Patents

Literature

1997 results about "Lauric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lauric acid or systematically, dodecanoic acid, is a saturated fatty acid with a 12-carbon atom chain, thus having many properties of medium-chain fatty acids, is a bright white, powdery solid with a faint odor of bay oil or soap. The salts and esters of lauric acid are known as laurates.

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

Alumina carrier with composite pore structure and preparation method thereof

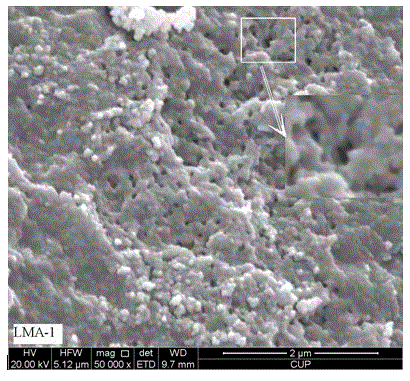

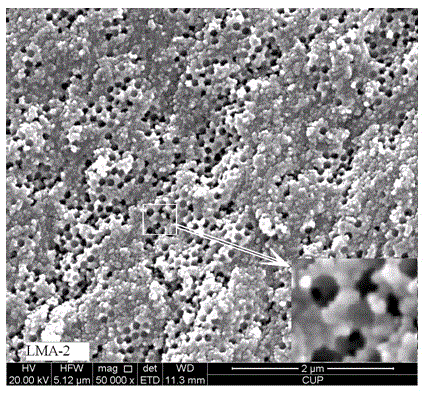

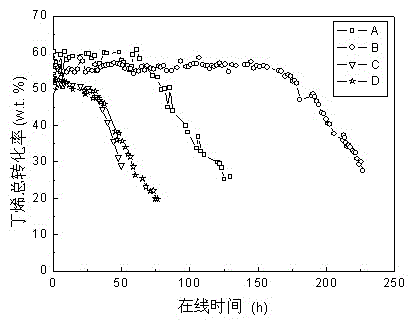

ActiveCN102614934AExtend your lifeHigh selectivityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceMicrosphere

The invention discloses a preparation method of an alumina carrier with a composite pore structure, which comprises the steps of mixing and roasting an aluminum-contained compound and a composite template, wherein the composite template comprises a mesoporous template selected from at least one of a polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer, polyethylene glycol, dodecylamine, hexadecyl trimethyl ammonium bromide, lauric acid, stearic acid and fatty alcohol polyoxyethylene ether and a macroporous particulate template selected from polystyrene microspheres with the particle size of greater than 50nm, polymethyl methacrylate microspheres, biomaterial particles, asphalt particles or heavy oil residues; and the weight ratio of the mesoporous template to the macroporous particulate template to the aluminum-contained compound (by alumina) is 0.1-2:0.1-0.7:1. The invention also discloses the alumina carrier simultaneously having mesoporous tunnels and macroporous tunnels prepared through the method, wherein mesopores account for 40-90% of the total pore volume, and macropores account for 10-60% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP

Fat compositions for infant formula and methods therefor

InactiveUS20040013787A1Improve the level ofLower levelVitamin food ingredientsFood preparationPhysiologyLinoleic acid

Fat compositions and infant formulas containing oleic acid in an amount of at least about 50% by weight of total fatty acids, lauric acid in an amount of at least about 10% by weight, palmitic acid in an amount of not more than about 10% by weight and, in certain embodiments, linoleic acid in an amount of not more than about 16% by weight. The fat compositions can be prepared to contain one or more oleic acid oils in a total amount of at least about 50% by weight, one or more linoleic acid oils in a total amount of not more than about 18% by weight and, in certain embodiments, one or more lauric acid oils in an amount of at least about 20% by weight. Also disclosed are methods of making the fat compositions and infant formulas and methods for providing a fat component to infant diets.

Owner:THEUER RICHARD C

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

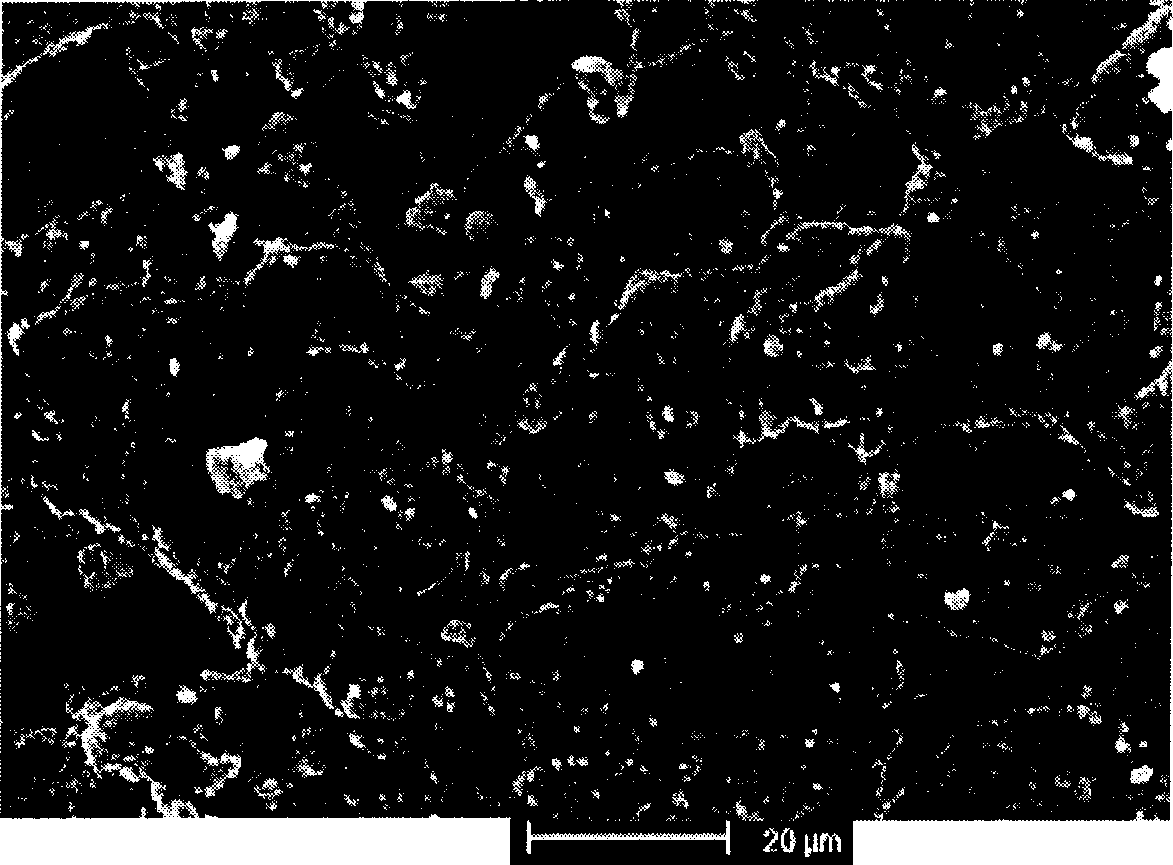

Composite absorption material for removing arsenic from water and its prepn. method

ActiveCN1751783AEfficient removalIncrease capacityOther chemical processesWater/sewage treatment by sorptionActivated carbonSorbent

A composite adsorption material for removing As from water is prepared from activated carbon and iron oxide through washing activated carbon by water, heating, drying, adding it to nitric acid, stirring, laying aside, water washing, drying, dissolving FeSO4*7H2O in water, adding it to NaOH solution, stirring to generate iron oxide deposit, using NaOH to regulate pH=9-10, water washing, adding lauric acid, dripping NaOH while stirring, heating to make pH=4-5, mixing said activated carbon with the suspension of iron oxide, and stirring. It has high capacity, selectivity, adsorptivity and mechanical strength.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

Semiaromatic moulding compositions and uses of these

ActiveUS20110123749A1Low process temperatureSufficient compatibilityNon-metal conductorsEnvelopes/bags making machineryLaurolactamPolymer science

A polyamide moulding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of moulding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give mouldings.

