Patents

Literature

976results about How to "Fully lubricated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

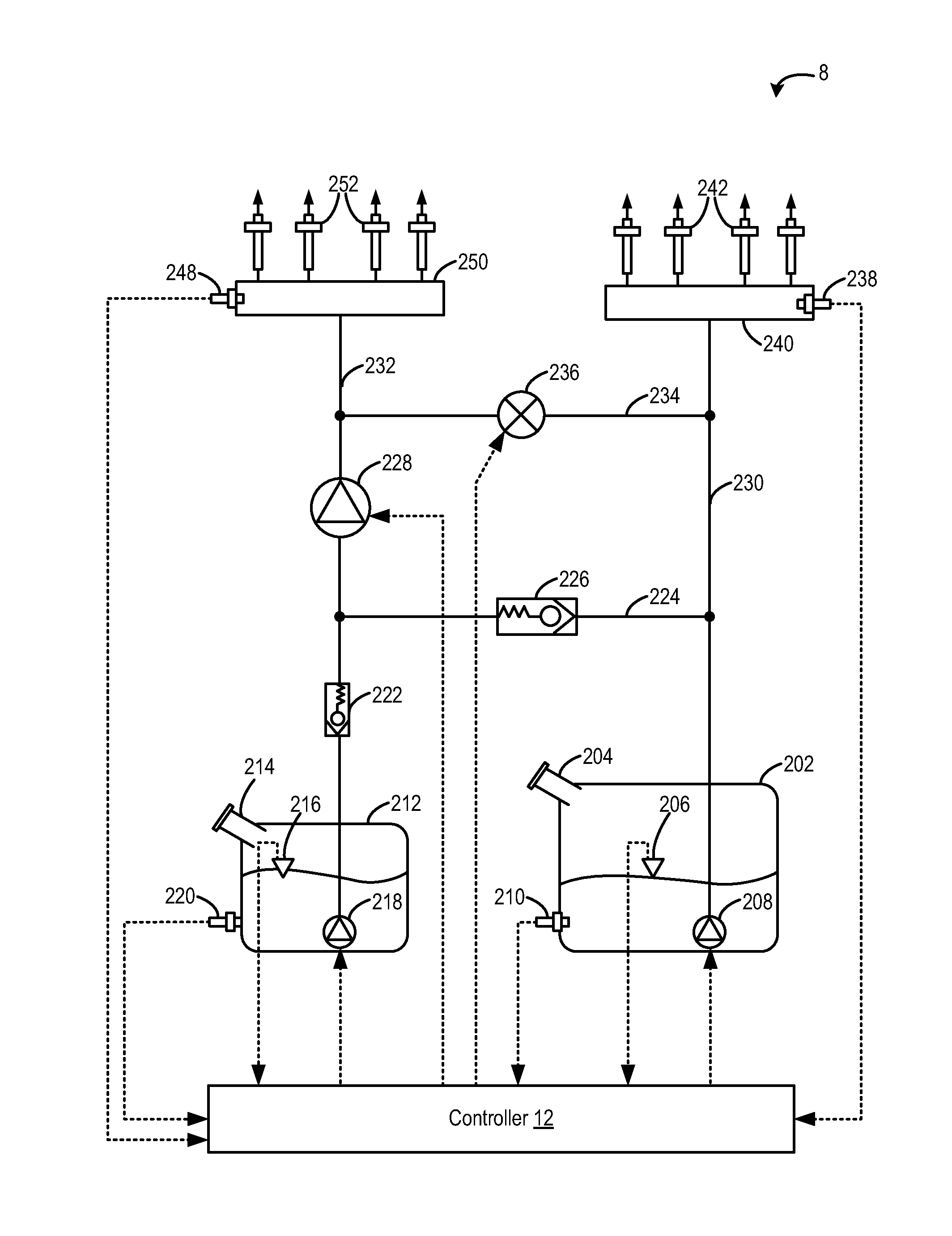

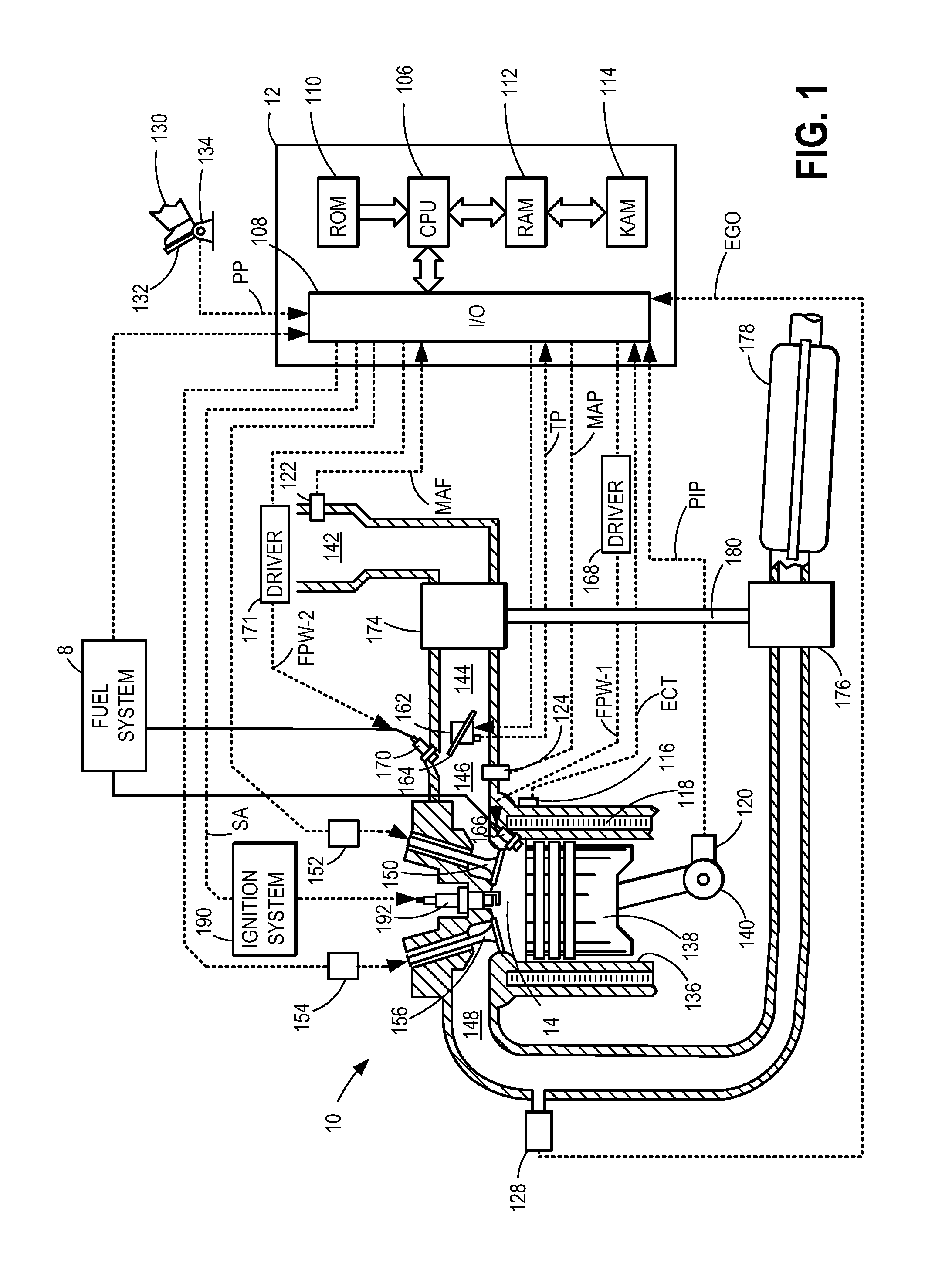

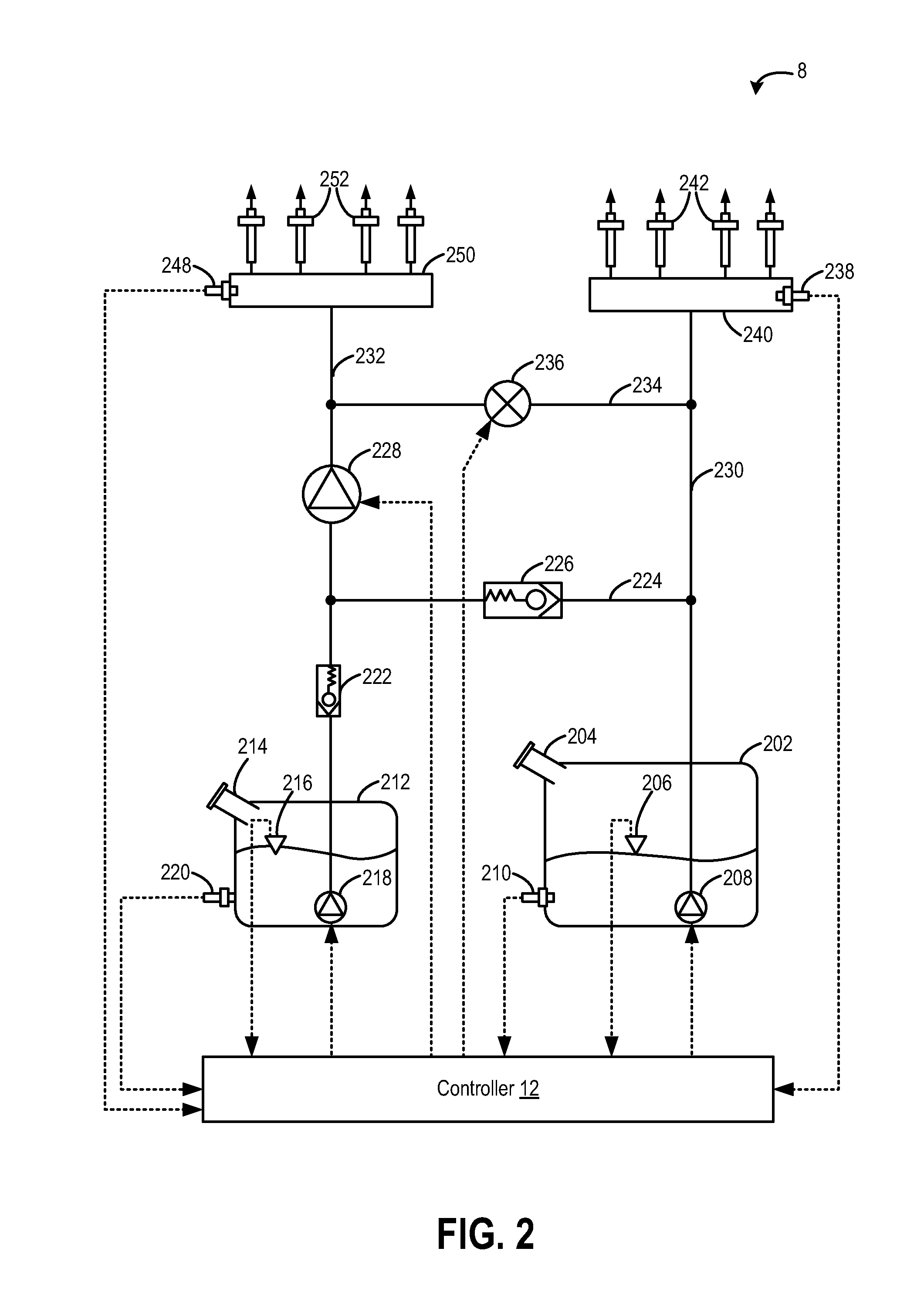

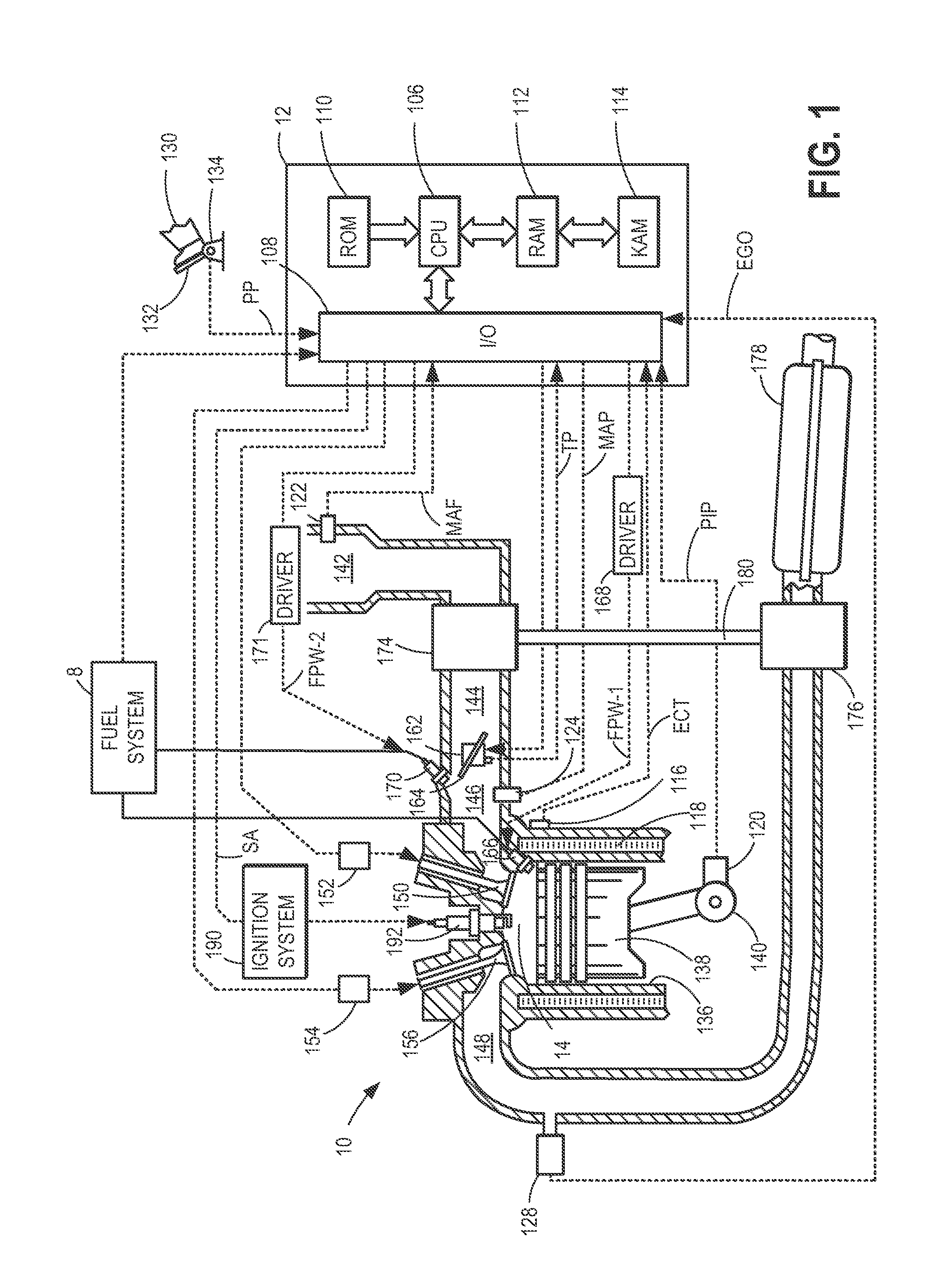

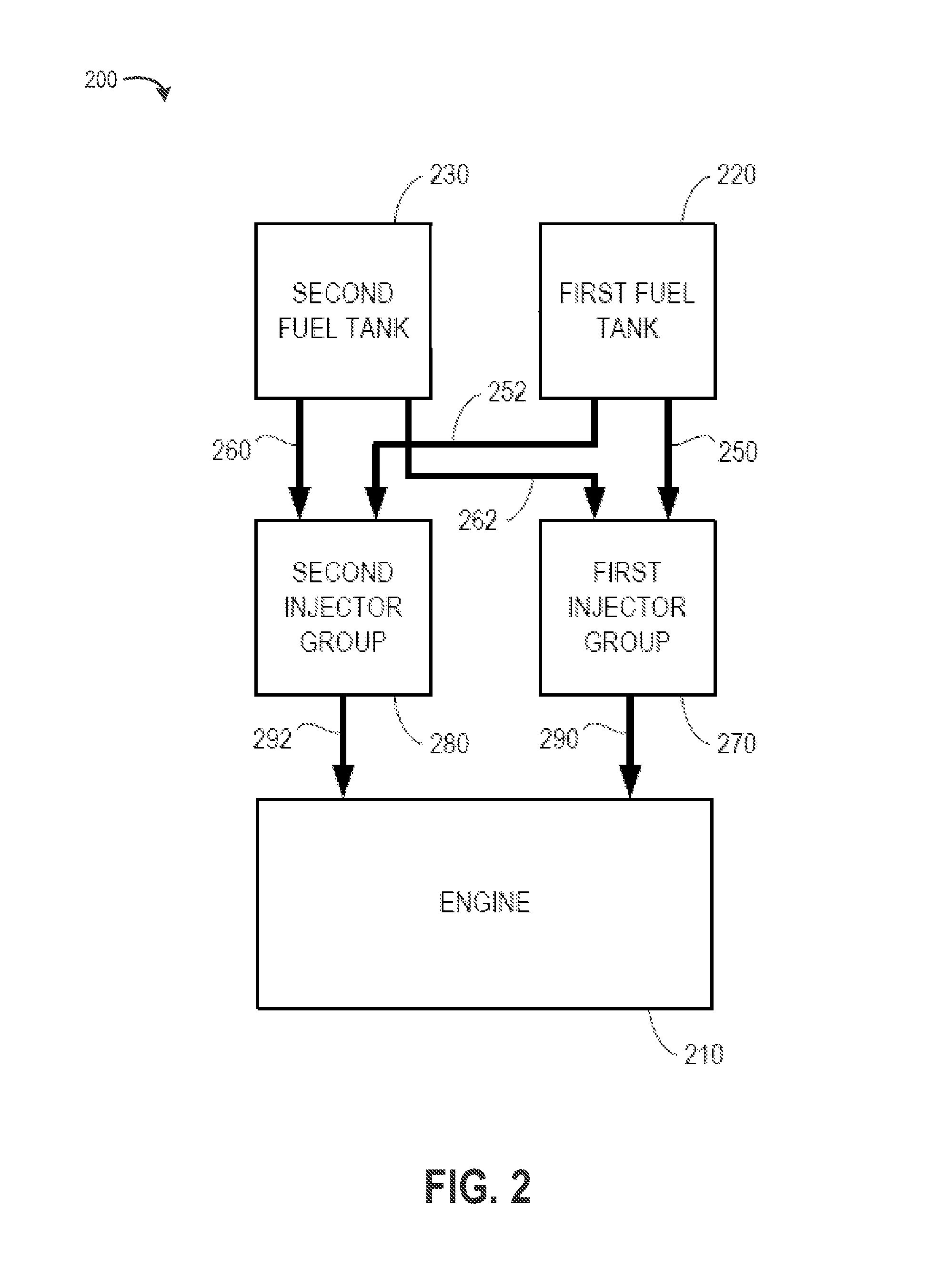

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

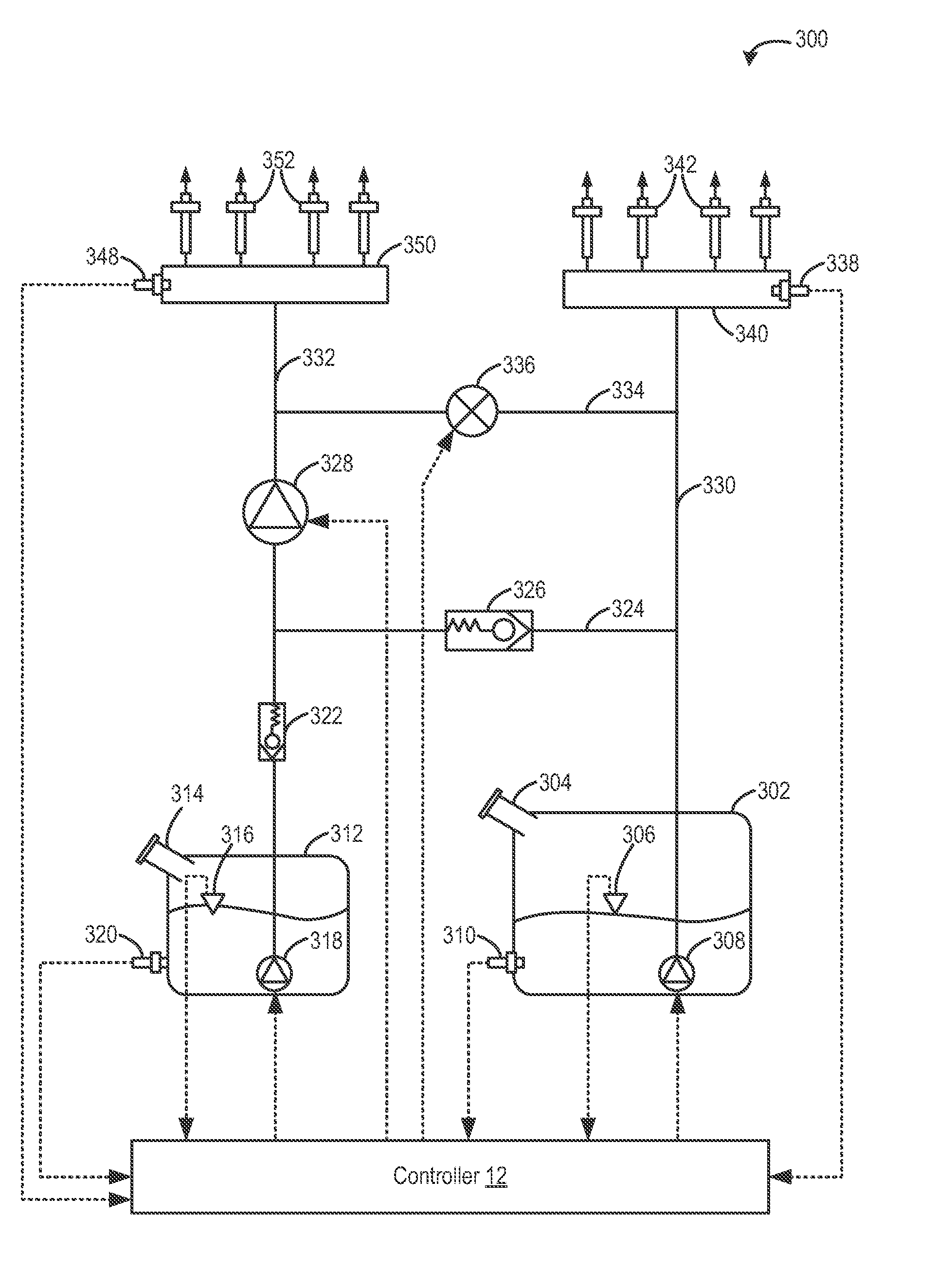

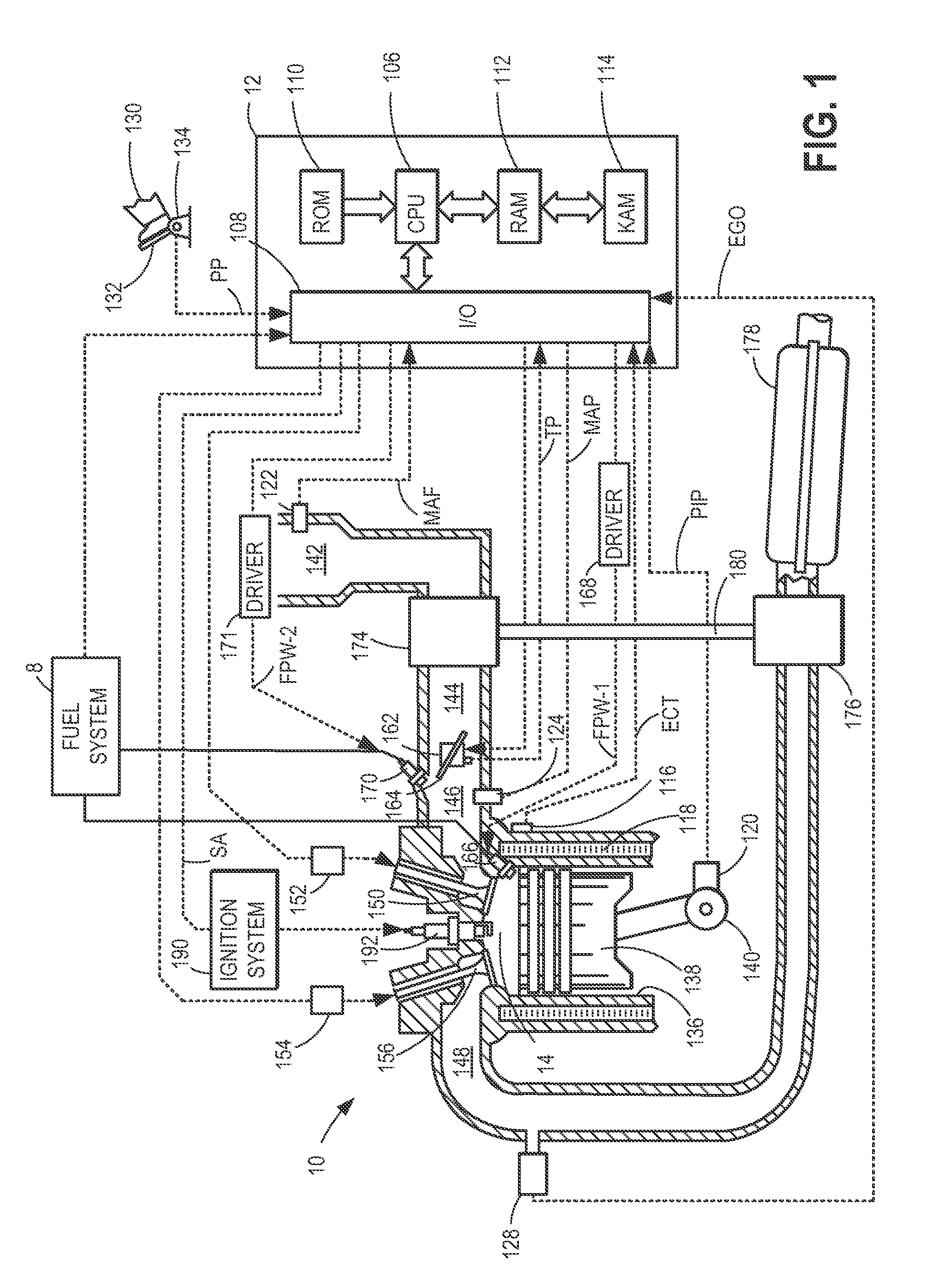

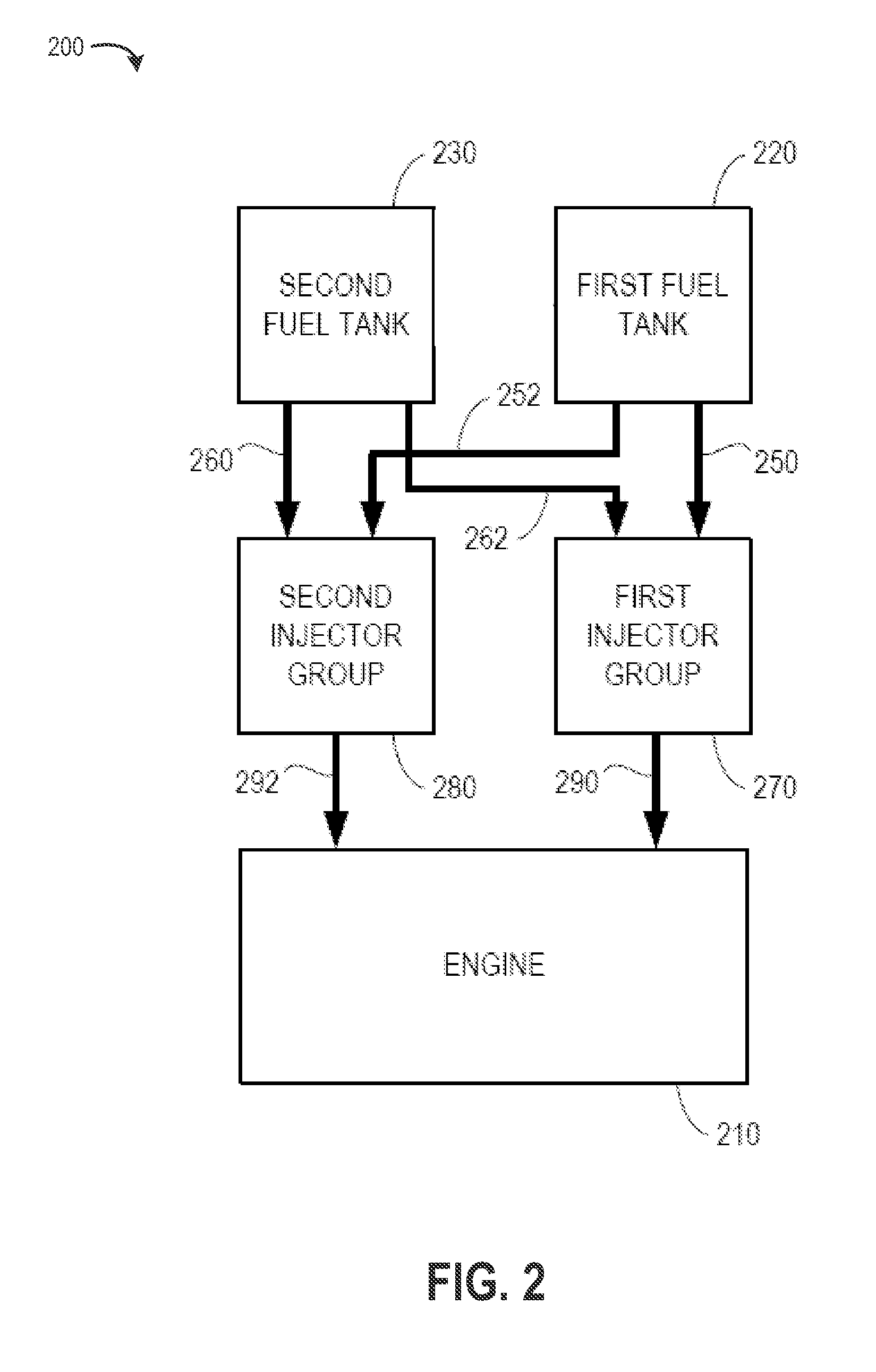

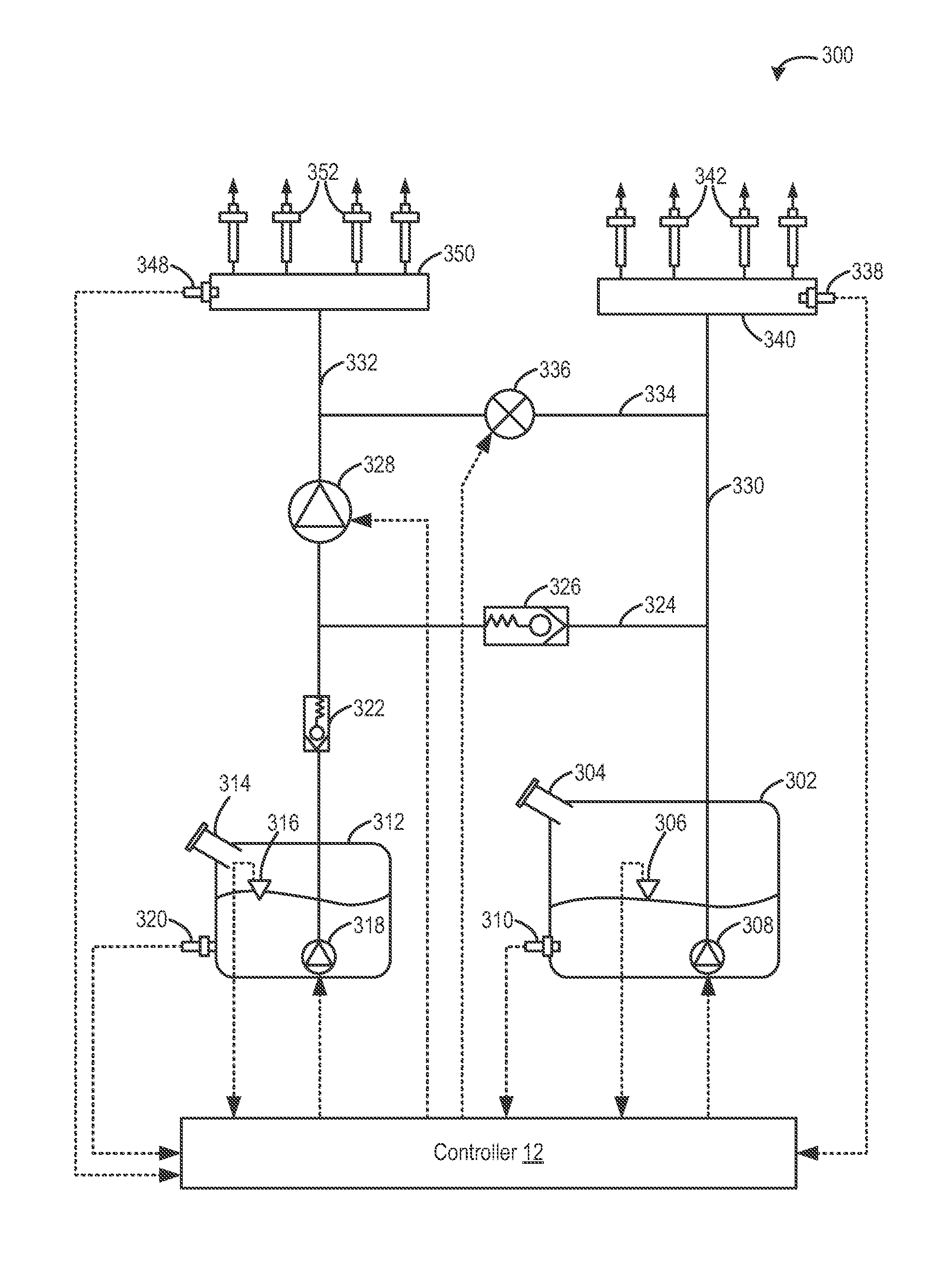

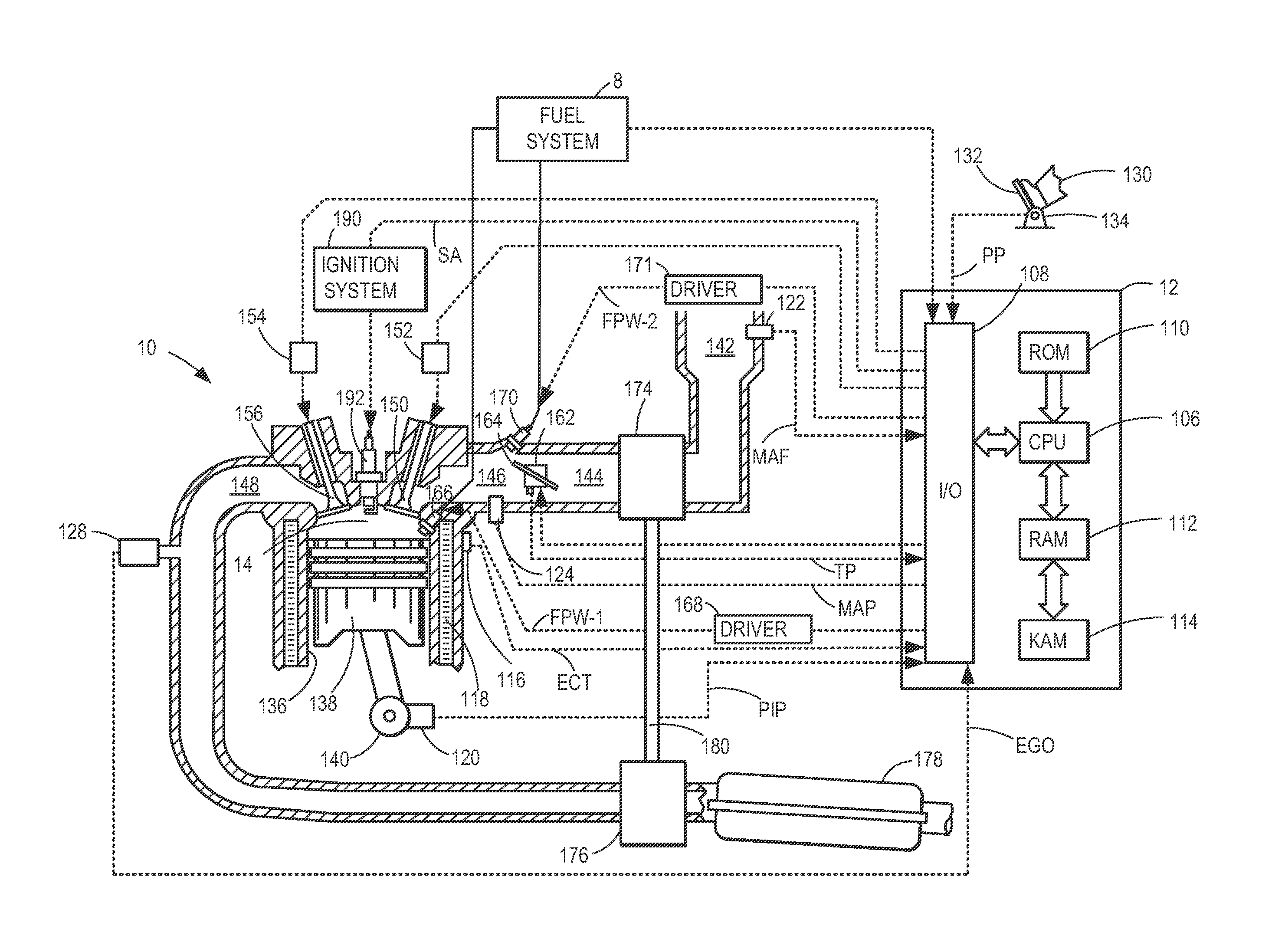

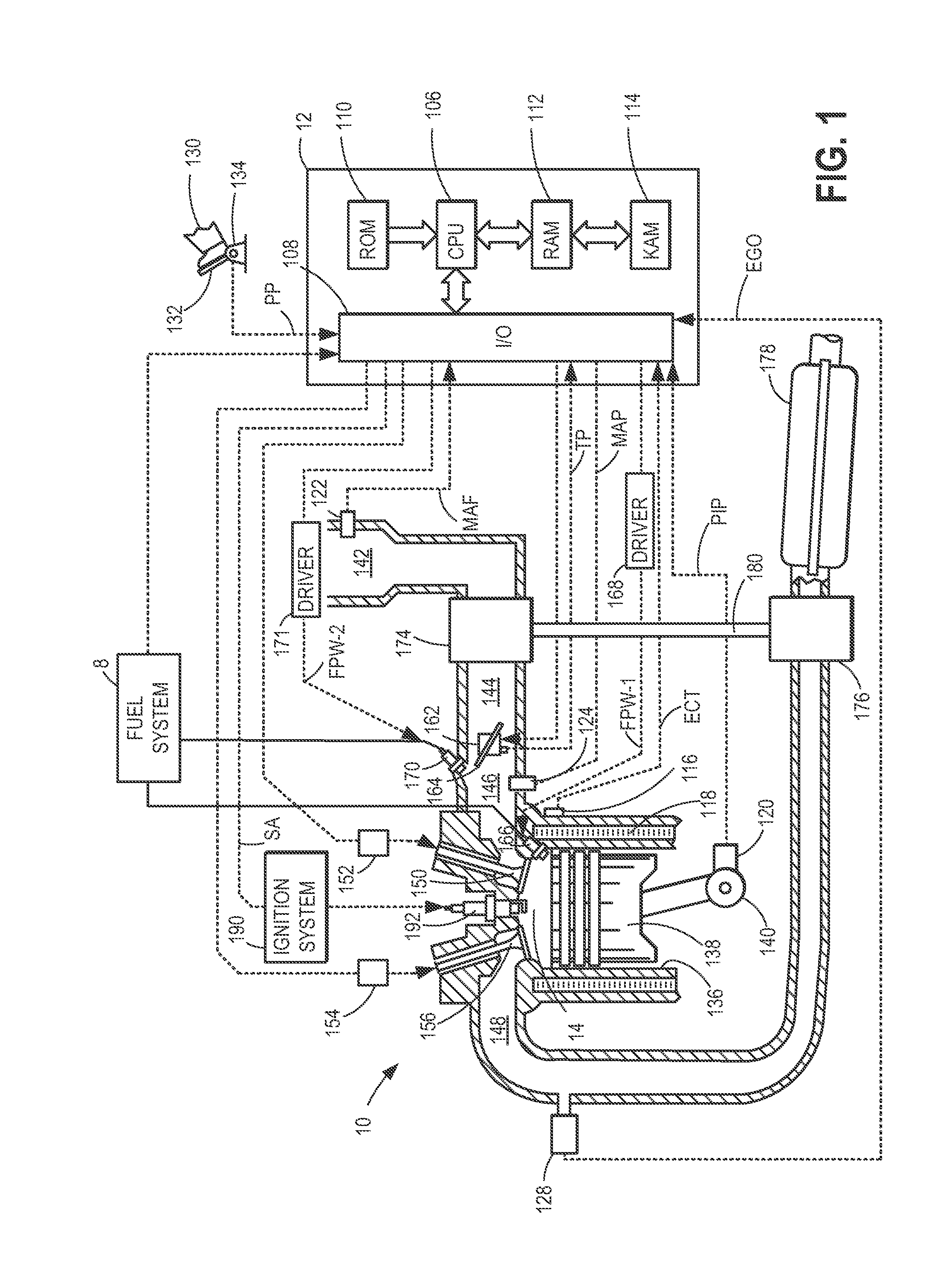

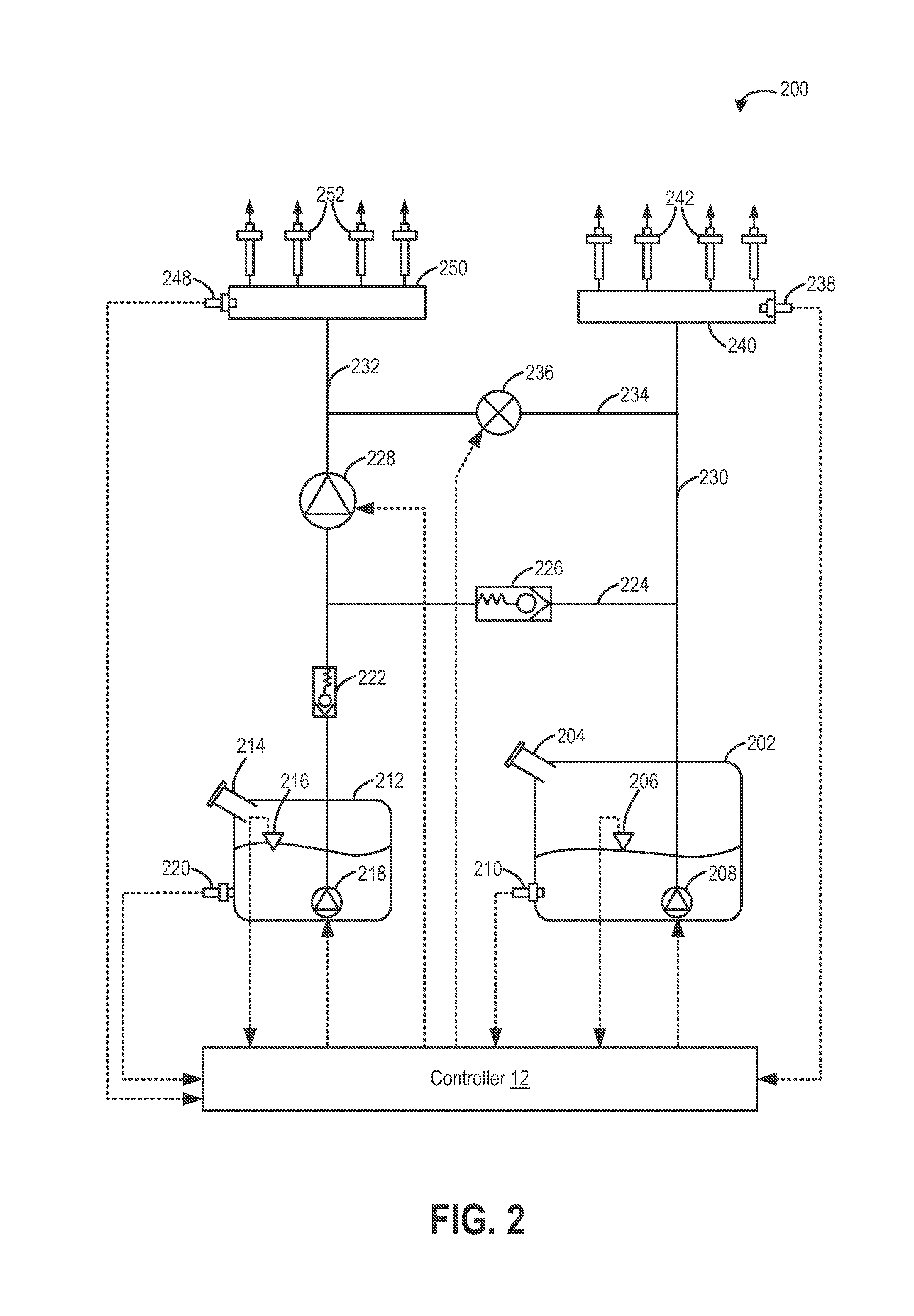

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

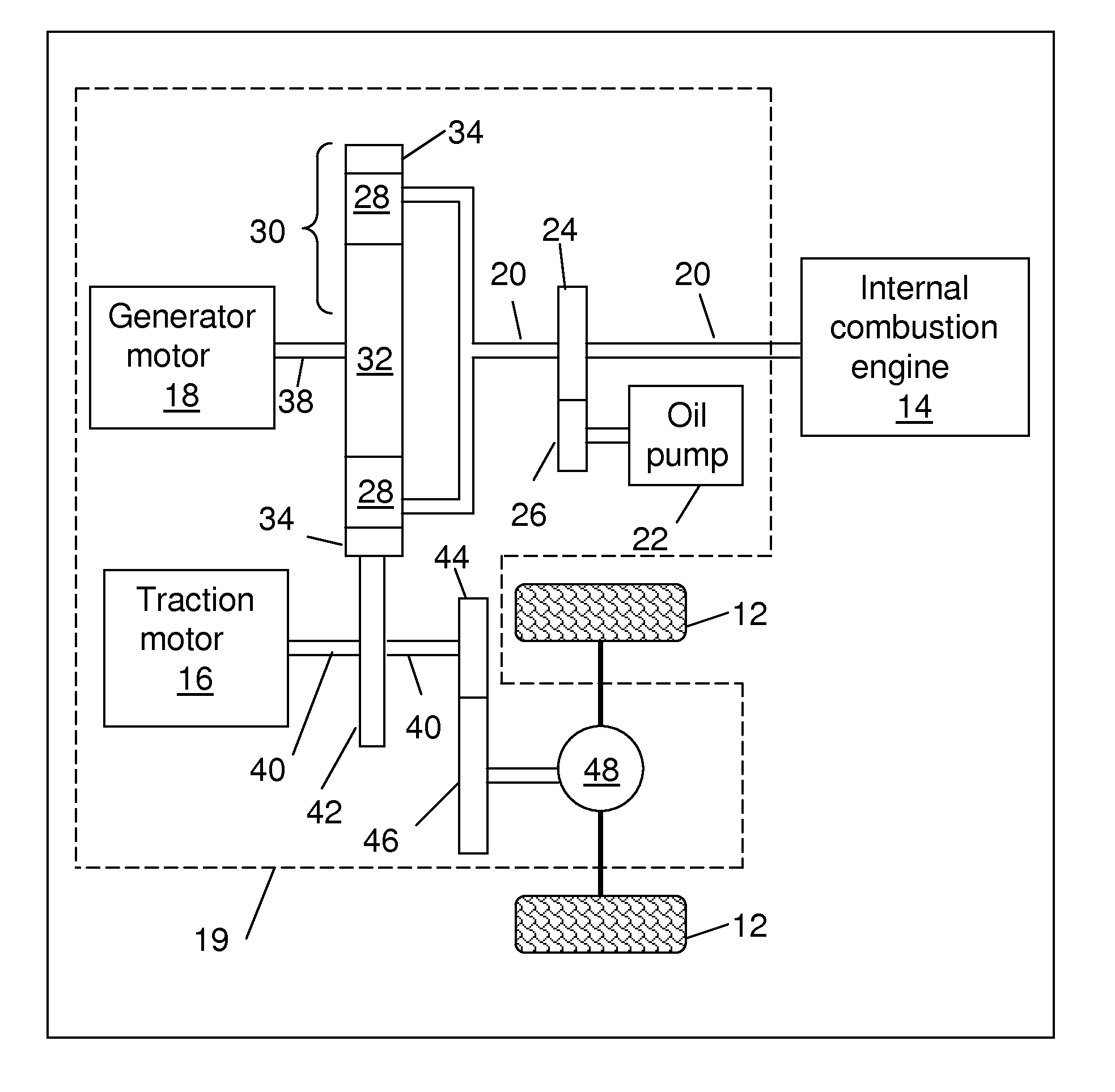

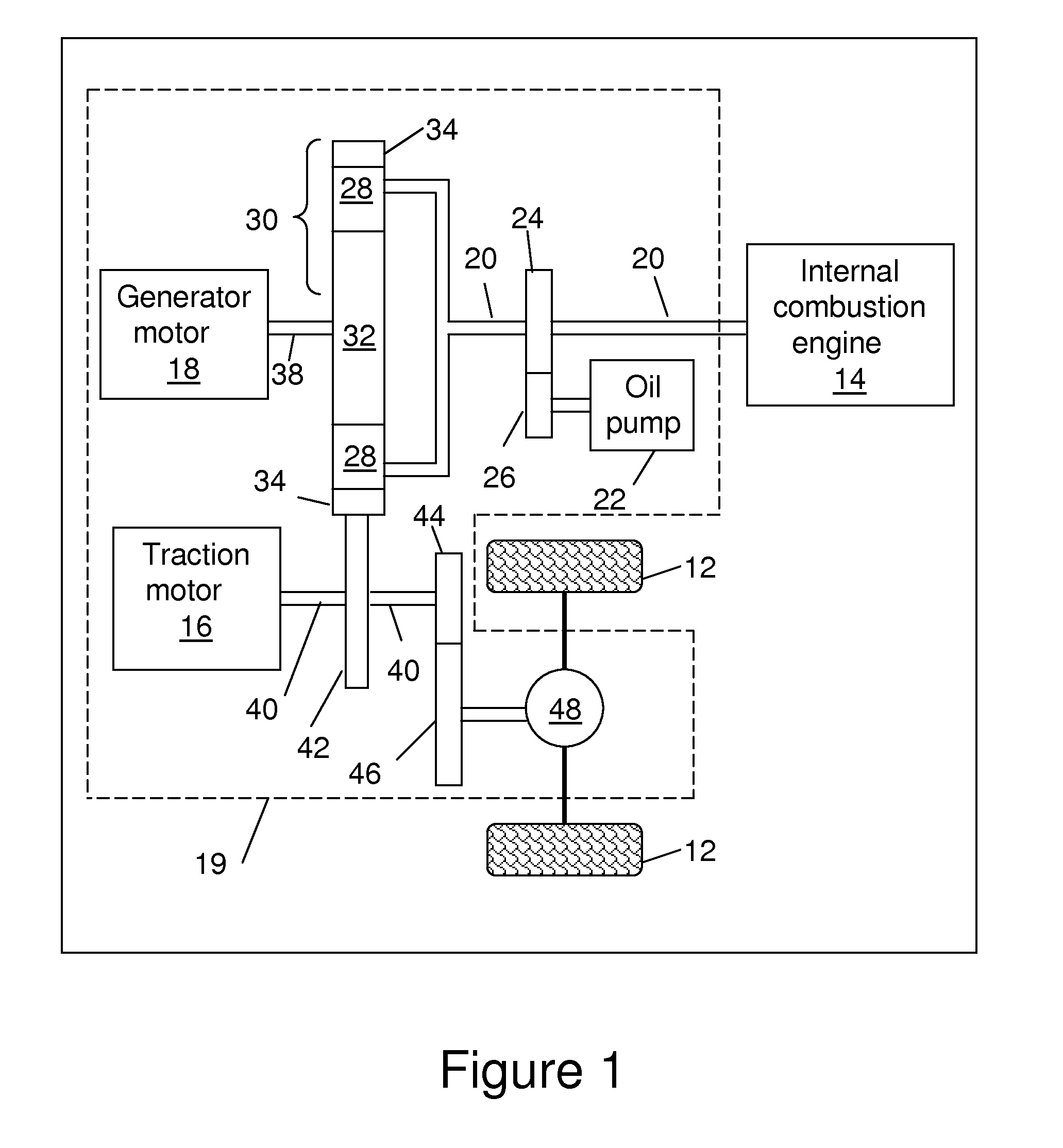

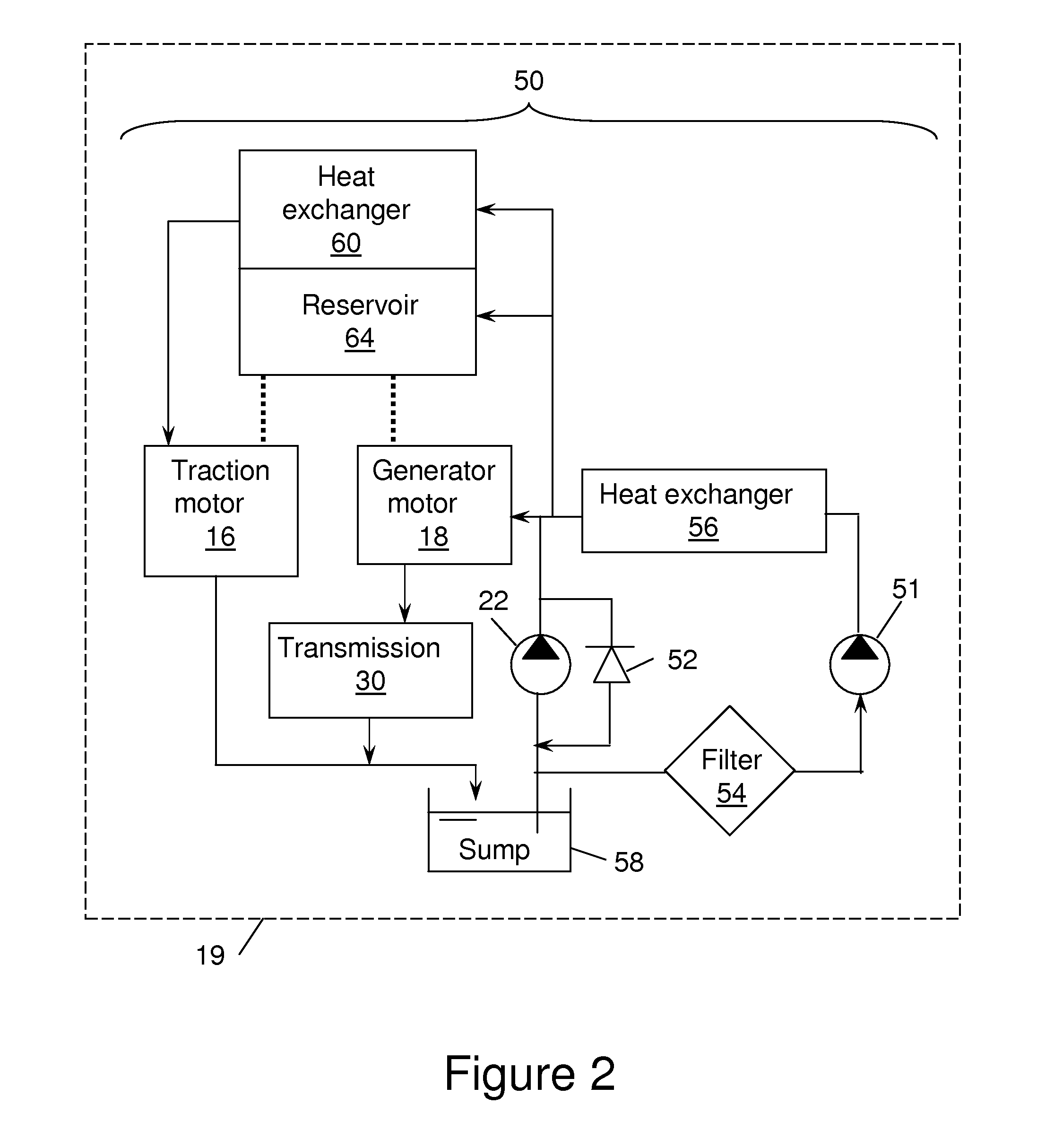

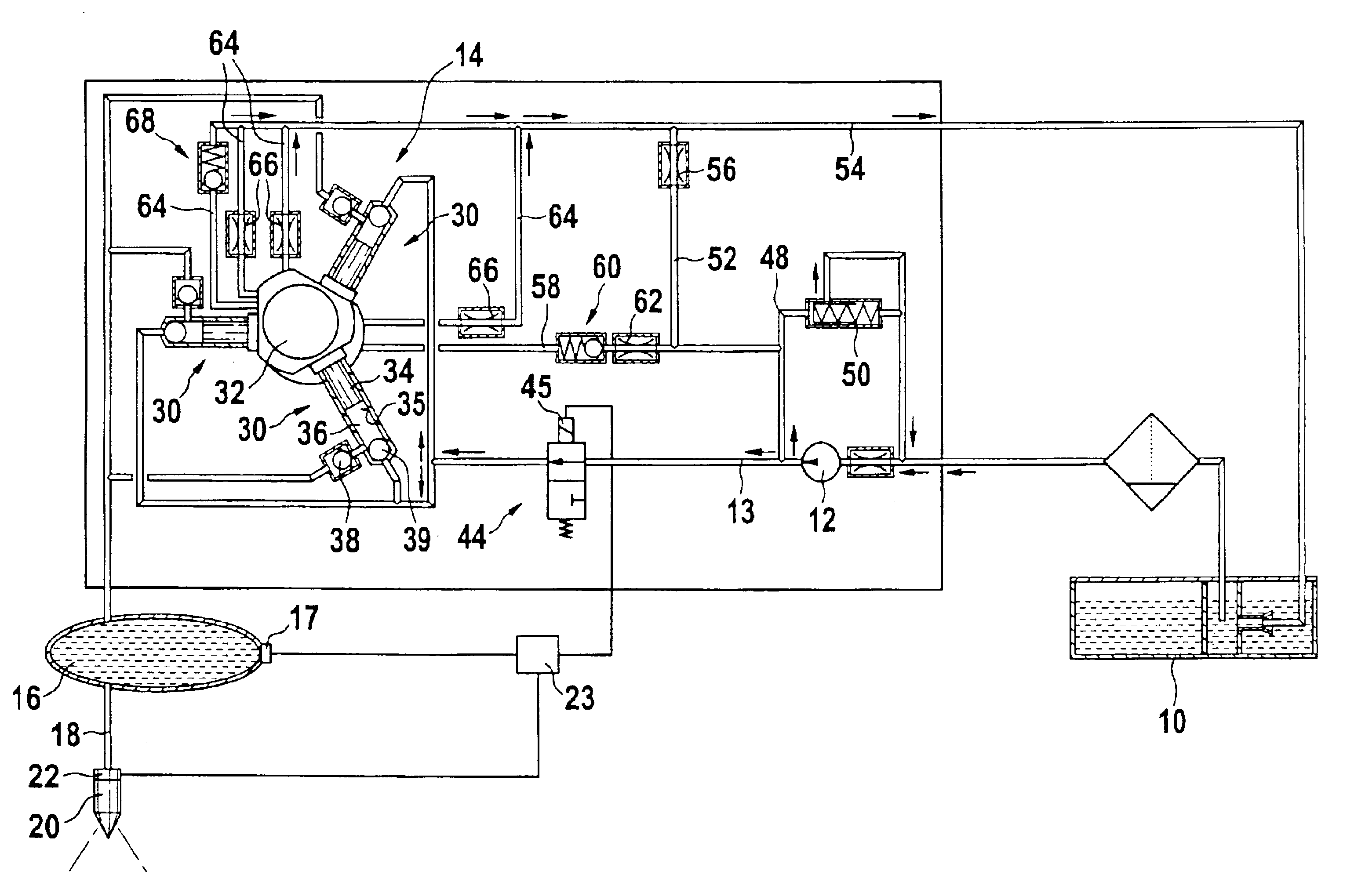

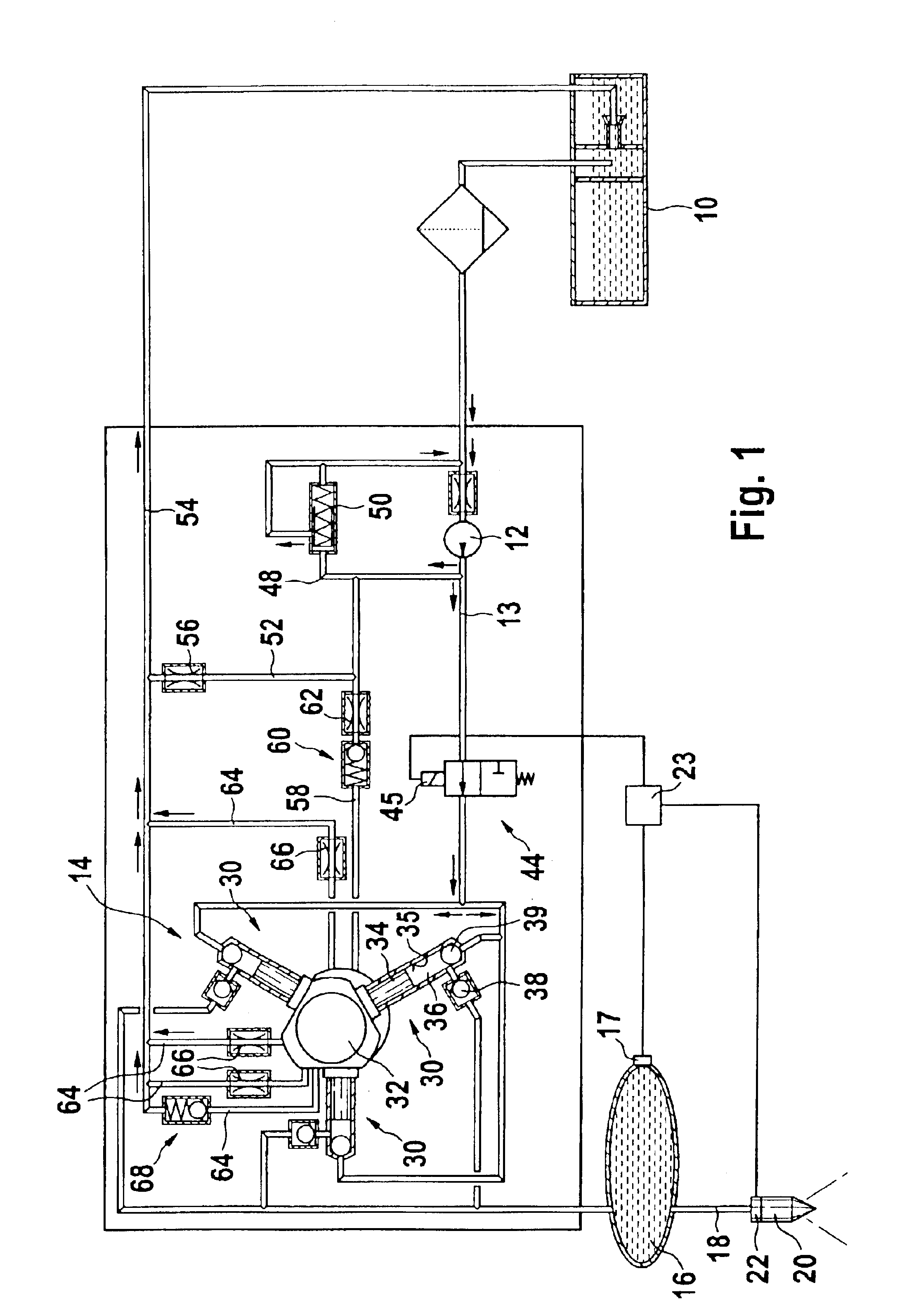

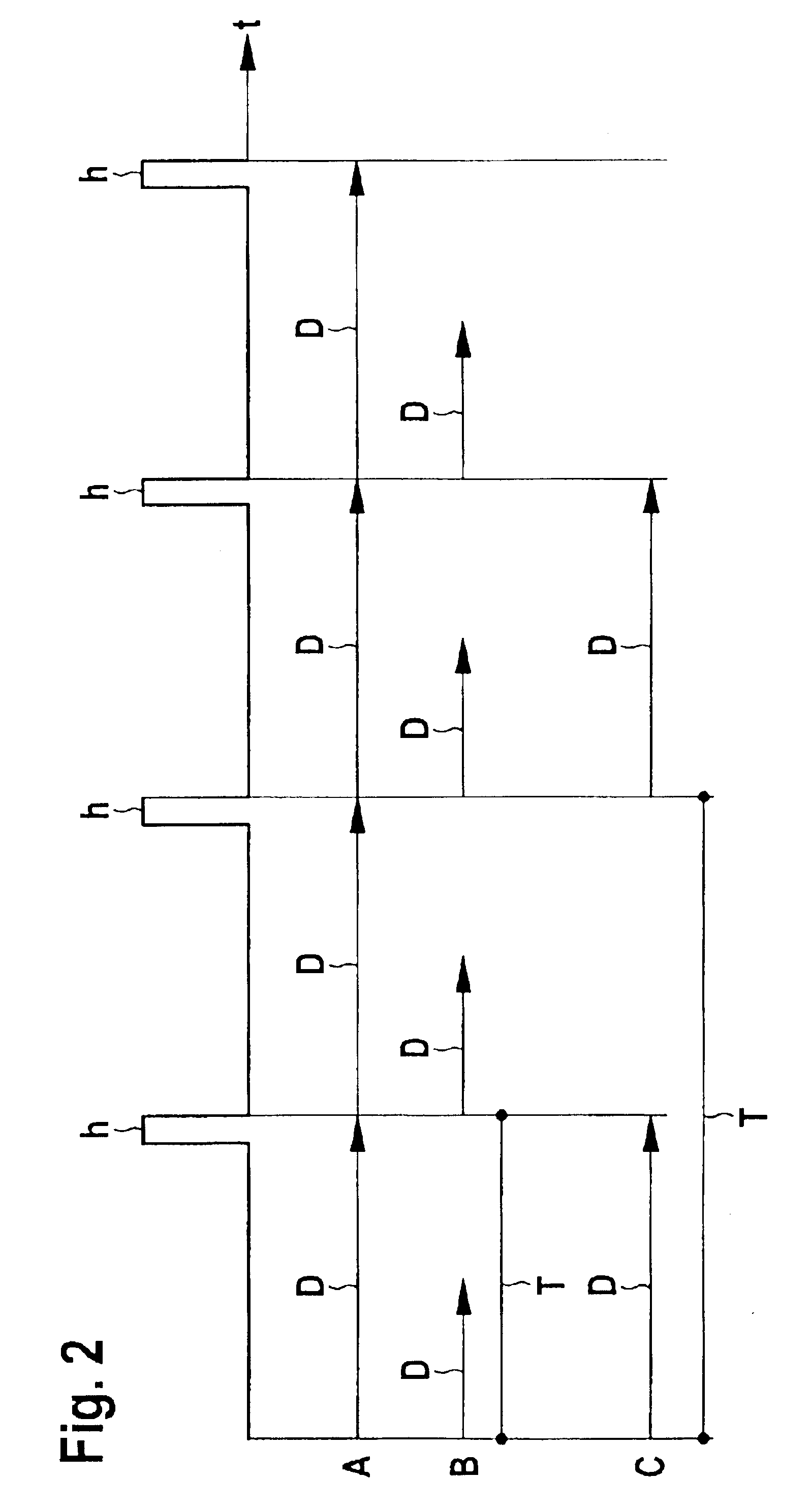

System and method to provide lubrication for a plug-in hybrid

ActiveUS20100320019A1Improve efficiencyLong durationHybrid vehiclesGearingLubricationElectric vehicle

In hybrid electric vehicles having increased battery storage capacity and plug-in capability, electric-only operation of significant duration is available. To supplement lubrication for the electric and mechanical component provided by an engine-driven mechanical pump, an electric pump is provided in parallel to the mechanical pump. A method to control the electric pump is also disclosed in which a first desired quantity of a first component and a second desired quantity of a second component are determined. The electric pump is commanded to provide the greater of the first and second quantities. The desired quantity can be based on preventing temperature in the component from exceeding a maximum design temperature and / or providing sufficient lubrication to rotating parts of the component.

