Patents

Literature

327 results about "Superplasticity" patented technology

Efficacy Topic

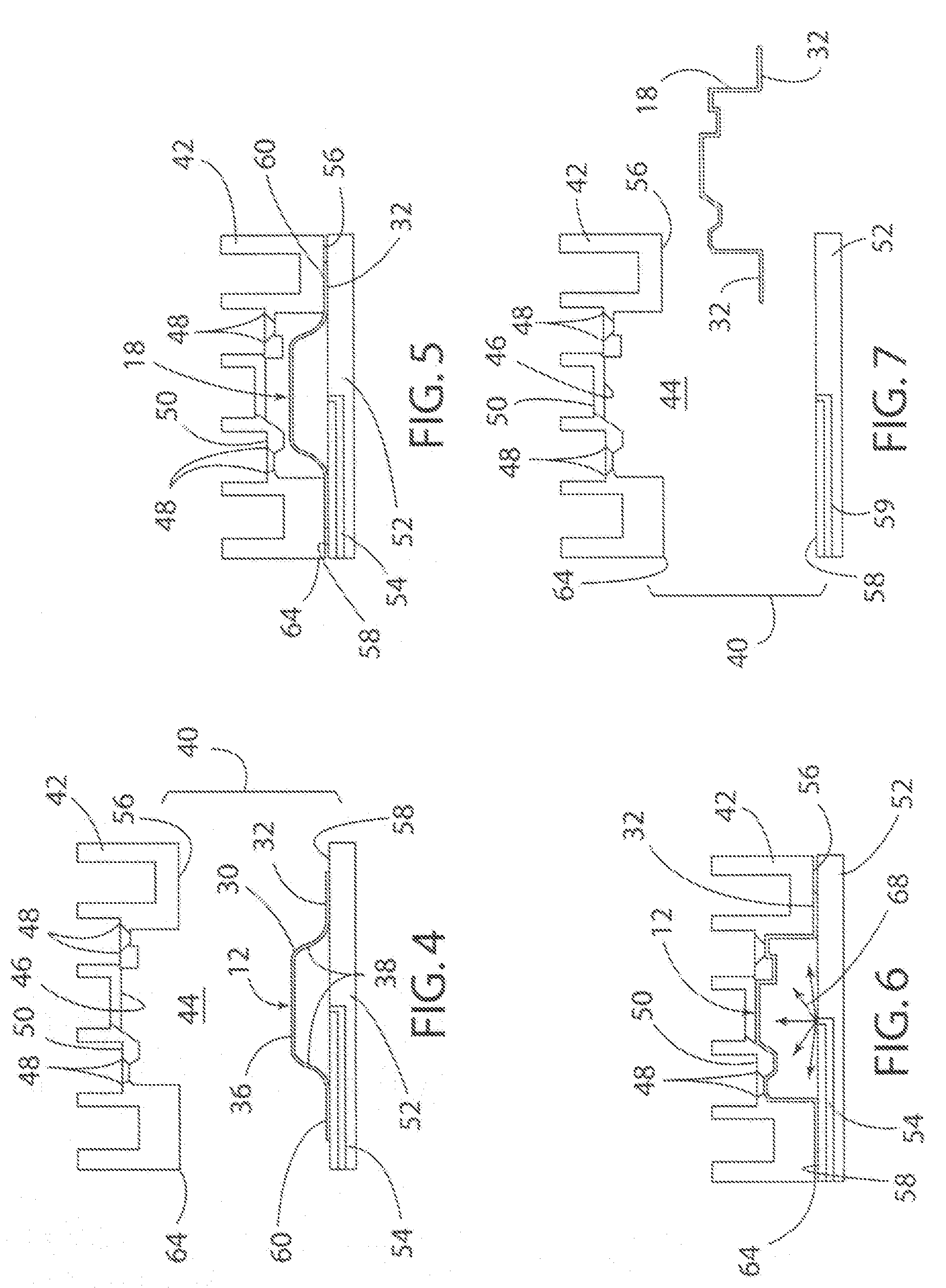

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

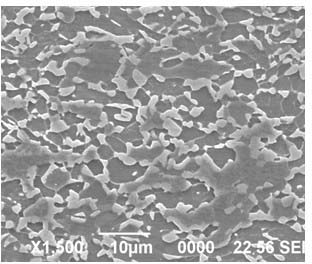

In materials science, superplasticity is a state in which solid crystalline material is deformed well beyond its usual breaking point, usually over about 600% during tensile deformation. Such a state is usually achieved at high homologous temperature. Examples of superplastic materials are some fine-grained metals and ceramics. Other non-crystalline materials (amorphous) such as silica glass ("molten glass") and polymers also deform similarly, but are not called superplastic, because they are not crystalline; rather, their deformation is often described as Newtonian fluid. Superplastically deformed material gets thinner in a very uniform manner, rather than forming a "neck" (a local narrowing) that leads to fracture. Also, the formation of microvoids, which is another cause of early fracture, is inhibited.

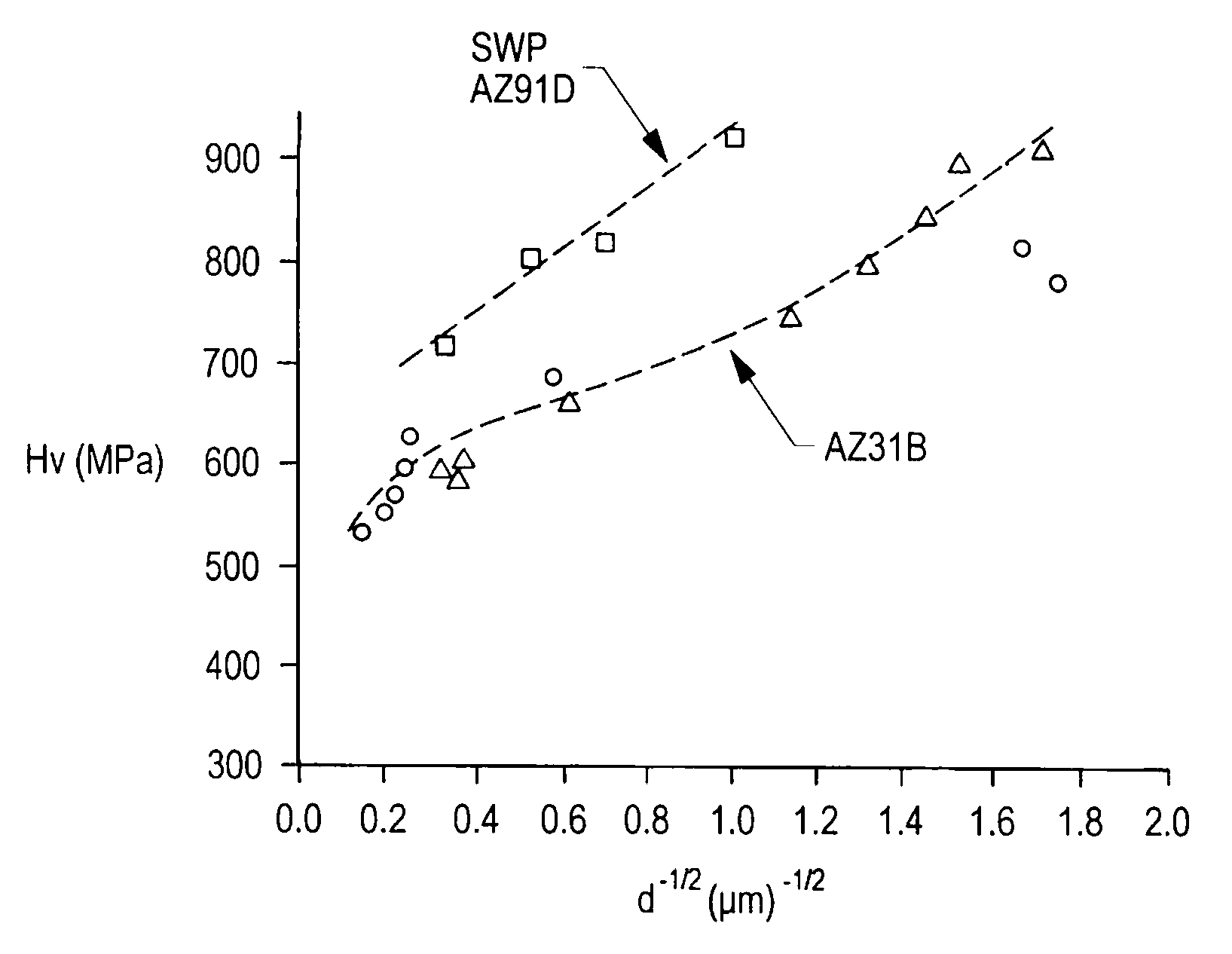

Selected processing for non-equilibrium light alloys and products

InactiveUS20030183306A1High valueEffectiveVacuum evaporation coatingSputtering coatingMagnesiumNet shape

A new class of light or reactive elements and monophase alpha'-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said alpha'-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable alpha'-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting alpha'-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

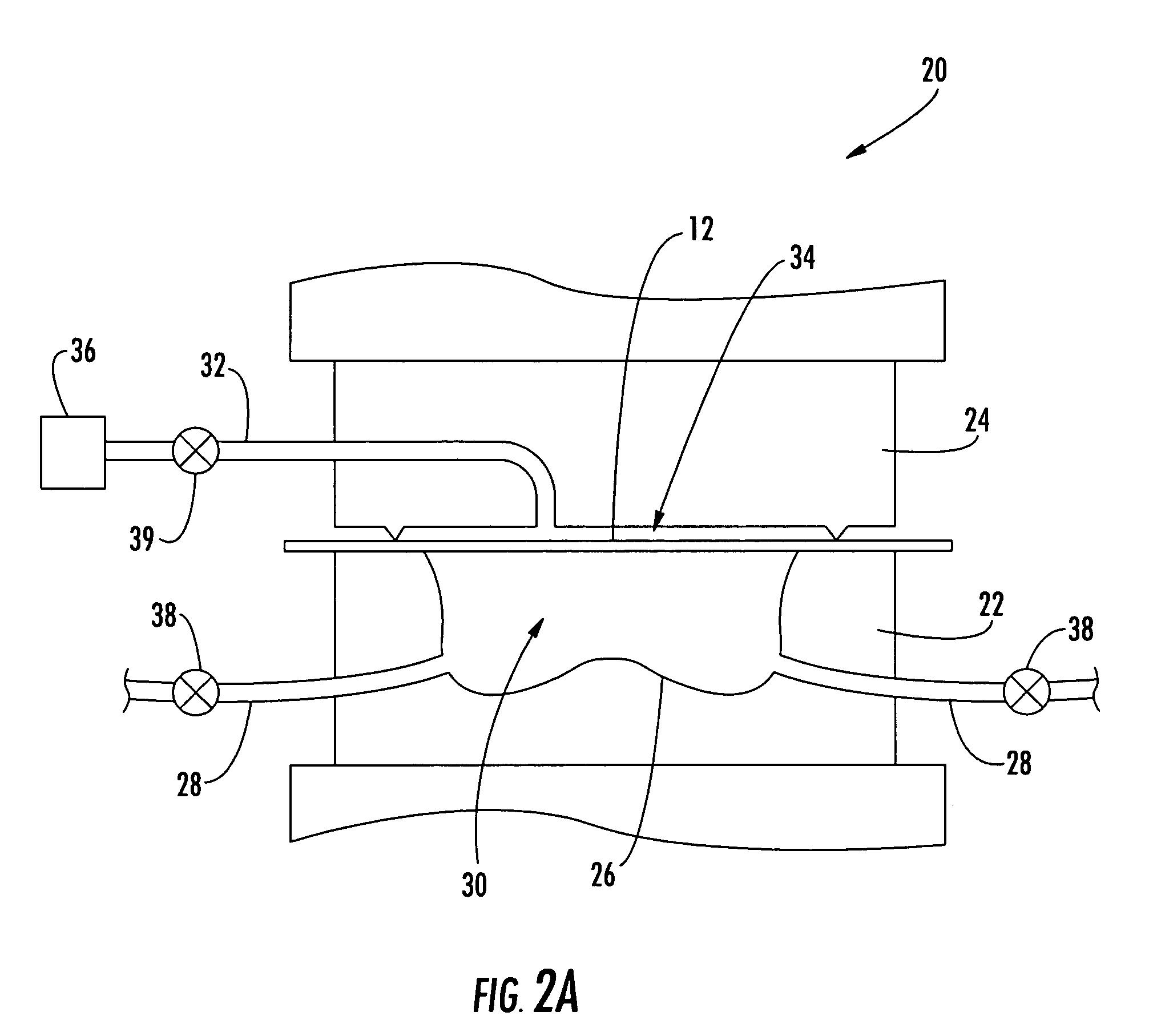

Process for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product

The present invention provides a process and apparatus for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product. The process comprises (a) coating one side of a superplastic alloy plate with a coupling agent or a hot melt adhesive; (b) placing the coupling agent- or hot melt adhesive-coated superplastic alloy plate in a mold, and superplastically forming the superplastic alloy plate to a superplastic alloy foil with a predetermined shape, such that another side of the superplastic alloy foil is attached to the mold and the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil is spaced apart from the mold to form a mold cavity, wherein an injection machine is attached to the mold cavity, and wherein the injection machine is capable of injecting softened plastic into the mold cavity; (c) introducing softened plastic from the injection machine to the mold cavity, such that plastic adheres on the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil, and an electromagnetic interference shielding metallic foil cladded plastic product is formed; and (d) removing the plastic product from the mold. The final metallic plastic product can not only have as intricate a shape as an ordinary plastic product, but also has a shielding effectiveness as high as an ordinary metallic shield.

Owner:NAT SCI COUNCIL

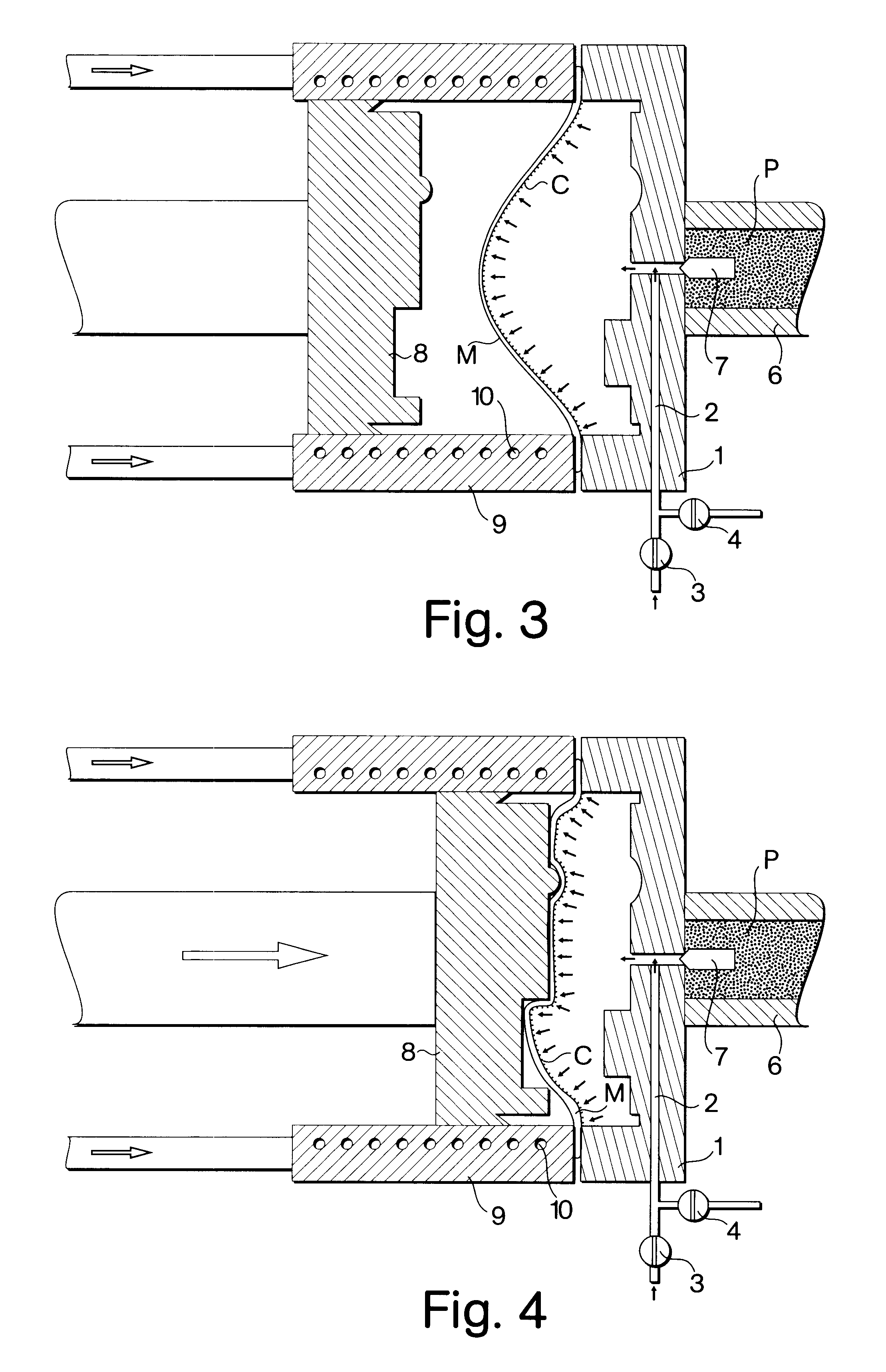

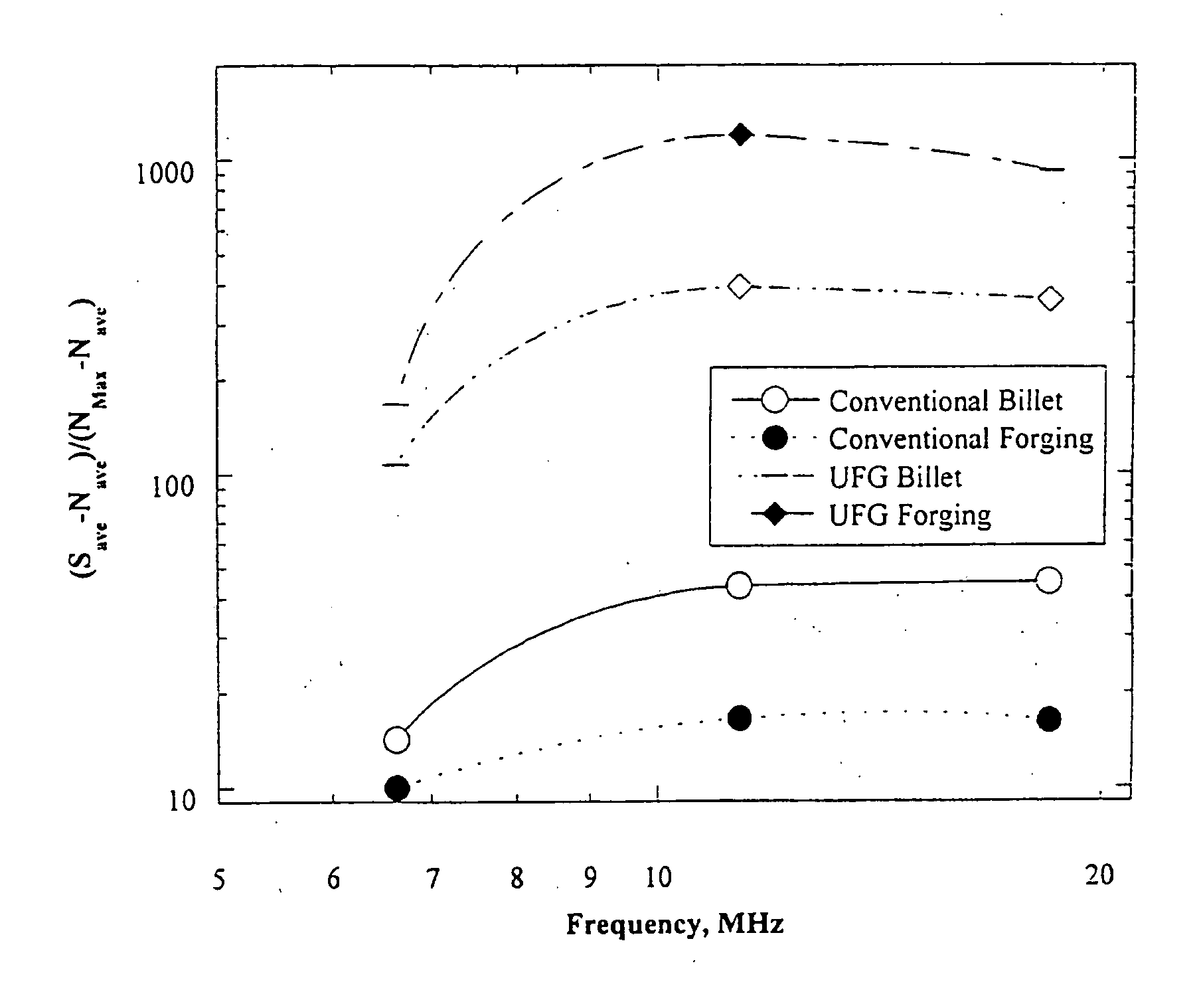

Method for producing homogeneous fine grain titanium materials suitable for ultrasonic inspection

A titanium material production method for producing homogeneous fine grain titanium material in which the titanium material has a grain size in a range from about 5 μm to about 20 μm. The method comprises providing a titanium material blank; conducting a first heat treatment on the titanium material blank to heat the titanium material blank to a β-range; quenching the titanium material blank from the β-region to the α+β-region; forging the titanium material blank; and conducting a second heat treatment on the titanium material blank. The titanium material production method subjects the titanium material blank to superplasticity conditions during part of the titanium material production method.