Owner:EMS PATENT AG

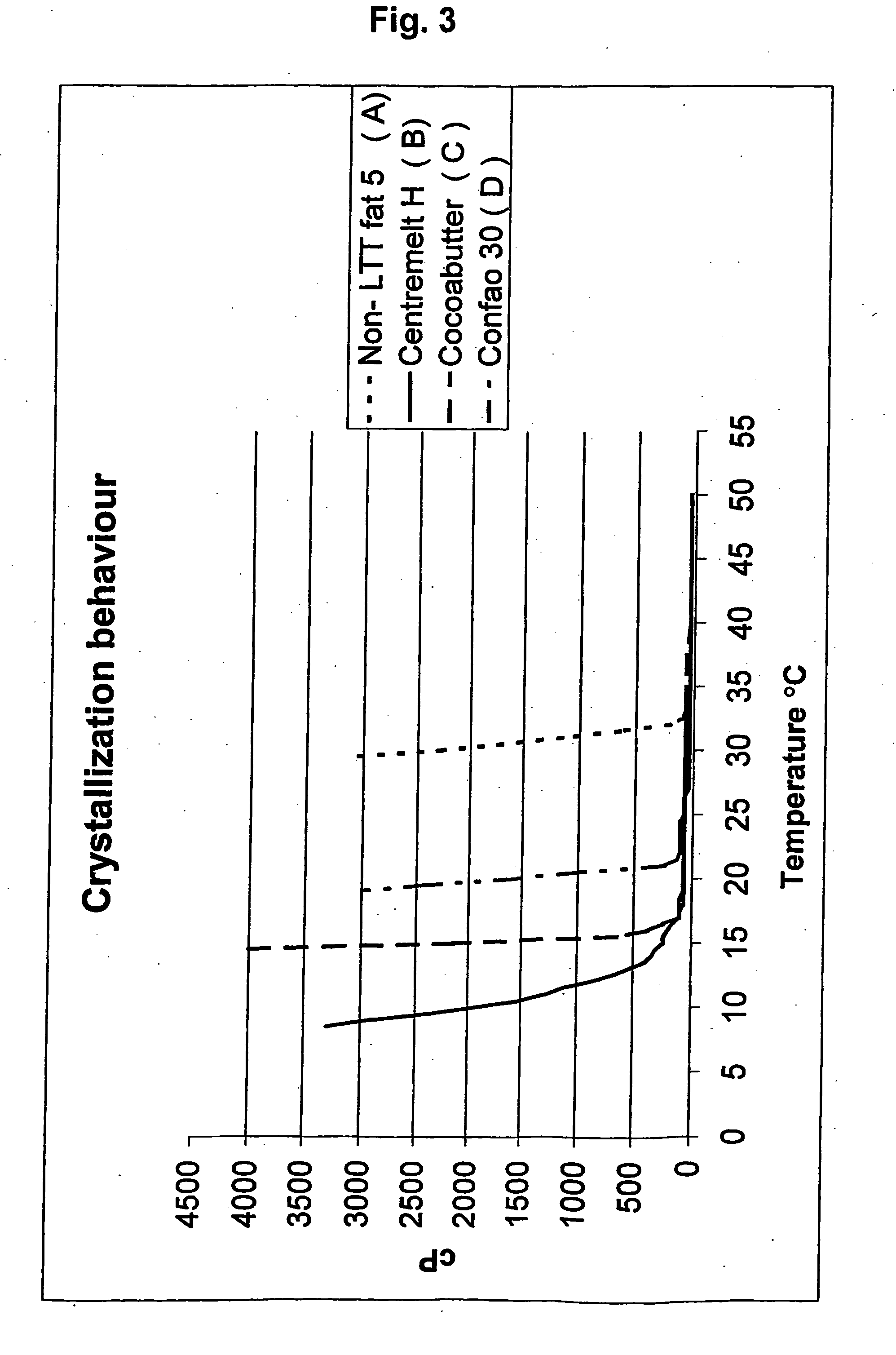

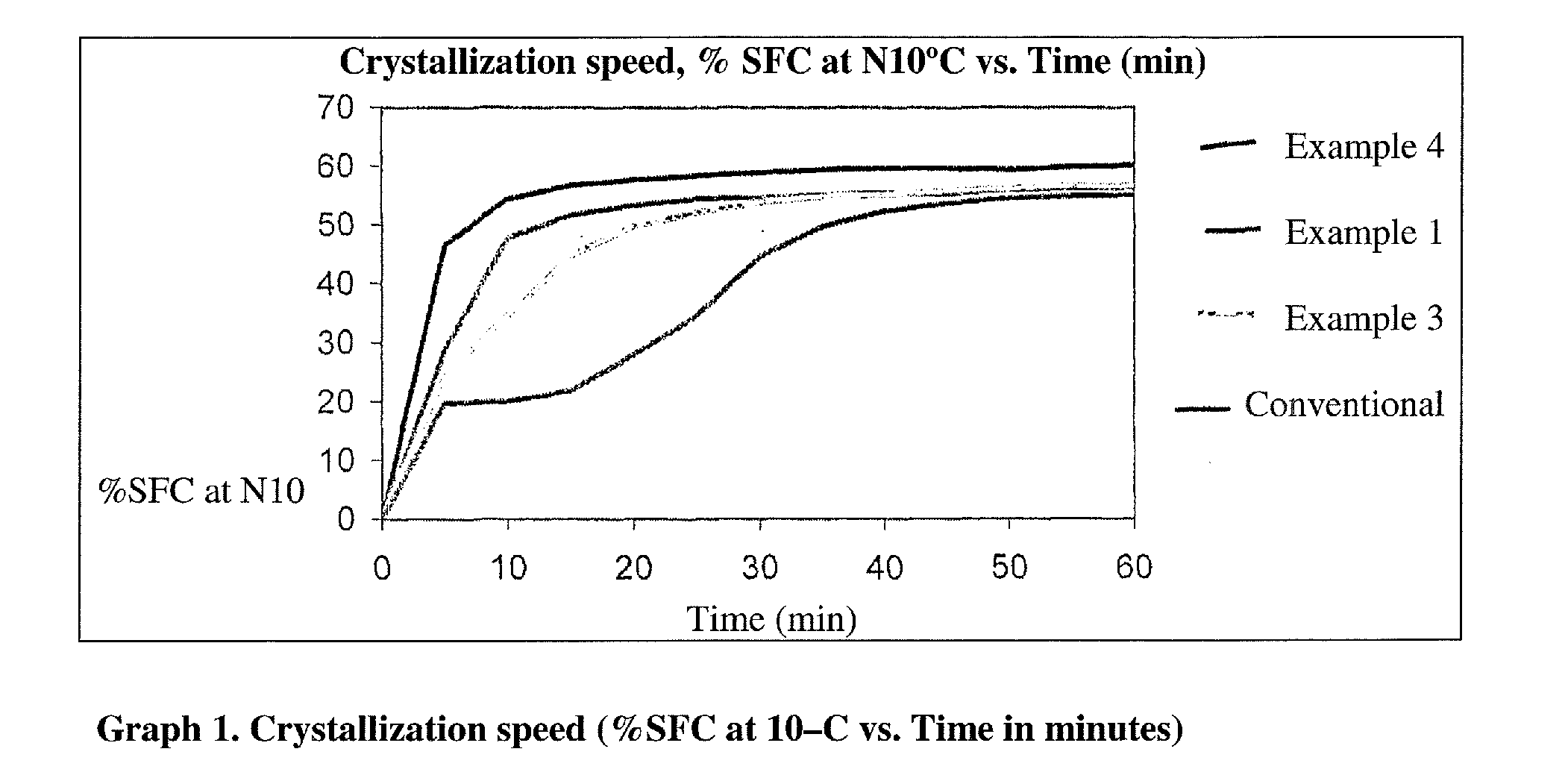

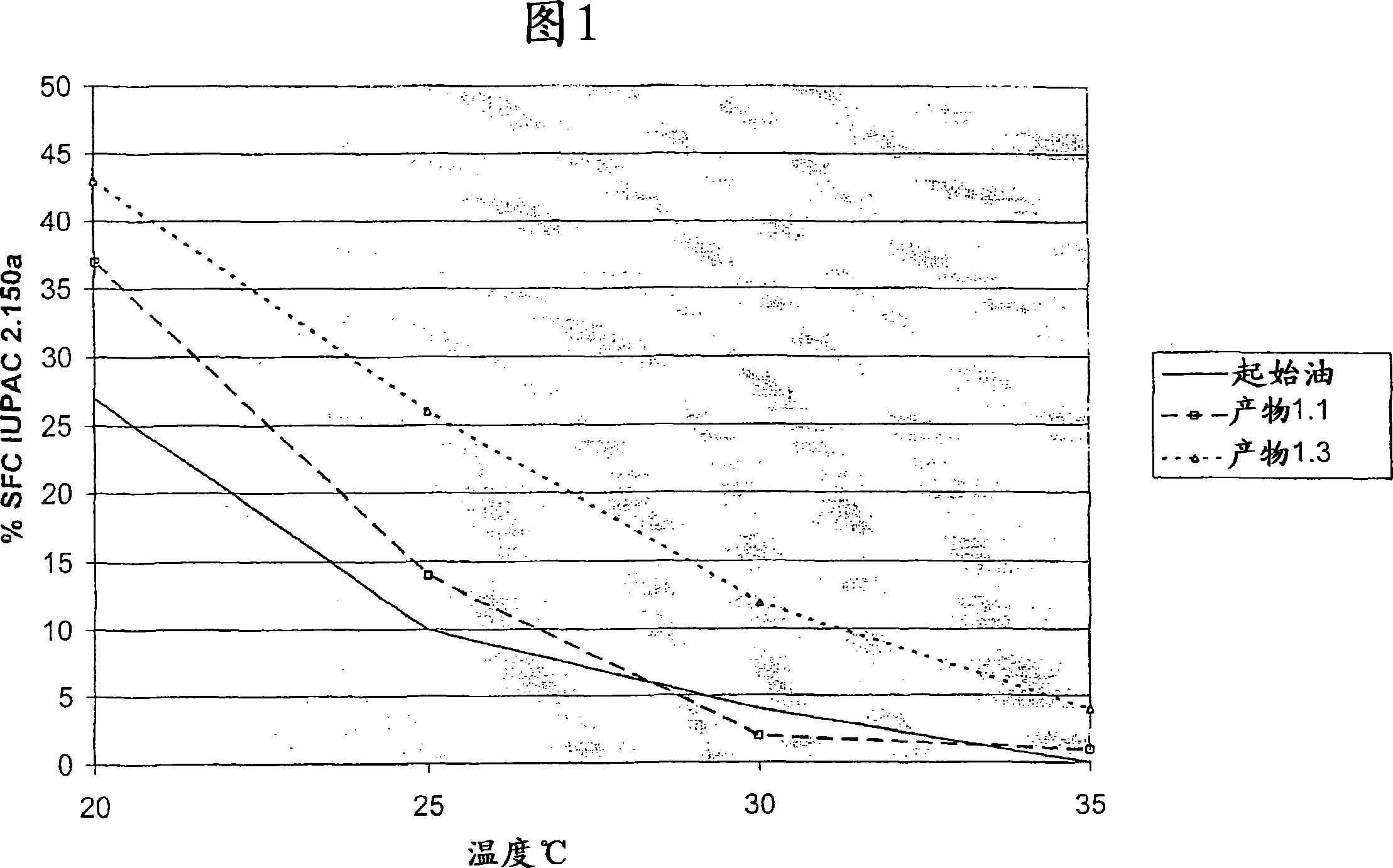

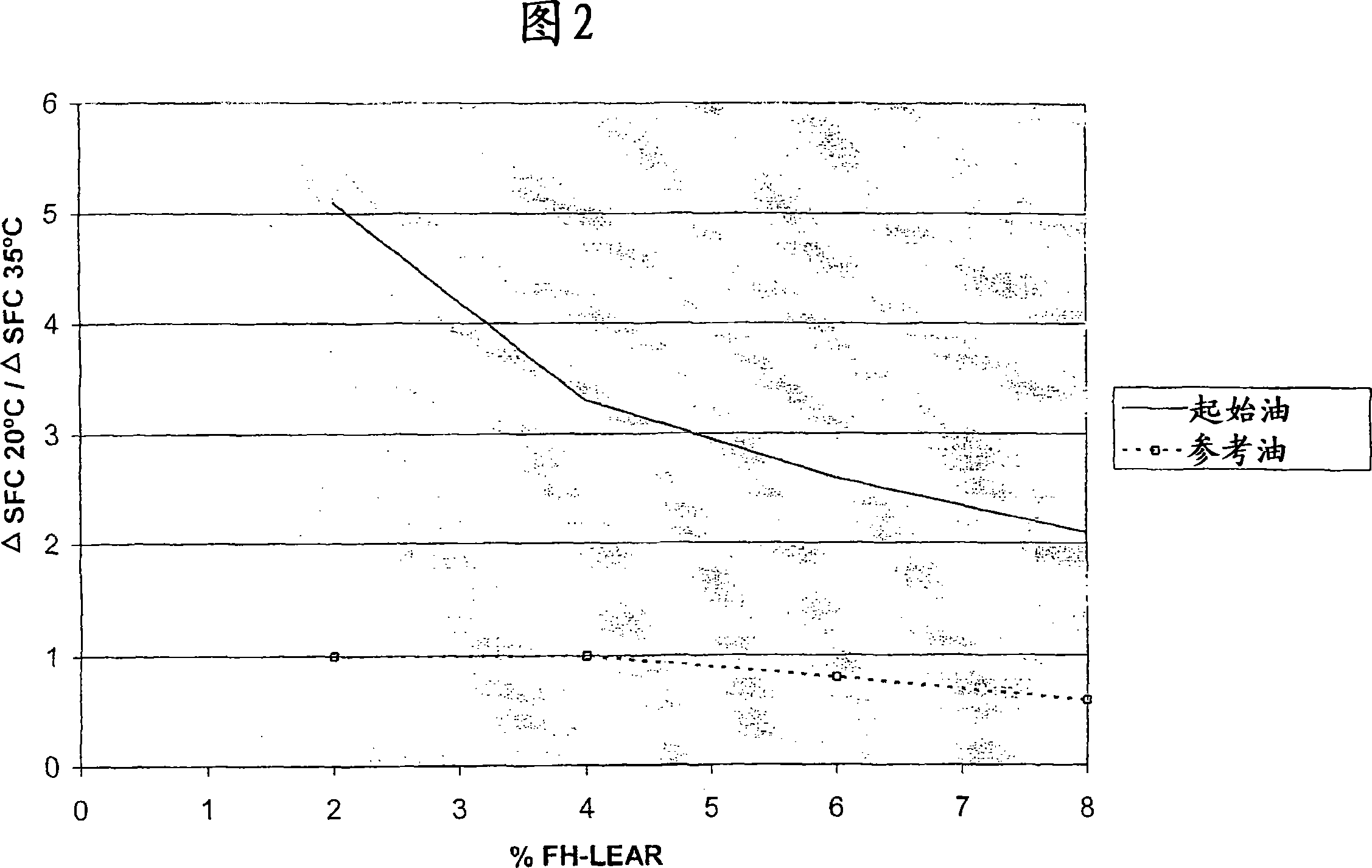

Non-lauric, non-trans, non-temper fat compositions

InactiveUS20050142275A1Crystallize fastDiversify rangeCosmetic preparationsDough treatmentArachidic acidTriglyceride