Owner:FORD GLOBAL TECH LLC

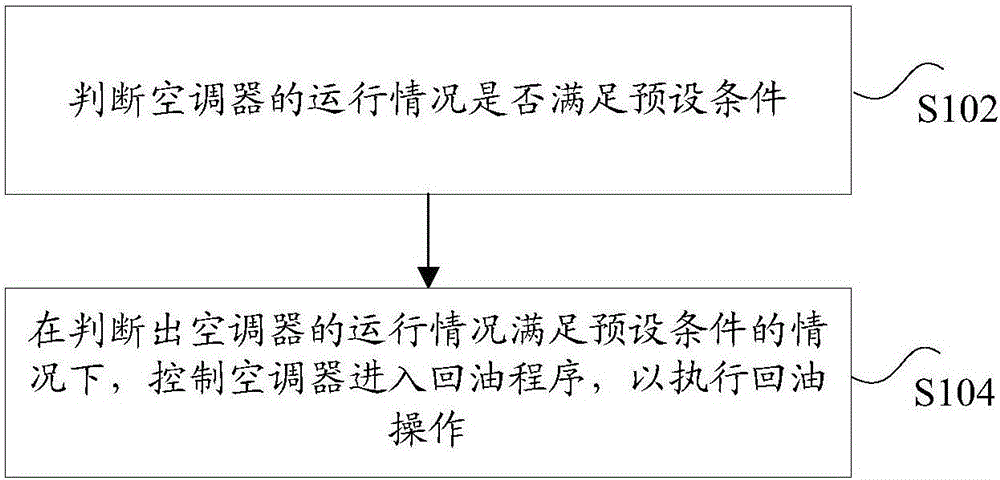

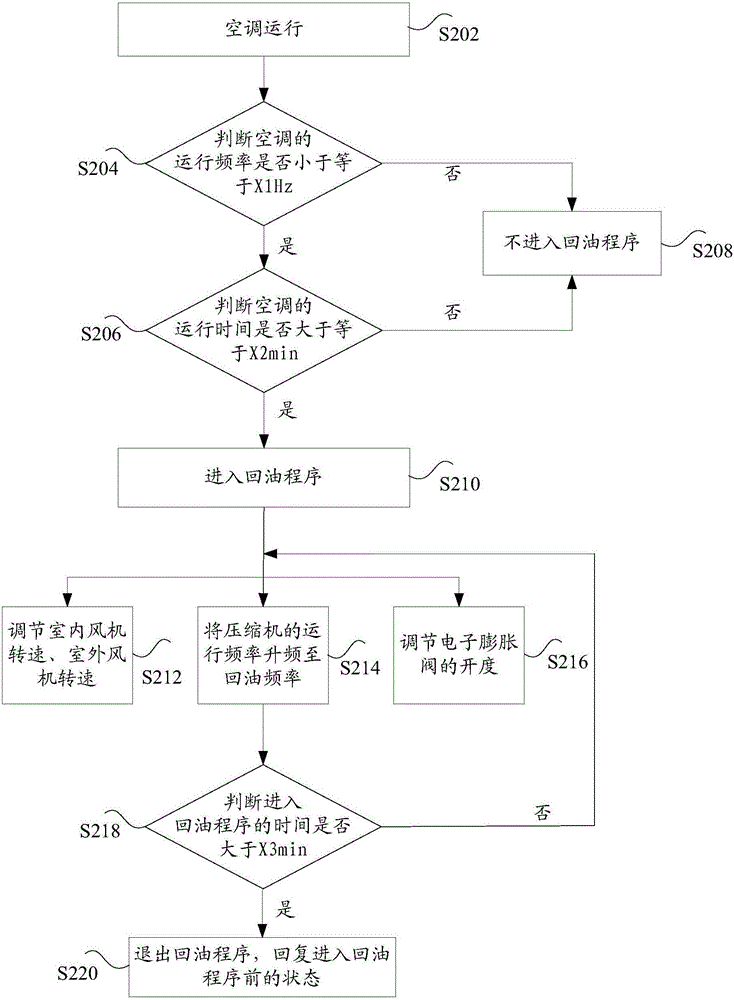

Air conditioner and oil return control method and device thereof

ActiveCN106091479AIncrease operating frequencyIncrease output powerCompressorRefrigeration safety arrangementIndustrial engineering

Owner:GREE ELECTRIC APPLIANCES INC

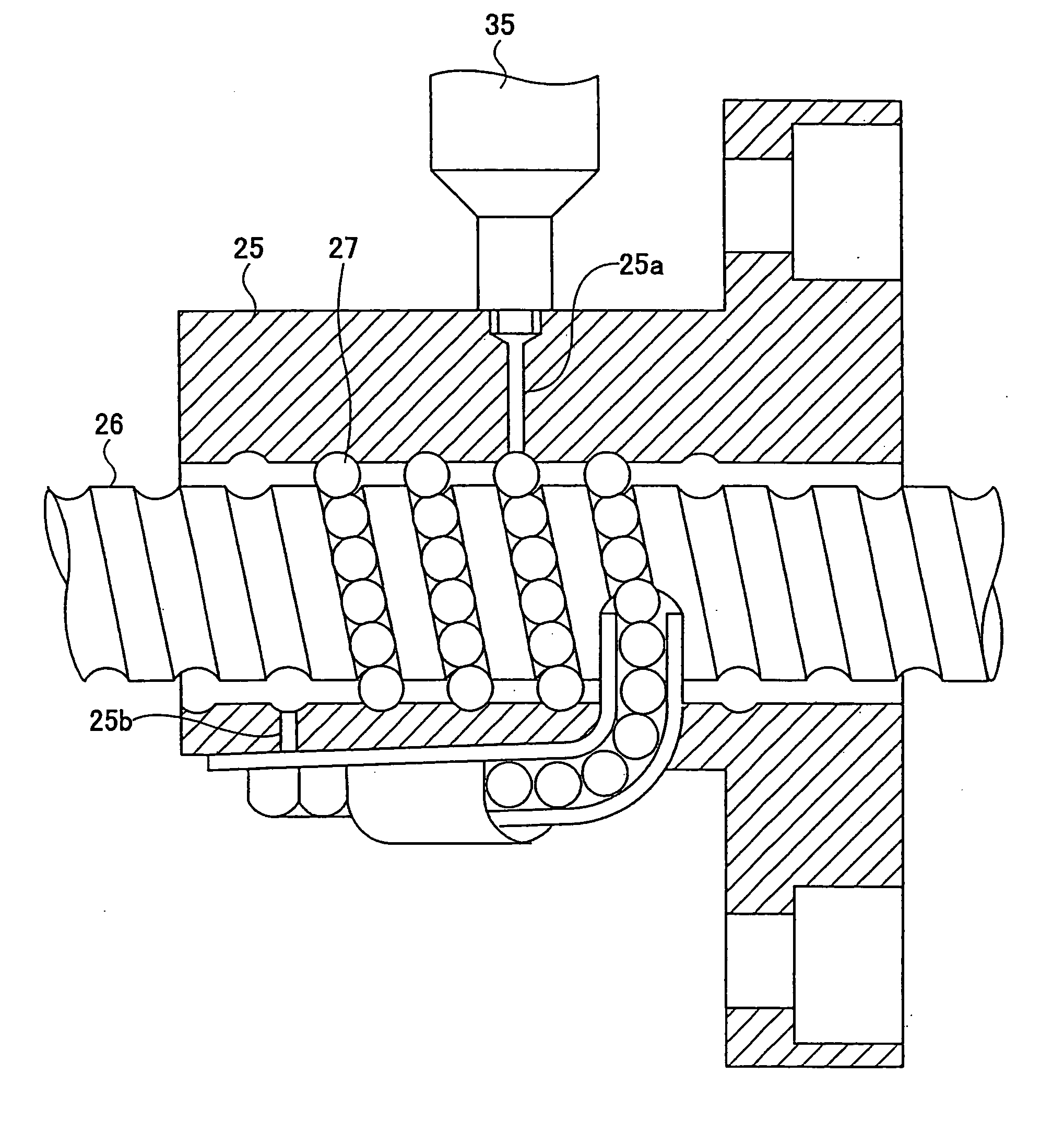

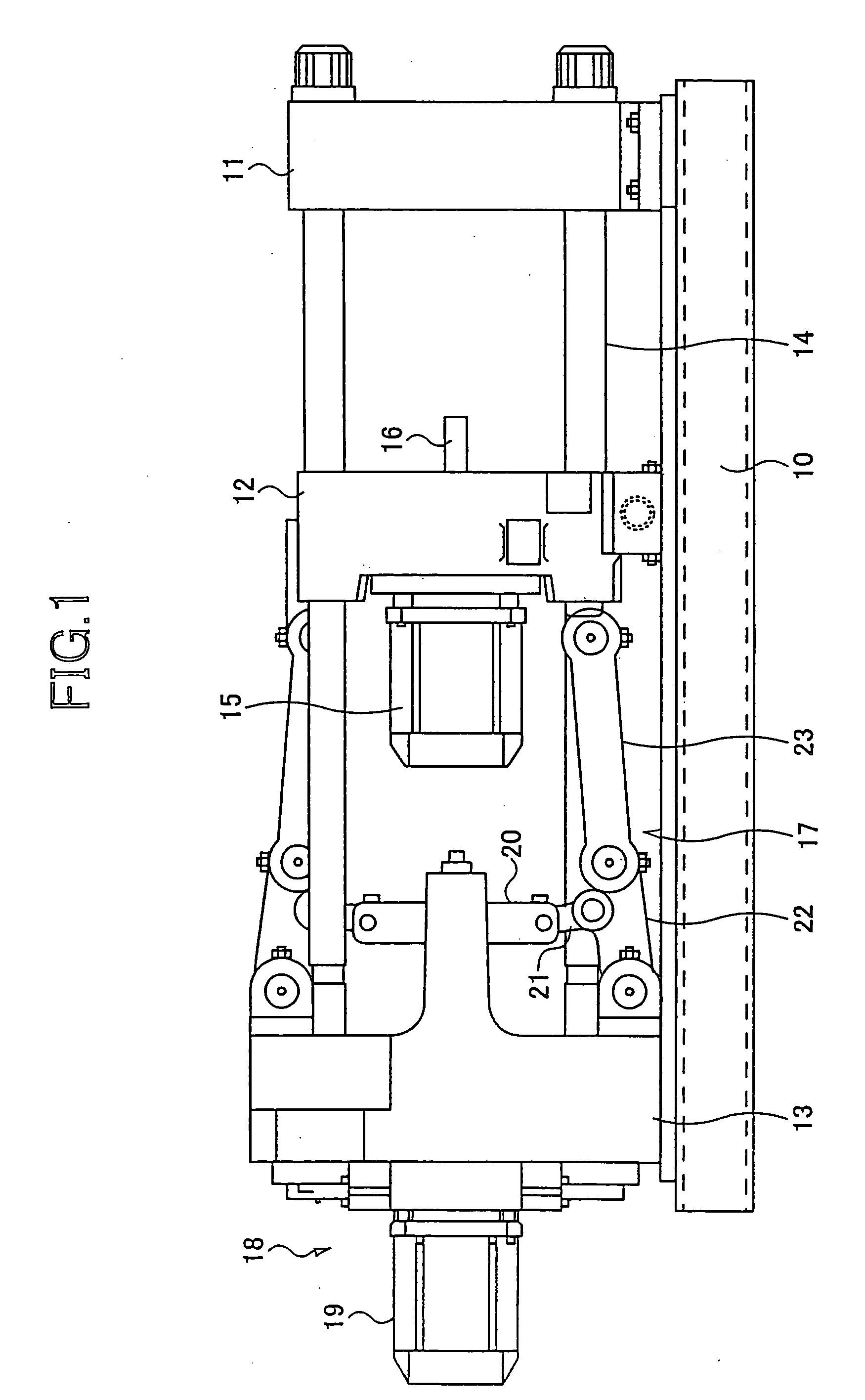

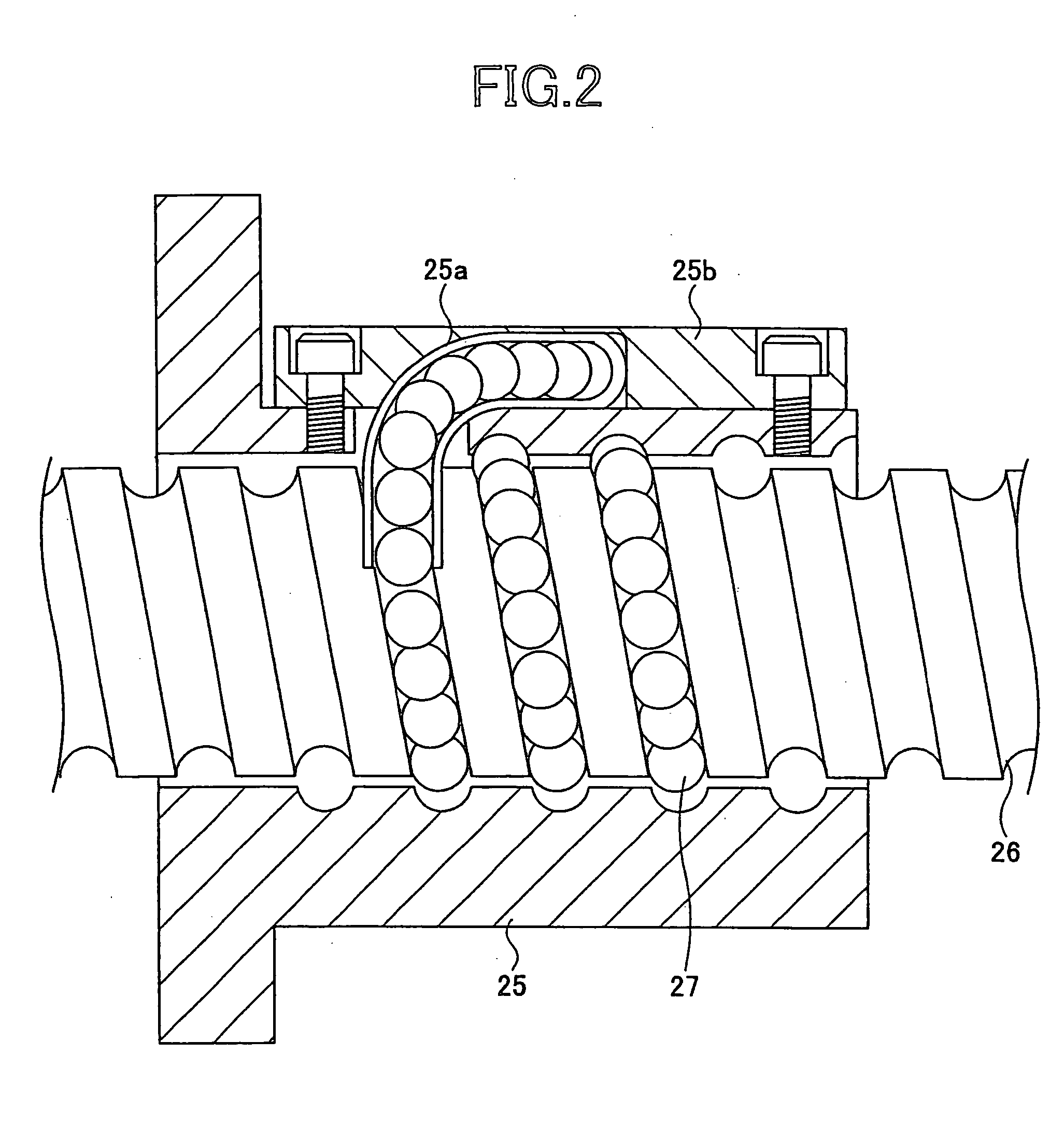

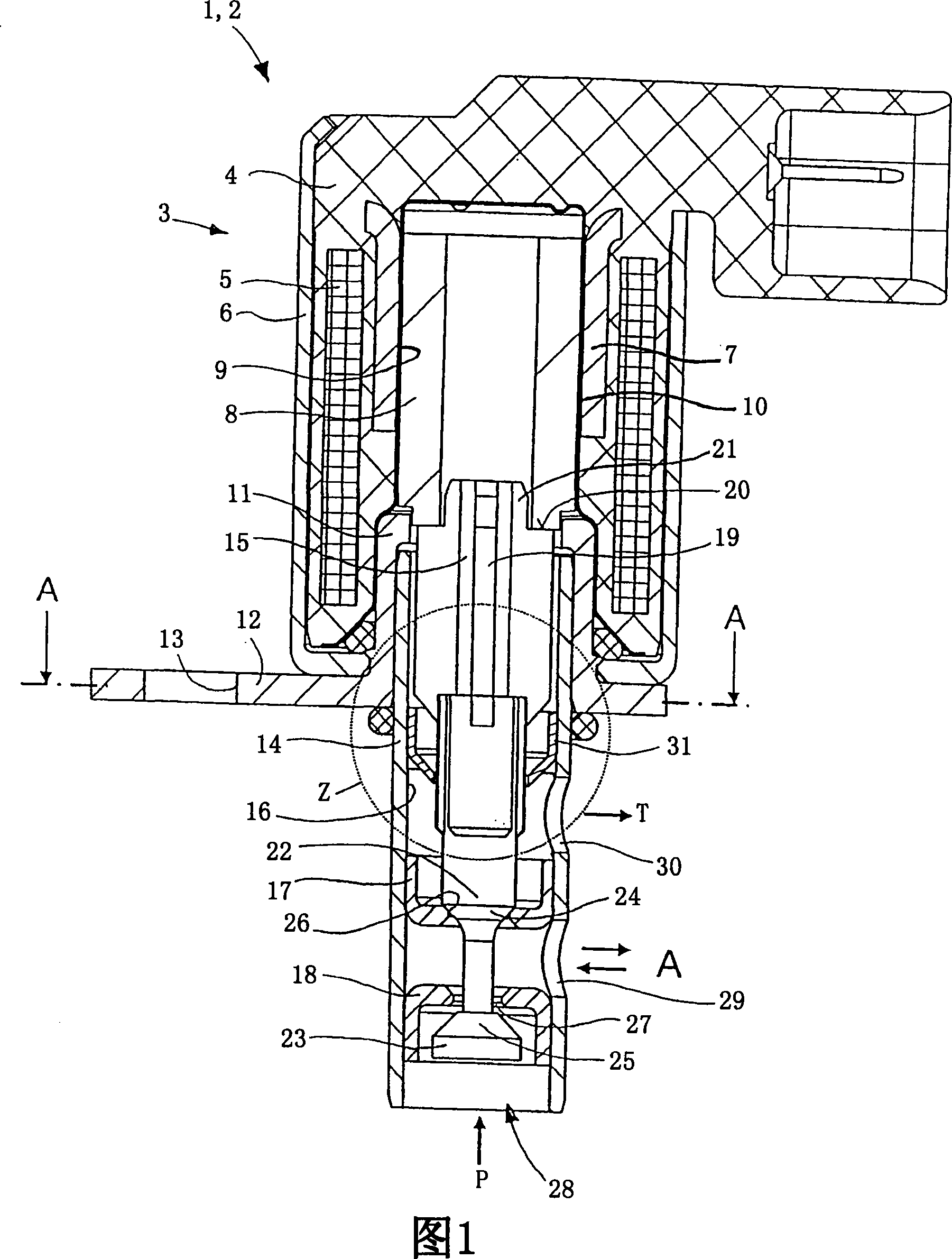

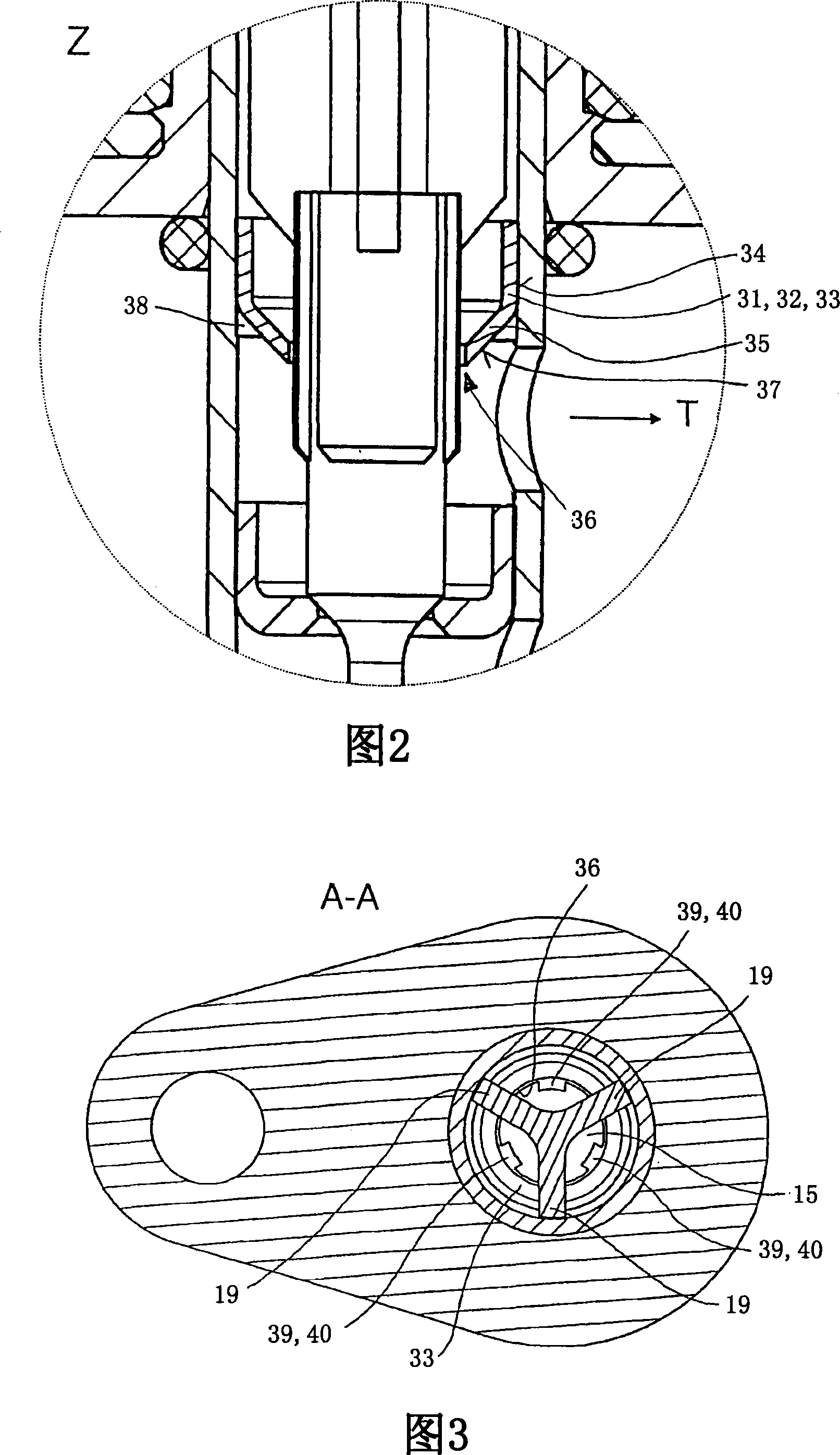

Injection machine having a lubrication mechanism and a lubrication method of an injection machine

InactiveUS20050255186A1Fully lubricatedInhibit temperature riseGear lubrication/coolingToothed gearingsMolding machineBall screw

A molding machine having a lubrication mechanism according to the present invention can effectively rubricate a ball screw and elongate a service life of the ball screw. In a clamping apparatus of an electric injection molding machine, a rotational movement of a rotational shaft of a motor is converted into a linear movement in an axial direction by a ball screw mechanism. Atomized lubrication oil is directly sprayed inside the ball screw nut from a spray nozzle. The lubrication oil, which has been sprayed from the spray nozzle, is recovered and reused.

Owner:SUMITOMO HEAVY IND LTD

Direct injection fuel pump

ActiveUS20140224209A1Reduce degradation rateImprove fuel pump lubricationElectrical controlWear reducing fuel injectionLubricationFuel pump

