Patents

Literature

328results about How to "Achieve homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

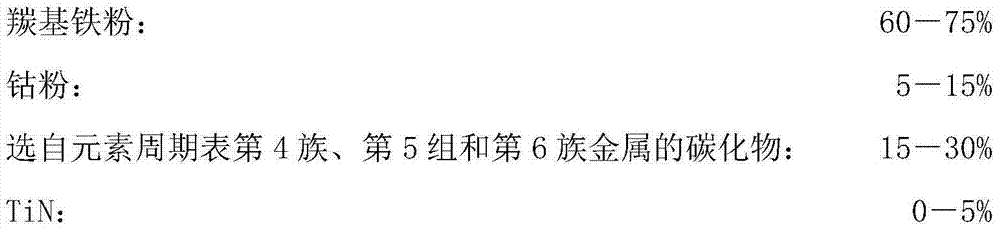

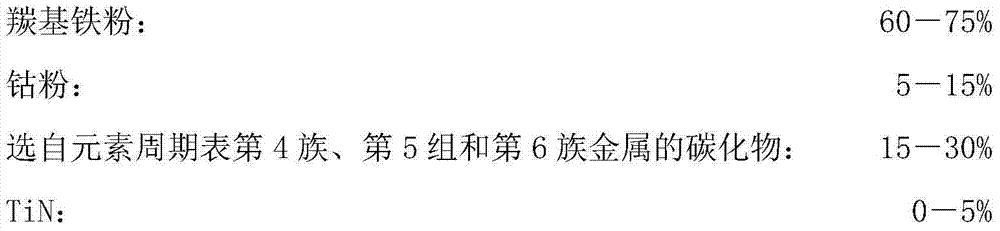

Powder metallurgy high-speed steel and preparation method thereof

The invention discloses powder metallurgy high-speed steel and a preparation method thereof. The method is simpler than the existing powder metallurgy high-speed steel preparation method, steps of high-speed steel mother alloy smelting, atomization for making powder and hot isostatic pressing are omitted, great equipment investment is not needed and the production cost of powder metallurgy high-speed steel is reduced. The impurity content of the powder metallurgy high-speed steel prepared by adopting the method provided by the invention is low and the using performance is excellent. The powder metallurgy high-speed steel provided by the invention is prepared through the steps of 1) preparing powder mixture: weighing raw materials according to set components and proportioning ratio, and mixing and ball-milling the raw materials in a roller-type ball mill to obtain the powder mixture; 2) molding: molding the powder mixture into pressed blanks through cold isostatic pressing; 3) sintering: sintering the pressed blanks in a vacuum or inert gas atmosphere by adopting a hot-pressing sintering technology, heating the pressed blanks to 1100-1250 DEG C during sintering, preserving heat for 30-90 minutes and keeping sintering pressure to be 10-40Mpa; 4) hot forging; 5) heat treatment.

Owner:长沙市萨普新材料有限公司

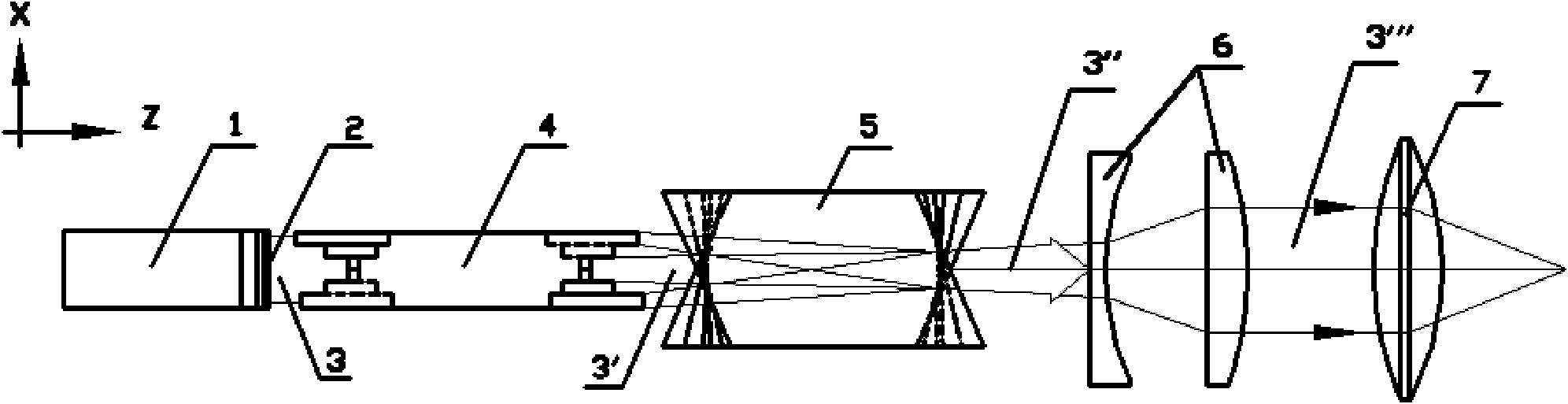

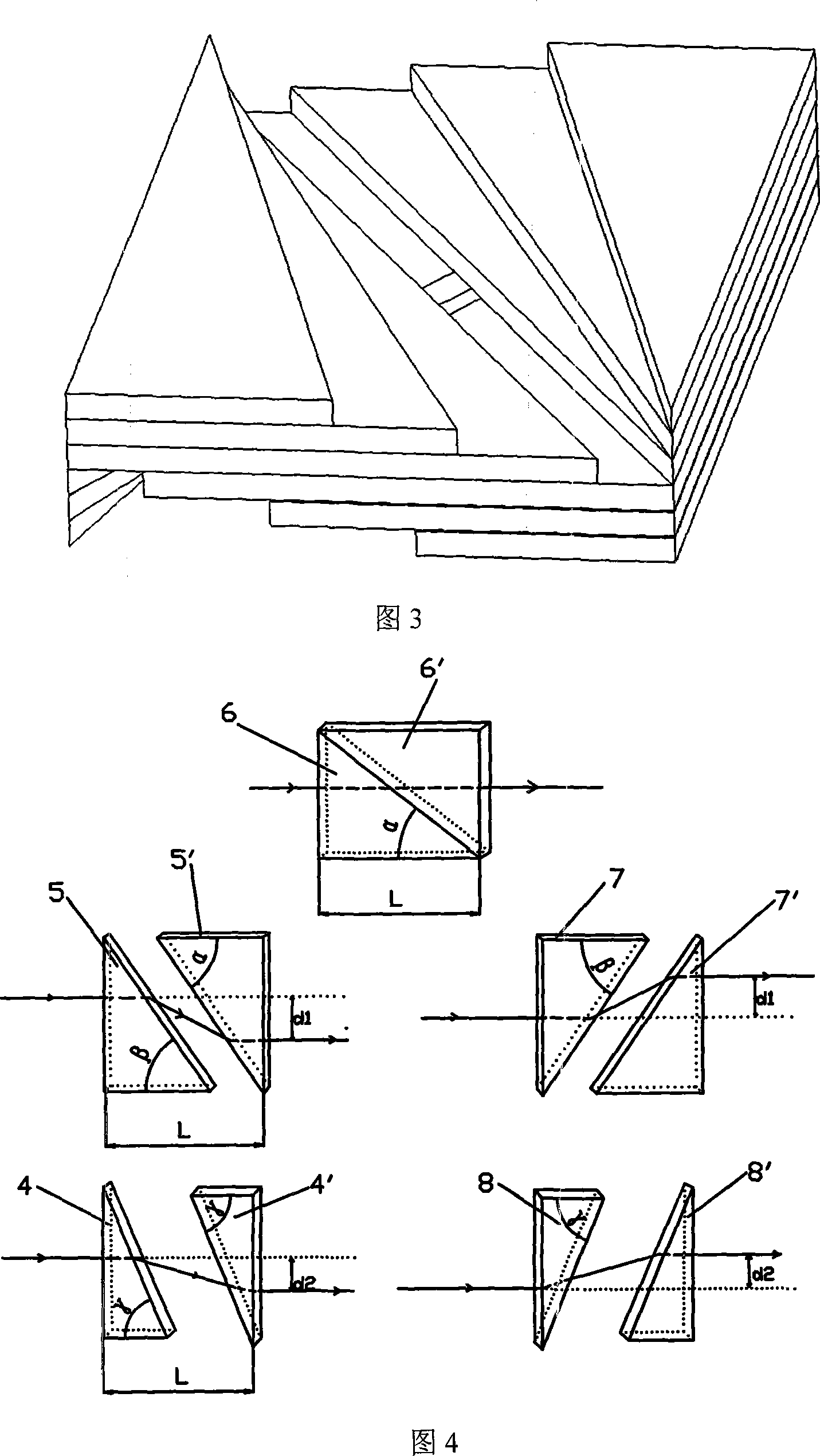

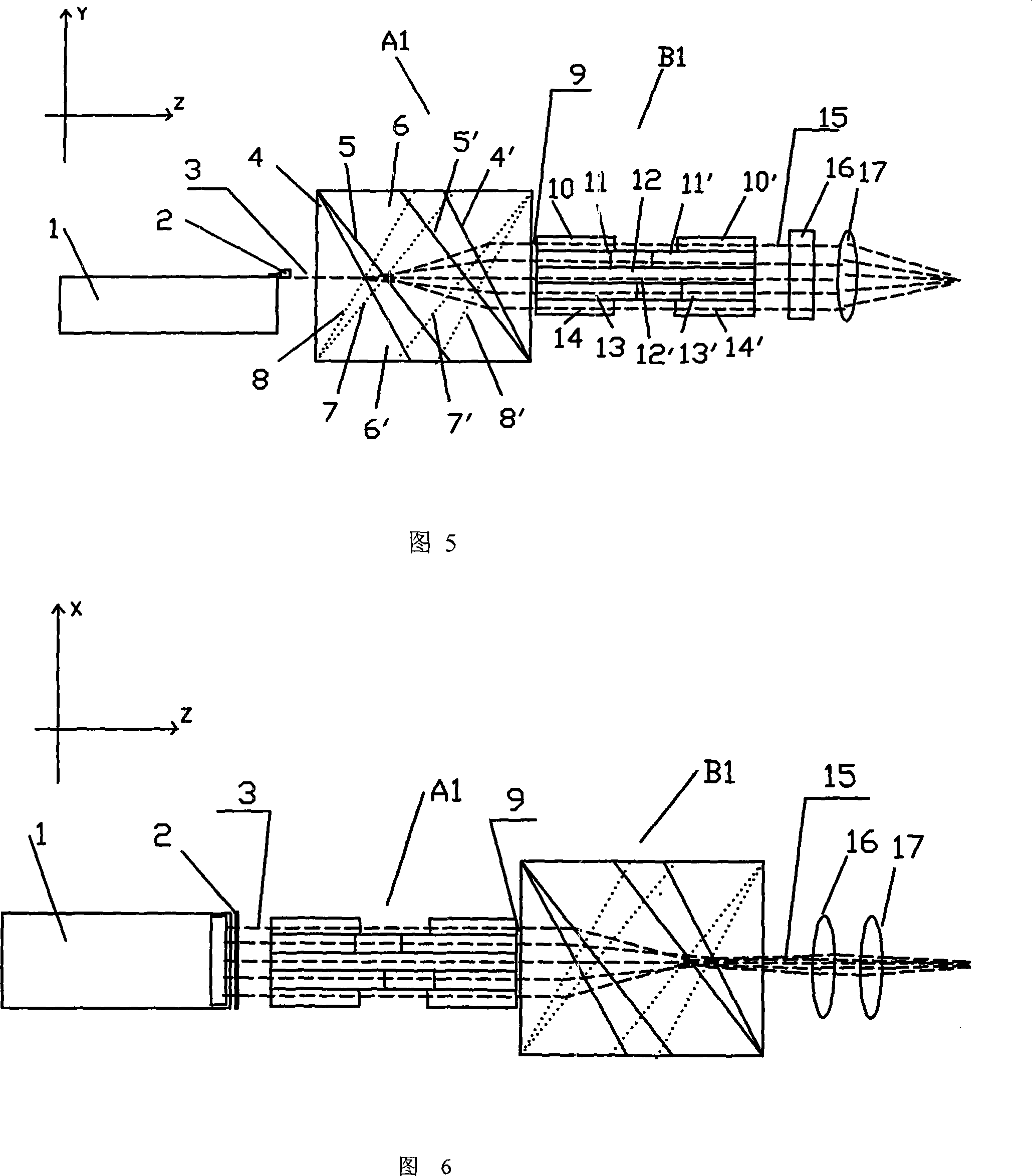

Semiconductor laser array fast and slow axis beam rearrangement device and manufacturing method

The invention discloses a semiconductor laser array fast-slow axis beam rearrangement device and a manufacturing method, and belongs to the field of laser technology application. By using the principle that the light produces different offsets after passing through parallel flat plates of the same thickness in different incident angles, an optical shaping element 4 and an optical shaping element 5 provided with a plurality of small surfaces are increased in the laser light path transmission process. The device can realize homogenization of fast and slow axis beam quality; by changing the conventional mode of waveguide transmission by means of a thin sheet, the loss of optical power is further reduced, and the shaping efficiency is improved; the device is particularly suitable for high-power semiconductor laser beam shaping; and meanwhile, the device has the advantages of more compact structure, no accumulated error, convenience in installation and adjustment and the like.

