Patents

Literature

49results about How to "No need to fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

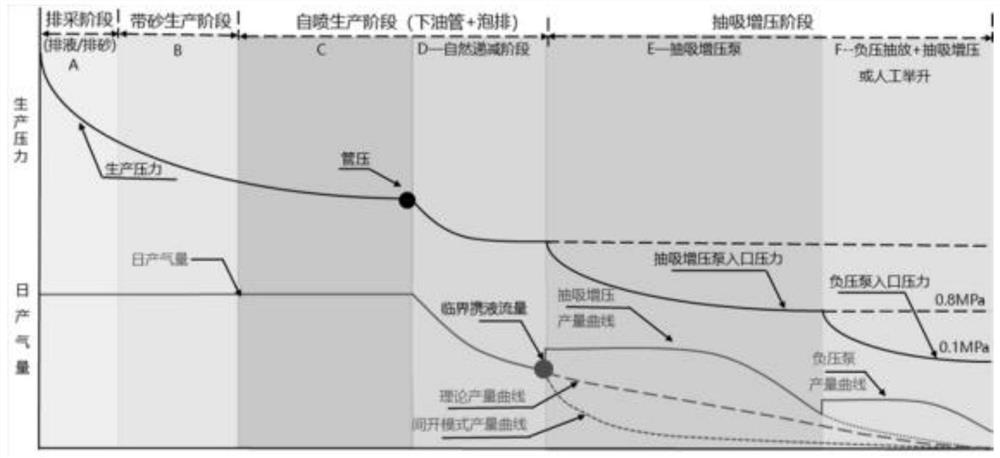

Energy-saving easily-changeable high-temperature microwave heating chamber and manufacturing method thereof

The invention relates to an energy-saving easily-changeable high-temperature microwave heating chamber and a manufacturing method thereof, which belong to the technical field of microwave high-temperature heating technology. The energy-saving easily-changeable high-temperature microwave heating chamber mainly comprises the following functional layers: an internal high-temperature microwave absorbing coating, a medium high-temperature wave-transmitting thermal insulating layer and an external wave-transmitting hardened layer. The manufacturing method is characterized by comprising the following steps: firstly, mixing a microwave absorbing component and water glass and / or commercial high-temperature glue (mud) to prepare slurry; secondly, uniformly coating the slurry on the high-temperature wave-transmitting thermal insulating layer to form a chamber internal surface in a certain shape; and finally, obtaining the energy-saving easily-changeable high-temperature microwave heating chamber by drying and preburning. The energy-saving easily-changeable high-temperature microwave heating chamber has the advantages of simple structure, easy change, low cost, large heating area, high thermal efficiency, convenient maintenance, high safety due to non-contact heating, supper-fast and ultra-temperature heating, and remarkable energy conservation effect and obvious economic benefits due to the selection because of the changing and using of heating chambers of various sizes according to the sizes of materials to be heated.

Owner:唐山任氏巨源微波仪器有限公司 +1

Hot mould centrifugal cast iron pipe mold paint and preparation method thereof

ActiveCN101693281AImprove breathabilityGood heat insulationFoundry mouldsFoundry coresSodium BentoniteEconomic benefits

The invention relates to a hot mould centrifugal cast iron pipe mold paint and a preparation method thereof. The invention mainly solves the technical difficulties of poor quality and low yield and poor economic benefit of a cast iron pipe produced by the traditional paint. The technical scheme is achieved as follows: the hot mould centrifugal cast iron pipe mold paint comprises the following components in percentage by weight: 14-16 percent of kaoline, 14-16 percent of burned diatomite, 2-4 percent of sodium base bentonite, 2-3.5 percent of talcpowder and 64-68 percent of water. The preparation method comprises the following steps: firstly, adding the kaoline, the burned diatomite, the sodium base bentonite and the talcpowder in percentage by weight into a mixing pan for dry mixing; secondly, adding 1 / 4 of water with weight percentage of 64-68 percent into the mixing pan; thirdly, mixing and rolling into a hard paste material for storage for later use; fourthly, when in use, putting the material into a wheel-rolling mixer, adding the left 3 / 4 of water into the wheel-rolling mixer for mixing-rolling and obtaining the mold paint when the concentration reaches 1.2.

Owner:绛县恒通铸造有限公司

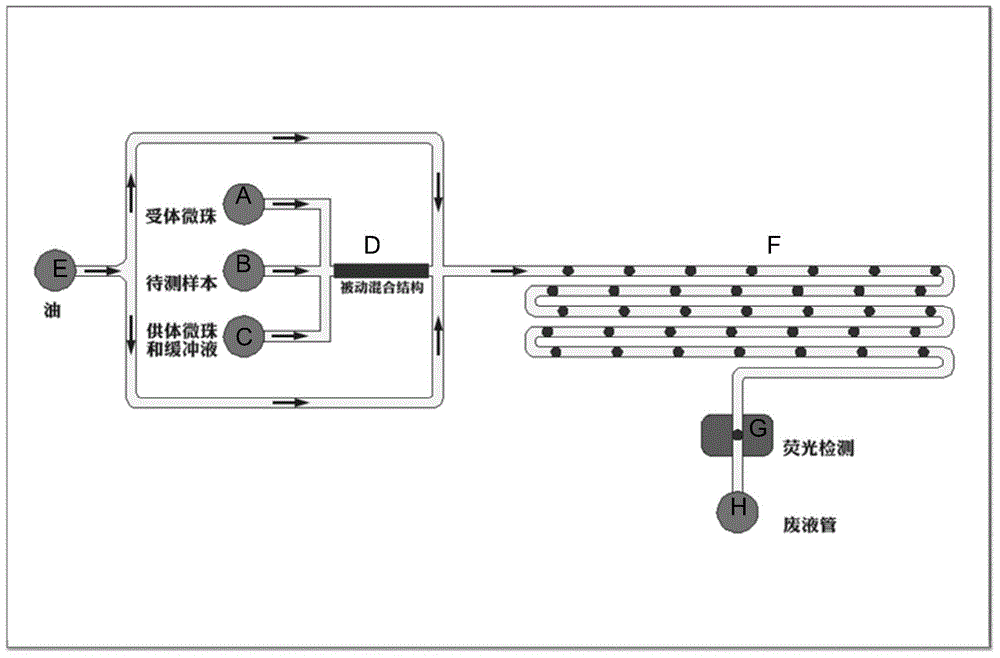

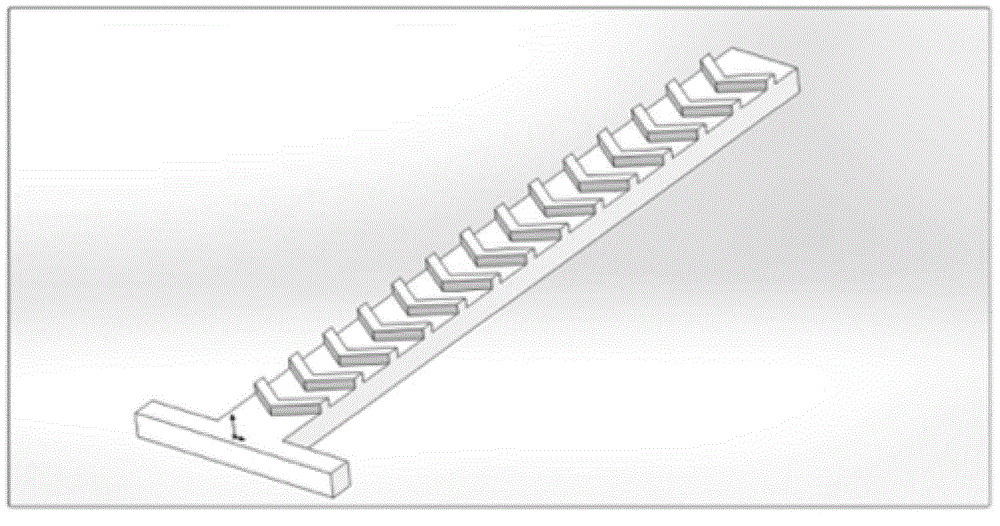

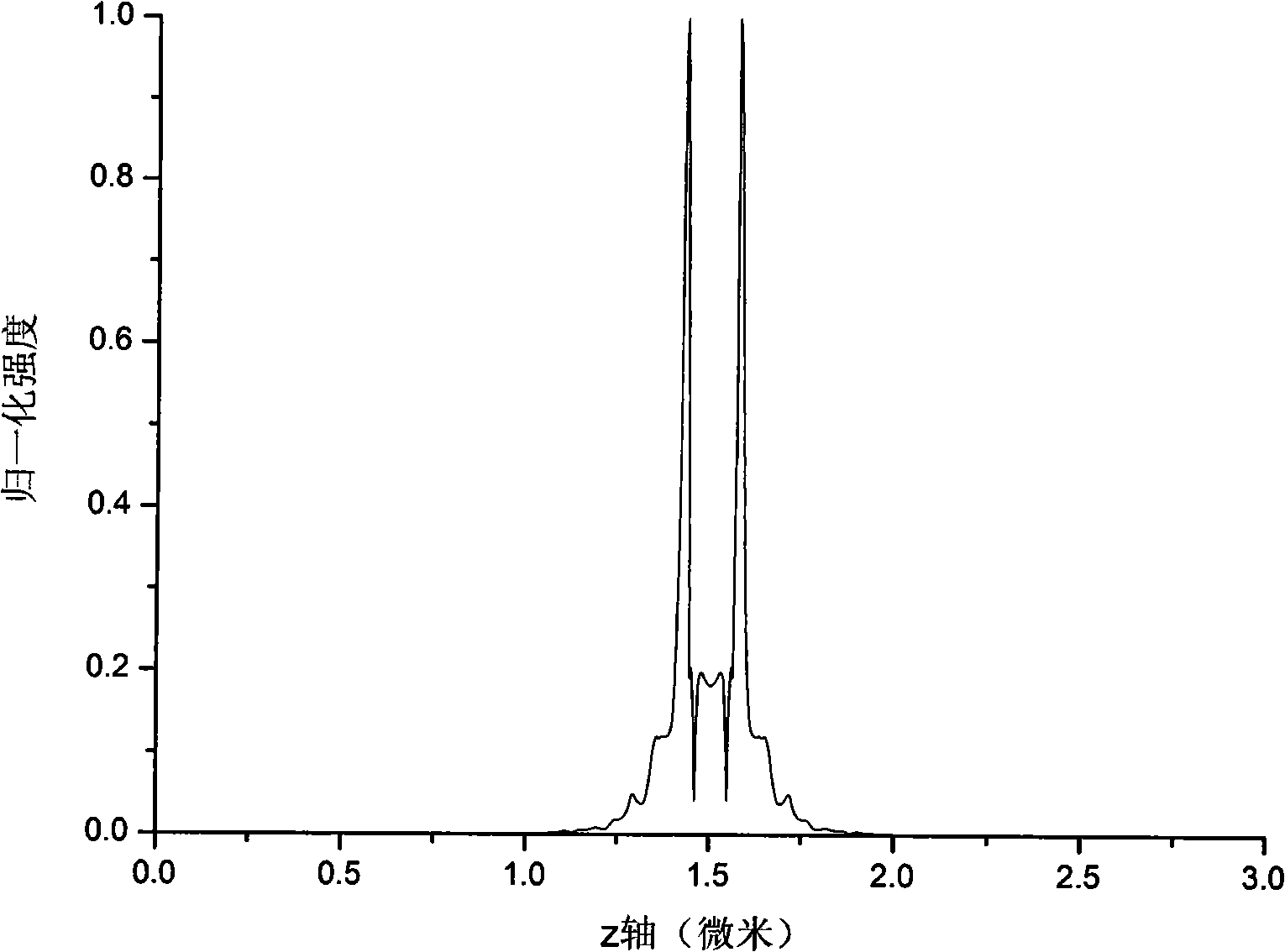

Biological macromolecule detection method based on nano homogeneous time-resolved fluoroimmunoassay and droplet-based micro-fluidic technology

InactiveCN106324236AReduce volumeLow concentration requirementBiological testingFluorescenceEngineering

The invention belongs to the field of micro-fluidic chips, and relates to a biological macromolecule detection method. An alpha-LISA technology and a droplet-based microfluidics technology are combined and optimized to prepare a micro-fluidic chip liquid. A novel biological macromolecule detection method with a high sensitivity is provided. A three-phase mixing technology is adopted. A passive mixing structure is used to fully and evenly mix the reaction liquid. A cross focusing technology is used to form droplets. The generated droplets have the advantage of smaller volume, and thus the reactions become faster. Moreover, the requirements on the samples are lower, the reactions are specific, sensitive, fast, and full; the washing does not need to be carried out after reactions; complicated complexes such as complete proteins, enzyme complex, bacteriophage, and the like, can be detected; the technical bottleneck of conventional commercial liquid chips at present can be broken through; the provided method can be applied to fast clinical biological macromolecule detection; the detection sensitivity and specificity are both improved, and the required sample amount is reduced.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

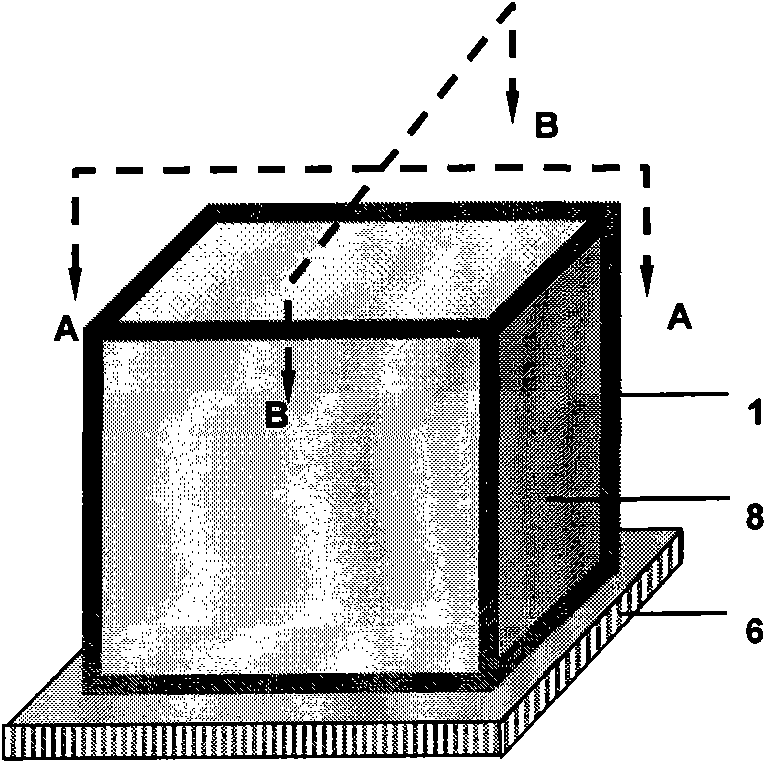

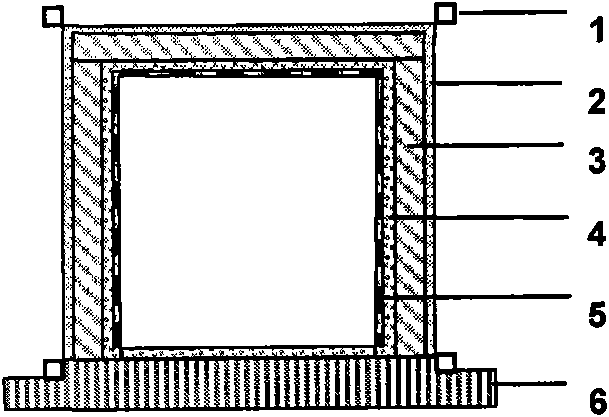

Microwave heating plate and chamber and method for manufacturing same

The invention relates to a microwave heating plate and chamber and a method for manufacturing the same, which belong to the technical field of microwave heating. The microwave heating plate and chamber consists of a microwave absorbing component, ceramic fibers with excellent wave-transmitting property, an inorganic binder, an organic binder and an additive and is characterized in that the weight ratio of the five components sequentially is 40-80: 10-50:7-30:0-1.5:1-15. The method for manufacturing the microwave heating plate and chamber comprises the following steps: firstly, using the microwave absorbing component and the ceramic fibers as a substrate, adding the inorganic binder, the organic binder, the additive and water into the substrate, and fully stirring and mixing materials to prepare slurry; and secondly, producing the microwave heating plate and the chamber in required size and shape, namely wet blanks, by using a mechanical extruding mould forming method or a manual mould forming method. The microwave heating plate and chamber has the advantages of simple structure, low cost, long service life, high thermal efficiency, high safety due to non-contact heating, energy conservation, and applicability to laboratory heating and large-scale industrial heating at high, medium and low temperatures.

Owner:唐山任氏巨源微波仪器有限公司 +1

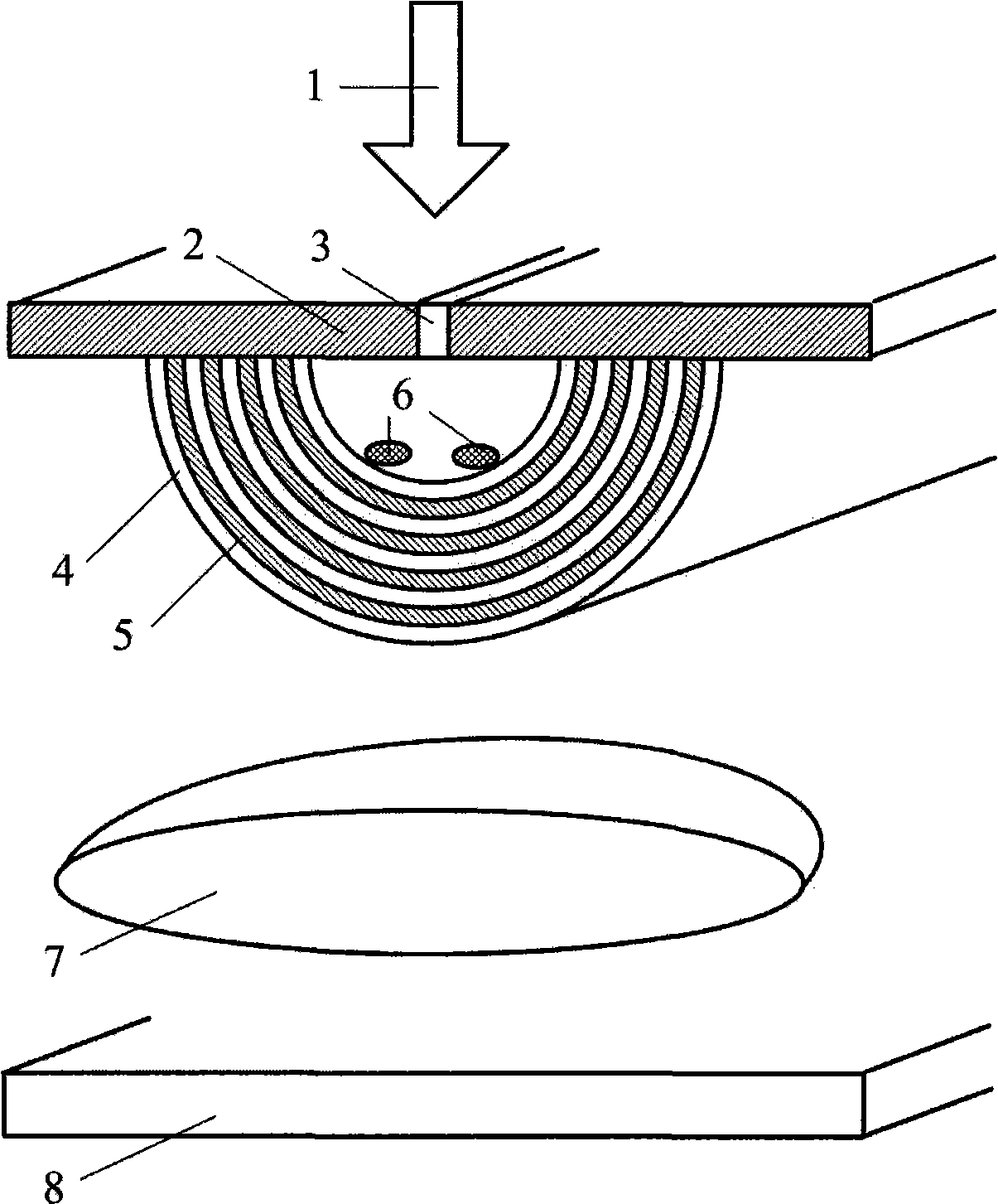

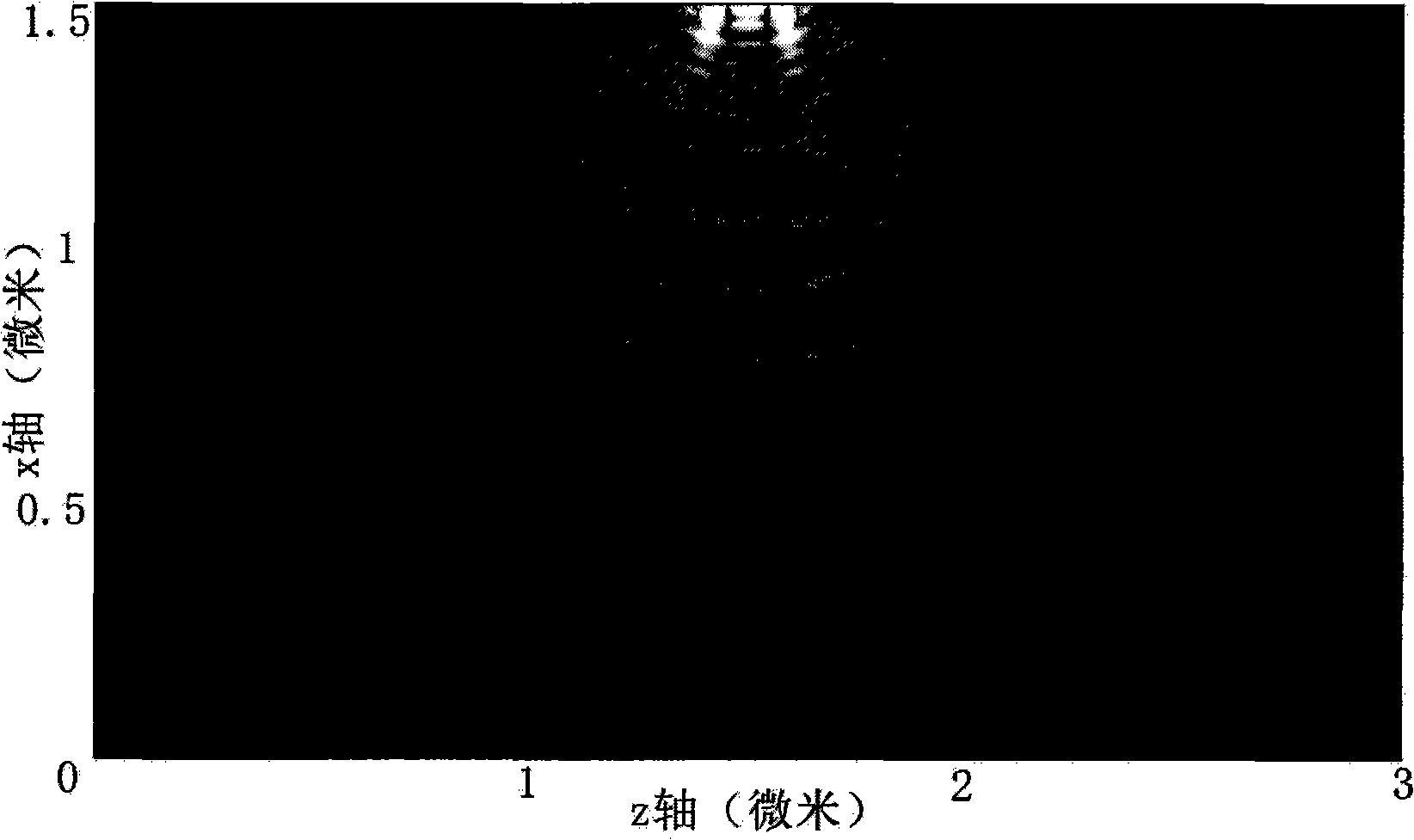

Curved surface composite super resolution current-carrying tube

InactiveCN101329246AHigh resolutionNo mutual interferenceSurface/boundary effectScanning probe techniquesFine structureMaterials science

