Patents

Literature

967results about How to "Improve slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

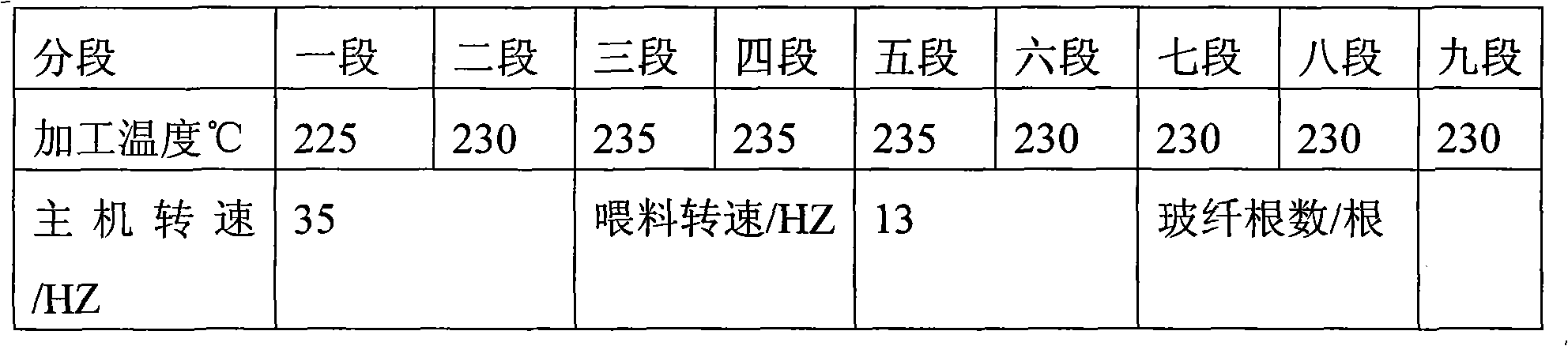

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

High-performance jet ink

The invention relates to a high-performance jet ink. The jet ink comprises the following components by weight percent: 20-80% of solvent, 1-45% of cosolvent, 4-20% of adhesive, 0.5-20% of colorant, 0-5% of adhesion force promoter, 0.01-2% of wax powder, 0-2% of brightening agent and 0-5% of other additives. As adhesion force promoter is added in the jet ink, the adhesion performance on base materials such as glass, metal, polypropylene or polyethylene is increased. In addition, wax is added to increase wear resistance and scratch resistance, and brightening agent is added to increase the lustrousness, brilliance and definition of the ink. The product has high adhesion force, good wear resistance, high lustrousness and definition and good compatibility, thus the defects of the existing ink such as low lustrousness, poor wear resistance and low definition can be greatly improved and the jet ink has good market prospect.

Owner:王学珍

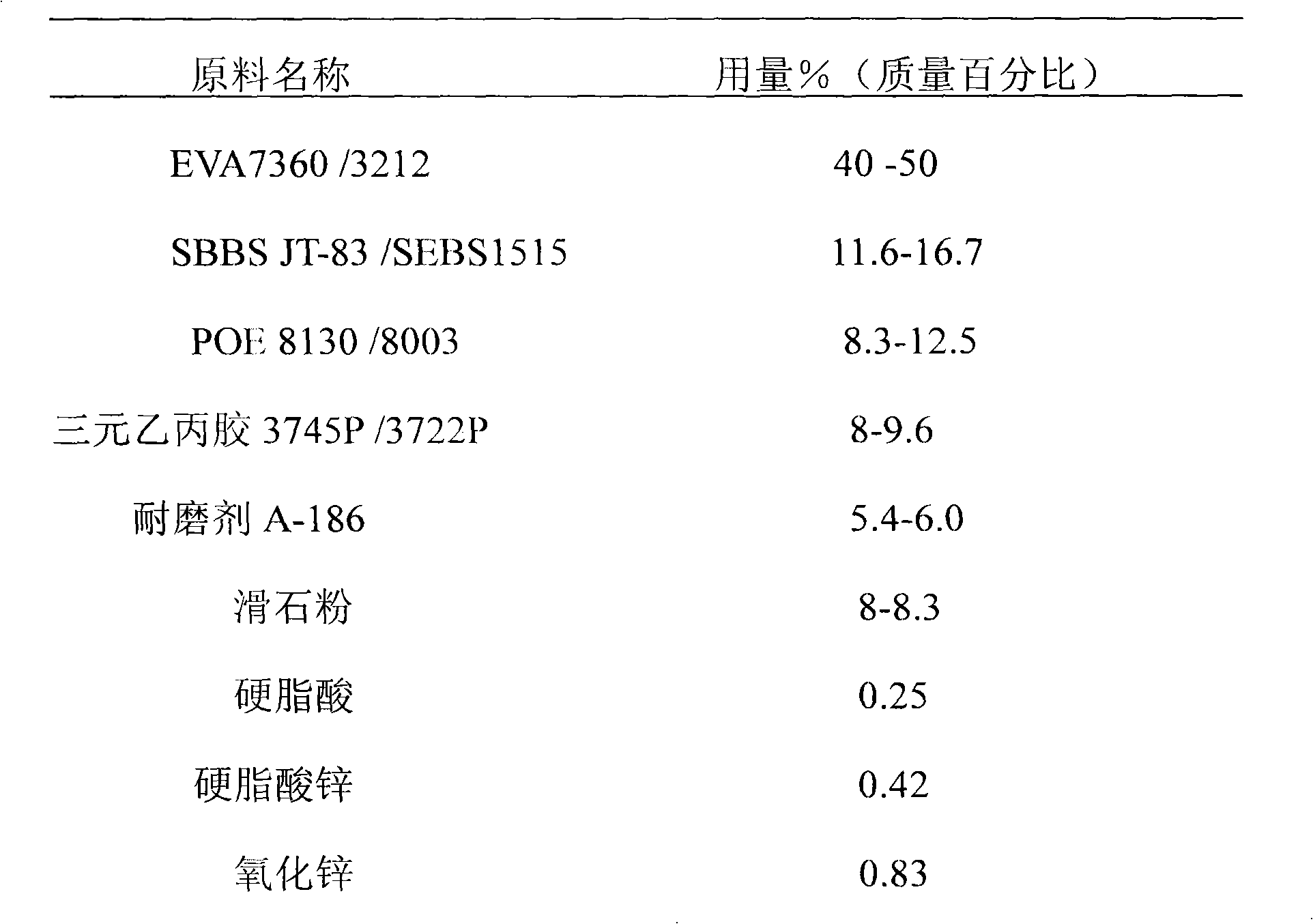

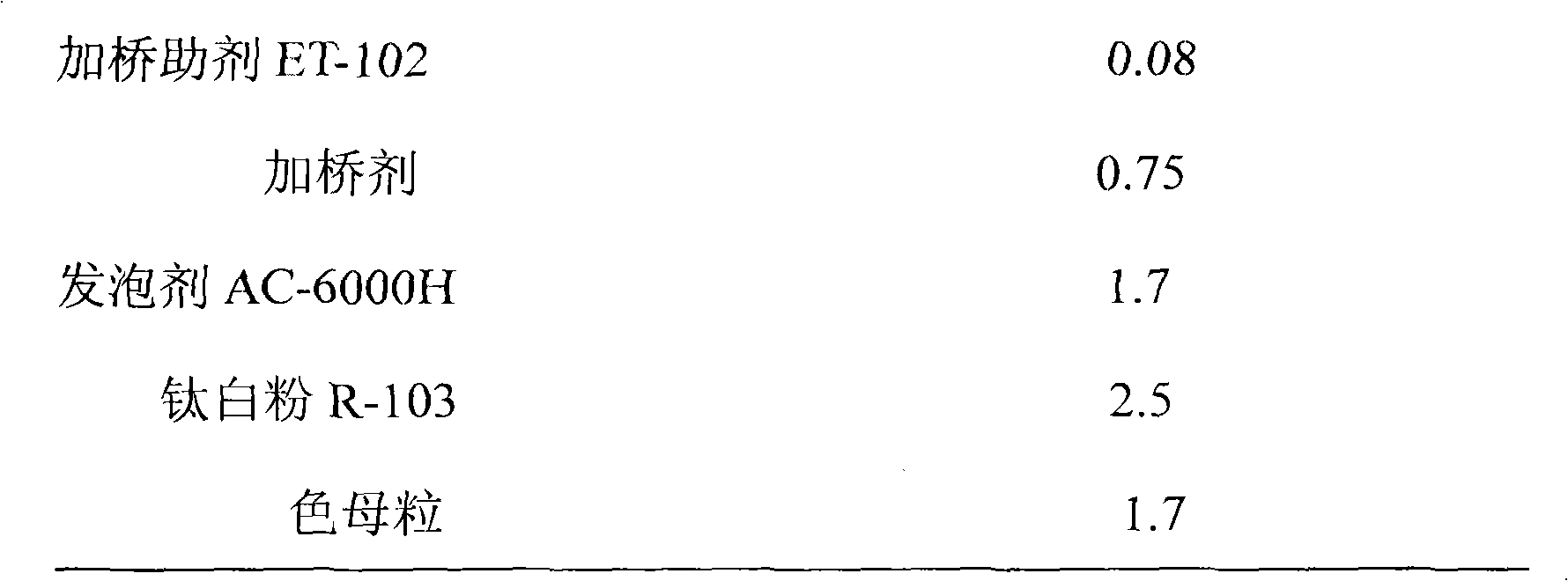

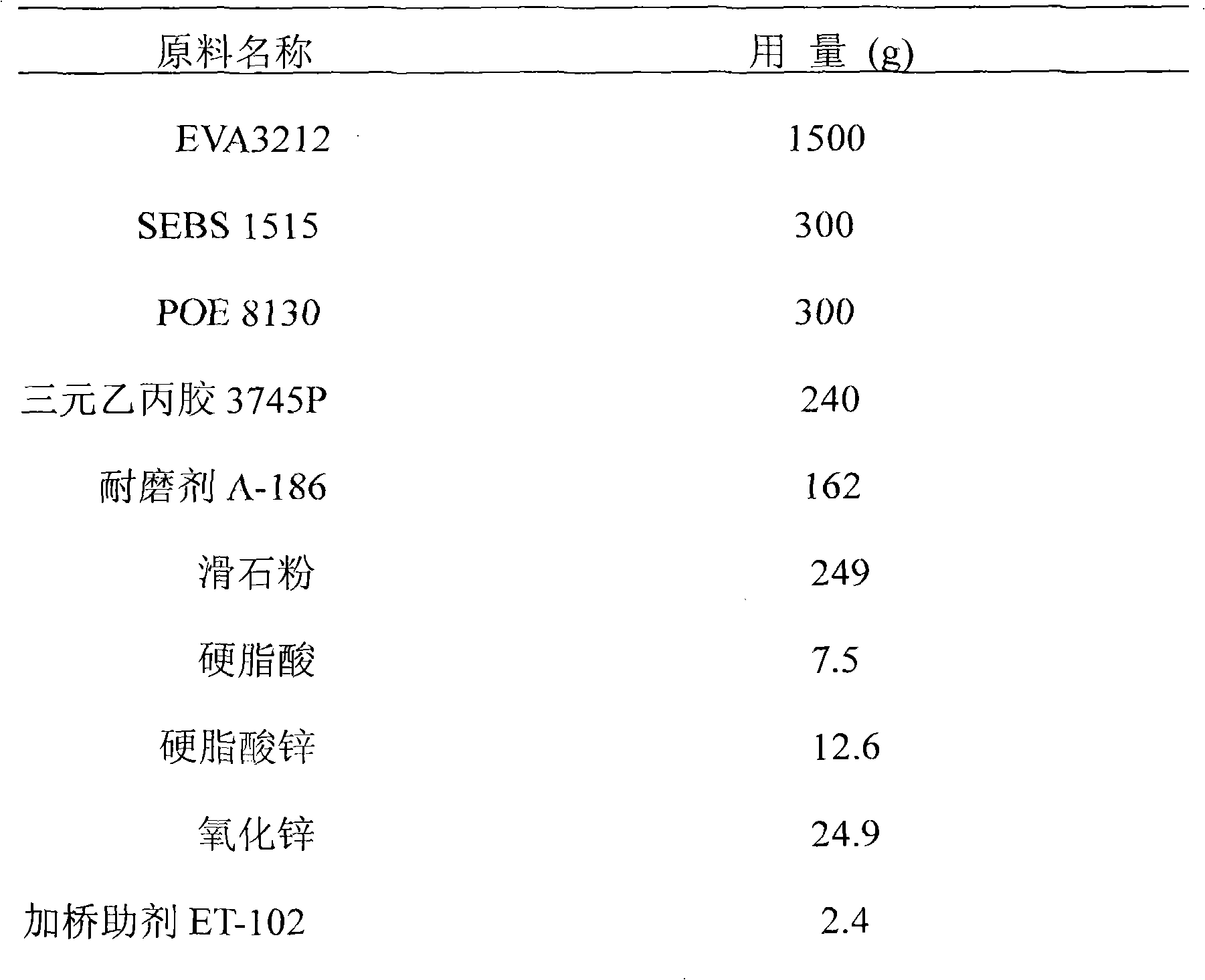

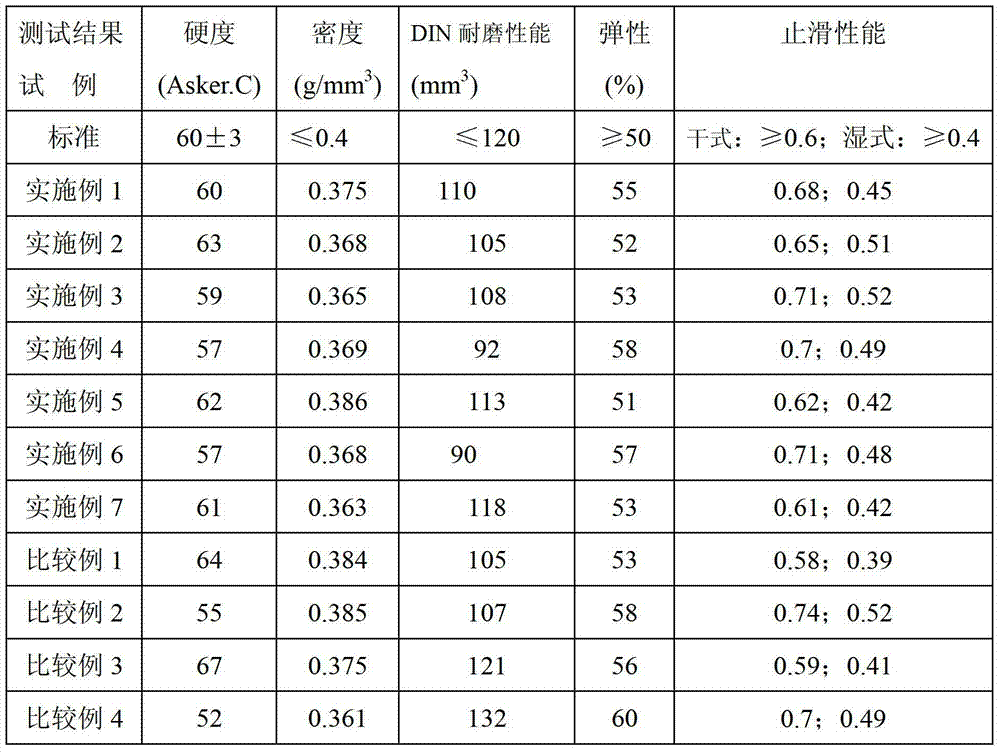

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Environment-friendly type aqueous aluminum foil protecting agent and preparation thereof

InactiveCN101407655ALow VOC contentReduce manufacturing costPolyurea/polyurethane coatingsPolyamide coatingsGeneral purposeOrganosolv

The invention relates to an environmental-friendly waterborne aluminum foil protective agent and a prepration method thereof, wherein, the protective agent comprises the following components according to the formula by weight: 45 percent to 70 percent main resin; 0 percent to 20 percent assisted resin; 10 percent to 50 percent water; 0 percent to 35 percent cosolvent; 0 percent to 0.5 percent film-forming auxiliary agent; 0 percent to 0.5 percent leveling agent; 0 percent to 0.5 percent defoamer; 0 percent to 2 percent anti-abrasion agent; and 0 percent to 0.5 percent pH regulator. Compared with the prior art, the environmental-friendly waterborne aluminum foil protective agent and the prepration method have the advantages: (1) the aluminum foil protective agent contains no organic solvent which is harmful to human body and has very low content of VOC, and water and ethanol are used for dilution during the using process, thereby being non-toxic and low in production cost; (2) the aluminum foil protective agent has good adhesion, good transparency, high smoothness and high thermal resistance performance; (3) the aluminum foil protective agent belongs to the general purpose products, and the range of application is broad; and (4) the production process is reasonable, the operation is simple and the production efficiency is high.

