Patents

Literature

91 results about "Saturated fatty acid ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sustained-Release Lipid Pre-Concentrate of Pharmacologically Active Substance And Pharmaceutical Composition Comprising The Same

ActiveUS20140206616A1Patient compliance is goodGood sustained releaseBiocidePeptide/protein ingredientsLipid formationSaturated fatty acid ester

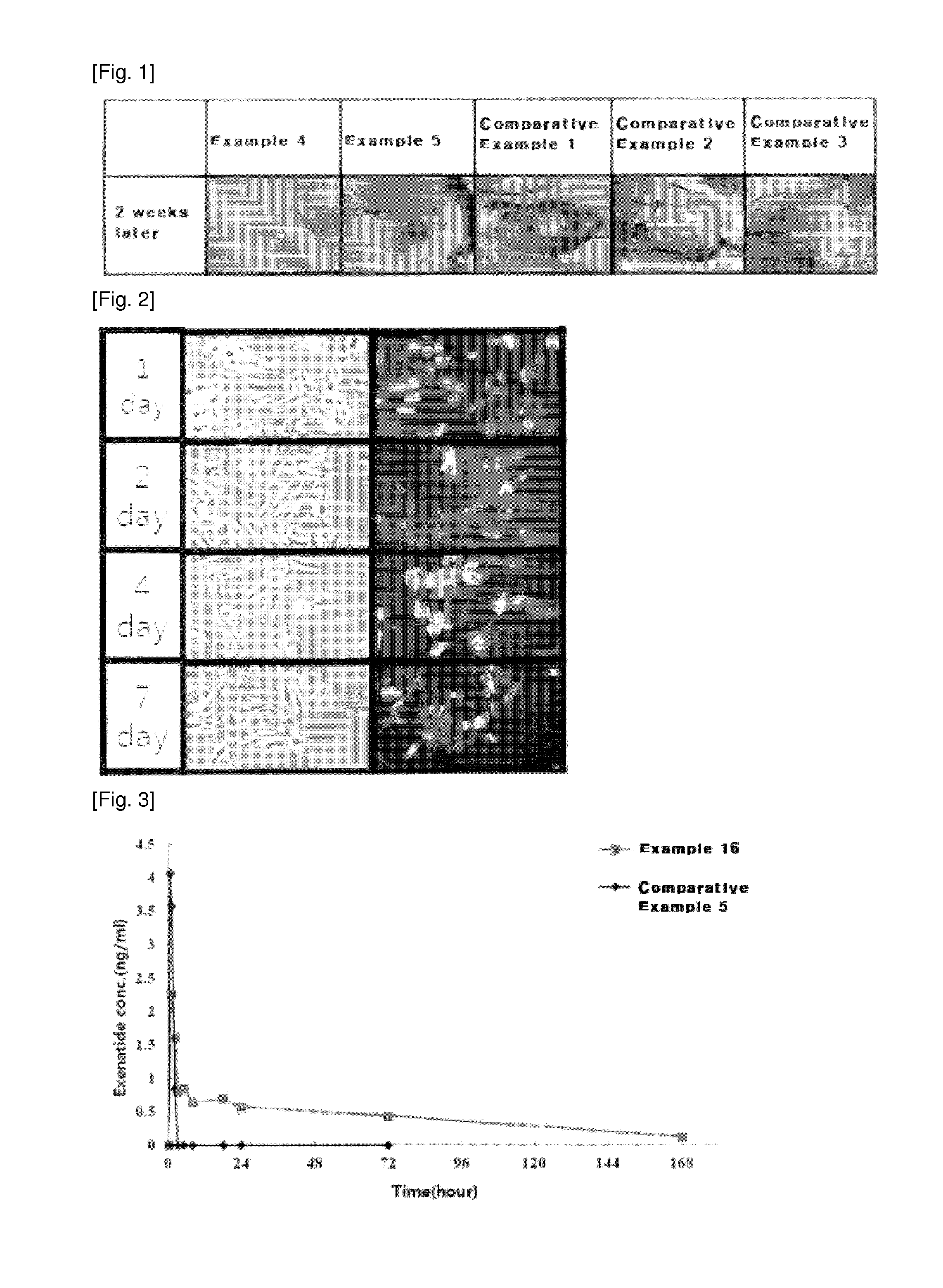

Disclosed is a sustained release lipid pre-concentrate, comprising: a) a sorbitan unsaturated fatty acid ester having a polar head with at least two or more —OH (hydroxyl) groups; b) a phospholipid; and c) a liquid crystal hardener, free of an ionizable group, having a hydrophobic moiety of 15 to 40 carbon atoms with a triacyl group or a carbon ring structure. The lipid pre-concentrate exists as a liquid phase in the absence of aqueous fluid and forms into a liquid crystal in the presence of aqueous fluid. Also, a pharmaceutical composition further comprising a pharmacologically active ingredient plus the pre-concentrate is provided.

Owner:CHONG KUN DANG PHARMA CORP

Lauric fat based structuring agents to reduce saturated fat

InactiveUS20160316778A1Low SFA contentMaintain good propertiesFatty acid esterificationFrozen sweetsSaturated fatty acid esterGlycerol

The present invention relates to a lipid composition comprising at least 5 wt % of a structuring agent dispersed in oil or fat wherein the structuring agent comprises at least 50 wt % of triacylglycerol containing a glycerin skeleton esterified with one type of saturated fatty acid having a chain length of either 10:0, 12:0 or 14:0. Further aspects of the invention are: the structuring agent, a food product comprising the lipid composition, the use of the lipid composition as a structure stabilizer or a moisture barrier in a food product; and a method for preparing the lipid composition.

Owner:NESTEC SA

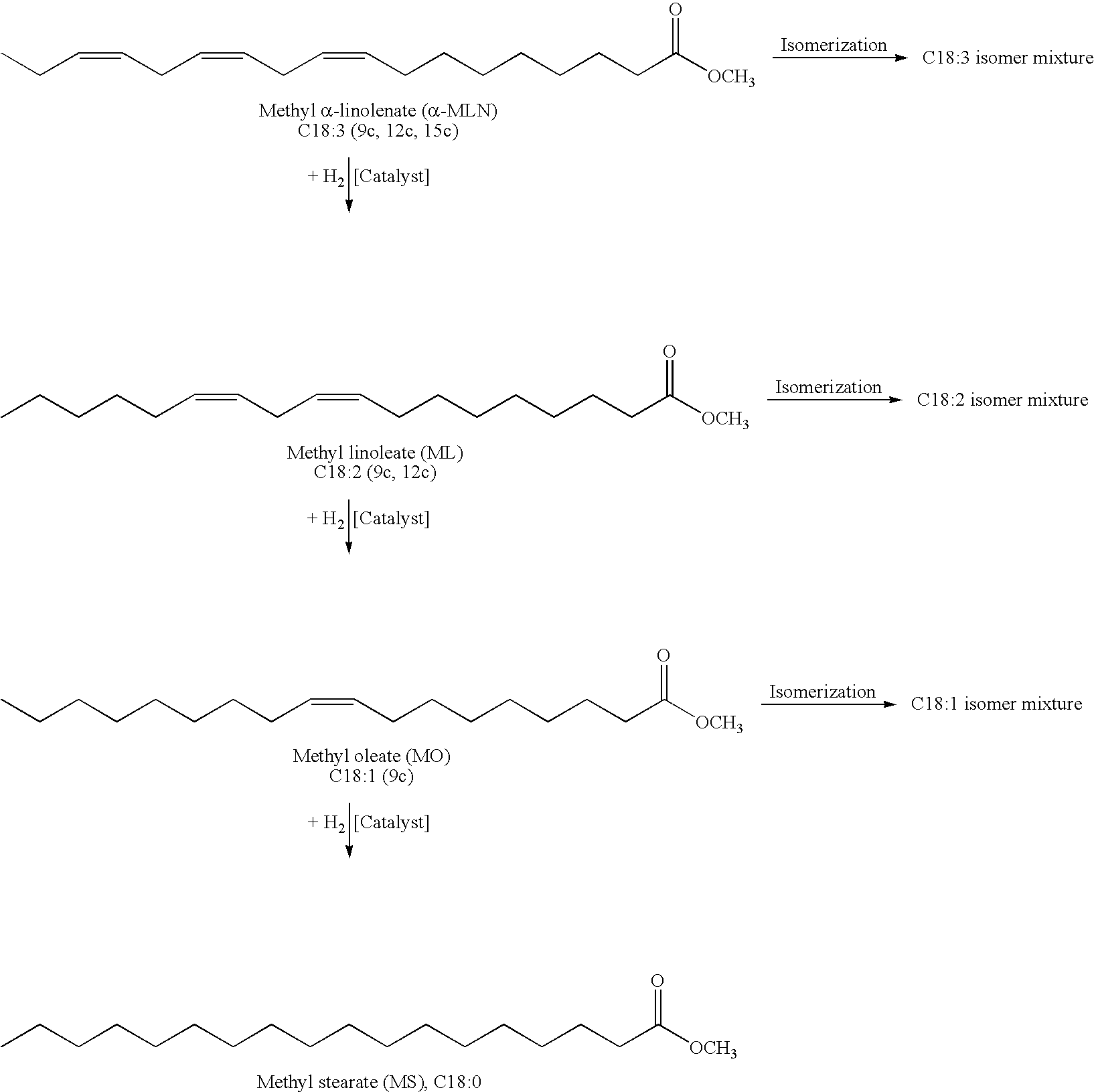

Method for Preparation, Use and Separation of Fatty Acid Esters

InactiveUS20070251141A1Optimized cost timeOptimized processing costFatty oils/acids recovery from wasteOrganic compound preparationSaturated fatty acid esterAlcohol

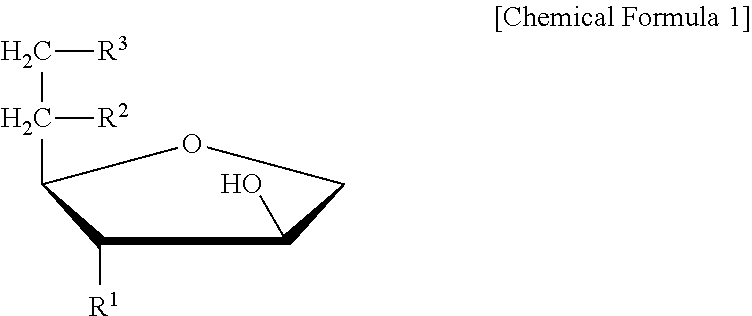

A method for treating a fatty acid methyl ester. The method can include mixing the fatty acid methyl ester with an amount of urea and an amount of alcohol to make (i) a urea / fatty acid methyl ester ratio of from about 0.1:1 to 1:1 wt / wt and (ii) an alcohol / fatty acid methyl ester ratio of from about 3:1 to 10:1 wt / wt; heating the fatty acid methyl ester / urea / alcohol mixture to a temperature at which a homogenous mixture is obtained, cooling the fatty acid methyl ester / urea / alcohol mixture to a temperature where a solid phase comprising a clathrate of urea and saturated fatty acid ester and a liquid phase comprising unsaturated fatty acid methyl ester are formed, and separating the solid phase from the liquid phase. The unsaturated fatty acid methyl ester is useful as a fuel resistant to gel formation at low temperature.

Owner:PURDUE RES FOUND INC

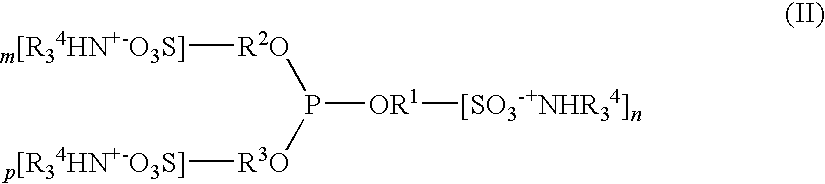

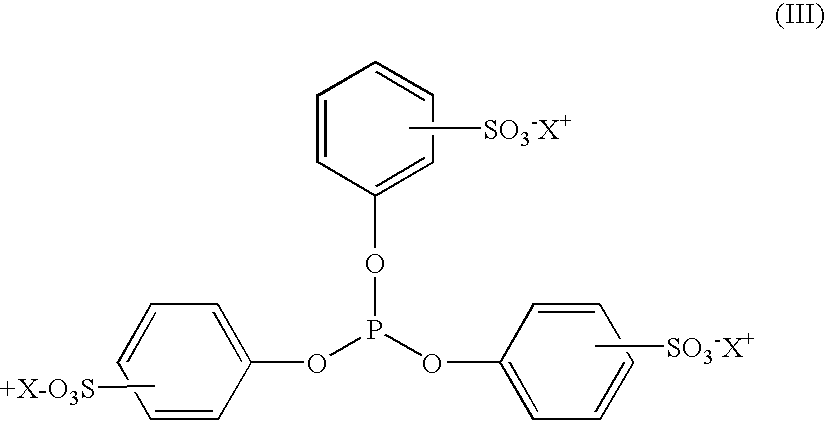

Process for the Manufacture of Saturated Fatty Acid Esters

InactiveUS20100234625A1Easy to disassembleCost-effectiveFatty acid chemical modificationOrganic compound preparationSaturated fatty acid esterUnsaturated fatty acid ester

