Intelligent spraying method based on image processing and spraying robot based on image processing

An image processing and robotic technology, applied in manipulators, devices for capturing or killing insects, and manufacturing tools, etc., can solve the problems of limiting the function and scope of spraying, causing great physical injury to the operator, and increasing the spraying area. Achieve the effect of speeding up agricultural precision, reducing bodily harm, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The intelligent spraying method based on image processing comprises the following steps:

[0035] ① Collect images of the front area in real time through the video acquisition module of the spraying robot, and send the collected images to the digital signal processor 3a for analysis and processing;

[0036] ②The digital signal processor 3a sends the processing results to the embedded controller 3f, and the embedded controller 3f controls the mobile platform 1 to move to the vicinity of the area to be sprayed according to the distribution of plants and weeds in the area where the mobile platform 1 is located; The formula controller 3f drives the spraying manipulator 5 through the spraying manipulator steering gear driver 3c to send the spraying rod 5e to the vicinity of the weeds in the area to be sprayed;

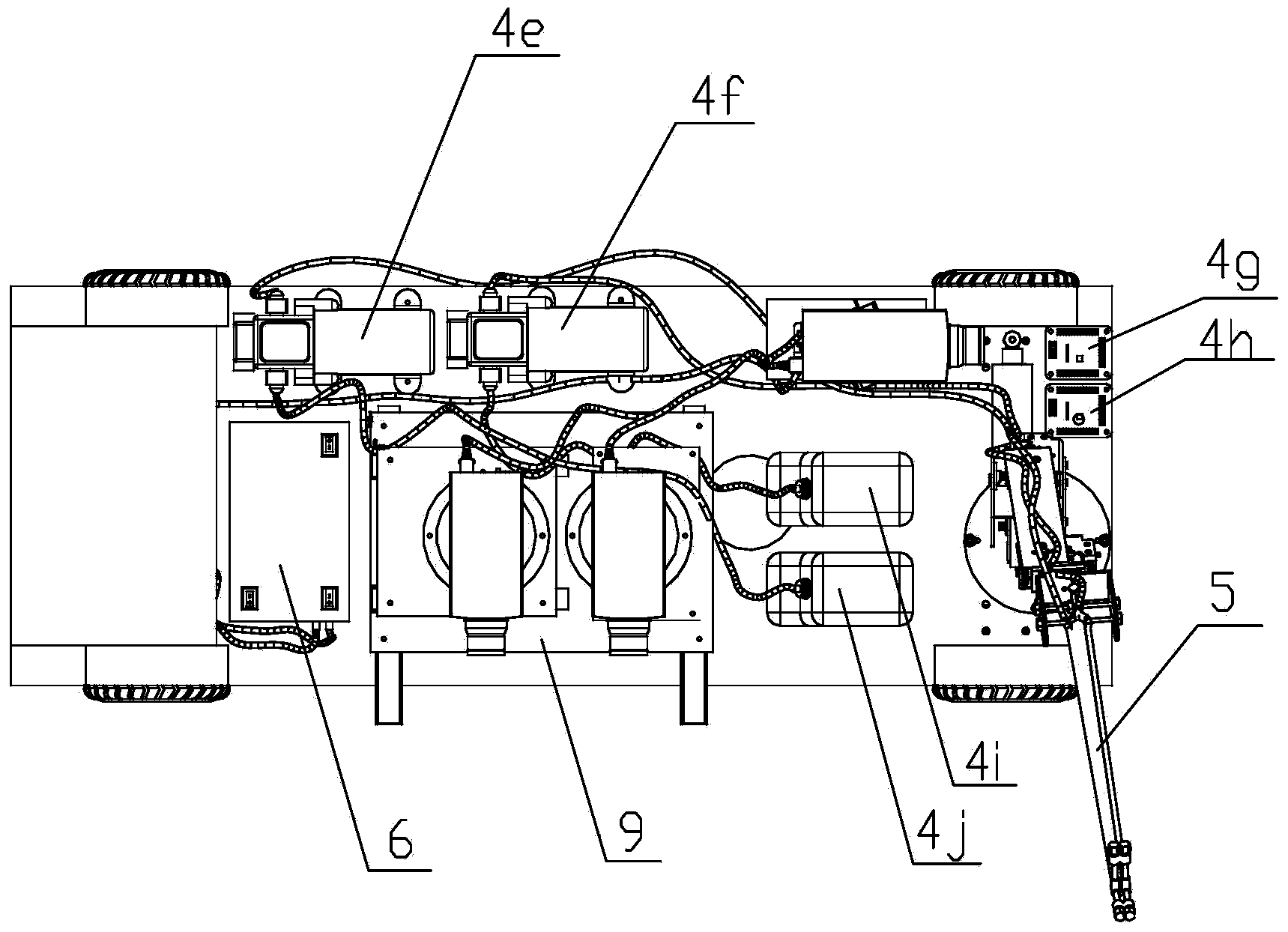

[0037] ③The embedded controller 3f controls the herbicide spraying motor relay 4g to pull in, and then controls the herbicide spraying motor 4e to rotate to spray th...

