Patents

Literature

1955results about How to "Not easy to stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

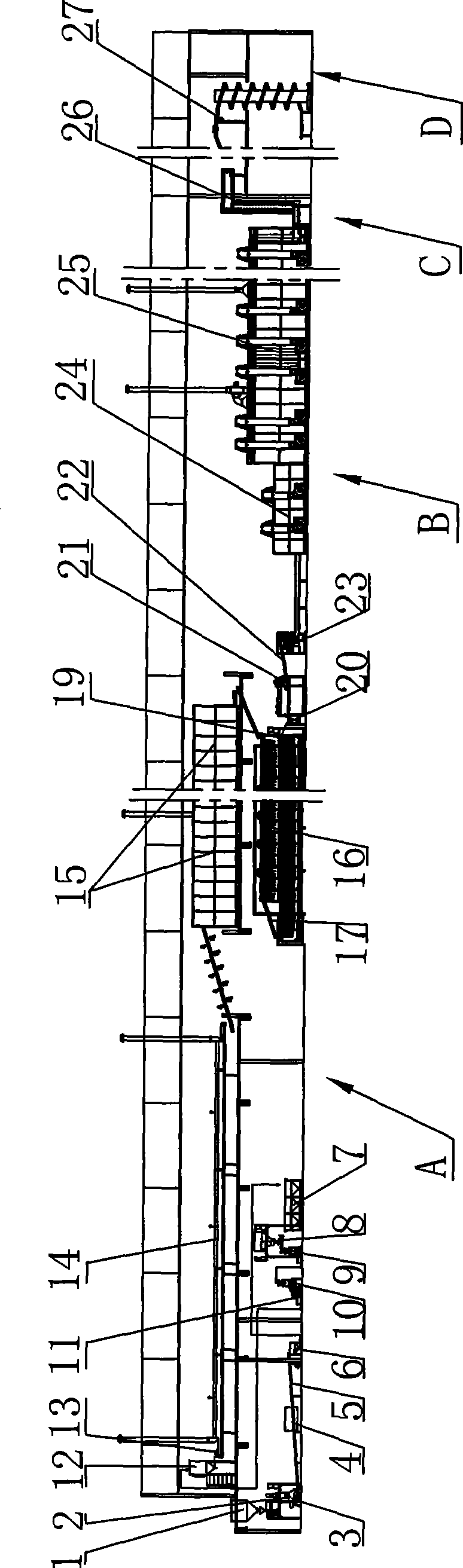

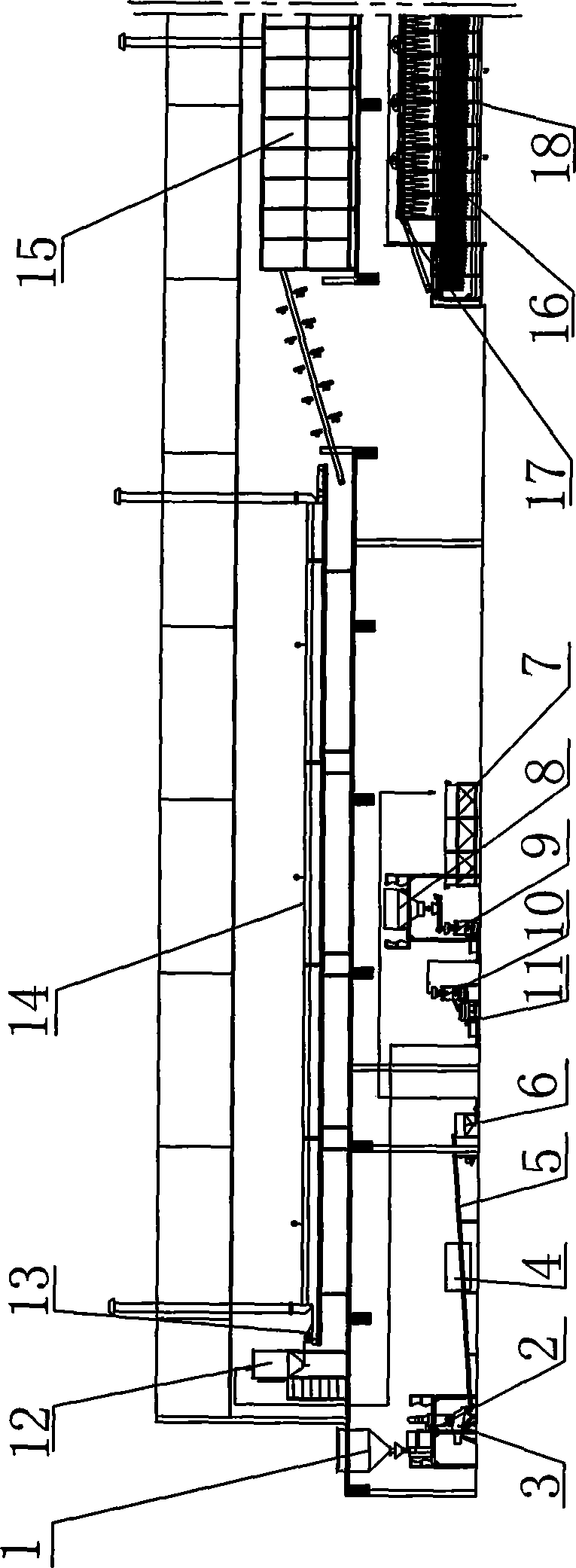

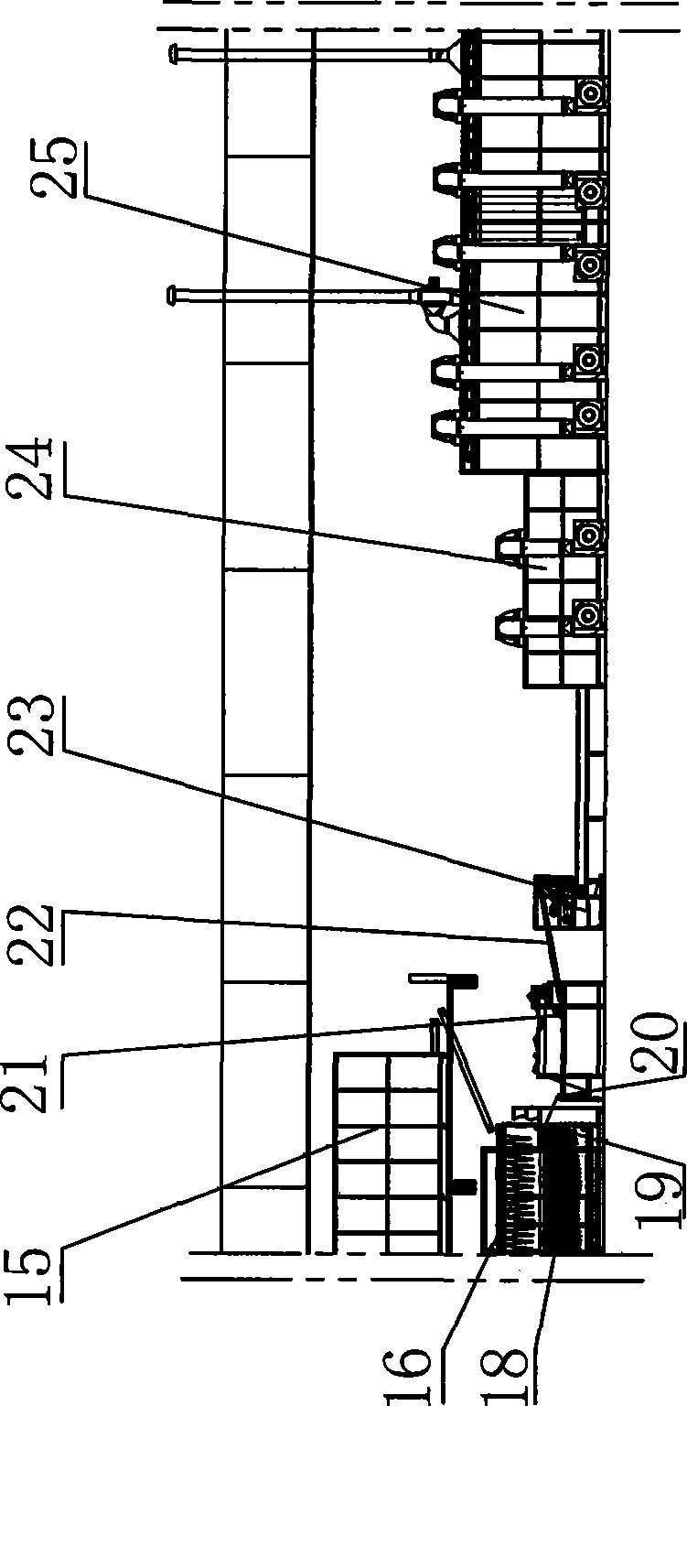

Down filling machine

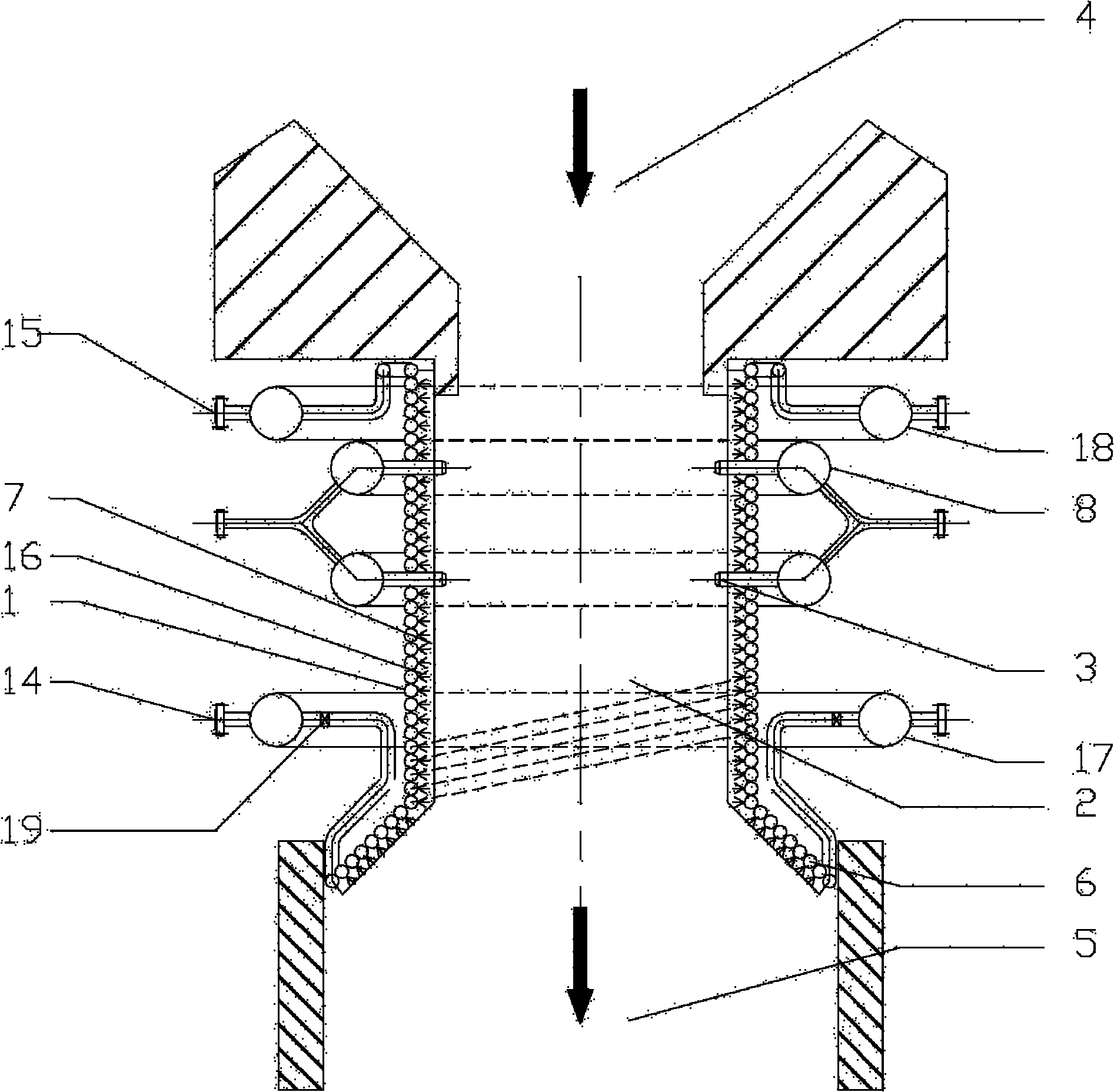

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

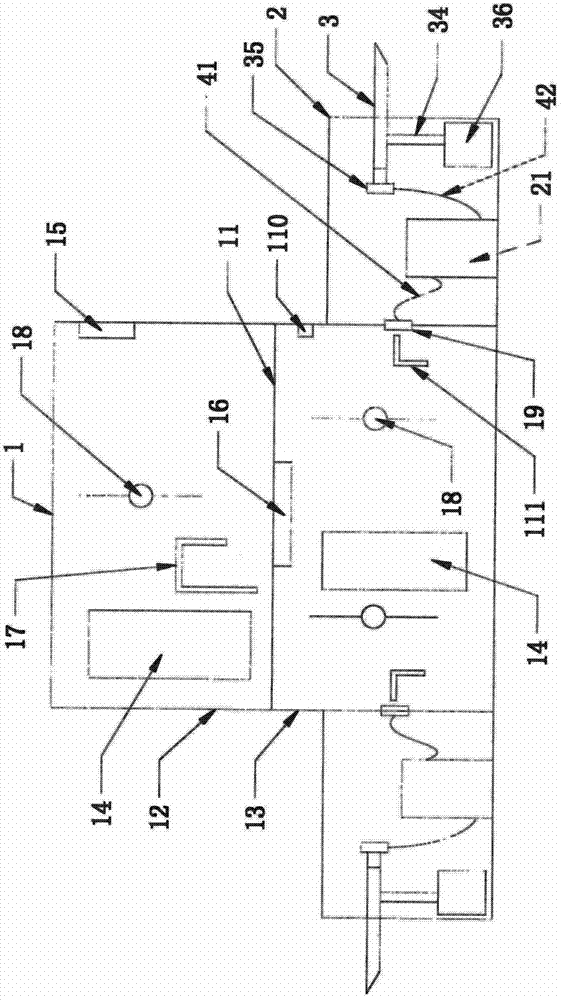

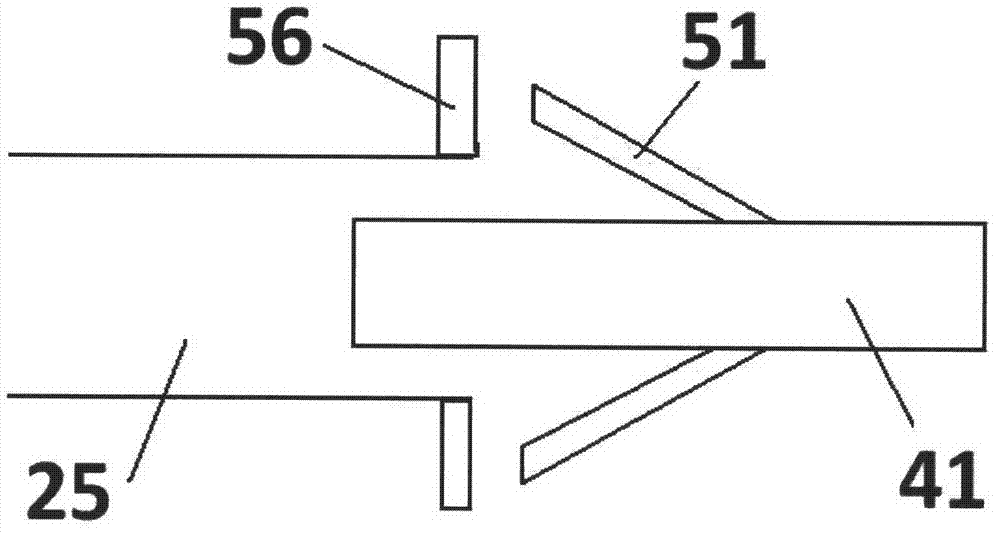

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

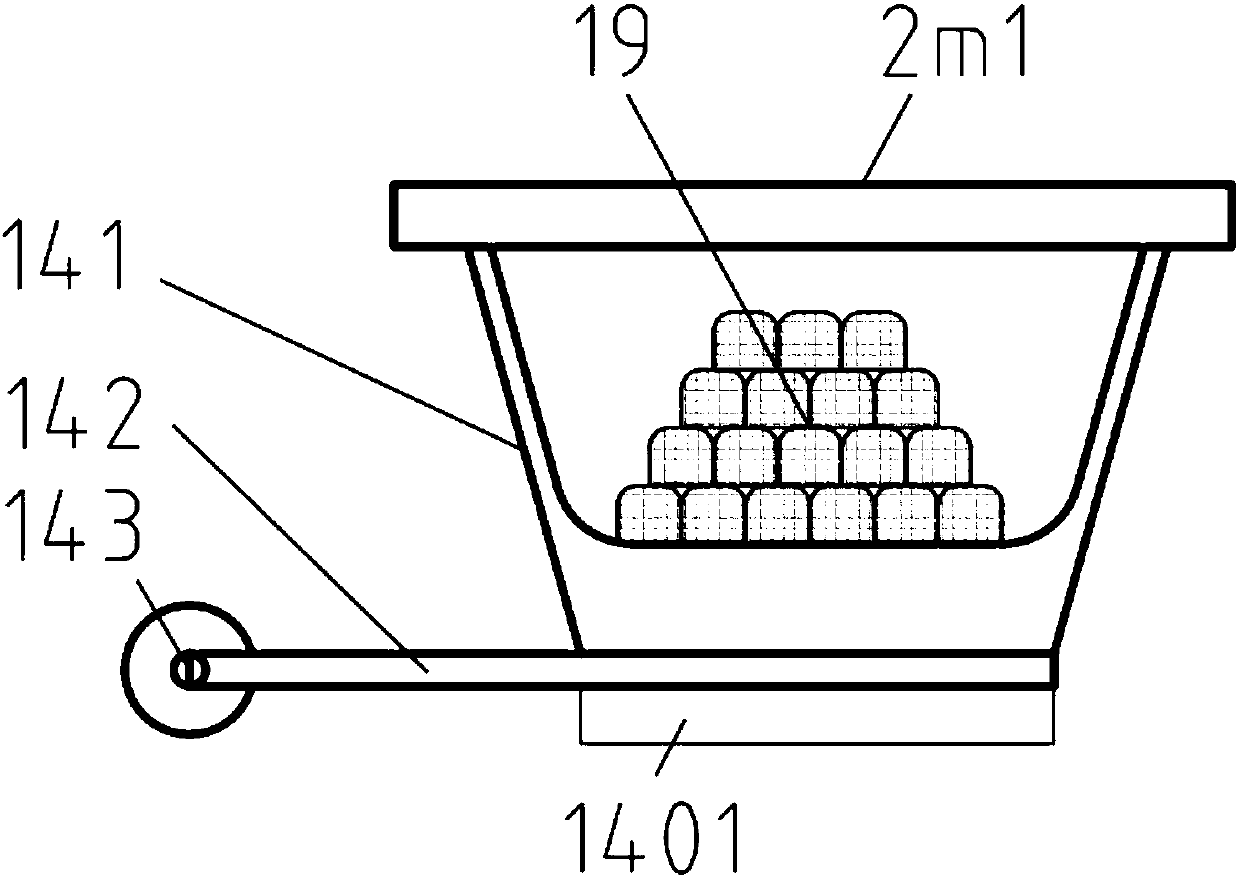

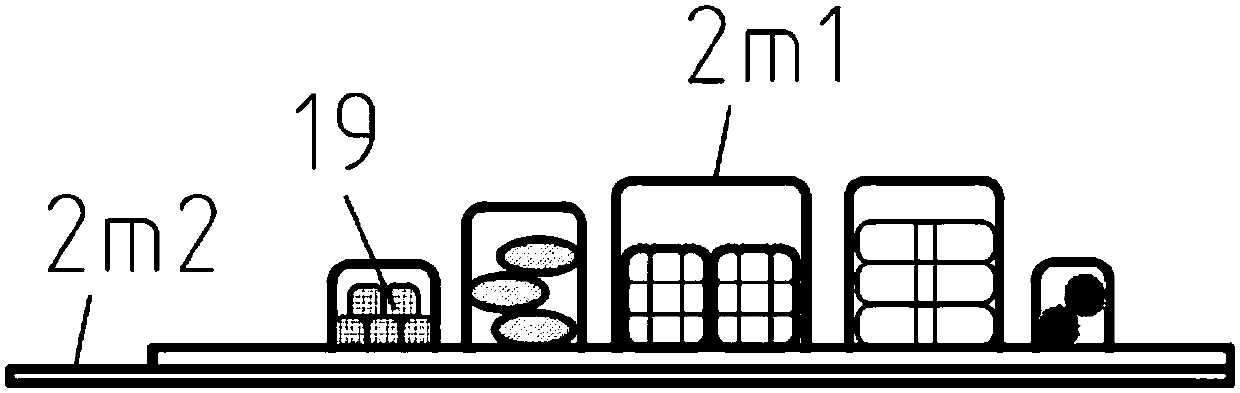

Bundling treating method for cooking raw materials, cooking raw materials and intelligent cooking machine