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

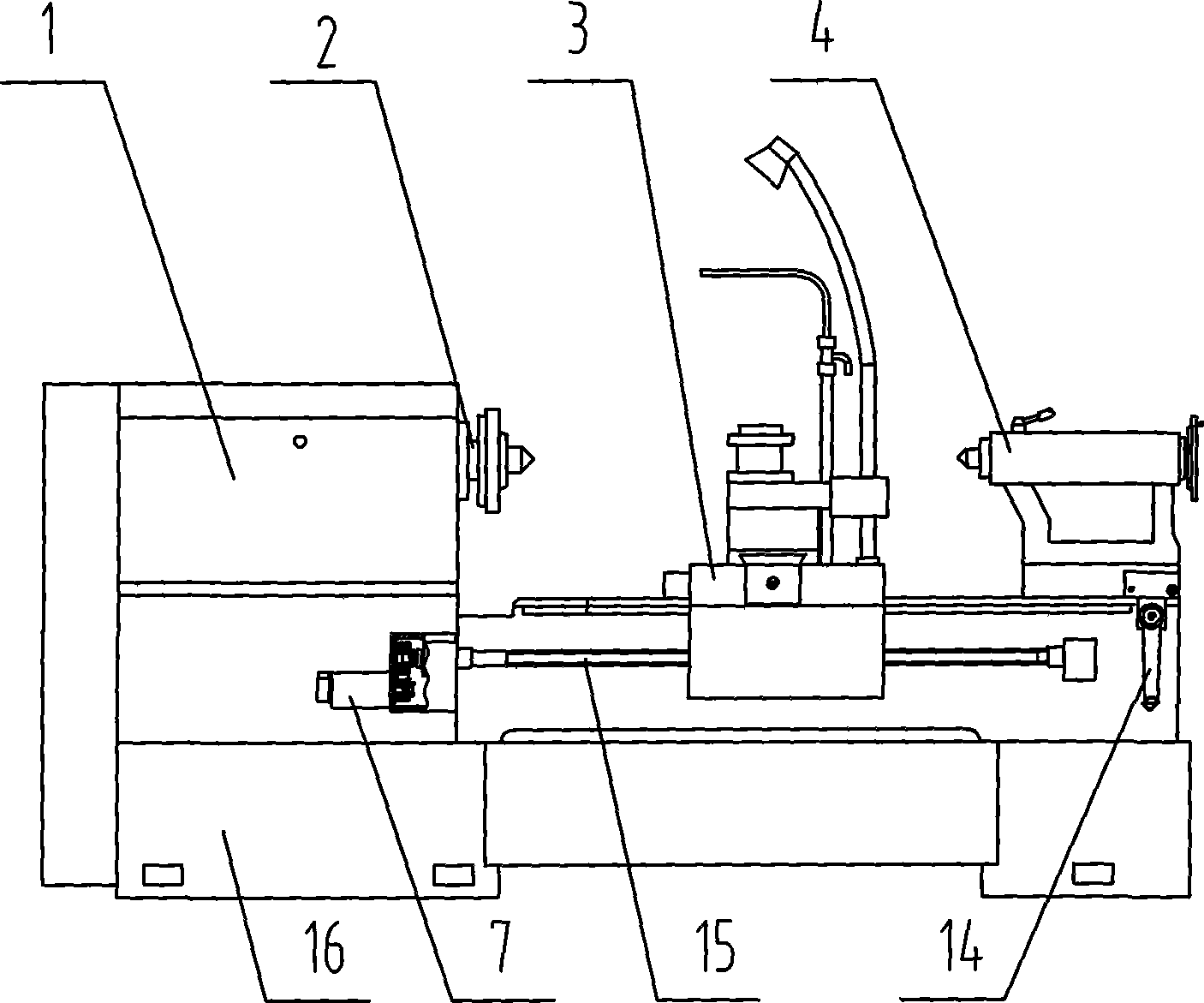

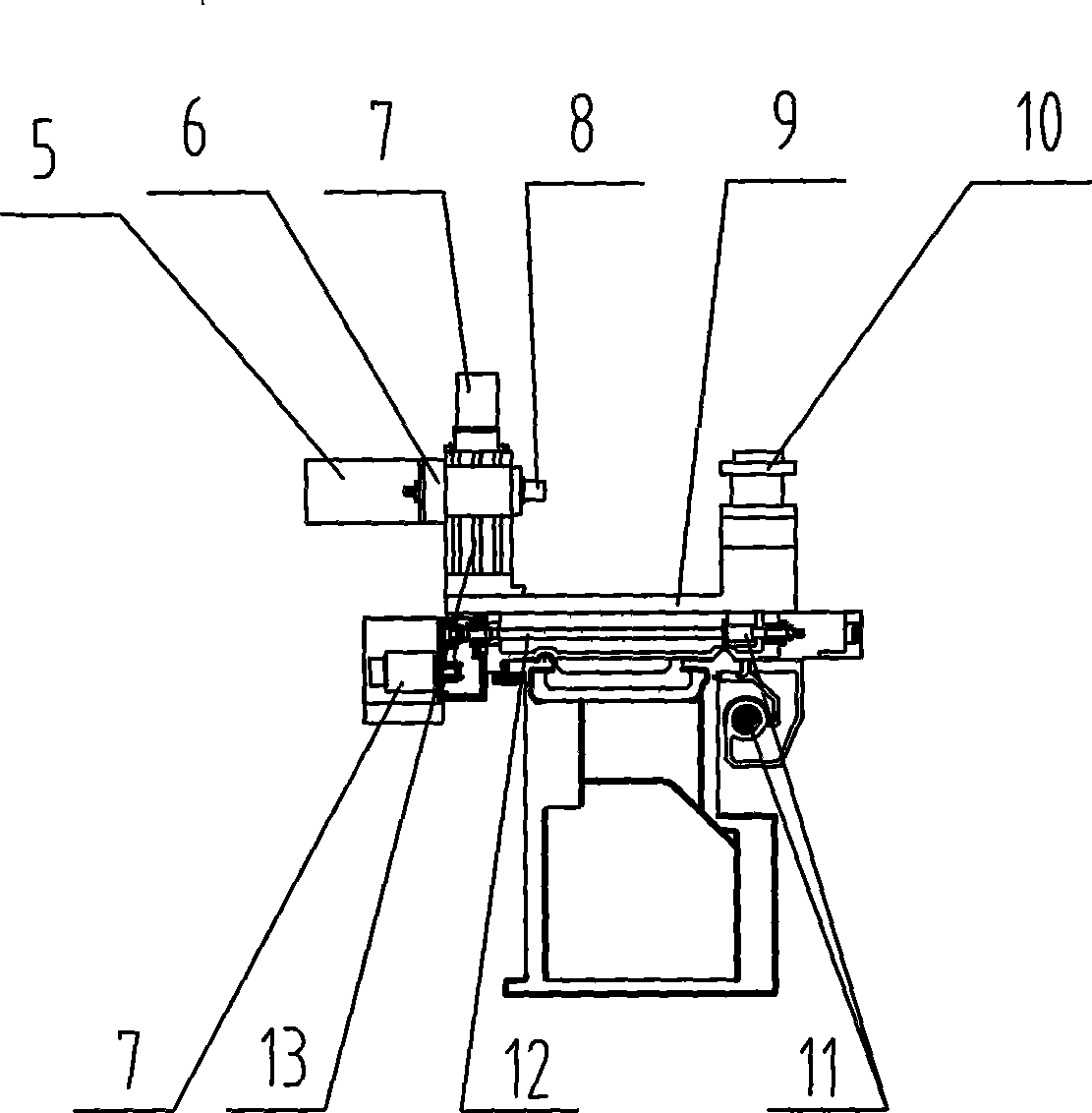

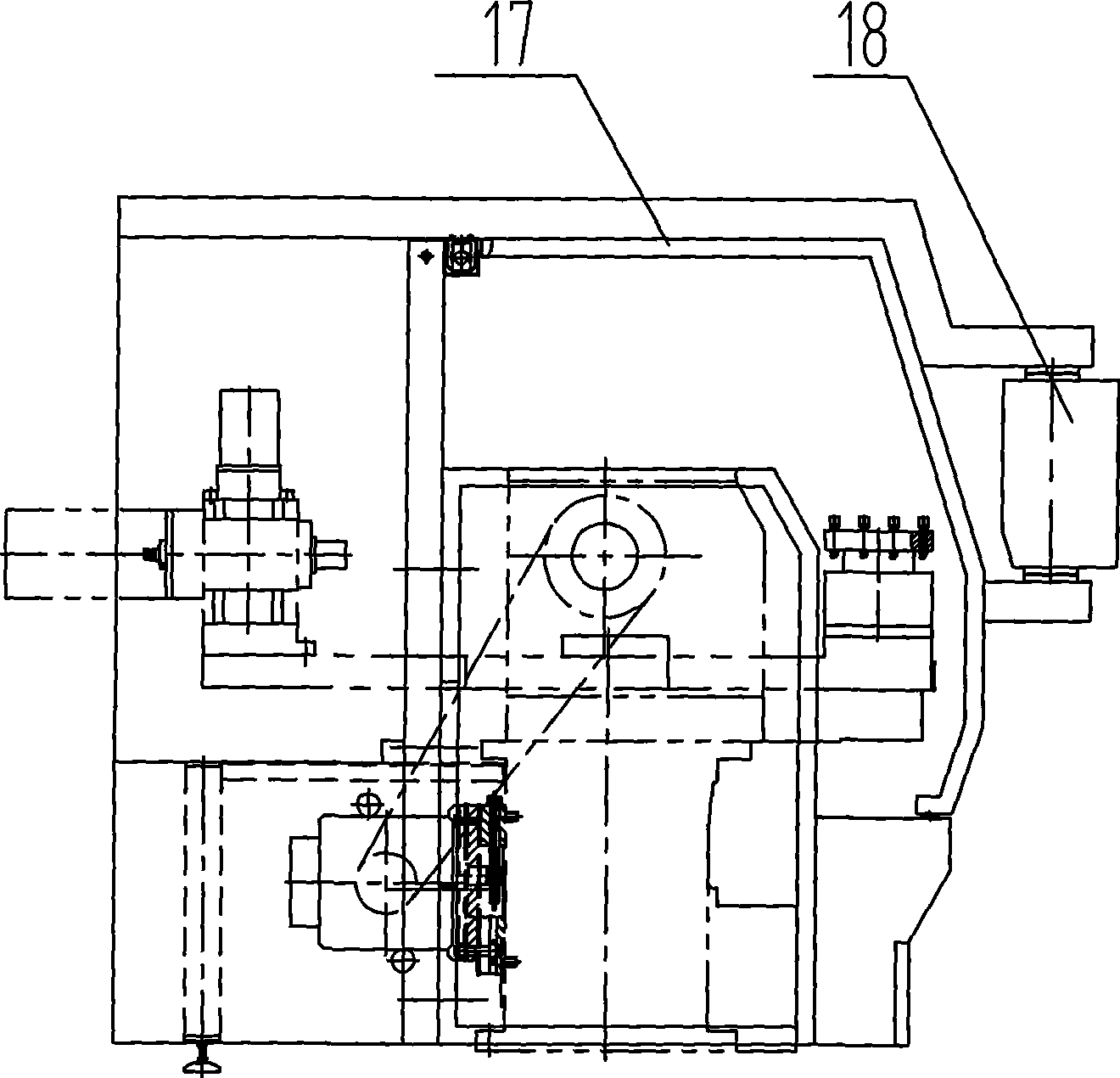

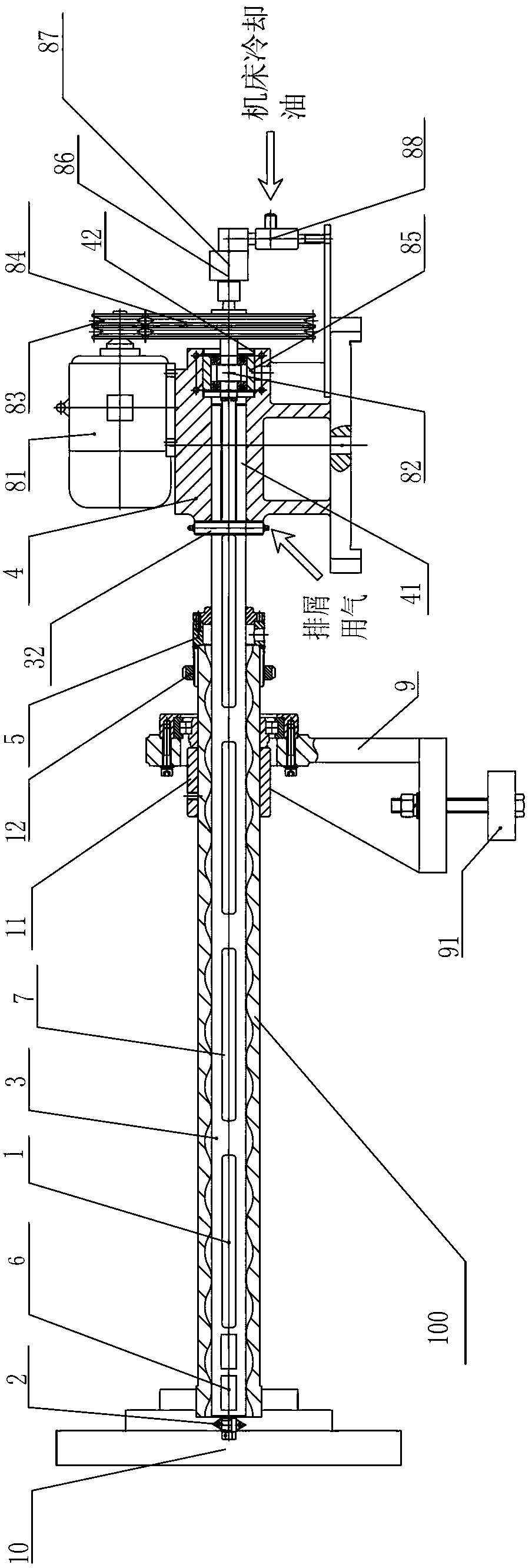

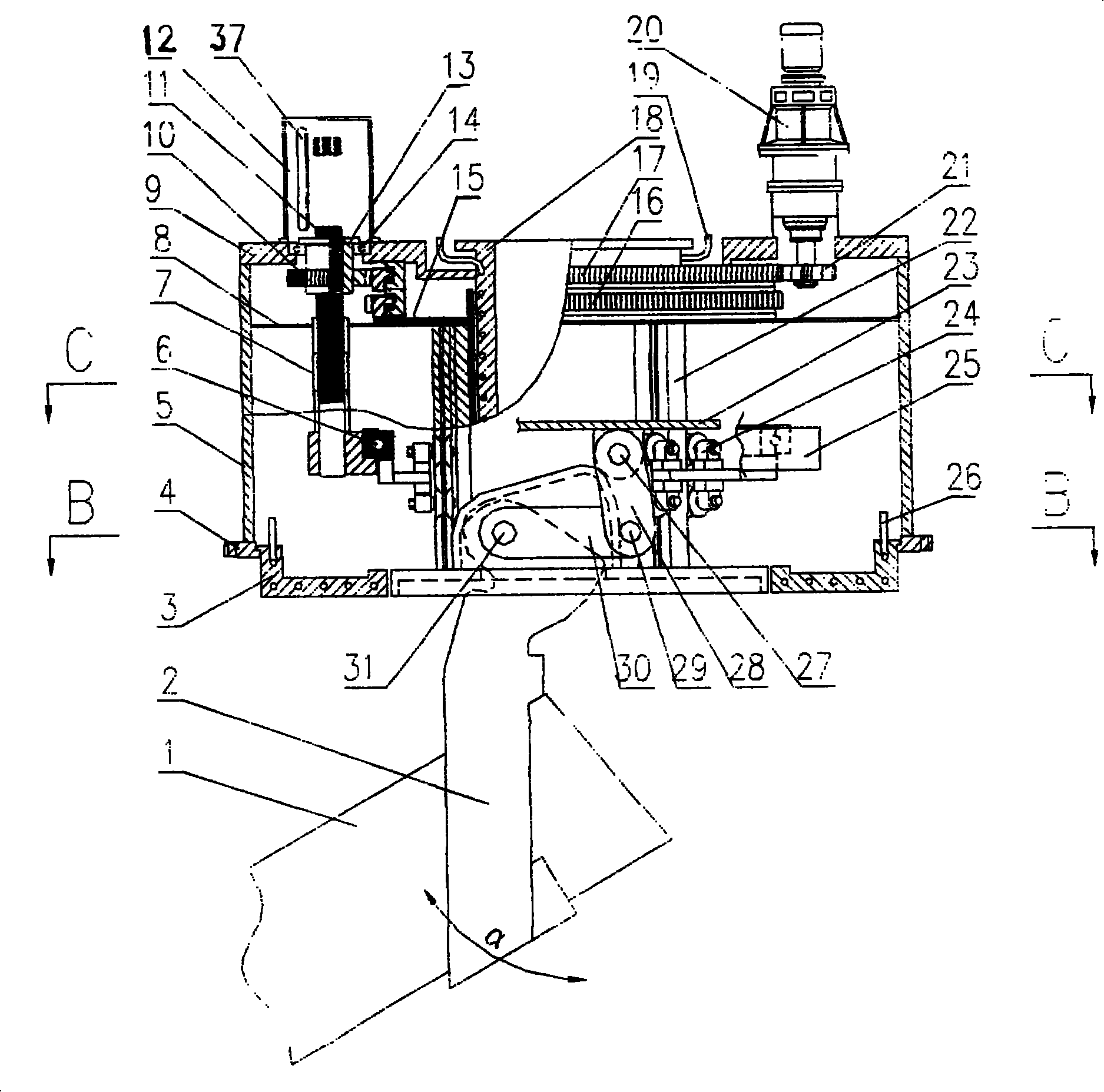

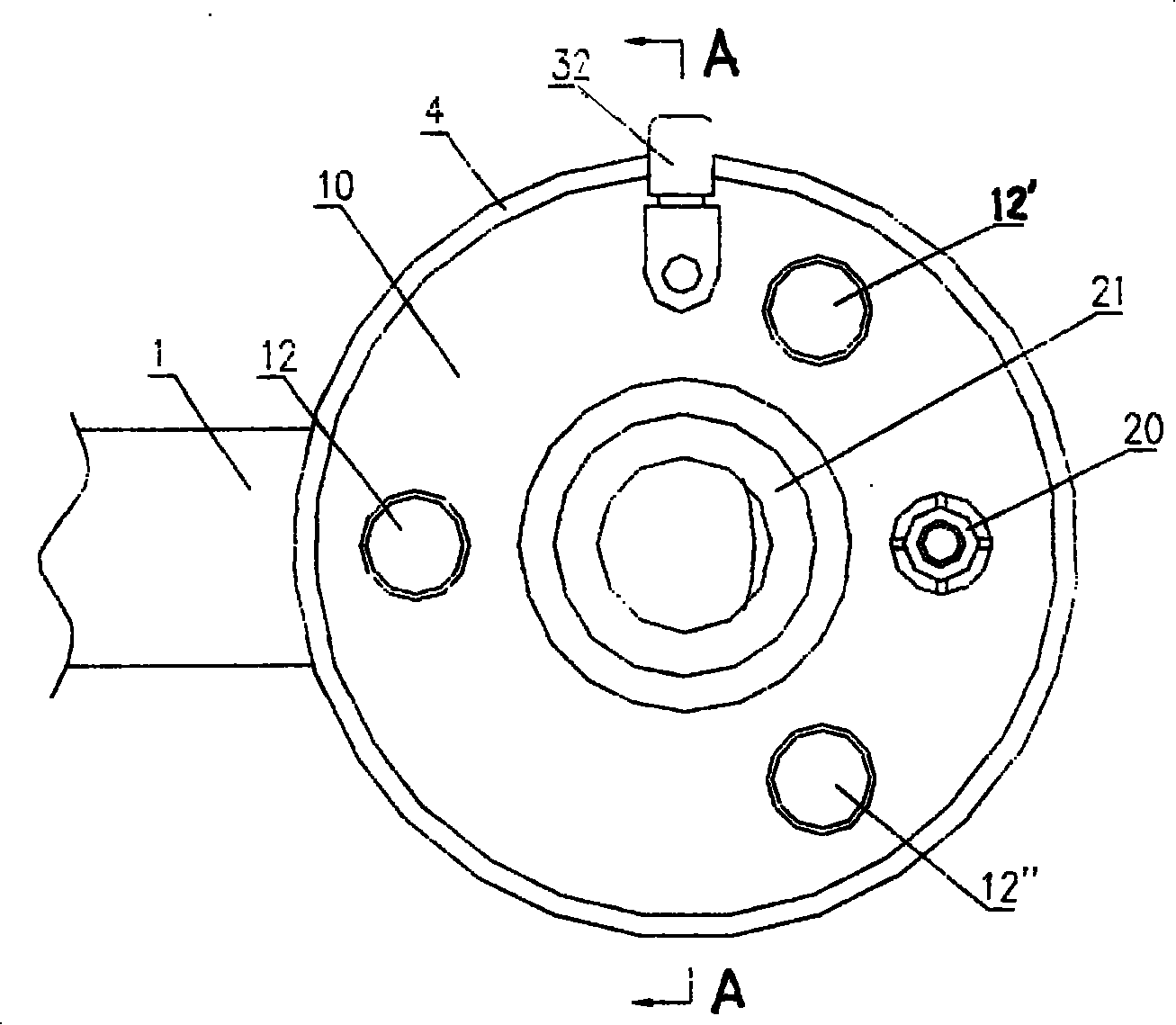

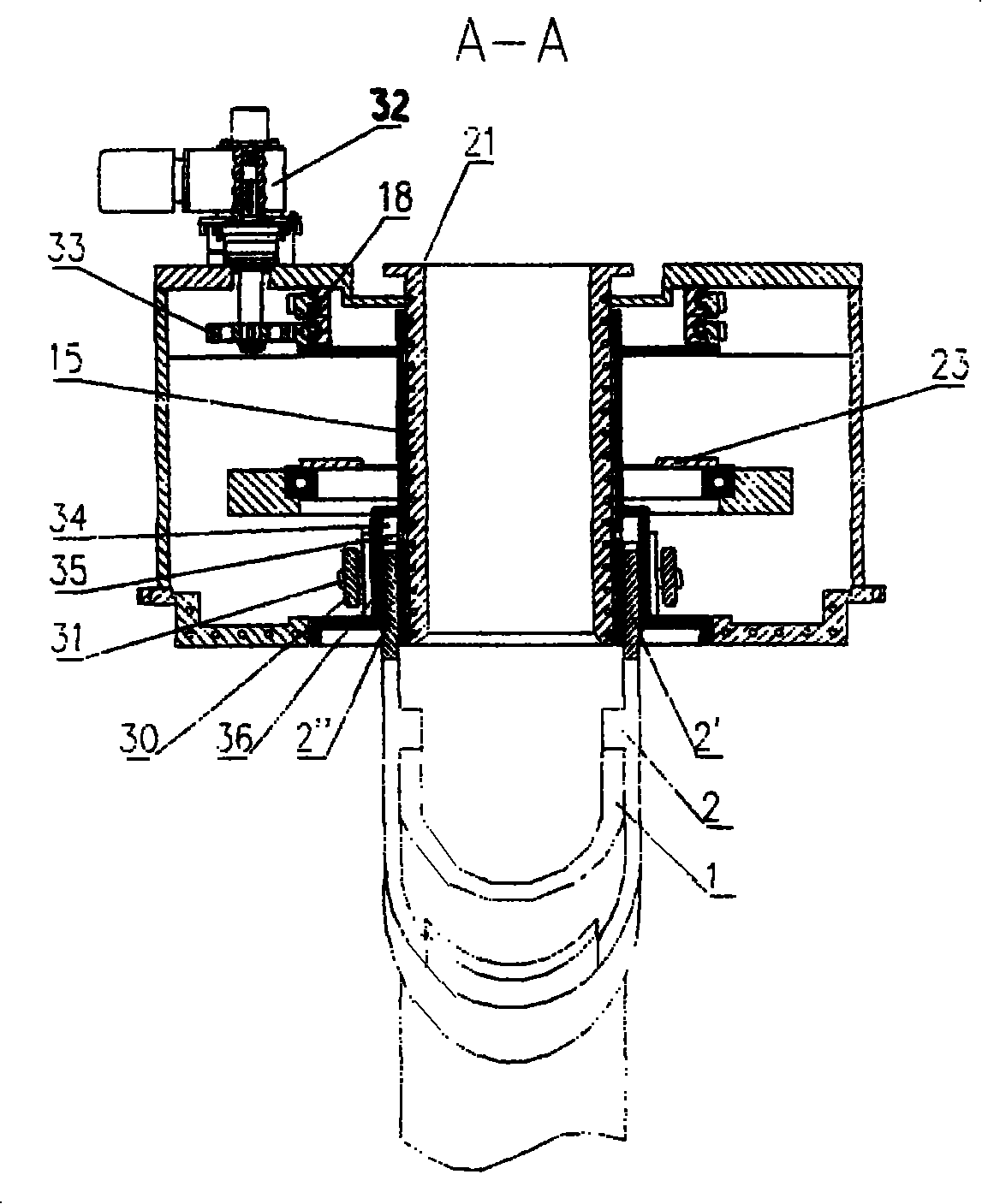

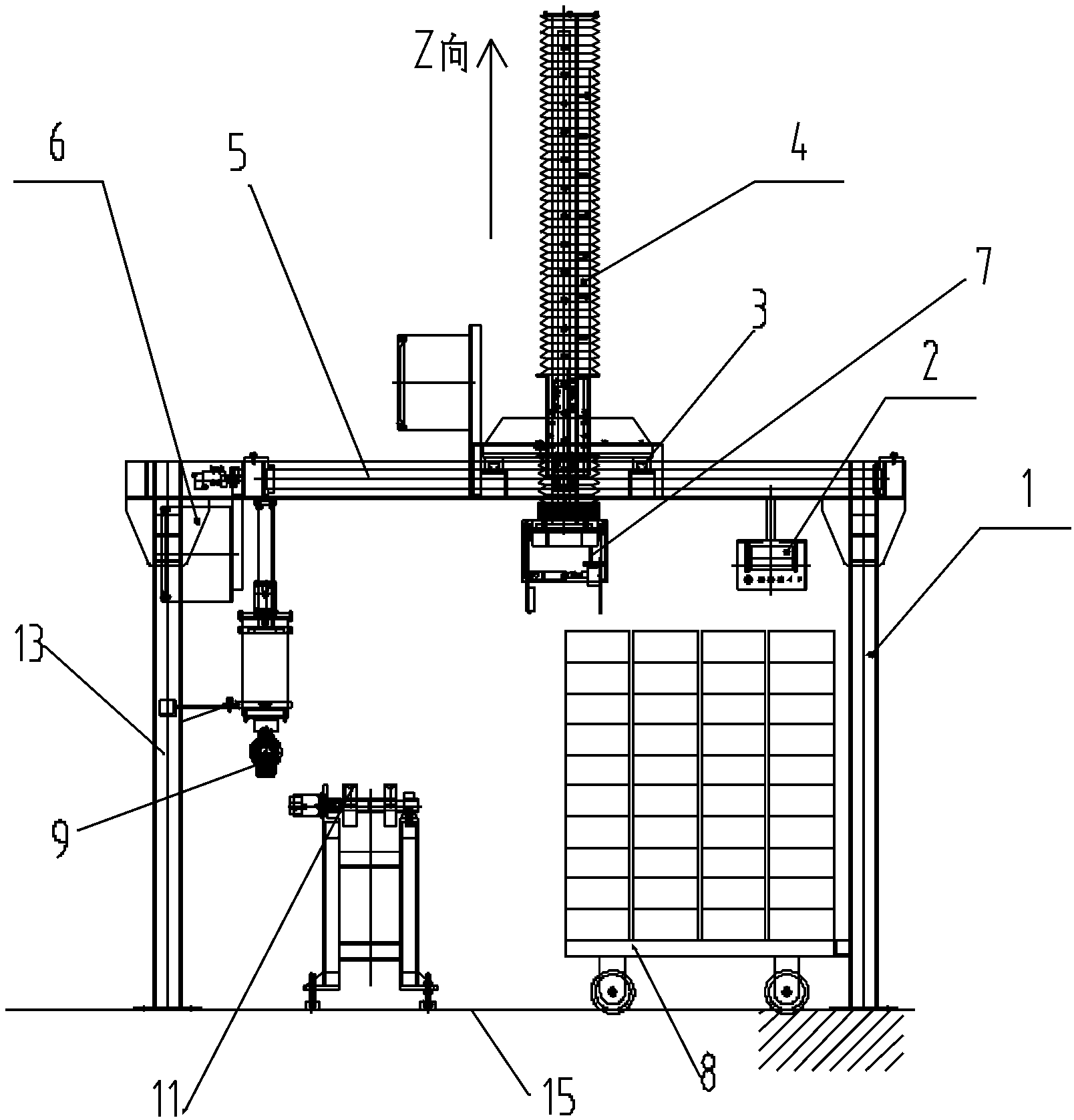

Numerically-controlled milking composite machine tool

InactiveCN101508069ASmall temperature rise and thermal deformationOperational securityTailstocks/centresOther manufacturing equipments/toolsDimensional precisionMotor drive

The invention discloses a digital control turning-milling complex machine tool, which comprises a digital control machine tool body, a spindle system, a milling unit head, a cutting off tool rest, a tailstock, a longitudinal and horizontal feed system and a lubricating system, and is characterized in that a lower slide block is arranged on a saddle of the machine tool; the front end of the lower slide block is provided with the four-station electric cutting off tool rest; the back end of the lower slide block is provided with the milling unit head capable of lifting; a mill head spindle of the milling unit head is provided with a milling cutter or a drill bit; the lifting of the milling unit head is realized by a servo motor driving a ballscrew pair to rotate; and a variable-frequency motor drives the mill head spindle to rotate, and the rotating speed of the mill head spindle is changed through adjustment of the frequency of the variable-frequency motor. Through once clamping, the digital control turning-milling complex machine tool can realize turning-milling complex processing to achieve the aim of multiple functions of one machine; the machine tool realizes four-axis linkage controlled by four axes combined by an X axis, a Y axis, a Z axis and a C axis together through a digital control system; and the whole machine has good rigidity, and the dimensional precision of processed parts reaches IT 7 and the surface roughness Ra is less than or equal to 3.2 mu m.

Owner:CHANGSHA JINLING MACHINE TOOL

Fuel system for a multi-fuel engine

InactiveUS8590510B2Improve fuel vaporizationEmission reductionElectrical controlInternal combustion piston enginesFuel typeEngineering

Owner:FORD GLOBAL TECH LLC

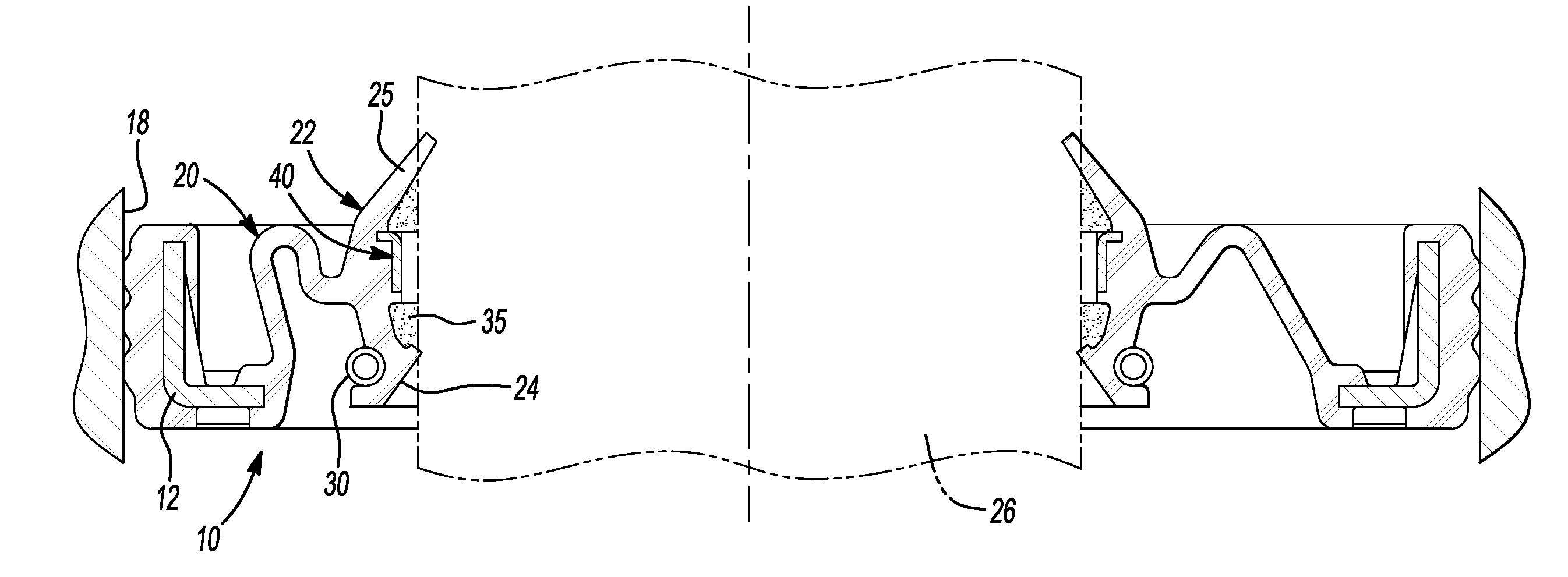

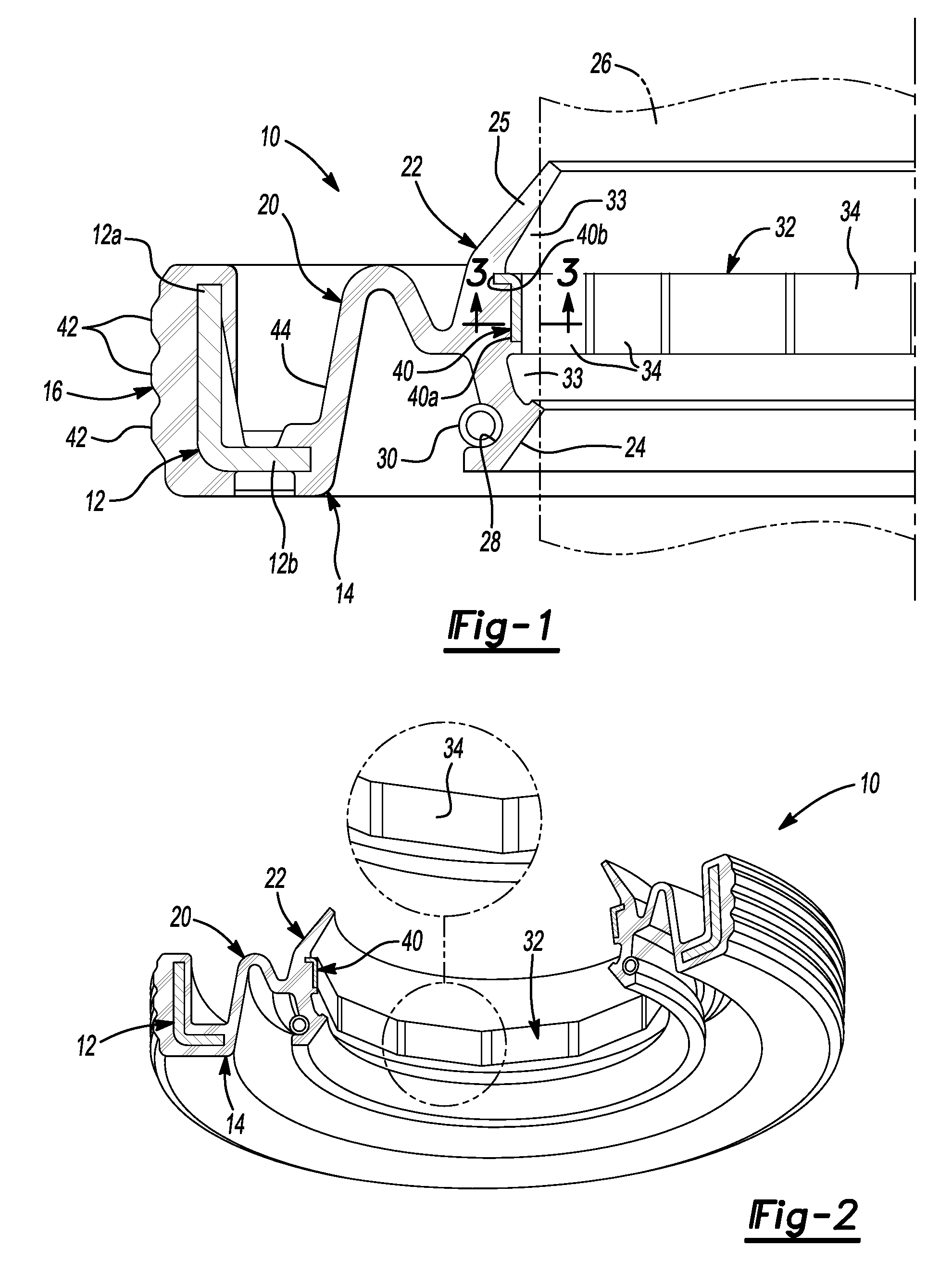

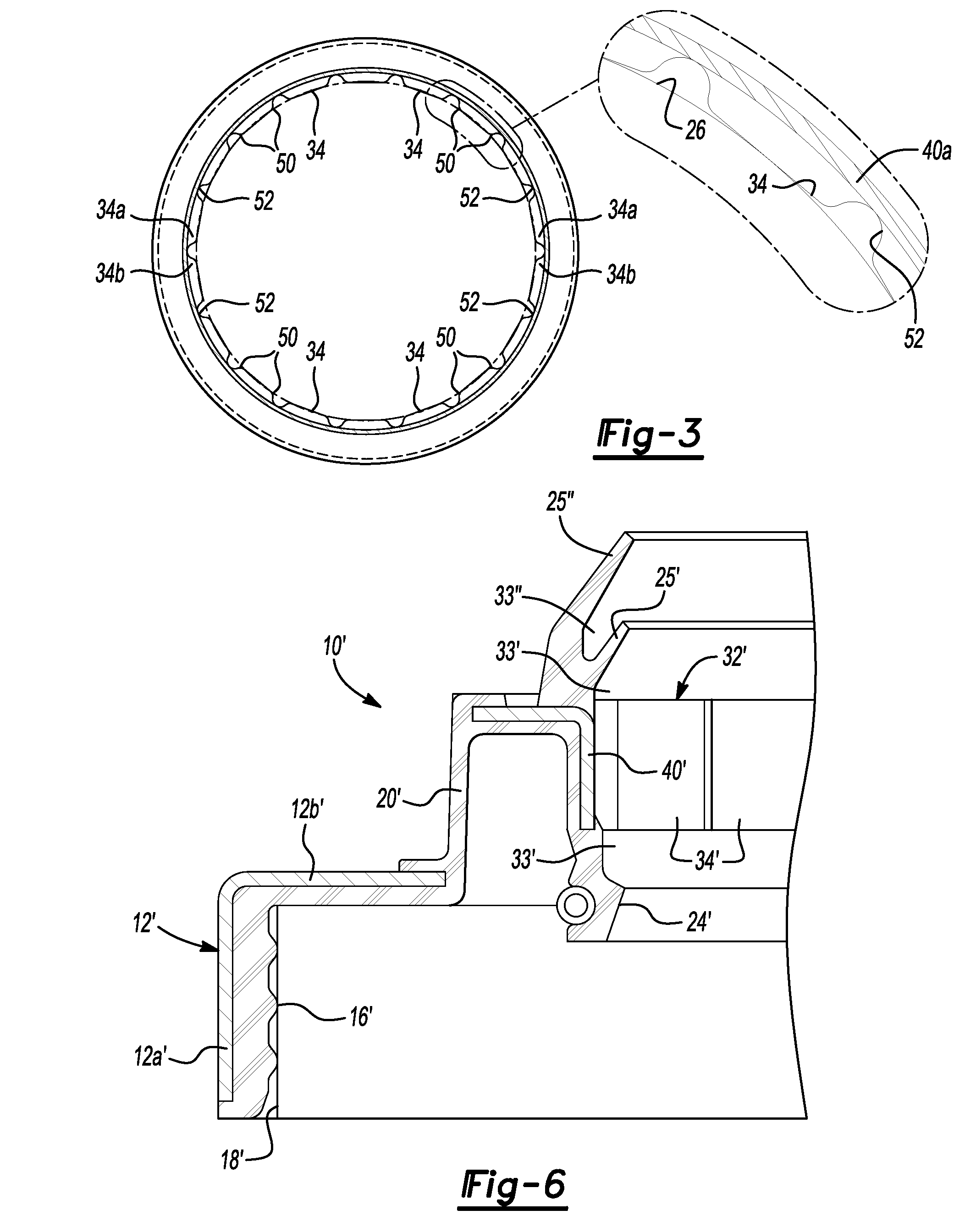

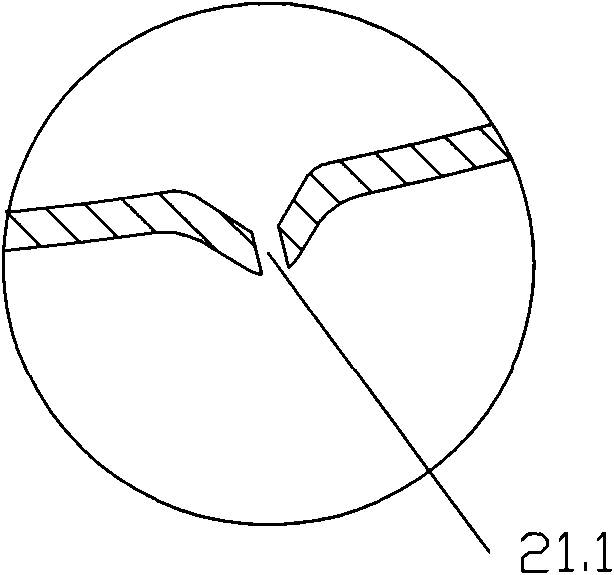

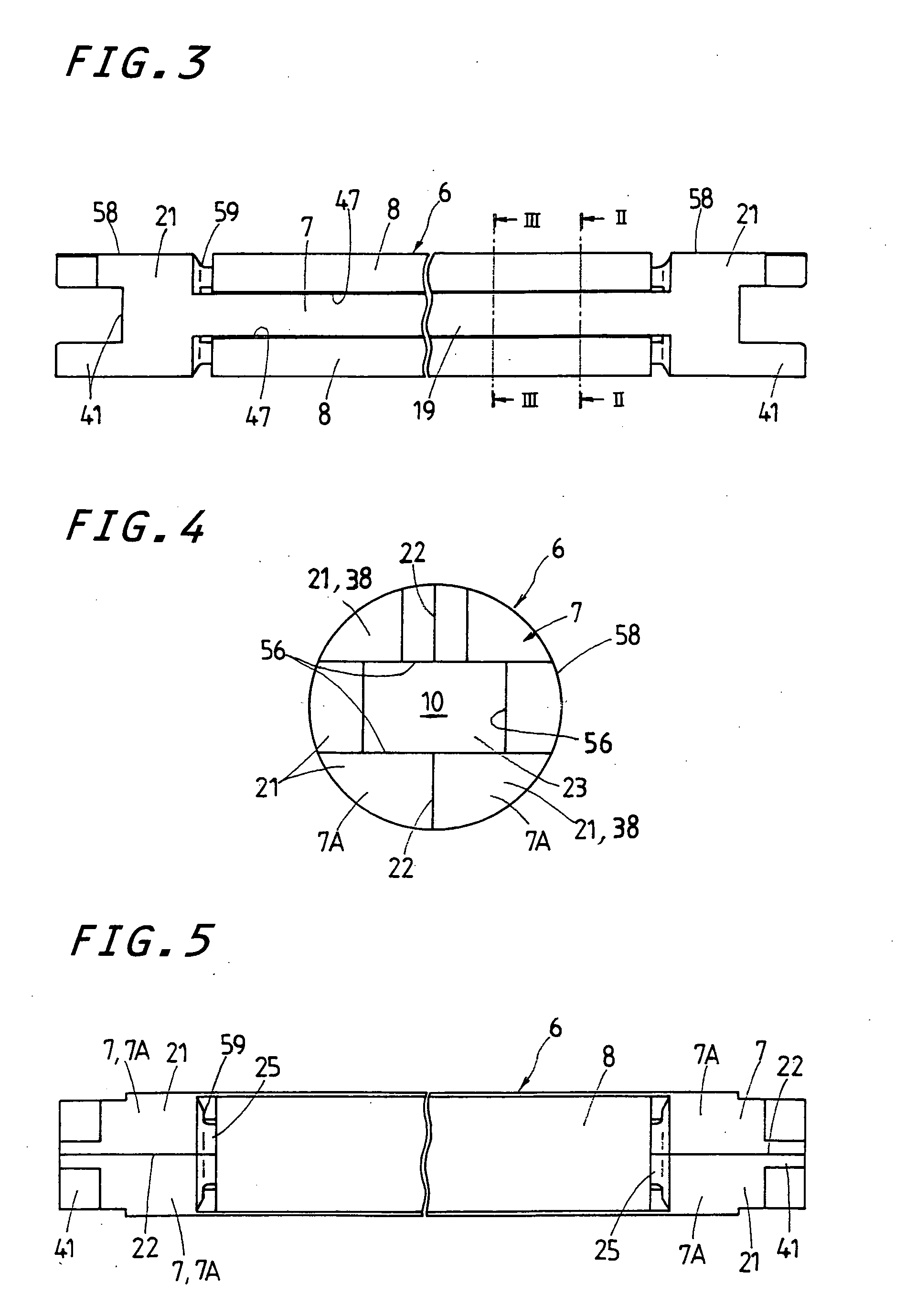

Prelubricated Multi-Lipped Radial Shaft Seal With Large Radial Offset Accommodation

InactiveUS20080284110A1Easy to carryImprove sealing efficiencyEngine sealsEngineeringBearing surface

A radial shaft seal is provided for accommodating large radial offset of the shaft relative to a housing. The seal includes an annular retainer insert provided for engaging the seal to a fixed housing. An annular elastomeric seal body is molded to the retainer insert and includes a flexible axially extending portion extending from an inner surface of the retainer insert. A seal portion extends from a radially inward end of the flexible portion and includes first and second seal lips and an elastomeric bearing surface disposed between the first and second sealing lips. The bearing surface includes a plurality of raised pads adapted to engage the shaft. The pads each include a rounded edge on lateral sides thereof for encouraging the creation of a lubricating film between the pads and shaft. The pads are lubricated by a lubricant disposed in a lubricant chamber disposed between the first and second seal lips.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

