Device for once blow molding of sand cores and chillers

A cold iron and sand core technology, which is applied to casting molding equipment, parts of molding machines, molding machines, etc., can solve the problems of left and right displacement of cold iron, inability to make cold iron, high cost, etc., and meet the requirements of ensuring product size, Save the production process and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

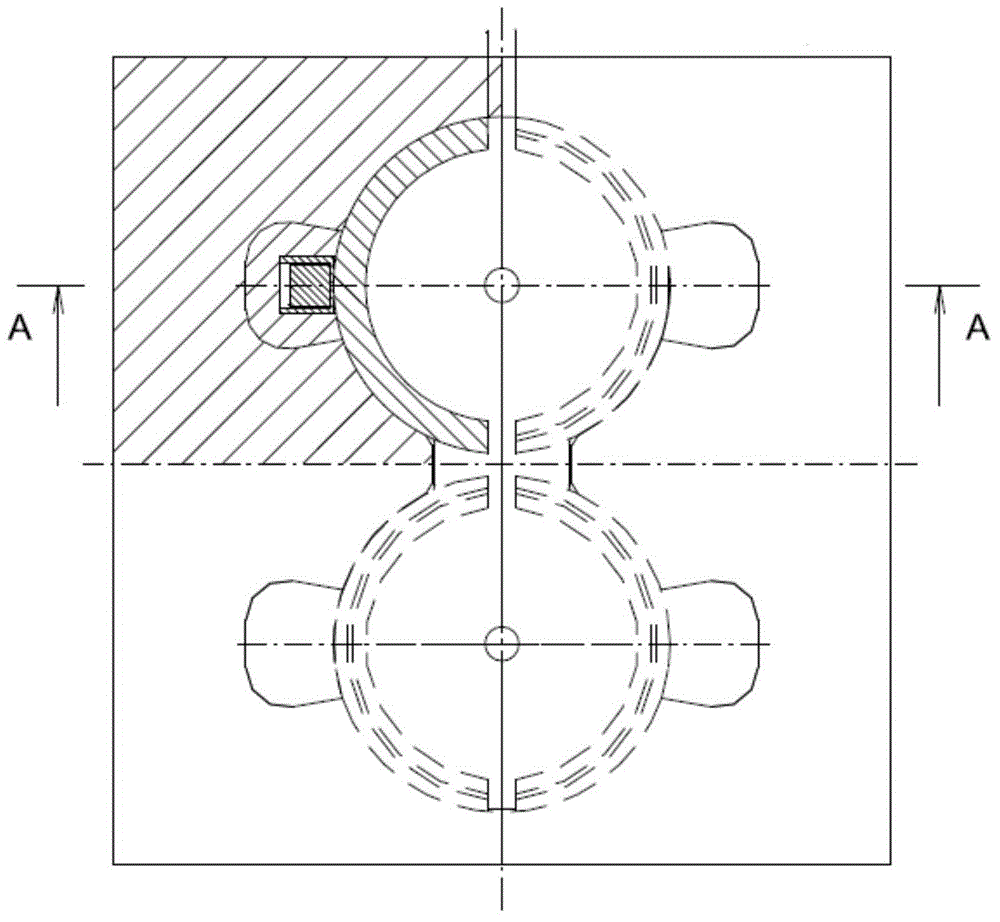

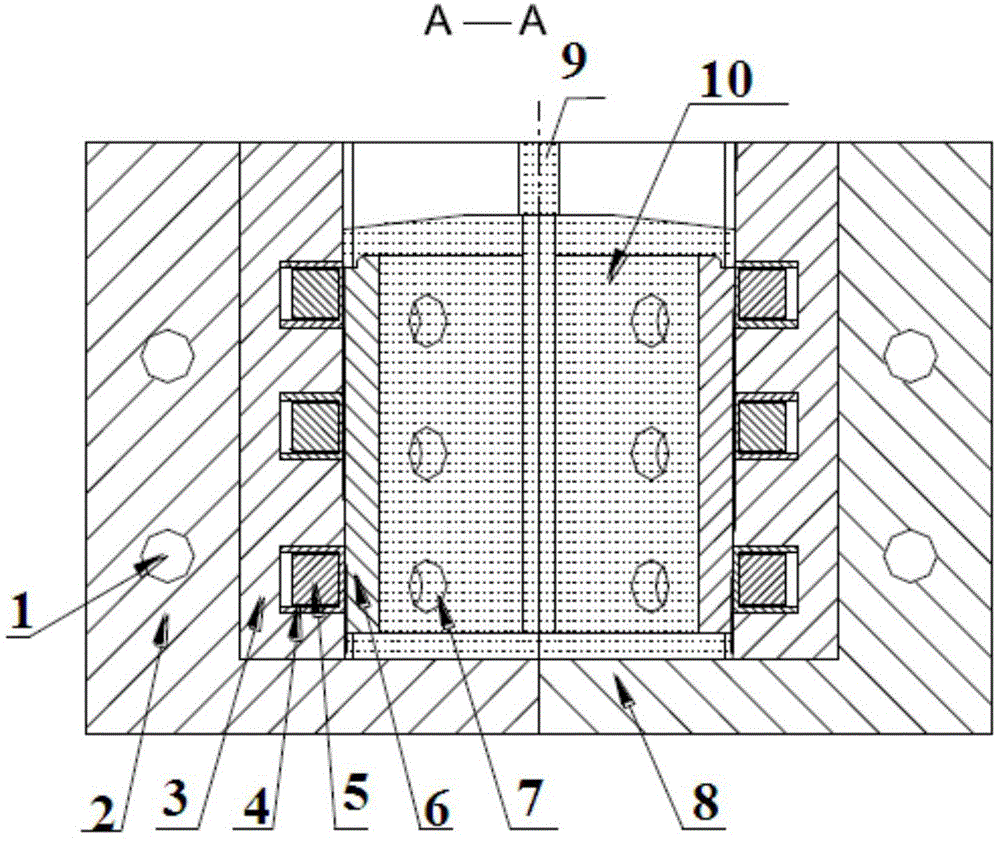

[0015] Such as figure 1 As shown, a device for sand core and cold iron one-time blow molding is characterized in that it includes two symmetrically arranged half-molds, which are respectively a left half-mold 2 and a right half-mold 8, and the half-molds are provided with Insert 3, three copper sleeves 4 are arranged on the insert 3, magnets 5 are arranged inside the copper sleeve 4, two heating tubes 1 are arranged on one side of the insert 3, and a semicircular cold iron 6 is arranged on the other side, and the semicircular cold iron 6 is adsorbed inside the half-mold by the magnet 5, and the inside of the semicircular cold iron 6 is provided with a cavity sand core 10, and the inside of the cavity sand core 10 is provided with three exhaust connection holes 7, and above the junction of the two half-molds is provided Sand mouth 9.

[0016] The magnet 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com