PendingCN110051228AAchieve solidificationNot easy to stickCooking-vessel lids/coversFood scienceLiquid stateFood material

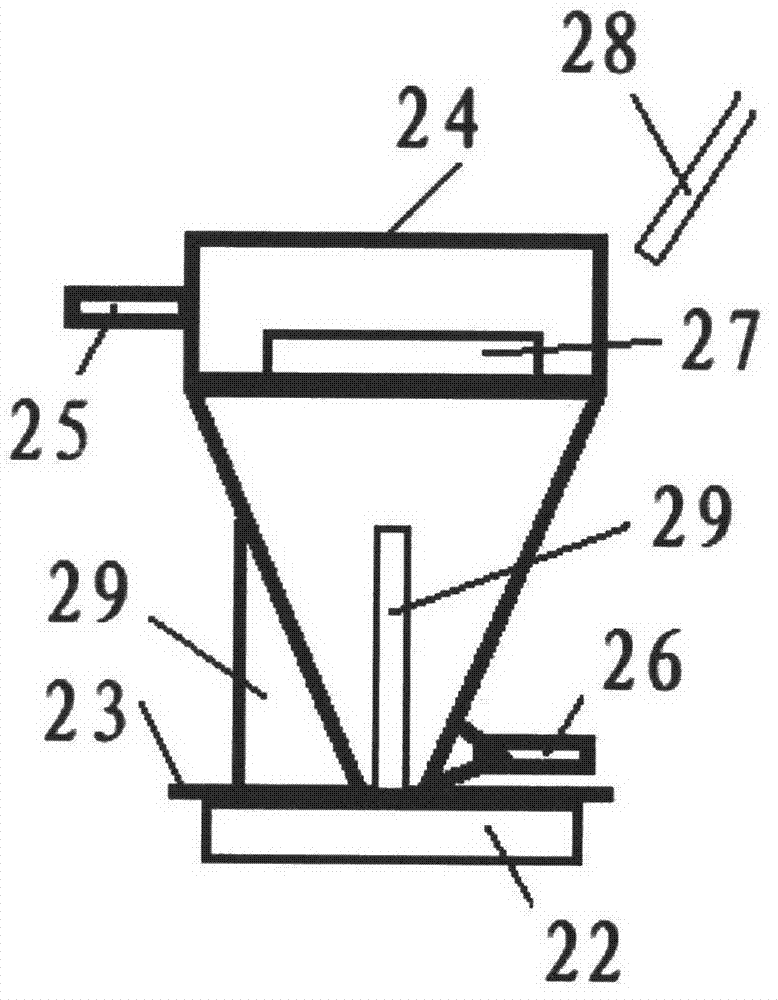

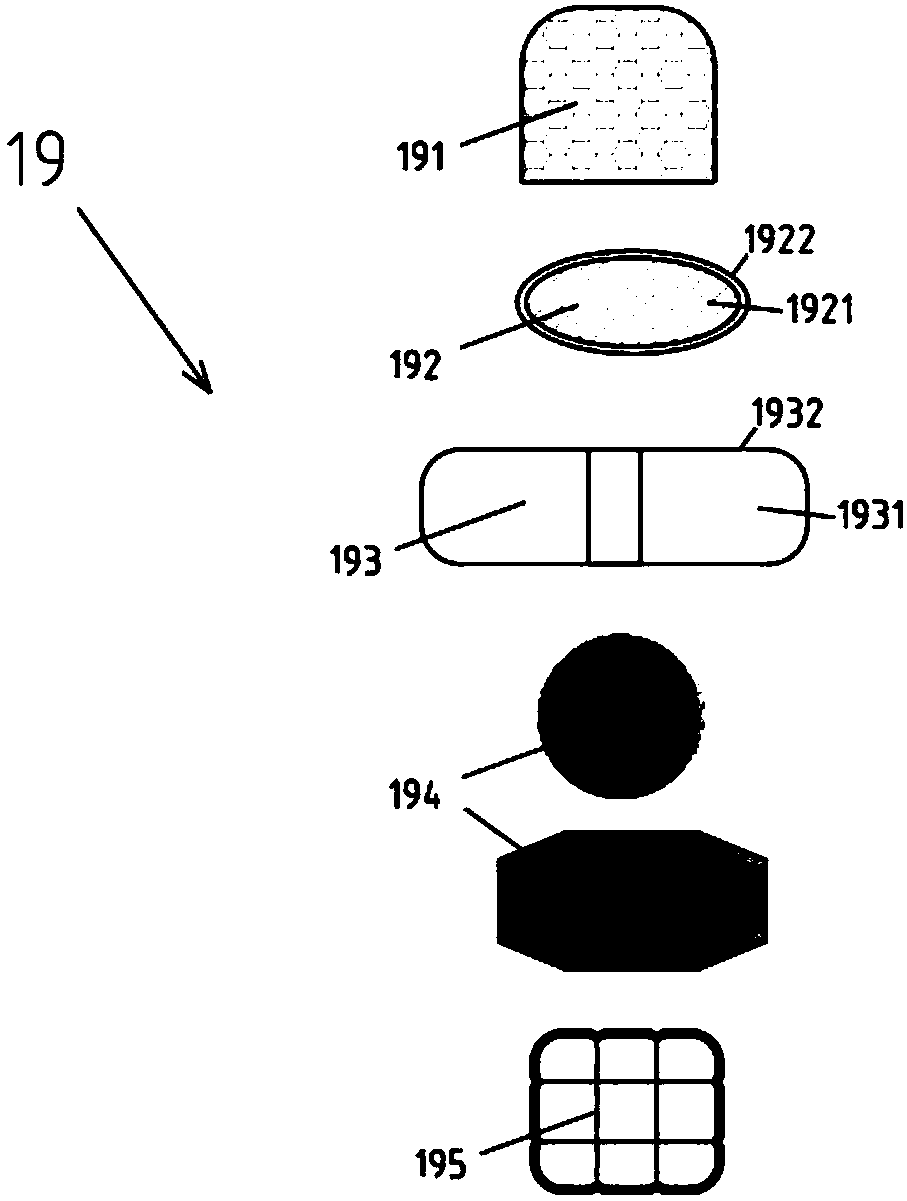

The invention relates to the technical field of intelligent home equipment, and discloses a bundling treating method for cooking raw materials, the cooking raw materials and an intelligent cooking machine. The bundling treating method includes the steps that liquid-state or powdery or fine-granular or pasty or dispersed cooking raw materials are subjected to solidifying or large-granular or blocking treatment, or small-sheet cooking raw materials are packaged / bundled so that the cooking raw materials cannot be easily stuck on a feeding box of the intelligent cooking machine, or the cooking rawmaterials with fluffy size are dense, and the cooking raw materials are matched with the feeding device, and are fed into a pot body of the cooking machine. According to the bundling treating methodfor the cooking raw materials, the cooking raw materials and the intelligent cooking machine, the liquid-state or powdery or granular or pasty or sheet-shape or disperse or fluffy cooking raw materials are solidified or made into large-granular materials or blocky materials or buckled / packaged, and the food materials are not easily stuck on the feeding box when being used in the intelligent cooking machine accordingly.

Owner:李亚锐

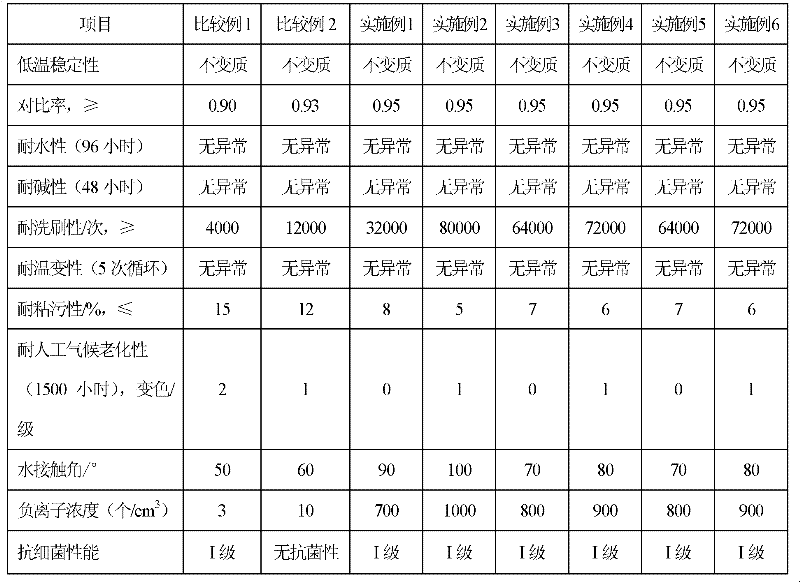

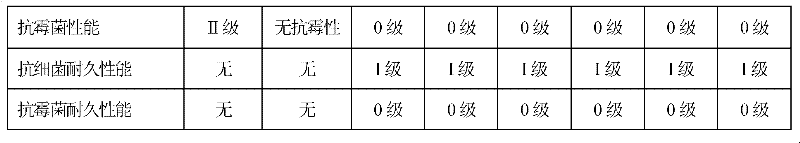

High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

ActiveCN102417748AEasy to disperseStorage stableAntifouling/underwater paintsPaints with biocidesVolatile organic compoundEmulsion

The invention relates to a paint technology, an environment-friendly technology and an antibacterial mould-proof technology, in particular to high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and a preparation method thereof. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint comprises the following components in percentage by weight: 0.5 to 5 percent of wetting dispersant, 0.01 to 20 percent of inorganic composite nano antibacterial agent concentrated pulp, 0.5 to 10 percent of hydrophobing agent, 0.5 to 10 percent of anionic powder, 0.5 to 8 percent of film-forming aid, 0.1 to 2 percent of anti-settling agent, 0.8 to 10 percent of antifreezing agent, 0.1 to 3 percent of defoaming agent, 4 to 30 percent of pigment, 0 to 30 percent of filler, 15 to 45 percent of emulsion, 0.1 to 4 percent of thickening agent, 0.1 to 3 percent of flatting agent, 0 to 3 percent of pH regulator and 0.5 to 45 percent of water. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint is mainly prepared by adding the inorganic composite nano antibacterial agent into the basic materials, so that the paint has the coating characteristic of high performance, is low is cost, and has a function of purifying air, can eliminate harmful gas volatile organic compounds (VOC), formaldehyde and the like and also has a durable and high-efficiency antibacterial mould-proof function, so that the sterilizing rate within 6 hours reaches 100 percent and the mould-proof grade reaches the first grade. By the high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and the preparation method thereof, self-cleaning performance, hydrophobicity, scrubbing resistance, dirt resistance and weather resistance of the coating are improved; and the high-efficiency and durable antibacterial and mould-proof effect is achieved.

Owner:广东腐蚀科学与技术创新研究院

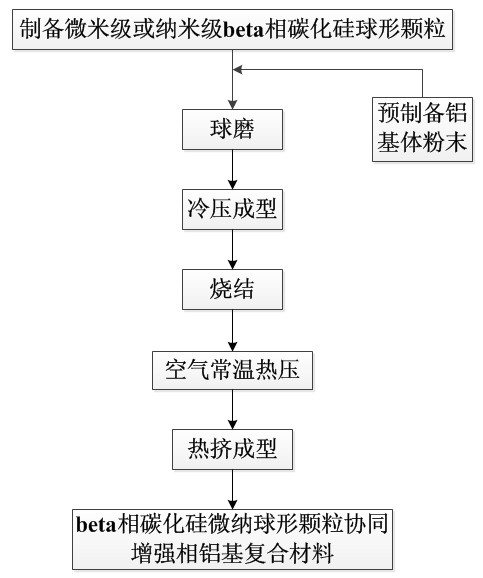

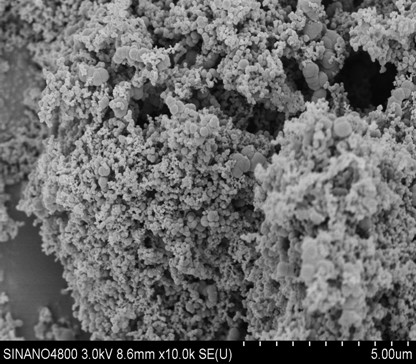

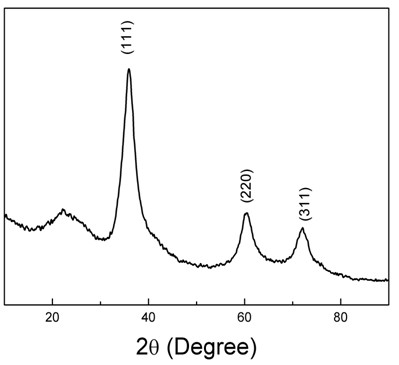

Silicon carbide reinforced aluminum-based composite material and its preparation method

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

Culture medium for cultivating agaricus bisporus and cultivating process thereof

InactiveCN101284750ALow costNot easy to stickSuperphosphatesBio-organic fraction processingCaladiumPhosphoric acid

The invention discloses a culture medium used for cultivating bisporic mushrooms as well as the cultivating method thereof. Per 100 square meters of culture medium contain the following cultural materials: cotton seed hull 1800 to 3200 catties, waste cotton 0 to 1200 catties, corncobs 0 to 1200 catties, cottonseed meal 0 to 200 catties, cattle manure 2 to 4 cubic meters, chicken manure 0 to 1.2 cubic meters, urea 0 to 60 catties, quicklime 80 to 120 catties, plaster powder 0 to 120 catties, calcium superphosphate 0 to 120 catties, enzyme microorganisms 2 to 4 catties, and water of proper amount. The method includes the following steps: firstly, the cultural materials are mixed; secondly, the mixed cultural materials are composted and fermented; thirdly, the cultural materials are processed in a shed; fourthly, sowing is carried out; fifthly, the culture medium is distributed; sixthly, the soil is covered; seventhly, the mushrooms are obtained. The culture medium has low cost, the conglutination of the cultural materials is not easy to happen, and the cultural materials have easy pile-turning, thereby causing the composting and the fermentation to be laborsaving and timesaving; the enzyme microorganisms can not only speed up the fermentation of the cultural materials and improve the fermentation quality, but also facilitate the absorption and utilization of the culture medium by the mycelium of the bisporic mushrooms.

Owner:贾恩茂

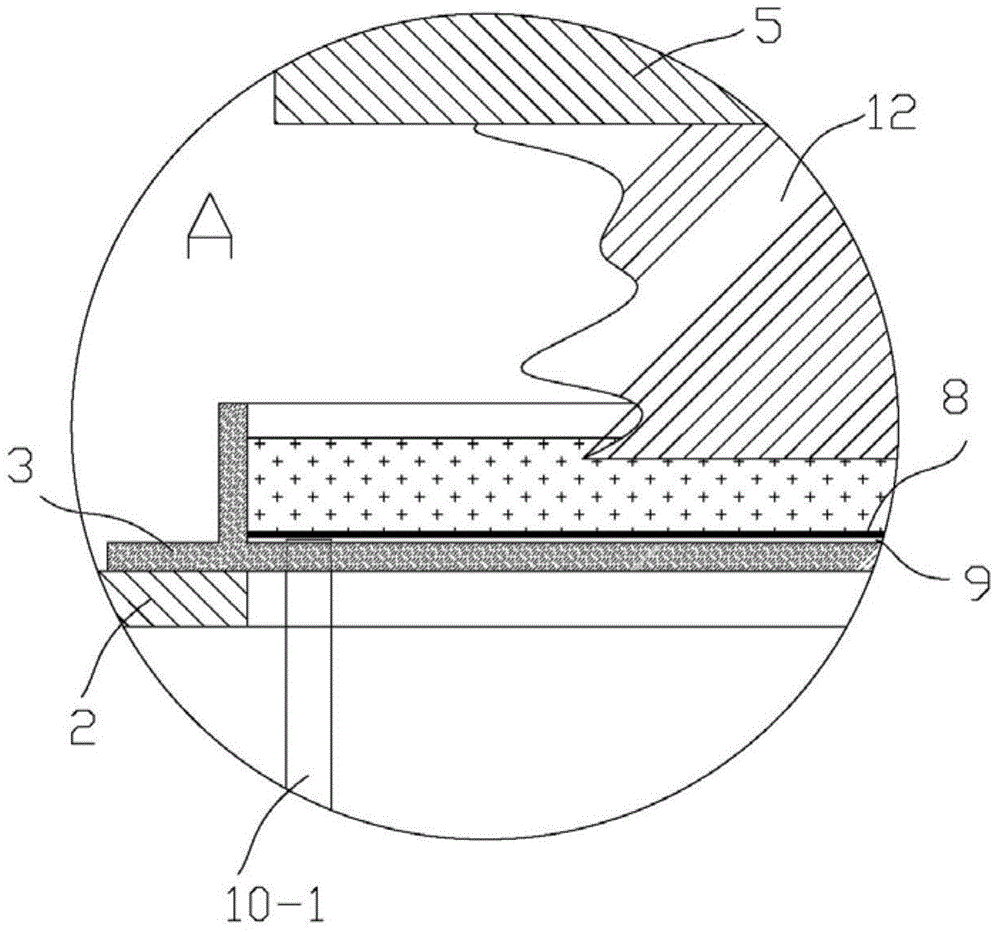

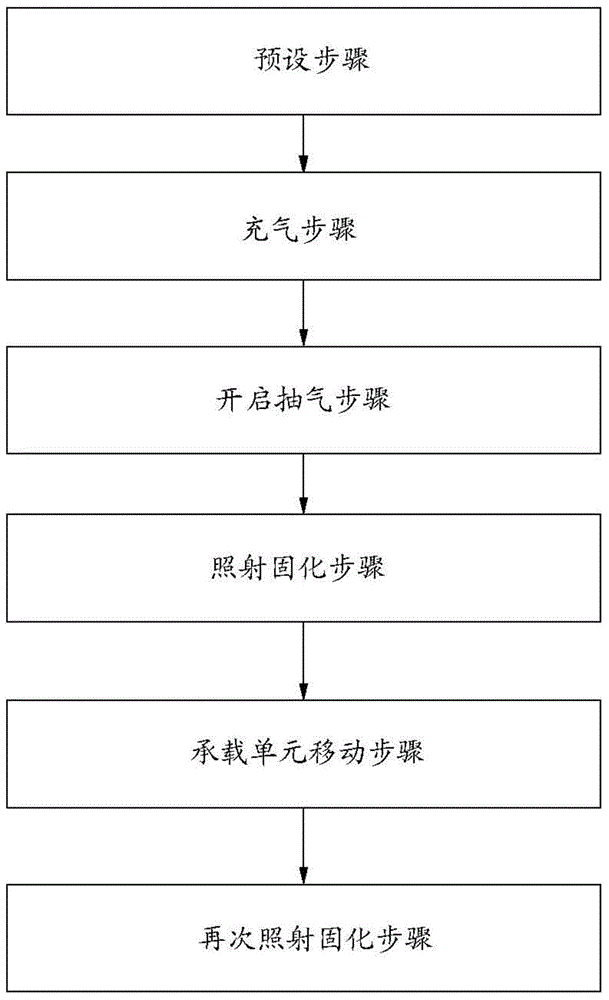

Photosensitive resin pool, photocuring 3D (three-dimensional) printer using photosensitive resin pool and printing method

ActiveCN104890245ASimple structureNot easy to stickAdditive manufacturing apparatusSemipermeable membraneOxygen

The invention provides a photosensitive resin pool. The photosensitive resin pool comprises a pool body, an oxygen molecule semipermeable membrane located above a bottom wall in the pool body as well as an air inlet and an air outlet, wherein the area of the oxygen molecule semipermeable membrane accords with that of the bottom wall of the pool body, and a cavity is formed between the oxygen molecule semipermeable membrane and the bottom wall of the pool body; the air inlet and the air outlet are formed in the side wall or the bottom wall of the pool body and communicated with the cavity. Besides, the invention further provides a 3D (three-dimensional) printer adopting the photosensitive resin pool and a printing method. The structures of the photosensitive resin pool and the 3D printer are simple, the printing quality is reliable, and the service life is longer. By means of the method, the starting time, the inflating volume and the air extracting volume of an inflation unit and an air extraction unit are correspondingly adjusted, the semipermeable membrane cannot swell while an oxygen molecule layer is formed on the upper surface of the semipermeable membrane, a print object cannot be easily bonded to the semipermeable membrane and is easy to separate, and the contact surface of the print object and the semipermeable membrane cannot be twisted or deformed.

