Patents

Literature

577 results about "Glycidyl ethers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SACHEM’s glycidyl ethers are versatile, reactive intermediates used to design new chemical routes for your process development needs. Utilizing glycidyl ether intermediates will eliminate the handling of hazardous materials like epichlorohydrin, simplify production processes and improve asset utilization.

Copper plating bath and plating method for substrate using the copper plating bath

InactiveUS6800188B2Excellent characteristic and uniformityImprove reliabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingCopper platingGlycidyl ethers

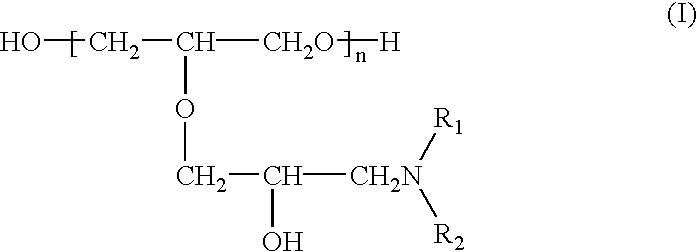

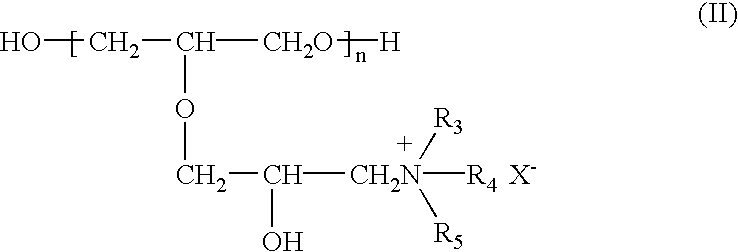

A copper plating bath comprising a reaction condensate of an amine compound and glycidyl ether and / or a quaternary ammonium derivative of this reaction condensate, and a plating method using this copper plating bath are disclosed. A copper plating bath capable of providing highly reliable copper plating on a substrate such as a silicone wafer semiconductor substrate or printed board having minute circuit patterns and small holes such as blind via-holes, through-holes, and the like, and a method of copper plating using the copper plating bath can be provided.

Owner:EBARA-UDYLITE CO LTD

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

Holographic media and photopolymers

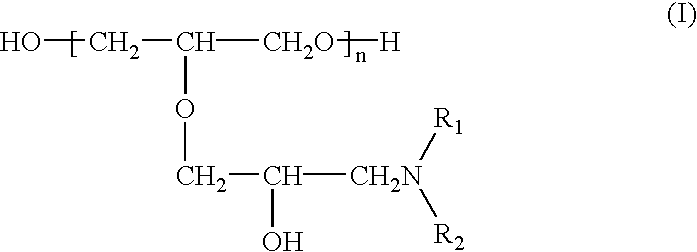

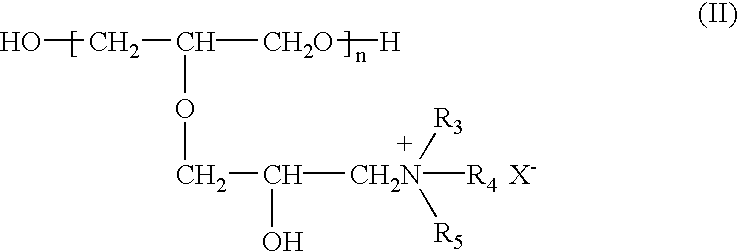

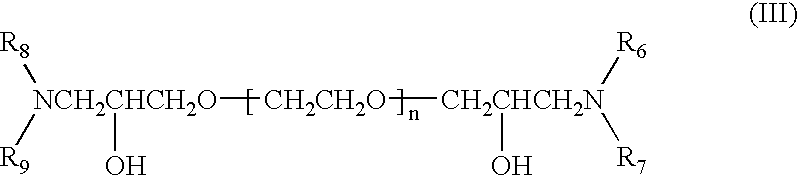

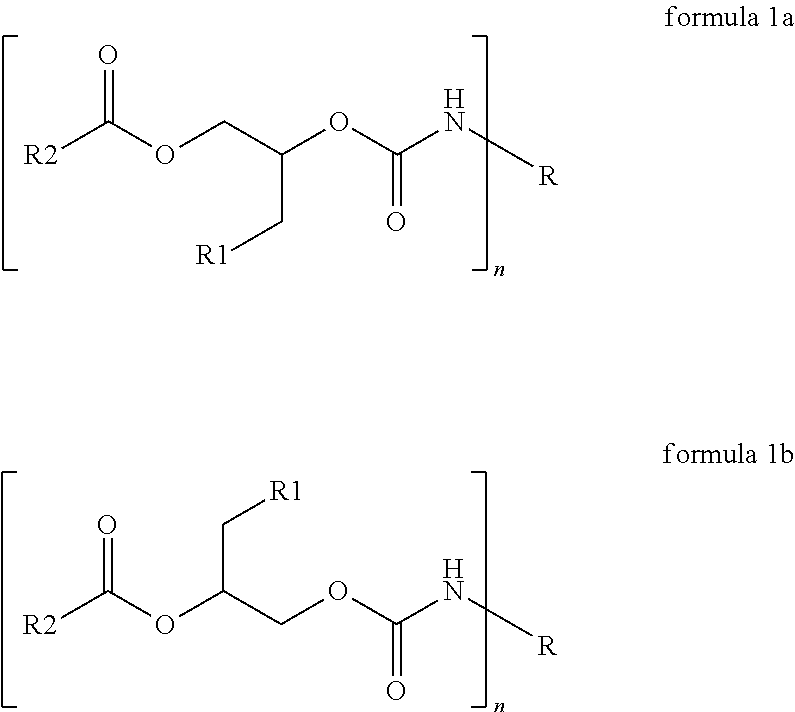

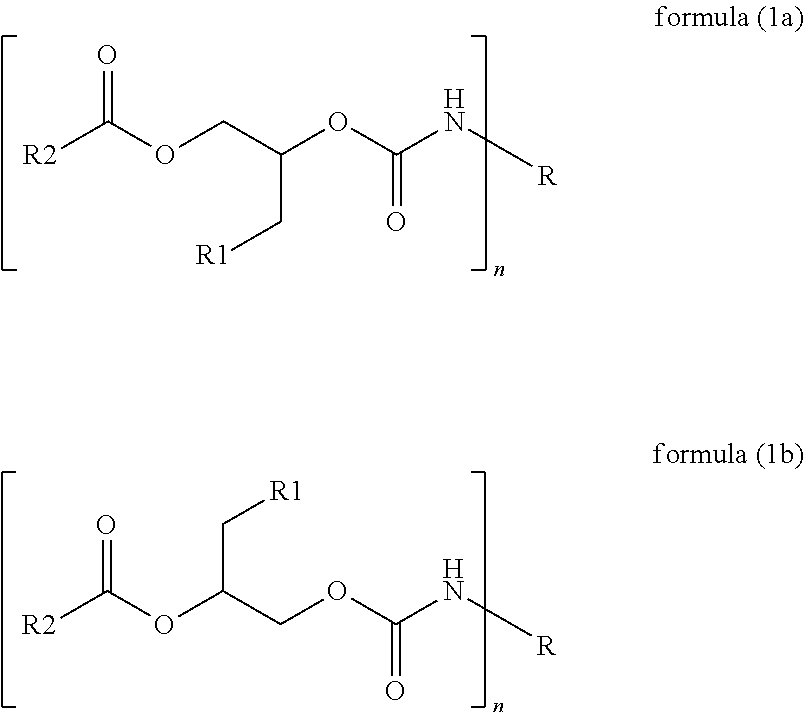

The invention relates to holographic media containing specific photopolymers, a process for the production thereof, and unsaturated glycidyl ether acrylate urethanes as writing monomers which are suitable for the preparation of photopolymers.

Owner:COVESTRO DEUTSCHLAND AG

Copper plating bath and plating method for substrate using the copper plating bath

InactiveUS20030106802A1Excellent characteristic and uniformityImprove reliabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingCopper platingGlycidyl ethers

A copper plating bath comprising a reaction condensate of an amine compound and glycidyl ether and / or a quaternary ammonium derivative of this reaction, condensate, and a plating method using this copper plating bath are disclosed. A copper plating bath capable of providing highly reliable copper plating on a substrate such as a silicone wafer semiconductor substrate or printed board having minute circuit patterns and small holes such as blind via-holes, through-holes, and the like, and a method of copper plating using the copper plating bath can be provided.

