Patents

Literature

200results about How to "Guaranteed size requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

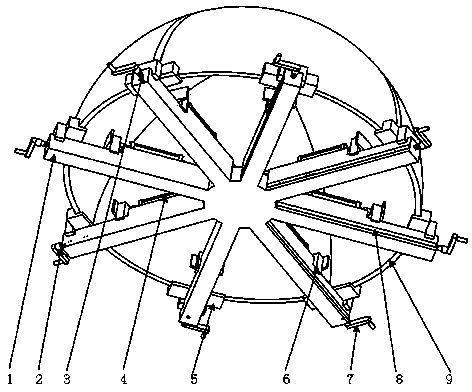

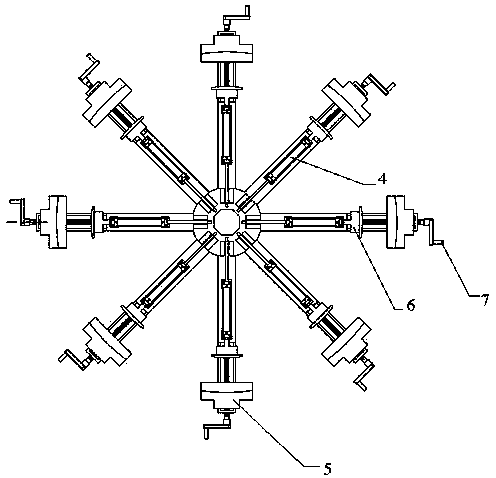

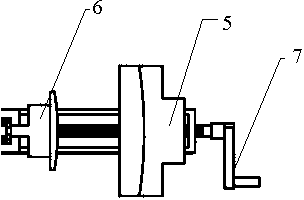

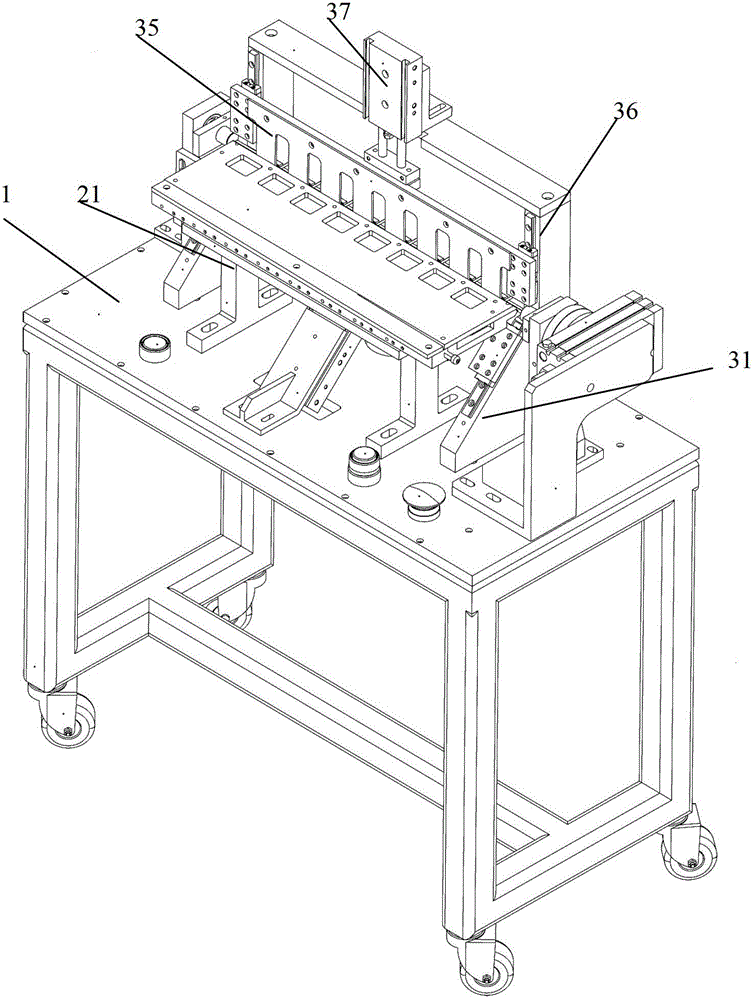

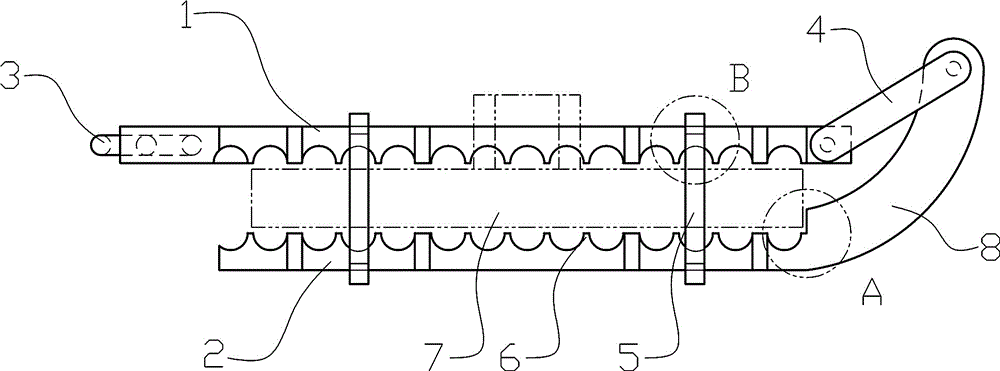

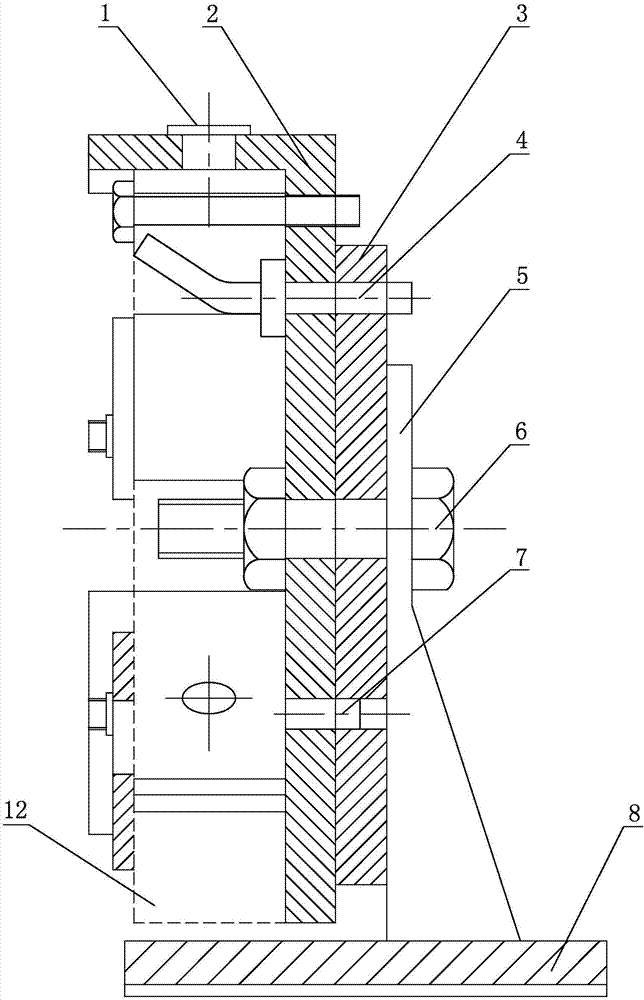

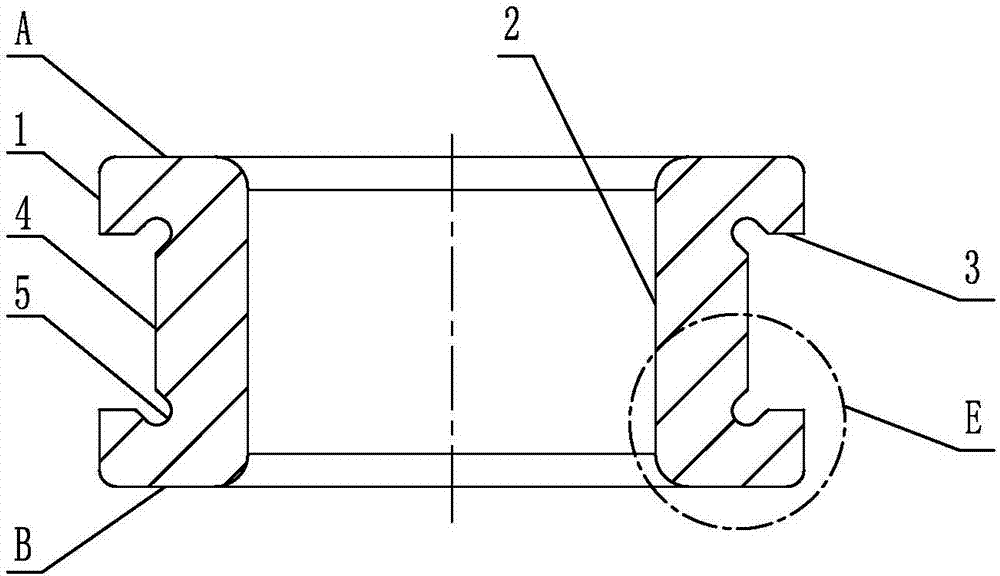

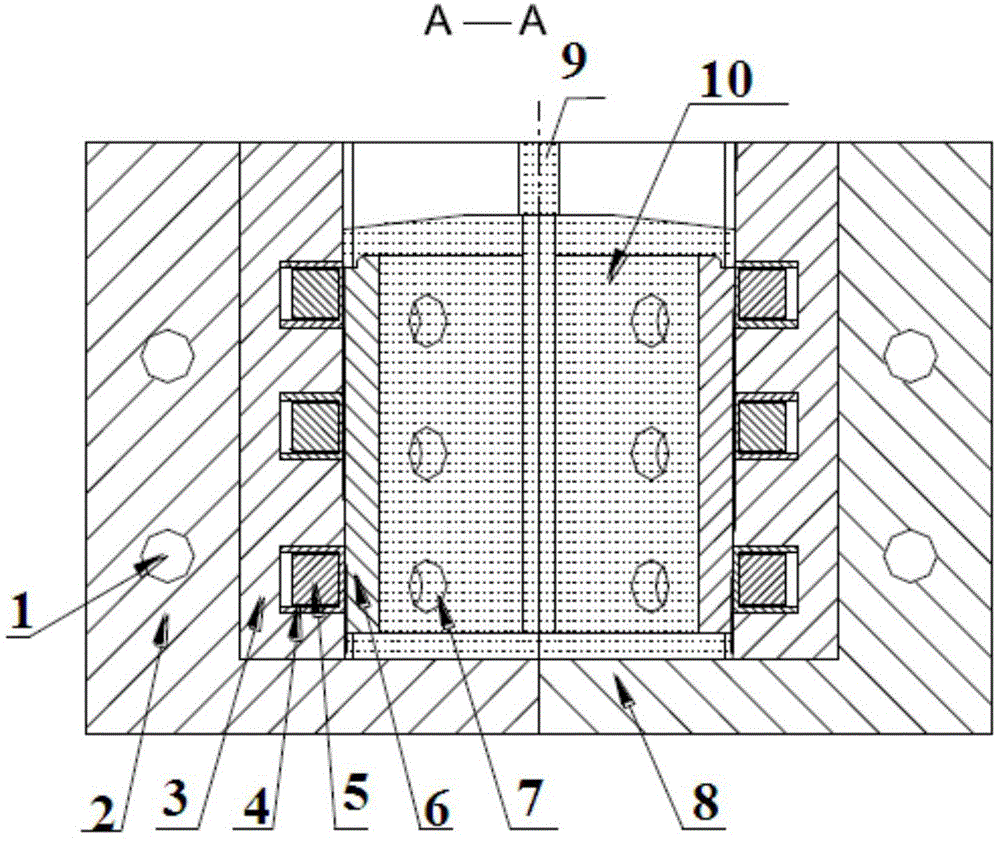

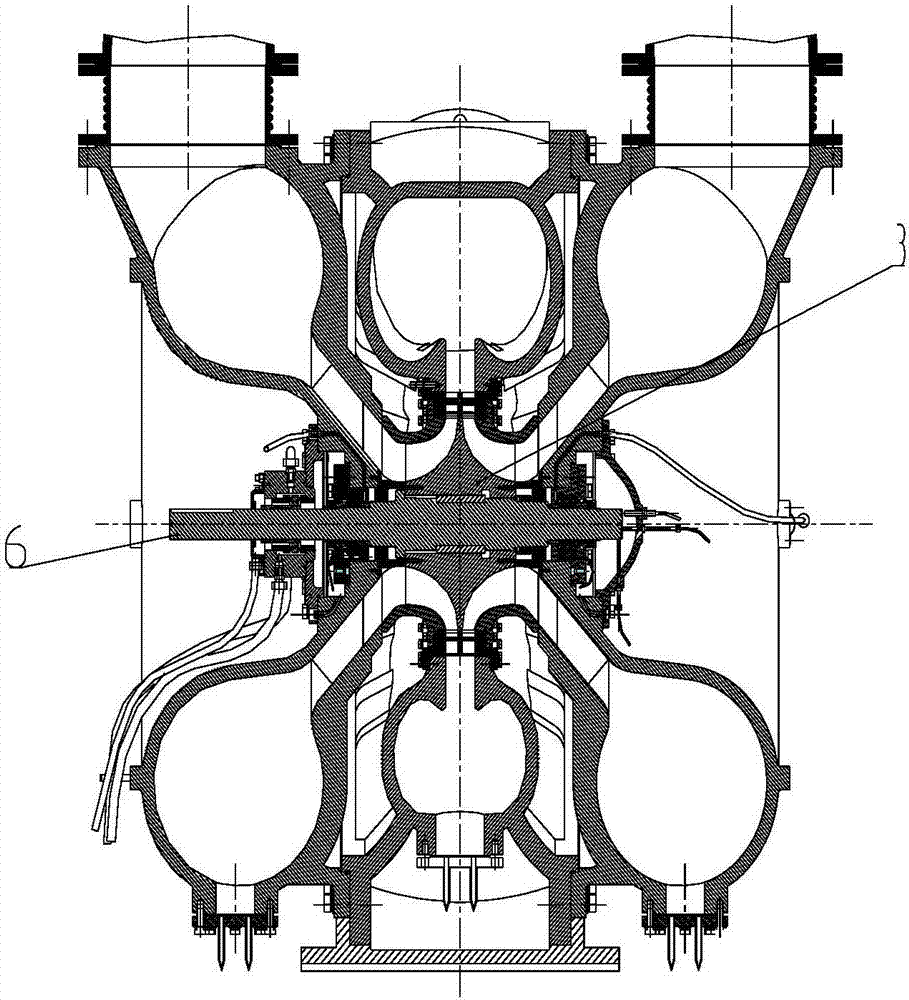

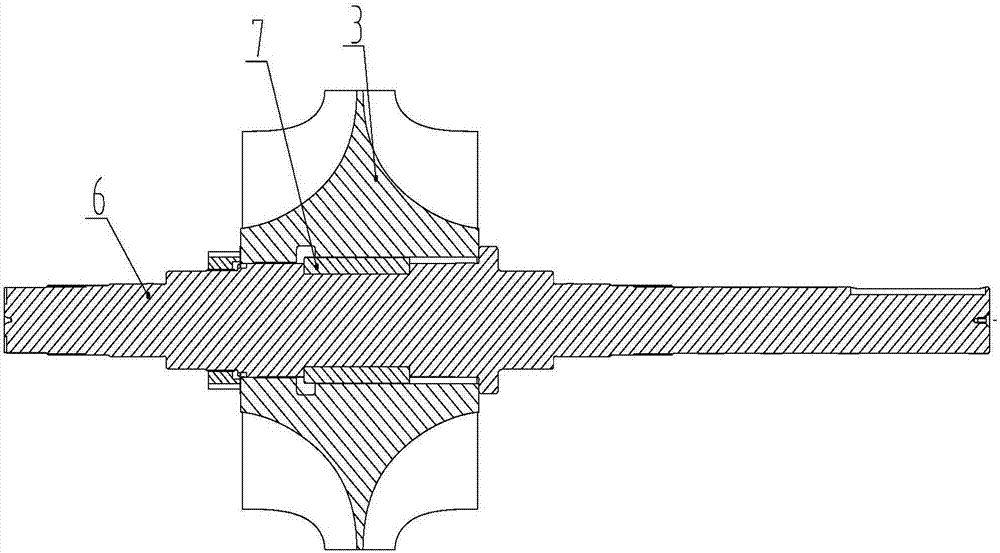

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

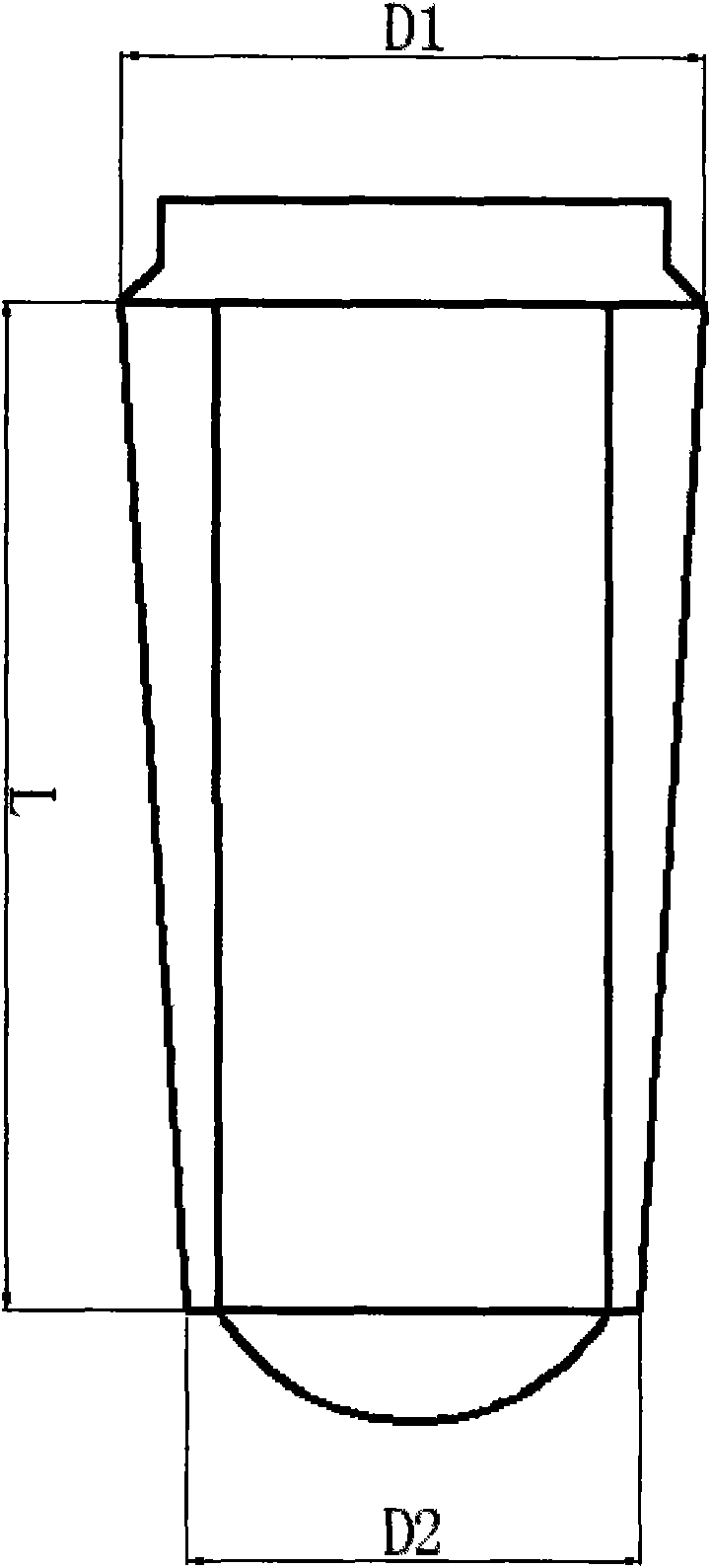

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

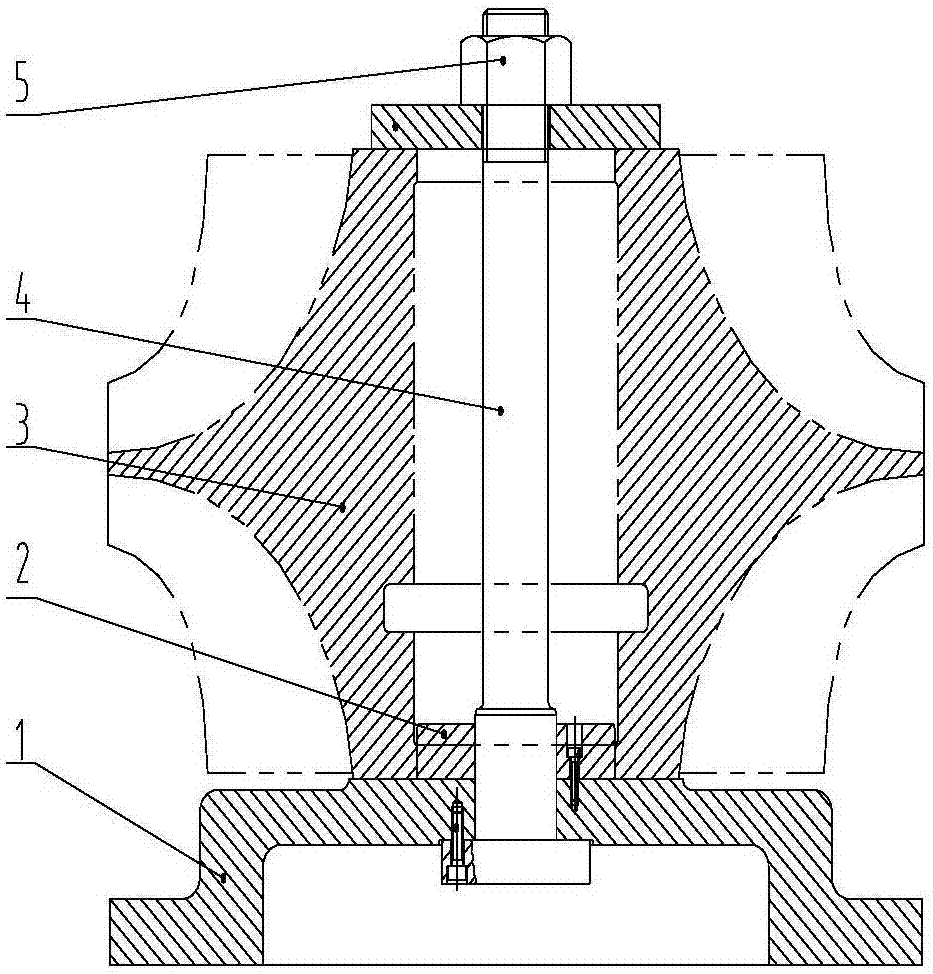

Forging method of AP1000 nuclear-power main pipeline forging piece

InactiveCN101954439AGuaranteed size requirementsGuarantee quality requirementsMetal-working apparatusEngine componentsNuclear powerMaterials science

The invention relates to a forging method of an AP1000 nuclear-power main pipeline forging piece, belonging to the technical field of forging. The forging method comprises the following steps of: firstly, forging an irregularly-shaped part of the forging piece; and then, integrally forging. The invention not only ensures the dimensional requirement of the irregularly-shaped part of the forging piece, but also ensures the quality requirement of the integral forging piece, can lower forging heating frequency, increases the utilization rate of raw materials and the qualified rate of the forging piece at the same time, achieves the expectation effect before forging and successfully solves the problem on forging the AP1000 nuclear-power main pipeline.

