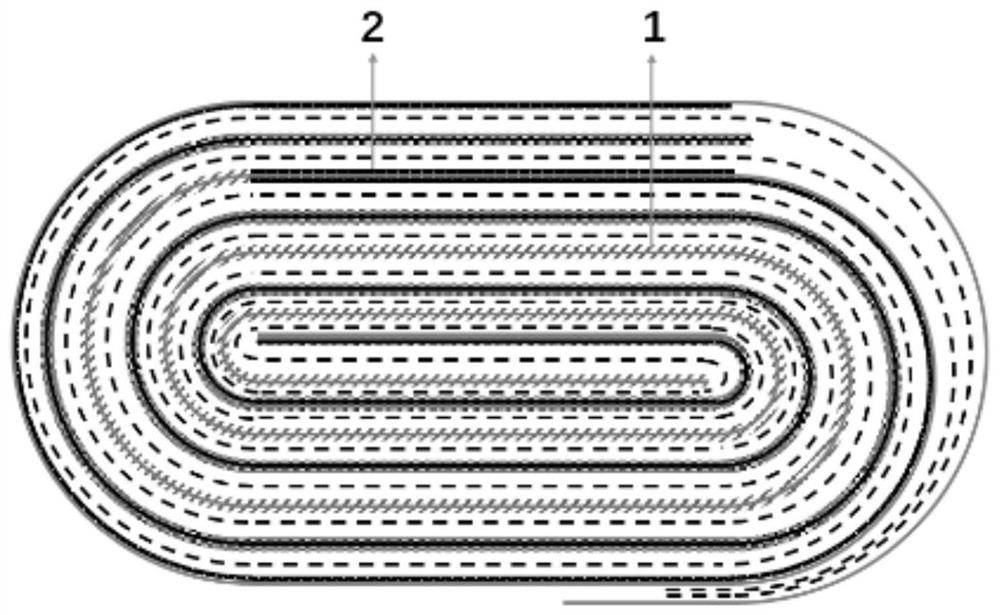

Roll core used for wound lithium ion battery and capable of reducing internal temperature rise

A lithium-ion battery, wound-type technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of battery temperature rise, high-temperature hot area heat generation, etc., to reduce the temperature rise of the battery and reduce the temperature rise , The effect of reducing energy density loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The positive electrode active material lithium cobaltate (particle size D 50 14 μm), binder PVDF, and conductive carbon black as a conductive agent were mixed according to a mass ratio of 90.5:4.5:5, and then N-methylpyrrolidone was added to stir and disperse to prepare positive electrode slurry 1 with an appropriate solid content.

[0047] The positive electrode active material lithium cobaltate (particle size D 50 14 μm), the binder PVDF, and the conductive agent conductive carbon black were mixed according to the mass ratio of 97.9:1:1.1, and then N-methylpyrrolidone was added to stir and disperse to prepare positive electrode slurry 2 with an appropriate solid content.

[0048] Use a coating machine to coat the positive electrode slurry 1 on both sides of the current collector at the head of the positive electrode current collector to form the first coating area; coat the positive electrode slurry 2 on the current collectors of other parts of the positive electrode ...

Embodiment 2-7

[0052] Other parts of Examples 2-7 are the same as Example 1, the only difference is that the areas of the first coating area and the second coating area are different, that is, the number of folds formed by the first coating area and the number of folds formed by the second coating area The number is different; the content of the conductive agent in the positive electrode slurry 1 and the positive electrode slurry 2 is different, and the D of the positive electrode active particles of the positive electrode slurry 1 and the positive electrode slurry 2 50 different, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com