Owner:SHANXI FEIHONG LASER TECH

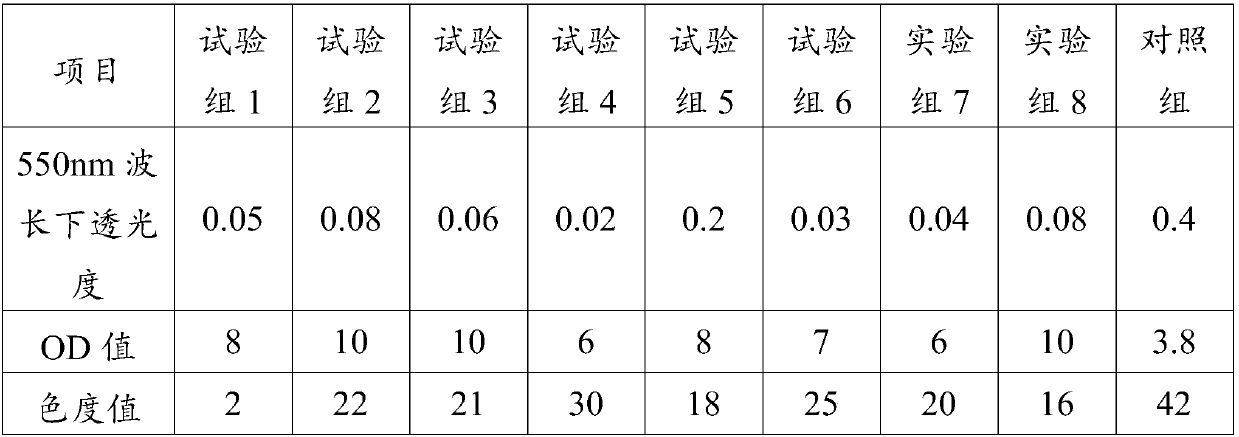

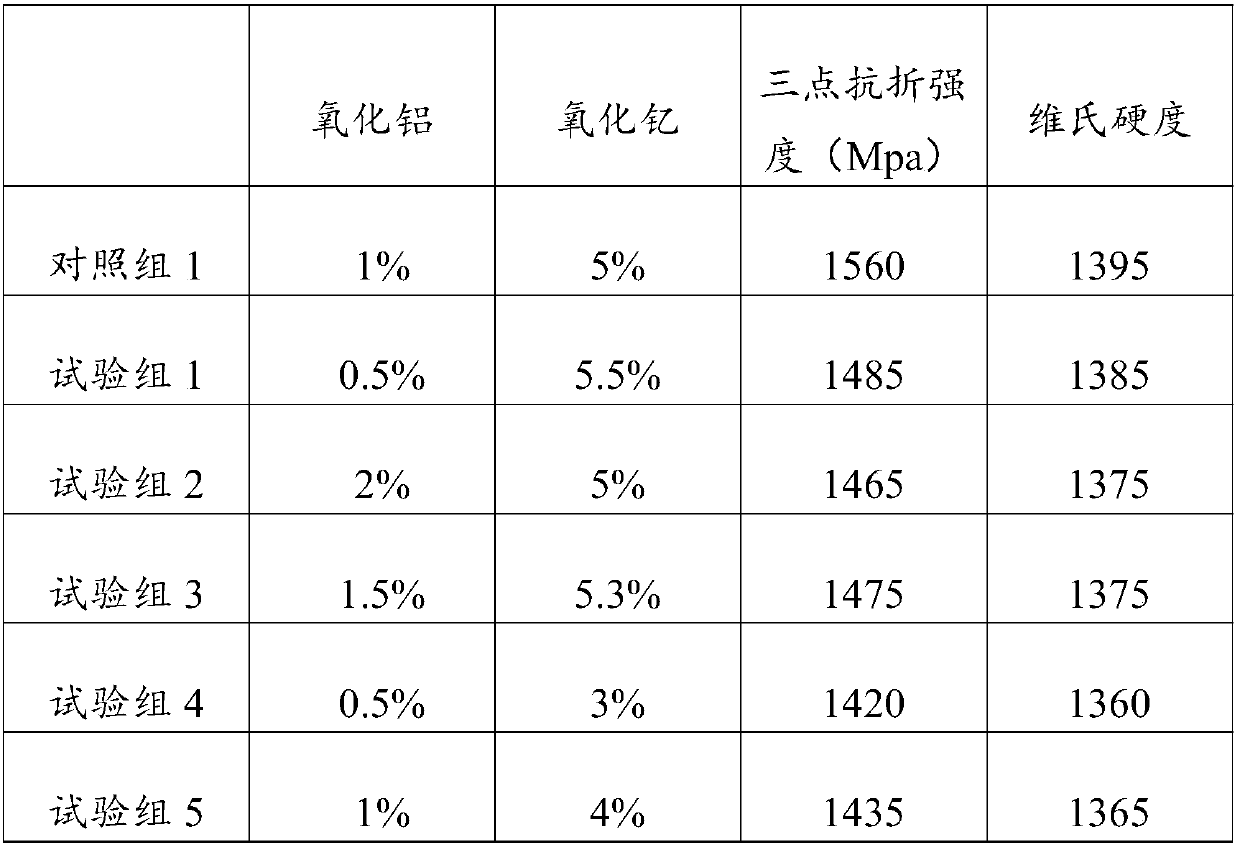

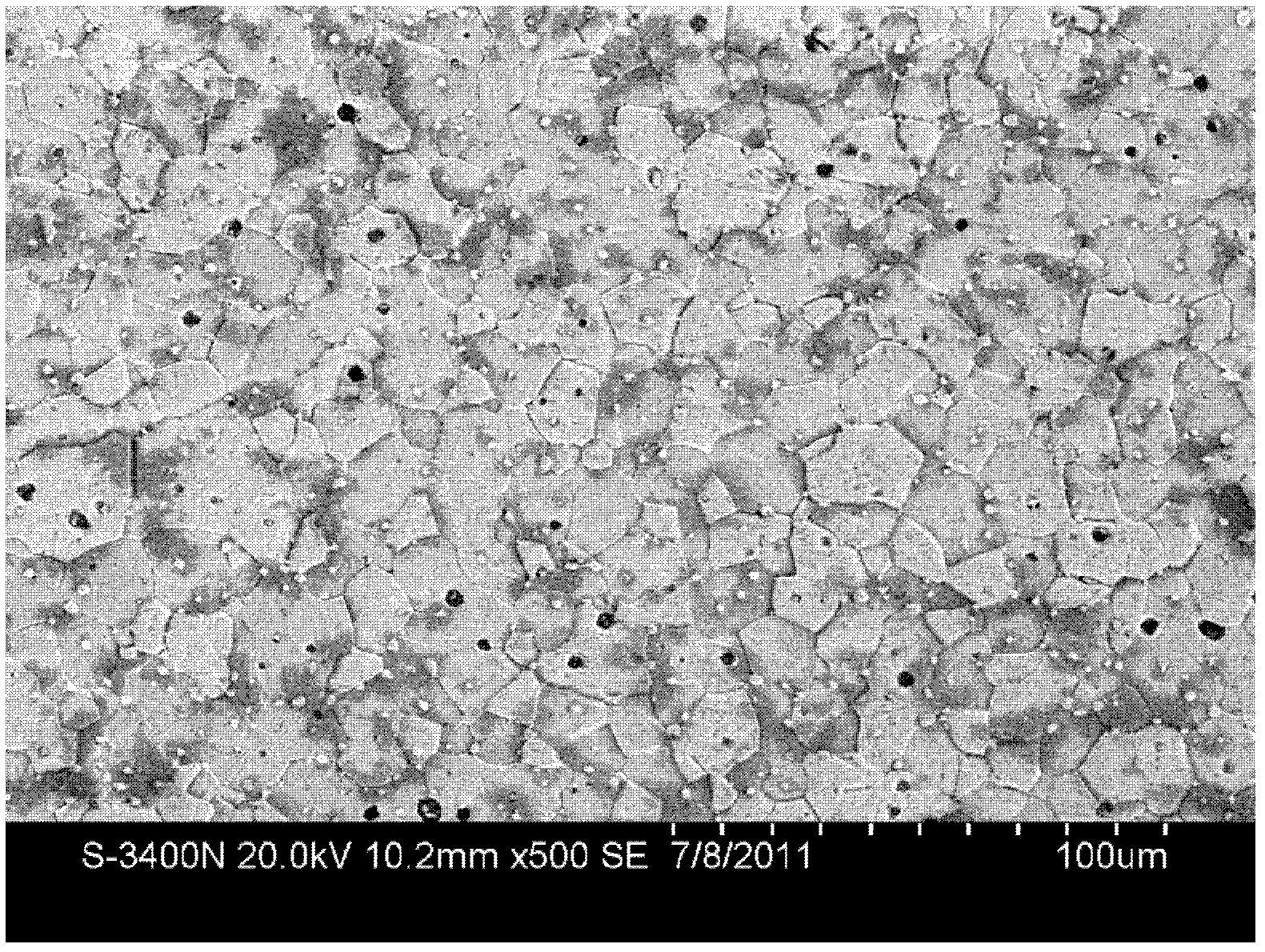

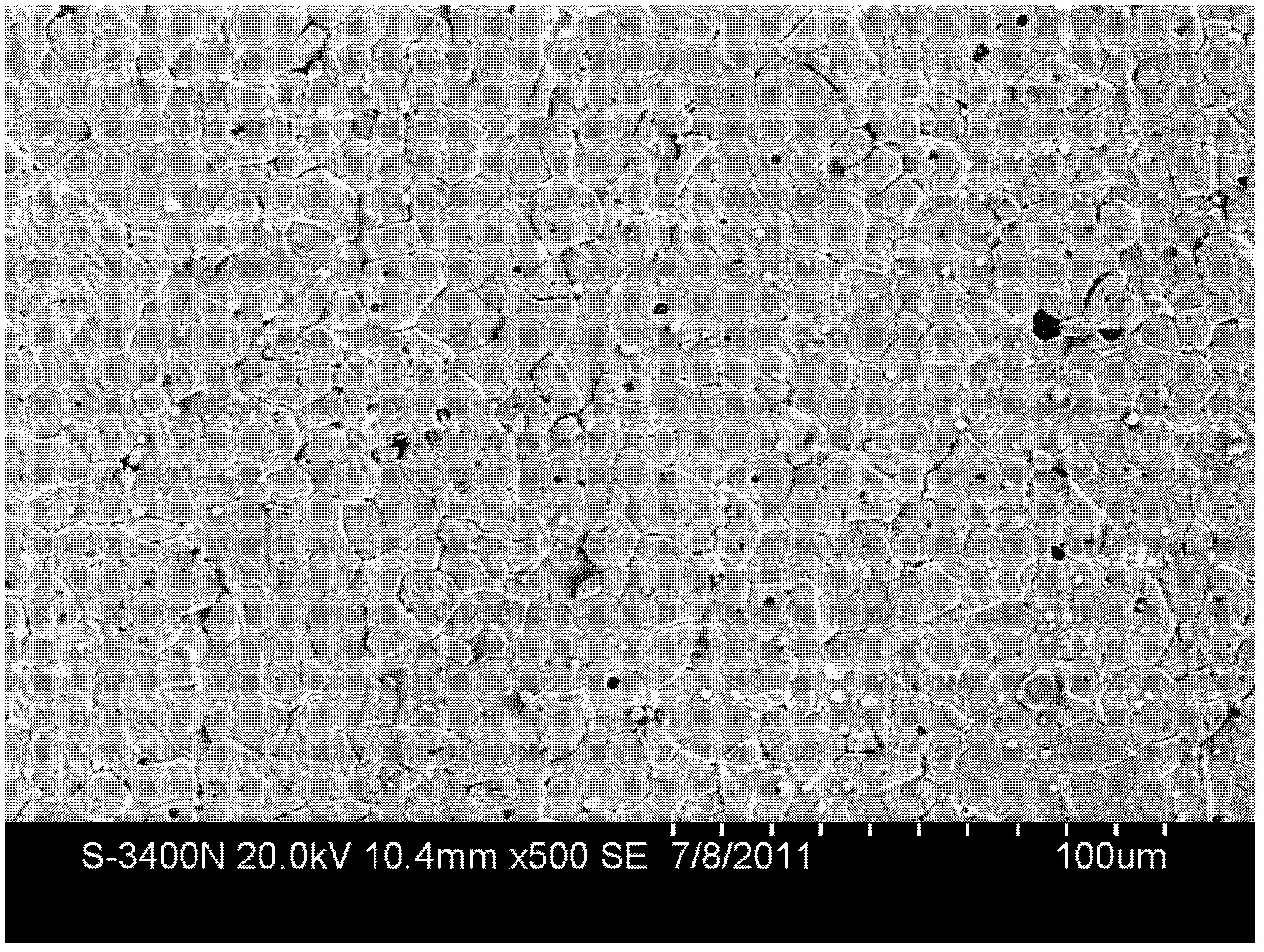

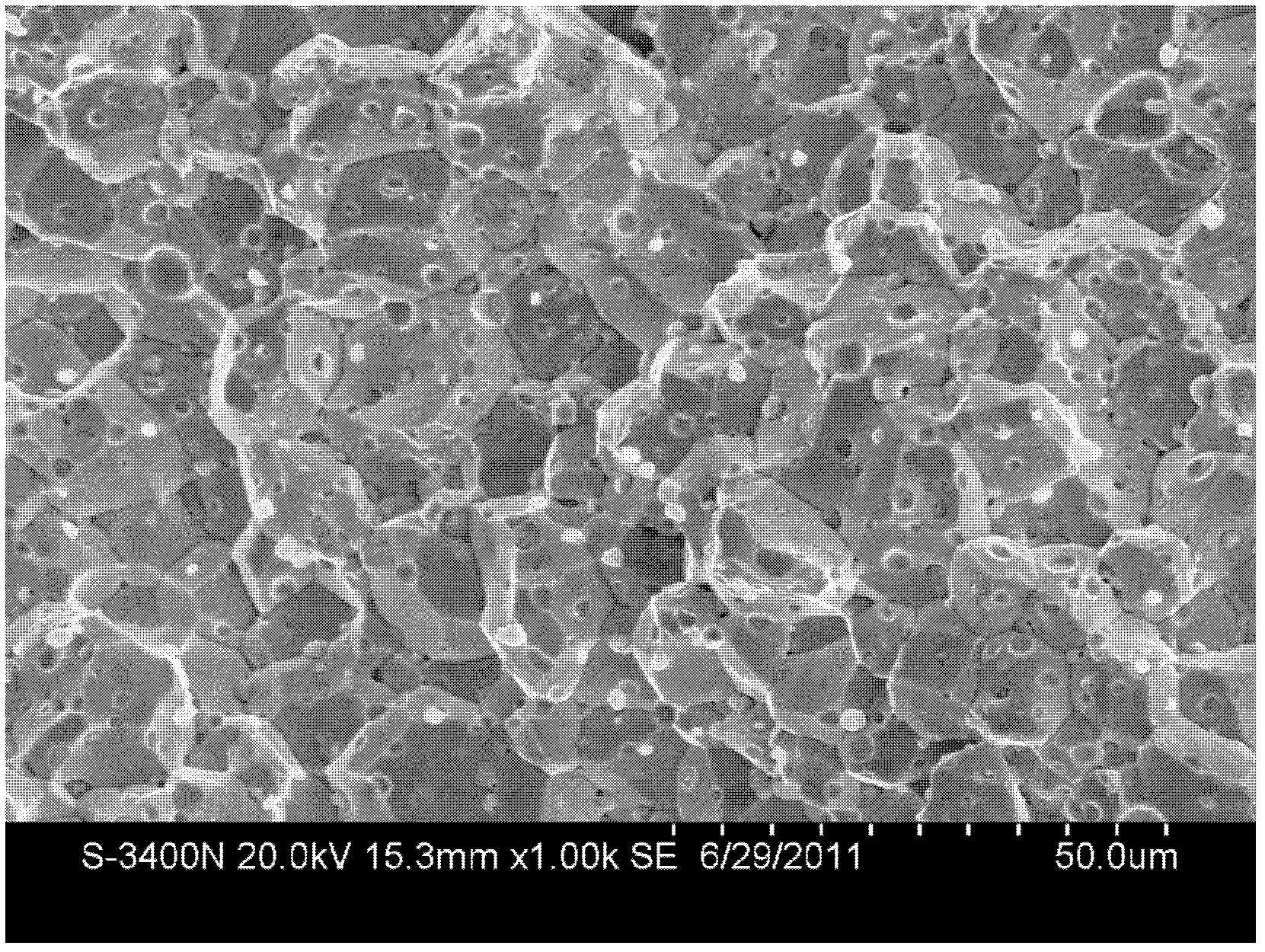

Black zirconia ceramic and preparation method thereof

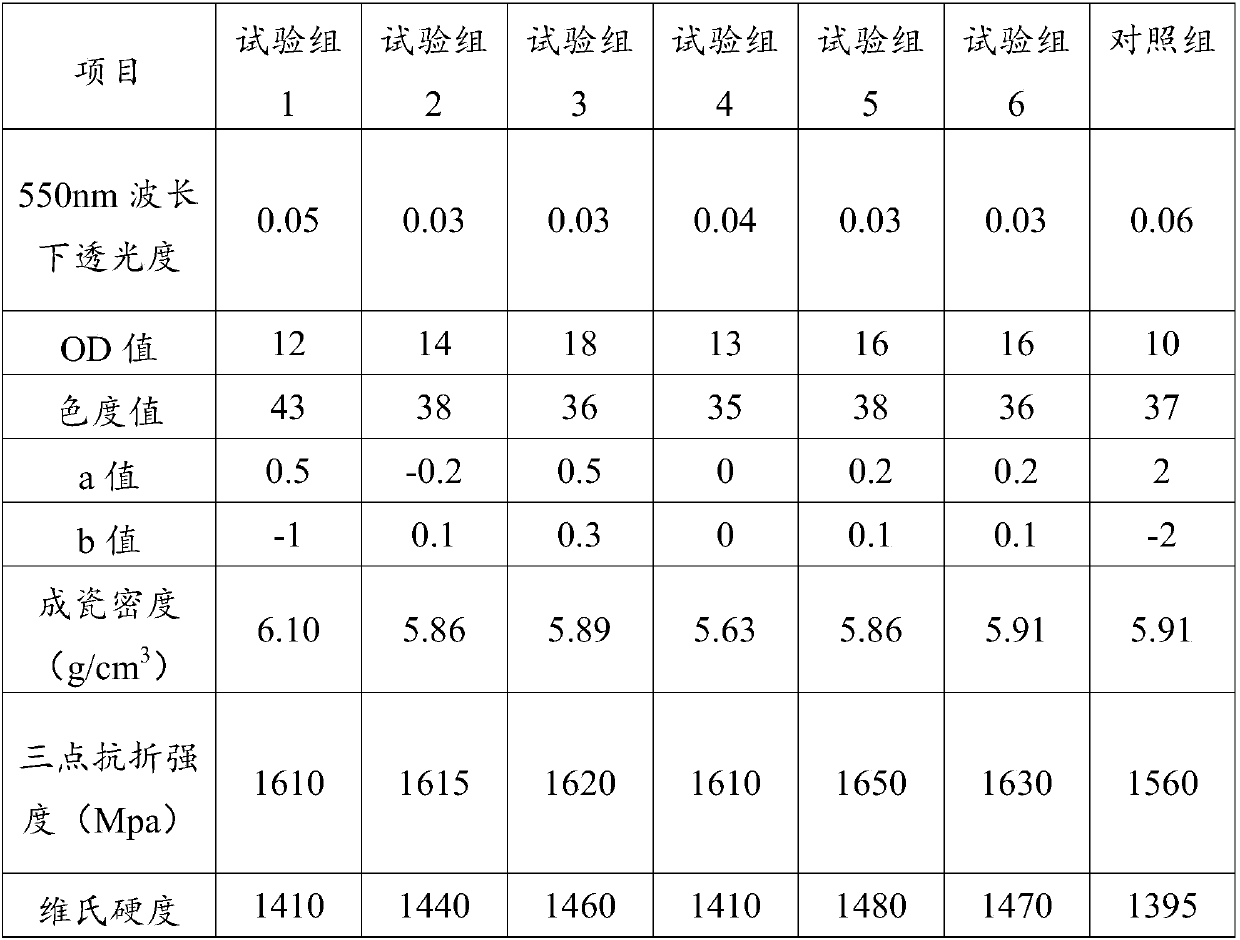

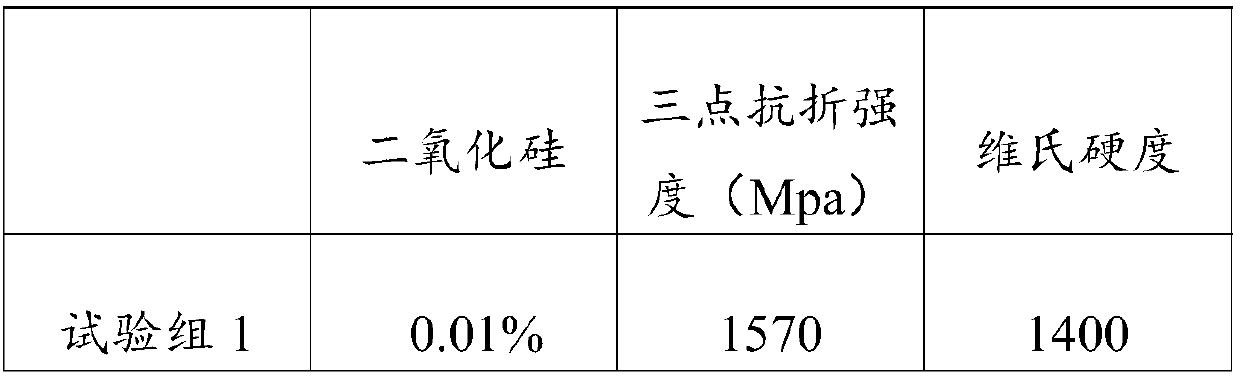

The invention discloses a black zirconia ceramic material composition. The black zirconia ceramic material composition is prepared from the following ingredients in percentage by mass: 0.01-4% of ferric oxide, 0.01-3.5% of cobaltous oxide, 0.01-3.5% of chromic oxide, 0.01-15% of aluminum oxide, 0.01-4% of nickel oxide, 0.01-3.5% of manganese oxide, 0-3.5% of zinc oxide, 2-7% of yttrium oxide, 0-4%of titanium oxide, 0-3% of silicon dioxide, 0-5% of cerium oxide and the balance of hafnium oxide-containing zirconium oxide. The black zirconia ceramic material composition disclosed by the invention is small in powder particle size and uniform in dispersion, and a black zirconia ceramic containing the black zirconia ceramic material composition has relatively high strength and rigidity, relatively high covering power and relatively low transmittance. Meanwhile, the invention further discloses the black zirconia ceramic prepared by adopting the black zirconia ceramic material composition anda preparation method of the black zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

Method for preparing fine-grain high-density TZM (Titanium-Zirconium-Molybdenum Allo) alloy

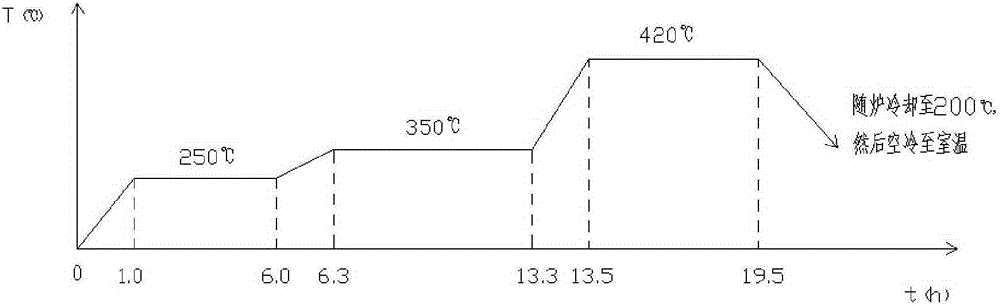

The invention discloses a method for preparing a fine-grain high-density TZM (Titanium-Zirconium-Molybdenum Allo) alloy. The method disclosed by the invention comprises the following steps of: with pure molybdenum powder, ZrH2 powder, La2O3 powder and graphite powder as raw materials, mixing the raw materials, and carrying out ball milling, press molding, presintering and high-temperature sintering to obtain the TZM alloy. The TZM alloy prepared by using the method disclosed by the invention has the characteristics of fine crystal grains, distribution uniformity, low porosity, high compactness, simple preparation process and strong operability and controllability and has the most remarkable advantages that: on the basis of the traditional ZTM alloy preparation method, rare earth oxide La2O3 is solid-solid doped in the alloy powders, a mode of combining mixing and ball-milling of the alloy powders and a mode of sectional sintering during high-temperature sintering are adopted, crystal grains are fined, the alloy density is remarkably improved, the sintering temperature of the TZM alloy is reduced to 1800-2000 DEG C from 2100-2300 DEG C in the traditional method, therefore energy resources are saved and requirements of an enterprise on the fine-grain TZM alloy material with high density can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