Owner:吉林昊宇电气股份有限公司

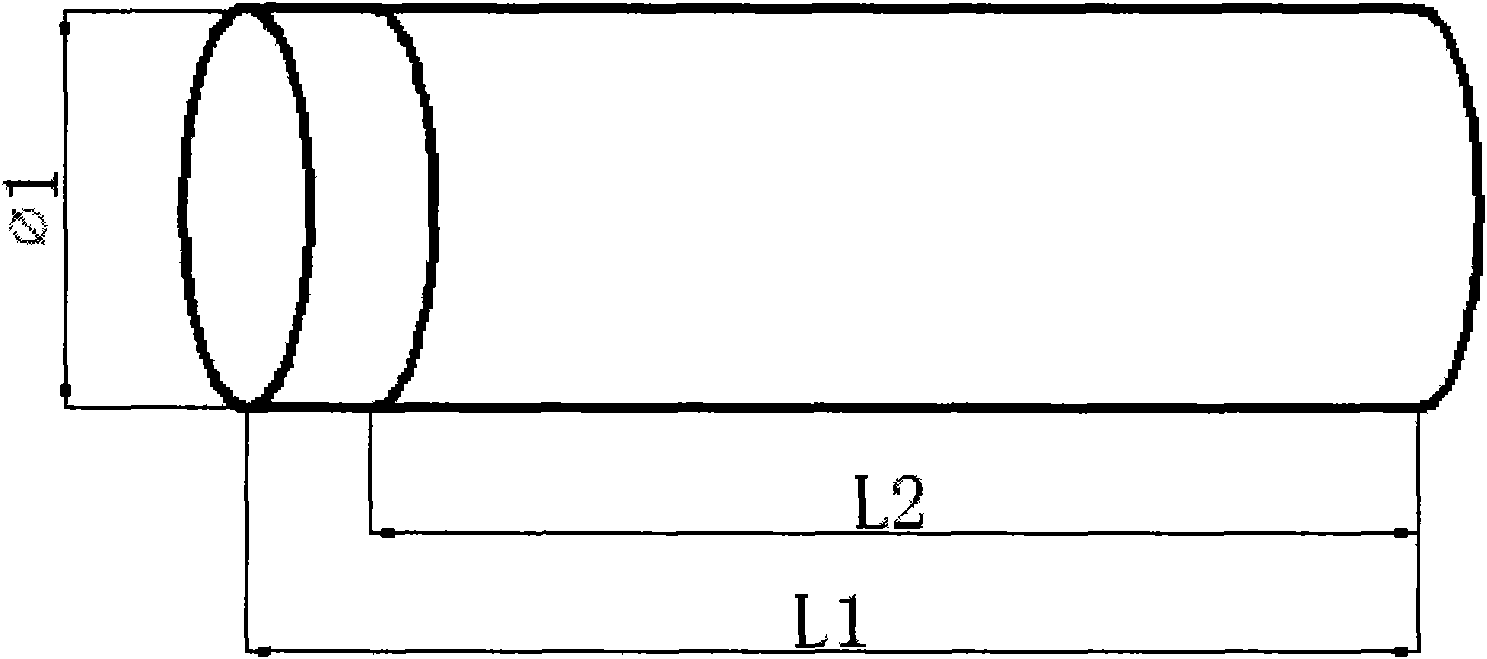

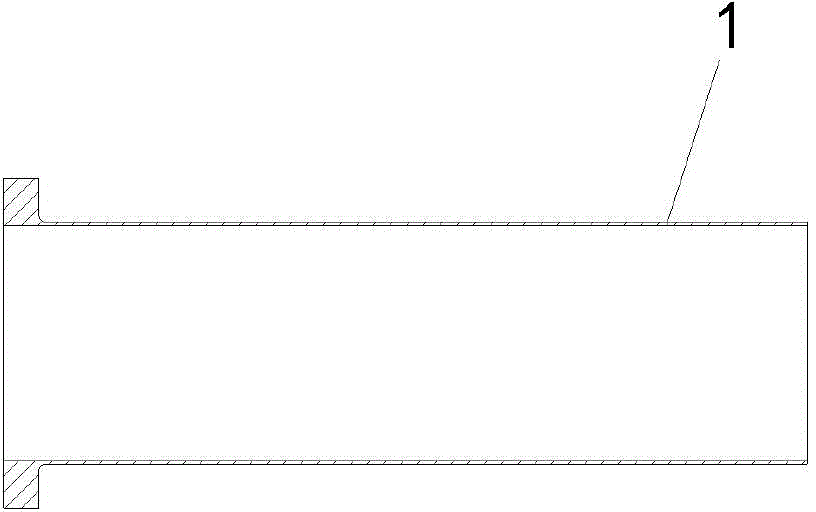

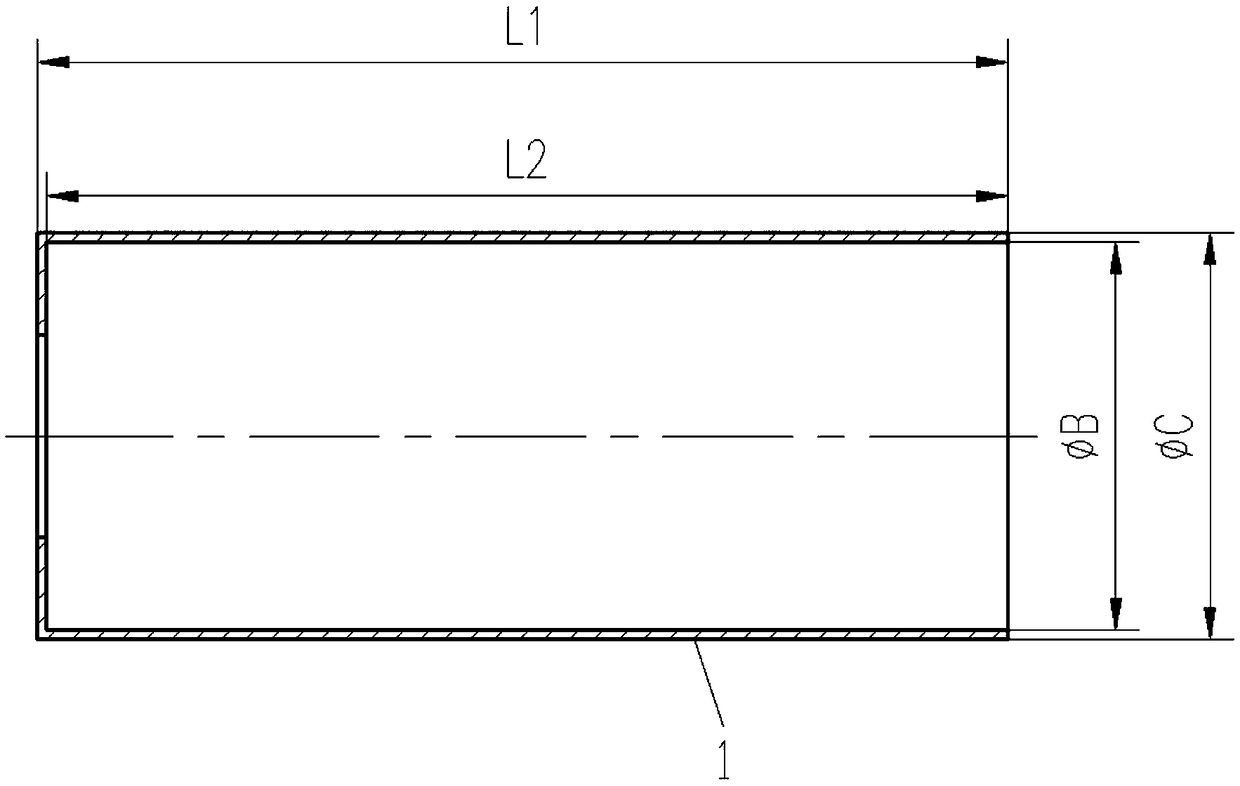

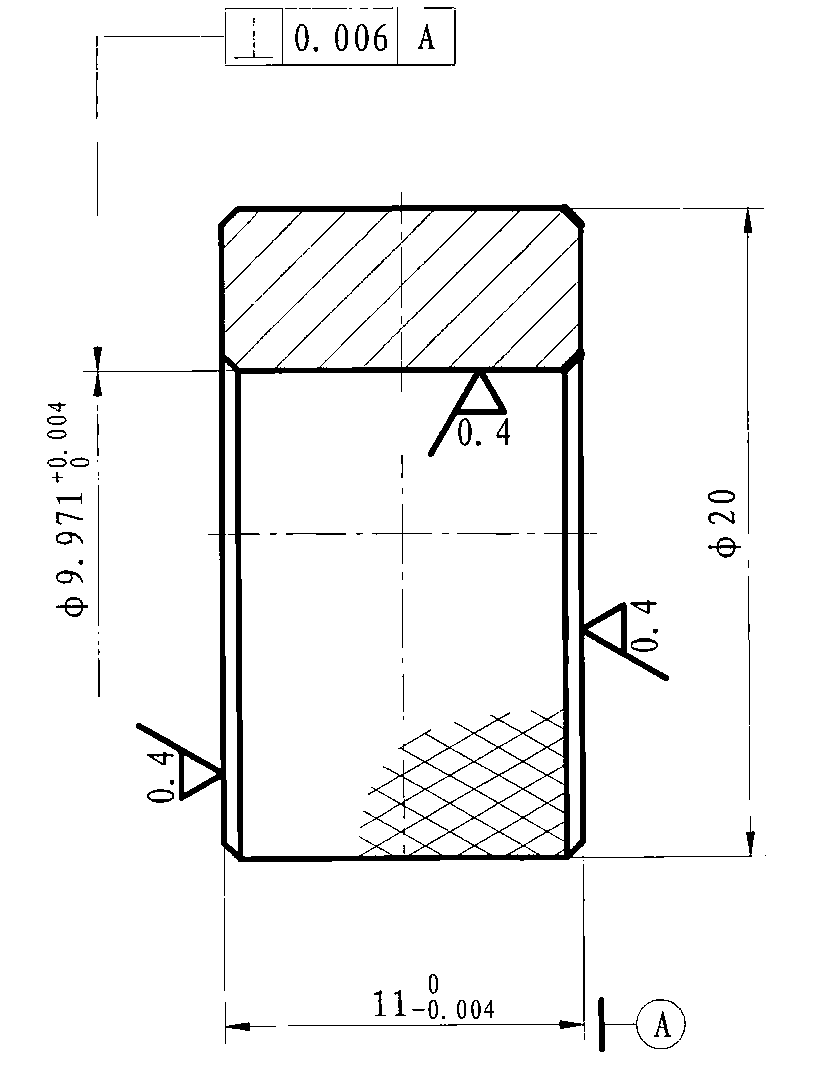

Lathe precise machining method for ultrathin-wall-thickness metal pipe part

The invention discloses a lathe precise machining method for an ultrathin-wall-thickness metal pipe part. The ratio of the pipe diameter to the wall thickness of the related part exceeds 100; and in the machining process, an appropriate clamping tool and a reasonable machining sequence are selected to reduce overall deformation of a workpiece in the machining process, and in the machining steps, the appropriate feed cutting quantity and a cutter matched with the feed cutting quantity are selected to reduce heat of the cutter in the cutting process, and stress exerted on the workpiece in the cutting process is reduced. According to the method, stress deformation caused by the fact that external force is exerted on the workpiece in the turning machining process can be effectively controlled, and therefore internal stress generated in the part cutting process can be fully released; the higher size and form and location tolerance requirement of the ultrathin-wall-thickness metal pipe part in the machining process is met, and the machined part is small in size deformation and has the long-term stability. The method has the common referential meaning in machining and manufacturing of the small-type ultrathin-wall-thickness metal pipe part which is urgently required in the special field.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

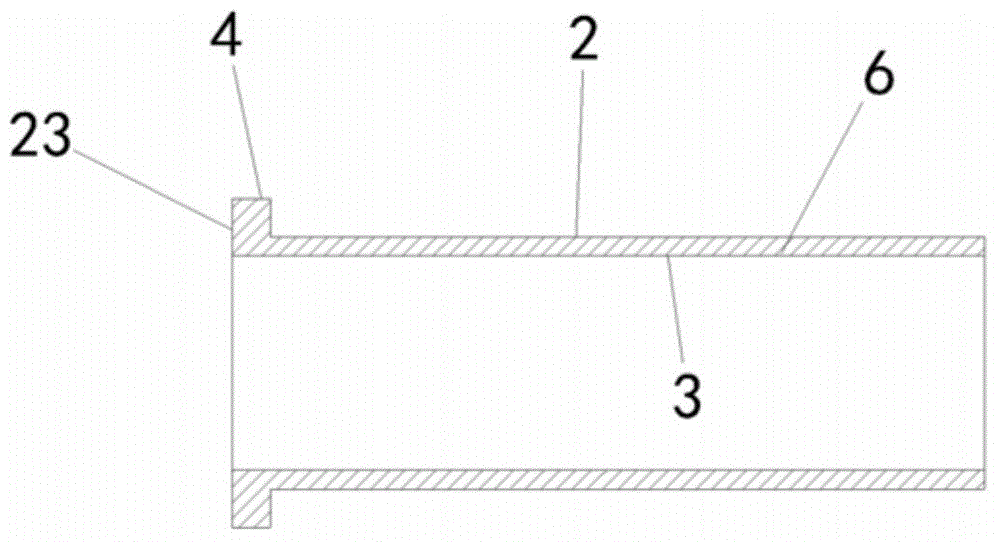

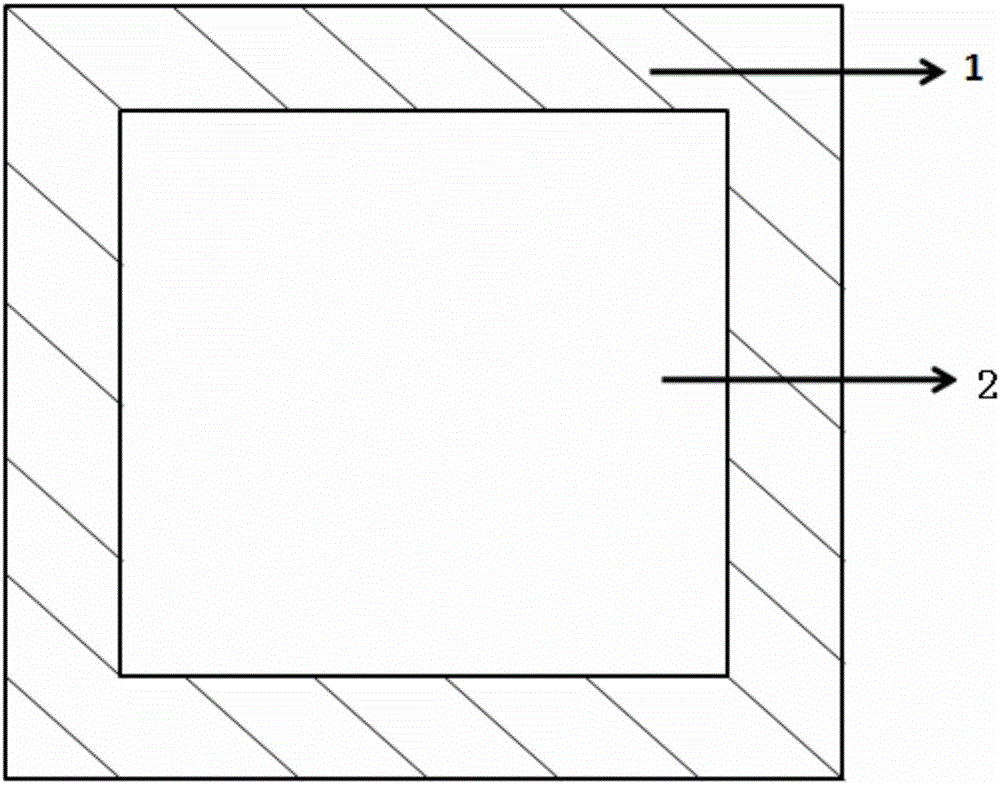

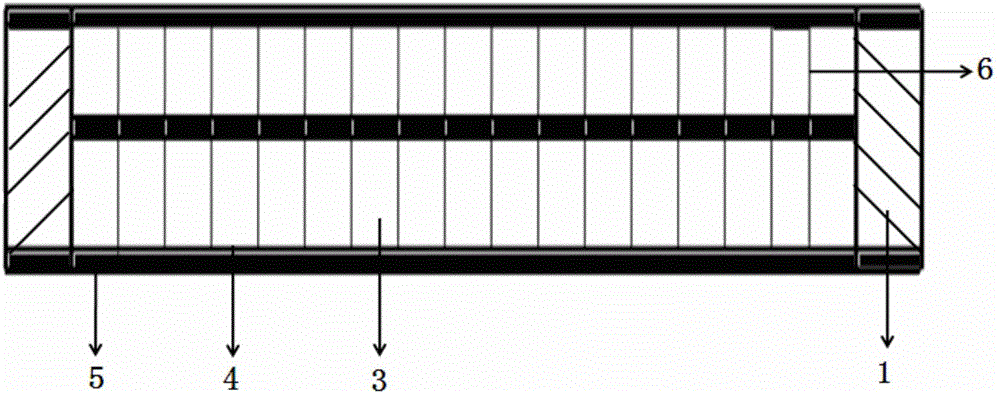

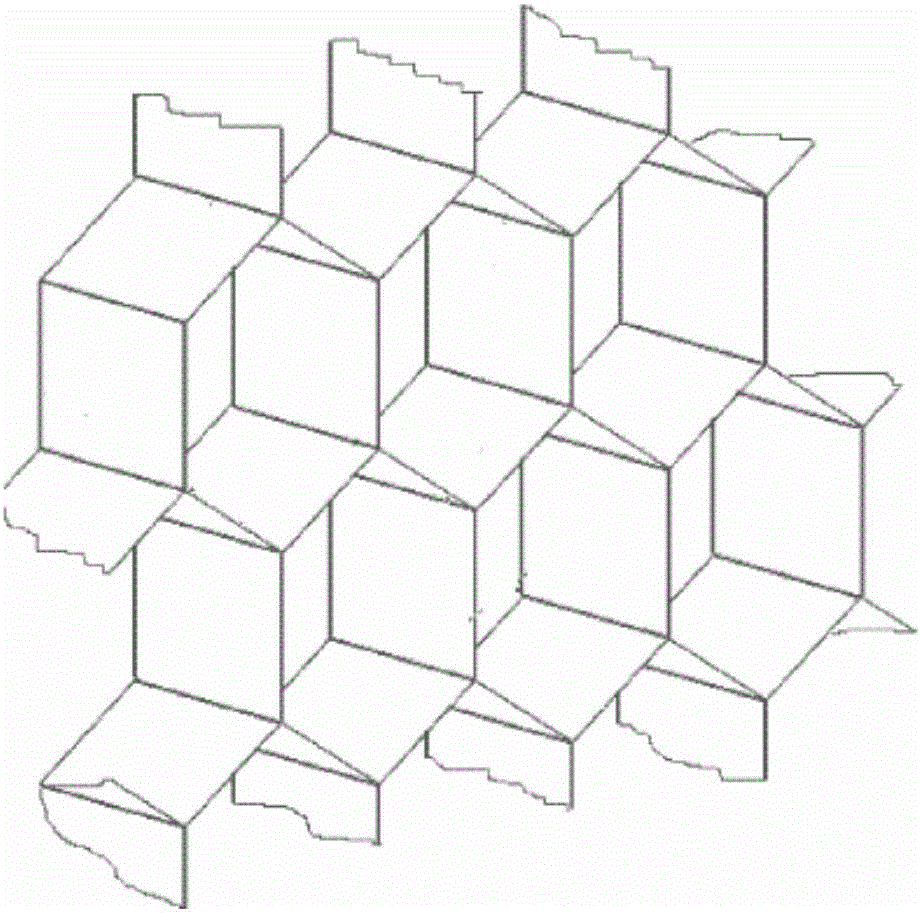

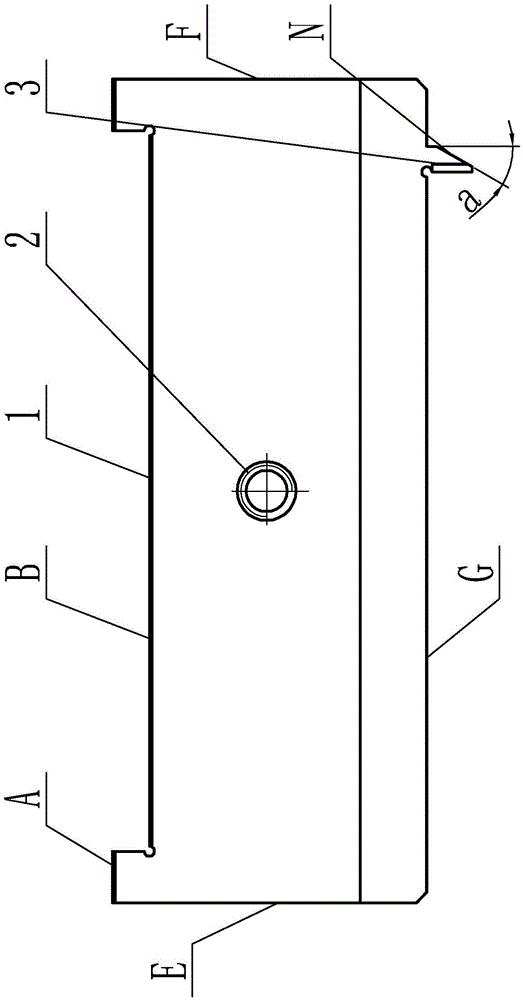

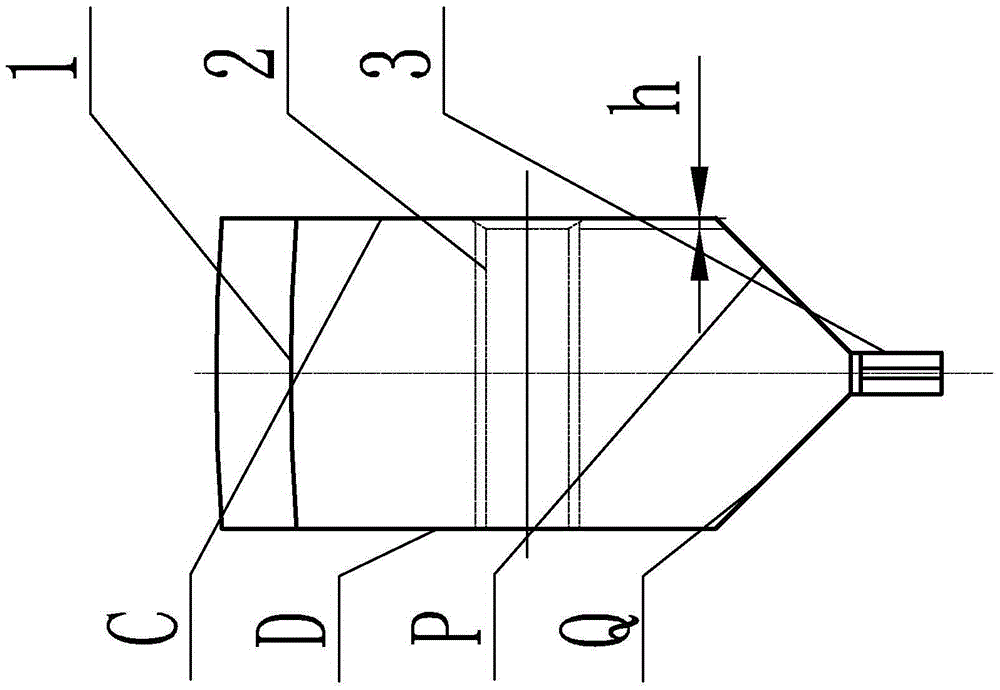

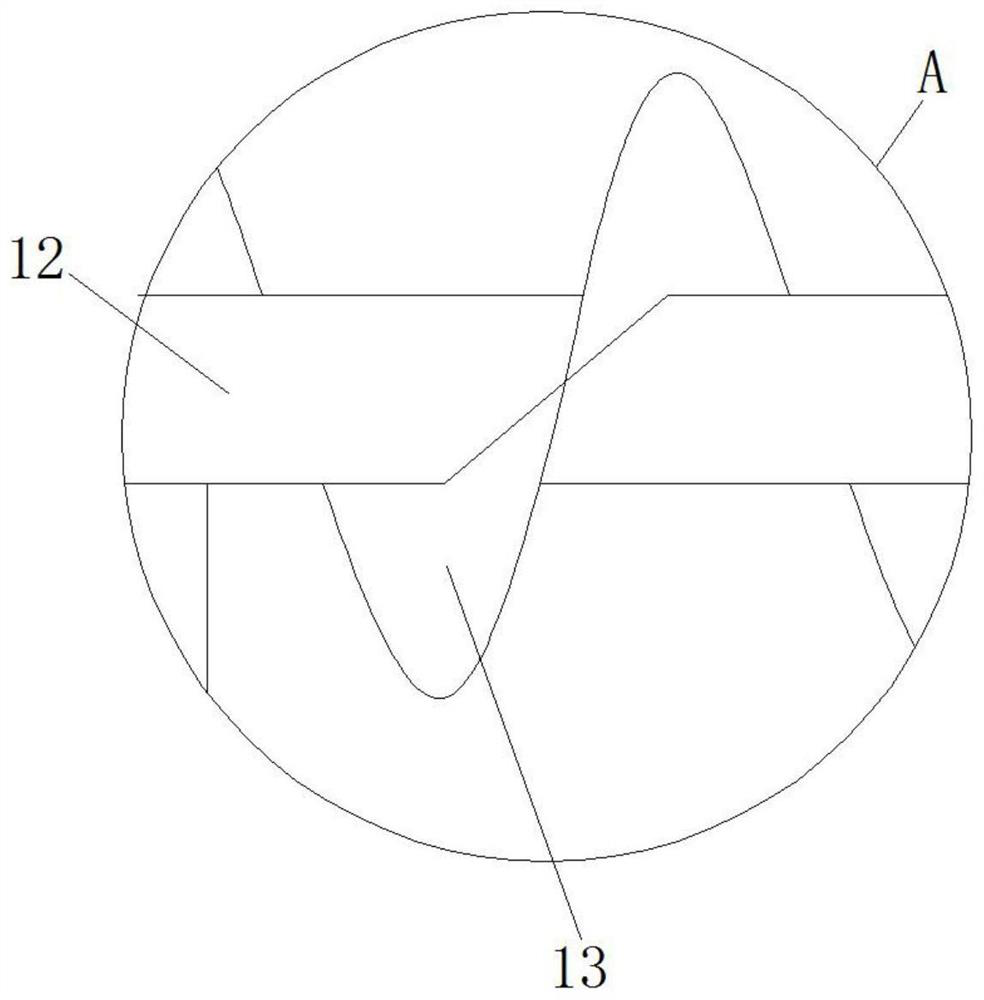

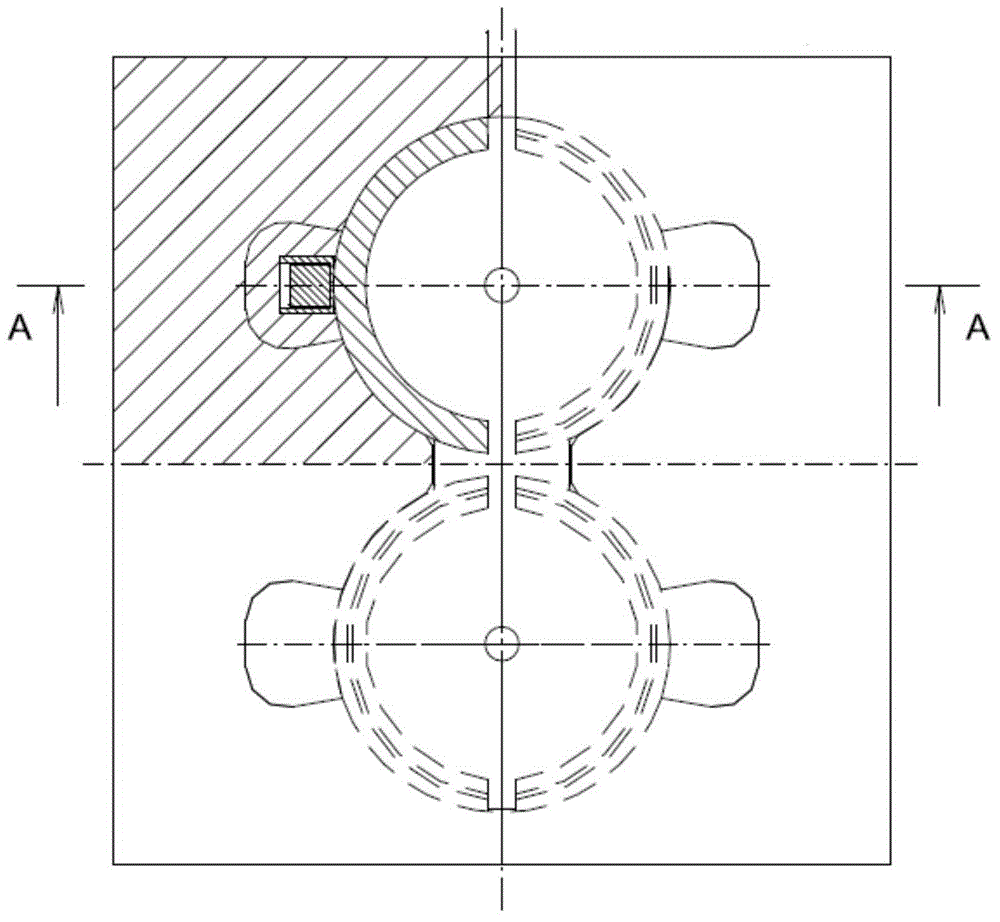

Integrated molding method for high-temperature-resistant heat-insulation wave-transmissive radome with honeycomb interlayer C

