Patents

Literature

36results about How to "Reduce plastic deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of aluminum alloy rim of large vehicle

InactiveCN102601587ALess investmentLow costExtrusion diesForging press detailsPunchingThermal treatment

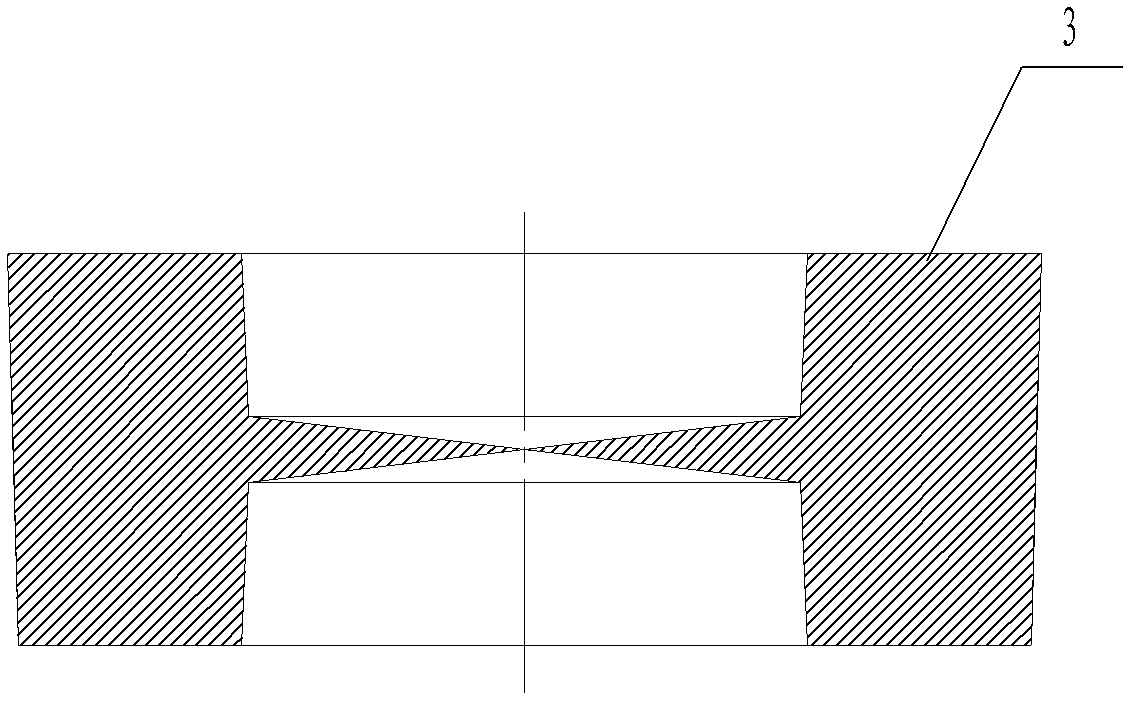

The invention discloses a manufacturing process of an aluminum alloy rim of a large vehicle, which relates to the manufacturing process of the rim. The manufacturing process of the aluminum alloy rim of the large vehicle comprises the steps of: A) blanking; B) prefabricating blank by swinging and grinding on a swing grinding machine; C) punching on a press; D) pre-forging by backward extrusion on the press through a backward extrusion mold; E) final forging on the press again; F) flaring and cutting edges; G) spinning on a spinning machine through a spinning wheel; H) performing thermal treatment; I) machining; and J) performing surface treatment. With adoption of a technique that combines swinging and grinding, backward extrusion and spinning, the manufacturing process not only improves the product quality, but also reduces the investment on the swing grinding device. The process has the advantages of being long in service life of mold, low in product cost, low in energy consumption during production process, and good in labor environment, and is suitable for mechanical automation and popularization.

Owner:HECHI UNIV

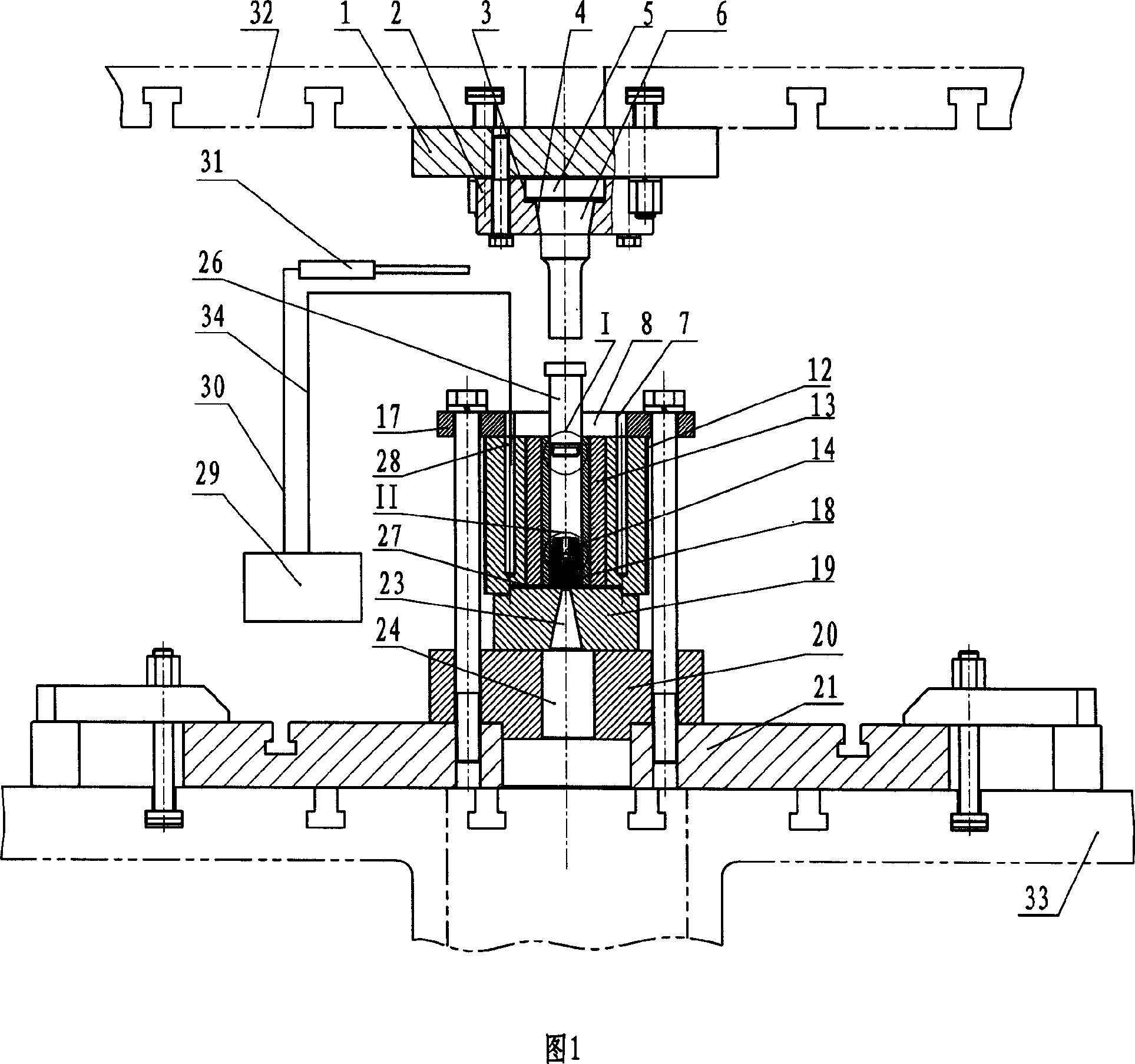

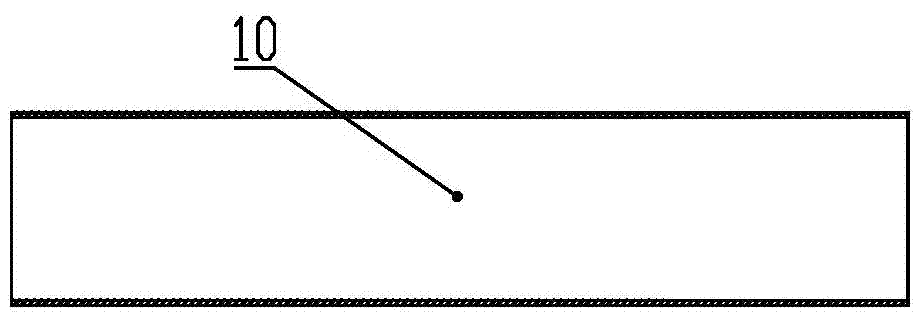

Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

InactiveCN101015841ASpeed up heat dissipationSlow down heat dissipationExtrusion diesExtrusion control devicesTemperature controlPhysical property

The invention relates to a hydraulic extruding method for producing magnesium alloy wire or rod, and relative specific extruding mould, which can avoid crack and high cost or the like. The inventive method comprises that processing magnesium alloy blank, coating lubricant, and heating with era oil, heating hydraulic extruding mould and controlling temperature, arranging magnesium alloy blank, filling era oil, arranging movable convex mould, pressurizing and extruding. The inventive mould comprises a movable convex mould (26), under a convex mould (6) and coaxial with the convex mould (6), wherein the lower end of the convex mould (26) is through a convex mould through hole (8) at the middle of a convex mould press plate (17) to be mounted on the upper part of an extruding barrel (13), and the extruding barrel (13) is a multilayer cold press extruding one. The invention can obtain better physical property and surface quality, or the like.