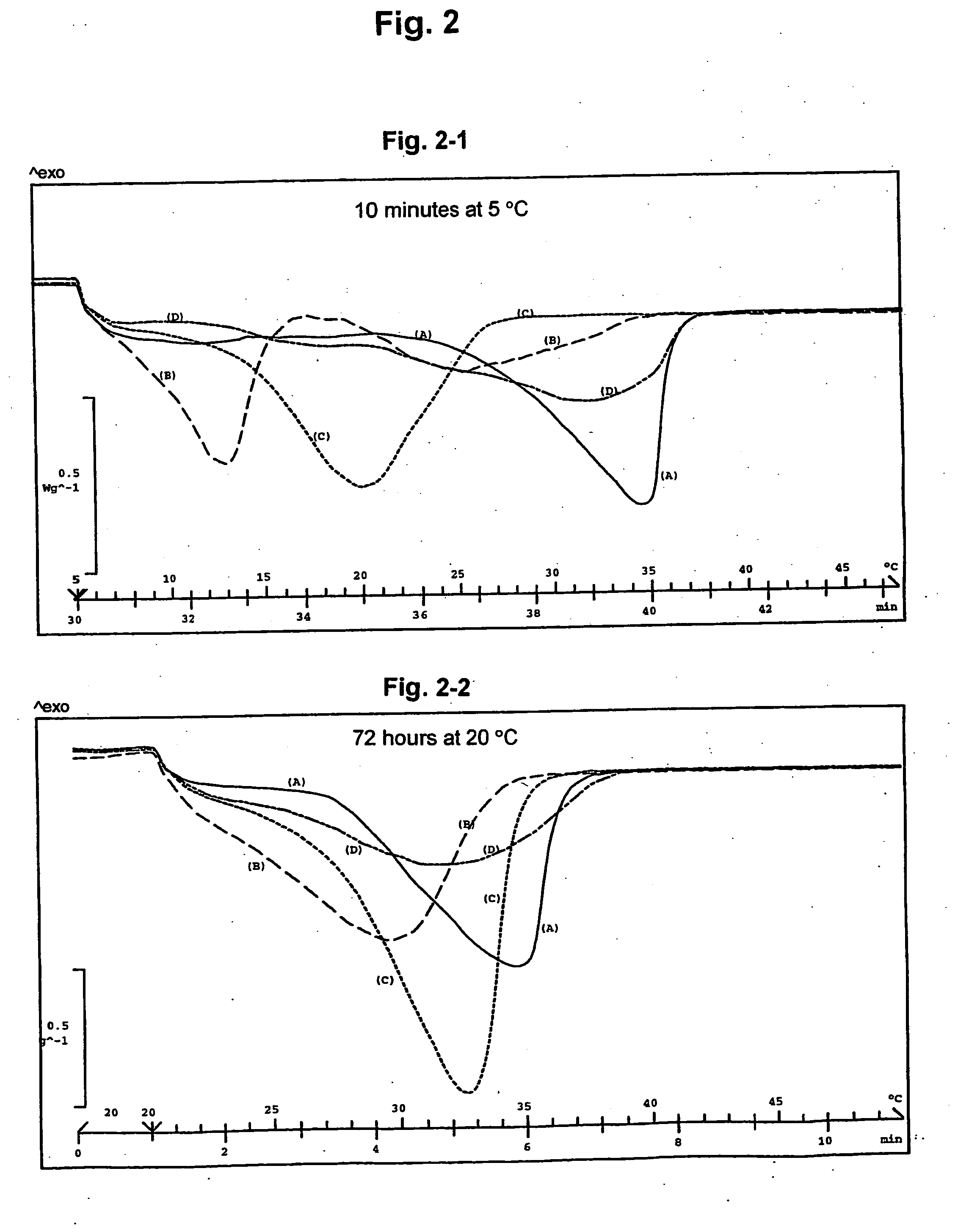

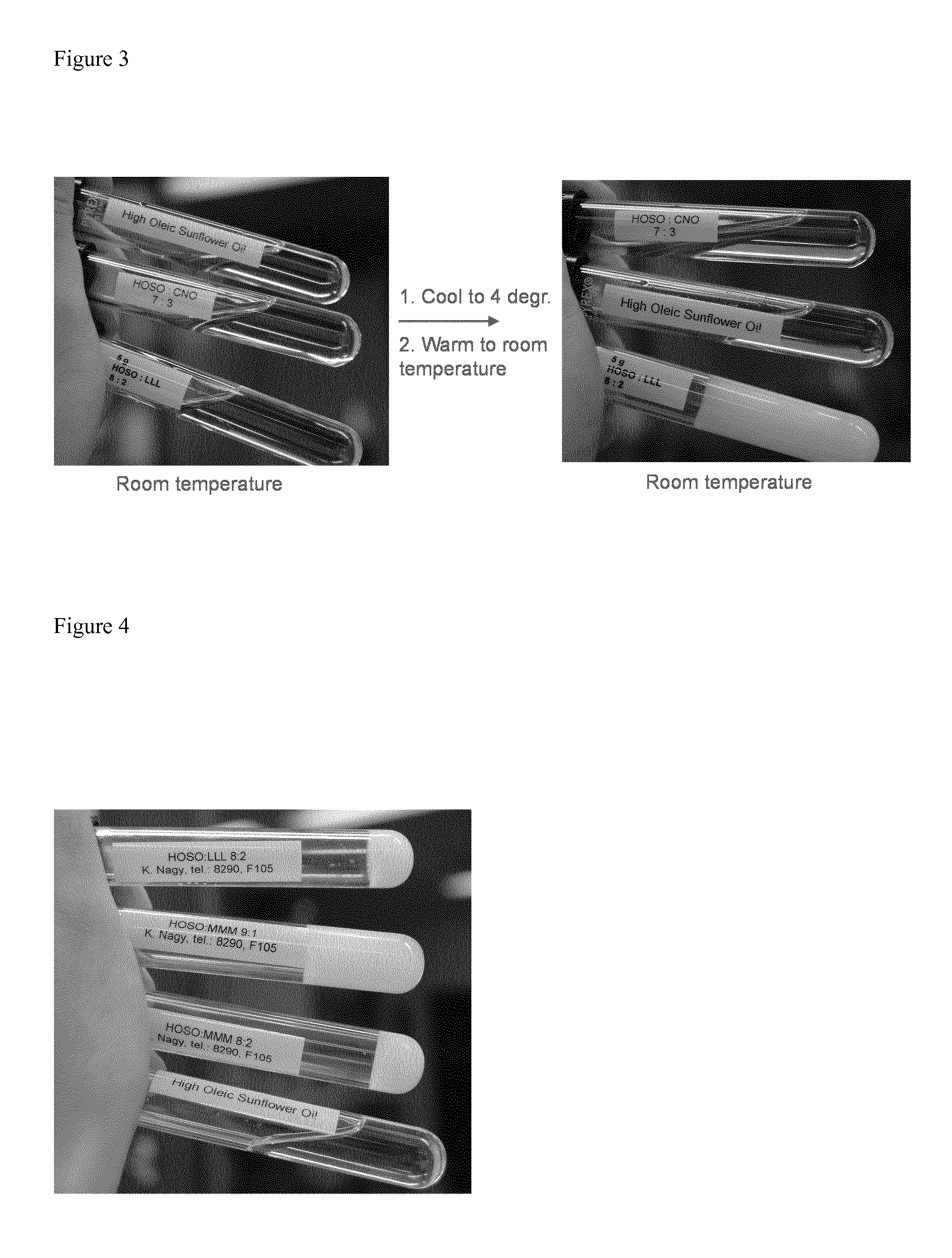

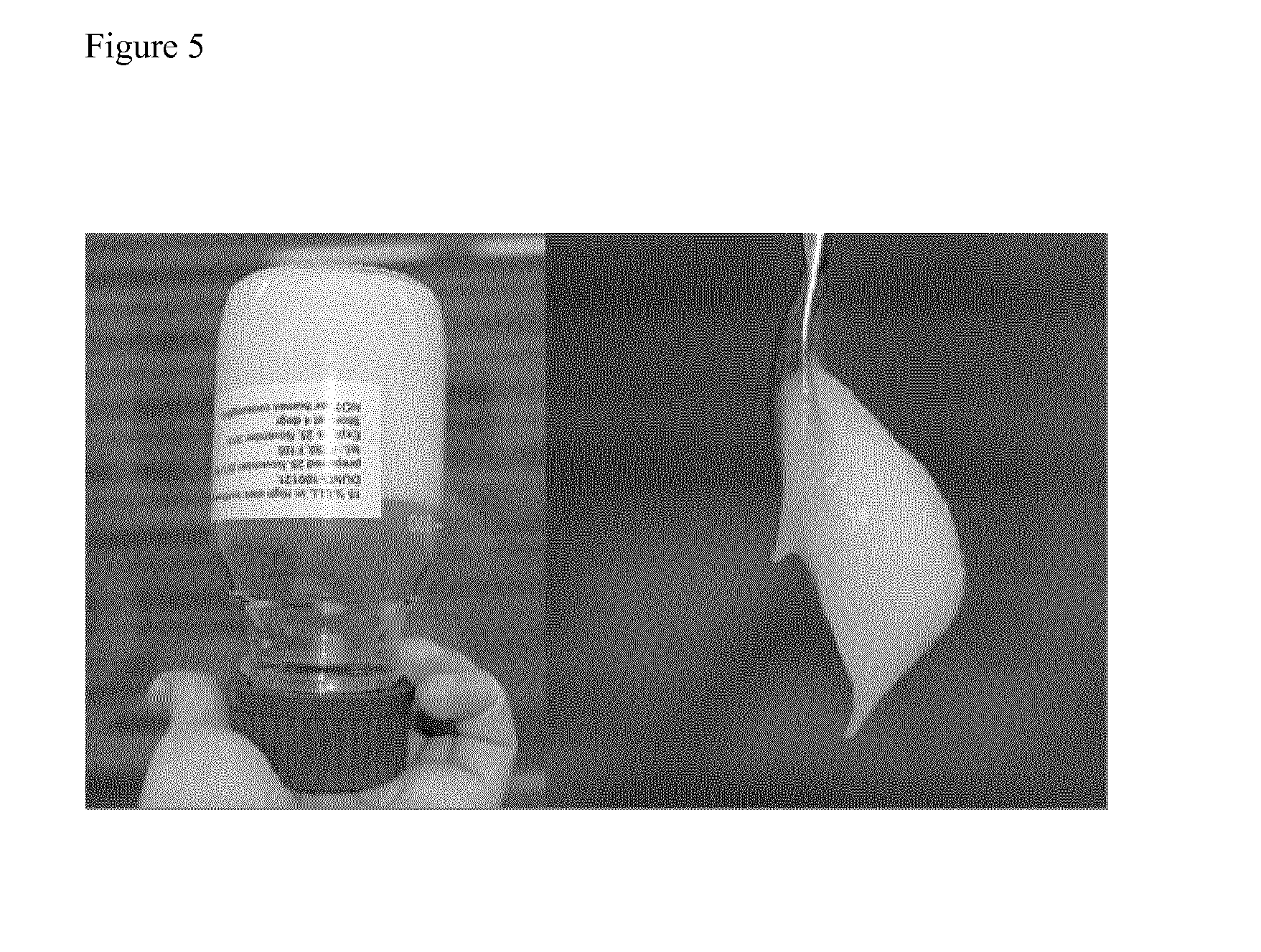

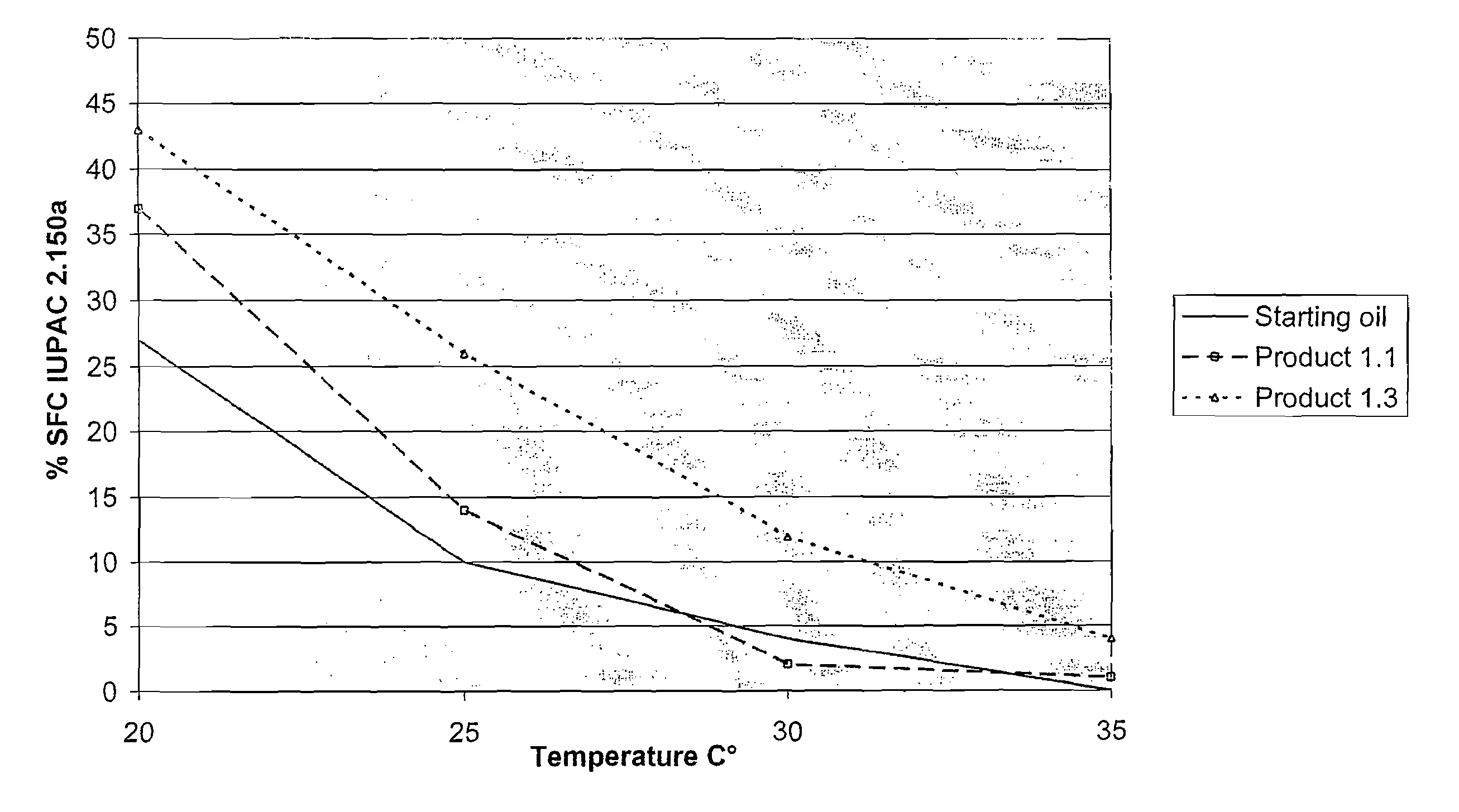

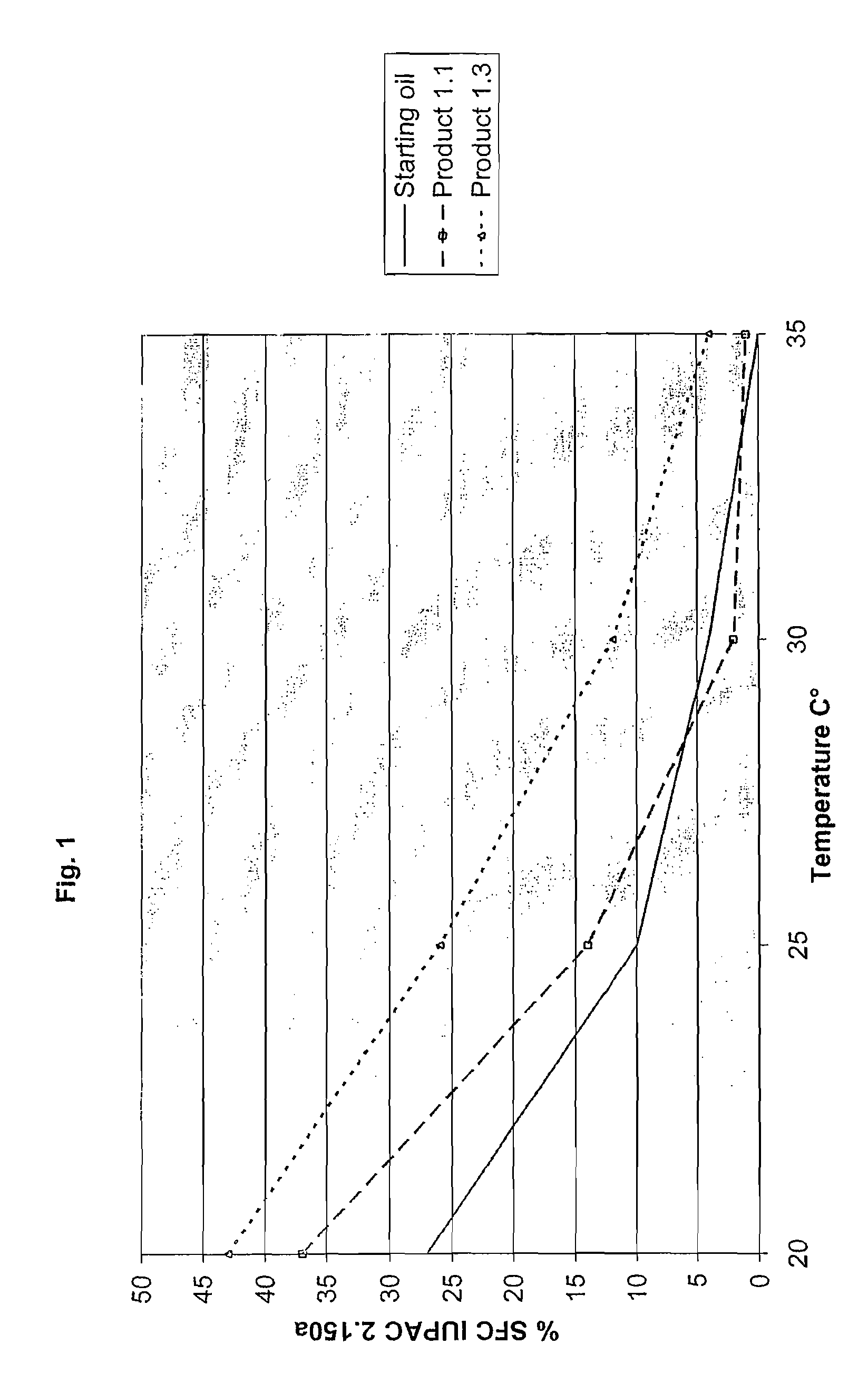

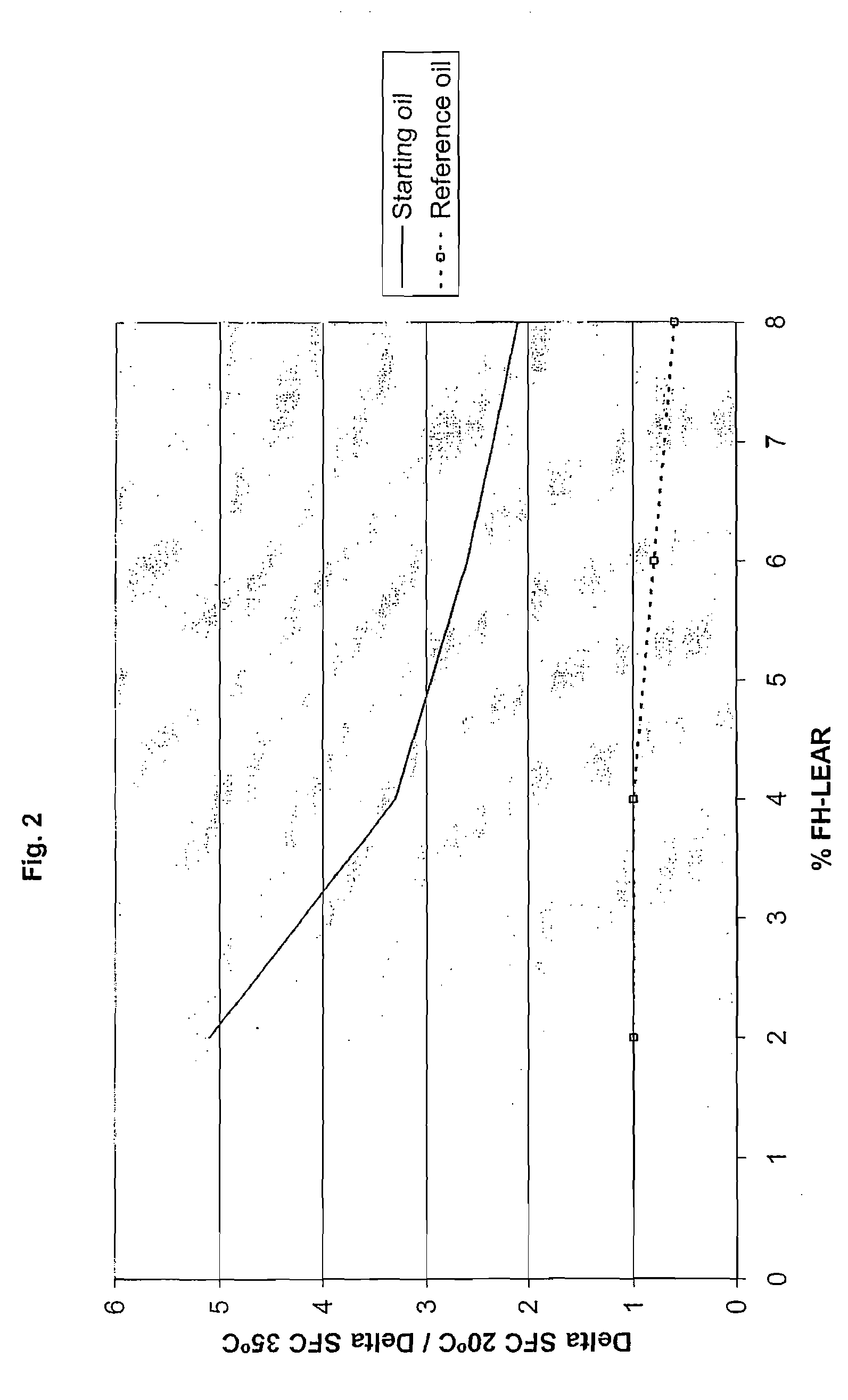

A non-lauric, non-trans, non-temper (Non-LTT) fat composition comprising a fraction obtained from a randomised triglyceride mixture in which min. 90% by weight of the constituent fatty acids are: palmitic (C16:0), stearic (C18:0), arachidic (C20:0) behenic (C22:0), oleic (C18:1) and linoleic (C18:2) acid and the total content of arachidic and behenic acid is 3-40% by weight and the total content of palmitic and stearic acids is 25-60% by weight, said fraction having the following physical and chemical properties: (1) slip melting point measured according to AOCS Cc 3-25: below 36° C. and solid fat content (SFC) measured according to IUPAC 2.150 mod. (stabilised at 20° C. for 24 h): above 25% by weight at 20° C.; (2) total content of saturated fatty acids measured according to IUPAC 2.301 and 2.304: 40-75% by weight, preferably 45-70% by weight; (3) total content of arachidic and behenic acids: 3-40% by weight, preferably 5-35% by weight, and total content of palmitic and stearic acids: 25-60% by weight, preferably 25-50% by weight, both measured according to IUPAC 2.301 and 2.304; (4) total content of triglycerides having triglyceride composition (TGC) of C56-C60 measured by number of total carbon atoms of constituent fatty acids according to IUPAC 2.323: min. 9% by weight, preferably min. 15% by weight; (5) total content of S2U-type triglycerides: min. 25% by weight, preferably min. 35% by weight, where S=saturated fatty acids and U=unsaturated fatty acids.

Owner:AAK DENMARK

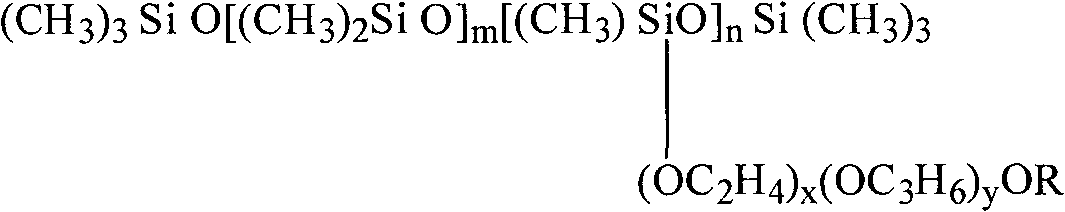

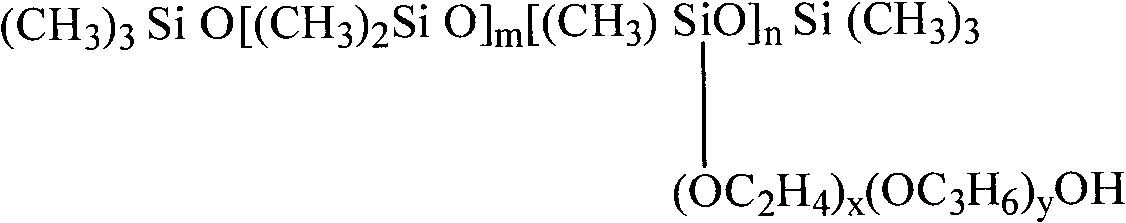

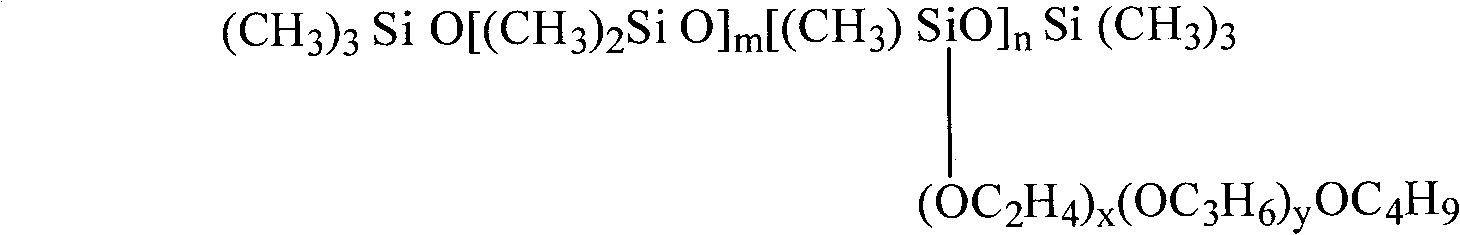

Modified talcpowder and preparation method thereof

ActiveCN102311669AImprove bindingGood dispersionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsAlcoholEther

