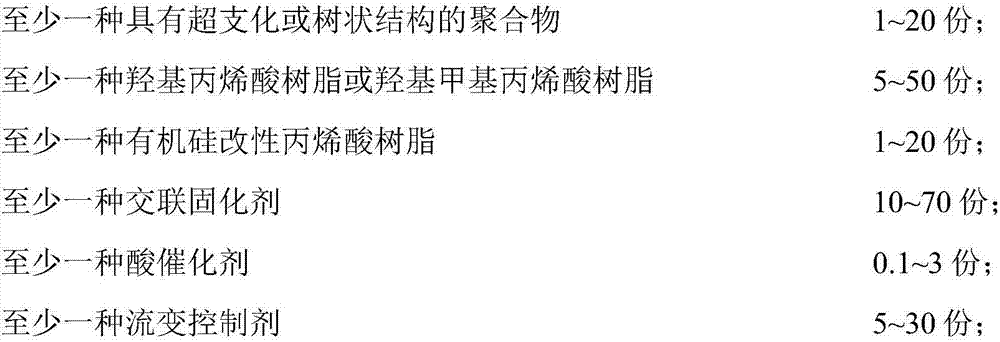

Mono-component varnish composition, preparation method and purpose thereof

A one-component, one-component technology that can be used in coatings, pre-treating surfaces, and devices for coating liquids on surfaces, and can solve problems such as negative effects on paint films, poor weatherability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

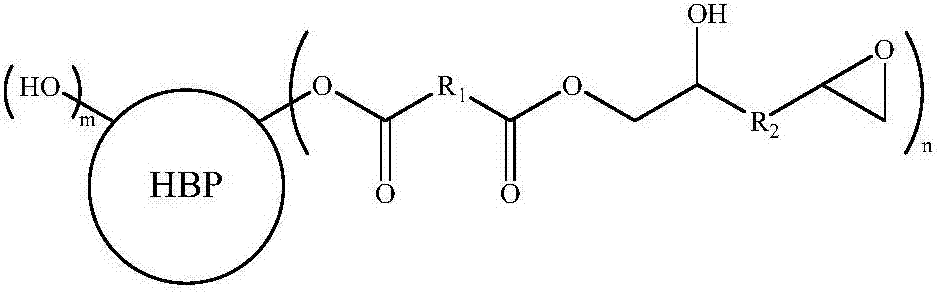

[0158] Preparation of polymers with hyperbranched or dendritic structures

[0159] Add 354.8g of Boltorn H40 and 74g of hexahydrophthalic anhydride into a 1L reaction kettle equipped with a stirrer, a thermometer, a nitrogen conduit and a reflux condenser, and then raise the temperature of the reaction system to 130°C. After the reaction temperature is constant, continue to insulate at this temperature for 4 to 5 hours, during which the acid value is measured by sampling every 1 hour. When the acid value (63mgKOH / g) reaches the theoretical value (62.8mgKOH / g), add 115.2g ring Glycidyl tert-carbonate with an oxygen equivalent of 240 and 0.5 g of N,N-dimethylbenzylamine, and keep warm at this temperature for 4 to 5 hours. During the heat preservation process, continuously monitor the change of the acid value, and stop the reaction when the acid value is less than 2mgKOH / g. When the reaction temperature dropped to 110° C., butyl acetate was added to reduce the viscosity and adju...

Embodiment 2

[0161] Preparation of polymers with hyperbranched or dendritic structures

[0162] Add 354.8g of Boltorn H40 and 98.6g of hexahydrophthalic anhydride into a 1L reaction kettle equipped with a stirrer, a thermometer, a nitrogen conduit and a reflux condenser, and then raise the temperature of the reaction system to 130°C. After the reaction temperature is constant, continue to keep warm at this temperature for 4 to 5 hours, during which the acid value is measured by sampling every 1 hour. When the acid value measured value (79mgKOH / g) reaches the theoretical value (79.2mgKOH / g), add 153.6g ring Glycidyl tert-carbonate with an oxygen equivalent of 240 and 0.5 g of N,N-dimethylbenzylamine, and keep warm at this temperature for 4 to 5 hours. During the heat preservation process, continuously monitor the change of the acid value, and stop the reaction when the acid value is less than 2mgKOH / g. When the reaction temperature dropped to 110° C., butyl acetate was added to reduce the ...

Embodiment 3

[0164] Preparation of Epoxy Modified Hyperbranched Polyester Resin

[0165] Prepare with reference to the synthesis method described in Example 1 of patent CN104628995, the specific synthesis steps are as follows: add 354.8g Boltorn H40 and 74g hexahydrophthalic anhydride to a 1L reactor equipped with a stirrer, a thermometer, a nitrogen conduit and a reflux condenser, Then the temperature of the reaction system was raised to 130°C. After the reaction temperature is constant, continue to keep warm at this temperature for 4 to 5 hours, during which the acid value is measured by sampling every 1 hour. When the acid value measured value (63mgKOH / g) reaches the theoretical value (62.8mgKOH / g), add 134.4g ring 1,4-butanediol diglycidyl ether with an oxygen equivalent of 140 and 0.6 g of triphenylphosphine, and continue to keep warm at this temperature for 4 to 5 hours. During the heat preservation process, continuously monitor the change of acid value and epoxy equivalent, and sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com