Owner:HARBIN INST OF TECH

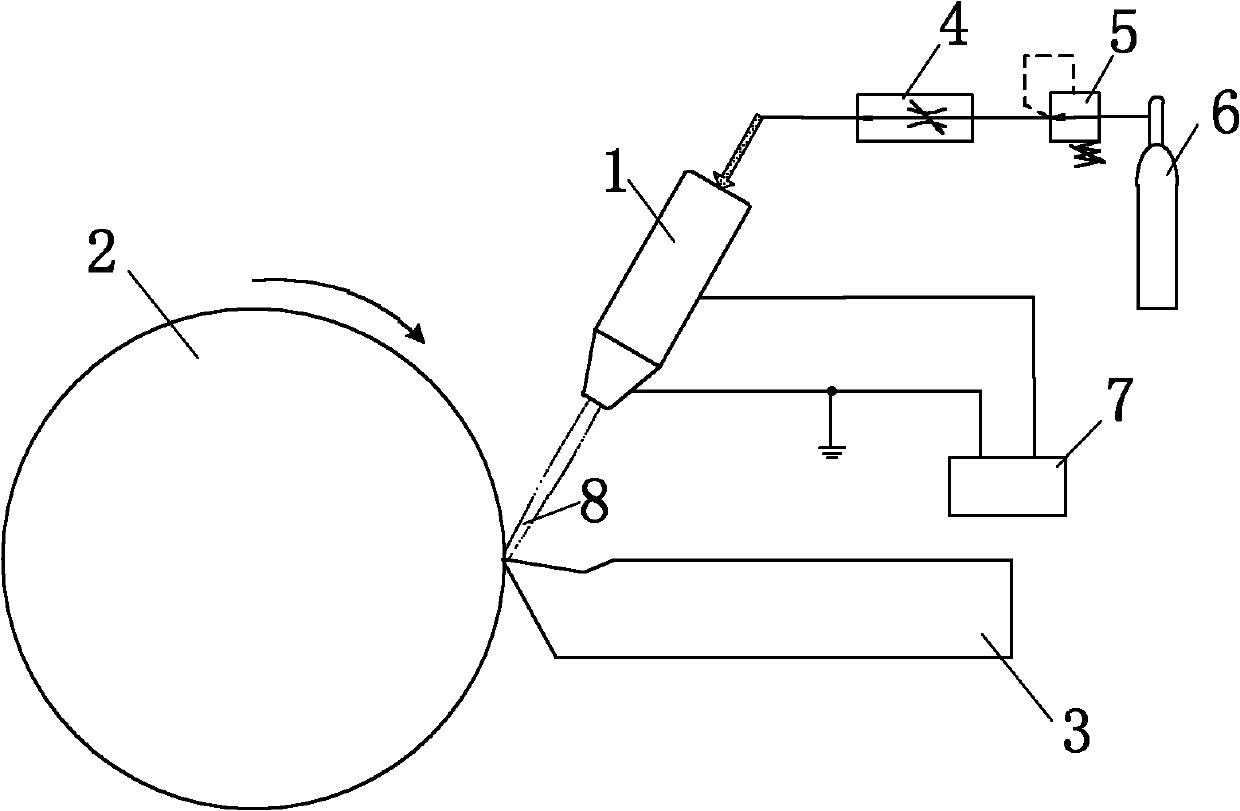

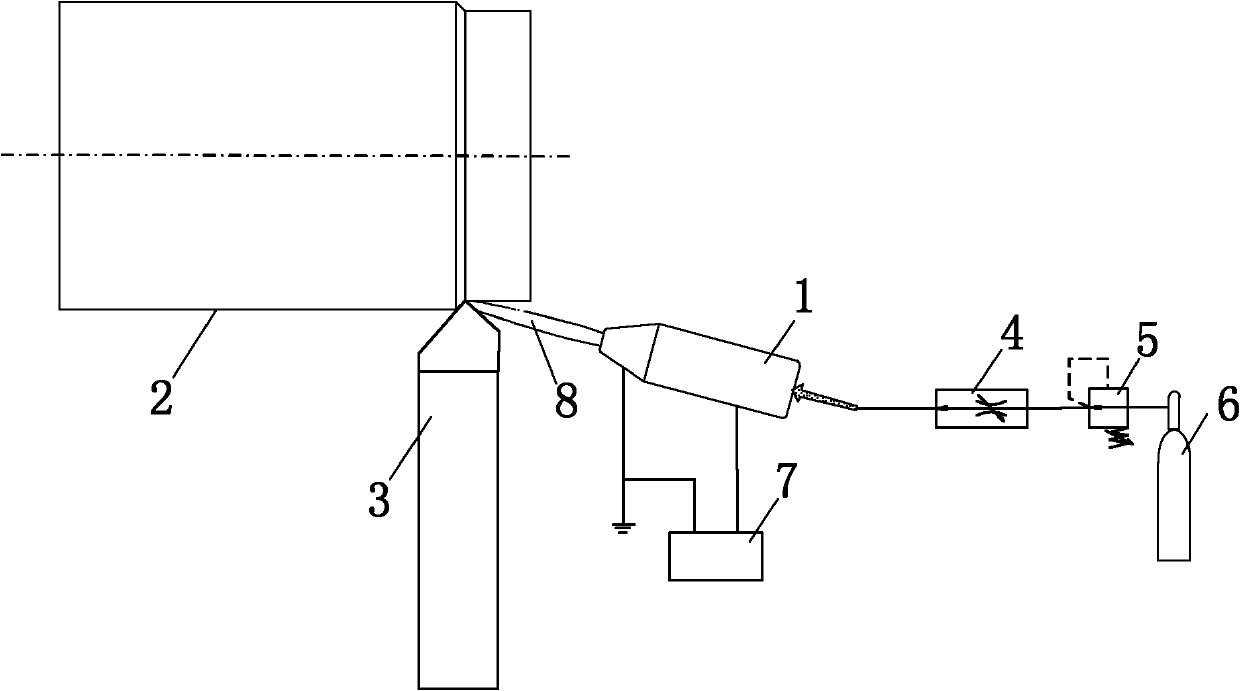

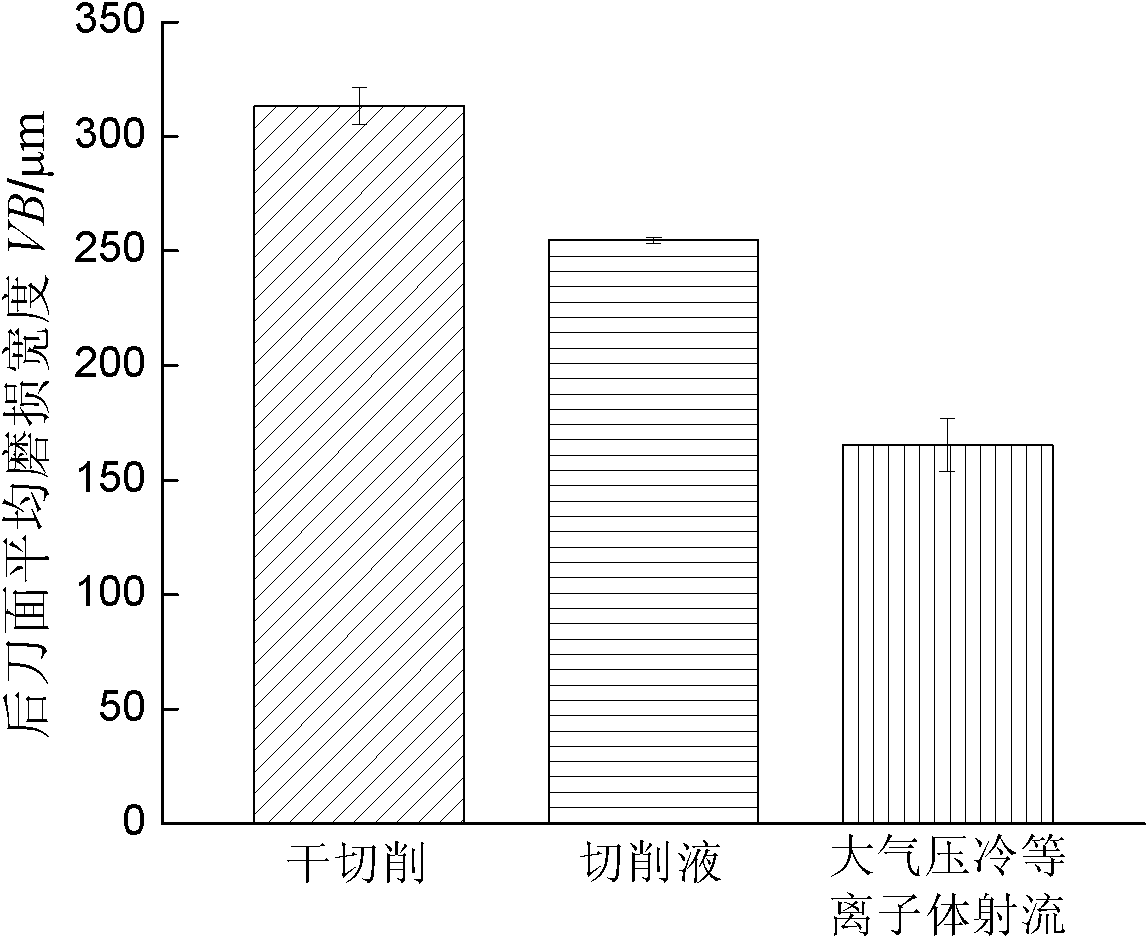

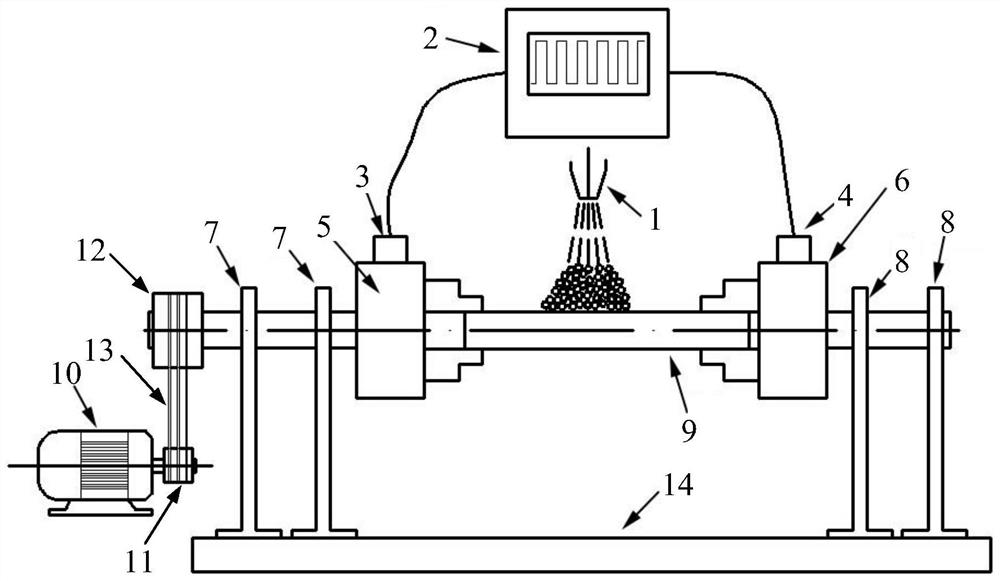

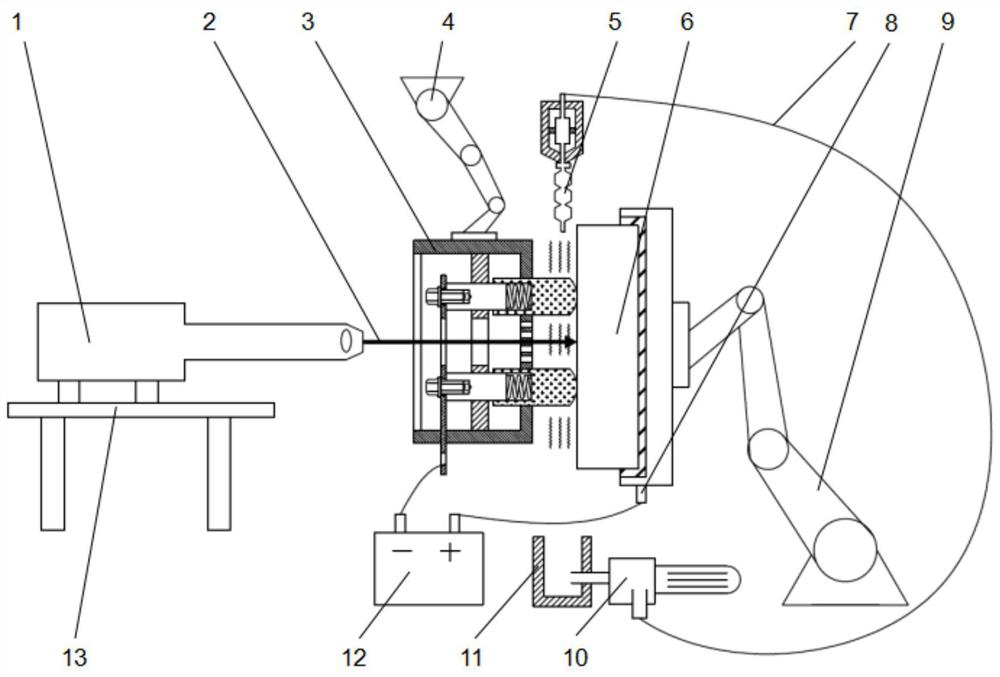

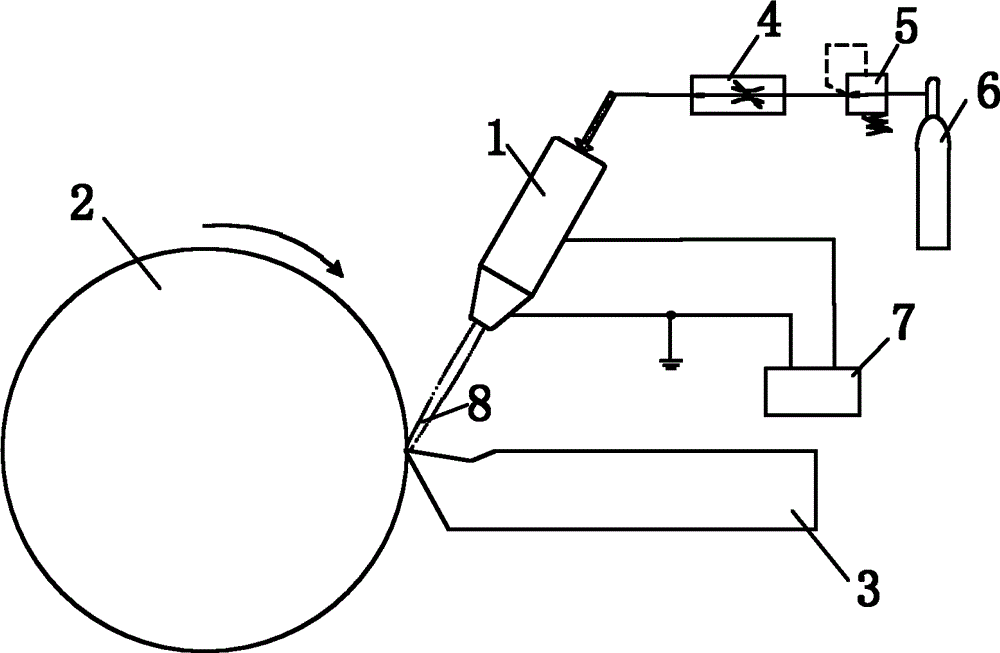

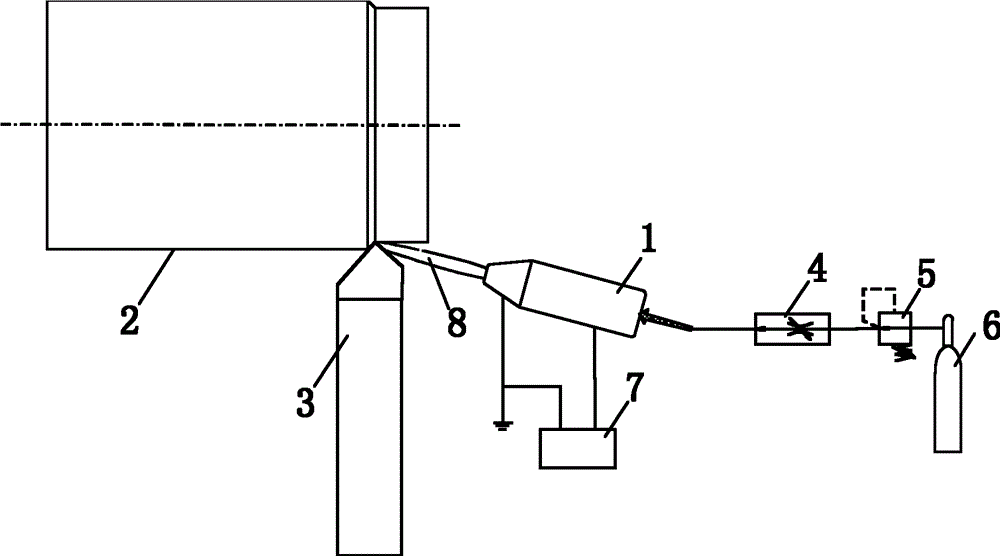

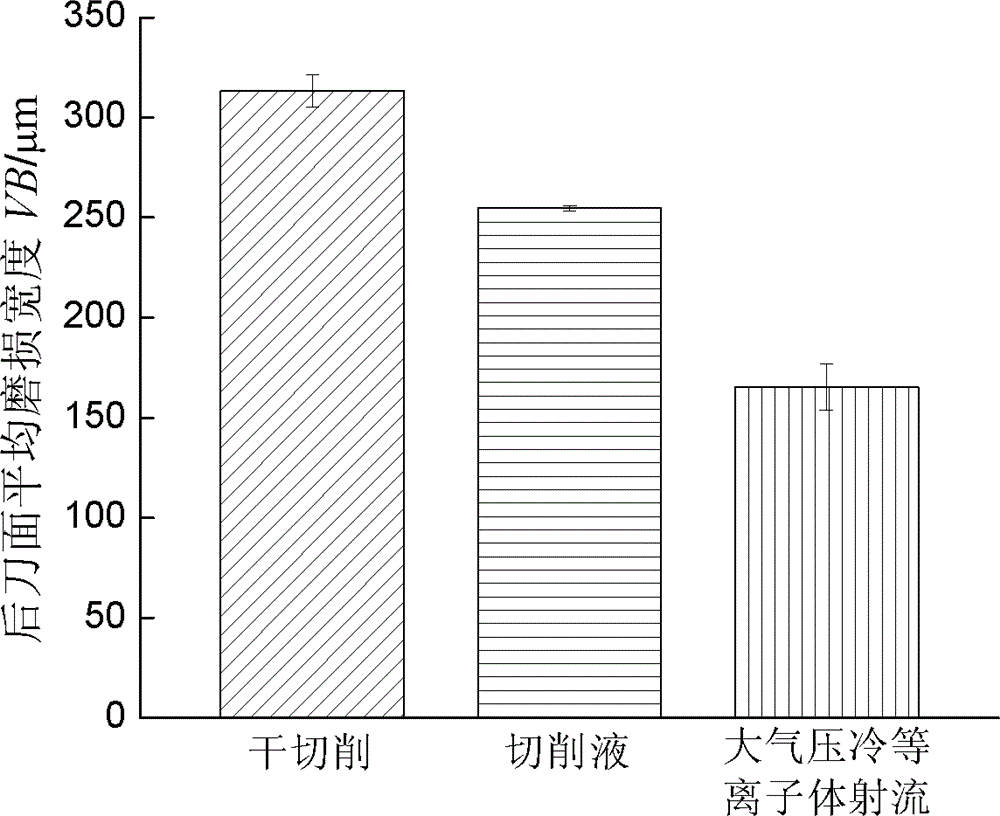

Atmospheric cold plasma jet auxiliary cutting method

ActiveCN102601677AReduce plastic deformation resistanceExtend your lifeMaintainance and safety accessoriesPlasma jetCooling effect

The invention provides an atmospheric cold plasma jet auxiliary cutting method. Cold plasma jet generated under atmospheric pressure is used as a lubricating cooling medium during material cutting. Working gas enters a cold plasma jet generator from a working gas source via a pressure reducing valve and an adjustable flow meter, the flow of the working gas and output voltage of a high-voltage power source are adjusted so that uniform cold plasma jet is sprayed out from a nozzle outlet of the cold plasma jet generator, the temperature of the jet is the room temperature or is slightly higher than the room temperature, and a tool and workpiece interface and a tool and chip interface are always soak in the cold plasma jet during cutting by means of adjusting a spraying angle. Plasma can be generated in a dielectric barrier discharge mode, a suspension electrode discharge mode or a bare electrode discharge mode. The atmospheric cold plasma jet auxiliary cutting method is an environment-friendly cutting method, an excellent lubricating and cooling effects for various metal and nonmetal materials can be realized during cutting, accordingly, cutting force is reduced, the service life of a tool is prolonged, and the quality of the surface of a workpiece is enhanced.

Owner:DALIAN UNIV OF TECH

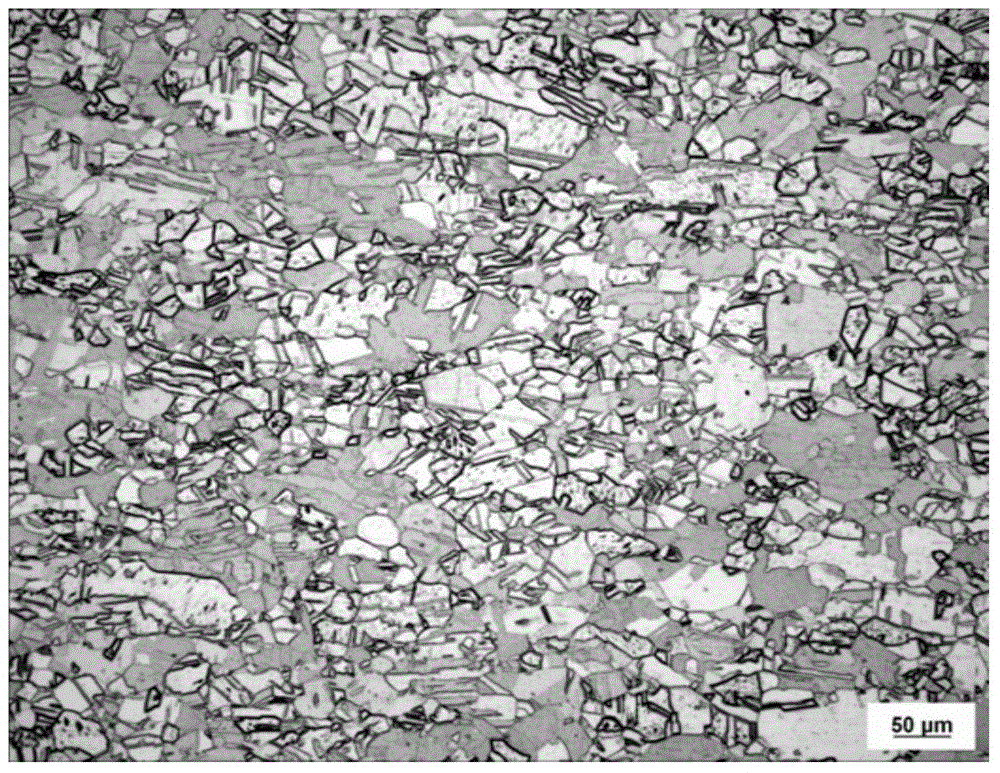

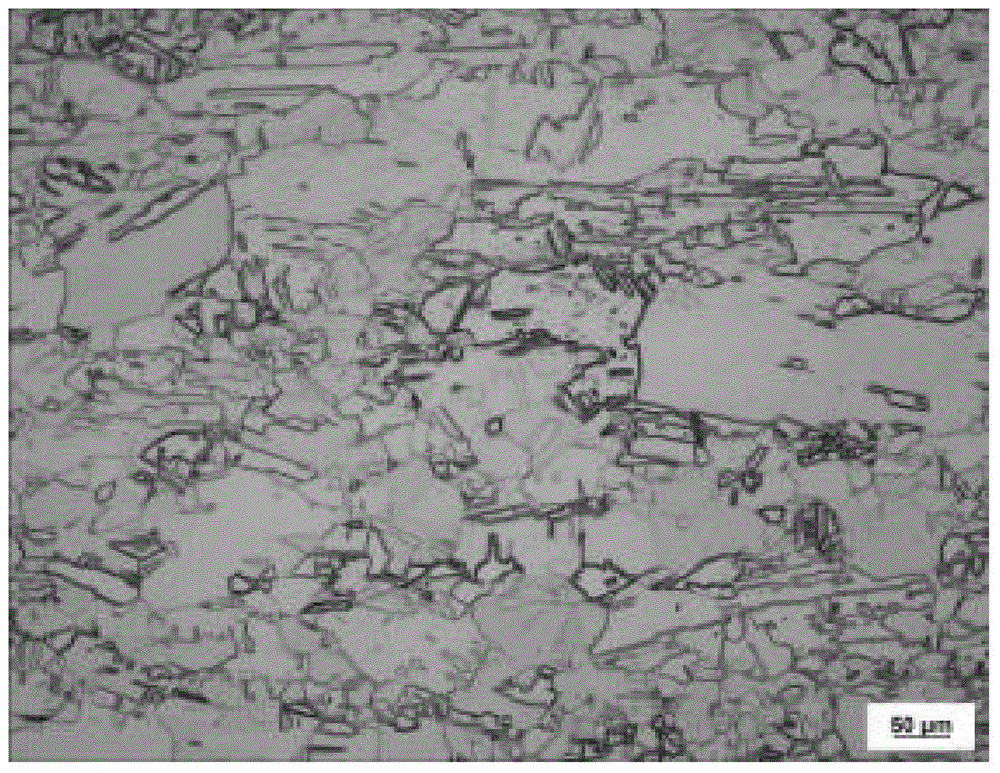

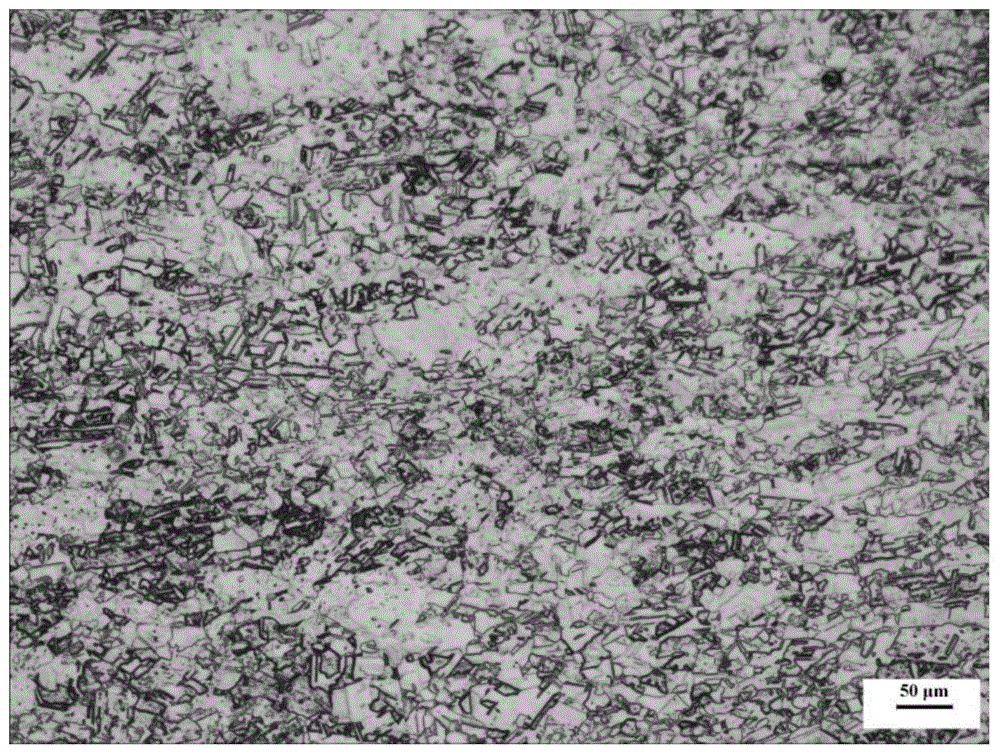

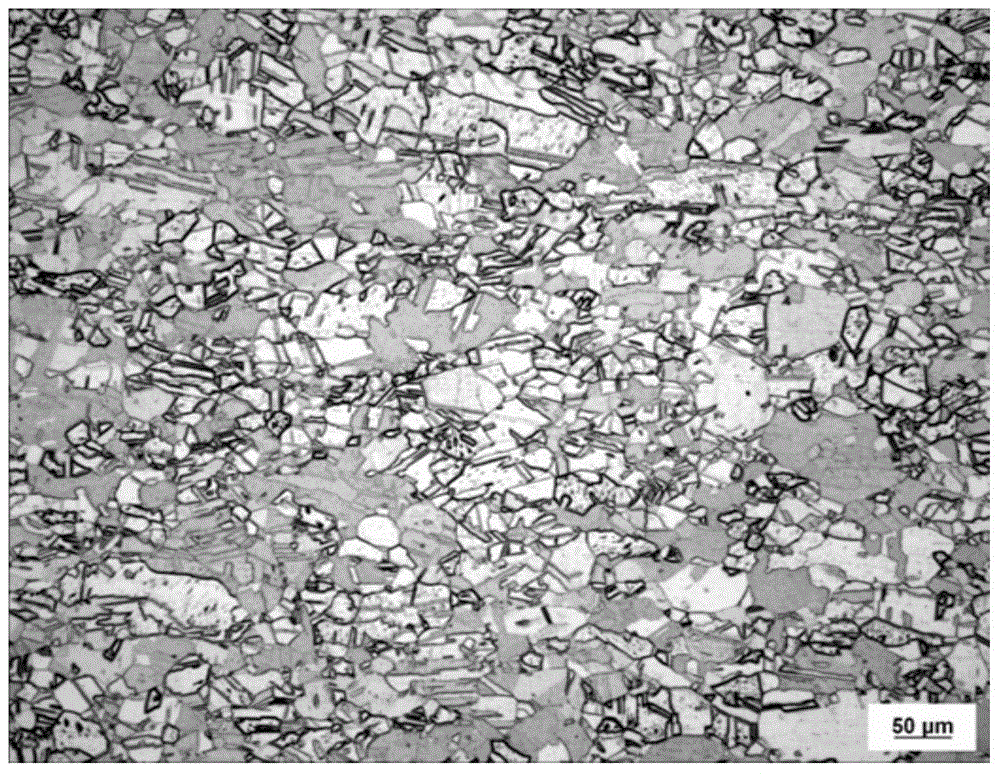

Preparation method of high-purity copper target

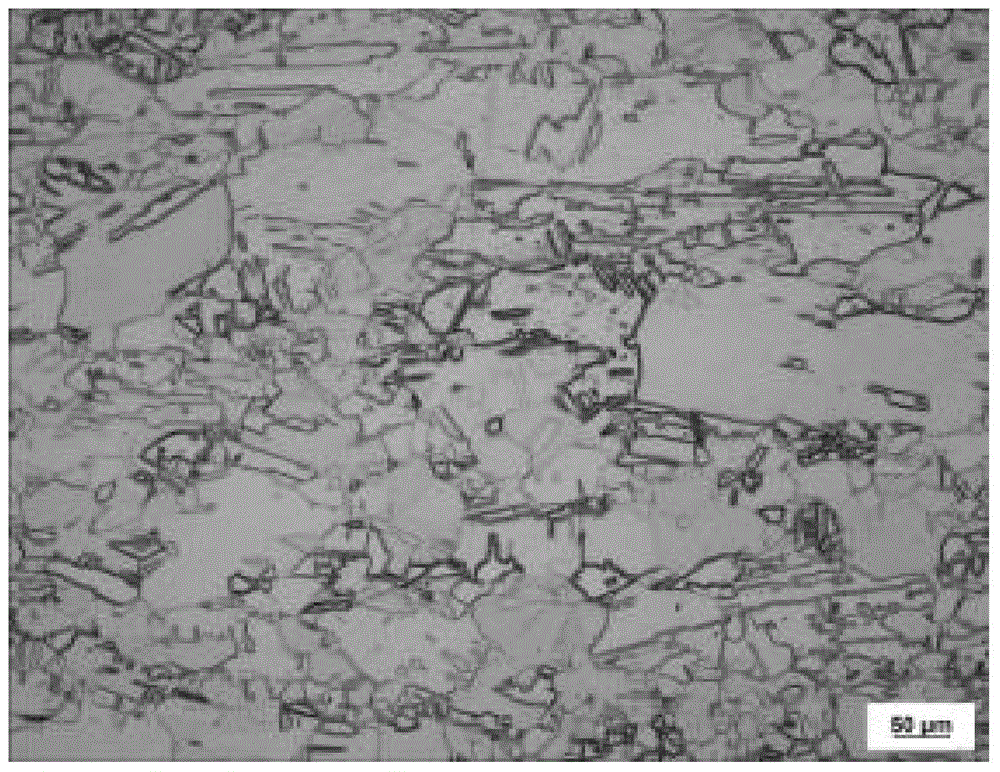

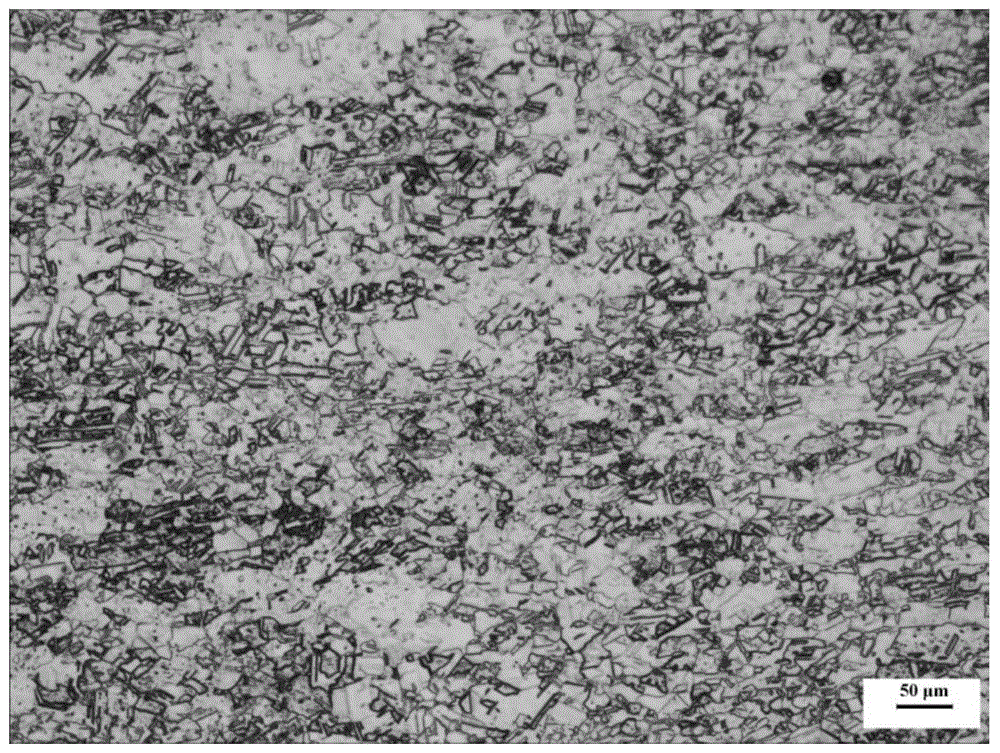

ActiveCN104694888AImprove processing efficiencyReduce plastic deformation resistanceVacuum evaporation coatingSputtering coatingSputteringCopper

The invention discloses a preparation method of a high-purity copper sputtering target, belonging to the technical field of sputtering targets. The method mainly comprises the following steps: carrying out upsetting and stretching plastic deformation on a high-purity copper target blank; cooling the target blank after multiple rounds of upsetting and stretching deformation; carrying out rolling deformation on the cooled high-purity copper target blank to prepare a high-purity copper target blank; and then carrying out thermal treatment on the target blank to obtain the high-purity copper target with fine and uniform tissues. The preparation method has the advantages that the high-purity copper target is prepared by adopting the method combining plastic deformation with thermal treatment; grains of the target prepared by the method are fine and are uniform in distribution, thus completely meeting the requirements of sputtering; meanwhile, the consistency and repeatability of the processing technology are ensured by adopting plastic processing equipment with controllability; the method is simple in process, flexible in equipment operation and high in production efficiency and is suitable for large-scale industrial production.