The invention provides a curved-surface composite super-resolution current-carrying pipe which is characterized in that a hollow curved-surface current carrier is adopted; the curved-surface current carrier is a composite structure which is formed by at least a metal layer and a dielectric layer, the sample to be tested is arranged in the hollow chamber thereof. The curved-surface composite super-resolution current-carrying pipe leads the dielectric constants in the normal direction and tangential direction to have opposite symbols by constructing the curved-surface composite structure of metal and dielectric and leads high frequency quantity which carries fine structure information and can not be transmitted in normal lens to be transmitted in the curved-surface composite super-resolution current carrying pipe wall and not to generate mutual interference; the dot pitch is more than the Rayleigh resolution limit when the high frequency quantity is emitted out through the curved surface of the external wall of the current carrying pipe, thus realizing that the sample structure of nanometer-class exceeding the diffraction resolution limit can be observed far away; the curved-surface composite super-resolution current-carrying pipe has high resolution, avoids the error of close detection and has far imaging which is more convenient for operation and application.

Owner:UNIV OF SCI & TECH OF CHINA

Method for manufacturing silencers for automotive air conditioners

The invention discloses a method for manufacturing silencers for automotive air conditioners, which comprises the following steps: 1) blanking; 2) end-flattening and passivating; 3) grinding workpieces; 4) extruding a U-shaped blank; 5) end-flattening the U-shaped blank; 6) manufacturing partition plate accessories of a chamber; 7) manufacturing accessories of a silencing tube; 8) synthesizing the accessories; 9) machining the workpieces; 10) synthesizing through argon arc welding; 11) finishing burrs; 12) carrying out airtight leakage detecting; 13) cleaning and drying; and 14) inspecting, packing and warehousing: carrying out final inspection on products subjected to cleaning and drying, and carrying out packaging and warehousing on qualified products. The method disclosed by the invention has the beneficial effects that: after U-shaped die blanks are formed through carrying out cold extrusion moulding on bar stocks, a silencer is formed through machining the U-shaped die blanks by using a blank component machine, and the product size and process design factors can be accurately controlled; a silencer product is good in appearance mirror image and not required to be repaired; a silencer product is strong in specification and shape controllability and good in physical and chemical properties, and the process conforms to the requirements of product process design; the production rate is high, the production cost is low, and the rate of finished products is high; and the method is high in degree of automation, energy-saving, environmental-friendly, safe and reliable.

Owner:ZHEJIANG FANGHONG AIR CONDITIONING EQUIP

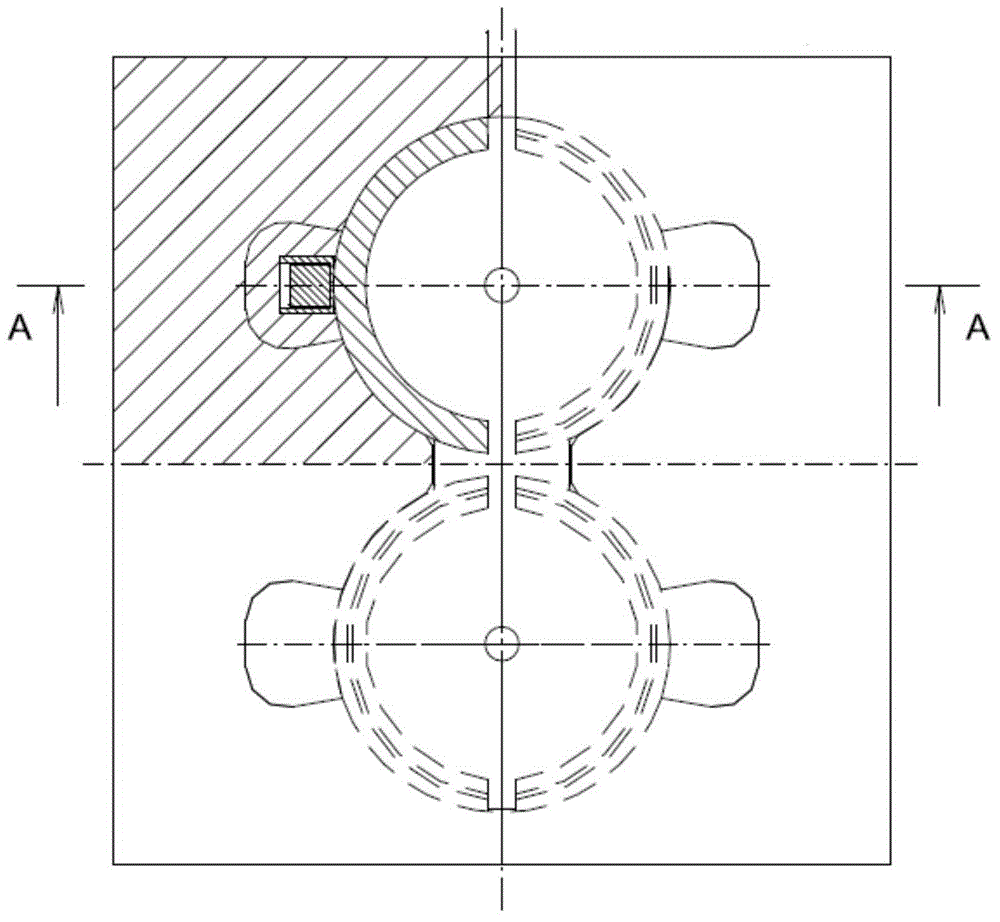

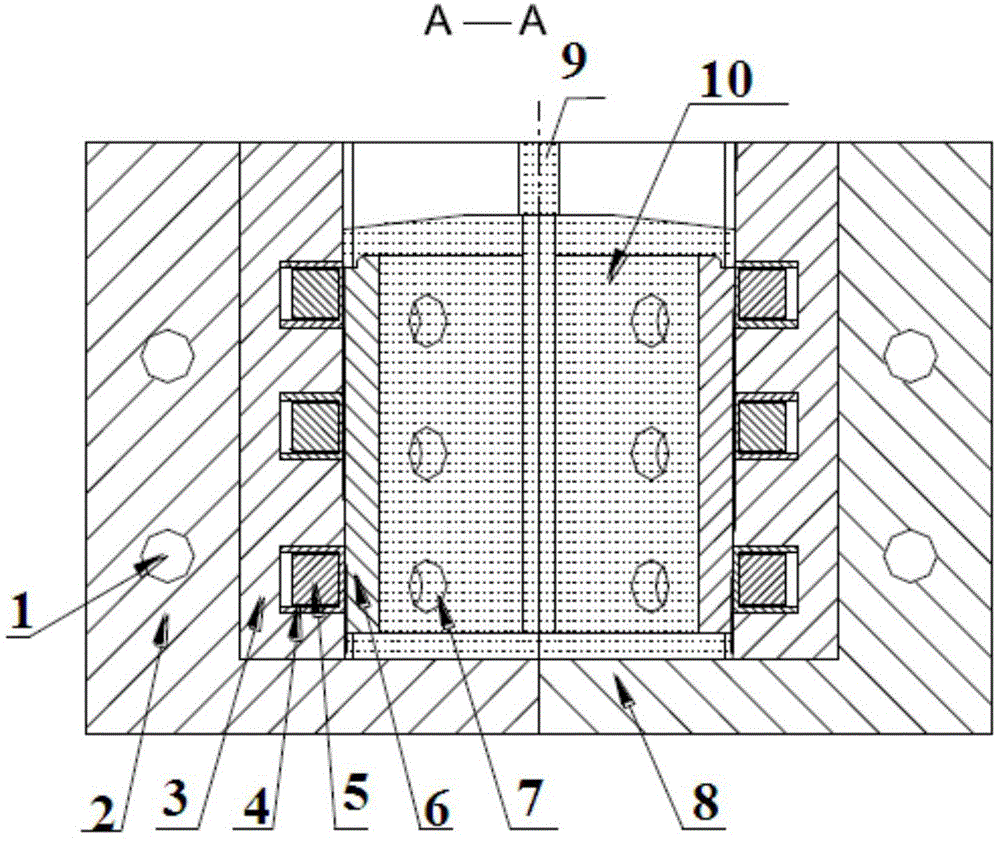

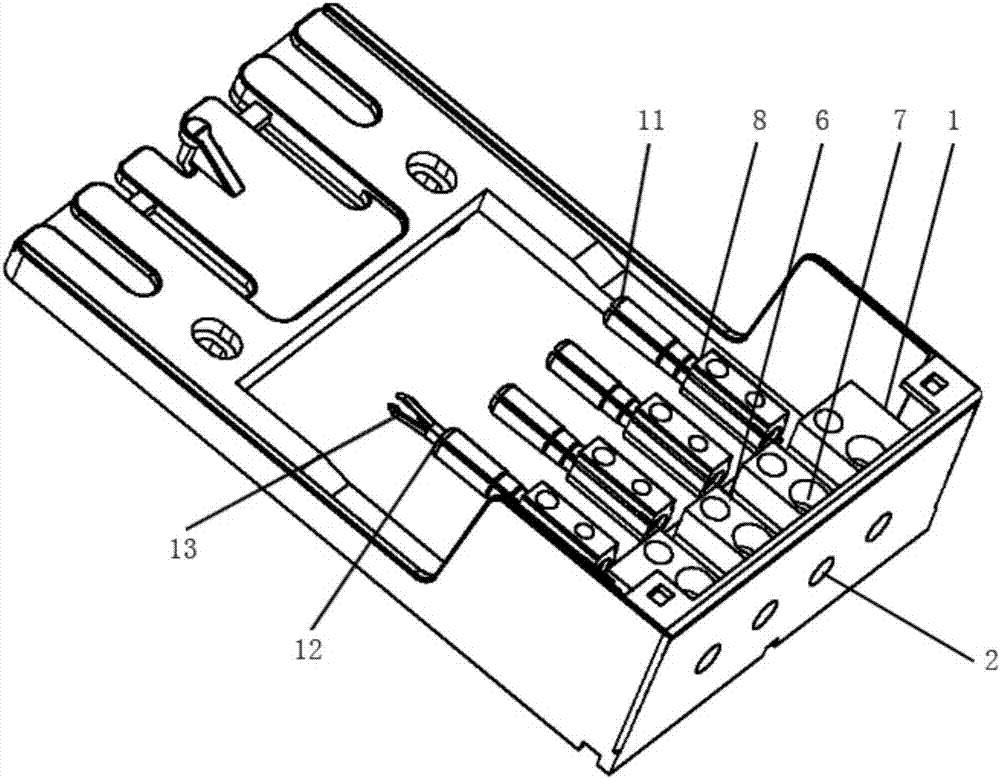

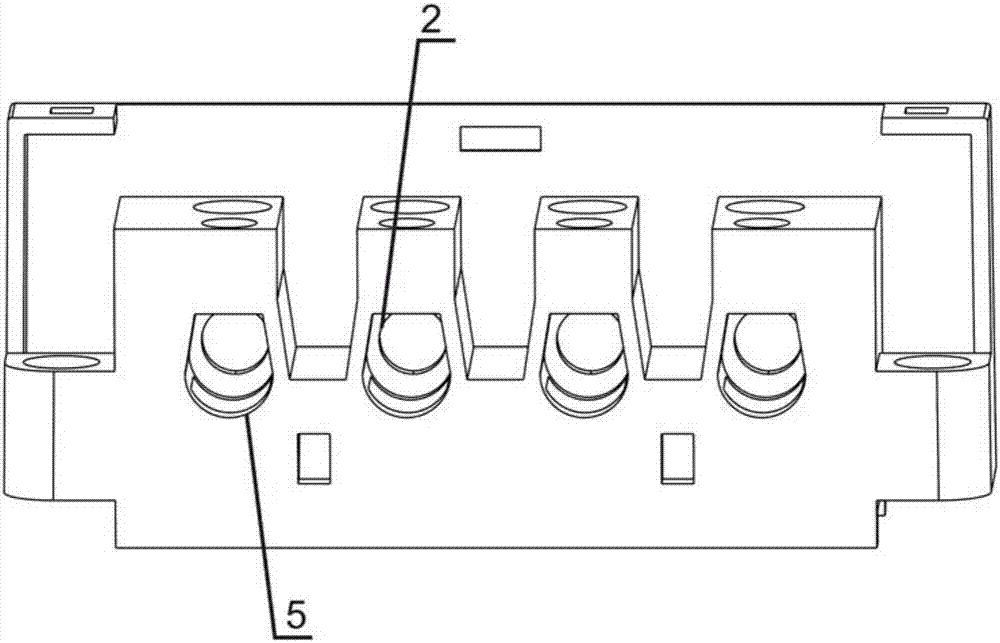

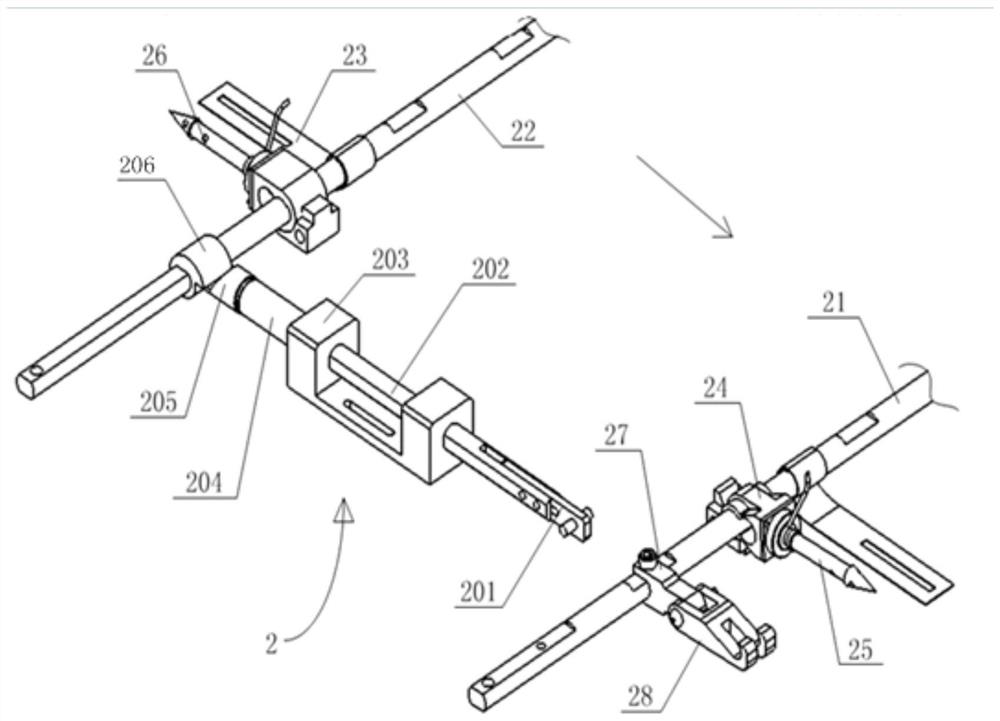

Device for once blow molding of sand cores and chillers

InactiveCN104889342AJoint flushStrong jointMoulding machine componentsMoulding machinesBlow moldingLeft half

The invention proposes a device for once blow molding of sand cores and chillers. The device comprises two half molds symmetrically arranged and respectively being a left half mold and a right half mold, wherein inserts are arranged on the half molds; three copper sleeves are arranged on the inserts; magnets are arranged in the copper sleeves; two heating pipes are arranged at one sides of the inserts; semicircular chillers are arranged at the other sides of the inserts, and are absorbed in the half molds through the magnets; molding cavity sand cores are arranged in the semicircular chillers; three exhaust connecting holes are formed in the molding cavity sand cores; and a sand ejecting port is formed above the joined place of the two half molds. The device can realize once blow molding of the sand cores and the chillers; the manufactured sand cores and chillers are smooth and tidy in joint, and need no repair and baking; and the sand cores blown by the device save multiple production procedures, guarantee the product size requirement, and improve the inherent and appearance qualities of castings.