Owner:SHANGHAI WEIKAI CHEM

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

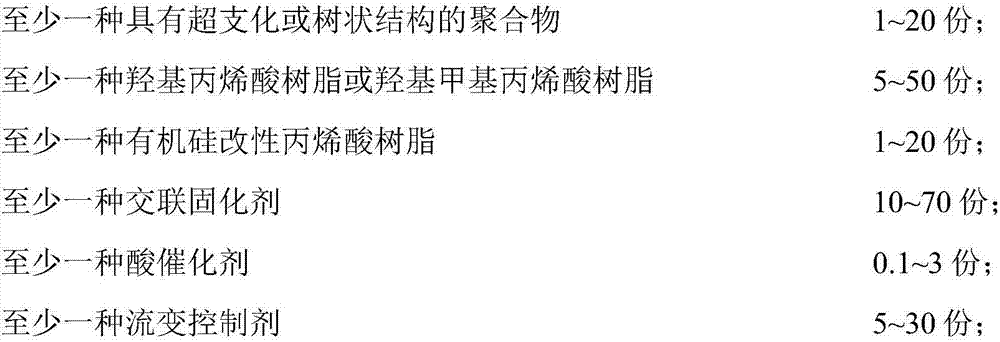

Mono-component varnish composition, preparation method and purpose thereof

ActiveCN106916503AImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

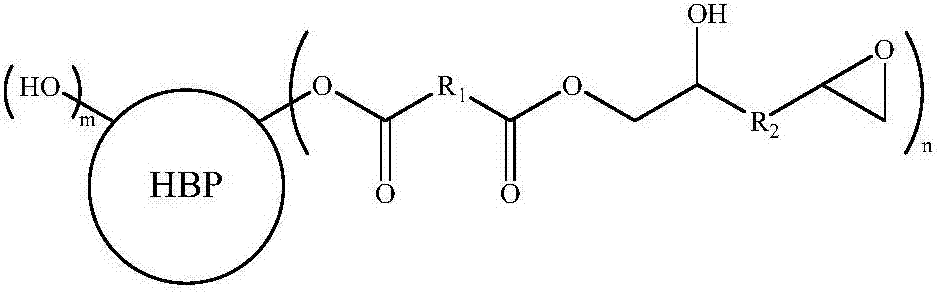

The invention discloses a mono-component varnish composition, which comprises at least a polymer having a hyper branched or dendritical structure; at least one type of hydroxyl acrylic resin or hydroxyl methacrylate resin; at least one type of organosilicon-modified acrylic resins; at least a crosslinking curing agent; at least an acid catalyst; at least a rheological control agent; at least an auxiliary agent and at least a solvent; and the mono-component varnish composition has the advantages of high scratch resistance and high weather resistance. The provided mono-component varnish composition can effectively increase the smoothness of the surface of a varnish composition film, and increases the rub resistance of the film; in addition, the introduction of the organosilicon-modified acrylic resin can further increase the weatherability of the varnish composition film.

Owner:LANGFANG NIPPON PAINT +2

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

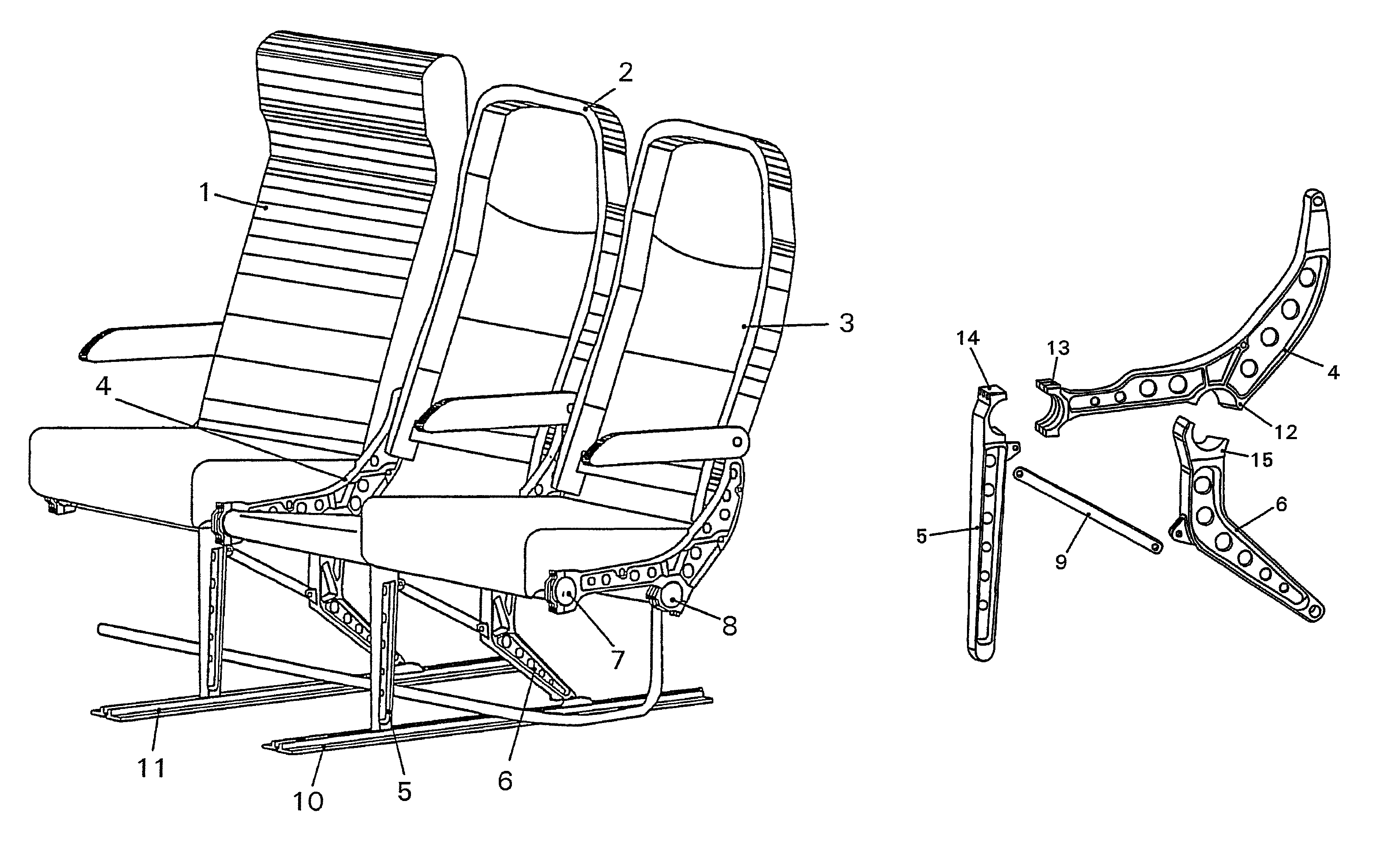

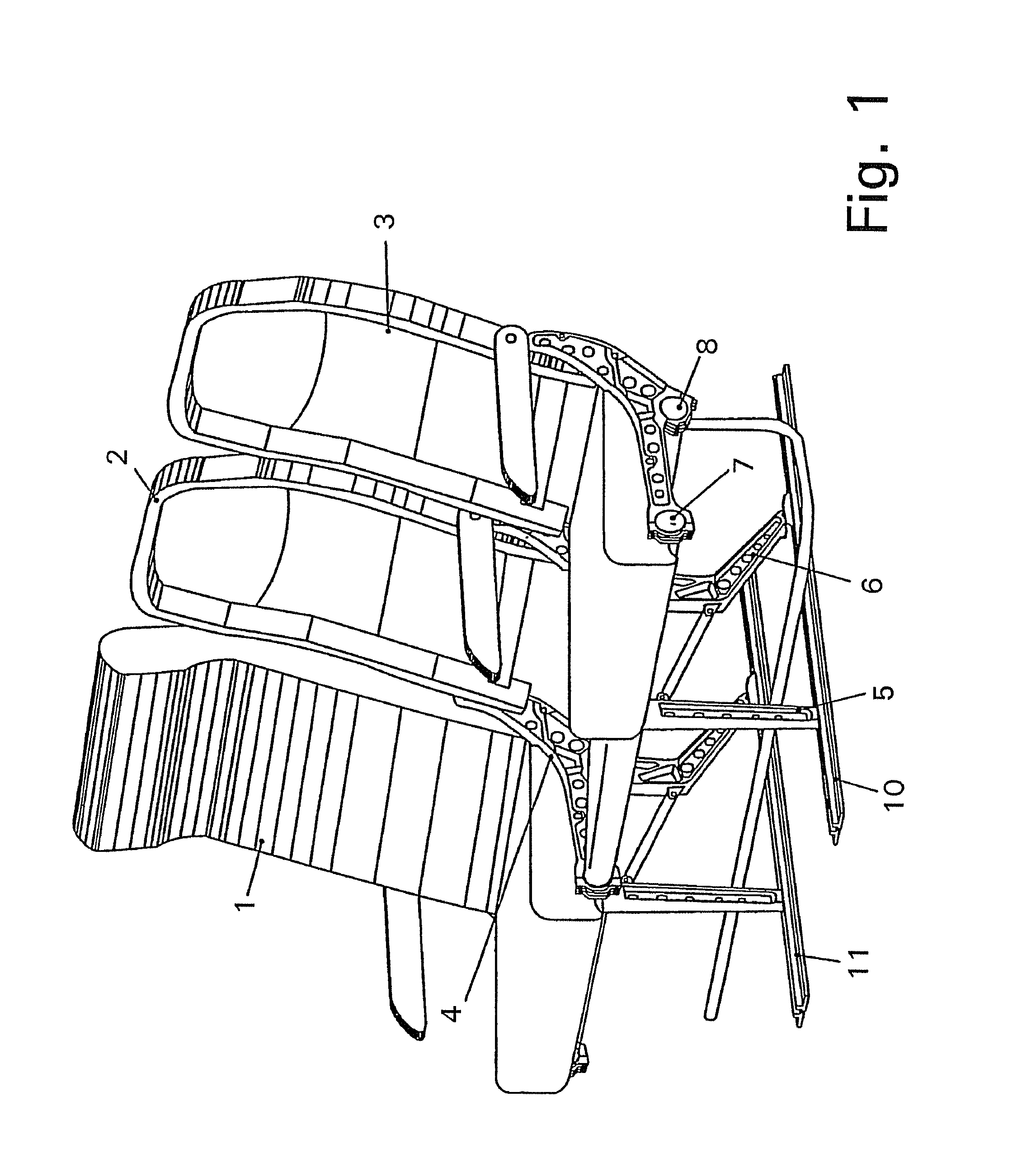

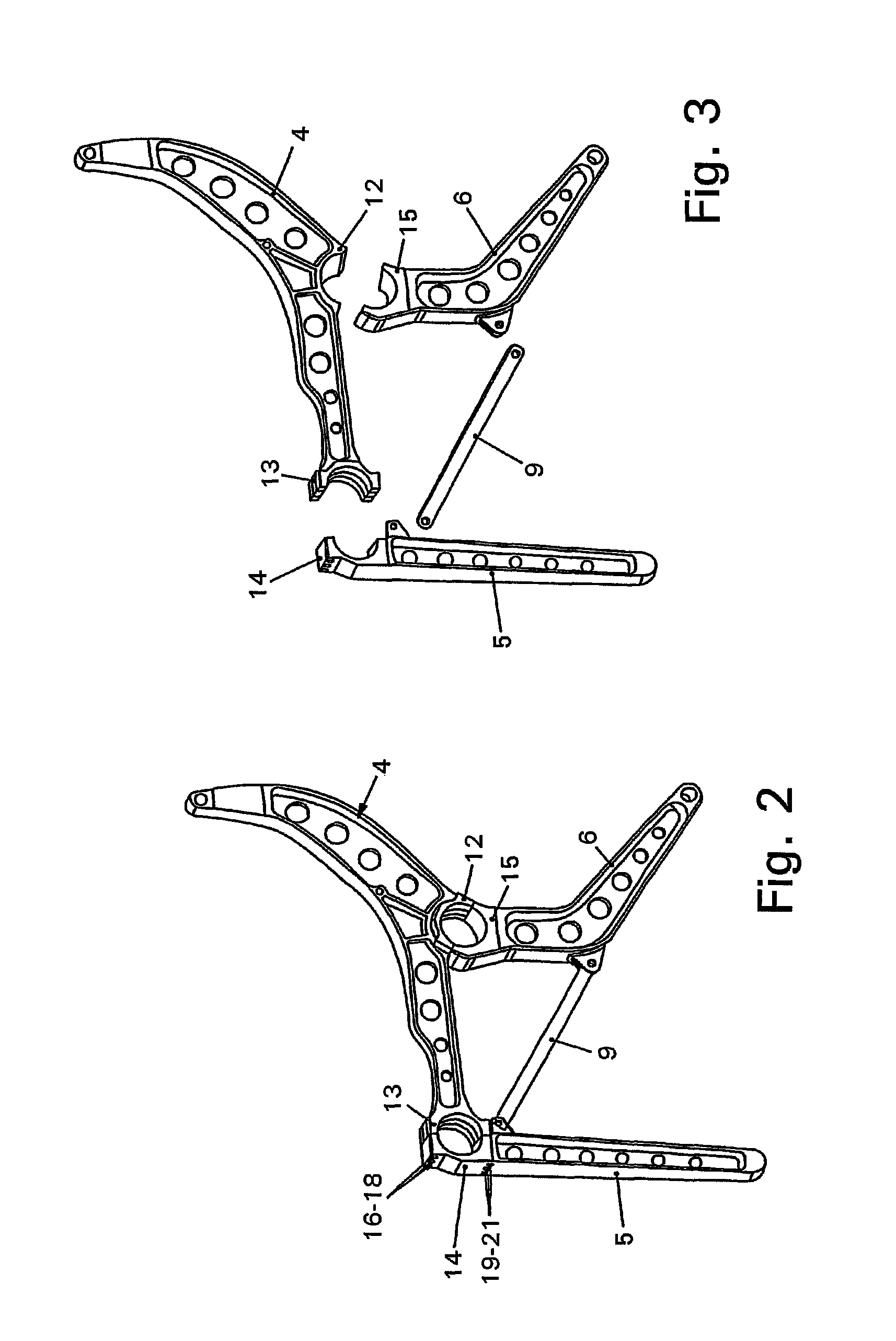

Kit for seat rows in aircraft

ActiveUS8393680B2Improve the level ofDesign moreSeating arrangementsAir-treatment apparatus arrangementsEngineeringAirplane

In seat rows, in particular in aircraft, the individual seats thereof being able to be adjusted in their usable seat width, and comprising seat dividers with support legs, which are held by spars running transversely to the seat direction, at least one seat divider may be adjusted in the direction of the spars.

