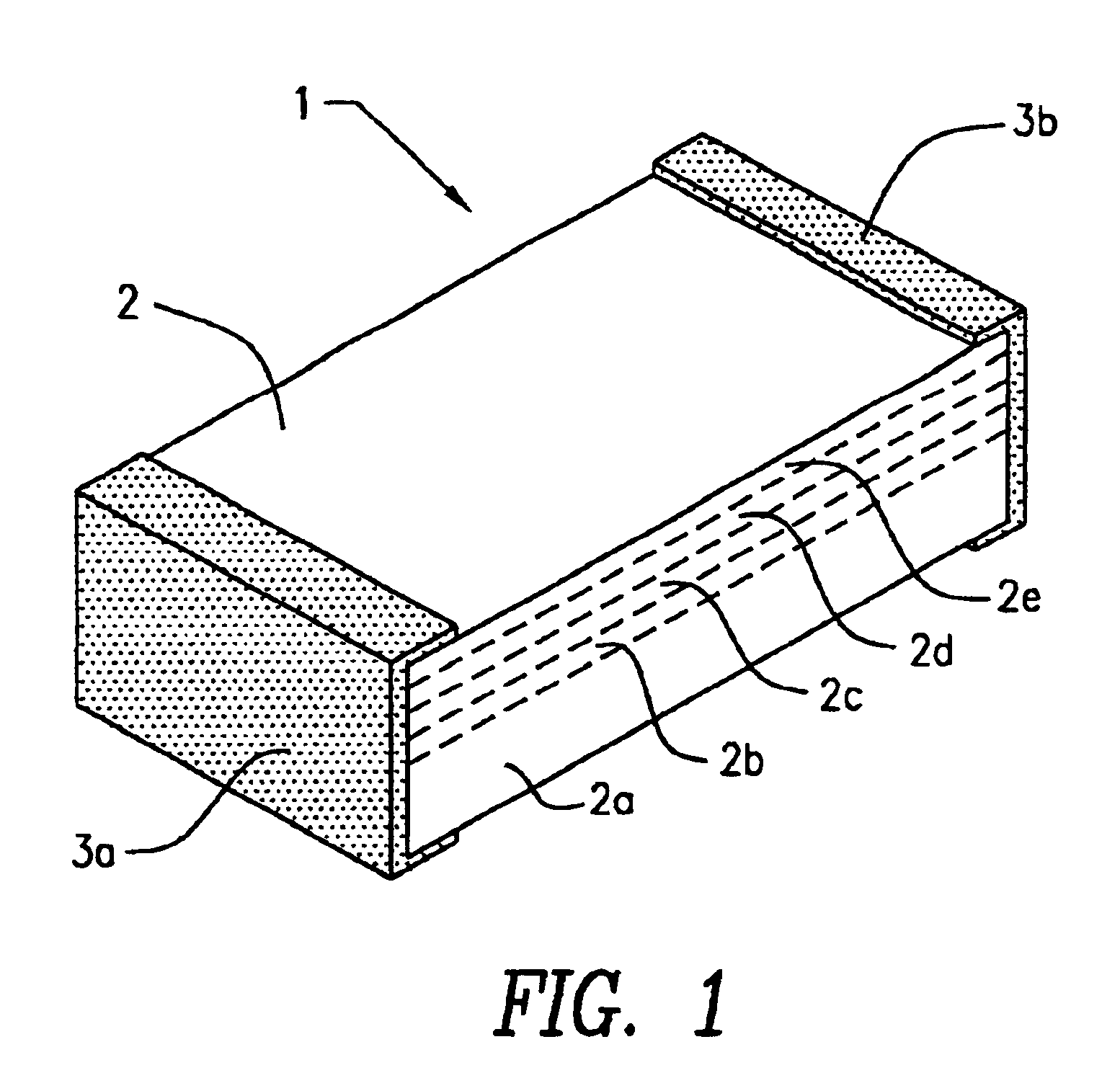

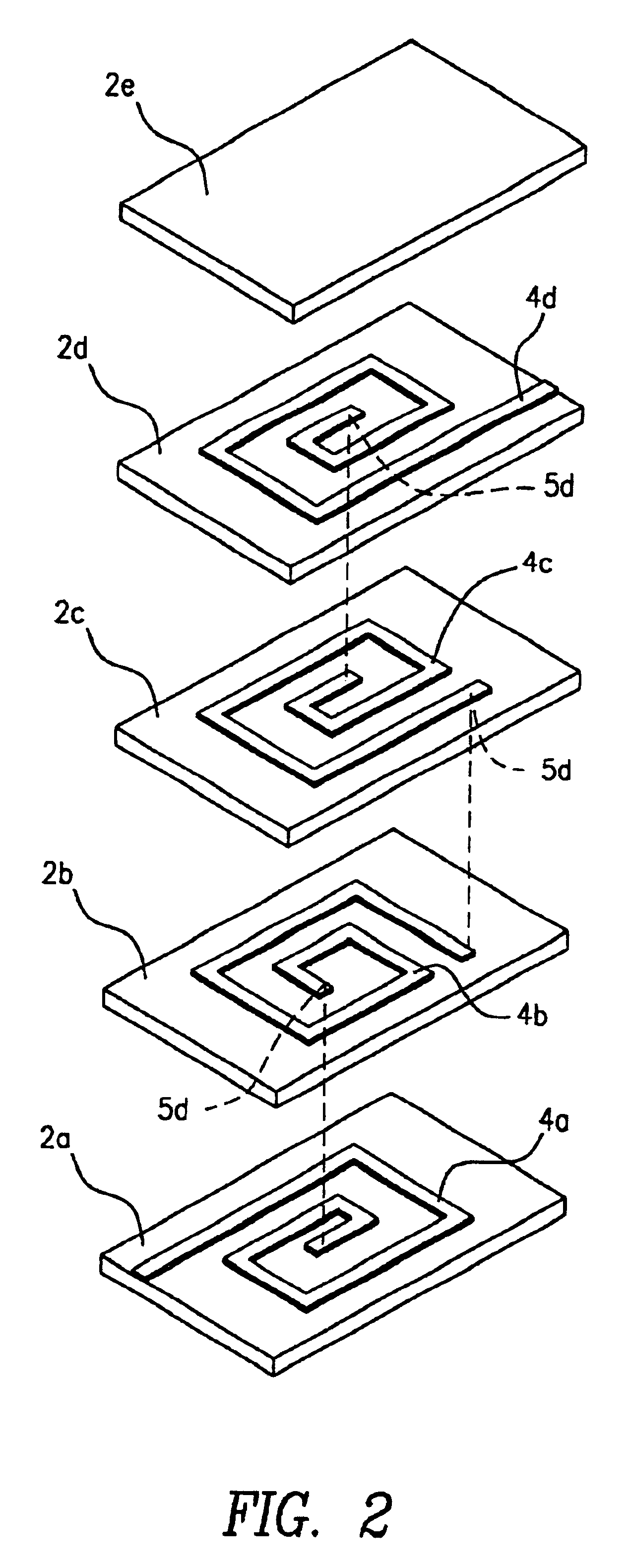

Photosensitive thick film composition and electronic device using the same

InactiveUS6885276B2High precisionImprove reliabilityTransformers/inductances casingsPhotoprinting processesAlcoholBorosilicate glass

A photosensitive thick film composition is provided which has superior storage stabilities and can be reliably processed by developing. The photosensitive thick film composition is composed of a photosensitive organic component containing an organic binder having an acidic functional group, such as a carboxyl group, an inorganic component containing a polyvalent metal oxide, such as borosilicate glass, and an alcohol having a plurality of hydroxyl group, such as glucitol.

Owner:MURATA MFG CO LTD

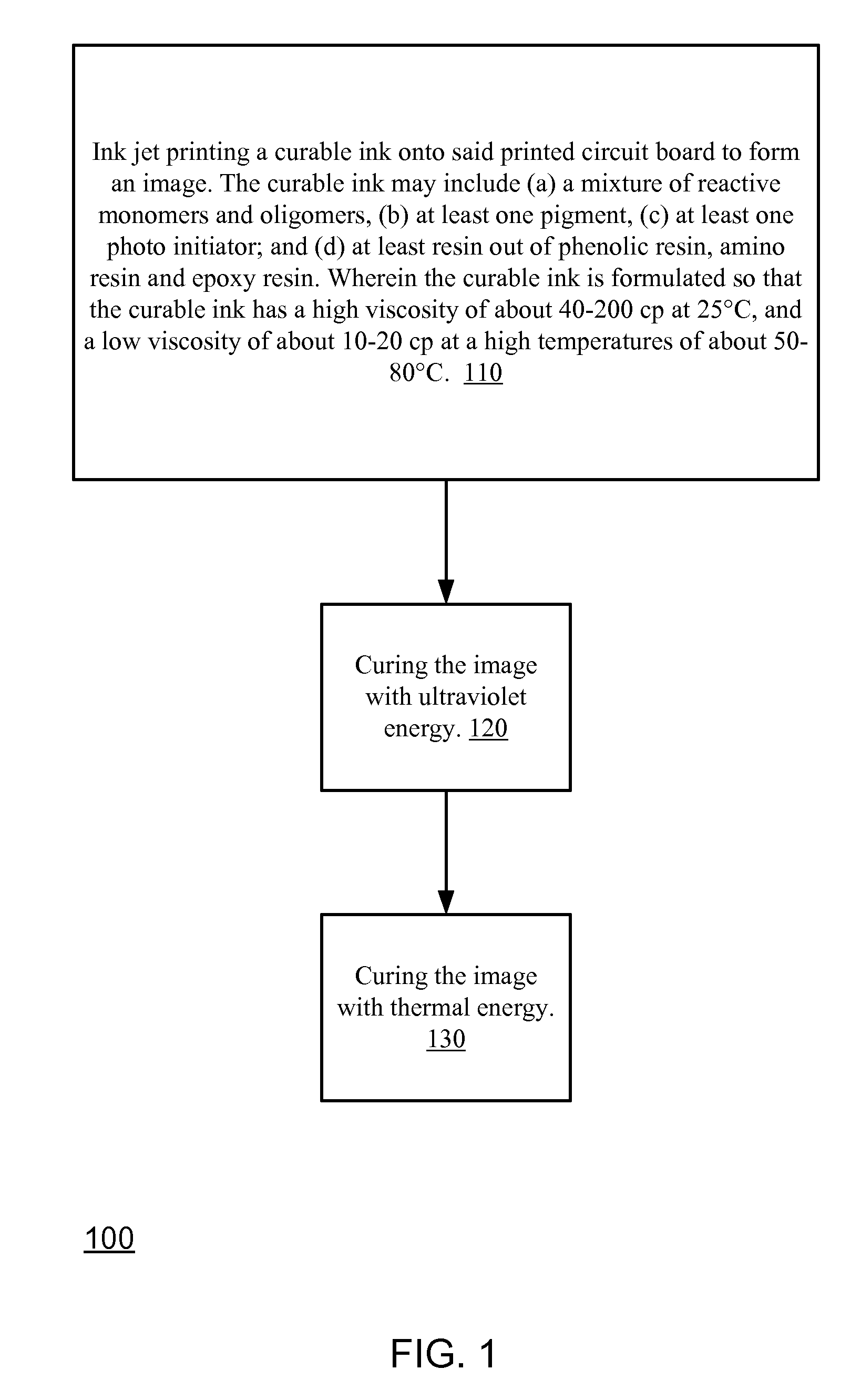

Curable ink and a method for printing and curing the curable ink

InactiveUS20140055544A1Improve hiding powerHigh optical densityInksPhotodevelopable thick filmEpoxyOligomer

A method for printing a curable ink, the curable ink comprises a mixture of reactive monomers and oligomers; at least one pigment; at least one photo initiator; and at least a resin out of phenolic resin, amino resin and epoxy resin.

Owner:CAMTEK LTD

Method of forming a patterned film of surface-modified carbon nanotubes

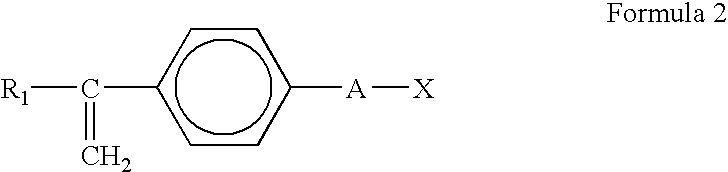

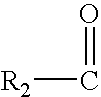

Disclosed herein is a method of forming a negative pattern of carbon nanotubes through: modifying the surfaces of carbon nanotubes to have double bond-containing functional group capable of participating in radical polymerization; coating a substrate with a liquid coating composition prepared by dispersing the surface-modified carbon nanotubes in an organic solvent along with a photoinitiator; exposing the film to UV light through a photomask to induce radical polymerization of the carbon nanotubes; and developing the film. By virtue of the present invention, desired patterns of carbon nanotubes can be easily made on the surfaces of various substrates according to the conventional photolithography procedure.

Owner:SAMSUNG ELECTRONICS CO LTD

Novel metal nanoparticle and formation of conductive pattern using the same

InactiveUS20080020317A1Easy to achieve nanoparticle arrangementOvercome problemsLiquid surface applicatorsPhotosensitive materialsSelf-assembled monolayerPhosphate

A metal nanoparticle which is prepared by forming a self-assembled monolayer including a terminal reactive group on the surface thereof, and introducing a functional group capable of being removed by the action of an acid or an base into the terminal reactive group wherein the self-assembled monolayer is built up of a thiol, an isocyanide, an amine, a carboxylate or a phosphate compound having the terminal reactive group, or built up of a thiol, an isocyanide, an amine, a carboxylate or a phosphate compound having no terminal reactive group followed by introducing the terminal reactive group thereto; and a method for forming a conductive pattern using the same are provided. Since the metal nanoparticle of exemplary embodiments of the present invention can easily form a high conductive film or a high conductive pattern through photo-irradiation and photo-degradation and randomly regulate its conductivity when occasions demand, it can be advantageously applied to an antistatic washable sticky film, antistatic shoes, a conductive polyurethane printer roller, an electromagnetic interference shielding, and the like.

Owner:SAMSUNG ELECTRONICS CO LTD

Resin composition, printed circuit board using the composition, and method of manufacturing the same

ActiveUS20150050473A1Improve adhesionPhotosensitive materialsDecorative surface effectsTetrazolePhotoinitiator

A resin composition, a printed circuit board using the composition, and a method of manufacturing the printed circuit board. The resin composition includes: a photopolymerizable compound, such as one having an ethylenically unsaturated bond which is polymerizable in a molecule, a photoinitiator, and a surface-modified silica by an alkyl sulfonated tetrazole compound.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