Owner:GENERAL ELECTRIC CO

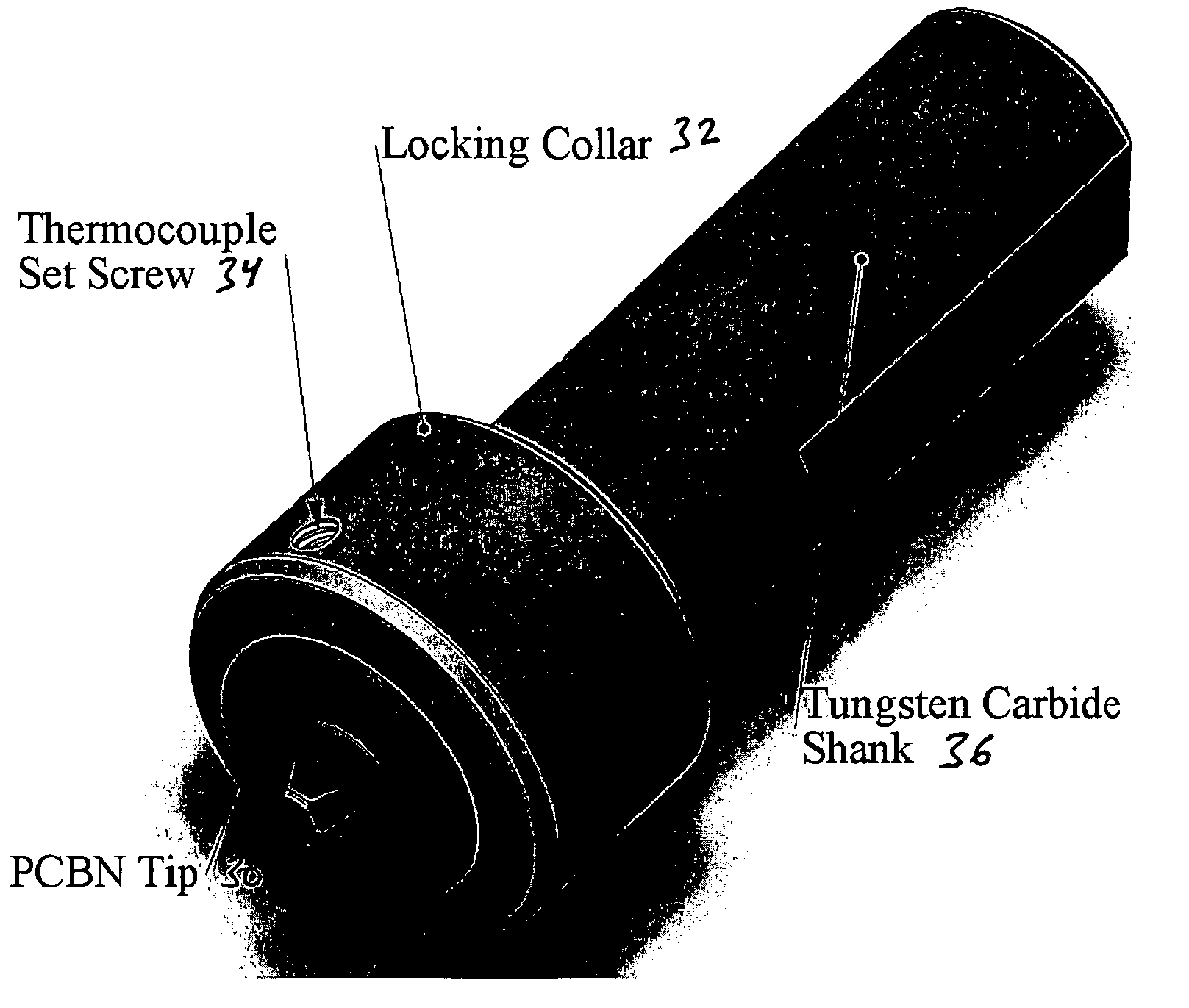

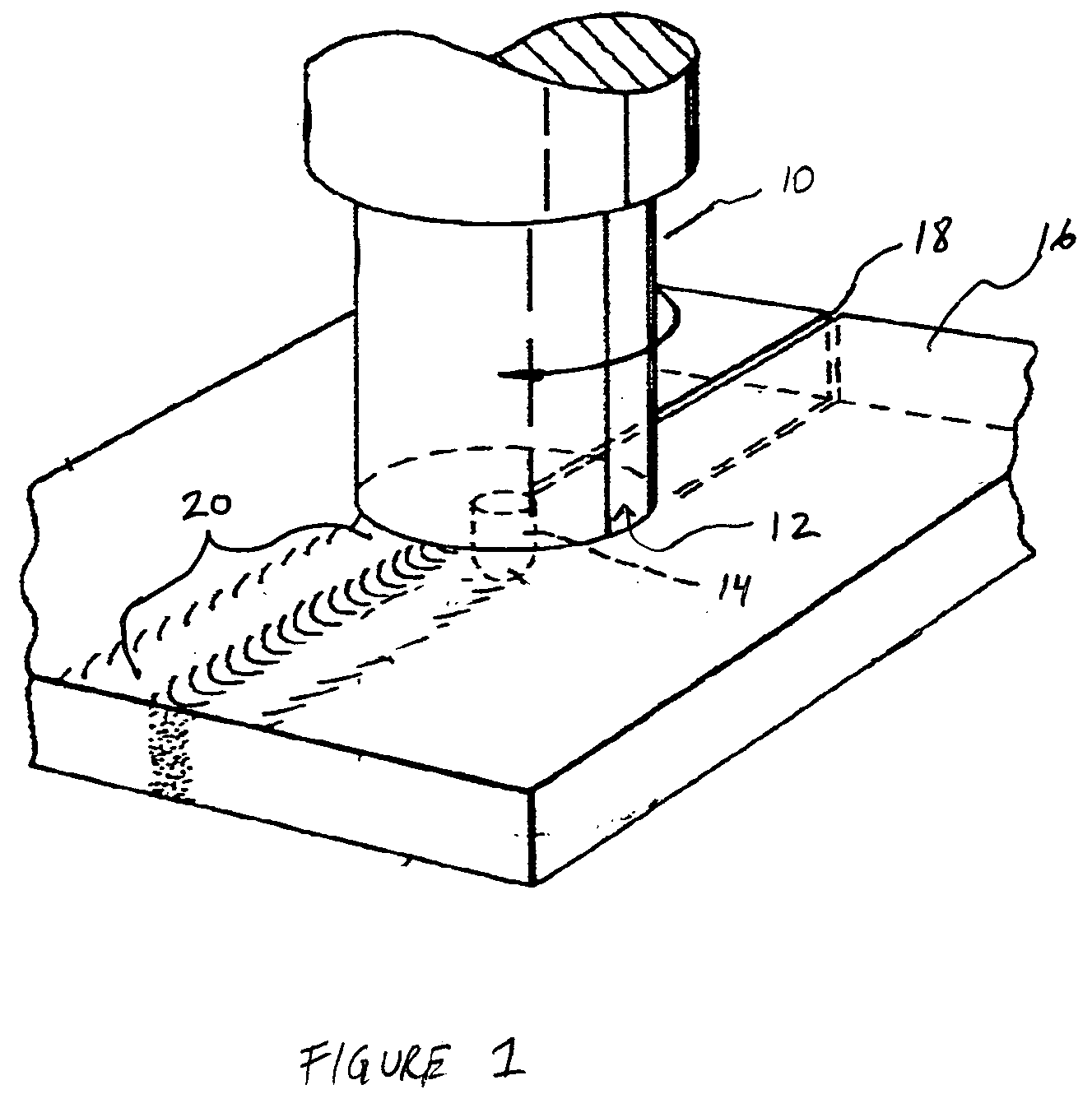

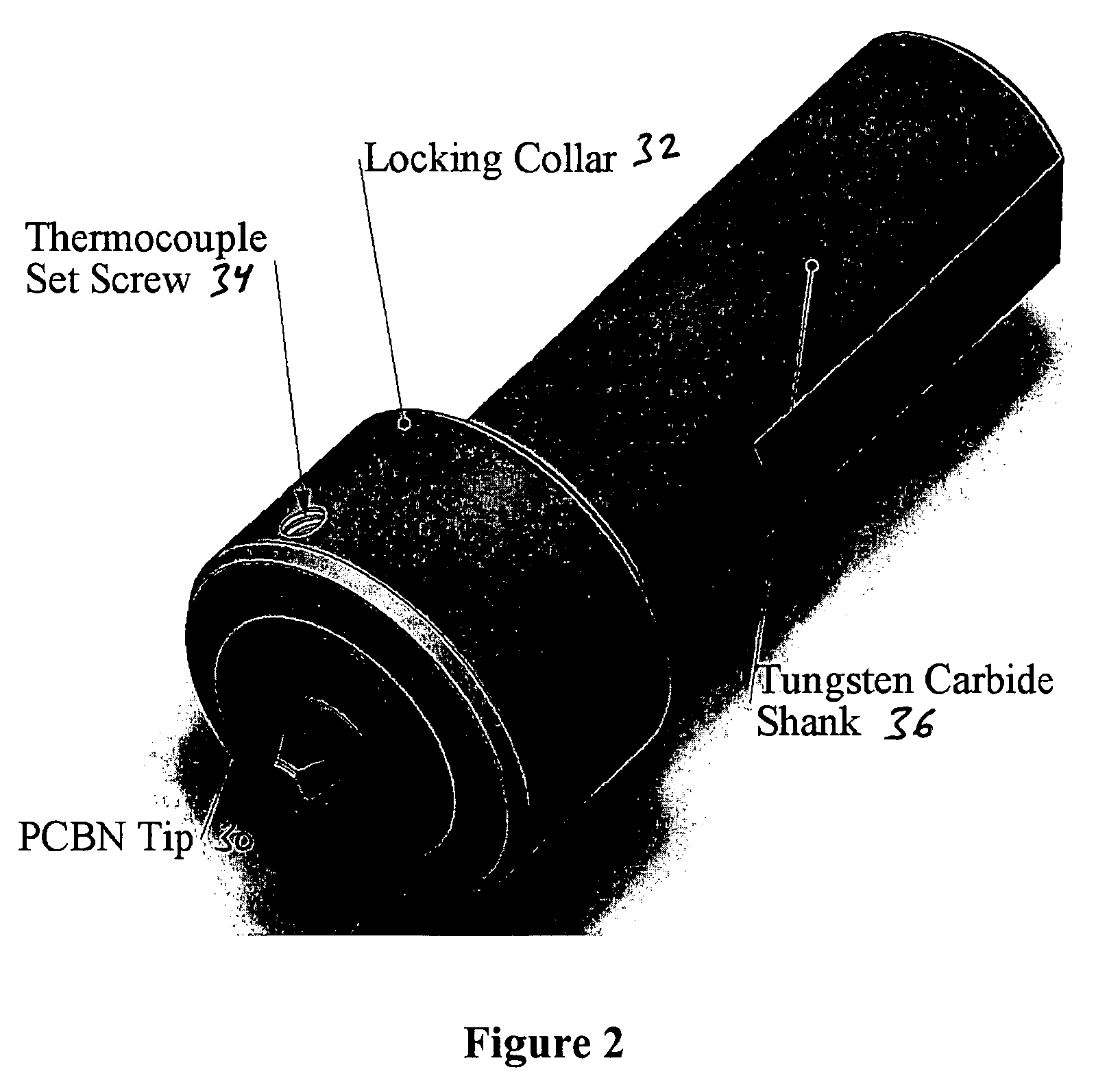

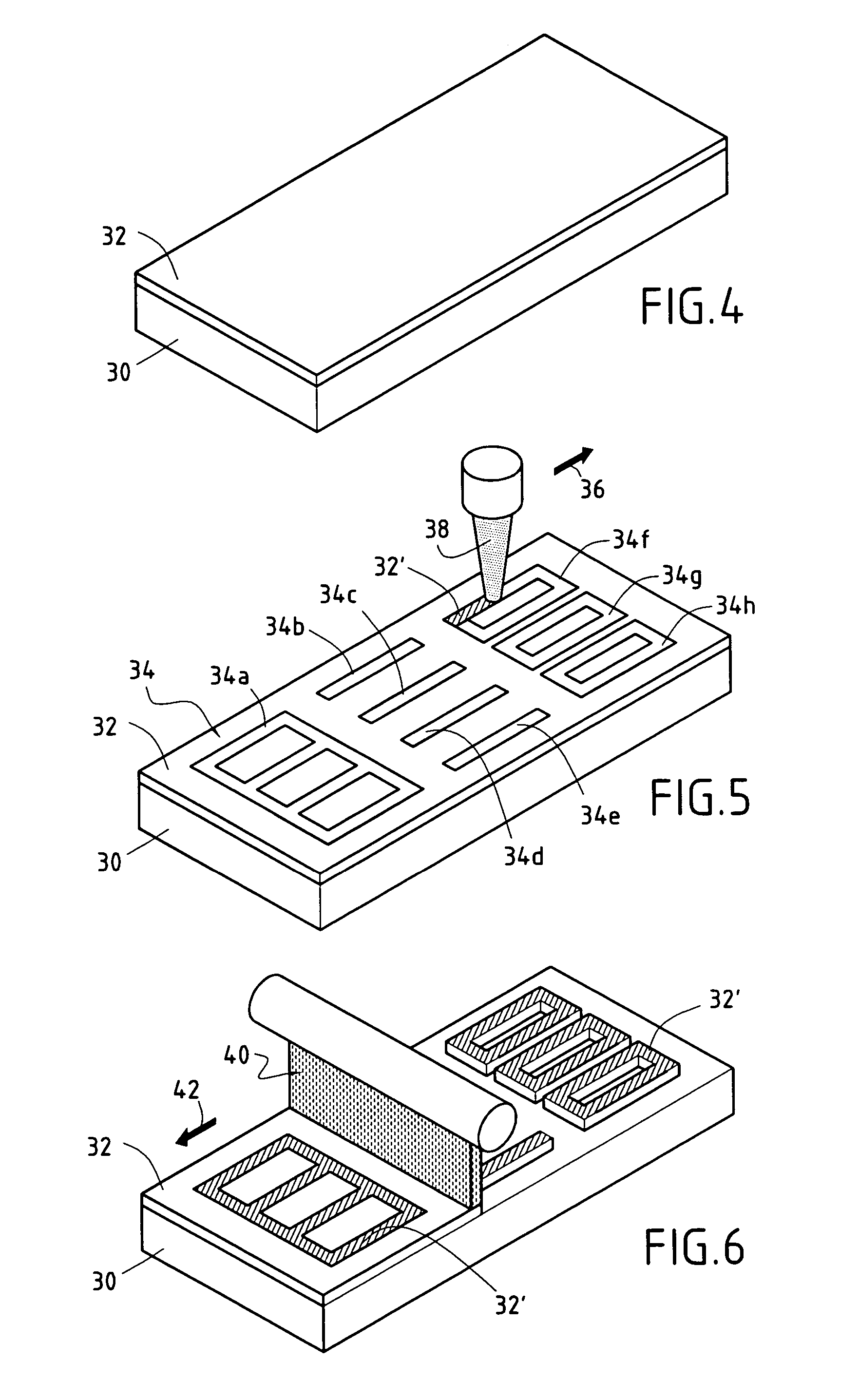

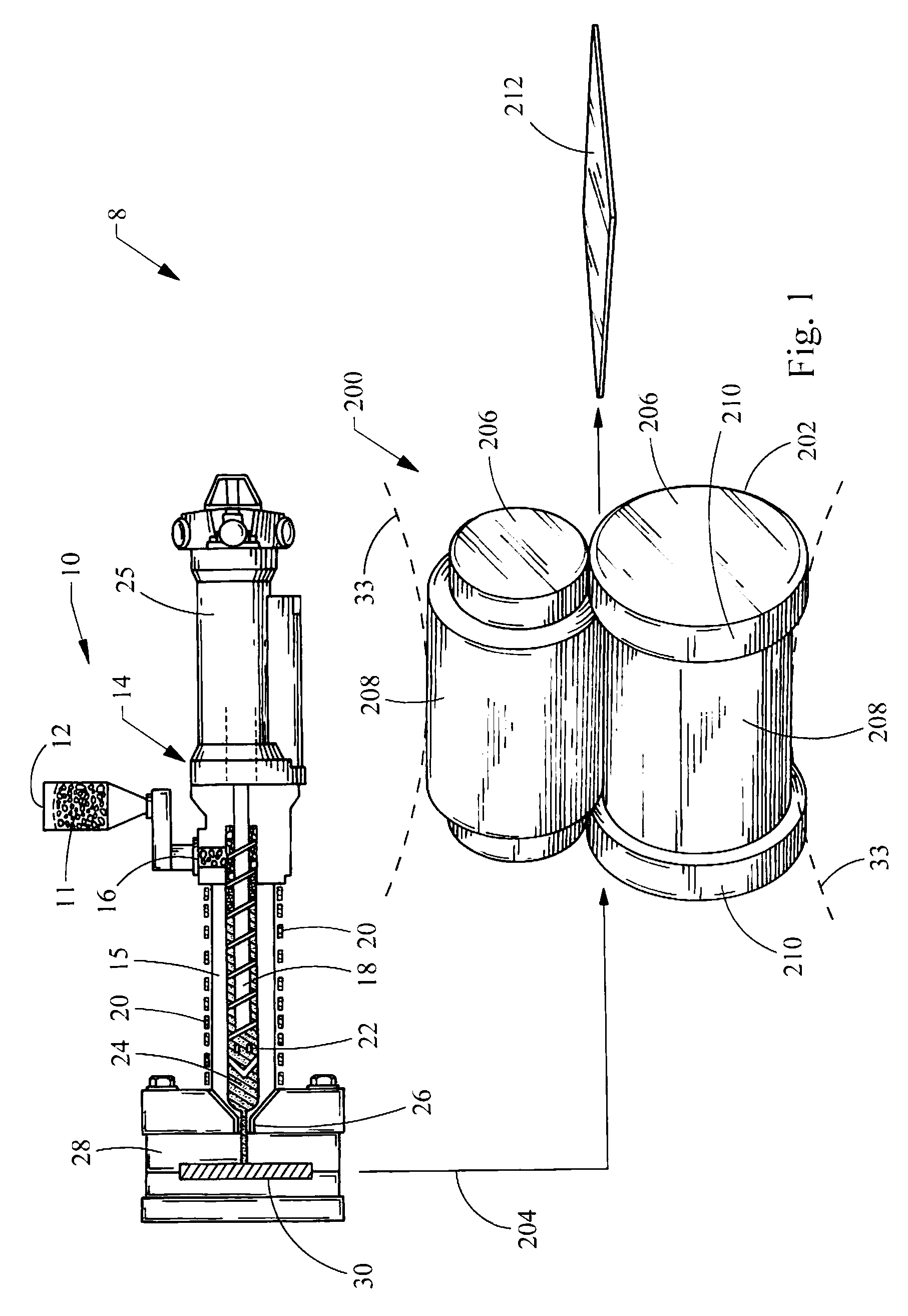

Solid state processing of materials through friction stir processing and friction stir mixing

InactiveUS20060032891A1Improve toughnessIncrease and decrease hardnessWelding/cutting auxillary devicesAuxillary welding devicesCompressibilityFriction stir processing

Solid state processing is performed on a workpiece by using a tool capable of friction stir processing, friction stir mixing, or friction stir welding, wherein solid state processing modifies characteristics of a workpiece while substantially maintaining a solid phase in some embodiments, allowing some elements to pass through a liquid phase in other embodiments, and wherein modified characteristics of the material include, but are not limited to, microstructure, macrostructure, toughness, hardness, grain boundaries, grain size, the distribution of phases, ductility, superplasticity, change in nucleation site densities, compressibility, expandability, coefficient of friction, abrasion resistance, corrosion resistance, fatigue resistance, magnetic properties, strength, radiation absorption, and thermal conductivity.

Owner:ADVANCED METAL PROD INC +1

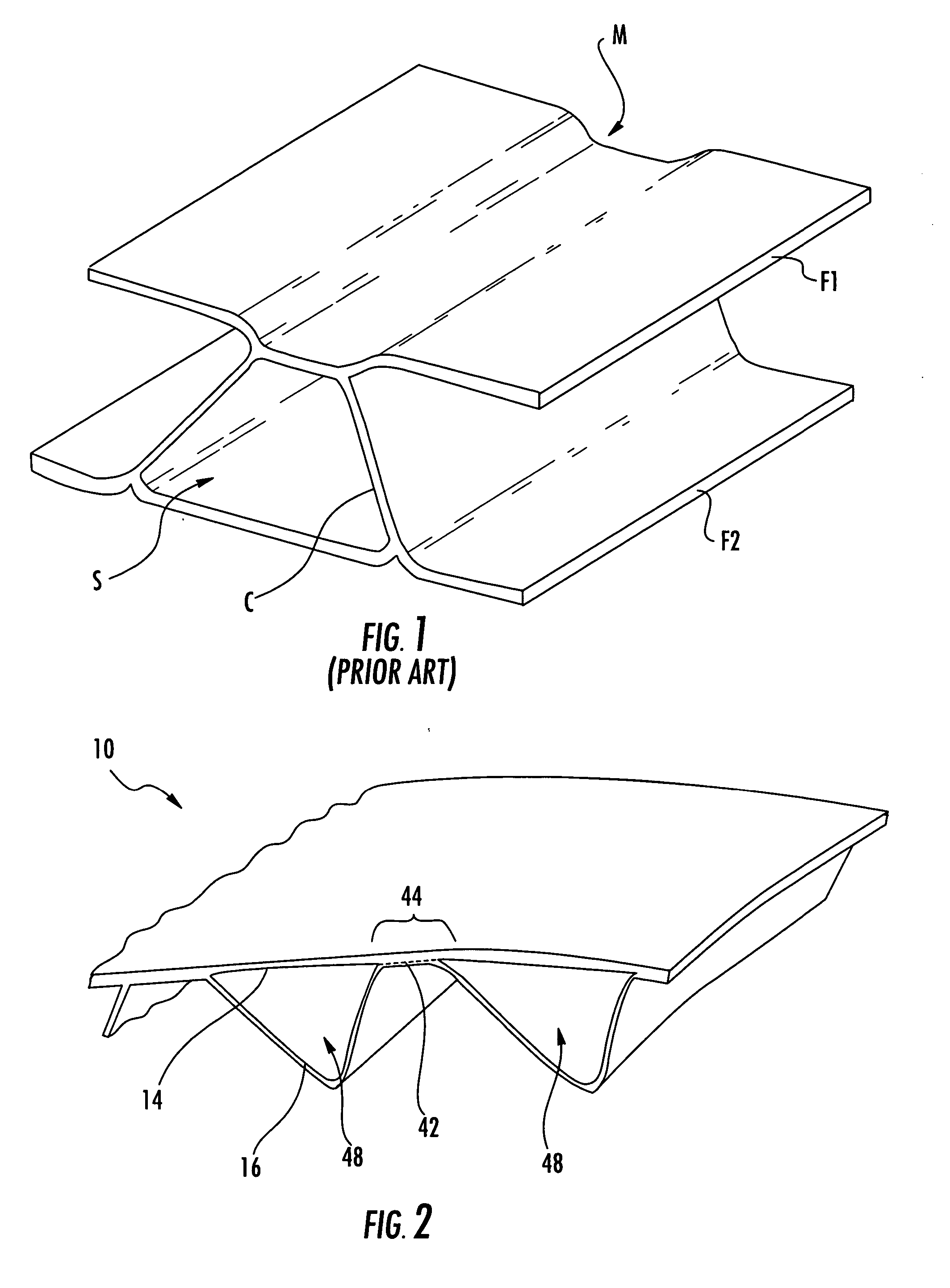

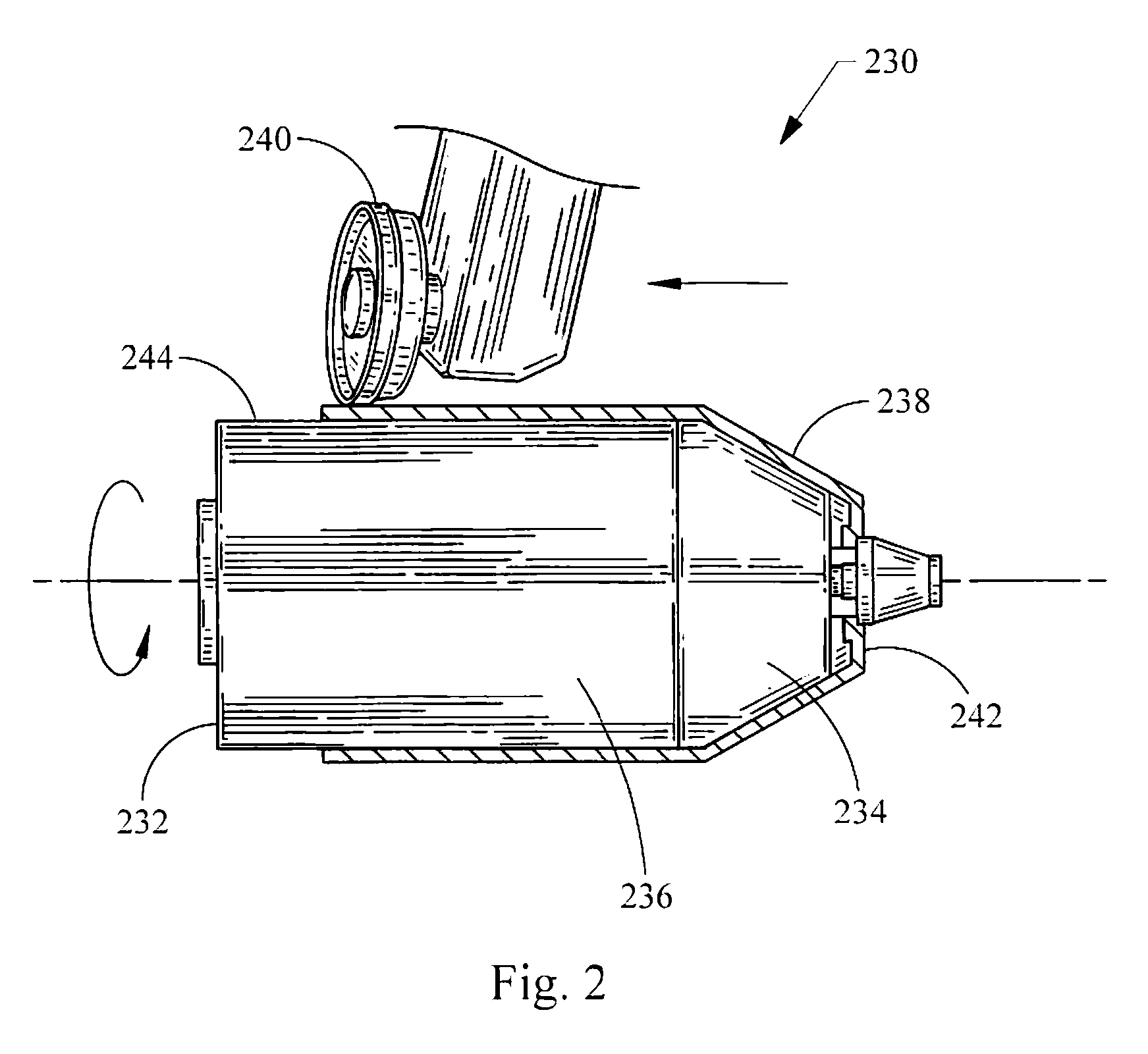

Superplastic forming of titanium assemblies

ActiveUS20070102494A1Reduce and eliminate formationPower plant exhaust arrangementsAircraft power plant componentsTitaniumSuperplasticity

A method of superplastic forming of titanium packs and an associated assembly is provided. The titanium packs can include sheets having different granular structures so that the different sheets are adapted to superplastically form at different temperatures. One or more of the sheets can be formed at a temperature that is below the superplastic forming temperature of another sheet in the pack. In some cases, the occurrence of markoff can be reduced or eliminated.

