Patents

Literature

755results about How to "Avoid nudity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

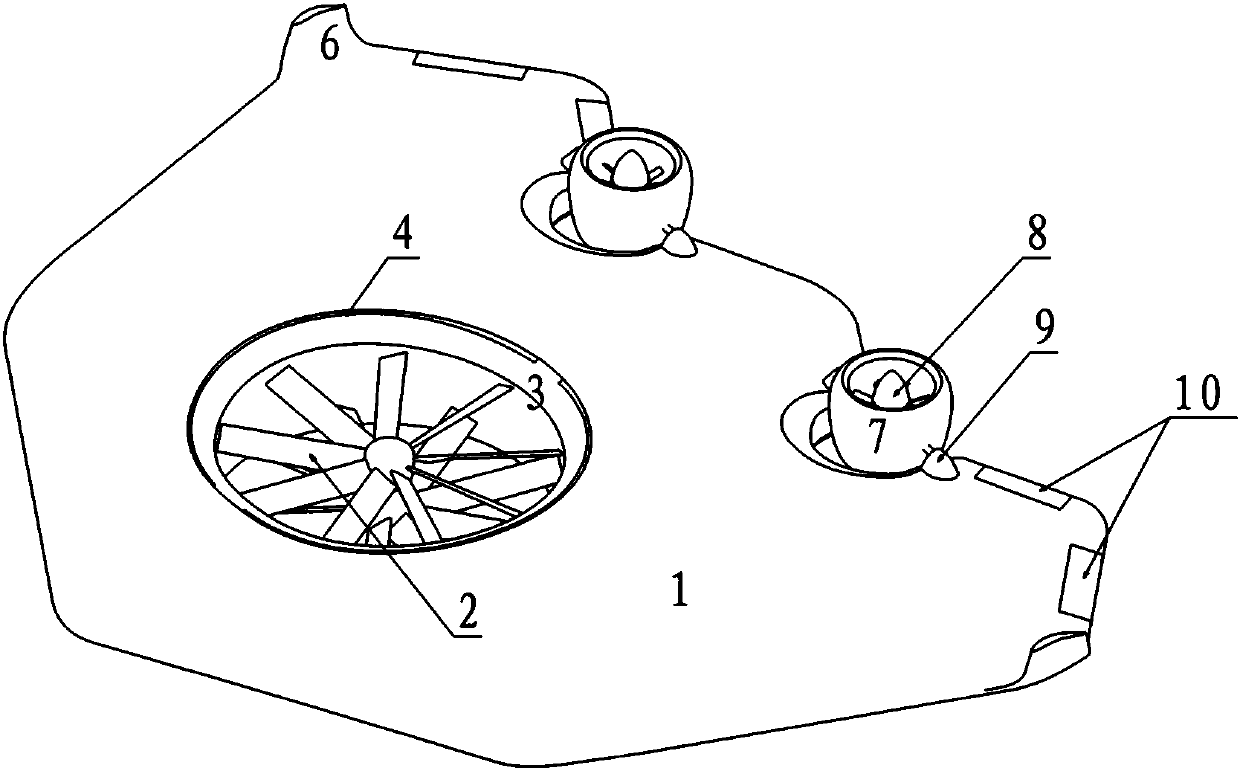

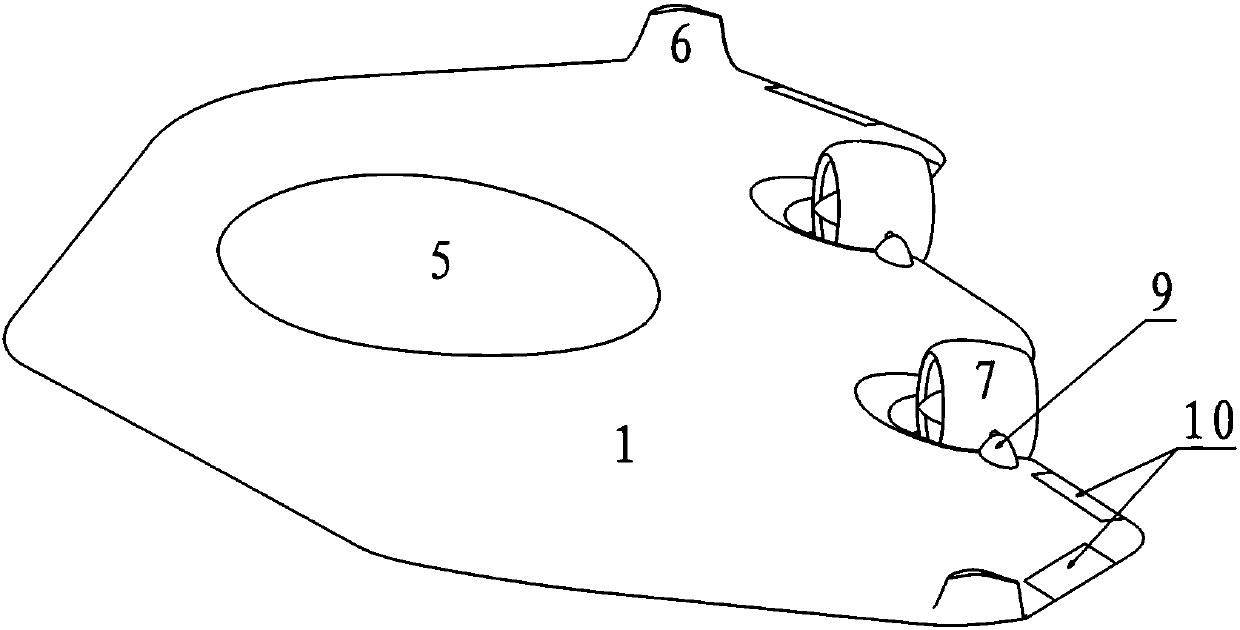

Vertical take-off and landing rotor aircraft with ducts built in wings

The invention relates to a vertical take-off and landing rotor aircraft with ducts built in wings, relates to the technical field of the vertical take-off and landing rotor aircraft, and particularly relates to the technical field of the vertical take-off and landing rotor aircraft with the ducts built in the wings. The wings are provided with lifting ducts; an inner bin is arranged on the inner wall of each lifting duct close to upper and lower wallboards of the wings so as to built in an duct cover; the duct cover can realize opening and closing of the lifting ducts; a diversion trench is arranged on the tail part of a fuselage; two sides of the diversion trench are provided with two supporting members and connect a tilting thrust duct arranged at the tail part of the fuselage to the fuselage through a tilting control mechanism; the tilting thrust duct is composed of coaxial tilting duct walls and coaxial thrust dual rotors; and engines are arranged in the fuselage and transmit power to the lifting duct and the tilting thrust duct through a reducer respectively. The aircraft increases an adjustable scope of the whole aircraft along an axis direction of the fuselage while not greatly weighting the whole aircraft, prevents bareness of the rotors, and increases propulsive efficiency of the aircraft.

