Patents

Literature

202results about How to "Slow down heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

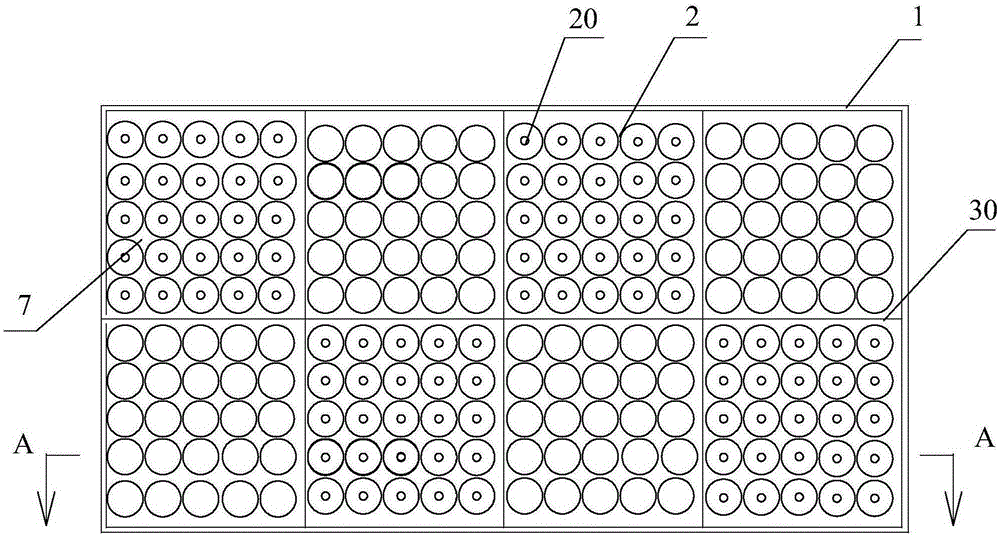

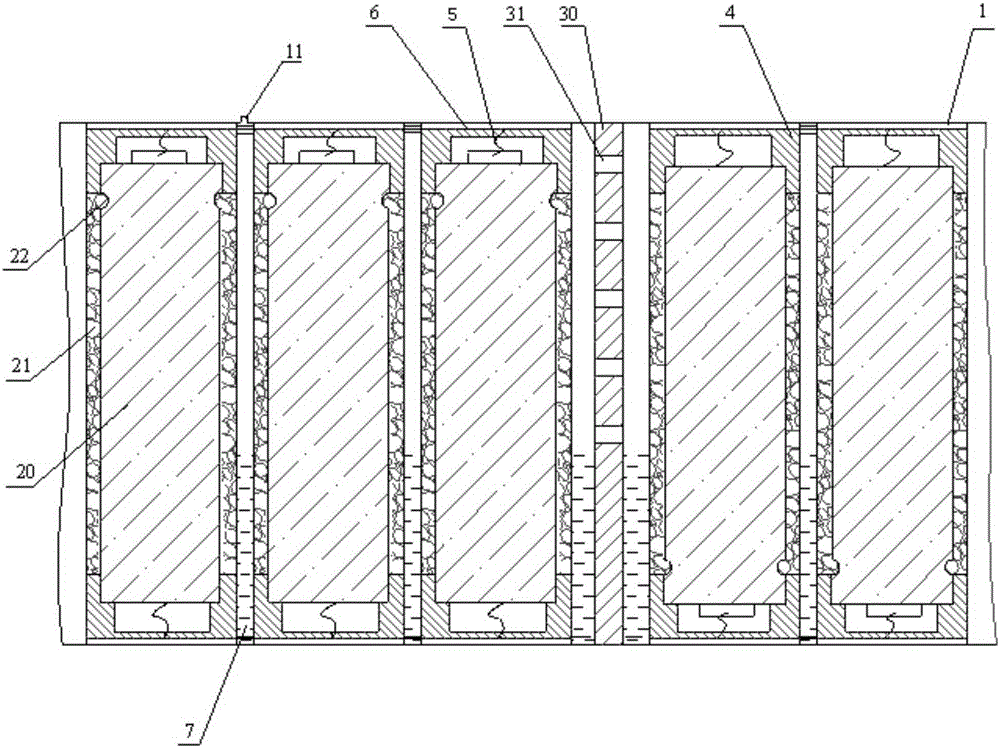

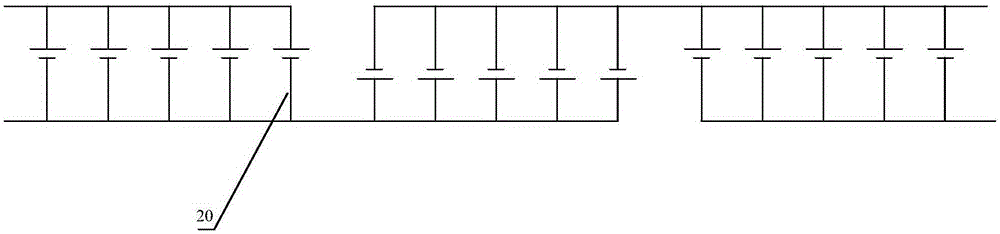

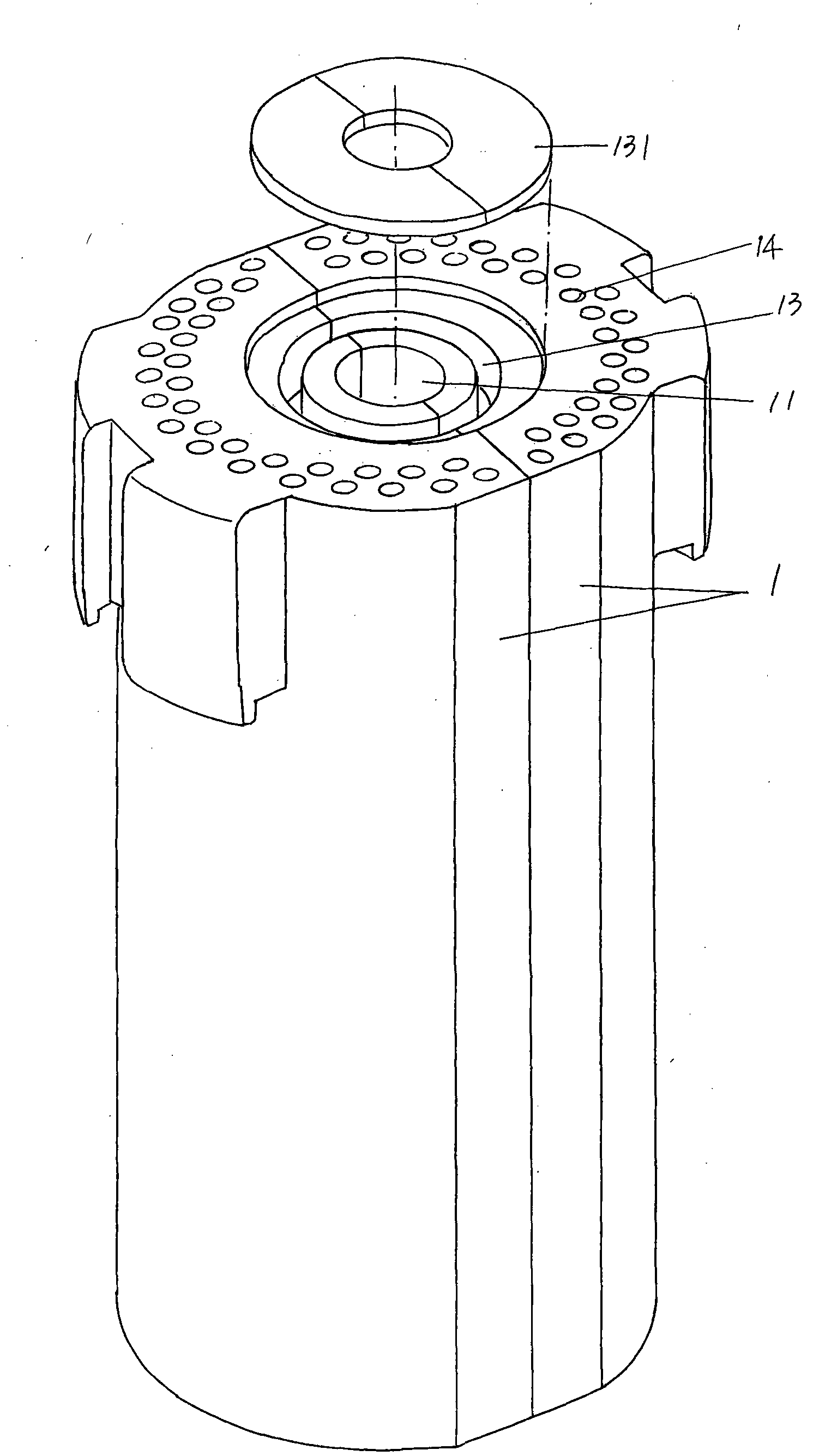

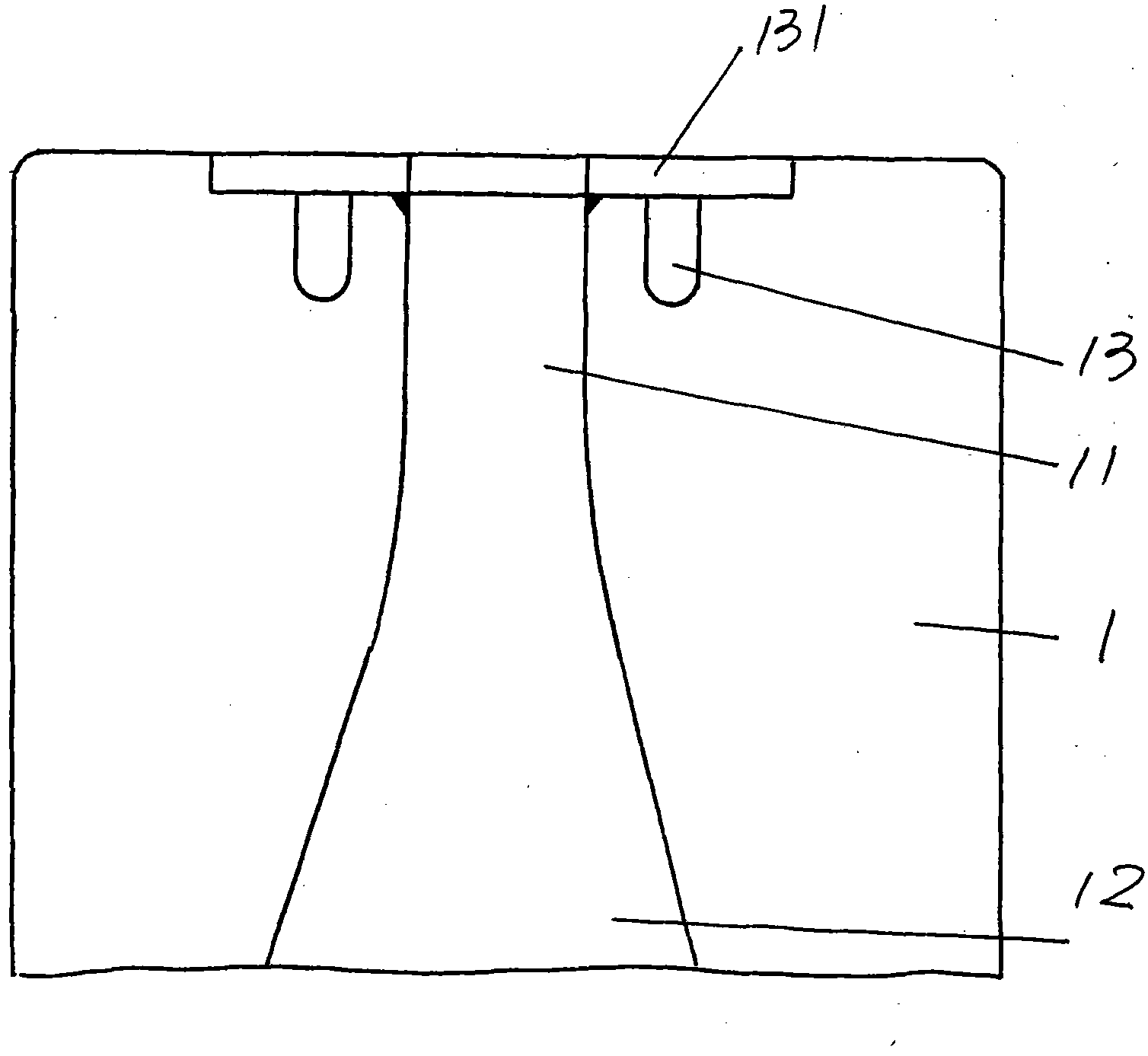

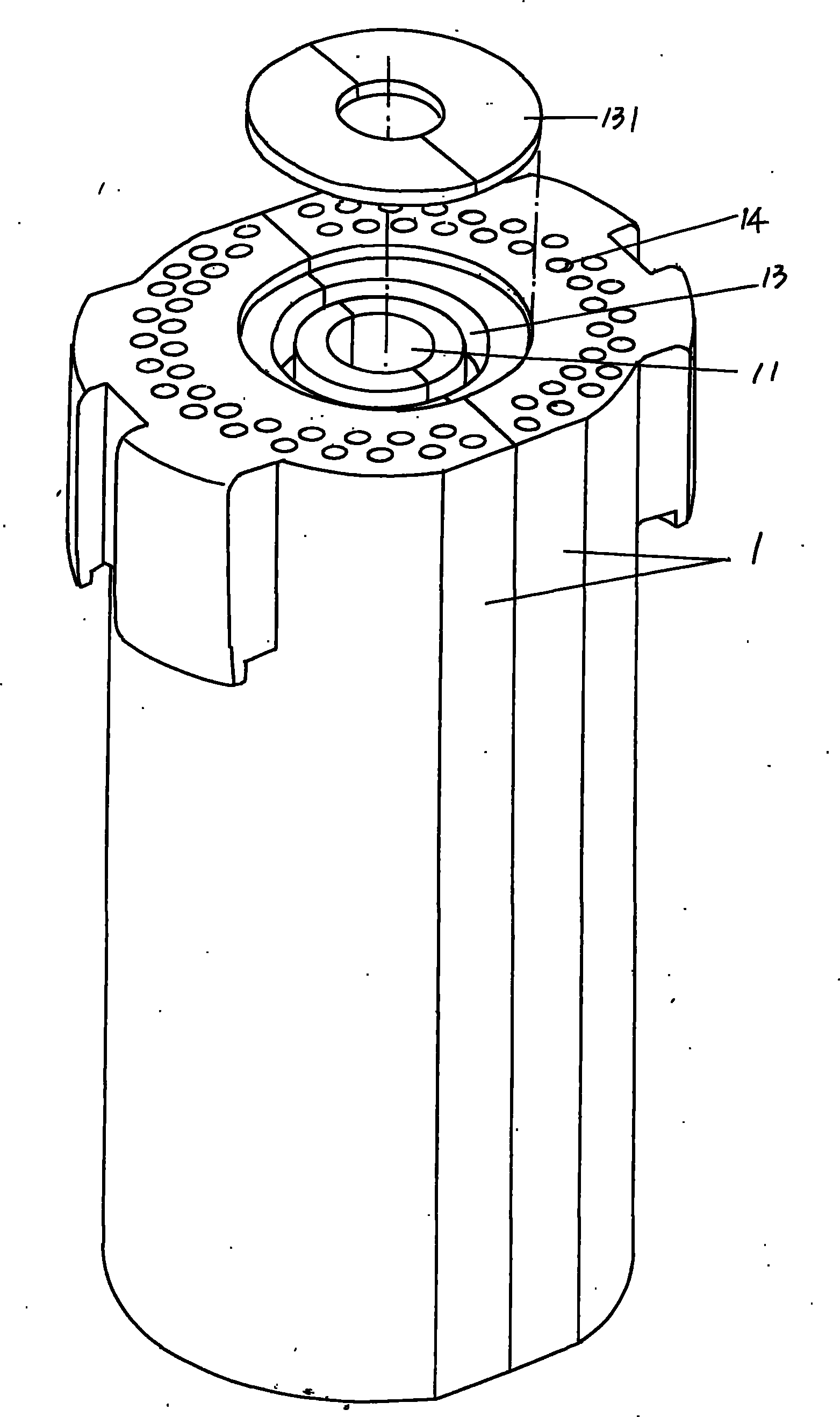

Cooling method of battery pack and battery pack with cooling device

ActiveCN105206895AAvoid thermal runawayAchieve uniform temperature controlSecondary cellsVapor pressureInternal pressure

Owner:方乐同

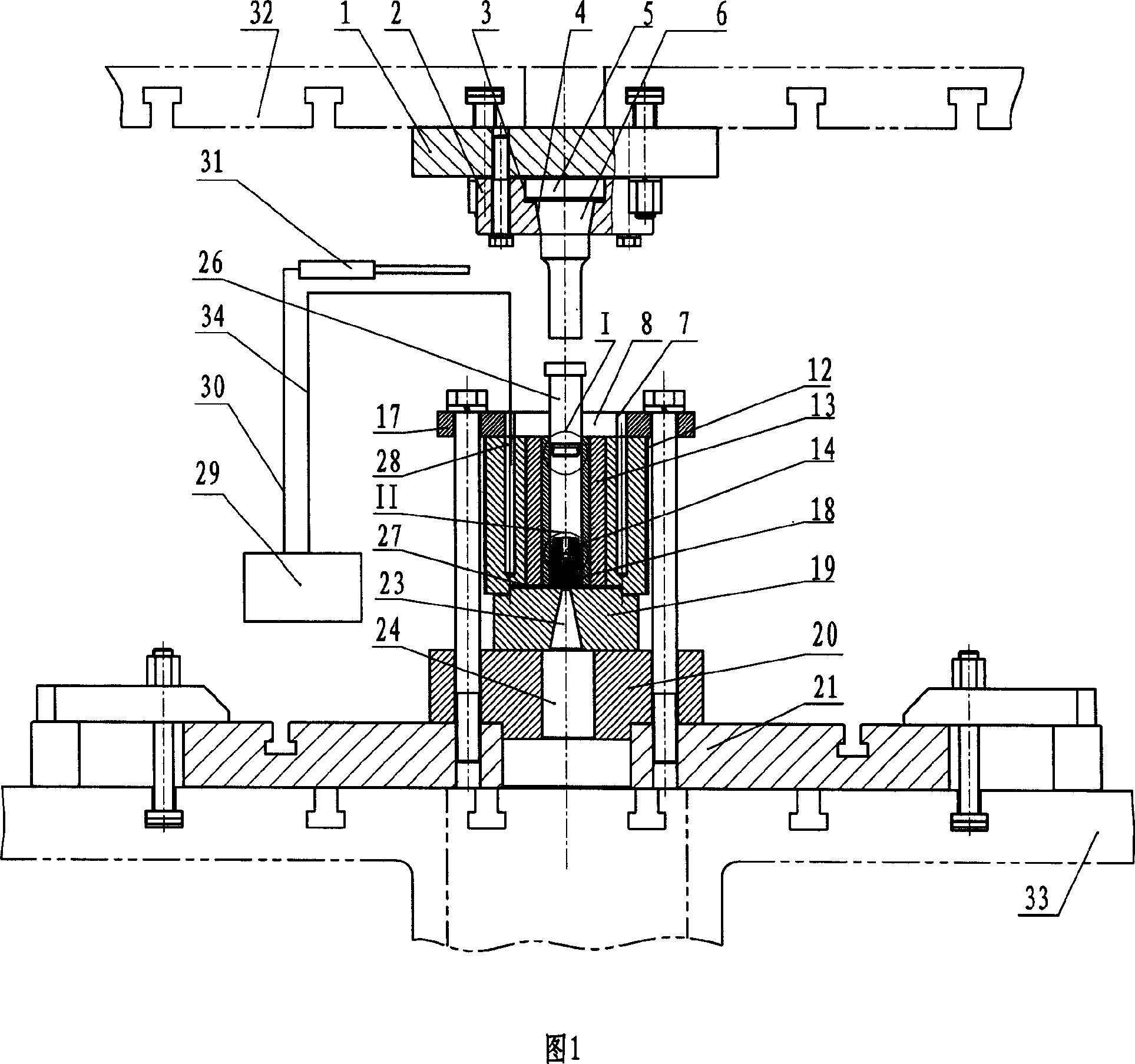

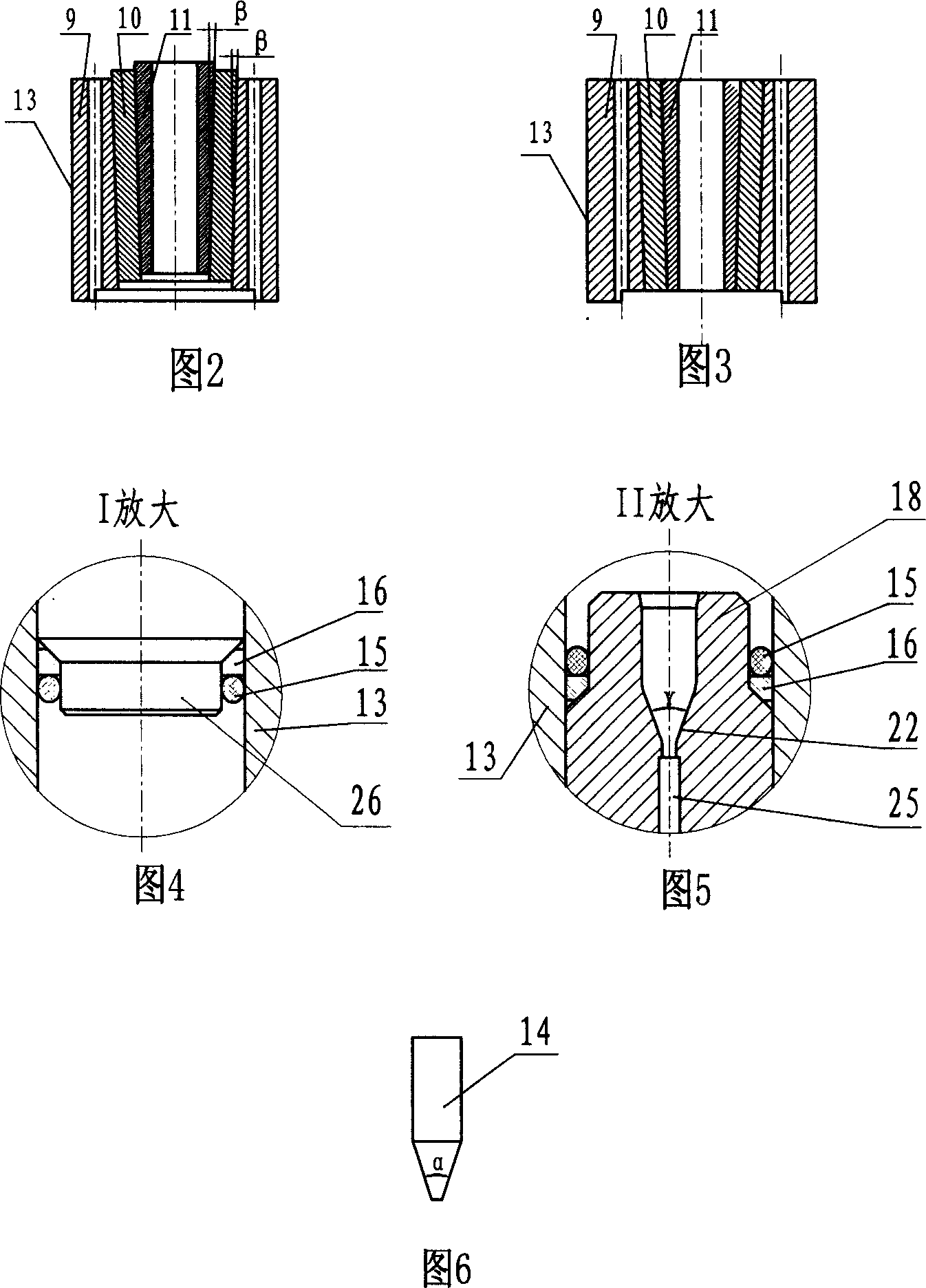

Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

InactiveCN101015841ASpeed up heat dissipationSlow down heat dissipationExtrusion diesExtrusion control devicesTemperature controlPhysical property

The invention relates to a hydraulic extruding method for producing magnesium alloy wire or rod, and relative specific extruding mould, which can avoid crack and high cost or the like. The inventive method comprises that processing magnesium alloy blank, coating lubricant, and heating with era oil, heating hydraulic extruding mould and controlling temperature, arranging magnesium alloy blank, filling era oil, arranging movable convex mould, pressurizing and extruding. The inventive mould comprises a movable convex mould (26), under a convex mould (6) and coaxial with the convex mould (6), wherein the lower end of the convex mould (26) is through a convex mould through hole (8) at the middle of a convex mould press plate (17) to be mounted on the upper part of an extruding barrel (13), and the extruding barrel (13) is a multilayer cold press extruding one. The invention can obtain better physical property and surface quality, or the like.

Owner:HARBIN INST OF TECH

Process of manufacturing cloisonne silverware

ActiveCN102173271AReduce heat conduction speedSlow down heat dissipationSpecial ornamental structuresHeat conductingCopper

The invention belongs to the technical field of cloisonne manufacture, in particular to a process for manufacturing cloisonne silverware. A body is made of silver, and filamentary silver is used for filigree; and the process comprises the following process steps of: rolling the body; soldering filigree; welding; filling enamel; firing the enamel; and polishing, wherein after an enamel filling procedure, the inner wall of a silver body is filled with a cool medium material, the cloisonne silverware filled with the cool medium material is put into a furnace for enamel firing, and the cloisonne silverware is immediately taken out of the furnace once the enamel is melted. In the process for manufacturing the cloisonne silverware, the adopted cool medium material effectively reduces the heat conducting or heat dissipating speed of the silver body, the problem of corrosion of a copper body is solved, and the silver is used as an inner body, so that the cloisonne has health-care effect and higher visual aesthetic feeling.