Owner:EBARA-UDYLITE CO LTD

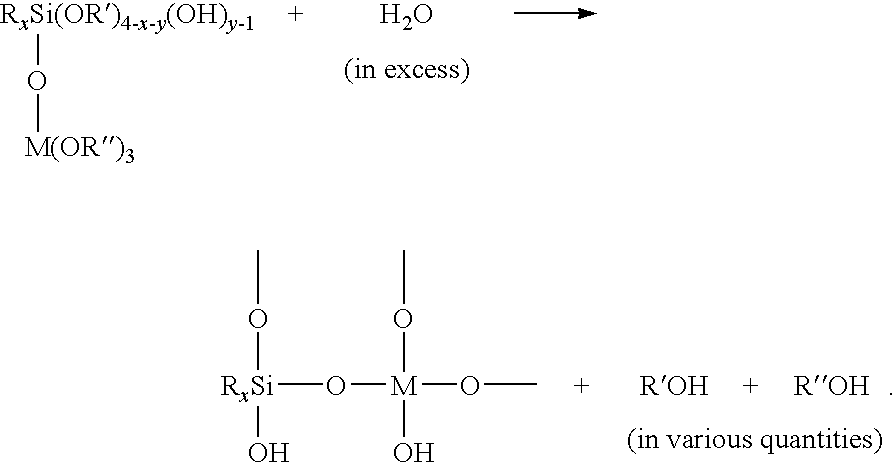

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

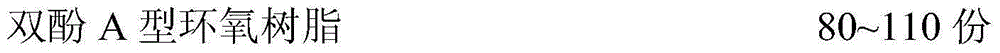

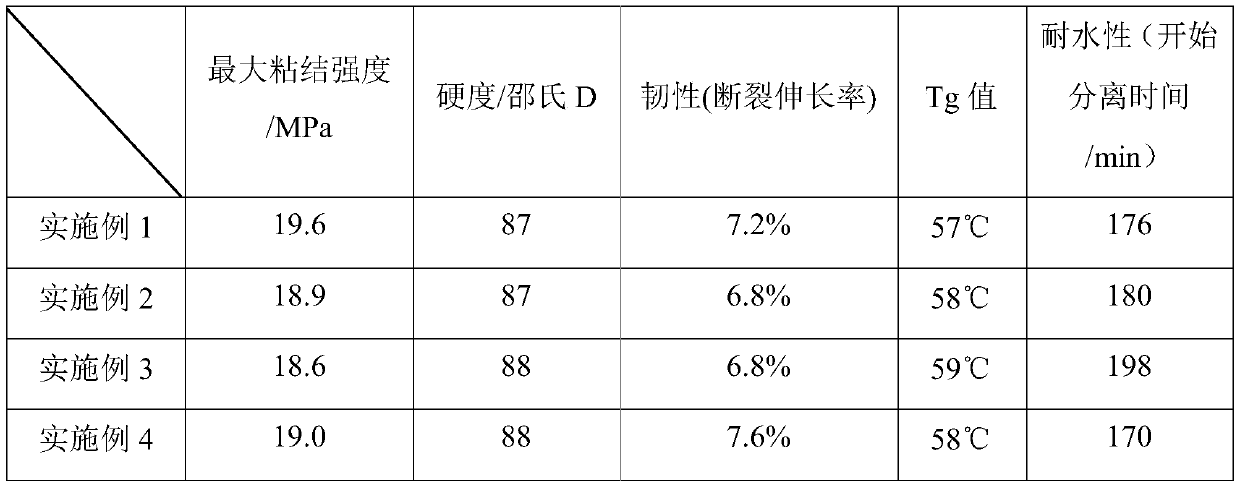

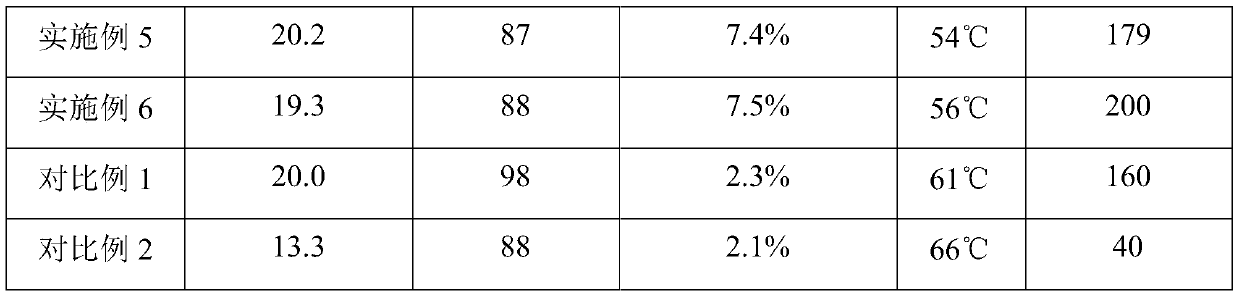

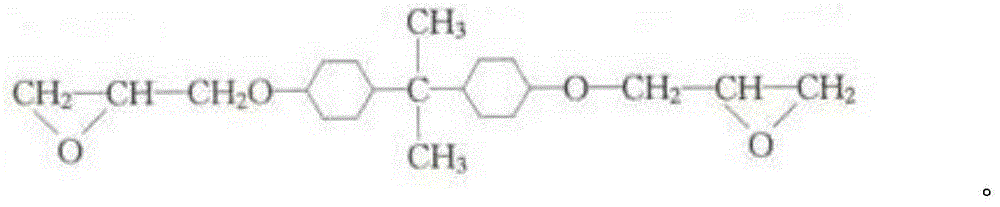

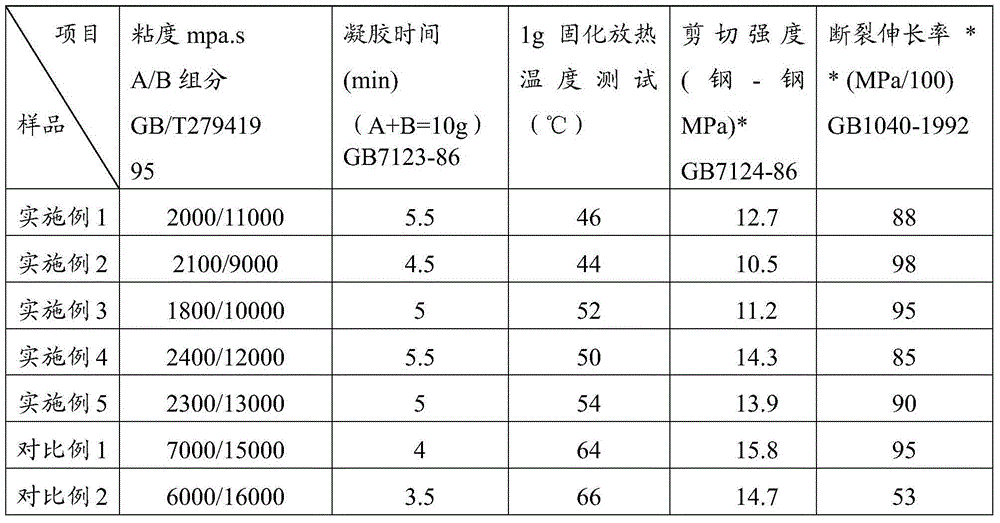

Double-component high-strength building epoxy structural adhesive and preparing method thereof

ActiveCN105062396AStir wellImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberGlycidyl ethers

The invention provides double-component high-strength building epoxy structural adhesive and a preparing method thereof. The structural adhesive is mainly formed by mixing a component A and a component B at the weight ratio of 1.8-2.5:1. The component A is mainly composed of bisphenol A type epoxy resin, bisphenol F type epoxy resin, glycidyl ether diluent, a flexibilizer, a coupling agent, a thixotropic agent I and filler I. The component B is mainly composed of a complex-amine curing agent, an accelerator, hixotropic agent II and filler II. The epoxy structural adhesive is used for reinforcing construction of carbon fiber plates, and the carbon fiber plates are light in mass, convenient to bond in construction (the structural adhesive does not flow) and high in strength. Compared with a steel bonding construction method, the procedures of welding, polishing, pressurizing and the like are not needed in the method. The complex-amine curing agent is adopted in the developed component B, and the curing object is high in bonding strength, good in water resistance and good in toughness. The epoxy resin adhesive component A is free of crystallization, easy to smear and convenient to construct.

Owner:CARBON TECH CO LTD

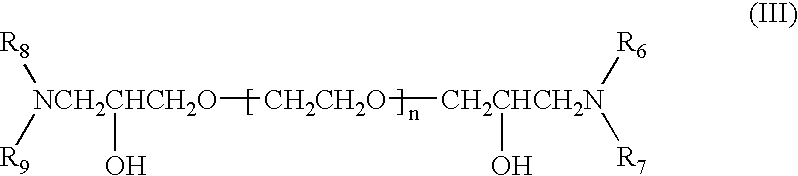

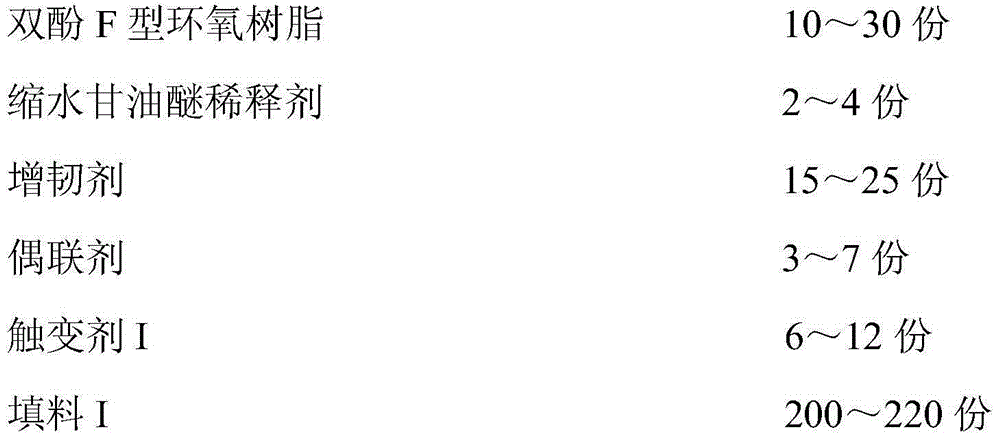

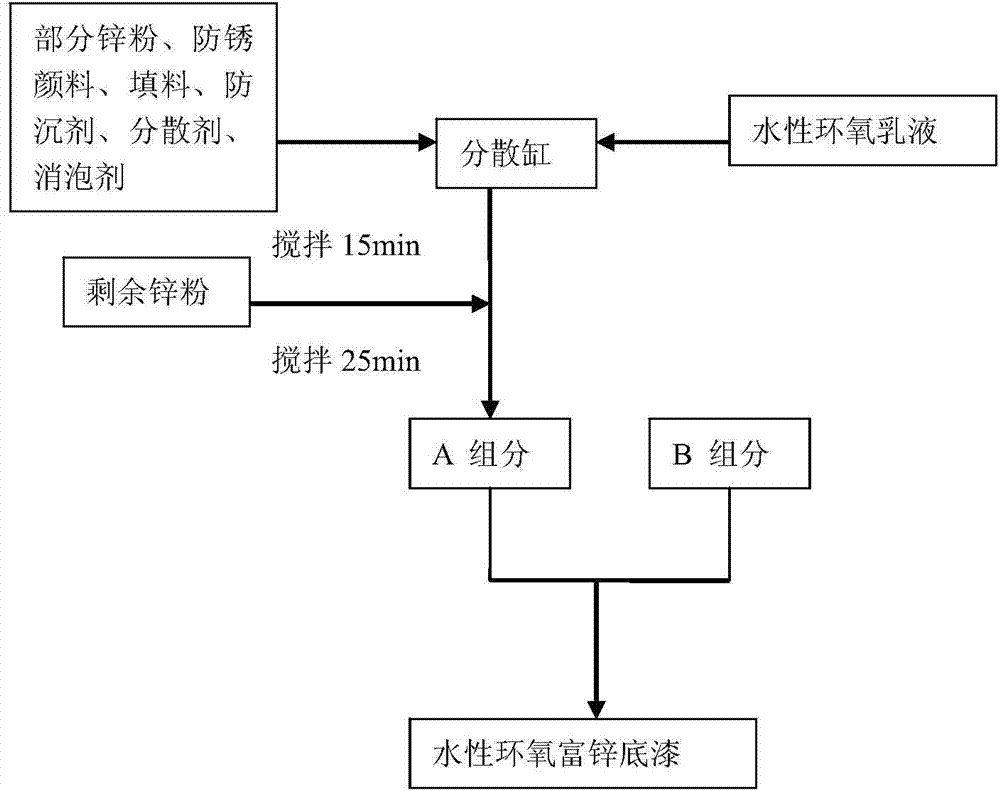

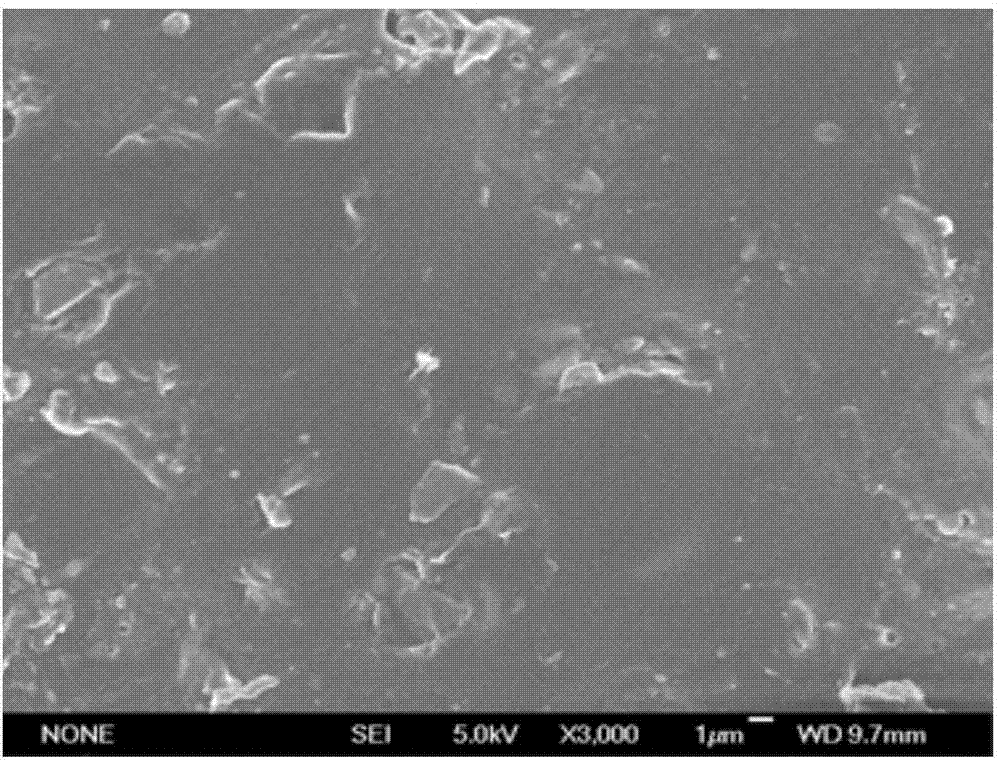

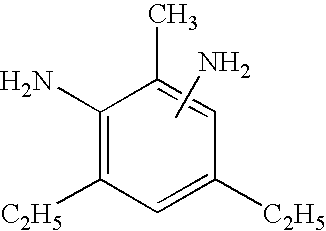

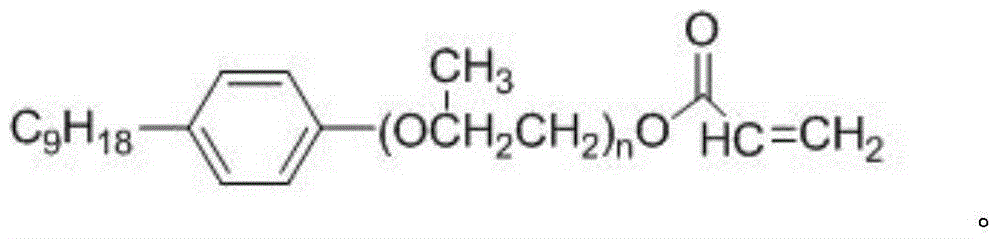

VOC (Volatile Organic Compounds)-free water-based epoxy curing agent

ActiveCN103788343AHas emulsifying effectGood compatibilityEpoxy resin coatingsWater basedPetrochemical

The invention belongs to the field of chemical coatings, and specifically relates to a VOC (Volatile Organic Compounds)-free water-based epoxy curing agent. The curing agent comprises the following components in percentage by weight: 12-25% of epoxy resin, 15-30% of terminal epoxy glycidyl ether, 3-11% of polyether amine, 18-35% of an amine compound and 40-60% of deionized water. The preparation method of the curing agent comprises the following steps: preparation of an intermediate, epoxy-amine addition and dispersion by using deionized water. The preparation method of the curing agent is simple, the reaction process is easy to control, no organic solvent is used in the preparation process and the storage stability of the curing agent is good. A water-based epoxy zinc-enriched primer which is made of the curing agent has the characteristics of high drying speed, low applicable temperature, good film flexibility, high hardness, excellent corrosion resistance and the like, and can be applied to the fields such as ocean engineering, bridges, grade levels, high-speed rail facilities, wind power equipment, petrochemical engineering and heavy machinery.