Owner:ZIM AIRCRAFT SEATING GMBH

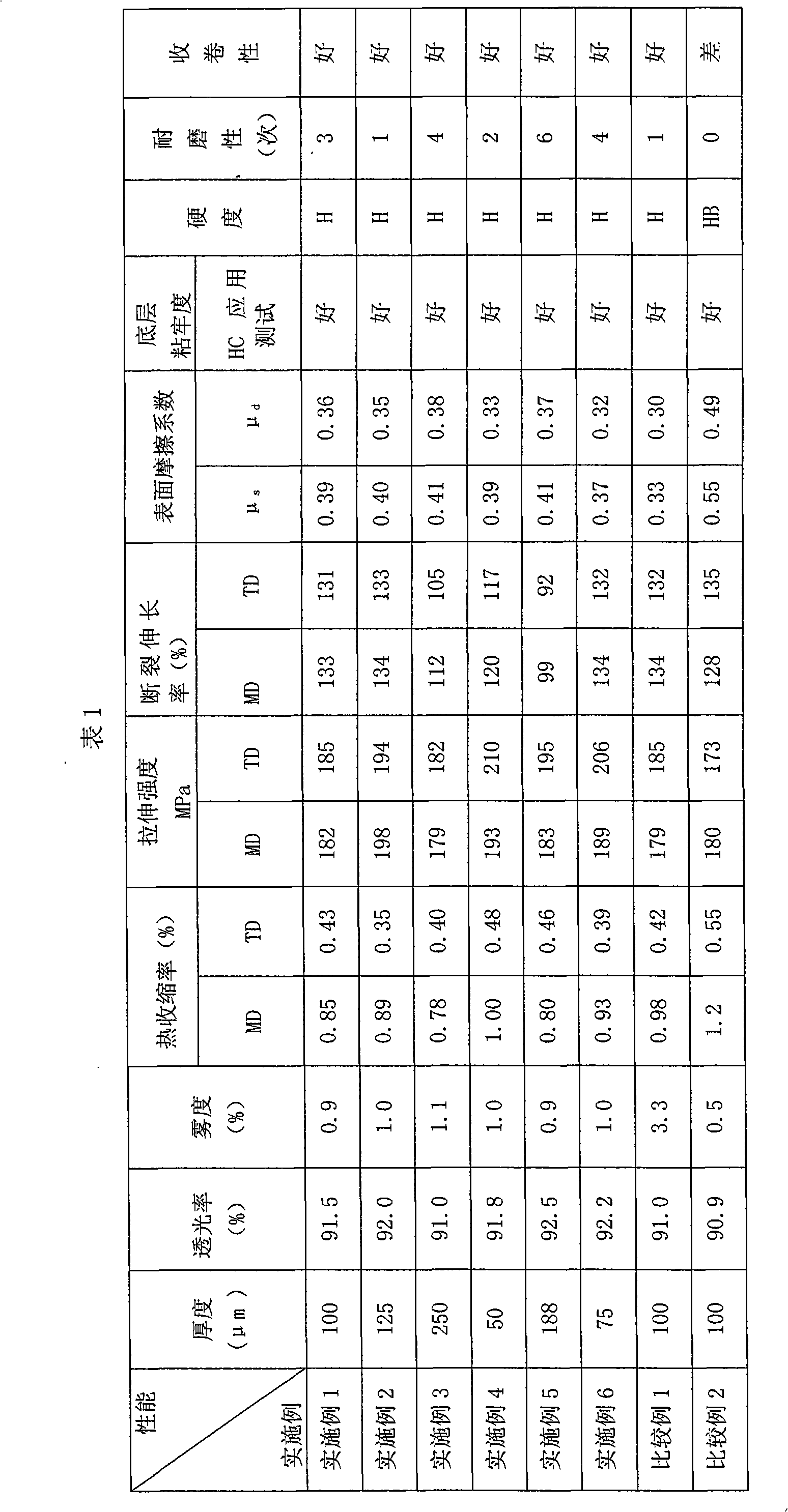

Optical polyester film with multilayer structure and preparation method thereof

InactiveCN101596801AImprove thermal performanceImprove apparent smoothnessSynthetic resin layered productsPolyesterSurface layer

The invention relates to an optical polyester film with multilayer structure and preparation method thereof. The film comprises a basement membrane, at least one side of the basement membrane is coated with a ground coat, the basement membrane comprises a sandwich layer and at least one surface layer, wherein the sandwich layer contains nano additive, and the surface layer contains nano additive and micron additive; the ground coat is an organic polymer adhesive layer, the surface hardness of the ground coat is more than or equal to 1H. The film obtained by the invention has low haze value, excellent optical property, favourable surface adhesiveness, heat resisting property, surface smooth property, anti-sticking property and processability, and can be applicable to the display device fields of LCD, CRT, PDP, EL and the like.

Owner:CHINA LUCKY FILM CORP +2

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

Glutinous rice product and preparation method thereof

The invention relates to the technical field of food processing, in particular to a glutinous rice product and a preparation method thereof. The glutinous rice product has an improved preparation recipe consisting of 80 to 120 parts of high-quality glutinous rice flour, 10 to 20 parts of corn modified starch, 300 to 400 parts of high maltose syrup, 50 to 70 parts of water and compound improving agents which are 5 to 10 percent of the weight of the glutinous rice flour, wherein wrappers account for 70 to 80 percent of the total weight, and the stuffing accounts for 30 to 20 percent of the total weight. The preparation method comprises the following steps of: preparing wrapper, preparing stuffing, filling stuffing automatically, shaping and processing by smoothening agent; then, carrying out ozone sterilization for 1h; and packing to obtain finished products. The invention is characterized in that through the recipe and the process optimization, the preparation process has high automation degree, and the prepared glutinous rice product has strong water preservation performance, high elasticity, good flavor and rich nutrition and is convenient to eat. The problem that the traditional glutinous rice product has short shelf life and can be easily hardened is solved, and the shelf life of the glutinous rice product can reach more than 6 months.

Owner:东莞市圣心食品有限公司

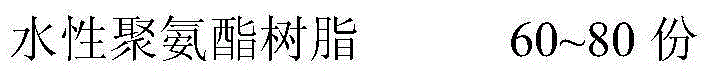

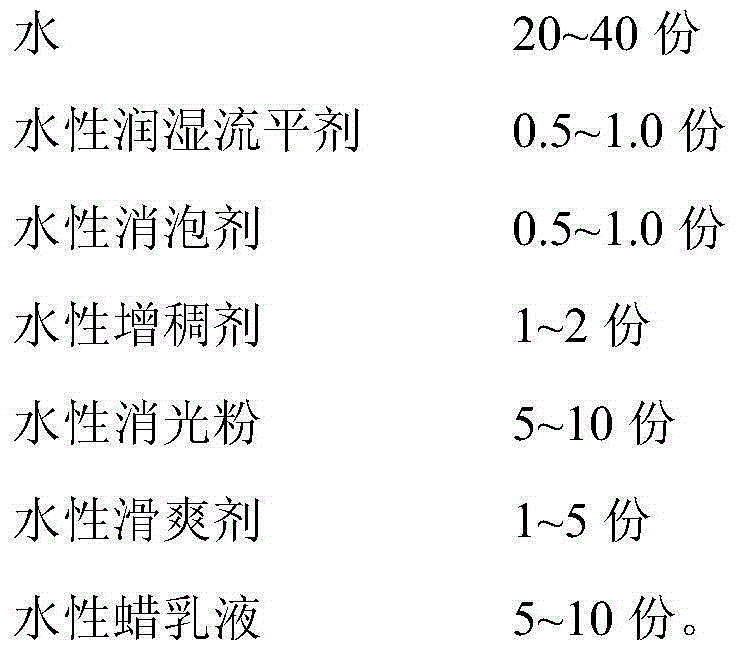

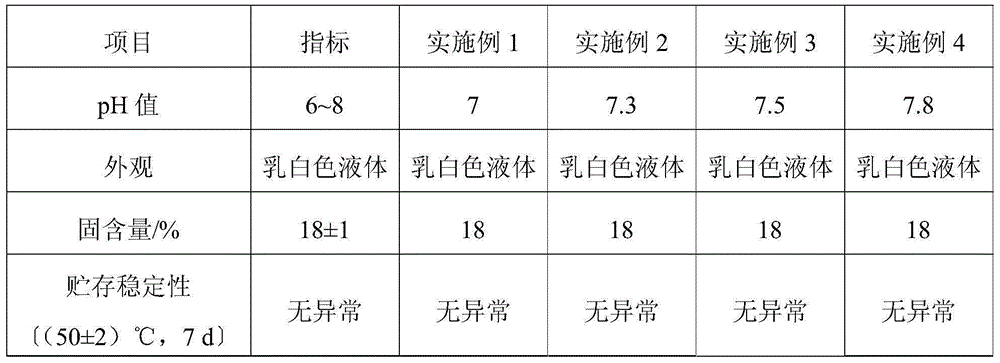

Synthetic leather surface conditioning agent

The invention provides a synthetic leather surface conditioning agent. The synthetic leather surface conditioning agent comprises, by weight, 60-80 parts of aqueous polyurethane resin, 20-40 parts of water, 0.5-1.0 part of an aqueous wetting leveling agent, 0.5-1.0 part of an aqueous antifoaming agent, 1-2 parts of an aqueous thickening agent, 5-10 parts of aqueous matting powder, 1-5 parts of an aqueous slip agent and 5-10 parts of an aqueous wax emulsion. The aqueous polyurethane surface conditioning agent has effects of dye fixation and wear resistance on the synthetic leather surface, makes synthetic leather surface fine and smooth, does not contain VOC, does not cause resource waste and environmental pollution, satisfies safety, environmental friendliness and energy saving requirements and is conducive to human health.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Handwork-dough-modeling and plasticine dual-purpose material

ActiveCN103651654AGood moisturizing effectImprove toughnessDough treatmentOrnamental structuresBiotechnologyKaolin clay

The invention relates to a handwork-dough-modeling and plasticine dual-purpose material. The handwork-dough-modeling and plasticine dual-purpose material comprises, by weight, 8 parts of wheat flour, 5 parts of glutinous rice flour, 1 part of malt sugar, 0.5 part of refined salt, 0.5 part of condensed milk, 2 parts of fresh milk, 0.8 part of honey, 2 parts of diatom soil, 2 parts of modified starch, 1 part of waxiness corn starch, 1.5 parts of kaolin, 0.5 part of bone glue, 1 part of calcium carbonate, 0.8 part of glycerin, 0.2 part of sodium diacetate, 0.5 part of potassium hydrogen tartrate, 0.5 part of food colorant, 1.5 parts of aloe gel, 0.1 part of olive oil, 0.2 part of sun screen and 5 parts of water. When children make handwork artware, the handwork-dough-modeling and plasticine dual-purpose material can be used as a dough modeling material so that dough modeling handwork artware can be made, and can also be used as a plasticine material for playing, multiple kinds of modeling can be made in a pinched mode, and the handwork-dough-modeling and plasticine dual-purpose material has the advantages of being green, nontoxic, harmless, free of cracking, antibacterial, long in retention time, good in modeling and proper in rigidity.

Owner:启东市清源环境检测技术有限公司

Water soluble acrylic resin and its prepn

The present invention relates to one kind of water soluble acrylic resin for ink, polish oil and paint and its preparation process. The organic silicone oil modified acrylic resin is prepared with acrylic acid monomer 15-57 wt%, organic silicone oil with double bond 1-15 wt%, organic solvent 20-60 wt% and initiator 0.1-10 wt%, and through free radical solution polymerization at 60-160 deg.c to obtain organic silicone oil modified acrylic resin, adding neutralizing agent and water through stirring, distilling to eliminate organic solvent, further adding neutralizing agent and water to reach solid content of 20-60 wt%. The organic silicone oil modified acrylic resin has high vitrification point, low filming temperature, high water tolerance and other advantages.