The invention relates to modified talcpowder and a preparation method thereof. The modified talcpowder comprises 100 mass parts of talcpowder and 0.5 to 2.5 mass parts of modifier, wherein the modifier is a mixture of polyatomic alcohol laurate and organic silicon / polyether copolymer; and the organic silicon / polyether copolymer is alpha,omega-di(trimethylsiloxyl)polydimethyl polymethyl (R-polyoxyethylene polyoxypropylene ether) siloxane, and R is H, alkyl or hydroxyl-containing alkyl. A preparation method for the modified talcpowder comprises the following steps of: loading dried talcpowder materials into a temperature controllable high mixer; weighing the modifier in a mass ratio of the talcpowder to the modifier of 100:(0.5-2.5); mixing the materials, adding the weighed modifier into the high mixer filled with the talcpowder uniformly, and stirring at the temperature of between 80 and 120 DEG C for 12 to 25 minutes; and taking out to obtain the modified talcpowder.

Owner:PETROCHINA CO LTD

Long chain fatty acids for reducing off-taste of non-nutritive sweeteners

InactiveUS20080226790A1Food ingredient as taste affecting agentFood preparationArachidic acidAdipic acid

Aspects of the invention relate to beverage compositions, including, for example, concentrated and ready-to-drink formulations sweetened with at least one non-nutritive sweetener and further including a long chain fatty acid compound in an amount sufficient to reduce the off-note taste of the non-nutritive sweetener. In certain embodiments, the long chain fatty acid may be one or more of the following: lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid, behenic acid, oleic acid, linoleic acid, alpha-linolenic acid, arachidonic acid, eicosapentaenoic acid, docosahexaenoic acid, erucic acid, adipic acid, and palmitic acid. In certain exemplary embodiments, a plurality of different long chain fatty acids are utilized. In another embodiments, the long chain fatty acids comprise both natural and synthetic fatty acids.