Owner:浙江纳宝莱化工科技有限公司

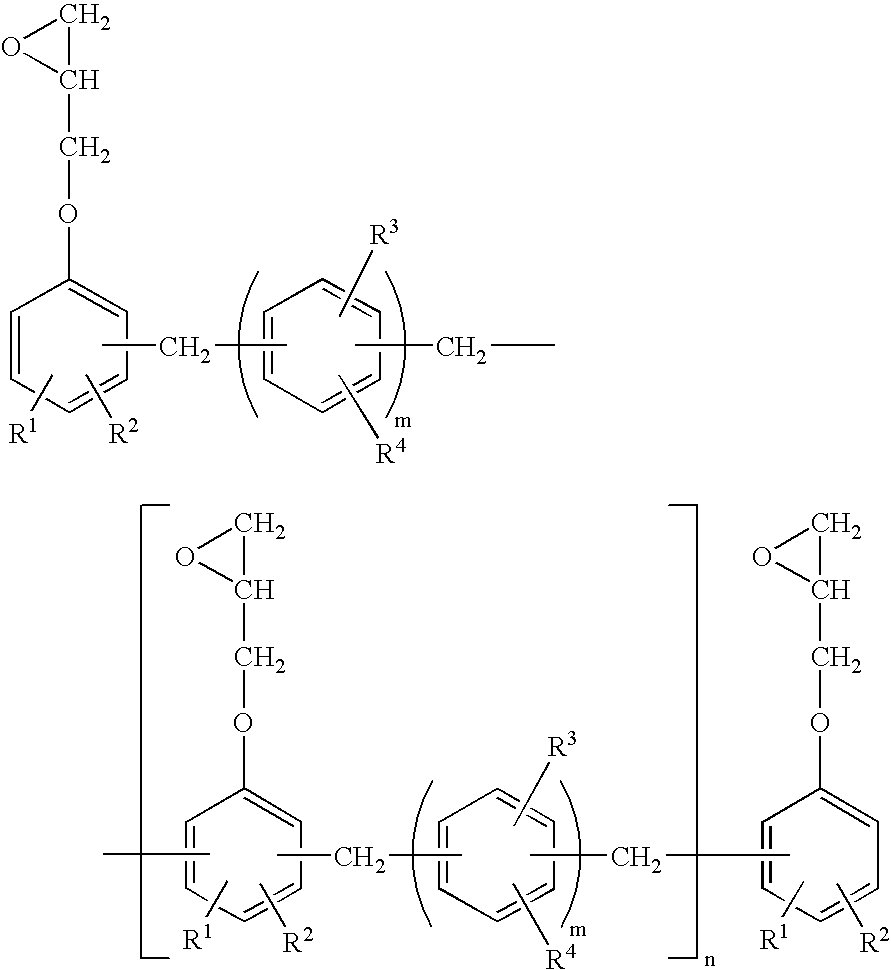

Epoxy resin compositions for fiber-reinforced composite materials, process for production of the materials and fiber-reinforced composite materials

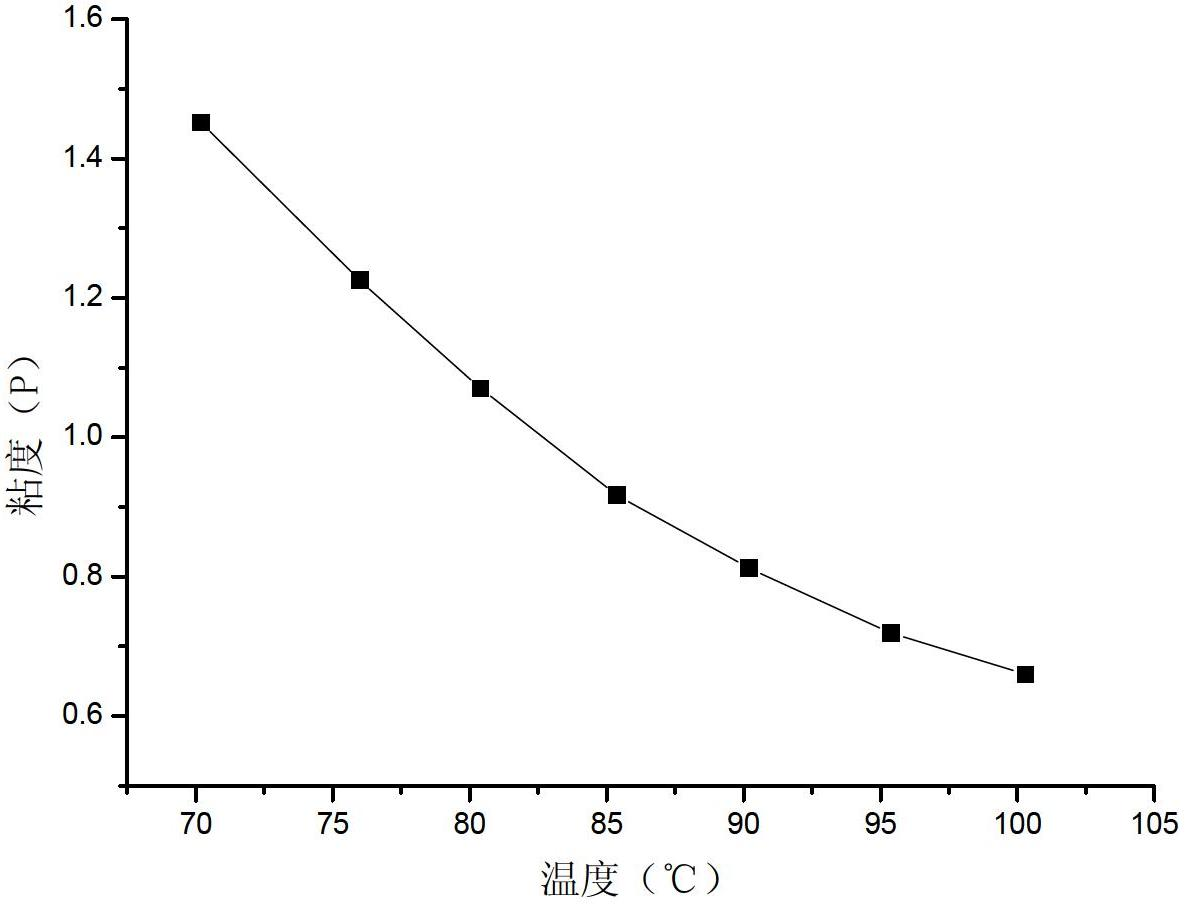

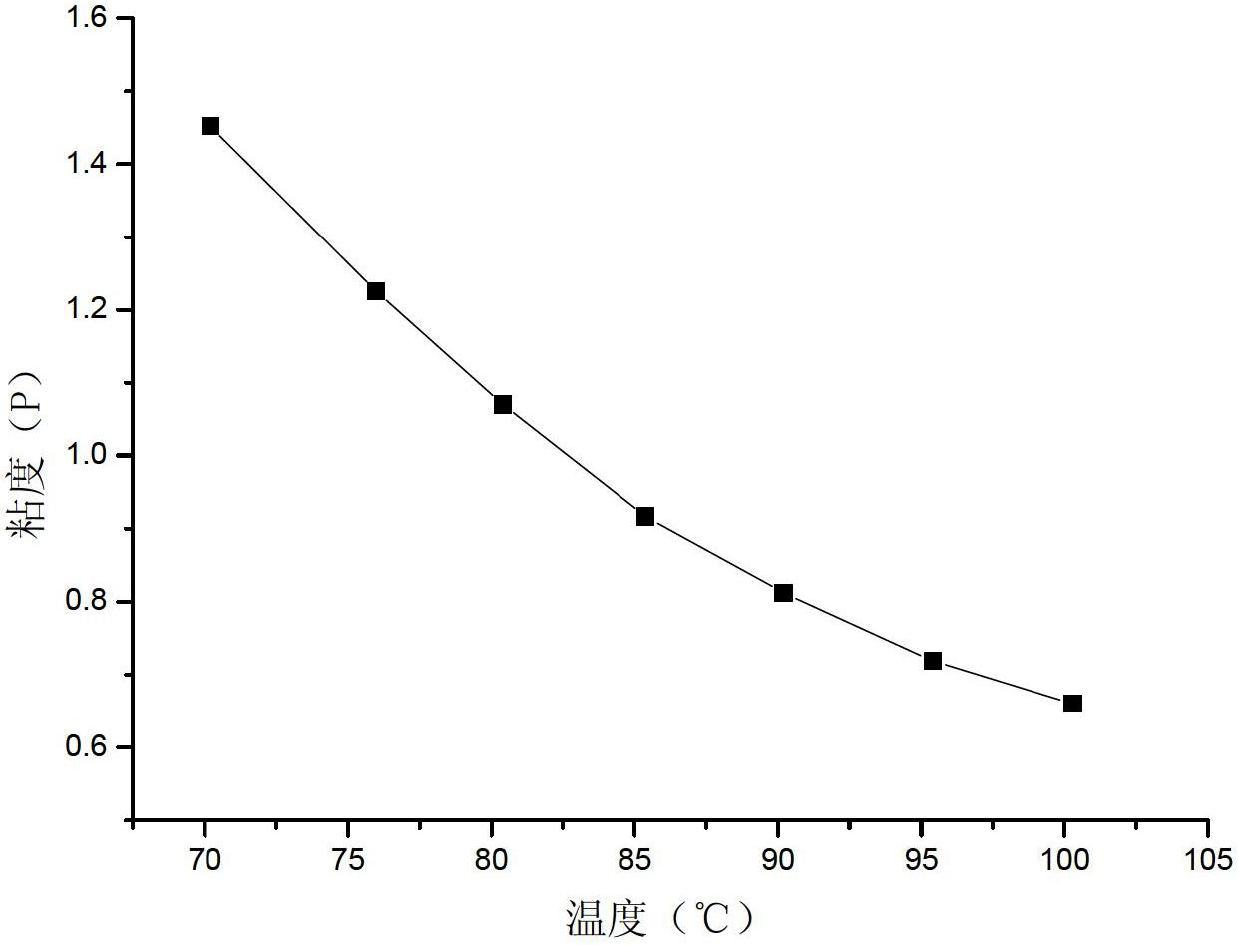

InactiveUS20040247882A1Low costLow viscositySynthetic resin layered productsEpoxy resin adhesivesSatelliteEther

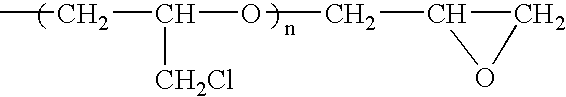

The present invention relates to an epoxy resin composition for fiber reinforced composite material comprising the following components (1)-(3) as essential components, their mixing ratios meeting the following conditions (I)-(IV), and component (3) being dissolved homogeneously: component (1): epoxy resin that is liquid at room temperature, component (2): aromatic polyamine that is liquid at room temperature, component (3): diaminodiphenylsulfone, condition (I): The proportion of component (1) relative to the entire epoxy resin in the composition is 60-100 wt %, condition (II): The sum of the proportions of components (2) and (3) relative to the entire polyamine in the composition is 70-100 wt %, condition (III): The proportion of component (3) relative to the entire polyamine in the composition is 25-60 wt %, and condition (IV): The stoichiometric ratio of the entire polyamine to the entire epoxy resin in the composition is 0.7-1.3. Another embodiment of the invention relates to an epoxy resin composition for fiber reinforced composite material that contains at least the following components (4)-(6), forms a cured product with a theoretical molecular weight between crosslinking points in the range of 250-350 g / mol, and has an initial viscosity at 80° C. of 1-500 MPa.s: (4): aromatic epoxy resin with tri- or higher functionality, (5): aromatic epoxy resin with di- or higher and lower than tri-functionality, and (6): aromatic polyamine, the molecular weight between crosslinking points being defined as the weight of the entire cured epoxy resin divided by the number of crosslinking points contained in the entire cured epoxy resin. The invention also relates to an epoxy resin composition for fiber reinforced composite material that consists of the following components (7) and (8): (7) a polyglycidyl ether of phenol aralkyl resin as represented by the following formula: where R<1>, R<2>, R<3 >and R<4>denote a hydrogen atom, an alkyl group having 1-8 carbon atoms, or a halogen atom, and m and n denote an integer of 1-4 and a real number of 0 or more and less than 1, respectively, and (8) polyamine. With the constitution described above, the present invention can provide a liquid epoxy resin composition for low cost production of high performance fiber reinforced composite material, that has a low viscosity at relatively low temperatures, and that after being cured, the cured product is high in glass transition temperature, elastic modulus and toughness while being small in the glass temperature decrease caused by water absorption and also small in the coefficient of linear expansion; and can provide a method to produce fiber reinforced composite material therefrom. Fiber reinforced composite material produced according to the present invention can serve as material for parts of aircraft, including main wing, tail, rotor blade, fairing, cowl, and door; parts of spacecraft, including motor case and main wing; and parts of space satellite body structure. They can also be used preferably as material for automobile chassis and railroad vehicle body structure.