Owner:广西玉林市由你造科技有限公司

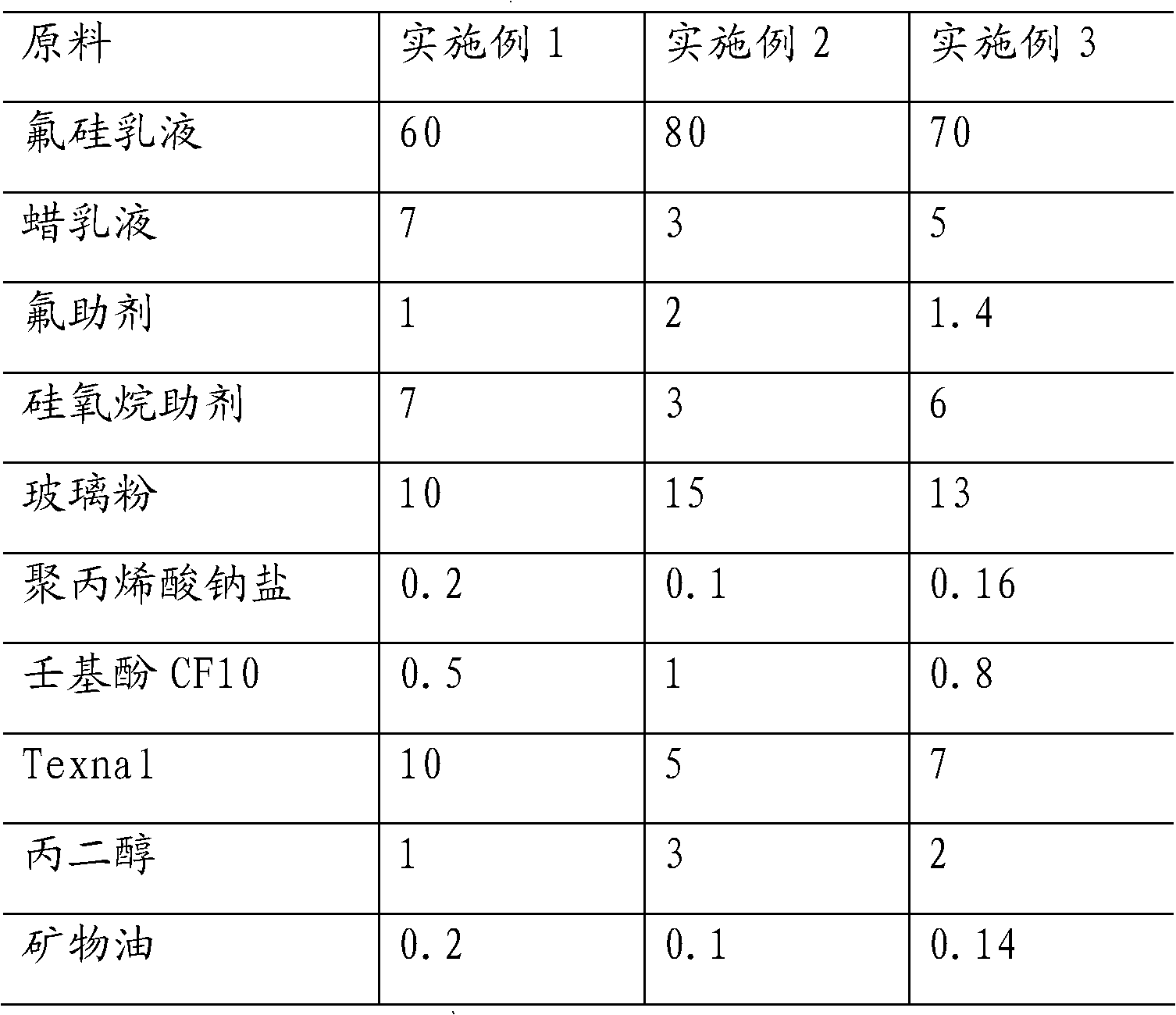

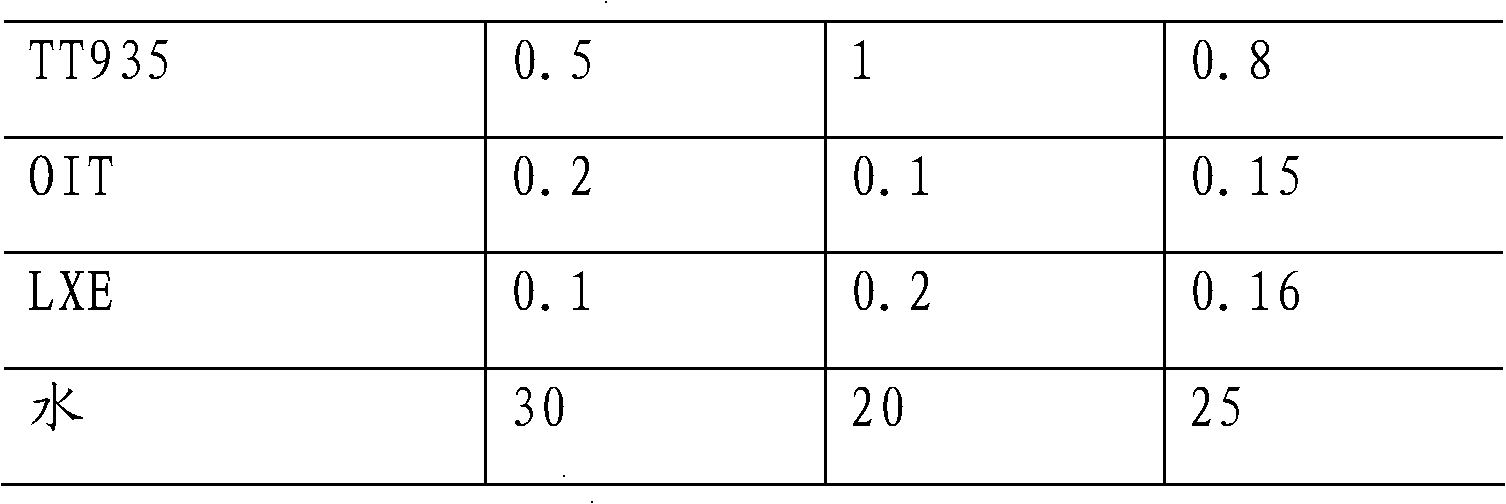

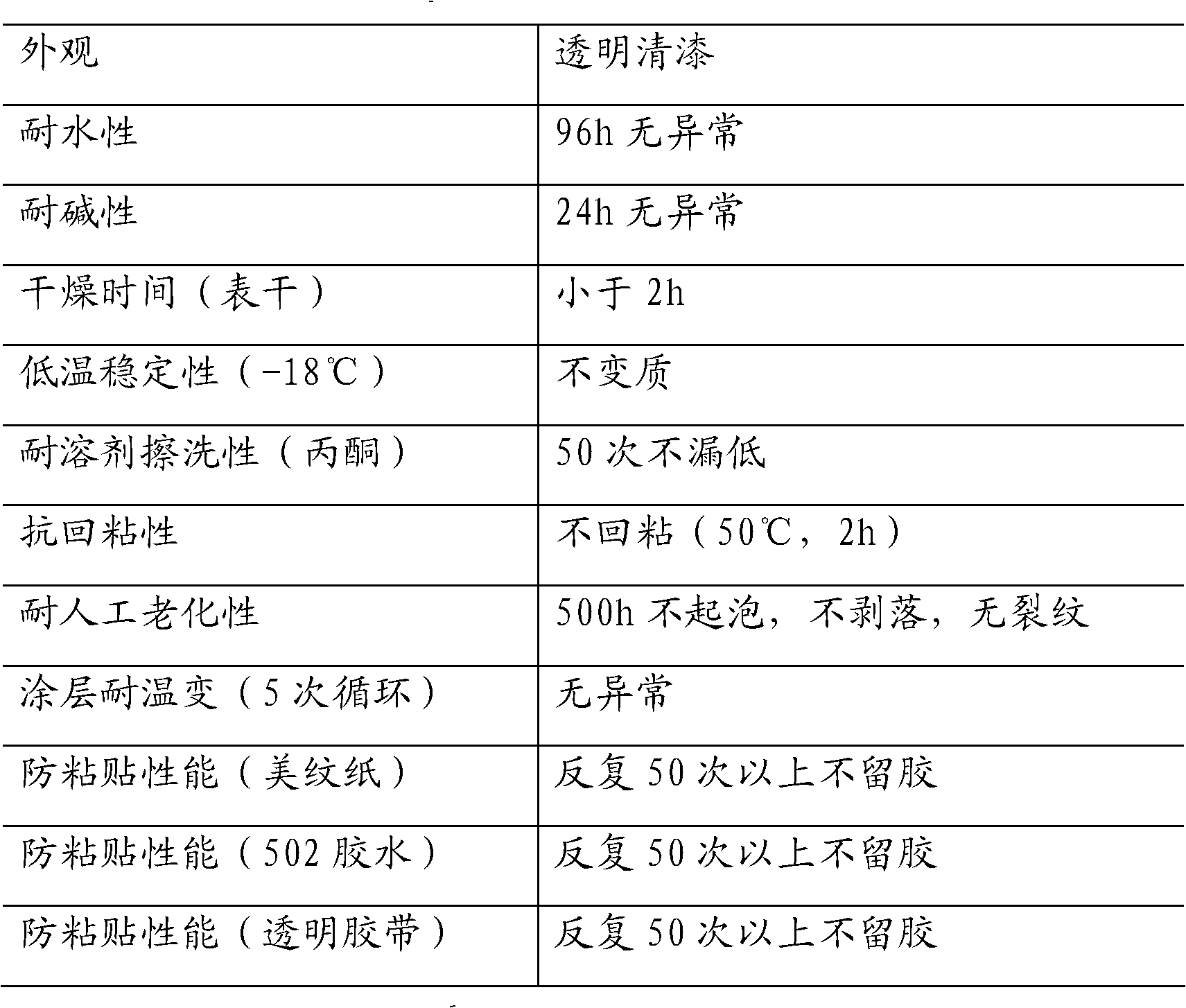

Aqueous antifouling adhesive preventing coating and production method thereof

InactiveCN102002298AHydrophobicWith anti-graffiti performanceAntifouling/underwater paintsPaints with biocidesSolventPolymer

The invention discloses an antifouling adhesive preventing coating which comprises the following components in parts by weight: 60-80 parts of polymer emulsion, 3-7 parts of water repellent agent, 1-2 parts of first adhesive preventing agent and 3-7 parts of second adhesive preventing agent, wherein the polymer emulsion is selected from one of fluorine and silicon modified acrylate emulsion, fluorine emulsion and silicon acrylic emulsion; the water repellent agent is water-soluble wax emulsion; the first adhesive preventing agent is a fluorine modified surface auxiliary agent with a water and oil repellent structure; and the second adhesive preventing agent is polyether modified hydroxyl functional polydimethylsiloxane. The invention also discloses a preparation method of the antifouling adhesive preventing coating. The coating of the invention has the performances of low surface energy, water and oil repellency, oil fouling resistance, adhesive sticker bonding prevention, and the like and has favorable antifouling adhesive preventing function and superhigh scrubbing resistance and is rapid and convenient for construction. Compared with the market sold solvent type product, the invention has the characteristic of environmental protection and can be suitable for indoor coating.

Owner:CARPOLY CHEM GRP

Low-odor antistatic and high tenacity polycarbonate composite

The invention discloses a low-odor antistatic and high tenacity polycarbonate composite, comprising 30-75 parts of polycarbonate by weight parts, and the polymerized ingredients are as follows by weight parts: 10-65 parts of acrylonitrile-butadiene-styrene grafting copolymer ABS, 5-15 parts of macromolecule antistatic agents and 2-10 parts of styrene-N-benzyl maleimide-maleic anhydride copolymer; the olycarbonate composite prepared by the technical proposal is manufactured into automobile plastic interior decorating products, has the advantages of low odor and high shock resistance and being hard to stick and adsorb the dust, and is used for manufacturing various automobile interior decorating products, such as automobile instrument panel, door panel and the like.

Owner:SHANGHAI PRET COMPOSITES

Antistatic and ultraviolet resistant PC/ASA material composition

InactiveCN101759982AImprove antistatic performanceReduce volatilityAntistatic agentWeather resistance

The invention discloses an antistatic and ultraviolet resistant PC / ASA material composition and belongs to the field of macromolecular composition materials. The composition is characterized by consisting of the following components in part by weight: 30 to 85 parts of polycarbonate, 5 to 30 parts of acrylonitrile-styrene-acrylic ester graft copolymer, 0 to 30 parts of acrylonitrile-styrene copolymer, 5 to 15 parts of macromolecular antistatic agent, 2 to 10 parts of compatilizer, 0.2 to 2 parts of light stabilizer and 0.2 to 1 part of antioxidant. The interior plastic parts of an automobile, which are made of the PC / ASA composition of the invention, have the advantages of high weather resistance, ultraviolet resistance and heat resistance, difficult adsorption of dust and the like, and can be used for manufacturing interior-exterior parts, such as automotive door plates and shells of inner-outer view mirrors, of various automobiles.

Owner:SHANGHAI PRET COMPOSITES

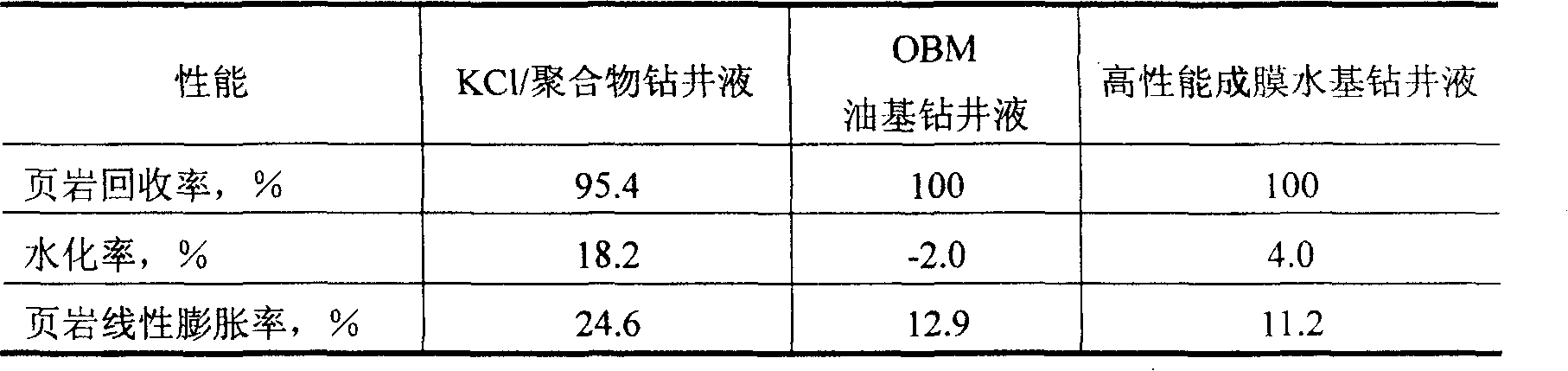

Method for preparing high-performance filming water-base drilling fluid

InactiveCN101200631AImprove the lubrication effectReduce frictionDrilling compositionWater basedFilm-forming agent

The present invention relates to a preparation method of a high-performance film-forming water-based drilling fluid system, which is characterized in that brine is used for confecting THE typical prescription of the high-performance film-forming water-based drilling fluid system, which is 10 percent of saturant NaCl solution, 1 percent to 3 percent of fluid loss additive, 0.3 percent to 0.5 percent of polymer viscosity increaser, 0.5 percent to 1 percent of coating agent, 2.5 percent to 5 percent of amine shale inhibitor, 3 percent to 4 percent of lubricant and 7 percent to 8 percent of film-forming agent. The drilling fluid system has the good performances of good film-forming character and strong inhibiting capability and is a novel drilling fluid system which can satisfy the requirement of the environmental protection and can replace oil-based drilling fluid (OBM).

Owner:张金波 +1

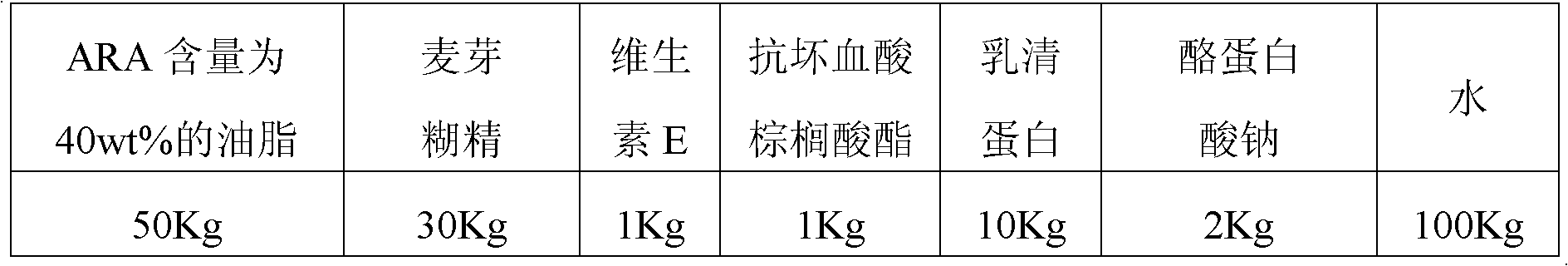

Microcapsule preparation method and product thereof

The invention relates to a microcapsule preparation method and a product thereof. The microcapsule preparation method is characterized by comprising the following steps that: the powder embedding material is put into a drying device in advance, and is kept in a suspension or boiling fluidized state under hot blast, and is lactose or lactose composite powder; and meanwhile, the emulsified liquid which is prepared from core materials, emulsifier and water is atomized into liquid drop to be sprayed into the drying device, the atomized liquid drop is contacted with the powder embedding material which is in the suspension or boiling fluidized state and is wrapped by the powder embedding material, meanwhile, particles are formed by the drying of the hot blast, and the microcapsule product is obtained after separation. The method adopts the lactose or lactose composite powder as the powder embedding material, the prepared microcapsule takes the single particle as the main part, and the particles are more regular in shapes, are not adhered with one another, have better stability, better liquidity and higher safety at the same time.

