Patents

Literature

375 results about "Squeeze casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

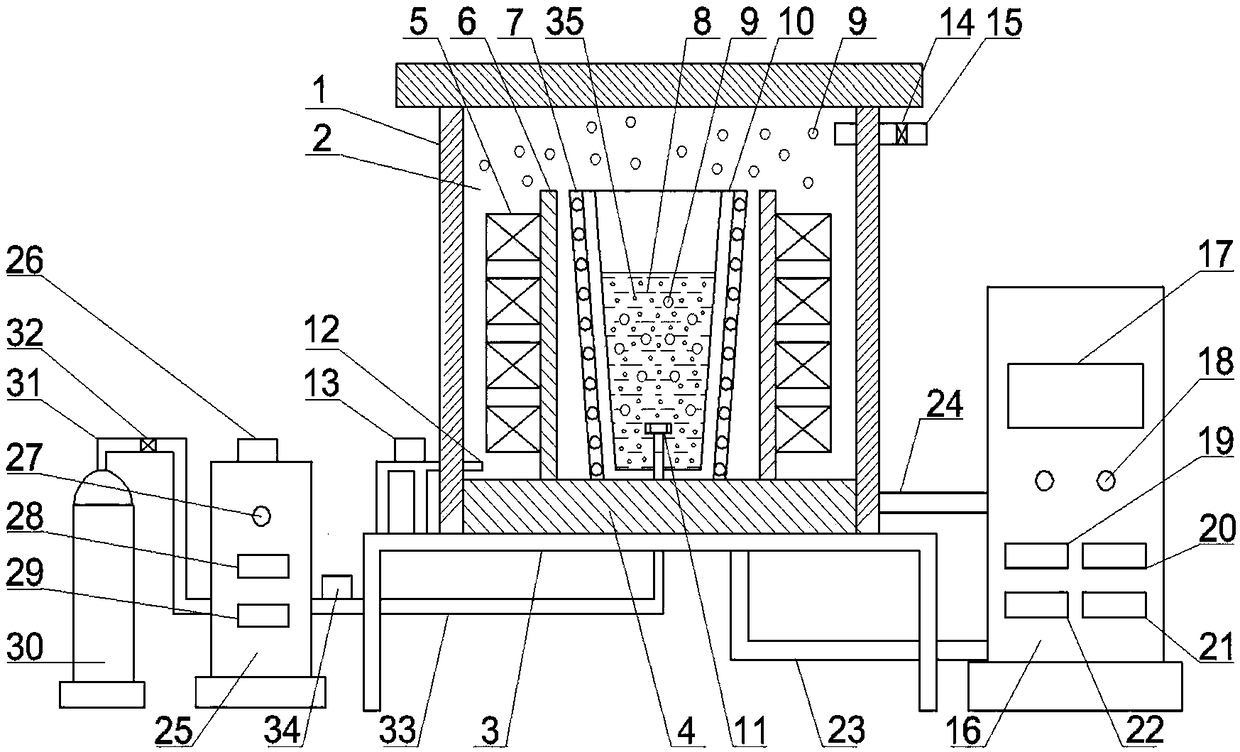

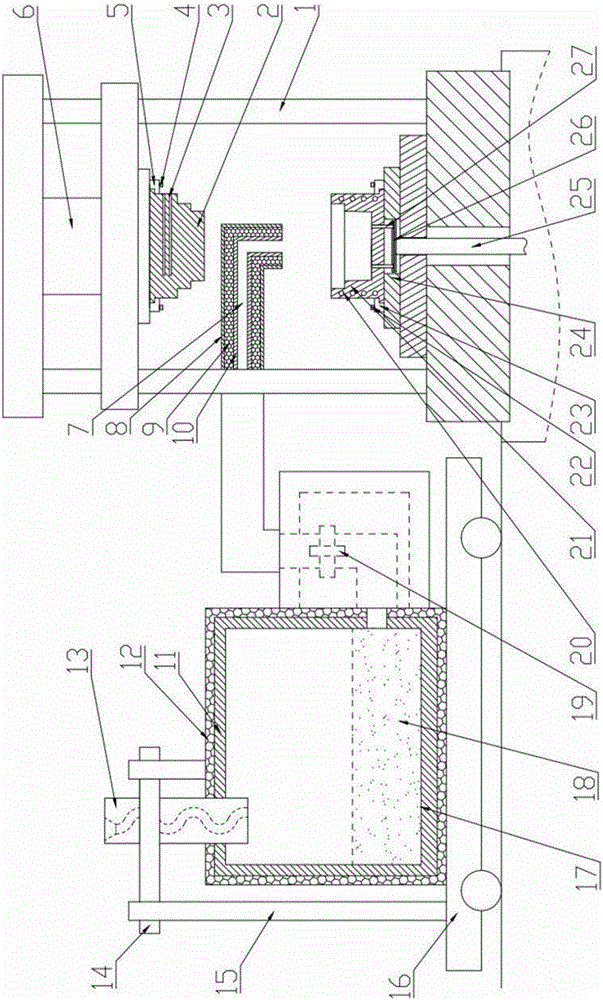

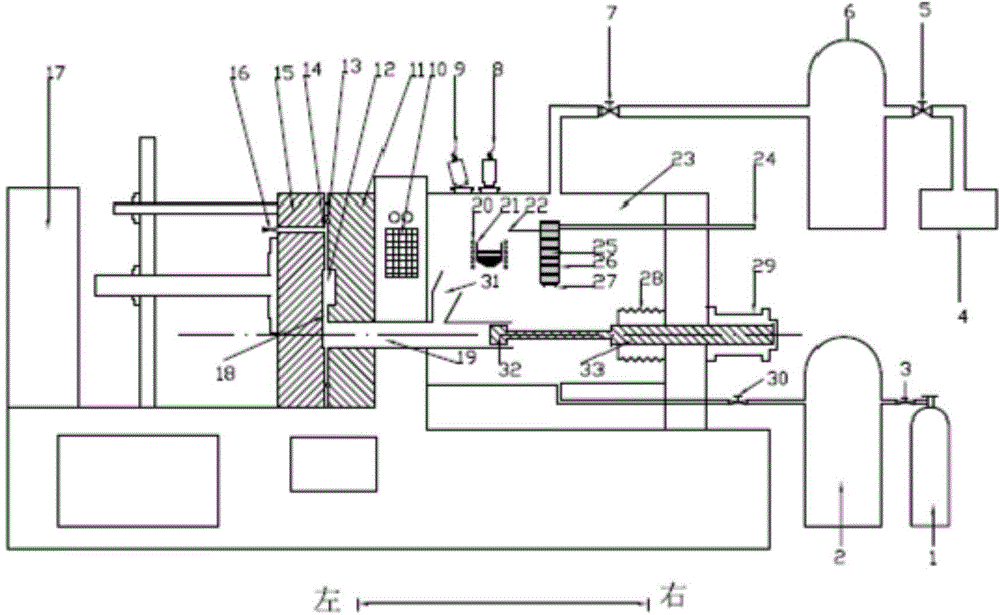

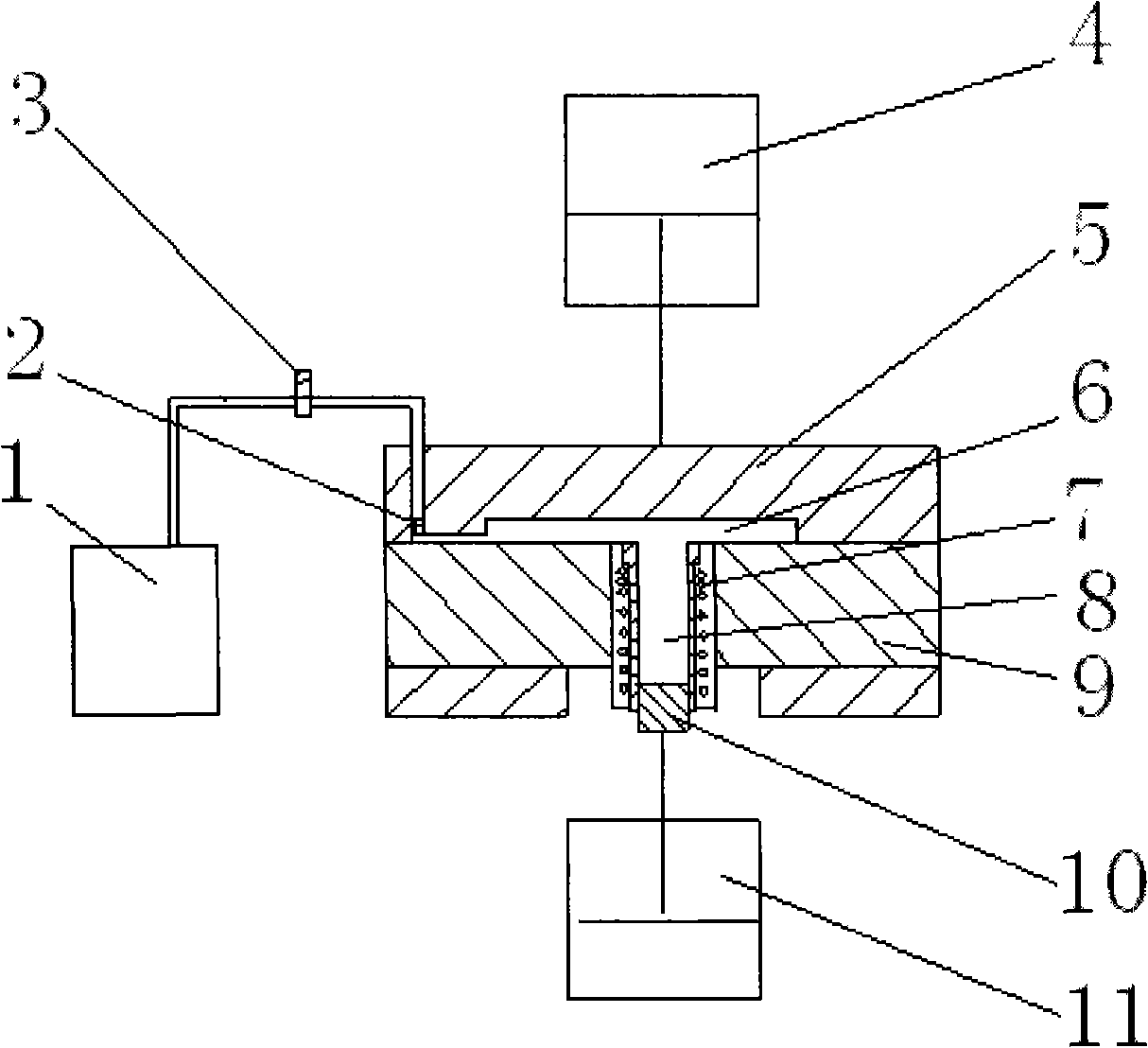

Preparation method of semisolid alloy slurry and rheoforging device

InactiveCN101007342AEnhanced ChillingAccurate control of solid phase fractionCasting plantsThermal conductivityTractor