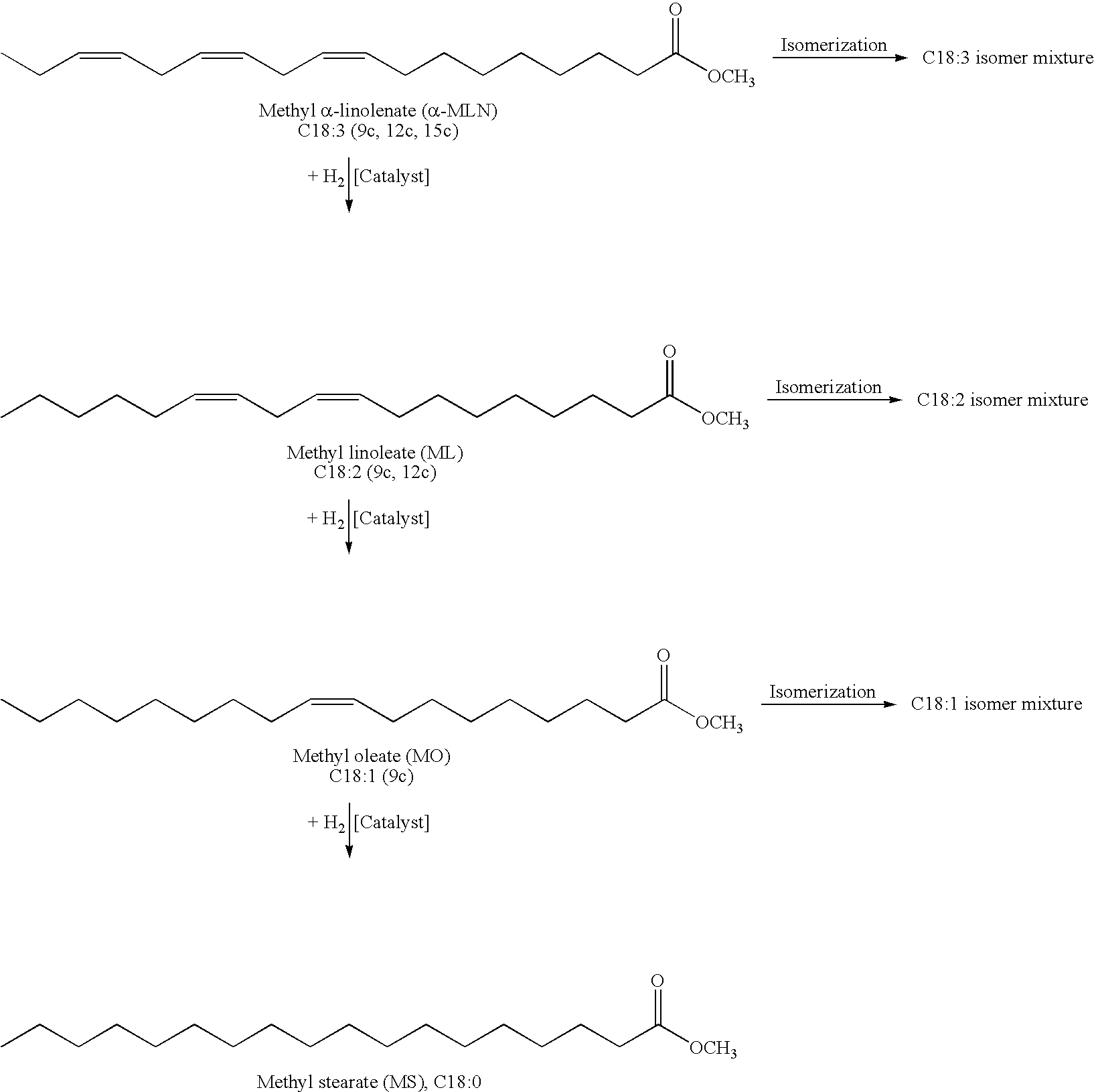

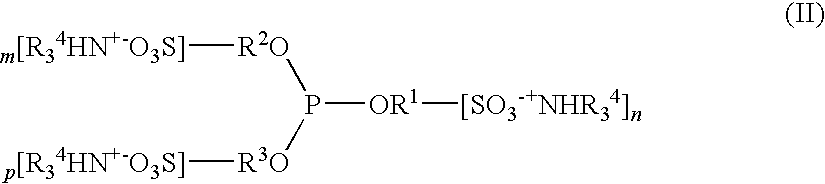

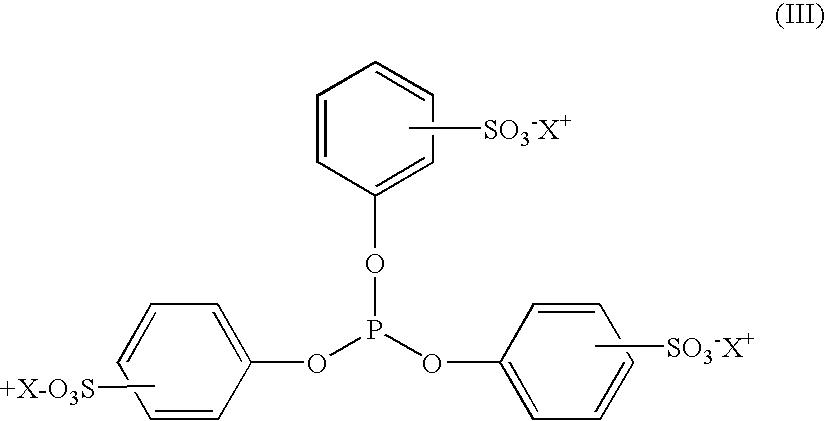

Disclosed is a process for the manufacture of saturated fatty acid esters by subjecting unsaturated fatty acid esters to hydrogenation in the presence of a catalyst suitable for catalysing the saturation of double bonds in the esters, which is characterised in that said catalyst represents a homogenous complex of a Group VIII metal and a sulfonated phosphite as the polar ionic ligand.

Owner:COGNIS IP MANAGEMENT GMBH

Method for purifying sucrose fatty acid esters

ActiveCN103087118ASolve the problem of high acid valueIncrease content levelEsterified saccharide compoundsSugar derivativesSaturated fatty acid esterSucrose

The invention relates to a method for purifying sucrose fatty acid esters. The method comprises the following steps: dissolving crude sucrose ester products in an organic solvent which can be separated from water, thereby obtaining a crude sucrose ester product solution; dropwise adding a salt aqueous solution while stirring, so that fatty acid soap substances in the crude sucrose ester product solution generate fatty-acid alkaline-earth metal salts, wherein alkaline-earth metal salts and / or alkaline-earth metal oxides are dissolved in the salt aqueous solution, and the fatty-acid alkaline-earth metal salts are not dissolved in the organic solvent; removing generated solid fatty acid alkaline earth metal salts; adding saline water into the obtained object to carry out stirring and extraction, and sanding for separating a lower water layer; cooling liquid supernatant to 0-40 DEG C through stirring, and separating out sucrose ester crystal substances in precipitation form; removing liquid and taking solid matters; and drying the solid matters so as to obtain a sucrose ester product. According to the invention, a technological process of cooling crystallization is introduced, so that the problem that reaction raw materials such as fatty acid methyl esters and the like remain in products is solved, therefore, the content level of products is further improved, and the total ester content of products is more than 98%.

Owner:LIUZHOU GAOTONG FOOD CHEM

Preparation method of pentaerythritol unsaturated fatty acid ester

InactiveCN105085259AShort reaction timeHigh catalytic efficiencyOrganic compound preparationCarboxylic acid esters preparationSaturated fatty acid esterPentaerythritol

The invention discloses a preparation method of pentaerythritol unsaturated fatty acid ester. The preparation method includes: adding pentaerythritol, fatty acid type diesel anti-wear agent and cerium dioxide according to a molar ratio of 1:(4-6):(0.02-0.05) into a reaction kettle for mixing and stirring. Cerium dioxide which is reusable is adopted as a heterogeneous catalyst and is short in reaction time and high in catalyzing efficiency; in the process of preparing pentaerythritol unsaturated fatty acid ester, using of a lot of azeotropic solvent and removing of the catalyst are not needed, only simple filtering is needed, processes of neutralizing and washing are not needed, and no wastewater is discharged in subsequent treatment processes, so that preparation efficiency is improved greatly, and the preparation method is enabled to meet national requirements on environment protection.

Owner:JIANGXI NORMAL UNIV

Process for the manufacture of saturated fatty acid esters

InactiveUS8334396B2Fatty acid chemical modificationOrganic compound preparationSaturated fatty acid esterUnsaturated fatty acid ester

Owner:COGNIS IP MANAGEMENT GMBH

Method for preparing polyol from waste grease and application thereof

ActiveCN104326911ALow costSolve pollutionFatty acid esterificationOrganic compound preparationSaturated fatty acid esterOil and grease

The invention discloses a method for preparing polyol from waste grease, comprising the following steps: a solid acid catalyst which has large hydrophobic surface and has both a sulfonic group and a carboxylic group is adopted to catalyze esterification and transesterification between waste grease and methanol so as to convert waste grease to fatty acid methyl ester and a by-product glycerin; saturated fatty acid ester in fatty acid methyl ester is separated; under the catalysis of a dual acid site solid acid and in cooperation of the dual acid site, 30% hydrogen peroxide is directly catalyzed for epoxidation of fatty acid methyl ester, an intermediate product is not separated, and the by-product glycerin is added for ring opening of alkoxylation after direct heating-up; and finally, filtration is carried out to recycle the catalyst, and reduced pressure distillation is carried out to remove water so as to obtain biological oil-based polyol. According to the method, waste grease is used as a raw material, thus turning waste into wealth. The polyol product obtained has good biodegradability; the preparation process is green; emission of three industrial wastes is low; product structure and hydroxyl value can be adjusted; the range of application is wide; and the level of effect on the environment is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Thickening systems and aqueous-coating compositions, and methods of making and using the same

ActiveUS20050192383A1Cosmetic preparationsToilet preparationsSaturated fatty acid esterUnsaturated fatty acid ester

Various non-limiting embodiments disclosed herein relate generally to aqueous-coating compositions and thickening systems that can be used in aqueous coating-compositions. More particularly, certain non-limiting embodiments disclosed herein relate to aqueous-coating compositions, such as latex paints, comprising xanthan gum and at least one ester of an unsaturated fatty acid that is essentially free of volatile organic compounds as determined by EPA Reference Method 24. Other non-limiting embodiments relate to thickening systems comprising a mixture of a xanthan gum and at least one ester of an unsaturated fatty acid, wherein the thickening system is essentially free of volatile organic compounds as determined by EPA Reference Method 24. Still other non-limiting embodiments relate to methods of making and using the aqueous coating-compositions and thickening systems disclosed herein.

