Patents

Literature

55results about How to "Thick enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

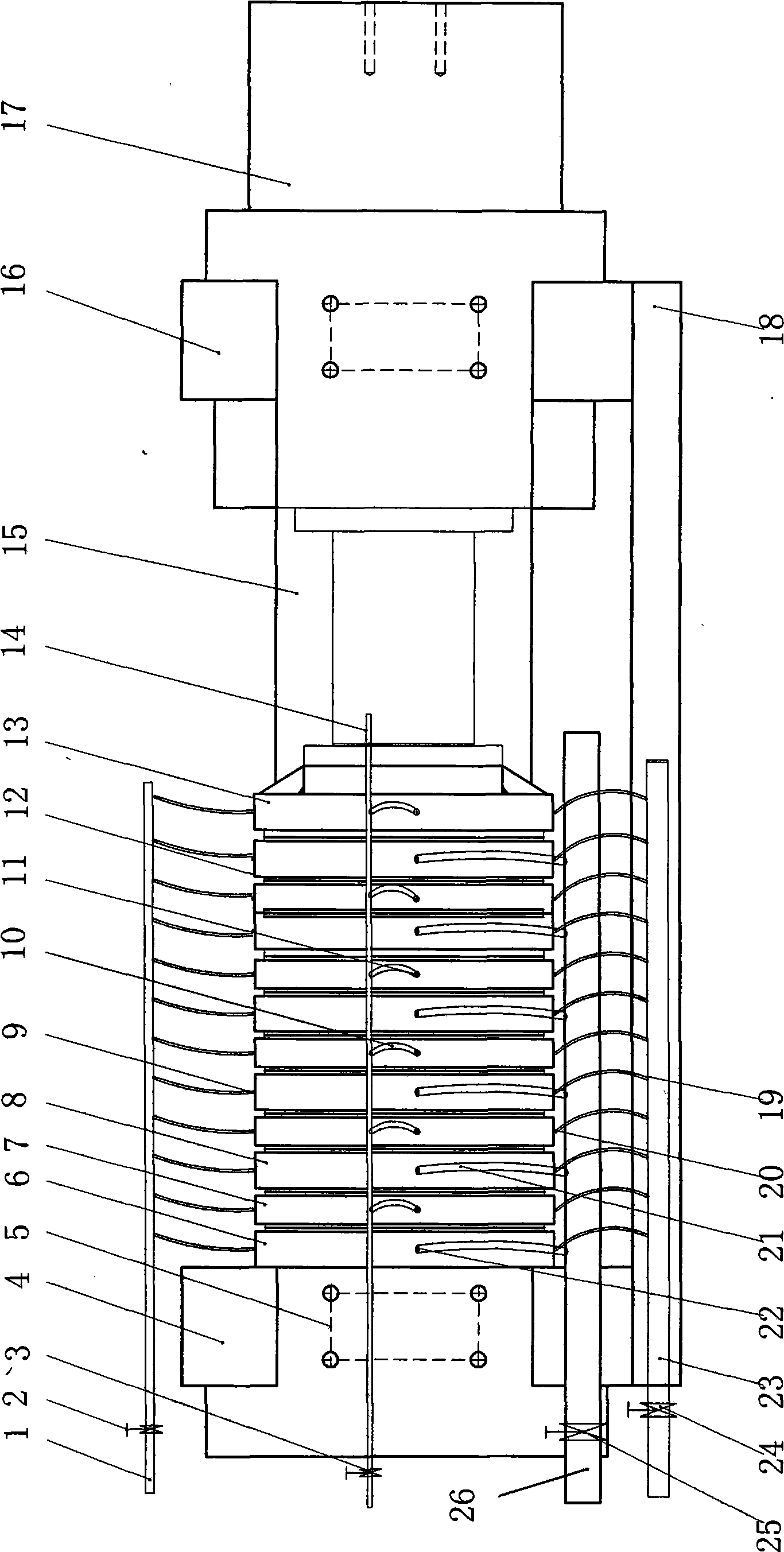

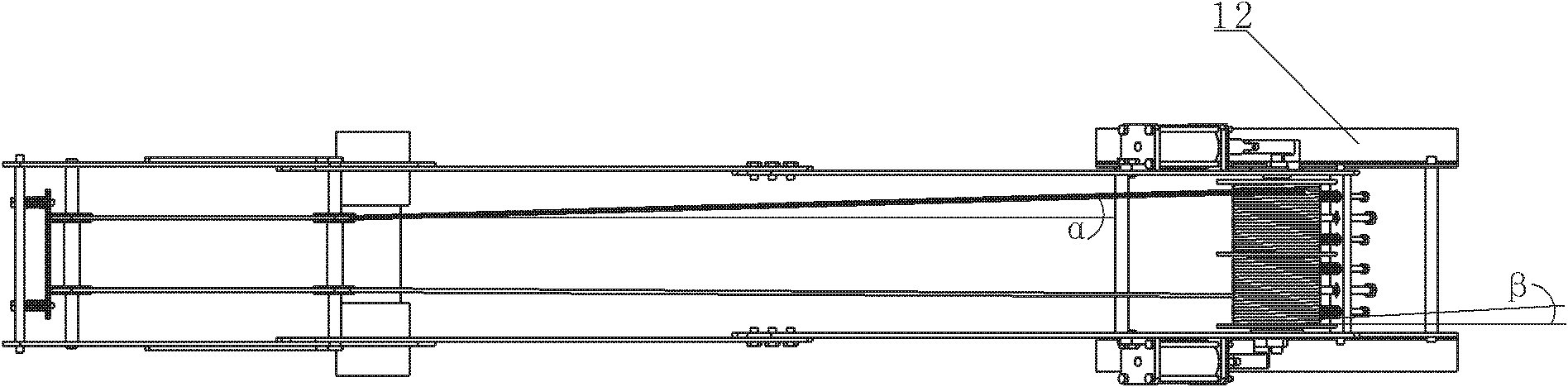

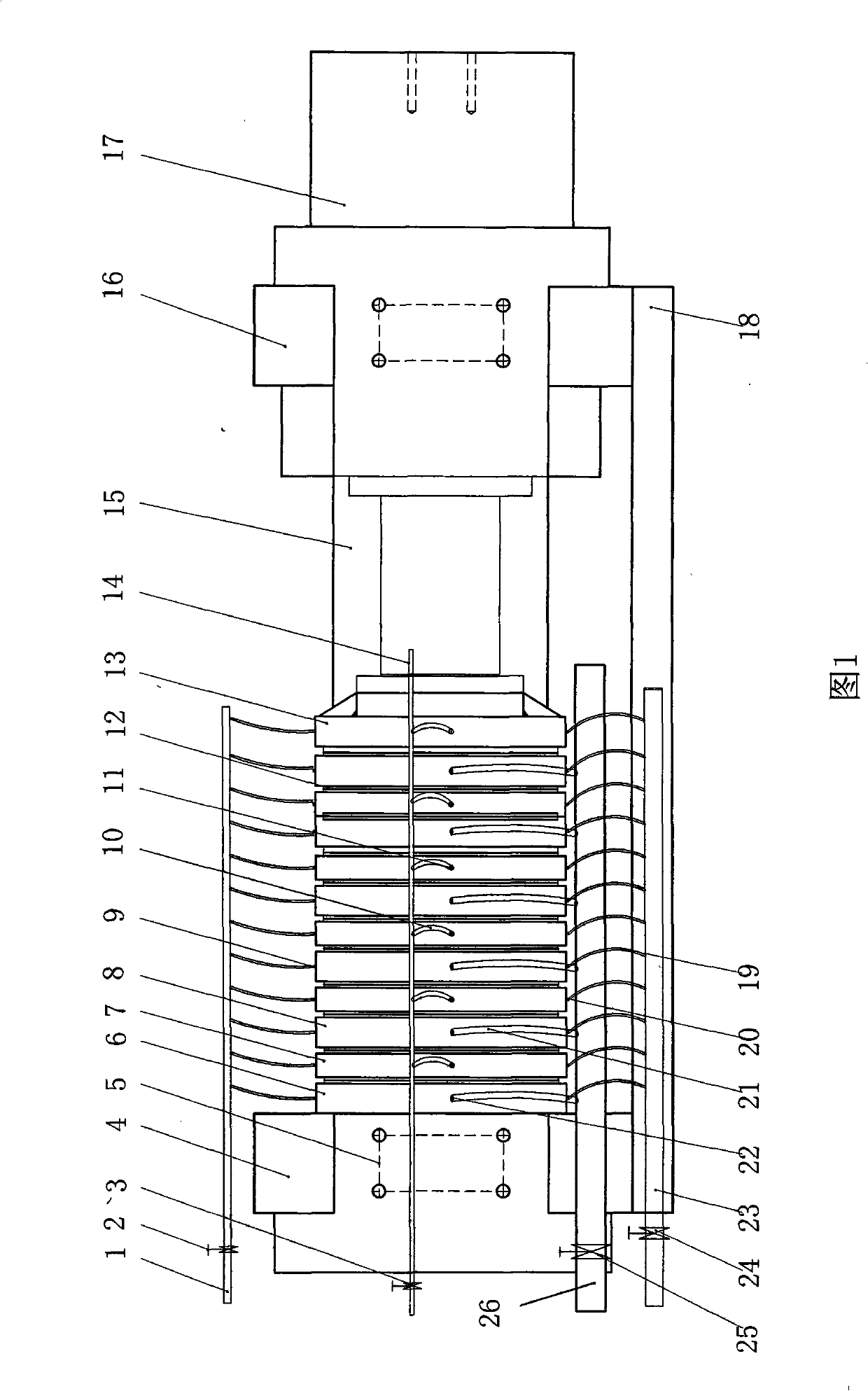

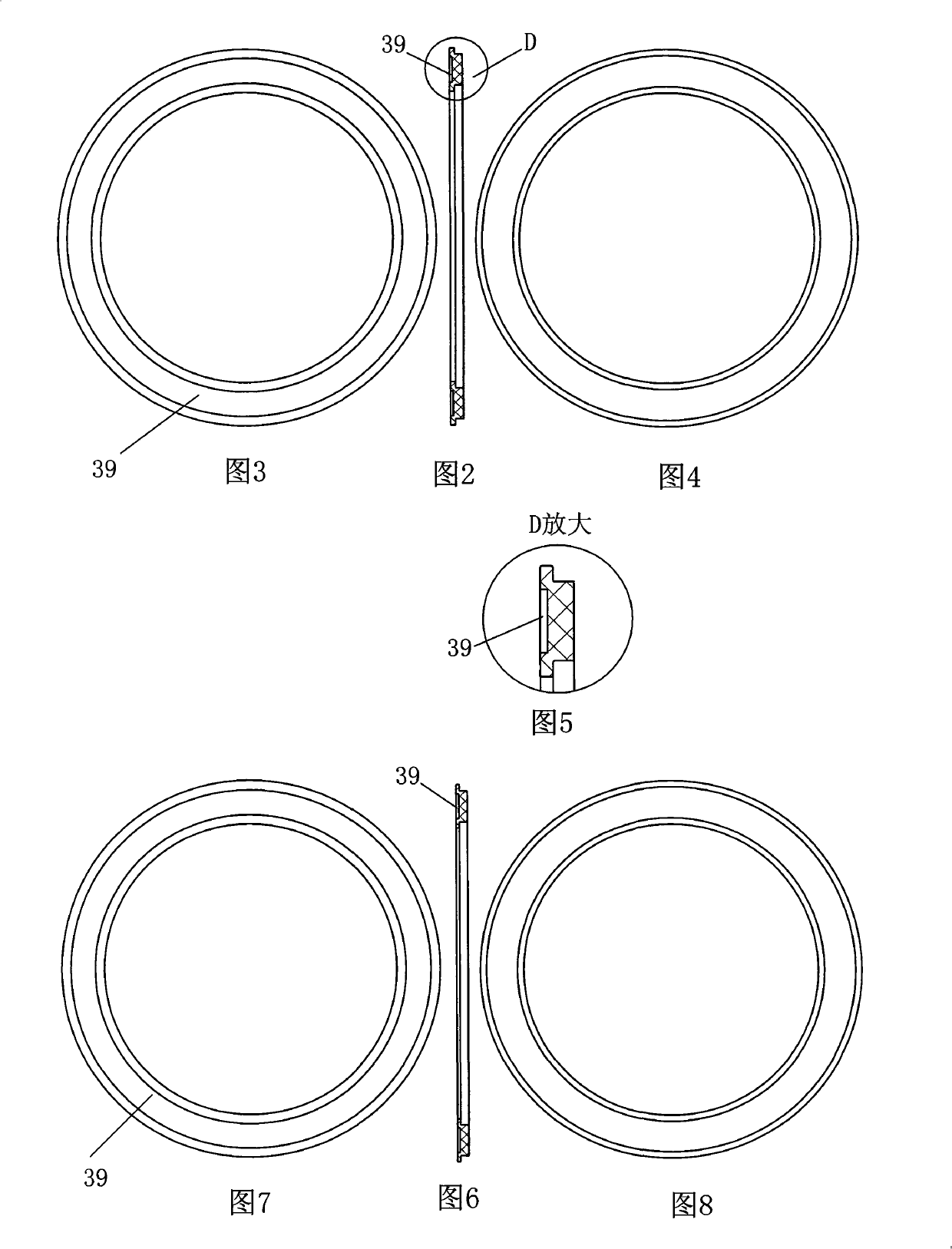

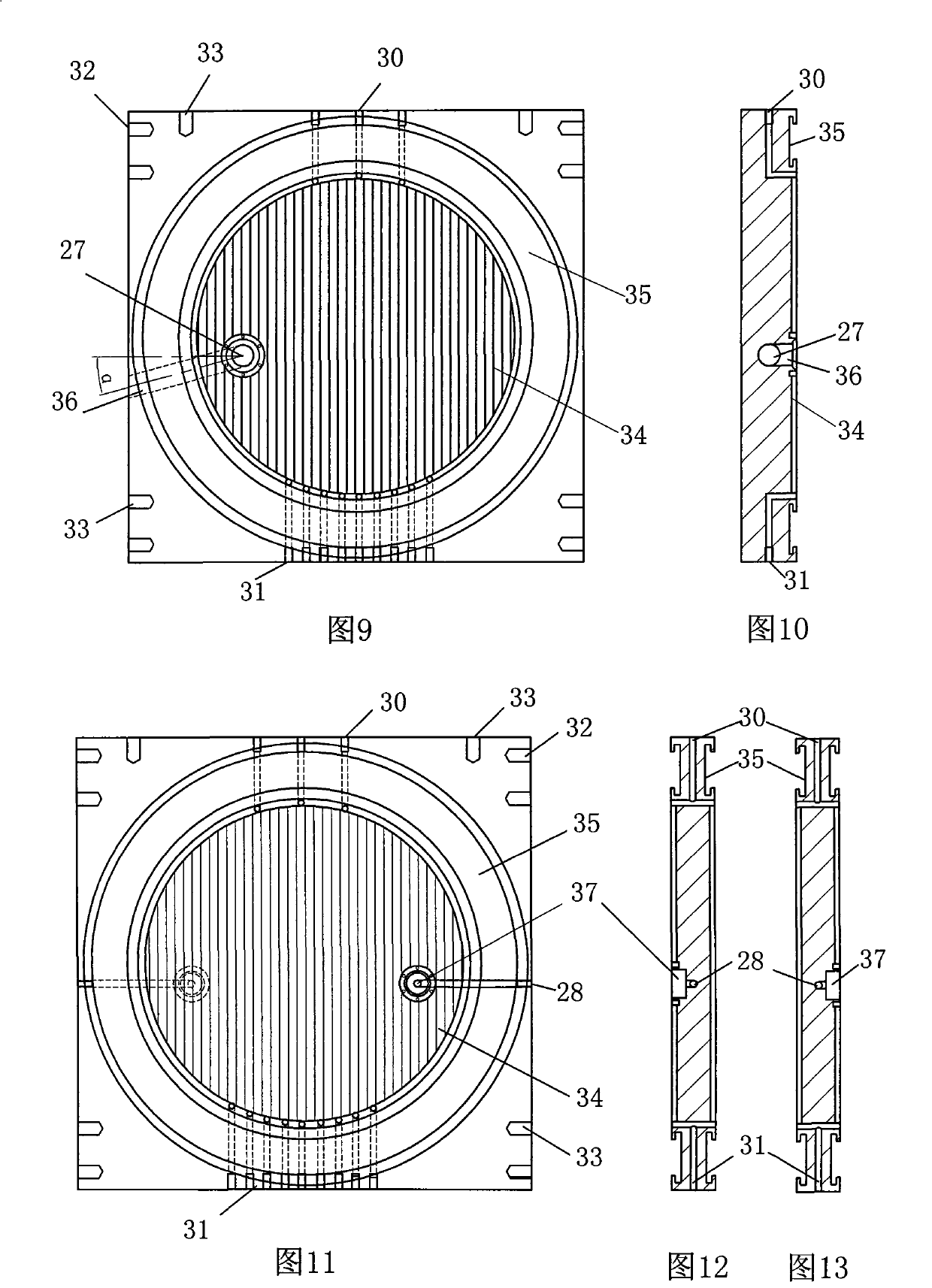

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

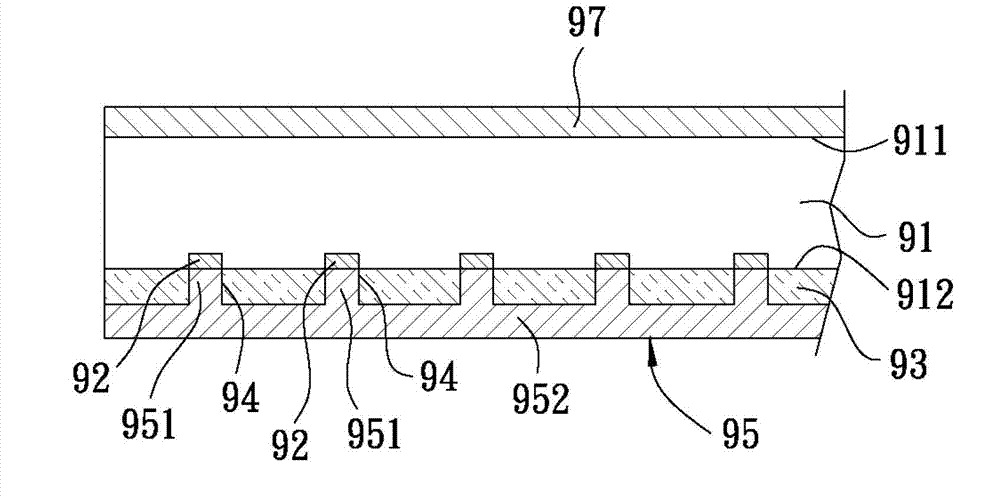

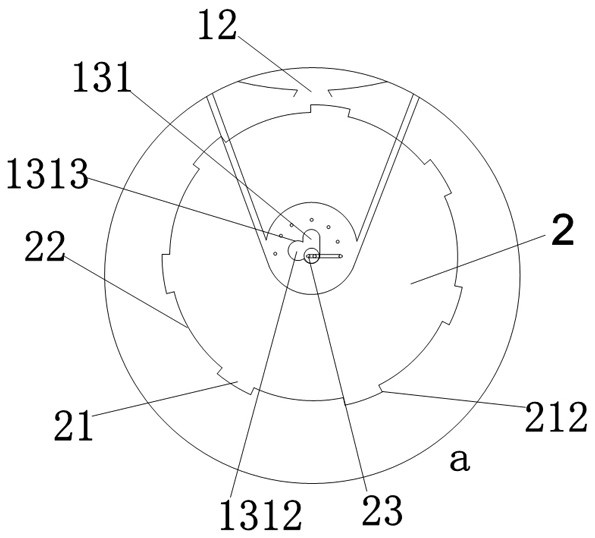

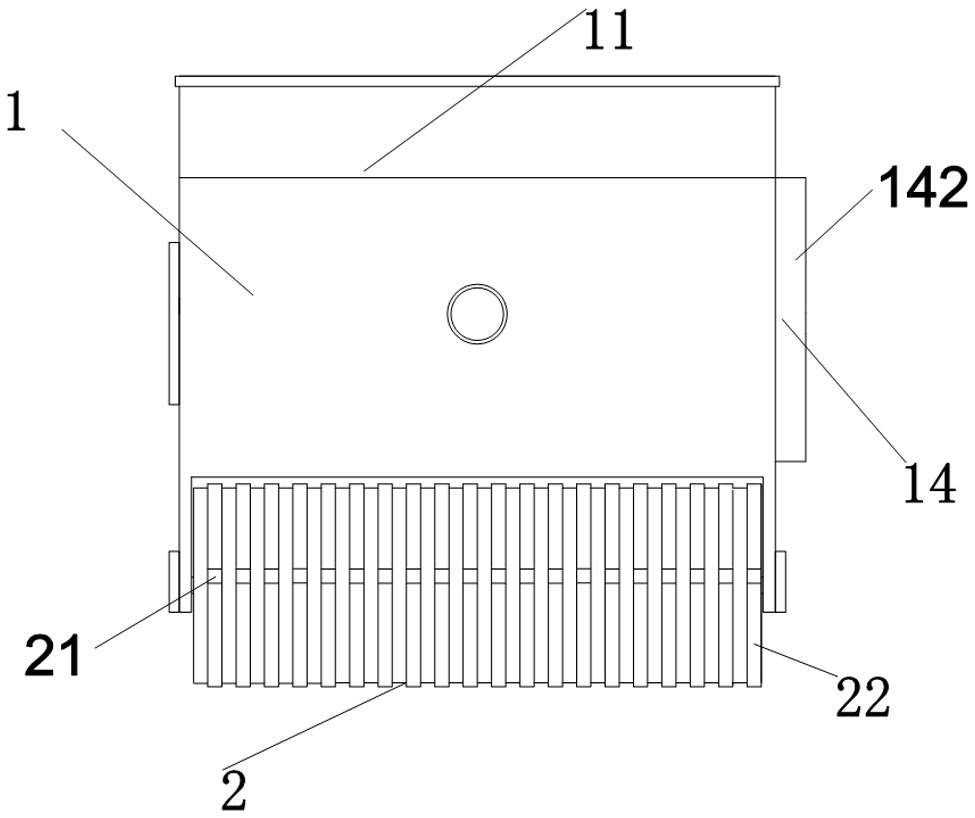

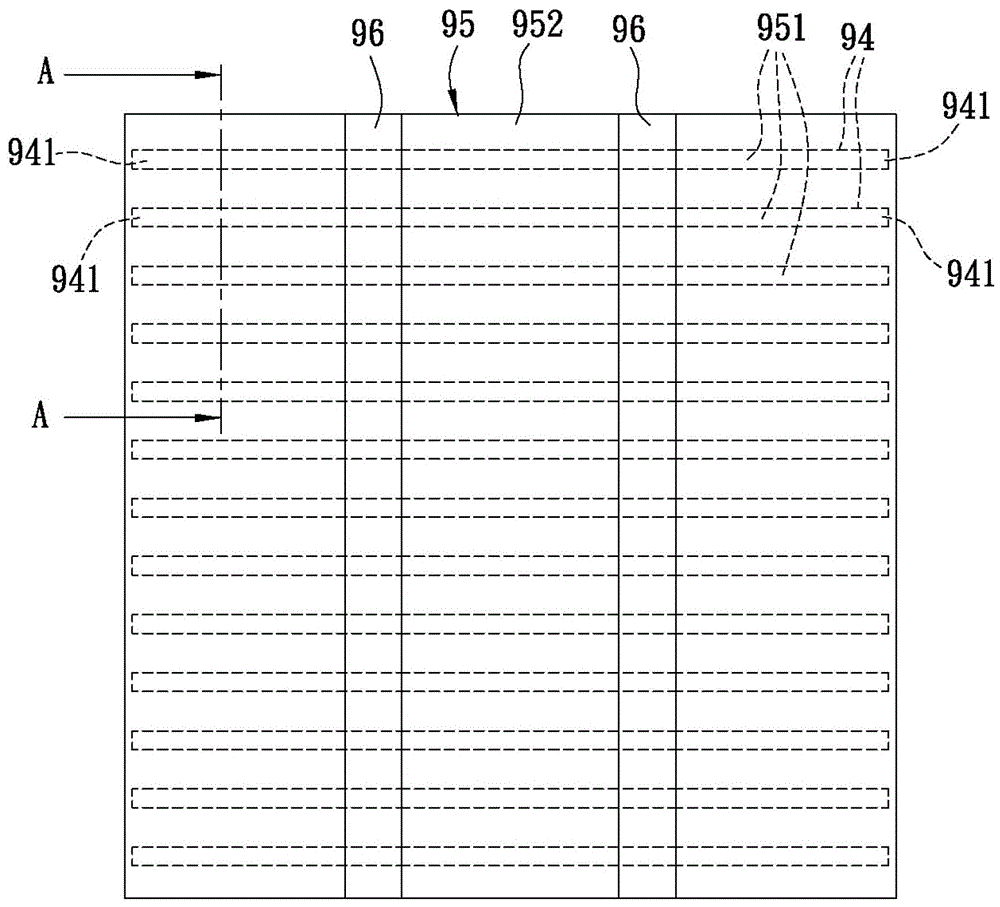

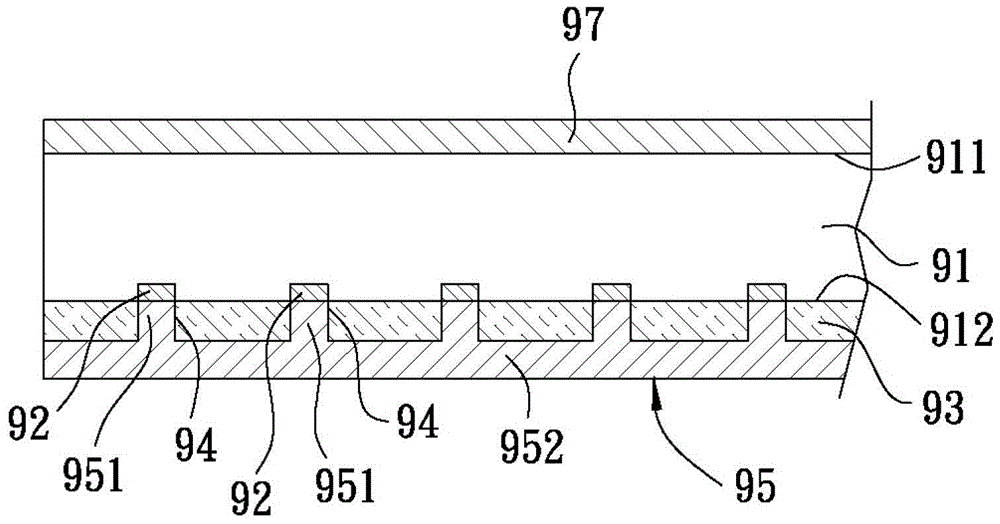

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

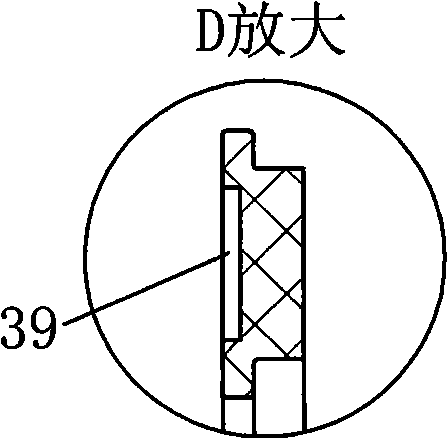

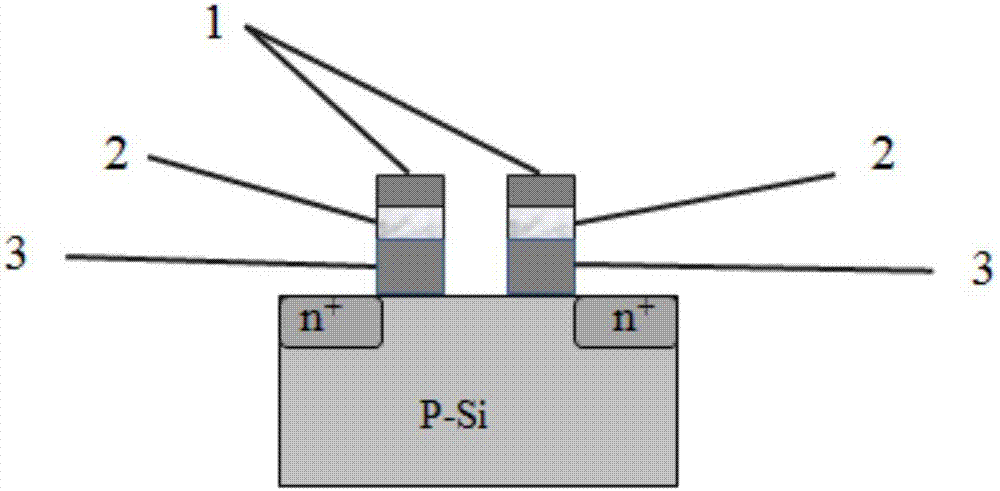

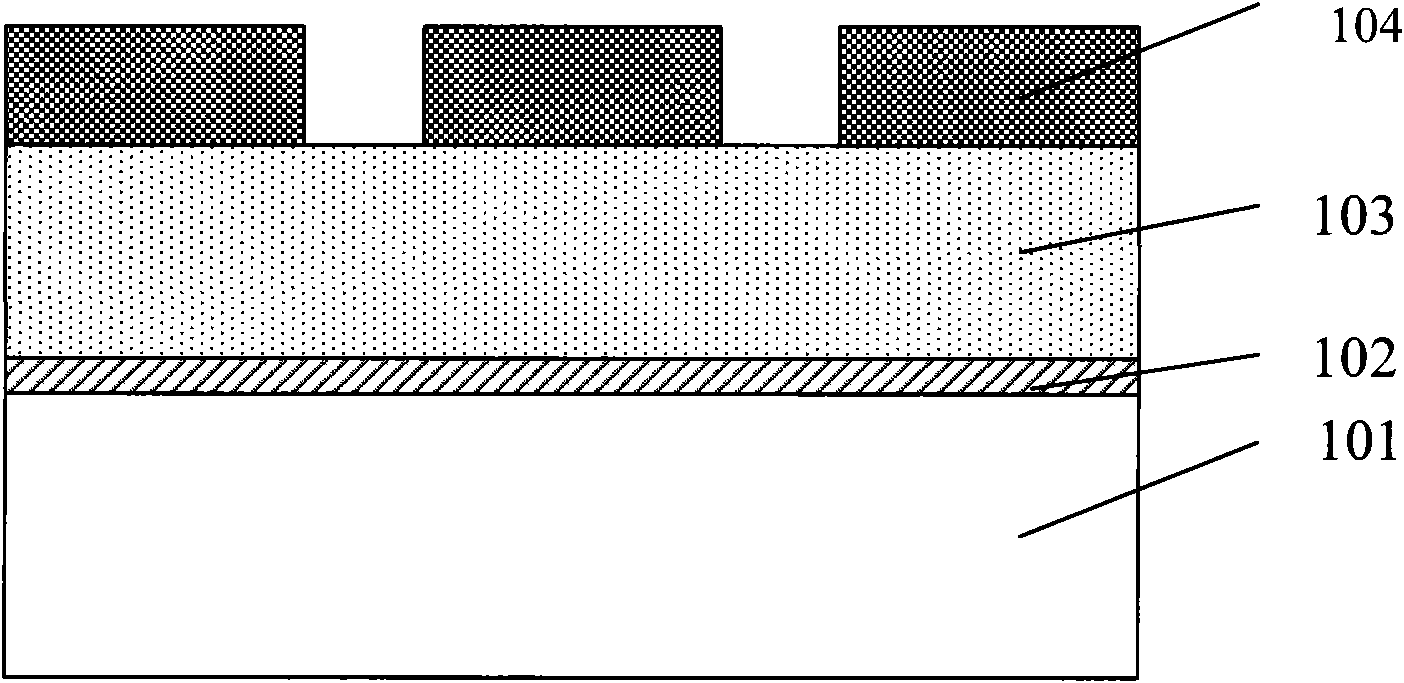

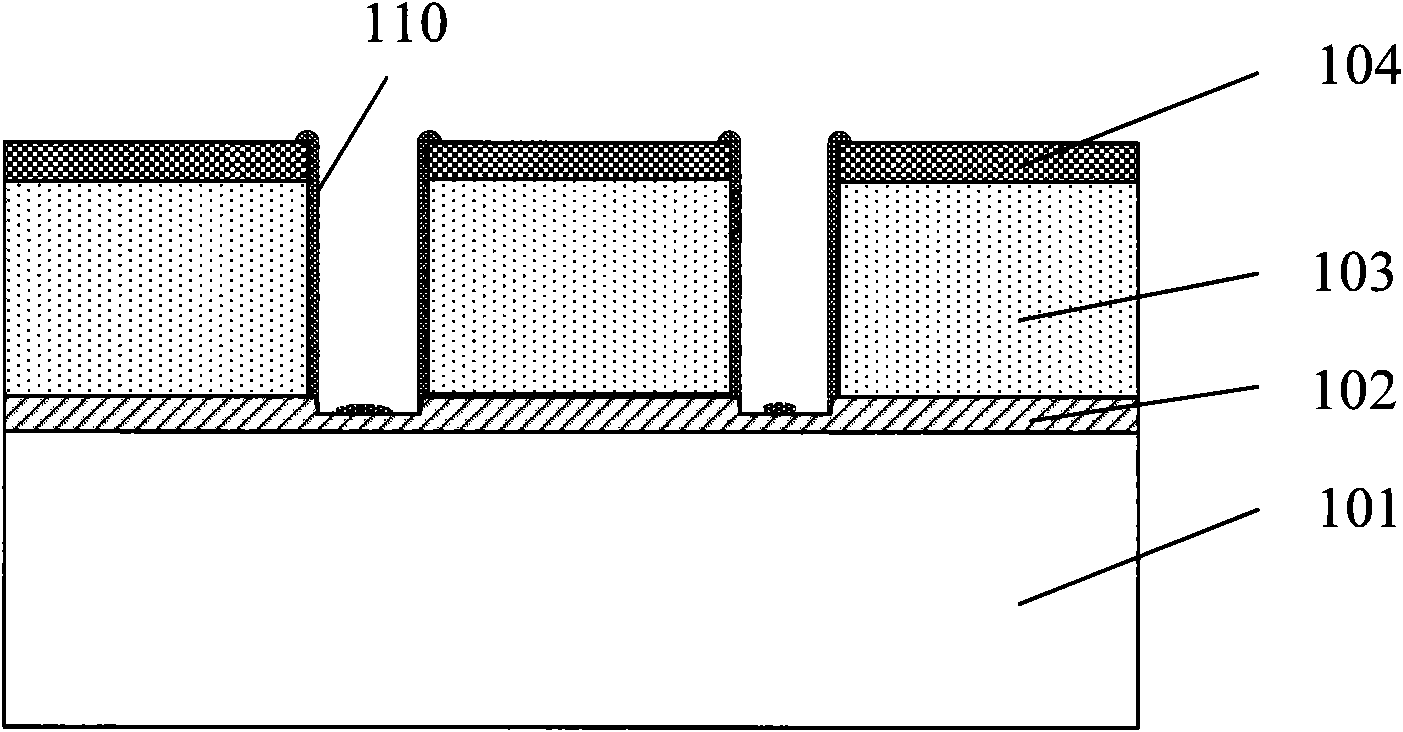

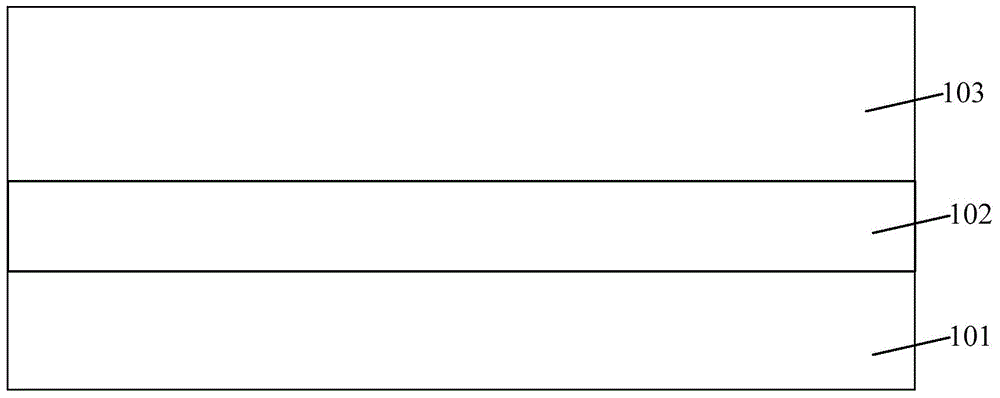

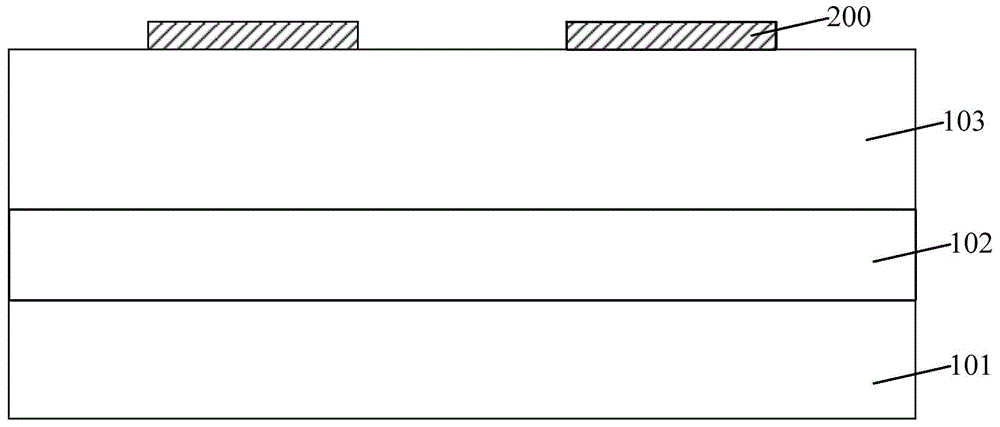

Ion implantation doping-based preparation method of hafnium oxide ferroelectric gate

ActiveCN107146759APrecise control of concentrationReduce interface effectsSemiconductor/solid-state device manufacturingSemiconductor devicesFerroelectric thin filmsThermal treatment

The invention provides an ion implantation doped HfO2 based preparation process of an HfO2 MIFS ferroelectric gate. The preparation process comprises the steps of firstly, cleaning a P-Si or n-Si substrate by a standard cleaning process to remove particles and other pollutants on a Si surface, afterwards depositing an appropriate