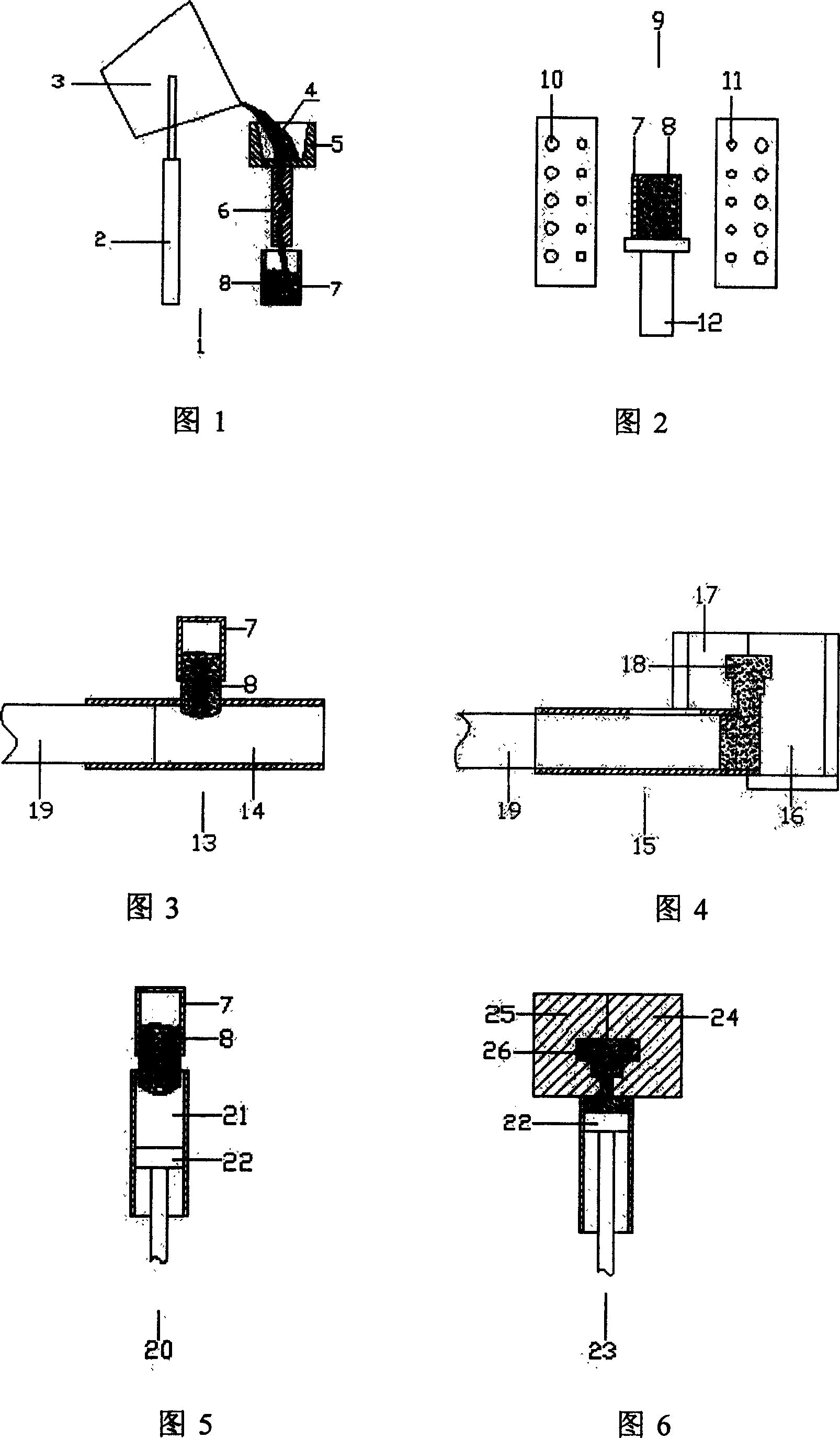

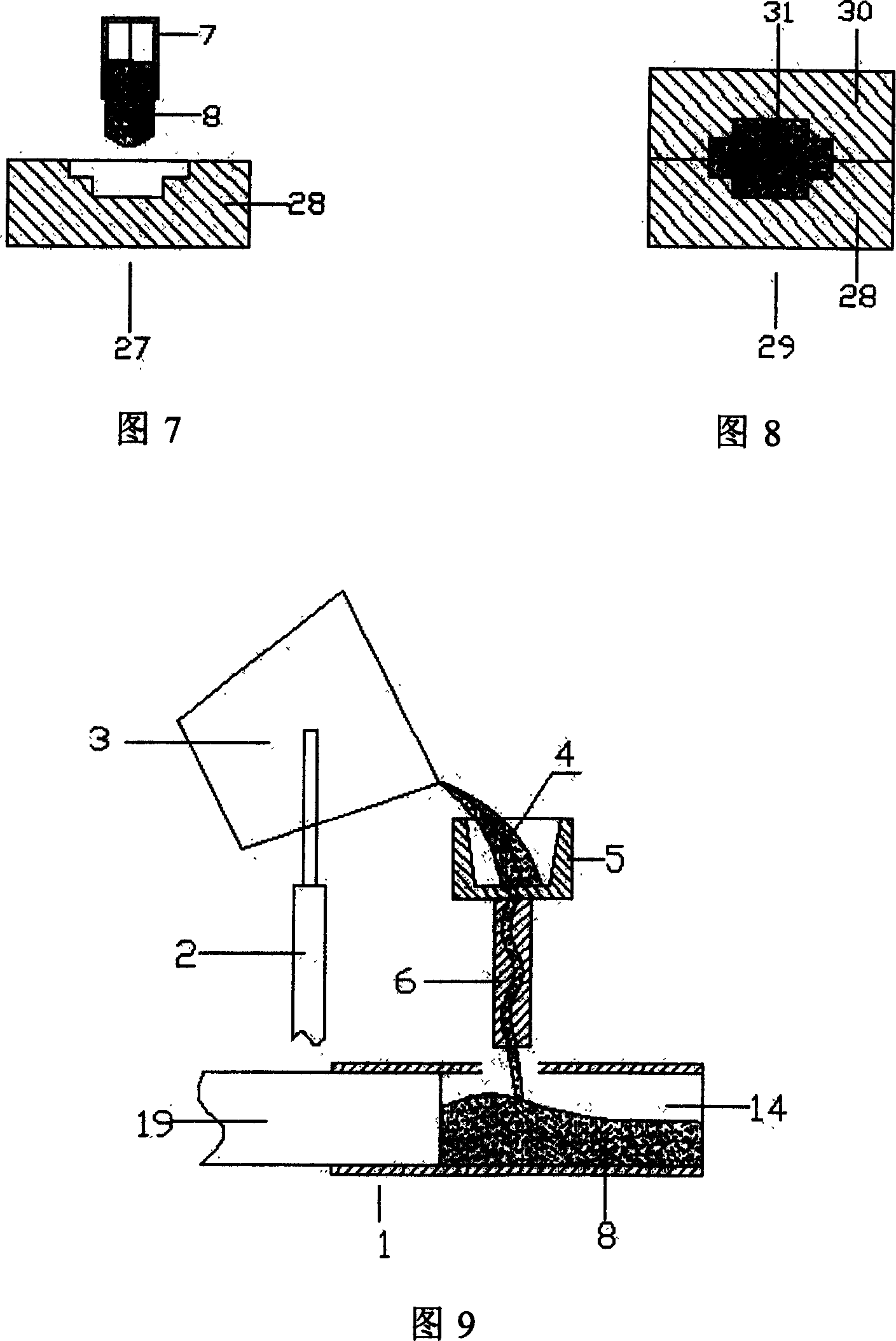

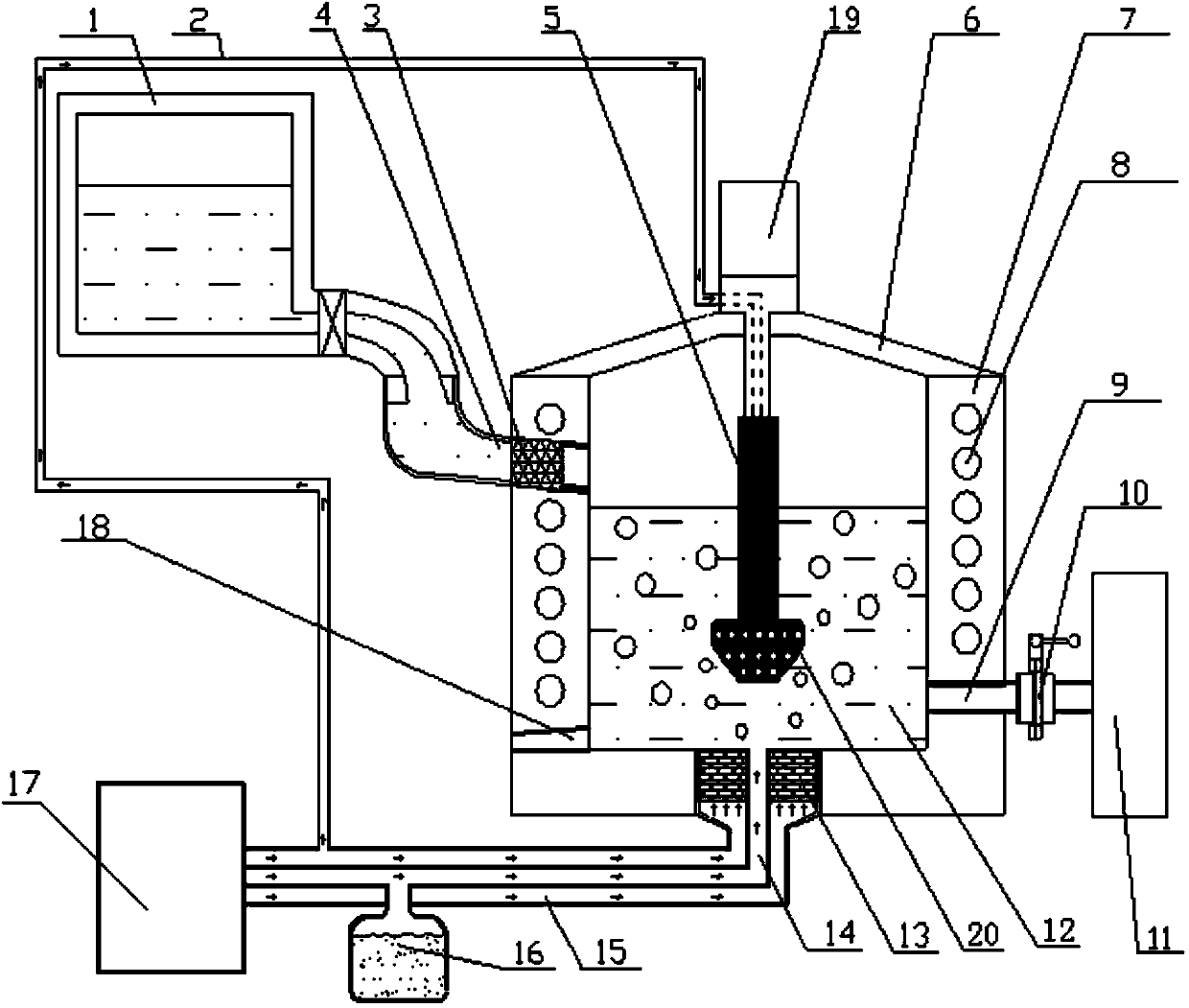

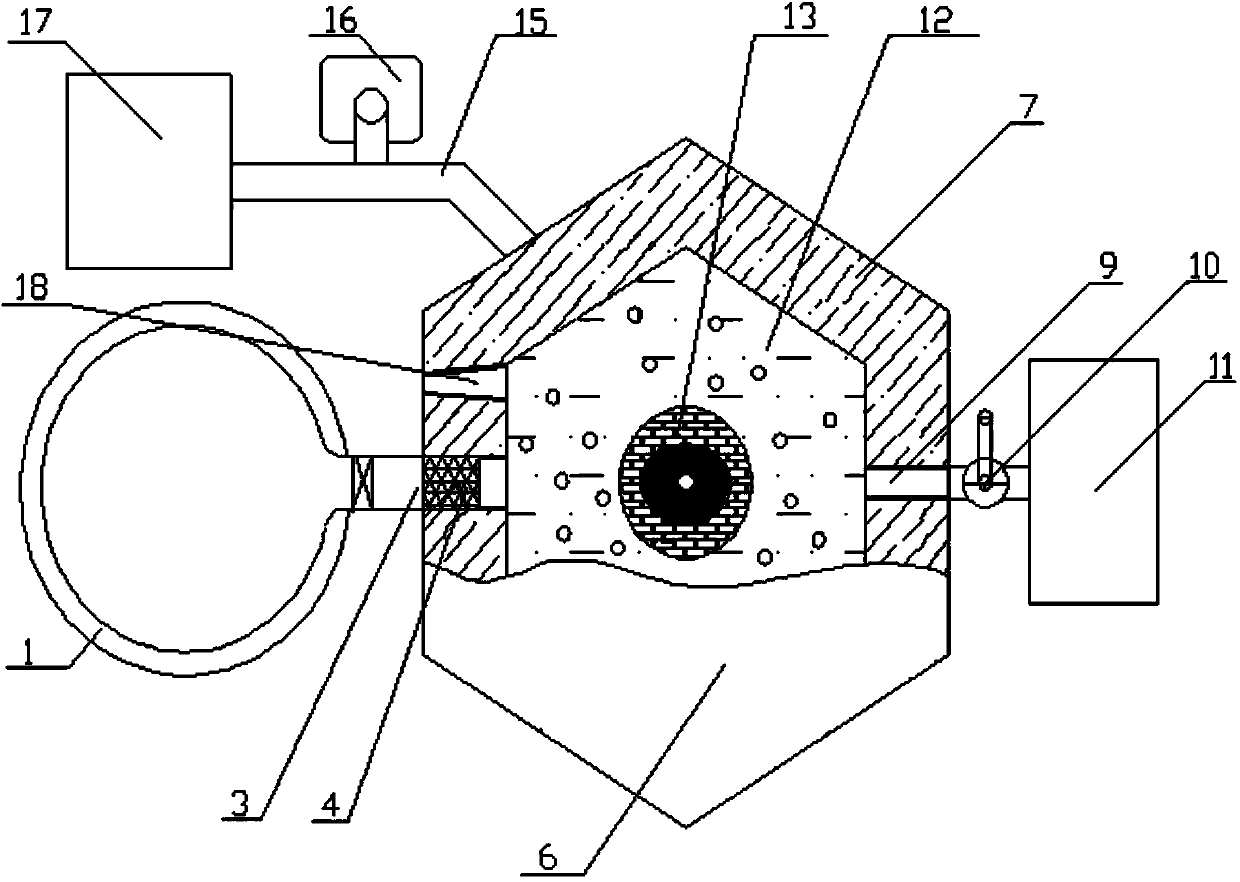

A semi-solid alloy slurry preparation and theological molding equipment belongs to semi-solid alloy slurry preparation technology field. It consists of lifting device, overheating alloy liquid smelting furnace, pouring cup, vertical snake-type pouring channel and low thermal conductivity liner, cooler and heater, preparation crucible, temperature controller and cooling components and heating components, support and push device for preparing crucible, die casting machines and injection chamber, mobile mould, shaping and injection drift pin, squeezing casting machine and injection chamber, injection drift pin, right and left mould, forging machines and upper mode and lower mold, continuous casting crystallizer, two cold water nozzle, tractor and dummy bar. The advantages are: simple construction and equipment, low investment, low production cost and it is very suitable for semi-solid alloy slurry or blank preparation and molding production.

Owner:UNIV OF SCI & TECH BEIJING

Indirect extruding and casting method of wrought aluminum alloy casting

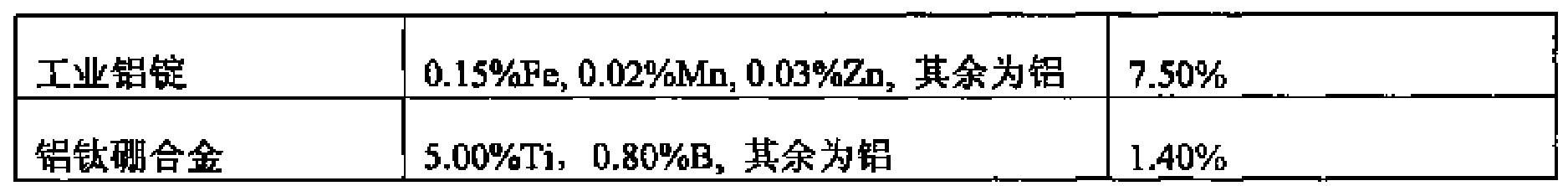

The invention relates to an indirect extruding and casting method of a wrought aluminum alloy casting. The method comprises the following steps of: (a) preparing alloy, wherein the alloy comprises the following components in percentage by weight: 0.4-1.2 percent of Si, 0.2-0.9 percent of Cu, 0.8-1.4 percent of Mg, 0.02-0.4 percent of Cr and the balance of Al, the Si, the Cu and the Cr in the alloy are respectively added in the form of intermediate alloys of an aluminum-silicon alloy, an aluminum-copper alloy and an aluminum-chromium alloy, and the Mg and the Al are respectively added in the form of pure magnesium and pure aluminum; (b) alloy smelting: adding the pure aluminum and the intermediate alloys of the aluminum-silicon alloy, the aluminum-copper alloy and the aluminum-chromium alloy firstly, and after smelting, raising the temperature to 700-740 DEG C; adding a refining agent for refining, and then cooling to 680-700 DEG C; then adding the magnesium and adjusting the temperature to 720-740 DEG C to begin indirect extruding and casting; (c) carrying out the indirect extruding and casting, wherein the process has the following technological parameters: the pressure applied is 50-200MPa, the pressure maintaining time is 15-35s, the pouring temperature is 690-730 DEG C, and the temperature of a mould is 60-160 DEG C; (d) carrying out heat treatment, wherein the solid solution temperature is 515+ / -5 DEG C, the solid solution time is 6-10h, the transferring time of the casting from discharging to water is 1-15s, and water cooling is carried at room temperature; carrying out primary aging immediately, wherein the aging temperature is (150-165)+ / -5 DEG C, the aging time is 6-14h, and cooling is carried out in air; and carrying out secondary aging, wherein the temperature is (165-175)+ / -5 DEG C, the aging time is 1-3h, and cooling is carried out in air.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP +1

Process of making oil cylinder body and cover with aluminium alloy

The process of making oil cylinder body and cover of aluminum alloy includes the following steps: heating in a smelting furnace the materials comprising Zn 1-8.0 wt%, Mg 1.0-5.0 wt%, Cu 0.8-2.5 wt%, Mn 0.2-1.0 wt%, Cr 0.1-0.3 wt% and Al for the rest; refining; casting in extruding and casting mold through fast closing mold, slowly applying pressure and maintaining pressure for the aluminum alloy to solidify and crystallize; and final solid solution ageing T6 heat treatment on the cast blank to obtain oil cylinder body and cover casting. The process has high material utilizing rate, high production efficiency and low production cost, and the product blank has light weight, compact and homogeneous structure and less faults.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Method for manufacturing metal-based composite materials by aid of 3D (three-dimensional) printing space structures

The invention relates to a method for manufacturing metal-based composite materials by the aid of 3D (three-dimensional) printing space structures, and belongs to the technical field of metal-based composite materials. The method includes building stereoscopic models of the space structures by the aid of graphics software and printing the stereoscopic models by the aid of 3D printing machines to obtain plastic templates of the space structures; preparing slurry from ceramic particles and adhesion agents, and filling space structure gaps of the plastic templates with the slurry; drying and gradually heating the plastic templates, removing plastics, and sintering the templates to obtain ceramic particle prefabricated blanks with certain strength and complex space structures; manufacturing the metal-based composite materials by the aid of pressure impregnation technologies such as vacuum suction casting and squeezing casting technologies. The method has the advantages that the composite materials which can be accurately controlled, are varied within large ranges and have the complex space structures can be manufactured by the aid of the method, processes are simple, and mechanical and automatic batch production can be facilitated.

Owner:KUNMING UNIV OF SCI & TECH

Automobile brake disc and manufacturing method thereof

ActiveCN105041921AImprove thermal conductivityReduce weightBraking discsMechanical engineeringBraking distance

The invention discloses an automobile brake disc which comprises a brake disc body. The brake disc body is made of aluminum alloy. The two work faces of the aluminum alloy brake disc body are each provided with an abrasion-resistant layer in a composite mode. The abrasion-resistant layers are made of a ceramic reinforcing material. The abrasion-resistant layers made of the ceramic reinforcing material are metallurgically combined with the aluminum alloy brake disc body through the squeeze casting technology. The brake disc is low in weight, good in abrasion resistance and cooling performance, long in service life, low in maintenance cost, and capable of reducing automobile oil consumption, improving the passage capacity of an automobile, shortening the brake distance and improving safety of the automobile. According to a manufacturing method of the brake disc, by means of selective local strengthening and the squeeze casting technology, the two work faces of the aluminum alloy brake disc body are each provided with one abrasion-resistant layer made of the ceramic reinforcing material in the composite mode, the abrasion-resistant layers made of the ceramic reinforcing material are metallurgically combined with the aluminum alloy brake disc body so that abrasion resistance of the work faces of the brake disc can be guaranteed, and raw material cost and machining cost of the brake disc are reduced.

Owner:NINGBO HIGHRISE NEW MATERIAL CO LTD

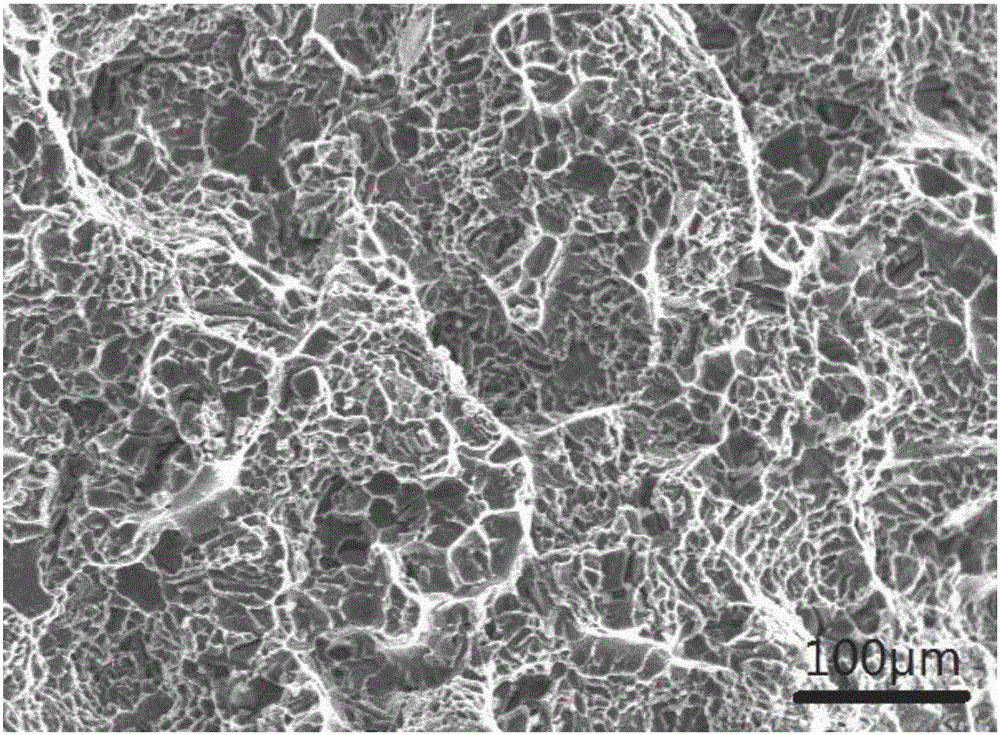

Preparation method of semisolid slurry of rare earth magnesium alloy

The invention discloses a preparation method of a semisolid slurry of a rare earth magnesium alloy. According to the guiding principle of promoting grain nucleation and inhibiting grain growth, pure aluminium is added into rare earth magnesium alloy melt, and a lot of fine dispersed Al2RE intermetallic compound particles which are generated by an in-situ reaction provide nuclei of heterogeneous nucleation for primary alpha-Mg so as to promote grain nucleation; and after the melt is transferred to a tundish, considering stability of a solid-liquid interface during the solidification process, the growth of a primary phase is delayed by reasonable control of cooling conditions in different stages of solidification so as to realize the effect of inhibiting grain growth. The invention provides a low-cost agitation-free green semisolid slurry preparation method. In comparison with a traditional semisolid slurry preparation technology, efficiency of the preparation method is improved greatly and cost is reduced remarkably. By the preparation method, a high-quality rheological slurry is provided for follow-up rheoforming of rare earth magnesium alloy, such as rheo-die casting, rheological squeeze casting and the like. The preparation method has a wide application prospect in rheoforming of a magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

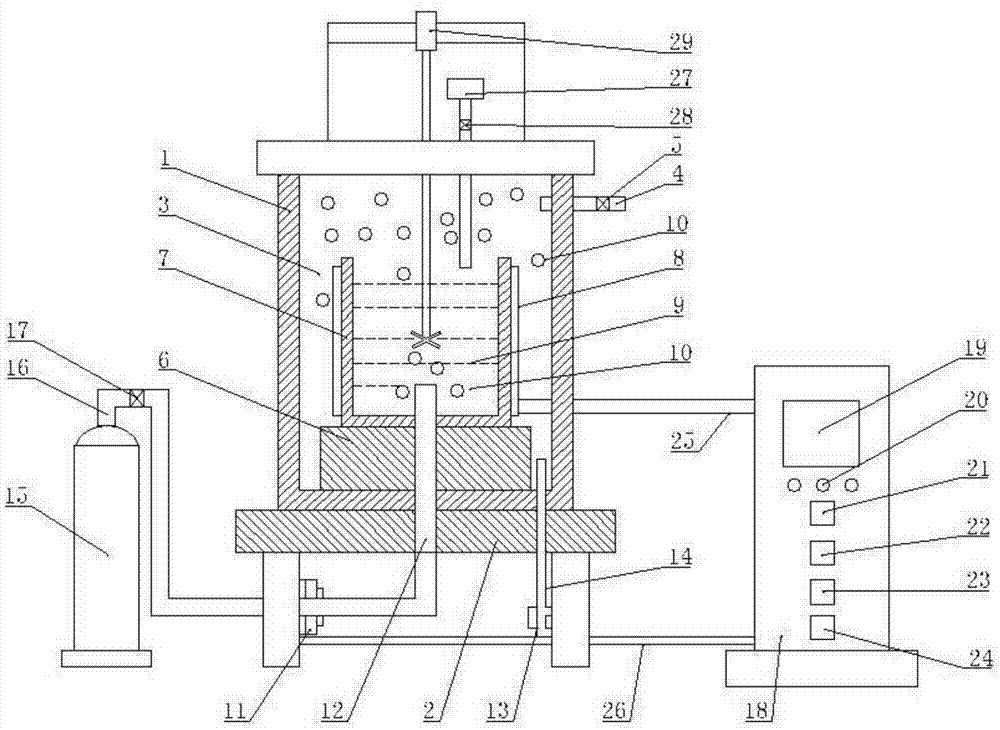

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

High strength corrosion resistant rare earth cast magnesium alloy and preparation method thereof

The invention discloses a high strength corrosion resistant rare earth cast magnesium alloy and a preparation method thereof, which is characterized in that: the magnesium alloy comprises the following components according to the weight percentage: 1.8 to 4.0 percent of Nd, 1.0 to 2.0 percent of Gd, 0.2 to 0.8 percent of Zn, 0.4 to 1.0 percent of Zr, 0.0 to 0.8 of Ca, not more than 0.02 percent of total content of impurity elements of Fe, Cu and Ni, and the balance of Mg complemented to 100 percent; and the preparation method comprises the following steps of: melting pure magnesium, adding Mg-Nd intermediate alloy, Mg-Gd intermediate alloy, Mg-Ca intermediate alloy and commercial pure Zn in sequence, heating up to 760 DEG C to 785 DEG C after the mixture is totally melted, adding Mg-Zr intermediate alloy, stirring fully and evenly after the Mg-Zr intermediate alloy is melted, standing for 10 to 20 minutes, removing dross, and then casting ingots or casting the cast products at the temperature of 720 DEG C to 750 DEG C. The cast magnesium alloy has the advantages of controllable melting process, appropriate cost, excellent mechanical property, corrosivity, good casting process property and the like; and the cast magnesium alloy can be used to manufacture various non-die casting magnesium alloy parts by adopting the processes of sand mold casting, low-pressure casting, counter-pressure casting or squeezing casting, etc.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

