Photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the directions of optics, optomechanical equipment, lithography/patterning, etc., can solve the problem that the stacking layer performance of multilayer printed circuit board cannot be exerted, the cured product of acrylate cannot obtain physical properties, Insufficient insulation reliability and other problems, to achieve the effect of excellent dielectric properties, excellent insulation reliability, excellent water resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

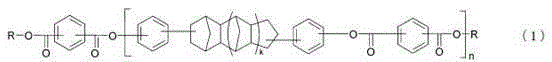

Image

Examples

Embodiment

[0154] The present invention is specifically illustrated by examples below, but the present invention is not limited by these examples. In addition, "part" means a mass part.

[0155]

[0156] The copper layer of the glass epoxy board|substrate in which the circuit was formed with the 18 mm thick copper layer was treated and roughened with CZ8100 (surface treatment agent containing an organic acid, Meck Co., Ltd. product). Next, the resin composition layer of the photosensitive film with a support obtained in Examples and Comparative Examples was laminated using a vacuum laminator (manufactured by Nichigo Motorton Co., Ltd., VP160) so that the surface of the copper circuit was in contact with the resin composition layer. , to prepare a laminate in which the above-mentioned glass epoxy substrate, the above-mentioned resin composition layer, and the above-mentioned support are sequentially laminated. The crimping conditions were performed at a crimping temperature of 80° C., ...

Synthetic example 1

[0187]

[0188] Add 2050 g (equivalent: 10.0) of cresol novolac epoxy resin [DIC Co., Ltd., EPICLONN-660, epoxy equivalent weight 205], 360 g (equivalent: 5.0) to 700 g of diethylene glycol monoethyl ether acetate. ), and 1.5 g of hydroquinone, heated and stirred at 90° C., and dissolved uniformly. Next, 5.9 g of triphenylphosphine was added, and the temperature was raised to 120° C. to react for 12 hours. The obtained reaction solution was diluted with a solvent to obtain an acrylate compound (Product A),

[0189] ? Epoxy equivalent: 427

[0190] ?Acid value: 0.49mgKOH / g

[0191] ?Weight average molecular weight: 2000

[0192] • A diethylene glycol monoethyl ether acetate solution having a solid content of 65% by mass.

Synthetic example 2

[0193]

[0194] Add bixylenol type epoxy resin (Mitsubishi Chemical Co., Ltd. YX4000, epoxy equivalent 185) 190g, bisphenol acetophenone (phenolic hydroxyl equivalent 145) 14g, biscresol fluorene (JFE Chemical ( Co., Ltd., 170 g of phenolic hydroxyl equivalent weight 190), and 150 g of cyclohexanone were stirred and dissolved. Next, 0.5 g of a tetramethylammonium ammonium chloride solution was added dropwise, and reacted at 180° C. for 5 hours under a nitrogen atmosphere. Next, the temperature was lowered to 60° C., and 100 parts of ethyl isocyanate methacrylate (manufactured by Showa Denko Co., Ltd., trade name Karenz MOI, methacryloyl equivalent weight: 155) and dibutyltin dimethacrylate were added dropwise through the dropping channel (dropping lot). The mixed solution of 0.04 parts of lauric acid esters, after completion|finish of dripping, kept the reaction system at 70 degreeC for 4 hours, and the isocyanate group disappeared by this, and the methacrylate compound was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com