Owner:THE BOEING CO

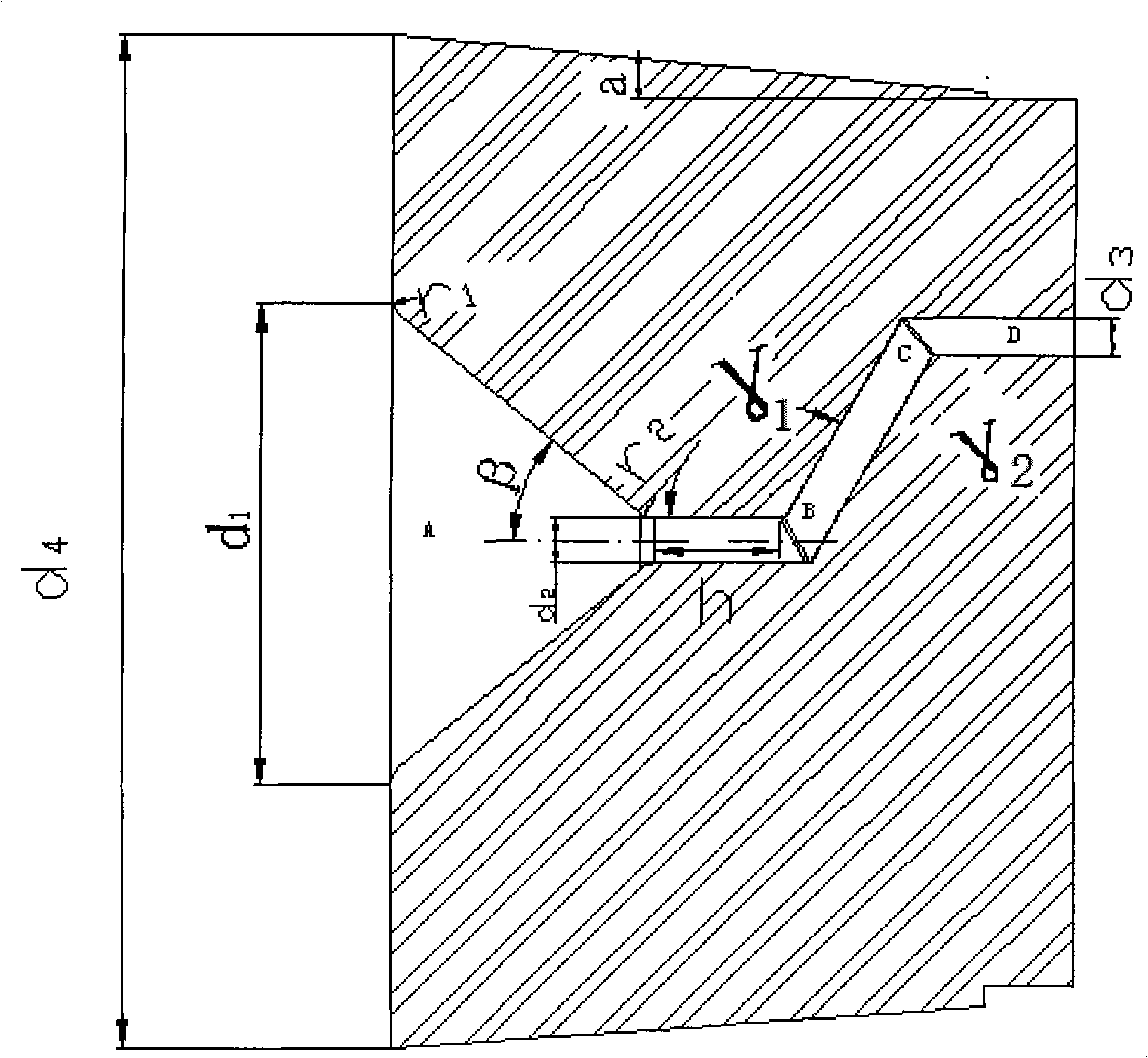

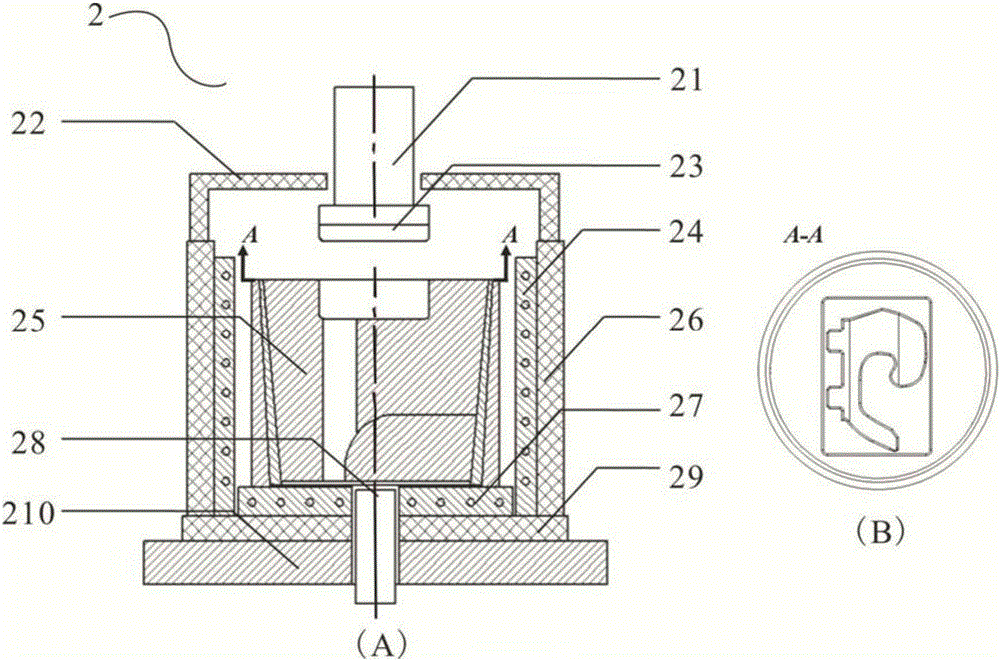

Amorphous alloy precision parts superplastic drop-forging shaper and method thereof

InactiveCN1456401AGood mechanical propertiesGuaranteed surface qualityMetal-working apparatusSurface finishAlloy

A superplastic die forging apparatus for forming precise non-crystal alloy part is composed of vacuum heater, exchangeable pressing head consisting of internal and external pressing heads, slide block and jointer, and die comprising main body and ejector. Its technology features that the blank and die must at first be heated in the vacuum heater by defined parameters. Its advantage is high precision and surface finish quality.

Owner:UNIV OF SCI & TECH BEIJING

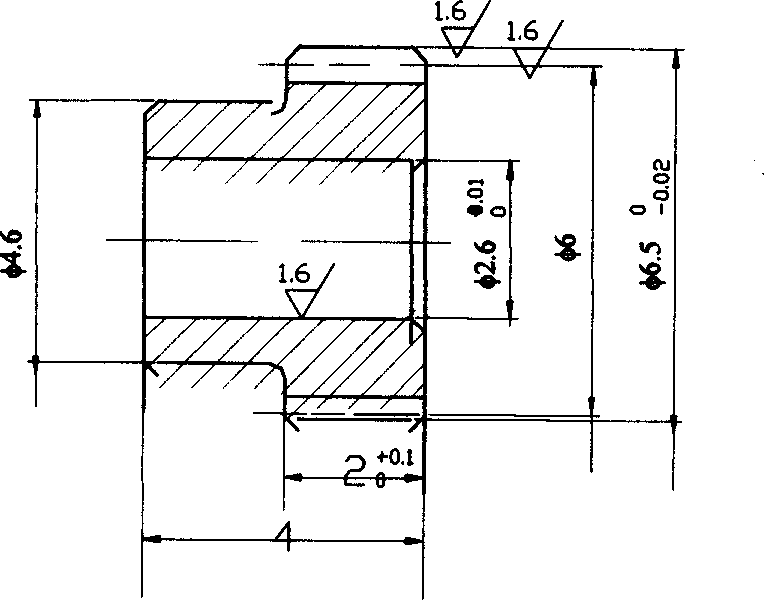

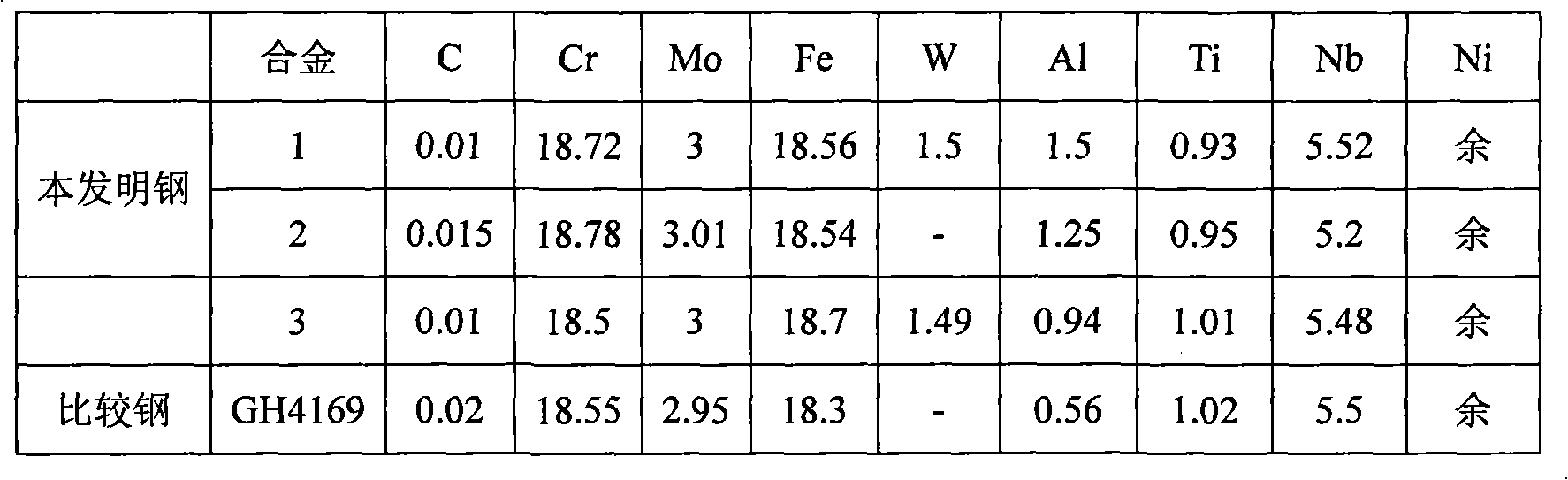

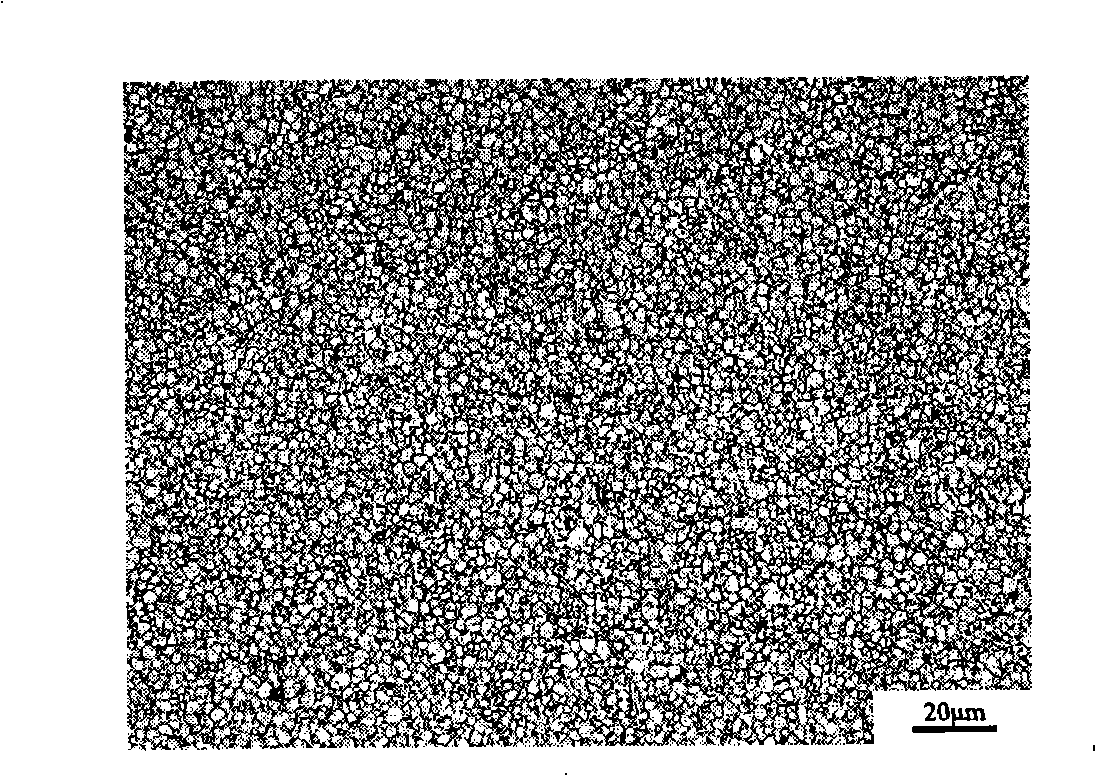

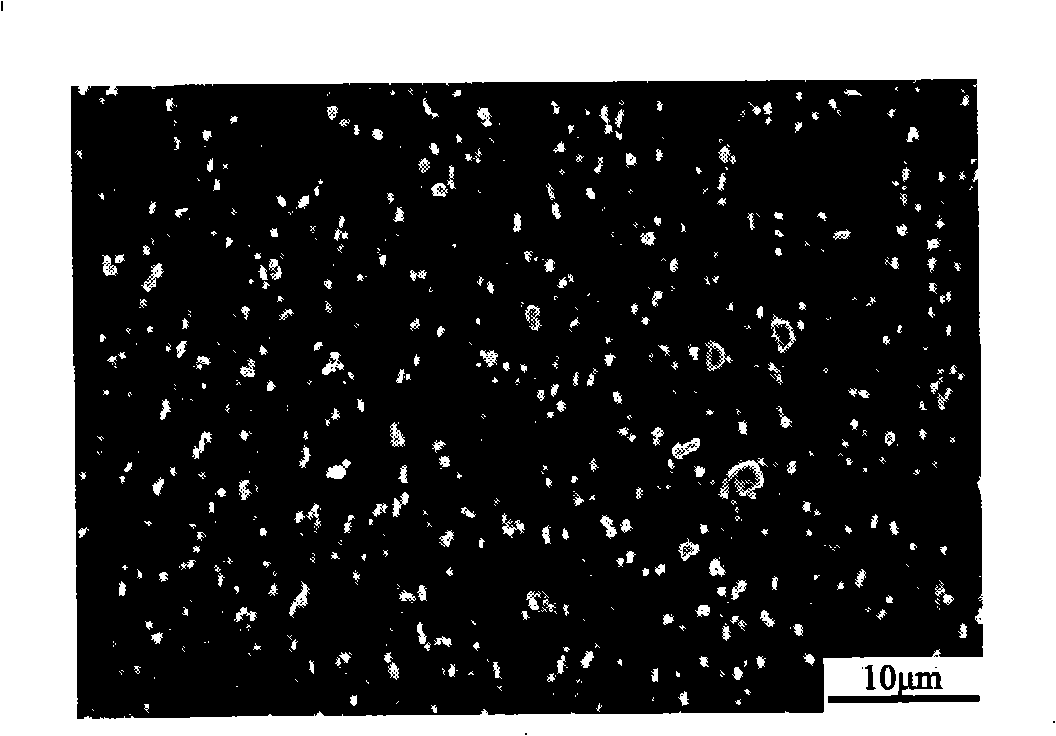

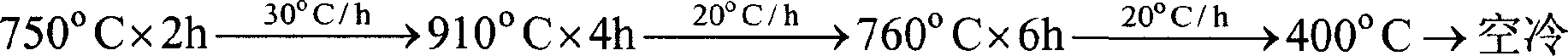

Superfine crystal nickel-based high-temperature alloy and method for preparing same

The invention provides an ultra-fine crystalline nickel base high-temperature alloy and a method for preparing the same, belonging to the high-temperature alloy steel field. The ultra-fine crystalline nickel base high-temperature alloy is particularly applicable to a high-temperature structural component which has high requirement to high-temperature strength and fatigue property, requires superplastic forming and has a complicated structure. The chemical compositions by weight percent of the ultra-fine crystalline nickel base high-temperature alloy are: 17 to 19 percent of Fe, 17 to 20 percent of Cr, 2.8 to 3.3 percent of Mo, 0 to 1.5 percent of W, 0.8 to 1.5 percent of Al, 0.3 to 1.3 percent of Ti, 4.7 to 5.7 percent of Nb, less than or equal to 0.015 percent of C, and the balance being Ni. The preparation method reasonably controls the parameter of a deformation process to allow the deformation temperature to be positioned in a grain boundary precipitated phase region and an austenite phase region which have higher solution temperatures, and uses powerful pinning action of a precipitated phase to the grain boundary to produce the ultra-fine crystalline alloy with a grade of grain fineness of between ASTM12 and ASTM13 grade. Compared with the prior art, the ultra-fine crystalline nickel base high-temperature alloy has simple alloy compositions, greatly reduces the resistance to deformation during forming, has small loss to forging and rolling equipment, and prevents crystal grains from growing when the ultra-fine crystalline nickel base high-temperature alloy is heated for a long time at a high temperature.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing magnesium alloy section bar by continuous corner shearing and squeezing shaping and mold

InactiveCN101406906AImprove material plasticityImprove plasticityExtrusion diesExtrusion control devicesGrain structureHigh strain

The invention relates to a method for preparing a magnesium alloy section through continuous angle rotation shearing, extrusion and shaping and a mould. The method comprises the following steps: (1) a magnesium alloy blank material is subjected to homogenization treatment; (2) a mould of an extrusion mould with a plurality of angle rotation and molding is preheated; and the inside of a mould passage is evenly coated with lube; (3) an extrusion cylinder is heated to a temperature of between 175 and 325 DEG C; and (4) the homogenized blank material is heated to a temperature of between 200 and 350 DEG C; the extrusion ratio of the extrusion mould is between 4 and 100; and the magnesium alloy blank material is subjected to unidirectional extrusion at an extrusion speed of between 3 and 6 m / min so that the magnesium alloy blank material is subjected to compression and extrusion with high extrusion ratio and equal passage extrusion with a plurality of angle rotation. The magnesium alloy material prepared through the method has an ultrafine crystal grain structure, has the advantages of substantially improving the plasticity, low temperature superplasticity and high strain speed of the magnesium alloy material and has high yield stress.