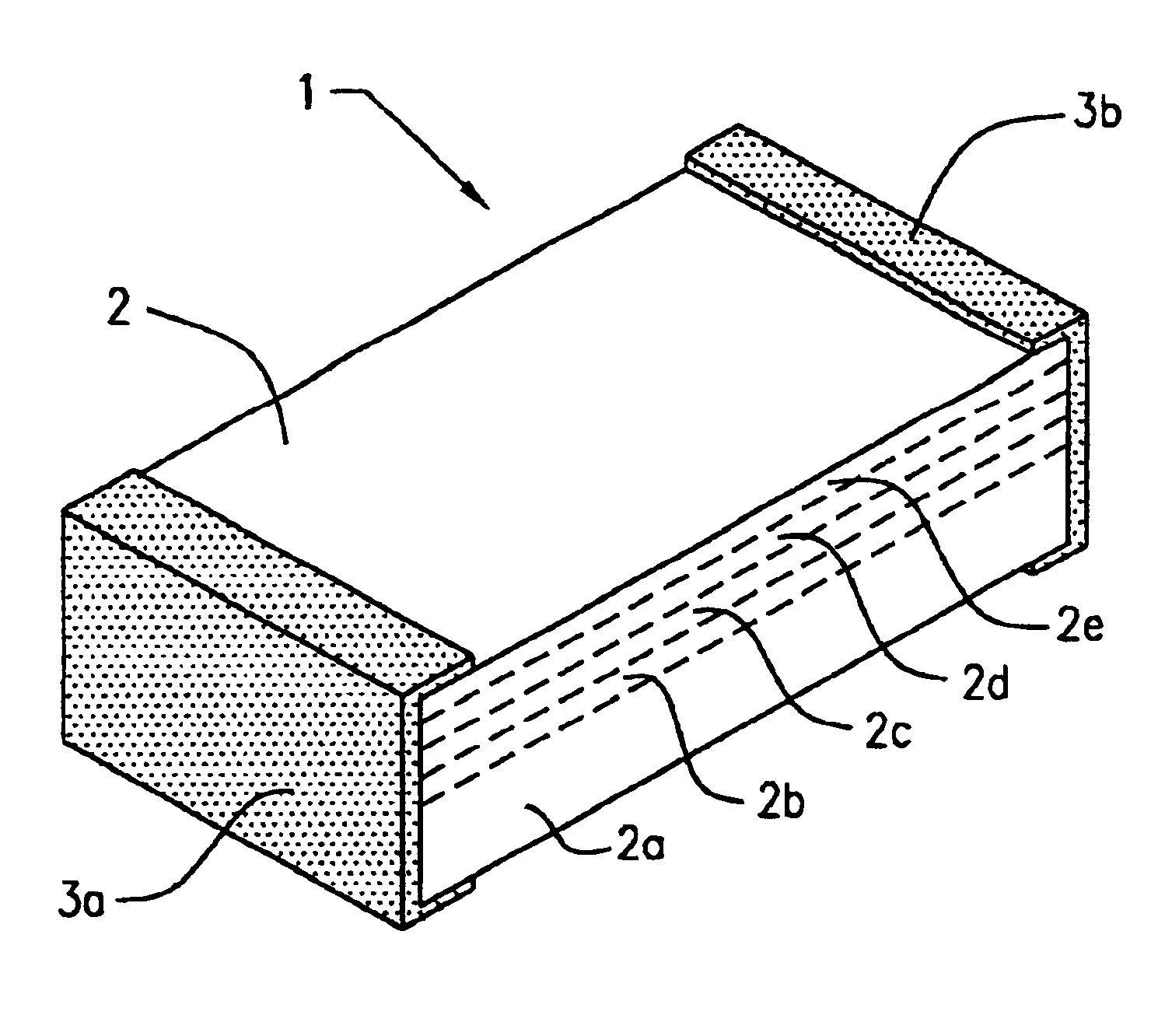

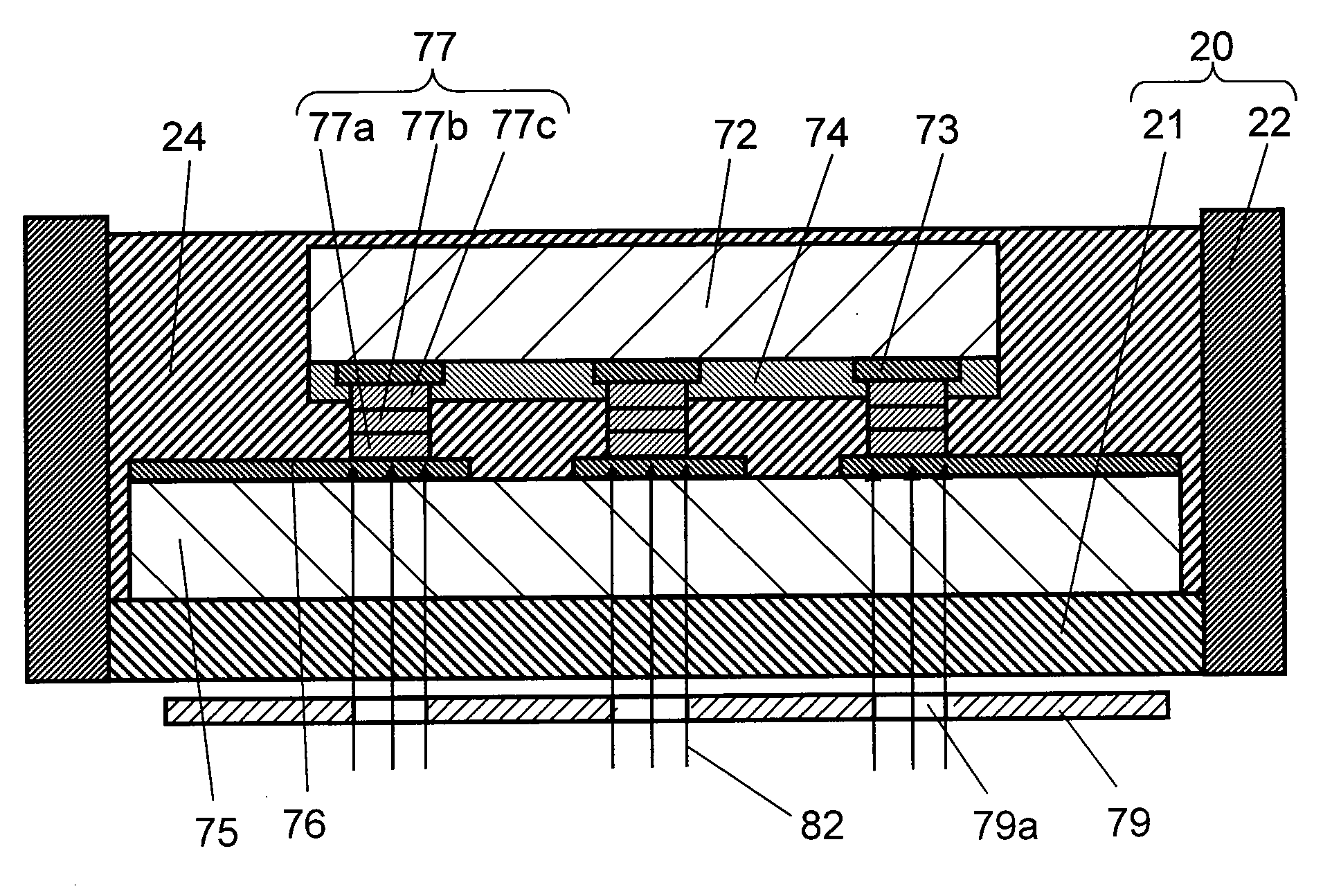

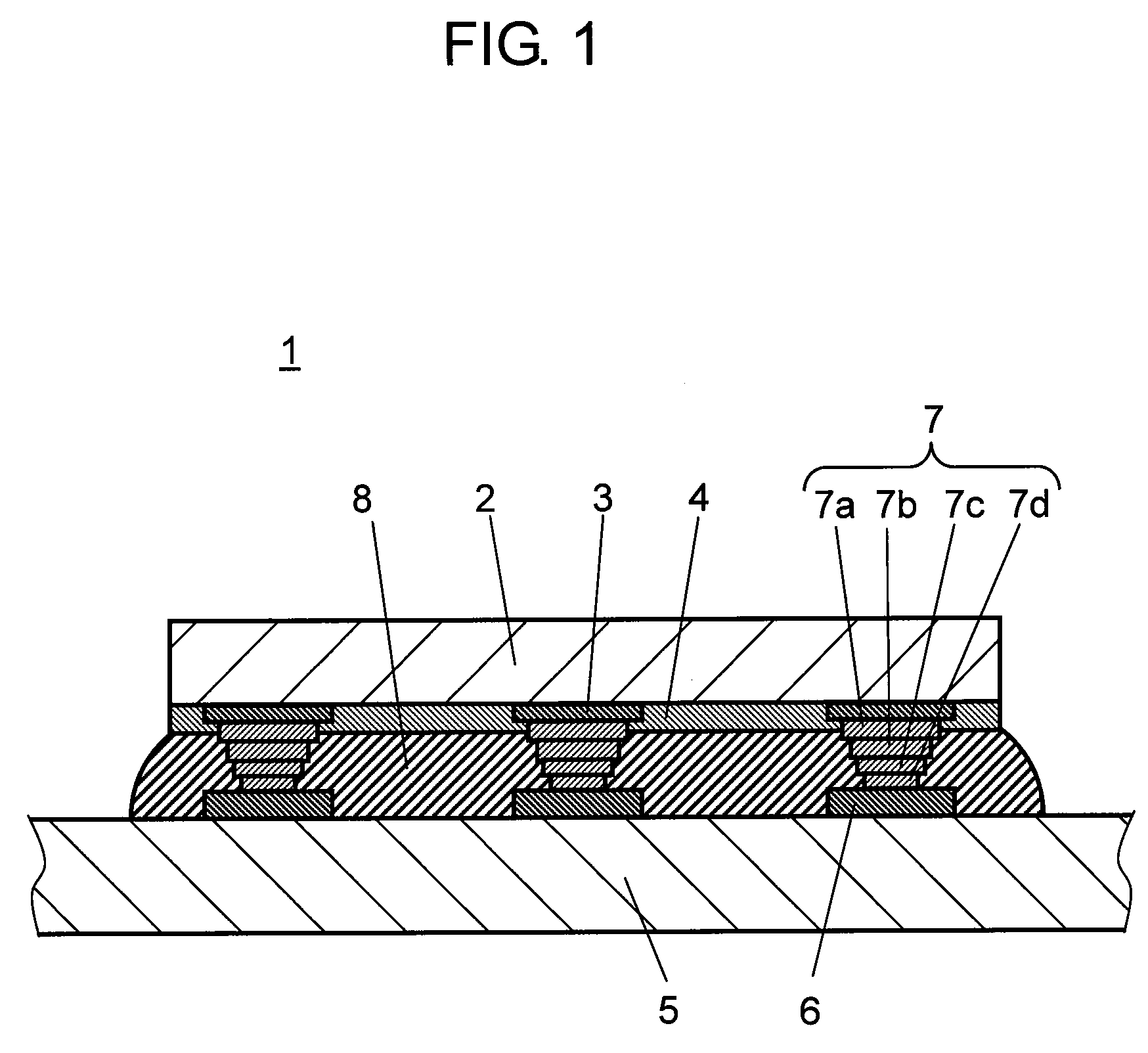

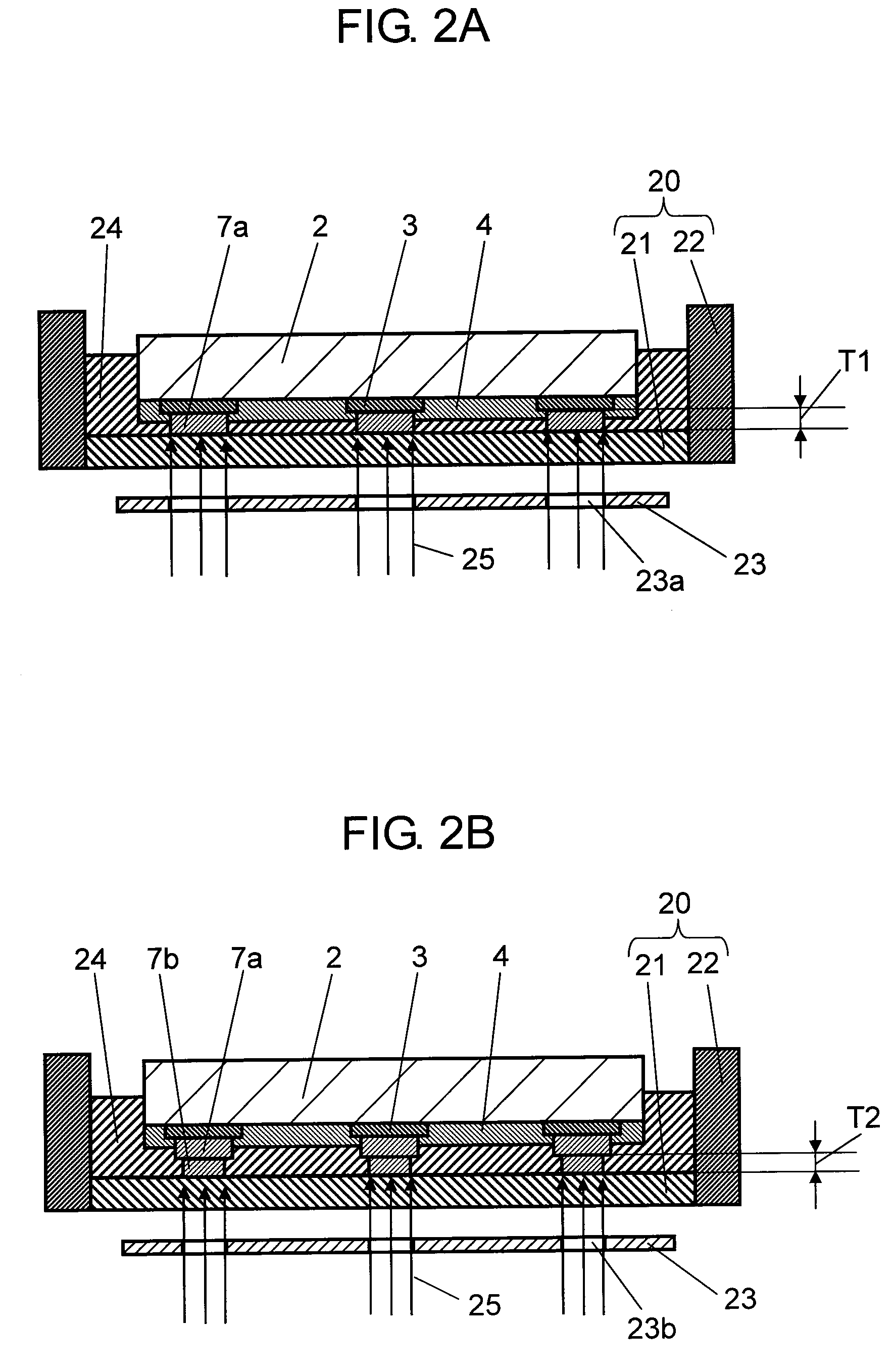

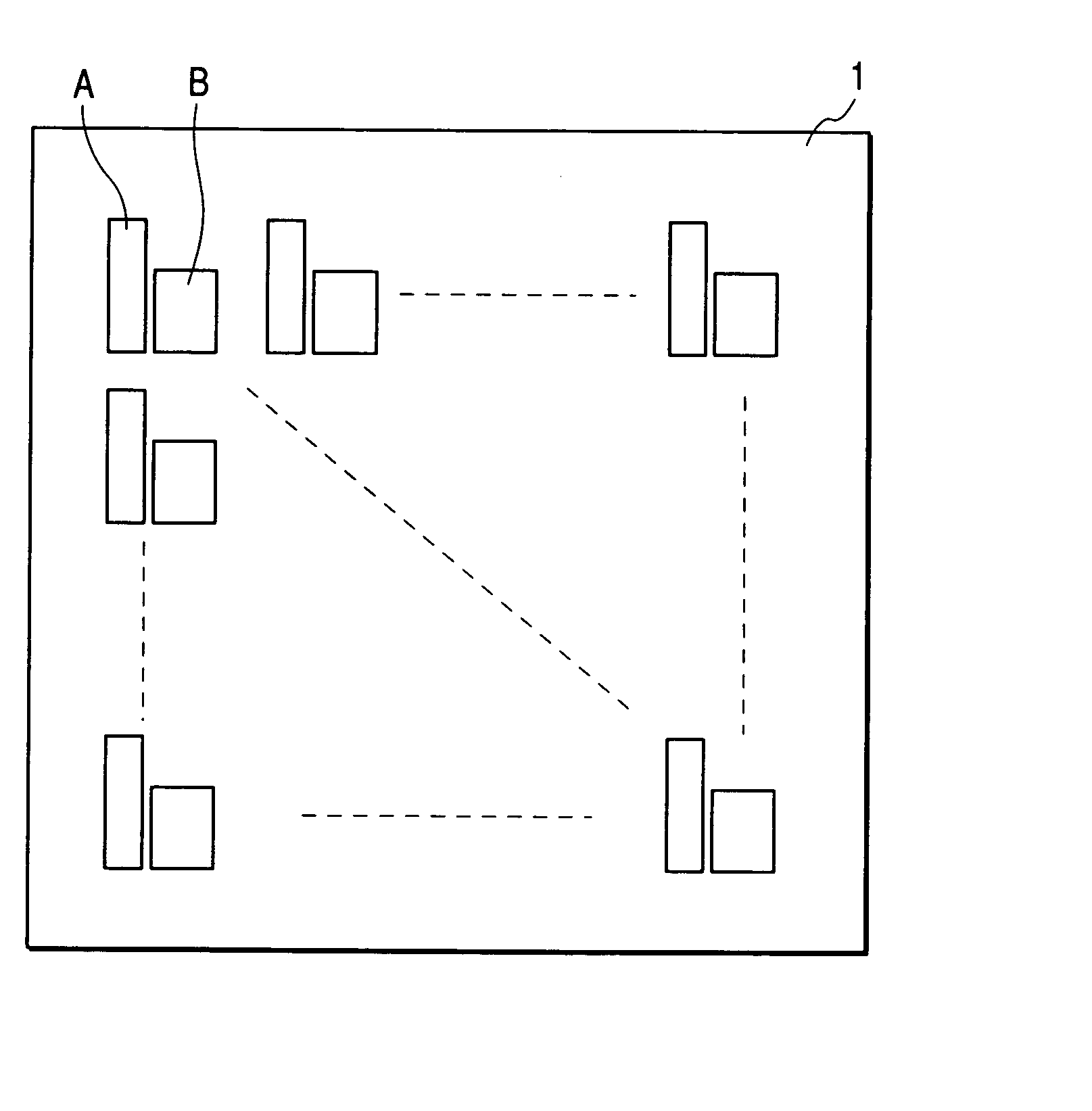

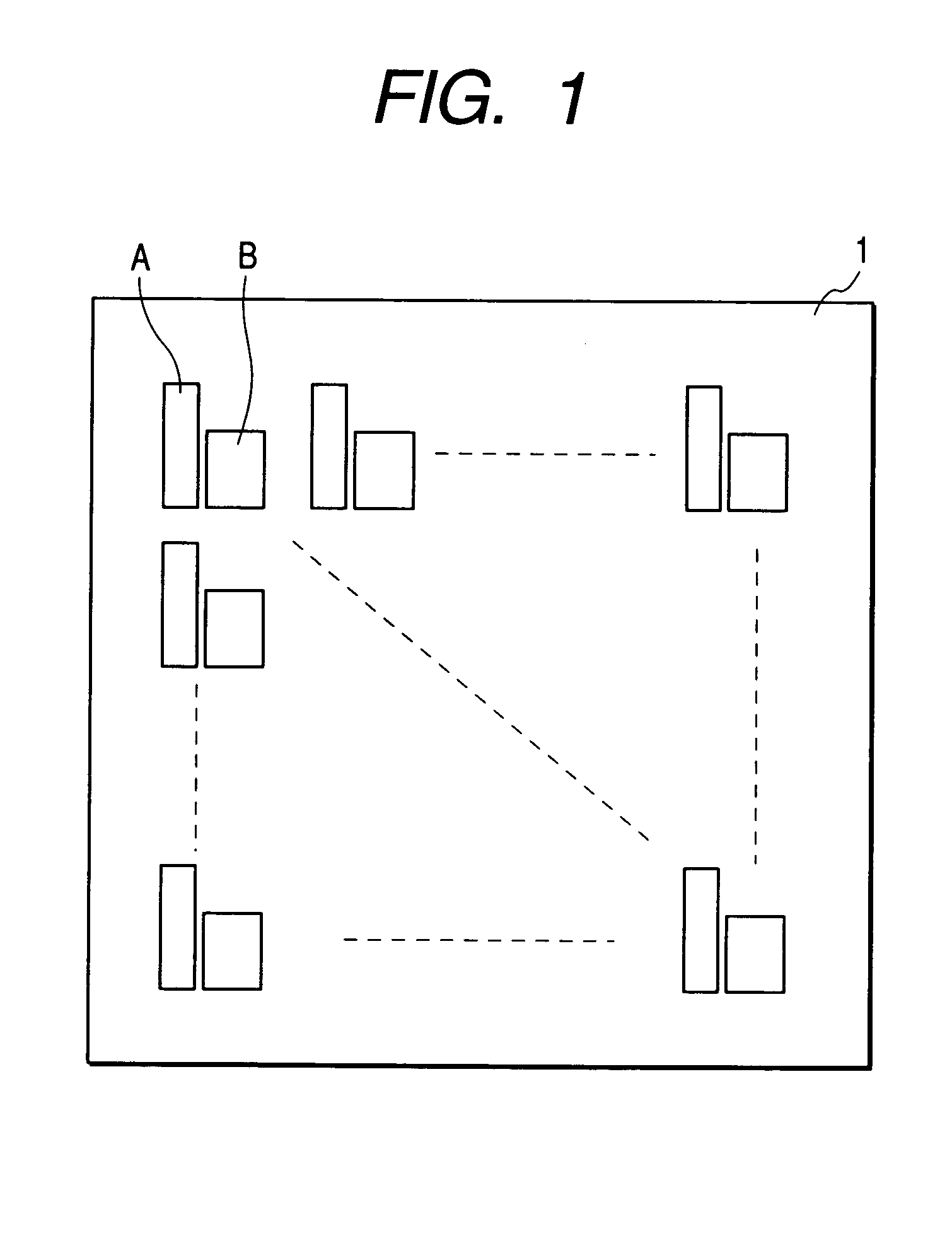

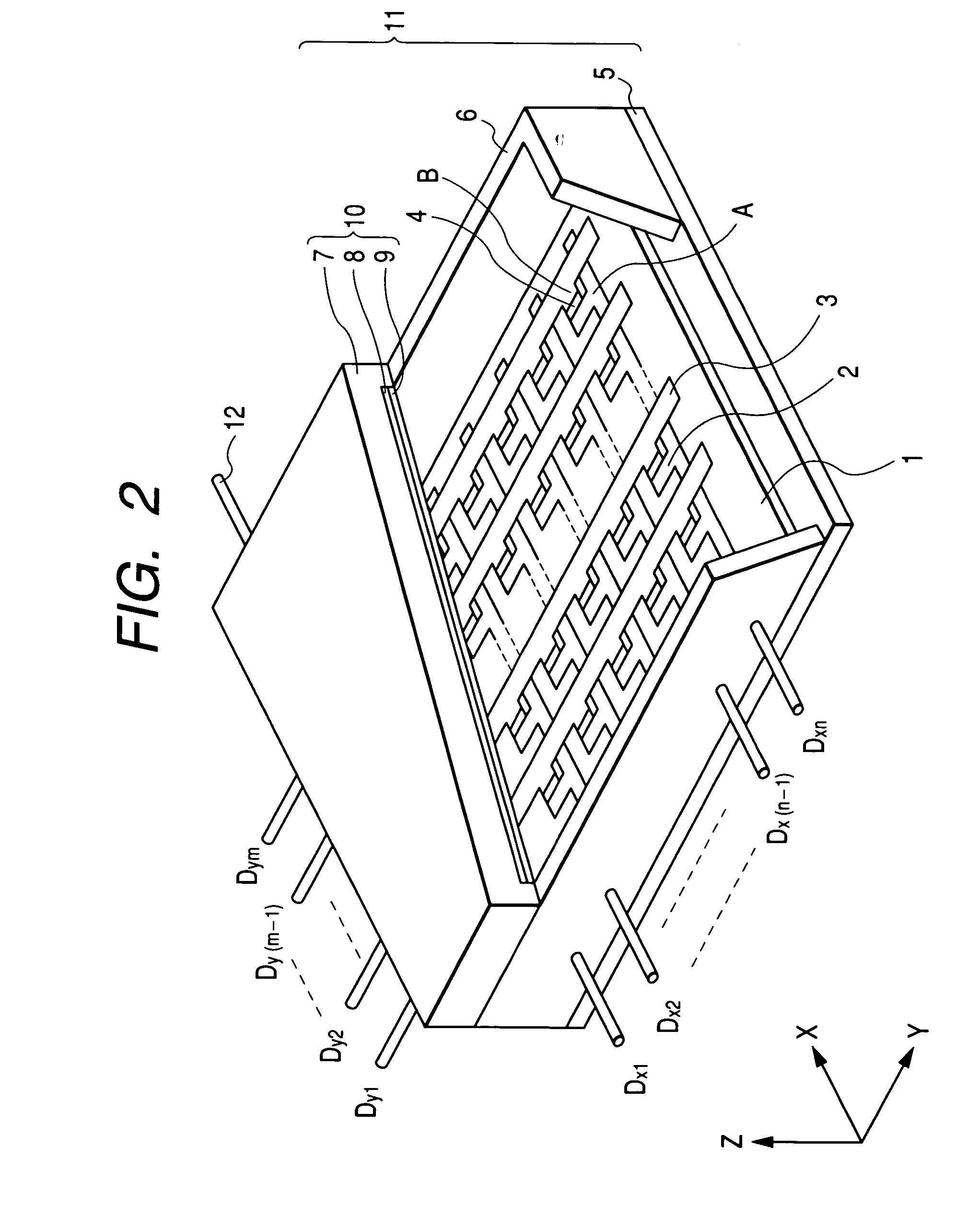

Electronic part mounting structure and its manufacturing method

ActiveUS20090026634A1Mounting step can be simplifiedWell formedSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringElectrode

An electronic part mounting structure includes electronic part (2) having a plurality of electrode terminals (3), a substrate provided with connection terminals (6) in locations corresponding to these electrode terminals (3), and protruding electrode (7) for connecting one of electrode terminals (3) and one of connection terminals (6), where electrode terminal (3) of electronic part (2) and connection terminal (6) of substrate (5) are connected through protruding electrode (7), and protruding electrode (7) is formed of a conductive resin including a photosensitive resin and a conductive filler.