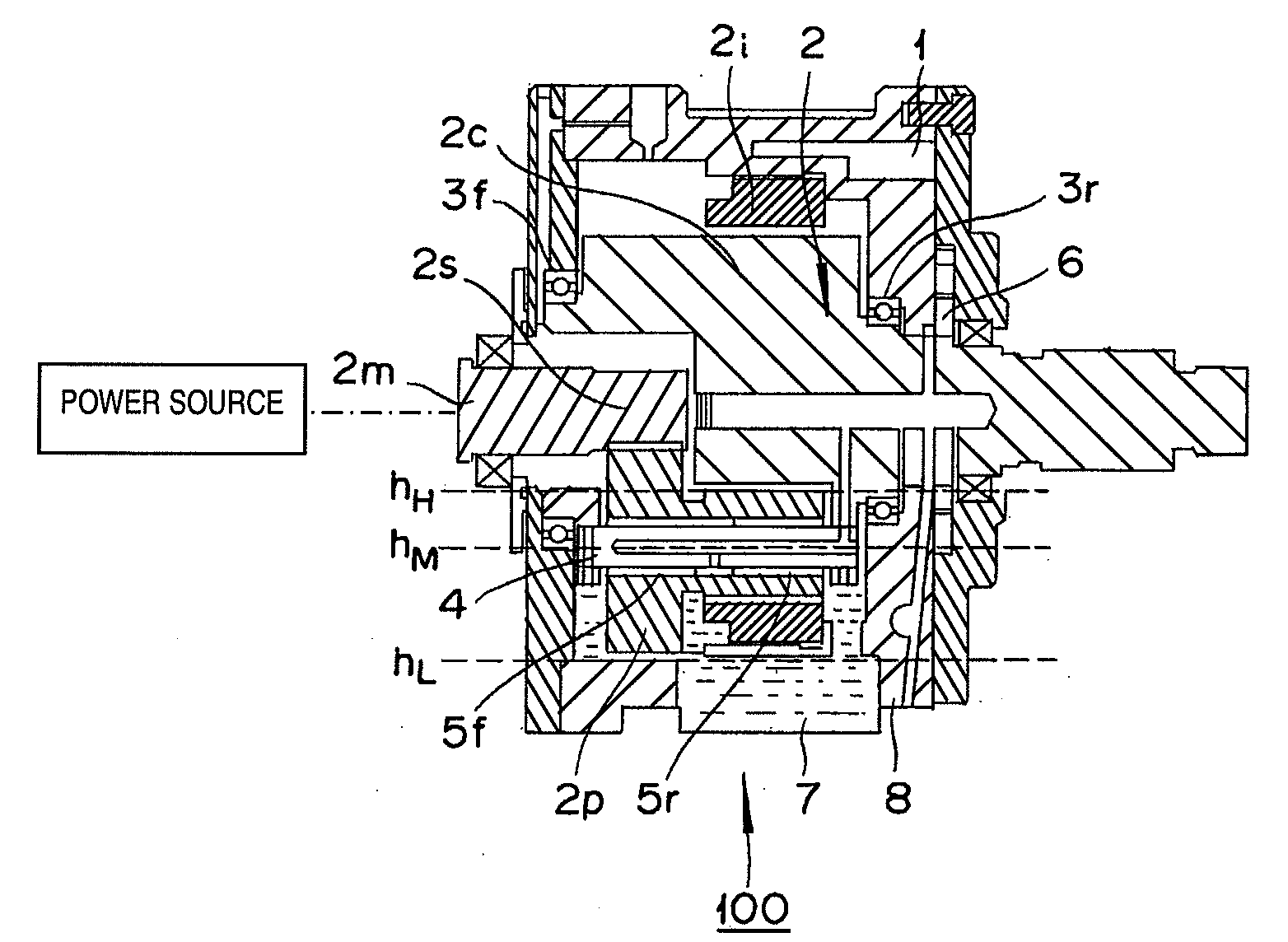

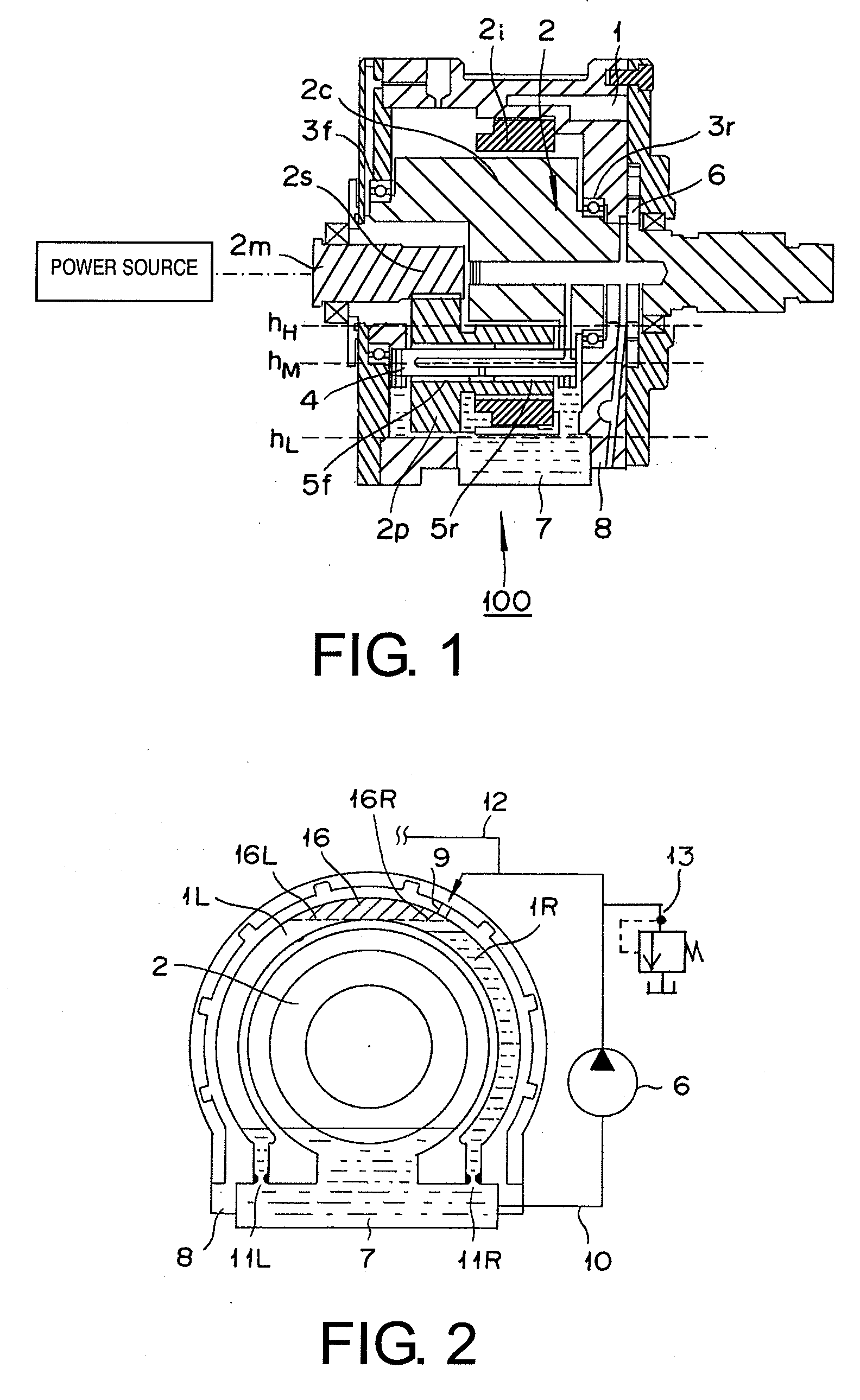

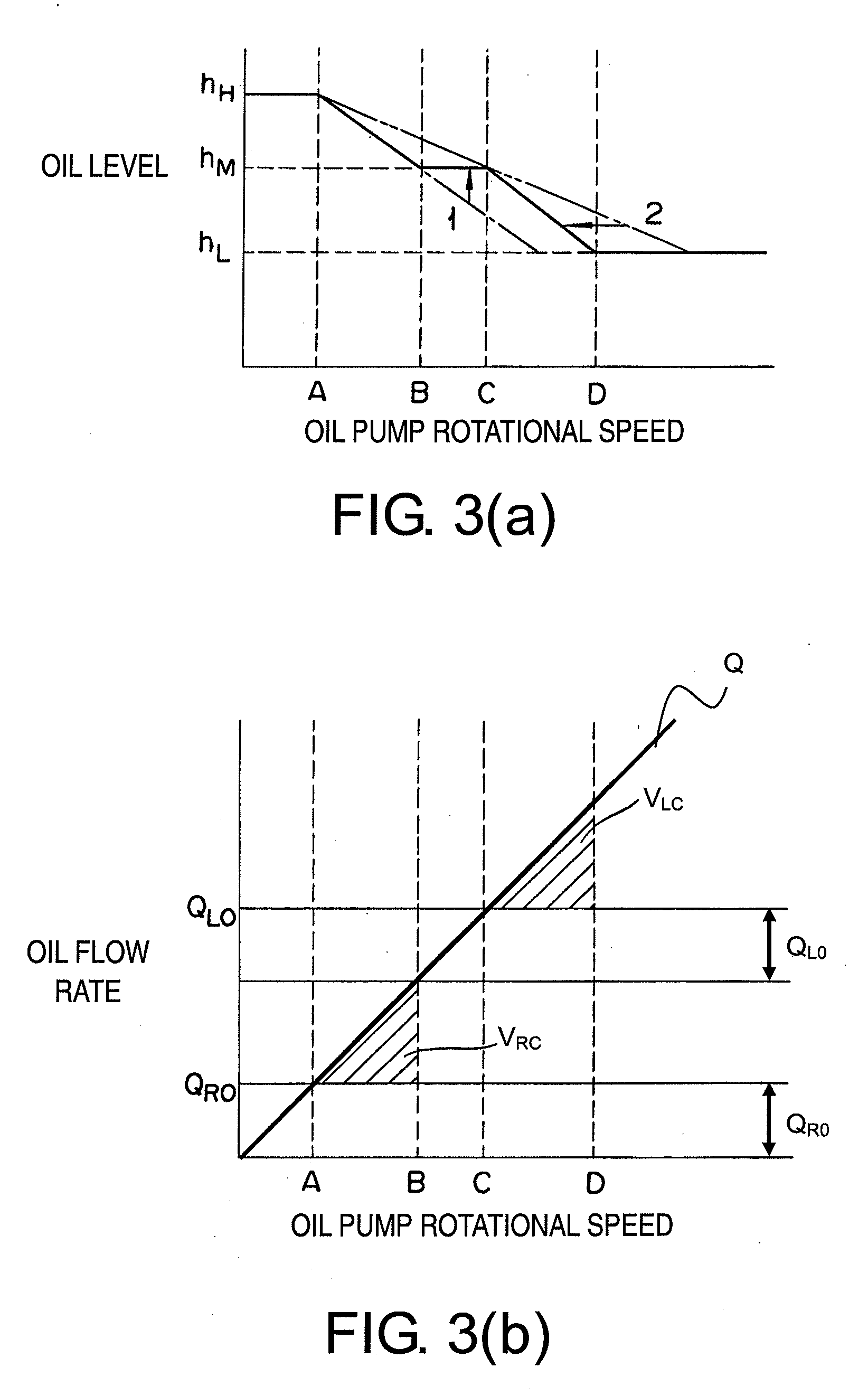

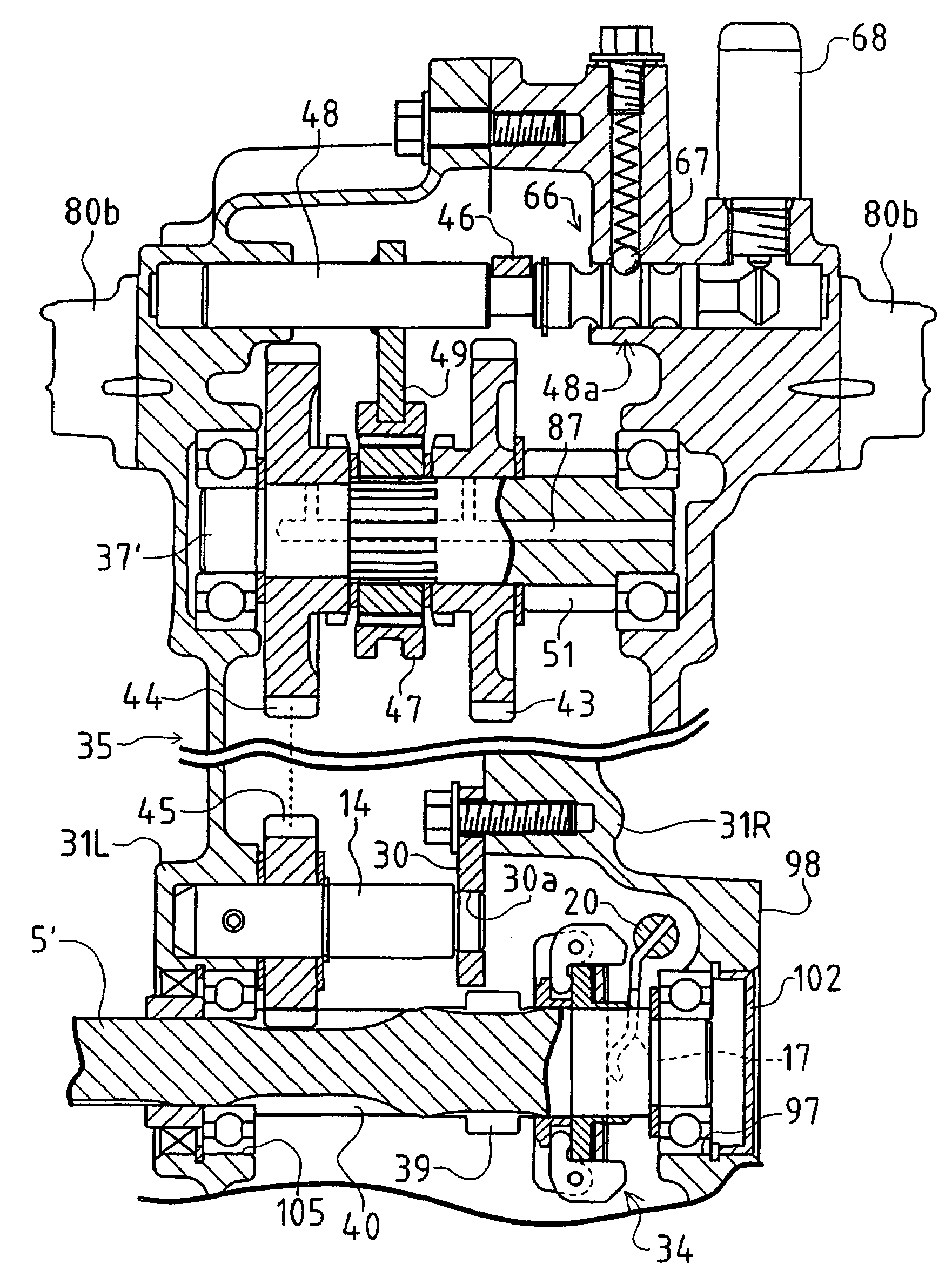

Power transmission device

InactiveUS20080045368A1Fully lubricatedIncrease speedGearboxesGear lubrication/coolingWaste managementPower transmission

A power transmission device is provided with a gear mechanism, a case, an oil pump and an oil tank. The gear mechanism is arranged to operate in coordination with a drive source. The case houses the gear mechanism and stores oil for lubricating the gear mechanism. The oil pump is arranged to operate in coordination with the drive source so as to pump the oil stored in the case to lubricate the gear mechanism. The oil tank is arranged to collect a portion of the oil pumped from the oil pump. The oil tank includes a first discharge outlet arranged to discharge the oil collected in the oil tank to the case and a second discharge outlet arranged to discharge collected oil to the case when an amount of the oil collected in the oil tank is equal to or larger than a prescribed amount.

Owner:NISSAN MOTOR CO LTD

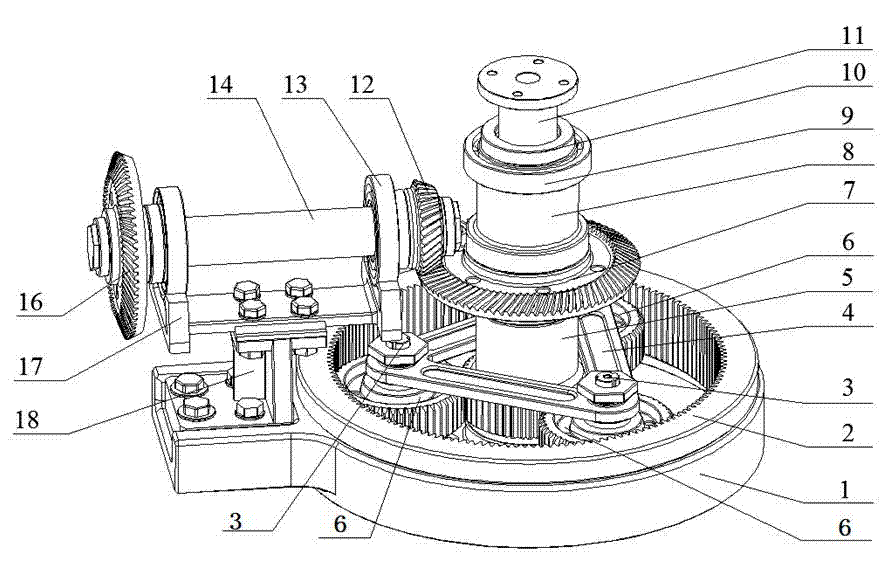

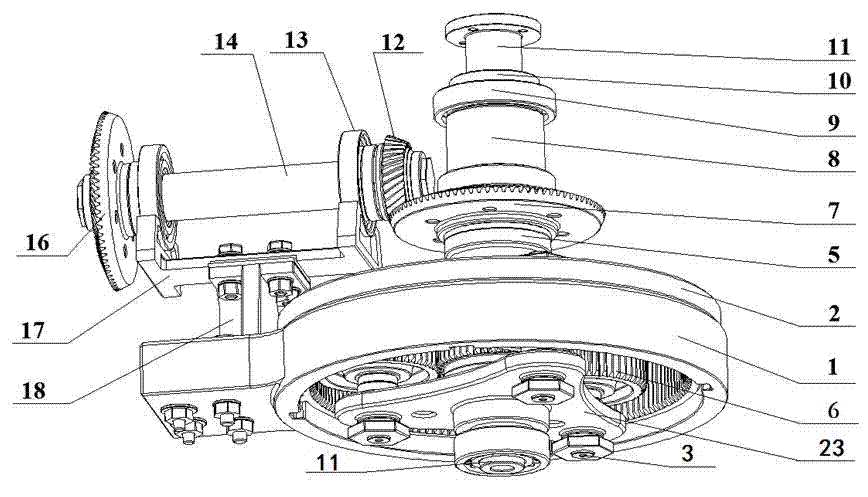

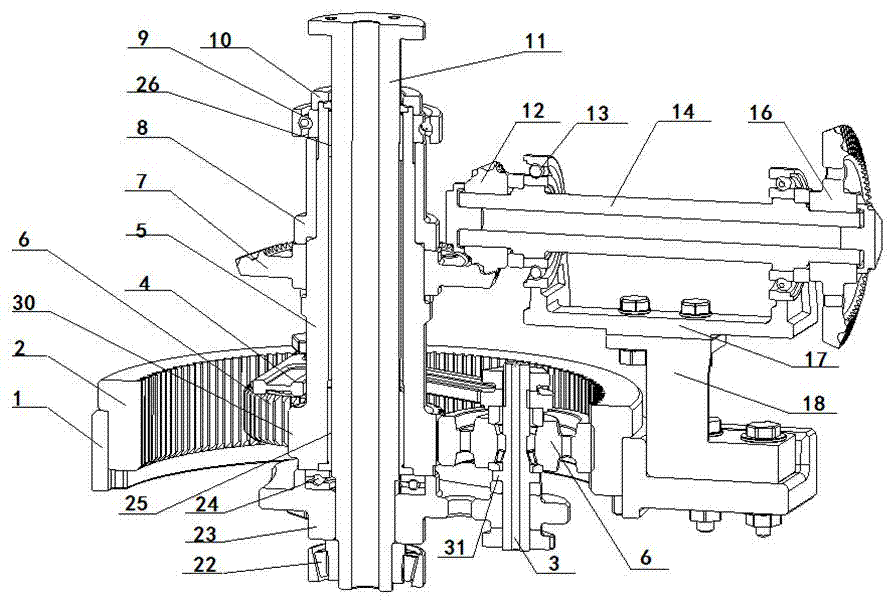

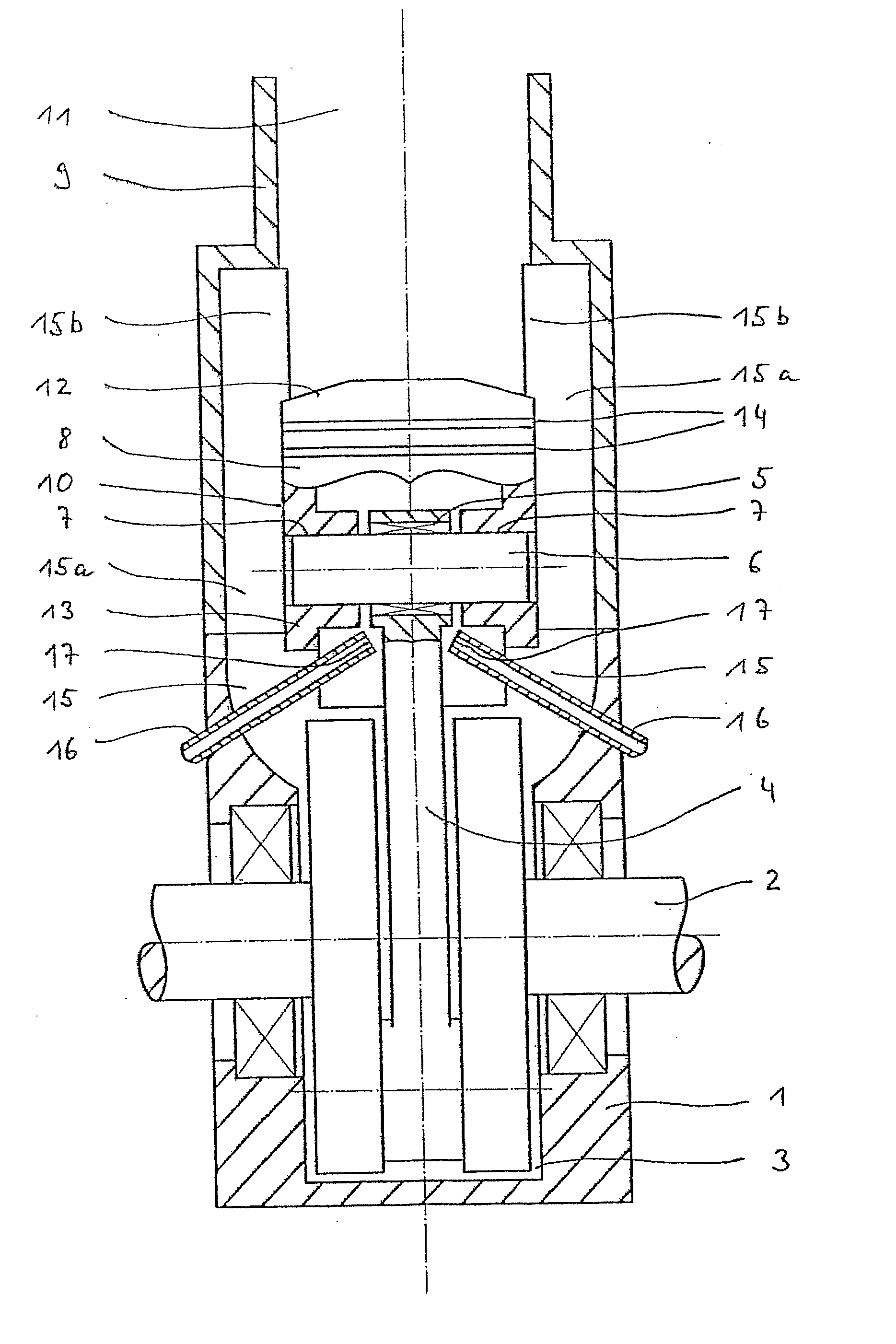

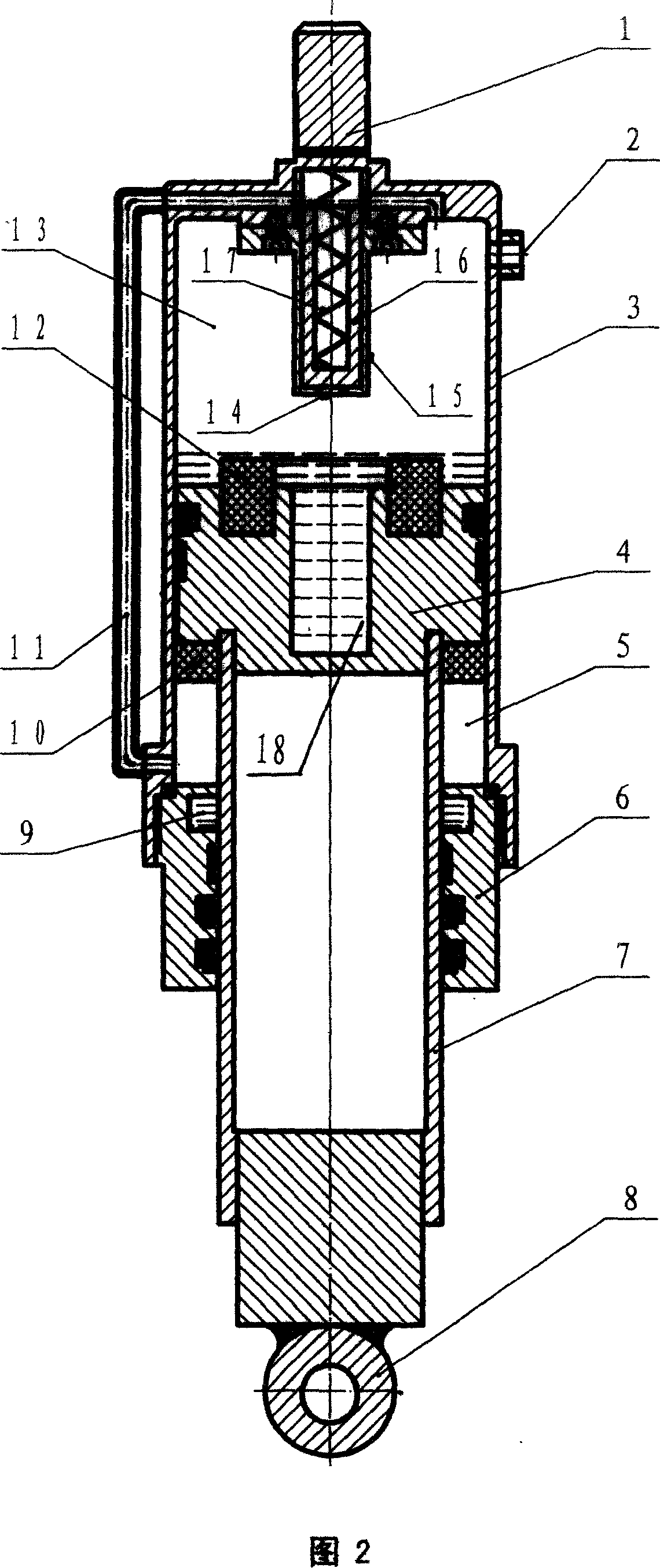

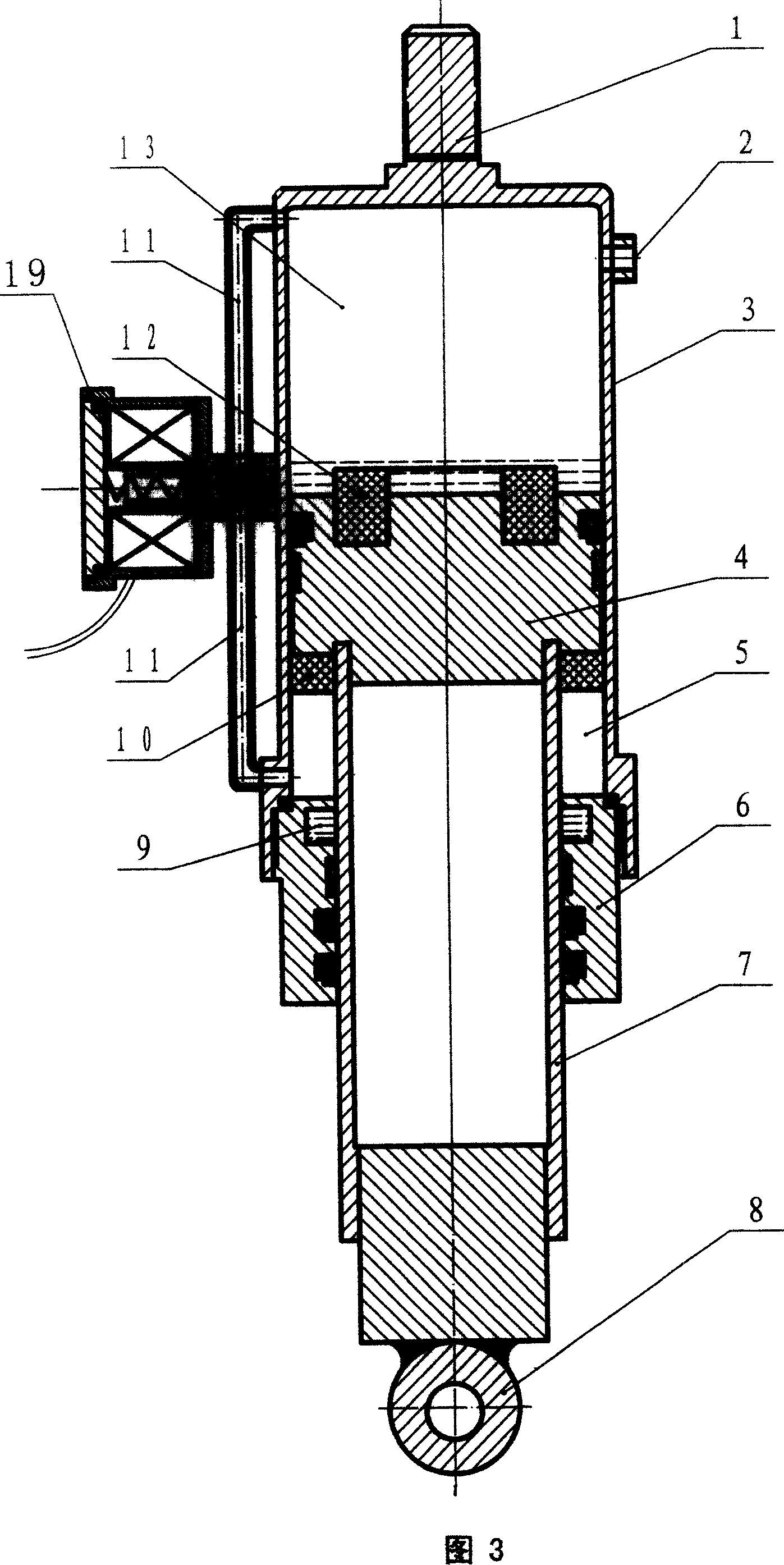

Main decelerator for middle and small size helicopters

The invention discloses a main decelerator for middle and small size helicopters. The upper end of a rotor shaft is the output end, and a shaft sleeve is arranged on the middle-upper part; a deep groove ball bearing is arranged on the upper part of the shaft sleeve, a secondary driven helical bevel gear is arranged on the middle part of the shaft sleeve, a jointed sun gear is arranged on the lower part of the shaft sleeve, three planetary gears are in mesh transmission with the sun gear respectively, and three planetary gears mesh with the gear ring respectively to form a planetary gear train; the gear ring is fixed on an annular base through a key, a horizontal transmission shaft is arranged on one side of the outer part of the base through supporting seats and a supporting board, a secondary driving helical bevel gear and a primary driven helical bevel gear are respectively arranged on two ends of the transmission shaft through splines, and the primary driven helical bevel gear is an input gear. The main decelerator disclosed by the invention adopts the technologies of nested installation for the sun gear shaft with the rotor shaft and integrated design for the planetary gear train bearing, the installation space is saved, the number of key parts is reduced, the system reliability is improved, the whole structure has the advantages of high carrying capacity, compact structure and easy maintenance, and the whole power transmission is U-shaped.

Owner:黄山市开发投资集团有限公司

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Preliminary melting type continuous casting crystallizer protecting slag and preparation thereof

The invention belongs to the field of auxiliary materials for smelting steel, in particular to a covering slag for a pre-melting continuous casting crystallizer. The weight percentage components of the covering slag are as follows: 31 to 36 percent of SiO2, 30 to 35 percent of CaO, 2 to 5 percent of MgO, not more than 1.5 percent of Fe2O3, 2 to 5 percent of Al2O3, 8 to 11 percent of Na2O, 5 to 8 percent of F, 0.8 to 1.5 percent of Li2O, 3 to 6 percent of C and the rest are unavoidable impurities. The covering slag has a good liquidity and spreadability, can uniformly cover the surface of molten steel, has no piling phenomenon, and has the advantages of active slag surface, uniform melting and no caking phenomenon. The invention has a better insulating performance and has no cold steel agglomerated on the liquid surface; can ensure a casting blank to be fully lubricated so as to realize a high pulling rate; has a stable performance after absorbing the impurities and can realize stable and smooth continuous manufacture; avoids the steel leakage phenomenon, improves the casting blank quality and can lead the longitudinal crack of a plate blank and the angle part cross crack to be reduced by more than two third averagely; the invention has a low cost and is convenient for popularizing.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Fuel system for a multi-fuel engine

ActiveUS8776764B2Improve fuel vaporizationEmission reductionInternal combustion piston enginesLow pressure fuel injectionRail pressureFuel oil

Methods and systems are provided for operating an engine fuel system including a low pressure pump and a high pressure pump. During conditions when direct injection is not requested, a fuel rail pressure is maintained by the low pressure pump and fuel is port injected. Further, a stroke amount of the high pressure pump is adjusted to maintain an outlet pressure of the high pressure pump just below the fuel rail pressure. By maintaining fuel flow within the high pressure pump when high pressure pump operation is not required, and without flowing fuel from the high pressure pump outlet into the fuel rail, the high pressure pump may be cooled and lubricated without affecting the fuel rail pressure.

Owner:FORD GLOBAL TECH LLC

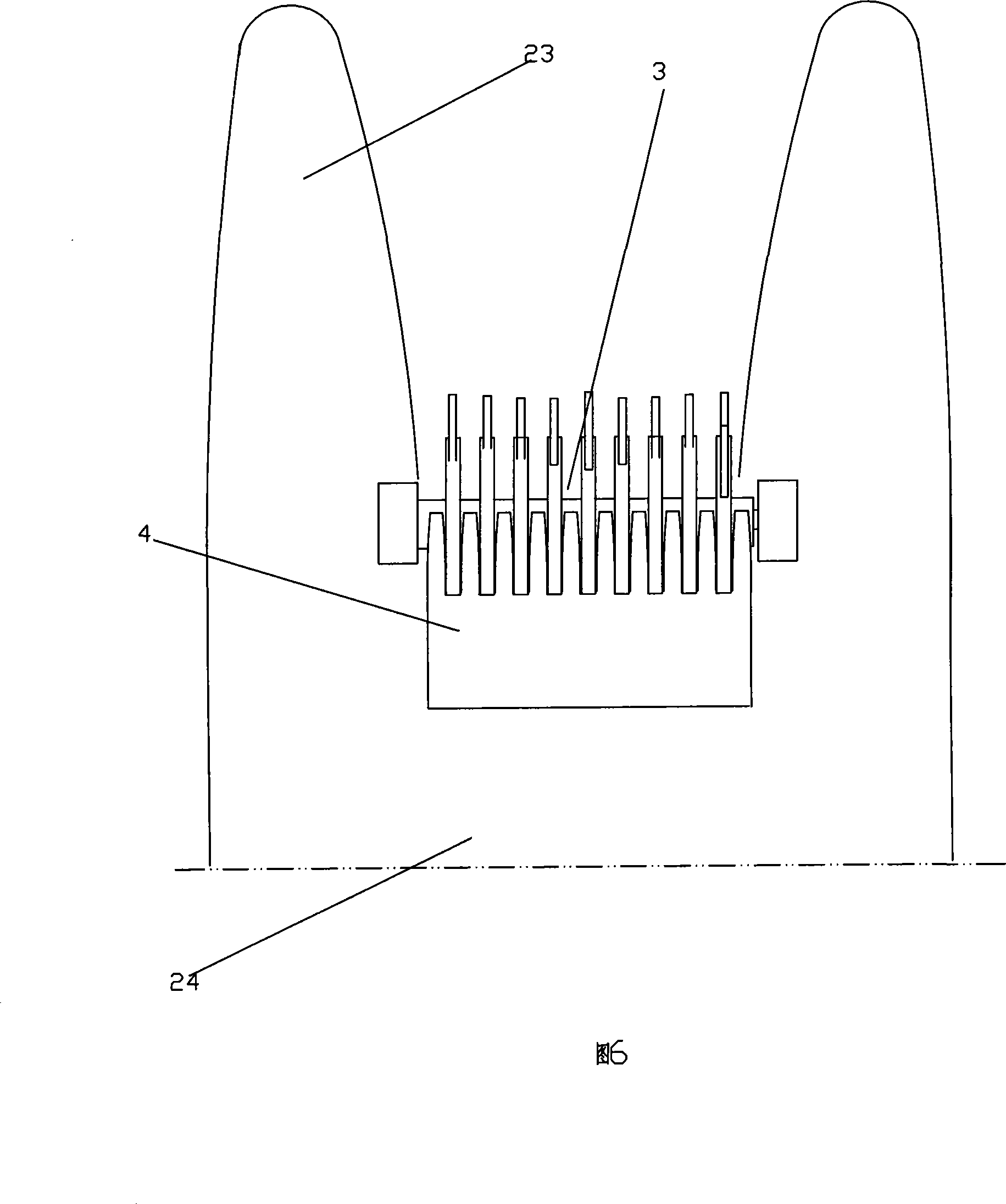

Walking dual-swing downhole drill

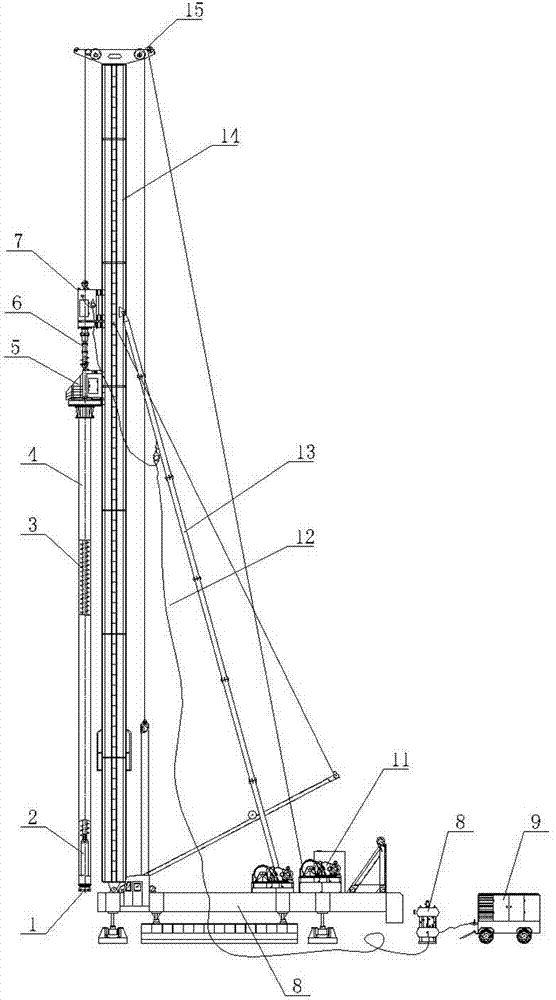

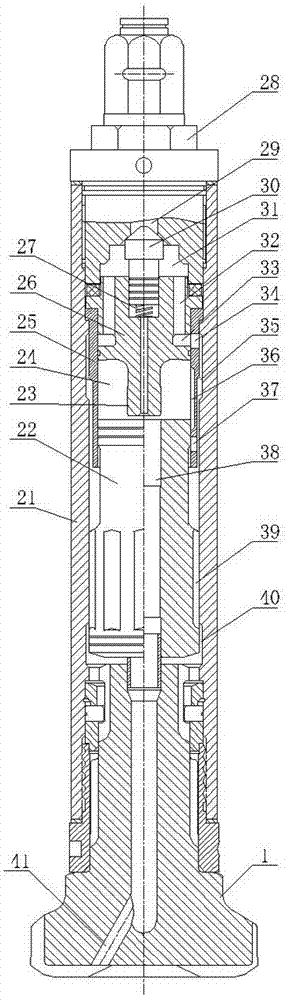

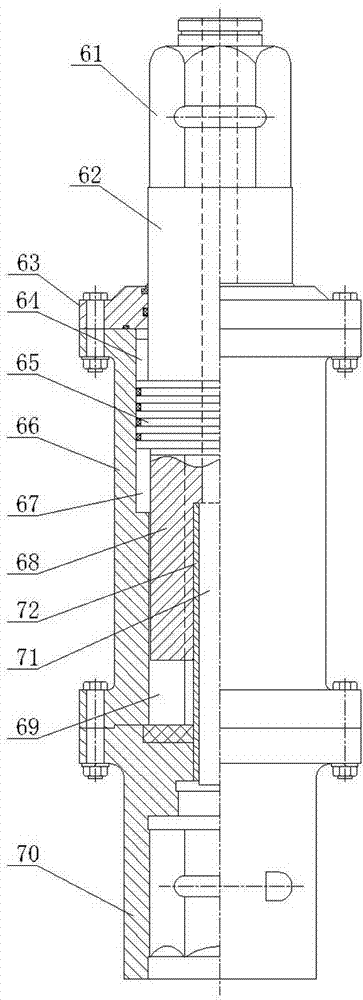

ActiveCN102828690AFully lubricatedOil Mist StabilizationConstructionsReciprocating drilling machinesEngineeringHigh pressure

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

Fuel injection system for an internal combustion engine

InactiveUS6976473B2Improve volumetric efficiencyImprove efficiencyElectrical controlLow pressure fuel injectionFuel tankEngineering

The fuel injection system has a high-pressure pump, by which fuel is pumped into a reservoir, with which injectors disposed on cylinders of the engine communicate. A feed pump pumps fuel out of a fuel tank to the high-pressure pump and a fuel metering device triggered by a control unit and disposed between the feed pump and the high-pressure pump controls the fuel quantity delivered to the high-pressure pump. The fuel metering device is formed by a clocking valve, which is opened and closed in pulse-width-modulated fashion by the control unit, and the fuel quantity delivered to the intake side of the high-pressure pump is proportional to the opening duration of the clocking valve.