thickness of HfO2 on a silicon wafer, and performing annealing; secondly, doping HfO2 by an ion implanter, and annealing the doped HfO2; thirdly, depositing a top electrode on the doped HfO2, namely halfnium oxide ferroelectric thin film, and performing rapid thermal treatment on the electrode; and finally, etching an MFIS multi-layer thin film structure to form an MFIS array unit which is matched with the sizes of a source, a drain and a channel by a reactive ion etching method. By the preparation process, the doping concentration of the HfO2 ferroelectric gate thin film can be accurately controlled, and the preparation process is a mature operation process for preparing the thin film relatively simple to prepare and with lower preparation temperature.

Owner:XIANGTAN UNIV

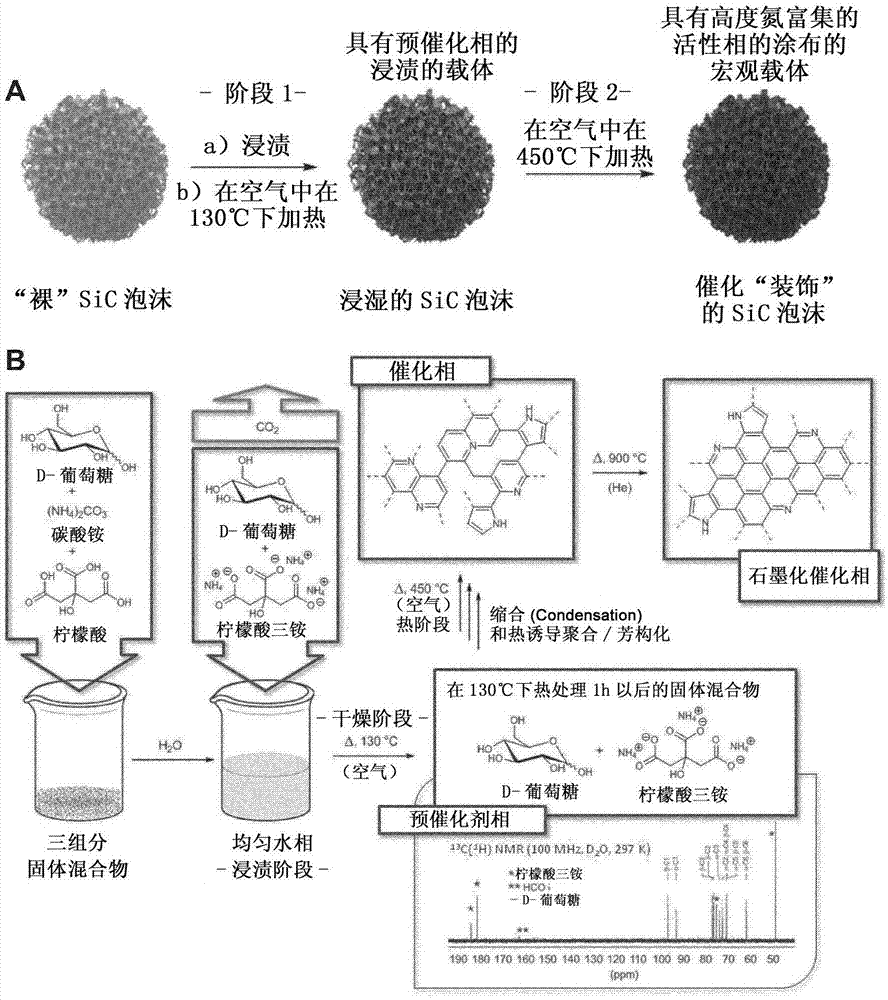

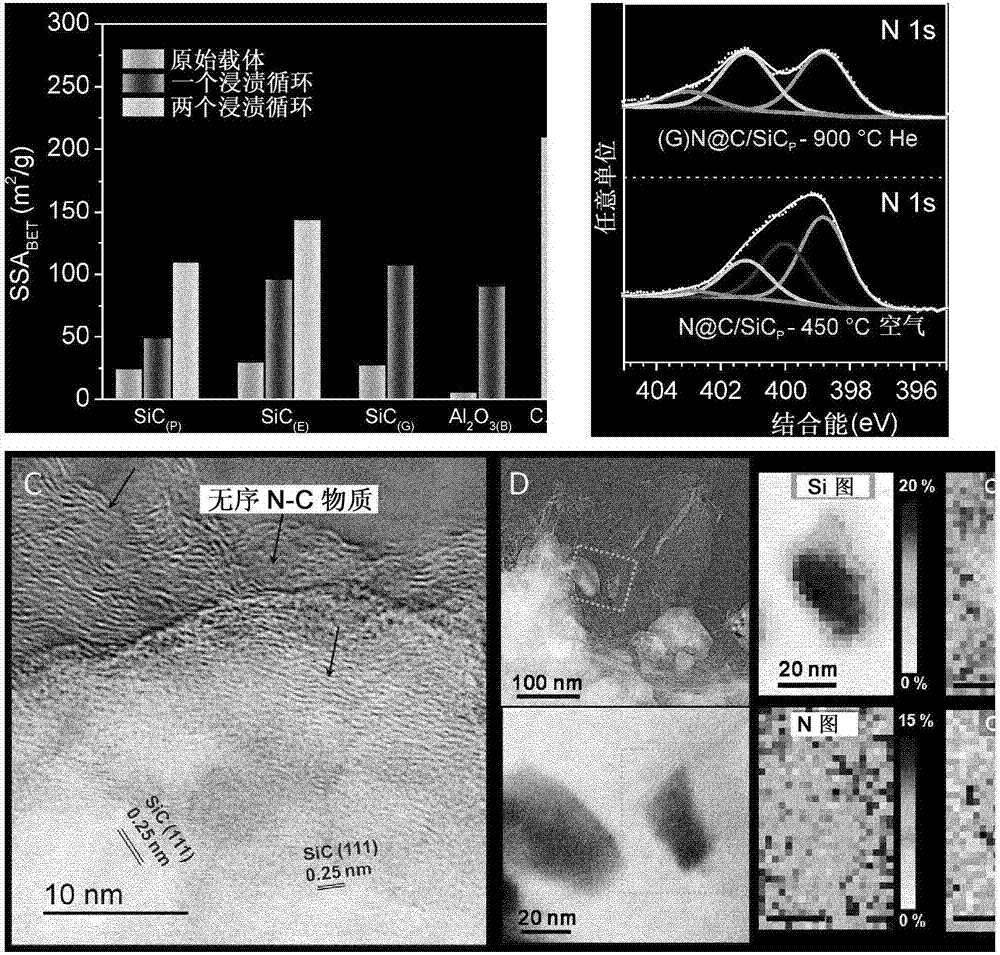

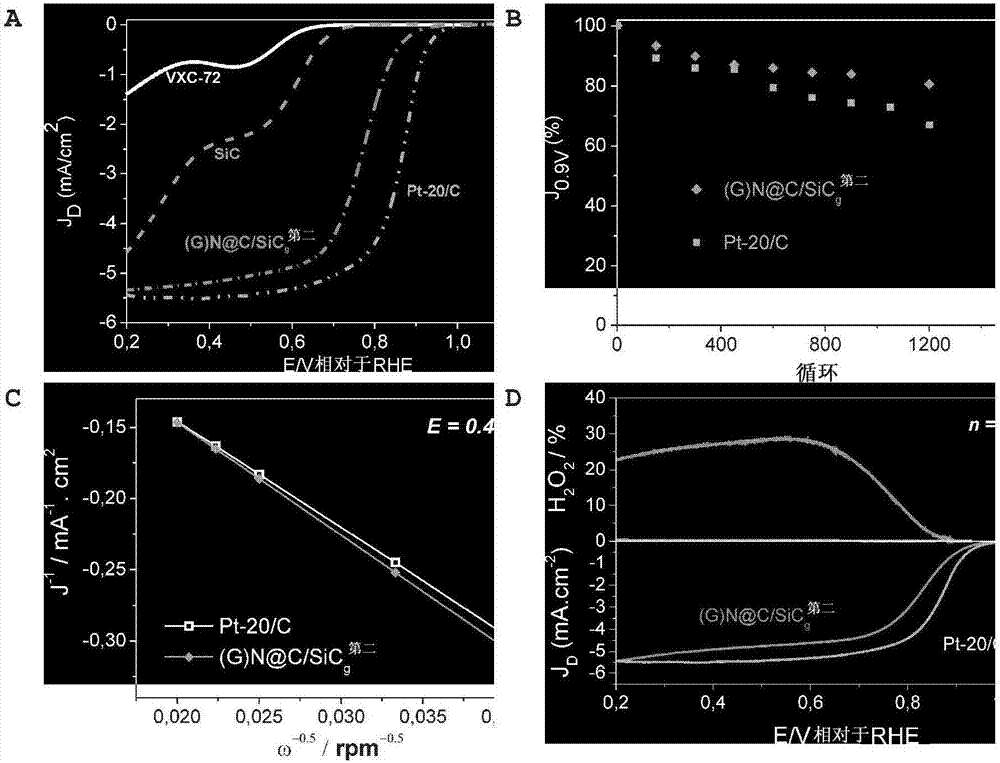

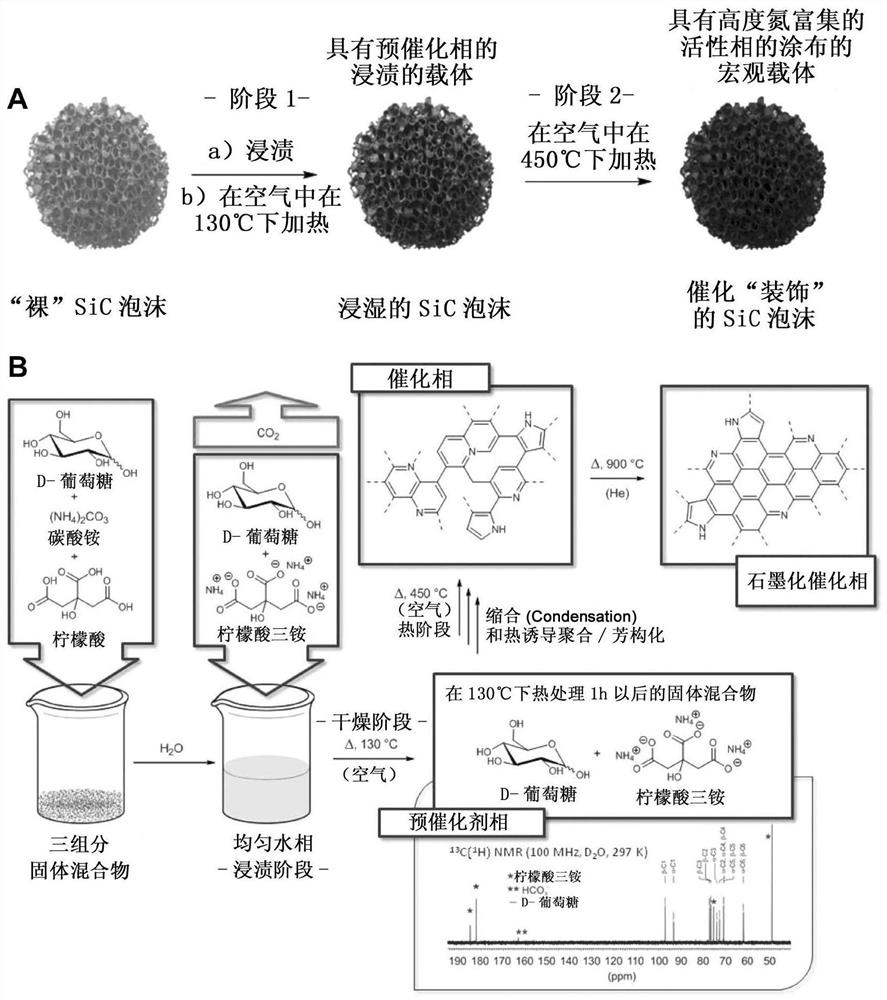

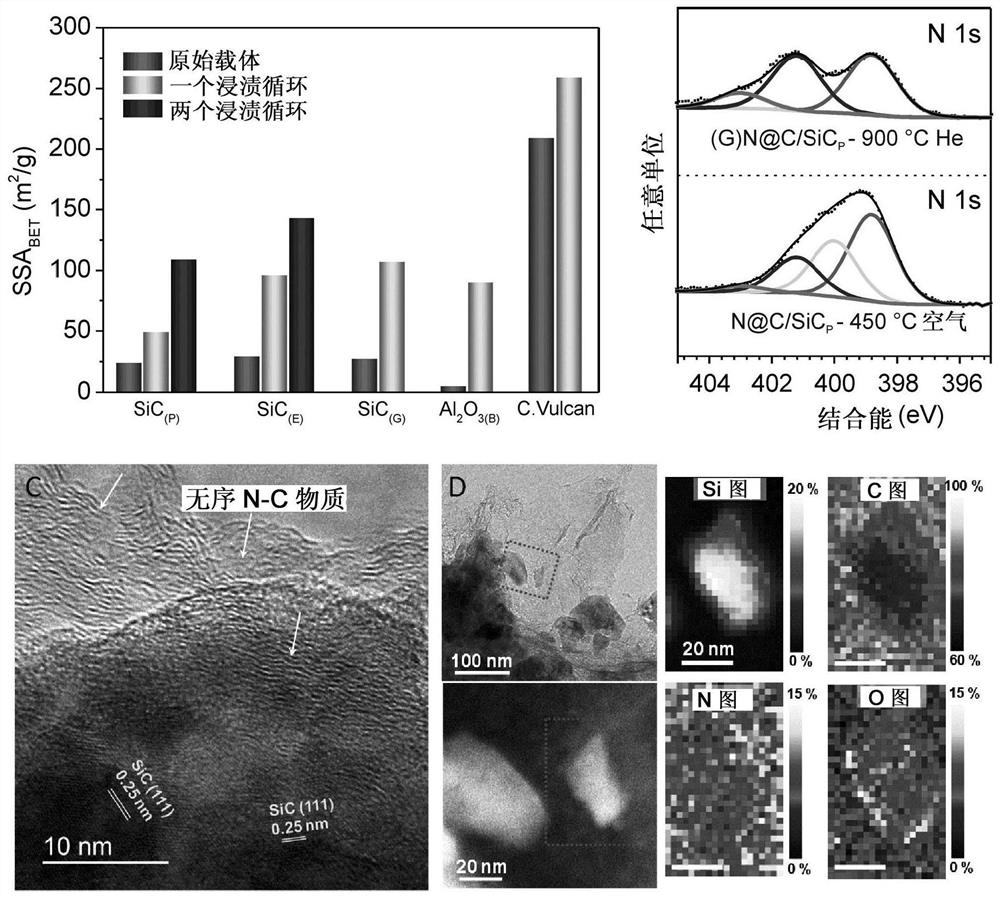

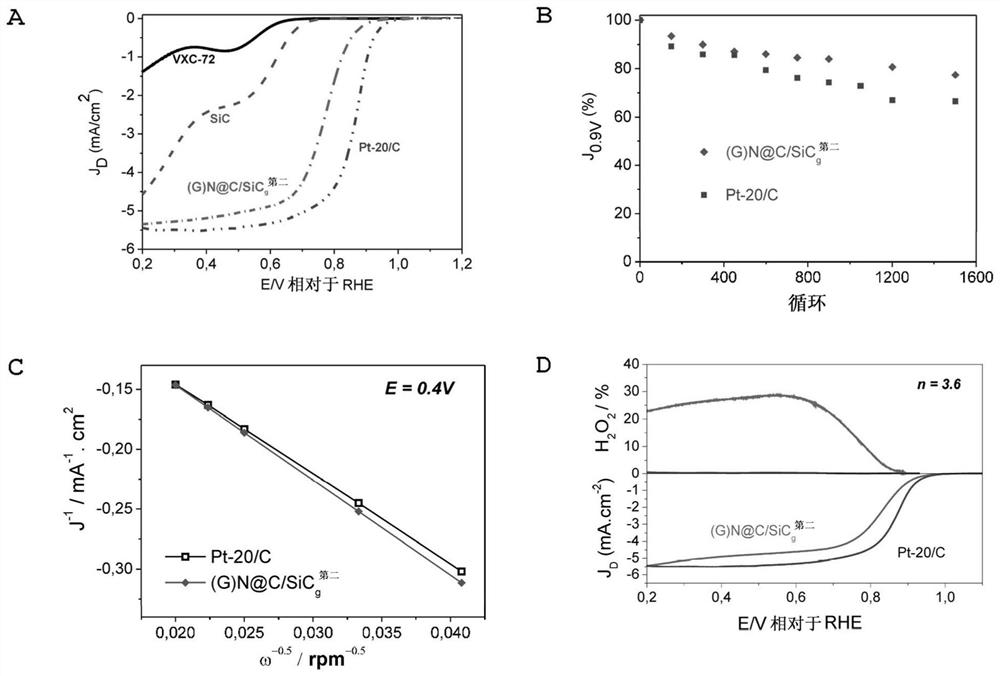

Method for preparing highly nitrogen-doped mesoporous carbon composites

ActiveCN107454861AFavorable and accessibleThick enoughCatalyst carriersCell electrodesCatalytic transformationCarbon composites

The present invention deals with a new methodology aimed at preparing highly N-doped mesoporous carbon macroscopic composites, and their use as highly efficient heterogeneous metal-free catalysts in a number of industrially relevant catalytic transformations.

