Intelligent force testing device of steel pipe scaffold based on wireless transmission

A technology of force measuring device and steel pipe, which is applied in signal transmission system, measurement of elastic deformation force through measuring gauges, instruments, etc. It can solve the problems of construction personnel damage, acquisition signal interruption, and transmission cables being vulnerable to falling objects on the upper floor, etc. , to achieve the effect of overcoming the vulnerability to damage and avoiding the exposure of lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

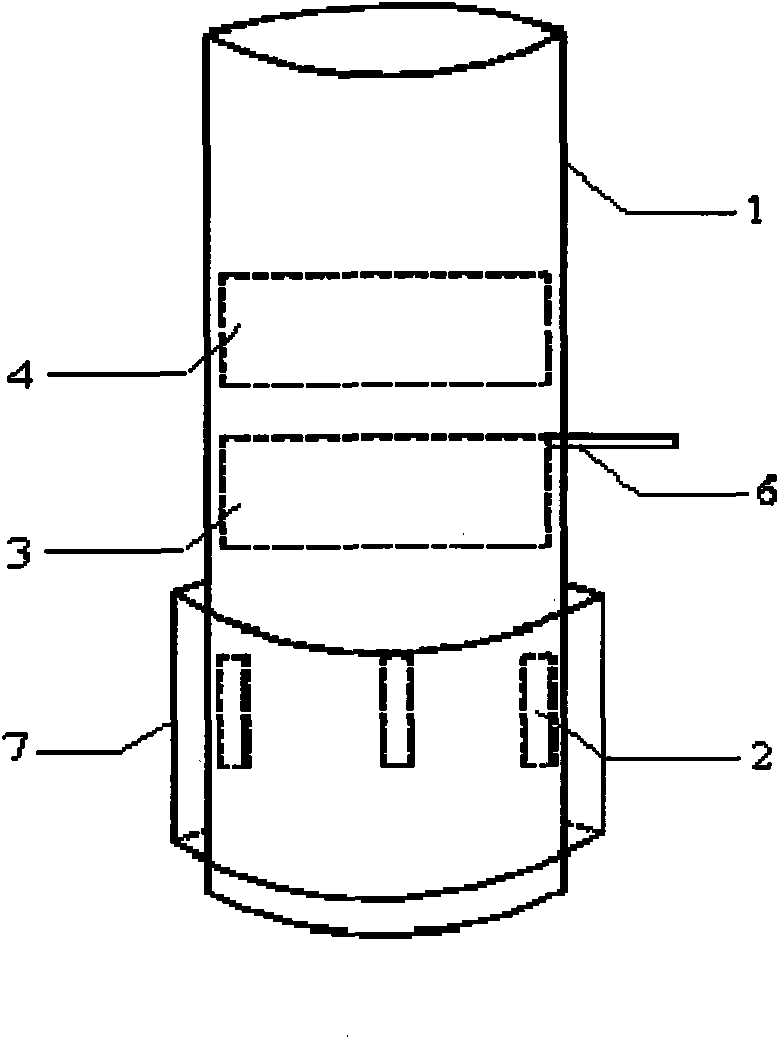

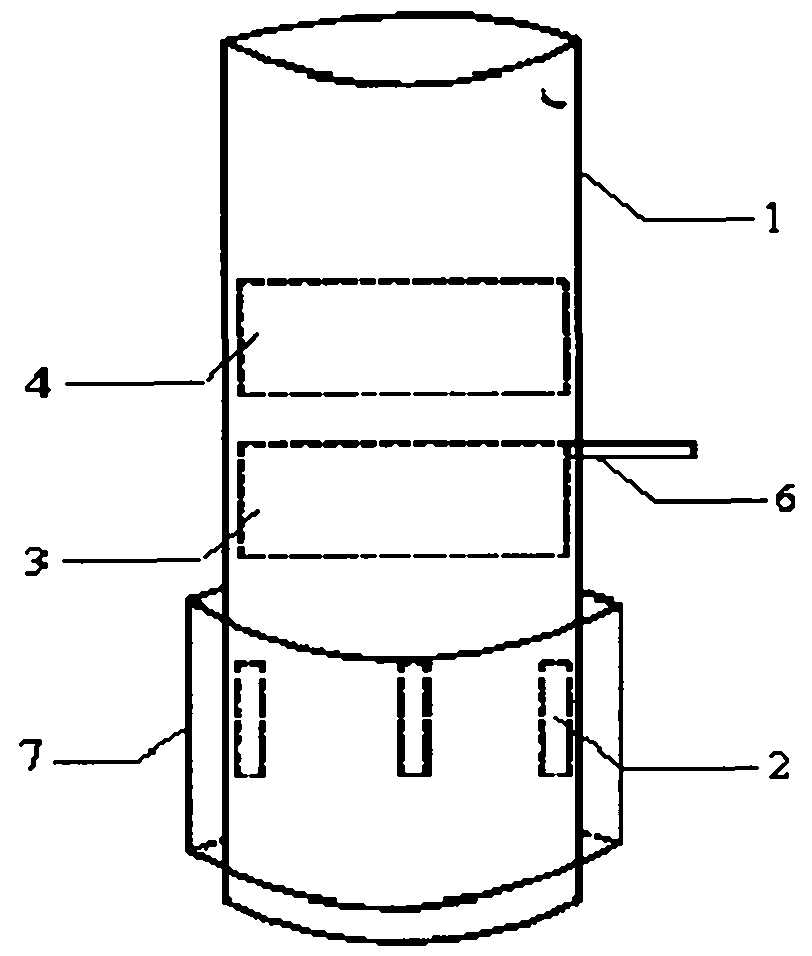

[0012] The intelligent force-measuring device of the present invention includes a wireless signal receiving and processing module, a power supply, a sensing element connected in sequence, an analog-to-digital conversion module, an intelligent logic module, and a wireless signal transmitting module. The sensing element is arranged outside the end of the steel pipe 1. The surface; the analog-to-digital conversion module, the intelligent logic module, and the wireless signal transmitting module are arranged in the steel pipe 1; wherein the power supply includes a battery 4 power supply arranged in the steel pipe 1 to drive each circuit element of the steel pipe 1; There is a through hole, and the wireless signal transmitting module includes a transmitting antenna 6 exposed outside the steel pipe 1 through the through hole. The sensing element is a metal-based strain gauge 2 , and the steel pipe 1 is also provided with a protective sleeve 7 at the position of the corresponding sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com