Owner:PANASONIC CORP

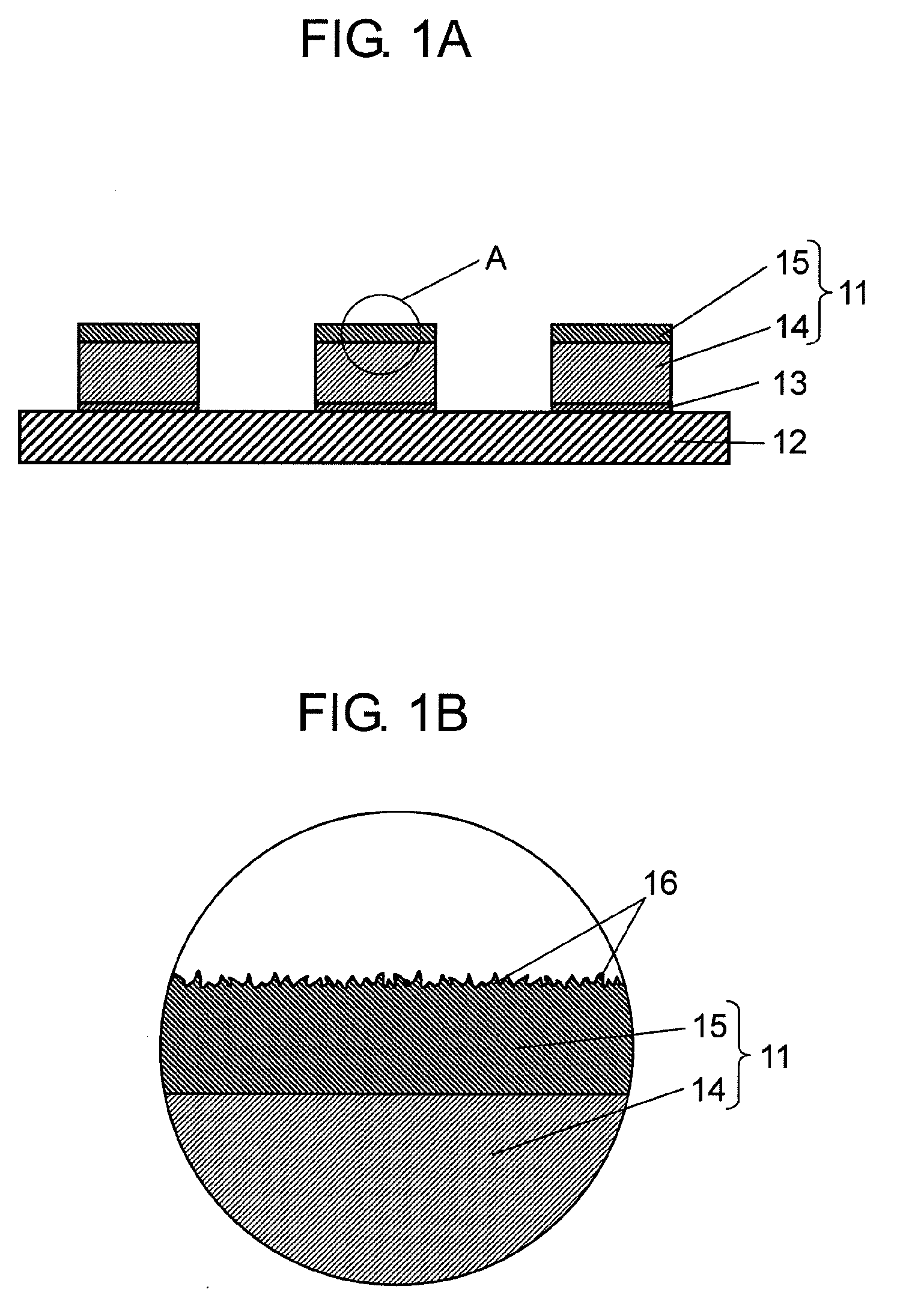

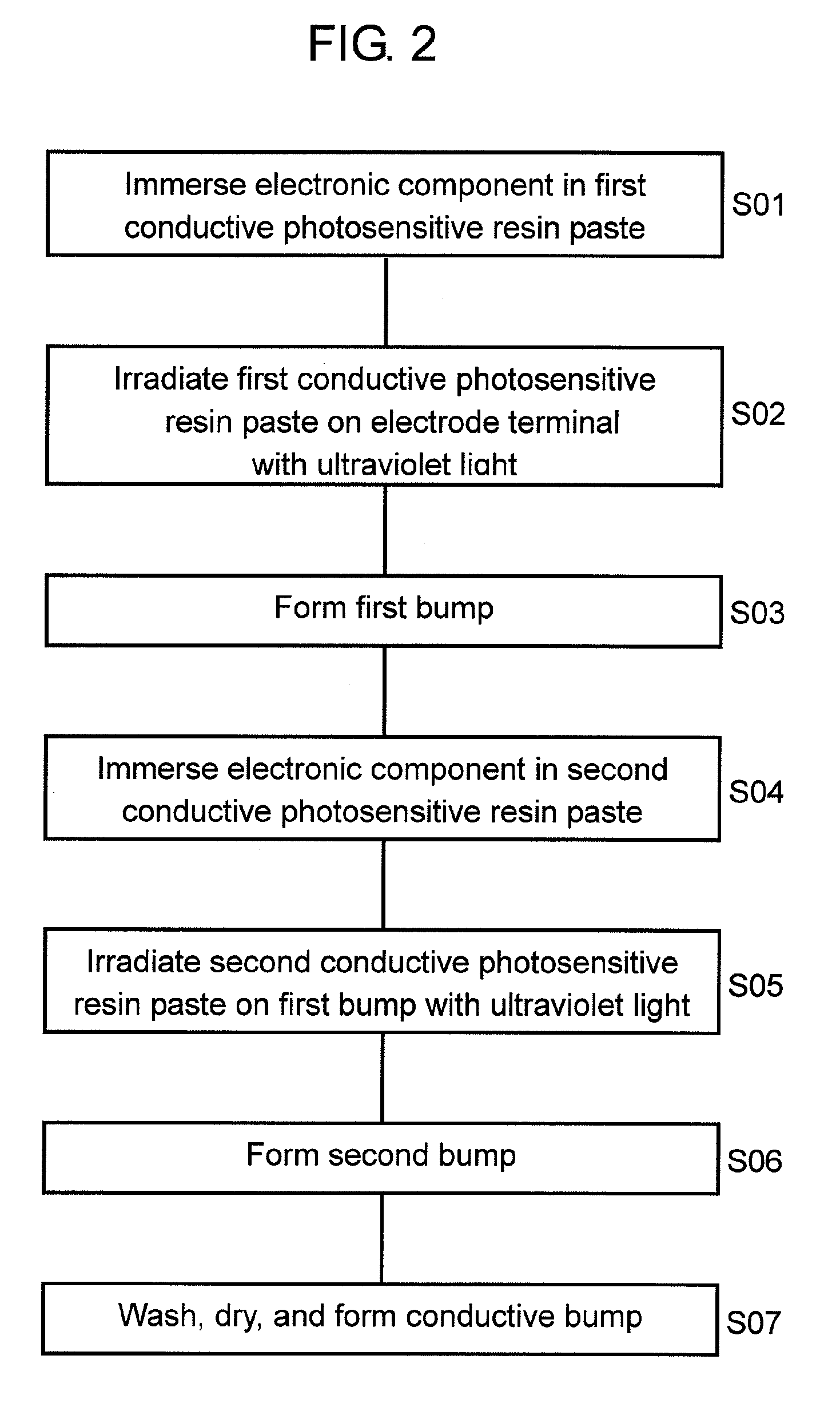

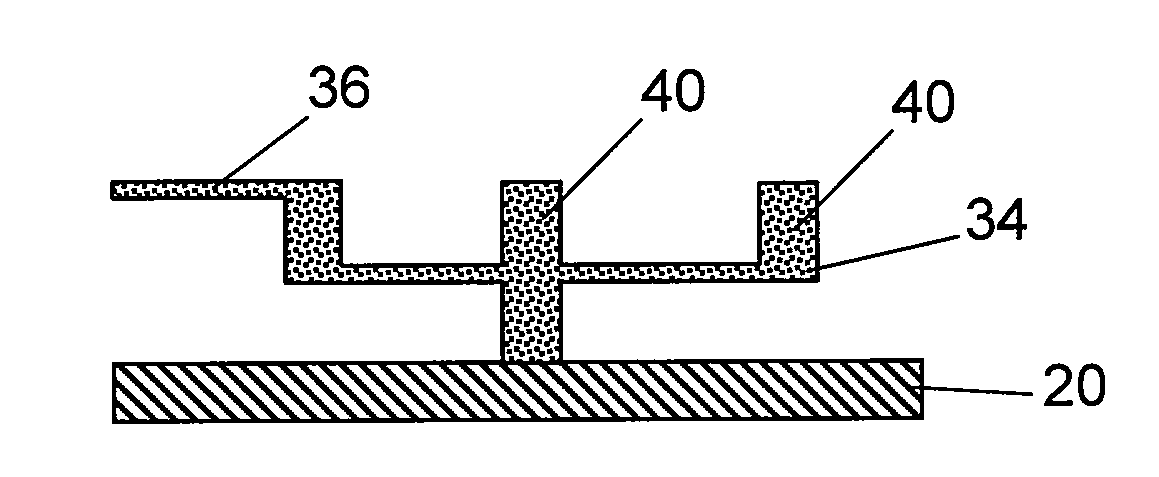

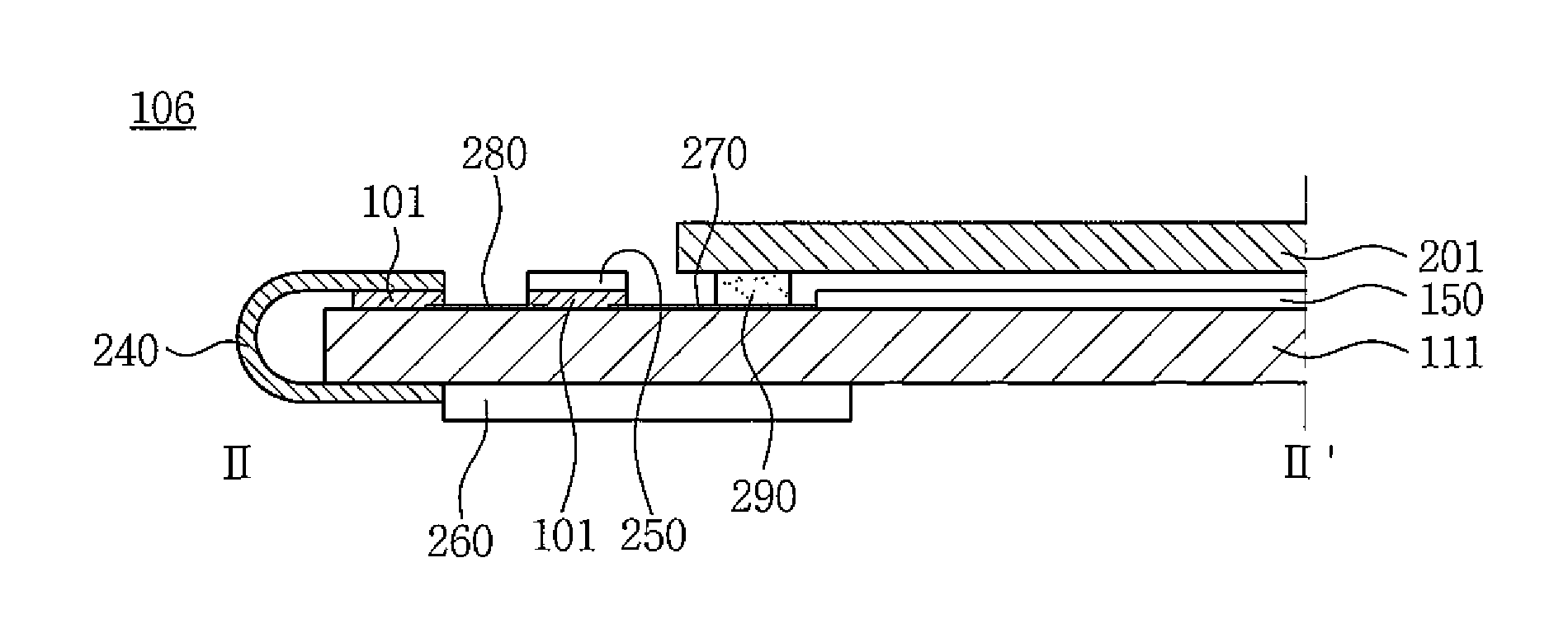

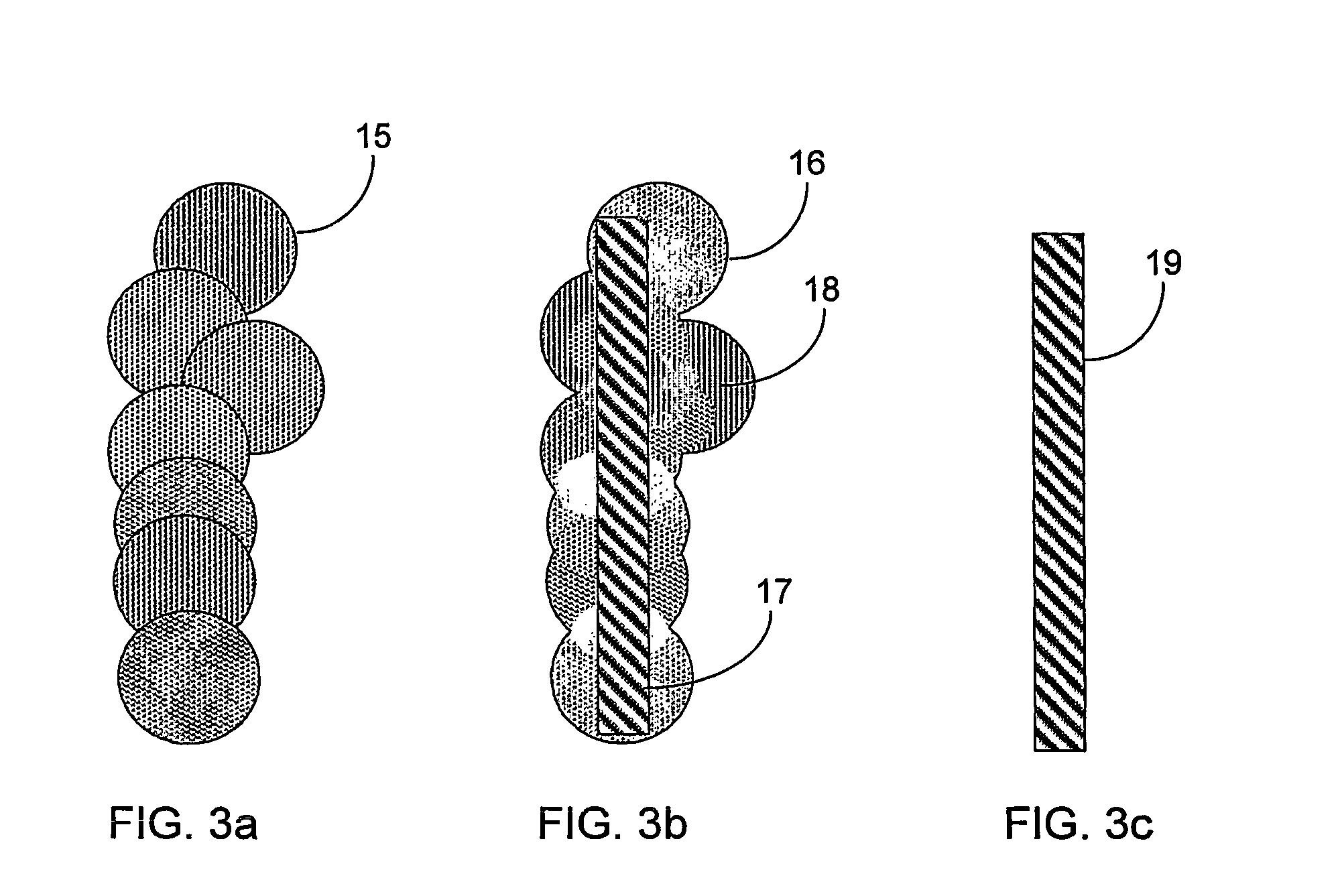

Conductive bump, method for forming the same, and electronic component mounting structure using the same

InactiveUS20090301771A1Improve connection strengthReduce connection resistanceLine/current collector detailsPrinted electric component incorporationEngineeringSpherical shaped

A conductive bump formed on an electrode of an electronic component. The conductive bump is composed of a first bump having one or more layers formed on the electrode and including resin containing at least a spherical-shaped conductive filler, and a second bump formed on an upper surface of the first bump and including photosensitive resin containing a scale-shaped conductive filler.

Owner:PANASONIC CORP

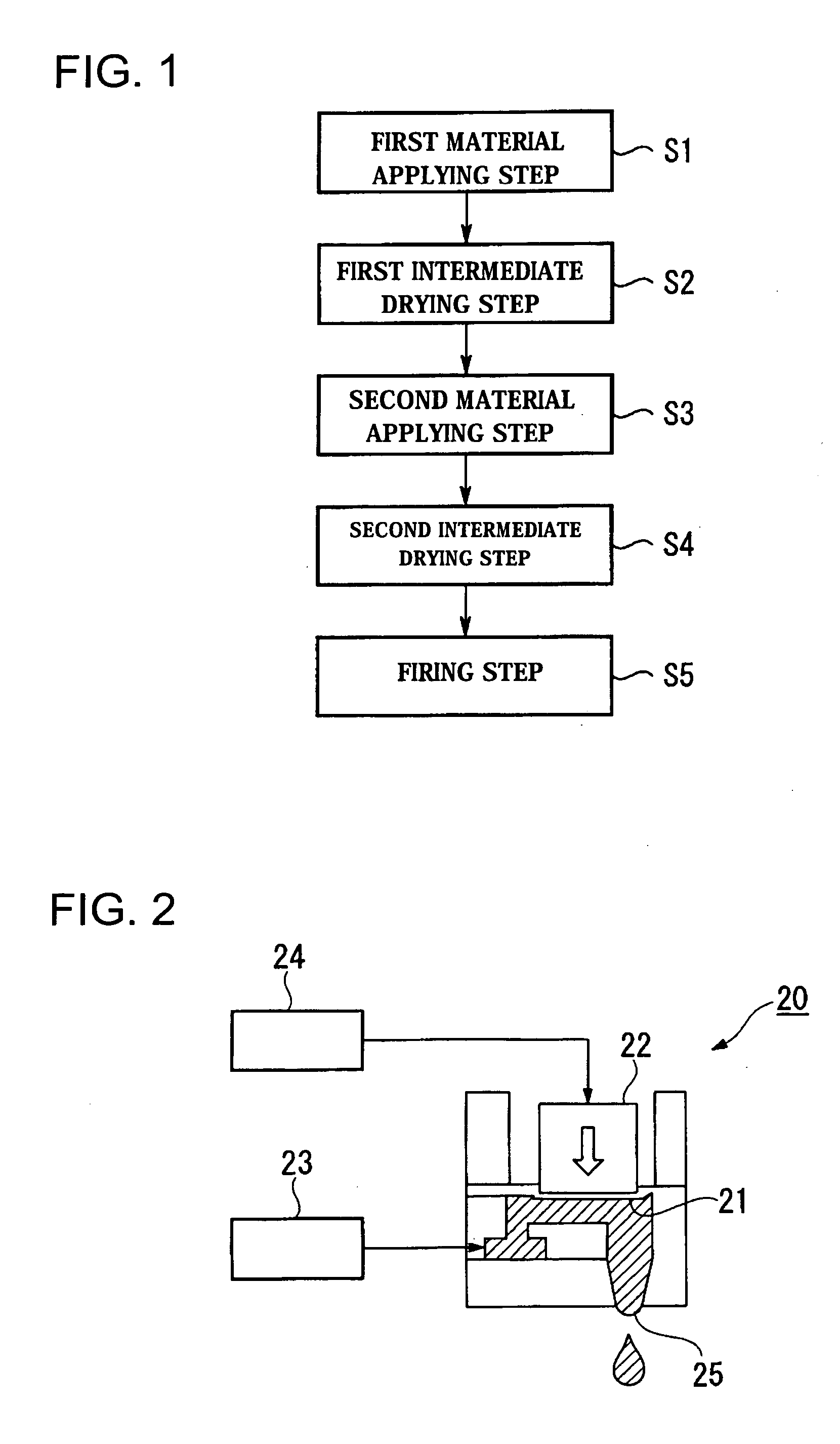

Base pattern forming material for electrode and wiring material absorption, electrode and wiring forming method, and method of manufacturing image forming apparatus

InactiveUS20040020689A1Photosensitive materialsSemiconductor/solid-state device manufacturingCooking & bakingWater based

A fine electrode and wiring pattern with a good adhesive property is easily formed using a water-based solution easy to handle and small in environmental load, thereby improving a stability of a manufacturing process of an image-forming apparatus in the case where the water-based solution is used in the manufacturing process. A base pattern is formed using a base pattern forming material for electrode and wiring material absorption which is a water-based solution containing a water-soluble photosensitive resin component and a water-soluble metallic compound including rhodium, bismuth, ruthenium, vanadium, chromium, tin, lead, or silicon. An organic metallic compound is absorbed in the base pattern and then baking is conducted to form electrodes and wirings.

Owner:CANON KK

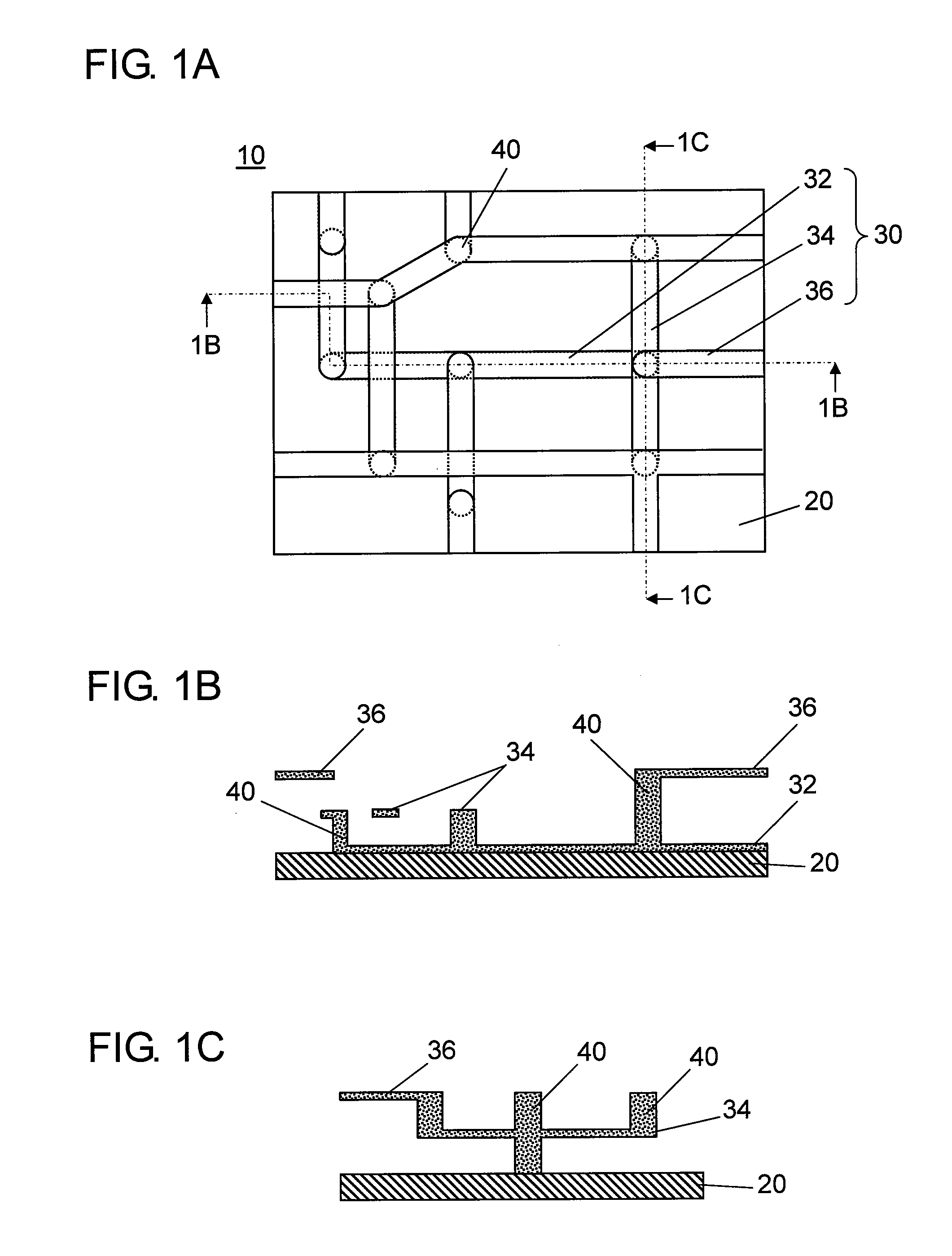

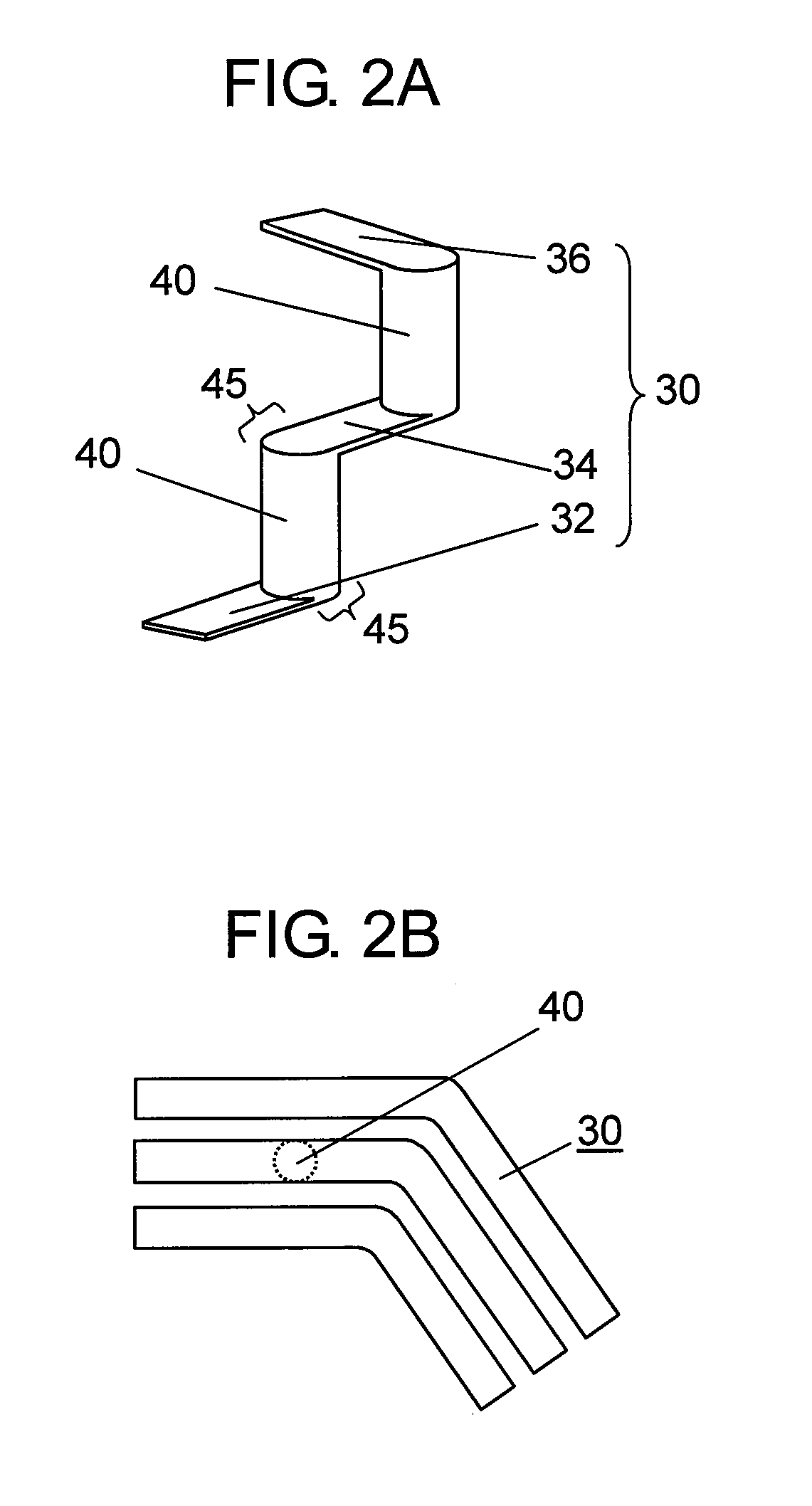

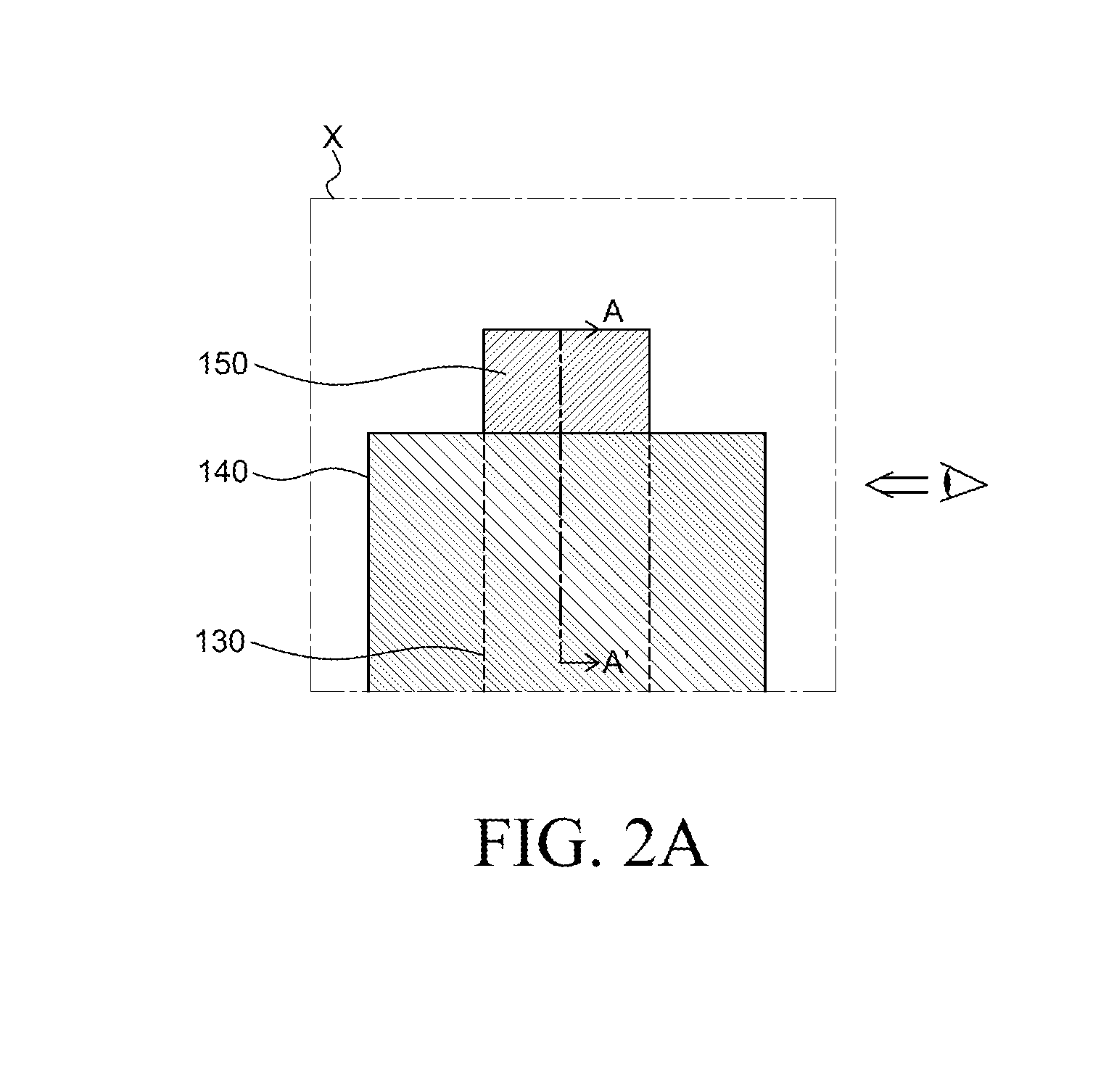

Three-dimensional circuit board and its manufacturing method

InactiveUS20090266582A1High densityImprove reliabilityPrinted circuit aspectsSolid-state devicesEngineeringElectrical and Electronics engineering

A three-dimensional circuit board is formed by comprising a board, a first wiring-electrode group provided on a plurality of steps above the board, and a second wiring-electrode connected to the first wiring-electrode group at least in an altitude direction, in which at least a connecting portion between the first wiring-electrode group and the second wiring-electrode is integrated in a continuously identical shape.