Owner:CHONGQING UNIV

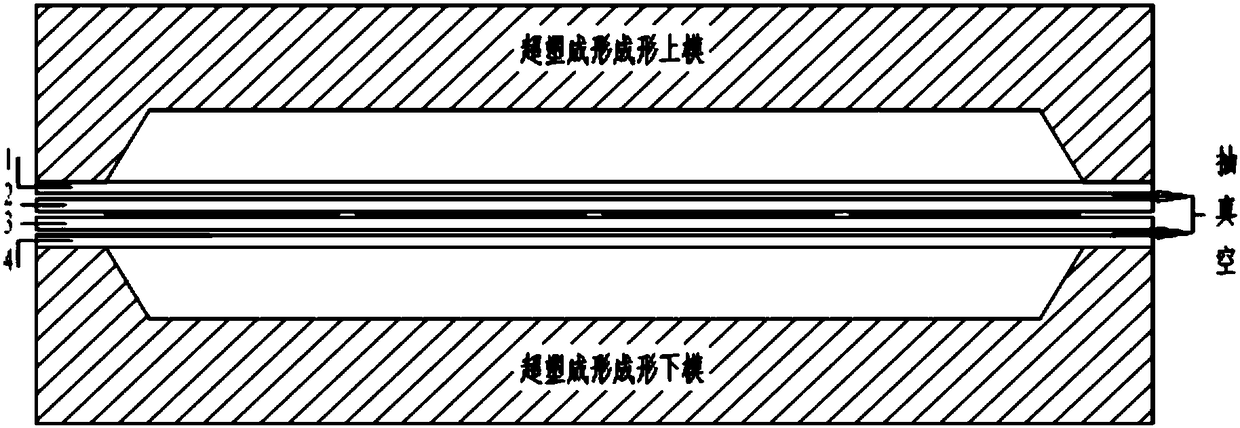

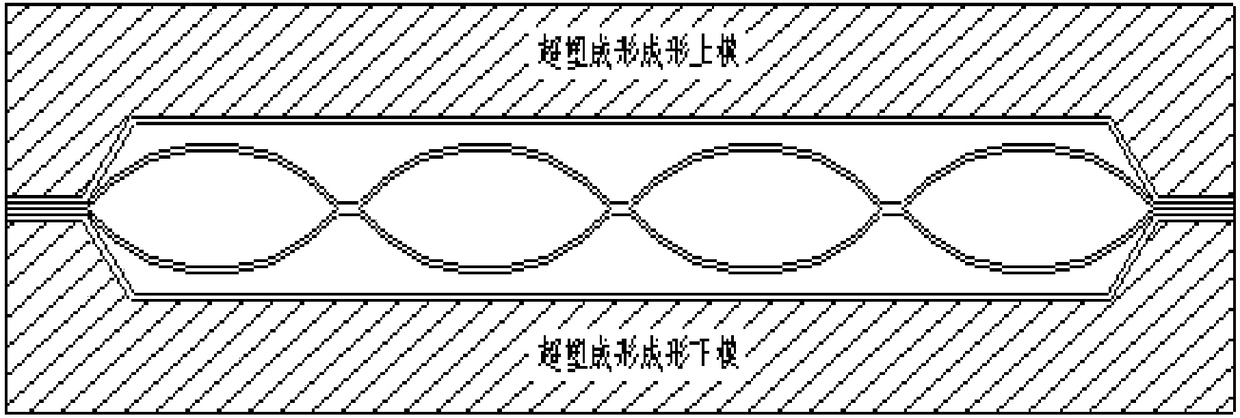

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

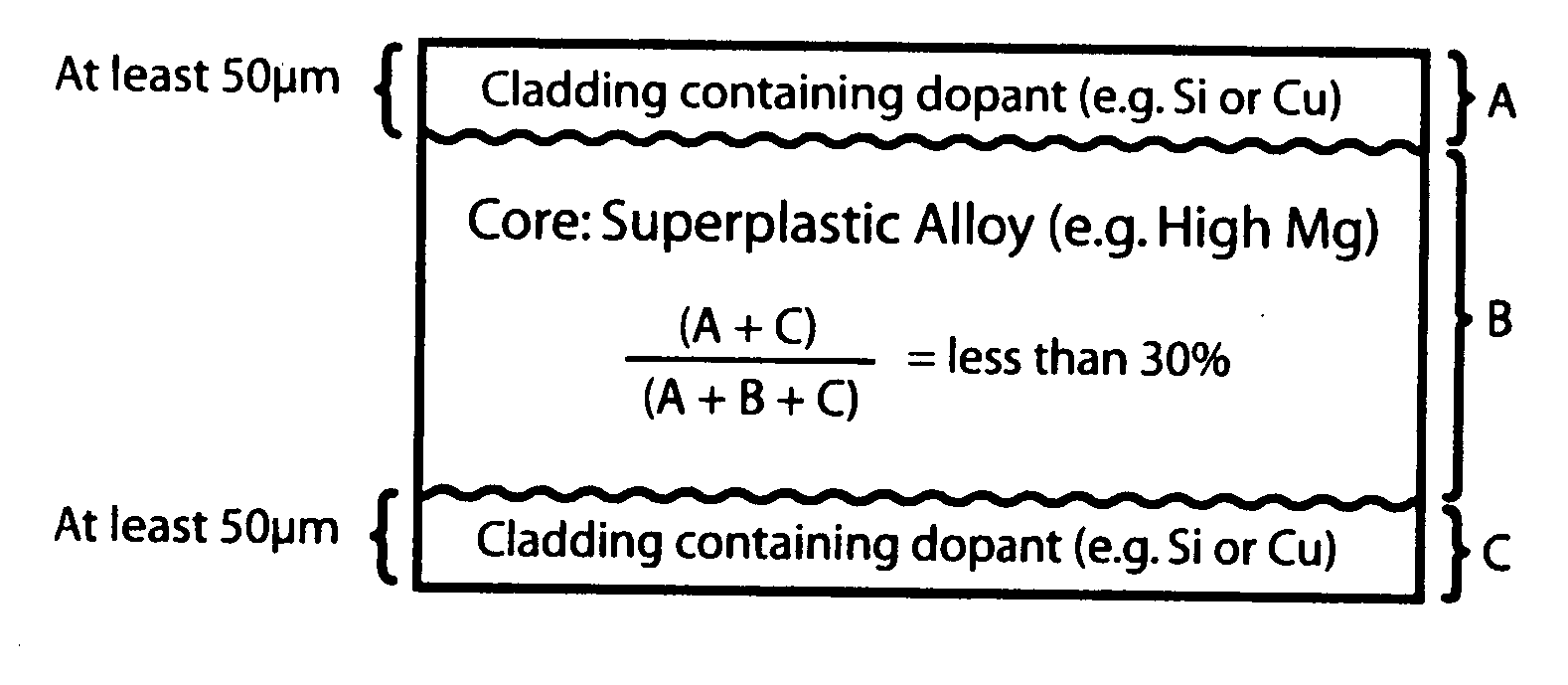

Cladding superplastic alloys

InactiveUS20080008903A1Reduce diffuseDeterioration of surface propertyThin material handlingMetal rolling arrangementsIngotMetal

A method of producing a clad sheet article having superplastic properties, and the resulting clad sheet article. The method involves producing a cladding layer onto at least one rolling face of a core ingot made of a metal having superplastic properties, preferably by co-casting, to form a clad ingot and then rolling said clad ingot to produce a sheet article. The core ingot includes an element that diffuses from an interior of the ingot to a surface at superplastic forming temperatures thereby deteriorating surface properties of the ingot. The cladding layer is provided with an element (dopant) that reacts with the element of the core to reduce the ability of the element to diffuse through the cladding layer.

Owner:NOVELIS INC

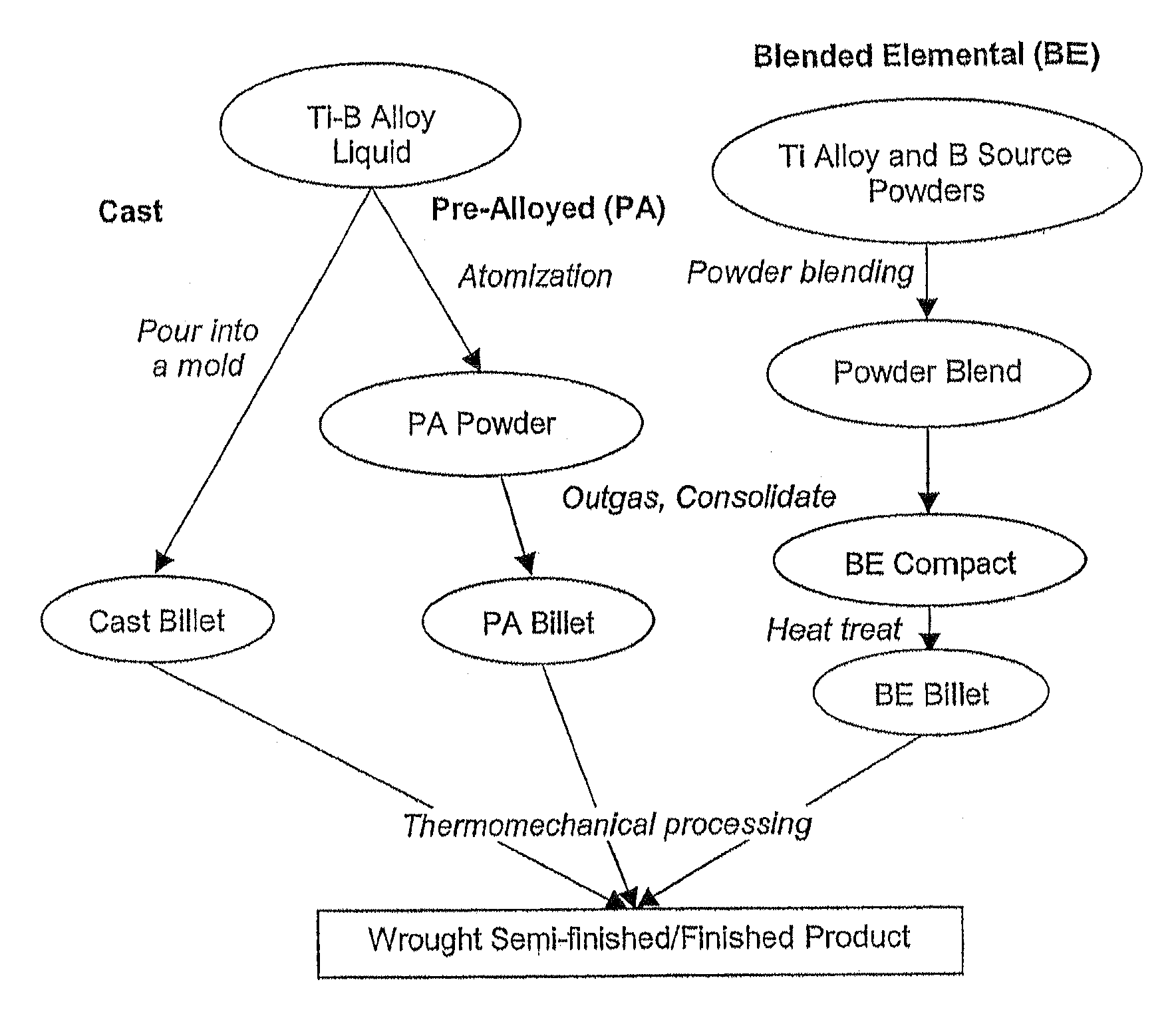

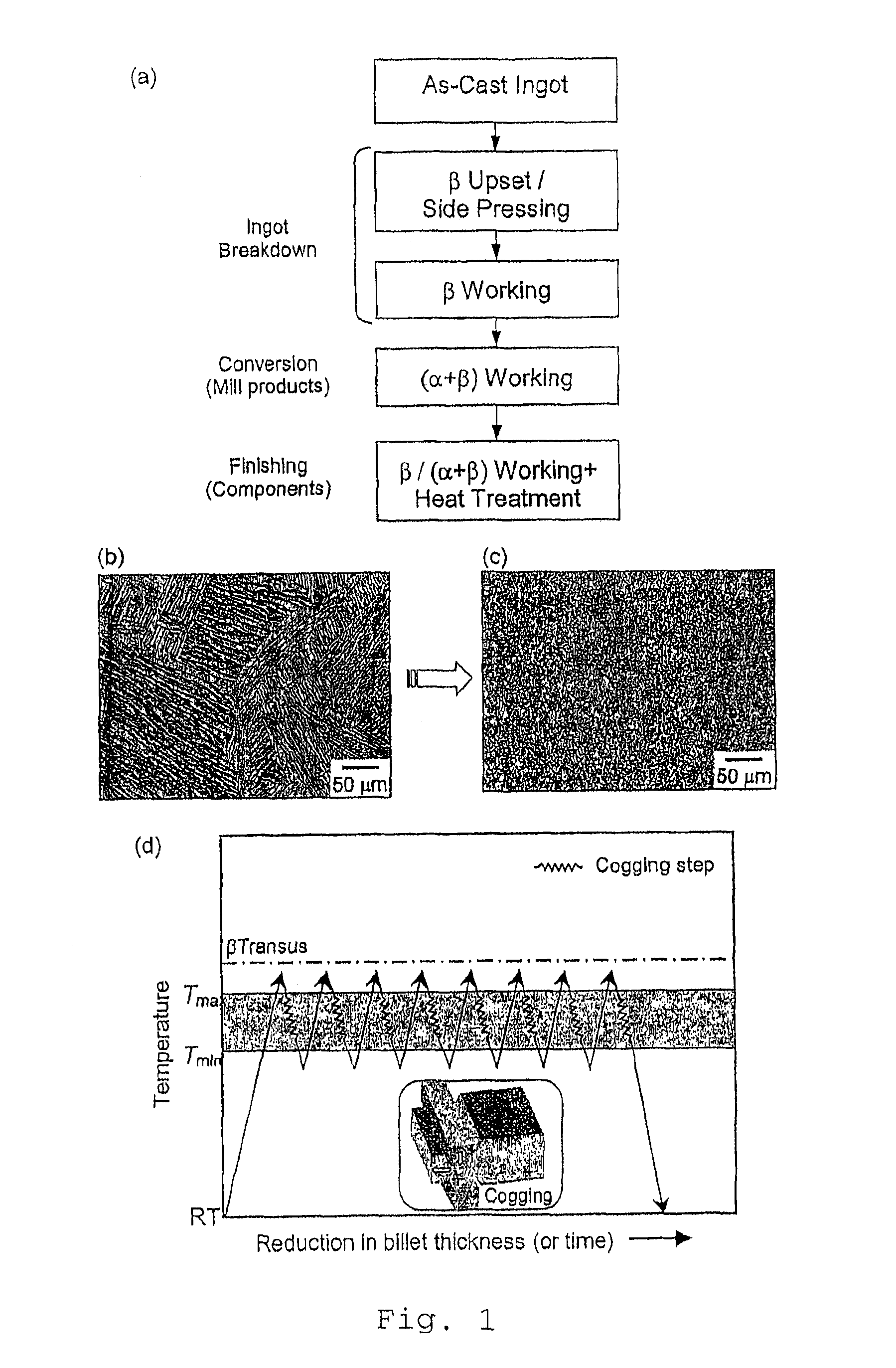

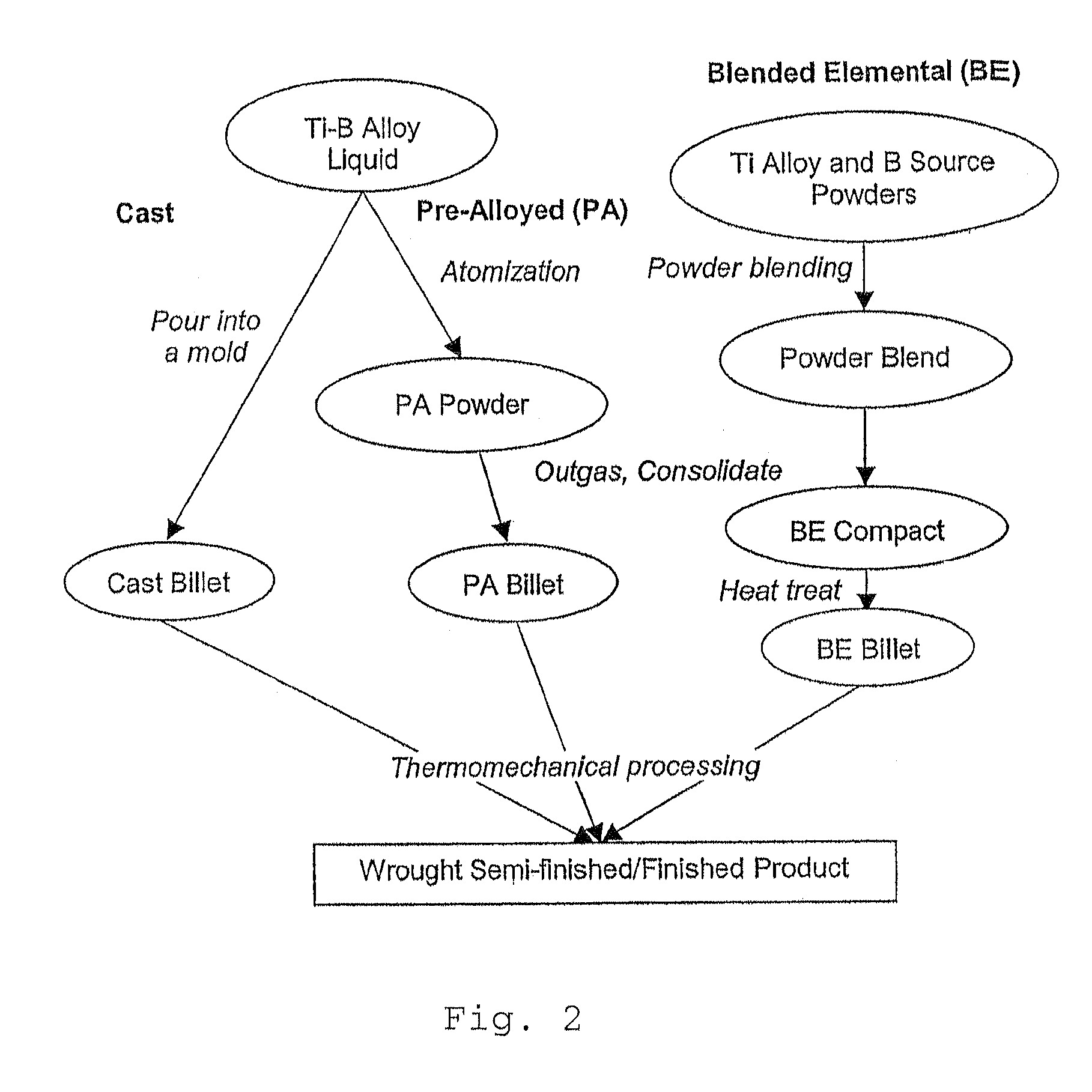

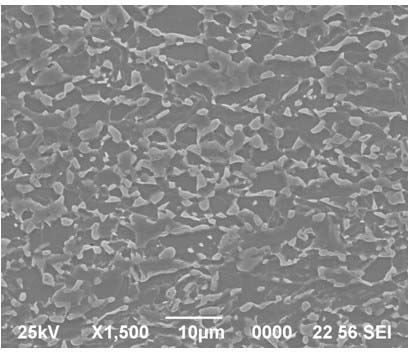

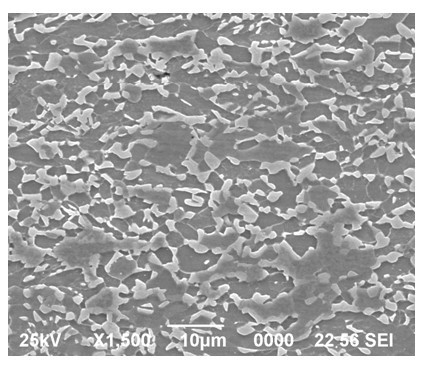

Titanium alloy microstructural refinement method and high temperature, high strain rate superplastic forming of titanium alloys

A method for refining the microstructure of titanium alloys in a single thermomechanical processing step, wherein the titanium alloy comprises boron. In some embodiments, the method comprises the steps of first adding boron to the titanium alloy then subjecting the boron-containing titanium alloy to a thermomechanical processing step. Also provided is a method for achieving superplasticity in titanium alloys comprising the steps of selecting a boron-containing titanium alloy, determining the temperature and strain rate necessary to achieve beta superplasticity, and applying sufficient temperature and strain rate to the boron-containing titanium alloy to deform the alloy to the desired shape. Also provided methods of forming titanium alloy parts and the parts prepared by these methods.

Owner:OHIO UNIV

A kind of low yield ratio high plastic ultrafine grain high strength steel and its manufacturing method

InactiveCN102277539AHigh yield strengthHigh tensile strengthRoll mill control devicesMetal rolling arrangementsChemical compositionGrain structure

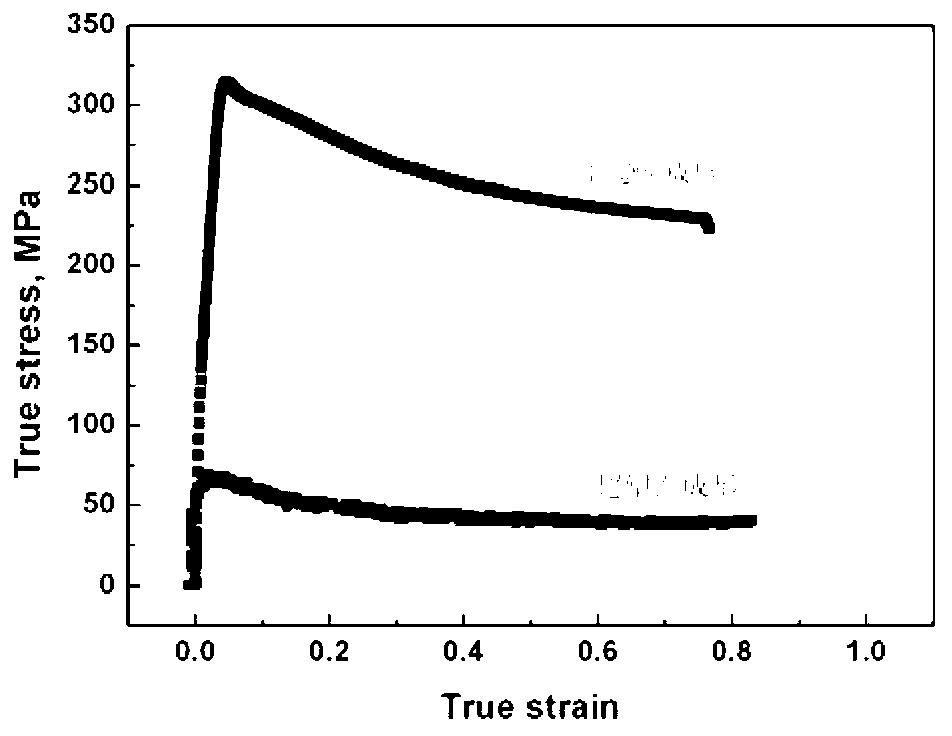

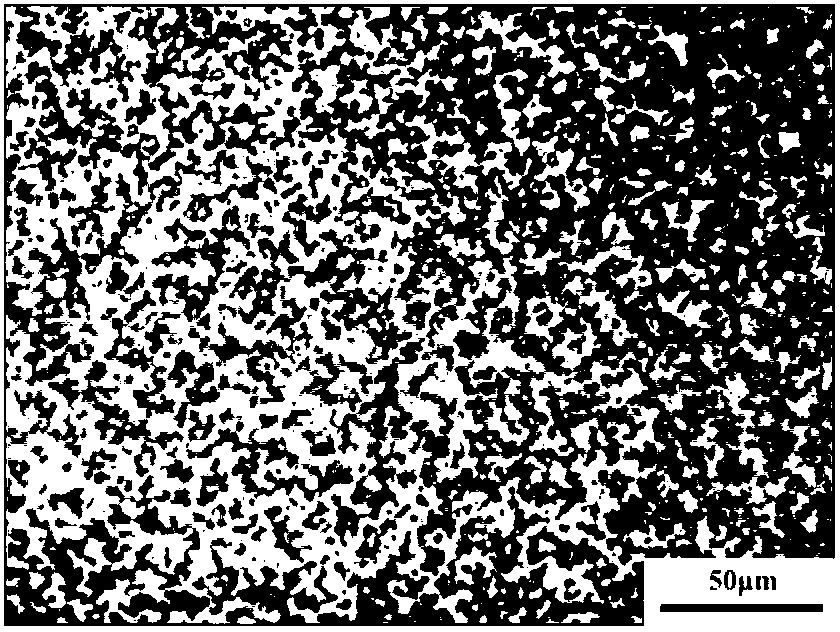

The invention discloses a high-strength steel with low yield ratio, high plasticity and ultra-fine grain and a manufacturing method. The chemical composition weight percentage of steel is: C: 0.06~0.09%, Si: 0.15~0.25%, Mn: 1.20~1.50%, P: ≤0.015%, S: ≤0.005%, Nb: 0.020~0.040%, V: 0.010~0.030%, Ti: 0.008~0.015%, Cr: 0.10~0.30%, Ni: 0.10~0.30%, Cu: 0.10~0.30%, Al: 0.010~0.050%, and the balance is Fe and unavoidable impurities. The invention obtains the bainite structure by adopting the controlled rolling and controlled cooling process. Through the heat treatment process, an ultra-fine grain structure with bimodal distribution is obtained, which makes the material have characteristics such as low yield ratio, superplasticity, and high strength. The production process is stable, the operability is strong, the cost is low, and the comprehensive performance of the obtained material is excellent.