Owner:ARCHER DANIELS MIDLAND CO

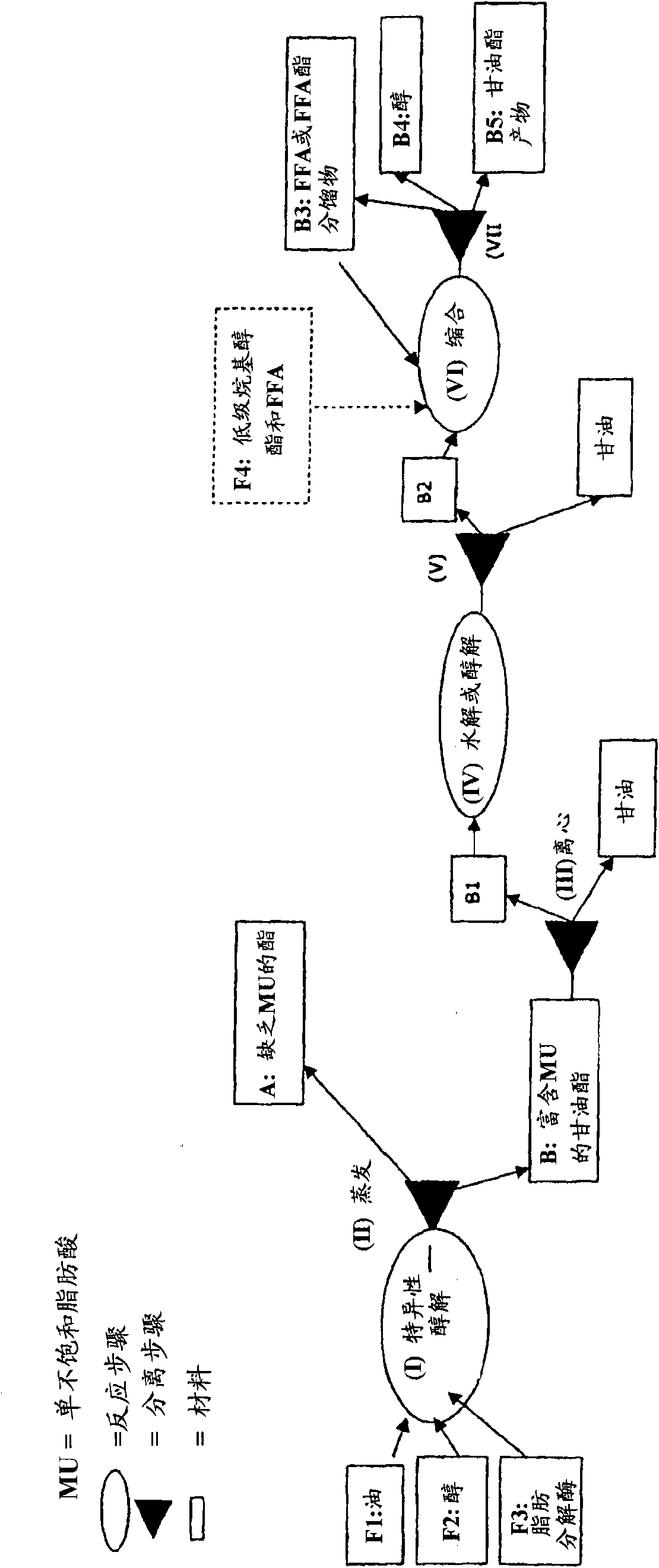

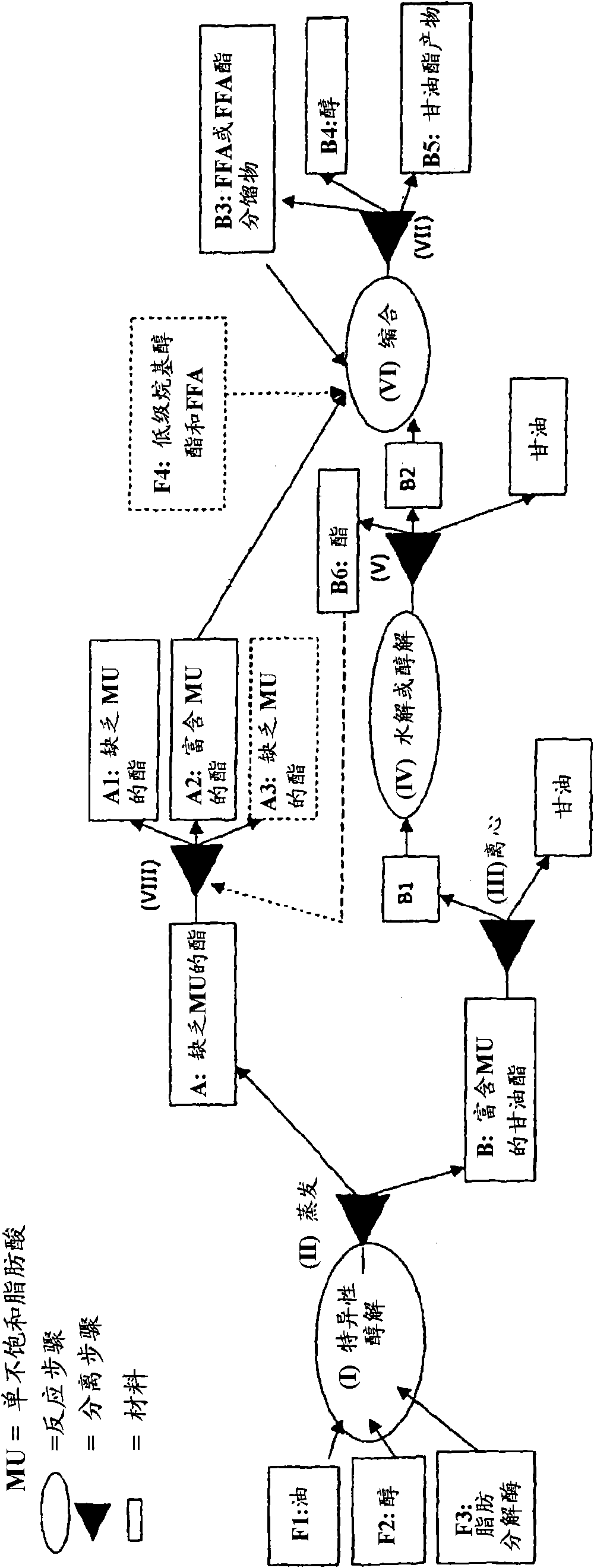

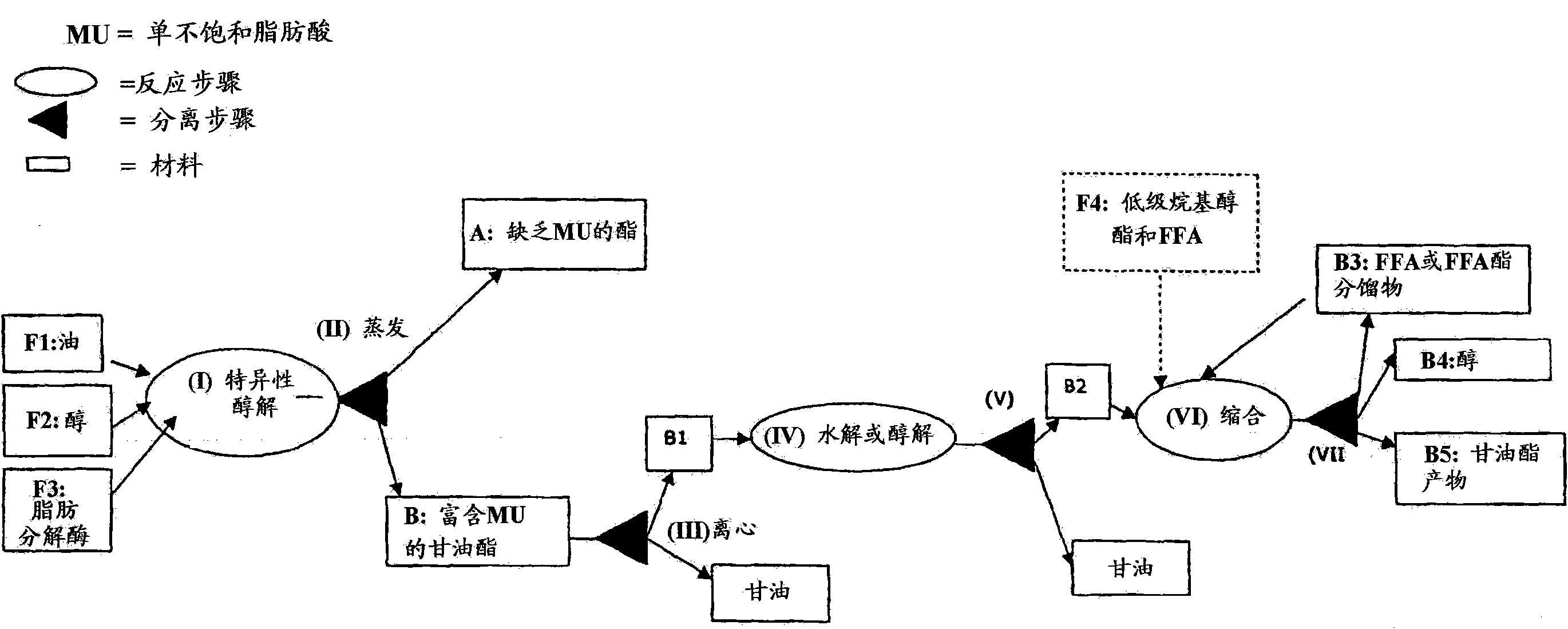

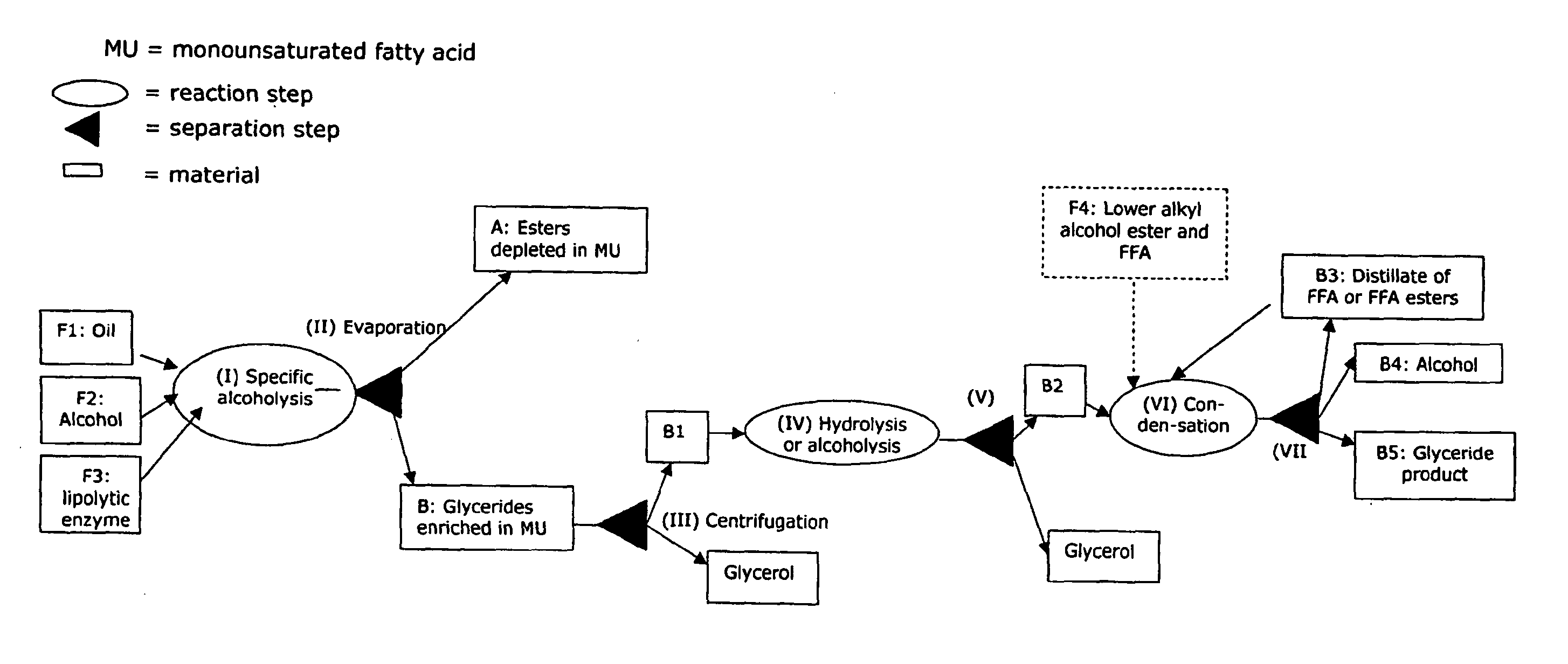

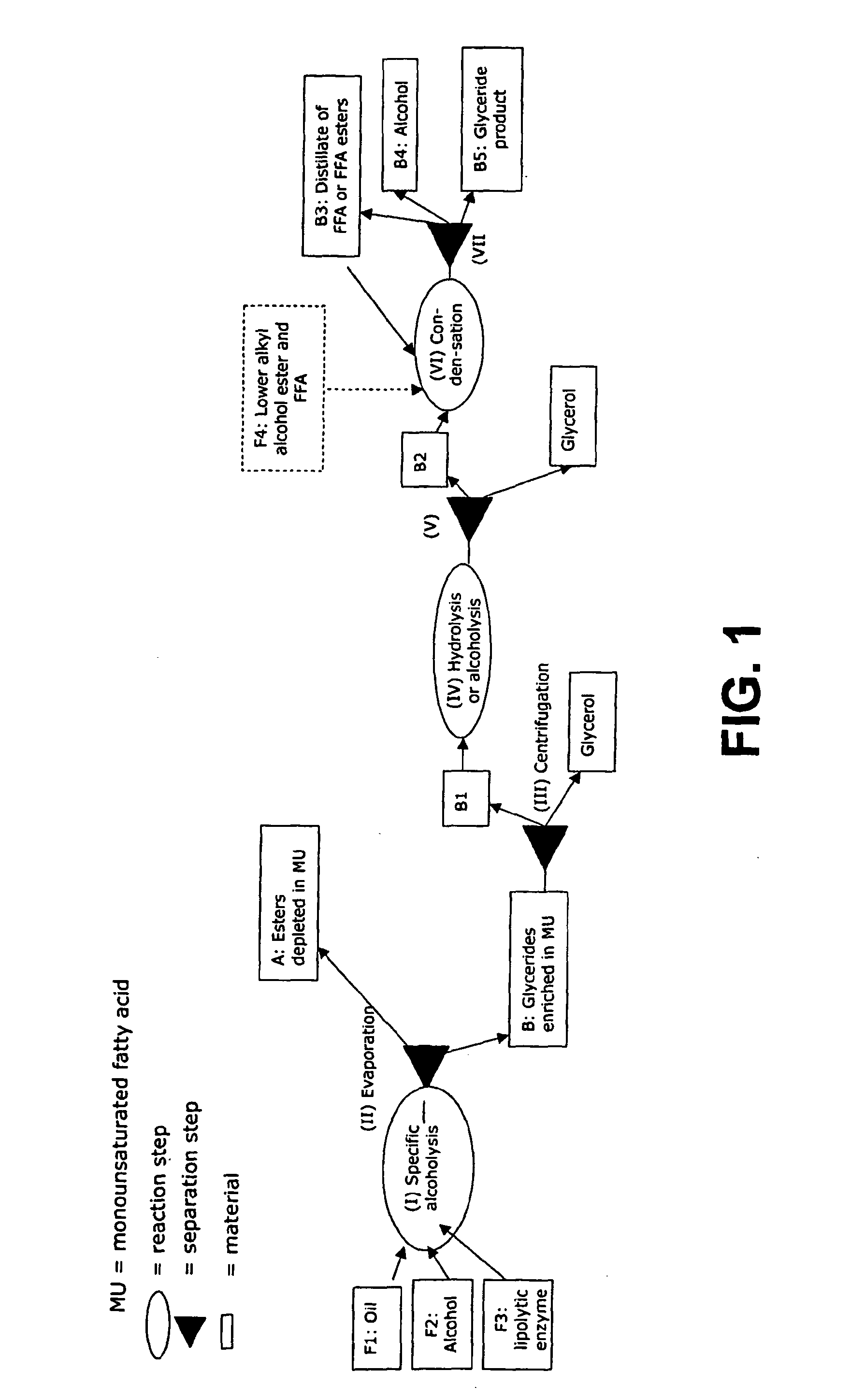

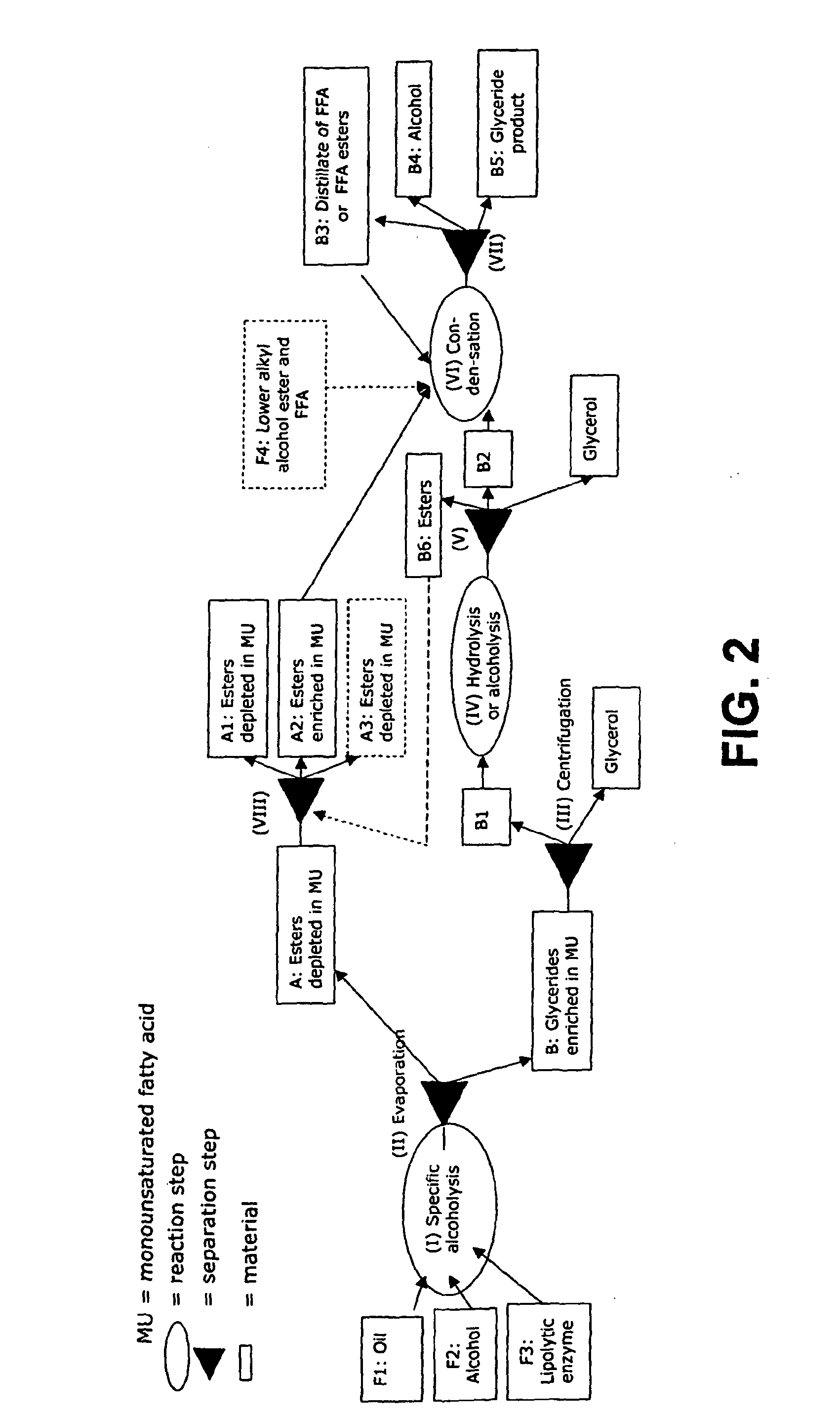

Method for producing monounsaturated glycerides

A process for producing a glyceride product which is enriched in monounsaturated fatty acids relative to the starting glyceride comprising the steps: (a) alcoholysis of triglycerides employing lipolytic enzymes selective for saturated fatty acids and / or lipolytic enzymes selective for the 1-position, the 3-position or both positions in a glyceride; and (b) separation of fraction A which is enriched in saturated fatty acid esters from fraction B which is enriched in monounsaturated glycerides.

