Aviation structural part high-precision lug group machining method

A technology for aerospace structural parts and processing methods, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to improve processing efficiency, ensure high-precision ear size requirements, and improve processing efficiency and processing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions for realizing the object of the present invention are further described below through specific examples. It should be noted that the technical solutions claimed in the present invention include but are not limited to the following examples.

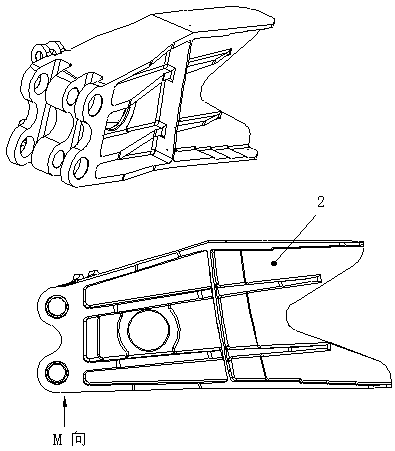

[0027] This embodiment provides a high-precision (tolerance zone within 0.05mm) numerical control machining method for lugs, such as Figure 1-5 The aerospace aluminum alloy structure shown has 3 lugs and 5 high-precision dimensions need to be processed, among which L1=39.20±0.05mm, L2=31.53±0.05mm, L3=107.61±0.05mm, L4=42.52±0.05 mm, L5=168.84±0.05mm.

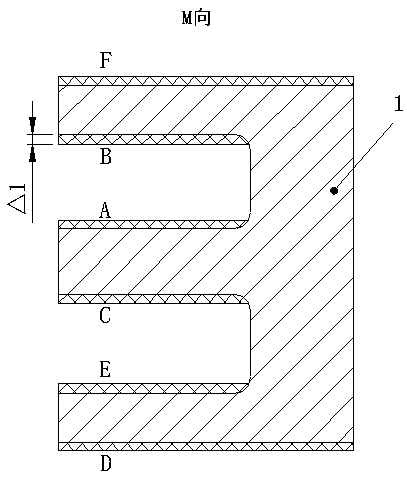

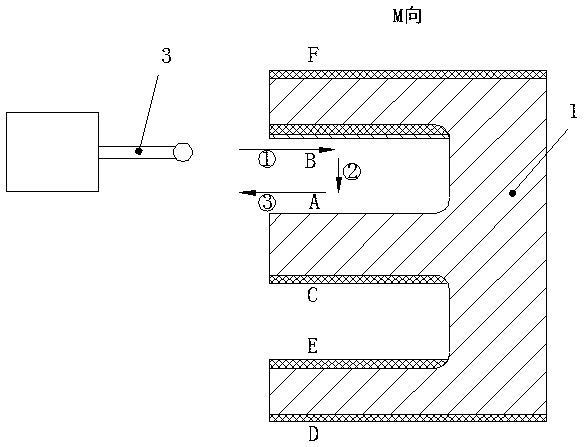

[0028] The part is processed by a horizontal machine tool, and the installation direction of the part is perpendicular to the axis of the machine tool spindle. The rough machined part is first processed by an end mill to form a figure 2 For the lug size shown, a margin of △1=0.20mm is left on the side of each lug, and then the surface A is finished in plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com