Patents

Literature

46results about How to "Small temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

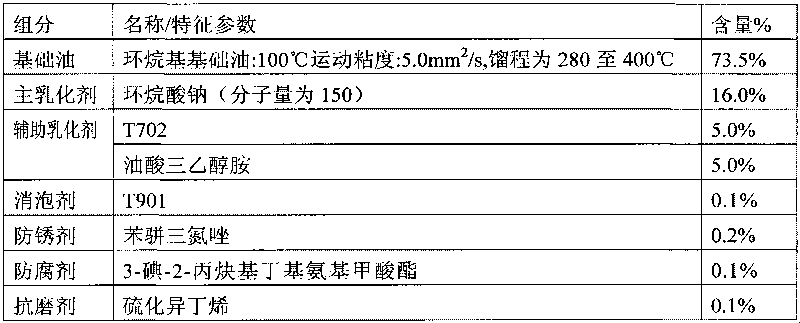

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

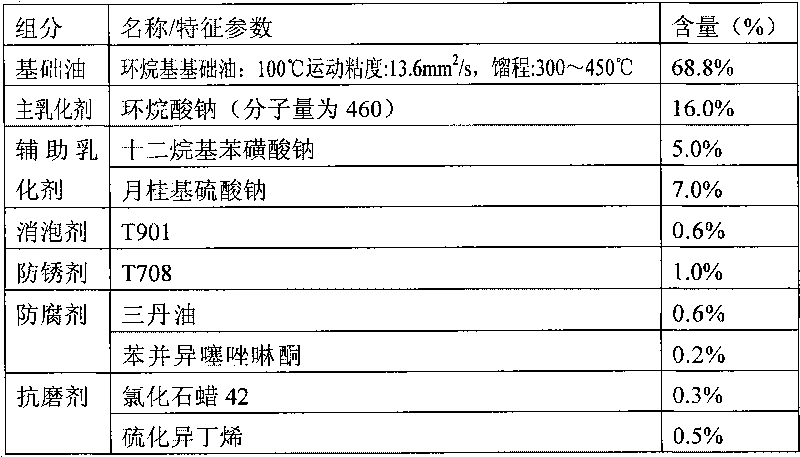

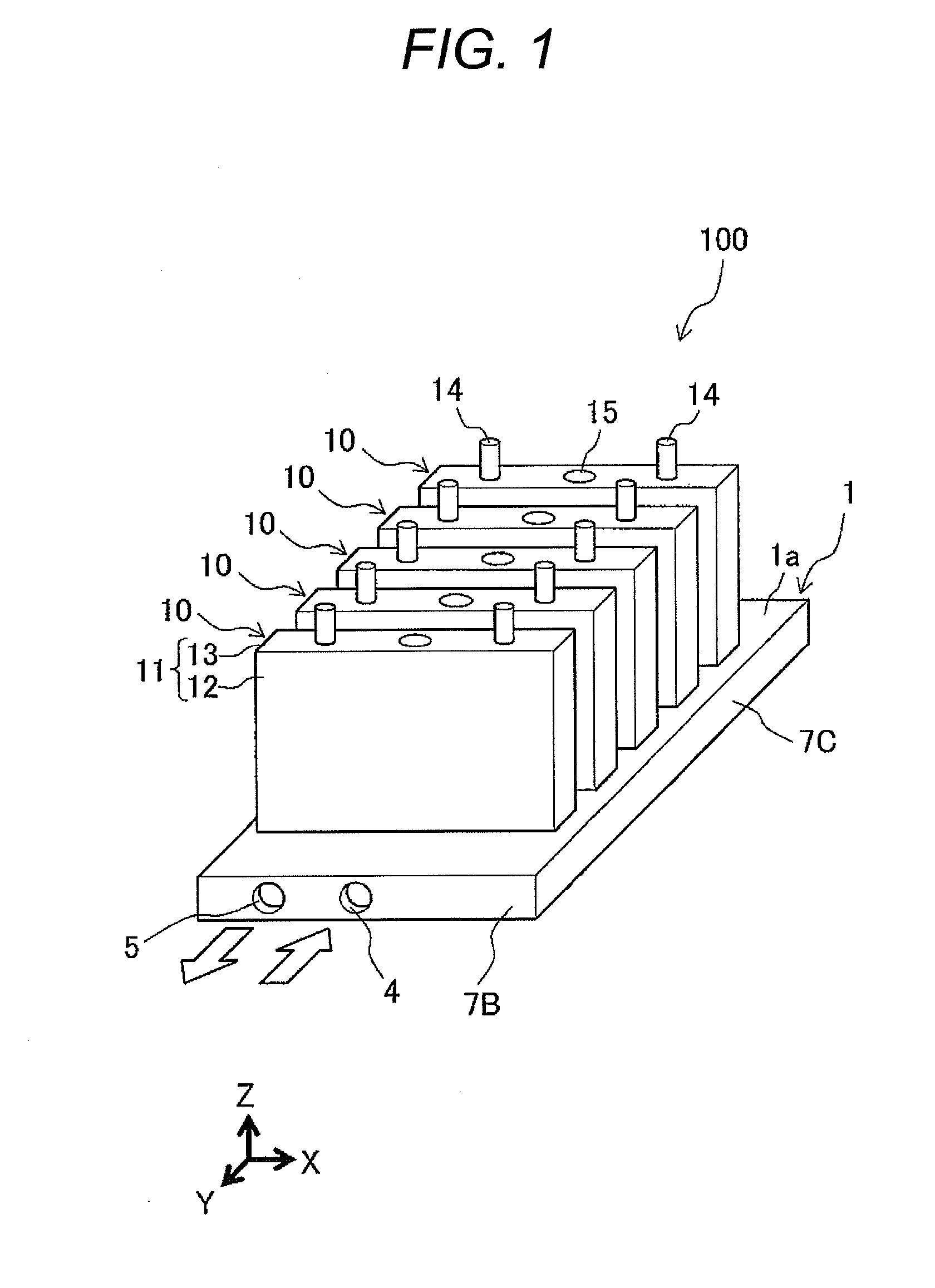

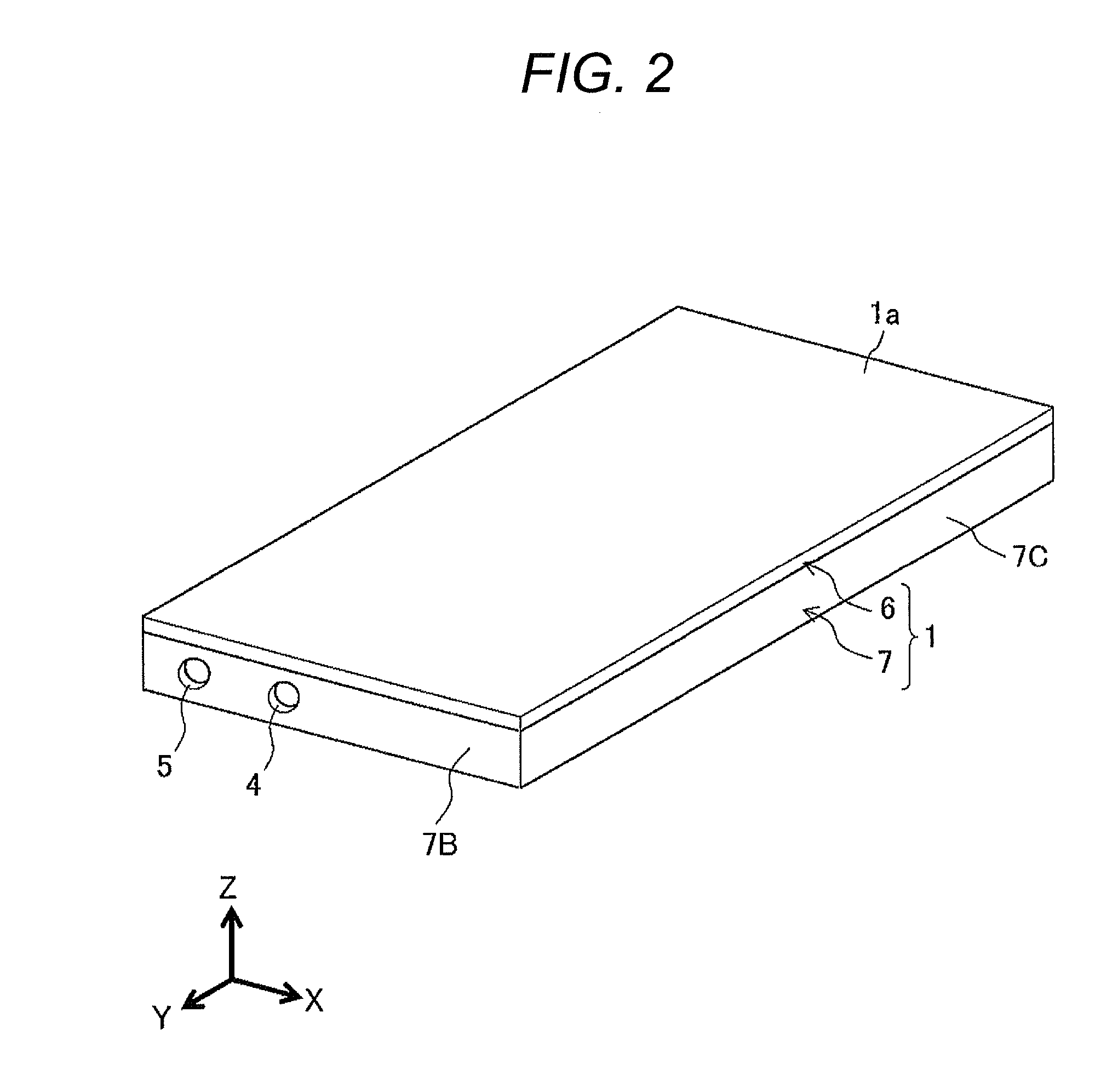

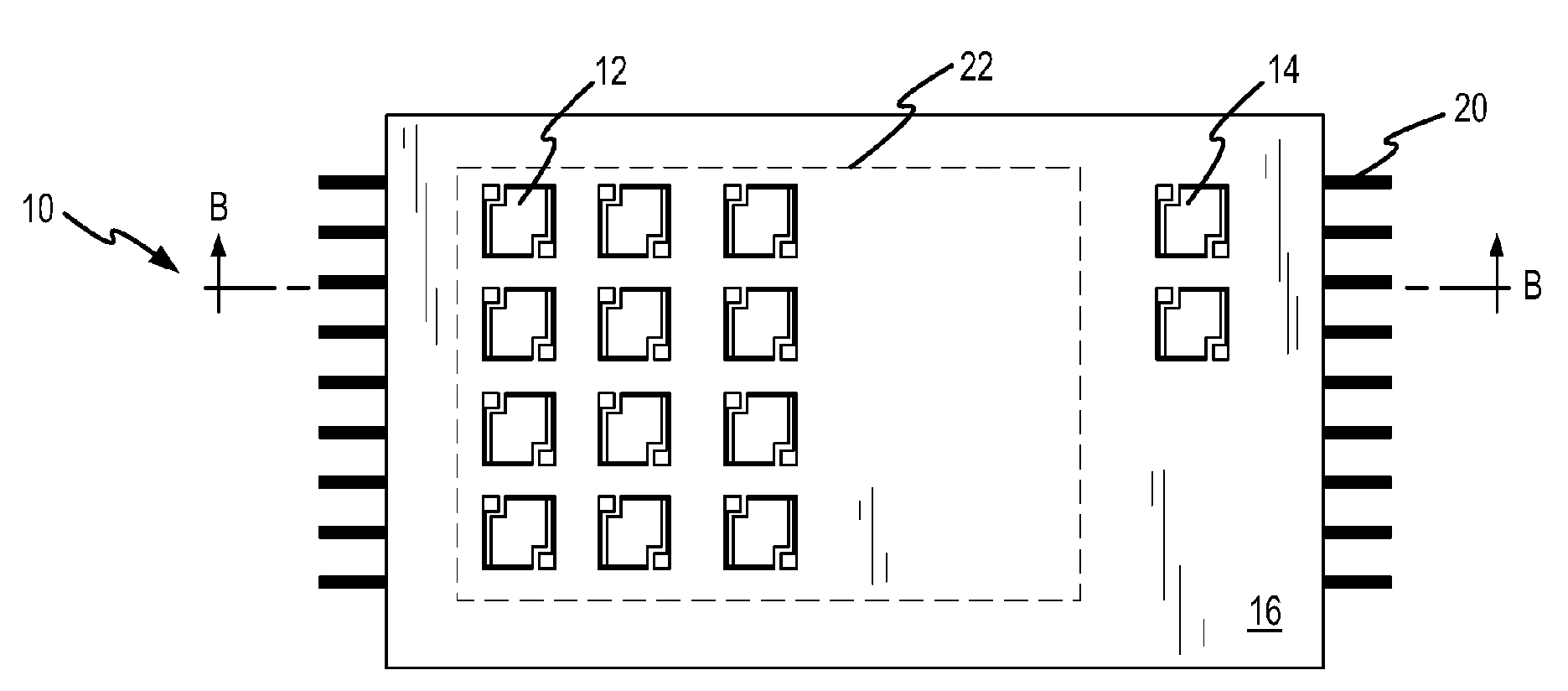

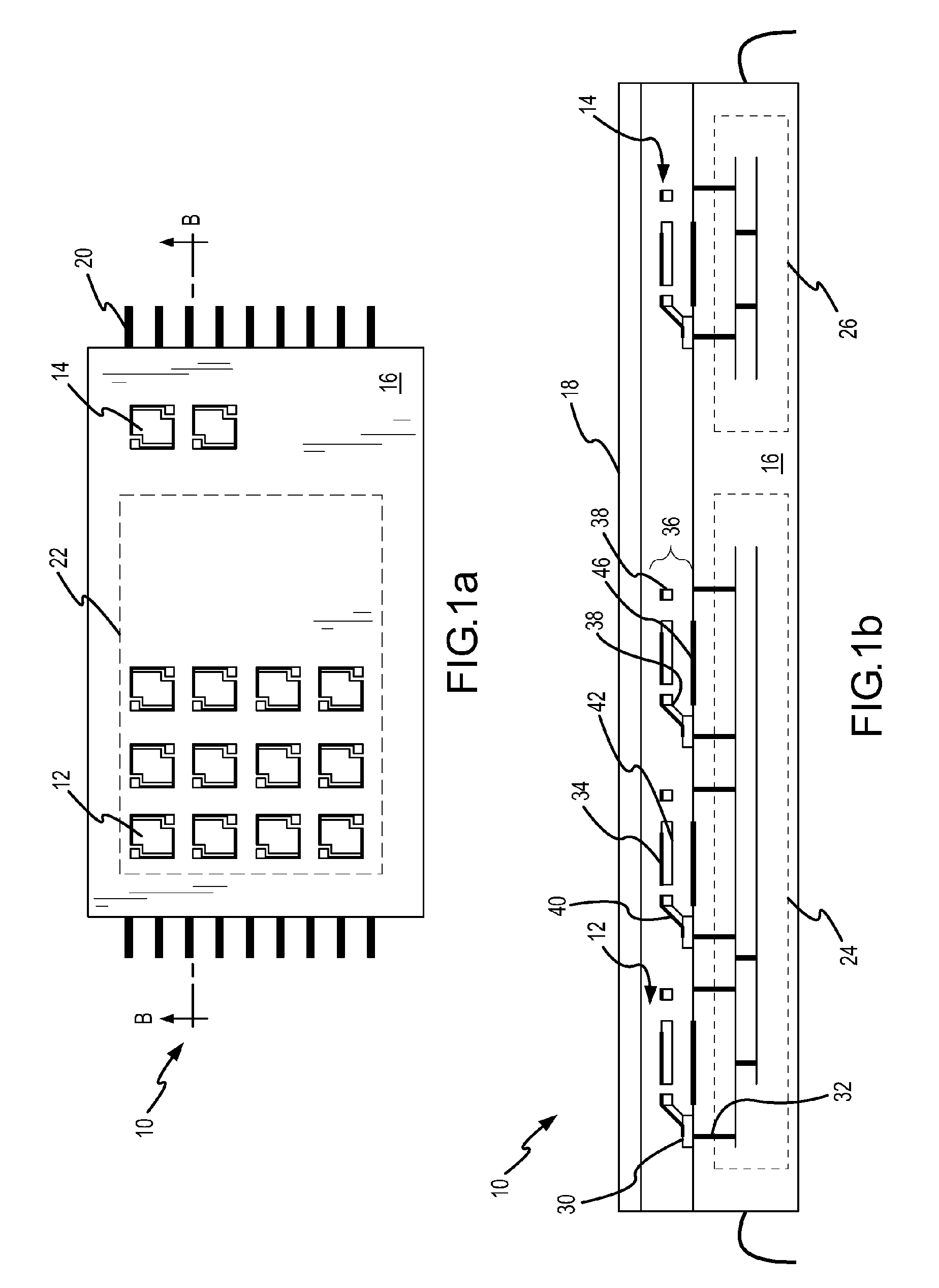

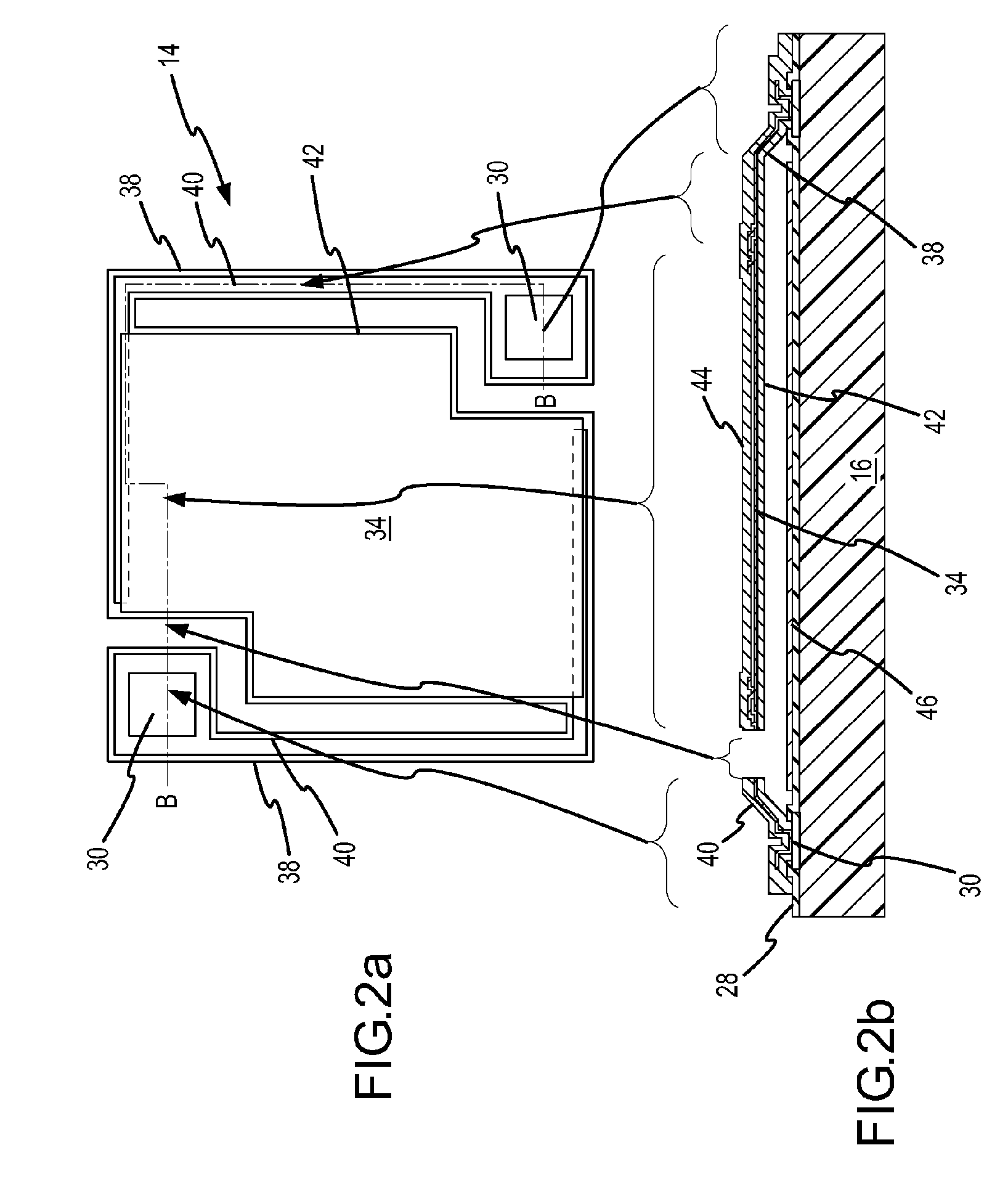

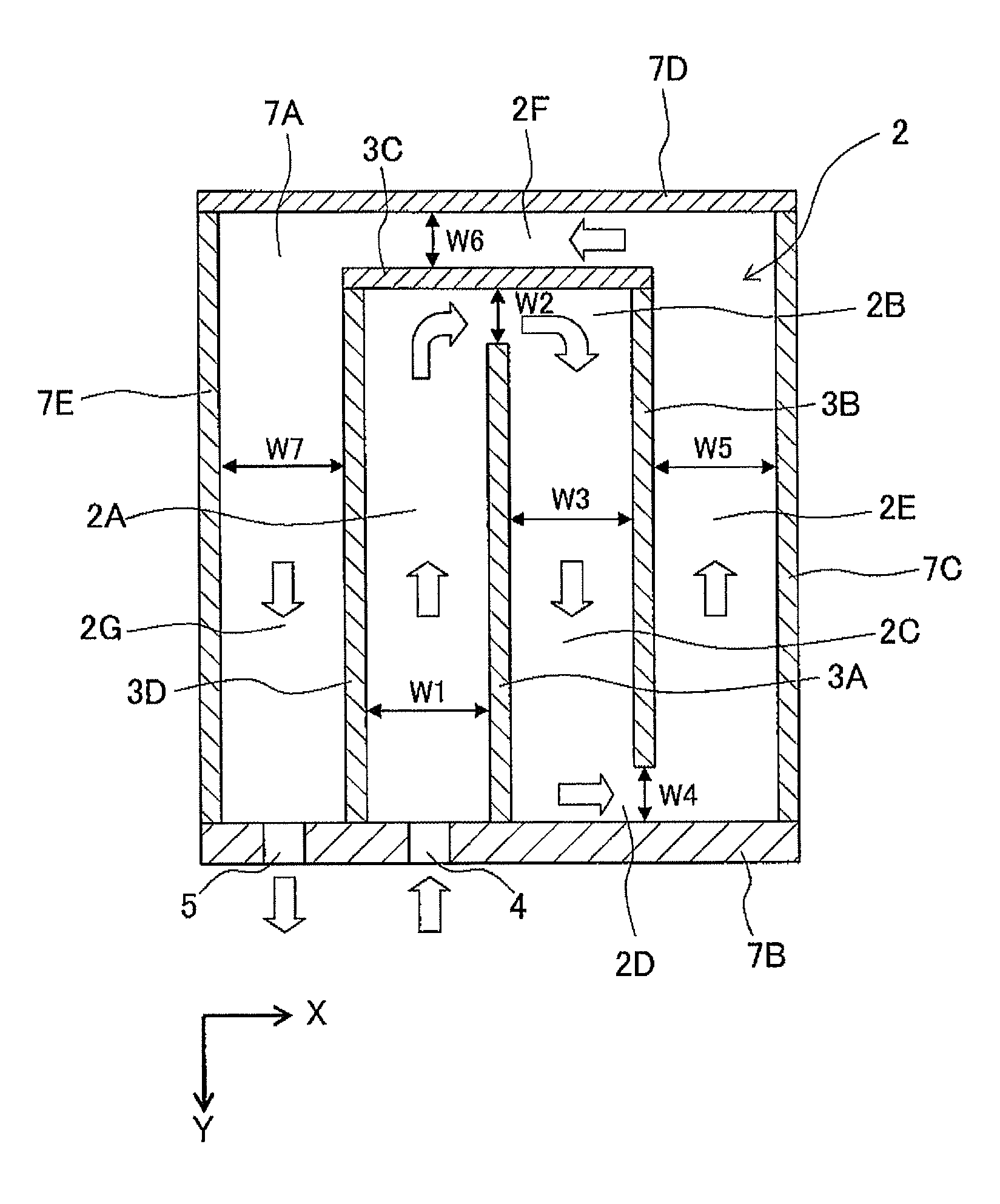

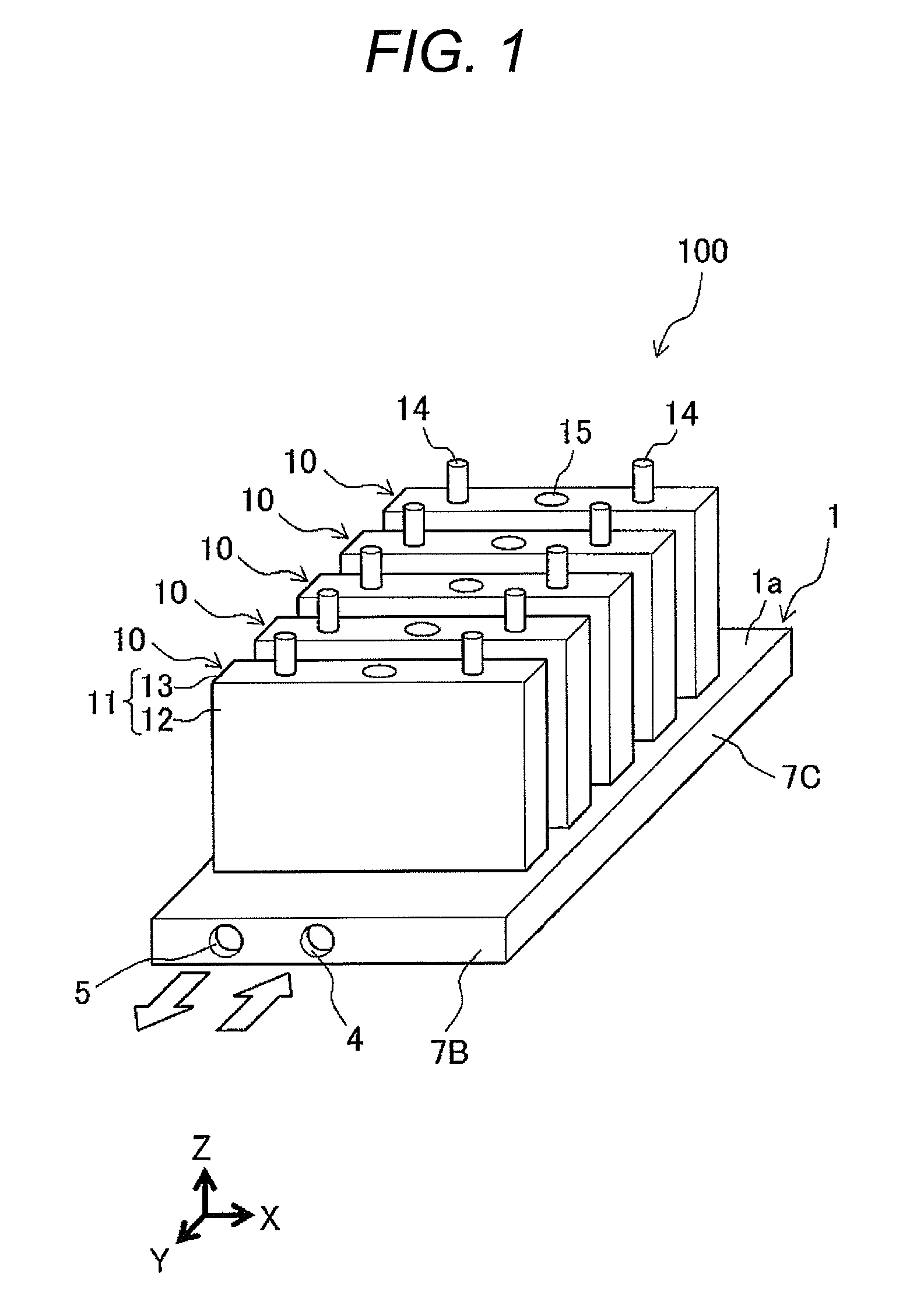

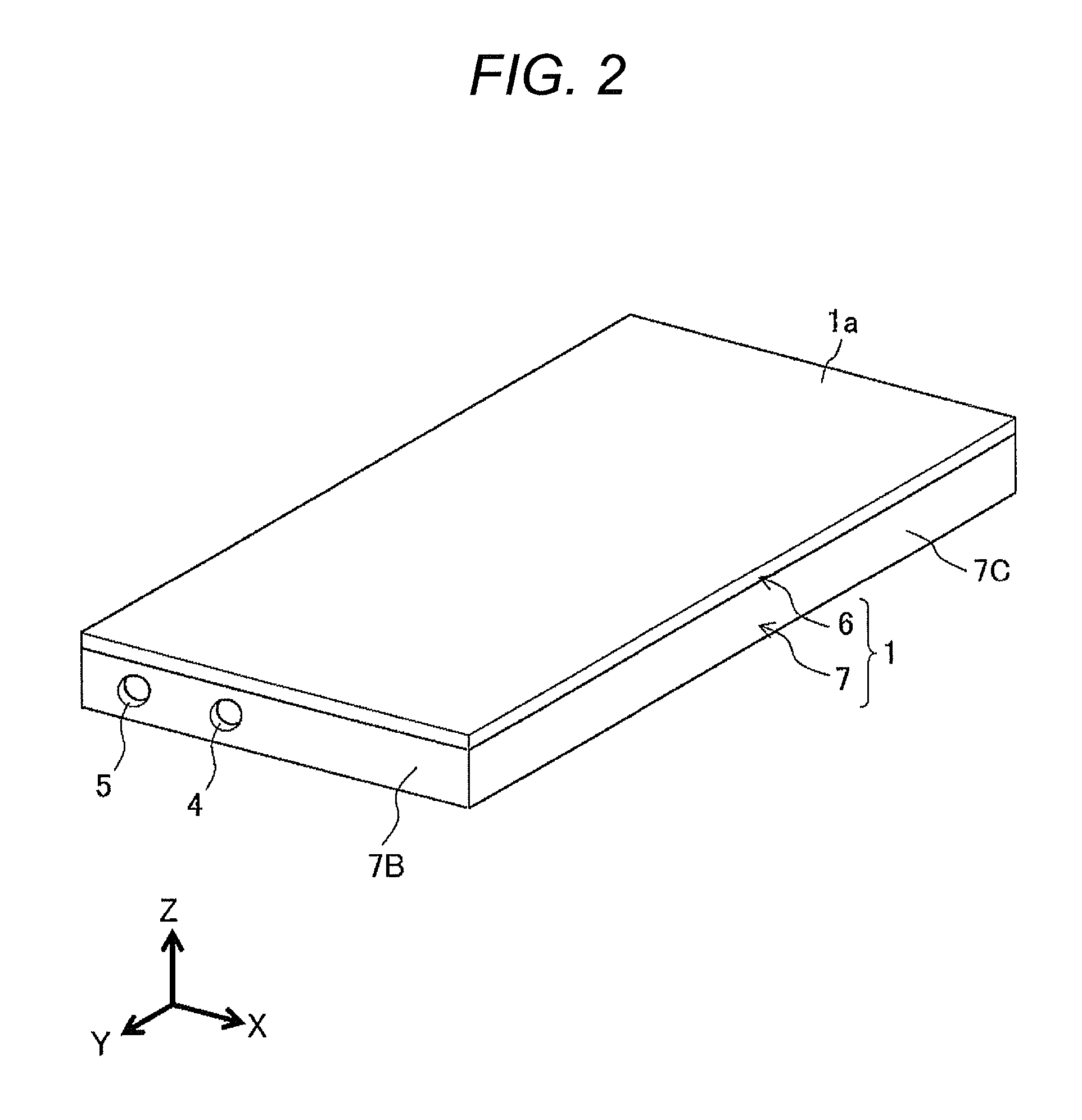

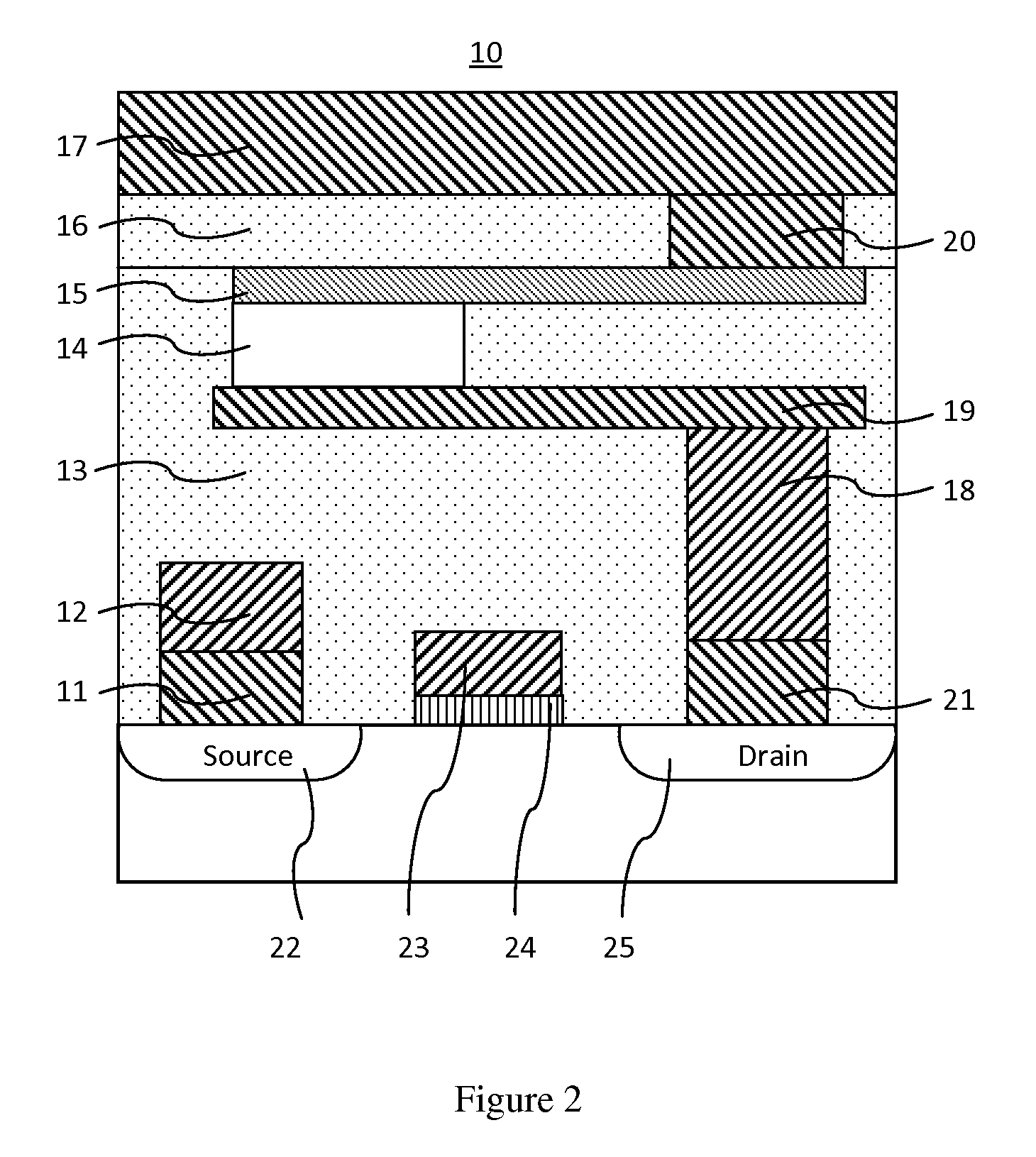

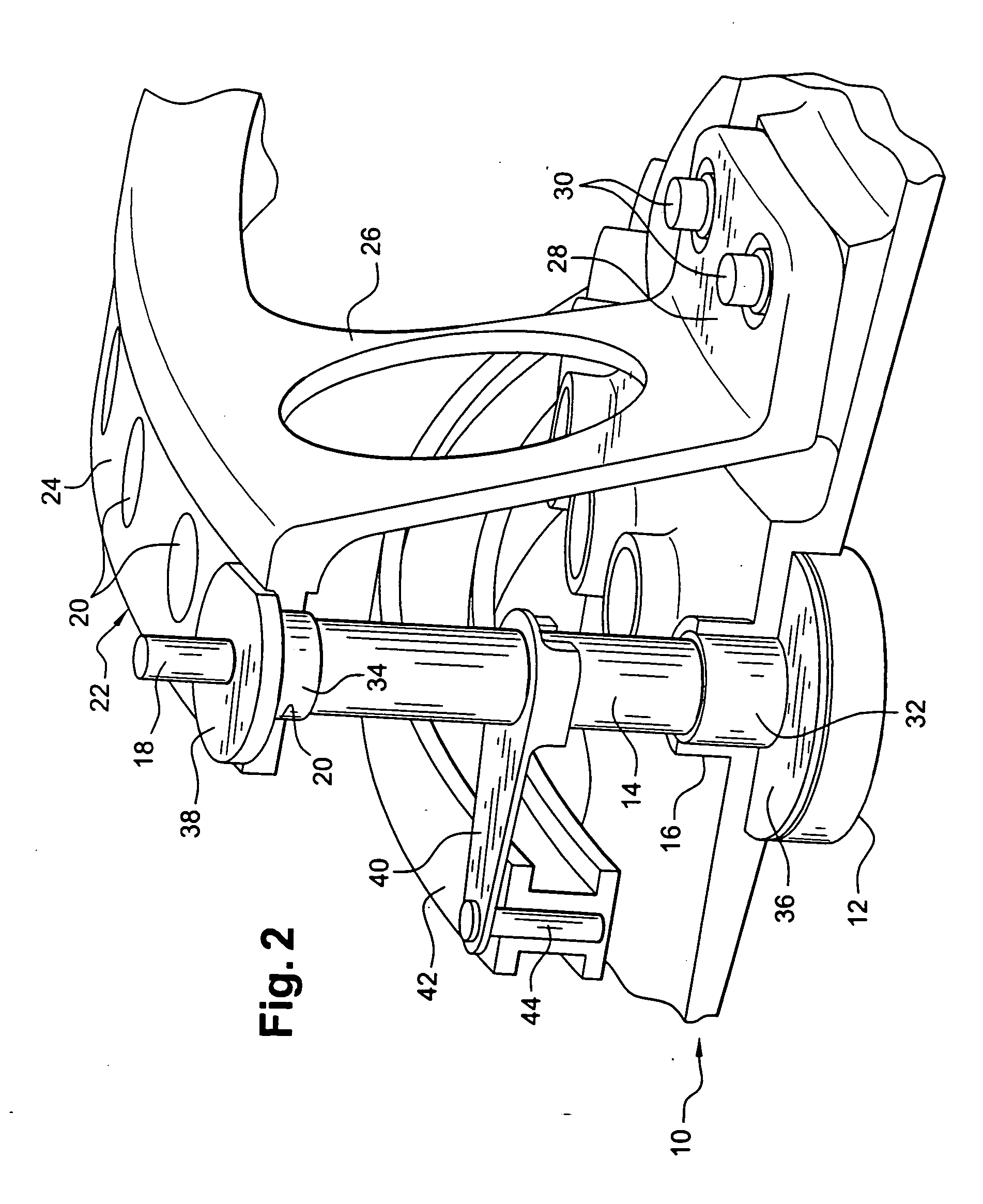

Battery module

ActiveUS20150140388A1Increase temperatureSmall temperature riseCell temperature controlCell lids/coversEngineeringCoolant

A battery module of includes a plurality of cells, a cooling plate, and a channel part formed in the cooling plate. The channel part includes a first channel part extending in an arrangement direction of the plurality of cells, a second channel part extending in parallel to the first channel part along the arrangement direction with a first partition part interposed between the first channel part and the second channel part, and a first communication part which brings one end of the first channel part of the arrangement direction and one end of the second channel part of the arrangement direction into communication with each other, and which turns a flowing direction of coolant in the first channel part and the second channel part.