Owner:CHINA HELICOPTER RES & DEV INST

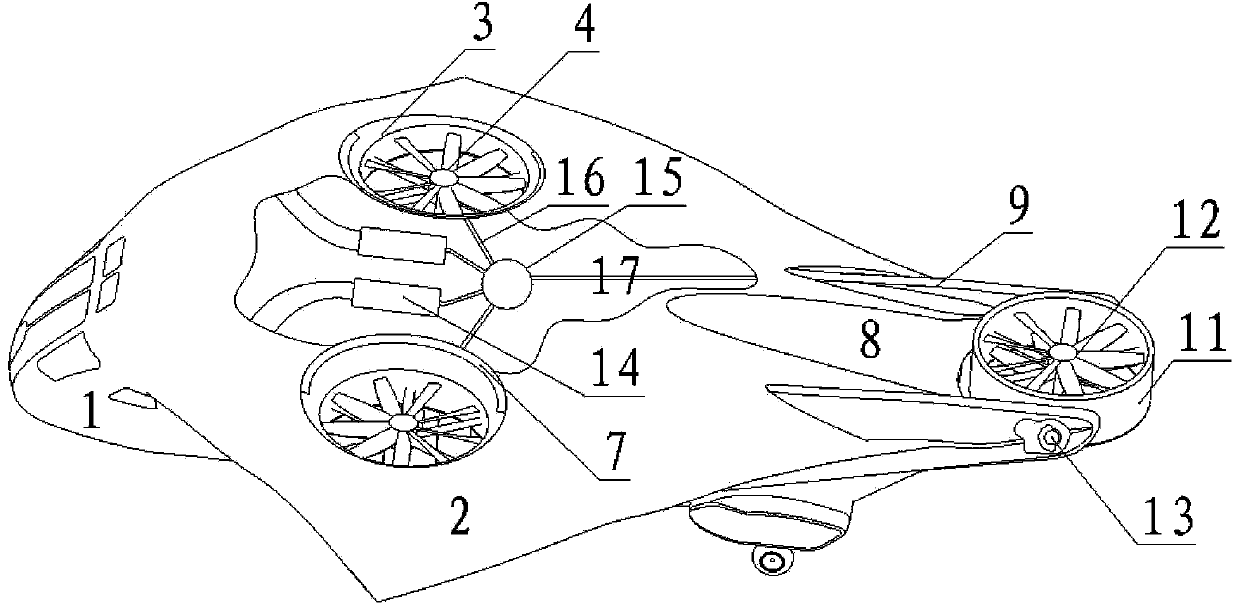

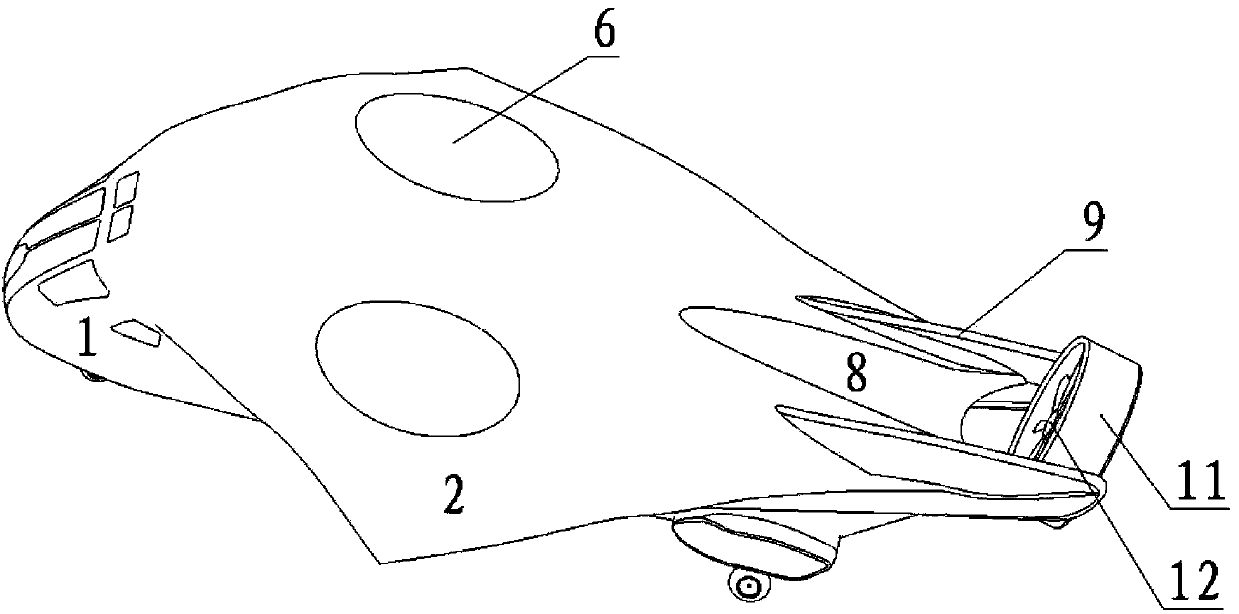

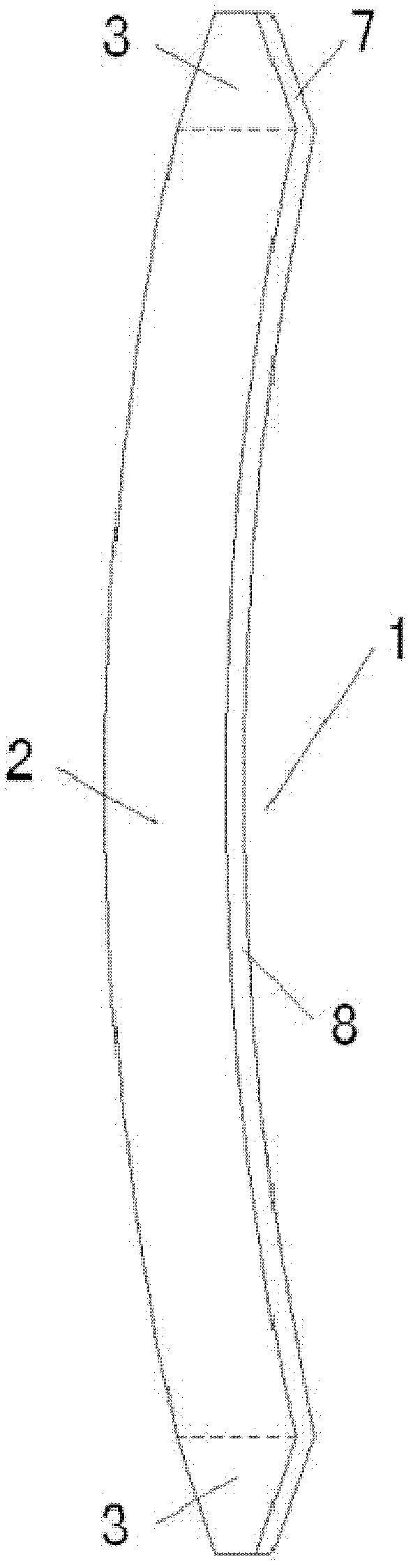

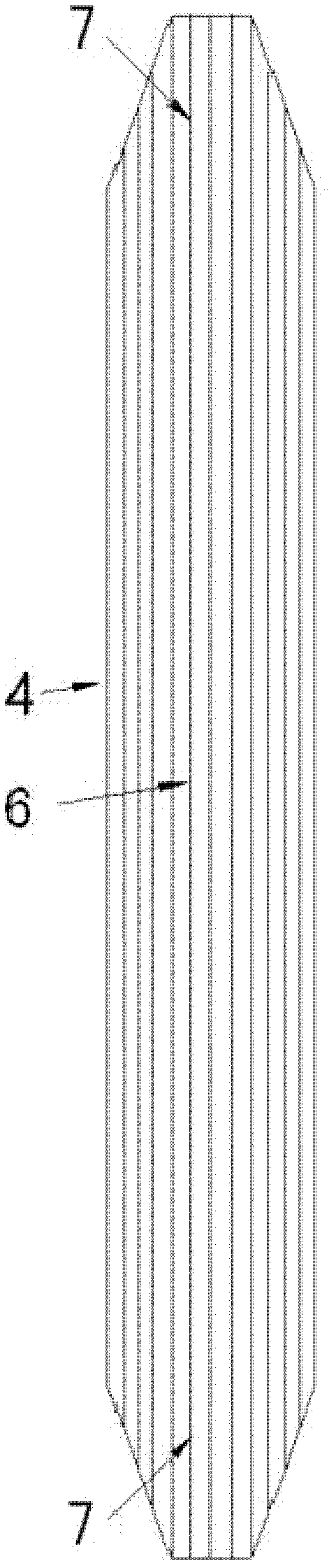

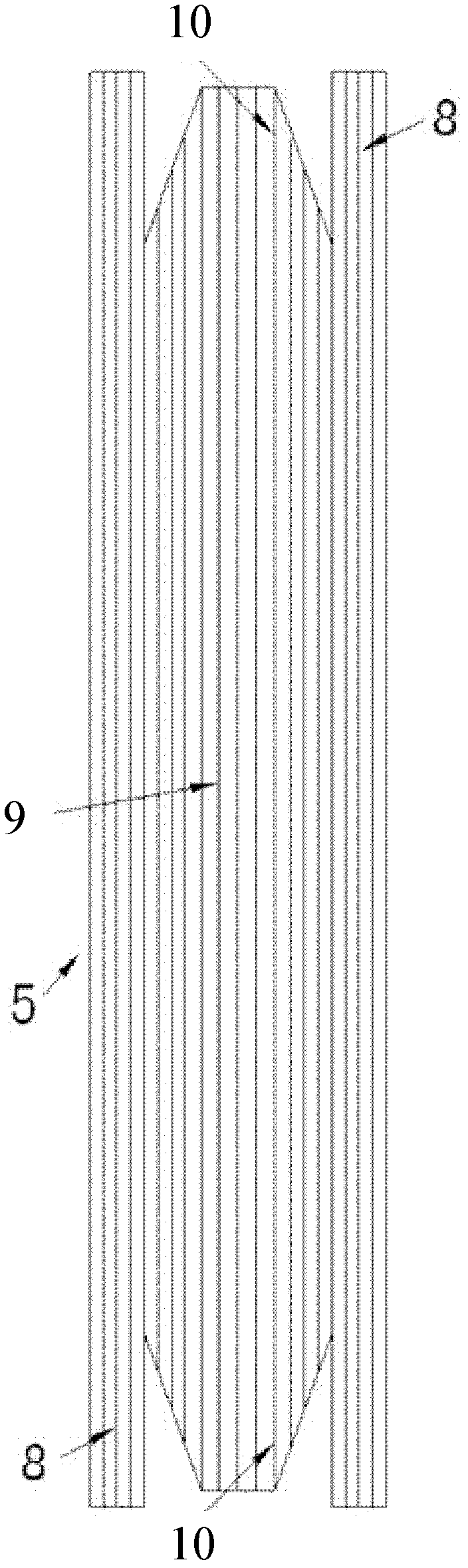

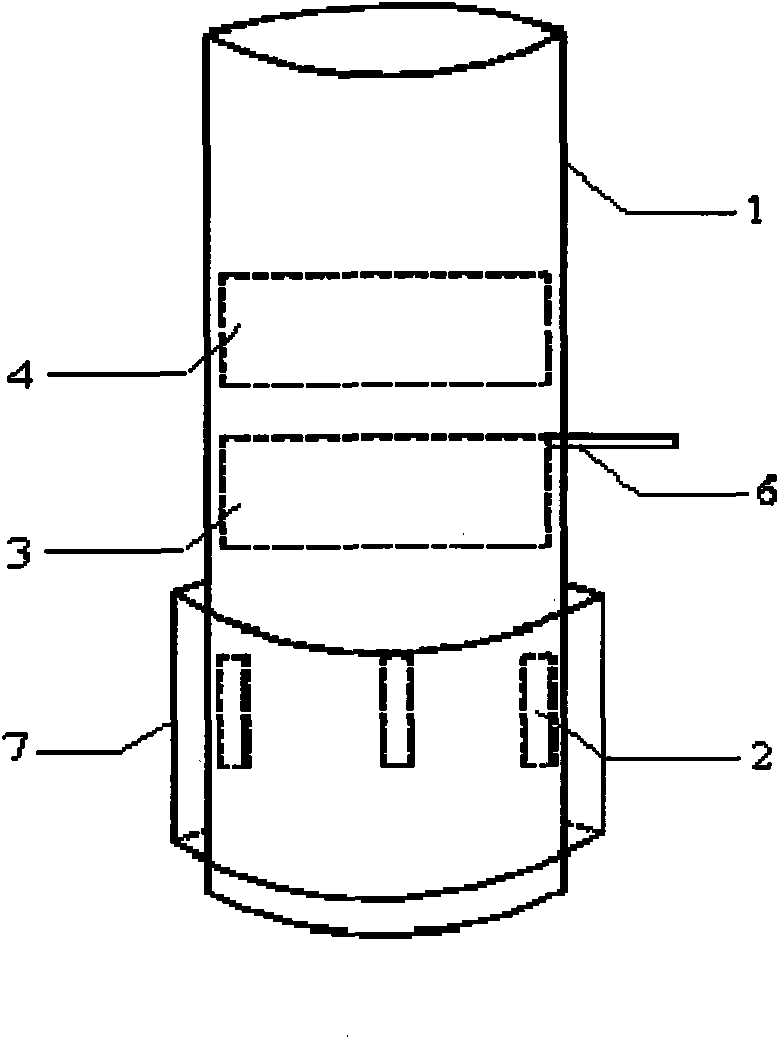

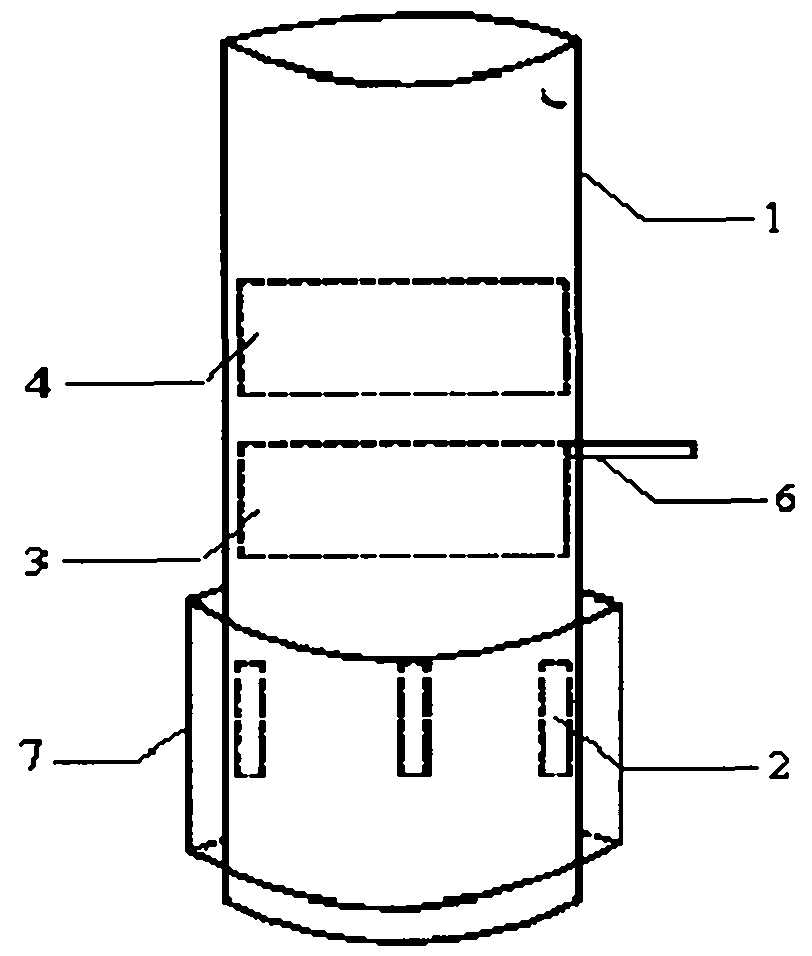

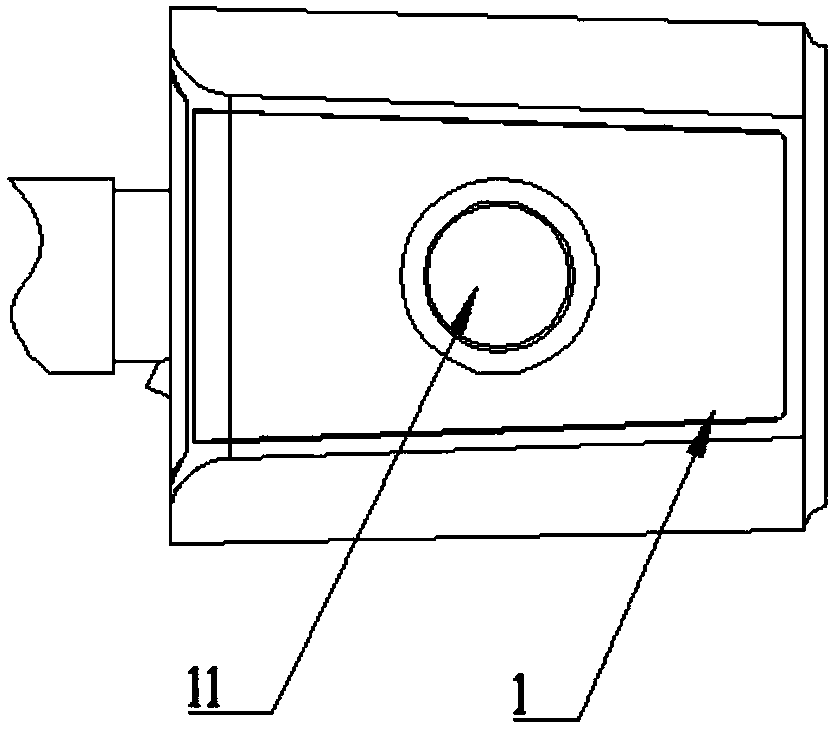

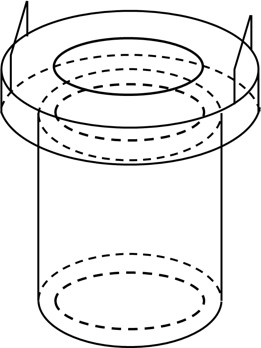

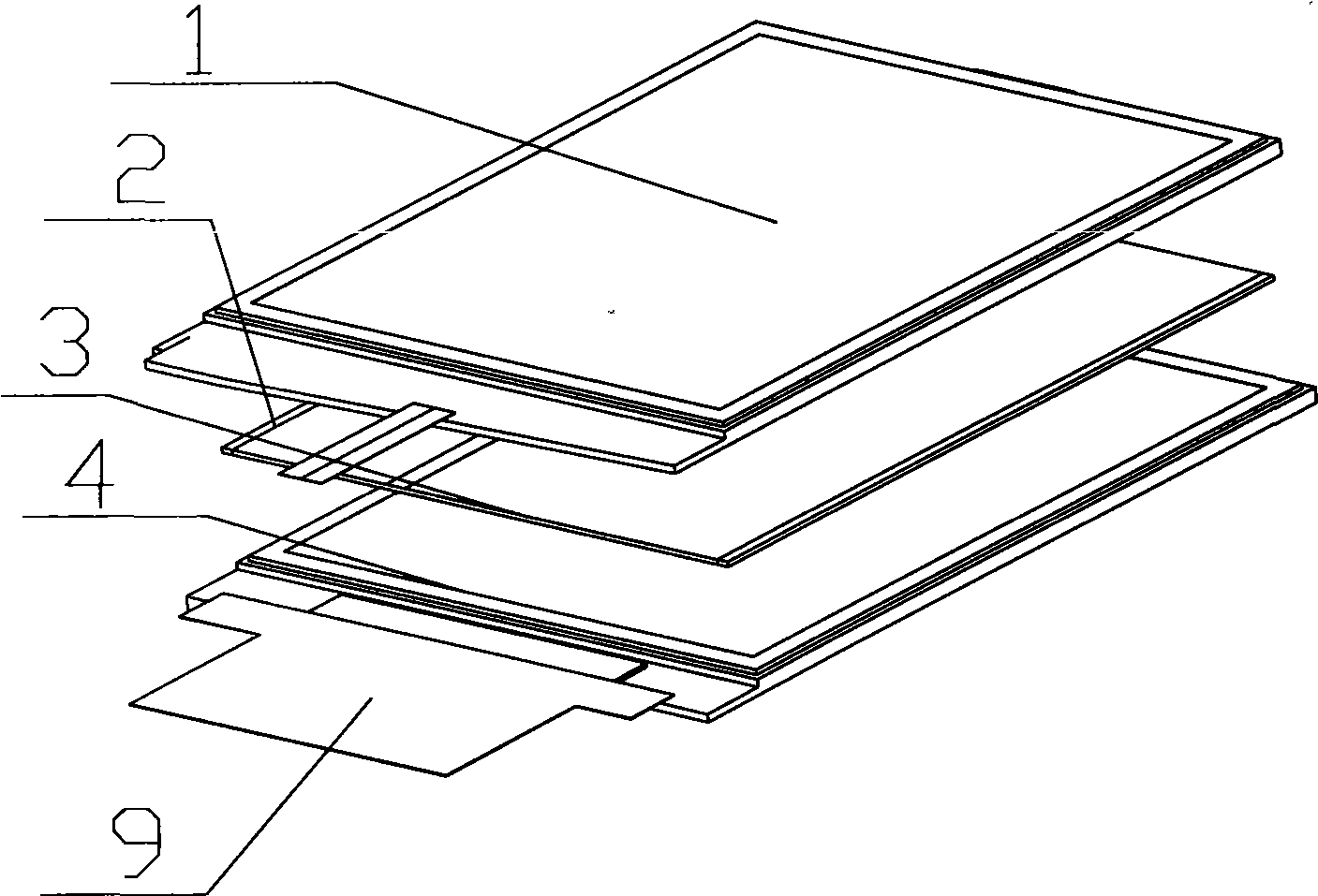

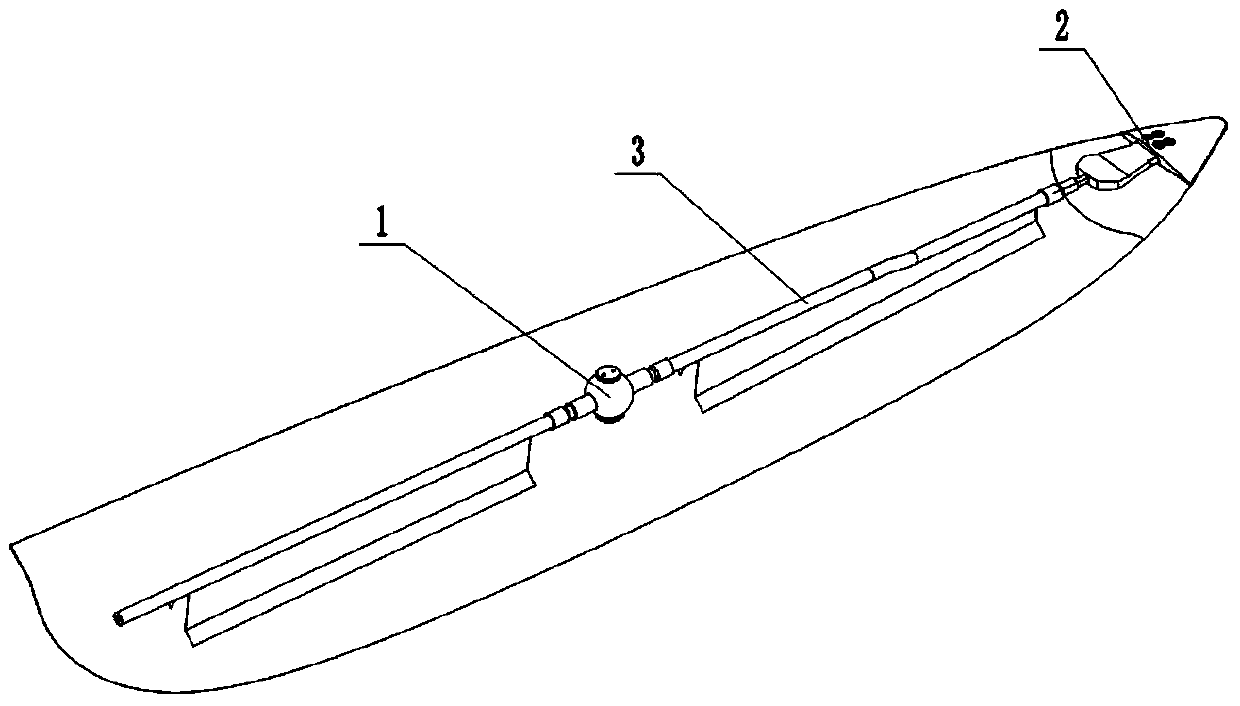

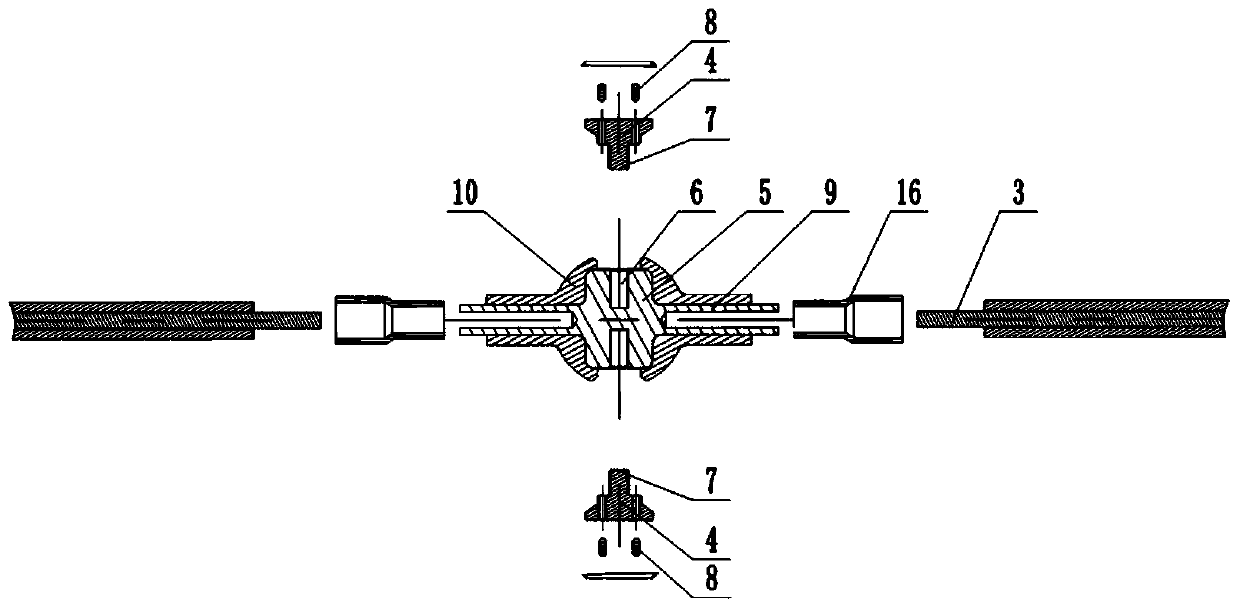

Culvert-type vertical take-off and landing lifting body unmanned aerial vehicle

InactiveCN107600405AReduce forward flight resistanceReduce resistanceVertical landing/take-off aircraftsRotocraftUncrewed vehicleFuselage

The invention discloses a culvert-type vertical take-off and landing lifting body unmanned aerial vehicle and relates to the technical field of vertical take-off and landing unmanned aerial vehicles.The culvert-type vertical take-off and landing lifting body unmanned aerial vehicle comprises a fuselage (1), lifting force rotor wings (2), a take-off and landing culvert (3), tilting-rotating thrustculverts (7) and tilting-rotating thrust rotor wings (8). The take-off and landing culvert (3) is composed of a through hole penetrating through the upper surface and the lower surface of the fuselage (1), and the lifting force rotor wings (2) are arranged in the take-off and landing culvert (3). The tilting-rotating thrust culverts (7) are hinged to the rear end of the fuselage (1) through tilting-rotating control mechanisms (9), the tilting-rotating control mechanisms (9) are configured to be capable of enabling the included angle between the axis of each tilting-rotating thrust culvert (7)and the axis of the fuselage (1) to be variable, and the tilting-rotating thrust rotor wings (8) are arranged in the tilting-rotating thrust culverts (7). Under the conditions that the vertical take-off and landing capacity of the unmanned aerial vehicle is maintained and the overall weight of the unmanned aerial vehicle is not excessively increased, the flight speed of the unmanned aerial vehicle is increased, the flight stability of the unmanned aerial vehicle is improved, the rotor wing exposed problem is avoided through the culverts, and the flight safety and the take-off and landing hovering efficiency are improved.

Owner:CHINA HELICOPTER RES & DEV INST

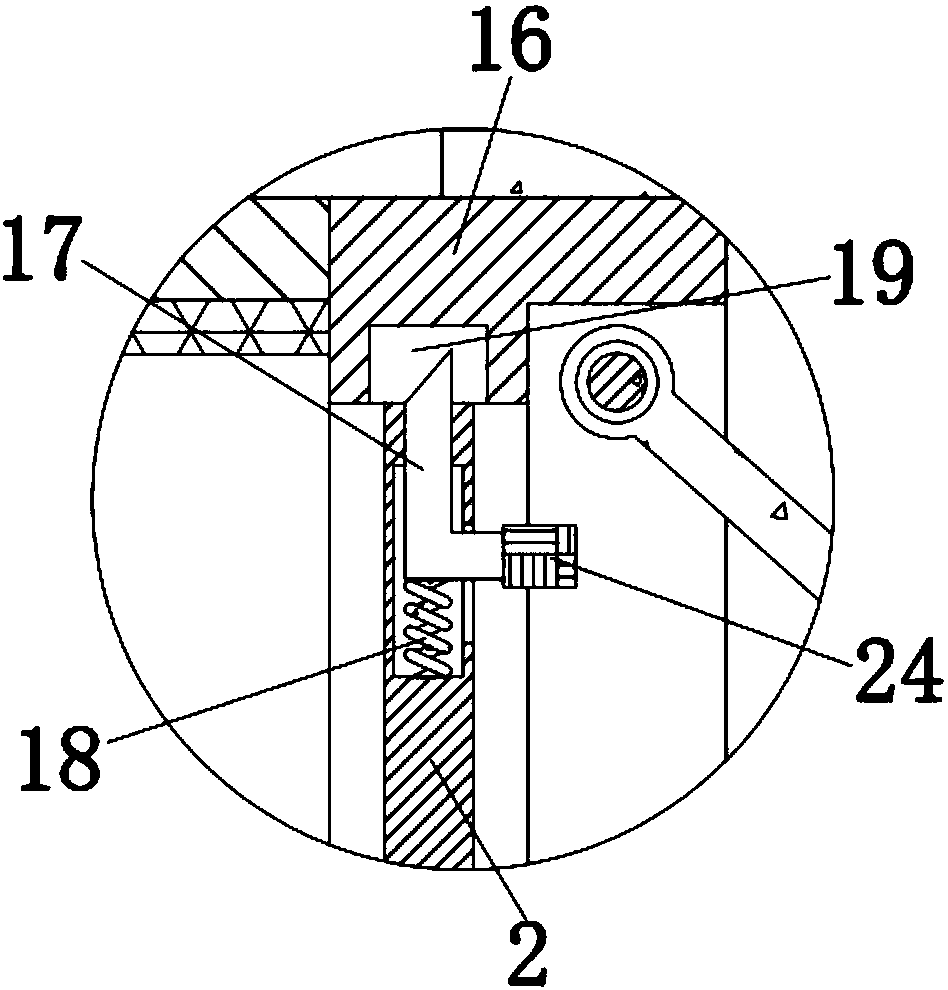

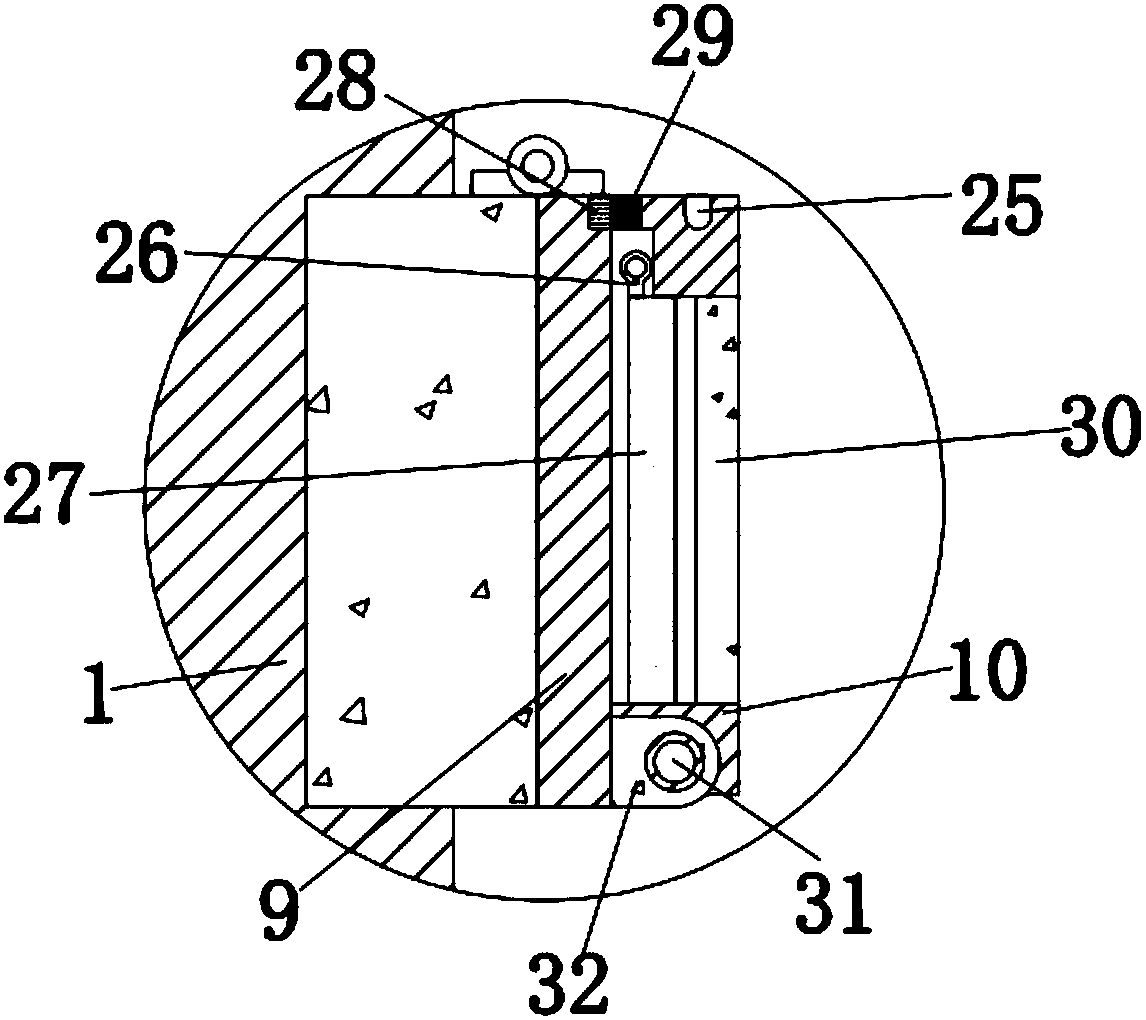

Solar yard lamp device being convenient for cleaning solar panels and easy to adjusting lamp direction

ActiveCN106090807AAvoid scratchesAvoid damagePhotovoltaic supportsSolar heating energyEffect lightEngineering

The invention relates to a solar yard lamp device being convenient for cleaning solar panels and easy to adjusting lamp direction. The solar yard lamp device comprises a column arranged in the vertical direction, wherein the left side of the top of the column is provided with a box body through a rotary hinge structure and an automatic retractable adjusting mechanism; the top of the box body is provided with a heat insulation plate; solar panels are spread on the heat insulation plate; a storage battery, a voltage stabilizer, a remote signal receiver and an intelligent controller are arranged in the box body; the lower surface of a mounting plate is provided with a fixed block; a ball is rotatablely arranged in the fixed block; the bottom of the ball is connected with an LED (light-emitting diode) illuminating lamp through a connecting rod; an electric push rod is arranged between the mounting plate and the LED illuminating lamp; and the box body is provided with an automatic reciprocating wiping unit for wiping the solar panels. The solar yard lamp device can make automatic adjustment on the irradiation direction of the LED illuminating lamp according to the inclination angle of the solar panels so as to adapt to the lighting demands of the yard, and can automatically clean the solar panels; and the solar panels are integrally installed on the storage battery, thereby avoiding the exposure of the circuit, and prolonging the service life of the components.

Owner:西藏世峰高科能源技术有限公司

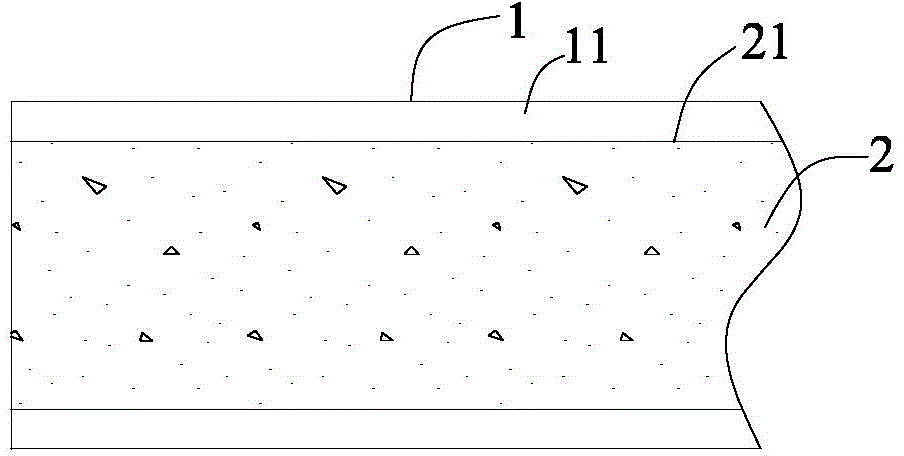

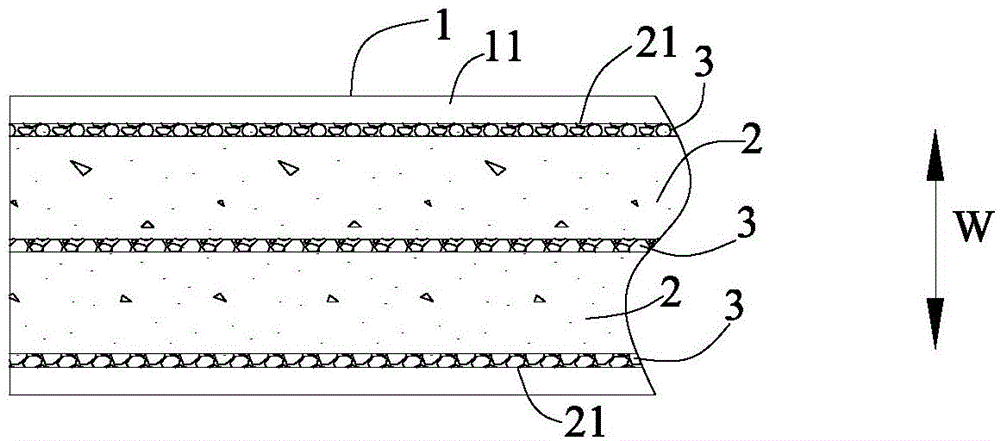

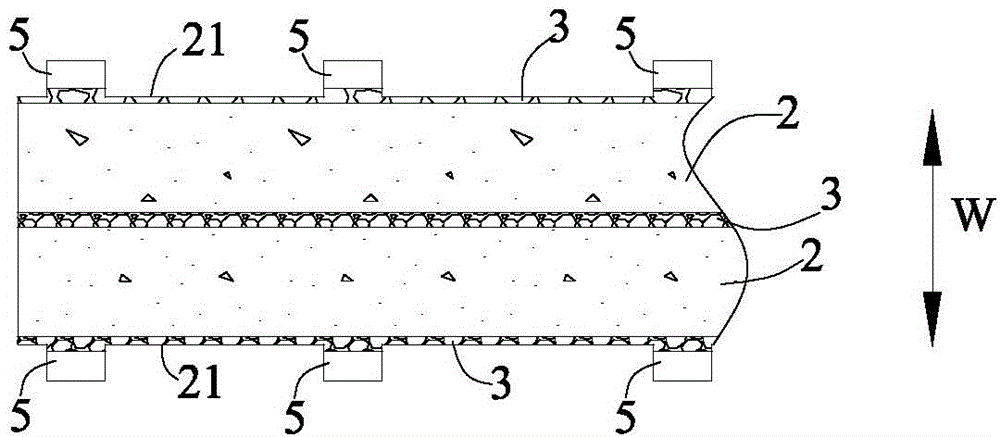

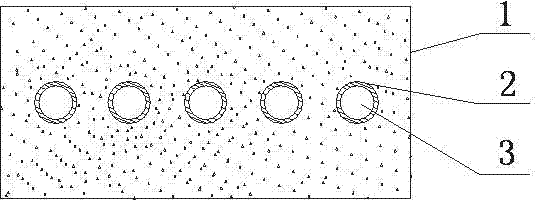

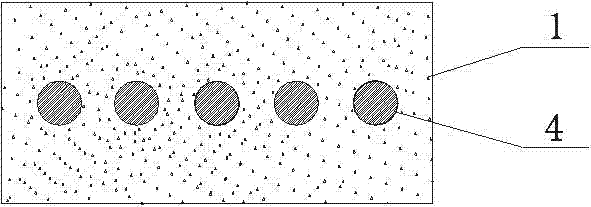

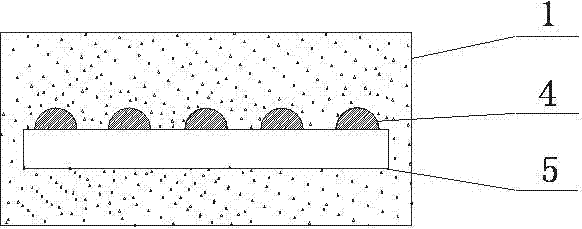

Fibrous composite plate spring and manufacturing process thereof

The invention discloses a fibrous composite plate spring. The fibrous composite plate spring comprises a plate spring body and a plate spring reinforcing layer, wherein the plate spring body consists of a central rectangular section and two end part sections which are positioned at two ends of the central rectangular section, and the width of the end part sections is gradually narrowed towards a direction away from the central rectangular section; the plate spring reinforcing layer and the plate spring body are made from the same material; the plate spring reinforcing layer comprises a reinforcing layer body which is covered on the upper surface or the lower surface of the plate spring body, and strengthening sections which are positioned on two sides of the reinforcing layer body; and the width of the strengthening sections is not less than the thickness of the plate spring body, the length of the strengthening sections is not less than that of the side surface of the plate spring body, and the strengthening sections are covered on the two sides of the plate spring body. By adoption of the fibrous composite plate spring, a fractured fiber layer at a chamfered part of an end part is prevented from being exposed, chamfered crackles and fiber flexing of the end part can be effectively avoided, and the carrying capacity of the plate spring is greatly improved. The invention also discloses a manufacturing process for the fibrous composite plate spring.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