Owner:GRIKIN ADVANCED MATERIALS

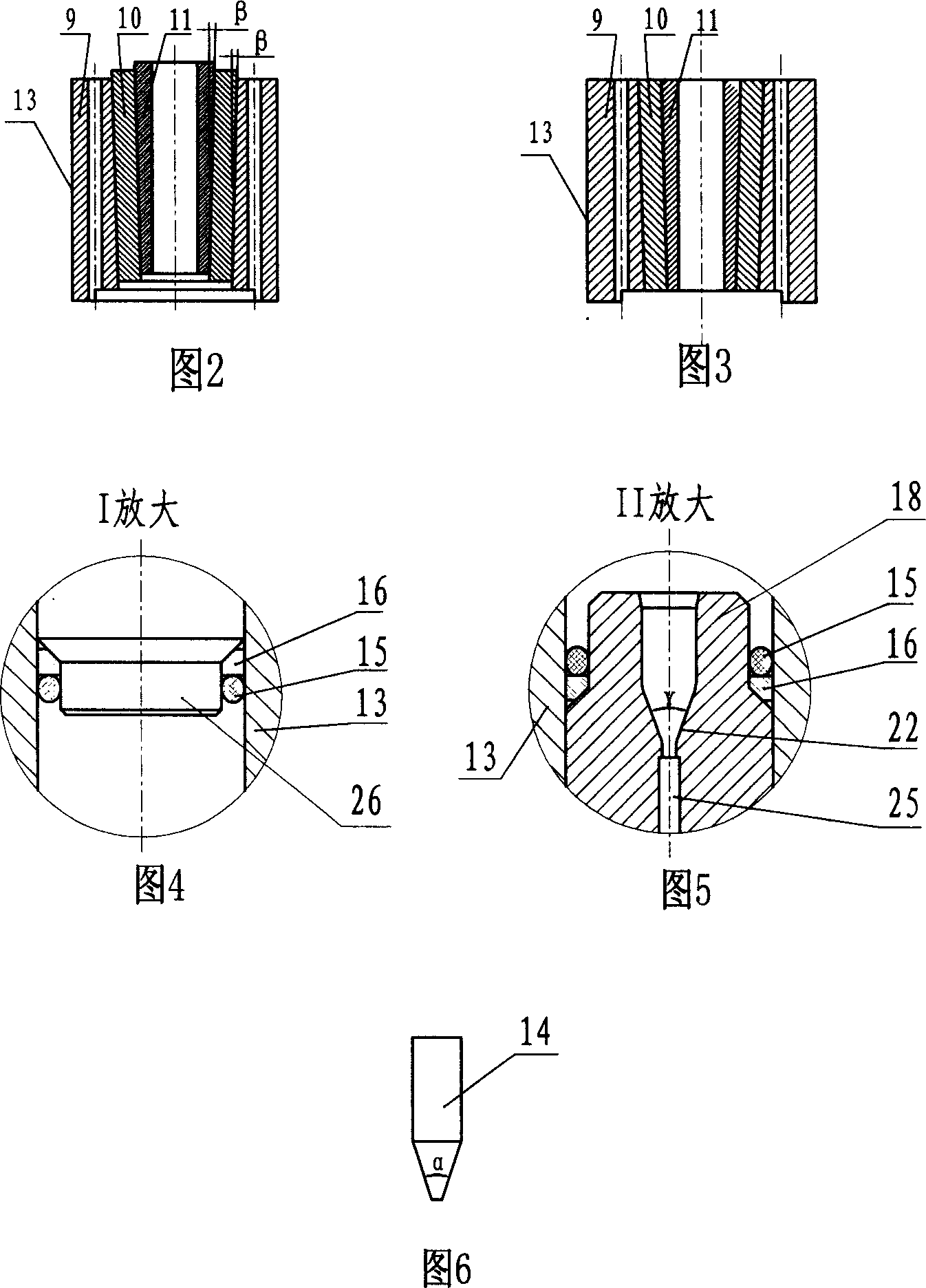

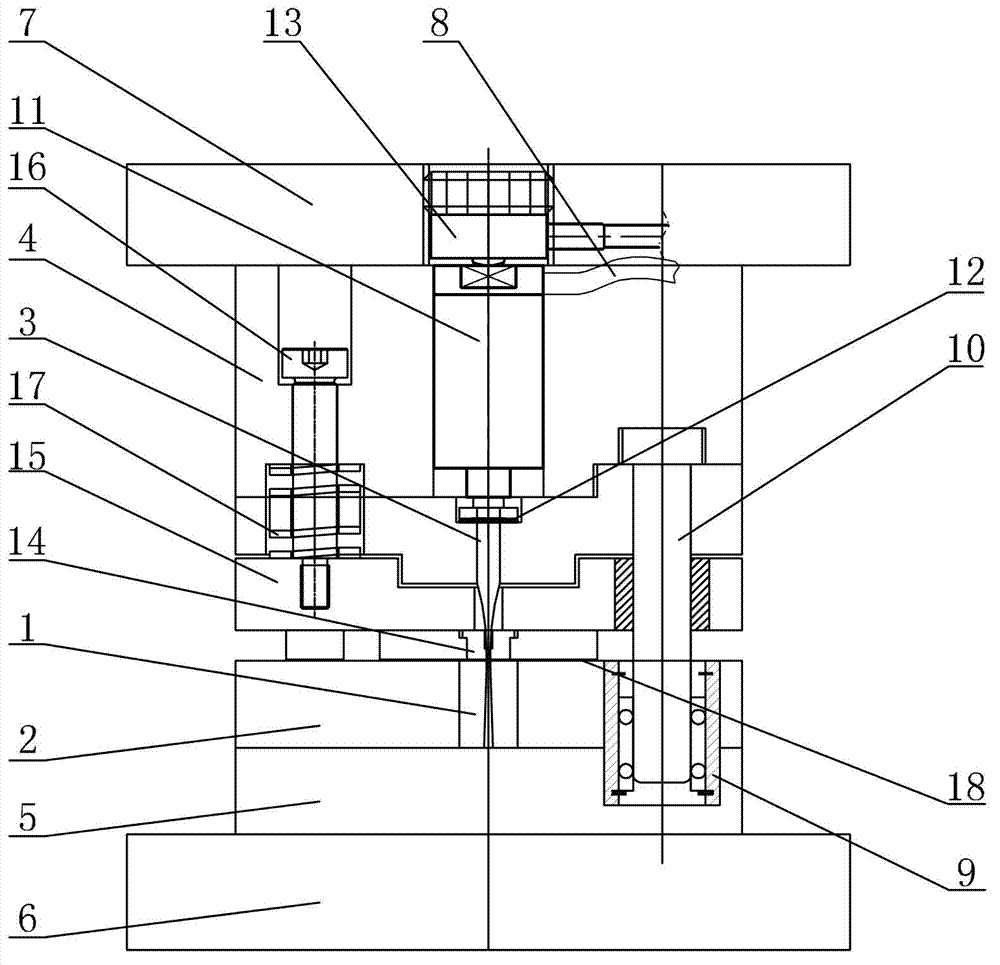

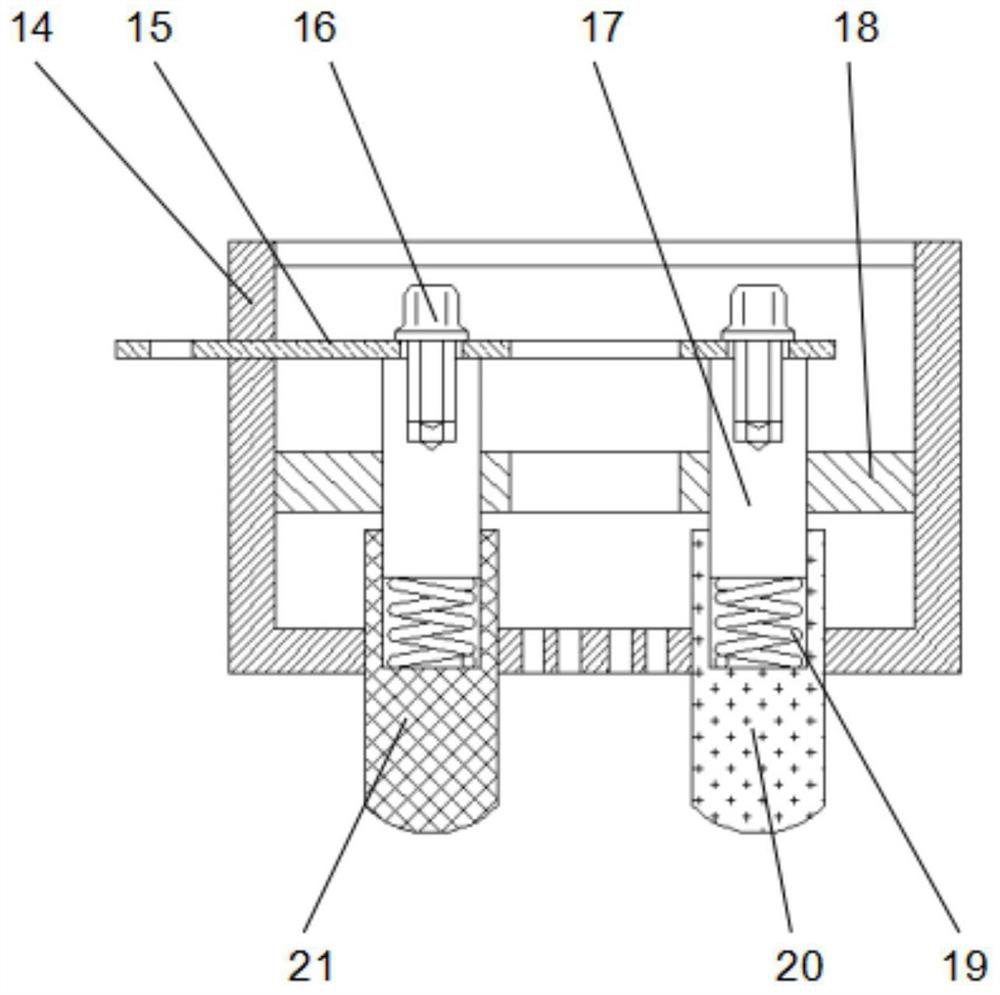

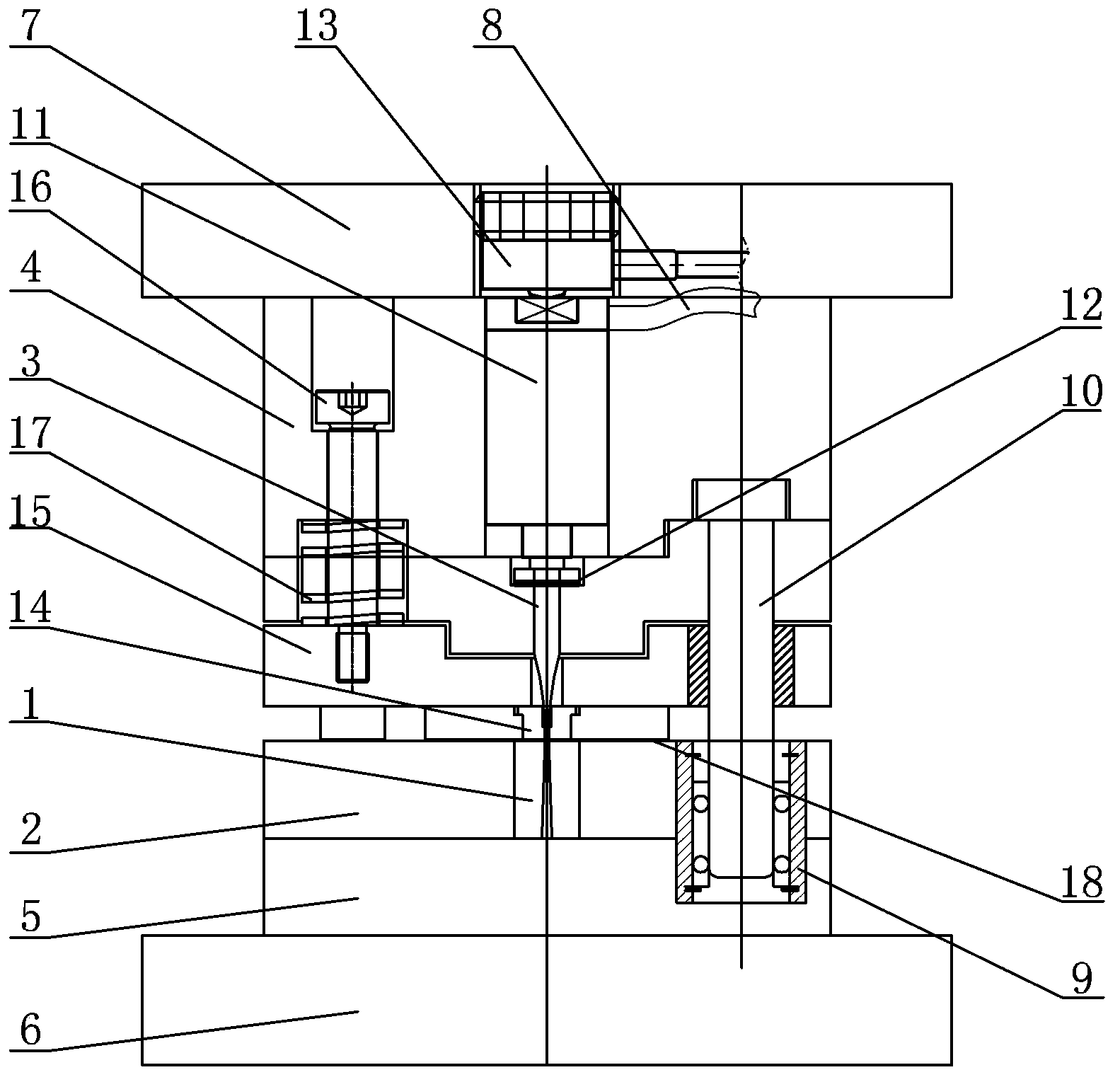

High-frequency vibration auxiliary micro-blanking forming device and method for foil plate

ActiveCN102962331AInhibition of germinationInhibition of scalabilityMechanical vibrations separationEjection devicesHigh frequency powerEngineering

The invention relates to a micro-blanking forming device and a forming method, in particular to a high-frequency auxiliary micro-blanking forming device and a method for a foil plate. The device and the method aim at solving the problems in the existing high-precision blanking forming of the foil plate that an interval between a female die and a male die is small, a blanking force is significantly increased by a size effect, and the dies are badly worn and have short service lives. The device comprises a female die fixing plate, a lower bolster and a lower die plate that are sequentially connected from the top down, wherein an upper die plate and a male die fixing plate are sequentially arranged above the female die fixing plate; a female die is embedded into the middle part of the upper surface of the female die fixing plate; a vibration component and a punch are sequentially mounted in the male die fixing plate from the top down in an inserting manner; a middle line of the punch is coincided with that of the female die; the vibration component is connected with a high-frequency power source; a guide sleeve is mounted on the upper surface of the female die fixing plate in an inserting manner; the upper end of a guide column is mounted in the male die fixing plate in an inserting manner; and the lower end of the guide column is mounted in the guide sleeve in an inserting manner. The device and the method are used for blanking forming of the foil plate.

Owner:HARBIN INST OF TECH

Cylindrical accessory machining method and system for metal mold

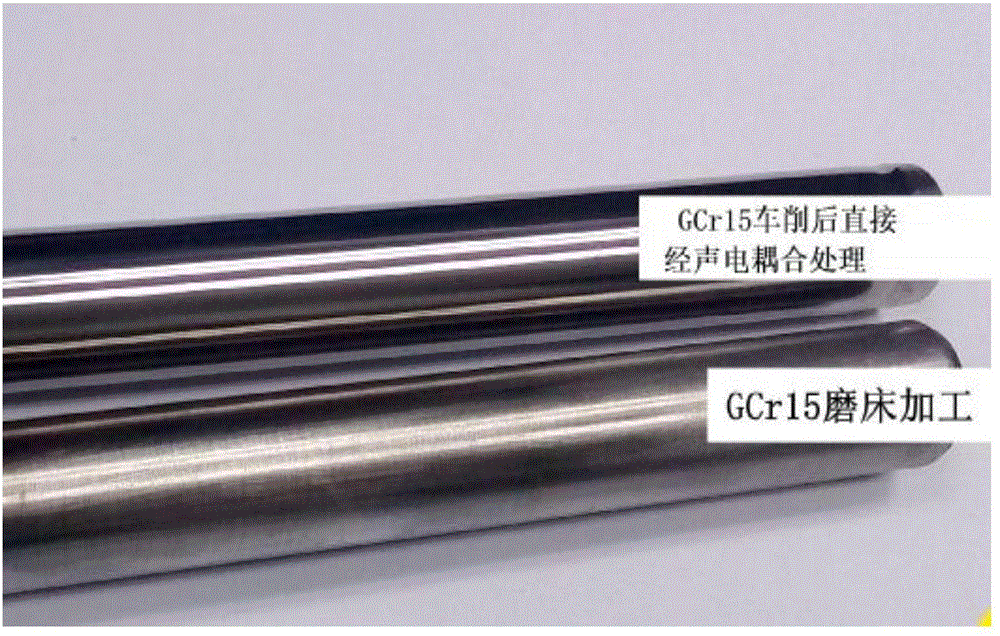

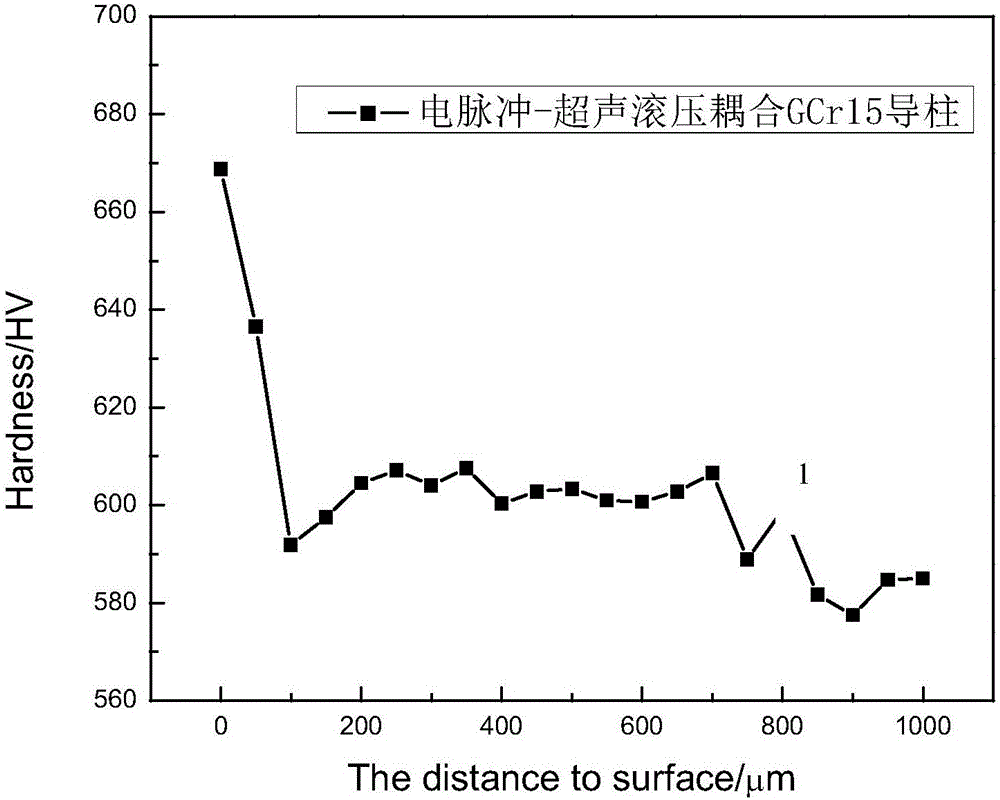

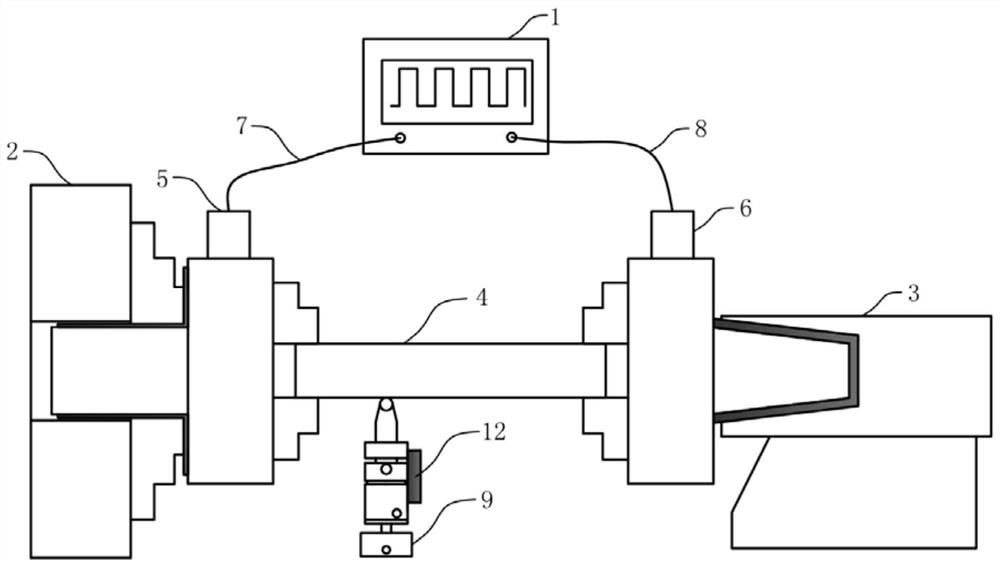

ActiveCN105081700AHigh hardnessImprove surface qualityOther manufacturing equipments/toolsTurning machinesSurface finishSurface layer

The invention relates to a cylindrical accessory machining method and system for a metal mold. The method comprises the steps that firstly, surface induction quenching pretreatment is carried out on a blank of a roughly-machined cylindrical accessory, and a hardening layer is formed on the surface of the blank; secondly, the pulse current is exerted on the blank, pulse current tempering treatment is carried out on the hardening layer on the surface of the blank, and meanwhile turning machining is carried out to form a semi-finished accessory; and thirdly, the semi-finished accessory rotates, the pulse current is further exerted on the semi-finished product, electroplastic treatment is carried out on the surface layer of the semi-finished accessory, and ultrasonic peening rolling is carried out on the surface of the semi-finished product through an ultrasonic rolling device. The system is formed through refitting on a lathe and is suitable for machining guide columns and various metal rotation body accessories through the method. Compared with a traditional technology, according to the method, the overall mechanical performance, the surface quality and the surface smoothness of the surface layers of the guide columns can be obviously improved, the production procedure is greatly simplified, the production efficiency is improved, and the production cost is reduced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