Owner:NOVOZYMES AS

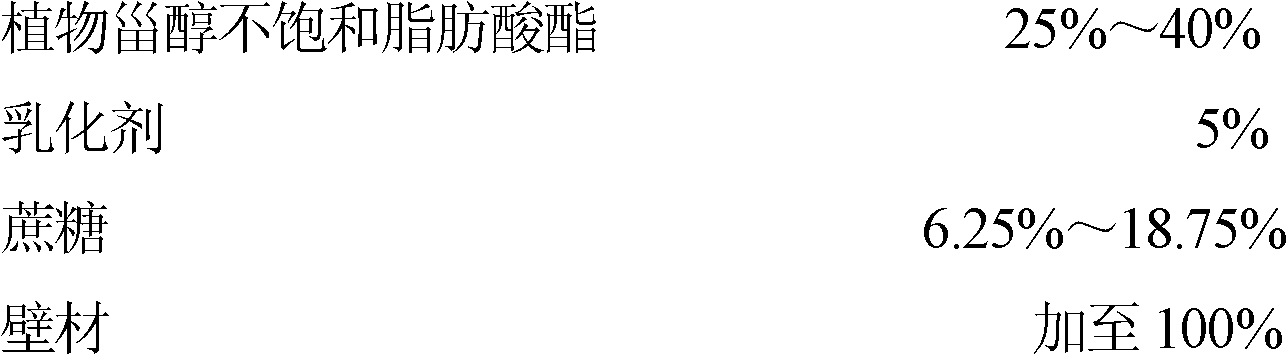

Water-soluble phytosterol unsaturated fatty acid microcapsule and preparation method of water-soluble phytosterol unsaturated fatty acid microcapsule

ActiveCN102613577AGood water solubilityEasy to prepareMilk preparationFood preparationSaturated fatty acid esterChemical industry

The invention belongs to the technical field of food and chemical industry and particularly relates to a water-soluble phytosterol unsaturated fatty acid microcapsule and preparation method of water-soluble phytosterol unsaturated fatty acid microcapsule. The microcapsule comprises 25 to 40 percent of phytosterol unsaturated fatty acid ester, 5 percent of emulsifying agents, 6.25 to 18.75 percent of sucrose and the balance wall materials, wherein the total quantity is 100 percent, the emulsifying agents are glycerin monostearate and sucrose ester, the mass ration of the glycerin monostearate to the sucrose ester is 1:(0.33-3), the ratio of the sucrose ester to the sucrose is 1:5, and the wall materials are dextrin and soy isolate protein. The water solubility of the phytosterol unsaturated fatty acid microcapsule is good, the phytosterol unsaturated fatty acid microcapsule can be mixed and dissolved with water-soluble matters, the application of the phytosterol ester to functional food, dairy products and beverages is widened, in addition, the preparation method disclosed by the invention is simple, the equipment requirement is low, and the preparation method is suitable for large-scale industrial production.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

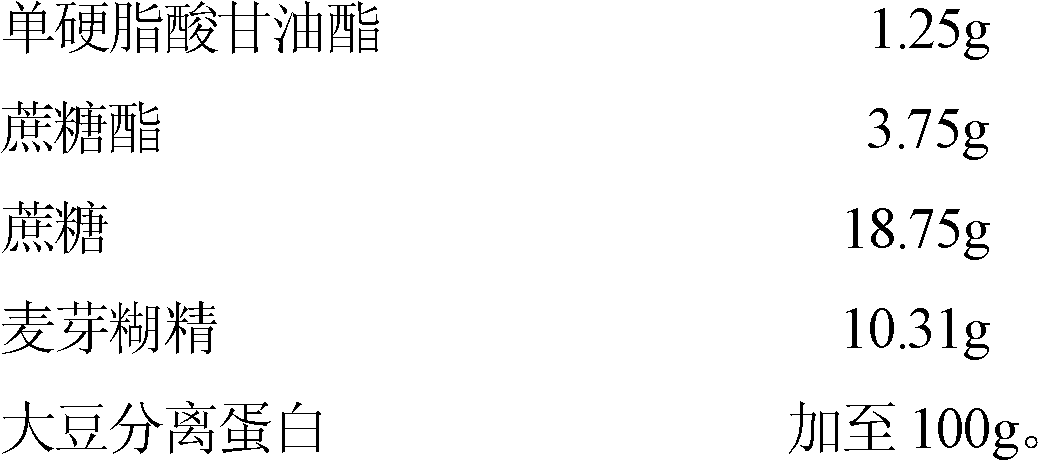

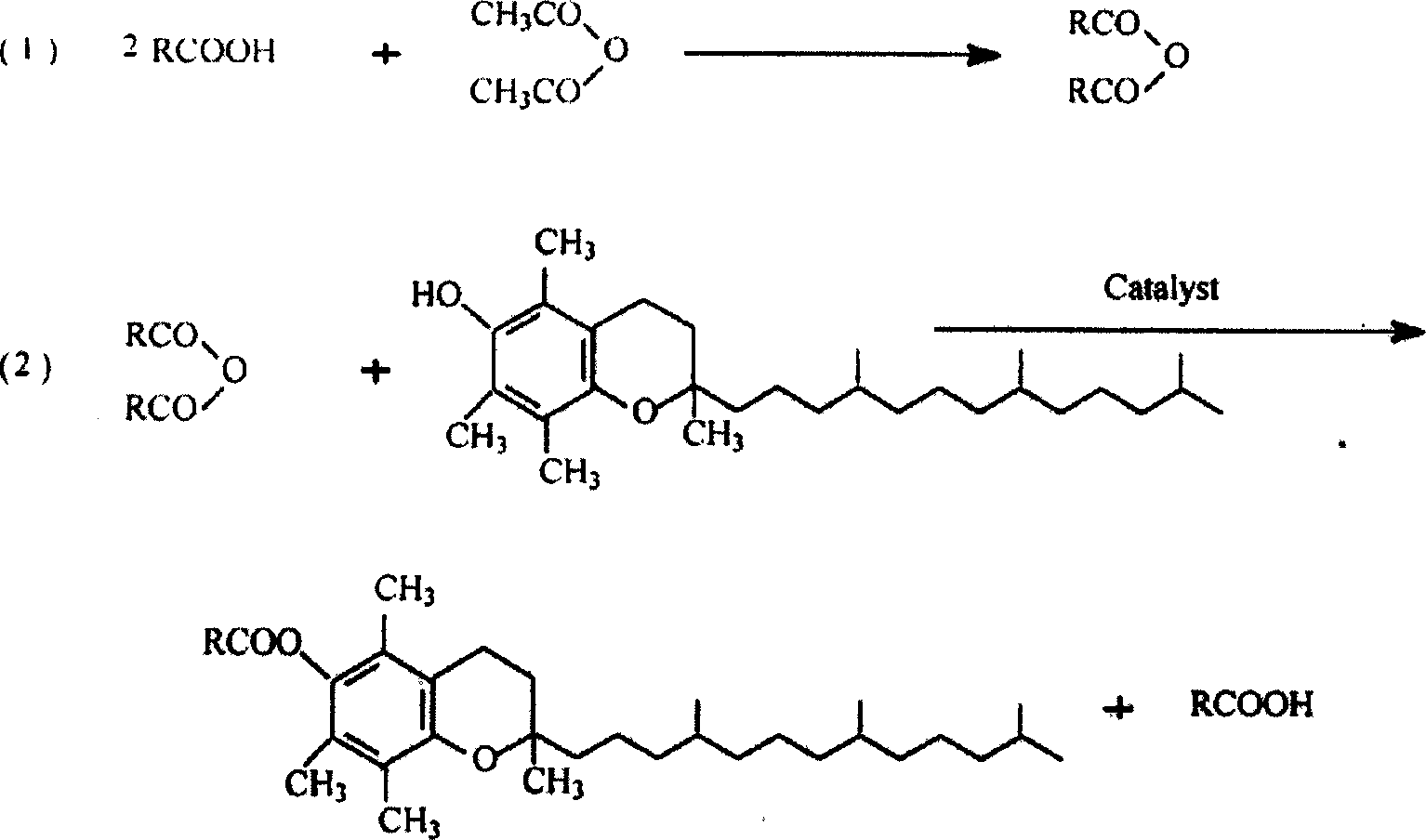

Preparation of vitamin E linolenin and vitamin E oleate

InactiveCN1800173AReduce the level of oxidative denaturationGood chemical stabilityOrganic chemistrySaturated fatty acid esterSynthesis methods

The invention relates to a method for preparing for vitamin E leukotrienes ester and vitamin E oleate. It is characterized in that the oleic acid, linoleic acid or the leukotrienes dose esterification reaction and then reacts with the vitamin E Eoleate or vitamin E leukotrienes ester. The esterification reaction of the oleic acid, linoleic acid or the leukotrienes adopts chloride synthesis method, the anhydride synthesis method and the ester exchange synthesis method to prepare.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Preparation method of polymer fatliquoring agent

InactiveCN101747480AMild reaction conditionsGraft polymerization is effectiveLeather impregnationSaturated fatty acid esterPolymer science

The invention provides a preparation method of polymer fatliquoring agent, comprising the following steps: (1) component A and component B are mixed, the component A is at least one of natural oil containing unsaturated fatty acid and long carbon chain unsaturated fatty acid ester, the component B at least comprises monoene which belongs to an unsaturated monomer, peracid is used as catalyst, so as to carry out copolymerization; (2) alkali is added in a polymer which carries out copolymerization, and the alkali and the polymer carry out neutralization reaction, the polymer is neutralized to have pH value from 6.0 to 8.5. In the invention, the peracid is used as the catalyst, the reaction condition is mild, no waste is discharged in the reaction process, and the product can be biologically degraded.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