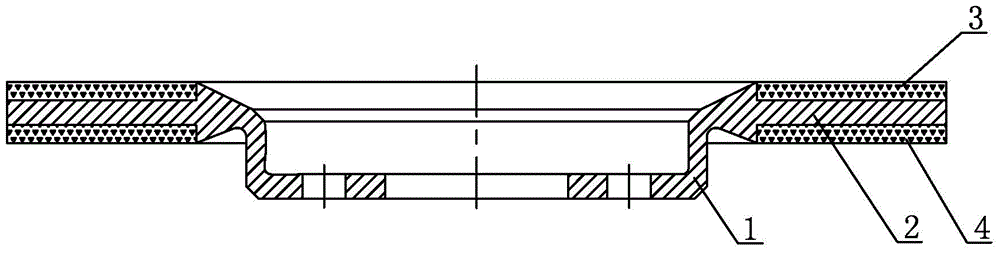

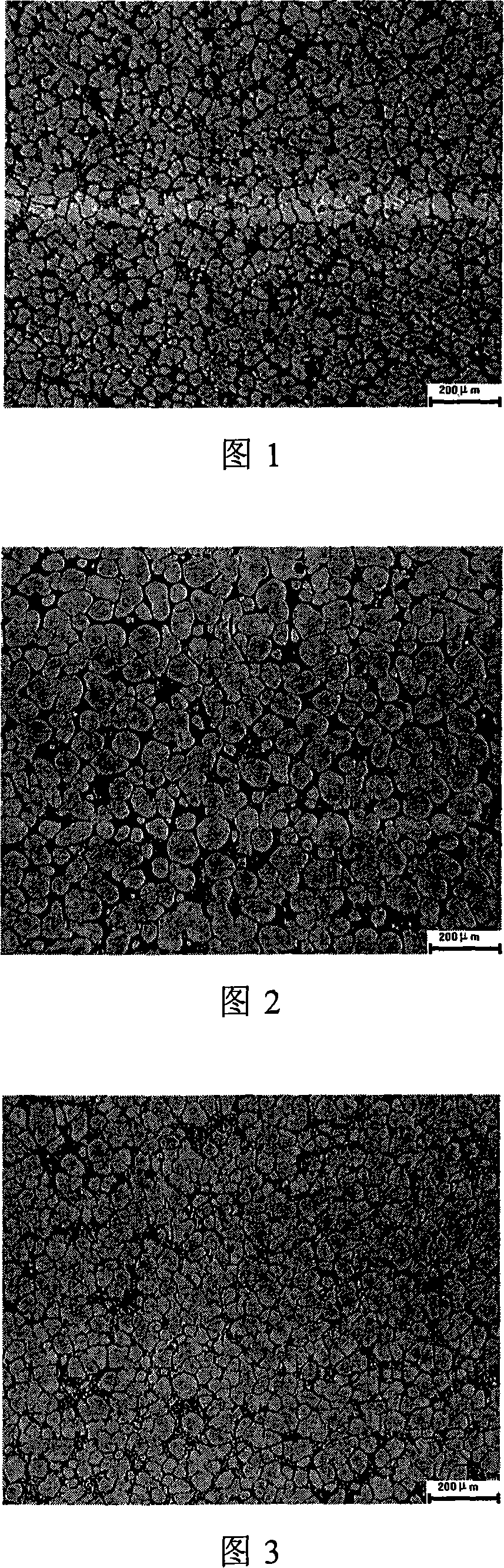

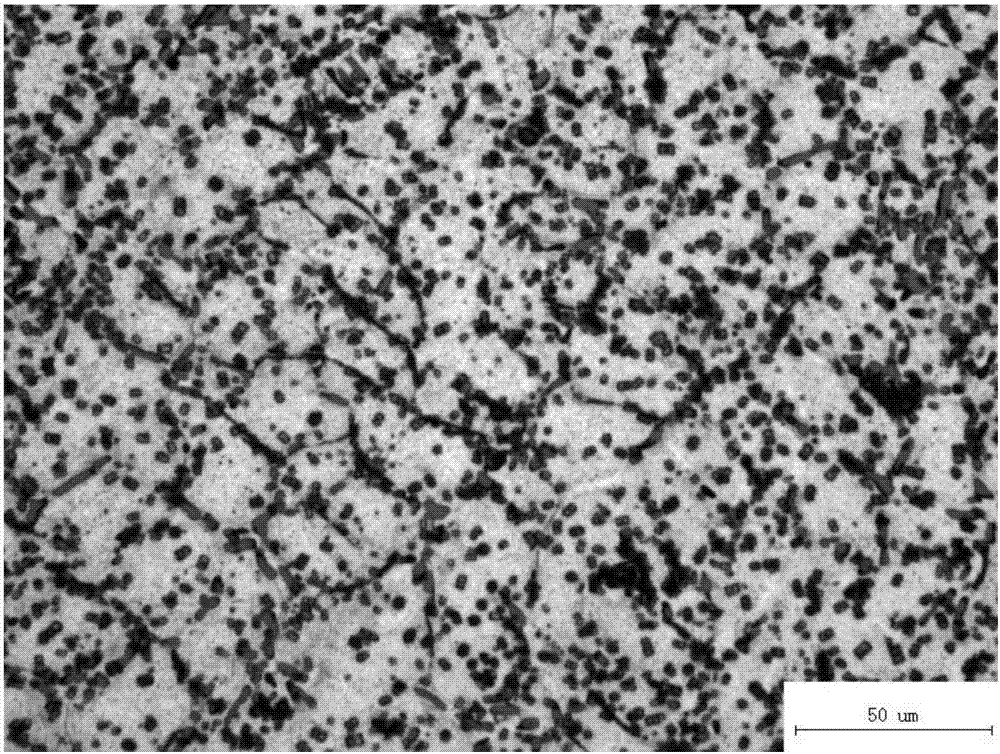

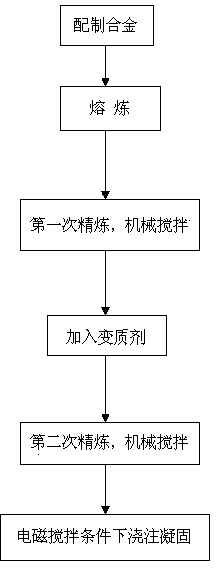

High-silicon aluminum alloy cylinder sleeve and preparation method thereof

InactiveCN104480357AGood metamorphic effectRapid coolingCylinder headsCylindersSmelting processSemi solid

The invention discloses a high-silicon aluminum alloy cylinder sleeve and a preparation method thereof. The high-silicon aluminum alloy cylinder sleeve disclosed by the invention comprises the following alloy elements in percentage by weight: 17-35% of Si, 0.5-5% of Mg, 0.3-1.5% of Ti, 1-2% of Mn, 0.03-0.3% of P or S, 0.3-2.5% of RE, 0.3-0.6% of Fe, 0.02-0.3% of C, and the balance of Al. The high-silicon aluminum alloy cylinder sleeve disclosed by the invention is prepared by comprising the specific steps of smelting, refining, carrying out internal cooling type semi-solid stirring, extruding, casting, carrying out T6 heat treatment, machining, grinding and the like after compounding the above formulae. According to the invention, the phenomena of being too high in centrifugal casting working allowance and easy to cause oxidization inclusion can be effectively avoided; simultaneously, because of adopting a semi-solid rheocasting process, the secondary heating and re-smelting processes can be avoided; the process complexity is reduced; the cost is reduced; and thus, the high-silicon aluminum alloy cylinder sleeve has great application value.

Owner:FUZHOU UNIV

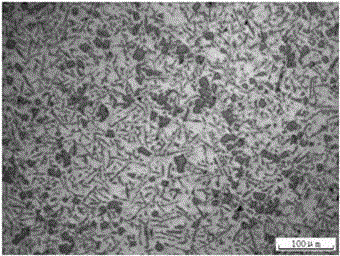

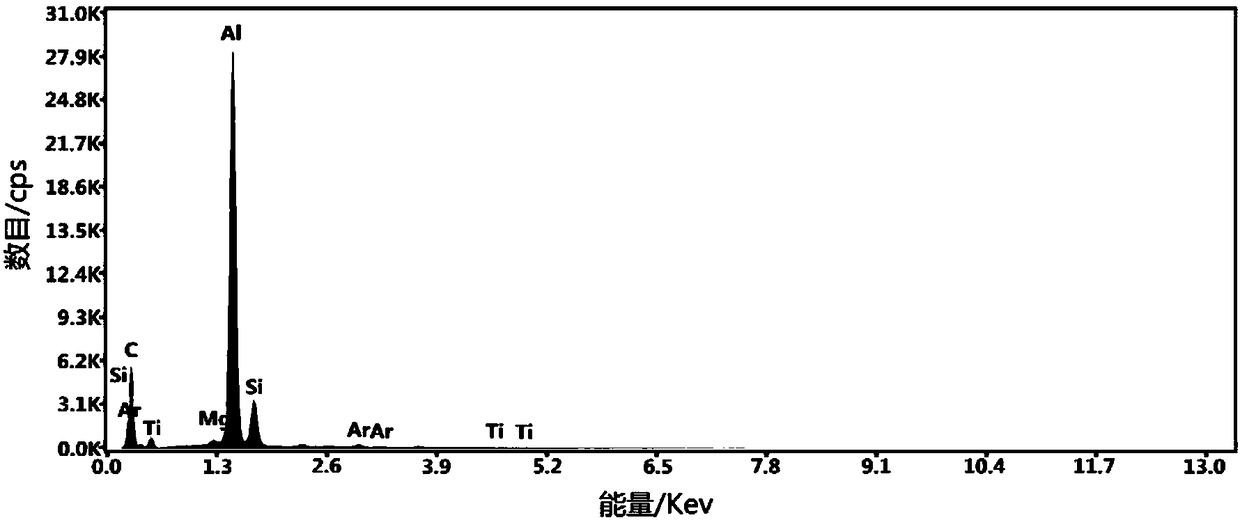

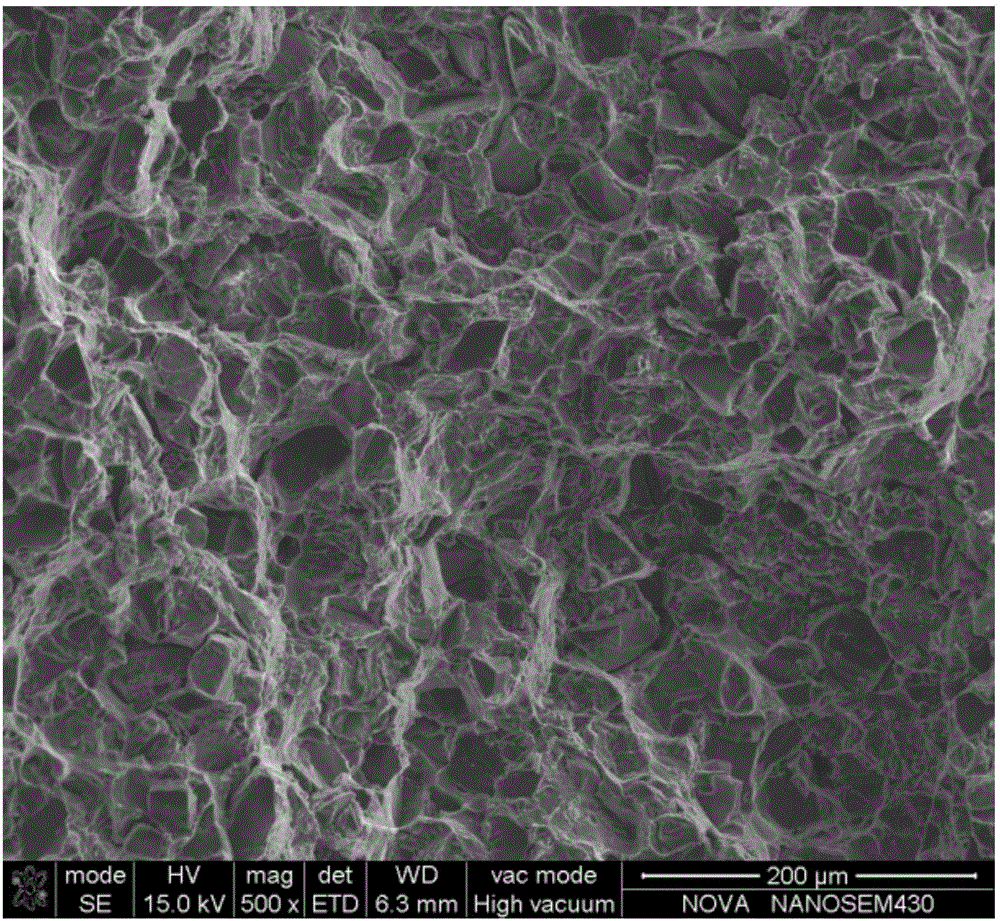

Preparation method of graphene-reinforced aluminum matrix composite

The invention relates to a preparation method of a graphene-reinforced aluminum matrix composite. Aiming at the conditions that graphene is nonuniformly dispersed in an aluminum alloy matrix and is difficult to combine with the matrix, the preparation method adopts a semi-solid squeeze casting method, and comprises the steps of smelting in a smelting and stirring atmosphere oven, electromagnetically stirring, pouring, and conducting squeeze casting to obtain the graphene-reinforced aluminum matrix composite. The preparation method is advanced in process, accurate and detailed in data, and precise in process; a slurry is pure; a metallographic structure is good in compactness without the phenomenon of shrinkage porosity; the prepared graphene-reinforced aluminum matrix composite has the hardness reaching to 87 HB, the tensile strength reaching to 255 MPa, the elongation reaching to 8%, and the compactness reaching to 99.6%; and the preparation method is the advanced preparation method of the graphene-reinforced aluminum matrix composite.

Owner:ZHONGBEI UNIV

Preparation method of aluminum-alloy gas meter end cover

InactiveCN101598585AReduce weightImprove anti-corrosion performanceVolume meteringMechanical pressureAir tightness

The invention discloses a preparation method of an aluminum-alloy gas meter end cover, which is characterized by comprising the following steps: (1) respectively configurating aluminum alloy material and magnesium; (2) melting and refining; (3) pretreating and extruding cast mould; (4) extruding and moulding; (5) carrying out heat processing; and (6) carrying out post-processing. Compared with the prior art, the invention has the advantages that aluminum alloy material and advanced indirect extruding and casting process are adopted, so that the moulding material of the gas meter end cover is light in weight and good in corrosion resistance performance; the aluminum alloy melt solution is crystallized at a higher mechanical pressure, the crystal grain is refined, the organizational density is increased, and the defects of porosity, shrinkage, needle eye and the like inside the casting are eliminated, thereby significantly increasing the air tightness, hardness and tensile strength of the casting.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

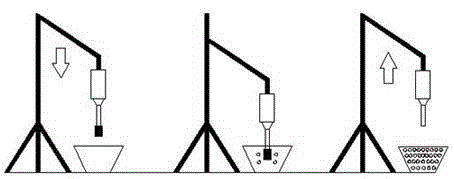

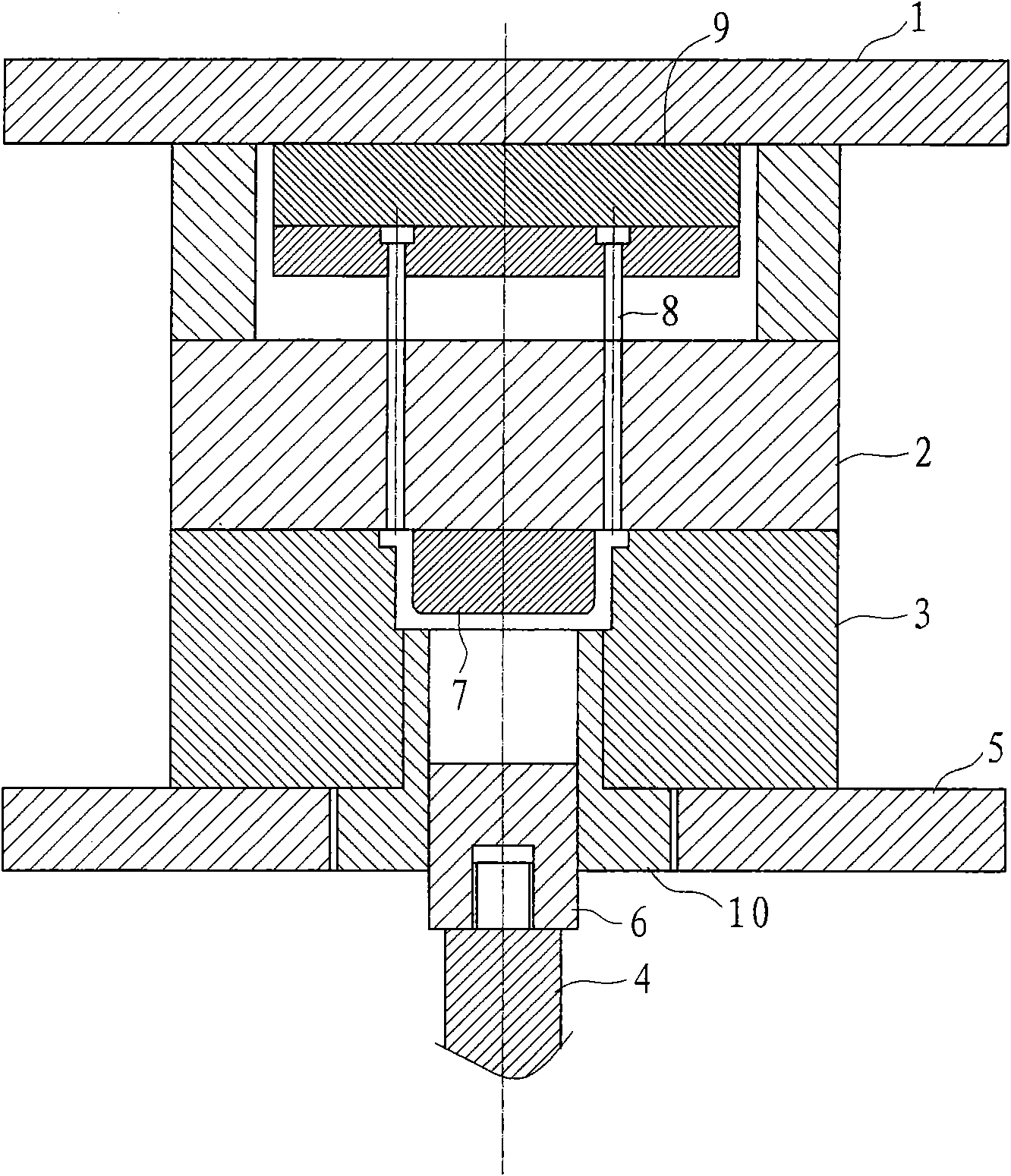

Method for preparing semi-solid metal slurry and rheologic molding

InactiveCN101130203AImprove liquidityEliminates the difficulty of pouringExtrusion control devicesVertical tubeCrucible

The invention discloses a preparing technique of semi-solid metal slurry and rheologic moulding equipment in the preparing technical domain of semi-solid metal slurry, which comprises the following steps: pouring the overheat metal liquid into straight-in composite tube path with an inclined tube and a vertical tube; moving the semi-solid metal slurry and preparing copper into the temperature controller after flowing the overheat metal liquid into the copper along the inner wall of the straight-in composite tube path; doing subsequent cooling or temperature field control for the semi-solid metal slurry; pouring the semi-solid metal slurry into pressing chamber with squeeze moulding machine or squeeze caster or forger to mould; opening or fetching the cast piece or squeeze cast or forge from mould. The invention simplifies the preparing technique, reduces energy consumption and shortens the technical flow path, which reduces the manufacturing cost of the semi-solid metal rheopectic casting die or rheopectic squeeze casting die or rheopectic forge.