Owner:TORAY IND INC

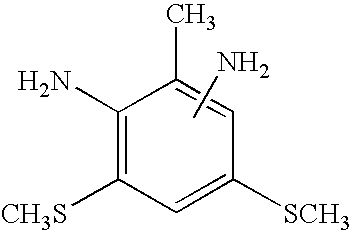

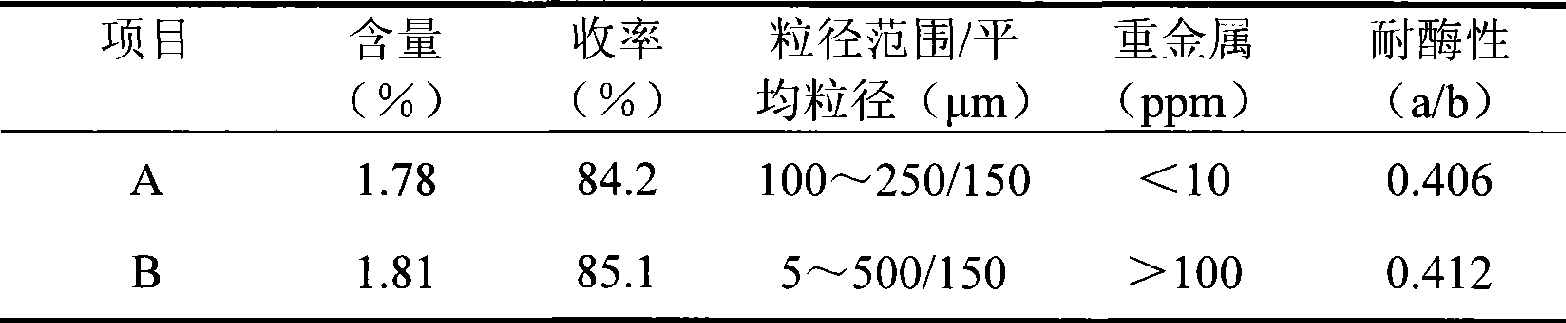

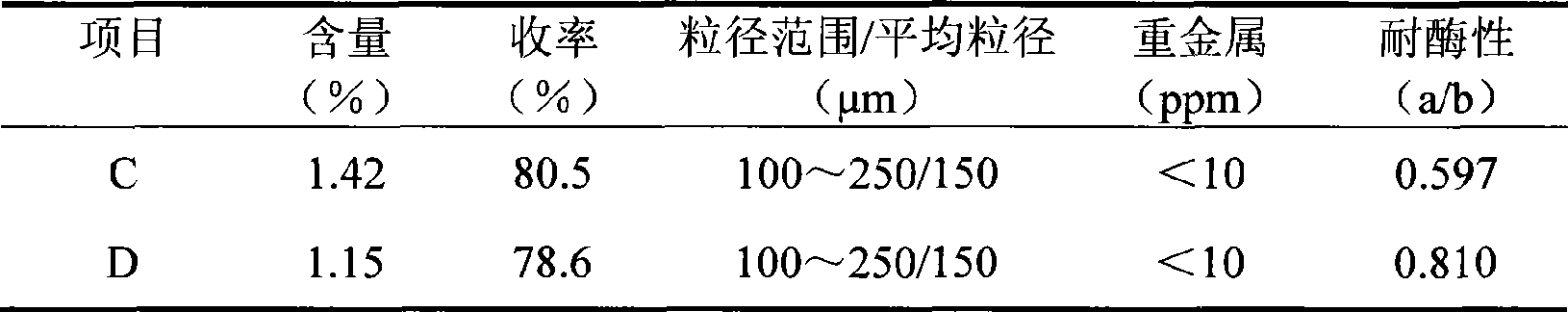

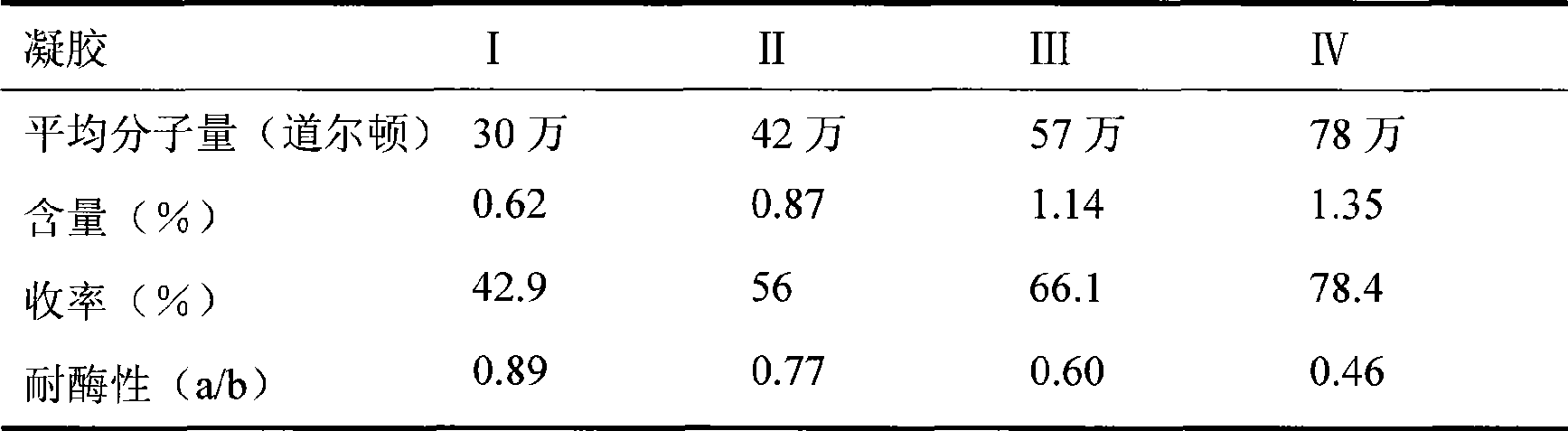

Crosslinking hyaluronic acid sodium gel for injection and preparation method thereof

The invention relates to a cross bonding sodium hyaluronate gel for injection and a preparation method thereof. The method is characterized in that sodium hyaluronate and glycidyl ether are mixed and react in alkaline solution to form water-insoluble gel, the gel is purified in deionized water and broken into particles of certain sizes; ionic strength of the deionized water is improved to contract the gel particles. The cross bonding sodium hyaluronate gel features asepsis, apyrogeneity and small and uniform particles; therefore the gel can be applied to prepare injection for beauty care and medical treatment.

Owner:SHANDONG FREDA PHARMA GRP CO LTD +1

Pyrophosphoric acid bath for use in copper-tin alloy plating

InactiveUS20050166790A1Optimization rangeReduce SO3 generation rateAnti-corrosive paintsLiquid/solution decomposition chemical coatingGeneration rateAlloy coating

The invention relates to a pyrophosphoric acid bath for use in cyanogen-free copper-tin alloy plating that contains an additive (A) composed an amine derivative, an epihalohydrin and a glycidyl ether compound with ratios of epihalohydrin to glycidyl ether compound being 0.5-2 to 0.1-5 on mol basis, per 1 mol of the amine derivative, has a pH of 3 to 9, and optionally contains an additive (B) composed of an organic sulfonic acid and / or an organic sulfonic acid salt, and to a copper-tin alloy coating obtainable by using the bath. The invention provides a pyrophosphoric acid bath for use in copper-tin alloy plating of the cyanogen-free type utilizable on an industrial scale, particularly, capable of performing uniform treatment to exhibit low defective product generation rates even with the current density being incessantly changing between a high state and a low state, as a barrel plating method, and a copper-tin alloy coating obtainable by using the bath.

Owner:NIHON NEW CHROME

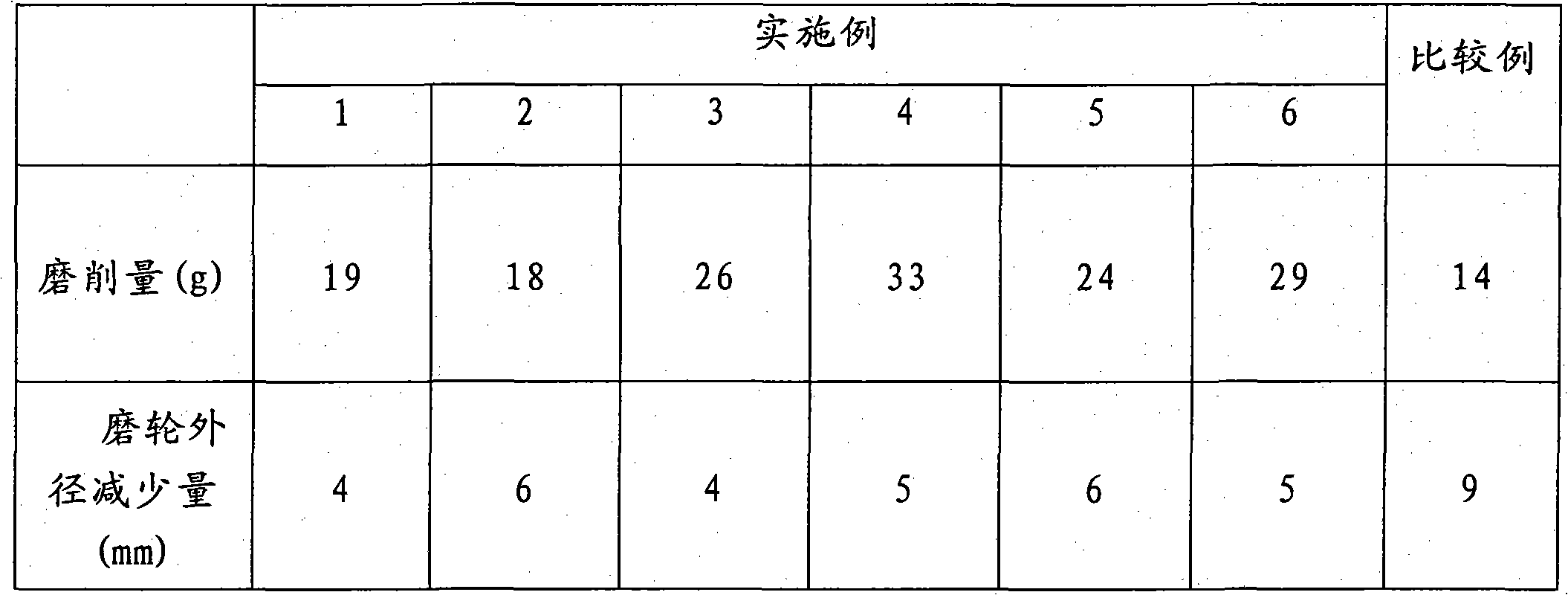

Method for preparing non-woven fabric polishing abrasive tool with high abrasion resistance

InactiveCN101913121AHigh viscosityImprove adhesionFibre typesGrinding devicesSilanesMagnesium stearate

The invention relates to a method for preparing a non-woven fabric polishing abrasive tool with high abrasion resistance. The method comprises the following steps of: taking 20 to 40 mass parts of epoxy resin, adding 4 to 25 mass parts of curing agent, 20 to 45 mass parts of abrasive, 8 to 15 mass parts of diluent, 2 to 8 mass parts of toughening agent, 1 to 3 mass parts of silane coupling agent and 3 to 8 mass parts of auxiliary materials into the epoxy resin, mixing the materials uniformly, then spraying the mixture onto a non-woven fabric, curing the mixture at a high temperature, and then performing punch forming, wherein the toughening agent comprises reactive epoxy toughening agent, terminal carboxyl liquid nitrile rubber and / or terminal carboxyl polybutadiene liquid rubber; the silane coupling agent comprises gamma-aminopropyltriethoxysilane, gamma-glycidyl ether oxypropyl trimethoxy silane and / or gamma-(methacryloyloxy) propyltrimethoxysilane; and the other auxiliary materials comprise 2,4,6-tri(dimethylaminomethyl) phenol DMP-30 accelerator, wax powder, graphite, pigment, magnesium stearate and / or zinc stearate. The non-woven fabric polishing abrasive tool is mainly used for polishing treatment of metal surfaces.