Owner:HITACHI VEHICLE ENERGY

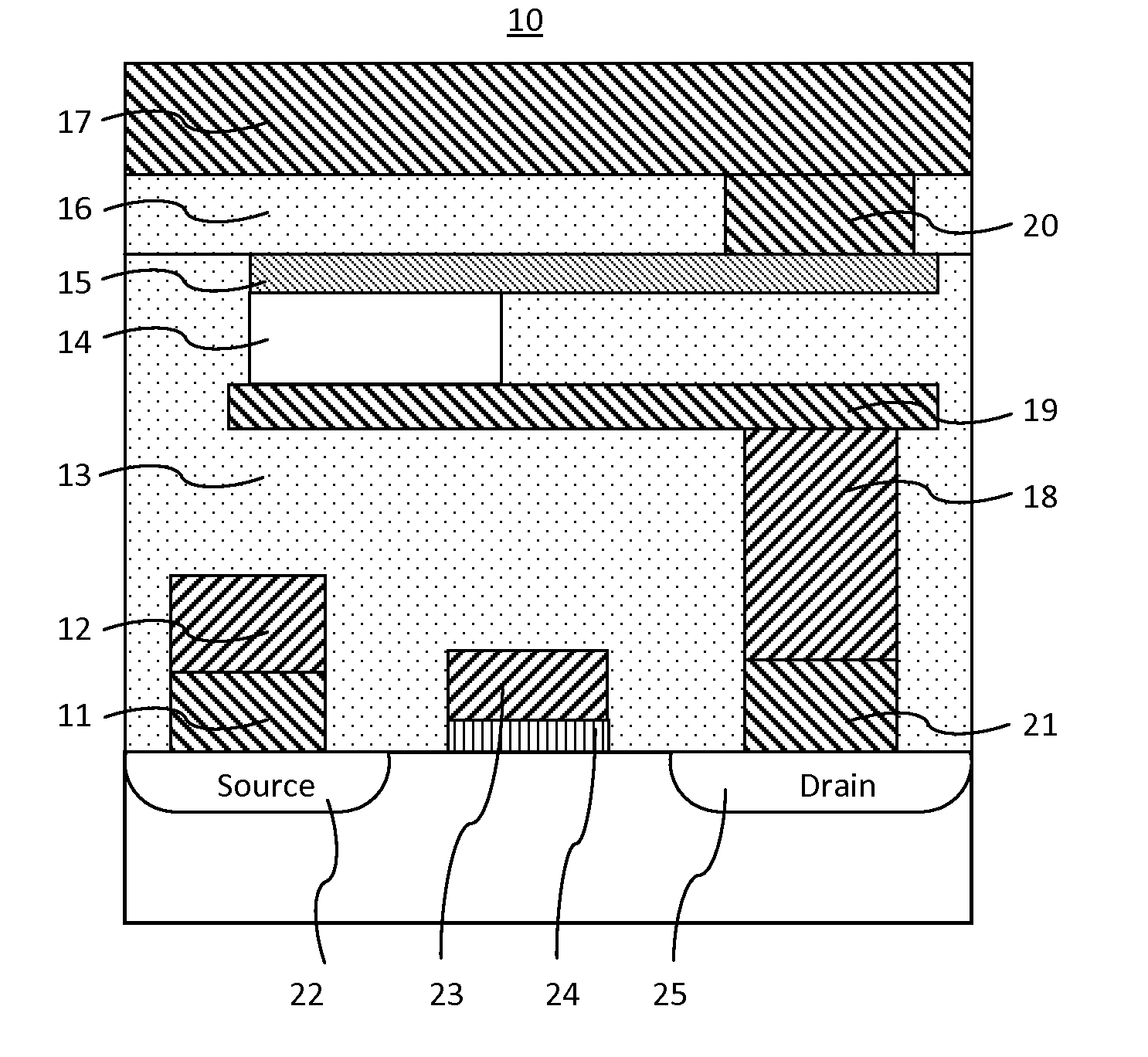

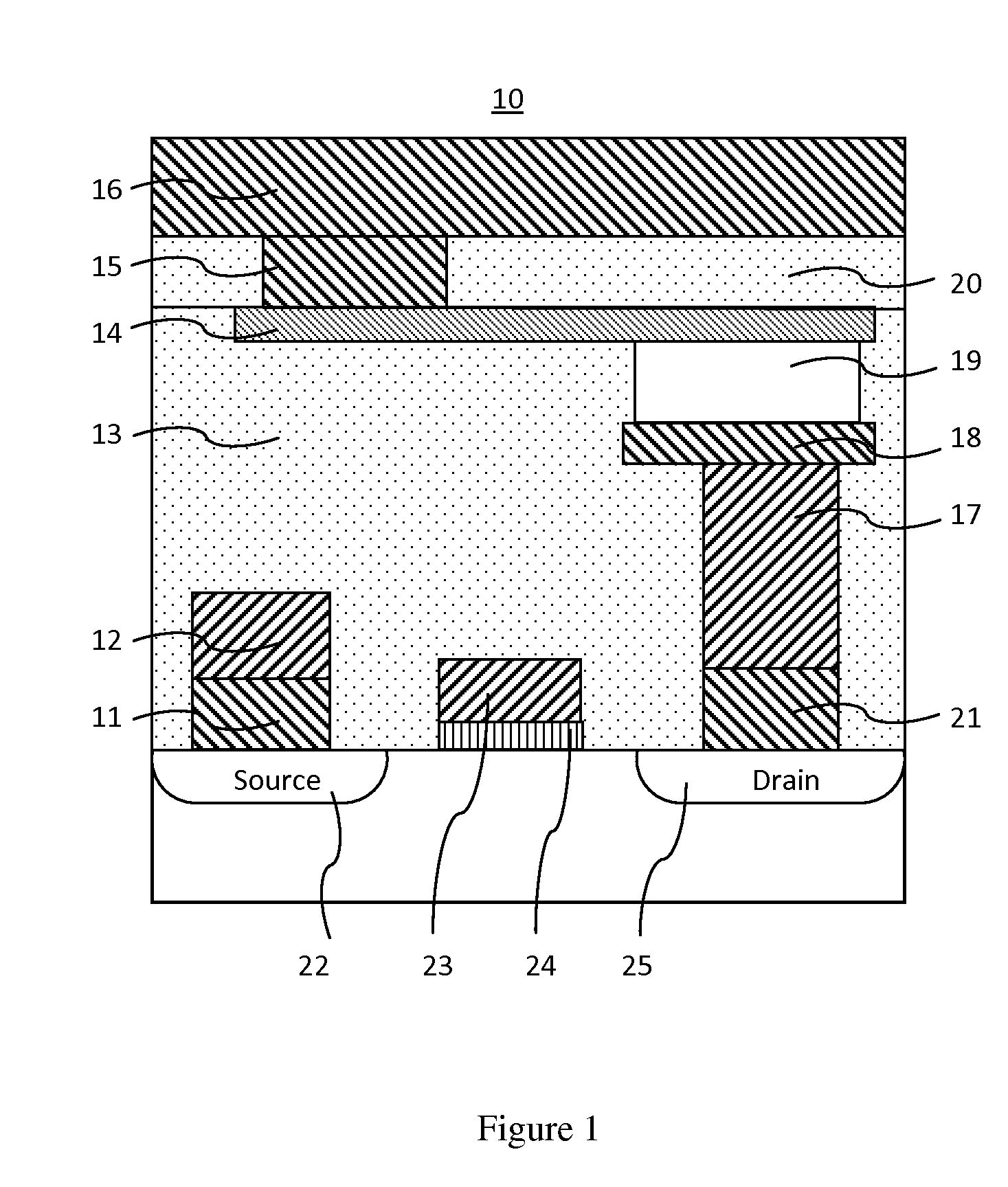

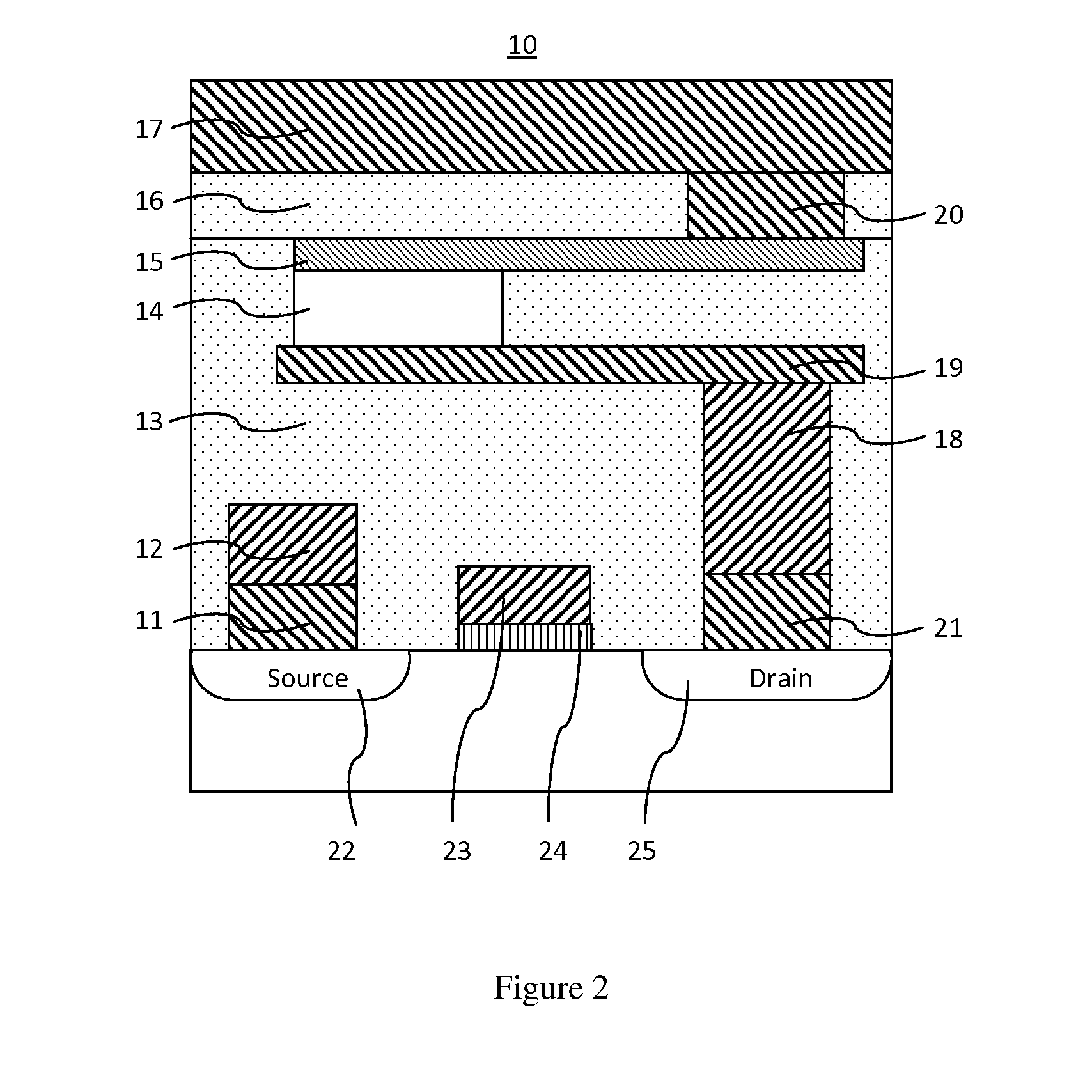

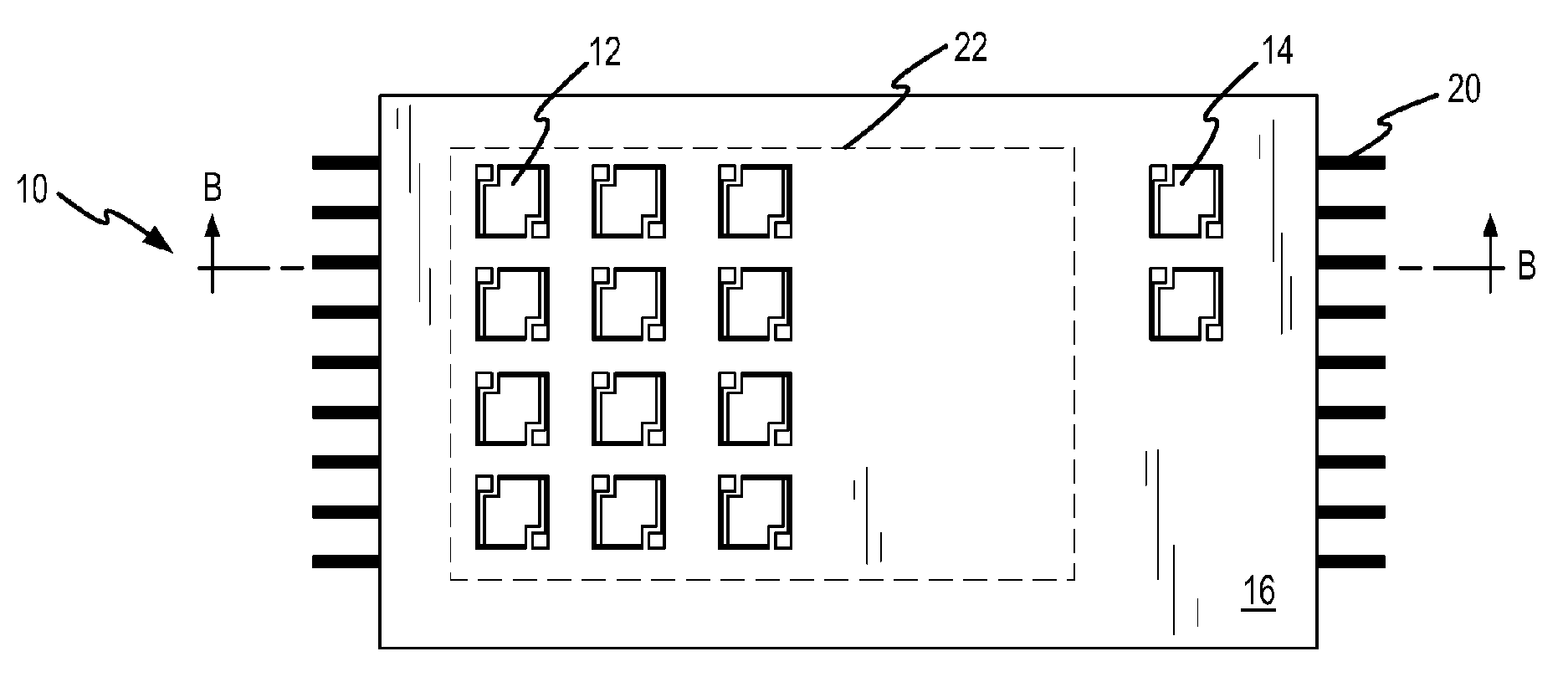

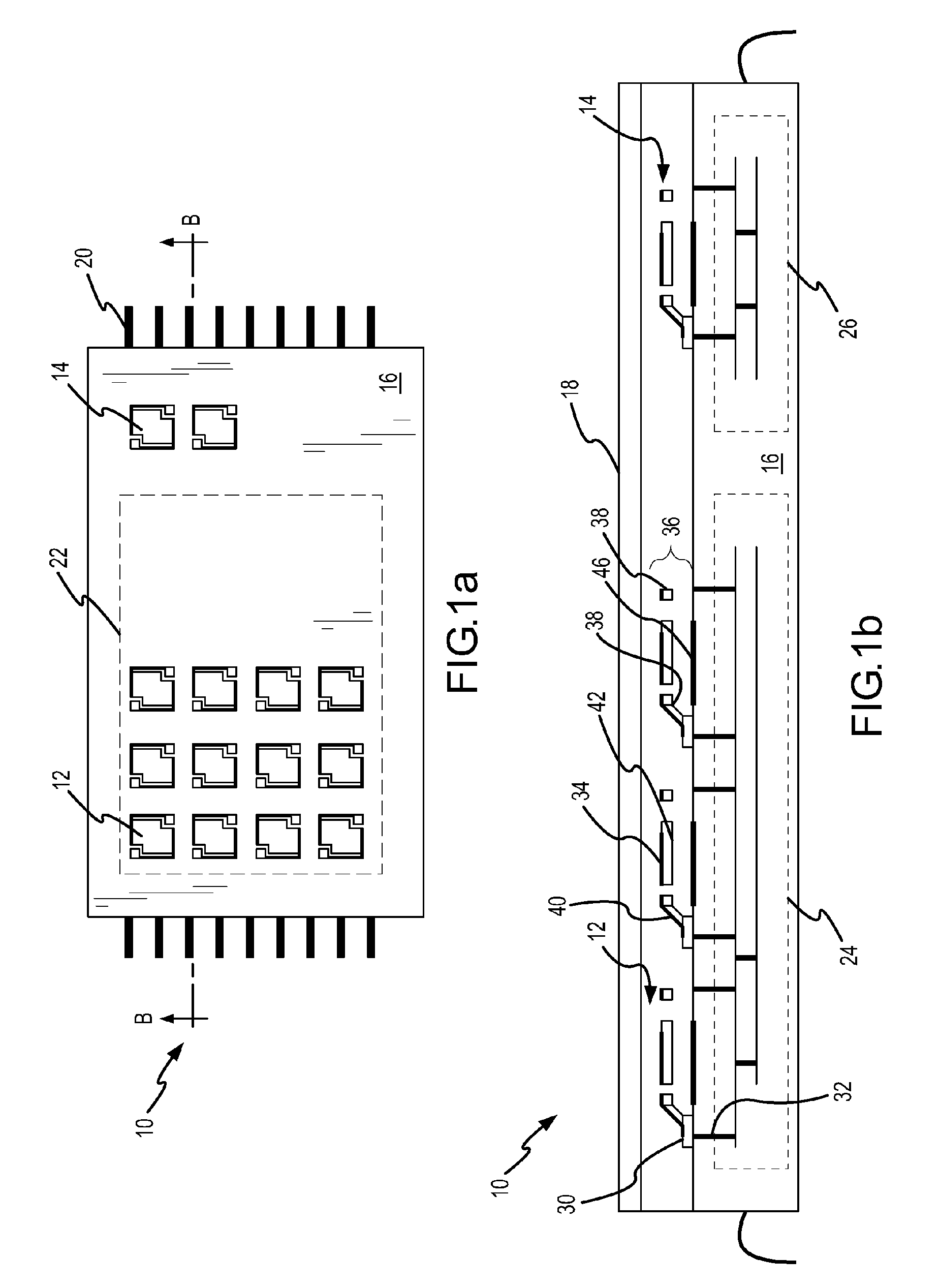

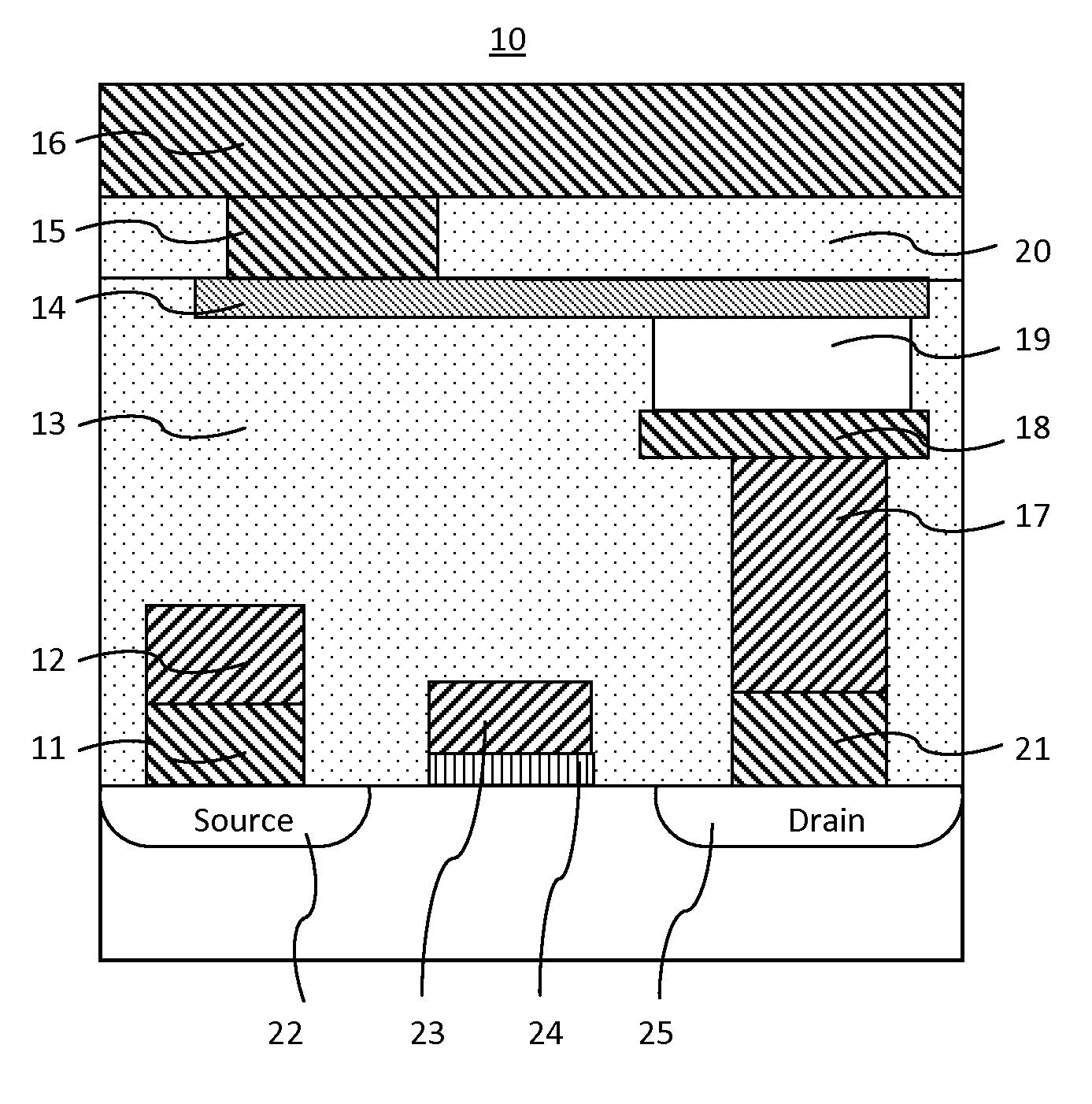

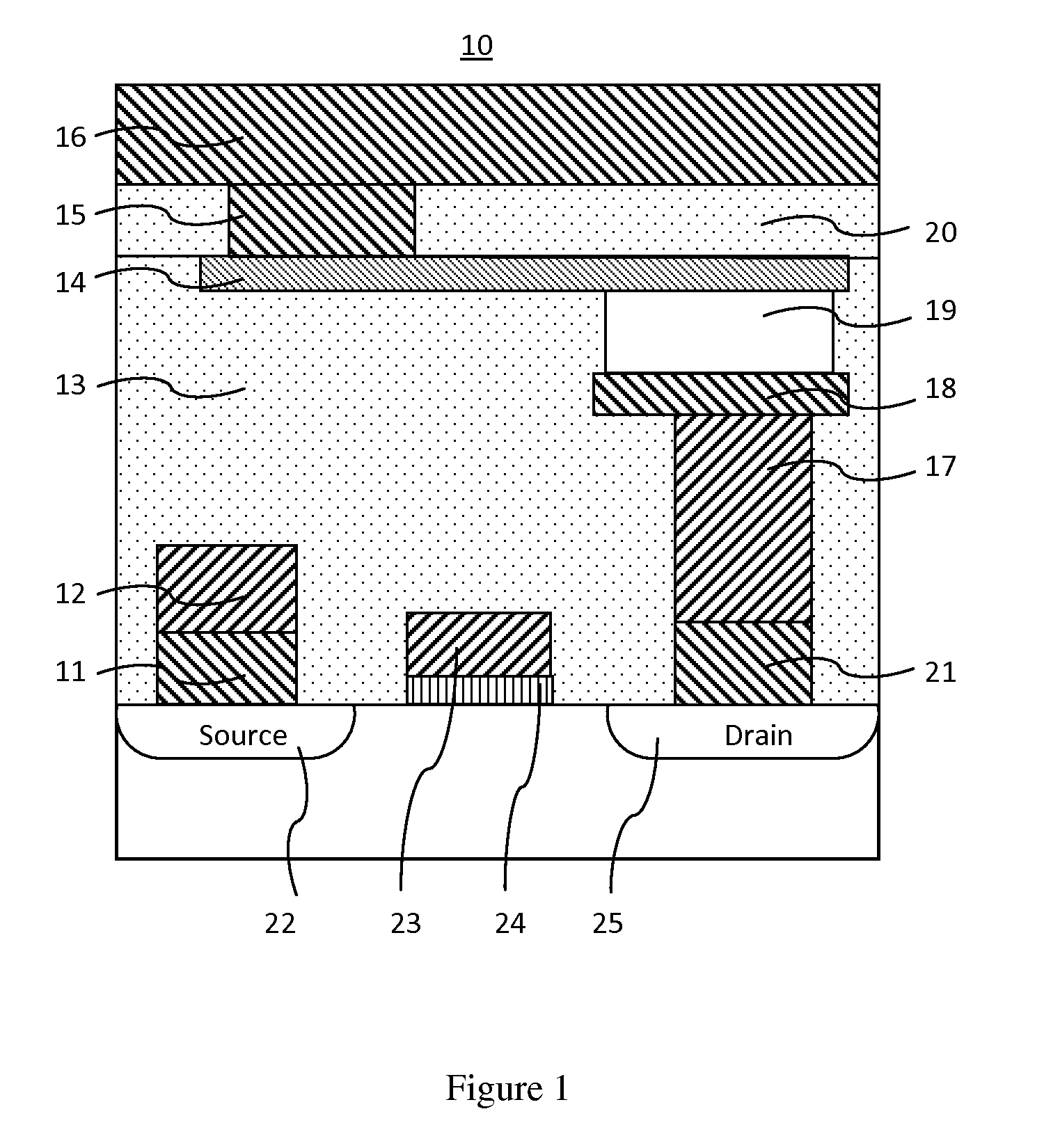

Magnetic memory devices

ActiveUS20140328116A1Reduce heatReduce direct heatingSemiconductor/solid-state device manufacturingDigital storageBit lineMagnetic memory

A STT-MRAM comprises apparatus and a method of manufacturing a plurality of magnetoresistive memory element having a dielectric thermal buffer layer between a thin top electrode of the MTJ element and a bit line, and a bit-line VIA electrically connecting the top electrode and the bit line having a vertical distance away from the location of the MTJ stack. In a laser thermal annealing, a short wavelength of a laser has a shallow thermal penetration depth and a high thermal resistance from the bit line to the MTJ stack only causes a temperature rise of the MTJ stack being much smaller than that of the bit line. As the temperature of the MTJ element during the laser thermal annealing of bit line copper layer is controlled under 300-degree C., possible damages on MTJ and magnetic property can be avoided.

Owner:GUO YIMIN

Microbolometer IR Focal Plane Array (FPA) with In-Situ Micro Vacuum Sensor and Method of Fabrication

ActiveUS20070069133A1Poor heat transferSubstantial temperature increaseVacuum gauge using heat conductivity variationMaterial analysis by optical meansElectrical resistance and conductanceElectricity

A microbolometer IR FPA is provided with in-situ vacuum sensing capability by realizing that the IR sensor microbolometer pixel element itself may be used as a vacuum sensor. The application of an electrical signal to the resistive element heats the bolometer material thereby producing a variable resistance related to vacuum level. The degree of variability for a given material depends on the efficiency of heat transfer from the material to the surrounding environment. In a good vacuum, heat transfer is poor, and thus heat will be retained in the material to produce a relatively large temperature increase and the resistance variability will be large. In a poor vacuum, heat is readily transferred to the environment and the temperature rise will be relatively small and thus resistance variability will be small. Consequently, the variable resistance magnitude can be readout to determine the vacuum level.