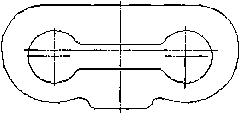

The invention discloses an integrated molding method for a high-temperature-resistant heat-insulation wave-transmissive radome with a honeycomb interlayer C and relates to the field of composite structure molding processes. The integrated molding method is realized through the steps of preparing a high-temperature-resistant polyimide honeycomb core; filling honeycomb core girds with aerogel; precuring a quartz / polyimide composite flanged connection frame; molding a quartz / polyimide skin; assembling through bonding by using a high-temperature-resistant glue film; coating; curing; machining and the like. The schematic diagram of the radome is as shown in figure 1; one-step integrated molding is realized by using an autoclave molding process and a stepwise preparation way of the core, the skin and a connecting flange, so that the problem that the high-temperature-resistant radome with the honeycomb interlayer structure has no multifunctional integration is solved, and the radome is enabled to be high-temperature-resistant and also meets the design requirements of heat insulation and wave transmission; and meanwhile, a flanged connection structure, shaped like a Chinese character Hui, of the radome is artfully and integrally molded together with a radome body, so that the connection process is simplified, the assembling quality is improved, and the assembling period is shortened.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

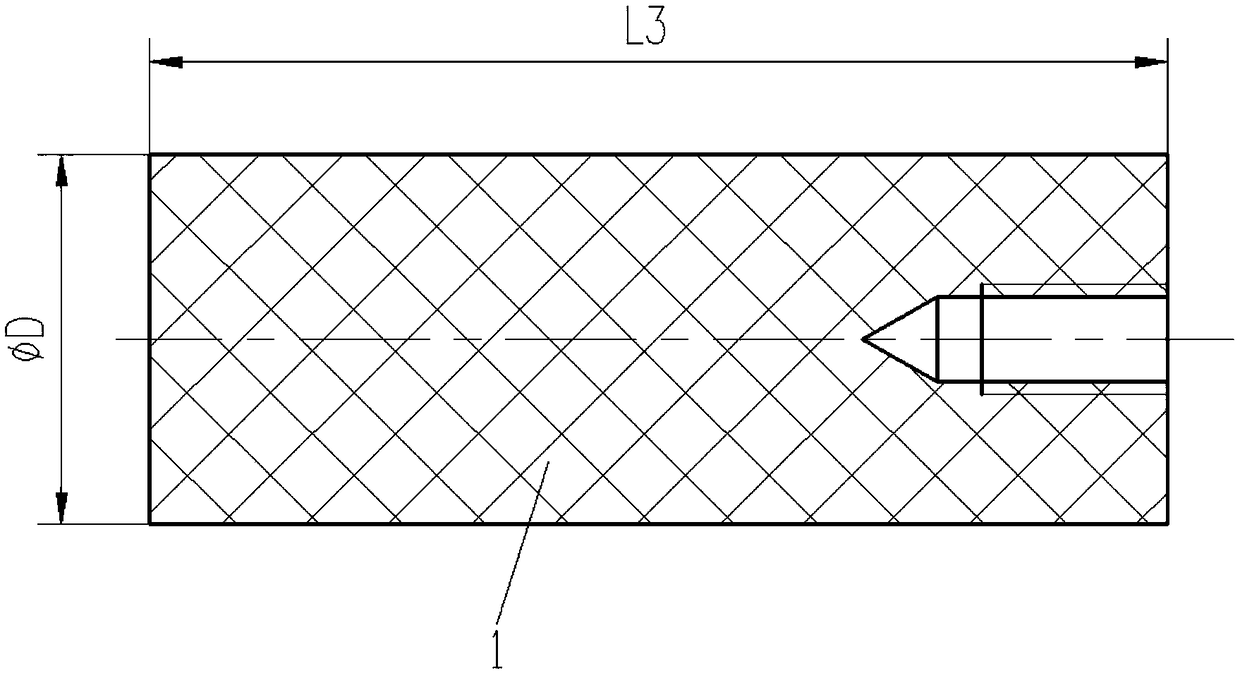

Machining method of high-precision deep and long hole thin-walled sleeve part

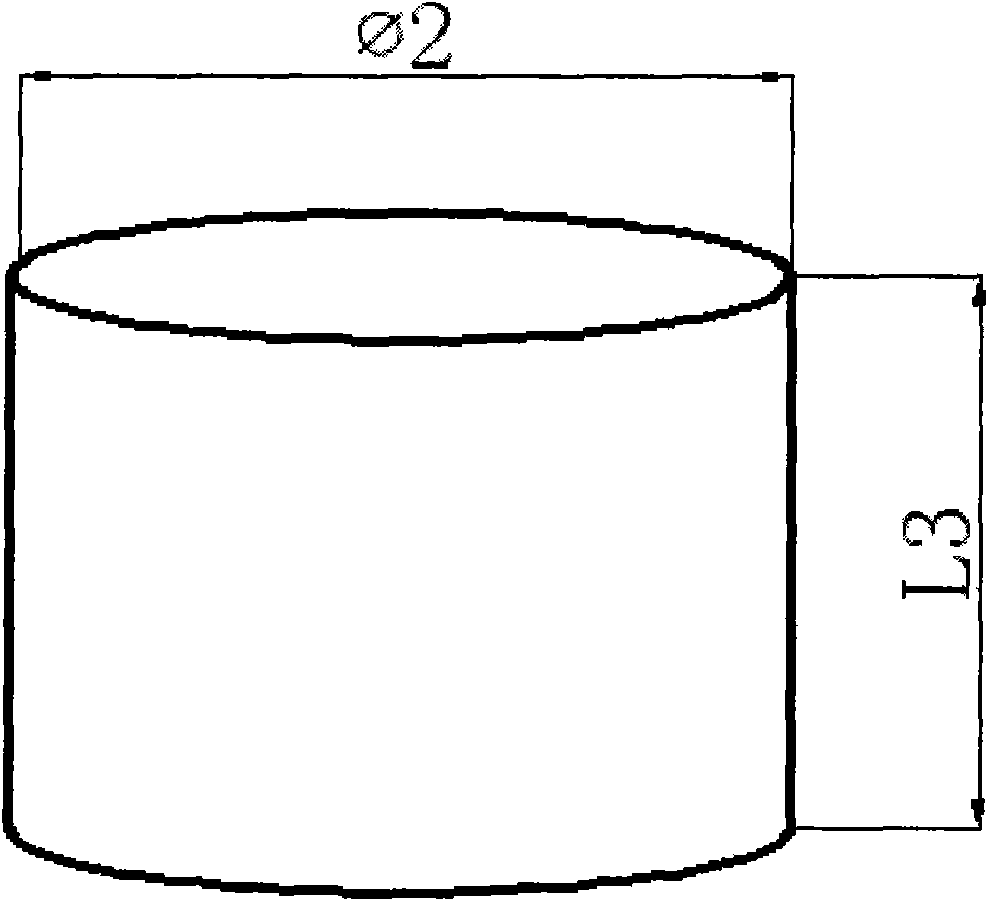

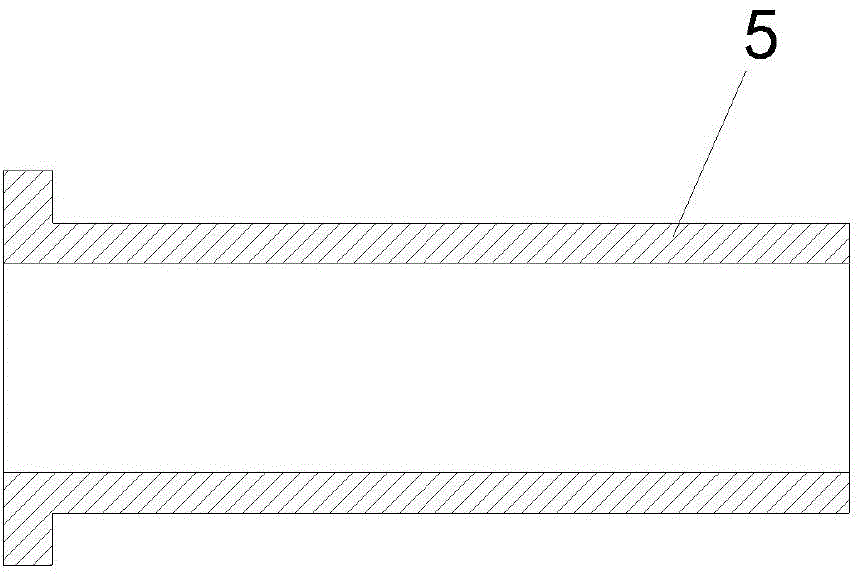

The invention provides a machining method of a high-precision deep and long hole thin-walled sleeve part. The machining method comprises the following steps that a rod is clamped and subjected to rough-machining forming, the machining allowance is reserved, and a process chuck is reserved; a roughly-machined workpiece is subjected to thermal treatment aging; and the process chuck of the workpieceis clamped by a lathe, finish machining of the workpiece is completed during primary clamping machining according to a workpiece drawing, and finish machining is divided into the following working steps that a core shaft, a lining and a screw are manufactured; the process chuck is clamped on the lathe, the core shaft is crammed into roughly-machined inner holes of the workpiece, and an outer circle of the part is machined to the required dimension; the screw is screwed into a core shaft threaded hole, and the core shaft is taken out of the workpiece; the lining sleeves the machined outer circle of the workpiece, the outer end face of the workpiece is machined, and the large and small inner holes and the bottom face are bored; tool setting is conducted from the bottom face, the outer end face of the workpiece is machined, and the length dimension L2 of the workpiece is ensured; and the workpiece is cut off, and the total length L1 of the workpiece is ensured. According to the machiningmethod of the high-precision deep and long hole thin-walled sleeve part, the rigidity of the part is improved, machining deformation of the part is reduced, vibration during thin-walled part machiningis reduced, and the machining quality and surface roughness are improved.

Owner:临沂产业研究院有限公司

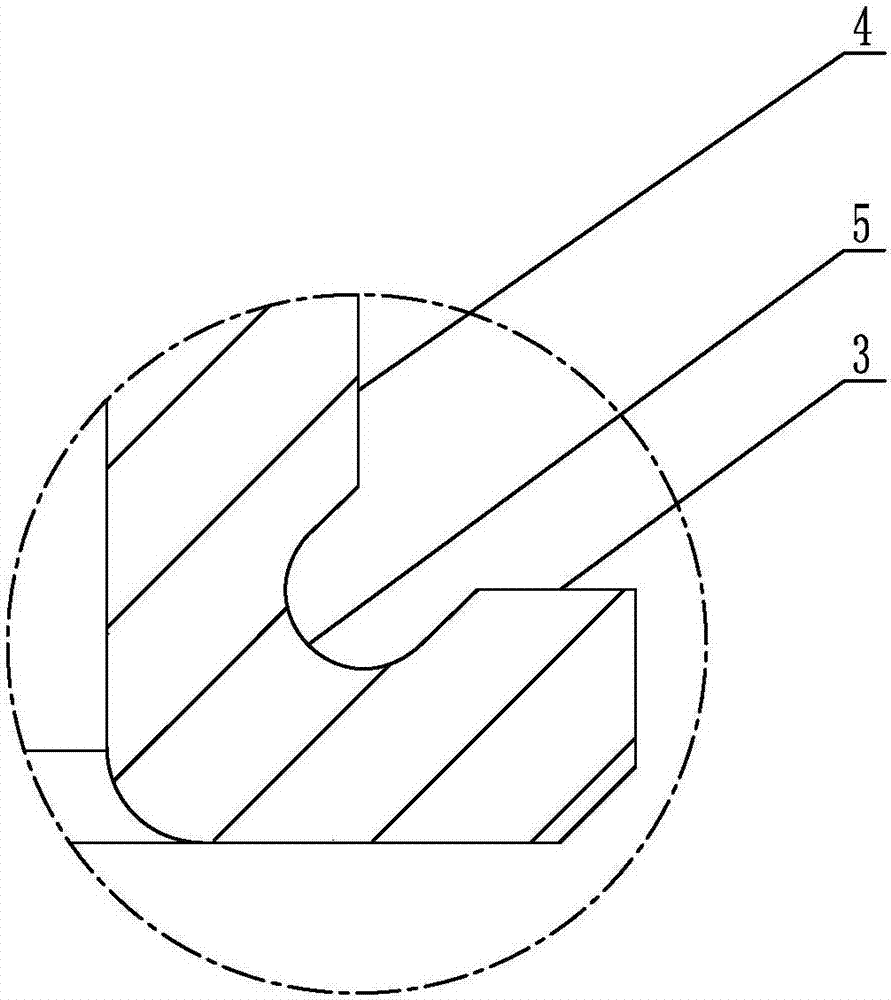

Bending device

ActiveCN102716946AGuaranteed uniformityImprove bending efficiencyMetal-working feeding devicesPositioning devicesEngineeringPress brake

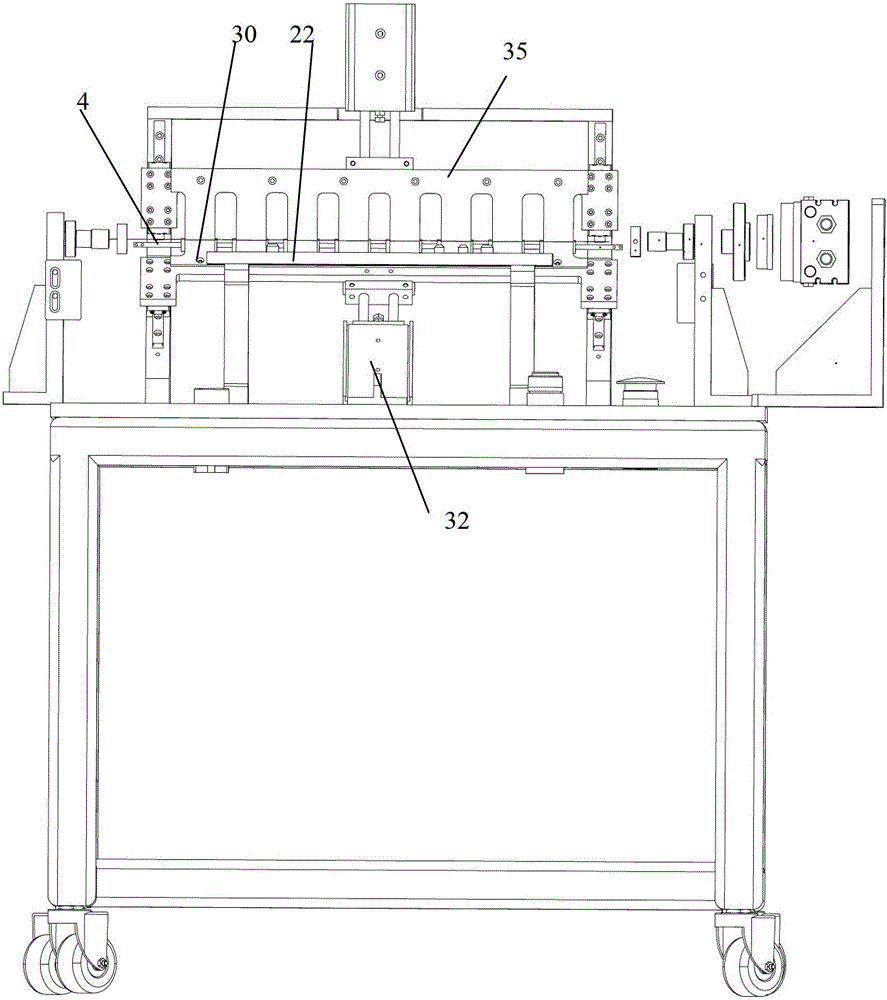

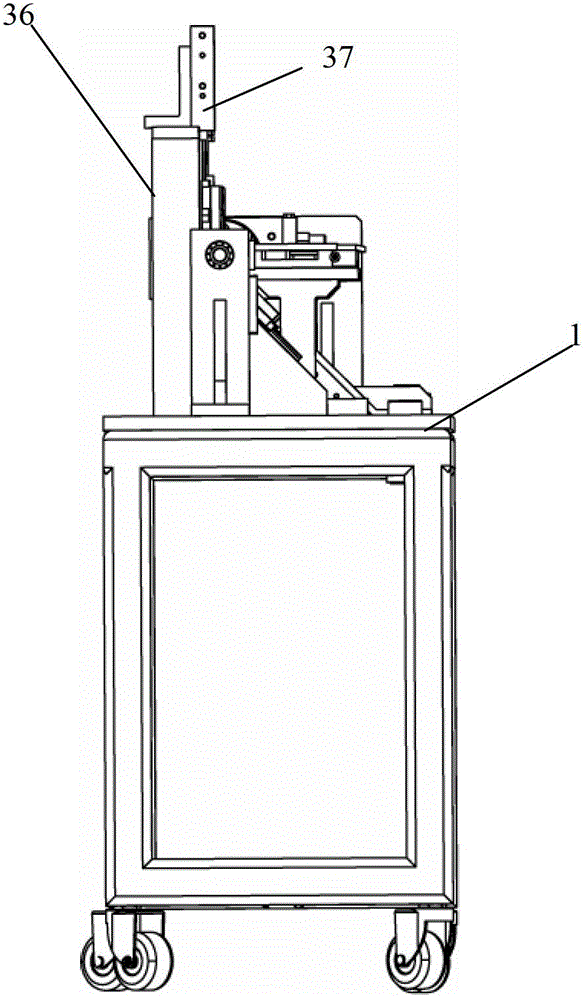

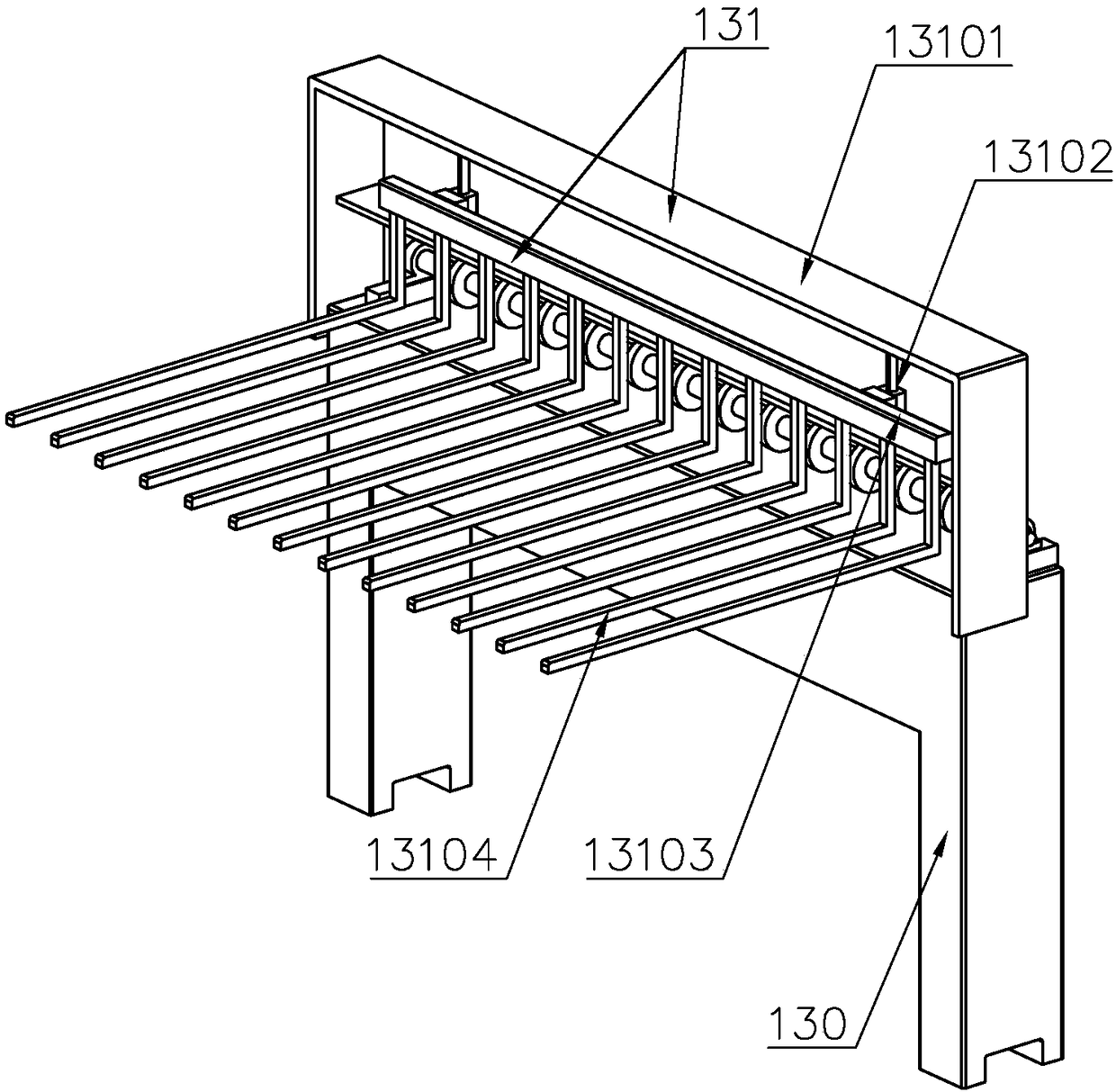

The invention discloses a bending device which comprises a bending machine and a battery clamp, wherein the bending machine comprises a platform, a battery location device which is arranged on the platform, a clamping device and a bending unit; the batter clamp comprises a battery lining plate and a cover plate, the battery lining plate can be separately and fixedly arranged on a clamp platform, a plurality of battery accommodating grooves which are linearly arrayed are arranged on the battery lining plate, and elastic location devices are respectively formed at the side parts and bottoms of the battery accommodating grooves; and the cover plate is separately and fixedly arranged on the battery lining plate. According to the bending device, the battery lining plate adopts a mechanism of precisely locating a plurality of batteries at the same time, and the product quality uniformity can be effectively ensured through utilizing the elastic location devices.