Owner:SHANXI YINMANLOU JINGTAILAN SILVER PRODS

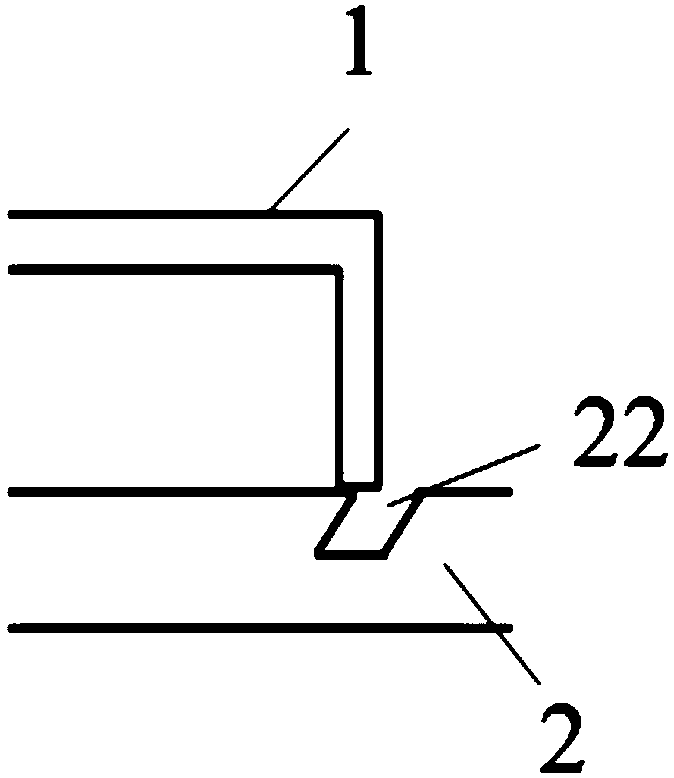

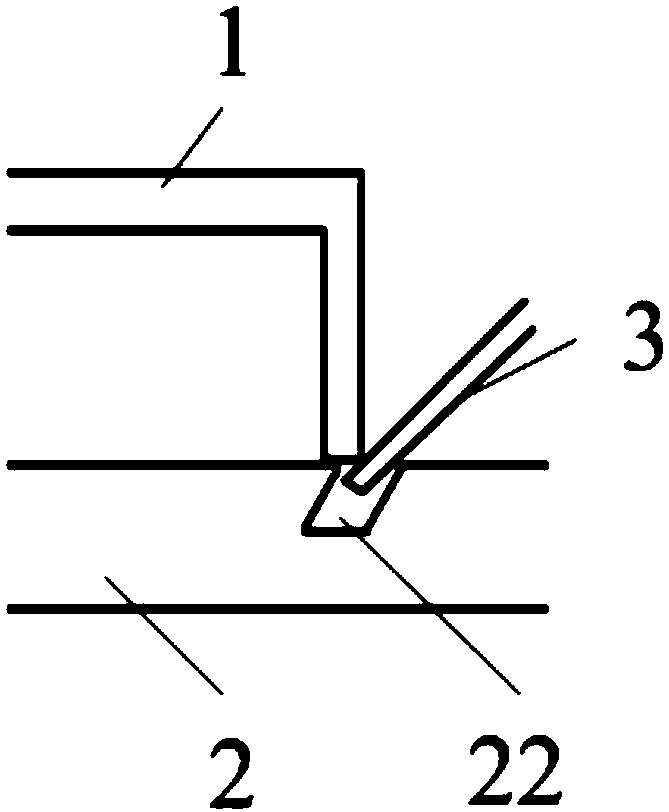

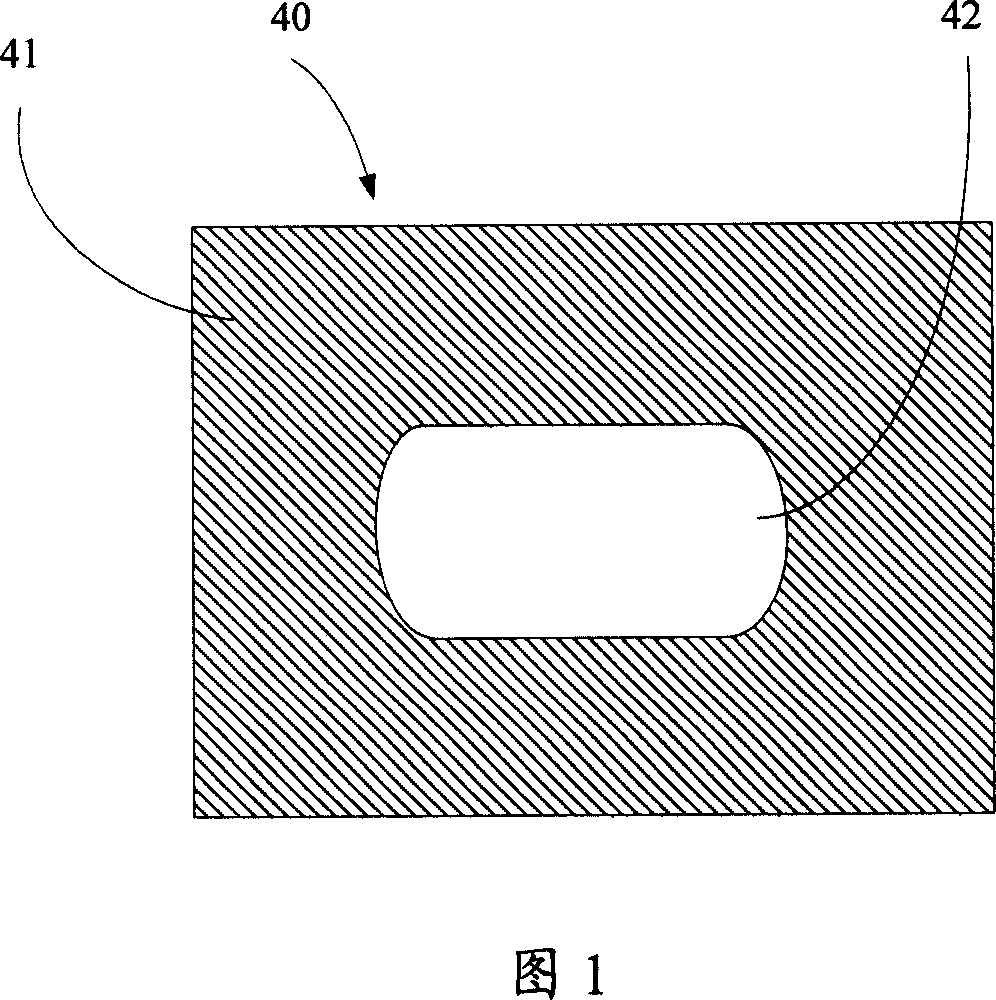

Mould for manufacturing glass container

InactiveCN101891371AQuality assuranceSlow down heat dissipationGlass blowing apparatusBottle neckEngineering

The invention discloses a mould for manufacturing a glass container and belongs to the technical field of glass moulds. The mould for manufacturing the glass container comprises a pair of bottle semi-moulds which have the same shape and are opposite to each other; and each of the bottle semi-moulds has a bottle-neck cavity and a bottle body cavity. The mould is characterized in that: a heat insulation groove is reserved on the bottle semi-mould around the mouth of the bottle-neck cavity, and the upper part of the heat insulation groove is sealed by a heat insulation groove cover. As the heat insulation groove is formed at the mouth of the bottle-neck cavity of the bottle semi-moulds, the heat dissipation speed of the bottle mouth is reduced in the mould forming process of a bottle, the cracking caused by too rapid heat dissipation is avoided and the quality of the bottle is assured.

Owner:CHANGSHU JIANHUA MOLD TECH

Method for improving heat insulation effect of open riser

InactiveCN101954462AEasy to operate and recyclableSlow down heat dissipationFoundry mouldsFoundry coresAluminium silicateSteel plates

The invention relates to a method for improving the heat insulation effect of an open riser, which is characterized in that after completing pouring castings, an insulation board covers the top of the open riser, according to the dimension of the open riser, the insulation board is a square case which is made of 5-12mm thick steel boards and is adaptive to the dimension of the open riser, the square case is filled with aluminium silicate Al2O3.3SiO2 and is compressed, the upper part of the square case is welded by an iron supporting and tensioning net with diameter of 10-14mm and the square case is fixed on the open riser. The method has the following beneficial effects: the cover board aims to prevent deformation under high temperature and play a role of good heat insulation; the insulation board is simple and convenient to operate and can be recycled; and after the insulation board covers the top of the open riser, the insulation board can well reduce radiation and convective heat transfer, reduce the heat dissipation speed of the molten steel, lengthen the solidification time, improve the feeding effect of the riser, effectively eliminate the shrinkage cavity and ensure the quality of the castings.

Owner:广东省韶铸集团有限公司

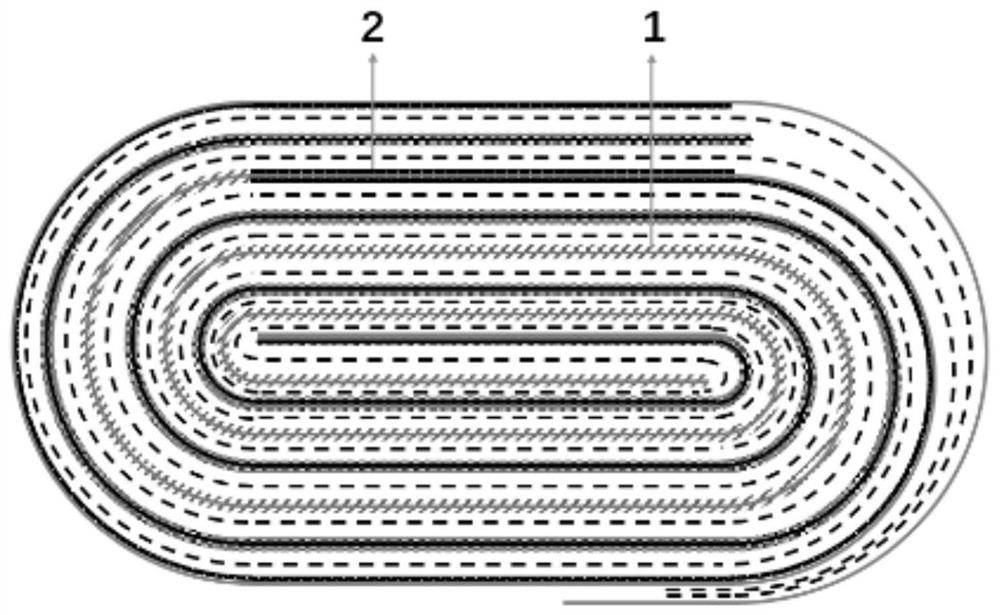

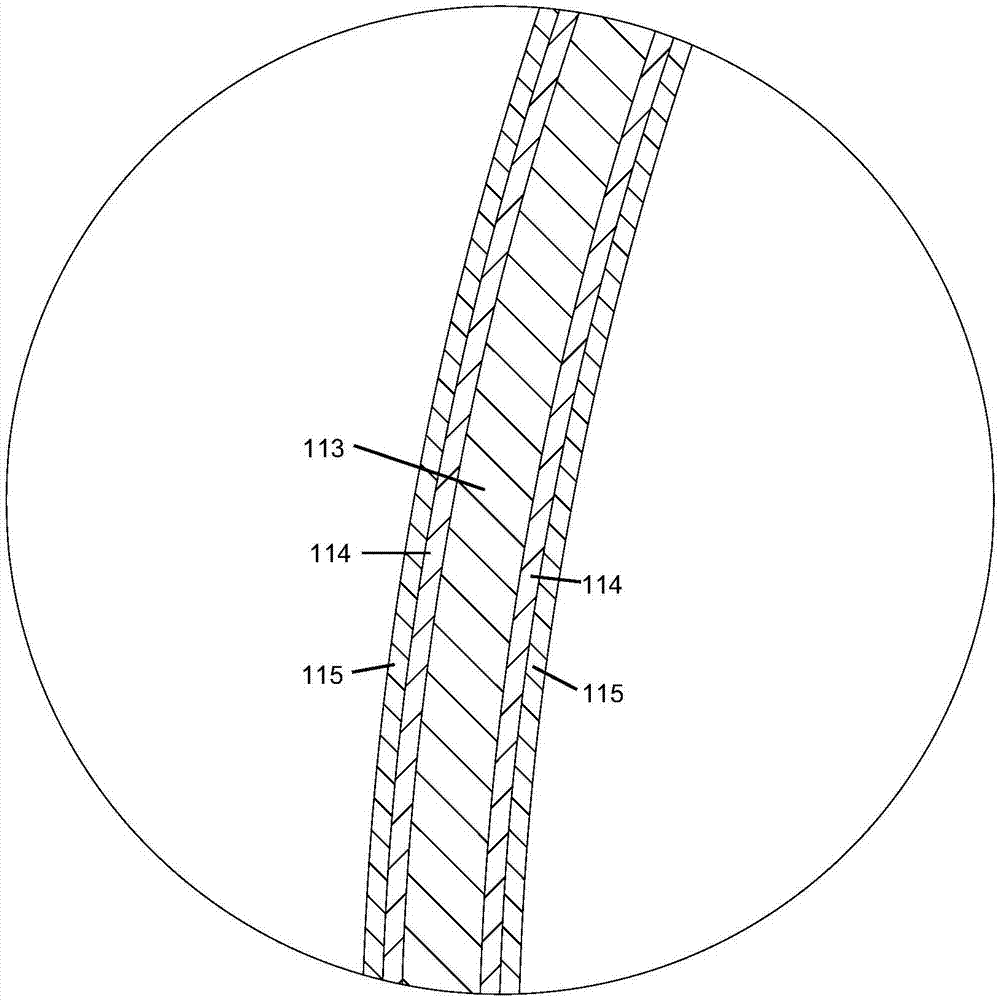

Roll core used for wound lithium ion battery and capable of reducing internal temperature rise

ActiveCN112186273AReduce temperature riseReduce the impedance valueFinal product manufactureSecondary cellsThermodynamicsEngineering

The invention provides a roll core used for a wound lithium ion battery and capable of reducing internal temperature rise. A positive plate is used in the roll core; the impedance value of the starting region of the positive plate is reduced by coating different positive active material layers on the starting region and other regions along the length direction of a positive current collector in the positive plate; and under high-rate charging, the heat production quantity of a high-temperature hot area which is difficult to dissipate heat in a battery is reduced, so that the temperature rise of the battery under high-rate charging is reduced. Besides, when the impedance is reduced by increasing the content of a conductive agent in the starting region of the positive plate, the other regions can still be coated with active substances with higher content, so that the technical effects of reducing the temperature rise of the battery and reducing the energy density loss are achieved.

Owner:ZHUHAI COSMX BATTERY CO LTD

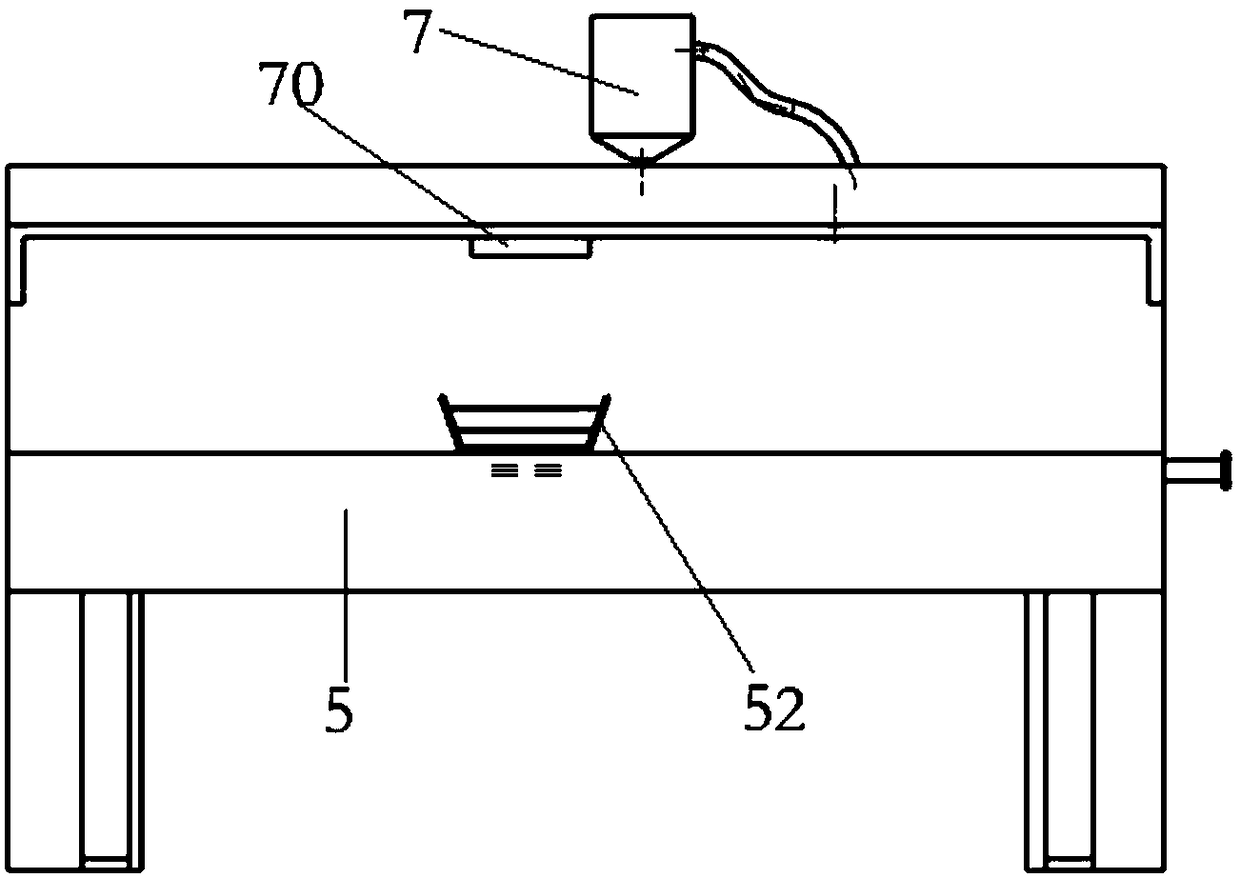

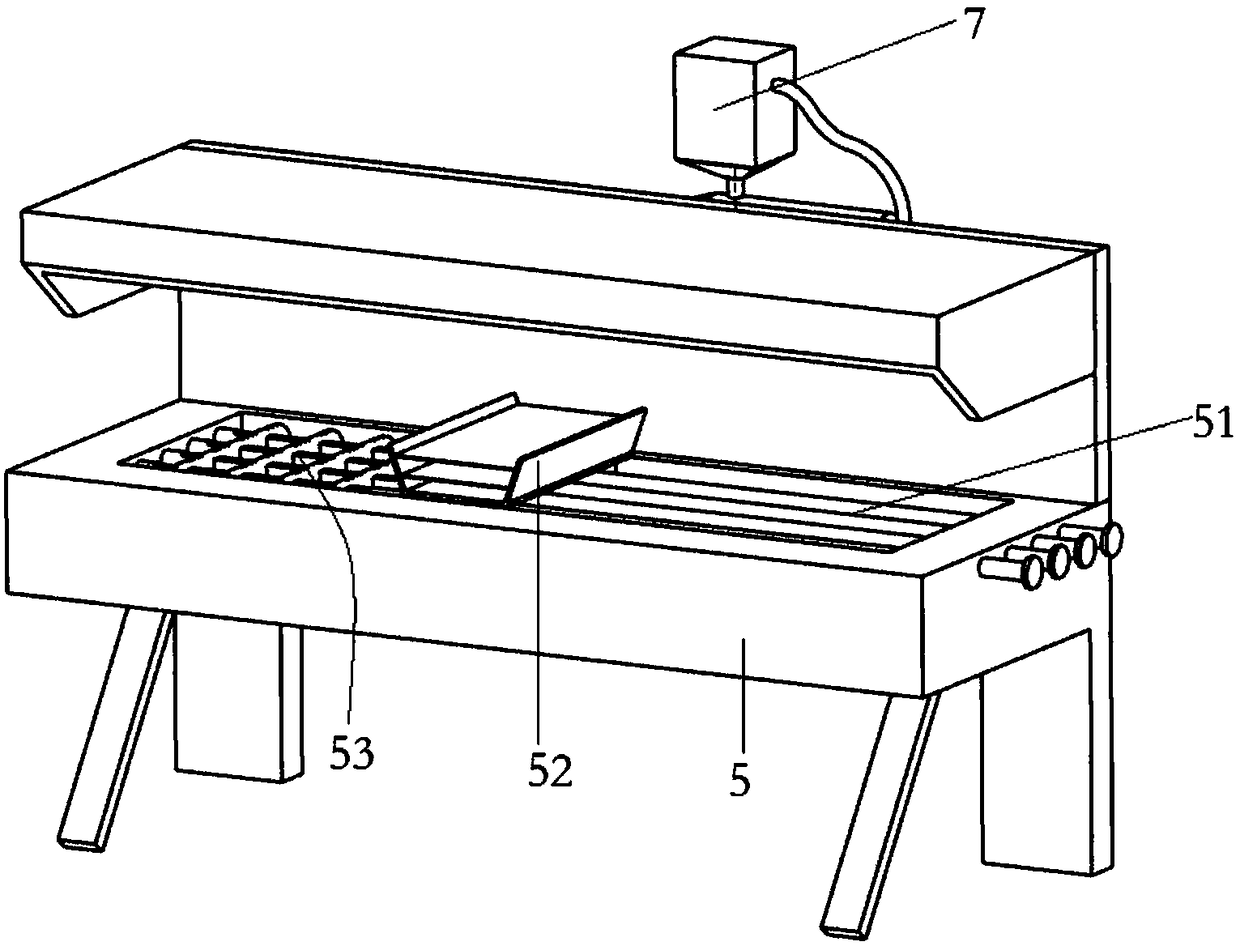

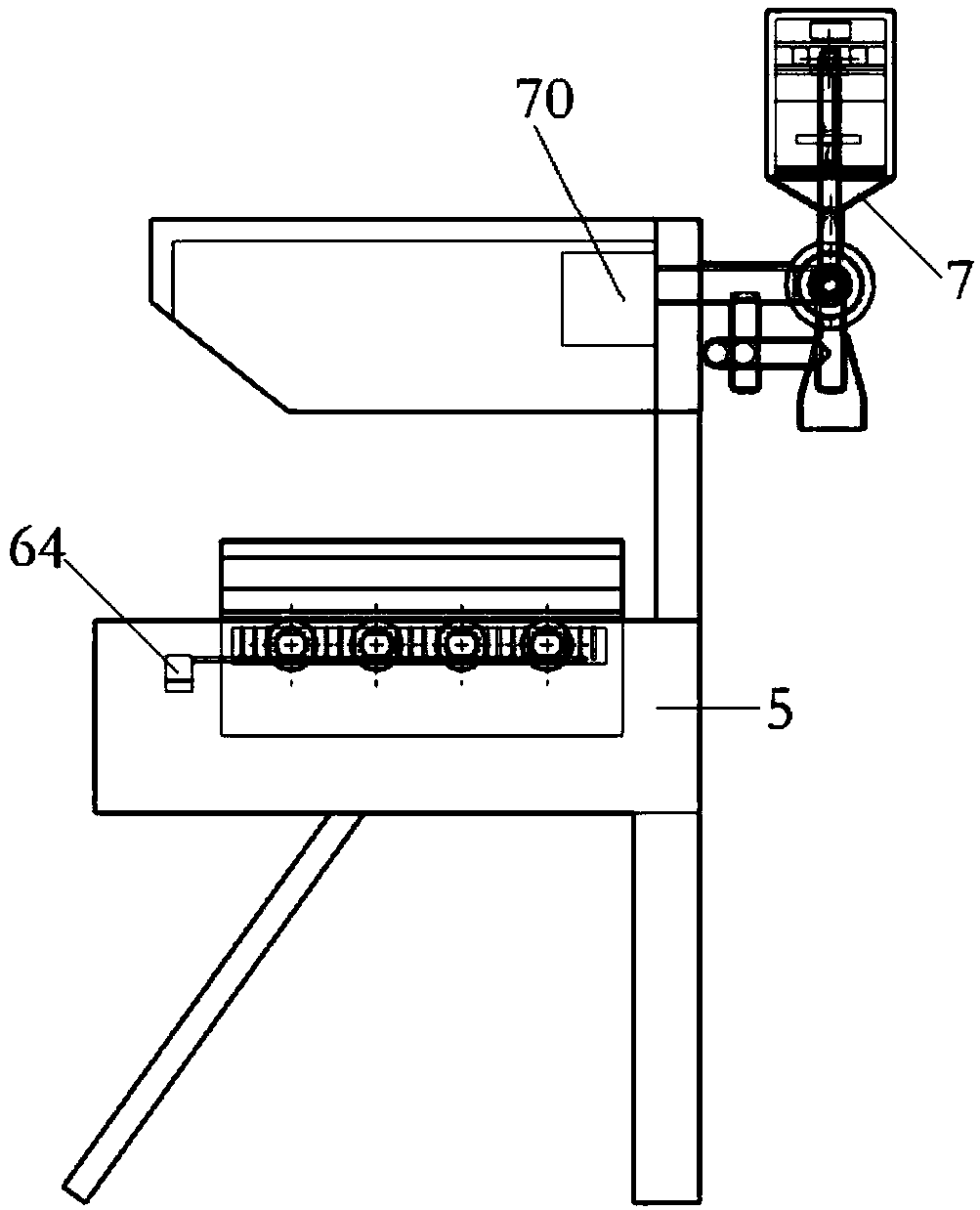

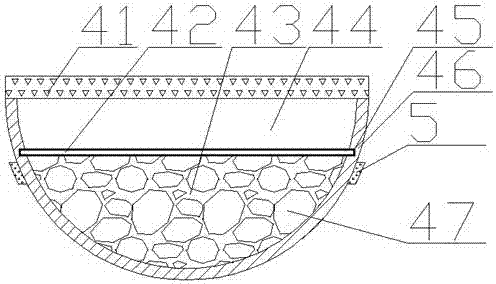

Environment-friendly grilling machine capable of absorbing smoke and method of environment-friendly grilling machine

ActiveCN108523691AEvenly heatedSlow down heat dissipationCombination devicesGas treatmentPulp and paper industrySmoke

The invention discloses an environment-friendly grilling machine capable of absorbing smoke and a method of the environment-friendly grilling machine. The environment-friendly grilling machine comprises a grilling machine body, the grilling machine body is in a rectangular groove shape, a grill of the grilling machine body comprises a first grill body and a second grill body, and the first grill body and the second grill body are adjacent in the length direction of the grilling machine body; a heat preservation assembly is arranged between the first grill body and the second grill body and arranged on the grilling machine body, the grilling machine body is further provided with a smoke absorbing assembly, and a smoke absorbing device is located above the grill and absorbs the smoke above the grill. According to the environment-friendly grilling machine capable of absorbing the smoke and the method of the environment-friendly grilling machine, the content of the smoke exhausted into airis reduced.