Owner:JIANGSU SANMU GROUP CORPORATION

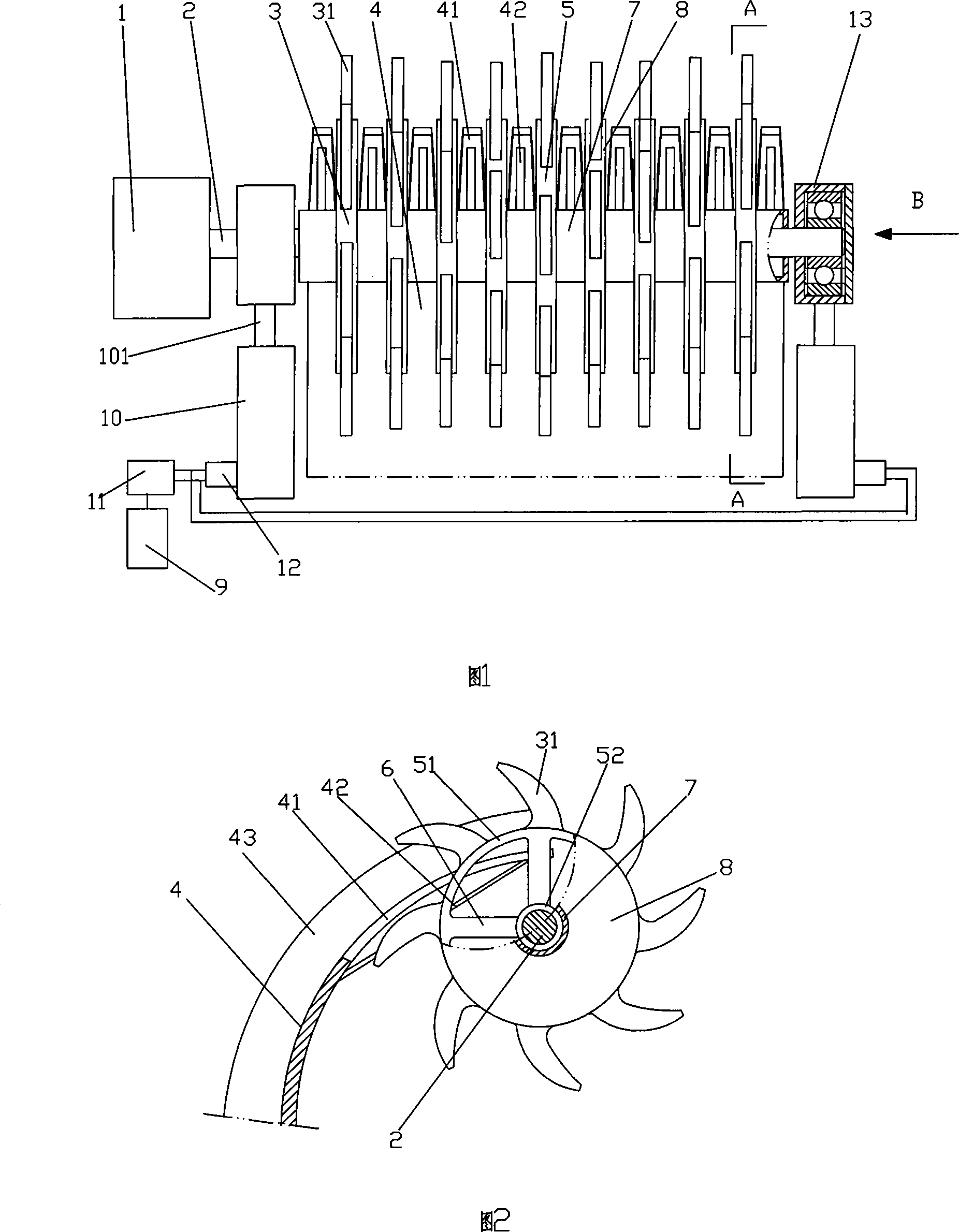

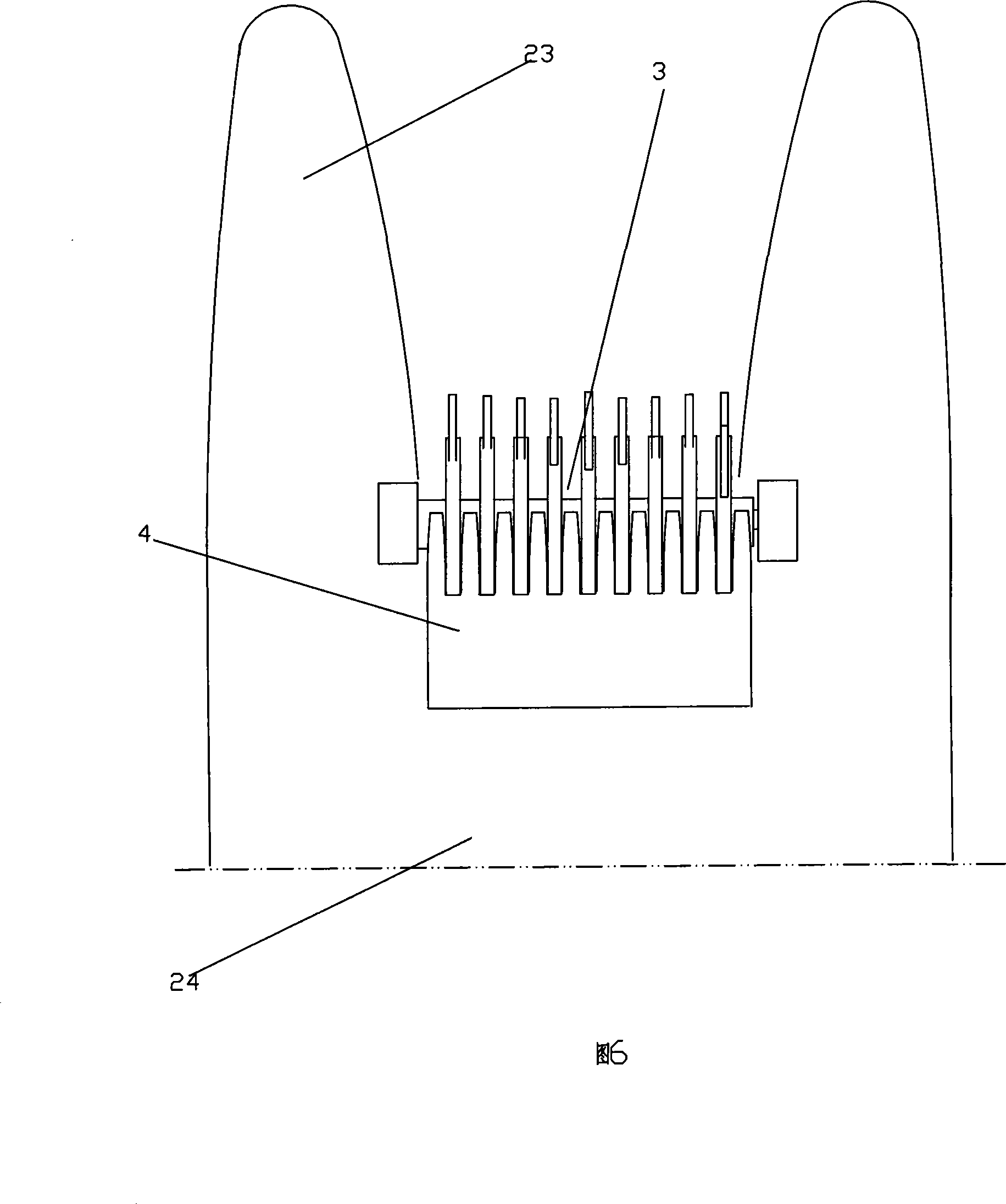

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

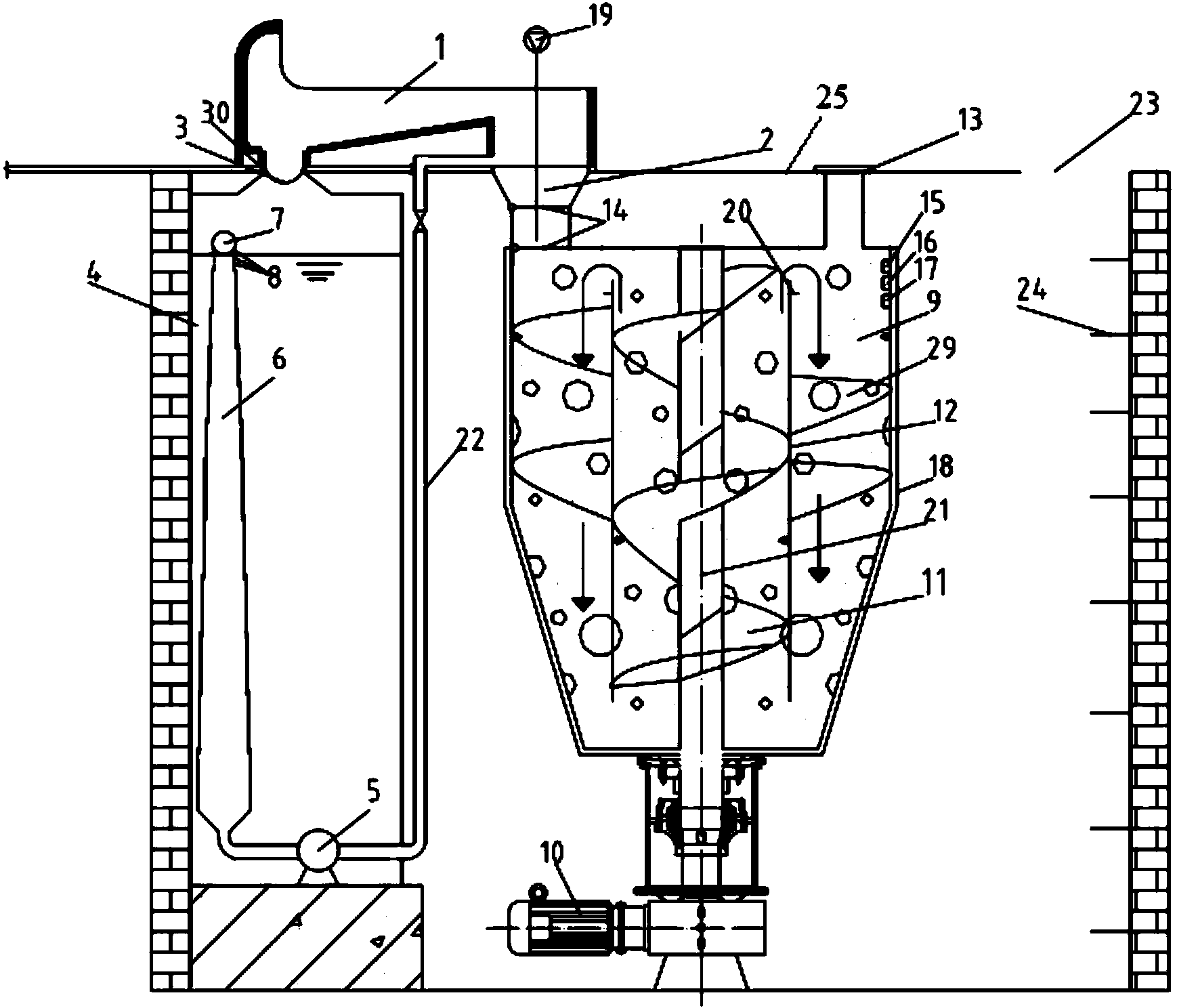

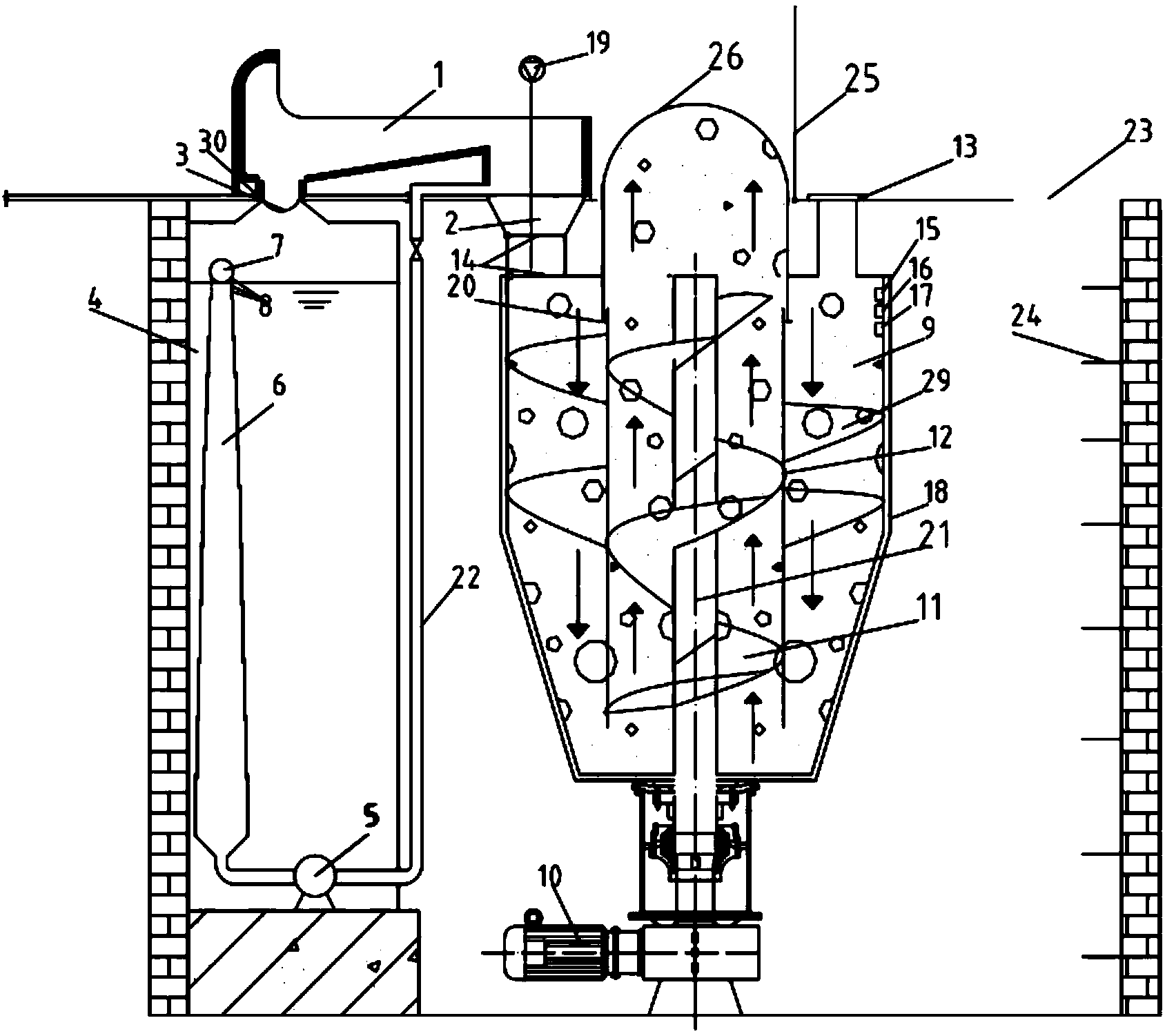

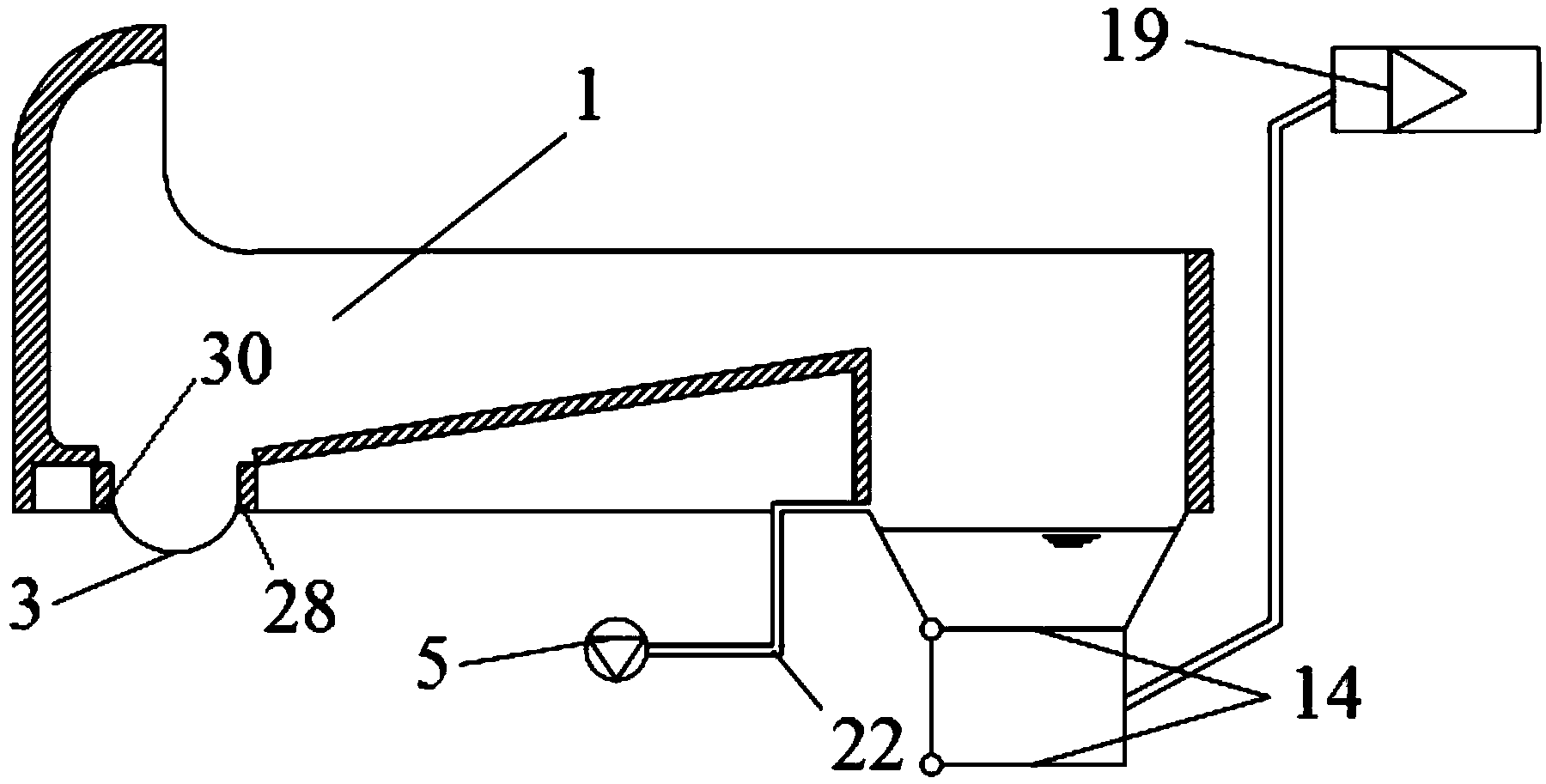

Feces-urine separated type water-saving ecological restroom

The invention discloses a feces-urine separated type water-saving ecological restroom. The feces-urine separated type water-saving ecological restroom comprises a feces-urine separated type squatting pan which collects urine and feces respectively. The urine enters a urine collecting pool through a filtering screen of a collecting port, and feces enters a conical compost reactor through a feces flushing groove. The urine collecting pool is internally provided with a floating ball, the bottom of the urine collecting pool is externally provided with a water pump, and the water pump can connect the urine in the urine collecting pool to the position above the feces flushing groove through a water inlet of a shrinkable type water absorbing pipe and a flushing pipe. The conical compost reactor is provided with a feed port, and is internally provided with an internal spiral agitator and an external spiral agitator, and a mechanical transmission device provides power for the internal spiral agitator and the external spiral agitator through a rotating shaft. The conical compost reactor is further provided with a temperature control device, a humidity detecting device, a temperature monitoring device and a heating layer. Feces and reaction media are mixed better, the water resource is saved, the pipe screen load is reduced, and environment pollution is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

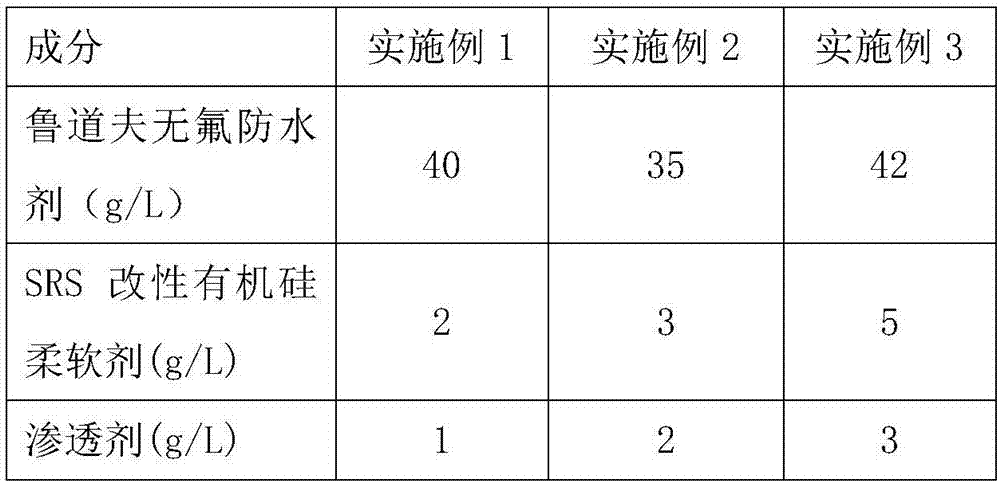

Production technology of medical fabric

ActiveCN107299540ASoft touchImprove tear resistanceMedical preparationsCoatingsEngineeringResin coating

The invention discloses a production technology of a medical fabric. The technology comprises the following steps of grey fabric weaving, desizing, drying, splashing and sizing, calendering treatment, and coating of a double-sided coating, wherein the calendered surface of the fabric is coated with a PU resin coating with water pressure resistance; the PU resin coating is divided into a PU polyether two-component base material and a PU one-component fabric for separate coating; after the calendered surface is coated, the fabric is dried through high-temperature oven until being rolled up, and the other side of the fabric is coated with an organic silicone coating, and high-temperature drying is carried out to obtain the medical fabric. The tissue style characteristics of the woven fabric are integrated, and coating finishing is carried out on the front and reverse sides of the fabric, so that the fabric has the characteristics of being waterproof, easy to decontaminate and high in tenacity, and the production technology is suitable for the medical fabric.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