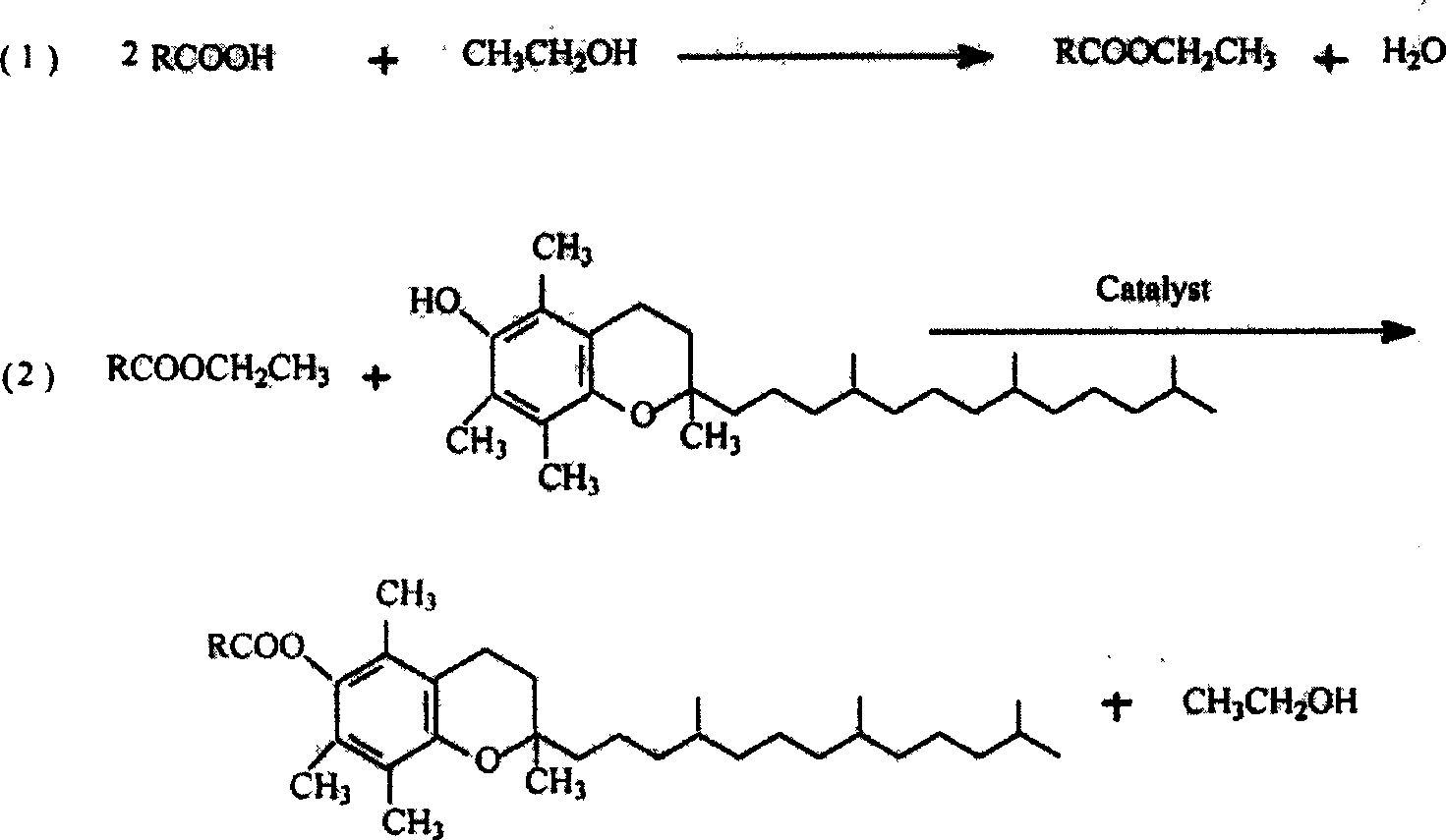

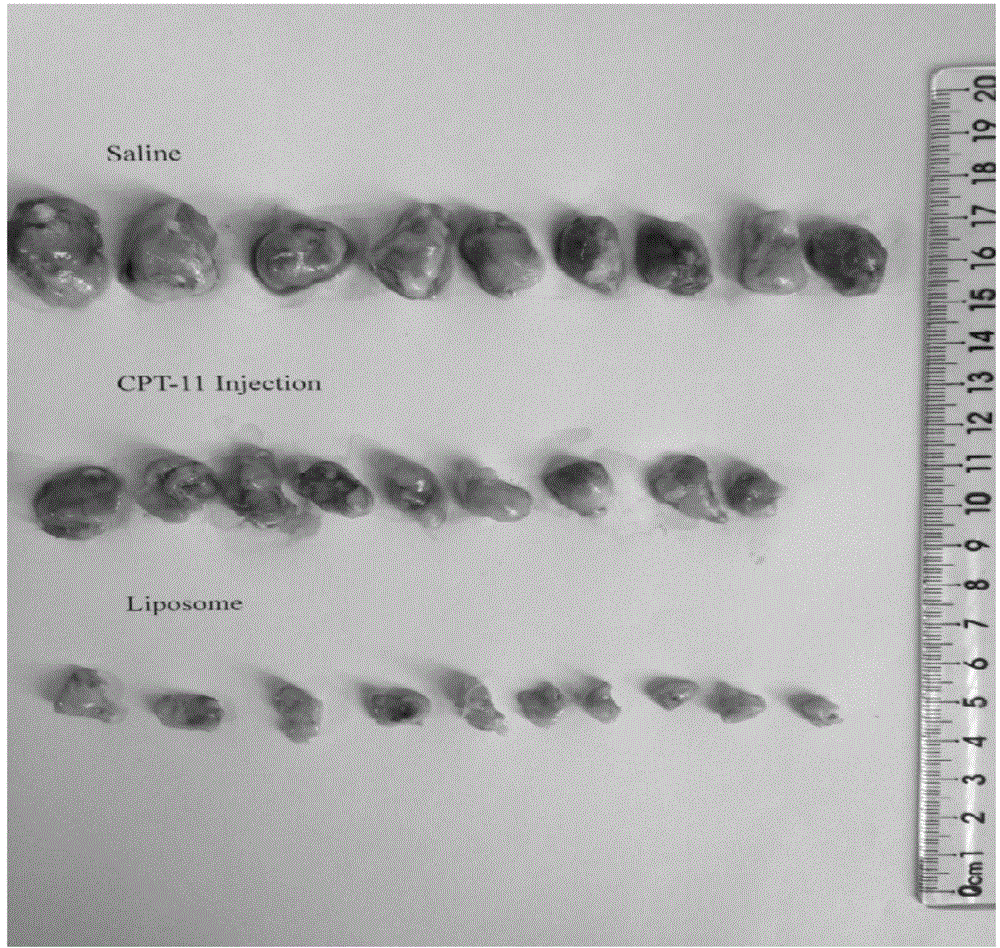

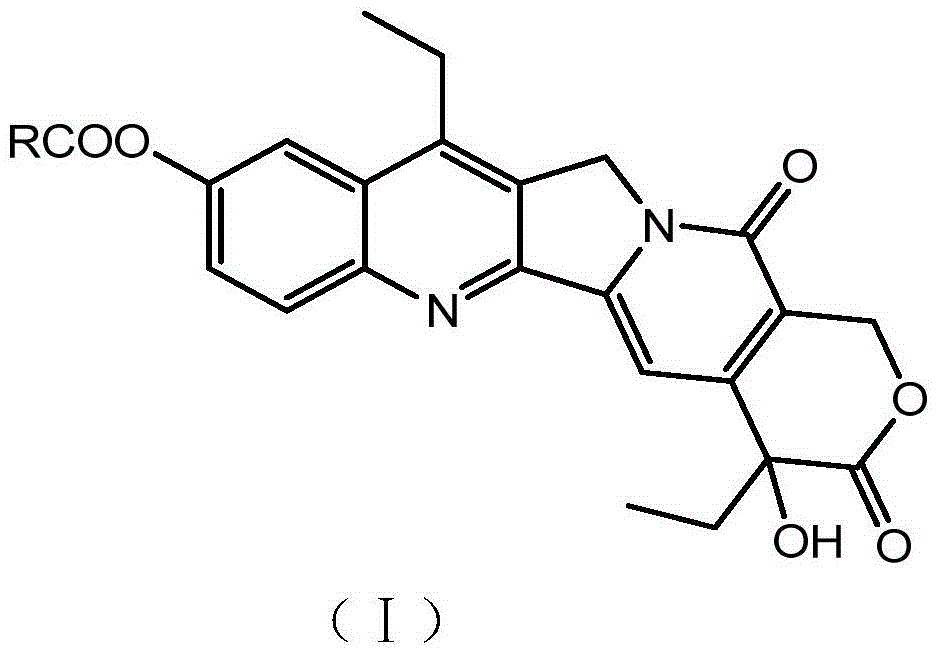

Saturated long-chain fatty acid-modified 7-ethyl-10-hydroxycamptothecin compound and long-circulating liposome thereof

InactiveCN105777770AStable in natureNot easily oxidizedOrganic active ingredientsOrganic chemistrySaturated fatty acid esterLong chain fatty acid

The invention relates to the technical field of medicine, and relates to a saturated long-chain fatty acid-modified 7-ethyl-10-hydroxycamptothecin (SN-38) compound and a long-circulating liposome thereof. Under substitution reaction conditions and the existence of an acid-binding agent, SN-38 is subjected to saturated long-chain fatty acid chloride, such that a SN-38 monounsaturated fatty acid ester compound is obtained. The compound has a following general formula (I). The long-circulating liposome prepared with the compound provided by the invention has the advantages of improving drug anti-tumor effect, enhancing drug stability, reducing drug toxic and side effects, and the like.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Preparation method of unsaturated fatty acid-estertype diesel antiwear agent

ActiveCN105154148AShort reaction timeHigh catalytic efficiencyOrganic compound preparationCarboxylic acid esters preparationSaturated fatty acid esterPtru catalyst

The invention discloses a preparation method of an unsaturated fatty acid-ester typediesel antiwear agent. The method includes adding glycerin, a fatty acid type diesel antiwear agent and a glycerin and manganese chloride complex into a reaction kettle for uniform mixing according to the mass ratio of 100-200:100:5-15. The reusable homogeneous glycerin and manganese chloride complex serving as a catalyst is adopted, reaction time is short, catalytic efficiency is high, both glycerin and the catalyst which are unreacted are recyclable, the non-acid non-basic homogeneous catalyst is used during preparation, product quality is improved beneficially, no wastewater is discharged in subsequent treatment processes, and requirements of national environmental protection are met.

Owner:JIANGXI NORMAL UNIV

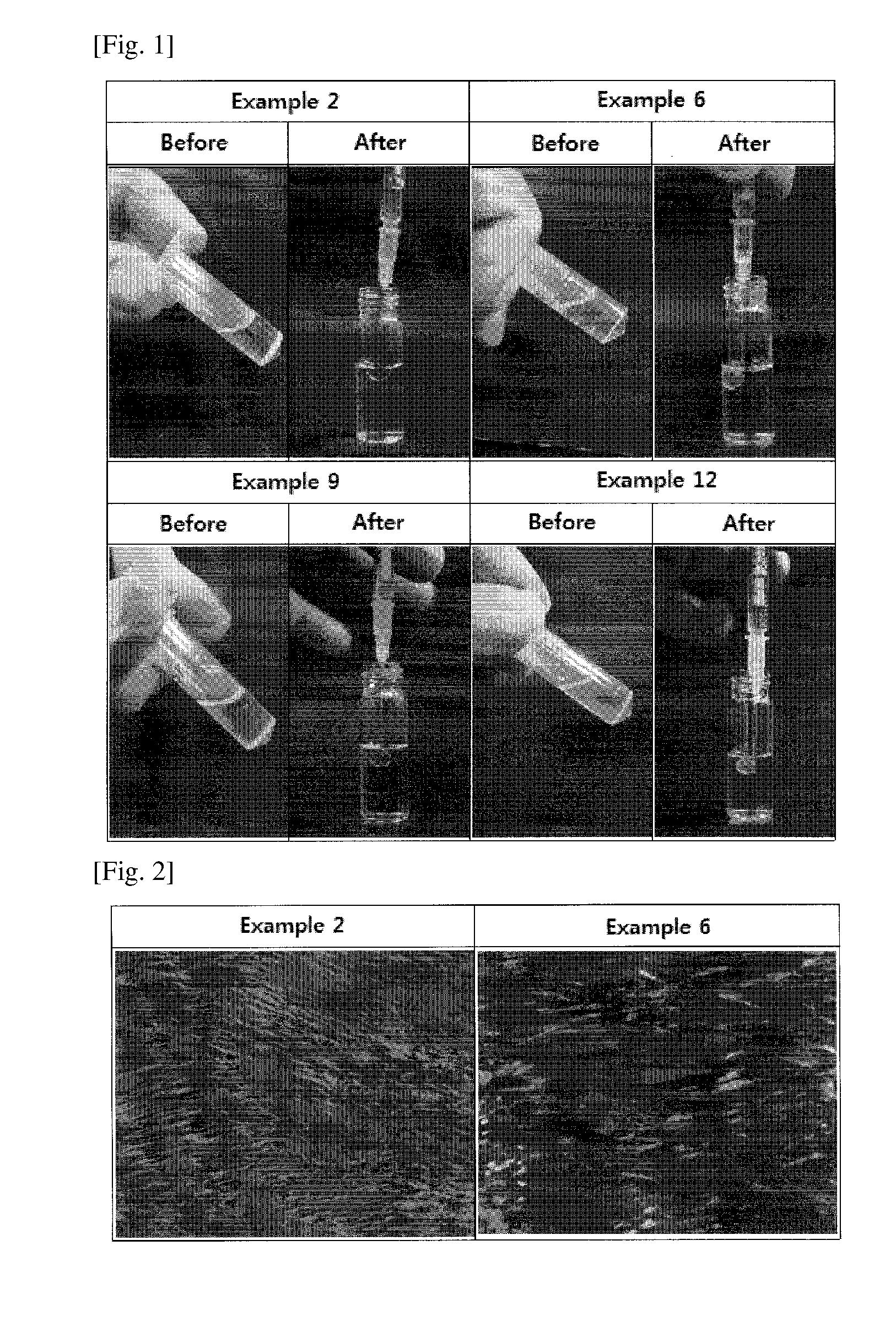

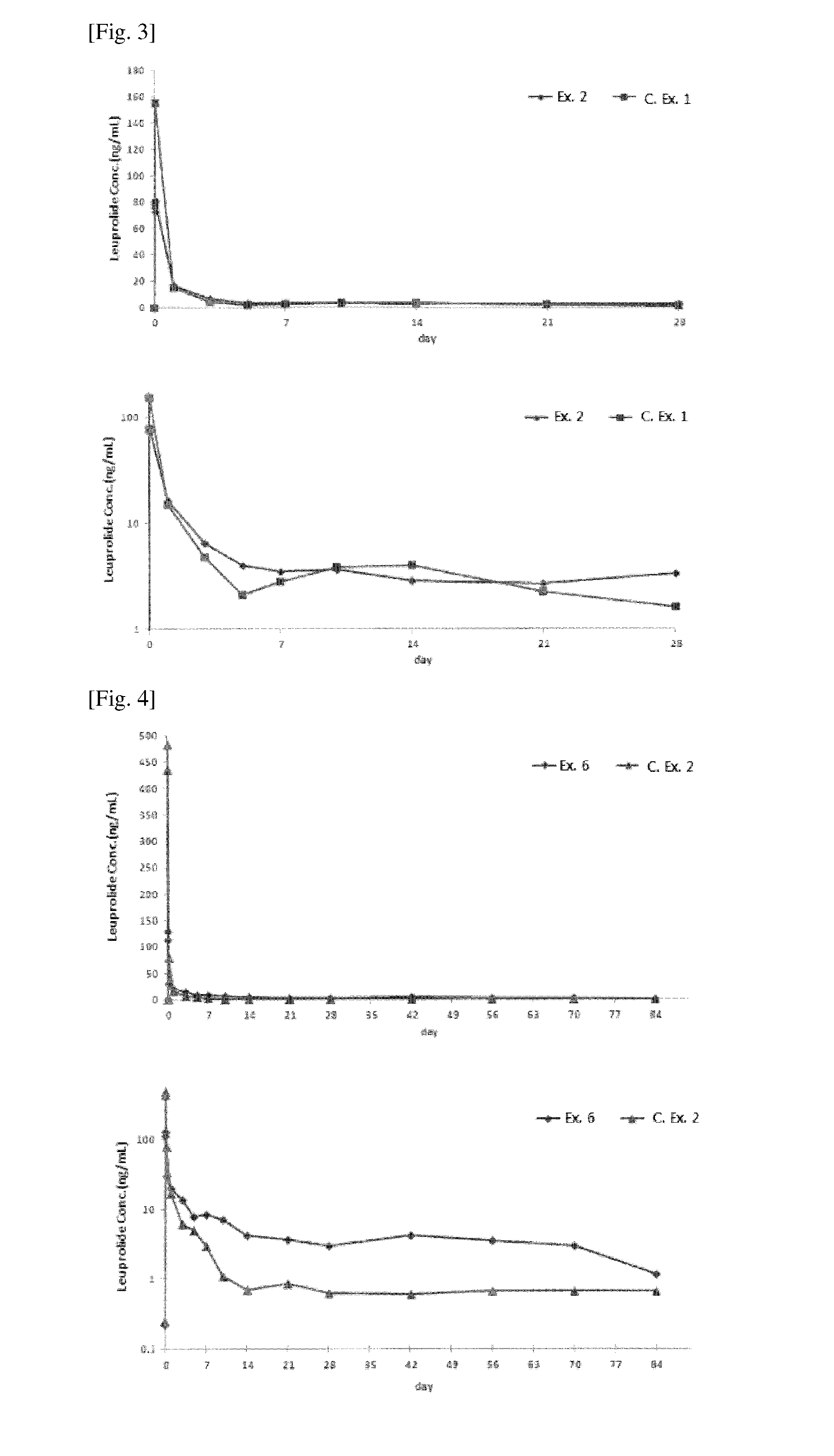

Sustained-release lipid pre-concentrate of gnrh analogues and pharmaceutical composition comprising the same

ActiveUS20150297726A1Easy to manageGood sustained releasePeptide/protein ingredientsOintment deliverySaturated fatty acid esterLipid formation

Disclosed is a pharmaceutical composition, comprising: a) at least one sorbitan unsaturated fatty acid ester having a polar head with at least two or more —OH (hydroxyl) groups; b) at least one phospholipid; c) at least one liquid crystal hardener which is free of an ionizable group and has a triacyl group with 15 to 40 carbon atoms or a carbon ring structure in a hydrophobic moiety; and d) at least one GnRH (gonadotropin-releasing hormone) analogue as a pharmacologically active substance, wherein said lipid pre-concentrate exists as a liquid phase in absence of aqueous fluid and forms into a liquid crystal in presence of aqueous fluid. The pharmaceutical composition is configured to enhance the sustained release of the pharmacologically active substance GnRH analogue.

