Fabricated non-damage energy-consumption frame shear wall structure system and construction method thereof

A shear wall, non-damaged technology, applied in building components, building structures, protective buildings/shelters, etc., can solve the problems of complicated structural repair work procedures, poor structural integrity, and high construction costs, and achieve uniform deformation. , excellent seismic performance, improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

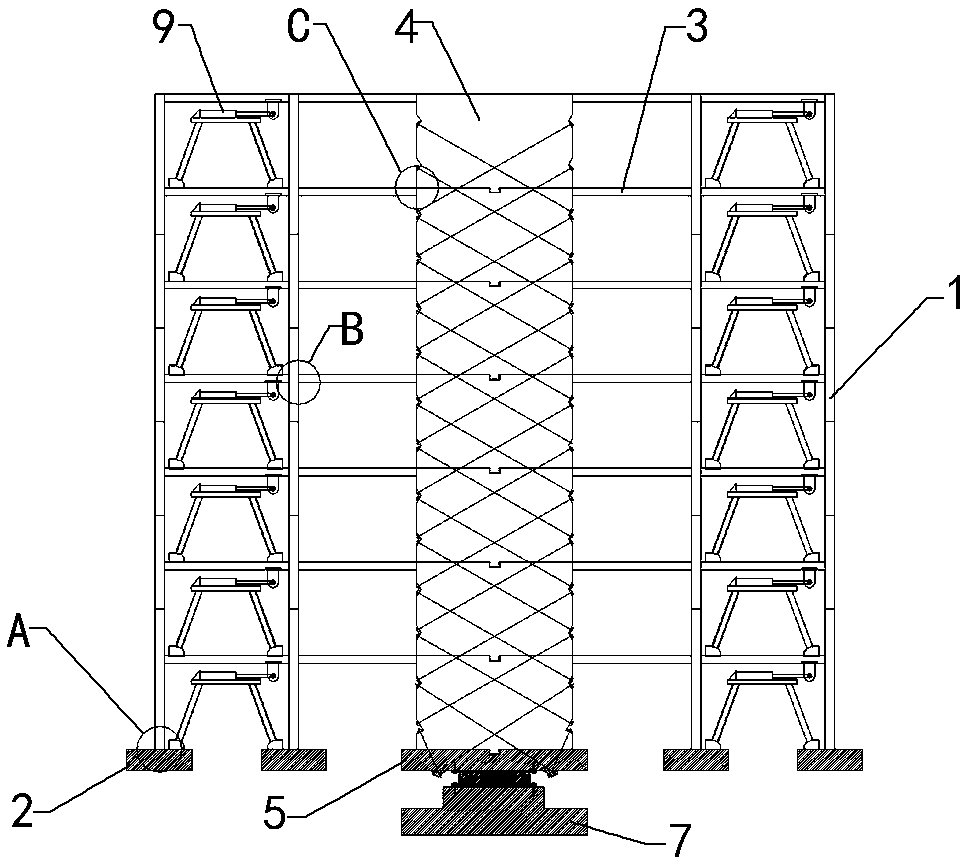

[0081] like Figure 1-Figure 15 As shown, the assembled non-damage energy-dissipating frame shear wall structure system of the present invention includes a frame structure connected by frame columns 1 and interstory beams 3, and energy-dissipating members 9 arranged between adjacent interstory beams 3, And the shear wall 4 formed by splicing the unit wall panels 43 up and down.