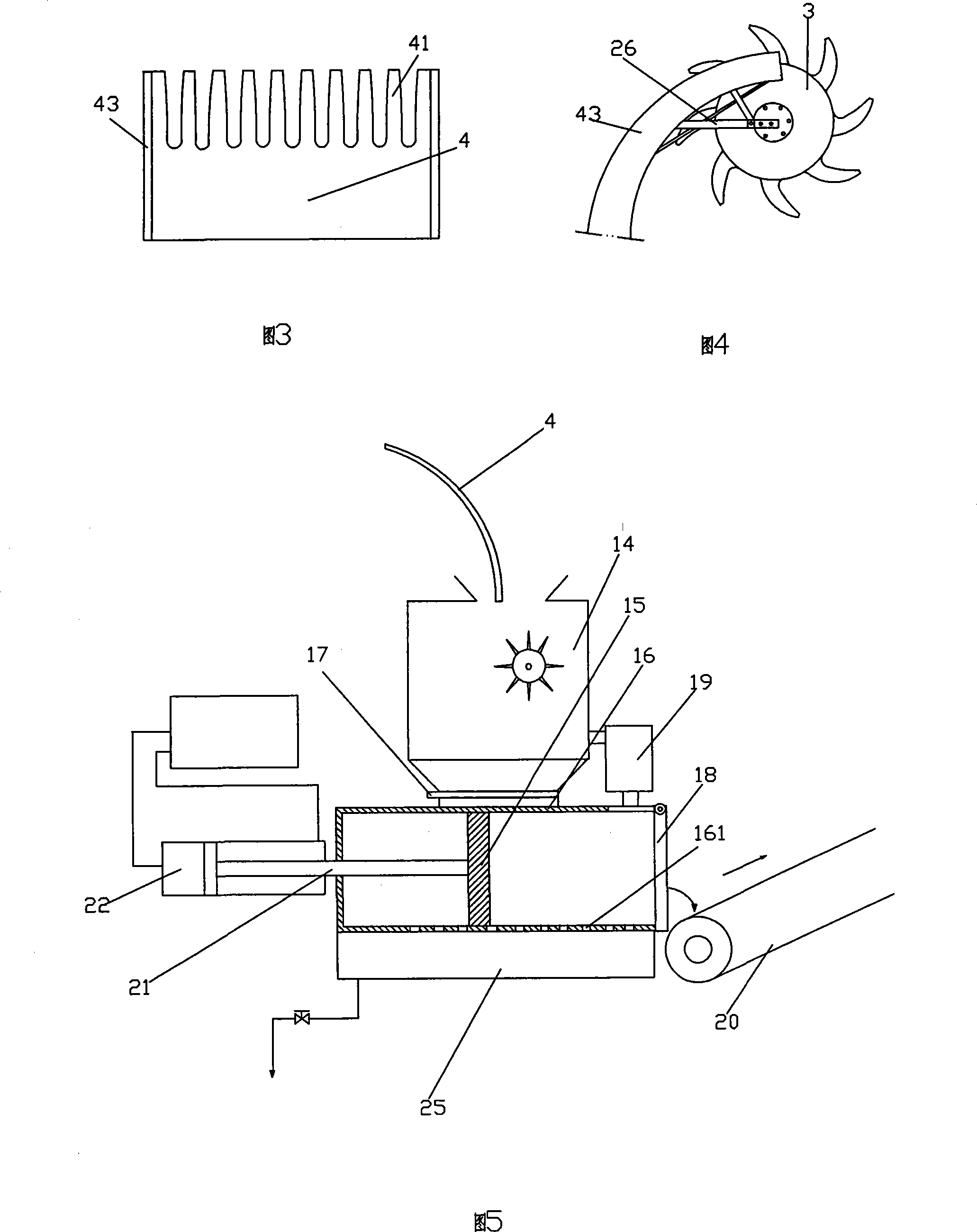

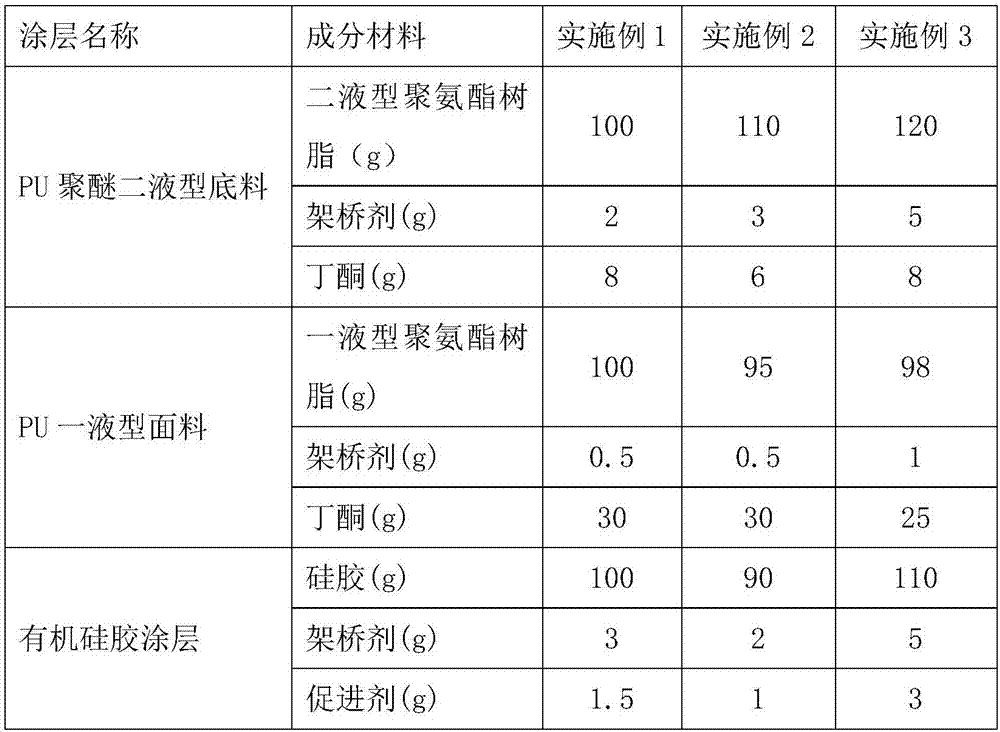

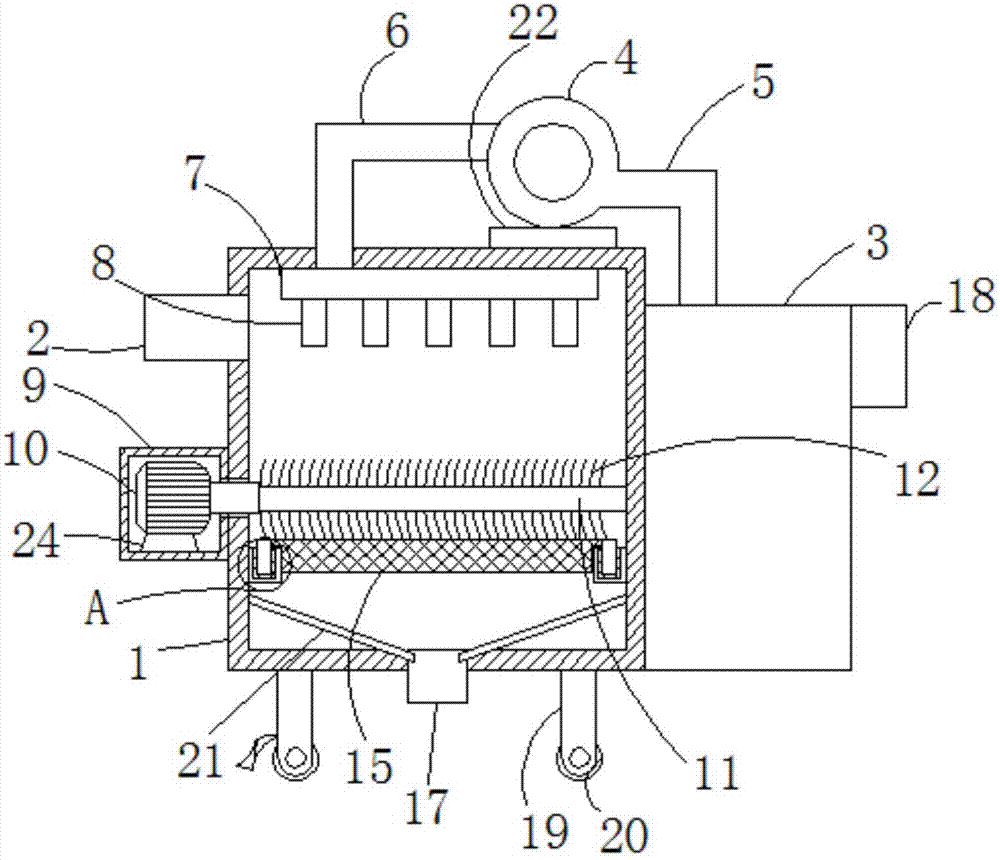

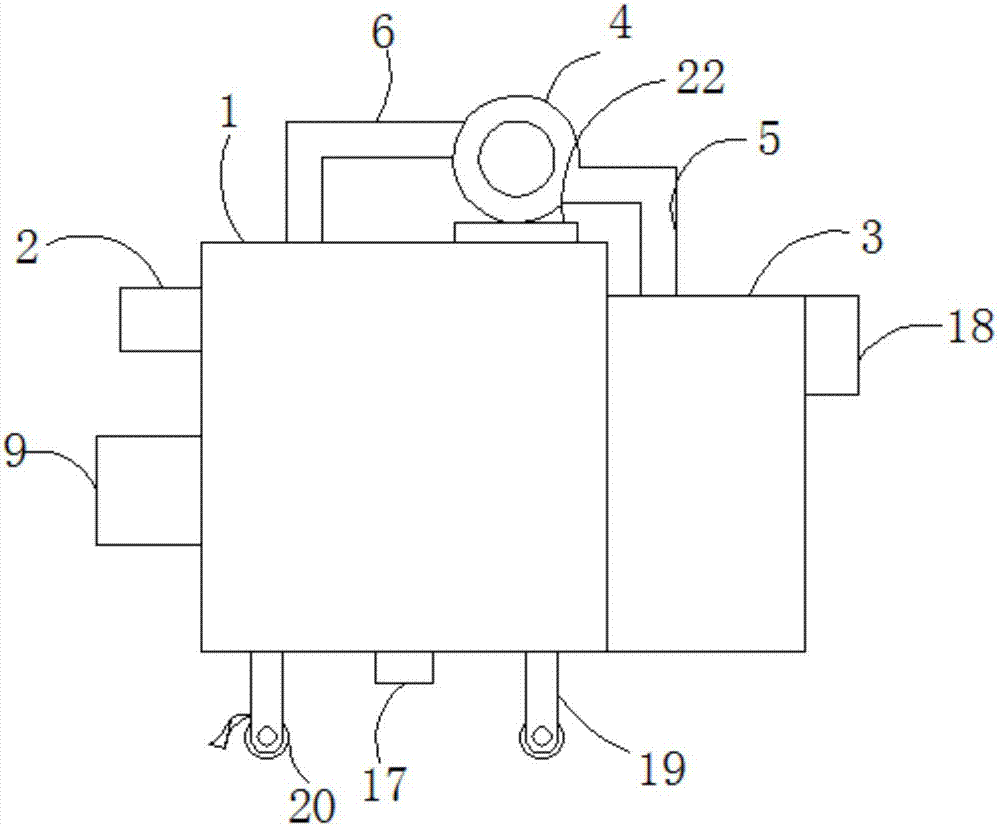

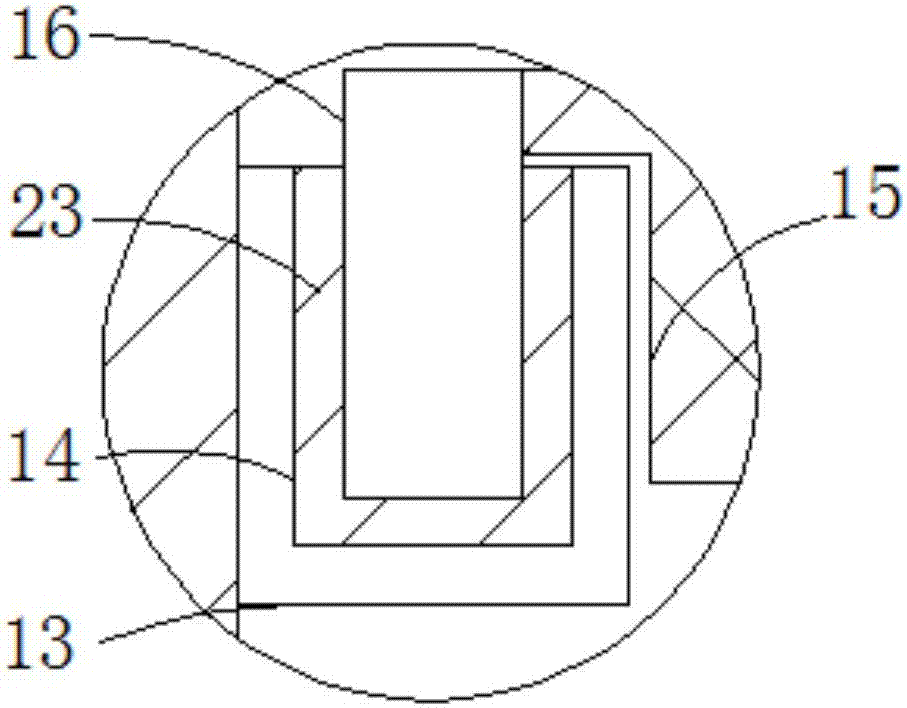

Agricultural grain drying device

InactiveCN107238273AImprove slipSolve the problem of drying efficiencyDrying gas arrangementsDrying solid materialsAgricultural engineeringConvenience food

The invention discloses an agricultural grain drying device, which comprises a machine body, the top of the left side of the machine body is connected with a feeding hopper, the top of the left side of the inner cavity of the machine body is fixedly connected with a connecting plate, and the bottom of the connecting plate is fixedly connected with There is a vibrating motor, a dryer is fixedly connected to both sides of the top of the body, and a baffle is fixedly connected to the right side of the inner cavity of the body. The invention