Owner:TIANJIN HANGYU METAL PROCESSING

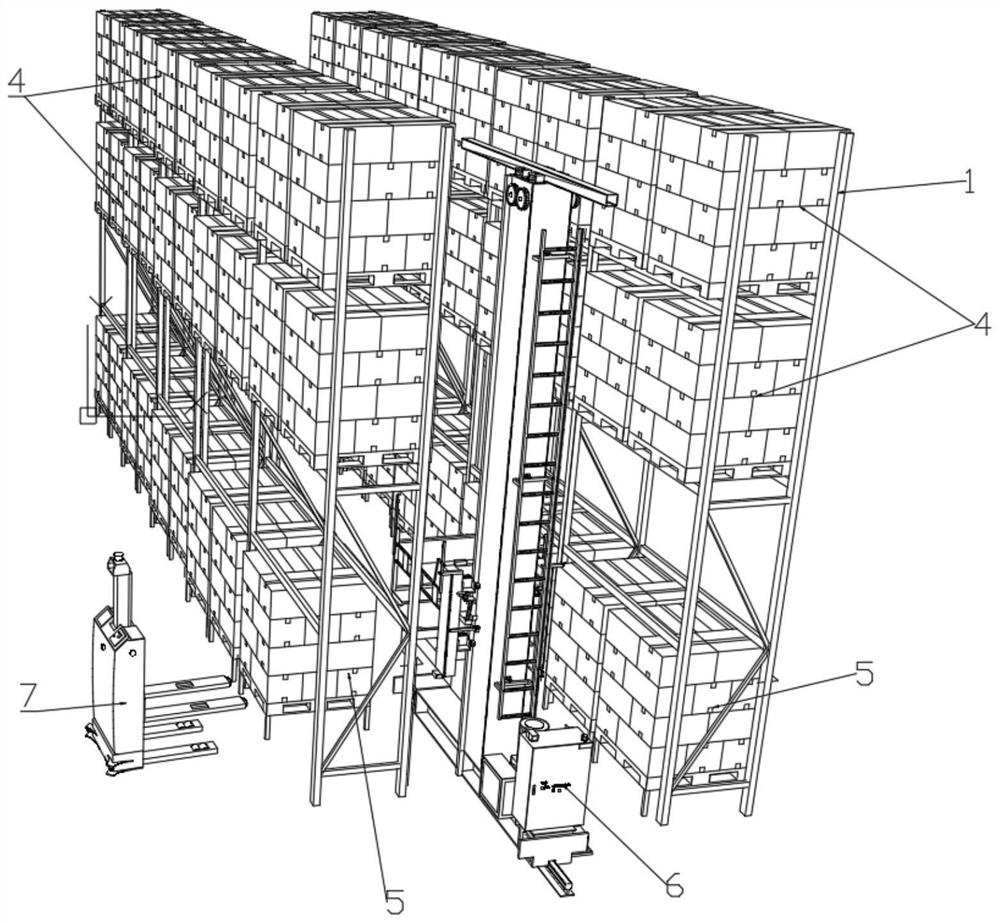

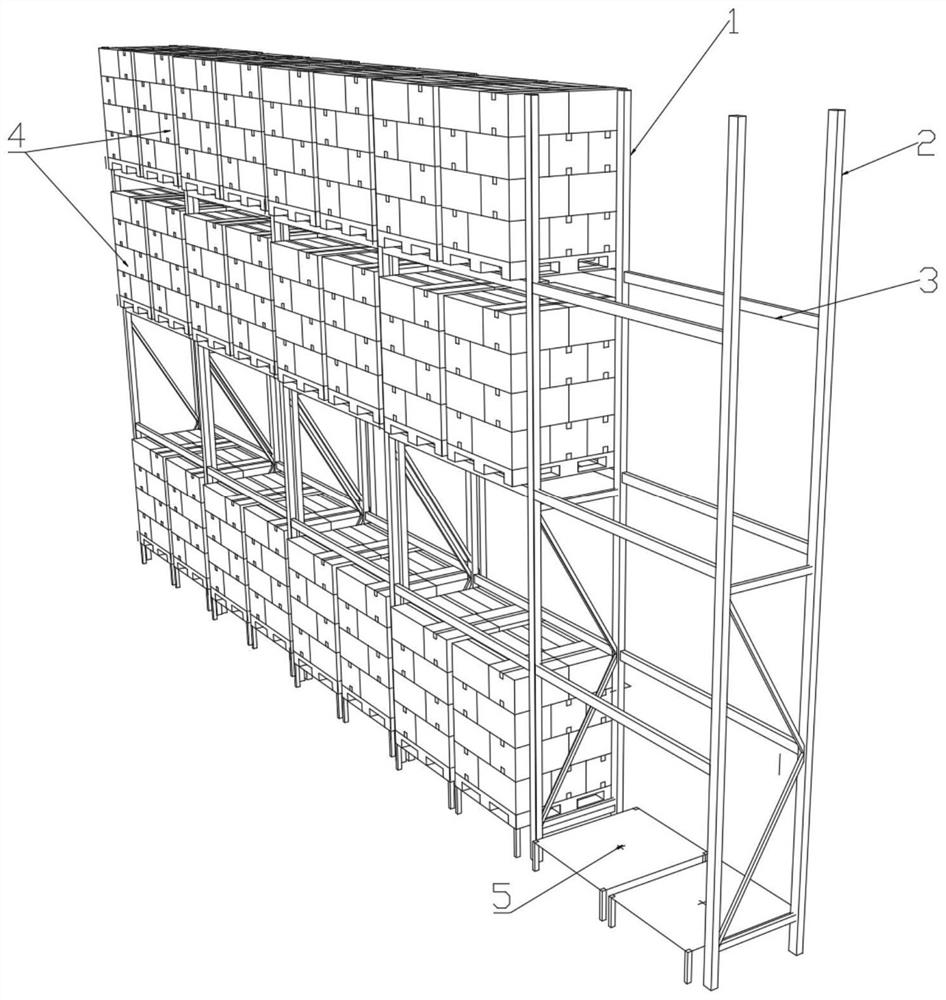

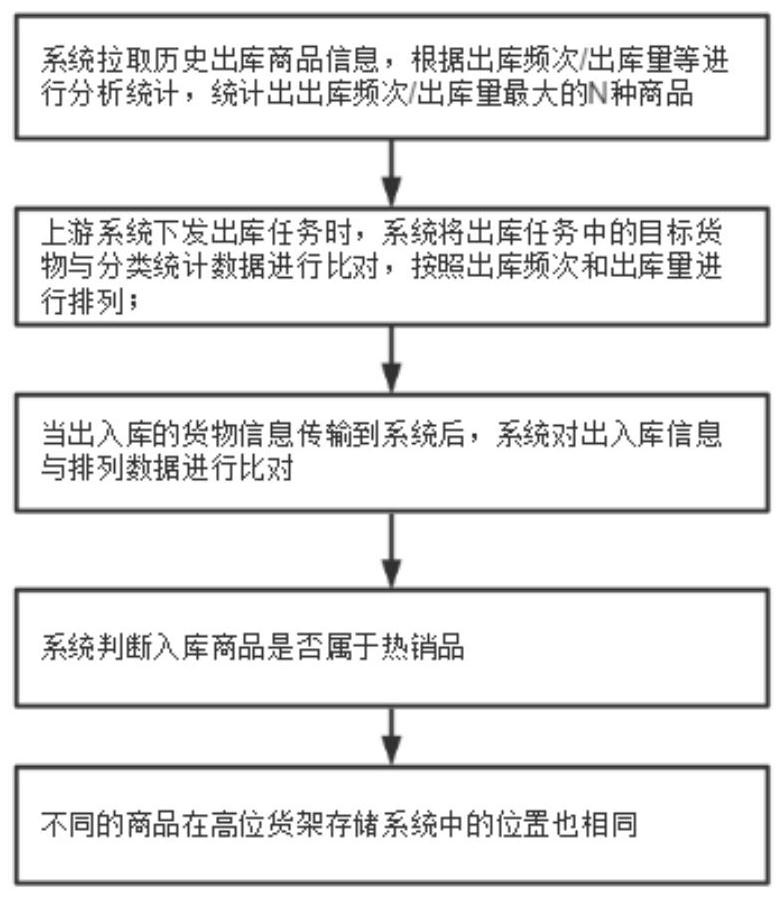

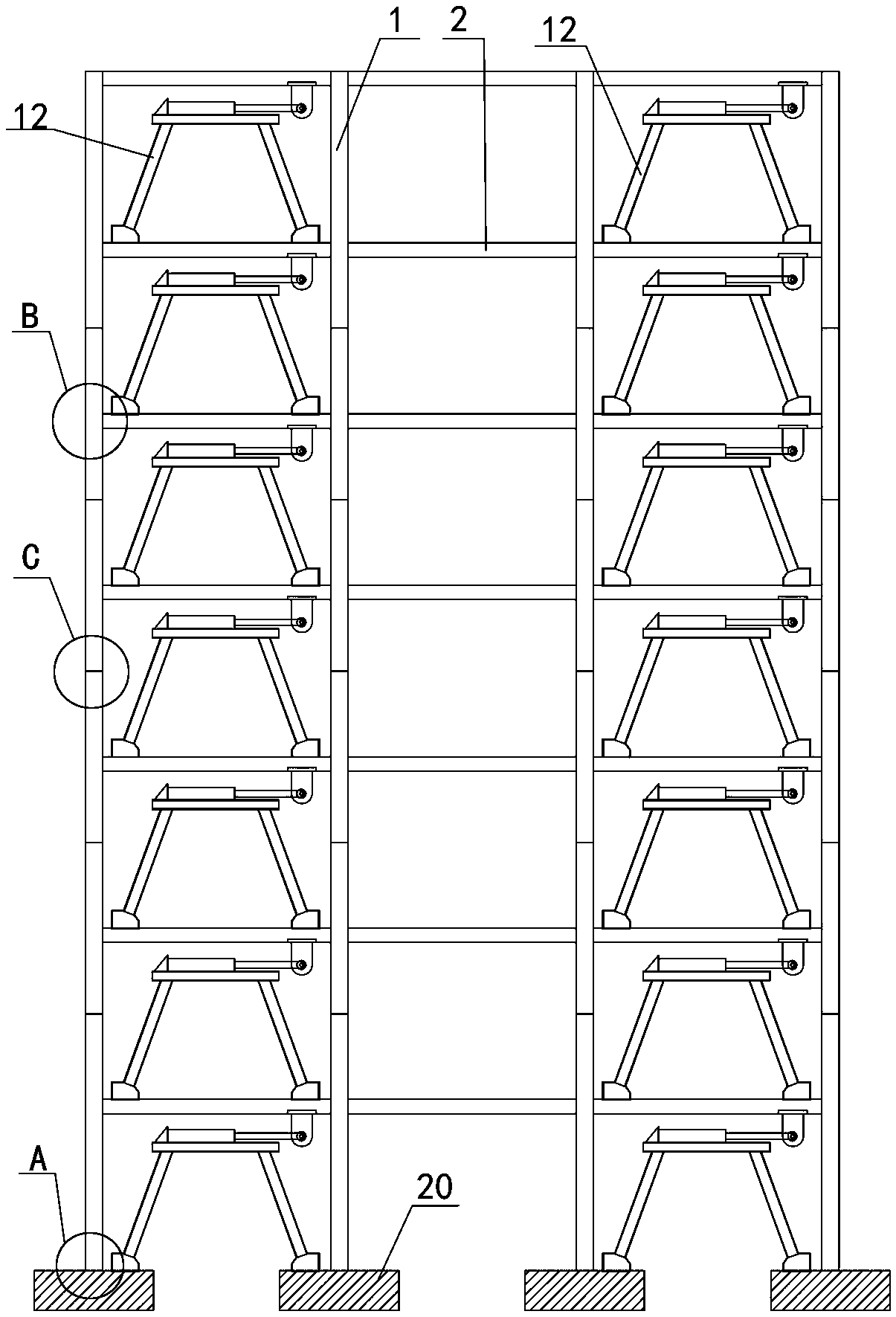

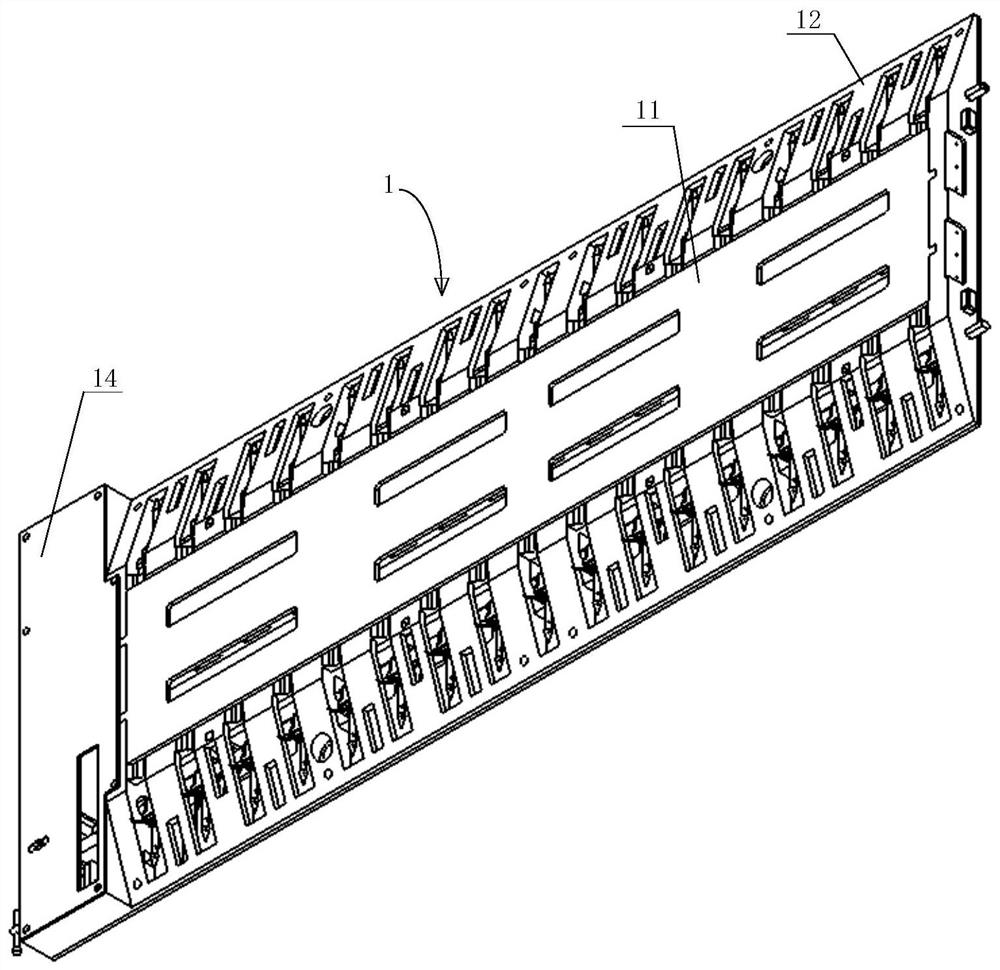

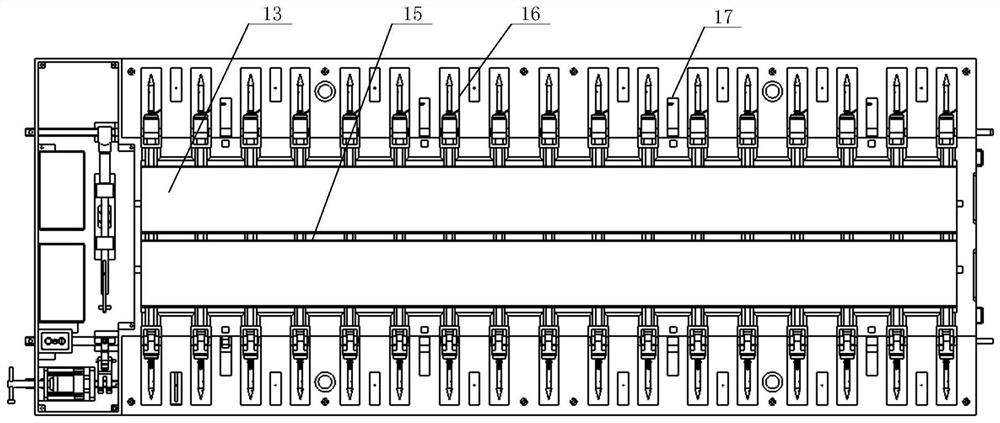

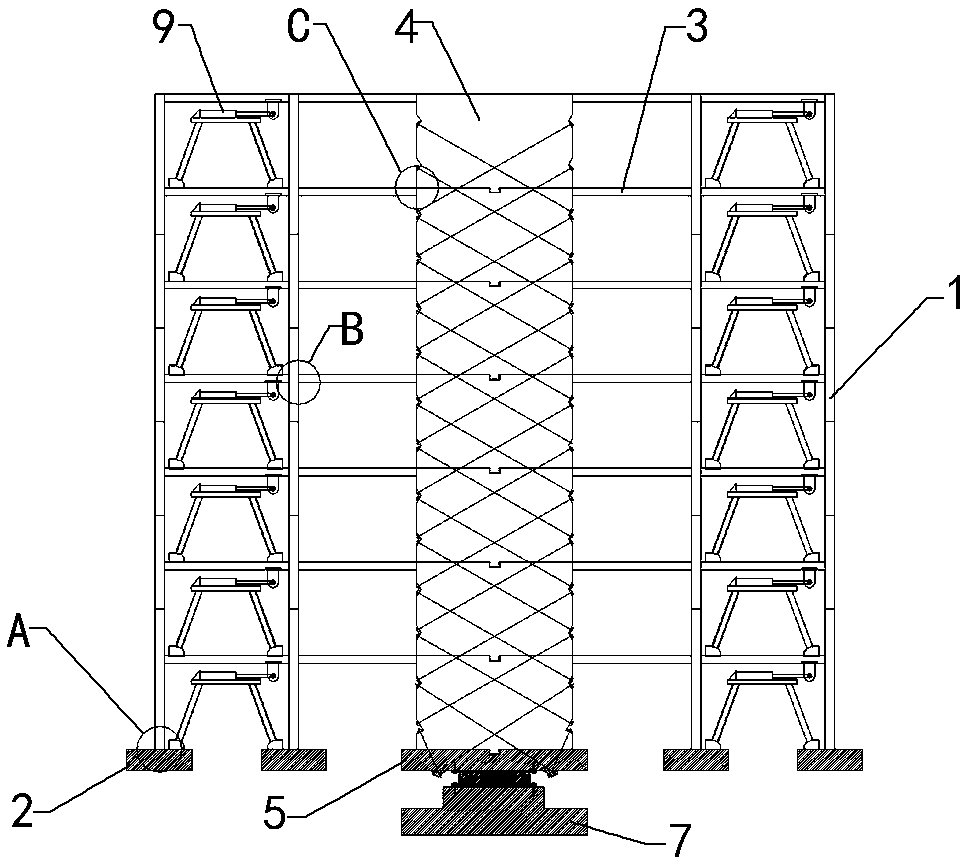

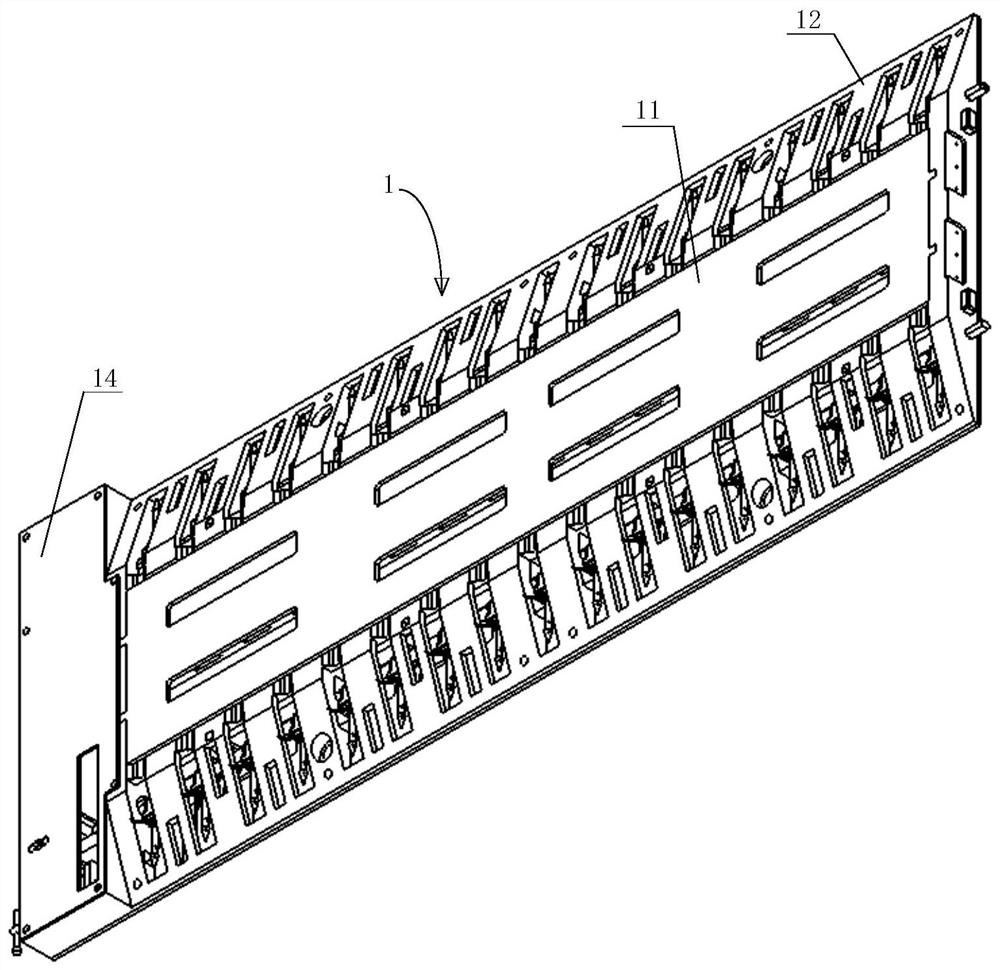

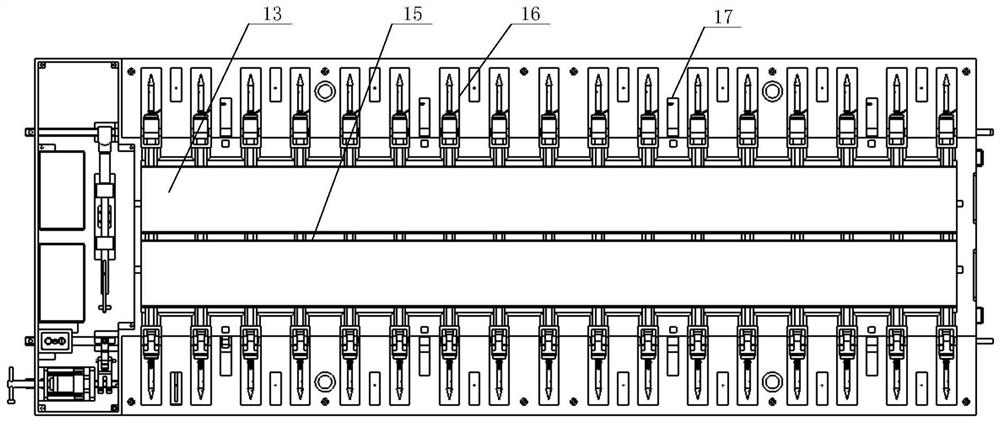

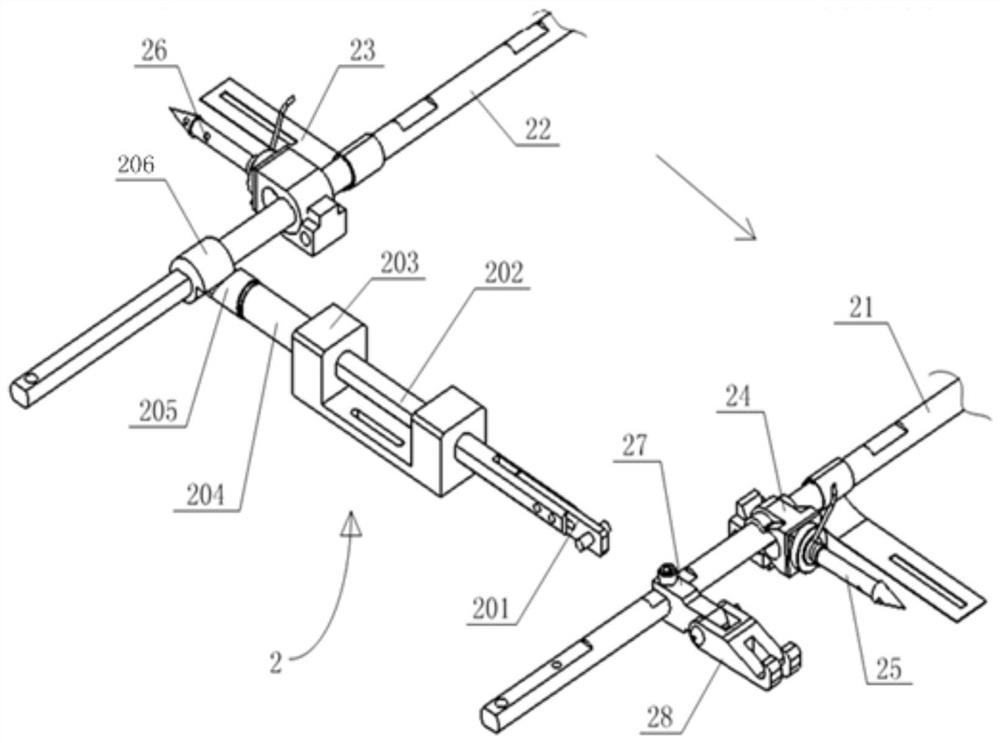

Flexible goods shelf warehousing system combined by multiple devices

PendingCN114772132AReduce horizontal displacementImprove handling efficiencyStorage devicesControl engineeringEngineering

The flexible goods shelf warehousing system comprises a high-position goods shelf and an operation system, the bottommost layer or multiple layers of the high-position goods shelf are connection positions, storage positions are arranged above the connection positions, a lifting robot is arranged on one side of the high-position goods shelf, and a carrying robot is arranged on the other side of the high-position goods shelf. The horizontal displacement of the stacking machine and other lifting robots is reduced, the matched ground carrying robot is added, the cargo carrying efficiency is improved, the lifting robots and the ground carrying robot do not need to be fixed, and the system flexibility is greatly improved.