Owner:TELEDYNE SCI & IMAGING

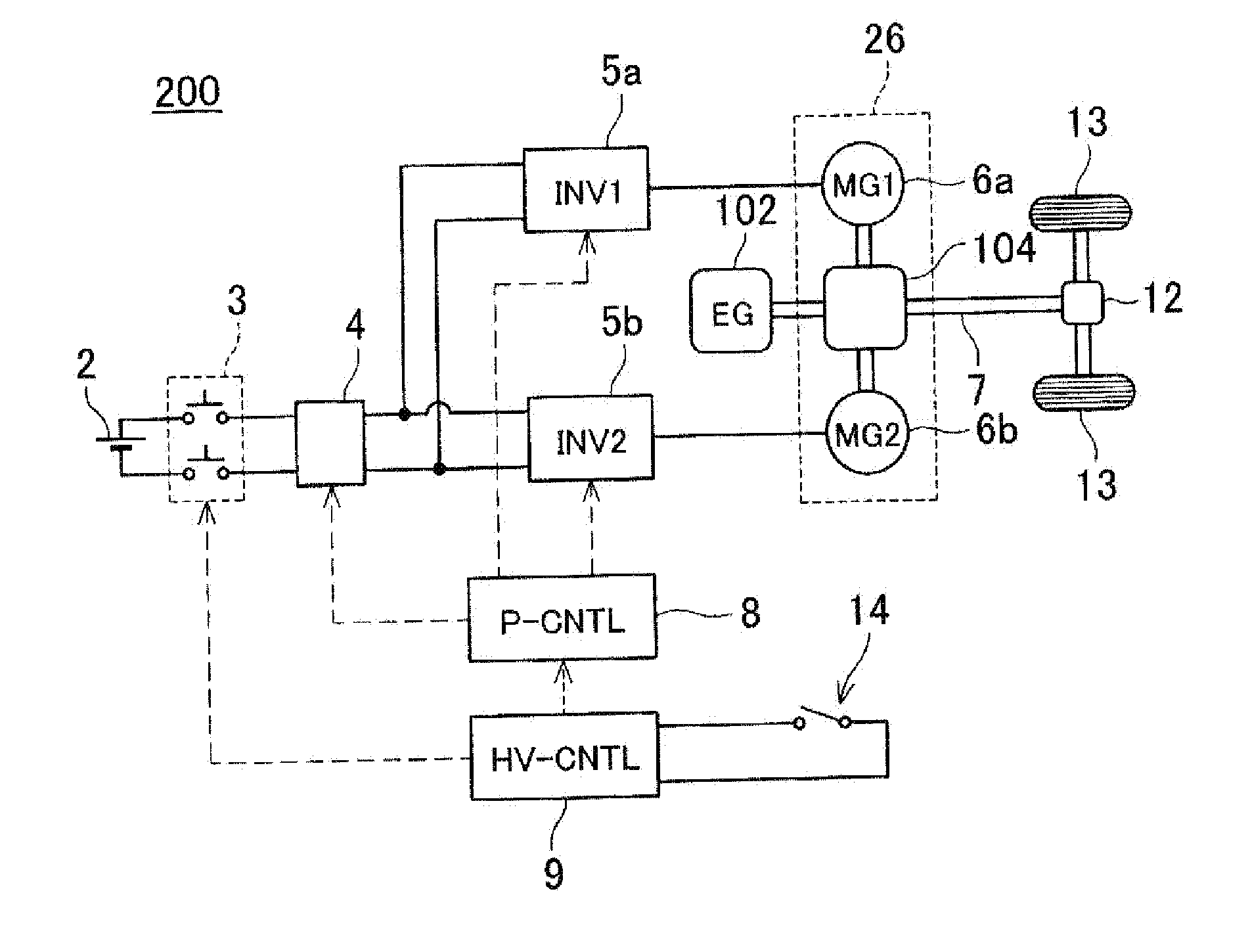

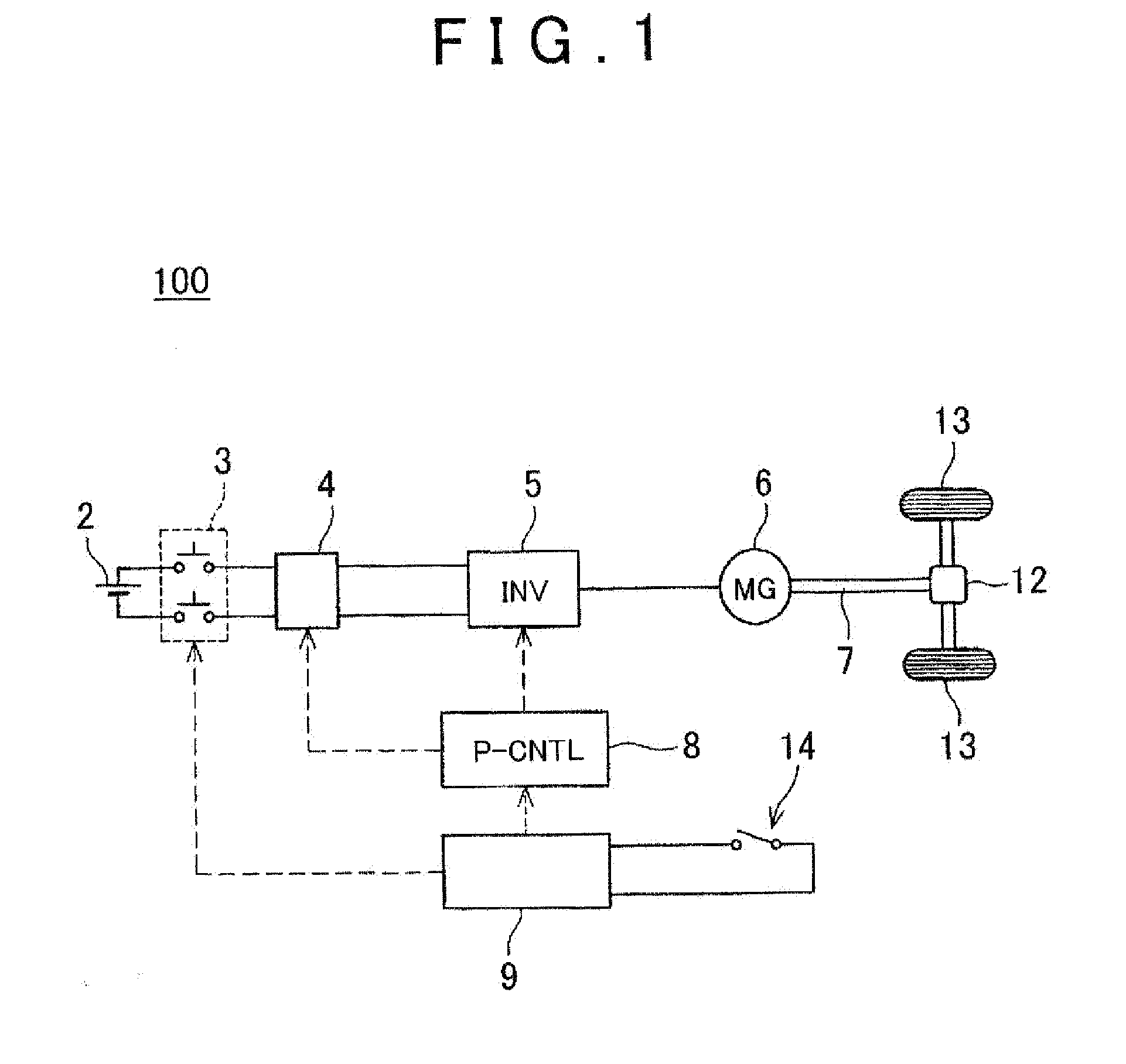

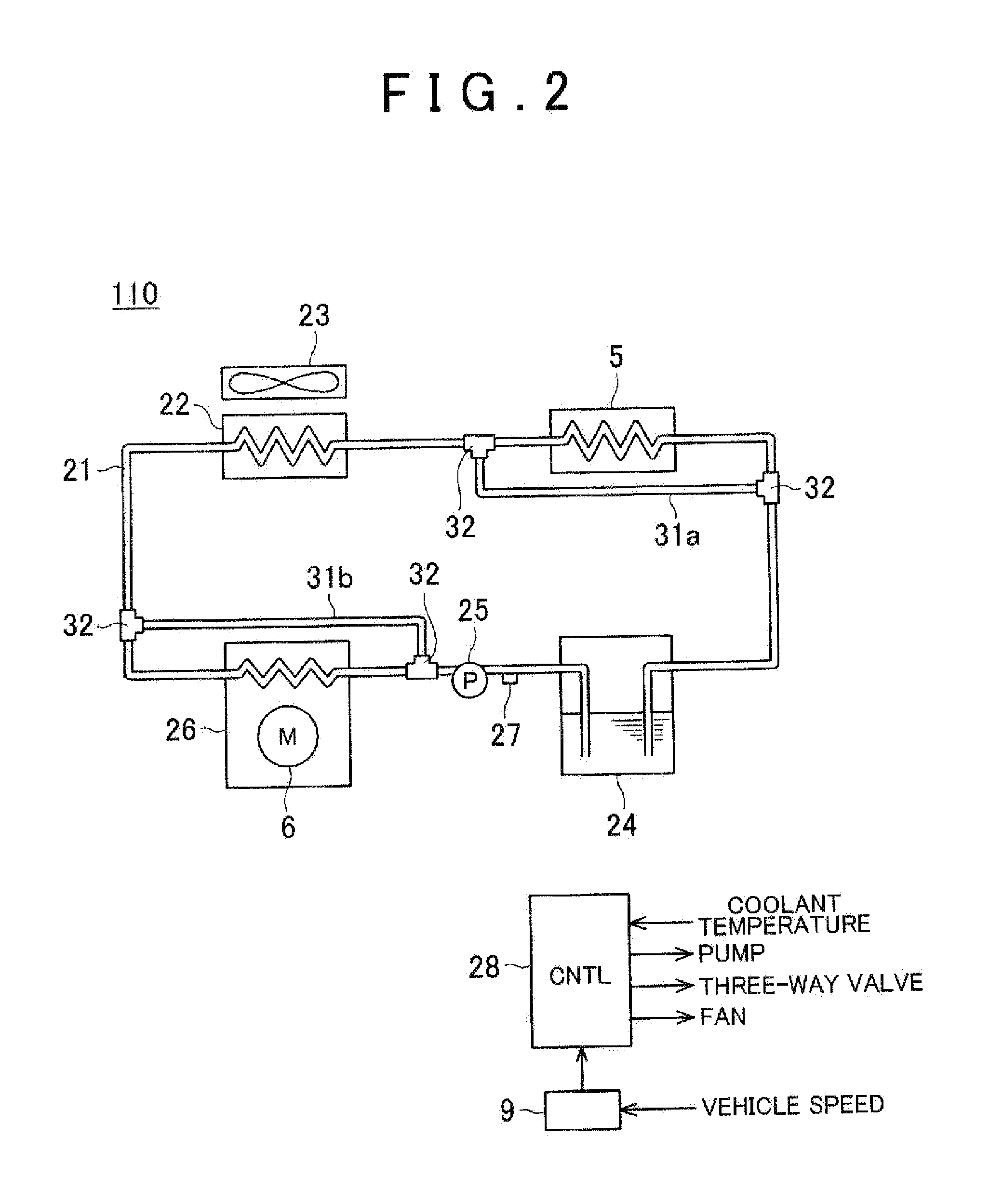

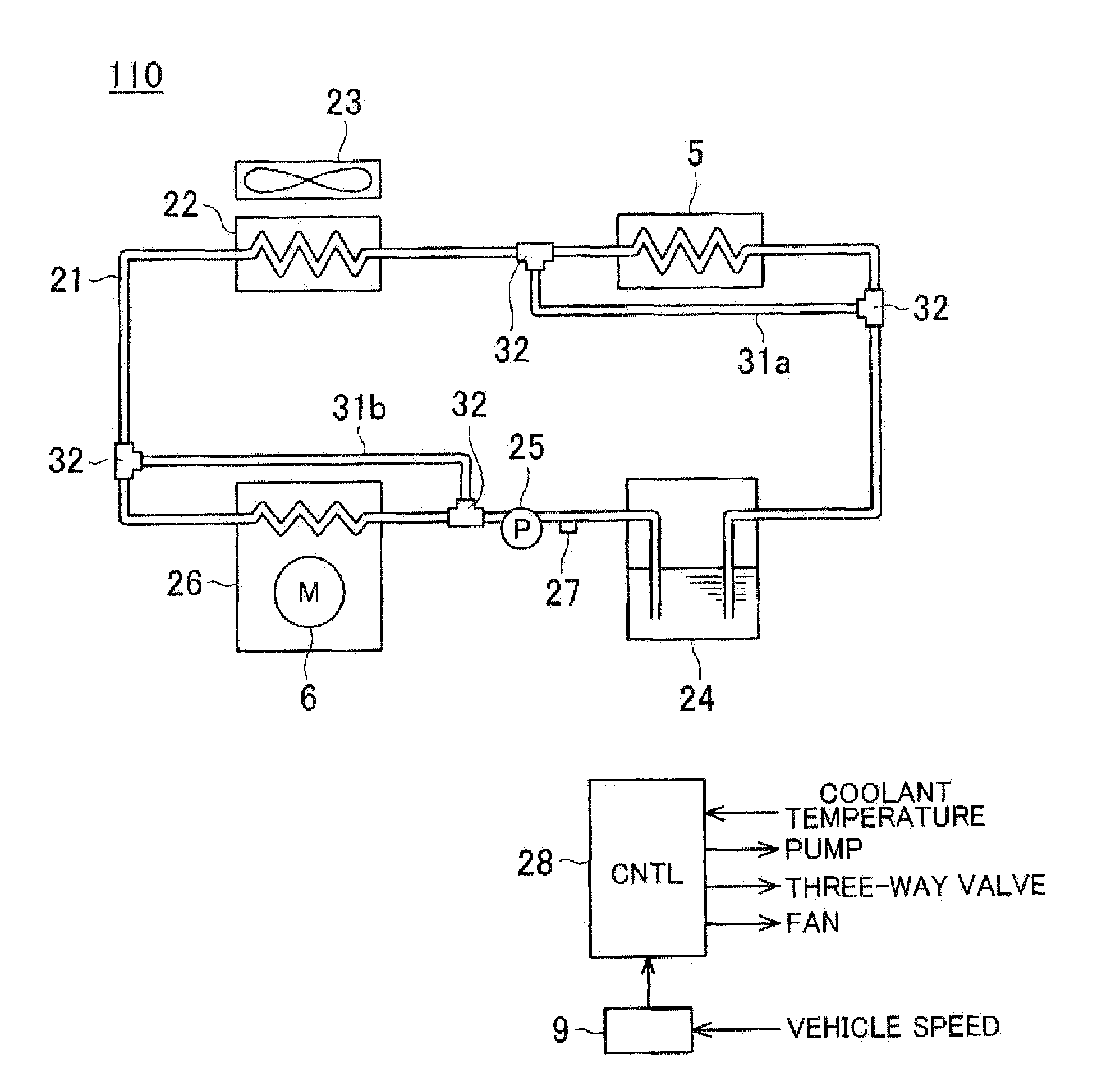

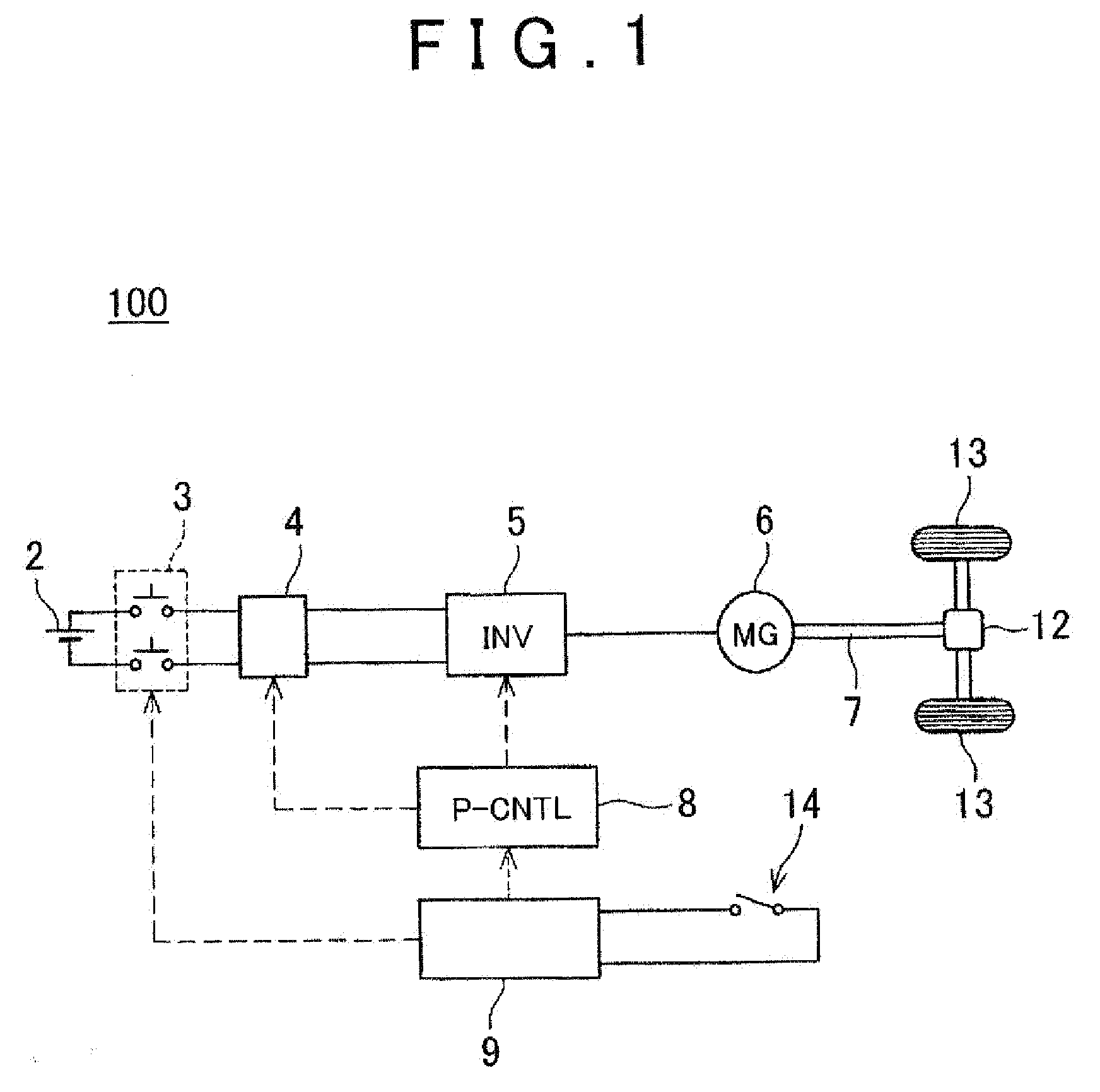

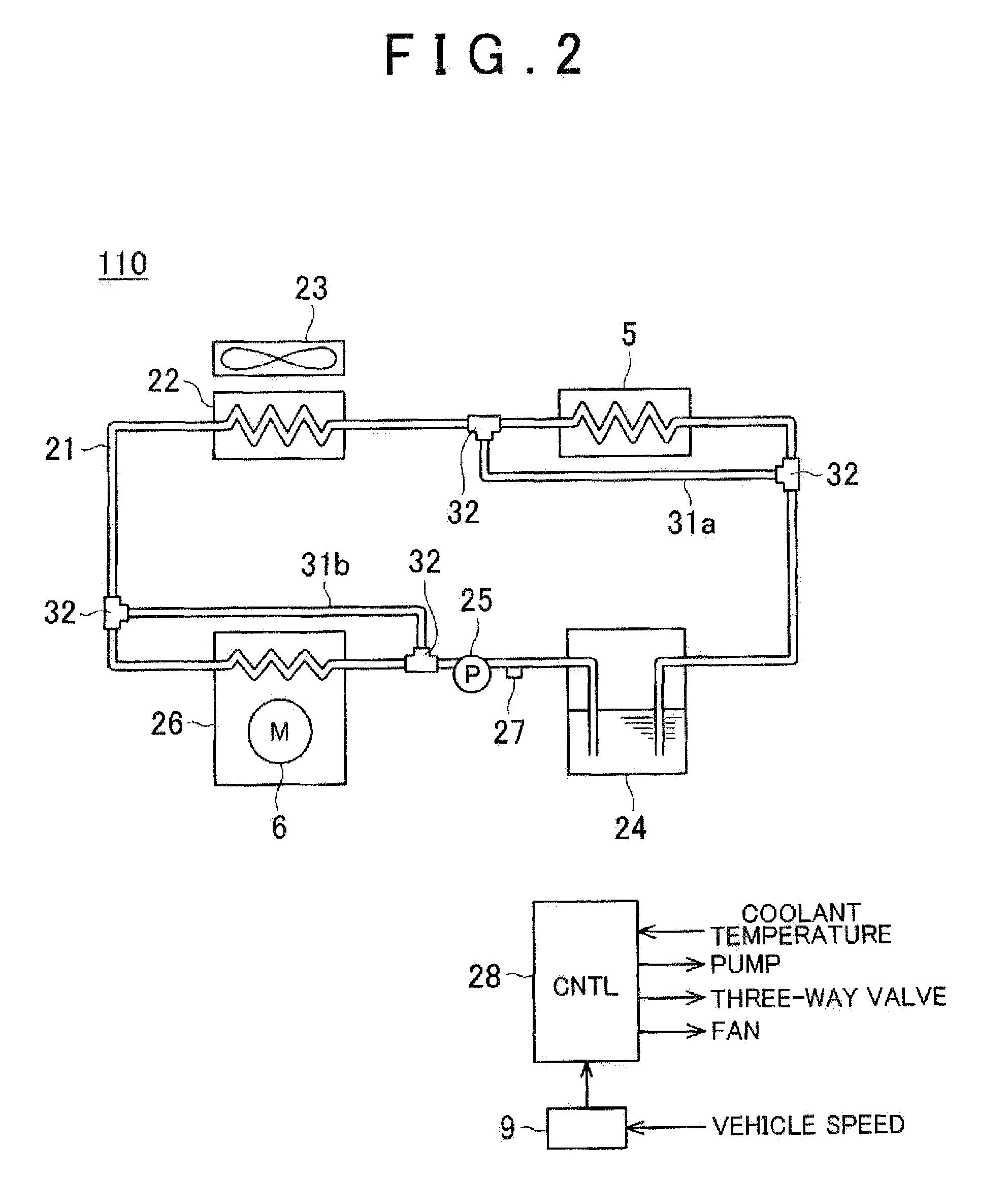

Electric vehicle

ActiveUS20130076126A1Low temperature of coolantSmall temperature risePower to auxillary motorsPropulsion by batteries/cellsAutomotive engineeringElectric vehicle

An electric vehicle includes: an electric motor; an inverter that supplies electric power to the electric motor; and a cooling system that cools at least one of the electric motor and the inverter, the cooling system having: a main coolant passage configured to circulate a coolant through a radiator and at least one of the electric motor and the inverter; a bypass coolant passage, connected to the main coolant passage, that bypasses at least one of the electric motor and the inverter; and a controller configured to switch from the main coolant passage to the bypass coolant passage when a main switch of the vehicle provided at a driver's seat is turned off while the electric vehicle is travelling, and to switch from the bypass coolant passage to the main coolant passage when the main switch is then turned on.

Owner:TOYOTA JIDOSHA KK

Battery testing system with energy circulation

InactiveUS20140055143A1Extended service lifeProlong lifeMaterial analysis by electric/magnetic meansElectrical testingPower batteryElectricity

A battery testing system with energy circulation includes a battery module to be tested, an electric power storage module, a bi-directional conversion module and a control module, and the control module controls the bi-directional conversion module to discharge the electric power storage module and charge the battery module to be tested, or discharge the battery module to be tested and charge the electric power storage module, so that the electricity can be fully and repeatedly used, and the electric power storage module can use a second-used power battery to save the cost of the electric power storage module while the battery testing system can be isolated from the grid of utility power to avoid creating a burden to the grid of the utility power.

Owner:NAT CHUNG SHAN INST SCI & TECH

Microbolometer IR focal plane array (FPA) with in-situ mirco vacuum sensor and method of fabrication