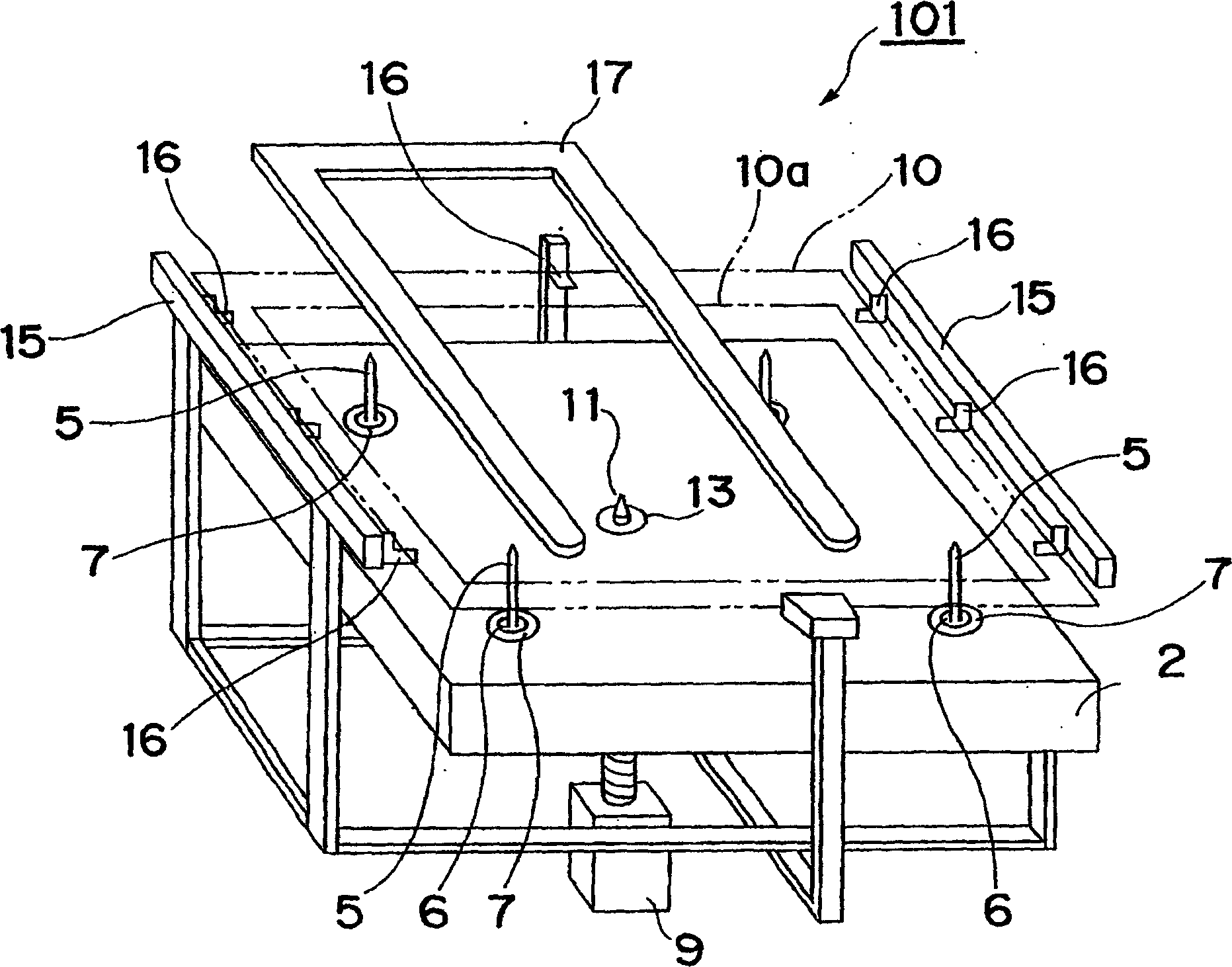

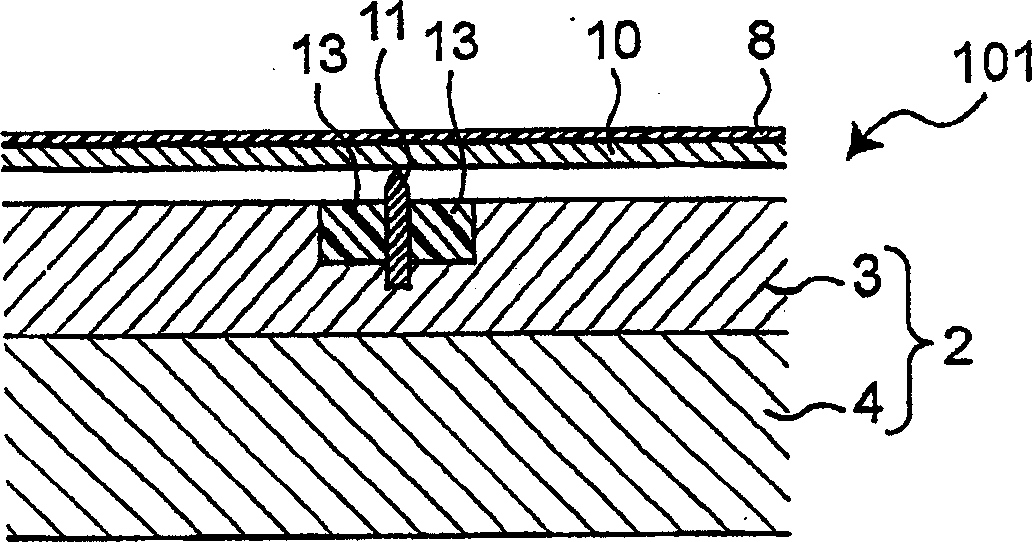

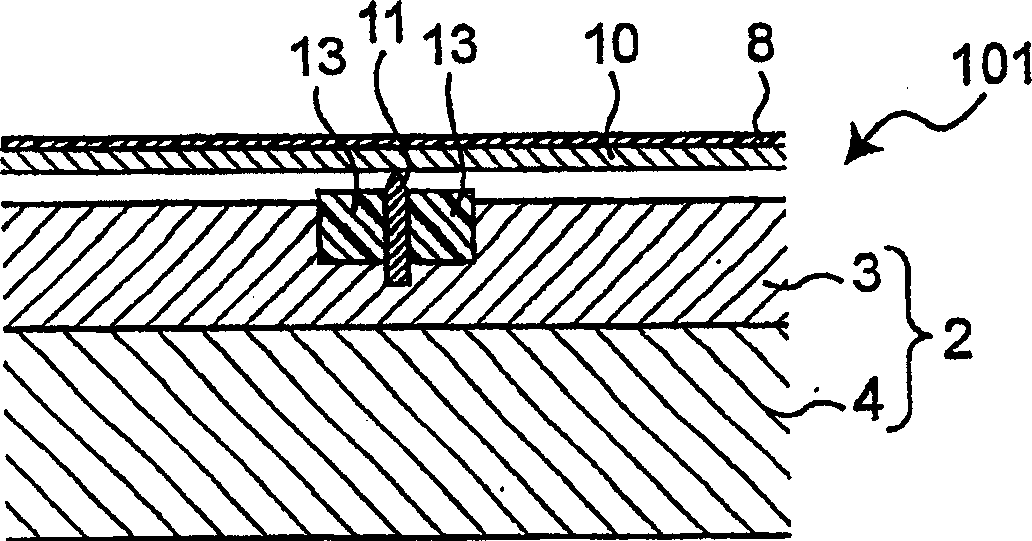

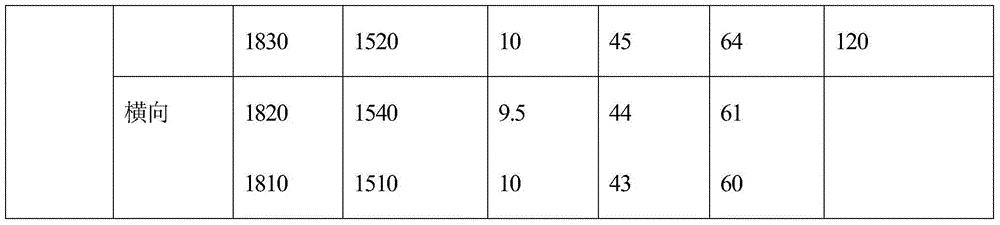

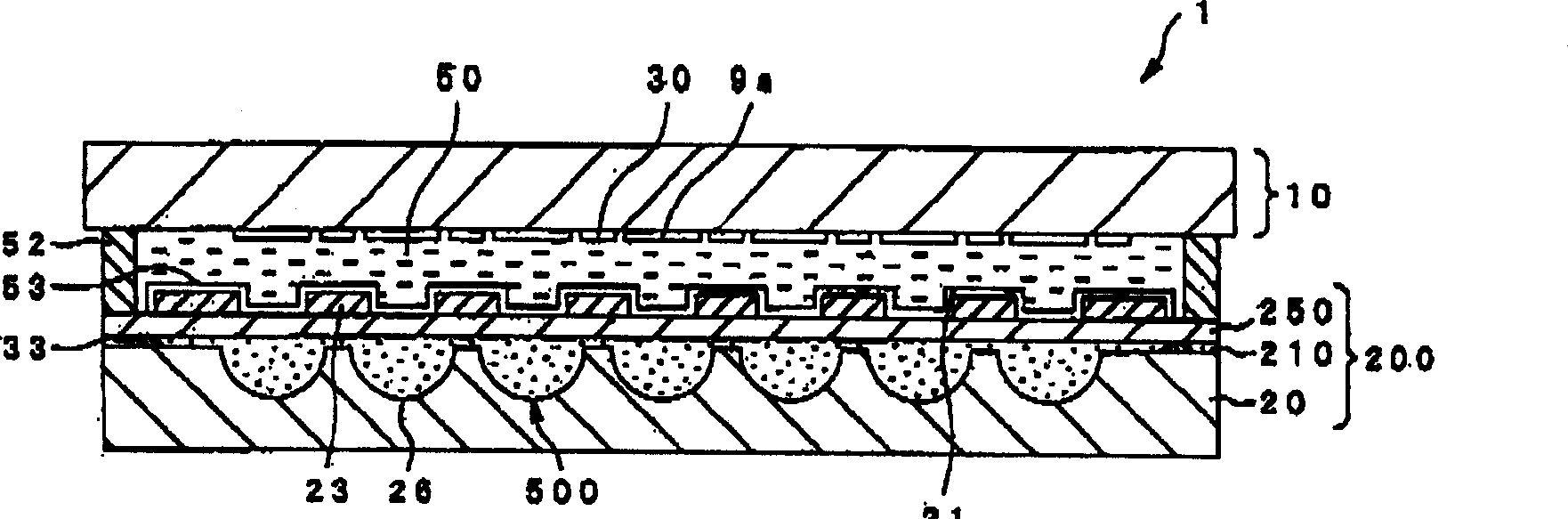

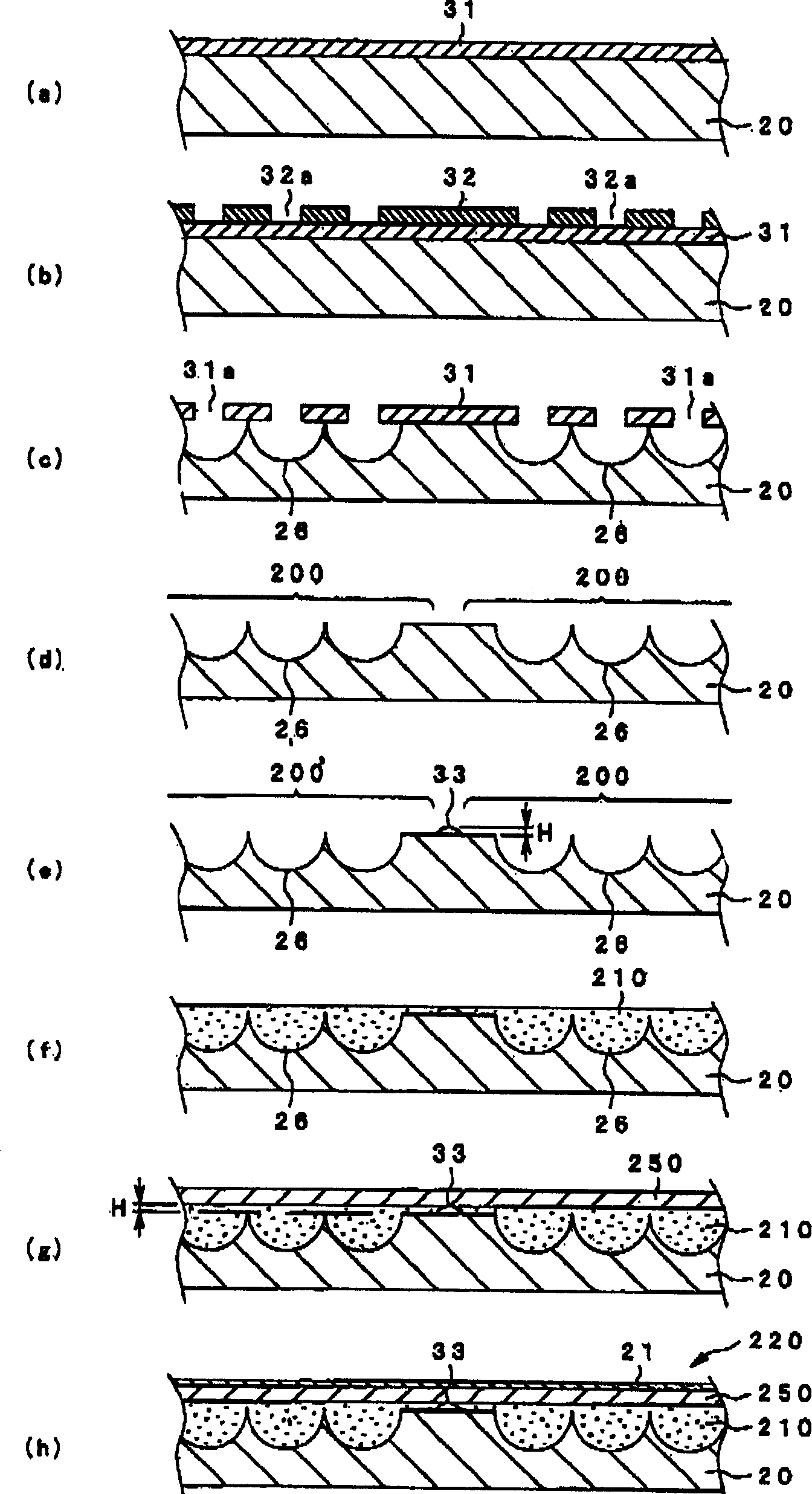

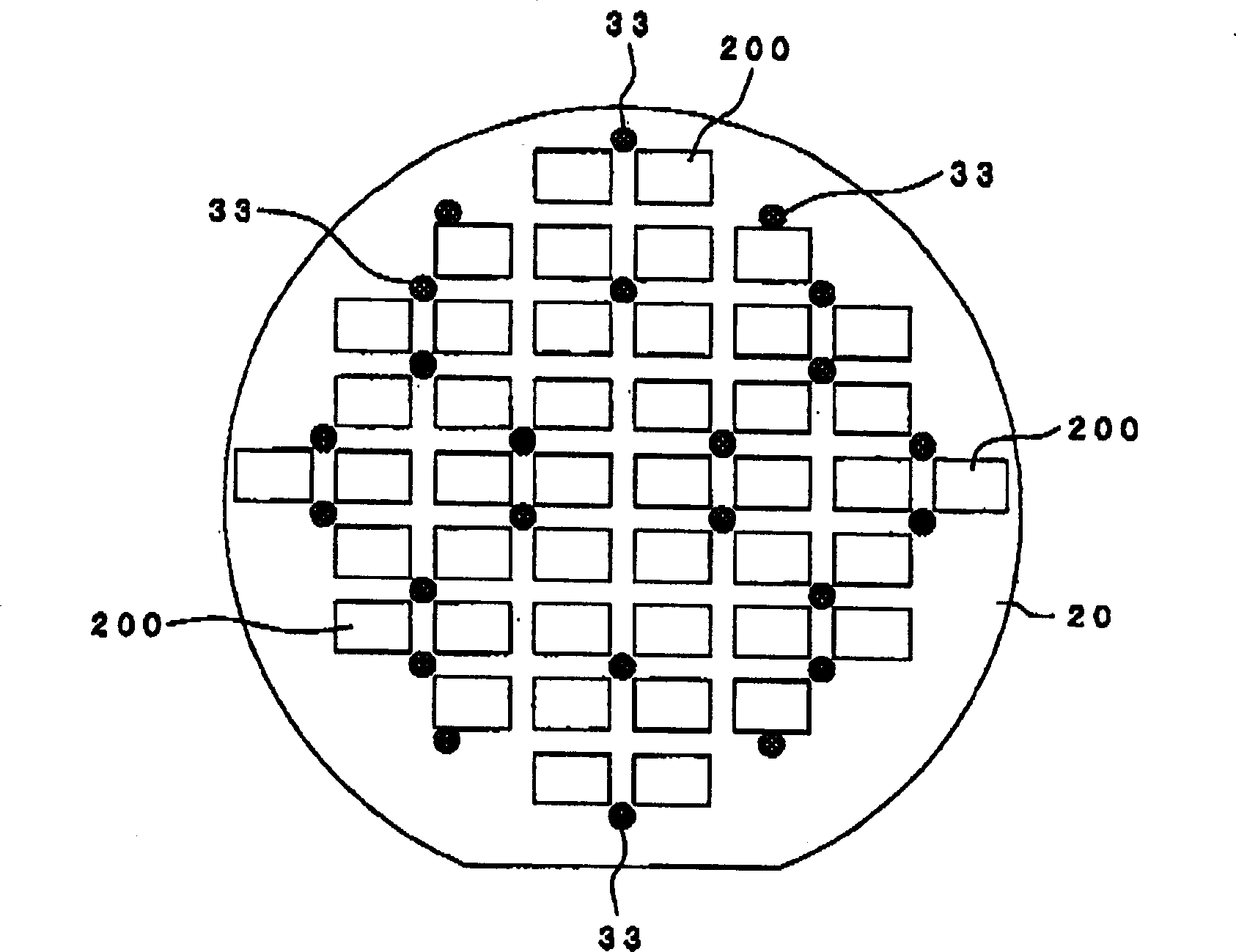

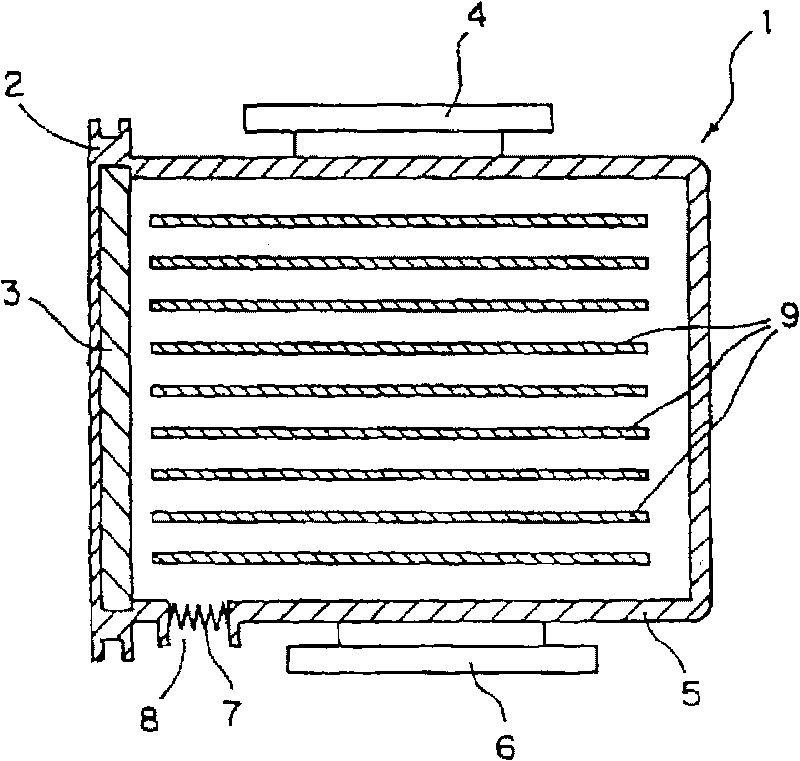

Heating apparatus

InactiveCN1745332AHeating evenlyAchieve homogenizationSemiconductor/solid-state device manufacturingHot plates heating arrangementsRadiant heatRadiant heating

A heating apparatus (101), comprising a hot plate (2) heating a heated substrate (10) by radiation, lift pins (5) liftably disposed in through-holes (6) formed in the hot plate and lifting the heated substrate, and a proximity pin (11) fixed to the hot plate and holding the heated substrate so as to be separated from the hot plate while the heated substrate is heated. Heat reducing parts (13, 7) reducing radiant heat are installed in the hot plate around the proximity pin or around the through-holes.

Owner:NISSHA PRINTING COMPANY

Casting manufacturing method of superconducting NbTi alloy

The invention discloses a casting manufacturing method of a superconducting NbTi alloy. The casting manufacturing method comprises the following steps of carrying out purification and ingot casting of high-melting point metal Nb to obtain an Nb rod, pressing low-melting point sponge active metal Ti into a semi-cylindrical tile, carrying out assembly welding of the Nb rod and the semi-cylindrical tile in an inert gas protective atmosphere to obtain a consutrode, and carrying out electric arc melting more than twice. The superconducting NbTi alloy obtained by the casting manufacturing method has no impurities, high uniformity, less interstitial elements and good plasticity, and is conducive to manufacture of thin core rods suitable for large-scale application and alloy materials having a high current-carrying capability and a low cost.

Owner:NINGXIA ORIENT TANTALUM IND

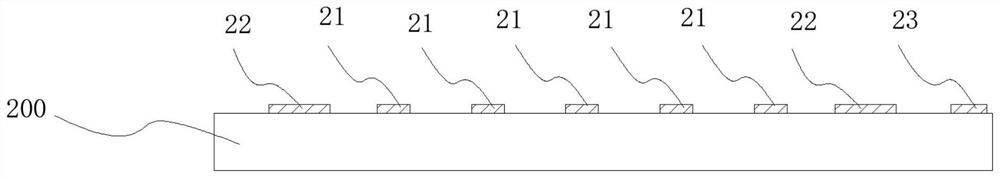

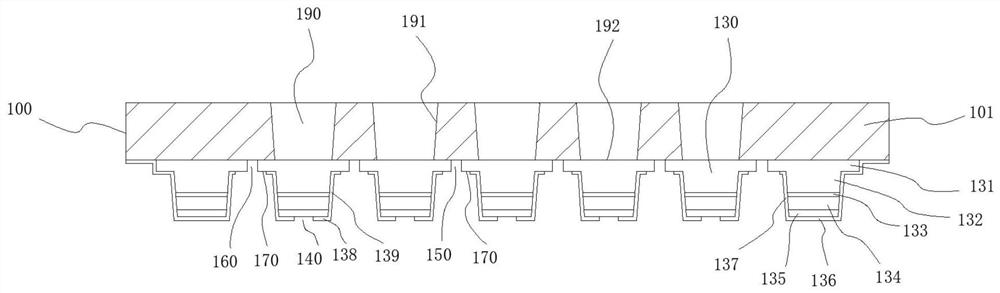

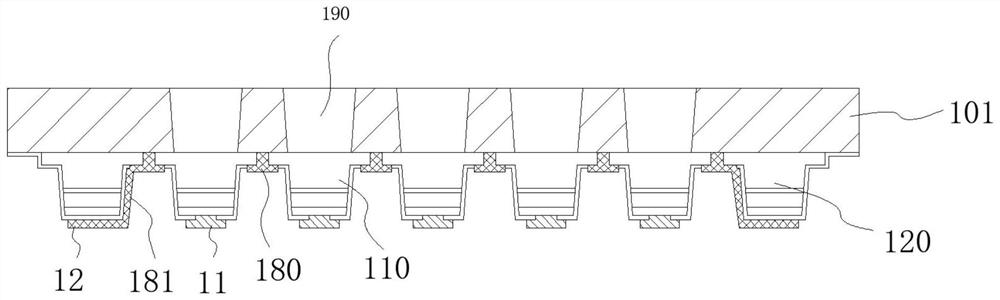

High-resolution full-color Micro LED display

ActiveCN111725251AOptical waveguide effect overcomesOvercoming Optical Crosstalk ProblemsSolid-state devicesSemiconductor devicesLED displayDisplay device

The invention relates to a high-resolution full-color Micro LED (Light Emitting Diode) display. A Micro LED light-emitting chip and a dummy chip are arranged on the display, wherein the MicroLED light-emitting chip and the dummy chip are respectively provided with a first semiconductor layer and an insulating layer, the insulating layer coats side walls of the MicroLED light-emitting chip and thedummy chip, a first spacing groove is formed between step parts of first semiconductor layers of the adjacent MicroLED light-emitting chips, a second spacing groove is formed between the first semiconductor layer step part of the MicroLED light-emitting chip and the first semiconductor layer step part of the adjacent dummy chip, part of a lower surface of the step part of the first semiconductor layer is not covered by the insulating layer, and metal circuits are arranged in the first spacing groove, the second spacing groove and the lower surface, not covered by the insulating layer, of the step part of the first semiconductor layer.

Owner:深圳市惠合显示有限公司

A homogeneous coagulation molding method for polyacrylonitrile precursor

InactiveCN102260919AAchieve homogenizationImprove performanceWet spinning methodsPolymer scienceDouble diffusion

The invention discloses a method for homogenizing, solidifying and forming polyacrylonitrile precursor. By adopting a wet spinning technology, a polyacrylonitrile spinning solution trickles in a coagulating bath to be subjected to double diffusions through solvent and precipitator and then solidified and separated so that the polyacrylonitrile precursor is formed. According to the method disclosed by the invention, an ammonia-containing compound is added in the a coagulating bath; the ammonia-containing compound is served as a third component and can be used for retarding the double-diffusion speed in the solidification process of the polyacrylonitrile spinning solution; therefore, the solidifying and forming homogenization is realized; and the high-performance polyacrylonitrile precursor and carbon fibre can be obtained.

Owner:ZHEJIANG TAIXIAN NEW MATERIAL

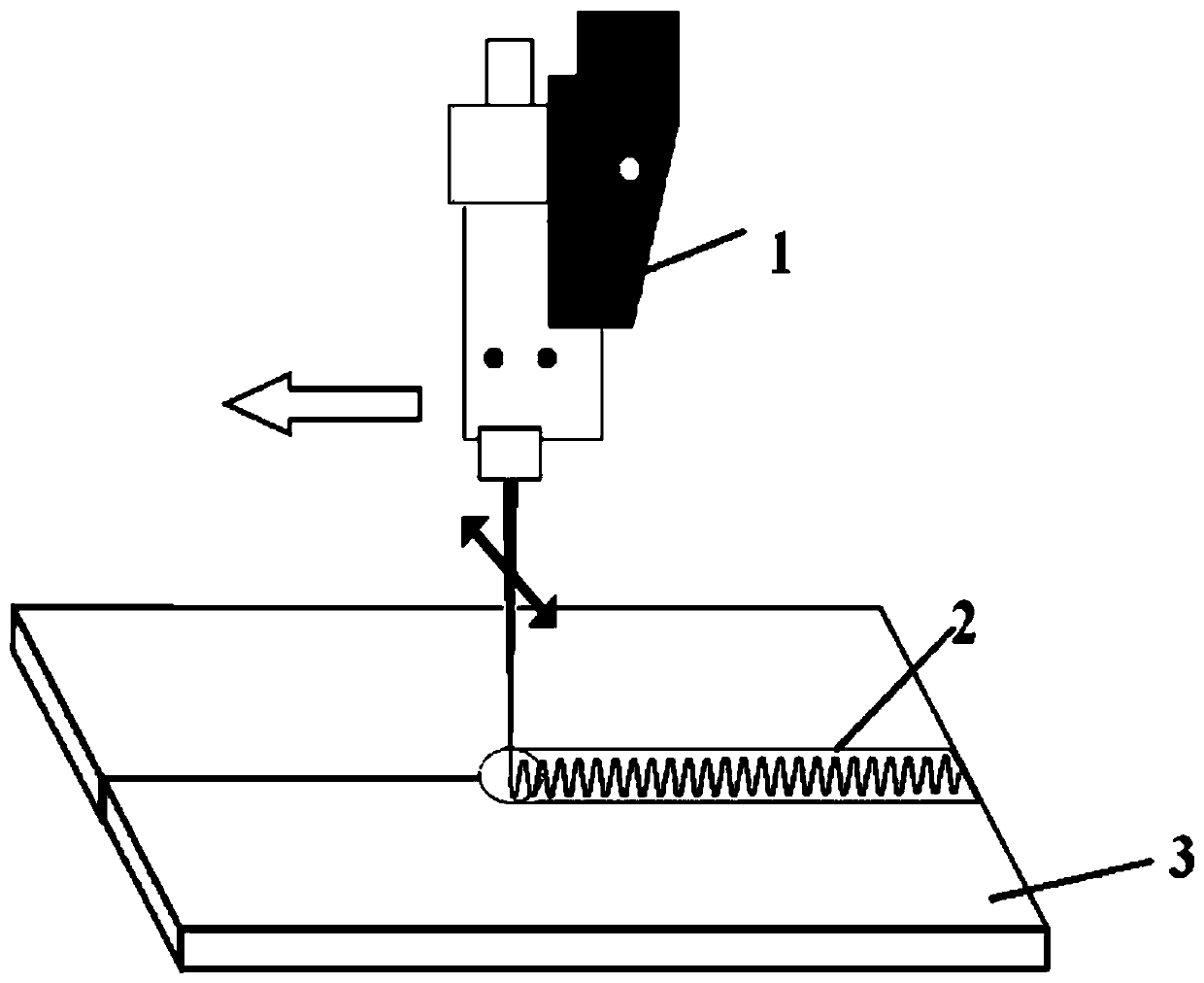

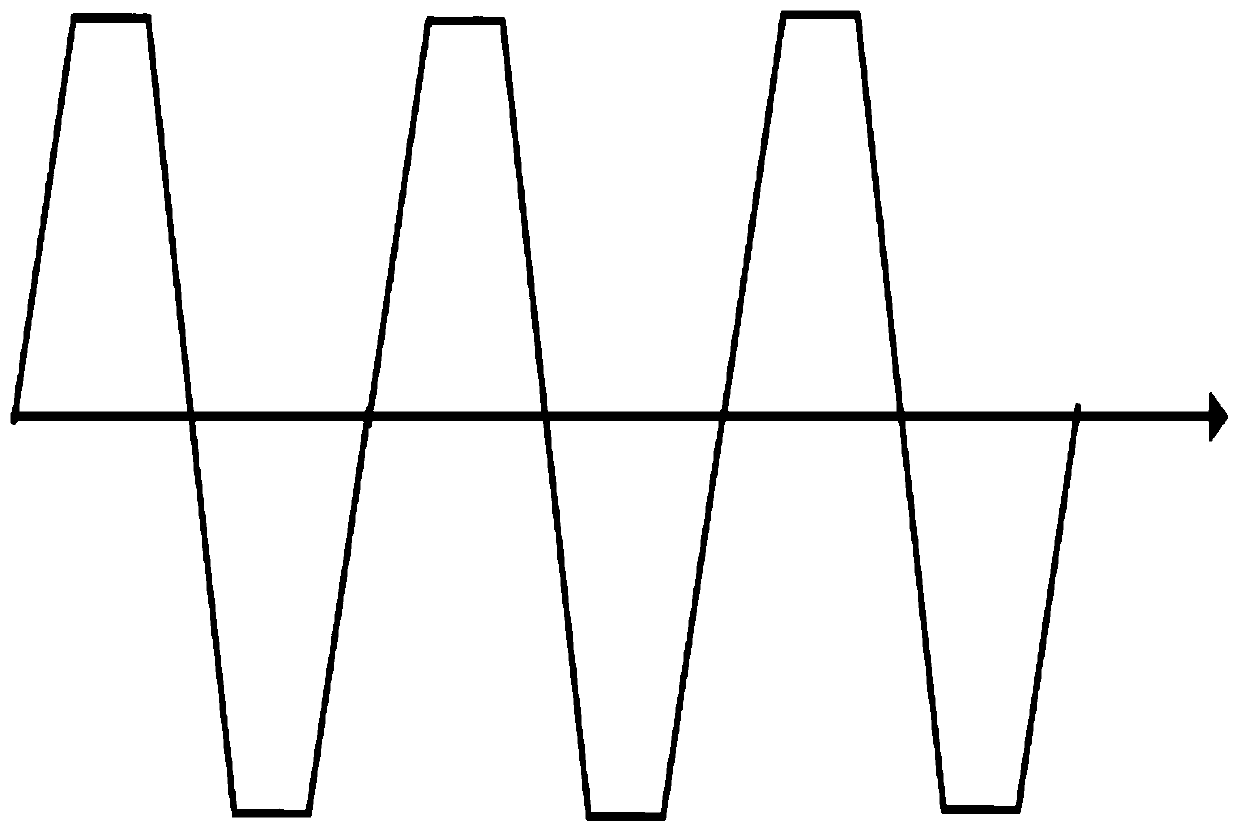

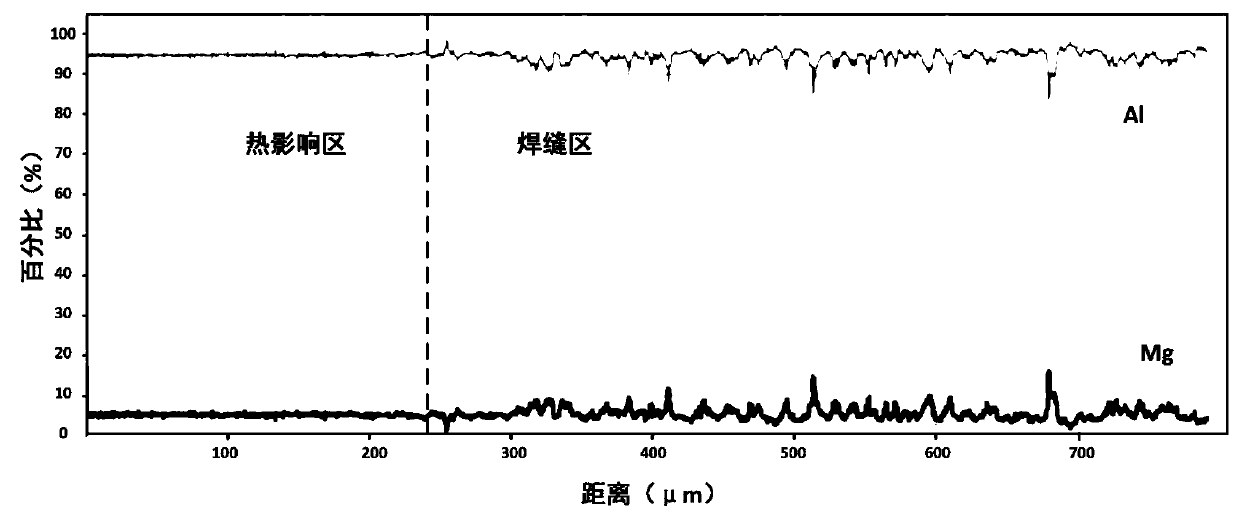

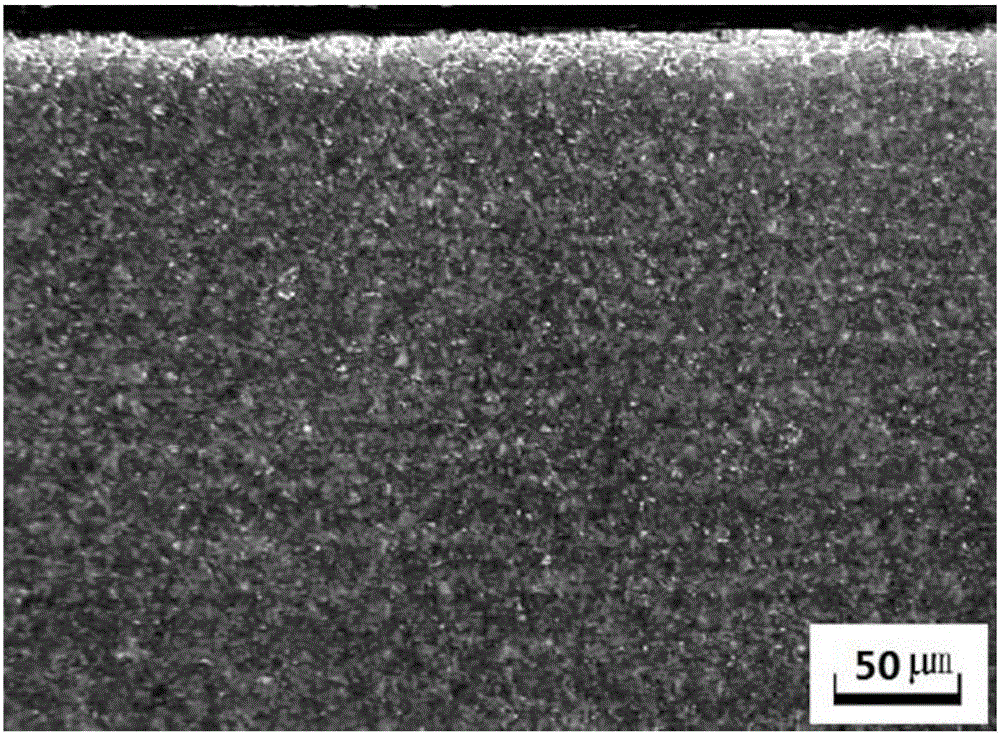

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

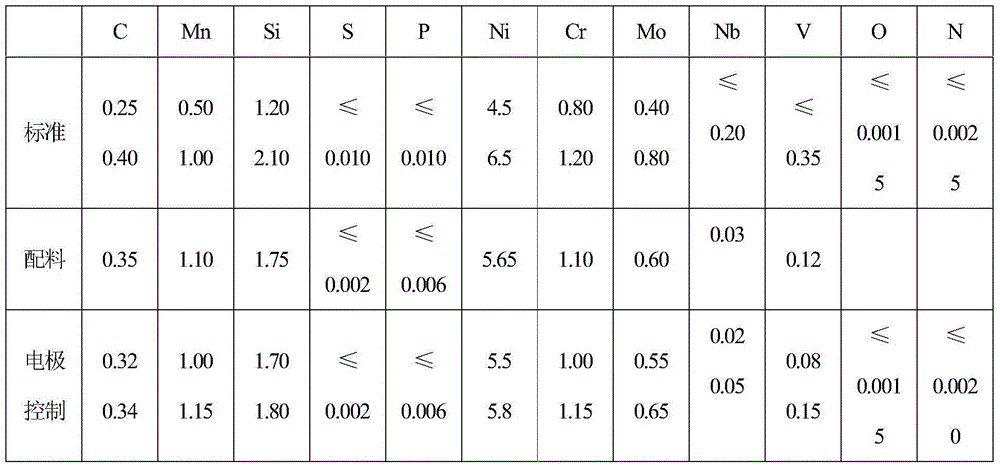

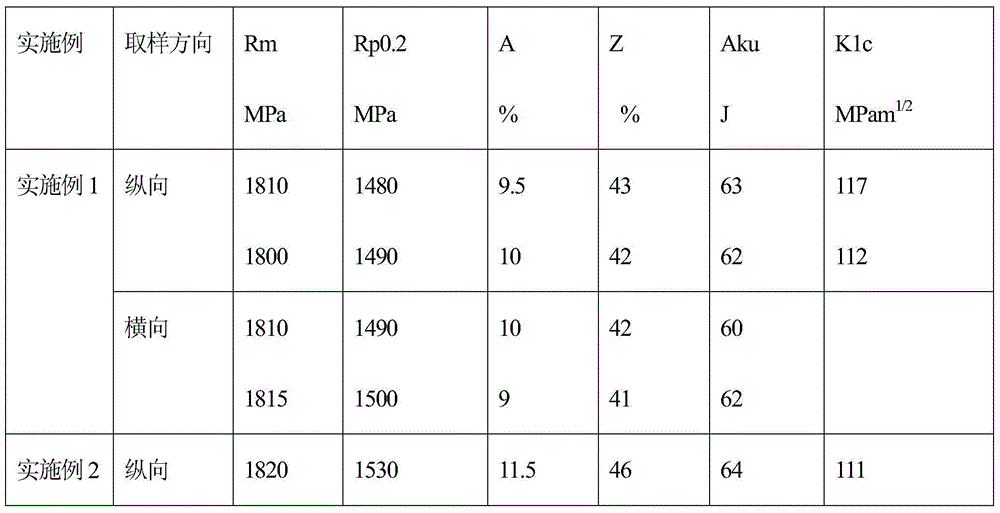

High-homogeneous large-size ultrahigh-strength steel bar and production method thereof