Owner:UNIVERSITY OF STRASBOURG +2

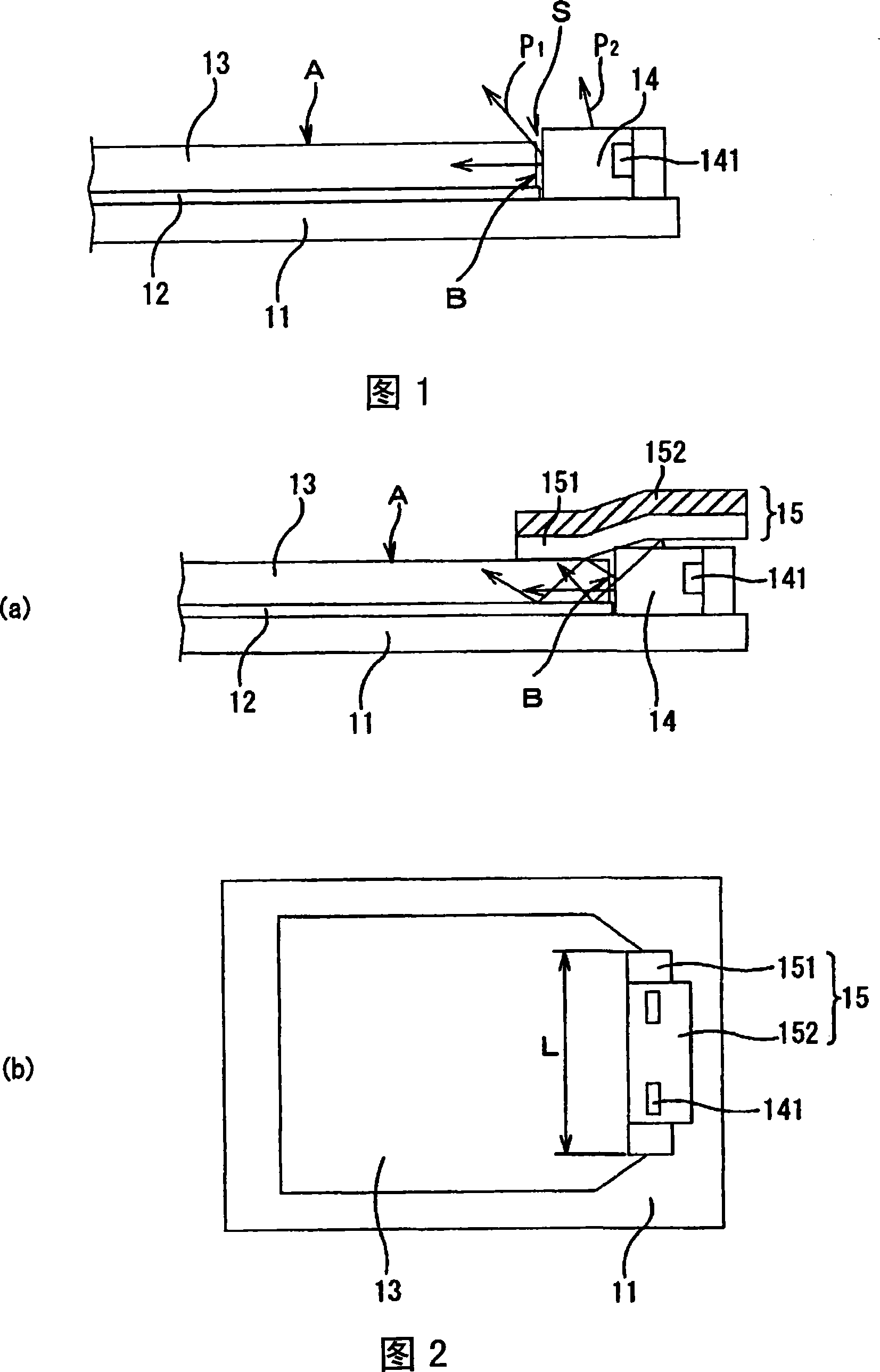

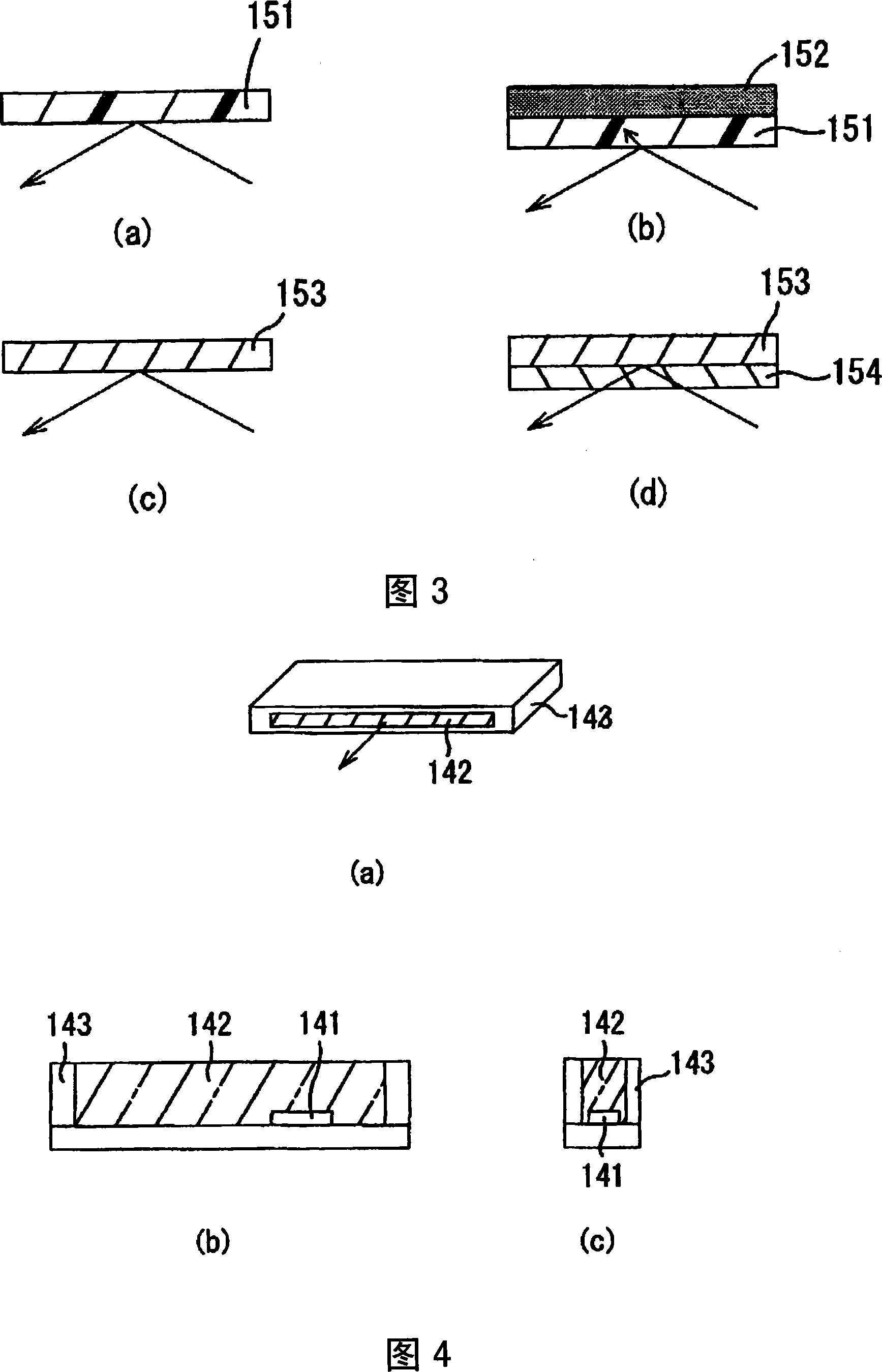

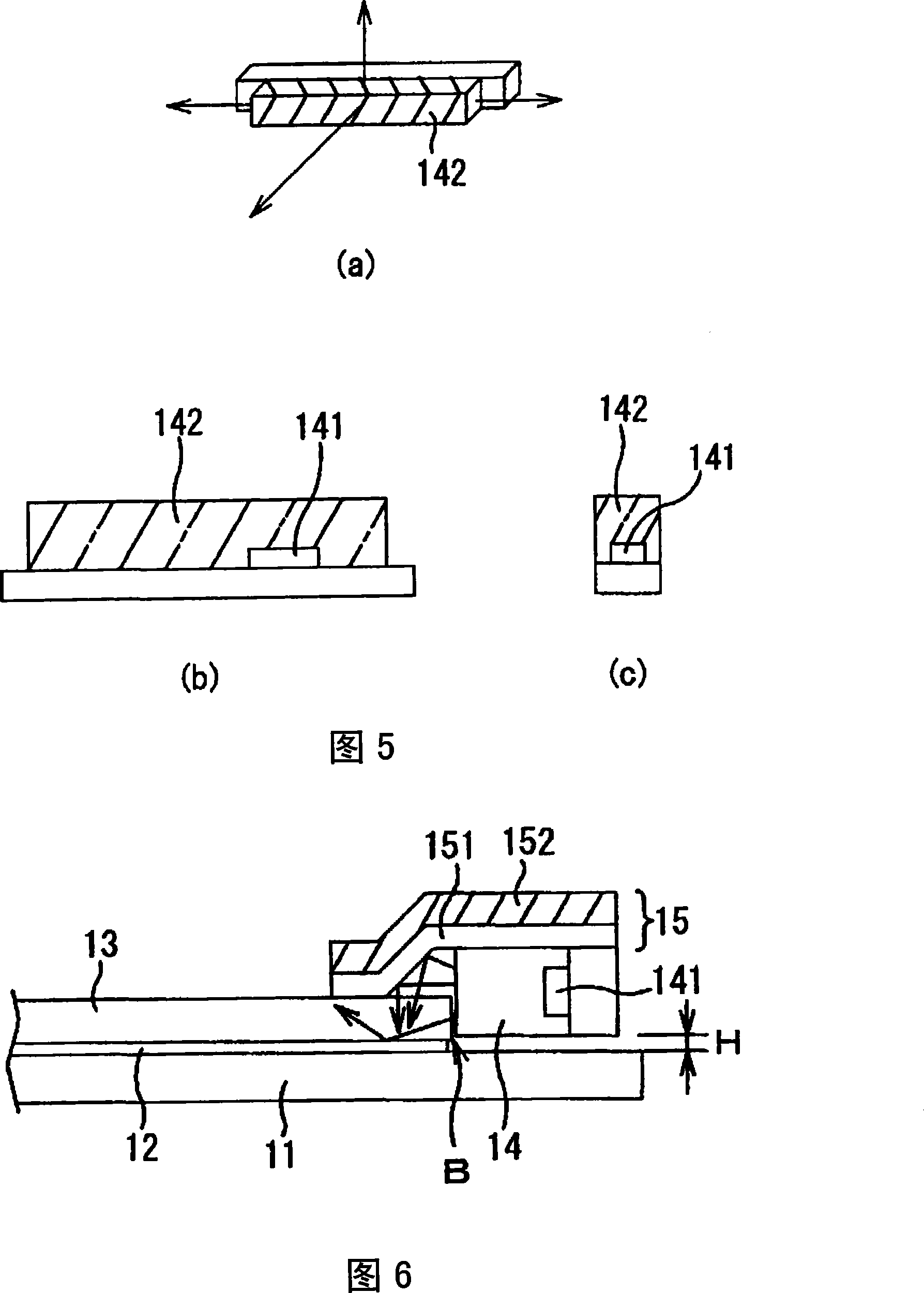

Illuminating unit

InactiveCN101230970AIncrease brightnessEfficient importMechanical apparatusLight guides for lighting systemsLight guideBrightness perception

Disclosed is an illuminating unit capable of effectively introducing light emitted from a light source into a light guide sheet to improve the brightness of light and emitting uniform color light. Light emitted from a light emitting diode of a light source unit is incident on a side surface of a light guide sheet. A spacer aligns the emission center of the light emitting diode with the center of the light guide sheet in the thickness direction thereof. The incident light travels in the light guide sheet and is then diffused in light emitting regions provided on the main surface of the light guide sheet. Then, the diffused light is emitted to the outside. In addition, light components emitted from a gap between the light emitting diode and the side surface of the light guide sheet or light components emitted from the upper surface of the light source unit to the outside are reflected to the light guide sheet by a cover member.

Owner:ALPS ALPINE CO LTD

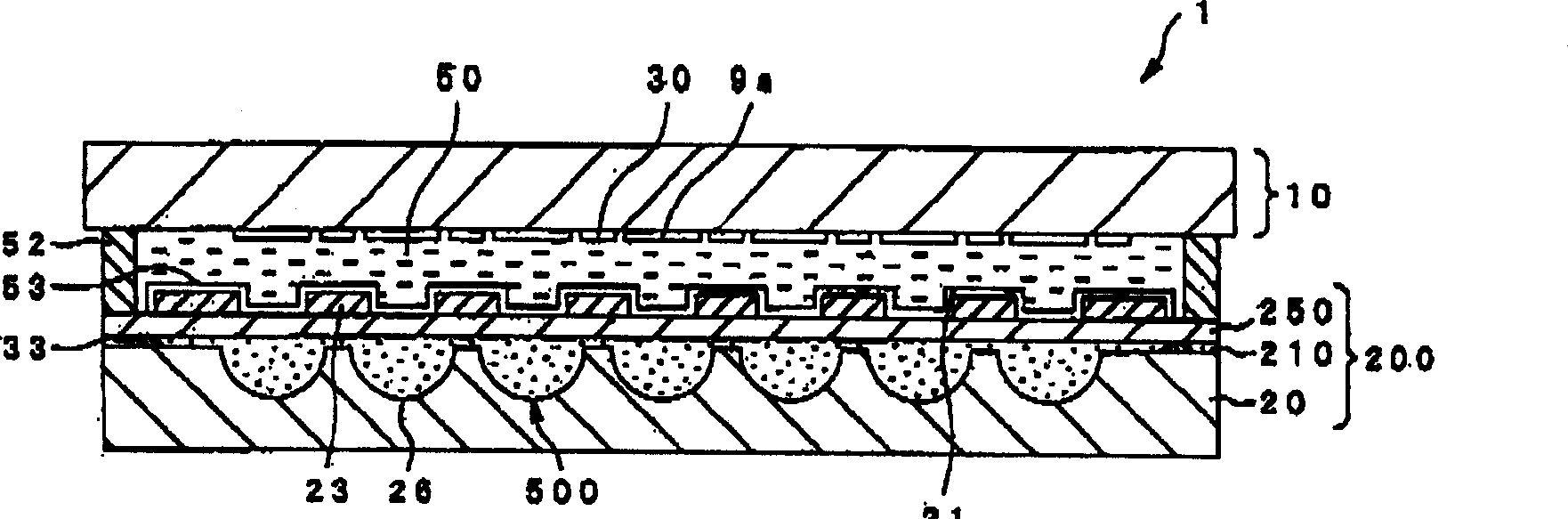

Electro-optical device, method of manufacturing the same, and electronic apparatus using electro-optical device

InactiveCN1721926AThickness increased and uniformThick enoughStatic indicating devicesNon-linear opticsCover glassElectron

Owner:SEIKO EPSON CORP

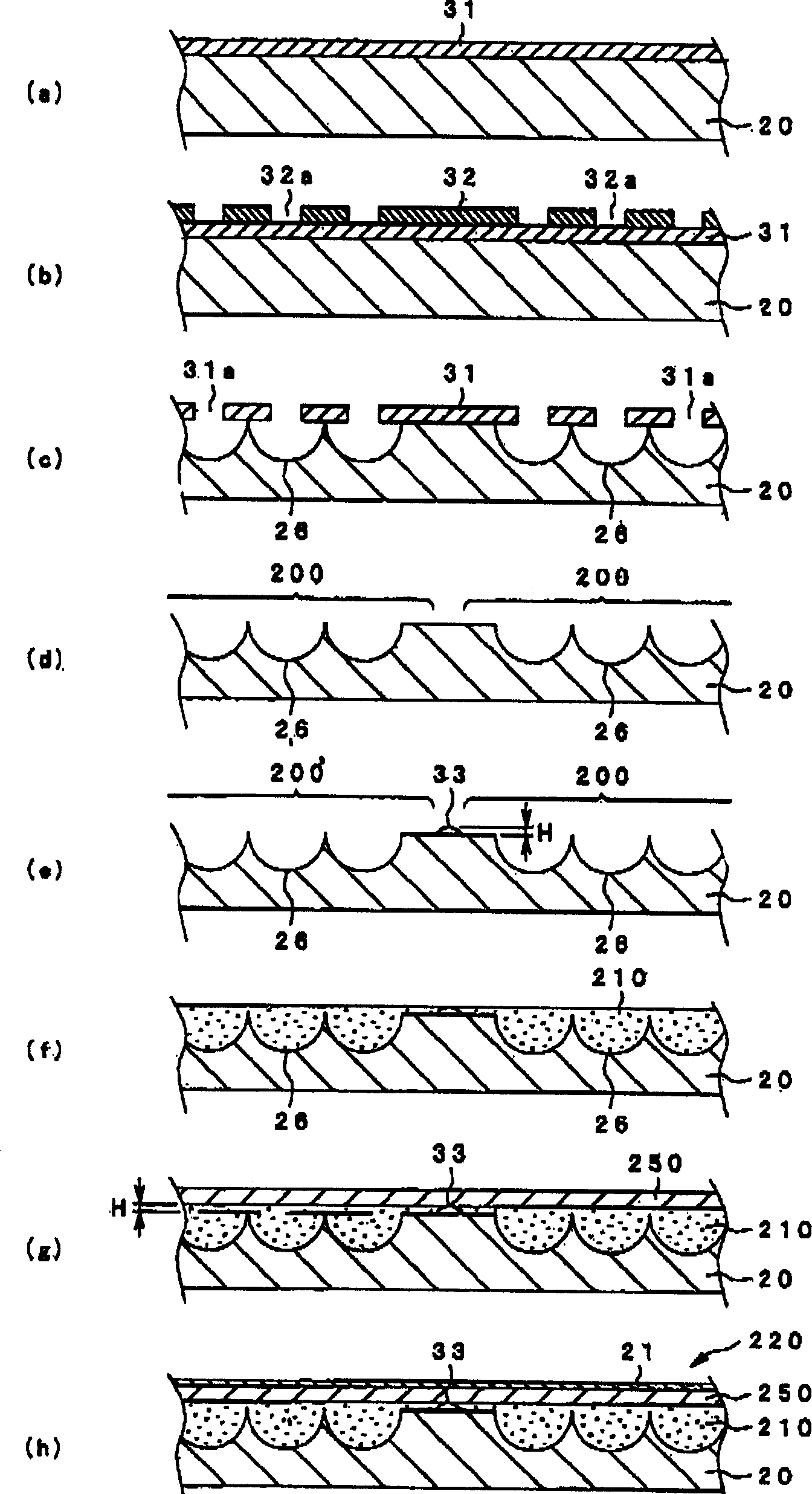

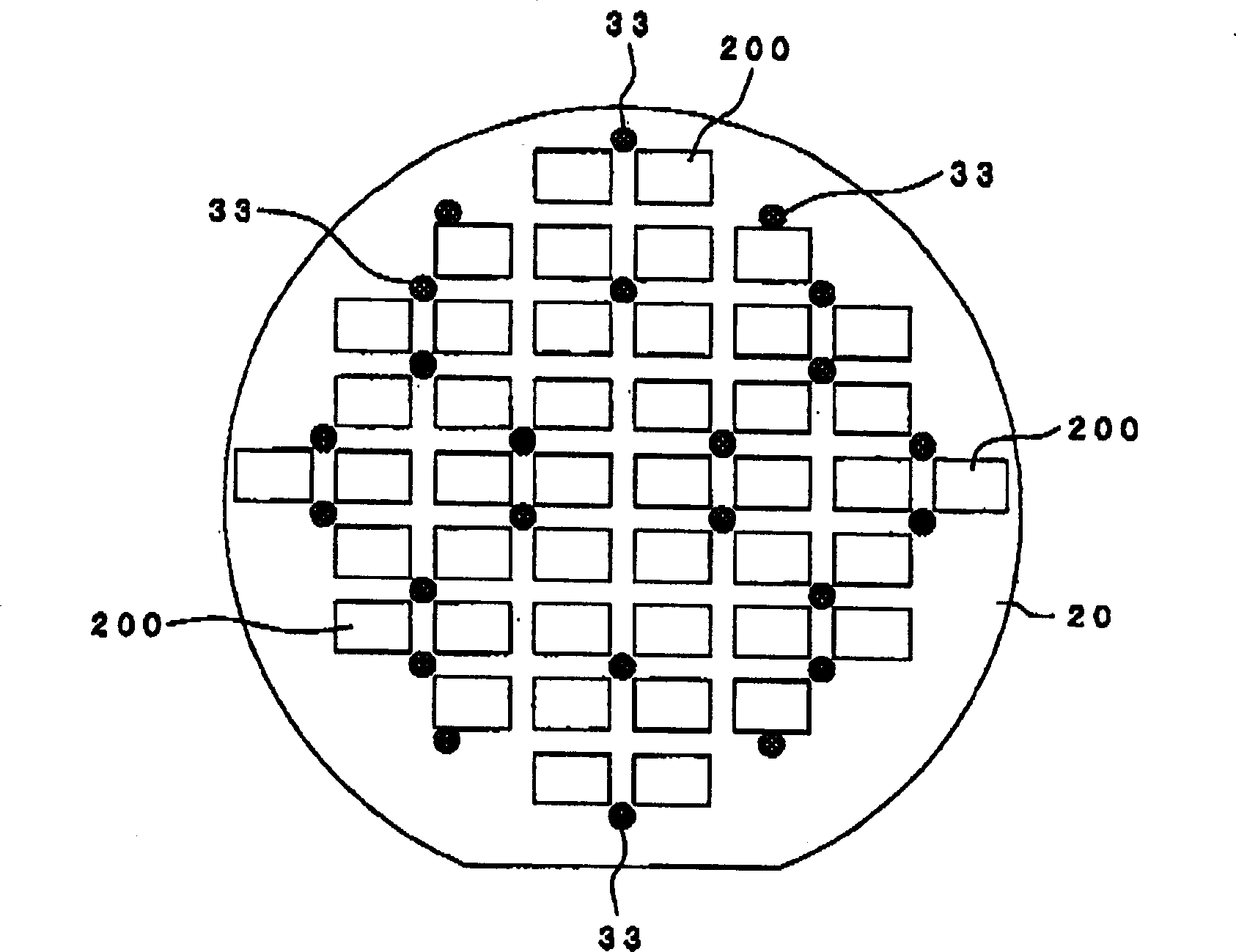

Method for incinerating etched substrate and method for forming etched structure

ActiveCN101572217AHigh energyAvoid lossSemiconductor/solid-state device manufacturingPhotosensitive material processingOptoelectronicsPlasma Gases

The invention discloses a method for incinerating an etched substrate, comprising the following steps: providing an etched substrate; putting the etched substrate in a processing chamber; guiding plasma gas into the processing chamber; incinerating the substrate for the first time by high radio frequency power supply; incinerating the substrate for the second time by low radio frequency power supply; and taking out the substrate. The invention also discloses a method for forming an etched structure with the method for incinerating the etched substrate. The method for incinerating an etched substrate and the method for forming an etched structure can ensure that the next layer of incinerated material is kept thick enough without thickening the next layer of material and narrowing an etching process window, thereby improving the quality of forming the etched structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