Owner:CONCENTRATE MFG OF IRELAND

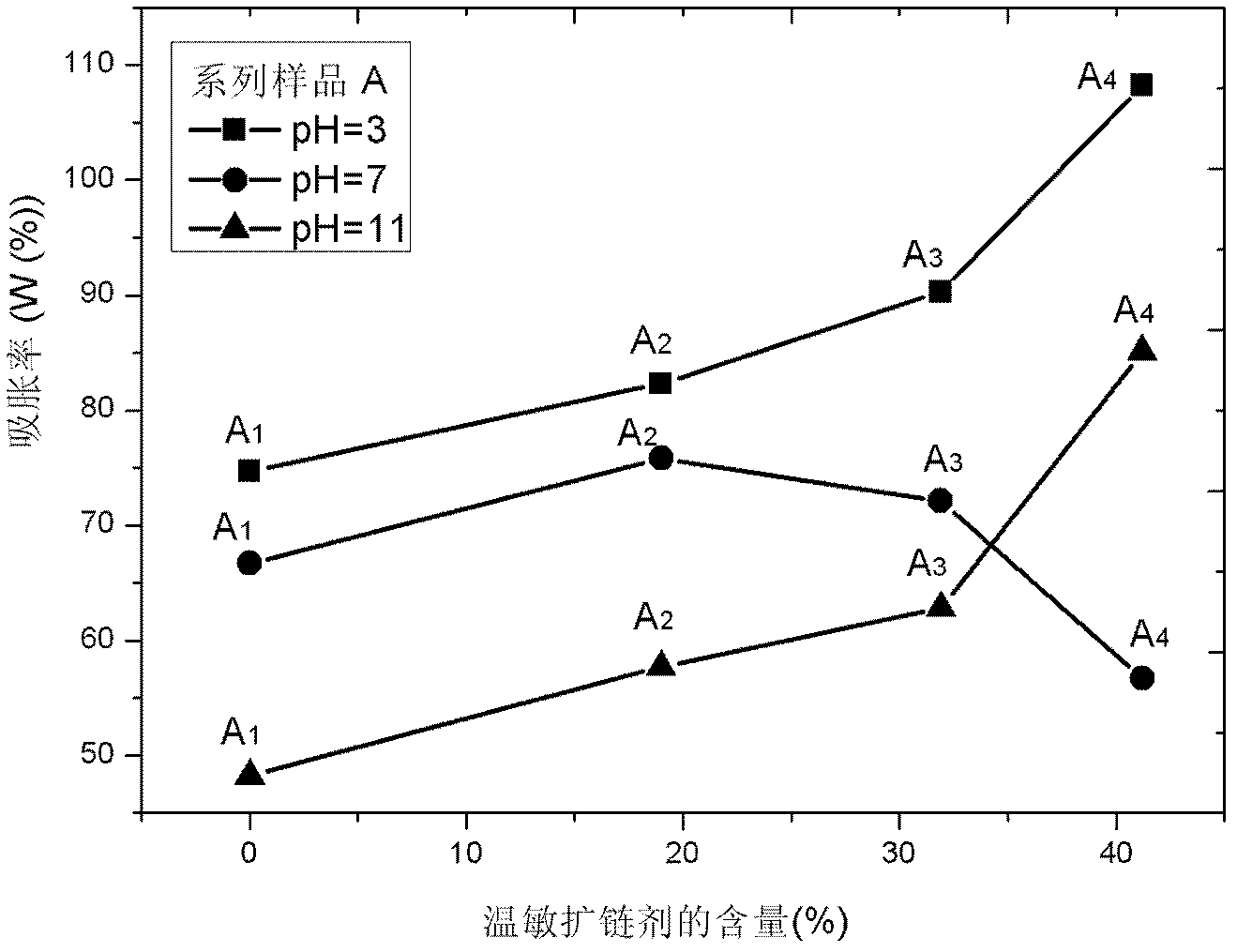

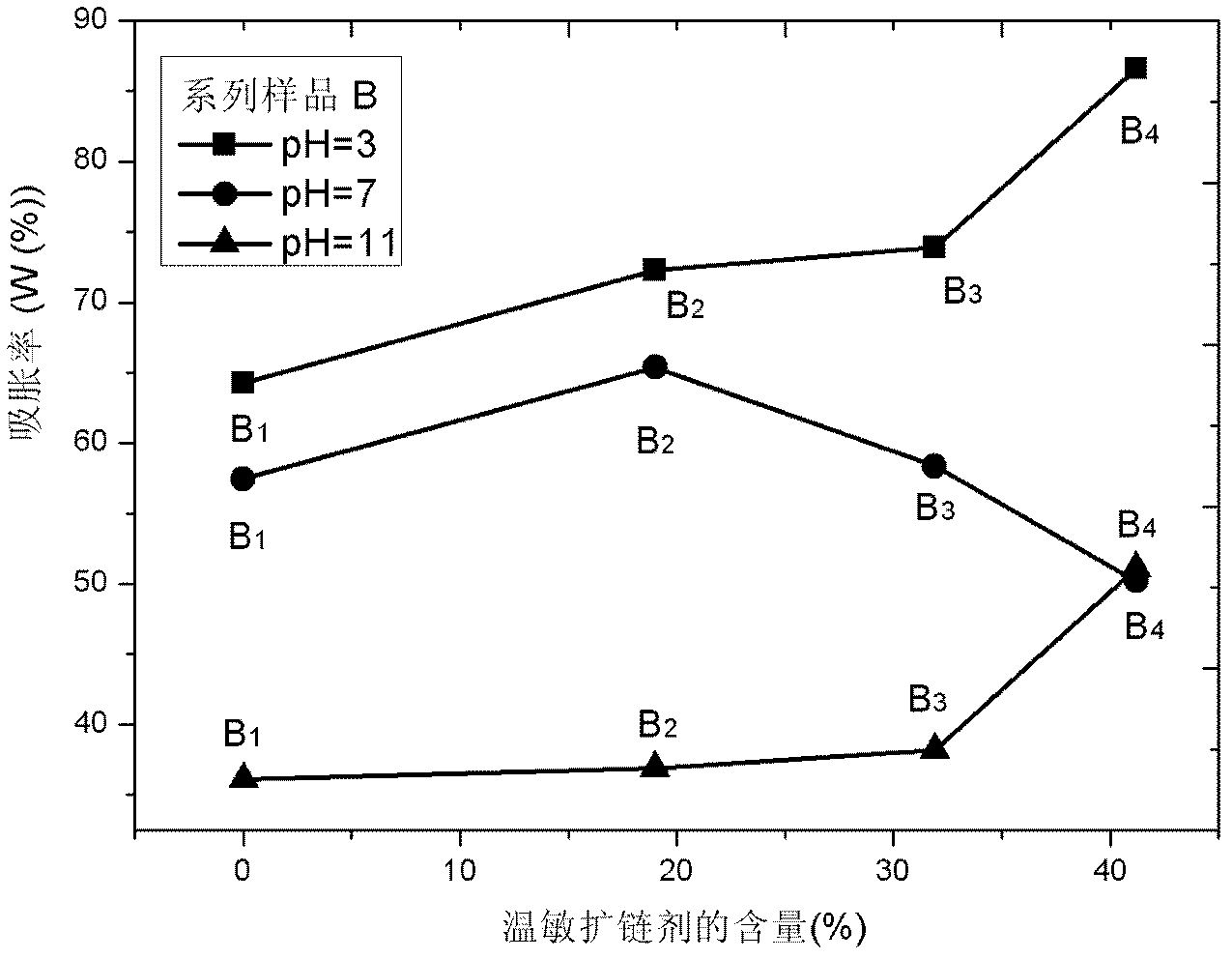

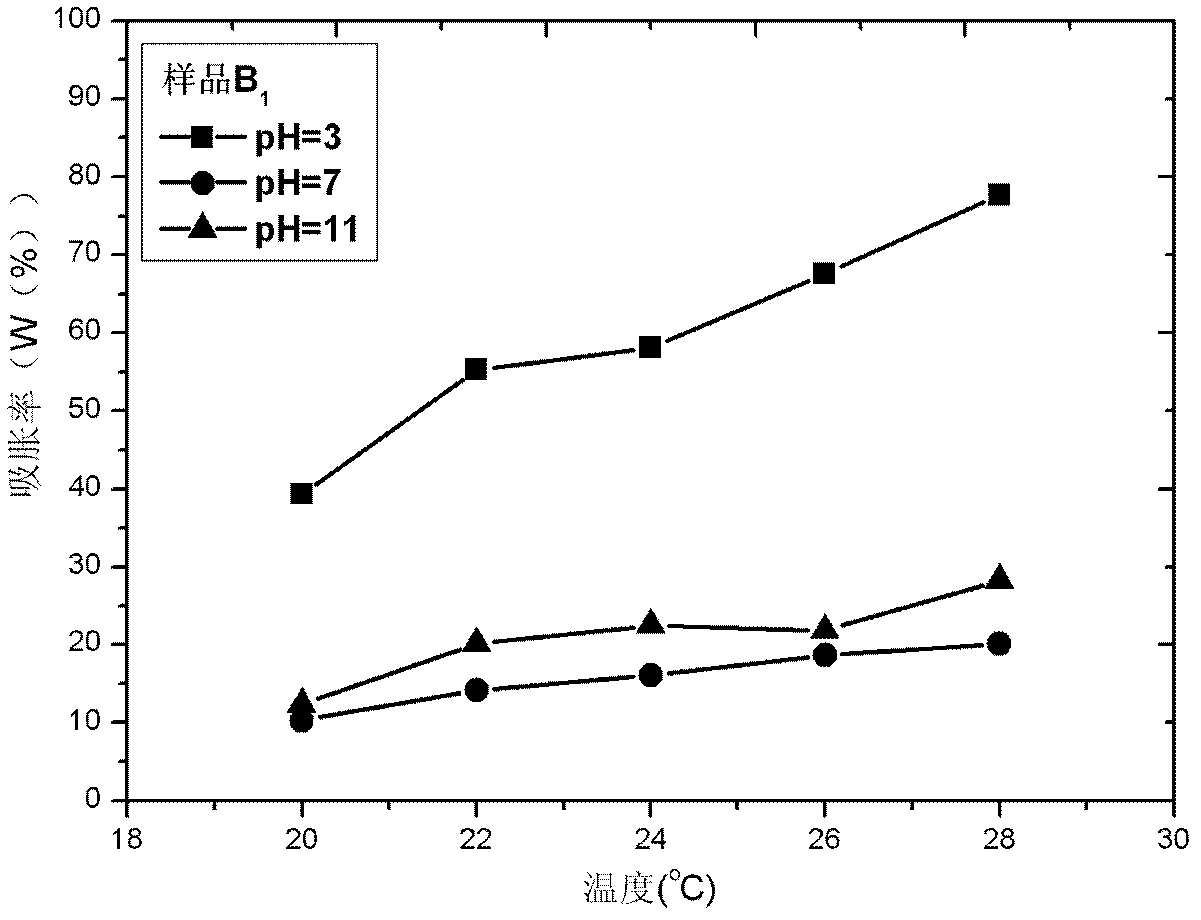

Thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH

The invention discloses a thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH. The hydrogel is prepared by the following methods: mixing 15-20.6 percent of polyethylene glycol, 6.7-9.2 percent of polyhydric carboxylic acid, 25.2-34.6 percent of multi-isocyanate and dibutyltin dilaurate used as a catalyst to perform pre-condensation polymerization reaction; adding organic solvent to stop reaction to obtain a pre-polymer; adding 15.3-36.5 percent of a thermo-sensitive chain extender to perform chain extension reaction; adding 3.1-4.3 percent of polyhydric alcohol amine stop end after the pre-polymer is subjected to the chain extension; and then, adding 11.6-19.4 percent of a curing crosslinking agent to perform crosslinking reaction to obtain polyurethane hydrogel with double sensitivity of temperature and pH. The thermo-sensitive chain extender is prepared by the method, and a method for introducing the thermo-sensitive chain extenderin polyurethane is provided, and the softness and hardness of the material are controlled in a post-crosslinking mode, so that the defects that introduction of groups and cross-linking solidity are carried out at the same time in the conventional way of excitation of double bonds are overcame, and the polyurethane hydrogel with double sensitivity of temperature and pH is prepared.