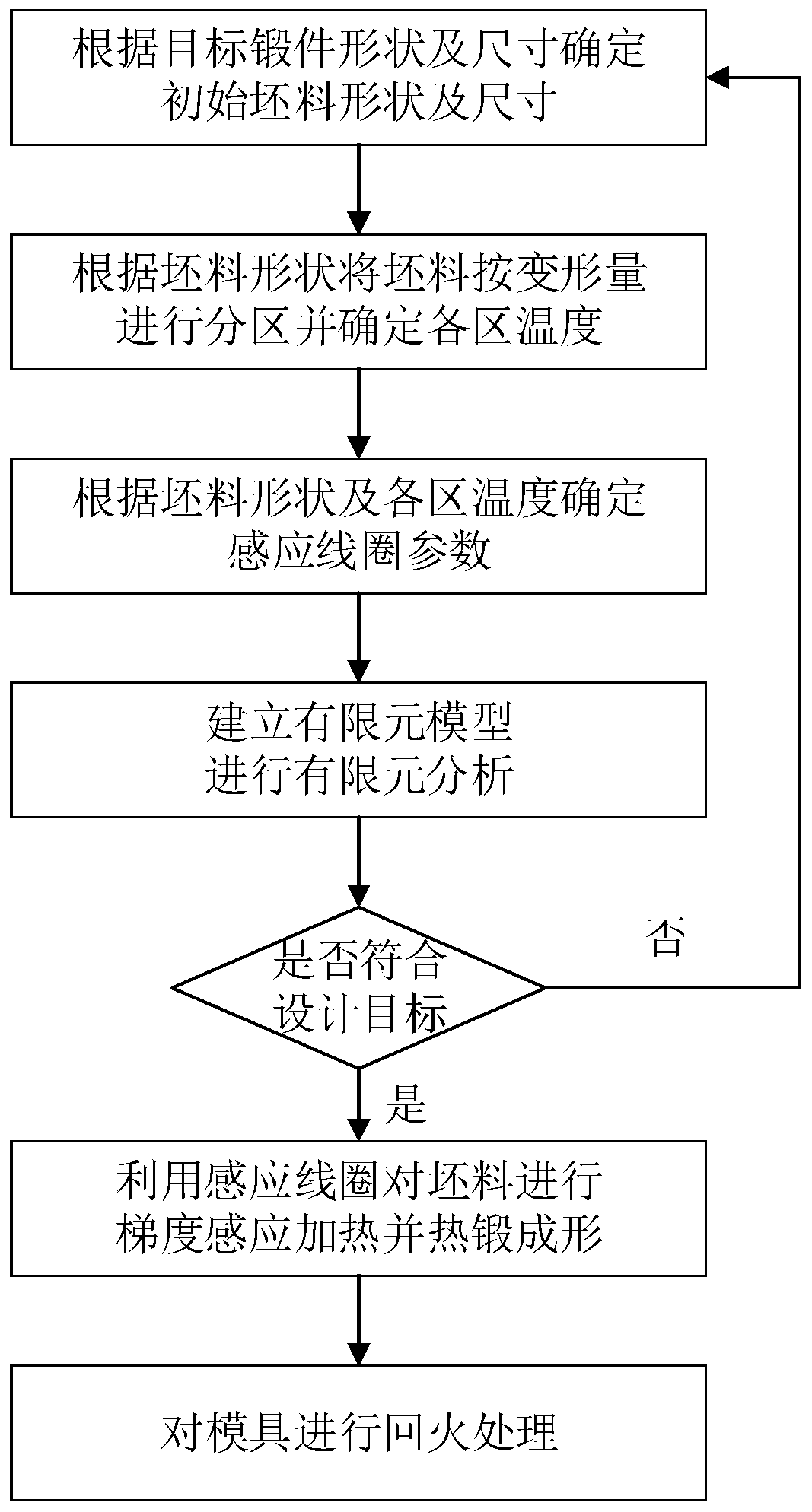

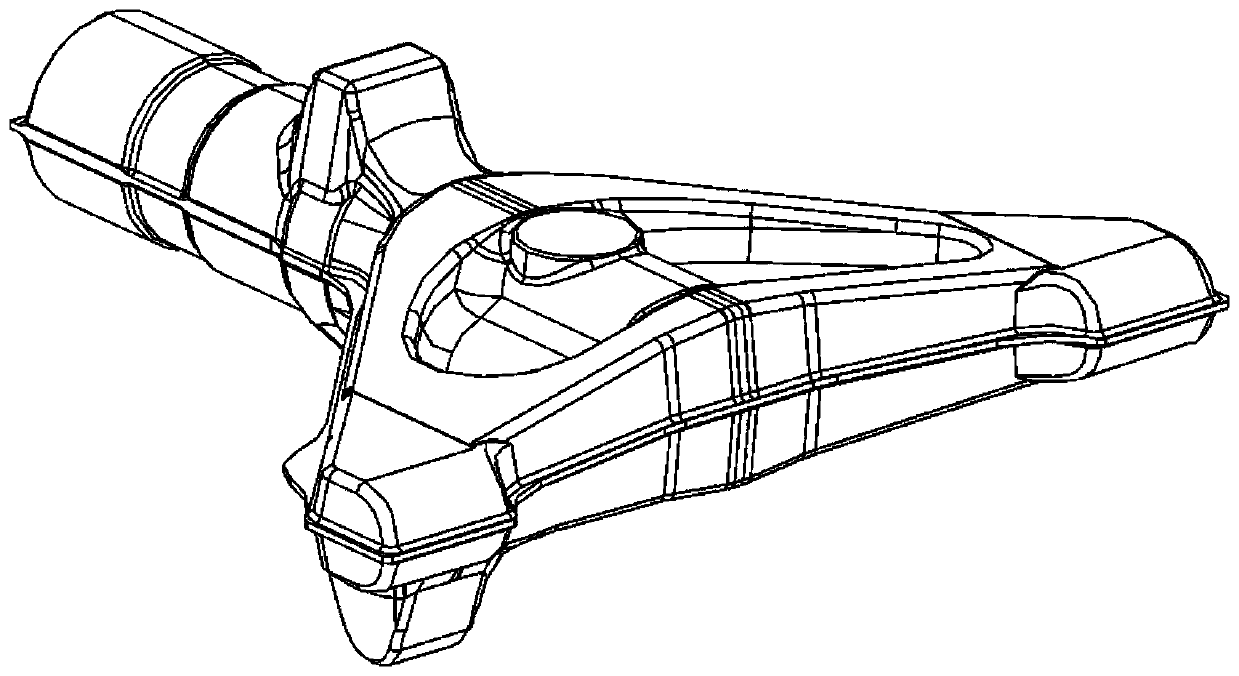

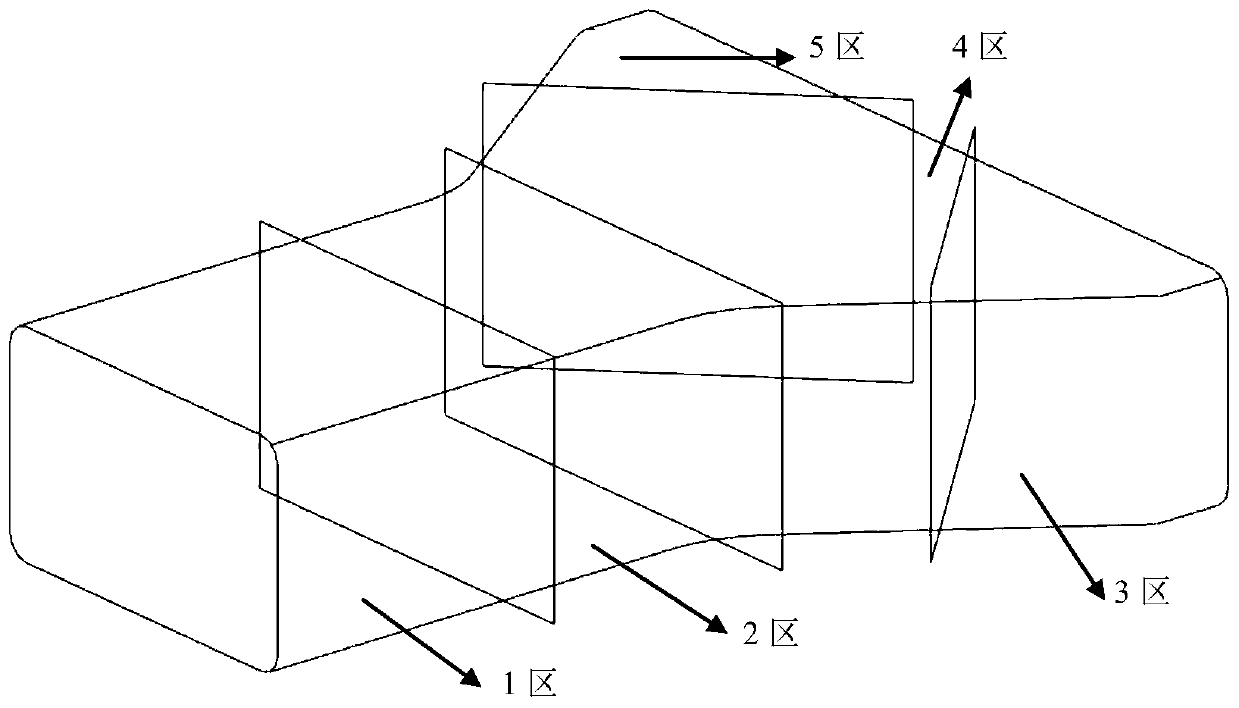

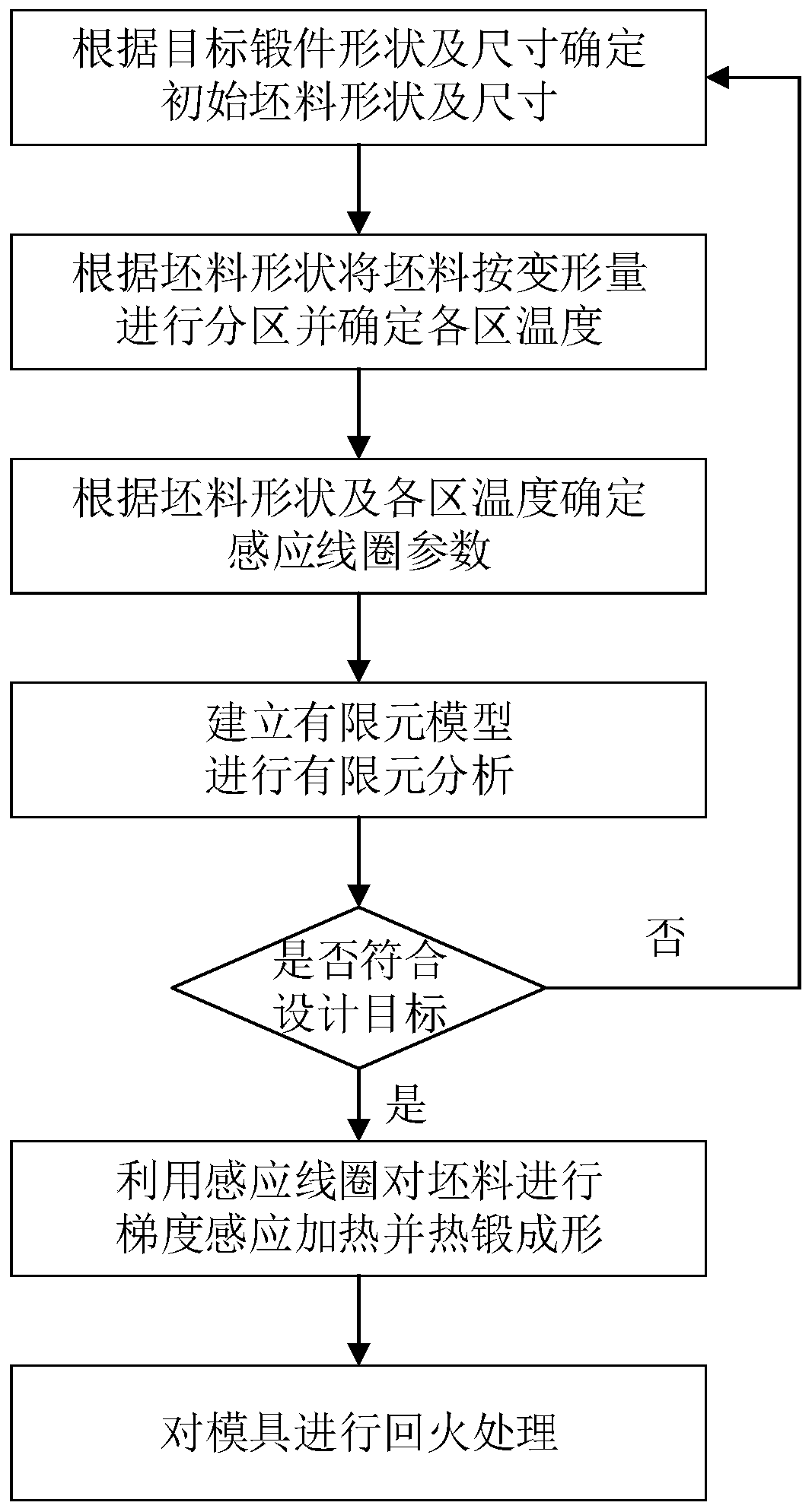

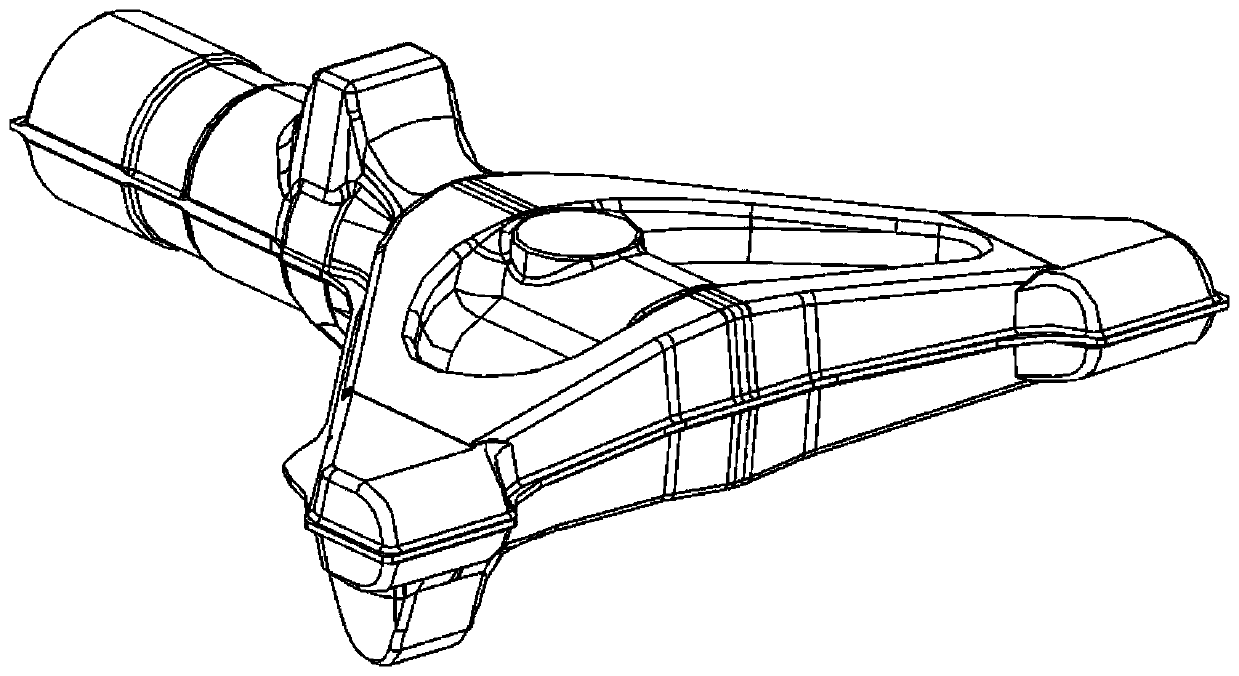

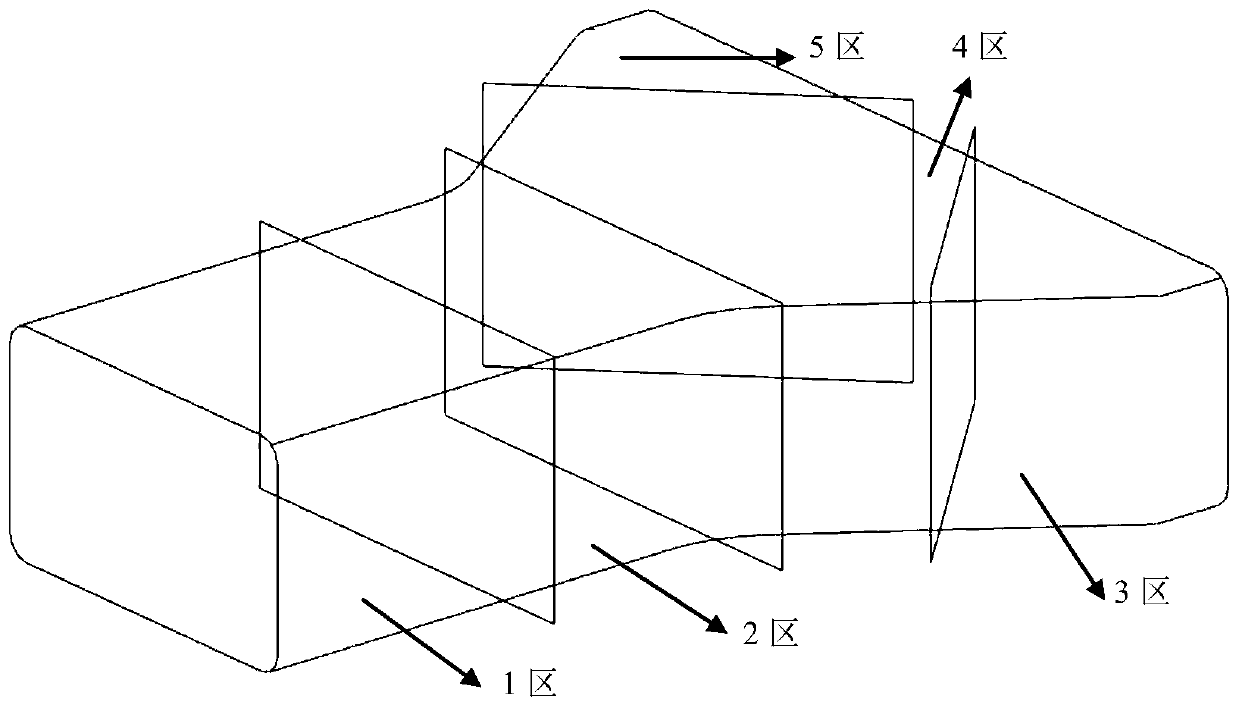

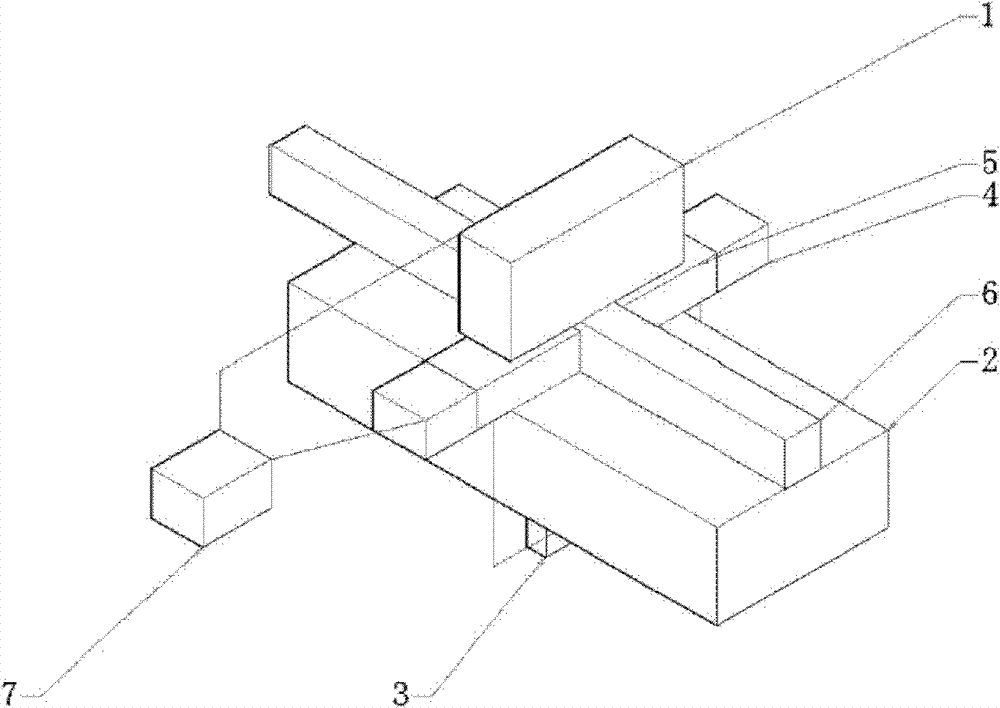

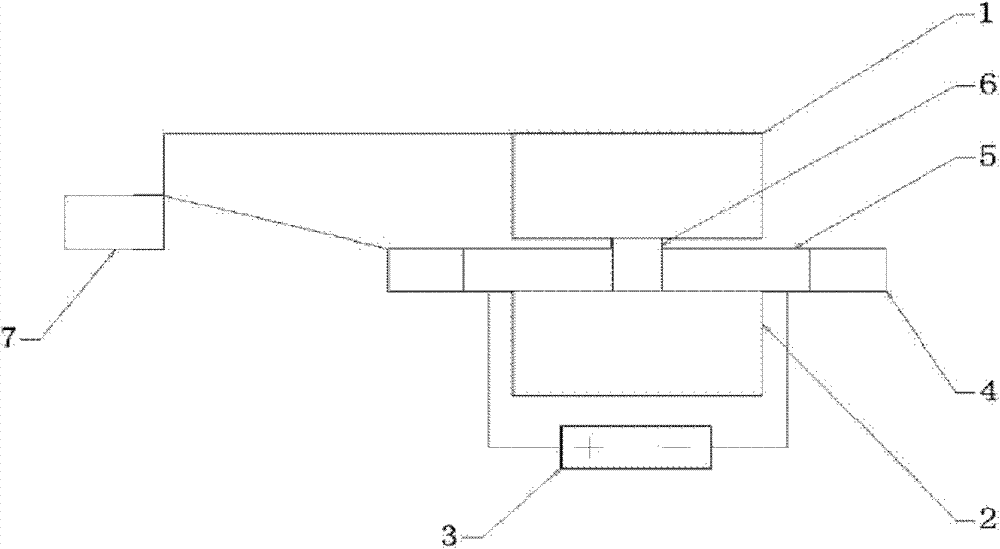

Gradient induction heating based thermal deformation workpiece blank heating method and machining method

ActiveCN109773099ARealize Controlled DesignGuaranteed dimensional accuracyHeating/cooling devicesThermoplasticThermal deformation

The invention discloses a gradient induction heating based thermal deformation workpiece blank heating method and a processing method and belongs to the field of meal thermoplastic forming. Accordingto the gradient induction heating based thermal deformation workpiece blank heating method and the processing method, a blank is designed according to the shape of a workpiece; parts, with different deformations, of the blank are subjected to rapid induction heating to different temperatures through a gradient induction heating coil, the temperature difference of different deformation parts of theblank is realized, and the continuity of the temperature of the surface of the blank is ensured. The plastic deformation resistance of areas hard to deformable is effectively reduced. The equipment tonnage can also be effectively reduced. Meanwhile, under the coupling effect of the temperature and deformation of the parts with the different deformations, the uniformity of the microstructure of awhole forged piece can be ensured, and the mechanical performance of a material is remarkably improved. Besides, the labor environment can be remarkably improved, the forged piece with the high dimensional precision, the uniform microstructure and excellent comprehensive performance is integrally formed, and automated and standardized production is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