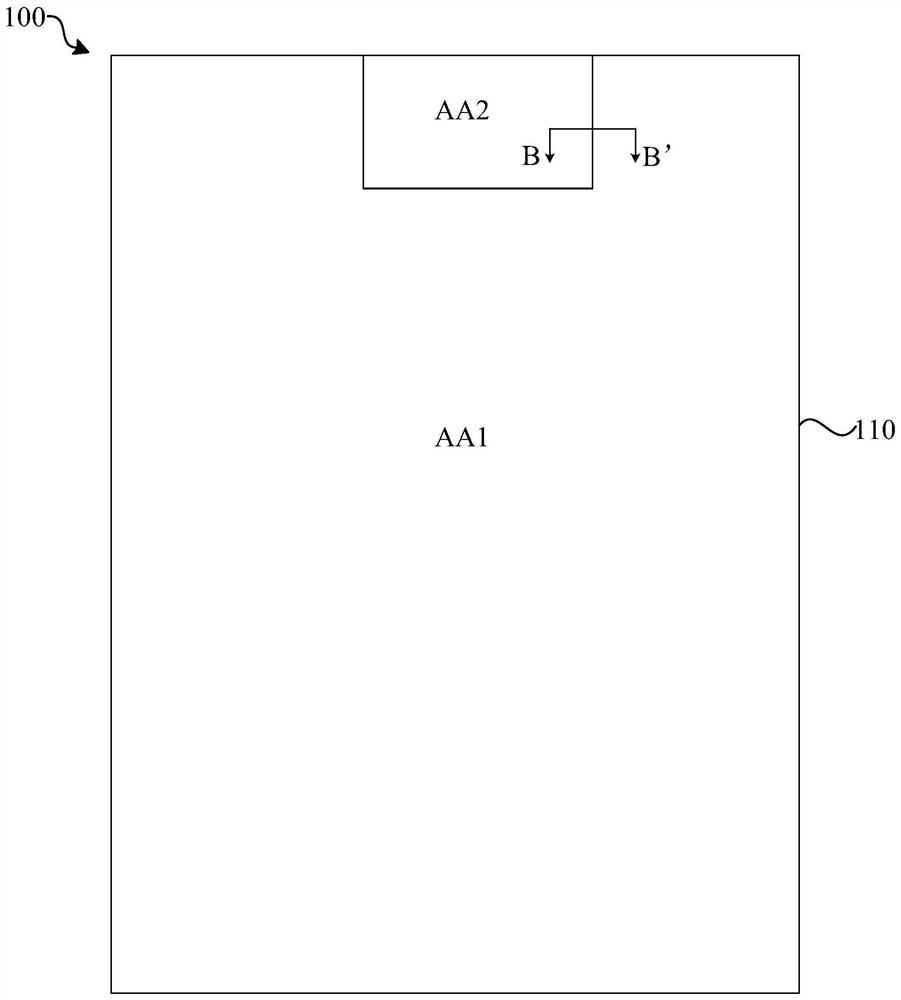

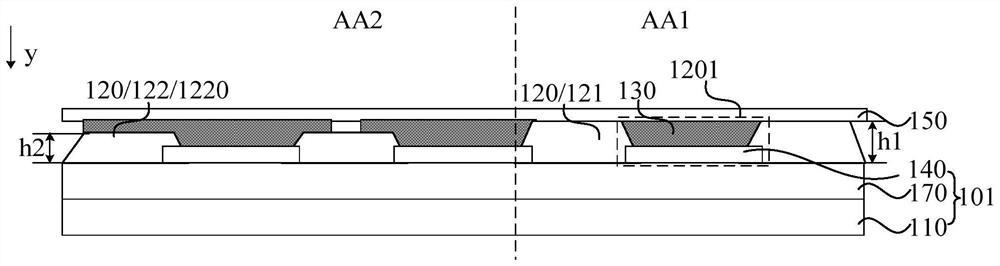

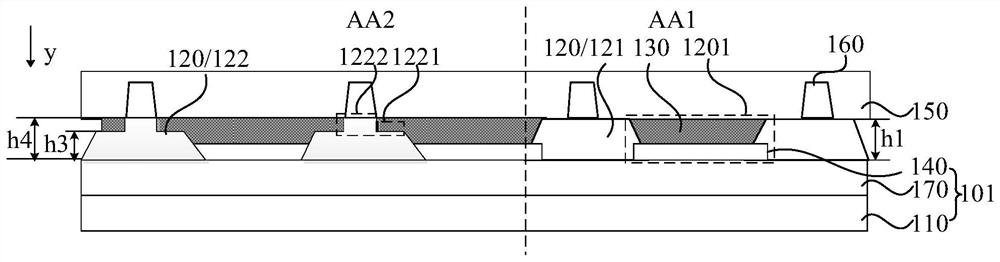

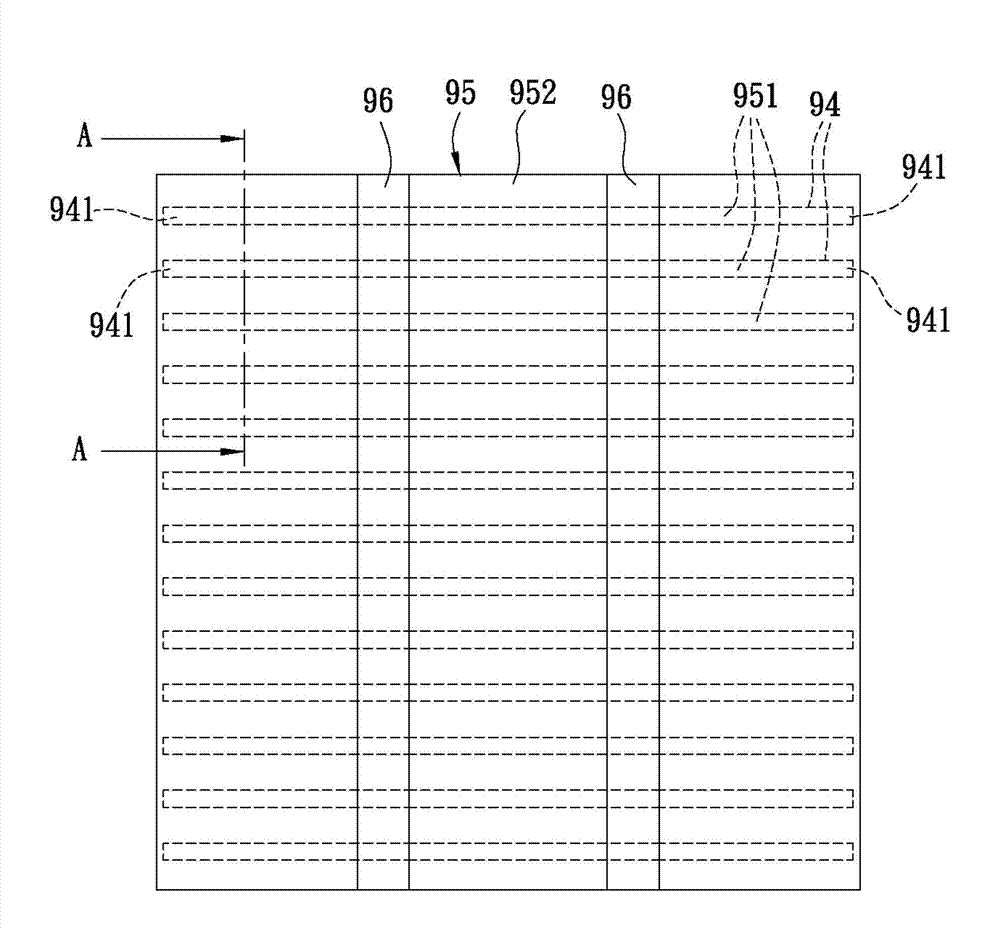

Display panel, manufacturing method thereof and display device

ActiveCN111834432AImprove the display effectThick enoughSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The embodiment of the invention discloses a display panel, a manufacturing method thereof and a display device. According to the invention, the thickness of at least part of the second pixel limitingparts is smaller than that of the first pixel limiting parts in the thickness direction of the display panel, so that the light transmittance of the light-transmitting display area can be improved, and a good shooting effect can be achieved when the photosensitive device is arranged below the second display area of the display panel. It can be ensured that the first pixel limiting part of the first display area has enough thickness, poor display caused by direct contact of the second electrode layer and the first electrode layer at the hole due to the fact that the first pixel limiting part covers the hole formed in the first electrode layer is avoided, and the display effect of the display panel is improved. According to the display panel provided by the embodiment of the invention, on the basis of ensuring a good shooting effect of the camera, the display panel is ensured to have a good display effect.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

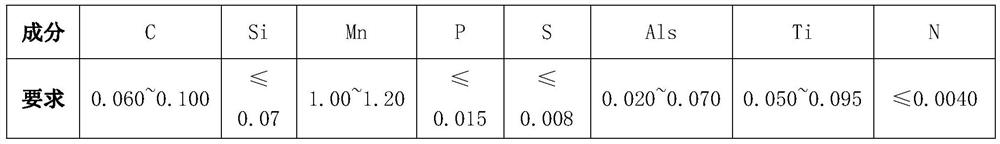

Method for controlling nitrogen content of steel grade in CV-LF-RH-CC process path

ActiveCN113403444AStable nitrogen contentBarrier contactManufacturing convertersSteelmakingRefining (metallurgy)

The invention discloses a method for controlling the nitrogen content of a steel grade in a CV-LF-RH-CC process path, and relates to the technical field of ferrous metallurgy. The method aims at achieving stable control over the nitrogen content and alloy components of the steel grade in the CV-LF-RH-CC process path. According to the method, stable control over the nitrogen content and the alloy components is achieved by strictly controlling the converter bottom blowing process, the steel tapping alloying process, the slag variety and adding amount, LF temperature rising, slagging and alloying process bottom blowing, the RH refining vacuum degree and time, the wire feeding speed, the casting process and other processes. According to the method, through strict control over the converter blowing process, the deoxidation alloying process of the primary molten steel, the LF and RH duplex refining process and the like, all alloy elements can stably reach target values, and the nitrogen content is stably controlled to be 30 ppm or below.

Owner:MAANSHAN IRON & STEEL CO LTD

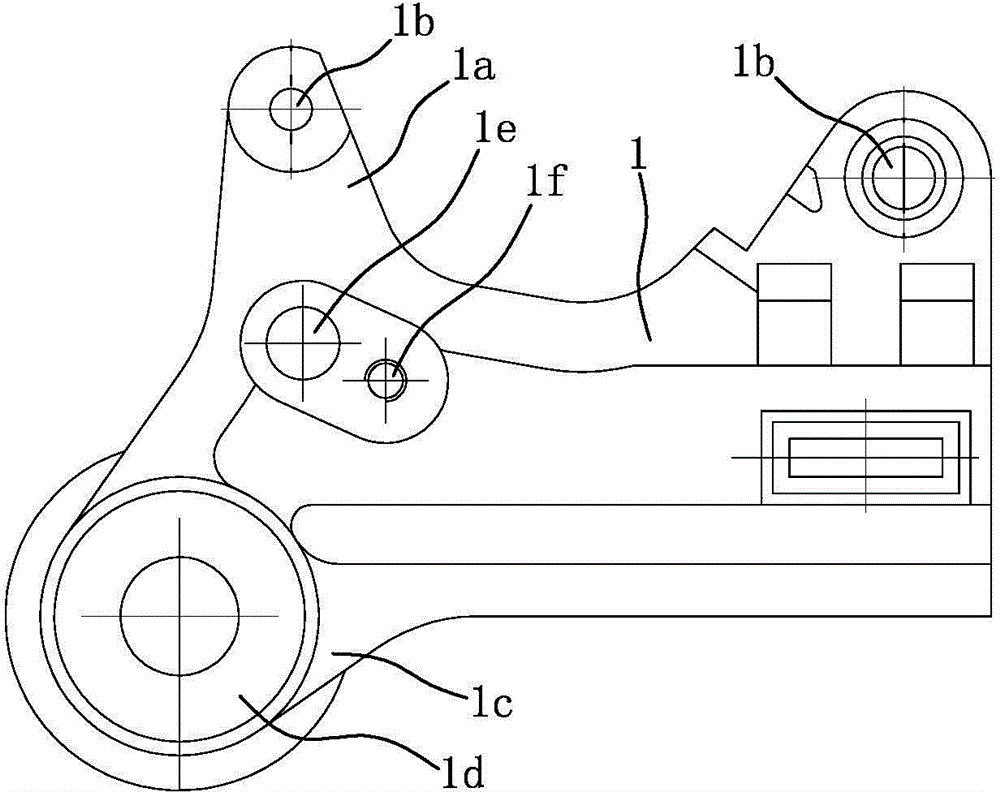

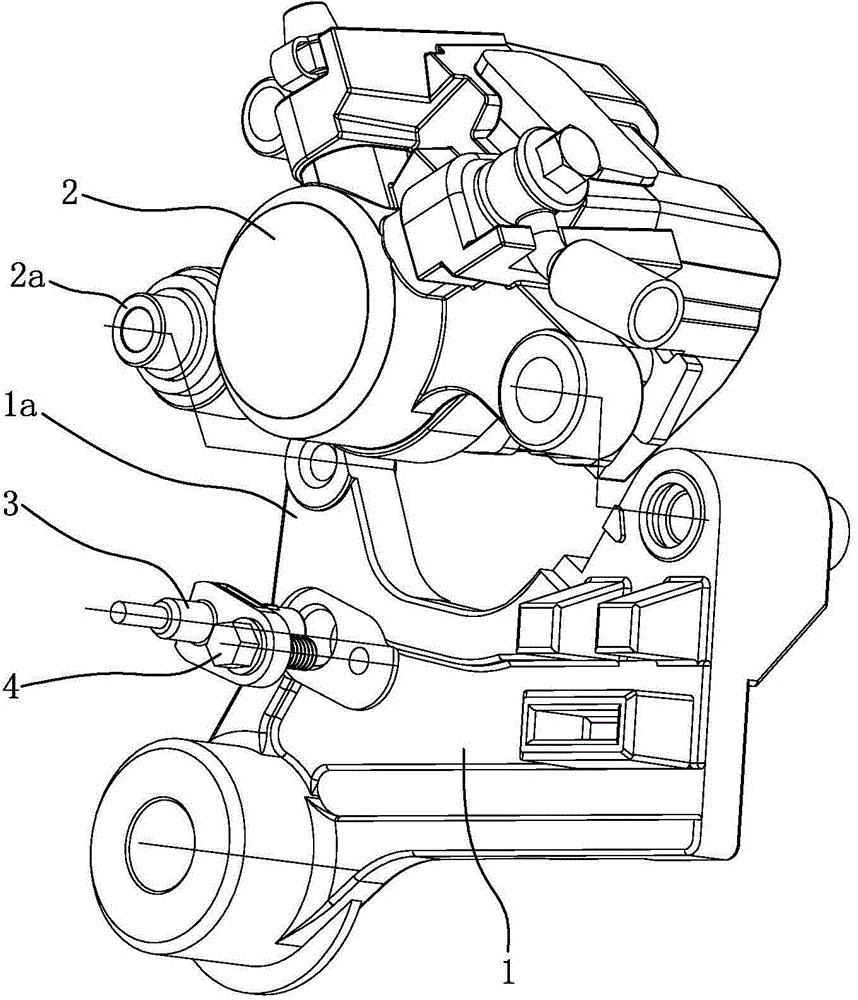

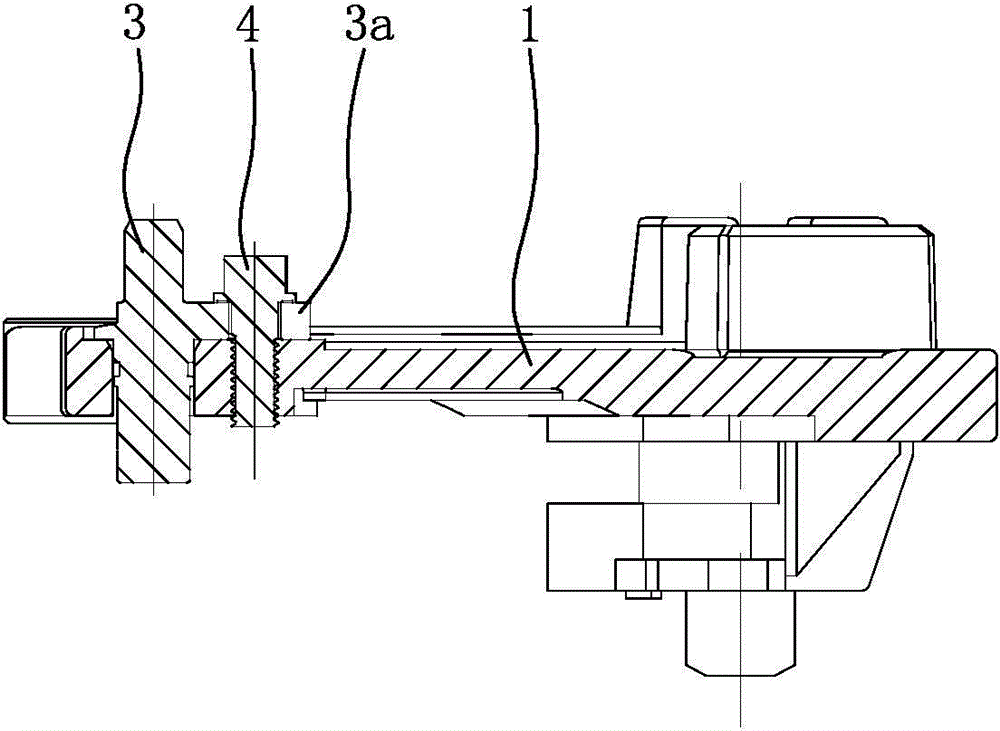

Installation structure for motorcycle ABS rear wheel speed sensor and rear brake cylinder

InactiveCN104859630AEasy to disassembleEasy to assemble and disassembleABS control systemsBrake cylindersWheel speed sensorFlange

The invention discloses an installation structure for a motorcycle ABS rear wheel speed sensor and a rear brake cylinder. An installation hole (1e) and a fastening hole (1f) are formed in a rear brake cylinder bracket (1), the installation hole (1e) is positioned between an upper flange (1a) and a lower flange (1c) in the rear, the depth of the installation hole (1e) is greater than 10.5mm, and the fastening hole (1f) is a threaded hole, is positioned at a position in front of and below the installation hole (1e) and is close to the installation hole (1e). The wheel speed sensor (3) is inserted into the installation hole (1e) in the rear brake cylinder bracket (1), a bolt penetrates through an assembly hole in the wheel speed sensor (3) and is screwed into the fastening hole (1f) in the rear brake cylinder bracket (1), and thus the wheel speed sensor (3) is installed in the rear brake cylinder bracket (1). By applying the installation structure, the wheel speed sensor is ingeniously installed in the rear brake cylinder bracket, the installation structure for the wheel speed sensor is simple, and the accuracy is reliable.

Owner:力帆科技(集团)股份有限公司

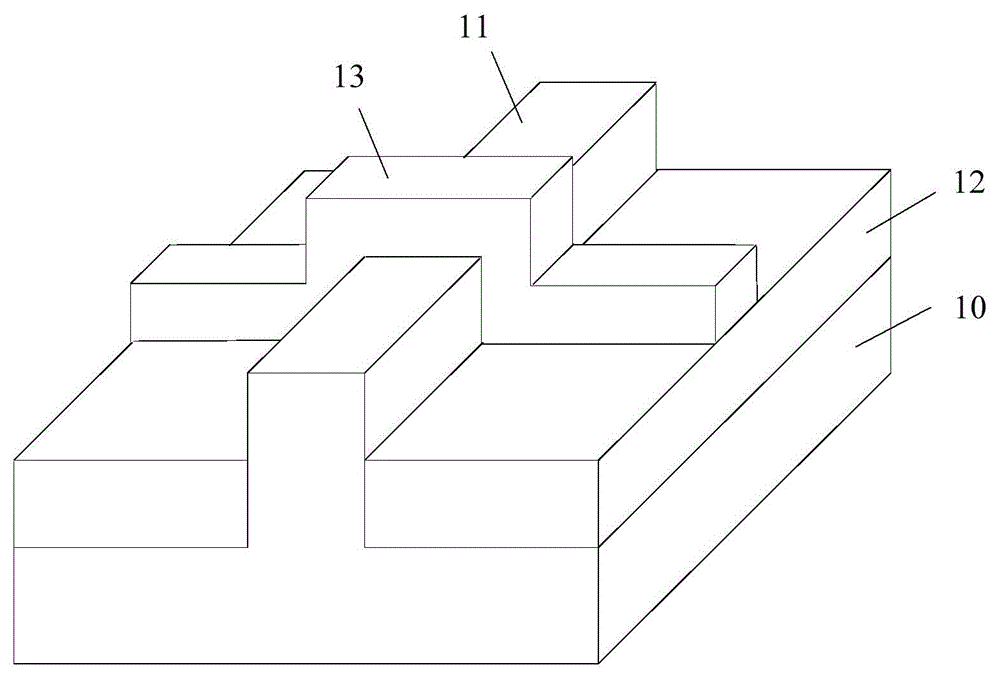

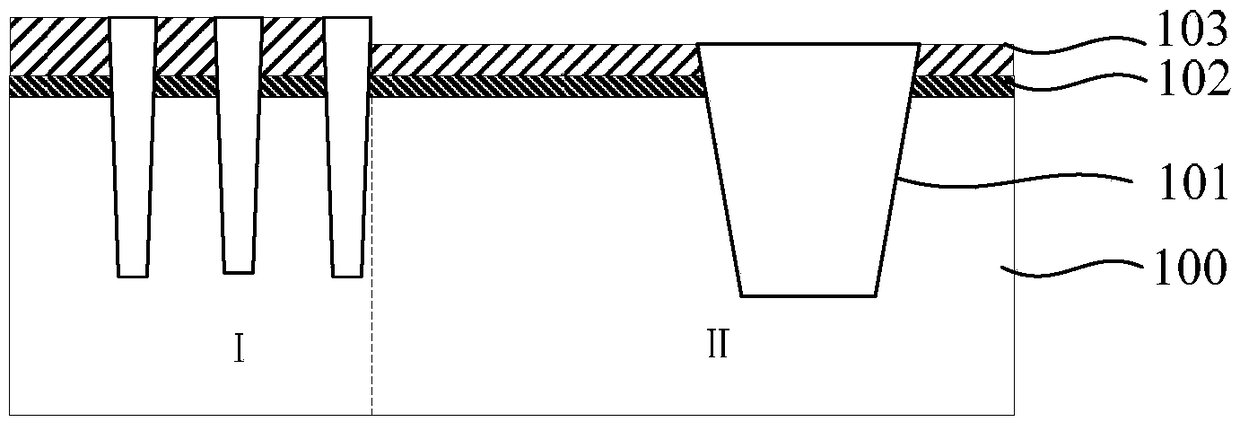

Formation method of semiconductor structure

ActiveCN105336616AUniform etch rateFully contactedSemiconductor/solid-state device manufacturingSemiconductor structureIsolation layer

A formation method of a semiconductor structure comprises the following steps of providing a semiconductor substrate; forming a fin portion on the semiconductor substrate; forming an isolation layer on the semiconductor substrate, wherein a surface of the isolation layer is lower than a top surface of the fin portion and covers a side wall of parts of the fin portion; forming a dielectric layer on a fin portion surface; forming a sidewall of the dielectric layer covering a fin portion sidewall surface; taking the side wall as a mask layer, using a wet etching process to etch the dielectric layer so that the top surface of the fin portion is exposed. By using the method, damages to the fin portion, which is generated through using dry etching, can be reduced, which is good for subsequent epitaxial growth; and performance of the formed semiconductor structure is increased.

Owner:SEMICON MFG SOUTH CHINA CORP

Solar Cell, Module Thereof And Manufacture Method Thereof

InactiveCN103928537AReduce or eliminate endpoint sitesImprove the effect of current collectionFinal product manufacturePhotovoltaic energy generationPower flowEngineering

The present invention provides a solar cell, a module thereof and a manufacture method thereof. The cell comprises a substrate possessing a right side and a back side, an emitter layer arranged on the right side, and a passivation layer arranged on the back side, an opening arranged on the passivation layer in an extension and bending manner, and a backside electrode arranged on the passivation layer and contacted with the back side via the opening. The projection area of the opening on the back side is 3% to 12% of the area of the back side. The present invention also provides another cell which comprises a plurality of annular openings surrounding annularly from inside to outside. By the design of the continuously extending and bending single opening or the plurality of annular openings, the current collection effect of the backside electrode can be enhanced. Moreover, a back electric field structure formed by sintering is enough in thickness and good in quality, thereby improving the photoelectric conversion efficiency of the cell.

Owner:MOTECH INDUSTRIES

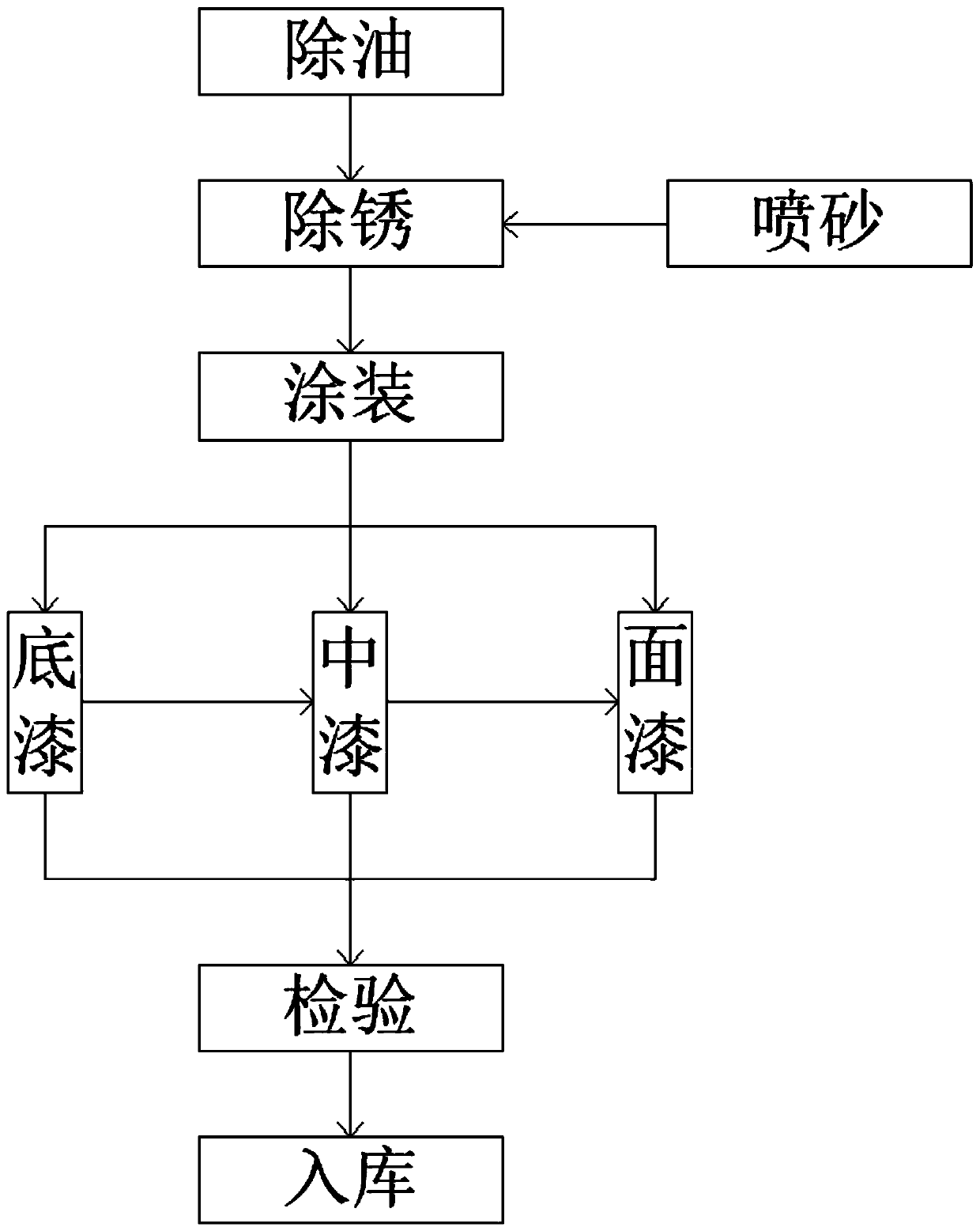

Surface treatment process of corrosion-resistant alloy seamless steel tube

The invention discloses a surface treatment process of a corrosion-resistant alloy seamless steel tube, and the process comprises the following steps: in a seamless steel tube processing operation room, putting a seamless steel tube into an oil removal area through a mechanical arm to remove oil, holding an alcohol cleaning agent in the oil removal area, and removing oil of the seamless steel tubein the oil removal area for 2 minutes until the seamless steel tube is completely removed; carrying out a derusting operation in a sand blasting manner; enabling the mechanical arm to transport the seamless steel tube subjected to oil removal from the oil removal area to the rust removal area for centralized rust removal treatment, enabling a sand blasting gun to be perpendicular to the axis of the preheated seamless steel tube, enabling the sand blasting gun to reciprocate at a constant speed along the axis of the pipeline, and stopping the gun when the surface of the seamless steel tube isin a metal natural color and has no black or red spots, wherein the coating comprises primer coating, intermediate paint coating and finish paint coating; enabling a quality inspector to inspect whether a paint film has pinholes, bubbles, cracks, shedding, sagging and missing coating or not, and storing the paint film in a warehouse after the paint film is inspected to be qualified. The surface ofthe seamless steel tube can be efficiently treated, so the safe use is achieved.