Owner:NANJING IRON & STEEL CO LTD

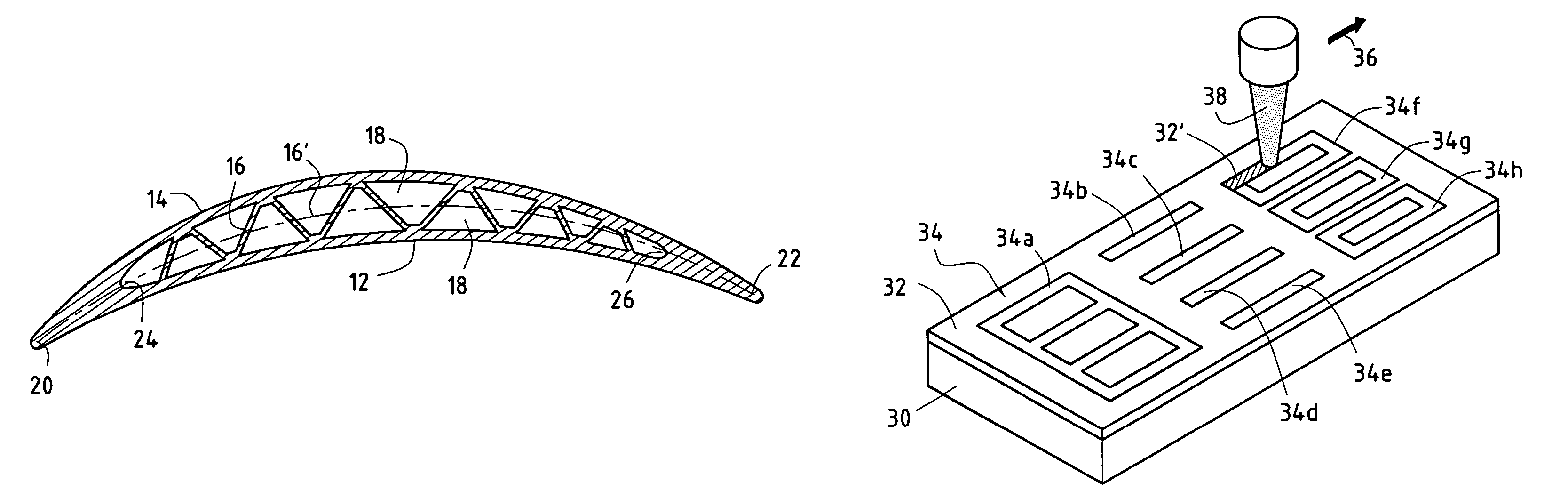

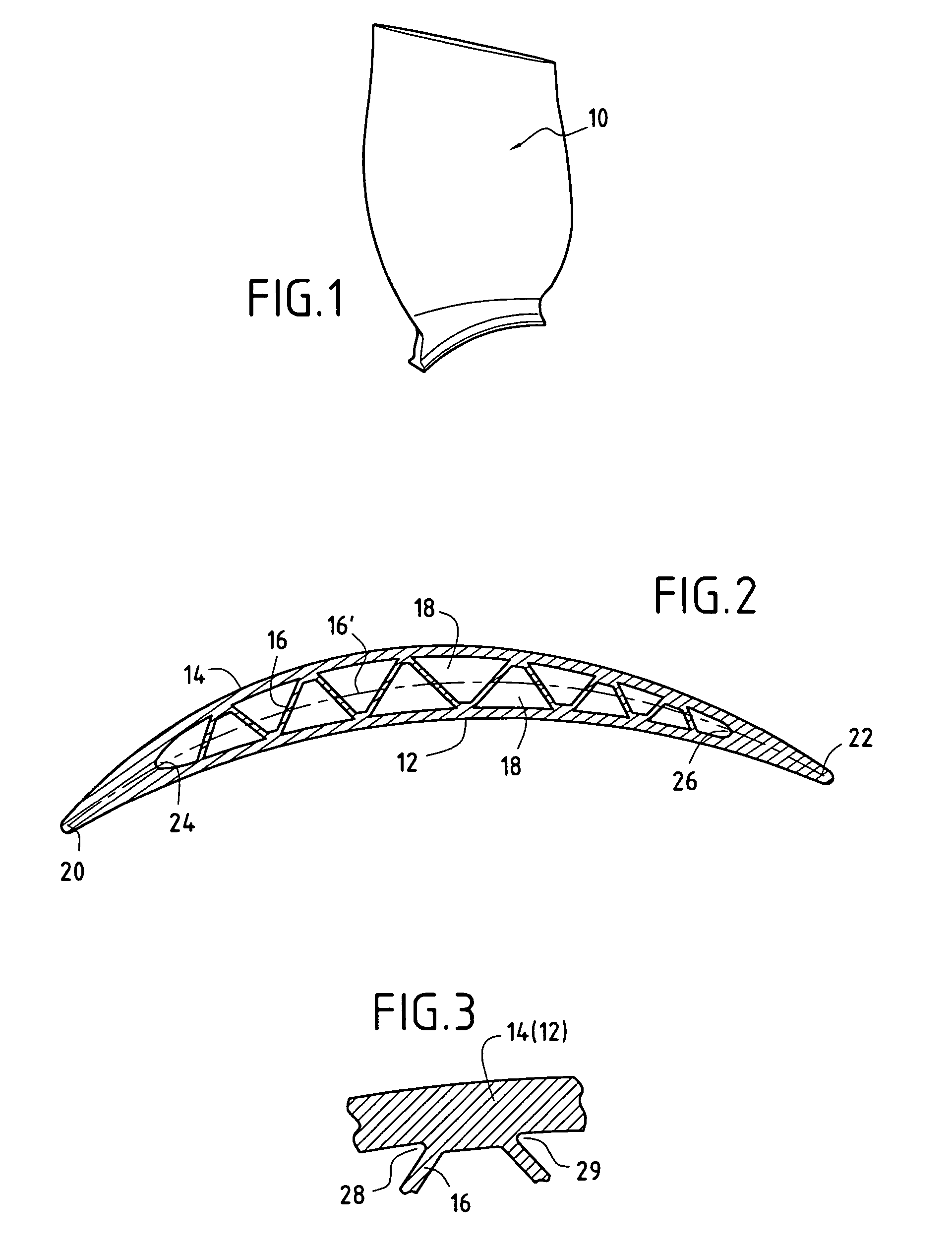

Method of fabricating a hollow mechanical part by diffusion welding and superplastic forming

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Electric impulse auxiliary superplastic forming device and method

InactiveCN101417299AIncreased superplasticityReduce deformation resistanceShaping toolsElectrical resistance and conductanceEngineering

The invention discloses a superplastic forming device with auxiliary of electrical pulse and a method thereof, which relate to the technical field of superplastic air bulking forming and solve the defect of low energy utilization. An upper mould and a lower mould of the device are respectively positioned at the upper side and the lower side of the blank to be formed, a forming part is placed inside a cavity of the mould, a pressure head tightly presses an insulation mould and the blank to be formed in a way of sealing, an air outlet of an air pressure device penetrates the pressure head and the insulation mould and is arranged inside the cavity; and a high frequency pulse power source, a blank holding electrode and the blank to be formed form an electrifying loop. The steps for applying the device are as follows: firstly, according to the cross sectional dimension of the blank to be formed and resistance data, a current parameter is chosen so as to lead the blank to be formed to be heated to the superplastic forming temperature, and the heating speed can be up to 50-100 DEG C per second; secondly, the edge-pressing force of a press ram is regulated, inert gas is introduced into the cavity by the pressure device so as to lead the blank to occur superplastic deformation. Applied in the complex parts manufacturing industry, the invention greatly improves the utilization of the manufacturing energy and the efficiency of heating.