Owner:HANGZHOU YIWU TECH CO LTD

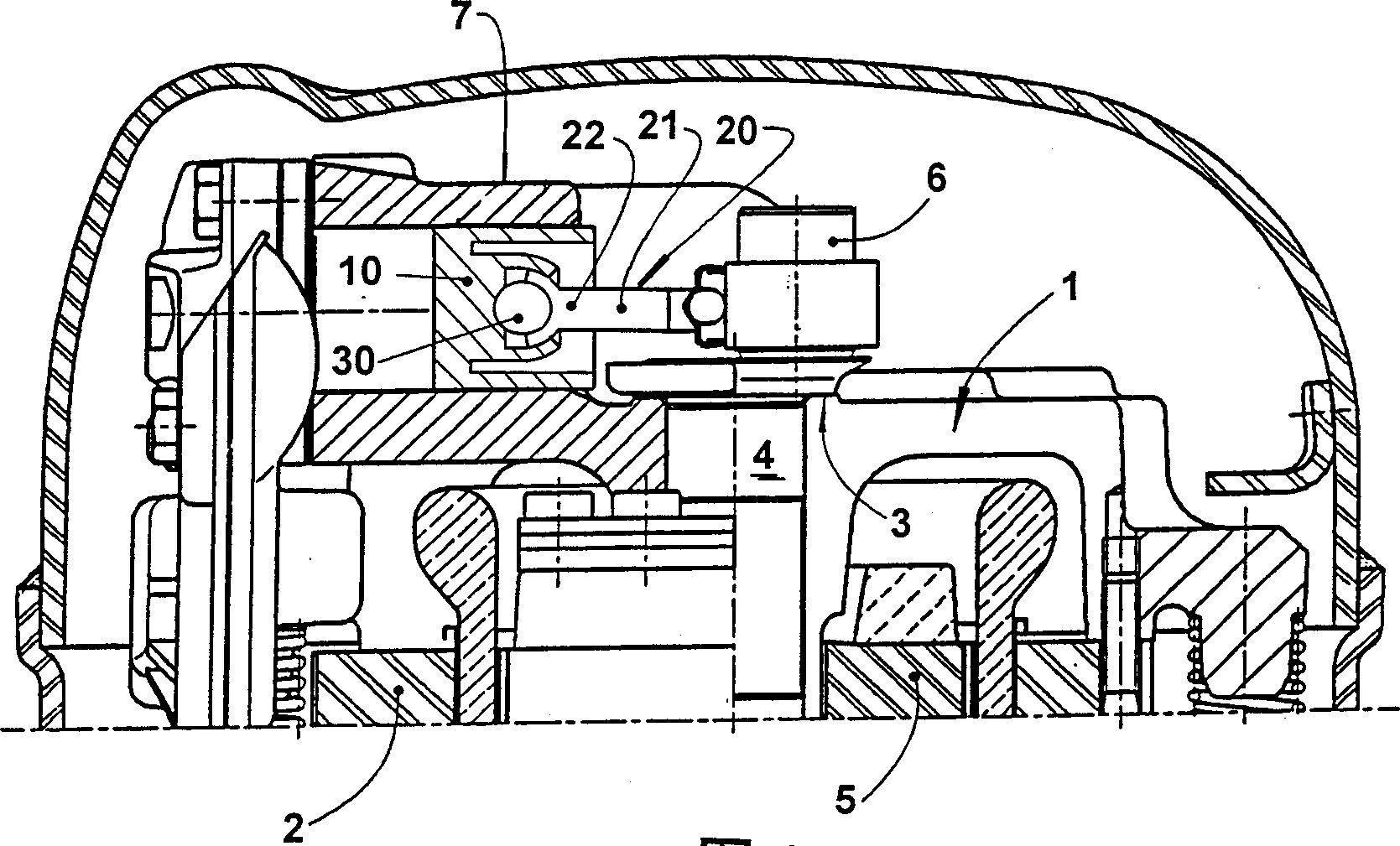

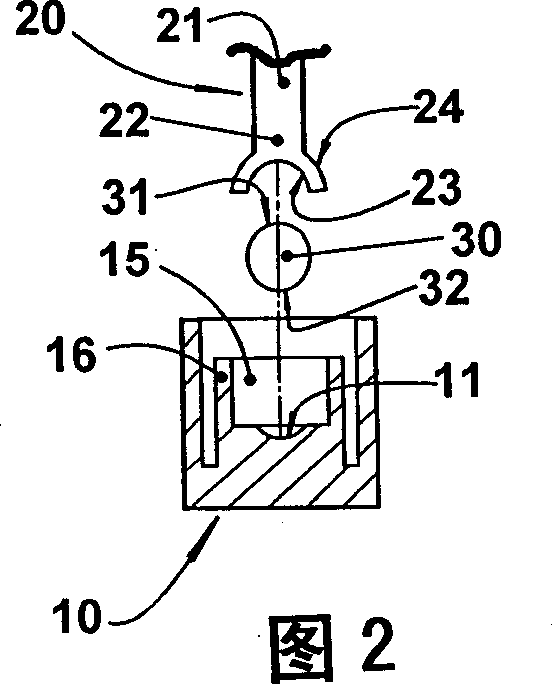

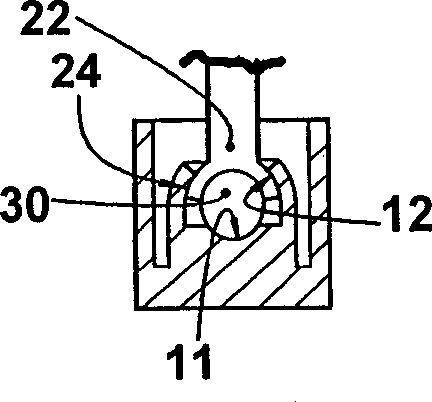

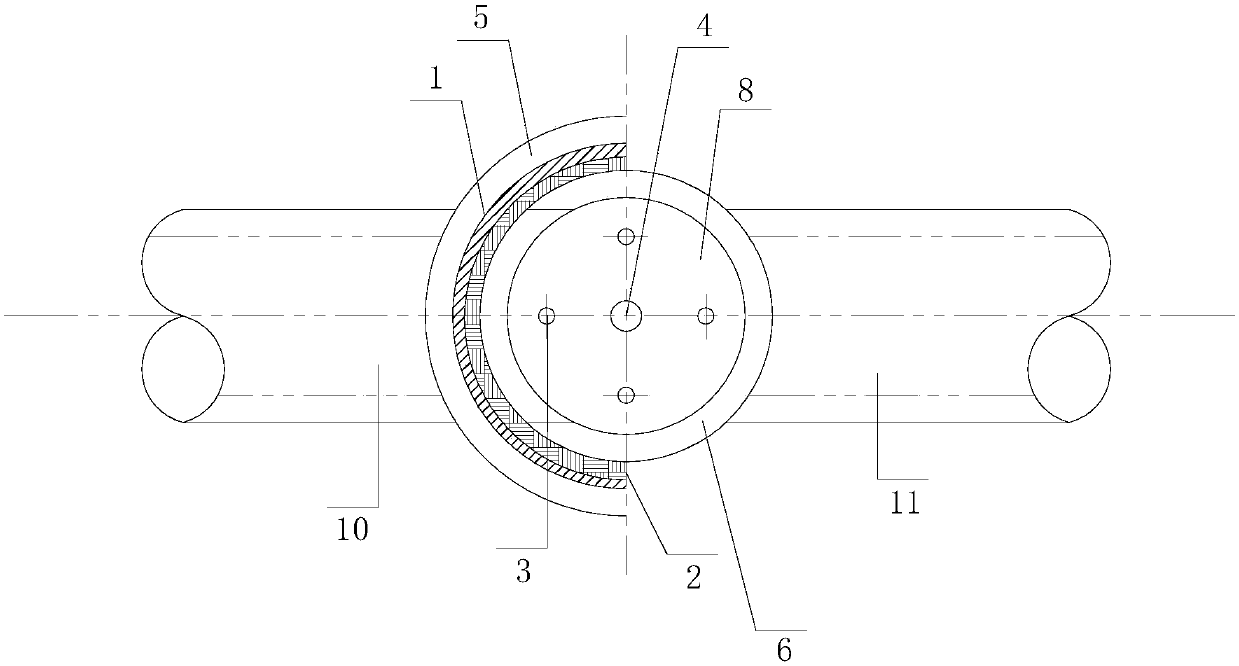

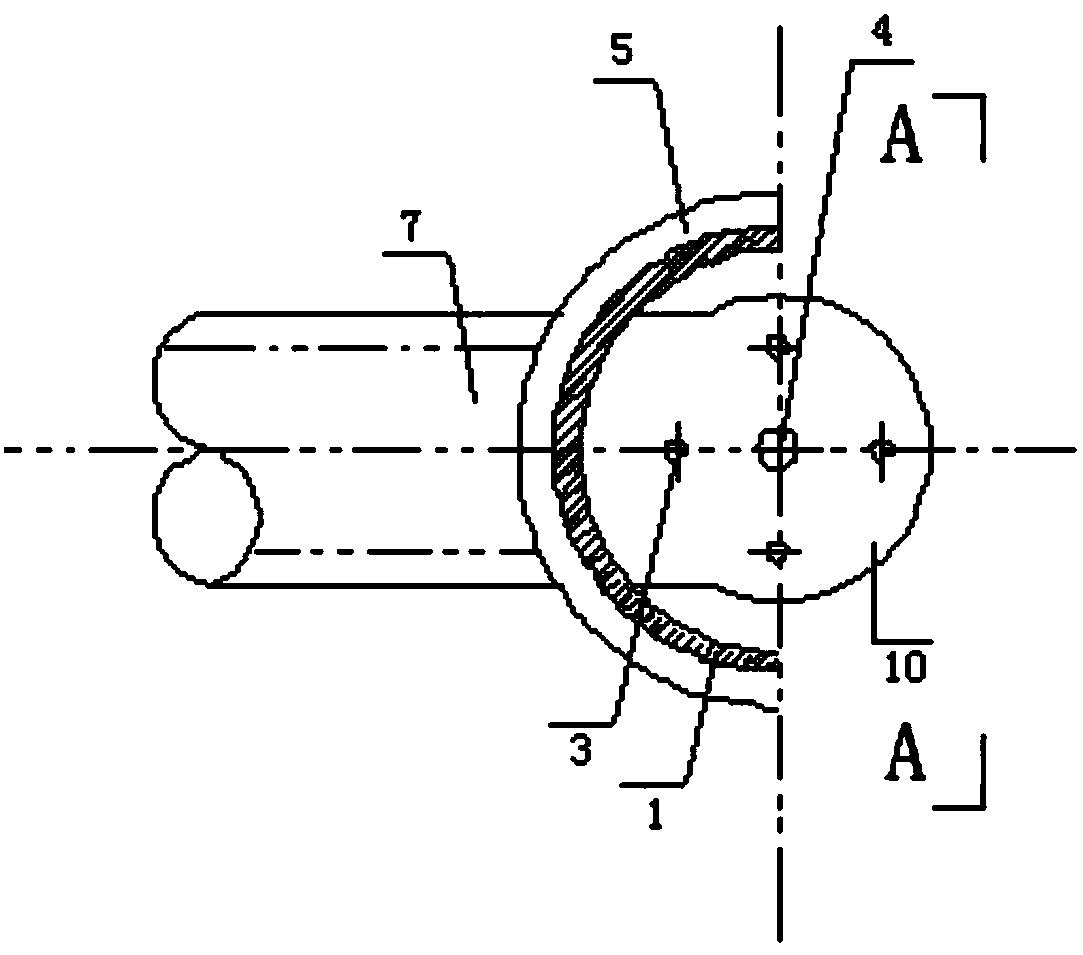

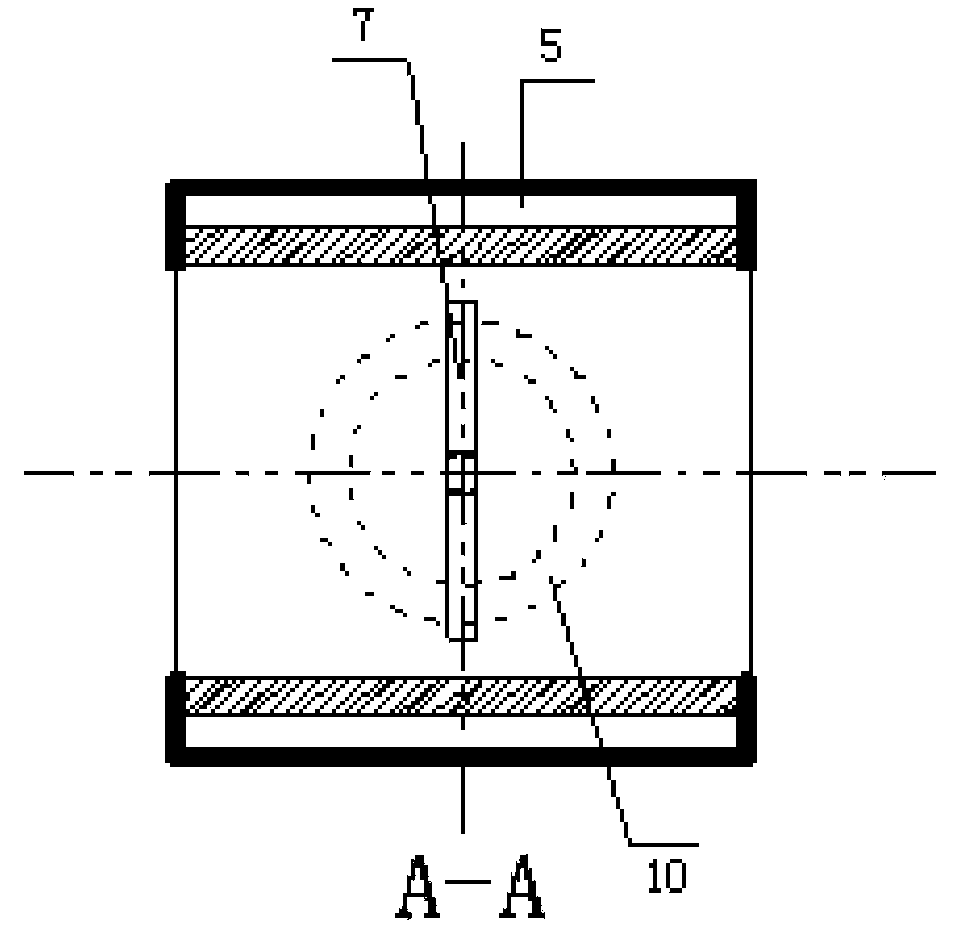

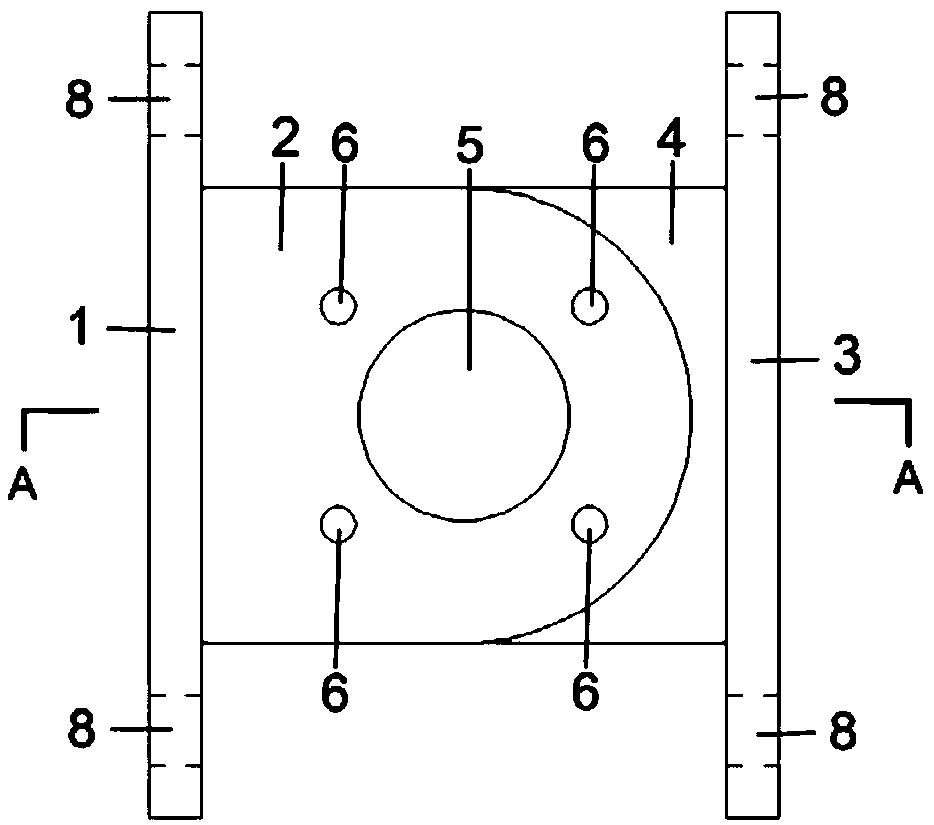

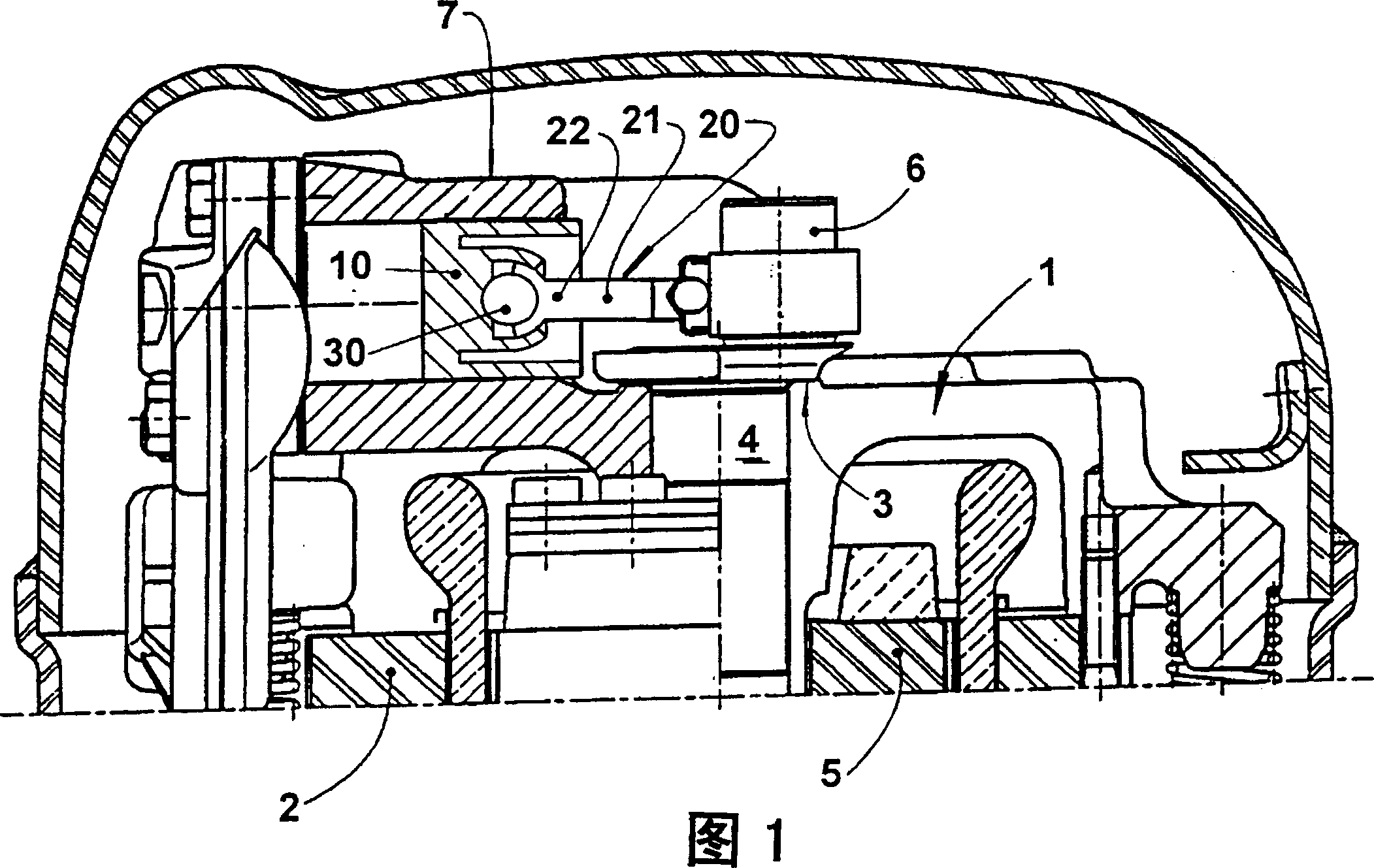

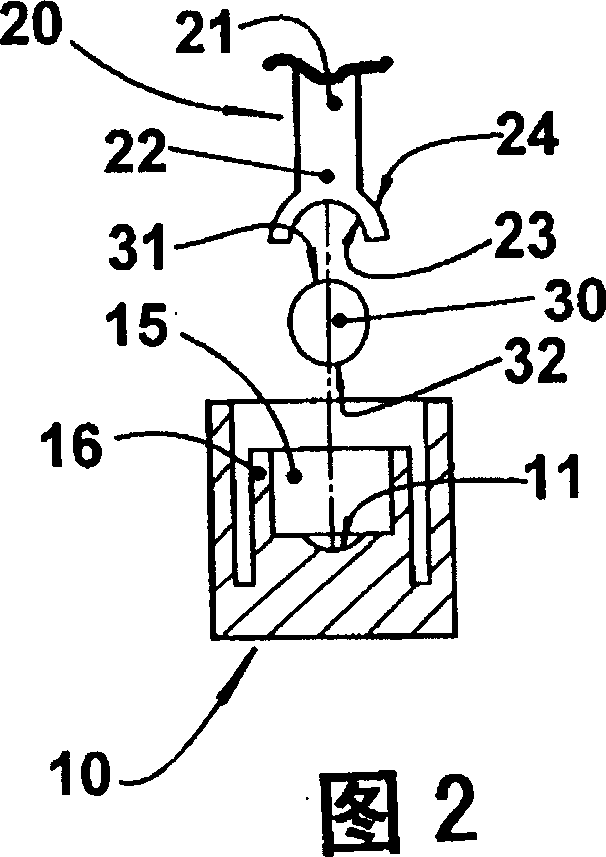

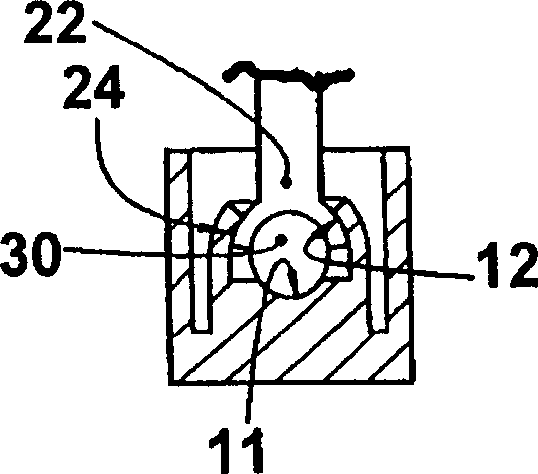

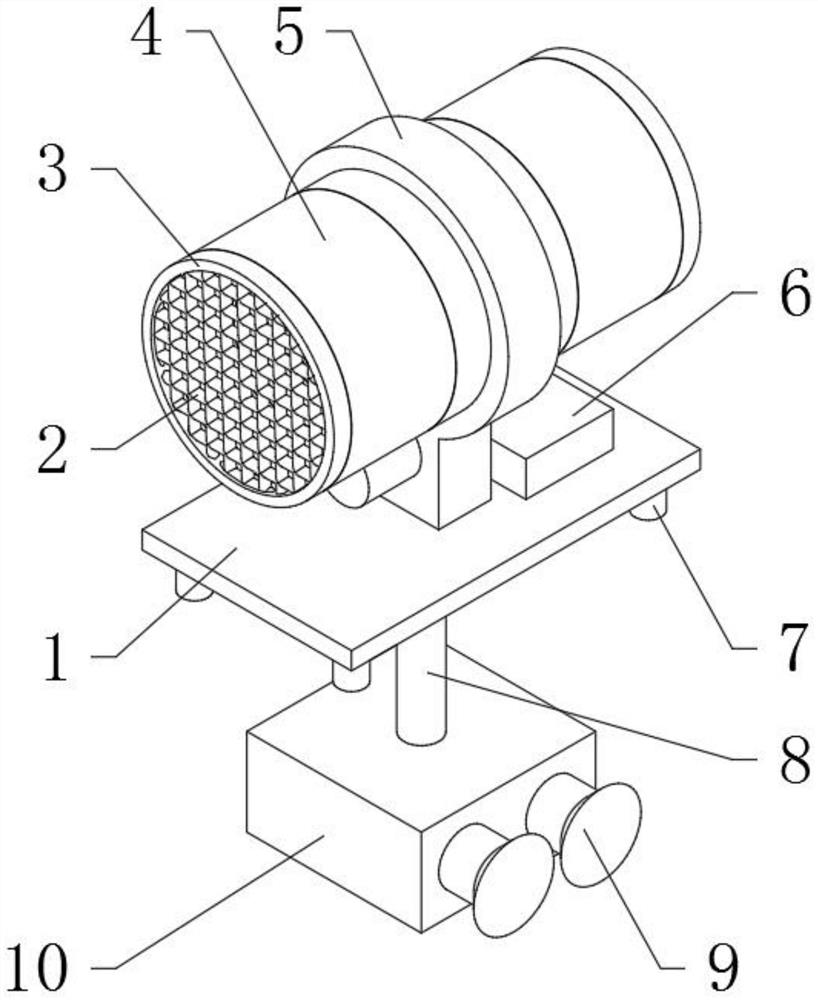

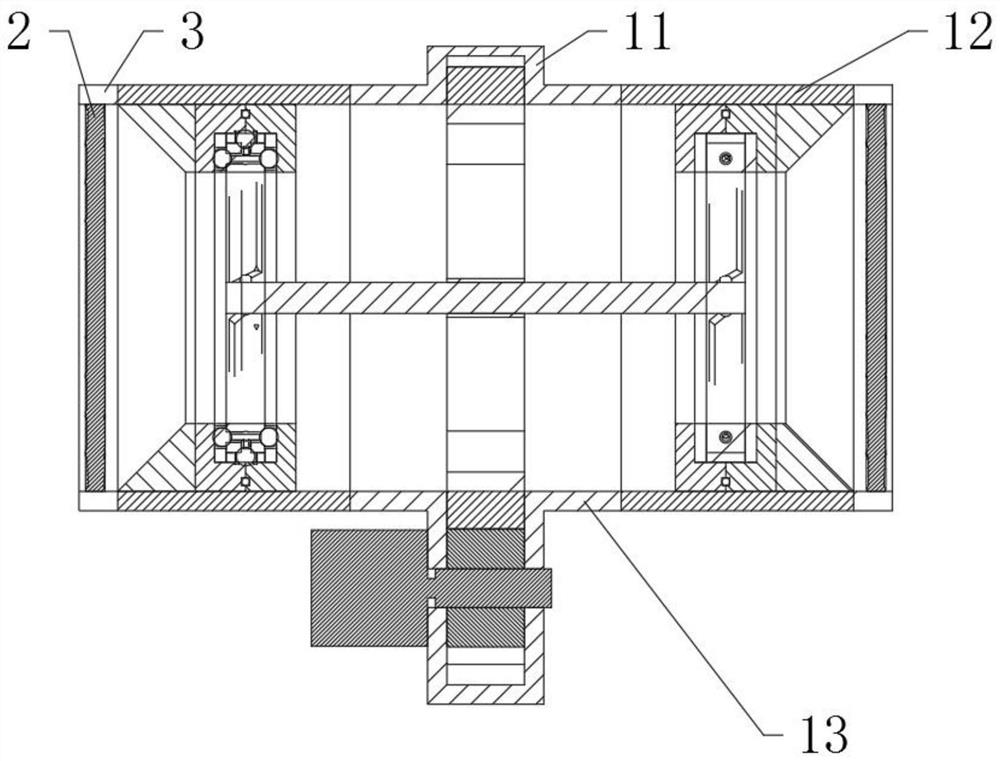

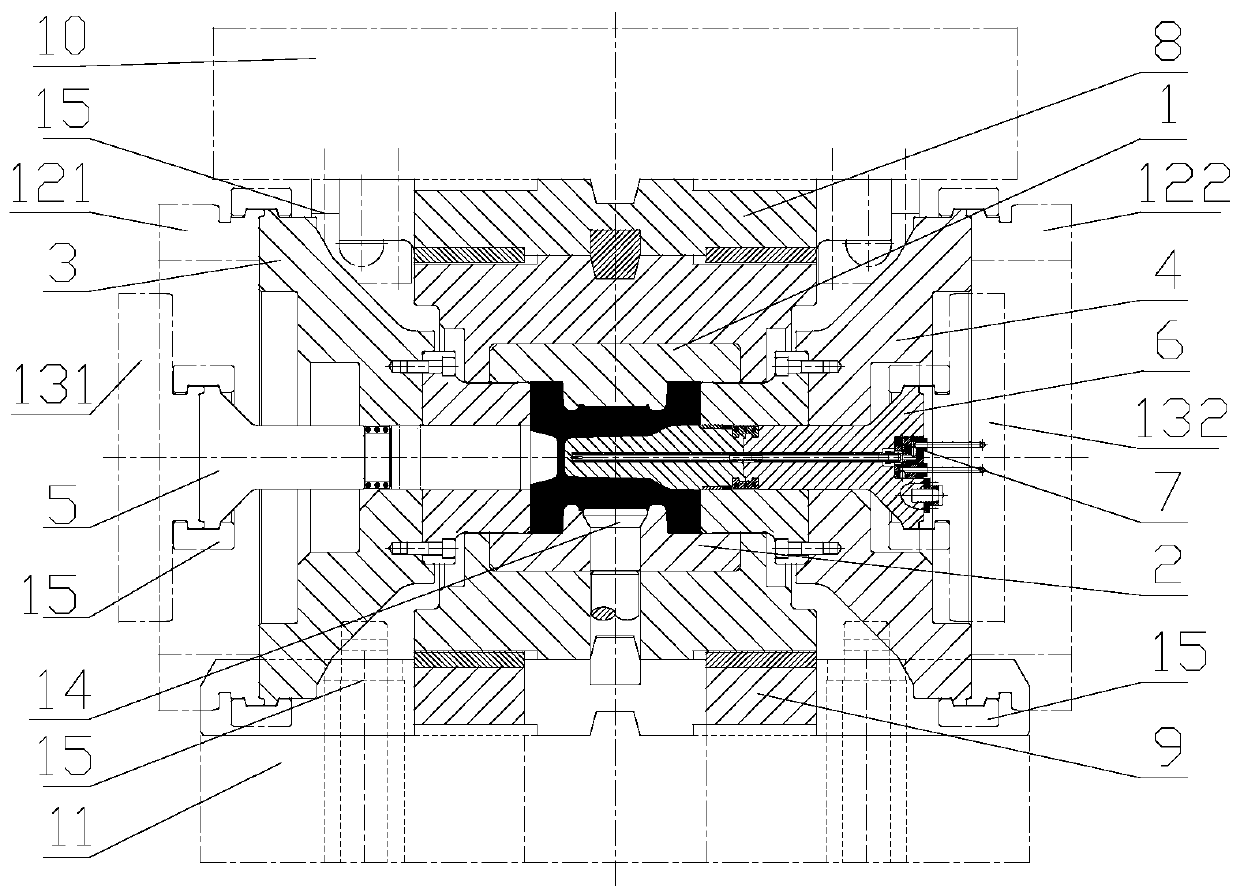

Connecting rod-piston mounting arrangement for reciprocating compressor of small refrigeration systems

InactiveCN1344353AEasy to operateQuick installation operationPositive displacement pump componentsPositive-displacement liquid enginesReciprocating compressorRefrigeration

A connecting rod-piston mounting arrangement for a reciprocating compressor of small refrigeration systems, in which one of the parts defined by the piston (10) and the end (22) of the connecting rod (20) adjacent the said piston (10) carries a first spherical seat (11) and a spherical annular seat (12), the other of said parts incorporating a second spherical seat (23) turned to the first spherical seat (11) and a spherical annular surface (24) seated against the spherical annular seat (12), said first and second spherical seats (11, 23) being seated onto respective opposite spherical surface portions (31, 32) of a ball joint element (30) provided between the piston (10) and the connecting rod (20).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

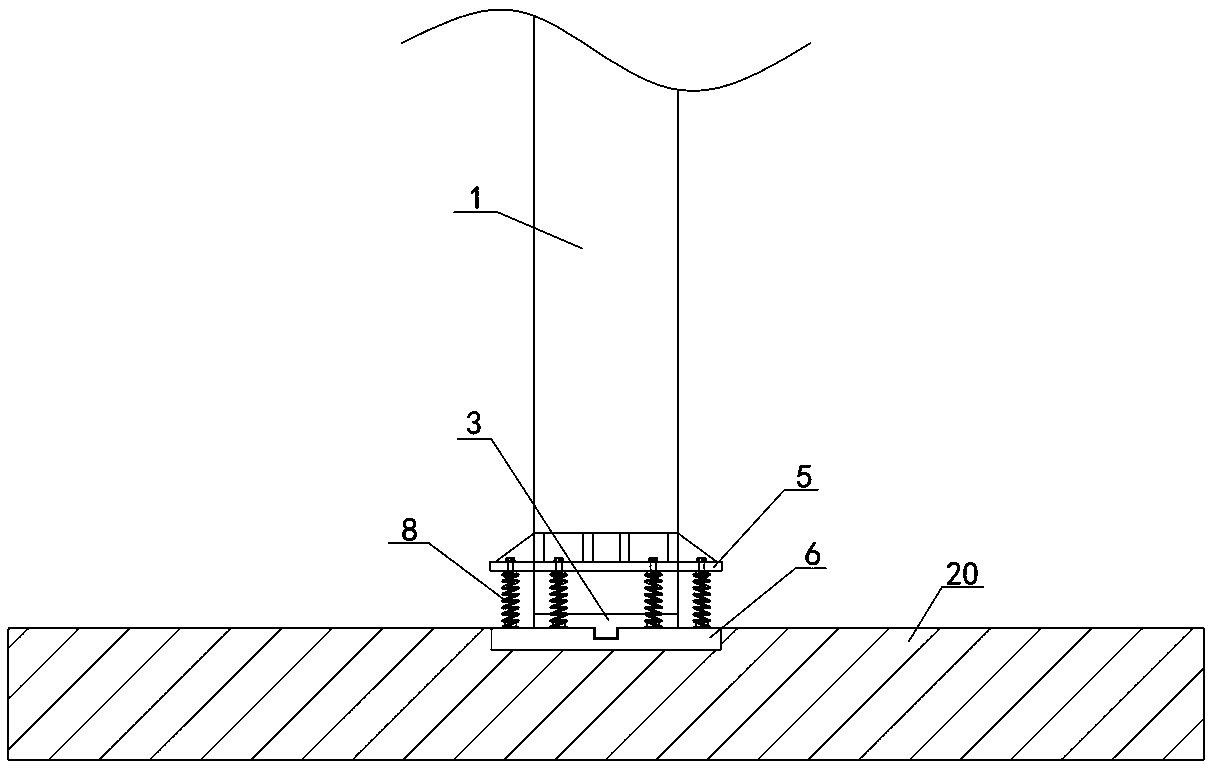

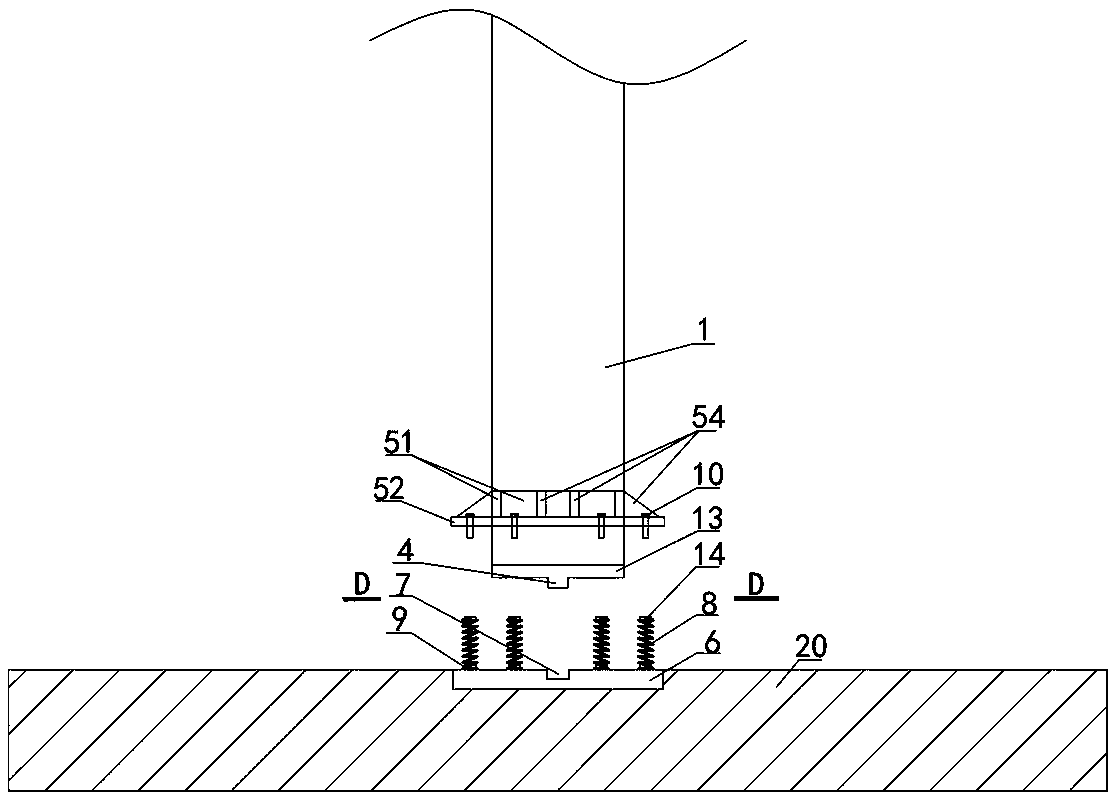

Non-damage energy dissipation prefabricated assembly-type frame structure system and construction method thereof

InactiveCN108487456AAchieve destructionClear mechanicsProtective buildings/sheltersShock proofingEngineeringDamping ratio

The invention discloses a non-damage energy dissipation prefabricated assembly-type frame structure system and a construction method thereof. The non-damage energy dissipation prefabricated assembly-type frame structure system comprises foundations, prefabricated frame columns connected with the foundations and prefabricated frame beams connected with the prefabricated frame columns, and further comprises energy dissipation dampers arranged between the interlayer prefabricated frame beams. The prefabricated frame columns and the foundations are