Owner:浙江永上特材有限公司

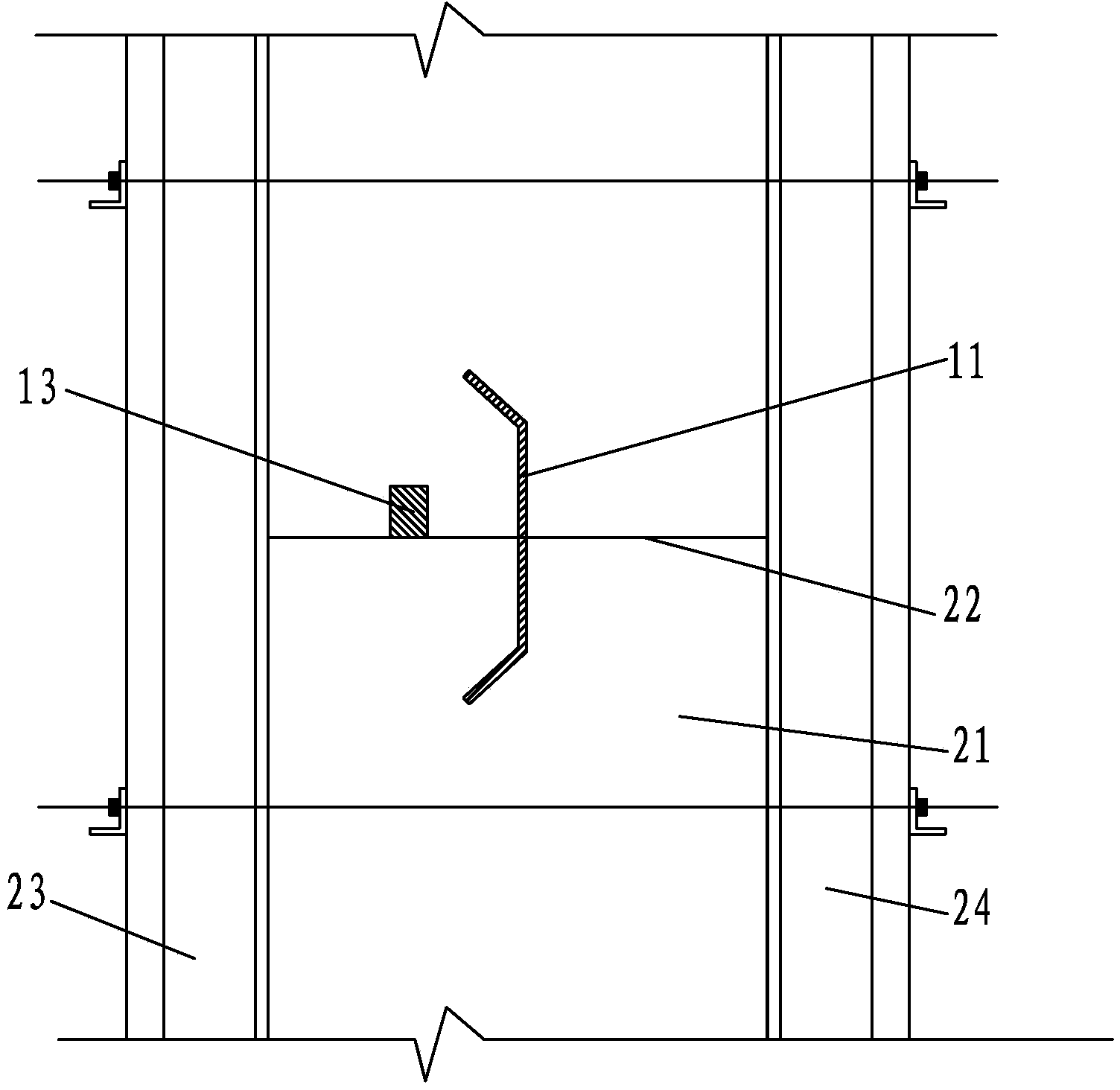

Combined water stop system of waterproof concrete wall

A combined water stop system of a waterproof concrete wall comprises a centrally-buried type water stop belt and a water swelling water stop rod. The centrally-buried type water stop belt is fixed to a framework of steel reinforcement of the waterproof concrete wall, located in the middle of the framework of steel reinforcement of the waterproof concrete wall in the thickness direction, and stretches from one end of a horizontal construction joint of the waterproof concrete wall to the other end of the horizontal construction joint, and the center, in the width direction, of the centrally-buried type water stop belt and the horizontal construction joint of the waterproof concrete wall are at the same height. The water swelling water stop rod is fixed to a concrete interface on the lower portion of the horizontal construction joint of the waterproof concrete wall and stretches from one end of the horizontal construction joint of the waterproof concrete wall to the other end of the horizontal construction joint. The combined water stop system of the waterproof concrete wall can solve the problem of waterproofing for the structure of the large waterproof concrete wall under the action of extra large head pressure.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

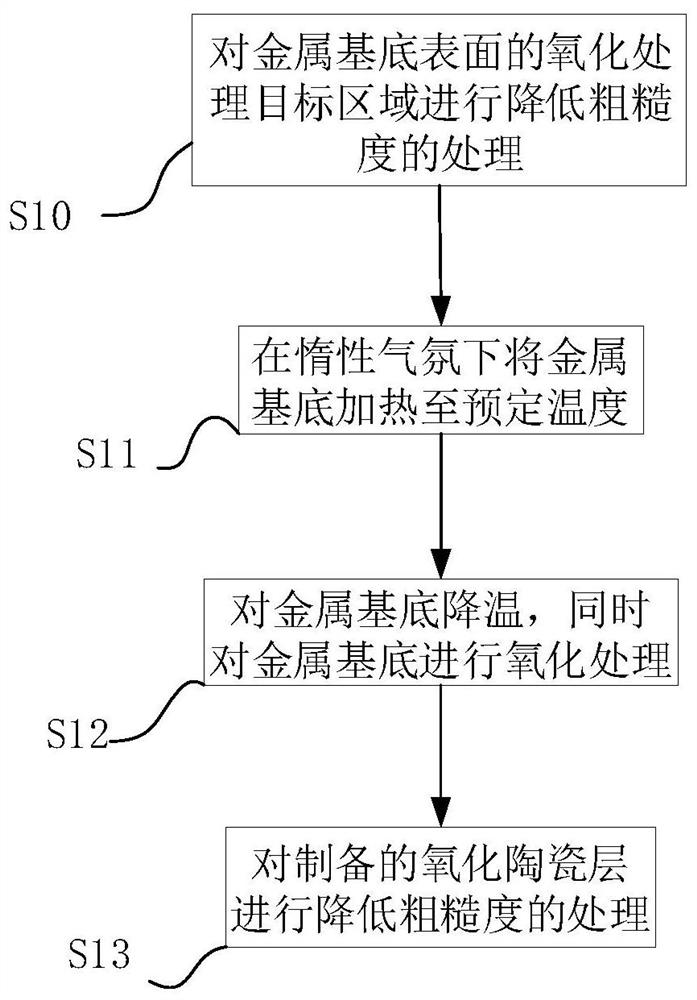

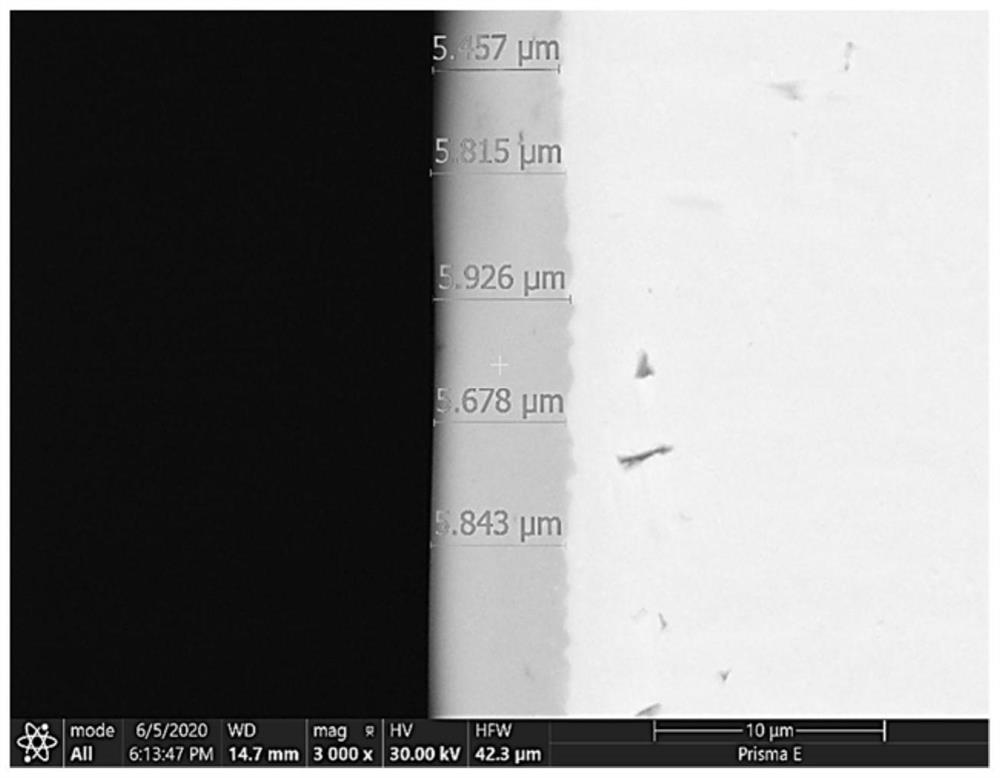

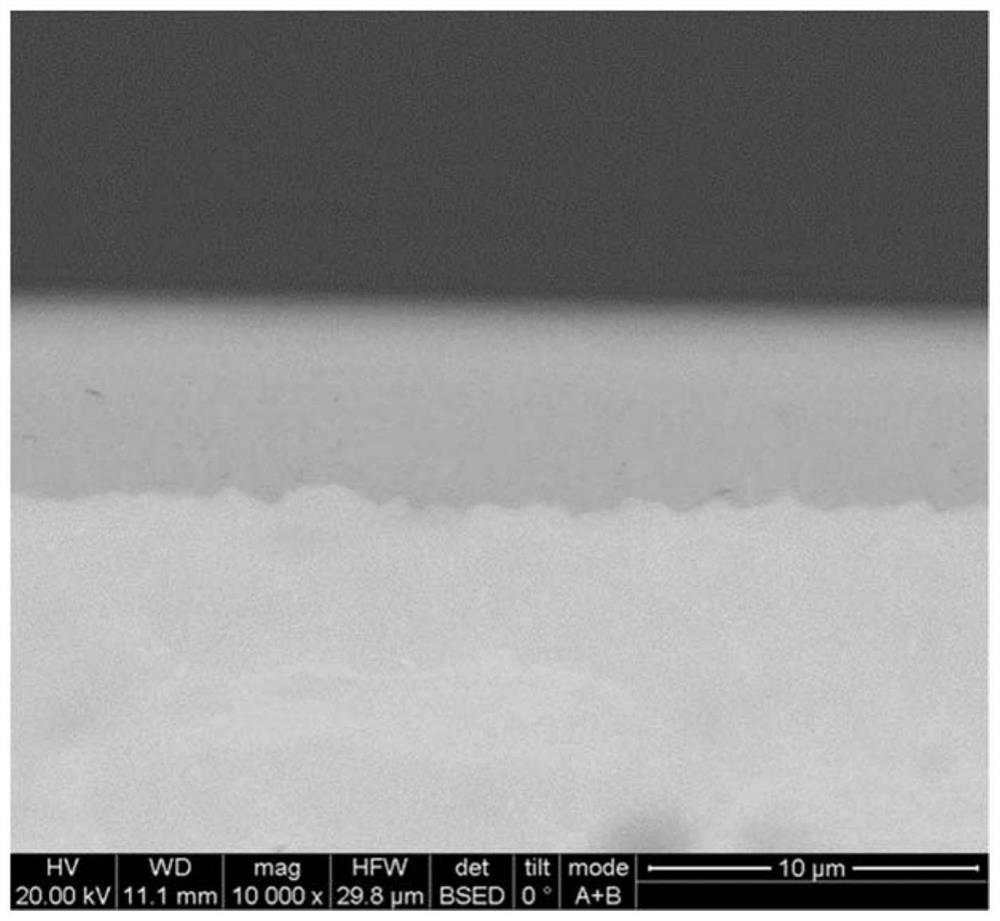

Method for preparing oxidization ceramic layer on surface of metal substrate and application of method

ActiveCN111826603AReduce internal stressQuality improvementPharmaceutical delivery mechanismSolid state diffusion coatingSurface oxidationInternal stress

The invention relates to a method for preparing an oxidization ceramic layer on the surface of a metal substrate and application of the method. The method comprises the following steps of heating themetal substrate to a predetermined temperature in an inert atmosphere and stopping heating; and cooling the metal substrate while introducing a mixed gas to perform oxidation treatment on the metal substrate in order to form the oxidization ceramic layer on the surface of the metal substrate, wherein the mixed gas comprises oxygen and an inert gas, and the content of the oxygen in the mixed gas rises with the decrease of the temperature. According to the method, the oxidation ceramic layer is formed on the surface of the metal substrate, the internal stress generated by the metal substrate canbe reduced, the bearing capacity of the metal substrate on the internal stress is improved, the release of the internal stress is reduced, the defects generated by the oxidization ceramic layer can be reduced, and the quality of the oxidization ceramic layer can be improved.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

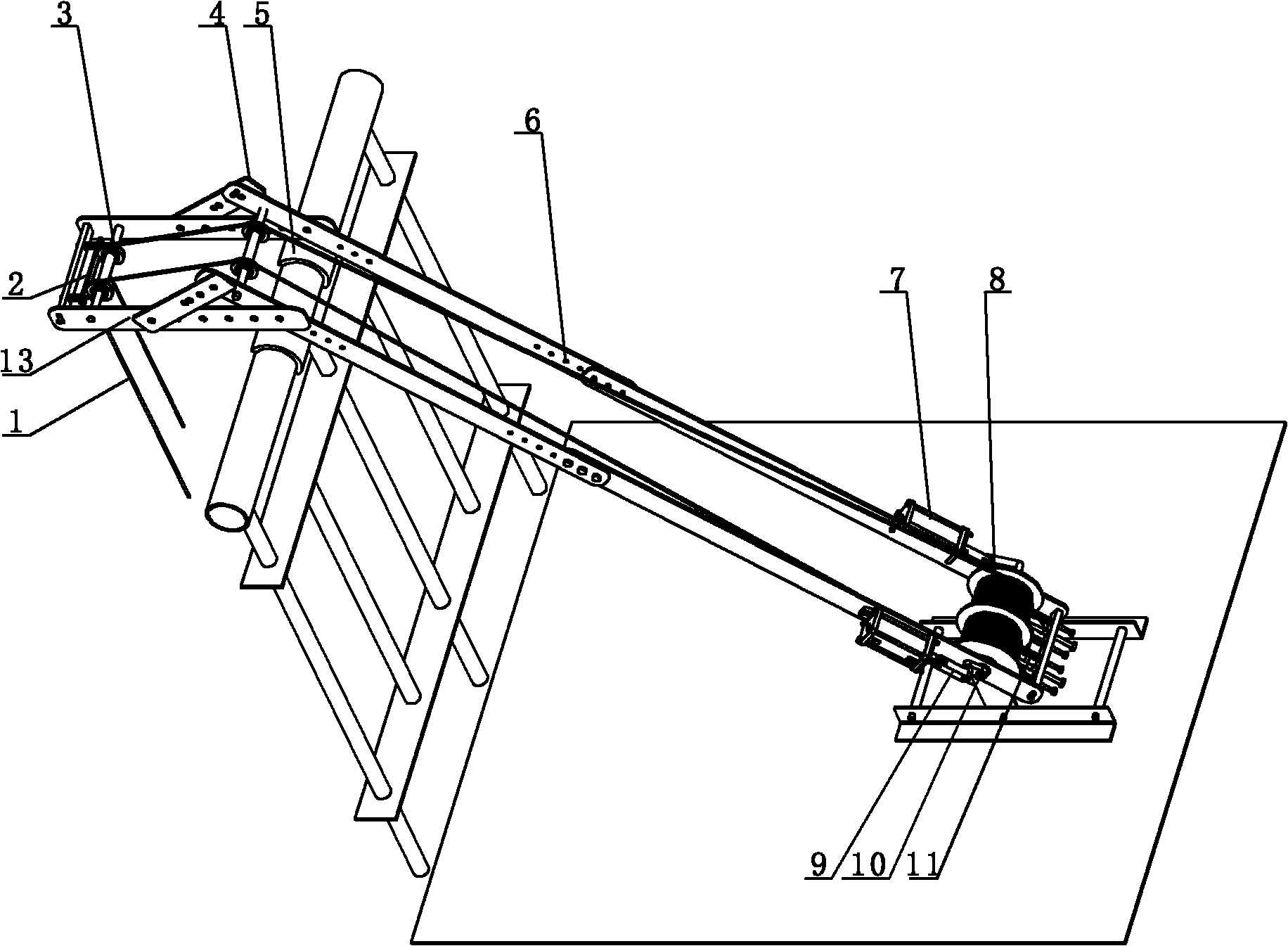

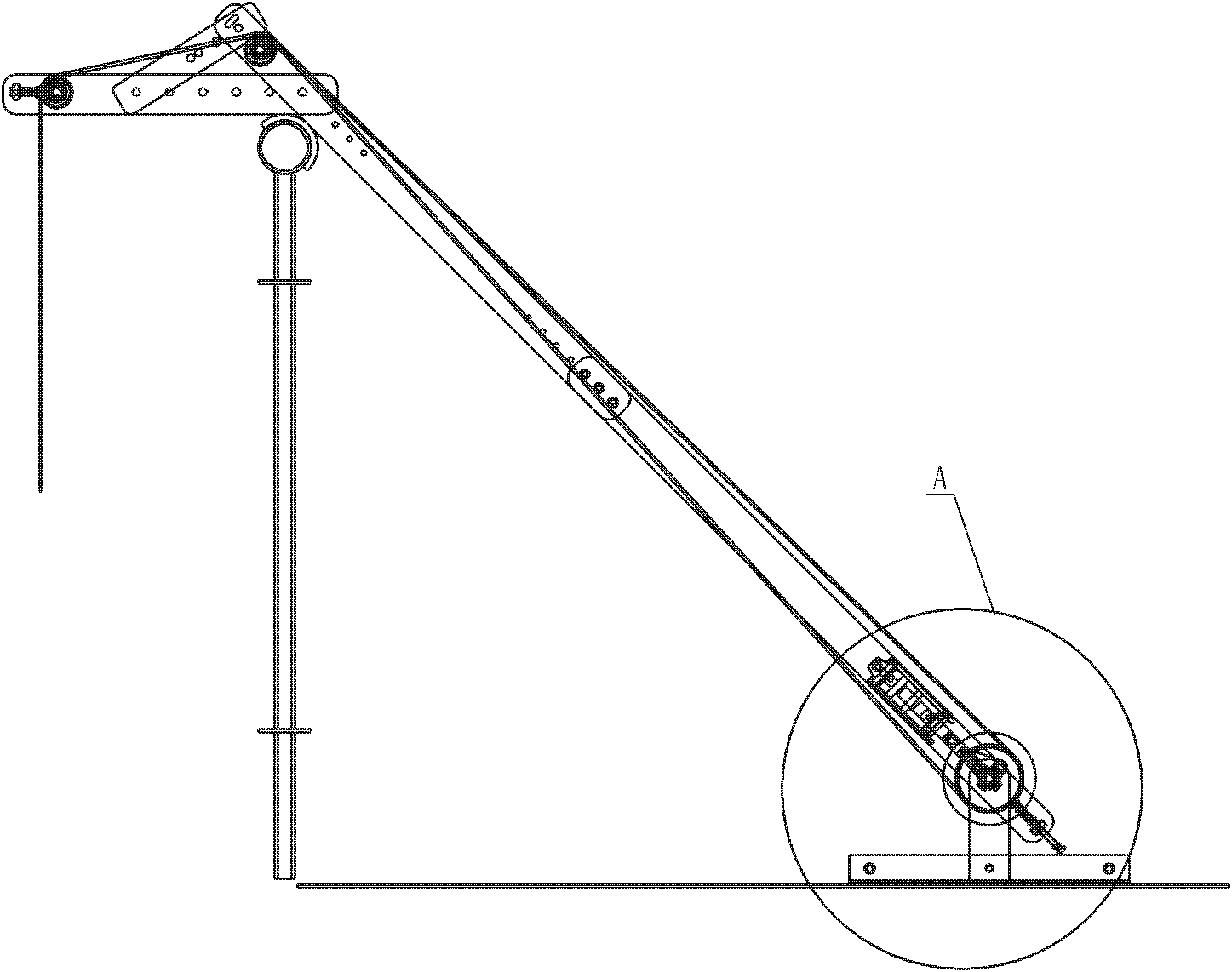

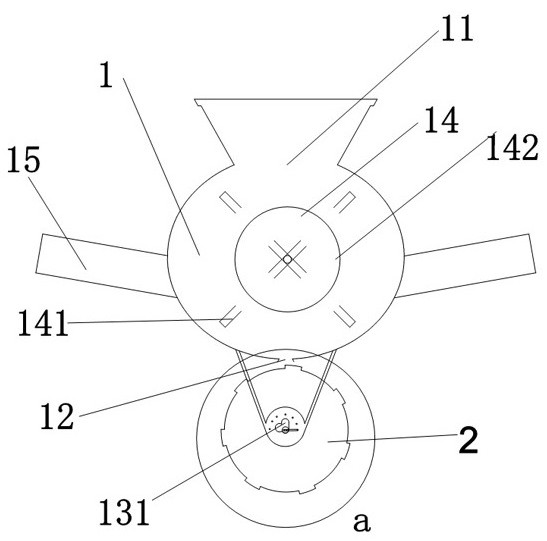

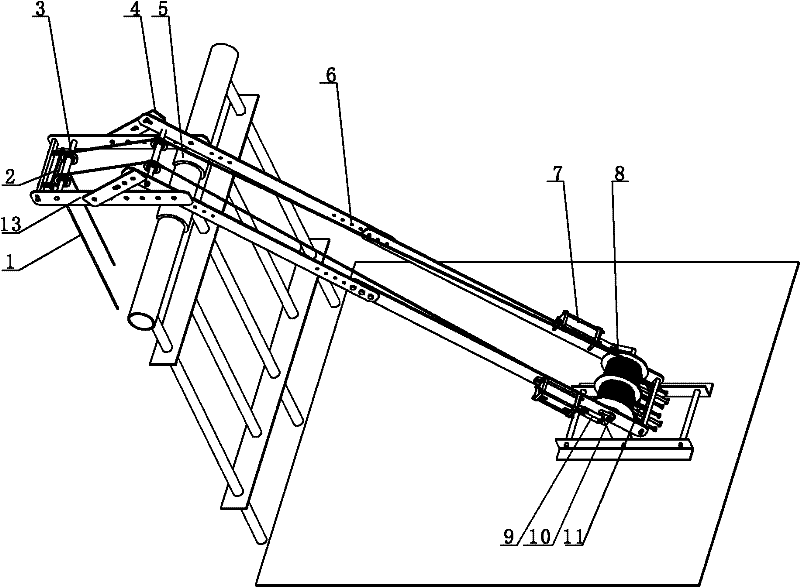

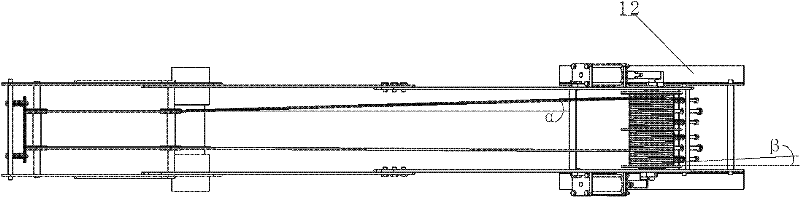

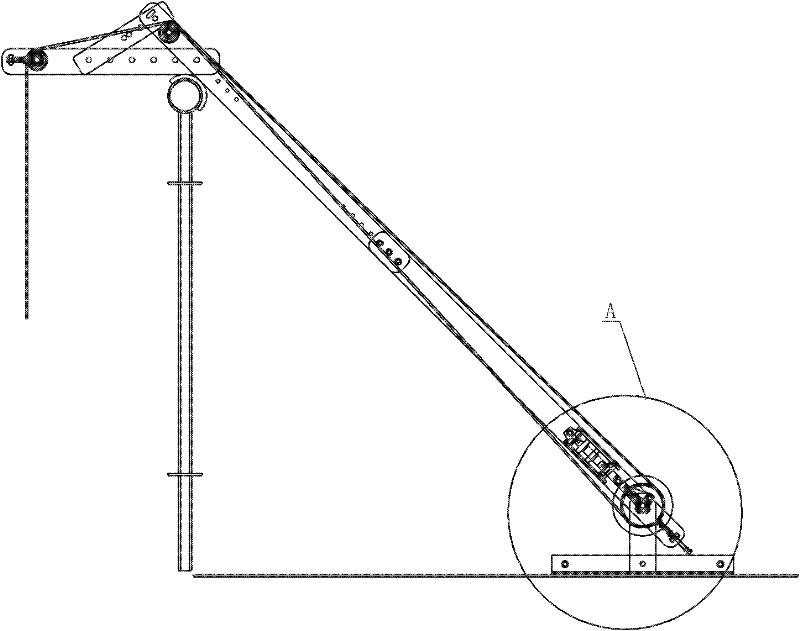

Reciprocating descent control device

The invention discloses a reciprocating descent control device. A rotating shaft is arranged on a bracket and is provided with a winding drum; a steel wire rope is wound on the winding drum around a pulley; a damping cylinder is arranged on the bracket close to the rotating shaft; a piston of the damping cylinder is connected with the rotating shaft through a crank slider mechanism; and a small hole is formed on the piston. The preferable scheme of the invention is that: the reciprocating descent control device is provided with two damping cylinders, and a rotation angle of the crank slider mechanism which is connected with the damping cylinders is staggered for 90 degrees. Therefore, the dead center of the crank slider mechanism is avoided, the speed is steady during descent control, and the winding of the steel wire rope due to the speed change is avoided. The reciprocating descent control device is not controlled by a user at all during use, can realize continuous descent control, and has the advantages of steady operation, safety and reliability, and low production cost.