Owner:盐城抱璞文化传媒有限公司

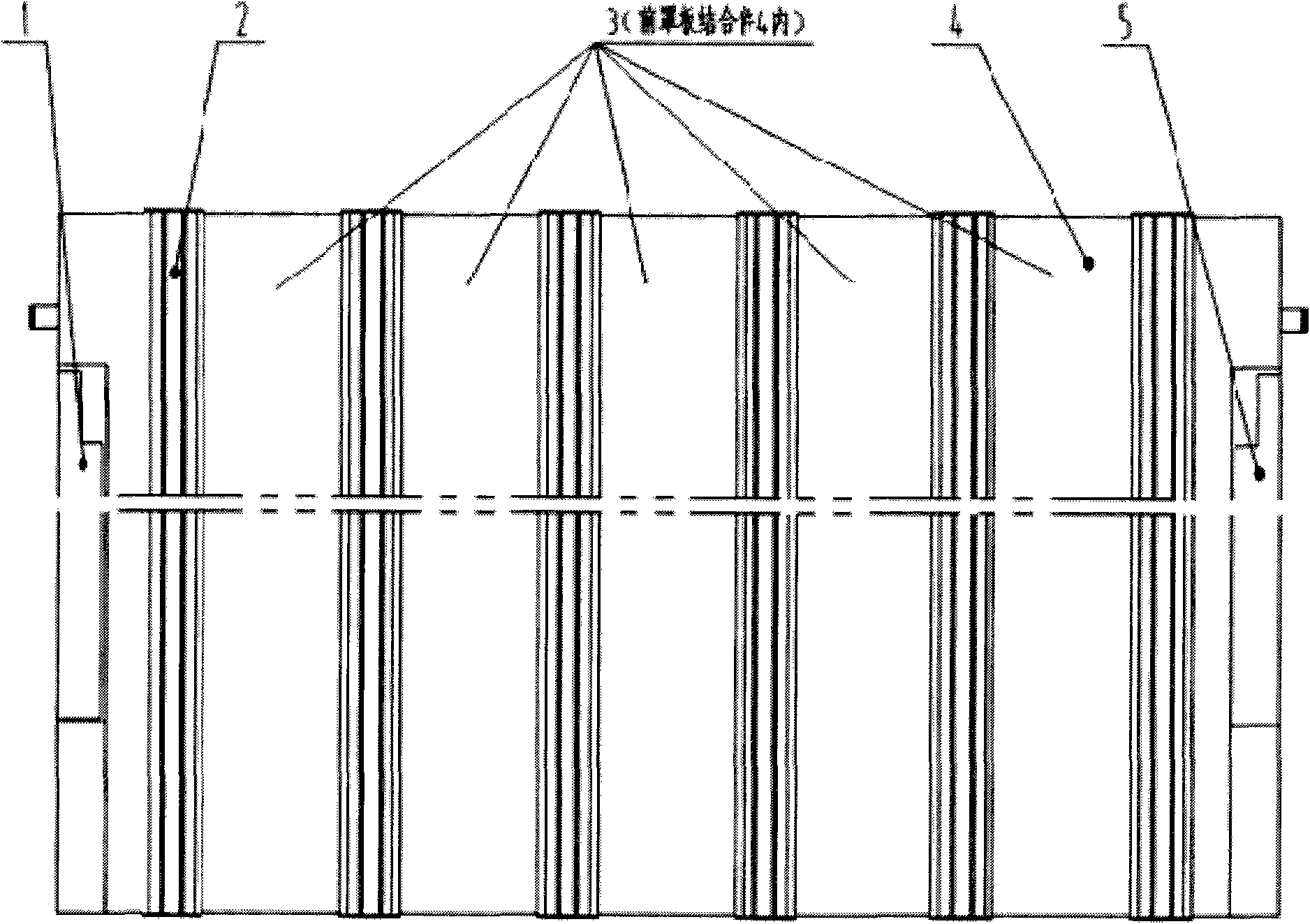

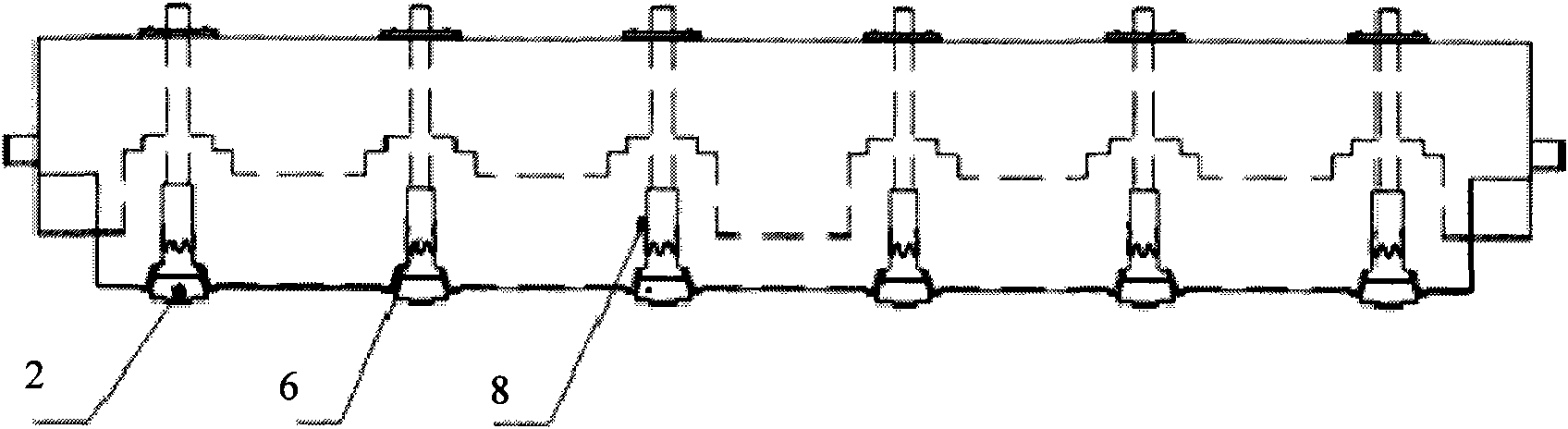

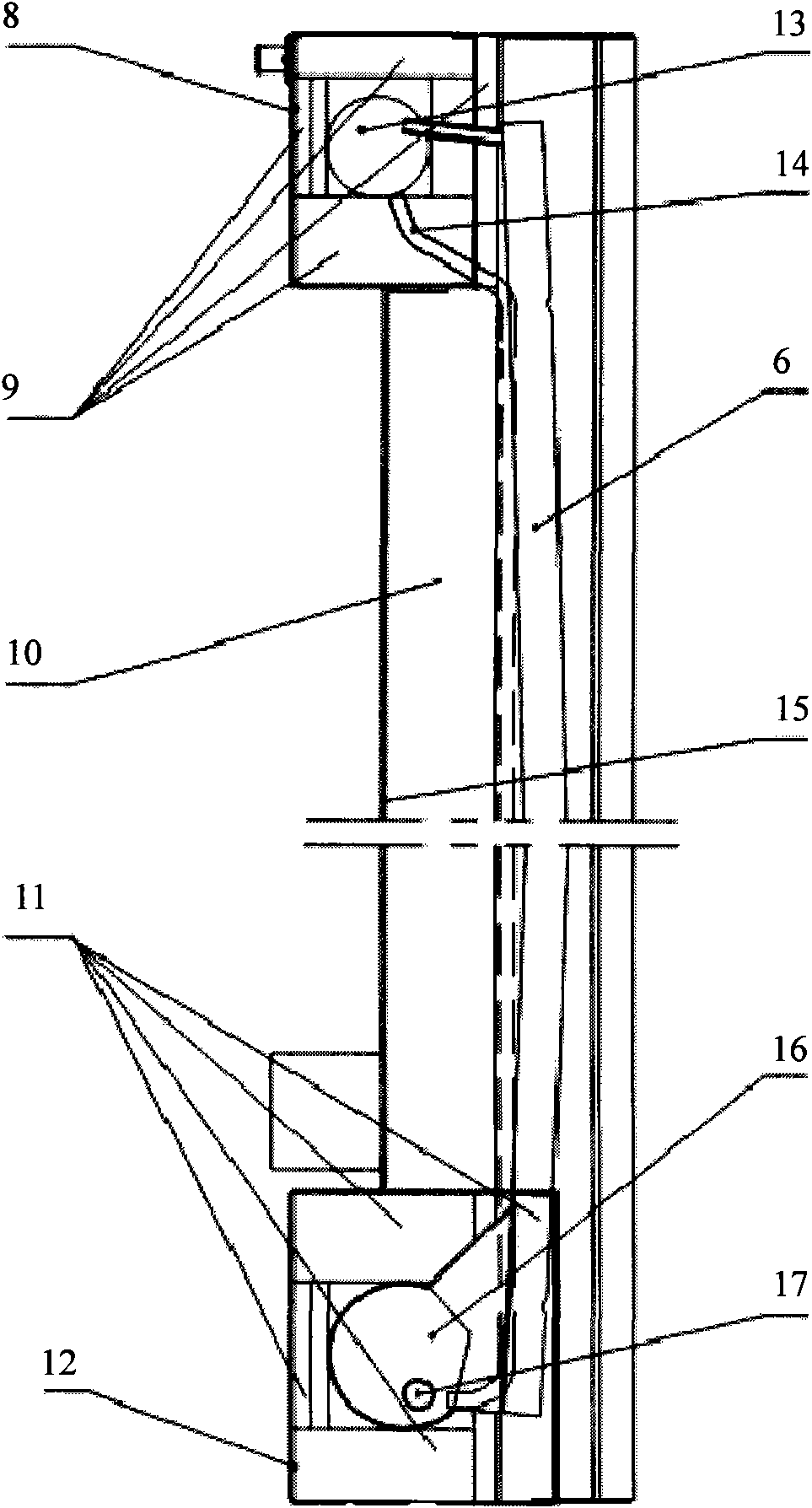

Deformation hot box

The invention relates to a deformation hot box. The deformation hot box comprises a box body, a heating track, a liquid-filling tube, a condensing tube, an electrical bar and a liquid return tube, wherein the heating track, the liquid-filling tube, the condensing tube, the electrical bar and the liquid return tube are installed in the box body; the box body comprises an upper shield plate combination piece, a lower shield plate combination piece, a left shield plate combination piece, a right shield plate combination piece, a front cover plate combination piece, a back cover plate combination piece and a heating track door combination piece, the internal side of the heating track door combination piece is provided with a plurality of heating tracks, the external side of the heating tracks is provided with an insulating block, the insulating block is used for preventing the heat generated by the heating tracks from dissipating so as to reduce the heat dissipation speed of the deformation hot box and generate the heat preservation effect, thereby the energy consumption cost is reduced and the quality of filamentization is improved.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

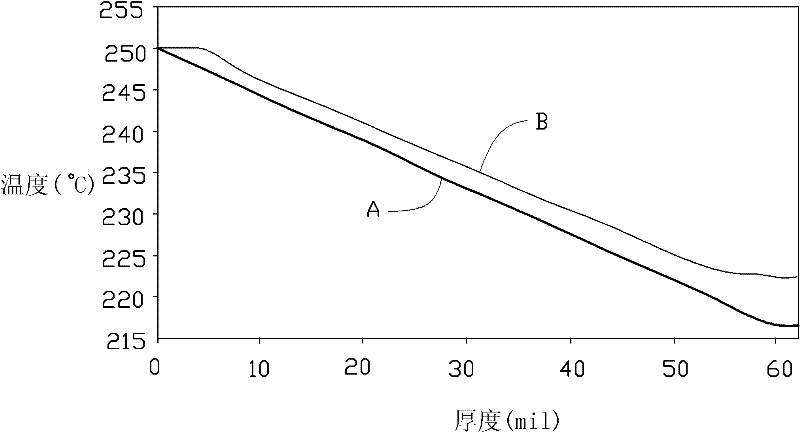

Improved structure of single crystal furnace for growing large-size sapphire

InactiveCN105088332ASufficient axial temperature gradientFast growthPolycrystalline material growthUsing seed in meltThermal insulationSingle crystal

The invention provides an improved structure of a single crystal furnace for growing large-size sapphire. The improved structure comprises an upper thermal insulation structure, side thermal insulation structures and a bottom thermal insulation structure, wherein the upper thermal insulation structure and the bottom thermal insulation structure are identical to those in patents of the earlier stage; the difference resides in that the thicknesses of the thermal insulation layers are gradually reduced from top to bottom instead of identical thicknesses of upper and lower structures of the side thermal insulation structures, the diameter of a birdcage-like heating body is gradually reduced from top to bottom, and the heating body is in a shape of an inverted cone. The thermal field is uniform and reasonable, the crystal growth rate is stable, defects that crystals generates clouds, are glued on pots and the like can be effectively reduced, the dependence on a process control worker is low, and the crystal growth yield is high.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Plateau area asphalt pavement construction method

InactiveCN110080066AImprove paving qualitySlow down heat dissipationRoads maintainenceMixed materialsRoad surface

The invention discloses a plateau area asphalt pavement construction method and relates to the technical field of highway construction. The plateau area asphalt pavement construction method comprisesthe step of correspondingly arranging mobile wind break walls along the two sides of a construction pavement during constructing a plateau area asphalt pavement, wherein the length of the wall arranged on single side every time is not less than 200 m, the height of the wall arranged on single side every time is not less than 50 m, the bottom of the wall is in close contact with the ground, and thematerials of the mobile wind break walls are wind proof materials used for reducing temperature loss of asphalt mixture in the paving process. The specific construction method comprises the steps of(1) blending asphalt mixture, (2) transporting a mixed material, (3) paving the mixed material; and in the construction process, arranging the mobile wind break walls when the wind power reaches grade4 or above, and (4) rolling the mixed material. According to the plateau area asphalt pavement construction method, through adoption of the wind break walls, the temperature loss of the asphalt mixture can be reduced, and the asphalt pavement paving quality can be improved; and the plateau area asphalt pavement construction method is very suitable for severe construction environments with low temperature, high wind speed, low surface temperature and the like in plateau areas.

Owner:青海省交通科学研究院

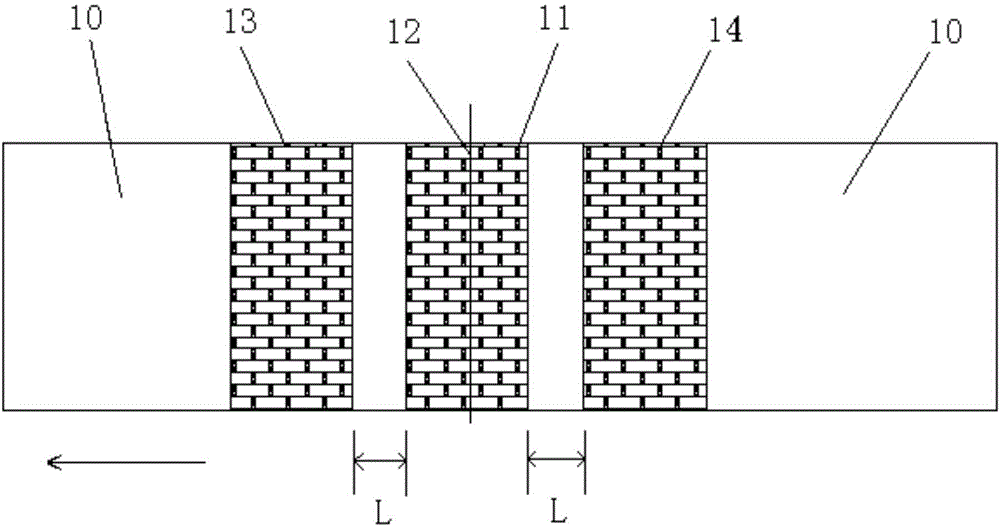

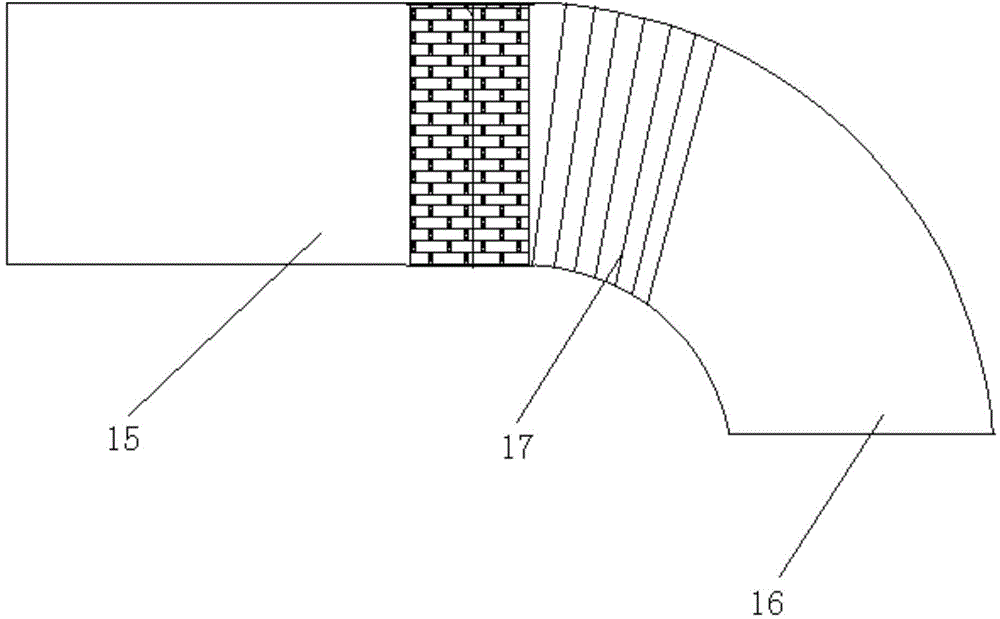

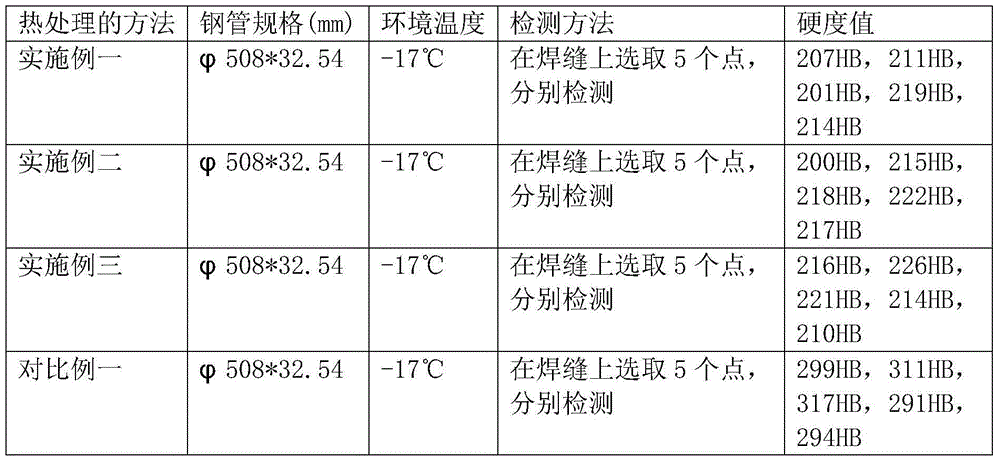

Method for assisting heat treatment of steel pipe welding seams

InactiveCN104561509AHeat dissipation fastSlow down heat dissipationFurnace typesHeat treatment furnacesSteel tubePipe welding

The invention belongs to the technical field of metal welding. In order to solve the problem that the hardness cannot reach the standard requirement of ASME through measurement after heat treatment of the welding seams when an A335GR.P91 large-diameter and thick-walled steel tube is welded in winter, the invention provides a method for assisting heat treatment of steel pipe welding seams. The method comprises the following steps: (1) wrapping heaters at the welding seams, and wrapping the heaters with heat insulating material; (2) for the welding seams at long tube sections, wrapping the heaters at the positions 550-700 mm away from the heaters wrapped at the welding seams on the steel tube, and using the heat insulating material to completely wrap the steel tube; (3) for the welding seams on short tubes and bends, using the heat insulating material to completely wrap the steel tube; (4) during the heat treatment process, for the welding seams at long tube sections, controlling the temperature of the steel tube wrapped by the heater at the position 550-700 mm away from the heaters wrapped at the welding seams to be 200-300 DEG C. By using the method provided by the invention, the hardness value at the welding seams meets the standard requirement of ASME.