Owner:CHONG KUN DANG PHARMA CORP

Method for synthesizing and separating phytosterol saturated fatty acid esters and phytosterol unsaturated fatty acid esters

ActiveCN102603845AAchieve separationEasy to operateSteroids preparationSaturated fatty acid esterDistillation

The invention relates to a method for synthesizing and separating phytosterol saturated fatty acid esters and phytosterol unsaturated fatty acid esters. The method comprises the following steps: reacting phytosterol and a mixture of saturated fatty acid esters and unsaturated fatty acid esters, sequentially washing the obtained products by a 70-80DEG C aqueous ethanol solution with the volume fraction of above 95% and an -10-10DEG C aqueous methanol solution with the volume fraction of above 80%, filtering, washing the obtained filter cake by the -10-10DEG C aqueous methanol solution with the volume fraction of above 80% to obtain the phytosterol saturated fatty acid esters with the purity of above 90%, carrying out reduced pressure distillation on the obtained filtrate, and carrying out film evaporation and molecular distillation to obtain the phytosterol unsaturated fatty acid esters with the purity of above 90%. According to the invention, the method is simple, conversion rates of raw materials are high, and the obtained products have the advantages of high purity and good color, and the phytosterol saturated fatty acid esters which can be used for antibiosis and anti-inflammation can be applied to the cosmetic field; and the phytosterol unsaturated fatty acid esters which have the antioxidation and cholesterol reduction effects can be applied to medicine and food fields.

Owner:XIAN HEALTHFUL BIOTECH

Thermoplastic compositions and method of use thereof for molded articles

ActiveUS20080128934A1Reduce surface frictionImprove performanceArtificial filament recoveryFibre treatmentSaturated fatty acid esterElastomer

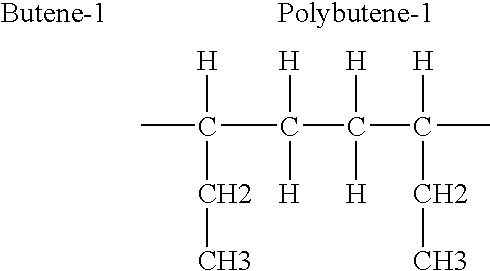

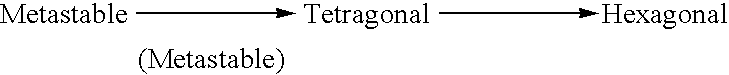

A polyolefin composition containing elastomers (plasticizers), crystalline polypropylene, modified by mixing with polybutene-1 and a coupling agent and a bicyclic dicarboxyl acid salt nucleating agent and / or a lubricant which comprises an unsaturated fatty acid ester which acts as a surface modifier in a molded article is described. The composition is adapted to be used with pigments to make finished molded articles which have an appearance of paint covered by a clear coat and which are scratch resistant and have good low temperature (−30° C.) impact properties.

Owner:INNOVATIVE POLYMERS LLC

Method for Producing Monosaturated Glycerides

A process for producing a glyceride product which is enriched in monounsaturated fatty acids relative to the starting glyceride comprising the steps: (a) alcoholysis of triglycerides employing lipolytic enzymes selective for saturated fatty acids and / or lipolytic enzymes selective for the 1-position, the 3-position or both positions in a glyceride; and (b) separation of fraction A which is enriched in saturated fatty acid esters from fraction B which is enriched in monounsaturated glycerides.

Owner:NOVOZYMES AS

A kind of purification method of sucrose fatty acid ester

ActiveCN103087118BSolve the problem of high acid valueIncrease content levelEsterified saccharide compoundsSugar derivativesSaturated fatty acid esterSucrose

Owner:LIUZHOU GAOTONG FOOD CHEM

Scratch resistant refinish clearcoat

ActiveUS20130202893A1Improve scratch resistanceIncreasing reflowSynthetic resin layered productsLaminationSaturated fatty acid esterPolyol

Scratch resistance and / or reflow of a refinish topcoat is improved by preparing the topcoat from a refinish topcoat coating composition comprising an unsaturated fatty acid ester polyol that does not undergo oxidative cure when the applied refinish topcoat coating composition is cured.

Owner:BASF COATINGS GMBH

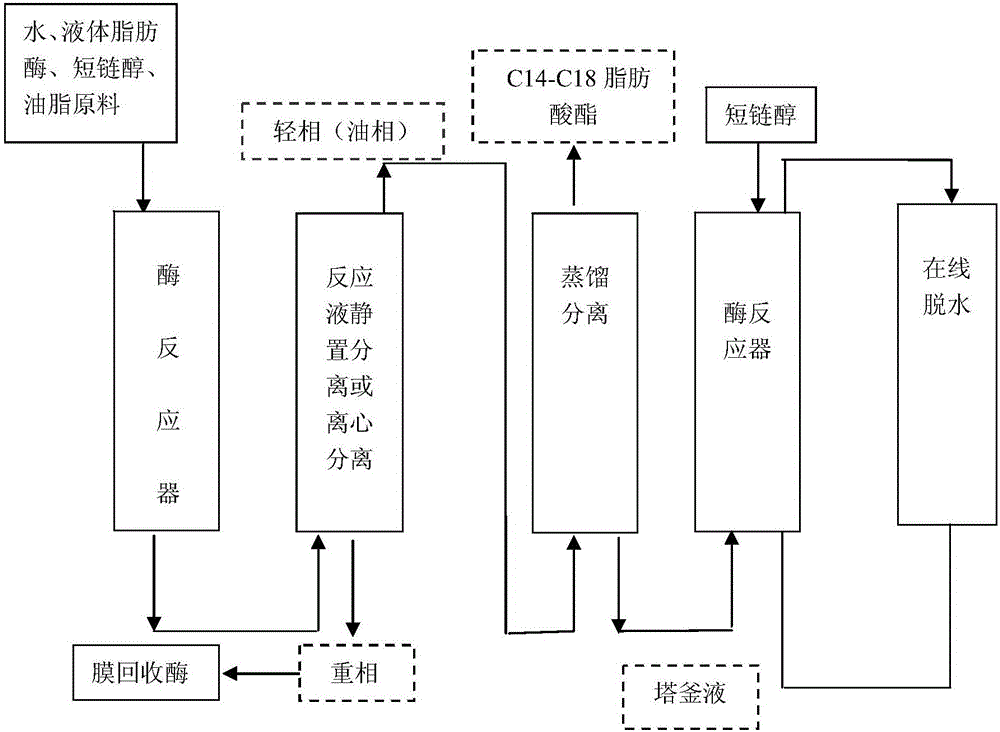

Coupling process for preparing biodiesel and enriching polyunsaturated fatty acid esters

InactiveCN106399406AImprove applicabilityHigh yieldBiofuelsFermentationSaturated fatty acid esterOil phase

The invention relates to a coupling process for preparing biodiesel and enriching polyunsaturated fatty acid esters. The coupling process comprises the following steps: reacting grease, short-chain alcohol, water and liquid lipase in a reactor, and then dividing reaction liquid into a heavy phase and a light phase; recycling and reusing enzyme in the heavy phase; and distilling the light phase so as to separate out a C14-C18 fatty acid ester which serves as the biodiesel. A tower oil phase is applied to subsequent immobilized enzyme transformation, and meanwhile, online dehydration is introduced to a reaction course. The process, without conducting pre-treatment on the grease raw material in a previous reaction process of liquid enzyme catalysis, can achieve the effective transformation of the grease, which is C14-C18 in fatty acid carbon-chain length, into corresponding fatty acid ester, with a transformation rate reaching 90% or above; and tower liquid is applied to immobilized lipase catalysis in the second stage, and polyunsaturated fatty acid esters higher than C19 are effectively transformed into corresponding fatty acid ester, with a transformation rate reaching 98% or above. The process has the advantages of being strong in grease raw material adaptability, environment-friendly and clean in process, high in product yield and the like.