Owner:HARBIN INST OF TECH

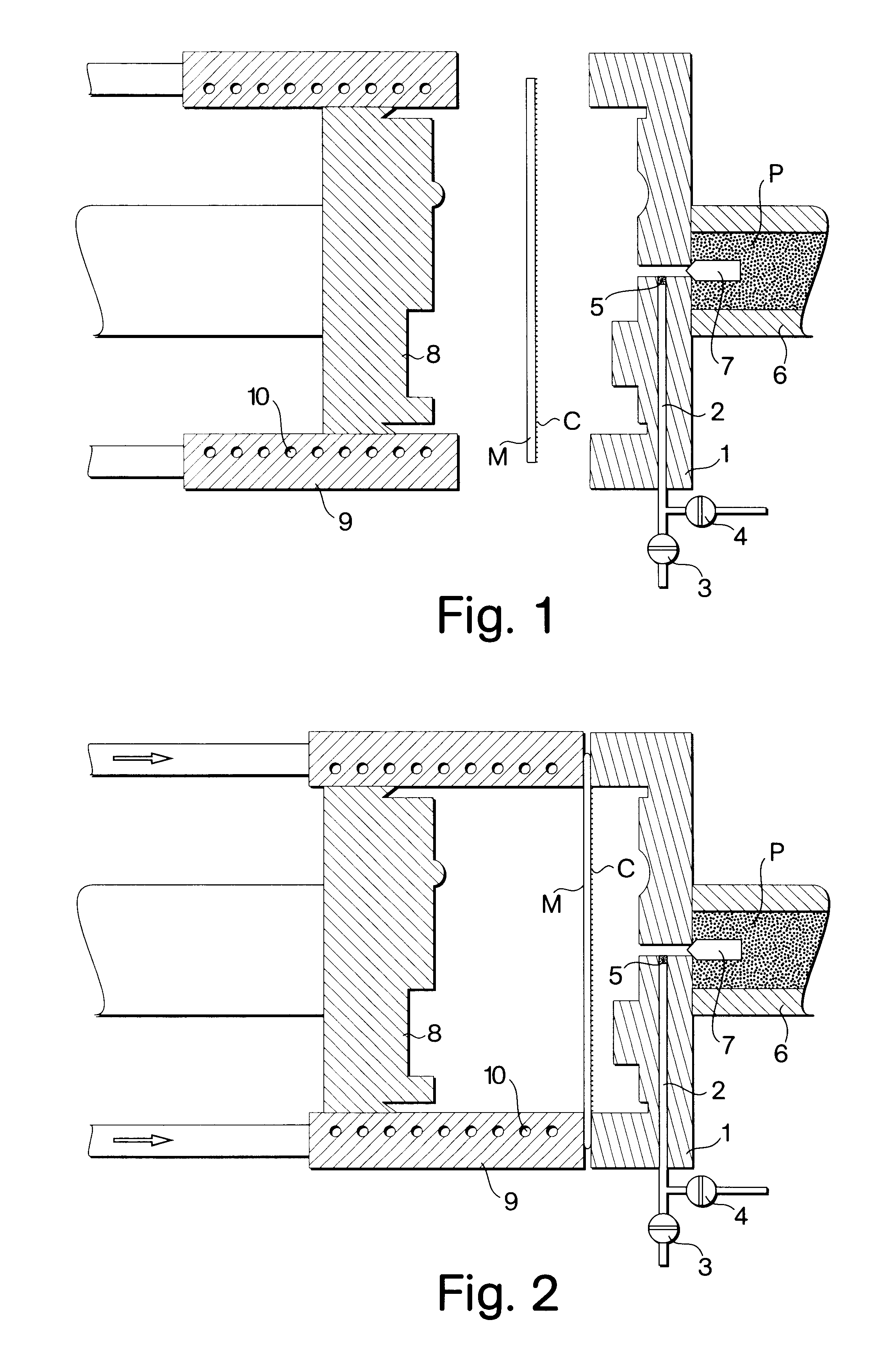

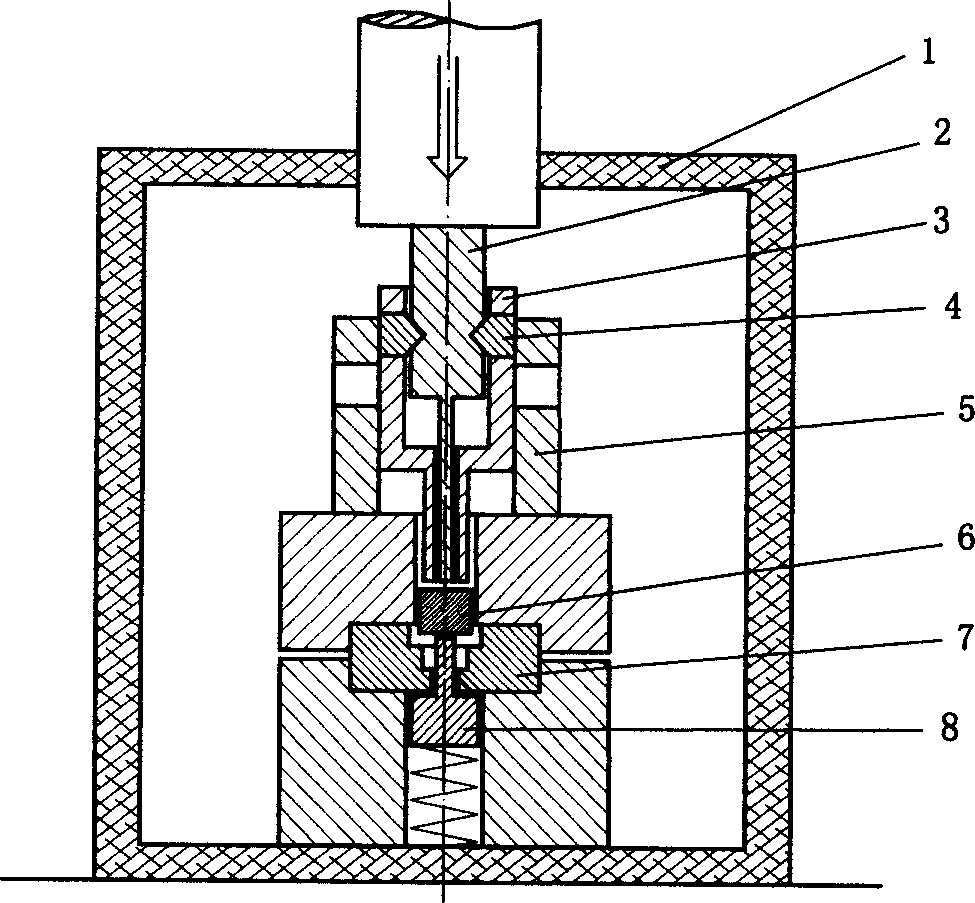

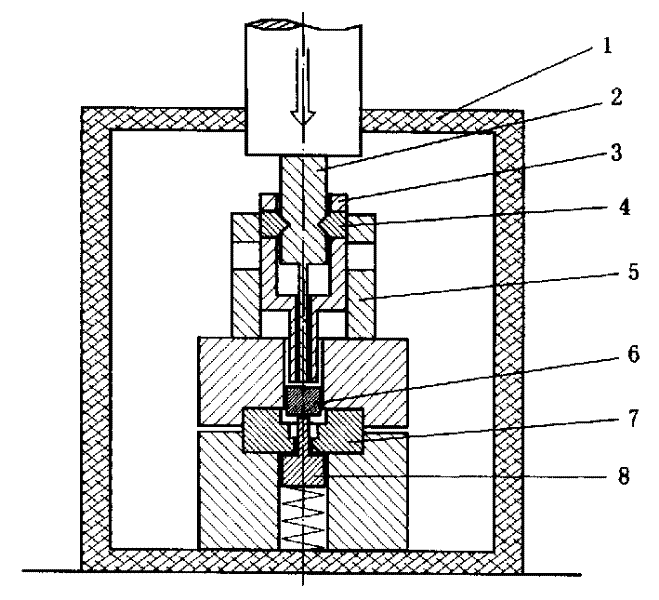

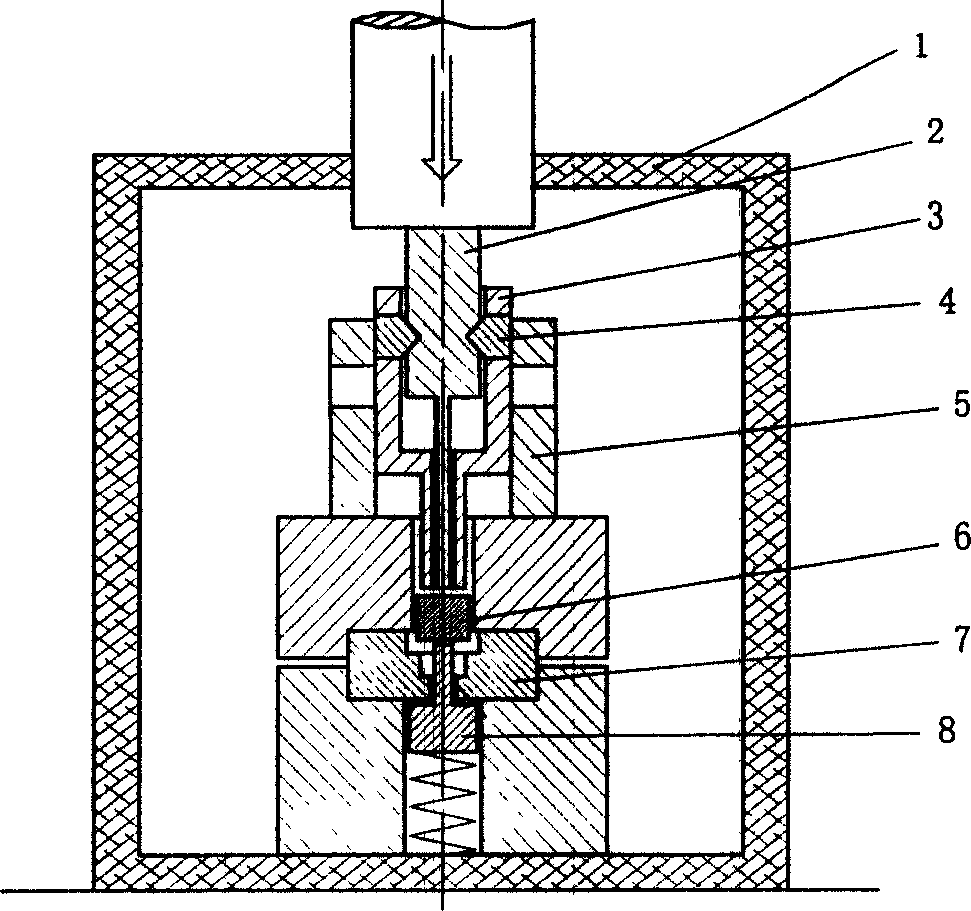

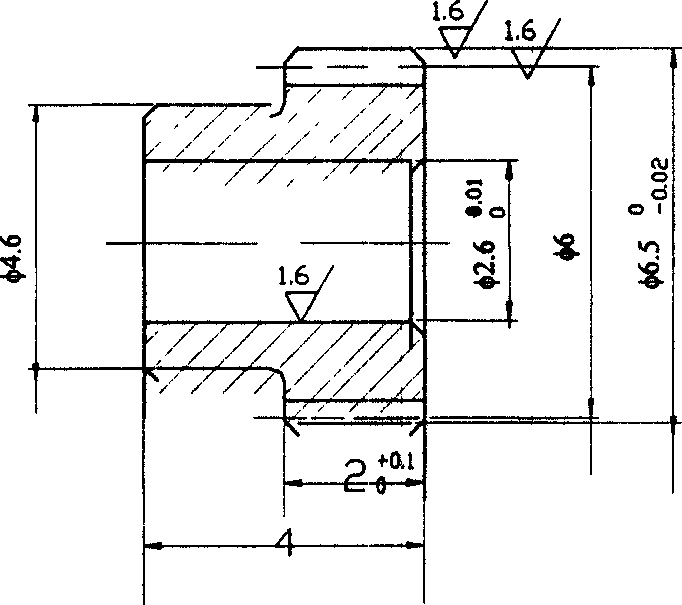

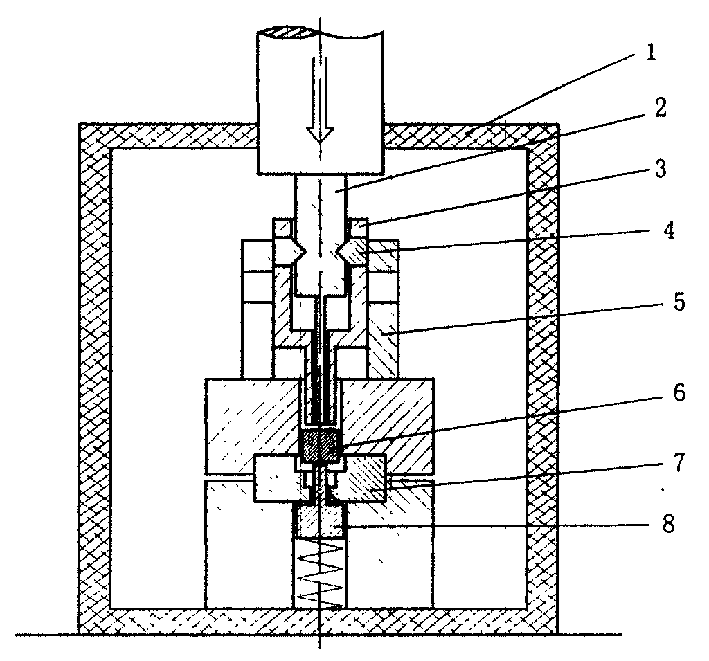

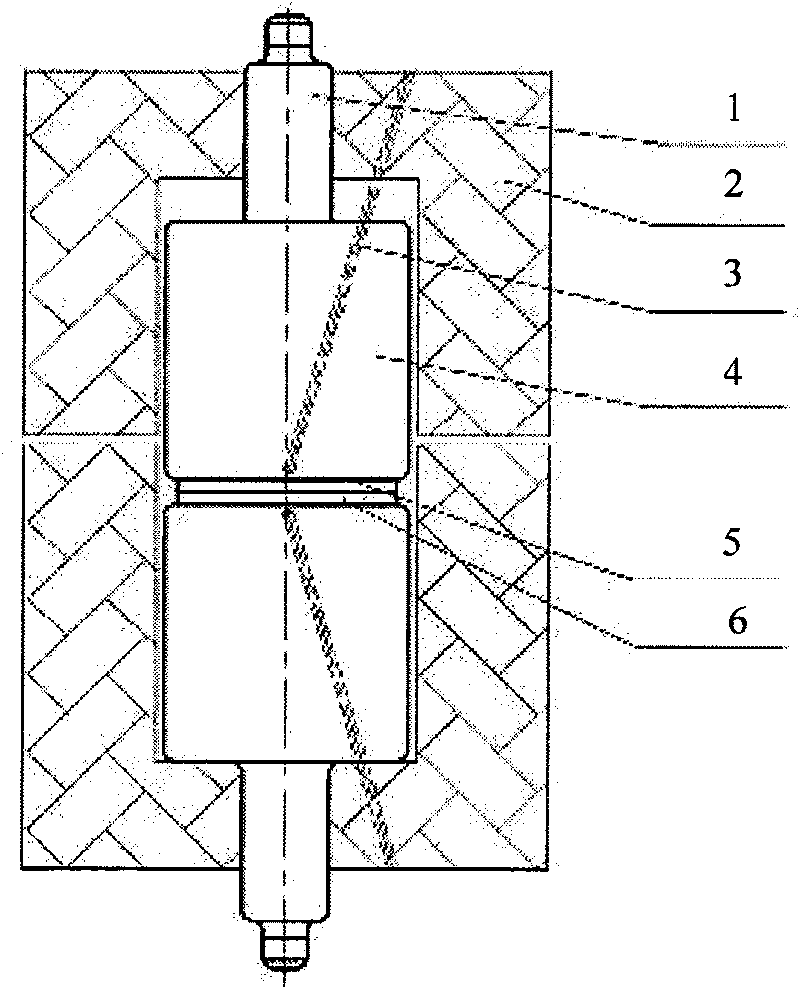

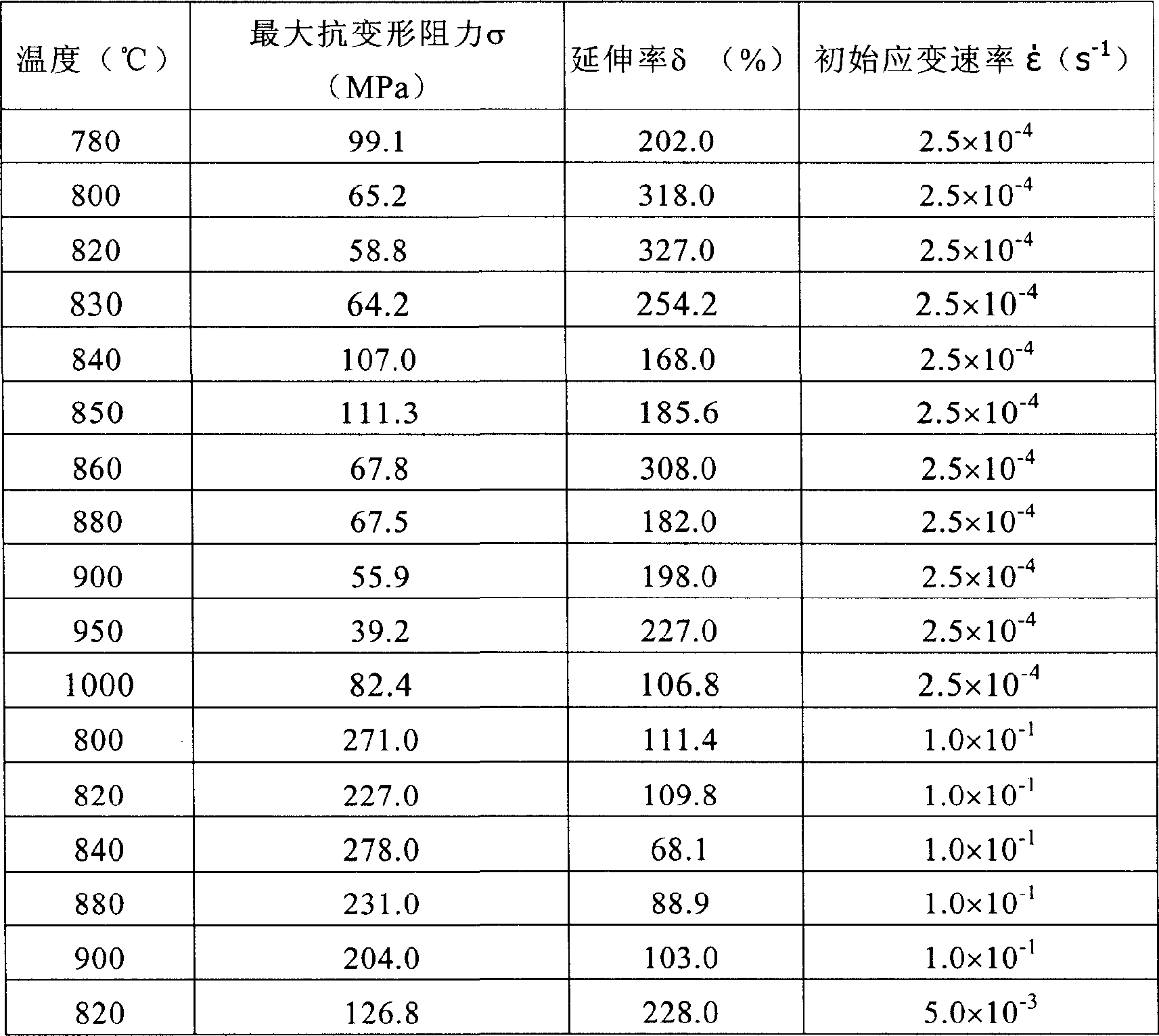

Amorphous alloy precision parts superplastic drop-forging shaper and method thereof

InactiveCN1199747CImprove mechanical propertiesGuaranteed surface qualityMetal-working apparatusSurface roughnessSuperplasticity

The invention provides a superplastic die forging forming device and method for amorphous alloy precision parts. The device is composed of a vacuum furnace (1), a replaceable pressure head and a mold. The replaceable indenter is made up of inner indenter (2), outer indenter (3), slide block (4), connecting seat (5), and mold is made up of mold (7), ejection mechanism (8). The process is to place the blank and the mold in a vacuum furnace, and when the vacuum degree reaches 8×10 -3 Pa, start heating, heating rate 0.5 ~ 3.0 ℃ / s; heating temperature should be between Tg ~ Tx; forming strain rate range of 1 × 10 -2 ~5×10 -4 the s -1 . The advantage is that it is suitable for the forming of bulk amorphous alloy materials with large supercooled regions such as Zr-based, La-based, and Pd-based. The dimensional accuracy of the prepared parts is between ±0.1% and ±0.3%, and the surface is rough. The degree Ra is less than 0.8μm, and it can even reach the nanoscale mirror surface.

Owner:UNIV OF SCI & TECH BEIJING

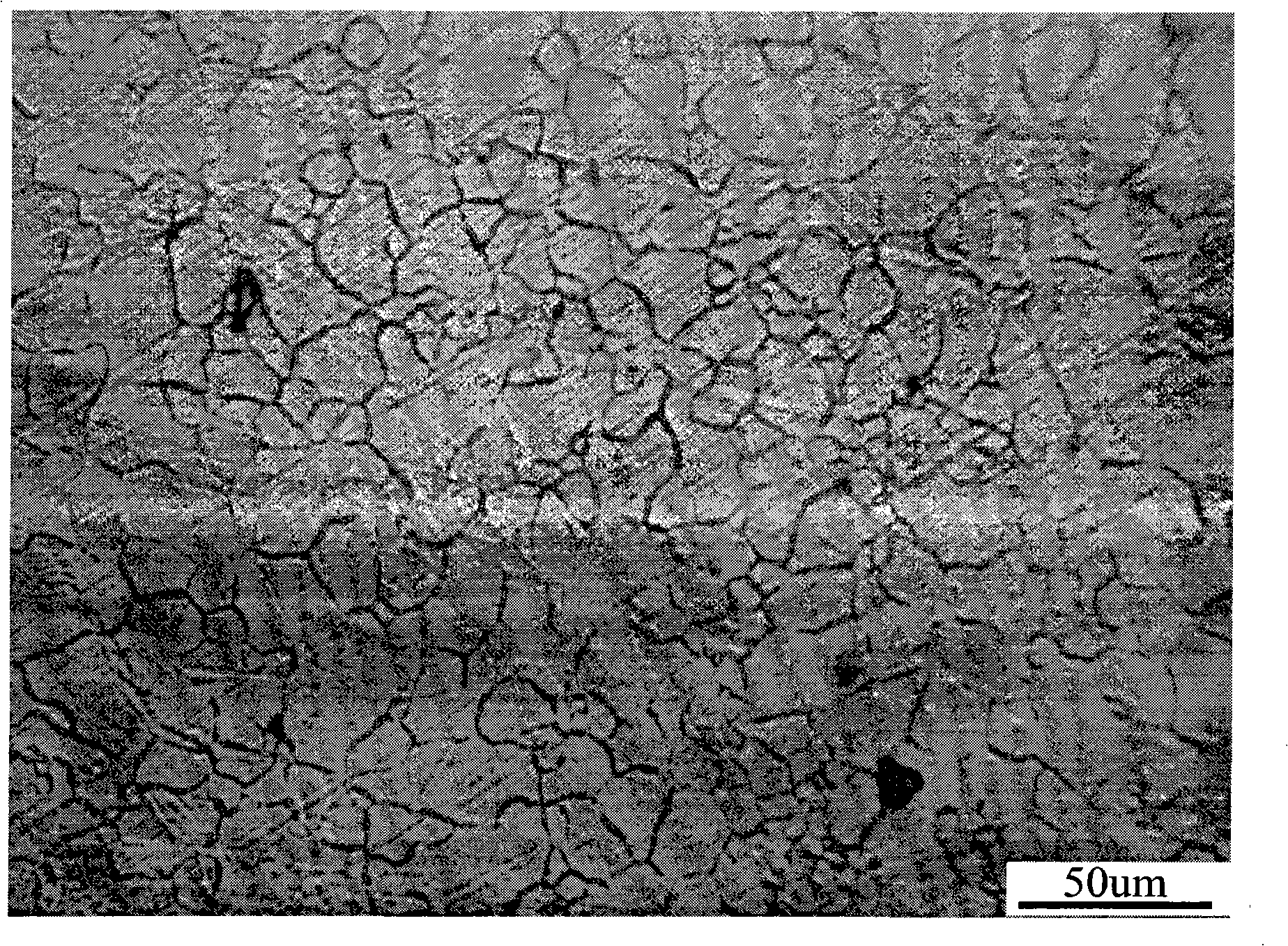

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Difficultly-deformed nickel-based superalloy superplastic forming method

The invention discloses a difficultly-deformed nickel-based superalloy superplastic forming method, relates to a difficultly-deformed nickel-based superalloy superplastic forming technique, and aims to solve the problems that during conventional preparation of the difficultly-deformed nickel-based superalloy with high strengthening phase content, the forming process is difficult, the deformation resistance is high, the difficultly-deformed nickel-based superalloy is easy to crack and difficult to recrystall. The difficultly-deformed nickel-based superalloy superplastic forming method is implemented by the following steps: 1, forging under an isothermal condition; 2, performing sub-solution temperature deformation; and 3, controlling the strain rate in a range of 0.0001-0.005 / s. By the difficultly-deformed nickel-based superalloy superplastic forming method, the thermal deformation of the difficultly-deformed superalloy is easier, thereby achieving superplastic forming; the difficultly-deformed nickel-based superalloy superplastic forming method is applicable to preparation of nickel-based superalloy turbine disk in the aerospace field and preparation of other high-temperature-resistant forged disks used in a high-temperature environment.

Owner:CENT IRON & STEEL RES INST +1

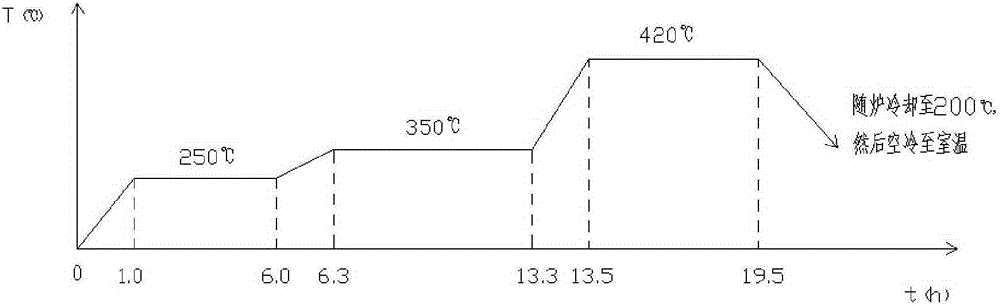

Spheroidizing annealing process of superplasticity fastener wire rod

InactiveCN102994710AImprove ductilityReduce hardnessFurnace typesHeat treatment furnacesWire rodMetallic materials

The invention relates to an annealing process of metal materials, in particular to a spheroidizing annealing process of a superplasticity fastener wire rod. The process includes the following steps that the fastener wire rod is placed in a thermal treatment furnace, protective gases are fed into the thermal treatment furnace, the interior temperature of the furnace is increased to 740 DEG C to 760 DEG C, and the temperature is maintained for 5 to 7 hours; according to first-stage cooling, the interior temperature of the furnace is decreased to 660 DEG C to 680 DEG C at the speed of 30 DEG C per hour, and the temperature is maintained for 4 to 6 hours; according to second-stage cooling, the interior temperature of the furnace is continued to be decreased to 390 DEG C to 410 DEG C at the speed of 50 DEG C per hour; and according to third-stage cooling, the fastener wire rod is naturally cooled to a room temperature. The fastener wire rod processed by the process has the advantages that the malleability is high, the hardness is low, the process is suitable for subsequent plastic working forming, and the product forming cracking rate is low.

Owner:DONGGUAN KELEE STEEL WIRE

Preparation method of 650 DEG C high-temperature titanium alloy sheet for superplastic forming

ActiveCN109750185AFully brokenWeaken phase transition textureMetal rolling arrangementsBeta phaseWork in process

The invention provides a preparation method of a 650 DEG C high-temperature titanium alloy sheet for superplastic forming. The preparation method adopts hot rolling machining to obtain 650 DEG C titanium alloy sheets with excellent superplastic properties. The preparation method comprises the steps that (1) after a 650 DEG C titanium alloy casting ingot is heated, cogging and forging are carried out, and a sheet blank for titanium alloy rolling is obtained; (2) after the obtained sheet blank is coated with a coating and is heated, cogging and rolling are carried out on a rolling machine; (3) after the sheet blank is heated, second rolling is carried out; (4) after the sheet blank is subjected to heat treatment above the beta phase transformation point, rapid water quenching cooling is carried out; (5) after the sheet blank is heated, third hot rolling is carried out; (6) after the sheet blank is heated, fourth reversing hot rolling is carried out; (7) the obtained blank is assembled and welded, and a coated overlapping rolling package is obtained; (8) after the overlapping rolling package is heated, hot rolling is carried out, and a semi-finished sheet is obtained; and (9) after the semi-finished sheet is subjected to creep deformation and forming correction, annealing and acid and alkali washing, a finished 650 DEG C titanium alloy sheet with thickness of 0.8-2.0 mm is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

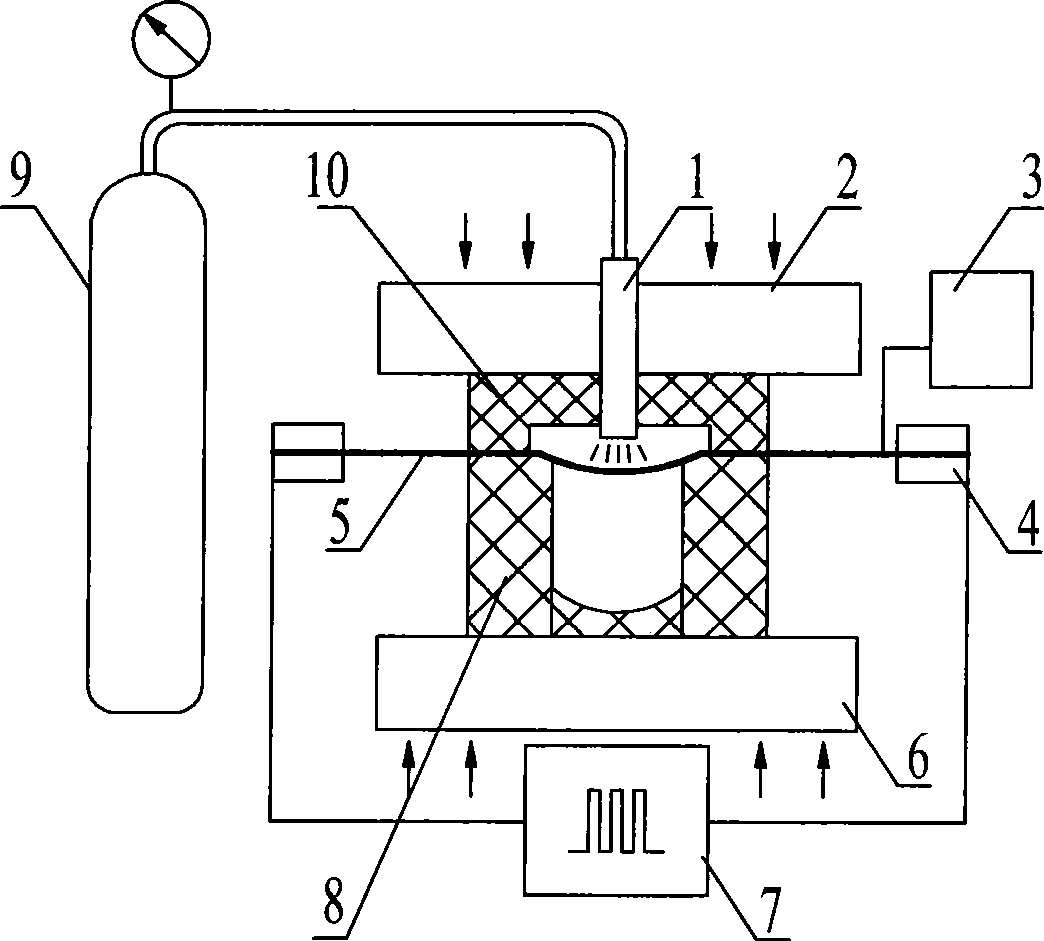

Method and device for preparing large-size bulk amorphous composite materials

The invention provides a method for preparing large-size bulk amorphous composite materials, which belongs to the field of preparing amorphous alloy (metallic glass) and composite materials thereof. The method applies to superplastic diffusion bonding of bulk amorphous substances and fiber, and is characterized in that the bulk amorphous substances and the fiber are arranged in a certain mode (such as a layered mode and the like), put into a mold, pressurized and thermally insulated under gas protection or vacuum for superplastic diffusion bonding; pressure is released after a certain period of time; and workpieces are taken out of the mold. The invention also provides a novel device for preparing large-size bulk amorphous, fiber / amorphous composite materials through superplastic diffusion bonding. The device consists of a heating system, a heat insulation system, a mold system, a loading system, a gas protection system and a cooling system. The method and the device have the advantages of reinforcing the fiber, enabling the shape of amorphous alloy-base composite materials to be designed, enabling the volume of the fiber in the composite materials to be controlled and enabling the fiber to be used in other various amorphous alloy systems low in amorphous formation capability, and are applicable to armor boards, armor-piercing shells and the like.