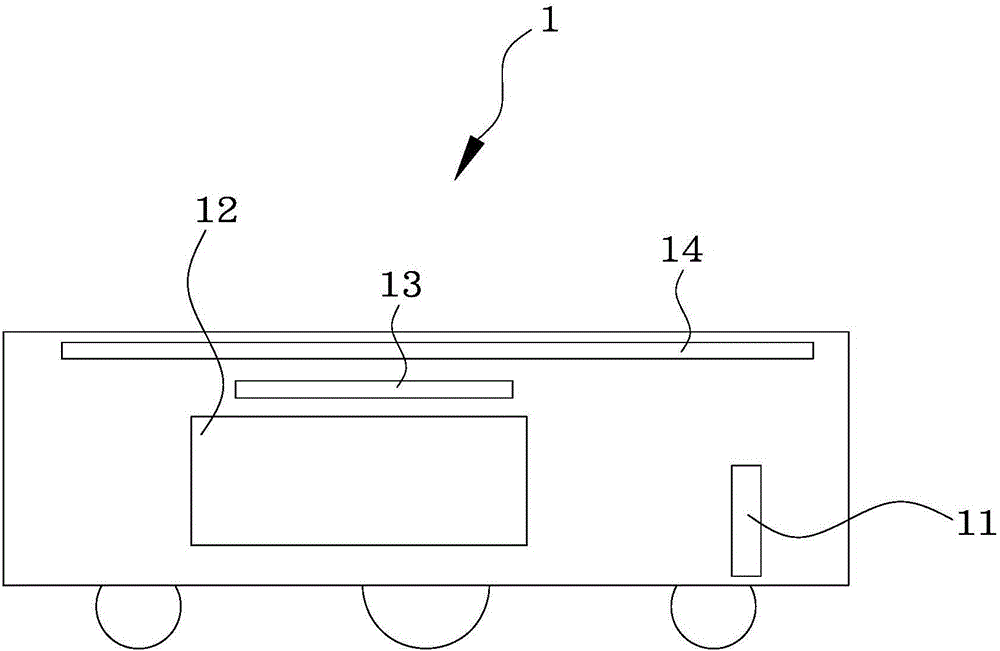

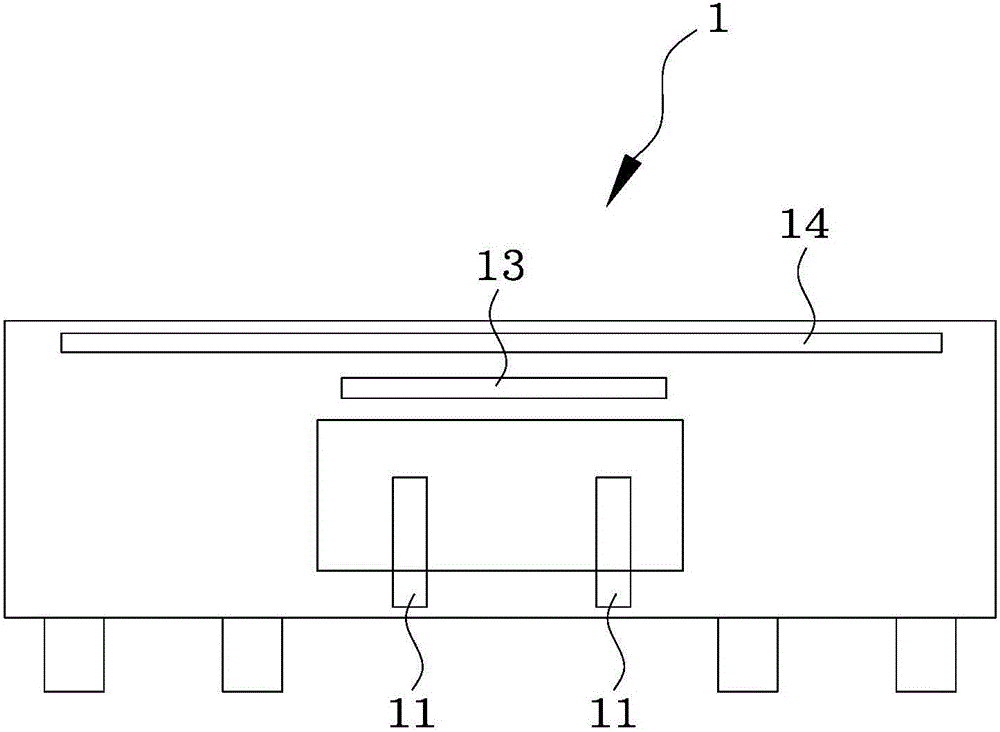

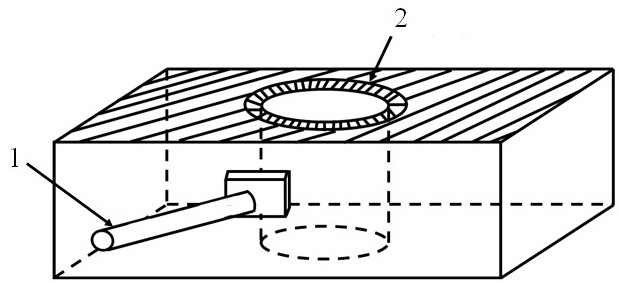

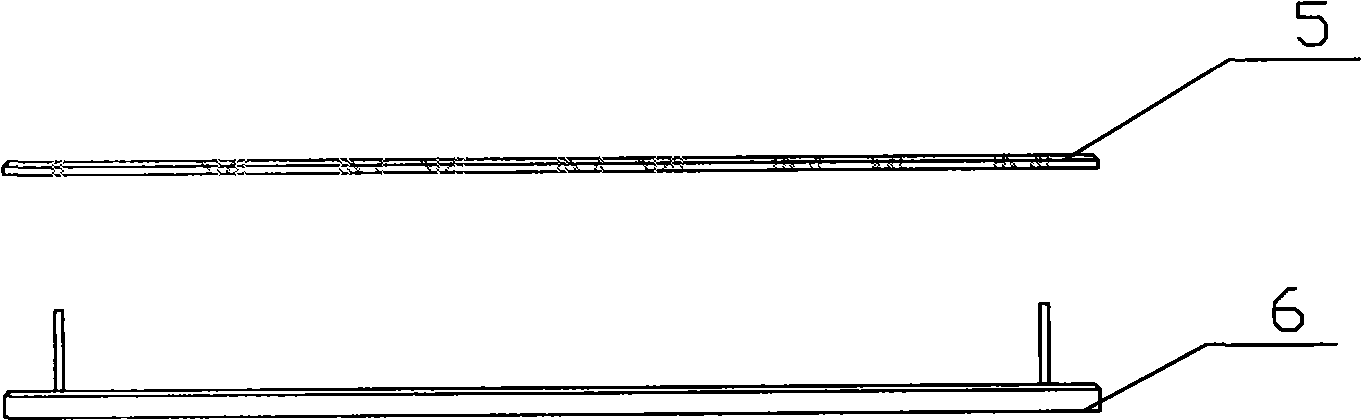

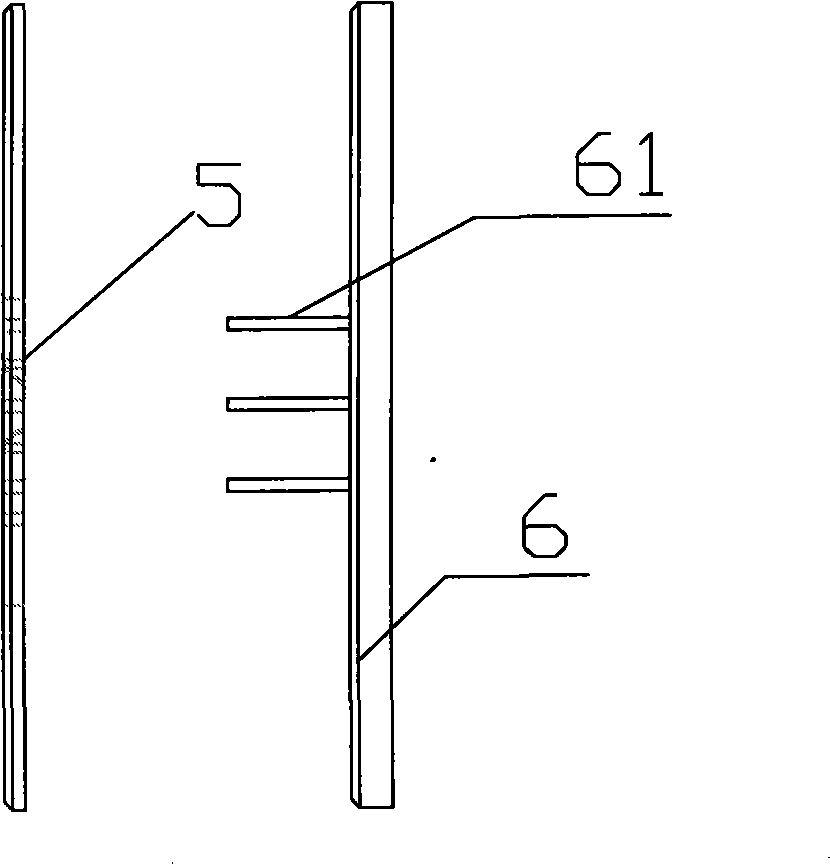

Mobile robot system and autonomous charging method thereof

The invention provides a mobile robot system and an autonomous charging method thereof. The mobile robot system comprises a robot body and a charging adapter. The robot body comprises a charging contact point, an energy storage module and a master control module. The charging contact point is configured to be able to extend to the exterior of the body or retract to the interior of the body. The energy storage module is used for providing a cruising capability for normal operation of the body. The master control module is connected with the energy storage module. The charging adapter comprises a sensing recognition module and a branch control module. The branch control module communicates with the master control module. When the robot body is in a charging state, the charging contact point extends to the exterior of the body and contacts the charging adapter. When the robot body stops charging, the charging contact point retracts to the interior of the body. Compared with the prior art, the charging point of the robot body is configured to be telescopic and is avoided to be exposed outside all the time, and abrasion, oxidation, poor contact and the like are reduced.

Owner:SHANGHAI SLAMTEC

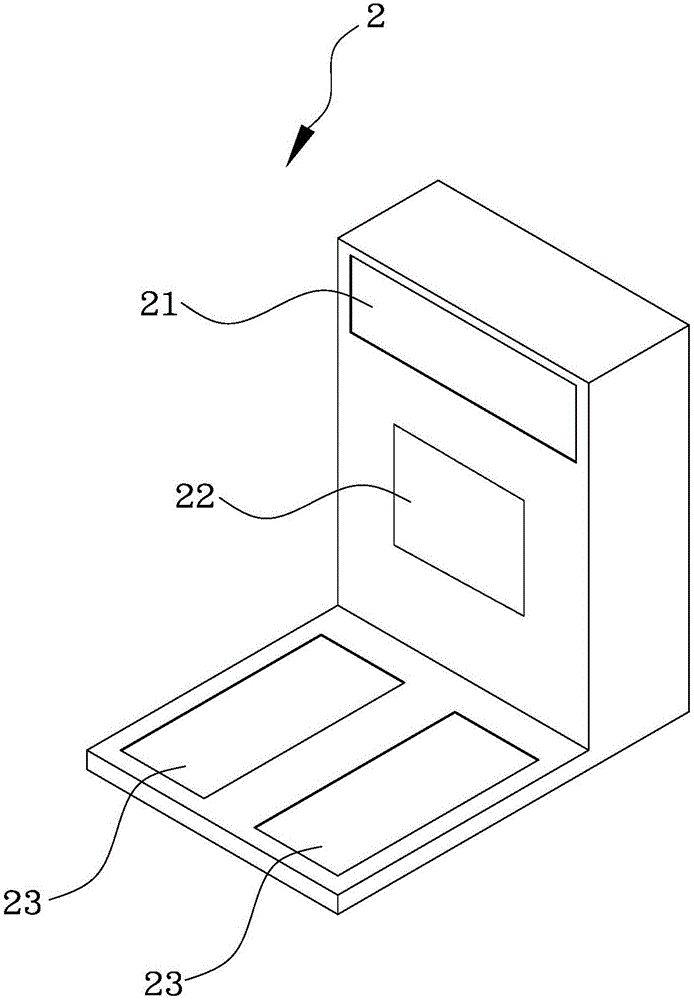

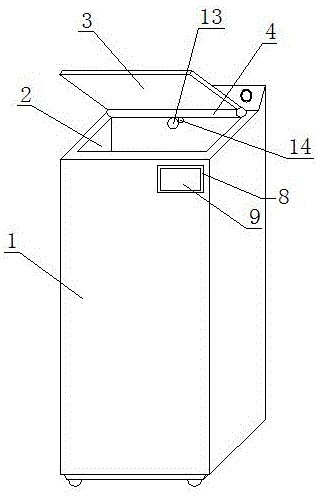

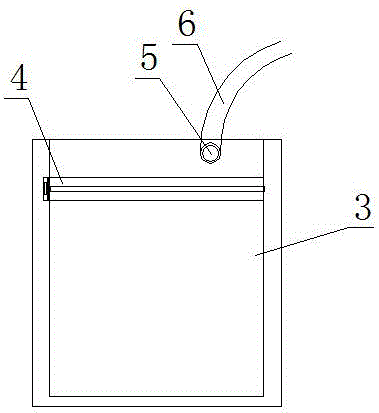

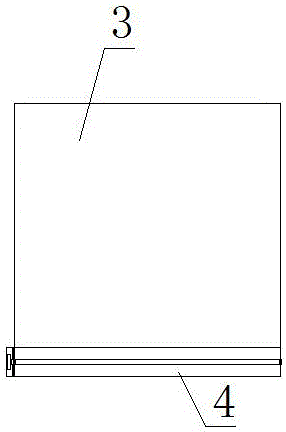

Intelligent washing machine and using method thereof

ActiveCN105002698AAvoid nudityExtend your lifeOther washing machinesControl devices for washing apparatusPulp and paper industryEngineering

The invention belongs to the technical field of household electrical appliances, and particularly relates to an intelligent washing machine and a using method thereof. The intelligent washing machine comprises a washing machine body, a control device and a machine cover opening device, wherein the washing machine body comprises a wash bucket, a machine cover and a camera; the machine cover is arranged at the top of the washing machine body; the wash bucket is arranged inside the washing machine body; the camera is arranged below the machine cover and towards the interior of the wash bucket; an LED light is arranged beside the camera; a touch screen is embedded and totally hermetically mounted in a separate groove with good moisture transpiring capacity in the washing machine body, and a main control chip is placed inside the washing machine body; the two parts are separated, so that the situation that moisture in the wash bucket influences the circuit, and further results in electric leakage, power failure and unclear display is avoided. After clothes washing, the washing machine sends the information to a user to remind the user, and the machine cover is automatically opened, so that bacterium breeding is avoided, and the washing machine is healthier and more reasonable.

Owner:HANGZHOU NAPA TECH

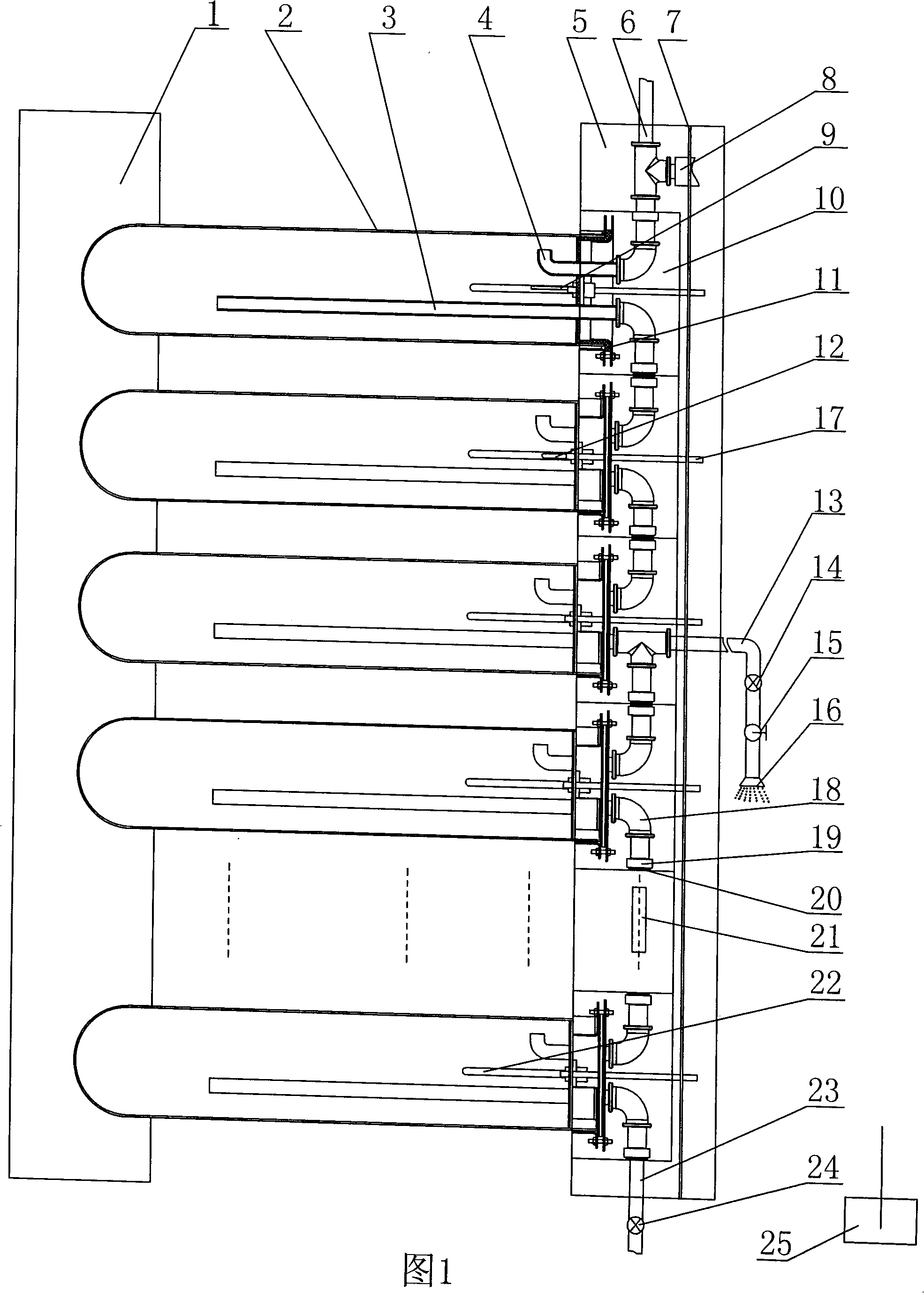

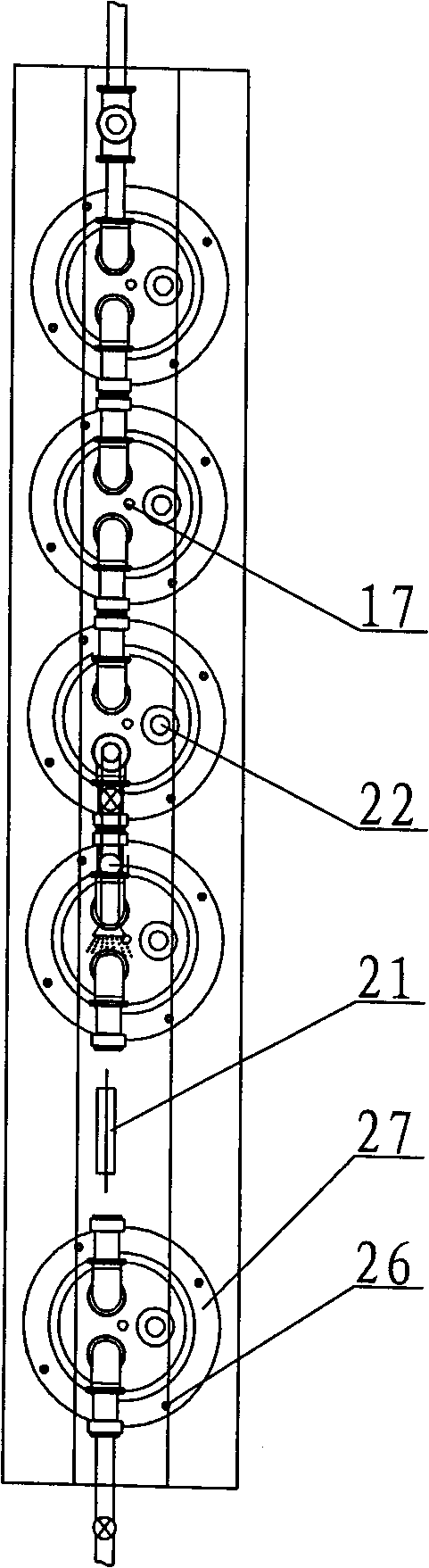

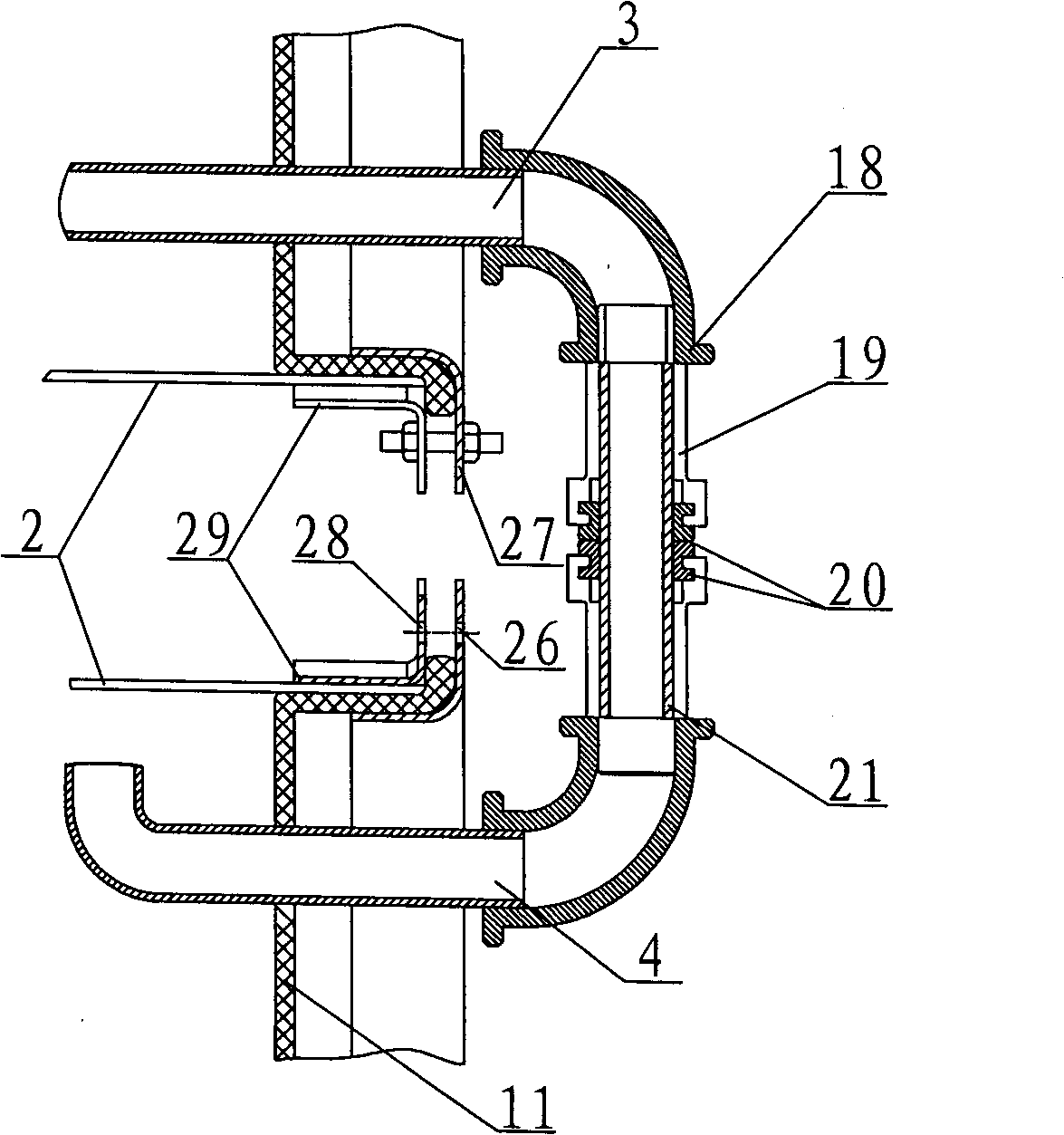

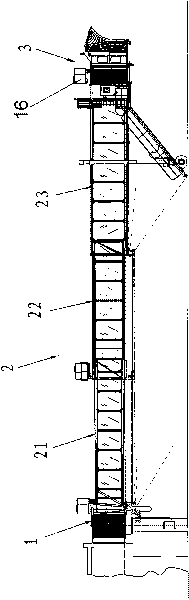

Modular non-water tank solar water heater

InactiveCN101349481AAvoid damageExtended service lifeSolar heating energySolar heat devicesSolar waterEngineering

The invention relates to a modular solar energy water heater without a water tank, which comprises vacuum glass insulation modules, wherein the vacuum glass insulation module is mainly composed of a glass vacuum pipe, a sealing pipe plug inserted in the mouth of the glass vacuum pipe, a water inlet pipe, a water outlet pipe and an electric heating pipe which penetrate through the sealing pipe plug, a pressure ring, an 'L'-shaped fastening seat, an elbow, a splicing head and polyurethane insulation blocks, the mouths of the water inlet pipe and the water outlet pipe extending out of the mouth of the sealing pipe plug are respectively connected with the elbow, and adjacent vacuum glass insulation modules are respectively spliced with a same splicing pipe via the splicing head. The modular solar energy water heater without a water tank utilizing a module splicing mode is convenient in mounting and maintenance, compact in structure, stable in sealing and fine safety property, can constantly provide hot water with stable temperature, can be perpendicularly and obliquely placed on the roof of a building, also can be mounted on a wall or be embedded in a wall of a building, is flexible in mounting, is convenient for forming a complete set with a building integrally, and is wide in application range.