Owner:ROBERT BOSCH GMBH

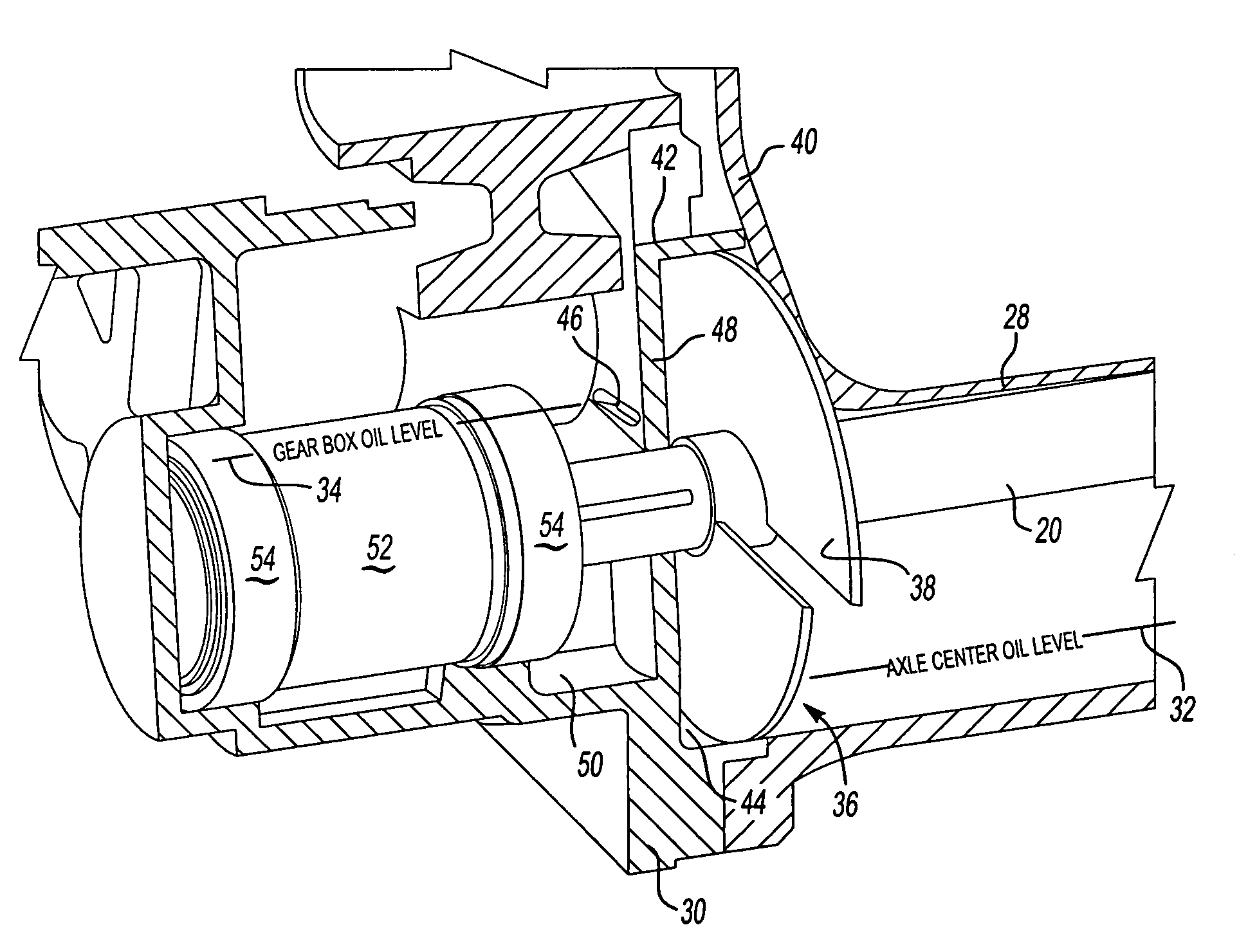

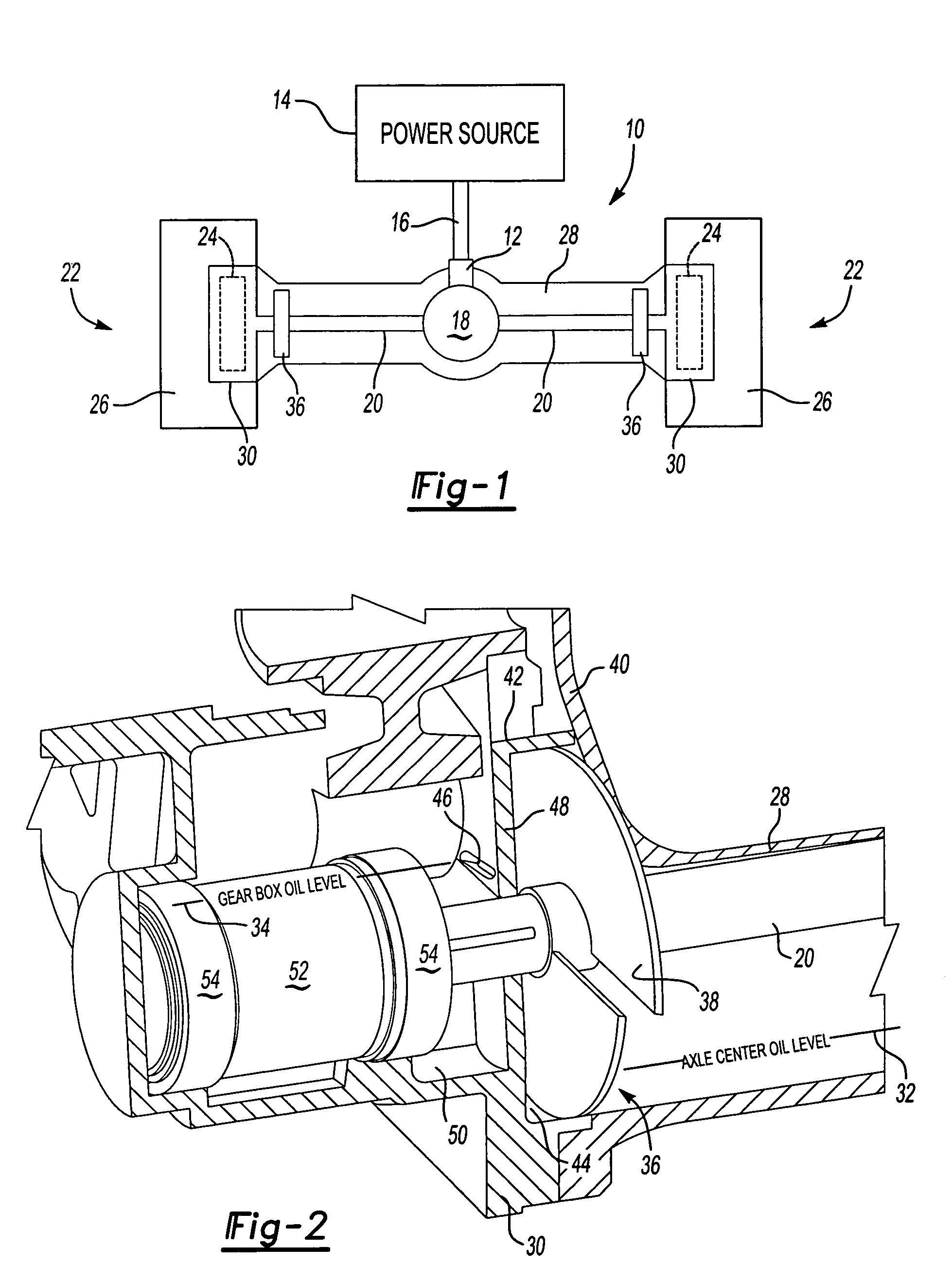

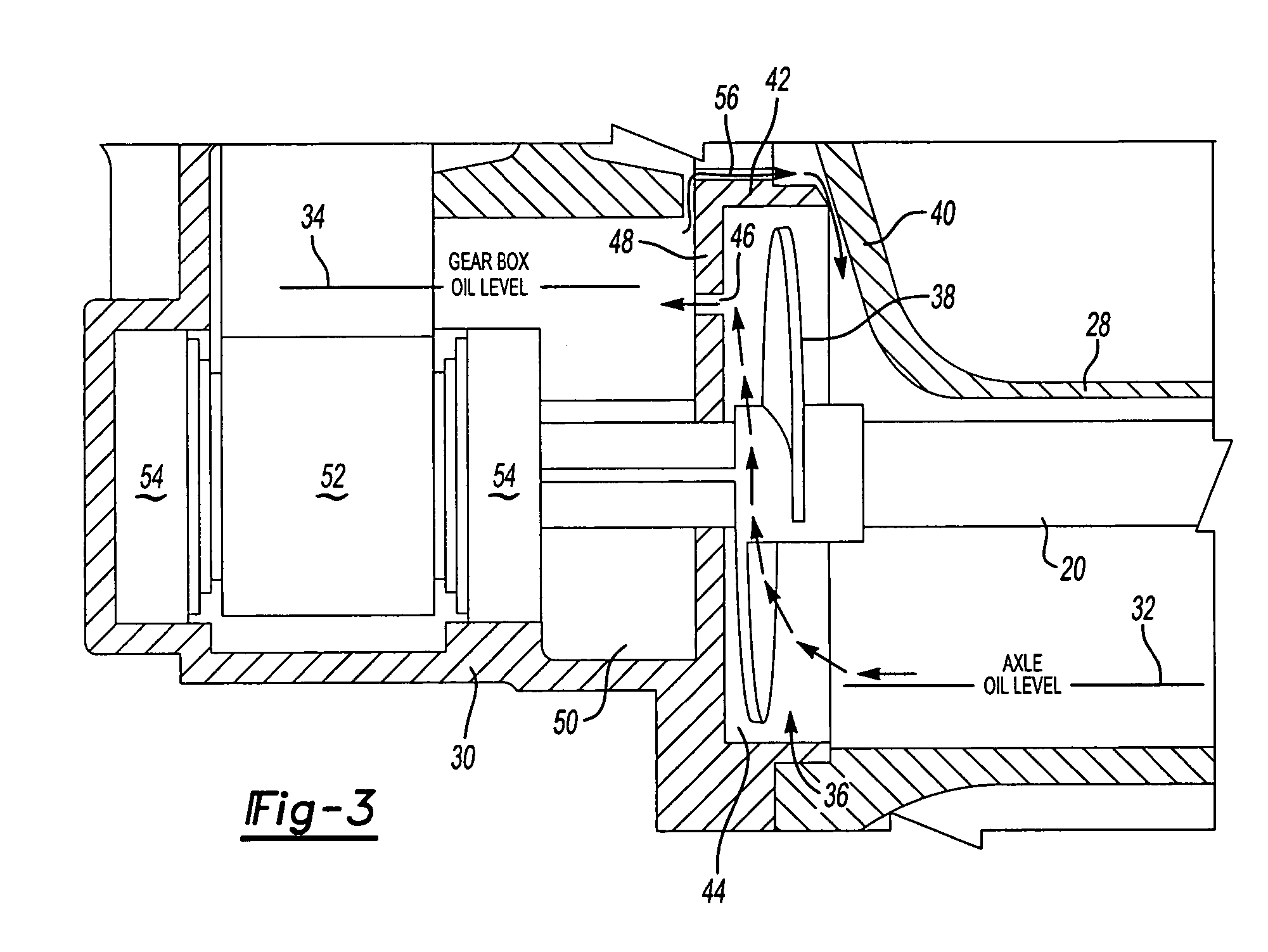

Dual level oil impeller for drive axle assembly

InactiveUS6991574B2Reduce the amount requiredFully lubricatedDrip or splash lubricationGear lubrication/coolingImpellerTransaxle

Owner:ARVINMERITOR TECH

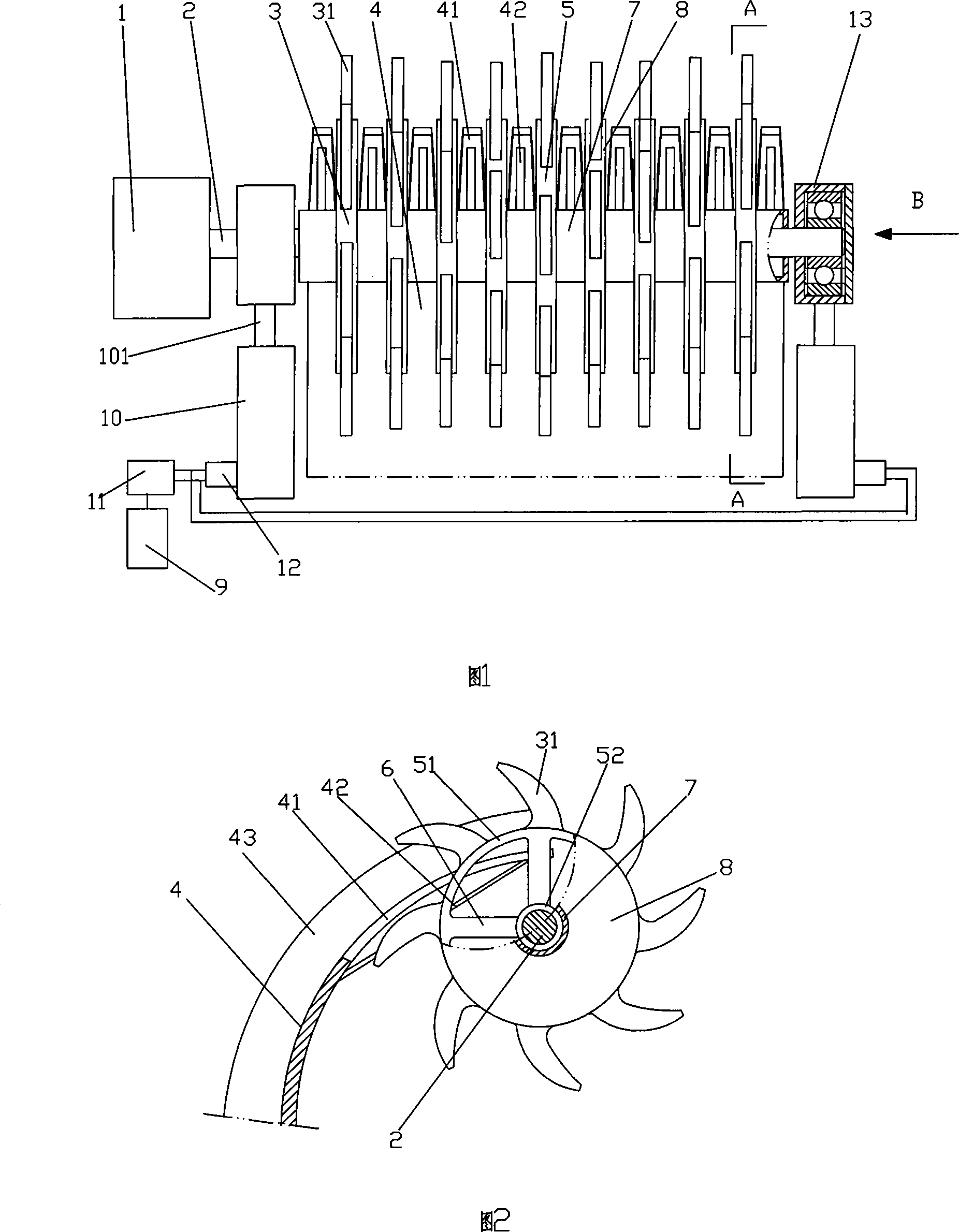

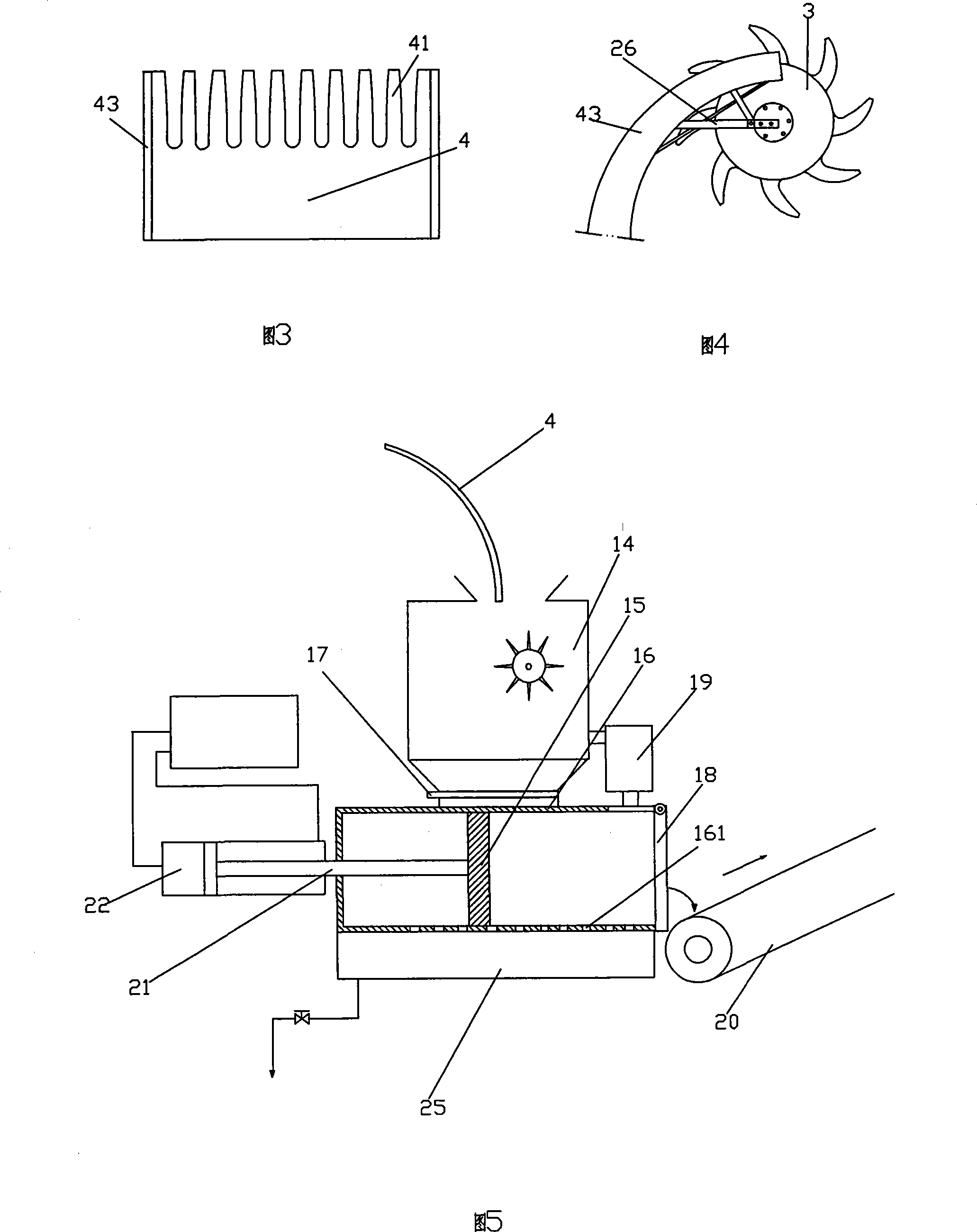

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

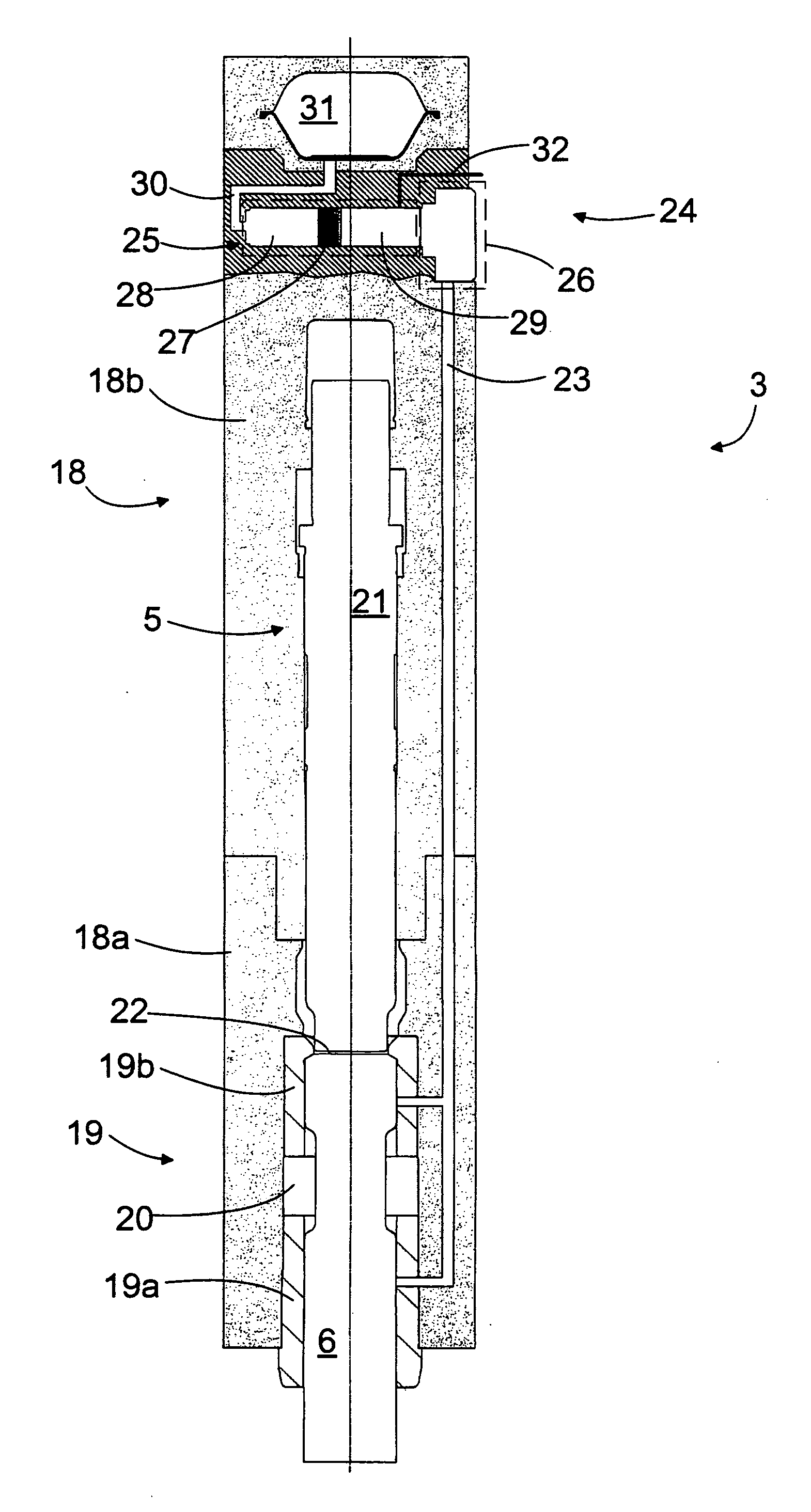

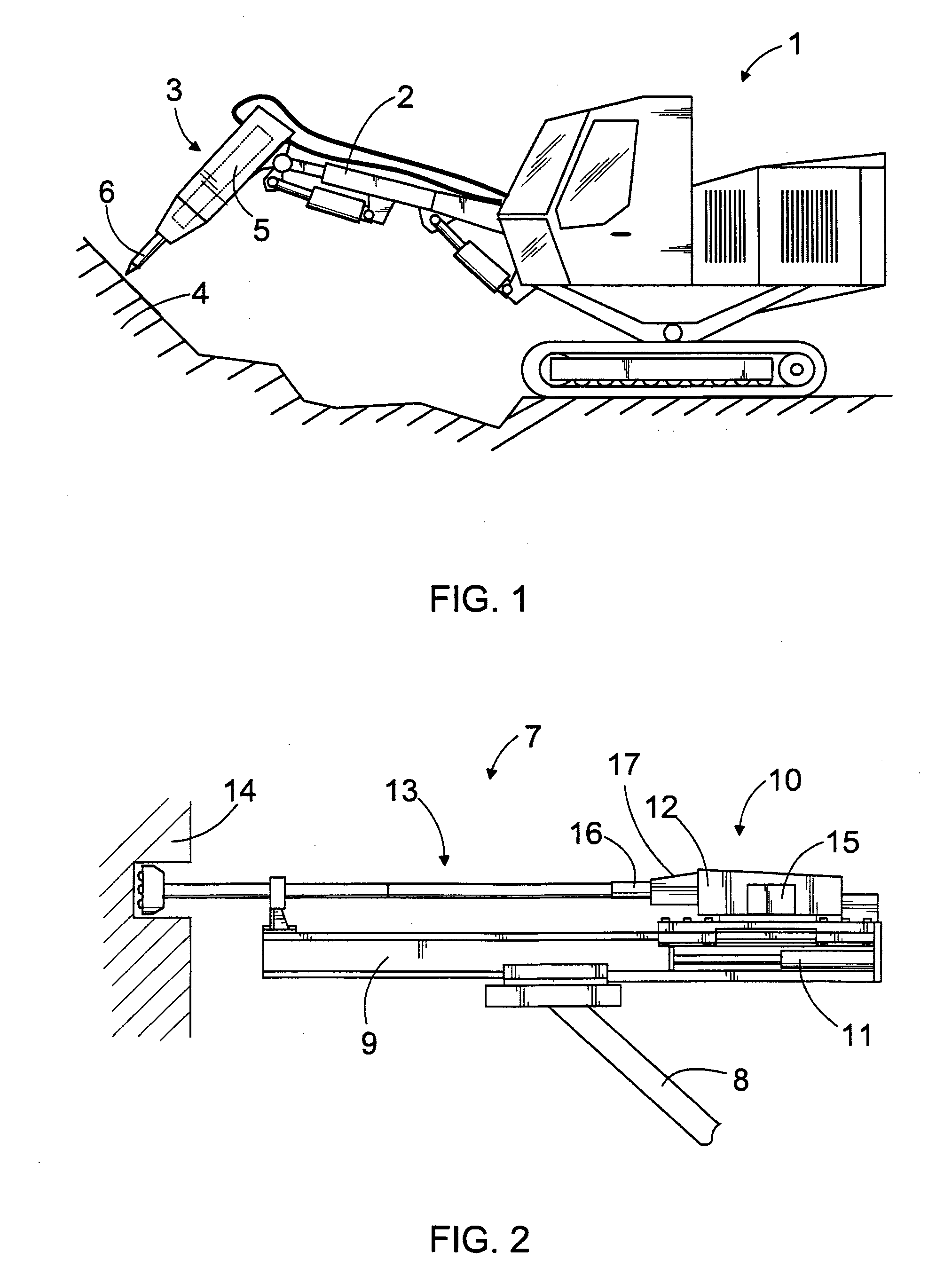

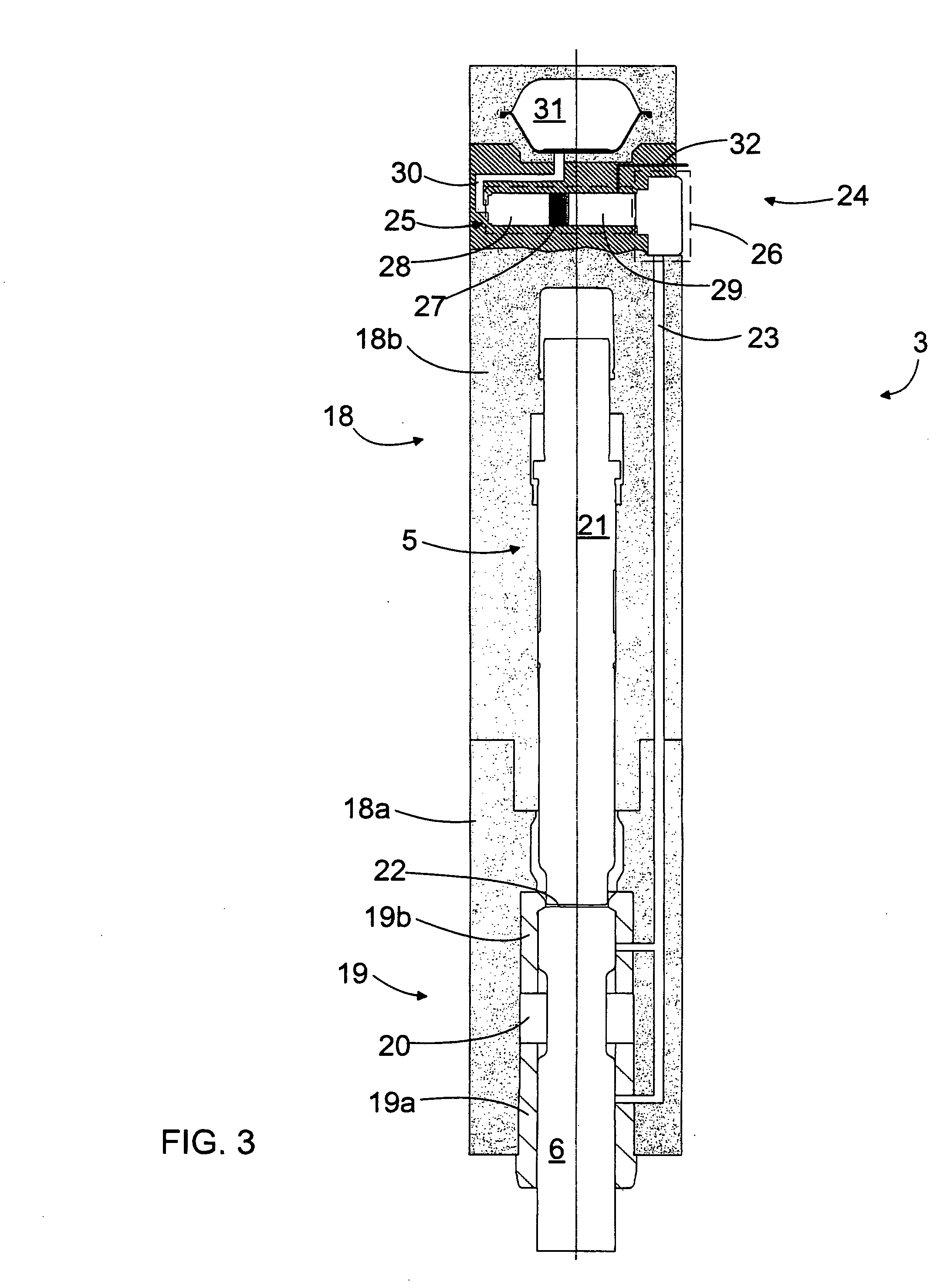

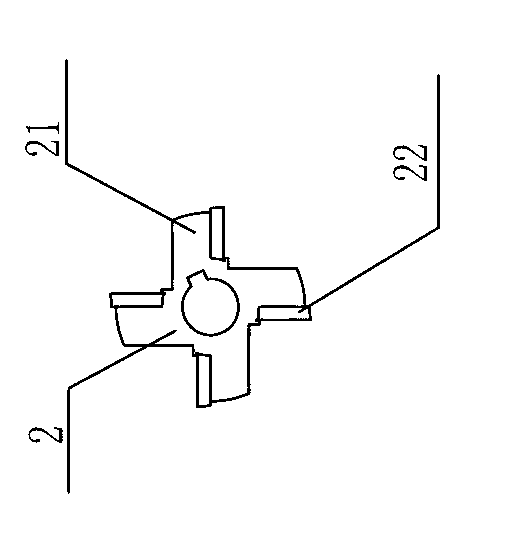

Rock breaking machine and lubricating method

InactiveUS20060048957A1Improve tool lifeEffective lubricationReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringCrusher

A rock breaking machine and to a method of lubricating a tool of a rock breaking machine. The lubricating system comprises at least one lubricant channel (23) into which lubricant is fed by a lubricating device (24). Lubricant is supplied to the bearing members (19) of the tool (6, 13) of the rock breaking machine. The lubricating device comprises a lubricant container (25) and a transfer device (26). The transfer device (26) controls the feed of lubricant into the lubricant channel. The lubricant container (25) is integrated into the body (17, 18) of the rock breaking machine.