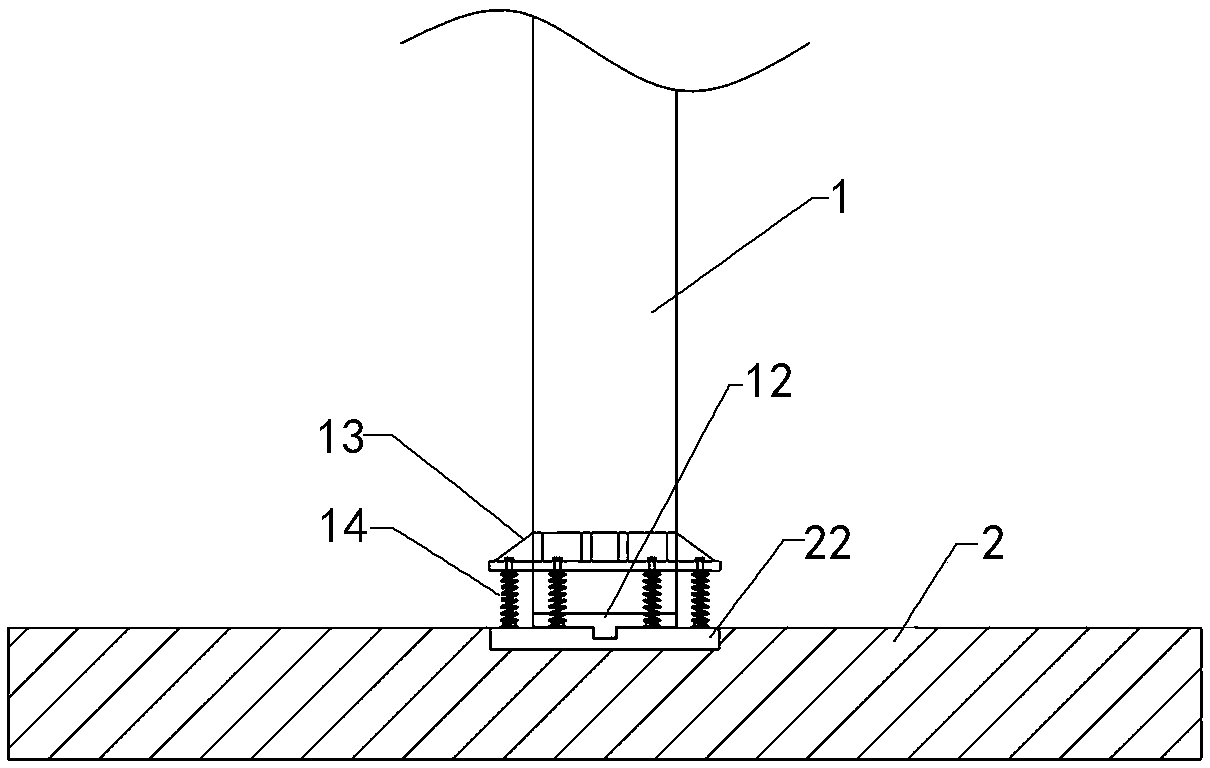

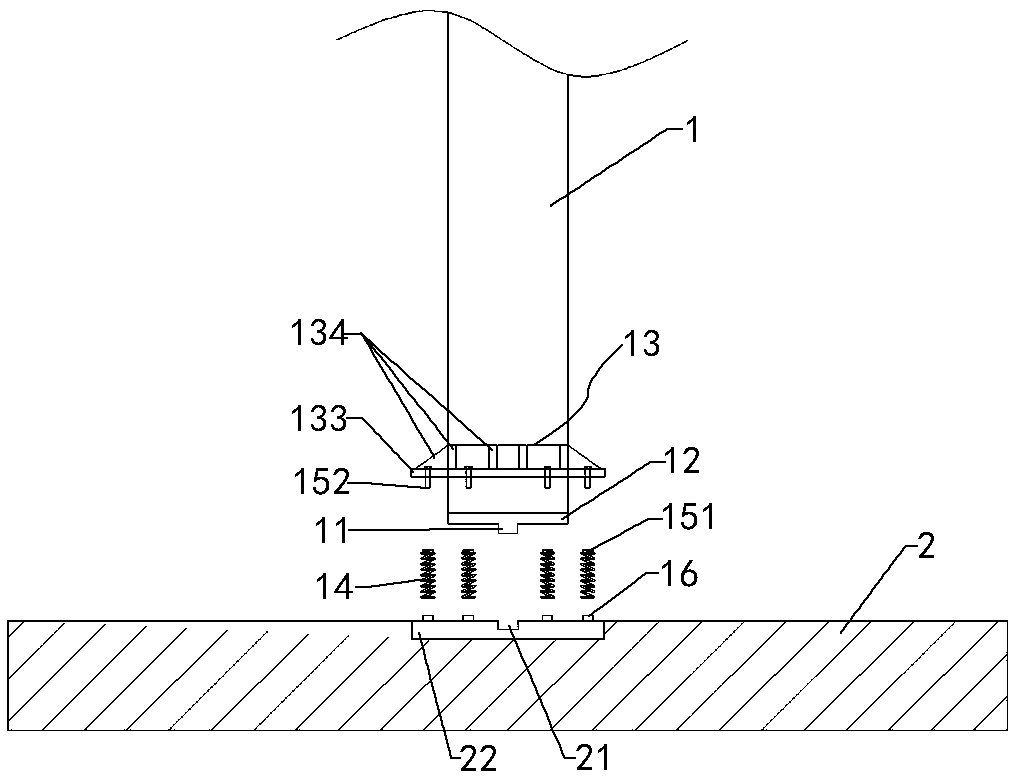

[0082] In this embodiment, the frame column 1 is a square column, and the frame column 1 and the building foundation 2 are connected separately by bending and shearing, and the transmission of bending moment and shear force is separated on two different components. A column shear key 11 is provided on the bottom end of the frame column 1, and a column shear groove 21 is correspondingly provided on the building foundation 2. The column shear key 11 and the column shear groove 21 are plugged and fixed, and the shear force is transmitted through the column shear key 11. .

[0083] The column shear key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com