Owner:SOUTH CHINA UNIV OF TECH +1

Two-component epoxy decorating sealant and preparation method thereof

ActiveCN105802451ANo saggingWon't flowAntifouling/underwater paintsPaints with biocidesGlycidyl ethersColloid

The invention provides a two-component epoxy decorating sealant, comprising component A and component B. The component A comprises, by weight: 70-90 parts of first epoxy resin, 0-7 parts of glycidyl ether type diluent, 1-5 parts of a coupling agent, 3-7 parts of a first thixotropic agent, 0.1-0.3 part of a yellowing aid, and 0.1-0.3 part of a defoaming agent; the component B comprises 20-25 parts of an alicyclic curing agent, 20-30 parts of second epoxy resin, 25-30 parts of benzyl alcohol diluent, 3-6 parts of an accelerant, 3-7 parts of a second thixotropic agent, and 5-10 parts of a pigment. After being constructed and cured, the two-component epoxy decorating sealant attaches tightly to ceramic tiles, and water and dust never enter a gap to cause mold or leakage. In addition, colloid of the decorating sealant of the invention never flows or sags during construction, construction is facilitated, and construction efficiency is improved. The invention also provides a preparation method of the two-component epoxy decorating sealant.

Owner:HUNAN KOSEN NEW MATERIAL

Method for preparing polyester modified organic silicon resin and coating containing the resin

ActiveCN102504265ALower surface energyLow surface energy coatings with good heat resistanceCoatingsPolyesterGlycidyl ethers

The present invention relates to a method for preparing polyester modified organic silicon resin which is prepared from 45-75 wt% of saturated polyester, 1-10 wt% of 3-glycidyl ether oxygen propyl trimethoxy silane and 20-45 wt% of organic silicon resin by reacting. The acid value of the saturated polyester is within a range of 60 to 120 mgKOH / g, and the weight-average molecular weight of the saturated polyester is within a range of 2000 to 6000. The weight-average molecular weight of an intermediate of the organic silicon resin is within a range of 800 to 2000, the content of alkoxy of the organic silicon resin is within a range of 2.5 to 15%, and the content of hydroxyl of the organic silicon resin is within a range of 3 to 20%. By combining with advantages of saturated polyester and organic silicon resin, the method has advantages of excellent heat resistant quality, good metal adhesion, low surface energy, excellent boiling resistant quality and acid-alkali resistant quality, and good temperature variation resistant quality. The polyester modified organic silicon resin prepared by the method can be used for preparing a high temperature resistant coating with low surface energy.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