Owner:北京启迪德清生物能源科技有限公司

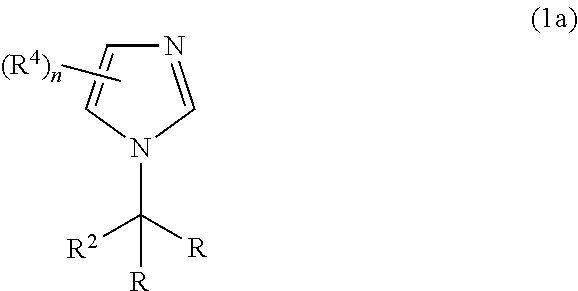

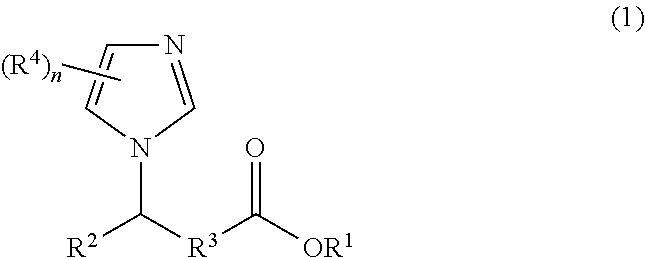

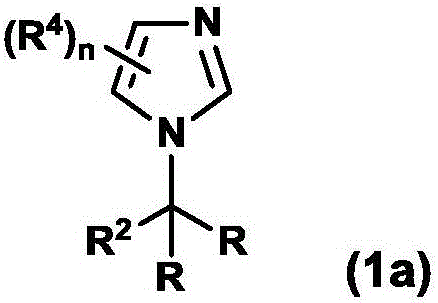

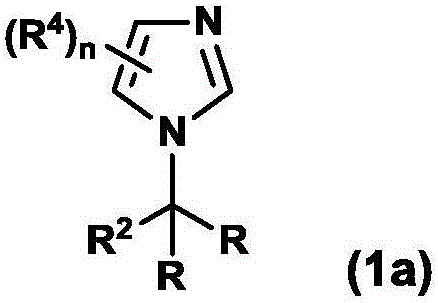

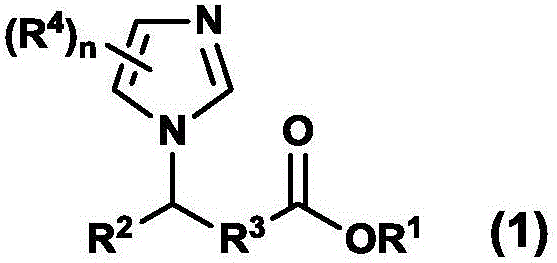

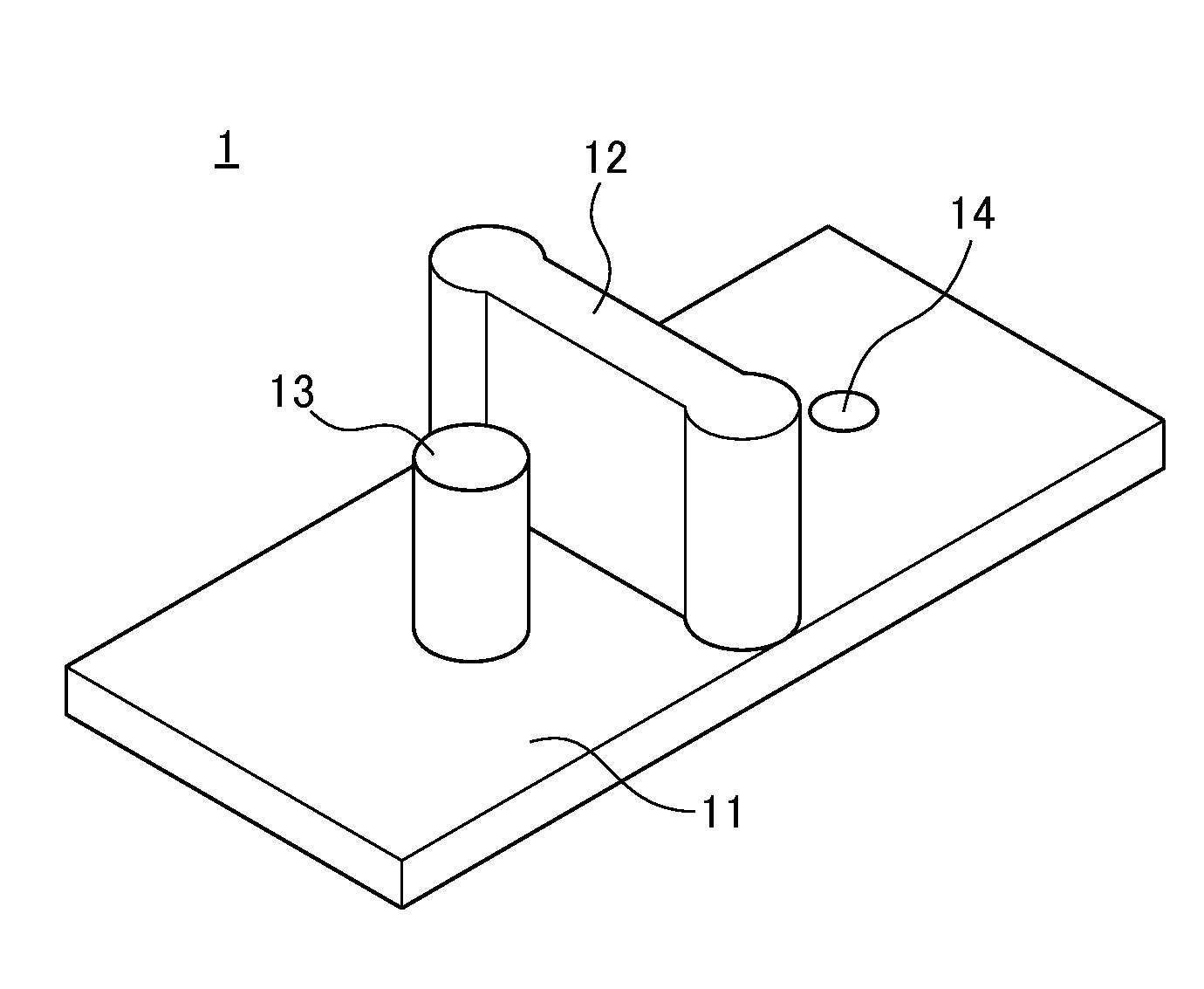

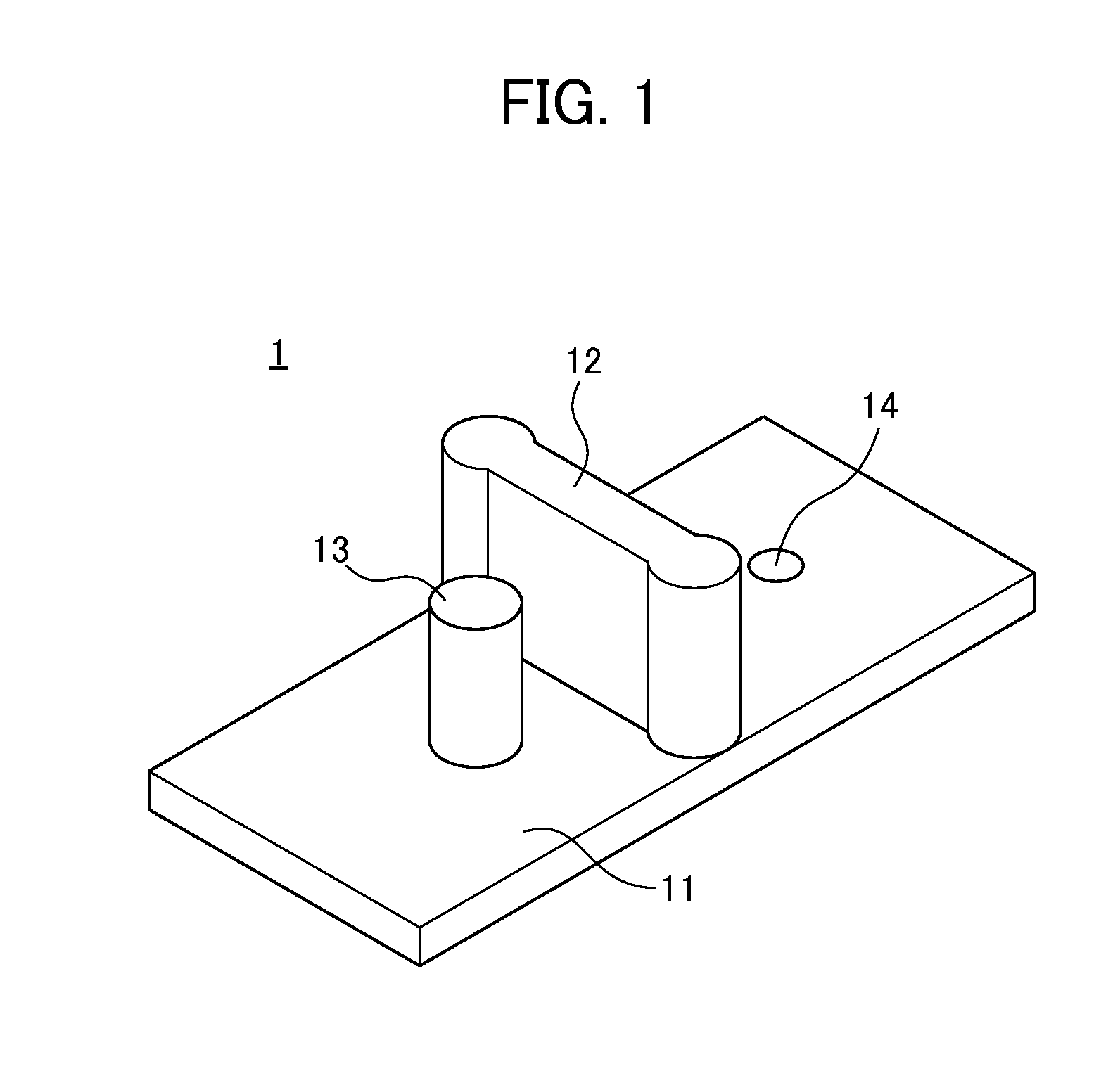

Imidazole compound, metal surface treatment liquid, metal surface treatment method, and laminate production method

ActiveUS20170247334A1Suppressing migrationSuppressing oxidizationOrganic chemistryPrinted circuit aspectsSaturated fatty acid esterChemical compound

A novel imidazole compound that yields a surface treatment liquid that is very effective at suppressing migration and oxidation of a wiring surface; a metal surface treatment liquid that contains the imidazole compound; a metal surface treatment method that uses the metal surface treatment liquid; and a laminate production method that uses the surface treatment liquid. A metal is surface-treated using the surface treatment liquid which includes a saturated fatty acid or a saturated fatty acid ester of a specific structure, in which a prescribed position is substituted by an aromatic group of a prescribed structure and an imidazolyl group that may have a substituent group.

Owner:TOKYO OHKA KOGYO CO LTD

Environment-friendly solvent-free polyurethane for synthetic leather and manufacturing method of polyurethane

PendingCN111041843AImprove protectionPromote sustainable developmentTextiles and paperSaturated fatty acid esterPolymer science

The invention discloses environment-friendly solvent-free polyurethane for synthetic leather. The polyurethane comprises base cloth, a water-based surface layer, a water-based adhesive layer, a foaming layer and a functional auxiliary agent, wherein the water-based surface layer comprises water-based polyurethane emulsion, a thickening agent, a water-based defoaming agent, water-based color pasteand a leveling agent; the water-based adhesive layer comprises water-based polyurethane emulsion, a water-based polyurethane crosslinking agent and water-based color paste; the foaming layer comprisesa polyol compound, white carbon black, an organometallic catalyst, hydroxyl silicone oil, fatty acid, an organic amine catalyst, a filler and toluene diisocyanate; and the functional auxiliary agentcomprises sorbitol, maltitol, oligosaccharide, glycerin saturated fatty acid ester, a coloring agent and a surfactant. The environment-friendly solvent-free polyurethane for the synthetic leather is clean and environment-friendly; the foaming layer is free of an organic solvent, so that the polyurethane is more environment-friendly and environmental protection and sustainable development are facilitated; and meanwhile, the polyurethane has the relatively good toughness.

Owner:福建成杰高分子材料有限公司 +1

Imidazole compound, metal surface treatment liquid, metal surface treatment method, and laminate production method

ActiveCN106687447AEnhanced inhibitory effectOrganic chemistryPrinted circuit aspectsSaturated fatty acid esterChemical compound

This invention provides: a new imidazole compound that yields a surface treatment liquid that is very effective at suppressing migration and the oxidation of a wiring surface; a metal surface treatment liquid that contains the imidazole compound; a metal surface treatment method that uses the metal surface treatment liquid; and a laminate production method that uses the surface treatment liquid. Metal is surface-treated using the surface treatment liquid which includes a saturated fatty acid or a saturated fatty acid ester of a specific structure, in which a prescribed position is substituted by an aromatic group of a prescribed structure and an imidazolyl group that may have a substituent group.

Owner:TOKYO OHKA KOGYO CO LTD

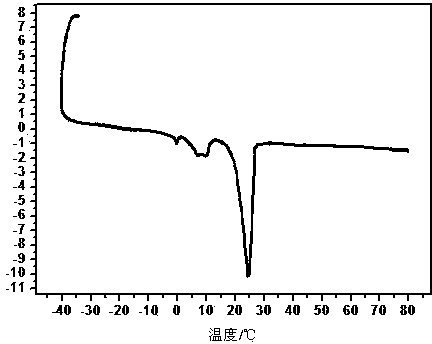

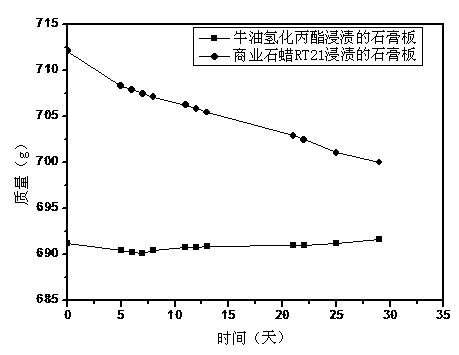

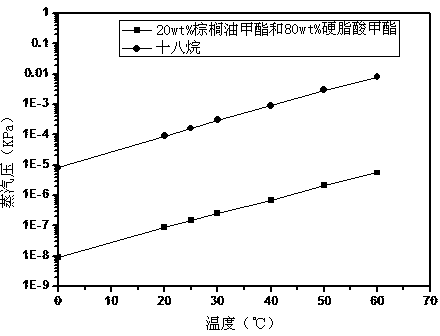

Preparation method for fatty acid ester phase-change energy storage material

InactiveCN103740336ASimple processLow costFatty acid hydrogenationFatty acid esterificationSaturated fatty acid esterAlcohol

The invention discloses a preparation method for a fatty acid ester phase-change energy storage material. The preparation method comprises the following operation steps: (1) carrying out an ester exchange reaction: enabling grease containing triglyceride and alcohols to react under the effect of a catalyst to generate a fatty acid ester, wherein the adding mol ratio of the grease to the alcohols is 1 to 6 and the catalyst is metal hydroxide or metal alcoholate; (2) carrying out a hydrogenation reaction: carrying out the hydrogenation reaction on the fatty acid ester to generate a saturated fatty acid ester, wherein the catalyst of the hydrogenation reaction is palladium active carbon; the mass percent of palladium is 4%-6%; the reaction temperature is 55-65 DEG C; the reaction pressure is 0.2-0.3MPa. According to the preparation method, raw materials for preparing the fatty acid ester are renewable and environment-friendly oil and fat and are cheap and easy to obtain. The invention provides an effective method which adopts the current grease as the raw material to prepare the high-quality fatty acid ester phase-change material by using a small cost.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

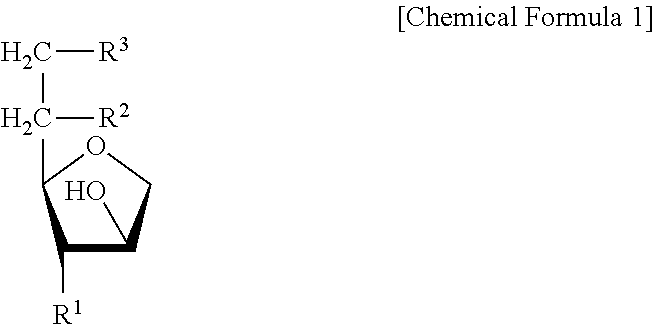

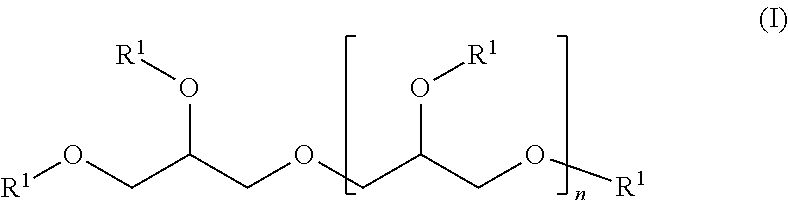

Polybutylene terephthalate resin composition and pellet thereof

ActiveUS20130309500A1Good release effectSuppress deterioration in molding stabilitySynthetic resin layered productsCellulosic plastic layered productsSaturated fatty acid esterPolytetramethylene terephthalate

Provided are a polybutylene terephthalate resin composition which is excellent in mold releasability and which can suppress deterioration in molding stability and aggregation of the polybutylene terephthalate resin composition due to blooming of a mold release agent; and a pellet thereof. The polybutylene terephthalate resin composition contains 0.01 to 5.0 parts by mass of (B) a saturated fatty acid ester of a polyglycerol represented by formula (I) described below with respect to 100 parts by mass of (A) a polybutylene terephthalate resin. In formula (I), R1s each may be the same or different and are C19-30 saturated aliphatic acyl groups, and n is an integer from 1 to 10.