Owner:SANDVIK MINING & CONSTR OY

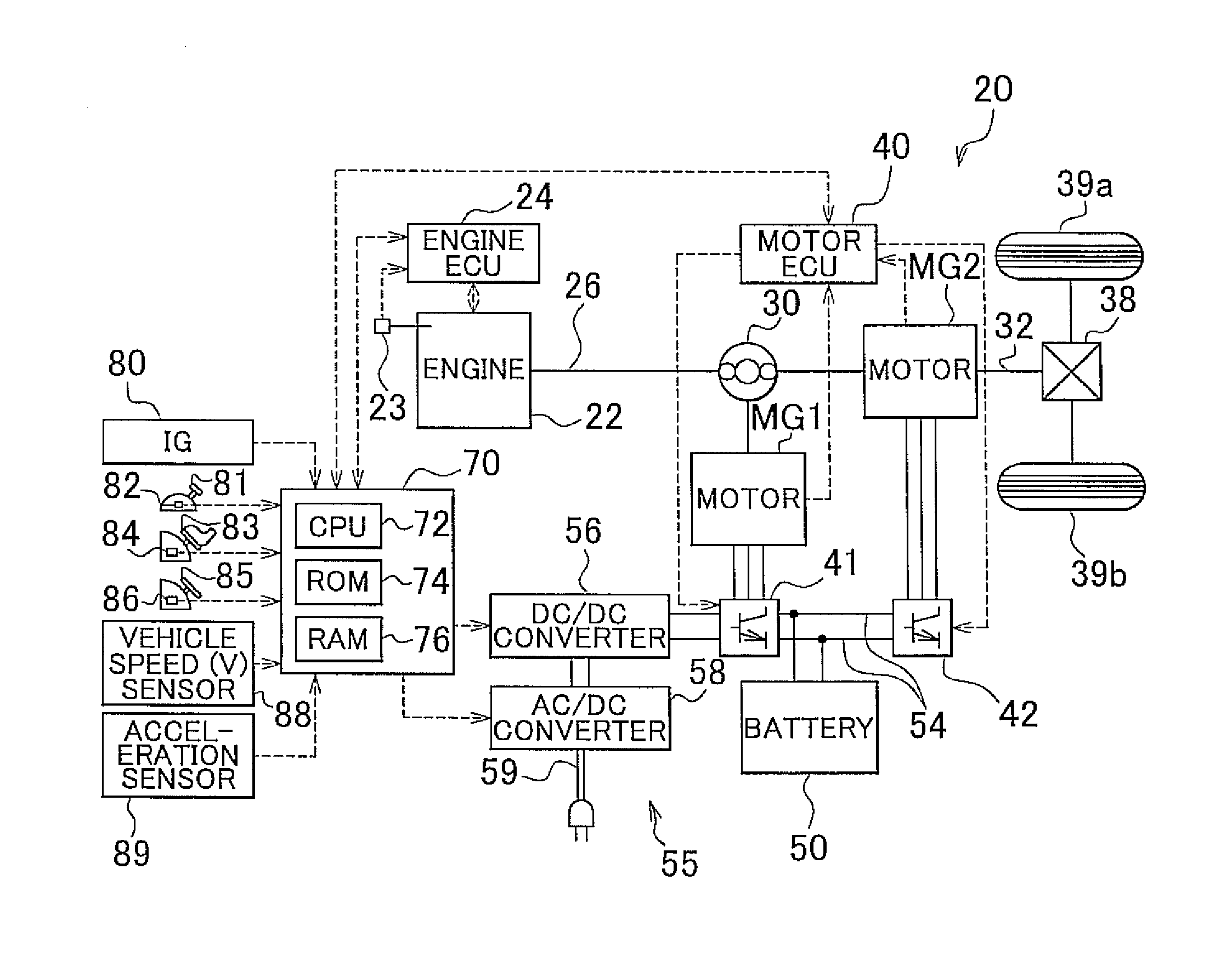

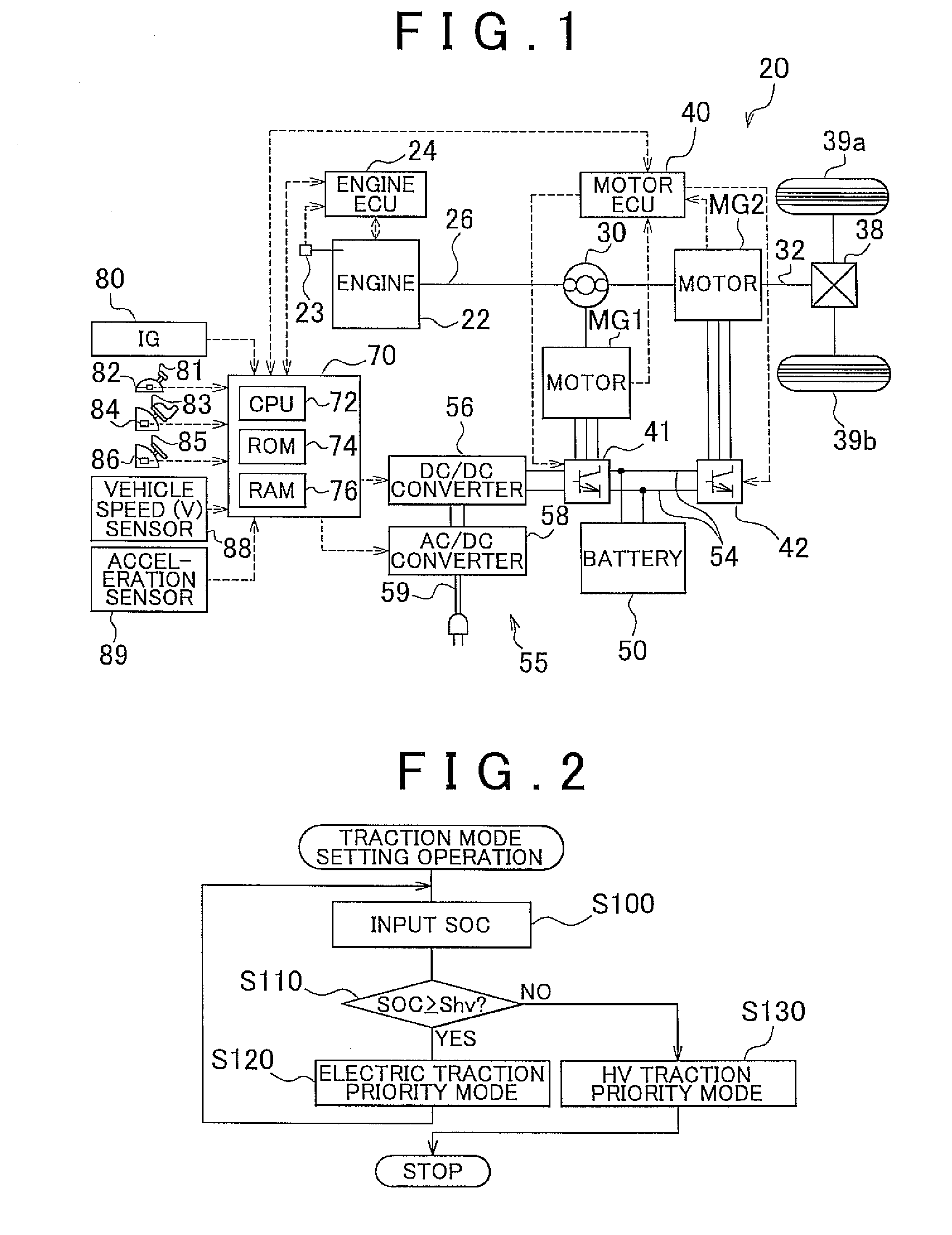

Hybrid motor vehicle and method of controlling hybrid motor vehicle

InactiveUS8579059B2Inhibit deteriorationFully lubricatedBatteries circuit arrangementsInternal combustion piston enginesInternal combustion engineHybrid electrical vehicle

A hybrid motor vehicle includes: an internal combustion engine that outputs motive power for vehicle traction; an engine-motoring electric motor that motors the internal combustion engine; a vehicle traction electric motor that outputs motive power for vehicle traction; a secondary battery that supplies electric power to the engine-motoring electric motor and to the vehicle traction electric motor; and a pre-engine-start control device that controls the internal combustion engine and the engine-motoring electric motor so as to motor the internal combustion engine in a reverse rotation direction without performing fuel injection or ignition when the hybrid motor vehicle is traveling on motive power from the vehicle traction electric motor without operating the internal combustion engine, after a system of the hybrid motor vehicle is started.

Owner:TOYOTA JIDOSHA KK

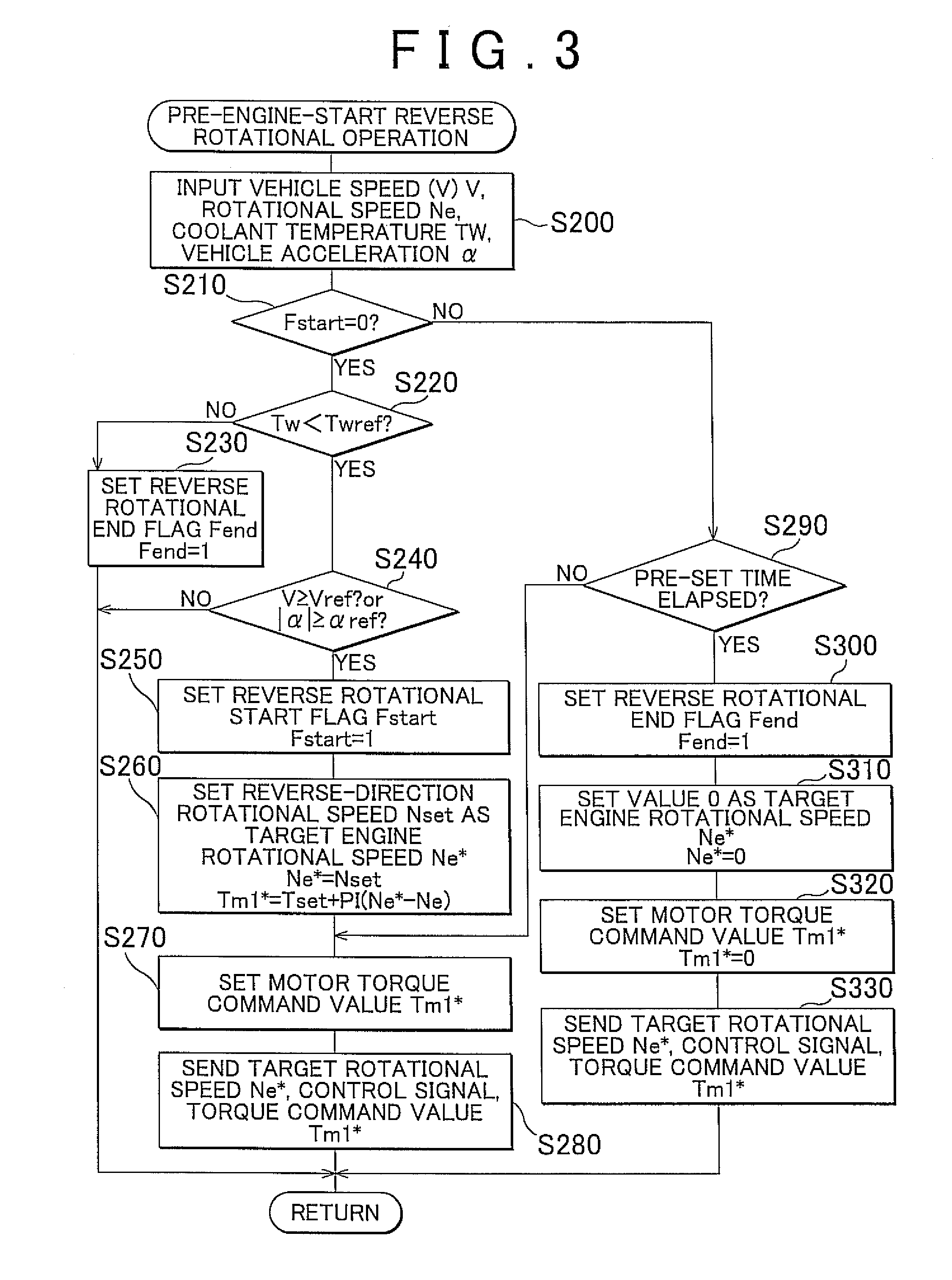

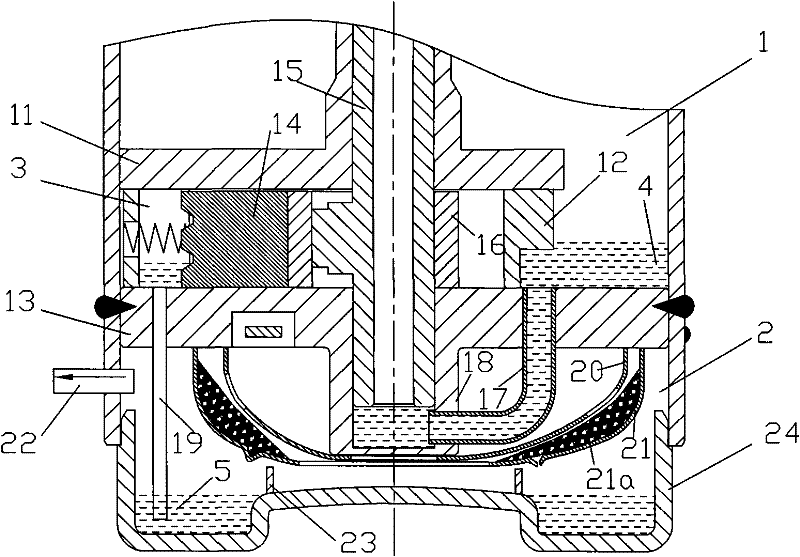

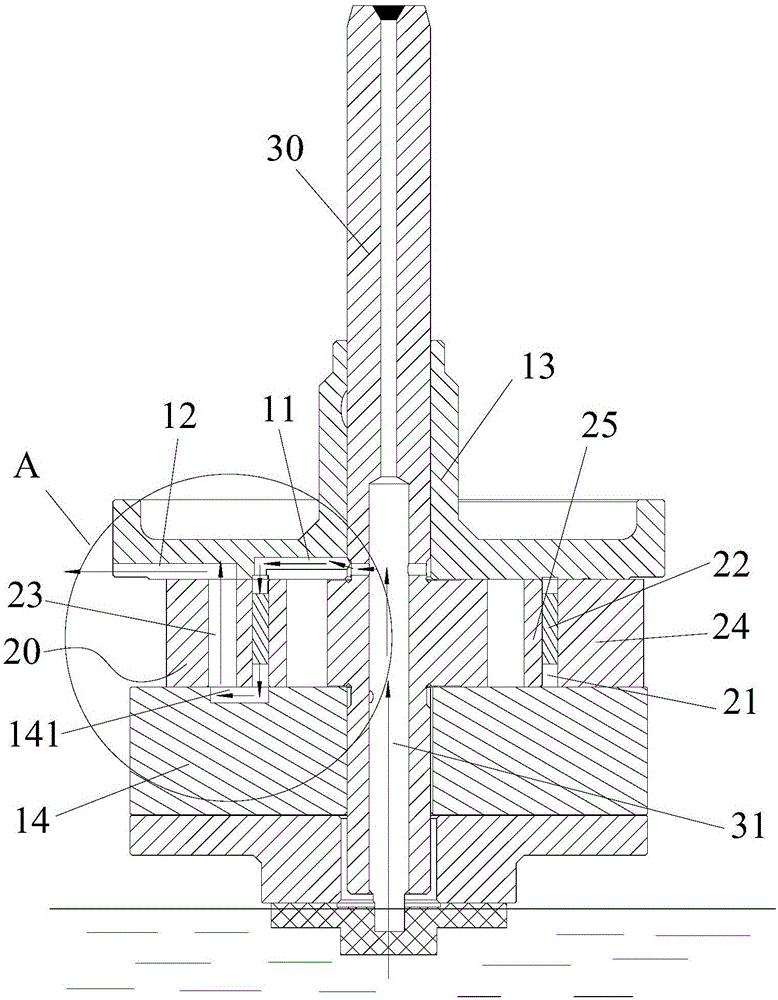

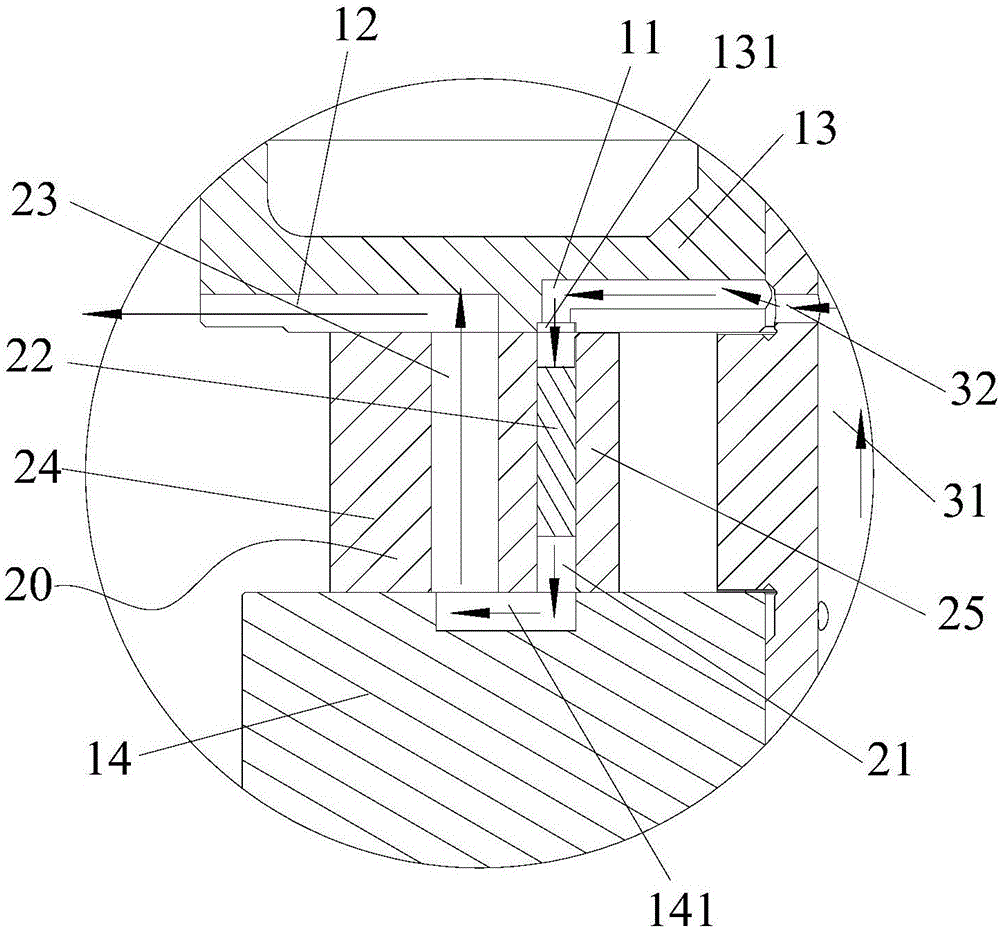

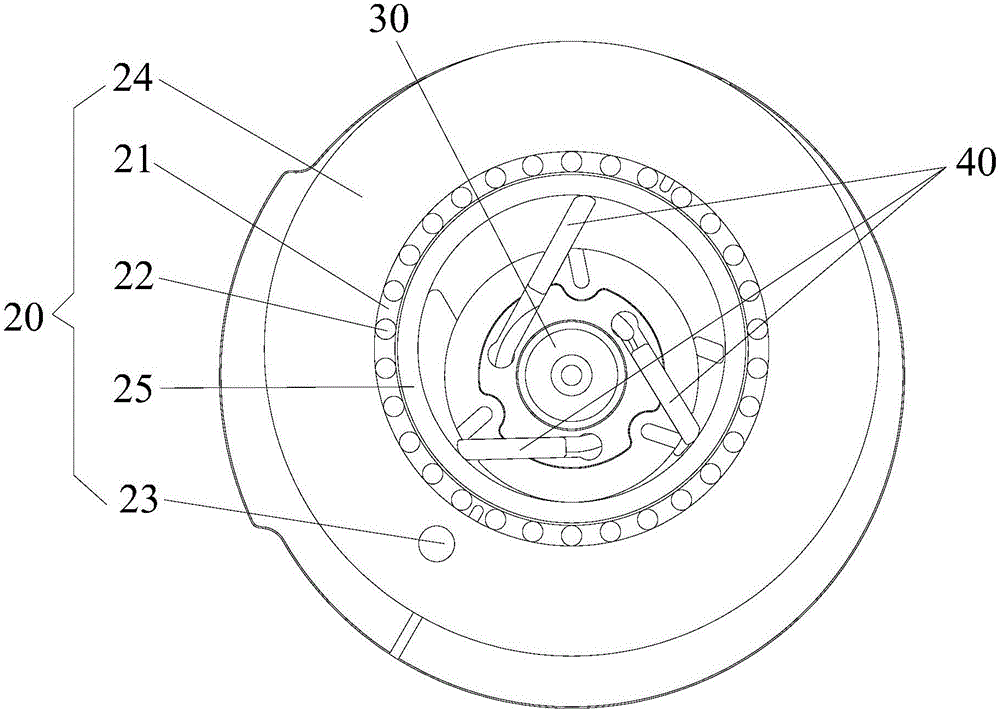

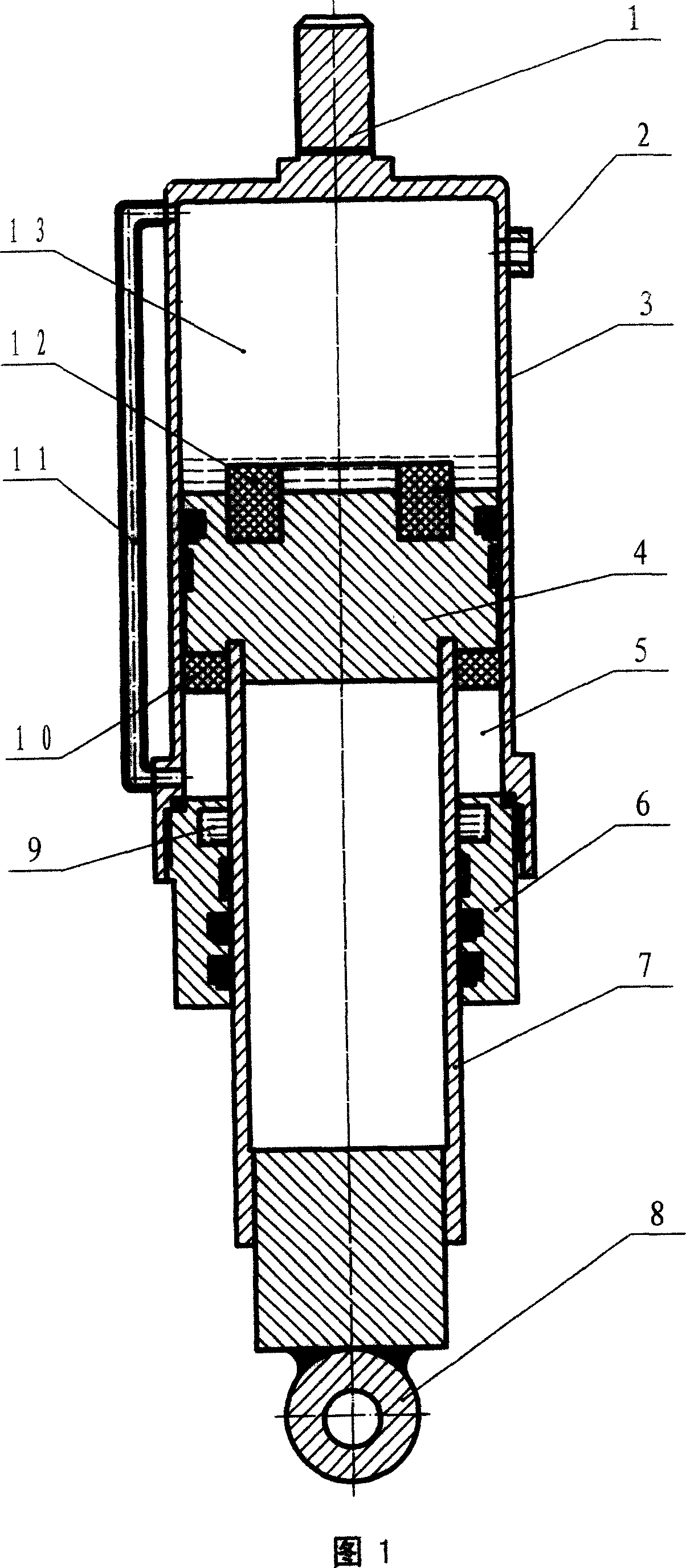

Rotary compressor

ActiveCN102192154AReduce noiseSmall pulsationRotary/oscillating piston pump componentsLiquid fuel engine componentsPistonLubrication

The invention provides a rotary compressor, comprising a compression component and a motor component which are arranged in a shell, wherein the compression component is arranged at the lower part of the shell; the motor component is arranged at the upper part of the shell; the compression component comprises an air cylinder, a piston arranged in the air cylinder and a slip sheet; a long bearing and a short bearing which are used for supporting an eccentric crankshaft are arranged on the air cylinder; the short bearing is used for dividing the inner space of shell into a low-pressure cavity atthe upper part and a high-pressure cavity at the lower part; the short bearing is provided with an upper oil pool, and an oil storage cavity is arranged at the lower end of the short bearing; the oilstorage cavity is communicated with the lubricant channel of the eccentric crankshaft; one end of an oil conduit is communicated with the upper oil pool and the other end of the oil conduit is communicated with the oil storage cavity; an oil conducting cover is arranged at the lower end of the short bearing; and the oil conducting cover, the lower end of the short bearing and the eccentric crankshaft form an oil storage chamber. The rotary compressor is simple and reasonable in structure, flexible in operation, good in lubrication performance, good in oil-gas separation effect, low in oil seal amount and high in safety degree.

Owner:GUANGDONG MEIZHI COMPRESSOR

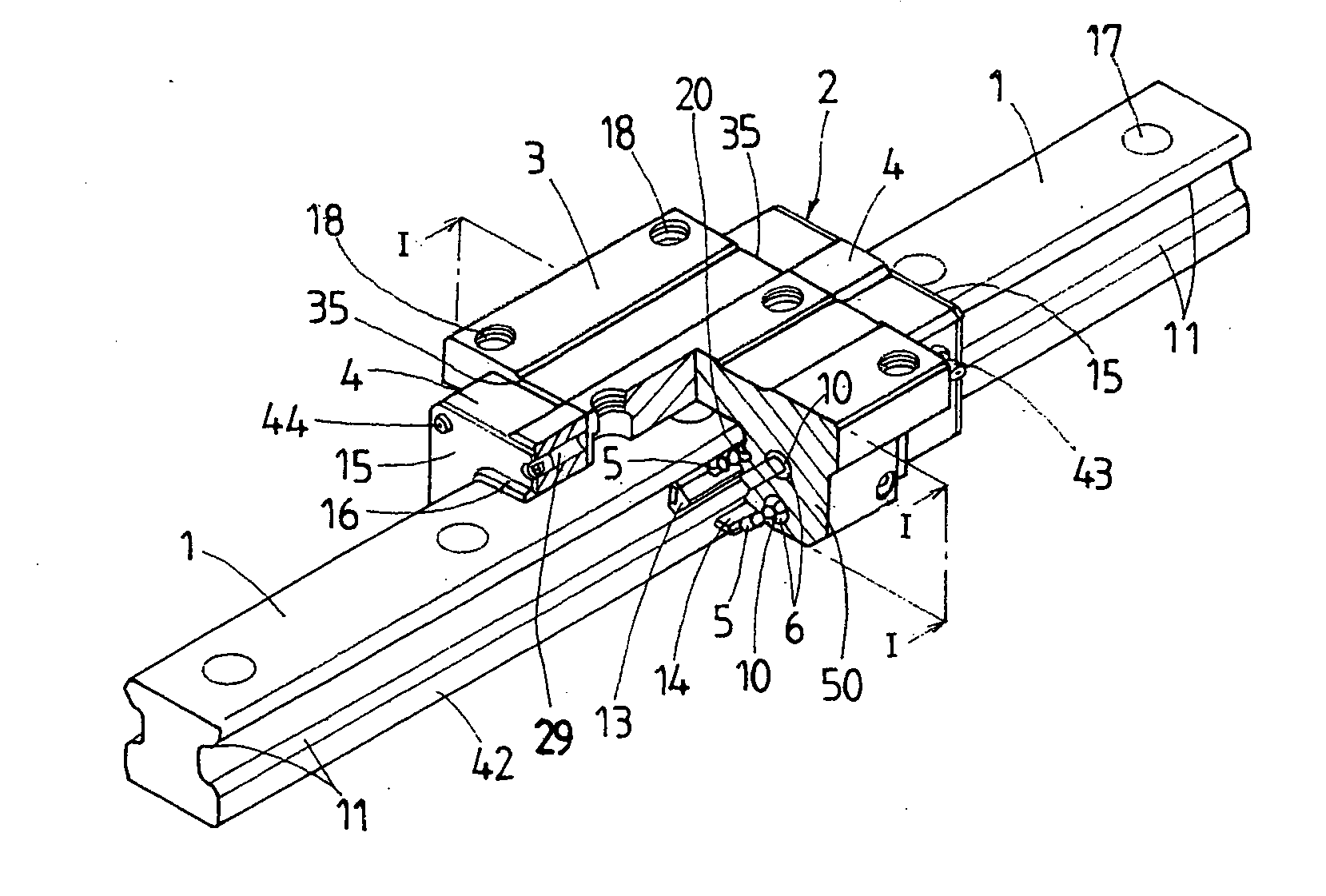

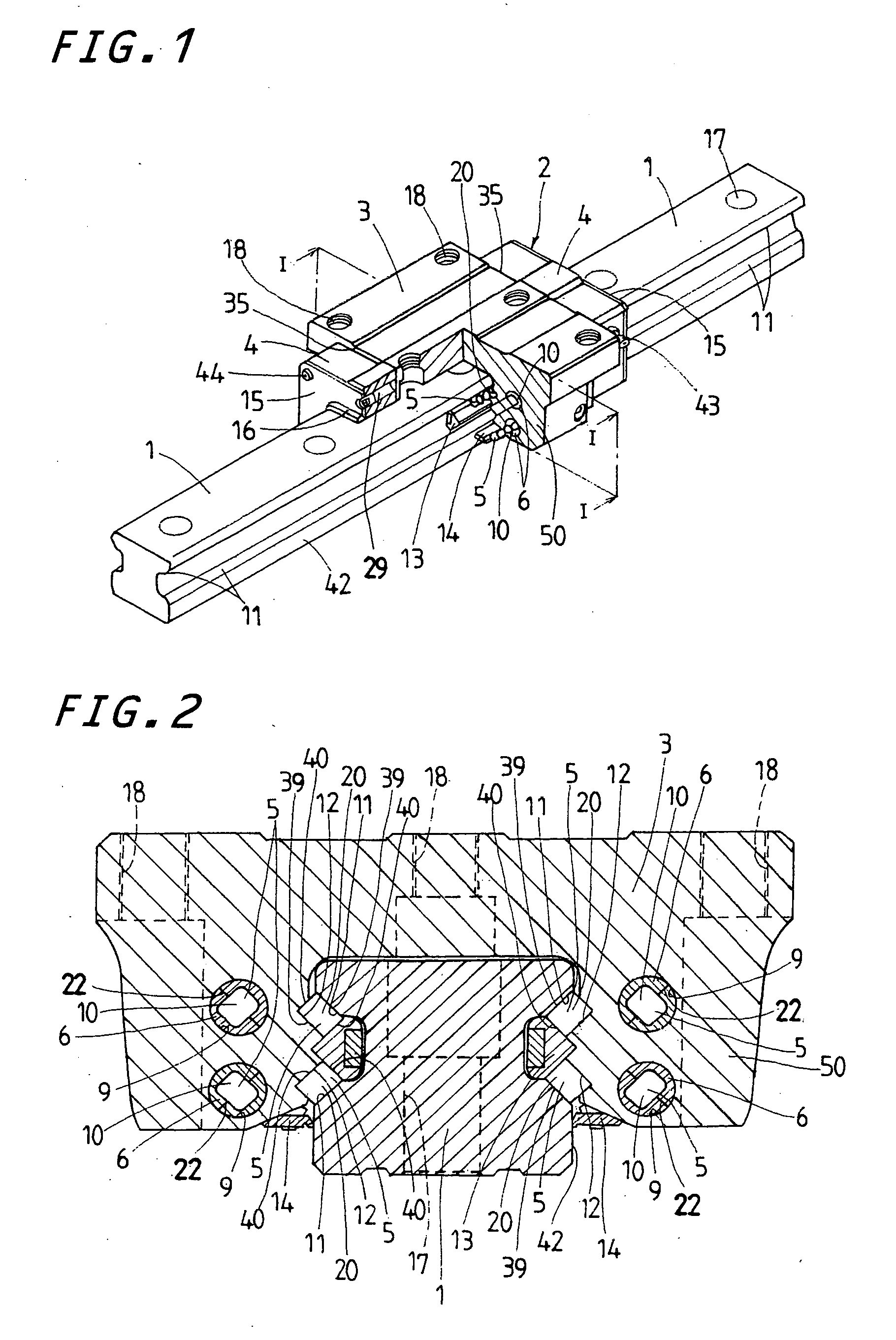

Linear motion guide unit

ActiveUS20070071372A1Relieve stressRelieve of impactLinear bearingsBearing componentsLinear motionEngineering

A linear motion guide unit is disclosed in which a tubular composition to provide a return passage is high in mechanical stiffness and also makes certain of sustainable application of lubricant to rolling elements rolling through the return passage, thereby ensuring proper lubrication under maintenance-free operation. The tubular composition to make the return passage is composed of a tubular skeleton to guide the rollers, and a porous compact impregnated with lubricant. The tubular skeleton is made up of forward and aft ends, a lengthwise column and a flexible spine, which extend between the ends. The flexible spine includes lengthwise opposite relief portions and a flexible middle section, which fit into the porous compact with separating from the porous compact to make a clearance between them. The flexible spine deflects as the rollers roll through the return passage, permitting the rollers coming into touch with the porous compact to lubricate the rollers.

Owner:NIPPON THOMPSON

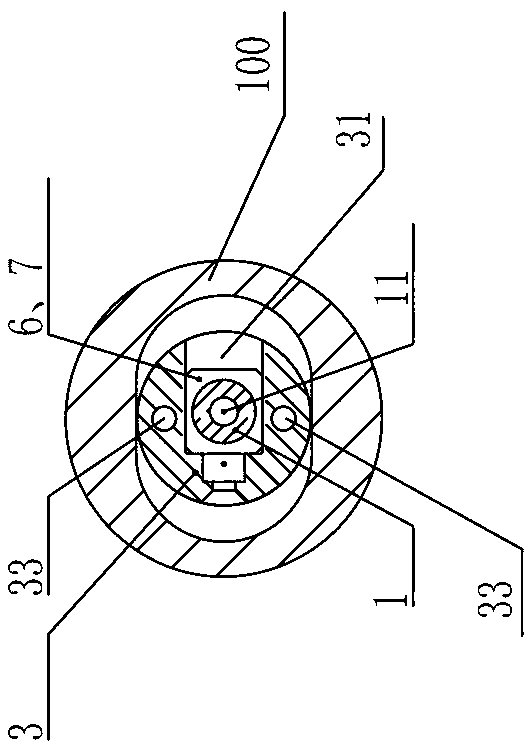

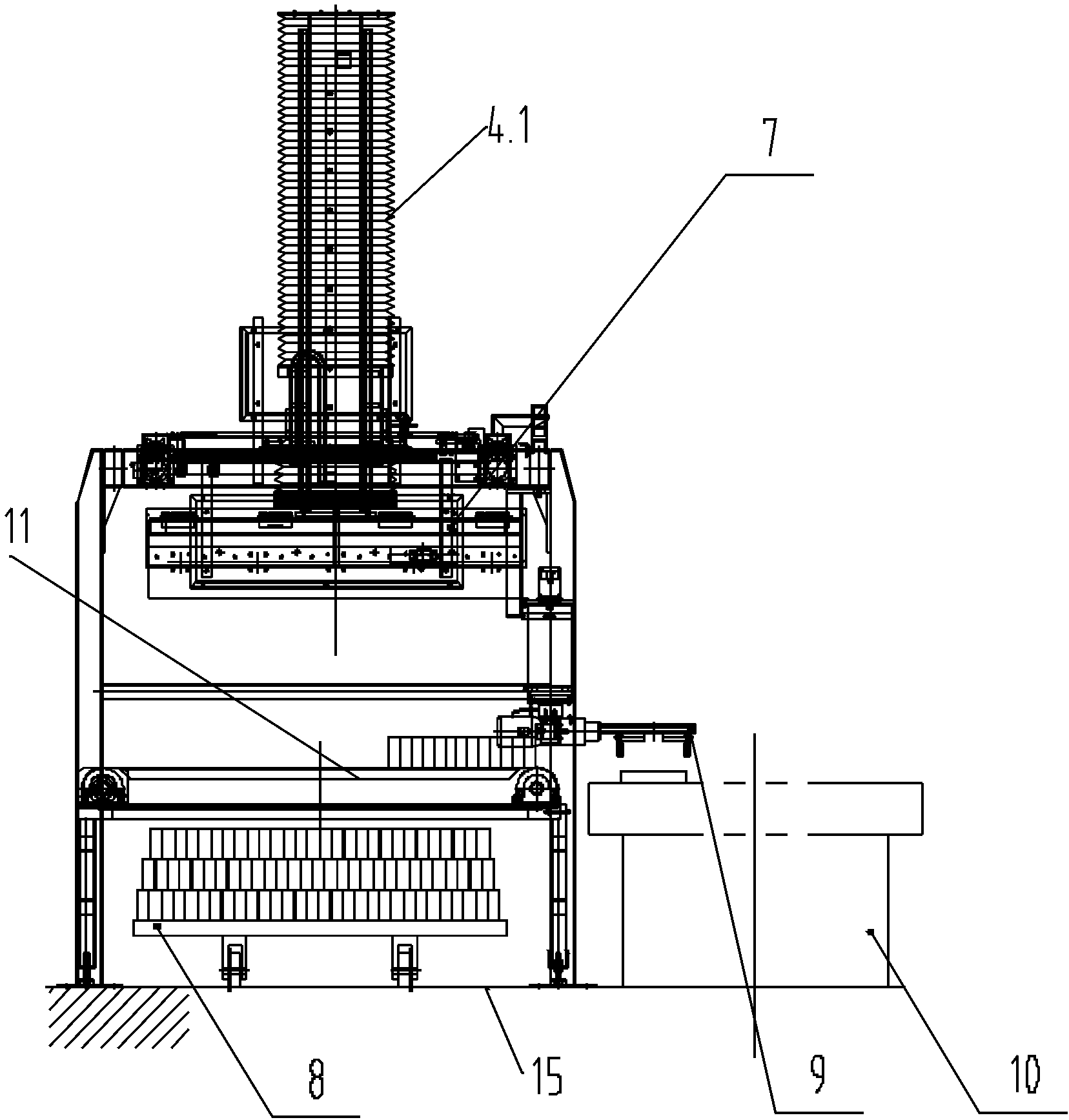

All-metal screw pump stator machining equipment

InactiveCN103008749AAvoid Hole DefectsExtend your lifeMilling cuttersAttachable milling devicesScrapStator

The invention discloses all-metal screw pump stator machining equipment. The all-metal screw pump stator machining equipment comprises a cutter bar, a cutter head, a guide rod, a supporting base, a workpiece fixing device and a cutter bar rotation driving device, wherein the supporting base is fixedly connected with a machine tool; a guide sleeve is arranged on the guide rod; a guide slot is formed on the guide rod; the guide rod is arranged on the supporting base; the cutter bar is arranged inside the guide slot through an adjustable shaft sleeve; the cutter head is arranged at the front end of the cutter bar; the back end of the cutter bar is connected with the cutter bar rotation driving device; the cutter bar is equipped with a translational mechanism moving in the radial direction of the guide slot; at least one axial air hole is formed on the guide rod; the outlet of the axial air hole is formed on the front end surface of the guide rod; the inlet of the axial air hole is connected with an air supplying device; an axially communicated cooling oil hole is formed in the center of the cutter bar; and a cooling oil supplying device is connected at the back end of the cooling oil hole. The all-metal screw pump stator machining equipment has the advantage as follows: metal scraps are discharged from a cutting point, thus avoiding the problems such as abrasion of the cutter head and blade flaking, and preventing defects of an internal hole caused by scratch of the internal hole by the metal scraps.