Owner:SOUTH CHINA UNIV OF TECH

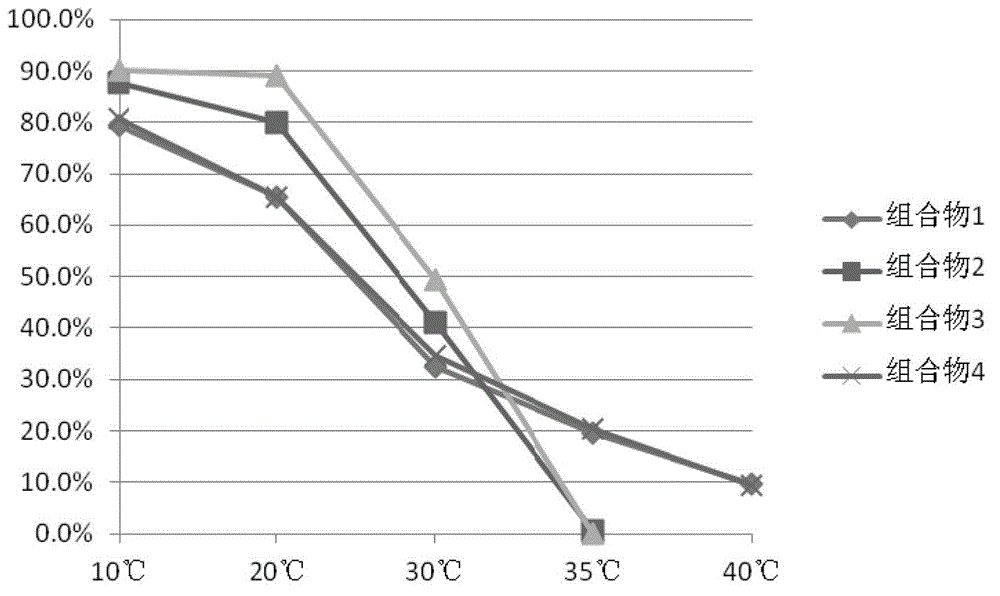

Lauric fat based structuring agents to reduce saturated fat

InactiveUS20160316778A1Low SFA contentMaintain good propertiesFatty acid esterificationFrozen sweetsSaturated fatty acid esterGlycerol

The present invention relates to a lipid composition comprising at least 5 wt % of a structuring agent dispersed in oil or fat wherein the structuring agent comprises at least 50 wt % of triacylglycerol containing a glycerin skeleton esterified with one type of saturated fatty acid having a chain length of either 10:0, 12:0 or 14:0. Further aspects of the invention are: the structuring agent, a food product comprising the lipid composition, the use of the lipid composition as a structure stabilizer or a moisture barrier in a food product; and a method for preparing the lipid composition.

Owner:NESTEC SA

Fat Compositions

Owner:AAK DENMARK

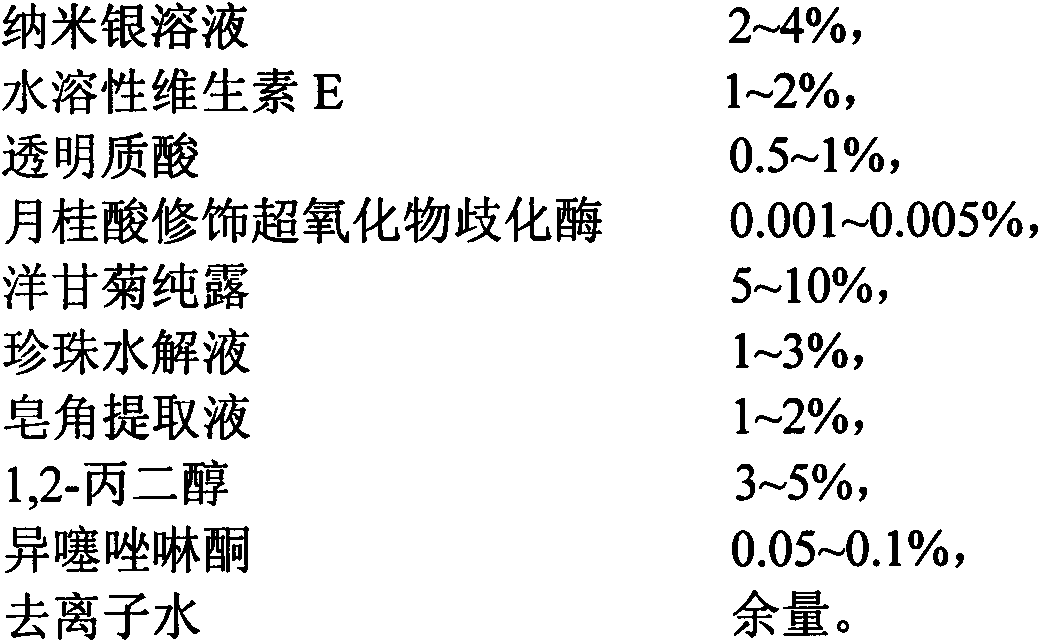

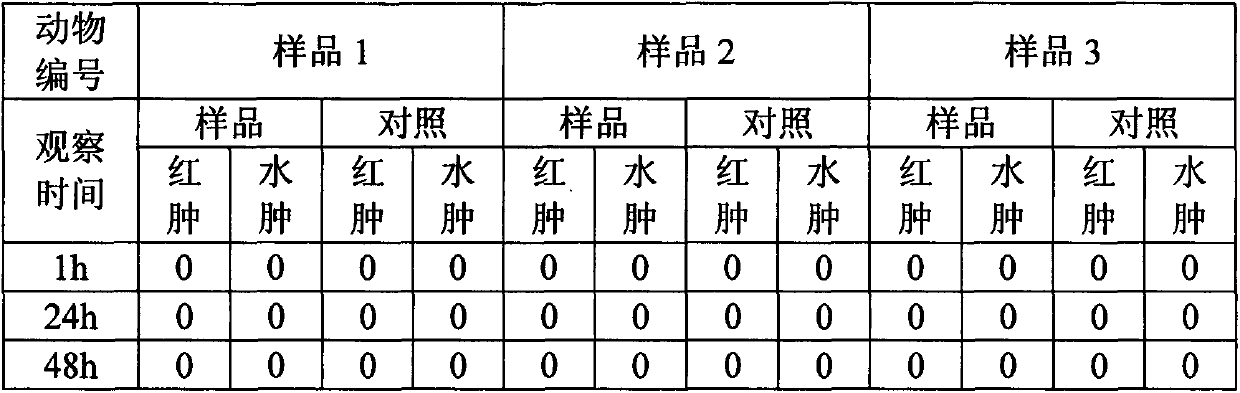

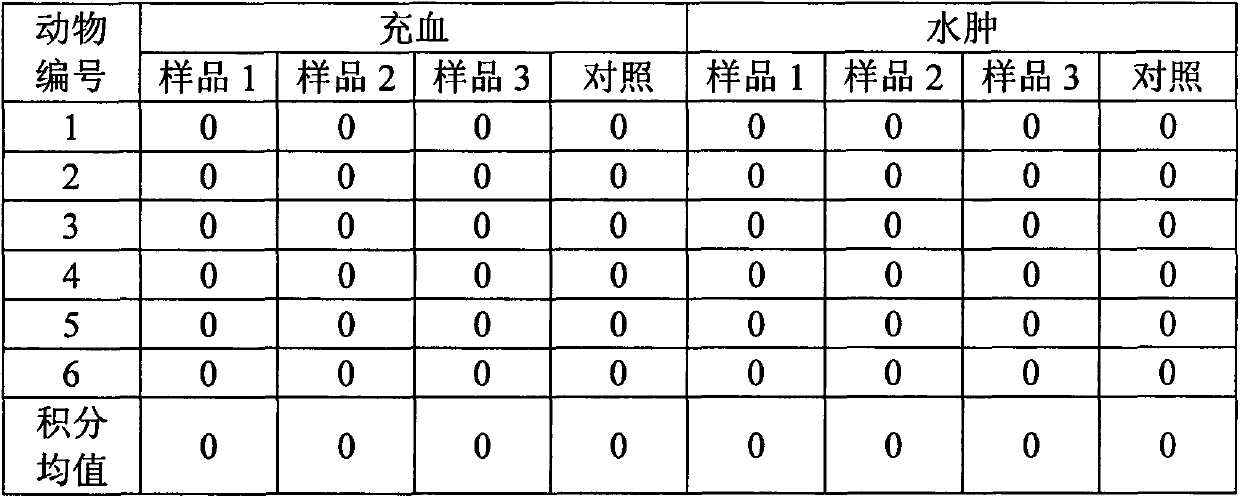

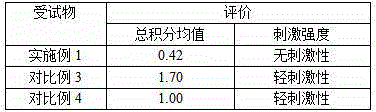

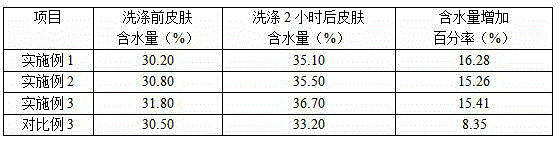

Special private care wet tissue for women

InactiveCN103340816AGood killing effectNo side effectsCosmetic preparationsToilet preparationsSide effectIrritation

The invention provides a special private care wet tissue for women. The private care wet tissue is produced through the following steps of: preparing a wet tissue stock solution from a nanosilver solution, water soluble vitamin E, hyaluronic acid, lauric acid modified superoxide dismutase, chamomile flower water, a hydrolyzed pearl solution, a saponin extract, 1,2-propylene glycol, isothiazolinone and deionized water at a certain ratio; evenly and dropwise adding the wet tissue stock solution on a nonwoven spunlace membrane; then hermetically packaging the nonwoven spunlace membrane. For use, the special private care wet tissue for women provided by the invention only needs to be put to flatly cover the private part of a woman, and after a short wait, the wet tissue is used for wiping the private part of the women back and forth a plurality of times. The private care wet tissue special for women provided by the invention is capable of sterilizing and disinfecting the private part of the woman, and also capable of moisturizing and cleaning the skin of the private part; the private care wet tissue has no any side effect and no any irritation.

Owner:深圳市妍倩科技有限公司

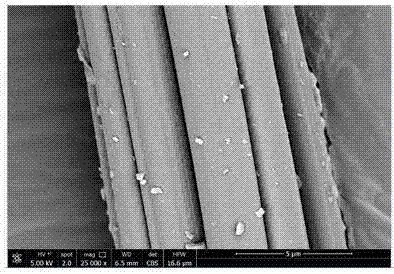

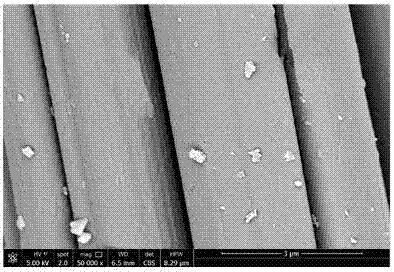

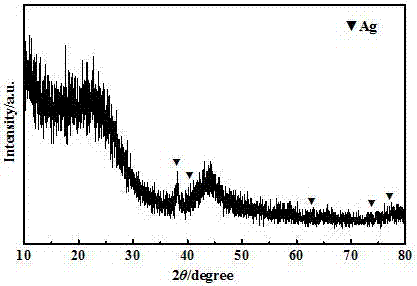

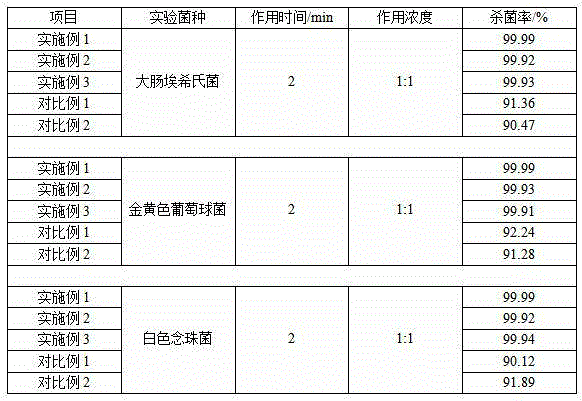

Nano-silver loaded activated carbon fiber and preparation method thereof

InactiveCN106958140AEvenly dispersedSmall diameterCarbon fibresFiltration separationActivated carbonStearic acid

The invention discloses a nano-silver loaded activated carbon fiber and a preparation method thereof. The preparation method comprises the following steps: (1) taking AgNO3 or CH3COOAg as a silver source; (2) utilizing a mixed solution of stearic acid, lauric acid and polyvinylpyrrolidone as a protecting agent; (3) taking the mixed solution of glycol, formaldehyde and glucose as a reducing agent; (4) fully dipping an activated carbon fiber in the AgNO3 or CH3COOAg solution, thereby loading silver ions on the surface of the activated carbon fiber; and (5) in an acetone system, utilizing the reducing agent to reduce the silver ions on the surface of the activated carbon fiber, thereby generating nano-silver particles on the surface of the activated carbon fiber. The product disclosed by the invention is characterized by adjustable silver loading capacity, monomer silver particle diameter of 10-20 nanometers, application to the filtering and sterilizing technology for drinking water and efficient function of killing escherichia coli and staphylococcus aureus in water. Besides, the nano-silver loaded activated carbon fiber has higher application value in improving water chrominance and turbidity and reducing residual chlorine in water.