ActiveUS7385199B2Poor heat transferSubstantial temperature increaseVacuum gauge using heat conductivity variationMaterial analysis by optical meansElectricityElectrical resistance and conductance

A microbolometer IR FPA is provided with in-situ vacuum sensing capability by realizing that the IR sensor microbolometer pixel element itself may be used as a vacuum sensor. The application of an electrical signal to the resistive element heats the bolometer material thereby producing a variable resistance related to vacuum level. The degree of variability for a given material depends on the efficiency of heat transfer from the material to the surrounding environment. In a good vacuum, heat transfer is poor, and thus heat will be retained in the material to produce a relatively large temperature increase and the resistance variability will be large. In a poor vacuum, heat is readily transferred to the environment and the temperature rise will be relatively small and thus resistance variability will be small. Consequently, the variable resistance magnitude can be readout to determine the vacuum level.

Owner:TELEDYNE SCI & IMAGING

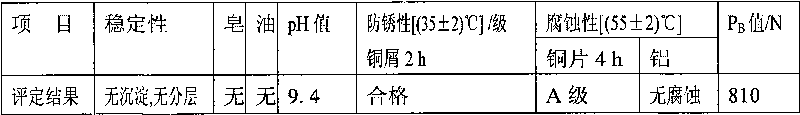

Aluminium wiredrawing lubricant and preparation method thereof

The invention provides an aluminium wiredrawing lubricant and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 0.3-0.4 parts of monoethanolamine, 0.6-0.8 parts of triethanolamine, 0.2-0.3 parts of mercapto benzimidazole, 1-2 parts of caprylic-capric acid blend, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of dibutyltin dilaurate, 1-2 parts of zinc acetate, 1-2 parts of tung oil, 2-3 parts of methyl trimethoxy silane, 3-4 parts of a film forming auxiliary agent and 150-160 parts of water. According to the invention, the tung oil is added to promote lubricity, water base is used to play a relatively good heat dissipating effect, the triethanolamine is added to improve an anti-corrosion effect, and the methyl trimethoxy silane is combined with the mercapto benzimidazole, the caprylic-capric acid blend and the film forming agent to improve a film forming performance and prolong an anti-corrosion time of the aluminium conductor after the wiredrawing.

Owner:安徽富华电子集团有限公司

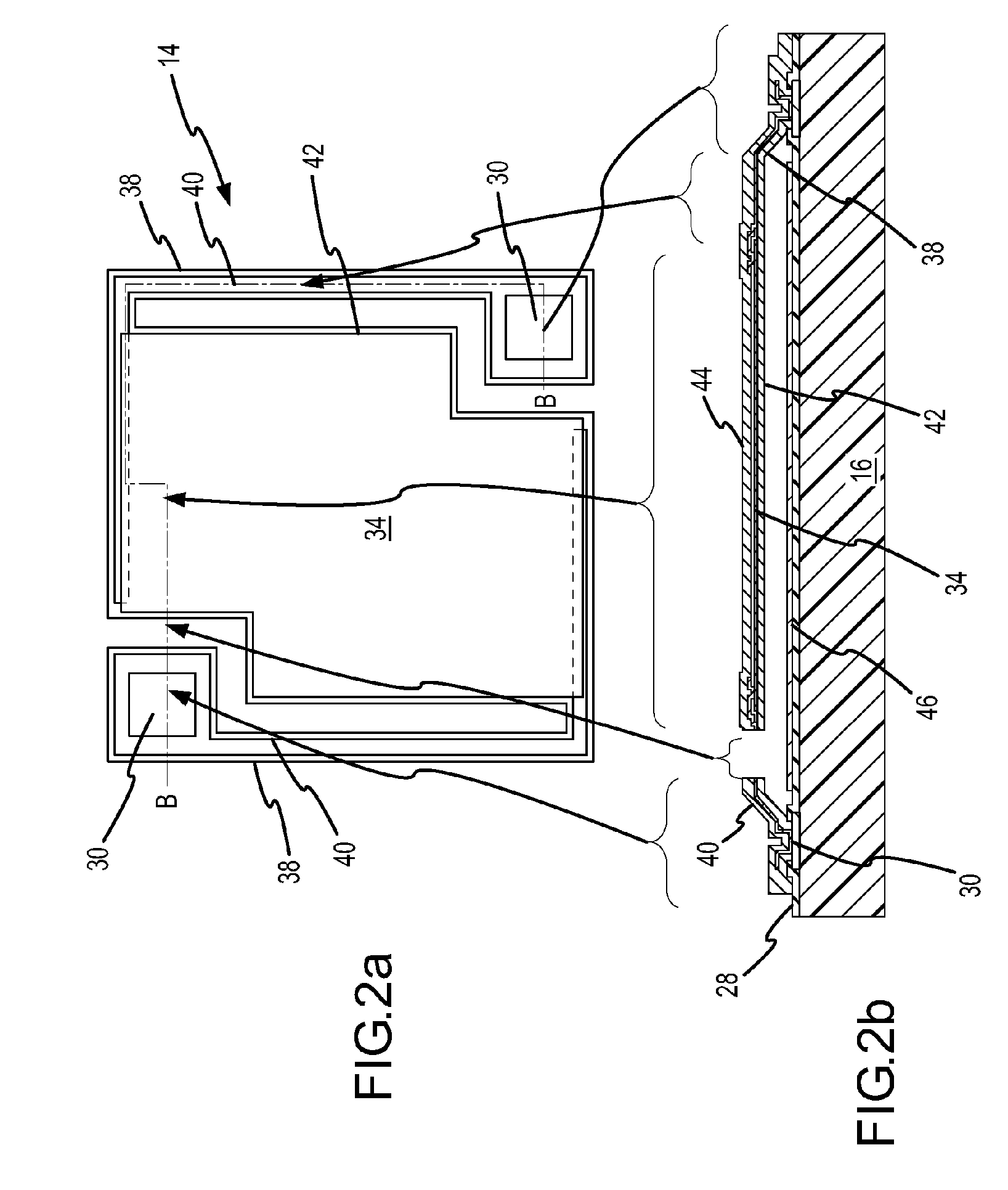

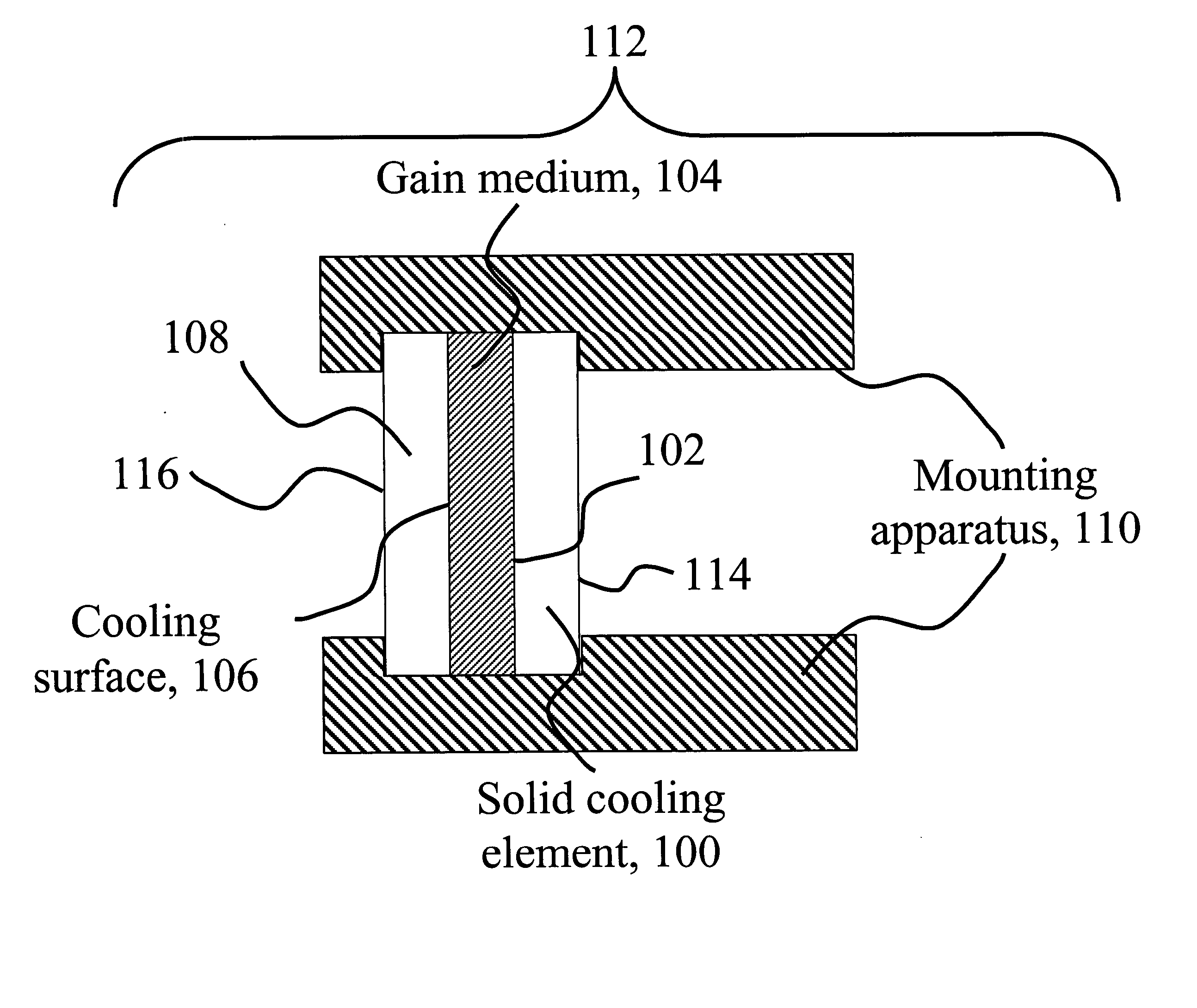

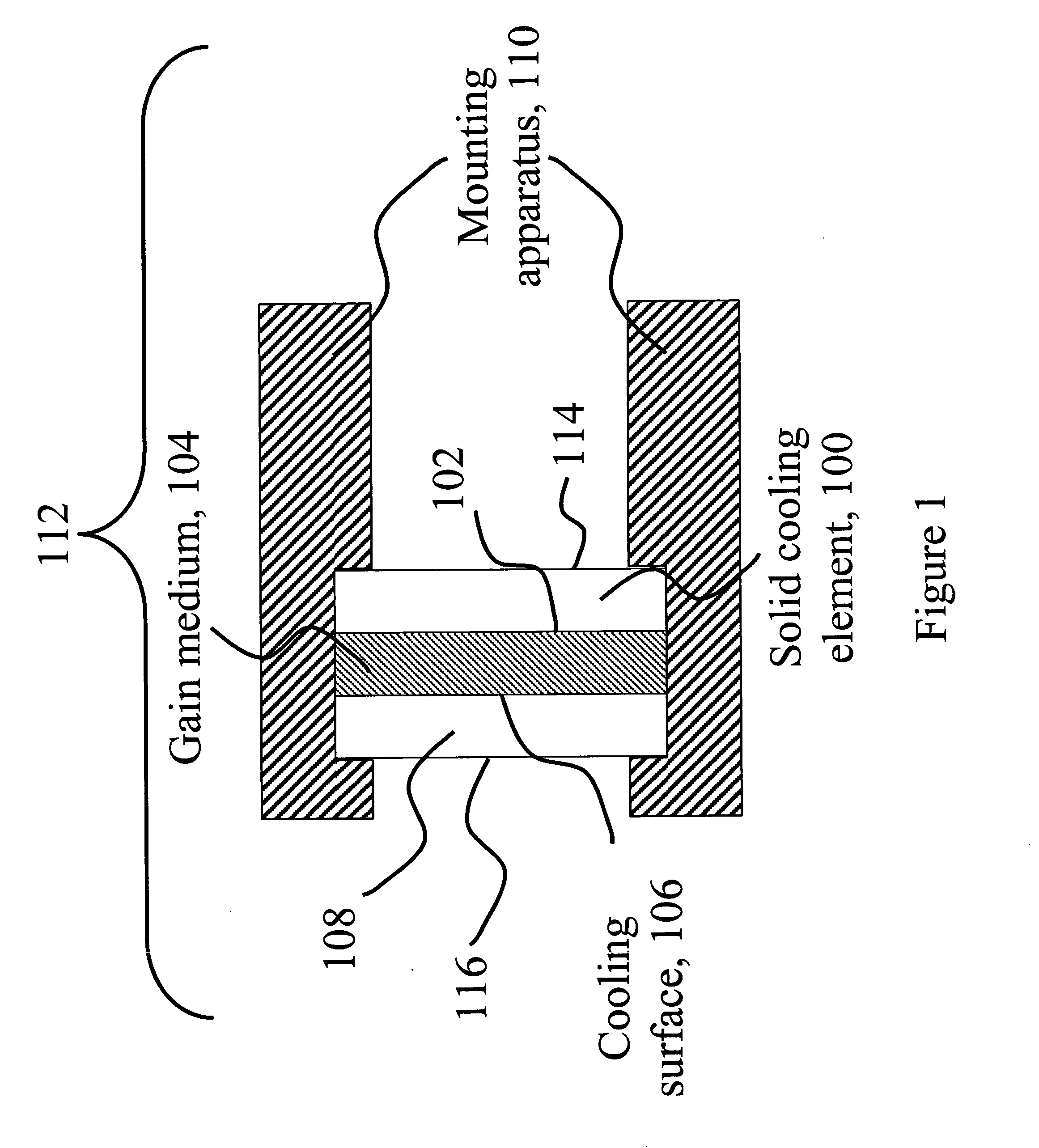

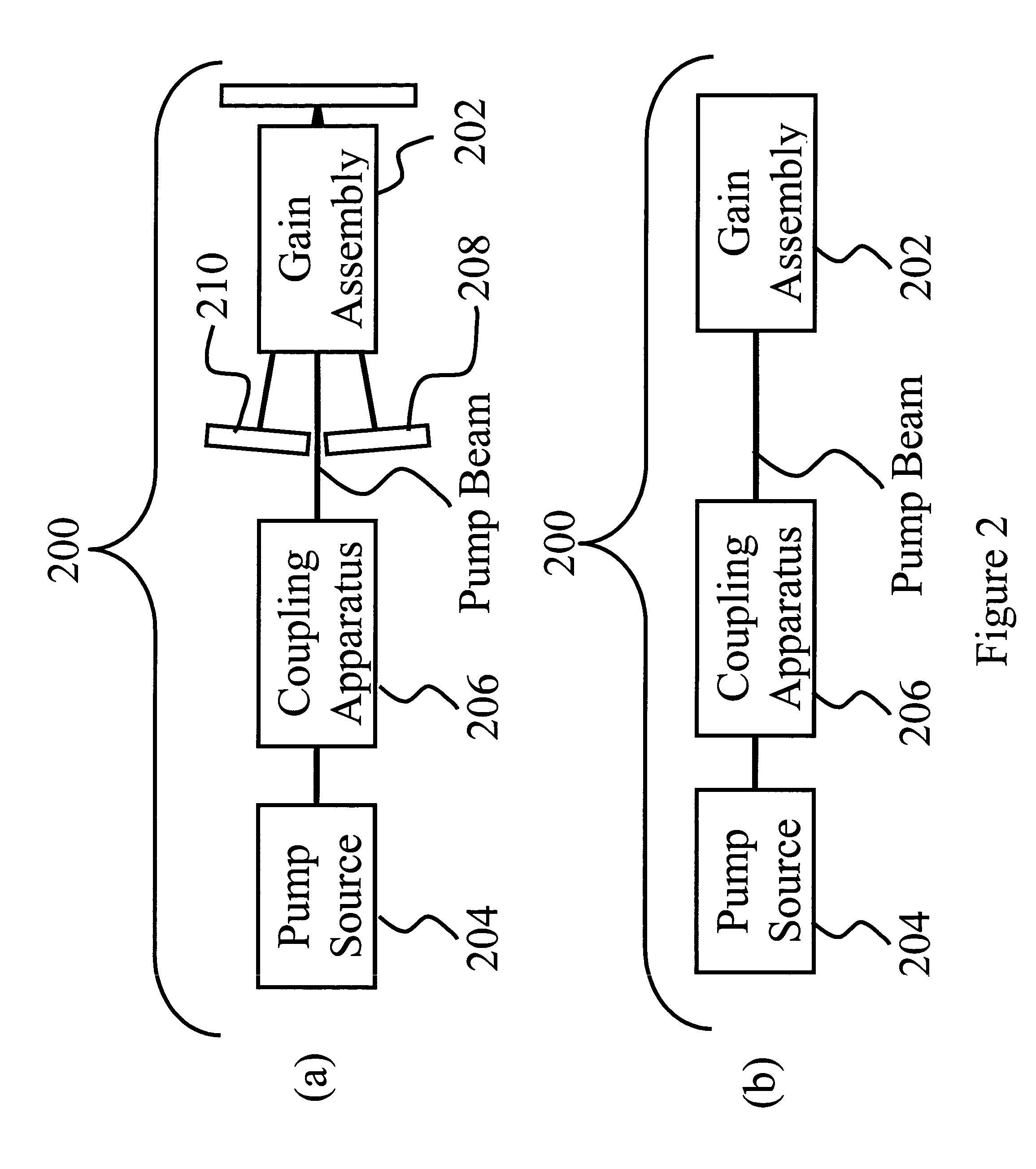

Diamond cooled laser gain assembly

InactiveUS20050074040A1Small temperature riseSimplified coating processLaser cooling arrangementsAudio power amplifierOptoelectronics