Owner:CHINA NUCLEAR IND 23 CONSTR

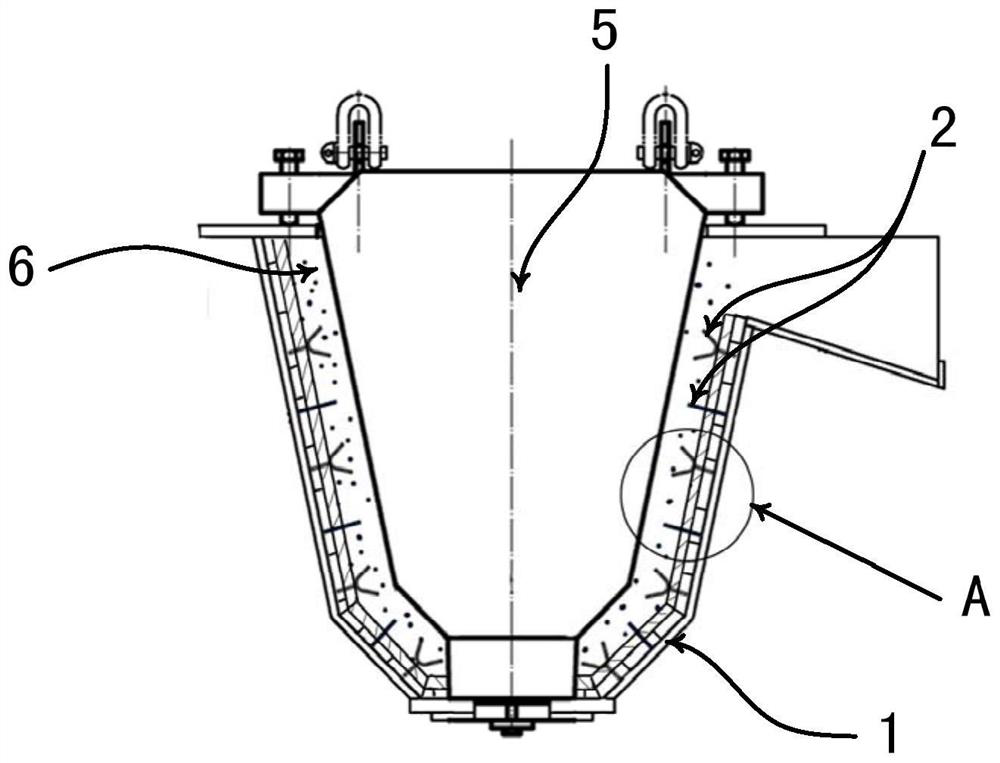

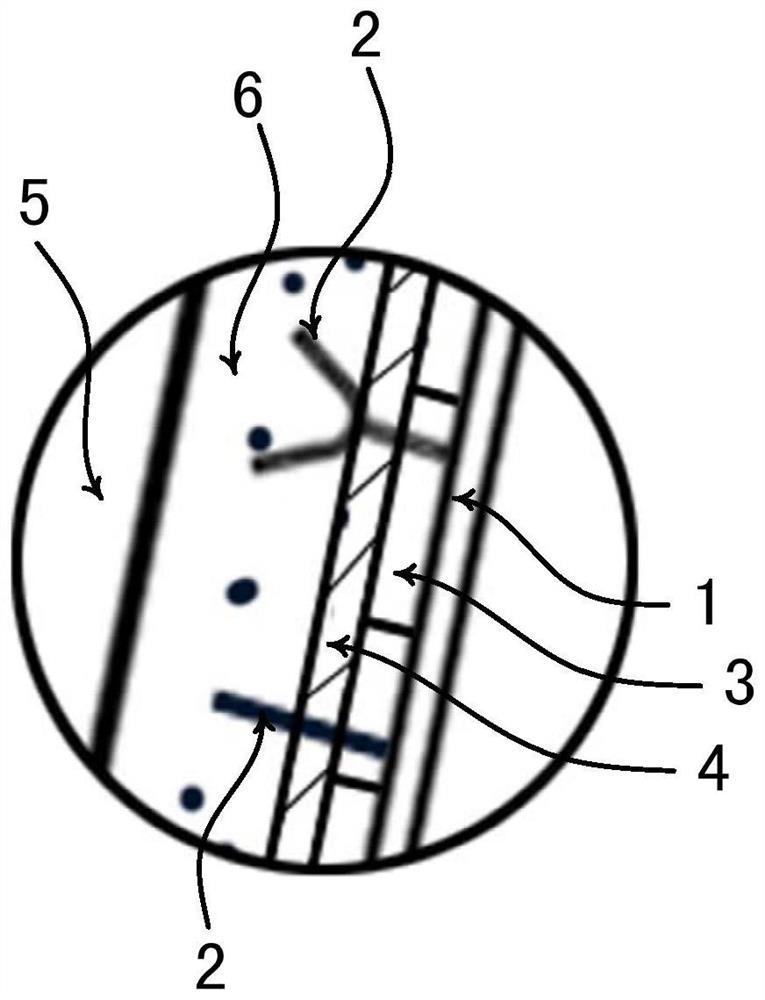

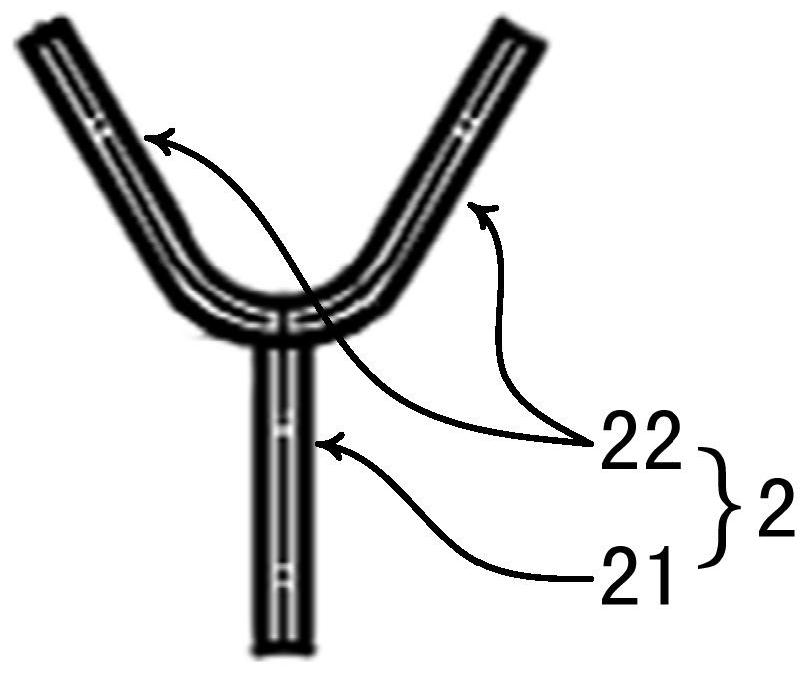

Thermal-insulating construction process for tundish

InactiveCN111687401AAvoid damagePlay the role of secondary fixationMelt-holding vesselsBrickHeat losses

The invention provides a thermal-insulating construction process for a tundish. The thermal-insulating construction process comprises the following steps: S1, anchoring nails are fixed, specifically,the anchoring nails which are distributed in an arrayed mode are fixed to the inner surface of an envelope of the tundish; S2, thermal-insulating plates are laid, specifically, the thermal-insulatingplates are laid on the inner surface of the envelope of the tundish to fully pave the inner surface of the envelope of the tundish; S3, light bricks are laid, specifically, the light bricks are laid on the other surfaces of the thermal-insulating plates to cover all the thermal-insulating plates; S4, a core mold is mounted, specifically, the core mold is placed into the envelope, and the core moldand the envelope are made to be relatively fixed; and S5, casting and demolding are conducted, specifically, a castable is poured into a cavity defined by the core mold and the envelope jointly, andafter the castable is solidified, the core mold is upwards moved out to complete demolding. The heat loss of molten steel can be reduced, the situation that the molten steel becomes sticky due to thefact that the temperature of the molten steel is lower than the smelting requirement is avoided, and thus the thermal-insulating effect of the thermal-insulating tundish is achieved.

Owner:MCC BAOSTEEL TECH SERVICE

Multifunctional washing basin

The invention discloses a multifunctional washing basin. The multifunctional washing basin comprises a basin body, wherein an outer shell is arranged outside the basin body; a heat insulating layer is arranged between the outer shell and the basin body; a detachable maintenance plate is arranged on the outer shell; a master controller, an ozone generator, a magnetically controlled switch and a cover are arranged on the basin body; the basin body and the cover enclose to form a chamber; a magnet is arranged on the cover and is arranged correspondingly to the magnetically controlled switch; the ozone generator has an opening at the bottom of the basin body through a conduit; the ozone generator and the magnetically controlled switch are respectively connected with the master controller; a heating device is arranged between the basin body and the cover; the cover is hinged with the basin body; and a lock device is arranged between the basin body and the cover. The multifunctional washing basin also comprises a power adapter for converting power supply into low-voltage direct current; the power adapter is connected with the master controller; a sealing strip is arranged on the cover; and the sealing strip is arranged on the matching surface, connected with the basin body, of the cover. The multifunctional washing basin has the characteristics of simple and reasonable structure, operating flexibility, easiness in installation, easiness in maintenance, and high safety degree.

Owner:佛山市爱够厨卫有限公司

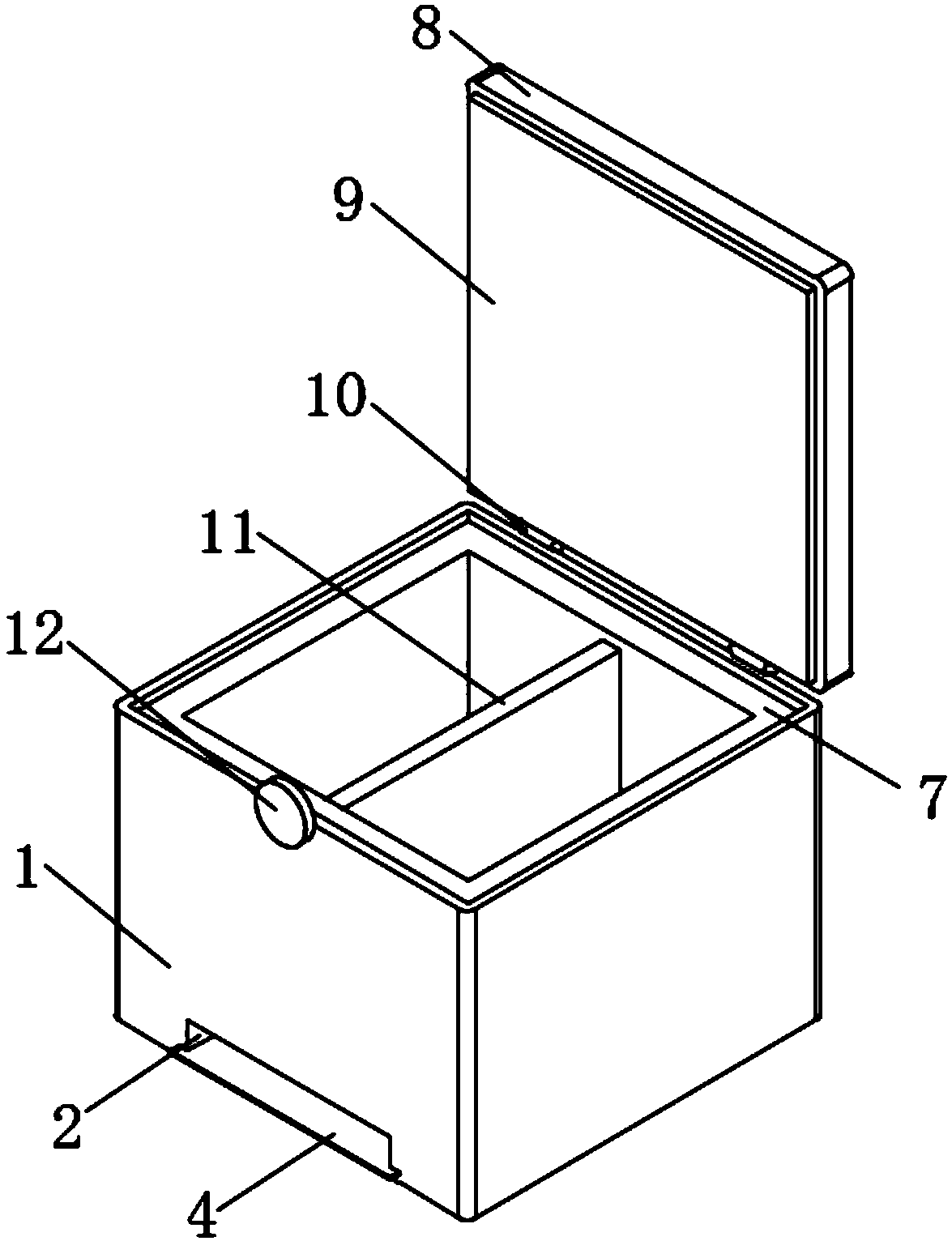

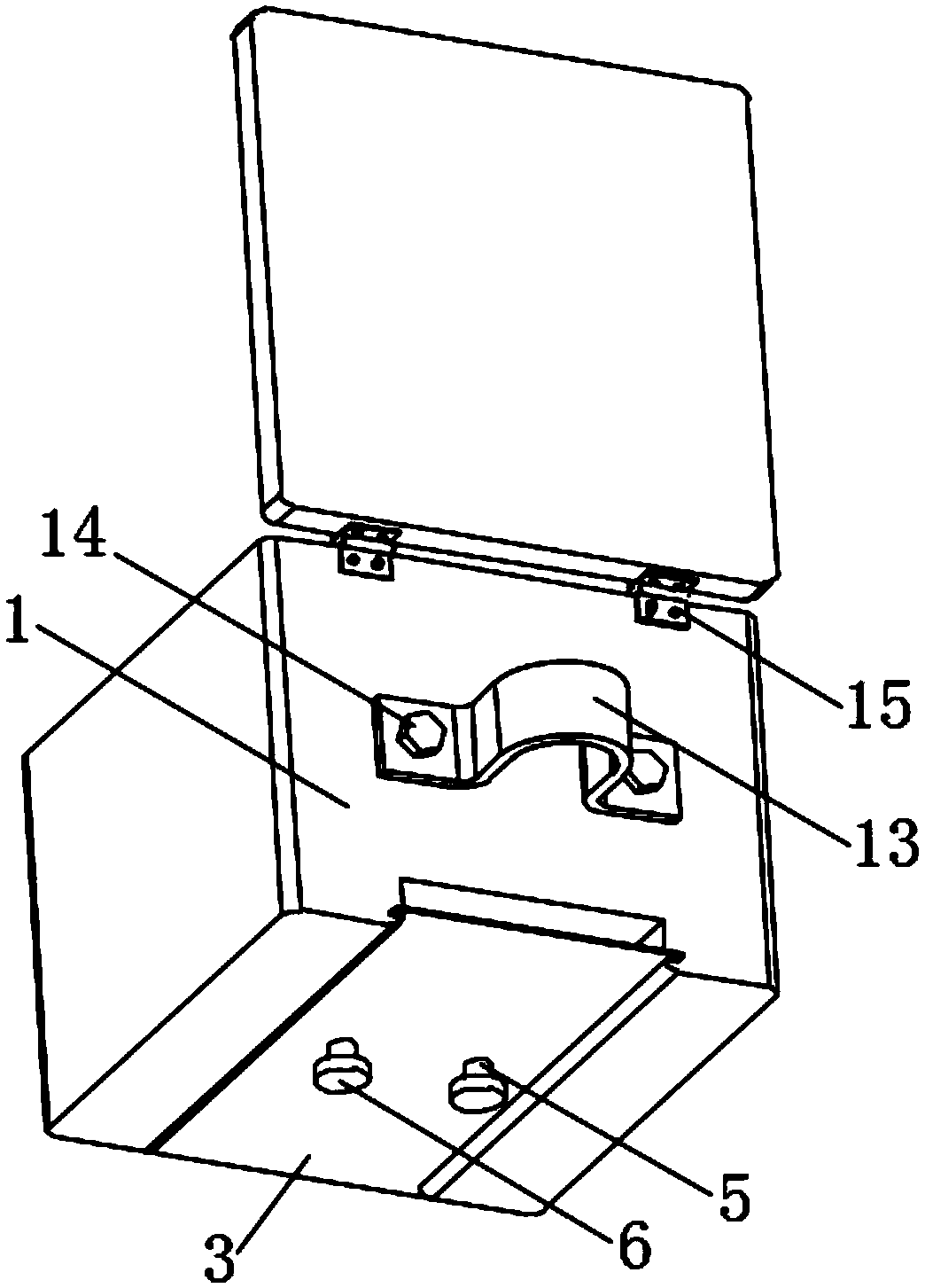

Toppling preventing takeout box

InactiveCN108891787AAchieve fixationRealize classification placementDomestic cooling apparatusLighting and heating apparatusInsulation layerSlide plate

The invention discloses a toppling preventing takeout box which comprises a box body. A clamping groove is formed in the bottom end face of the box body, and a sliding plate is arranged at the lower end in the through groove. Threaded holes are formed in the sliding plate, screw rods are arranged in the threaded holes, and adjusting hand wheels are arranged at the lower ends of the screw rods. A separation plate is arranged in the middle of the box body, foam heat insulation layers are arranged on the inner walls of the box body, and the thickness of the foam heat insulation layers is not smaller than 2 cm. The toppling preventing takeout box is simple in structure and convenient to use, a corresponding fixing structure is arranged, and the takeout box can be fixed from multiple angles; then the problem that a takeout box is not firmly fixed and is likely to topple is effectively solved, and great convenience is brought to a user; a corresponding lock is arranged, and therefore the safety of objects in the takeout box can be effectively improved; a corresponding heat insulation structure is arranged, the heat radiating speed of foot can be reduced, the objects in the takeout box can be classified and placed, a delivery worker can store the food conveniently, and delivery is convenient.

Owner:SUZHOU BIAOGAN INTPROP OPERATION CO LTD

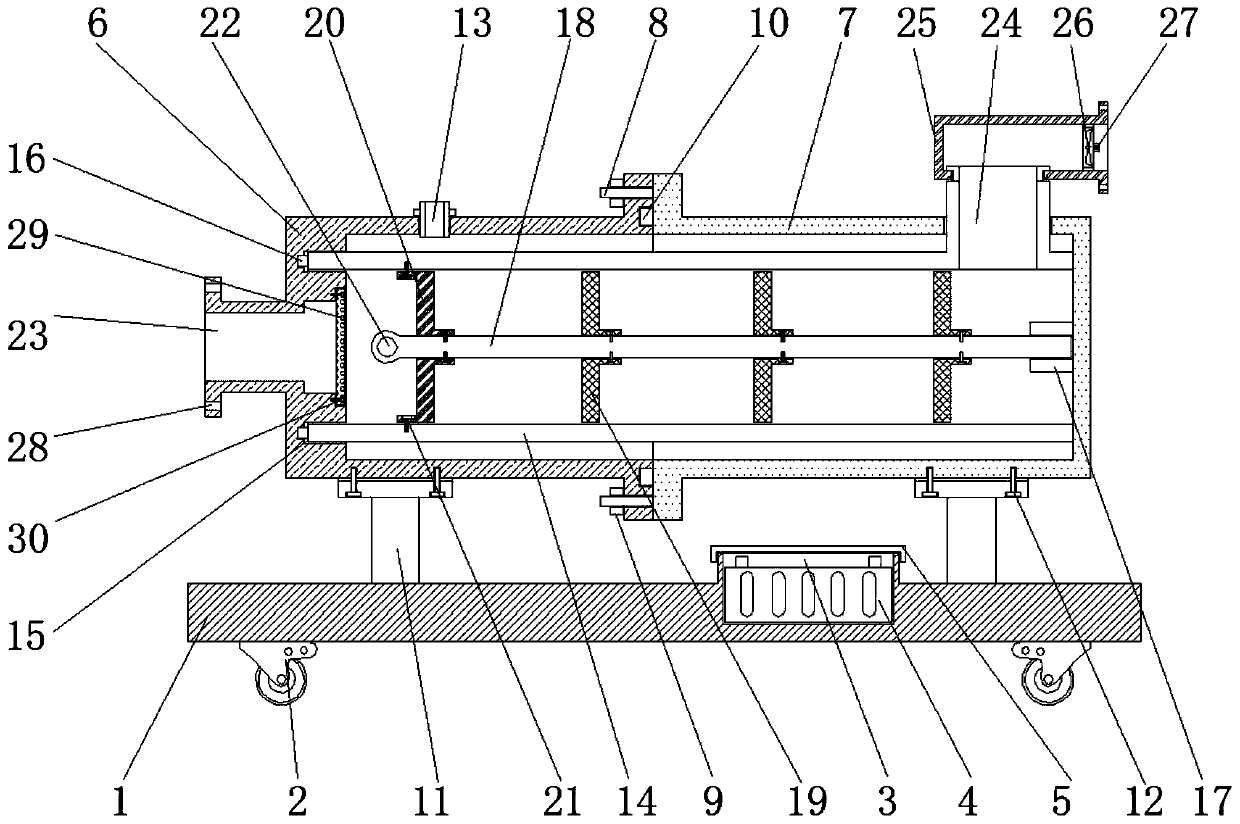

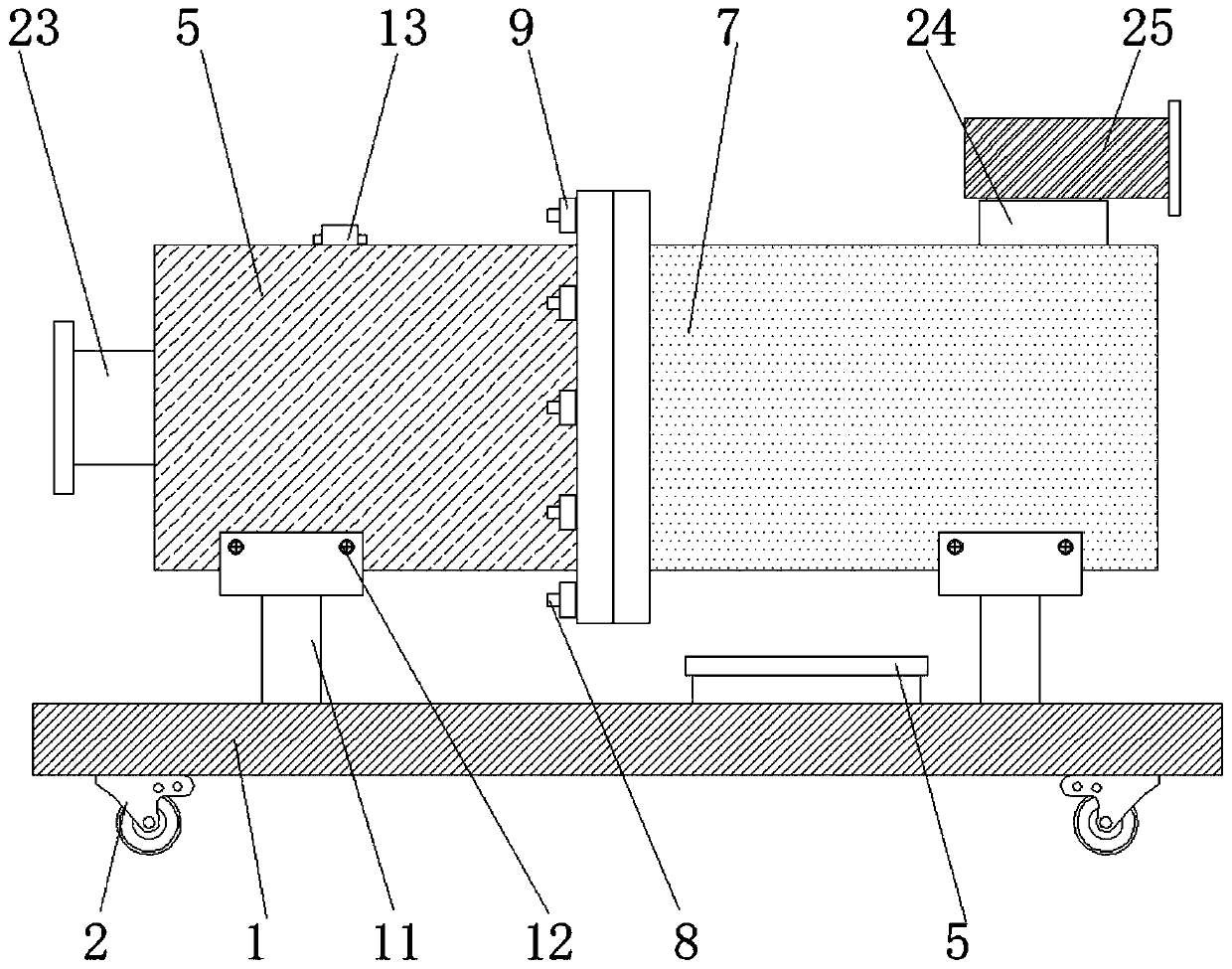

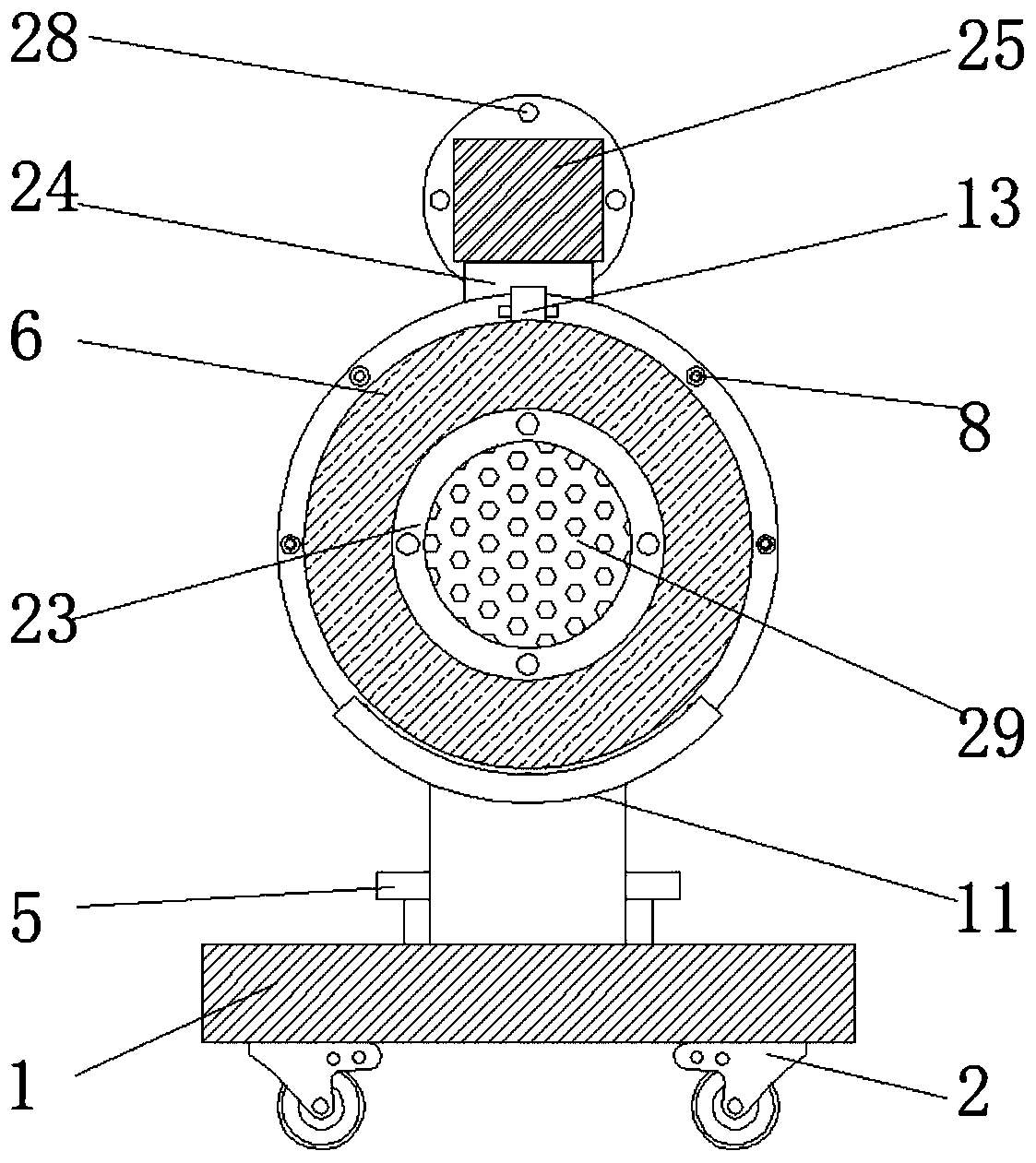

Baking and shaping device based on vacuum switch tube

PendingCN111863487ASmooth rotationAvoid shakingLighting and heating apparatusDispersed particle separationElectric machineVacuum switch

The invention discloses a baking and shaping device based on a vacuum switch tube. The device comprises a baking box, wherein partition plates are welded to an inner wall of the baking box at equal intervals, a slave moving groove is formed in a front surface of an inner wall of the baking box corresponding to a top end edge of the partition plate, heaters are fixedly mounted in positions, corresponding to edges of top ends of the moving grooves, of the front surface of the inner wall of the baking box, and clamping rotating mechanisms are fixedly mounted on two sides of the inner walls of thepartition plates. The device is advantaged in that the structure is scientific and reasonable, safe and convenient use, a positioning gear, a rotating gear, a rotating plate, a groove, a wedging holeand a mold plate are arranged, a mold plate can be conveniently mounted, mounting difficulty of the mold plate is reduced, meanwhile, the position of the mold plate can be limited, a phenomenon thatthe position shakes when the mold plate rotates is prevented, the rotating plate can rotate conveniently through the motor, and therefore a surface of the mold plate can rotate conveniently, and a vacuum switch tube on a surface of the mold plate can be rotated and baked.