Owner:UNIV OF SCI & TECH BEIJING

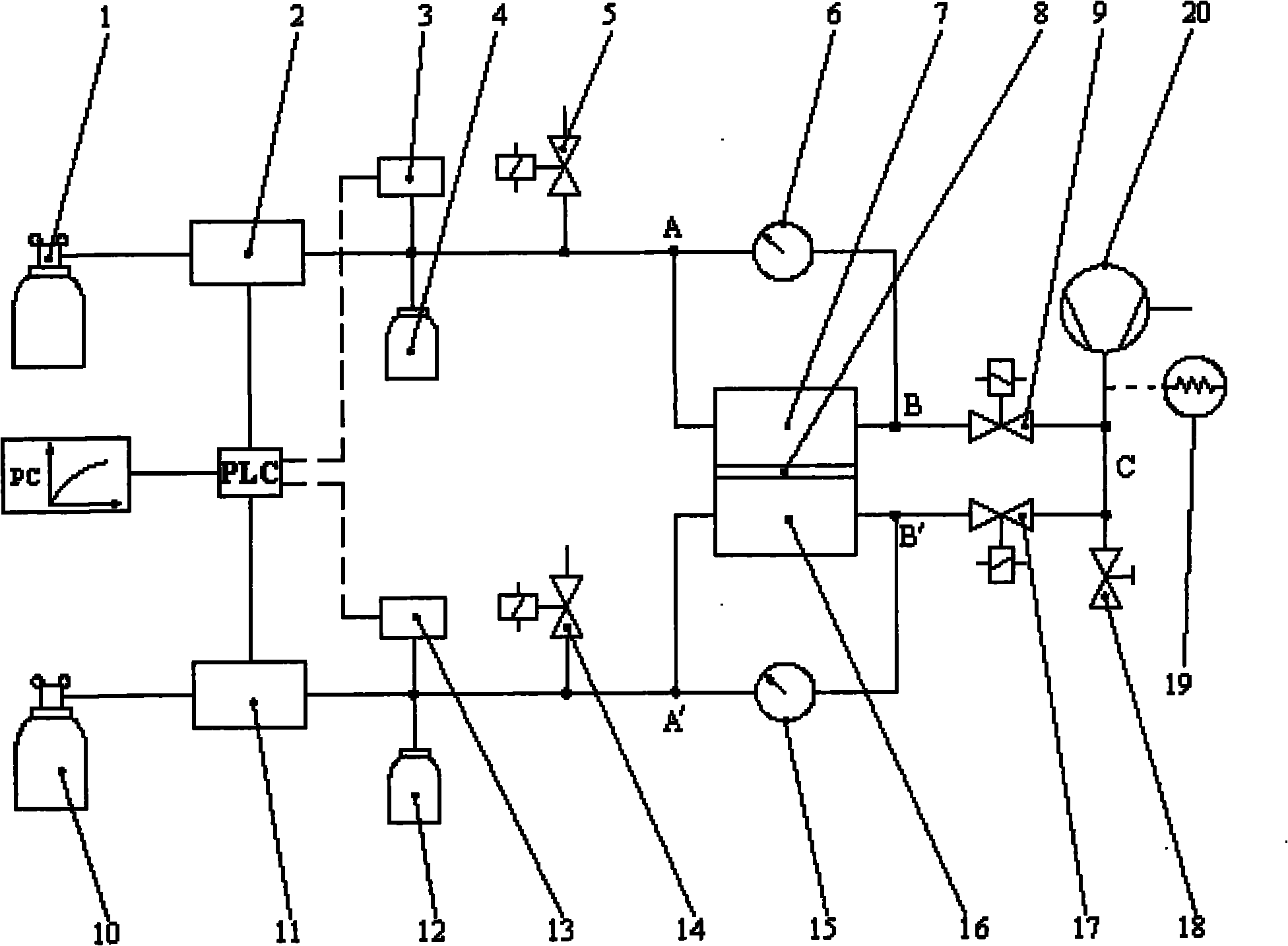

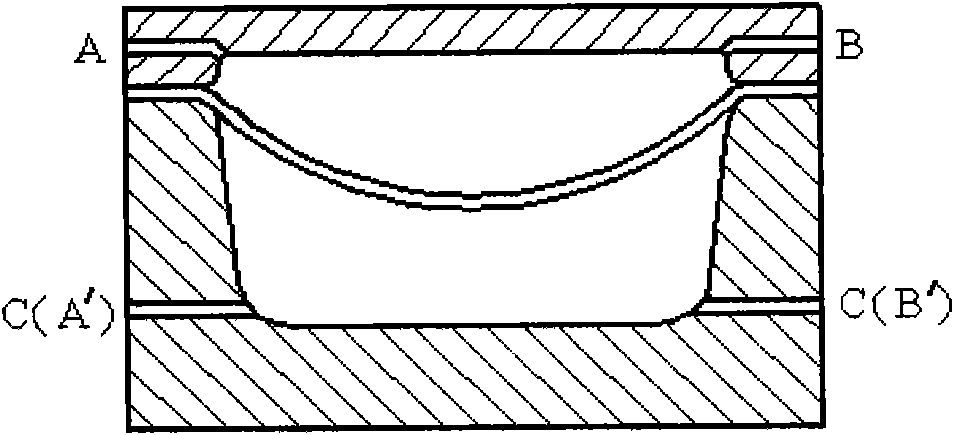

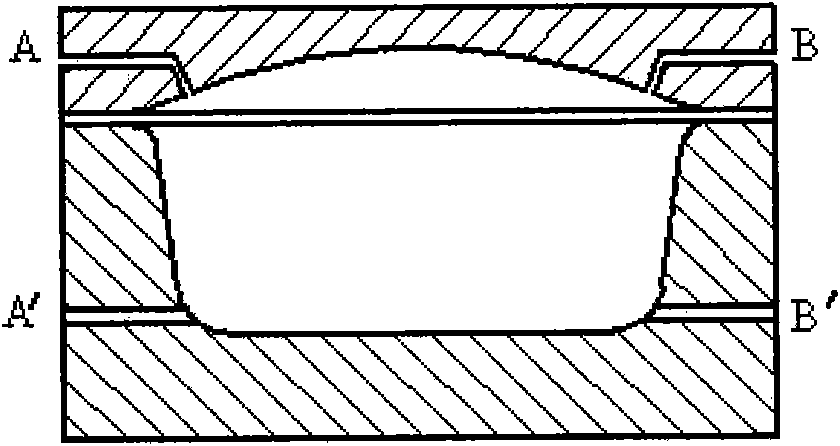

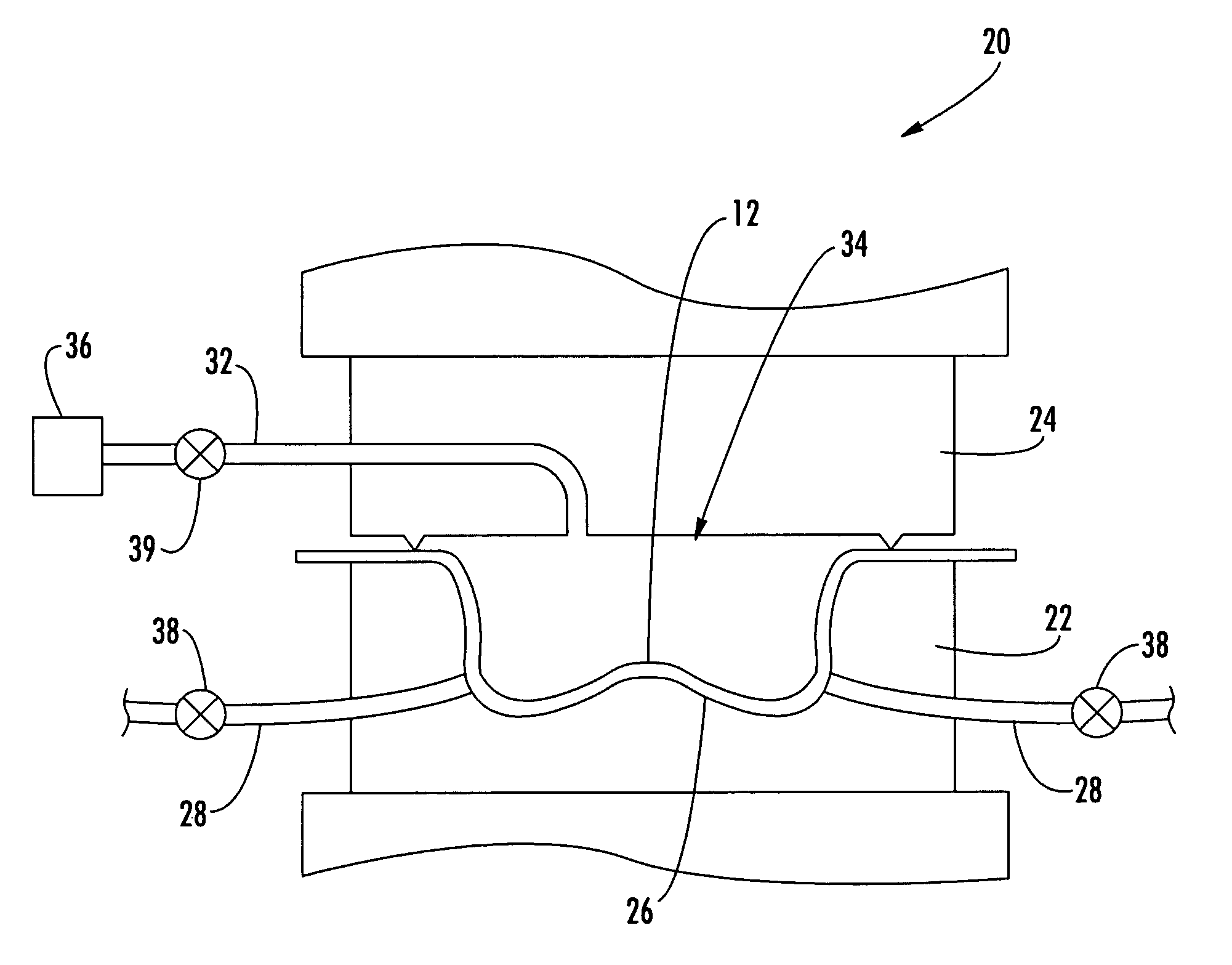

Superplastic forming and processing method for sheets and superplastic-forming air pressure loading device thereof

The invention discloses a superplastic forming and processing method for sheets and a superplastic air pressure loading device, and belongs to the technical field of superplastic forming and processing of the sheets. The method and the air pressure loading device are characterized in that: the superplastic deformation of the sheets is always controlled within or close to the range of an optimal strain rate so as to give full play to the superplastic performance of the materials and improve the wall thickness uniformity and use performance of formed parts. The air pressure loading device comprises a control system, an upper mold air pressure loading system, a lower mold air pressure loading system and a vacuum system for the upper and lower molds. The superplastic forming and processing method and the air pressure loading device can perform processes of superplastic forming, back pressure forming and positive and negative forming on the sheets such as high-temperature alloys, titanium alloys, aluminum alloys, magnesium alloys, metal matrix composites, intermetallic compounds and the like to form complex part shapes.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Preparation method of Ti2AlNb/TA15 bi-metal titanium alloy composite hollow structure

The invention provides a preparation process of a Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure part. The Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure wing type component is prepared through the steps of blank preparation, surface treatment, welding stop agent coating, superplastic forming / diffusion bonding, cooling, out of a furnace and the like. The superplastic forming / diffusion bonding process method of the dissimilar material hollow structure part breaks through the key technology of the multi-layer hollow structure prepared by combining a Ti2AlNb intermetallic compound and an ordinary titanium alloy, the high-temperature resisting characteristic of the Ti2AlNb intermetallic compound and the good superplasticity of the TA15 titanium alloy are givento full play, structure weight losing is achieved, the guided missile thrust-weight ratio is increased, the application of the Ti2AlNb intermetallic compound to types is promoted, the material application range is expanded, the material utilization rate is increased, and the cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

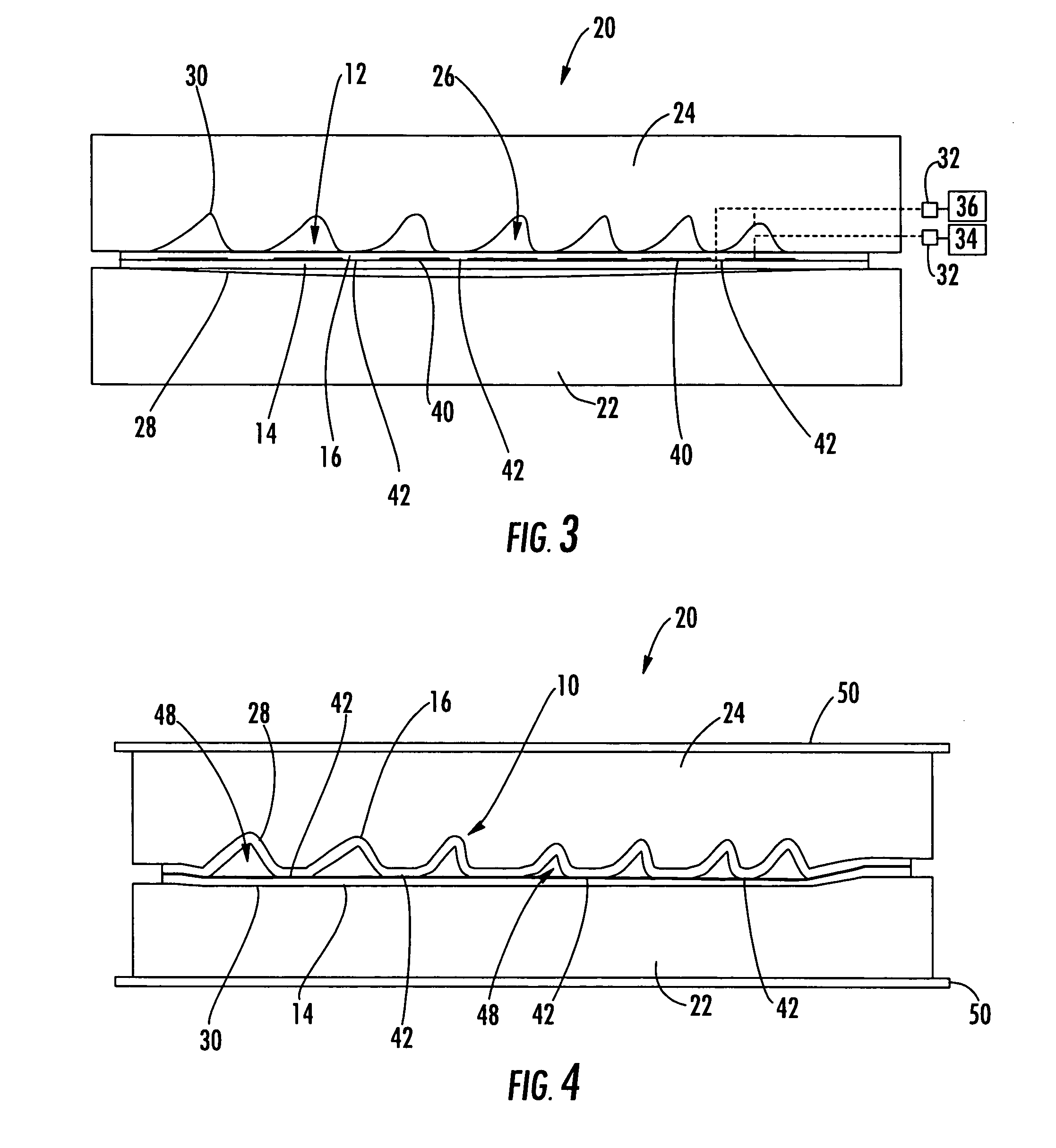

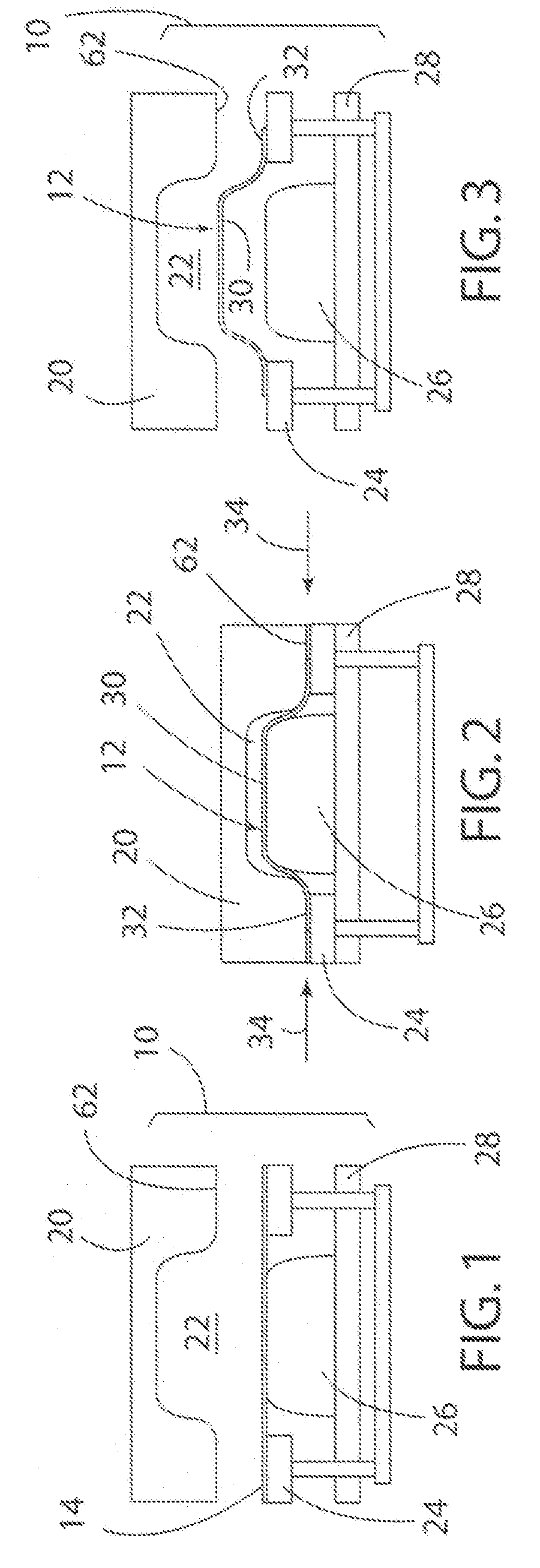

Superplastic forming and diffusion bonding of fine grain titanium

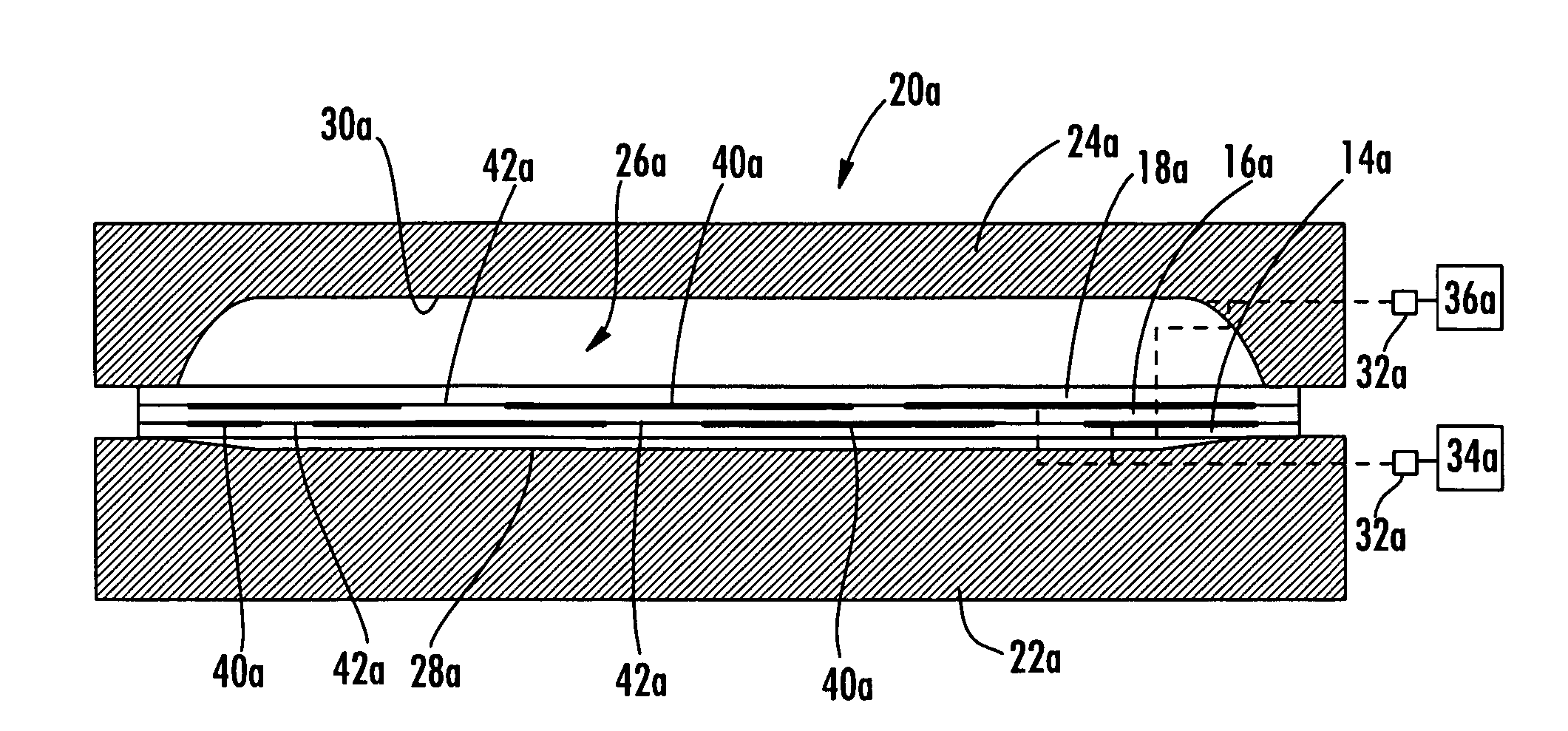

ActiveUS20050218193A1Less heatReduce the impactWelding/soldering/cutting articlesNon-electric welding apparatusThermal energyTitanium

A method for superplastically forming and / or diffusion bonding a structural member and an associated structural member are provided. The structural member is formed at least partially of titanium, e.g., Ti-6Al-4V, and has a fine grain structure. For example, the grain size of the material of the structural member can be less than 2 micron. The member can be superplastically formed and / or diffusion bonded at a reduced temperature, thereby potentially reducing the thermal energy required for forming and bonding, and also reducing the effects of heating on the structural member and the forming apparatus. In addition, the structural member can be formed at an increased strain rate.