An optical system includes a laser oscillator or a laser amplifier. The optical system includes a gain medium that is optically coupled to a pump source. A solid cooling element is in physical contact with, but not bonded to, a cooling surface of the gain medium. A mounting apparatus holds the solid cooling element to the gain medium. In a preferred embodiment the gain medium is a thin disk gain medium and the solid cooling-element is made from CVD-diamond.

Owner:SPECTRA PHYSICS

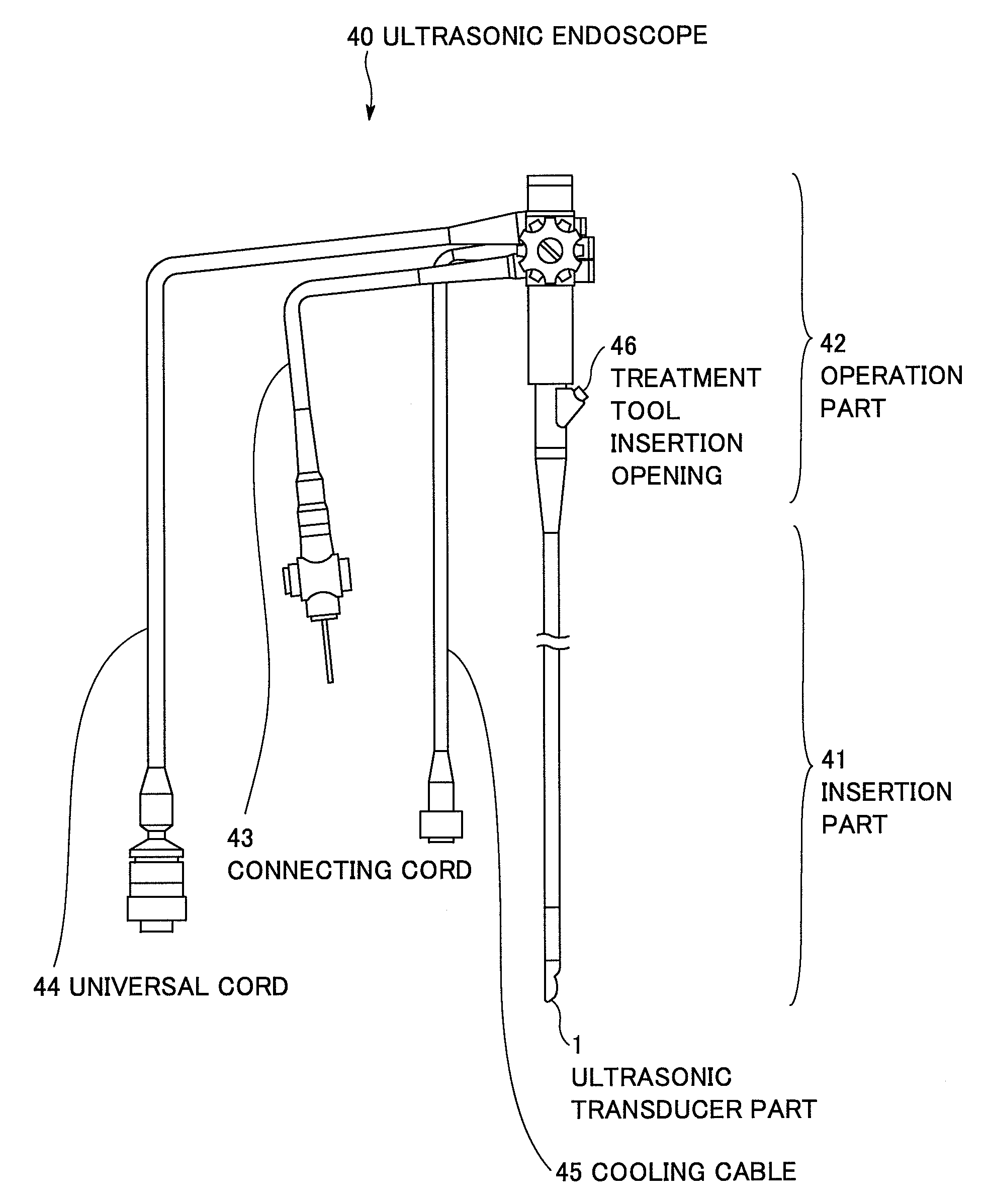

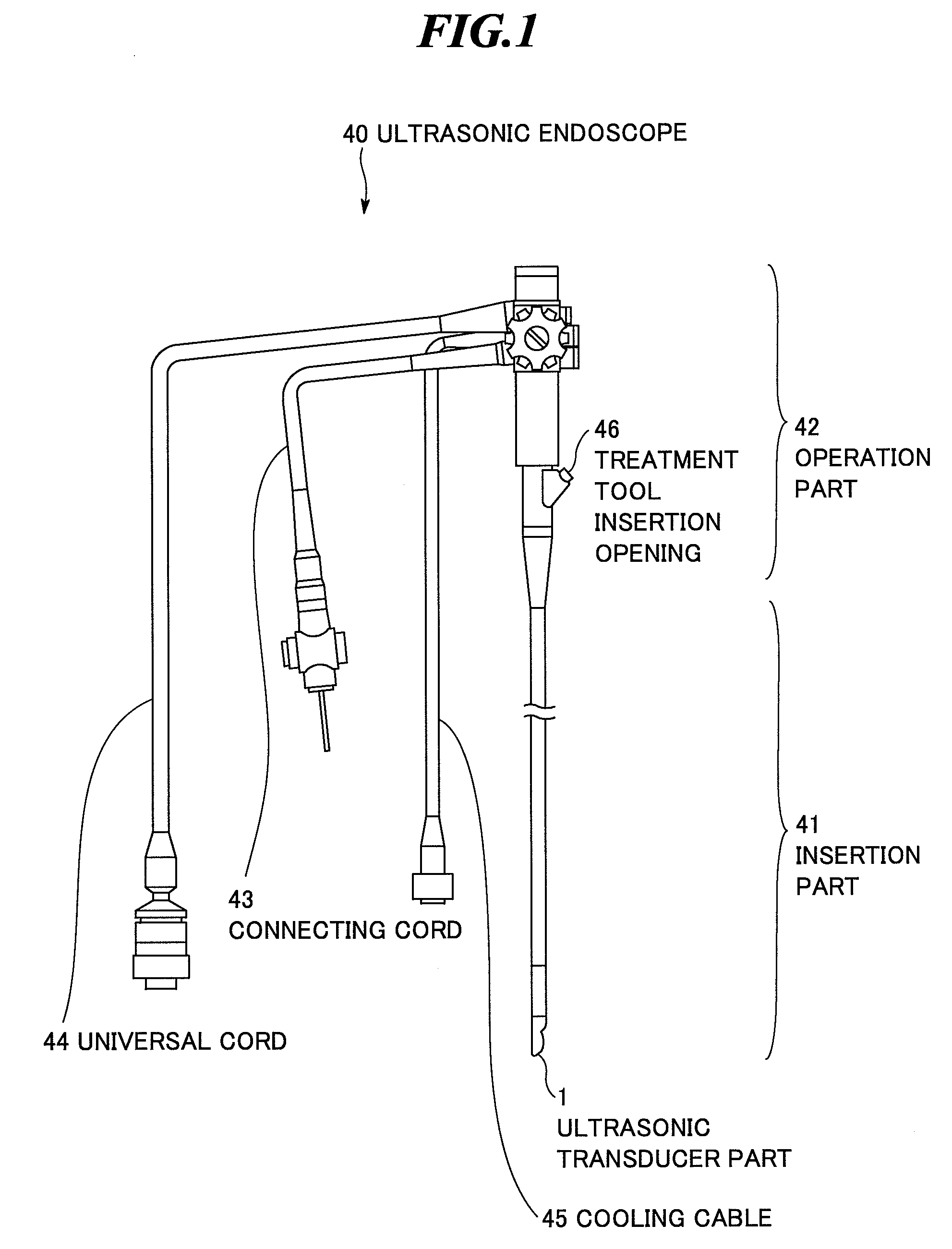

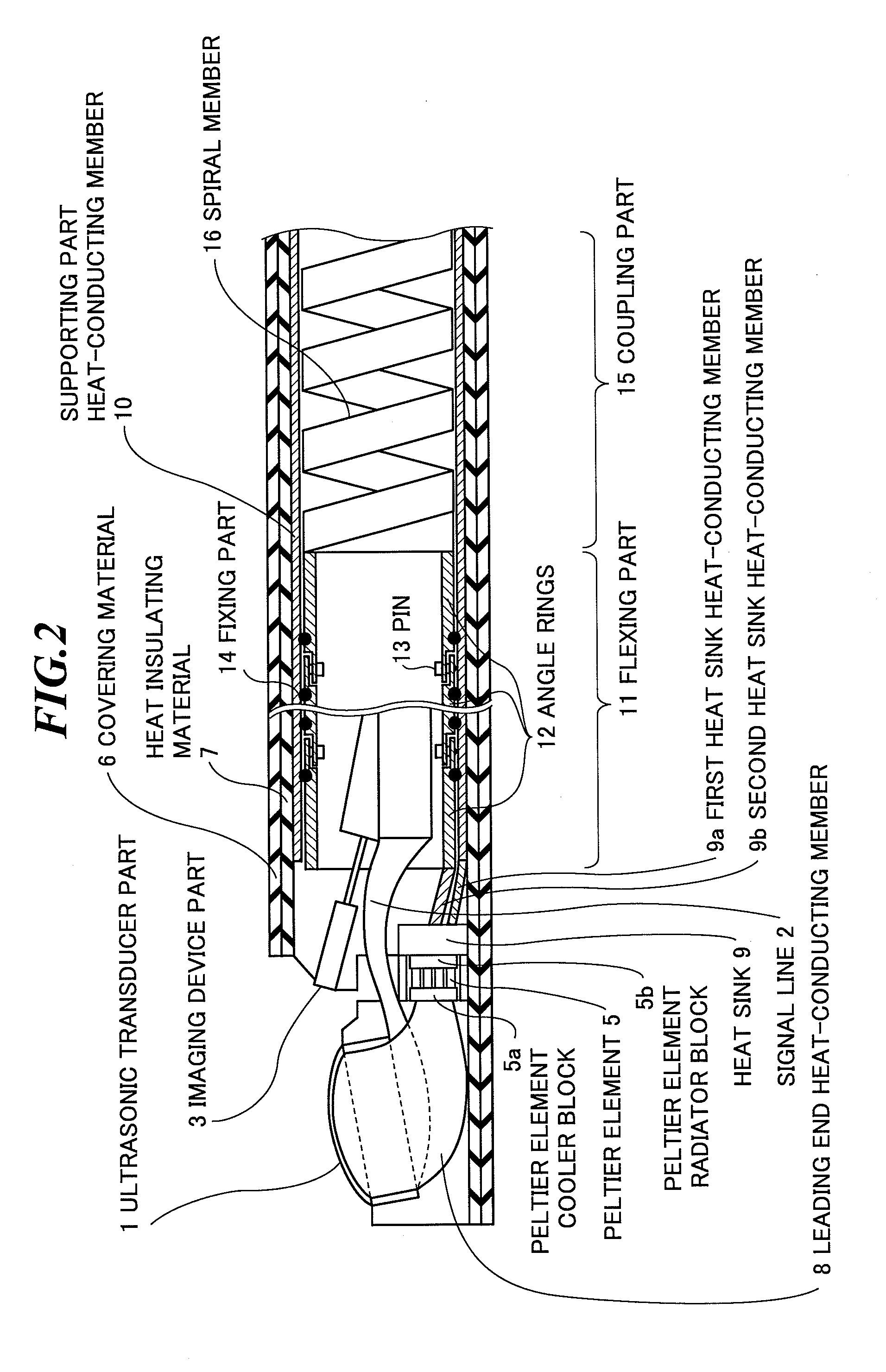

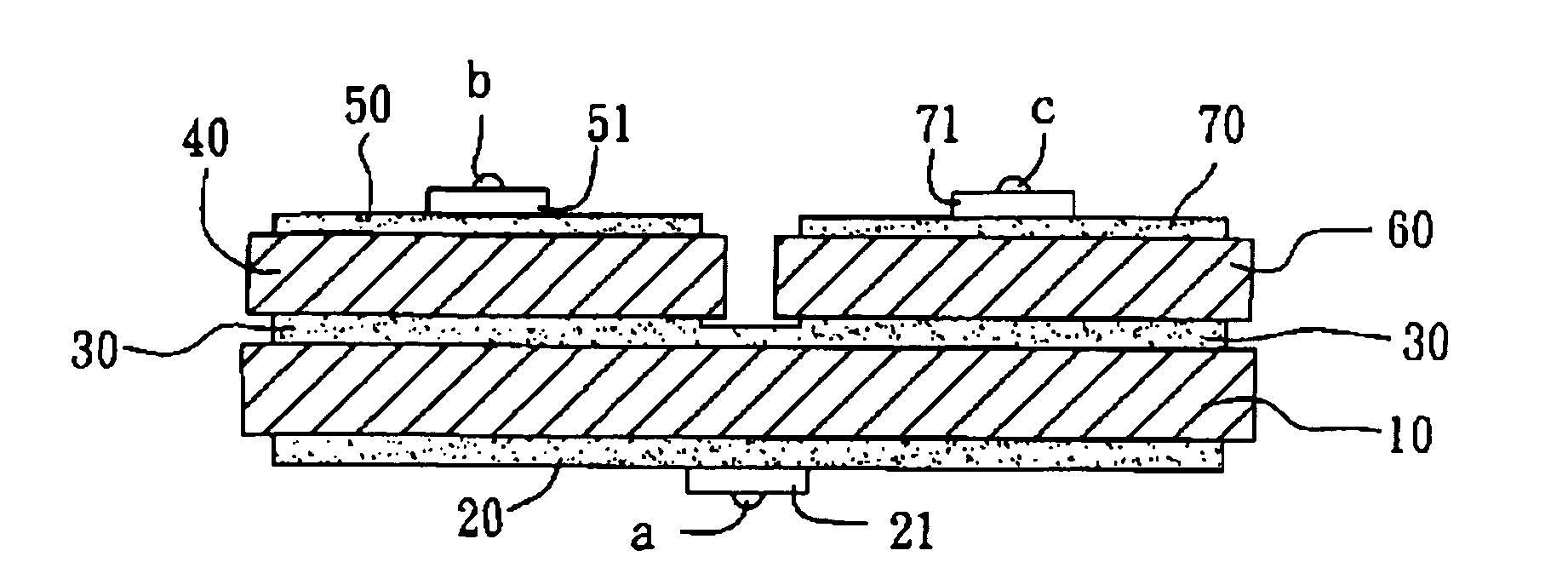

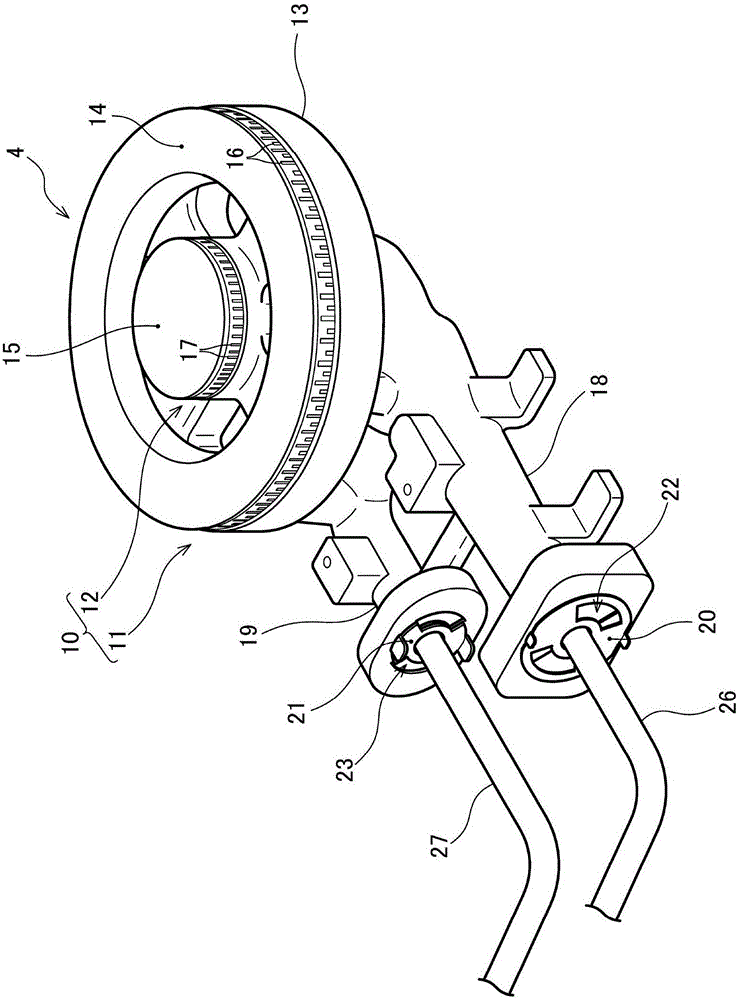

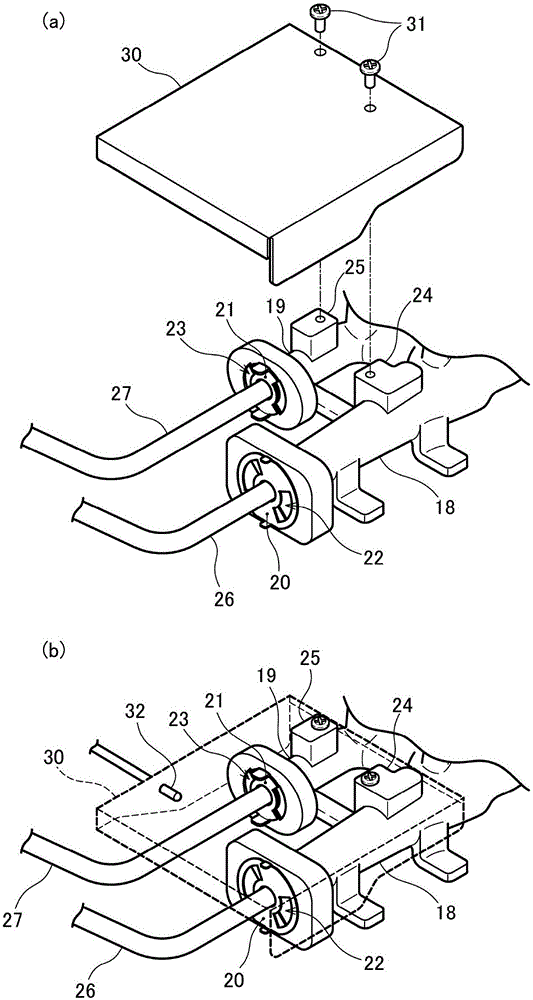

Ultrasonic endoscope and ultrasonic endoscopic apparatus

InactiveUS20080306389A1Small sizeSmall temperature riseUltrasonic/sonic/infrasonic diagnosticsBronchoscopesHeat conductingUltrasonic Endoscopy

An ultrasonic endoscope having a small size and a slight temperature rise even when the transmission output is increased. The ultrasonic endoscope includes: an ultrasonic transducer part; a Peltier element having a cooling surface coupled to the ultrasonic transducer part and a radiating surface; a flexing part for supporting the ultrasonic transducer part and the Peltier element; a coupling part for coupling the flexing part to an operation part; a covering material for covering the flexing part and the coupling part; a thermal insulating material provided inside of the covering material, for thermally insulating a part from the radiating surface of the Peltier element to the operation part from outside; and a heat-conducting member provided inside of the thermal insulating material and coupled to the radiating surface of the Peltier element, for transferring heat generated in the ultrasonic transducer part to the operation part.