Embodiment 2

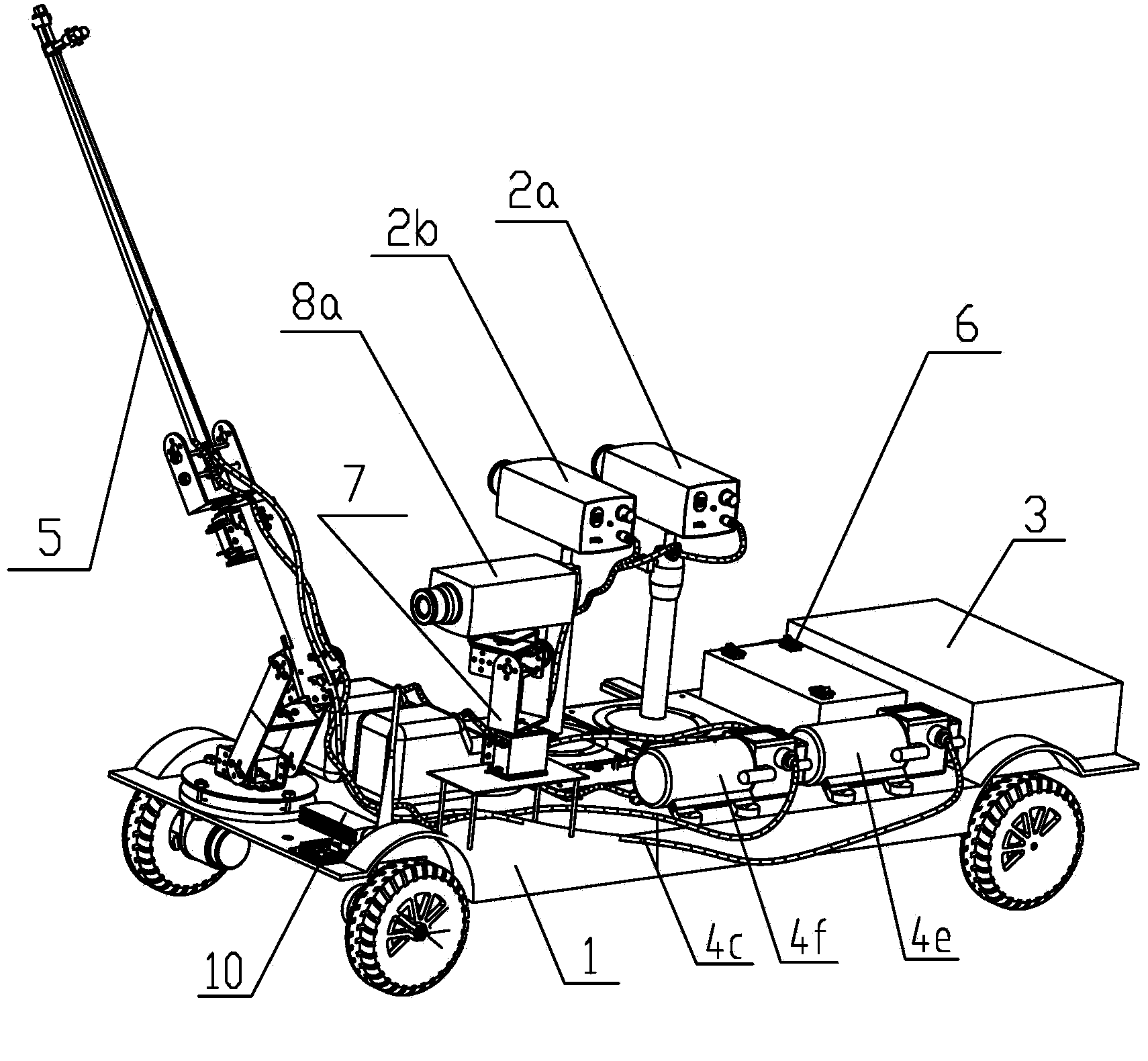

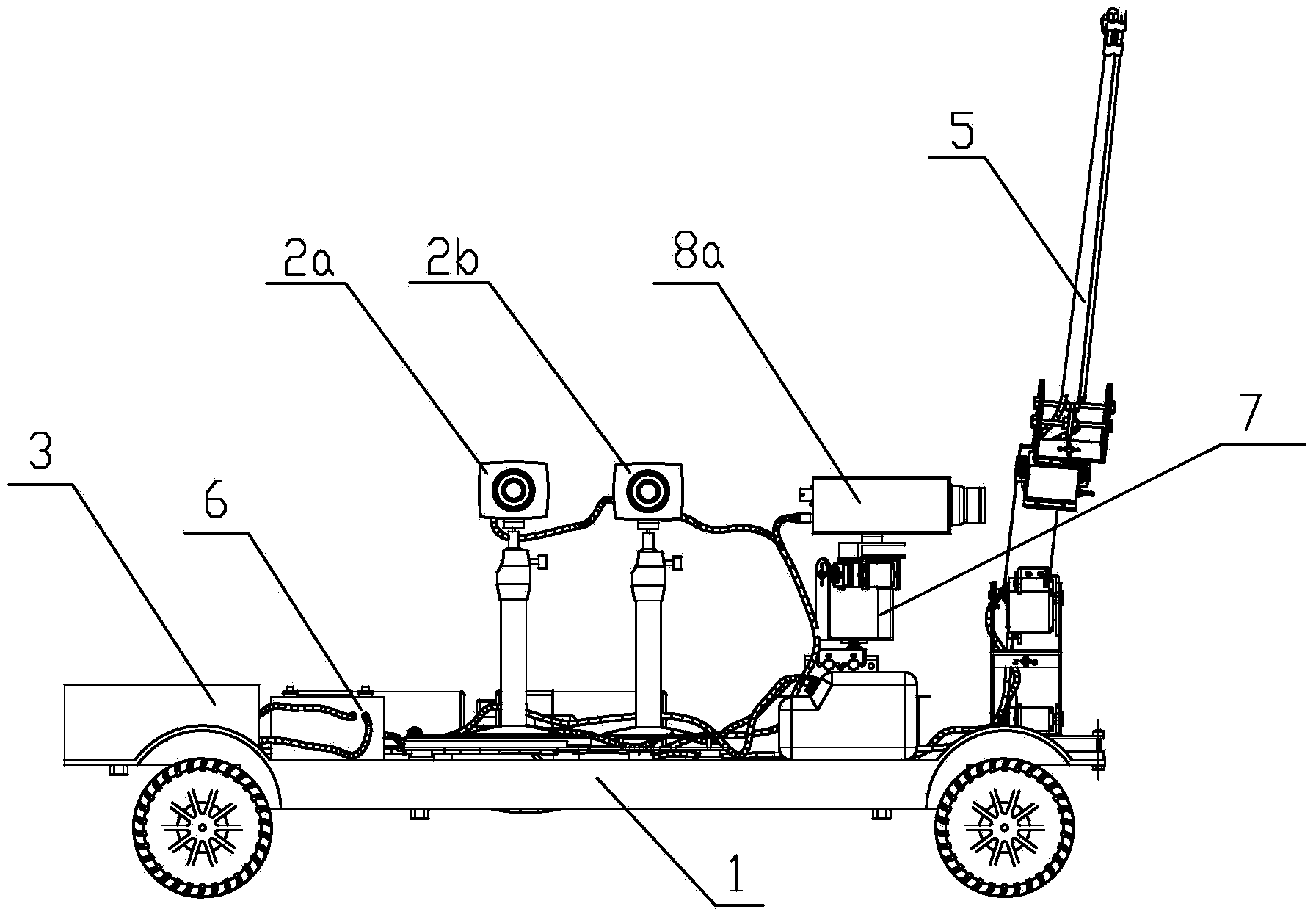

[0047] The difference between this embodiment and Embodiment 1 is that the spraying robot based on image processing also includes a road condition acquisition system, and the road condition acquisition system includes a road condition camera 8a, a two-degree-of-freedom pan / tilt 7 and a wireless video receiver 10, The road condition camera 8a is fixed on the mobile platform 1 by a two-degree-of-freedom platform 7, and the wireless video receiver 10 is connected with the road condition camera 8a by an AV line; the power supply system is connected with the road condition camera 8a and provides power for it; Described two-degree-of-freedom cloud platform 7 comprises two steering gears and steering gear bracket, U-shaped support 7c, base 7d, and described steering gear comprises steering gear A7a1 and steering gear B, and described steering gear A7a1 is connected with steering gear bracket by its steering gear. The U-shaped support 7c is connected, and the U-shaped support 7c is con...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that the method for intelligent spraying using the image processing-based spraying robot also includes manual intervention steps:

[0050] (a) When spraying pesticides, the wireless video transmitting module transmits the video collected by the road condition camera 8a to the wireless video receiver 10 in real time. Real-time observation of the working environment and working status of the area where the intelligent spraying robot is located;

[0051] (b) According to the results of real-time observation, the staff operates the button module 11g and then transmits the signal through the ZIGBEE coordinator 11c, and the ZIGBEE node 3e transmits the signal to the MSP430 controller 11d after receiving the signal, and the MSP430 controller 11d controls the two-degree-of-freedom cloud The platform driver 3d then controls the action of the two-degree-of-freedom pan-tilt 7, thereby controlling the image acquisition rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com