Owner:天津聚元新能源科技有限公司

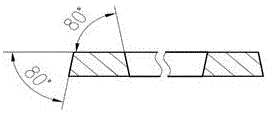

Chute machining method for inner wall face of case of aero-engine

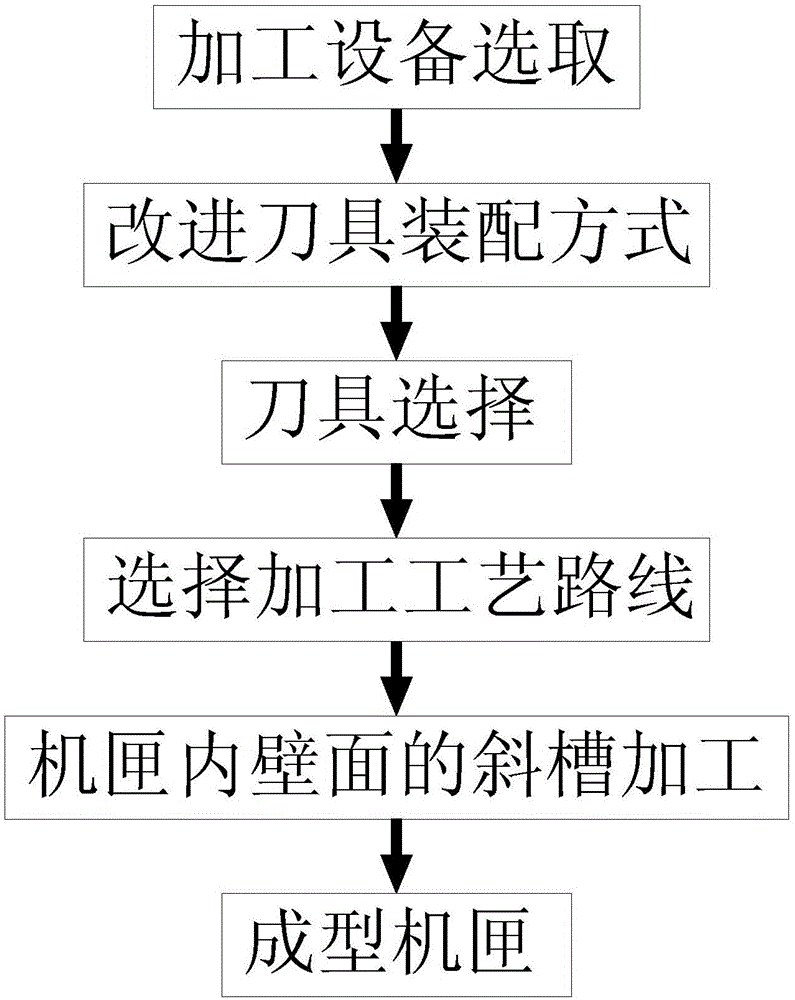

ActiveCN106312158ASolve the processing size control and frequent tool breakageEliminate knife diggingMilling cuttersMilling equipment detailsDiameter ratioMachining process

The invention discloses a chute machining method for the inner wall face of a case of an aero-engine. The method comprises the following steps that a, a five-axis numerical control machine tool is selected as machining equipment; b, the tool assembly manner is improved, a through-connection angle head is used for carrying out through connection on a tool on a machine tool spindle, and the machine tool spindle stretching into the case in the axial direction of the case and the tool for machining the inner wall face of the case in the radial direction of the case are formed; c, the tool is selected, the diameter of a handle of the tool ranges from phi6 to phi10, the diameter of a cutting part ranges from phi4 to phi7, the length-diameter ratio of the tool ranges from 1:7 to 1:10, and therefore tool vibration brought by through connection of the tool in the machining process is reduced; d, a chute machining process path is selected, and a circulation machining manner is adopted so as to guarantee the surface roughness of chutes and improve the machining efficiency; and e, all chute design positions on the inner wall face of the case are machined, and the formed case is obtained. The requirements for the sizes and the roughness of the chutes are guaranteed; and tool consumption is greatly reduced, and the machining cost is reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

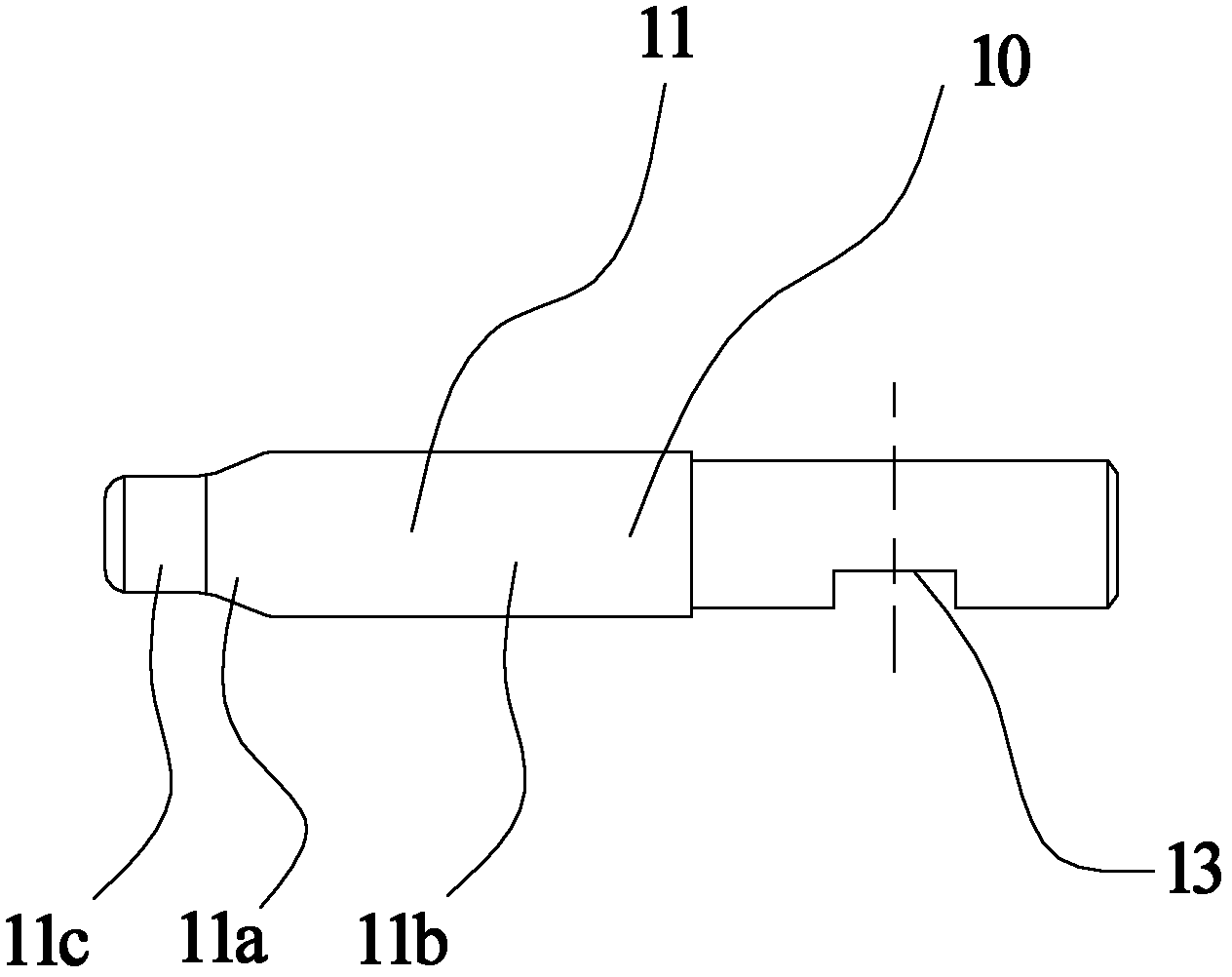

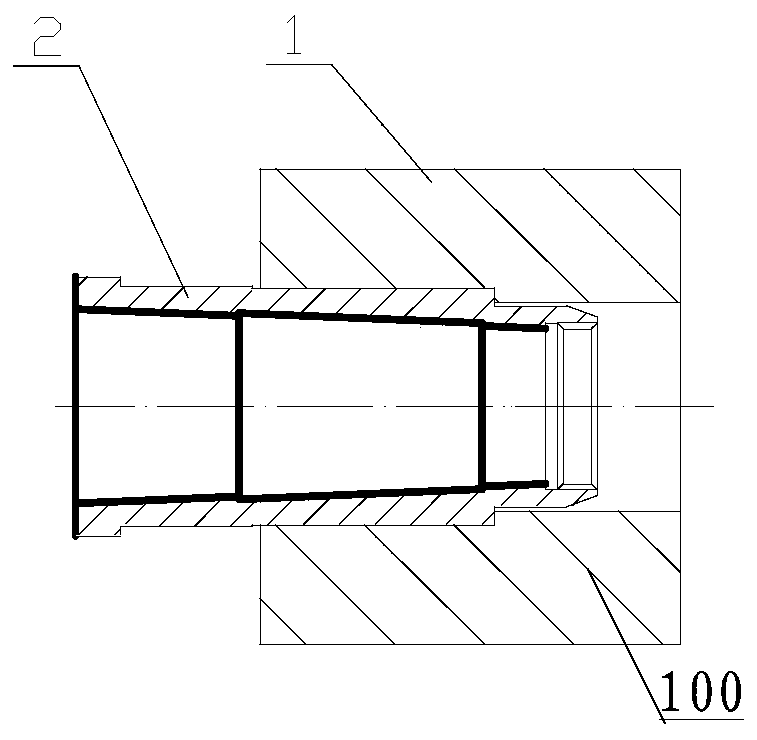

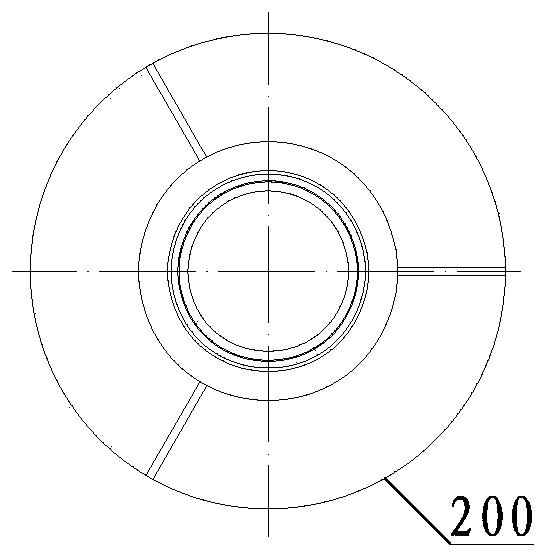

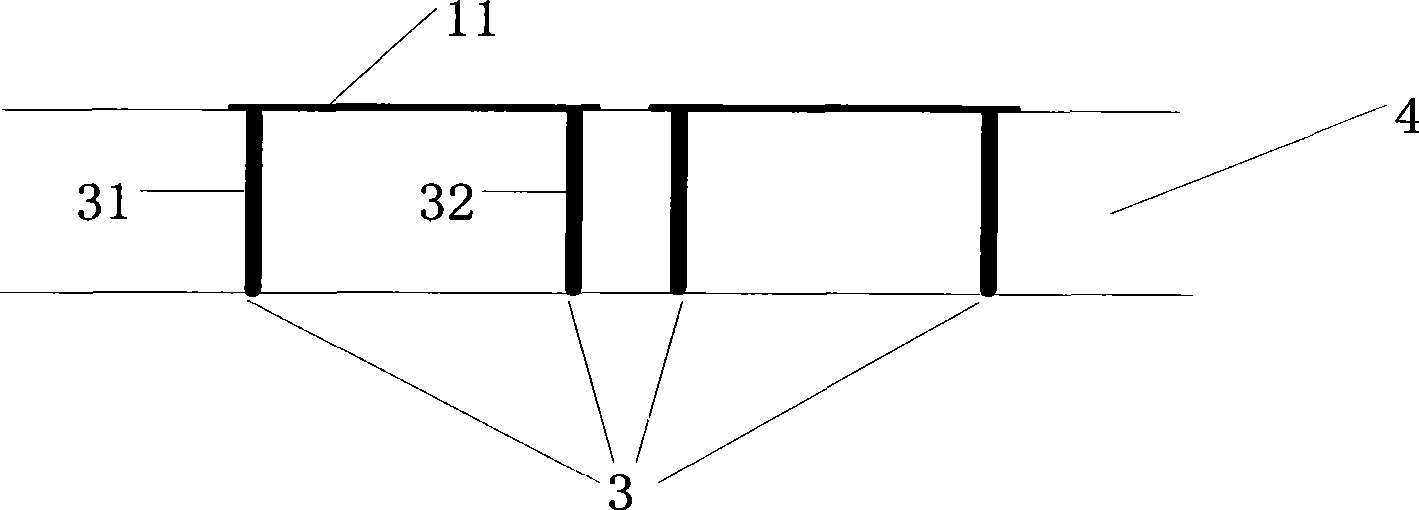

Punching head

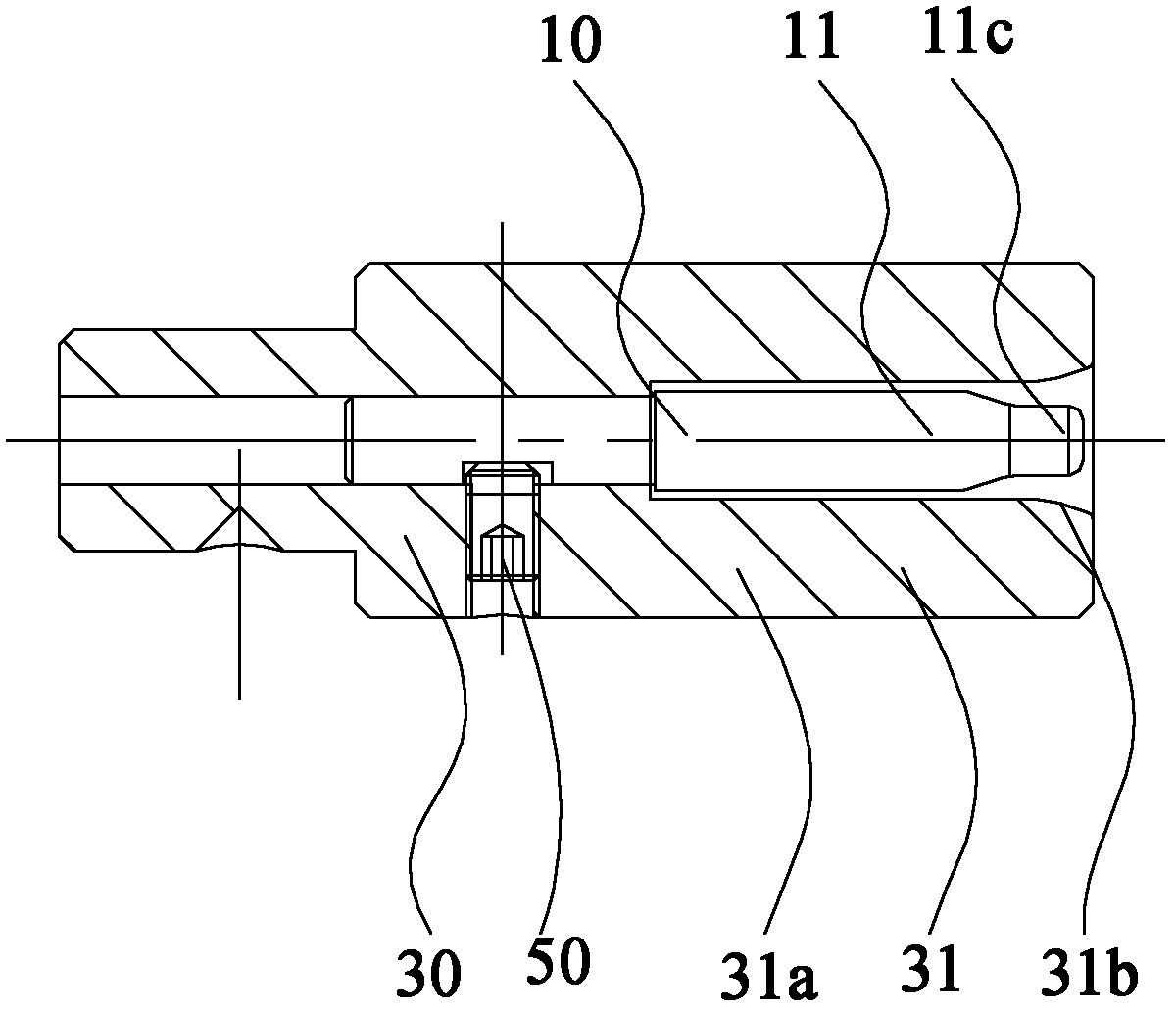

ActiveCN102962333AGuaranteed inner diameterSimplify the production processShaping toolsEngineeringPunching

The invention provides a punching head, which comprises an expanding mold core (10) and a reducing jacket (30), wherein the first end of the expanding mold core (10) is an expanding end (11) and the second end of the expanding mold core (10) is a connecting end; and the expanding mold core (10) is installed in the inner hole of the reducing jacket (30), the first end of the reducing jacket (30) is a reducing end (31), and a gap is kept between the reducing end (31) and the expanding end (11). The punching head has the advantages of high production accuracy, simple production process and high efficiency.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

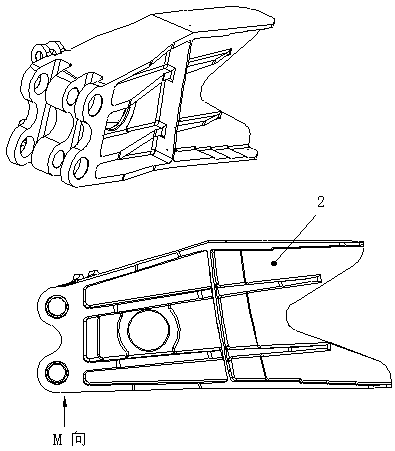

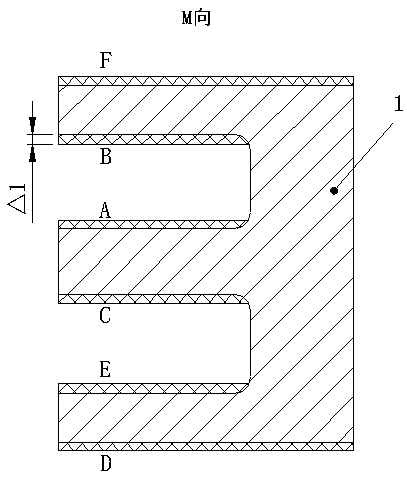

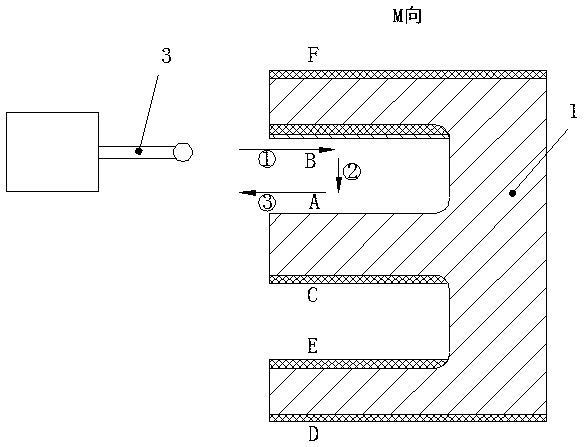

Milling clamp for thin-wall shifting forks

InactiveCN105619117AGuaranteed size requirementsSimple structurePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to the field of mechanical machining, in particular to a milling clamp for thin-wall shifting forks. The milling clamp comprises a clamp body. Two cushion blocks are arranged on the same side of the clamp body. The clamp body is further provided with three straight pins which are a center positioning pin, a limiting pin and a pressure positioning pin correspondingly. The upper end of the pressure positioning pin is provided with a thread and fixedly connected with a pressure board through a nut. The upper end of the center positioning pin is also provided with a thread. The center positioning pin is connected with a nut through a thread. The clamp body is arranged on a machine table. The milling clamp for thin-wall shifting forks is simple in structure, easy to manufacture, convenient to use and high in universality, requirements for the machining dimension of workpieces can be ensured, and the production efficiency and the qualified rate of products are increased.

Owner:陕西天财工程造价咨询有限公司

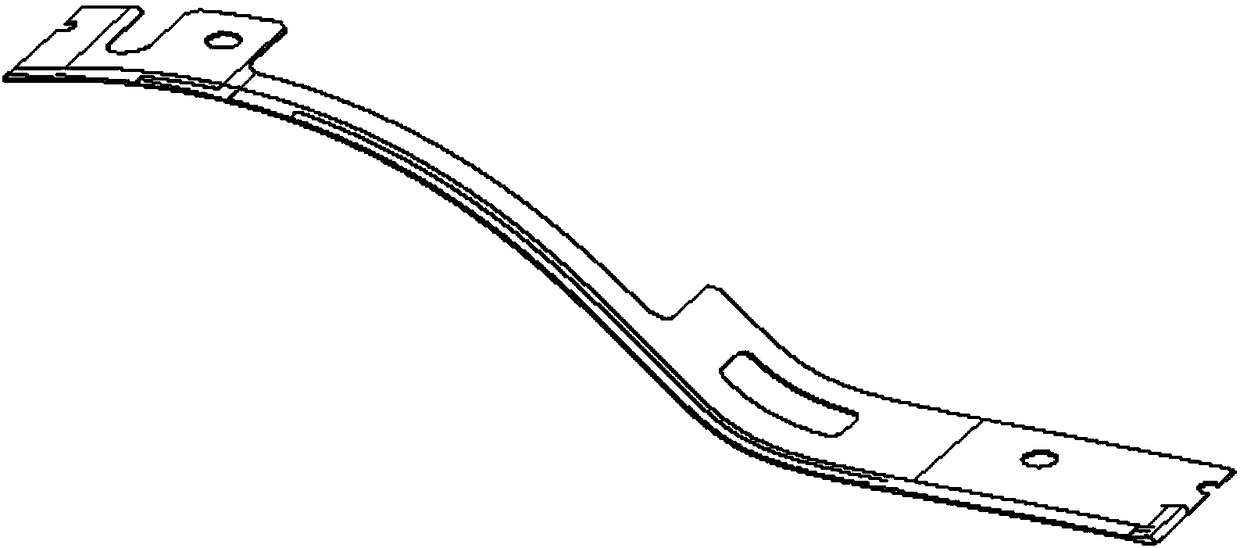

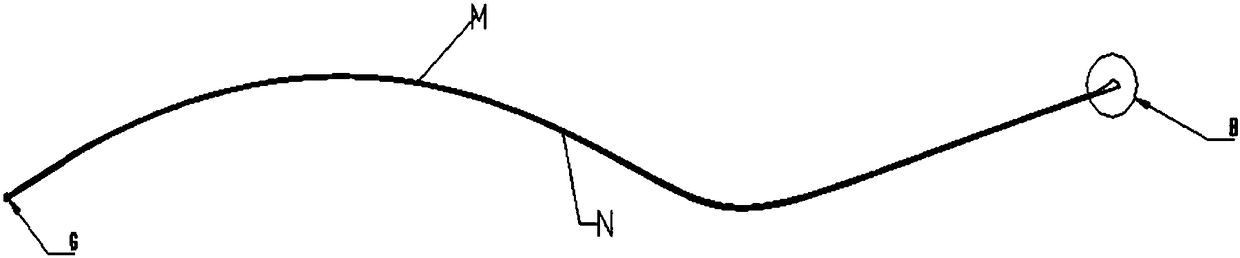

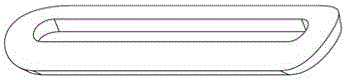

Method using 0 chromium (Cr) 17 nickel (Ni) 4 copper (Cu) 4 niobium (Nb) thin wall square pipes to machine and manufacture linkage ring guide pipe parts

InactiveCN102837159ASimple structureGuaranteed size requirementsShaping toolsNiobiumMartensitic stainless steel

The invention belongs to the field of machining and particularly relates to a method using 0 chromium (Cr) 17 nickel (Ni) 4 copper (Cu) 4 niobium (Nb) thin wall square pipes to machine and manufacture linkage ring guide pipe parts. The method is characterized in that the 0 Cr 17 Ni 4 Cu 4 Nb thin wall square pipes with 0.6 + / - 0.03 millimeter wall thickness are used as pipe materials, after burrs are removed, rosin or sand is poured into the pipe materials which are disposed in a roll bending forming mould to be molded in a roll bending mode, the rosin or the sand in the pipe materials is removed after the pipe materials are molded in a roll bending mode, and the pipe materials are disposed on a shape rectifying mould to be rectified for 2-4 hours, and then ports of the pipe materials are cut off, after the pipe materials are in fluoroscopy examination, a heat treatment of the pipe materials at temperature of 1030-1050 DEG D under a vacuum condition for 10-30 minutes is carried out, then the pipe materials are disposed on the shape rectifying mould again to be rectified for 2-4 hours, after the pipe materials are in end cutting and the fluoroscopy examination after being rectified, the linkage ring guide pipe parts can be obtained. The technical scheme fully solves the problems that precipitation hardening type martensitic stainless steel 0 Cr 17 Ni 4 Cu 4 Nb thin wall square pipes are low in plasticity and difficult to machine, and the linkage ring guide pipe parts which meet requirements of aero-engine use are manufactured and machined.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