Owner:PANASONIC CORP

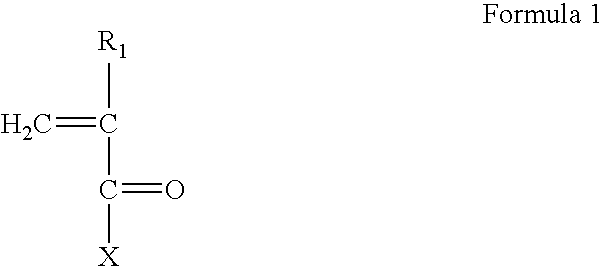

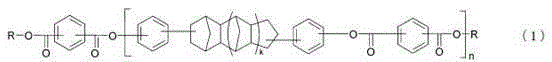

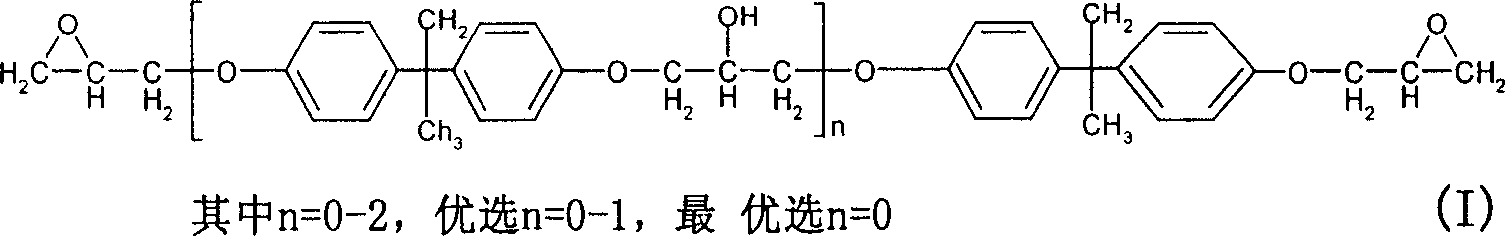

Conductive member, method for producing conductive member, touch panel, and solar cell

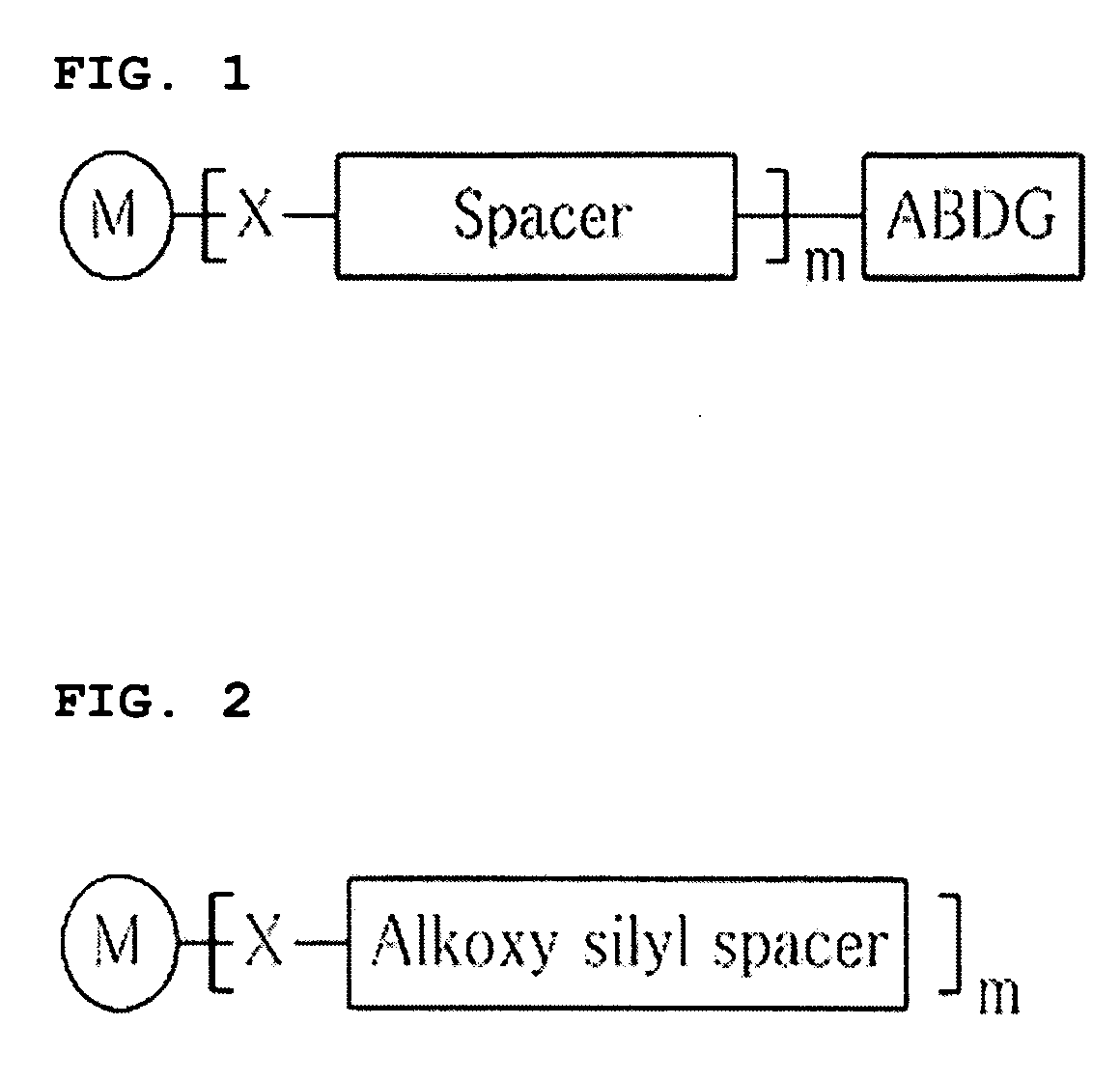

InactiveCN103493147AImprove toleranceHigh transparencyCircuit bendability/stretchabilityConductive layers on insulating-supportsHigh resistanceNanowire

A conductive member containing: a base material; a conductive layer provided on the base material, wherein the conductive layer includes a metallic nanowire having an average short axis length of 150 nm or less and a matrix; and a protective layer including a three-dimensional crosslinked structure represented by the following Formula (I), sequentially in this order, and which has a surface resistivity measured at a surface of the protective layer of 1,000 Omega / □ or less, a production method of the conductive member, and a touch panel and a solar cell, each of which uses the conductive member. The conductive member may provide high resistance against scratches and abrasion, excellent conductivity, excellent transparency, excellent heat resistance, excellent moisture and heat resistance, and excellent bendability. -M1-O-M1-Formula (I): In the Formula (I), M1 represents an element selected from the group consisting of Si, Ti Zr and Al.

Owner:FUJIFILM CORP

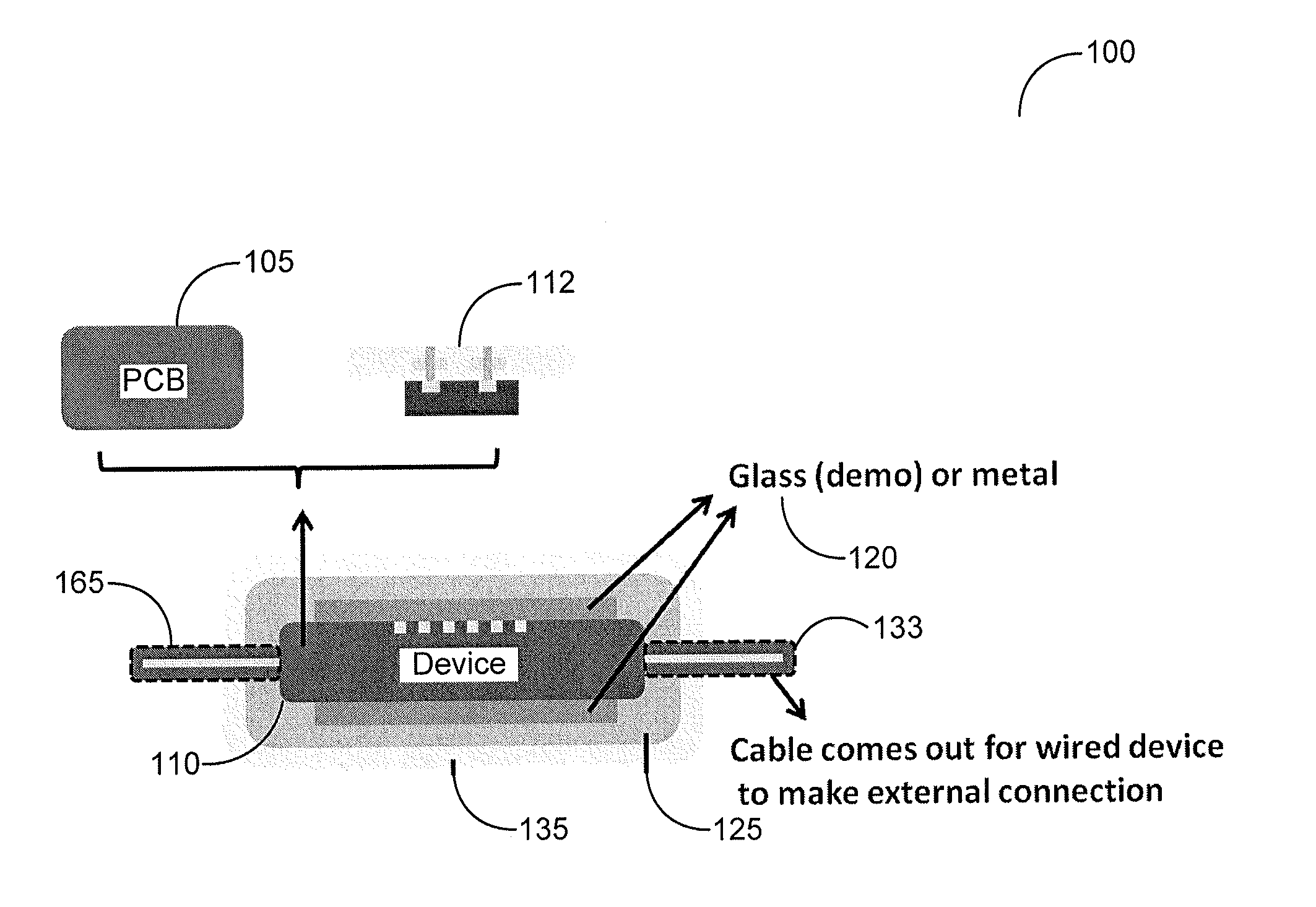

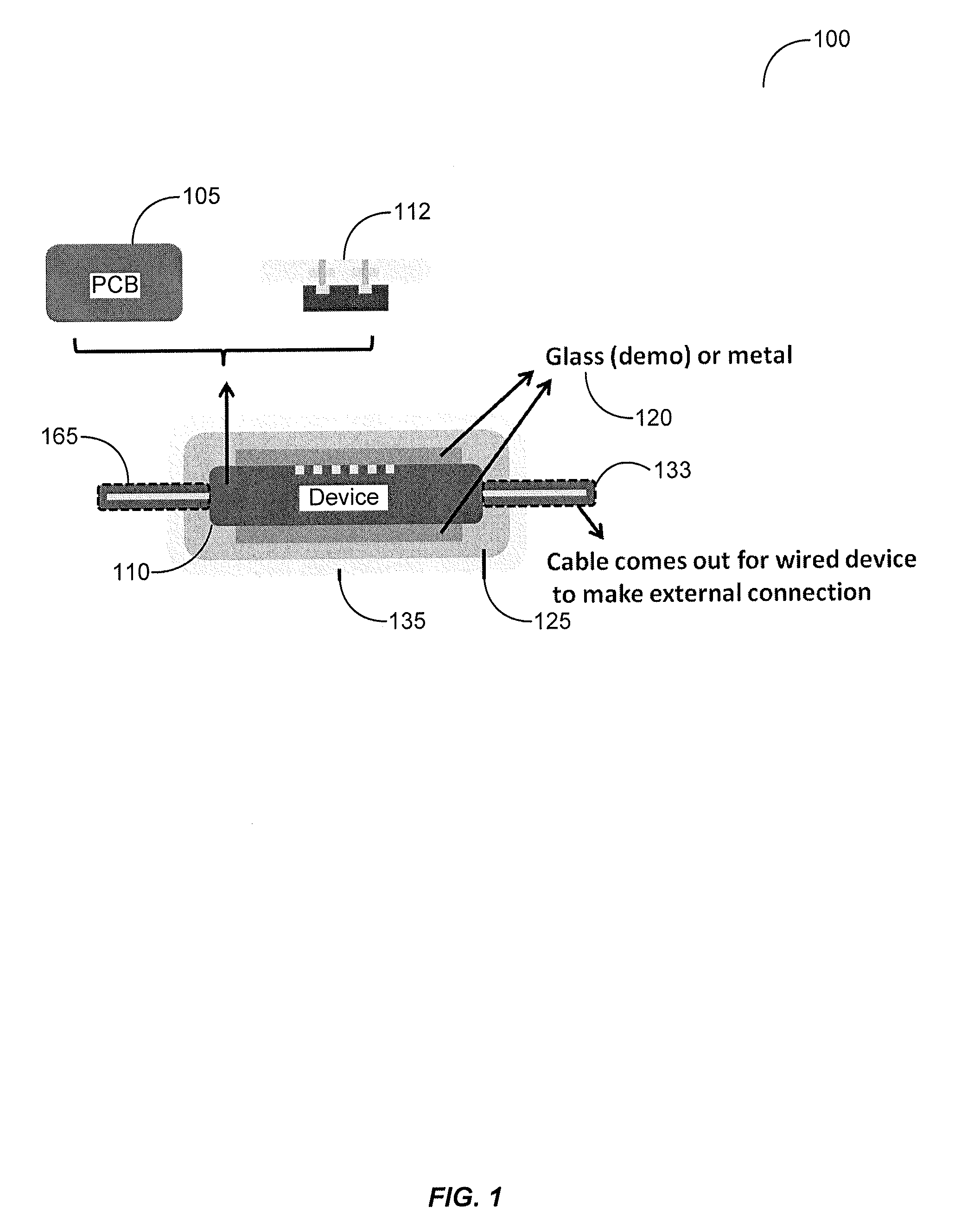

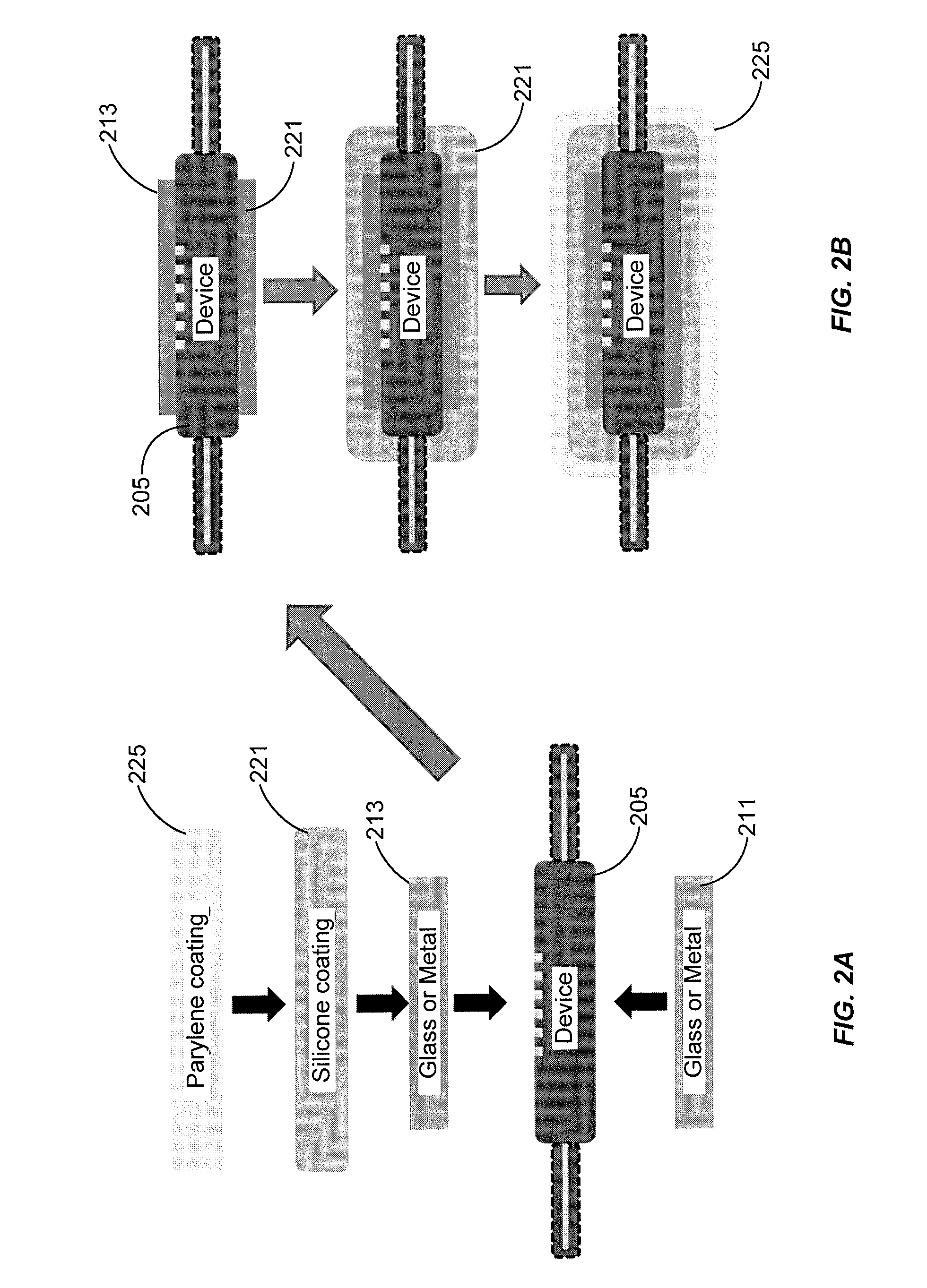

Long-term packaging for the protection of implant electronics

ActiveUS20150036302A1Low water vapor transmission rateDielectric materialsSemiconductor/solid-state device detailsBiomedical engineeringElectronics

The present invention provides a micropackaged device comprising: a substrate for securing a device; a corrosion barrier affixed to said substrate; optionally at least one feedthrough disposed in said substrate to permit at least one input and or at least one output line into said micropackaged device; and an encapsulation material layer configured to encapsulate the micropackaged device.

Owner:CALIFORNIA INST OF TECH

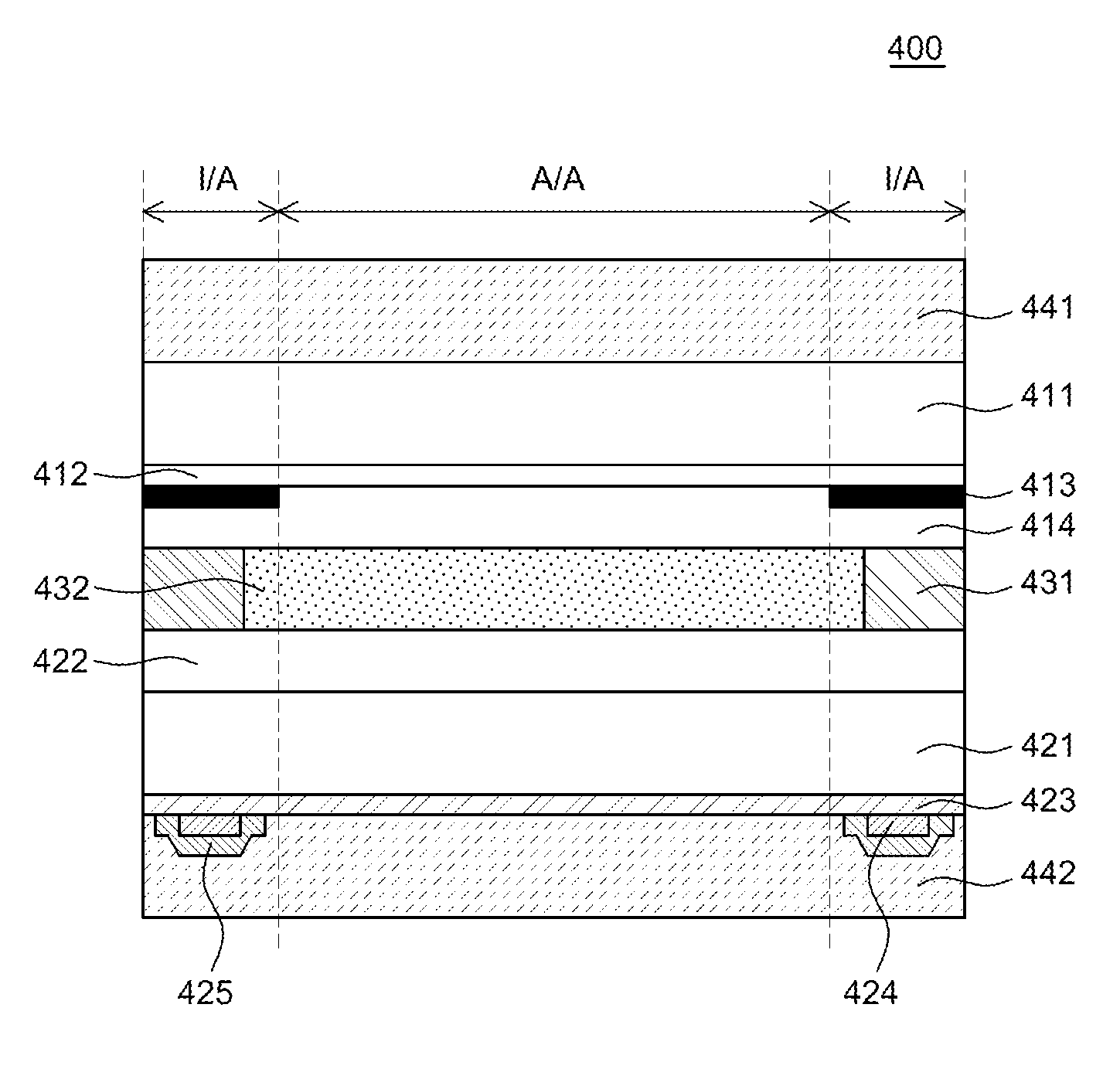

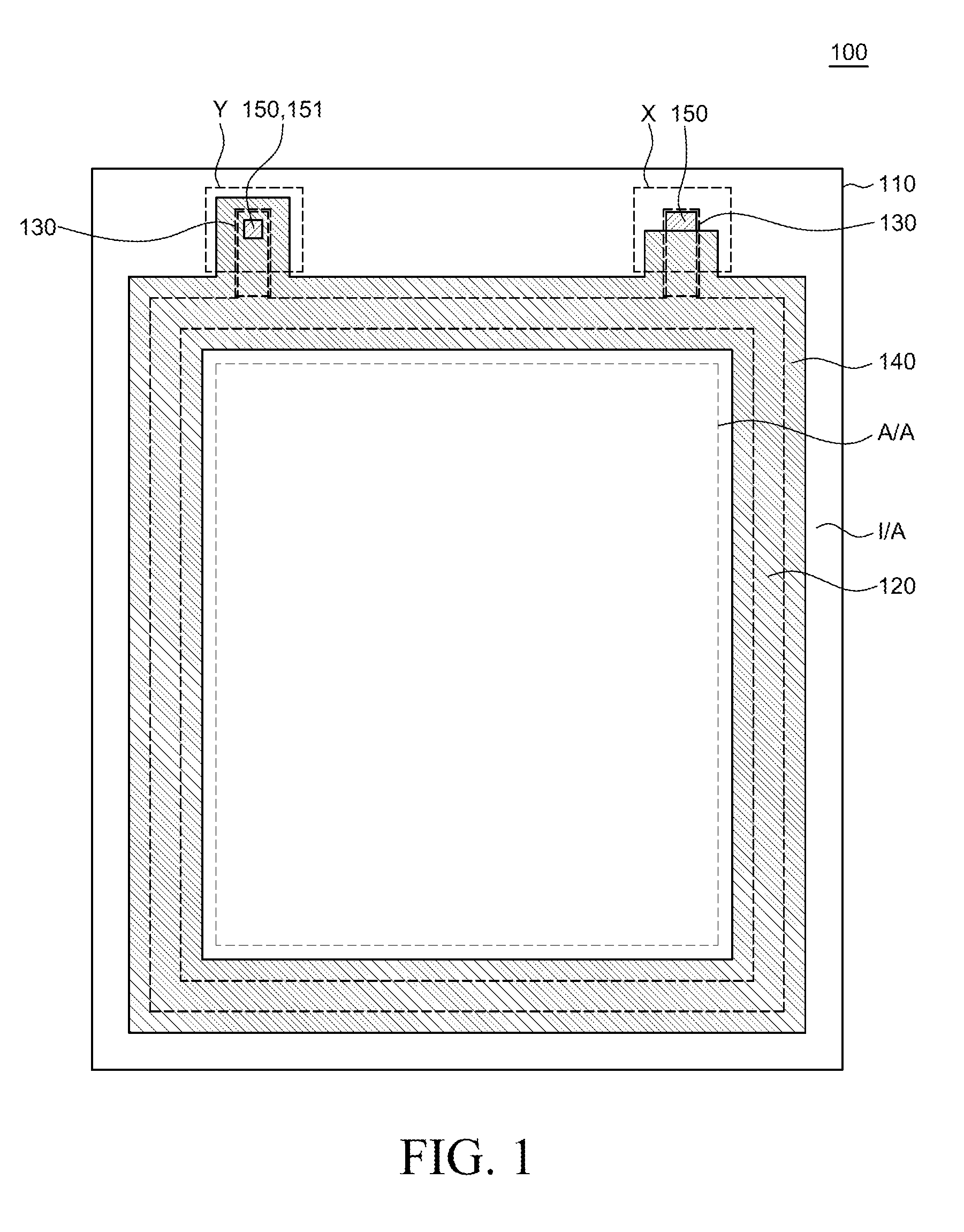

Display panel and method of manufacturing the same

ActiveUS20160092011A1Improve stabilityUniform thicknessPrinted circuit aspectsPhotodevelopable thick filmBoiling pointEngineering

Provided is a display panel including a loop-shaped conductive path which is manufactured by performing a conductive ink jetting process and a high-degree vacuum removal process to effectively vaporizing a solvent in a conductive ink line at lower temperature than the boiling point at atmospheric pressure of the solvent. The conductive path manufactured as such does not allow a stain or a trace, such as a pull-back region, to be left around the conductive path. Thus, it is possible to obtain the loop-shaped conductive path having an initially intended design without being damaged during a process.