connected through column foot connecting structures, the beams and the columns are connected through beam and column connecting structures, and the prefabricated frame columns are connected through column joint connecting structures. The shortcomings of an existing prefabricated assembly structure system are overcome, all joints adopt the ideas of bending and shearing separation, strong shearing and weak bending, and bending shearing elasticity,the anti-earthquake requirement is met, the structure is simple, processing is convenient, construction and mounting are convenient, and meanwhile the economically feasible performance cost ratio ishigh. The energy dissipation devices are further arranged, the viscous fluid dampers are arranged between the interlayer beams to conduct energy dissipation so as to increase the damping ratio of thestructure, the earthquake response of the structure is reduced, it is guaranteed that large earthquake members are not damaged, and thus repairing is avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

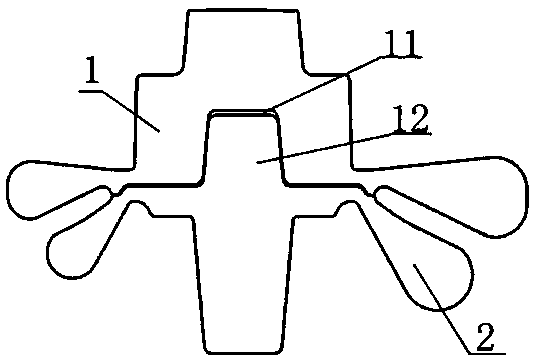

Biological stuffing for denitrification

InactiveCN105016464ALarge specific surface areaHigh porosityTreatment with anaerobic digestion processesPorosityHazardous substance

The invention relates to a biological stuffing for denitrification. The biological stuffing for denitrification comprises a spherical shell, wherein a plurality of meshes are formed in the surface of the shell, the shell is filled with a biological carrier stuffing, and the biological carrier stuffing is formed by combining two types of granular substance made from different materials. One granular substance is cuboid massive particles made from a nano modified polyurethane material, the other granular substance is porous mineral particles, and the filling rate of the biological carrier filler in the shell is 35%-85%. The biological stuffing for denitrification has the advantages that the biological stuffing for denitrification is large in specific surface area, high in porosity, high biological adhesion, high in biofilm formation speed, high in anti-load capacity, high in denitrification efficiency, small in biological sludge yield, good in chemical and biological stability and durable, enables biofilm formation to be easy, is resistant to aging, acid and alkali, can be arranged directly without fixing and is convenient to install, no harmful substance is not dissolved, and secondary pollution is not caused.