Owner:FUJIFILM CORP

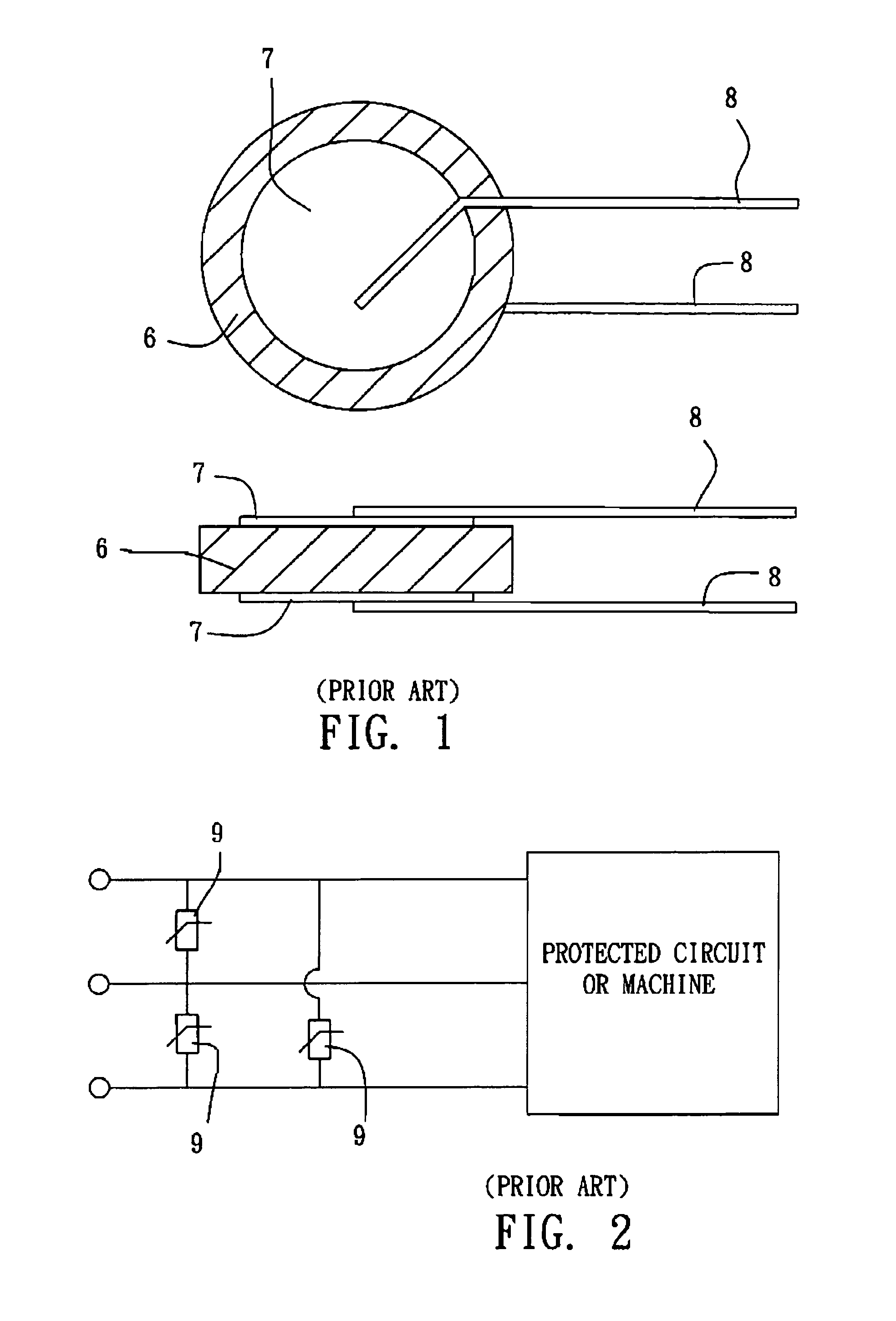

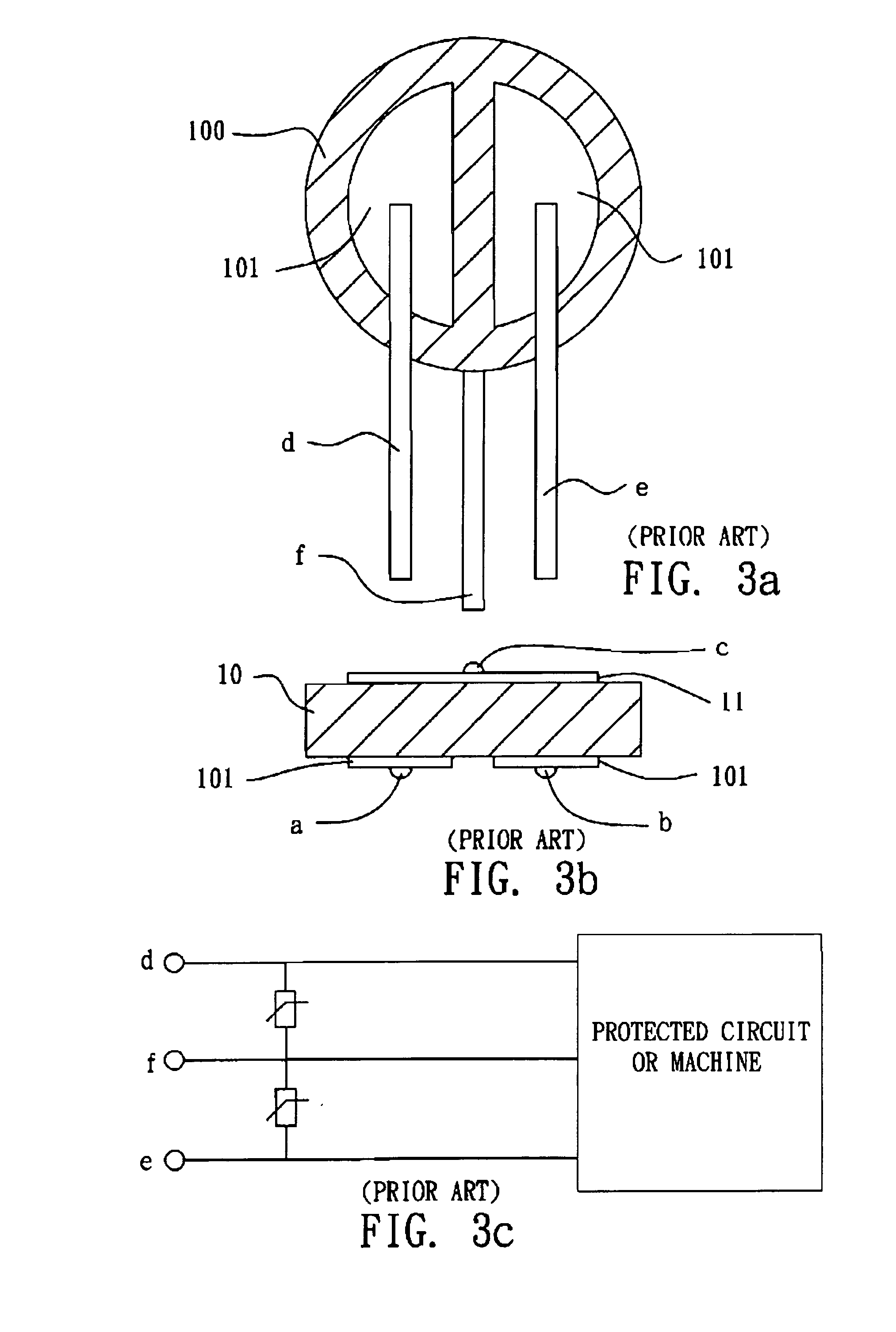

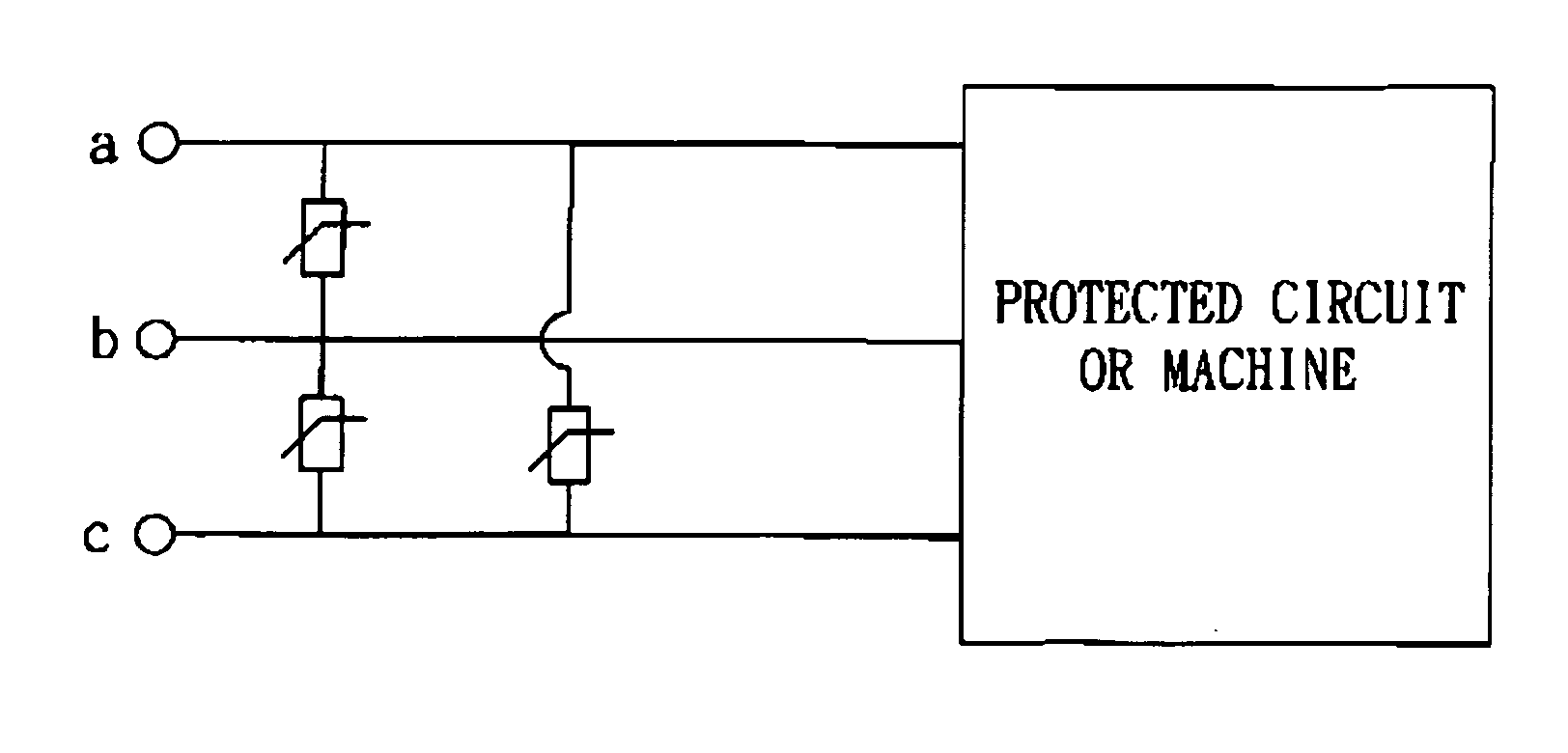

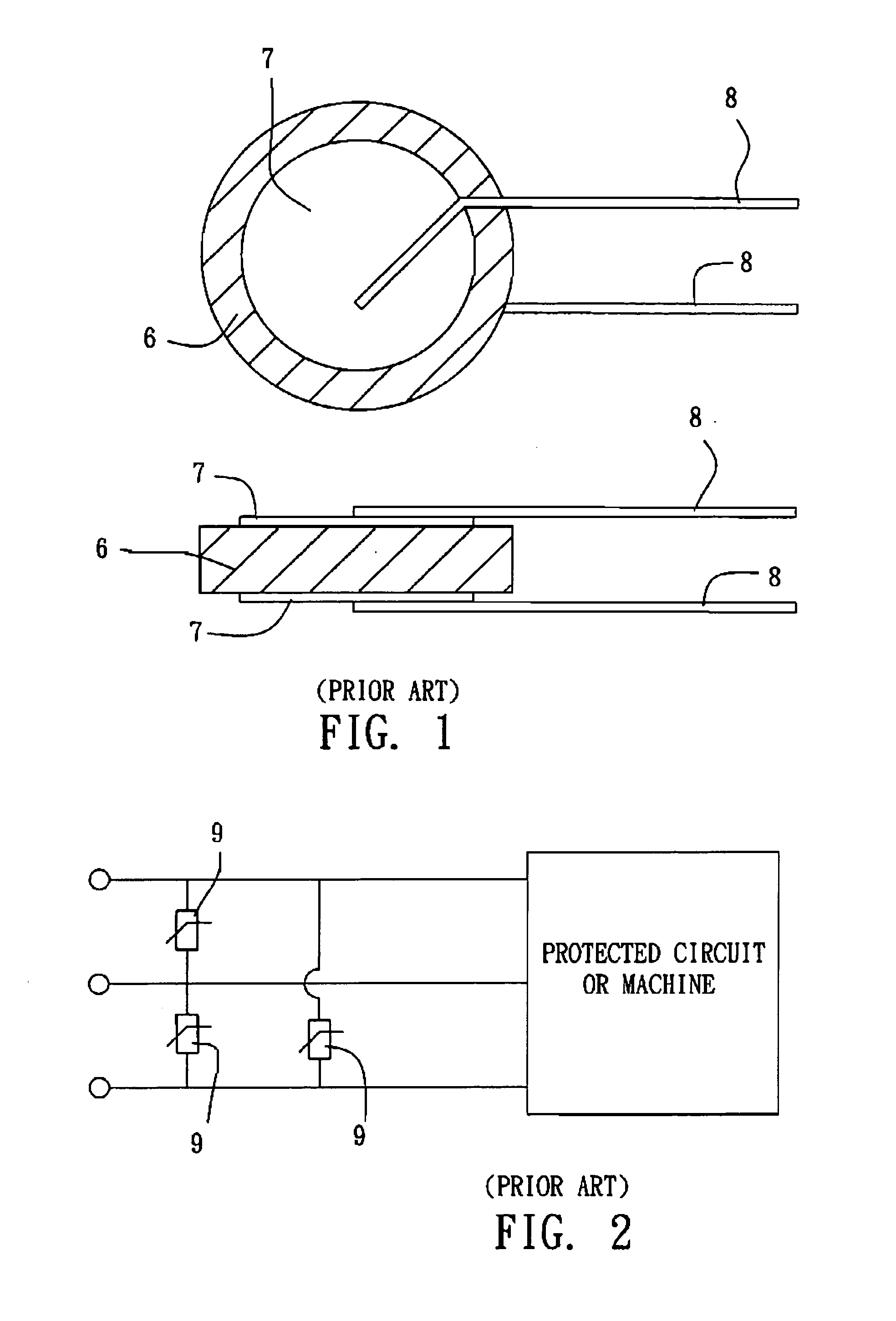

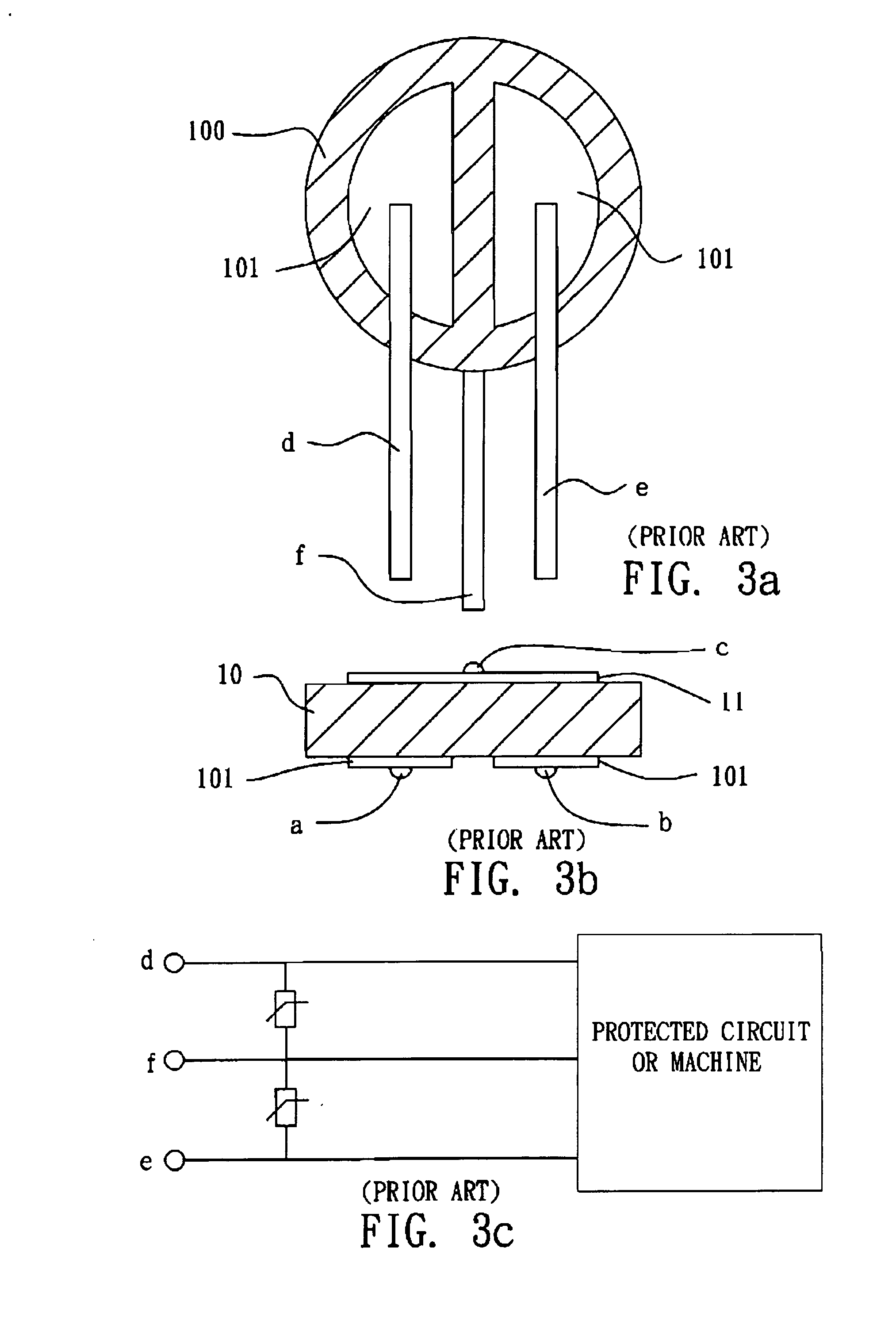

Tri-phase surge protector and its manufacturing method

ActiveUS7375943B2Prolong lifeImprove reliabilityCurrent responsive resistorsEmergency protective arrangement detailsOxide ceramicZinc

Owner:POWERTECH INDAL

Fast, non-heat change and high-efficiency method for breaking ganoderma lucidum spore

ActiveCN101697981ASlow heatingIncrease profitImmunological disordersAntineoplastic agentsHigh pressureCell wall

The invention provides a fast, non-heat change and high-efficiency method for breaking ganoderma lucidum spore, belonging to the technical field of biology. The method comprises the steps of: 1. adding the ganoderma lucidum spore into water or 20-100% alcohol-containing solution or edible acid solution with the pH value of 3-7 or edible alkali solution with the pH value of 7-10, and evenly stirring to prepare mixture, wherein the weight ratio of the ganoderma lucidum spore to the solution is 1:5-15:2; and 2. processing the mixture under normal temperature though high-pressure pulse electric field to break, wherein the electric-field intensity is 10-110 kilovolt / cm and the number of the pulse is 1-800. By using the high-pressure pulse electric field, the method has less heat energy in the process of breaking, low raised temperature of a breaking target, and short breaking time. The breaking mechanism is not breaking the cell wall in the high-pressure pulse electric field but breaking the cell wall by forming a plurality of through holes on the surface of the cell wall by polar molecules in the solution under the function of the high-pressure pulse electric field, thereby improving the use ratio of bioactive substances.

Owner:JILIN AGRICULTURAL UNIV

Metal drawing oil and preparation method thereof

InactiveCN103614204AImprove corrosion resistanceExtended service lifeLubricant compositionCooling effectPolyethylene glycol

The invention discloses a metal drawing oil and preparation method thereof. The metal drawing oil is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of cottonseed oil, 1-2 parts of propylene glycol, 1-2 parts of fatty alcohol polyoxyethylene ether AEO-3, 1-2 parts of EDTA disodium salt, 1-2 parts of benzotriazol, 6-8 parts of polyethylene glycol, 1-2 parts of coconut oil alcohol acylamide, 1-2 parts of tween 80, 4-5 parts of larinol, 10-14 parts of an anti-grinding agent and 1000 parts of water. According to the drawing oil, nanometer aluminium nitride powder added into the anti-grinding agent helps to promote heat radiation, increase film-forming ability and prolong the service life of a drawing mold; because of the addition of coconut oil alcohol acylamide, the drawing oil helps to increase the antirust property of metal subjected to drawing; the drawing oil provided by the invention is good in lubrication property, good in storage stability and cooling effect, fast in heat transferring speed, small in temperature growth during usage, not flammable and easy to clean; and metal wires processed by employing the drawing oil provided by the invention is uniform in appearance, bright in surface and not easy to corrode.

Owner:全威(铜陵)铜业科技有限公司

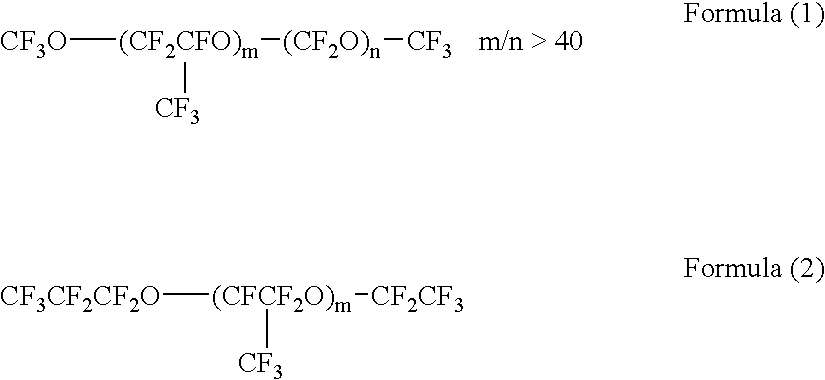

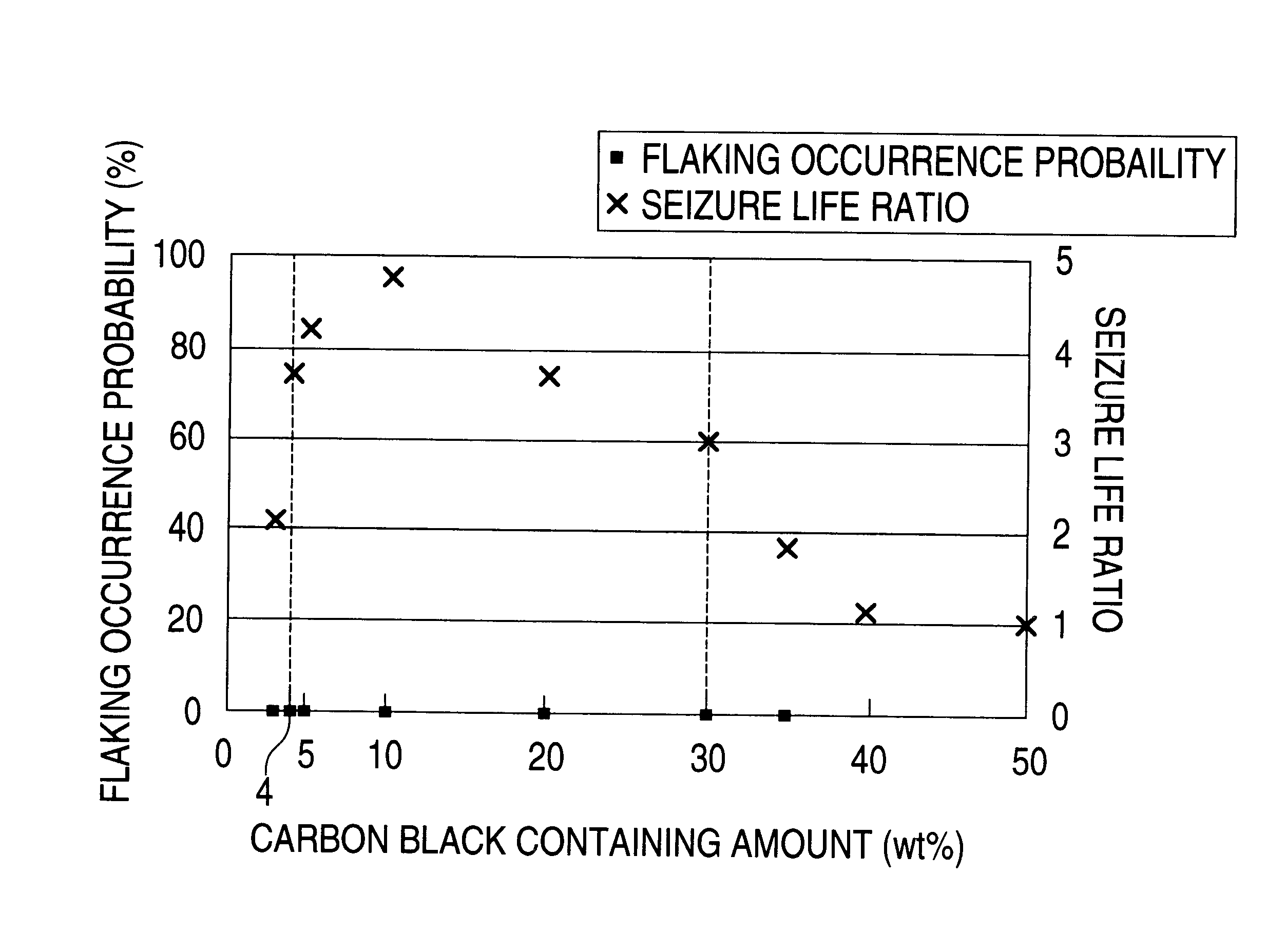

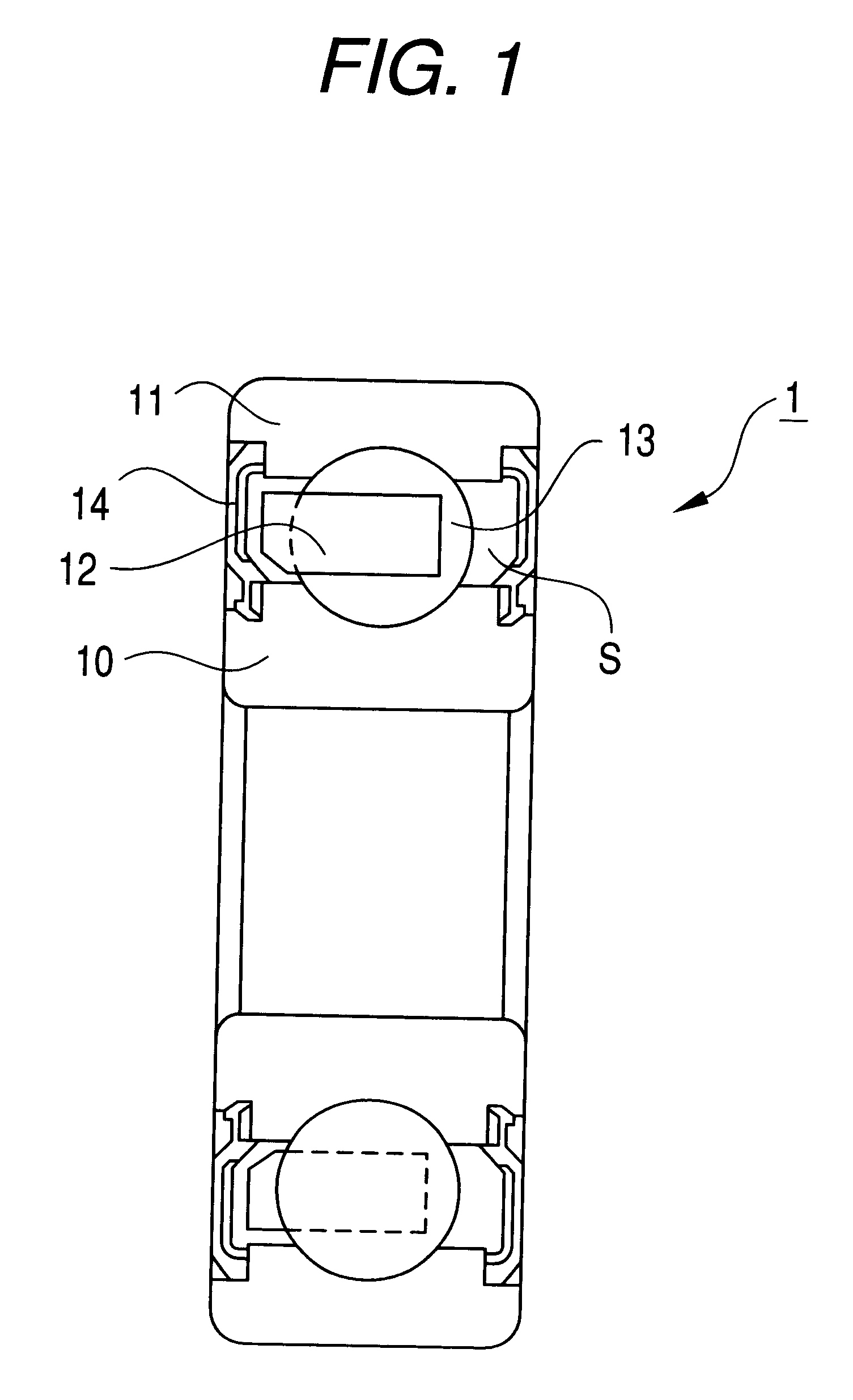

Rolling bearing

InactiveUS6652149B2Long lastingIncrease speedBall bearingsBearing componentsPolymer scienceRolling-element bearing

In a rolling bearing, a plurality of rolling elements are rollably retained by a retainer between an inner ring and an outer ring, while being substantially equidistantly arranged. The rolling bearing is filled with a grease composition which contains a base oil including of fluorocarbon polymer oil, and a thickening agent including a polytetrafluoroethylene. A conductive material is added in an amount of 0.1 to 10 wt %, based on the total weight of the grease composition, to the grease composition.