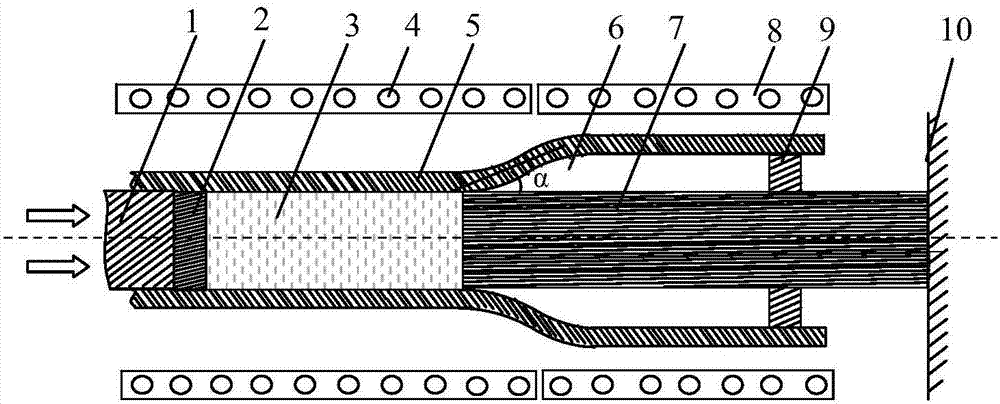

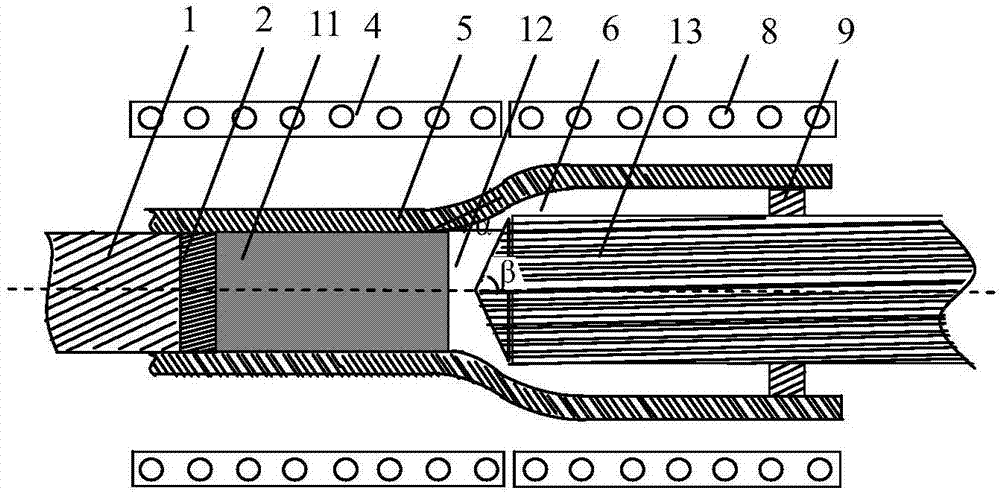

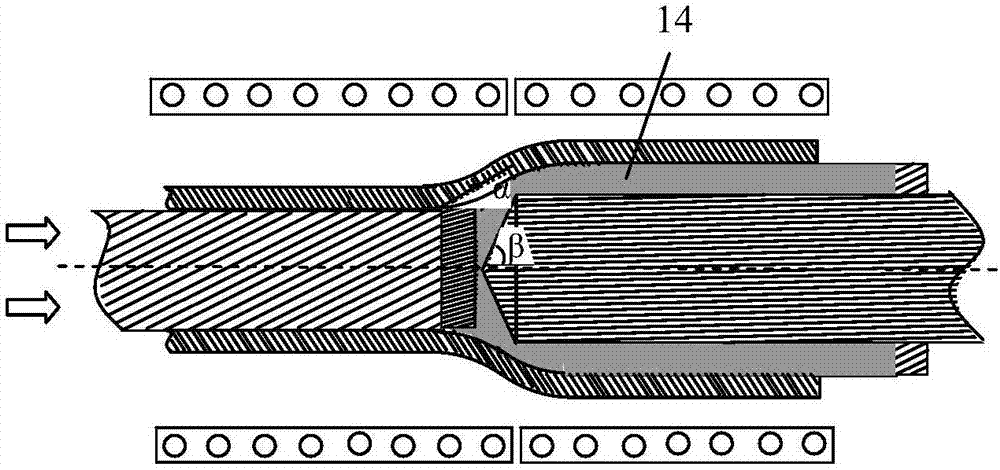

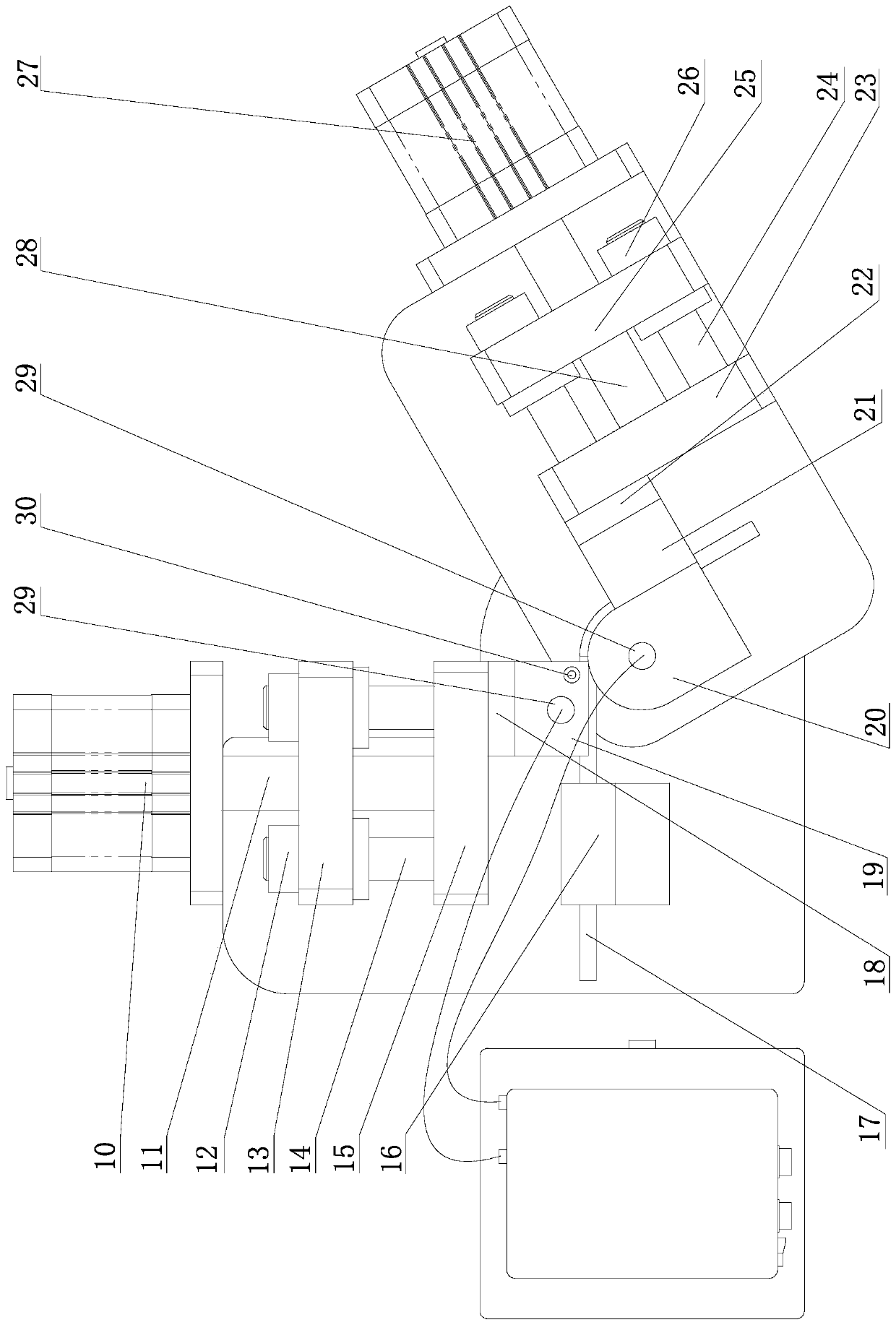

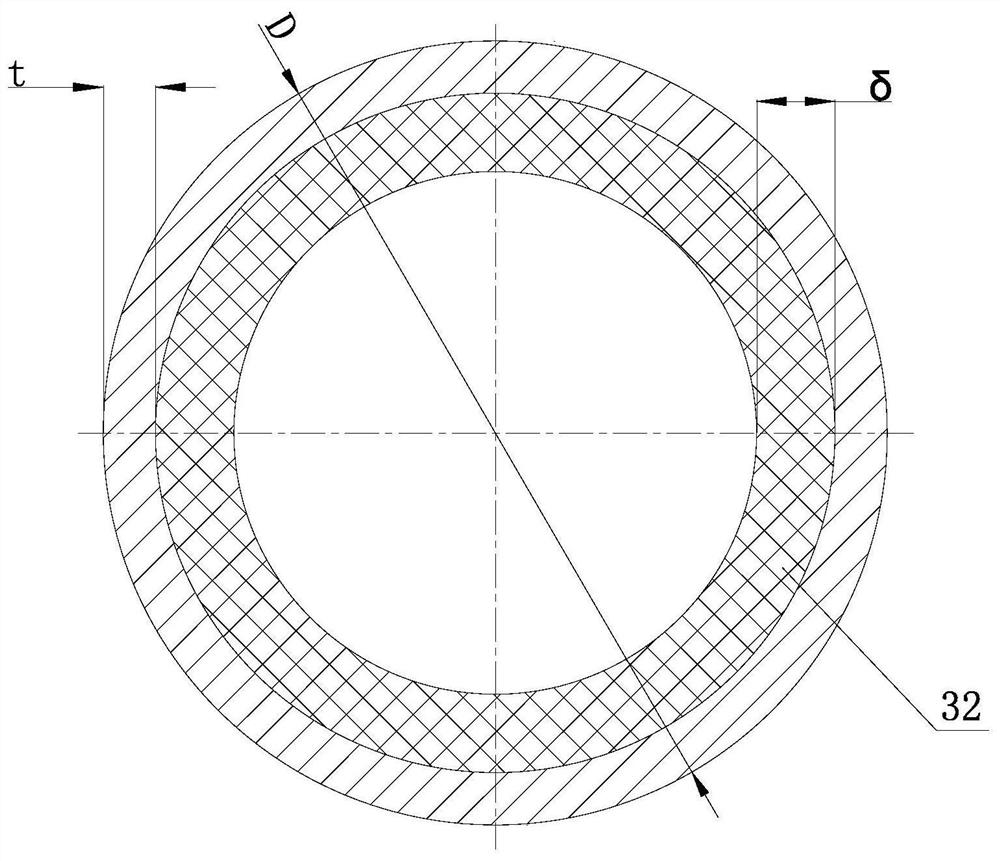

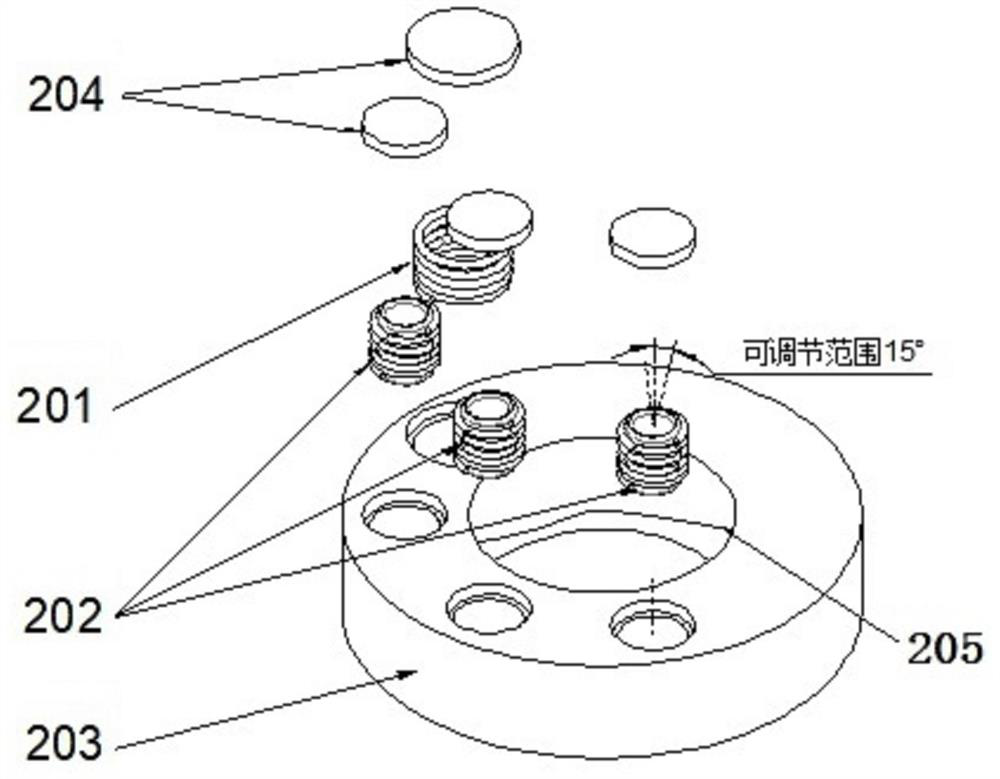

High-performanceradialorientation rare-earth permanent magnetic tube and thermal-deformationforming method thereof

ActiveCN106887293AIncrease productivityEasy to producePermanent magnetsInductances/transformers/magnets manufactureRare earthLanthanide

The invention discloses a high-performanceradialorientation rare-earth permanent magnetic tube and a thermal-deformationforming method thereof, and belongs to the technical field of rare-earth permanent magnetic seamless tube manufacture. A raw-material component of the permanent magnetic tube is RE-(Fe,Co)-B, wherein RE is or one or more ofyttrium or lanthanide elements which are represented by Nd, and one or more other transition metal elements can be added at the same time; a horizontal loading horizontal-type rotation double-motion extrusion device of which a connecting angle alpha is greater than or equal to zero degree and smaller than or equal to 90 degrees is adopted, firstly, hot pressing is conducted on rapid-quenching magnetic powder to form a full-densityisotropousmagnet, then, horizontal positive shuntextrusion is conducted on the full-densityisotropousmagnet to form the radialorientation permanent magnetic tube, the tube length is greater than 50 mm, and the tube diameter is adjustable in a range of 0-150 mm.The horizontal extrusion technology overcomes the spatial height limit of a vertical device, the long-range rheological property improves the magnetism and microstructure uniformity of the permanent magnetic tube, the permanent magnetic tube of which the length, diameter and wall thickness can be freely adjusted in a large size range can be prepared, which is beneficial for the batch production of the radialorientation rare-earth permanent magnetic tube. Through conducting saw cutting on the permanent magnetic tube, nanometer rare-earth permanent rings, magnetic tiles and ceramic chips can be obtained.

Owner:CENT IRON & STEEL RES INST

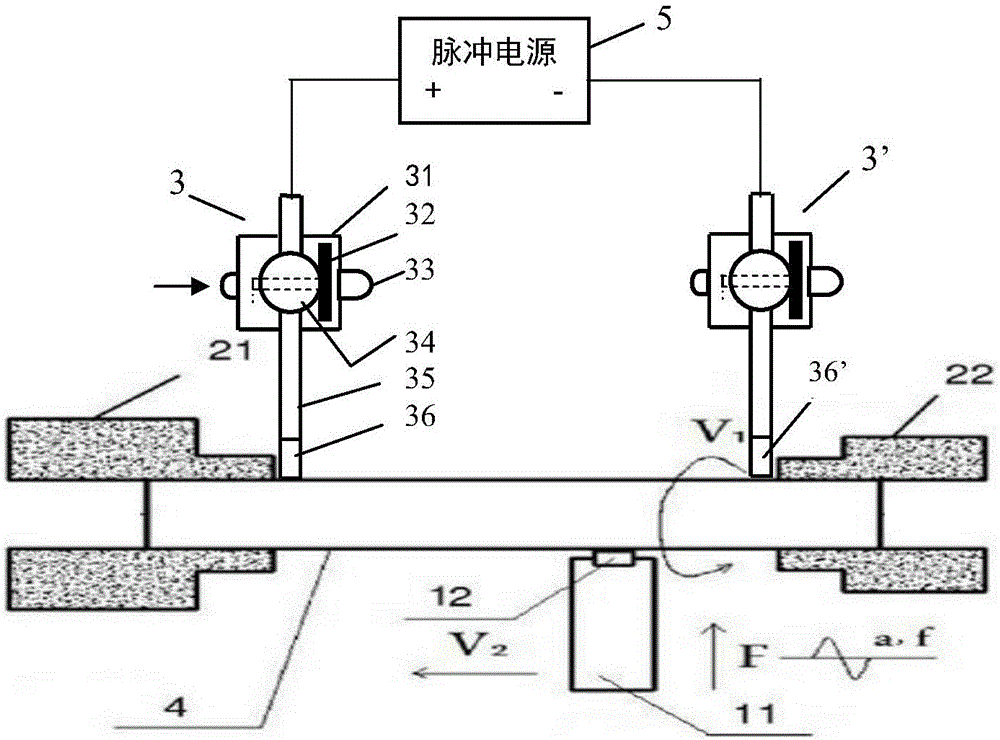

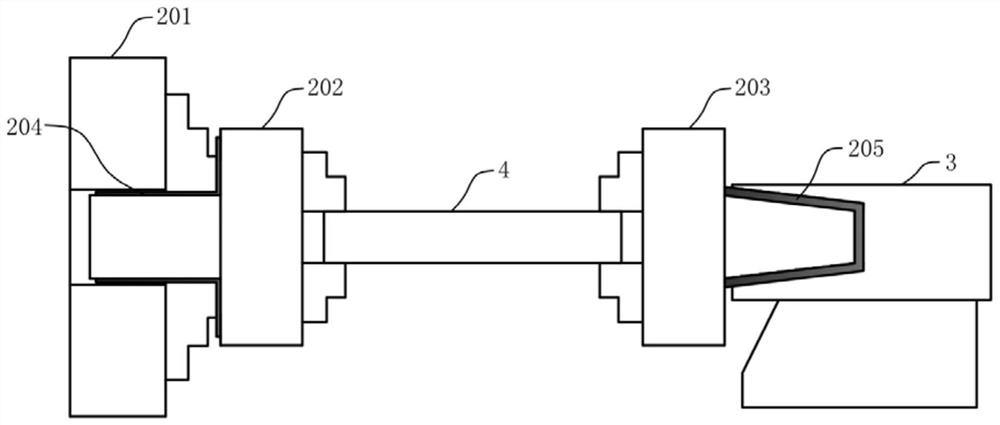

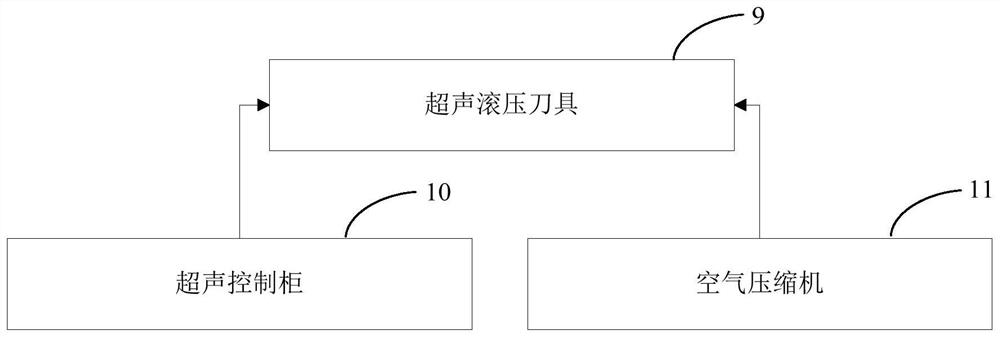

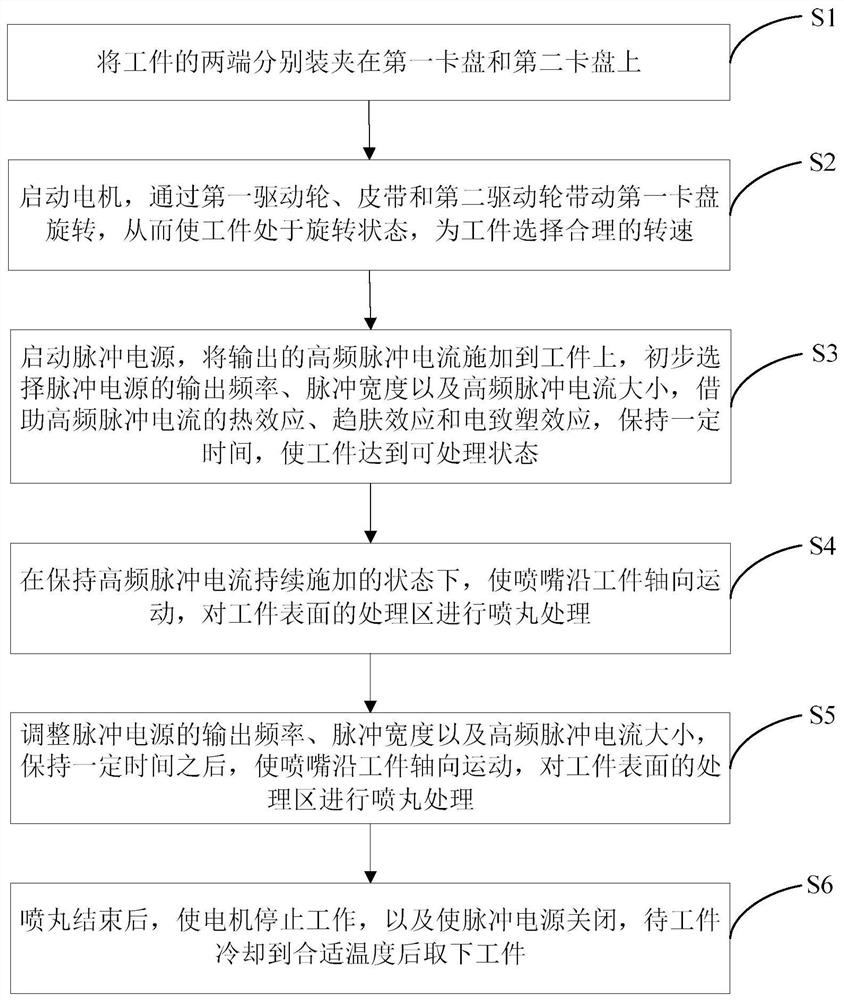

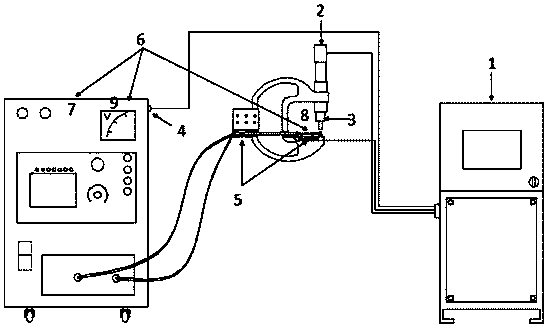

Pulse current assisted ultrasonic rolling surface strengthening device and method

The invention discloses a pulse current assisted ultrasonic rolling surface strengthening device and method. The device comprises a pulse power supply, a conductive part, a clamping mechanism and an ultrasonic rolling module, the clamping mechanism is used for clamping a workpiece, the clamping mechanism is driven by a lathe to rotate, the conductive part is in contact with the clamping mechanism, the pulse power supply is connected with the conductive part and used for applying pulse current to the workpiece, and the ultrasonic rolling module is used for conducting pulse current assisted ultrasonic rolling surface strengthening treatment on the surface of the workpiece. According to the pulse current assisted ultrasonic rolling surface strengthening device and the method, the electroplastic effect, the skin effect and the heat effect of pulse current are compounded with severe plastic deformation caused by ultrasonic rolling, so that the strengthened surface layer is thicker, the surface layer performance is better, the surface strengthening effect of the metal material can be improved, the surface appearance of the metal material is better, and the performance of the metal material is improved.