Owner:刘丽娟

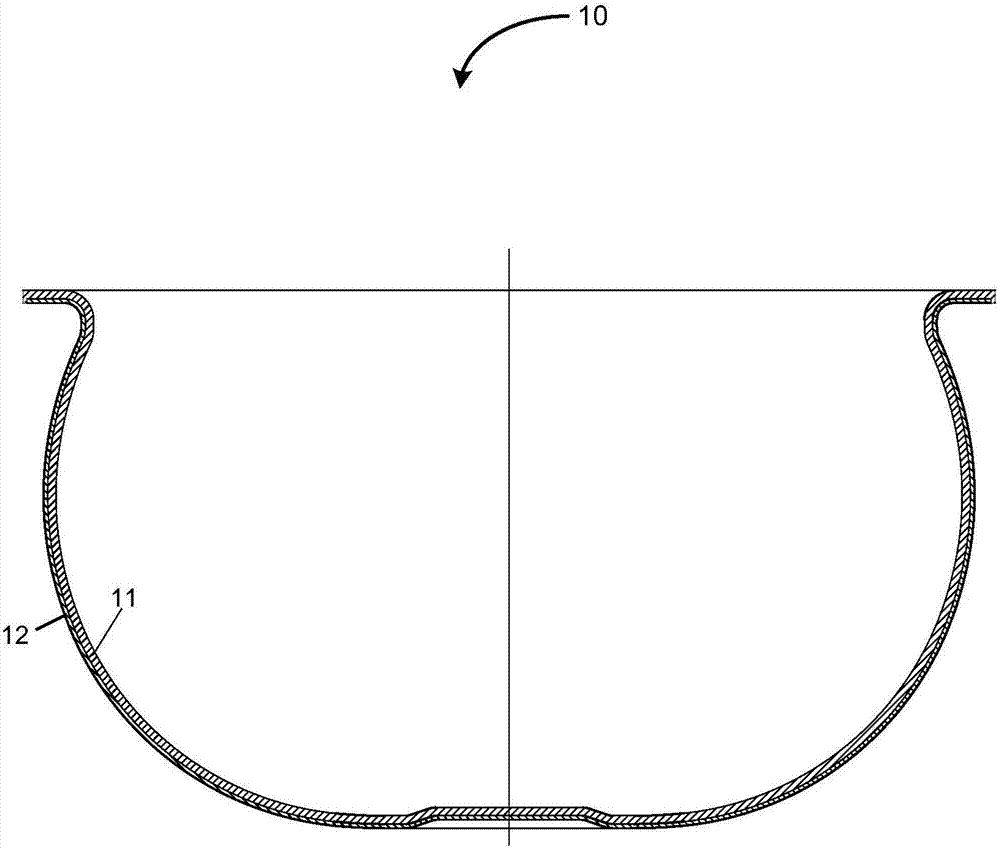

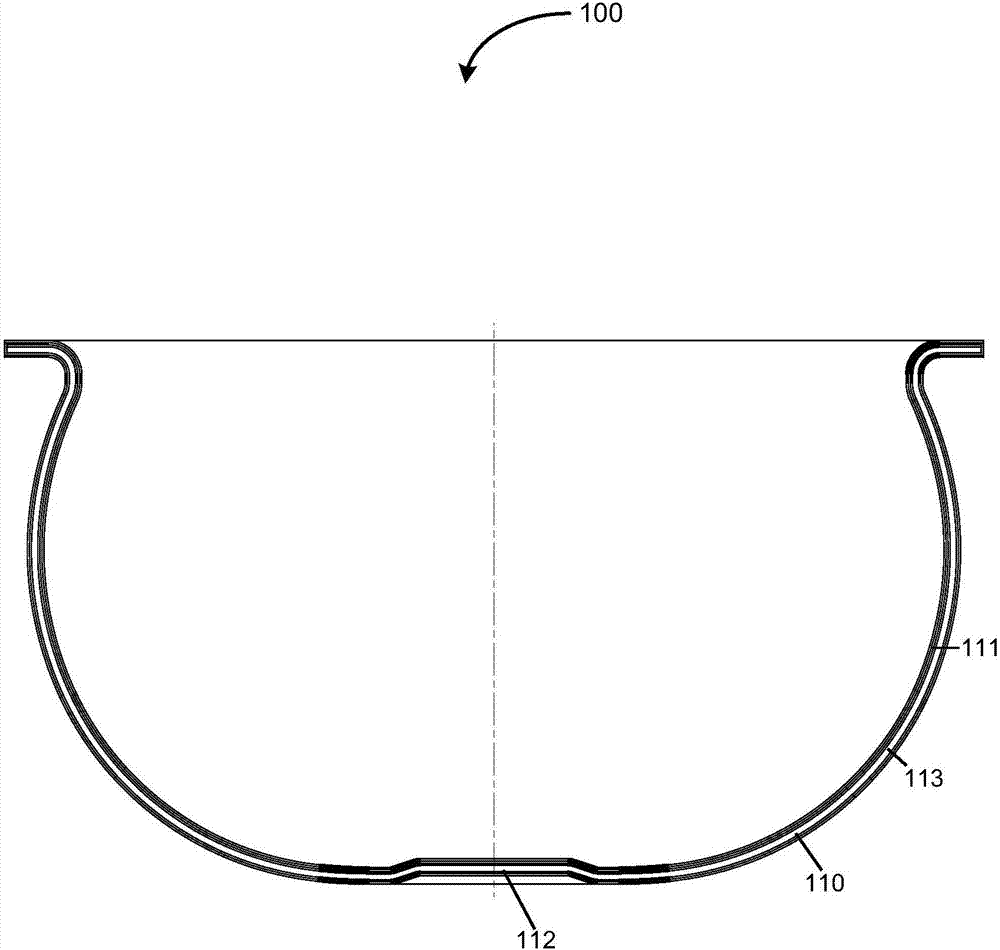

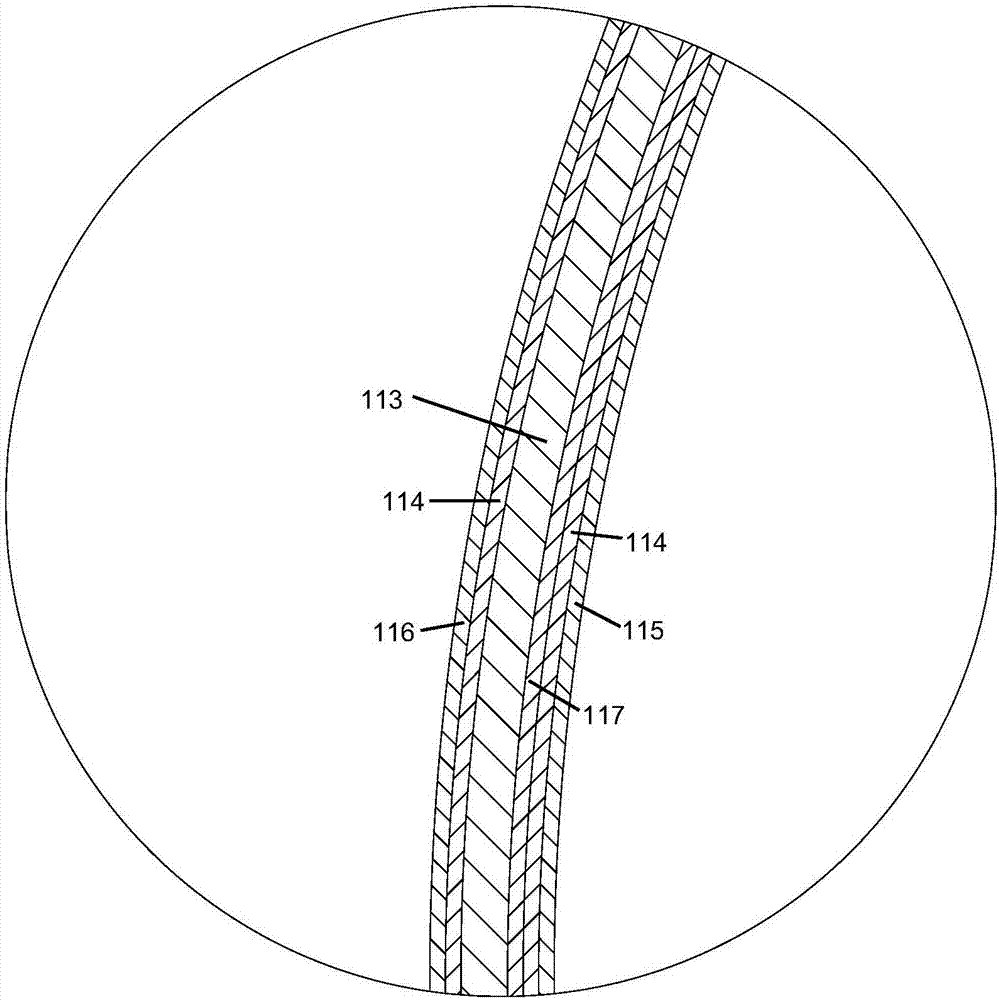

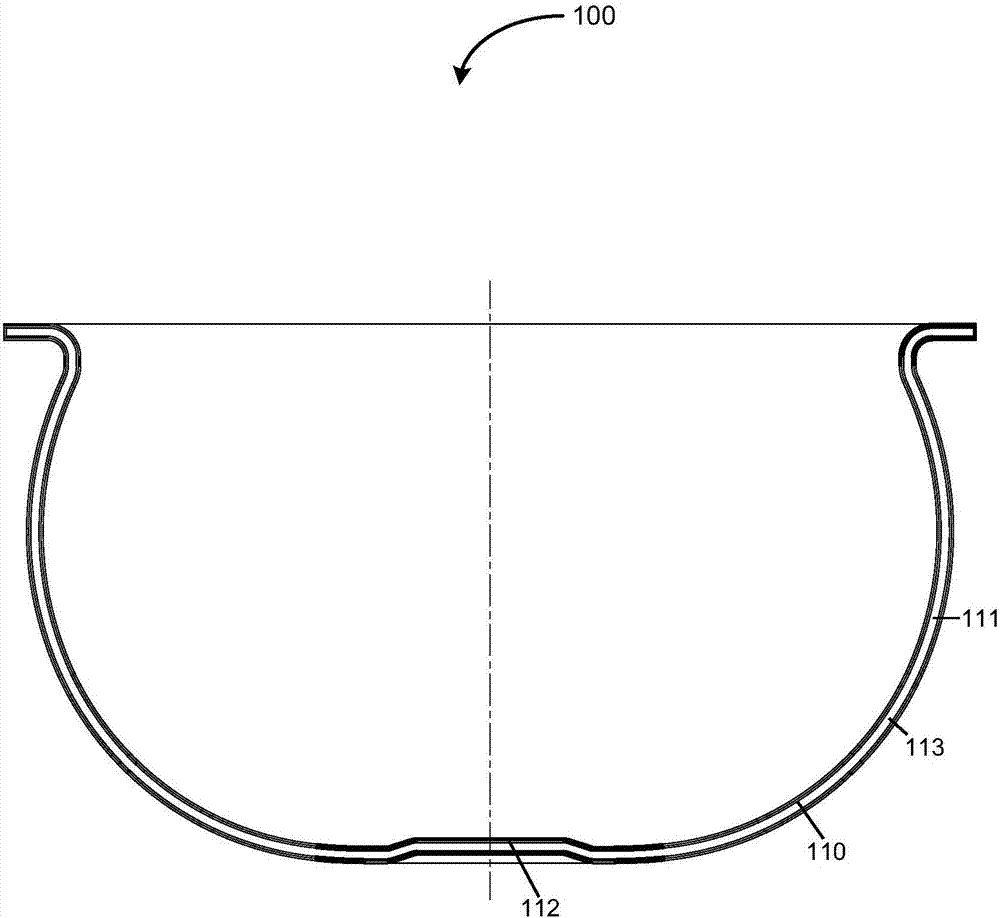

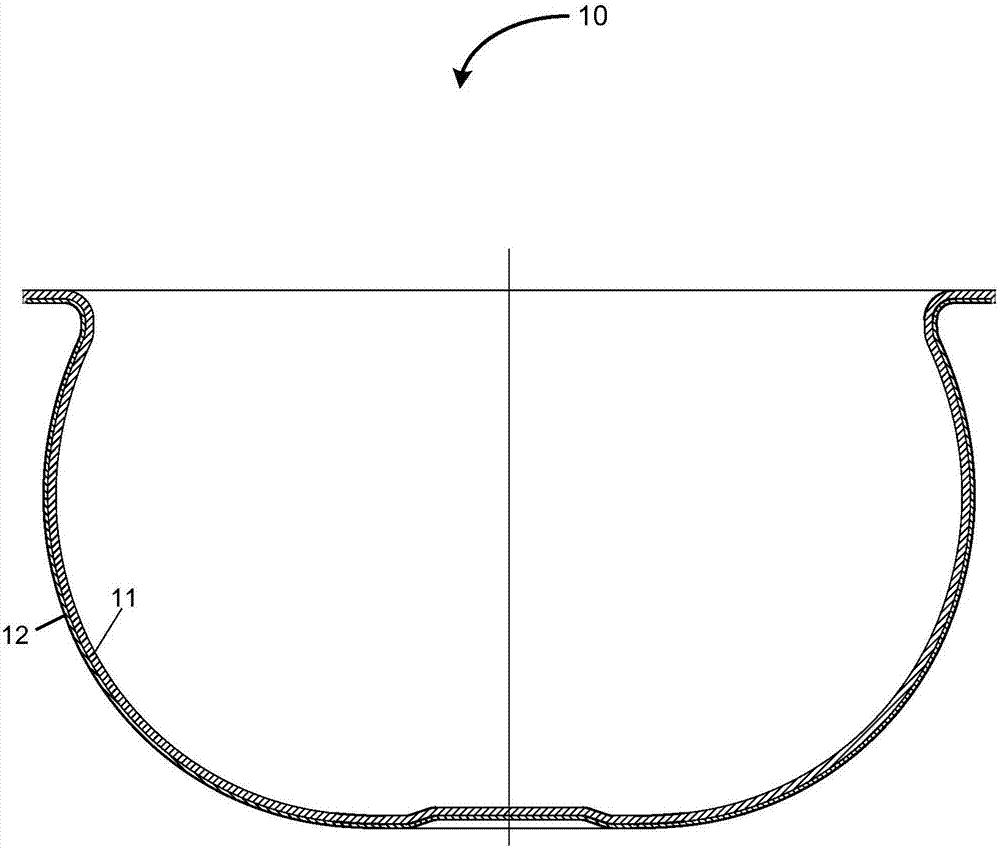

Inner pot used for cooking utensil, cooking utensil and method for manufacturing inner pot

PendingCN107348828ALow costHigh strengthCooking-vessel materialsSpecial surfacesMono layerMaterials science

The invention provides an inner pot used for a cooking utensil, the cooking utensil and a method for manufacturing the inner pot. The inner pot comprises a pot wall forming an opening in the top, the pot wall is made of a single layer material and includes an iron base layer, each of the internal surface and the external surface of the iron base layer is provided with a ceramic film, and the inner side of the ceramic film arranged on the internal surface of the iron base layer is provided with a first metallic film. According to the invention, the inner pot used for the cooking utensil is lower in cost and can be manufactured more conveniently.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

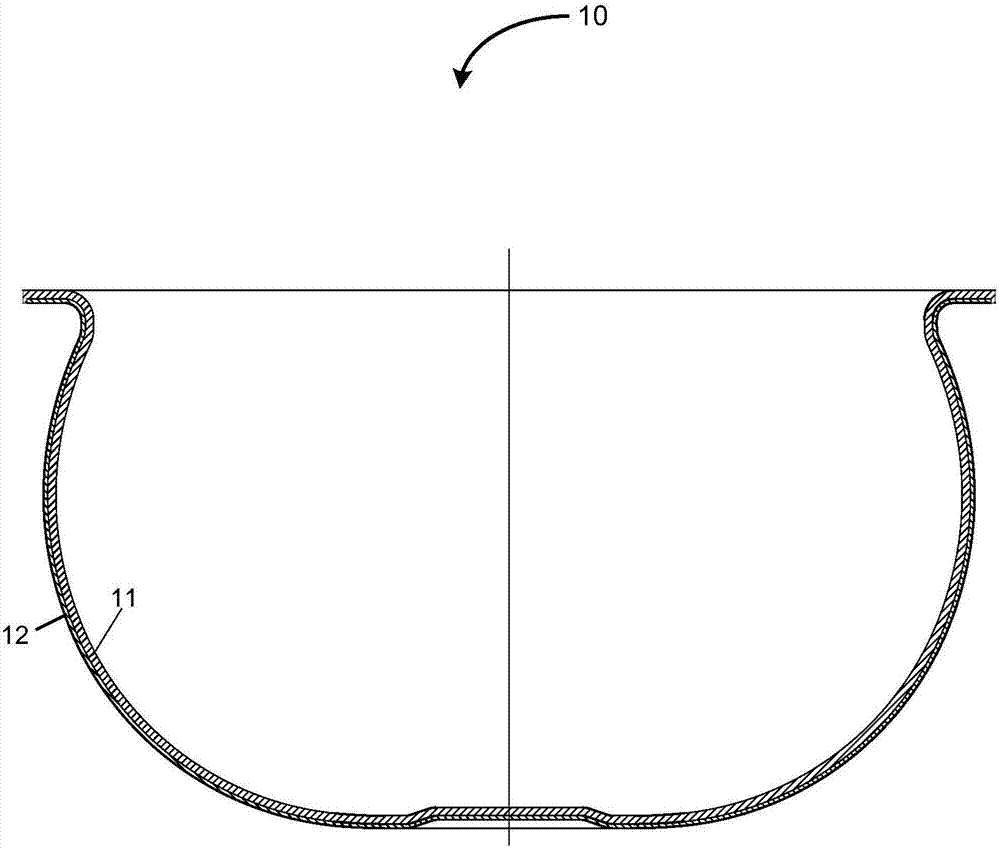

Inner pot for cooking appliance, cooking appliance and method for manufacturing inner pot

PendingCN107343744ALow costHigh strengthCooking-vessel materialsSuperimposed coating processEngineering

The invention provides an inner pot for a cooking appliance, the cooking appliance and a method for manufacturing the inner pot. The inner pot comprises a pot wall, and an opening is formed in the top of the pot wall; the pot wall has a single-layer structure and comprises an iron-based layer; the inner surface and the outer surface of the iron-based layer are respectively provided with a ceramic protective film. The inner pot for the cooking appliance provided by the invention is lower in cost and more convenient to manufacture.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