Owner:NSK LTD

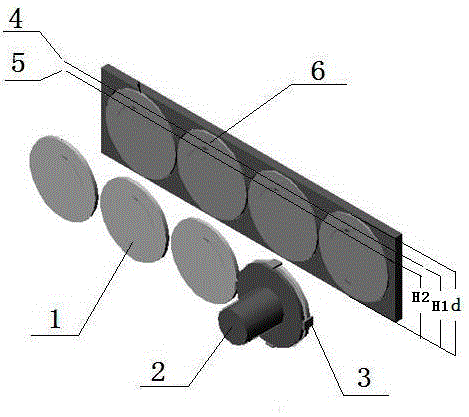

Method for chemically and mechanically polishing sapphire substrate slices in immersed mode

The invention relates to a method for chemically and mechanically polishing sapphire substrate slices in an immersed mode. The polishing method comprises the following steps that firstly, preprocessing is conducted, wherein the sapphire substrate slices are attached to a hard ceramic disk, the hard ceramic disk is installed on a main shaft of a polishing machine, a polishing gasket is installed on a rotating bottom disk, reverse osmosis pure water and a silicon dioxide polishing solution are mixed and added into the polishing machine, and the liquid level is kept between the upper liquid level line and the lower liquid level line of the polishing liquid; secondly, polishing is conducted, wherein the polishing machine is started for polishing the sapphire substrate slices, the polishing time ranges from 40 min to 80 min, and then the polished sapphire substrate slices are obtained; and thirdly, the finished sapphire substrate slices are washed. According to the chemical and mechanical polishing method, the temperature rising of the surface of the polishing gasket in the polishing process is small, the service life of the polishing gasket and an adsorption gasket is long, and no tiny scratch exists on the surfaces of the sapphire substrate slices in the polishing process.

Owner:TUNGHSU GRP

Tri-phase surge protector and its manufacturing method

ActiveUS20070217110A1Extend product lifeImprove reliabilityCurrent responsive resistorsEmergency protective arrangement detailsOxide ceramicZinc

A tri-phase surge protector comprises a first zinc oxide ceramic body; a first electrode layer on a surface of the first zinc oxide ceramic body and having a first electrode, and the first electrode includes a first terminal; a second electrode layer on another surface of the first zinc oxide ceramic body; a second zinc oxide ceramic body on the second electrode layer; a third electrode layer on another surface of the second zinc oxide ceramic body and having a second electrode, and the second electrode includes a second terminal; a third zinc oxide ceramic body on the second electrode layer and at the second zinc oxide ceramic body; and a fourth electrode layer on another surface of the third zinc oxide ceramic body and having a third electrode, and the third electrode includes a third terminal. The invention also discloses a method for manufacturing a tri-phase surge protector.

Owner:POWERTECH INDAL

Battery module

ActiveUS9515361B2Increase temperatureSmall temperature riseCell lids/coversLi-accumulatorsCoolantElectrical and Electronics engineering

A battery module of includes a plurality of cells, a cooling plate, and a channel part formed in the cooling plate. The channel part includes a first channel part extending in an arrangement direction of the plurality of cells, a second channel part extending in parallel to the first channel part along the arrangement direction with a first partition part interposed between the first channel part and the second channel part, and a first communication part which brings one end of the first channel part of the arrangement direction and one end of the second channel part of the arrangement direction into communication with each other, and which turns a flowing direction of coolant in the first channel part and the second channel part.

Owner:HITACHI VEHICLE ENERGY

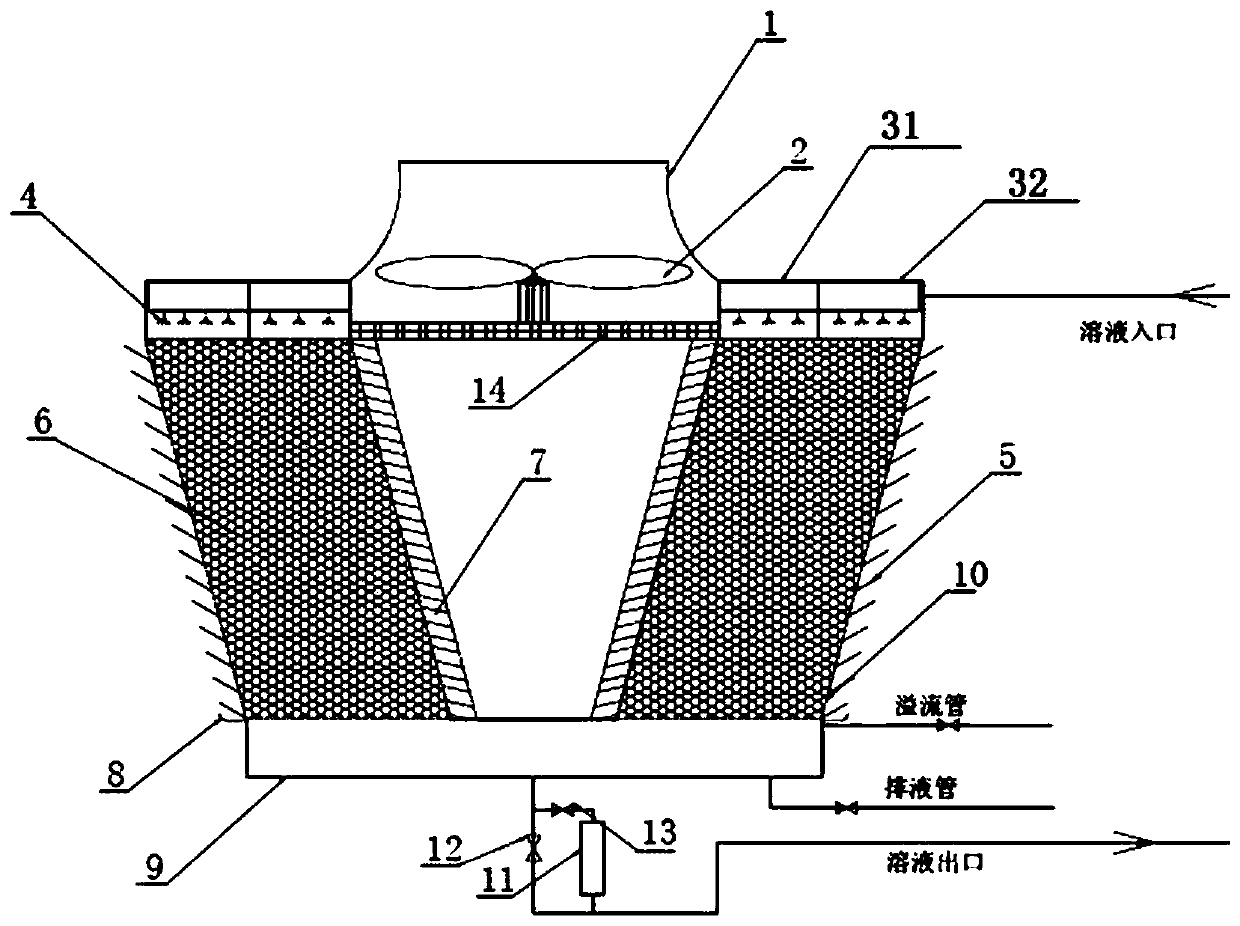

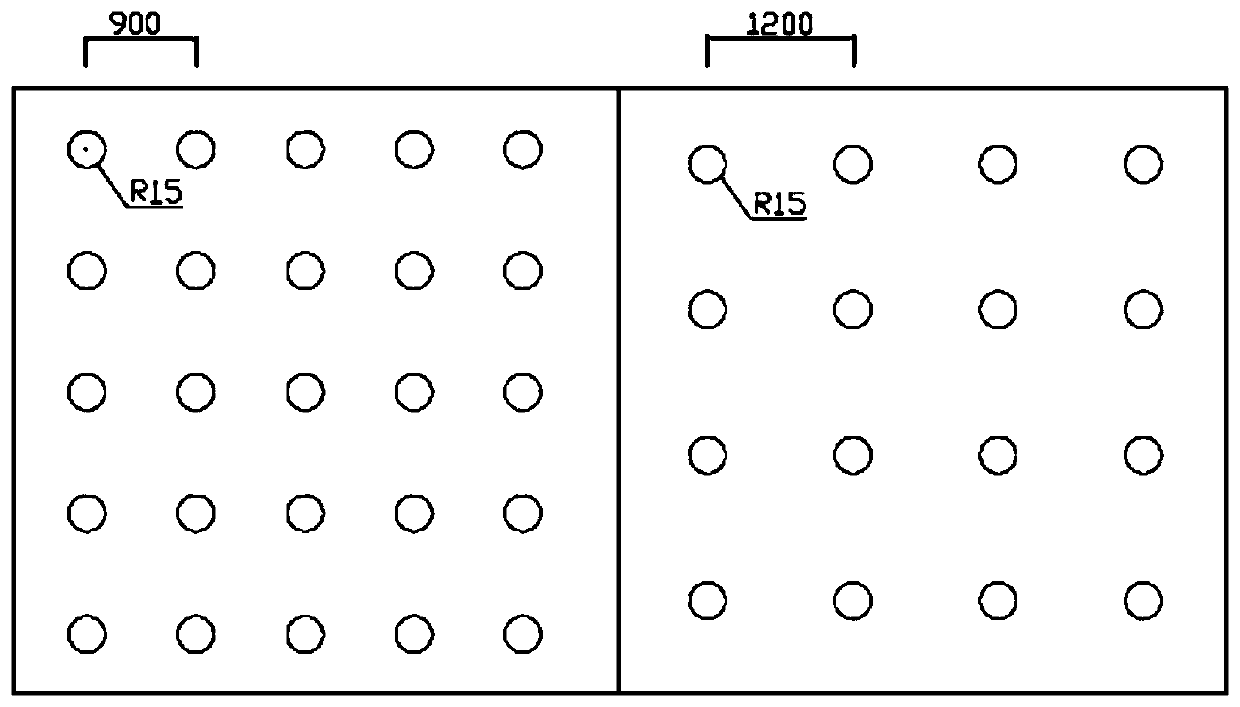

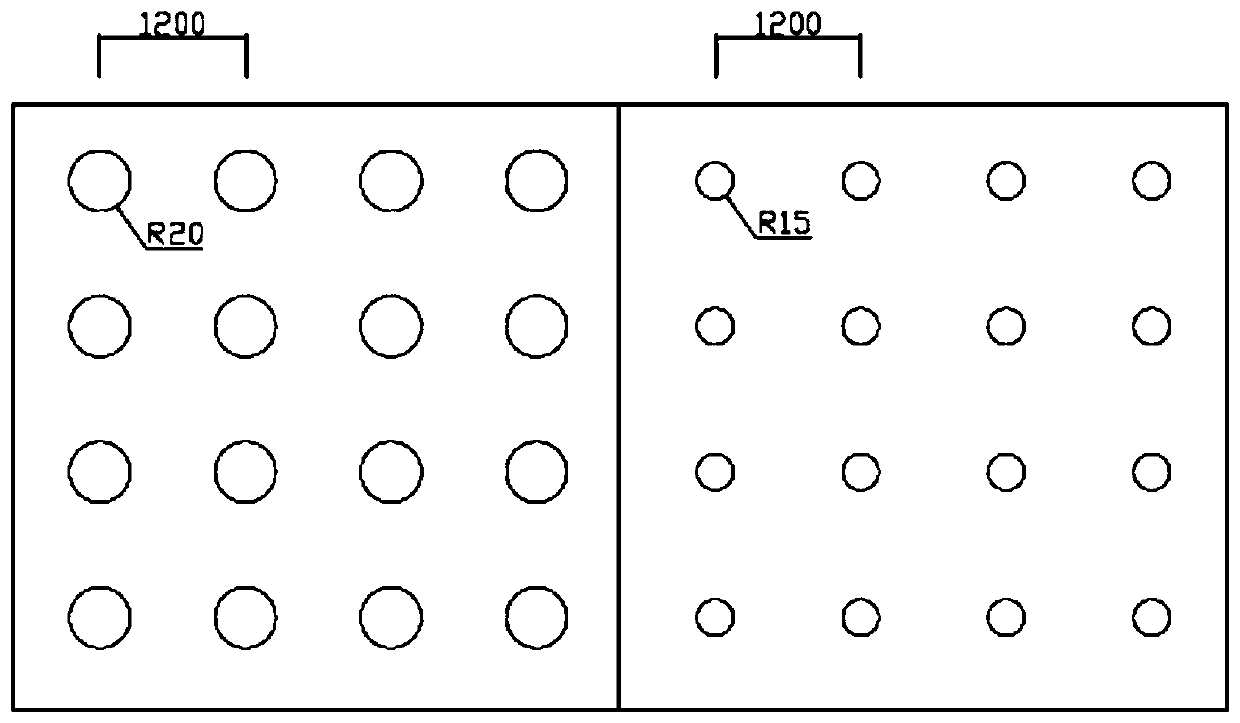

Cross-flow hear source tower based on phase change microcapsule solution

InactiveCN109798615AReduce volumeWon't clogLighting and heating apparatusSpace heating and ventilation detailsCooling towerEngineering

The invention relate to a cross-flow hear source tower based on a phase change microcapsule solution, and belongs to the technical field of refrigeration air conditioners. A heat source tower body isconnected with a flow fluid pipeline of a cooling tower; an air inlet is formed in the outer side wall of the heat source tower body; a heat transferring cavity is formed in the heat source tower body, and the air inlet communicates with the heat transferring cavity; the center of the heat transferring cavity of the heat source tower body is a central through hole cavity penetrating through the upper part and the lower part of the heat source tower body; the heat transferring cavity is internally filled with PVC fillers absorbing heat from air, and the PVC fillers are the phase change microcapsule solution; the top of the heat transferring cavity of the heat source cavity body communicates with a fluid inlet pipeline of the cooling tower flow fluid; the bottom end of the heat source towerbody communicates with a fluid outlet pipeline of the cooling tower flow fluid; and fluid flows from the fluid inlet pipeline to a filling part in a heat transferring cavity and flows back from the fluid outlet pipeline at the bottom end of the heat source tower body into the cooling tower. According to the cross-flow hear source tower based on the phase change microcapsule solution, phase changing are conducted on phase change materials during falling of the phase change microcapsule solution, so that specific heat capacity of the phase change microcapsule solution is larger, and when the solution absorbs heat, a temperature remains unchanged or has a small rangeability.

Owner:SOUTHEAST UNIV

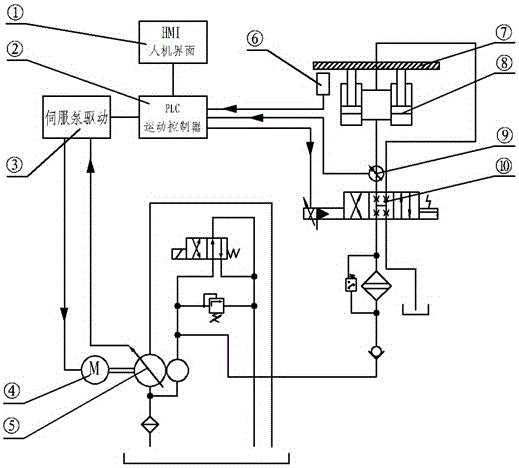

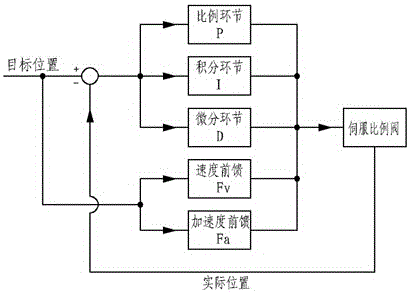

Stamping servo compensation system and working process thereof

PendingCN106640857APrecise torque controlAccurate speed controlFluid-pressure actuator componentsHydraulic cylinderControl system

The invention relates to a stamping servo compensation system and a working process thereof. The stamping servo compensation system is composed of a human-computer interaction interface, a PLC motion controller, a hydraulic servo pump system, a servo proportional valve, a position sensor, pressure sensors, an electric control element, a hydraulic cylinder body and a stamping fixing template. One way of the PLC motion controller is connected with a servo pump drive which is connected with the servo pump. The servo pump is connected with the first pressure sensor. The other way of the PLC motion controller is connected to the servo proportional valve controlled by the PLC motion controller. The other way of the PLC motion controller is connected with the second pressure sensor and a displacement sensor. The displacement sensor is used for detecting the position of the stamping fixing mould plate. The stamping servo compensation system has the beneficial effects that by the utilization of the servo hydraulic drive and a position sensor feedback position closed-loop control system, high-precision pressure, position and synchronous control can be achieved; the servo pump driven by a servo motor is utilized, during standby, the motor does not rotate, and the energy-saving effect is remarkable; and torque and rotating speed of the servo motor are controlled precisely, and high-precision pressure and flow control is achieved.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

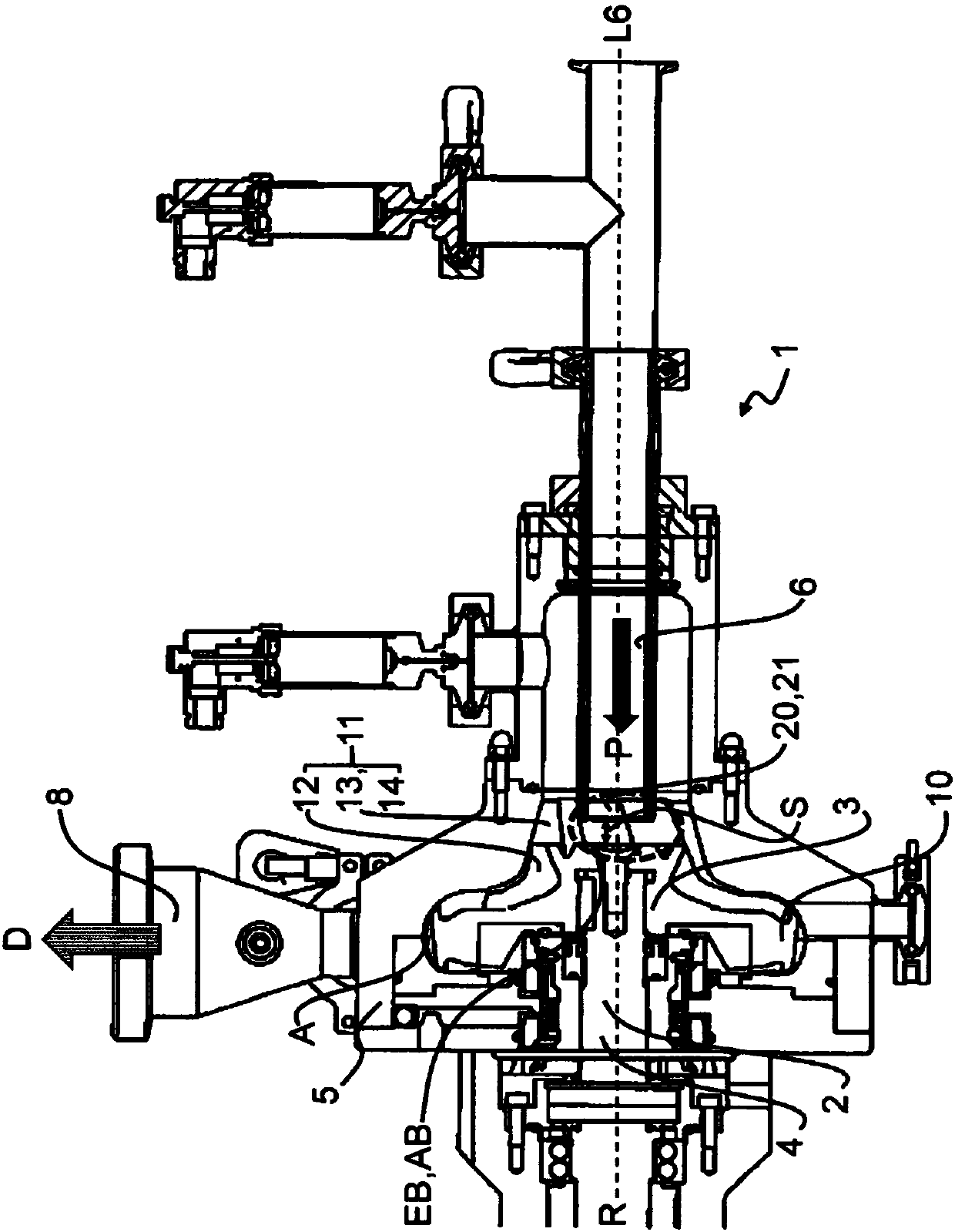

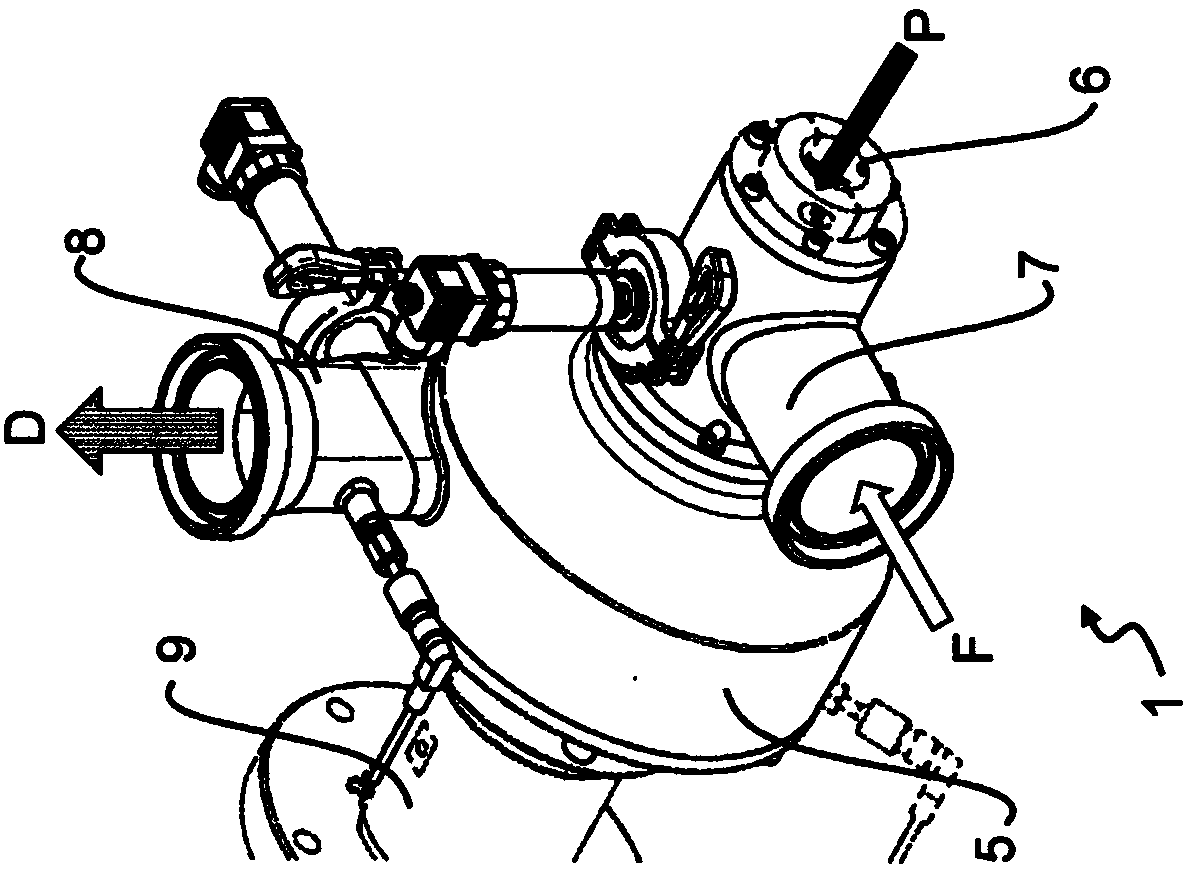

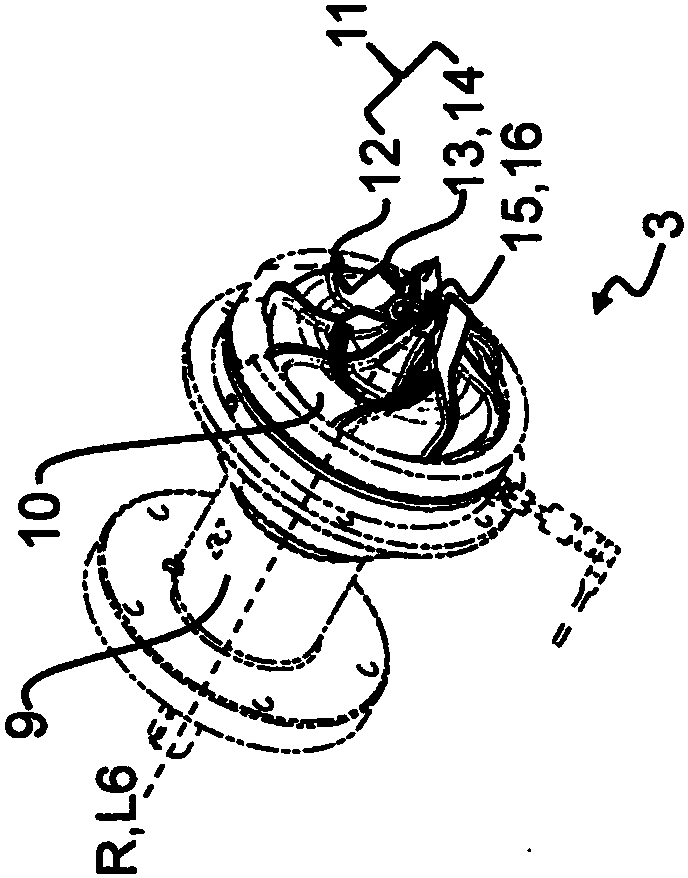

Device and method for dispersing at least one substance in a fluid

ActiveCN107921382AImprove functionalityAvoid stickingFlow mixersTransportation and packagingBiomedical engineeringFluid supply

The invention relates to a device and a method for dispersing at least one substance in a fluid. Said device comprises a process housing (5) with a rotor (3), a fluid supply (7), a feed line (6) for the at least one substance being dispersed and having at least one outlet opening (21), and a product outlet (8). The rotor (3) causes, in at least some sections, a supplied fluid to be conveyed axially. The rotor (3) also causes, in at least some sections, the supplied fluid to be conveyed radially.