Owner:黄永生

Improved boarding bridge

ActiveCN101734378AAvoid nudityEliminate potential safety hazardsPassenger handling installationsMechanical engineeringEngineering

Owner:THYSSENKRUPP AIRPORT SYSTEM (ZHONGSHAN) CO LTD

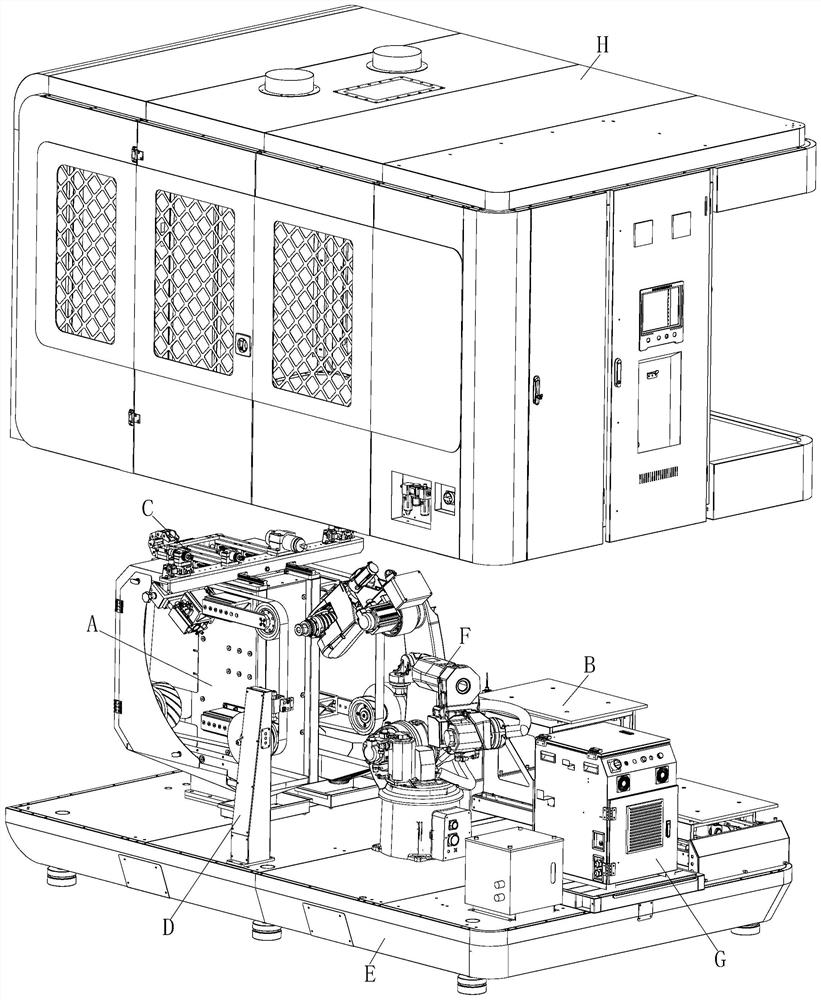

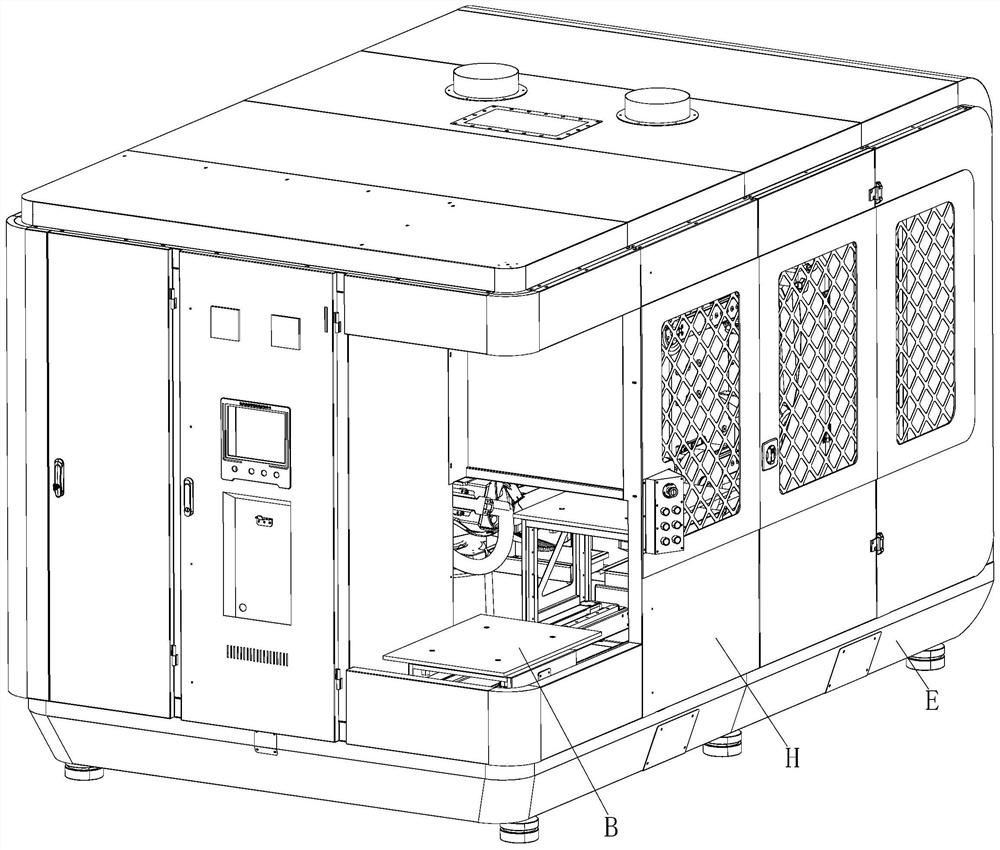

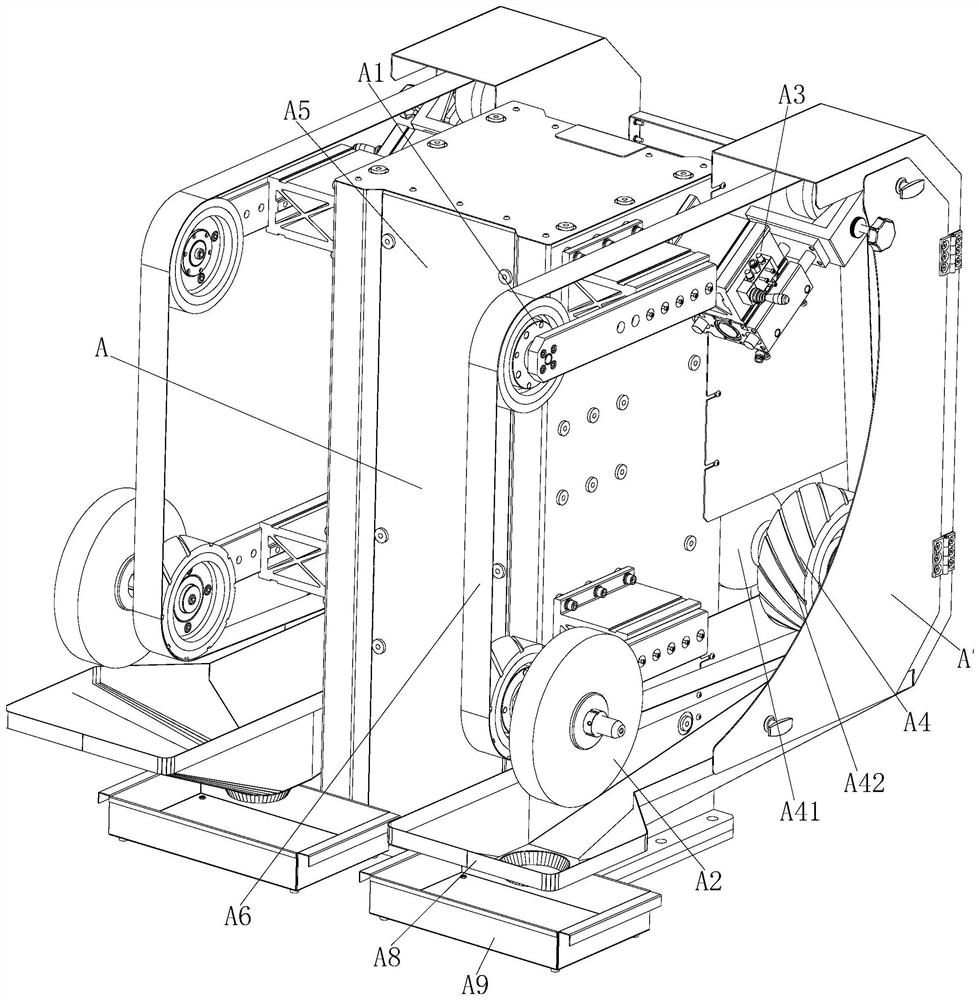

Polishing equipment and working method thereof

The invention relates to polishing equipment and a working method thereof, and belongs to the field of mechanical equipment. The problems that the polishing equipment in the prior art is unreasonablein layout, so that the work efficiency is reduced, the polishing effect is not ideal, most of bases are made of steel, large vibration and noise are generated in the operation process, meanwhile, thestructure of a material table driving device is relatively complex and the production cost is high are solved. The polishing equipment comprises a manipulator, a control cabinet and an equipment outercover, and is structurally characterized in that a belt sander, a double-layer material table and an equipment base are further included, the belt sander, the manipulator and the control cabinet areall located in the equipment outer cover, the belt sander and the double-layer material table are both matched with the manipulator, and the belt sander, the double-layer material table, the manipulator, the control cabinet and the equipment outer cover are all installed on the equipment base. According to the polishing equipment and working method thereof, programs are set through the control cabinet, and workpieces located on the double-layer material table are placed on the belt sander through the manipulator to be polished.

Owner:杭州龙砺智能科技有限公司

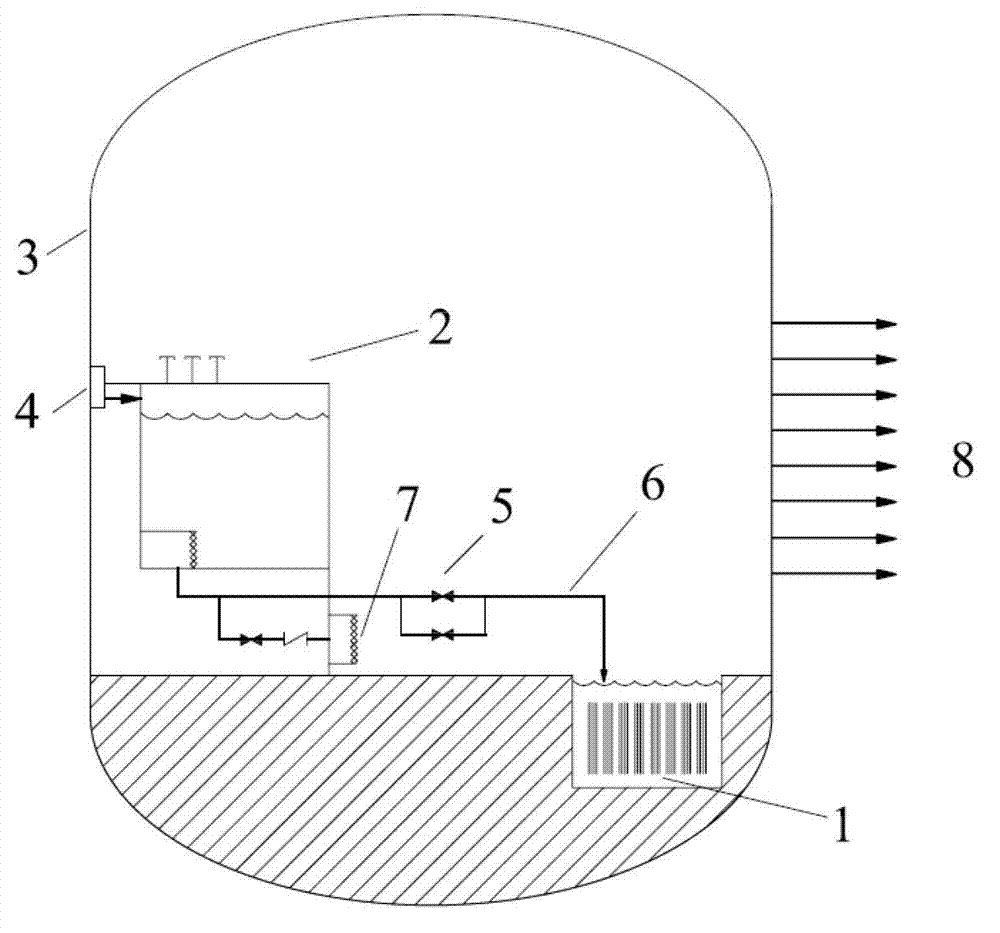

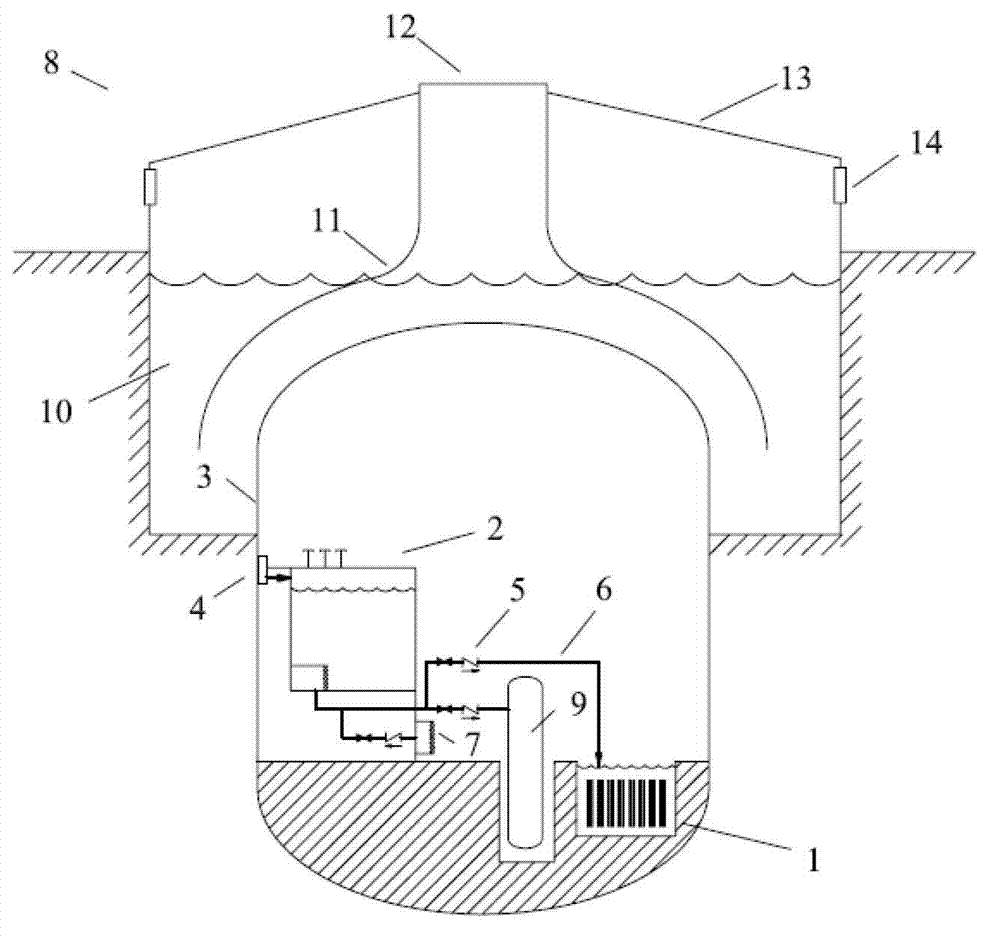

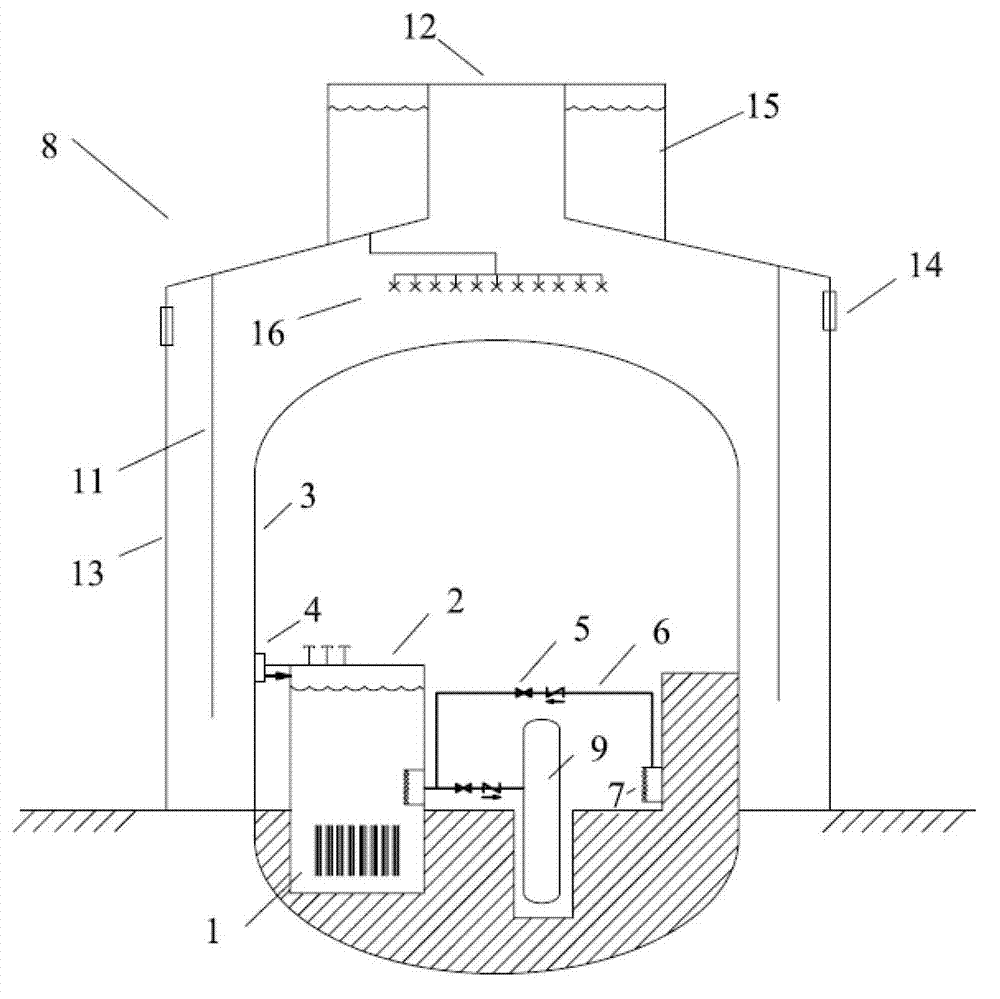

Containment built-in spent fuel pool

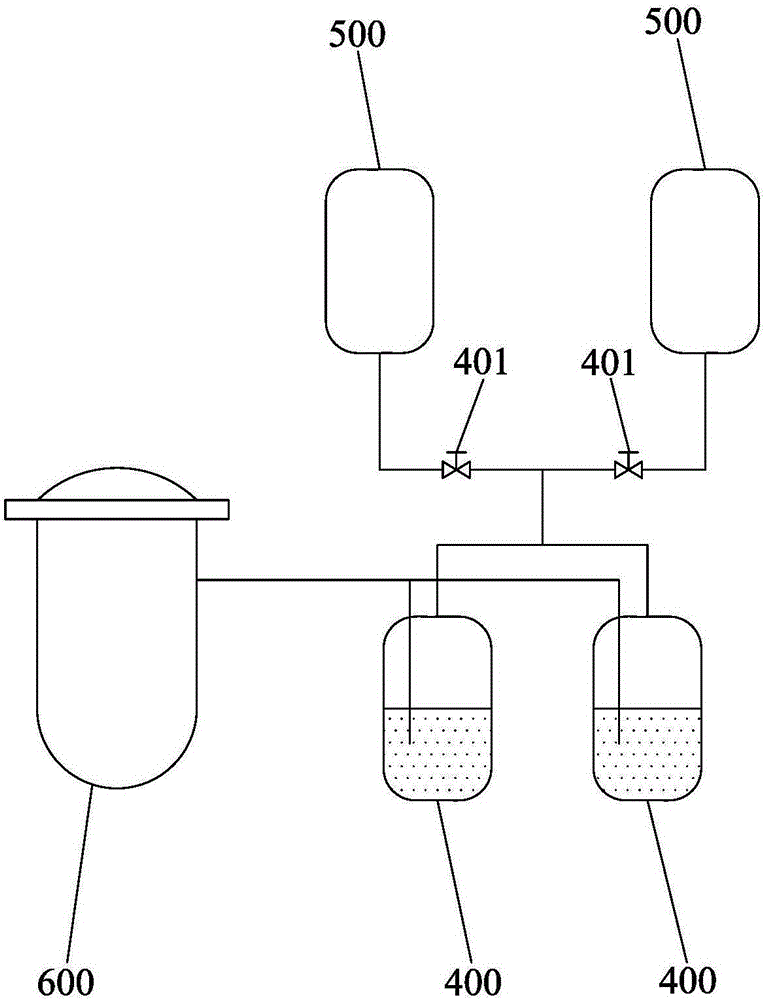

ActiveCN103928069AImprove air cooling efficiencyEnsure safetyNuclear energy generationReactor fuel elementsDesign technologyCondensed water

The invention belongs to the technical field of nuclear power plant spent fuel pools and safe protection measure design thereof, and particularly relates to a containment built-in spent fuel pool, which comprises a spent fuel pool, a containment built-in water tank, a containment shell, a condensed water collector, valves, pipelines, a recirculation port and a containment cooling system, wherein the spent fuel pool and the containment built-in water tank are arranged inside the containment and are connected, the top of the containment built-in water tank is provided with the condensed water collector, the condensed water collector is connected with the inner wall of the containment shell, the lower end of the containment built-in water tank is connected with a reactor pressure vessel through the pipeline, the pipeline is provided with the valve, the recirculation port is connected on the outlet pipeline of the containment built-in water tank, and the containment cooling system is arranged on the outer portion of the containment shell. According to the present invention, the passive manner is adopted to cool the spent fuel without dependence on the external power supply so as to improve safety of the spent fuel pool under accidents and ensure radioactivity packaging and safe cooling of the spent fuel.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

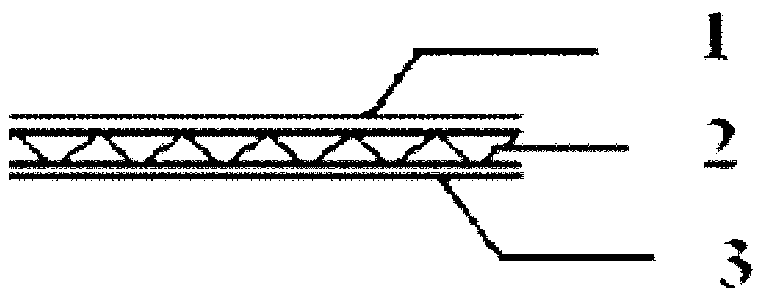

Electrode sheet and lithium ion battery

InactiveCN105655540AReduce edge sheddingImprove adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryColloid

The present invention provides an electrode sheet and a lithium ion battery. The electrode sheet comprises a current collector and an active-material-containing active material layer arranged on at least a surface of the current collector, wherein the electrode sheet further comprises an insulating colloid substance coated on at least an edge of the active material layer. The lithium ion battery comprises the electrode sheet. According to the present invention, the insulating colloid substance is coated on at least an edge of the active material layer, can enhance the adhesion between the edge of the active material layer and the current collector, and can reduce the shedding of the edge of the active material layer, such that the metal exposing of the current collector due to the shedding of the edge of the active material layer can be avoided, and the battery micro-short circuit caused by burr produced during the electrode sheet cutting process can be avoided so as to improve the safety performance of the lithium ion battery using the electrode sheet.

Owner:CONTEMPORARY AMPEREX TECH CO

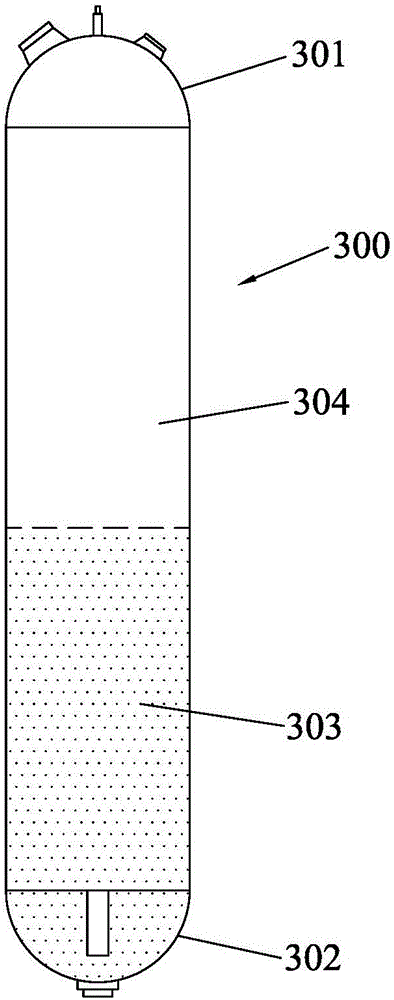

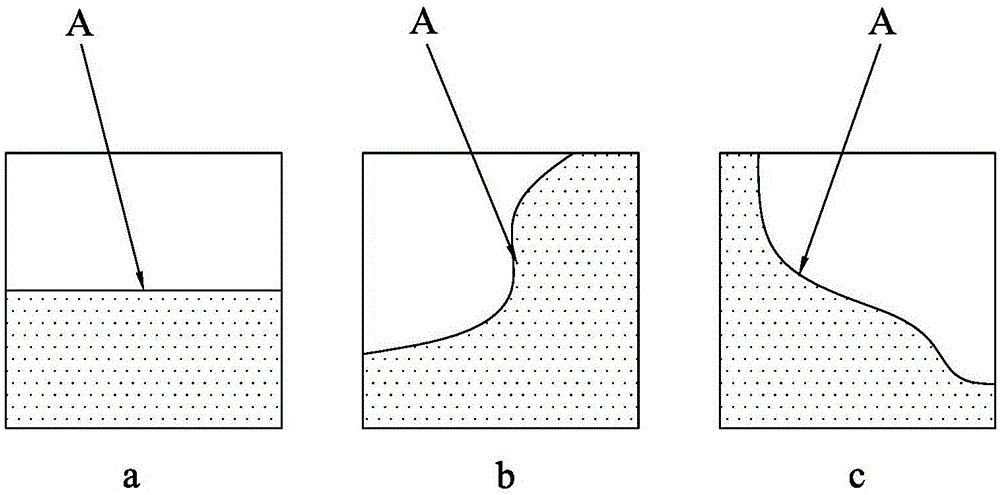

Nuclear power plant voltage stabilizer for inhibiting liquid level sloshing

InactiveCN106024074ASimple structureEasy to processNuclear energy generationHeterogenous reactorsNuclear plantNuclear engineering

The invention discloses a nuclear power plant voltage stabilizer for inhibiting liquid level sloshing. The voltage stabilizer comprises a voltage stabilizer main body, the upper portion of the voltage stabilizer main body serves as a gas storage space, the lower portion of the voltage stabilizer main body serves as a liquid storage space, a plurality of spacing boards for preventing liquid sloshing are arranged in the voltage stabilizer main body, and the spacing boards are arranged at intervals. The voltage stabilizer is suitable for being used in a marine environment, has a good sloshing inhibiting effect and effectively enhances the environmental adaptive capacity of a nuclear power plant.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Intelligent force testing device of steel pipe scaffold based on wireless transmission

InactiveCN102087151AOvercoming the Vulnerability DeficienciesSo as not to damageTransmission systemsForce measurement by elastic gauge deformationWireless transmissionComputer module

The present invention discloses a wireless transmission device for a steel pipe scaffold bearing test. The wireless transmission device comprises a wireless signal receiving and processing module, a power supply, a sensing element, an analog-to-digital conversion module, an intelligent logic module and a wireless signal transmission module; wherein the sensing element, the analog-to-digital conversion module, the intelligent logic module and the wireless signal transmission module are electrically connected in proper order; the sensing element is arranged on the external surface of the end portion of a steel pipe; the lead-out / lead-in wires of the sensing element are connected with other elements in the steel pipe through the steel pipe port; through holes are arranged on the shell of the steel pipe; and the wireless signal transmission module includes a transmitting antenna which is exposed from the steel pipe by means of the through holes. The wireless sensing device provided by the present invention adopts a mode that wireless elements and circuit elements are built-in so as to prevent the circuit from exposing and to overcome the shortage that a transmission cable is prone to breakage when the current pressure transducer carries out a bearing test for the steel pipe scaffold.