Owner:UNIV OF SCI & TECH BEIJING

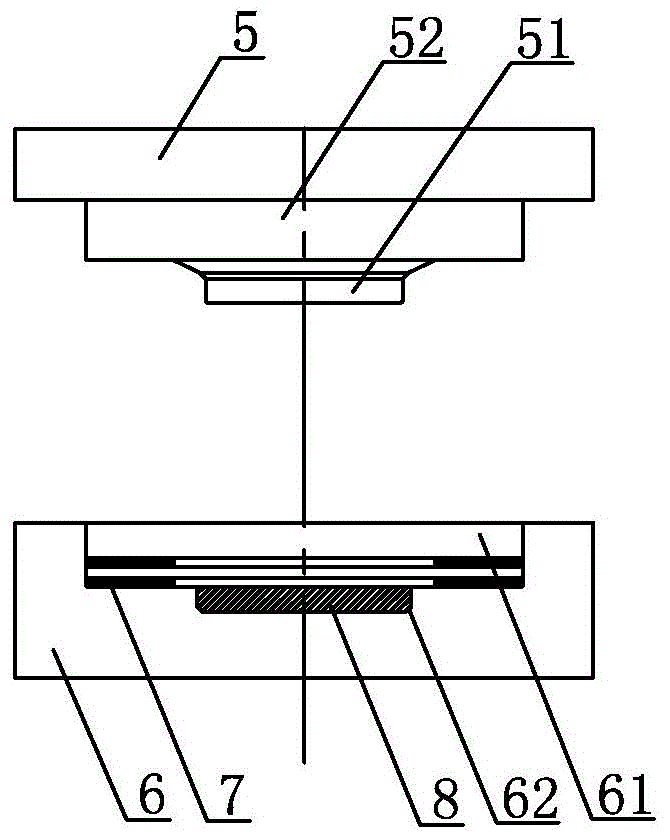

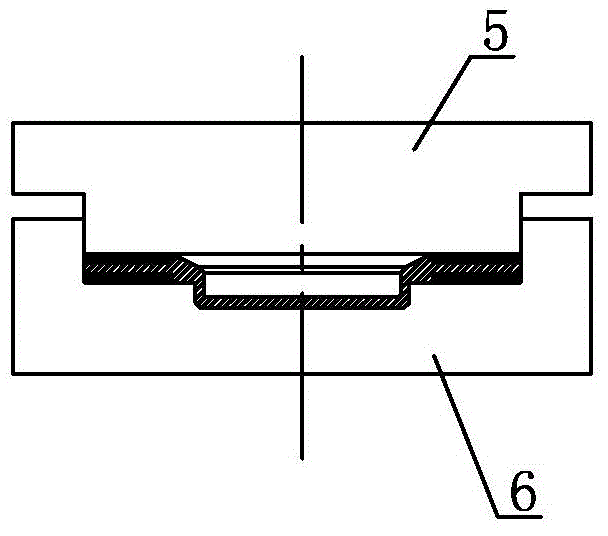

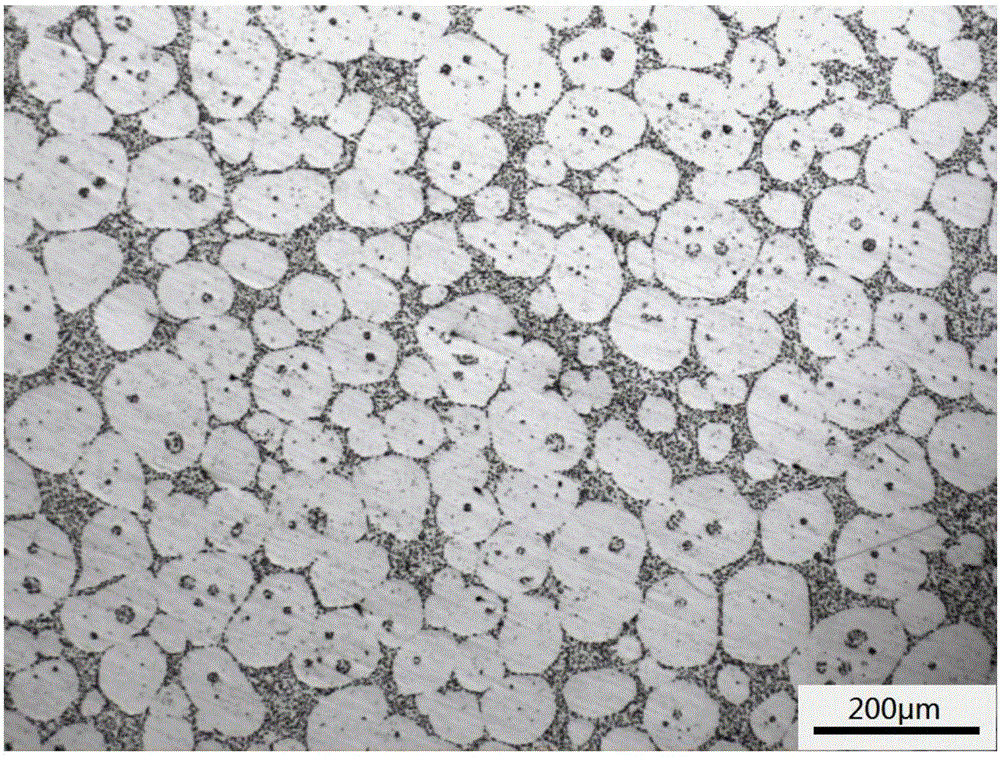

Semi-solid squeezing casting method and system for aluminum alloy

The invention relates to a semi-solid squeezing casting method and system for aluminum alloy and belongs to the technical field of preparation and application of nonferrous materials. The method comprises the following steps that firstly, an aluminum alloy block is cut into aluminum alloy pieces, the aluminum alloy pieces are wrapped with aluminum foil correspondingly, and then the wrapped aluminum alloy pieces are preheated; the preheated aluminum alloy pieces are smelted, so that molten aluminum alloy is obtained; the molten aluminum alloy is poured into a heat preservation device for heat preservation via a sprue with a bent channel or an inverted conical channel, and semi-solid aluminum alloy slurry is obtained; the semi-solid aluminum alloy slurry is poured into a heat preservation squeezing mold to be subjected to squeezing molding treatment; and finally, pressure application continues after the squeezing molding treatment is completed, then a casting is jacked out and subjected to air cooling, and an semi-solid aluminum alloy squeezed casting is obtained. According to the preparation method, the advanced process is achieved, procedures are precise, data are accurate and full, and after heat treatment of the prepared semi-solid aluminum alloy squeezed casting, the hardness of the casting can be up to 82.9 HB and the tensile strength of the casting can be up to 279 Mpa.

Owner:ZHONGBEI UNIV

Casting forming equipment and process for amorphous alloy component

ActiveCN104668504ALong cycleShorten the working cycleElectric heating for furnacesManufactured materialSqueeze casting

Provided is a device for the casting forming of amorphous alloy components. The device comprises an injection system, an alloy smelting system, a raw material feeding system, a mould system, a vacuum system and a protective atmosphere system, which are used for the preparation of the amorphous alloy components, and can realize the formation by squeezing casting of the amorphous alloy components under a vacuum or a protective atmosphere with a positive pressure. The device is provided with an exhaust port on the mould to effectively solve the problem of forming micro shrinkage cavities on the surface in the process of forming the alloy components so as to improve the quality of the amorphous alloy components. Also provided is a process for the casting forming of the amorphous alloy components. A high vacuum tank or a protective atmosphere tank is used to reach an acquisition time of the vacuum or protective atmosphere with a positive pressure so as to shorten the forming period, save the production cost, and improve the production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Squeeze casting method for mixed-particle-reinforced type aluminum matrix composite

The invention relates to a squeeze casting method for a mixed-particle-reinforced type aluminum matrix composite. The squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite aims at the problem that the tension strength and the hardness of an aluminum matrix composite are low. According to the squeeze casting method, an aluminum alloy serves as a matrix material, aluminum-copper-iron-beryllium quasicrystal and zirconium carbonate serve as reinforcing agents, an al-sc master alloy serves as a modificator, the aluminum alloy, aluminum-copper-iron-beryllium quasicrystal, the zirconium carbonate and the al-sc master alloy are subjected to melting in a vacuum melting furnace, mechanical stirring, argon bottom blowing protecting, squeezing and heat treatment, and then the mixed-particle-reinforced type aluminum matrix composite is prepared. According to the squeeze casting method, the technology is advanced, the processes are rigorous, and data are precise, full and accurate; the mechanical performance of the aluminum matrix composite is enhanced greatly, the tension strength reaches to 409 MPa, the hardness reaches to 150.2 HV, and the elongation reaches to 4.7%; and the squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite is an advanced method.

Owner:WENXI COUNTY REGAL MAGNESIUM

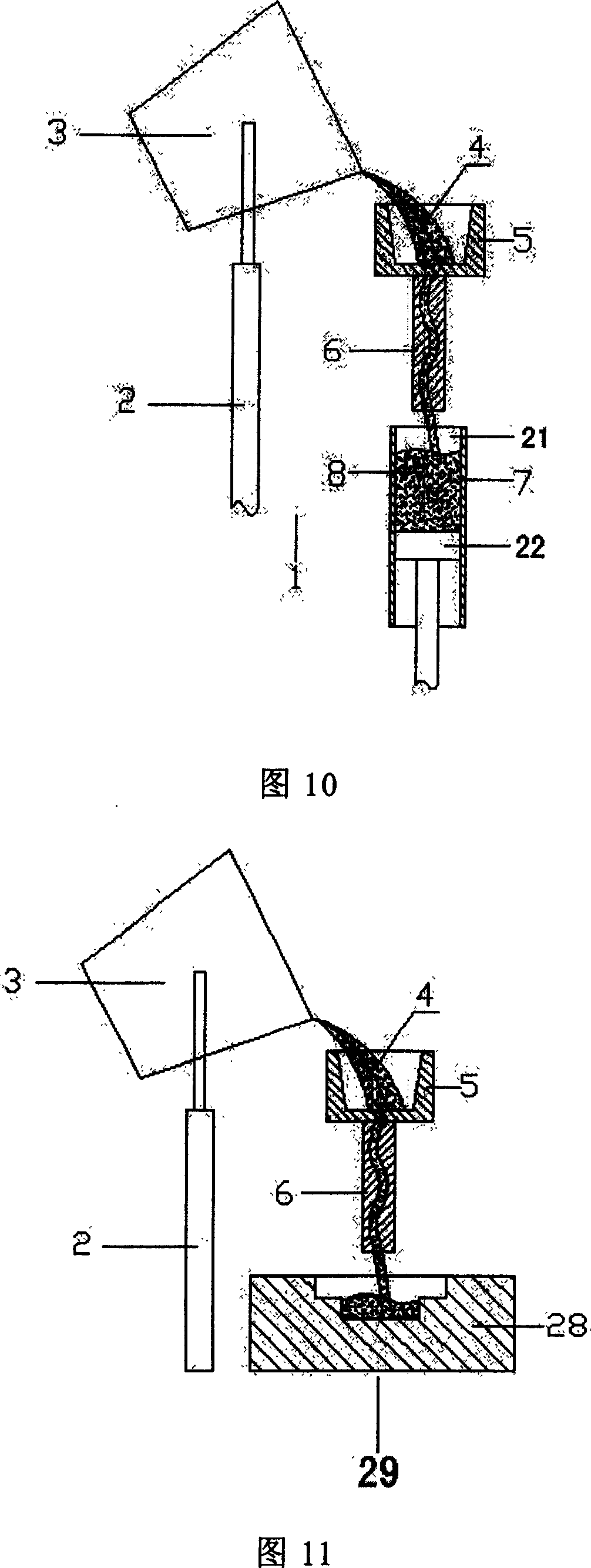

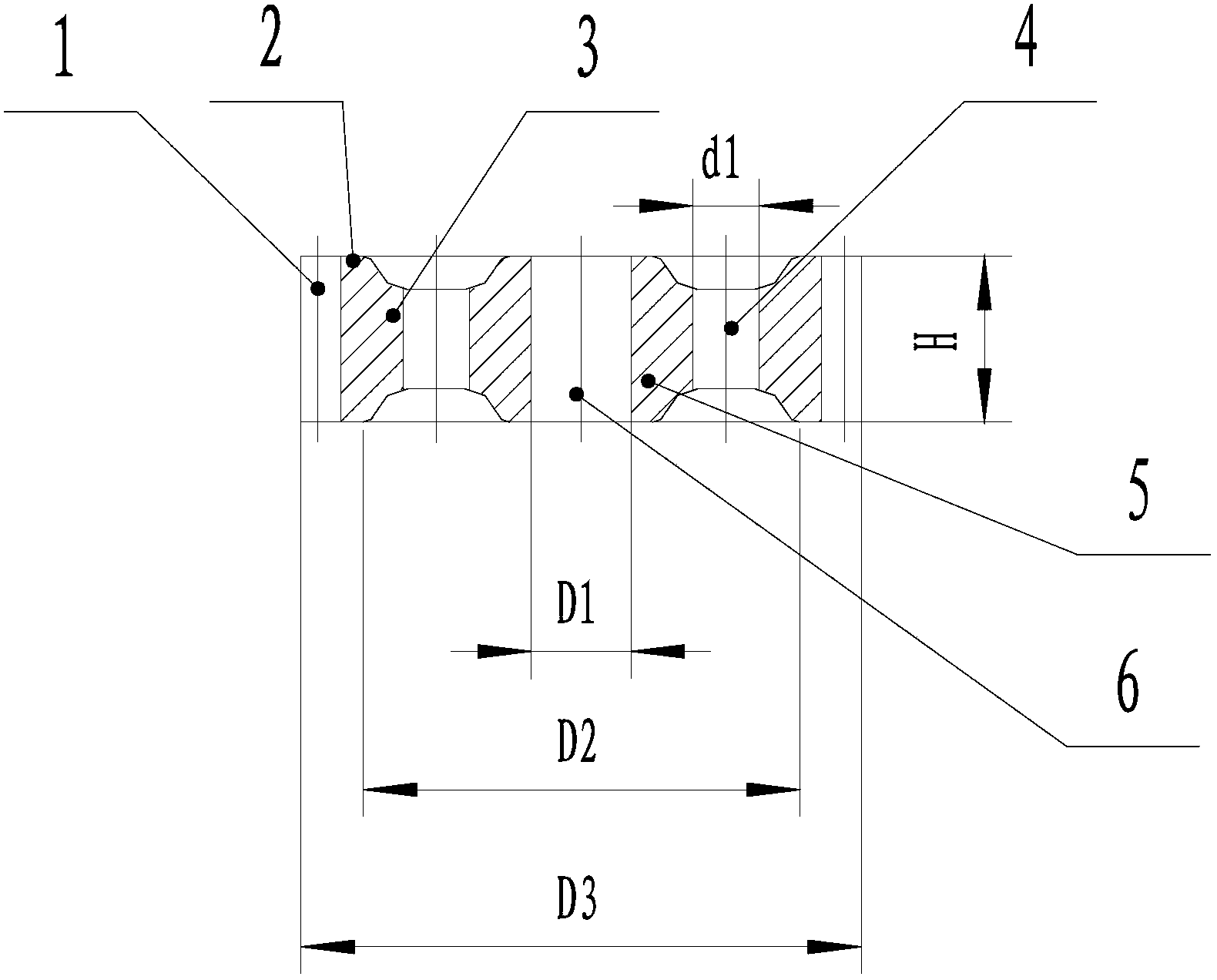

Squeeze casting die and casting method for straight toothed spur gears

The invention discloses a squeeze casting die and a squeeze casting method for straight toothed spur gears. The squeeze casting die comprises an upper die, a middle die, a lower die, a bottom die, web plate hole cores and a shaft hole core. The upper die, the middle die, the lower die, the bottom die and the shaft hole core are coaxially arranged, the middle die is fixed to the upper end of the lower die, a sliding inner cavity is arranged on the lower die, and the bottom die is nested in the sliding inner cavity and is slidably sealed in the sliding inner cavity; the web plate hole cores and the shaft hole core are fixedly arranged on the bottom die, and positioning exhaust holes which correspond to the web plate hole cores and the shaft hole core are formed in the upper die; a sealed pouring cavity is formed among the upper die, the middle die, the lower die and the bottom die in an enclosed manner when the upper die and the middle die are closed; the web plate hole cores and the shaft hole core are inserted into the corresponding positioning exhaust holes formed in the upper die. The squeeze casting die and the squeeze casting method have the advantages of high material utilization rate of 95%, high production efficiency, zero pollution due to waste sand, energy conservation, environmental protection, small gear blank machining allowance, fine crystal grains, good mechanical property and capability of carrying out continuous operation.

Owner:BEIJING TIMES RUIZHI TECH TRADE

Preparation method of casting aluminum alloy automobile engine by ultra-low speed laminar flow

The invention relates to a preparation method of casting an aluminum alloy automobile engine by an ultra-low speed laminar flow. The preparation method comprises the following steps: heating the aluminum alloy as an alloy material in a concentrated melting furnace; sequentially melting, deslagging, and carrying out refining and modification and degassing; transferring to an electric heating heat-preserving furnace to preserve heat after being qualified; and after determining that the temperature of a mould is qualified, casting by a low speed laminar flow filling technology. The mould is a double-cavity mould with symmetrical cavities to transfer an alloy liquid to a horizontal cold chamber die casting machine, an injection punch head propels the alloy liquid to an engine bracket mould cavity through an adjustable temperature melting cup and increases the pressure to recrystalize the aluminum alloy so as to obtain a squeeze casting part of the engine bracket; and then, carrying out solution treating and aging strengthening treatment on the part to obtain the engine bracket with excellent mechanical property for automobiles. The aluminum alloy automobile engine bracket prepared by the invention is compact and uniform in tissue, small in shrinkage blowhole, good in appearance of the casting, high in production efficiency and low in production cost. Particularly, the Rockwell hardness can be improved from HRC50 to HRC90 after T6 thermal treatment.

Owner:ZHUHAI RONGTAI PRECISION DIE CASTING

Low speed vacuum squeeze casting technology

The invention provides a low speed vacuum extruding casting technique which comprises the steps of: (1) the design of dies, a vacuum system and a hot runner; (2) the installation, the preheating and the coating of the hot runner and the dies; (3) the pouring of molten metal into the hot runner, die matching and vacuum pumping; (4) low speed and vacuum filling; (5) extruding and solidifying; (6) the opening of the dies to take finished products. The technical effects of the technique are the improvement of a temperature field during the casting process and the realization of the casting method of injection at low speed, solidification under high pressure and hole shrinkage without vacuum. The low speed vacuum extruding casting technique can effectively reduce the probability of containing pores and shrinkage and loose defects, heat treatment can be carried out to die casts, and both the tensile strength and the percentage elongation of the die casts after the heat treatment are increased by 25 percent, thereby greatly improving the quality of the die casts.

Owner:NANCHANG HANGKONG UNIVERSITY

Heat treatment process for scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy

InactiveCN103866216AAvoid overheatingPrevent excessive solid solution residual crystalline phasesStress concentrationThermal insulation

The invention belongs to the field of aluminum alloy heat treatments, and particularly relates to a heat treatment process for a scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy. The heat treatment process adopts a three-stage strengthening solid-solution treatment process and a single-stage aging treatment process, wherein the three-stage strengthening solid-solution treatment comprises: carrying out thermal insulation for 24 h at a temperature of 460 DEG C, heating to a temperature of 470 DEG C, carrying out thermal insulation for 8 h, continuously heating to a temperature of 480 DEG C, carrying out thermal insulation for 2 h at a temperature of 480 DEG C, immediately taking, and carrying out water quenching, and then the single-stage aging heat treatment is performed and comprises: carrying out thermal insulation for 24 h at a temperature of 120 DEG C. According to the present invention, the coarse non-equilibrium phase in the alloy can be sufficiently dissolved and homogenized, the supersaturation degree of the solid solution is increased, the stress concentration tendency with the grain boundary eutectic phase is reduced, the matrix structure after aging is fine GP zones distributed in a diffusion manner and an eta<,> phase, the grain boundary is a grain boundary precipitation phase distributed in a discontinuous manner, the ultra high strength ([sigma]s is more than or equal to 500 MPa) is achieved, and the good plasticity (delta is more than or equal to 10%) is provided.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