Owner:HUBEI THREE GORGES POLYTECHNIC

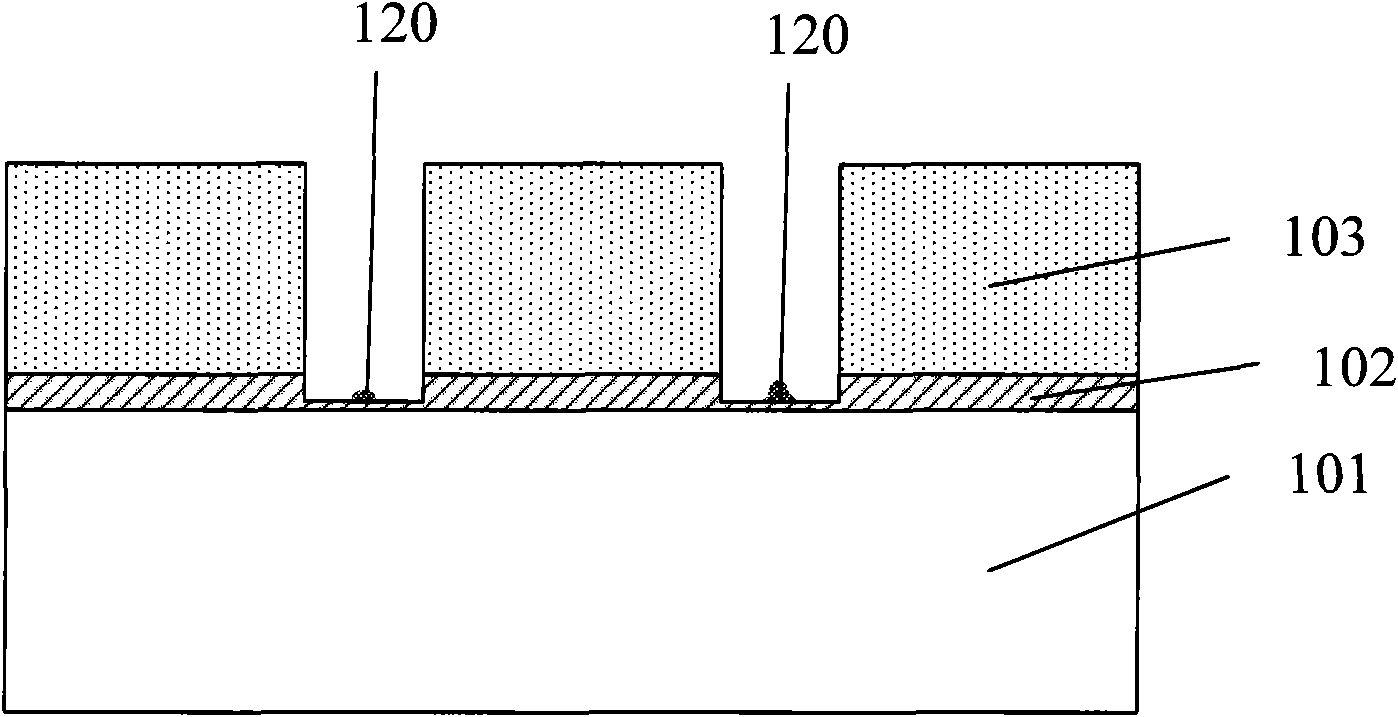

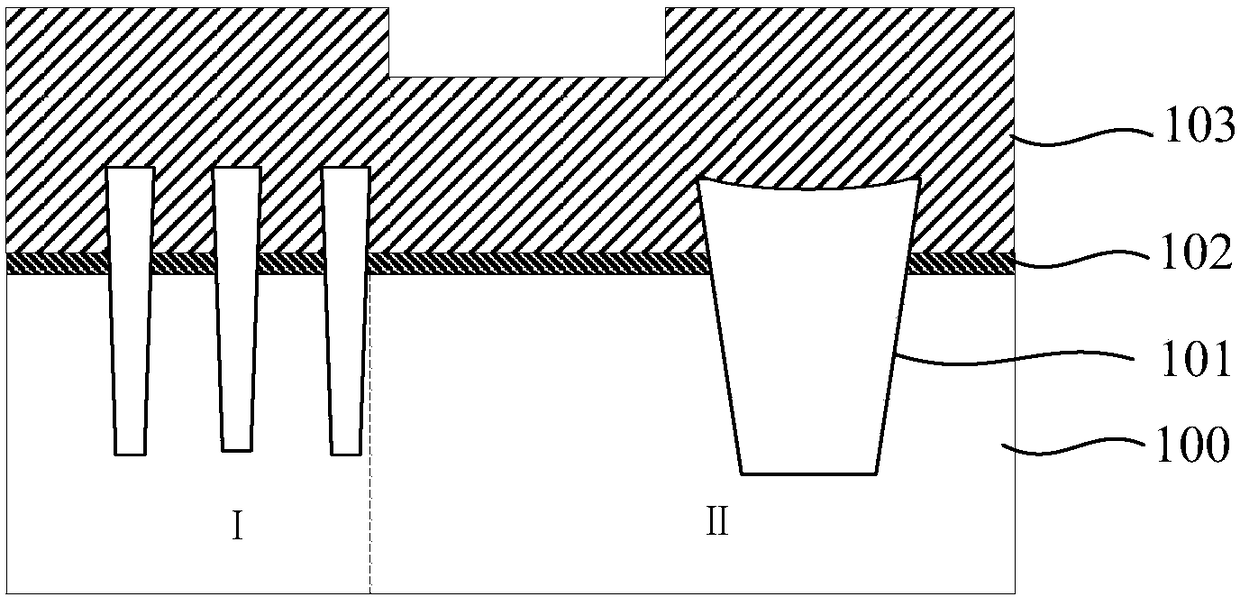

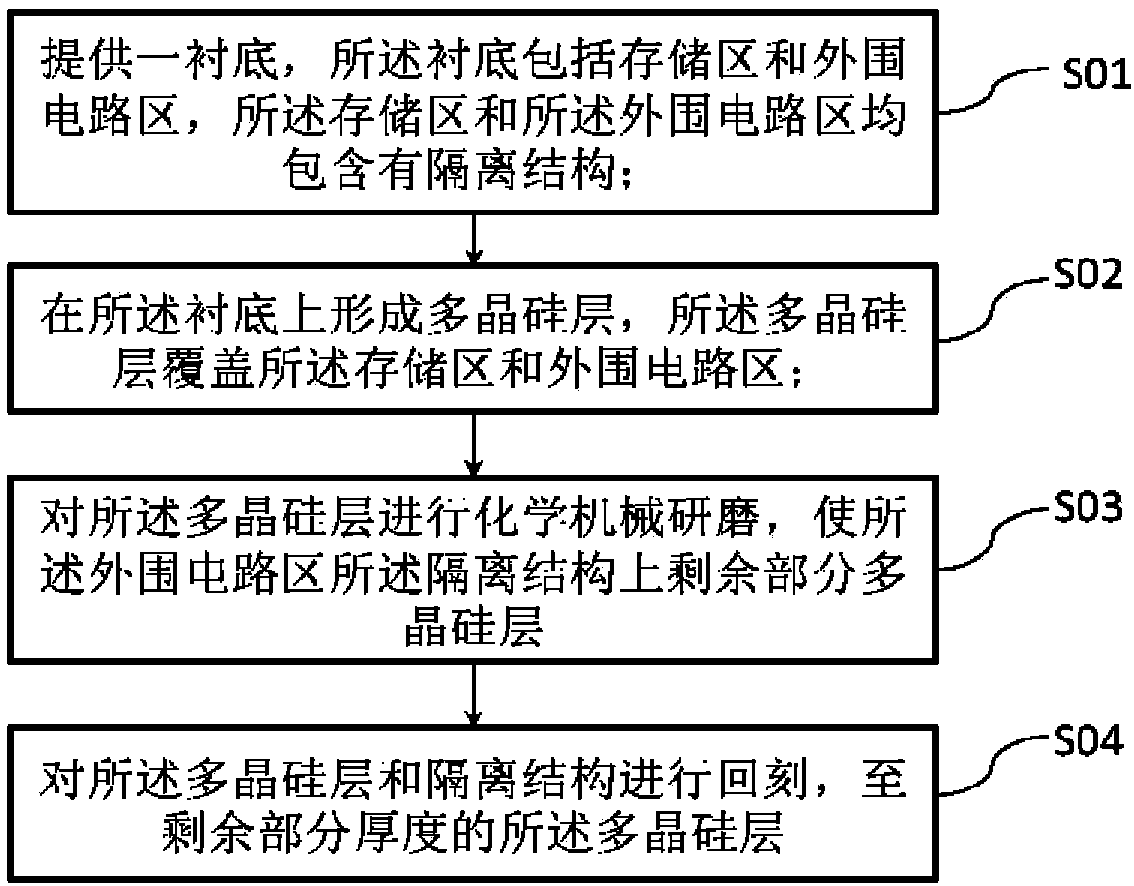

Method for forming floating gate

ActiveCN108321087AImprove uniformityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingPolycrystalline silicon

The present invention provides a method of forming a floating gate. The method includes the following steps that: a substrate is provided, the substrate includes a memory region and a peripheral circuit region, wherein the storage region and the peripheral circuit region each include an isolation structure; a polysilicon layer is formed on the substrate, wherein the polysilicon layer covers the storage region and the peripheral circuit region; chemical mechanical polishing is performed on the polysilicon layer, so that a part of the polysilicon layer can be left on the isolation structure of the peripheral circuit region; and back-etching is performed on the polysilicon layer and the isolation structure until a part of polysilicon layer of a certain thickness can be left. According to themethod of the invention, the uniformity of the polysilicon layer of the storage region and the peripheral circuit region after chemical mechanical polishing is performed can be improved, and the performance and yield of the product can be improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

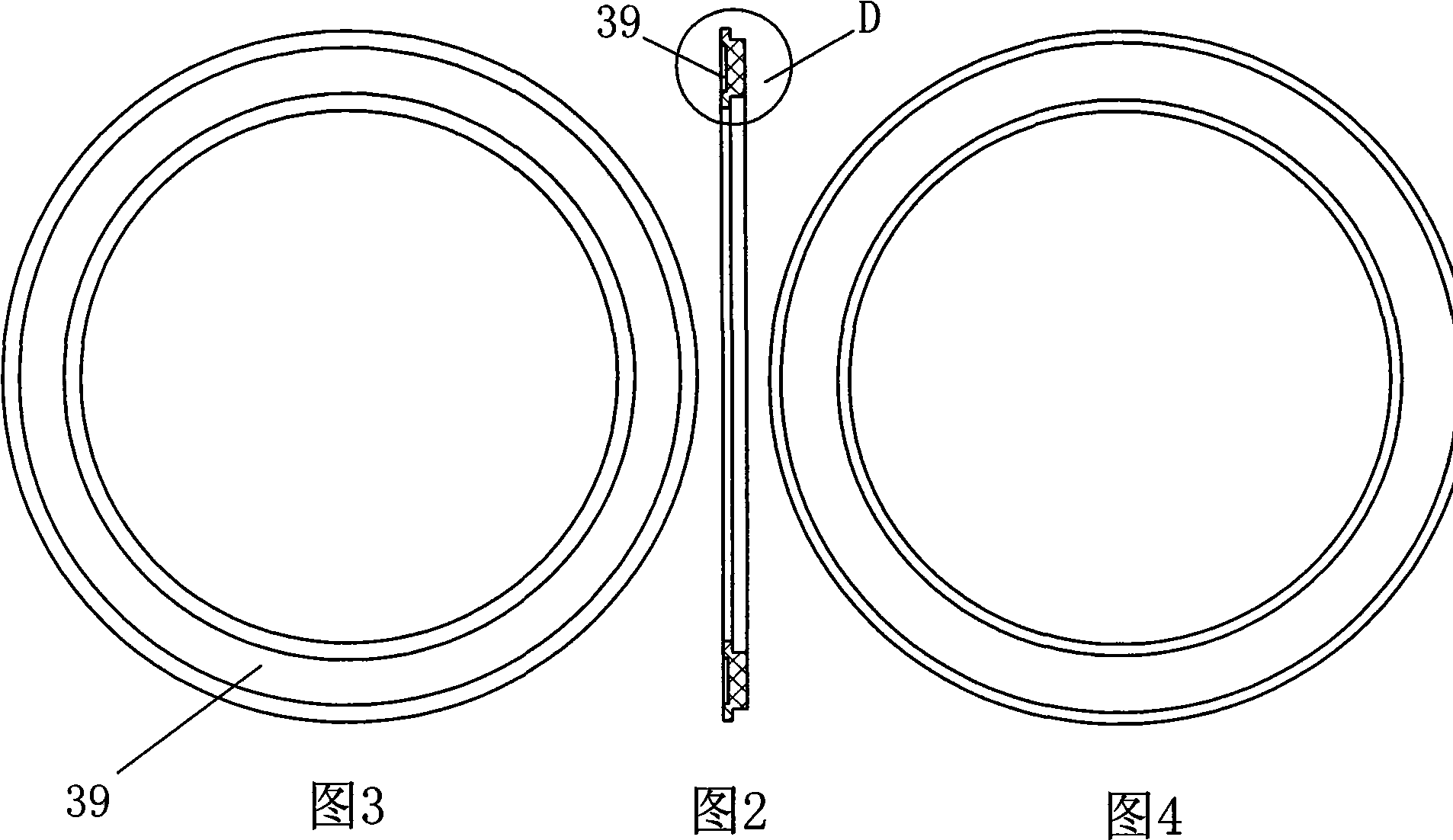

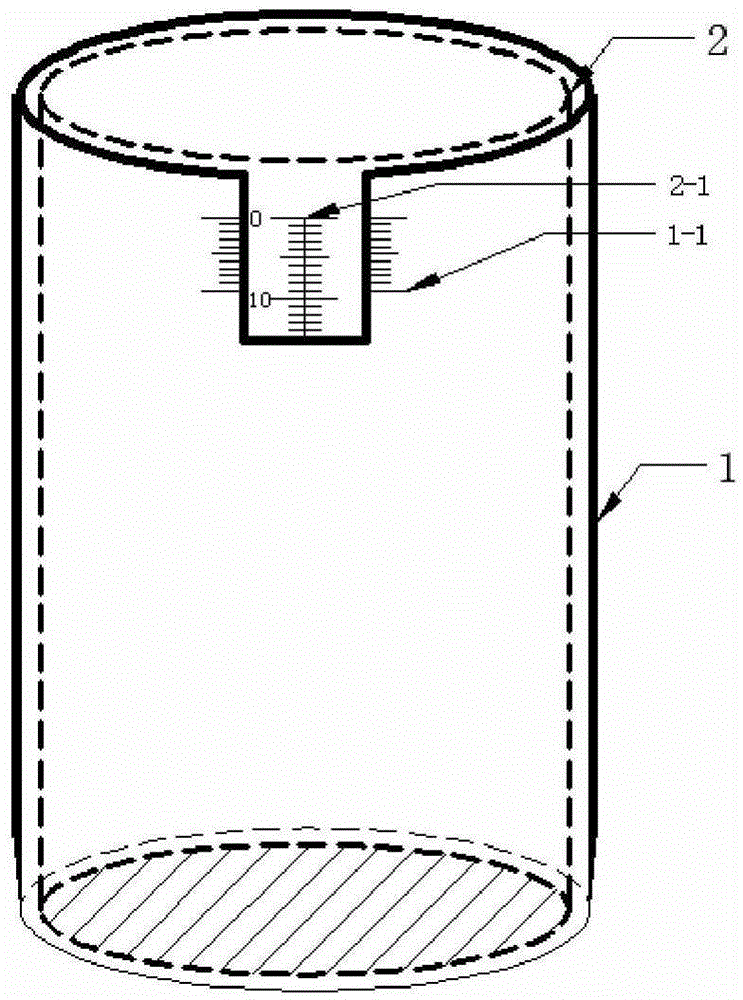

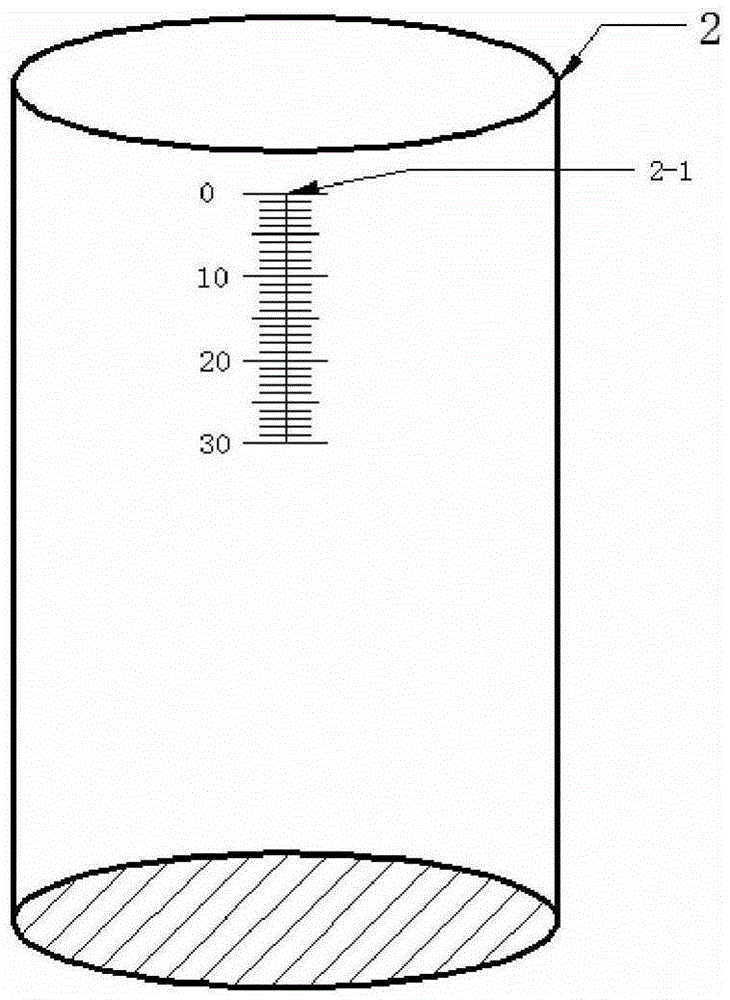

Device and method for measuring thickness of cement mortar at surface layer of pavement concrete

InactiveCN105423857ASimple design principleStrong operabilityMechanical thickness measurementsSurface layerCement mortar

The invention relates to a device and method for measuring the thickness of cement mortar at the surface layer of pavement concrete. The device comprises an outer-ring cylinder and an inner-ring cylinder, the external diameter of the inner-ring cylinder is lower than the internal diameter of the outer-ring cylinder, both the upper and lower ends of the outer-ring cylinder are open, the inner-ring cylinder is provided with a bottom, the upper end of the inner-ring cylinder is open, the inner-ring cylinder is nested in the outer-ring cylinder, the upper end of the outer wall of the outer-ring cylinder is provided with graduation lines of the outer-ring cylinder, and the upper end of the outer wall of the inner-ring cylinder is provided with graduation lines of the inner-ring cylinder. According to the invention, the thickness of the cement mortar at the surface layer of the concrete can be rapidly and effectively measured.

Owner:北京中企卓创科技发展有限公司

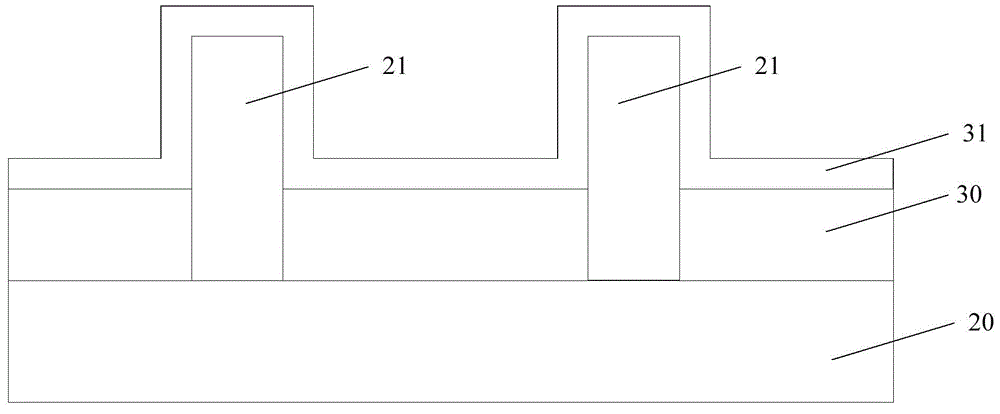

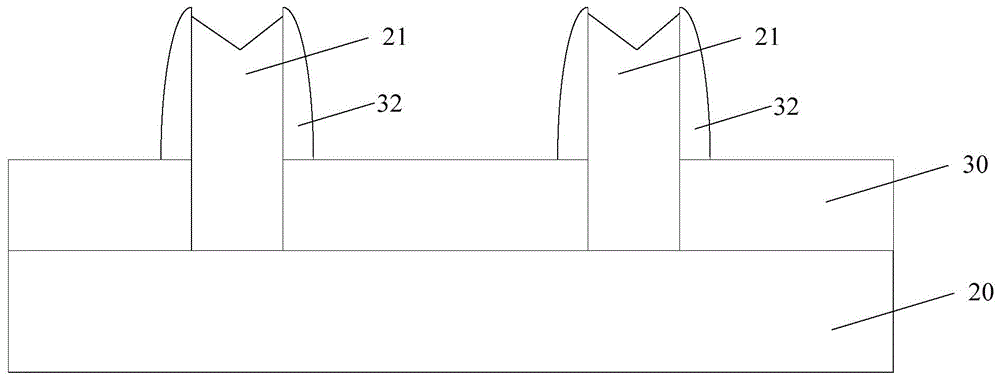

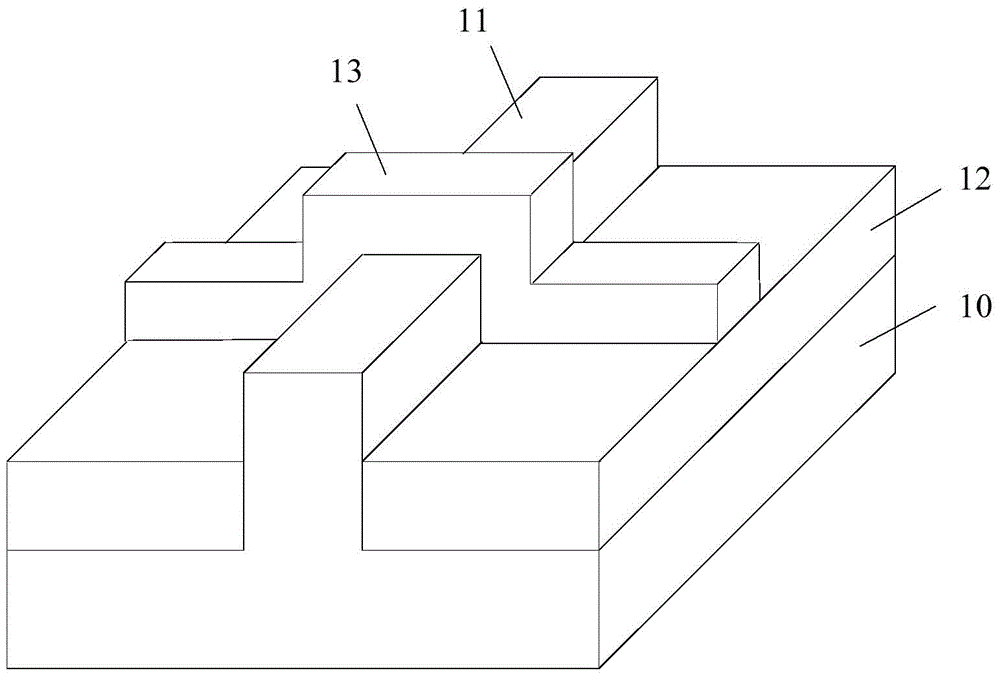

FinFET (Fin Field Effect Transistor) and formation method thereof

ActiveCN105826187AImprove short channel effectImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorEngineering

The invention relates to a FinFET (Fin Field Effect Transistor) and a formation method thereof. The formation method of the FinFET comprises the steps of providing a substrate, wherein the substrate comprises a first semiconductor layer, an insulating layer and a second semiconductor layer, forming a mask layer at partial surface of the second semiconductor layer and etching the second semiconductor layer by taking the mask layer as a mask to the insulating layer so as to form a fin portion, forming a sacrificial layer at the surface of the sacrificial layer, wherein the surface of the sacrificial layer is lower than top surface of the fin portion and covers partial side wall of the fin portion, and the part, which is higher than the sacrificial layer, of the fin portion acts as a first sub-fin portion, forming a protection layer at the side wall surface of the first sub-fin portion, removing the sacrificial layer, carrying out transverse etching on the fin portion along the exposed side wall of the fin portion so as to enable the width of partial fin portion to be reduced and enable the first sub-fin portion to be partially suspended, wherein the part, which is reduced in width, of the fin portion acts as a second sub-fin portion, and removing the protection layer and the mask layer and forming a gate structure which stretches across the first sub-fin portion and the second sub-fin portion. The formation method provided by the invention can improve the performance of the formed FinFET.