Owner:CHONGQING NO 3 CONSTR

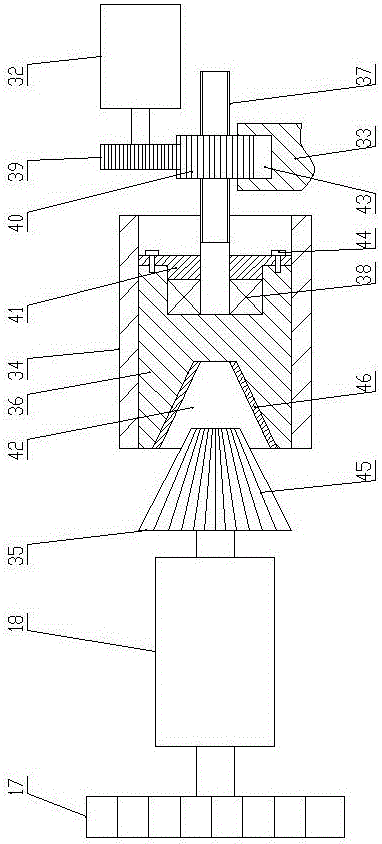

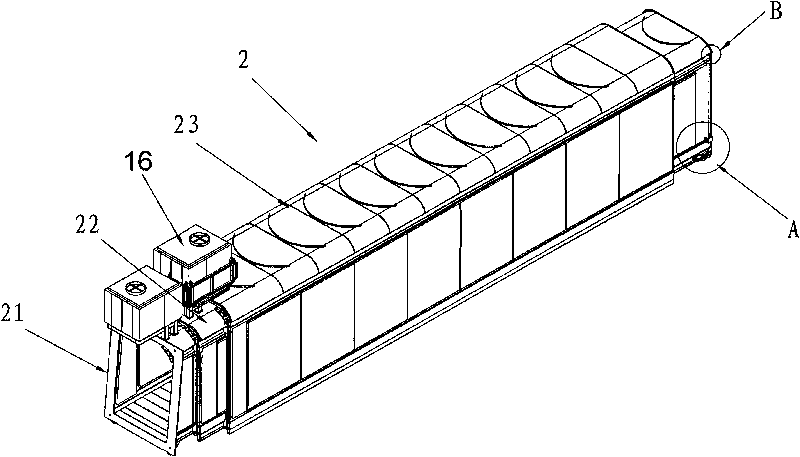

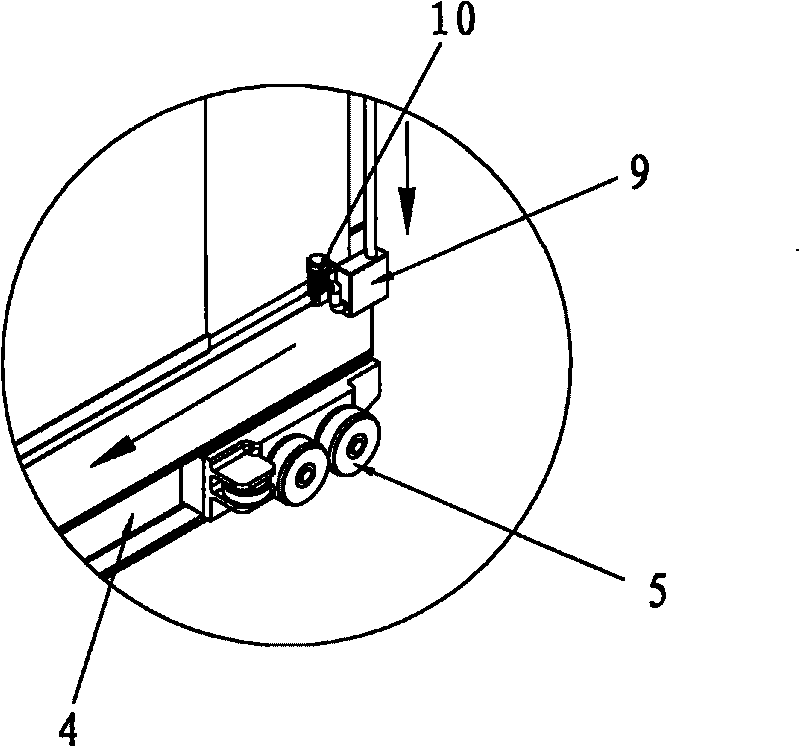

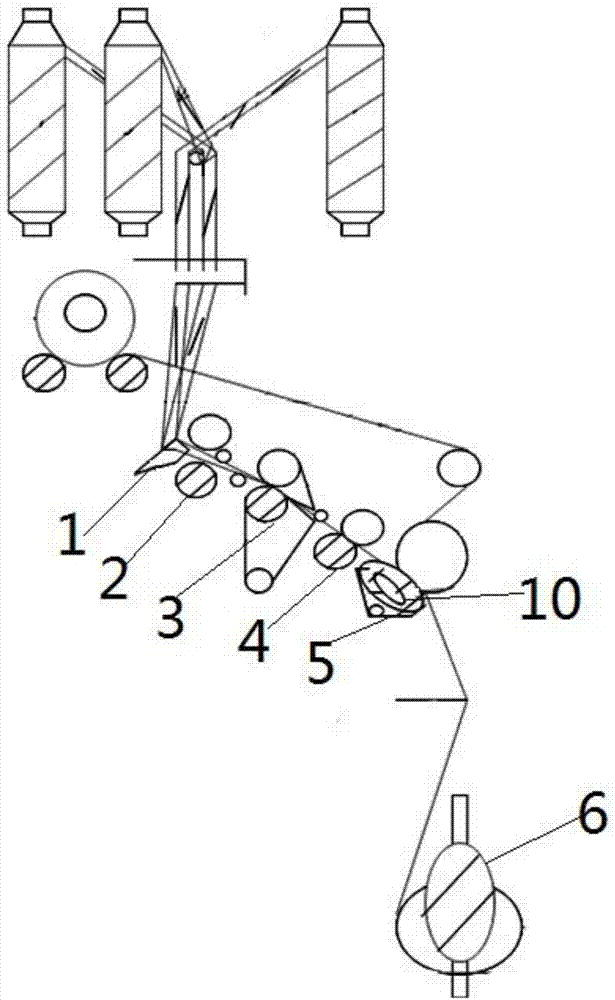

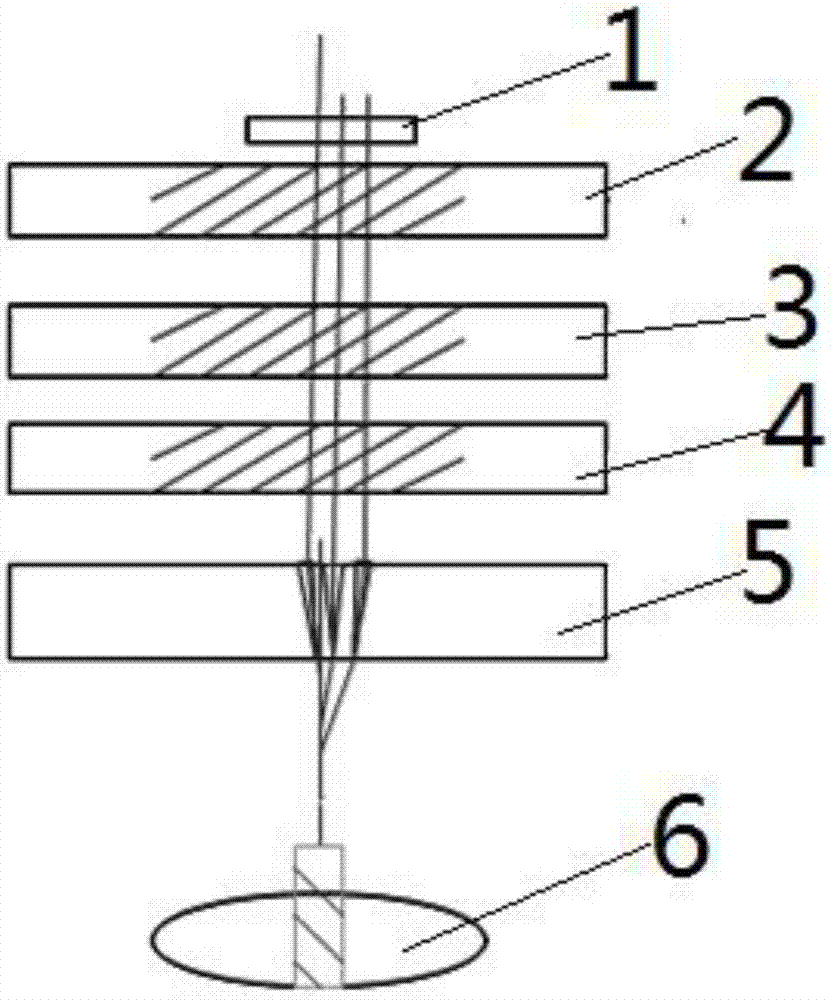

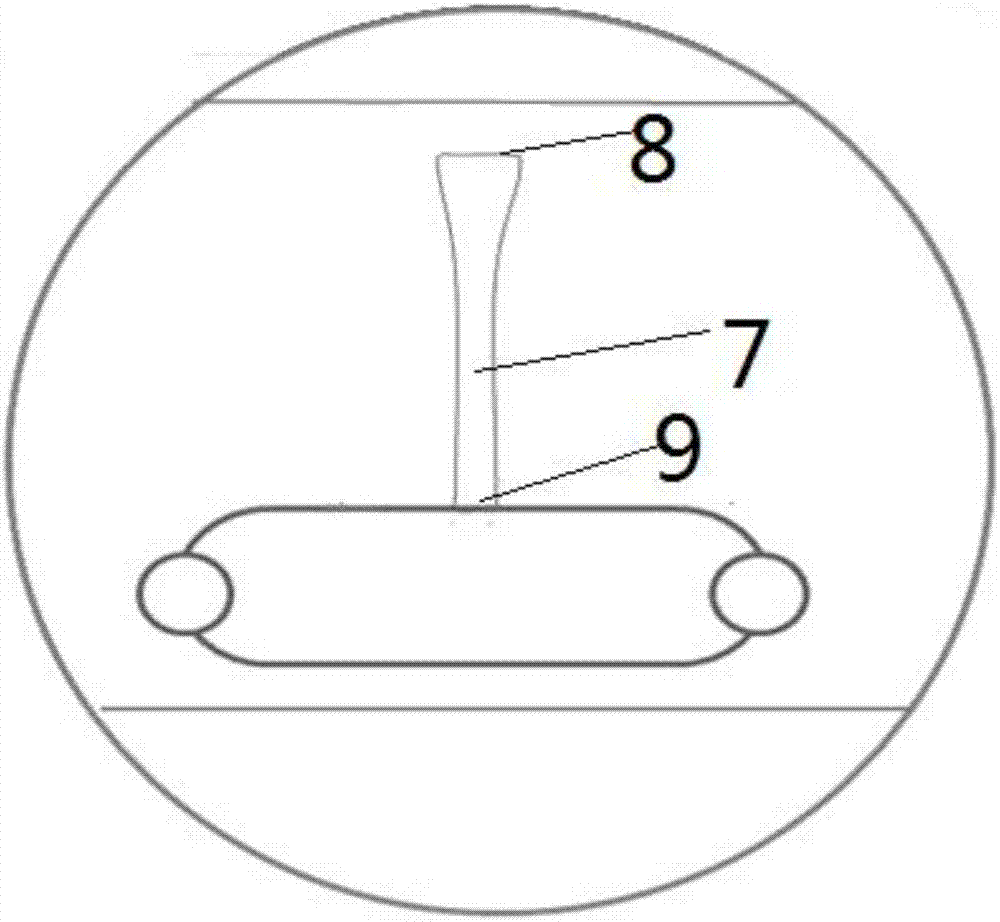

Covering yarn production device and method

The invention relates to the technical field of textile manufacturing and processing, in particular to a covering yarn production device and method. In order to solve the technical problem that an existing compact spinning cotton web is too narrow to benefit filament covering, so that the quality of covering yarn is affected, the covering yarn production device comprises a flare opening, a first roller, a second roller, a third roller, a negative pressure pipe and a ring from top to bottom in sequence. A groove formed in the ring comprises a first end opening and a second end opening, wherein the first end opening is formed above the second end opening, and the width of the first end opening is larger than that of the second end opening. Fiber strands are subjected to drafting, stretching and reducing and then fed into the groove, namely a negative-pressure suction port, a filament volume is subjected to active unwinding and rotation of a loading roller, filaments are drawn forth, the filaments pass through a filament guide wheel and then are fed into a compact spinning leather roller, the compact spinning leather roller applies pressure on the negative-pressure suction port, core yarn covering is facilitated, filament covering cotton is avoided from being exposed to the outside, and the production quality of the covering yarn is improved.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

Method for making metalized half hole

ActiveCN104853544AAvoid nudityNot easy to damagePrinted element electric connection formationCopperMetal

The invention introduces a method for making a metalized half hole. The method comprises the steps of filling the position of a metalized half hole to be machined of a printed board with tin in the production process of the printed board after completion of photosensitive resistance welding, milling the half hole according to the design requirements, and performing hot air leveling. As lead tin in the hole supports a copper layer in the hole, hole wall copper skin upwarp and burr residual problems of the metalized half hole after forming can be avoided effectively. Excess solder in the position of the metalized half hole is removed naturally in the process of hot air leveling. The cut of the metalized half hole is coated with solder to avoid copper bareness. The process is simple, lines are not easy to damage, control is easy, and the production efficiency and quality of metalized half hole circuit boards are improved.

Owner:LUOYANG WEIXIN ELECTRONICS TECH

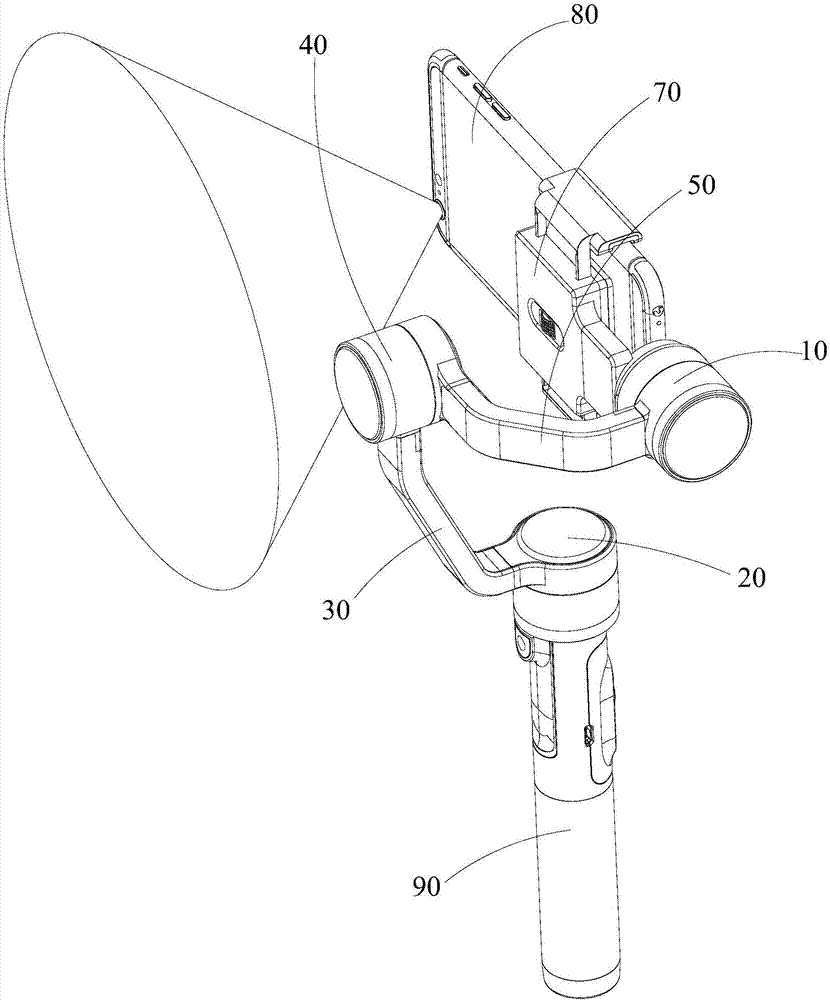

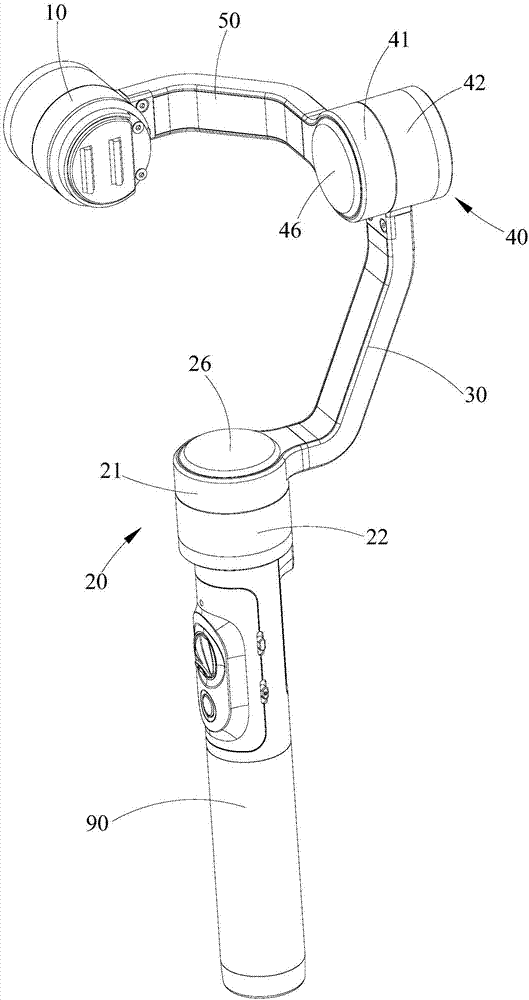

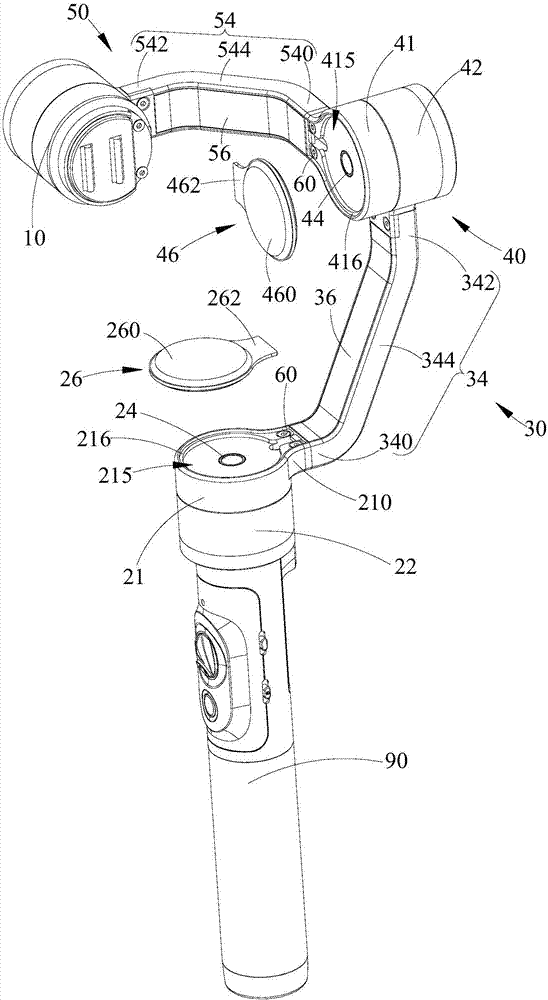

Three-axis holder device

ActiveCN106870891AAvoid nudityGuaranteed stabilityStands/trestlesCamera body detailsVertical channelElectrical and Electronics engineering

The invention is suitable for the technical field of holders, and provides a three-axis holder device. The three-axis holder device comprises a pitch axis motor, a heading axis motor, a rolling axis motor, a transverse connection arm with a transverse channel and a vertical connection arm with a vertical channel, wherein the pitch axis motor, the heading axis motor and the rolling axis motor are distributed in an orthorhombic manner in space. The heading axis motor comprises a heading axis rotor, a heading axis stator, a heading axis circuit board, a heading hollow shaft, a heading axis cover and an output wire. A heading channel is formed between the heading axis rotor and the heading axis cover. The vertical connection arm is fixedly connected to the heading axis rotor in the radial direction, and the heading axis cover covers the joint between the vertical connection arm and the heading axis rotor. The three-axis holder device utilizes the heading axis cover for covering the vertical connection arm and the heading axis rotor so that the vertical connection arm and the heading axis motor can be connected in the radial direction, the joint between the vertical connection arm and the heading axis rotor is prevented from being exposed, and the firmness and coordination of the joint between the vertical connection arm and the heading axis rotor are guaranteed.

Owner:SHENZHEN YUEJIANG TECH CO LTD

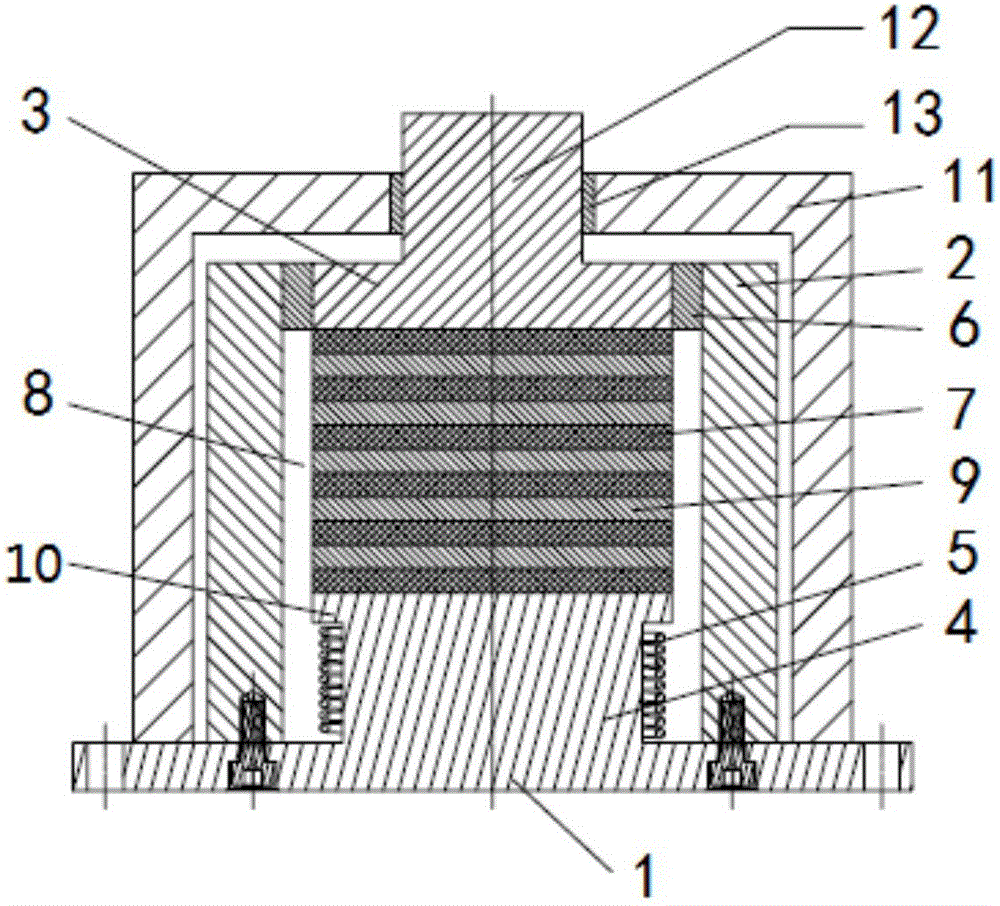

Compression-shear mixed multi-layer magnetorheological elastomer shock absorber

InactiveCN106321702AIncrease stiffnessExpand the scope ofRubber-like material springsLow internal friction springsElastomerEngineering

A compression-shear mixed multi-layer magnetorheological elastomer shock absorber comprises a magnetic conductive tube mounted on a base, a piston mounted in the magnetic conductive tube, a magnet exciting coil mounted on the outer wall of a mounting seat arranged on the base as well as magnetorheological elastomers, wherein the magnetorheological elastomers comprise a shear type first magnetorheological elastomer and compression type second magnetorheological elastomers; the first magnetorheological elastomer is mounted between the piston and the magnetic conductive tube; a shock absorbing layer structure is mounted between the mounting seat and the piston and comprises the second magnetorheological elastomers and magnetic conductive plates, and the second magnetorheological elastomers and the magnetic conductive plates are arranged alternately. According to the compression-shear mixed multi-layer magnetorheological elastomer shock absorber, under joint action of the shear type magnetorheological elastomer and the compression type magnetorheological elastomers, the adjusting ranges of the rigidity and damping of the shock absorber are increased, the shock absorbing effect is enhanced, and the shock absorber can attenuate vibration load of different frequency and amplitudes.

