Method for controlling nitrogen content of steel grade in CV-LF-RH-CC process path

A CV-LF-RH-CC, nitrogen content technology, applied in the direction of manufacturing converters, etc., can solve the problems of reducing impact toughness, welding performance thermal stress zone toughness, reducing steel forming and cold bending properties, and increasing steel brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] In order to further illustrate the idea of the present invention, the present invention will be further described by taking 300T converter, refining and continuous casting production as examples below.

[0072] (1) Steel type: QStE600TM;

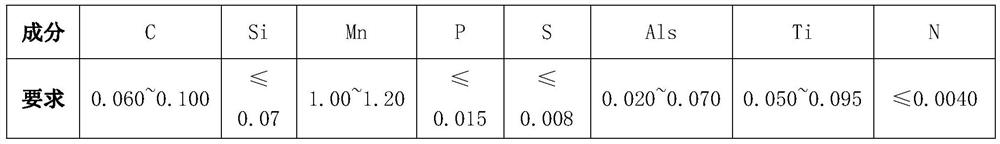

[0073] (2) The composition requirements of QStE600TM steel RH hollow-breaking molten steel, see Table 1 for details:

[0074] Table 1: QStE600TM steel RH broken steel composition requirements

[0075]

[0076] (3) Oxygen blowing volume 0-15% stage, bottom blowing flow rate 0.03Nm 3 / t.min; During the oxygen blowing period of 16-45%, the bottom blowing flow rate is 0.04Nm 3 / t.min; During the oxygen blowing period of 46-70%, the bottom blowing flow rate is 0.06Nm 3 / t.min; Oxygen blowing volume 71-85% stage, bottom blowing flow rate 0.08Nm 3 / t.min; Oxygen blowing volume 86-100% stage, bottom blowing flow rate 0.14Nm 3 / t.min, gas type argon;

[0077] (4) The principle of temperature control at the end of the converter is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com