Owner:CABIO BIOTECH WUHAN CO LTD

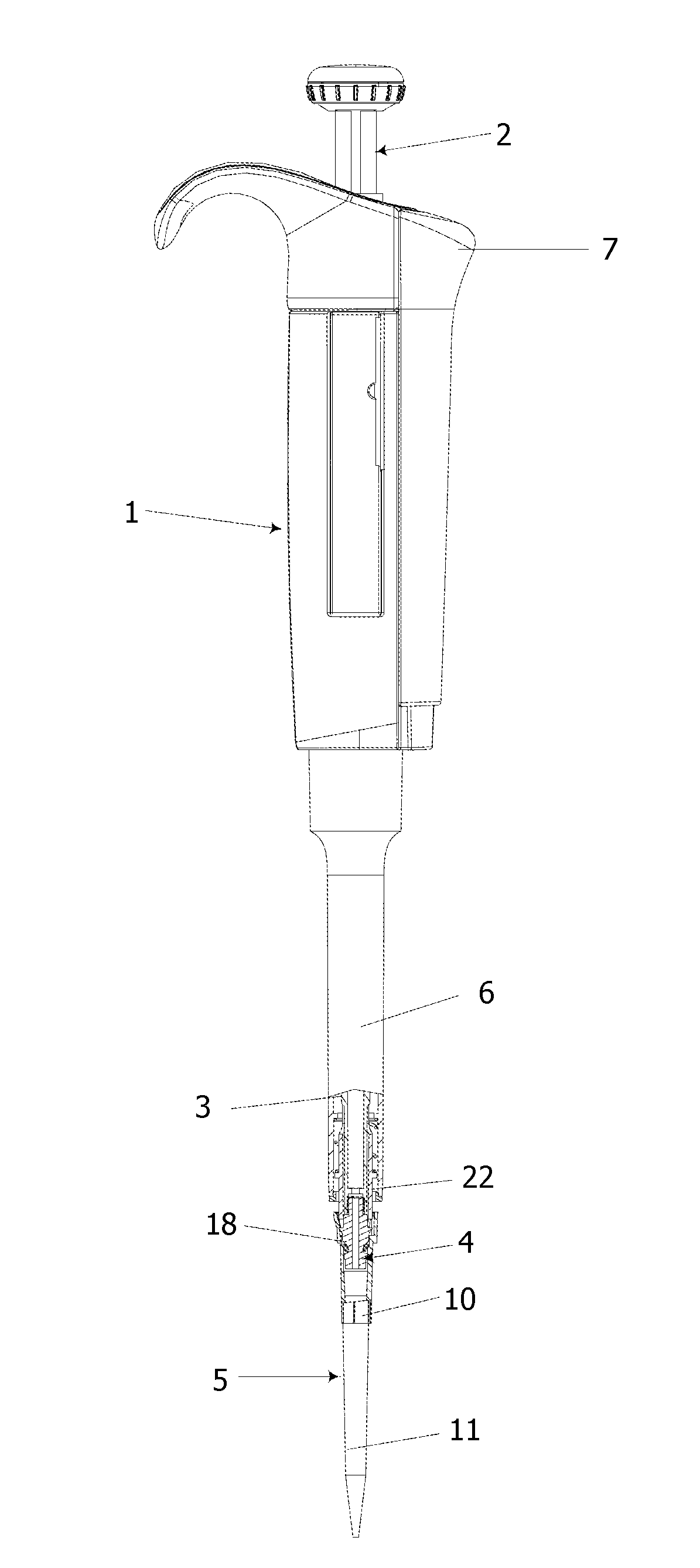

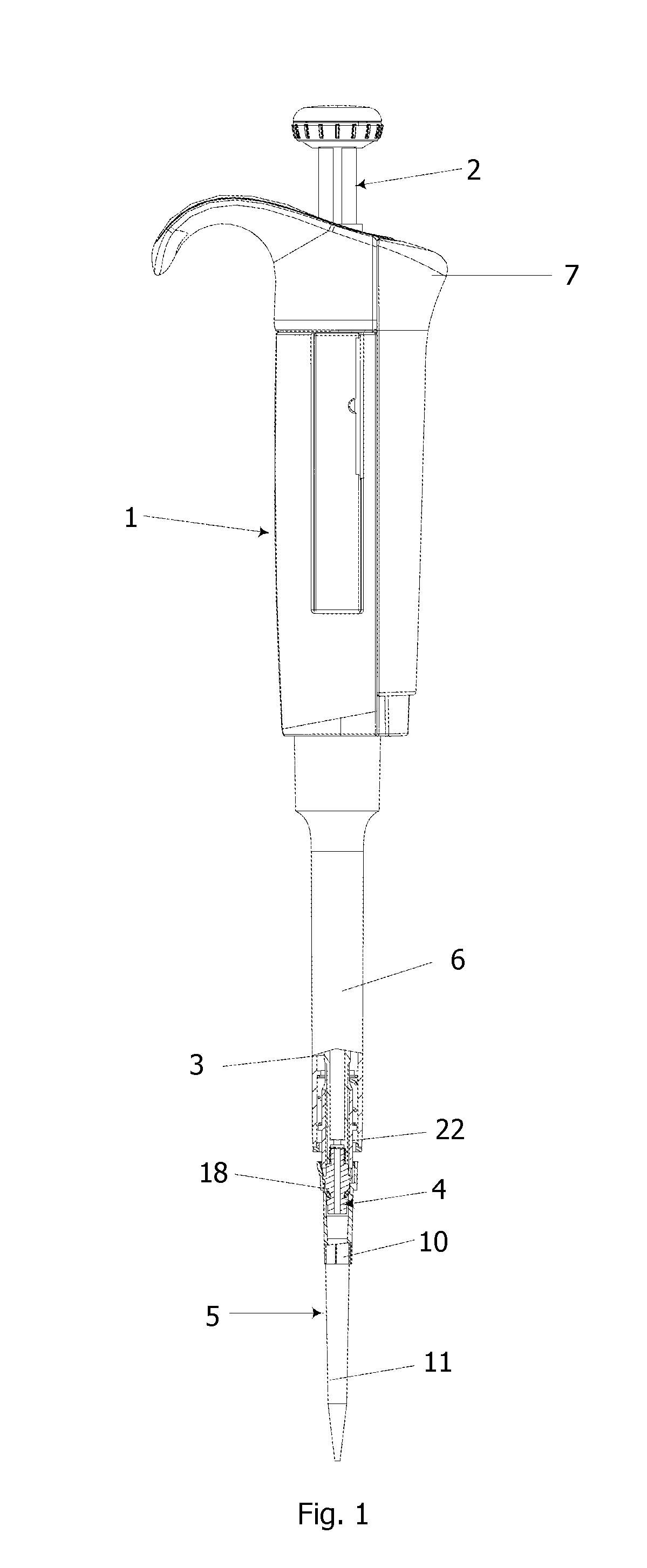

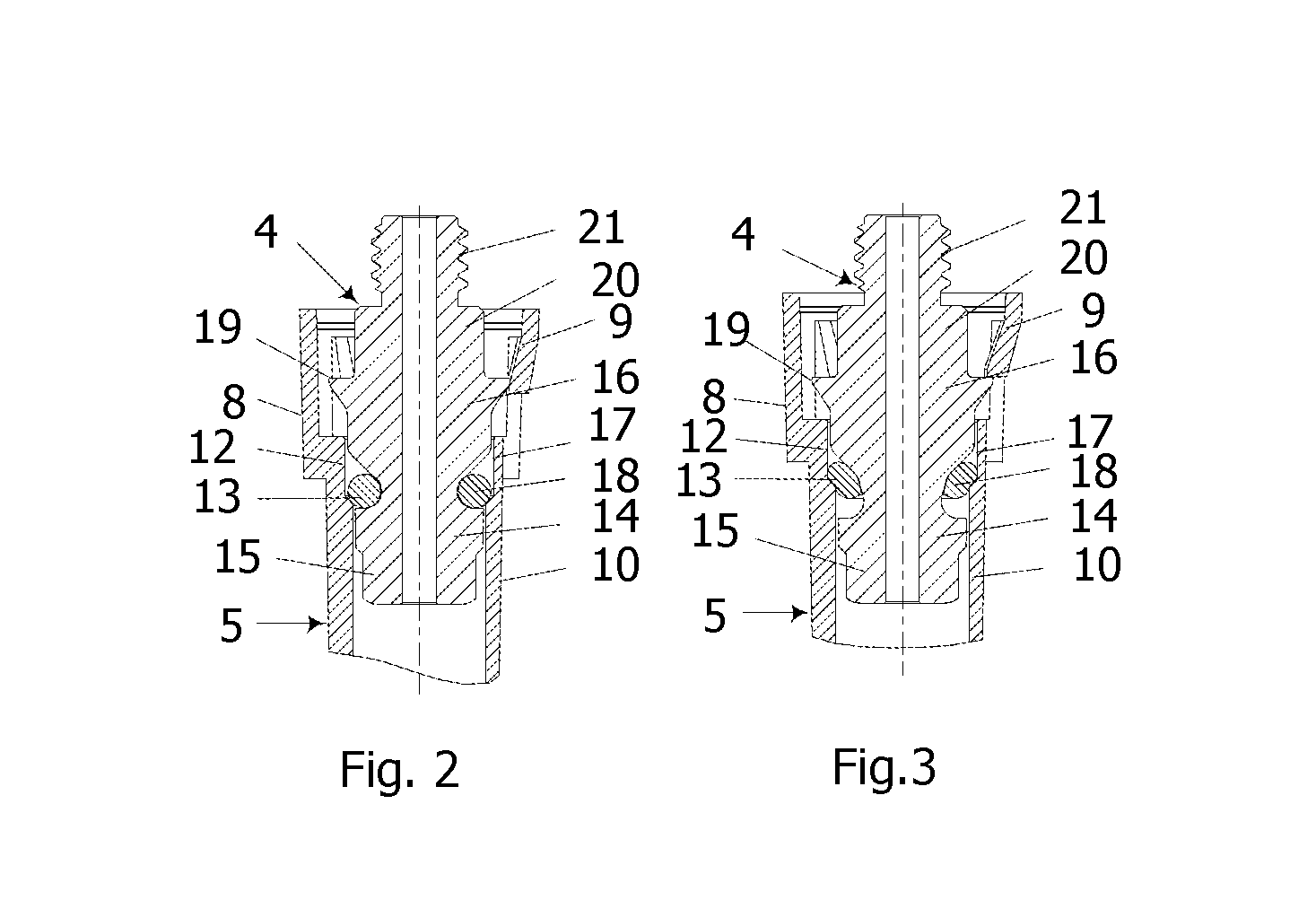

Sealed pipette

ActiveUS20140056781A1Improve sealingNot easy to stickBurettes/pipettesMetal working apparatusPipetteEngineering

The invention relates to liquid dispensing and concerns a pipette comprising at least one aspiration channel with a piston. At the lower end of the aspiration channel there is an extension channel (3) and at its end a pipette tip mounting piece (4) onto which a pipette tip (5) is attached. On the pipette tip mounting piece there is a surrounding groove (17) and in the groove a sealing ring (18). The width of the groove in the axial direction is at least 1.1 times the thickness of the sealing ring in the axial direction. When the mounting piece is pushed into the pipette tip, the inner wall of the tip can move the sealing ring upwards in the groove. The construction can provide a reliable sealing despite of inherent dimension differences between different tips and mounting pieces.

Owner:THERMO FISCHER SCI OY

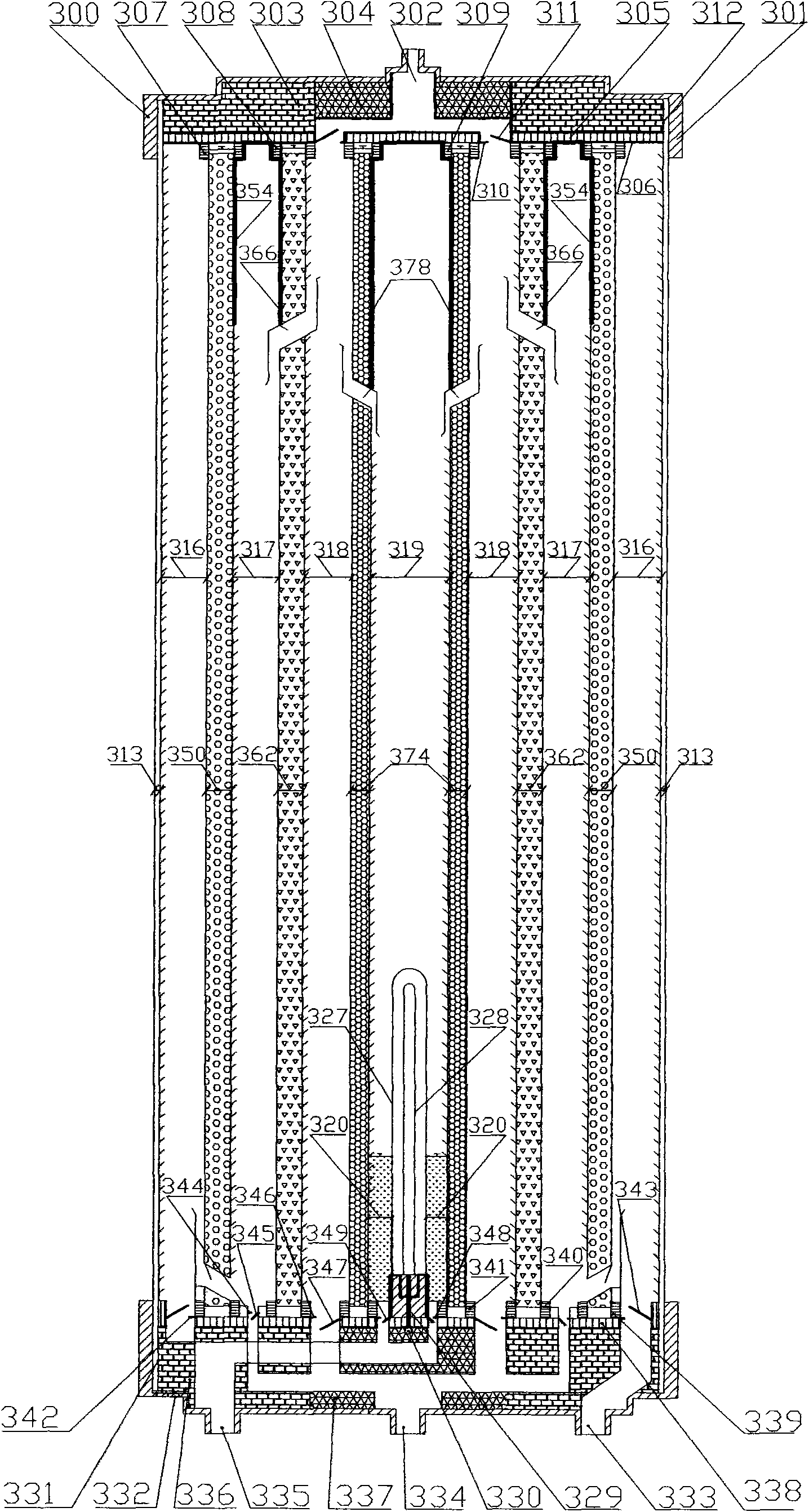

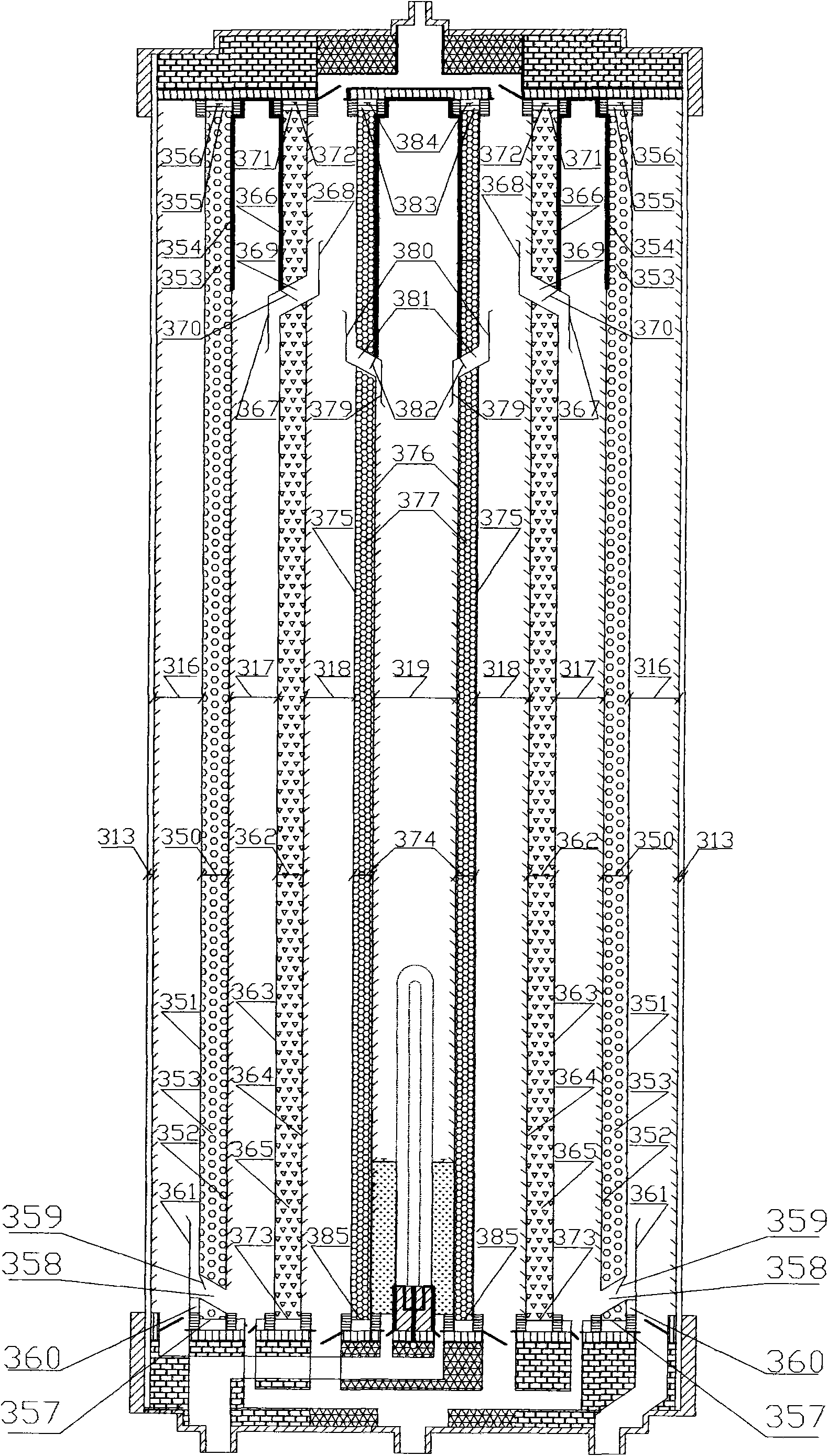

Combined type quality-divided water purification and supply device

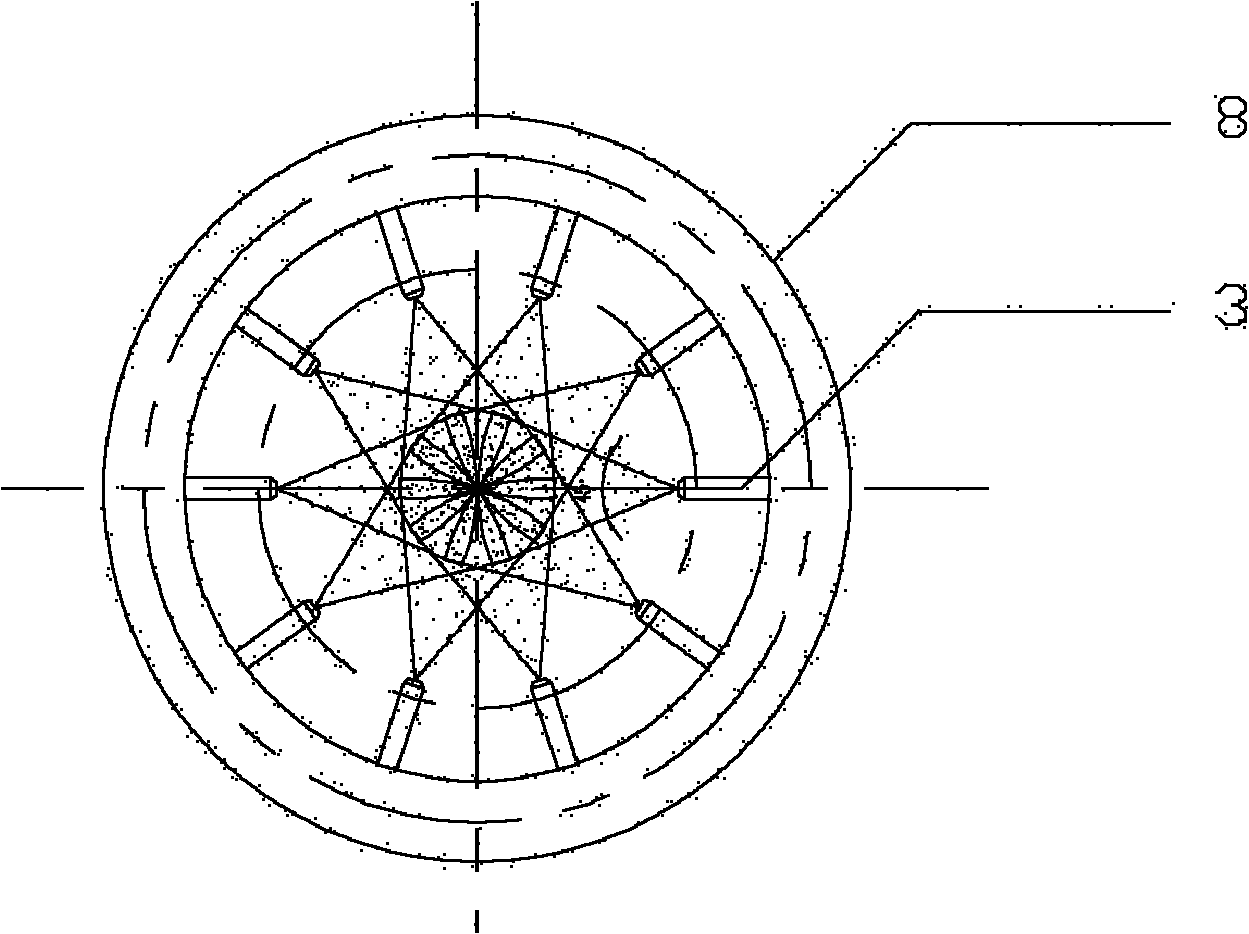

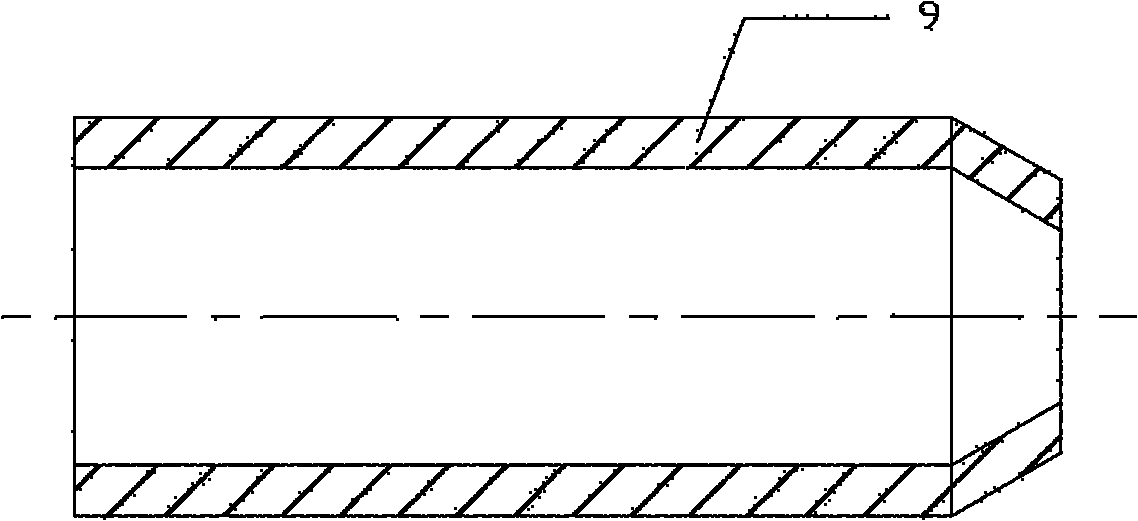

ActiveCN101805088ADoes not affect daily lifeAdaptableWater/sewage treatment by irradiationWater/sewage treatment by ion-exchangeWash waterFilter media

The invention relates to the technical field of quality-divided water purification and supply, in particular to a combined type quality-divided water purification and supply device, the inside of which is formed by three layers of multifunctional quality-divided water purification annular sleeve barrels and a four-layered quality-divided water supply chamber with different functions, wherein the three layers of multifunctional quality-divided water purification annular sleeve barrels respectively contain high-quality direct drinking water of an internal layer, middle-quality domestic water of a middle layer and elementary wash water of an external layer and have different functions; the inner walls of the barrels are provided with small round holes or linear wall slot lines as well as round oblique diversion tunnels of a water-proof backflow round baffle and a vertical water diversion baffle arranged outside the tunnels; an ultraviolet lamp and a most advanced annular filtration barrel component are arranged at the lower bottom part of the middle of the barrel; the upper end and the lower end of the barrel are respectively and fixedly installed in an upper and a lower fixed holding slot components; annular permanent magnetic and tourmaline gaskets are installed at the upper sides of the outsides of the holding slot components; and regulating rings capable of regulating the size and the flow of pores and the water-proof backflow baffles are respectively arranged in a water inlet passage and a water outlet passage of an upper cover shell and a lower cover shell. The invention has unit modular industrialized production, can be assembled on site according to the requirements, has ingenious design and complete functions, low cost and obvious effect, is widely used and is conveniently maintained and changed, all the water is utilized without waste, and filter mediums can be repeatedly used.