Owner:THE BOEING CO

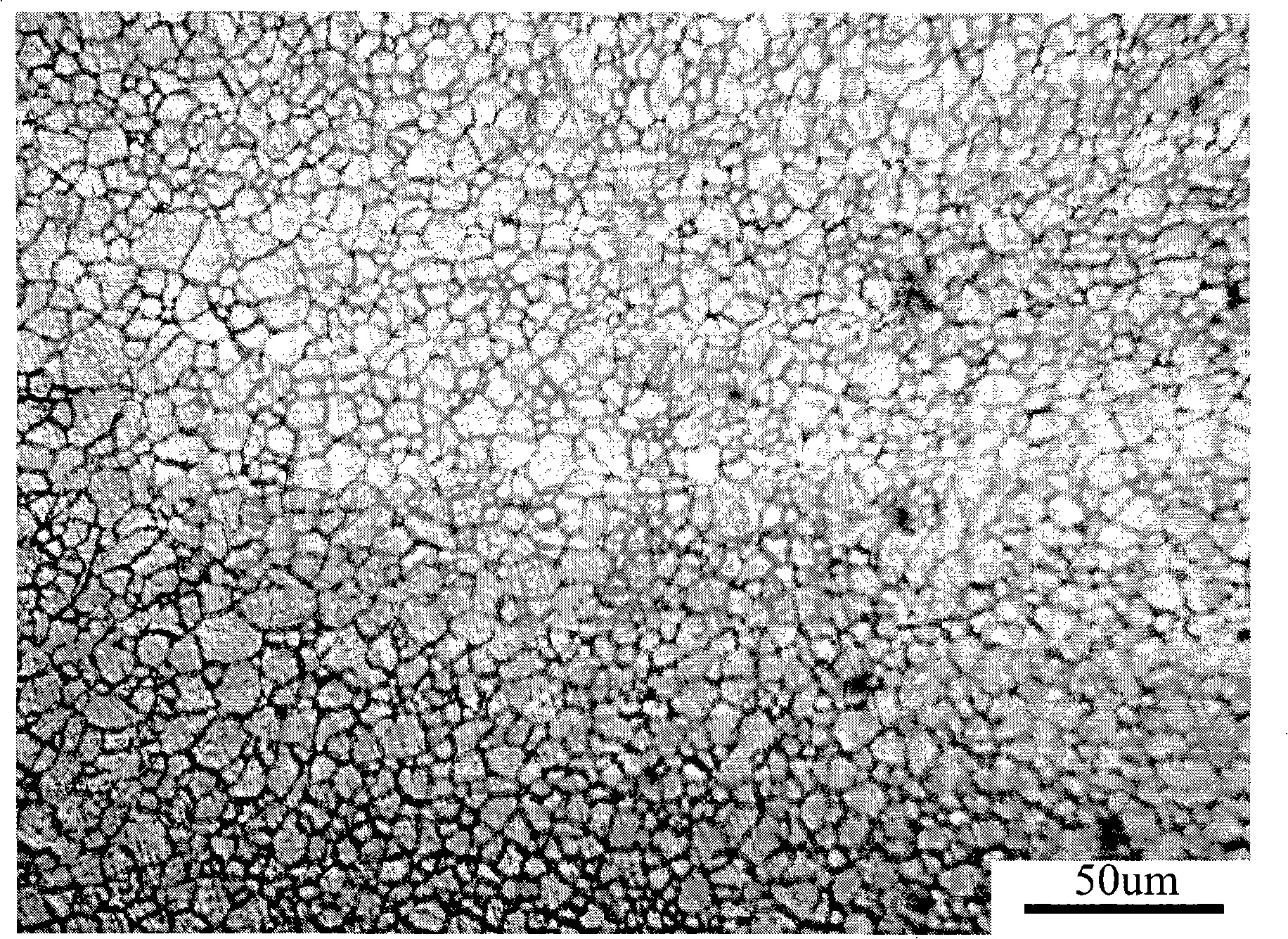

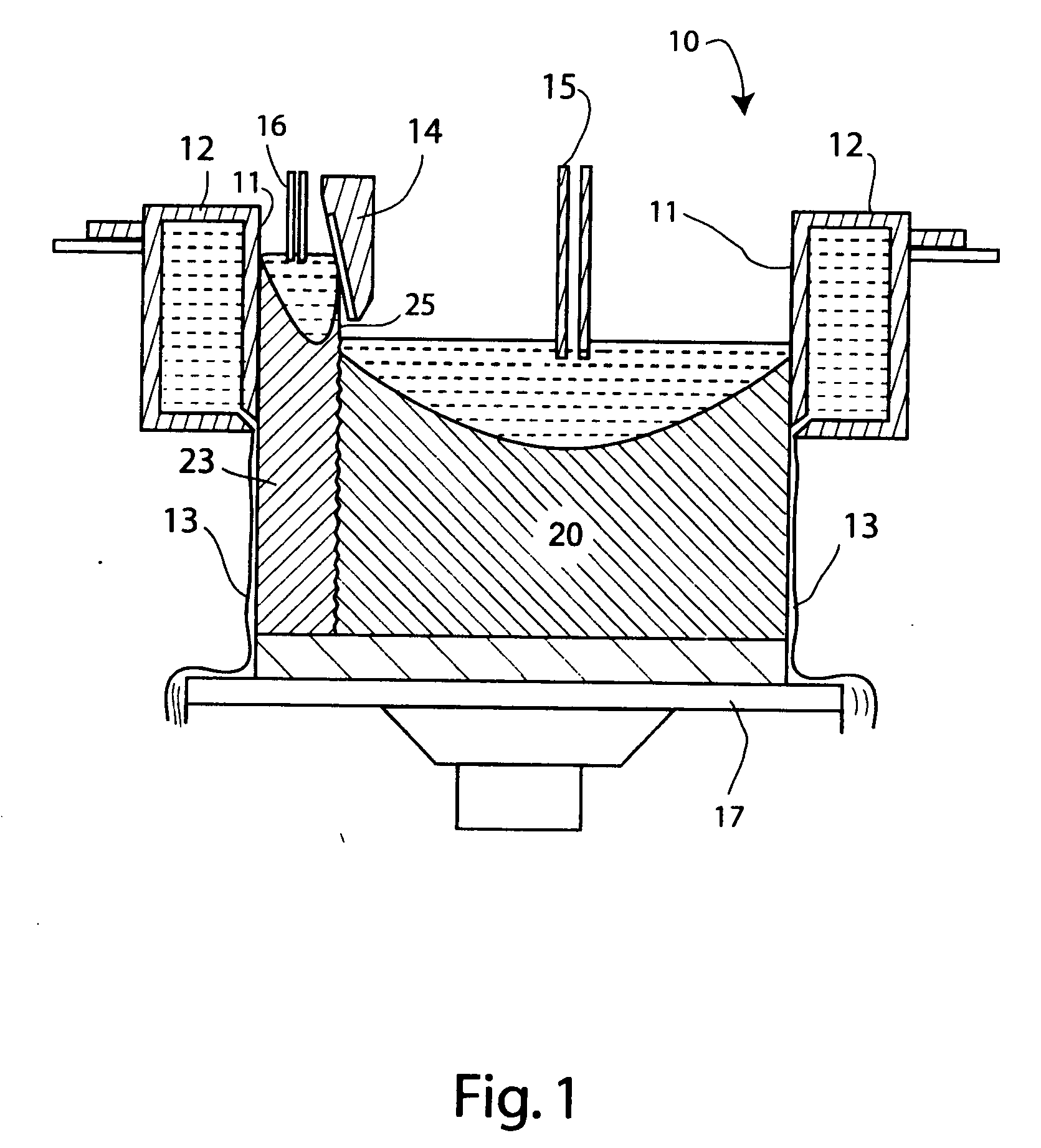

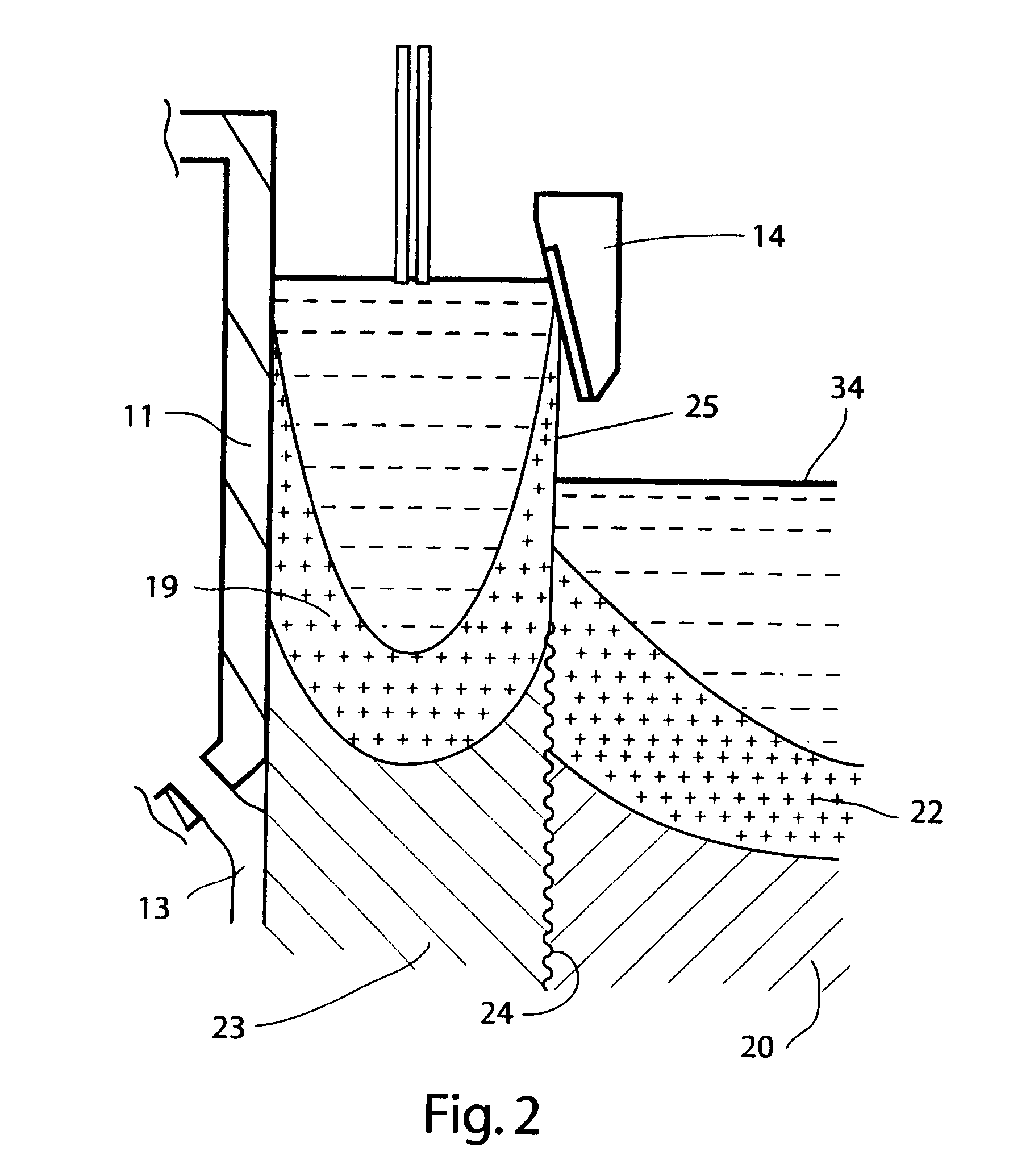

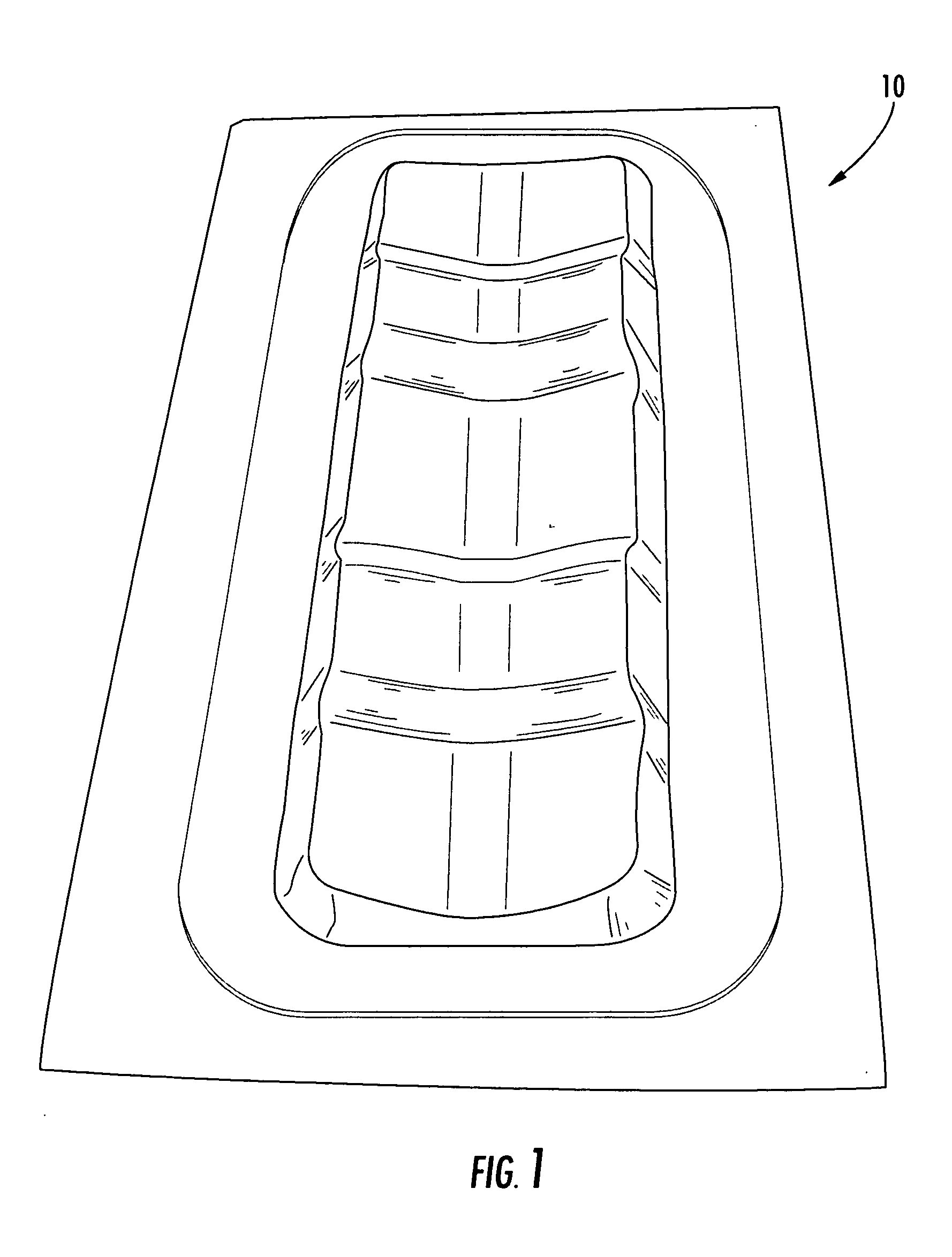

Apparatus and method of producing a fine grained metal sheet for forming net-shape components

InactiveUS20080000557A1Reduce assemblyLow costMelt-holding vesselsFurnace typesMetal alloyUltra fine

A method and apparatus for producing ultra-fine grained magnesium metal alloy material sheets. The apparatus molds and rapidly solidifies a metal alloy material to form a fine grain precursor. The precursor is then subjected to deformation strains that alter the grain structure of the precursor so as to form a ultra fine grained structure in sheet form. The sheet form may then be subjected to superplastic forming to form a net shaped article.

Owner:THIXOMAT

A method for enduing high-vanadium high-cobalt high-speed steel with superplasticity property

Disclosed is a method for enduing high-vanadium high-cobalt high-speed steel with superplasticity property which comprises the following steps, selecting master alloys, obtaining high speed steel block body with high vanadium and cobalt content with spraying forming technology, carrying out hot-rolling at a temperature of 950-1100 deg. C, keeping the reduction in pass to be 50-80%, and controlling the cooling down process. The invention can realize the one-time forming for knife tools and die arrangements with rather complex shapes.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminium alloy plate with superplasticity and manufacturing method thereof

InactiveCN105200285AHas high temperature superplastic propertiesDimensionally stableIngotMechanical property

An aluminium alloy plate with superplasticity and a manufacturing method thereof. The invention relates to an aluminium alloy plate with superplasticity and a manufacturing method thereof and aims to solve the problem that plasticity of existing 5083 alloy is low. The manufacturing method comprises the following steps: 1, weighing alloy raw materials including 4.0-5.0 wt% of Mg, 0.50-0.90 wt% of Mn, 0.05-0.20 wt% of Cr, 0.05-0.15 wt% of Zr, 0.02-0.08 wt% of Ti and the rest of Al; 2, smelting the alloy raw materials; 3, casting to prepare an ingot; 4, annealing the alloy ingot; 5, hot-rolling; and 6, carrying out medium-temperature coiling rolling to obtain the aluminium alloy plate. Horizontal elongation rate of the aluminium alloy plate is 220-240%, and its vertical elongation rate is 240-260%. The aluminium alloy plate has good superplasticity and also has good mechanical property.

Owner:NORTHEAST LIGHT ALLOY CO LTD

3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy

The invention discloses a 3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy. Within the superplastic deformation temperature range of the magnesium alloy, a non-hollow magnesium alloy casting obtained after forging pretreatment passes through at least two cycles to obtain a forging stock of the set size, and 3D super-plasticizing treatment is finished, wherein the non-hollow magnesium alloy casting passes through the axis Z, the axis X and the axis Y in sequence to press down the stock to achieve a cycle. By means of 3D super-plasticizing forging treatment, through large plastic deformation in all directions, homogenizing, grain refining and structure densifying of materials are fully achieved, refined grains are averagely smaller than 20 microns, the equiaxial grain refining effect is remarkable, and the strength performance of the casting can be greatly improved. Through the superplasticity precision shaping method for the magnesium alloy based on 3D super-plasticizing treatment, a light magnesium alloy transition car coupler with high strength is prepared out; and compared with an existing transition car coupler, the weight is reduced by about 75%, the strength is above 350 MPa, and the requirement for the service life of the transition car coupler of this type can be met.

Owner:崇州天智轻量化制造有限公司

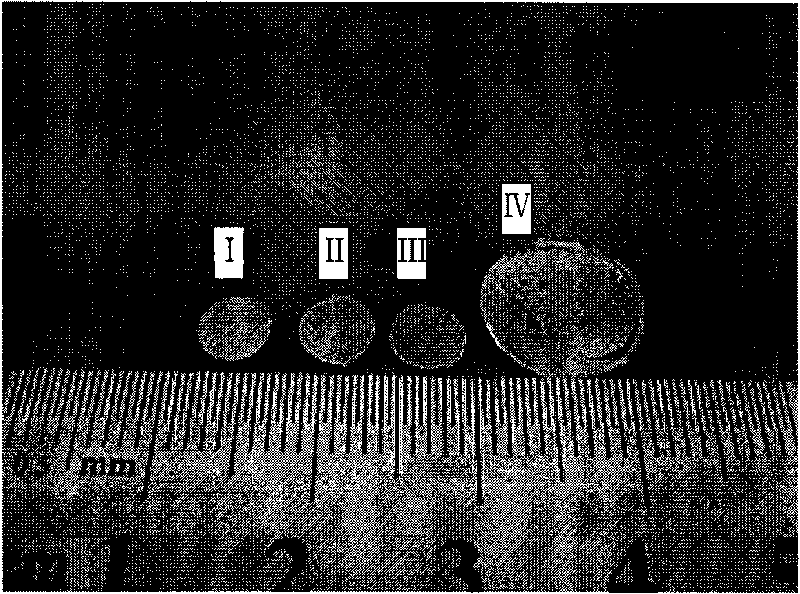

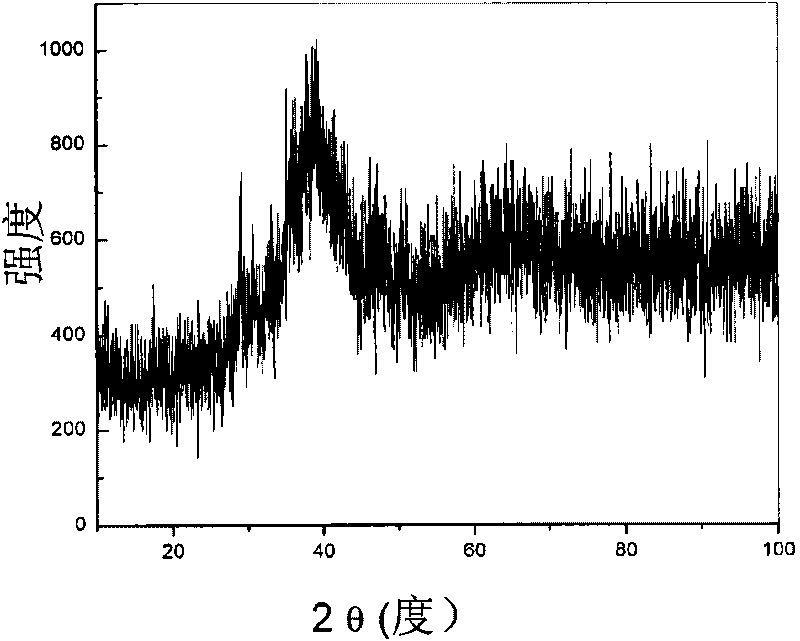

Zr-Al-Ni-Cu bulk metallic glass achieving room temperature compression superplasticity

The invention belongs to the field of new materials and discloses Zr-Al-Ni-Cu bulk metallic glass achieving room temperature compression superplasticity. Zr with purity being 99.99wt%, Al with purity being 99.99wt%, Ni with purity being 99.99wt% and Cu with purity being 99.99wt% are smelted according to a vacuum melting method, and then a vacuum suction pouring method is adopted, so that the Zr-Al-Ni-Cu bulk metallic glass with the diameter being 2 mm is obtained. The Zr-Al-Ni-Cu bulk metallic glass has room temperature compression superplasticity and comprises ingredients of Zr62Al12Ni15Cu11, Zr62.5Al11.3Ni13.85Cu12.35, Zr63Al10.6Ni12.7Cu13.7, Zr63.5Al10Ni11.75Cu14.75, Zr64Al9.3Ni10.6Cu16.1, Zr64.5Al8.6Ni9.45Cu17.45, Zr65Al8Ni8.5Cu18.5, Zr65.5Al7.3Ni7.35Cu19.85 and Zr66Al6.6Ni6.2Cu21.2.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

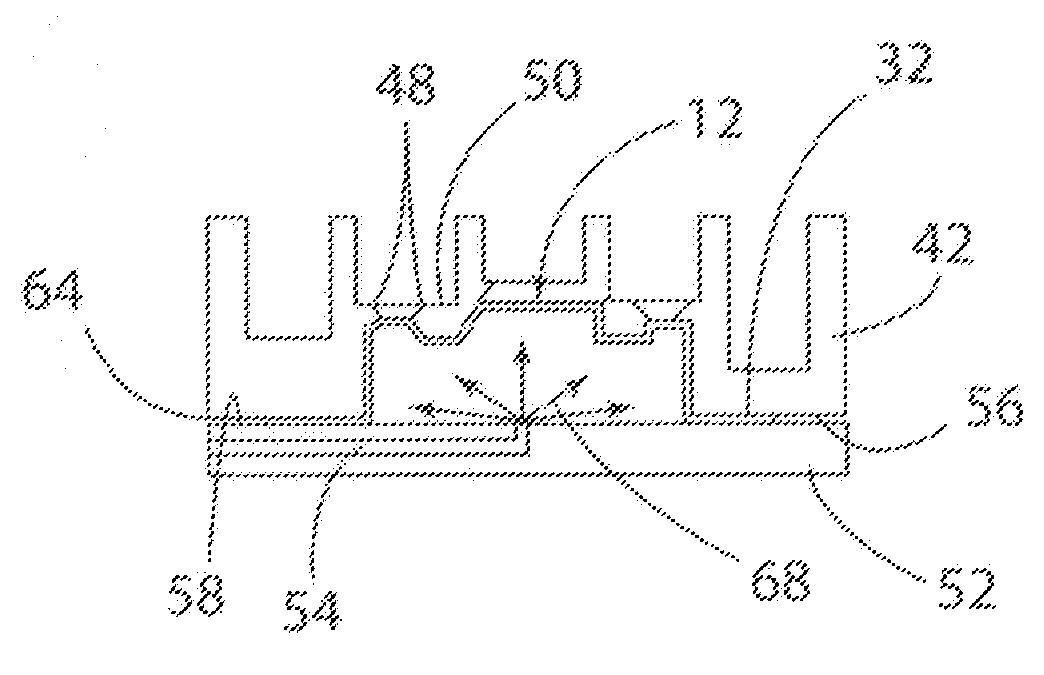

Sheet metal forming process

InactiveUS20080127697A1Shorten molding timeImprove mobilityShaping toolsMetal forming processMaterials science

A sheet metal forming process and apparatus using both a mechanical forming step and a superplastic forming step. The mechanical forming step includes using a double-action draw die to create a preform. The preform is then transferred to a superplastic forming tool that uses a superplastic forming process to complete the forming process and create a finished workpiece. Using the mechanical forming step enables rapid creation of a preform having a geometry that reduces overall forming time and provides the ability to draw in additional material to reduce part thinning.

Owner:FORD GLOBAL TECH LLC +2

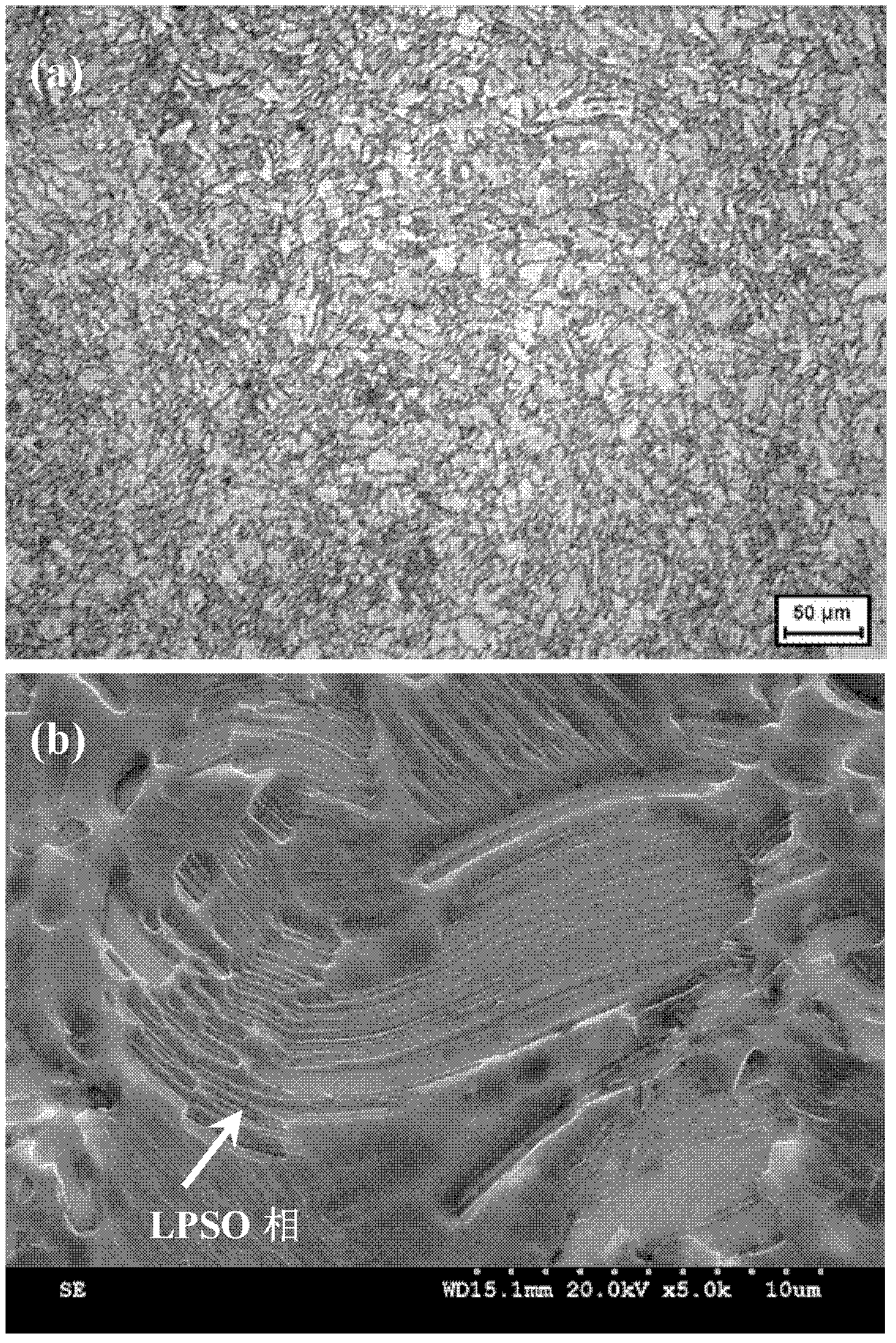

Magnesium-base rare-earth alloy material and preparation method thereof

InactiveCN102628135AImproved superplastic formabilityImproved deformation coordinationRare earthImpurity

The invention provides a magnesium-base rare-earth alloy material and a preparation method thereof. The magnesium-base rare-earth alloy material comprises the components by weight percent: 7.0-1.0% of Y, 1.0-2.5% of Er, 2.0-3.0% of Zn, less than 0.03% of inevitable impurities of Fe, Cu, Ni and Si, and the balance of Mg. The methods of conventional smelting, homogenizing treatment, hot extrusion treatment, and the like, are adopted by the invention, and meanwhile a superplastic magnesium rare-earth alloy material with high strain rate is obtained. Under lower temperature (300-380 DEG C), the alloy has high strain rate (0.8*10-2-1*10-2s-1) and superplasticity, the coefficient of elongation of the alloy after being broken is 350%-520%. The production cost is effectively lowered, the production efficiency is increased, the operation is easily performed and the magnesium-base rare-earth alloy material is beneficial to large-scale application and popularization.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com