Owner:SOUTH CHINA UNIV OF TECH

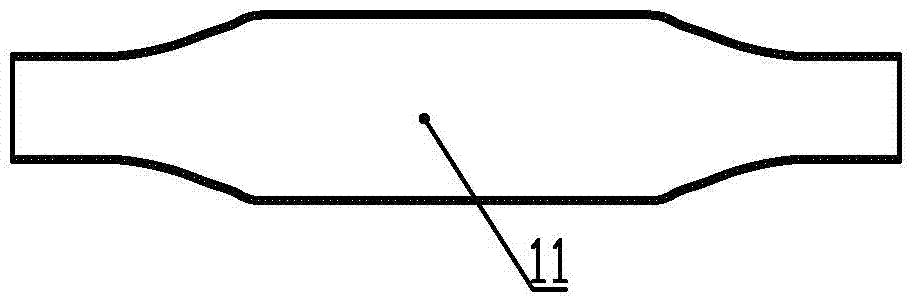

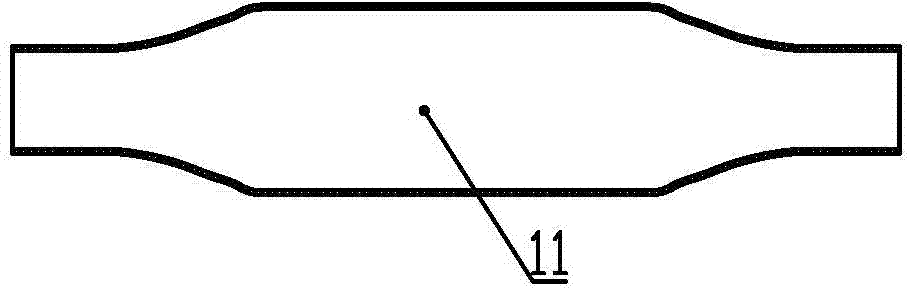

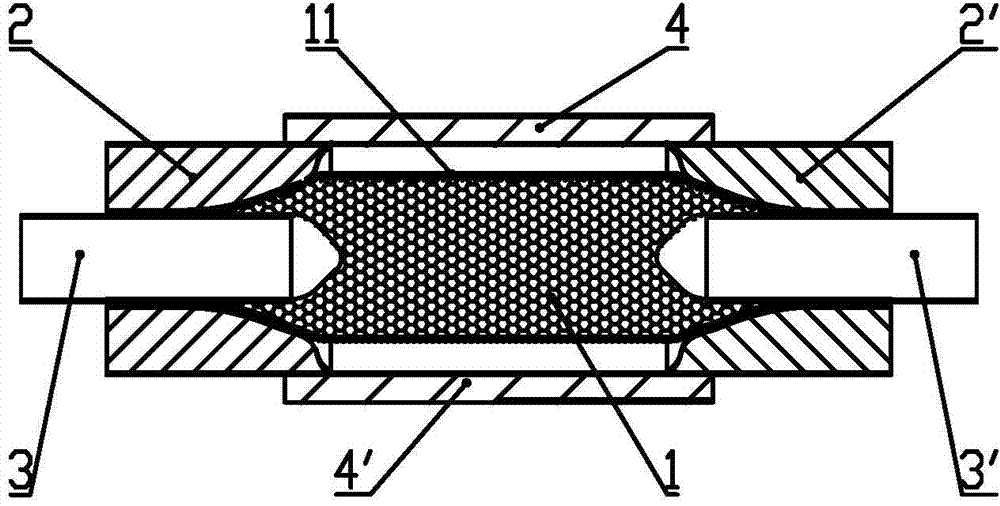

Solid particle thermal expansion vibration composite forming process of car rear axle housing

A solid particle thermal expansion vibration composite forming process of a car rear axle housing includes: shrinking diameter to obtain a reducing pipe blank, heating, assembling a primary-bulging die, performing primary bulging to obtain a primary-bulging pipe blank, heating again, assembling a secondary-bulging die, performing secondary bulging to obtain a secondary-bulging pipe blank, heating for the third time, assembling a pressing die, and pressing to obtain the car rear axle housing. The process has the advantages that the problem of equipment seal in transitional car rear axle housing hydraulic bulging is solved; formability of the car rear axle housing is increased evidently, die assembly force is reduced during forming, and the thinning ratio even crack probability of the formed car rear axle housing are reduced; vibration plastic forming is used, so that pipe blank plastic deformation resistance can be lowered, machining quality of the car rear axle housing can be improved, and machining energy consumption of the car rear axle housing can be lowered; the relative motion conditions between the die and a workpiece is improved, and 'self-locking' among solid particles during car rear axle housing forming is avoided.

Owner:XI AN JIAOTONG UNIV

High-frequency pulse current and shot blasting compounding metal surface strengthening device and method

InactiveCN111705197AReduce plastic deformation resistanceGrain refinementFurnace typesHeat treatment furnacesSkin effectEngineering

The invention discloses a high-frequency pulse current and shot blasting compounding metal surface strengthening device and method. The device comprises a rotating mechanism, a nozzle, a pulse power supply, a first electric brush, a second electric brush, a first chuck, a second chuck, a first supporting base and a second supporting base, wherein the center lines of the first chuck and the secondchuck are located on the same horizontal line, the centers of the first chuck and the second chuck are opposite, the first chuck and the second chuck are used for installing a workpiece, a chuck shaftof the first chuck is rotationally connected with the first supporting base and driven by the rotating mechanism to rotate, a chuck shaft of the second chuck is rotationally connected with the secondsupporting base, the two output ends of the pulse power supply are connected with the first electric brush and the second electric brush correspondingly, the first electric brush makes contact with the first chuck, the second electric brush makes contact with the second chuck, and the nozzle is aligned with the workpiece and used for conducting shot blasting on the surface of the workpiece. According to the device, the electroplastic effect, the skin effect and the heat effect of high-frequency pulse electricity are compounded with severe plastic deformation of shot blasting, so that a thicker plastic deformation layer is obtained after shot blasting, and the shot blasting effect is better.

Owner:SOUTH CHINA UNIV OF TECH

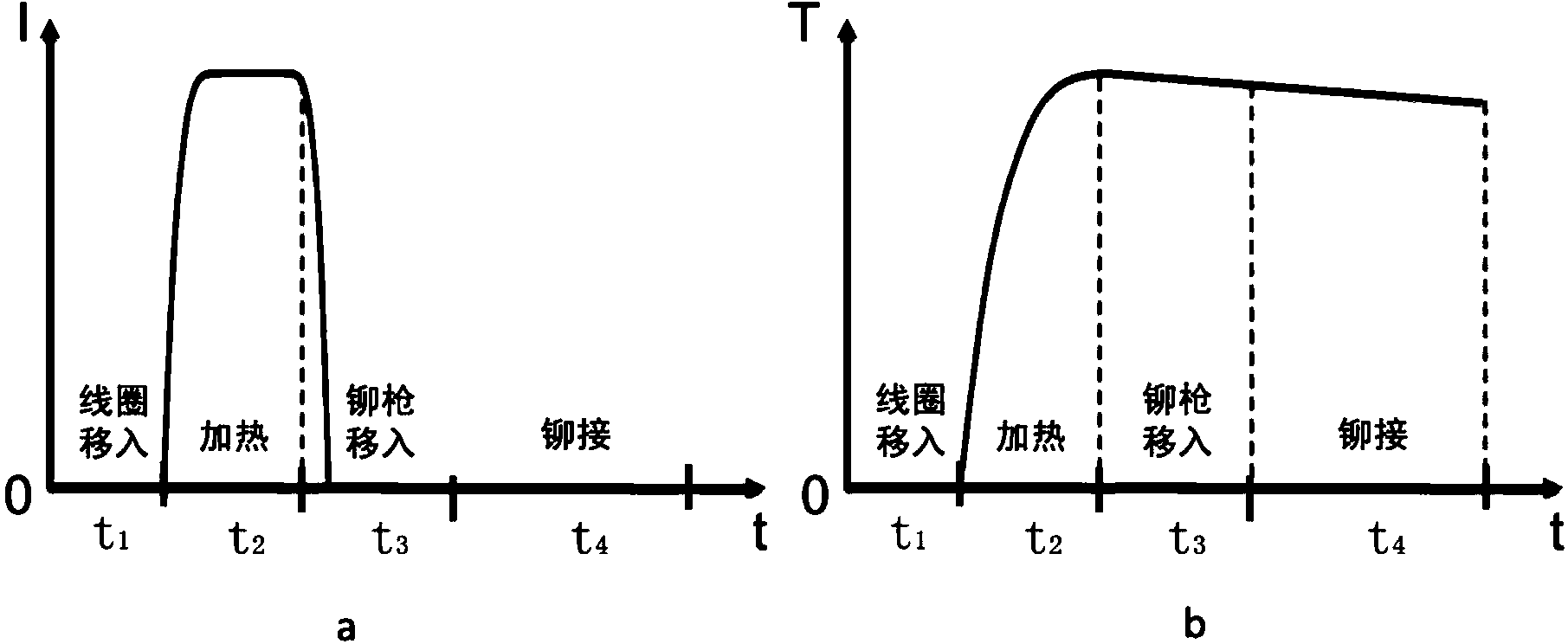

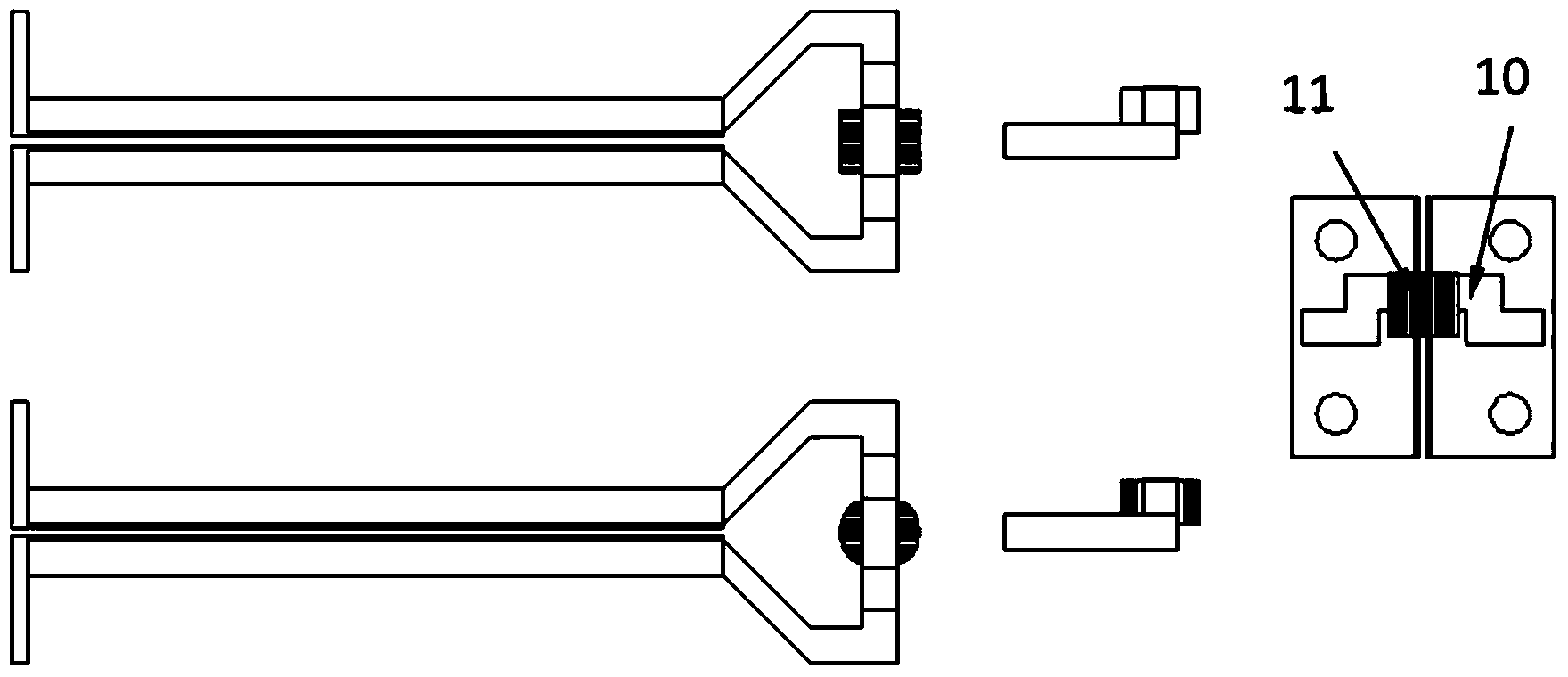

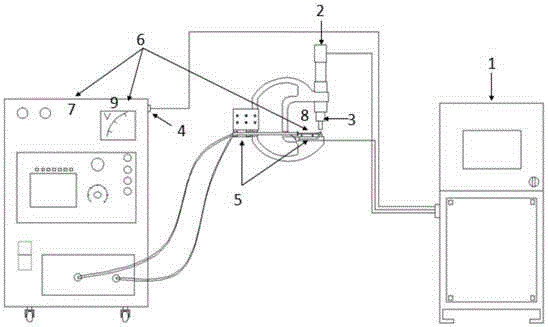

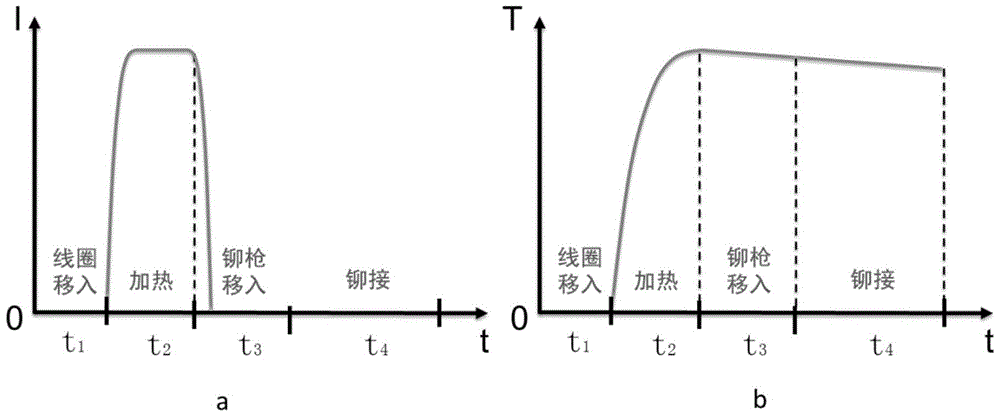

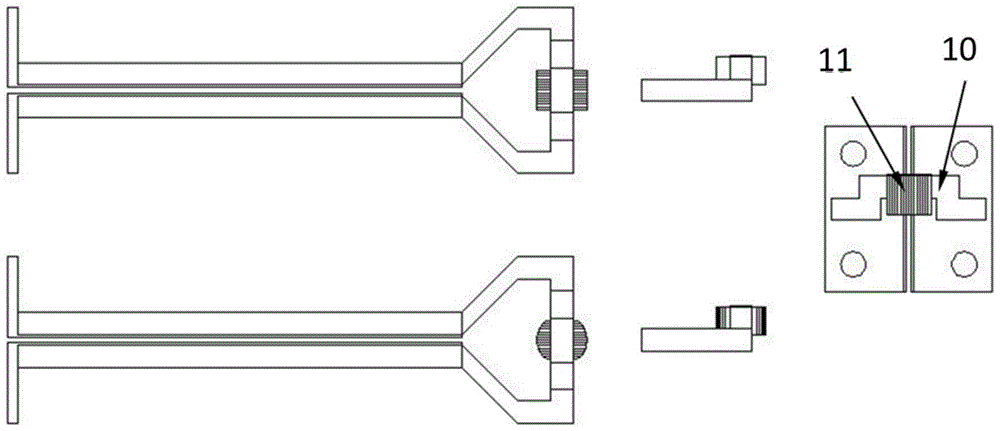

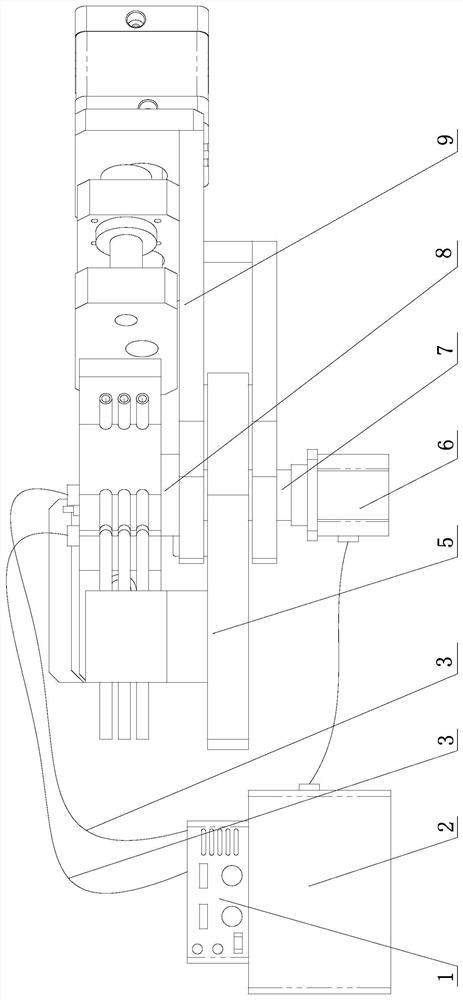

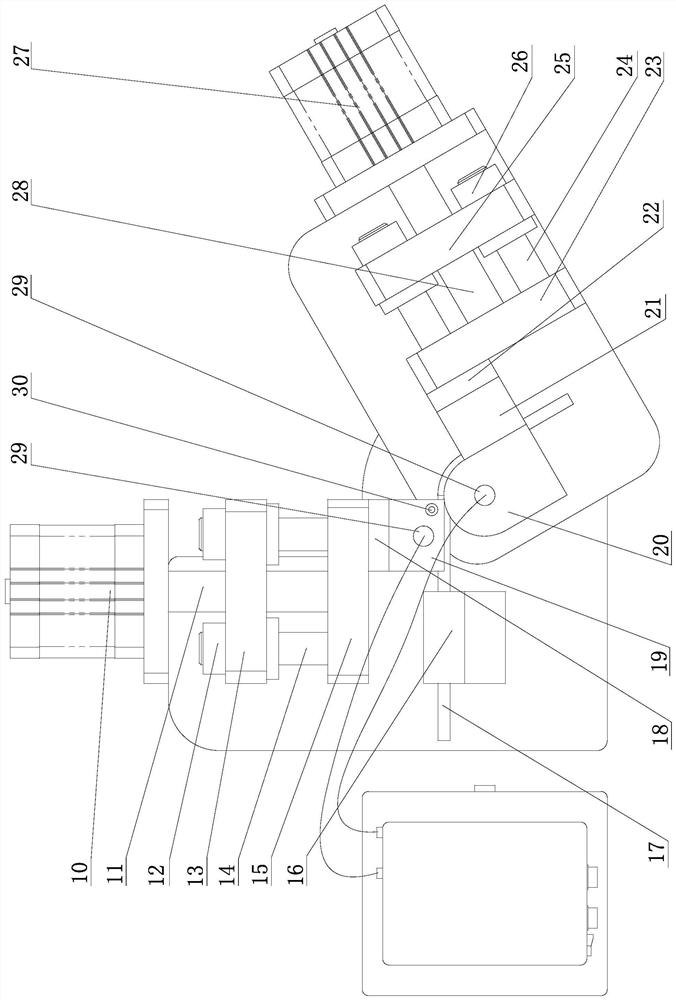

Self-piercing riveting device and method oriented to ultrahigh-strength steel and light metal

The invention provides a self-piercing riveting device and method oriented to ultrahigh-strength steel and light metal. The self-piercing riveting device comprises a power control cabinet, a gas-liquid reinforcing power unit, a riveting execution mechanism, a time relay, a delivery system, a silicon steel sheet enhancing induction heating system and low-heat-conductivity structural glue. The method comprises the following steps: before riveting, coating the structural glue between the ultrahigh-strength steel and the light metal; moving the induction heating system into a riveting position by using the delivery system according to position information; locally heating the ultrahigh-strength steel rapidly and concentrically through the induction heating system; after heating, moving a coil out rapidly; meanwhile, rapidly moving the riveting execution mechanism into the riveting position; rapidly riveting a plate to be riveted which is heated to a specific temperature by pushing the riveting execution mechanism through the gas-liquid reinforcing power unit. Through the thermal restraining effect of the low-heat-conductivity structural glue and accurate control of the time sequence in a thermal riveting process, the problems of severe upsetting of rivets, small joint undercut amount, easiness in forming fractures in the ultrahigh-strength steel and the like during riveting of advanced ultrahigh-strength steel are solved.

Owner:SHANGHAI JIAO TONG UNIV

Electroplasticity and laser shock composite strengthening method and device for large workpiece

The invention discloses an electroplasticity and laser shock composite strengthening method and device for a large workpiece. The device comprises a current applying component, a laser component and a water spraying component, wherein the current applying component is used for providing current in order to enable a workpiece to be machined to be electroplastic; the laser component is used for providing laser energy in order to machine the workpiece to be machined; and the water spraying component forms a flat water curtain on the workpiece to be machined to serve as a restraint layer for laser shock treatment. The electroplasticity and the laser shock are combined to reinforce the material, and compared with single laser shock, a series of problems of strain hardening, non-uniform and non-deep stress distribution, cracks, dislocation and the like can be solved. Meanwhile, for the large workpiece, a current collector is provided, the current can be fully led to a machining area, a large amount of loss of the current in the large workpiece is reduced, and the high-density current is formed in a to-be-strengthened area. The method can solve the problem that current energy is small, the machining quality is remarkably improved, and the machining efficiency is improved.