can dry the grain through the setting of the dryer, through the setting of the vibrating motor and the connecting plate, it is convenient for the grain to slide down, and at the same time, the uniformity of drying is increased. Through the setting of the motor, the turntable and the fixed rod can be driven to rotate, Through the setting of movable rods, connecting rods and movable racks, the sieve can be driven to shake and the grain can be screened. At the same time, it solves the problem of uneven drying when drying the grain and the impossibility of screening the impurities in the grain, which reduces the The problem of drying efficiency of grain.

Owner:乐陵市鑫地园金银花种植专业合作社

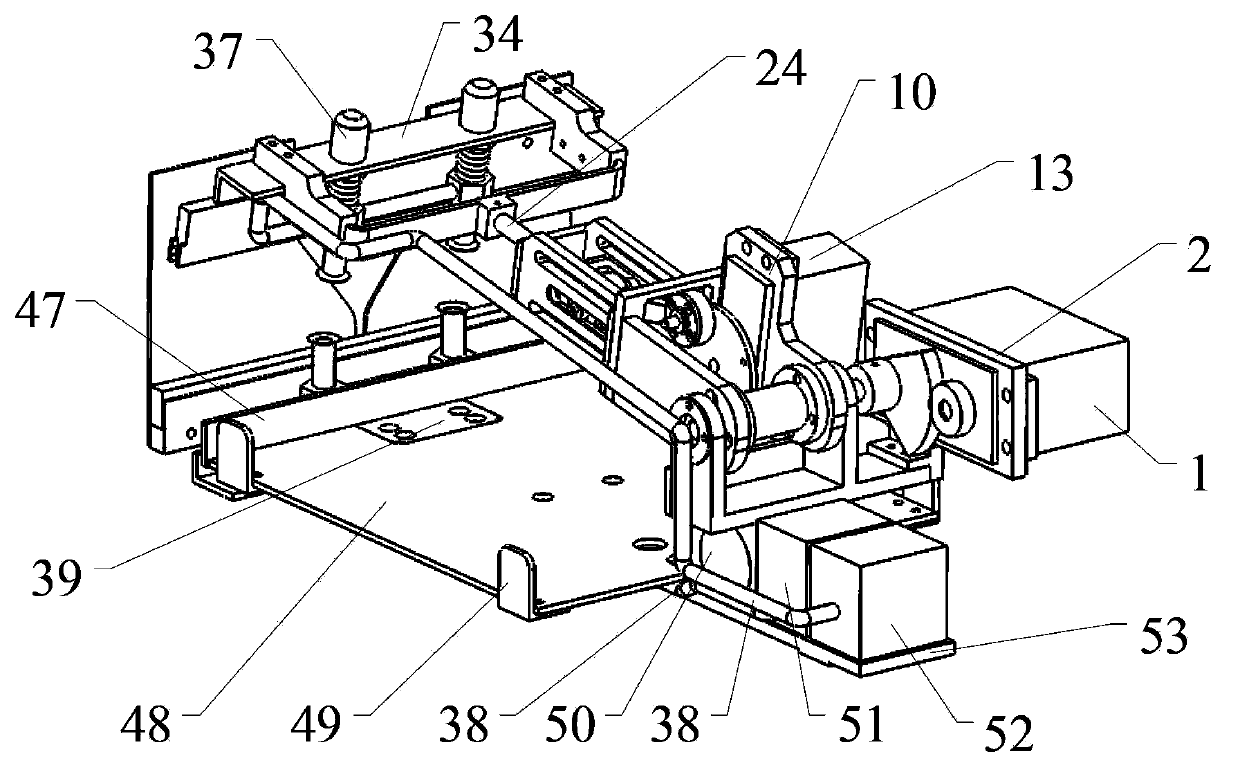

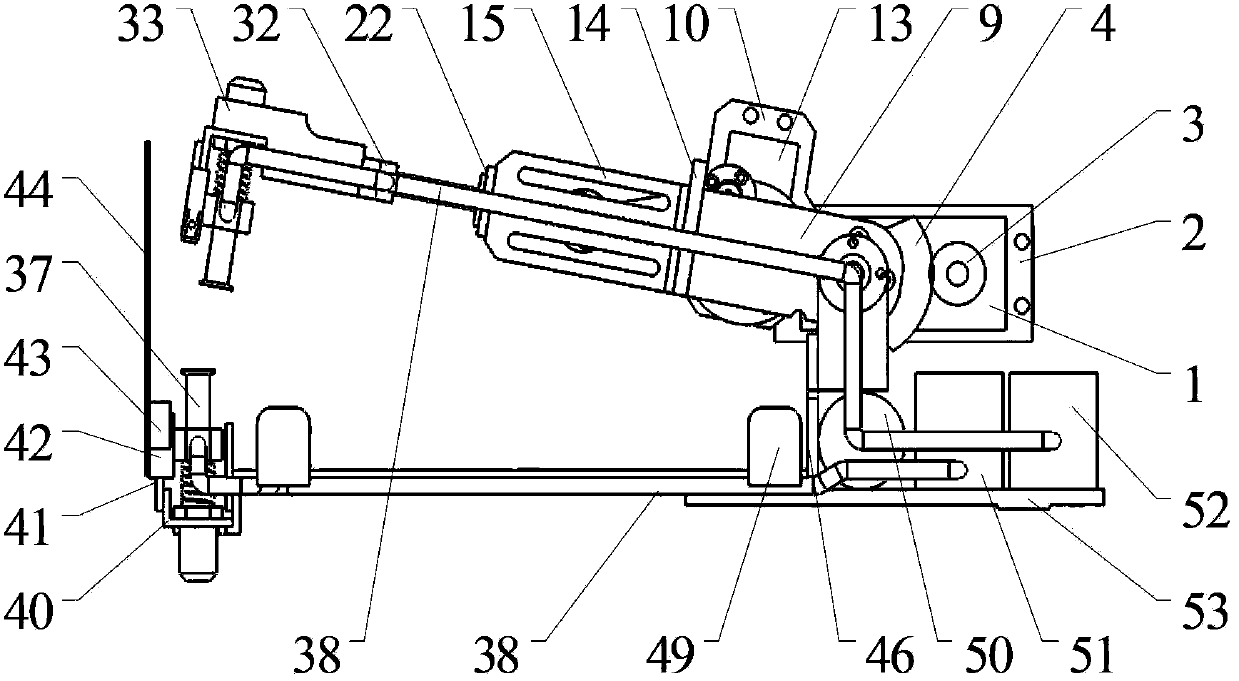

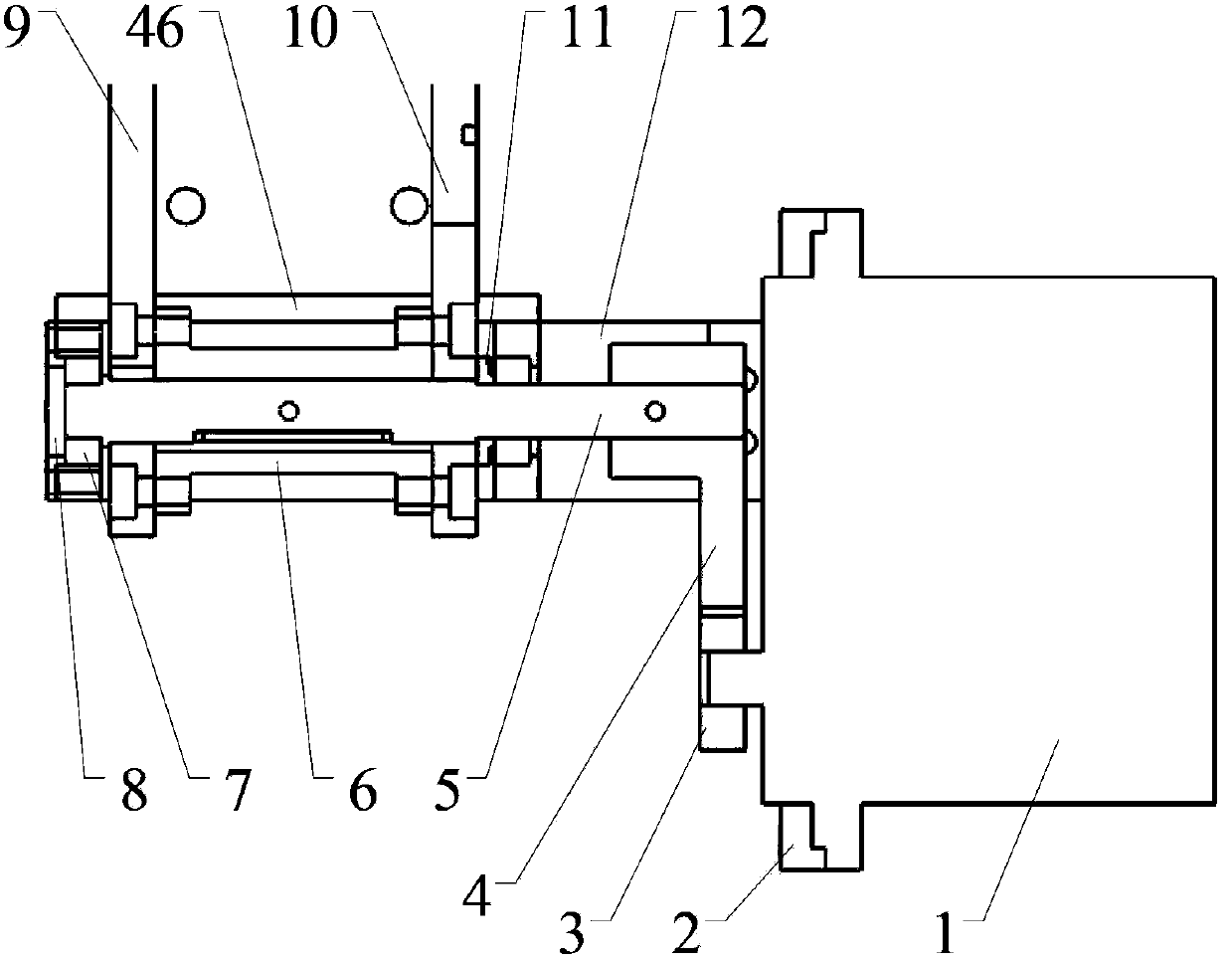

Apple bagging mechanism

InactiveCN103858715ACompact structureEasy installationPlant protective coveringsCushionElectric heating

