Mould for manufacturing glass container

A glass container and mold technology, applied in glass blowing, manufacturing tools, glass forming, etc., can solve the problems of insufficient glass melt blowing, accelerated heat dissipation, and increased cooling speed, so as to ensure quality and avoid cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

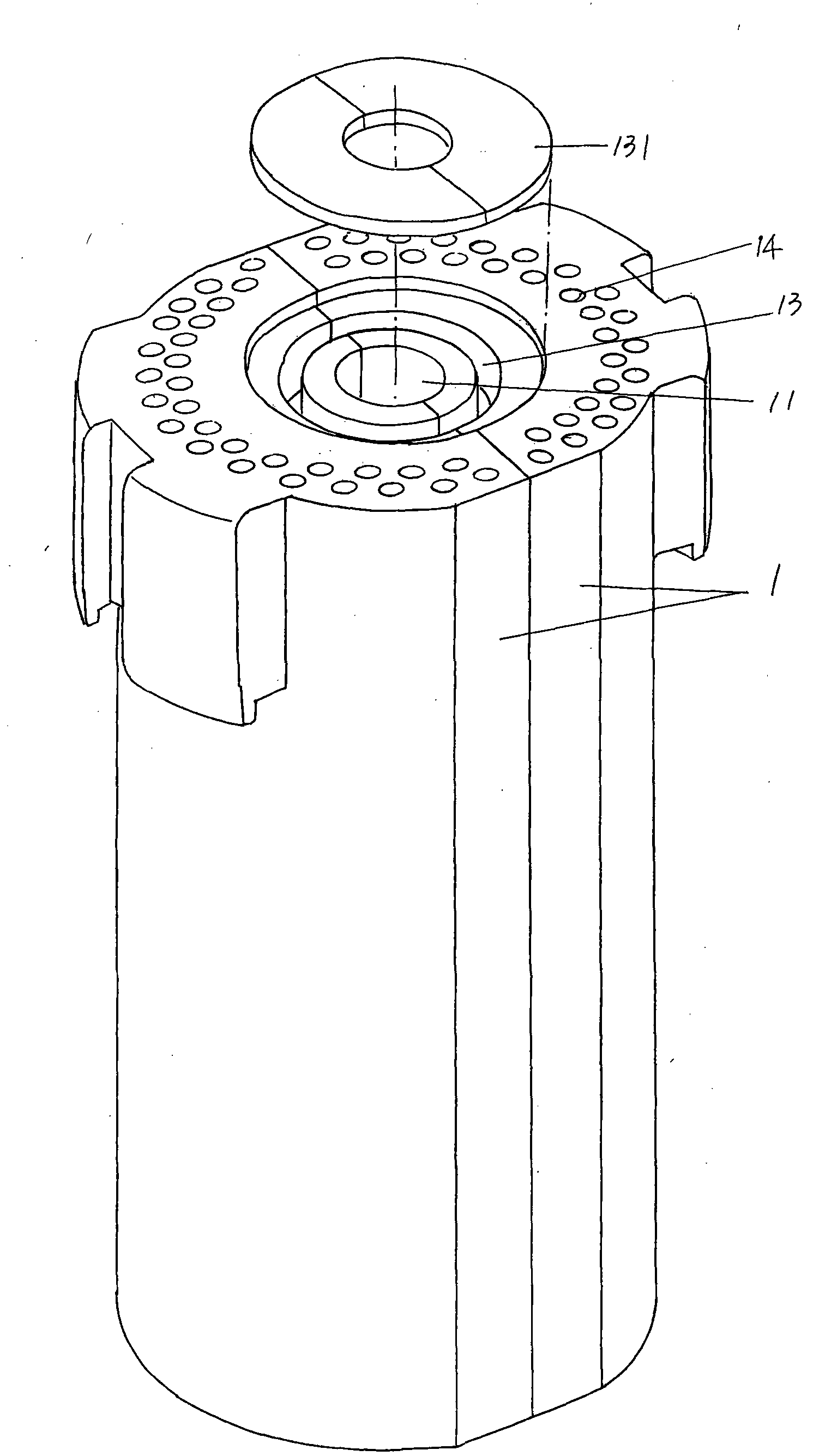

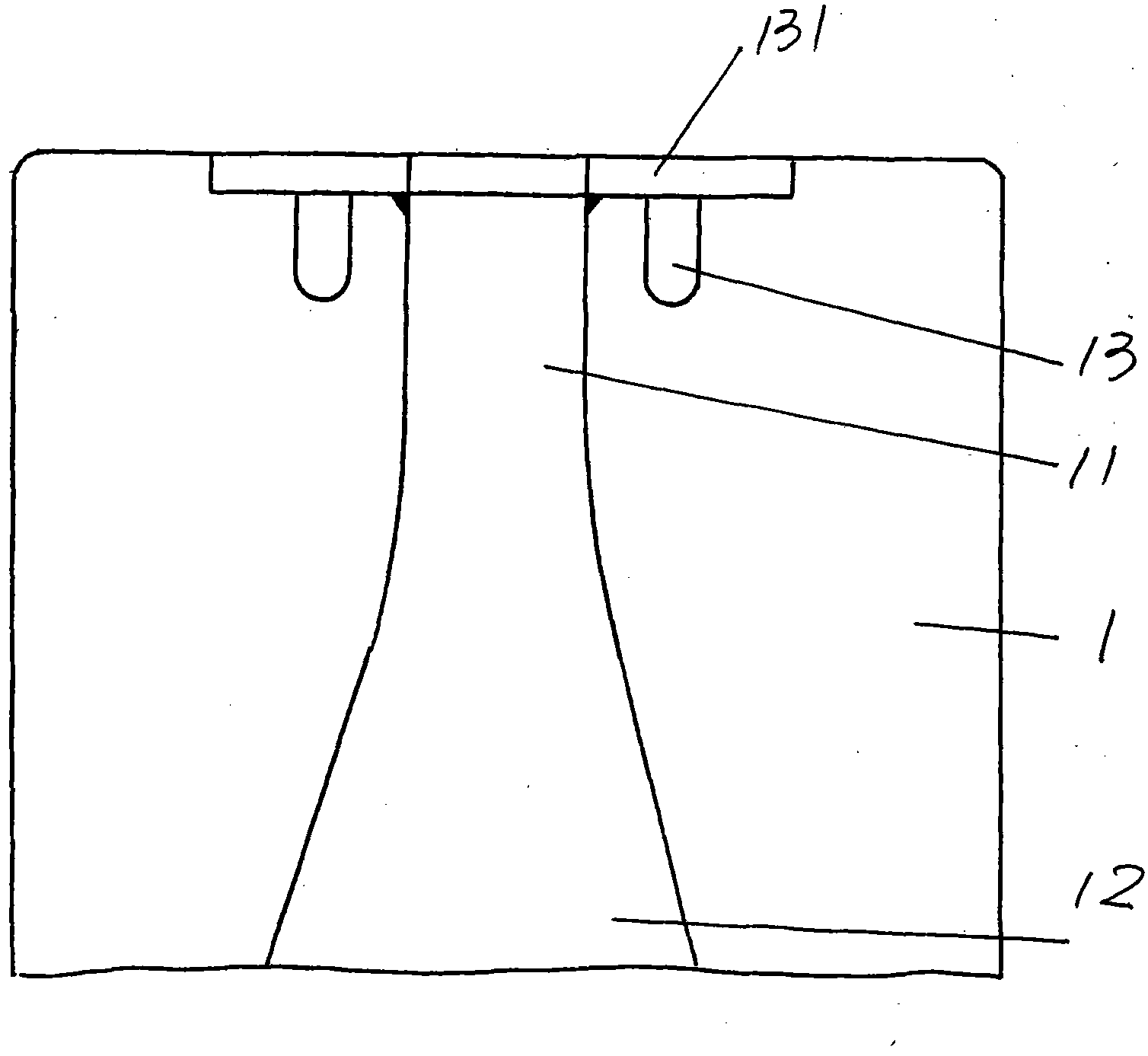

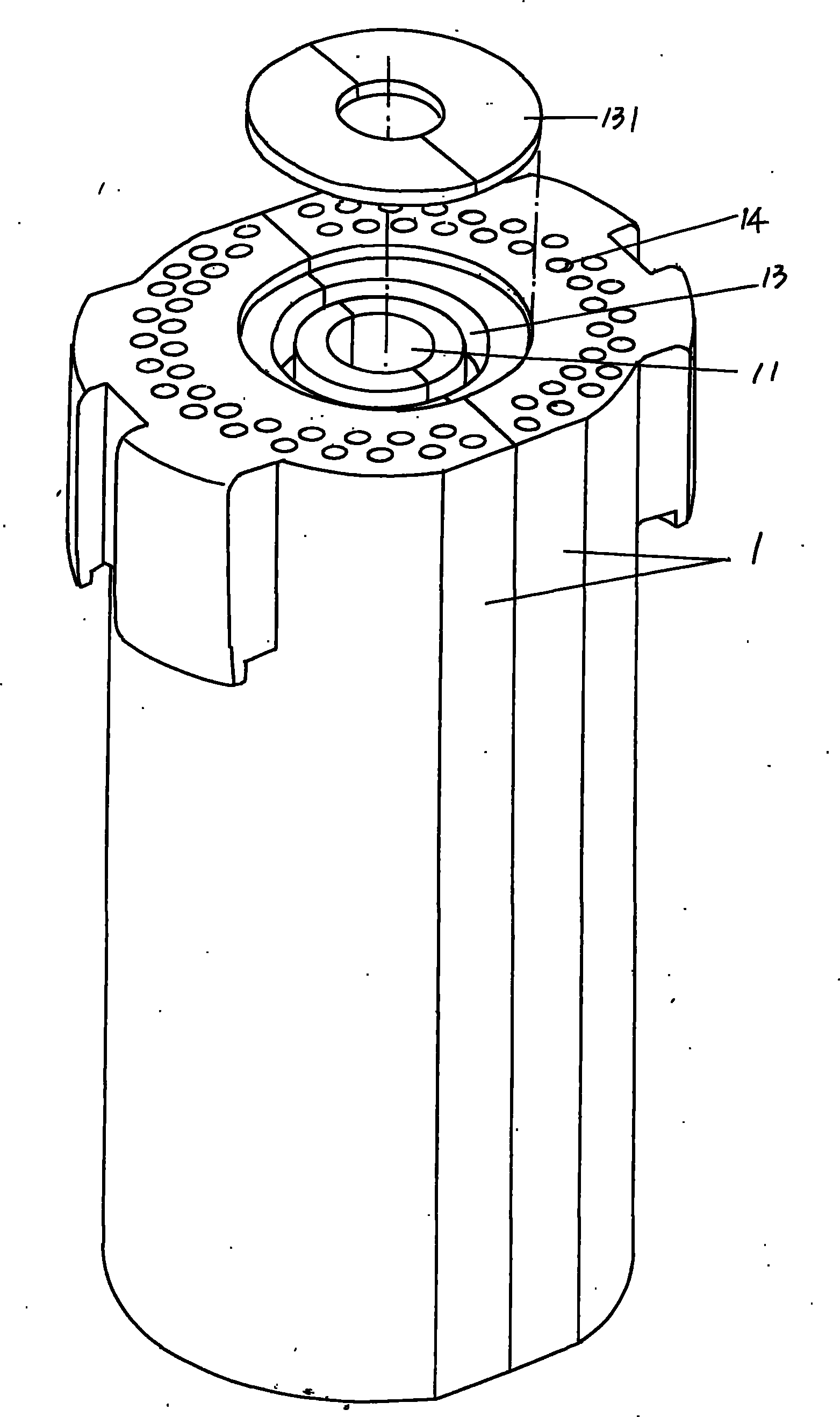

[0011] please see figure 1 and figure 2 , a pair of bottle half-molds 1 having the same shape and size and facing each other are given, each bottle half-mold 1 has a bottle neck cavity 11 and a bottle body cavity 12, on each bottle half-mold 1 and around the mouth of the bottle neck cavity 11 The position is provided with a semicircular arc-shaped heat preservation groove 13. When a pair of bottle half molds 1 are opposed to each other and the mold is closed, a circular heat preservation groove 13 is formed, and the heat preservation groove 13 is closed by a heat preservation groove cover 131. Groove cover 131 is welded and fixed with bottle mold half 1. In addition, a heat dissipation hole 14 is provided around the bottle neck cavity 11 and outside the heat preservation tank 13, and the function of the heat dissipation hole 14 can be referred to CN101298355A.

[0012] The mold manufactured by the technical solution provided by the invention was compared with the mold in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com