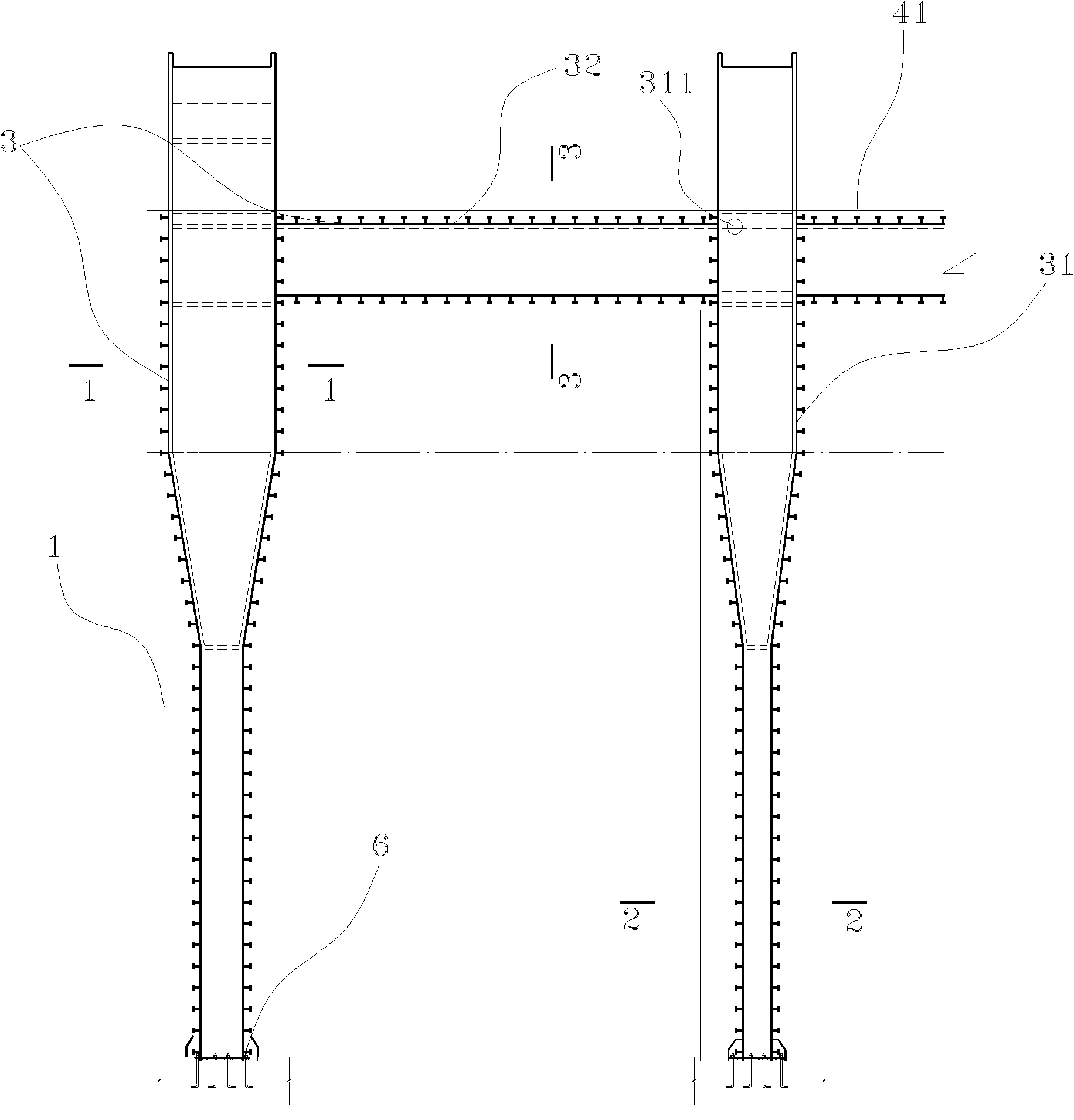

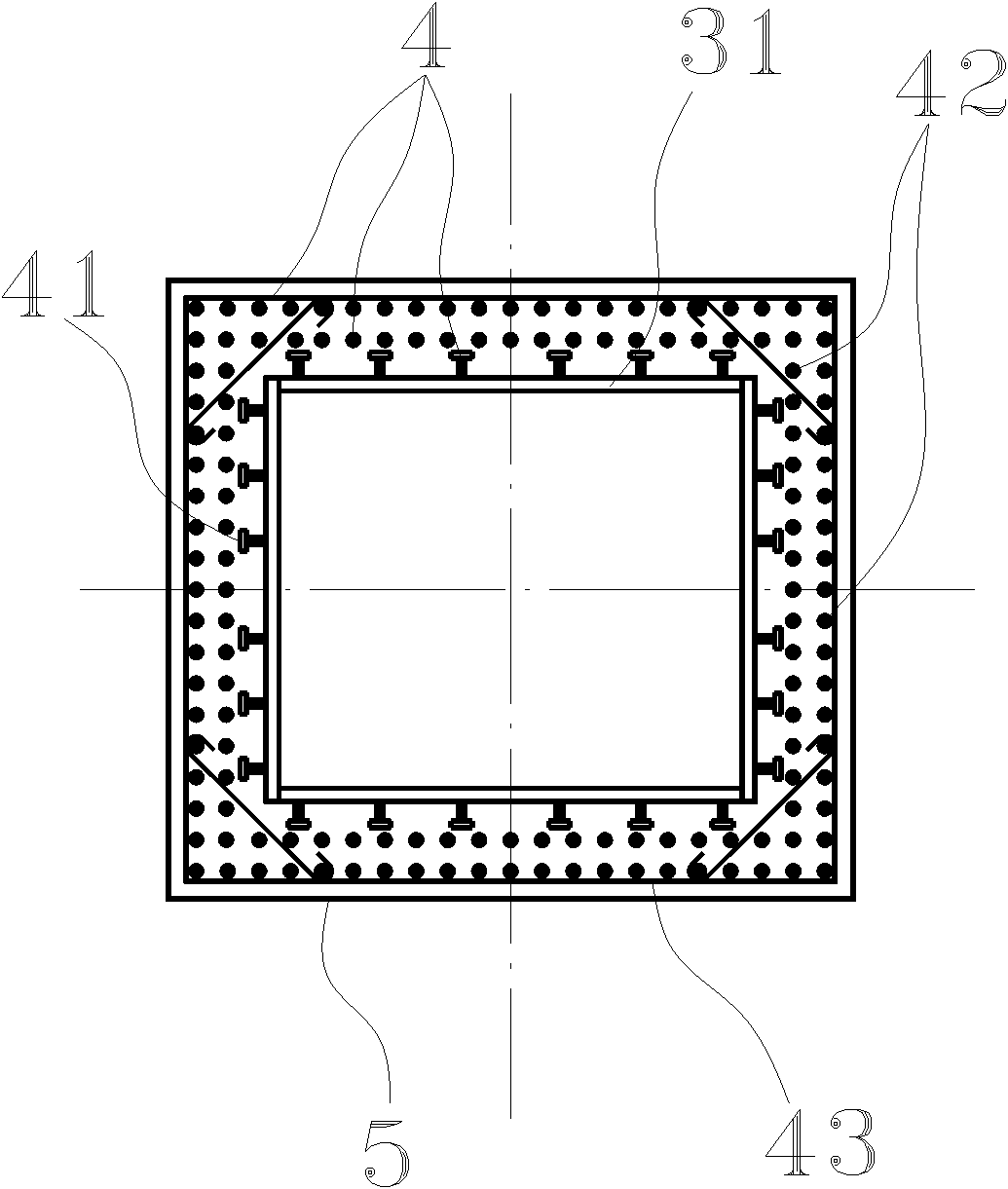

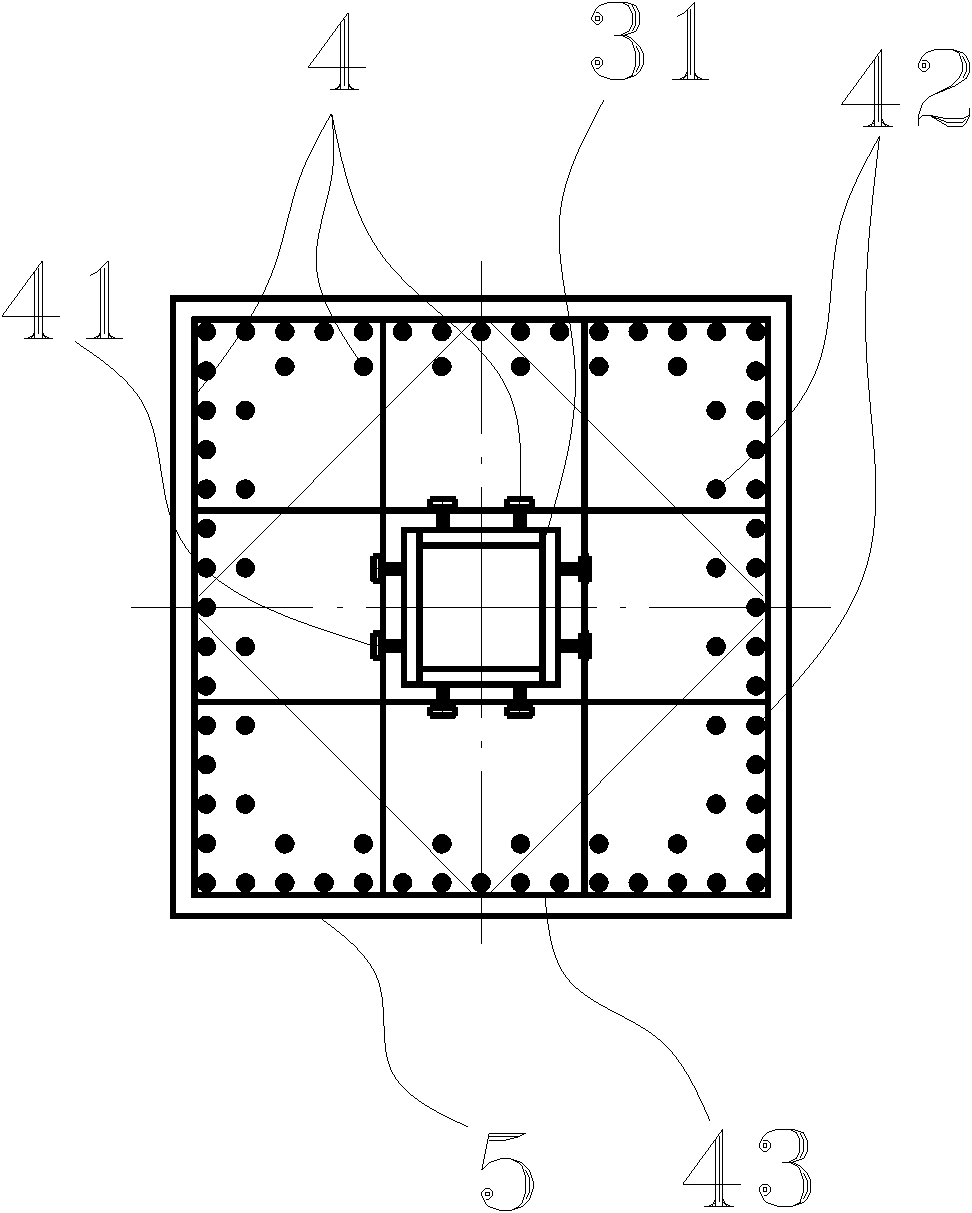

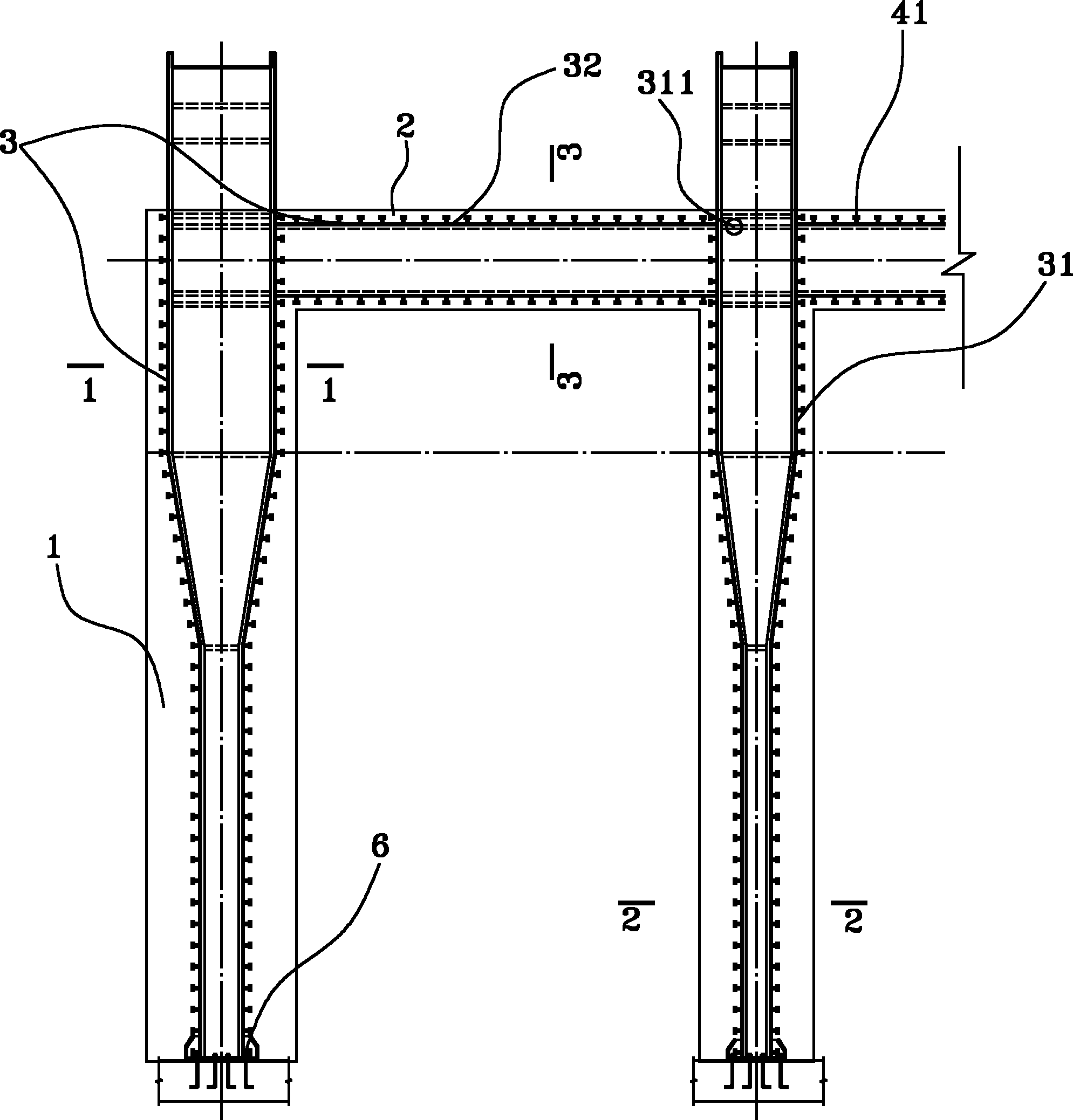

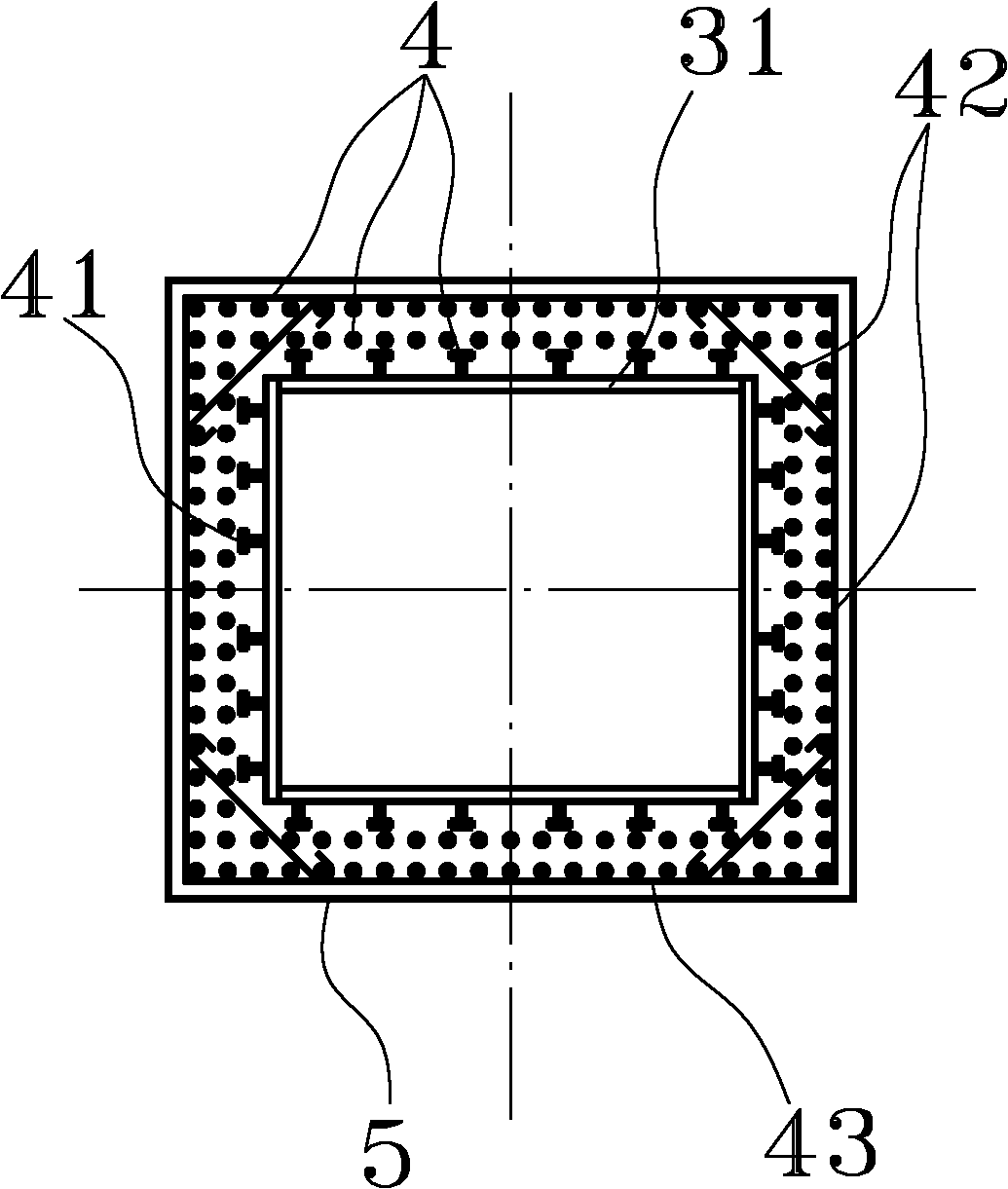

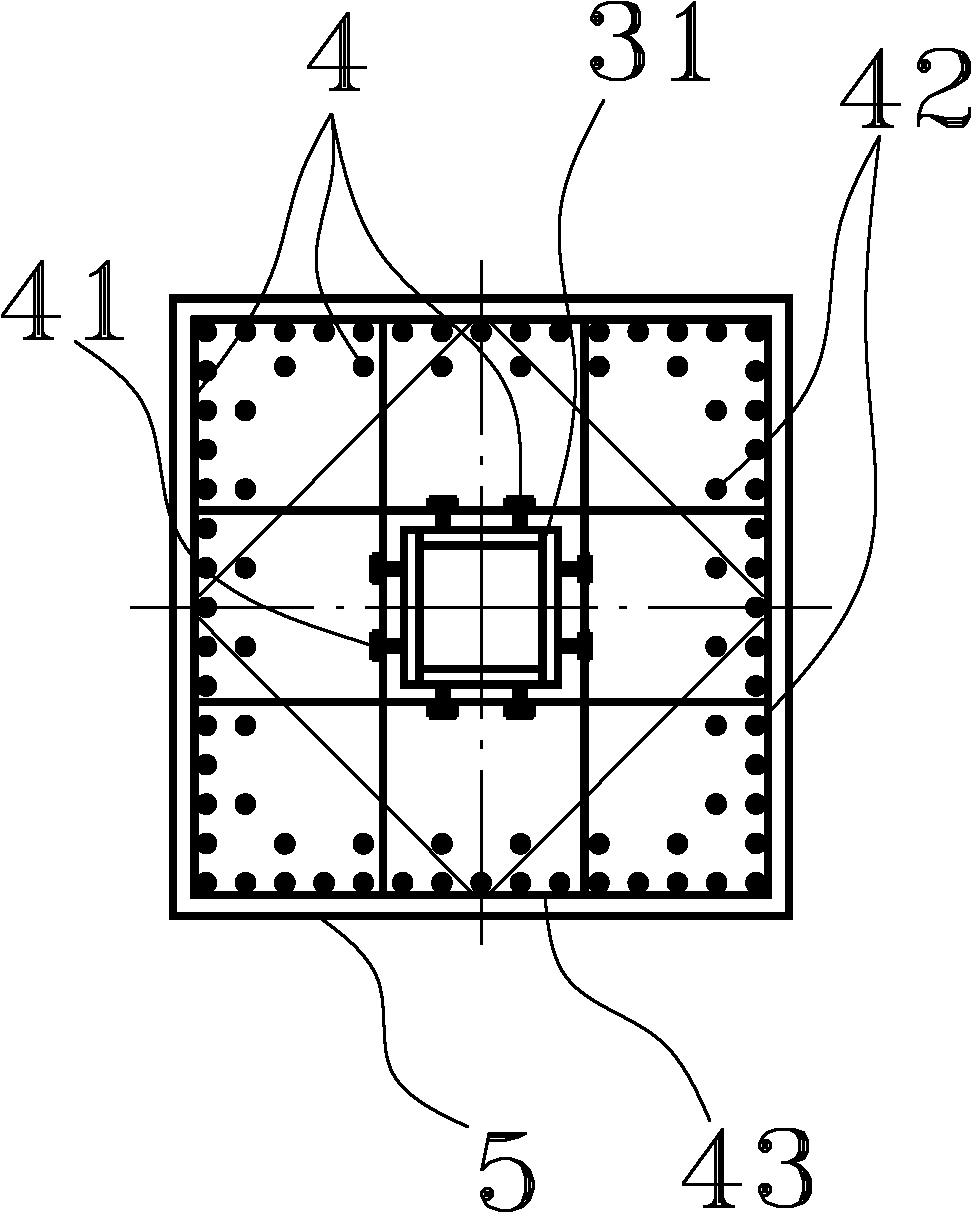

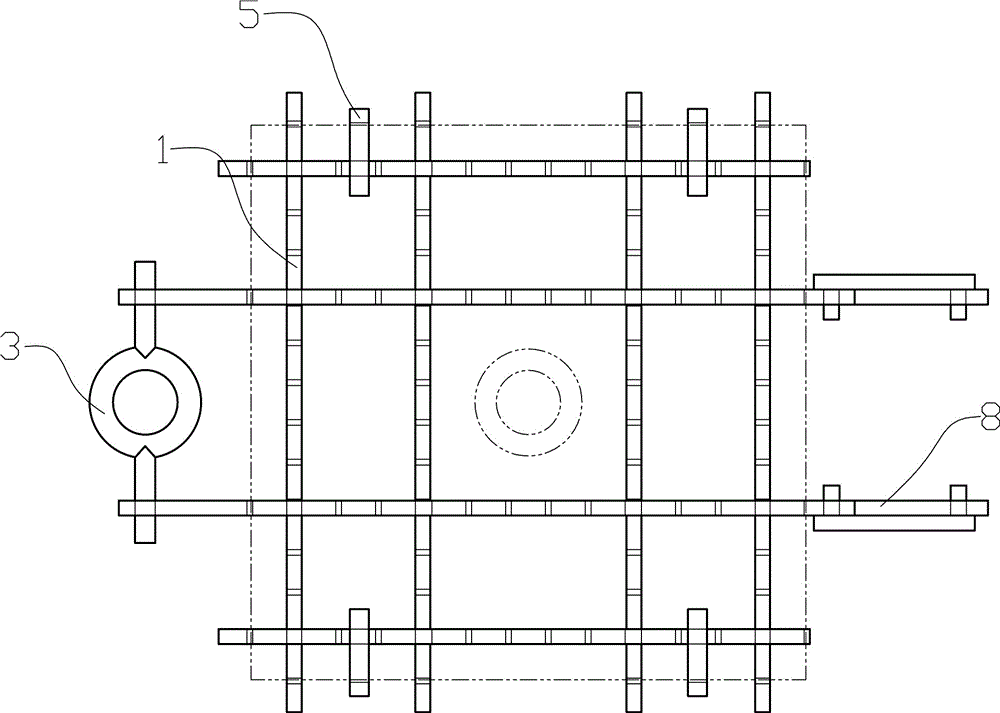

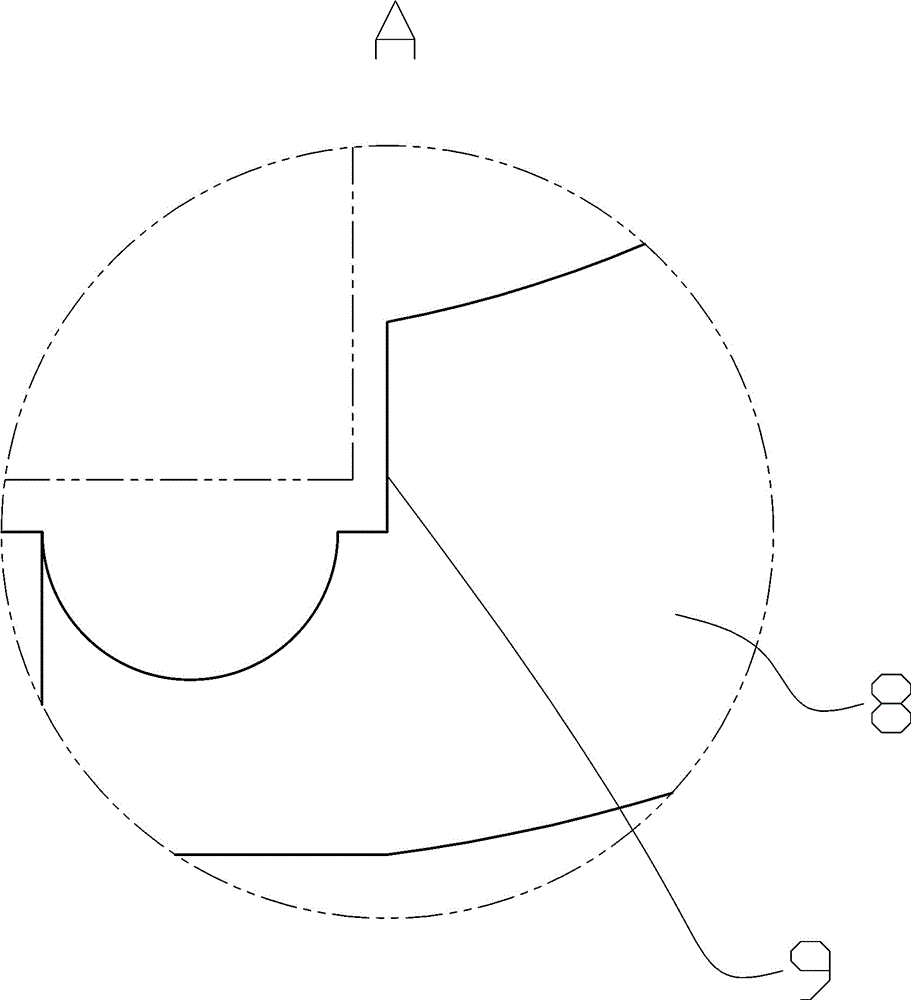

Method for constructing combined steel and concrete column of large metallurgy industrial factory building

ActiveCN102102443AEasy to installGuaranteed installation qualityBuilding material handlingSteel columnsRebar

The invention discloses a method for constructing a combined steel and concrete column of a large metallurgy industrial factory building, belongs to the technical field of factory building construction and production, and provides a method for constructing the combined steel and concrete column of the large metallurgy industrial factory building, which can guarantee the manufacturing quality of the combined steel and concrete column. The method for constructing the combined steel and concrete column of the large metallurgy industrial factory building comprises the following steps of: firstly, arranging a steel framework which consists of a steel column and a steel beam on the basis of arrangement, and regulating the arrangement quality of the steel column by arranging a regulation base plate and a cable wind rope; secondly, arranging the outer side of the steel column and the outer side of the steel beam on the steel framework sequentially; then arranging concrete reinforcement on the connection part between the steel column and the steel beam sequentially, and supporting a concrete casting template of the steel column on the outer side of the concrete reinforcement of the steel column, wherein the concrete on the inner side and the outer side of the steel column box body are cast by a high toss and vibrating casting method and a fixed point positioning vibrating casting method; and finally, removing casting template curing concrete after the concrete strength meets the design requirement.

Owner:CHINA 19TH METALLURGICAL CORP

Machining method and device of curved-surface workpiece

The invention discloses a machining method and device of a curved-surface workpiece. A shape follow-up tool and a fixing piece are utilized, one side of the shape follow-up tool is a horizontal plane,and the other side of the shape follow-up tool is a curved surface. The curved surface can be tightly attached to the first curved surface of the to-be-prepared curved-surface workpiece. The fixing piece comprises a bottom plate and a plurality of supporting parts arranged on the bottom plate. The bottom surface of the bottom plate is a horizontal plane. The arrangement positions and heights of all the supporting parts are different. The ends of the supporting parts are matched with the second curved surface to bear and fix the to-be-prepared curved-surface workpiece, and mutual matching of the curved-surface workpiece and the shape follow-up tool as well as the fixing piece is achieved. According to the machining method and device of the curved-surface workpiece, the machining difficultproblem of the curved-surface workpiece is solved through building of a datum plane and matching of the shape follow-up tool and the fixing piece.

Owner:山东豪迈精密机械有限公司

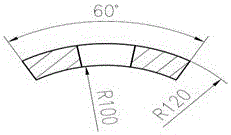

Machining method of steam seal measuring snap-gauge

ActiveCN105563040AGuaranteed dimensional accuracyGuaranteed size requirementsMechanical measuring arrangementsMachiningEngineering

The invention relates to a machining method of a steam seal measuring snap-gauge, and solves the problems that in the prior art, a steam seal measuring snap-gauge is high in manufacturing cost, and long in machining period. The machining method comprises the following specific steps: 1, preparing a blank; 2, roughly machining the side surfaces of the blank; 3, machining a circular arc on the upper surface of the blank; 4, conducting clean-up processing; 5, polishing; 6, drilling threaded holes; 7, finely machining the side walls of a straight slot; 8, roughly machining a measuring tooth; 9, chamfering; 10, conducting heat treatment on the measuring tooth; 11, polishing the measuring tooth; 1, finely machining the measuring tooth; 13, finely grinding the measuring tooth; 14, finely grinding the slope of the measuring tooth; and 15, chamfering and finely grinding the measuring tooth. The machining method is used in the machining field of steam seal measuring snap-gauges.