Owner:上海理想家园工程营造有限公司

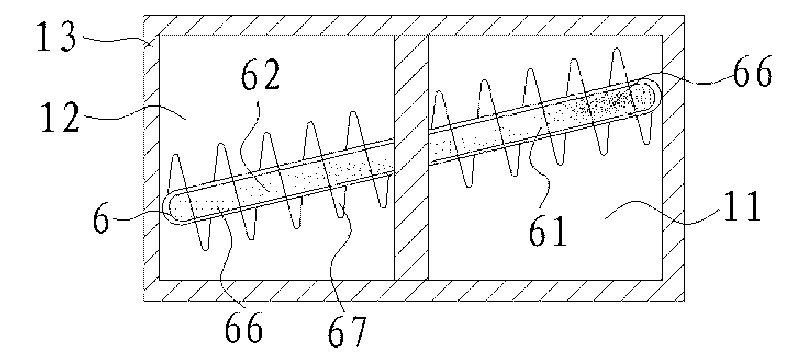

Multifunctional noodle machine

ActiveCN103190566AAchieving stirringReduce noiseDough extruding machinesFood preparationGear driveGear wheel

The invention relates to a multifunctional noodle machine comprising a machine body and a motor arranged in the machine body. A dough-making tank is arranged on the machine body. Stirring blades and a stirring rotation shaft are arranged in the dough-making tank. A dough-pressing tank is arranged on the front side of the machine body. A dough-pressing screw is arranged in the dough-pressing tank. A replaceable noodle shaping module is sleeved on the front end of the dough-pressing screw. A movable door with which the dough-pressing tank can communicate with the dough-making tank is provided on the upper end of the dough-pressing tank. When the movable door is opened, the dough in the dough-making tank can be thrown into the dough-pressing tank under a centrifugal force effect of the stirring device. Gear transmission devices are arranged between the motor and the double-pressing screw and the stirring rotation shaft. The invention aims at providing the multifunctional noodle machine with simpler structure.

Owner:何剑波

Self-cleaning nona composite environment-friendly type emulsion paint and preparation method thereof

The invention discloses a self-cleaning nanometer composite environmental protection latex paint and preparing method, which comprises the following parts: 0.5-5% wetting disperser, 0.5-50% nanometer concentrated slurry, 0.5-10% hydrophobic agent, 0.5-10% anion powder, 0.5-8% filming adjuvant, 0.1-2% anti-settling agent, 0.8-10% antifreeze agent, 0.1-3% defoamer, 4-30% dye, 0-30% filler, 15-45% emulsion, 0.1-4% thickener, 0.1-3% levelling agent, 0-3% pH adjuster, 0-4% microbe eliminating agent and 0.5-45% water. The preparing method comprises the following steps: 1) placing water in the container with high-speed disperser; adding microbe eliminating agent, nanometer condensing slurry, hydrophobic agent, anion powder; blending evenly; adding dye and filler; dispersing until finesse reaches 20-60um; 2) adding emulsion, pH value adjuster, thickener and leveling agent continuously.

Owner:中科纳米涂料技术(苏州)有限公司

Method for preparing semi-solid metal slurry and rheologic molding

InactiveCN101130203AImprove liquidityEliminates the difficulty of pouringExtrusion control devicesVertical tubeCrucible

The invention discloses a preparing technique of semi-solid metal slurry and rheologic moulding equipment in the preparing technical domain of semi-solid metal slurry, which comprises the following steps: pouring the overheat metal liquid into straight-in composite tube path with an inclined tube and a vertical tube; moving the semi-solid metal slurry and preparing copper into the temperature controller after flowing the overheat metal liquid into the copper along the inner wall of the straight-in composite tube path; doing subsequent cooling or temperature field control for the semi-solid metal slurry; pouring the semi-solid metal slurry into pressing chamber with squeeze moulding machine or squeeze caster or forger to mould; opening or fetching the cast piece or squeeze cast or forge from mould. The invention simplifies the preparing technique, reduces energy consumption and shortens the technical flow path, which reduces the manufacturing cost of the semi-solid metal rheopectic casting die or rheopectic squeeze casting die or rheopectic forge.

Owner:UNIV OF SCI & TECH BEIJING

Water-borne perfluoroalkyl fluorocarbon emulsion, water-borne cable anti-icing paint containing same and preparation method thereof

ActiveCN101798366AImprove stabilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCelluloseEmulsifying wax

The invention relates to a water-borne cable anti-icing paint containing water-borne perfluoroalkyl fluorocarbon emulsion, which comprises the following raw materials in percentage by weight: 58 to 62 percent of aqueous perfluoroalkyl fluorocarbon emulsion, 1.5 to 2.5 percent of water-borne polytetrafluoroethylene emulsifying wax, 15 to 20 percent of water-borne color paste, 0.1 to 0.5 percent of pH regulator, 1 to 2 percent of amino resin cross-linking agent or water-borne polyurethane cross-linking agent, 0.1 to 0.2 percent of antiseptic preservative, 1 to 1.2 percent of cellulose and the balance of deionized water, wherein the water-borne color paste is the mixture of the water-borne color paste with one color or the water-borne color paste with more than two colors. The water-borne cable anti-icing paint of the invention is big in water repellent angle, low in surface energy, excellent in water repellent and oil repellent properties, safe and environment-friendly, can firmly adhere to the surface of a cable in a low temperature and cold environment and is obvious in anti-icing function.

Owner:CHANGZHOU GUANGHUI CHEM

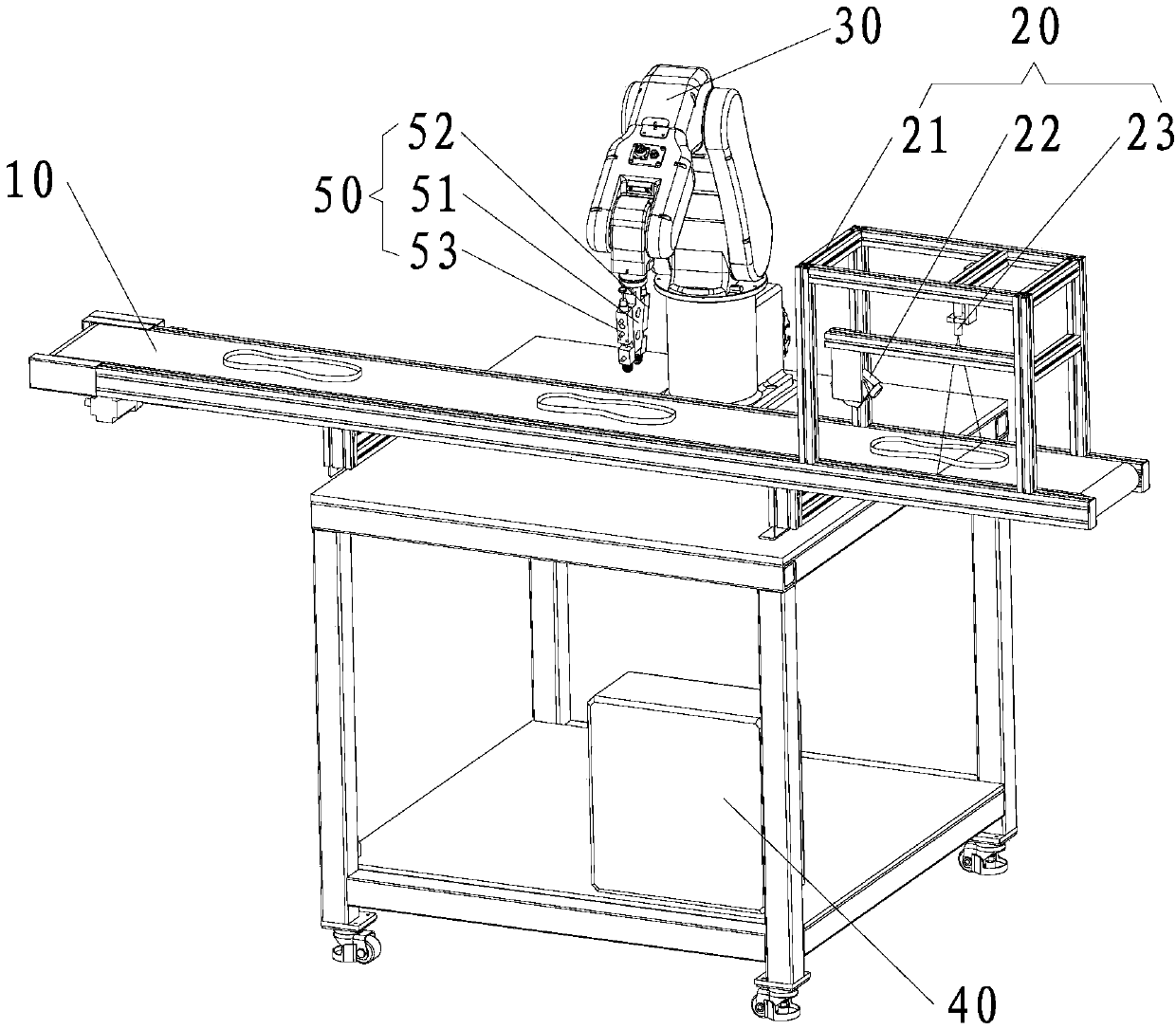

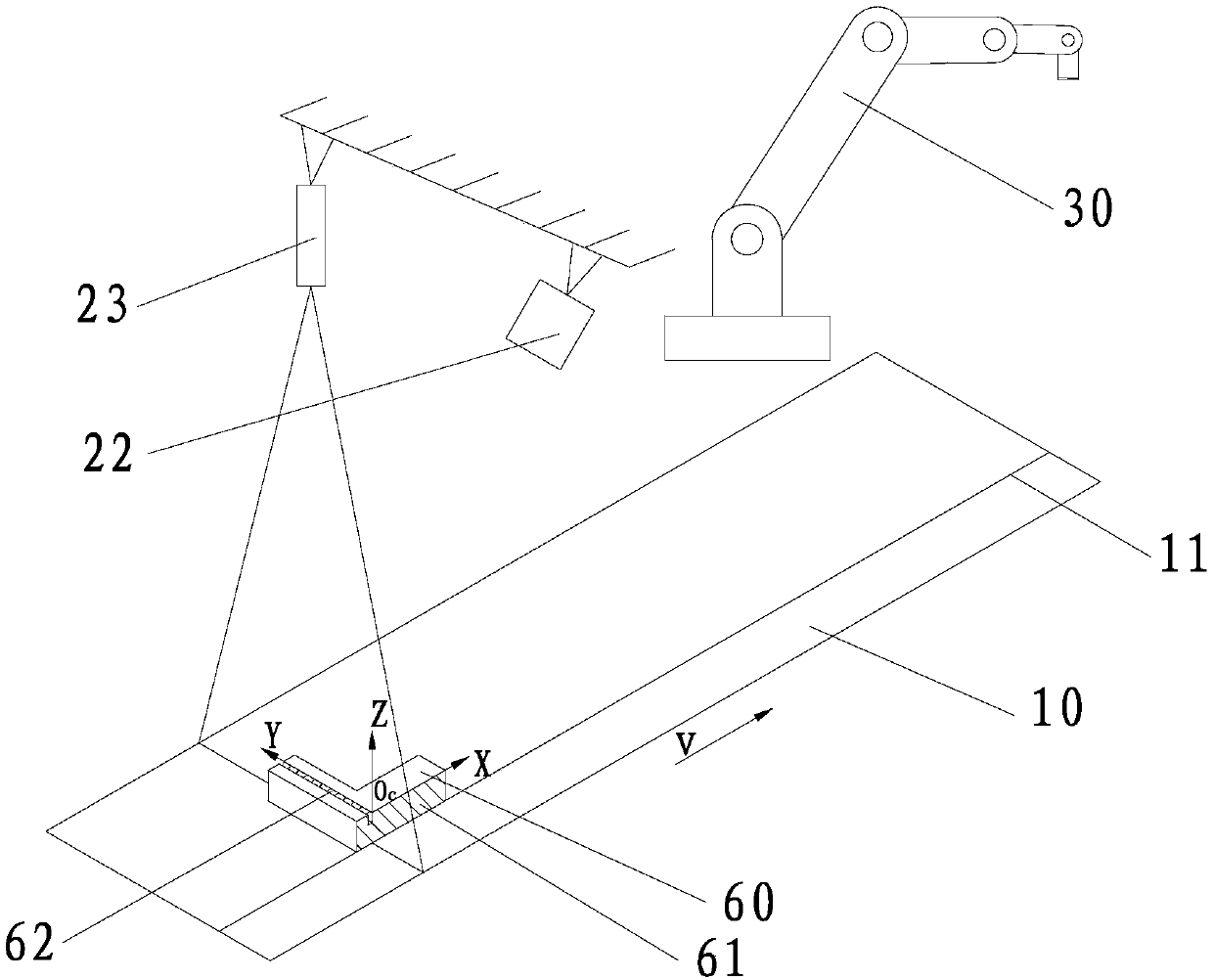

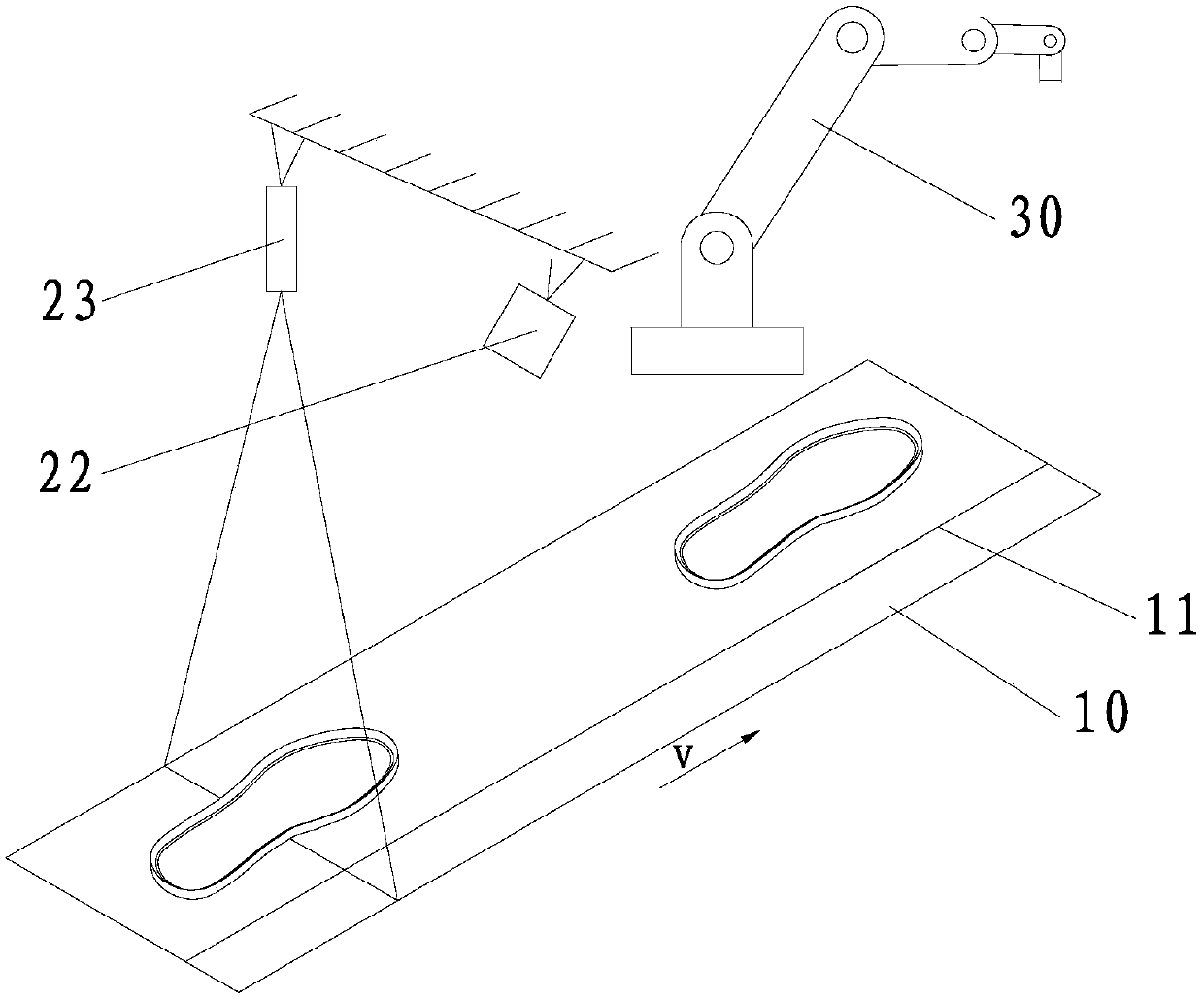

Sole glue spraying device and method based on monocular vision

The invention provides a sole glue spraying device based on monocular vision. The sole glue spraying device comprises a conveyor belt device, a visual device, a manipulator device and a control system. The invention further provides a sole glue spraying method based on monocular vision. The sole glue spraying method comprises the following steps of equipment debugging, image acquisition, image processing, measurement coordinate acquisition, track point position extraction, coordinate transformation, glue spraying action and the like. According to the device and the method, the monocular camerais adopted to replace an existing double-sided visual system; the cost is relatively low, the advantages of high three-dimensional vision measurement and detection speed, high robot glue spraying efficiency and high universality are combined, the glue application work can be rapidly completed for any shoe size and any shoe shape outline, the glue application quality meets the requirements of theshoemaking process, the labor is saved, and the labor intensity of workers and possible damage of chemical adhesives to the human body are reduced.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG +1