The invention discloses a high-homogeneous large-size ultrahigh-strength steel bar comprising the chemical composition by the mass percentage: 0.25-0.40% of C, 0.50-1.50% of Mn, 1.20-2.50% of Si, 0.80-1.20% of Cr, 4.50-6.50% of Ni, 0.40-1.00% of Mo, not more than 0.35% of V, not more than 0.20 % of Nb, not more than 0.005% of S, not more than 0.01% of P, not more than 20 ppm of O, not more than 25 ppm of N, and the balance Fe. At the same time, a production method of the steel bar is also provided; the forging process includes steel ingot heating, first upsetting and stretching, second upsetting and stretching, third upsetting and stretching, and stretching. The high-homogeneous large-size ultrahigh-strength steel bar has excellent mechanical properties; macrostructures comprise that white spots, dark spots, radial segregation and annual ring-shaped segregation all reach an AAAA level, the transverse performance reaches more than 90% of the longitudinal performance and a homogenization effect is achieved.

Owner:宝武特种冶金有限公司

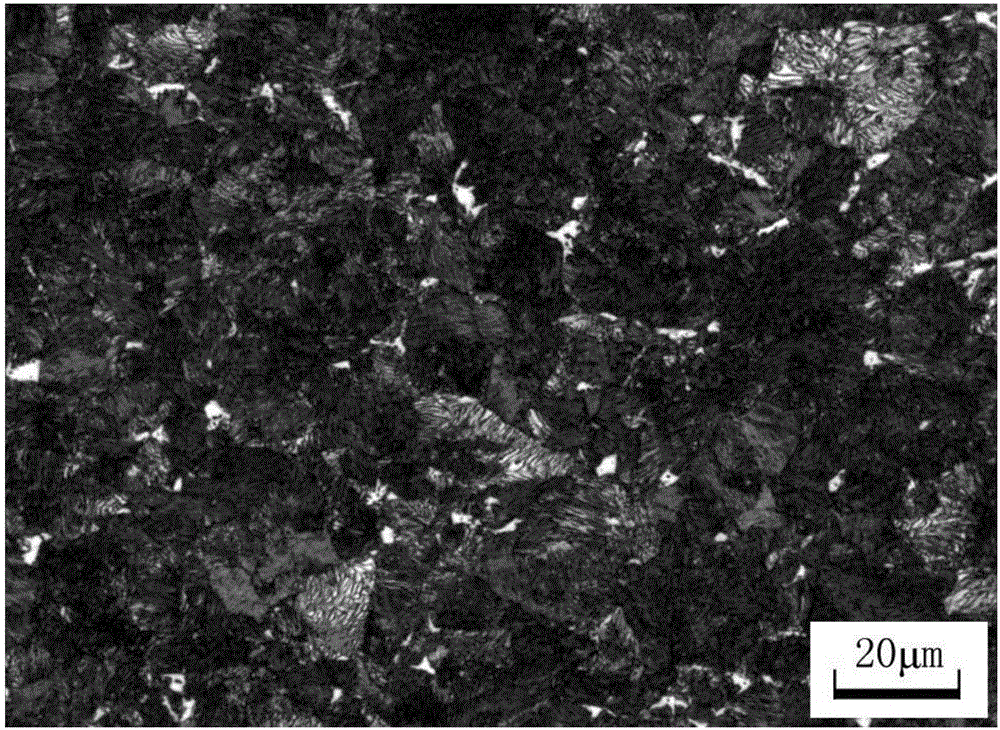

3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy

The invention discloses a 3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy. Within the superplastic deformation temperature range of the magnesium alloy, a non-hollow magnesium alloy casting obtained after forging pretreatment passes through at least two cycles to obtain a forging stock of the set size, and 3D super-plasticizing treatment is finished, wherein the non-hollow magnesium alloy casting passes through the axis Z, the axis X and the axis Y in sequence to press down the stock to achieve a cycle. By means of 3D super-plasticizing forging treatment, through large plastic deformation in all directions, homogenizing, grain refining and structure densifying of materials are fully achieved, refined grains are averagely smaller than 20 microns, the equiaxial grain refining effect is remarkable, and the strength performance of the casting can be greatly improved. Through the superplasticity precision shaping method for the magnesium alloy based on 3D super-plasticizing treatment, a light magnesium alloy transition car coupler with high strength is prepared out; and compared with an existing transition car coupler, the weight is reduced by about 75%, the strength is above 350 MPa, and the requirement for the service life of the transition car coupler of this type can be met.

Owner:崇州天智轻量化制造有限公司

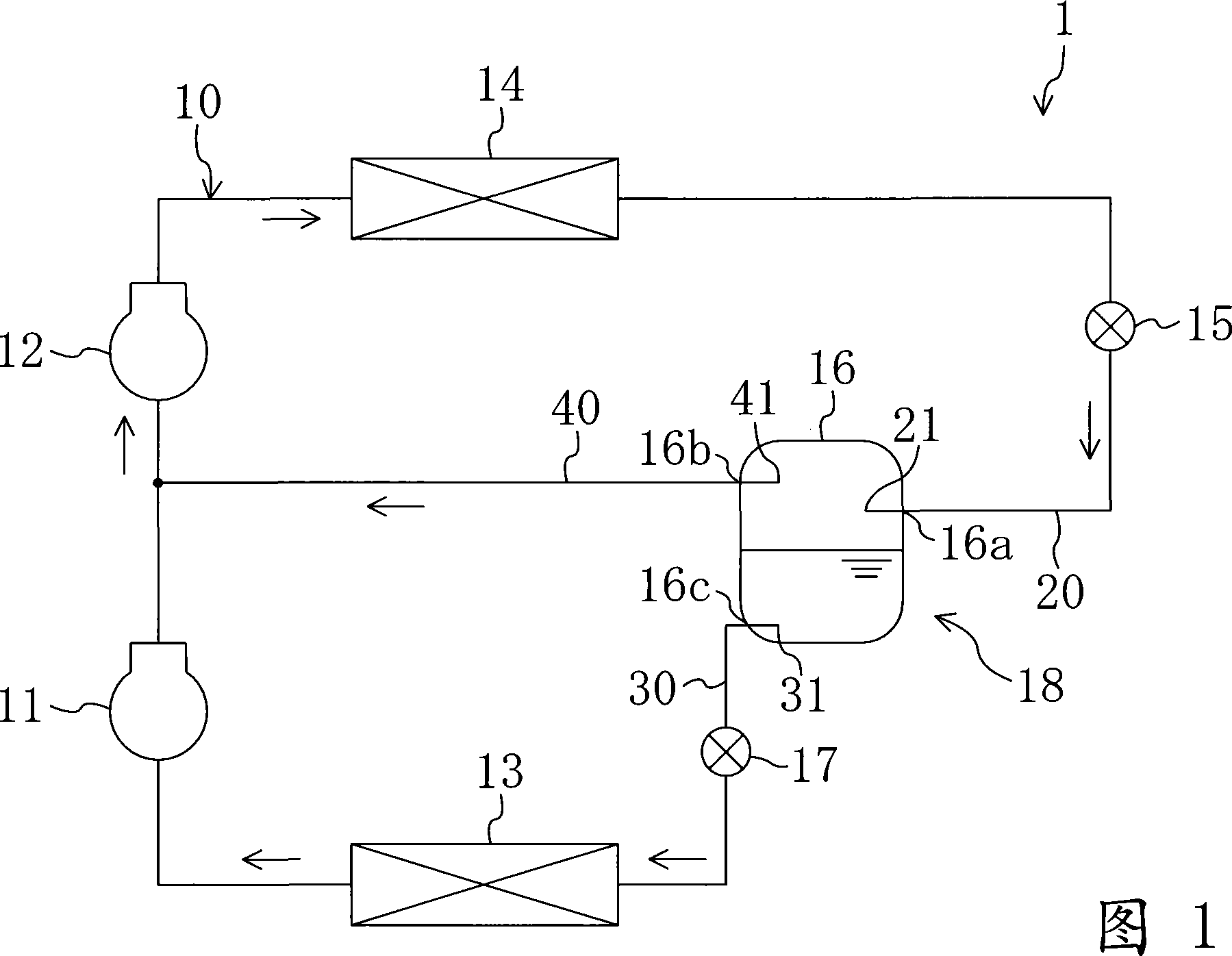

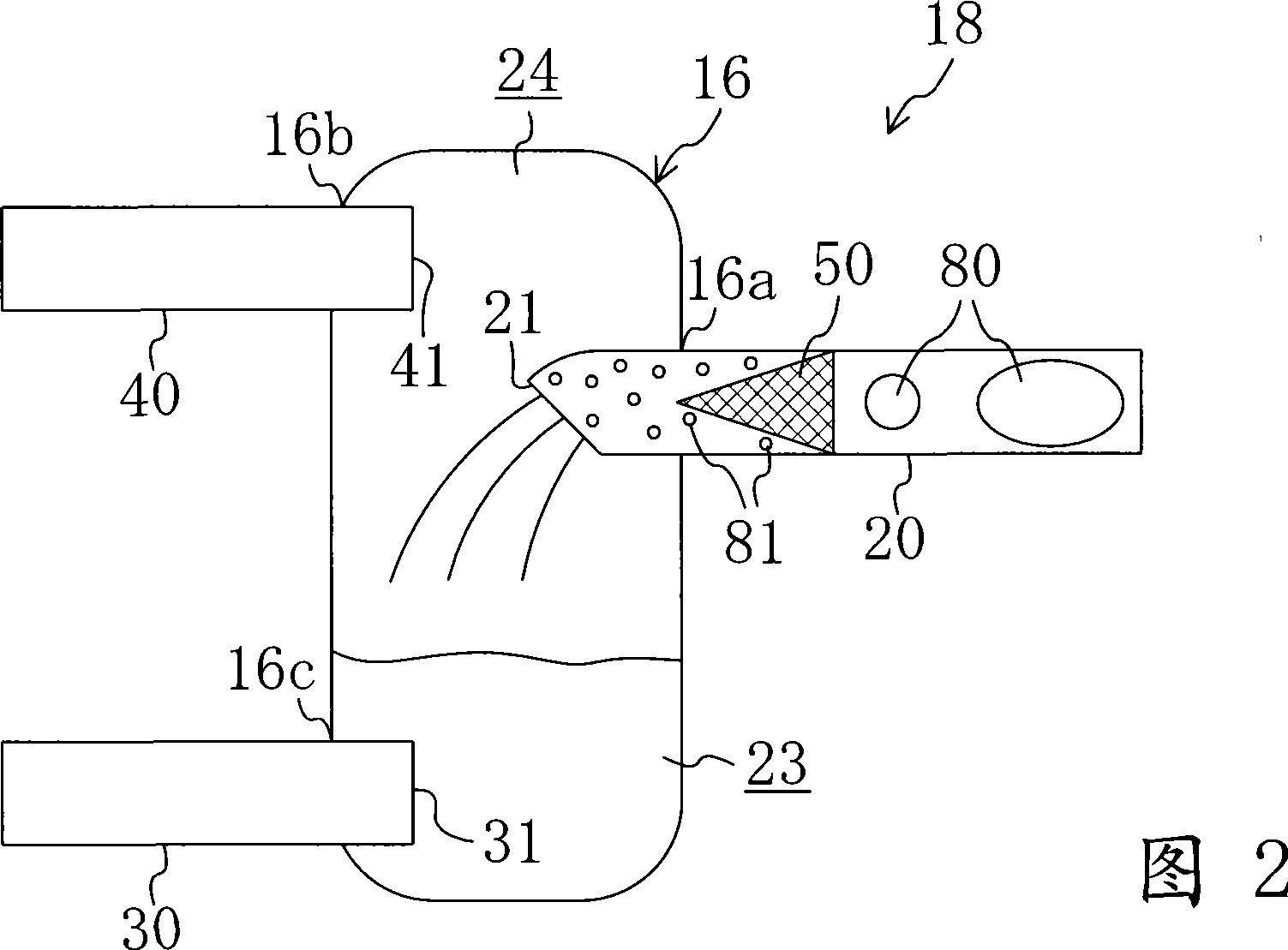

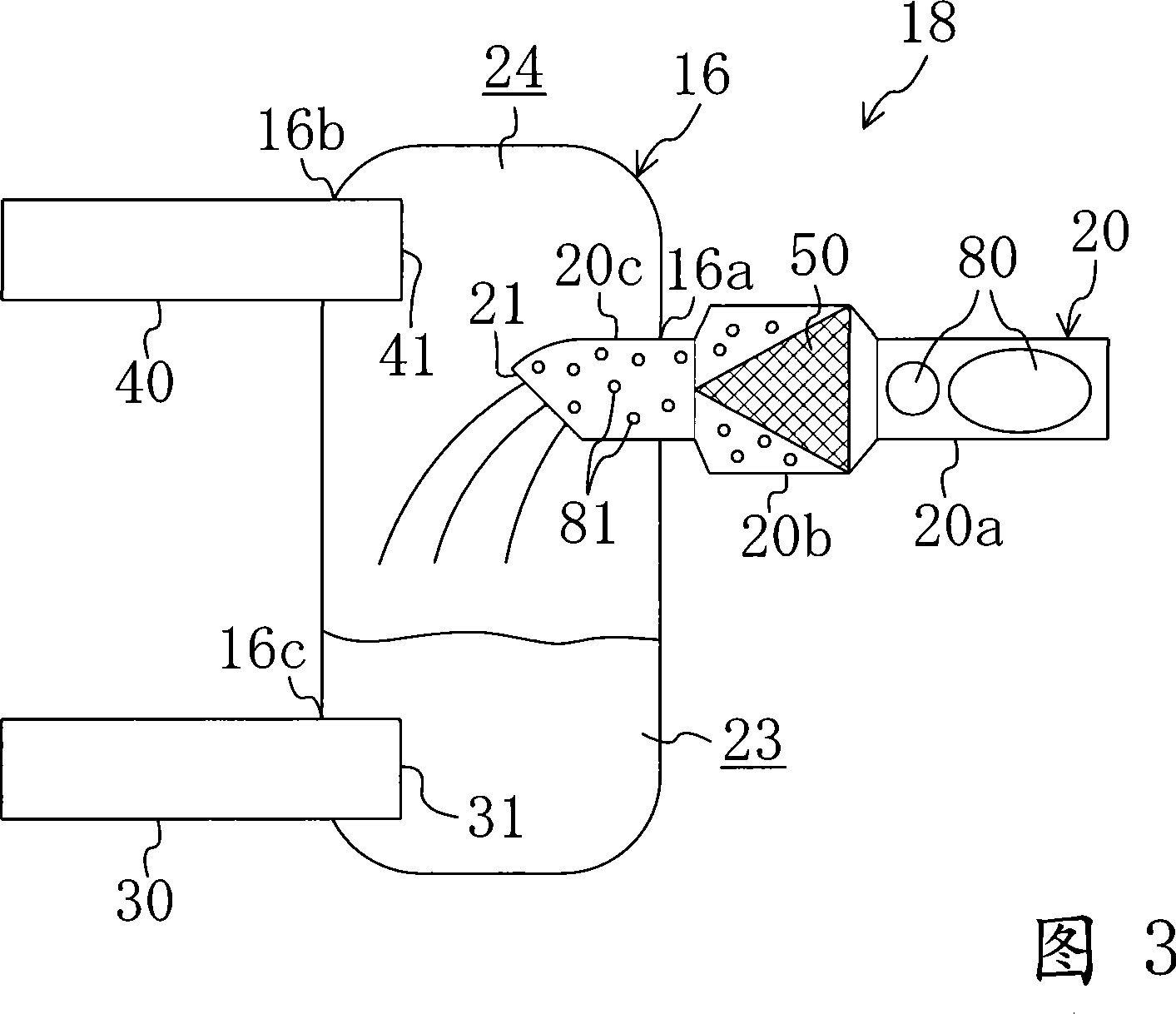

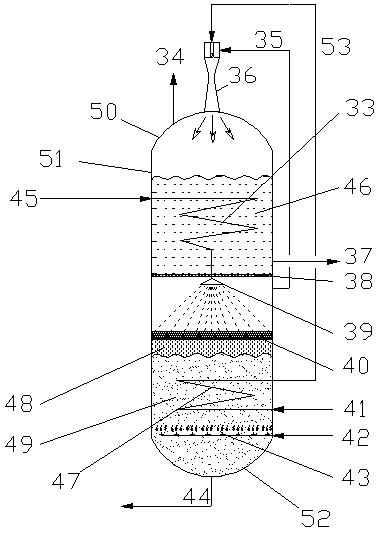

Gas-liquid separator and refrigeration device with the gas-liquid separator

InactiveCN101371085AAchieve homogenizationRegular and stable importCompression machines with non-reversible cycleFluid circulation arrangementVapor–liquid separatorEngineering

The invention discloses a gas-liquid separator and a refrigeration deivce with the same. A refrigeration device has a gas-liquid separator (18) and a refrigerant circuit for performing a two-stage compression, two- stage expansion refrigeration cycle. In the refrigeration circuit, an intermediate-pressure, gas-liquid two-phase refrigerant passed from an outdoor heat exchanger to an intermediate expansion valve is introduced into a container body (16) via an inlet tube (20) of the gas-liquid separator (18) and separated into liquid refrigerant and gas refrigerant. The liquid refrigerant flows out of a liquid outlet tube (30), flows through a refrigerant heat exchanger via a main expansion valve, and is then drawn into a low-stage-side compressor. The gas refrigerant flows out of a gas outlet tube (40) to be supplied to the suction side of a high-stage-side compressor and is then drawn into the high-stage-side compressor together with refrigerant discharged from the low-stage-side compressor. A mesh member (50) for breaking up bubbles (80) formed of the gas refrigerant in the gas-liquid two-phase refrigerant is provided in the inlet tube (20).

Owner:DAIKIN IND LTD

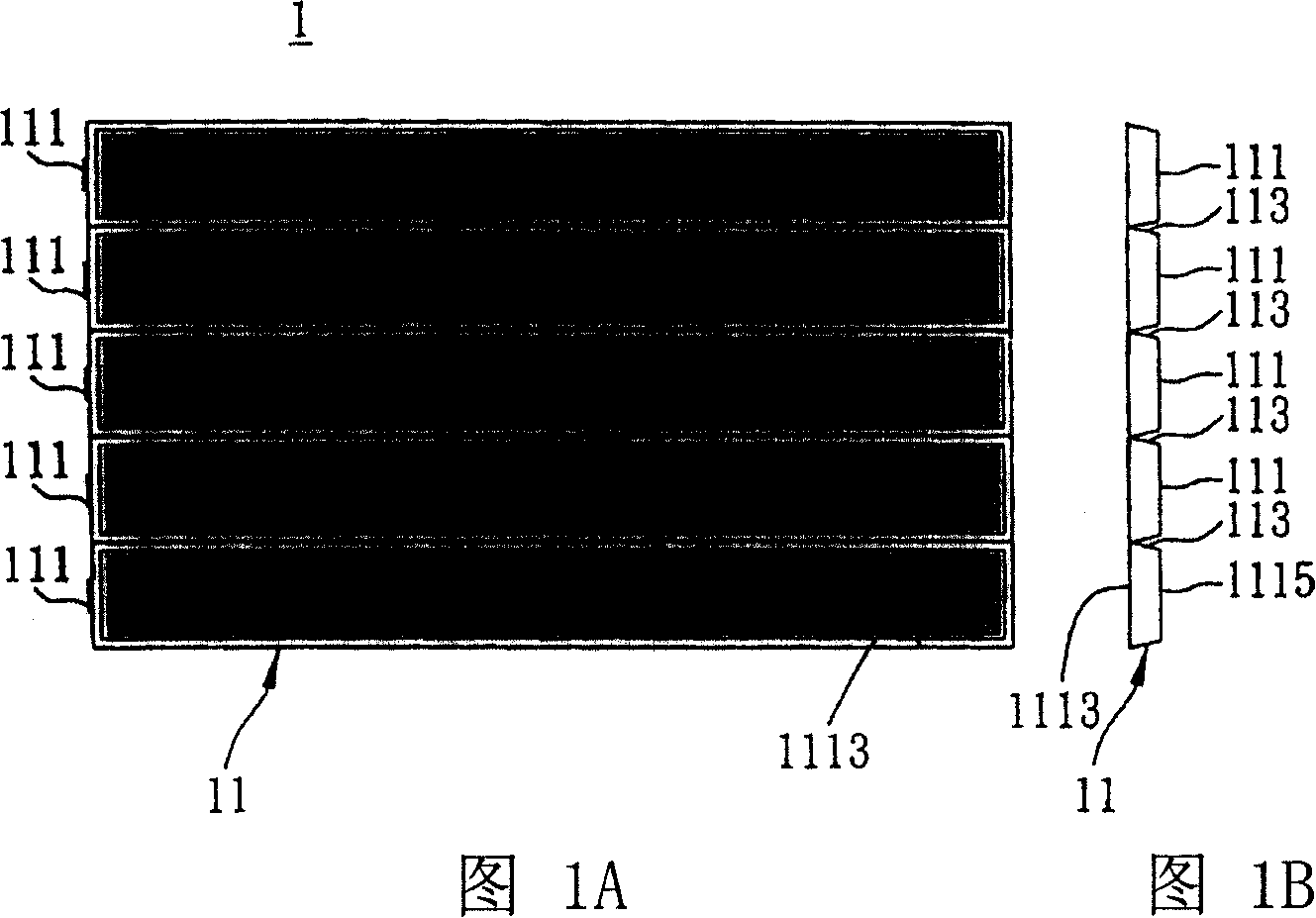

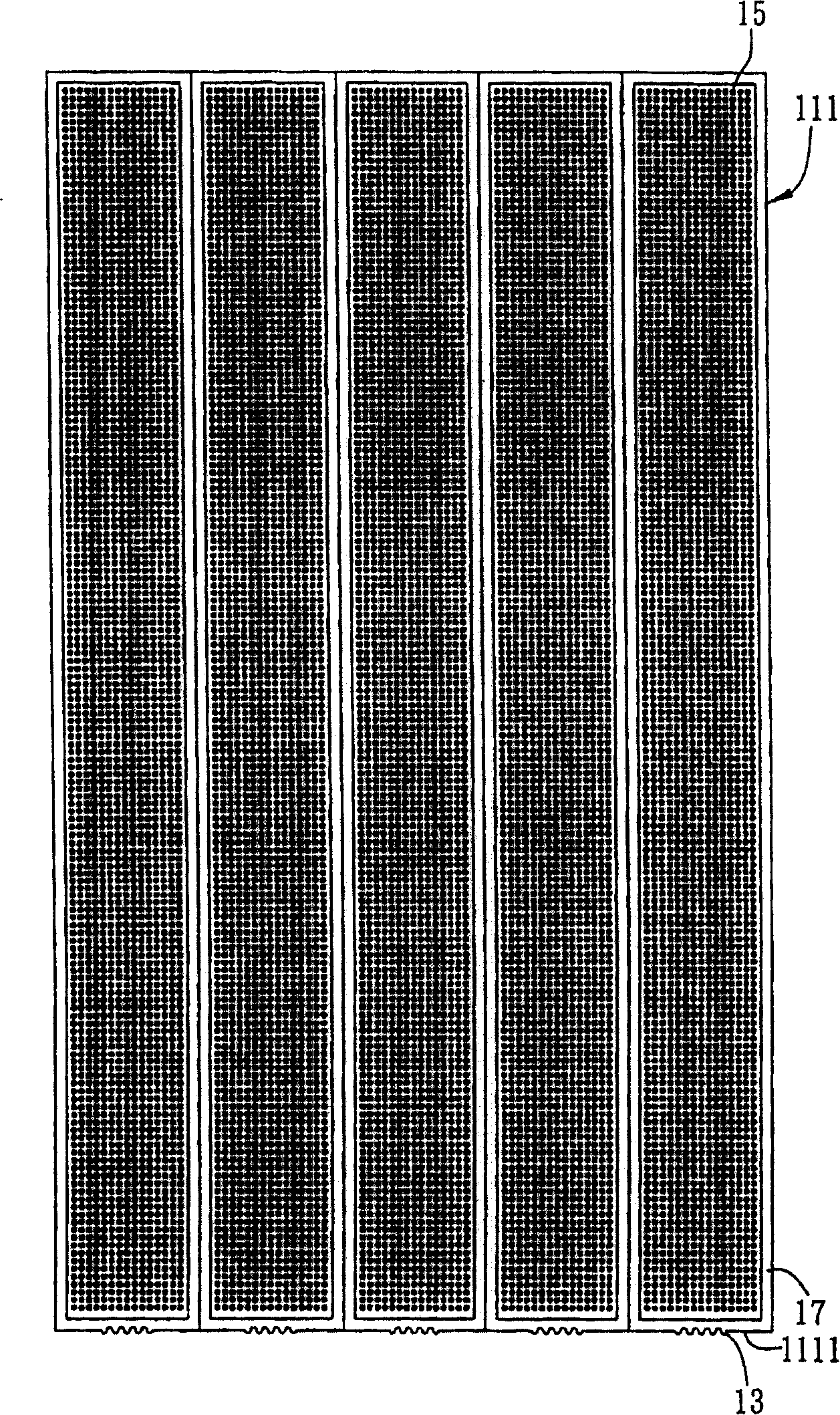

Light conductive board and the backlight module possessing same

InactiveCN101165515AShorten the mixing distanceLess discomfortOptical light guidesNon-linear opticsGratingLight guide

The invention is a backlight module comprising a transparent substrate partitioned into multi areas, a grating structure located at the incident face of each area, and astigmatism structure of optical face used for receiving the incident light. The transparent substrate can be used to make partition sequential scan so as the grating structure can shorten the light-mixing distance; said astigmatism structure can evenly scatter the light out of the light-guiding plate.