Owner:LG DISPLAY CO LTD

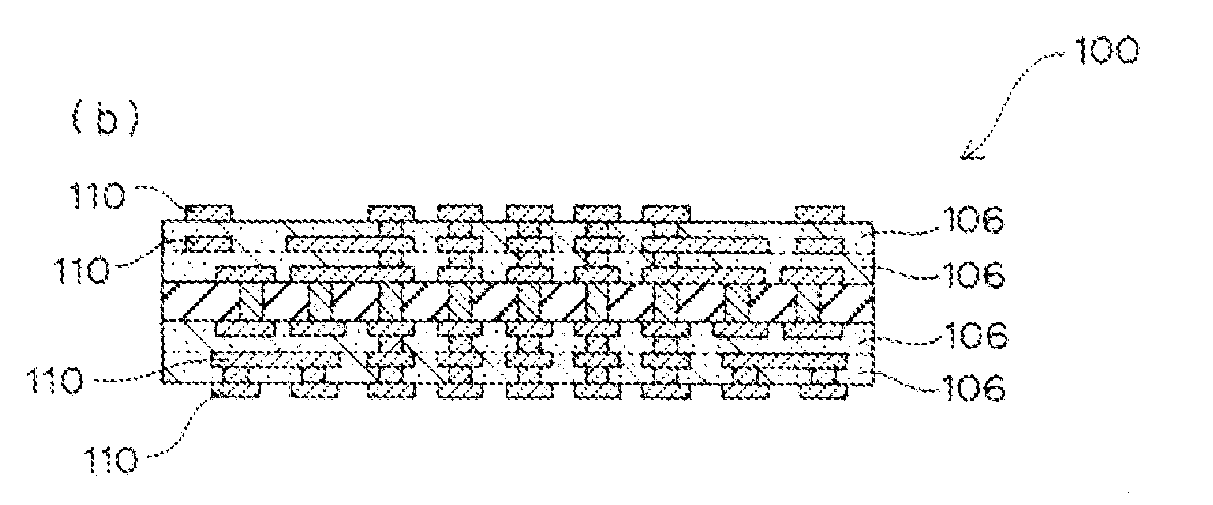

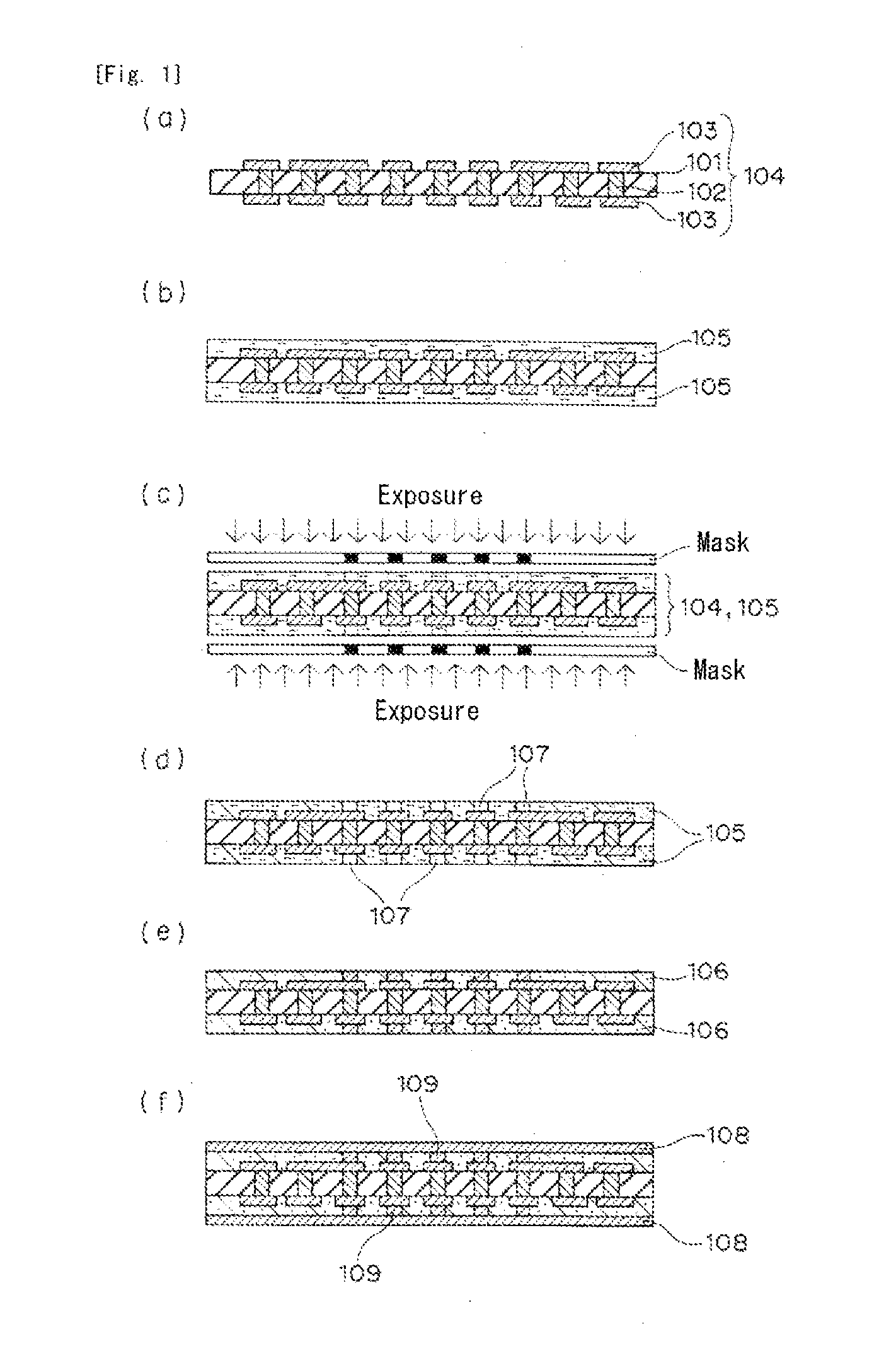

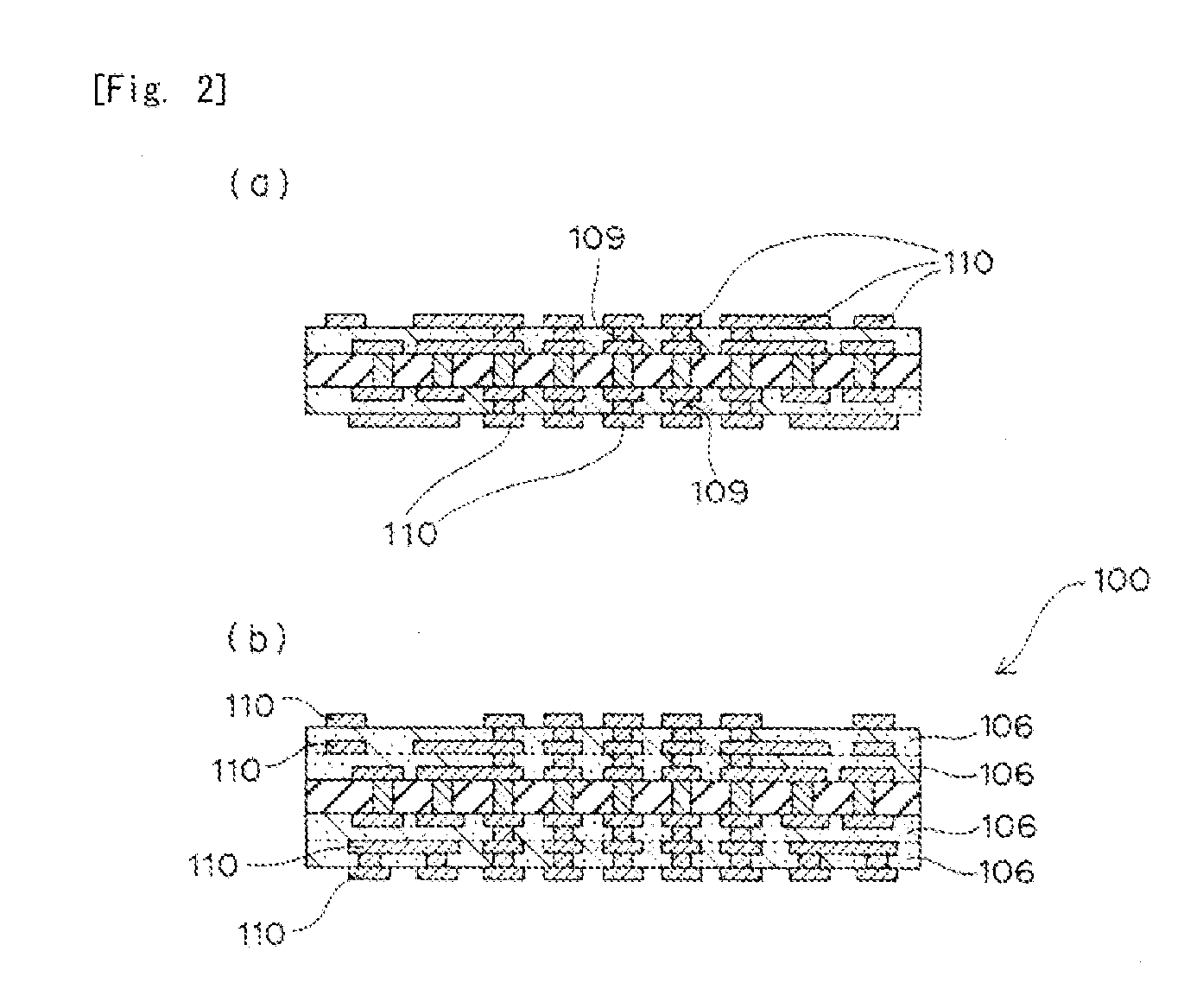

Built-up substrate, method for manufacturing same, and semiconductor integrated circuit package

ActiveUS20140124777A1Improve insulation reliabilityPrecise positioningDielectric materialsSemiconductor/solid-state device detailsEngineeringSemiconductor

A method for manufacturing a build-up substrate, the build-up substrate comprising an insulating layer and a wiring pattern layer stacked over a circuit substrate, said method comprising the steps of: (i) applying a photoactive metal oxide precursor material to one or both sides of the circuit substrate with a wiring pattern, and drying the applied photoactive metal oxide precursor material to form an insulating film; (ii) forming an opening for a via hole in the insulating film by exposure and development of the insulating film; (iii) applying a heat treatment to the insulating film to convert the insulating film into a metal oxide film, thereby forming a build-up insulating layer of the metal oxide film; and (iv) plating the build-up insulating layer to form via holes in the openings, forming a metal layer on the build-up insulating layer, and etching the metal layer to form a build-up wiring pattern; and (v) repeating the steps from (i) to (iv) at least one time.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

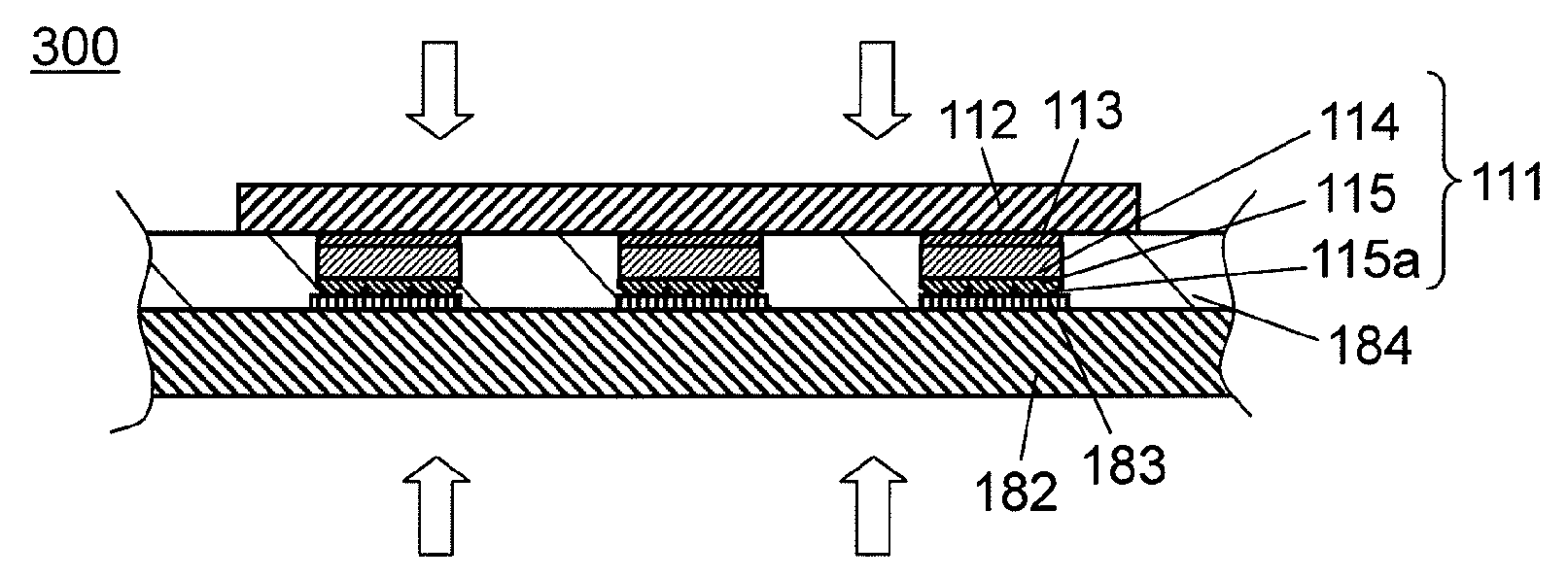

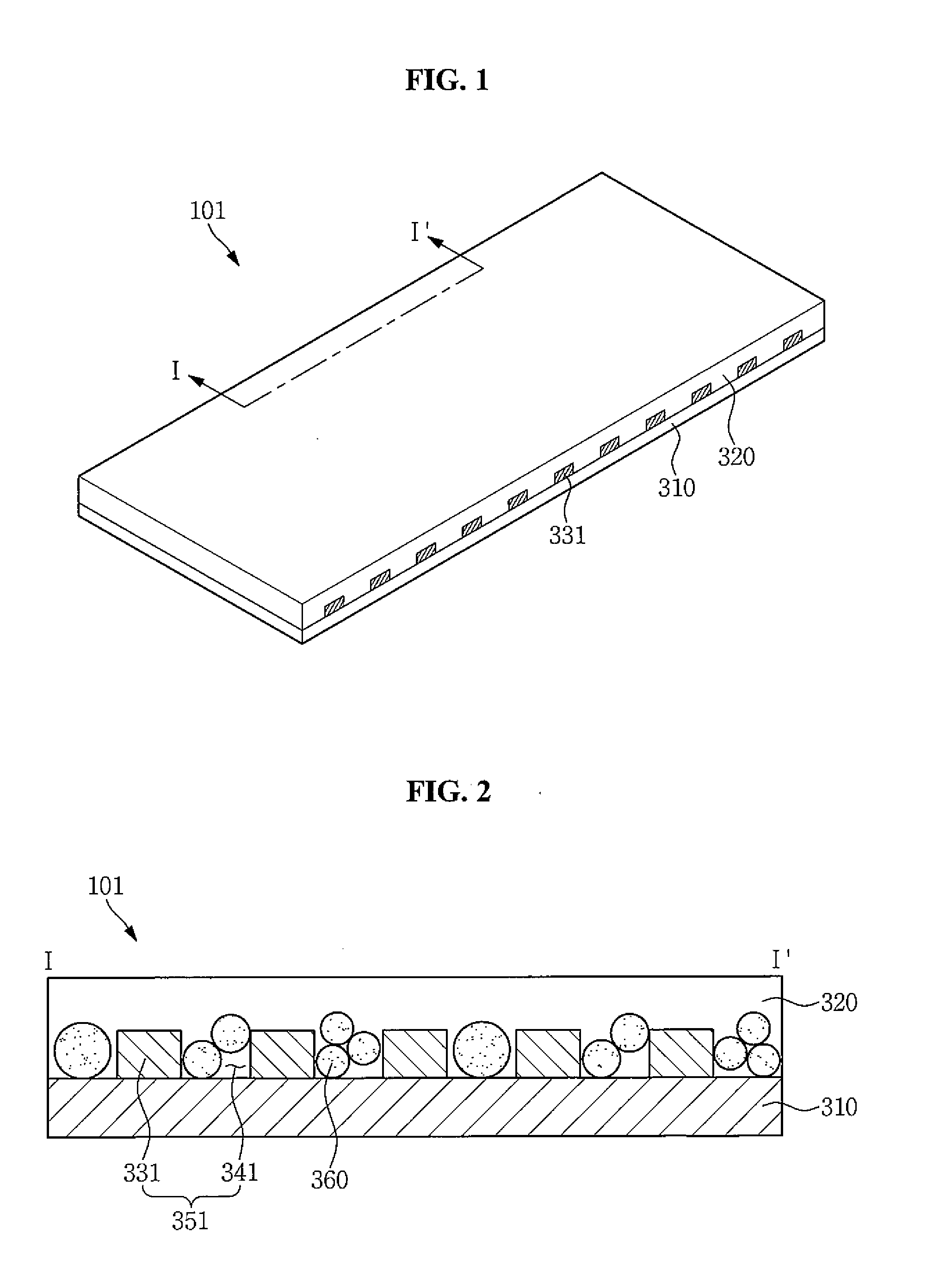

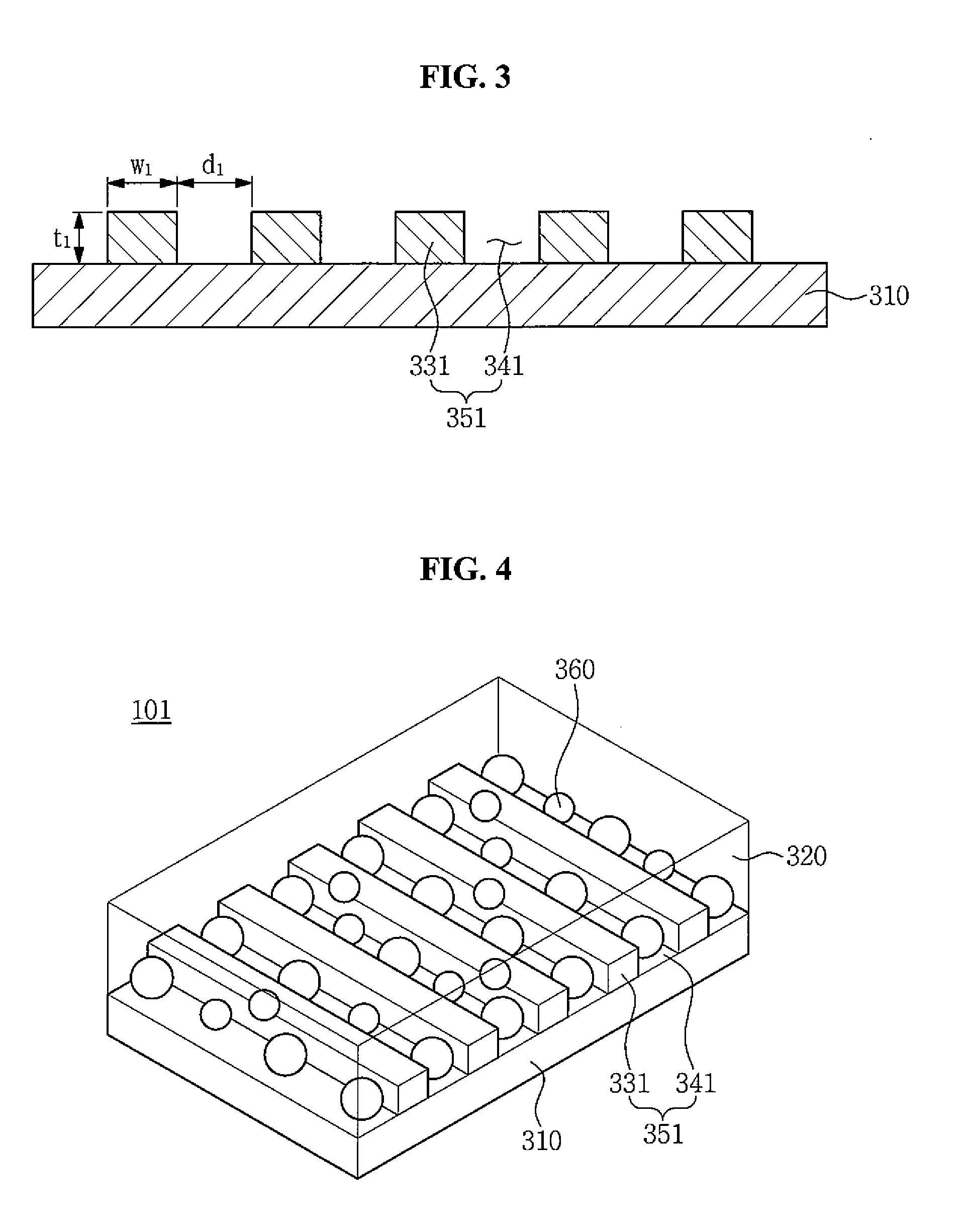

Anisotropic conductive film and method for manufacturing the same

ActiveUS20170013722A1Flexible printed circuitsFilm/foil adhesivesAnisotropic conductive filmEngineering

An anisotropic conductive film (ACF) including a base film, a support unit on the base film, the support unit defining at least one opening, at least one conductive particle in the opening, and an adhesive layer on the support unit and the conductive particle.