Owner:SEMICON MFG INT (SHANGHAI) CORP

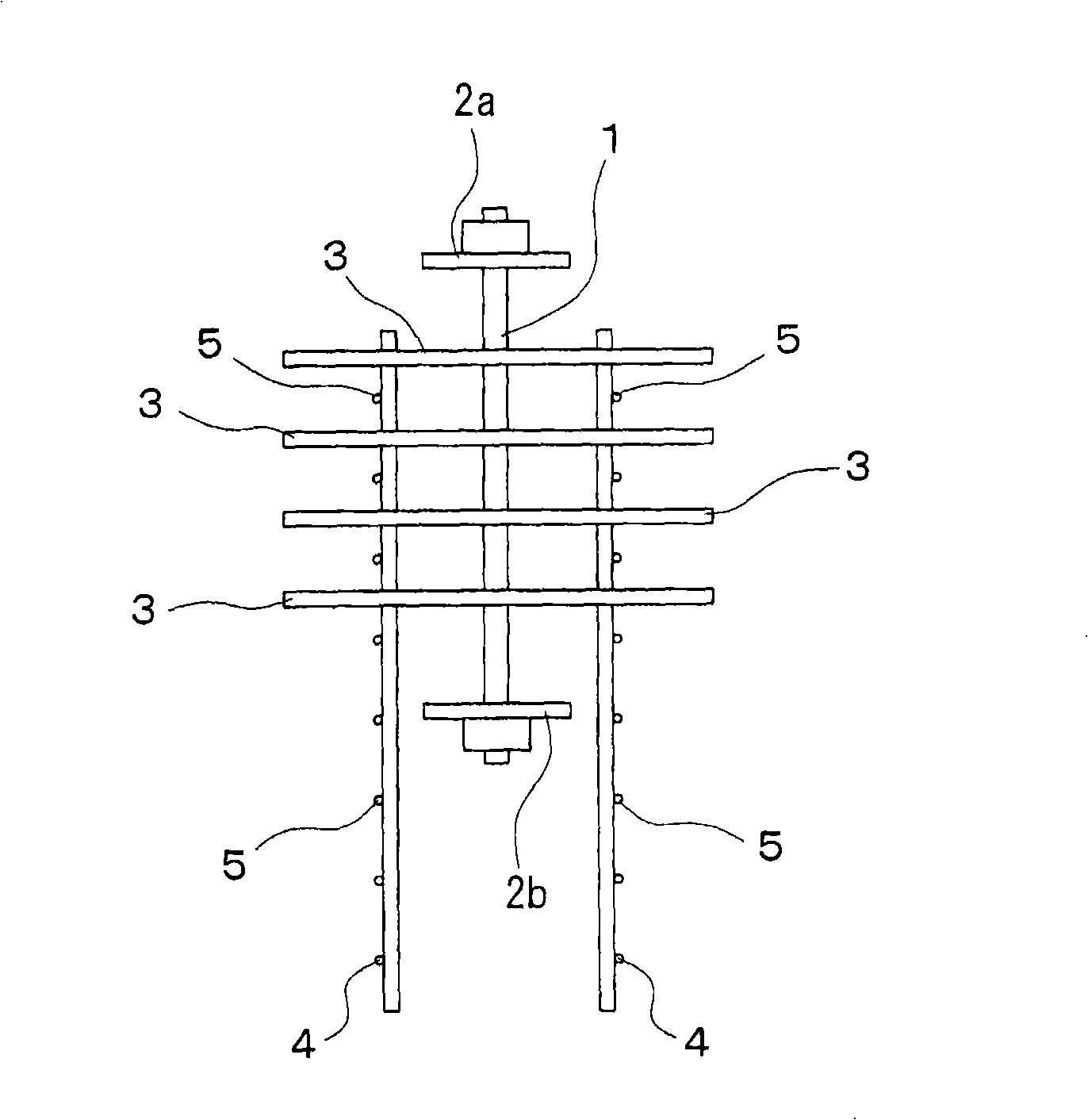

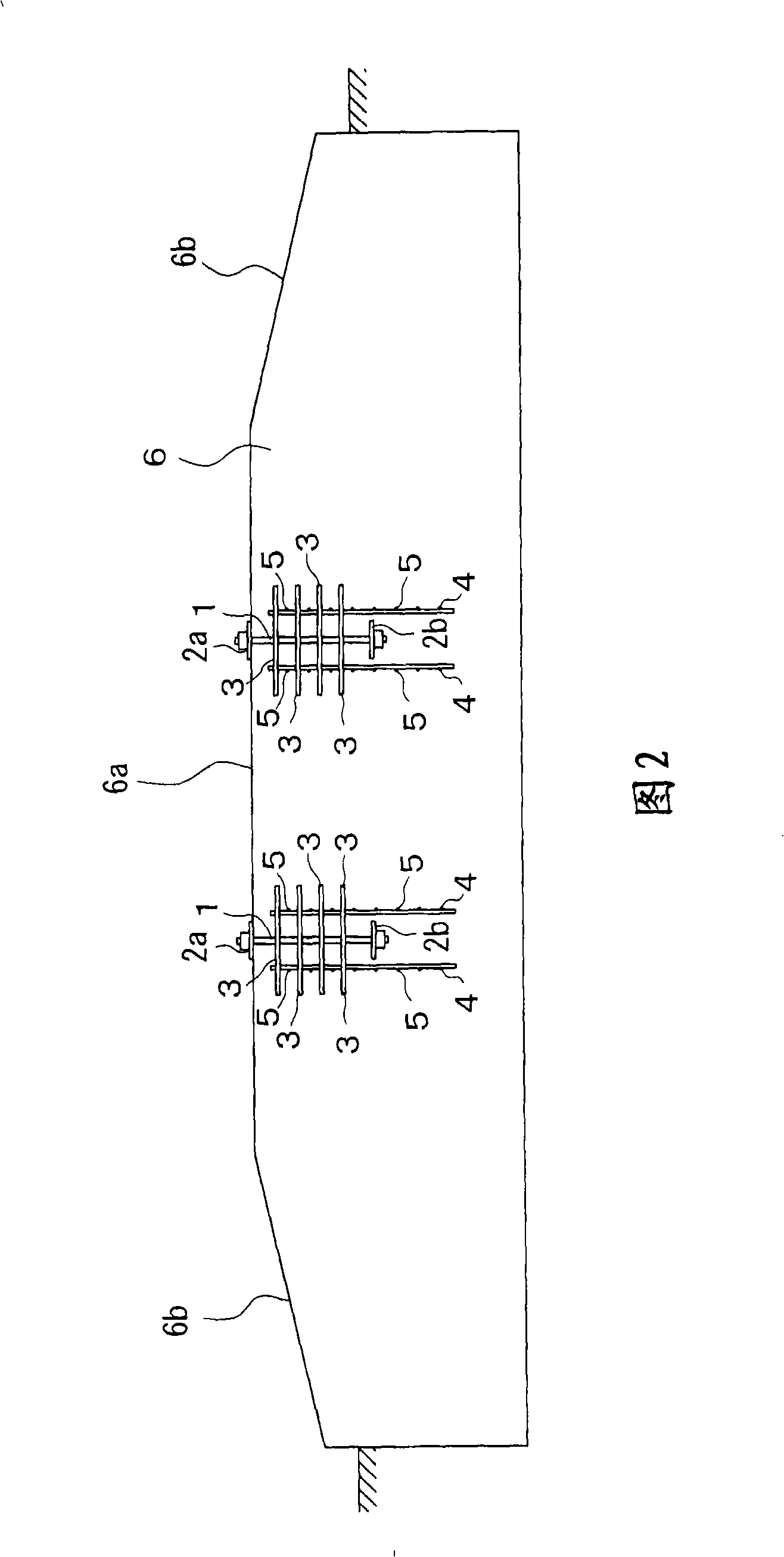

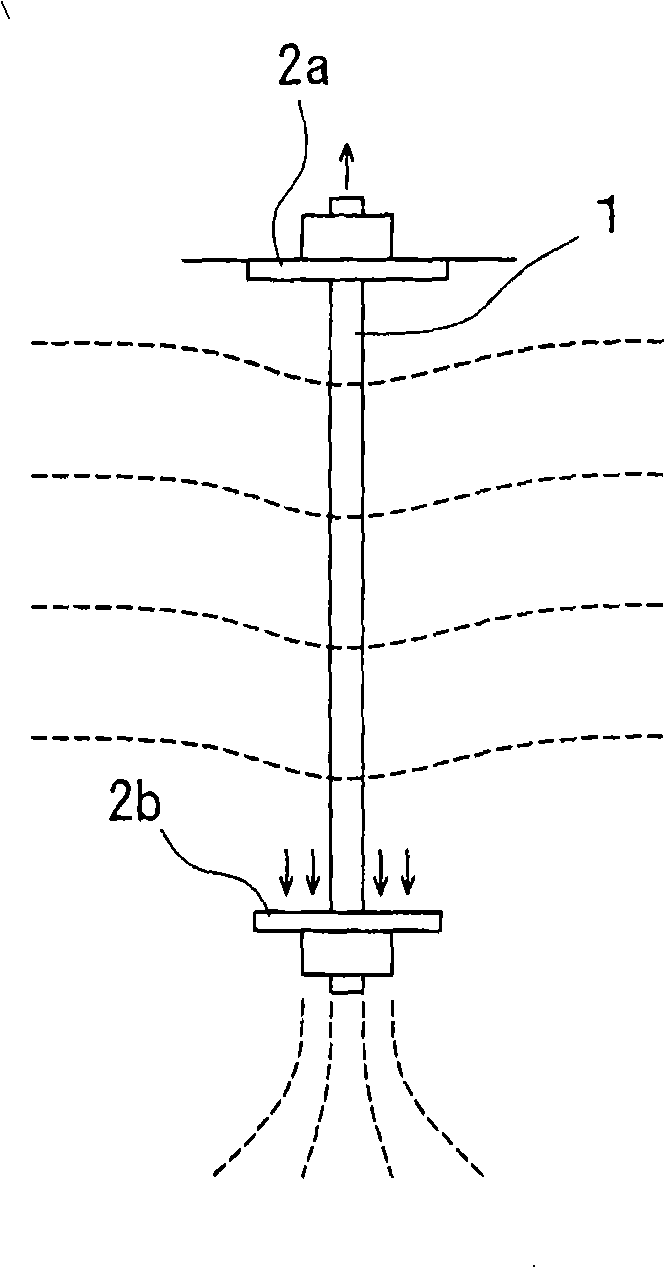

Foundation structure for tower-like construction

InactiveCN101265708ACrack suppressionAvoid breakingFoundation engineeringWind energy generationPre stressAdhesive

The invention provides a basic structure of a tower-shaped works which is the basic structure of the pillar or tower and other tower-shaped works. The basic structure has a totally fixed pillar pin potion which enables the guided pre-stress without the adhesive; the potion inhibits the generation of the cracks for the concrete. A transverse steel bar (3) and annular steel bar (5) are distributed on the crossing direction with the length corresponding to the non-adhesive anchor bolt (1) arranged on the substrate (2a) and the anchor bolt board (2b) and the pre-stress; a vertical steel bar (4) is distributed in the parallel direction of the length. While distributing the steel bar and casting the concrete (6), the invention significantly increases the thickness of the concrete (6) of the crossing direction of the length direction of the non-adhesive anchor bolt (1).

Owner:MITSUI ENG & SHIPBUILD CO LTD

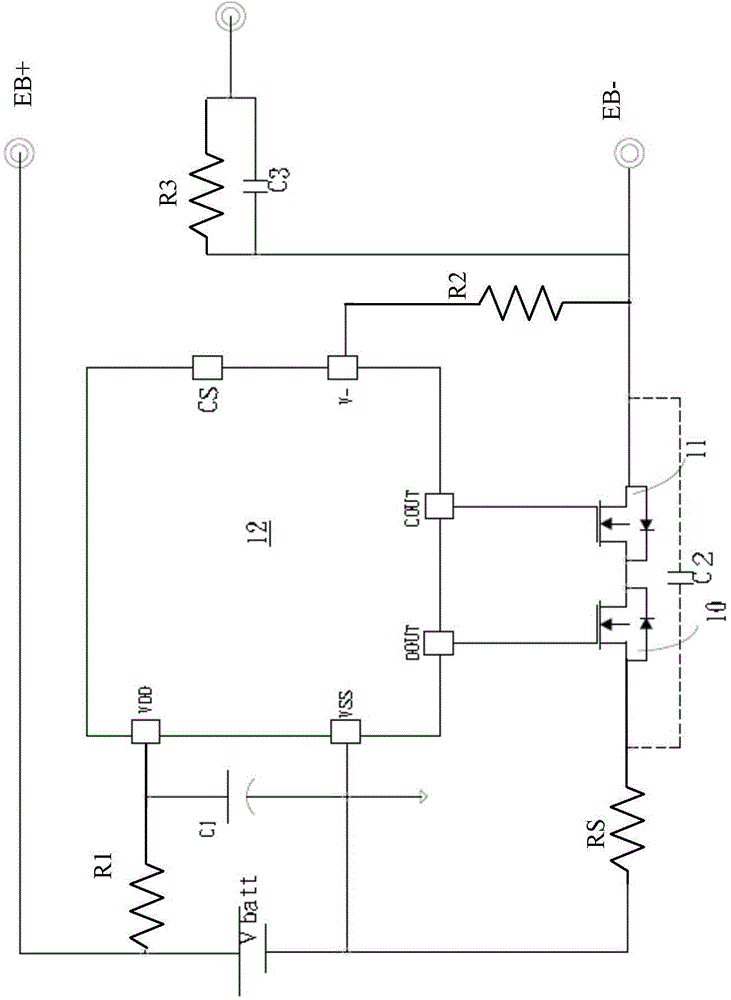

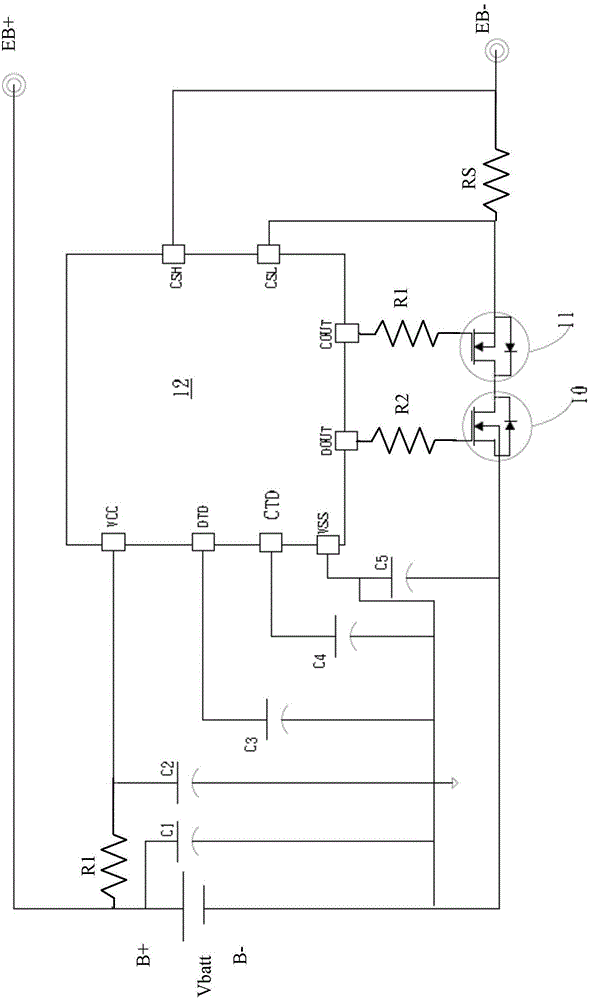

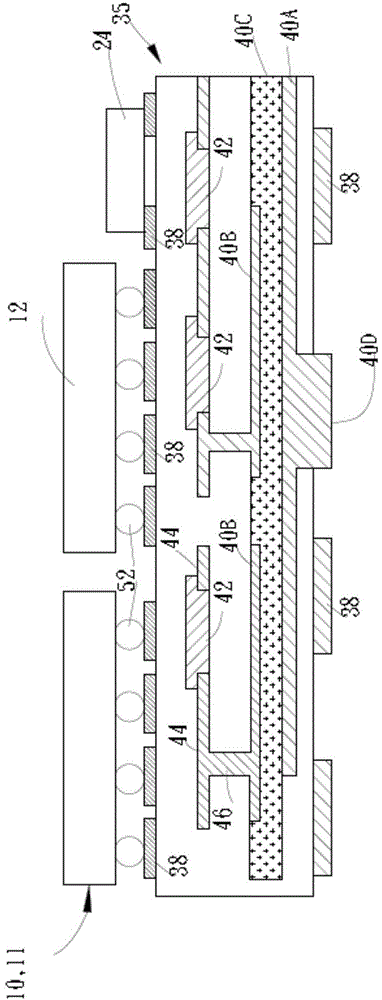

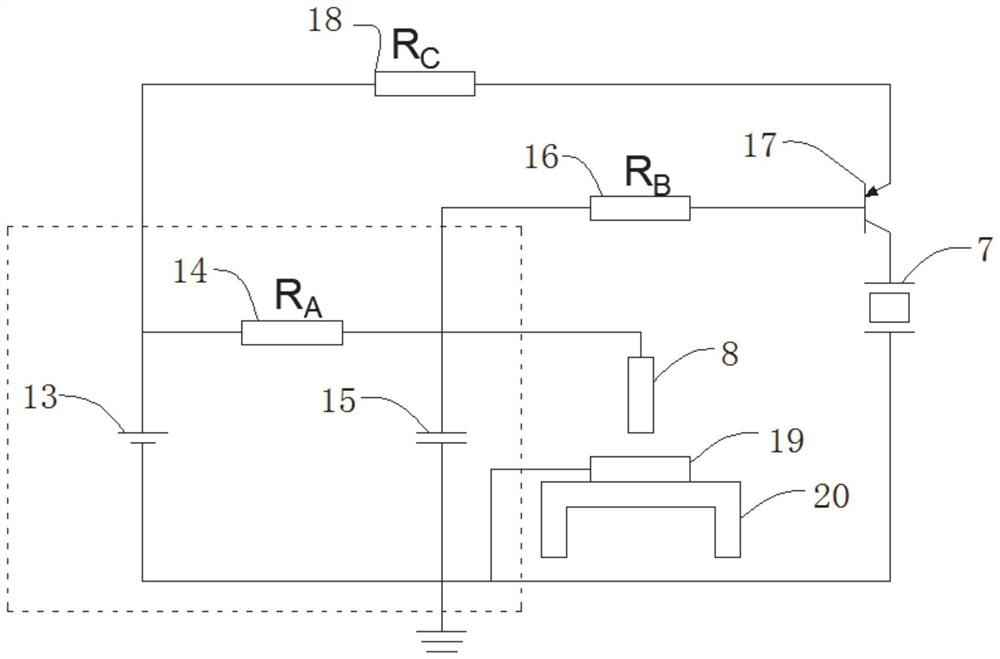

Packaging structure for battery management integrated circuit

InactiveCN105336713ASimple processLow costSemiconductor/solid-state device detailsSolid-state devicesCapacitanceContact pad

The invention provides a packaging structure for a battery management integrated circuit. The packaging structure comprises a wire frame, a battery management chip, a charging and discharging controlled metal oxide semiconductor transistor, a resistor and a capacitor, wherein the wire frame is formed on a support; the wire frame is provided with a first contact pad, a second contact pad, and a pin and a connecting wire of the battery management chip; the battery management chip is connected with the first contact pad; the charging and discharging controlled metal oxide semiconductor transistor is connected with the second contact pad; the resistor and the capacitor are connected between the pin of the battery management chip and a pin of the battery management integrated circuit; and the wire frame of the packaging structure for the battery management integrated circuit is on one plane. The packaging structure for the battery management integrated circuit can be dramatically reduced.

Owner:NEOTEC SEMICON

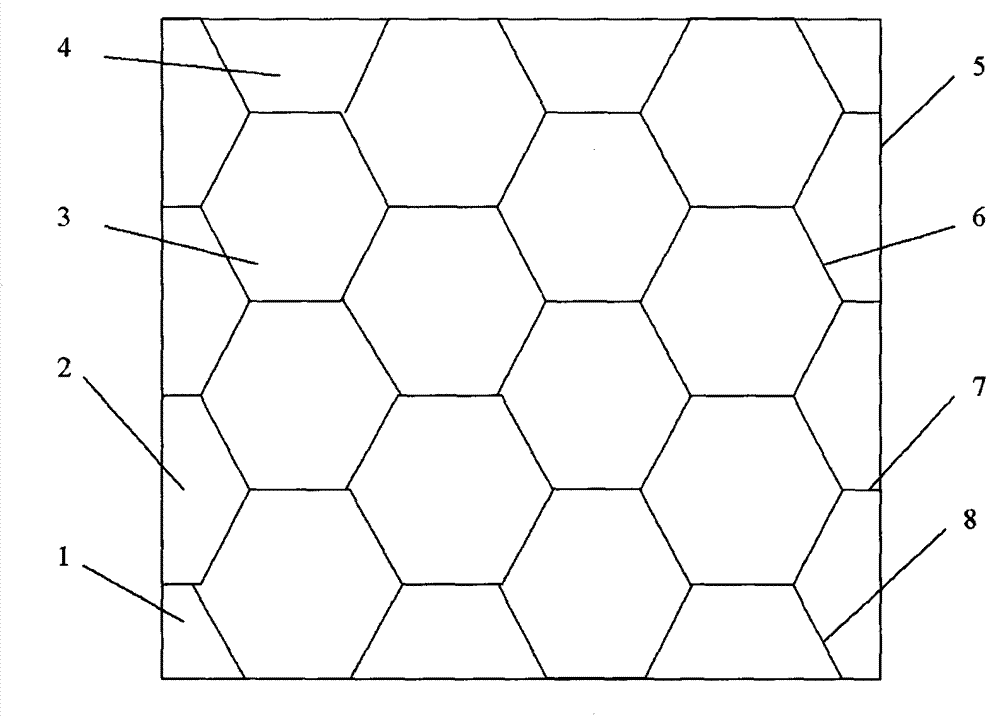

Inorganic material outer wall heat insulation and preservation board and production method thereof

InactiveCN104264847AThick enoughReduce dropCeramic shaping apparatusHeat proofingFoam concreteInorganic materials

The invention discloses an inorganic material outer wall heat insulation and preservation board. The inorganic material outer wall heat insulation and preservation board is in a regular hexagon shape, and is made of foam concrete. The inorganic material outer wall heat insulation and preservation board further comprises side blocks and corner blocks, the side blocks and the corner blocks are matched with regular hexagon main blocks for use and are made of foam concrete, and the side blocks, the corner blocks and the main blocks are spliced to form a rectangle or a square. The invention further provides a production method of the inorganic material outer wall heat insulation and preservation board. The inorganic material outer wall heat insulation and preservation board is novel in structure, and is pasted on an outer wall to form a honeycomb structure, the inorganic material outer wall heat insulation and preservation board is attractive and elegant and more even in stress, the pasting blocks are prevented from falling off, anchoring is reduced or is not needed, and construction efficiency is high. The production method of the inorganic material outer wall heat insulation and preservation board is convenient, easy to implement and high in production efficiency, the regular hexagon main blocks, the side blocks and the corner blocks can be simultaneously produced at a time, the side blocks and the corner blocks are matched with the regular hexagon main blocks for use, the rectangle or the square can be spliced, and outer wall construction is facilitated.

Owner:廖来松

Glue spreading equipment and gluing process of decorative plate

PendingCN113877760AAppropriate thickness of glue coatingGood glue effectLiquid surface applicatorsCovering/liningsAdhesive glueEngineering

Glue spreading equipment comprises a glue mixing barrel used for mixing and containing glue, and a glue spreading roller used for receiving the glue in the glue mixing barrel, and the glue mixing barrel is provided with at least one feeding port and a discharging port; supporting legs are arranged on the two sides of the glue mixing barrel, and two limiting grooves are symmetrically formed in the two supporting legs; a shaft of the glue spreading roller is movably cooperated with the limiting grooves, and a plurality of thickness fixing units with a thickness fixing function are arranged on the glue spreading roller; and each thickness fixing unit is provided with a rolling curved surface, and an absorbing groove is formed between every two adjacent thickness fixing units. When the glue spreading equipment provided by the invention is used for glue spreading, the gluing strength can be improved, and the quality of plates is improved.