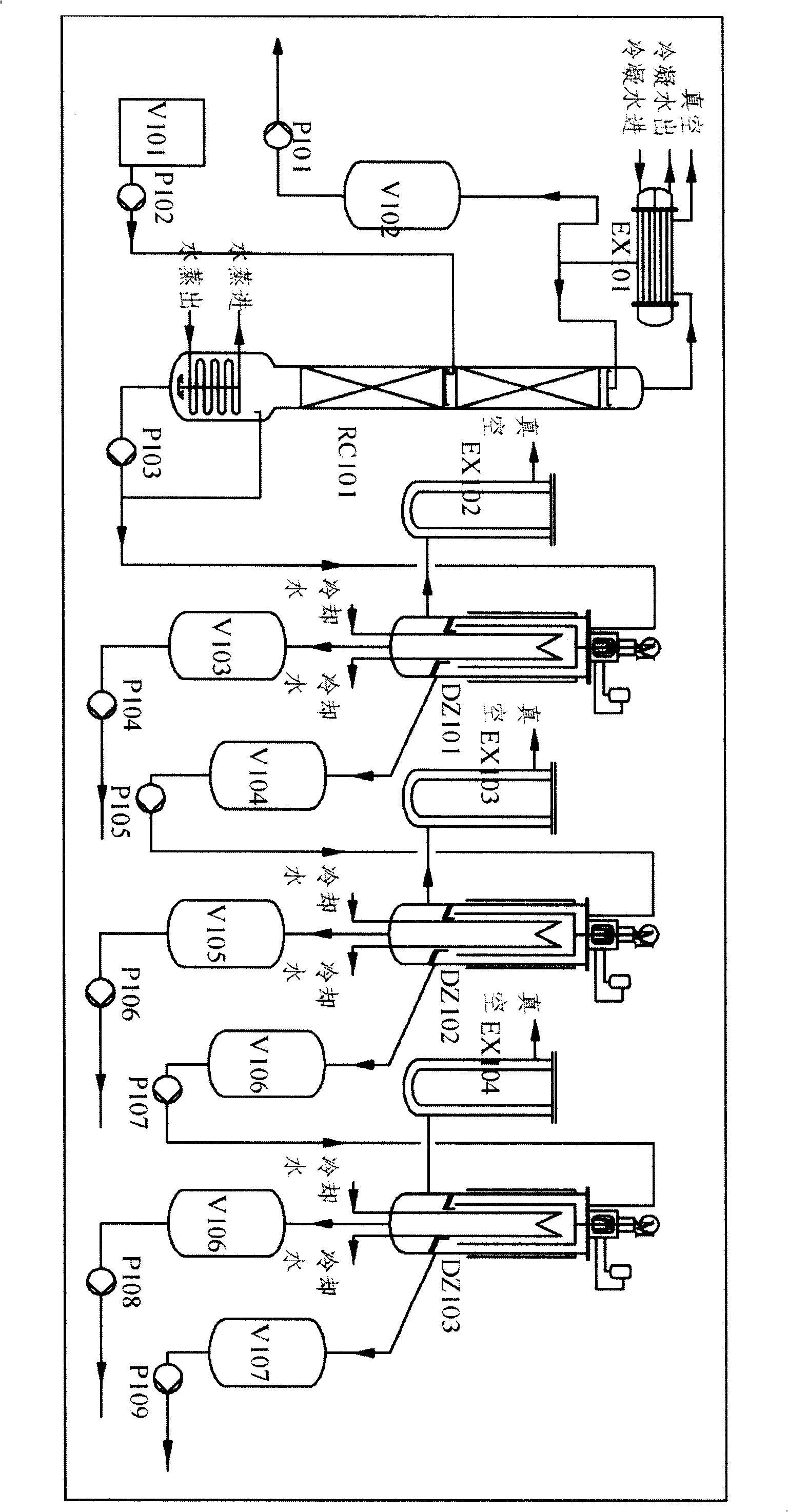

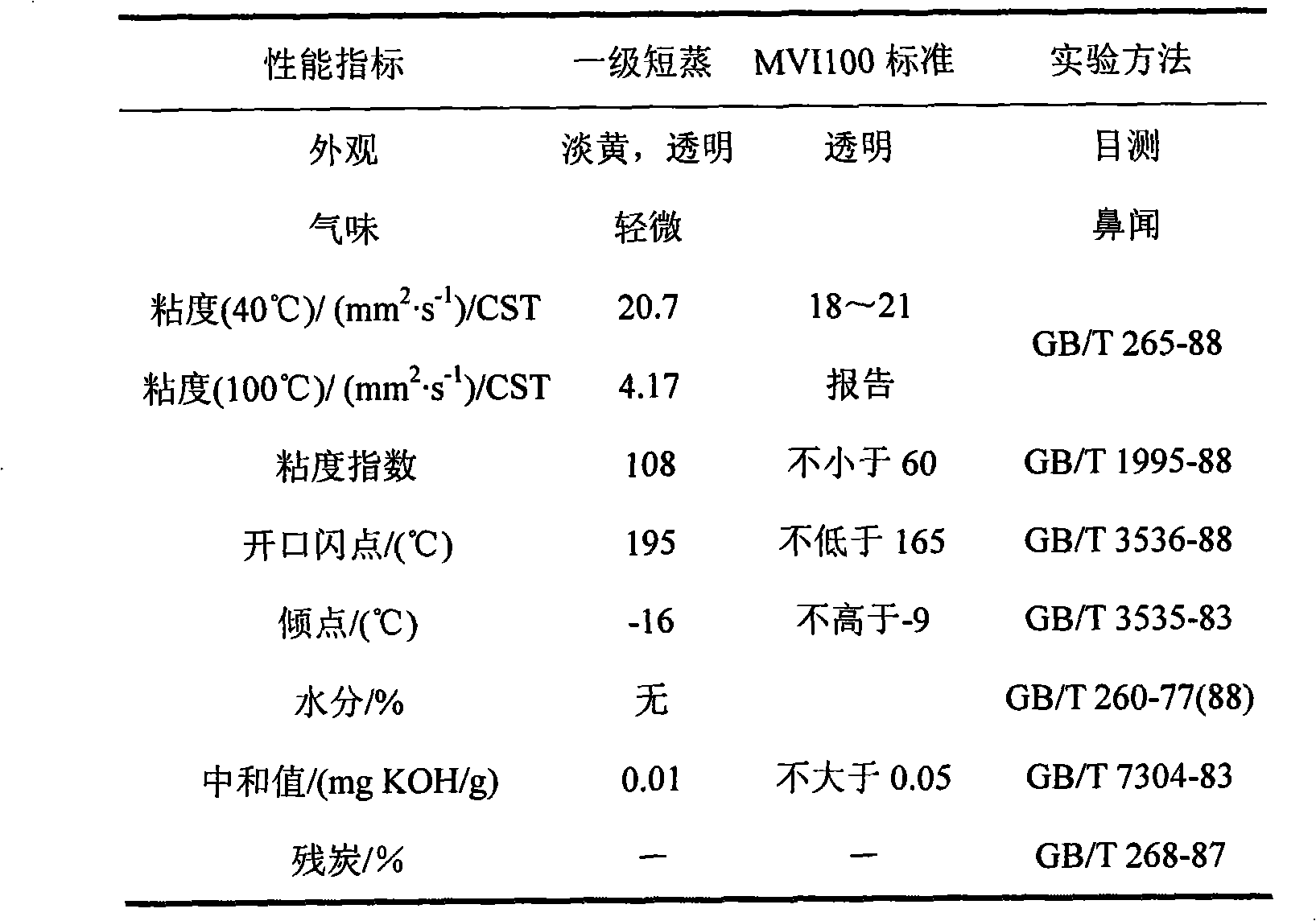

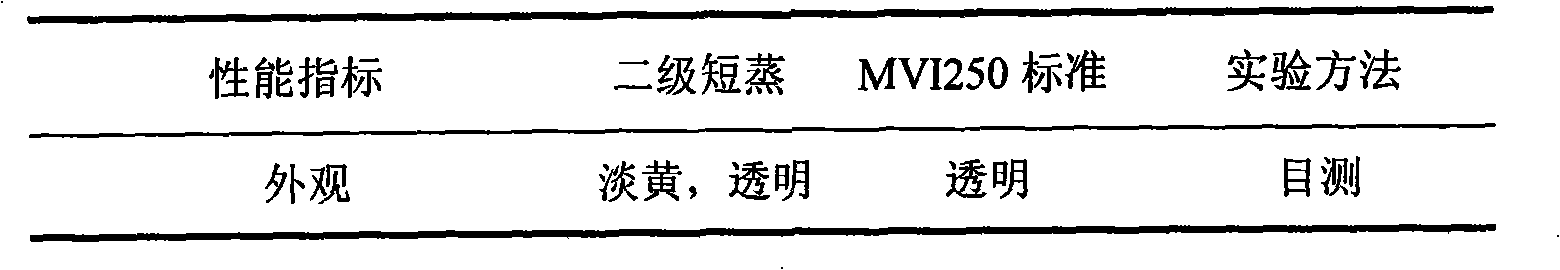

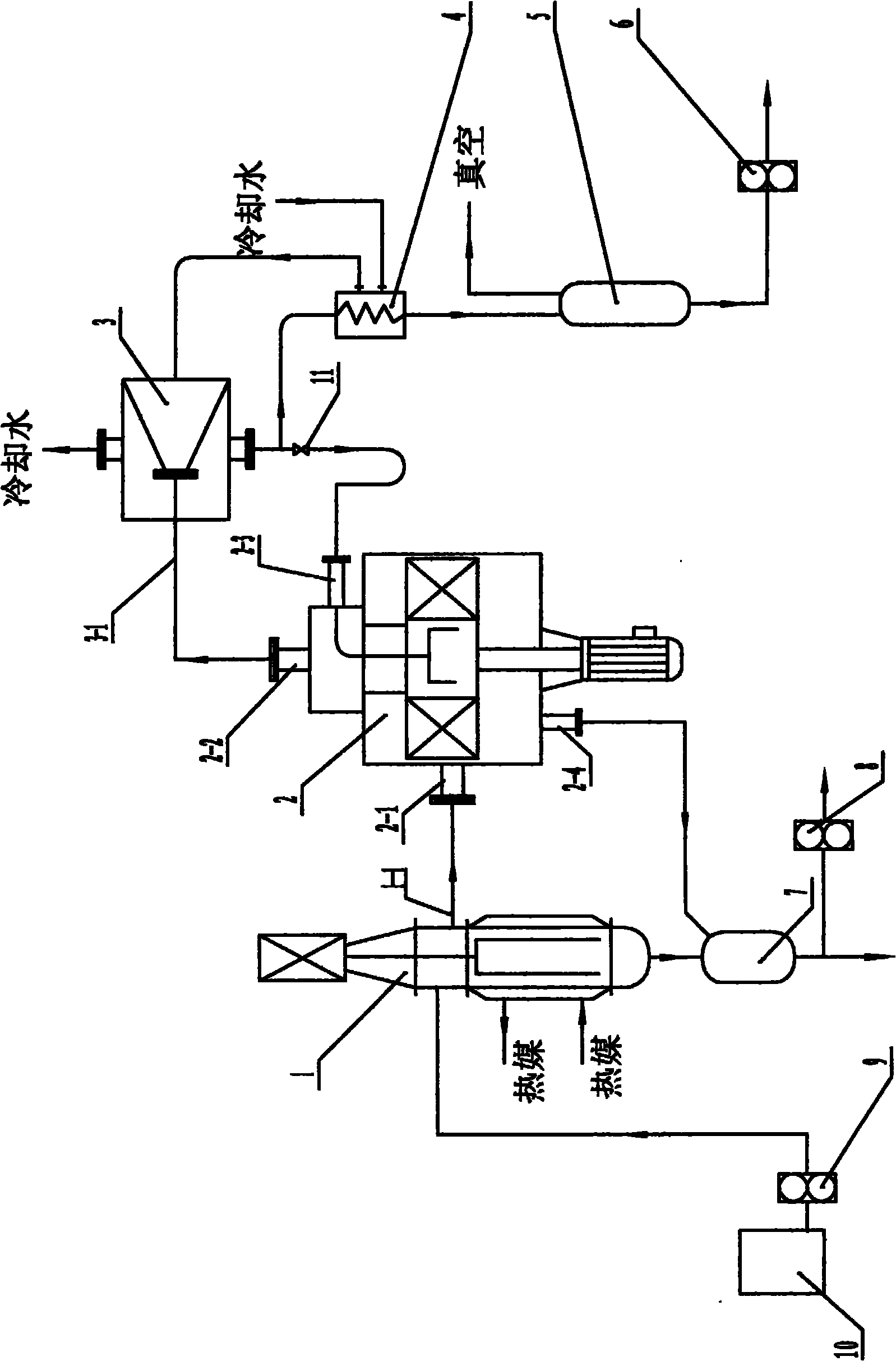

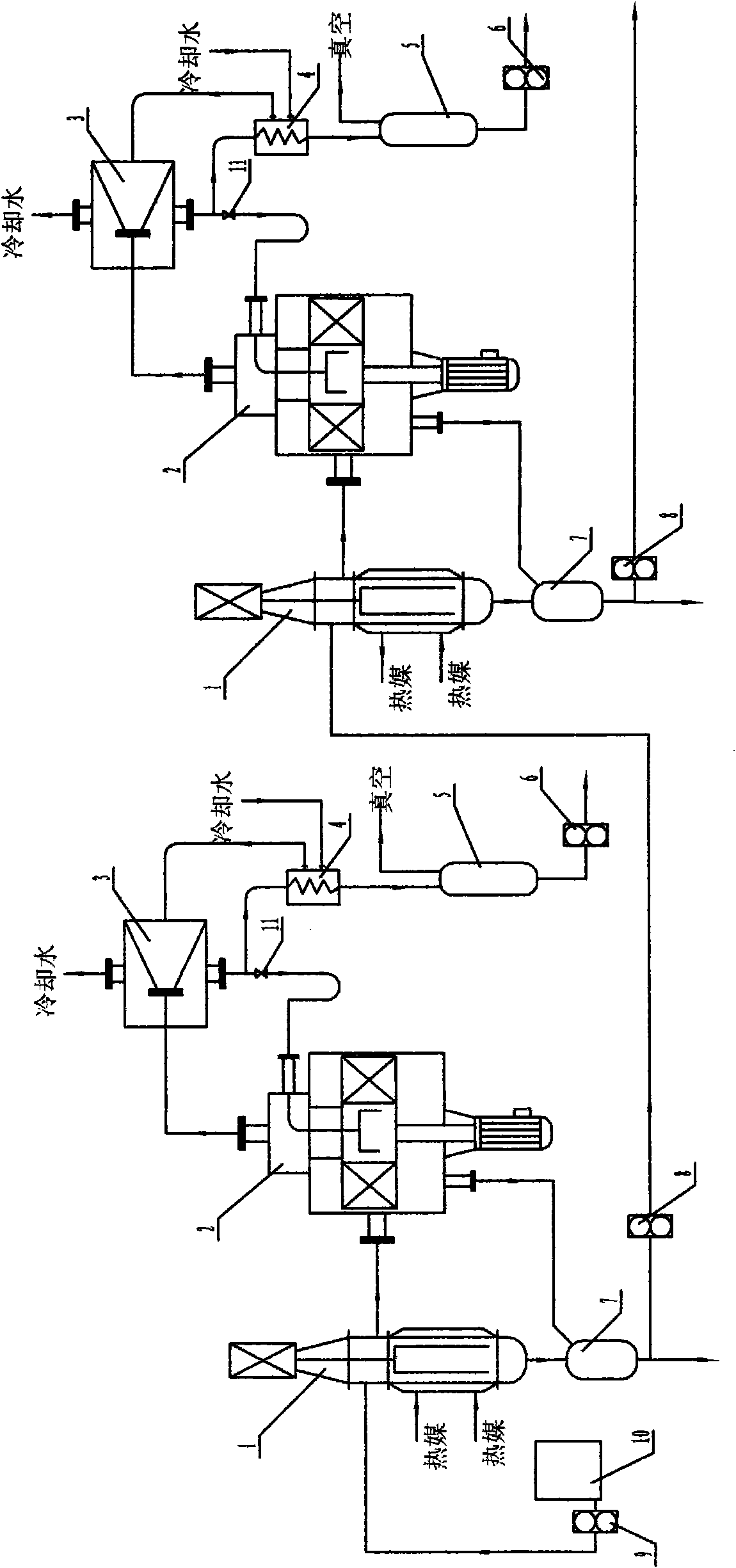

Application of distillation and multi-stage molecular distillation technique in regeneration process for waste lubricant oil

InactiveCN101319166ANot easy to stickShort stayHydrocarbon distillationLubricant compositionDistillationPre treatment

The invention discloses a novel process of regenerating base oil from waste lubricating oil. The process which applies an advanced molecular distillation technology to regenerate base oil from waste lubricating oil can not only regenerate better base oil, but also carry out effluent fraction through multilevel series connections. The waste lubricating oil is deprived of light diesel oil in a rectification tower through pretreatment and deprivation of light components, and then the waste lubricating oil is pumped into a first-level molecular still through a first-level feed pump to distill off a relatively lighter base oil component as a product. Heavier components which are left by the first-level distillation and serves as the raw material of a second-level molecular still are pumped into the second-level molecular still through a second-level feed pump to distill off a component heavier than the first-level molecular distillation product to serve as a product, and the distillation residuals are taken as the raw material of a third-level distillation. The process is repeated in the manner until a required n level is reached, wherein n is more than or equal to 2 and is less than or equal to 5, and the recommended optimal level number is 3 or 2. The process has the advantages that: the obtained product only contains the base oil component, while other impurities including additives are discharged in the form of residuals; the process also can produce a plurality of products with good quality and varied viscosities, thereby bringing about great convenience for the preparation of product lubricating oil.

Owner:尹英遂 +2

Production chain of instant dry rice noodles and technique for producing the same

The invention discloses an instant dried rice noodle production line and production technology, The production line comprises: rich falling bucket, air-jetting rice polisher, specific gravity sand removing machine, rice color sorting machine, rice conveyor, rice pumping machine, jet rich washing machine, water riche separating tank, first stage pulp mill, second stage pulp mill, pulp screen, pulp storing machine, stirring type automatic pulp falling machine, noodle steaming machine, sheet jelly pre-drying machine, sheet jelly freezing machine, first sheet jelly recovering machine, second sheet jelly recovering machine, drum type transition conveyor, noodle cutting machine, rice noodle conveyor, quantitative cutting machine, automatic shaping machine, drying machine, air-cooling machine and packaging and conveyor disposed according to the material conveying flow. The production line and production technology of the present invention can realized the full-automatic production from raw material to finished product of instant dried rice noodle, achieve instant dried rice noodle with good quality, and high production efficiency.