Owner:IND TECH RES INST

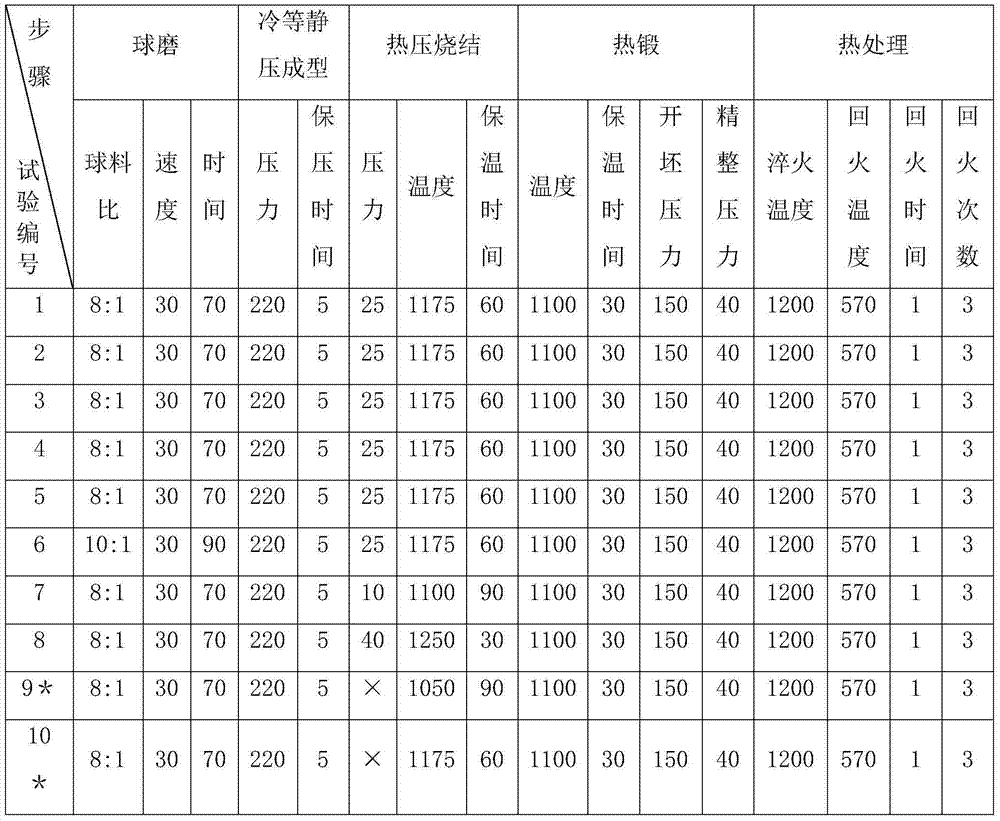

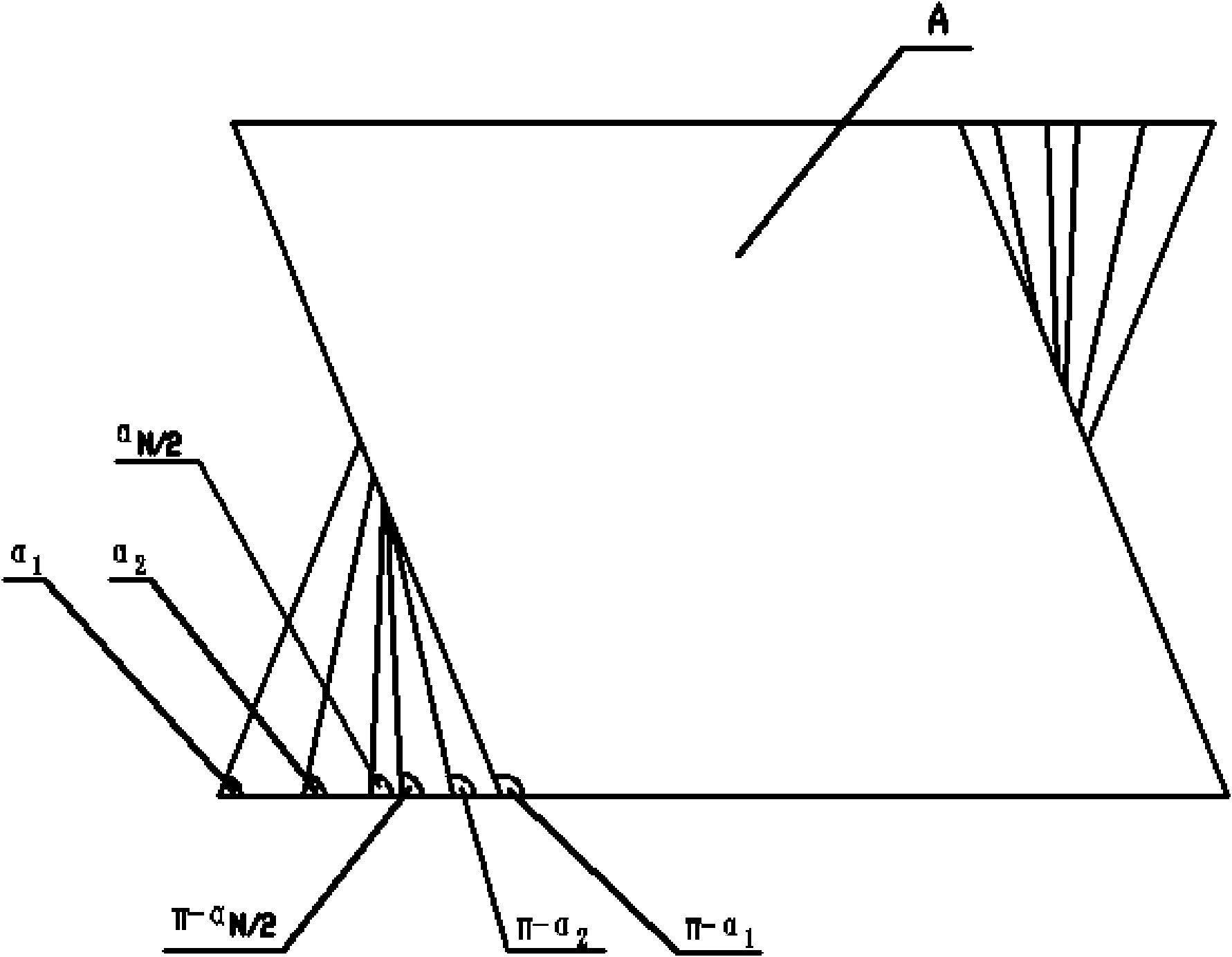

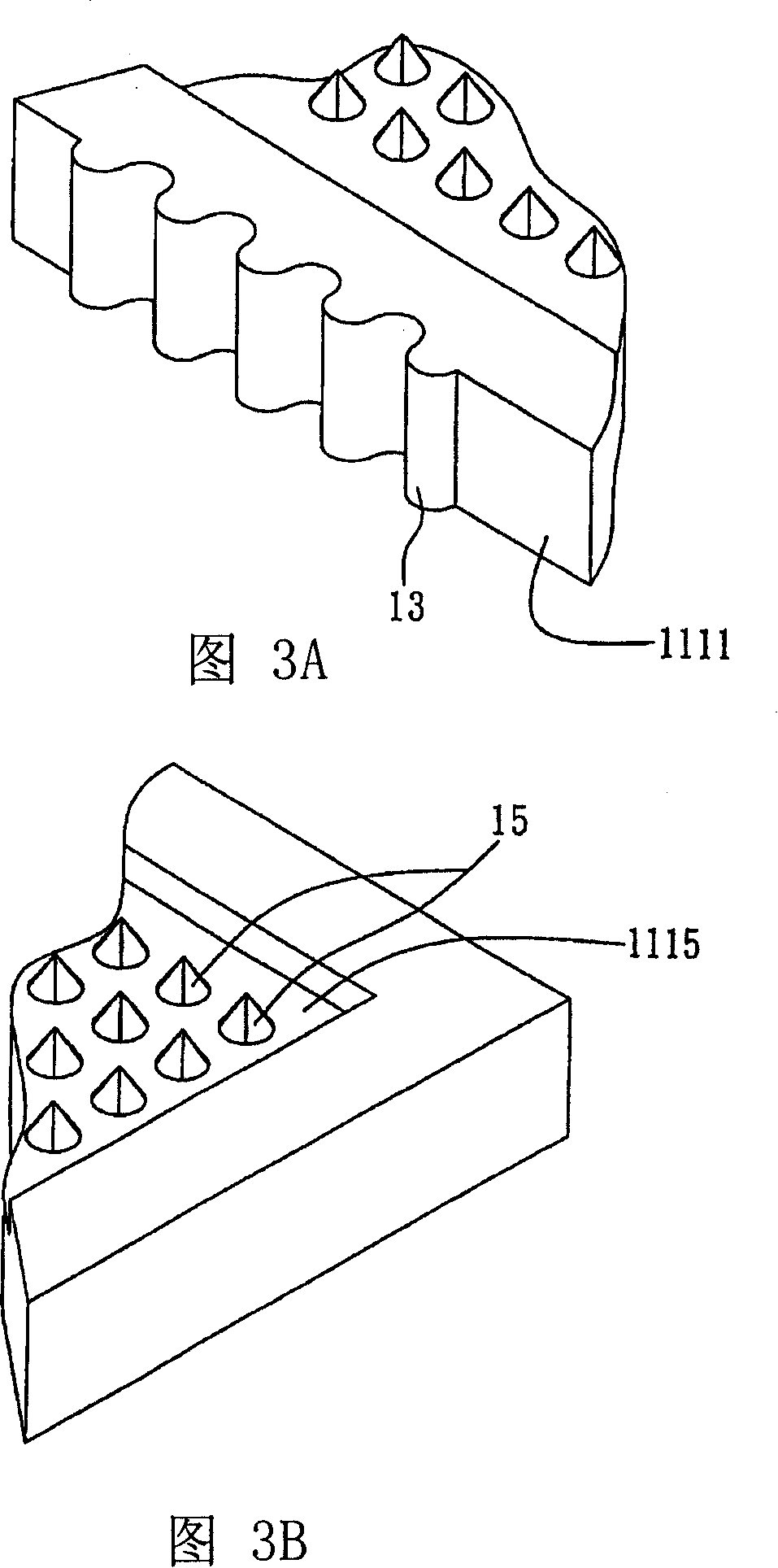

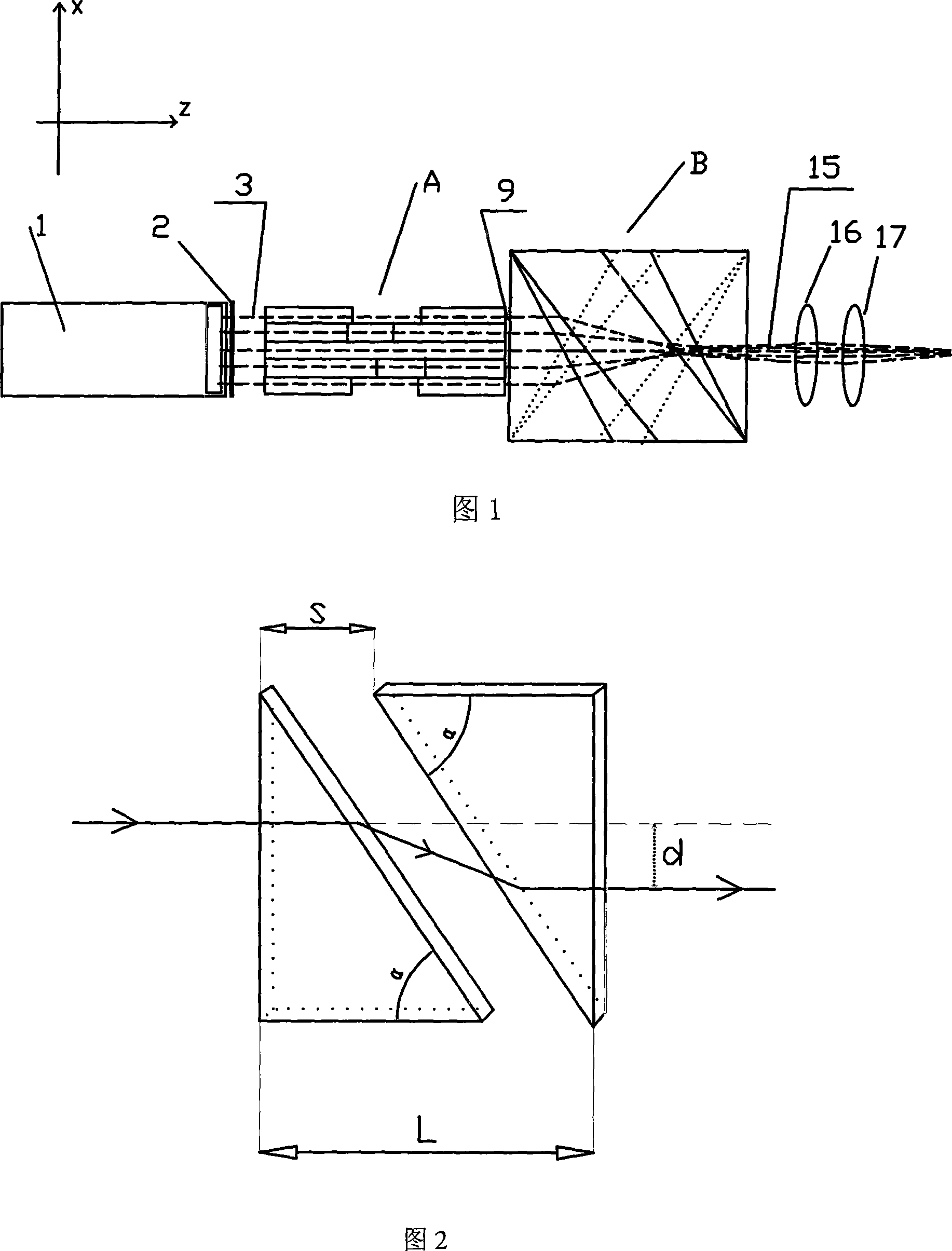

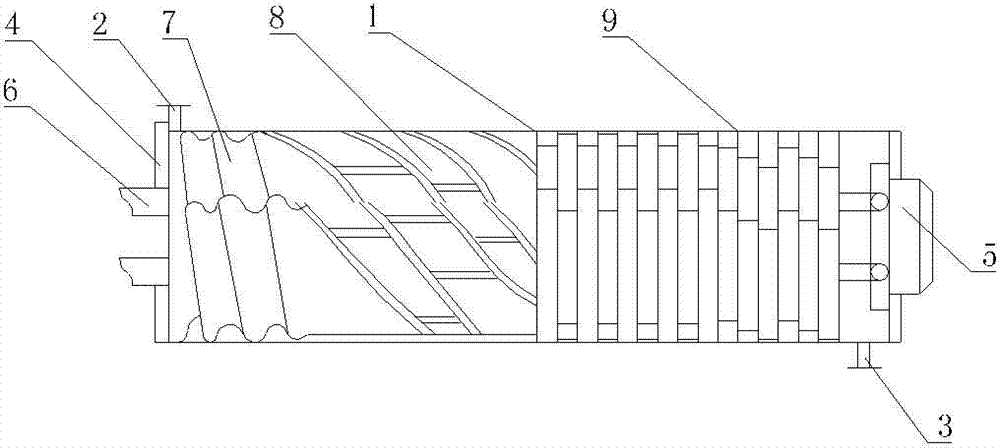

Optical beam parameter product symmetrization device of semiconductor laser array fast and slow axis

InactiveCN101221288AAchieve homogenizationEasy to installSemiconductor laser arrangementsLaser arrangementsHigh power densitySemiconductor laser theory

The invention relates to a homogenization device of a product of the beam parameters of a semiconductor laser array fast-slow shaft, belonging to the application field of laser technology and including a group of semiconductor laser array fast-slow shaft aligning micro-lens unit, a flat glass pile A, B and a focusing lens set. The light passing through the fast-slow shaft aligning micro-lens vertically injects on the flat glass pile A, a beam is divided into a plurality of portions and generates refraction excursion in the flat glass corresponding to each beam to obtain linear beams distributed in a ladder shape along the direction of the fast shaft of the laser array. The ladder shape linear beams pass through the flat glass pile B and the beams are led to generate reflection excursion along the direction of the slow shaft of the array and are further redistributed as linear beams according to a same beam recombining principle; consequently the beams given out by the semiconductor laser array have a more approximate beam parameter product on the fast-slow shaft, namely, a balanced beam quality in the fast-slow shaft direction. Finally, a uniform focusing spot with high power density and brightness in the fast-slow shaft direction can be obtained by the focusing of the focusing lens set.

Owner:JIAXING DAHE LASER EQUIP

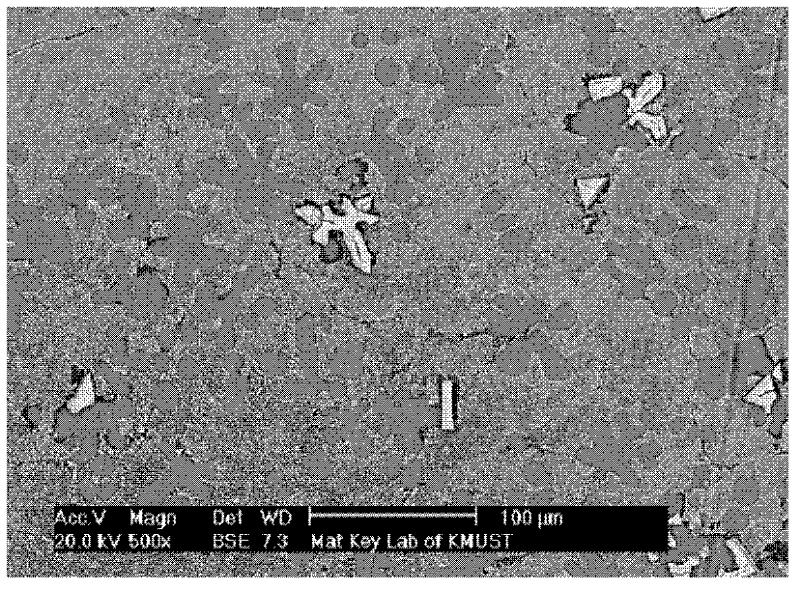

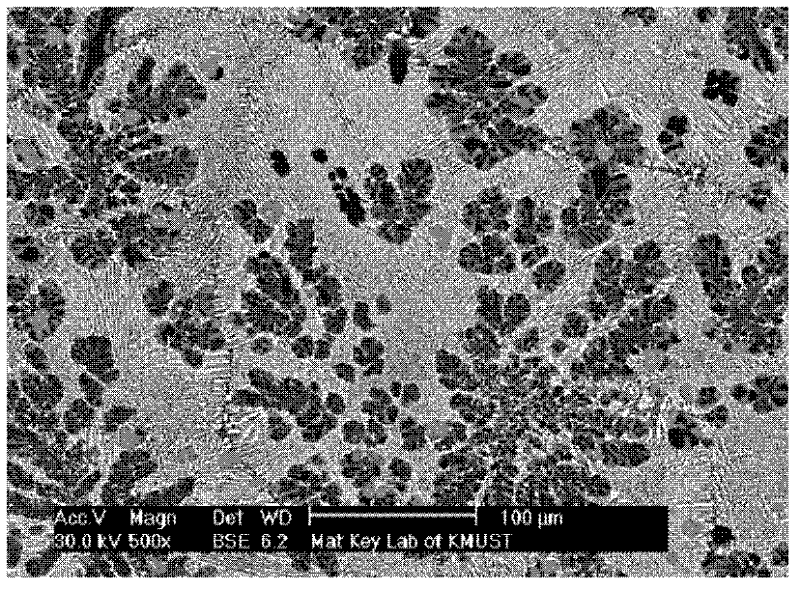

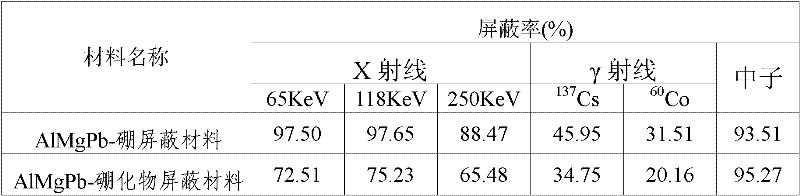

Aluminum-based material with integrated radiation and neutron shielding effect

The invention belongs to an aluminum-based shielding material with comprehensive shielding effects of X, gamma rays and neutrons, in particular a shielding material with high strength, light weight and multiple shielding effects. The composition of the shielding material is: the matrix is aluminum-based alloy AlMgPb (15%-30% Mg, 15%-35% Pb, the balance is aluminum, mass percentage), and boron or boride is a neutron absorber. The component distribution ratio of the shielding material is as follows: the mass percentage of aluminum-based alloy is between 90% and 99.7%, and the mass percentage of boron or boride is between 0.3% and 10%. Compared with traditional aluminum-based materials, Pb / B4C and lead-boron-polyethylene composite materials, the aluminum-based shielding material containing boron or borides of the present invention not only has excellent comprehensive shielding effects for X, γ-rays and neutrons, but also has The tensile strength and Brinell hardness are much higher than the existing Pb-B polyethylene and Pb-B4C composite shielding materials.