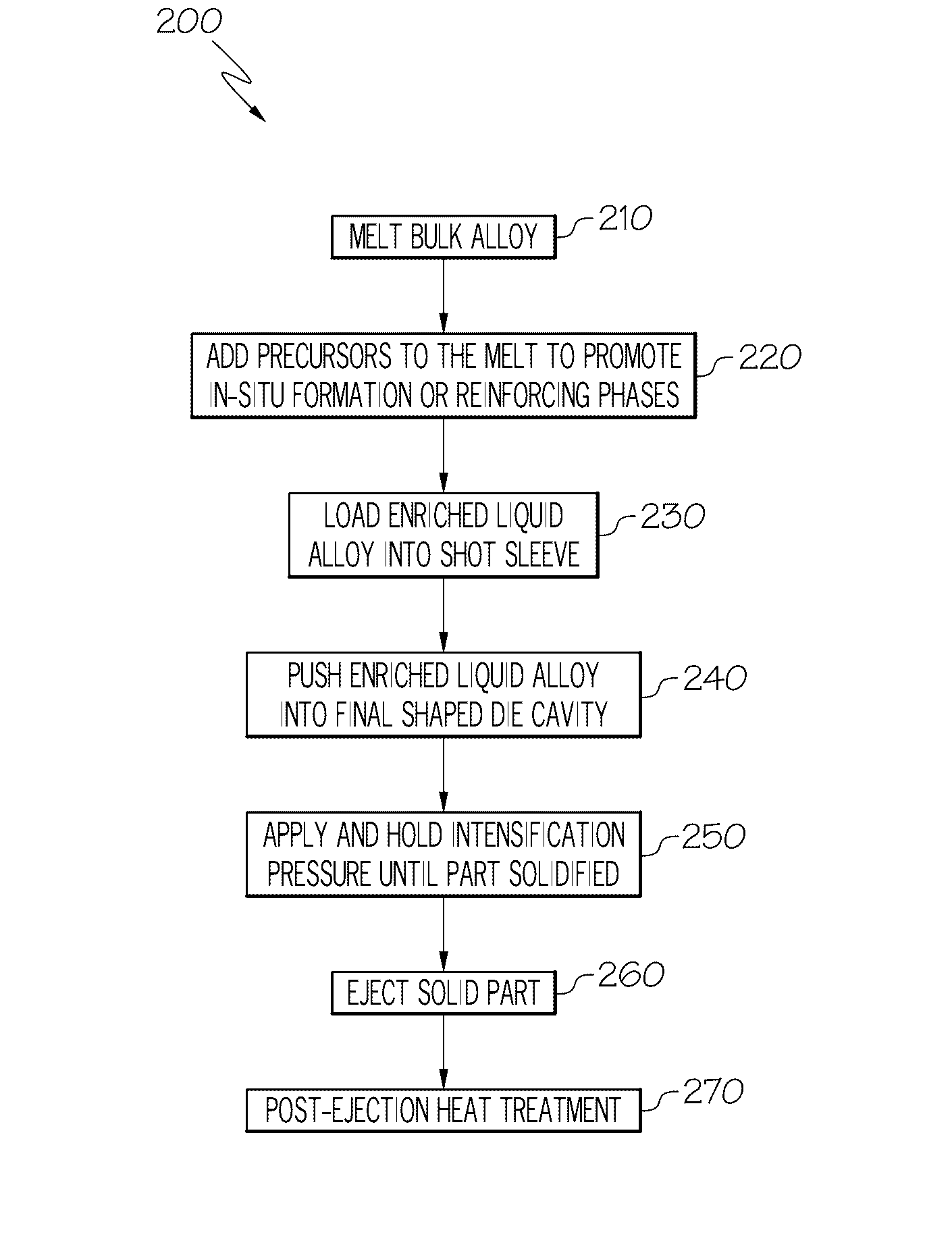

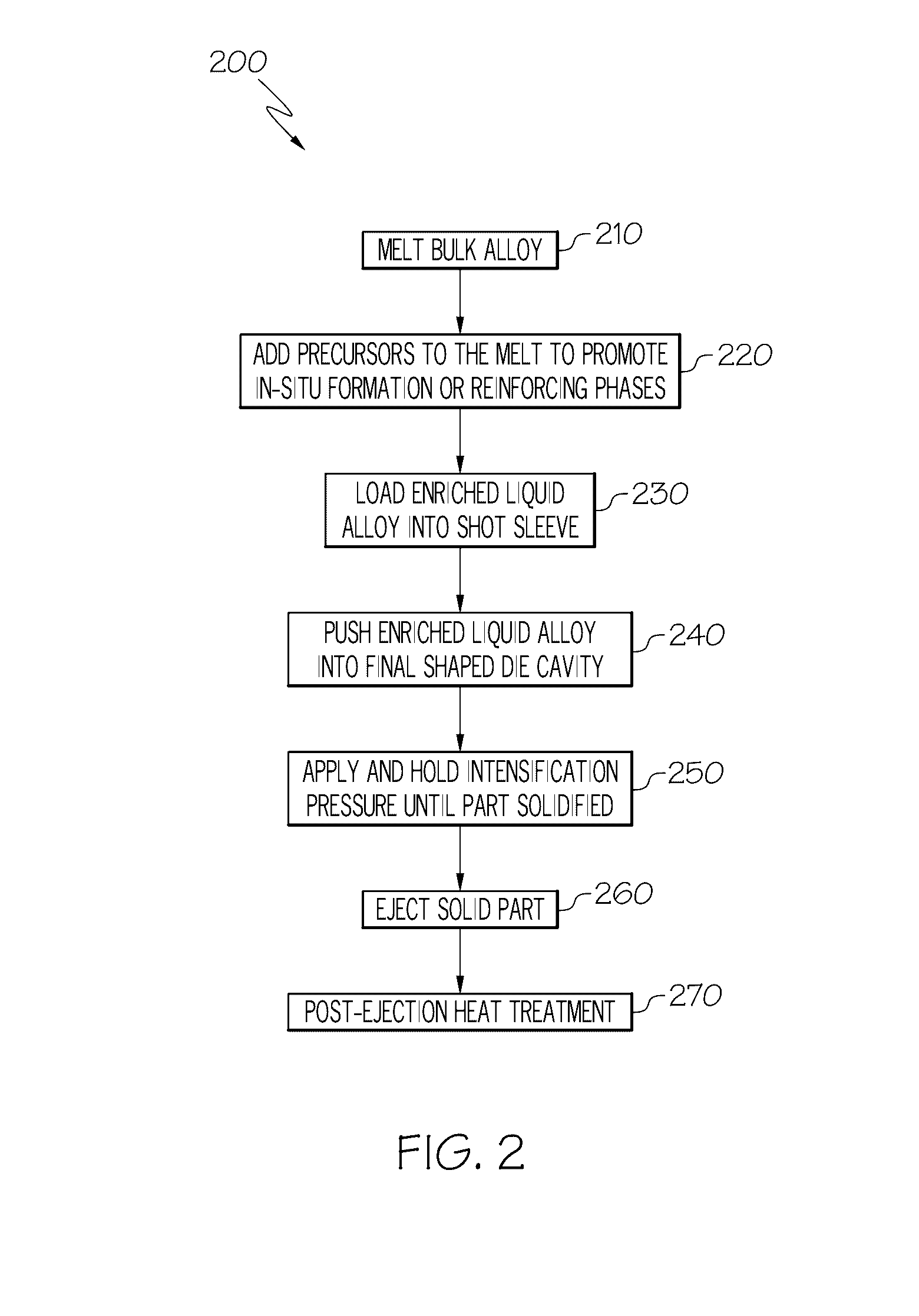

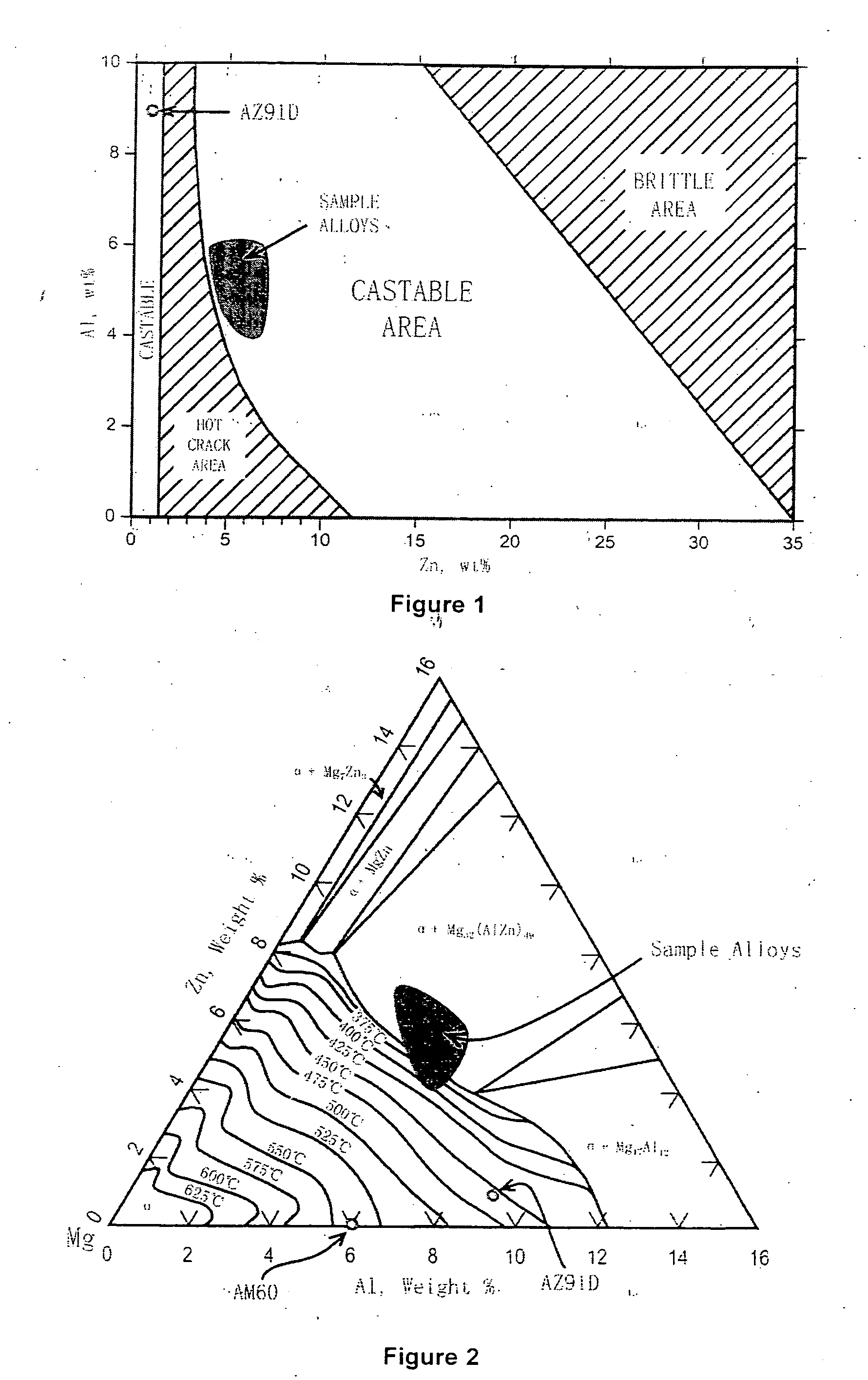

Method of Making Aluminum or Magnesium Based Composite Engine Blocks or Other Parts With In-Situ Formed Reinforced Phases Through Squeeze Casting or Semi-Solid Metal Forming and Post Heat Treatment

InactiveUS20160361764A1Improve mechanical propertiesHigh specific mechanical propertyEngine componentsMetal formingHigh entropy alloys

A method of making a reinforced metal alloy component, the method including introducing a reinforcing phase precursor into a bulk alloy that is selected from the group consisting of high-entropy alloys, aluminum-based alloys, magnesium-based alloys and combinations thereof. The precursor is converted to a reinforcing phase by exposing the bulk alloy and precursor to an elevated temperature during one or more of a subsequent heat treating step, squeeze casting shaping or semi-solid metal shaping.

Owner:GM GLOBAL TECH OPERATIONS LLC

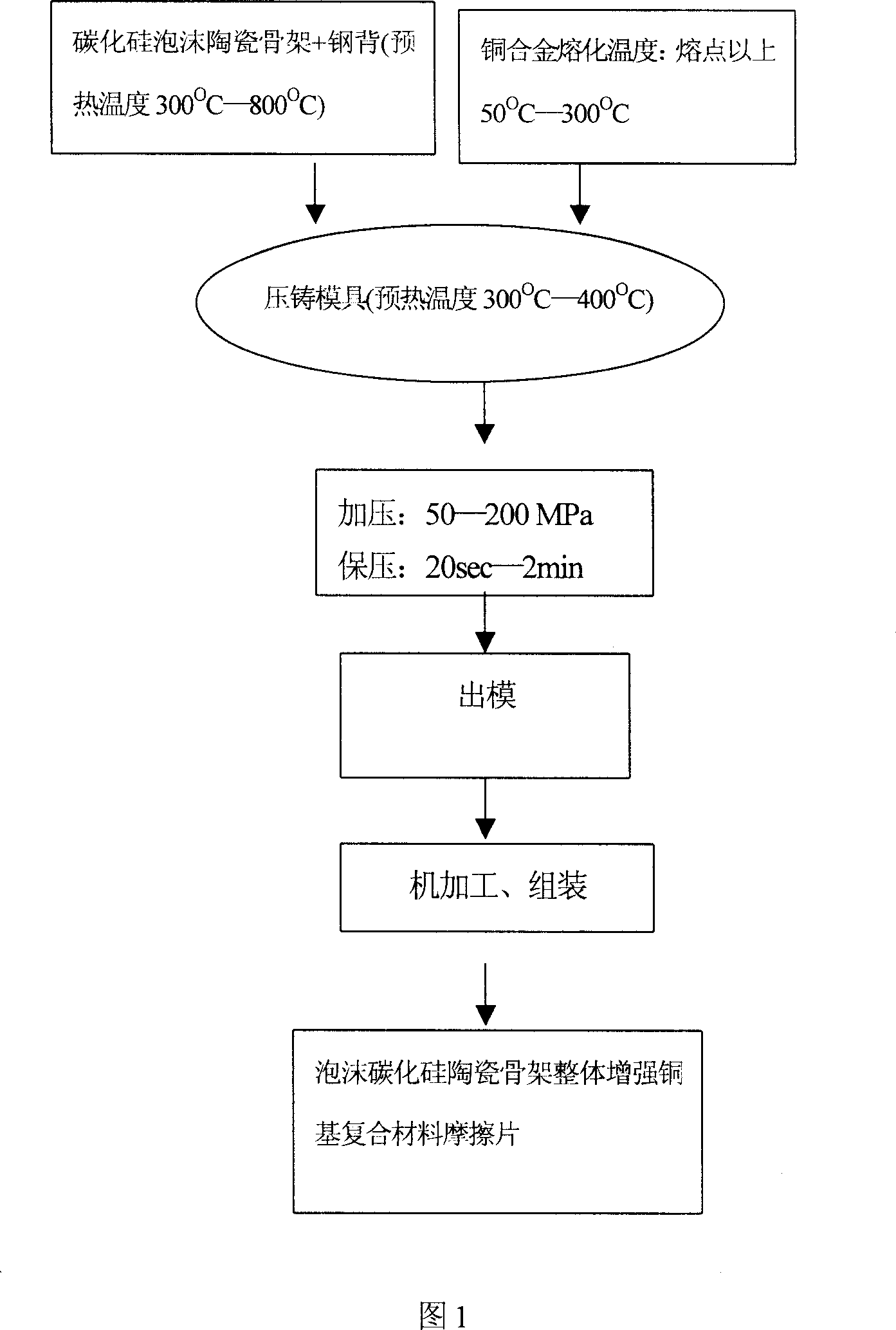

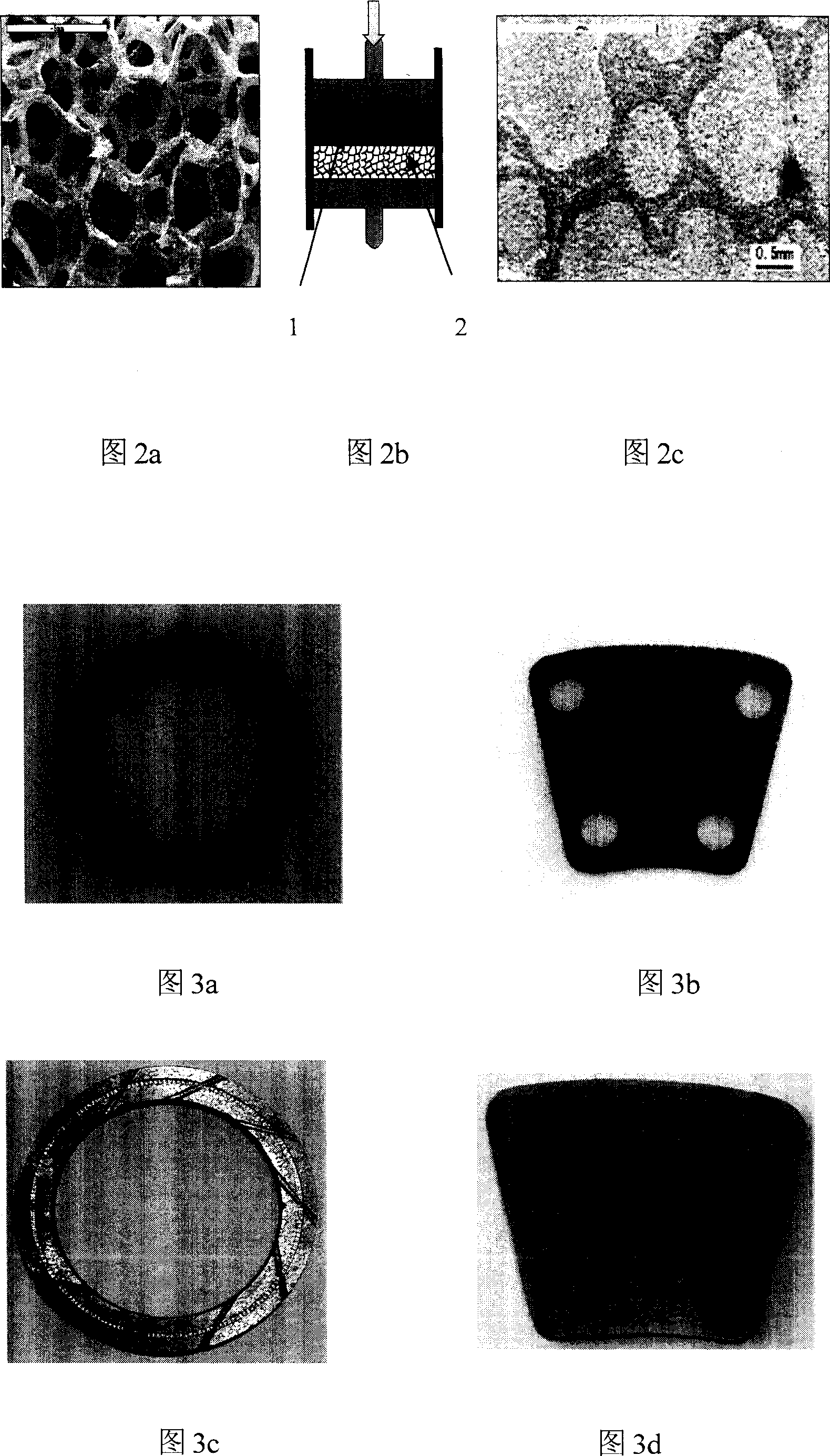

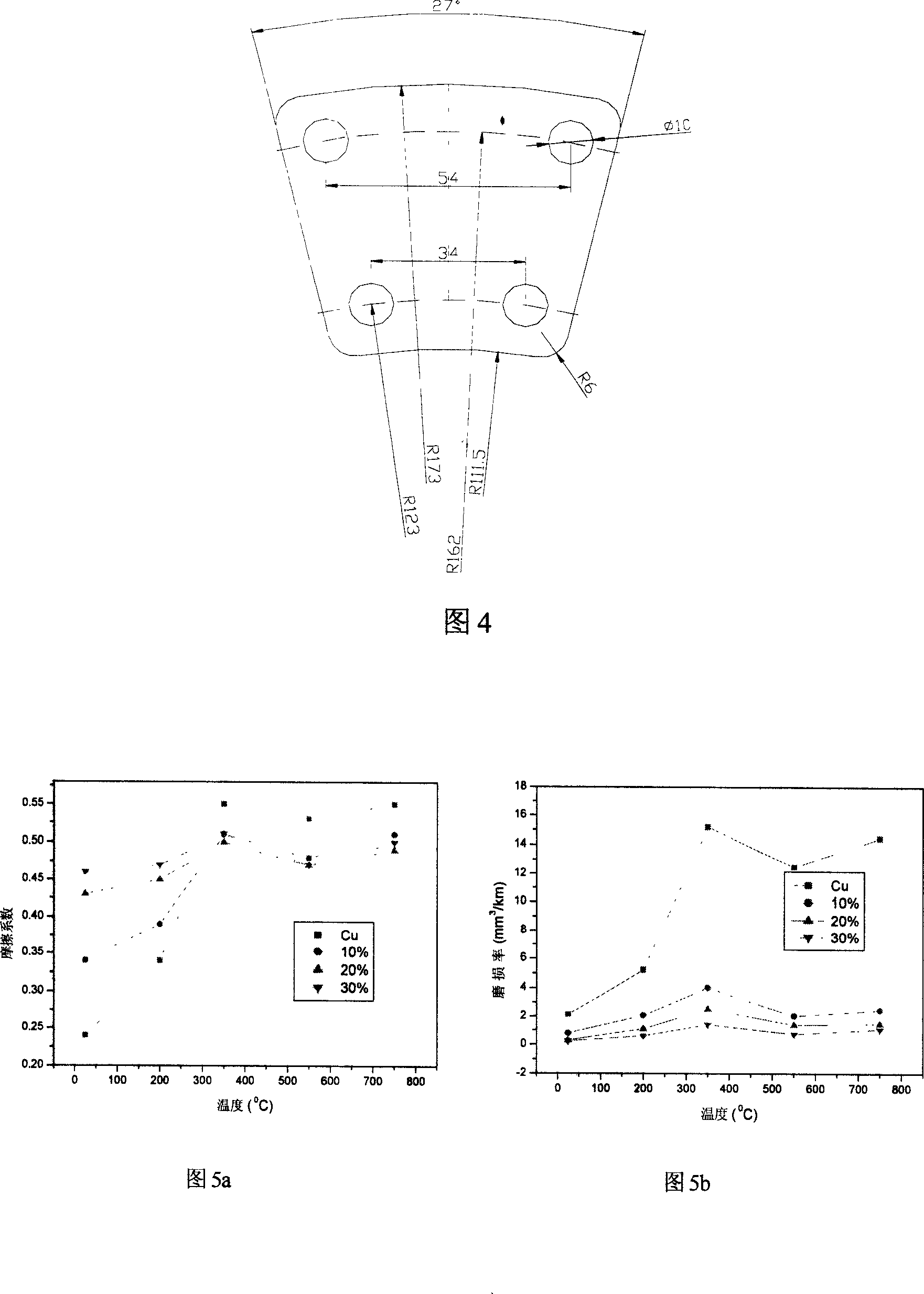

Foaming silican carbide ceramic strengthening copper base composite abrasive sheet and preparation process thereof

