Casting forming equipment and process for amorphous alloy component

A casting molding and amorphous alloy technology is applied in the field of casting molding equipment and process for amorphous alloy components, and can solve the problem that the amorphous alloy components are easy to form pores or shrinkage holes, the molding efficiency of the amorphous alloy components is reduced, and the amorphous alloy workpieces work. Cycle extension and other problems, to achieve the effect of shortening the working cycle, shortening the molding cycle, and prolonging the supply cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

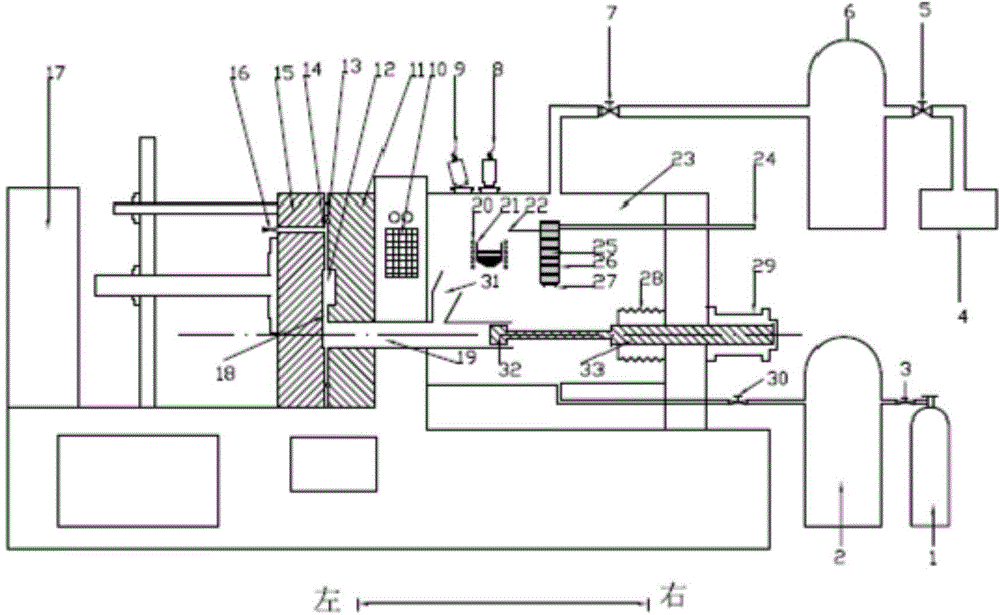

[0040] Such as figure 1 As shown, the casting and molding equipment for amorphous alloy components of the present invention includes an injection system, an alloy melting system, a raw material feeding system, a mold system, a vacuum system and a protective atmosphere system, wherein:

[0041] Alloy smelting system: used for alloy smelting, set in a vacuum chamber 23, including a melting crucible 21 and a heating device 20, the melting crucible 21 is made of aluminum oxide or boron nitride; or, the melting crucible 21 is a belt A graphite crucible with a ceramic coating; the heating device 20 uses induction coils or resistance wires to heat the melting crucible 21; the heating device 20 is arranged outside the melting crucible 21.

[0042] Injection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com