Owner:KUNMING UNIV OF SCI & TECH +1

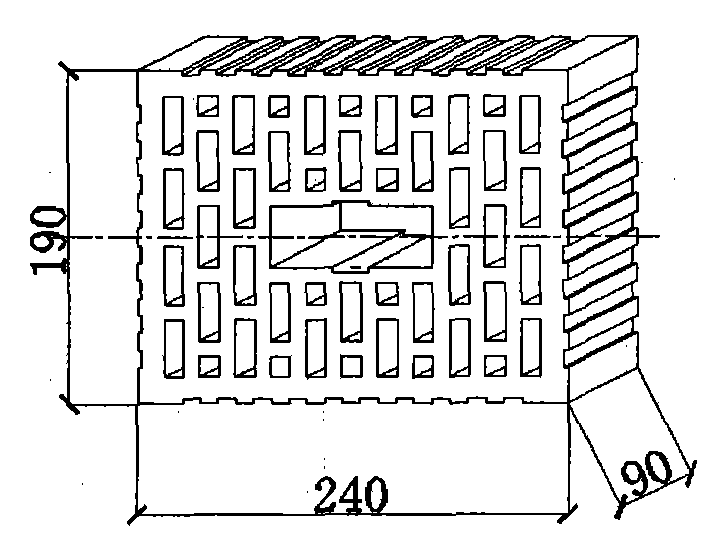

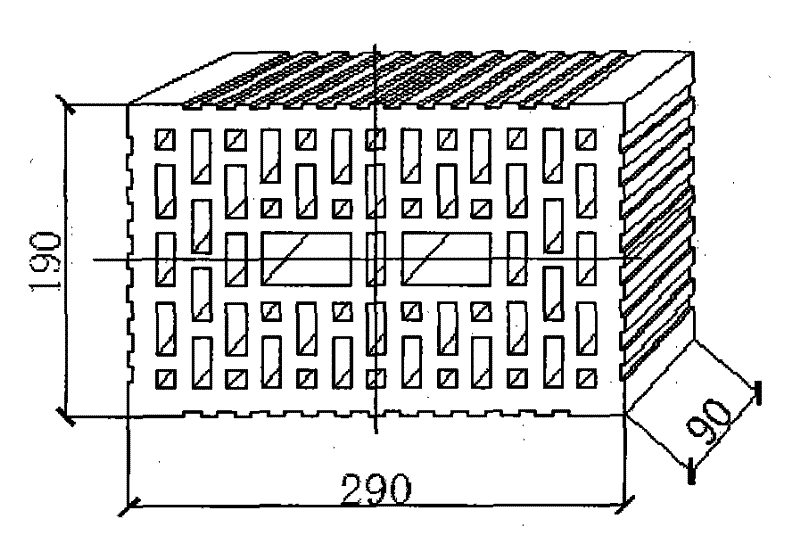

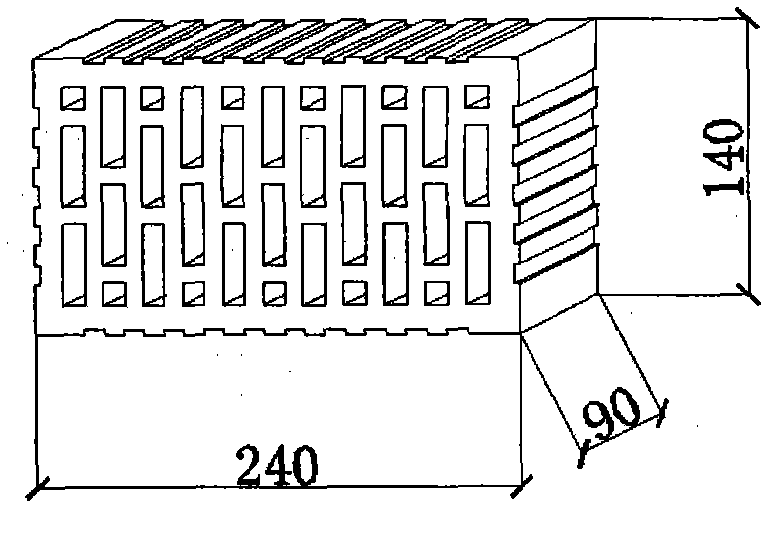

Sintered product of rejects and shale modular cellular bricks and preparing method thereof

InactiveCN101747077ADehydration fastAchieve homogenizationCeramic extrusion diesCeramicwareSocial benefitsBrick

The invention discloses a sintered product of rejects and shale modular cellular bricks and a preparing method thereof. The preparing method of the product comprises the following steps of: ensuring that the raw material with the fineness being lower than 0.5 to 0.25 mm occupies 65 percent of all the raw materials through rough crushing, fine crushing and sifting; blending rejects and shale in proportion by weight of 70 to 85 percent: 15 to 30 percent, and adding water and uniformly stirring, and putting the material into a storage warehouse to be stored, wherein the quantity of water added is excessive; feeding the stored material into a molding machine to be conducted to semi-hard plastic extrusion molding; sintering at the maximum temperature of 1000 to 1080 DEG C for 8 to 16 hours; ensuring that the firing time is 28 to 36 hours; and slacking the material in water after kiln discharging and sorting. The main material of the product adopts rejects which are abandoned by most mines and required to be conducted to safe disposal, the preparing method can effectively and conjunctively utilize rejects, change waste into valuable, meet the requirements of energy saving and emission reduction, and achieve significant social benefit and economic benefit.

Owner:南京鑫翔环保产业有限公司

Black zirconia ceramic material composition and application thereof

The invention discloses a black zirconia ceramic material composition which comprises the following components in percentage by mass: 0.01-4% of ferric oxide, 0.01-3.5% of aluminum oxide, 0-3.5% of zinc oxide, 2-7% of yttrium oxide, 0-4% of titanium oxide, 0.01-1.0% of silicon dioxide and the balance of zirconia with hafnium oxide. Due to addition of a black coloring agent in zirconia ceramic powder, the granularities of the silicon dioxide and the aluminum oxide are controlled, the shielding property and the blackness of a zirconia ceramic are improved, the light permeability of the zirconiaceramic is degraded, the mechanical strength of a molded ceramic is improved, and excellent effects of colors and strength of a product can be ensured. Meanwhile, the invention further discloses a black zirconia ceramic prepared from the black zirconia ceramic material composition, and a preparation method of a black zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

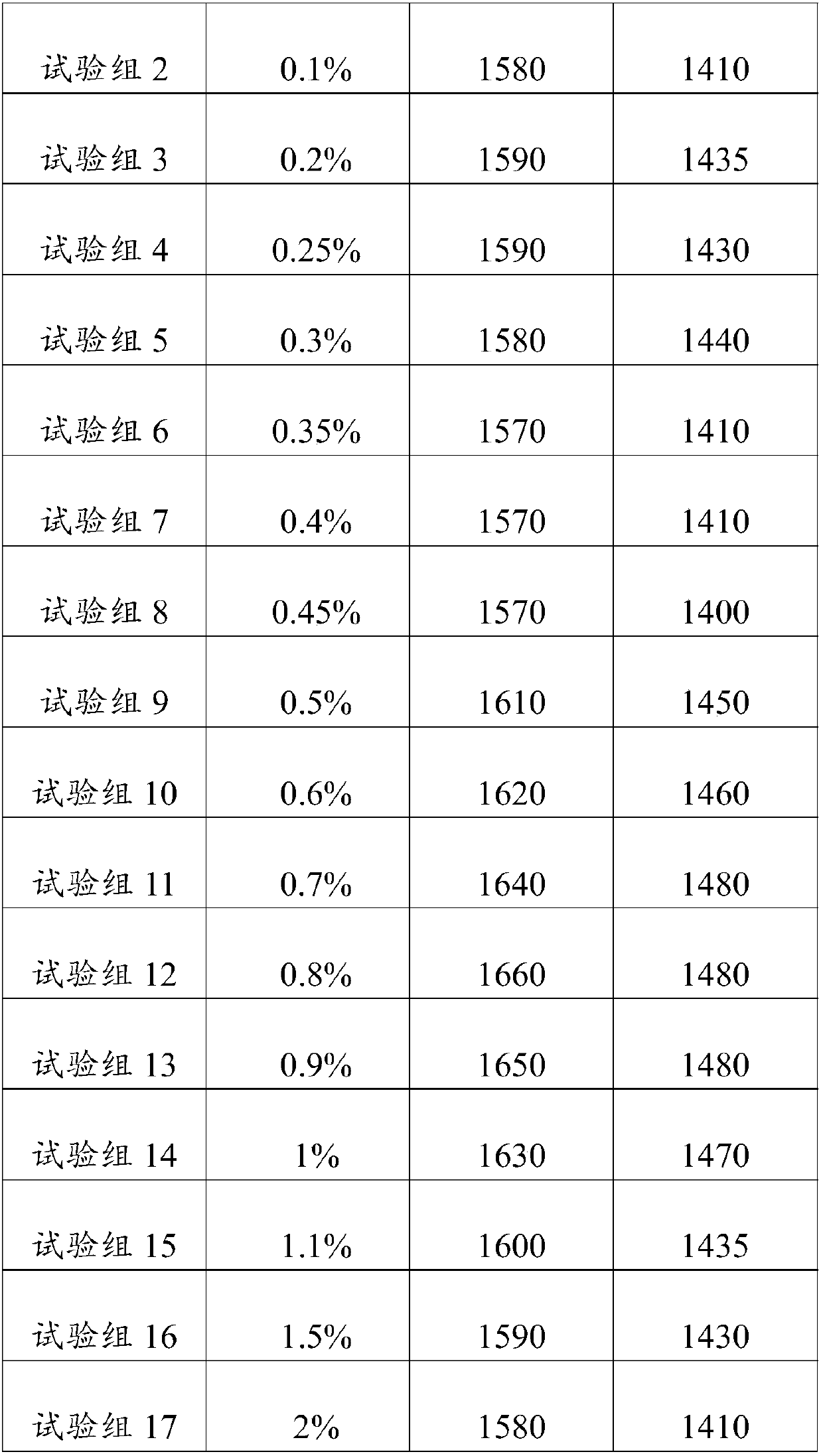

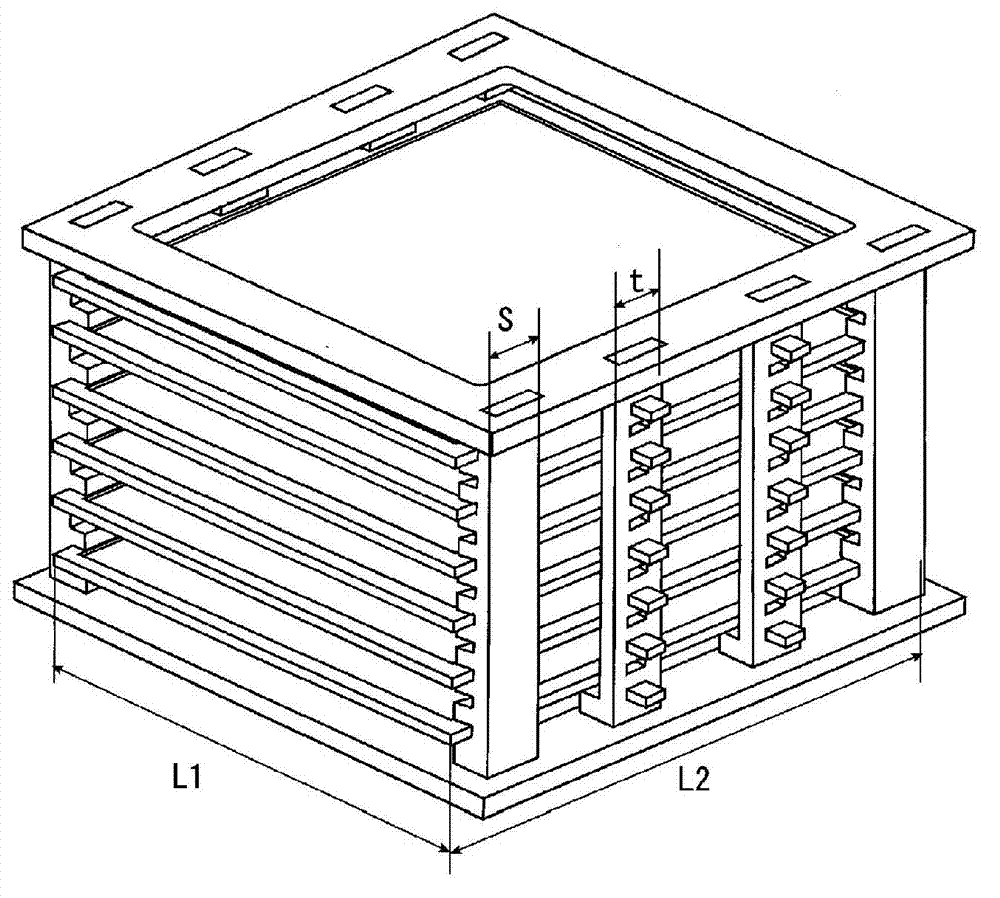

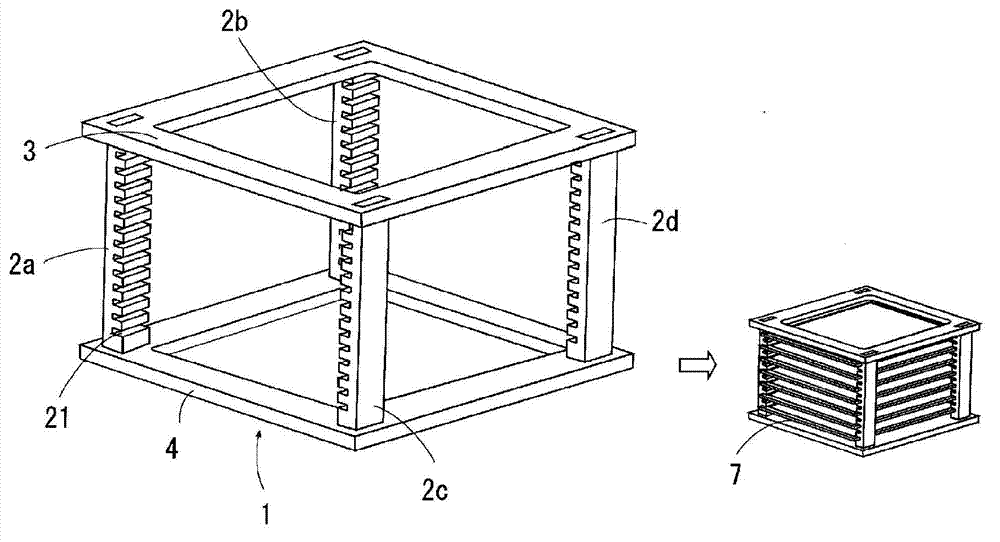

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

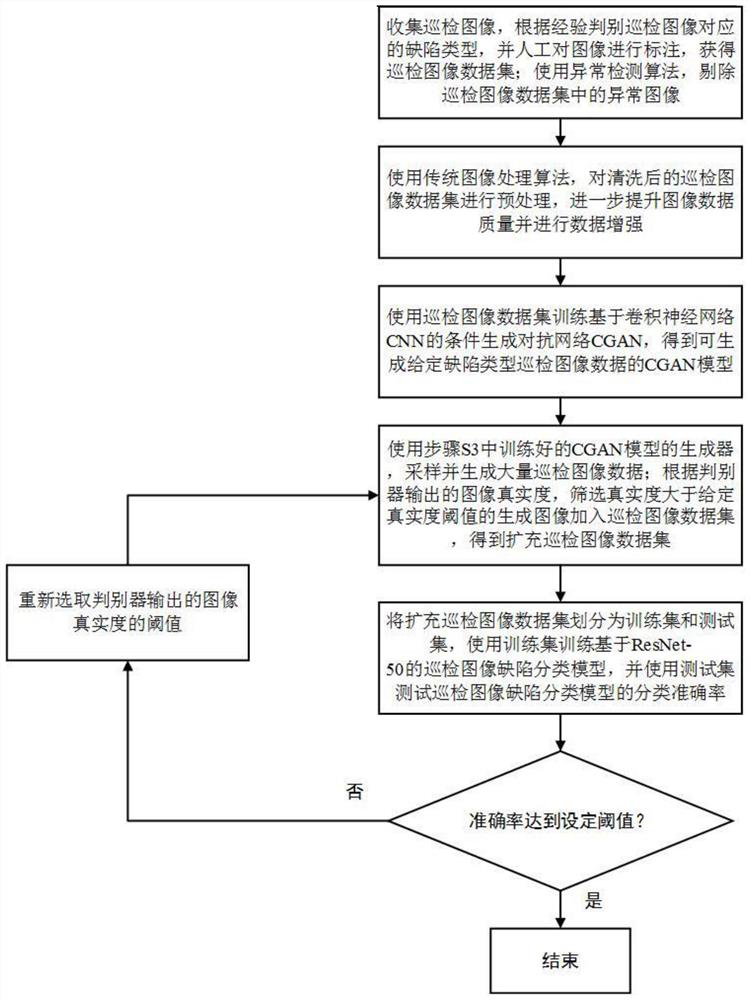

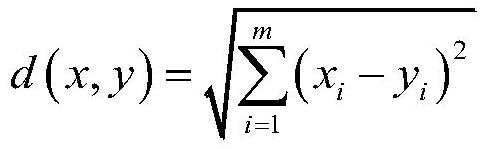

CGAN-based inspection image data small sample expansion method

ActiveCN112446429AEquilibrium sample sizeImprove data qualityCharacter and pattern recognitionNeural architecturesData setImaging processing

The invention relates to a CGAN-based inspection image data small sample expansion method. The method comprises the steps: firstly, collecting inspection images, judging defect types corresponding tothe inspection images, carrying out marking, and removing abnormal images in an inspection image data set by using an abnormality detection algorithm; preprocessing the cleaned inspection image data set by using a traditional image processing algorithm, and training a conditional generative adversarial network based on a convolutional neural network by using the inspection image data set to obtaina CGAN model capable of generating inspection image data of a given defect type; sampling and generating a large amount of inspection image data by using a trained CGAN model generator; and accordingto the image truth output by a discriminator, screening the generated images of which the truth is greater than a given truth threshold, and adding the screened images into the inspection image dataset to obtain an expanded inspection image data set.

Owner:GUANGDONG POWER GRID CORP ZHAOQING POWER SUPPLY BUREAU

Electro-optical device, method of manufacturing the same, and electronic apparatus using electro-optical device

InactiveCN1721926AThickness increased and uniformThick enoughStatic indicating devicesNon-linear opticsCover glassElectron

Owner:SEIKO EPSON CORP

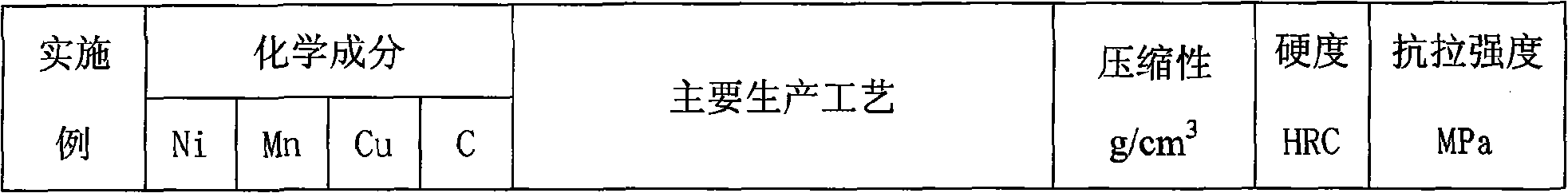

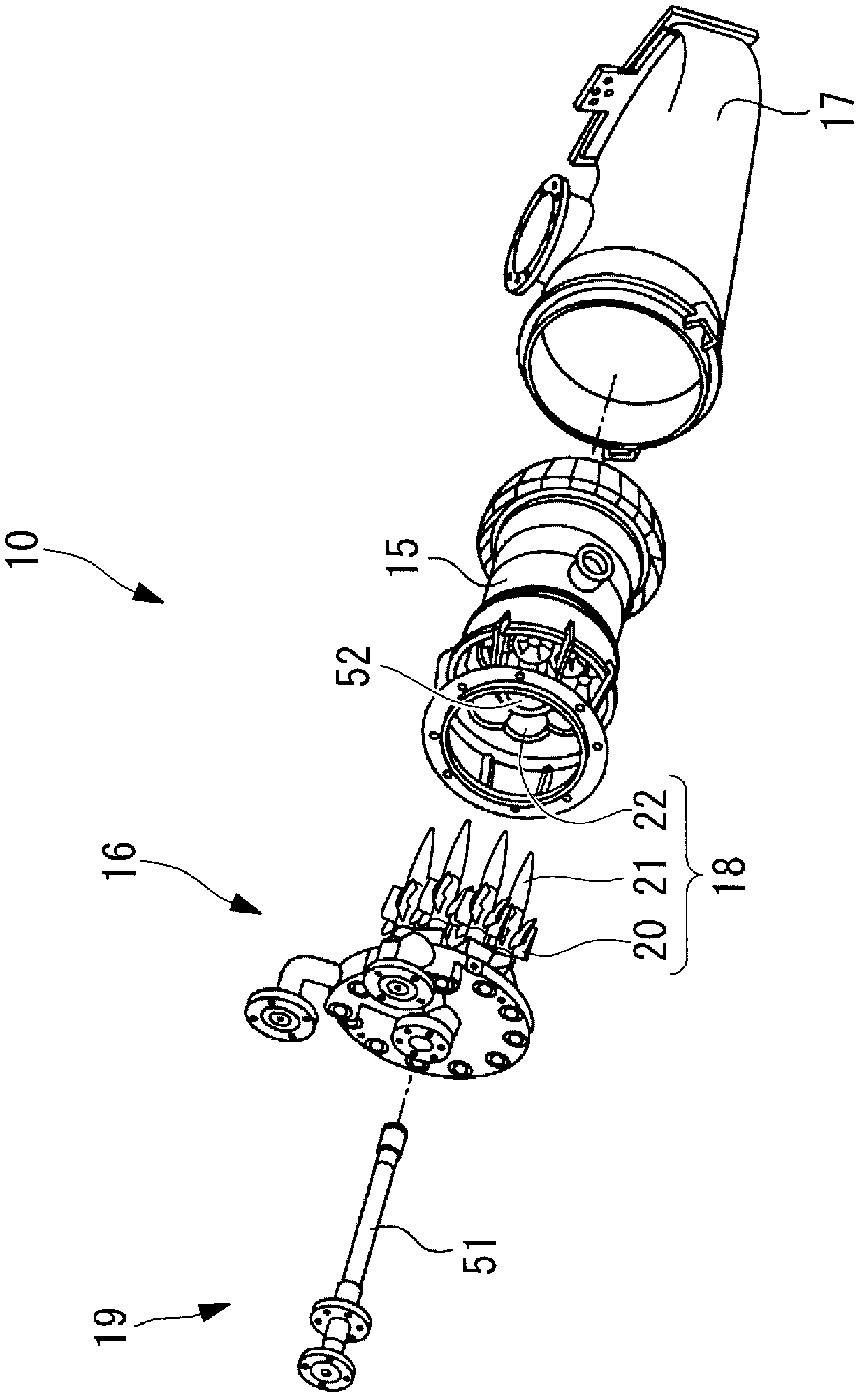

Water atomizing steel powder used for high-compressibility sintering hardening and production method thereof

InactiveCN101658930AReduced strong sinter hardening abilityHardening abilityManganeseCompressibility

The invention relates to water atomizing steel powder used for high-compressibility sintering hardening and a production method thereof. The water atomizing steel power comprises the following raw material components by weight percent: 1.0% of nickel, 1.0% of manganese, 2.0% of copper and the balance of iron, wherein water atomizing pure iron powder with compressibility more than 7g / cm<3> under the condition of 600Mpa is adopted as basal power, and is dispersed in a reduction annealing furnace together with 300 meshes of copper powder and Ni-50Mn alloy powder atomized by adopting inert gases,thus obtaining the water atomizing steel powder used for high-compressibility sintering hardening; and when powder metallurgy parts are produced, 0.7-0.8% of graphite powder of 500 meshes and 0.7-0.8%of lubricant stearic acid zinc powder are added according to weight percent, mixed for 1 hour in a V-shaped blender mixer, and sintered for 1 hours in a sintering furnace under the temperature of 112DEG C. The invention has the beneficial effects that the sintering hardening powder has high compressibility. Therefore, the strong sintering hardening capability of Mn is utilized effectively, and the reduction of the compressibility of the iron powder is avoided. The material cost is reduced by more than 20%, and simultaneously, the diffusion technology is more energy-saving compared with the vacuum annealing technology.