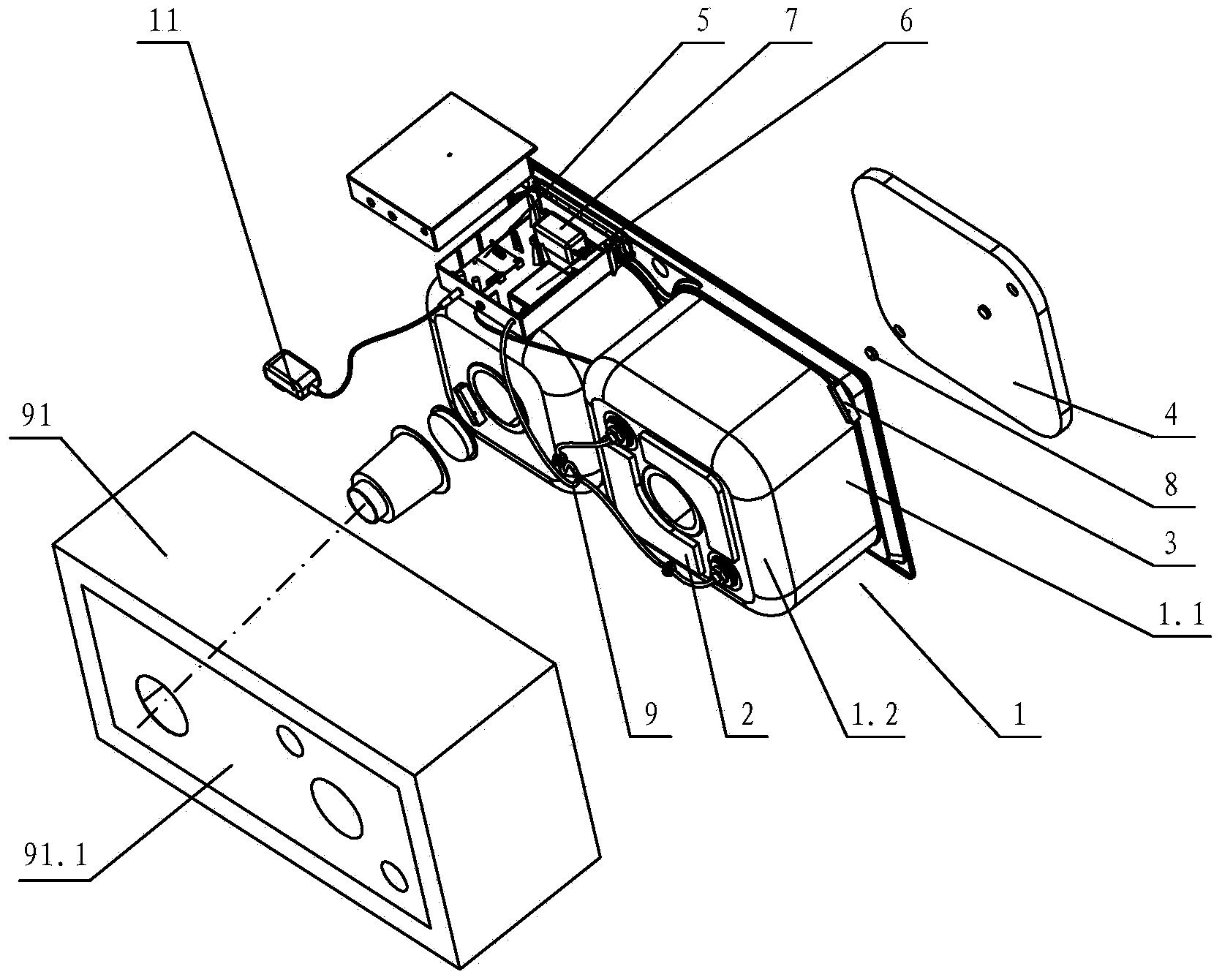

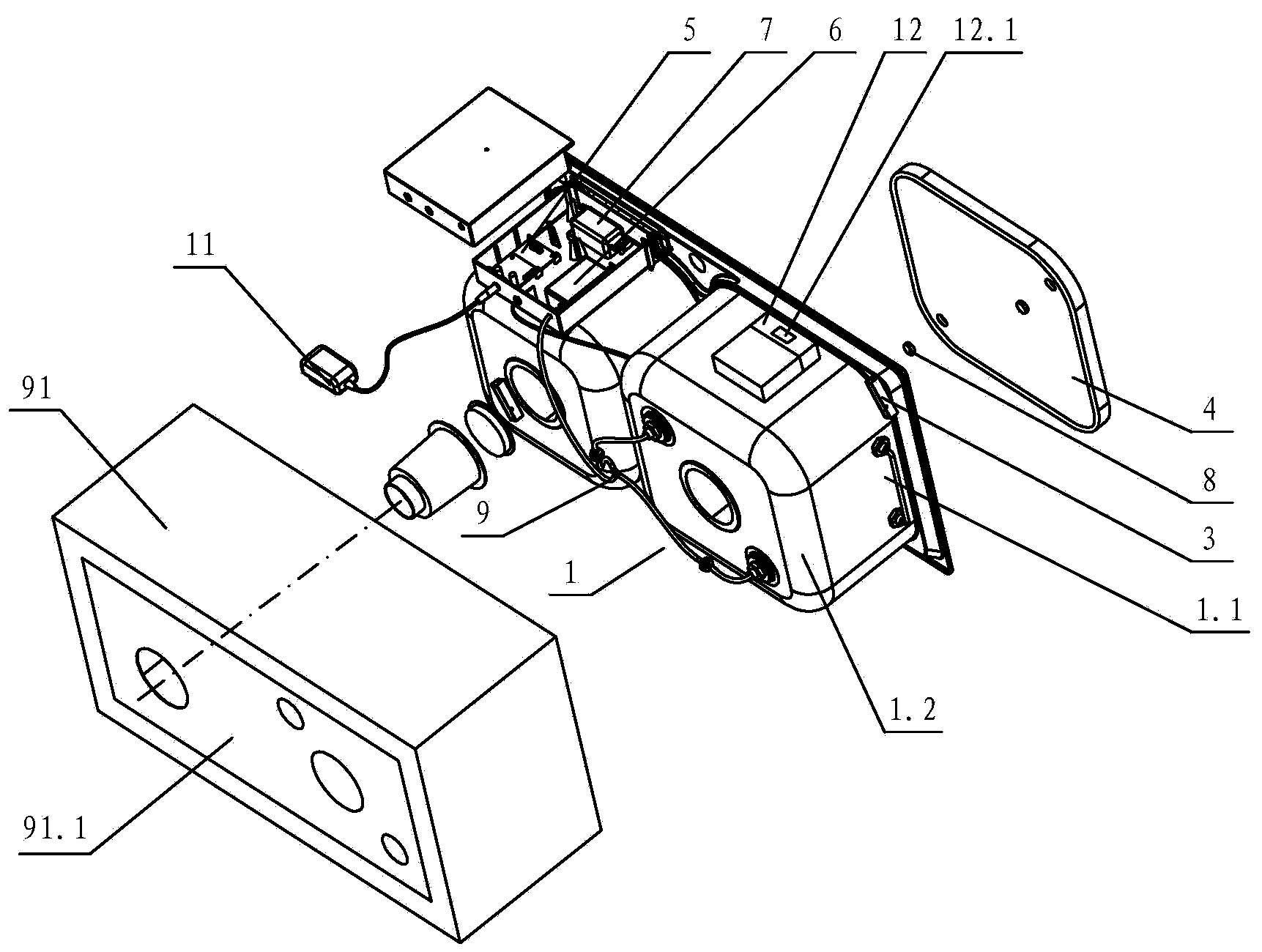

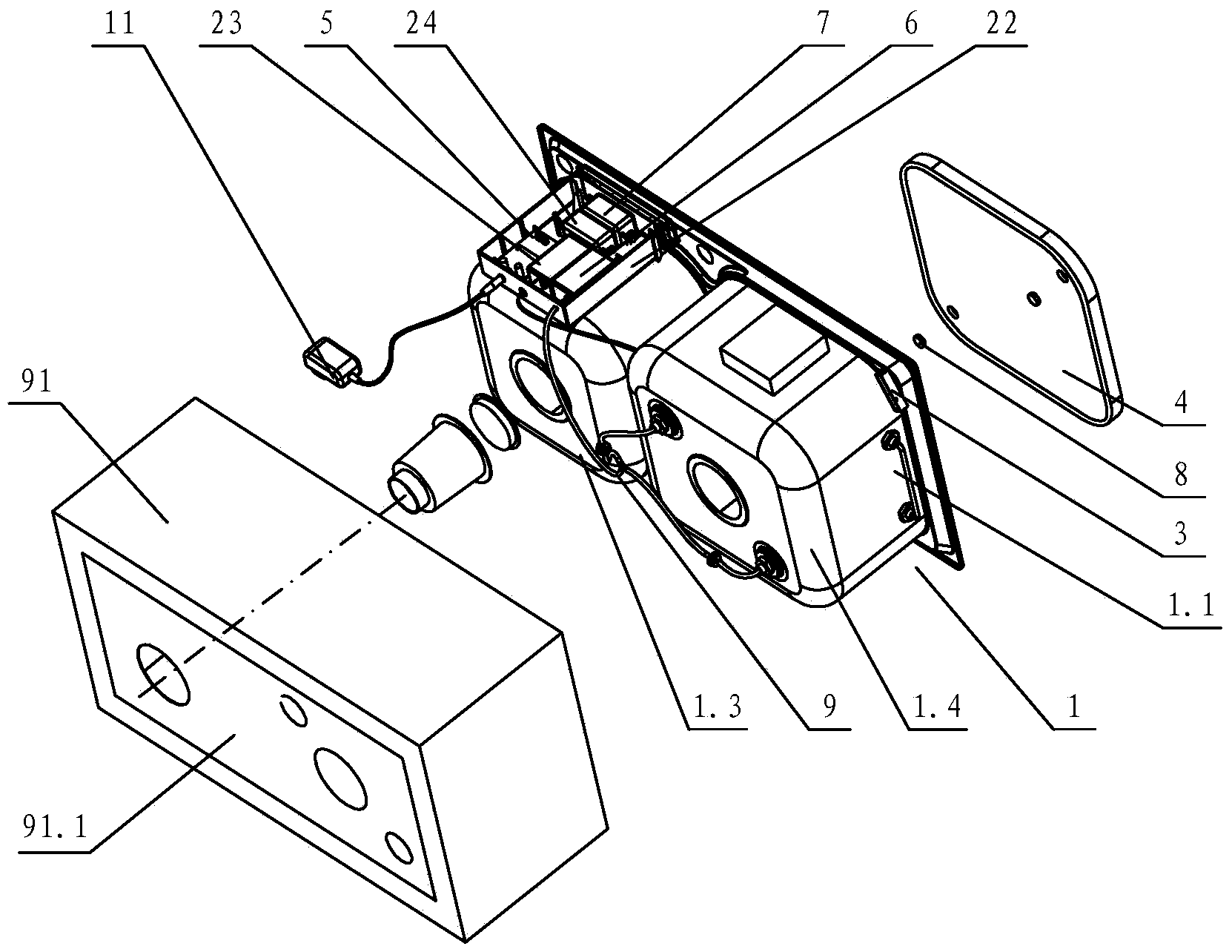

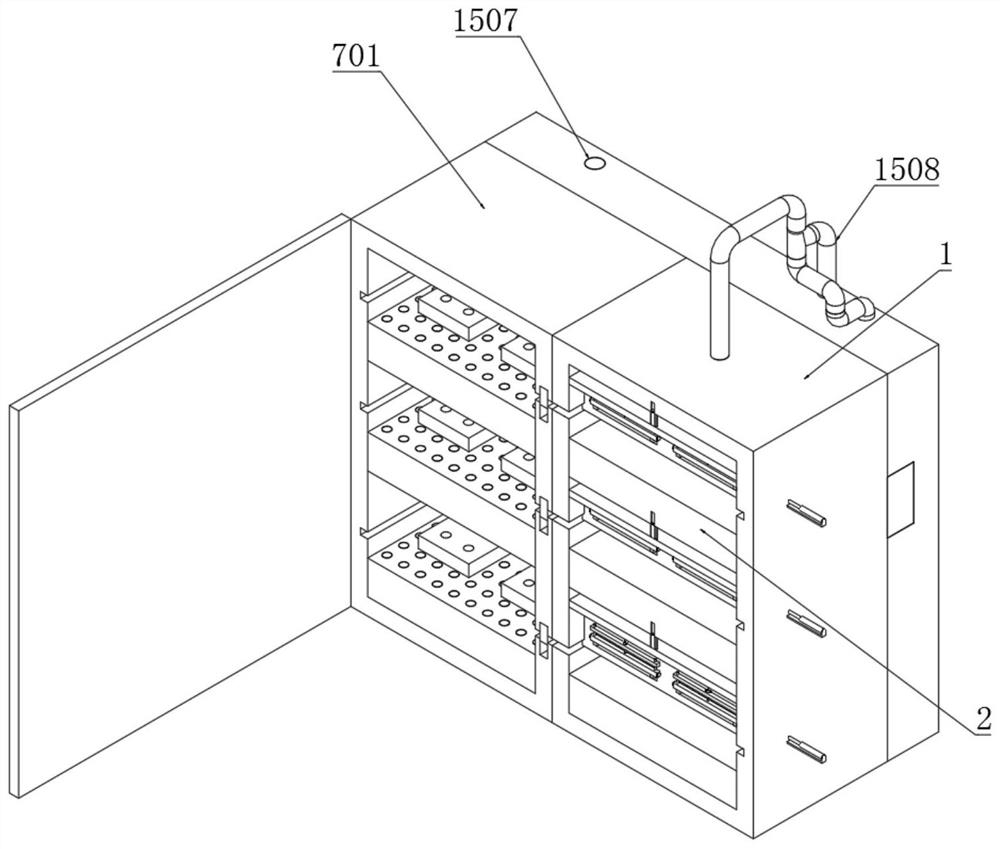

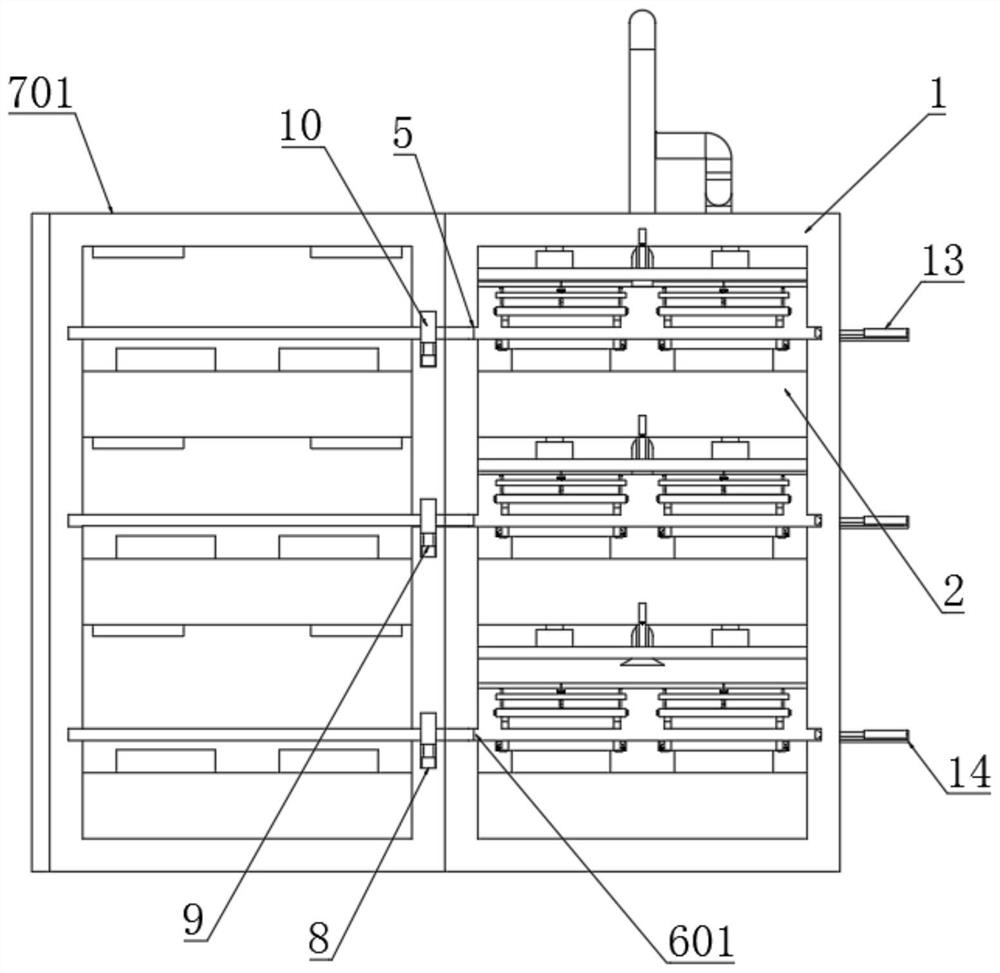

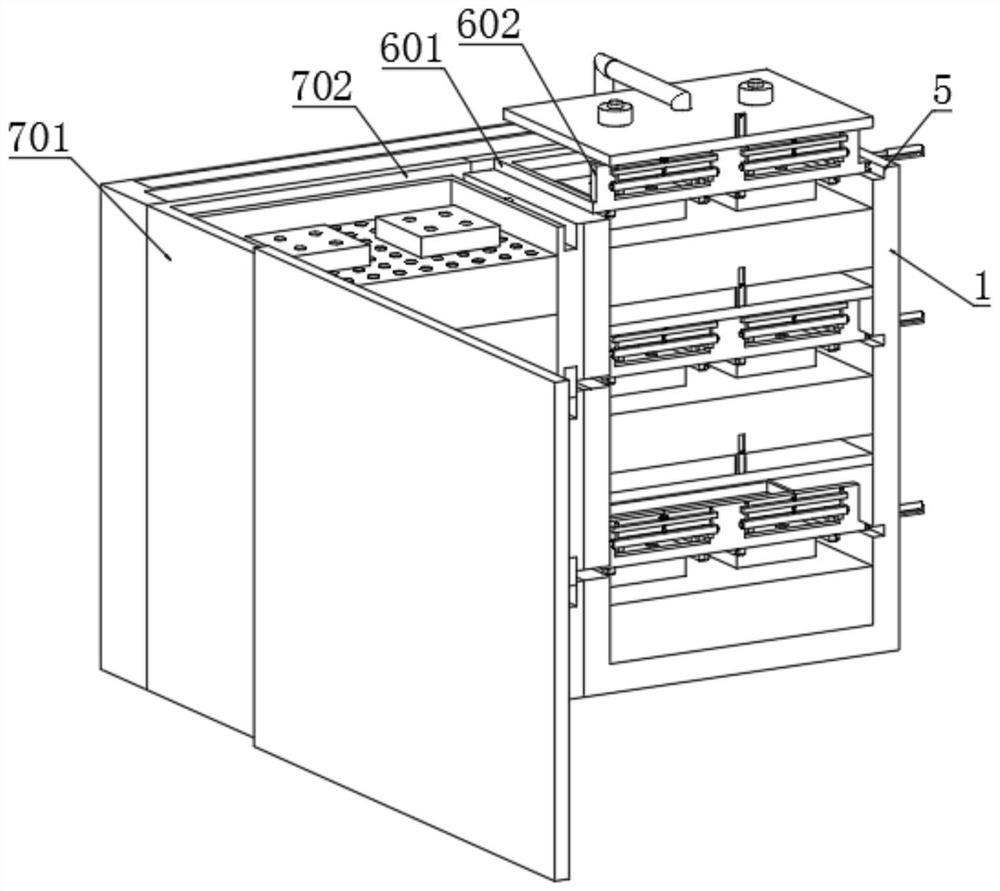

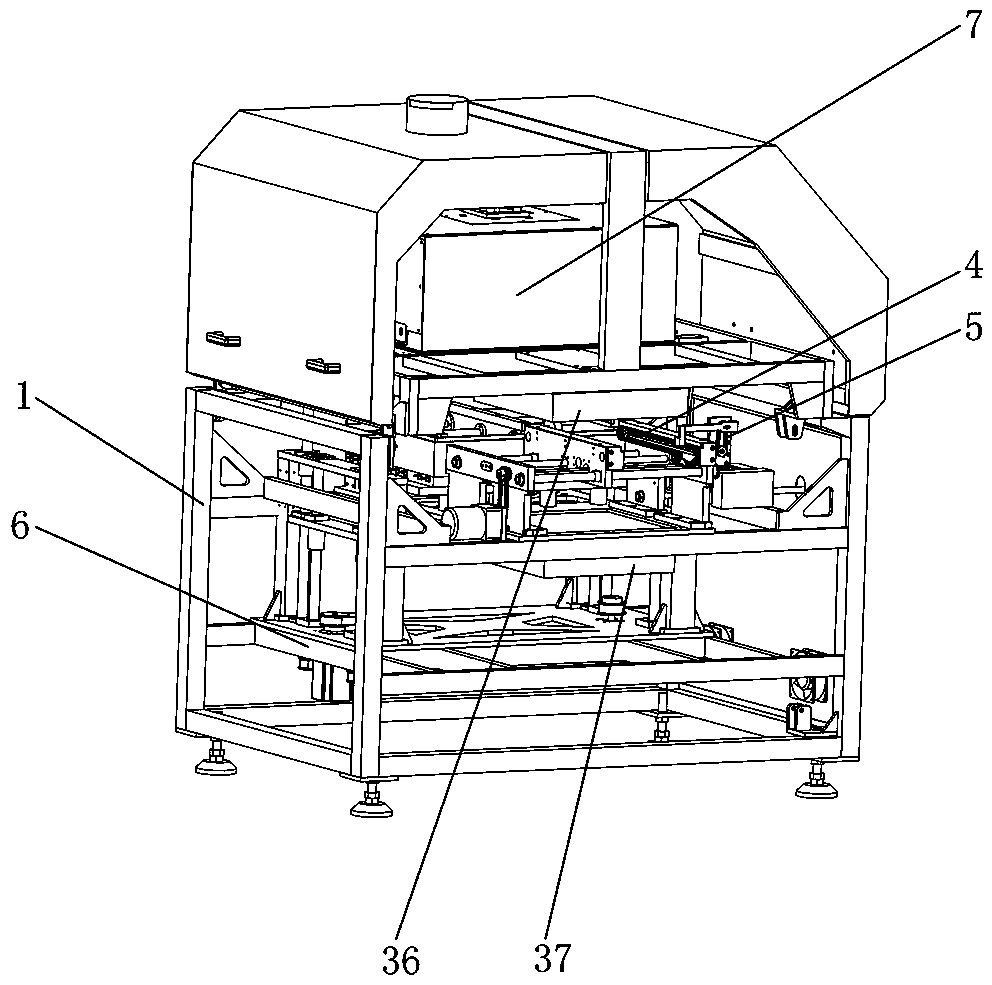

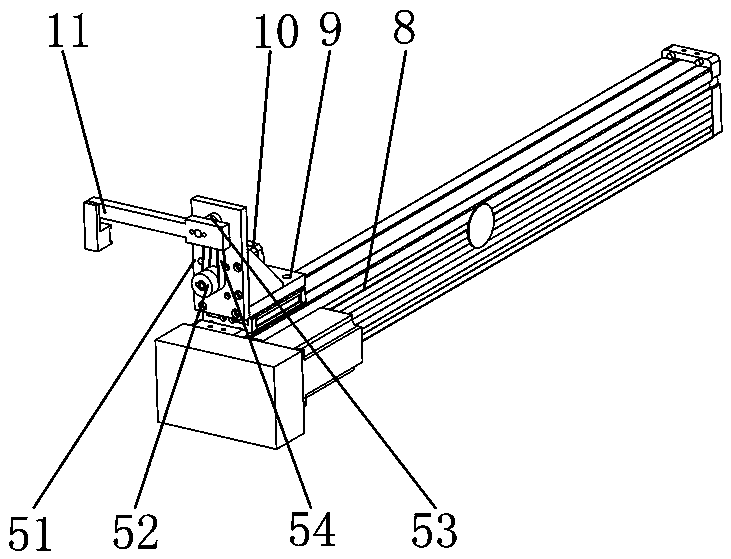

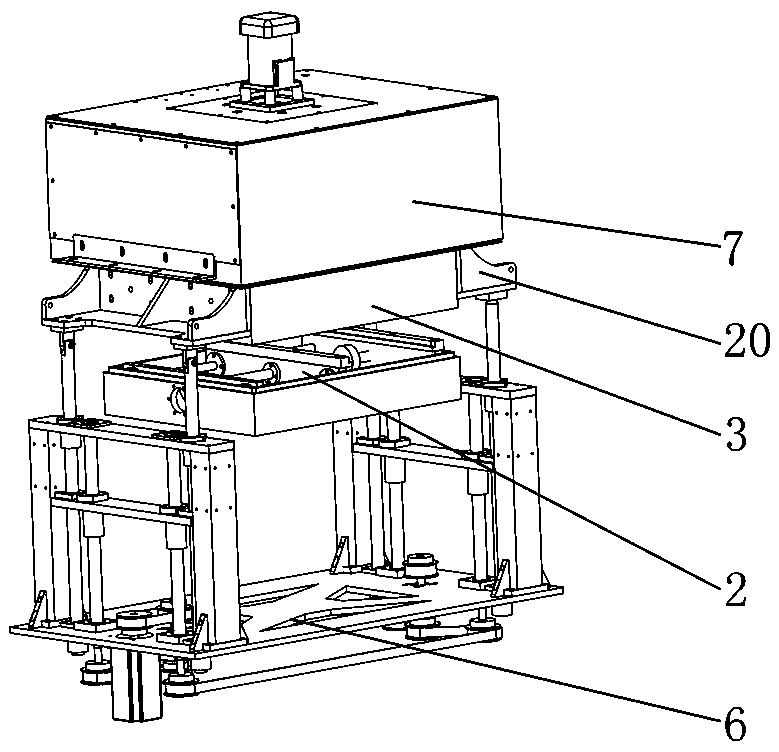

Vacuum furnace equipment for reflow soldering machine

PendingCN110788436APrevent feeding errorsGuaranteed smooth productionHeating appliancesPrinted circuitsEngineeringMechanical engineering

A vacuum furnace equipment for a reflow soldering machine comprises a rack (1), a lower furnace body (2), an upper furnace body (3) and a furnace entering conveying assembly (4), wherein the two endsof the rack (1) are provided with the lower furnace body (2) and the furnace entering conveying assembly (4) which are matched with each other respectively. The vacuum furnace equipment further comprises a furnace inlet poking assembly (5), an upper furnace body jacking assembly (6) and an upper furnace body heating assembly (7); and a plurality of grids (19) are arranged on the outer wall of a top plate of the upper furnace body (3). In the use process, the yield of an existing reflow soldering machine during production can be improved in a variety of ways such as improvement of stroke precision of workpiece conveying and heating temperature compensation of the furnace bodies of a vacuum furnace.

Owner:东莞市健时自动化设备有限公司

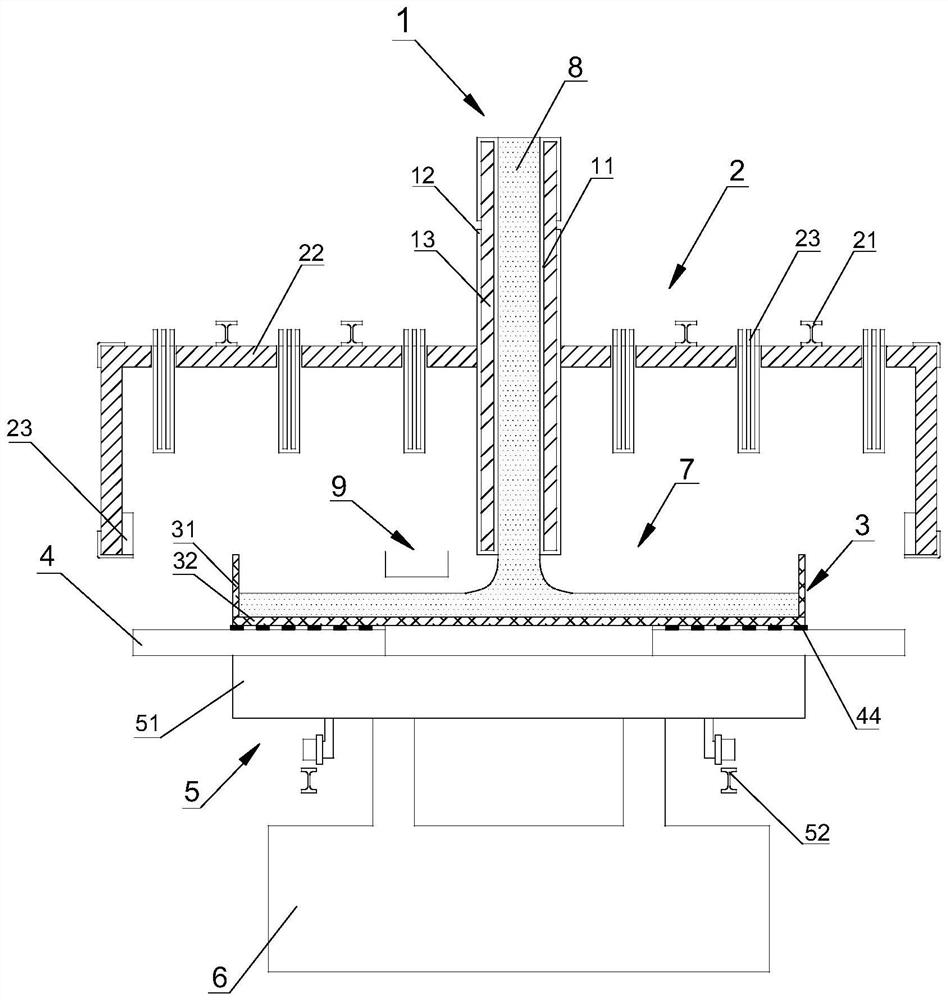

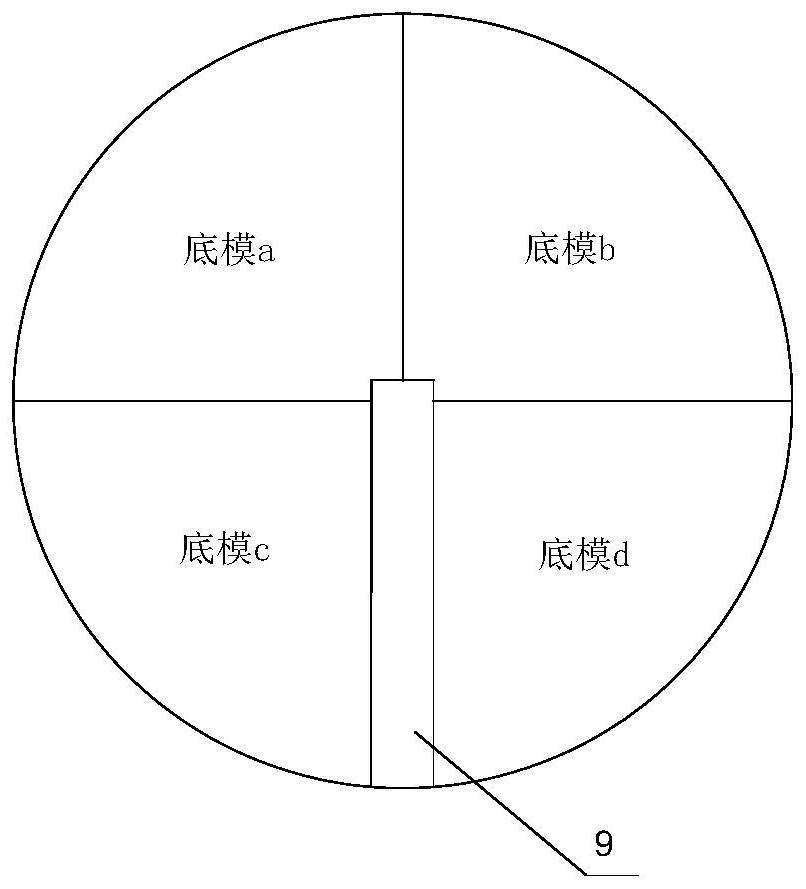

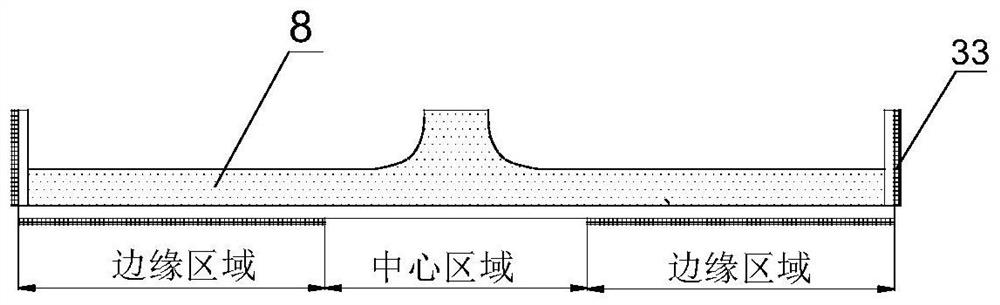

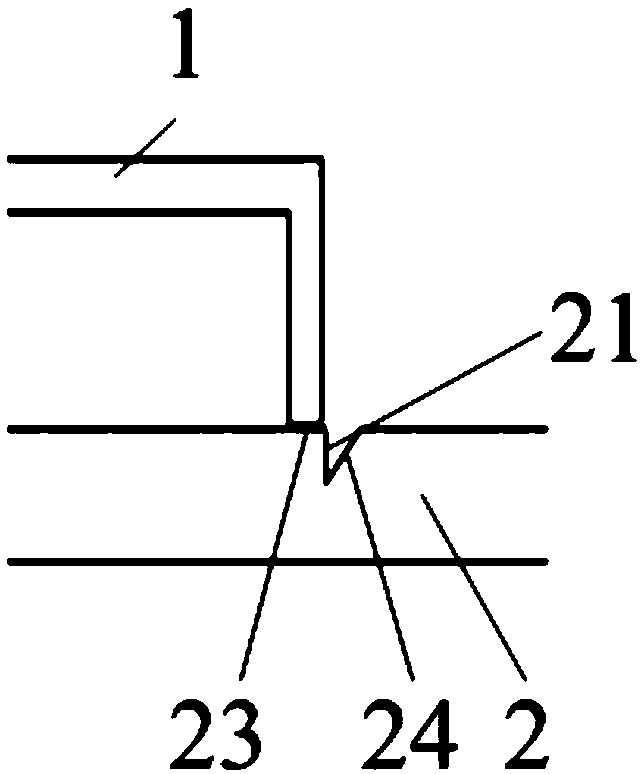

Glass block forming device and forming method thereof

PendingCN114409233AOptimization of cooling bracket structureImprove fluidity and uniformity of temperature fieldGlass shaping apparatusGlass productionMoulding deviceMolten glass

The invention provides a glass block forming device capable of improving the fluidity of molten glass in the forming process and the uniformity of a temperature field. According to the glass block forming device, a discharging pipe penetrates through the top of a soaking cover to enter a forming space formed by the soaking cover and a forming mold; the forming mold is located under the soaking cover; the heat dissipation support is placed below the forming die. The transfer device is located on the lower portion of the heat dissipation support and supports and transfers the heat dissipation support and the forming die. The lifting device is located below the transfer device and supports and controls the vertical movement speed of the forming mold, the heat dissipation support and the transfer device. The heat dissipation rate of the center area of the bottom die is increased, the heat dissipation speed of the edge area of the bottom die is reduced, the temperature field uniformity of the bottom die is improved, and the temperature uniformity of radial flow in molten glass forming flow is improved; bubbles formed by micropores on a contact interface and the growth overflow speed of the bubbles when the inner surface of the bottom die is in contact with molten glass can be controlled, and the defect that interface bubbles enter the molten glass to form formed bubbles is avoided.