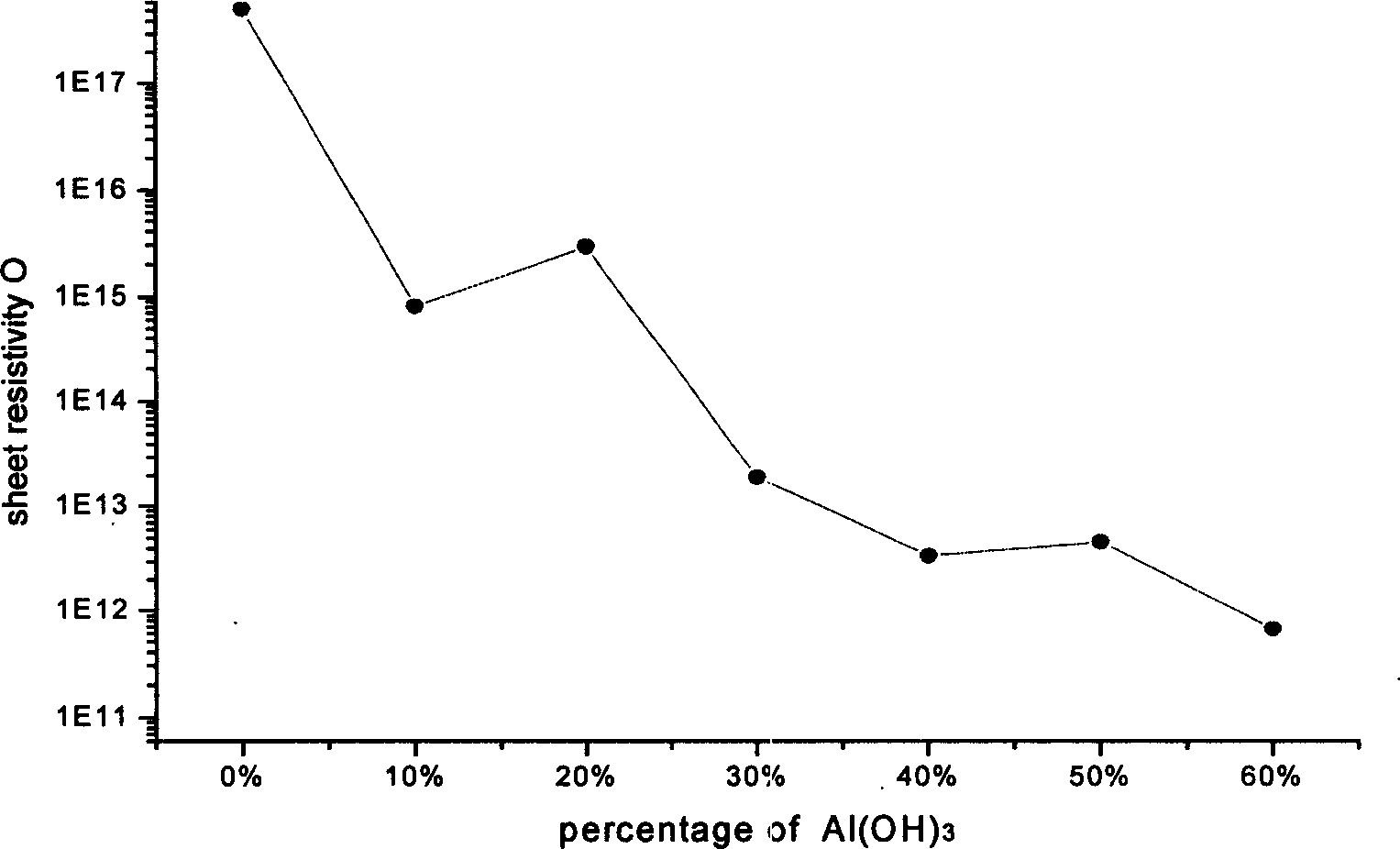

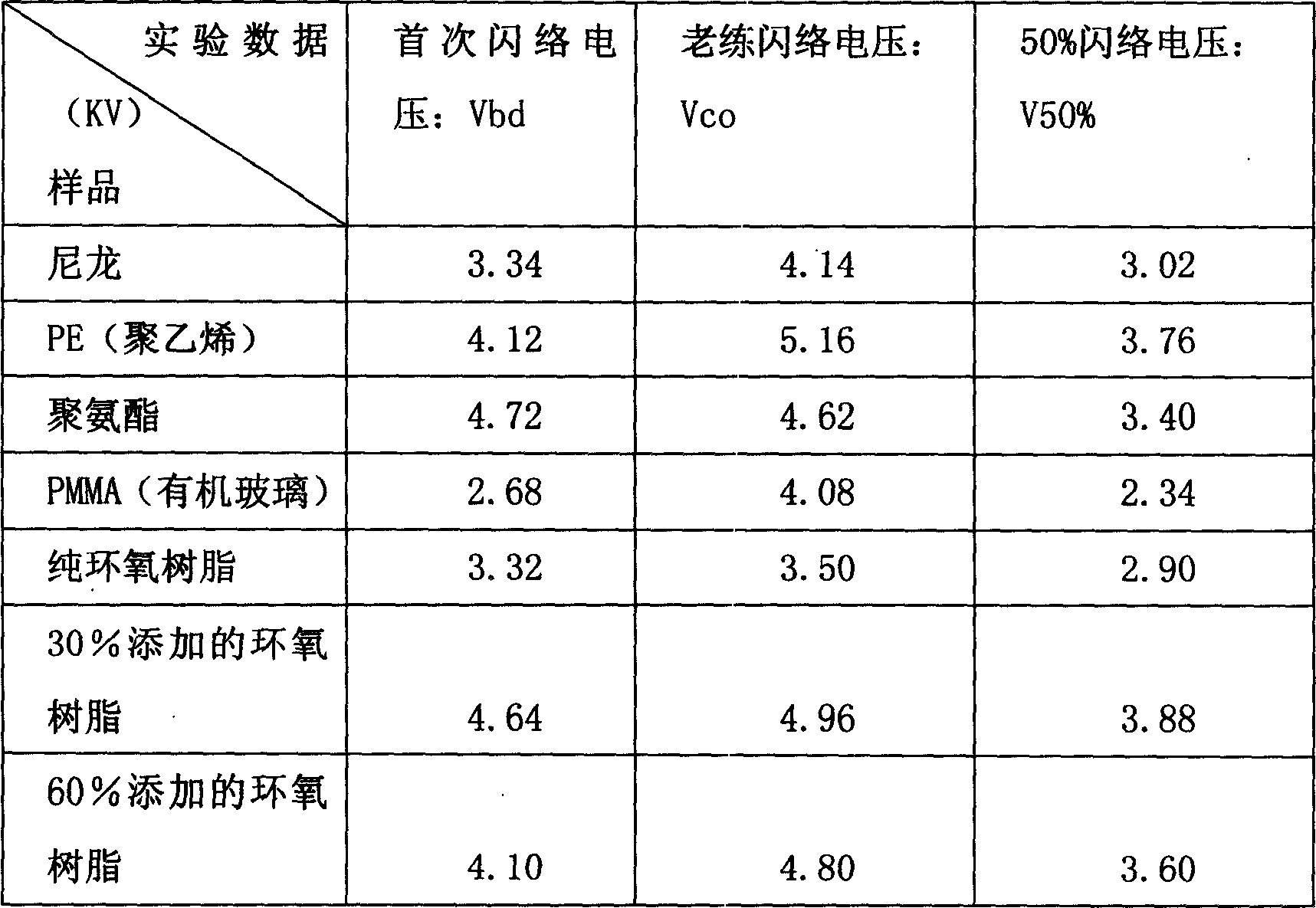

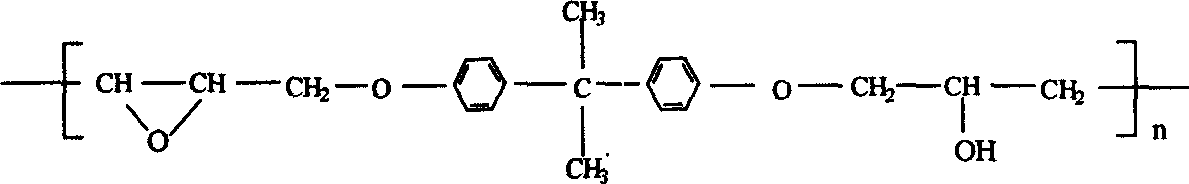

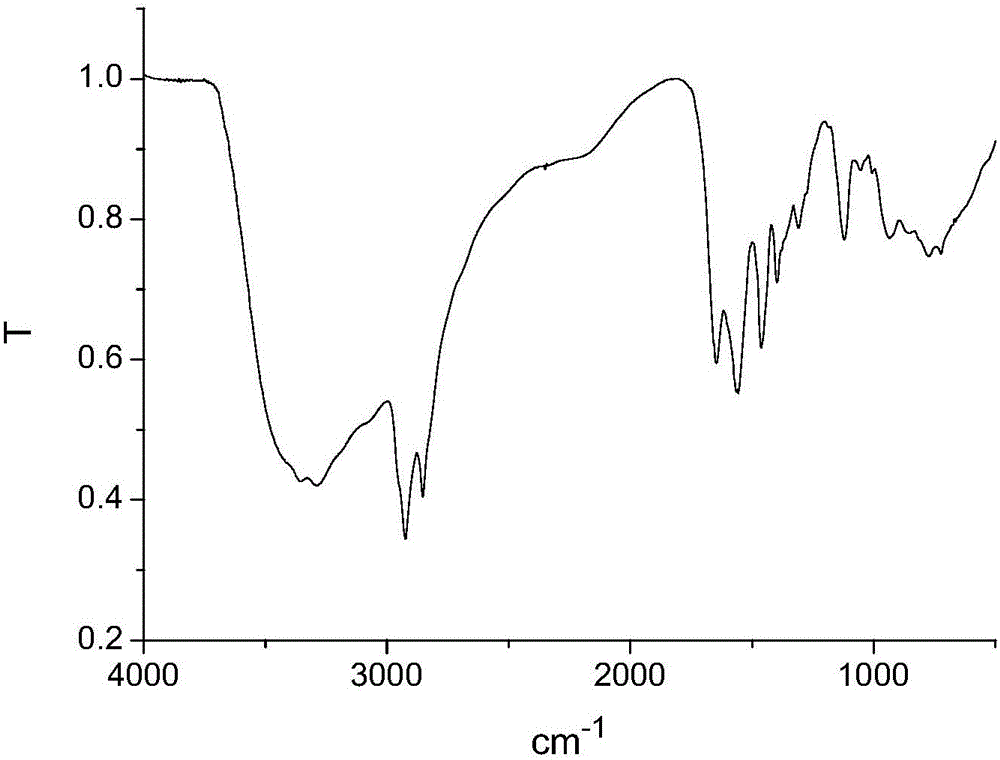

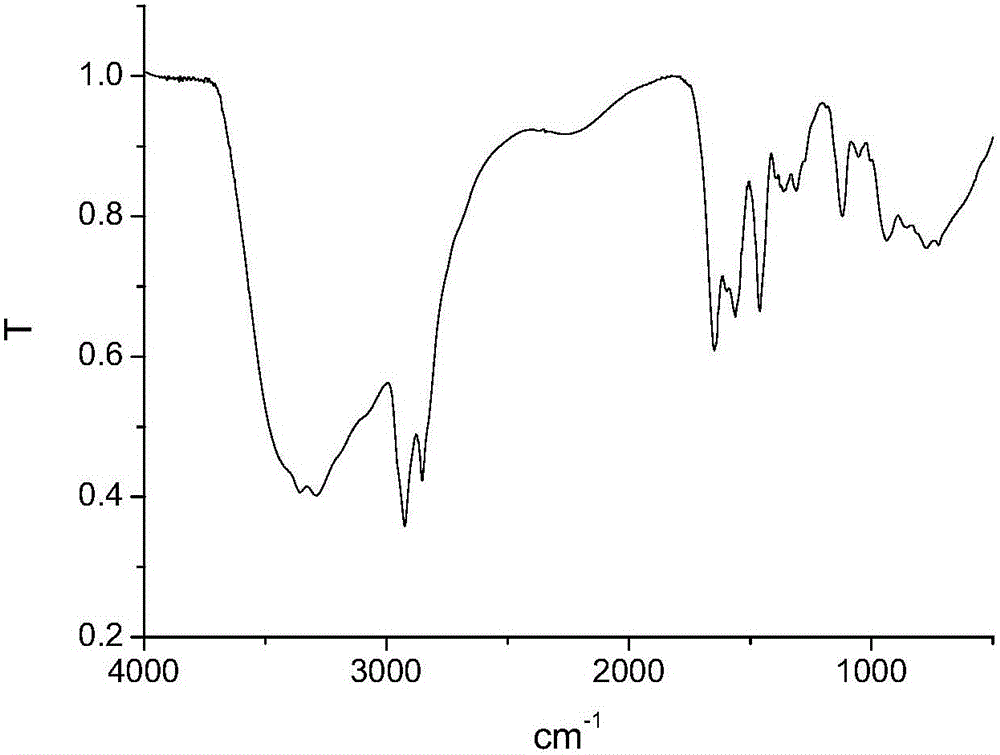

Vacuum insulator coating capable of increasing flashover voltage and method of preparation thereof

InactiveCN1604237AExcellent tracking resistanceImprove thermal conductivityPlastic/resin/waxes insulatorsFirming agentHigh surface

This invention relates to a vacuum isolation sub-coating and its process to improve the surface flashover voltage, wherein, the coating is composed of epoxide resin, aluminum hydroxide, modified synthesized amine firming agent, butyl epihydrin aether thinner. The process comprises the steps of materials, bacon, vacuum, mixture, heating and solidifying and cooling and demoulding Comparing with current material, the coating in this invention has higher surface flashover voltage and high flash burn endurance.

Owner:XI AN JIAOTONG UNIV

Two-component urethane resin adhesive for polymer lithium ion battery flexible package film

InactiveCN102329594ANot easy to peel offPeeling does not affectPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterStrong acids

The invention provides a two-component urethane resin adhesive for a polymer lithium ion battery flexible package film, and aims to provide an adhesive which has the advantages of high bonding strength, stripping resistance, excellent barrier property, impact resistance, high bonding compatibility with a nonmetallic film or an aluminum foil, resistance to swelling, dissolving, permeation and absorption of electrolyte organic solvents and high-volatility substances, resistance to strong acid and strong alkali and difficulty in breaking a molecular chain after becoming dry and hard. The two-component urethane resin adhesive consists of components, wherein a first component (A) is an emulsion waterborne Poly Urethane (PU) performed polymer which is obtained by compounding polyester and isocyanate / benzene ring-containing polyether in the mass ratio 75 / 25-55 / 45 and adding an aid for reacting; a second component (B) is a composition consisting of glycidyl ether epoxy resin with the epoxy resin 0.25-0.45 and a melamine-formaldehyde resin additional crosslinking agent; the weight ratio of the first component to the second component is 10 / 1-10 / 2; and a certain amount of additional crosslinking agent is added into a PU emulsion in a certain mass ratio.

Owner:刘继福

Environment-friendly permeable high-strength waterborne epoxy slurry and preparation method and application thereof

ActiveCN105885755APromote environmental protectionImprove permeabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesMass ratioPolyamide

The invention discloses environment-friendly permeable high-strength waterborne epoxy slurry and a preparation method and an application thereof. The method comprises the following steps: mixing 40-70wt% of liquid epoxy resin and 60-30wt% of glycidyl ether to obtain a 100wt% of a component A; mixing 10-50wt% of water-swellable self-emulsified polyamide-amine, 85-30wt% of hydrophobic modified aliphatic amine and 5-20wt% of aliphatic amine polyoxyethylene-polyoxypropylene to obtain a 100wt% of a component B; premixing the component A and the component B at the mass ratio of 100 to (60-90) to obtain environment-friendly permeable epoxy net slurry with low initial viscosity; and mixing the epoxy net slurry and a component C (including 50-100wt% of an inorganic filler, 0-50wt% of water and 0-1wt% of an assistant) at the mass ratio of 100 to (60-300), and curing to obtain a high-strength non-shrinkage epoxy-based composite material. The high-strength non-shrinkage epoxy-based composite material can be used for preparing a high-strength open-cell or closed-cell material, and has a wide application prospect in the field of grouting, a mold and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

Preparation of hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as application thereof

ActiveCN104707579AOther chemical processesWater/sewage treatment by sorptionPolymer scienceGlycidyl ethers

The invention relates to a preparation method of a hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as an application thereof. The hyperbranched polyetheramine-grafted GO adsorbent is characterized in that polyether diglycidyl ether and a polyamine monomer are employed to prepare the hyperbranched polyetheramine HPEA, an alkalescence catalyst grafting oxidation graphene GO is used, so that the hyperbranched polyetheramine-grafted oxidized graphene GO-HPEA. The adsorbent preparation method is simple and easy, the adsorption quantity for the heavy metal ion or cation dye can be more than 500mg / g, and the hyperbranched polyetheramine-grafted GO adsorbent has the advantages of easy solid-liquid separation and repeatable utilization, and can be used for high efficiency treatment of heavy metal and dye in waste water.

Owner:UNIV OF JINAN

Graphene oxide-based curing agent as well as preparation and use thereof

InactiveCN104262588AImprove thermal stabilityLow resistivityNon-macromolecular adhesive additivesEpoxy resin adhesivesArray data structureGlycidyl ethers

The invention discloses a preparation method of a graphene oxide-based curing agent and application of the graphene oxide-based curing agent in epoxy resin conductive glue. The conductive glue consists of the following components in parts by weight: 1-2 parts of a graphene oxide-based curing agent, 3-10 parts of a conventional curing agent, 10-20 parts of E-51 epoxy resin, 10-20 parts of AG-80 epoxy resin, 15-25 parts of carbon black, 15-25 parts of silver precipitate powder, 1-8 parts of amine accelerants, 1-5 parts of a liquid imidazole defoaming agent and 1-20 parts of glycidyl ether diluents. The preparation method of the graphene oxide-based curing agent comprises the following steps: firstly, preparing graphene oxide and then modifying the graphene oxide to obtain a graphene oxide-based curing agent capable of conducting and toughening; and then, blending according to a formula of the conductive glue and curing to obtain a graphene oxide-based epoxy resin composite material. The graphene oxide-based curing agent with capacity of conducting and toughening is obtained by the preparation method; and an epoxy-based composite adhesive material prepared by taking the graphene oxide as the curing agent has good conducting capacity, acid and alkaline resistance, thermal stability and mechanical performance; and the adhesive is suitable for adhering electronic elements.

Owner:HUNAN UNIV

Low-stress transparent epoxy resin adhesive capable of curing fast at room temperature

ActiveCN104479607ALow viscosityEasy to apply glueNon-macromolecular adhesive additivesMacromolecular adhesive additivesShock resistanceBisphenol A

The invention belongs to the technical field of adhesives, and in particular relates to a low-stress transparent epoxy resin adhesive capable of curing fast at room temperature. The low-stress transparent epoxy resin adhesive is prepared by mixing an epoxy resin component A and a curing agent component B at the volume ratio of 1:1, wherein the epoxy resin component A comprises hydrogenated bisphenol A epoxy resin, bisphenol A glycidyl ether epoxy resin, functional acrylate monomer, an acrylate diluent, a tackifying accelerator and a silane coupling agent; the curing agent component B comprises polymercaptan, a tertiary amine accelerator, a vulcanizing accelerator, a stabilizer, a curing accelerator I and a curing accelerator II. While keeping 5-minute fast curing, high transparency and better bonding strength, the adhesive prepared by the invention has low exothermal temperature and small stress during curing, achieves better applicability in assembly of electronic devices, and has excellent electric insulativity, voltage breakdown resistance, shock resistance and aging resistance, and the application range of mercaptan-epoxy resin type adhesives in manufacturing of electronic devices is greatly expanded.

Owner:信泰永合(烟台)新材料有限公司

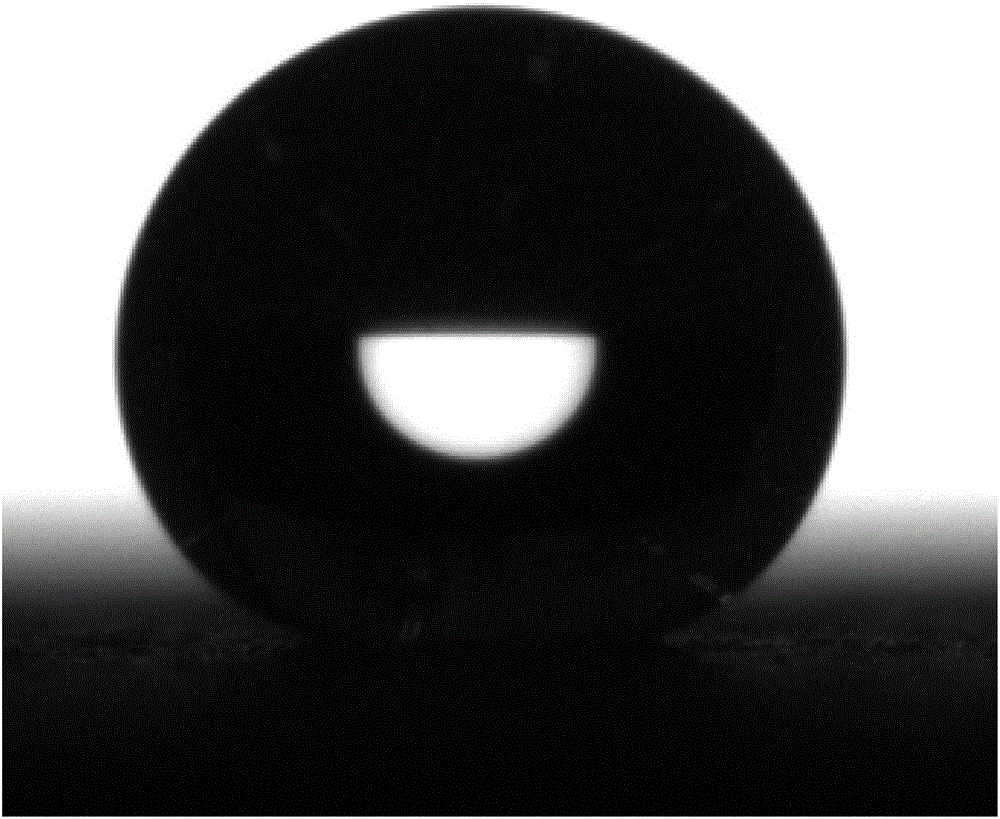

Preparation method of super-hydrophobic polymeric fiber

The invention relates to the technical field of high polymer material and particularly relates to a preparation method of a super-hydrophobic fiber. The preparation method of the super-hydrophobic fiber provided by the invention comprises the following steps: (a) constructing a nano-micro structure, namely coating the surface of polymeric fiber with a coating, thereby obtaining the polymeric fiber with surface subjected to functionalization, wherein the coating is dopamine, gamma-glycidyl ether oxygen propyl trimethoxy silane, tetraethoxy-silicane or aminopropyl triethoxysilane; and (b) performing surface modification, namely modifying the polymeric fiber with surface subjected to functionalization by use of a material with low surface energy, thereby obtaining the super-hydrophobic polymeric fiber, wherein the material with low surface energy is alkyltrichlorosilane or hexamethyl bisilazane. A contact angle between a fiber membrane manufactured by the fiber prepared by the method and water can be 168 degrees, the rolling angles of water drops on the fiber membrane are 4.5 degrees, and the fiber membrane has excellent affinity with ordinary organic solvents such as hexane and gasoline.