Owner:JIAXIN METAL POWDER

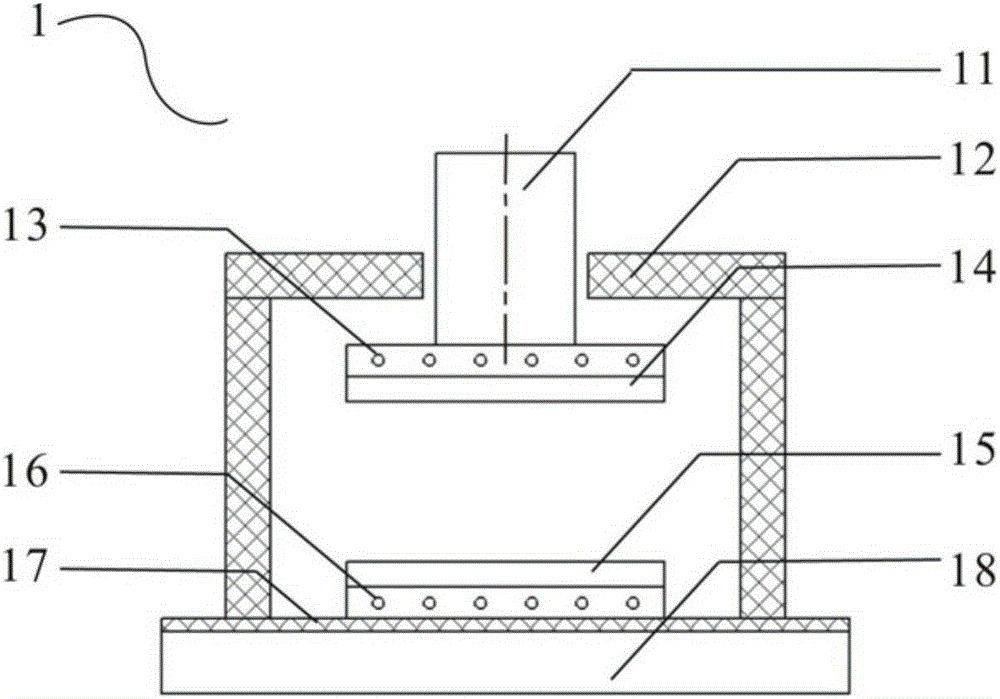

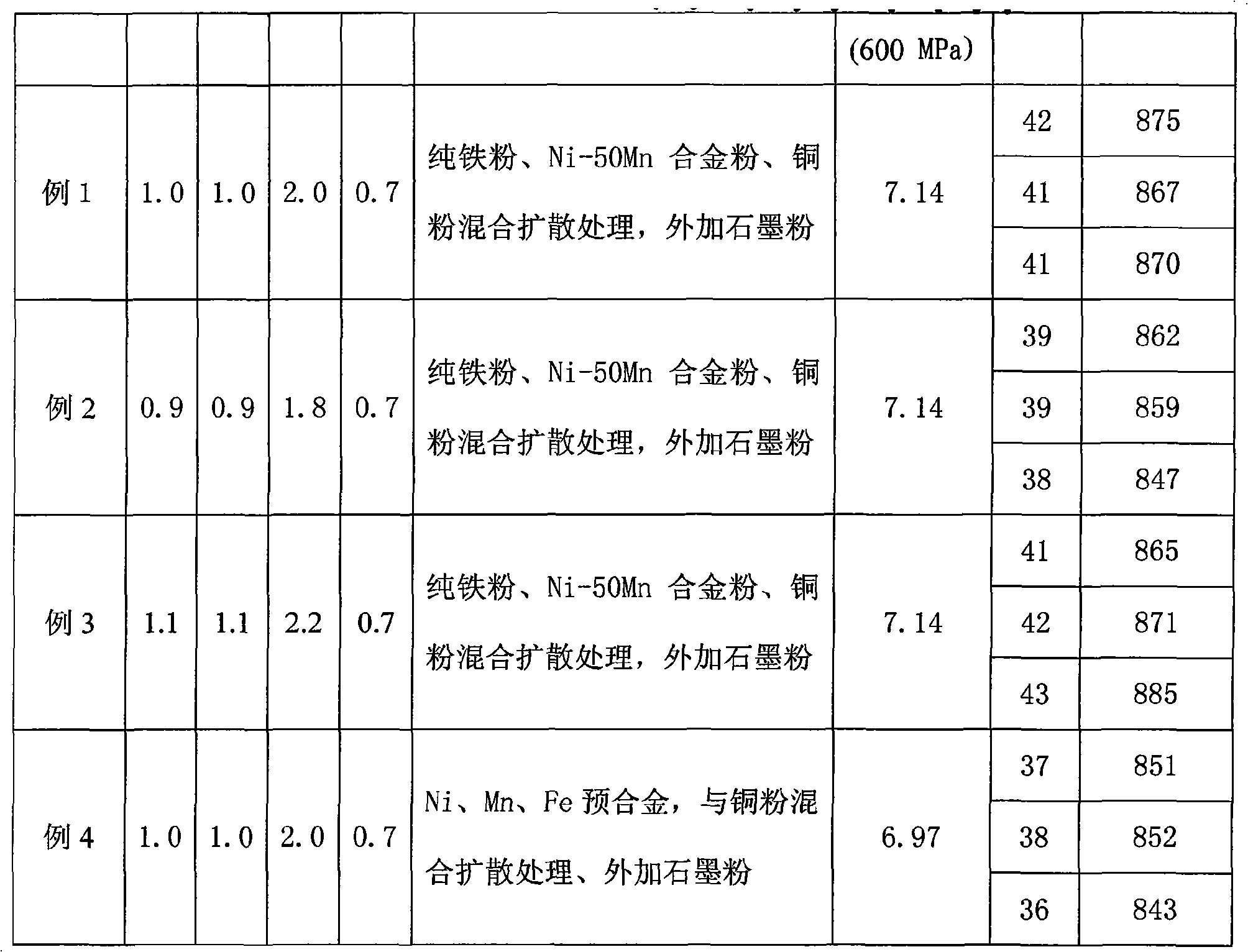

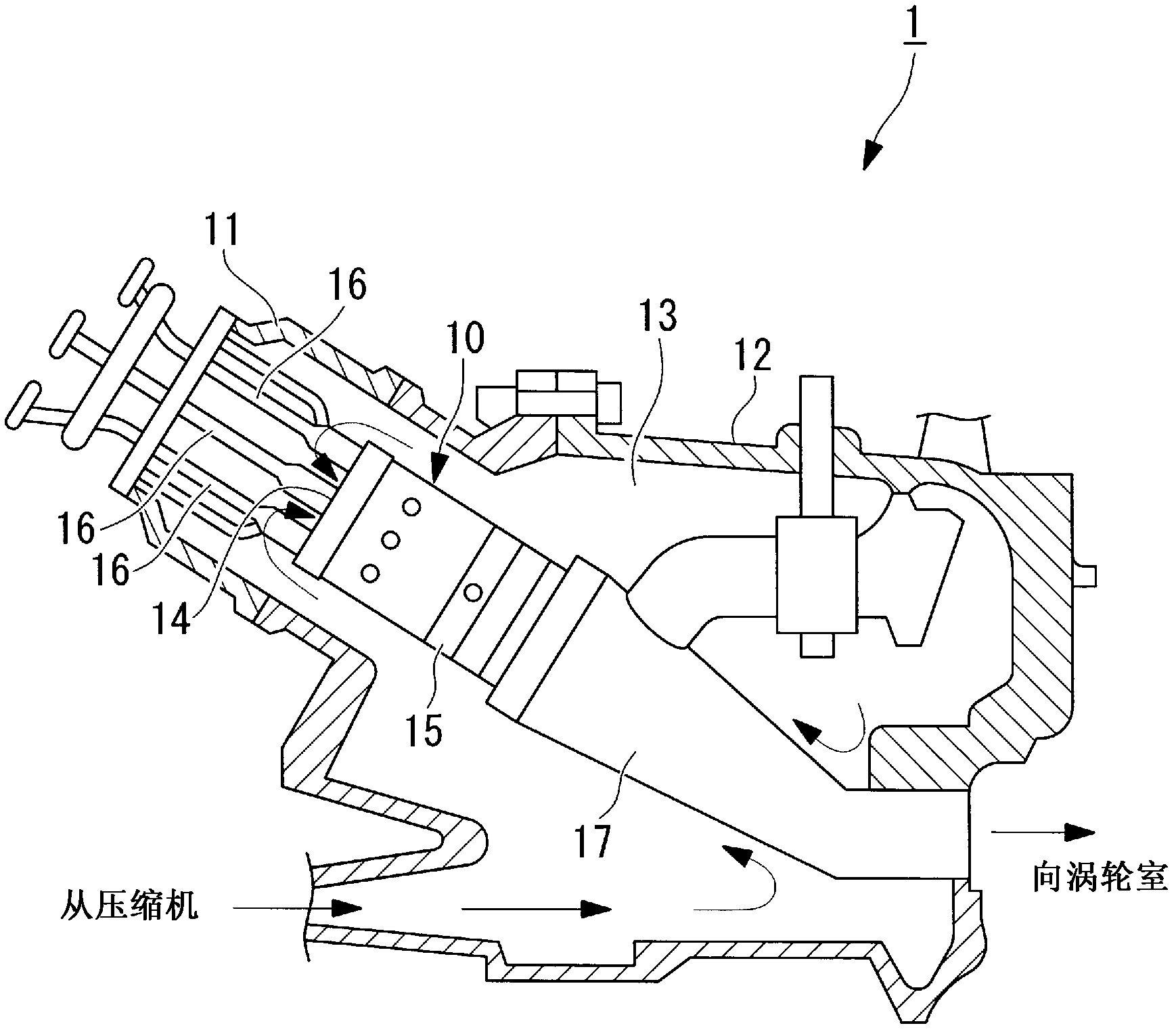

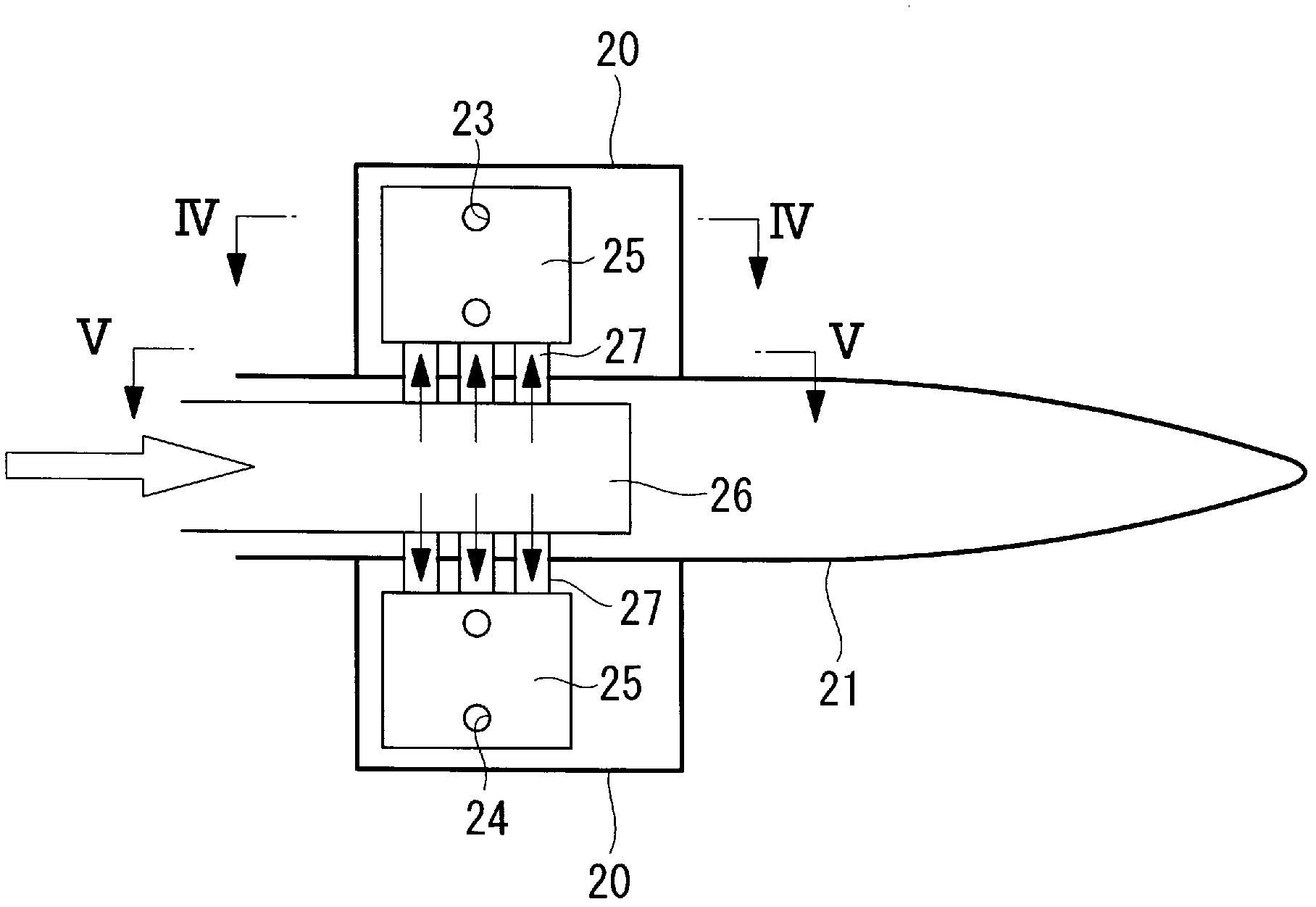

Combustion burner for gas turbine

ActiveCN102695919AAchieve homogenizationAchieving low NOxBurnersContinuous combustion chamberCombustorMixed gas

A combustion burner for a gas turbine, configured so that fuel is uniformly ejected from ejection holes to reduce the NOx generation of the gas turbine combustor. A combustion burner for a gas turbine, provided with: rotating vanes (20) for ejecting fuel from fuel ejection holes (23, 24) to air or a mixture gas of air and fuel, which flows from the upstream side, and applying a swirling force to the air or the mixture gas to create a swirling mixture gas flow; and a nozzle (21) which have the rotating vanes (20) disposed in a radiating manner on the outer peripheral surface thereof and which have formed therein a first fuel flow path (26) for guiding the fuel to the fuel ejection holes (23, 24). The rotating vanes (20) have provided therein cavities (25) which communicate with the fuel ejection holes (23, 24), and at least two second fuel flow paths (27) are provided between each cavity (25) and the first fuel flow path (26) so as to extend in the axial direction.

Owner:MITSUBISHI POWER LTD

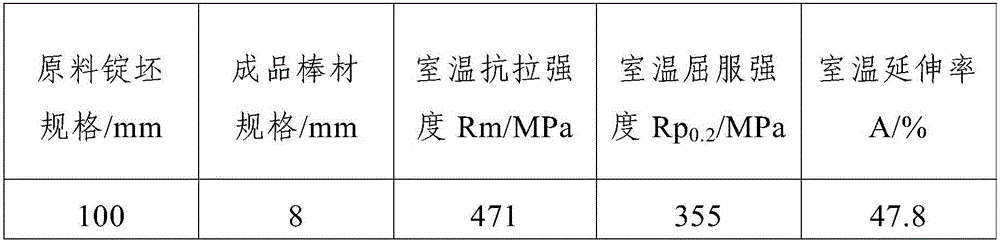

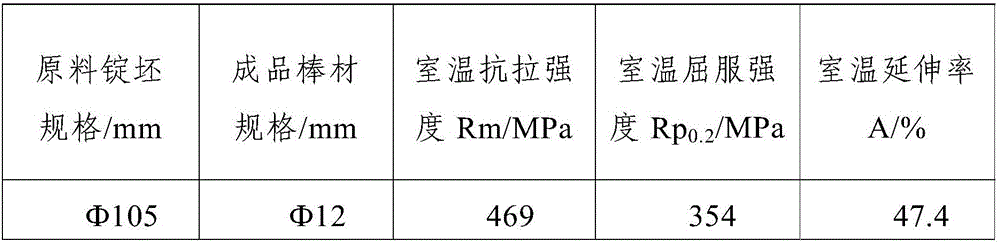

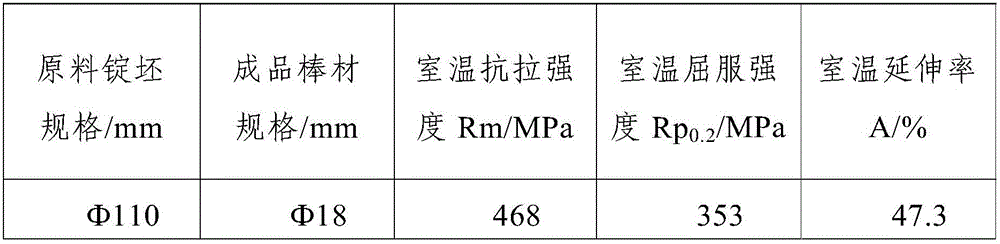

Processing method for small-size and high-strength niobium-hafnium alloy bar

The invention provides a processing method for a small-size and high-strength niobium-hafnium alloy bar. The processing method comprises the following steps that 1, a niobium-hafnium alloy ingot blank is sawn, and after being heated, the sawn niobium-hafnium alloy ingot blank is coated with an anti-oxidative protective lubricant; 2, the niobium-hafnium alloy ingot blank coated with the anti-oxidative protective lubricant is forged through upsetting and stretching to obtain a bar billet; 3, the bar billet is sequentially turned, ground and vacuum-annealed for the first time; 4, the vacuum-annealed bar billet is heated, the heated bar billet is coated with an anti-oxidative protective lubricant, and the bar billet coated with the anti-oxidative protective lubricant is formed through die forging to obtain a forging stock; 5, the forging stock is sequentially turned, ground and vacuum-annealed for the second time; 6, the vacuum-annealed forged stock is rolled with grooved rolls to obtain a small-size bar billet; and 7, the small-size bar billet is sequentially straightened, scalped, polished, pickled and annealed to obtain the small-size and high-strength niobium-hafnium alloy bar. The diameter of the section of the bar obtained according to the processing method is 8-20 mm, the room temperature tensile strength of the bar is up to above 465 MPa, the yield strength of the bar is up to above 350 MPa, the elongation of the bar is above 47%, and the grain structure of the bar is fine and uniform.

Owner:西安诺博尔稀贵金属材料股份有限公司

Homogeneous free machining steel and production process thereof

The invention discloses a homogeneous easy-cutting steel and a method for producing the same. The homogeneous easy-cutting steel comprises the following compositions (in percentage by weight): less than or equal to 0.12 percent of C, less than or equal to 0.07 percent of Si, 0.803 to 1.31 percent of Mn, less than or equal to 0.07 percent of P, 0.23 to 0.37 percent of S, less than or equal to 0.001 percent of Al and the balance being Fe and residual elements. The homogeneous easy-cutting steel has the advantages of heat processing, good cutting performance, etc. In the homogeneous easy-cutting steel produced by adopting the method, elements are uniformly distributed; sulfide impurities are uniformly distributed in a cambiform or an elongated cambiform, thereby removing adverse influence of the heat processing of FeS impurities and obviously improving the heat processing and easy-cutting performances of the produced homogeneous easy-cutting steel; and the part surface after being cut has better smoothness.

Owner:LIAONING KAIRUI SPECIAL STEEL

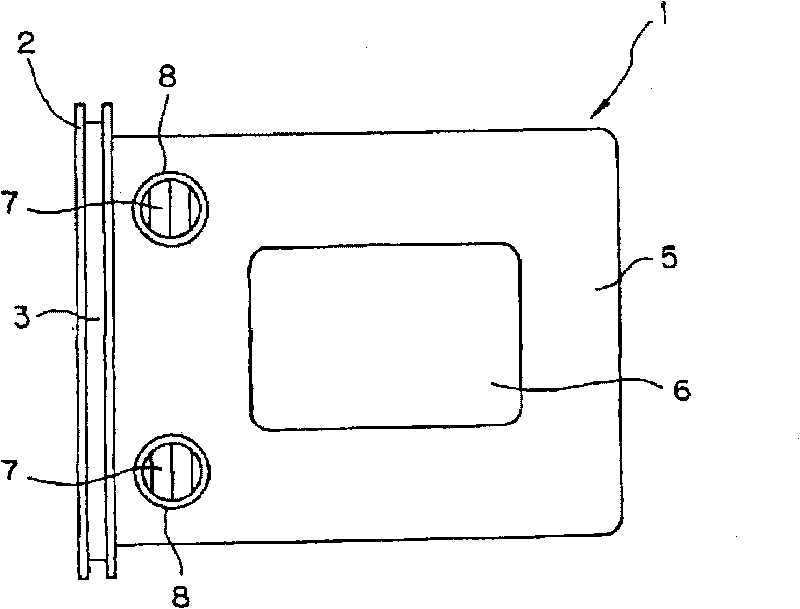

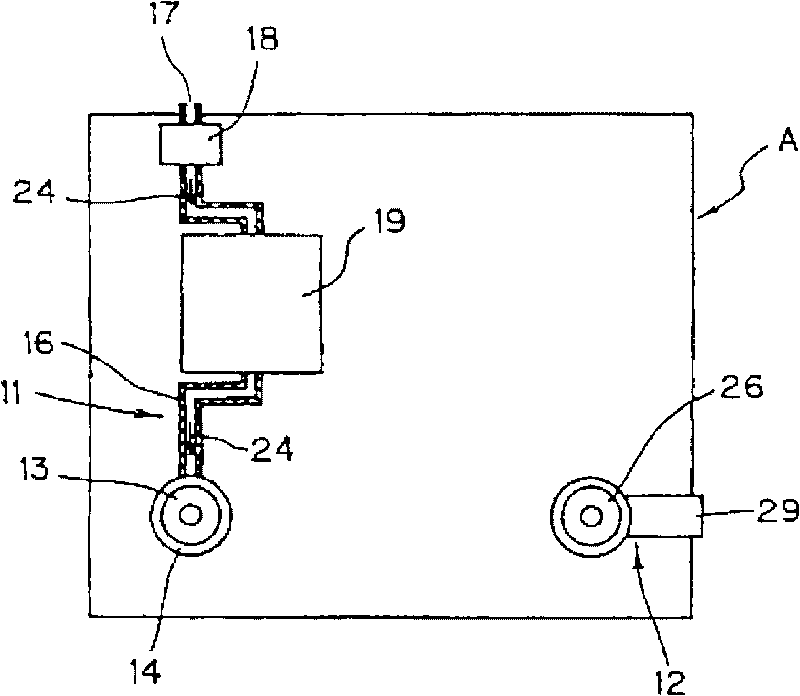

Device for charging dry air or nitrogen gas into semiconductor wafer storage container and wafer static charge removing apparatus utilizing the device

InactiveCN101730933AAvoid corrosionAvoid generatingSemiconductor/solid-state device manufacturingEngineeringProduct gas

Without the need to open the lid of semiconductor wafer storage container, there can be attained removal of any chemical gas present in the semiconductor wafer storage container and inhibition of acid generation therein. There is provided dry air or nitrogen gas charging device (A) connected and fixed to supply-side respiration orifice (8a) and discharge-side respiration orifice (8b) among multiple respiration orifices (8) disposed in bottom board (5) of semiconductor wafer storage container (1) accommodating semiconductor wafers (9), each of the respiration orifices (8a,8b) equipped with PTFE filter (7), which charging device (A) comprisesdry air / nitrogen gas supply part (11) for supplying dry air or nitrogen gas into the semiconductor wafer storage container (1) and used dry air / nitrogen gas discharge part (12) for discharging the dry air or nitrogen gas after, by means of the dry air or nitrogen gas fed into the semiconductor wafer storage container (1), not only removal of chemical gas within the semiconductor wafer storage container (1) but also inhibition of acid generation on the surface of semiconductor wafers by moisture removal.