Owner:耐驰精细研磨技术有限公司

Electric vehicle

ActiveUS9242560B2Reduce the temperatureSmall temperature risePower to auxillary motorsPropulsion by batteries/cellsElectric vehicleElectric power

An electric vehicle includes: an electric motor; an inverter that supplies electric power to the electric motor; and a cooling system that cools at least one of the electric motor and the inverter, the cooling system having: a main coolant passage configured to circulate a coolant through a radiator and at least one of the electric motor and the inverter; a bypass coolant passage, connected to the main coolant passage, that bypasses at least one of the electric motor and the inverter; and a controller configured to switch from the main coolant passage to the bypass coolant passage when a main switch of the vehicle provided at a driver's seat is turned off while the electric vehicle is travelling, and to switch from the bypass coolant passage to the main coolant passage when the main switch is then turned on.

Owner:TOYOTA JIDOSHA KK

Magnetic Memory Devices

InactiveUS20160126288A1Reduce heatReduce direct heatingMagnetic-field-controlled resistorsSolid-state devicesBit lineMagnetic reluctance

Owner:SHANGHAI CIYU INFORMATION TECH CO LTD

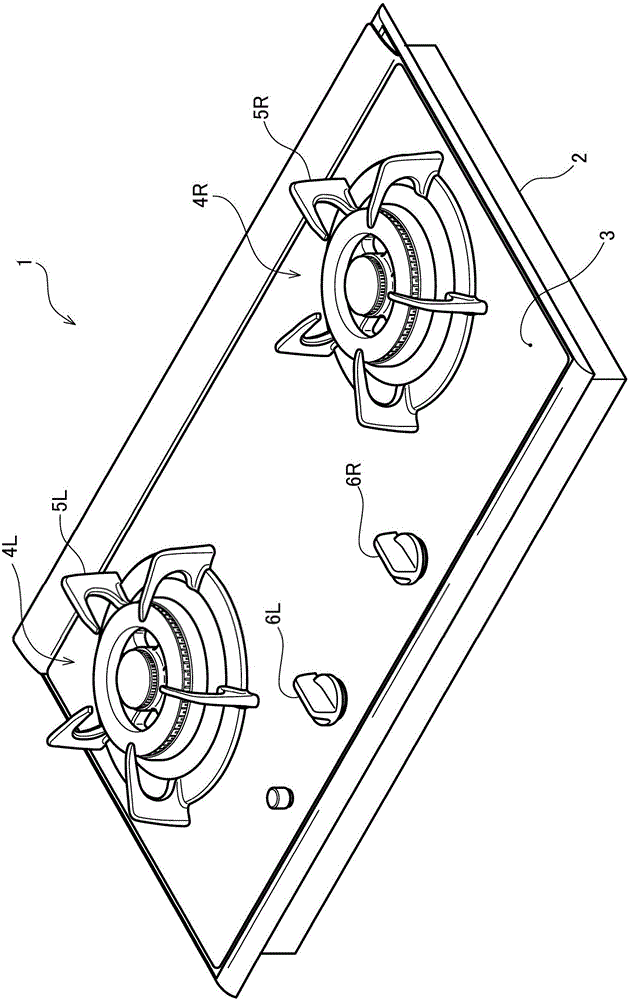

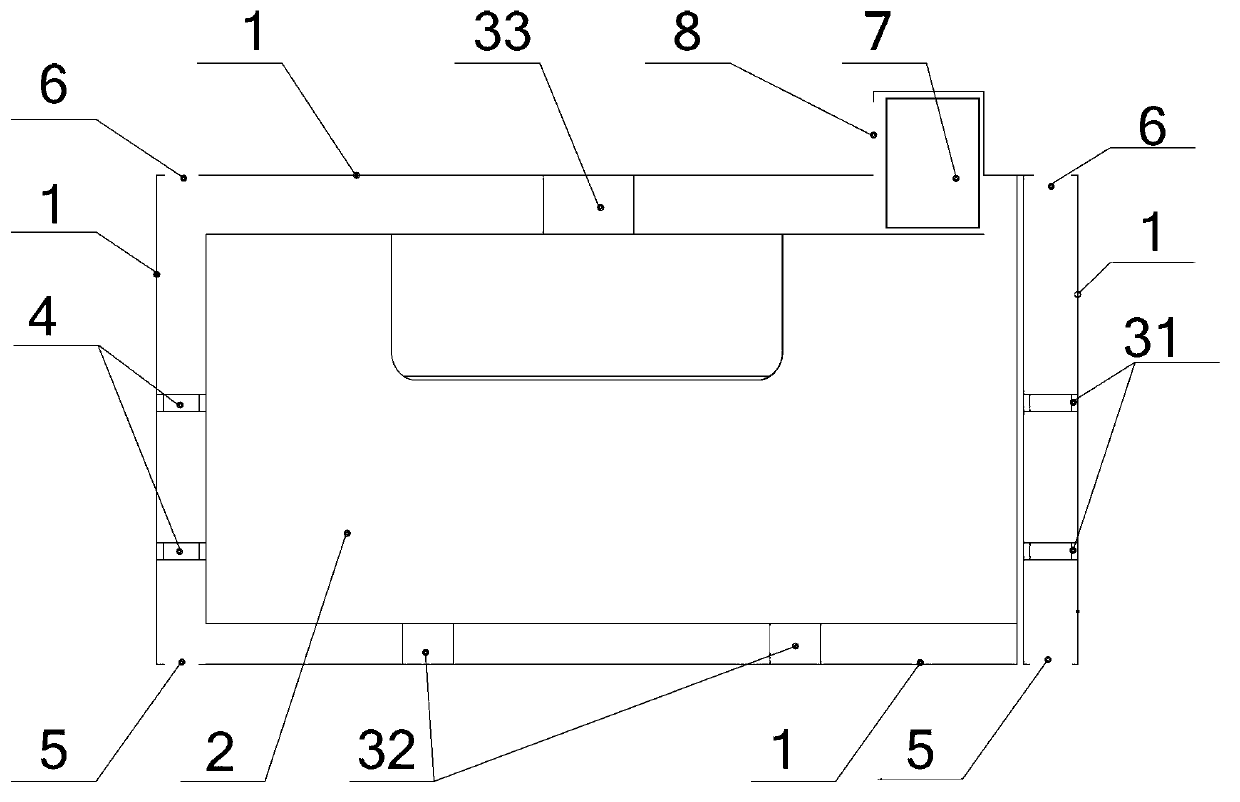

Gas stove

ActiveCN107435954ASuppress false detectionSmall temperature riseDomestic stoves or rangesLighting and heating apparatusEngineeringFalse detection

Provided is a gas stove capable of detecting a flashback with a small amount of temperature rise using a temperature sensor and suppressing erroneous detection. A cover for covering a mixing pipe of a stove burner is provided, and an inner temperature is measured with a temperature sensor attached to a cover. Periodically acquires an increase amount of the measurement temperature with a predetermined determination time width, and detects a flashback based on the fact that the increase amount exceeds the flashback threshold value. This flashback threshold is set according to the temperature inside the cover. By doing so, not only when the flashback occurs in the state that the inside of the cover is cold and the amount of increase in the measured temperature is large, but also when the inside of the cover warms up, flashback occurs and the amount of increase in measured temperature It is possible to detect a flashback by increasing the flashback threshold by exceeding the flashback threshold by changing the flashback threshold. In addition, in the state where the inside of the cover is cold, since the flashback threshold can be set larger than the warmed state, false detection can be suppressed.

Owner:RINNAI CORP

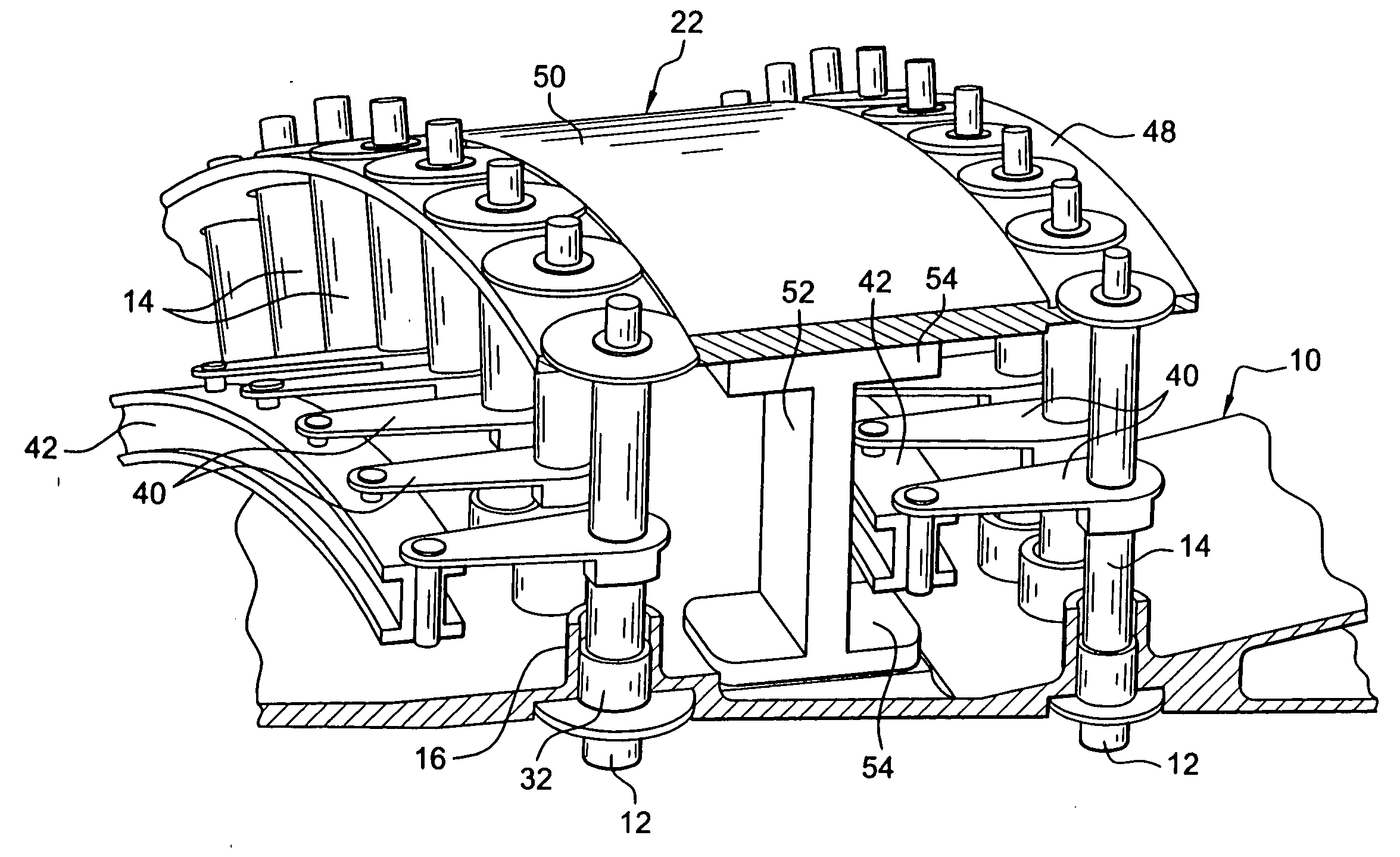

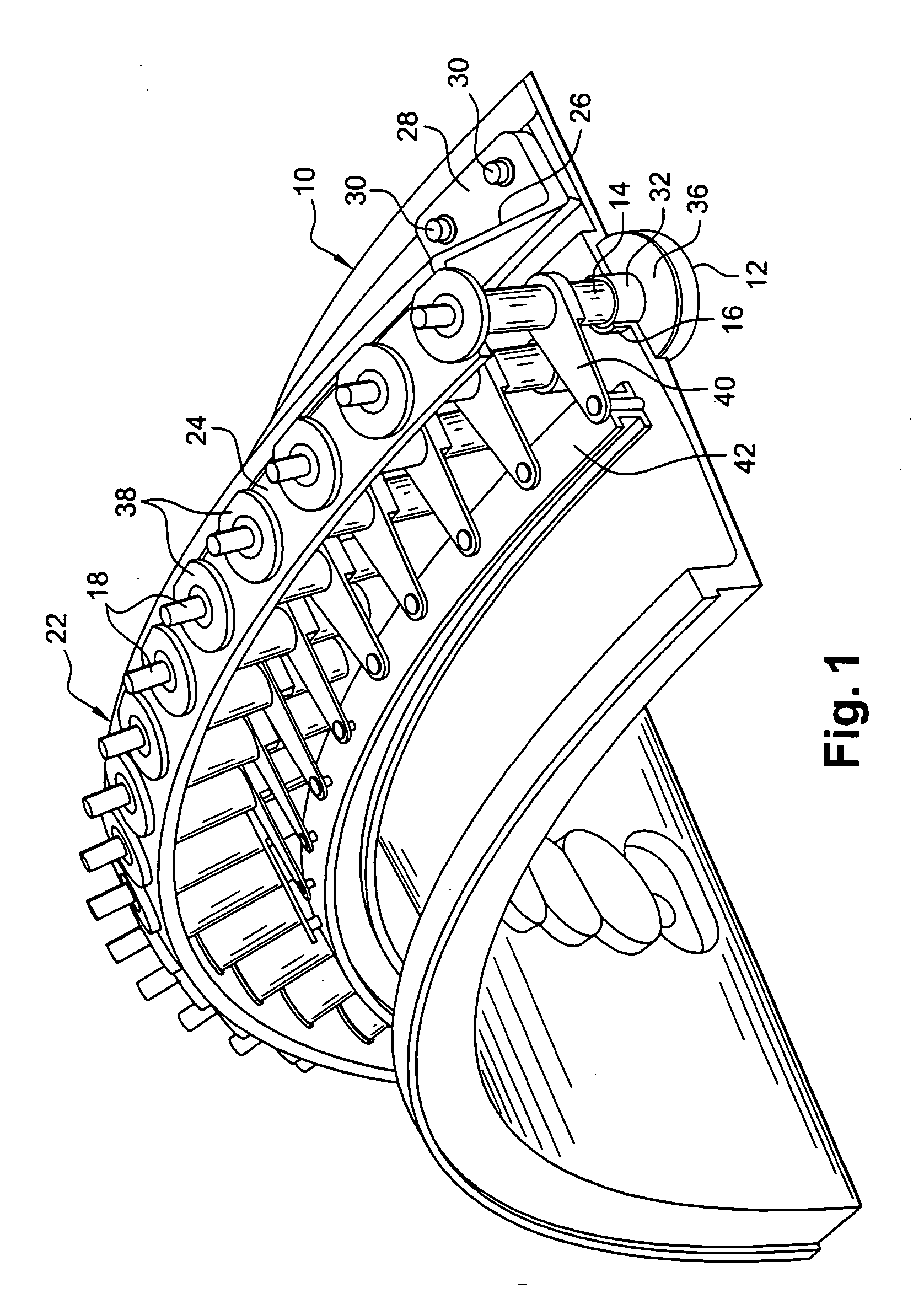

Device for pivotally guiding variable-pitch vanes in a turbomachine

ActiveUS20050042079A1Shorten the lengthEasy to processWind motor controlPump componentsEngineeringMechanical engineering

A device for guiding pivoting of variable-pitch vanes in a turbomachine, each vane having a pivot formed by a cylindrical axial shank which is guided in a cylindrical chimney of the casing and in a cylindrical orifice of a stationary element which surrounds the outside of the casing and which is centered and fixed relative thereto. The invention improves pivotal guidance of variable-pitch vanes.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Micro evaporator, oscillator-integrated micro evaporator structure and frequency correction method thereof

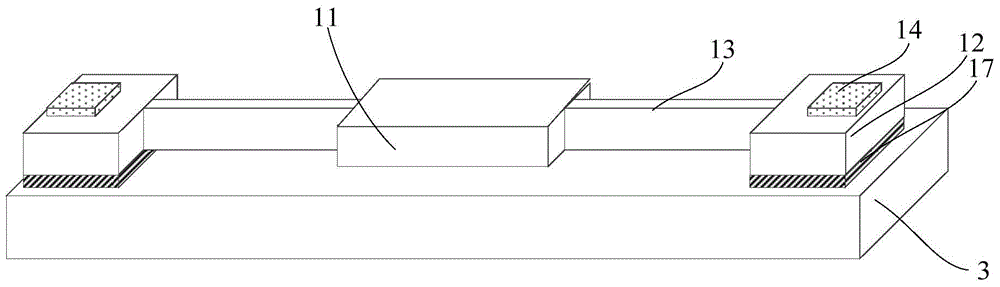

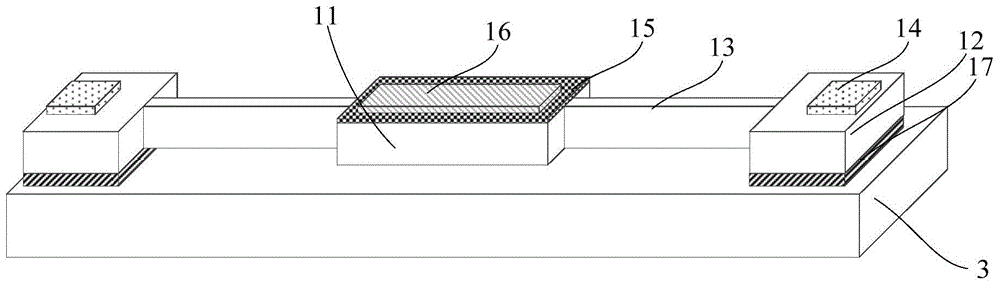

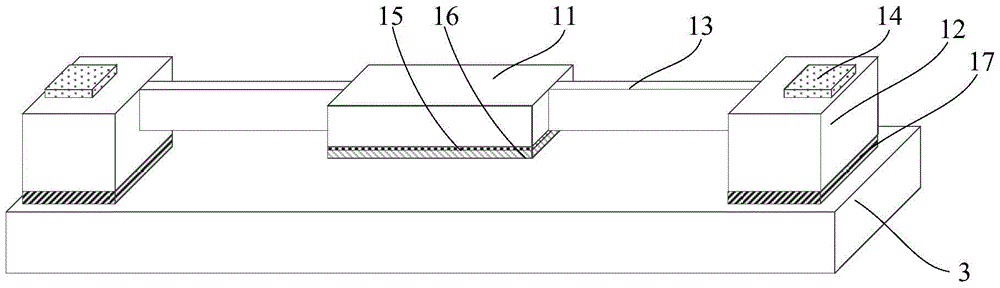

InactiveCN106803744AImprove accuracySmall heat capacityImpedence networksVacuum evaporation coatingEngineeringMetal electrodes

The invention provides a micro evaporator, an oscillator-integrated micro evaporator structure and a frequency correction method thereof. The micro evaporator comprises a micro evaporator table, anchor points, supporting beams and metal electrodes, wherein one surface of the micro evaporator table is an evaporation surface; the anchor points are located at two sides of the micro evaporator table, and a certain distance is left with the micro evaporator table; the supporting beams are located between the micro evaporator table and the anchor points, one end of each supporting beam is connected with the micro evaporator table and the other end is connected with the anchor point; the size of the supporting beam meets the following relation as is shown in the specifications; and the metal electrode is located on the surface of the anchor point. The micro evaporator table is connected with the anchor points with the metal electrodes formed on the surfaces through the supporting beams, through adjusting and setting the size of the supporting beam, features of small thermal capacity and little cooling of the supporting beam are realized; as the micro evaporator table and the supporting beam have a small size, needed evaporation temperature can be achieved on the micro evaporator table through applying small power to the surface of the metal electrode; and due to heat insulation of the supporting beam, the temperature rise at the anchor point is little, and the stability of the device is not influenced.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Fire-resistant dustbin

InactiveCN102991910AImprove fire resistanceExtended service lifeRefuse receptaclesNarrow rangeEngineering

The invention provides a fire-resistant dustbin. The dustbin comprises a storage box which is used for storing garbage and is made a metal material, an outer box which is sleeved outside the storage box and a connection gusset which is used for connecting the storage box to the outer box and is made of the metal material, wherein the outer box and the storage box are isolated through the connection gusset. The garbage in the storage box is lighted caused by accidental fire in the storage box, the temperature in the storage box can be raised gradually, the affect of the temperature of the outer box is little due to the fact that the outer box and the storage box are isolated, the temperature raises little although the temperature of the outer box raises, the raised temperature is in a narrow range, the fire-resistant performance of the dustbin is improved, the dustbin is burnt difficultly and the service life of the dustbin is prolonged.

Owner:HUNAN YUNMA HUASHENG AUTOMOBILE TECH

Copper and aluminum wiredrawing liquid and preparation method thereof

The invention provides a copper and aluminum wiredrawing liquid and a preparation method thereof. The liquid is characterized by comprising the following raw materials by weight parts: 10-12 parts of base oil, 1-2 parts of castor oil potassium soap, 2-3 parts of vulcanized whale oil, 0.3-0.5 parts of sodium benzoate, 10-12 parts of 3-iodo-2-propynyl butyl carbamate, 2-3 parts of 3-aminopropyl trimethoxysilane, 1-2 parts of an anti-oxidant 1010, 1-2 parts of dodecanedioic acid, 0.3-0.5 parts of zirconium dioxide, 2-3 parts of sorbitan fatty acid ester, 2-3 parts of a film forming auxiliary agent and 200-220 parts of water. According to the invention, the 250 SN base oil is used to promote lubrication performance, a water base is used to play a relative good heat dissipation effect, and the anti-oxidant are added to prevent deterioration after the wiredrawing liquid is stored for a long time. Meanwhile, a corrosion inhibitor and the film forming auxiliary agent are added in the formula provided by the invention, so as to play roles of corrosion inhibition and protection.

Owner:安徽富华电子集团有限公司

Fixation and drying technology for chrysanthemum flowers

The invention provides a fixation and drying technology for chrysanthemum flowers. The fixation and drying technology comprises the following steps of transferring the chrysanthemum flowers into a drying chamber, spreading the chrysanthemum flowers in the drying chamber, regulating the temperature of the drying chamber to be 30-35 DEG C, and performing preliminary drying for 2-3h; after preheat treatment, regulating the temperature of the drying chamber to be 35-40 DEG C, performing heat preservation for 2-3h, regulating the temperature of the drying chamber to be 40-45 DEG C, performing heat preservation for 4-5h, regulating the temperature of the drying chamber to be 50-55 DEG C, and performing heat preservation for 4-5h; regulating the temperature of the drying chamber to be 58-62 DEGC, performing baking for 5-7h, then enabling the temperature to rise to 65-70 DEG C, and performing baking for 2-3h; enabling room temperature to rise to 72-78 DEG C, and performing baking for 5-8h; and enabling the room temperature to rise to 87-93 DEG C, performing baking for 12-20h, and completing color fixation. Through the adoption of the fixation and drying technology disclosed by the invention, the problems that when a conventional chrysanthemum flower drying manner is used, the cycle is long, the efficiency is low, the quality and the yield of the obtained dried chrysanthemum flowers are not ideal enough, the quantity of broken leaves is large, the fragrance of the chrysanthemum flowers can gradually dissipate after long-term airing, and the mouth feel is poor are solved. The invention belongs to the field of processing of the chrysanthemum flowers.

Owner:贵州绿太阳制药有限公司

Fast, non-heat change and high-efficiency method for breaking ganoderma lucidum spore

ActiveCN101697981BSlow heatingIncrease profitImmunological disordersAntineoplastic agentsElectrical field strengthCell wall

The invention provides a fast, non-heat change and high-efficiency method for breaking ganoderma lucidum spore, belonging to the technical field of biology. The method comprises the steps of: 1. adding the ganoderma lucidum spore into water or 20-100% alcohol-containing solution or edible acid solution with the pH value of 3-7 or edible alkali solution with the pH value of 7-10, and evenly stirring to prepare mixture, wherein the weight ratio of the ganoderma lucidum spore to the solution is 1:5-15:2; and 2. processing the mixture under normal temperature though high-pressure pulse electric field to break, wherein the electric-field intensity is 10-110 kilovolt / cm and the number of the pulse is 1-800. By using the high-pressure pulse electric field, the method has less heat energy in the process of breaking, low raised temperature of a breaking target, and short breaking time. The breaking mechanism is not breaking the cell wall in the high-pressure pulse electric field but breaking the cell wall by forming a plurality of through holes on the surface of the cell wall by polar molecules in the solution under the function of the high-pressure pulse electric field, thereby improving the use ratio of bioactive substances.

Owner:JILIN AGRICULTURAL UNIV

Microemulsion semisynthetic copper wiredrawing liquid composition and preparation method thereof

The invention provides a microemulsion semisynthetic copper wiredrawing liquid composition and a preparation method thereof. The composition is prepared from the following raw materials by weight parts: 20-25 parts of soybean oil, 1-2 parts of di-t-butyl-p-cresol, 3-4 parts of tri potassium borate, 1-2 parts of benzotriazole, 2-3 parts of sodium butyl naphthalene sulfonate, 2-3 parts of a film forming auxiliary agent, 1-2 parts of alkenyl succinic acid, 3-4 parts of a silane coupling agent KH-5503, and 100-120 parts of water. According to the invention, the soybean oil is used as a lubricating component, thereby being environmental friendly and reducing harm of a wire drawing environment on worker's health; the silane coupling agent KH-5503 is used, thereby improving a film forming effect of the wiredrawing liquid, increasing a wiredrawing speed, facilitating corrosion inhibition components to form films, and prolonging an anti-corrosion time.

Owner:安徽富华电子集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com