Stereo-display, manufacturing method thereof and fixture used for manufacturing stereo-display

A three-dimensional display and fixture technology, applied in chemical instruments and methods, three-dimensional systems, instruments, etc., can solve the problems of unstable product quality, influence display effect, easy generation of bubbles, etc., to increase light transmittance and improve display effect. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

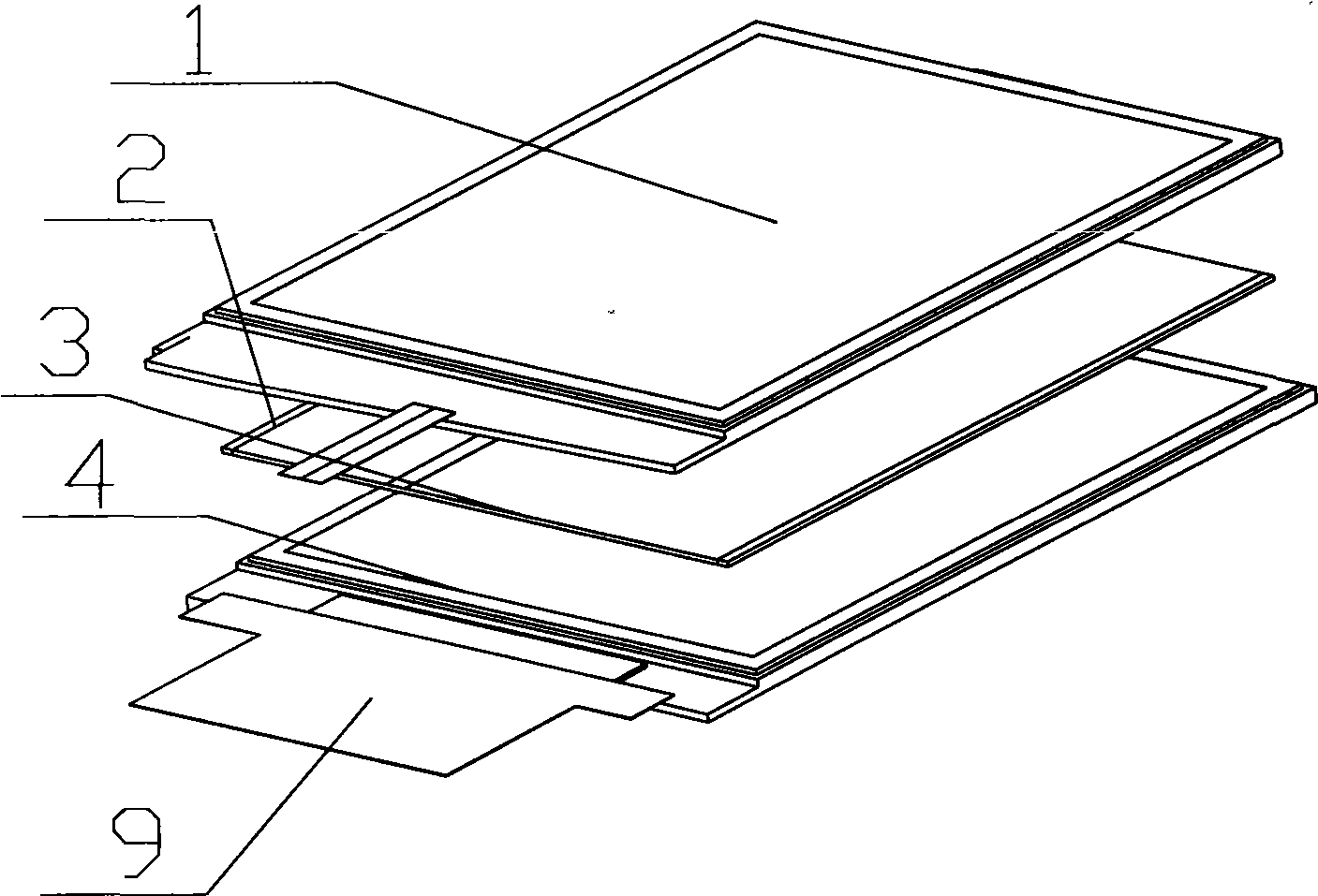

[0025] Such as figure 1 As shown, a kind of three-dimensional display comprises display screen 4, grating 1, double-sided adhesive tape 2 and transparent glue layer 3, and described double-sided adhesive tape 2 is sandwiched between display screen 4 edge and grating 1 edge, and described transparent glue layer 3 is sandwiched between the display area of the display screen 4 and the grating 1. The double-sided adhesive tape 2 can be pre-fixed, and the transparent glue layer 3 can completely fix the display screen 4 and the grating 1, thus playing a double fixing role. The transparent glue layer 3 can also play the role of increasing the light transmittance and improving the display effect. The transparent glue layer 3 also has a certain buffering effect on the force of the grating 1 . The transparent glue layer 3 is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com