Owner:OCEAN UNIV OF CHINA

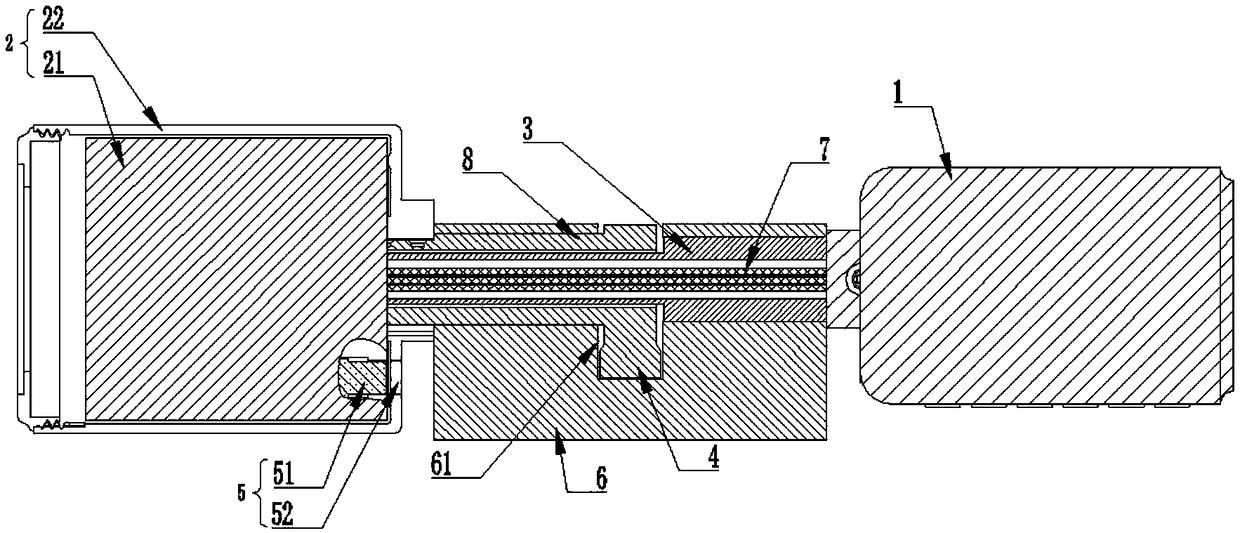

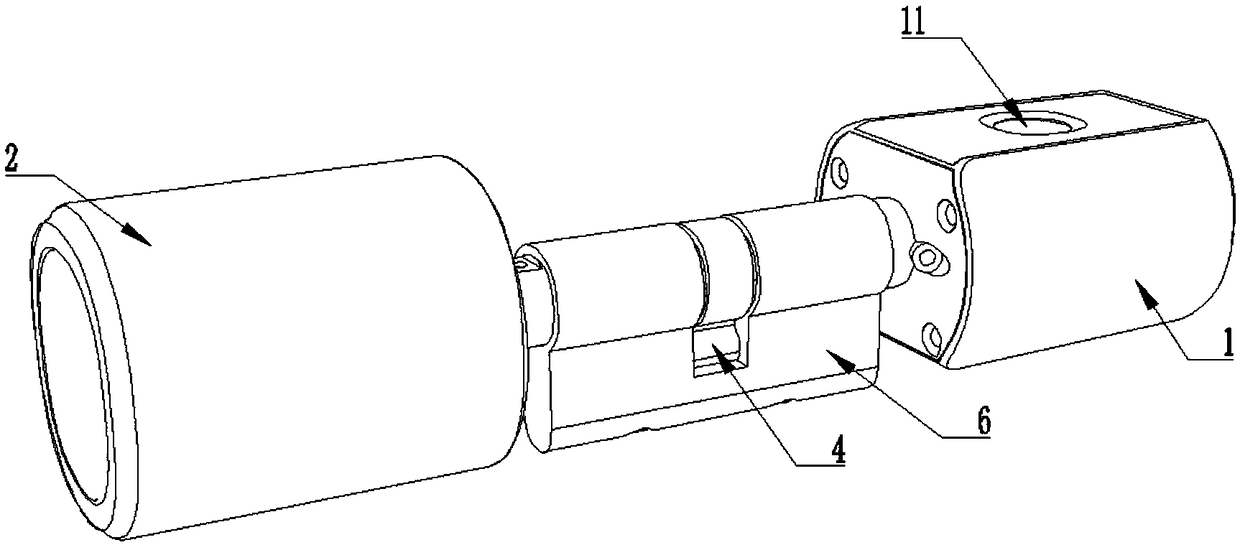

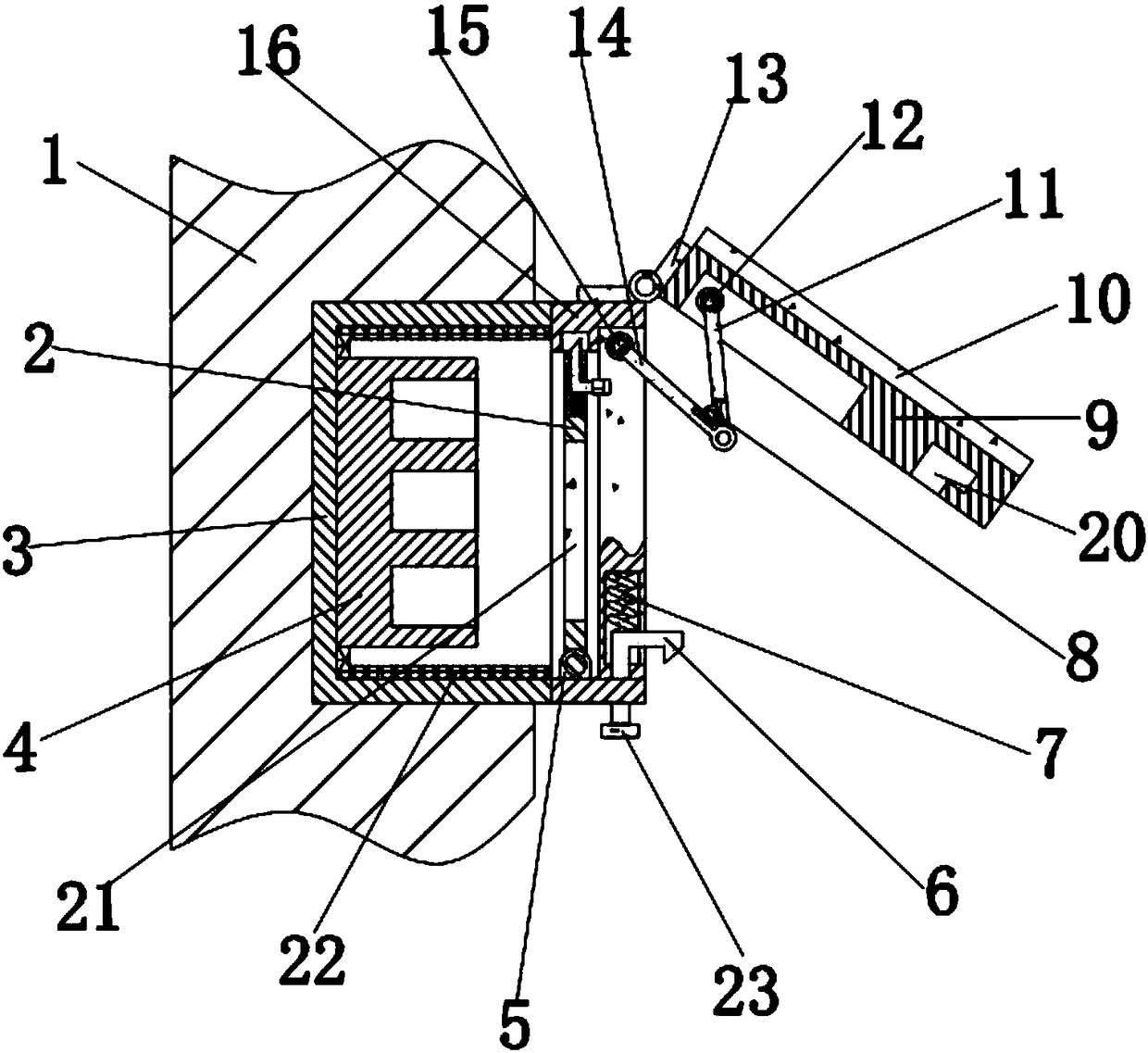

Lock cylinder structure for intelligent door lock, intelligent door lock and antitheft door

ActiveCN109025531AImprove protectionAvoid nudityBurglary protectionElectric permutation locksElectricityComputer module

The invention provides a lock cylinder structure for an intelligent door lock, the intelligent door lock and an antitheft door and belongs to the technical field of intelligent door locks. The lock cylinder structure comprises an outer handle assembly and an inner handle assembly and further comprises a linkage part and a separating-combining structure, wherein an information collecting module ismounted in the outer handle assembly and receives, collects and sends user information; the inner handler assembly comprises a first rotating part provided with a control module, and the control module is electrically connected with the information collecting module through a conducting wire; a shifting wheel is suitable for rotating relative to a lock box to achieve unlocking or locking; one endof the linkage part is connected with the outer handle assembly, and the other end of the linkage part is connected with the first rotating part; and the separating-combining structure is disposed between a linkage mechanism and the shifting wheel and is suitable for enabling the linkage mechanism to be in linkage with or be separated from the shifting wheel according to a control instruction. Bymeans of the lock cylinder structure provided by the invention, the conducting wire can be prevented from being twisted and cracked, and meanwhile the advantages of being high in forcible entry difficulty, long in service life, convenient in operation, high in adaptability and the like are achieved.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

Method for obtaining low-nitrogen steel by reducing nitrogen content in steel in electric furnace steelmaking process

ActiveCN112981038AReduce nitrogen uptakeGood emulsificationElectric furnaceSteelmakingElectric arc furnace

The invention relates to a method for obtaining low-nitrogen steel by reducing nitrogen content in steel in an electric furnace steelmaking process. The method comprises the following steps that in the smelting process of an electric arc furnace, a mode of mixed smelting of waste steel and molten iron is adopted, a rapid slagging technology is assisted, and silicon iron is added in the tapping process to carry out weak deoxidation on molten steel; in the LF refining procedure, a high-temperature-resistant material sealing sleeve is installed at an electrode opening, refining synthetic slag is added in the smelting process for slagging, and the appropriate bottom blowing argon flow is adjusted; in the VD vacuum treatment process, a high vacuum degree, treatment time prolonging and bottom blowing argon flow increasing strong stirring mode is adopted; and in the continuous casting process, protective pouring and immersion type sleeve sealing measures are adopted. According to the method, the nitrogen content in the steel is obviously reduced on the basis of molten steel nitrogen absorption and denitrification mechanisms and in combination with the operation characteristics of all the procedures, the method is easy to operate, nitrogen control of the whole process in the electric furnace steelmaking process is stable, and it can be effectively guaranteed that the nitrogen content in a finally obtained product is smaller than 30ppm.

Owner:UNIV OF SCI & TECH BEIJING

Household hidden-type power distribution box capable of preventing accidental touch

InactiveCN108336668AAvoid occupyingAvoid nuditySubstation/switching arrangement detailsEngineeringTorsion spring

The invention discloses a household hidden-type power distribution box capable of preventing accidental touch. The power distribution box includes a wall body and a box body; the box body is installedon the right side of the interior of the wall body, a base is installed on the left side of the interior of the box body, a frame is arranged on the right side of the wall body, and the box body penetrates through the wall body to be connected with the frame; a baffle is arranged on the left side of the interior of the frame and connected with the frame through a first support, and a first clamping hook is arranged on the right side of the interior of the frame. According to the household hidden-type power distribution box, through cooperation of the box body and the wall body, the power distribution box body can be hidden in the wall body; through cooperation of the baffle and the first support, children can be prevented from opening a pressing cover by accident; through cooperation of afirst connecting rod, a second connecting rod and a torsion spring, the pressing cover can be automatically pushed to rotate around a hinge and is maintained open; through cooperation of the pressingcover and a panel, the pressing cover can be shielded and hidden; through cooperation of a first clamping rod and a first compression spring, the pressing cover can be easily clamped and fixed.

Owner:湖州嘉和电脑技术服务有限公司

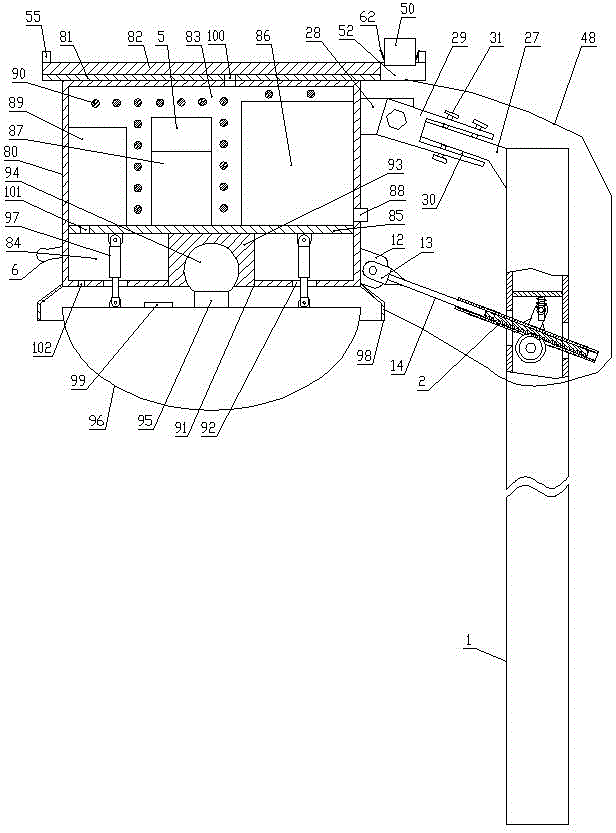

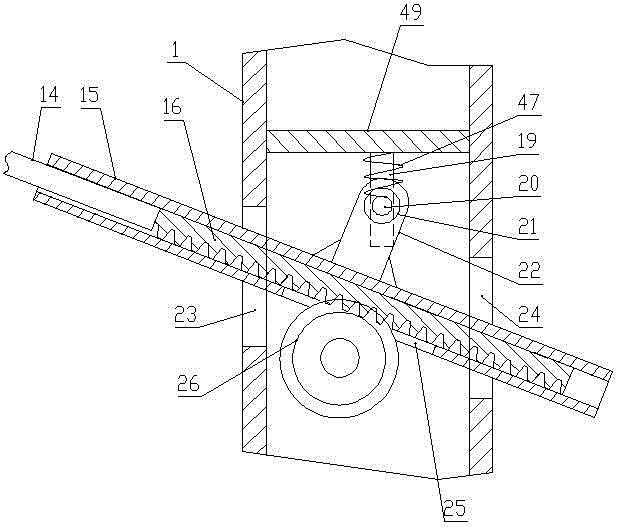

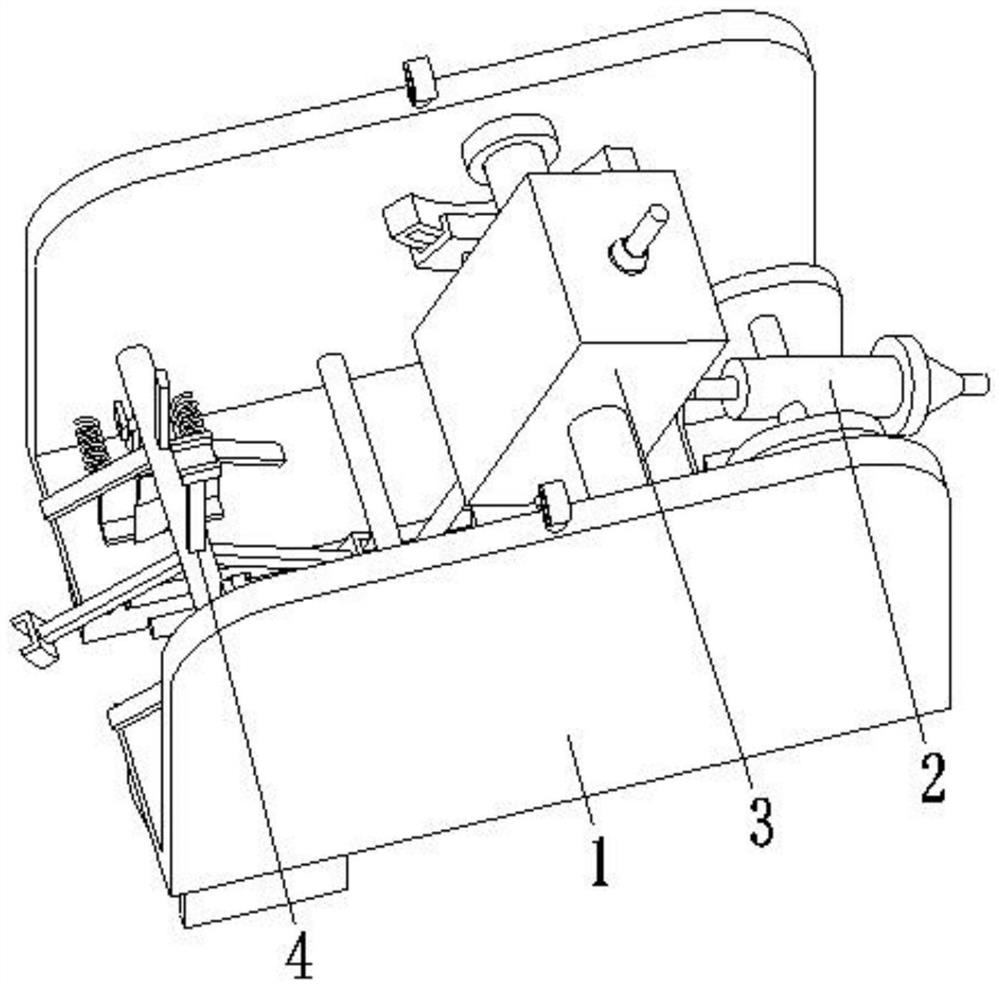

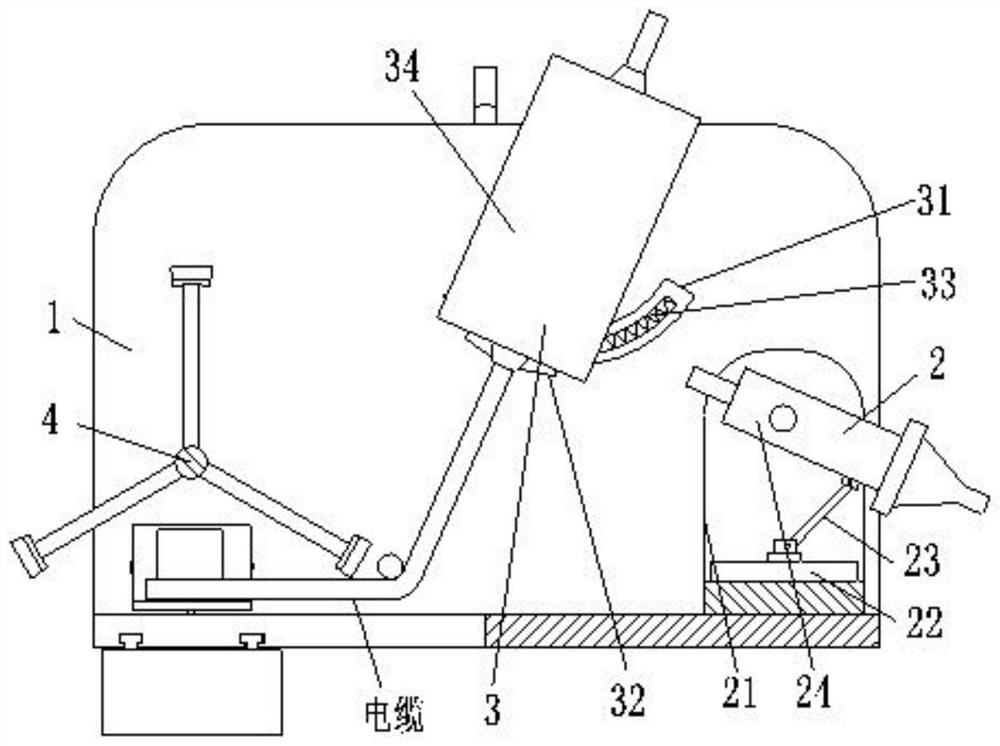

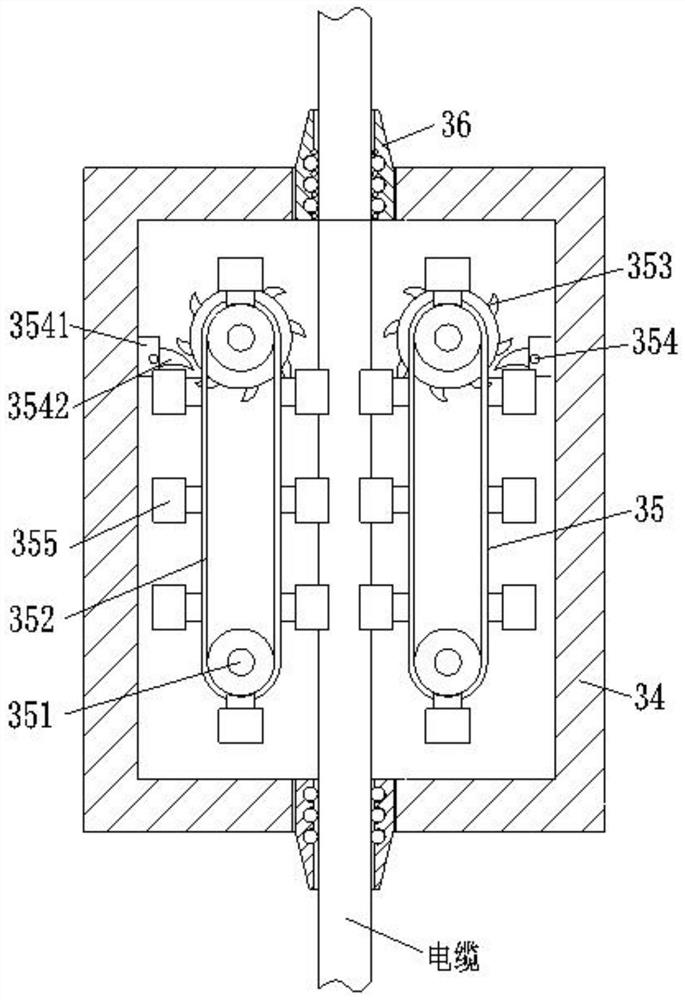

Marine submarine cable laying device and laying method thereof

InactiveCN112382988AEnsure safetyAvoid damageCable installations on groundApparatus for laying cablesStructural engineeringSubmarine cable

The present invention relates to a marine submarine cable laying device and a laying method thereof. The marine submarine cable laying device comprises a fixing frame, a slotting device, a cable pulling device and a landfill device, the fixing frame is of a U-shaped structure, and the slotting device is installed at the right side of the interior of the fixing frame. The cable pulling device is installed in the middle of the interior of the fixing frame, and the landfill device is installed at the left side of the interior of the fixing frame. The marine submarine cable laying device and the laying method thereof can solve the problems that when an existing device is used for laying submarine cables, the cable pulling effect is poor, slipping is likely to happen in the cable pulling process, a protection layer at the outer side of the cables is damaged, the service life of the cables is shortened; and when the existing device is used for laying the submarine cables, only the cables canbe laid on the submarine ground generally, and the cable cannot be protected, so that the cable is easily broken by external environmental factors, and the use effect of the cable is influenced.

Owner:杨定娟

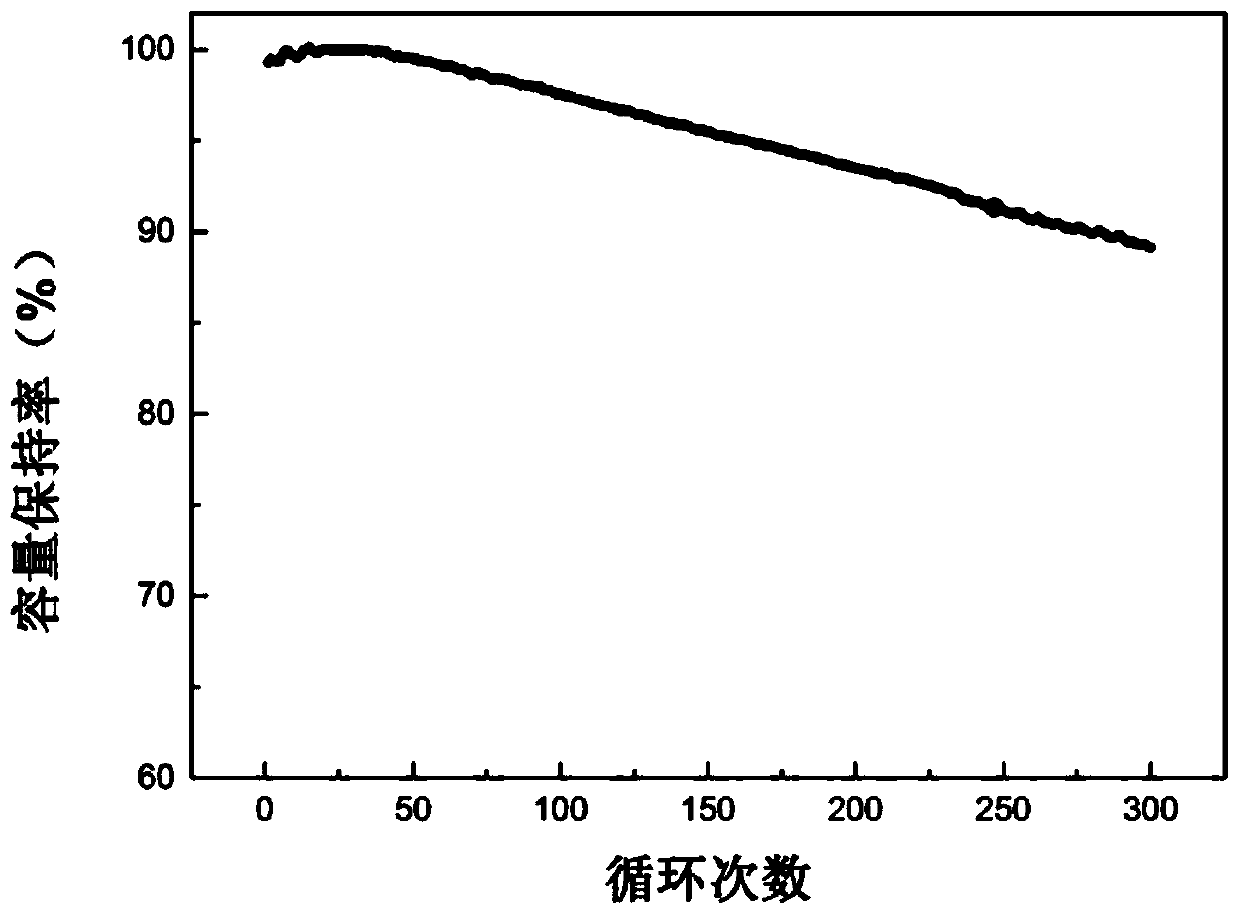

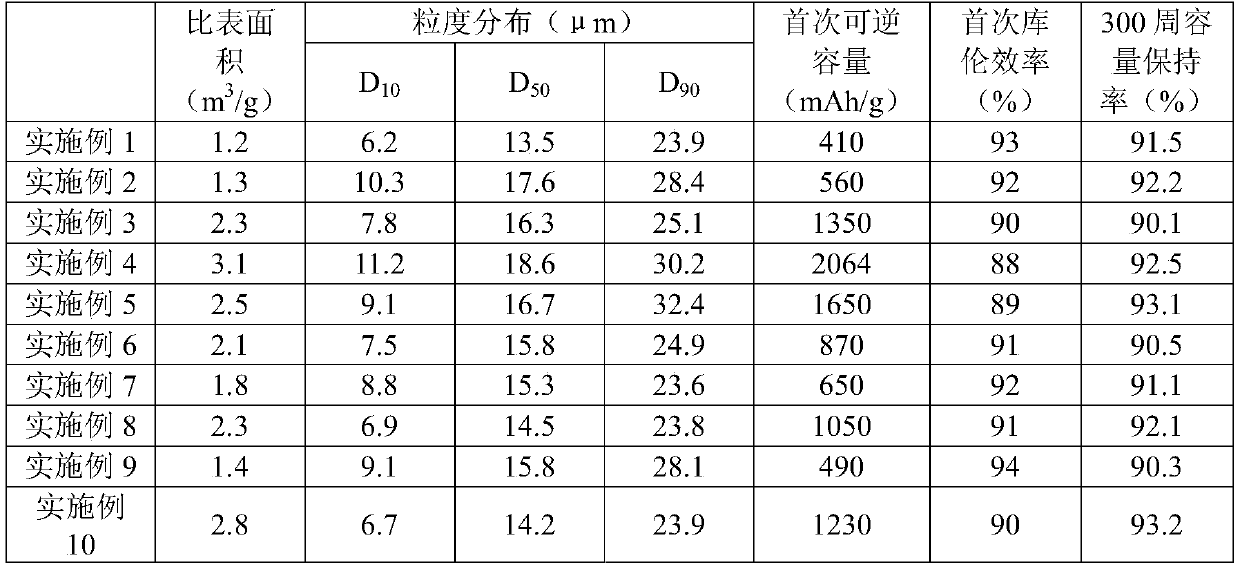

Silicon-carbon composite negative electrode material for lithium-ion battery and preparation method thereof

InactiveCN109755517AAvoid reunionPrevent floatingMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention provides a silicon-carbon composite negative electrode material for a lithium-ion battery and a preparation method thereof. The method includes steps: step 1, dispersing micron silicon in a solvent, and performing grinding to form nanometer silicon slurry; step 2, adding a carbon matrix, a binder and a conductive agent to the solvent for uniform mixing to obtain slurry 1, and addingthe nanometer silicon slurry in step 1 into the slurry 1 for uniform mixing to obtain slurry 2; step 3, drying the slurry 2 to obtain a precursor material 1, performing fusion on the precursor material 1 and a covering agent to obtain a precursor material 2, and placing the precursor material 2 in a protection atmosphere for thermal treatment to obtain a precursor material 3; step 4, crushing theprecursor material 3, mixing the crushed precursor material 3 with the covering agent, and performing high-temperature thermal covering to obtain a precursor material 4; and step 5, placing the precursor material 4 in the protection atmosphere for high-temperature carbonization treatment to obtain the silicon-carbon composite negative electrode material. According to the material and the preparation method thereof, the silicon-loaded carbon matrix is wrapped by conductive carbon so that direct contact of the silicon negative electrode and electrolyte is isolated, and the cycle performance of the battery is enhanced.