Owner:JIANGSU UNIV

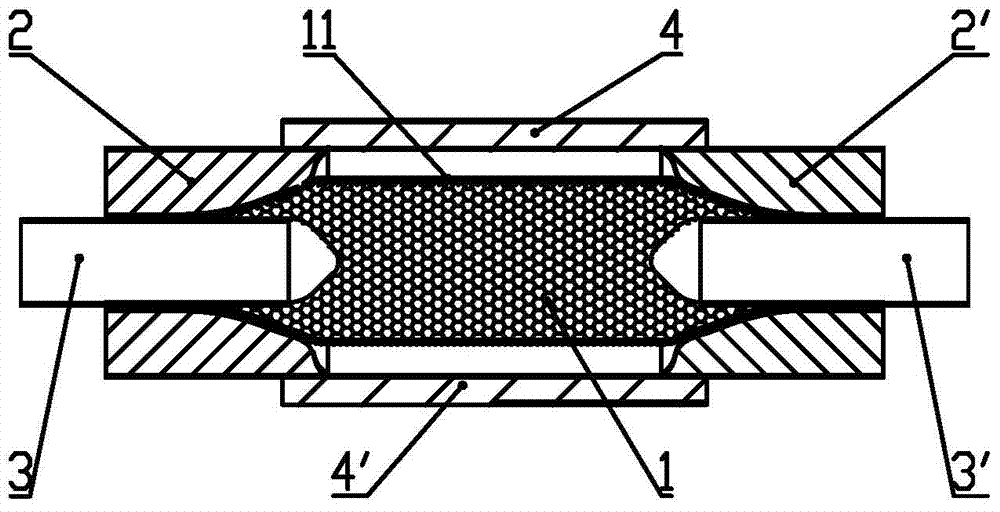

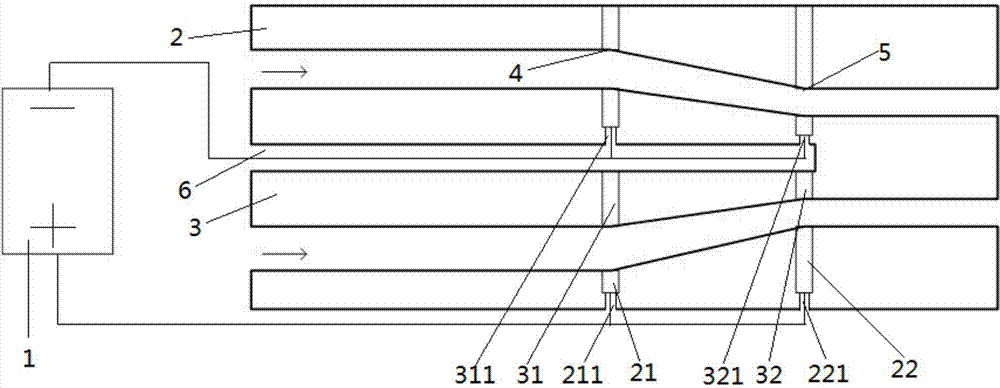

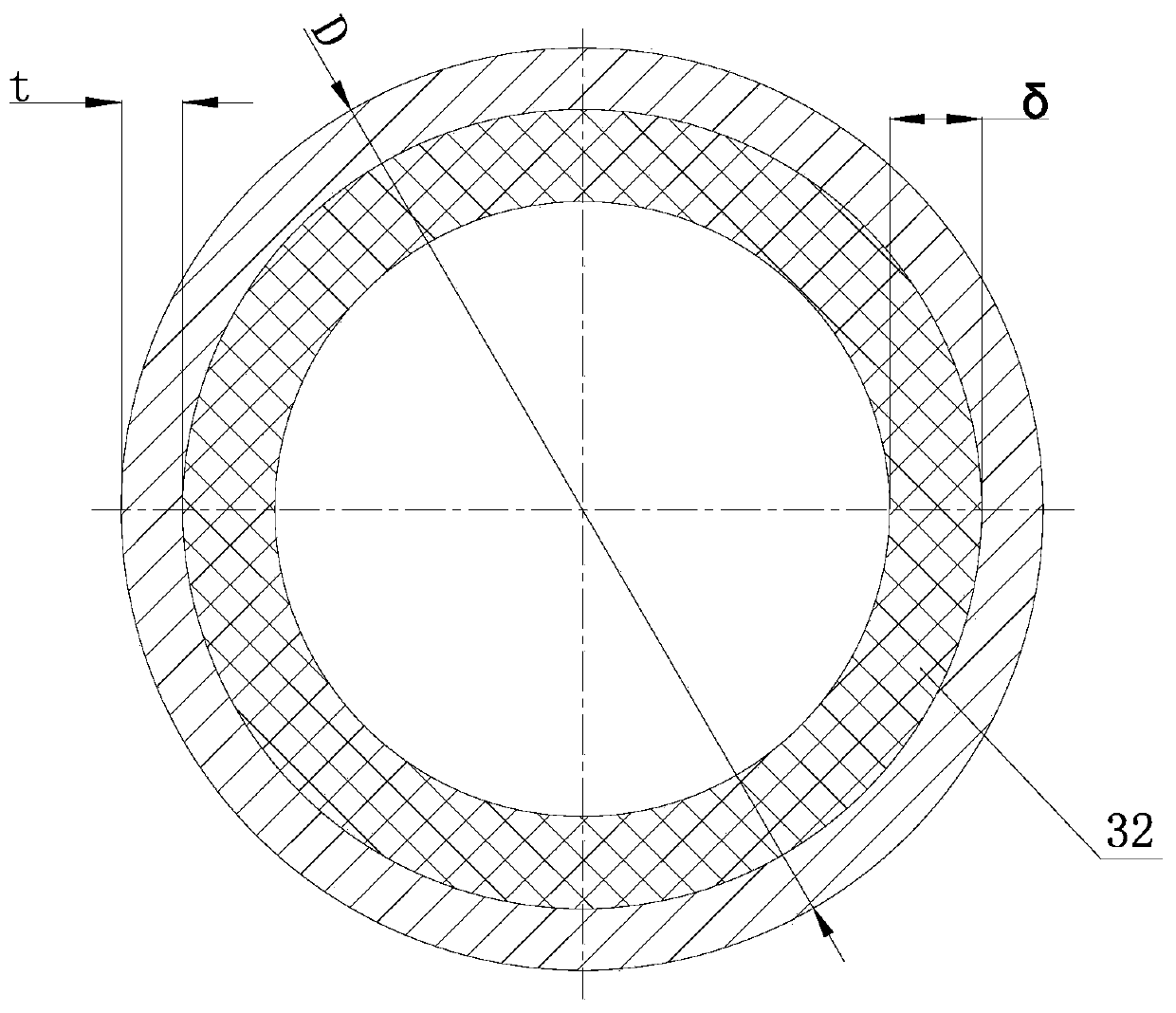

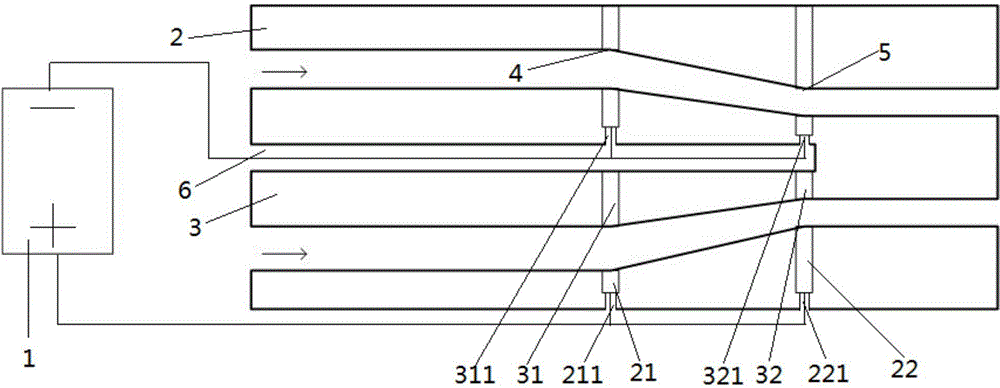

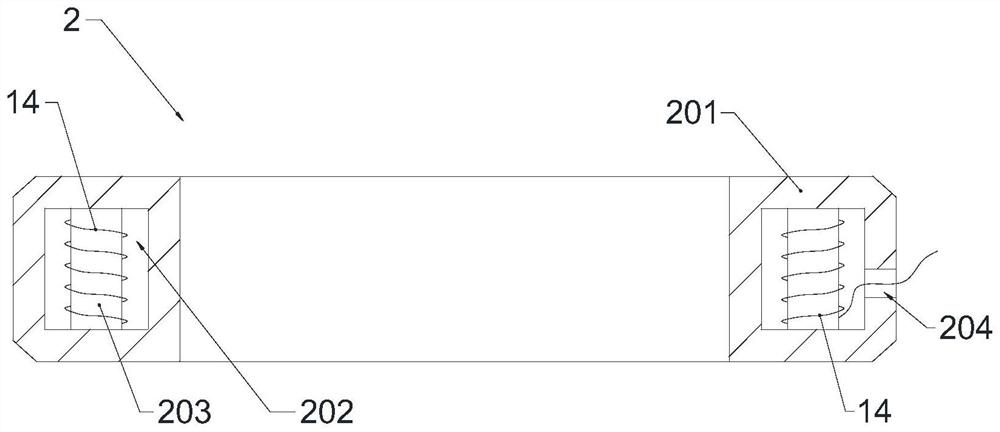

Auxiliary processing device for electric pulse pipe fitting

The invention discloses an auxiliary processing device for an electric pulse pipe fitting. The auxiliary processing device comprises a pulse power supply, a concave die, a core rod, insulating layers, a first positive electrode, a second positive electrode, a first negative electrode and a second negative electrode, wherein the first positive electrode and the second positive electrode are arranged on the inner surface of the concave die; the first negative electrode and the second negative electrode are arranged on the outer surface of the core rod; the first positive electrode, the second positive electrode, the first negative electrode and the second negative electrode are annular electrodes; the first positive electrode, the second positive electrode, the first negative electrode and the second negative electrode are connected with a pulse power supply; the insulating layers are uniformly distributed on the surfaces of the concave die and the core rod except the positive electrodes and the negative electrodes. According to the auxiliary processing device for the electric pulse pipe fitting, pulse current is introduced and an electro-plastic effect is used for enabling a raw material pipe fitting to be easily extruded and molded; the device disclosed by the invention is simple in structure, rapid in heating and high in working efficiency, and the cost loss and the energy source loss are reduced.

Owner:SHANGHAI JIAO TONG UNIV

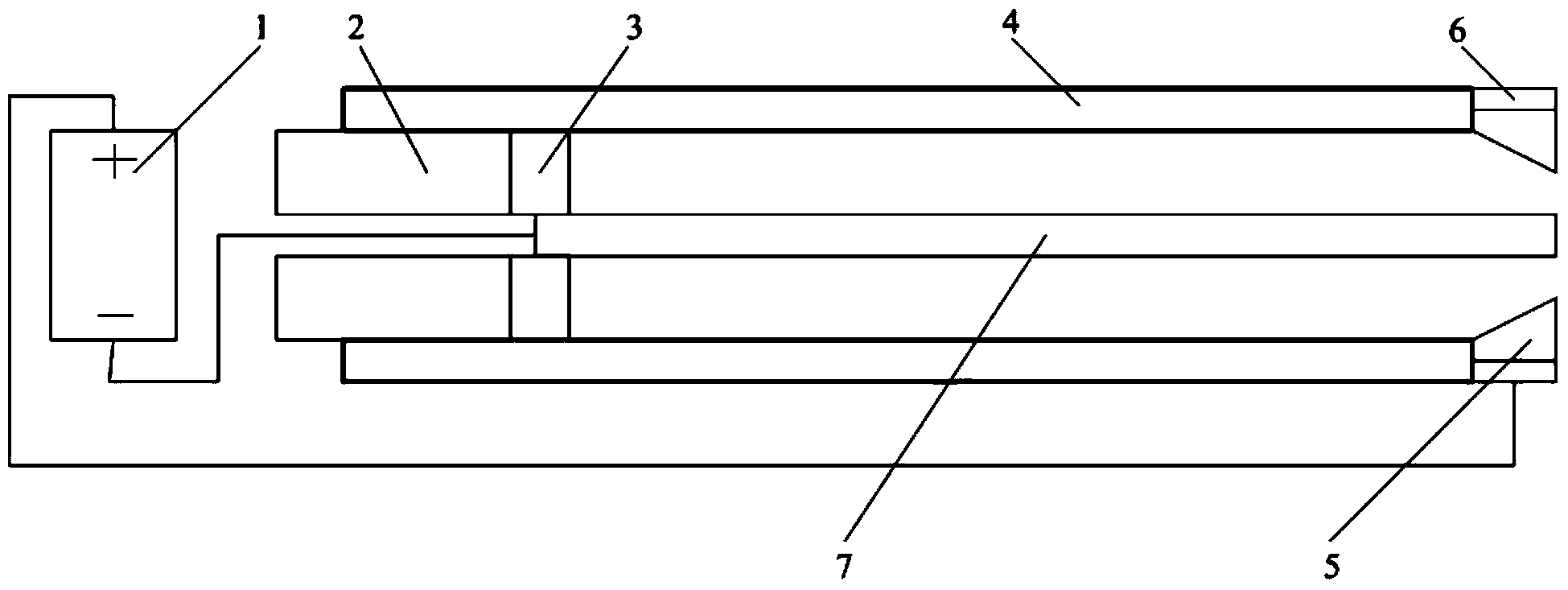

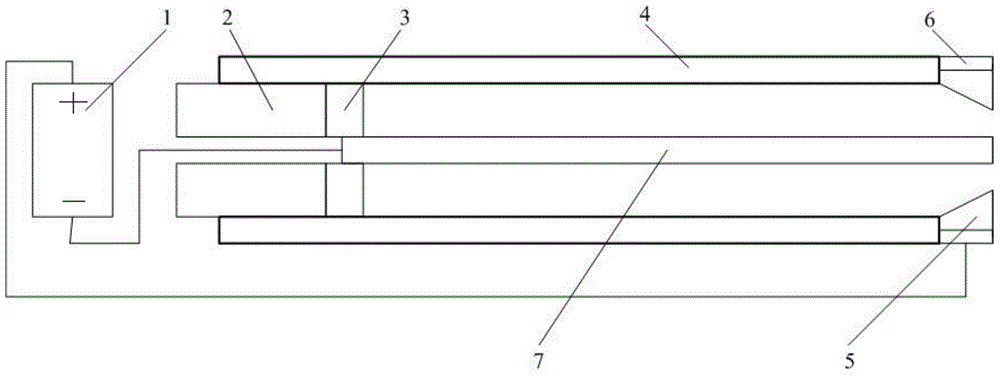

Extrusion forming device for electro-plastic pipe

InactiveCN103624098ASmall diameterReduce lossExtrusion diesExtrusion containersPower flowPulse power supply

The invention discloses an extrusion forming device for an electro-plastic pipe. The extrusion forming device comprises a pulse power supply, a moving extrusion mold, an extrusion cushion, an extrusion cylinder, a static extrusion mold and a core shaft, wherein the static extrusion mold comprises a resistance module and a conductive module; the extrusion cushion and the core shaft are connected together; the moving extrusion mold drives the extrusion cushion, the core shaft and a blank to move in the extrusion cylinder; the static extrusion mold and the extrusion cylinder are detachably connected together; the core shaft is connected with a negative wire of the pulse power supply; the conductive module of the static extrusion mold is connected with a positive wire of the pulse power supply. The sizes of the resistance module and the core shaft are determined through the size of a machined pipe, and current supplied by the pulse power supply is determined according to the material of the blank. A machining device according to the invention is used for manufacturing the pipe through extrusion processing, pulse current is introduced to the static extrusion mold, and the resistance module is energized to generate heat so as to locally heat the blank; meanwhile, the blank is easy to form through extrusion by virtue of an electro-plastic effect, so that the working efficiency is improved, and the cost and the energy loss are reduced.

Owner:SHANGHAI JIAO TONG UNIV

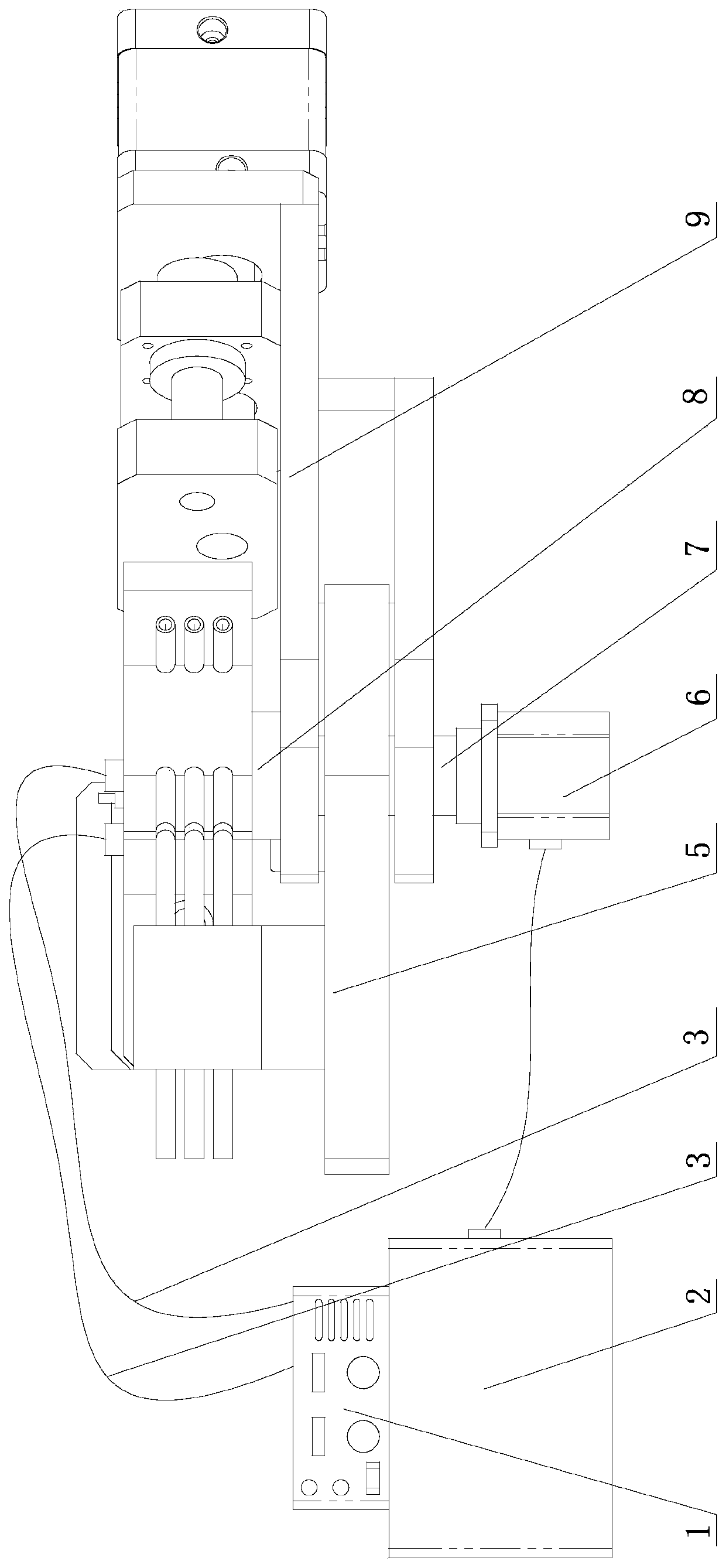

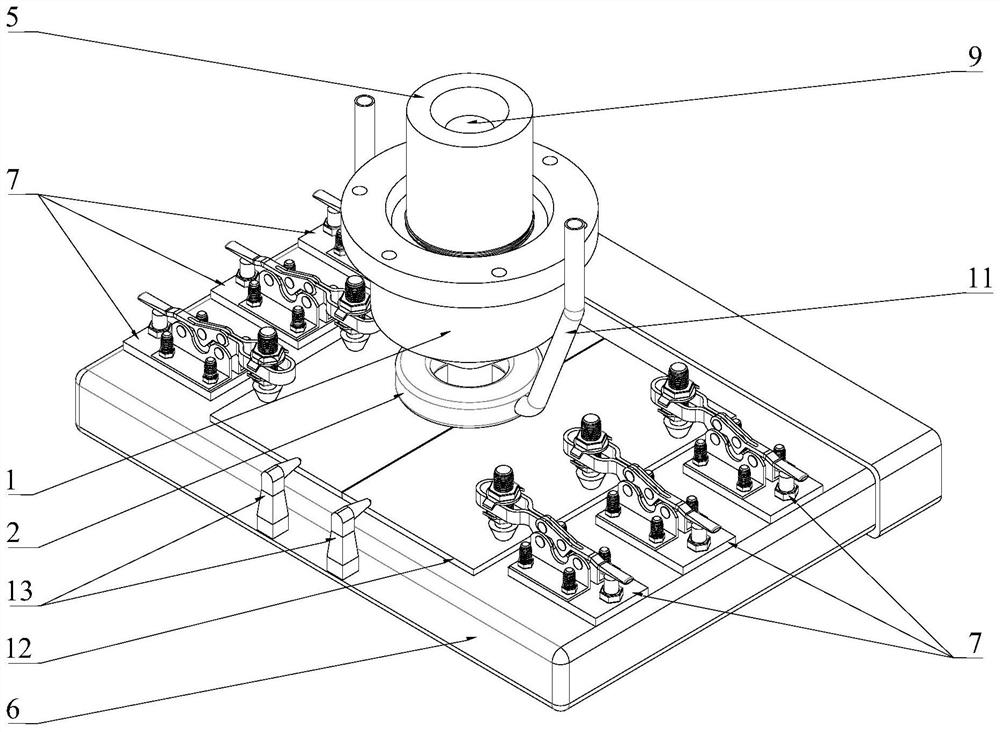

Micro heat pipe electric-current-assisted rotary draw bending forming device and method

ActiveCN110014060ASuppress section distortionReduce compressive stressShaping toolsHeat exchange apparatusControl systemEngineering

The invention provides a micro heat pipe electric-current-assisted rotary draw bending forming device and method, and belongs to the technical field of bent pipe manufacture plastic micro forming. Themicro heat pipe electric-current-assisted rotary draw bending forming device comprises a rotary draw bending forming machine, a mold assembly and a forming assisting power system. The mold assembly is installed on the rotary draw bending forming machine. The rotary draw bending forming machine is mainly composed of a fixed bottom plate, a pipe pressing assembly, a pipe bending assembly, a rotating shaft, a rotation drive mechanism and a control system. The rotating shaft is installed on the pipe bending assembly and is matched with a shaft hole in the fixed bottom plate. The pipe pressing assembly is fixed to the fixed bottom plate. The forming method includes the steps that firstly, the mold assembly is selected; secondly, a power-on loop is established; thirdly, parameters are set; fourthly, micro heat pipe blank heating and bending forming are conducted; fifthly, a bent piece is obtained through bending forming; and sixthly, the bent piece is taken out. By means of the micro heat pipe electric-current-assisted rotary draw bending forming device and method, micro heat pipe bending forming defects and forming precision can be controlled, and the problem that the heat conduction capacity is lowered after micro heat pipe bending is solved.

Owner:HARBIN INST OF TECH

Self-piercing riveting device and method for ultra-high strength steel and light metal

The invention provides a self-piercing riveting device and method oriented to ultrahigh-strength steel and light metal. The self-piercing riveting device comprises a power control cabinet, a gas-liquid reinforcing power unit, a riveting execution mechanism, a time relay, a delivery system, a silicon steel sheet enhancing induction heating system and low-heat-conductivity structural glue. The method comprises the following steps: before riveting, coating the structural glue between the ultrahigh-strength steel and the light metal; moving the induction heating system into a riveting position by using the delivery system according to position information; locally heating the ultrahigh-strength steel rapidly and concentrically through the induction heating system; after heating, moving a coil out rapidly; meanwhile, rapidly moving the riveting execution mechanism into the riveting position; rapidly riveting a plate to be riveted which is heated to a specific temperature by pushing the riveting execution mechanism through the gas-liquid reinforcing power unit. Through the thermal restraining effect of the low-heat-conductivity structural glue and accurate control of the time sequence in a thermal riveting process, the problems of severe upsetting of rivets, small joint undercut amount, easiness in forming fractures in the ultrahigh-strength steel and the like during riveting of advanced ultrahigh-strength steel are solved.

Owner:SHANGHAI JIAO TONG UNIV

A micro heat pipe current assisted bending forming device and method

ActiveCN110014060BSuppress section distortionReduce compressive stressShaping toolsHeat exchange apparatusRotational axisControl system

The invention provides a micro heat pipe electric-current-assisted rotary draw bending forming device and method, and belongs to the technical field of bent pipe manufacture plastic micro forming. Themicro heat pipe electric-current-assisted rotary draw bending forming device comprises a rotary draw bending forming machine, a mold assembly and a forming assisting power system. The mold assembly is installed on the rotary draw bending forming machine. The rotary draw bending forming machine is mainly composed of a fixed bottom plate, a pipe pressing assembly, a pipe bending assembly, a rotating shaft, a rotation drive mechanism and a control system. The rotating shaft is installed on the pipe bending assembly and is matched with a shaft hole in the fixed bottom plate. The pipe pressing assembly is fixed to the fixed bottom plate. The forming method includes the steps that firstly, the mold assembly is selected; secondly, a power-on loop is established; thirdly, parameters are set; fourthly, micro heat pipe blank heating and bending forming are conducted; fifthly, a bent piece is obtained through bending forming; and sixthly, the bent piece is taken out. By means of the micro heat pipe electric-current-assisted rotary draw bending forming device and method, micro heat pipe bending forming defects and forming precision can be controlled, and the problem that the heat conduction capacity is lowered after micro heat pipe bending is solved.

Owner:HARBIN INST OF TECH

An electroplastic pipe extrusion molding device

InactiveCN103624098BSmall diameterReduce lossExtrusion diesExtrusion containersPower flowEngineering

The invention discloses an extrusion forming device for an electro-plastic pipe. The extrusion forming device comprises a pulse power supply, a moving extrusion mold, an extrusion cushion, an extrusion cylinder, a static extrusion mold and a core shaft, wherein the static extrusion mold comprises a resistance module and a conductive module; the extrusion cushion and the core shaft are connected together; the moving extrusion mold drives the extrusion cushion, the core shaft and a blank to move in the extrusion cylinder; the static extrusion mold and the extrusion cylinder are detachably connected together; the core shaft is connected with a negative wire of the pulse power supply; the conductive module of the static extrusion mold is connected with a positive wire of the pulse power supply. The sizes of the resistance module and the core shaft are determined through the size of a machined pipe, and current supplied by the pulse power supply is determined according to the material of the blank. A machining device according to the invention is used for manufacturing the pipe through extrusion processing, pulse current is introduced to the static extrusion mold, and the resistance module is energized to generate heat so as to locally heat the blank; meanwhile, the blank is easy to form through extrusion by virtue of an electro-plastic effect, so that the working efficiency is improved, and the cost and the energy loss are reduced.