The invention relates to the friction material preparing technique, concretely a foam SiC ceramic-copper alloy two phase-combined, foam SiC ceramic frame whole reinforced copper-base composite friction plate and the preparing method thereof, and by volume fraction, the friction plate is composed of foam SiC ceramic 15%-50% and copper alloy 85%-50%; and the preparing method comprises the two key process steps of preparing high intensity, compact foam SiC ceramic and combining foam SiC ceramic with copper alloy: firstly preparing high intensity compact foam SiC ceramic, then making liquid copper alloy enter 3D connecting hole spacing of foam SiC ceramic by extrusion casting and solidify to make it. And it has characters of good heat resistance, excellent friction performance, high mechanical intensity and good process performance, able to act as novel high performance frictional brake and transmission material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

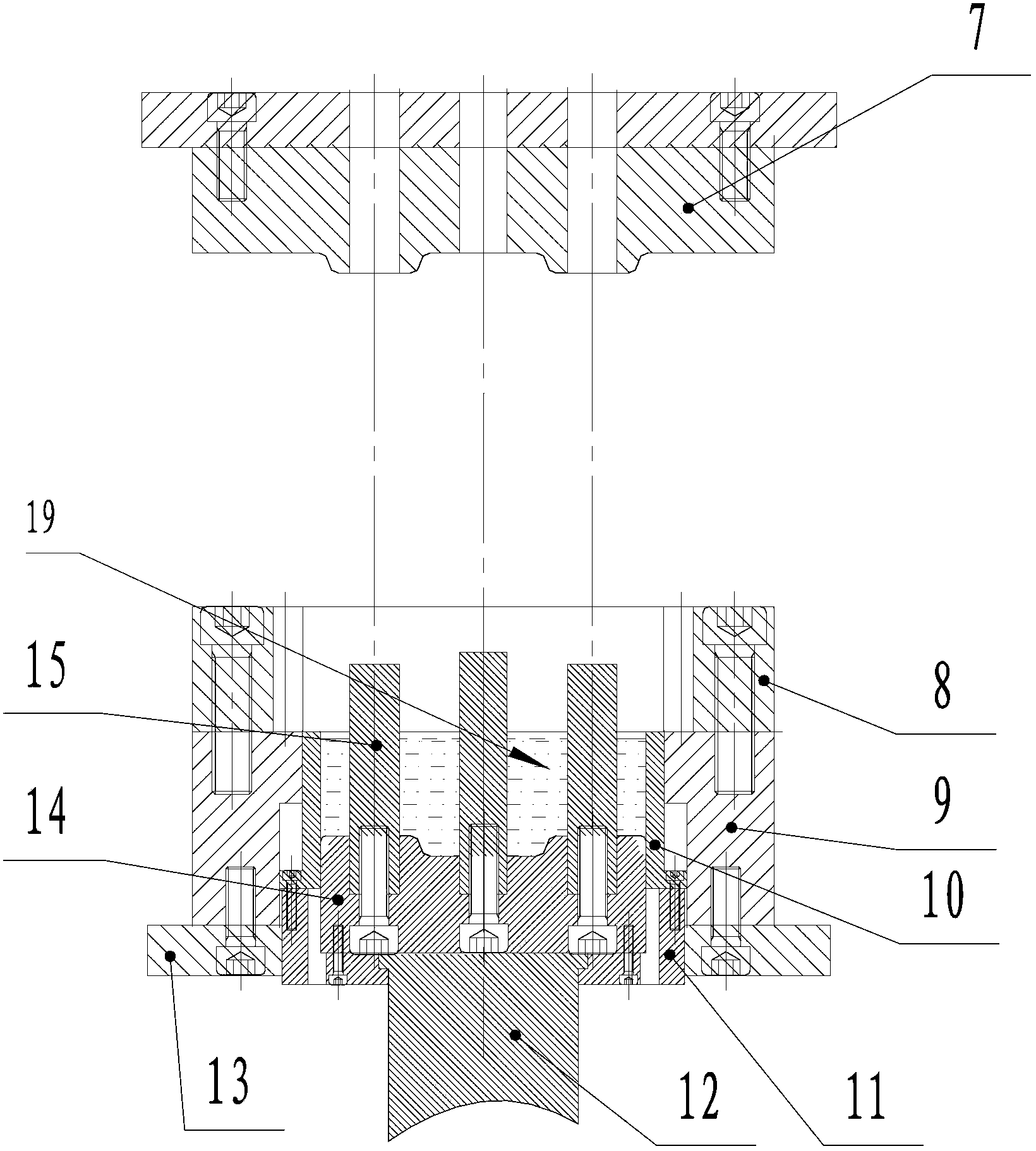

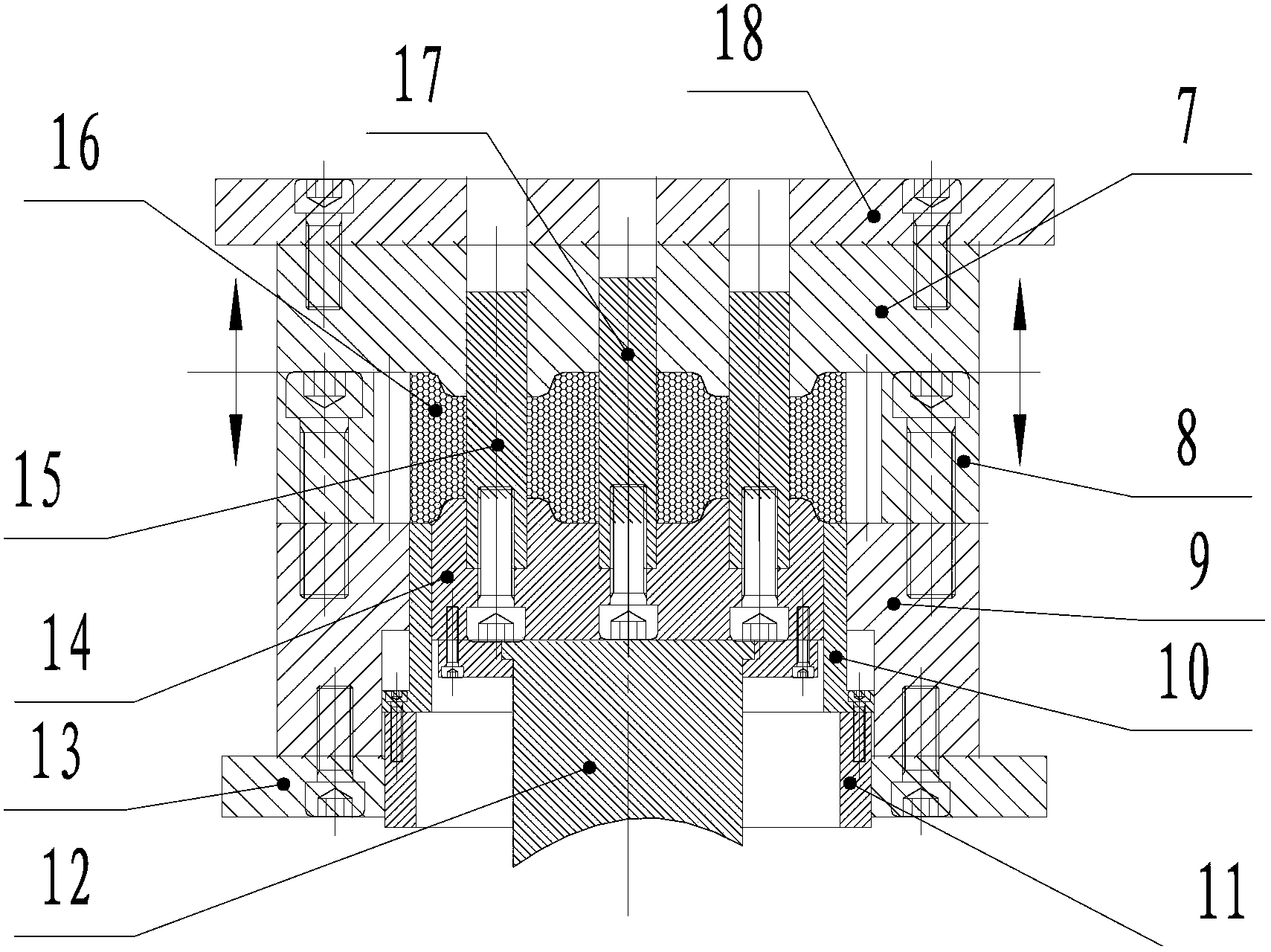

Composite squeeze casting method for magnesium alloy special-shaped parts

The invention relates to a composite squeeze casting method for magnesium alloy special-shaped parts in order to avoid the situations that in the casting process of the magnesium alloy special-shaped parts, the hole shrinkage phenomenon and the shrinkage loosening phenomenon are serious, and the structural compactness of a metallographic structure is poor. According to the composite squeeze casting method, firstly, a composite squeeze casting mold is prepared; gas protection is performed in the whole process of magnesium alloy liquid; the magnesium alloy liquid is smelted through a vacuum furnace, cast and subjected to composite squeeze casting; and the magnesium alloy special-shaped parts are manufactured. The technology of the preparation method is advanced; data are accurate and detailed; the magnesium alloy special-shaped parts manufactured through composite squeeze casting are accurate in shape, good in metallographic structure compactness and free of the hole shrinkage phenomenon and the shrinkage loosening phenomenon, and the tensile strength can be 180 MPa; and the composite squeeze casting method for the magnesium alloy special-shaped parts is advanced.

Owner:KANG MEI TECH DEV

Carbon fiber mixing reinforced magnesium-base high modulus composite material and its preparing process

The present invention relates to one kind of carbon fiber mixture reinforced magnesium-base high modulus composite material and its preparation process. The composite material consists of magnesium-base alloy and added reinforcing mixture phase comprising carbon fiber 30-70 wt% and hollow micro bead grain 1-5 wt%. The preparation process includes the first prefabricated body preparation and the subsequent extrusion casting to prepare final composite material. The addition of the hollow micro bead results in the homogeneous dispersion of the carbon fiber, solves the problem of wetting between magnesium and carbon fiber and avoids the cutting of mixture grain to carbon fiber. The composite material has high modulus performance, simple preparation process and low production cost.

Owner:SHANGHAI JIAO TONG UNIV

Squeeze casting Al-Si-Cu alloy material

The invention relates to an aluminum alloy material, in particular to an extrusion casting Al-Si-Cu alloy prepared by solution heat treatment (T4 heat treatment) and solution heat treatment plus full artificial aging (T6 heat treatment) processes; the main components and the mass percentage thereof are as follows: 5.30 percent to 6.20 percent of silicon, 3.80 percent to 4.30 percent of copper, 0.60 percent to 0.91 percent of trace alloy strengthened element, 0.20 percent to 0.30 percent of impurity element iron, and the rest are aluminum and inevitable trace impurities. The material not only has quite high strength and good plasticity, but also has good casting shaping performance, low raw material cost and convenient sources, is in particular applicable in manufacturing parts with light weight and less weight requirements, and has very broad application prospect in automobile, aviation and other industries.