Owner:HARBIN TURBINE

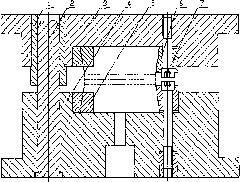

Method and die carrier for forging and molding special-shaped cross section metal blank with through holes

InactiveCN101823113AReasonable connectionMeet reliabilityForging/hammering/pressing machinesPunchingMolding machine

The invention relates to a method and a die carrier for forging and molding a special-shaped cross section metal blank with through holes. The molding method comprises that: three die setting stations are arranged on a set of die carrier and are provided with specific dies for preforming, extrusion molding and wad punching respectively; and the blank passes through the dies of the three stations respectively in three strokes of a sliding block of pressure equipment, and the pressure equipment performs the preforming, extrusion molding and wad punching so as to finish the whole molding process of the work piece. The method and the die carrier have the advantages of finishing the whole molding machining process of a forge piece on one piece of pressure equipment by adopting the machining processes of preforming, extrusion molding and wad punching, and meeting the objective requirements of a design process and actual operation because the three-station die carrier structure with an independent clamping function and a die offset adjustment function is arranged on the tool structure.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

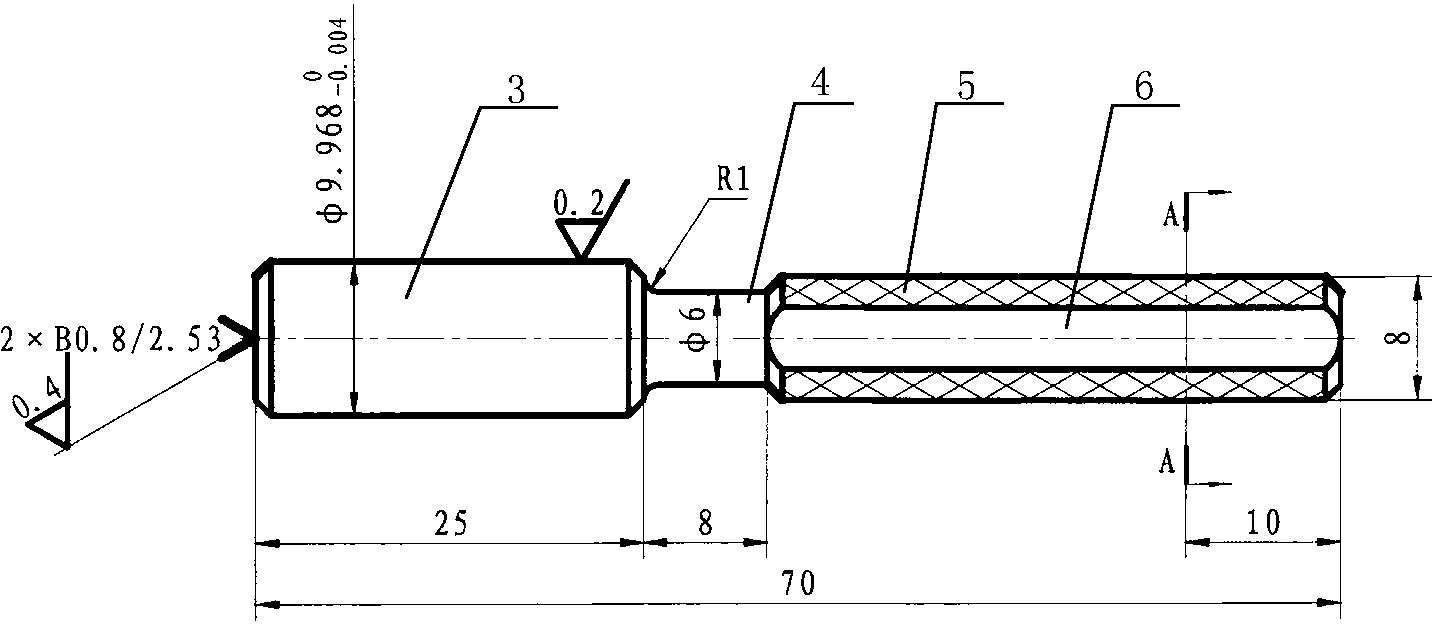

Method for machining perpendicularity gauge

The invention discloses a method for machining a perpendicularity gauge. A process for machining a movable gauge by the method includes 1), material preparation; 2), a lathing procedure implemented by lathe operators for lathing an outer circle and an inner hole and forming protective tables at two ends of the movable gauge; 3), a heat treatment procedure; 4), a sand blowing procedure; 5), a surface treatment procedure; 6), an inner hole grinding procedure; 7), an artificial aging procedure; 8), inner hole grinding; 9), a procedure for lathing off the protective tables at the two ends of the movable gauge; 10), a procedure for grinding two end surfaces of the movable gauge; 11), polishing sharp edges of a working portion of the movable gauge. The method has the advantages that the working step for forming the protective tables and the working procedure for lathing off the protective tables are added to the method, and forming ranges of flared openings are included within ranges of the protective tables, so that the problem that flared openings are formed at two ends of an existing movable gauge is effectively solved.

Owner:SHENYANG AIRCRAFT CORP

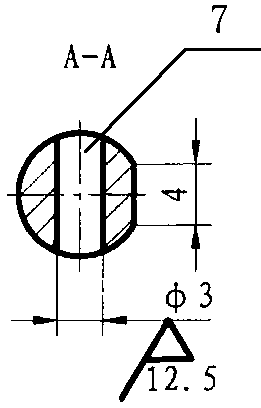

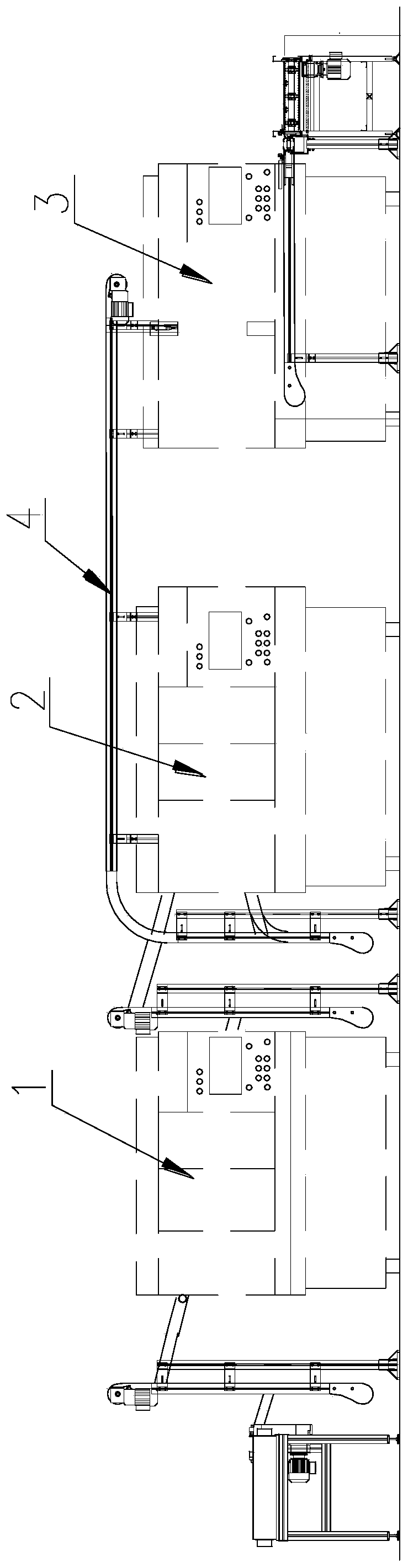

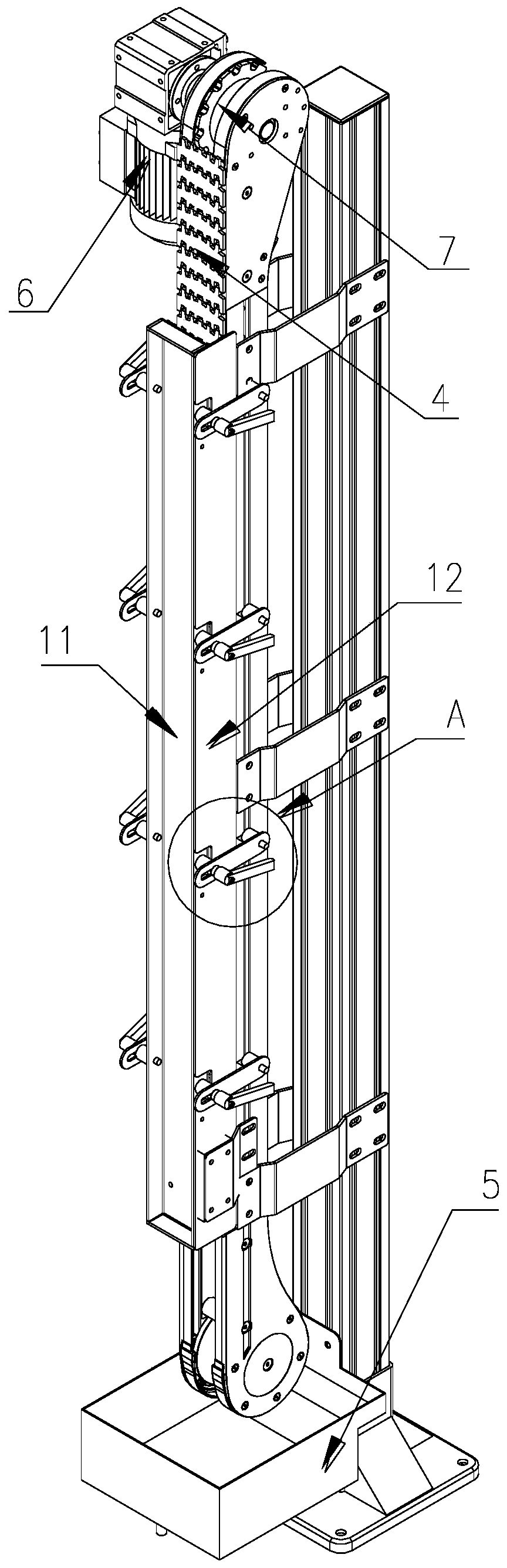

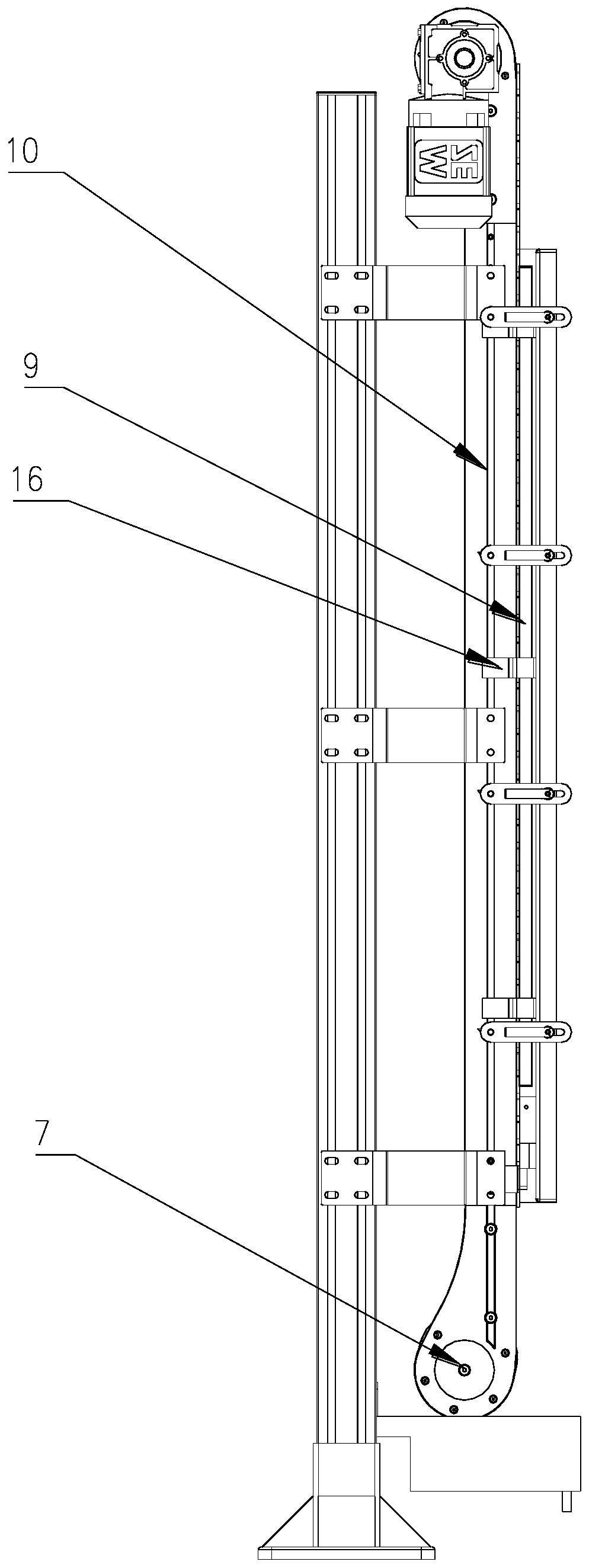

Multilayer plywood fully-automatic production line

PendingCN108082880ARealize automatic crawlingImprove work efficiencyMechanical conveyorsProduction lineStack machine

The invention discloses a multilayer plywood fully-automatic production line. The multilayer plywood fully-automatic production line comprises a fully-automatic lifting table, a horizontal feeding machine, a single sheet conveying line, a vertical feeding machine, an automatic glue applicator, a top guiding rule, a plywood conveying line, a horizontal movement guiding rule and an automatic stacking machine, wherein the conveying chains of the single sheet conveying line are provided with the horizontal movement guiding rule; the upper portion of one edge of the frame of the single sheet conveying line is provided with the top guiding rule, and the horizontal movement guiding rule and the top guiding rule achieves a positioning right angle of assembly single sheets; the frame of the singlesheet conveying line is provided with a plurality of lifting roller groups I and lifting roller groups II, which are arranged in an alternate mode, and one side of the upper portion of every lifting roller group is provided with a lifting rack. The multilayer plywood fully-automatic production line can achieve automatic single sheet gripping, automatic gluing, automatic alignment, automatic compounding, automatic stacking and fully automatic production, thereby improving the working efficiency and save a large amount of labor.

Owner:山东昶兴智能科技有限公司

Construction method of steel reinforced concrete beam of large metallurgical industry plant

ActiveCN102182309AGuaranteed installation qualityGuarantee the quality of layoutBuilding material handlingReinforced concreteRebar

The invention discloses a construction method of a steel reinforced concrete beam of a large metallurgical industry plant, and belongs to the technical field of plant building construction production. The provided construction method of the steel reinforced concrete beam of the large metallurgical industry plant can ensure the manufacturing quality of the steel reinforced concrete beam. The construction method comprises the following steps of: arranging a steel skeleton, and adjusting the installation quality of a steel reinforced post by adjusting a shim plate and a wind cable; arranging a concrete steel rib outside the steel skeleton in an order of arranging the outer side of the steel reinforced post, arranging the outer side of the steel reinforced beam and finally arranging a concrete steel rib at the joint of the steel reinforced post and the steel reinforced beam; supporting a concrete cast template of the steel skeleton, and casting concrete inside and outside a steel reinforced post box body; finally, casting concrete on the steel reinforced beam by adopting a single-side feeding vibrating and single-side driving casting method, a two-side symmetrical layered feeding vibrating casting method and a middle feeding symmetrical driving vibrating casting method; and detaching the cast template after the strength of the concrete meets the design requirement, and curing the concrete.

Owner:CHINA 19TH METALLURGICAL CORP

Aviation structural part high-precision lug group machining method

ActiveCN111390252AGuaranteed size requirementsImprove processing efficiencyMeasurement/indication equipmentsMilling equipment detailsAviationMilling cutter

The invention relates to an aviation structural part high-precision lug group machining method, and belongs to the technical field of machinery. The method comprises the following steps that firstly,a part lug group is subjected to rough machining and semi-fine machining through a milling cutter; then, a machining allowance is measured through a probe and is compared with a theoretical allowanceto form a program offset allowance P; and finally, the offset allowance P is automatically called by a program to finish high-precision lug group machining in place. According to the method, in the machining process, the manual intervention is not needed, high-quality machining on the high-precision lug group is rapidly completed, the machining efficiency is improved, the machining risk is reduced, the characteristics of simple operation method, reliable use, easy and wide use and the like are achieved, the machining quality of the part high-precision lug group can be effectively guaranteed, the rejection rate of parts is reduced, and therefore the cost is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Quenching anti-deformation device and method

ActiveCN106367570AAvoid deformationControl deformationFurnace typesHeat treatment furnacesEngineeringQuenching

The invention provides a quenching anti-deformation device and method. A lower pressing frame is hinged to an upper pressing frame through a connecting rod, and a space used for pressing a workpiece is formed between the lower pressing frame and the upper pressing frame. The lower pressing frame and the upper pressing frame are connected in a pressing mode through a plurality of pressing claws. The pressing claws are in a C shape. An extending part is arranged on one side of the lower pressing frame or the upper pressing frame. A turning ring is rotationally connected with the extending part. Through the locked upper pressing frame and the lower pressing frame, enough pressing strength is achieved so that deformation during quenching of the workpiece can be prevented, the deformation amount of the workpiece can be controlled and is smaller than 5 mm, subsequent machining is well guaranteed, and the product quality is improved. Through the arrangement of the turning ring, the large-sized workpiece can be heated in the horizontal state, after heating is completed, the turning ring is hooked with a hoisting device, a workpiece (7) is hoisted vertically and placed in a quenching bath to be quenched, energy consumption is reduced, and the quenching quality is improved.

Owner:YICHANG MARINE DIESEL ENGINE

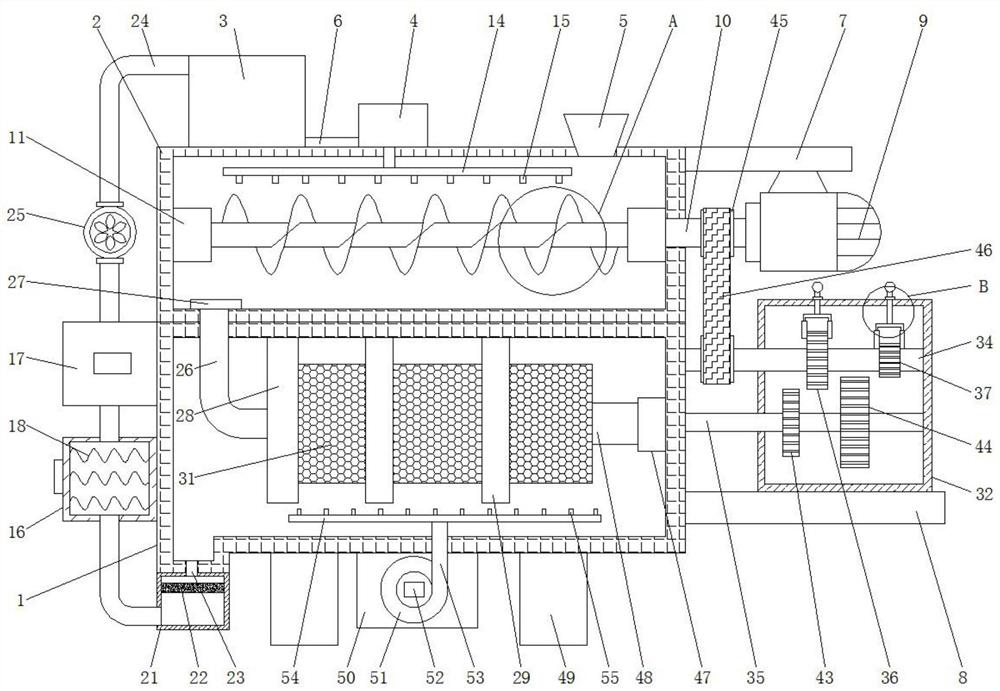

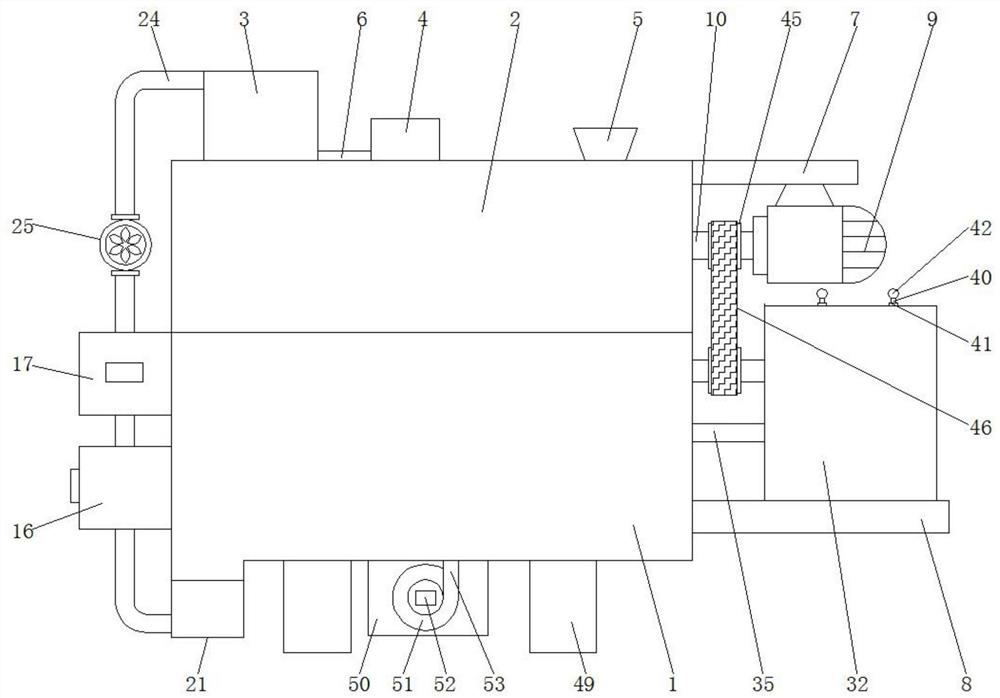

Multi-functional rice stalk processing device for making winter feed for goats

ActiveCN111700294AStrong flexibilityAvoid the loss of nutrientsFeeding-stuffDrying solid materials without heatElectric machineryDrive motor

The invention discloses a multi-functional rice stalk processing device for making winter feed for goats. The multi-functional rice stalk processing device comprises a dewatering box and a washing box, wherein the washing box is located at the top of the dewatering box; a water box, a pressurizing pump and a feeding hopper are sequentially and fixedly mounted at the top of the washing box from left to right; water guiding pipes are arranged on the left side and the bottom of the pressurizing pump; the water guiding pipe on the left side communicates with the water box; a top plate and a bottomplate are sequentially and fixedly mounted on the right side surface of the washing box from top to bottom; a driving motor is fixedly mounted at the bottom of the top plate through a machine frame;a rotating shaft is fixedly mounted at the output end of the driving motor; first bearing pedestals are fixedly mounted on the inner walls of the left side and the right side of the washing box; a first rotating rod is rotatably connected between the two first bearing pedestals; spiral crushing knifes are arranged on the external surface of the first rotating rod; the right end of the first rotating rod penetrates through the washing box and is fixedly connected with the left end of the rotating shaft; and a water collecting pipe communicates with the water guiding pipe which is arranged at the bottom of the pressurizing pump, and penetrates through the top of the washing box. The multi-functional rice stalk processing device disclosed by the invention can complete washing, disinfecting, sterilizing and drying.