The invention relates to bagging equipment for fruits, in particular to an apple bagging mechanism. A fruit bag device and a suction device are respectively arranged on a mechanical arm connecting substrate, an upper bag gluing device is connected with the fruit bag device through a pitch device and a retractor device, and a lower bag gluing device is connected on the fruit bag device; the upper bag gluing device is moved up and down through the pitch device, and the upper bag gluing device is moved back and forth through the retractor device; a sucker of the upper bag gluing device separately picks up fruit bags, and the suckers of the upper and lower bag gluing device work together to unfold the openings of the fruit bags; colloids in the fruit bags are heated by electric heating members in the upper bag gluing device, so that the colloids are melted to glue the upper and lower layers of the fruit bags under the function of extrusion force; the lengths of the suckers can be changed by reset springs on the suckers, in the process of unfolding the bags, the reset springs function and the suckers of the sucking discs are contacted, but the electric heating members and the heating cushion blocks are not contacted; in the bag sealing process, the reset springs are shortened under the function of extrusion force, the electric heating members and the heating cushion blocks are contacted to generate the extrusion force. According to the apple bagging mechanism, manpower can be saved and the efficiency is high.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

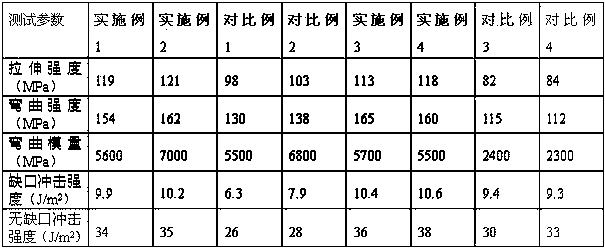

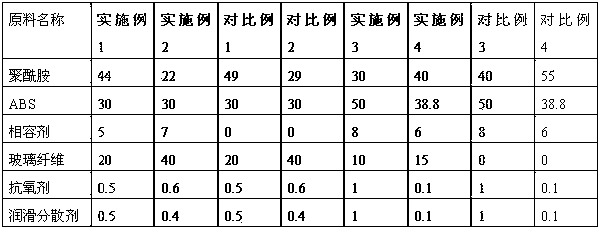

High-strength high-toughness glass-fiber-reinforced PA/ABS (polyamide/acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention discloses a high-strength high-toughness glass-fiber-reinforced PA / ABS (polyamide / acrylonitrile-butadiene-styrene) composite material which is prepared from the following raw materials in percentage by weight: 10-65% of polyamide, 10-50% of ABS, 5-15% of compatilizer, 10-40% of glass fiber, 0.1-1% of antioxidant and 0.1-1% of lubricating and dispersing agent. The invention also discloses a preparation method of the high-strength high-toughness glass-fiber-reinforced PA / ABS composite material. The glass-fiber-reinforced PA / ABS composite material disclosed by the invention has the advantages of high strength, high toughness, stable quality and excellent comprehensive mechanical properties, and can be widely used in products in the fields of automobile interior and exterior components, electronic and electric appliances and the like.

Owner:SHANGHAI SUNNY

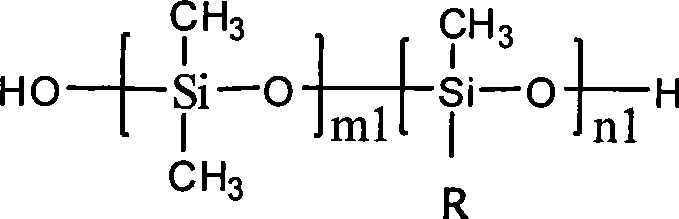

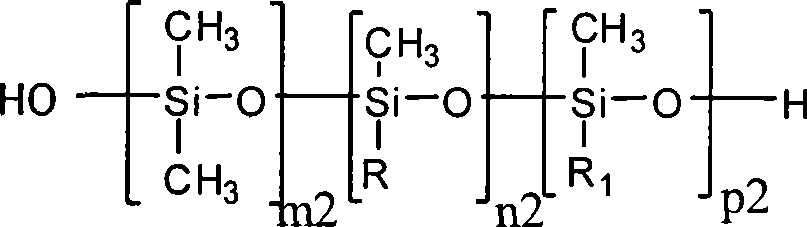

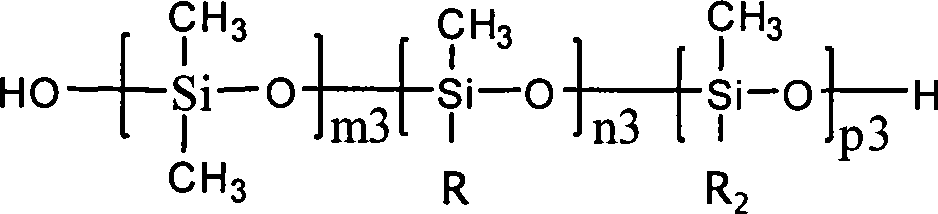

Organosilicon fluorine multifunctional fabric finishing agent and preparing method thereof

The invention discloses an organic fluosilicic multifunctional textile finishing agent. Aiming at the problem existing in the current commercially available organic silicone finishing agent, a small amount of organic fluorin radical is introduced to the organic silicone finishing agent; under the condition of not changing the original effect of the organic silicone finishing agent, the smooth property of the finishing agent is further improved, simultaneously, water-and-oil-repellent effect is increased to a certain extent; the finishing agent is innocuous and pollution-free, and has high cost performance and wide application prospect. The invention also discloses a preparation method of the organic fluosilicic multifunctional textile finishing agent which has simple technological operation, the prepared latex has strong stability and difficult emulsion breaking, delamination does not happen after the latex is placed for a long time, the use is simple, the hand-feeling of the textile is obviously improved and the additional value is increased.

Owner:ZHEJIANG RUNTU +1

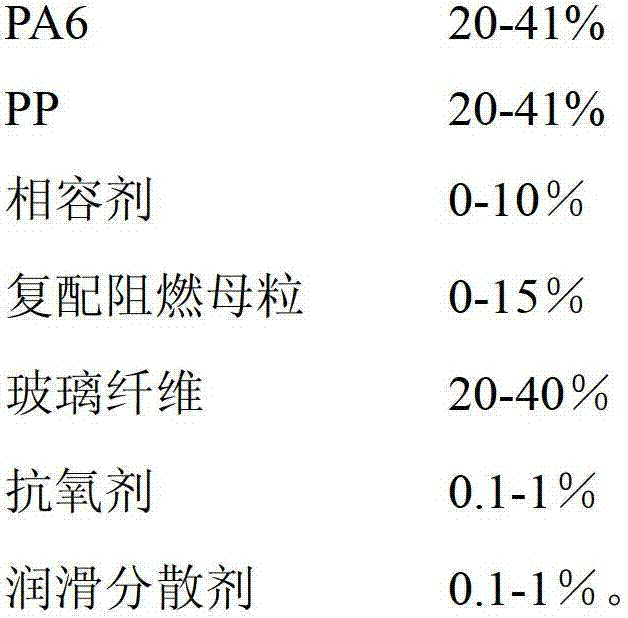

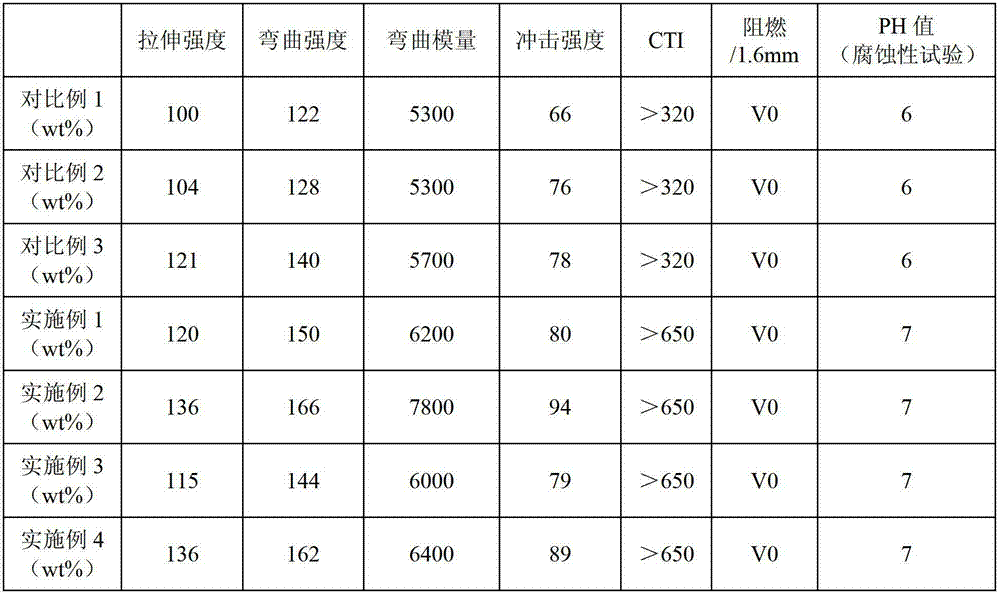

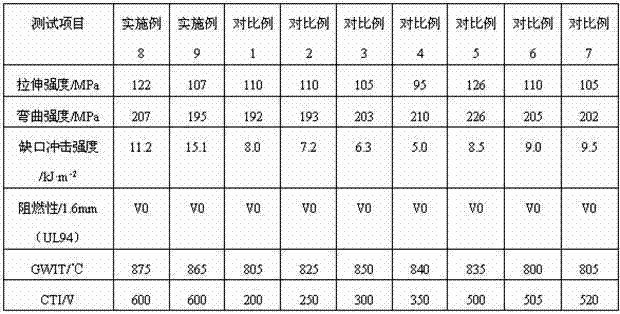

Flame-retardant glass fiber reinforced polyamide 6/polypropylene (PA6/PP) alloy composite and preparation method thereof

InactiveCN102775771AImprove mechanical propertiesCTI improvementMasterbatchComparative Tracking Index

The invention relates to a flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite and a preparation method of the flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite. The composite comprises the following components in percentage by weight: 20-40 percent of polyamide 6 (PA6), 20-41 percent of polypropylene (PP), 0-10 percent of a compatilizer, 0-15 percent of compound flame-retardant masterbatch, 20-40 percent of glass fiber, 0.1-1 percent of an antioxygen and 0.1-1 percent of a lubricant dispersing agent. The preparation method of the composite comprises the following steps of: weighing each component according to the weight proportions; putting the components into a high mixing machine to mix for 2-5 minutes; discharging; and extruding and pelleting by a twin-screw extruder to process at the temperature of 200-225 DEG C under the condition of screw revolution of 30-40HZ. Compared with the prior art, the composite has the advantages of high comparative tracking index (CTI) value, low flame-retardant precipitation property, halogen-free environment friendliness, comprehensive performance equalization and the like, and can be widely applied to products of contacts, leakage protectors, circuit breaker shells and the like in the electronics field.

Owner:SHANGHAI SUNNY

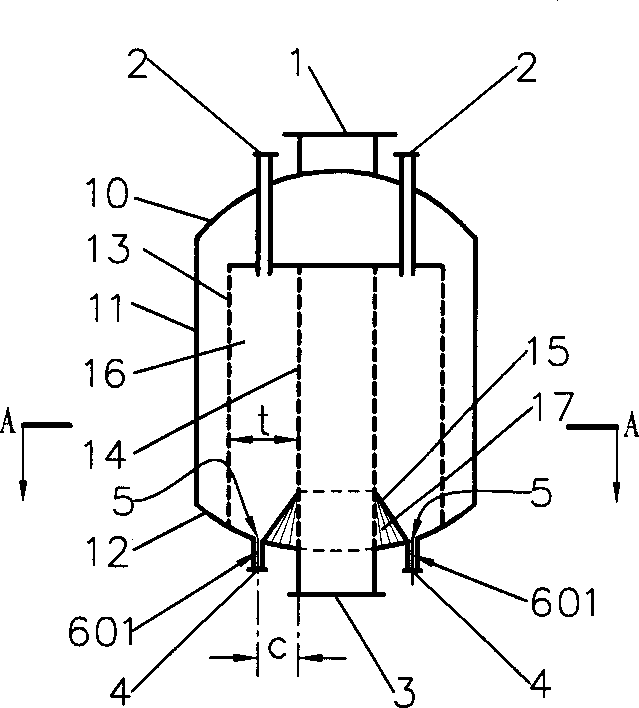

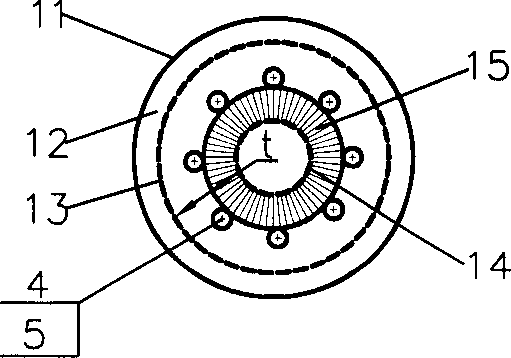

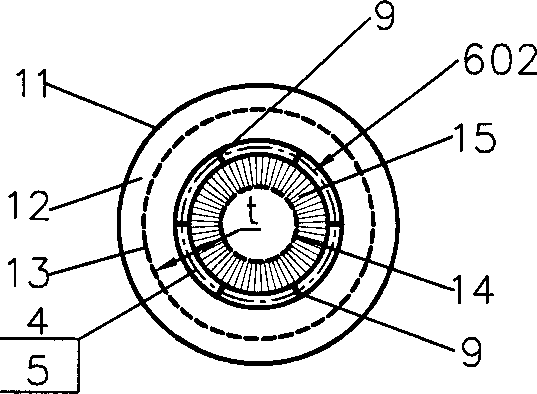

Gas and solid radial reactor for moving-bed

InactiveCN1333084ASimple structureReduce or eliminate flow dead zonesChemical/physical processesChemical industryOil processing