Owner:SOUTH CHINA UNIV OF TECH

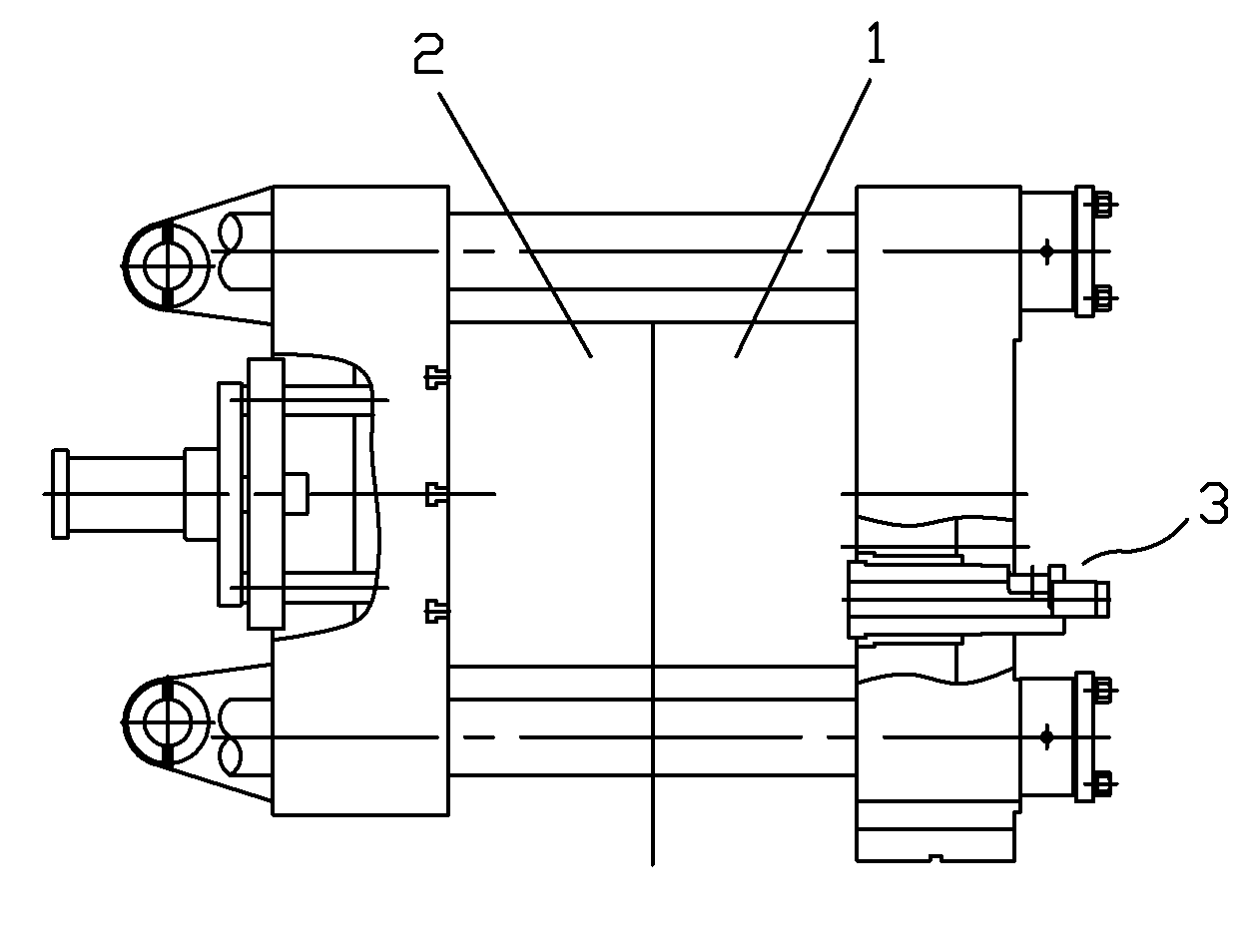

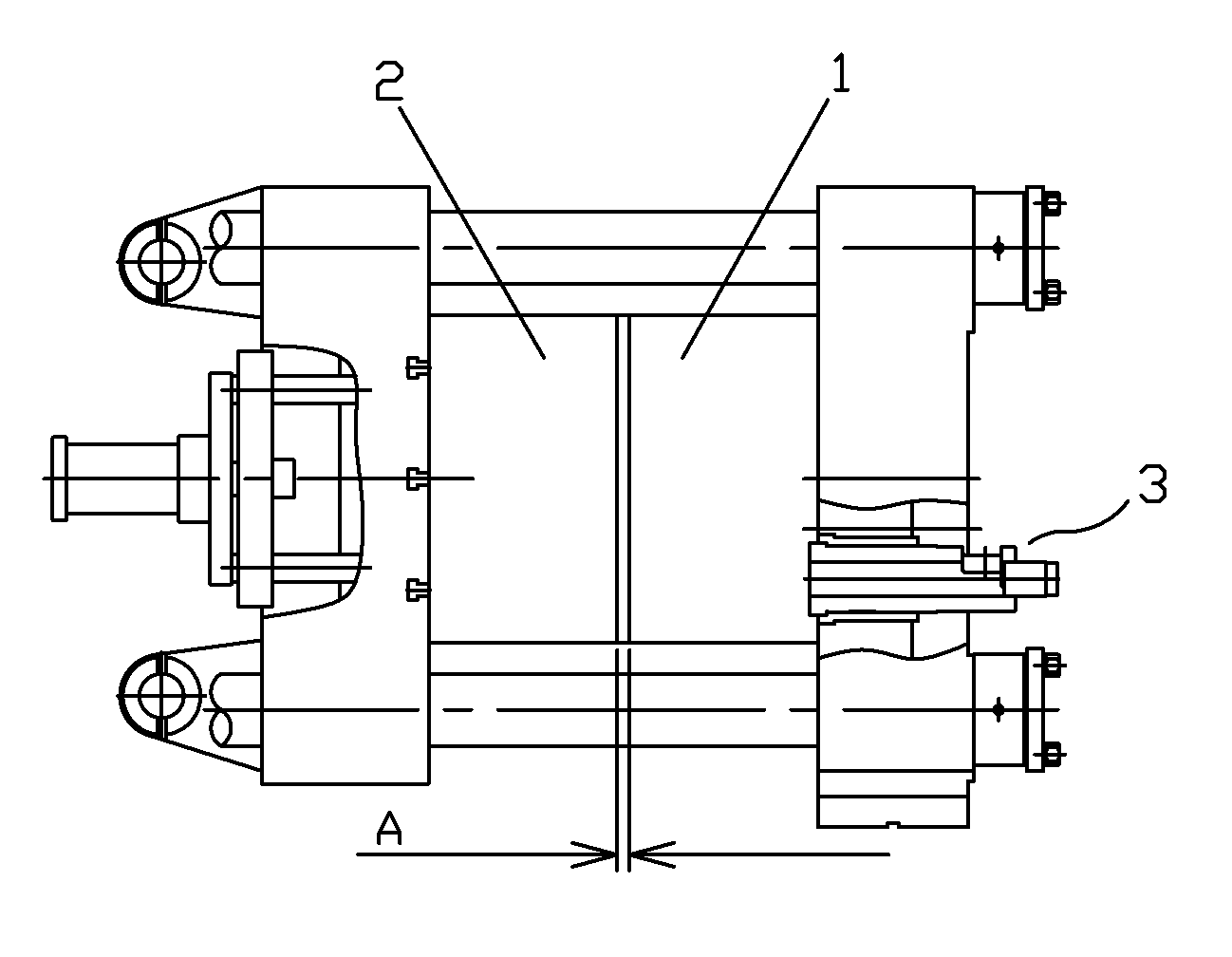

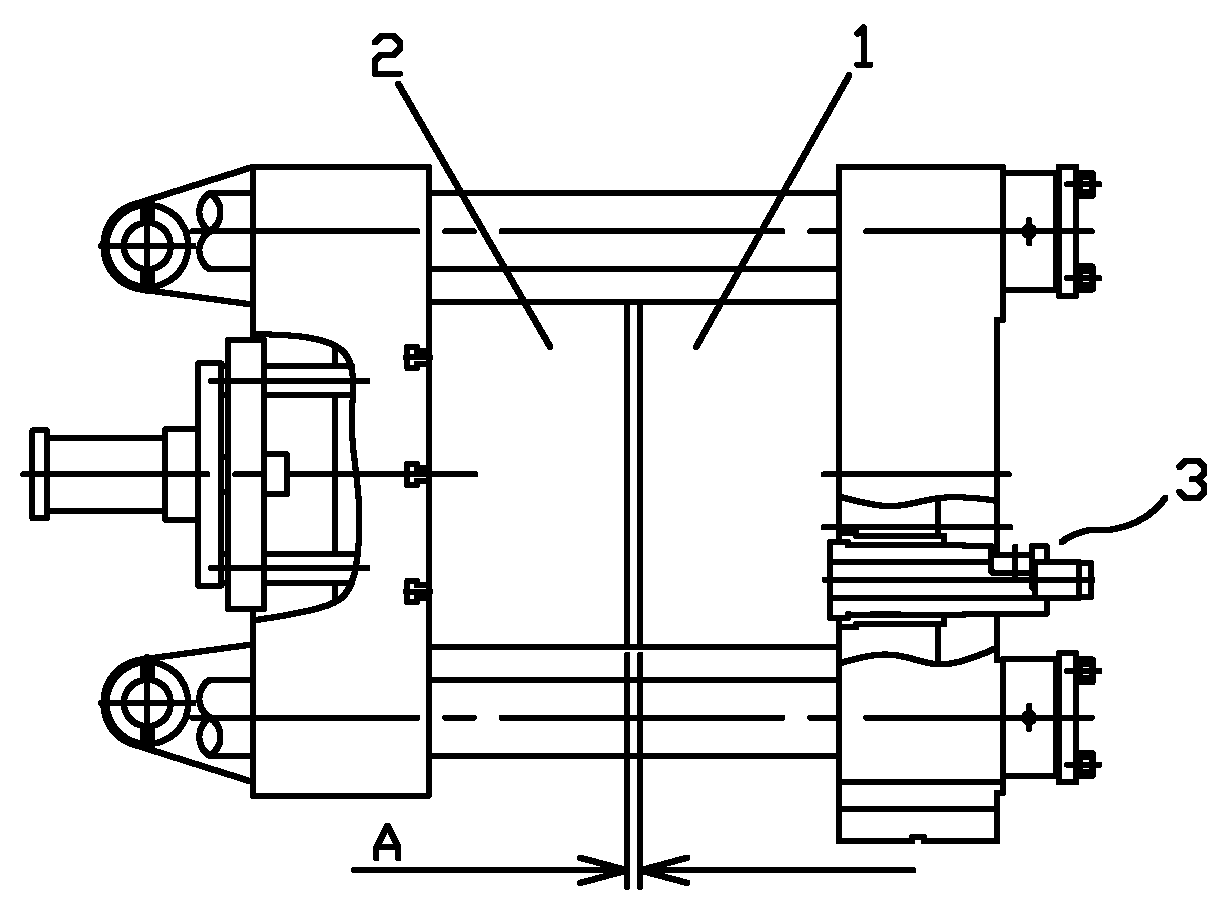

Squeeze casting machine and squeeze casting method thereof

The invention provides a squeeze casting machine, which comprises a base, a mold closing and locking mechanism, an injection mechanism and a hydraulic control system, wherein the mold closing and locking mechanism comprises a static mold, a movable mold, a main cylinder and a main cylinder piston rod; a seal safety belt is arranged in a seal matching structure between the static mold and the movable mold; the mold closing and locking mechanism comprises a monitoring control device which is used for monitoring a distance between the static mold and the movable mold and ensures that the static mold and the movable mold have a safe distance in the seal safety belt; and the hydraulic control system comprises a main cylinder feeding oil path which ensures that the movable mold and the static mold are driven by the main cylinder and completely closed after injection mold filling of the injection mechanism is completed. The squeeze feeding pressure is about 5 to 10 times that of the conventional casting injection pressure. The squeeze casting machine can realize 'common casting mold filling, squeeze casting and feeding' which is remarkably superior to 'common casting mold filling, high-speed punch squeeze' of the conventional casting machine.

Owner:马保庆

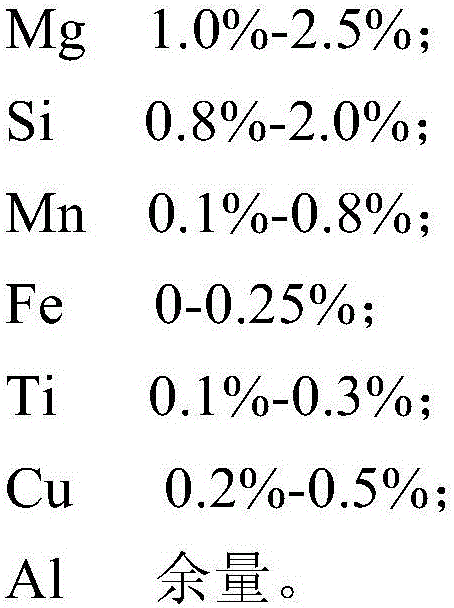

Directly extrusion cast high strength aluminium alloy

The present invention relates to aluminum alloy material, and is especially one kind of directly extrusion cast high strength aluminum alloy. The aluminum alloy consists of Cu 4.0-5.0 wt%, Mg 1.0-2.0 wt%, Mn 0.4-0.8 wt%, trace alloy elements including Ti 0.05-0.25 wt%, B 0.01-0.05 wt%, V 0.05-0.20 wt% and Zr 0.05-0.20 wt%, and mixed RE 0.05-0.15 wt% except Al and inevitable impurities, including Fe less than 0.2 wt% and Si less than 0.1 wt%. The aluminum alloy is prepared through direct extrusion casting, quenching and perfect artificially ageing process, has the features of capacity of being heat treated to reinforce, high strength, low cost, etc, and is suitable for use in making heavy bearing aluminum alloy structures.

Owner:SOUTH CHINA UNIV OF TECH

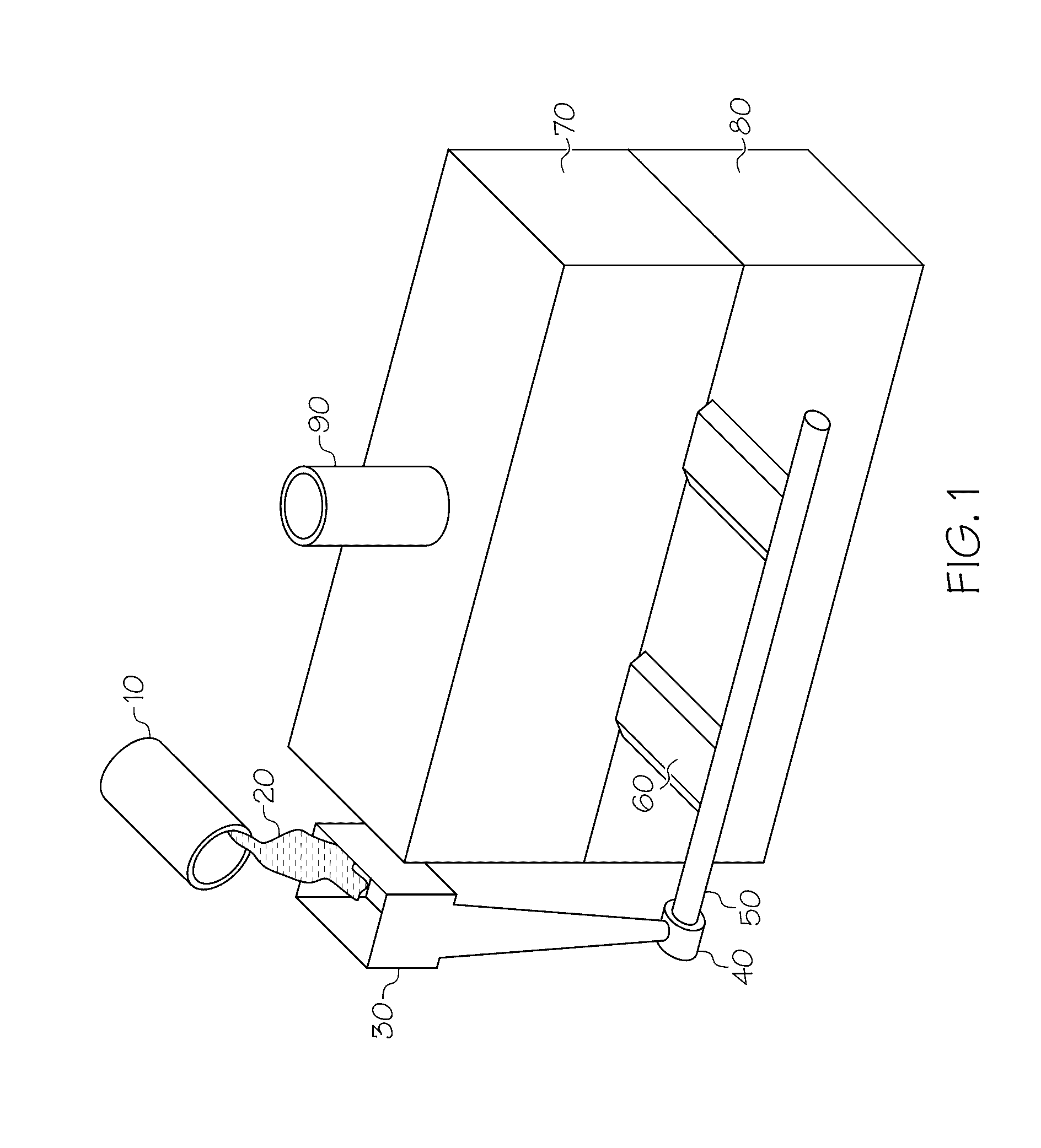

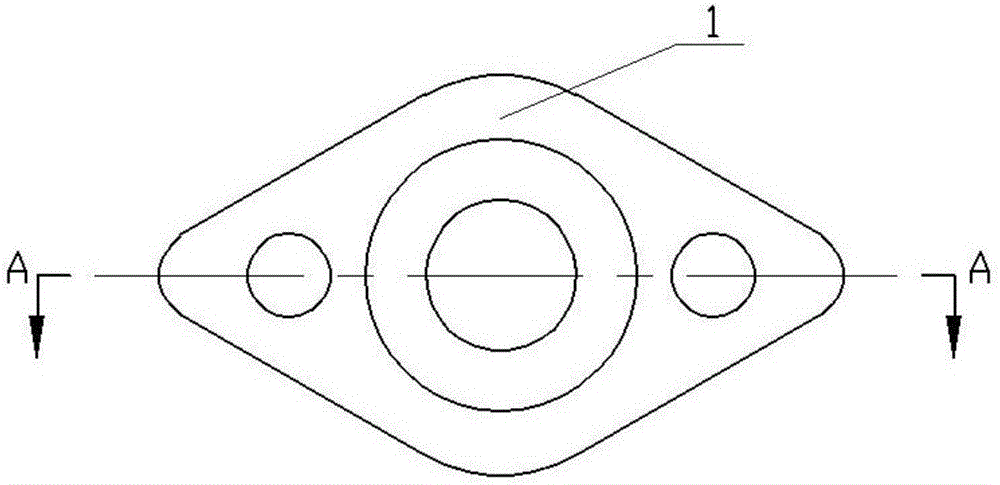

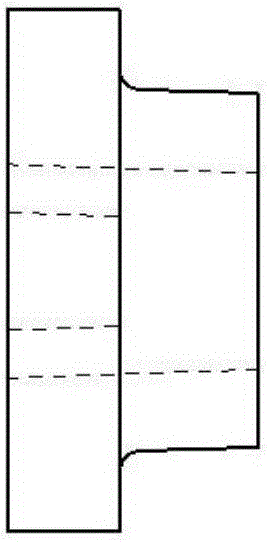

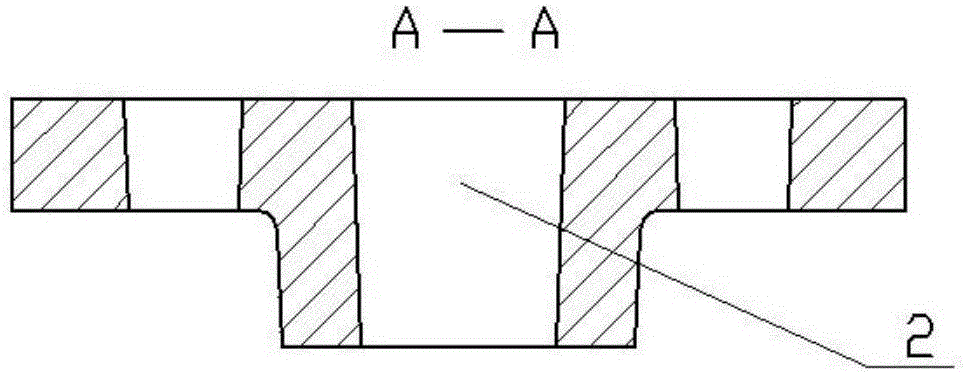

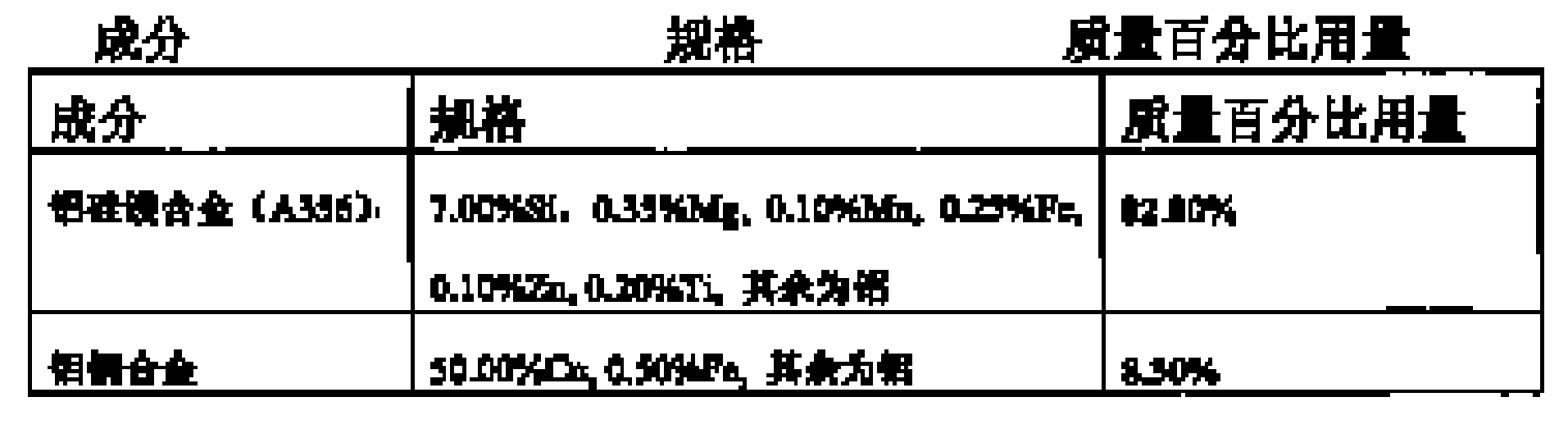

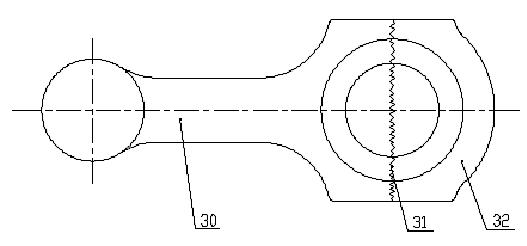

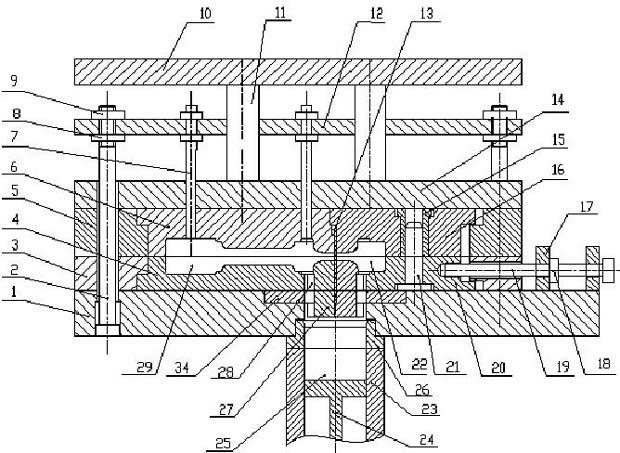

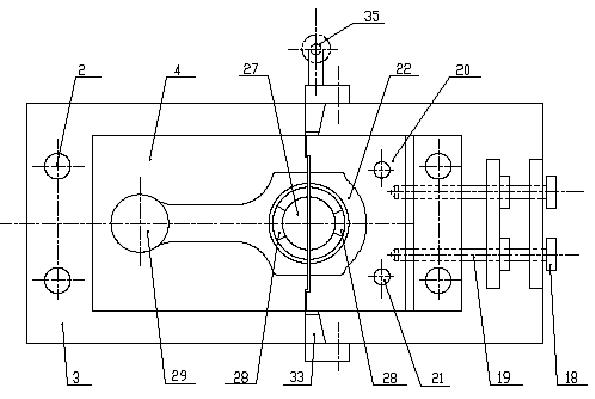

Antigravity squeeze casting device of aluminum alloy connecting rod and manufacture method

The invention relates to a method and a mould using an antigravity squeeze casting process to manufacture an aluminum alloy connecting rod, and particularly relates to a manufacturing method and a mould of a splitting type aluminum connecting rod. The technical scheme is that suitable foils are imbedded in the mould in advance, aluminum melting liquid is filled in to form a shape in a squeeze casting mode, the aluminum liquid enters a cavity from bottom to top through bypassing and controlling of a bypass flow cone pair, and liquid levels on two sides of the foils synchronously rise to enable a splitting interface to form inside a casting of the connecting rod. A screw mechanism is arranged on the mould, and a gap between joint surfaces of a body cavity of the connecting rod and a cover cavity of the connecting rod to bring convenience in foil placing and changing. The device and the method guarantee that the splitting interface formed when the connecting rod is cast in a pre-breaking area of a big head of the connecting rod, avoid defects of crack branching or splitting surface excursion and the like in a follow-up splitting manufacture process of the connecting rod, enable the castings to be free of entrapped air, cold shut and insufficient pouring, tight in organization and capable of conducting heat treatment, and enable mechanical property and mechanical behavior to be obviously improved.