Owner:SAMSUNG DISPLAY CO LTD

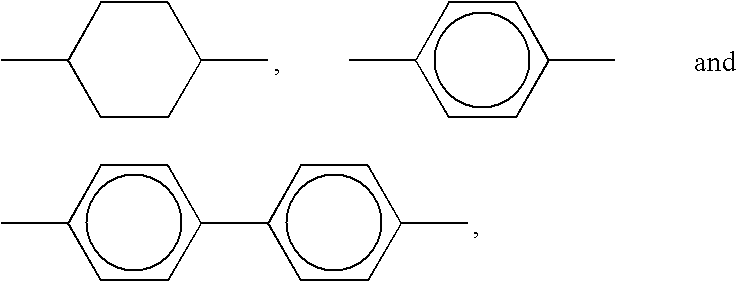

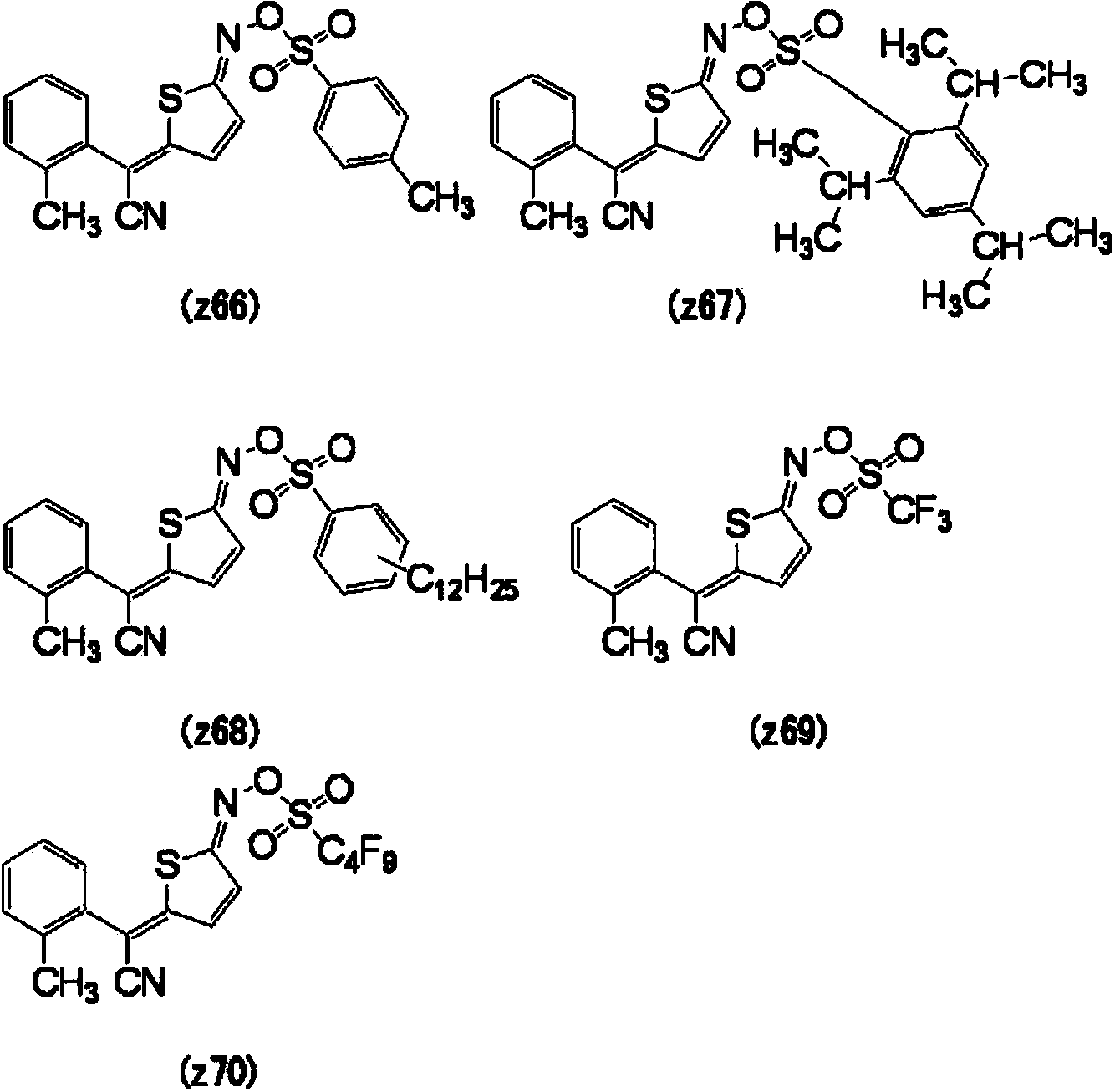

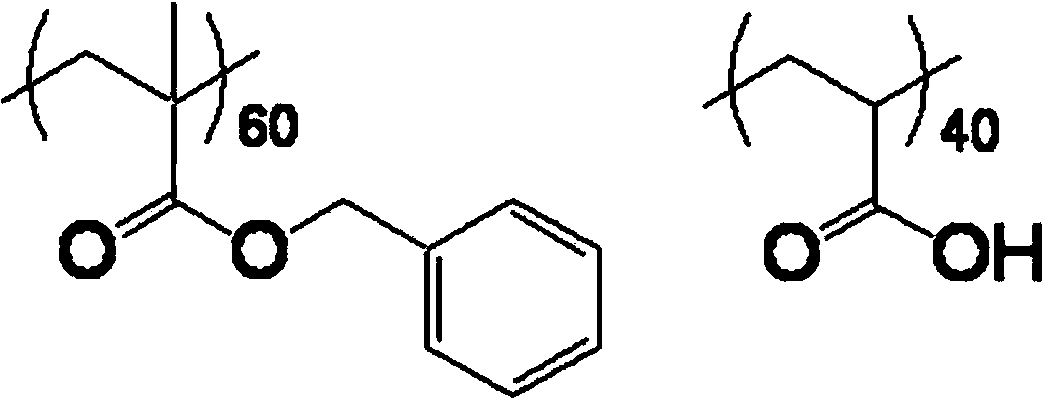

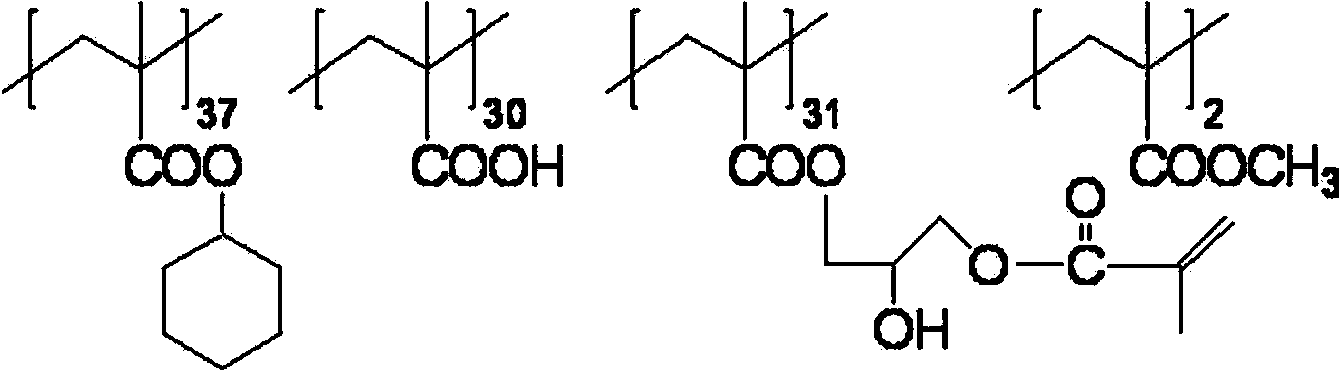

Photosensitive resin composition

ActiveCN105308506AExcellent dielectric propertiesImprove water resistancePhotodevelopable thick filmPhotosensitive materials for photomechanical apparatusPolymer chemistryCyanate ester

Provided is a photosensitive resin composition which exhibits excellent insulation reliability and has physical properties suitable for a buildup layer (interlayer insulating layer) of a multilayer printed wiring board, while having photosensitivity. This photosensitive resin composition contains (A) an epoxy resin, (B) one or more curing agents that are selected from the group consisting of active ester curing agents, cyanate ester curing agents and benzoxazine curing agents, and (C) a compound having a (meth)acrylate structure.

Owner:AJINOMOTO CO INC

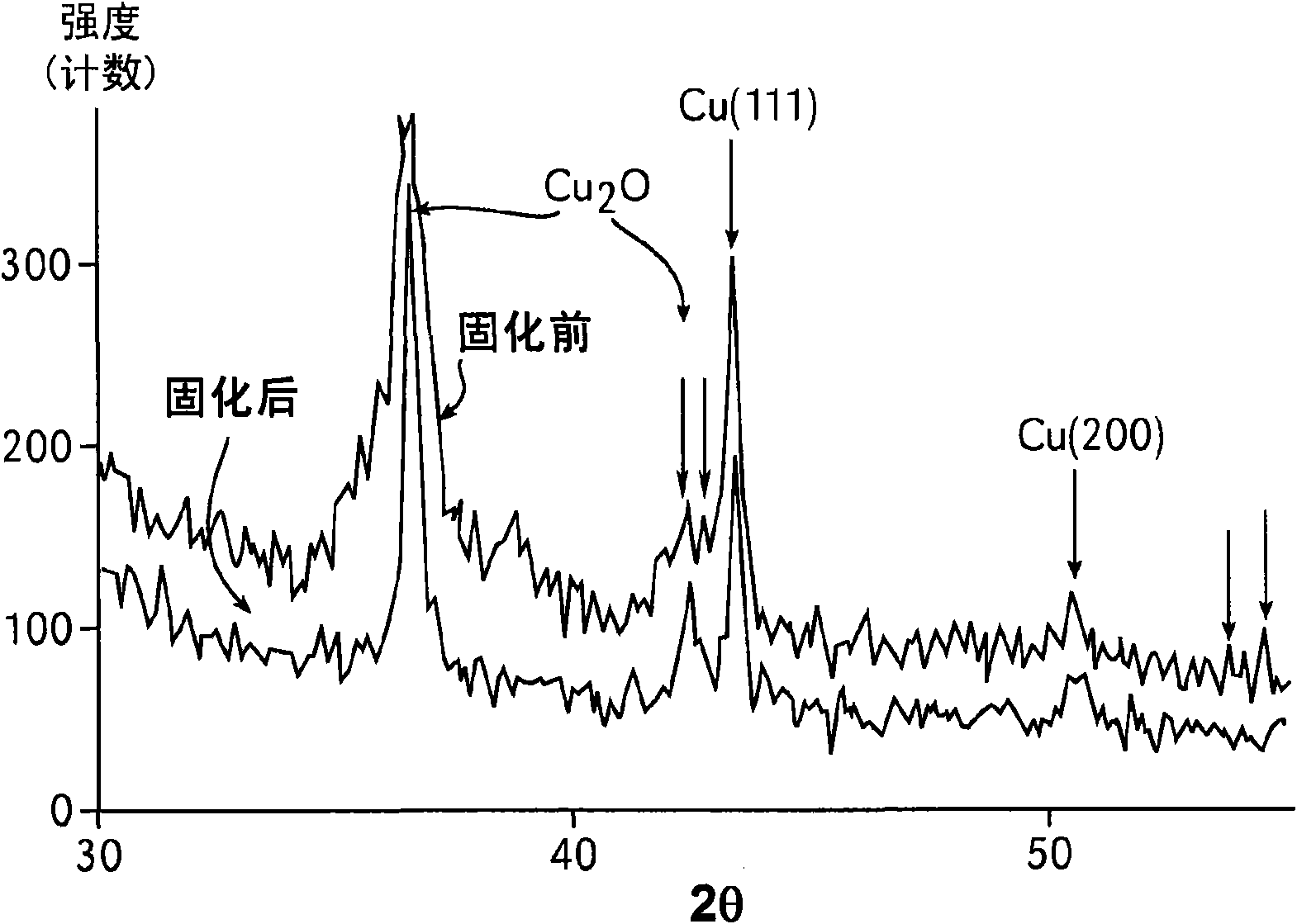

Performance of conductive copper paste using copper flake

InactiveUS20140287158A1Enhanced sintering latitudeRadiation applicationsSemiconductor/solid-state device detailsConductive pasteMean diameter

A conductive paste for screen application has a mixture of copper flake having a mean diameter between 1.0-8.0 micrometers and copper nanoparticles having a mean diameter from 10 nm to 100 nm, wherein the ratio of the copper flake to the nanoparticles is between 2:1 and 5:1 by weight; and a resin comprising about half of a polymer having a molecular weight in excess of 10,000 and one or more solvents.