Owner:SICHUAN UNIV

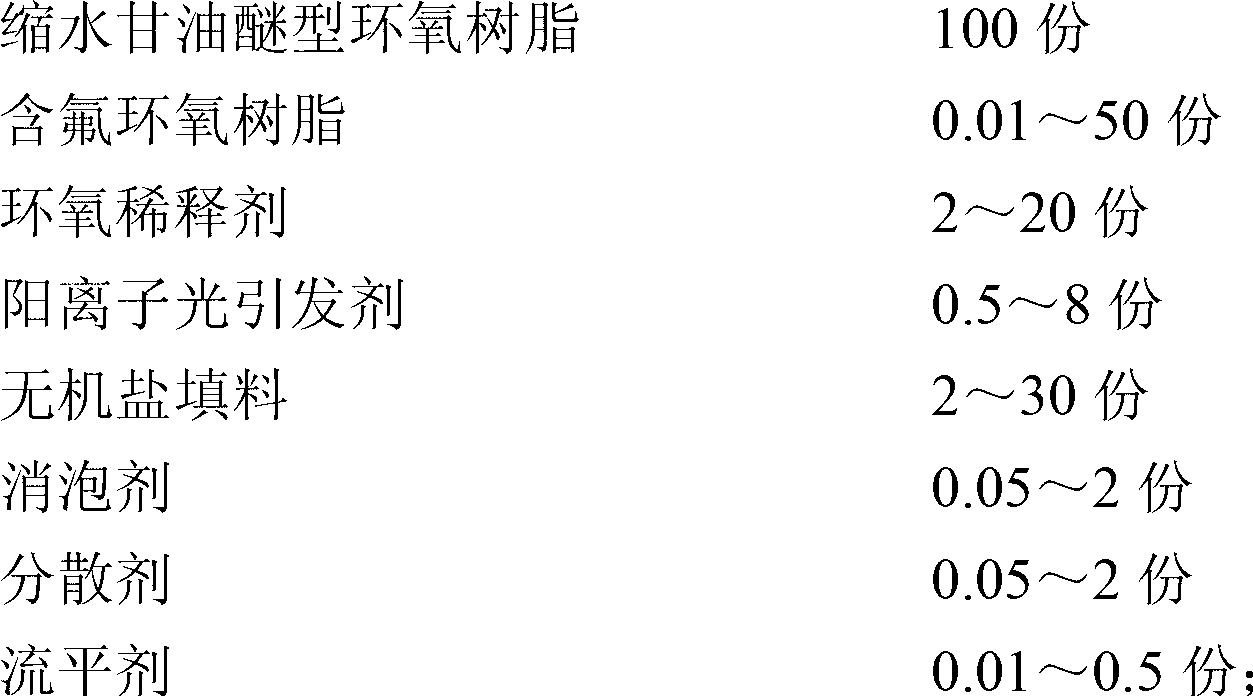

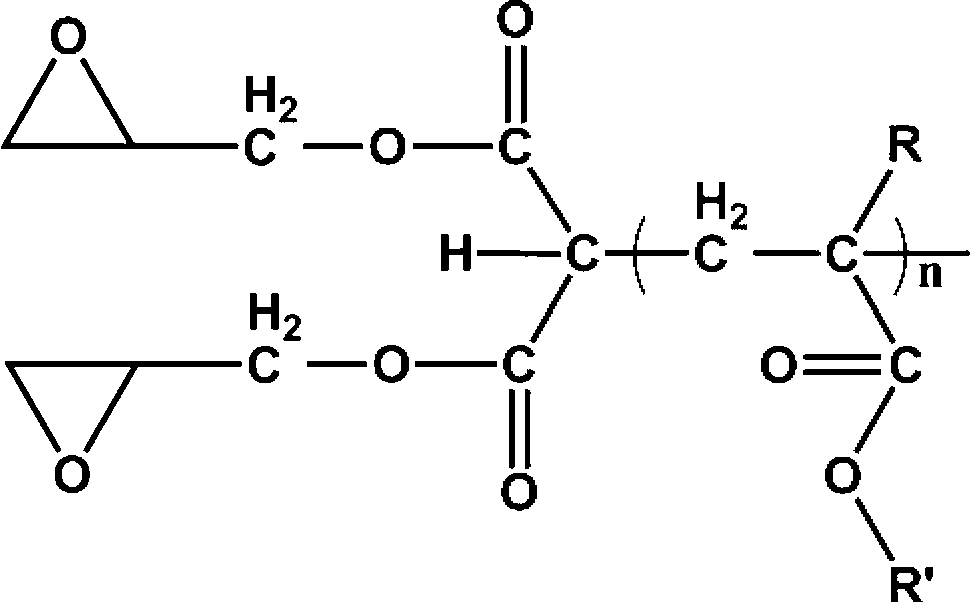

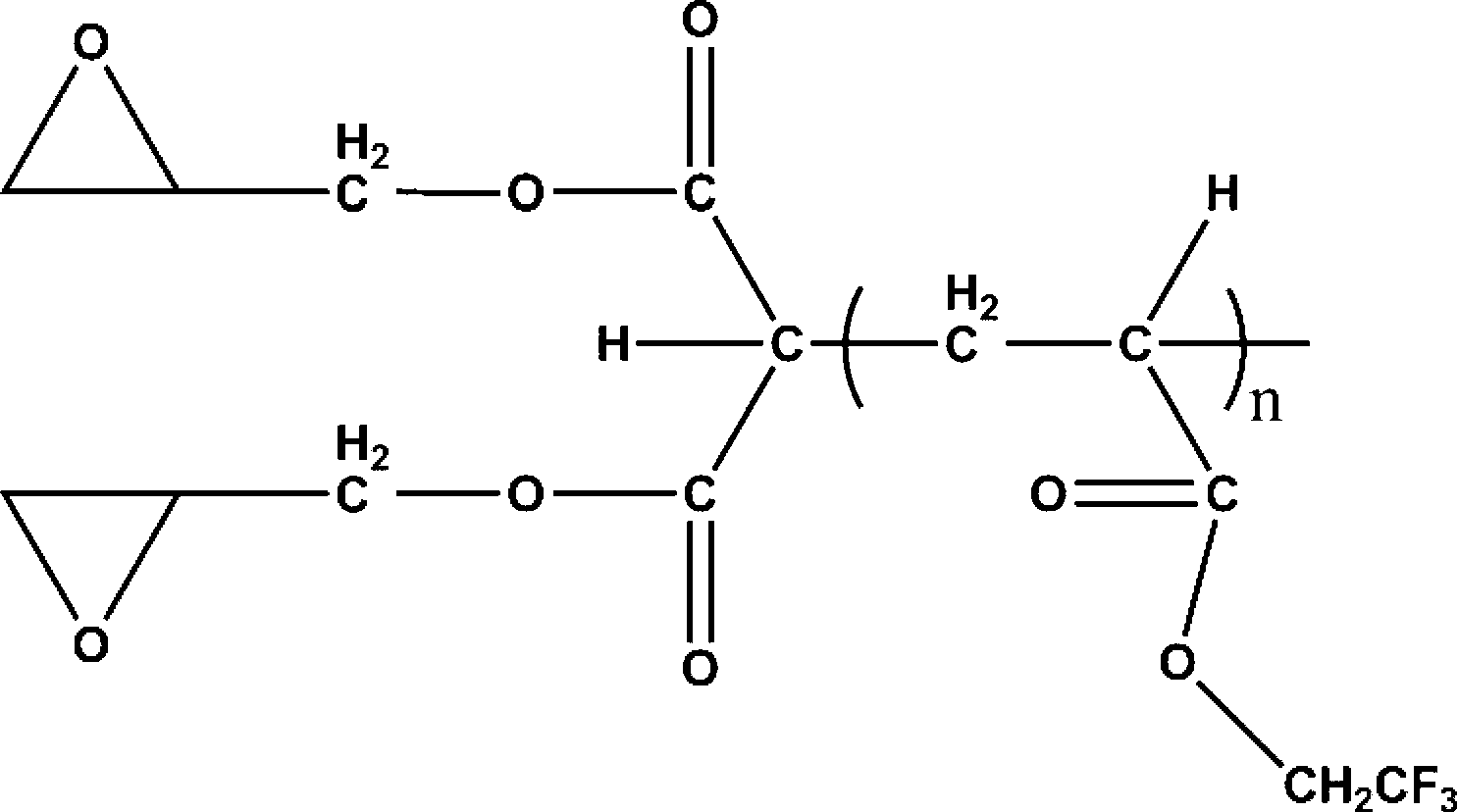

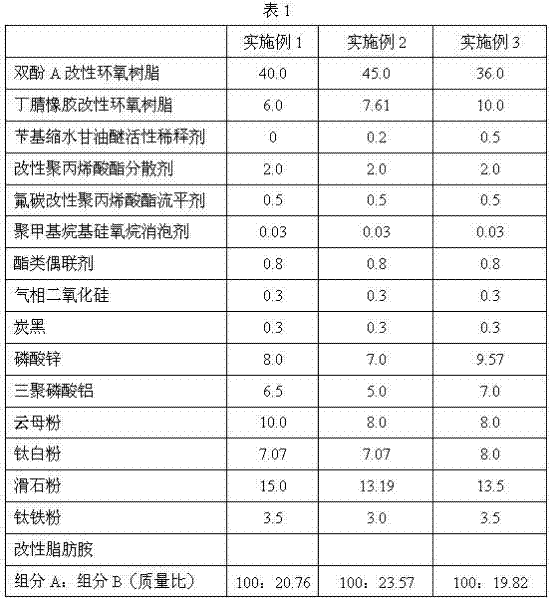

Fluorine-containing epoxy composite cation photocureable coating as well as preparation method and application thereof

ActiveCN103013287AImprove hydrophobicityImprove stain resistanceEpoxy resin coatingsInorganic saltsFoaming agent

The invention discloses a fluorine-containing epoxy composite cation photocureable coating as well as a preparation method and an application thereof. The coating comprises the following components: 100 parts of glycidyl ether type epoxy resin, 0.01-0.5 parts of fluorine-containing epoxy resin, 2-20 parts of epoxy diluting agent, 0.5-8 parts of cation photoinitiator, 2-30 parts of inorganic salt filler, 0.05-2 parts of de-foaming agent, 0.05-2 parts of dispersant and 0.01-0.5 parts of flatting agent. The fluorine-containing epoxy composite cation photocureable coating is obtained by adding the fluorine-containing epoxy resin into the glycidyl ether type epoxy resin and then photocuring the mixture. The fluorine-containing epoxy resin has the relatively higher molecular weight and fluorine content so that fluorine-containing atoms are more easily transferred to the air-coating surface of the composite coating, and the fluorine content of the surface is greatly more than the fluorine content of the body; and therefore, less fluorine-containing epoxy resin enables the composite photocureable coating to have the advantages of excellent lyophobic performance, pollution resistance, weather resistance and the like, and the application range is wide.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Low temperature cured solvent-free epoxy anticorrosion paint and its preparation method

ActiveCN102382552ASimple construction processSave energyAnti-corrosive paintsEpoxy resin coatingsGas phaseLow temperature curing

The invention discloses a low temperature cured solvent-free epoxy anticorrosion paint and its preparation method. The low temperature cured solvent-free epoxy anticorrosion paint comprises a component A and a component B with weight ratio of 100:12.90-24.12, wherein, the component A comprises the following ingredients by weight percentage: 26.75-50.0% of bisphenol A modified epoxy resin, 6.71-18% of auxiliary agent and 43.29-55.75% of inorganic pigments and fillers. The auxiliary agent comprises nitrile rubber modified epoxy resin, benzyl glycidyl ether, modified polyacrylate, fluorocarbon modified polyacrylate, polymethyl alkyl siloxane, an ester coupling agent and gas phase silica; the inorganic pigments and fillers comprise carbon black, zinc phosphate, aluminium triphosphate, mica powder, titanium dioxide, talcum powder and ferrotitanium powder; the component B is modified aliphatic amine. The solvent-free epoxy anticorrosion paint of the invention can be rapidly cured at the low temperature of 4 DEG C in winter, and the method of the invention has the advantages of simple and convenient construction, no special device requirement, energy saving and low cost.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

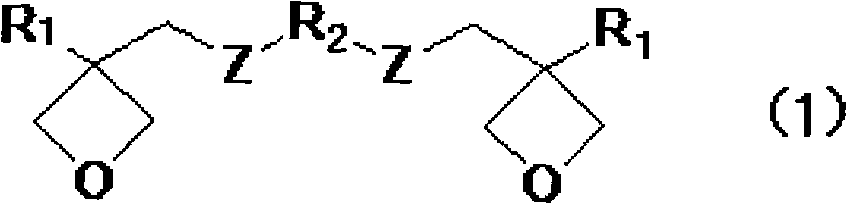

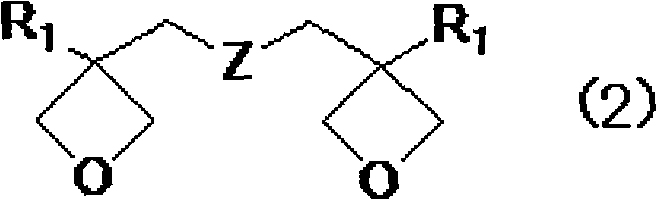

Cation-polymerizable adhesive and polarizing plate using the same

InactiveCN101824296AExcellent abnormal bond strengthNormal adhesive strength is goodNon-macromolecular adhesive additivesSynthetic resin layered productsTectorial membranePolymer science

The object of the present invention is to provide a cation-polymerizable adhesive which can maintain the excellent normal state adhesion strength and can not be affected by the heat and light, and to provide a polaroid sheet formed via adhering a polarizer and a protection film by the adhesive. The invention relates to the cation-polymerizable adhesive, charaterized in that, the adhesive contains heterocyclic butane compound (A) which has more than two oxygen heterocyclic butyls and molecular weights of 100 - 800, aromatic glycidyl ether (B) and cation-polymerizabl initiator (C), the chlorine remained in the total amount of the adhesive is below 1500 ppm. The invention also relates to the polaroid sheet formed via adhering the polarizer and the protection film by the adhesive.

