Combustion burner for gas turbine

A gas turbine and combustion head technology, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve problems such as uneven fuel injection, and achieve the effect of low NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

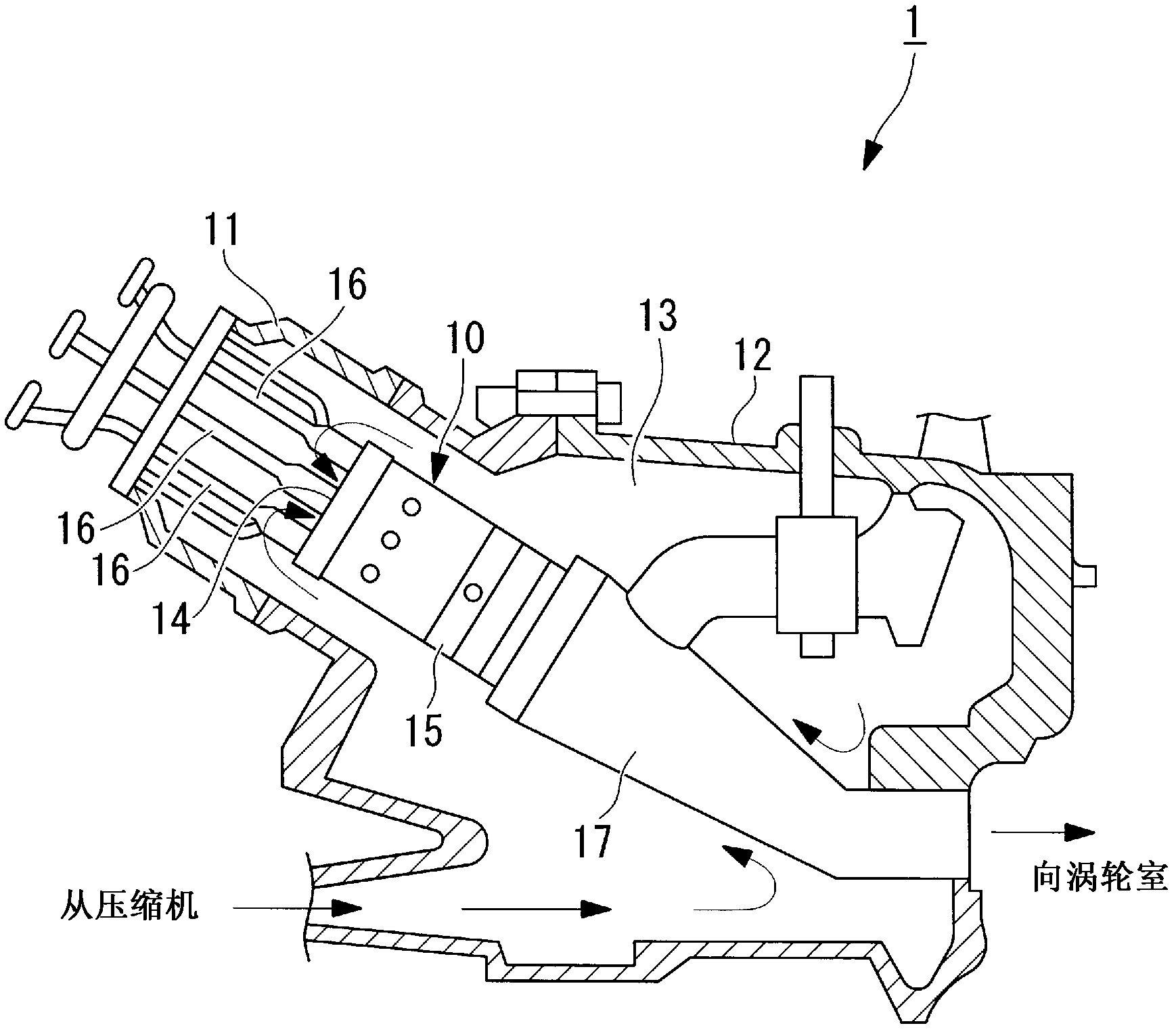

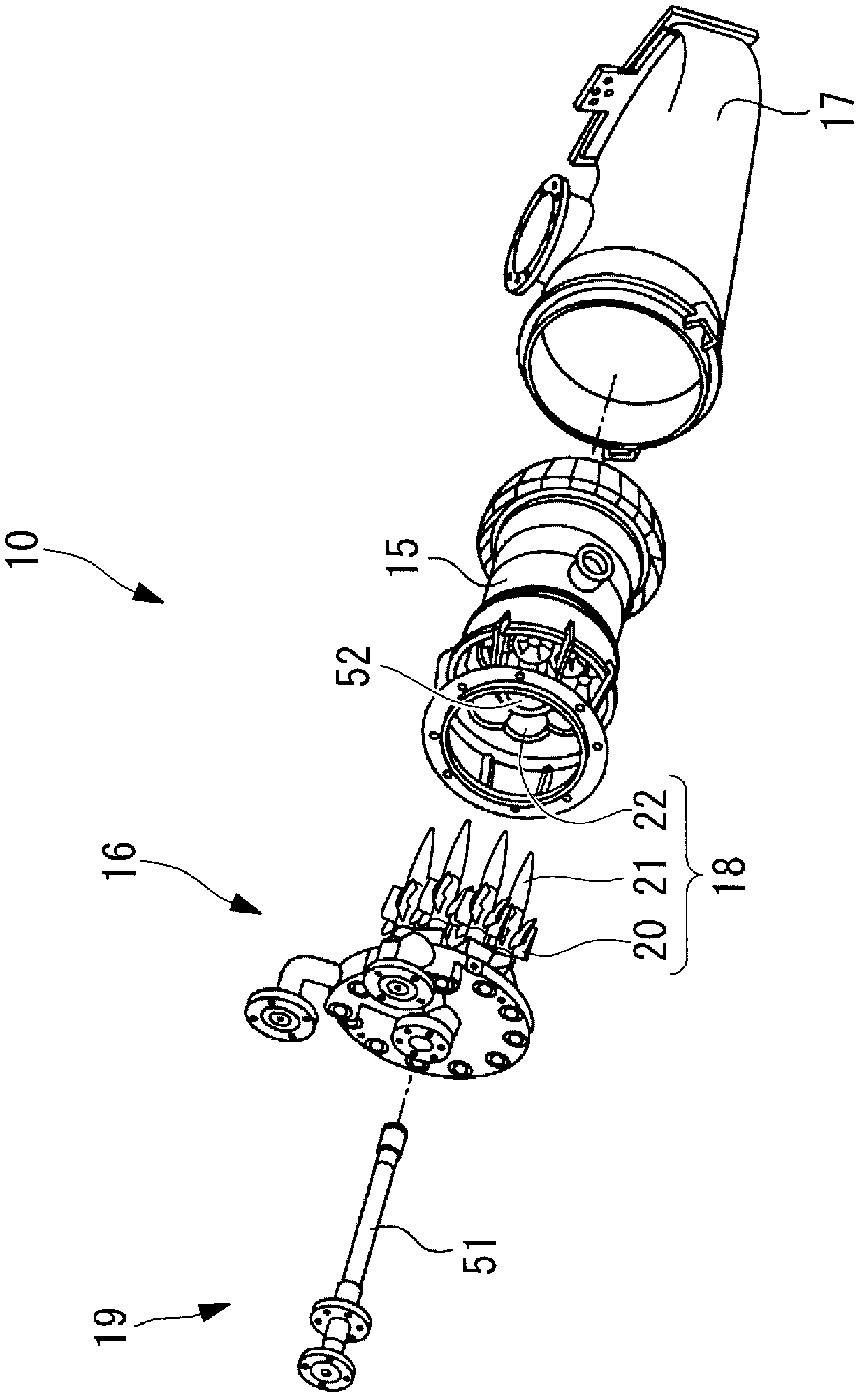

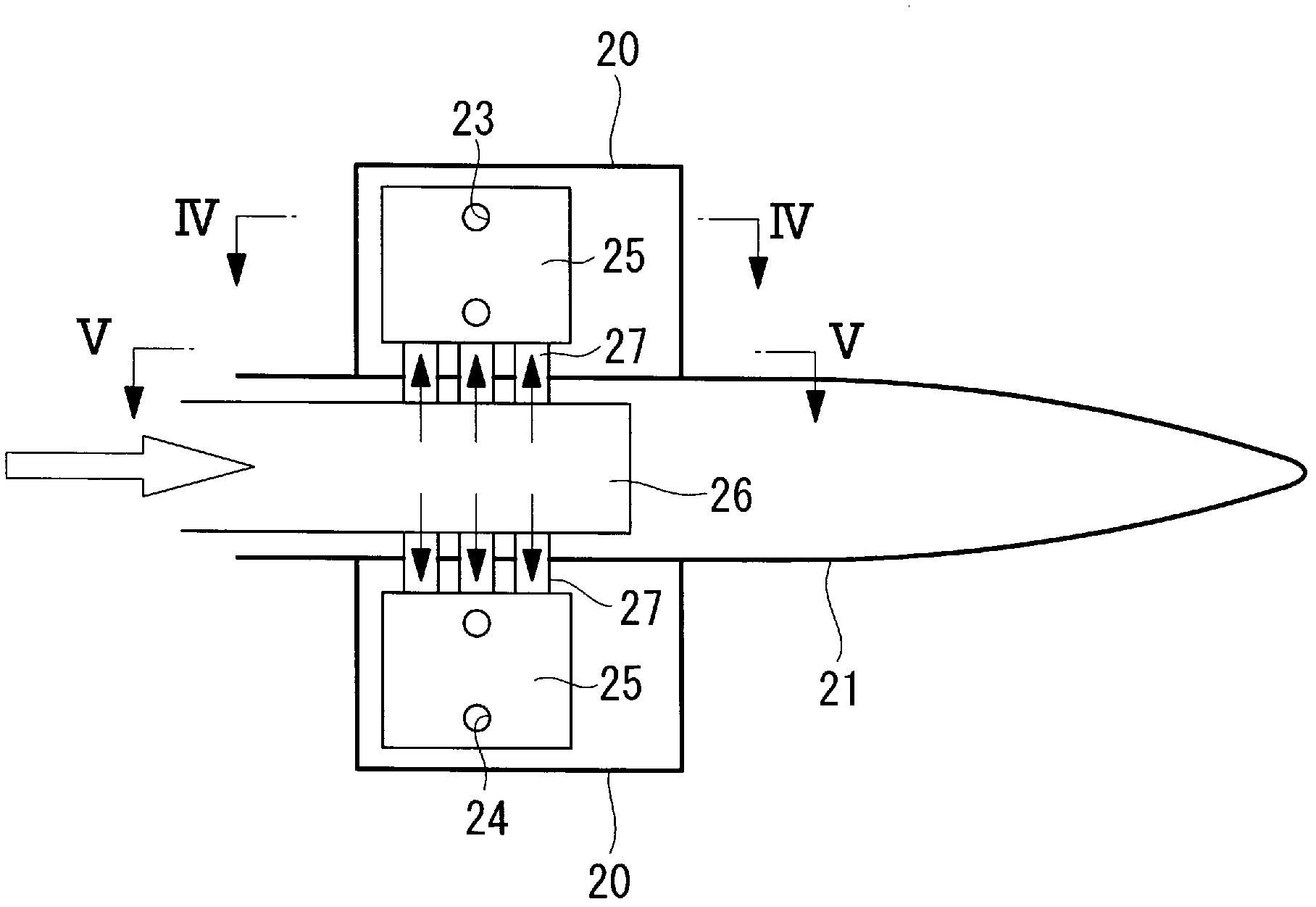

[0034] Below, refer to Figure 1 to Figure 5 A combustion head for a gas turbine according to a first embodiment of the present invention will be described. figure 1 is a schematic configuration diagram showing a gas turbine combustor provided with a combustion head for a gas turbine according to the present invention, figure 2 yes means figure 1 The diagram of the gas turbine combustor shown is an exploded perspective view of the fuel nozzle, inner tube and transition tube, image 3 It is an enlarged cross-sectional view showing a main part of the combustion head for a gas turbine according to the present embodiment, Figure 4 yes image 3 Sectional view of IV-IV direction, Figure 5 yes image 3 V-V cross-sectional view.

[0035] have figure 1 and figure 2 Gas turbine 1 (refer to figure 1 ) includes a compressor (not shown) and a turbine (not shown) in addition to the combustor 10 . A gas turbine often has a plurality of combustors 10 , mixes air (compressed air)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com