Owner:鲁首佳(山东)工业设计有限公司

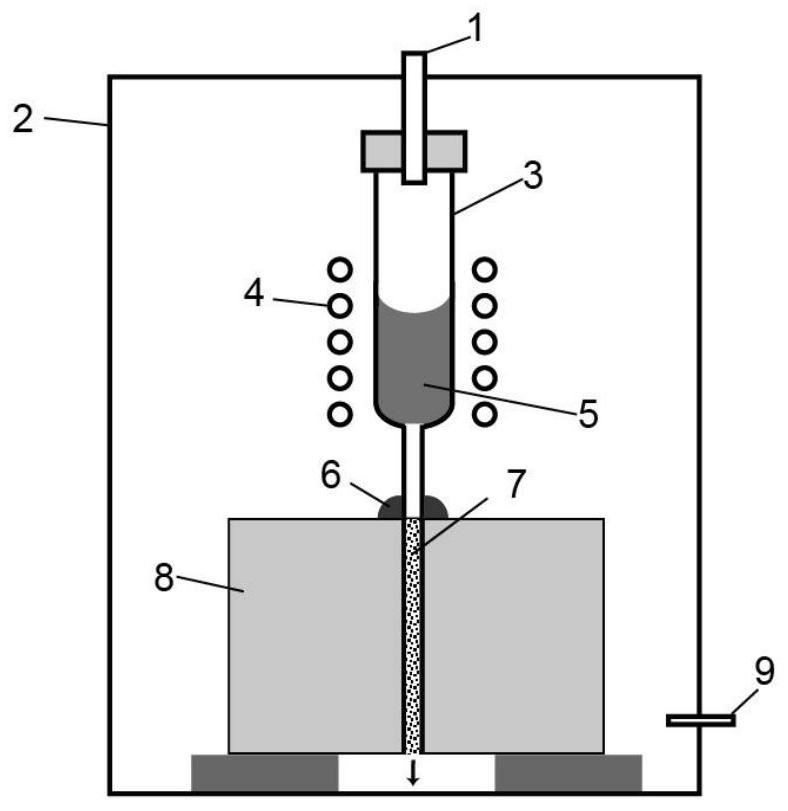

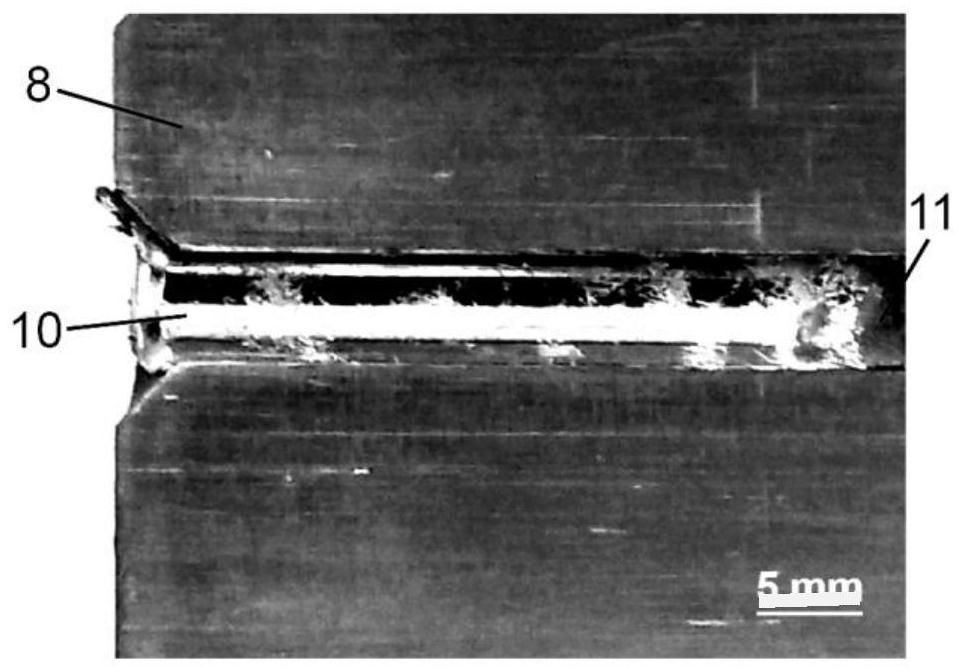

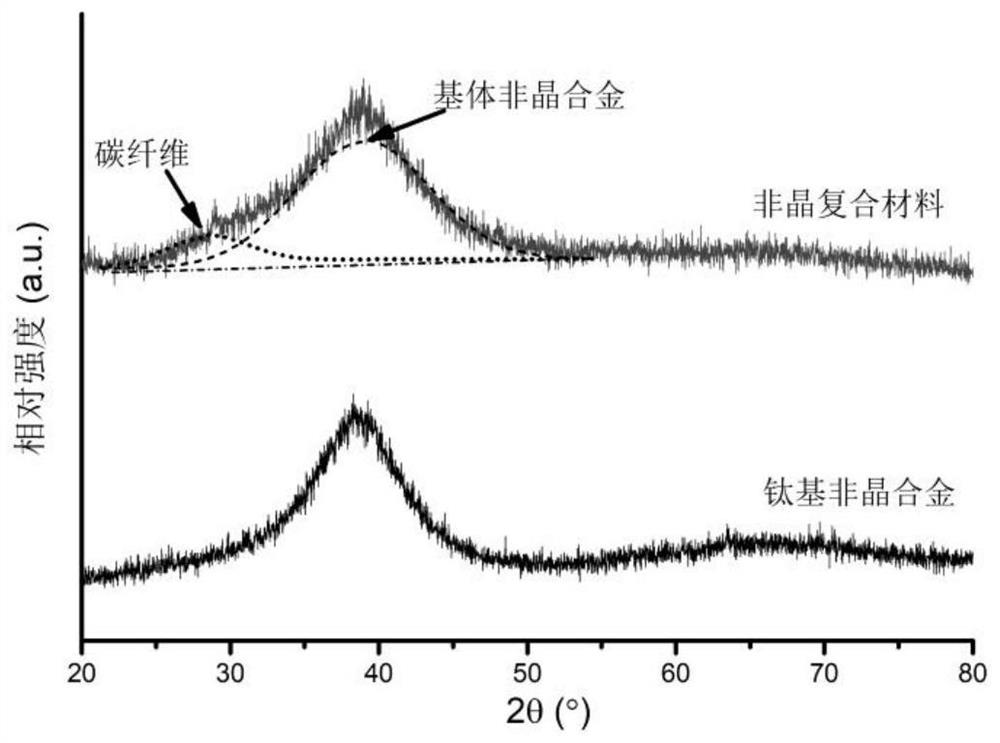

Method for preparing chopped carbon fiber reinforced amorphous composite material and a device thereof

The invention discloses a method for preparing a chopped carbon fiber reinforced amorphous composite material and a device thereof, and relates to the technical field of forming an amorphous compositematerial by contacting fibers with molten metal and performing rapid solidification. The method adopts a chemical plating method to improve the wettability of the carbon fibers, a carbon fiber preform is prepared through a copper mold, furthermore, the chopped carbon fiber reinforced amorphous composite material is prepared by using a vacuum low-pressure casting method, namely a spray casting method, and the defects that in the prior art, the fiber agglomeration phenomenon caused by non-uniform dispersion of reinforced fibers in a matrix or an interface structure with brittleness equal to that generated by the carbon fibers and the matrix at an interface, the method is only suitable for a traditional magnesium alloy matrix, a high cooling speed cannot be achieved, an amorphous matrix cannot be obtained, and the amorphous composite material cannot be prepared for various amorphous alloy matrixes needing vacuum melting are overcome.

Owner:HEBEI UNIV OF TECH

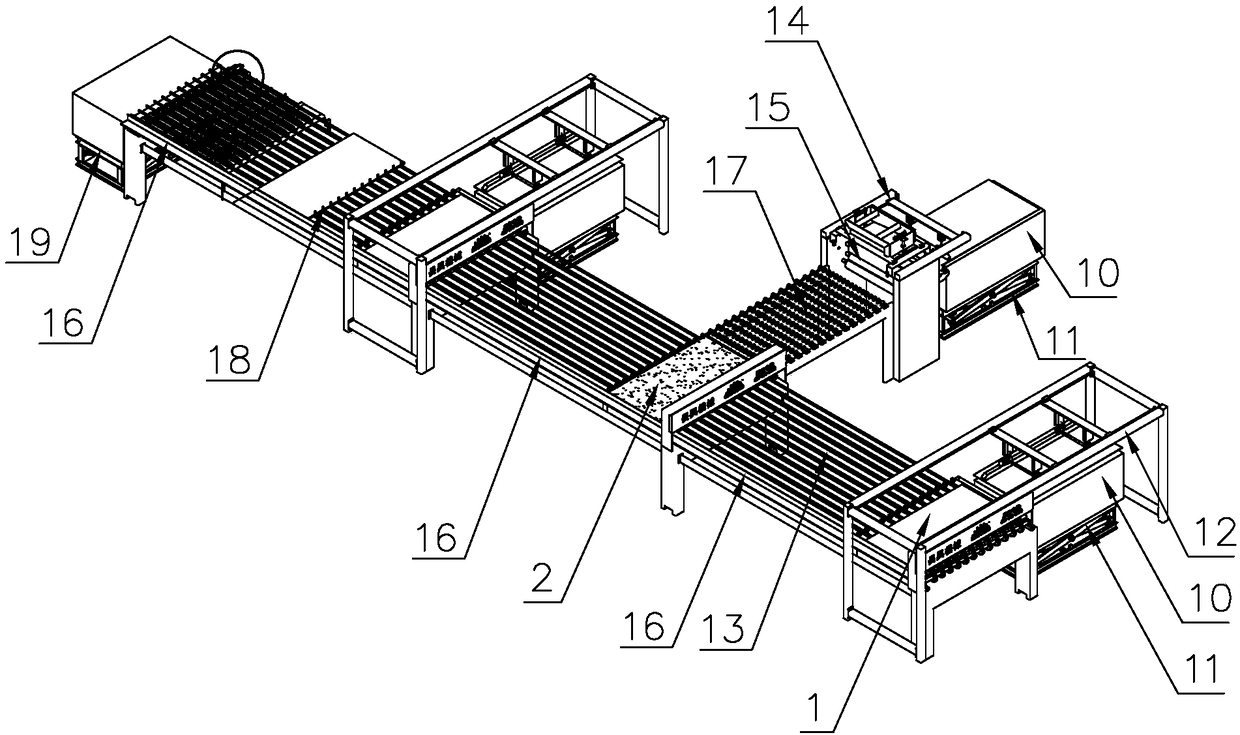

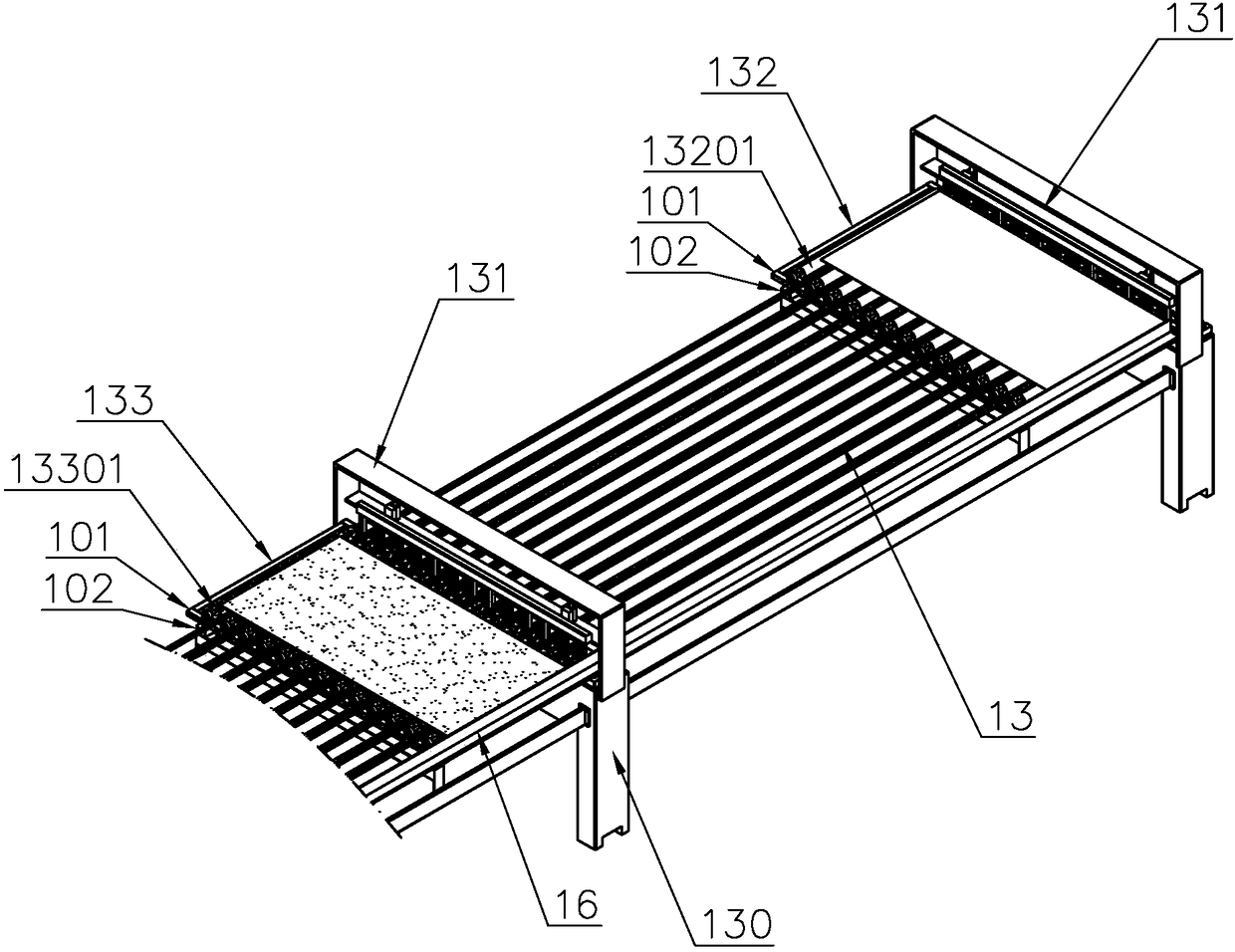

Workpiece machining flexible production line and machining method implemented through same

ActiveCN110227951AGuaranteed sizeEasy clearanceOther manufacturing equipments/toolsMetal working apparatusProduction lineNumerical control

The invention discloses a workpiece machining flexible production line and a machining method implemented through the same. The flexible production line comprises production units used for machining amachine part, and a conveying system connected between the production units; the production units include a rough machining unit, a finish machining unit and a station unit; and the roughing unit comprises a rough grinding unit. By adopting the technical scheme, according to the universal joint retainer flexible production line, three numerical control horizontal grinding machines and an automatic conveyor belt form a window, inner circle and outer circle grinding machining process control automatic line, complicated machining operation is achieved, the dimensional requirements, precision requirements and position requirements are effectively guaranteed, the part machining quality is stable, optimal fit clearances of produced universal joint retainers can be ensured, and impact, noise andvibration generated by universal joint assemblies during usage are reduced.

Owner:温州华义信息技术有限公司

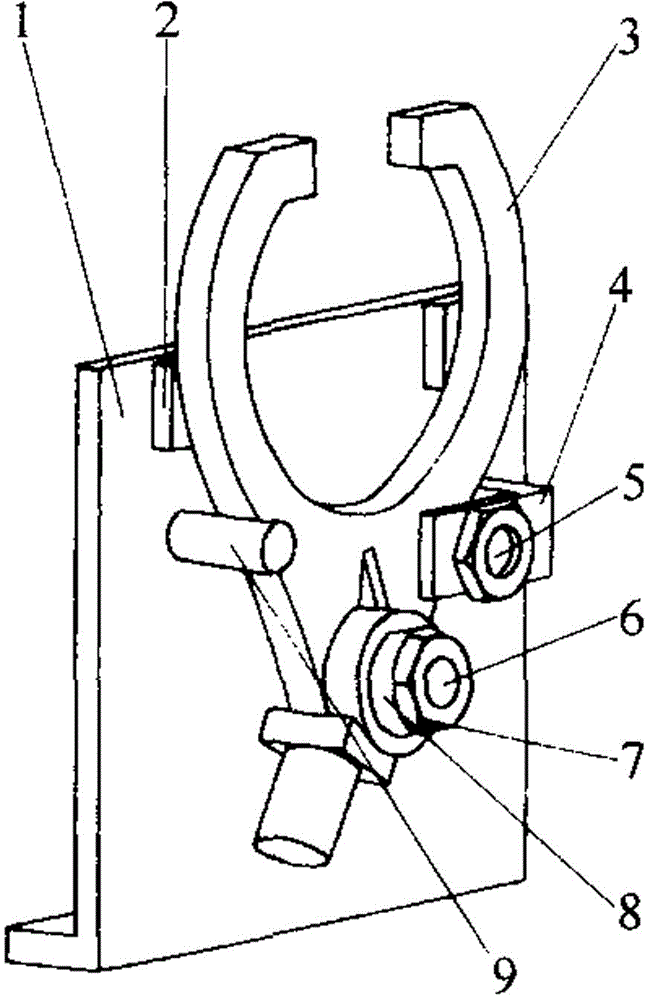

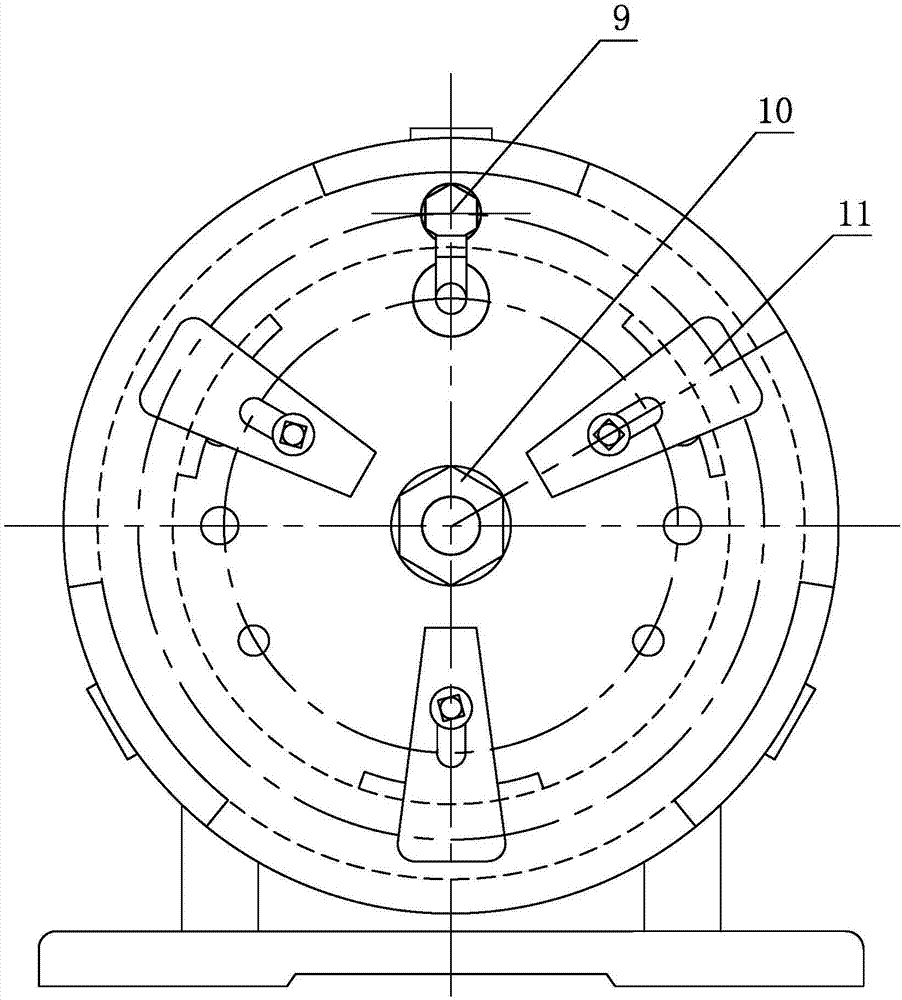

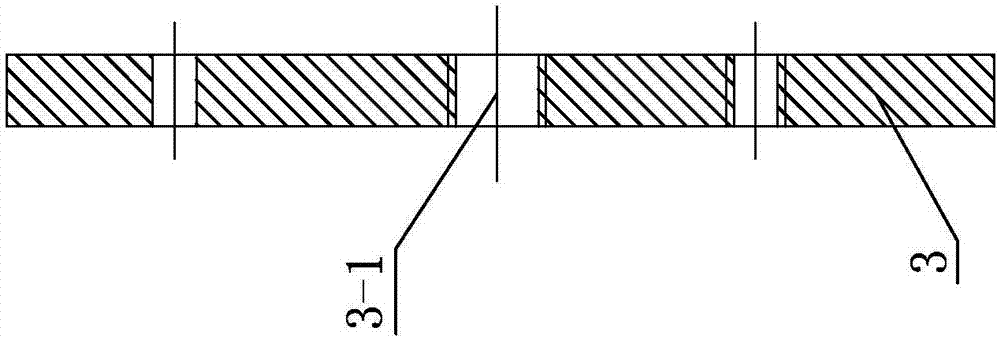

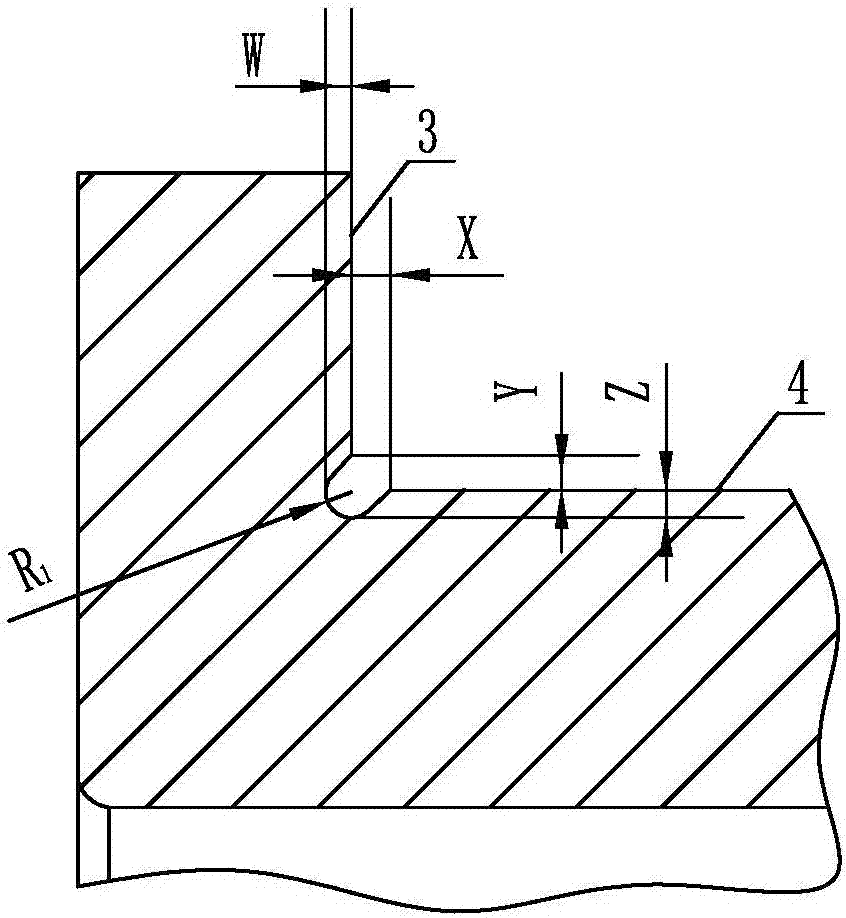

Rotatable clamp for circumferential hole drilling of ring-like parts with end face holes

PendingCN107877204AGuaranteed size requirementsGuaranteed coincidenceLarge fixed membersPositioning apparatusEngineeringMachining

The invention provides a rotatable clamp for circumferential hole drilling of ring-like parts with end face holes and relates to the technical field of machining. The problems that in existing ring-like part radial hole machining, a drill bit directly drills in a circular arc, and a machining plane does not exist, so that the positioning difficulty of the drill bit is large, vibration is large, the size and position accuracy of a machined radial hole are poor, the technological requirement is not met, the part machining quality is affected, and the drill bit is extremely prone to being brokento cause the low production efficiency are solved. A rotatable clamp body and a fixed clamp body are sequentially positioned and mounted on a support through hexagonal head screws and nuts, a workpiece is placed in an ring-shaped area of the rotatable clamp body, three pressing plates are pressed on the workpiece and three arc-shaped fixing plates, the three pressing plates are fixed to the rotatable clamp body through three first fixing screws, and the workpiece is positioned on the rotatable clamp body through a second fixing screw. The rotatable clamp is used for drilling machining of circumferential holes of the ring-like parts.

Owner:HARBIN JIANCHENG GRP

Machining method of narrow and small grinding undercuts of roller bearing

InactiveCN107984172AReduce residual stressMachining accuracy is easy to controlBearing componentsPulp and paper industryMachining process

The invention relates to the technical field of machining, in particular to a machining method of narrow and small grinding undercuts of a roller bearing. According to the machining method, the problems that in the machining process of existing narrow and small grinding undercuts of a roller bearing, tools are worn severely, the large size dispersion of the grinding undercuts is prone to being caused, consequently, dimension deviation of the grinding undercuts is caused, and the percent of pass of finished products is low are solved. The method comprises the following steps that firstly, a tool-by-tool cutting method is adopted, the first plane, the second plane, the sleeve ring outer diameter and the sleeve ring inner diameter of a roller bearing sleeve ring are sequentially subjected tofinish lathing machining through two tools; then, flanges, roller ways and the grinding undercuts of the roller bearing sleeve ring are sequentially subjected to finish lathing machining; the first end face and the second end face of the sleeve ring are subjected to soft grinding, and after the flanges and the roller ways of the bearing sleeve ring are subjected to rough lathing machining, the roller ways continue to be subjected to finish grinding; and finally, the grinding undercuts are finally checked, and the bearing sleeve ring is subjected to heat treatment. The machining method is usedfor machining the narrow and small grinding undercuts of the roller bearing.

