Environment-friendly permeable high-strength waterborne epoxy slurry and preparation method and application thereof

A water-based epoxy, penetrating technology, applied in the direction of epoxy resin glue, adhesive type, polymer adhesive additives, etc., can solve the problems of short construction time, too many materials, not suitable for large-scale use, etc. To achieve the effect of excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Direct preparation of water-swellable self-emulsified polyamido-amine:

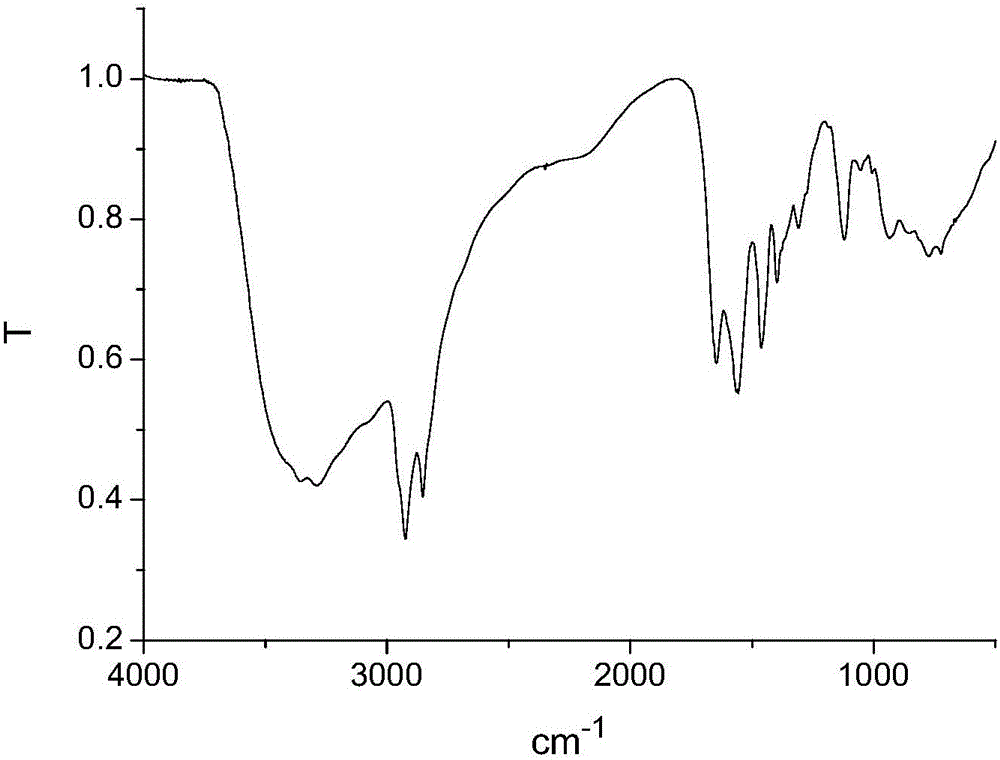

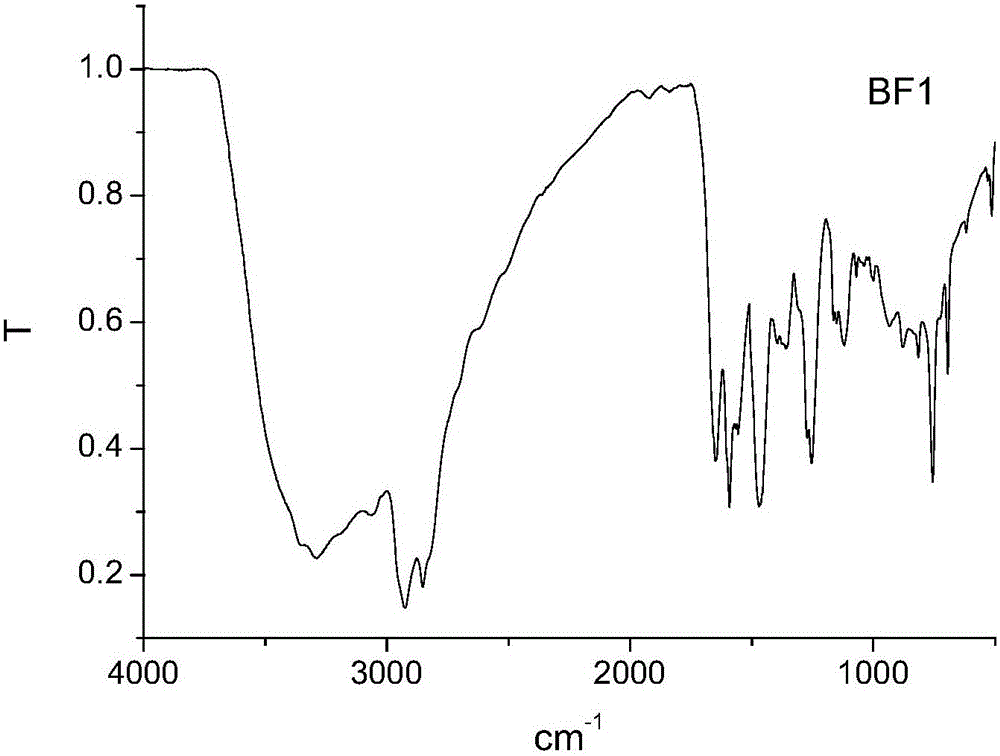

[0063] In a 5000mL three-necked flask, add 1000g of linoleic acid dimer (dimer acid, acid value 195, (Lianyungang Hexing Chemical Industry) (1000g dimer acid contains 3.48 moles of carboxyl groups), heat up to 80 ° C, stir Slowly add 1000g of triethylenetetramine (molecular weight 146), then raise the temperature to 140°C for 2 hours, then keep the temperature and stir to remove water vapor, stop heating after 3 hours, and obtain water-swellable self-emulsifying polyamide-amine PA1 after cooling .Sampling PA1, testing its infrared spectrum (see attached figure 1 ).

