Installation structure for motorcycle ABS rear wheel speed sensor and rear brake cylinder

A wheel speed sensor, brake wheel cylinder technology, applied in the direction of brake wheel cylinder, ABS control system, brake, etc., to achieve the effect of increasing production cost, convenient disassembly and assembly, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

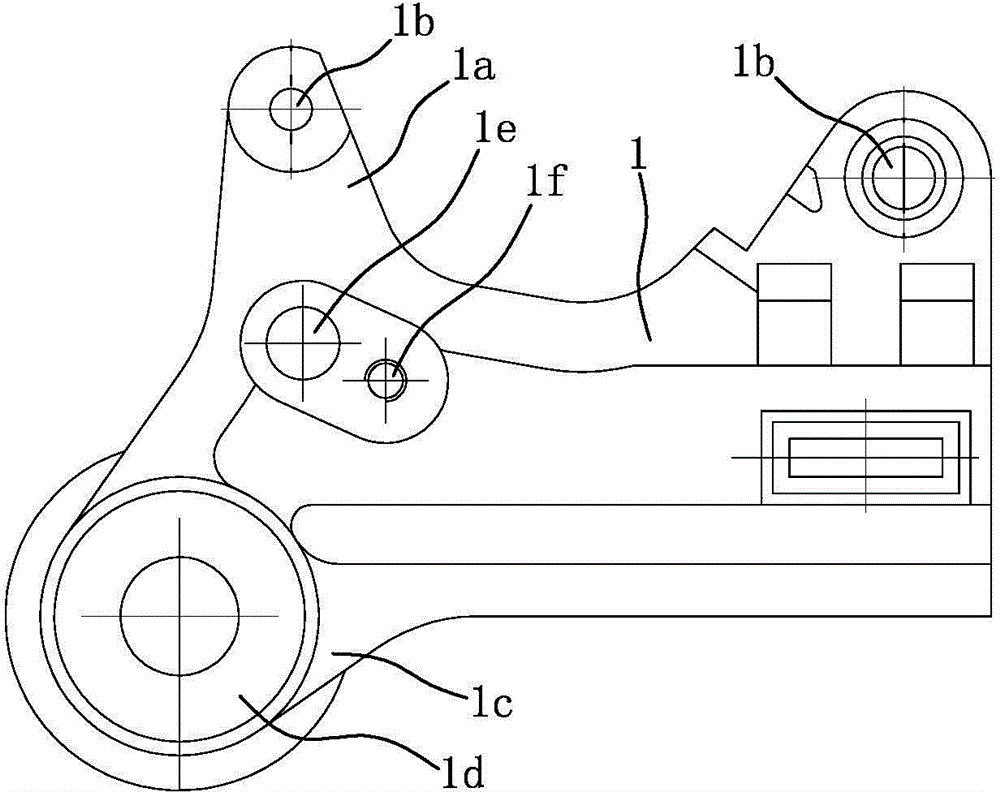

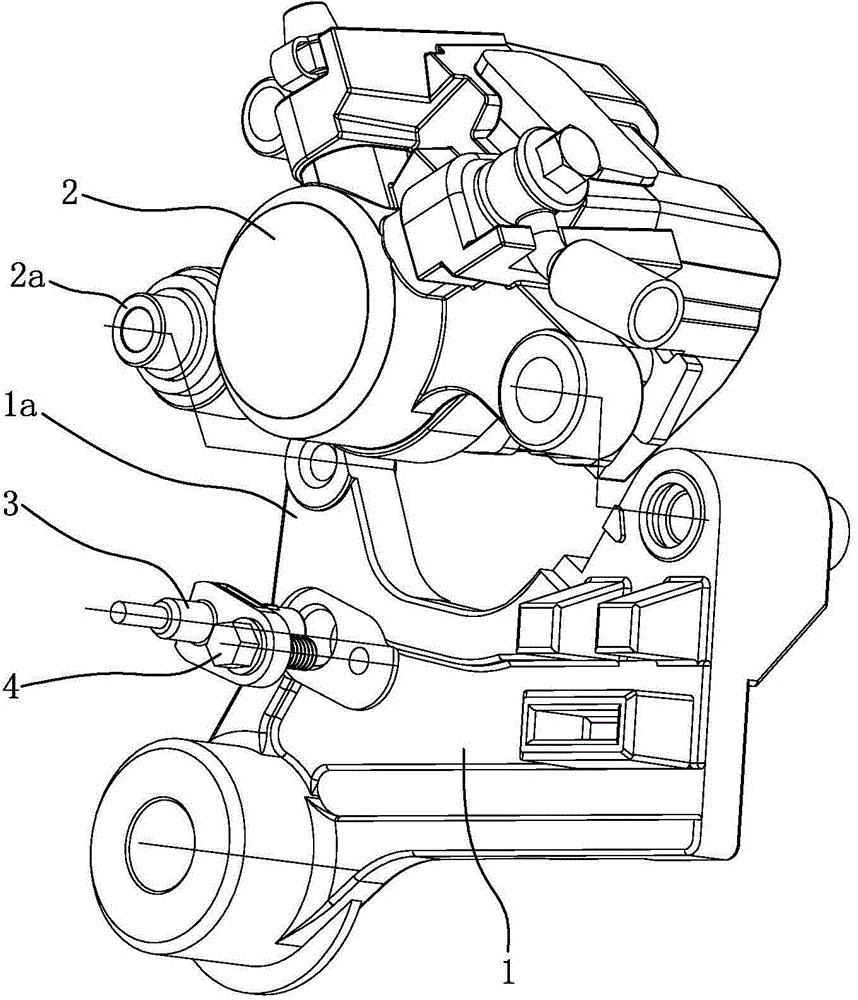

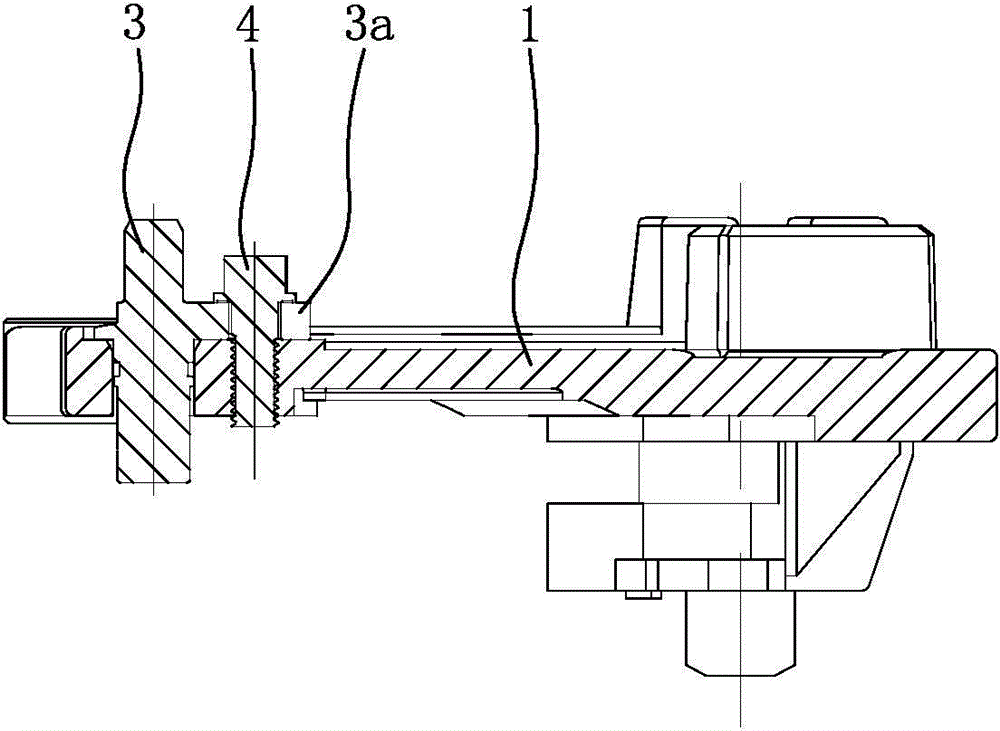

[0013] Such as figure 1 , figure 2 As shown, the rear brake cylinder support 1 is a special support for installing the rear brake cylinder on the motorcycle, and its shape is the same as that of the prior art, so it will not be repeated here. The rear brake cylinder bracket 1 is made of aluminum alloy die-casting. There are upper flanges 1a at the front and rear ends of the top of the rear brake cylinder bracket 1. The upper flange 1a is integrated with the rear brake cylinder bracket 1. A gap is formed between the two front and rear upper flanges 1a, and each upper flange 1a is provided with a positioning hole 1b. Part of the pump body of the rear brake cylinder 2 is embedded in the gap at the upper end of the rear brake cylinder bracket 1, and the two mounting columns 2a on the rear brake cylinder 2 correspond to the two upper flanges 1a one by one, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com