Owner:ZHEJIANG YASHA DECORATION

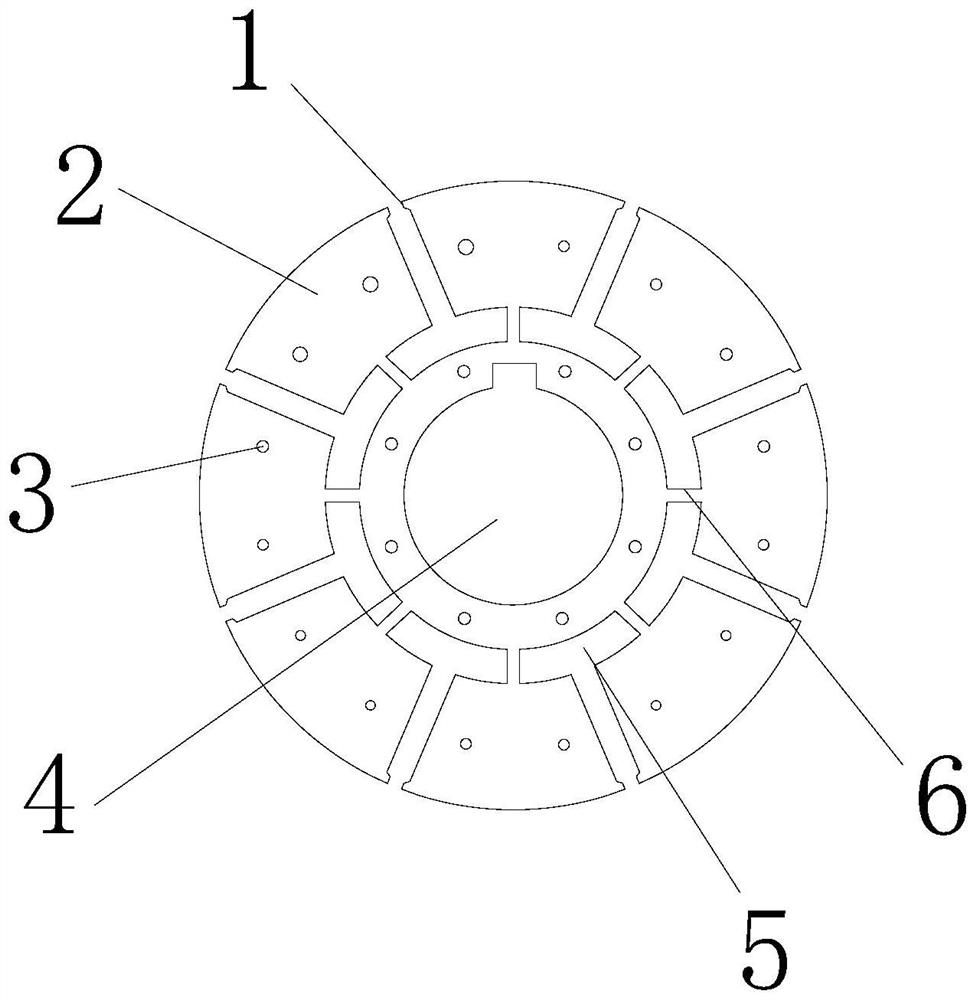

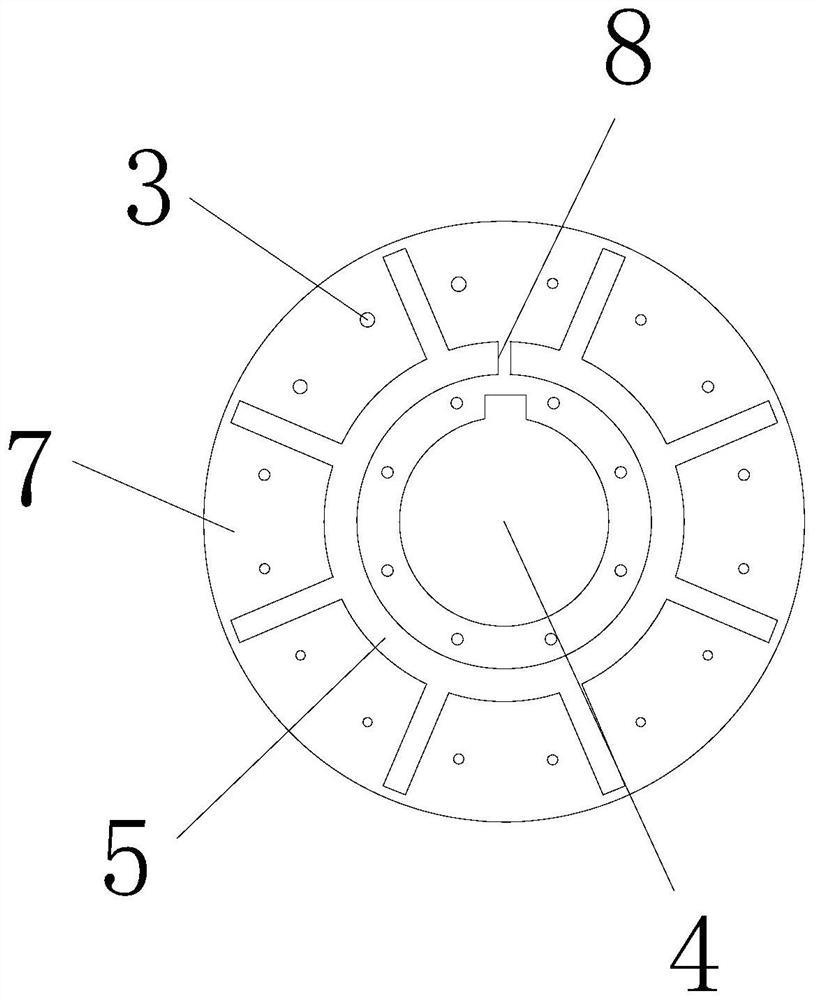

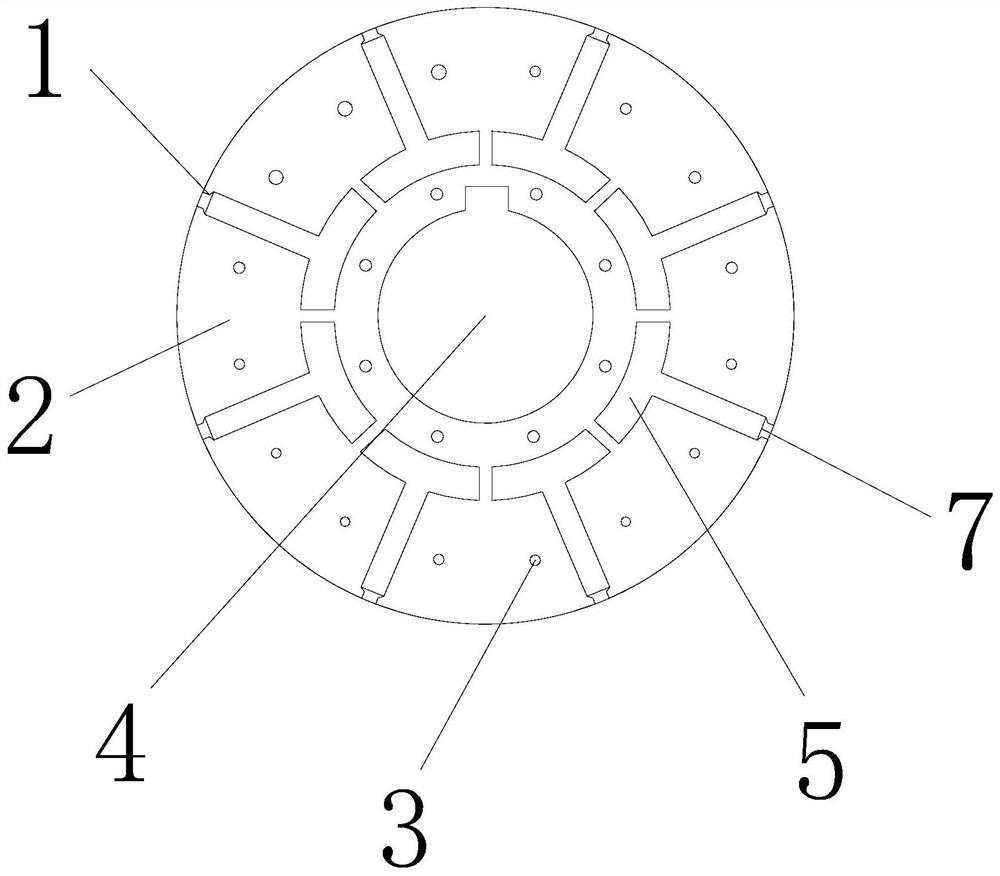

Open-close opening interval tangential built-in permanent magnet motor rotor core

InactiveCN112583157AReduce Flux LeakageImprove applicabilityMagnetic circuit rotating partsElectric machineryStructural engineering

The invention discloses an opening-closing opening interval tangential built-in permanent magnet motor rotor core, which belongs to the technical field of permanent magnet motors, and comprises a first rotor punching sheet and a second rotor punching sheet, riveting buckle holes are uniformly formed in the surface of the first rotor punching sheet along the circumferential direction at intervals,and inner ring connecting ribs are arranged between the riveting buckle holes. Connecting rib fractures are evenly formed in the inner ring connecting rib at intervals, outer ring fractures are evenlyformed in one side of the riveting buckle hole at intervals, the second rotor punching sheet is arranged at the bottom end of the first rotor punching sheet, and the first rotor punching sheet and the second rotor punching sheet are combined, stacked and riveted to form a rotor iron core. By arranging the first rotor punching sheet and the second rotor punching sheet, different structural strength requirements are met, the applicability of the rotor iron core is improved, the working quality is ensured, and after laminating and riveting, the rotor magnetic flux leakage can be reduced, the motor performance is improved, the working cost is reduced, the working efficiency is improved, the production cost is reduced, and the use quality is improved.

Owner:ZHEJIANG JINLONG ELECTRICAL MASCH CO LTD

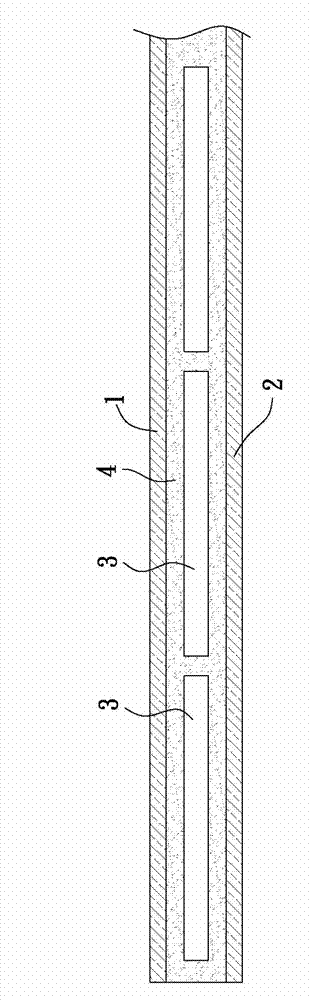

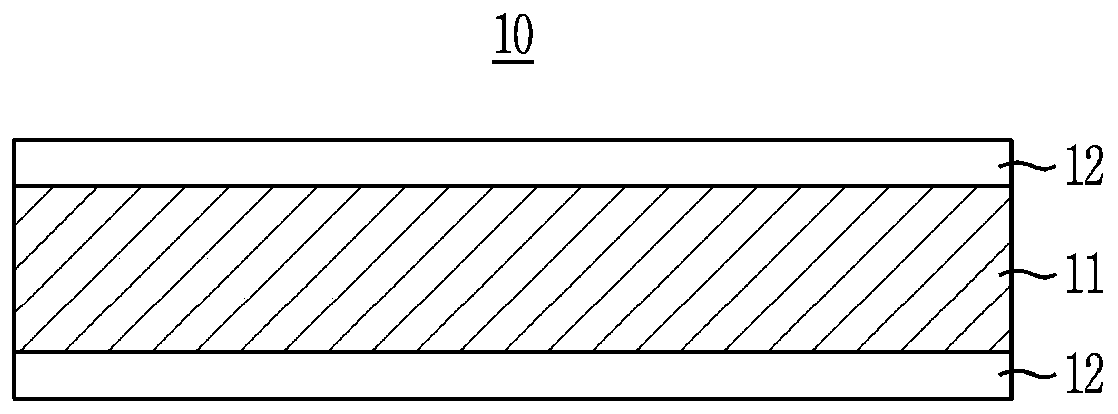

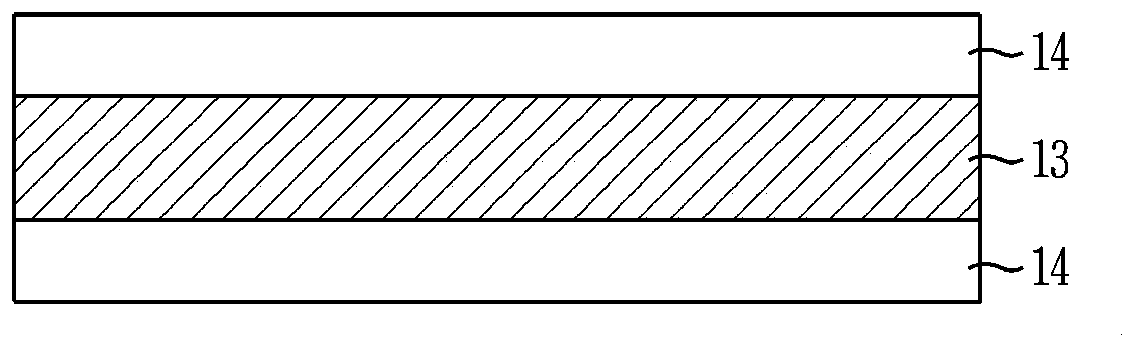

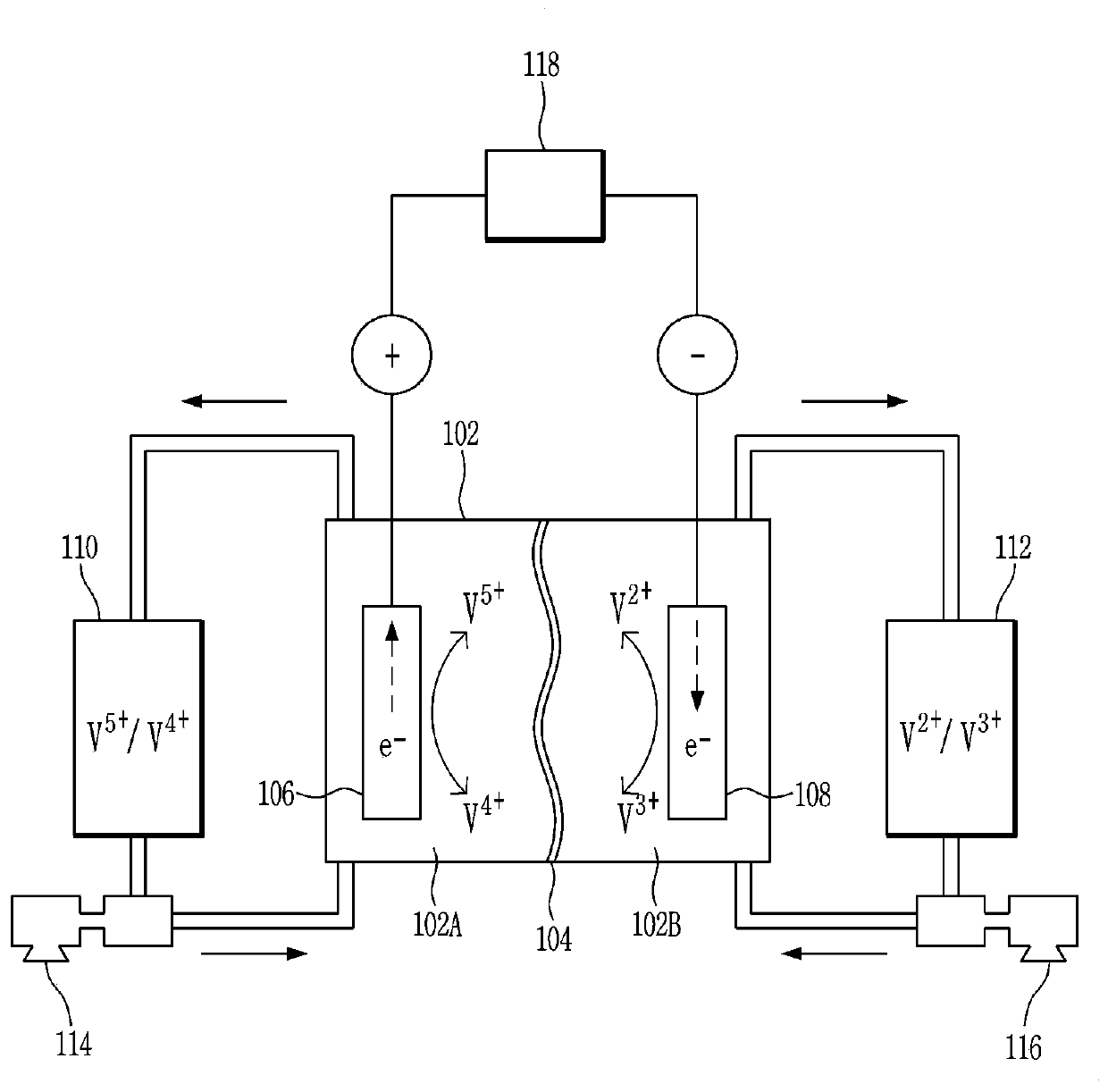

Ion exchange membrane, manufacturing method therefor, and energy storage device comprising same

ActiveCN110462906AImprove ionic conductivityGood chemical stabilitySolid electrolytesFinal product manufactureElectrical conductorChemical physics

The present invention relates to an ion exchange membrane, a manufacturing method therefor, and an energy storage device comprising the same. The ion exchange membrane comprises: a porous support including a plurality of pores; and an ion conductor filling the pores of the porous support, wherein the porous support includes a micropore having a size of 31 to 1000 Mum. In addition, the ion exchangemembrane has high charge / discharge cycle durability, high ion conductivity, and excellent chemical and thermal stability, and thus can achieve a high energy efficiency when applied to an energy storage device, such as a vanadium redox flow cell.

Owner:KOLON IND INC

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459BReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

Method for preparing highly nitrogen-doped mesoporous carbon composites

ActiveCN107454861BFavorable and accessibleThick enoughCatalyst carriersCell electrodesCatalytic transformationCarbon composites

Owner:UNIVERSITY OF STRASBOURG +2

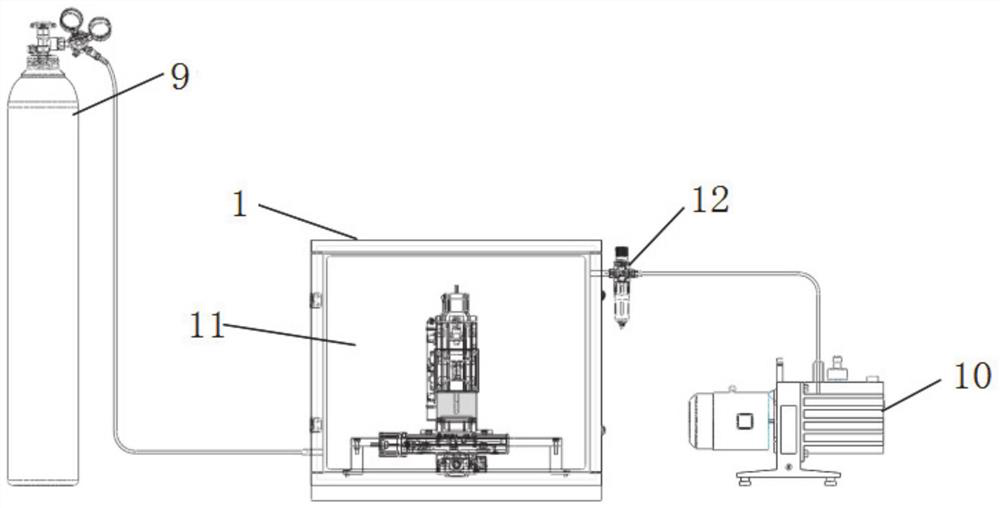

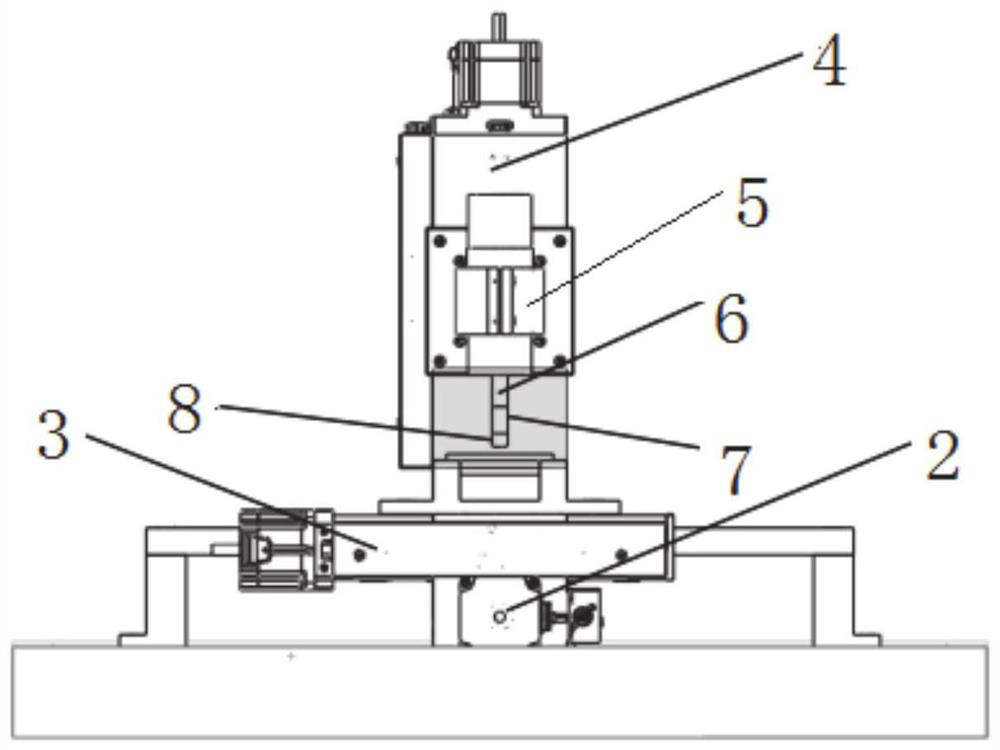

Device and method for preparing high-entropy alloy coating through electric spark deposition

ActiveCN112941510ANot easy to slipSolve the problem of poor deposition surface qualityMetallic material coating processesPiezoelectric actuatorsShielding gas

The invention relates to a device and method for preparing a high-entropy alloy coating through electric spark deposition. The device comprises a machining mechanism and a shielding gas supply mechanism, wherein the machining mechanism comprises a sealing cover, a two-axis linkage mechanism capable of containing a workpiece is arranged in the sealing cover, a vertical lifting mechanism is arranged at one side of the two-axis linkage mechanism, the vertical lifting mechanism is connected with a power system, the power system is connected with a main shaft, and the main shaft is connected with a tool electrode through a piezoelectric actuator; and the shielding gas supply mechanism is connected with the sealing cover through a pipeline, a pressure regulating part and a power supply assembly are installed on the pipeline, the positive electrode of the power supply assembly is used for being connected with the tool electrode, and the negative electrode of the power supply assembly is used for being connected with the workpiece. The coating prepared through the device is good in quality.

Owner:SHANDONG UNIV

Reciprocating descent control device

The invention discloses a reciprocating descent control device. A rotating shaft is arranged on a bracket and is provided with a winding drum; a steel wire rope is wound on the winding drum around a pulley; a damping cylinder is arranged on the bracket close to the rotating shaft; a piston of the damping cylinder is connected with the rotating shaft through a crank slider mechanism; and a small hole is formed on the piston. The preferable scheme of the invention is that: the reciprocating descent control device is provided with two damping cylinders, and a rotation angle of the crank slider mechanism which is connected with the damping cylinders is staggered for 90 degrees. Therefore, the dead center of the crank slider mechanism is avoided, the speed is steady during descent control, andthe winding of the steel wire rope due to the speed change is avoided. The reciprocating descent control device is not controlled by a user at all during use, can realize continuous descent control, and has the advantages of steady operation, safety and reliability, and low production cost.

Owner:HUBEI THREE GORGES POLYTECHNIC

Solar cell, its module and its manufacturing method

InactiveCN103928537BReduce or eliminate endpoint sitesImprove the effect of current collectionFinal product manufacturePhotovoltaic energy generationPower flowEngineering

The present invention provides a solar cell, a module thereof and a manufacture method thereof. The cell comprises a substrate possessing a right side and a back side, an emitter layer arranged on the right side, and a passivation layer arranged on the back side, an opening arranged on the passivation layer in an extension and bending manner, and a backside electrode arranged on the passivation layer and contacted with the back side via the opening. The projection area of the opening on the back side is 3% to 12% of the area of the back side. The present invention also provides another cell which comprises a plurality of annular openings surrounding annularly from inside to outside. By the design of the continuously extending and bending single opening or the plurality of annular openings, the current collection effect of the backside electrode can be enhanced. Moreover, a back electric field structure formed by sintering is enough in thickness and good in quality, thereby improving the photoelectric conversion efficiency of the cell.

Owner:MOTECH INDUSTRIES

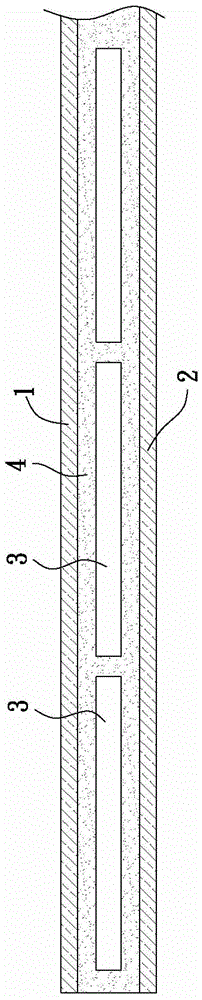

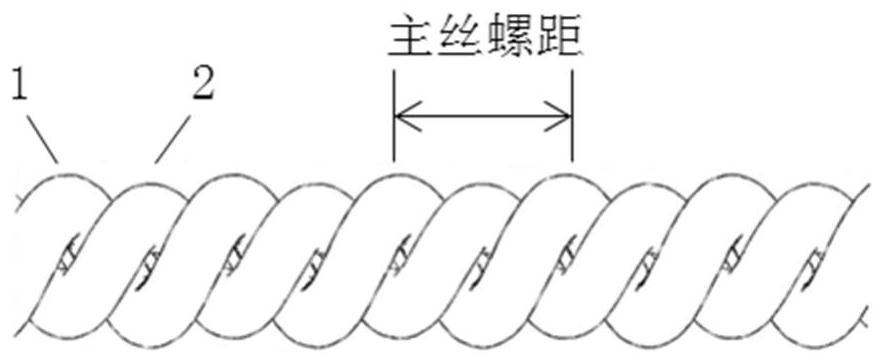

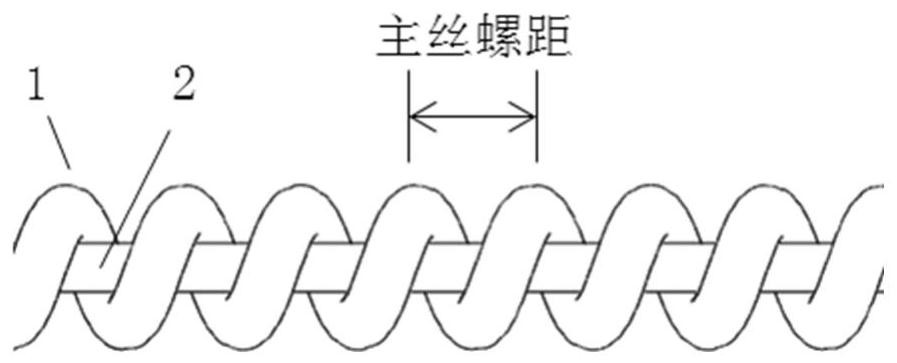

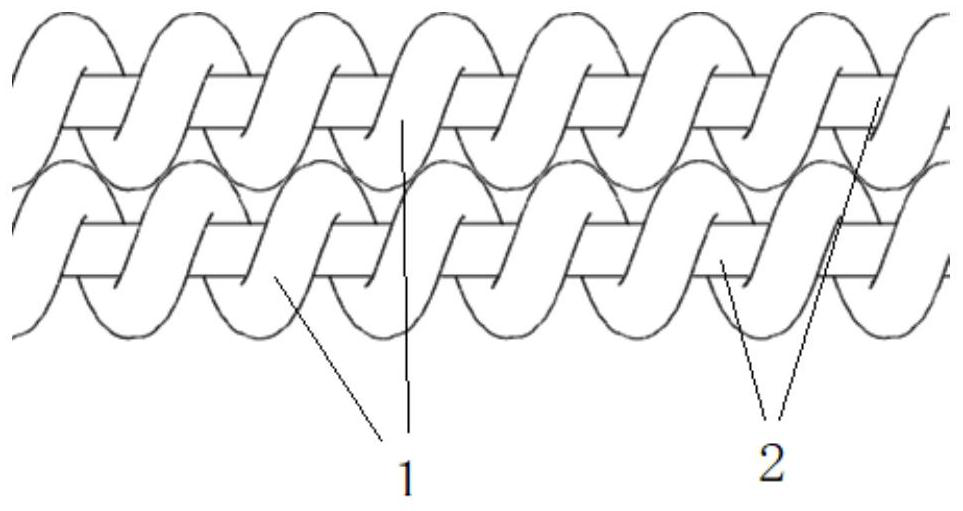

Structured packing, packing layer structure and application thereof

ActiveCN111644143AImprove mass transfer efficiencyImprove separation efficiencyChemical/physical/physico-chemical processesFractional distillationPolymer scienceHigh surface

The invention provides structured packing and a packing layer structure which are applied to separation of substances with relatively low viscosity or relatively high surface tension. The structured packing is formed by corrugating, stamping, cutting and binding silk screen strips; the silk screen strip piece is formed by weaving spiral winding type double-strand silk threads, is of a non-uniformweaving density structure and comprises high weaving density areas located on the two sides of the silk screen strip piece and with the width being a and low weaving density areas located in the middle of the silk screen strip piece, thereby forming the weaving density area distribution of a dense-sparse-dense structure. Compared with the prior art, on the premise that no wall flow prevention ringexists, the problems of wall flow and poor separation effect on low-viscosity or high-surface-tension materials are solved from the two aspects of improving the structure of the woven silk threads and improving the woven structure of the silk screen strip pieces; a longitudinal wall flow prevention structure is adopted to replace a transverse structure, so that a wall flow prevention area is increased, the wall flow prevention effect is improved, and gas phase is prevented from flowing in a gap between the outer wall of the filler and the inner wall of the tower.

Owner:SHANGHAI RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com