Supper barrier rectifier integrating Schottky diodes and manufacturing method thereof

A Schottky diode and gate technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problem of high-precision rectifiers that cannot suppress reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

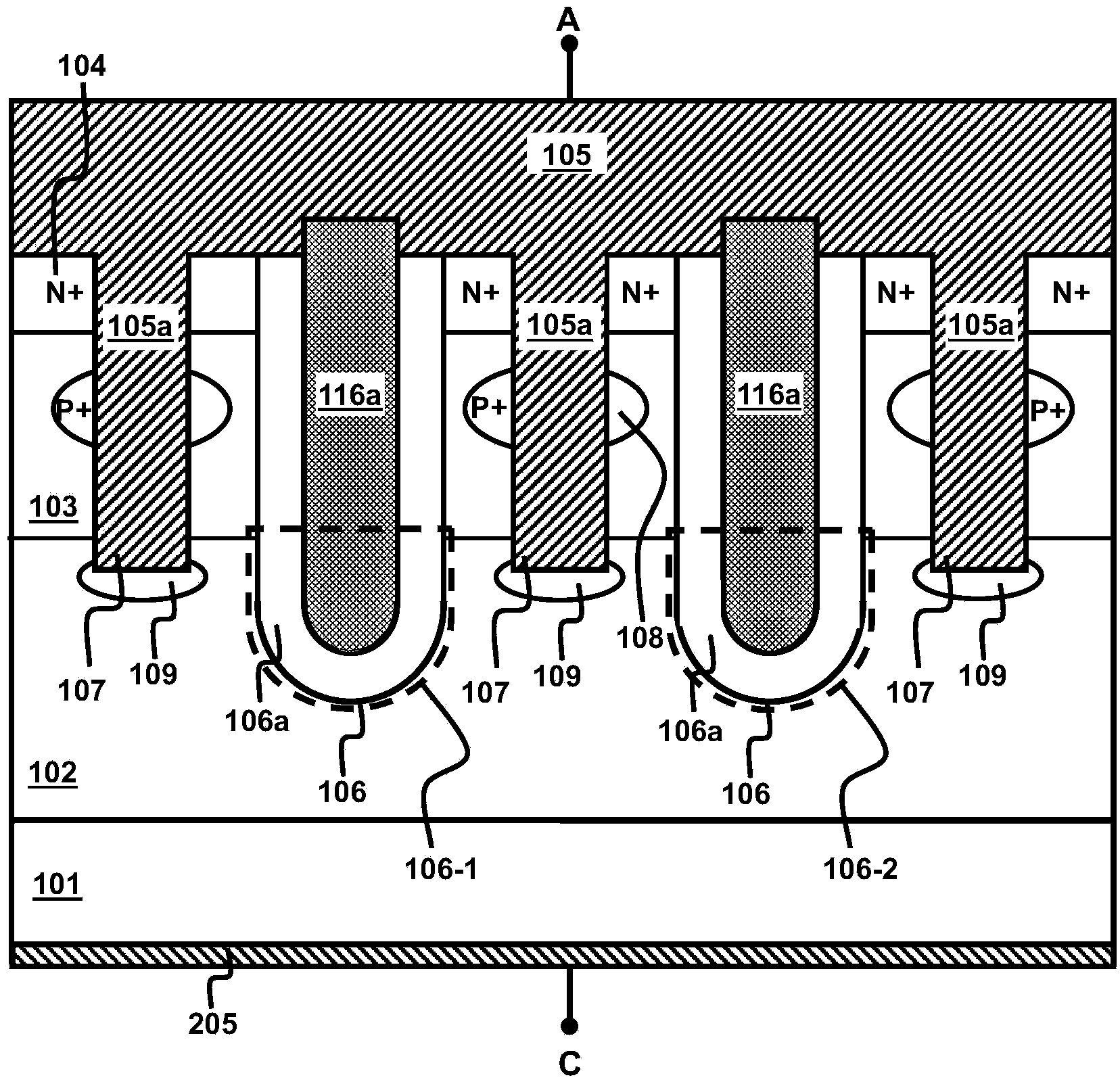

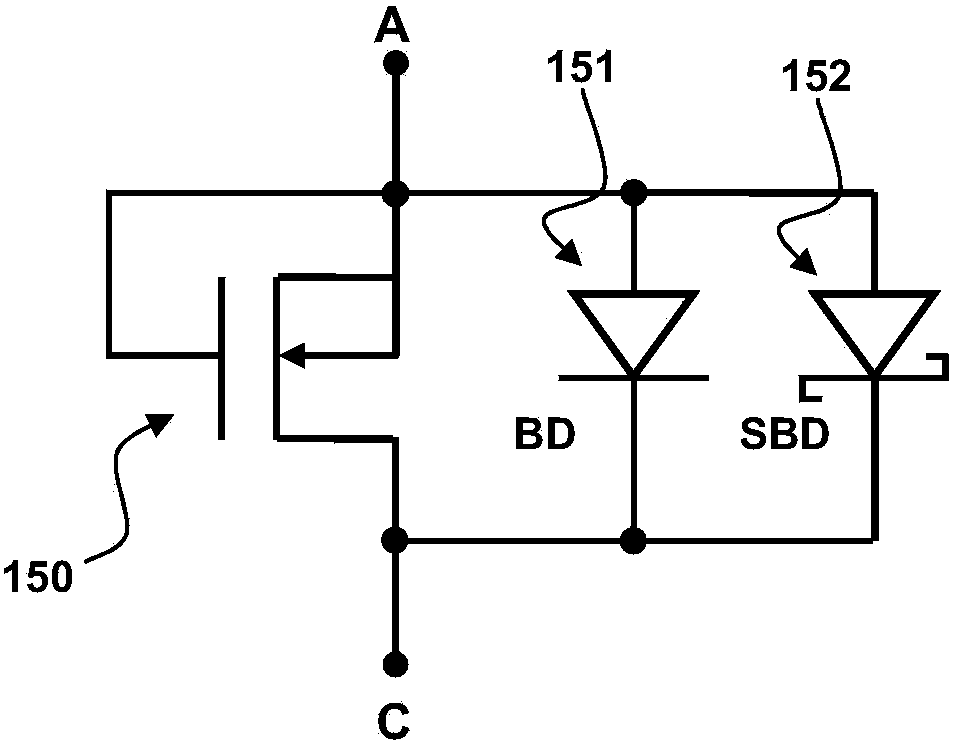

[0021] see Figure 1A , shows a cross-sectional view of a super-barrier rectifier SBR integrated with a Schottky Barrier Diode (SBD). A semiconductor substrate includes a base substrate 101 and an epitaxial layer 102 carried on the base substrate 101, a body layer 103 is formed on the top of the epitaxial layer 102, and a top doped layer is formed on the top of the body layer 103 104. The top surface of the epitaxial layer 102 is the front surface of the semiconductor substrate or wafer, and the bottom surface of the bottom substrate 101 is the back surface opposite to the front surface. In the present invention, the top doped layer 104 can also be defined as a source / drain top doped layer. For the convenience of description, it is assumed that the bottom substrate 101 is heavily doped N+ type, the doping concentration of the epitaxial layer 102 is lower than that of the bottom substrate is N- type, the body layer 103 is P type and the top doped layer 104 is doped N+ type wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com