Crystallization kettle

A technology of crystallization kettle and heating device, which is applied in the direction of crystallization separation, chemical instruments and methods, separation methods, etc., can solve the problems of large energy consumption, enterprise cost burden, and large heat dissipation of crystallization kettle, so as to reduce energy consumption , the effect of slowing down the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

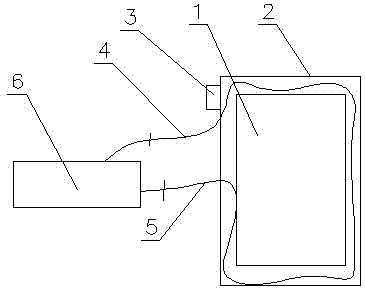

[0009] The present invention is equipped with heat preservation cover 2 outside crystallization kettle body 1, and described heat preservation cover 2 is provided with temperature detecting device 3 and heating device; Heating device 4 of the present invention comprises gas pipe 4 and boiler 6, and gas pipe of the present invention is arranged on heat preservation cover 2 and boiler 6, including air inlet pipe 4 and air outlet pipe 5.

[0010] The working process of the present invention is: the present invention determines whether to turn on the heating device through the detection of the temperature detection device 3; if the heating device is turned on, the boiler steam flows out from the boiler 6, and flows into the heat preservation cover 2 and the crystallization kettle body 1 through the air intake pipe 4 In the formed cavity, flow back in the boiler 6 again through the gas outlet pipe 5, until the temperature detection device 3 detects that the crystallization kettle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com