Owner:CDGM GLASS LLC

PCH module disassembly method

InactiveCN108990300AReduce churn rateAvoid damagePrinted circuits repair/correctingHeating timeSoftware engineering

The invention discloses a PCH module disassembly method, which comprises the following steps: removing a heat dissipation cover fixed on a PCB board of the PCH module; Heat the BGA pad at the bottom of the PCH module to melt the solder to remove the PCH module from the motherboard. In this disassembly method, adding the process of removing the heat dissipation cover in the PCH module before removing the PCH module, After removing the heat dissipation cover, the PCH module is removed, so as to reduce the heat dissipation speed when heating the BGA pad and the heat loss speed when heating, so that the melting point temperature of the solder can be quickly reached at the BGA pad, the heating time is shortened, and the damage to the main board caused by long-time heating can be avoided.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

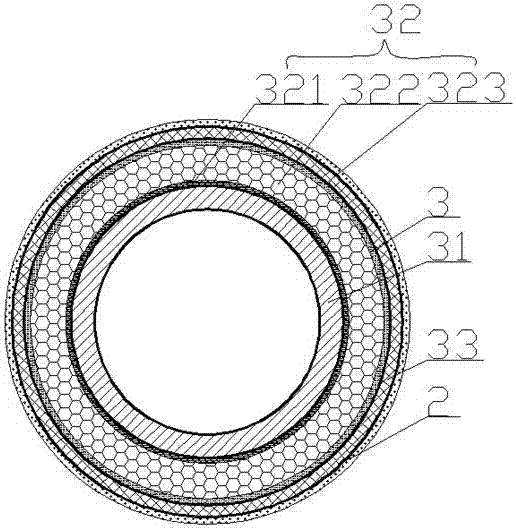

Heat-insulating and drop-resistant ceramic cup and manufacturing method thereof

InactiveCN107981664AImprove insulation effectSlow down the spreadDrinking vesselsCeramicwareCardboardMetallurgy

The invention provides a heat-insulating and drop-resistant ceramic cup and a manufacturing method thereof. The heat-insulating and drop-resistant ceramic cup comprises a cup body, a honeycomb paperboard, a tumbler-shaped base and a cup lid, wherein the cup body consists of an inner cup body and an outer cup body which are formed integrally; a placement cavity for the honeycomb paperboard is arranged between the inner cup body and the outer cup body; the bottom of the cup body is fixed on the tumbler-shaped base; and the cup lid is connected with the cup body in a hinged or threaded manner. The invention further discloses a manufacturing method of the heat-insulating and drop-resistant ceramic cup. By the cup body with the built-in honeycomb paperboard, the heat-insulating and drop-resistant ceramic cup is simple in structure and good in heat-insulating property; and the upper end of the tumbler-shaped base is a honeycomb ceramic heat-insulating plate, the heat-insulating property of the bottom of the ceramic cup is improved, a magnetic stone on the bottom of the ceramic cup has a balance weight effect, inclination or falling of the ceramic cup is prevented, and water in the magnetic cup can further be magnetized.

Owner:BAOJING COUNTY JINFENG CERAMIC

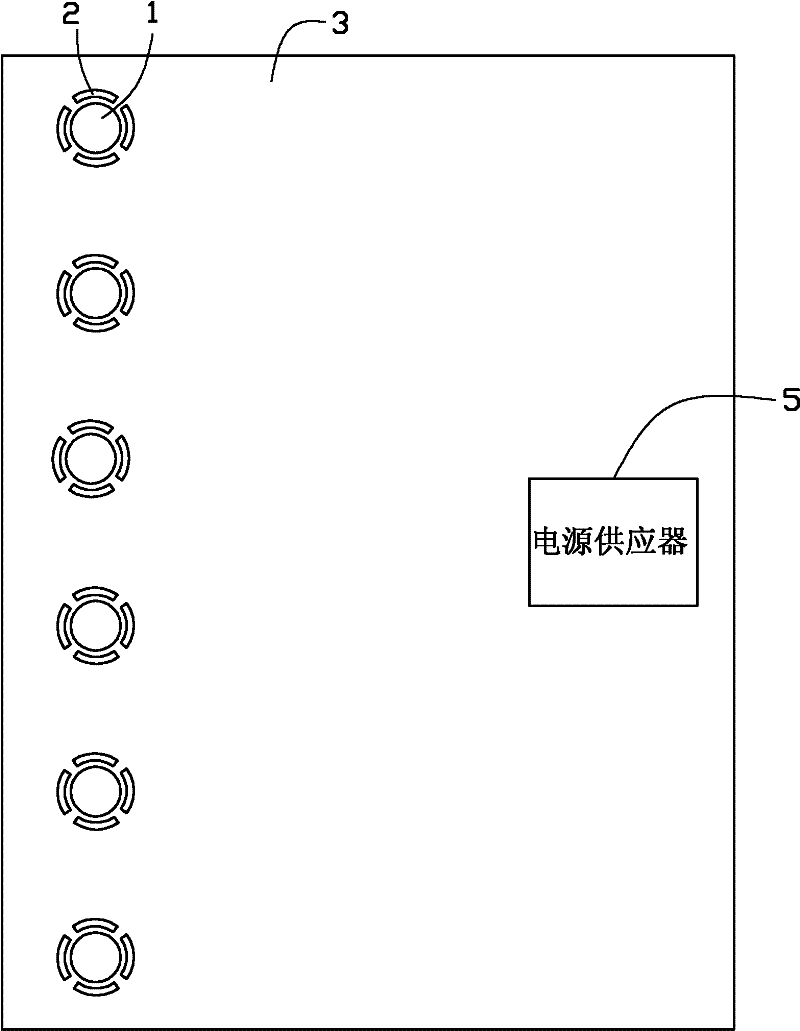

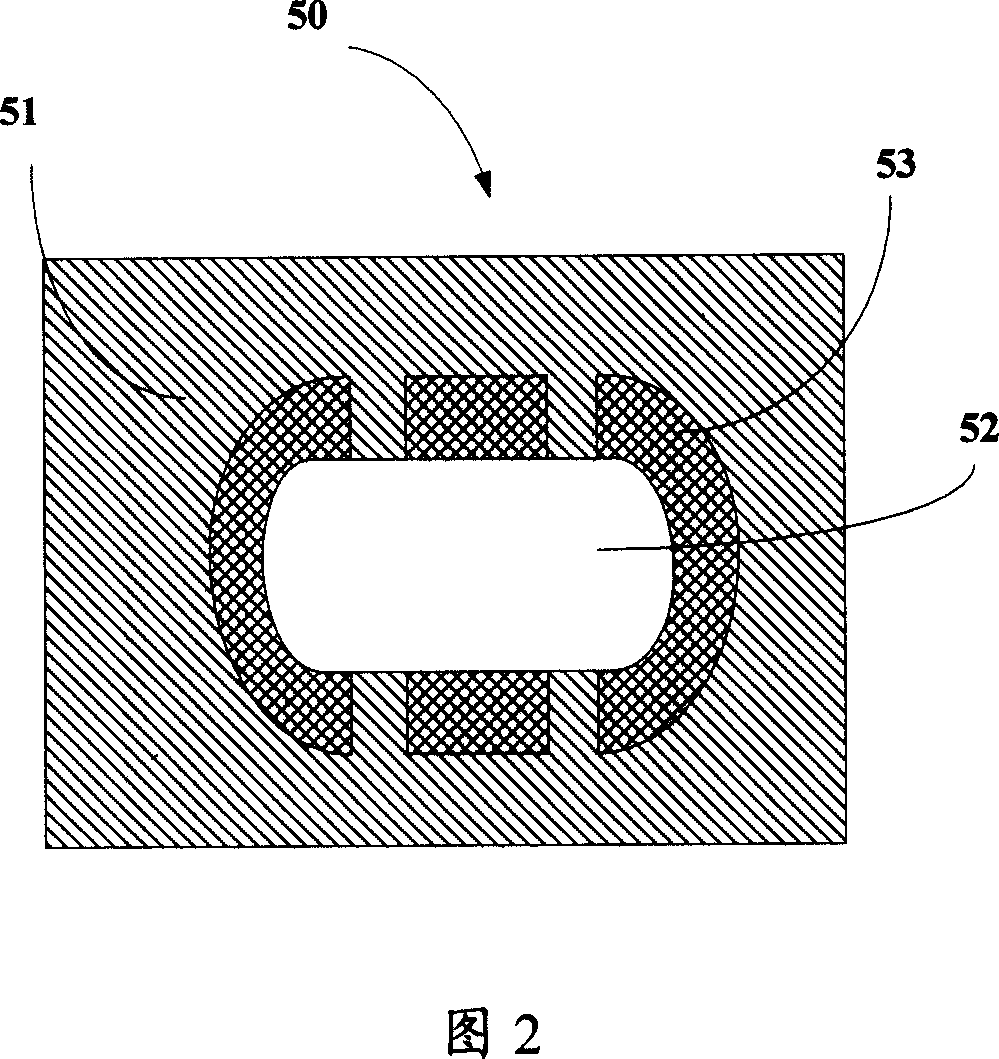

Printed circuit board

InactiveCN102348322ASlow down heat dissipationReduce cooling areaPrinted circuit detailsPrinted circuit non-printed electric components associationThermal reliefEngineering

The invention provides a printed circuit board. A copper foil, an insert hole and an anti-thermal relief groove are arranged on one layer of the printed circuit board, wherein the copper foil is paved on the surface of the layer; the insert hole runs through the whole printed circuit board; and the anti-thermal relief groove is formed on the surface of the layer and not covered by the copper foil, surrounds the insert hole and comprises an opening fading a power supply positioned on the printed circuit board. By the printed circuit board, not only the condition of insert hole cold-welding caused by over-high thermal relief speed can be avoided, but also a resistance value between a pin of an insert and the power supply is relatively lower.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Convenient-to-move air heater

InactiveCN110966754AEasy to moveQuality improvementDispersed particle filtrationTransportation and packagingStructural engineeringLeft lateral wall

The invention discloses a convenient-to-move air heater. The air heater comprises a base, a liner and a bearing rod; a first sealing ring is clamped to the right end surface of a first sleeve; an airexhaust pipeline penetrates through the top of the first sleeve; the right side of the liner is fixed to the right side wall of a second sleeve; an annular clamping groove is formed in the left side wall of the first sleeve; the right end of the bearing rod is clamped to a limiting sleeve; the bearing rod penetrates through a first annular electric heating net and a second annular electric heatingnet; the first annular electric heating net and the second annular electric heating net are both fixed to the bearing rod through second bolts; a pull ring is fixed to the left end of the bearing rod; an air incoming channel and an air outgoing channel are formed in the left end surface of the first sleeve and the top of the liner respectively; and mounting holes are formed in the left end surface of the air incoming channel and the right end surface of a rotating frame respectively. The convenient-to-move air heater of the invention can be moved to a required place under the action of self-locking rolling wheels, so that the moving operation of the device is more labor-saving.

Owner:盐城市正龙电热科技有限公司

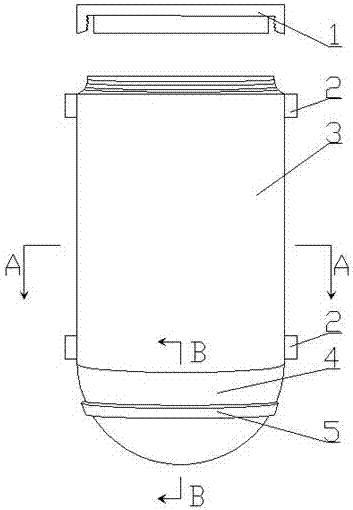

Crystallization kettle

InactiveCN102949862AGuaranteed to workSlow down heat dissipationCrystallization separationThermal insulationEngineering

The invention relates to a crystallization kettle. A thermal insulation cover is arranged outside a crystallization kettle body; and a temperature detection device and a heating device are arranged on the thermal insulation cover. The crystallization kettle has the advantages that 1) the thermal insulation cover is arranged outside the crystallization kettle body, so that the heating dissipation speed of the crystallization kettle body is greatly reduced and the energy consumption is greatly reduced; 2) the temperature detection device is arranged on the thermal insulation cover, the temperature of the crystallization kettle can be detected in real time and the heating device can be started according to the requirement, so that the crystallization kettle can be in a normal working condition and the energy consumption can achieve the optimum volume; and 3) boiler steam is used as a heating source and can be recycled, the steam originally discharged into the air is reutilized and the normal work of the crystallization is ensured, so that the effect of killing two birds with one stone is achieved.

Owner:JIANGSU PENGYU CHEM

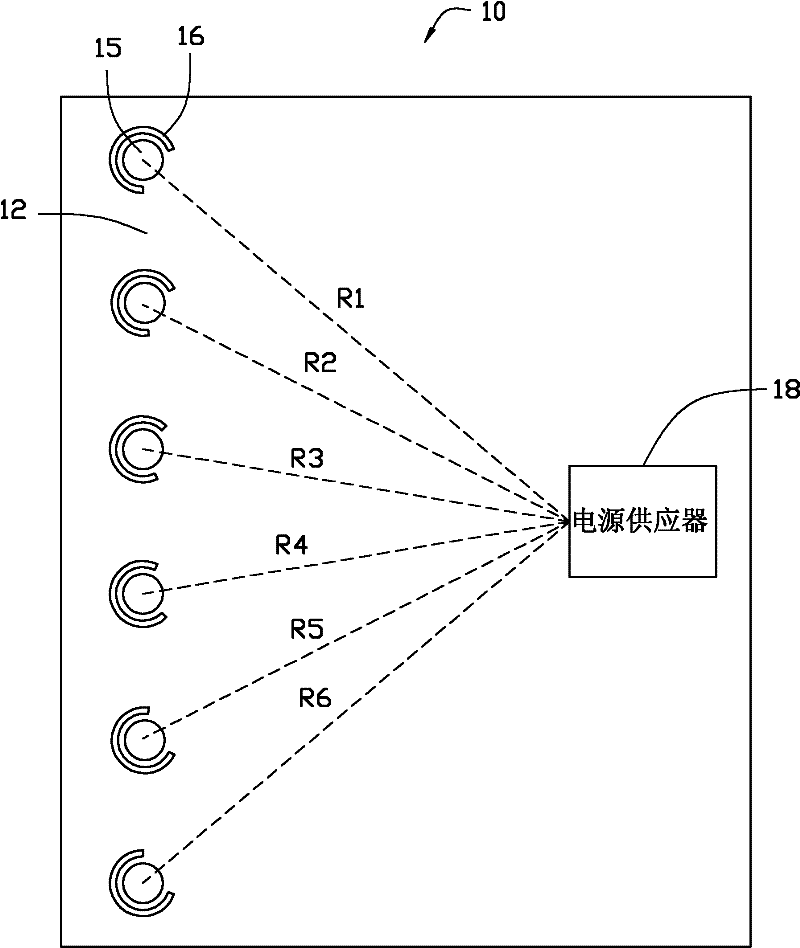

Printed circuit board

InactiveCN1956625AReduce areaSlow down heat dissipationPrinted circuit assemblingPrinted circuit aspectsInsulation layerCopper foil

A PCB includes a metal layer and a plug hole characterizing that the metal layer of said PCB also includes several insulation regions surrounding the plug hole in intervals and the metal around the plug hole is isolated by the insulation regions, and said metal layer is conducted with the plug components in the hole by the metal isolated by the insulation layer, which reduces area of copper foil around the plug hole and slows down the radiation speed of said PCB after reflow soldering.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

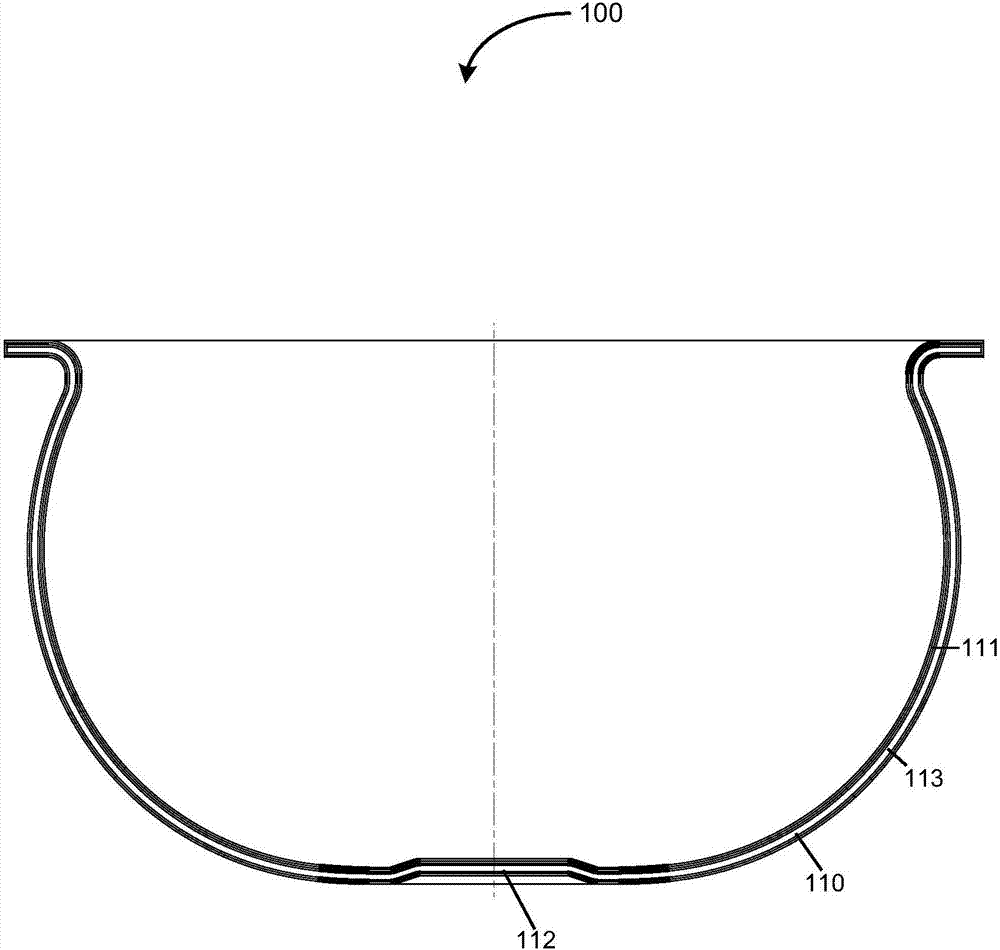

Inner pot for cooking appliance, cooking appliance and method for manufacturing inner pot

PendingCN107343746ALow costHigh strengthCooking-vessel materialsCooking vessel constructionsEngineeringMono layer

The invention provides an inner pot for a cooking appliance, the cooking appliance and a method for manufacturing the inner pot. The inner pot comprises a pot wall, and an opening is formed in the top of the pot wall; the pot wall has a single-layer structure and comprises an iron-based layer; the inner surface and the outer surface of the iron-based layer are respectively provided with a ceramic film. The inner pot for the cooking appliance provided by the invention is lower in cost and more convenient to manufacture.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