Owner:SHANGHAI JIAO TONG UNIV

Heating method and processing method of thermally deformed workpiece blank based on gradient induction heating

ActiveCN109773099BRealize Controlled DesignGuaranteed dimensional accuracyHeating/cooling devicesThermoplasticThermodynamics

The invention discloses a gradient induction heating based thermal deformation workpiece blank heating method and a processing method and belongs to the field of meal thermoplastic forming. Accordingto the gradient induction heating based thermal deformation workpiece blank heating method and the processing method, a blank is designed according to the shape of a workpiece; parts, with different deformations, of the blank are subjected to rapid induction heating to different temperatures through a gradient induction heating coil, the temperature difference of different deformation parts of theblank is realized, and the continuity of the temperature of the surface of the blank is ensured. The plastic deformation resistance of areas hard to deformable is effectively reduced. The equipment tonnage can also be effectively reduced. Meanwhile, under the coupling effect of the temperature and deformation of the parts with the different deformations, the uniformity of the microstructure of awhole forged piece can be ensured, and the mechanical performance of a material is remarkably improved. Besides, the labor environment can be remarkably improved, the forged piece with the high dimensional precision, the uniform microstructure and excellent comprehensive performance is integrally formed, and automated and standardized production is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

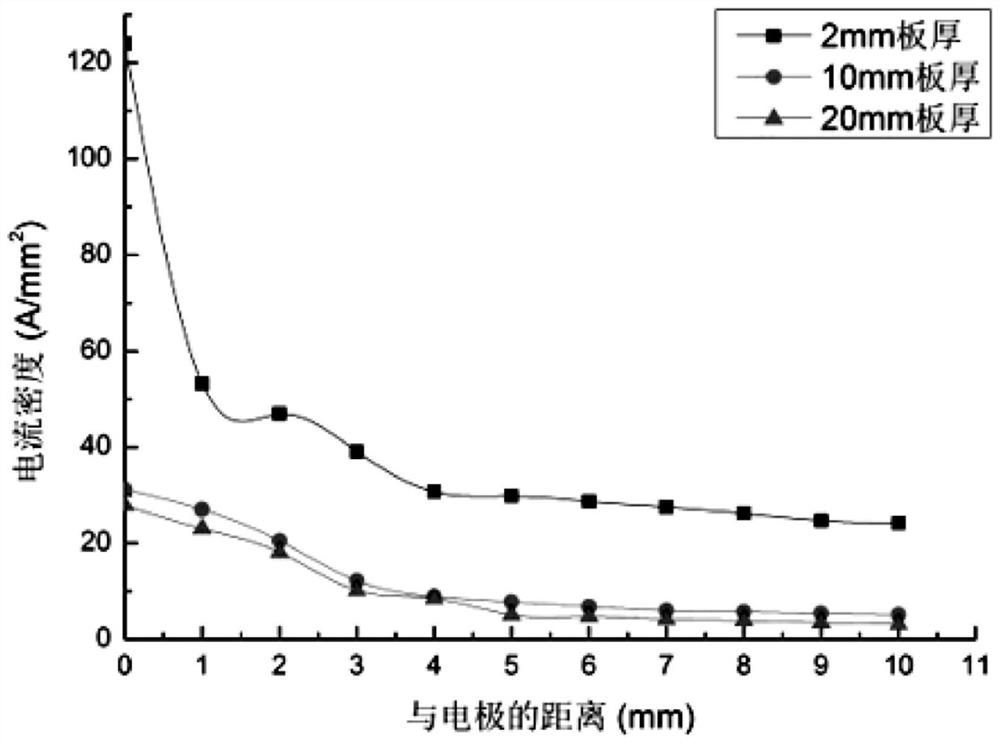

Electro-plastic open die forging device and method

InactiveCN102489651BMeet special handling needsReduce plastic deformation resistanceForging press drivesBrush deviceElectrical impulse

An electro-plastic open die forging device comprises an electric brush device, a driving device and a control device, wherein the electric brush device is connected with a pulse power supply, and the control device is capable of controlling the driving device to drive the electric brush device to be contacted with or separated from blank. The control device controls the time of the electric brush device for being contacted with or separated from the blank based on the position of an upper chopping board. Therefore, when the blank is forged, under the control of the control device, the driving device drives the electric brush device to be contacted with the blank, and transverse continuous electric pulses are led to the blank. The invention further provides an electro-plastic open die forging method. The device and the method improve forming property by utilizing electro-plastic effect of metal during an open die forging process.

Owner:SHANGHAI JIAOTONG UNIV

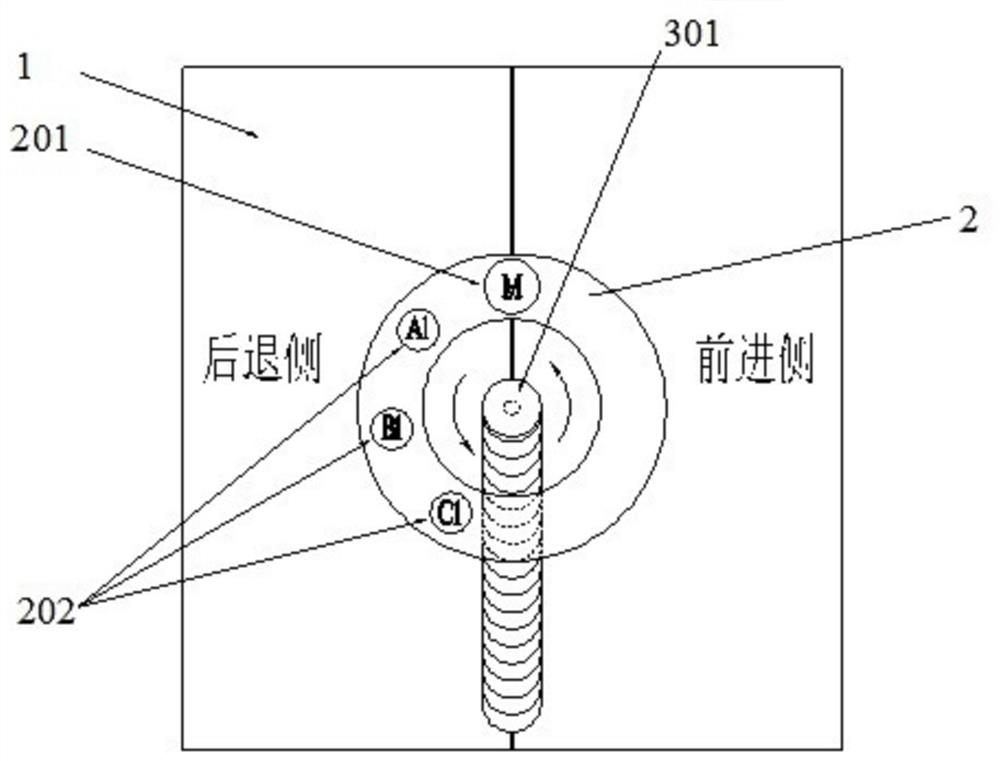

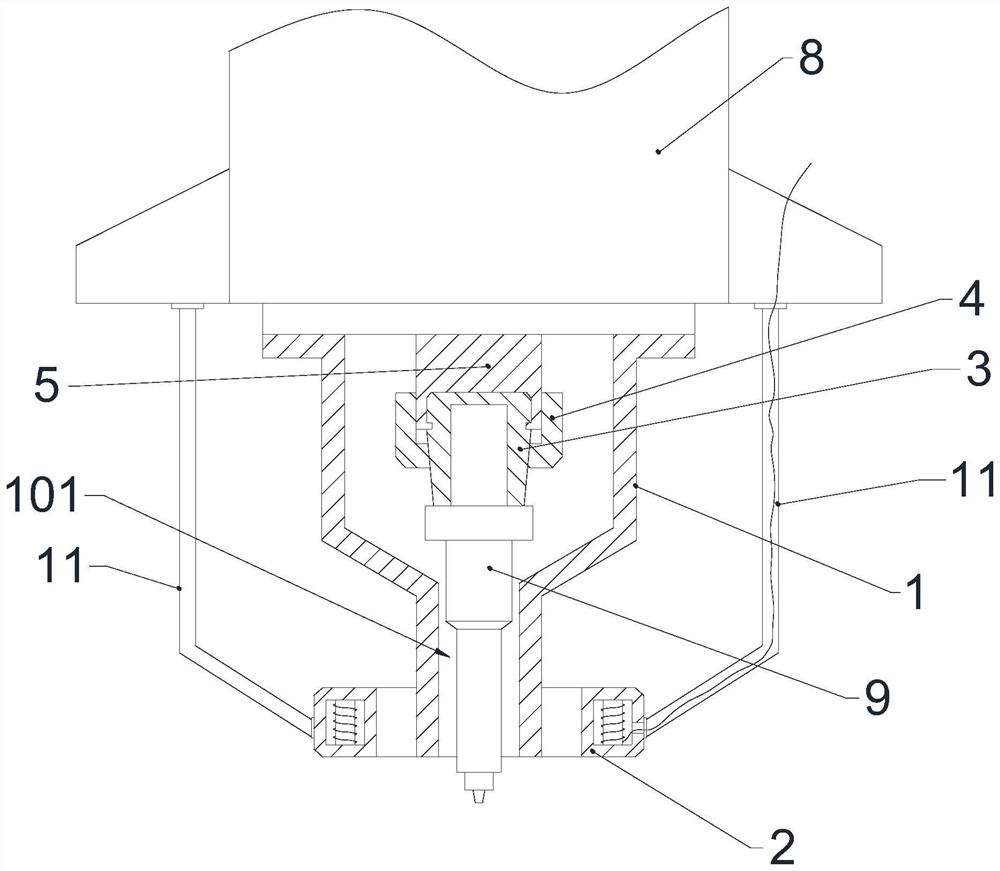

Magnetization-degree-adjustable center magnet-embedded type friction stir welding device

ActiveCN113953651ASpeed up the flowImprove plastic deformationNon-electric welding apparatusMagnetizationElectric machinery

The invention discloses a magnetization-degree-adjustable center embedded magnet type friction stir welding device. The magnetization-degree-adjustable center embedded magnet type friction stir welding device comprises a hollow-structure motor spindle, a clamping device, a stirring head, a cooling system and a welding workbench, the stirring head is installed in a hollow inner cavity of the motor spindle through the clamping device, a cavity of the stirring head is filled with a cylindrical strong magnet, a hole groove structure is formed in a shaft shoulder, the motor spindle rotates at a high speed to drive the stirring head filled with the cylindrical strong magnet to rotate, the magnetic field intensity of the end face of the shaft shoulder of a magnetic conductive stirring head is changed, and a unlike strong magnet is arranged in a magnetic conductive base plate, so that magnetic field collection is enhanced in a welding seam, electromagnetic force is formed, and plastic metal mechanical stirring in a welding area is enhanced; and plasticized metal flow is promoted, grain structure refinement in the friction stir welding process is improved, and the comprehensive performance is remarkably improved.

Owner:JIANGSU UNIV OF SCI & TECH

Thermal expansion and vibration composite forming process of solid particles of automobile rear axle housing

A solid particle thermal expansion vibration composite forming process of a car rear axle housing includes: shrinking diameter to obtain a reducing pipe blank, heating, assembling a primary-bulging die, performing primary bulging to obtain a primary-bulging pipe blank, heating again, assembling a secondary-bulging die, performing secondary bulging to obtain a secondary-bulging pipe blank, heating for the third time, assembling a pressing die, and pressing to obtain the car rear axle housing. The process has the advantages that the problem of equipment seal in transitional car rear axle housing hydraulic bulging is solved; formability of the car rear axle housing is increased evidently, die assembly force is reduced during forming, and the thinning ratio even crack probability of the formed car rear axle housing are reduced; vibration plastic forming is used, so that pipe blank plastic deformation resistance can be lowered, machining quality of the car rear axle housing can be improved, and machining energy consumption of the car rear axle housing can be lowered; the relative motion conditions between the die and a workpiece is improved, and 'self-locking' among solid particles during car rear axle housing forming is avoided.

Owner:XI AN JIAOTONG UNIV

High-frequency vibration auxiliary foil plate micro-blanking forming method

ActiveCN102962331BInhibition of germinationReduce plastic deformation resistanceMechanical vibrations separationEjection devicesHigh frequency powerEngineering

The invention relates to a micro-blanking forming device and a forming method, in particular to a high-frequency auxiliary micro-blanking forming device and a method for a foil plate. The device and the method aim at solving the problems in the existing high-precision blanking forming of the foil plate that an interval between a female die and a male die is small, a blanking force is significantly increased by a size effect, and the dies are badly worn and have short service lives. The device comprises a female die fixing plate, a lower bolster and a lower die plate that are sequentially connected from the top down, wherein an upper die plate and a male die fixing plate are sequentially arranged above the female die fixing plate; a female die is embedded into the middle part of the upper surface of the female die fixing plate; a vibration component and a punch are sequentially mounted in the male die fixing plate from the top down in an inserting manner; a middle line of the punch is coincided with that of the female die; the vibration component is connected with a high-frequency power source; a guide sleeve is mounted on the upper surface of the female die fixing plate in an inserting manner; the upper end of a guide column is mounted in the male die fixing plate in an inserting manner; and the lower end of the guide column is mounted in the guide sleeve in an inserting manner. The device and the method are used for blanking forming of the foil plate.

Owner:HARBIN INST OF TECH

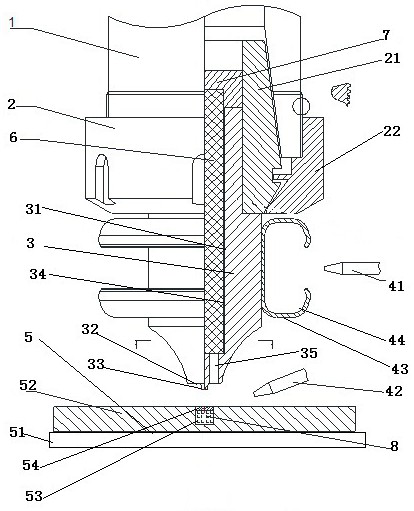

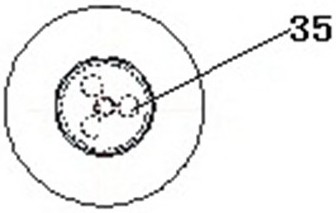

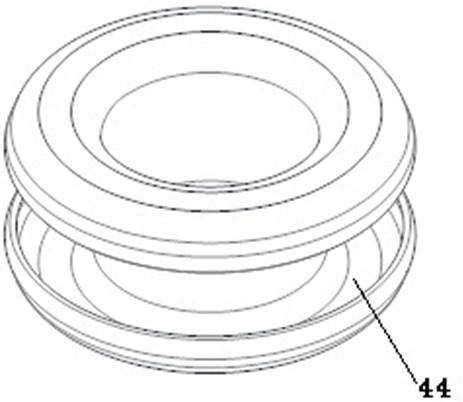

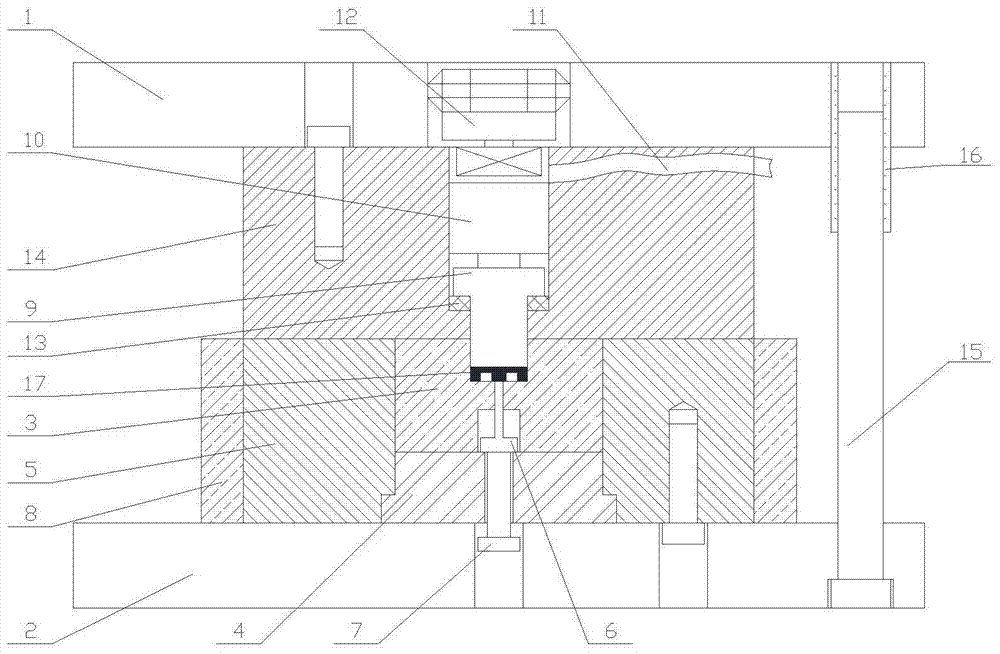

Ultrasonic vibration assisted metal micro-molding forming device and its application method

ActiveCN105215246BSmall feature sizeImprove mechanical propertiesForging/hammering/pressing machinesHeating/cooling devicesDie castingEngineering

The invention provides an ultrasonic vibration-assisted metal micro die forming device which comprises a lower die holder, a female die, a female die base plate, a female die fixing plate, an ejector rod, an ejection screw, a piezoelectric element, a male die, a male die fixing block and a pressure sensor, wherein the female die fixing plate is fixedly arranged on the upper surface of the low die holder, both the female die base plate and the female die are embedded into the female die fixing plate, the female die is fixedly arranged at the top of the female die base plate, the ejection screw penetrates through the center of the lower die holder and extends into the female die base plate, the ejector rod is arranged at the bottom of the female die, the male die fixing block is arranged at the top of female die fixing plate, the male die is embedded into the bottom of the male die fixing block, the piezoelectric element is arranged at the top of the male die, and the pressure sensor is arranged at the top of the piezoelectric element. The ultrasonic vibration-assisted metal micro die forming device has the advantages that a required micro die casting part can be formed directly with an ultrasonic vibration-assisted metal micro die forming method, secondary processing is avoided, the processing efficiency is improved, and the cost is low.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Atmospheric cold plasma jet auxiliary cutting method

ActiveCN102601677BReduce plastic deformation resistanceExtend your lifeMaintainance and safety accessoriesPlasma jetCooling effect

The invention provides an atmospheric cold plasma jet auxiliary cutting method. Cold plasma jet generated under atmospheric pressure is used as a lubricating cooling medium during material cutting. Working gas enters a cold plasma jet generator from a working gas source via a pressure reducing valve and an adjustable flow meter, the flow of the working gas and output voltage of a high-voltage power source are adjusted so that uniform cold plasma jet is sprayed out from a nozzle outlet of the cold plasma jet generator, the temperature of the jet is the room temperature or is slightly higher than the room temperature, and a tool and workpiece interface and a tool and chip interface are always soak in the cold plasma jet during cutting by means of adjusting a spraying angle. Plasma can be generated in a dielectric barrier discharge mode, a suspension electrode discharge mode or a bare electrode discharge mode. The atmospheric cold plasma jet auxiliary cutting method is an environment-friendly cutting method, an excellent lubricating and cooling effects for various metal and nonmetal materials can be realized during cutting, accordingly, cutting force is reduced, the service life of a tool is prolonged, and the quality of the surface of a workpiece is enhanced.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of high-purity copper target material

ActiveCN104694888BImprove processing efficiencyReduce plastic deformation resistanceVacuum evaporation coatingSputtering coatingSputteringCopper

Owner:GRIKIN ADVANCED MATERIALS

An electric pulse assisted pipe processing device

Owner:SHANGHAI JIAOTONG UNIV

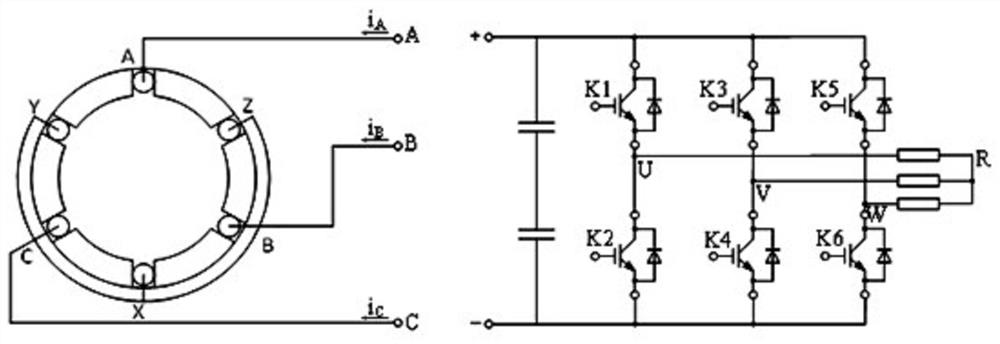

Thin-wall metal selective magnetic vibration stirring friction welding device and welding method

PendingCN114769834AImprove welding qualityReduce plastic deformation resistanceNon-electric welding apparatusMagnetic tension forceEngineering

The invention discloses a thin-wall metal selective magnetic vibration stirring friction welding device which comprises a stirring head driven by a spindle of a rotating motor and a pulsating magnetic field generator fixed to the stirring head. A high-frequency induction line heating coil M and a three-phase coil module are arranged at the end, facing the to-be-welded thin-wall metal part, of the pulsating magnetic field generator, so that a welding area of the thin-wall metal part is heated and a high-frequency vibration magnetic field is provided; and the three-phase coil module is provided with three independent power supplies A, B and C of which the phase difference is 120 degrees in sequence, and the phase sequence and the frequency of the three-phase power supplies A, B and C are adjustable. According to the magnetic vibration stirring friction welding device and the welding method thereof, the temperature uniformity in the welding circumferential direction of the thin-wall metal part and the uniformity of a pulsating magnetic field are guaranteed, weld joint structure grains are evenly refined, the welding performance of the thin-wall metal part is remarkably improved, continuous operation can be conducted, a long-size to-be-welded part can be prepared, and the welding quality is improved. And the yield is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

Static shoulder friction stir welding device and method applied to container side wall splicing

ActiveCN114247982AOvercome the breakOvercome the technical problems of welding failureNon-electric welding apparatusStructural engineeringWeld seam

The invention relates to a static shaft shoulder friction stir welding device and method applied to container side wall splicing. A magnetic field vector module is arranged on the periphery of the bottom of a static shaft shoulder, and a magnetic field which rotates at a high speed relative to a to-be-welded plate with a stirring needle as the axis is generated through the magnetic field vector module; and the to-be-welded plate in the welding area is preheated, so that the welding efficiency of container side wall splicing is greatly improved, and the technical problems that traditional static shoulder friction stir welding is low in efficiency, even a stirring needle is broken, and welding fails are solved. Meanwhile, the welding area of the to-be-welded plate can be heated and pulsating vibration can be generated through the magnetic field vector module, the metal flowability in the welding process is improved, particularly, the metal flowability at the bottom of the to-be-welded plate is improved, a cavity behind a stirring needle is filled in time, the defect of dispersively distributed cavities is overcome, and the welding quality is improved. Grain refinement of a welding seam structure is facilitated, the welding seam structure is more uniform, the plastic deformation resistance of materials is reduced, the stirring head loss is reduced, and the welding quality is improved.

Owner:张家港市海星集装箱制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com