The present invention discloses a gas-solid radial reactor of moving bed for chemical industry and petroleum processing industry, and is characterized by that the lower portion of inner not of said reactor is equipped with a skirt, and the external surface of said skirt is inclined from top to bottom along the direction from inner net toward outer net, its upper edge is connected with inner net, and its lower edge is connected with internal surface of closure head of the bottom, and the radial position of the lower edge is positioned in internal side of radial position of catalyst outlet pipe, and the external surface of said skirt is generally made into circular truncated cone side face or frustum side face. Said invention can effectively reduce or eliminate flow dead zone of catalyst inthe reactor, at the same time the structure of said skirt is simple, and easy to implement. It is specially applicable to hydrocarbon conversion reaction and catforming reaction.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

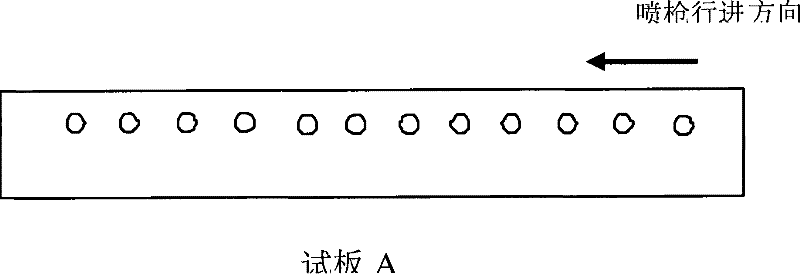

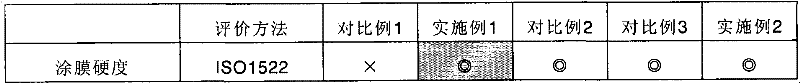

Acrylic-amino type coating varnish composition for automobiles, varnish and application thereof

The invention provides an acrylic-amino type coating varnish composition for automobiles, which comprises the following components in parts by weight: (a) 20-48 parts of high-solid-content thermosetting hydroxy acrylic resin, (b) 20-30 parts of n-butyl alcohol etherified melamine resin, (c) 10-30 parts of diurea compound modified acrylic resin, (d) 1-10 parts of 3,5-dimethylpyrazole (DMP) closed aliphatic polyisocyanate resin, (e) 0.2-1.0 part of leveling agent and (f) acceptable amount of assistant for varnish, wherein the hydroxyl value of the high-solid-content thermosetting hydroxy acrylic resin is 120-160 mg KOH / g, and the solid content is at least 70 wt%; and the leveling agent is a polyester modified dimethyl polysiloxane solution. The film obtained by coating the acrylic-amino type coating varnish composition has the advantages of high luster and high hardness, and the sagging limit is higher than 50 mu m; and the acrylic-amino type coating varnish composition is especially suitable for exterior application of automobiles, and is also suitable for exterior application of automobile wheel hubs, motorcycles, engineering machinery, light industry products and the like.

Owner:NIPPON PAINT GUANGZHOU

Environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952379AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PBT, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PBT material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in composite material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

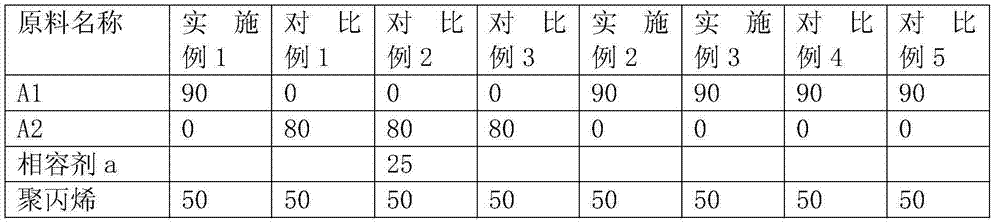

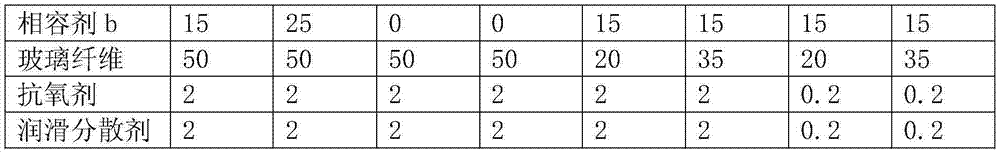

Low-shrinkage glass fiber reinforced PP/PA (Polypropylene/Polyamide) composite material composition and preparation method thereof

The invention discloses a low-shrinkage glass fiber reinforced PP / PA (Polypropylene / Polyamide) composite material composition and a preparation method thereof. The composition comprises 10-80 parts of polypropylene, 10-80 parts of polyamide, 5-25 parts of compatilizers, 10-80 parts of glass fiber, 0.1-5 parts of antioxidant and 0.1-5 parts of lubrication dispersing agent. The preparation method comprises the following steps: when the composition material is prepared, commixing the polyamide and a compatilizer a (ethylene-octylene copolymerization thermoplastic elastomer grafted maleic anhydride), discharging, and extruding to pellet so as to obtain polyamide master batch A; and commixing the polyamide master batch A with polypropylene, an antioxidant, the lubrication dispersing agent and a compatilizer b (homo-polypropylene grafted maleic anhydride), discharging, and extruding to pellet by using a double-screw rod extruding machine so as to obtain the composition. The glass fiber reinforced PP / PA composite disclosed by the invention has the advantages of high strength, high toughness, low shrinkage, stable quality and excellent comprehensive mechanics property, and can be widely applied to products of fields such as inner and outer automobile components and electronic devices.

Owner:SHANGHAI SUNNY

High-efficiency environment-friendly dust removal device

InactiveCN107081023AIncrease the adsorption areaImprove cleaning efficiencyDispersed particle filtrationTransportation and packagingEngineeringPollution

The invention discloses a high-efficiency environment-friendly dust removal device. The device includes a device body, the top of the left side of the device body is communicated with a first passing pipe, the right side of the device body is fixedly connected with a dust storage box, the top of the device body is provided with a blower, the outlet of the blower is communicated with a dust outlet pipe, the end, away from the outlet of the blower, of the dust outlet pipe is communicated with the top of the dust storage box, the inlet of the blower is communicated with a dust inlet pipe, and the end, away from the inlet of the blower, of the dust inlet pipe penetrates through the device body, extends into the device body and is communicated with a communication pipe. According to the high-efficiency environment-friendly dust removal device, through the arrangement of the blower, dust in the device body can be sucked into the dust storage box through the dust inlet pipe and the dust outlet pipe, and the dust can be collected and treated; through the arrangement of the communication pipe and the arrangement of a dust suction pipe, the area of dust absorption is increased, the cleaning efficiency is improved, and at the same time, the problems are solved that the dust cannot be cleaned thoroughly, it is difficult to collect treated dust because the treated dust is directly discharged into air, and then the treated dust causes pollution to the environment and is harmful to human-body health.

Owner:长兴悍将环保机械制造有限公司

Method for preparing gold noodles

The invention provides a method for preparing gold noodles. With the adoption of the method, high lysine superfine corn starch, degreased soybean meal, high gluten wheatmeal, fresh hen eggs, grain milk powder, soy protein, lactalbumin, konjak powder, potato starch, vital gluten, edible salt, a thickening agent (407 carrageenan) and a thickening agent (415 xanthan gum) are taken as raw materials. The method comprises the following steps: directly grinding high lysine corns, wheat and degreased soybean; uniformly mixing the obtained high lysine superfine corn starch, degreased soybean meal and wheatmeal with other raw materials according to a certain ratio; adding water to make dough; and then carrying out the processes of combining, rolling, cutting into strips and drying and the like. The gold noodles have the characteristics of natural raw materials, comprehensive and balanced nutrition, and matched coarse grain and refined grain, thereby being beneficial for health; and the noodles are thin and smooth, golden in color, and golden silk type in shape, and the noodles are chewy and no thick soup is produced after the noodles are cooked thoroughly.

Owner:张世锋

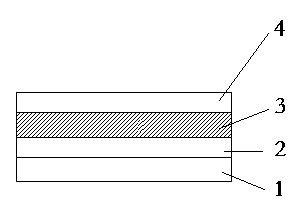

Aluminum plastic film for packaging lithium battery and manufacturing process of aluminum plastic film

ActiveCN104466040AImprove slipCorrosion will not occurJackets/cases materialsMetal layered productsPlastic filmAluminum foil

The invention relates to an aluminum plastic film for packaging a lithium battery. The aluminum plastic film comprises a CPP layer (1), an inner bonding layer (2), an aluminum foil layer (3) and a fluorine-containing transparent coating (4), wherein the fluorine-containing transparent coating (4) comprises a fluorine-modified high-temperature-resistant acrylic acid coating, a fluorine-modified high-temperature-resistant polyurethane coating, an FEVE coating or a PVDF coating. The invention also provides a manufacturing process of the aluminum plastic film for packaging the lithium battery. When the aluminum plastic film is in contact with accidentally-dropping electrolyte in the process of packaging and injecting the electrolyte, the aluminum plastic film cannot be corroded, and the slippery property of the outer surface of the film is improved.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

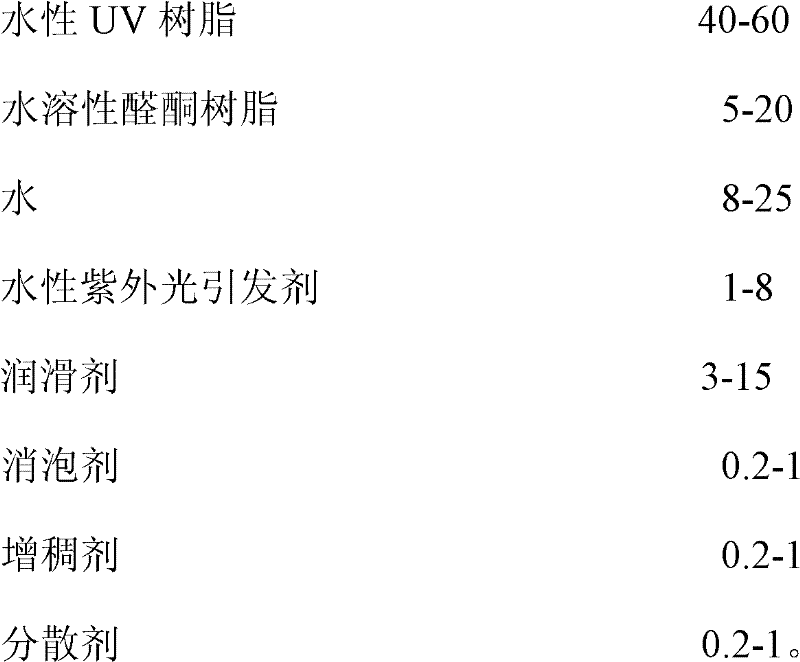

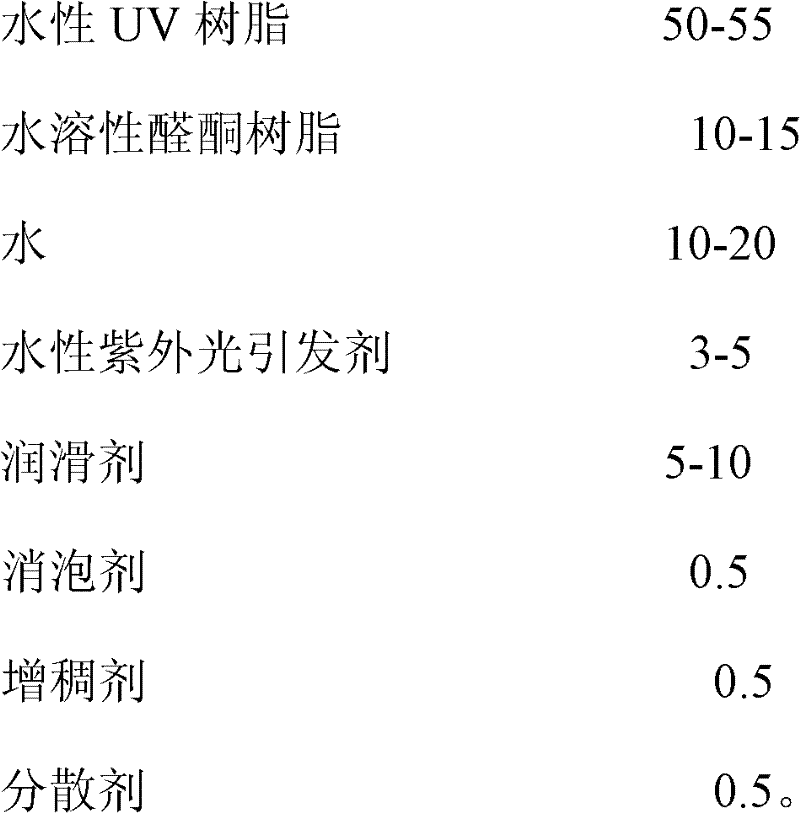

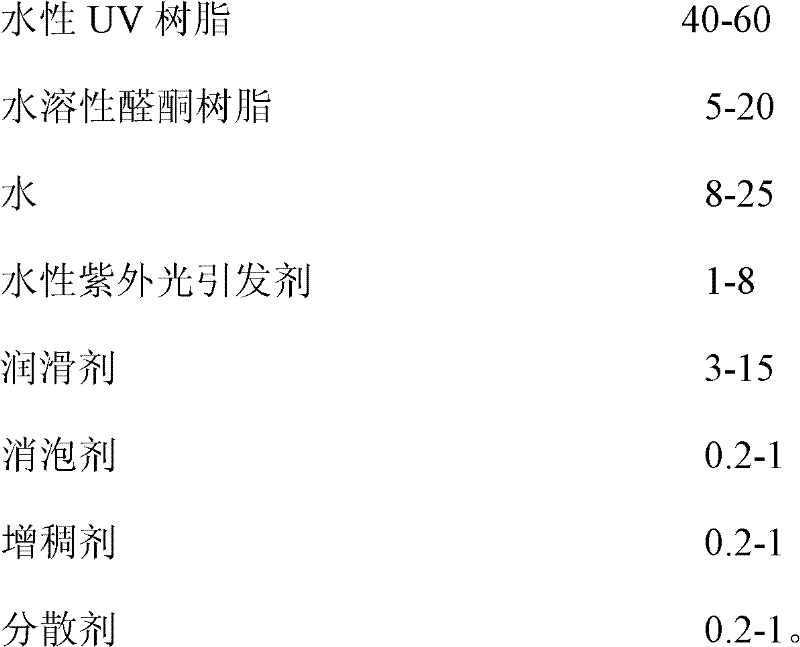

Water-based ultraviolet (UV) curing silk screening snowflake ink

The invention discloses water-based ultraviolet (UV) curing silk screening snowflake ink, which is prepared from the following raw materials in part by weight: 40 to 60 parts of water-based UV resin, 5 to 20 parts of water-soluble aldehyde ketone resin, 8 to 25 parts of water, 1 to 8 parts of water-based UV initiator, 3 to 15 parts of lubricating agent, 0.2 to 1 part of defoaming agent, 0.2 to 1 part of thickening agent and 0.2 to 1 part of dispersant. The invention provides the environment-friendly water-based UV curing silk screening snowflake ink for obviously reducing the peculiar smell of presswork due to ink.

Owner:SHENZHEN KECAI PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com