Owner:宁波正鼎石油机械设备制造有限公司

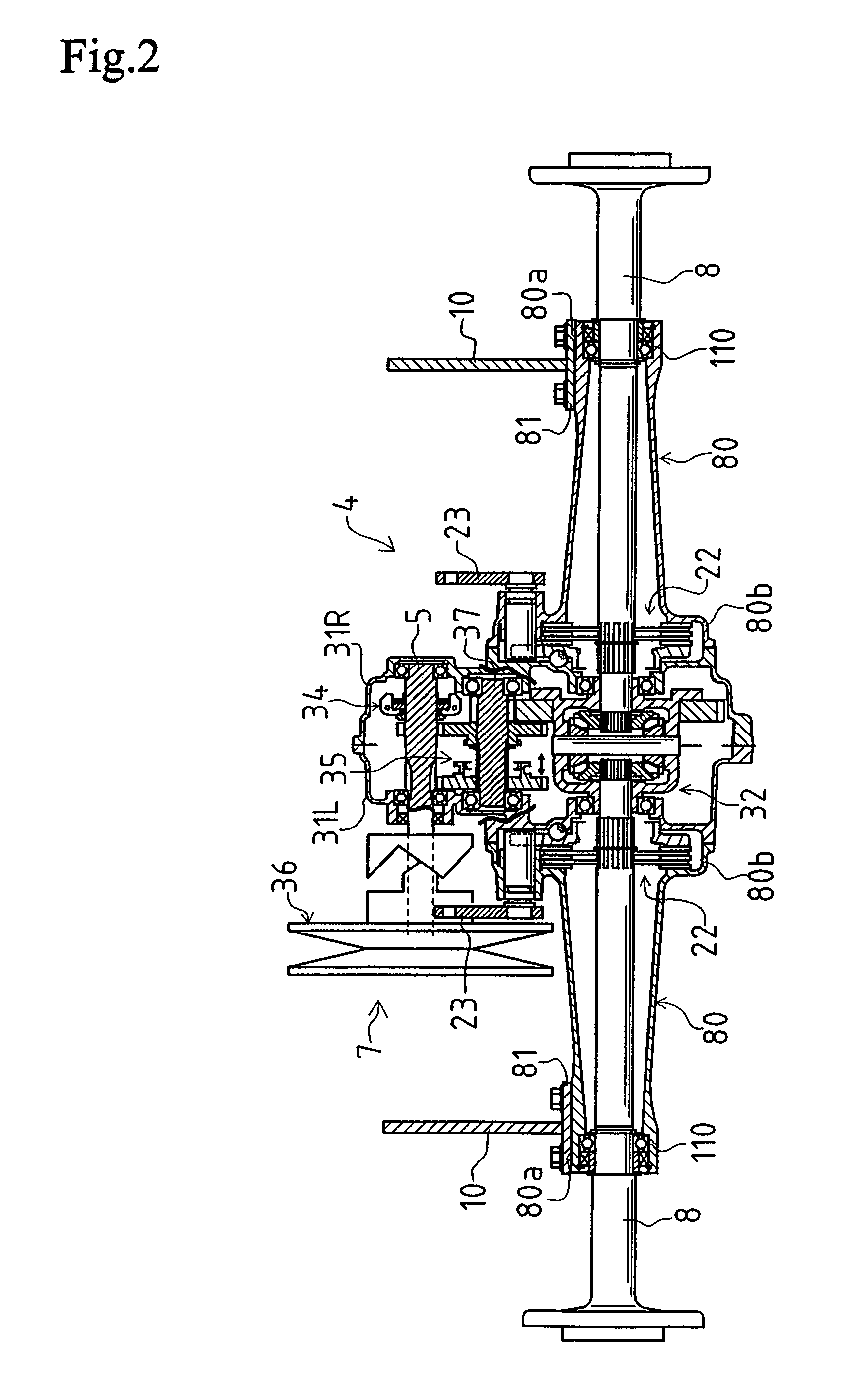

Blast furnace bellless furnace top distributor

ActiveCN101173321AExtended service lifeFully lubricatedBell-and-hopper arrangementBlast furnace detailsEngineeringShaft furnace

The invention discloses a bell-less top distributing gear of furnace, belonging to technical field of metallurgical industry. The invention adopts sealed cooling, a water-cooling venturi tube with pipe laying and a water-cooling chassis. A motor drives a chute to rotate and tilt; wherein, the motor drives the nut of the ball screw assembly to rotate and then drives the lead screw and the lifting rotary frame connected with the lead screw to move up and down in order to achieve chute to tilt for Alpha angle. The invention has the advantages of high coaxiality, high transmitting precision, long service life of the critical component, easy manufacture, light weight and low cost. The tilting Alpha angle of the chute and the stationarity of the tilting movement of the chute can be checked during the producing process of the furnace by the invention. The invention can be used in charging operation of furnace roof and also is suitable for shaft furnace or smelting reduction furnace which need to feed from the roof to the closed space and distribute regularly.

Owner:CISDI ENG CO LTD

Oil Supply For An Internal Combustion Engine

InactiveUS20080035101A1Improving oil supplyReliable functionLiquid coolingLubrication of auxillariesReciprocating motionInternal combustion engine

The invention relates to an oil supply for an internal combustion engine, comprising an oil supply device for the supply of oil to a piston, reciprocating in a cylinder. The oil supply device is embodied such that at least at a point at which the piston is in the region of bottom dead centre, oil is introduced directly into a region below the piston, by means of the oil supply device, in particular, beneath the piston crown and within the piston skirt. The oil supply device thus comprises at least one tube element, extending into a region beneath the piston crown. The tube element terminates as close as possible to a gudgeon pin, when the piston is at bottom dead centre. A targeted lubrication of the mechanically and thermally highly loaded gudgeon pin can thus be guaranteed. It is also possible by means of the oil supply to supply transfer ports of a two-stroke engine with oil, counteracting a tendency to coke up.

Owner:WACKER NEUSON SE

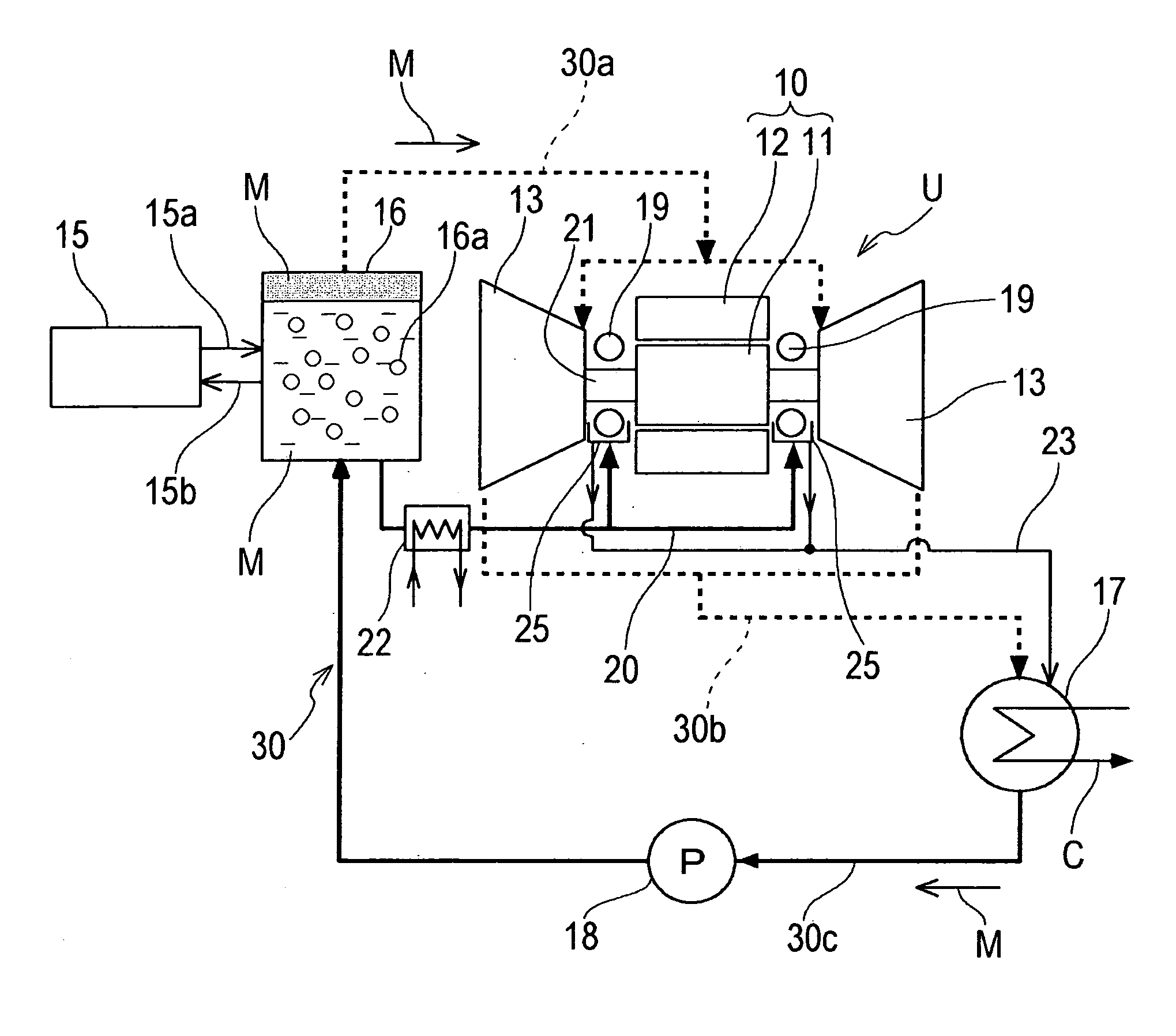

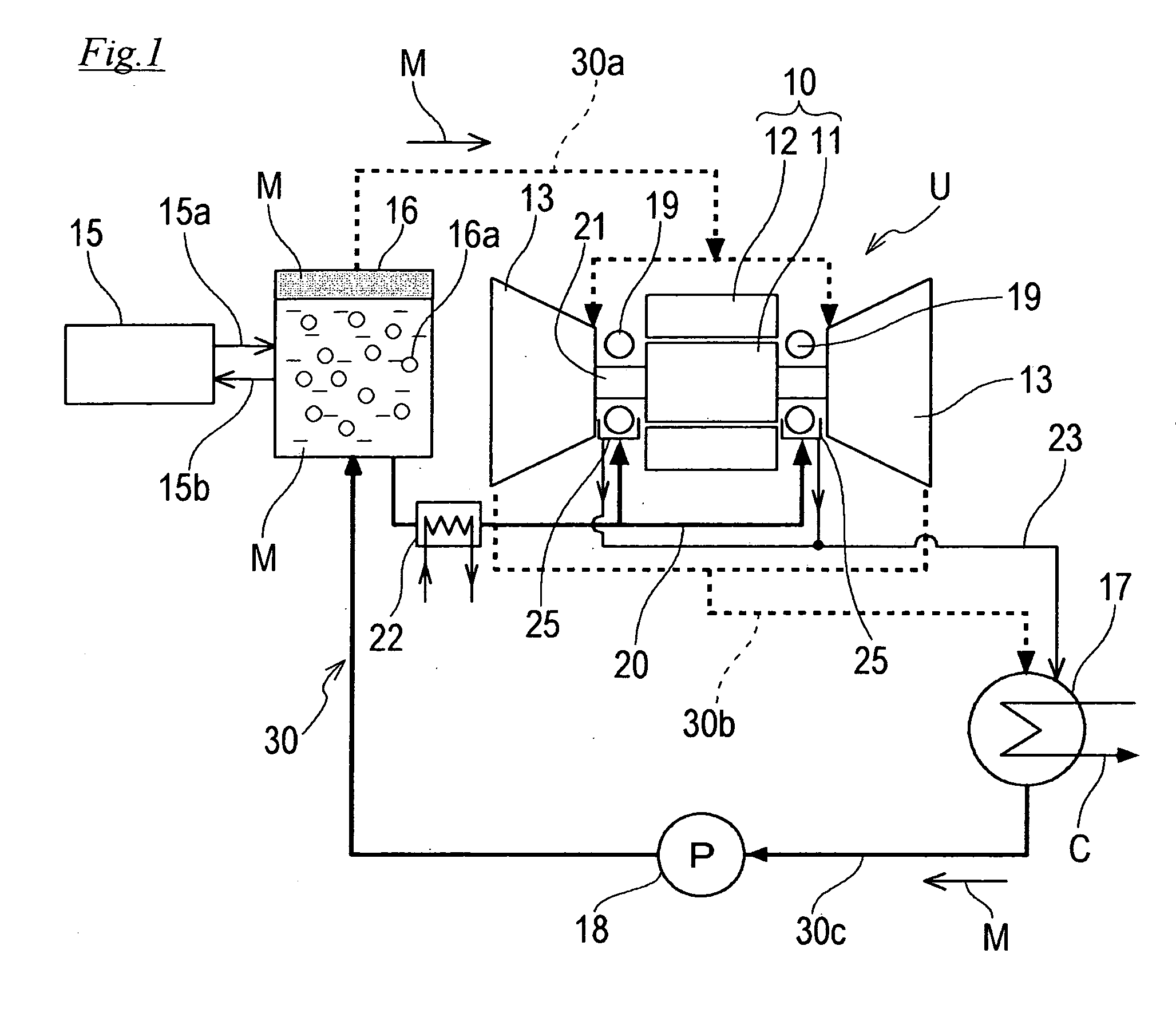

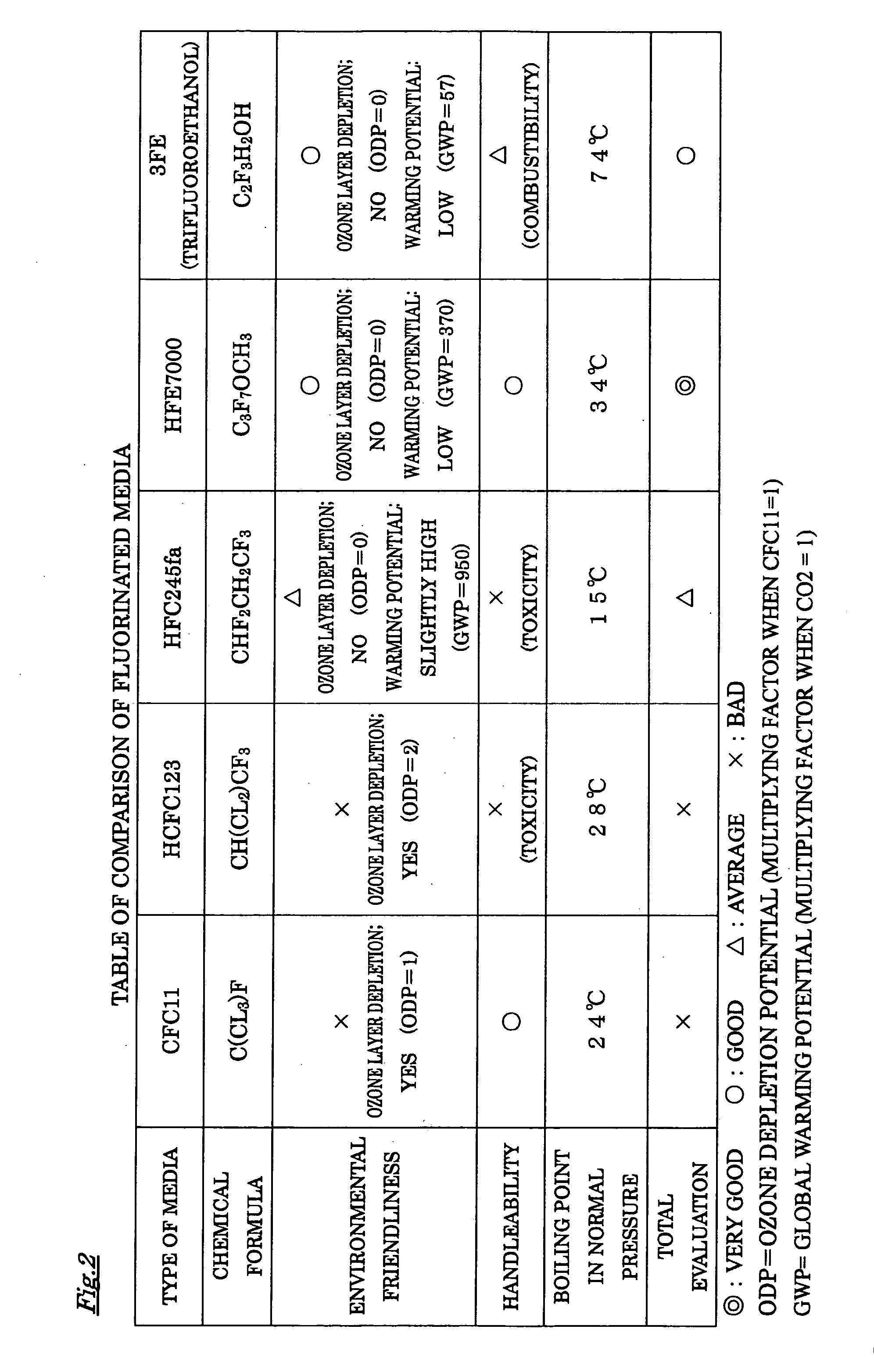

Turbine generator system

ActiveUS20110047958A1Fully lubricatedImprove the lubrication effectTurbine/propulsion engine coolingWorking fluid for enginesGas phaseEngineering

Provided is a turbine generator system capable of sufficiently lubricating a bearing without impeding heat transmissibility of an evaporator and a condenser. The turbine generator system comprises a turbine power generation unit including a generator and a turbine for driving the generator, an evaporator which receives heat from a heat source and supplies the working medium in a vapor phase containing a lubricant to the turbine power generation unit, a condenser which condenses the working medium which has flowed through the turbine a medium feeding pump which raises a pressure of the condensed working medium and feeds the working medium to the evaporator, and a feeding passage through which the working medium extracted from the evaporator is supplied to bearings in the turbine power generation unit.

Owner:KAWASAKI HEAVY IND LTD

Pump body component and compressor comprising same

PendingCN107524600AFully lubricatedAchieving cooling operationRotary piston pumpsRotary piston liquid enginesEngineeringFlange

The invention provides a pump body component and a compressor comprising the same. The pump body component comprises a flange and a bearing type air cylinder, wherein the flange is provided with a flange liquid inlet structure and a flange liquid outlet structure; the bearing type air cylinder is provided with a rolling body accommodating cavity; and a lubricating medium can lubricate the rolling body in the rolling body accommodating cavity through the flange liquid inlet structure and is discharged through the flange liquid outlet structure. According to the pump body component and the compressor comprising the same, the problem in the prior art that the bearing type air cylinder is lubricated and cooled insufficiently during the operation process of the pump body component is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

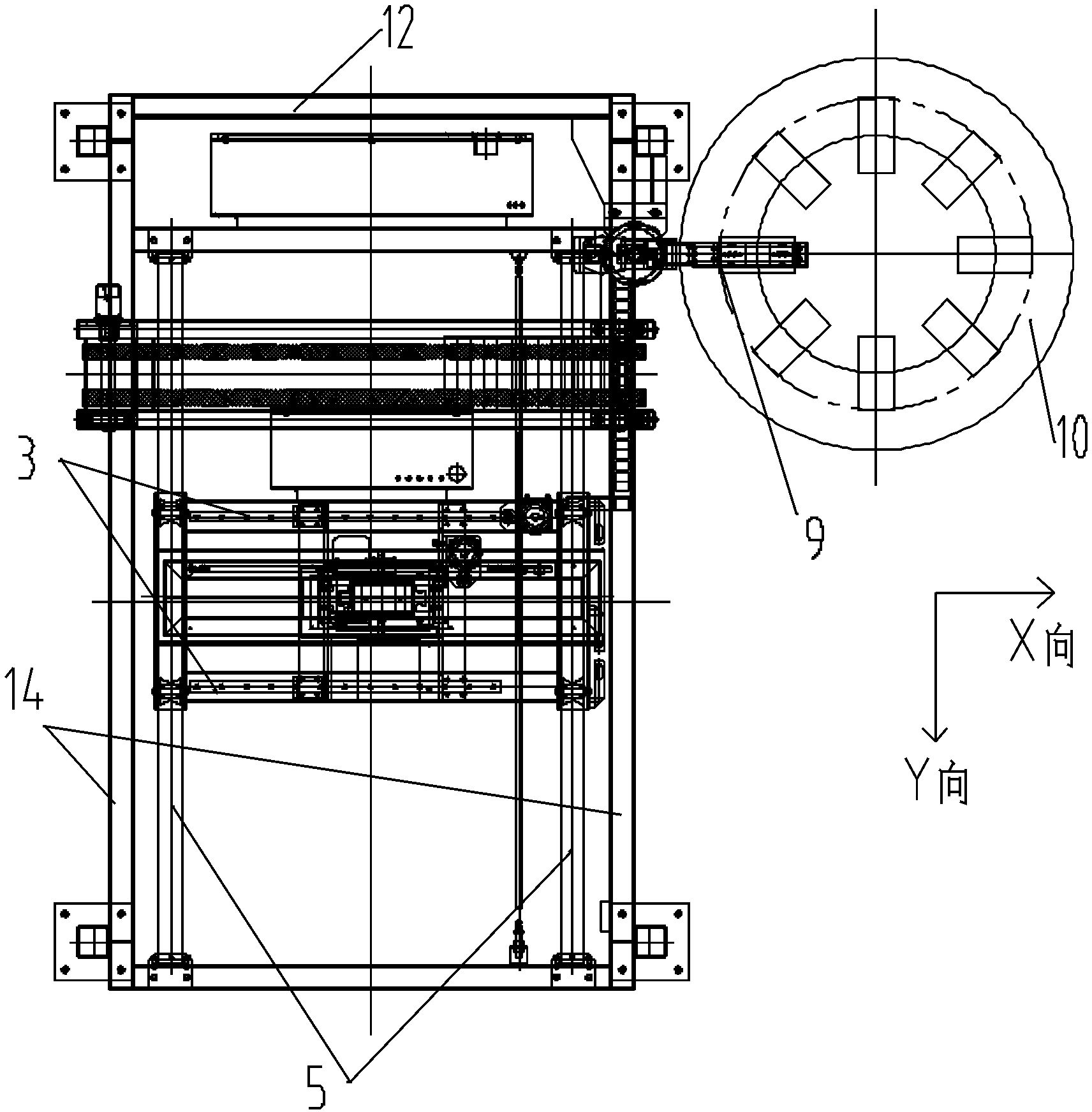

Air brick stacking manipulator system and control method

ActiveCN103832840AImprove beat matching problemsIncreased coherence of movementConveyorsStacking articlesBrickBarrel Shaped

The invention discloses an air brick stacking manipulator system and a control method. An air blank grabbing manipulator and an air brick stacking manipulator are integrated into a uniform connecting body through a portal frame foundation, after air bricks are grabbed by the air brick grabbing manipulator, the air bricks are transferred and carried subsequently by the air brick stacking manipulator, movement continuity is enhanced, working efficiency is substantially improved, the takt matching problem between two work procedures is solved, a lifting and swinging device of the whole small manipulator is integrated in a closed barrel-shaped structure, and the system is simple in structure, small in size, beautiful in appearance and convenient to mount in an inverted hanging mode; double-side supporting is formed by the large manipulator through an X-direction guide rail and a Y-direction guide rail on the two sides, and the problems that a traditional stacking manipulator is of a single stand column cantilever structure and is uneven in stress, and eccentric abrasion to the rails is caused are solved; both the two manipulators are installed in the inverted hanging mode, idle space in the portal frame space is utilized, the space utilization rate is high, and operation is not disturbed.

Owner:湖北成吉智能机械科技有限公司

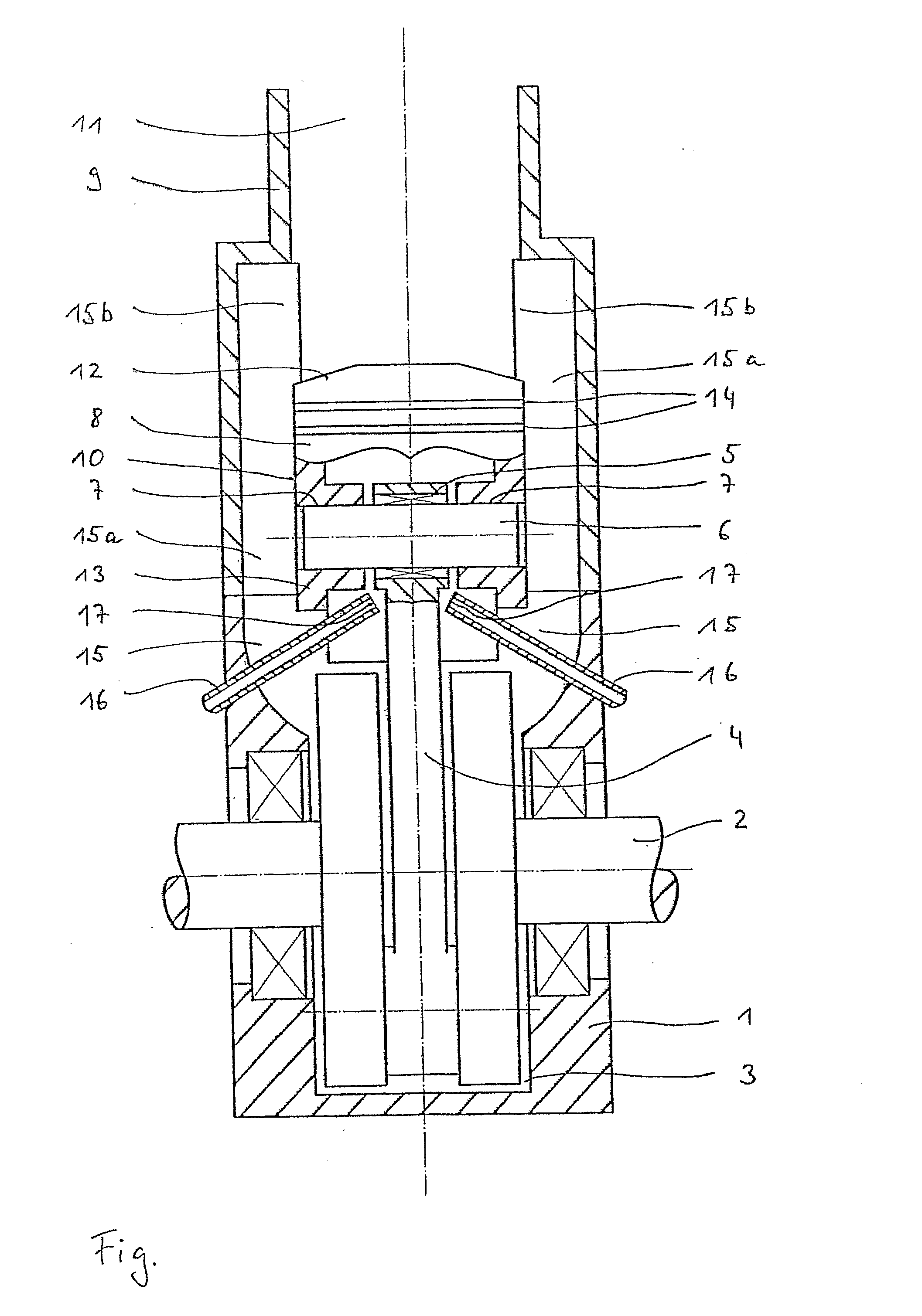

Electromagnetic hydraulic valve

ActiveCN101233355AReduce manufacturing costEasy to installOperating means/releasing devices for valvesServomotor componentsCorrosion resistantHydraulic pressure

The invention relates to an electromagnetic hydraulic valve (1) comprising an armature (8) guided in longitudinal movement in an armature guide (9) actuating valve tappets (15) distributed in a valve box (14) ). Said valve lifters control the connection between interface holes (28, 29, 30) for hydraulic medium formed in the valve box (14), wherein the valve lifters (15) are connected to one or more sealing bodies (22 , 23) form an effective connection, and the sealing body corresponds to one or more sealing sleeves (17, 18) supported on the valve box (14). The hydraulic valve (1) has a mechanism for depositing dirt particles, which consists of a partition (31) arranged between the armature guide (9) and the connecting holes (28, 29, 30). Said partition forms a hydraulic seal with the inner surface (16) of the valve box (14), wherein the valve box (14) consists of a magnetizable material for the purpose of depositing ferromagnetic dirt particles.

Owner:SCHAEFFLER TECH AG & CO KG

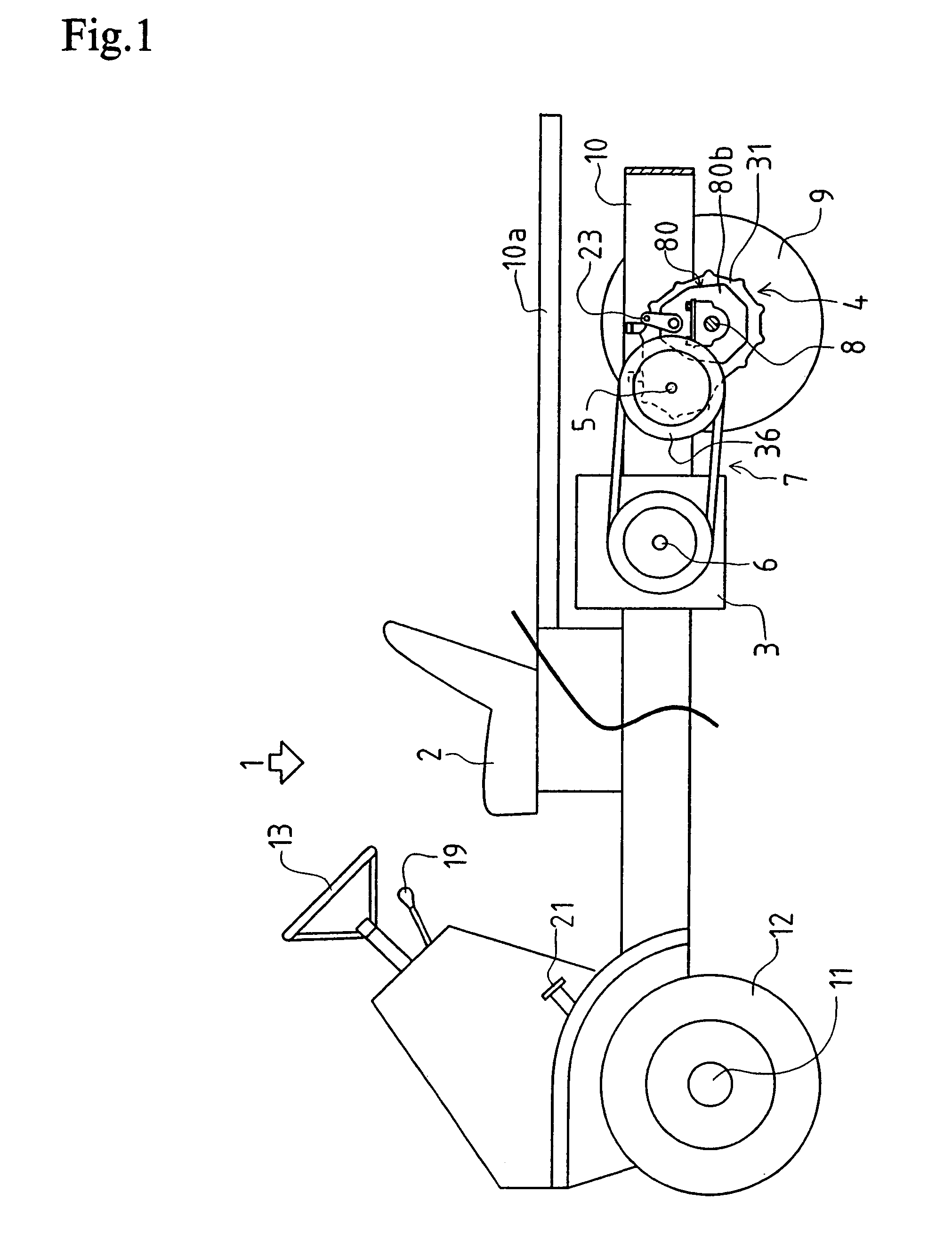

Transmission of working vehicle

InactiveUS7331423B2Simple structureReduce manufacturing costGearboxesDrip or splash lubricationDrive shaftEngineering

An oil supply system for a transmission includes a transmission casing; a transmission shaft disposed in the transmission casing; a plurality of gears relatively rotatably fitted on the transmission shaft; an oil passage axially formed in the transmission shaft; a trough portion formed on an inside wall of the transmission casing so as to receive oil splashed from the gears; and a connection passage formed in a side wall of the transmission casing and extending downwardly from the trough portion to the oil passage. The oil passage is opened at outer peripheral portions of the transmission shaft adjacent to the gears, and opened at one axial end of the transmission shaft. The trough portion is disposed above the transmission shaft and is extended axially along the transmission shaft.

Owner:KANZAKI KOKYUKOKI MFG

Gas spring

InactiveCN1975194AAvoid Rigid CollisionsTimely opening and closingSpringsGas based dampersMobile vehicleAuto regulation

There is disclosed a gas springs, in which a closed air compression system made up of a damping air passage is disposed between main and secondary elastic air cavities formed by separating the cylinder body via the piston. By using the damping force action of the damping air passage on the medium, there is unequal gas pressure in the main and secondary air cavities. When the piston up and down moves under the action of the external force, i.e., the gas spring is expressed externally as compression or extension, it can automatically regulate its rigid change to balance the action adapted to external force.

Owner:杨德君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com