Powder synthesis solid processing technology for plastic products

A technology for plastic products and processing technology, applied in the field of plastic product processing, can solve the problems of inability to clean the mixing tank, insufficient mixing of raw materials, and inability to quickly locate a plaster model, so as to avoid waste and increase efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

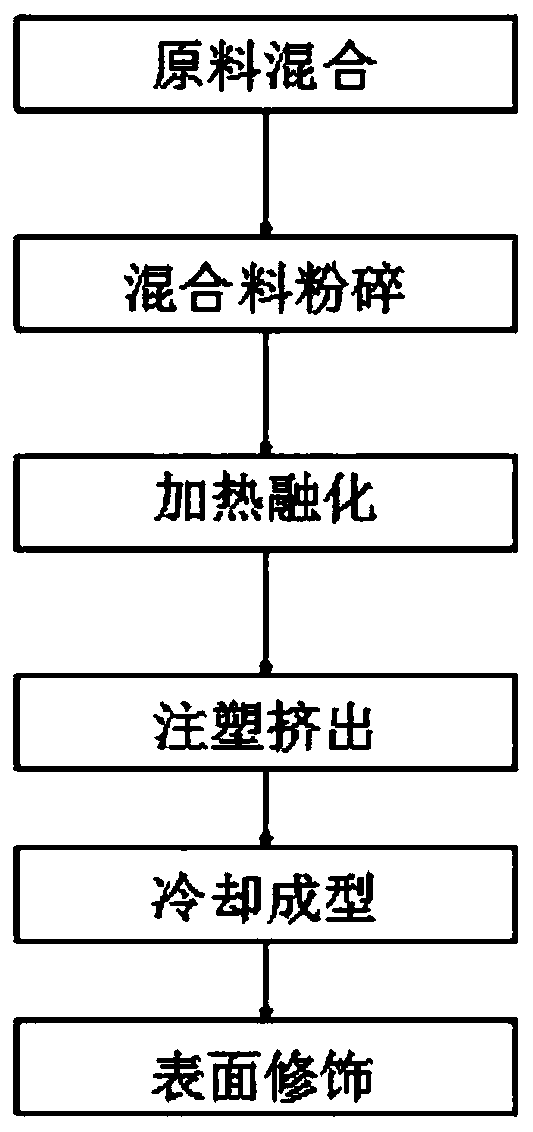

[0027] A powder synthesis solid processing technology for plastic products, comprising the following steps:

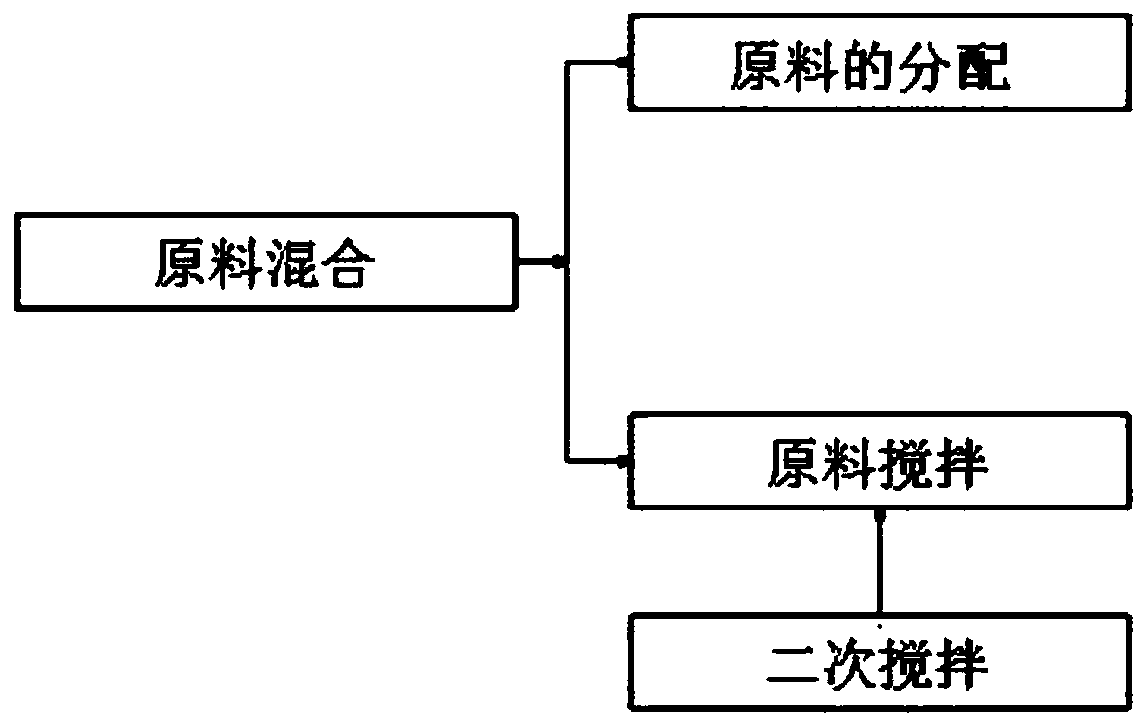

[0028] S1. Mix raw materials, add polycarbonate, polyethylene, polystyrene, wood powder, colorant, antistatic agent, antioxidant, flame retardant into the stirring device for stirring, the second stirring mechanism in the stirring device to stir;

[0029] S2, the mixture is pulverized, and the batch mixture obtained in step S1 is transported to a pulverizer through a conveying device, and the pulverizer pulverizes the batch mixture;

[0030] S3, heating and melting, heating the uniformly stirred mixed material raw material in step S2 through a high-temperature heating furnace, heating it for a period of time to make it into a molten state, and stopping heating;

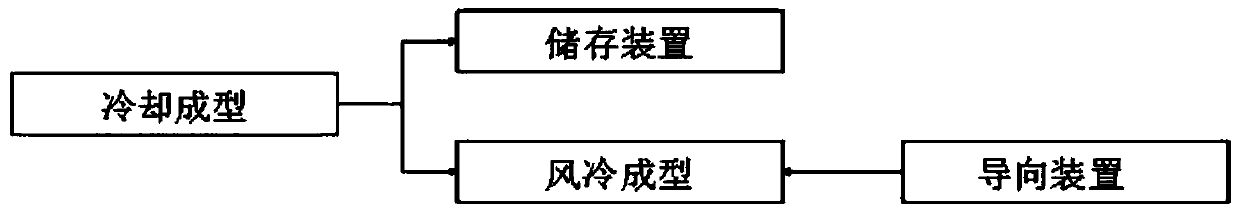

[0031] S4, injection molding extrusion, transporting the obtained mixture in molten state to an injection molding machine, and injecting it into a required solid shape through the injection molding machine; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com