Owner:POLYPLASTICS CO LTD

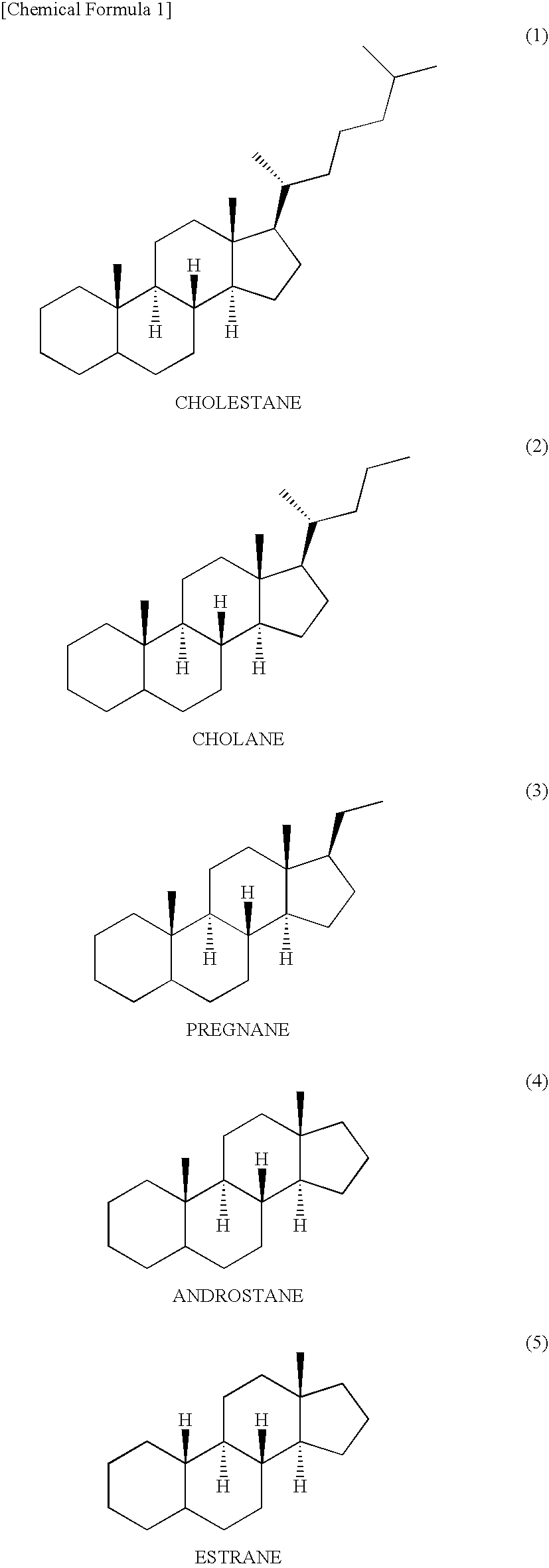

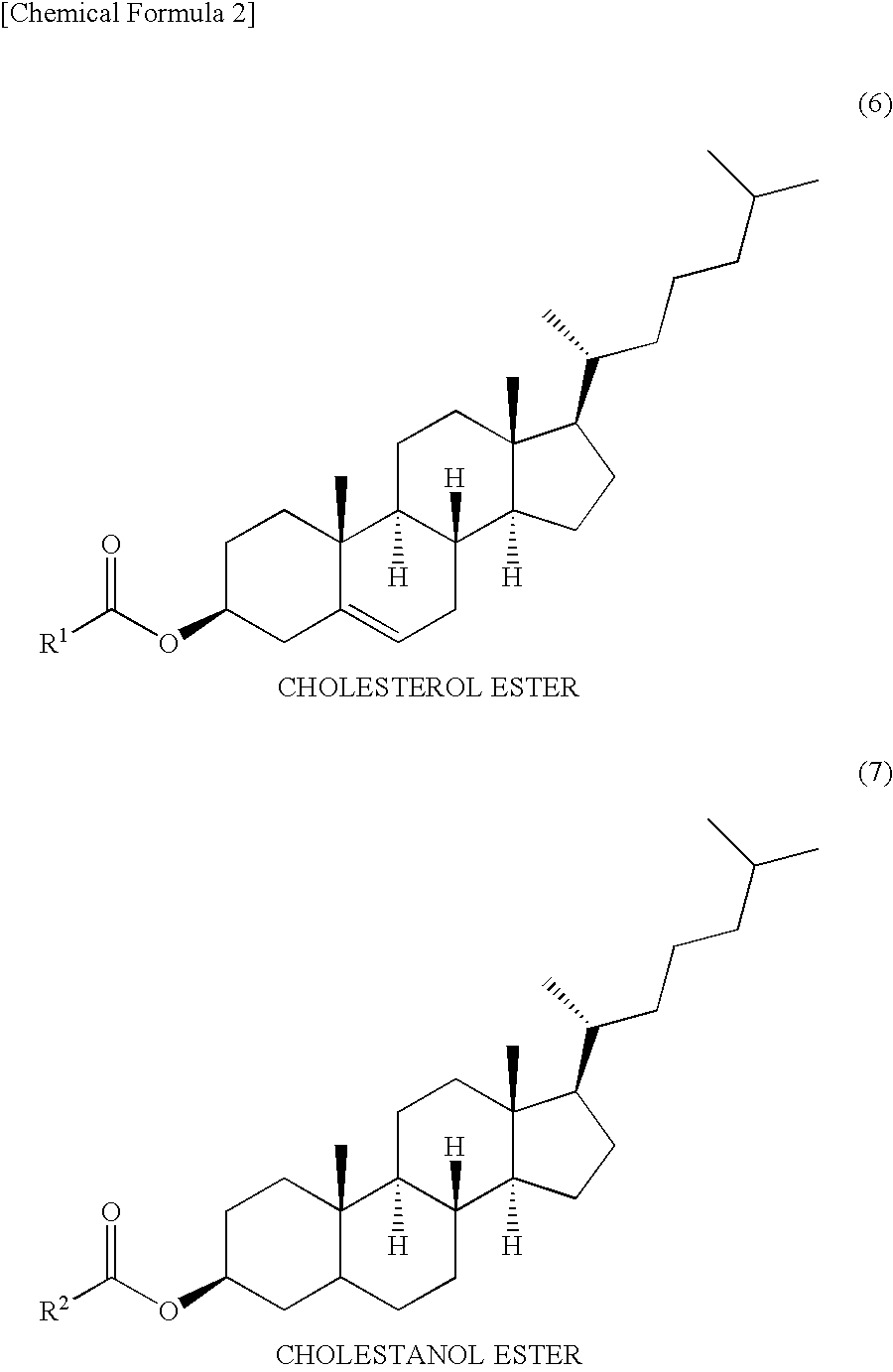

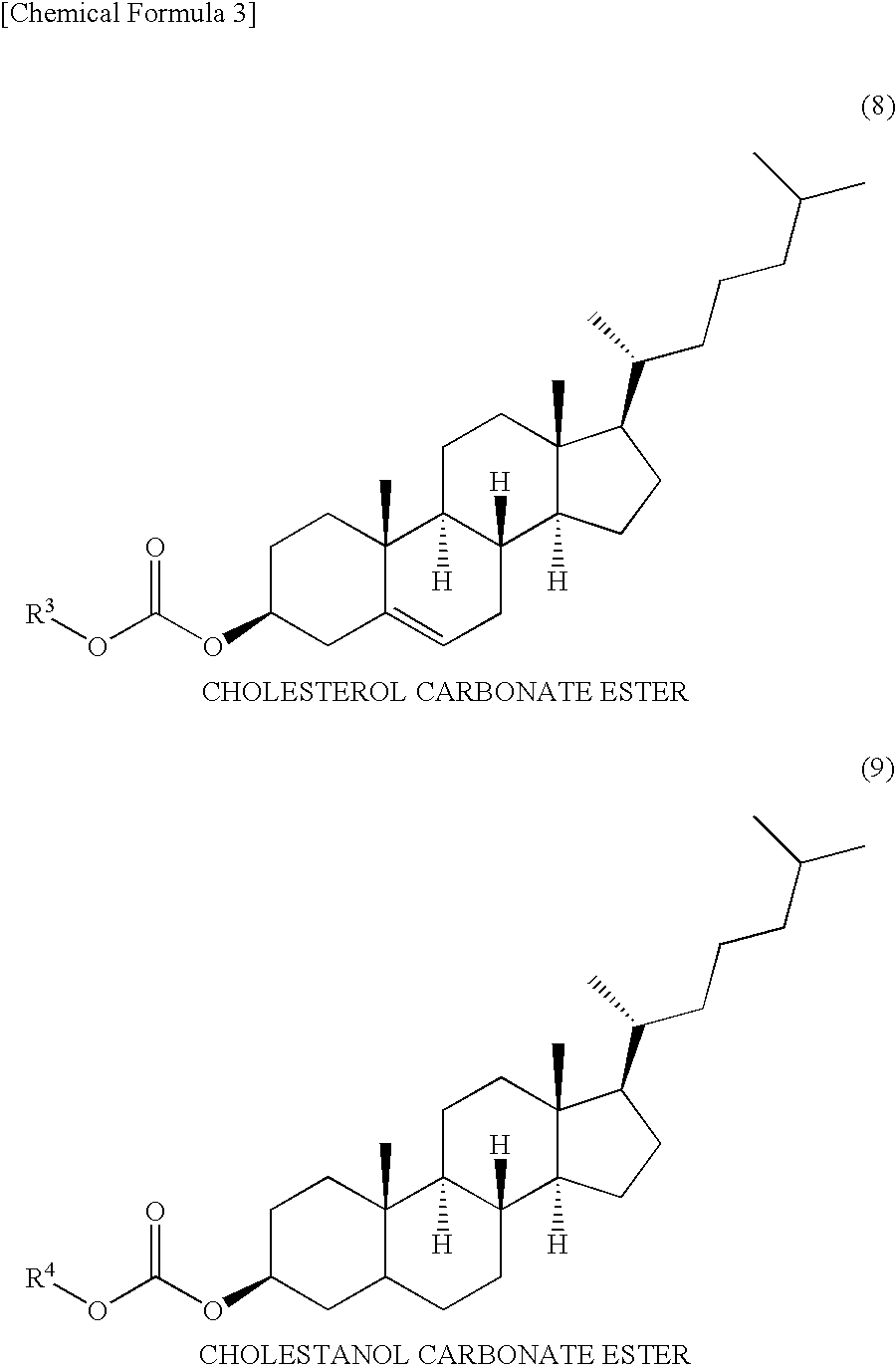

Lubricant additive and lubricant composition

InactiveUS20100190670A1Fully lubricatedReduce coefficient of frictionLiquid carbonaceous fuelsAdditivesSaturated fatty acid esterChemical composition

A lubricating oil additive contains at least one steroid derivative selected from steroid saturated fatty acid ester, steroid carbonate ester and steroid ether. A lubricating oil composition added with the lubricating oil additive exhibits a low friction coefficient and excellent wear resistance, heat resistance and oxidation resistance stability.

Owner:IDEMITSU KOSAN CO LTD

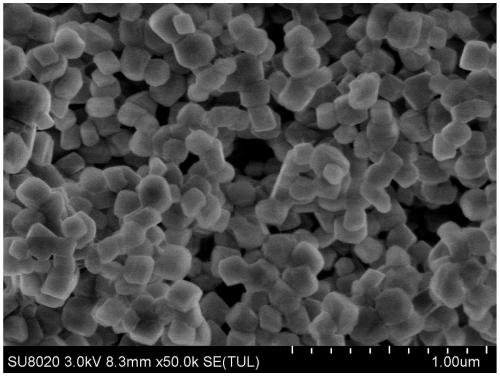

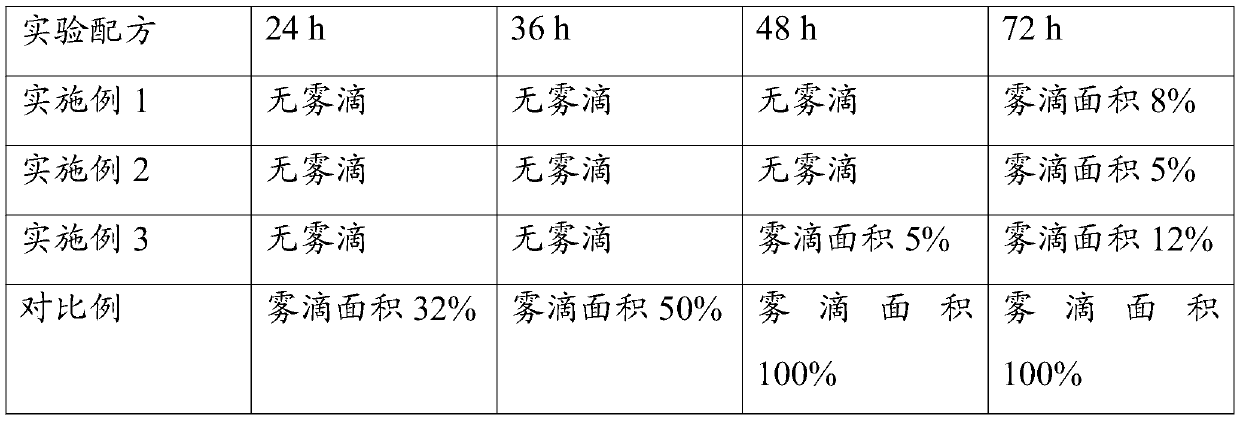

Preparation method of special nanometer calcium carbonate for antifogging polyethylene films

InactiveCN109971216AImprove mechanical propertiesGood optical performancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSaturated fatty acid esterFiltration

The invention discloses a preparation method of special nanometer calcium carbonate for antifogging polyethylene films. The method concretely comprises the following steps: diluting lime milk, and conveying the diluted lime milk into a film reaction carbonizer; introducing a purified and cooled kiln gas into the above film reactor, and carrying out a carbonizing reaction to obtain a nanometer calcium carbonate slurry; adding sodium carboxymethylcellulose into the film reactor the after the completion of the reaction, performing uniform stirring, conveying the obtained slurry into a homogenization tank, and carrying out heat insulation aging; conveying the aged calcium carbonate slurry into a surface treatment tank, heating the aged slurry, adding a composite emulsion of a saturated fatty acid ester and polyphenyltrimethoxysiloxane to carry out secondary cladding modification, and performing stirring to obtain a modified nanometer calcium carbonate slurry; and carrying out pressure filtration dehydration, and drying, crushing, classifying and packaging the hydrated modified slurry to obtain the special nanometer calcium carbonate for antifogging polyethylene films. The nanometer calcium carbonate obtained in the invention can meet the requirements for the dispersibility, transparency and compatibility of a filler in the polyethylene system, and also can effectively prevent the films from fogging.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

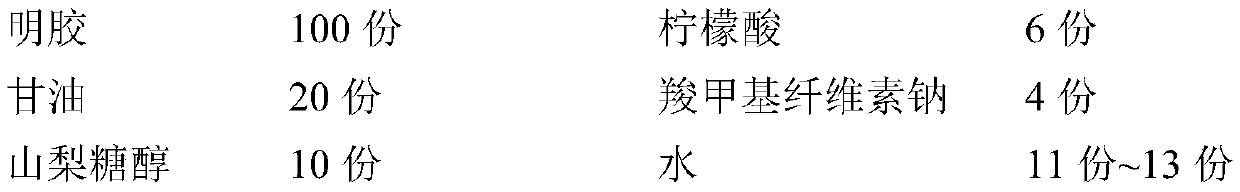

Water-soluble haematococcus pluvialis astaxanthin soft capsules and preparation method therefor

PendingCN111567805AGood water solubilityIncrease disintegration rateFood homogenisationFood preservationSaturated fatty acid esterCellulose

The invention discloses water-soluble haematococcus pluvialis astaxanthin soft capsules and a preparation method therefor. Capsule walls of the astaxanthin soft capsules comprise the ingredients in parts by mass: 100 parts of gelatin, 6 parts of citric acid, 20 parts of glycerine, 4 parts of sodium carboxymethyl cellulose, 10 parts of sorbitol and 11-13 parts of water; and capsule cores comprise the ingredients in percentage by mass: 10.0%-18.0% of haematococcus pluvialis astaxanthin oil, 10.0%-20.0% of polyethylene glycol-400, 20.0%-40.0% of mono- / bis-glyceryl unsaturated fatty acid ester, 2.0%-5.0% of sorbitol and 30.0%-45.0% of decapolyglyceryl monooleate. The preparation method for the astaxanthin soft capsules further comprises a step of carrying out high-pressure homogenizing mixingunder nitrogen protection so as to prepare the capsule cores. According to the water-soluble haematococcus pluvialis astaxanthin soft capsules and the preparation method therefor, all adjuvants employed are used by health-care foods according to production needs, an emulsifier is an unsaturated fatty acid processed product, the astaxanthin soft capsules are safe, non-toxic, compliant and legal, are low in health security risk and are suitable for an aqueous nutrient absorption system of the intestines and stomach of a human body, and the bioavailability of an active ingredient, i.e., astaxanthin can be improved.

Owner:YUNNAN AIERKANG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com