Owner:AVIC HARBIN BEARING

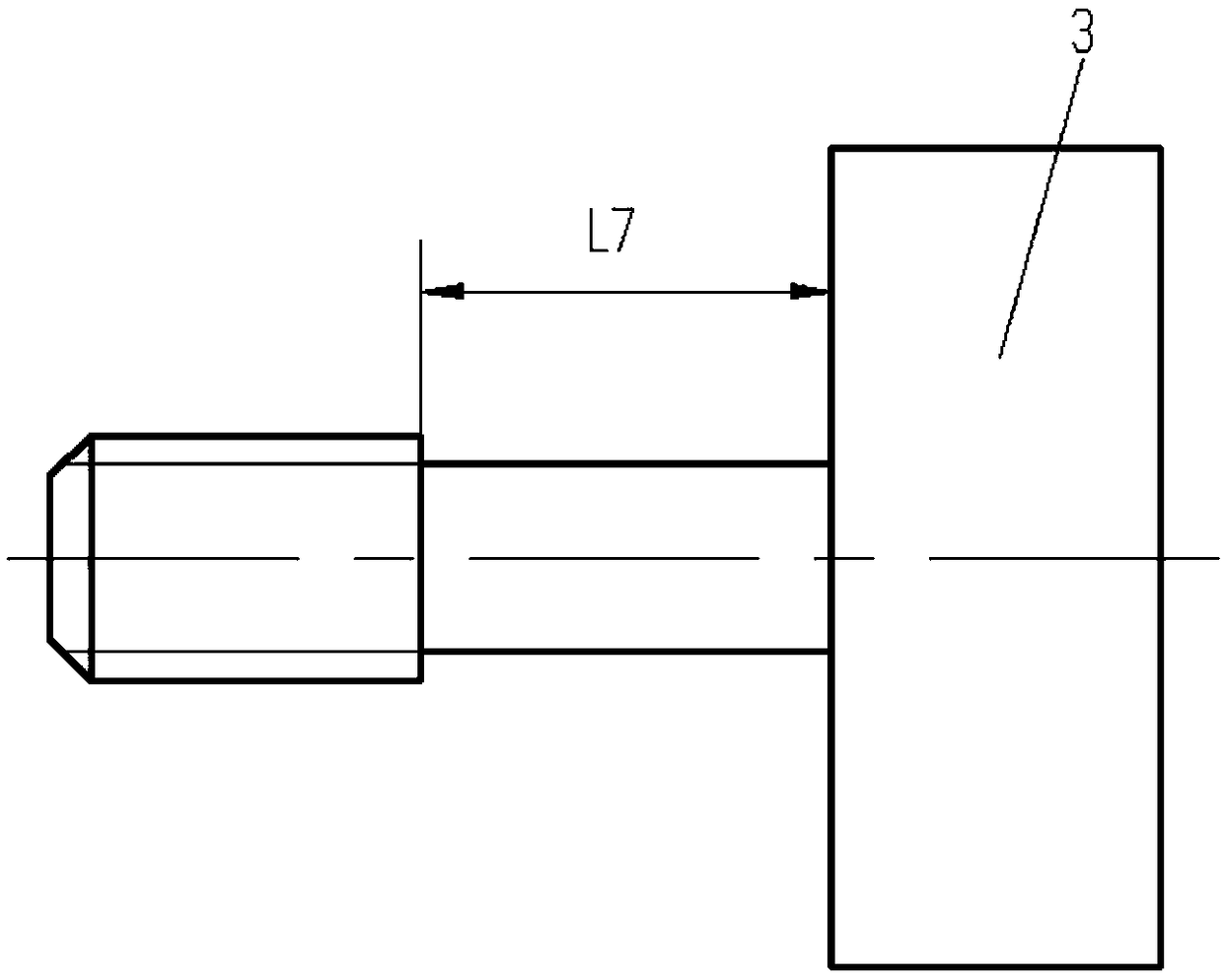

Machining method of titanium alloy thin-wall part

ActiveCN111037226AImprove stabilityReduce cutting force and control deformationTitanium alloyScrew thread

The invention discloses a machining method of a titanium alloy thin-wall part. The machining method of the titanium alloy thin-wall part comprises the following steps that a holding body holds the small end of a thin-wall shaft sleeve, the inner wall of the thin-wall shaft sleeve is subjected to rough machining operation through a lathe, and the thin-wall shaft sleeve which is subjected to rough machining operation is subjected to heat treatment; semi-finish machining operation and finish machining operation are conducted, and an inner conical hole is obtained through a boring tool; the innerconical hole serves as the standard, and a mandrel is embedded into the inner conical hole; a lathe chuck clamps the large end of the mandrel, internal threads at the tail end of the thin-wall shaft sleeve are connected with external threads of a technological plug head, and a bolt passes through an inner cavity formed in the technological plug head and is connected with the mandrel in a threadedmode; tool withdrawal grooves of excircles of the thin-wall shaft sleeve are subjected to finish machining operation, and then the thin-wall shaft sleeve is separated from the mandrel; the lathe chuckclamps the large end of the mandrel, the internal threads at the tail end of the thin-wall shaft sleeve are connected with the external threads of the technological plug head, and the bolt passes through the inner cavity formed in the technological plug head and is connected with the mandrel in a threaded mode; and the excircles of the thin-wall shaft sleeve are subjected to finish turning operation and finish machining operation. By the adoption of the machining method of the titanium alloy thin-wall part, the dimensional stability and the surface roughness are improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

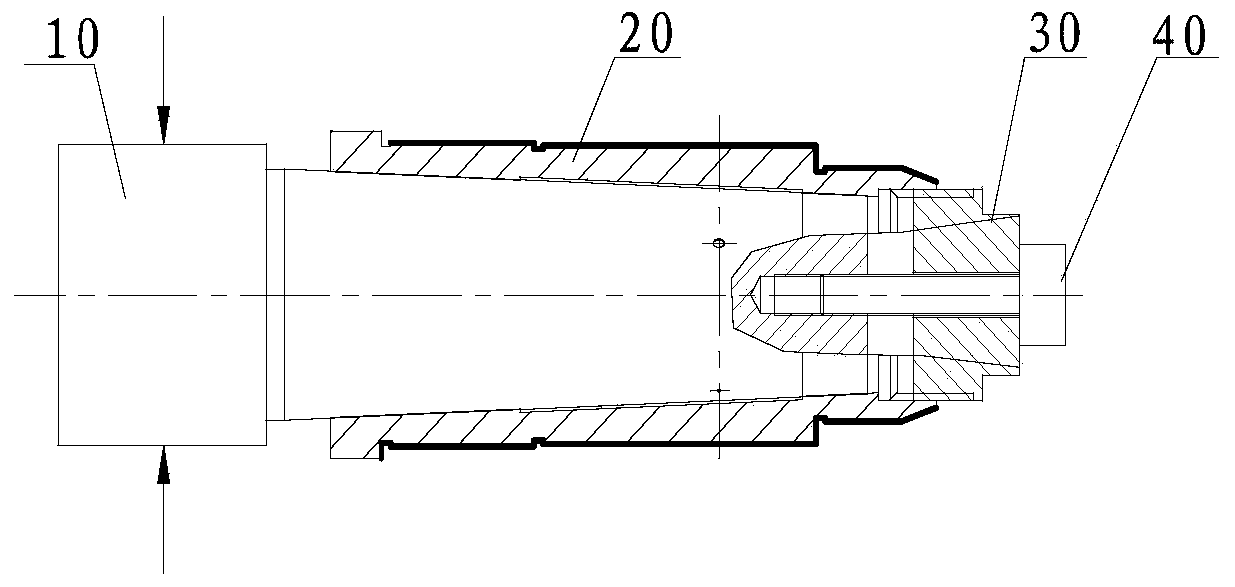

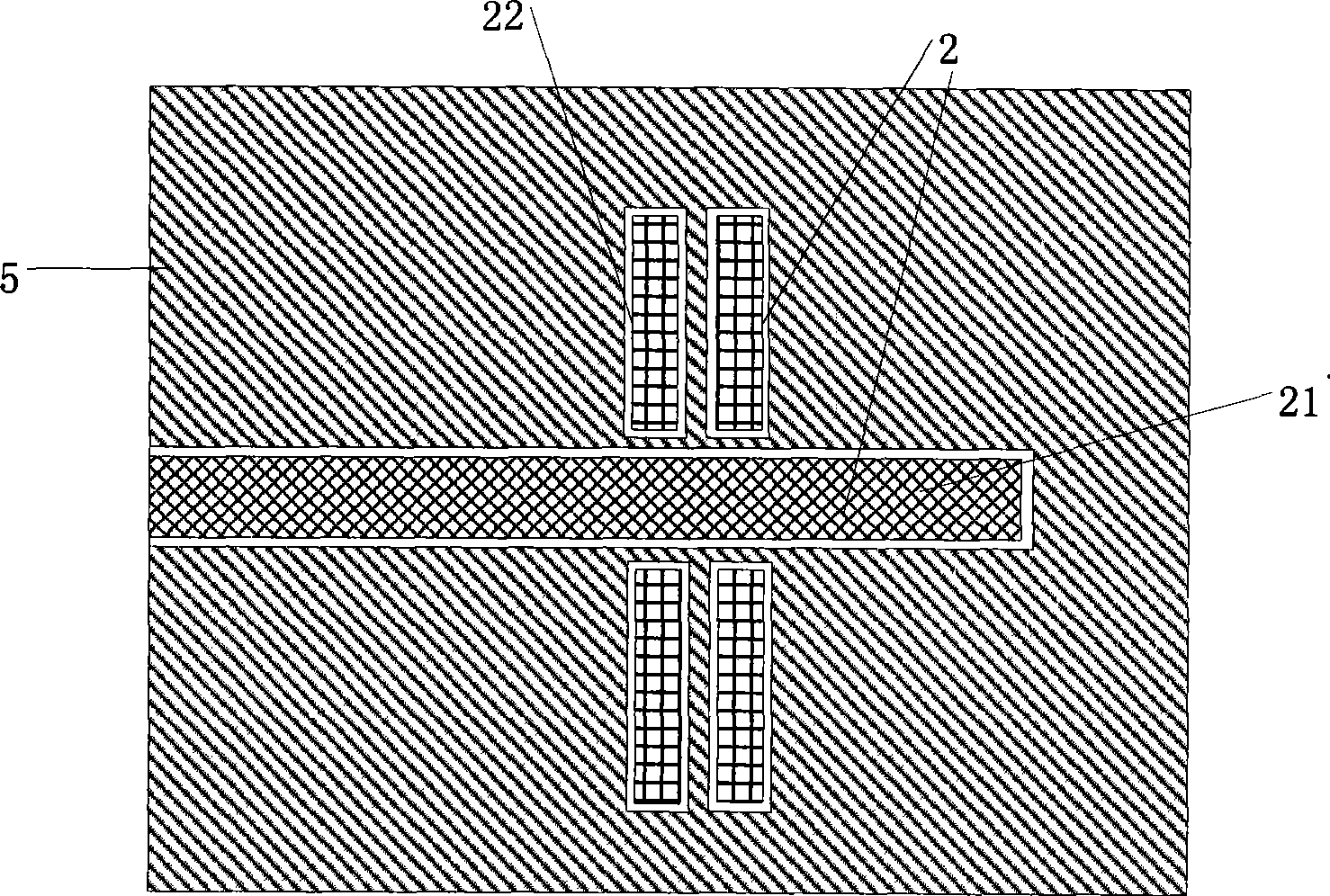

Device for once blow molding of sand cores and chillers

InactiveCN104889342AJoint flushStrong jointMoulding machine componentsMoulding machinesBlow moldingLeft half

The invention proposes a device for once blow molding of sand cores and chillers. The device comprises two half molds symmetrically arranged and respectively being a left half mold and a right half mold, wherein inserts are arranged on the half molds; three copper sleeves are arranged on the inserts; magnets are arranged in the copper sleeves; two heating pipes are arranged at one sides of the inserts; semicircular chillers are arranged at the other sides of the inserts, and are absorbed in the half molds through the magnets; molding cavity sand cores are arranged in the semicircular chillers; three exhaust connecting holes are formed in the molding cavity sand cores; and a sand ejecting port is formed above the joined place of the two half molds. The device can realize once blow molding of the sand cores and the chillers; the manufactured sand cores and chillers are smooth and tidy in joint, and need no repair and baking; and the sand cores blown by the device save multiple production procedures, guarantee the product size requirement, and improve the inherent and appearance qualities of castings.

Owner:TIANJIN HANGYU METAL PROCESSING

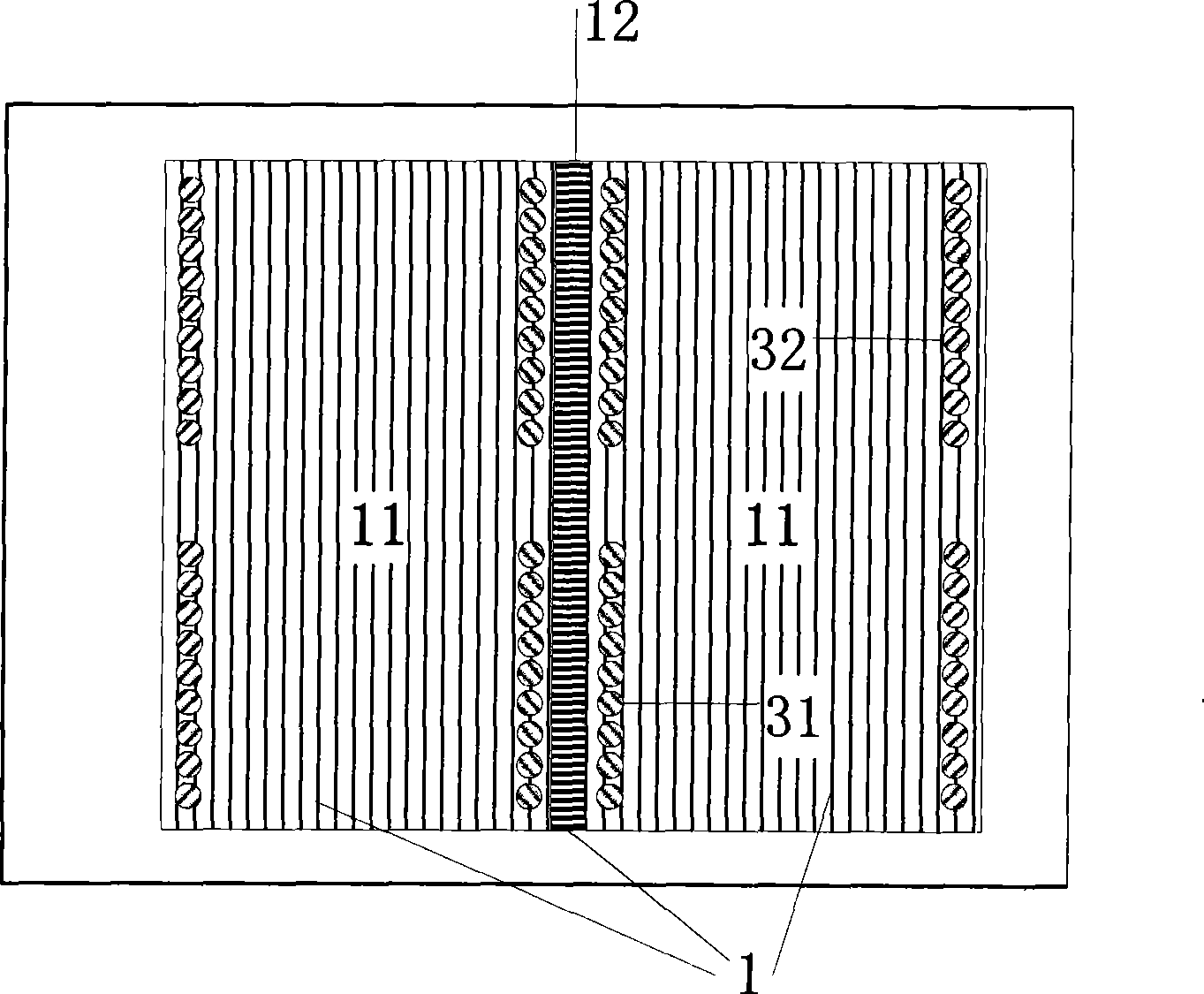

Electric little dimension antenna based on opening resonance loop structure

An electrical small-sized antenna based on an opening resonant ring structure is composed of an antenna radiation unit 1, a bottom-surface etching coplanar waveguide structure 2 and plated through-holes 3, wherein a coplanar waveguide feeder line 21 feeds to an antenna system through a magnetic coupling method, the plated through-hole 31 is used to connect a metal patch and a coplanar waveguide ground to form a resonance circuit, the plated through-hole 32 is used to form a metal arm in a PCB substrate to increase equivalent capacitance of the system, an isolated metal sheet 22 and the coplanar waveguide feeder line 21 are on an identical ground plane, but are mutually separated to prevent resonant short-circuit. The invention has the advantages of small size, compact structure, low cost, high efficiency and the like, and can be conveniently integrated in a microstrip or a coplanar waveguide system to realize radio frequency front-end seamless connection.

Owner:SOUTHEAST UNIV

Method for processing turbine of ORC expander generator

InactiveCN107414434AQuality assuranceSolution to short lifeBlade accessoriesMachines/enginesDynamic balanceReference line

The invention discloses a method for processing a turbine of an ORC expander generator. The method comprises the steps: (1) roughly turning the end face of a blank, and thus obtaining a part; conducting flaw detection for the part; (2) roughly turning the part, and removing large allowance of the part; (3) inspecting the mechanical performance of material of the part; (4) conducting semi-finish turning for the end face of the part and the outer meridian plane, and turning an inner hole in the inner part of the part in one step; (5) drawing milling reference lines of two sides of runners; (6) milling the runners; (7) conducting semi-finish turning for the outer meridian plane and the inner hole, and adjusting the bouncing requirement of the outer meridian plane and the inner hole; (11) drawing position reference lines of a key groove and an end face hole; (12) machining the key groove; (13) drilling the end face hole; (14) conducting a dynamic balance test; (15) conducting flaw detection for the part; (16) and gripping the part to remove burrs. The method has the advantages of small error and high precision.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

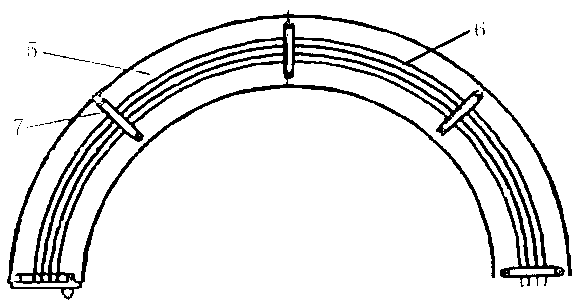

Device for winding runway-type superconducting coil

ActiveCN106710866ARealize the winding processGuarantee the quality of windingCoils manufactureWinding machineBobbin

A device for winding runway-type superconducting coil comprises a rotary shaft, a fixing vertical plate, a motor, a coupling, a center, a convex plate, a bobbin, a concave plate, and a compressing mechanism; one end of the rotary shaft is fixed to a winding unit through screws, the other end of the rotary shaft is fixedly connected to the fixing vertical plate through screw , the motor is mounted at the upper side of the fixing vertical plate through screws, the center is mounted at the lower side of the fixing vertical plate in threaded manner, the coupling is connected to a motor shaft, one side of the convex plate is connected to the motor through the coupling, the other side of the convex plate is fixed through the center, the compressing component is fixed to the surface of the convex plate through screws, the bobbin is connected to the convex plate through screws, and the convex plate is connected to the frame through screws; the whole device rotates synchronously with a horizontal shaft of the winding unit and may be vertically and angularly rotated through the motor, the motor is controlled via programming, the rotational angle is kept consistent with the theoretically designed coil angle, coil winding quality is guaranteed, and the device is easy to mount and adjust.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

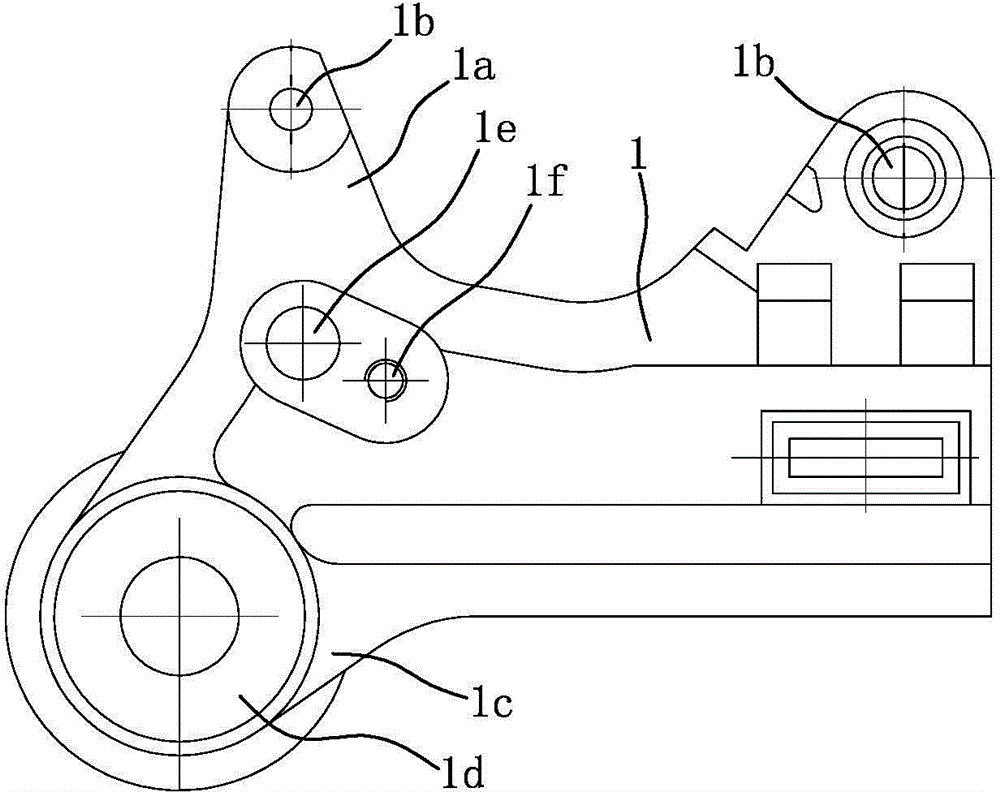

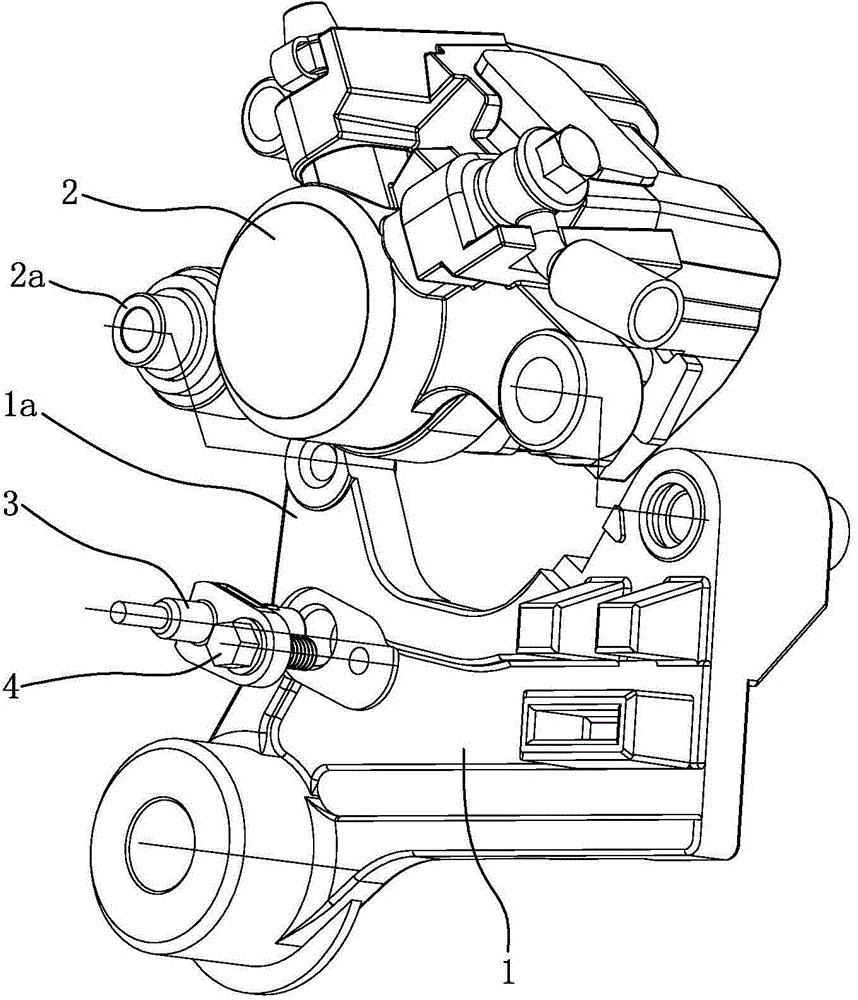

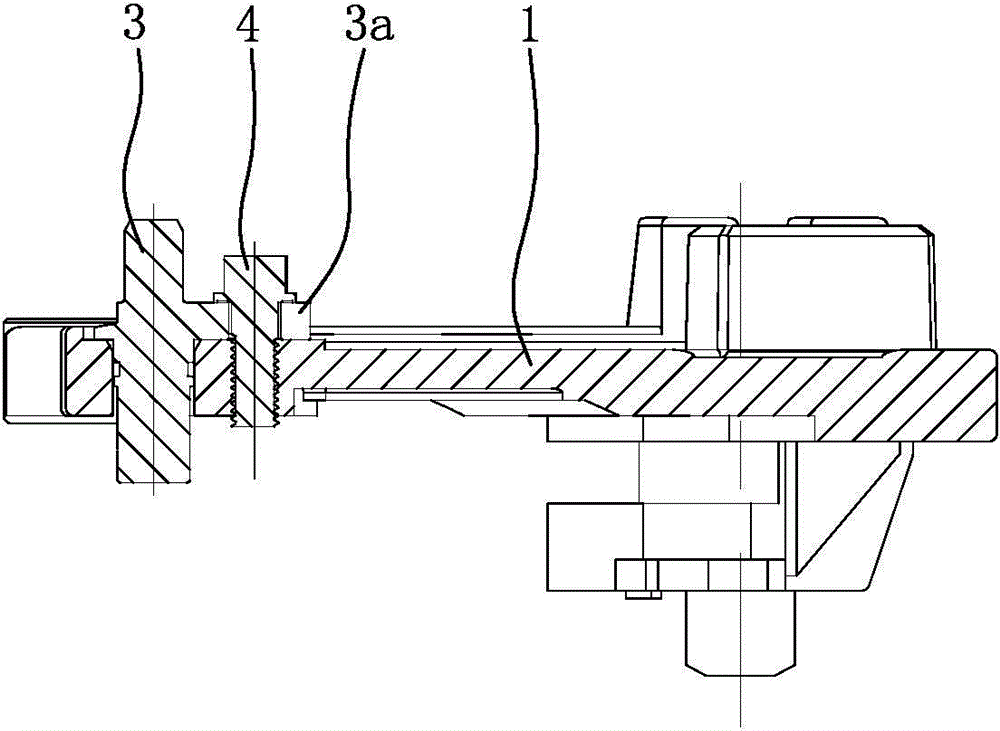

Installation structure for motorcycle ABS rear wheel speed sensor and rear brake cylinder

InactiveCN104859630AEasy to disassembleEasy to assemble and disassembleABS control systemsBrake cylindersWheel speed sensorFlange

The invention discloses an installation structure for a motorcycle ABS rear wheel speed sensor and a rear brake cylinder. An installation hole (1e) and a fastening hole (1f) are formed in a rear brake cylinder bracket (1), the installation hole (1e) is positioned between an upper flange (1a) and a lower flange (1c) in the rear, the depth of the installation hole (1e) is greater than 10.5mm, and the fastening hole (1f) is a threaded hole, is positioned at a position in front of and below the installation hole (1e) and is close to the installation hole (1e). The wheel speed sensor (3) is inserted into the installation hole (1e) in the rear brake cylinder bracket (1), a bolt penetrates through an assembly hole in the wheel speed sensor (3) and is screwed into the fastening hole (1f) in the rear brake cylinder bracket (1), and thus the wheel speed sensor (3) is installed in the rear brake cylinder bracket (1). By applying the installation structure, the wheel speed sensor is ingeniously installed in the rear brake cylinder bracket, the installation structure for the wheel speed sensor is simple, and the accuracy is reliable.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com