A kind of high nitrogen stainless steel powder and preparation method thereof, stainless steel

A high-nitrogen stainless steel and stainless steel technology, applied in the field of steel materials, can solve the problems of difficult balance between nitrogen content and density, low yield rate, etc., and achieve the effect of high strength and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

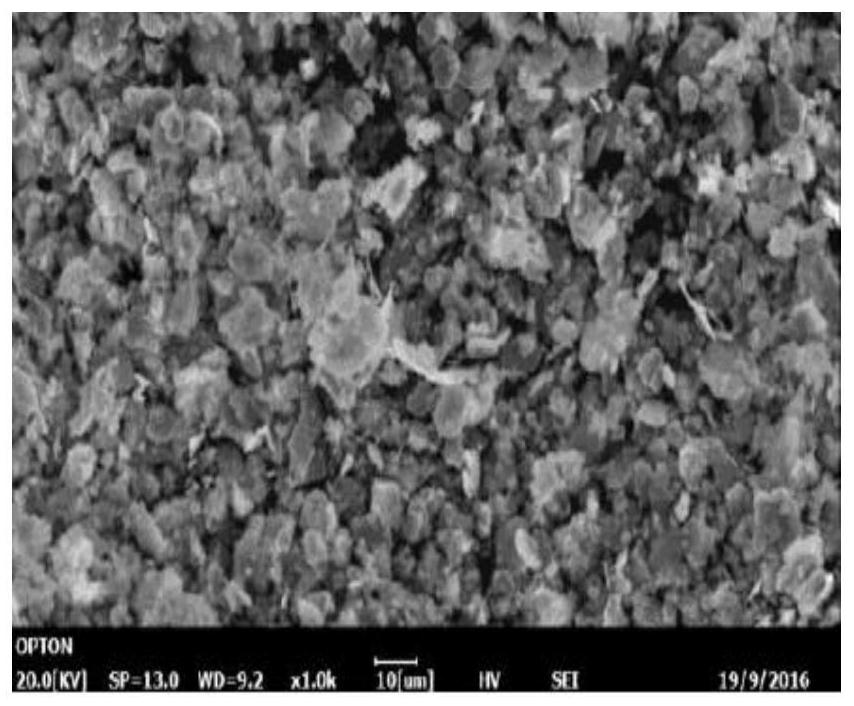

[0025] A high-nitrogen stainless steel powder is composed of stainless steel powder matrix 0Cr17Mn11Mo3N and titanium powder. Among them, the amount of titanium powder added accounts for 1% of the total powder mass, the particle size of the stainless steel powder matrix is 10-25 μm, of which D50 is 17 μm, and the particle size of titanium powder is 5-10 μm, of which D50 is 8 μm.

[0026] The preparation method of the above-mentioned high-nitrogen stainless steel powder comprises the following steps: weighing 200 g of the stainless steel powder matrix, weighing titanium powder according to 1% of the total mass of the powder, and putting the two kinds of powders into a stainless steel ball mill tank with a volume of 1 L; Put 1000g of stainless steel balls with a diameter of 5mm, adopt a ball-to-material ratio of 5:1, use stearic acid as a ball milling aid (amount of 1wt.%), feed Ar gas as a protective atmosphere, and the stirring axis speed of the ball mill is 3m / s, ball mill...

Embodiment 2

[0045] A high-nitrogen stainless steel powder is composed of a stainless steel powder matrix 0Cr17Mn11Mo3N and niobium powder. Among them, the amount of niobium powder added accounts for 0.8% of the total powder mass, the particle size of the stainless steel powder matrix is 10-25 μm, of which D50 is 17 μm; the particle size of niobium powder is 7-12 μm, of which D50 is 9 μm.

[0046] The preparation method of the above-mentioned high-nitrogen stainless steel powder comprises the following steps: taking 200 g of the stainless steel powder matrix, weighing niobium powder according to 0.8% of the total mass of the powder, and putting the two kinds of powders into a stainless steel ball mill tank with a volume of 1 L; Load 1000 g of stainless steel balls with a diameter of 5 mm, adopt a ball-to-material ratio of 5:1, use absolute ethanol as a ball milling aid (amount of 5 wt.%), feed Ar gas as a protective atmosphere, and the stirring axis speed of the ball mill is 5 m / s, ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com