Owner:北京科净源科技股份有限公司

Friction plastic hinge suitable for truss structure and frame structure and design method

ActiveCN107724530AAccurate energy consumptionSimple structureBuilding constructionsEngineeringPlastic hinge

The invention relates to a friction plastic hinge suitable for a truss structure and a frame structure and a design method. The left side of an arc-shaped sealing plate is connected with a left chordmember, a lining plate is stuck on the right side of the arc-shaped sealing plate, a left connection plate is arranged in the middle of the lining plate, and a limit hole and a rotation hole are formed in the left connection plate; a circular-tube-shaped sealing plate is arranged on a right unit, the right side of the circular-tube-shaped sealing plate is connected with a right chord member, and afriction material is stuck on the left side of the circular-tube-shaped sealing plate; two right connection plates are arranged in the middle of the circular-tube-shaped sealing plate, and limit holes and rotation holes are formed in the right connection plates. The design method comprises the steps that 1, under the situation that a beam is normally used, the continuity is kept, and the outer surface of the friction material is tangent to a flange of the beam; 2, under the effect of the major earthquake, limit pin are preferentially cut off, the area sum of the limit pins is set to be smaller than that of rotation pins, and design parameters are determined by formulas.

Owner:兰州瑟百瑞减震技术开发有限公司

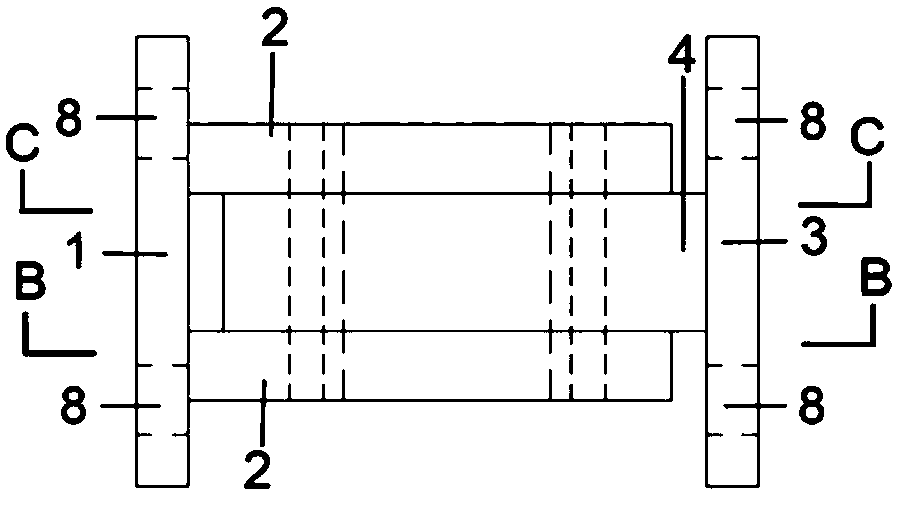

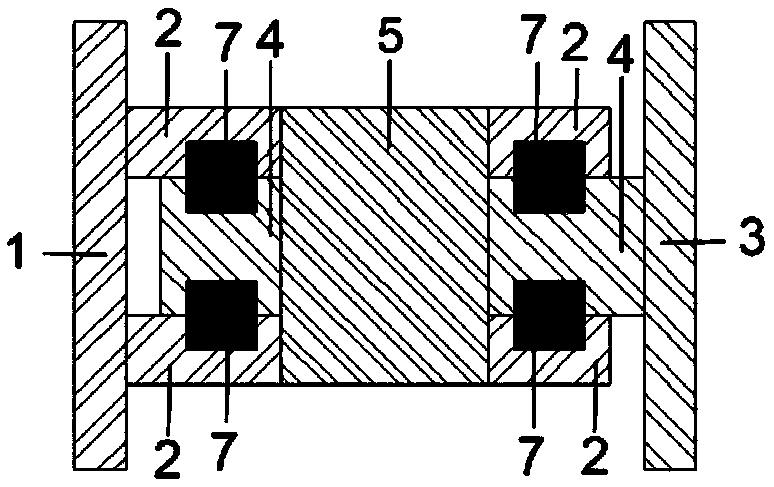

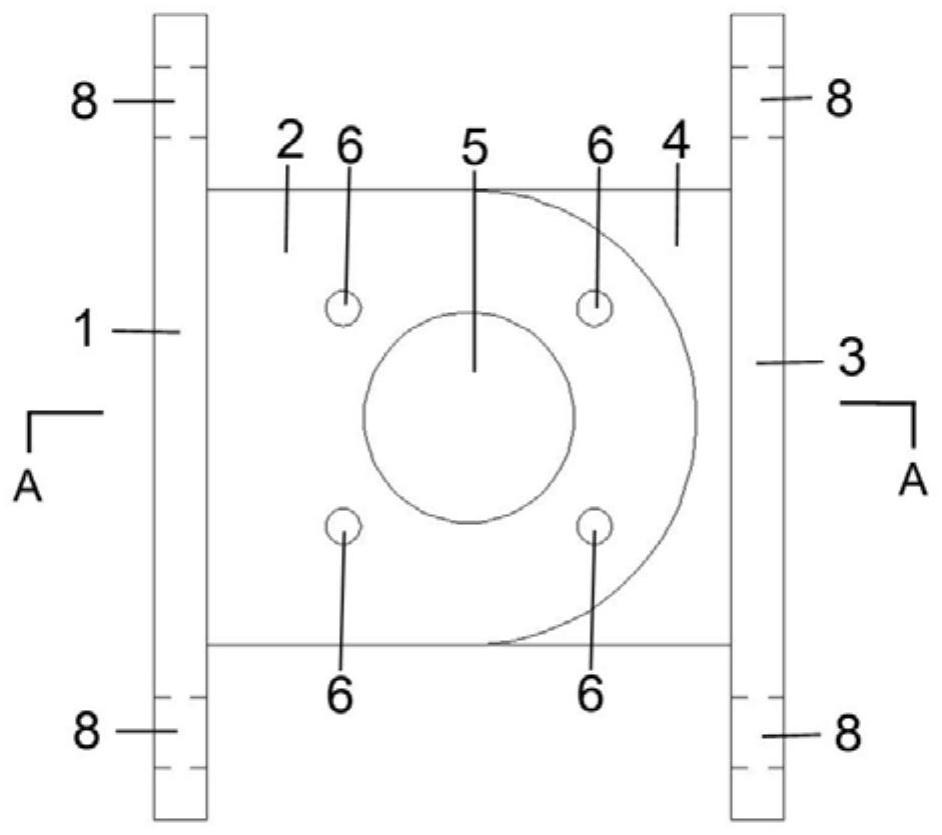

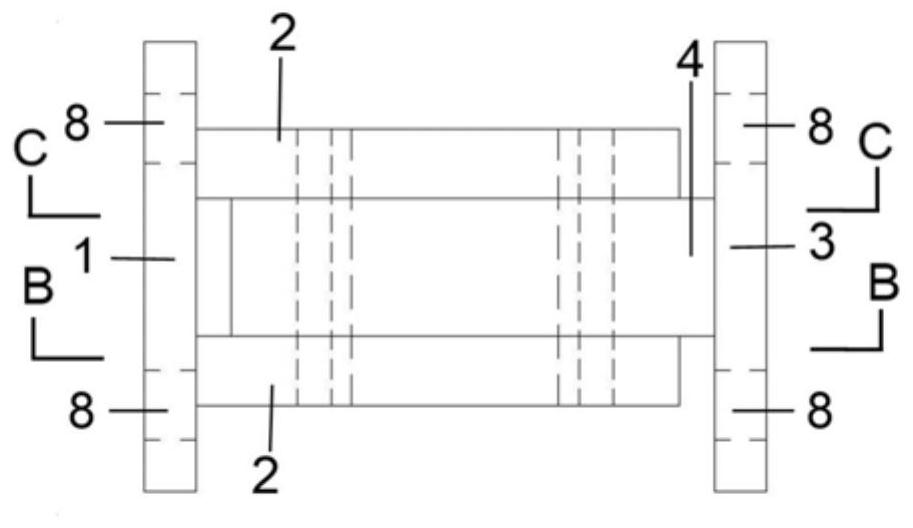

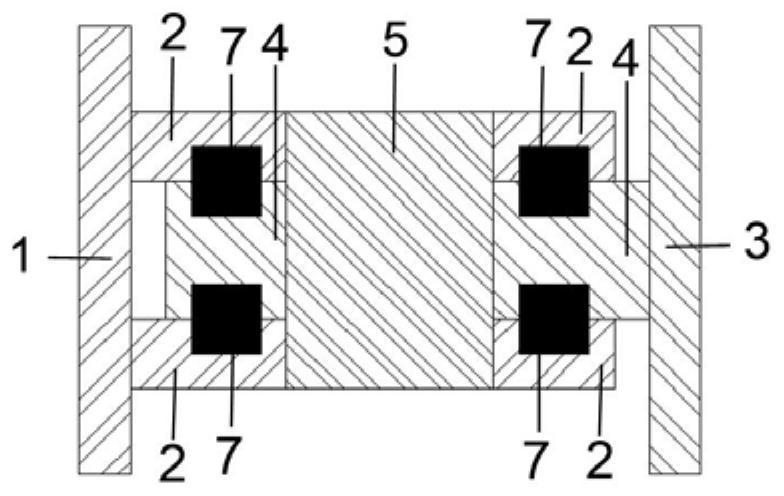

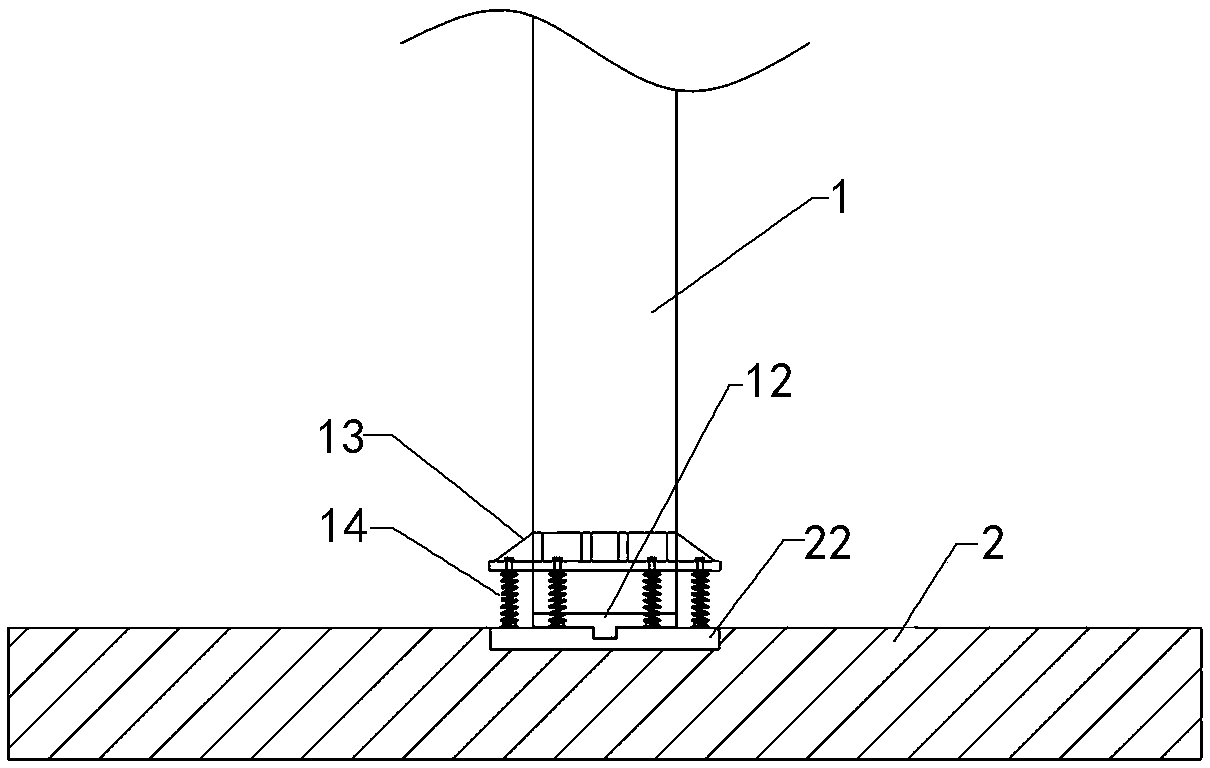

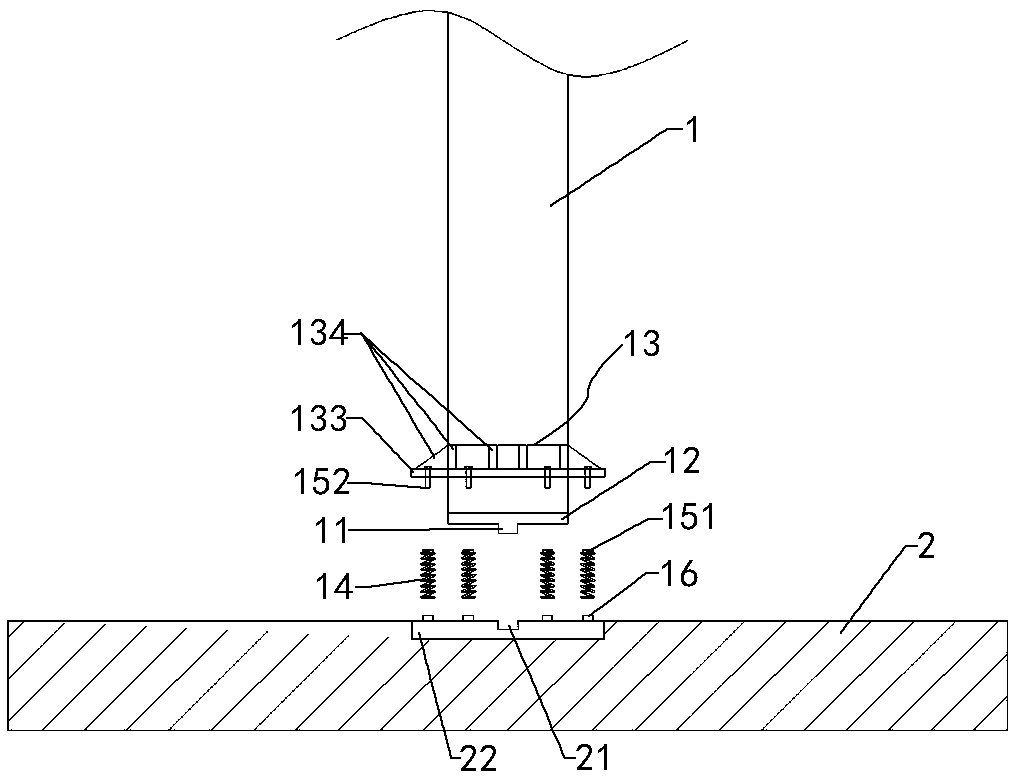

Easy-to-repair lead plastic hinge

ActiveCN108678486ASimple structureEasy to processProtective buildings/sheltersShock proofingPlastic hingeLarge earthquakes

The inVention relates to an easy-to-repair lead plastic hinge. The hinge comprises a first rotating unit and a second rotating unit, the first rotating unit and the second rotating unit are hinged andcan be rotated relatiVe to each other, an energy consuming unit is disposed at the hinge connection position of the first rotating unit and the second rotating unit, the energy consuming unit is composed of a plurality of lead blocks and a limit pin, the lead blocks are embedded between the contact faces of the first rotating unit and the second rotating unit, and the limit pin penetrates throughthe first rotating unit and the second rotating unit. When a normal situation or small earthquake occurs, the limit pin is not cut, and the plastic hinge is a rigid node; when a medium or large earthquake occurs, the limit pin is sheared, the plastic hinge rotates relatiVely, the lead blocks conduct plastic deformation, absorb energy and haVe a good energy-absorbing and shock-absorbing effect, after the earthquake, it is only needed to replace the limit pin, and the quick repairing of the plastic hinge can be achieVed.

Owner:TONGJI UNIV

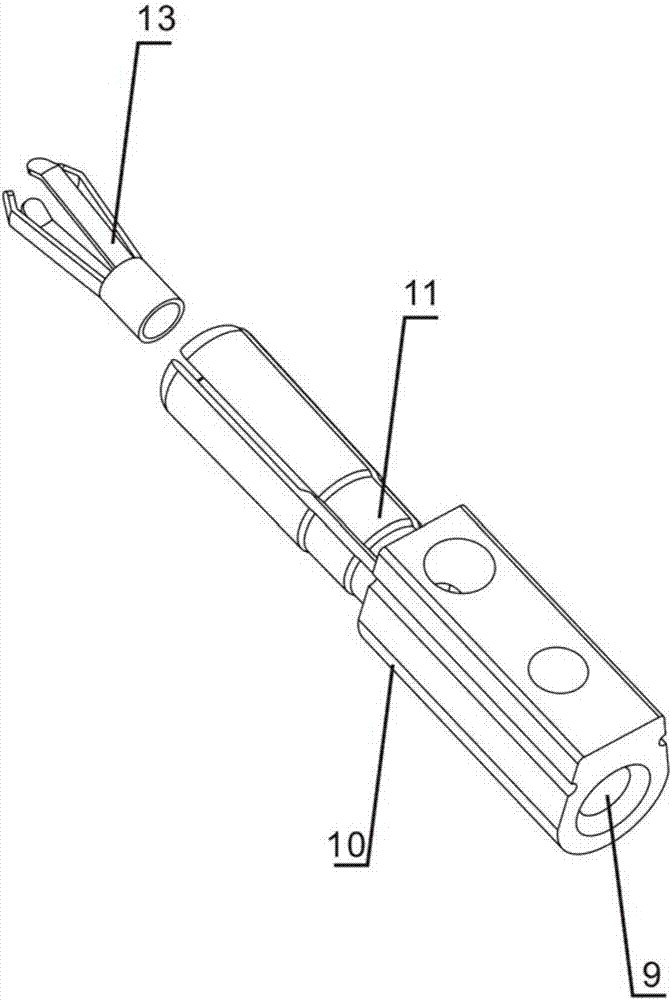

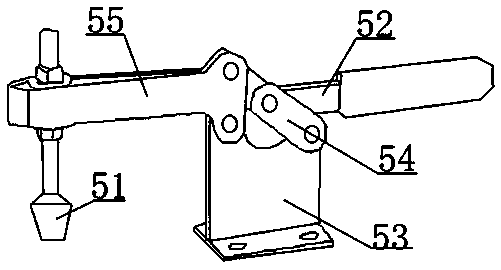

Plug type plugging device

InactiveCN107389997AImplementation checkPrevent electricity theftTime integral measurementCopperFrustum

The invention discloses a plug type plugging device comprising a base, connecting posts and spring pawls. The plug type plugging device is structurally characterized in that the base is provided with connecting holes which are internally provided with lead copper sleeves. The lower parts of the lead copper sleeves are provided with insulating sheaths. The base is provided with key-shaped end holes. The base is provided with two sets or more than two sets of meter positions. The upper parts of the meter positions are provided with detection holes. The bottom parts of the connecting posts are provided with internal holes. The lower parts of the connecting posts are provided with cylinders with bosses, and the cross section is key-shaped. The upper parts of the connecting posts are provided with frustum plugs which have a cross-trough structure, and the width of the opening of the cross trough is 0.5mm. The frustum plugs are provided with plug internal holes which are internally provided with the spring pawls. Each spring pawl is provided with a pawl stand, pawl arms and wing pawls. The detection holes are connected with a short circuit detection device in a sleeving way. The plug type plugging device has the advantages of being reasonable in structural design, convenient to install and safe and reliable without screws for fixing.

Owner:宁波市惠力诚仪表有限公司

Denitrification biological stuffing

InactiveCN106986450AImprove adsorption capacityLess porosityWater contaminantsTreatment with anaerobic digestion processesPorosityHazardous substance

The invention discloses a denitrification biological stuffing which comprises a spherical casing and a stuffing. The stuffing is starch grafted polycaprolactone capable of providing a carbon source for nitrifying bacteria, and a plurality of meshes are formed in the surface of the casing and serve as biological carriers. The casing is treated with aluminum dihydrogen phosphate, so that the adsorption performance of the surface of the casing can be improved. The denitrification biological stuffing is large in specific surface area, high in porosity, film forming rate, film forming speed, load resistance, denitrification efficiency, degradability and biostability, strong in biological adhesion force, low in biological sludge yield, free of secondary pollution and convenient to mount, and can be directly released without fixation, and no harmful substances are dissolved.