Owner:SHAANXI COAL & CHEM TECH INST

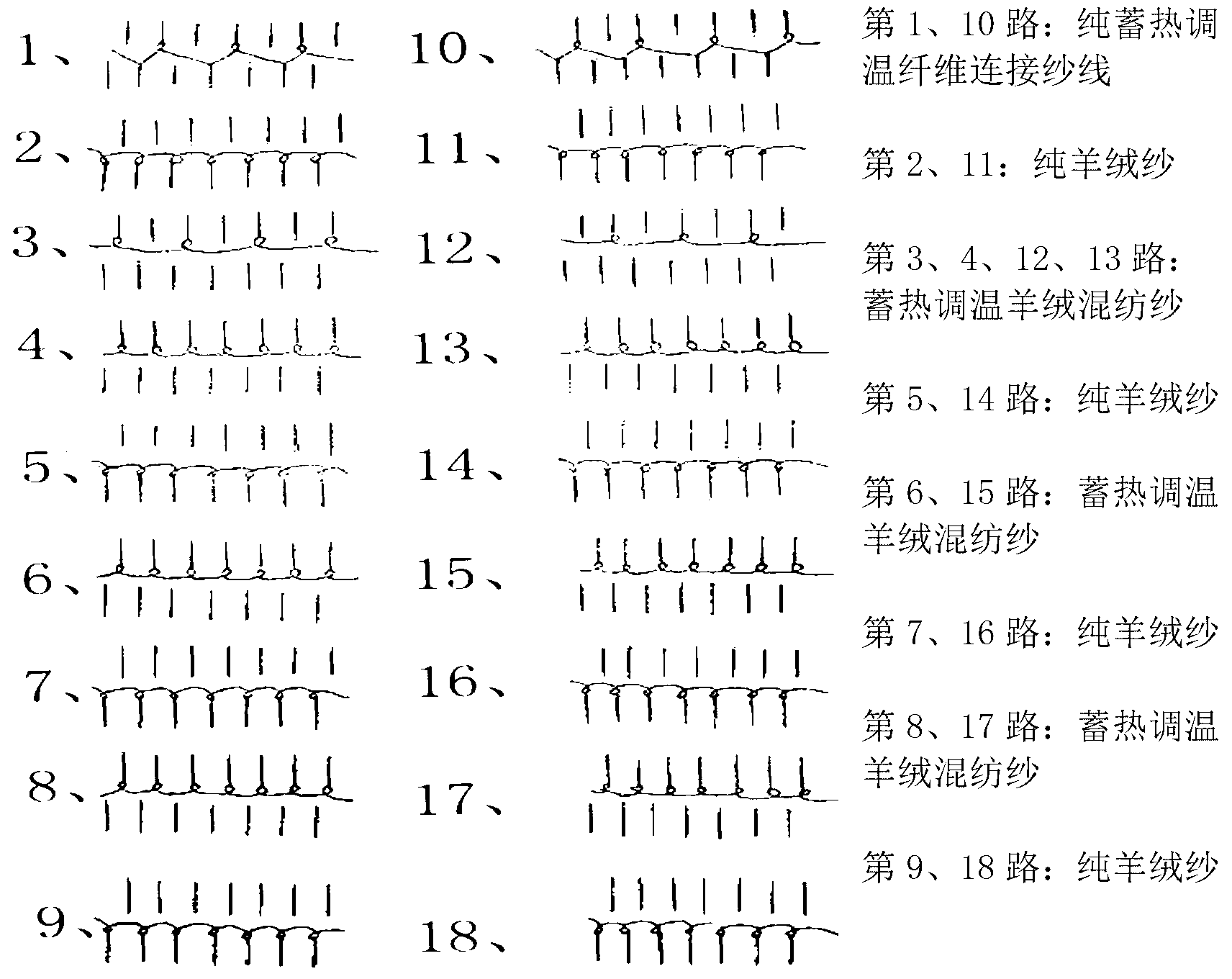

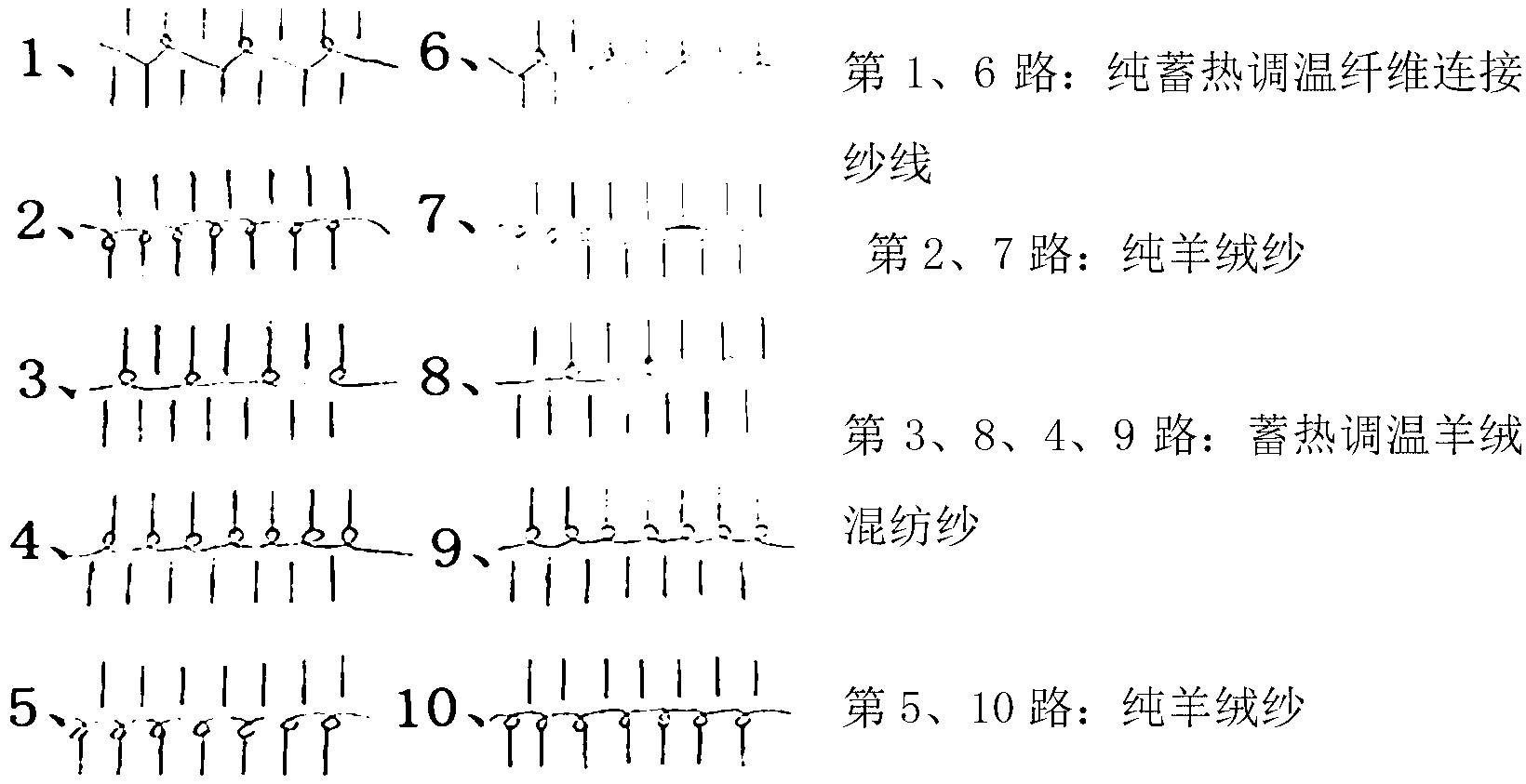

Double-layer knitted fabric and weaving method thereof

InactiveCN103061018ADifferent temperature regulation abilityGood thermostat functionWeft knittingFiberYarn

The invention discloses a double-layer knitted fabric and a knitting method thereof. The double-layer knitted fabric comprises a surface fabric and an inner fabric and is characterized in that the surface fabric is knitted by surface yarn, the inner fabric is formed by interweaving the inner yarn and connecting yarn, the connecting yarn is used to connecting the surface fabric and the inner fabric to form a whole of the double-layer knitted fabric, the surface yarn is made by spinning cashmere fibers, the inner yarn is made by mixedly spinning thermal-storage and temperature-regulated fibers and cashmere fibers under the mass ratio of 30-70 to 70-30, and the connecting yarn is made by pure spinning the thermal-storage and temperature-regulated fibers. The connection method of the connecting yarn is that according to the design requirements of density of connection points, tucking stitch is used in doing the lower stitch, looping stitch is used in doing the upper stitch, and the process repeats, and thus, the loop system of the connecting yarn of the thermal-storage and temperature-regulated fibers is achieved, and the thermal-storage and temperature-regulated fibers and coils of the inner yarn form a full column. The knitting method is used to complete the knitting of the double-layer knitted fabric on a computerized flat knitting machine.

Owner:TIANJIN POLYTECHNIC UNIV

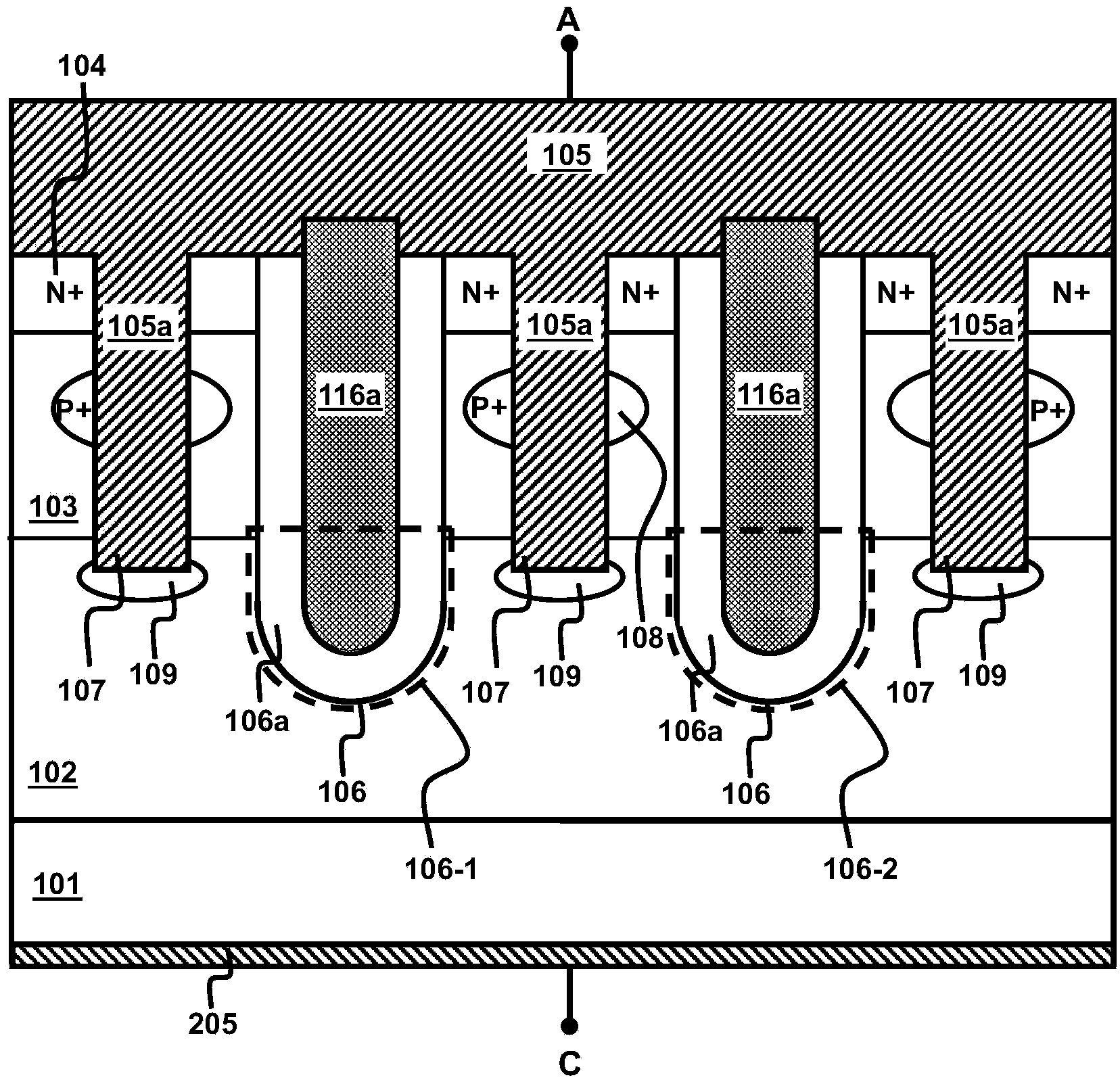

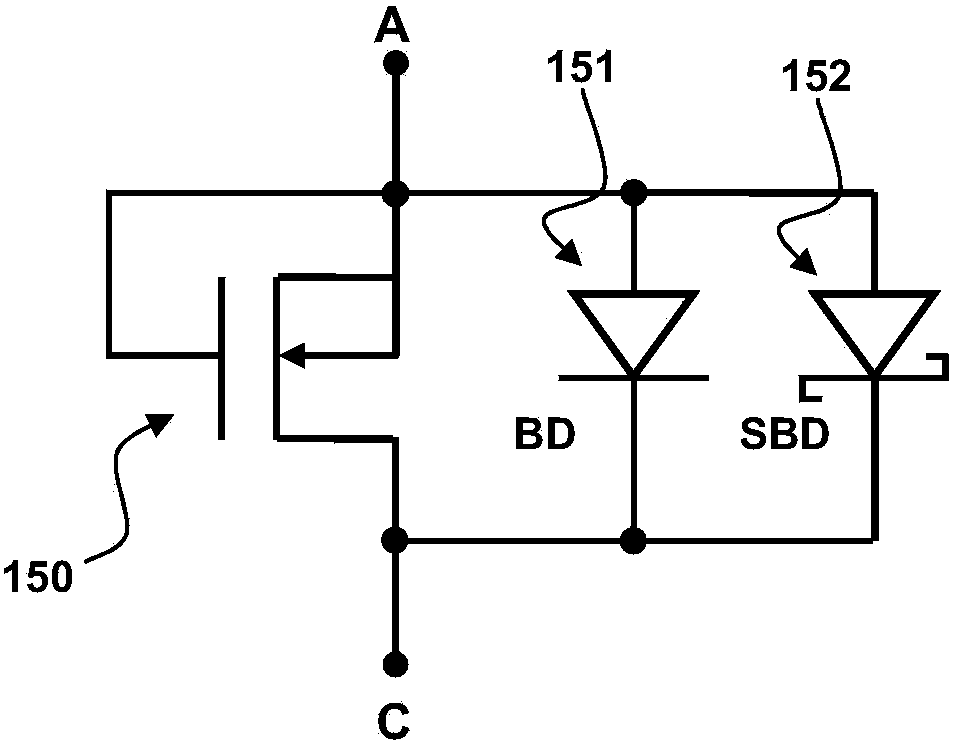

Supper barrier rectifier integrating Schottky diodes and manufacturing method thereof

ActiveCN103887308AAvoid nuditySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSchottky diode

The invention mainly relates to power semiconductor rectifiers, in particular to a super barrier rectifier integrating Schottky diodes and a manufacturing method thereof. A groove type SBR component is manufactured, and is provided with body diodes connected with MOS tubes in parallel and the Schottky diodes, the threshold voltage of the barrier MOS tubes is lower than the barrier voltage of a conventional PN junction, and the voltage of the forward connection of the SBR is lower than the forward connection voltage of a conventional PN diode, the SBR is made to have fast on-off speed, and have high reverse withstand voltages.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

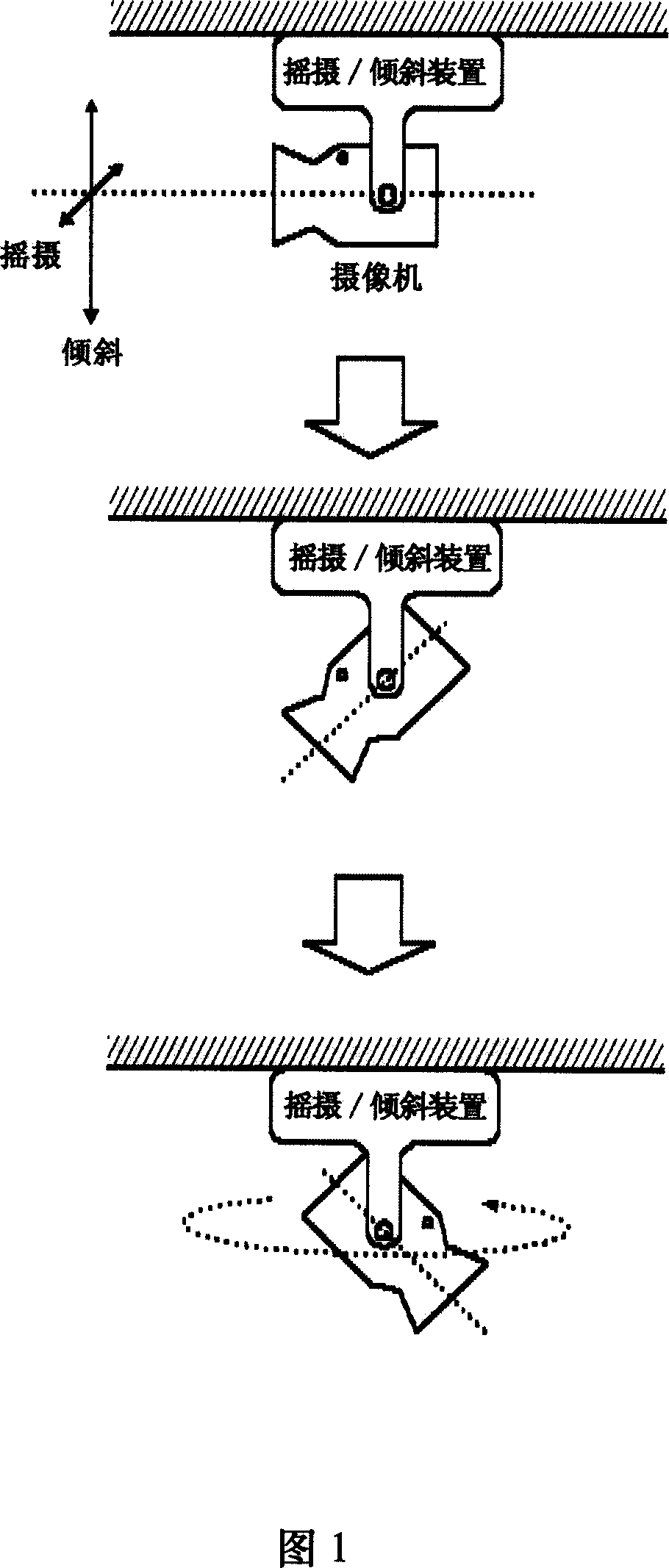

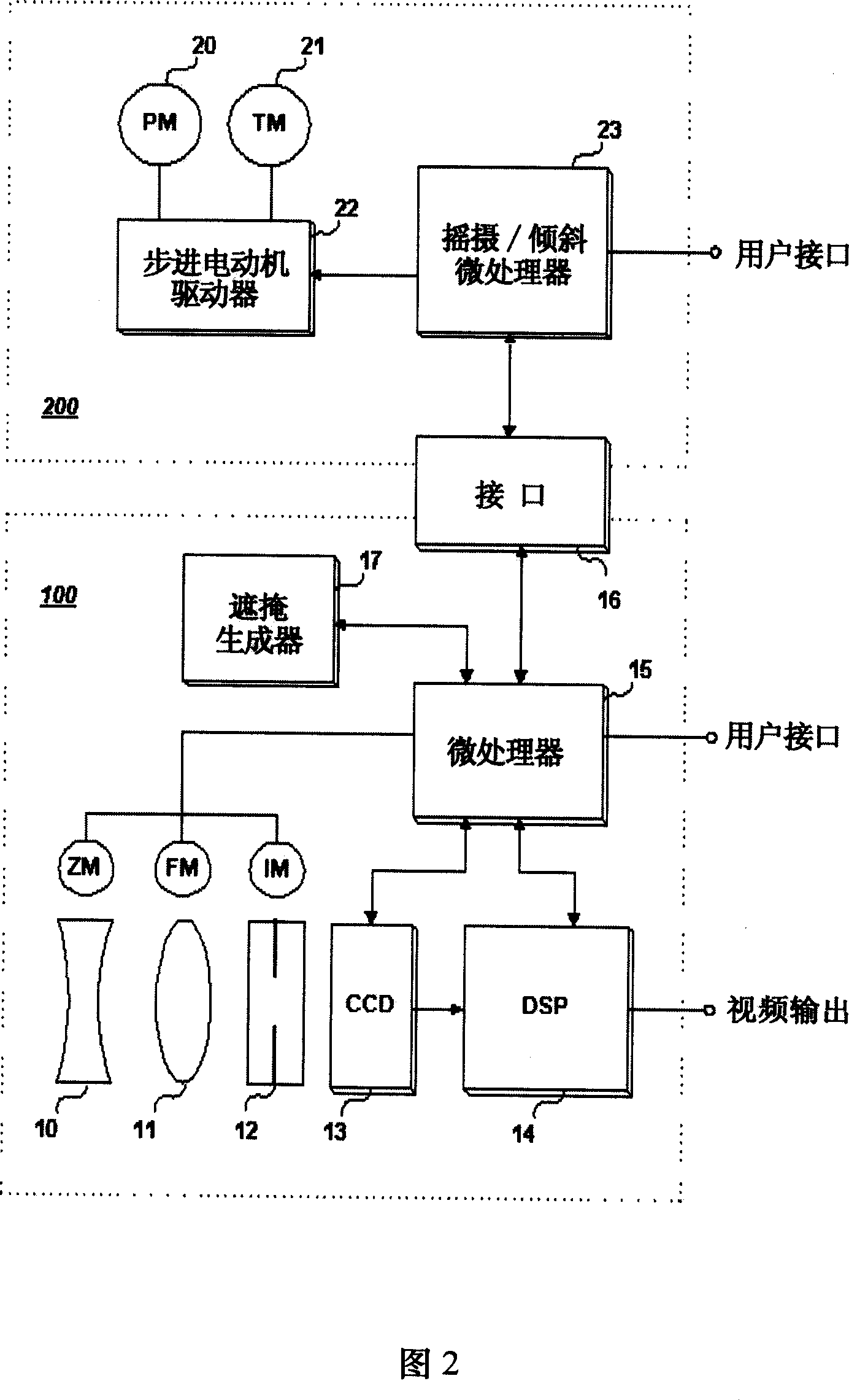

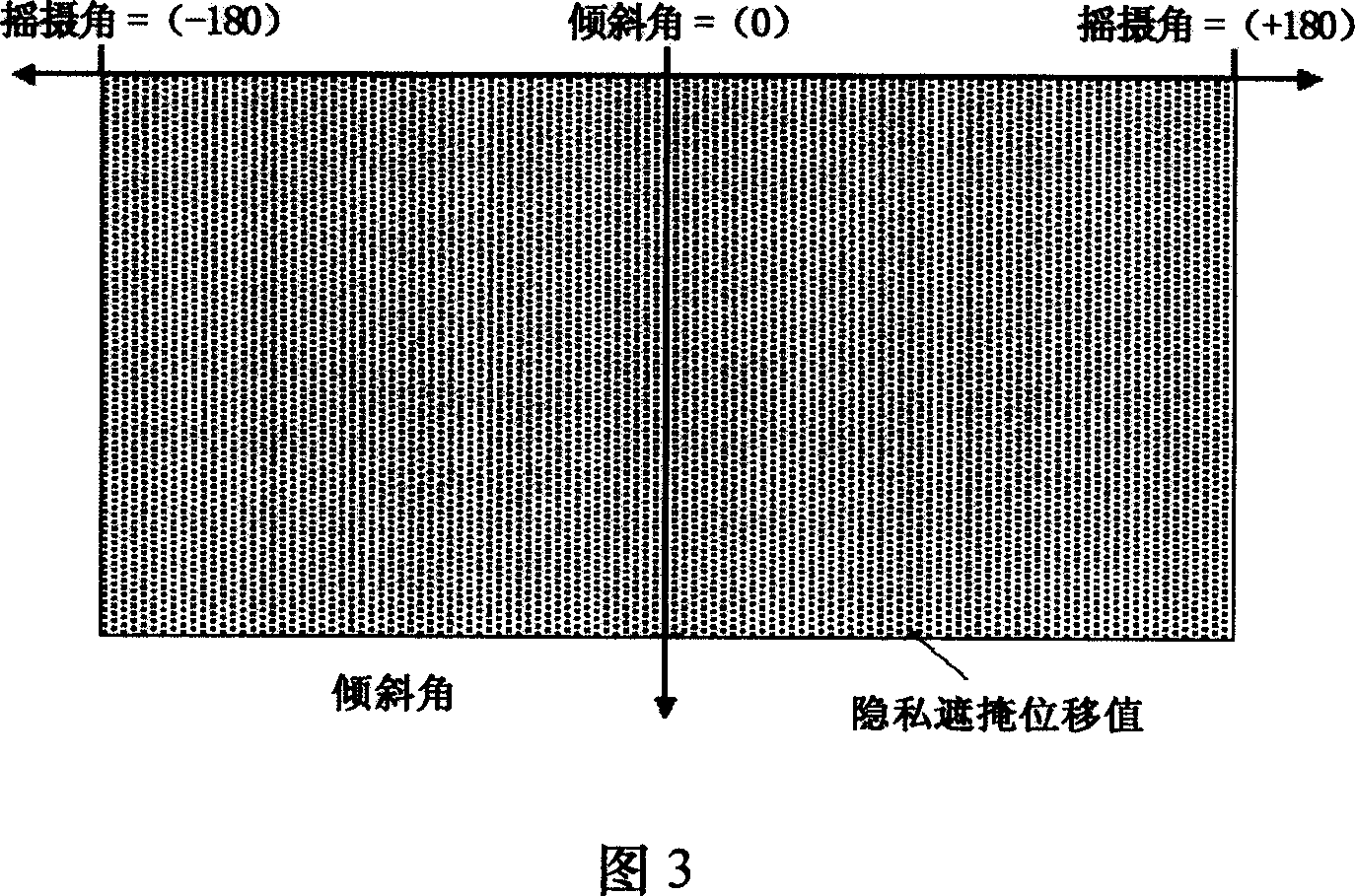

Intimity hiding, displaying control method

InactiveCN101035267AAvoid nudityTelevision system detailsCathode-ray tube indicatorsSurveillance cameraVirtual control