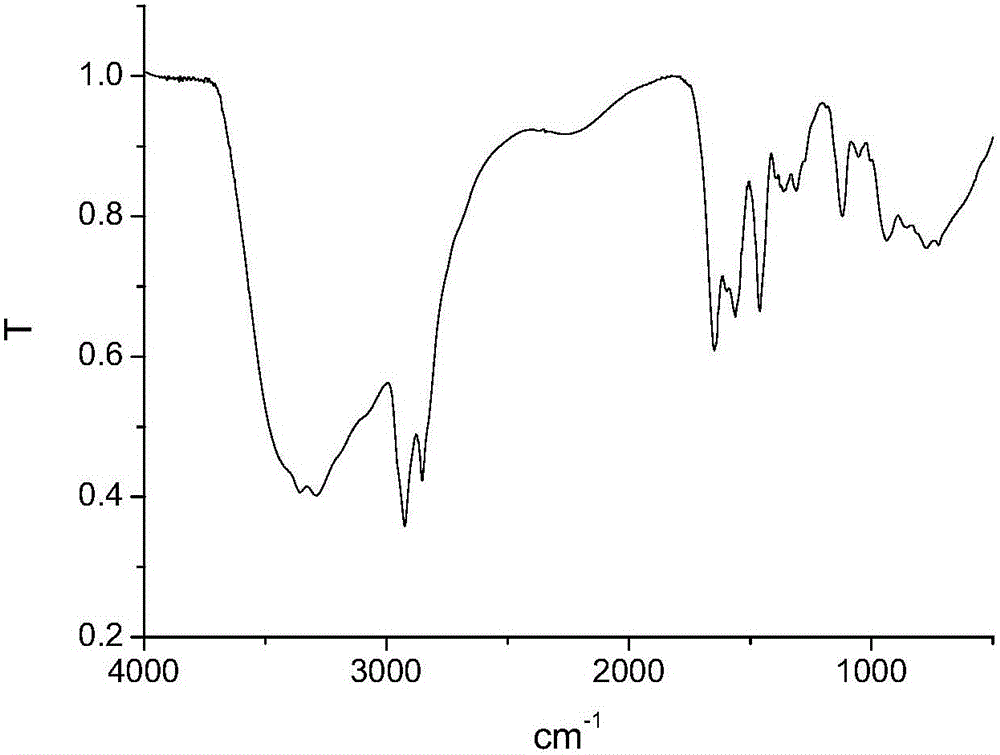

[0064] Add 1000g of dimer acid into a 5000mL three-neck flask, heat up to 80°C, slowly add 2000g of pentaethylenehexamine under stirring, then raise the temperature to 160°C for 2 hours, then keep the temperature and stir to remove water vapor, like this for 3 Heating was stopped after 1 hour, and water-swellable self-emulsifying...

Embodiment 2

[0073] Preparation of hydrophobic modified fatty amine:

[0074](1) Cardanol-modified fatty amine MFA1: Add 2 moles of cardanol (Shanghai Meidong Biomaterials Co., Ltd.) ℃, add 20g of paraformaldehyde, add 20g after 30 minutes, add the remaining 20g of paraformaldehyde after 30 minutes, then heat up to 130℃ for 2-4 hours of reaction dehydration, cool to obtain cardanol modified fat Amine MFA1.

[0075] (2) Dimeric ricinoleic acid ester modified fatty amine MFA2: Add 2 moles of triethylenetetramine into a 2000mL three-necked flask, heat up to 80°C and add 2 moles of dehydrated dimeric ricinoleic acid ester (Zibo Entrepreneurial Biotechnology Co., Ltd.), make it evenly mixed into a liquid, then raise the temperature to 140°C for a preliminary dehydration amidation reaction for 2 to 5 hours, then raise the temperature to 160°C for further dehydration reaction for 2 hours, and then raise the temperature to 180°C for 1 hour dehydration reaction , after a total reaction of 5 to 8 ...

Embodiment 3

[0077] Preparation of fatty amine polyoxyethylene polyoxypropylene ether (refer to literature [1] "Zhang Jiehui et al. Synthesis, structure and demulsification performance of multi-block polyether. Oilfield Chemistry, 1997,14(4):324-328" ):

[0078] (1) Add the starter tetraethylenepentamine, the catalyst calcium acetate and potassium hydroxide into a 0.5-liter high-pressure reaction kettle, fully purge the pipeline and the kettle with N2, stir and heat up to 90°C, vacuumize and continue to heat up, Stop vacuuming at 120°C (about 0.5 hours), add propylene oxide dropwise, react at 135±5°C, ≤0.4MPa, until the molar ratio of initiator to propylene oxide reaches 1:14, and the lipophilic head is obtained . In the high-pressure reactor, heat up to 120°C according to the same operation steps, stop vacuuming, add ethylene oxide dropwise, react at 125±5°C, ≤0.3MPa, add ethylene oxide until the initiator and ring The molar ratio of oxyethane to 1:14, and then reacted at 125±5°C for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com