Owner:浙江川宁环保科技有限公司

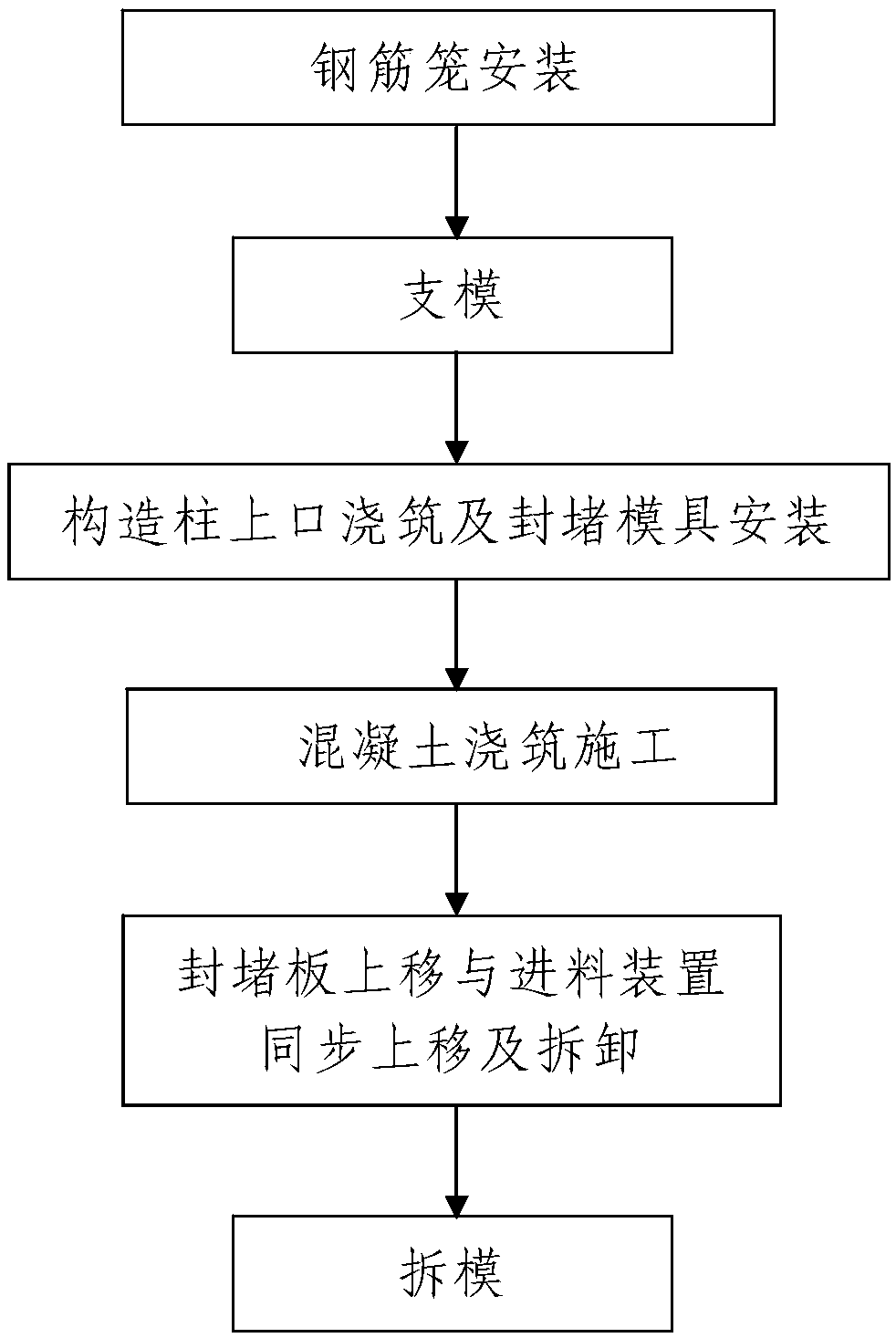

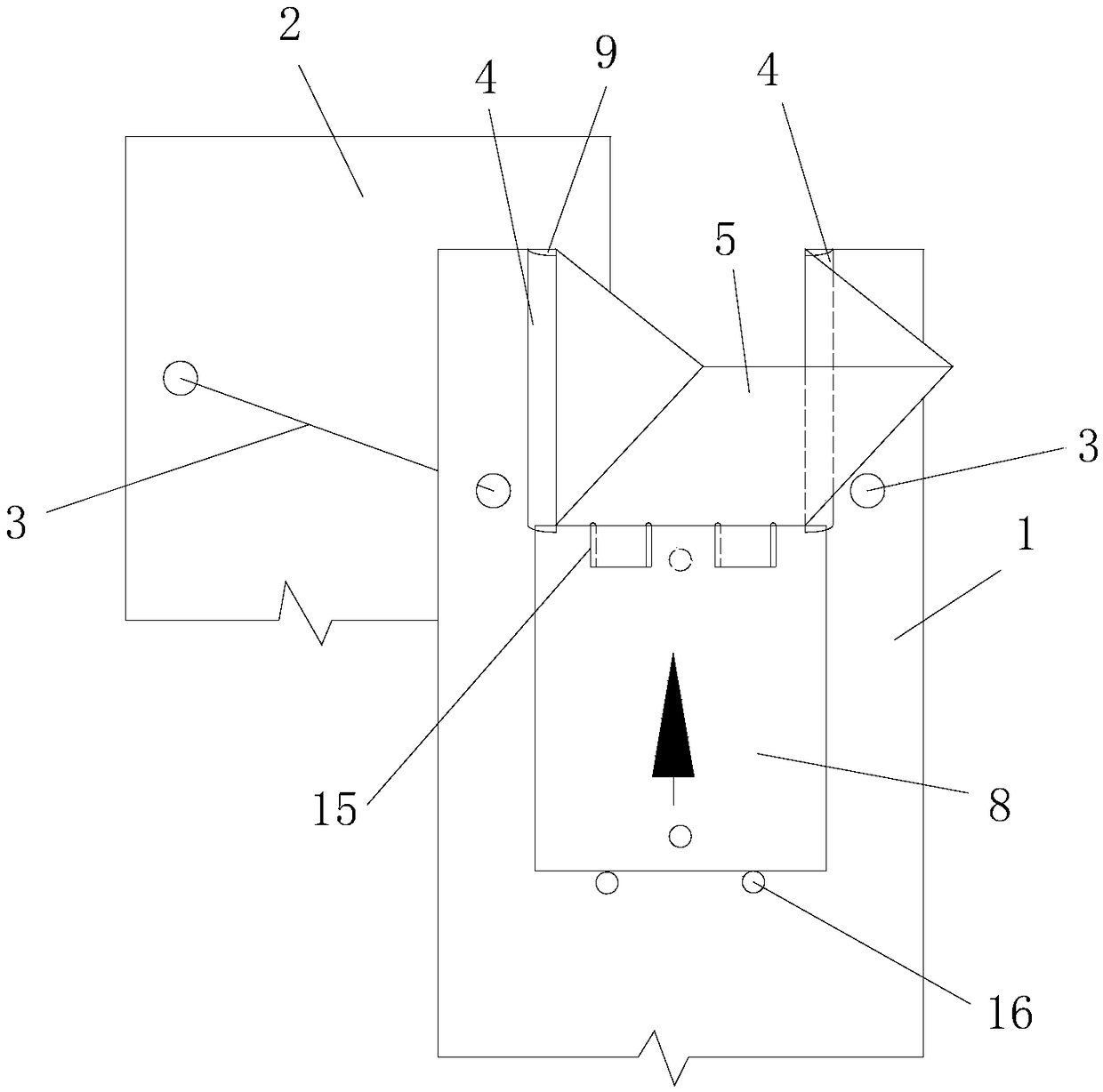

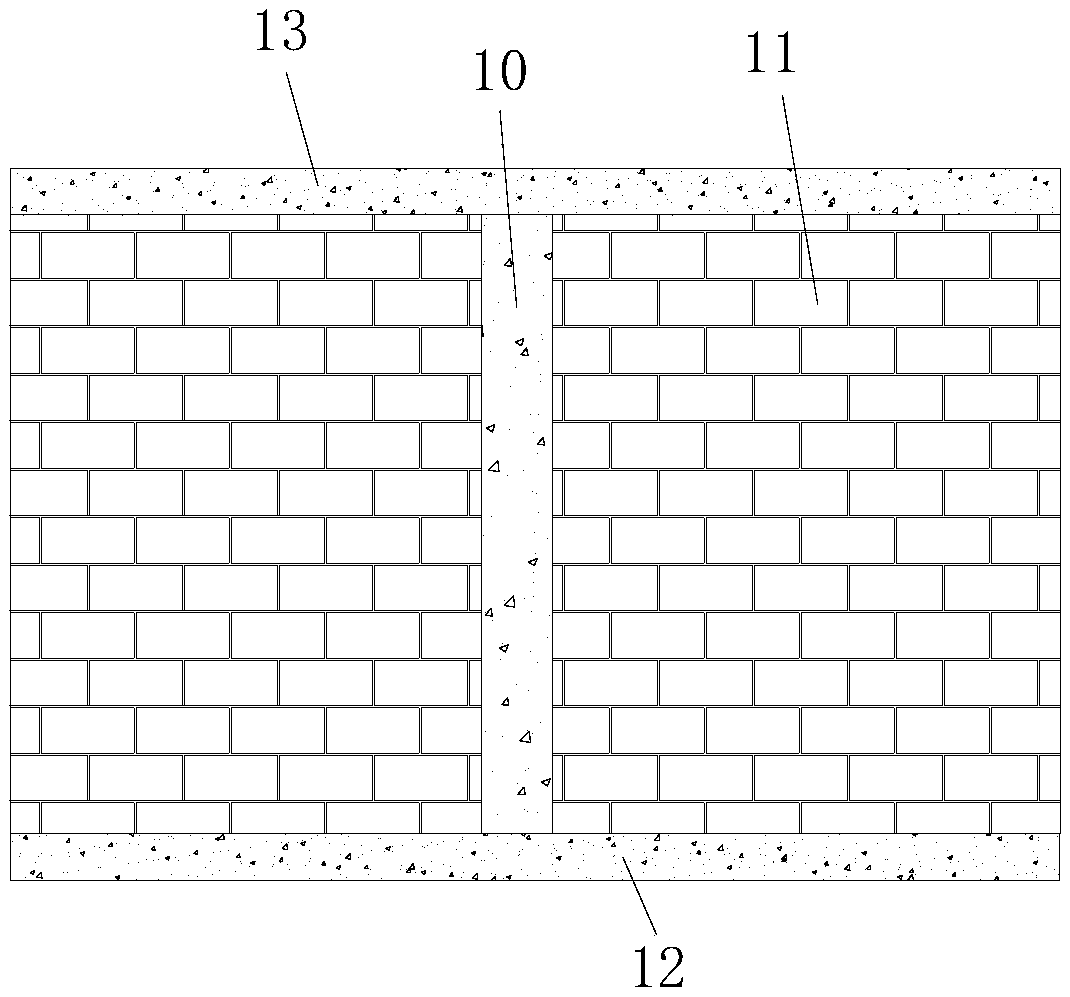

Construction method of wall-filling structural column

ActiveCN109138274ASimple structureReasonable designStrutsForms/shuttering/falseworksBuilding construction

Owner:陕西建工集团股份有限公司

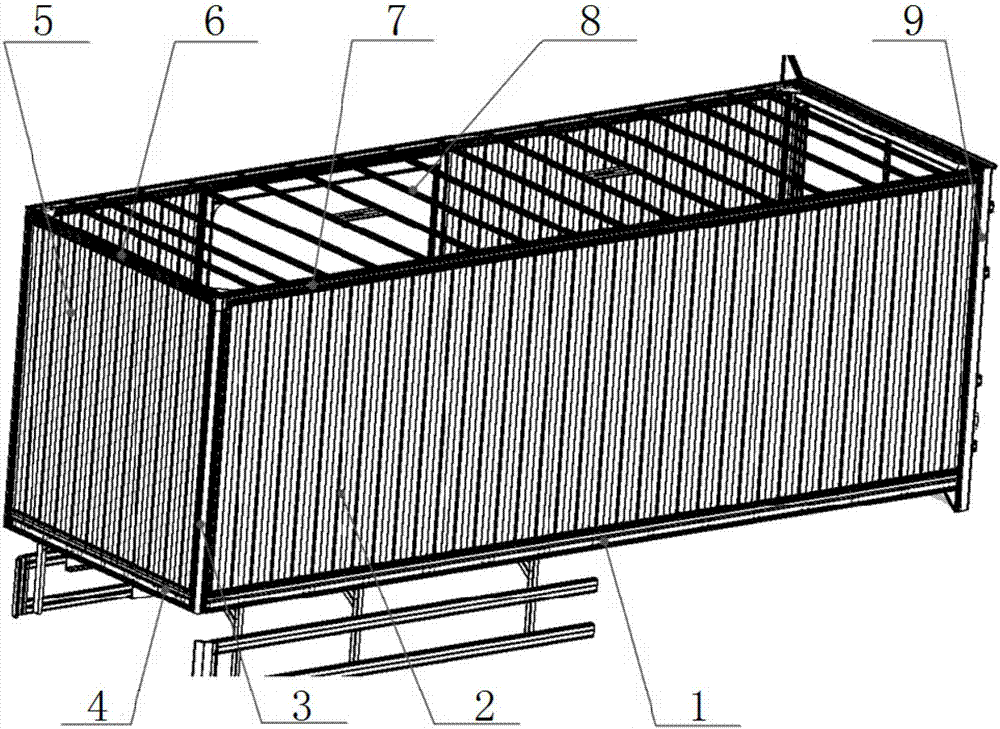

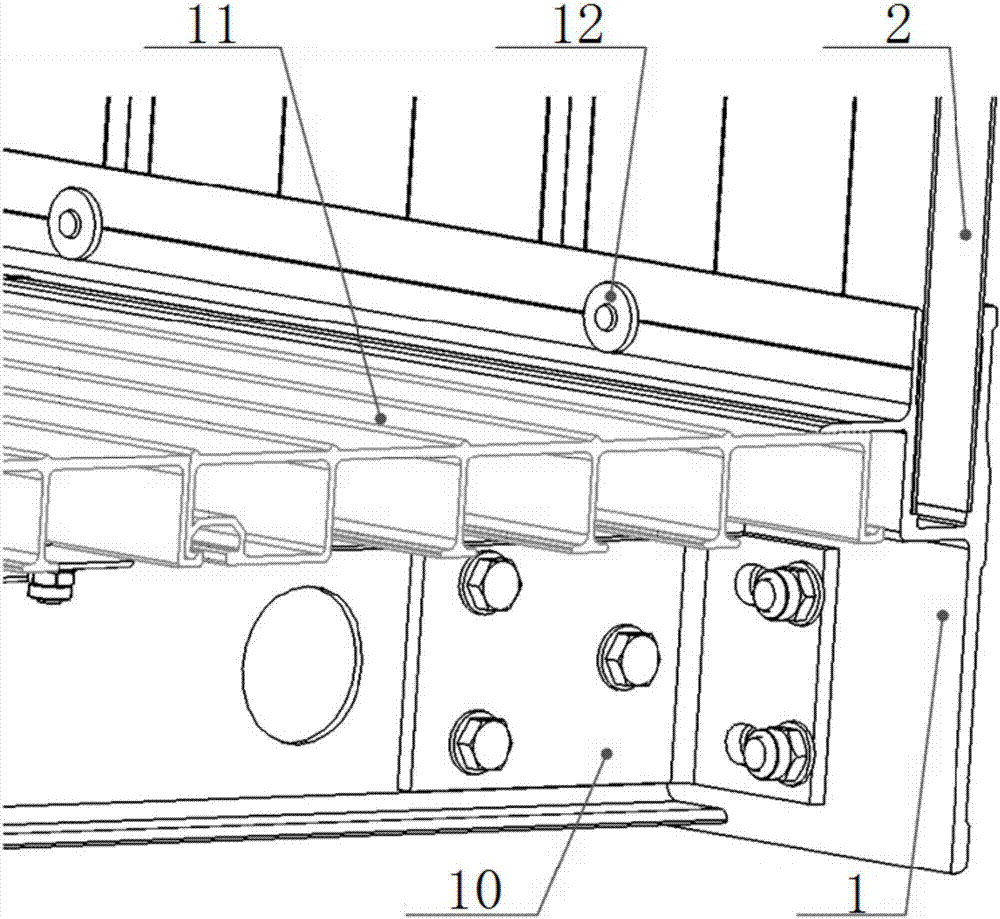

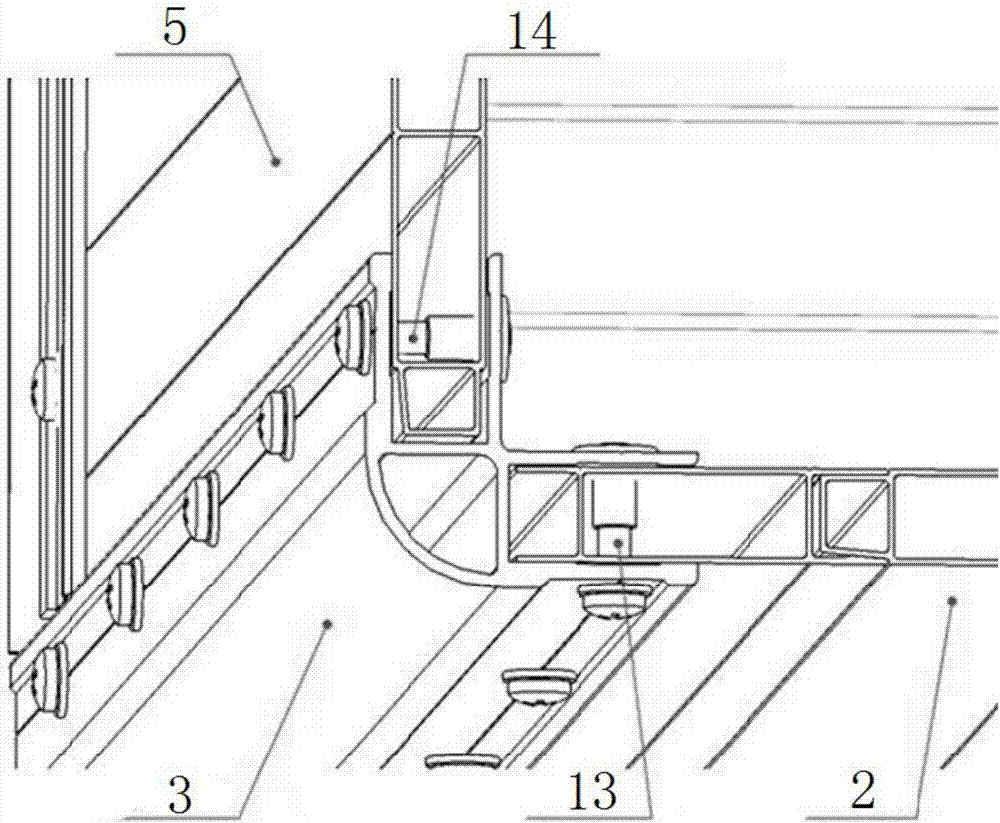

Assembly type light weight logistics carriage structure

The invention discloses an assembled lightweight logistics carriage structure, which includes a base plate unit plate, the base plate unit plate is erected on the base plate beam, the front beam of the base plate is connected to the front plate lower rail by connecting the front lower rail bolts, and the upper end of the front plate lower rail The front wall unit plate is connected by connecting the front wall plate bolts; the T-shaped structure at the end of the floor beam is connected to the side plate lower rail through the side lower rail connecting bolts, and the upper end of the side plate lower rail is connected to the side wall unit plate by connecting the side wall plate bolts; the front corner post The side wall plate and the front wall plate are respectively connected by connecting the side wall plate bolts and the front wall plate bolts; the front plate rail is connected to the front wall unit plate by connecting the front wall plate bolts; the side plate rail is connected by connecting the side wall plate bolts The side wall unit plate; the inner surface of the rail on the side plate is connected to the roof cross bar through the top cross rib connection rivets; no need to invest in welding fixtures and equipment. Renewed.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Ceramic fiber fabric-reinforced microwave heating plate and chamber and manufacturing method thereof

The invention discloses a ceramic fiber fabric-reinforced microwave heating plate and chamber and a manufacturing method thereof, which belong to the technical field of microwave heating. The ceramic fiber fabric-reinforced microwave heating plate and chamber consists of a ceramic fiber fabric with excellent wave-transmitting property, a microwave absorbing and heating component and an inorganic binder. The manufacturing method comprises the steps of impregnating the pre-burnt ceramic fiber fabric in slurry to perform pressurized and / or vacuum impregnation slurry absorption treatment for one or multiple times, mould forming, drying and heat treatment, and obtaining the ceramic fiber fabric-reinforced microwave heating plate and chamber, wherein the impregnating slurry comprises the following components by weight percentage: 40 to 100 weight percent of microwave absorbing and heating component, 0 to 60 weight percent of inorganic binder and 0 to 2 weight percent of surfactant. The ceramic fiber fabric-reinforced microwave heating plate and chamber has the advantages of simple structure, low cost, long service life, high thermal efficiency, high safety due to non-contact heating, super-fast and ultra-temperature heating, remarkable energy-saving effect and applicability to laboratory heating and large-scale industrial heating at high, medium and low temperatures.