Owner:BUHLER WUXI COMML

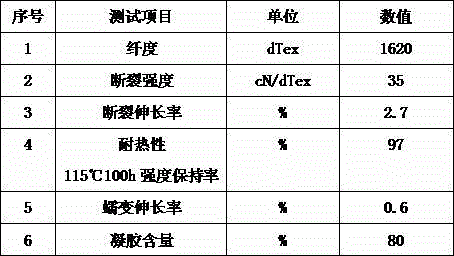

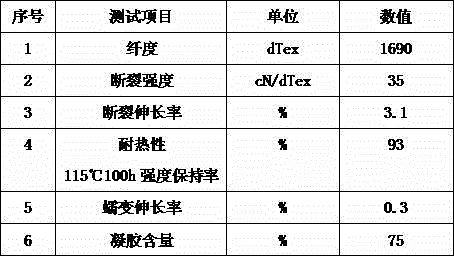

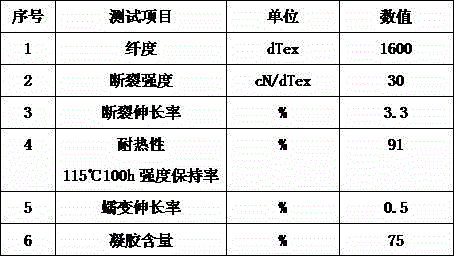

Heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber and preparation method thereof

InactiveCN104695038AHeat resistantHeat resistance and creep resistance haveMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCross-link

The invention discloses a heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The fiber comprises ultra-high molecular weight polyethylene powder, graphene, a cross-linking agent, a curing agent, an initiator and an anti-oxidant. The preparation method comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by a solvent so as to form pores; then adding a composite modifying agent wetted by the cross-linking agent, the curing agent, the initiator, the anti-oxidant, the graphene and the solvent together; penetrating the composite modifying agent evenly into the ultra-high molecular weight polyethylene powder pores, and mixing evenly; and finally, carrying out irradiation crosslinking to obtain the heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber has the comprehensive performances of heat resistance, creep resistance, abrasion resistance, impact resistance, self lubrication, corrosion resistance, low temperature resistance, hygiene, no toxicity, difficulty in adhesion and water absorption and relatively low density, is wide in applicability, and is long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

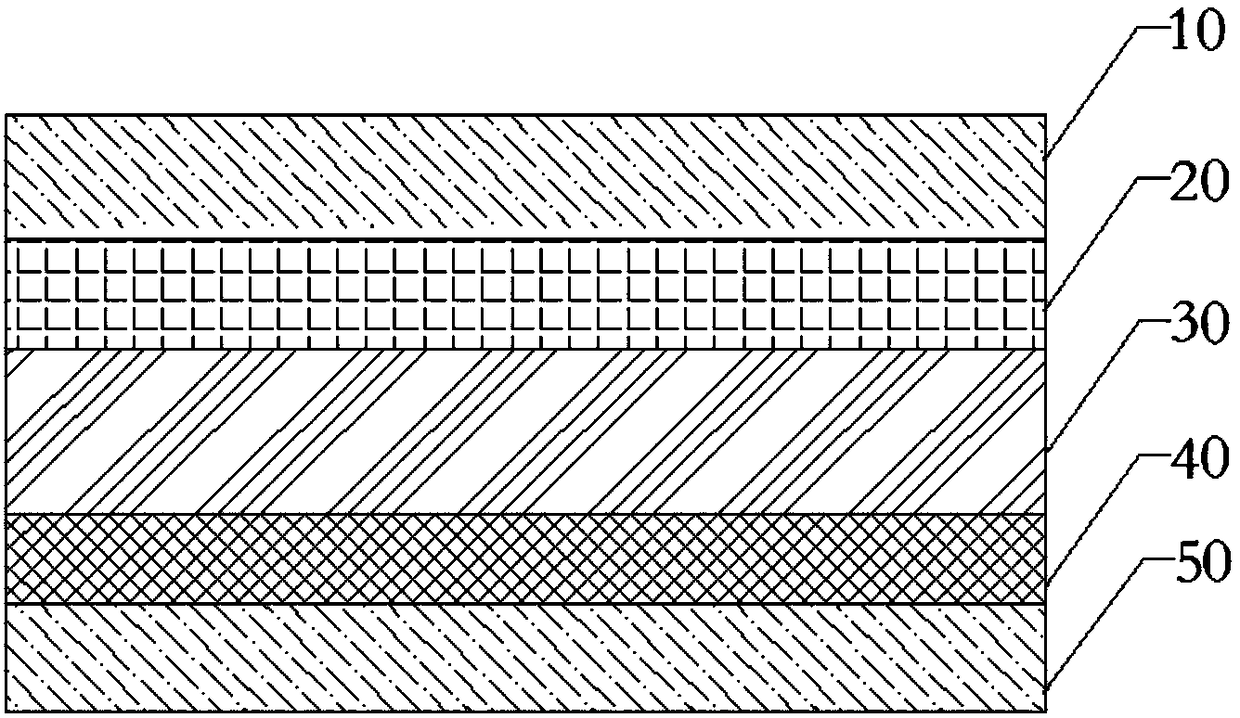

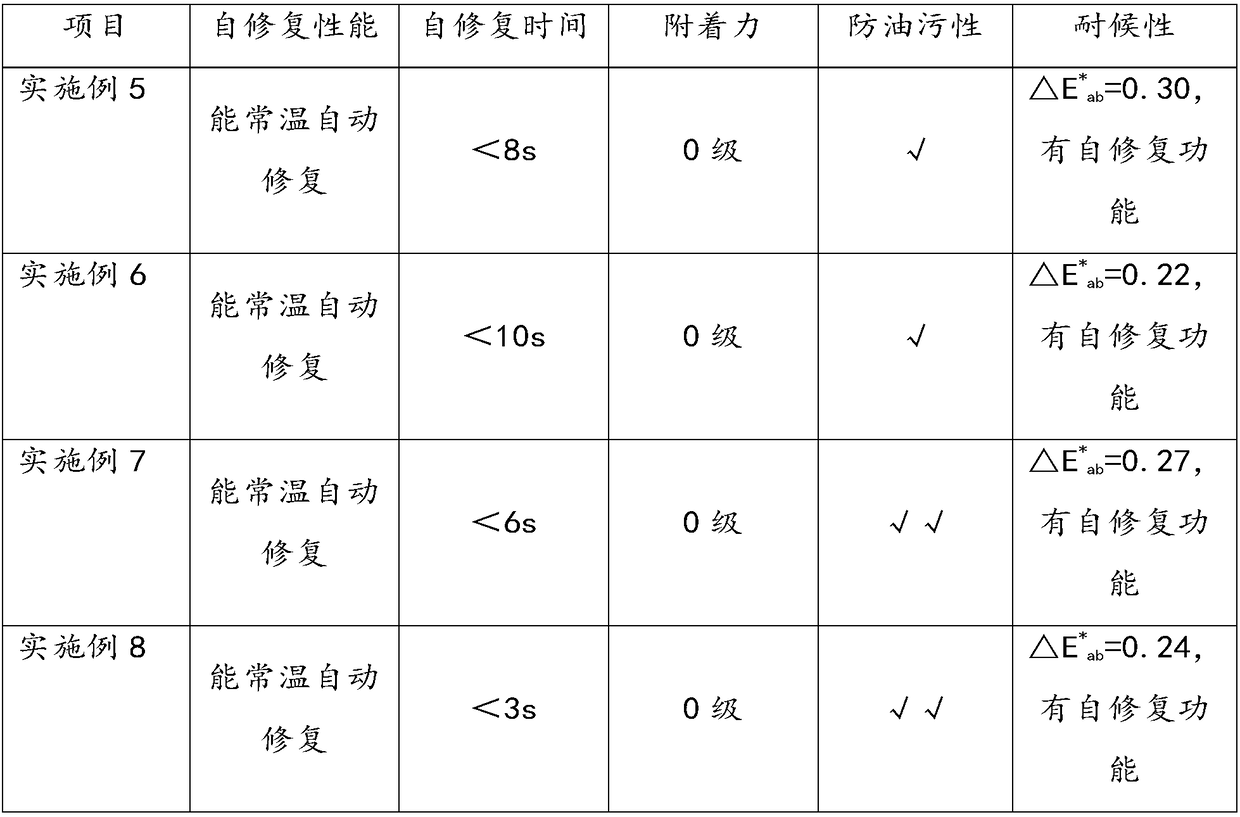

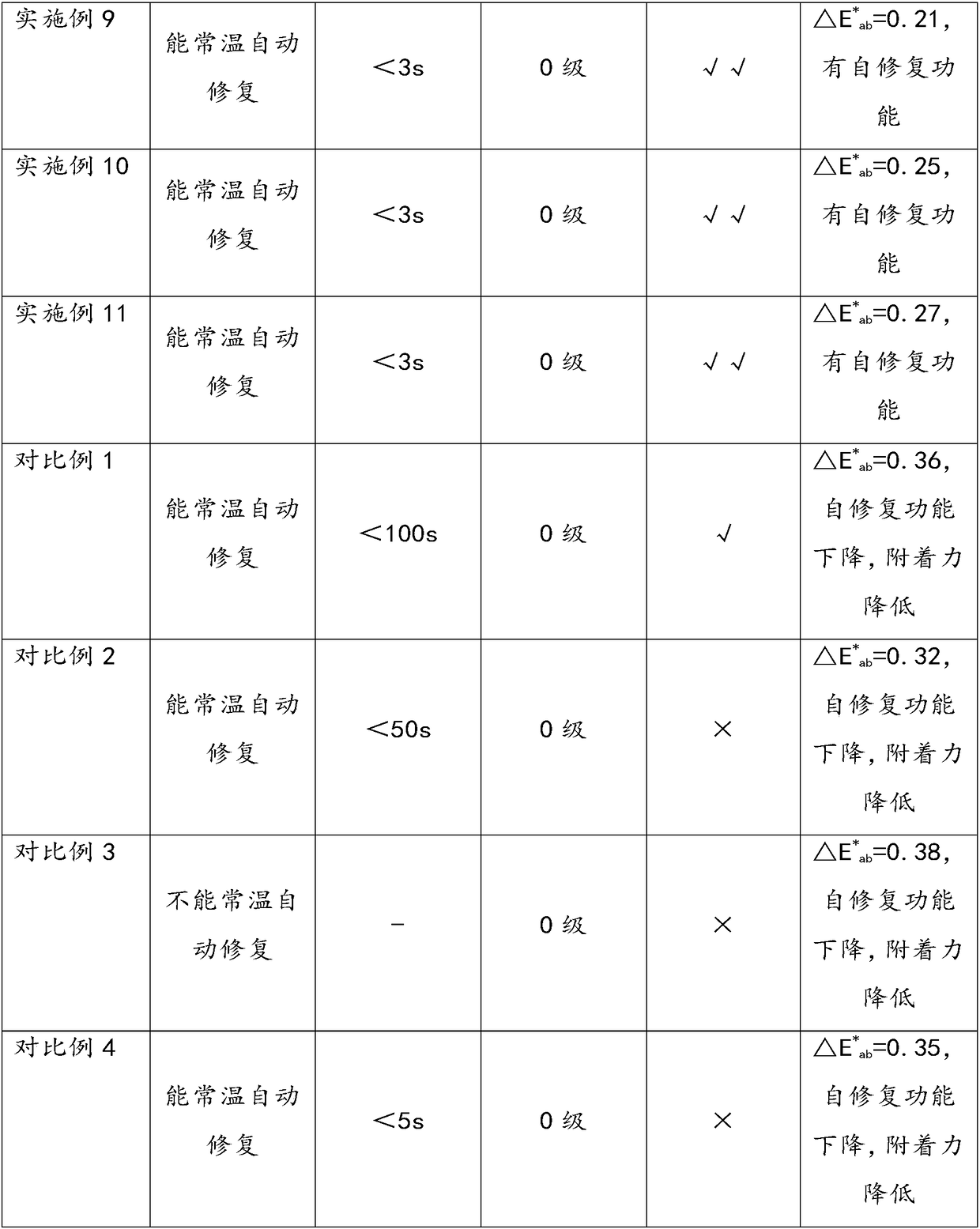

Self-repairing and oil stain-preventing coating and preparation method thereof, and protective film containing same and preparation method thereof

PendingCN108084861AWith self-healing functionNot easy to stickAntifouling/underwater paintsFilm/foil adhesivesSolventChemistry

The invention relates to a protective film with self-repairing and oil stain-preventing functions, in particular to self-repairing and oil stain-preventing coating and a preparation method thereof, and a protective film containing the same and a preparation method thereof. The self-repairing and oil stain-preventing coating is prepared from the following raw materials in parts by weight: 10-80 parts of polyol, 1-50 parts of isocyanate, 1-10 parts of an auxiliary agent, 0.1-10 parts of an ultraviolet light absorber, 0.01-10 parts of an antistatic agent and 1-50 parts of a solvent. The protective film sequentially comprises a first release film, the self-repairing and oil stain-preventing coating, a film substrate, an ultraviolet blocking pressure-sensitive adhesive layer and a second release film. The protective film has a more excellent self-repairing function, a more excellent oil stain-preventing function and more excellent weathering resistance, can be self-repaired at room temperature within a short time, and has a better protective effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