Owner:北京璟胜科技有限公司

Nutritional blend oil with balanced fatty acid component and active component for middle and old aged

The invention relates to a nutritional blend oil with balanced fatty acid components and active components for the middle and old aged, which is prepared by a plurality of plant oils selected from flaxseed oil, walnut oil, double-low rapeseed oil, soybean oil, wheat germ oil, corn oil, teal oil, peanut oil, grape seed oil, rice bran oil, camellia oil, evening primrose seed oil, sunflower seed oil and the like, wherein, Omega 6 serial polyunsaturated fatty acids (PUFA) and Omega 3 serial PUFA are contained to enable the ratio of saturated fatty acid (SFA) to monounsaturated fatty acid (MUFA) to PUFA to be 0.6-0.8:1:1, the ratio of Omega 6 to Omega 3 to be 4:1 in the comprehensive evaluation of the blend oil absorbed by the middle and old aged and the fat from other sources, thereby meeting the recommended value of Chinese Nutrition Society; the nutritional blend oil contains 2% of gama-linolenic acid, thereby beneficial to improving the contents of DH-gama-linolenic acid and arachidonic acid; the total content of lauric acid, myristic acid and palmitic acid contained in the nutritional blend oil is below 8.5% in order to avoid over rising the level of Low density lipoprotein (LDL) in the plasm of the middle and old aged; in addition, the nutritional blend oil also comprises a plurality of active components with oxidation resistant property, so other antioxidants do not need to be added in the blend oil.The blend oil provided by the invention is characterized by low cost, balanced fatty acid nutrition, a plurality of abundant active components and higher security, thereby better improving the health and intelligence of eaters, preventing cardiovascular and cerebrovascular diseases, and avoiding fatness, hyperlipidemia, thrombotic diseases and the like caused by unbalanced fatty nutrition.

Owner:ZHEJIANG OIL MASTER

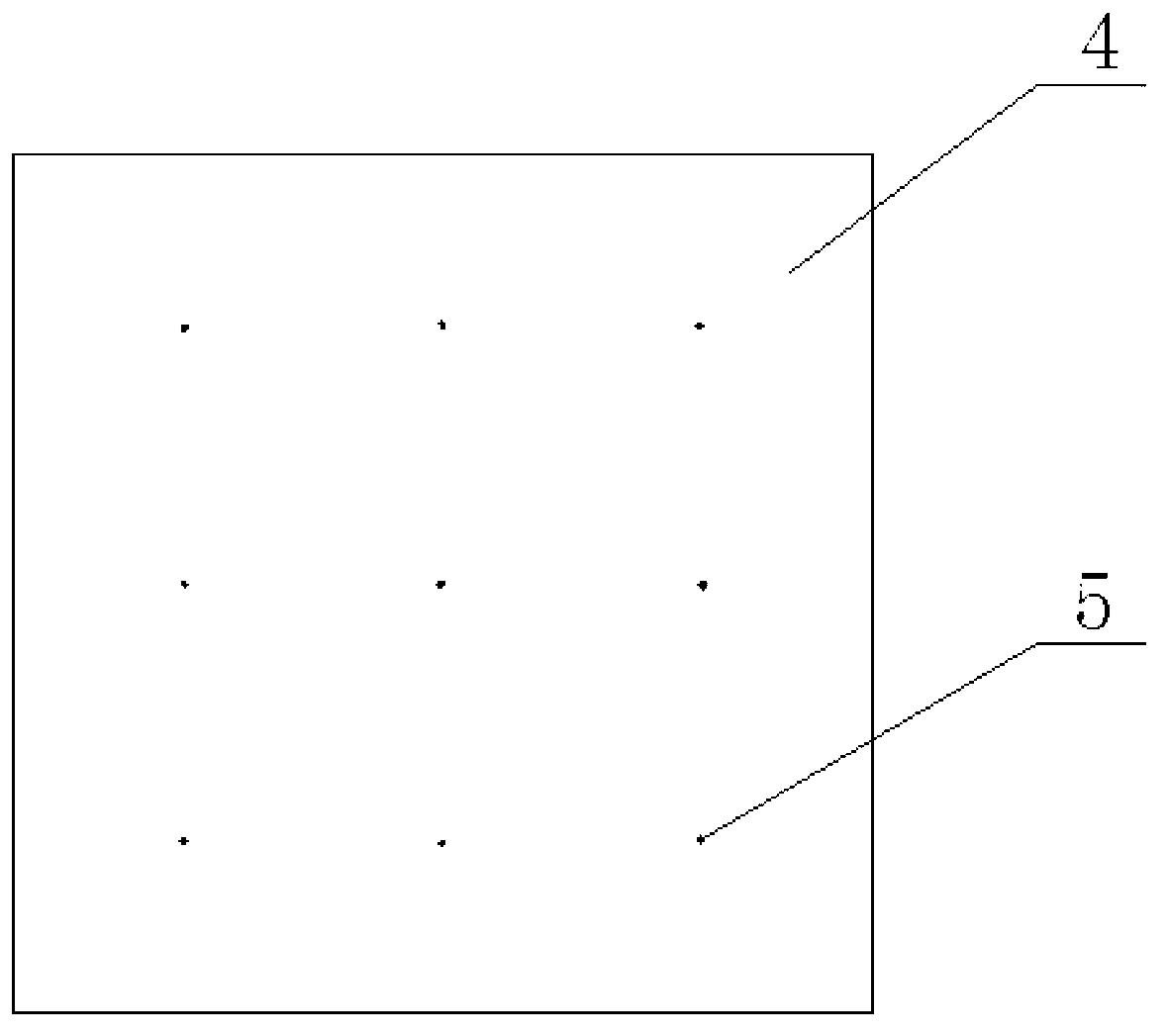

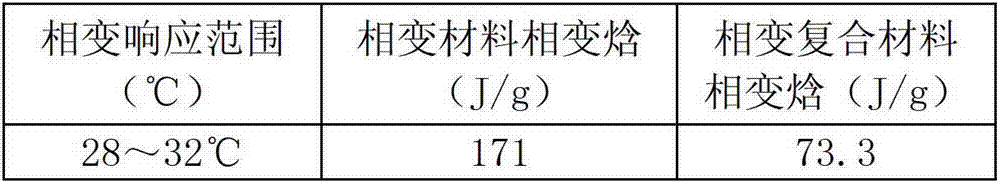

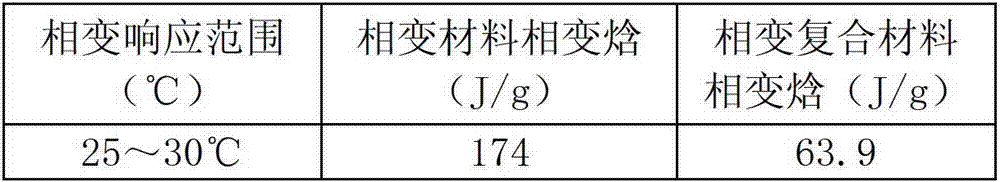

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

Antibacterial soap-based shower gel and preparation method thereof

ActiveCN104800123AImprove antibacterial propertiesGood moisturizing effectCosmetic preparationsToilet preparationsShower gelGlycerol

The invention discloses an antibacterial soap-based shower gel and a preparation method thereof. The shower gel comprises the following ingredients: thymol, salicylic acid, plants extracts, ethyl alcohol, propylene glycol, erythritol, lauric acid, myristic acid, palmitic acid, potassium hydroxide, glycol distearate, dihexyl sodium sulfosuccinate, cocamidopropyl betaine, sodium cocoyl glycinate, polyquaternium-7, polyglyceryl fatty acid ester composition, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid, essence, a preservative and water. The antibacterial soap-based shower gel is soft and friendly to skin, can effectively resist bacteria and moisturize skin and is particularly applicable to people with thicker cuticle, high grease secretion, skin pruritus and tinea corporis.

Owner:WALCH GUANGZHOU COMMODITY

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

Super-concentrated clothes washing sheet

InactiveCN105238584AEasy to filmEasy to carryInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBetaineFatty alcohol

The invention provides a super-concentrated clothes washing sheet. The super-concentrated clothes washing sheet comprises the following components in percentages by weight: 10-30% of a film forming agent, 1-10% of kaolin, 1-10% of silicon dioxide, 3-40% of sodium lauryl sulfate, 0.5-10% of fatty acid diethanol amide, 0.1-10% of dodecanol polyoxyethylene ether sodium sulphate, 0-10% of lauric acid betaine, 0-10% of fatty alcohol polyoxyethylene ether, 0-10% of polyalcohol, 0.1-5% of a chelate agent, and 1-50% of deionized water. Active components, the film forming agent and the like are scientifically collocated, so that the super-concentrated clothes washing sheet is easy to form a film.

Owner:GUANGZHOU LANJIEBAO BIOTECH CO LTD

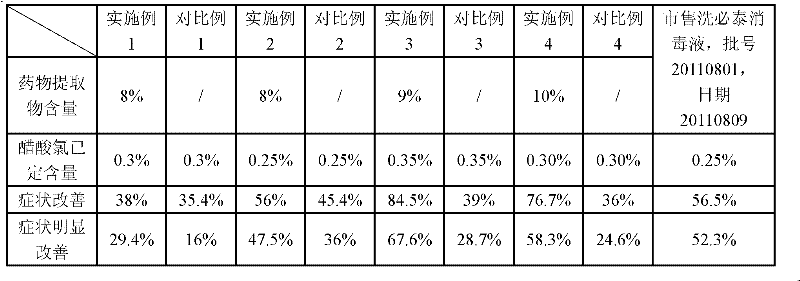

Compound lightyellow sophora root-selinum japenious seed bacteriostatic lotion and preparation method thereof

InactiveCN102526301ADefense against intrusionSuitable for useAntibacterial agentsOrganic active ingredientsChlorhexidine AcetateToxic material

The invention discloses a compound lightyellow sophora root-selinum japenious seed bacteriostatic lotion and a preparation method thereof. The lotion contains an extract of lightyellow sophora root, amur corktree bark and selinum japenious seed, chlorhexidine acetate, a surfactant, ethanol and water, wherein the surfactant is selected from lauryl dimethylamine oxide, Alcohol Ethoxylate (AEO-9), Lauric Acid Ethoxylate (LAE-9) and nonylphenol polyoxyethylene ether (NPE-10); the extract is prepared by performing reflux extraction on 10-25 percent of lightyellow sophora root, 35-45 percent of amur corktree bark and 35-45 percent of selinum japenious seed by taking 50-70 percent by volume of an ethanol aqueous solution as an extraction solvent for 1-3 times, every time for 1-1.5 hours, combining extracting solutions, filtering, recovering a filtrate under reduced pressure in vacuum, and concentrating with ethanol till the relative density is 1.08-1.12; and the using amount of the ethanol aqueous solution is 6-8 times of the total mass of the lightyellow sophora root, amur corktree bark and selinum japenious seed. The compound lotion consisting of Chinese native medicament and western medicament components has the effects of killing parasites to relieve itching, clearing heat, drying dampness and clearing away heat and toxic materials, can play a role in protecting private skin mucosa and preventing bacteria invasion, has low cost, and is suitable for young and middle-aged women.

Owner:上海豪源生物制品有限公司

Trans-free fat base for application in filling creams

InactiveUS20110177227A1Great tasteAvoid layeringFatty acid esterificationFatty-oils/fats separationStearic acidOleic Acid Triglyceride

A fat base is described comprising a mixture containing from 4 to 20% C12:0 lauric acid, preferentially from 5 to 17%, from 30 to 50% C16:0 palmitic acid, preferentially from 34 to 45%, and 4 to 10% C18:0 stearic acid, preferentially from 4.5 to 7.5%, and from 20 to 40% C18:1 oleic acid, preferentially from 25 to 35%, the balance being a mixture of other C4:0 to C22:0 fatty acids, having application, for example, as filling for wafer biscuits.

Owner:TEAM FOODS COLOMBIA

Synthetic method of laurel acyl amino acid sodium

ActiveCN102875409AReasonable workmanshipHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationActive agentN acylaminoacid

The invention relates to a synthetic method of lauric acyl amino acid sodium, particularly to a synthetic method which uses lauric acid and phosgene as raw materials. The synthetic method comprises the following steps: ensuring that the reaction lasts for 1 to 20 hours at a temperature of 60 to 100 DEG C with the effect of organic amide catalyst; obtaining acyl chloride through vacuum distillation after the reaction is finished; dripping lauric acyl chloride obtained according to the phosgene method into amino acids alkaline solution for reaction; controlling and ensuring the pH value to be within the range of 8 to 10, the reaction temperature to be 15 to 20 DEG C, and the reaction time to be 4 to 5 hours; carrying out cooling after the reaction is finished; acidizing the reaction solution to pH 1 to 2 with hydrochloric acid solution; filtering, washing and drying white sediment to obtain lauric acyl amino acid; dissolving the prepared lauric acyl amino acid with alcohol; adding alcohol solution with sodium hydroxide of equal molar amount; and crystallizing, sucking, filtering and drying after cooling to obtain the lauric acyl amino acid sodium. According to the invention, the synthetic method is reasonable in process, high in reaction efficiency and good in product quality; the three wastes are seldom generated; and no residual phosphorus and sulfur are contained in the product. Therefore, the synthetic method can be widely used in the production of high-end surface active agents, and has significant utility value and social and economic benefits.