Owner:INTRINSIQ MATERIALS INC

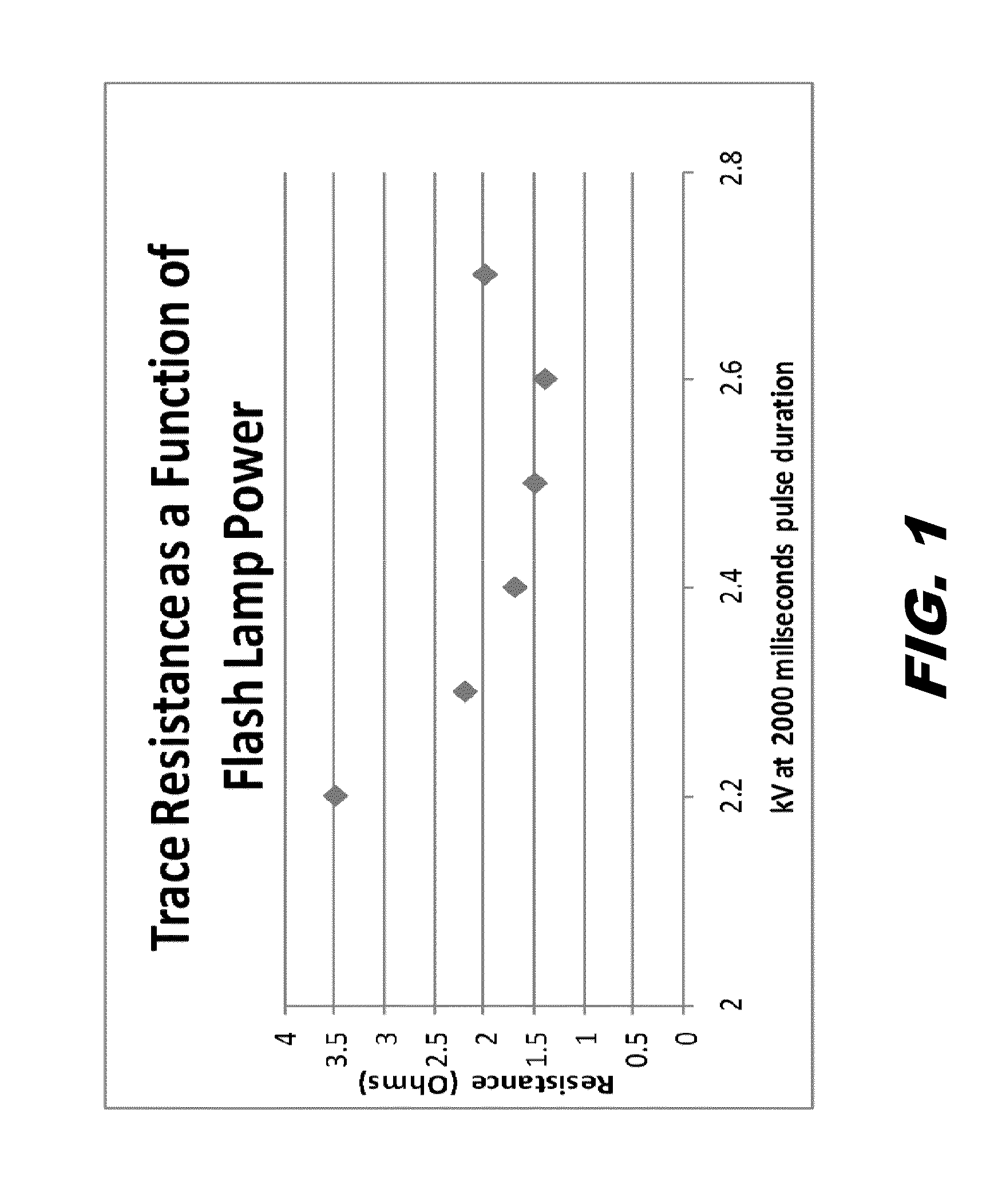

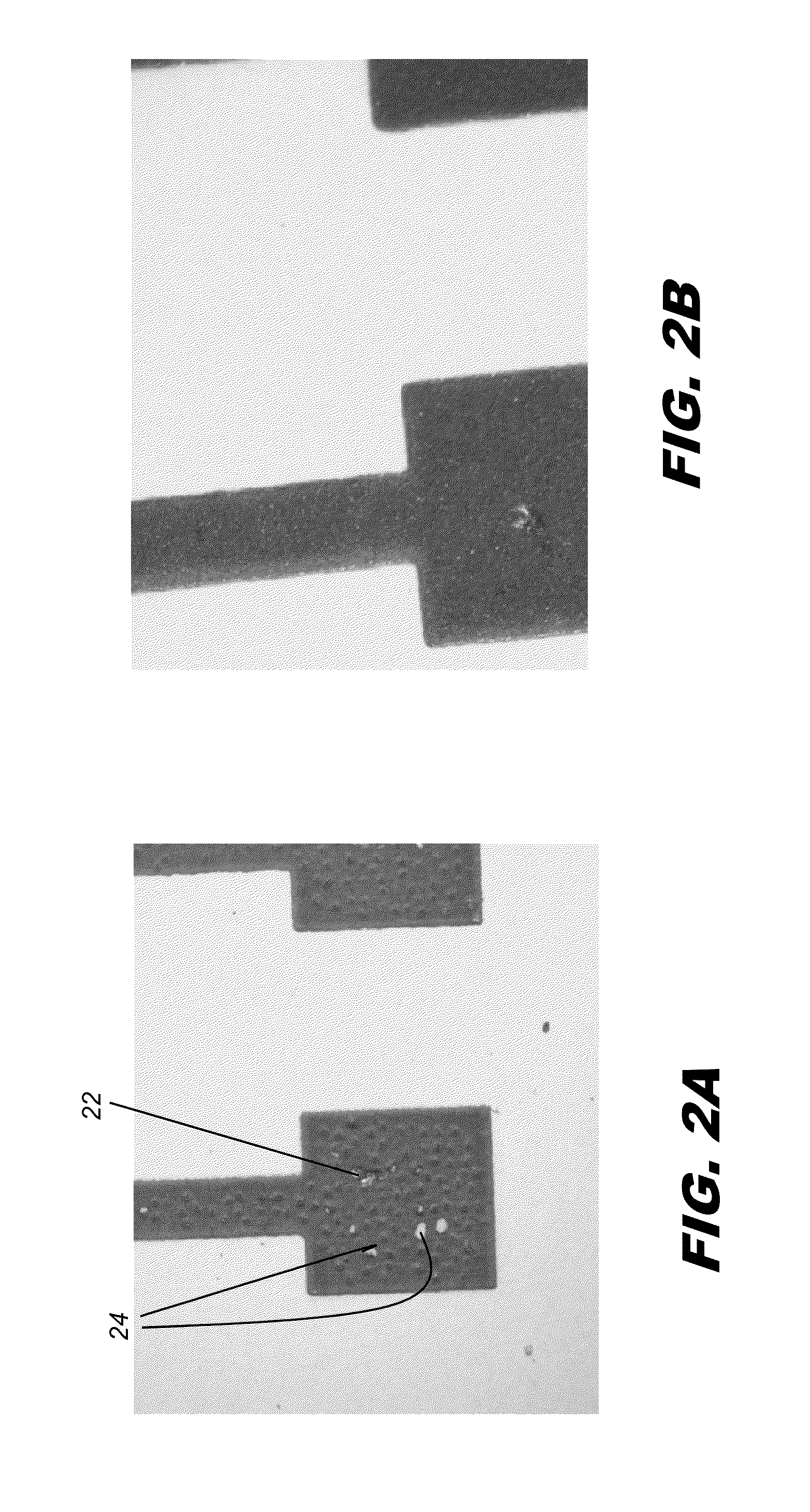

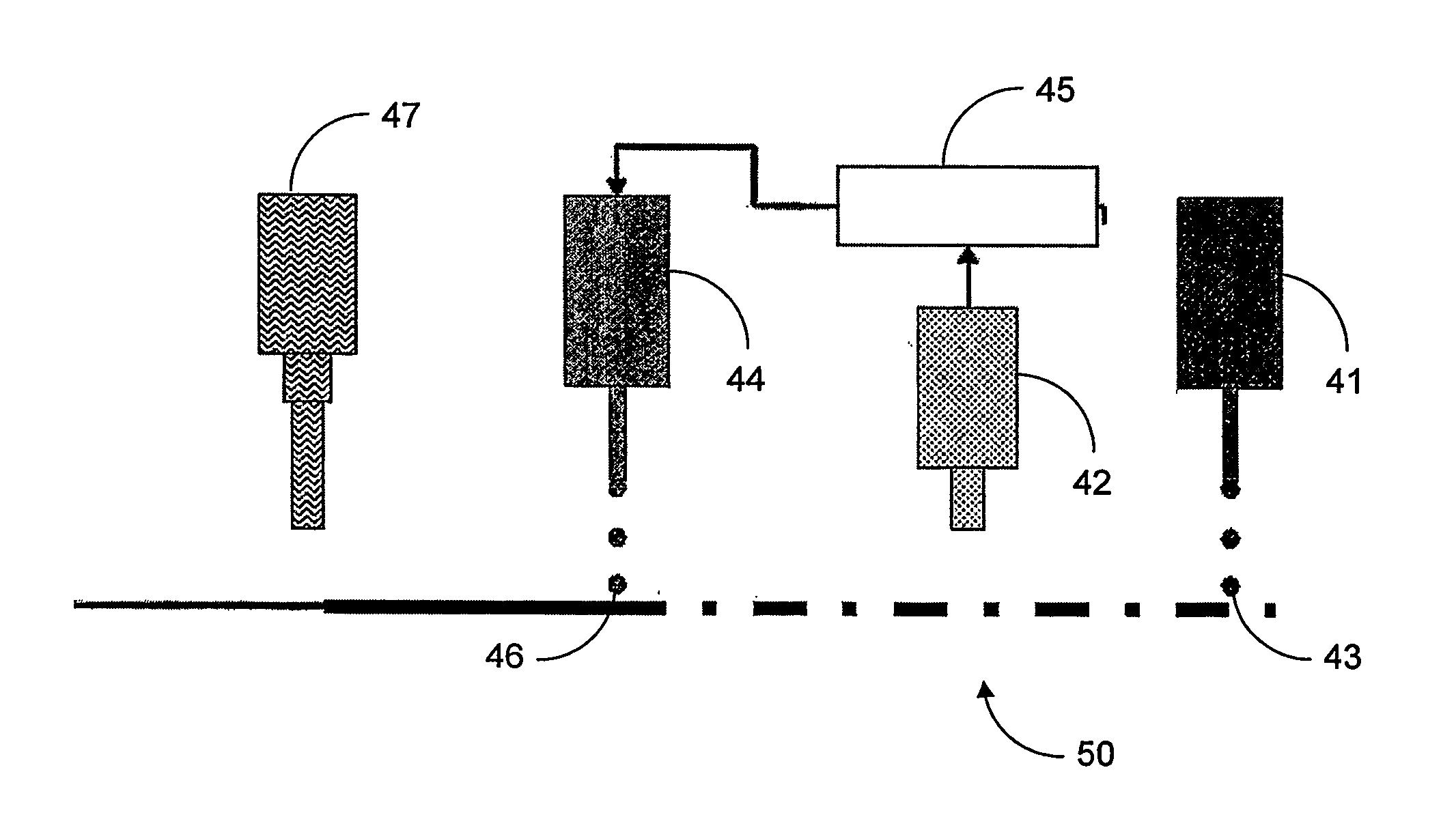

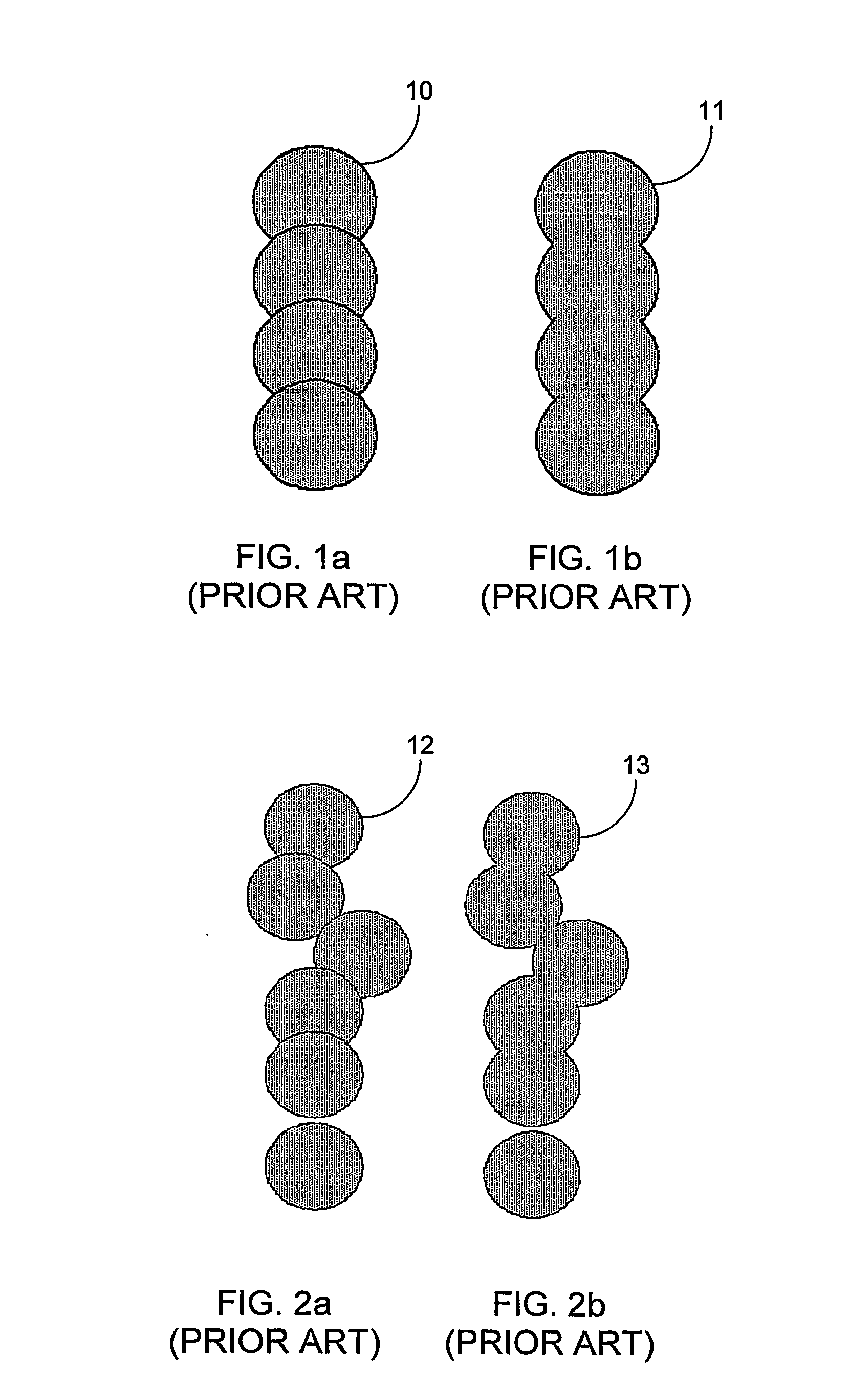

Method and system for creating fine lines using ink jet technology

InactiveUS20070014974A1Solid-state devicesSemiconductor/solid-state device manufacturingFine lineEngineering

In a method and system for producing a geometry (24, 35) of desired dimension on a substrate, successive droplets (43) of a material are dropped on to the substrate so as to form a pattern (22, 32) that is of sufficient dimension to accommodate the geometry within a boundary thereof; and a redundant area of the pattern that surrounds an intermediate portion of the pattern defining the geometry is removed. The redundant material may be removed by curing those portions of the pattern that define the pattern and then flushing the surplus; or by ablation of the surplus material.

Owner:PIXDRO

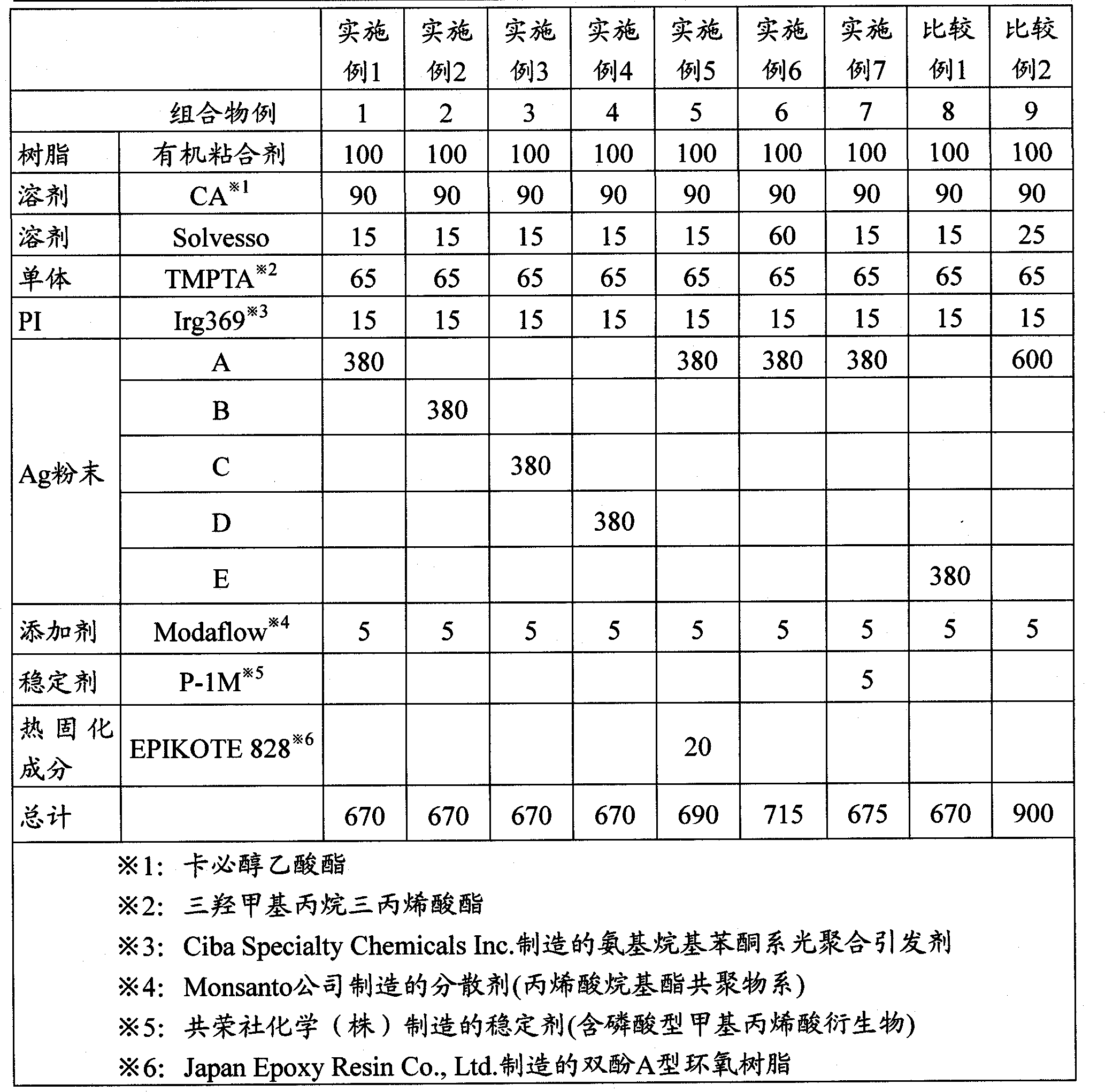

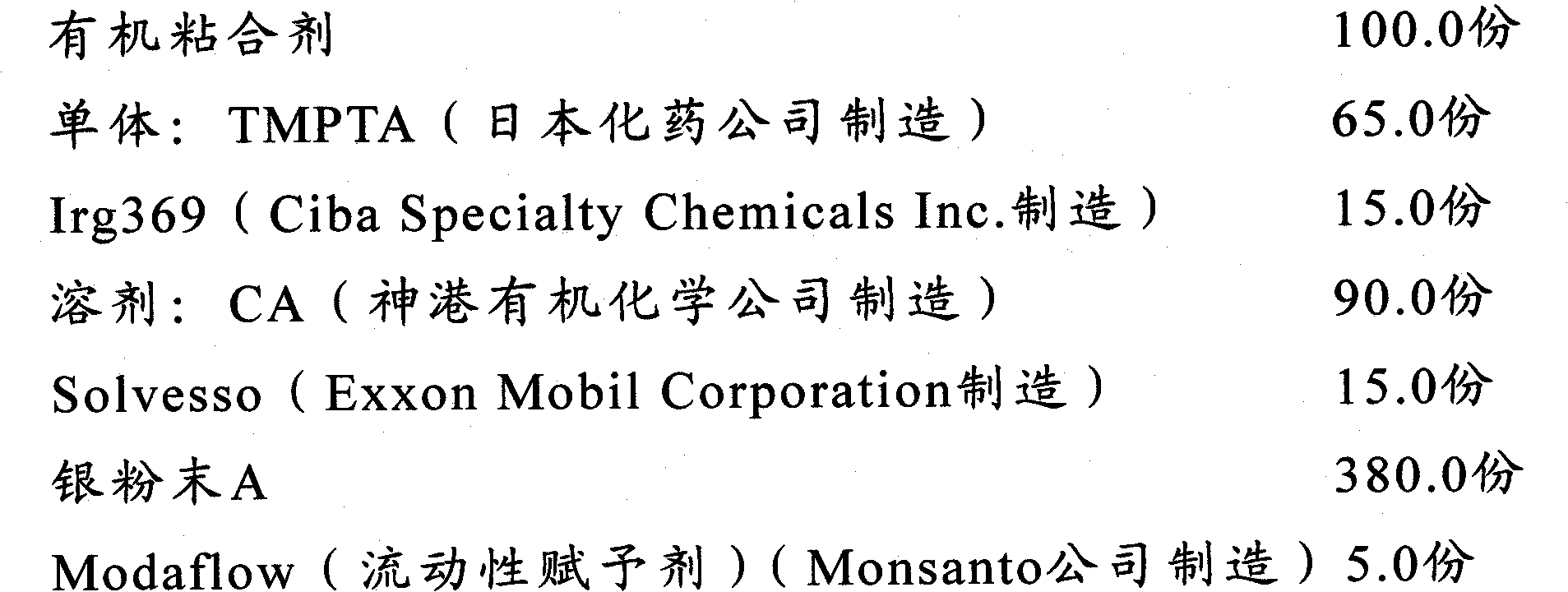

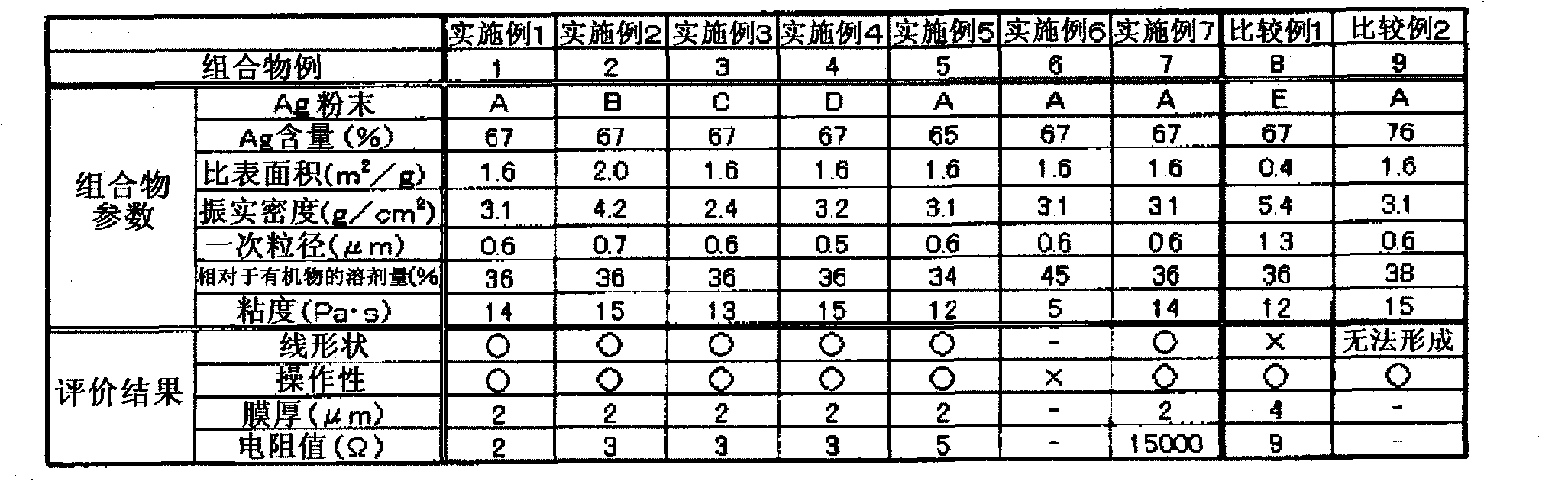

Photosensitive electrically conductive paste and electrode pattern

ActiveCN102365690AAchieve high precisionAchieve thin filmPhotodevelopable thick filmNon-conductive material with dispersed conductive materialOrganic solventMetallurgy

Provided is a photosensitive electrically conductive paste containing silver powder, organic binder, photopolymerizable monomer, photopolymerization initiator and organic solvent. The silver powder, having a primary particle diameter of not more than 1.0 [mu]m, a specific surface area from 1.5 m2 / g to 2.0 m2 / g and a tap density from 2.0 to 5.0 g / cm3, is included in an amount of less than 70 mass%of the electrically conductive paste excluding the organic solvent.

Owner:TAIYO INK MFG

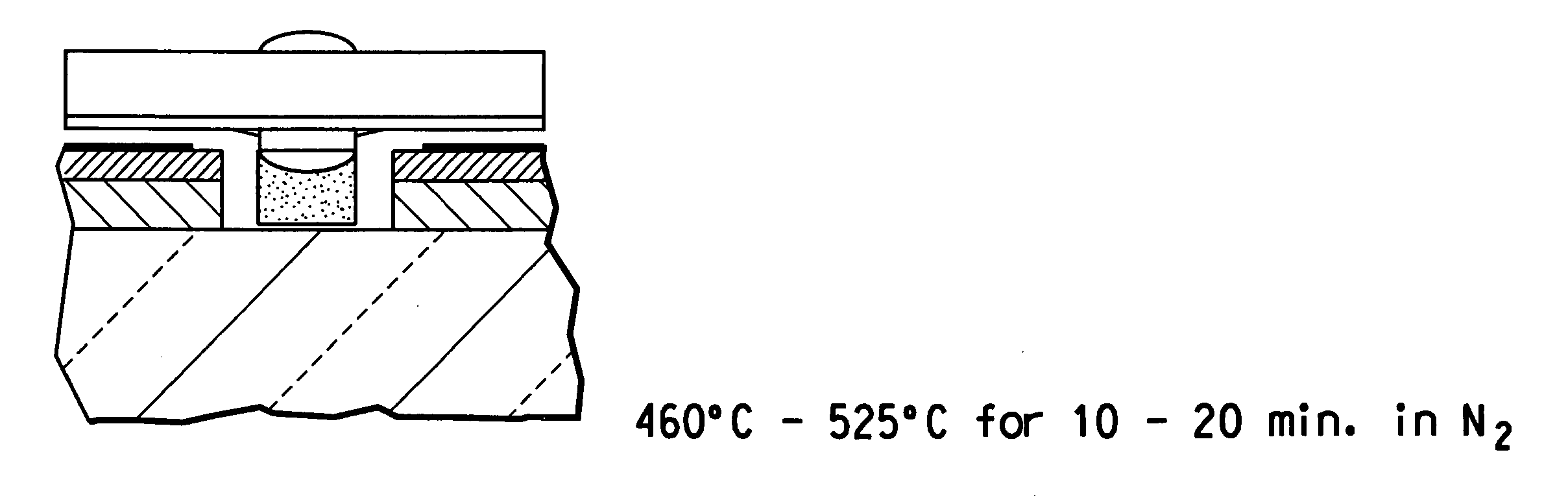

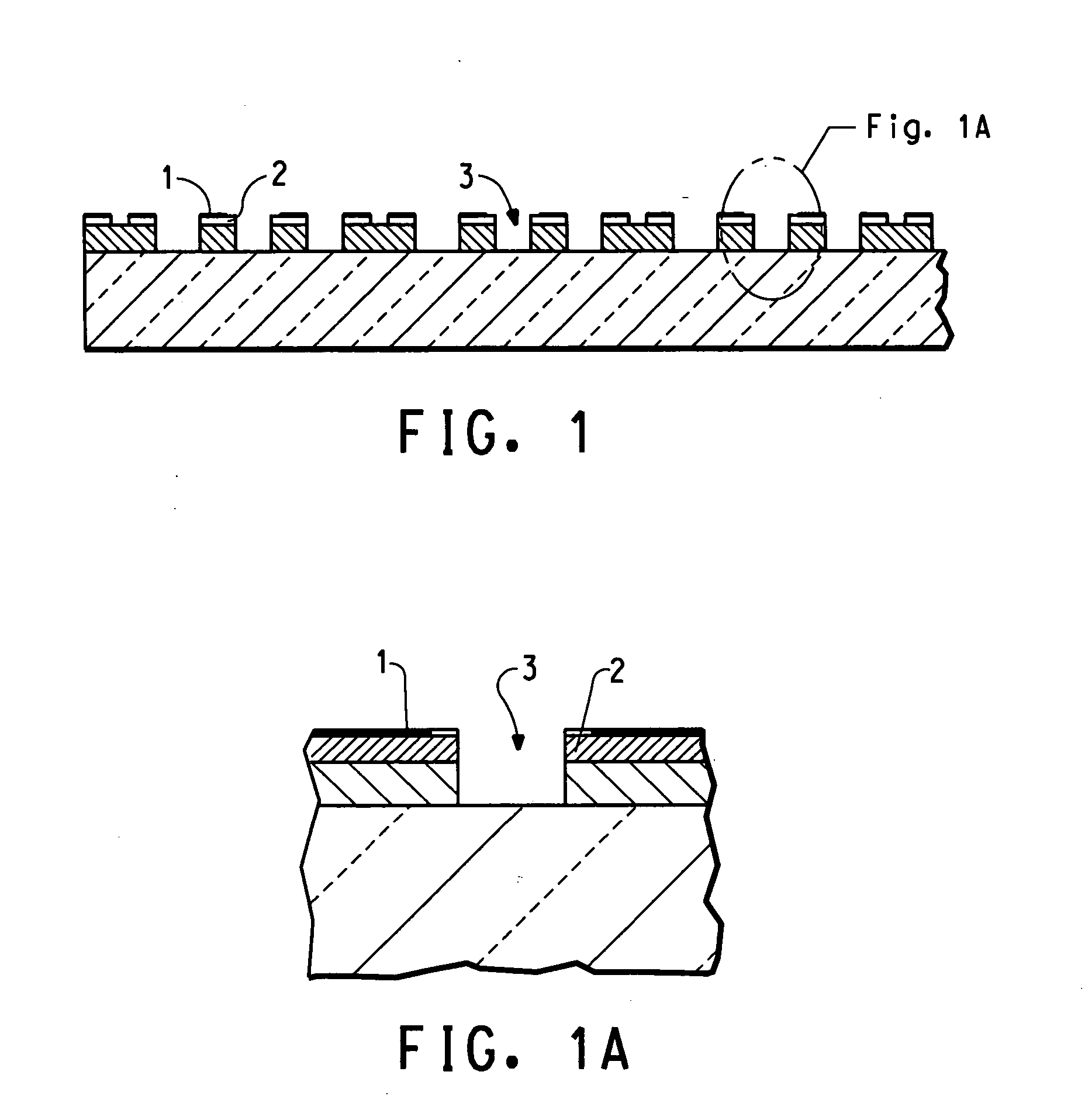

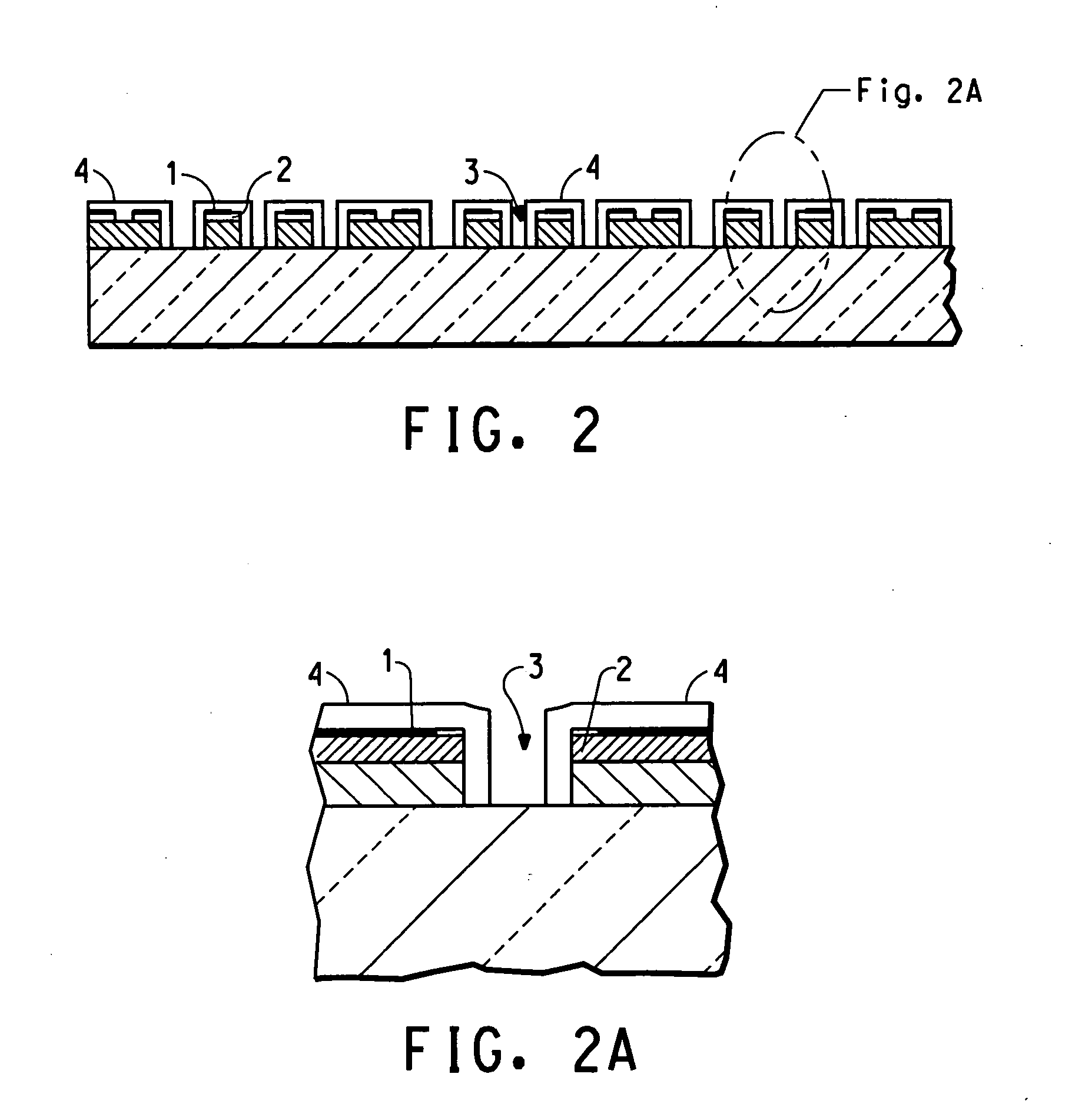

Filling vias with thick film paste using contact printing

InactiveUS20050032254A1Preventing paste run-offNanoinformaticsSemiconductor/solid-state device manufacturingElectronic structureCarbon nanotube

The present invention relates to a process for filling vias in an electronic structure with thick film paste. The vias may be preexisting in a substrate comprised of thick film materials or fabricated in a photoresist layer over-coating the substrate. The invention is particularly useful in fabrication of electron field emission triode arrays where the vias are of fine dimension (<100 μm in diameter) and the electron emitter thick film paste, which may contain carbon nanotubes, is of high value.