The invention relates to privacy cover up the display-and-control methods. In order to protect privacy, and so on and rely on the shake perturbation / tilt to operate mobile surveillance images shown by the overlapping shows Intra the privacy of concealment, use surveillance cameras in the reader to search for the tilt angle of the benchmarks set incompatible with the shake perturbation angle privacy concealment displacement values, so that the proper privacy to cover up a shake perturbation / Mobile operators to tilt, or when equipped with surveillance camera shake by perturbation / tilt devices shake perturbation / tilt operation, retrieval read tilt angle to set benchmarks for the different perspective shake perturbation compensation values used in the calculation of a mobile display with surveillance cameras privacy to cover up the virtual control of shaking after perturbation , available to use surveillance cameras to rely on surveillance cameras showed that with the privacy to cover up properly conducted shake perturbation / tilt to mobile operators, which can effectively prevent intra surveillance images shown by the result of specific clip shake perturbation / tilt and exposed out.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

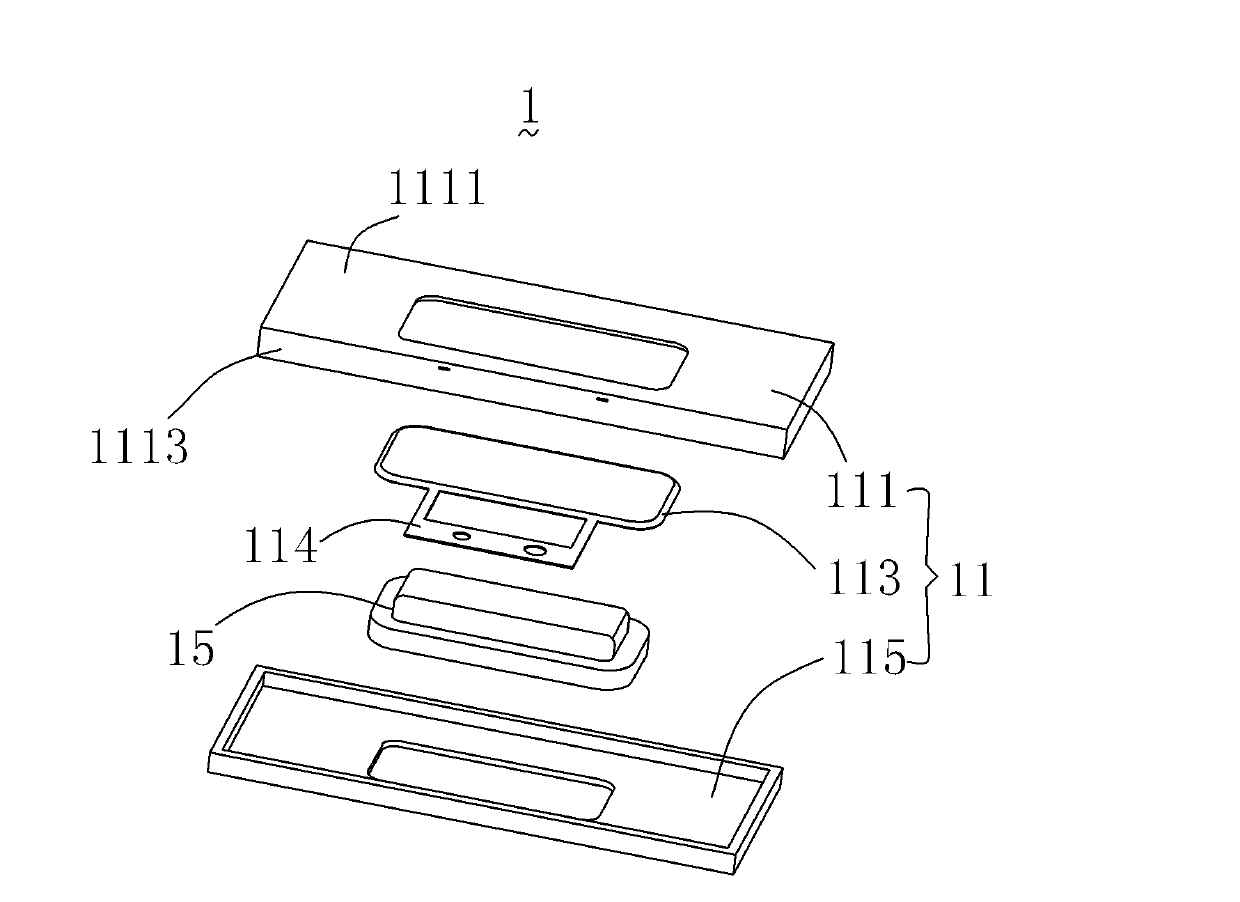

Stereo-display, manufacturing method thereof and fixture used for manufacturing stereo-display

ActiveCN101533158AHigh light transmittanceAvoid displacementLamination ancillary operationsLaminationGratingAdhesive

The invention discloses a stereo-display, a manufacturing method thereof and a fixture used for manufacturing the stereo-display. The display comprises a display screen, grating, a double-sided adhesive and a transparent glue layer, wherein the double-sided adhesive is clamped between a frame of the display screen and a frame of the grating; and the transparent glue layer is clamped between a display area of the display screen and the grating. The fixture comprises a first fixture body and a second fixture body, wherein the first fixture body is provided with a placing area for the display screen and a first positioning hole; and the second fixture body is provided with a positioning pin which corresponds to the first positioning hole and a second positioning hole on a carrier of the double-sided adhesive, and the double-sided adhesive on the carrier of the double-sided adhesive corresponds to the frame of the display screen placed in the placing area for the display screen. The manufacturing method comprises the following steps of: fixing the double-sided adhesive on the frame of the display screen by using the fixture; combining the grating and the display screen adhered with the double-sided adhesive by alignment marks; and filling an air layer between the display screen and the grating with transparent glue by using a glue dispenser and curing. The invention can improve the display effect, the production efficiency and the yield.

Owner:BYD CO LTD

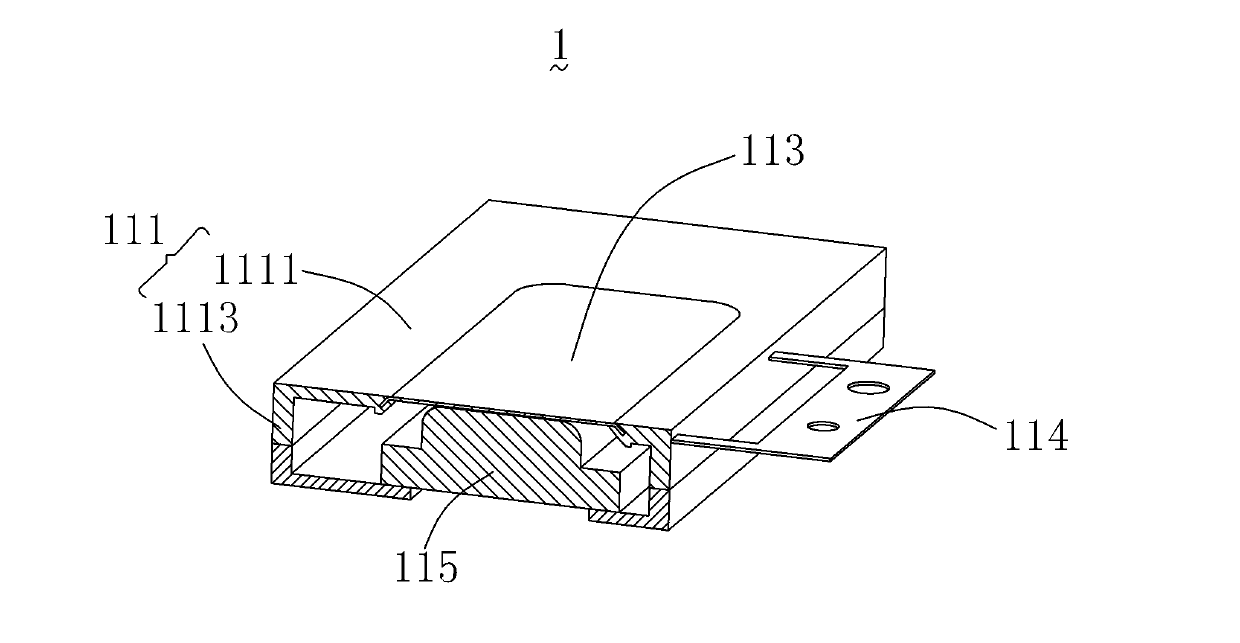

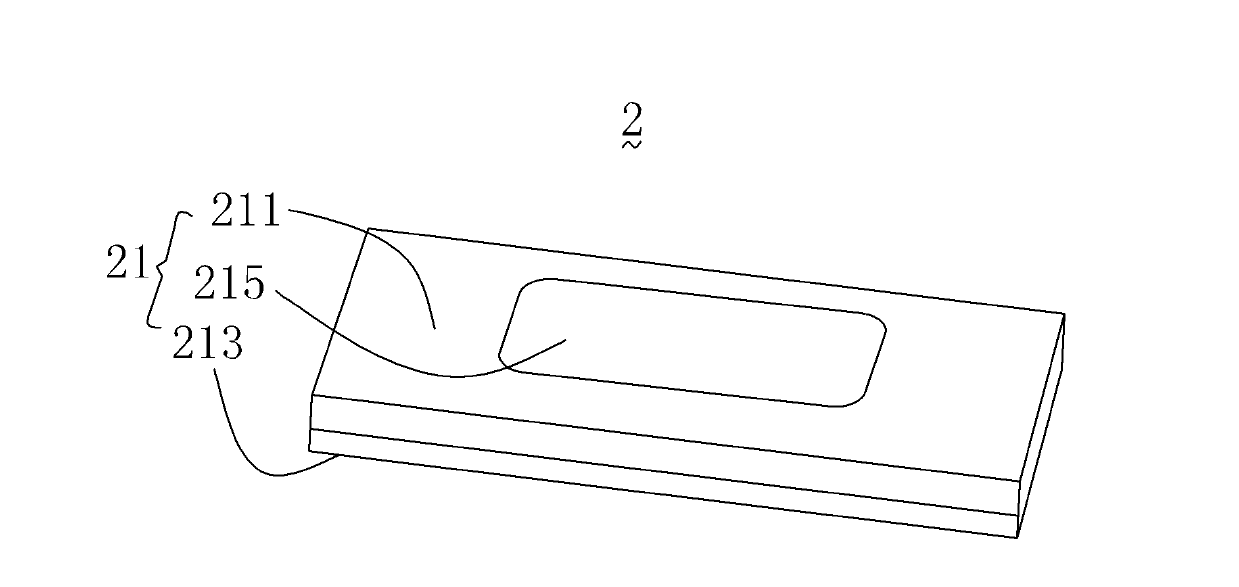

Loudspeaker, loudspeaker casing and manufacturing method of loudspeaker casing

InactiveCN102711003AReduce corrosion damageAvoid nudityTransducer casings/cabinets/supportsLoudspeakerCorrosion

The invention provides a casing of a loudspeaker. The casing comprises a first housing and a reinforcing steel part, wherein the first housing is provided with a first accommodation space, the reinforcing steel part comprises a body and a supporting connecting plate which extends from the body, the reinforcing steel part and the first housing are formed integrally, the first housing comprises an accommodation hole and a cavity which is communicated with the first accommodation space, the body is arranged corresponding to the accommodation hole, one end of the supporting connecting plate is embedded inside the first housing, and the other end of the supporting connecting plate extends to a position of the cavity. In the casing of the loudspeaker, the integral reinforcing steel part is formed by an injection moulding technology, and the supporting connecting plate of the reinforcing steel part is directly embedded inside the first housing, so that the integral appearance is flat and attractive, the probability of corrosion damage of the reinforcing steel part is greatly reduced, and the reliability of a product is improved. Simultaneously, the invention also provides the loudspeaker using the casing and a manufacturing method of the casing.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

Lightning protection system for wind turbine blade

PendingCN110454335ASufficient electrical contact areaPrevent fire and other phenomenaWind motor assemblyMachines/enginesElectricityTurbine blade

The invention relates to the technical field of lightning protection devices, and discloses a lightning protection system for a wind turbine blade. The lightning protection system comprises a blade body lightning arresting unit, a blade tip lightning arresting unit and a lead wire; the blade body lightning arresting unit comprises a blade body lightning arrester and a blade body lightning arresterbase; threaded holes perpendicular to the upper end surface and the lower end surface are correspondingly formed in the upper end surface and the lower end surface of the blade body lightning arrester base; threaded columns matched with the threaded holes are arranged at the lower end of the blade body lightning arrester; the blade tip lightning arresting unit comprises a blade tip lightning arrester and a blade tip lightning arrester base; a clamping groove is formed in the end part of the blade tip lightning arrester; a clamping block matched with the clamping groove is arranged at one endof the blade tip lightning arrester base; threaded holes are formed in the clamping block; and counterbores paired with the threaded holes in the clamping block are formed in the clamping groove. In the scheme, the blade body lightning arresting unit and the blade tip lightning arresting unit are separately connected in a matching manner, so that the surface-surface fit of the lightning arrestersand the lightning arrester bases is realized, the electrical contact area is sufficient, the lightning protection system is stable and reliable, and the phenomenon of sparking is prevented, so that abetter lightning protection effect is achieved.

Owner:JILIN CHONGTONG CHENGFEI NEW MATERIAL

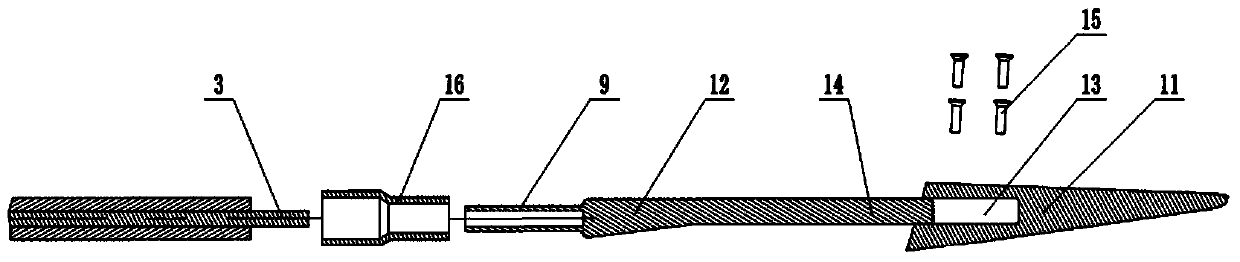

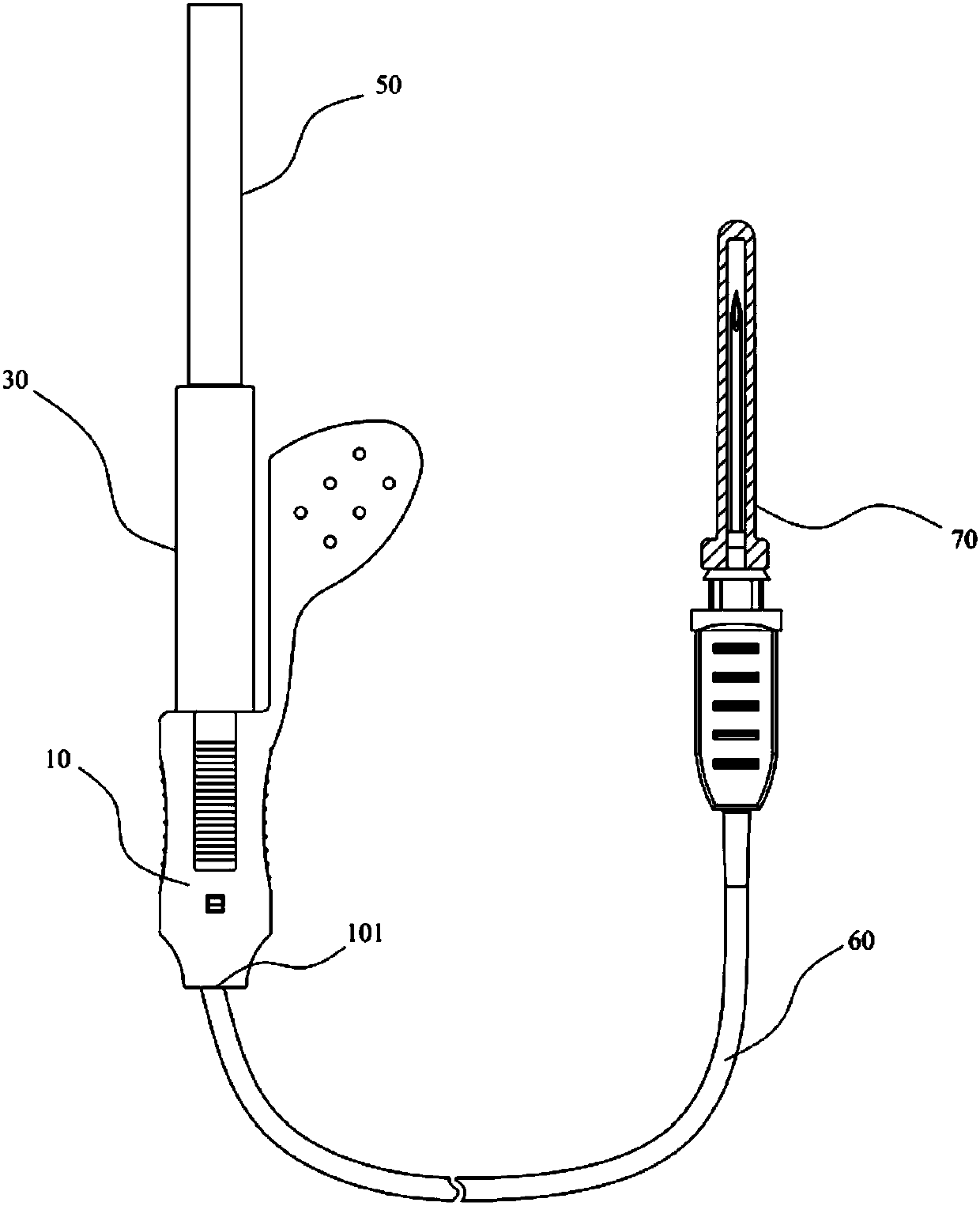

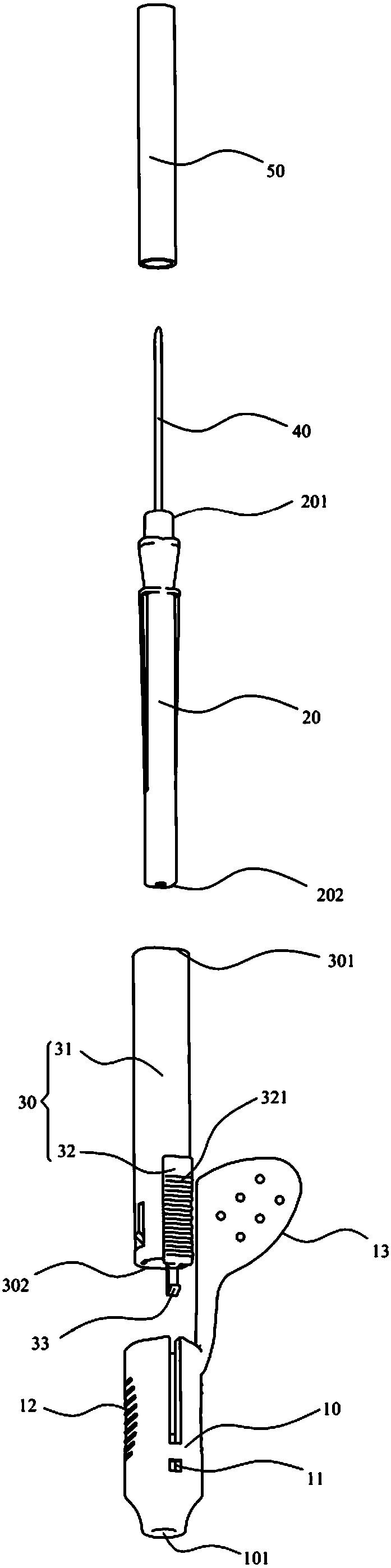

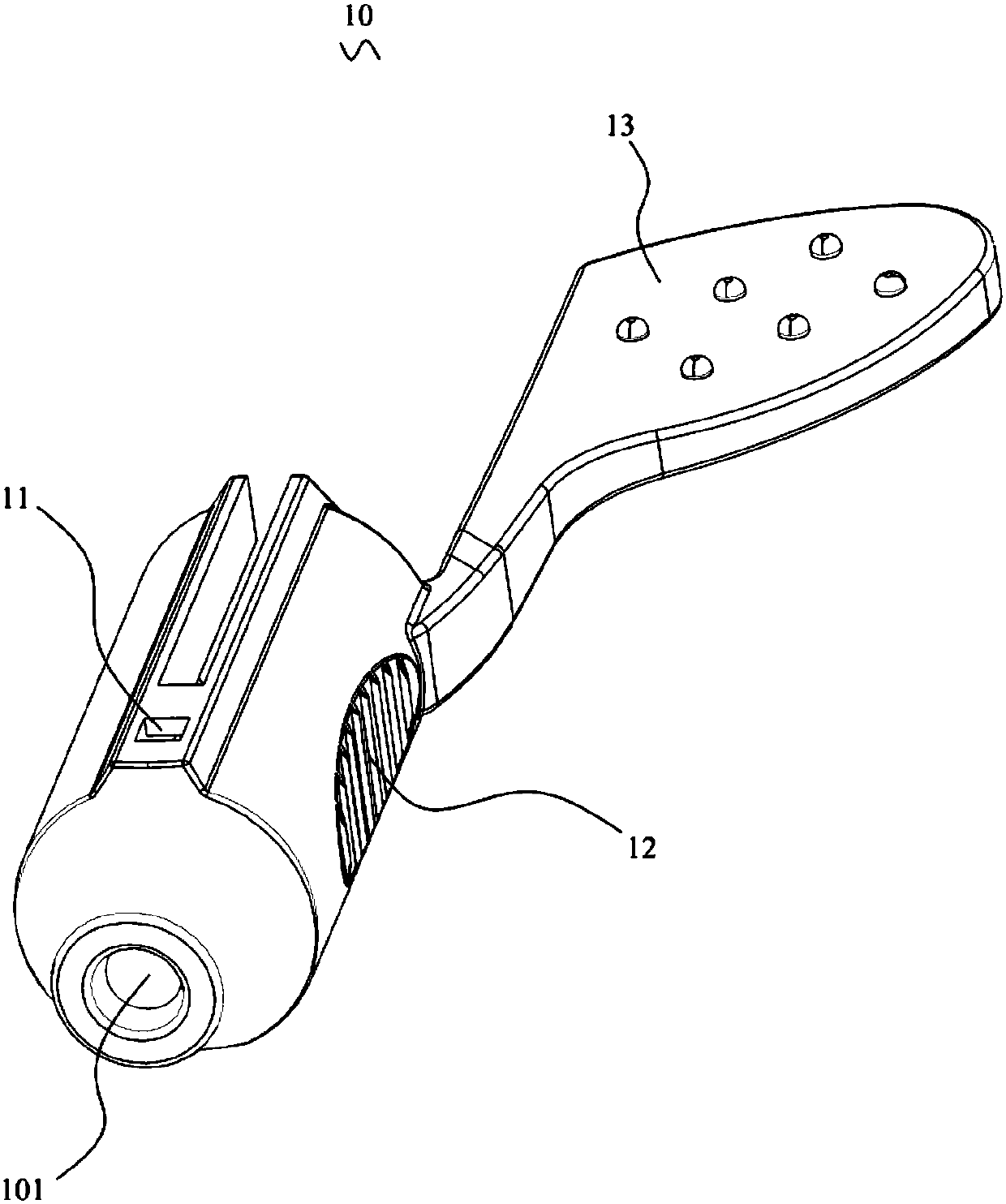

Blood taking needle

PendingCN107811644AAvoid nudityAvoid accidentally stabbing someoneDiagnostic recording/measuringSensorsNeedle guardNeedle holder

The invention provides a blood taking needle. The blood taking needle comprises a needle seat and a needle tube and also comprises a base, a sliding mechanism and a needle sheath, wherein a first endof the needle seat is connected with the needle tube, a second end of the needle seat is connected with the base, the needle sheath is assembled on the first end of the needle seat and is in contact with a first end of the sliding mechanism, a second end of the sliding mechanism is movably connected with the base, the needle seat is arranged inside a cavity of the sliding mechanism in a sheathingmanner, the second end of the sliding mechanism is smaller than the first end of the needle seat, the sliding mechanism can slide relative to the needle seat, a clamping slot is formed in the first end of the needle seat, a clamping projection is formed at the second end of the sliding mechanism, when the sliding mechanism slides to the position at which the second end of the sliding mechanism isin contact with the first end of the needle seat, the clamping projection is clamped into the clamping slot, and the sliding mechanism completely wraps the needle. The blood taking needle provided bythe invention can effectively prevent acupuncture.

Owner:JIANGXI FENGLIN MEDICAL APPLIANCES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com