Owner:CHANGSHA PUJI BIOTECH

Modifier for black metal surface matrix and production method thereof

InactiveCN102021552AExtended service lifeWide range of usesMetallic material coating processesDiethylenetriamineDissolution

The invention discloses a modifier for a black metal surface matrix. The modifier comprises the following raw material components in part by weight: 7 to 9 parts of aminotriacetic acid, 7 to 9 parts of lauric acid, 5 to 7 parts of malic acid, 3 to 5 parts of sorbic acid, 0.3 to 0.5 part of diethylenetriamine and 78 to 90 parts of water. A production method for the modifier comprises the following steps of: putting the water into a reaction kettle, then putting the aminotriacetic acid into the reaction kettle, fully stirring the water and the aminotriacetic acid till full dissolution, putting the lauric acid, the malic acid, the sorbic acid and the like into the reaction kettle respectively, fully stirring the components uniformly and melting the mixture, raising the temperature to be between 60 and 70 DEG C, keeping the temperature constant, reacting and chelating the melt for 1 hour at the constant temperature with stirring, then standing and performing natural complex reaction for 1 hour, finishing chelating when the solution is converted into a clear substance, obtaining a modifier finished product, and discharging, packing and selling the product. The modifier can be used for a long term; and the production method does not need discharge, only needs to continuously add raw agents, does not produce acid mist, acid gas or sour, does not drain waste water, and has no environmental pollution. The modifier enhances black metal facilities and equipment, and high-temperature resistance and oxidation corrosion resistance of products reaches over 2 times; and the modifier enhances the friction impact resistance of the black metal by over 2 times, and has quite considerable economic benefit and wide application.

Owner:邵阳市创捷化工有限公司

Synthesis method of organosilicon-modified aqueous polyurethane acrylate

The invention provides a synthesis method of organosilicon-modified aqueous polyurethane acrylate, which takes different aliphatic diisocyanates, alcoholic hydroxyl-terminated polysiloxane and acrylic acid monomer as main raw materials, and utilizes a stepwise synthesis method. The stepwise synthesis method comprises the following steps of: synthesizing organosilicon-modified polyurethane, introducing a hydrophilic group, and introducing the acrylic acid monomer, wherein a mixed solution of dibutyl tin laurate and organic carboxylic acid rare earth is taken as a catalyst for reflowing at the certain temperature so as to optimize the reaction condition; therefore, the invention provides a synthesis method of photo-cured aqueous polyurethane acrylate with great performances of yellowing resistance, high hardness and the like. The invention has the characteristics of high yield, easy operation and control and the like.

Owner:东莞市贝特利新材料有限公司

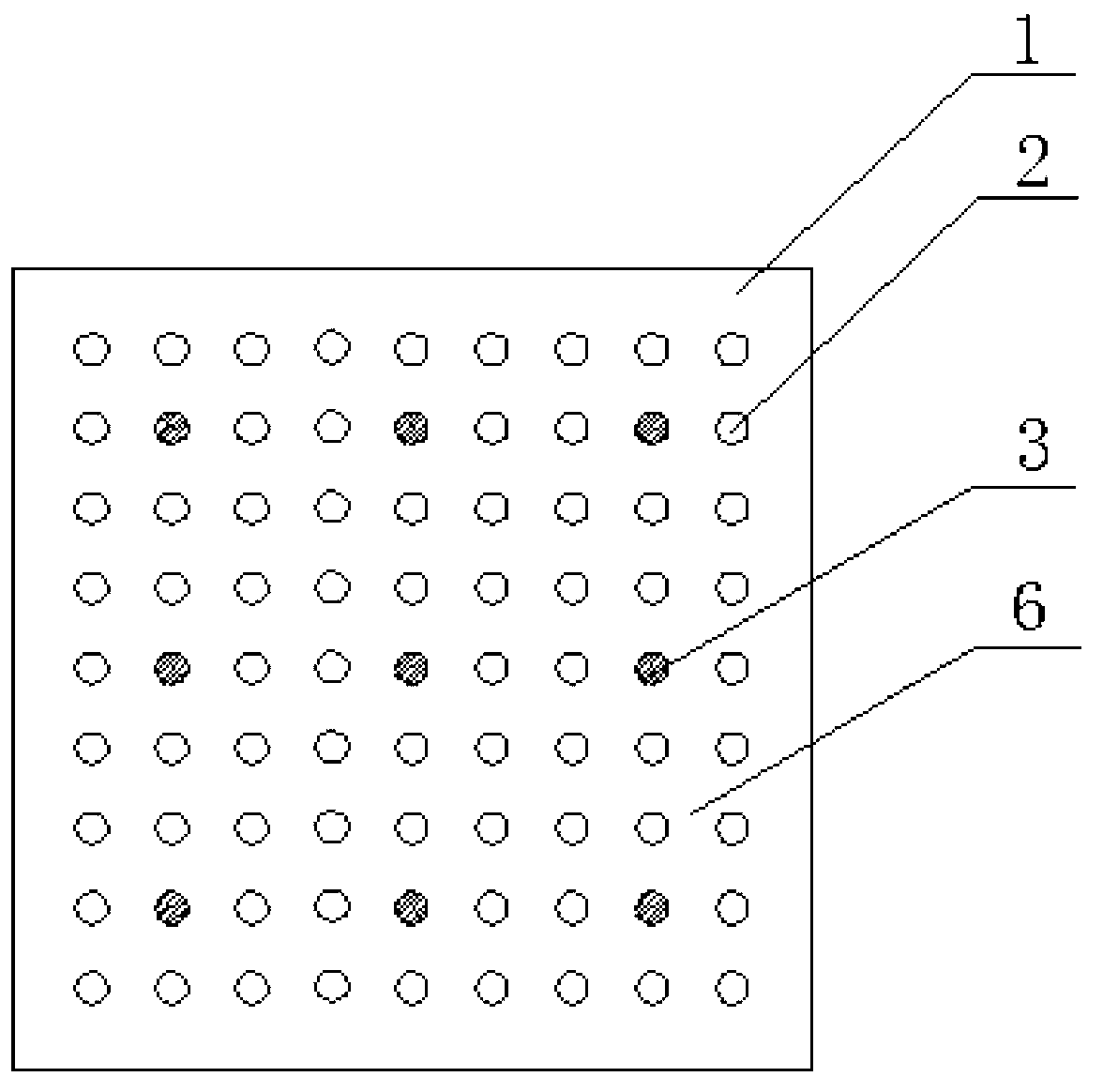

Polypropylene hollow fiber ultrafiltration membrane coated with polymer composite coating

ActiveCN105080361AImprove antibacterial propertiesHigh strengthAntifouling/underwater paintsUltrafiltrationEpoxyFiber

The invention relates to a polypropylene hollow fiber ultrafiltration membrane coated with a polymer composite coating. The polypropylene hollow fiber ultrafiltration membrane comprises a water inlet surface and a water outlet surface which are respectively coated with a coating; the coating on the water inlet surface comprises the following raw materials: tricresyl phosphate, dioctyl phthalate, a modified polysiloxane polymer, polyether-ether-ketone (PEEK), methenamine and the like; and the coating on the water outlet surface comprises the following raw materials: allyl polyoxy alkyl epoxy ether, pentaerythritol, polyethylene glycol lauric acid diester, polyoxyethylene alkylamine, nano silver and the like. The polypropylene hollow fiber ultrafiltration membrane is capable of increasing the retention rate for macromolecular organic matter and emulsified oil, so that the COD removal rate of sewage is greatly increased, the electrostatic effect on the surface of the membrane is changed, the adsorption for contaminants of the surface of the membrane is prevented, the membrane can be continuously used for a long time under the condition of high membrane flux, and the service life of the membrane is prolonged. The addition of the nano silver effectively improves the antibacterial mildew properties of the membrane.

Owner:广州市纳清环保科技有限公司

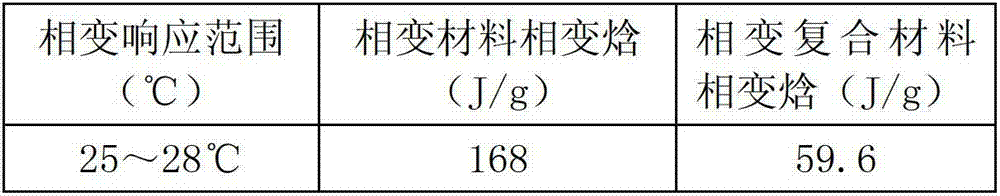

Phase change composite material and preparation method thereof

InactiveCN102827583AHigh phase change enthalpyCrystal stableHeat-exchange elementsThermal insulationStearic acid

The invention relates to a phase change composite material and a preparation method thereof. The phase change composite material is composed of a phase change material, expanded perlite particles and polymer emulsion in a weight ratio of (0.55-0.75): 1: (0.5-2.0), wherein the polymer emulsion is coated over the surface of the expanded perlite particles which have adsorbed the phase change material, and the phase change material is a blend of three or four selected from the group consisting of decanoic acid, lauric acid, tetradecanoic acid, palmitic acid and stearic acid. The preparation method comprises a step of combining the phase change material and the expanded perlite particles together by using a vacuum adsorption process and a step of coating a compound of the phase change material and the expanded perlite particles with the polymer emulsion. The phase change composite material provided by the invention has the advantages of great phase change energy storage capacity, good sealing capacity, wide material sources and low cost, can be used to substitute or partially substitute thermal insulation aggregate in conventional inorganic thermal insulation mortar for indoor and outdoor insulation of a building and can be mixed with inorganic cementing materials like cement and gypsum to prepare a sheet material product.

Owner:上海英硕聚合材料股份有限公司

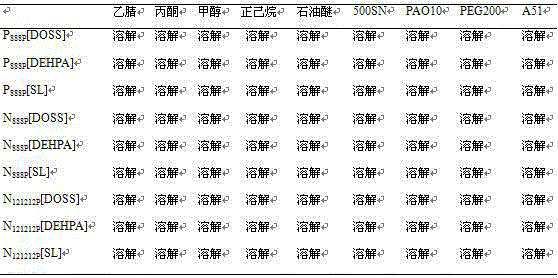

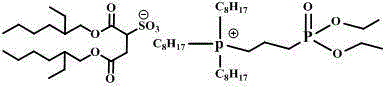

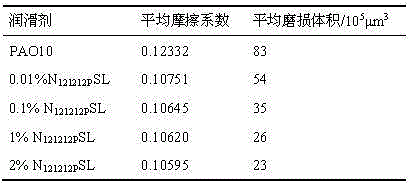

Functionalized oil-soluble ionic liquid and preparing method and application thereof

ActiveCN105254667AImprove solubilityEffective dissolutionGroup 5/15 element organic compoundsSulfonic acids salts preparationPhosphoric Acid EstersQuaternary ammonium cation

The invention discloses functionalized oil-soluble ionic liquid. The ionic liquid is phosphate functionalized quaternary phosphorus and quaternary ammonium oil-soluble ionic liquid. The positive ions of the ionic liquid are quaternary phosphorus or quaternary ammonium positive ions with phosphate functional groups and different alkyl chain lengths. The negative ions of the ionic liquid are EDHPA, DOSS, DDSSP and SL. The ionic liquid can effectively reduce the corrosion of base oil on metal, restrain the generation of carbon deposition and improve the lubricating performance of lubricating oil. The invention further discloses a preparing method and application of the ionic liquid.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fat compositions

Owner:AAK DENMARK

Composition for controlling the respiratory effects of inhaled pollutants & allergens

InactiveUS20070082071A1Eliminate the effects ofReduced responseBiocidePharmaceutical delivery mechanismPeppermintsRespiratory effect

An anti-inflammatory composition for application to the nasal mucosa includes a combination of essential oils. The composition is intended to help prevent and / or alleviate the effects of exposure caused by the inhalation of pollutants and allergens. Preferred embodiments of the composition include jojoba oil, rosemary oil, any of a variety of citrus oils, coconut oil, sesame oil, soy oil, thyme oil, oregano oil, chamomile oil, peppermint oil, cardiospermum halicacabum, galphimia glauca, luffa operculata, bee's milk, bee's wax, and aloe vera in various combinations and sub-combinations. The composition may further include lauric acid, d-limonene and luteolin.

Owner:GLOBAL LIFE TECH

Fat composition used for chocolate coating

The invention relates to a fat composition used for chocolate coatings, a preparation method thereof, and the chocolate coatings and food containing the fat composition. The fat composition is rich in SSU (1, 2-di-saturated fatty acid-3-unsaturated fatty acid triglyceride), low in trans fatty acid content, low in content of saturated fatty acids, free of lauric acid and high in crystallization rate, and can be solidified into a stable form CBR (cocoa butter replacer) without temperature adjustment.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com