Containment built-in spent fuel pool

A spent fuel pool and containment technology, applied to reactor fuel elements, cooling devices, nuclear power generation, etc., can solve problems such as loss of off-site power and inability to perform cooling functions, and achieve the effect of improving air cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

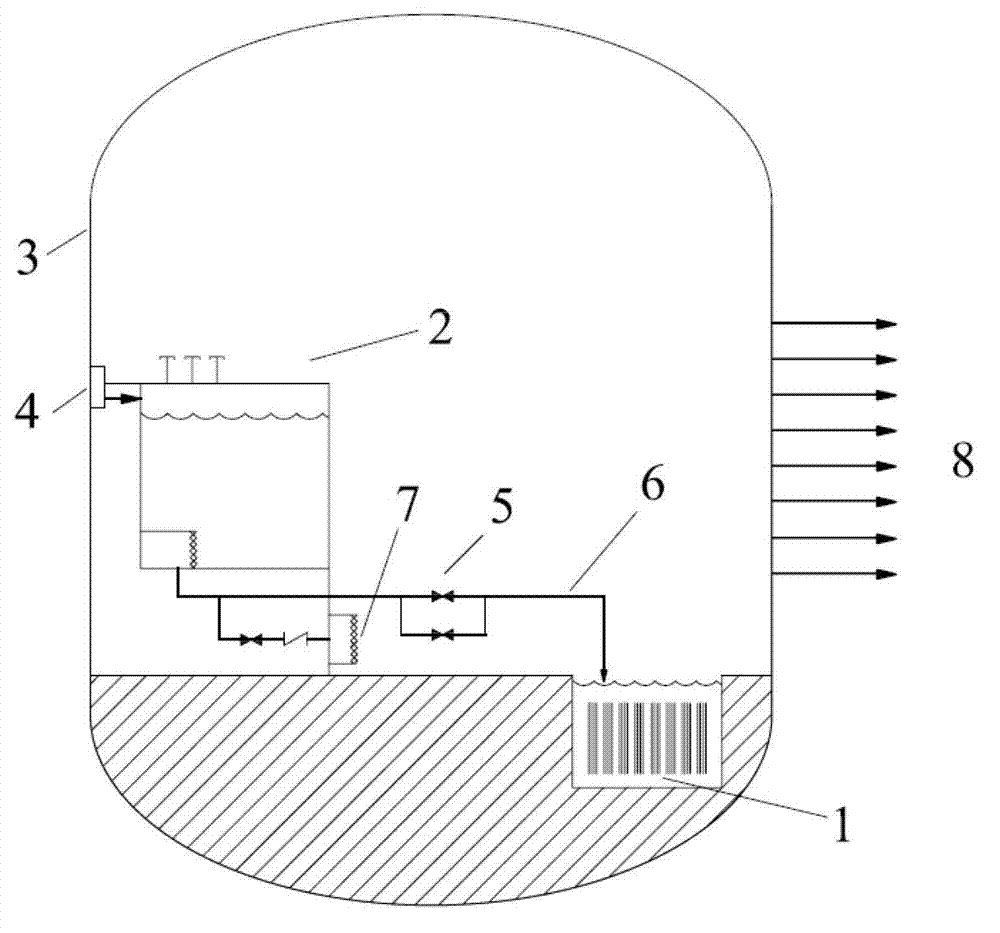

specific Embodiment 1

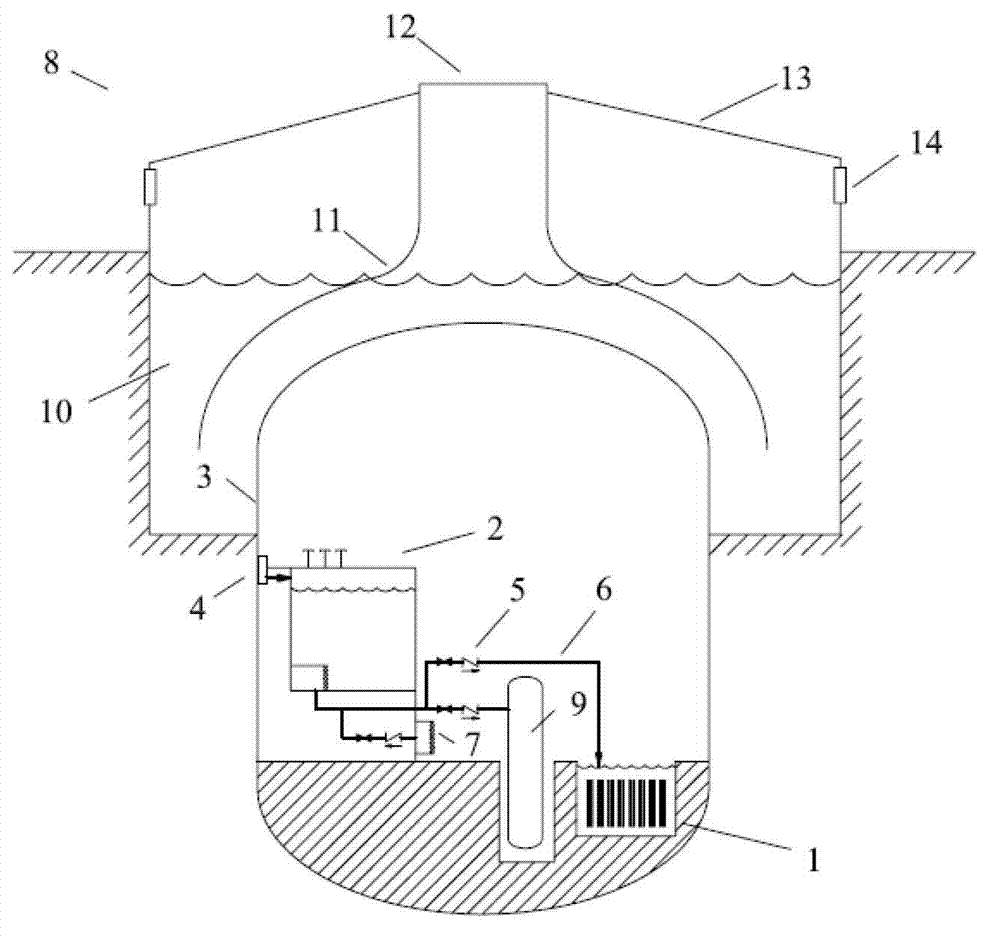

[0032] like figure 2Shown is the specific embodiment 1 of the spent fuel pool inside the containment according to the present invention. In this embodiment, the containment vessel 3 and the containment cooling water pool 10 are located in the reactor building 13, and the spent fuel pool 1 is arranged in the containment vessel 3. The height of the spent fuel pool 1 inside the containment vessel 3 is basically the same as that of the reactor cavity. The containment built-in water tank 2 is arranged in the containment vessel 3 at a higher level than the spent fuel pool 1. The top of the containment built-in water tank 2 is provided with The condensed water collector 4 is connected to the inner wall of the containment vessel 3, and the lower end of the water tank 2 inside the containment vessel is respectively connected to the spent fuel pool 1 and the reactor pressure vessel 9 through the pipeline 6, and the valve 5 is arranged on the pipeline 6 to ensure safety. The water tank ...