Owner:DIC CORP

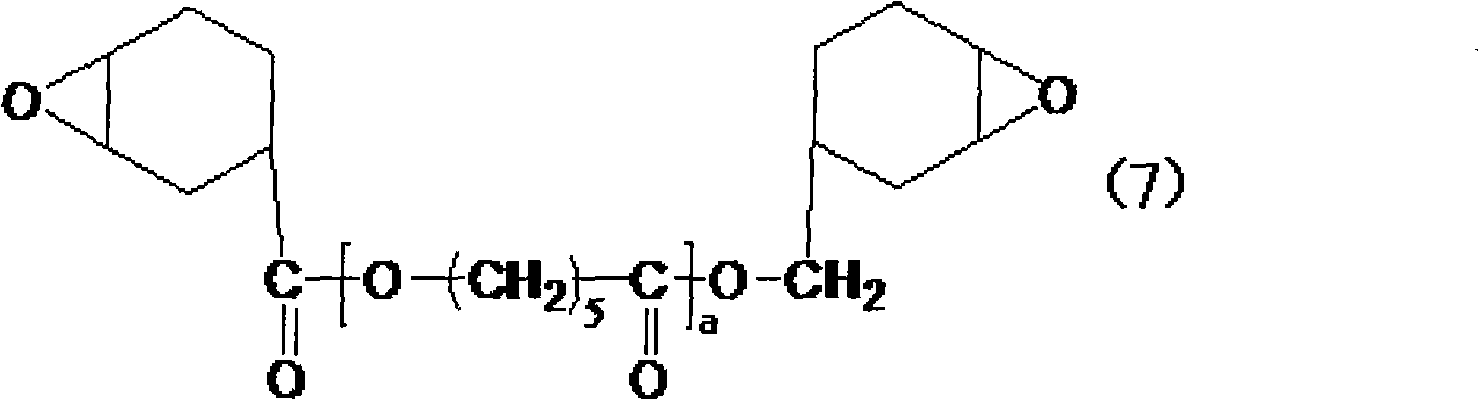

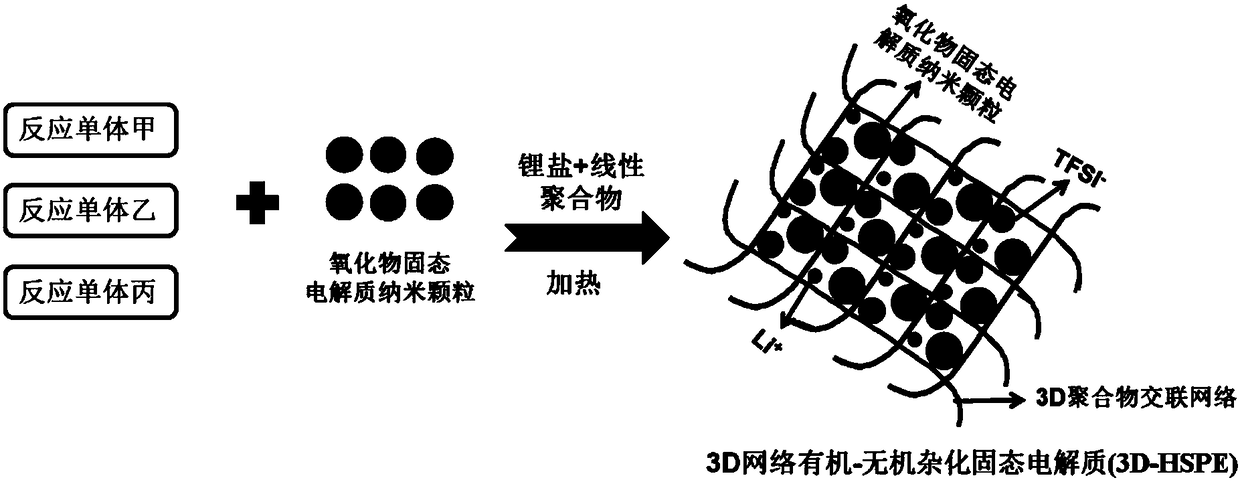

3D network organic-inorganic hybrid all-solid-state electrolyte and lithium secondary battery

PendingCN108365262AGrowth inhibitionGood flexibilitySolid electrolytesLi-accumulatorsCross-linkPolymer electrolytes

The invention provides a 3D network organic-inorganic hybrid all-solid-state electrolyte. The 3D network organic-inorganic hybrid all-solid-state electrolyte comprises a three-dimensional network polymer electrolyte matrix, oxide electrolyte nanoparticles or oxide electrolyte nanoparticle aggregation substance and a lithium salt, wherein the three-dimensional network polymer electrolyte matrix isused as a 3D network organic-inorganic hybrid all-solid-state electrolyte framework, the oxide electrolyte nanoparticles or the oxide electrolyte nanoparticle aggregation substance and the lithium salt are dispersed in the three-dimensional network polymer electrolyte matrix, and the three-dimensional network polymer electrolyte matrix is obtained by ring-opening polymerization of a reaction monometer with epoxy group, glycidyl ether-type epoxy resin, a derivative of the glycidyl ether-type epoxy resin, a cross-linking agent and a linear polymer.

Owner:GUANGDONG DYNAVOLT NEW ENERGY TECH CO LTD

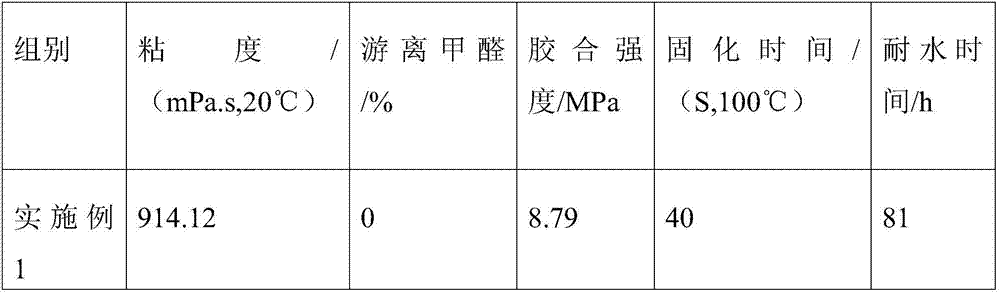

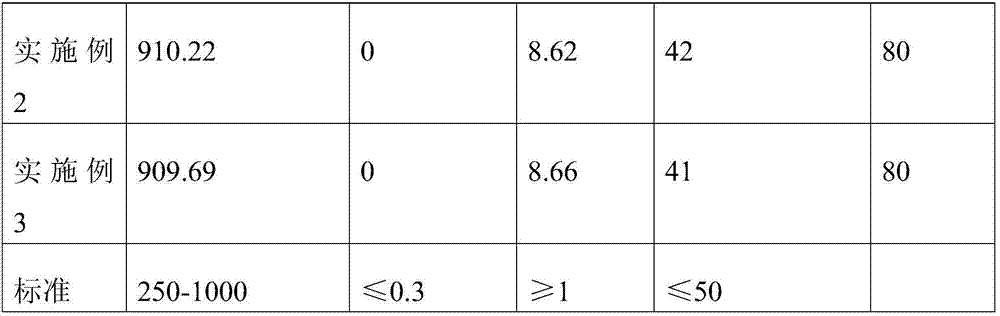

Special adhesive for wood veneer board

InactiveCN107083208AImprove adhesionGood modelNon-macromolecular adhesive additivesStarch derivtive adhesivesDispersityAdhesive

The invention discloses an adhesive glue specially used for wood plywood, which is mainly made of the following raw materials: mung bean starch, bisphenol A epoxy resin, modifier, urea, formaldehyde, melamine rubber powder, lignin, biological enzyme, Potassium hydrogen sulfate, polyglycidyl ether, chitosan, polyvinyl alcohol and sodium hexametaphosphate. The adhesive glue special for wood plywood of the present invention has the advantages of strong adhesion, good modeling and dispersibility, and reduces the consumption of formaldehyde, and the free formaldehyde emission of the synthesized adhesive glue product reaches the EO level standard (≤ 0.5mg / L), reducing the emission of formaldehyde, no harm to the human body, belongs to the green environmental protection adhesive. High bonding strength and strong water resistance. The method for preparing the adhesive is simple, does not require very high equipment, and reduces production costs.

Owner:贵港市鑫宏木业有限公司

Self-lubricating polyimide wire enamel and preparation method thereof

The invention relates to self-lubricating polyimide wire enamel and a preparation method thereof. The self-lubricating polyimide wire enamel comprises a component A and a component B, wherein the component A is a polyamide acid solution and accounts for 90 wt% to 98 wt% of the total mass of an enamel solution; and the component B is a blend of stearic acid, glycidyl ether propyl trimethoxy silane and tung oil anhydride, of which the mass ratio is 1: (1-3): (0.1- 0.8), and accounts for 2 wt% to 10 wt% of the total mass of the enamel solution. The self-lubricating polyimide wire enamel is obtained only by mixing the component A with the component B at room temperature. The preparation method has the advantages that raw materials are easy to obtain, the operation is simple, the preparation can be completed on general equipment and the industrialization is easy to realize; and a wire enamel film is smooth, even and flexible, is suitable for manufacturing electromagnetic wires of wire rods such as round copper wires, flat copper wires and aluminum wires and has a broad market prospect.

Owner:DONGHUA UNIV +1

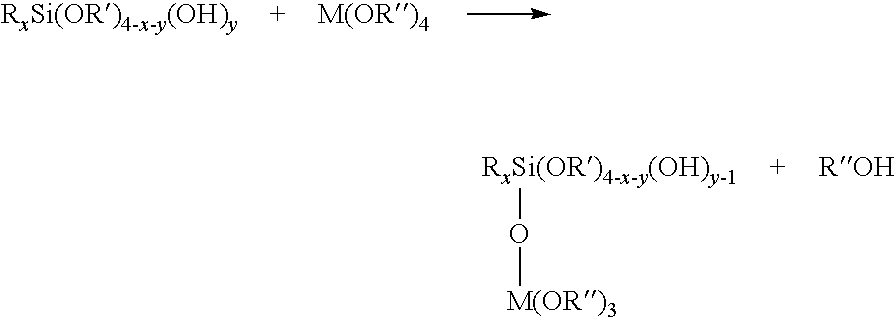

Tintable film-forming compositions having high refractive indices and coated optical articles using same

Provided are curable film-forming compositions are provided including:(a) a binder of an alkoxysilane;(b) a metal oxide compound containing titanium, zirconium, cerium, niobium, tantalum, and / or tin; and(c) a polyglycidyl ether. Also provided are optical articles including a substrate and the curable film-forming composition superposed on a surface thereof.

Owner:PPG IND OHIO INC

Chromium-free passivating liquid for surface treatment of electrogalvanized steel plate and use method thereof

InactiveCN101289741AImprove stabilityLong storage timeMetallic material coating processesChromium freeElectrogalvanization

The invention discloses a chromium-free passivating solution for the surface treatment of electro-galvanized steel plates, as well as a method for using the same. The mass percentages of the composition of the chromium-free passivating solution are: 0.2-20 percent of gamma-glycidyl ether oxygen propyl trimethoxy silane, 0.01-1.0 percent of polyvinyl alcohol, 0.1-3.0 percent of ammonium zirconium carbonate, water as a solvent, and the balance. The application method comprises the following steps that: the surface of a clean electro-galvanized steel plate is coated with the passivating solution, and then the passivating solution is baked to become a film; the thickness of a film layer is between 0.2 and 2.0 g / m<2>. The process treatment of the invention remarkably improves the corrosion resistance of the electro-galvanized steel plate, which is equivalent to chromate color passivation. In addition, through the treatment of the process, the coating performance of the electro-galvanized steel plate is remarkably improved as well.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com