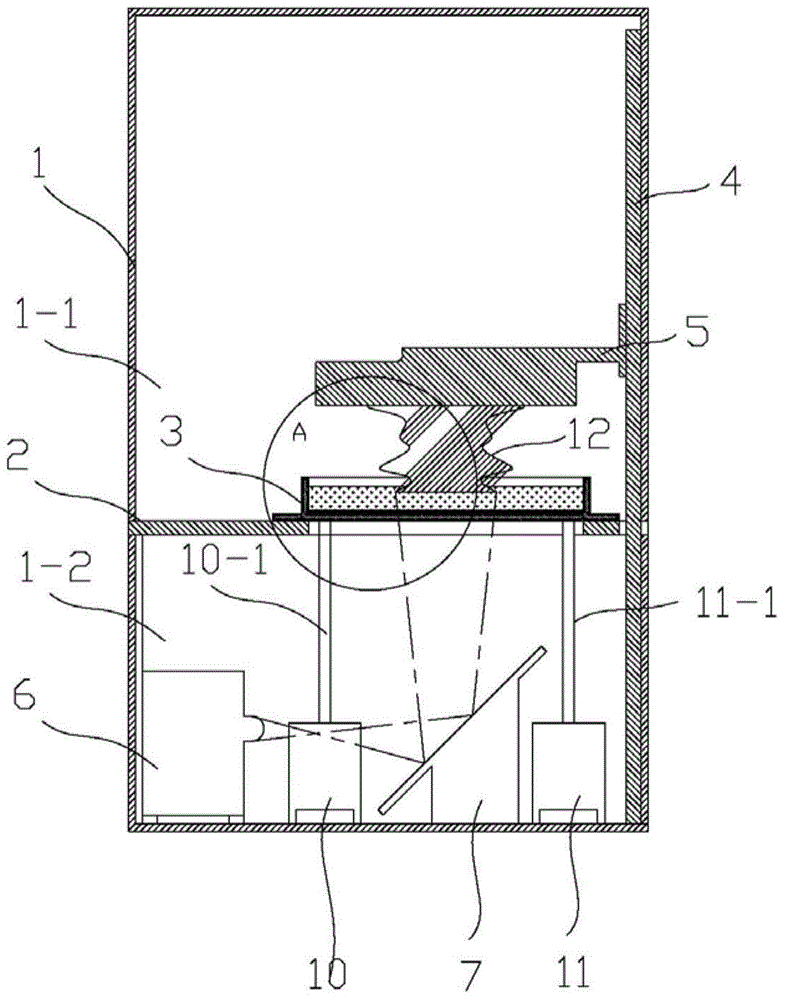

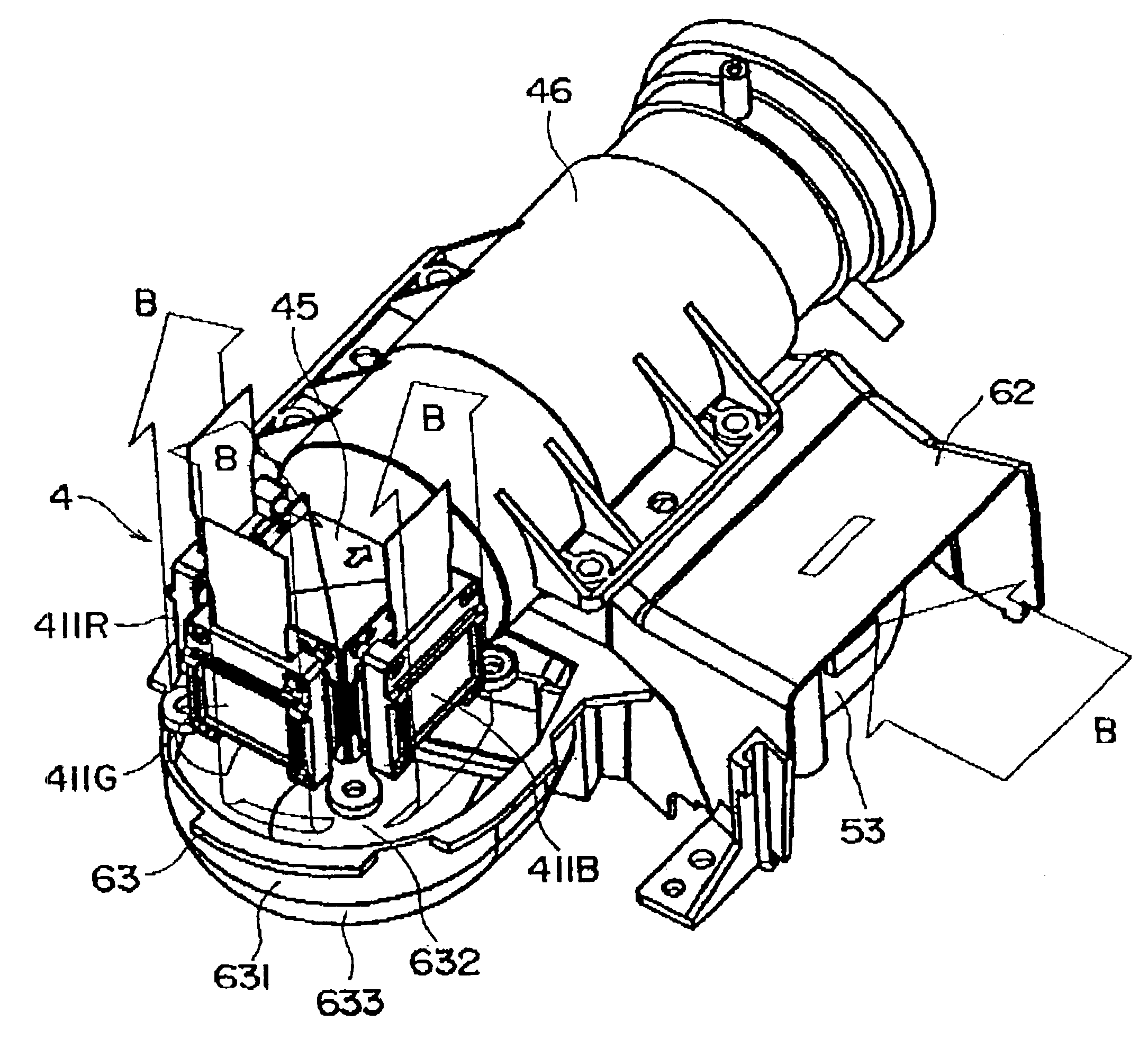

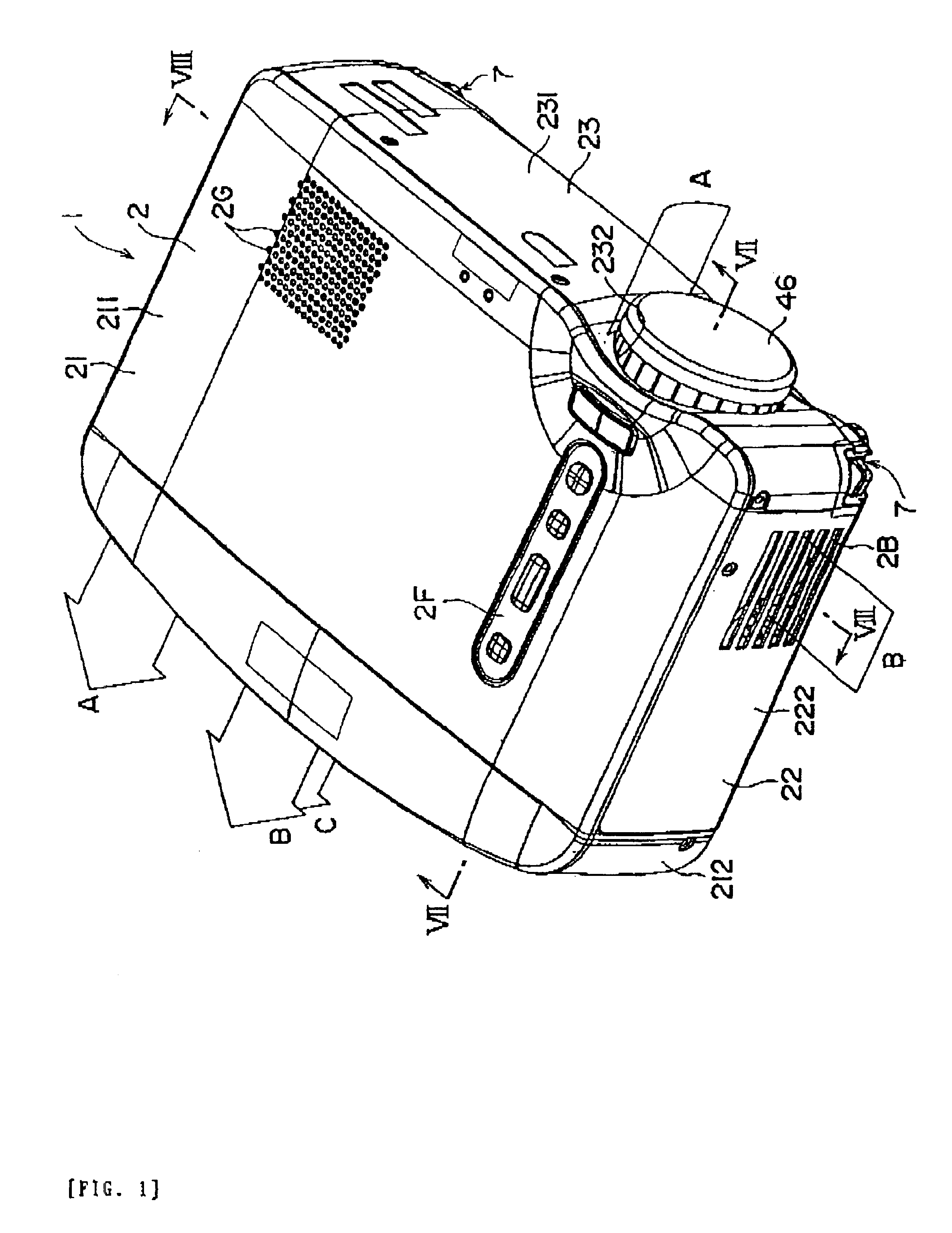

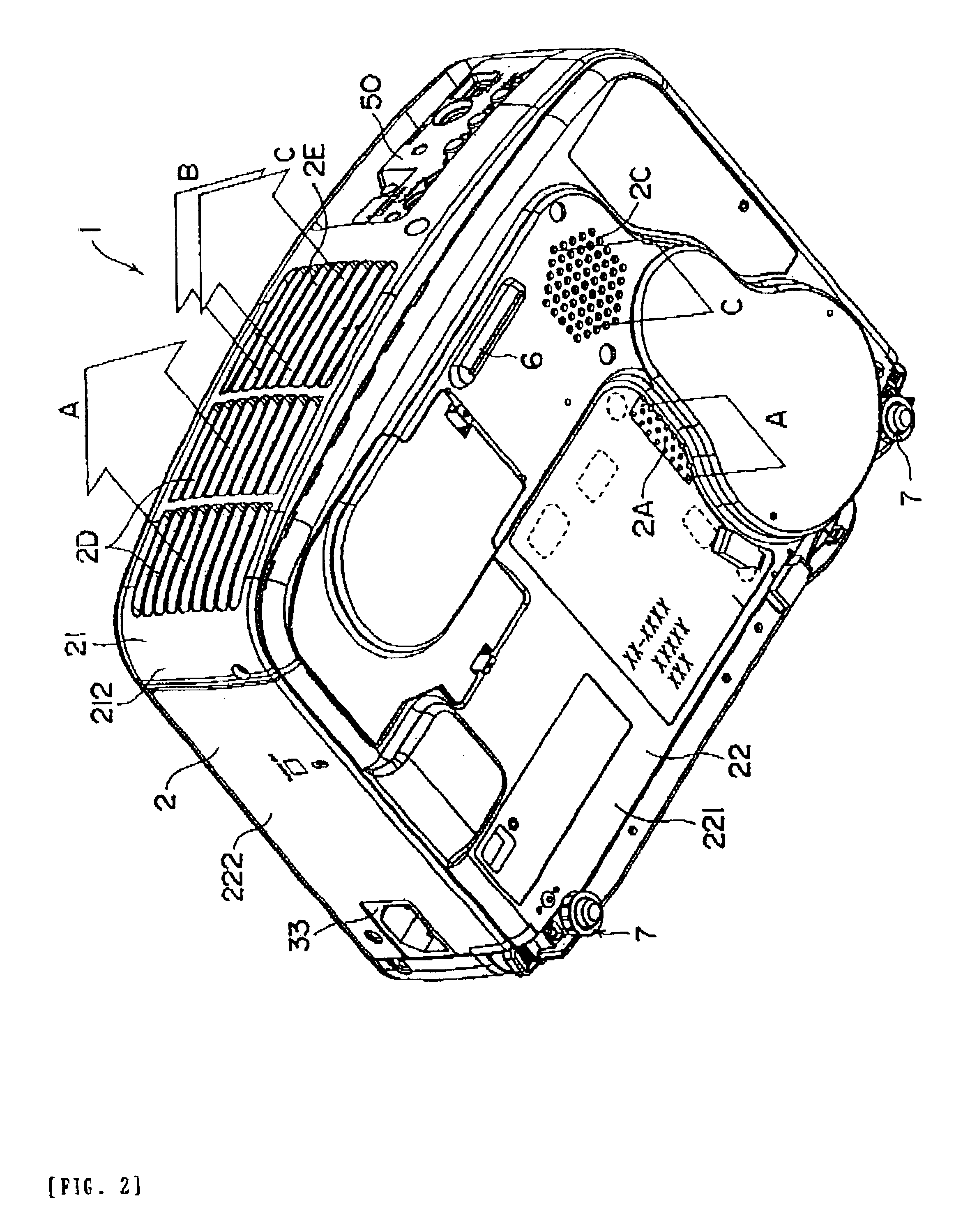

Projector

InactiveUS6540364B2Reduce the possibilityReduce in quantityTelevision system detailsProjectorsMiniaturizationEngineering

The invention provides a projector capable of reducing costs and promoting miniaturization while also being dust-proof. A second sirocco fan with an air-inlet opposing a projection lens is used, and an air-inlet of an outer case is formed on a side face thereof. Thereby, it is difficult for dust to be sucked therein compared with an air-inlet formed on the bottom or top face of the outer case, enabling the projector to be dust-proof without any filter. Since the filter is not required, the number of parts is reduced, thereby reducing costs. Furthermore, the second sirocco fan is placed by utilizing a space under the projection lens, which is liable to be a dead space, enabling the arrangement space to be efficiently used thereby promoting miniaturization of a projector.

Owner:SEIKO EPSON CORP

Preparation method of CAD/CAM personalized resin pre-formed crown and bridge

InactiveCN105616020ALess discomfortReduce the possibility of postoperative infectionDental implantsDesign softwareDentistry

The invention discloses a preparation method of a CAD / CAM personalized resin pre-formed crown and bridge. According to the method, data are acquired through oral clinical examination and oral CBCT, an implant scheme is designed by six-dimensional tooth implantation design software with repair as guide, implantation data are acquired, and a corresponding repair working model is obtained; a corresponding implantation replacement body is inserted into the repair working model, the position, the direction and the depth of the obtained replacement body and data of remaining teeth within a mouth are scanned with a scanner, a pre-formed crown and bridge module is designed with EXOCAD software according to the pre-designed upper repair body requirement by the combination of patient gingiva thickness, and a gap is reserved for placing a temporary drill base and a screw hole; finally, the CAD / CAM personalized resin pre-formed crown and bridge is obtained through cutting processing and finishing and polishing of a resin disc. According to the method, the immediate repair body can be put on at the same day after operation, modeling is not required in the patient mouth after the operation, the possibility of postoperative infection is reduced compared with the traditional technology, the time is saved, and the discomfort of the patient is effectively reduced.

Owner:杭州口腔医院集团有限公司

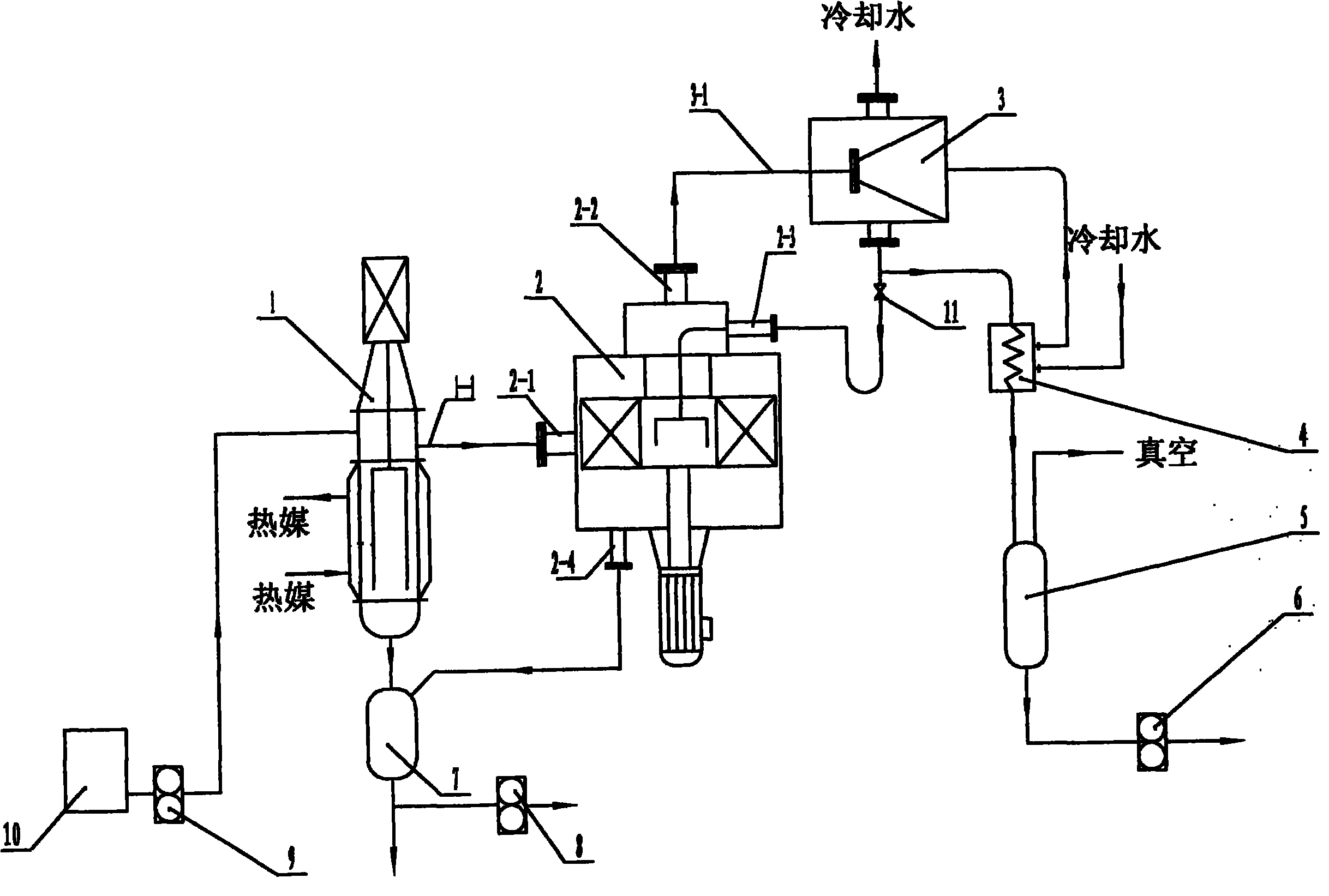

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

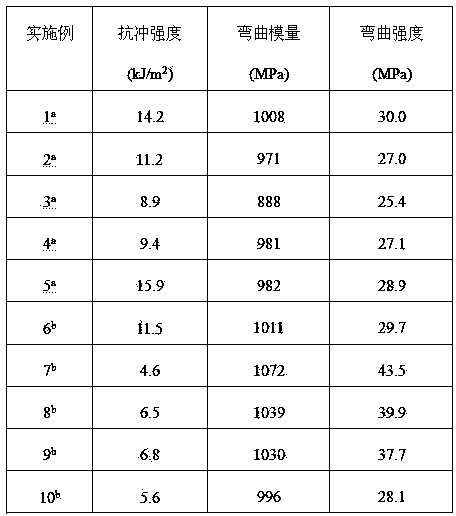

Preparation method of high-impact-strength polypropylene kettle internal alloy

The invention discloses a preparation method of a high-impact-strength polypropylene kettle internal alloy. The preparation method comprises the following steps: with propylene and ethylene as monomers, carrying out sectional polymerization, namely, firstly, carrying out propylene homopolymerization by using a MgCl2 / ID / TiCl4-supported catalyst as a primary catalyst, using Al(C2H5)3 as a cocatalyst and using R2R2Si(OCH3)2 as an external electron donor; after the homopolymerization is ended, adding another cocatalyst Al(i-C4H9)3 or another different external electron donor R3R4Si (OCH3)2 into a polymerization system to carry out ethylene-propylene copolymerization to prepare the high-impact-strength polypropylene kettle internal alloy. The prepared high-impact-strength polypropylene kettle internal alloy has excellent rigidity / toughness equilibrium characteristic; under the same condition, compared with normal conventional catalytic system only using Al(C2H5)3 and R1R2Si (OCH3)2, The preparation method has the advantages that the impact strength of the high-impact-strength polypropylene kettle internal alloy prepared by the method disclosed by the invention is higher than that of the conventional catalytic system while bending modulus is lowered a little; meanwhile, the prepared polypropylene kettle internal alloy particles have better mobility and are not easily adhered onto the kettle.

Owner:CHINA PETROLEUM & CHEM CORP +1

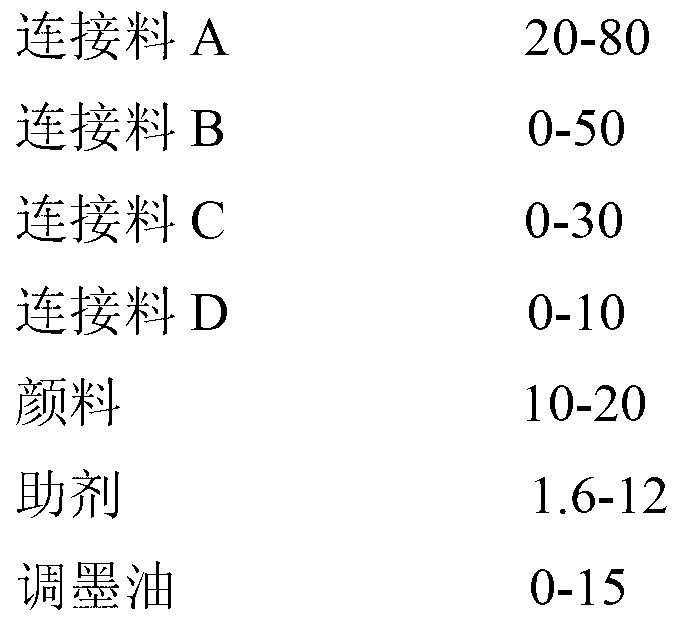

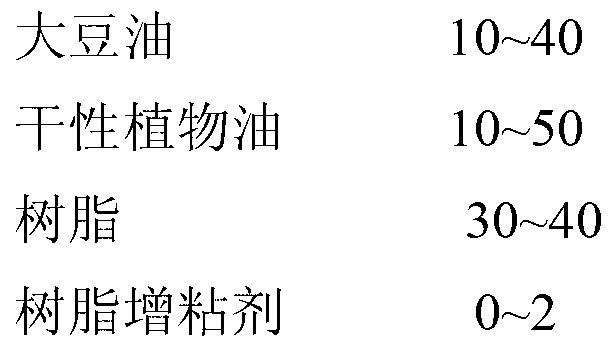

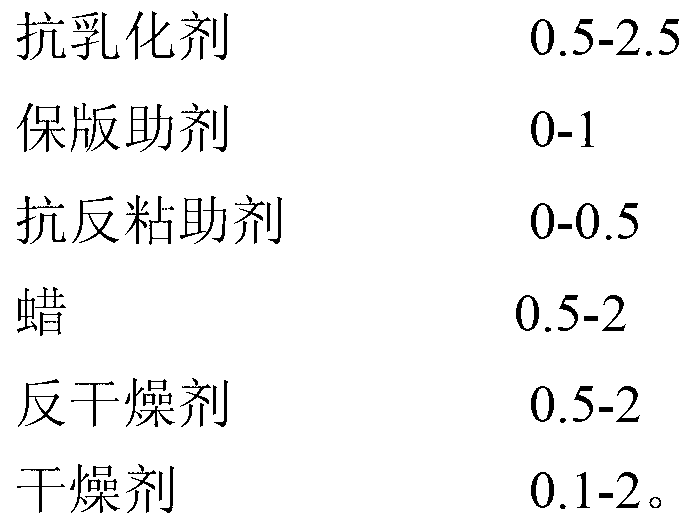

All vegetable oil high-speed planographic printing ink

The invention relates to all vegetable oil high-speed planographic printing ink. The all vegetable oil high-speed planographic printing ink comprises the following components in parts by weight: 20-80 parts of a binder A, 0-50 parts of a binder B, 0-30 parts of a binder C, 0-10 parts of a binder D, 10-20 parts of a pigment, 1.6-12 parts of an auxiliary and 0-15 parts of a vanish, wherein the binder A, the binder B, the binder C and the binder D are respectively composed of soybean oil, dry vegetable oil, resin and / or a resin tackifier. According to the all vegetable oil high-speed planographic printing ink, vegetable oil is used for substituting petroleum base mineral oil in the traditional printing ink, and no petroleum solvent is contained, so that the all vegetable oil high-speed planographic printing ink has excellent environmental protection property; and under middle and high speed printing conditions, the all vegetable oil high-speed planographic printing ink has the advantages of good suitability, high speed, stability on a printing machine and quick drying on a piece of paper and can meet the requirement of a printing company on an increasing printing speed as the modern printing machine is improved.

Owner:XINXIANG WENDE XIANGCHUAN PRINTING INK

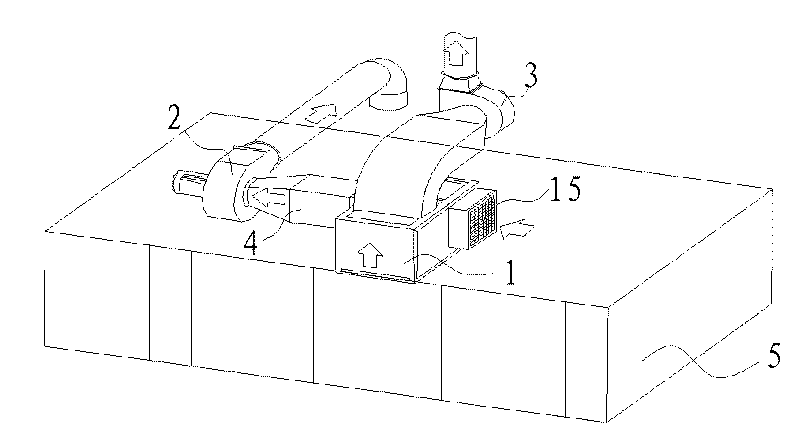

High-temperature crude synthesis gas chilling device

ActiveCN102140372AIncrease contact areaSimple structureChemical industryCombustible gas productionWear resistantChiller

The invention relates to a high-temperature crude synthesis gas chilling device, which comprises a gas flow channel of a chiller and an atomizing nozzle arranged on the side wall of the gas flow channel, wherein the gas flow channel is connected with a reaction chamber and a cooling chamber of a gasification furnace and provides a mixing space for a chilling medium and high-temperature crude synthesis gas; the atomizing nozzle is a single-flow-channel pressure nozzle or a double-flow-channel gas-liquid two-phase nozzle, and is partitioned into 1-20 layers; each layer is uniformly distributed on the circumference and is used for uniformly spraying the chilling medium into the high-temperature crude synthesis gas and chilling the synthesis gas to be in a specific temperature range; the gas flow channel is a water cooled-wall or a fire-resistant and wear-resistant liner or the combination of the water-cooled wall and the fire-resistant and wear-resistant liner; and the gas flow channel has a cylindrical structure or a conical structure or the combination of the cylindrical structure and the conical structure. The chilling device has the advantages of high chilling efficiency, large gas-liquid contact area, high chilling rate, small dosage of the chilling medium, mature manufacturing technology, high reliability and capability of reducing the consumption and the discharge of cleaning black water, and relates to an environmentally-friendly and-energy saving technology.

Owner:WISON ENG

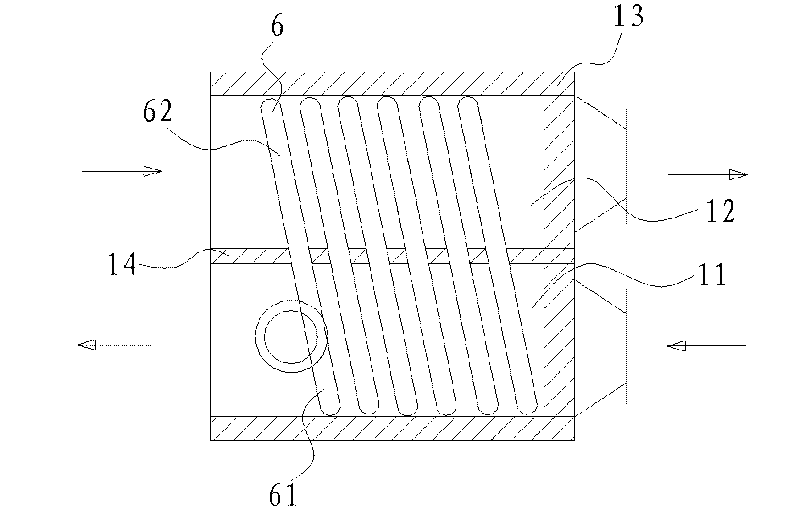

Coating machine heat recovery utilization energy-saving device

InactiveCN101693230AAvoid corrosionNot easy to stickPretreated surfacesIndirect heat exchangersThermal energyProcess engineering

The invention provides a coating machine heat recovery utilization energy-saving device, and belongs to the technical field of laser holographical product production equipment. The device solves the problems that a large amount of heat is also discharged outdoors simultaneously when existing coating machines discharge mixed waste gas outdoors, thereby generating heat energy waste. The coating machine heat recovery utilization energy-saving device comprises a residual heat recoverer, a new air induced fan and a smoke discharging fan, wherein the residual heat recoverer is provided with a new air channel and a mixed waste gas channel which are mutually sealed and insulated, a heat exchange structure is arranged between the new air channel and the mixed waste gas channel, one end of the new air channel is communicated with the environment, the other end of the new air channel is connected with a heater, the heater is communicated with a new air inlet of an oven through the new air induced fan, one end of the mixed waste gas channel is communicated with the mixed waste gas outlet of the oven, and the other end of the mixed waste gas channel is communicated with the smoke discharging fan. The device can reclaim heat of mixed waste gas to heat new air to enable fed new air to achieve certain temperature, and has the advantages of safety, reliability, energy-saving, has flexible installation and structure arrangement.

Owner:绍兴京昇光信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com