Owner:KONDO IND +1

Nutrition-enriched recombinant translucent meat slices and preparation method thereof

The invention discloses nutrition-enriched recombinant translucent meat slices and a preparation method thereof. The translucent meat slices comprise the raw materials of meat stuffing, cane sugar, mixed powder of puffed peanut powder, puffed sesame powder and puffed tartary buckwheat flour or a pulp-powder mixture of mashed fruit and melon earthnut pulp and puffed tartary buckwheat flour, edible salt and food additives. The preparation method comprises the steps of mincing of meant, puffing, pulping, chopping, emulsifying, slicing of the quick-frozen meat and then curing, thus obtaining the recombinant translucent meat slices. The method is capable of preparing the translucent meat slices from the minced meat fully; tartary buckwheat, peanuts and semen sesami nigrum, or fruit and melon earthnut can be added into the meat slices as binding agent or seasoning materials, and the tartary buckwheat also covers meat taint, so that the prepared recombinant nutrition-enriched translucent meat slices are thicker in taste, and balanced and rich in nutrition; the preparation process is exquisite; and the types of products are varied to meet the requirements of different people. Besides, after being baked, the translucent meat slices are crisper, are more balanced in nutritional ingredient and do not generate harmful substances.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

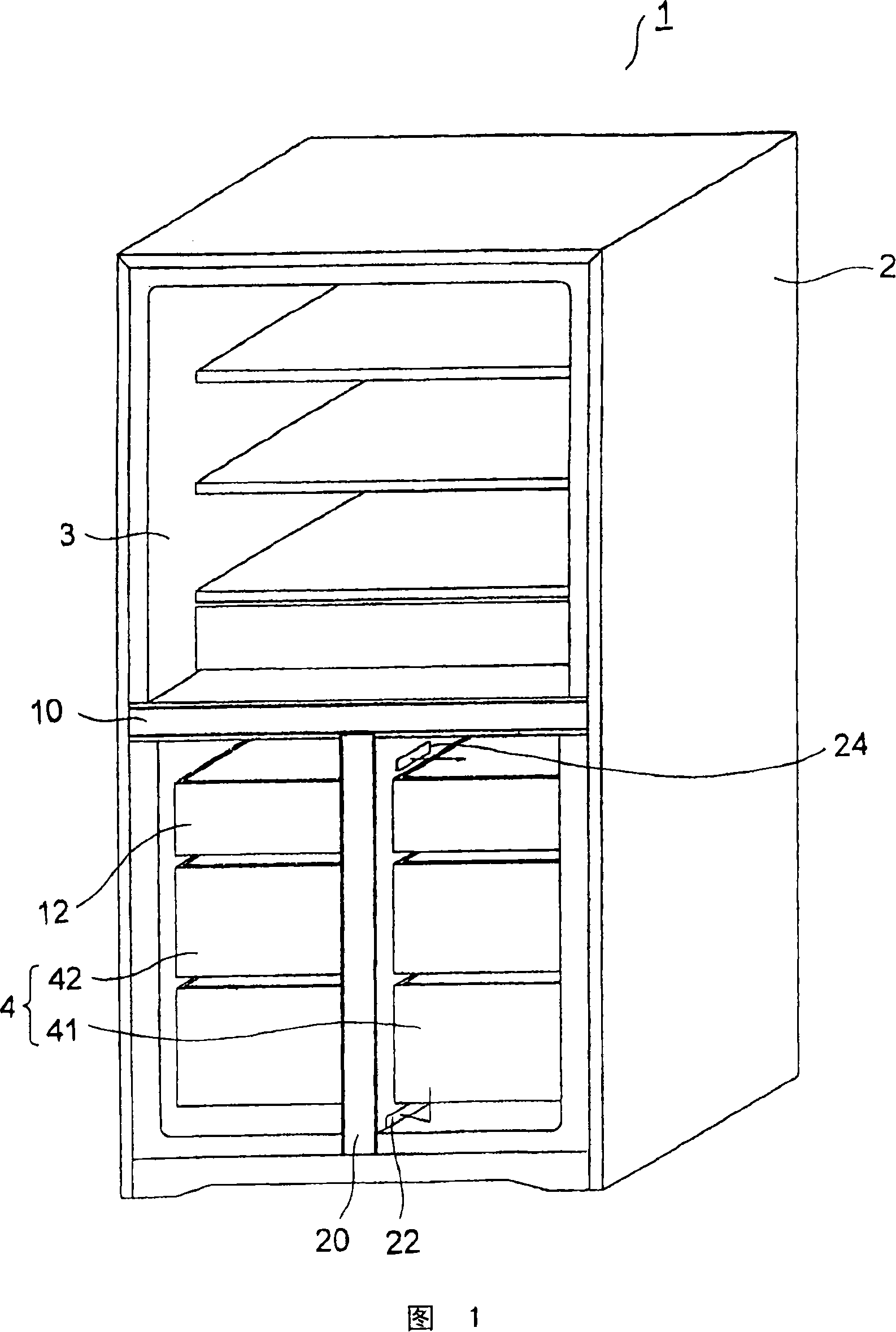

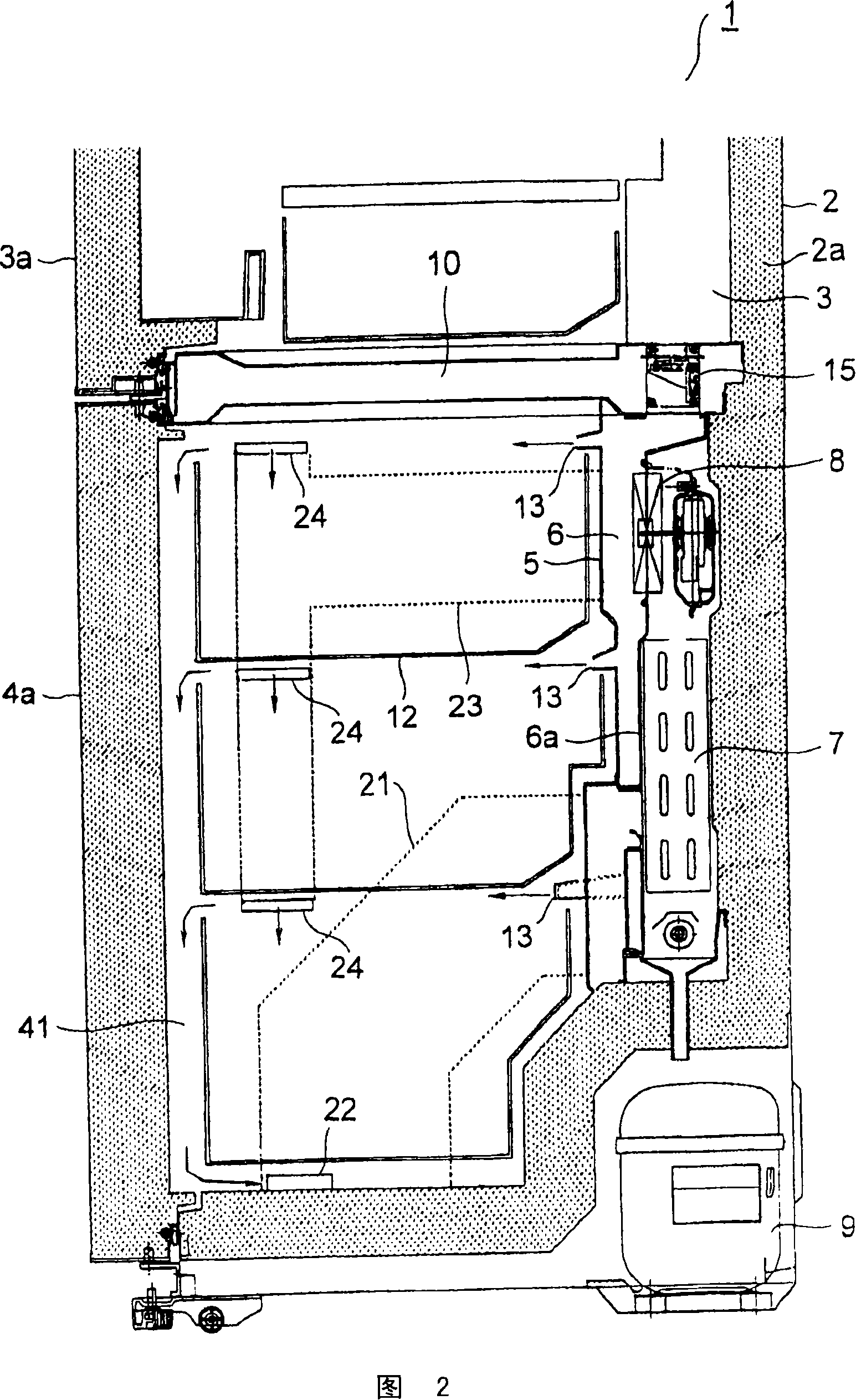

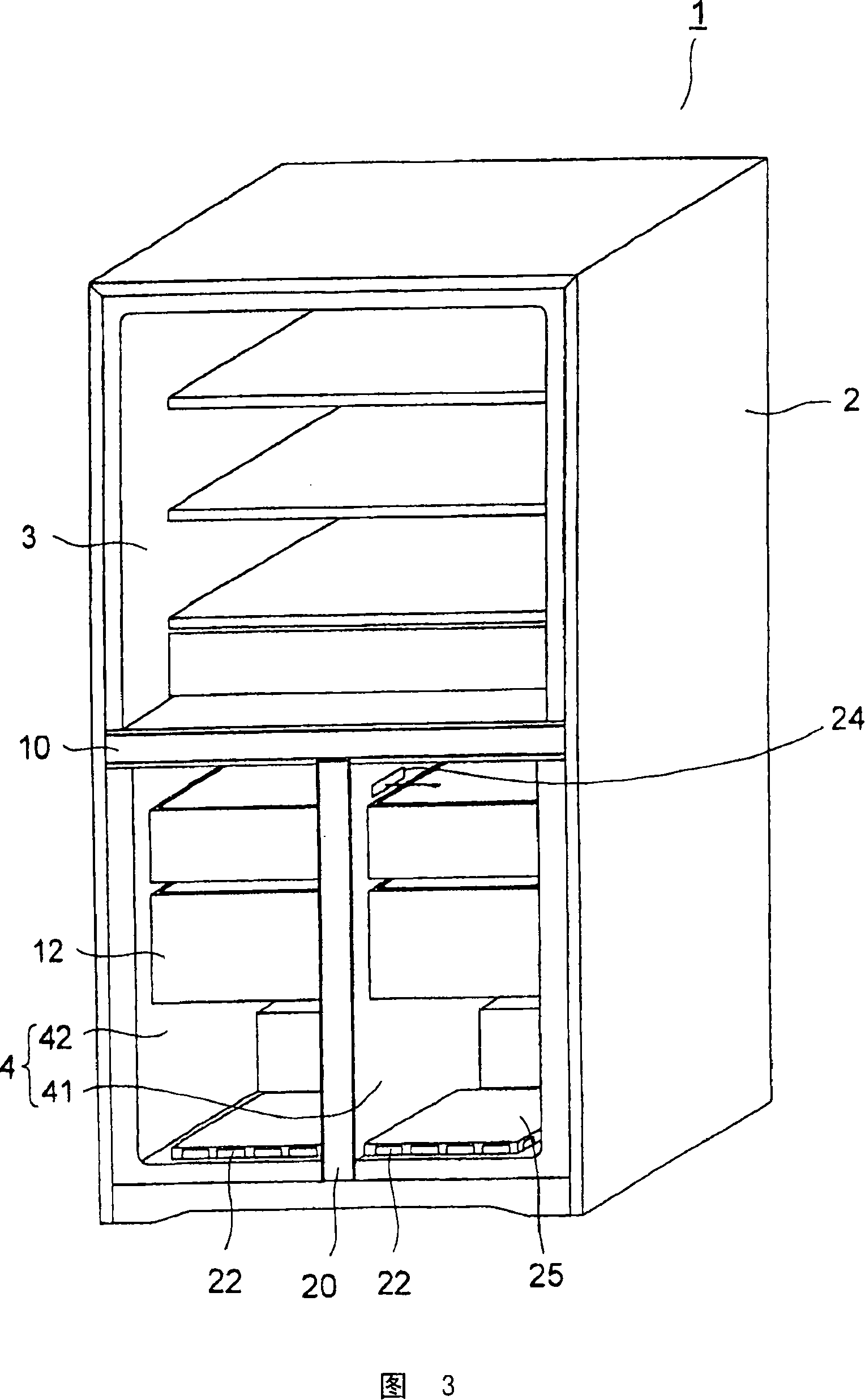

Refrigerator

InactiveCN101238338AReduce the storage volumeAchieve homogenizationLighting and heating apparatusCooling fluid circulationFreezing chamberChiller

In a refrigerator (1) having a freezer compartment (4) divided left and right by a vertical partition wall (20), there is a cooler (7) for generating cold air, which is arranged on the back of the freezer compartment (4) and discharged from the cooler. (7) The back discharge port (13) of the generated cold air, the first and second cold air ducts (21), (23) provided on the vertical partition wall (20), are formed by the openings provided on the first cold air duct And the cold air return port (22) that is arranged at the front portion of the freezer compartment (4), and the side discharge port ( 24), the cold air discharged from the back outlet (13) and the side outlet (22) into the freezer compartment (4) and circulated in the room flows into the first cold air duct (21) through the cold air return port (22), and returns to the cooler (17).

Owner:SHARP KK

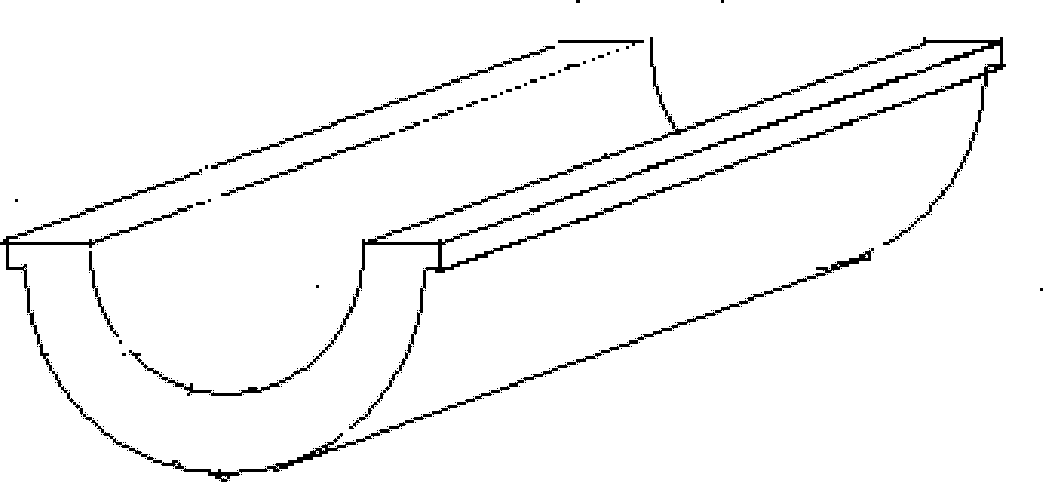

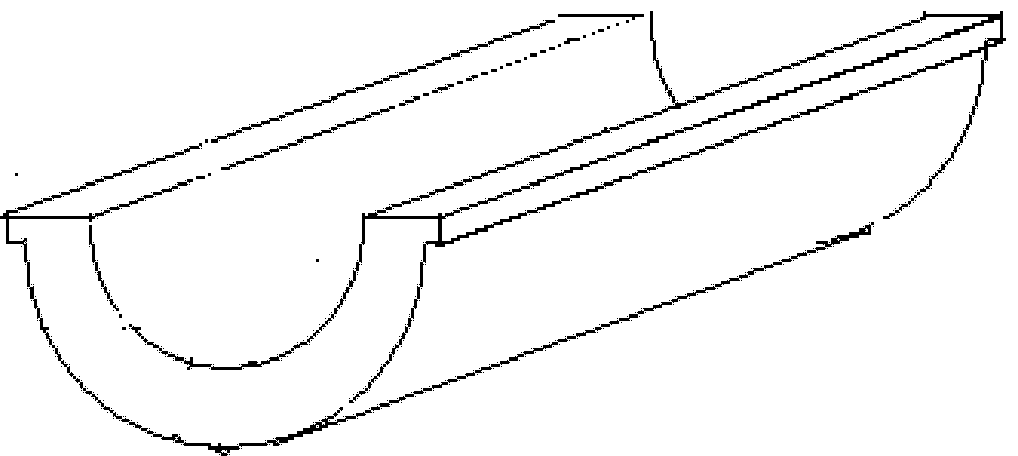

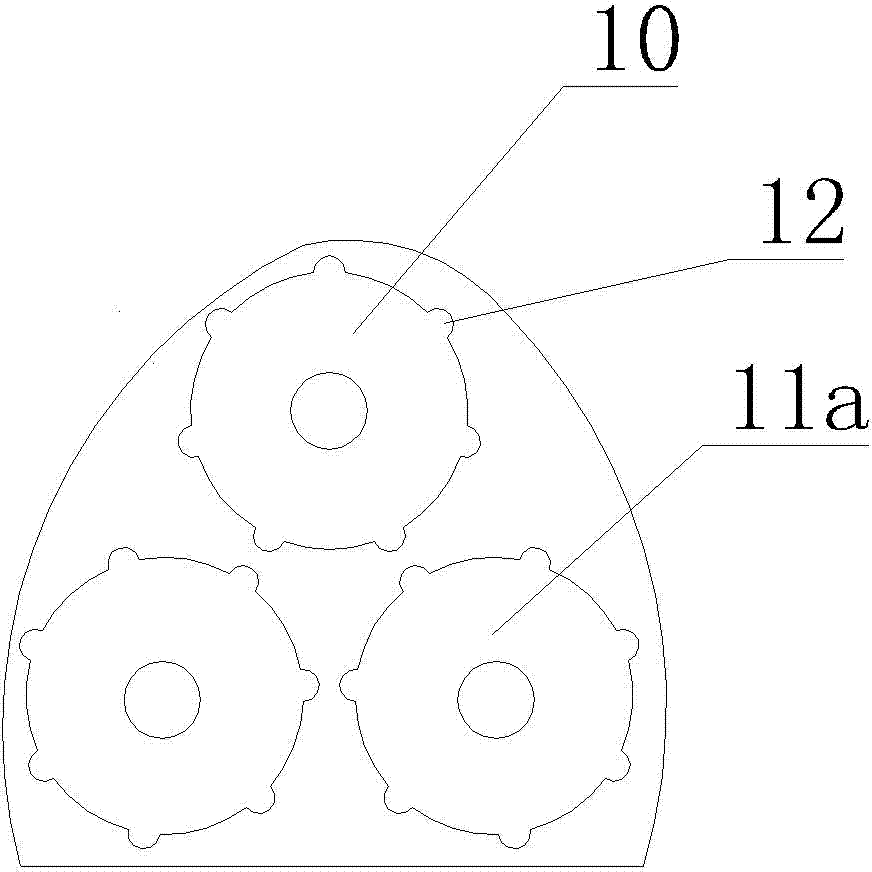

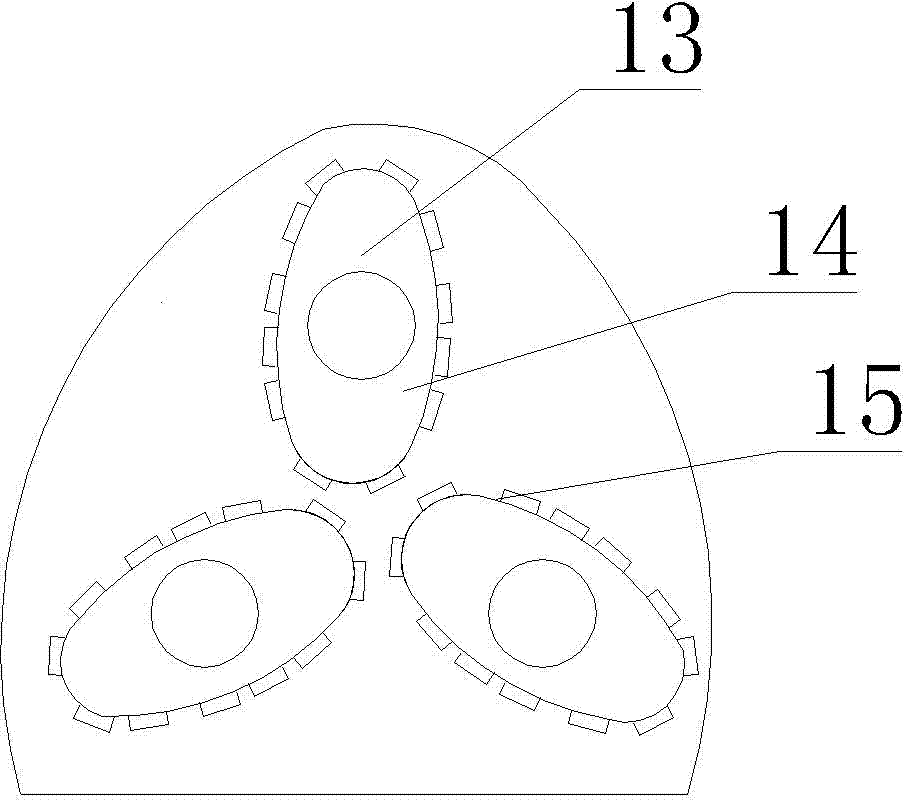

Three-screw extruder

ActiveCN104494103AImprove the mixing effectIncrease the number of stirringIsoetes triquetraEngineering

The invention provides a three-screw extruder which has a simple structure, has more shearing zones for shearing, mixing, compounding, exhausting, reacting and self-cleaning compared with a single screw extruder and the double-screw extruder, and is particularly suitable for uniformly dispersing and compounding high-sensitivity and high-viscosity materials and materials which contain moisture and volatile components and are required to be degassed. The three-screw extruder comprises an outer barrel and is characterized in that the outer barrel is a semi-elliptical, a feeding hole is formed in the upper end of the front side of the outer barrel, a discharge hole is formed in the lower end of the rear side of the outer barrel, a driving end is connected at one end, which is provided with the feeding hole, of the outer barrel, an output end is connected at one end, provided with the discharge hole, of the outer barrel, three screws which rotate in the same direction and are distributed in an equilateral triangle manner are arranged in the outer barrel, and a first mixing zone, a second mixing zone and a third mixing zone are sequentially arranged on the screw rod in an axial direction of the screw rod respectively.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

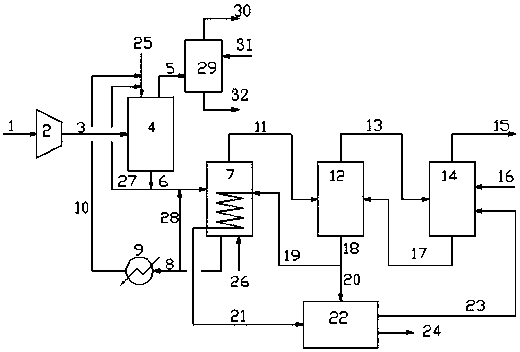

Treating method and device for carbon dioxide and hydrogen sulfide containing gas

ActiveCN108722148AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a treating method and device for carbon dioxide and hydrogen sulfide containing gas. The device comprises a hydration reactor, a hydrate decomposing device, an exhaust gas treating device, a first-stage absorbing reactor, a second-stage absorbing reactor and a product tank. The invention further provides a method for treating the carbon dioxide and hydrogen sulfide containing gas through the abovementioned device. With the adoption of the device and the method, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the method has the advantages that the carbon dioxide and hydrogen sulfide containing gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

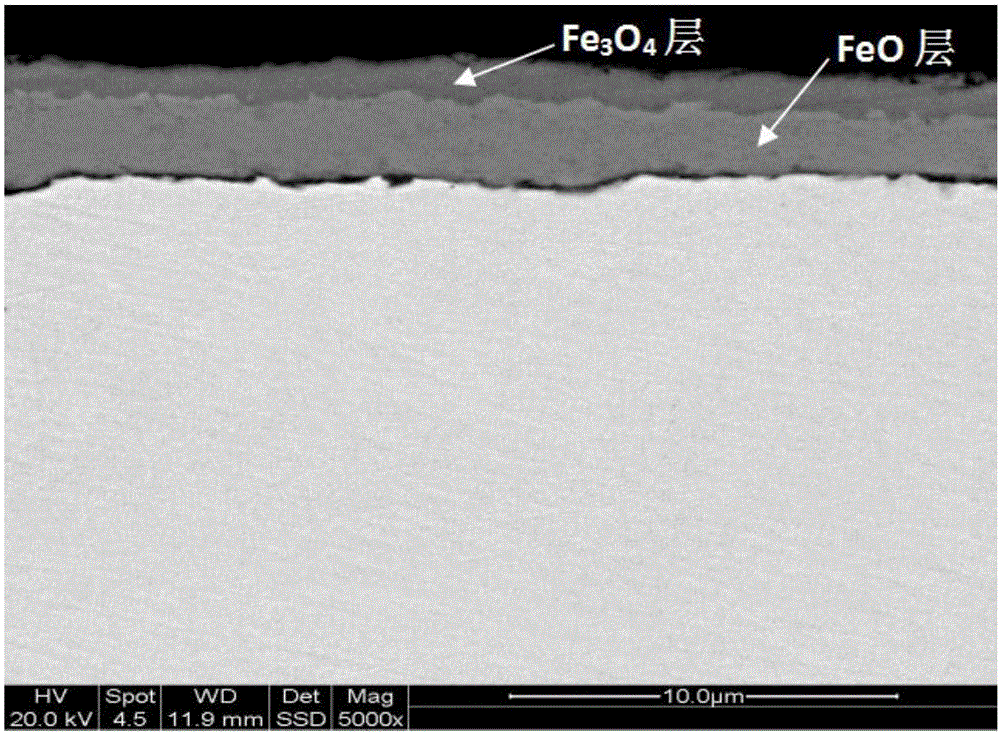

Manufacturing method of thin slab casting and rolling high-surface-quality medium-high carbon steel

ActiveCN106544485AAchieve homogenizationReduce scaleMetal rolling arrangementsScale structureThin slab

The invention discloses a manufacturing method of thin slab casting and rolling high-surface-quality medium-high carbon steel. The manufacturing method comprises the following steps that (1) smelting and continuous casting are carried out to obtain a blank, and the thickness of the casting blank ranges from 50 mm to 70 mm; (2) the continuous casting blank is heated in a heating furnace, the temperature of the casting blank fed in the furnace ranges from 812 DEG C to 1053 DEG C, the temperature of the casting blank discharged out of the furnace ranges from 1107 DEG C to 1182 DEG C, the time of the casting blank in the furnace ranges from 26 min to 41 min, the volume fraction of oxygen in a hearth is controlled to range from 1.1% to 4.8%, and high-pressure water descaling is carried out before the casting blank is fed in the heating furnace and after the casting blank is discharged out of the heating furnace; (3) at least six passes of finish rolling are carried out, in the finish rolling process, the rolling reduction rate of a first rack and the rolling reduction rate of a second rack are controlled to range from 50% to 60%, high-pressure water descaling is carried out between the finish rolling first rack and the finish rolling second rack and between the second rack and a third rack, and the finish rolling temperature of finish rolling ranges from 880 DEG C to 910 DEG C; and (4) cooling and rolling are carried out to obtain a finished steel roll. According to the thin slab casting and rolling high-surface-quality medium-high carbon steel produced through the method, the thickness of oxide scale is only 3.9 micrometers to 6.9 micrometers, the volume fraction of FeO in the oxide scale structure reaches 51%-72%, the acid pickling difficulty is greatly reduced, and the product surface quality is improved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com