Owner:EI DU PONT DE NEMOURS & CO

Photosensitive resin composition and method for the formation of a resin pattern using the composition

ActiveCN1542547ALow costHigh bonding strengthPrinted circuit aspectsSemiconductor/solid-state device manufacturingCatalytic metalElectroplating

A photosensitive resin composition and a method for the formation of a resin pattern using the photosensitive resin composition are provided. The photosensitive resin composition contains, as a catalyst precursor, a catalytic metal element with a metal-deposition catalytic activity suitable for electroless metal plating. The method for the formation of a resin pattern uses a photosensitive resin composition, which contains, as a catalyst precursor, a catalytic metal element with a metal-deposition catalytic activity suitable for electroless metal plating. By using the method of this invention, it is possible to form a conductive film selectively on a resin pattern formed through exposure and development of the photosensitive resin composition of this invention.

Owner:SHIPLEY CO INC

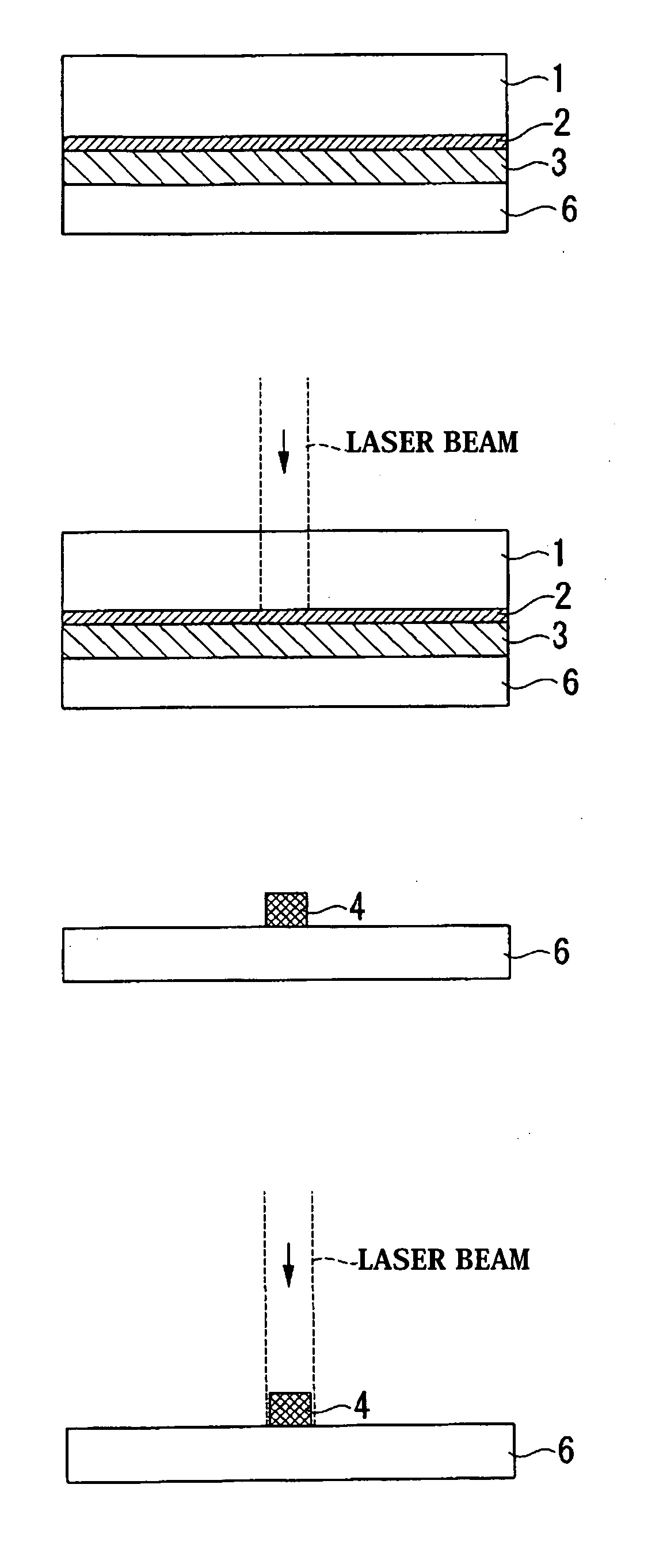

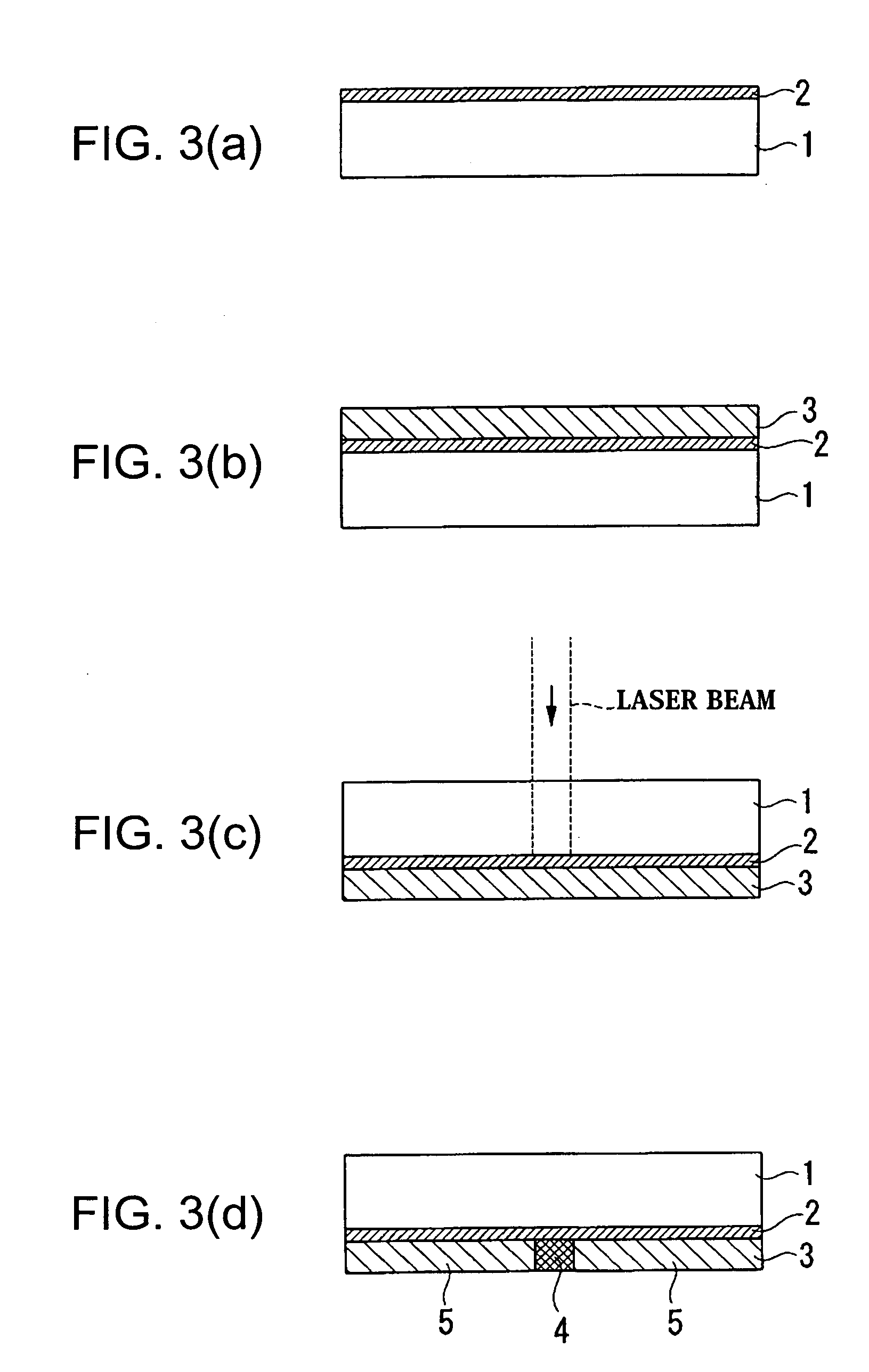

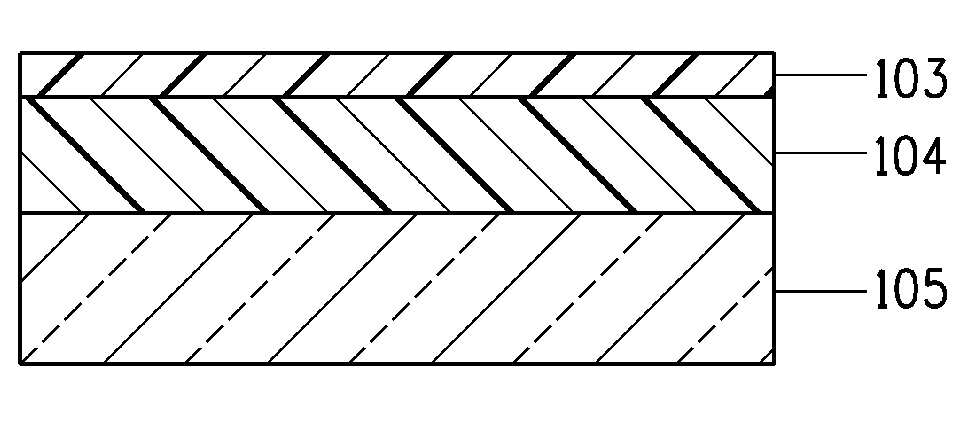

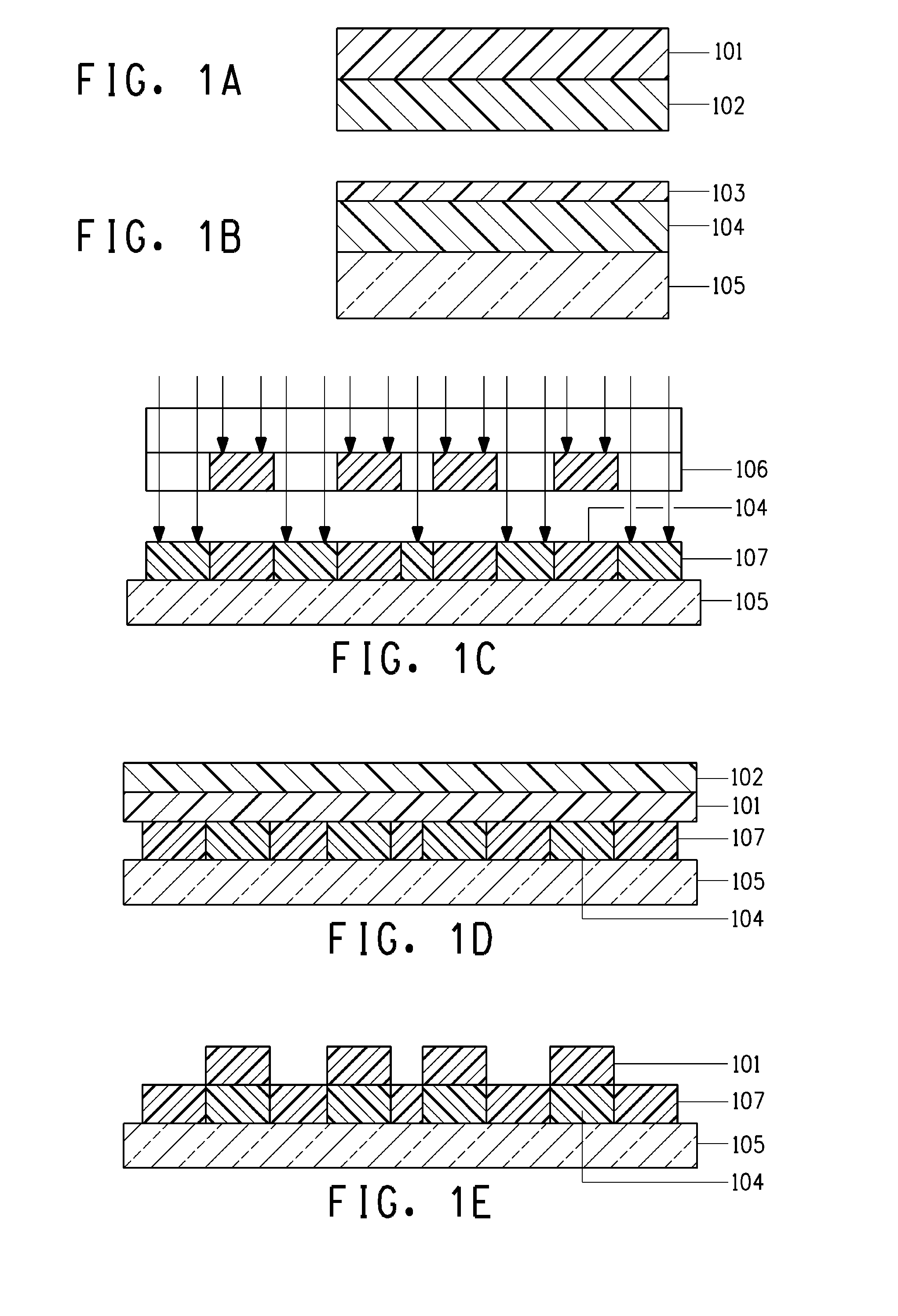

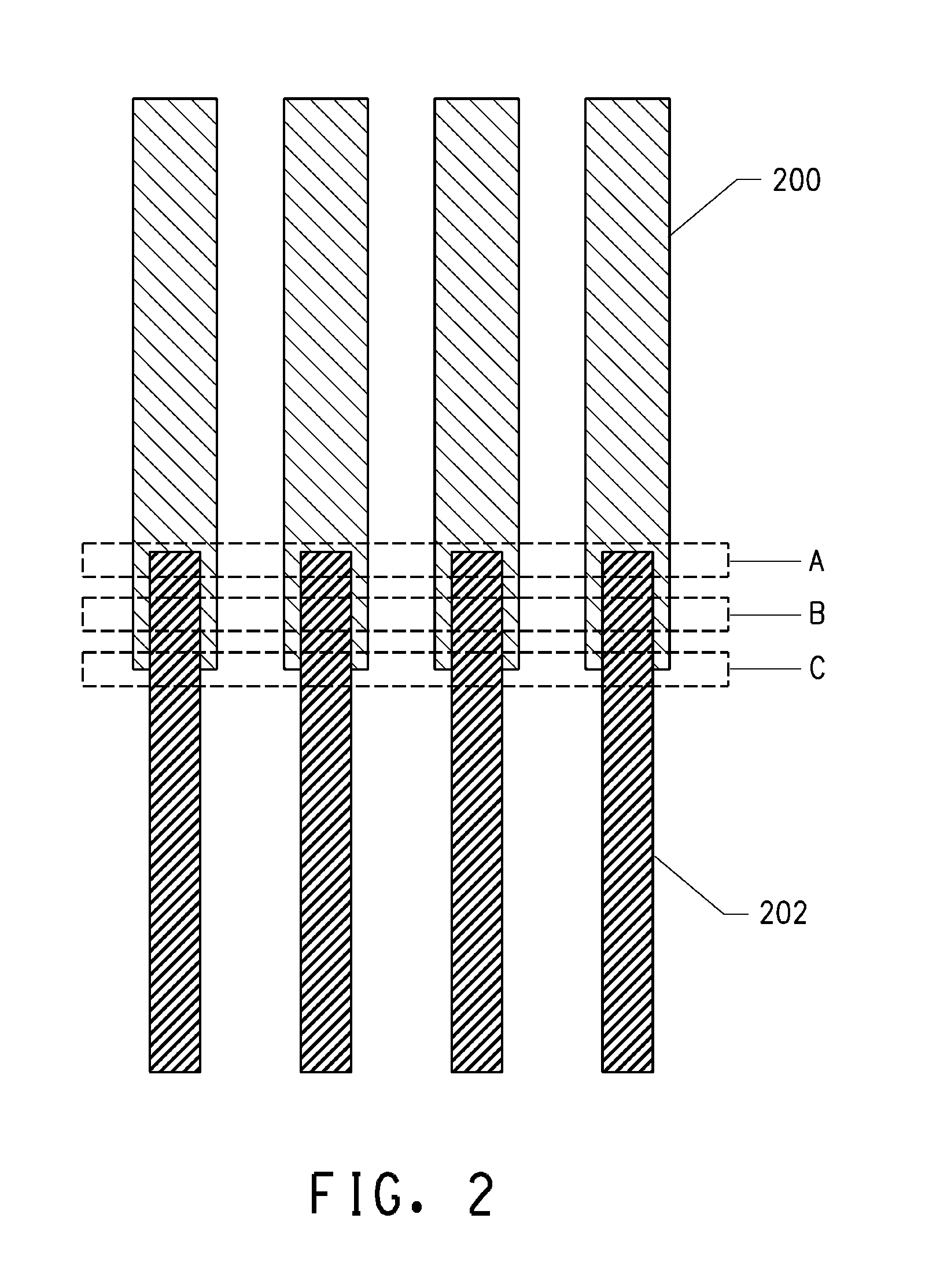

Method for forming patterned conductive film, electrooptical device, and electronic appliance

ActiveUS20050095866A1Develop its conductivityValid conversionDiffusion transfer processesPhotography auxillary processesLight energyPhotothermal conversion

Exemplary embodiments of the present invention provide a method to form a patterned conductive film by modifying a conductive thin film on a substrate irrespective of the material used for the substrate. Exemplary embodiments include a substrate having a conductive layer containing a conductive material and a photothermal conversion layer containing a photothermal conversion material that converts light energy into heat energy that is irradiated with a laser beam to fire at least part of the conductive layer with the photothermal conversion material.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Copper particulate dispersion, conductive film forming method and circuit board

InactiveUS20140216798A1Avoid cloggingLow viscosityConductive layers on insulating-supportsTransportation and packagingParticulatesBoiling point

An object is to provide a copper particulate dispersion which is suited to discharge in the form of droplets.The copper particulate dispersion includes copper particulates, at least one kind of a dispersion vehicle containing the copper particulates, and at least one kind of dispersant which allows the copper particulates to disperse in the dispersion vehicle. The copper particulates have a center particle diameter of 1 nm or more and less than 100 nm. The dispersion vehicle is a polar dispersion vehicle having a boiling point within a range from 150° C. to 250° C. Whereby, when the copper particulate dispersion is discharged in the form of droplets, clogging at the discharge portion caused by drying of the dispersion vehicle is prevented and the viscosity is low for its high boiling point, and thus the copper particulate dispersion is suited to discharge in the form of droplets.

Owner:ISHIHARA CHEM +1

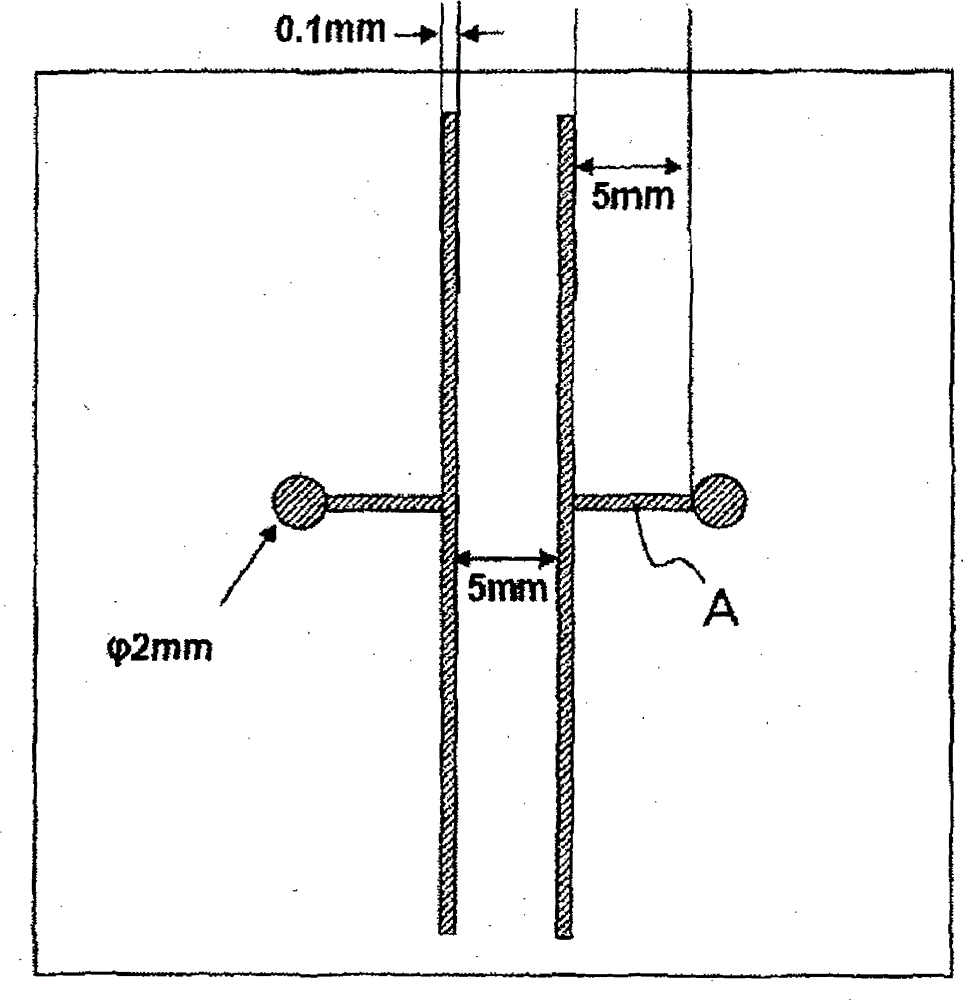

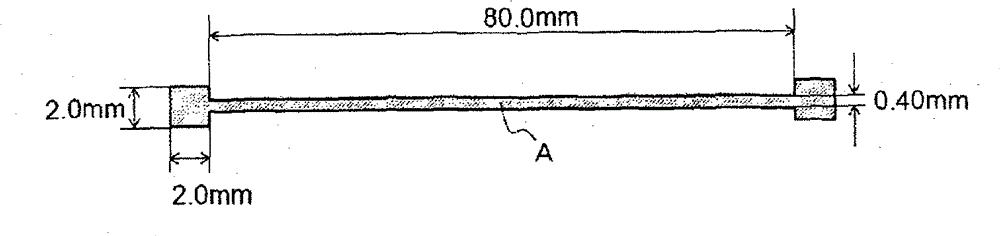

Method for forming fine electrode patterns

The present invention is an electrode of an electric device, having a portion at which a pattern is formed using a photosensitive paste, and a portion at which a pattern is formed using a transfer method. Described is a method in which migration at an electrode portion is curtailed by using a photosensitive paste to form a pattern at areas where electrode width is comparatively large, and by forming a pattern using a transfer method at areas where electrode width becomes narrower.

Owner:EI DU PONT DE NEMOURS & CO

Photosensitive conductive paste for electrode formation and electrode

InactiveUS7655864B2High resolutionAvoid it happening againGas discharge electrodesSoldered/welded conductive connectionsConductive pasteUltraviolet

A photosensitive conductive paste for electrode formation containing conductive metal particles, a glass binder, a monomer, a photoinitiator, an organic polymer binder, an organic medium and an ultraviolet absorber which does not substantially change reflectance of a paste in a visible light range.

Owner:EI DU PONT DE NEMOURS & CO

Conductive paste and method for producing conductive pattern

ActiveCN104040640AGood connection reliabilityCircuit optical detailsPrinted circuit aspectsConductive pasteChemical compound

The objective of the present invention is to obtain: a conductive paste favorable for obtaining a conductive pattern, capable of fine patterning, and having a high connection reliability with ITO despite containing a compound having a high acid number; and a method for producing a conductive pattern. The conductive paste is characterized by containing: composite particles (A) resulting from an antimony-containing compound being coated onto the surface of a core material comprising an inorganic material; a compound (B) having an acid number in the range of 30-250 mgKOH / g; and a conductive filler (C).

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com