3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy

A processing method, magnesium alloy technology, applied in the field of short-process rapid prototyping of new materials, can solve problems such as high cost, difficulty in manual movement and alignment, and difficulty in forming complex microstructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] For ease of understanding, this embodiment first provides an implementation of a magnesium alloy 3D superplasticizing treatment device.

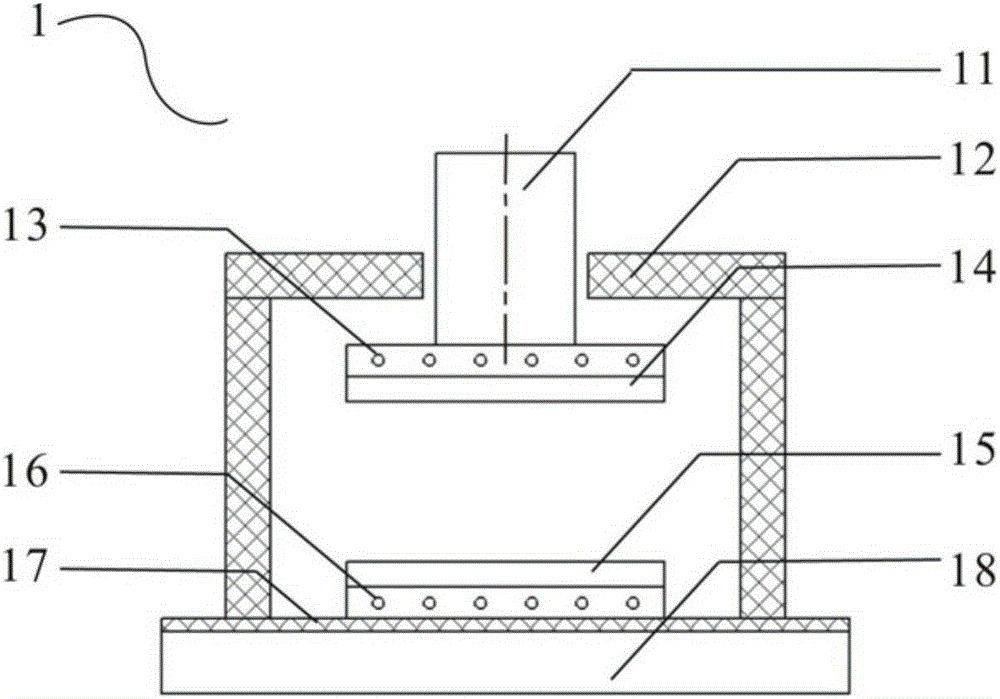

[0072] like figure 1 As shown, the magnesium alloy 3D superplasticizing treatment device 1 includes an upper anvil 14 and a lower anvil 15; the upper anvil 14 is fixedly connected with the pressure column 11 that moves up and down; the lower anvil 15 is fixedly connected with the lower pressing table 18; the upper anvil 14 And lower anvil 15 are all provided with constant temperature heating device (13,16); Form the accommodating space of metal alloy casting between upper anvil 14 and lower anvil 15, and the outside of accommodating space is provided with insulation cover 12; The pressure column 11 protrudes out of the heat insulation shell.

[0073] The pressure column 11 in this embodiment is a hydraulic column, and other power components such as cylinders can also be used; the pressure column 11 is connected to a motor through a c...

Embodiment 2

[0080] For ease of understanding, this embodiment first presents an implementation of a superplastic isothermal precision die forging device.

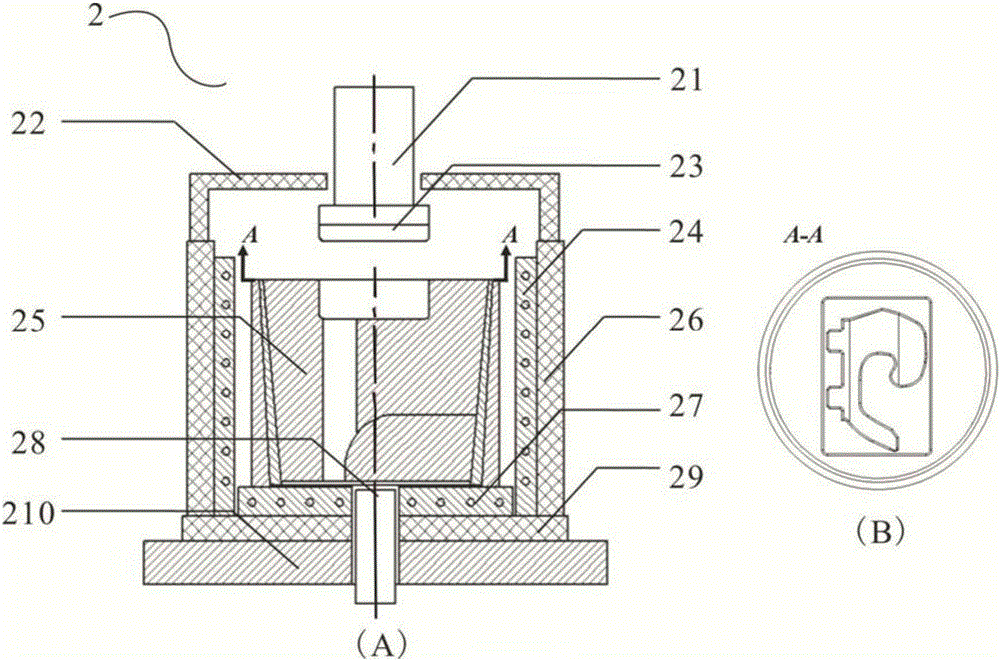

[0081] like figure 2 As shown in (A), this superplastic isothermal precision die forging forming device 2 includes a forging mold 25 installed on the second pressing table 210 and a heat preservation bucket 26 covering the periphery of the forging mold 25; the inner side of the heat preservation bucket 26 and the forging A second constant temperature heating device (24, 27) is arranged between the bottom of the mold 25 and the second pressing table 210; the top of the heat preservation barrel 26 is provided with a heat preservation cover 22; the second pressure column 21 for providing pressure passes through the heat preservation cover 22 enters the insulation barrel 26; the second pressure column 21 is below the second upper anvil 23; after the forging is completed, the lower ejector 28 used to eject the forging die passes through th...

Embodiment 3

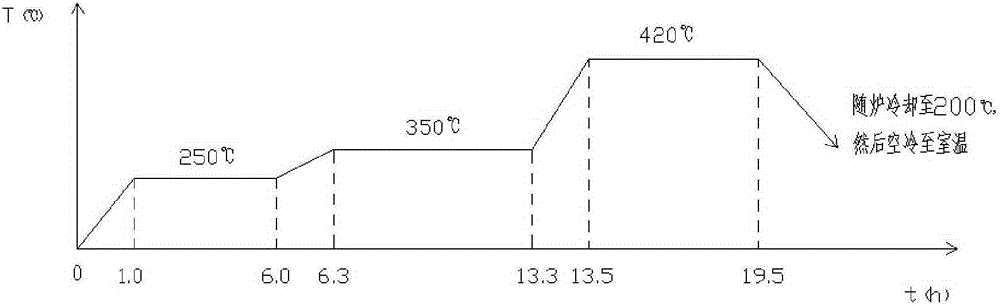

[0095] The 3D superplasticizing treatment method of the magnesium alloy will be further explained below in combination with Examples 3.1-3.3, and the forging blanks obtained in the examples will be analyzed experimentally. If it needs to be explained, this embodiment is a further explanation of the 3D superplasticizing treatment method for magnesium alloys, and does not constitute a limitation of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com