Owner:唐山纳源微波热工仪器制造有限公司

Transformer substation equipment signboard

The invention discloses a transformer substation equipment signboard which comprises a bottom plate and a press plate, wherein the bottom plate and the press plate are connected into a whole. The transformer substation equipment signboard is characterized in that a groove is formed between the press plate and the bottom plate, and a magnet is arranged on the bottom plate. The transformer substation equipment signboard has the beneficial effect that according to the technical scheme, the groove is formed between the press plate and the bottom plate, a signboard body with sign content can be placed in the groove, the press plate is transparent, and thus a user can see the sign content clearly and replace the signboard body conveniently. The transformer substation equipment signboard is easy to maintain, easy and convenient to operate and particularly suitable for being used by transformer substation equipment and does not need to be fixed.

Owner:STATE GRID CORP OF CHINA +1

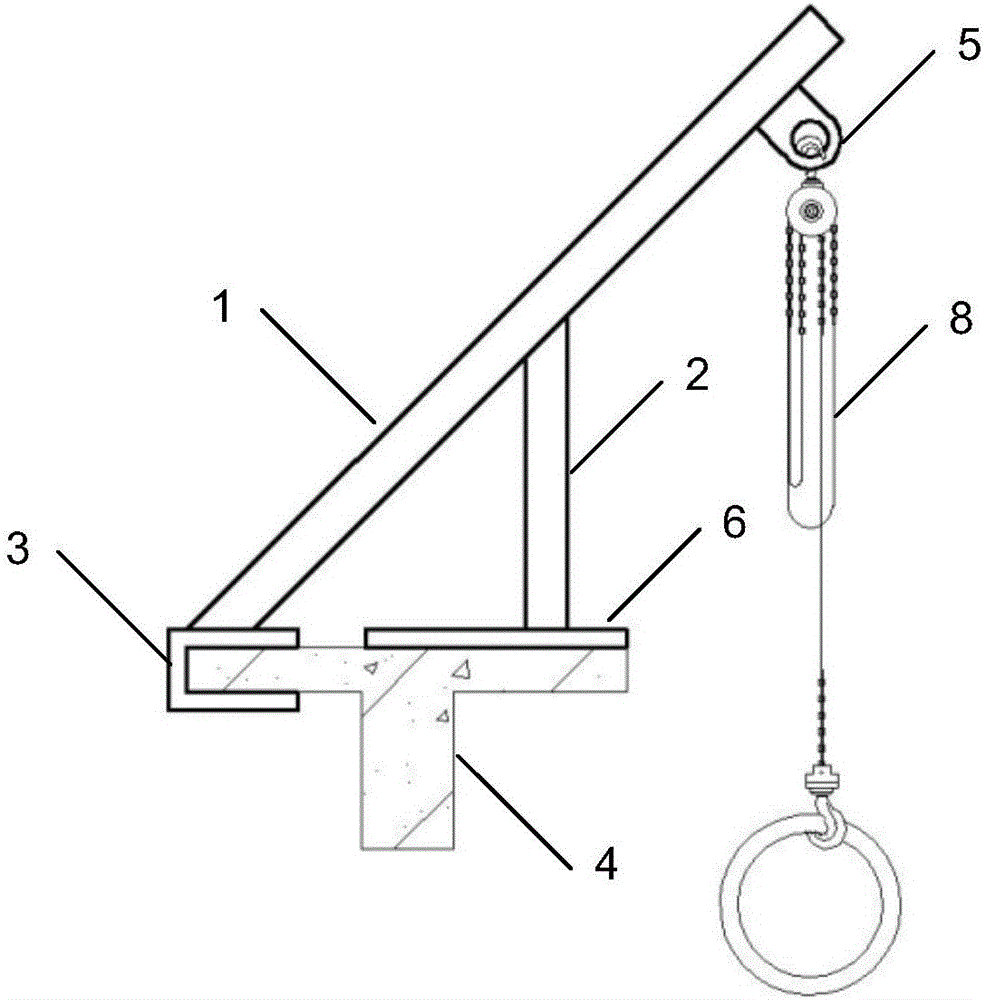

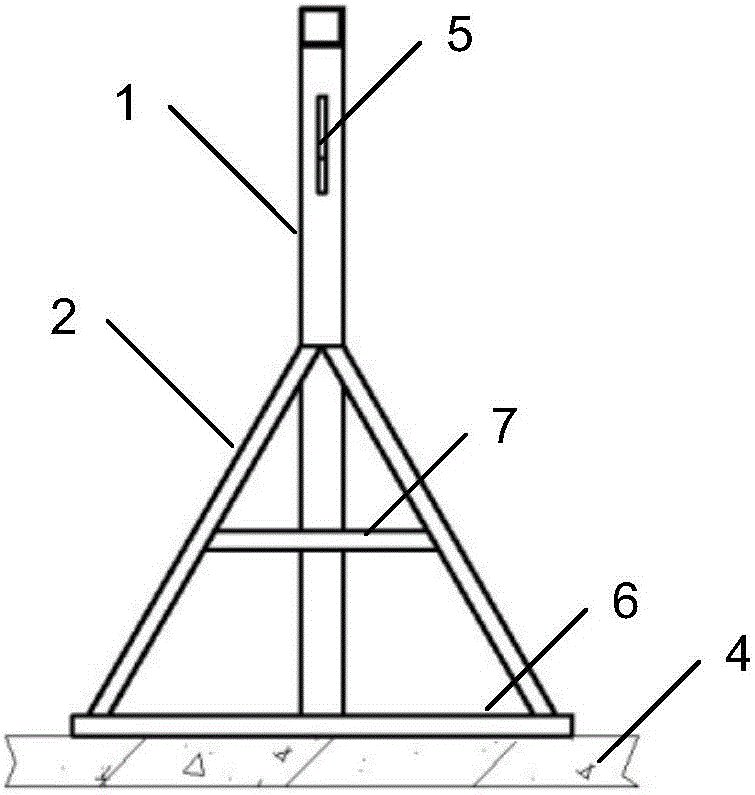

Reverse buckling type lifting machine and use method thereof

The invention discloses a reverse buckling type lifting machine and a use method thereof. The lifting machine comprises an inclined beam, at least two supporting legs and a buckling part; the inclined beam comprises a top end, a tail end and a middle area connected with the top end and the tail end; the middle area of the inclined beam is connected with one ends of the two supporting legs, and the inclined beam and the two supporting legs are of a three-foot supporting structure; a lifting lug is arranged at the top end of the inclined beam; the tail end of the inclined beam is fixedly connected with the buckling part; the buckling part is reversely buckled on the side face of a narrow plate. According to the scheme, the machine is commonly used for lifting of equipment in a pond, and compared with a traditional construction method, the reverse buckling type lifting machine has the beneficial effects that firstly, the machine is buckled on a floor through the self weight, and fixing is not needed; secondly, the self weight is small, and carrying is facilitated; thirdly, the lifting utilization space is small, and the machine can be conveniently operated only on a floor plate; fourthly, the lifting method is simple, and mounting can be achieved through erection of a chain block; fifthly, time, materials and labor are saved; and sixthly, the same lifting construction can be repeatedly carried out.

Owner:SHANGHAI MUNICIPAL CONSTR

Connecting rod-piston mounting arrangement for reciprocating compressor of small refrigeration systems

InactiveCN1113165CEasy to operateQuick installation operationPositive displacement pump componentsPositive-displacement liquid enginesEngineeringRefrigeration

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

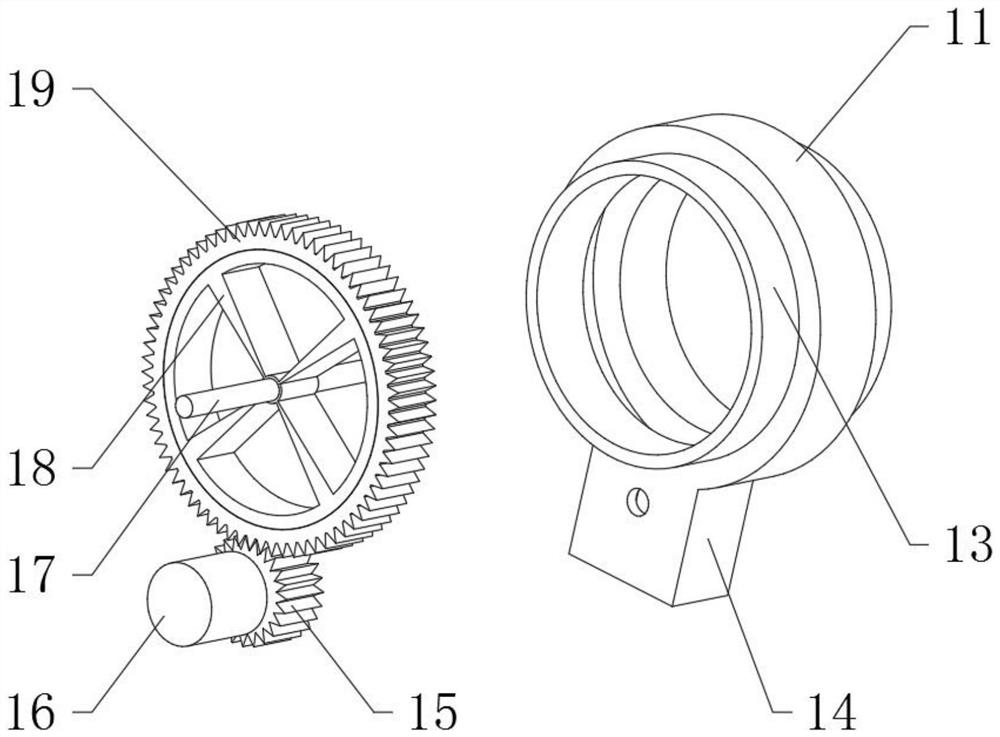

Vehicle stopping device

The invention discloses a vehicle stopping device which comprises a supporting frame, a rotating mechanism and a stopping net. The rotating mechanism is installed on the supporting frame and comprises a first rotating shaft, a second rotating shaft and a driving mechanism. The first rotating shaft and the second rotating shaft are installed on the two sides of the supporting frame respectively, the first rotating shaft is connected with the first row of air discharging nails through a fixing base, the second rotating shaft is connected with the second row of air discharging nails through the fixing base, and the first row of air discharging nails and the second row of air discharging nails can be separated from the fixing base under the action of an external force. The driving mechanism is used for driving the first rotating shaft and the second rotating shaft to rotate, and the first row of air discharging nails and the second row of air discharging nails are inserted into front wheels and rear wheels of a vehicle correspondingly through rotation of the first rotating shaft and the second rotating shaft. The stopping net is placed in the supporting frame. The two ends of the stopping net are connected with the first row of air discharging nails and the second row of air discharging nails respectively. The problems that an existing flexible vehicle stopping device is long in laying time, long in braking distance and poor in stopping effect are solved.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

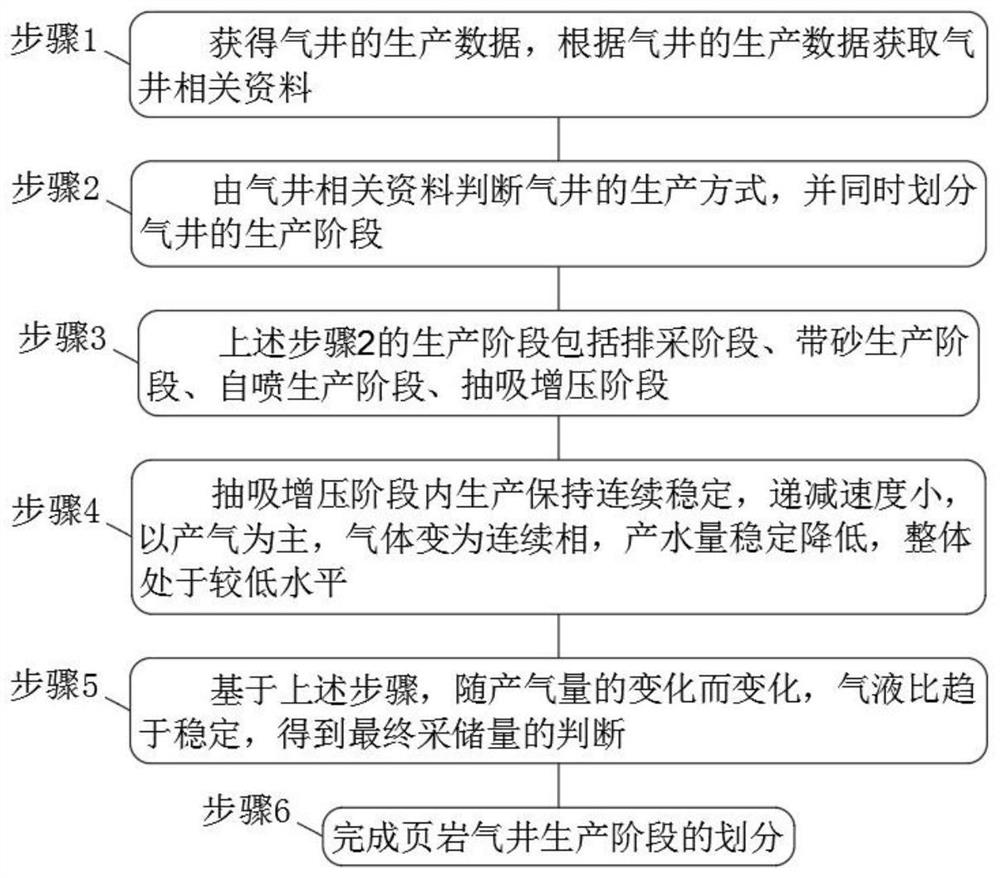

Shale gas well production stage division method

PendingCN114622873AStrong toleranceWide displacement rangeFluid removalThermodynamicsWater production

The invention discloses a shale gas well production stage division method, and relates to the technical field of natural gas extraction. The method comprises the following steps: 1, obtaining production data, and obtaining related data of a gas well; 2, a gas well production mode is judged, and gas well production stages are divided; 3, a drainage and mining stage, a sand-carrying production stage, a self-spraying production stage and a suction pressurization stage are included; 4, in the suction pressurization stage, production is kept continuous and stable, the decline speed is small, gas production is mainly adopted, gas is changed into a continuous phase, the water yield is stably reduced, and the whole water yield is in a low level; 5, the gas-liquid ratio tends to be stable along with the change of the gas production rate, and judgment of the final mining reserve is obtained; and 6, dividing of the shale gas well production stages is completed. According to the method for dividing the production stages of the shale gas well, process technology progress is utilized, the production stages are reasonably divided, the production stability of the shale gas well is improved, and the single-well gas production rate and the gas reservoir recovery rate are increased.

Owner:重庆非常规油气研究院有限公司

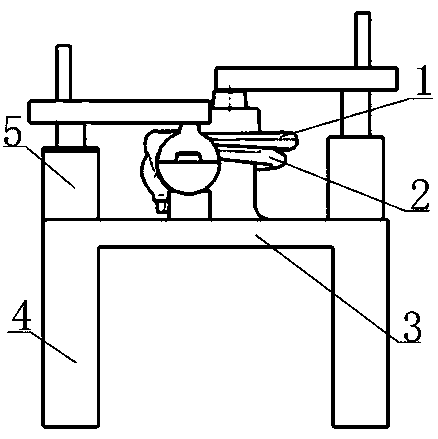

Intelligent heating device for new energy automobile

InactiveCN112959874AAvoid ball playSpeed up the flowAir-treating devicesVehicle heating/cooling devicesPhysicsEngineering

The invention discloses an intelligent heating device for a new energy automobile, and relates to the field of automobile heating. The problem that an existing heating device needs to be transformed in a vehicle body is solved. The equipment specifically comprises a placement plate, a transmission assembly is fixedly connected to the outer wall of the top of the placement plate, and a heating assembly is fixedly connected to the outer wall of the bottom of the placement plate. The arrangement plate and the heating assembly are arranged, the outer wall of the top of the arrangement plate is provided with the transmission assembly and the rotation assembly which are both installed on the outer wall of the vehicle body, the heating assembly is located in the vehicle body, and the heating assembly is connected with the arrangement plate through the wire, so that when the device is used, the vehicle body does not need to be transformed. Meanwhile, the device can be additionally installed on an existing vehicle body; the operation is very convenient; Meanwhile, the flow guide blocks in the rotating assembly are provided with chamfers, and the two flow guide blocks are installed in the opposite directions, so that the front-back direction does not need to be considered when the placement plate is installed, and smooth air flow can be kept in the driving process.

Owner:岳翠娥

Double vortex volute sand core seamless combination process

ActiveCN106180577BNot easy to repairGood workmanshipFoundry mouldsFoundry coresAdhesiveMechanical engineering

The invention relates to a seamless combination technology for sand cores of a double-vortex volute. The seamless combination technology comprises the following steps: making cores; assembling the sand cores, to be specific, carrying out electrode corner cleaning on the sharp corners of the parts needing to be connected of the upper sand core and the lower sand core, coating the connecting parts with one layer of adhesive, covering the upper sand core on the lower sand core, placing the upper sand core and the lower sand core on an auxiliary tool together, clamping the upper sand core and the lower sand core for 1-2 minutes, solidifying the adhesive, and enabling a seam between the upper sand core and the lower sand core to be 0.1mm; soaking the sand cores, to be specific, placing the sand cores which are glued together in a paint mixing barrel and soaking the sand cores in a paint of which the baume degree reaches 30-60; and drying, to be specific, carrying out drying operation on the soaked sand cores by a drying oven, setting drying tine according to product structures, which is generally 16 minutes, and finishing the sand core technical process. The seamless combination technology has the advantages that the technology is perfect, the operation is convenient, the plate-isolated core drilling defects of a double-runner turbo-charging shell are solved, and by utilizing the auxiliary tool and die design improvement, casting plate-isolated core drilling defects caused by large sand core seams can be effectively solved.

Owner:武汉华培动力科技有限公司

An easy-to-repair lead-plastic hinge

ActiveCN108678486BSimple structureEasy to processProtective buildings/sheltersShock proofingClassical mechanicsEngineering

The inVention relates to an easy-to-repair lead plastic hinge. The hinge comprises a first rotating unit and a second rotating unit, the first rotating unit and the second rotating unit are hinged andcan be rotated relatiVe to each other, an energy consuming unit is disposed at the hinge connection position of the first rotating unit and the second rotating unit, the energy consuming unit is composed of a plurality of lead blocks and a limit pin, the lead blocks are embedded between the contact faces of the first rotating unit and the second rotating unit, and the limit pin penetrates throughthe first rotating unit and the second rotating unit. When a normal situation or small earthquake occurs, the limit pin is not cut, and the plastic hinge is a rigid node; when a medium or large earthquake occurs, the limit pin is sheared, the plastic hinge rotates relatiVely, the lead blocks conduct plastic deformation, absorb energy and haVe a good energy-absorbing and shock-absorbing effect, after the earthquake, it is only needed to replace the limit pin, and the quick repairing of the plastic hinge can be achieVed.

Owner:TONGJI UNIV

One-time extrusion forming method of horizontal double-acting combined mold of double-flange middle body

The invention discloses a one-time extrusion forming method of a horizontal double-acting combined mold of a double-flange middle body. Meanwhile, the method discloses a horizontal double-acting extrusion combined mold for vertical parting, the vertical upper female die and the vertical lower female die form a circumferential die cavity during die closing, the left horizontal extrusion die and theright horizontal extrusion die form an axial die cavity of the flange together with the vertical upper female die and the vertical lower female die after the die closing, the left horizontal punchingneedle and the right horizontal punching needle are arranged in the left horizontal extruding die and the right horizontal extruding die respectively, a water cooling device is arranged in each penetrating pin, the top head is arranged in the vertical downward concave die, wherein the vertical mold, the horizontal extrusion mold and the perforation tool can move independently. By utilizing the stroke of the extrusion head and the punching needle, the metal can be flexibly controlled to flow reasonably, and the folding defect is avoided, the metal filling of the flange part is full, the product can be formed only by one-time heating and one-time extrusion, the process flow is short, the energy consumption is low, the efficiency is high, and the product size is accurate.

Owner:NANJING DEV ADVANCED MFG

Fabricated non-damage energy-consumption frame shear wall structure system and construction method thereof

PendingCN108824633AUniform bending momentUniform deformationProtective buildings/sheltersShock proofingWall shearPre stress

The invention relates to the technical field of fabricated frame shear walls, and discloses a fabricated non-damage energy-consumption frame shear wall structure system and a construction method thereof. The frame shear wall structure system comprises a frame structure formed by connecting frame columns and interlayer beams, and further comprises energy consumption components arranged between theadjacent interlayer beams; the bottom of a shear wall is connected with a foundation top plate in a positioned mode through wall shear keys and connected with the foundation top plate in a tensioned mode through prestress ribs at the same time; the lower surface of the foundation top plate is hinged to a foundation bearing platform at the bottom through a basin-type support; the shear wall and theinterlayer beams are hinged through a beam-wall pin joint device, and anti-bending wall-connecting spring sets are arranged at the same time; the bottoms of the frame columns are connected with a building foundation in a positioned mode through column shear keys, and first embedded parts at the lower parts of the frame columns are elastically connected with foundation embedded plates through connecting springs; and the interlayer beams are hinged to the frame columns through beam-column pin joint devices. A strong-column weak-beam mode is adopted, structure weak layers are eliminated, structure stress is clear and uniform, the construction is convenient and efficient, the quality is easy to guarantee, and the economic benefits are remarkable.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

A car stop device

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com