Owner:JIANGSU UNIV

High strength and high ductility magnesium alloy and its preparation method

The present invention relates to a high strength and high ductility magnesium alloy and its preparation method. The magnesium alloy in the present invention contains 3˜9 wt % of aluminum, 3.5˜9 wt % of zinc, 0.15˜1 wt % of manganese, 0.01˜2 wt % of antimony, and balanced magnesium. The alloy may further comprise 0˜2 wt. % of one element selected from the group consisting of mischmetal, calcium, and silicon. The room temperature mechanical properties of the T6 heat-treated typical alloy in the present invention are as following: Ultimate Tensile Strength of more than or equal to 270 Mpa, Yield Tensile Strength of more than or equal to 140 Mpa, Elongation of more than or equal to 6%, Brinell hardness of more than or equal to 70, Impact Energy of more than or equal to 12 J. Some of the alloys in the present invention not only possess superior room temperature mechanical properties, but also have very good high temperature mechanical properties. The main alloying elements are easily obtainable and the preparation cost is low enough to meet the demands of large-scale production. The alloy according to the present invention was applicable for most of the casting processes, such as permanent casting, sand casting, die casting, and squeeze casting.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

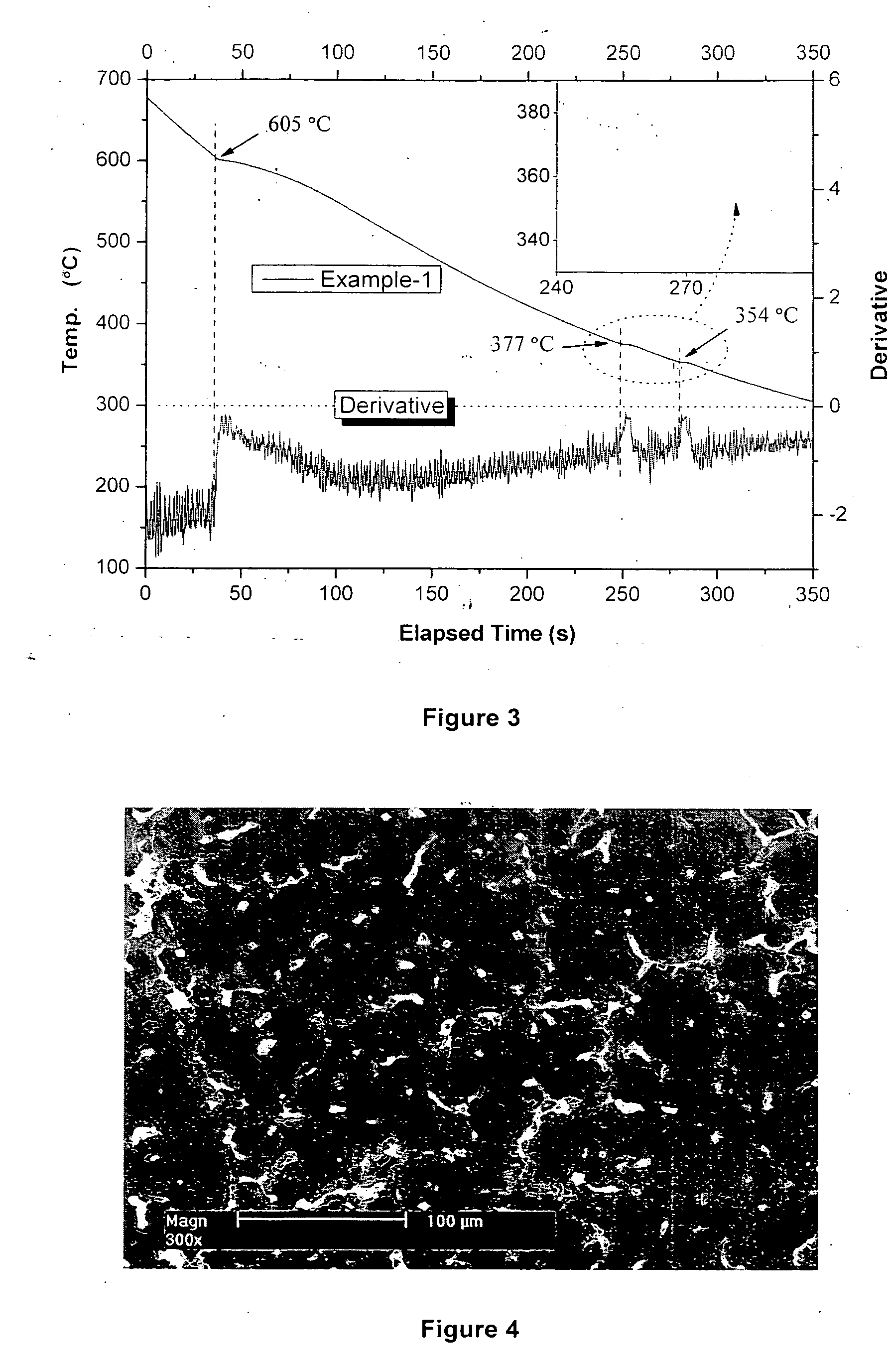

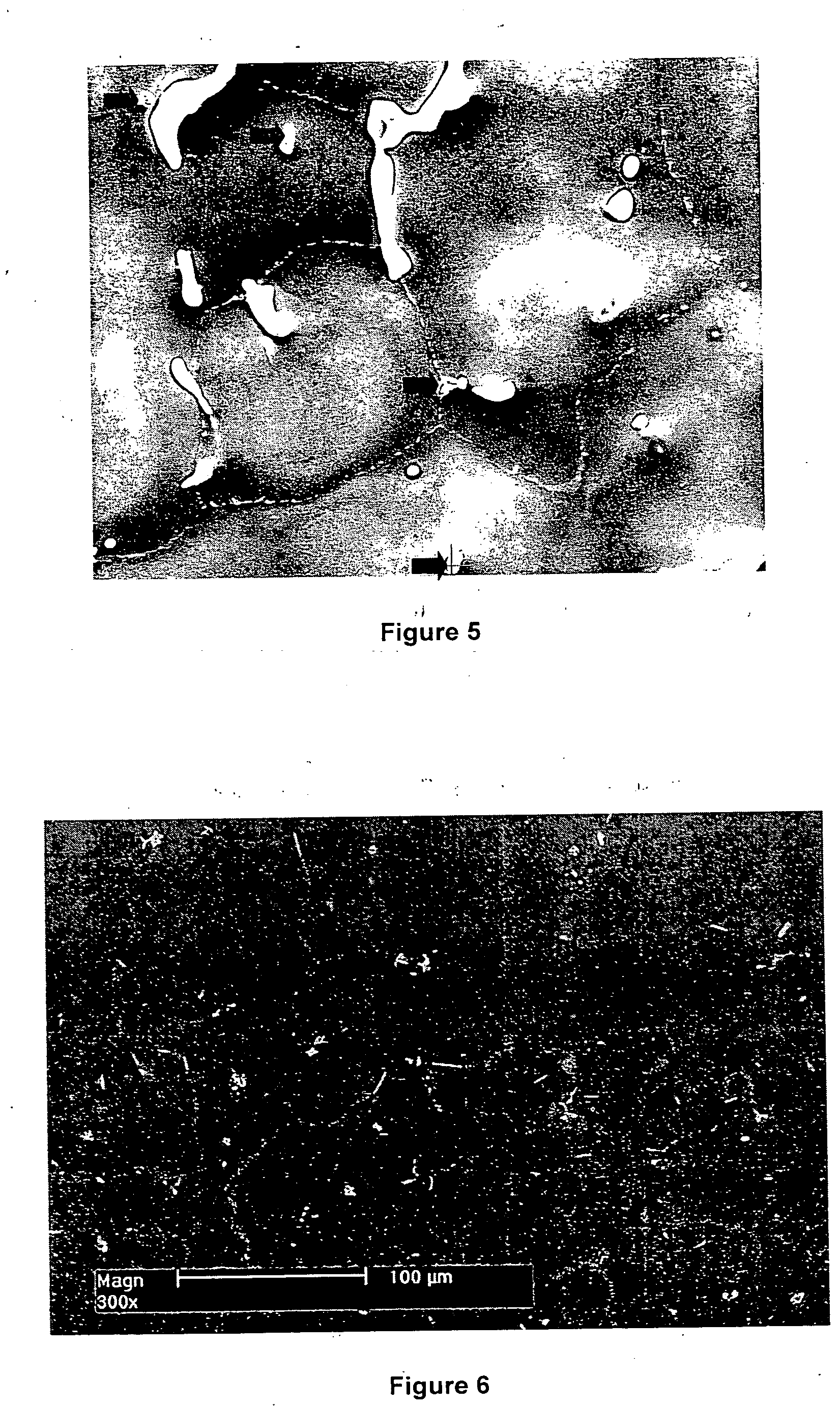

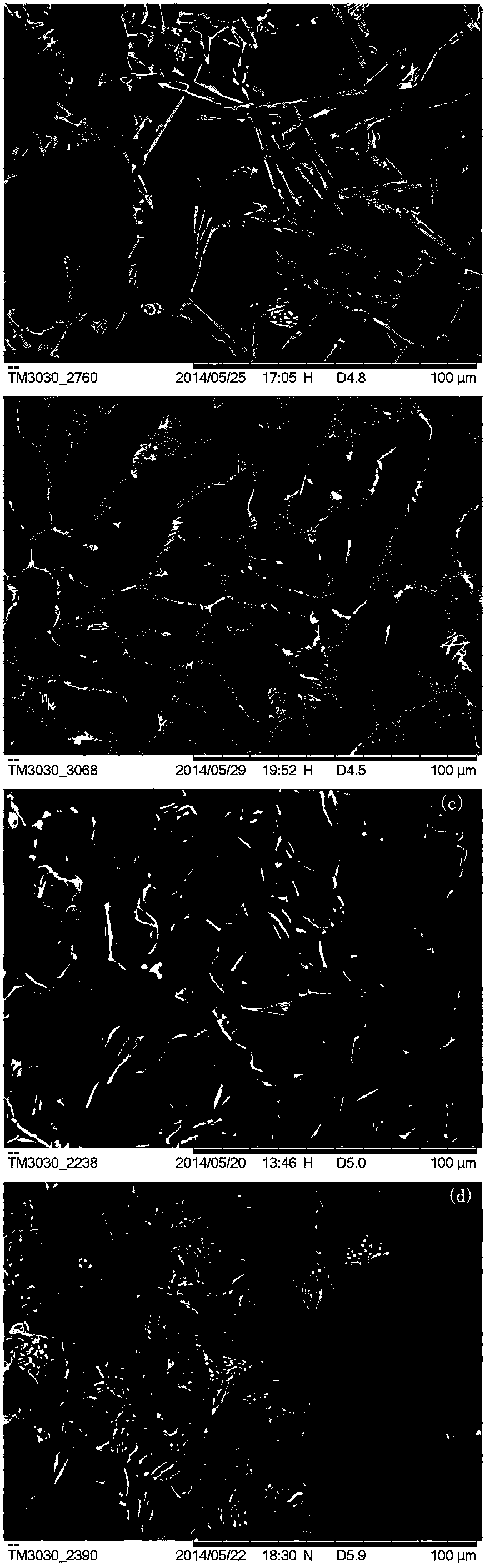

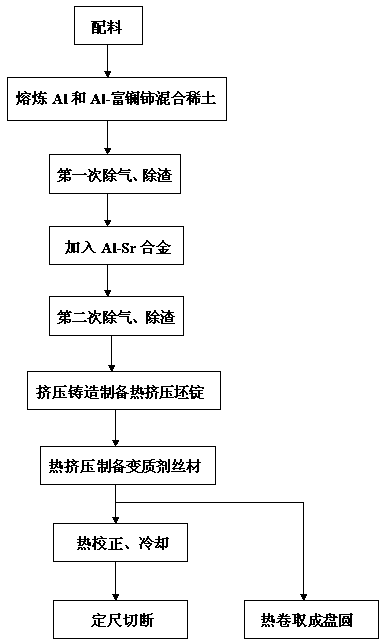

Permanent modifier capable of improving electrical conductivity of hypo eutectic Al-Si alloy as well as preparation method and using method of permanent modifier

The invention belongs to the metallurgical field and particularly relates to a permanent modifier capable of improving electrical conductivity of a hypo eutectic Al-Si alloy as well as a preparation method and a using method of the permanent modifier. The permanent modifier comprises the following components in percentage by weight: 1-4% of Sr, 5-20% of lanthanum-cerium-rich mixed rear earth and the balance of Al, wherein a weight ratio of the Sr to the lanthanum-cerium-rich mixed rear earth is 1 to (5-10). The preparation method for the permanent modifier comprises the following steps: firstly, preparing materials and smelting the prepared materials; and then, carrying out alloying and carrying out thermal extrusion by virtue of billets prepared by extruding and casting to prepare a modifier wire, thus obtaining the permanent modifier product capable of improving electrical conductivity of the hypo eutectic Al-Si alloy, wherein effective modifying time is at least 5 hours. The permanent modifier disclosed by the invention is convenient to use, stable in effect, long in effective modifying time, free of a modifying incubation period, and has effective modifying time of at least 5 hours according to detection. And moreover, the electrical conductivity of the alloy treated by virtue of the modifier wire is obviously improved.

Owner:SHENYANG POLYTECHNIC UNIV

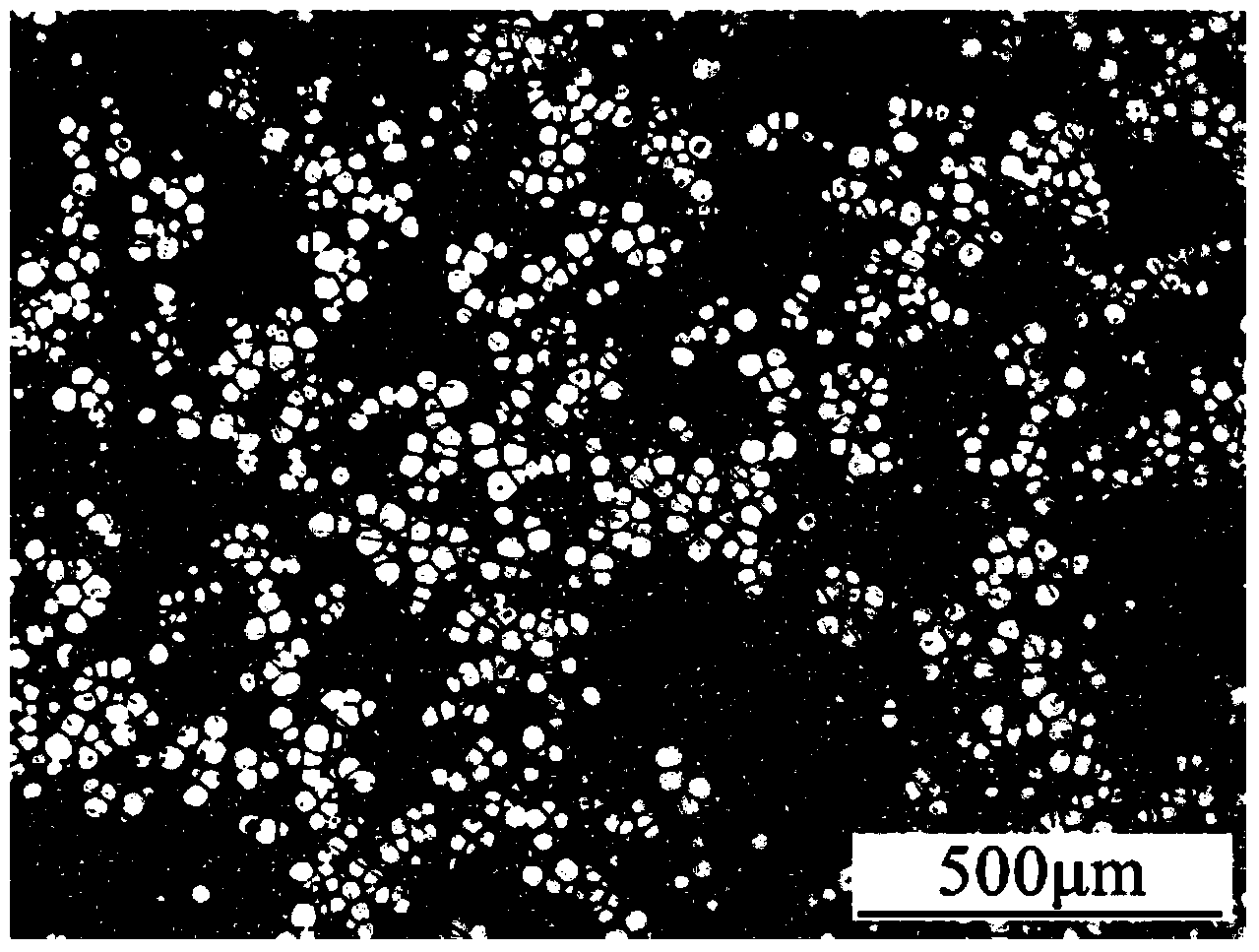

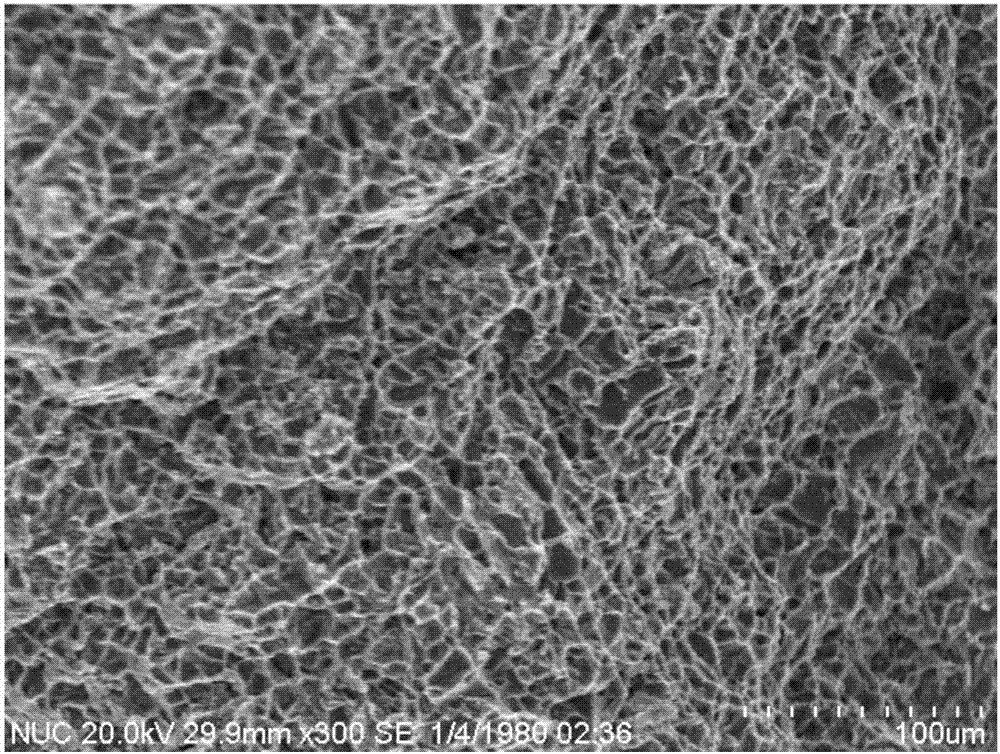

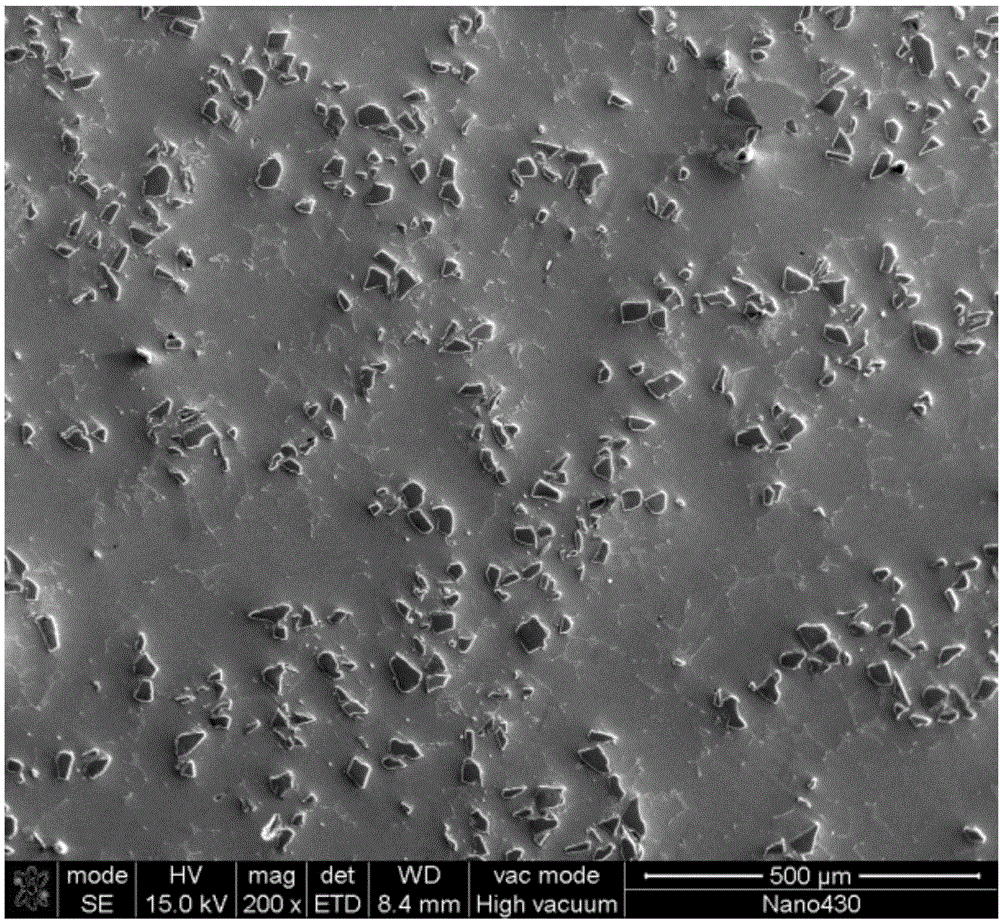

SiC particle reinforced aluminium-based composite and preparation method thereof

The invention discloses an SiC particle reinforced aluminium-based composite. The SiC particle reinforced aluminium-based composite is characterized in that AlMgSi alloy is adopted as a matrix; SiC particles are adopted as reinforcement bodies; the size of the SiC particles is 10 to 20 <mu>m; and the total volume of the SiC particles takes up 9 to 13% of the total volume of the composite. The invention further discloses a preparation method of the SiC particle reinforced aluminium-based composite. The preparation method is characterized in that stir casting and squeeze casting preparation methods are combined. According to the SiC particle reinforced aluminium-based composite and the preparation method, the particle distribution uniformity of the SiC particle reinforced aluminium-based composite is improved, SiC particle aggregation and shrinkage porosity and cavity defects of the composite are effectively decreased, and the SiC particle reinforced aluminium-based composite which has good strength and toughness and achieves uniform particle distribution is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com