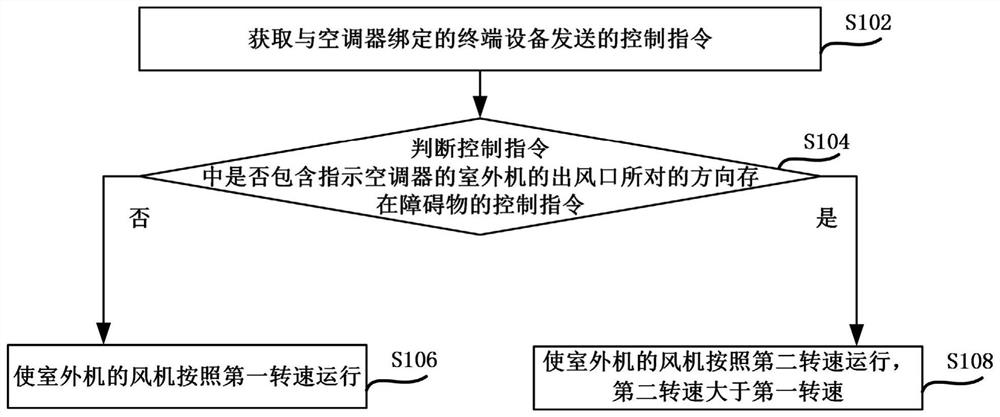

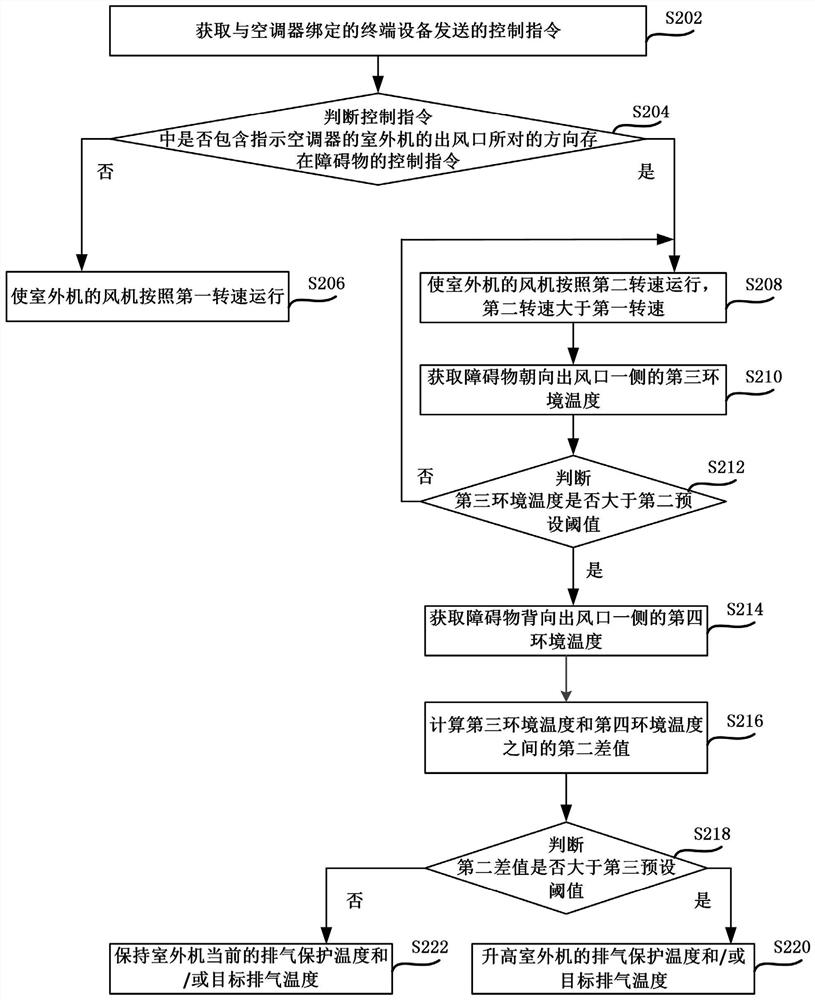

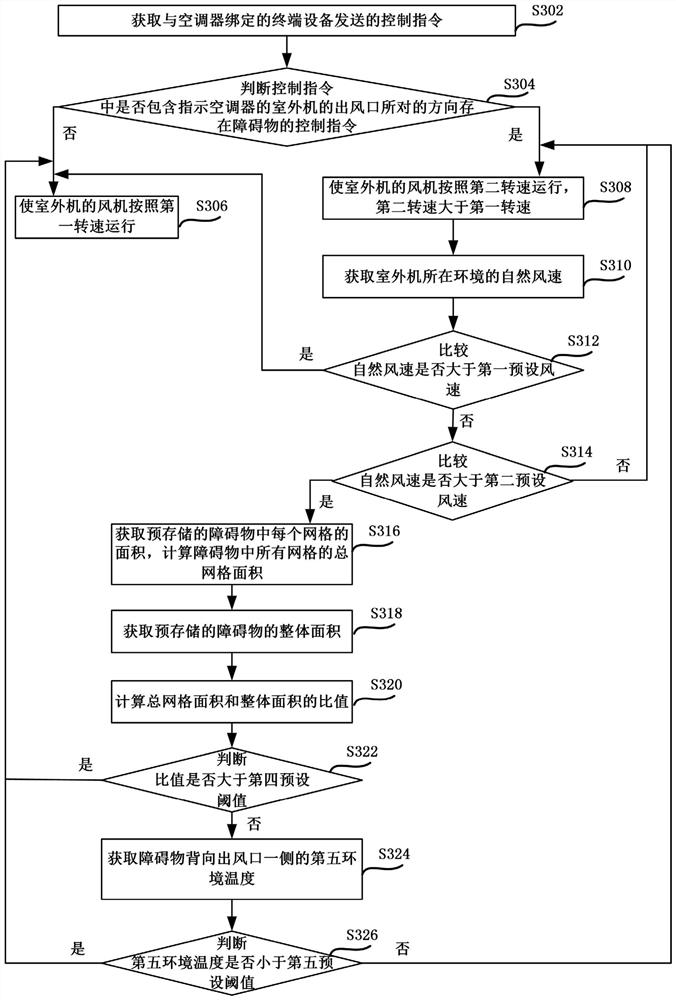

Control method of air conditioner and air conditioner

ActiveCN112254295AGuaranteed cooling effectImprove the level of intelligenceMechanical apparatusSpace heating and ventilation safety systemsControl engineeringTerminal equipment

The invention provides a control method of an air conditioner and the air conditioner. The control method comprises the steps that a control instruction sent by terminal equipment bound with the air conditioner is obtained; whether the control instruction comprises a control instruction for indicating that an obstacle exists in the direction opposite to an air outlet of an outdoor unit of the airconditioner or not is judged; if not, a draught fan of the outdoor unit is made to operate at a first rotating speed; and if yes, the draught fan of the outdoor unit operates at a second rotating speed, and the second rotating speed is larger than the first rotating speed. Under the condition that the control instruction comprises the control instruction for indicating that the obstacle exists inthe direction opposite to the air outlet of the outdoor unit of the air conditioner, the draught fan of the outdoor unit is made to operate at the second higher rotating speed, the heat dissipation speed of the outdoor unit can be increased, and therefore the refrigerating effect of the air conditioner is guaranteed, and the intelligent level of the air conditioner is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

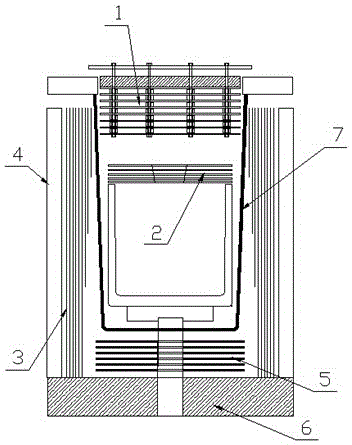

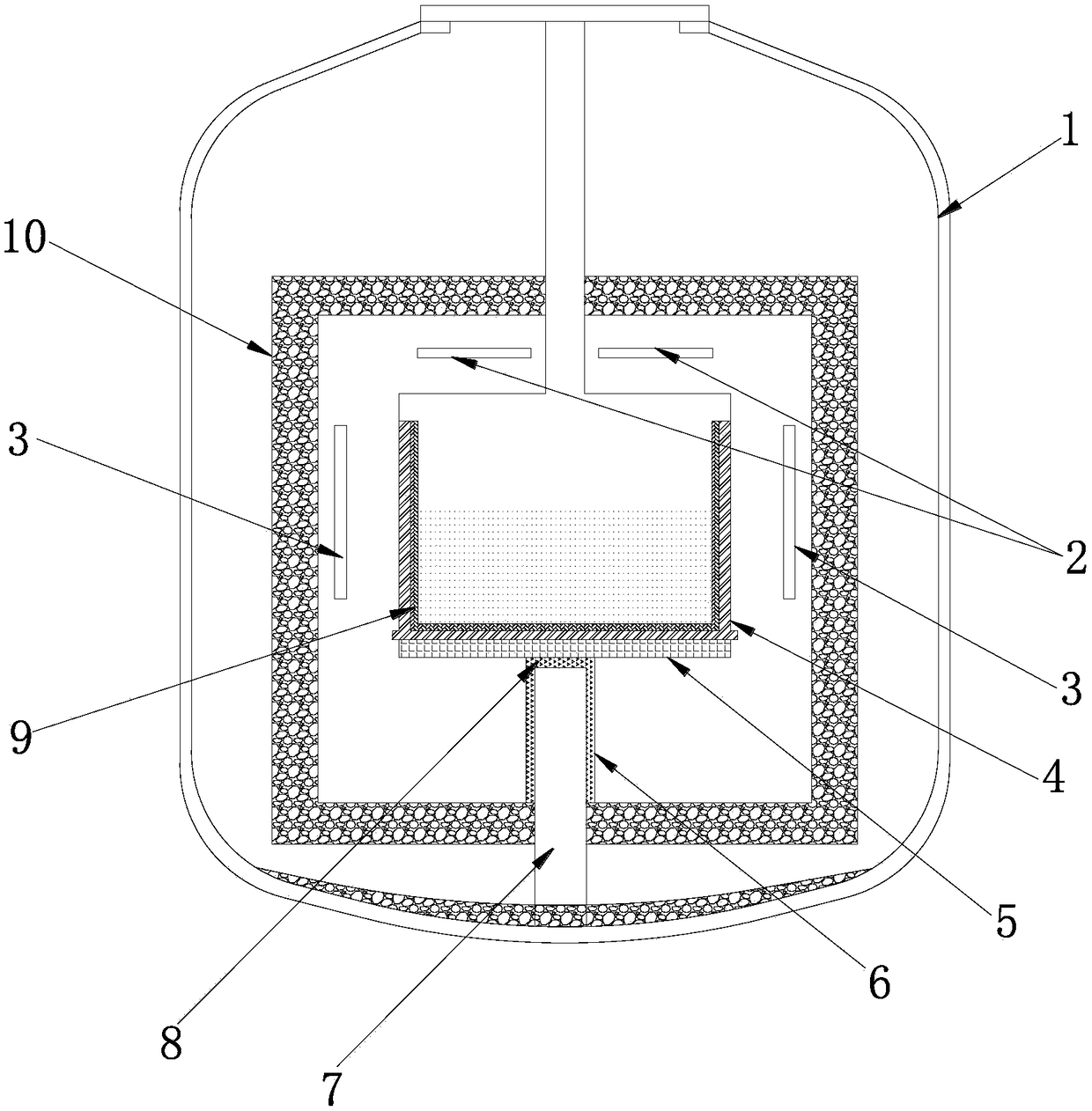

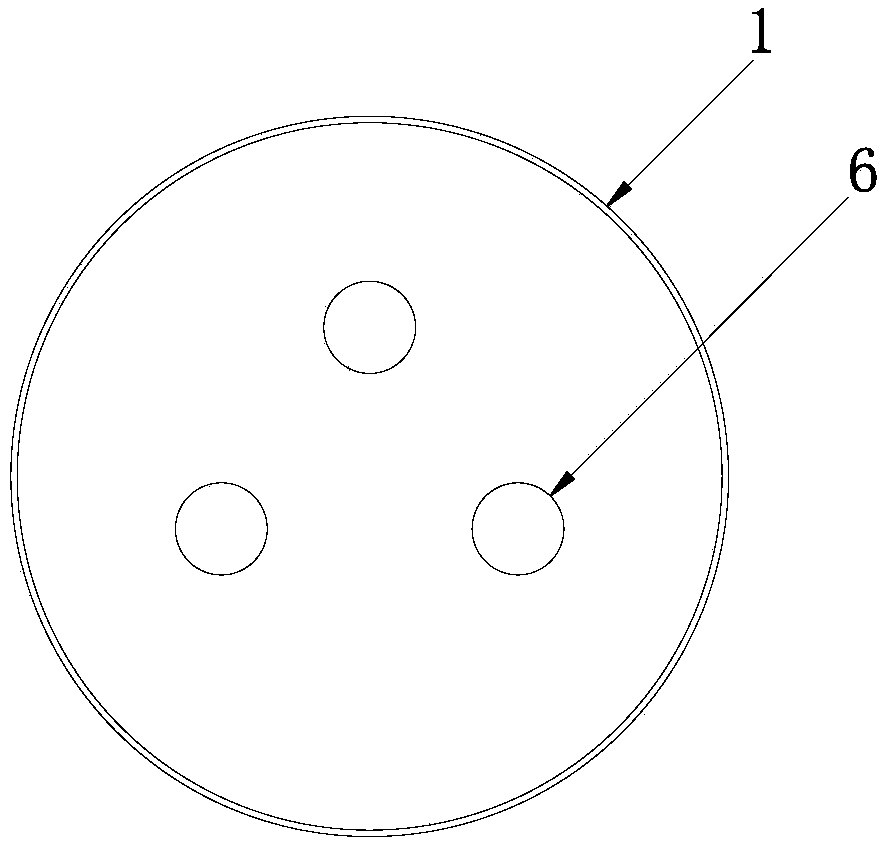

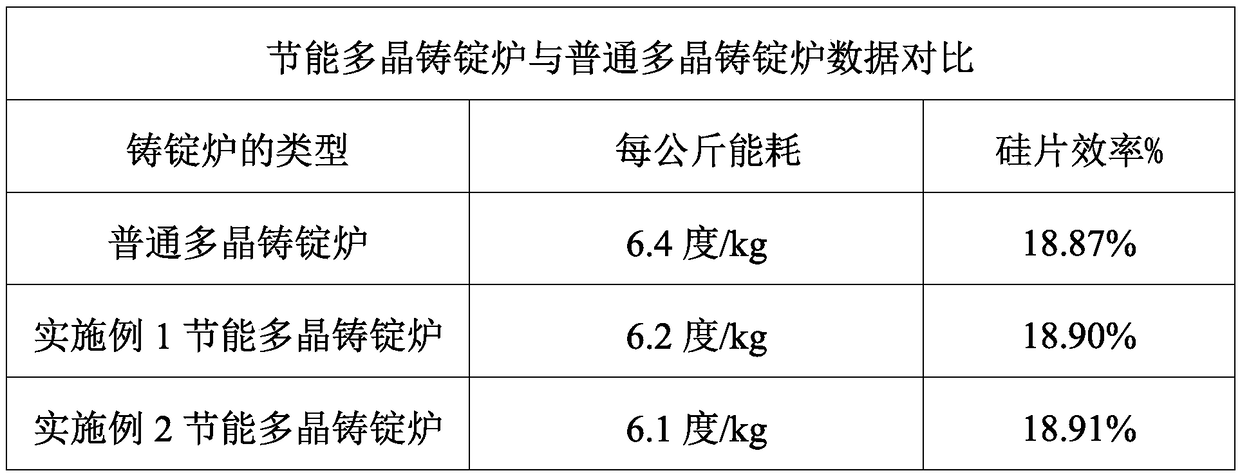

Energy-saving polycrystalline ingot casting furnace

PendingCN108842181AReduce lossesLow costPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention discloses an energy-saving polycrystalline ingot casting furnace. The energy-saving polycrystalline ingot casting furnace comprises a furnace body, a crucible arranged in the furnace body as well as a graphite supporting column for supporting the crucible; graphite protective plates are arranged at the periphery and the bottom of the crucible; a heat exchange platform is arranged below the graphite protective plate at the bottom of the crucible; side heaters are arranged on the outer sides of the graphite protective plates at the periphery of the crucible; a top heater is arranged above the crucible; the energy-saving polycrystalline ingot casting furnace also comprises a thermal field heat-insulating felt; the thermal field heat-insulating felt encloses the crucible, the graphite protective plates, the heat exchange platform, the side heaters and the top heater; one end of the graphite supporting column is connected with the heat exchange platform at the bottom, and theother end passes through the thermal field heat-insulating felt and then is supported on the furnace body; a heat-insulating piece is arranged on the graphite supporting column; and the heat-insultingpiece is arranged on the outer wall of the graphite supporting column in a wrapping mode. The energy-saving polycrystalline ingot casting furnace effectively reduces the loss of heat in the crucible,reduces energy consumption and reduces cost.

Owner:深圳市石金科技股份有限公司

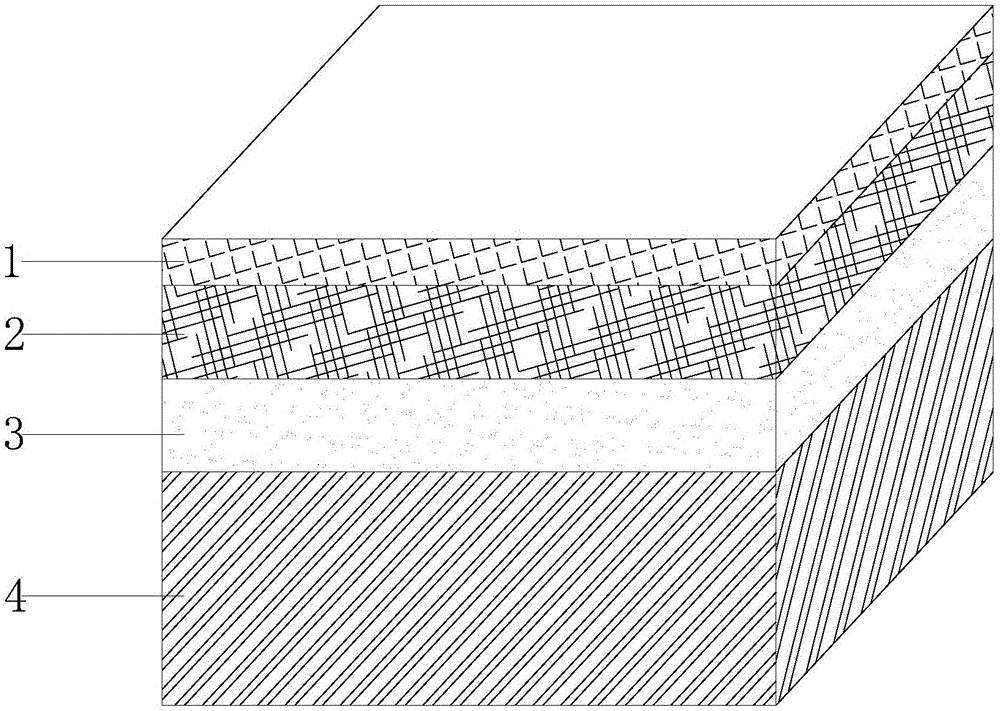

Composite board for high temperature mixture product mold and production process

ActiveCN105058924AHigh surface finishImprove temperature stabilitySynthetic resin layered productsLaminationSheet steelBoundary temperature

Belonging to composite boards for molds and production processes, the invention provides a composite board for a high temperature mixture product mold and a production process. The composite board is composed of an outer wall structural layer and an inner wall structural layer which are an ordinary plate, a pyrophillite and high temperature glue mix, a mica plate, and a flame retardant polycarbonate film respectively. The ordinary plate is steel plate, high strength rigid plastic plate or wood plate. The production process includes: stirring pyrophillite and high temperature glue fully, then laying the mix on the surface of the ordinary plate, covering the pyrophillite and high temperature glue mix with the mica plate, and performing compression moulding, bonding the flame retardant polycarbonate film on the mica plate surface by high temperature glue, and carrying out vacuum bubble removal treatment, thus forming the four-layer structure composite board. The composite board for the high temperature mixture product mold can eliminate the influence of a high temperature mixture to the product mold, ensures the mold temperature stability, balances the mixture internal and boundary temperature gradient, effectively guarantees each direction homogeneity and surface smoothness and finish of test pieces, greatly improves the product success rate, and saves material and time cost.

Owner:CHINA UNIV OF MINING & TECH

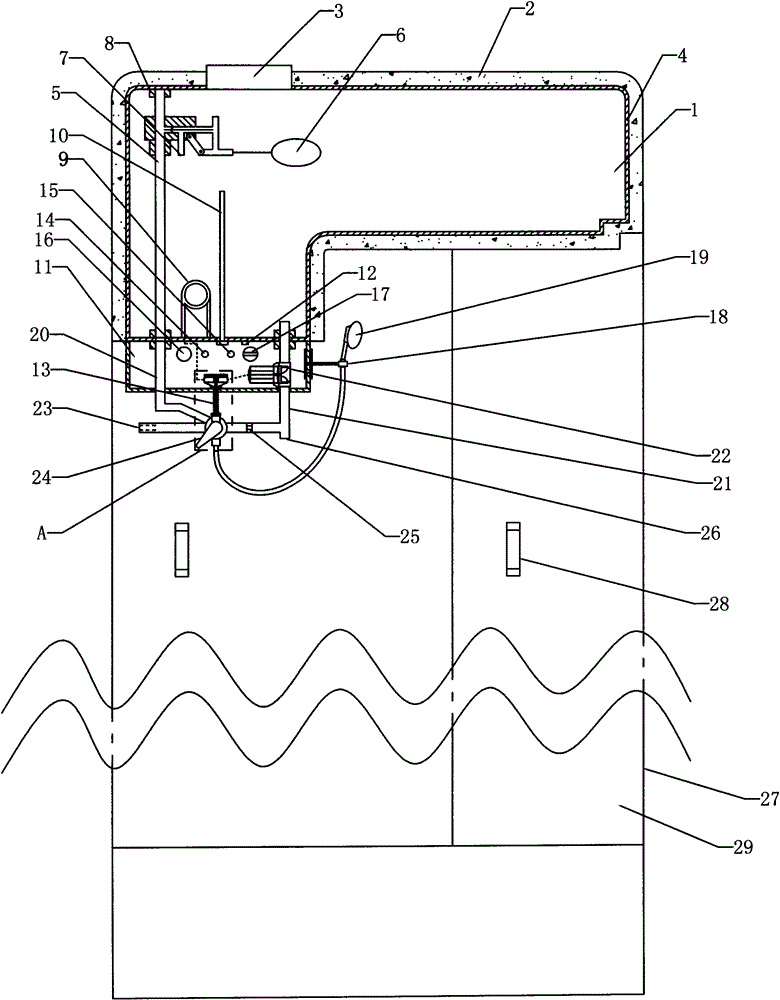

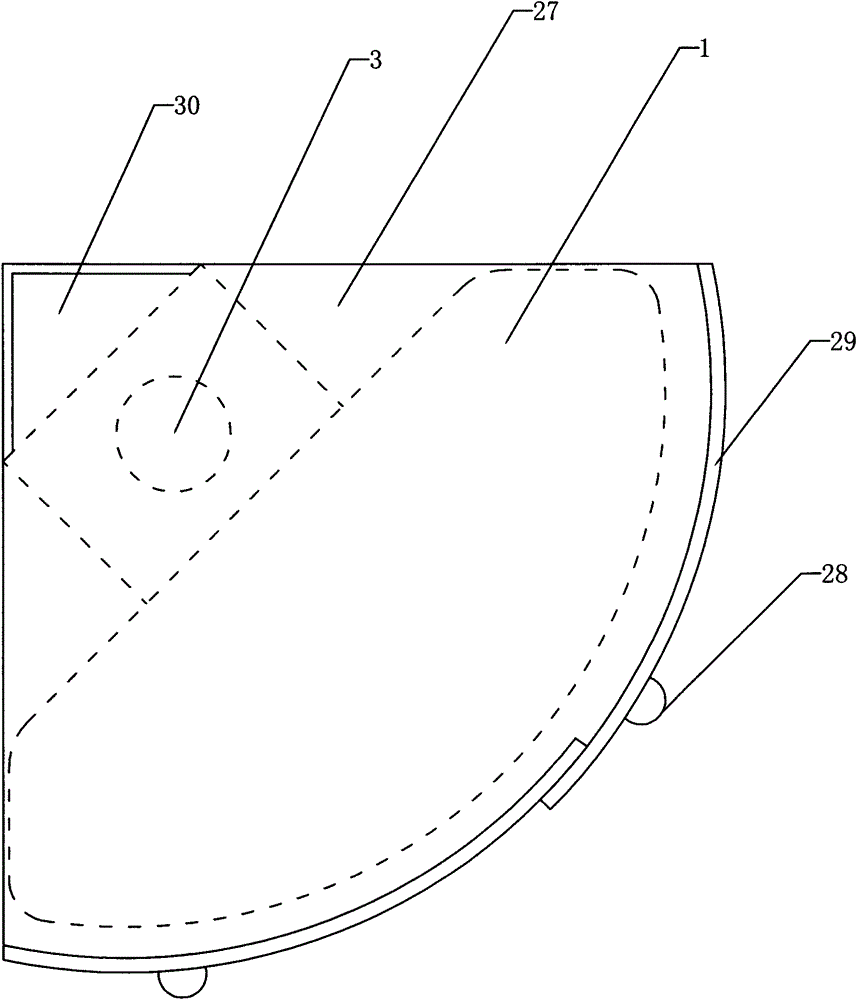

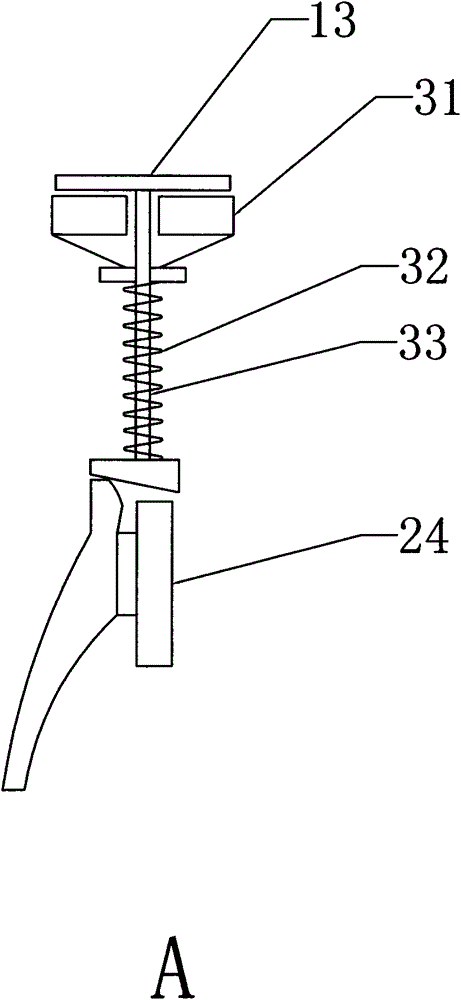

Energy-saving and safe type anti-creeping water heater shower room

InactiveCN104453283AUse less lengthEmission reductionFluid heatersMechanical apparatusWater dischargeEngineering

The invention aims at providing an energy-saving and safe type anti-creeping water heater shower room which is composed of a water heater insulating layer, a water heater container, a water heater upper cover, a stainless steel pipe, a water level floating ball, a heating pipe, a temperature control pipe, a temperature limiter, an electric appliance box, a power cutting device, a shower nozzle hook, a cold and hot water mixing valve, a jet flow hole, a micro water pump, a shower nozzle and a shower room. The energy-saving and safe type anti-creeping water heater shower room has the advantages that the electric water heater and the shower room are combined into a whole and the use length of a pipeline is reduced, so that cold water discharged from the pipeline before hot water is used is reduced and water resources are saved; due to the fact that the shower room is used, heat is diffused slowly when a user takes a bath in winter, the indoor temperature in the bathing process is ensured, the water heater container is formed in a plastic blowing mode so that the water heater container can be resistant to corrosion, the service life of the container is prolonged, the service life of the container is not shorter than 20 years, the insulating layer is foamed through polyurethane, the heat dissipating speed is lowered, energy conservation and environmental friendliness are achieved, after the shower nozzle is taken off from the shower nozzle hook, the power cutting device automatically cuts off power, and therefore the water heater is safer, capable of saving more energy and more durable.

Owner:王锦林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com