specific Embodiment 2

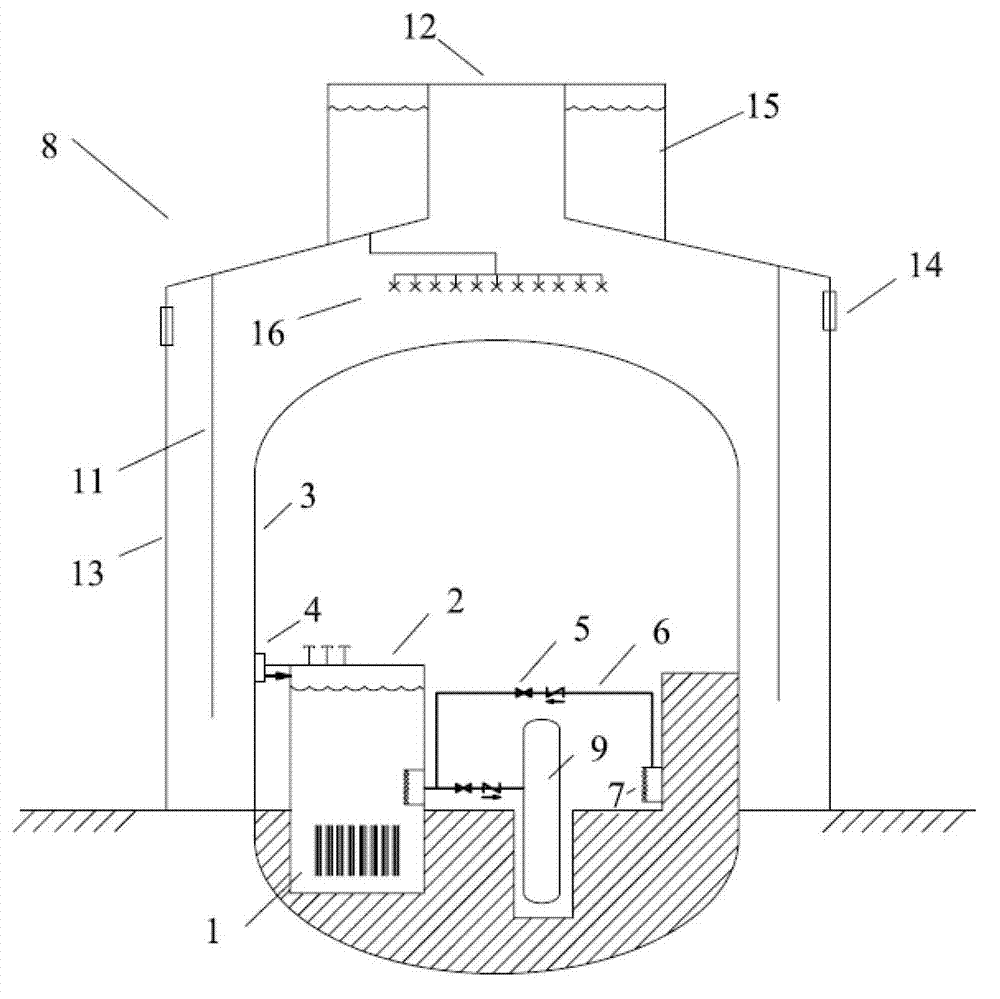

[0039] like image 3 As shown, it is the specific embodiment 2 of the spent fuel pool built in the containment of the present invention. The difference between this embodiment and the first embodiment is: (1) The spent fuel pool 1 is integrated in the lower part of the water tank 2 built in the containment, which eliminates the safety The water tank 2 inside the shell is the pipeline and valve for replenishing water to the spent fuel pool 1; the lower end of the water tank 2 inside the containment is connected to the reactor pressure vessel 9 through the pipeline 6, and the valve 5 is arranged on the pipeline 6; The shell cooling system 8, the containment cooling system 8 includes a deflector 11, an air outlet 12; a reactor building 13, an air inlet 14, a spray water tank 15, and a sprinkler 16, and the top of the reactor building 13 is provided with a spray water tank 15, The bottom of the spray water tank 15 is provided with a sprinkler 16, and the sprinkler 16 is located ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com